Patents

Literature

780results about How to "Good corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

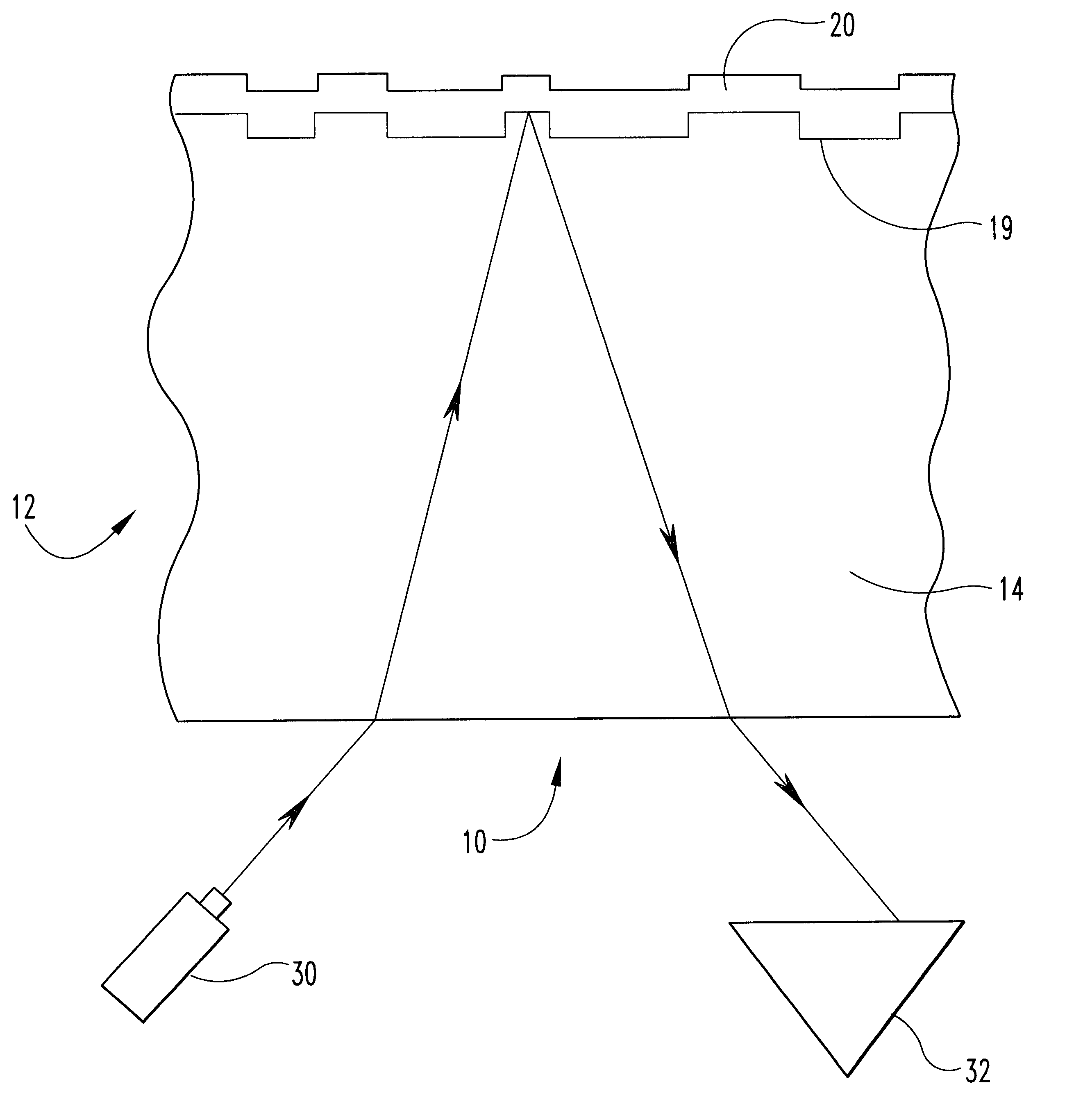

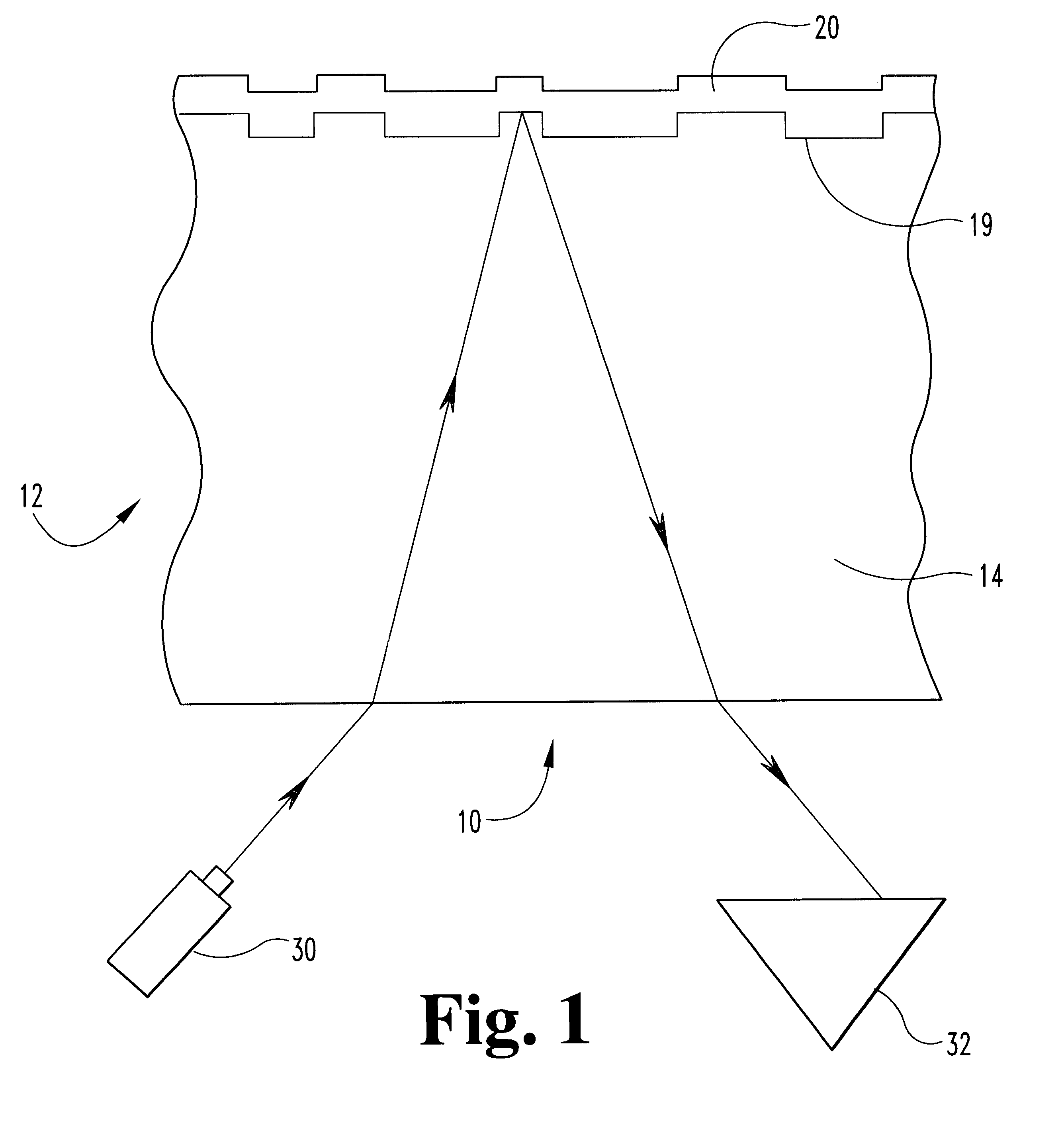

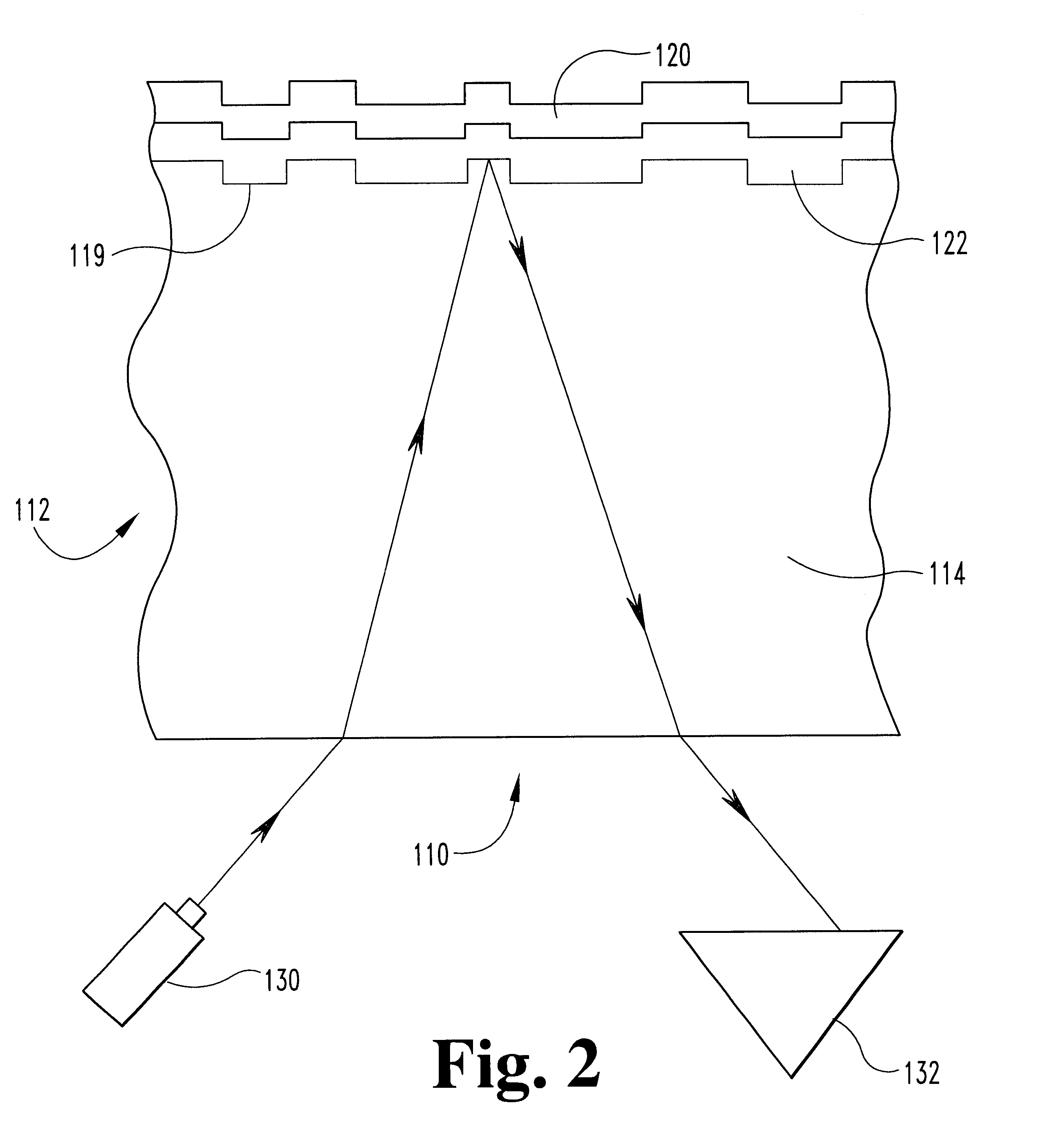

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6451402B1Good corrosion resistanceHigh reflectivityRecord information storageThin material handlingIridiumCorrosion

A silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, palladium, copper, rhodium, ruthenium, osmium, iridium, and platinum. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

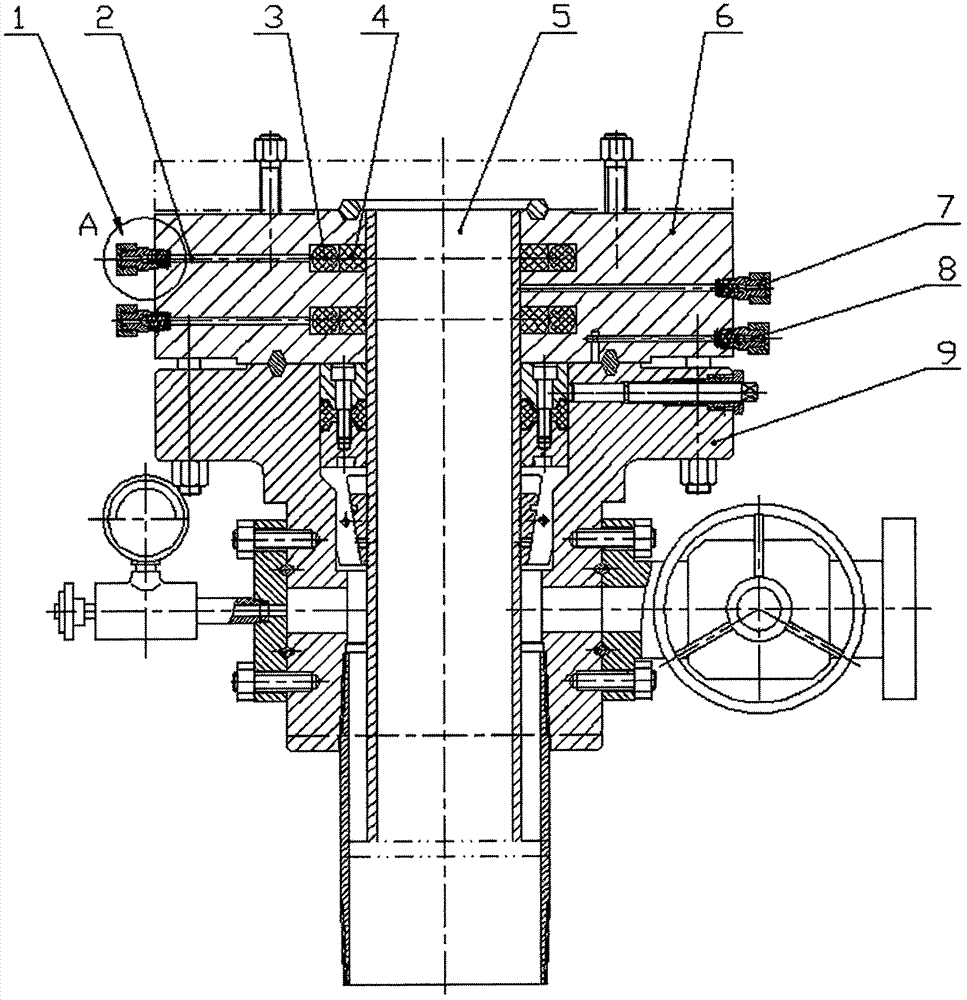

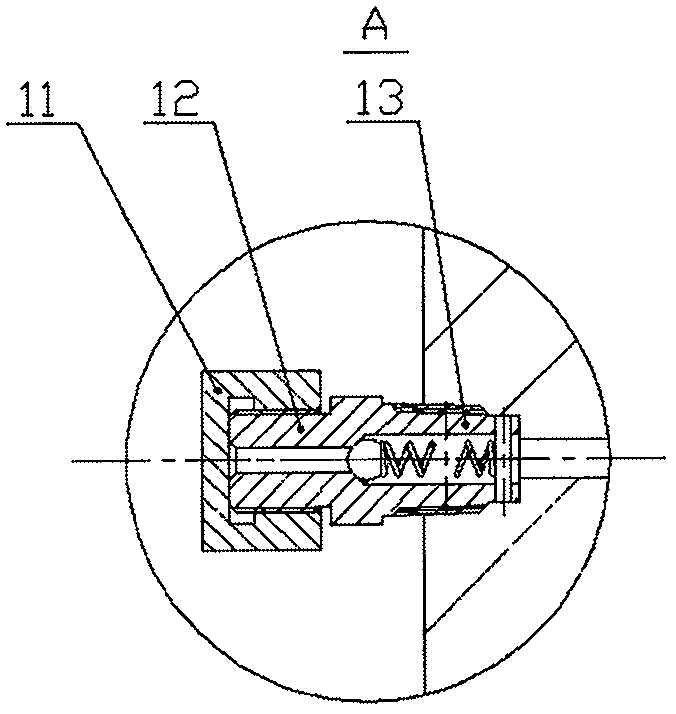

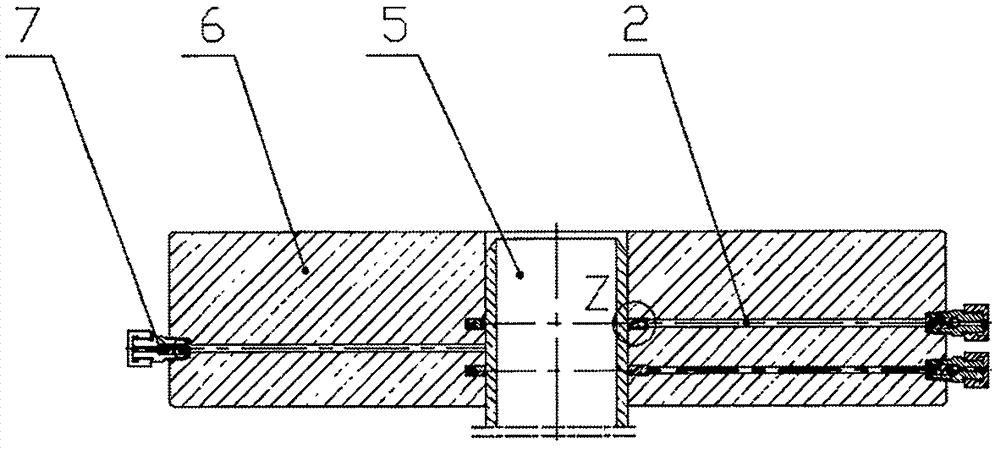

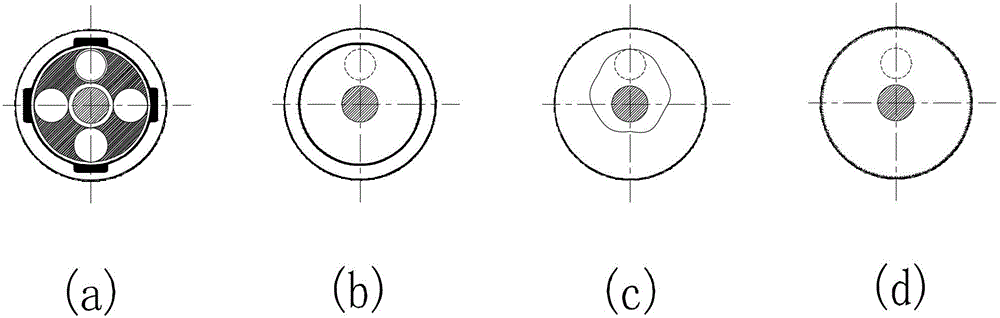

Petroleum wellhead annular space sealing device

PendingCN107143298AGood corrosion resistanceDirectionalSealing/packingWellheadMechanical engineering

The invention discloses a petroleum wellhead annular space sealing device. The petroleum wellhead annular sealing device is used for sealing an annular space between a wellhead sealing body and a petroleum pipe, at least one annular groove is formed in the inner wall surface of the sealing body, and the sealing body is provided with an injection hole which is communicated to a centrifugal end of the annular groove; the petroleum wellhead annular space sealing device further comprises a sealing ring, a power ring, and an injection component, wherein the sealing ring is embedded into the annular groove, the sealing ring is used for sealing the groove in the radial direction by being jointed to the wall surface of the annular groove, and is used for sealing the annular space by being jointed to the outer wall of the petroleum pipe, the power ring is installed in the annular groove and is located between the groove bottom of the annular groove and the sealing ring, and the injection component is installed in an inlet of the injection hole, and is used for injecting fluid with given pressure so as to make the power ring push the sealing ring to tightly press the petroleum pipe. In the petroleum wellhead annular space sealing device, the requirement for deformation capability of a sealing part is low, and meanwhile the sealing capability can be effectively improved.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

High temperature-resistant composite inorganic binder, as well as preparation method and application thereof

ActiveCN103740284AStrong adhesionGood corrosion resistanceInorganic adhesivesCoatingsTemperature resistanceRepair material

The invention provides a high temperature-resistant composite inorganic binder, as well as a preparation method and an application thereof. The binder is a waterborne binder containing aluminum dihydrogen phosphate, zirconium sol and water. The binder comprises the following components in percentage by weight: 10-70% of aluminum dihydrogen phosphate, 10-80% of zirconium sol and 0-80% of water. The preparation method comprises the following steps: weighing the aluminum dihydrogen phosphate, the zirconium sol and the water according to the proportion, uniformly mixing under the conditions that the temperature is 20 DEG C-100 DEG C and the stirring speed is 200rpm-1000rpm, cooling and then obtaining the required high temperature-resistant composite inorganic binder. The binder has excellent high temperature resistance and can withstand the temperature of 2000 DEG C for a long time. The high temperature-resistant composite inorganic binder can be used for high temperature-resistant materials, ceramic coatings, fireproof materials, ceramic materials, high-temperature kiln repair materials, refractory materials, flame-retardant materials, high temperature-resistant adhesives and the like.

Owner:武汉双虎涂料股份有限公司

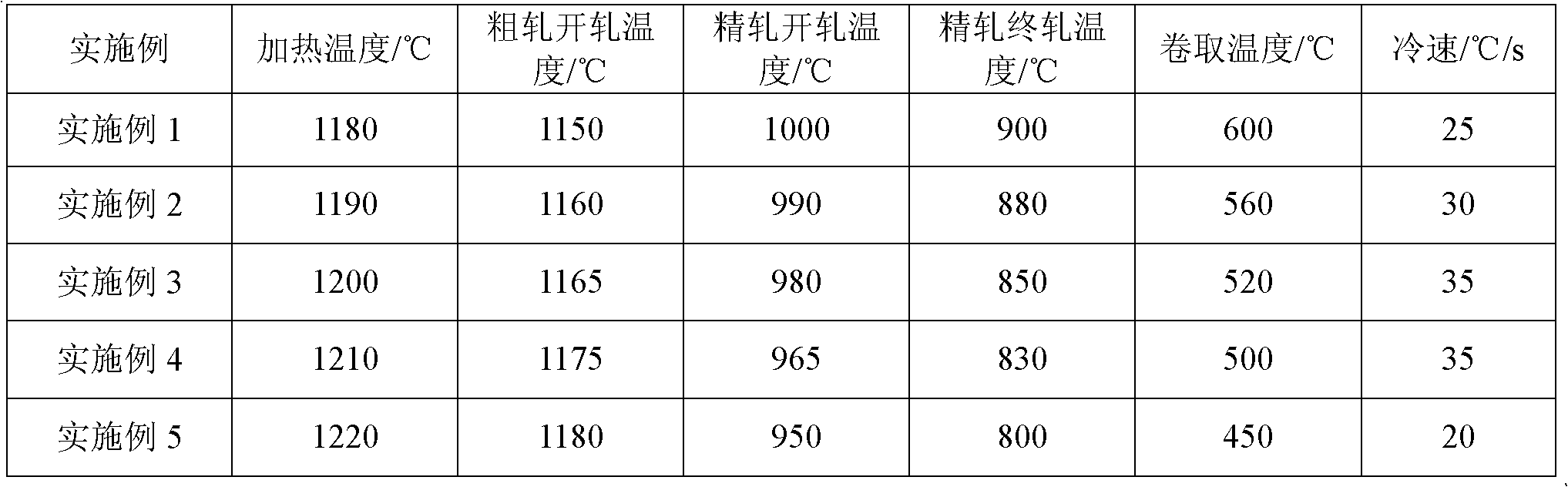

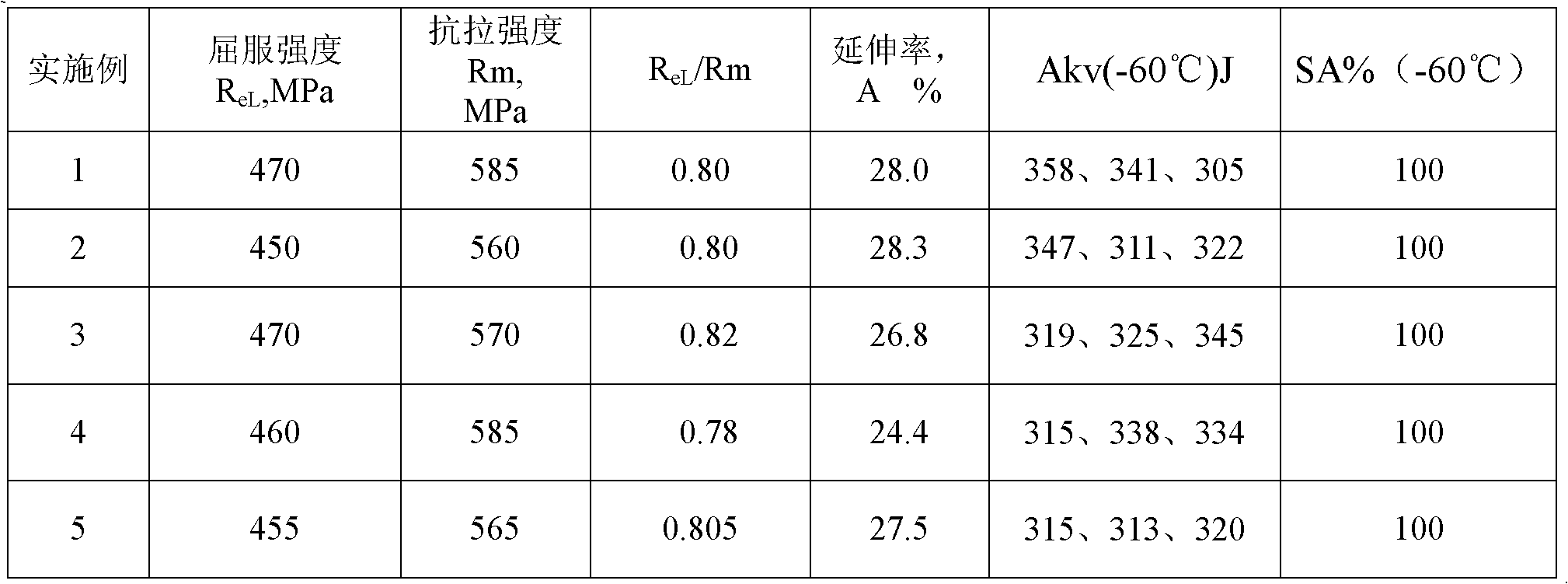

420 MPa weatherproof bridge steel with high ductility and method for manufacturing hot rolled coil of 420 MPa weatherproof bridge steel with high ductility

InactiveCN102021495AGood corrosion resistanceImproves corrosion resistance and toughnessCorrosionAluminium

The invention discloses a 420 MPa weatherproof bridge steel with high ductility, which is characterized by comprising the following chemical compositions in percentage by weight: 0.015-0.045% of carbon, 0.20-0.35% of silicon, 1.20-1.50% of manganese, less than or equal to 0.018% of phosphorus, less than 0.0005% of sulfur, 0.030-0.050% of niobium, 0.010-0.020% of titanium, 0.015-0.040% of aluminum, 0.25-0.40% of nickel, 0.25-0.50% of chromium, 0.25-0.40% of copper, 0.0002-0.003% of B, less than or equal to 0.006% of nitrogen, less than or equal to 0.002% of oxygen, and the balance of ferrum and trace impurities. The rolled coil of the 420 MPa weatherproof bridge steel with high ductility has the advantages of good intensity, ductility, weldability, corrosion resisting property, and proper production cost.

Owner:MAANSHAN IRON & STEEL CO LTD

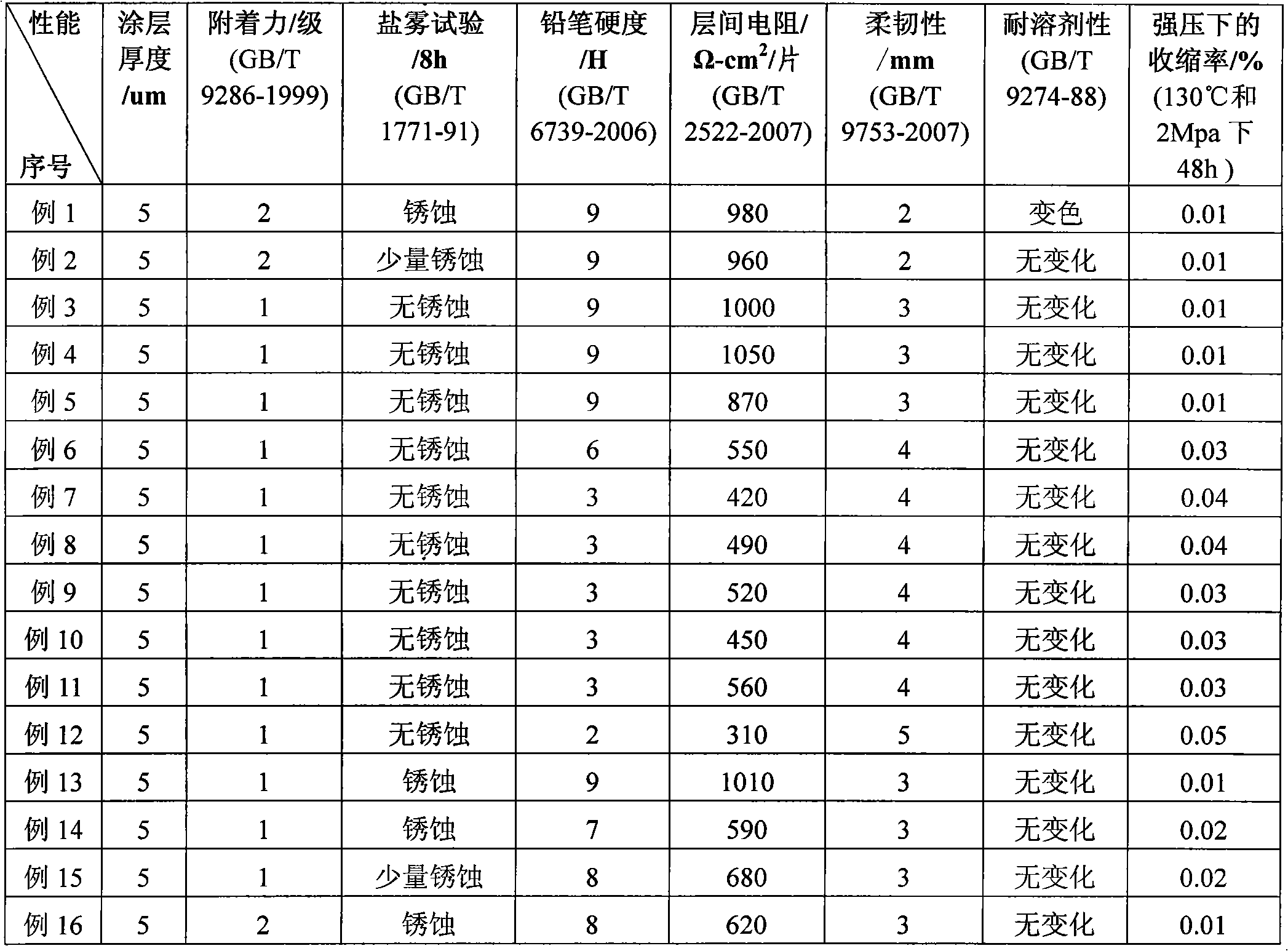

Strong-pressure resisting water-based insulting paint for electric steel and preparation method thereof

InactiveCN101792635AImprove surface resistivityGood corrosion resistanceEpoxy resin coatingsPolyester coatingsSurface resistivityMicrometer

The invention relates to a strong-pressure resisting water-based insulting paint for electric steel and a preparation method thereof. The strong-pressure resisting water-based insulting paint can be prepared by the following steps of: mixing 10-40 percent by weight of water-borne acrylic resin, 2-20 percent by weight of water-borne amine resin, 30-60 percent by weight of pigment, 0-10 percent by weight of addition agent, 0.1-5 percent by weight of catalyst, 0-5 percent by weight of corrosion inhibitor and 1-30 percent by weight of deionized water; and grinding the mixture in a sand mill until the fineness is below 15 micrometers and packaging. The components have no chromate and toxic and harmful ingredients, so that the strong-pressure resisting water-based insulting paint is environment-friendly; the prepared paint is coated on the surface of the electric steel and forms a protective layer with strong adhesion performance after being subjected to high-temperature braking and curing; and the protective layer has the advantages of very high surface resistivity, excellent corrosion resistance and very high strong pressure resistance and creep resistance.

Owner:WUHAN UNIV OF SCI & TECH

MIM manufacturing process for non-magnetic 17-4P stainless steel parts

The invention discloses an MIM manufacturing process for non-magnetic 17-4P stainless steel parts. The MIM manufacturing process comprises the following steps: putting a 17-4PH stainless steel powder and a binder into a kneading machine for mixing; cooling to a room temperature and then crushing by using a crusher, and then extruding a crushed material for pelletizing in an injection molding machine; processing a prepared feeding material in the injection molding machine into blanks; then catalyzing, debinding and removing polyformaldehyde from the injection blanks in a catalytic debinding furnace; putting well catalyzed and debound blanks into a vacuum furnace for debinding and sintering; and carrying out solution treatment on well sintered parts in a shielding gas protected continuous furnace or the vacuum furnace. The MIM manufacturing process provided by the invention adopts an MIM process and uses a 17-4PH powder sintered through nitrogen, and then the non-magnetic MIM metal parts with good compactness and corrosion resistance, and high tensile strength and yield can be obtained after solution treatment.

Owner:SHANGHAI FUTURE HIGH-TECH CO LTD

Self-lubricating passivation solution and hot galvanizing self-lubricating coating steel sheet coated thereby

InactiveCN103289569AGood corrosion resistanceGood paintability and adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsCorrosion resistantLubrication

The invention discloses a self-lubricating passivation solution and a hot galvanizing self-lubricating coating steel sheet coated thereby. The self-lubricating passivation solution is formed by modified solid lubricants, a film forming matter, a film forming additive, an accelerant, a pH modifier, an organic solvent and deionized water through compounding. The solid content after compounding is 15-25%, and the modified solid lubricants are modified nanometer MoS2 and modified nanometer teflon particles. According to the total weight of 1000g, the self-lubricating passivation solution comprises the following components: 10-20g / kg of modified nanometer MoS2, 10-20g / kg of modified nanometer teflon particles, 80-120g / kg of film forming matter, 10-30g / kg of film forming additive, 5-15g / kg of the accelerant and the balance of mixed solution of the organic solvent and the deionized water; and the pH value is adjusted to 3-6 by the pH modifier. The hot galvanizing self-lubricating coating steel sheet coated by the self-lubricating passivation solution comprises a hot galvanizing substrate and a self-lubricating coating attached to the hot galvanizing substrate. The self-lubricating passivation solution does not contain Cr<6+> and other environmentally harmful substances and has environmental protection property, corrosion resistance, wear extreme pressure resistance as well as coating and self-lubrication properties.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

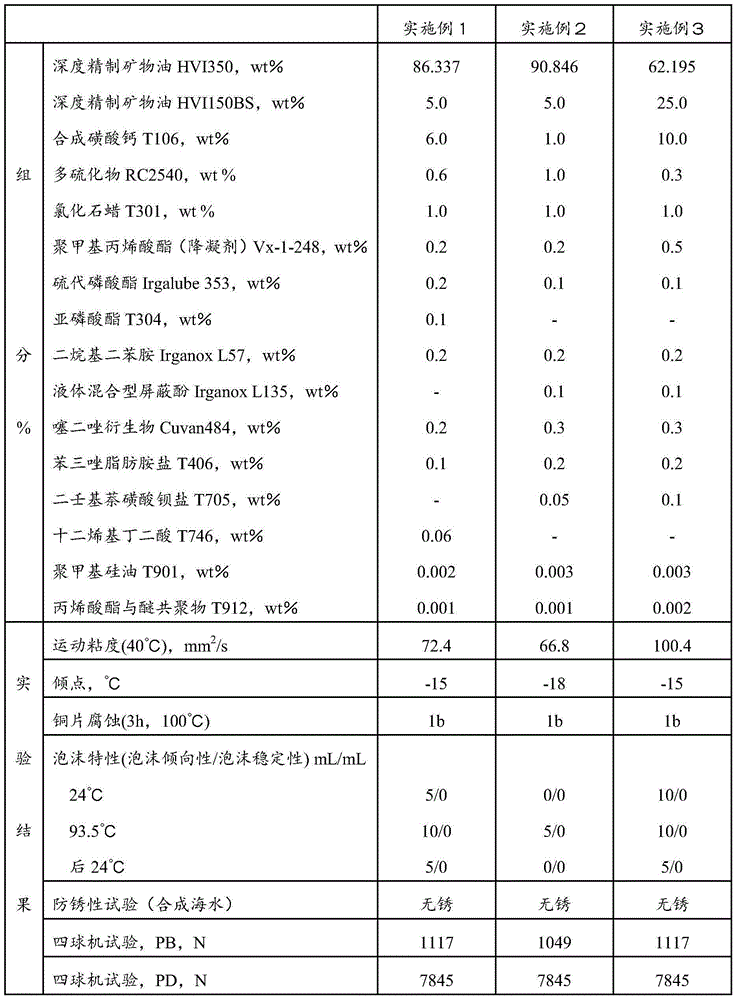

Lubricant composition and application thereof

InactiveCN105238519AExcellent extreme pressure and anti-wear propertiesGood corrosion resistanceLubricant compositionMineral oilAntioxidant

The invention relates to a lubricant composition and application thereof. The lubricant composition is prepared from, by weight, 80-98% of mineral oil, 0.5-10.0% of purification dispersant, 0.5-2.0% of extreme pressure agent, 0.1-1.0% of pour point depressant, 0.1-0.5% of phosphorus anti-wear agent, 0.1-0.5% of antioxidant, 0.1-0.5% of metal deactivator, 0.01-0.2% of friction modifier, 0.01-0.1% of antirust agent and 0.001-0.05% of anti-foaming agent. The lubricant composition can be used for lubricating during cold heading forming and machining.

Owner:CHINA PETROLEUM & CHEM CORP

High isolation protection material and preparation method thereof

InactiveCN101185532AGood corrosion resistanceReduce weightLamination ancillary operationsSynthetic resin layered productsFilm materialBinding force

The invention relates to a protective material with high barrier property and a method of preparation of the material. The protective material is composed of an anti-tear layer, an adhesive layer, a high barrier layer, and a seal layer from outer to inner successively, wherein, the high barrier layer can prevent biochemical toxic agent and toxic gas from passing and has the function of corrosion resistance; the seal layer is made of film materials with better thermal stability and mechanical strength, and has the protective effect for high barrier layer; the adhesive layer can mainly increase the binding force between fabric and barrier film, and prevent delamination; the anti-tear layer is made of fabric which is flame retardant or non-flame retardant and can increase the anti-tear function of the composite layer and strength force of all directions of the composite material. The layers are adhered together by adhesive, and then made into protective materials with high barrier property which has multilayer and various protective functions. The protective material has the advantages of excellent anti-tear property, excellent corrosion resistance, and light weight, which can be used for emergency rescue clothing, biochemical protective clothing, risk chemical dealer protective clothing, missile and rocket inflowing protective clothing, etc.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

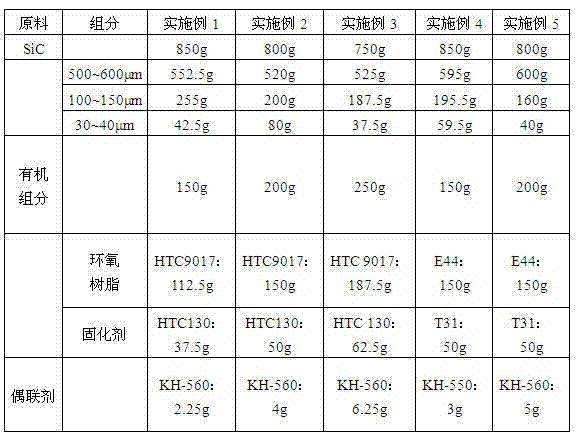

SiC/epoxy resin composite material and method for manufacturing pump components with it

ActiveCN102408677AImproved erosion and wear resistanceClosely arrangedPump componentsPumpsEpoxyEpoxy resin composite

The invention discloses a SiC / epoxy epoxy resin composite material, wherein raw material components based on weight percentages are as follows: 75-85 wt% of SiC particles, 15-25 wt% of organic component and coupling agent with a mass of 1.5-2.5% of the organic component; the particle size distributions of the SiC particles are as follows: 500-600 microns taking up 65-75 wt%, 100-150 microns taking up 2-30 wt% and 30-40 microns taking up 5-10wt%; the organic component is composed of epoxy resin and curing agent; the mass ratio of the epoxy resin to the curing agent is 3: 1. A preparation method for pump component with SiC / epoxy epoxy resin composite material, comprising the following steps: (1), heating and stirring in vacuum way; (2), pressure pouring; (3), vacuum vibrating and forming; (4), heating and curing. The invention is characterized by simple technology and low production cost. The prepared SiC / epoxy epoxy resin composite material pump component can resist abrasion and corrosion.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Method for preparing middle ladle dry vabrative material

The present invention relates to the preparation process of dry vibrating material for middle ladle. The dry vibrating material is prepared with magnesite or forsterite in 85-97 wt% and sodium metasilicate in 3-15 wt%, and through mixing, vibration forming, stoving at 100-400 deg.c and demolding. The magnesite or forsterite is graded with 0.088-2 mm components in 80-90 wt% and 0.088 mm below components in 10-20 wt%. The present invention adopts non-toxic, smell-less and harmless sodium metasilicate as bonder, so that the dry vibrating material may be low temperature smelted during the stoving process to polymerize constantly to raise strength. The dry vibrating material has no carbon increment to the molten steel, high corrosion resistance, easy degradation and environment friendship.

Owner:WUHAN UNIV OF SCI & TECH

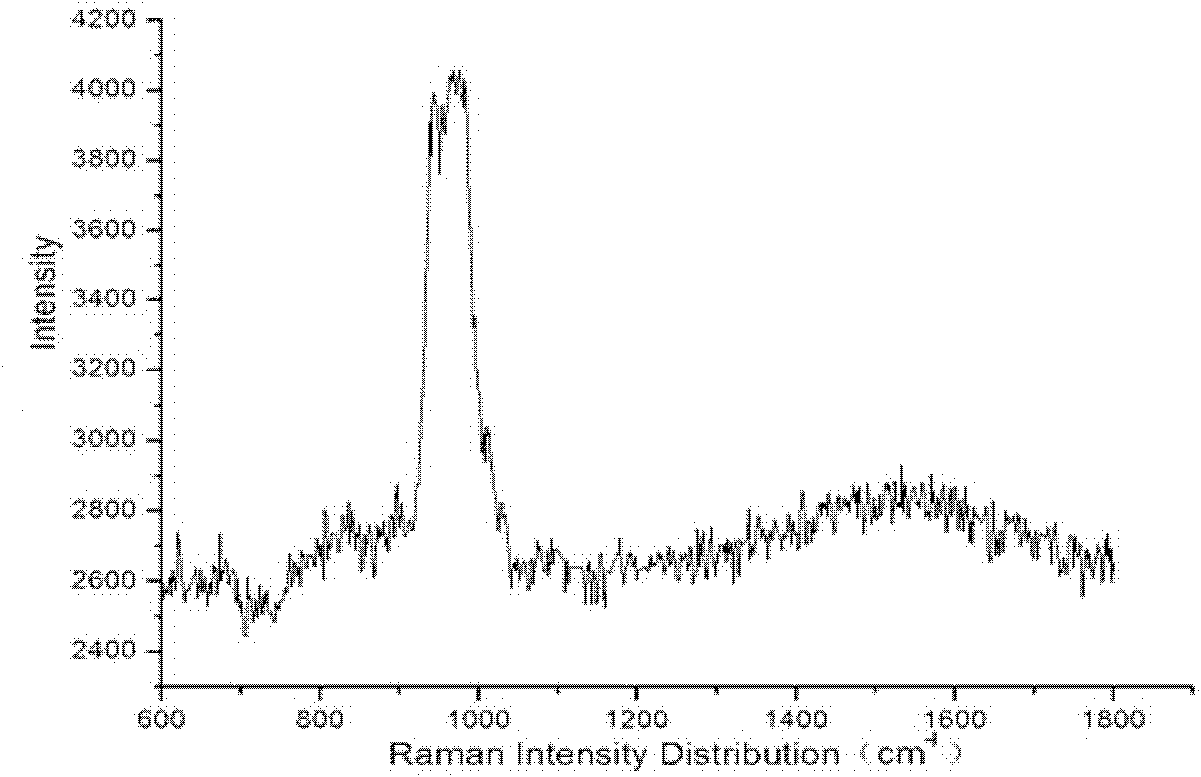

Nanometer Zn crystal boundary modified sintered NdFeB magnet with high corrosion resistance and preparation method thereof

InactiveCN101615461AImprove magnetic propertiesGood corrosion resistanceInorganic material magnetismQuenchingBatch production

The invention discloses a preparation method of nanometer Zn crystal boundary modified sintered NdFeB magnet with high corrosion resistance, comprising the following steps: 1) main-phase alloy and crystal boundary phase alloy are respectively prepared, wherein, the main-phase alloy adopts casting technology or rapid hardening melt-spun technology to prepare a cast ingot or a rapid hardening thin strip, and the crystal boundary phase alloy adopts rapid quenching technology to prepare a rapid quenching strip; 2) the prepared main-phase alloy and crystal boundary phase alloy are respectively prepared into powder; 3) nanometer Zn powder is mixed with the crystal boundary phase alloy powder to evenly disperse the mixture on the crystal boundary phase alloy powder surface; 4) after nanometer Zn modified crystal phase alloy powder is evenly mixed with the main-phase alloy powder, orientation compression in a magnetic field is prepared into a green body; 5) the green body is sintered in a high vacuum sintering furnace and tempered to prepare the final magnet. The sintered NdFeB magnet prepared by the method of the invention has high performance, favourable corrosion resistance, simple technology and simple operation, and is favourable for batch production on large scale.

Owner:ZHEJIANG UNIV

Air-permeability aluminum foil and preparation method thereof

ActiveCN101628644AGood corrosionGood corrosion resistanceFlexible coversWrappersMaximum diameterCorrosion

The invention relates to an air-permeability aluminum foil and a preparation method thereof, wherein the aluminum foil is mainly suitable for air-permeability packaging in requirements of agricultural production and daily life. The aluminum foil is characterized by being made of 3003 alloy, the thickness of the aluminum foil is 0.03-0.05 mm, pinholes which can reach more than 10,000 every square meter are densely distributed on the surface of the aluminum foil, and the maximum diameter of each pinhole is not more than 0.05 mm. The preparation method comprises the following process steps: batching, smelting, cast-rolling, cold-rolling, interannealing, cold-rolling, and foil-rolling to reach the finished thickness, slitting into a finished specification, and finished annealing. The invention has the advantages of good air permeability, strong corrosion resistance and strong oxidation resistance.

Owner:新疆生产建设兵团第八师天山铝业有限公司

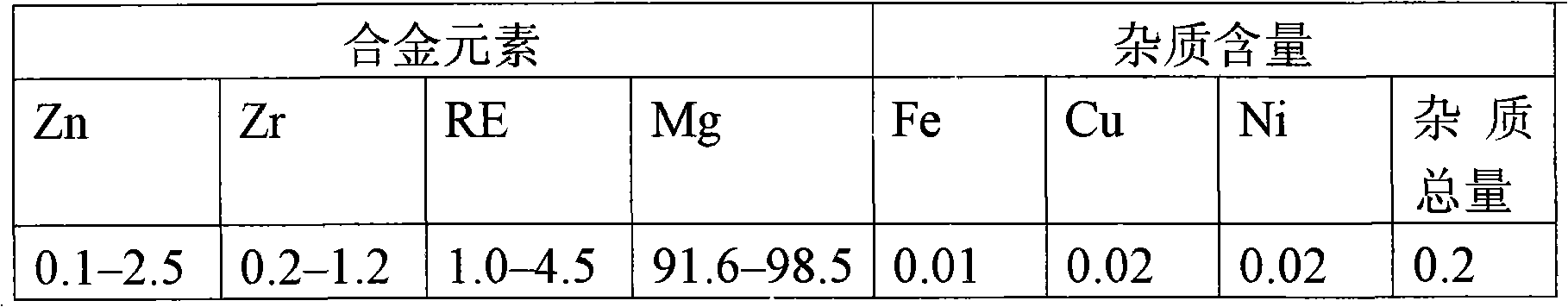

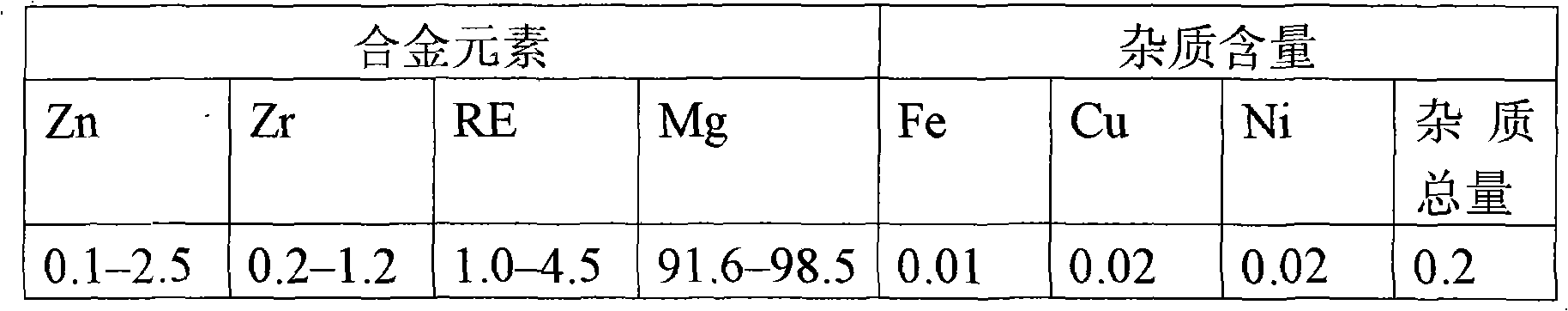

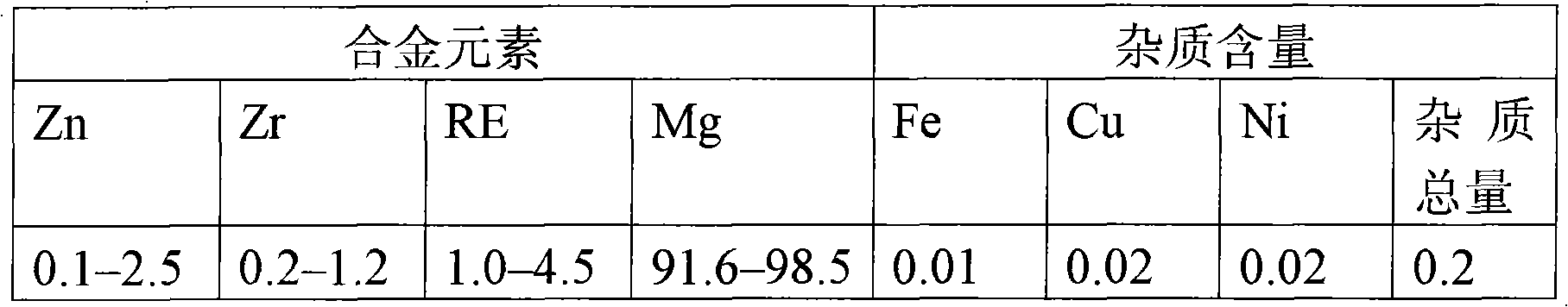

Rare earth magnesium alloy micro arc oxidation green ceramic film preparation method

InactiveCN101187049AGood corrosion resistanceGuaranteed machinabilityAnodisationMicro arc oxidationHardness

The invention belongs to the technical field of magnesium alloy surface treatment, and relates to a process for preparing green ceramic membrane by micro-arc oxidation of a rare earth magnesium alloy. Using oil removaling, cleaning, washing, micro-arc oxidation coloring, hole sealing and drying for the surface of the rare earth magnesium alloy, thereby obtaining a series of ceramic membranes whose color are uniform and are from light green, medium green to dark green and are oxidized by micro-arc of SJDM-1 rare earth magnesium alloy. The ceramic membrane which is prerared through the process has an excellent wear resistance and hardness, at the same time the machinability of the ceramic membrane is further guaranteed, and the ceramic membrane has the characteristics of uniform colors, color diversity and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

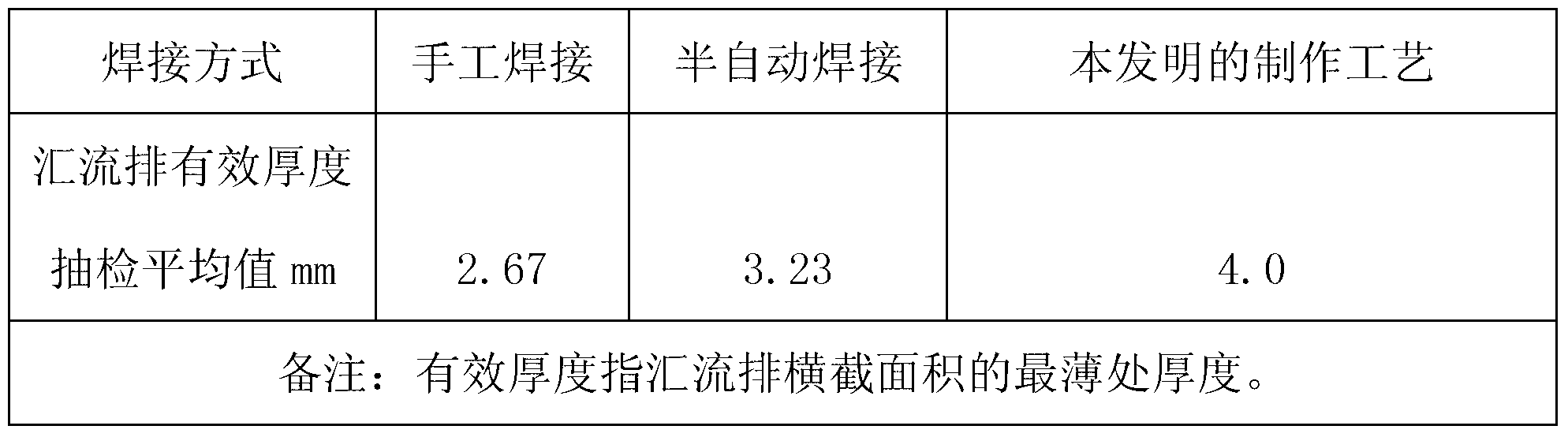

Production process of inner formation storage battery

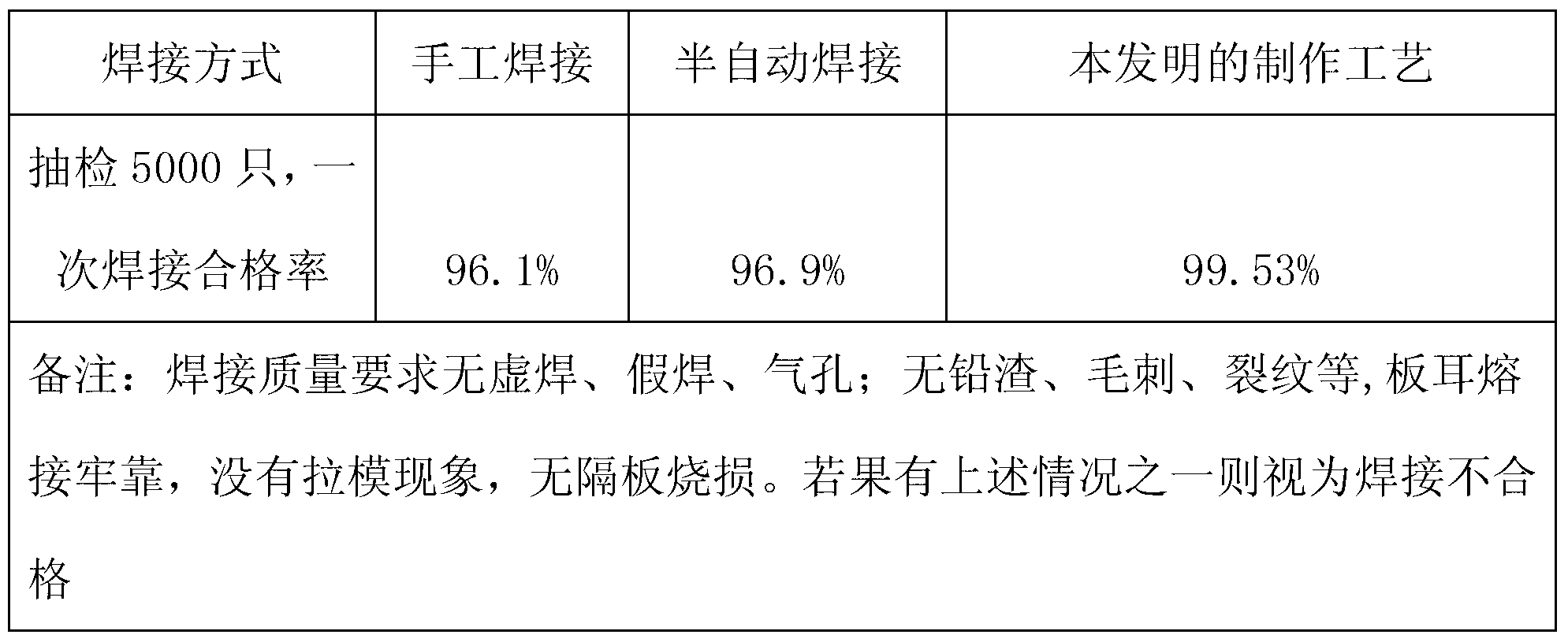

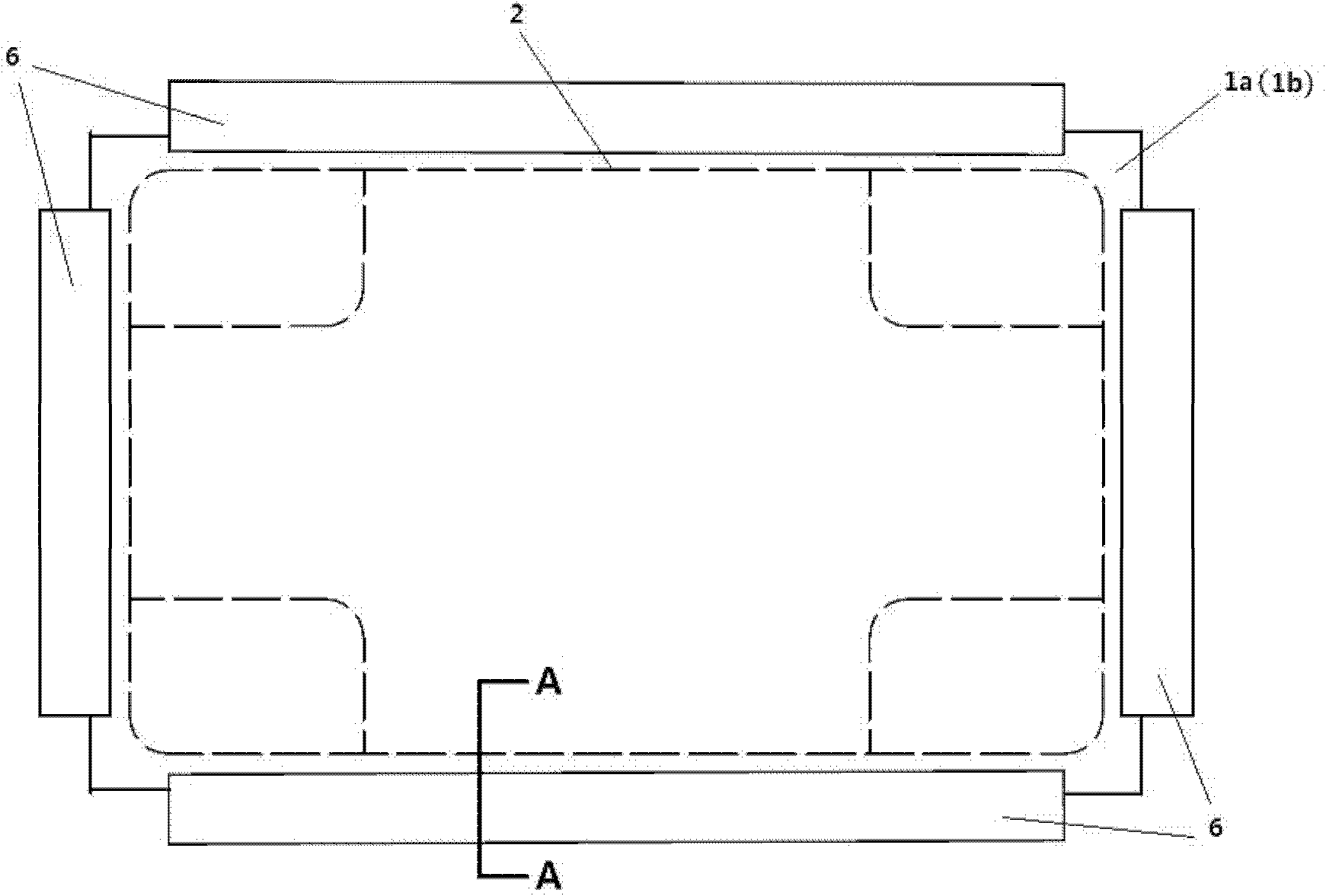

ActiveCN103268963AGood corrosion resistanceNo burning lossFinal product manufactureCell component detailsGrid alloyL&D process

The invention discloses a production process of an inner formation storage battery, and belongs to the field of a lead-acid storage battery, and solves the easily occurring welding quality problem of a bus-bar and a lug. The process comprises the following steps of loading a plate group into an assembling box, arranging a lug, cutting and brushing the lug, dipping soldering flux, cast welding, inspecting and qualification and down-conversion, wherein the cast welding flow is carried out by adopting a cast welding machine. The cast welding flow comprises the following steps of (1) heating a lead pot; (2) loading a mold and preheating the mold; (3) scraping the lead liquid; (4) cast welding the plate group; (5) cooling the plate group through water; (6) cooling the plate group collectively through water and air; (7) cooling the plate group through the air; (8) loading the mold and preheating the mold again; and (9) loading the plate group into a tank. The production process is suitable for the cast welding of the inner formation storage battery with positive grid alloy being lead calcium tin aluminum or lead calcium alloy series grid.

Owner:CHAOWEI POWER CO LTD

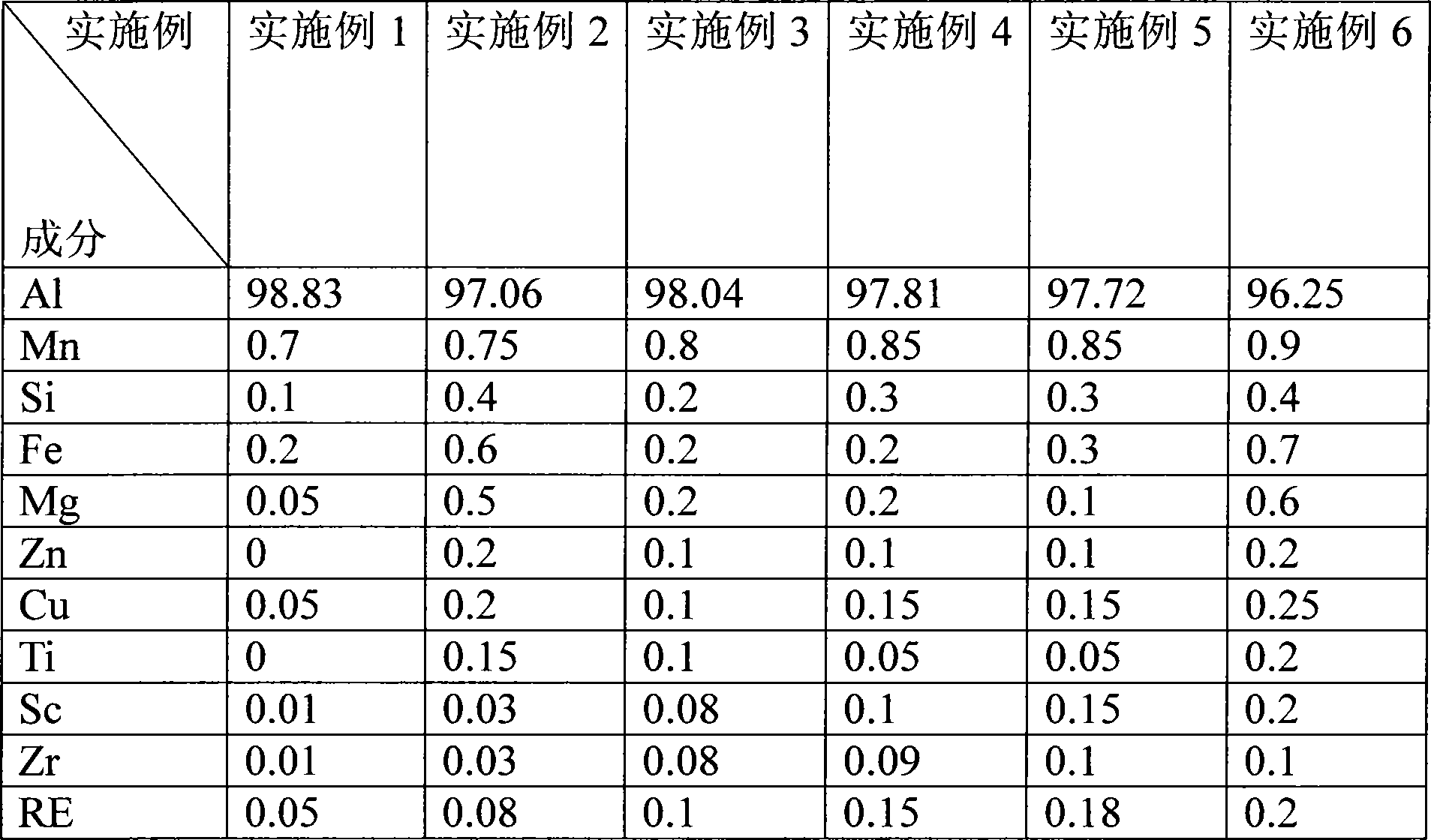

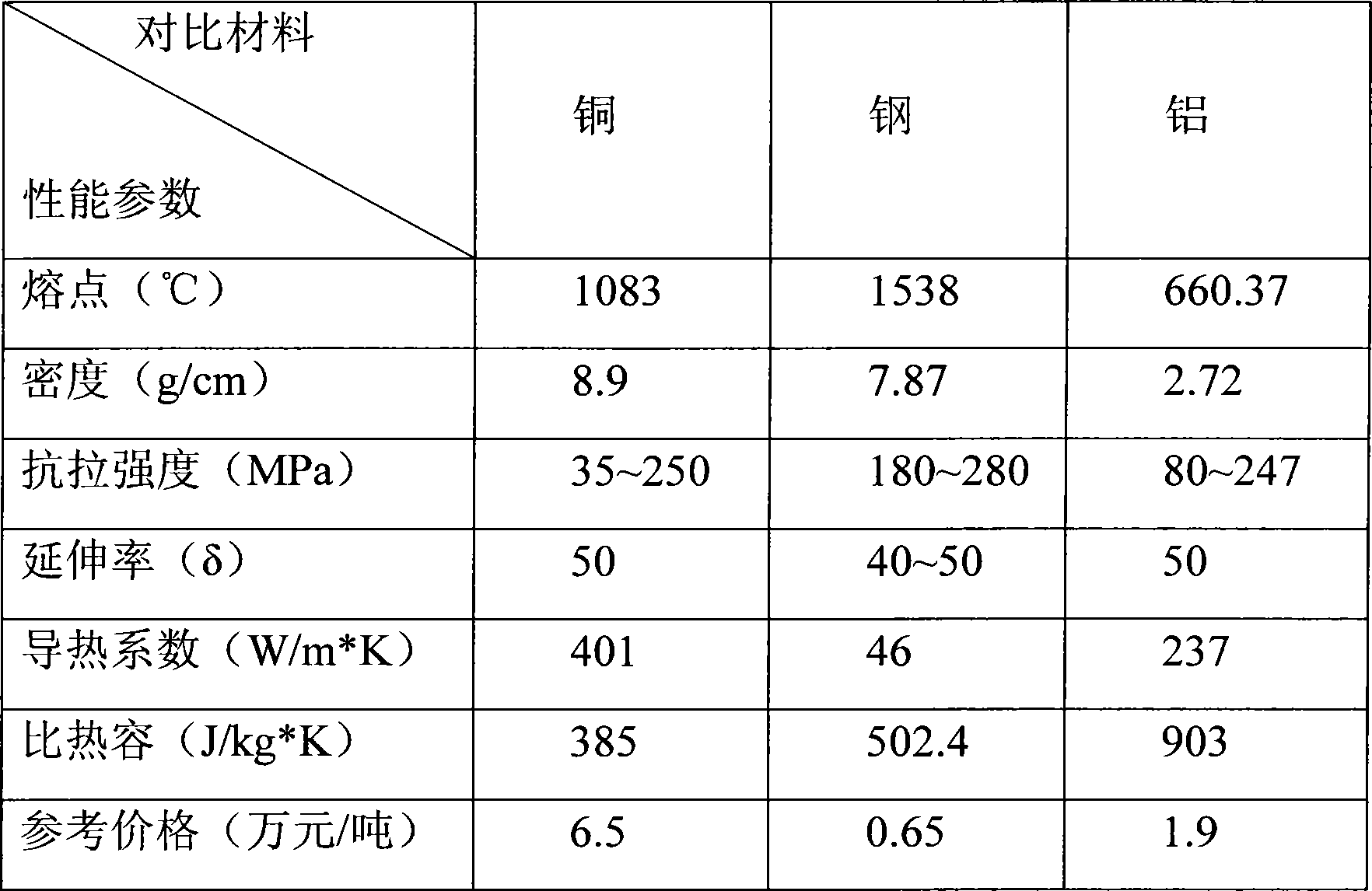

Aluminum alloy for air conditioner tube and method for manufacturing same

The invention relates to an aluminum alloy and the manufacturing method, which particularly relates to aluminum alloy for air-conditioning ducts and the manufacturing method. The invention mainly aims at the problem of the existing technique which has the disadvantages of bad property of iron air-conditioning duct and over-high cost of copper air-conditioning ducts and the like, which provides an aluminum alloy for air-conditioning ducts which has the advantages of excellent corrosion resisting property, high tensile strength and high percentage of elongation and the manufacturing method. The proposition of components of the invention comprises 0.7wt%-0.9wt%Mn,0.1wt%-0.4wt%Si,0.2wt%-0.7wt%Fe, 0.05wt%-0.6wt%Mg, Zn<=0.2wt%, 0.05wt%-0.25wt%Cu, Ti<=0.2wt%, 0.01wt%-0.2wt%Sc, 0.01wt%-0.1wt%Zr, 0.05wt%-0.2wt%RE, and others are Al.

Owner:ZHEJIANG KANGSHENG CO LTD

Argentiferous gold-simulating copper alloy and preparation method thereof

The invention relates to argentiferous gold-simulating copper alloy and a preparation method thereof and belongs to the technical field of alloy materials. The argentiferous gold-simulating copper alloy aims to solve the technical problems of poor color change resistance and gold-simulating effect of copper alloy in the prior art, and mainly comprises, by weight, 1%-20% of Ag, 0.5%-40% of Zn, not more than 1% of Si, not more than 1% of RE, 0.4-5.0% of color matching agents and the balance Cu. The preparation method includes: melting the raw materials at the temperature of 1200-1300 DEG C, performing annealing treatment at the temperature of 500-600 DEG C, forging and performing hot rolling so that the argentiferous gold-simulating copper alloy is obtained. The argentiferous gold-simulating copper alloy is high in color change resistance and good in gold-simulating effect and has the advantages of capability of achieving apparent color and luster of 14K-18K gold, simple technical process, good processability and easiness in processing.

Owner:HANGZHOU ZHENDA HARDWARE MACHINERY

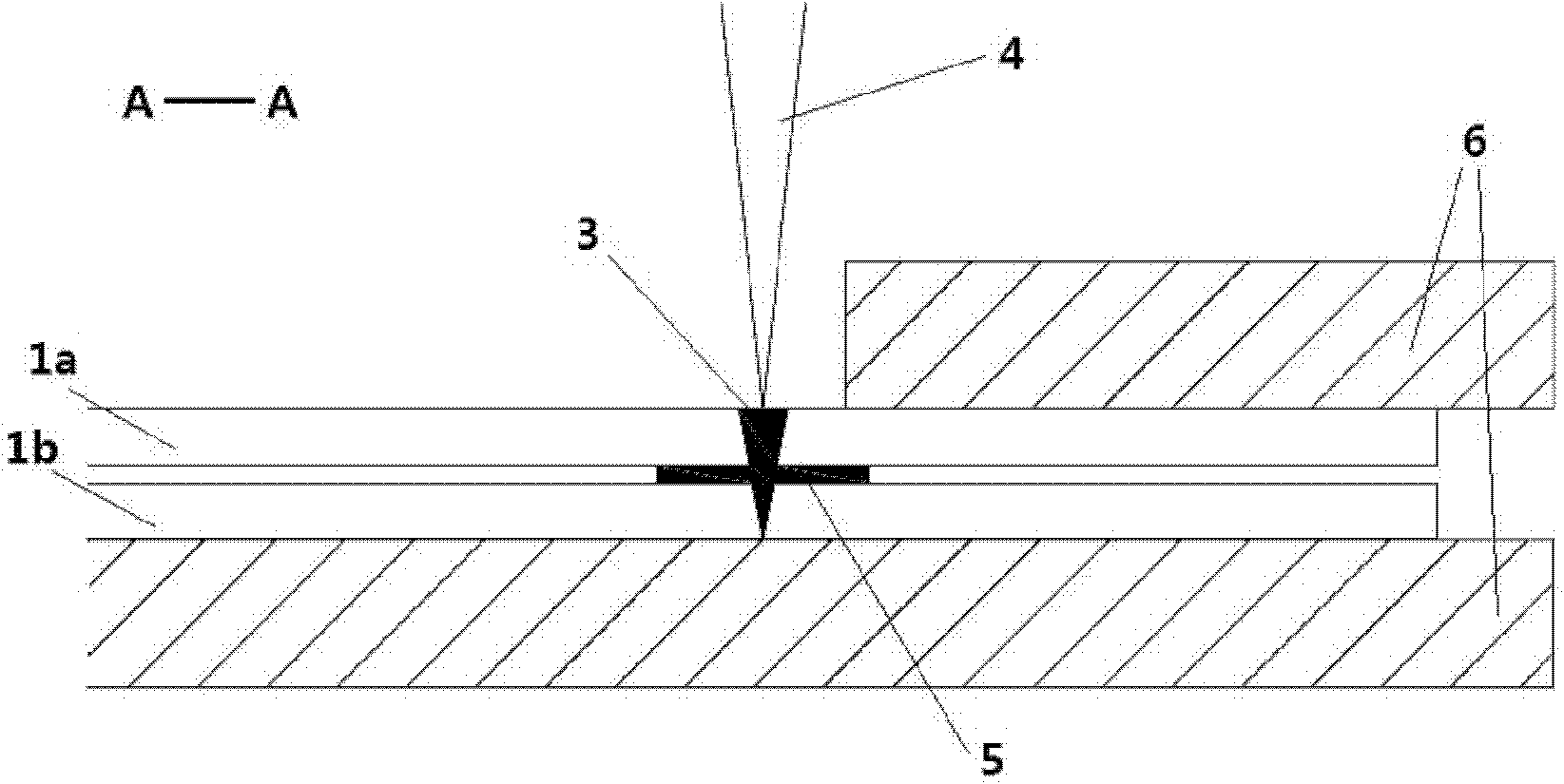

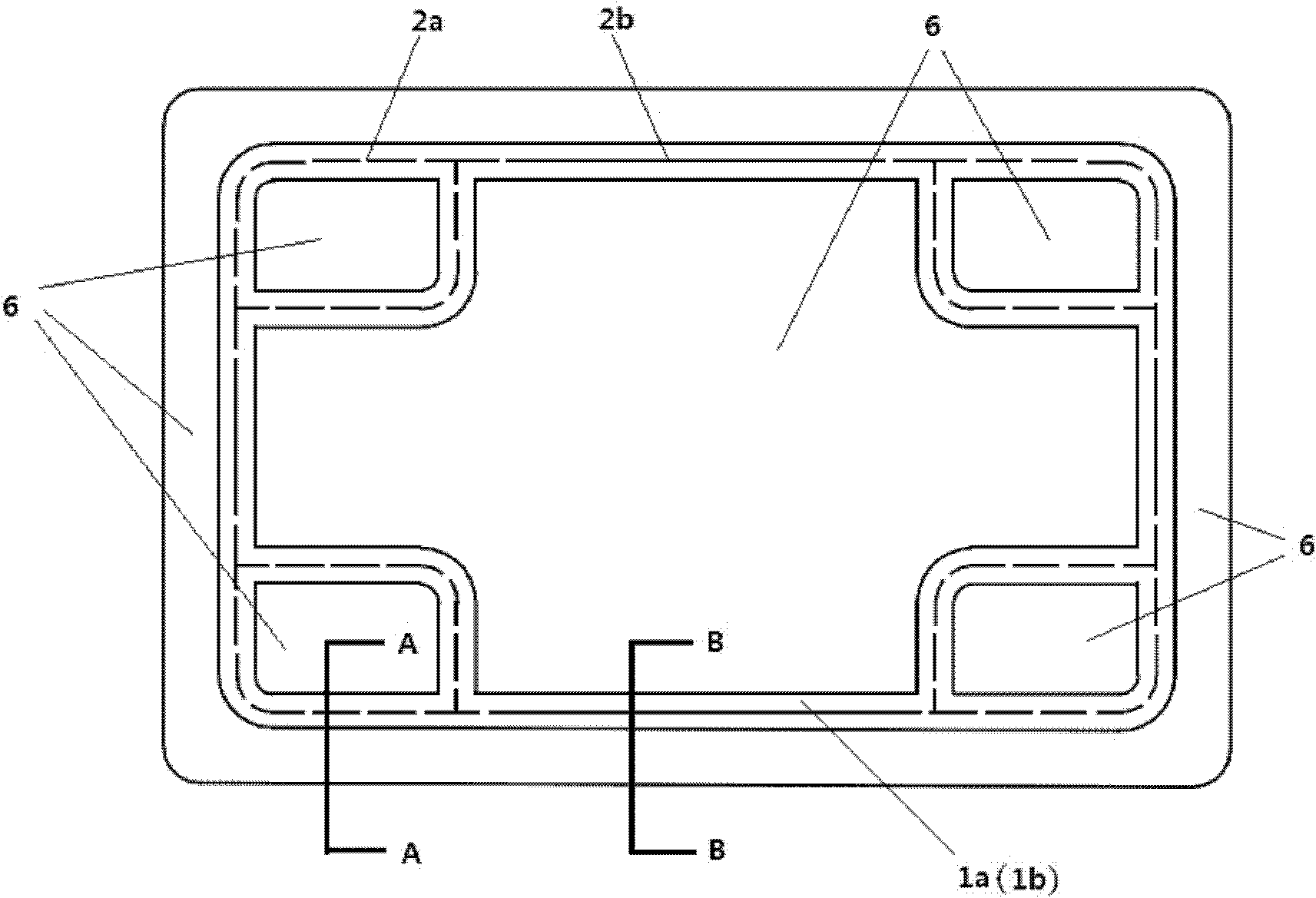

Laser weld-bonding method of bipolar plate of fuel cell

ActiveCN102581487AHigh mechanical strengthGood corrosion resistanceFinal product manufactureCell electrodesCorrosion resistantArc welding

The invention relates to a laser weld-bonding method of bipolar plates of a fuel cell. The method combines a bonding process and a laser welding process to connect the bipolar plates of the fuel cell, namely a normal-temperature curing adhesive is used to bond welding areas of the bipolar plates of the fuel cell, and then the laser welding is carried out to finish the connection of the bipolar plates of the fuel cell. Compared with the prior art, the laser weld-bonding method has the advantages that: because an adhesive bonding method is adopted to bond the bipolar plates of the fuel cell tightly, the phenomenas of sealing-off and welding seam breakage caused by assembling gaps in the laser welding are eliminated, the laser welding quality is improved, and the welding seam is high in mechanical strength and is corrosion resistant; a bond layer can evaporate rapidly under the high-heat input of a laser beam, the requirement of the bonding position is reduced; because the normal-temperature curing adhesive is adopted, the secondary heat input caused by high-temperature curing is avoided; and due to the introduction of the bonding process, the designs of a welding clamp, a welding path and welding parameters can be more flexible and simpler, so that the laser weld-bonding method is easy in large-scale production.

Owner:SHANGHAI JIAO TONG UNIV +3

Method for preparing dark green ceramic membrane by magnesium alloy differential arc oxidation

InactiveCN101302641ABroaden the field of applicationGood corrosion resistanceAnodisationMicro arc oxidationSodium silicate

The invention belongs to the magnesium alloy surface treatment technical field, mainly relating to the following steps that: colouring additive metal cation Cu<2+> undergoes ammonia water complexation so as to generate Cu(NH3)2<2+> which is added in alkaline basic electrolyte with sodium silicate as main salt; and electrical parameters adapted to the electrolyte are set to simultaneously carry out micro-arc oxidation and colouring of magnesium alloy, thereby making a series of bottle-green ceramic membranes with excellent corrosion resistance and stable color and luster. Different electrolytes have different coloring effects on a film, and the luster of an oxide film is mainly determined by the metal oxide formed in the oxide film and the structure of the salt of the metal oxide.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

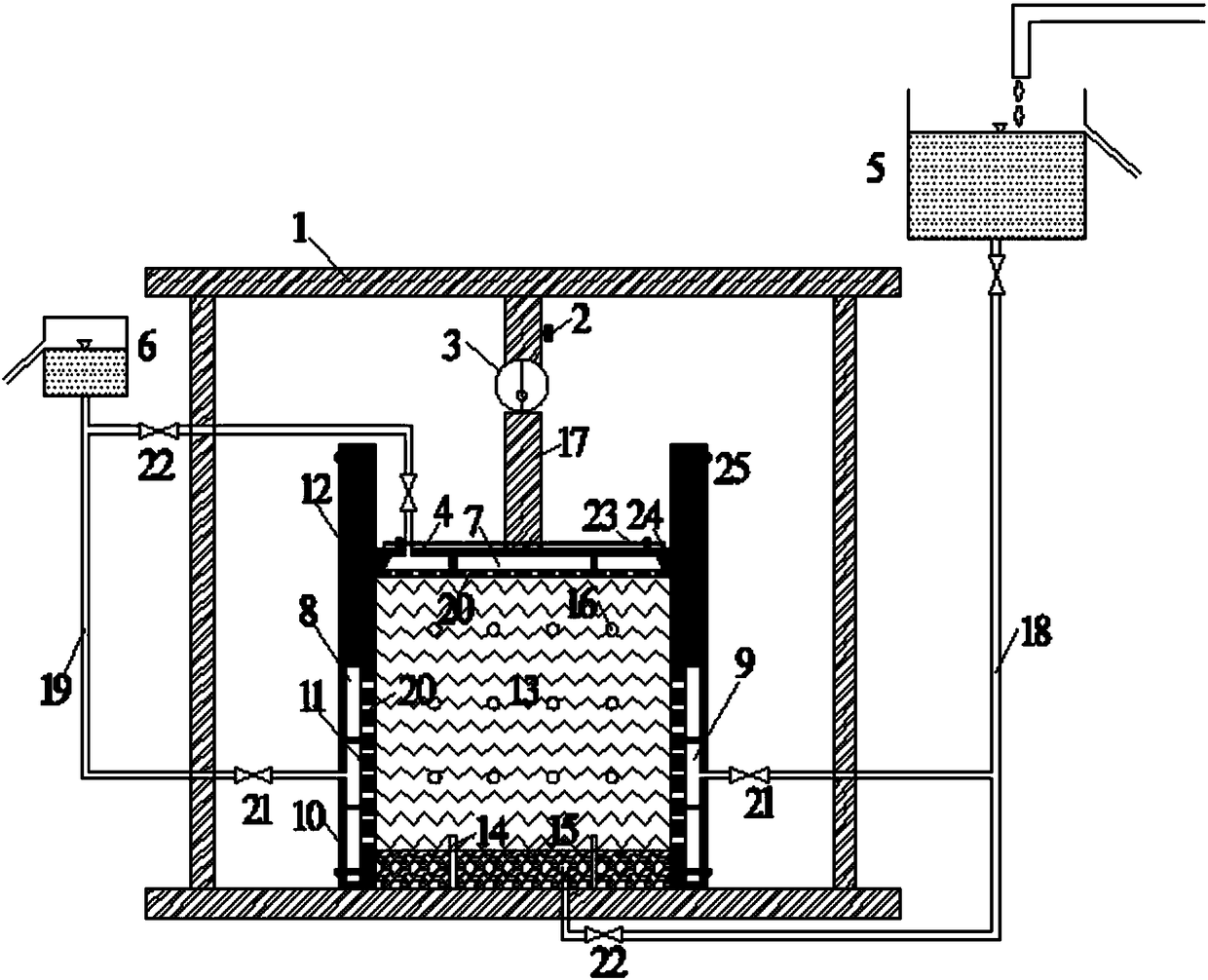

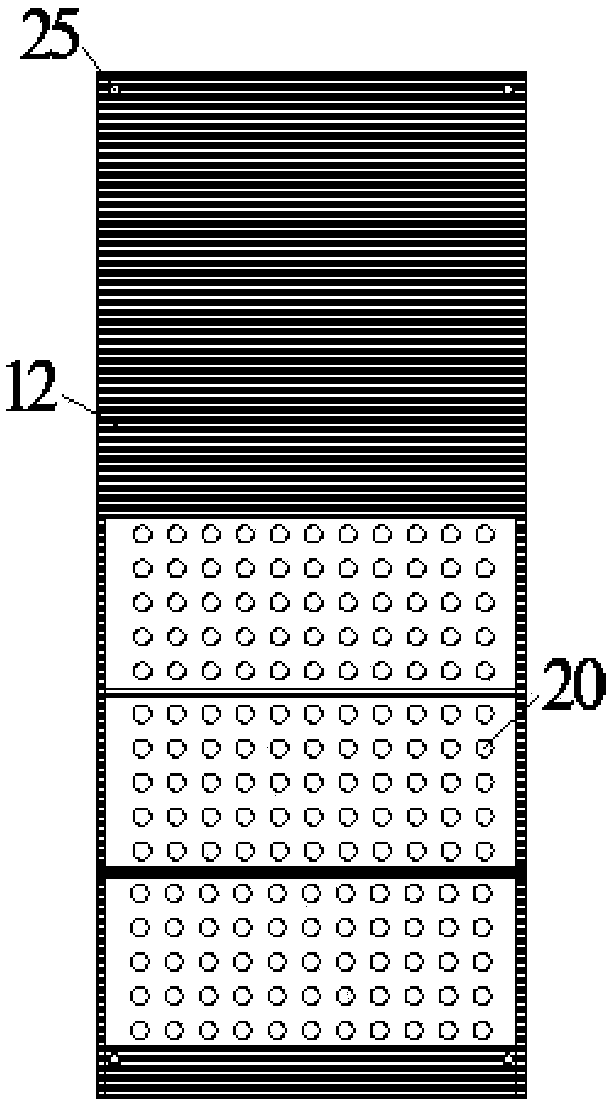

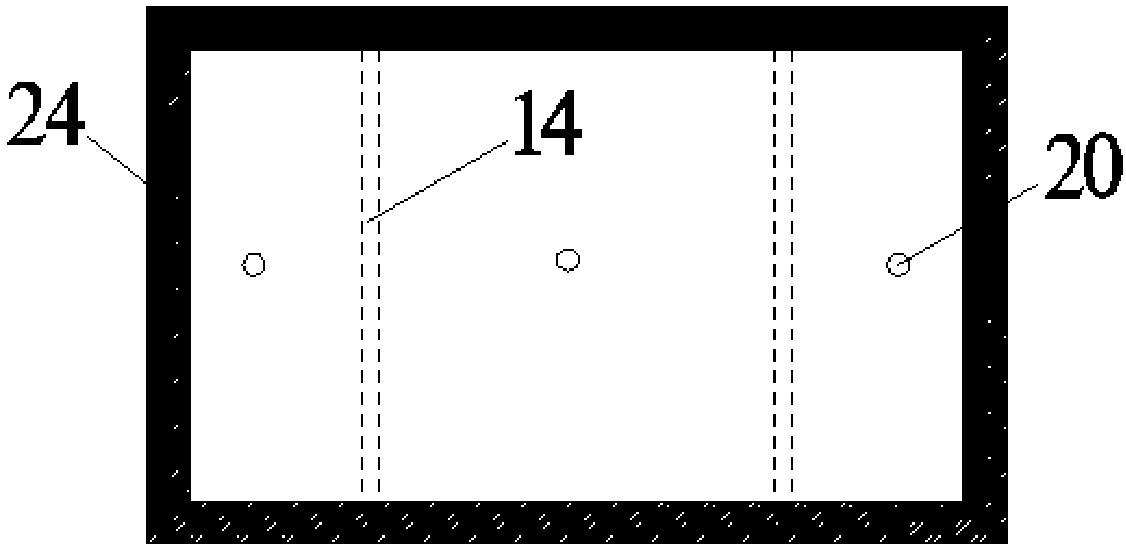

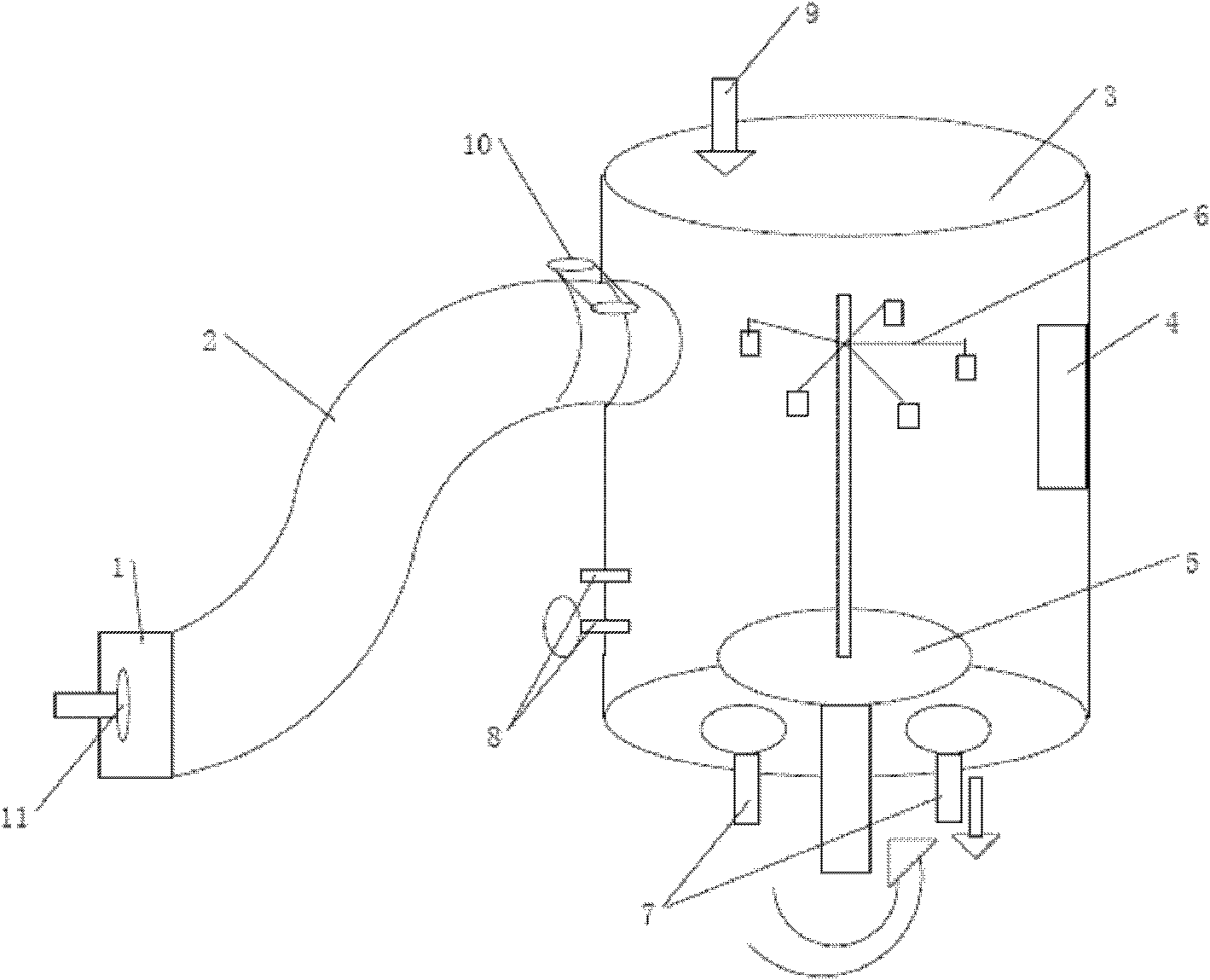

Test device for testing horizontal and vertical saturated infiltration coefficients of coarse-grained soil simultaneously indoors under different pressure

PendingCN108181220AAvoid randomnessGood corrosion resistancePermeability/surface area analysisWater supply networkWater storage tank

The invention discloses a test device for testing horizontal and vertical saturated infiltration coefficients of coarse-grained soil simultaneously indoors under different pressure. The device comprises a loading system, a water supply system, a soil sample chamber and a pressure measurement system, wherein the loading system comprises a reaction frame, a pressure adjusting valve, a gas-pressure meter and a double-layer loading plate; the double-layer loading plate is a hollow hexahedron and comprises an upper-layer porous plate, a lower-layer porous plate, a middle partition board and a sideinclined plate; the water supply system comprises a water supply tank, a water storage tank, a vertical water supply cavity formed by the double-layer loading plate, a left horizontal water supply cavity and a right horizontal water supply cavity; each of the left horizontal water supply cavity and the right horizontal water supply cavity is formed by an outer porous plate, an inner porous plate and a silicon base plate filling a gap between the two porous plates. The horizontal and vertical saturated infiltration coefficients of the same sample are simultaneously tested under different pressures, the test device is not required to be dismounted in the testing process, the test device is convenient to operate, and the testing efficiency and accuracy are greatly improved.

Owner:ZHEJIANG UNIV

Ferritic stainless steel for biofuel supply system part, biofuel supply system part, ferritic stainless steel for exhaust heat recovery unit, and exhaust heat recovery unit

ActiveUS20140069619A1Good corrosion resistancePart can be usedInternal combustion piston enginesRecuperative heat exchangersOxideWaste heat recovery unit

An aspect of a ferritic stainless steel contains, by mass %: C: 0.03% or less; N: 0.03% or less; Si: more than 0.1% to 1% or less; Mn: 0.02% to 1.2%; Cr: 15% to 23%; Al: 0.002% to 0.5%; and either one or both of Nb and Ti, with the remainder being Fe and unavoidable impurities, wherein Expression (1) and Expression (2) illustrated below are satisfied, an oxide film is formed on a surface thereof, and the oxide film contains Cr, Si, Nb, Ti and Al in a total cationic fraction of 30% or more,8(C+N)+0.03≦Nb+Ti≦0.6 (1)Si+Cr+Al+{Nb+Ti−8(C+N)}≧15.5 (2).

Owner:NIPPON STEEL STAINLESS STEEL CORP

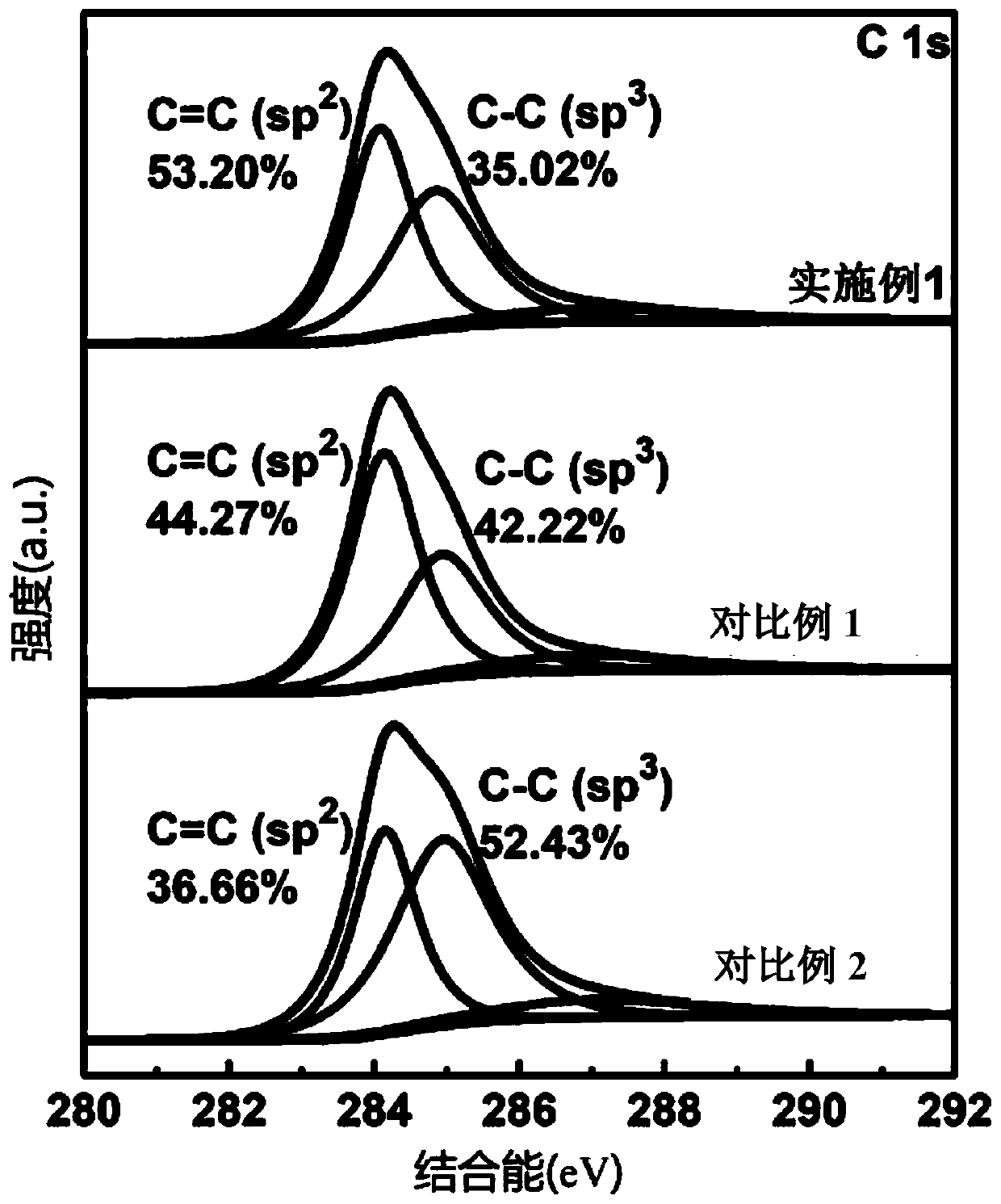

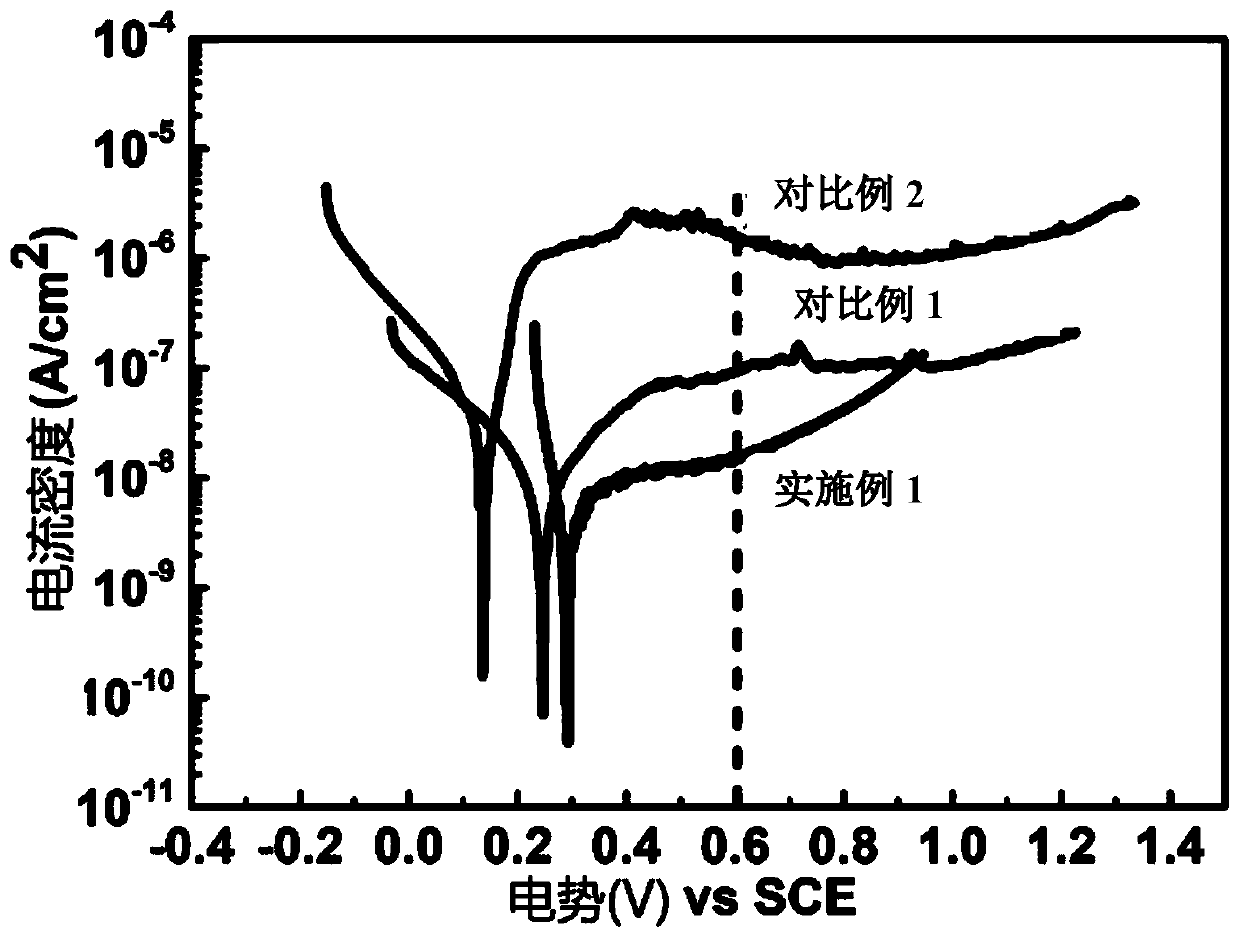

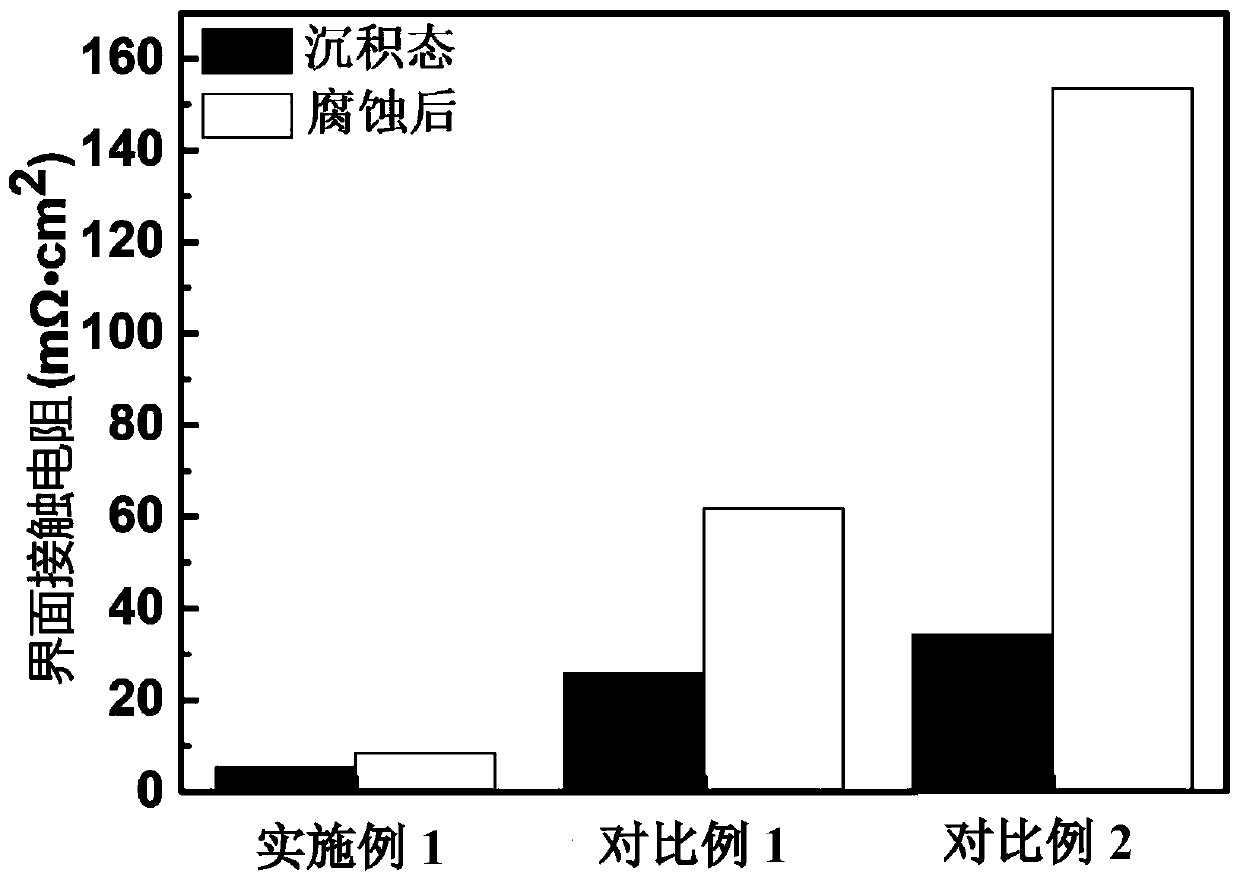

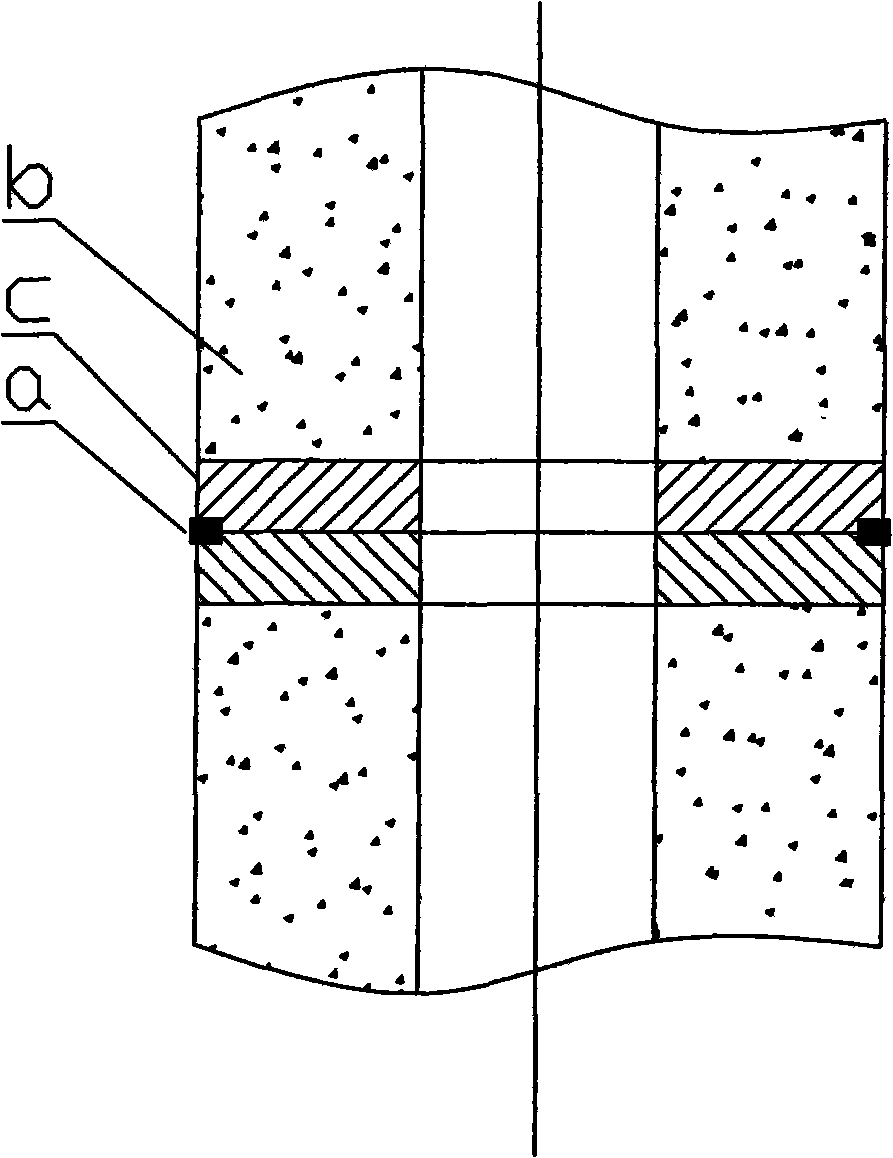

Metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and preparation method and application thereof

ActiveCN110684946ASmooth structureSmooth internal structure Dense structureVacuum evaporation coatingSputtering coatingCarbon layerFilm base

The invention discloses a metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer and a preparation method and application thereof. The preparation method of the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer comprises the following steps: with a chromium target as the target, a high-power pulse magnetron sputtering technology is adopted to deposit a chromium transition layer on the surface of a metal bipolar plate; with a graphite target as the target, a direct-current magnetron sputtering technology isadopted to deposit an amorphous carbon layer on the surface of the chromium transition layer to obtain the metal bipolar plate high-electric-conductivity and corrosion-resistance protective coating layer; and process conditions adopted by the direct-current magnetron sputtering technology comprises the sputtering source center magnetic field intensity of 40-60 mT, the edge magnetic field intensity of 10-20 mT and the power of 0.8-1.0 kW. The provided chromium transition layer is smooth in surface and compact in internal structure, and can effectively improve the film base bonding strength; and meanwhile, through optimization of an amorphous carbon layer preparation process, the amorphous carbon layer achieves excellent electric conductivity and corrosion resistance, and can permanently and effectively protect the metal bipolar plate.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Anti-corrosive pre-stressed concrete pipe pile foundation

ActiveCN101581095AReduce C

<sub>3</sub>

A contentImprove performanceCement productionBulkheads/pilesSlagPre stress

The invention relates to an anti-corrosive pre-stressed concrete pipe pile foundation, which is characterized in that the cementing material adopted by the concrete for preparing the pipe pile body is a granular micro-powder material with different varieties and fineness; and a cascaded matching method is adopted for matching. The anti-corrosive pre-stressed concrete pipe pile foundation has the obvious advantages of (1) needing not to change the production process of the pipe pile or increase the manufacture equipment, obviously improving the impermeability and sulfate resistance of the concrete, and leading the anti-corrosive effect to be better and more durable; and (2) utilizing the waste slag raw material and being cheaper than the method of coating and the method of permeation and rust retardant agent.

Owner:FUJIAN DADI CONCRETE PILE

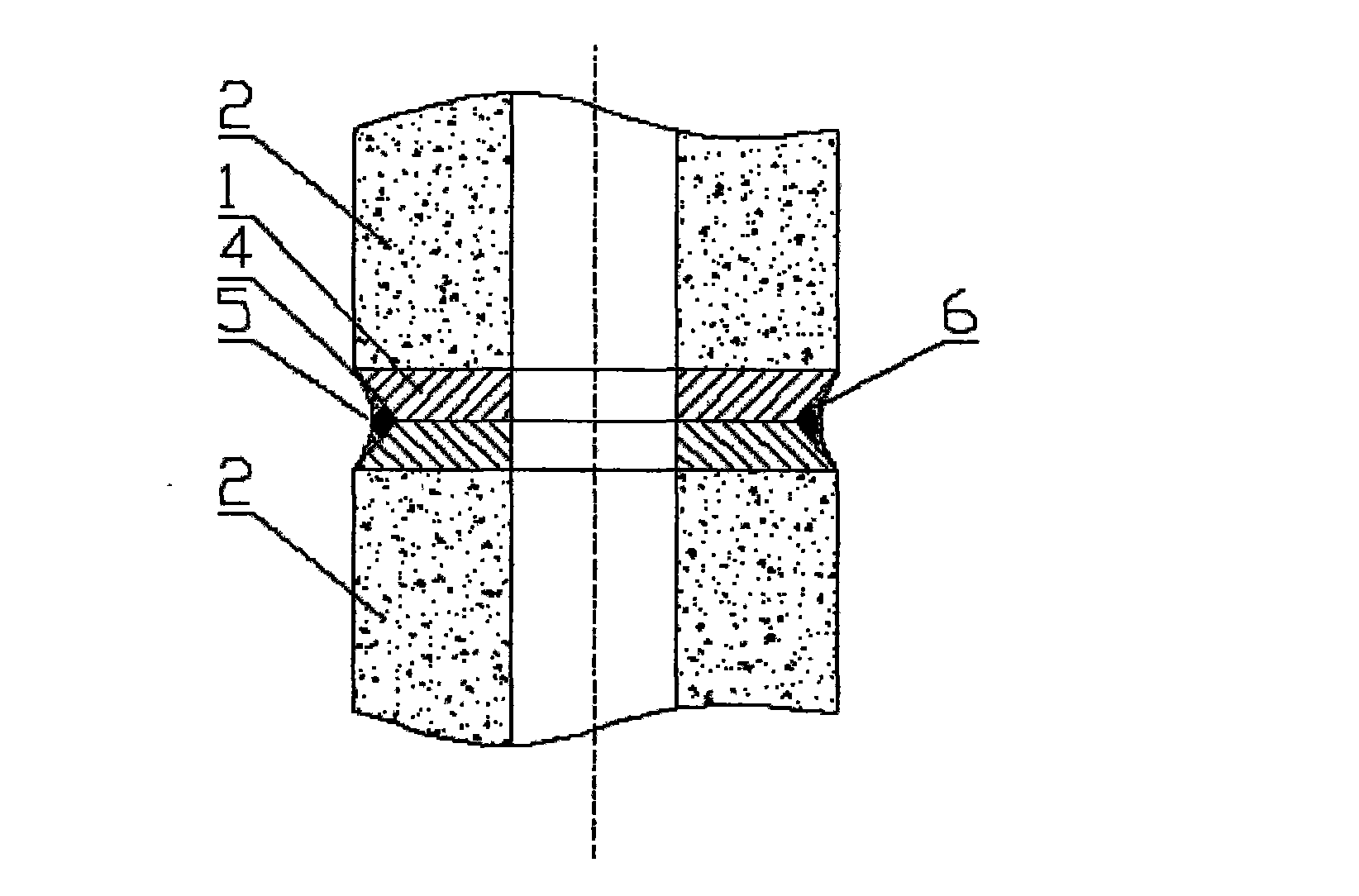

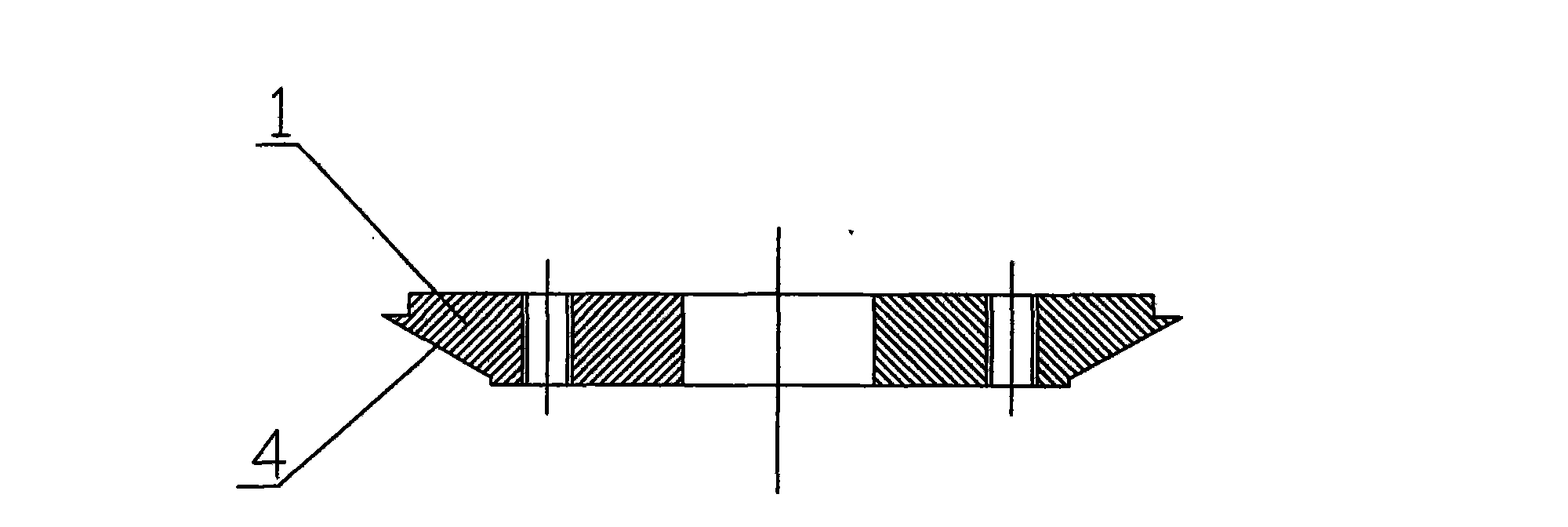

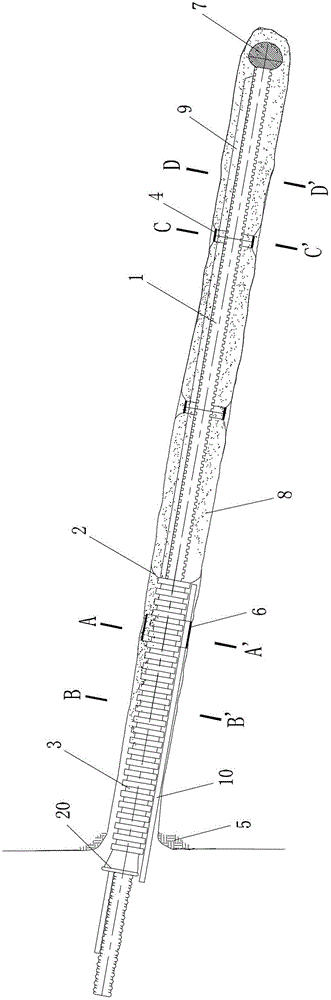

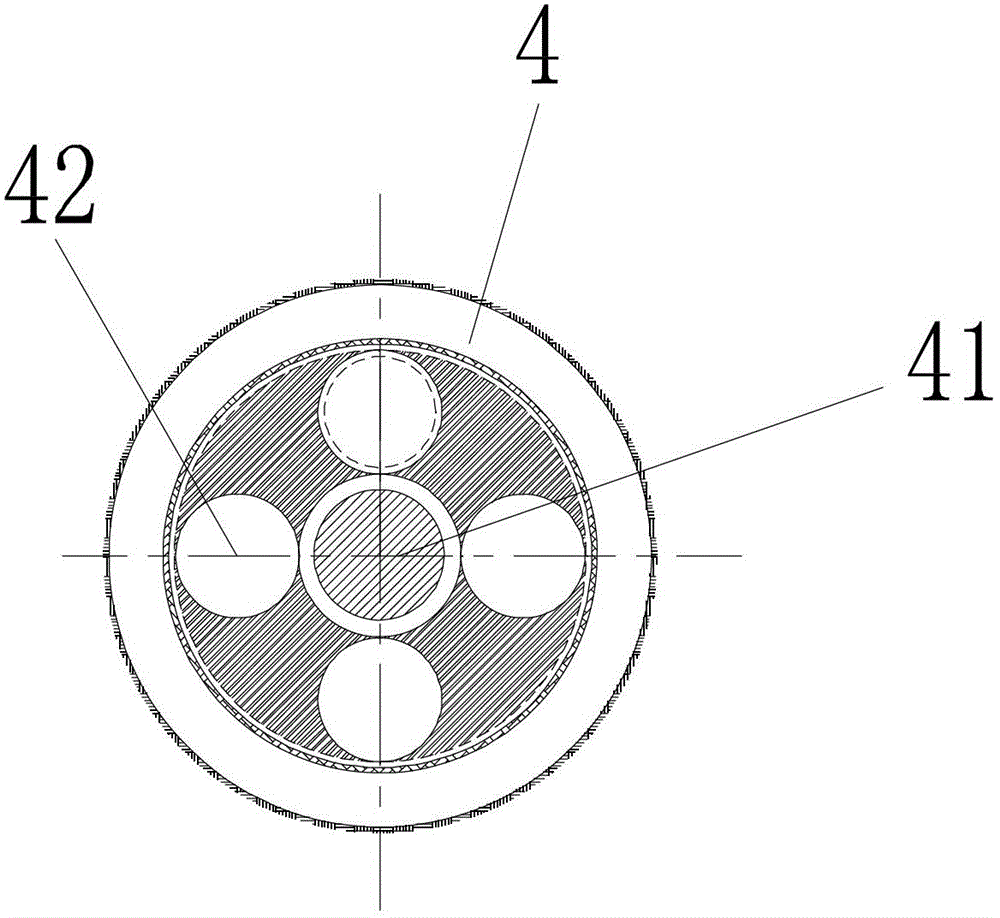

Anticorrosive anchor rod capable of preventing slurry from leaking

ActiveCN102720196AImprove burst strengthGuaranteed filling compactness requirementsProtective foundationBulkheads/pilesInjection pressureArchitectural engineering

The invention discloses an anticorrosive anchor rod capable of preventing slurry from leaking. The anchor rod comprises a rod body, wherein the rod body is sleeved with a sleeve bag; one end of the rod body is extended out of a sleeve bag opening, and an area section of the rod body, which is inserted into a drill hole, is packaged by the sleeve bag; and a sleeve pipe is sleeved on the sleeve bag and is positioned on one side of the sleeve bag close to the sleeve bag opening. The slurry is compactly injected into the sleeve bag on an anchoring section, so that the filling compaction requirement of the anchoring section of the anchor rod can be met, all-around overflow of cement slurry on the anchoring section under the action of slurry injection pressure is prevented, and the control over slurry injection project amount and the economization of construction cost are facilitated; a free section of the anchor rod is protected by a corrugated sleeve, so that the free section can pass through an orifice to crush a rock-soil area, the reduction in severe slurry leakage risks of the anchor rod in a rock-soil crushing area is facilitated while the thickness of a steel bar concrete slurry protective layer is ensured, and the economization of the construction cost is facilitated; and simultaneously, the free section is subjected to secondary slurry injection, so that the free section of the anchor rod can be provided with a plurality of anticorrosive structural layers, and the anchor rod is high in corrosion resistance.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

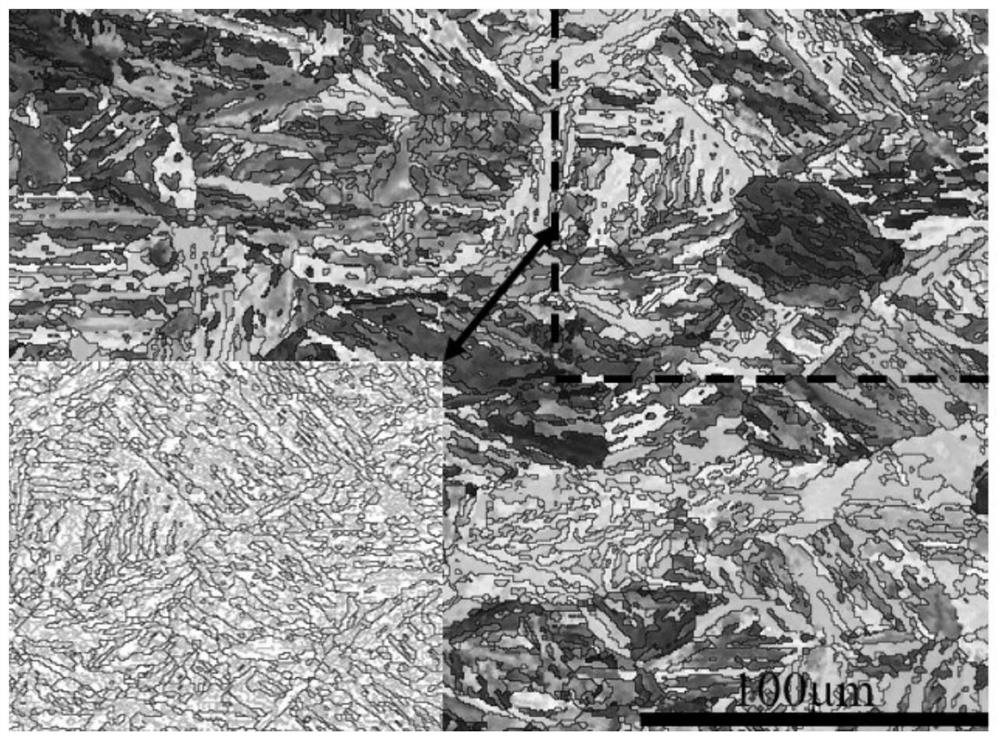

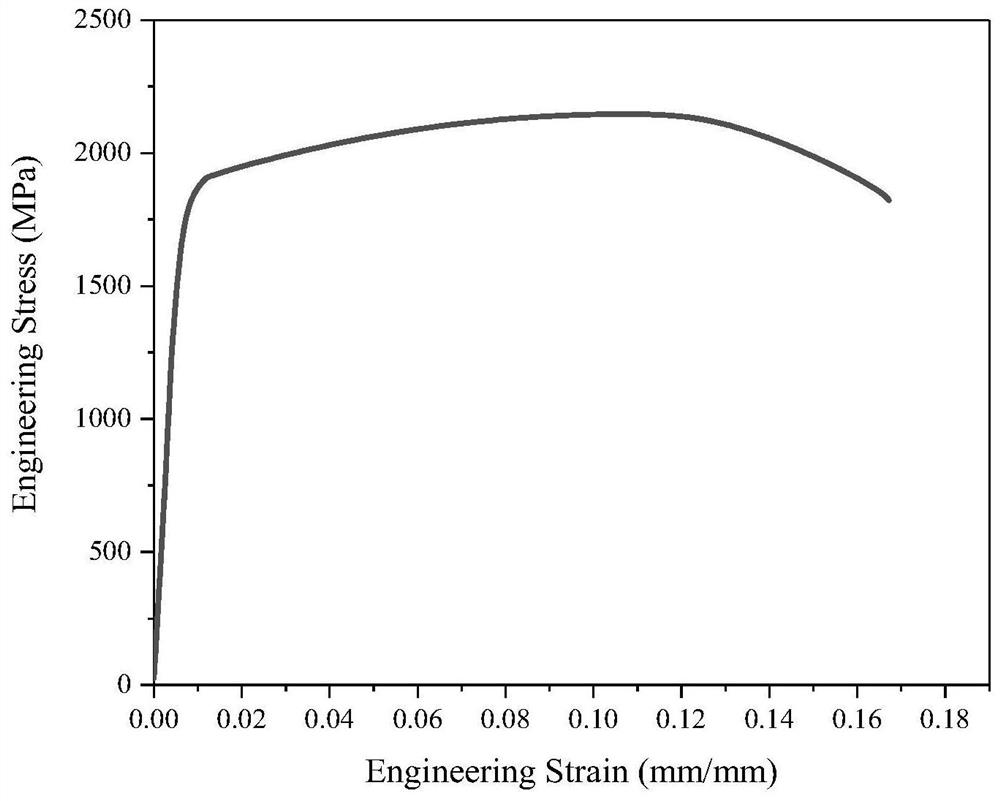

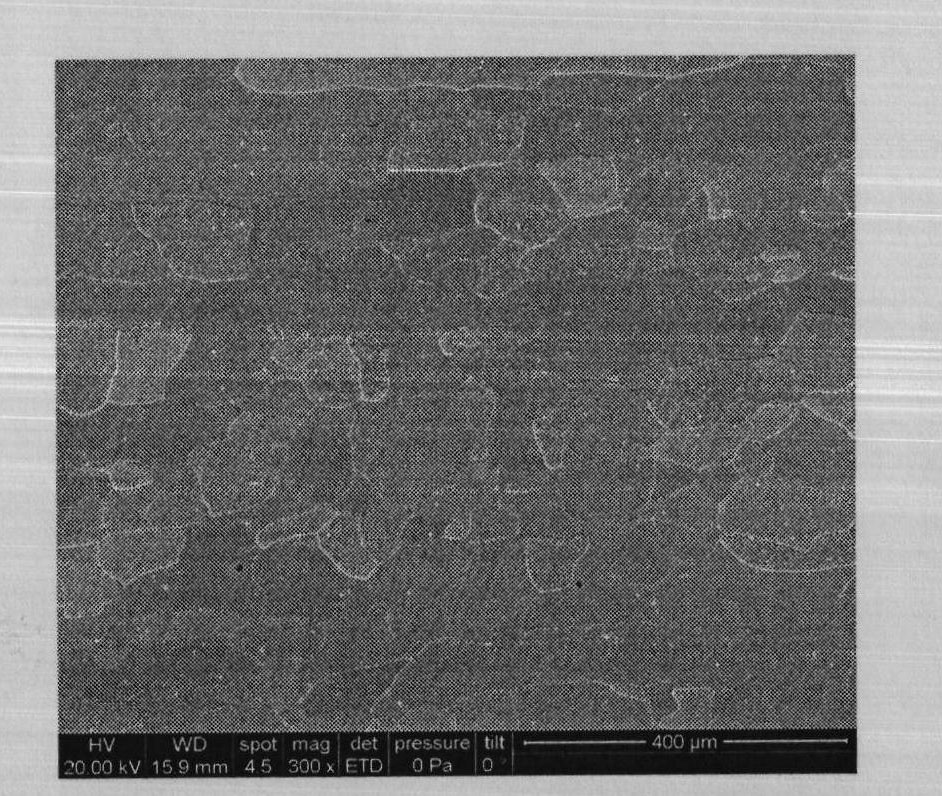

Stainless steel with low cost, high strength and high corrosion resistance and preparation method thereof

PendingCN113046642AGood corrosion resistanceGood mechanical propertiesMetal-working apparatusProcess efficiency improvementCorrosion resistantDuctility

The invention provides stainless steel with low cost, high strength and high corrosion resistance and a preparation method thereof. The stainless steel comprises the following components of, in percentage by mass, 1.0%-6.0% of Co, 6.0%-9.0% of Ni, 9.0%-14.0% of Cr, 0.3%-1.5% of Ti, 4.0% to 7.0% of Mo, 0.08%-1.0% of Mn, 0.08%-0.2% of Si, less than or equal to 0.05% of C, less than or equal to 0.035% of P, less than or equal to 0.030% of S and the balance Fe. The method comprises the following steps of smelting and casting stainless steel; forging or hot rolling cogging; and heat treatment. The tensile strength of the stainless steel can reach 2150 MPa or above, the ductility of the stainless steel is 17% or above, and the spot corrosion potential Epit of the stainless steel is greater than 0.36 VSCE; and the stainless steel with low cost, high strength and high corrosion resistance can be used for key structures of ships, oceanographic engineering, aerospace engineering and the like.

Owner:HARBIN ENG UNIV

Ferritic stainless steel and method for manufacturing same

The invention relates to a ferritic stainless steel which comprises the following chemical components in percent by weight: 0.001-0.025% of C, less than1.0% of Si, less than 1.0% of Mn, less than 0.03% of P, less than 0.010% of S, 17-20% of Cr, 1.70-2.00% of Mo, less than 0.02% of Al, 0.005-0.025% of N, less than 0.0100% of O, less than 0.2% of Nb, 0.10-0.15% of V, less than 0.5% of Ni and the balance of Fe and inevitable impurities. A method for manufacturing the ferritic stainless steel comprises the following steps: smelting by using a vacuum induction furnace, or by using an electric arc furnace through external refining or by using a converter through external refining; continuously casting, wherein the degree of superheat is controlled at 30-50 DEG C, and the slab pulling speed is controlled at 0.8-2m / min; pouring at 1,580-1,600 DEG C; heating the continuously-cast billet to 1,050-1,100 DEG C, and hot rolling, wherein the finish rolling temperature is 800-900 DEG C, and the hot rolling reduction is more that 90%; cooling in air; continuously annealing the hot-rolled strip steel, and pickling, wherein the annealing temperature is 950-1,050 DEG C, the temperature is preserved for 1-1.5t min, and the t represents the thickness (mm) of the strip steel. The ferritic stainless steel has excellent impact toughness, corrosion resistance and mechanical properties.

Owner:BAOSHAN IRON & STEEL CO LTD

Zirconium-tin-niobium corrosion-resistant zirconium-base alloy for nuclear fuel cans

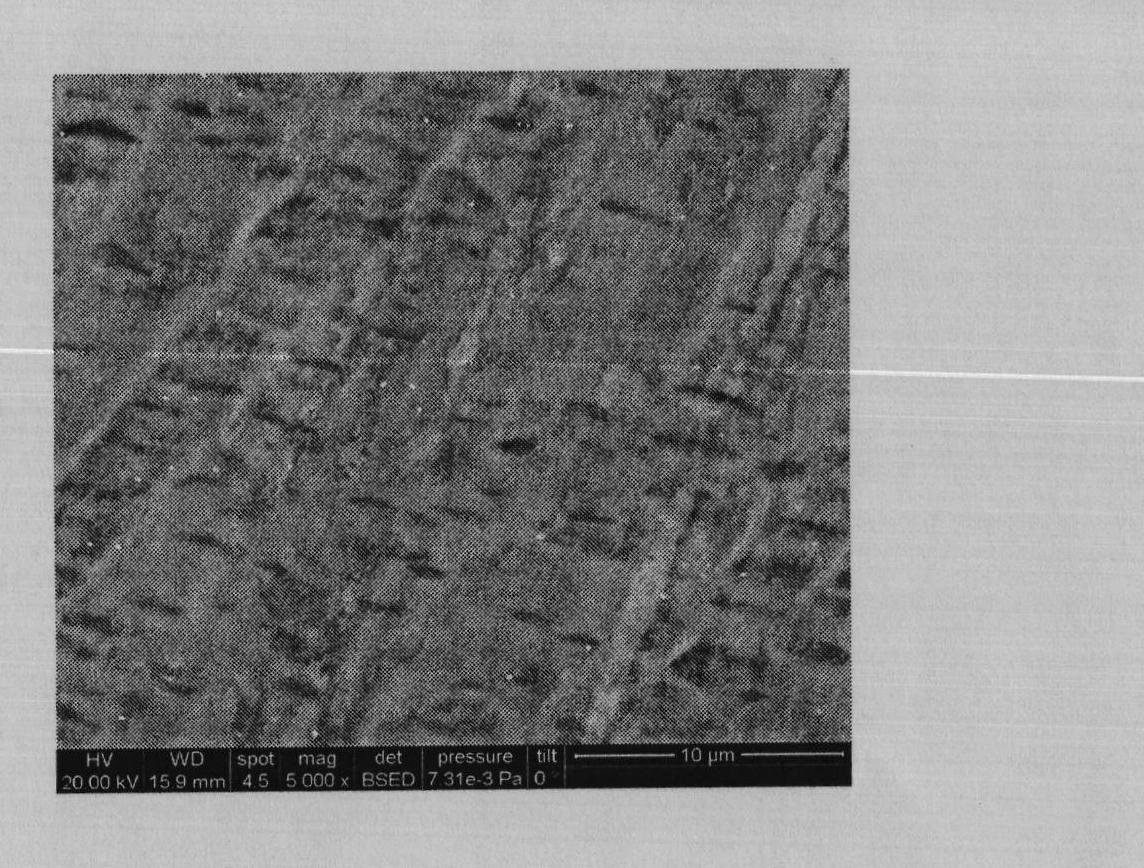

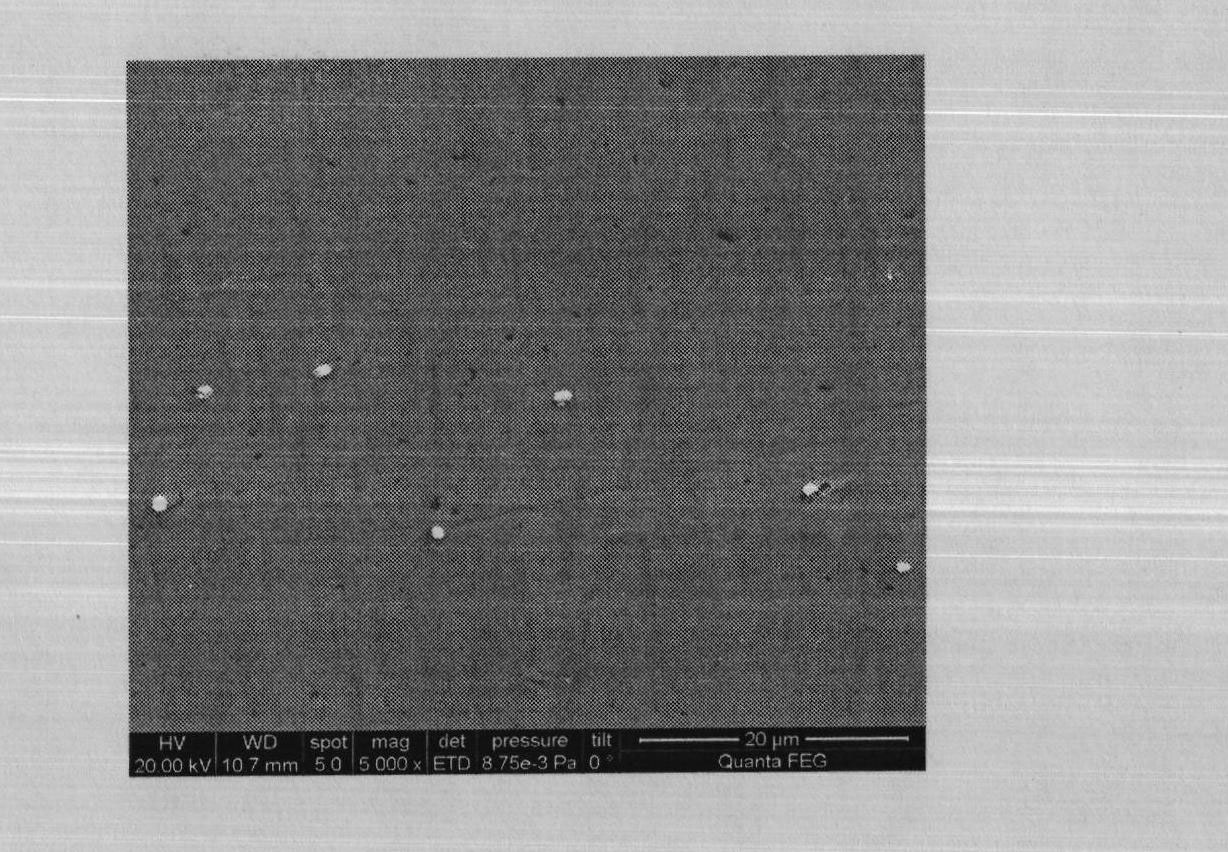

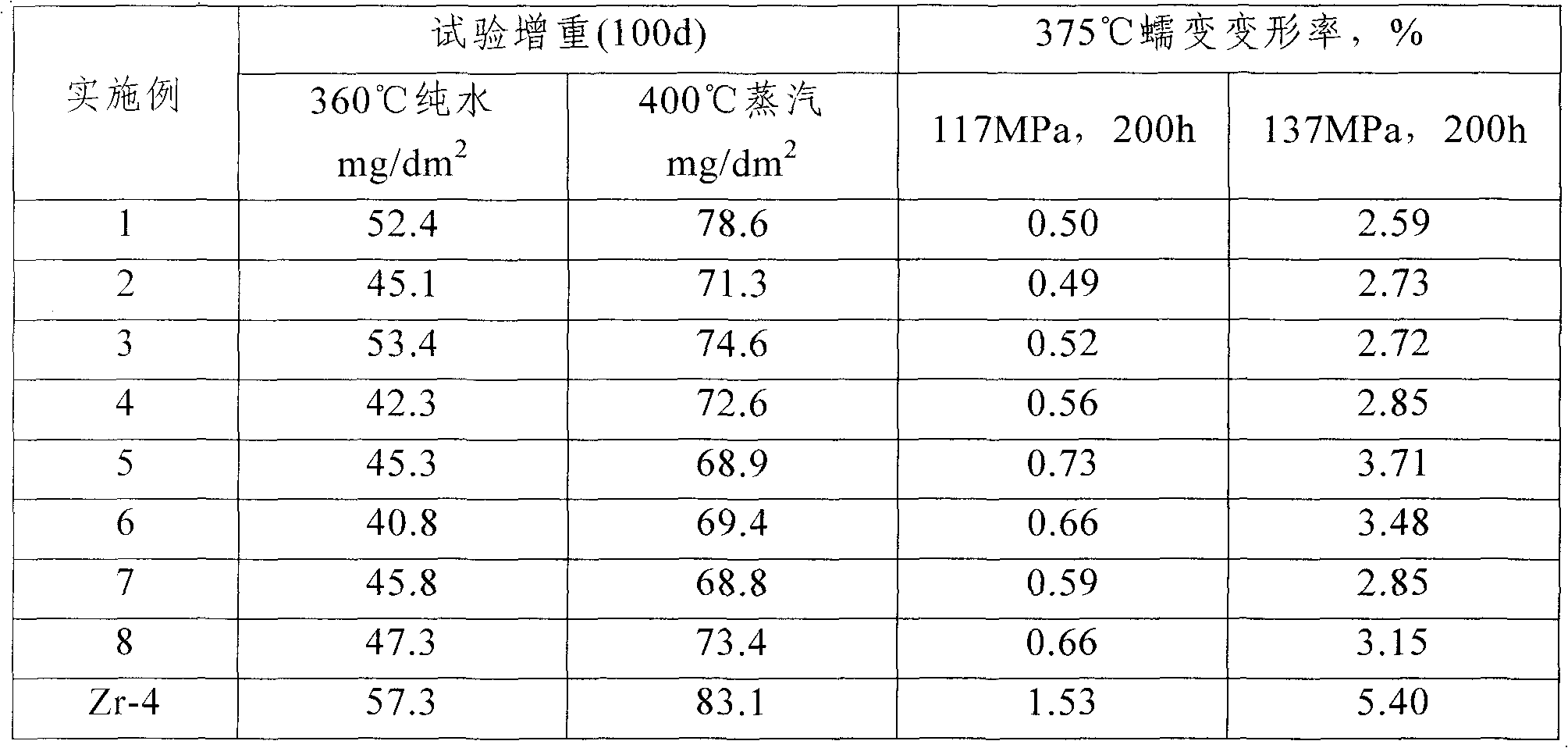

ActiveCN101805842AGood creep resistanceGood corrosion resistanceOptical rangefindersNuclear energy generationCorrosion resistantNiobium

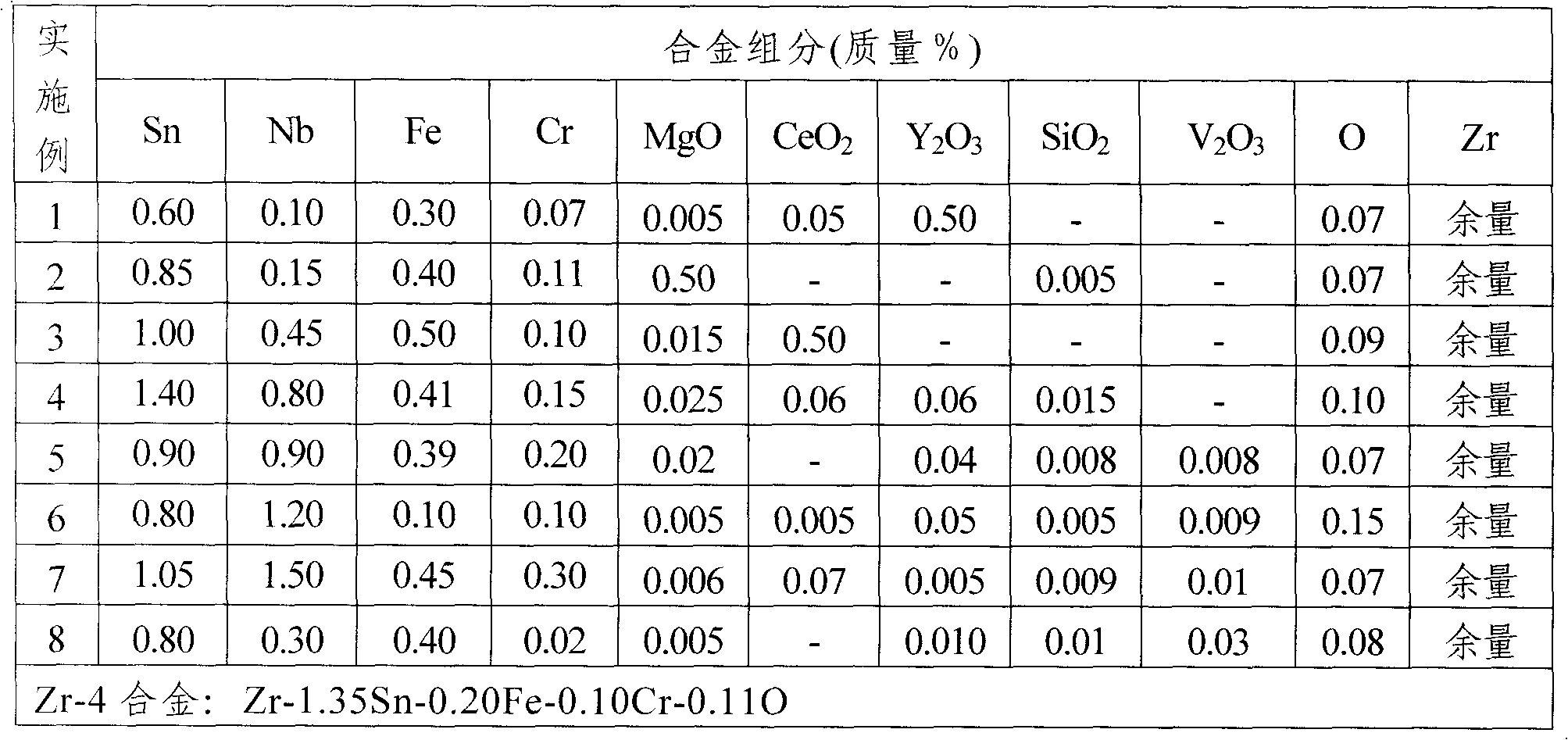

The invention discloses a zirconium-tin-niobium corrosion-resistant zirconium-base alloy for nuclear fuel cans, which comprises the following components in percentage by mass: 0.6-1.4% of Sn, 0.10-1.5% of Nb, 0.1-0.5% of Fe, 0.02-0.3% of Cr, 0.005-0.5% of MgO, 0-0.5% of CeO2, 0-0.5% of Y2O3, 0-0.015% of SiO2, 0-0.03% of V2O3, 0.07-0.15% of O, and balance of Zr and inevitable impurities. Compared with the prior Zr-4 alloy, the zirconium-base alloy of the invention has better high temperature creep resistance and excellent corrosion resistance, and is suitable for can materials, grids and other structural members for reactor fuel rods in a nuclear power station.

Owner:西安西部新锆科技股份有限公司

Hard resin lens and organic glass lens surface ultra-hard coat coating method

InactiveCN101806928AReduce the impactGood light transmissionVacuum evaporation coatingSputtering coatingCarbon filmCarbon ion

The invention discloses a hard resin lens and organic glass lens surface ultra-hard coat coating method, which comprises the following steps that: an amorphous tetrahedral carbon film is formed on the surface of the lens through pretreatment, glow discharge cleaning, electric arc discharge and carbon ion precipitation, the film has good light transmission and good corrosion resistance, the abrasion resistance of the coated lens is remarkably improved compared with that of the non-coated lens, the coherence force between the amorphous tetrahedral carbon film and the resin and organic glass substrate is strong, the film is difficult to drop of, and the ultraviolet light test indicates that the ultraviolet transmission rate can be effectively reduced by the coat; and the hardness of the coated lens which is prepared with the method can reach more than 85 GPa, the SP3 key structure content in the coat is more than or equal to 85 percent, the friction coefficient is small, the abrasion resistant time is long, and the abrasion resistance is greatly improved.

Owner:XI AN JIAOTONG UNIV

Two-phase stainless steel alloy and preparation method thereof

The invention discloses a two-phase stainless steel alloy and a preparation method thereof. The two-phase stainless steel alloy is composed of the following chemical components in percentage by mass: 0.01-0.03 percent of C, 0.1-2.0 percent of Si, 1.0-3.0 percent of Mn, 20-22 percent of Cr, 1.7-2.5 percent of Ni, 0.7-1.0 percent of Cu, 0.1-0.2 percent of N, 0.2-1.0 percent of W, as well as Fe and unavoidable impurity elements in balancing amount. According to the invention, the two-phase stainless steel has good performance of mechanics, hot working performance and high corrosion resistance, and can be manufactured by the prior art. The adopted low-cost N and Mn substitute Ni to stabilize the Austenite phase of the two-phase stainless steel, and the low-cost W substitutes Mo, so that the cost is lowered; and meanwhile, the lower content of the element M is controlled via reasonably regulating the mixture ratio of the elements Ni, N and Mn, a situation that low-melting-point sulphides exist at a phase boundary is avoided, and the hot working performance of the two-phase stainless steel is effectively ameliorated.

Owner:ZHEJIANG UNIV +1

Preparation method of ZrO2/Al2O3 composite membrane on surfaces of aluminium and aluminium alloy

InactiveCN103074660AImprove corrosion resistanceGood corrosion resistanceAnodisationElectrolytic inorganic material coatingMicro arc oxidationWater soluble

The invention provides a preparation method of a ZrO2 / Al2O3 composite membrane on surfaces of aluminium and aluminium alloy. The method comprises the following steps that 1, water-soluble zircon salt, sodium dihydrogen phosphate, glycerol, disodium edetate, sodium citrate and deionized water are mixed; a zircon salt system solution is prepared; and 2, the zircon salt system solution is placed in a microarc oxidation treatment tank as a microarc oxidation electrolyte; aluminium or an aluminium alloy serves as an anode; a stainless steel plate serves as a cathode; microarc oxidation treatment is conducted; and then the uniform and dense ZrO2 / Al2O3 composite membrane is obtained on the surface of aluminium or the aluminium alloy. The ZrO2 / Al2O3 composite ceramic membrane prepared by the method has neutral NaCl salt mist corrosion resistance above 500h, and microhardness above 950Hv. The method has no special requirements on materials, shapes, dimensions and the like of aluminium or the aluminium alloy, and has wide applicability.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com