Laser weld-bonding method of bipolar plate of fuel cell

A fuel cell and bipolar plate technology, applied to fuel cell parts, battery electrodes, laser welding equipment, etc., can solve the problems of complex vacuuming process, low production efficiency, high production cost, etc., and achieve poor corrosion resistance, connection The effect of high reliability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

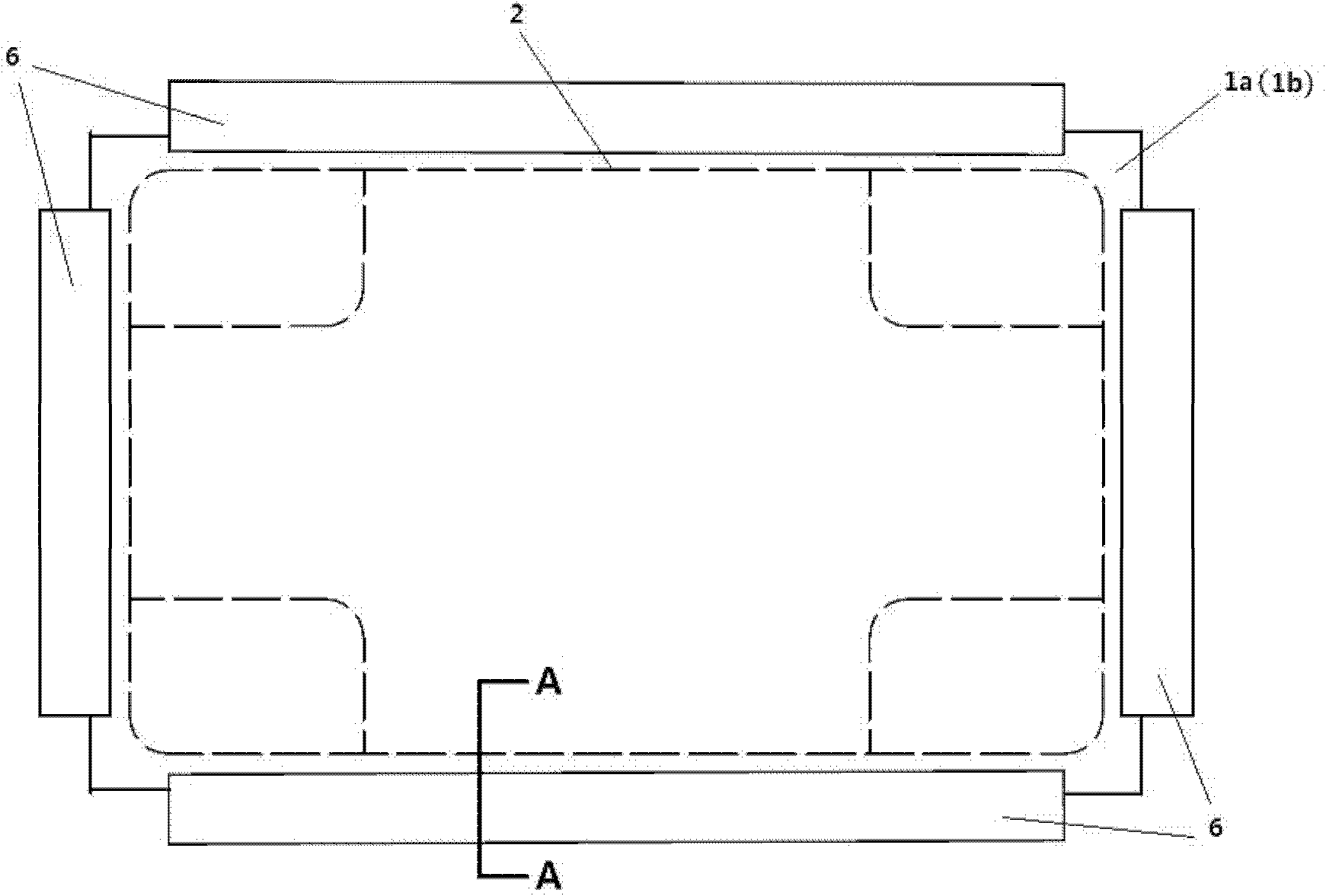

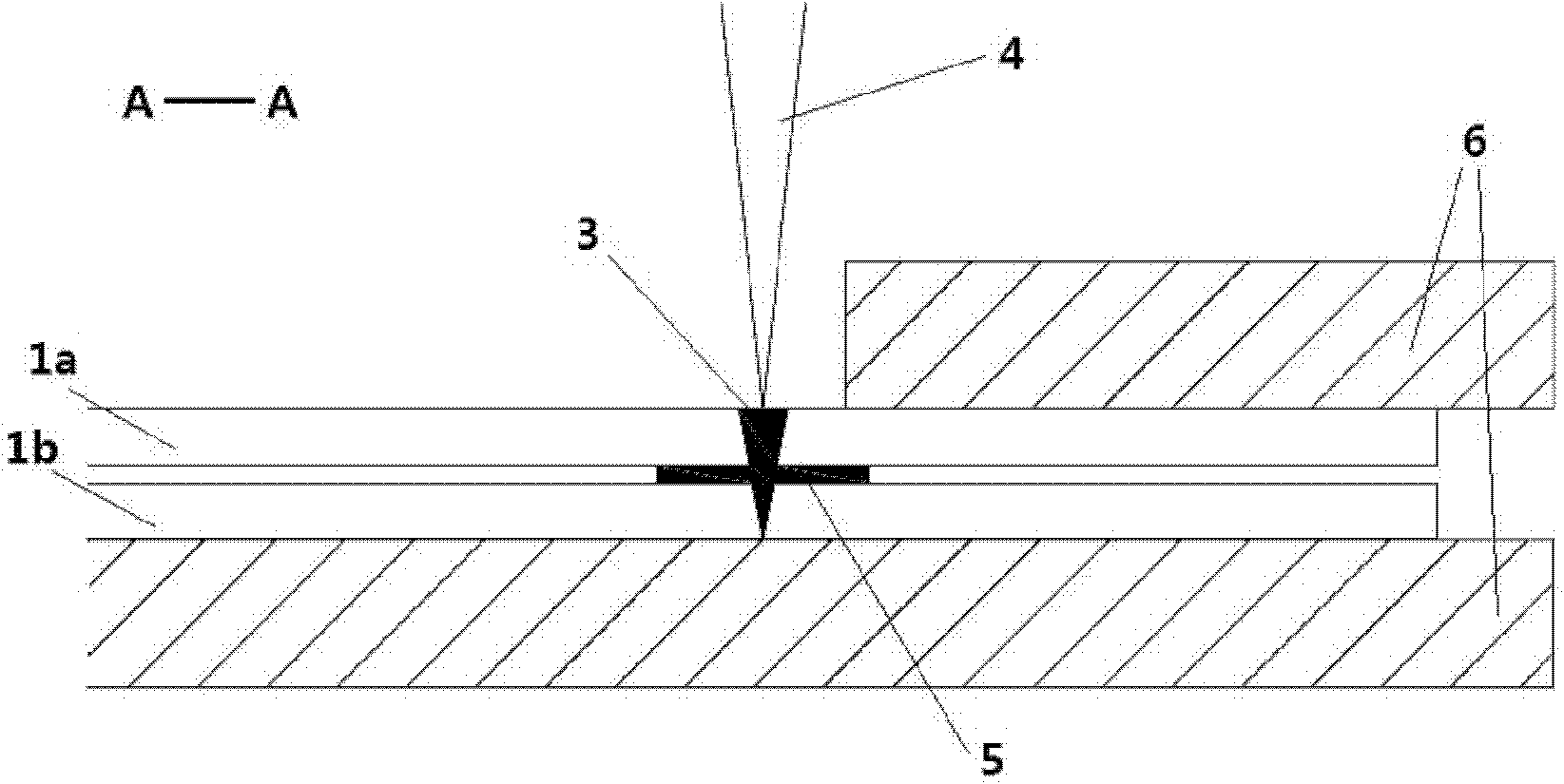

[0027] Such as Figure 1-2 As shown, a fuel cell thin metal bipolar plate includes a metal unipolar plate 1a, a metal unipolar plate 1b, a welding path 2 and a welding joint 3, wherein the welding path 2 is based on the fuel cell metal bipolar plate Sealing requires a designed heat source moving track, and the welded joint 3 is a lapped joint of double-layer metal sheets.

[0028] The specific working process of the laser glue welding method of the thin metal bipolar plate of the fuel cell is as follows: firstly, the normal temperature curing glue is applied to the welding path 2 on the contact surface of the metal unipolar plate 1a and the metal unipolar plate 1b to form a glue layer 5. The width of the adhesive layer 5 is 0.5mm, and the thickness of the adhesive layer is 0.05mm; then, the metal unipolar plate 1a and the metal unipolar plate 1b are positioned and pressed tightly with the welding fixture 6; the heat source 4 is welded by laser welding, and formed at one time. ...

Embodiment 2

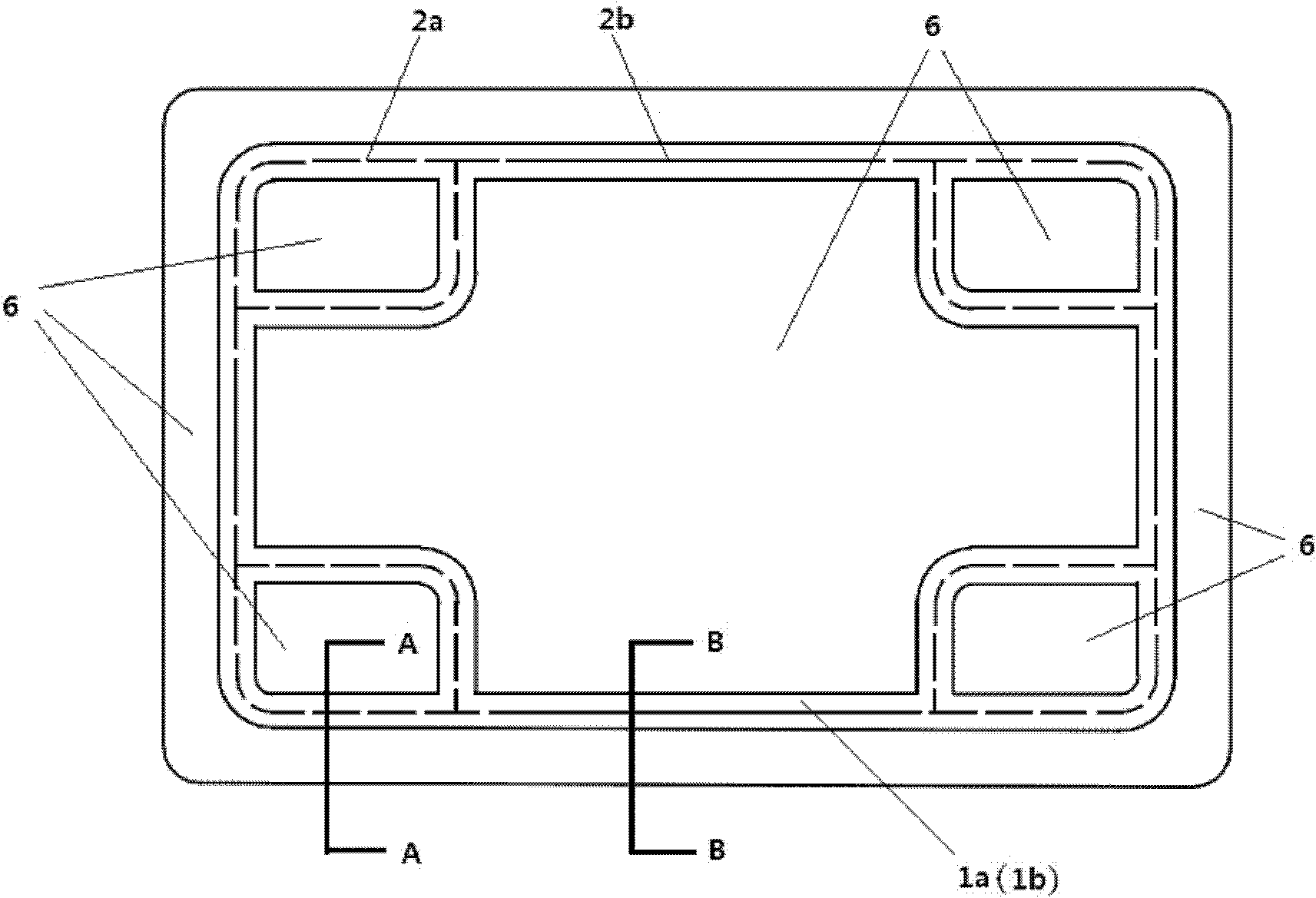

[0032] Such as Figure 3-5 As shown, a fuel cell thin metal bipolar plate includes a metal unipolar plate 1a, a metal unipolar plate 1b, a welding path 2a, a welding path 2b and a welding joint 3, wherein the welding path 2a is based on the fuel cell metal Bipolar plate sealing requires a designed heat source movement track, and glue coating on the welding path. The welding path 2a is often on the welding path, the intersection area of multiple paths, the area where the path turns sharply, the area where the clamping force is unevenly distributed, and the adjacent welding fixture has a worn welding path, but it is not limited to the above areas; Welding path 2b is a heat source movement track designed according to the sealing requirements of fuel cell metal bipolar plates, and the welding path is not coated with glue; welding joint 3 is a lap joint of double-layer metal thin plates.

[0033] The specific working process of the laser glue welding method of the thin metal bip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com