Patents

Literature

41results about How to "Poor corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

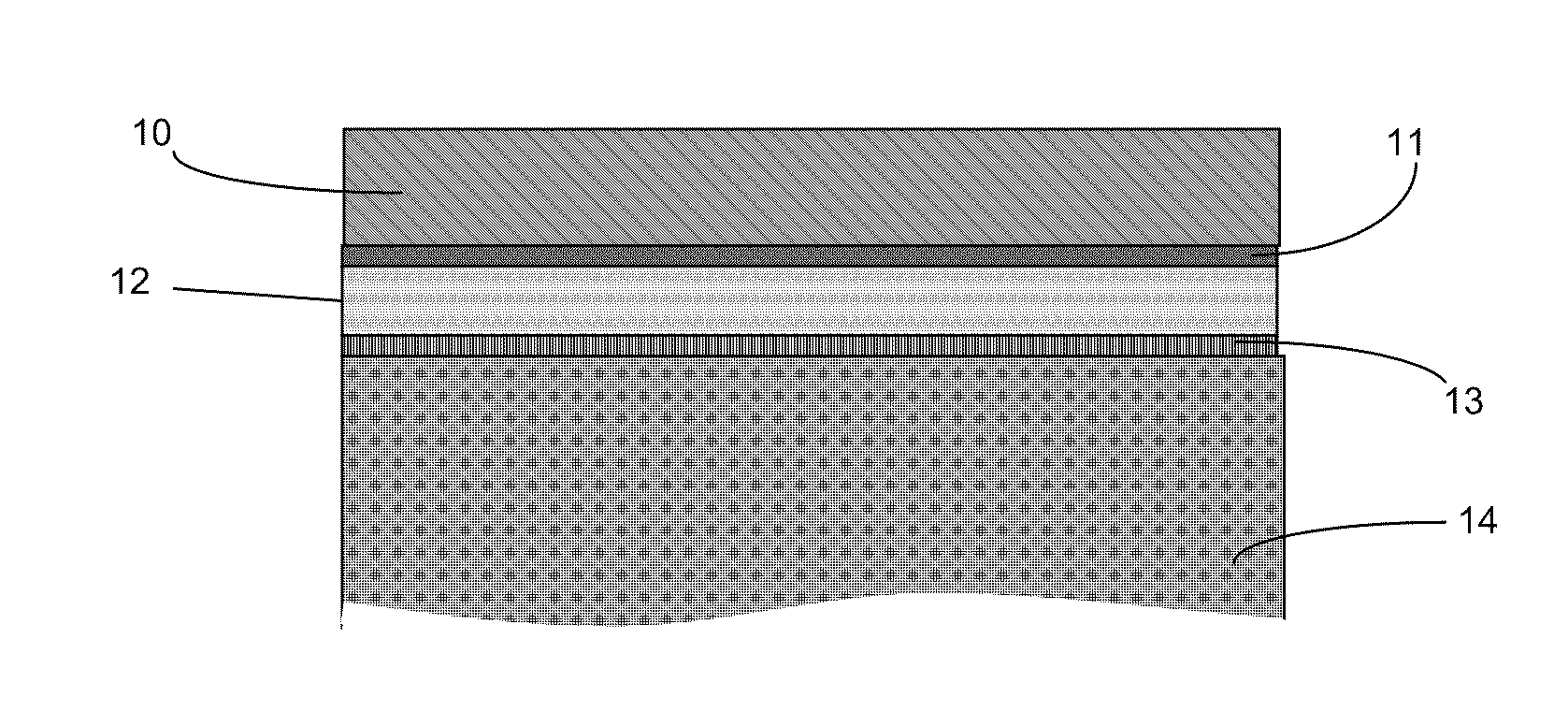

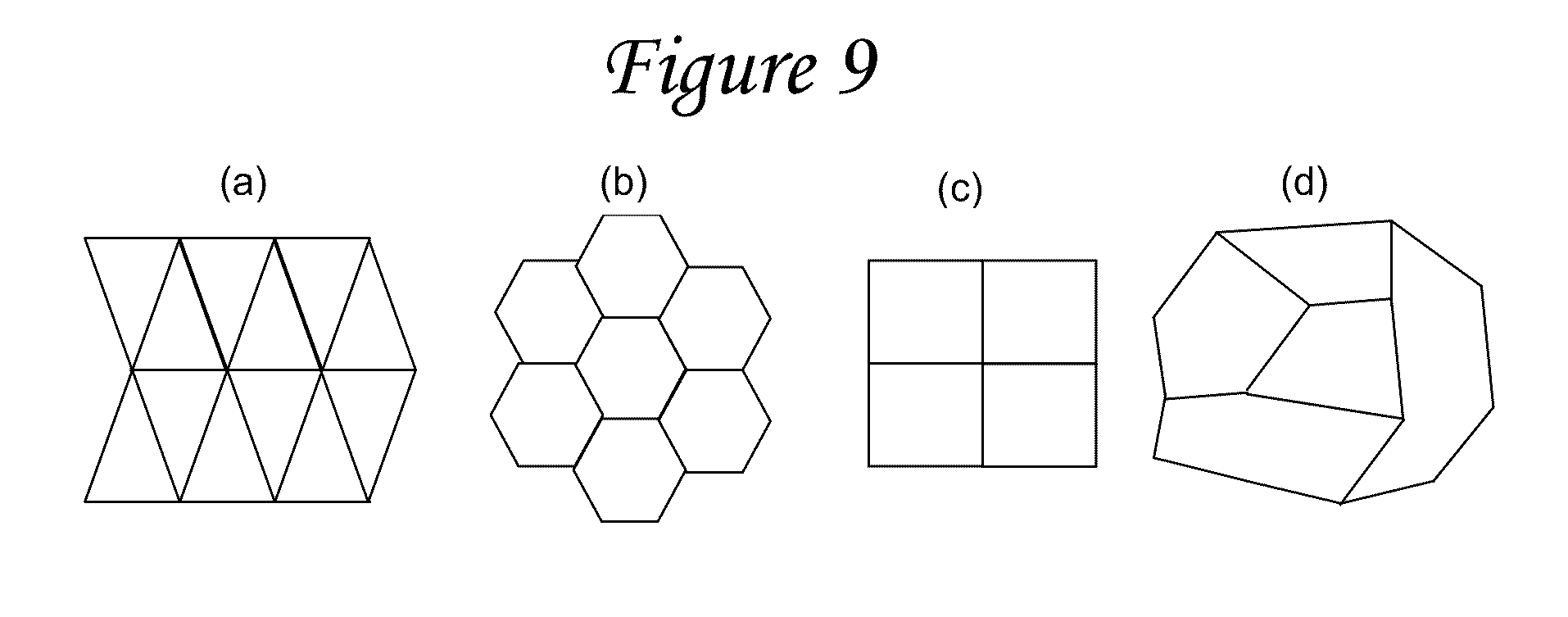

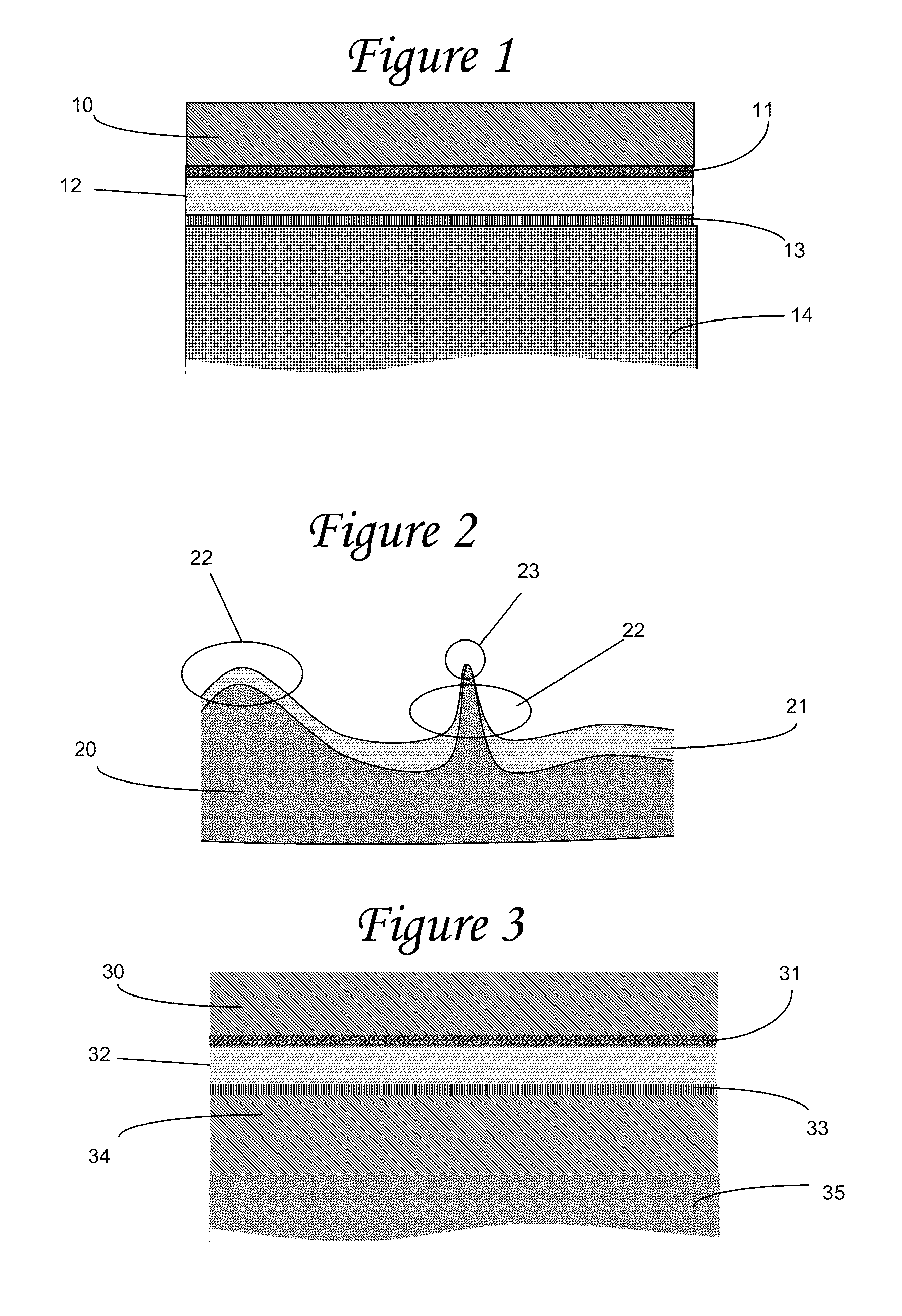

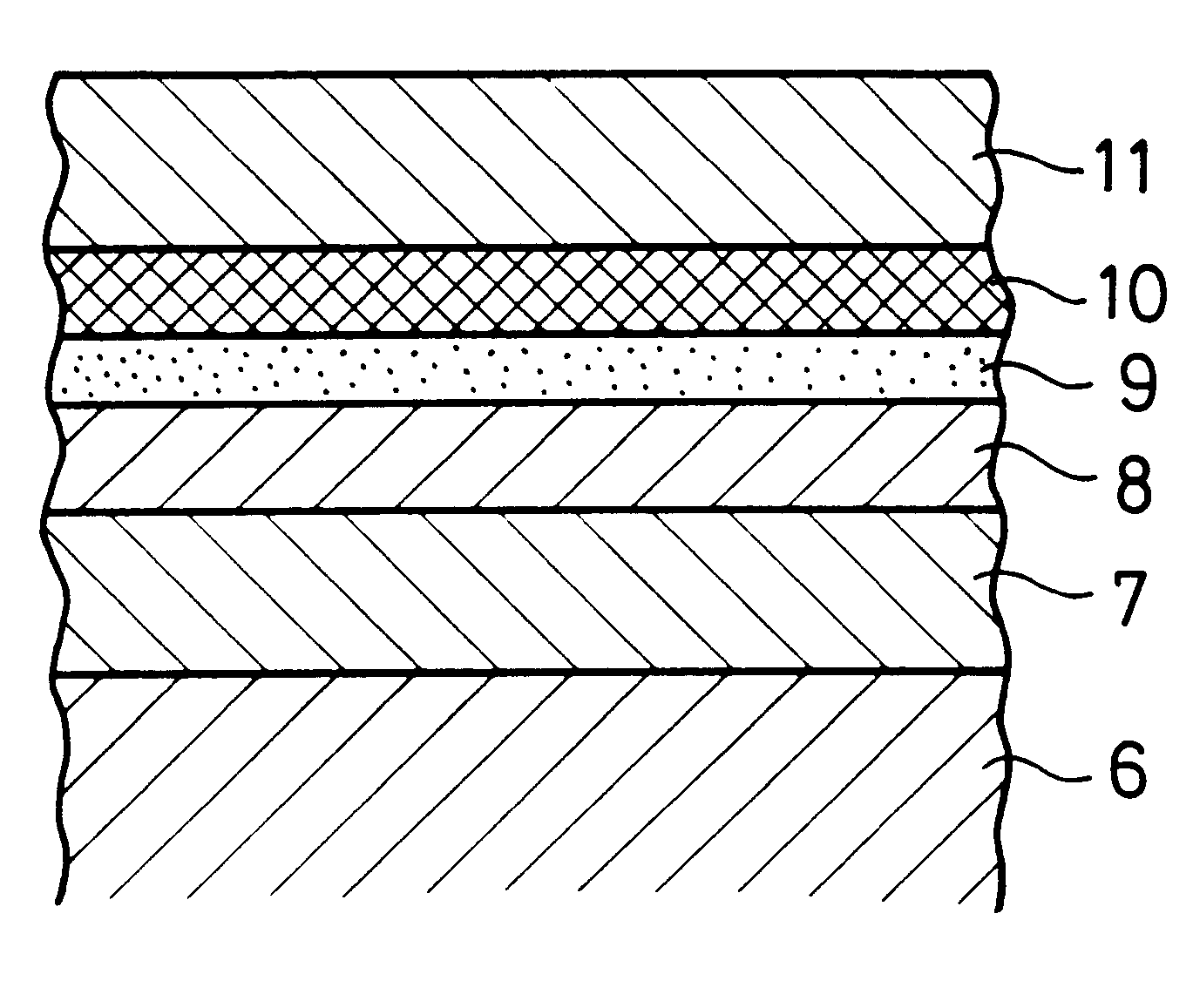

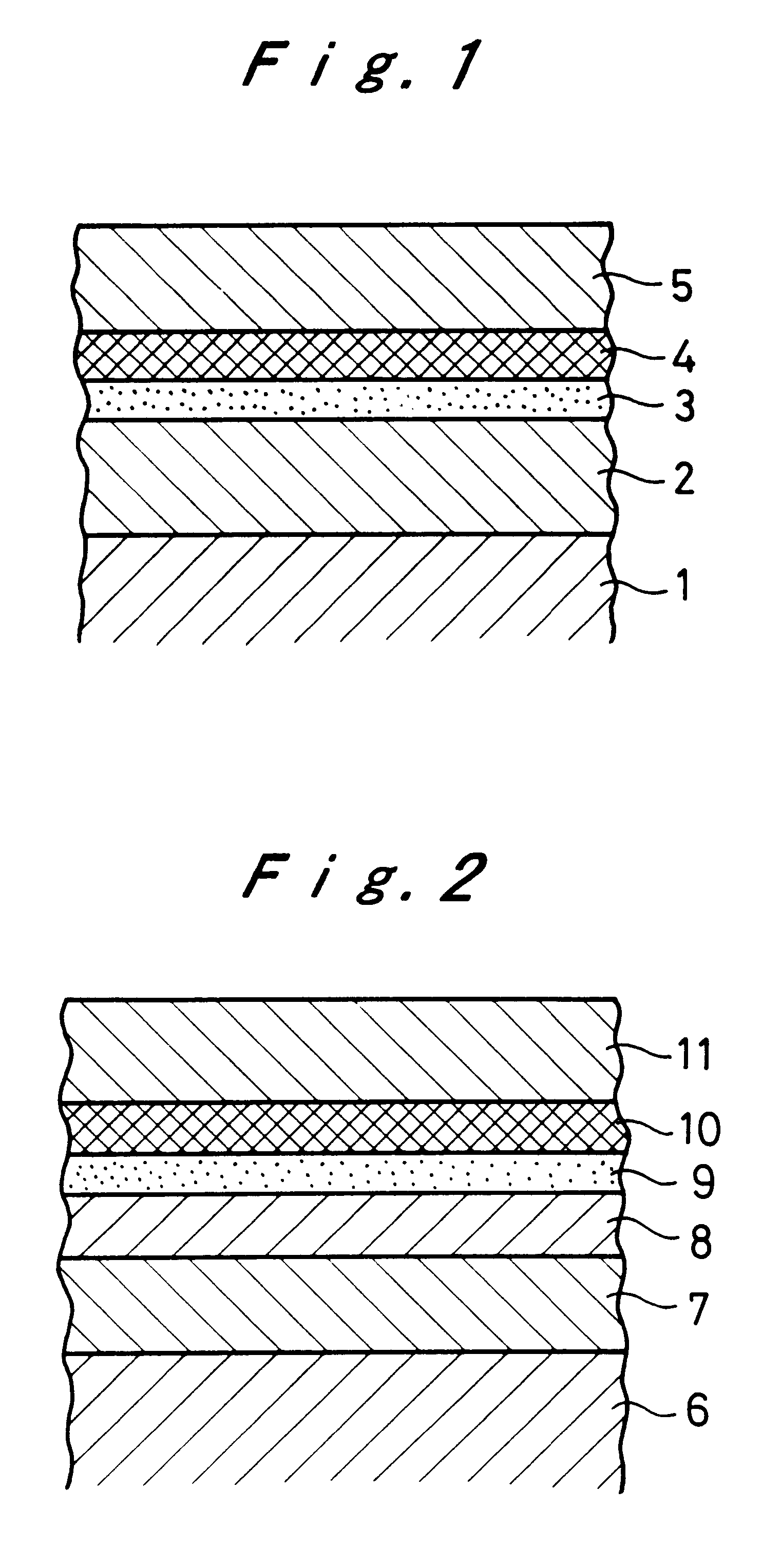

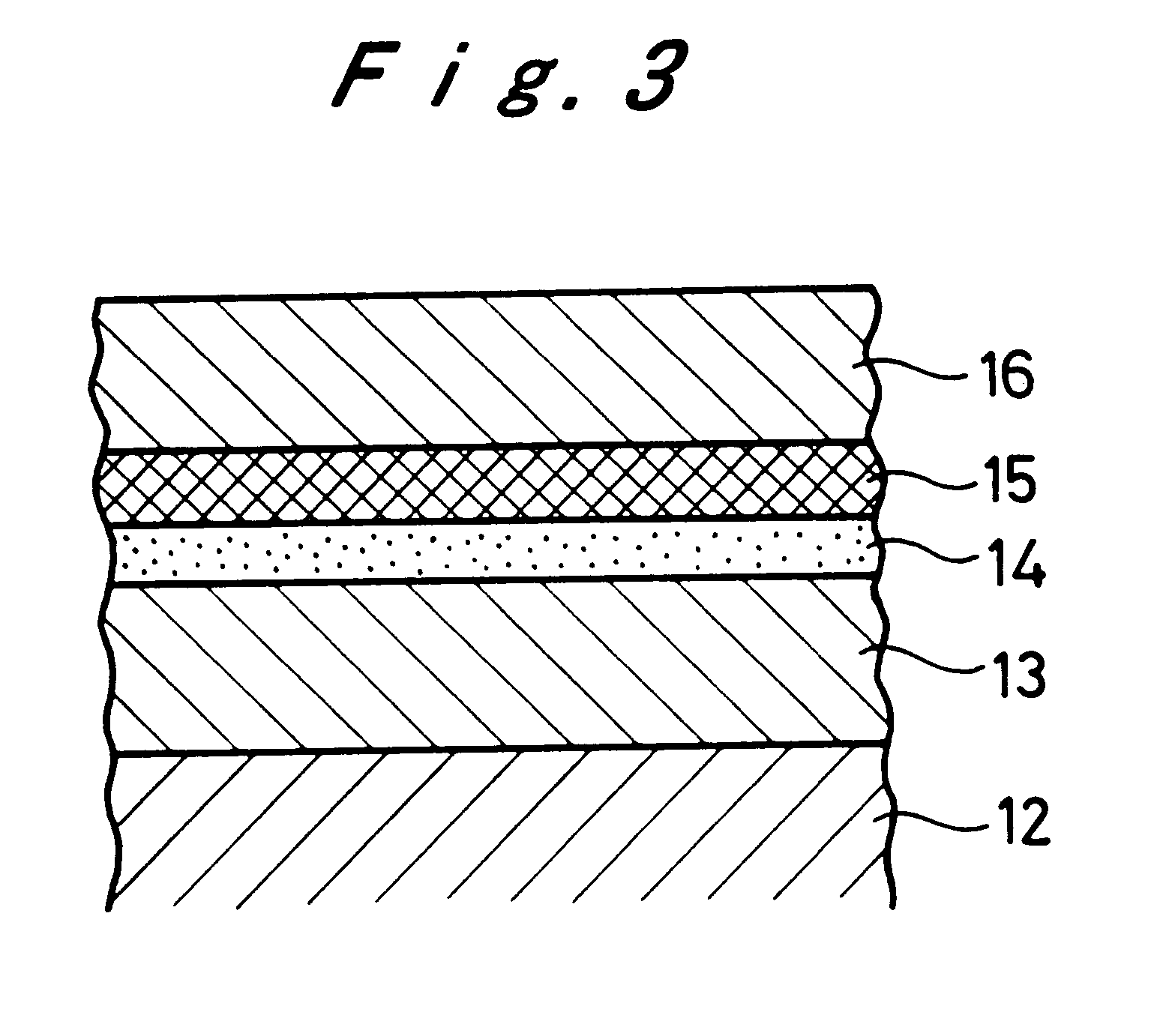

Low-emissivity structures

InactiveUS20110262699A1Reduce performanceMinimize wettingNanoinformaticsVacuum evaporation coatingLow emissivityEngineering

A multilayer radiant-barrier structure is formed on one or both sides of a substrate that can be attached to an insulating layer to produce a reflective insulating material. The metallized layer is protected from environmental degradation without interfering with flammability properties that are critical for radiant and reflective insulation materials used in housing applications. The metal layer is modified to insulate enclosures without blocking cellular communications and the protective functional layer in modified to minimize emissivity, create a hydrophobic and / or oleophobic surface, and / or prevent mold, fungi and bacteria growth. Solutions are provided to solve occupational-hazard problems associated with the use of these materials in enclosures that include power wires.

Owner:SIGMA LAB OF ARIZONA

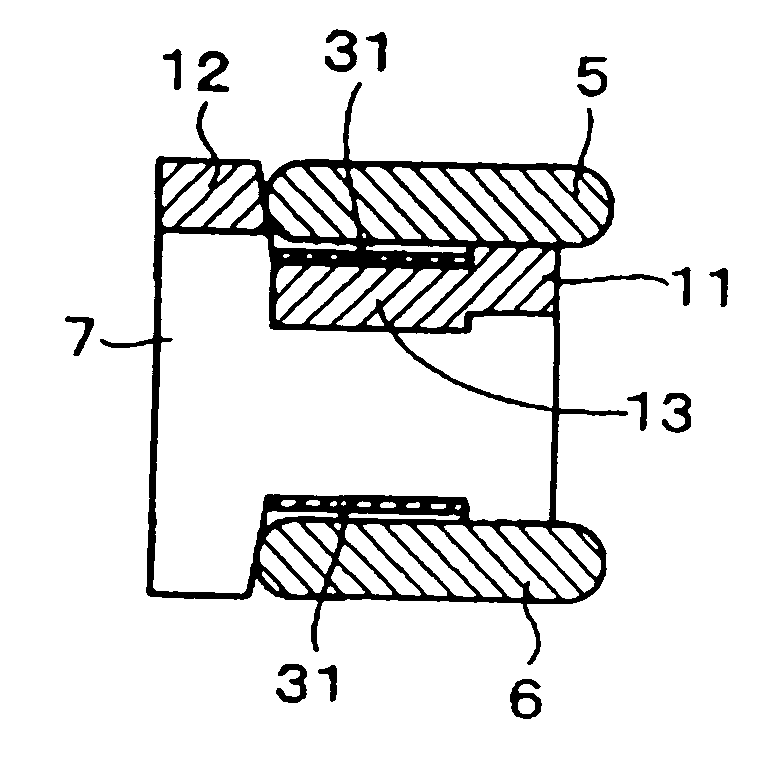

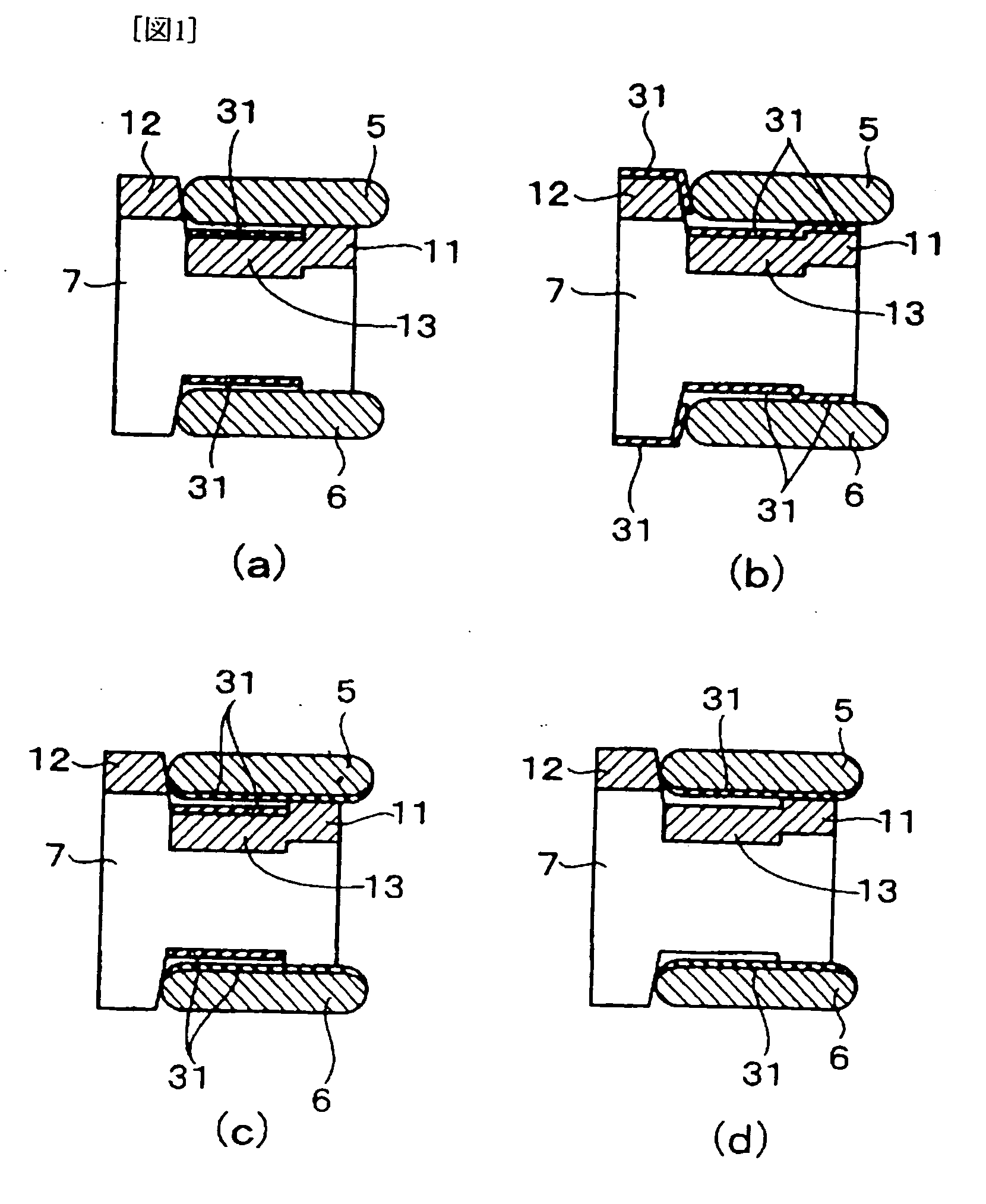

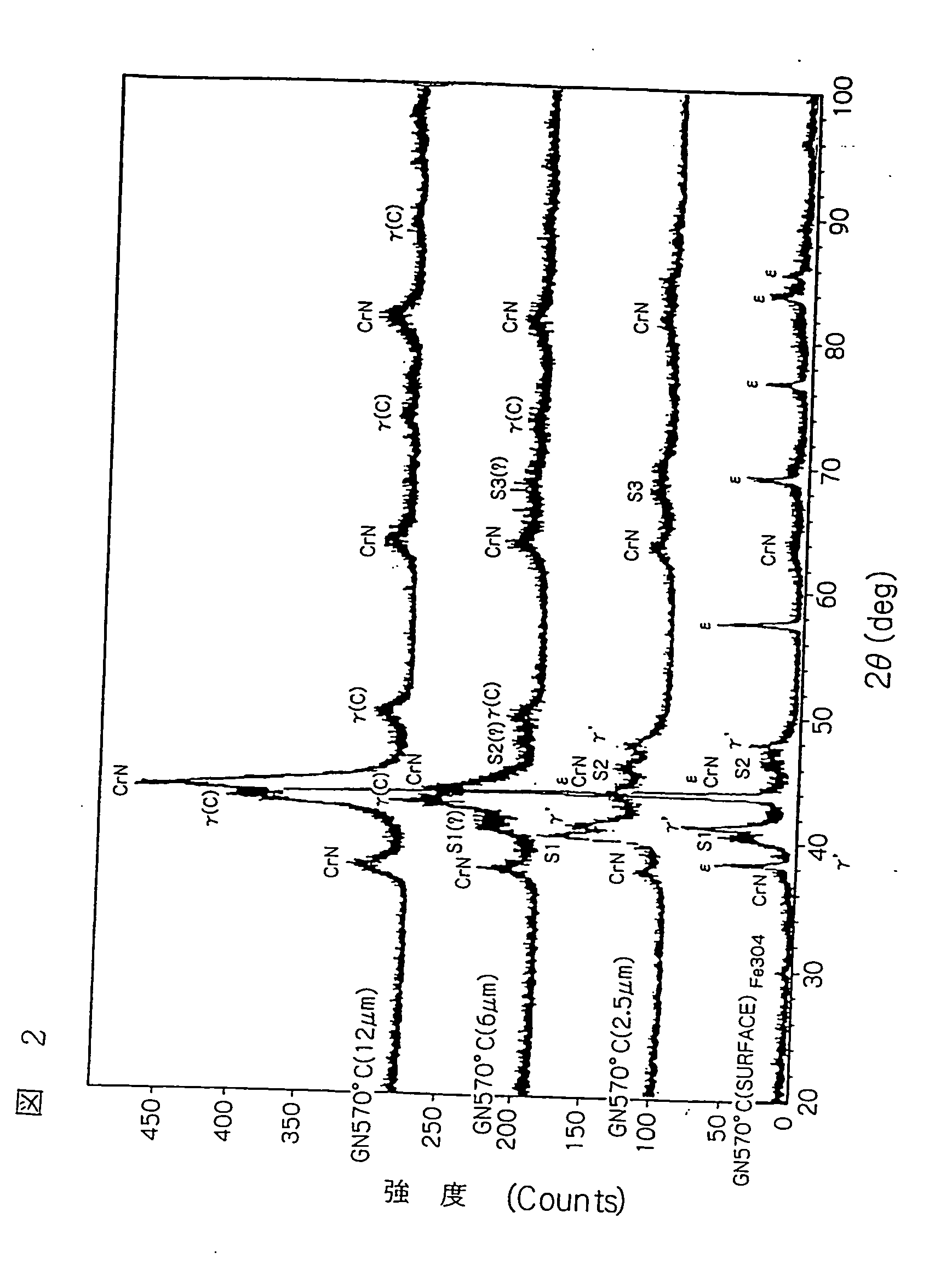

Three piece-combined oil ring

InactiveUS20060061043A1Poor corrosion-resistanceReduce tensionPiston ringsBraking action transmissionSurface layerX-ray

A three-piece combined oil-control ring comprises a pair of upper and lower side rails 222 in the axial direction and a spacer expander 224. The spacer expander is located between the side rails 222, and pushes the side rails from their inner peripheral side to generates the tension of the side rails 222. The ears of the spacer expander made of austenitic stainless steel in contact with inner peripheral surfaces of the side rails, are subjected to gas-nitriding at a temperature of 470° C. or higher to form a 10 to 60 μm thick gas-nitriding surface-layer comprising a phase having peaks at 2θ=40° and 2θ=46° by Cu—K α X-ray diffraction. In addition or alternatively, a resin coating film (31) is formed on at least surfaces of the spacer expander (7) faced to the side surfaces of the side rails or on at least surfaces of the side rails (5,6) faced to the spacer expander (7).

Owner:RIKEN CO LTD

A steel rebar and a production method thereof

InactiveUS20170029919A1Poor corrosion resistance performanceExcellent resist performanceFurnace typesManufacturing convertersRare-earth elementRebar

The present invention relates to a steel rebar comprising the following ingredients: 0.005%-0.030% of C, 0.3%-0.6% of Si, 1.2%-2.5% of Mn, 0.01% or less of P, 0.01% or less of S, 8.0%-10.0% of Cr, 1.0%-3.0% of Mo, 0.2%-0.4% of Sn, 0.01%-0.05% of Rare Earth element, and the remainder being Fe and unavoidable impurities. The present invention also provides a production method of steel rebar. The steel rebar of the present invention has excellent comprehensive mechanical properties and corrosion resistance performance, while meeting the requirements of anti-knock, the service life in sea water of the steel rebar is increased, thus it can be widely used in reinforced concrete structures in ocean environment.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

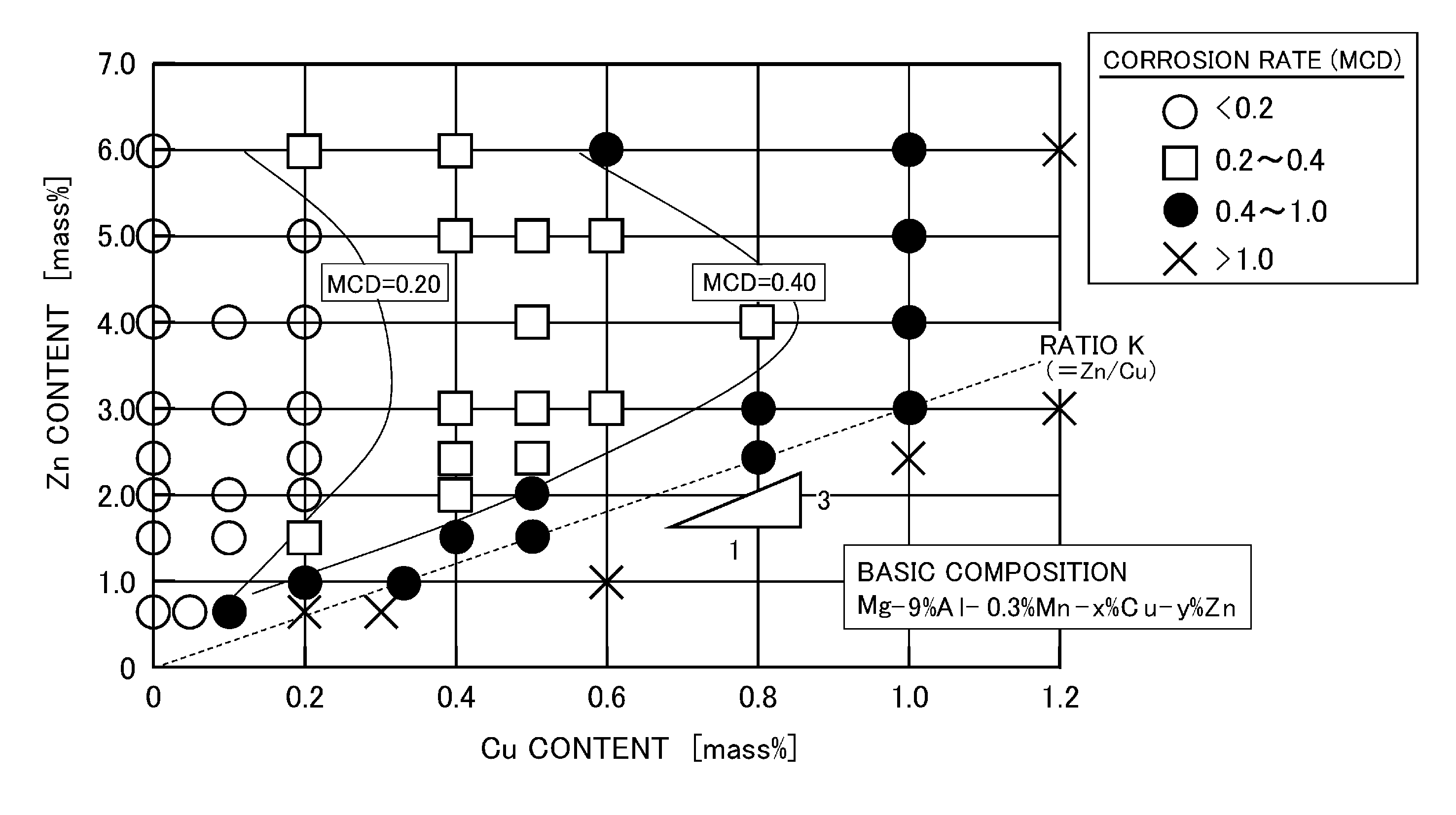

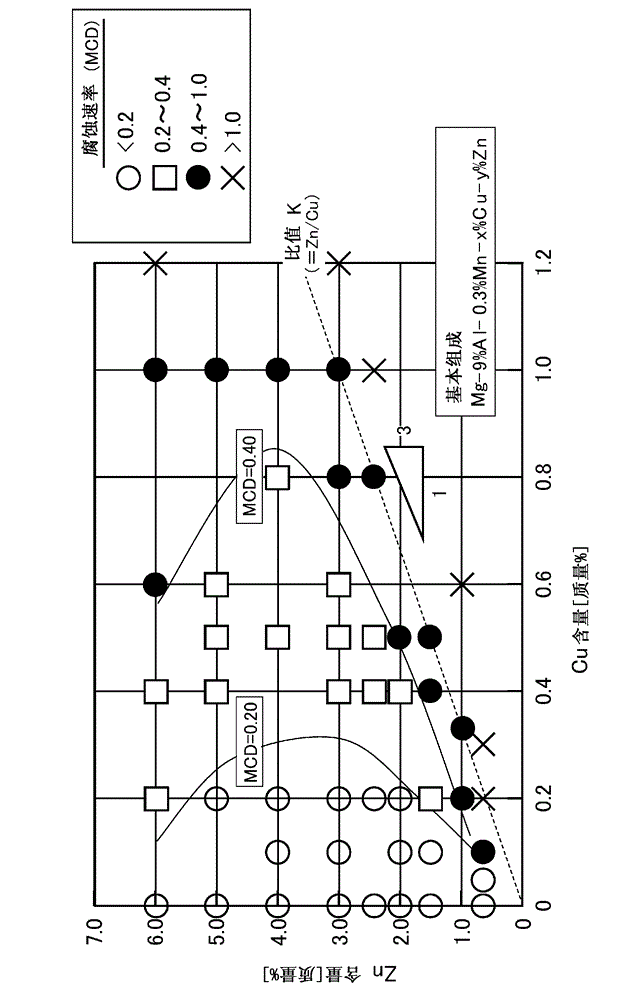

Recycled magnesium alloy, process for producing the same, and magnesium alloy

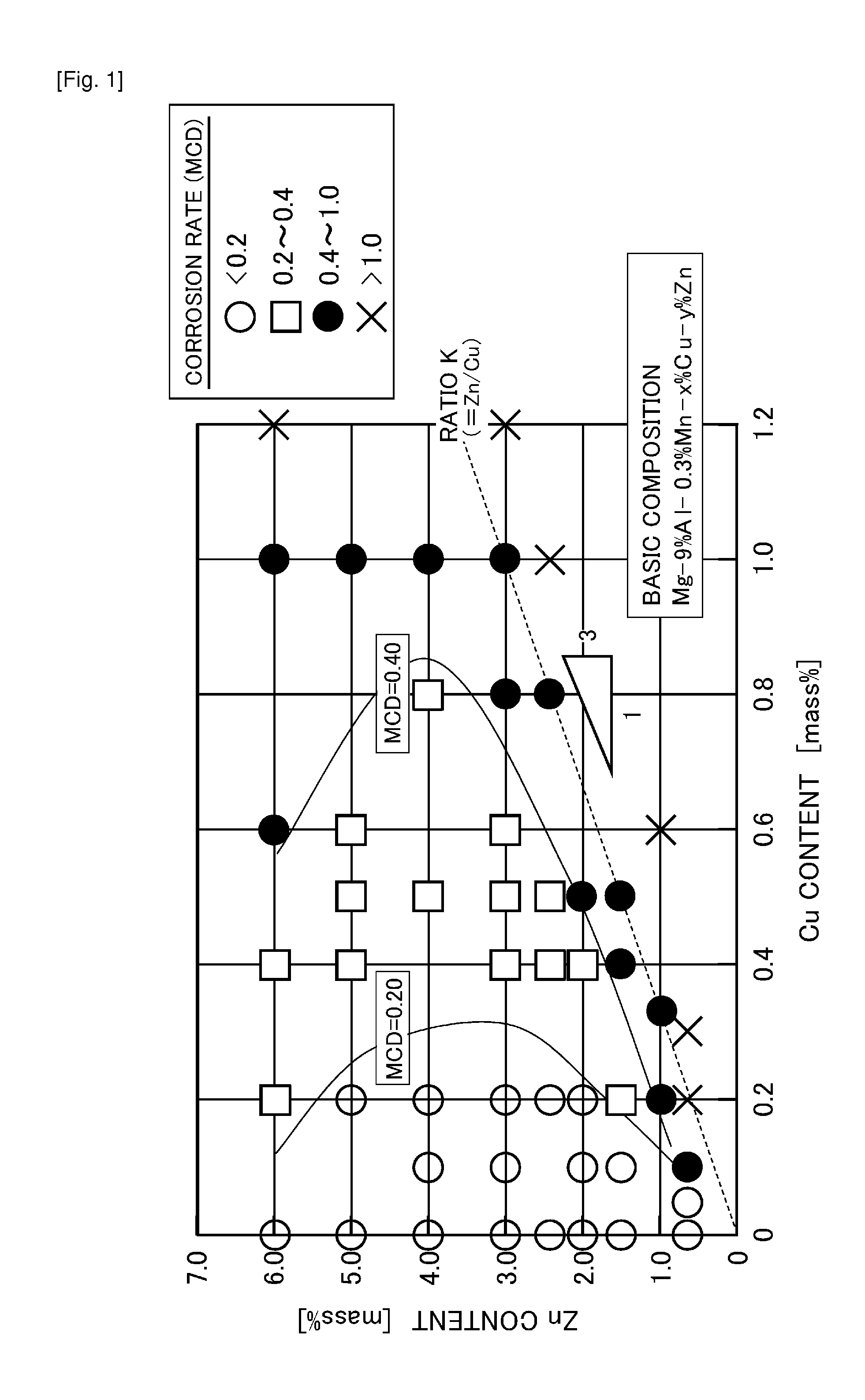

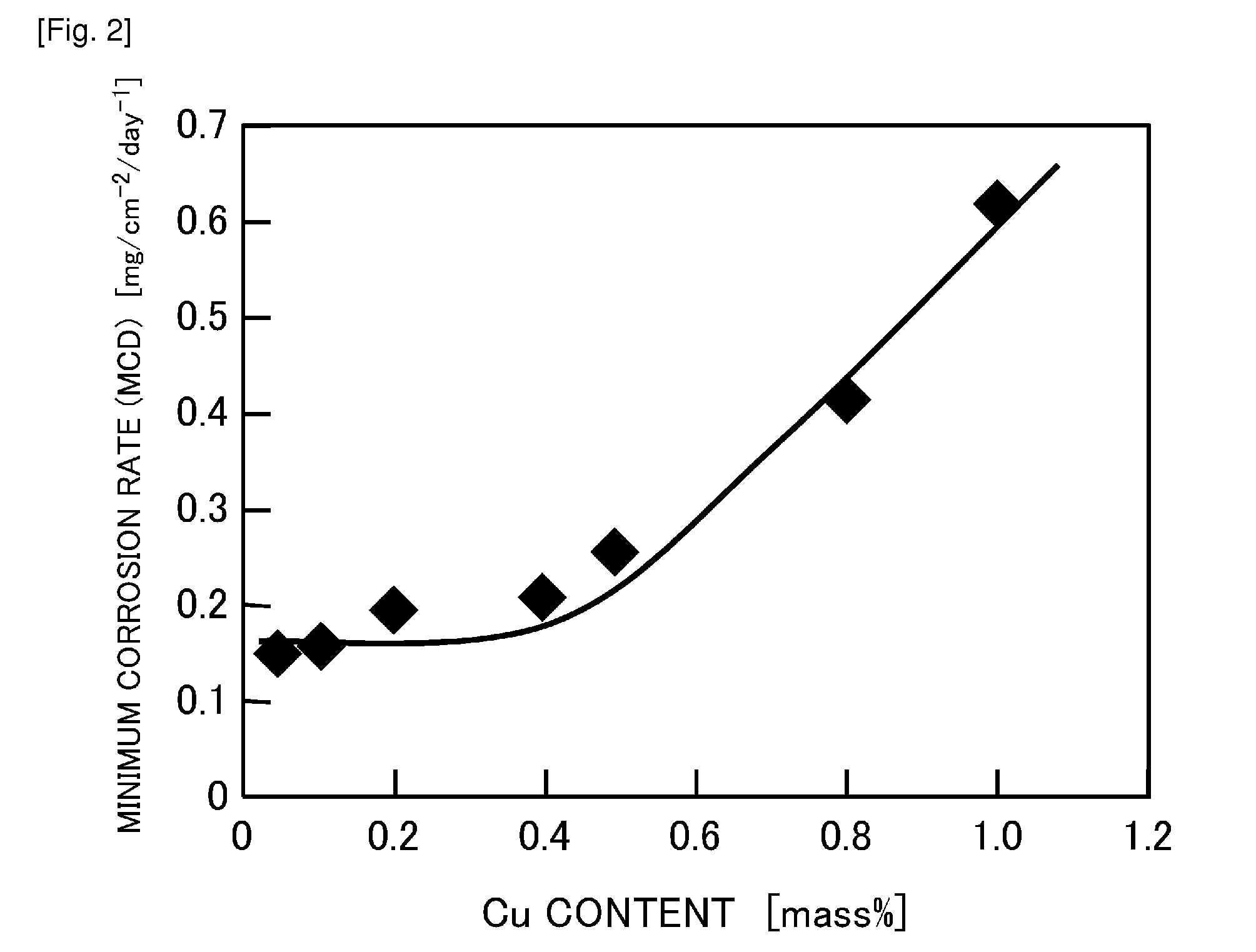

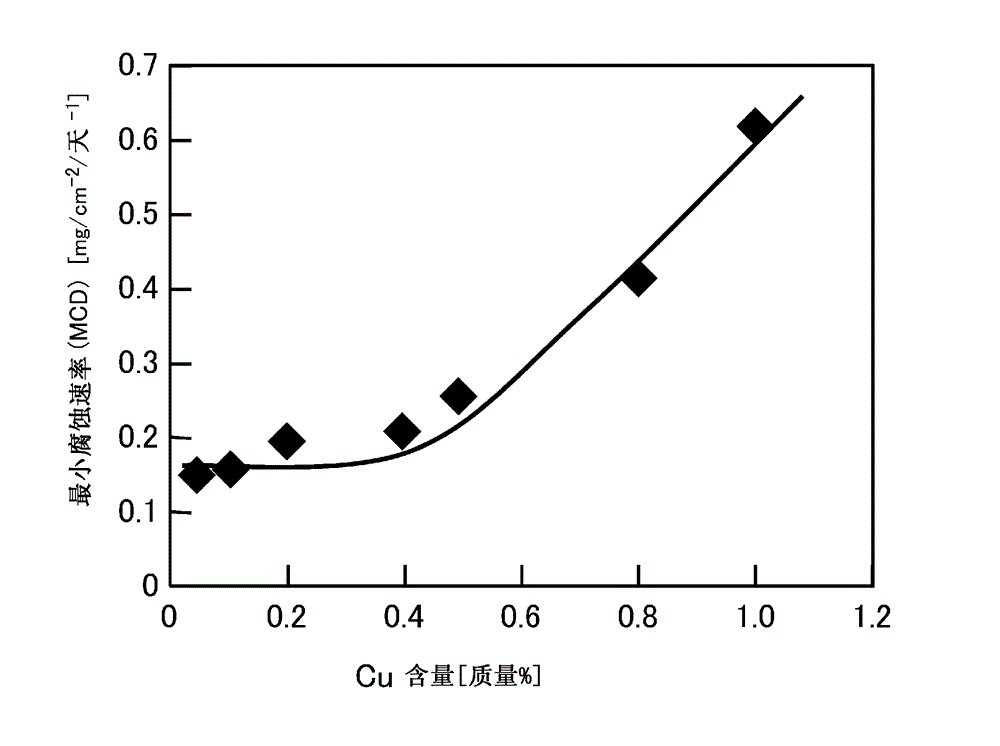

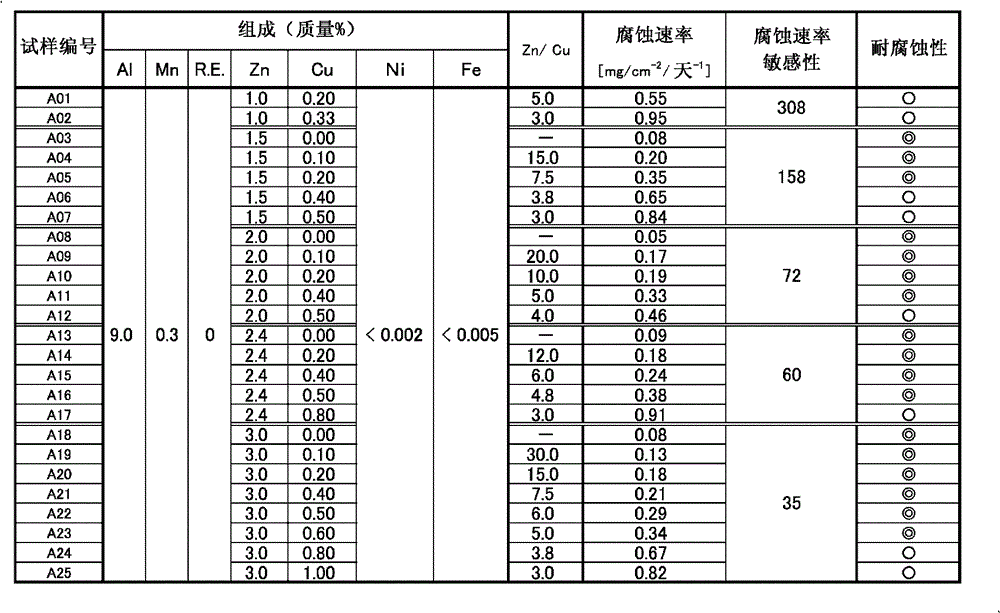

ActiveUS20120156087A1Poor corrosion resistanceImprove corrosion resistanceRecycling and recovery technologiesProcess efficiency improvementImpurityMaterials science

This invention aims to provide a recycled magnesium alloy having a good corrosion resistance and a process for producing the same. The process of the present invention comprises an adjusting step of adjusting composition of molten metal of a magnesium alloy so as to comprise, by mass: Al: 5 to 10%, Zn: not less than 1% and not less than three times of Cu content (%), Mn: 0.1 to 1.5% and the remainder: Mg and impurities with or without one or more reforming elements. While the upper limit of the Al content is restricted to a low level, the Zn content is increased in accordance with the Cu content. Therefore, the recycled magnesium alloy produced by this process can effectively suppress corrosion caused by Cu, which is one of corrosion-causing elements.

Owner:TOYOTA JIDOSHA KK +1

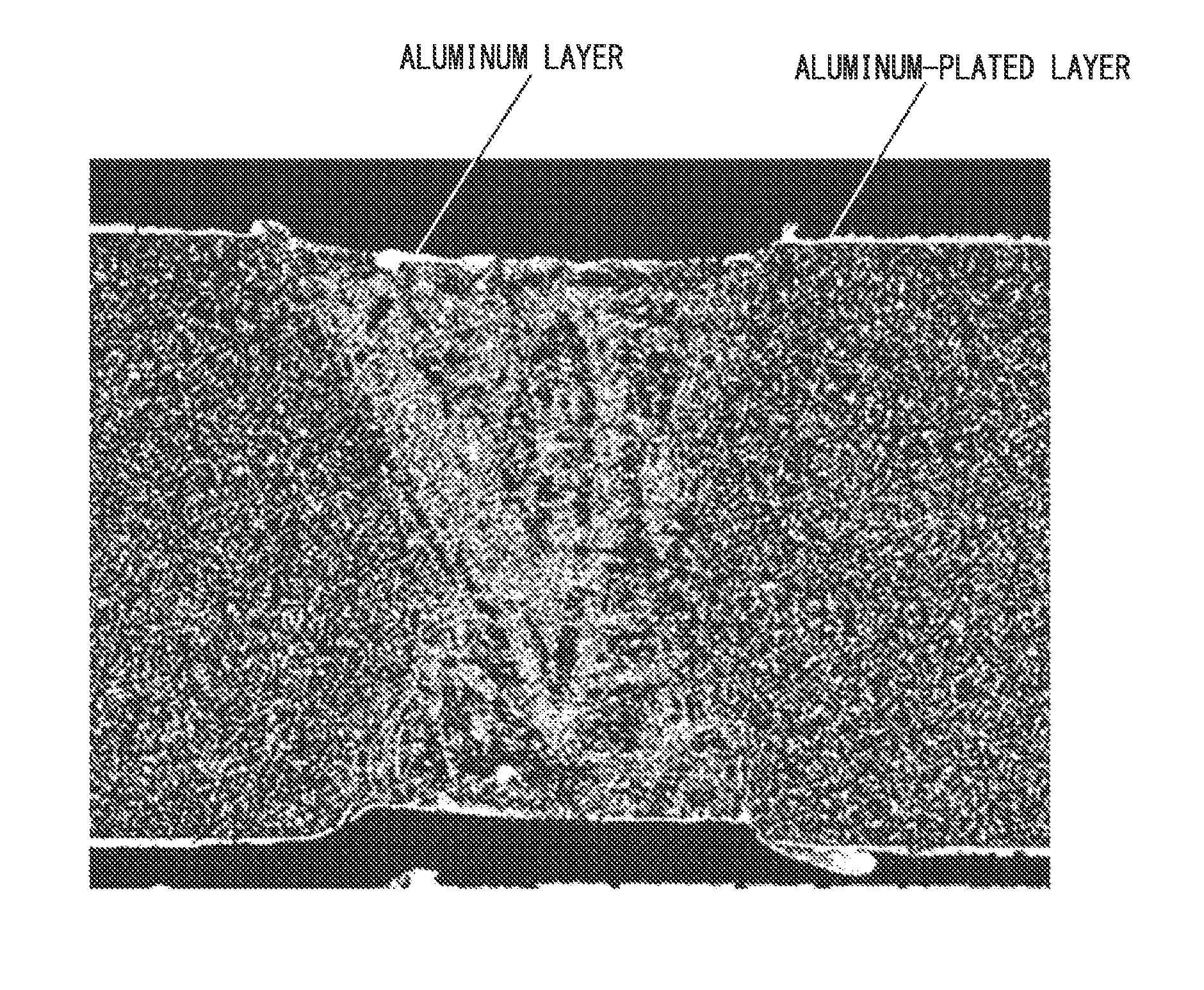

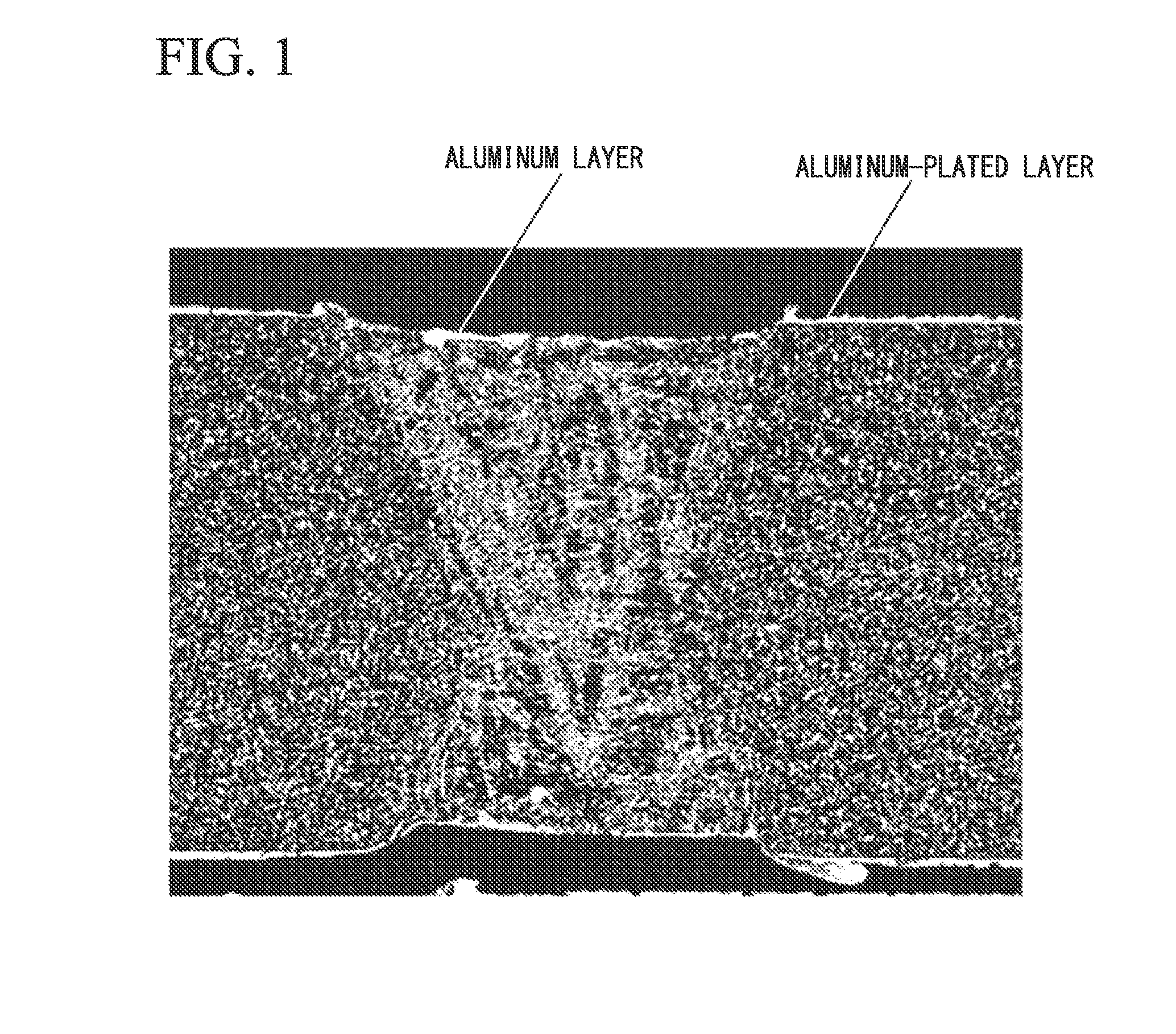

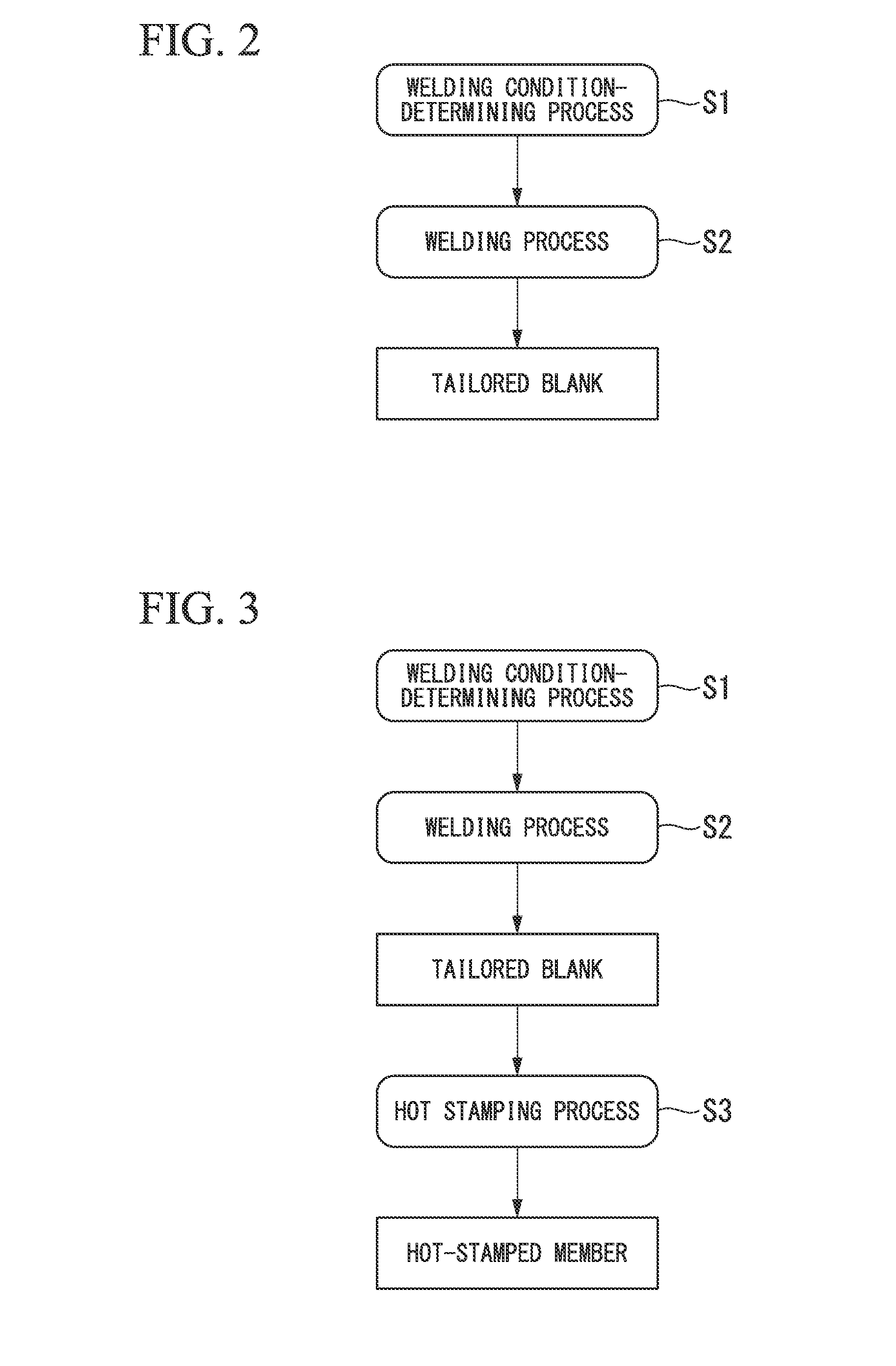

Tailored blank for hot stamping, hot stamped member, and methods for manufacturing same

ActiveUS20150043962A1Improve joint strengthPoor corrosion resistanceArc welding apparatusFurnace typesHot stampingAlclad

A tailored blank for hot stamping includes a welded portion formed by butt-welding a first aluminum-plated steel sheet and a second aluminum-plated steel sheet, an Average Al concentration of a weld metal in the welded portion is in a range of 0.3 mass % to 1.5 mass %, an Ac3 point of the weld metal is 1250° C. or lower, and furthermore, an aluminum layer formed during the butt-welding is present on a surface of the welded portion.

Owner:NIPPON STEEL CORP

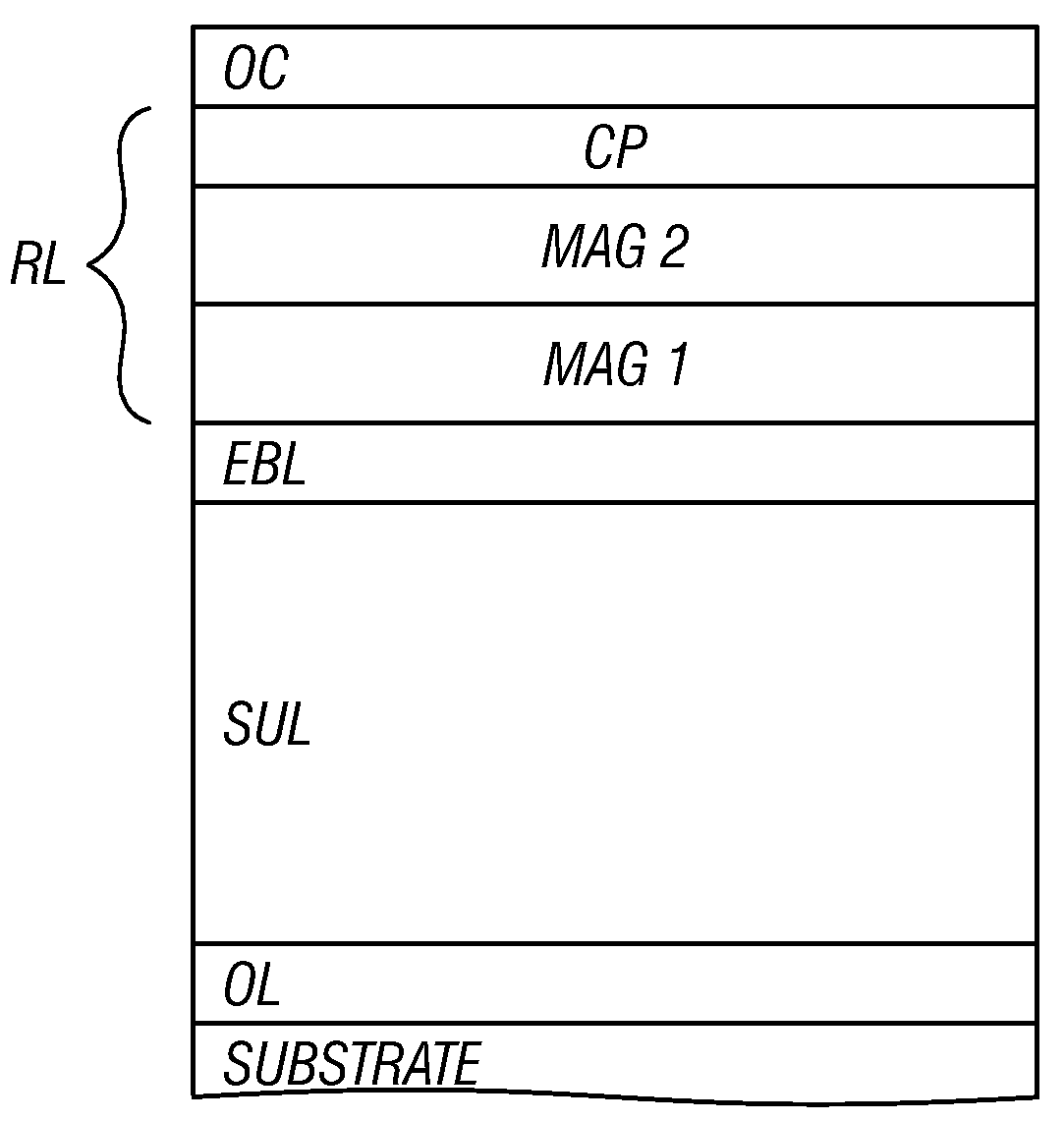

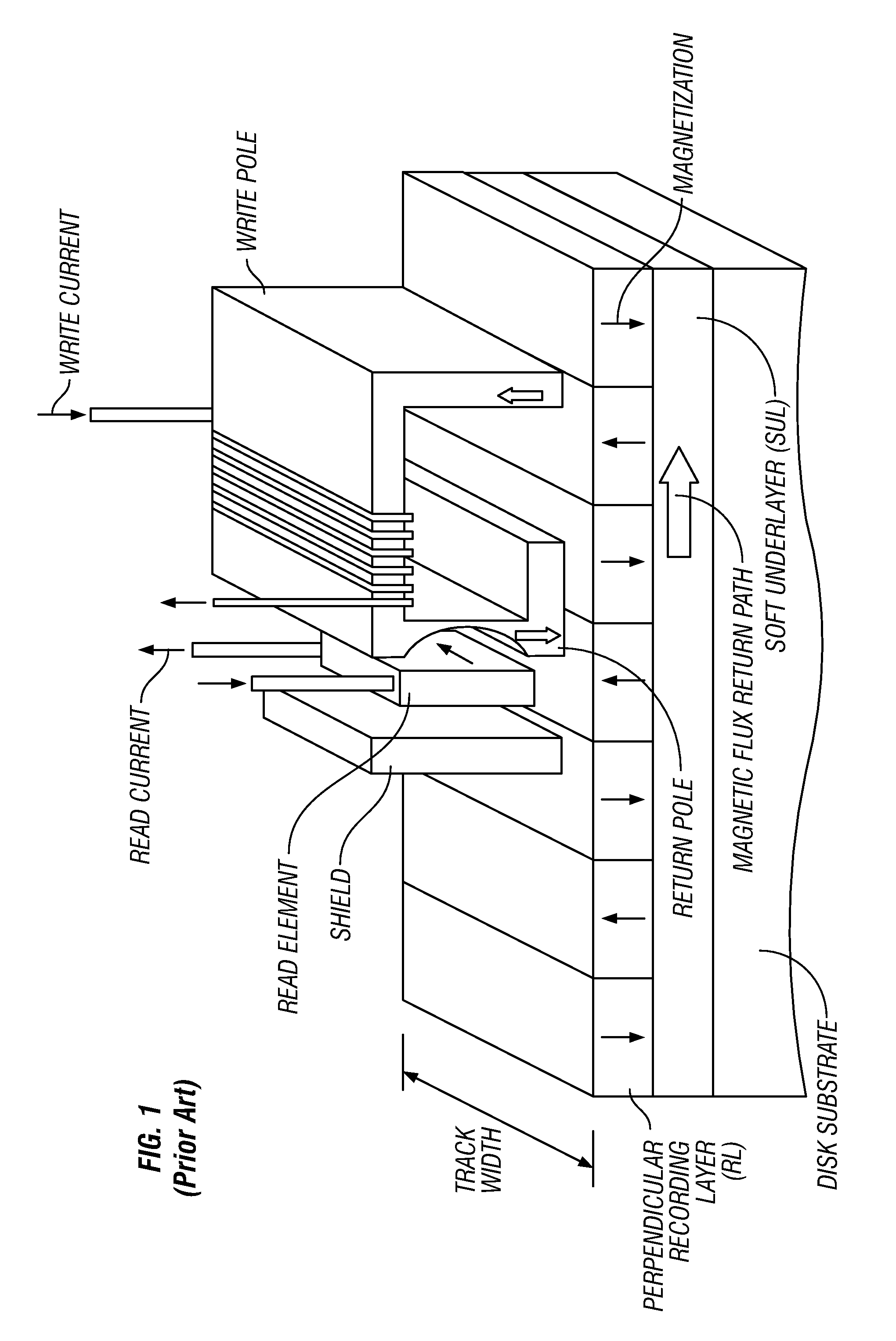

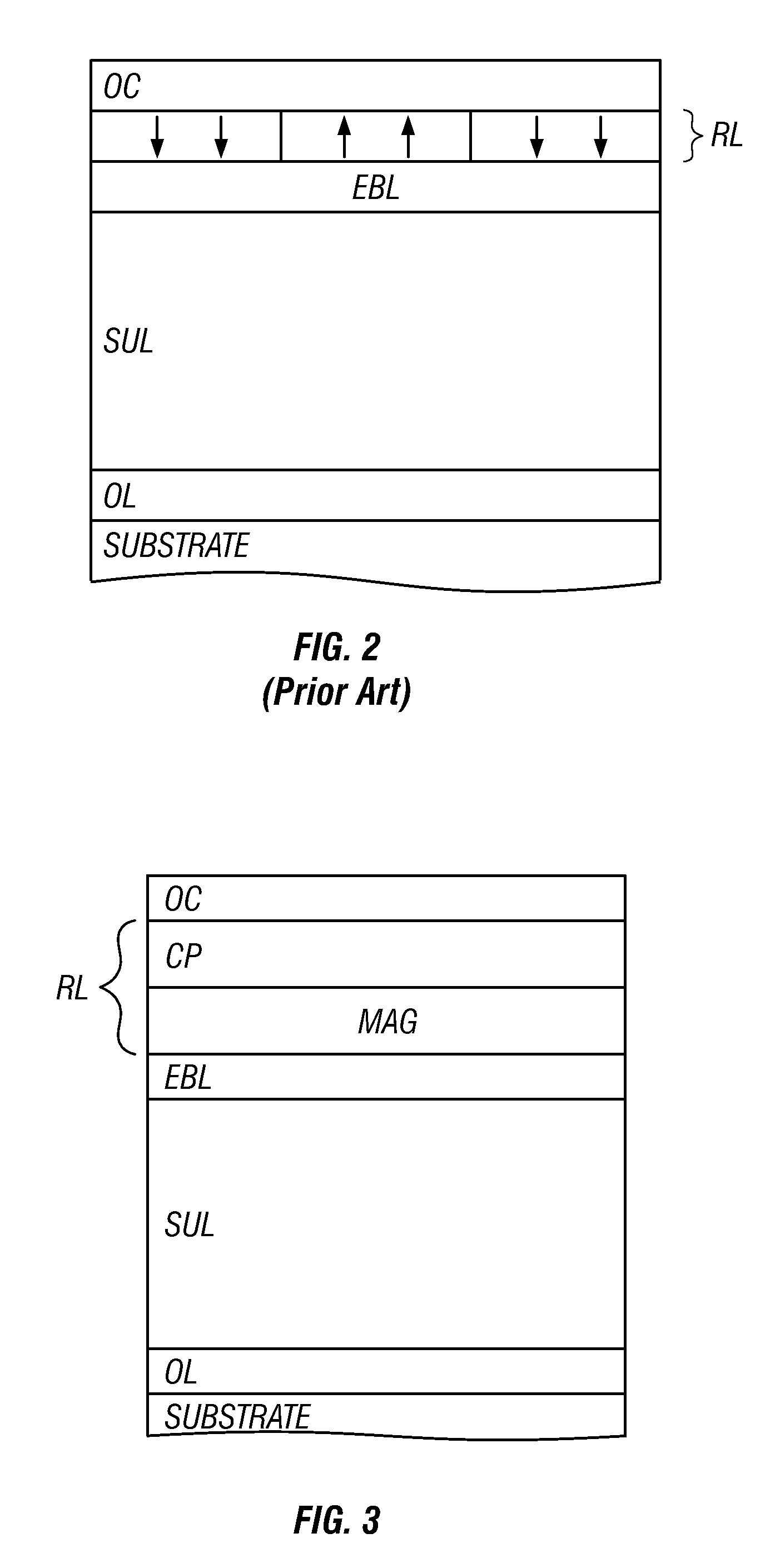

Perpendicular magnetic recording medium with multilayer recording structure including intergranular exchange enhancement layer

InactiveUS20080138662A1Not easy to corrodeImprove recording effectMagnetic materials for record carriersRecord information storageCouplingMaterials science

A perpendicular magnetic recording medium has a multilayer recording layer (RL) structure that includes a ferromagnetic intergranular exchange enhancement layer for mediating intergranular exchange coupling in the other ferromagnetic layers in the RL structure. The RL structure may be a multilayer of a first ferromagnetic layer (MAG1) of granular polycrystalline Co alloy with Ta-oxide, a second ferromagnetic layer (MAG2) of granular polycrystalline Co alloy with Si-oxide, and an oxide-free CoCr capping layer on top of and in contact with MAG2 for mediating intergranular exchange coupling in MAG1 and MAG2. The RL structure may also be a multilayer of an intergranular exchange enhancement interlayer (IL) in between two ferromagnetic layers, MAG1 and MAG2, each with reduced or no intergranular exchange coupling. Because the IL is in direct contact with both MAG1 and MAG2, it directly mediates intergranular exchange coupling in each of MAG1 and MAG2.

Owner:INT PAPER CO +1

Hard carbon coating-clad base material

InactiveUS6180263B1Excellent in abrasionImprove adhesionSuperimposed coating processThin material handlingCarbon coatingMetal coating

The hard carbon coating-clad base material of the present invention comprises a base material, a substratal metal coating formed on the base material by a wet plating process, an intermediate metal coating comprising a titanium or chromium coating formed on the substratal metal coating by a dry plating process and a silicon coating formed on the titanium or chromium coating by a dry plating process, and a hard carbon coating formed on the silicon coating by a dry plating process. According to the present invention, a highly reliable hard carbon coating which is excellent in corrosion resistance, adhesion and abrasion resistance can be formed even on brass or an iron base material having poor corrosion resistance, such as SK steel and martensitic and ferritic stainless steels.

Owner:CITIZEN WATCH CO LTD

Recycled magnesium alloy, process for producing the same, and magnesium alloy

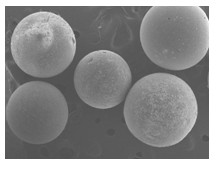

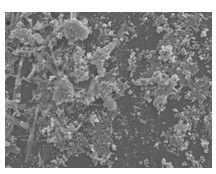

ActiveCN102803534APoor corrosion resistanceImprove corrosion resistanceRecycling and recovery technologiesProcess efficiency improvementImpurityMolten metal

This invention aims to provide a recycled magnesium alloy having a good corrosion resistance and a process for producing the same. The process of the present invention comprises an adjusting step of adjusting composition of molten metal of a magnesium alloy so as to comprise, by mass: Al: 5 to 10 %, Zn: not less than 1 % and not less than three times of Cu content (%), Mn: 0.1 to 1.5 % and the remainder: Mg and impurities with or without one or more reforming elements. While the upper limit of the Al content is restricted to a low level, the Zn content is increased in accordance with the Cu content. Therefore, the recycled magnesium alloy produced by this process can effectively suppress corrosion caused by Cu, which is one of corrosion-causing elements.

Owner:TOYOTA JIDOSHA KK

Chemical plating Ni-P alloy technology of glass micro beads

The invention discloses a chemical plating Ni-P alloy technology of glass micro beads. A common chemical plating nickel liquid formula is adopted, the temperature is controlled to be 50-60 DEG C in the chemical plating nickel process, the plating application time is 30 minutes, and finally the chemical plated Ni-P alloy of glass micro bead with an even Ni-P deposition layer is obtained. After chemical plating, the contents of surface elements O and Si of the micro beads are lowered, but the contents of Ni and P are maximum, wherein the content of Ni reaches 58.76-68.41wt%, and the content of P reaches 8.87-10.04wt%. Compared with the chemical plating Ni-P alloy technology in the prior art, the content of Ni on the surface of the micro beads of the technology optimized by the invention is improved by 21.68-31.33wt%, and the content of P is improved by 8-9wt% compared with those of the technology which is not optimized.

Owner:SHANGHAI INST OF TECH

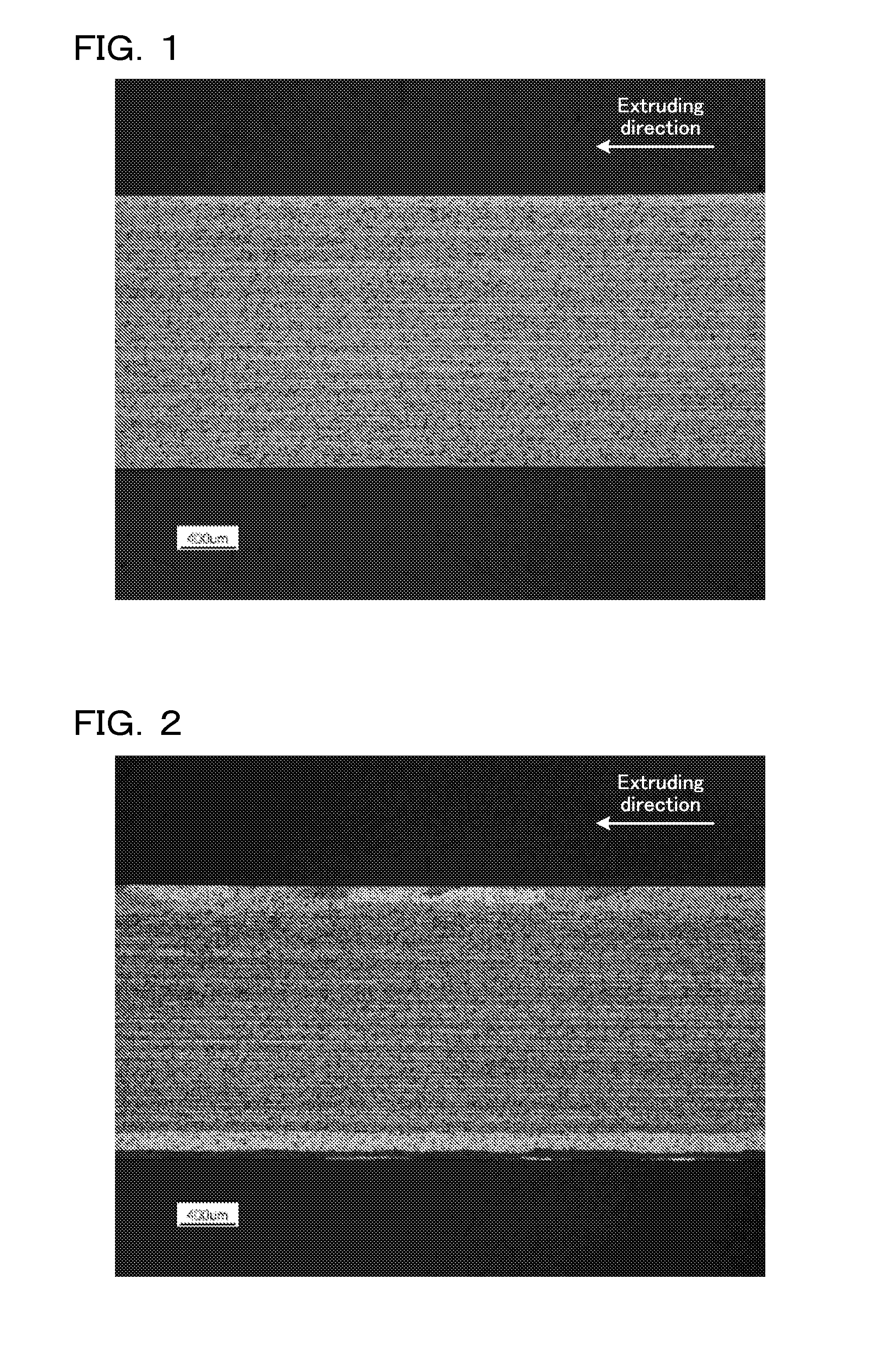

High-strength aluminum alloy extruded material and method for manufacturing the same

InactiveUS20140096878A1Excellent corrosion resistanceExcellent surface qualityHigh intensityAluminium alloy

A high-strength aluminum alloy extruded material contains Si: 0.70 to 1.3 mass %; Mg: 0.45 to 1.2 mass %; Cu: 0.15 to less than 0.40 mass %; Mn: 0.10 to 0.40 mass %; Cr: more than 0 to 0.06 mass %; Zr: 0.05 to 0.20 mass %; Ti: 0.005 to 0.15 mass %, Fe: 0.30 mass % or less; V: 0.01 mass % or less; the balance being Al and unavoidable impurities Crystallized products in the alloy have a particle diameter of a is 5 μm or less. Furthermore, an area ratio of a fibrous structure in a cross section parallel to an extruding direction during hot extrusion is 95% or more.

Owner:SUMITOMO LIGHT METAL INDS LTD

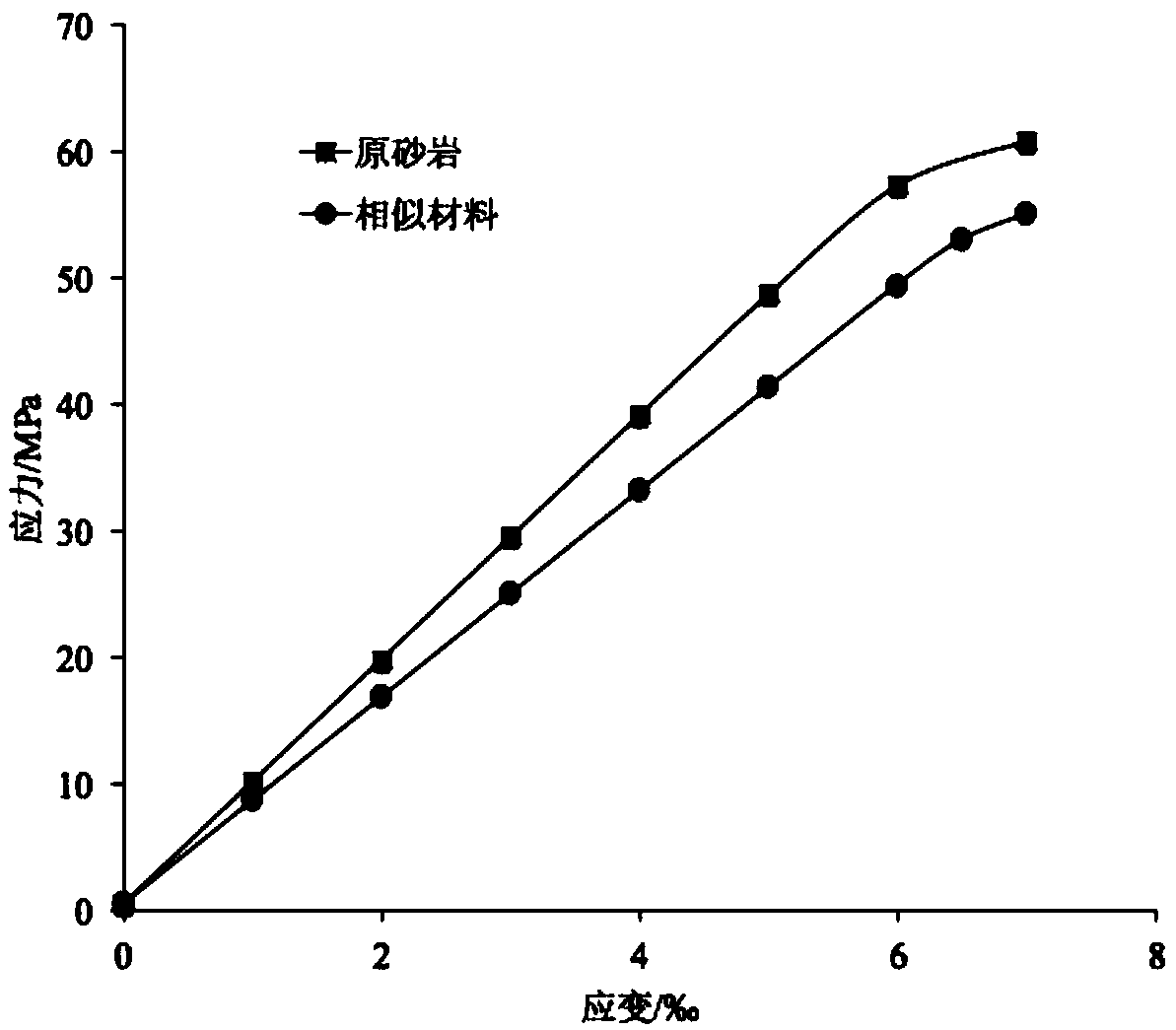

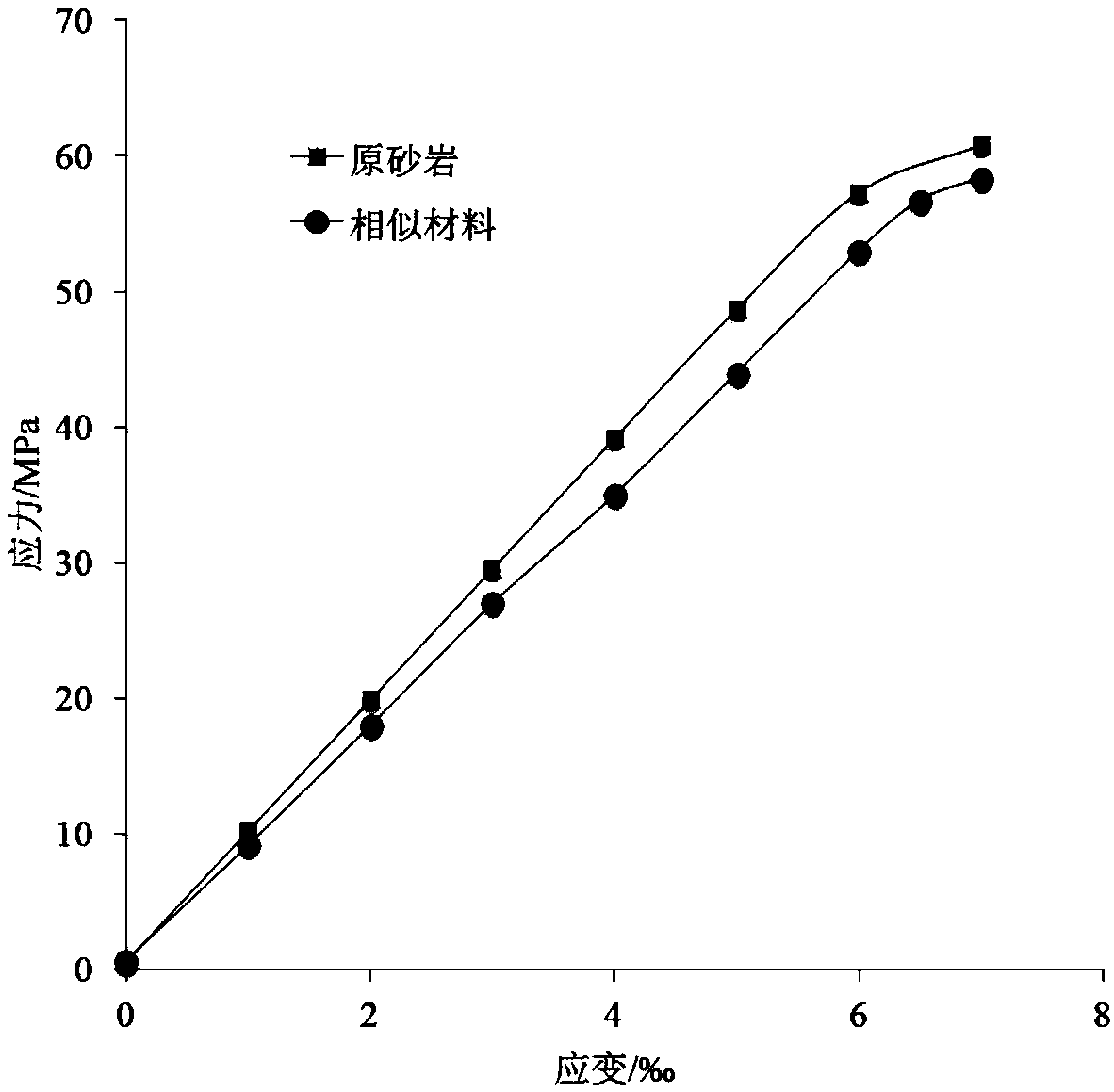

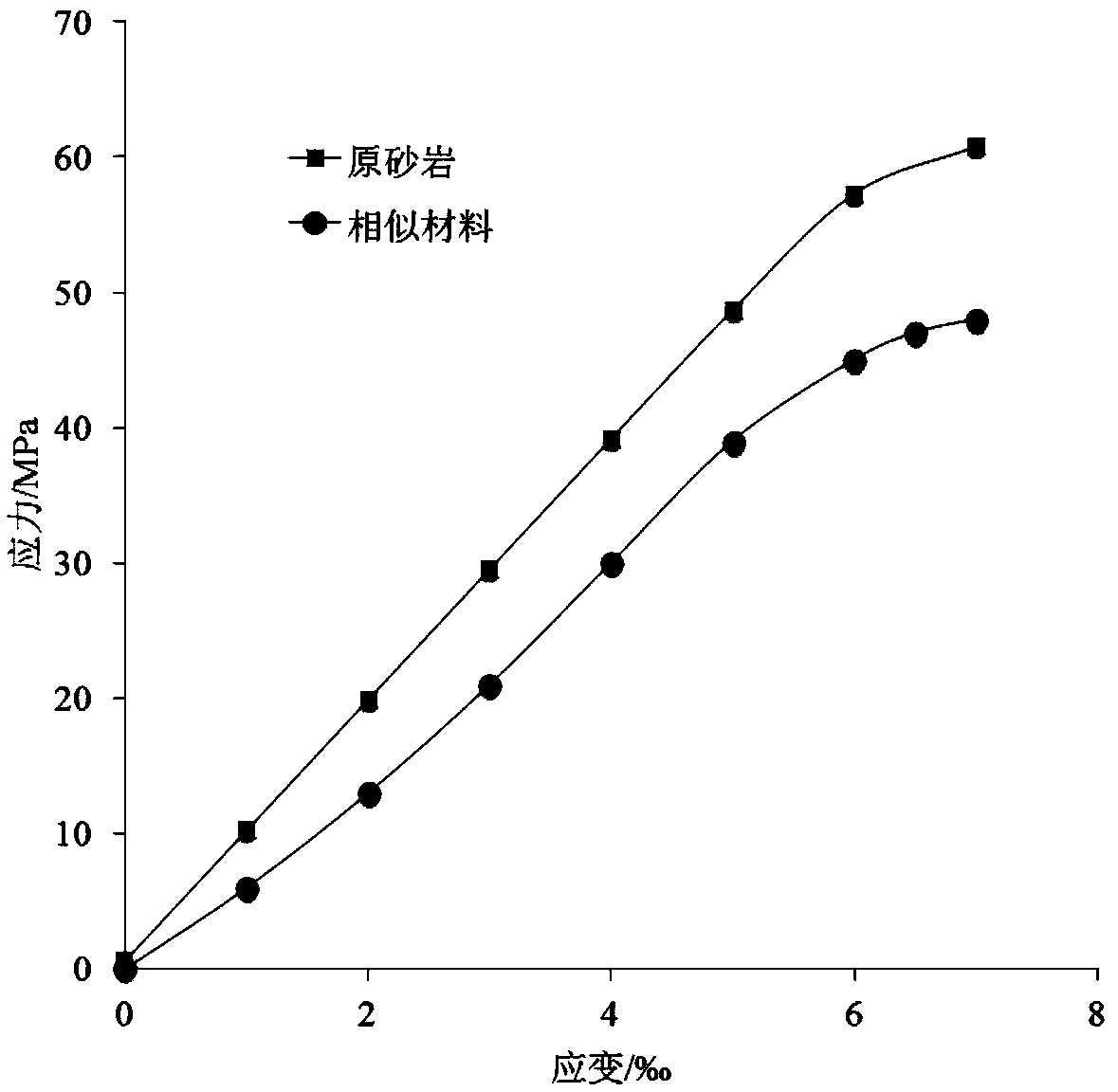

Sandstone similar material and preparation method thereof

InactiveCN109020364AImprove brittlenessHigh strengthSolid waste managementPreparing sample for investigationMechanical propertyWater reducer

The invention provides a sandstone high-strength high-brittleness similar material and a preparation method thereof. Raw materials comprise quartz sand, silicon powder, cement, distilled water and a water reducer. based on physical and mechanical properties and microscopic features of protolith, a method of regulating material properties by using aggregate is adopted, quartz sand is selected to improve brittleness of the material, and silicon powder is selected to raise strength of the material. Thereby, brittleness and strength of the sandstone similar material are achieved, and main physicaland mechanics parameters (density, elastic modulus, cohesion, internal friction angle, uniaxial compressive strength, tensile strength and Poisson's ratio, etc.) of the similar material and protolithmeet the similarity theory. Features of sandstone in rock slope of Xinjiang Tianshan highway are successively simulated. The types of required materials are less, and the cost is low. The manufactureefficiency is high. The material of the invention has wide practicality.

Owner:HUBEI ENG UNIV

Method for preparing thick type shaving board through waste outdoor heat-treated wood and conventional wood and shaving board

ActiveCN105216089ALow hygroscopicityDimensionally stableLaminationLamination apparatusWood shavingsSurface layer

The invention provides a method for preparing a thick type shaving board through waste outdoor heat-treated wood and conventional wood. The thick type shaving board prepared through the method is small in hygroscopicity, stable in size and good in comprehensive mechanical property. According to the method, the waste outdoor heat-treated wood and the conventional wood are crushed into wood shavings respectively, and the two wood shavings are dried until the moisture content is 2%-4%, and then sizing and stirring are conducted; the wood shavings are made into a board blank through mat formation and are formed through hot pressing; when the mat formation is conducted, the wood shavings of the waste outdoor heat-treated wood are paved in a sandwich layer of the board blank, and the wood shavings of the conventional wood are paved in a surface layer of the board blank; in the sizing process, the adhesive is a urea-formaldehyde resin adhesive, or a phenolic resin adhesive, or a isocyanate adhesive; in the hot pressing process, the hot pressing pressure is 2.5-3.5 Mpa, the hot pressing time is 0.2-0.5 min / mm, and if the urea-formaldehyde resin adhesive is used, the hot pressing temperature is 110 DEG C to 160 DEG C; and if the phenolic resin adhesive or the isocyanate adhesive is used, then the hot pressing temperature is 150 DEG C to 200 DEG C.

Owner:广西东林木业有限公司

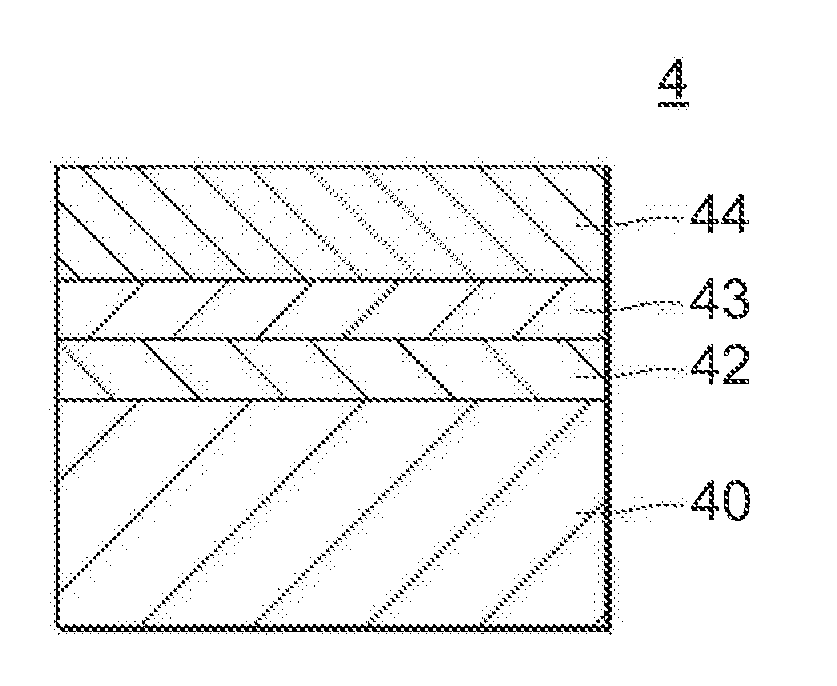

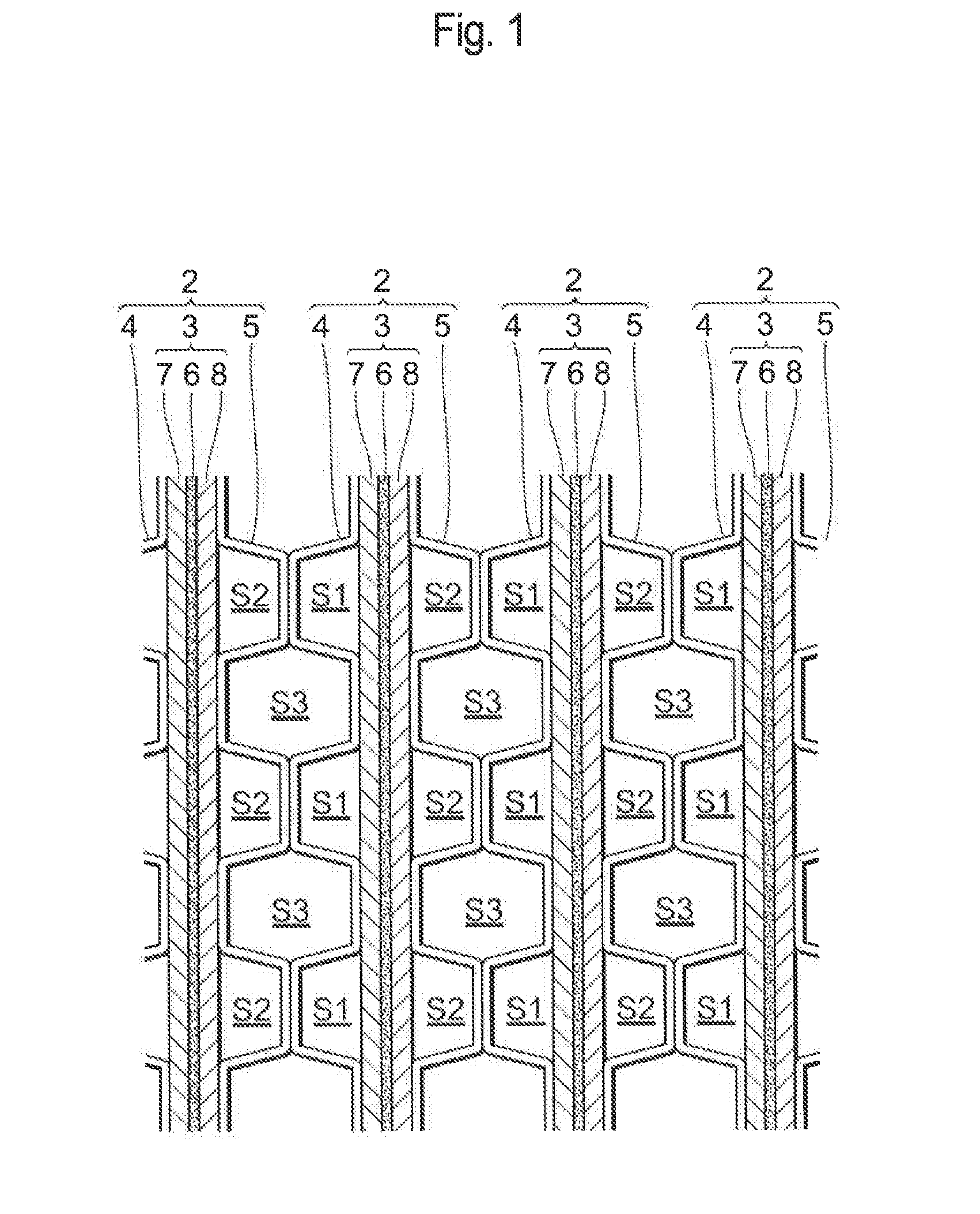

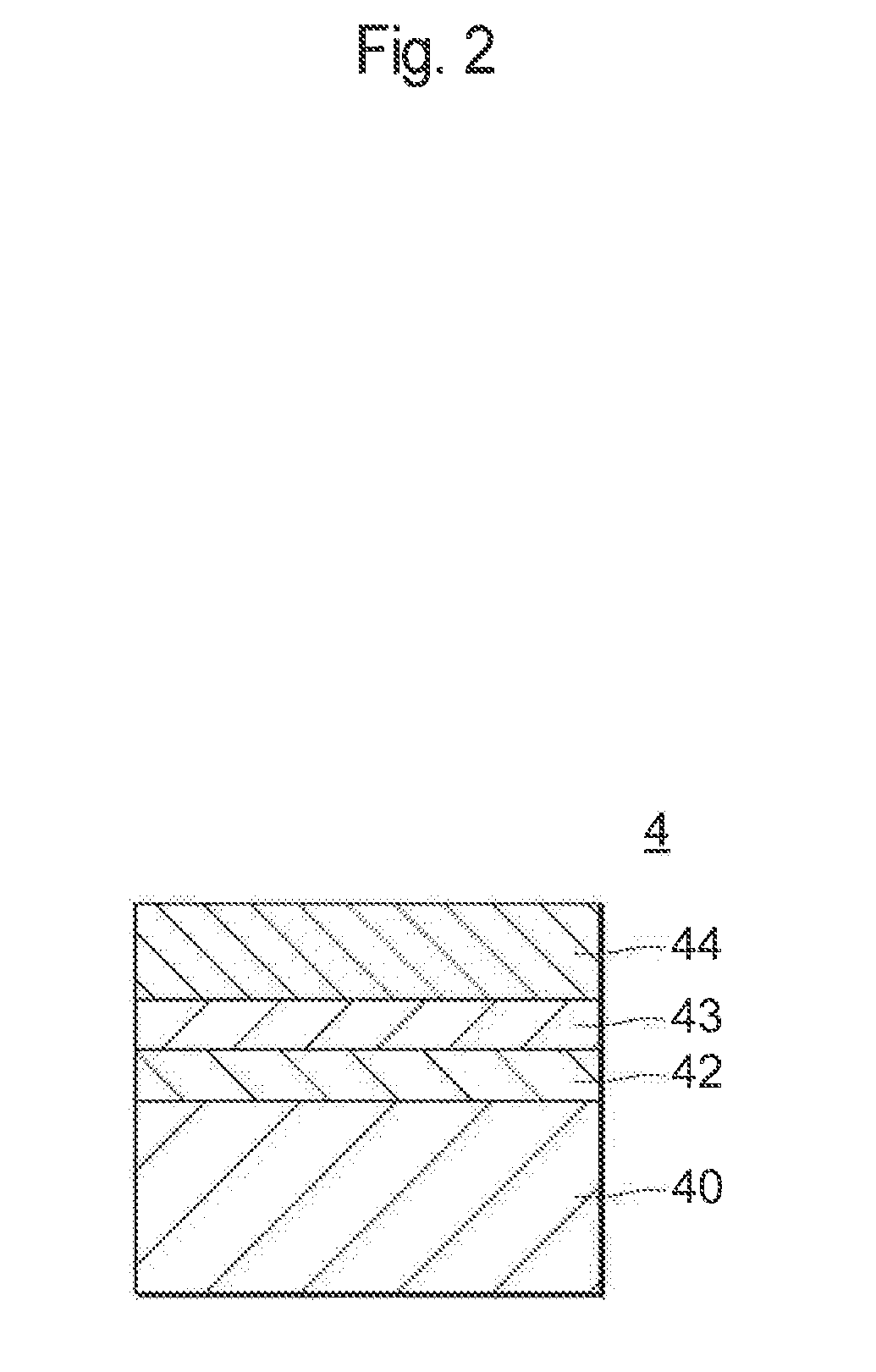

Fuel cell separator and manufacturing method of fuel cell separator

ActiveUS20160301087A1Increase surface free energyImprove adhesionCell seperators/membranes/diaphragms/spacersFinal product manufactureCarbon filmFuel cells

A manufacturing method of a fuel cell separator is provided, whereby the adhesion of a carbon film against a titanium base substrate can be improved and favorable corrosion resistance can be obtained at the same time. A fuel cell separator having such improved adhesion and favorable corrosion resistance is also provided.The method for manufacturing a fuel cell separator according to an embodiment of the invention includes the steps of: forming a TiOx (1<x<2) layer 42 on a titanium base substrate 40; and forming a carbon film 44 on the TiOx layer 42 by plasma CVD so that a binder layer 43 including Ti, O and C is formed between the TiOx layer 42 and the carbon film 44.

Owner:TOYOTA JIDOSHA KK

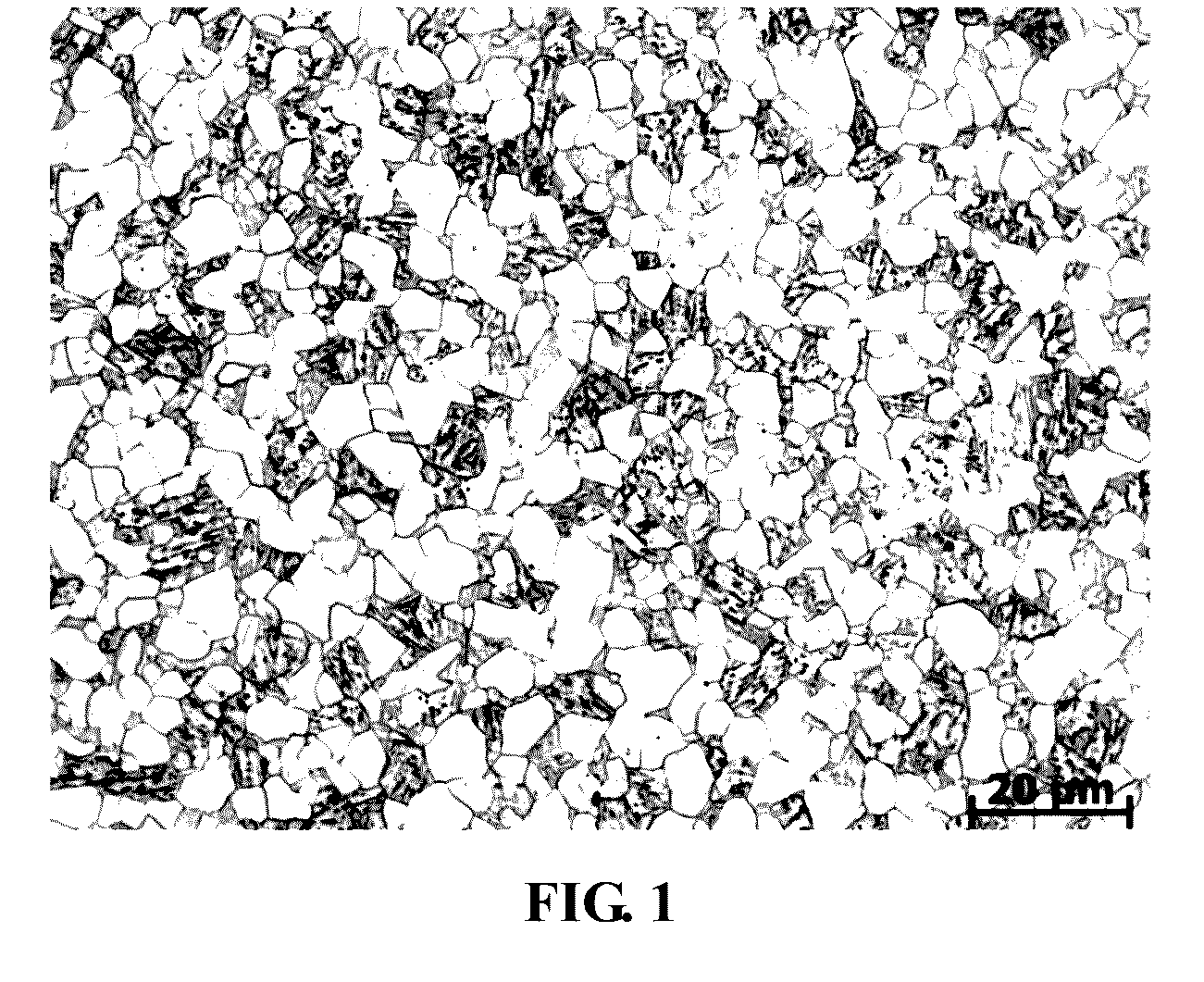

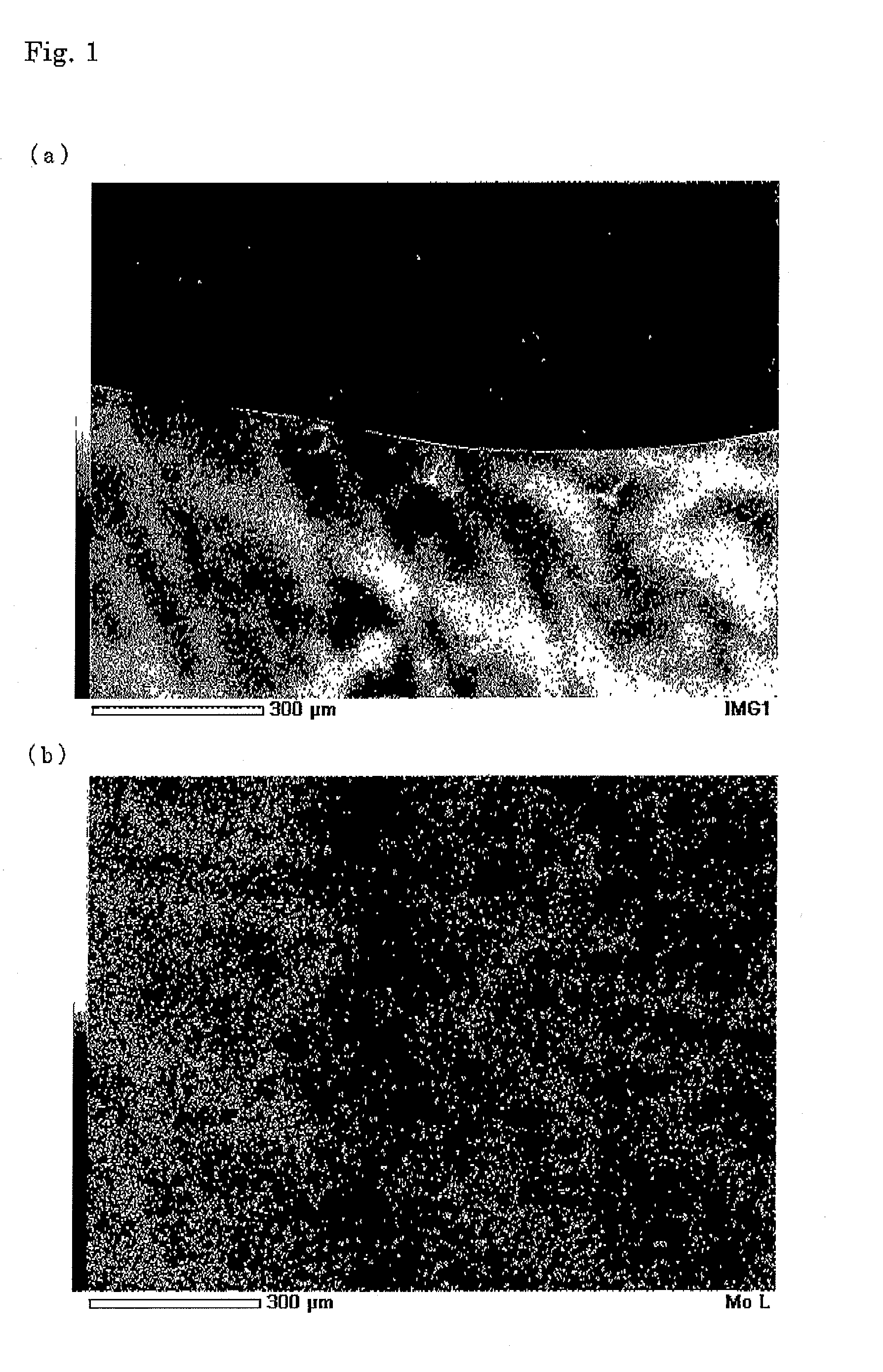

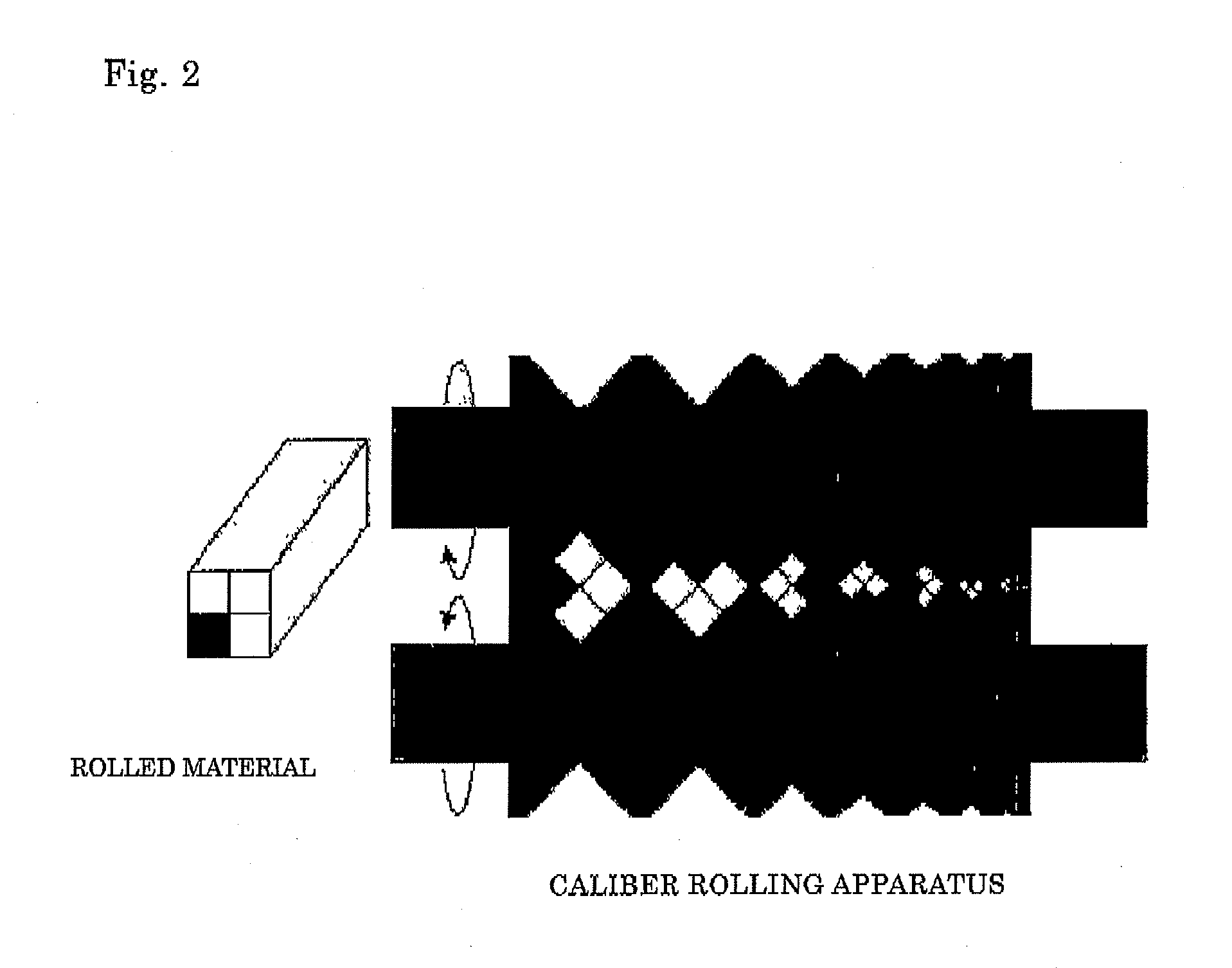

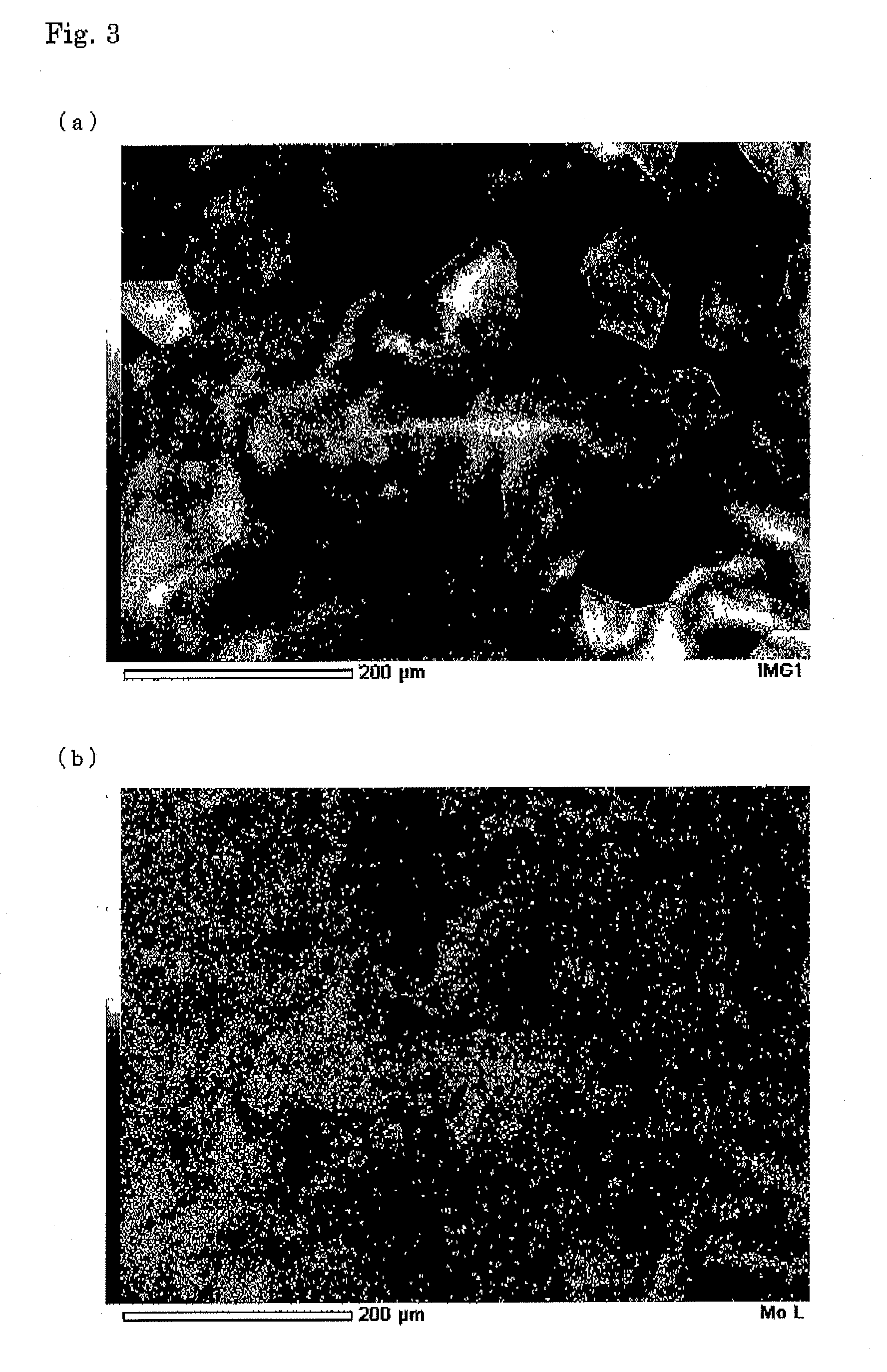

Ti-Mo ALLOY AND METHOD FOR PRODUCING THE SAME

A task of the present invention is to provide a Ti—Mo alloy material which can be improved in the yield stress at room temperature by the precipitation of an aged omega phase in the Ti—Mo alloy while maintaining large ductility at room temperature, and a method for producing the same.Provided is a Ti—Mo alloy collectively having an Mo content of 10 to 20 mass %, wherein the Ti—Mo alloy has a winding belt-like or swirly segregation portion having a width of 10 to 20 μm in the plane of a backscattered electron image (BEI) or an energy dispersive X-ray spectroscopy (EDS) image of the Ti—Mo alloy, as examined under a scanning electron microscope, in which Mo content is larger than the collective Mo content of the Ti—Mo alloy. When generally observing the entire plane examined, a segregation structure in a swirly form can be observed.Further, provided is the Ti—Mo alloy which has been subjected to aging treatment so that an aged omega phase is precipitated along the segregation portion. When generally observing the entire plane examined, an aged omega phase structure in a swirly form can be observed.

Owner:NAT INST FOR MATERIALS SCI

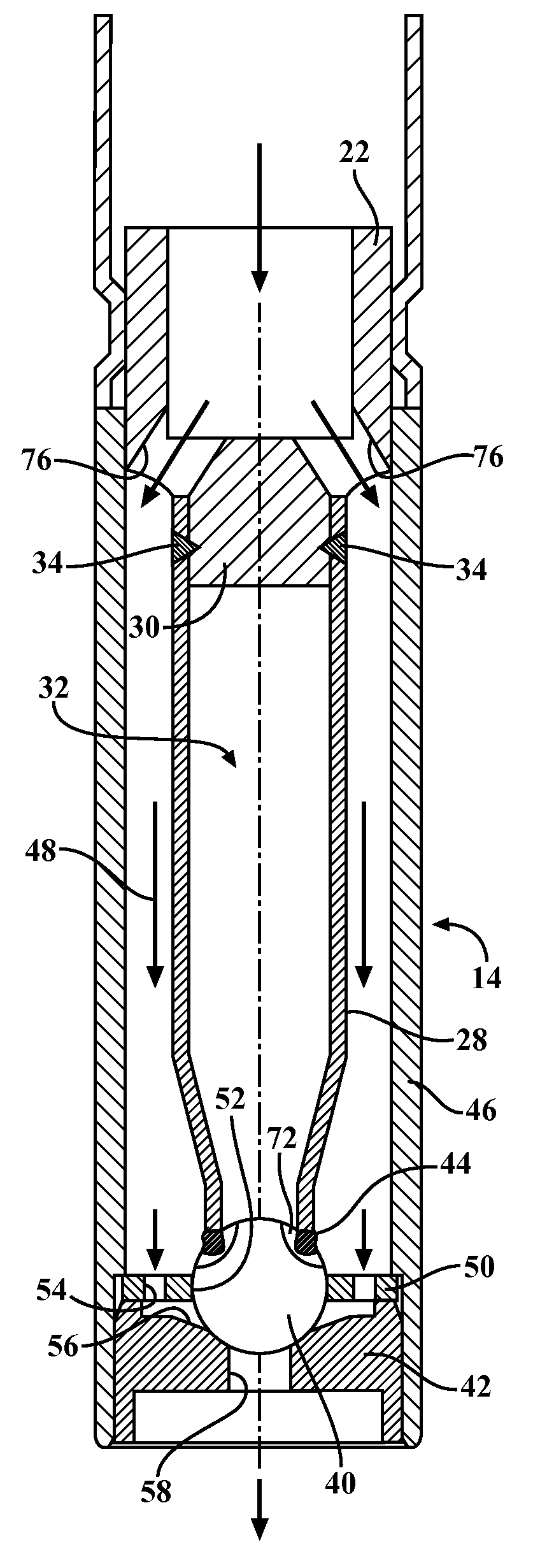

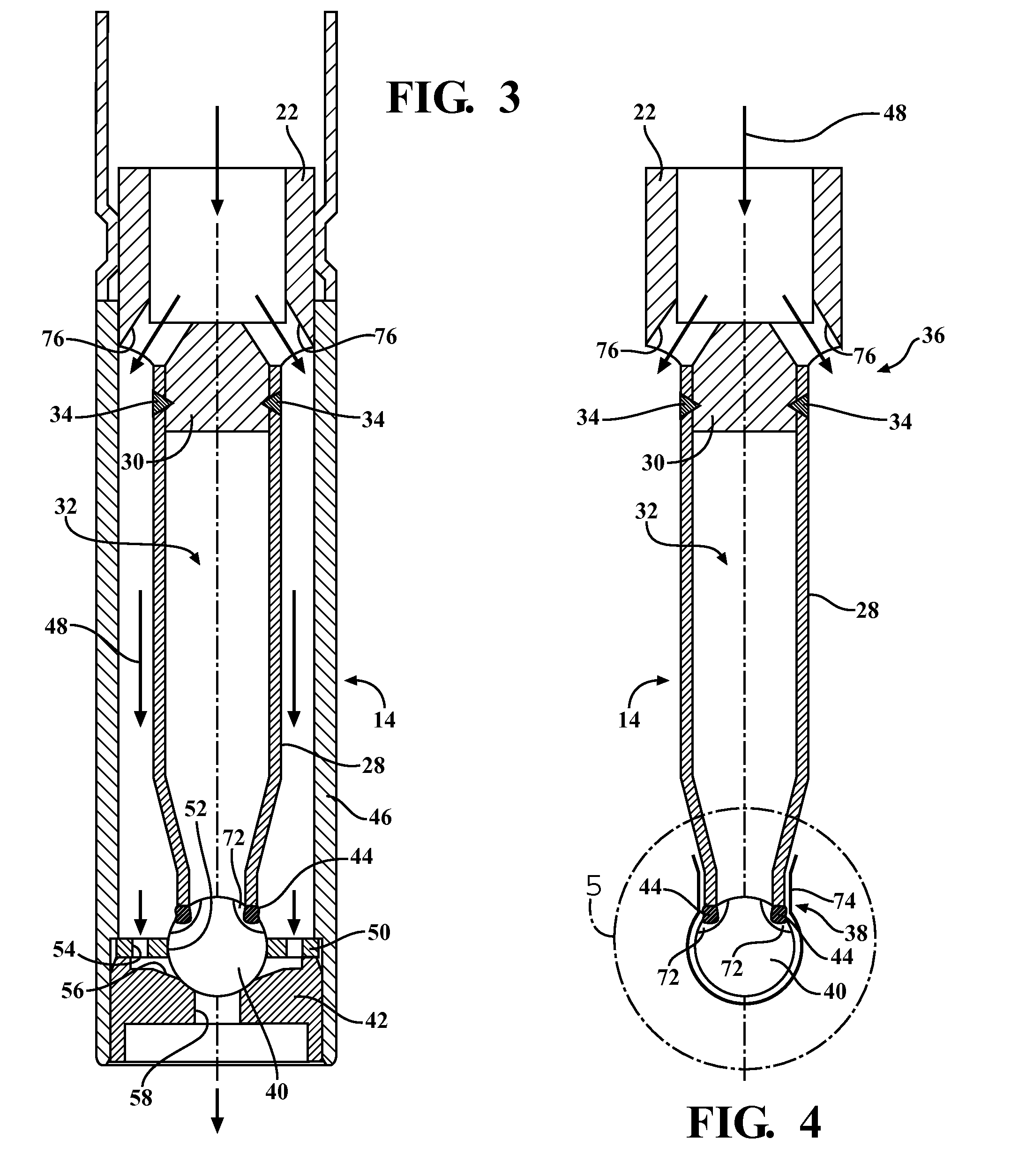

Sealed armature ball tube assembly

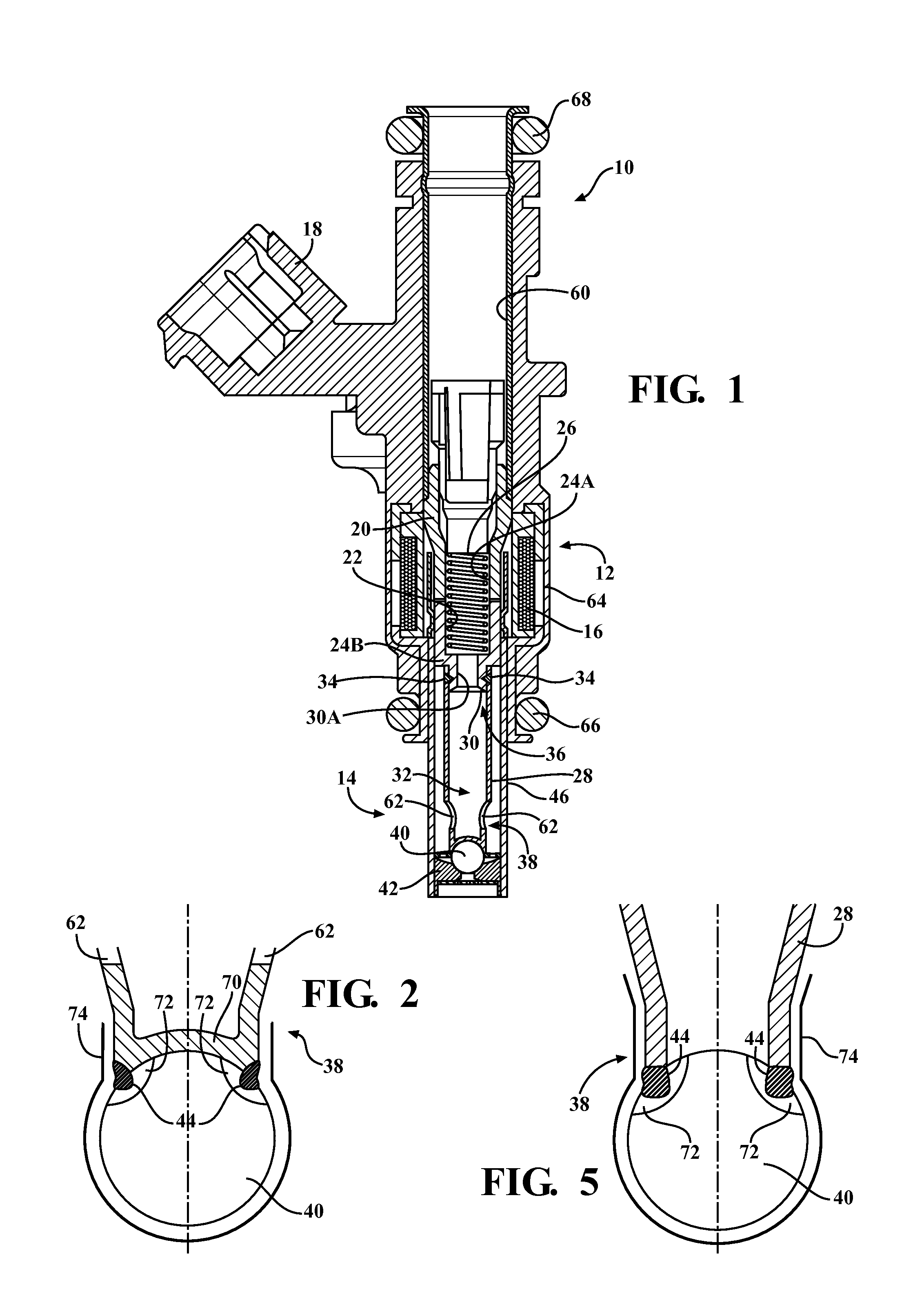

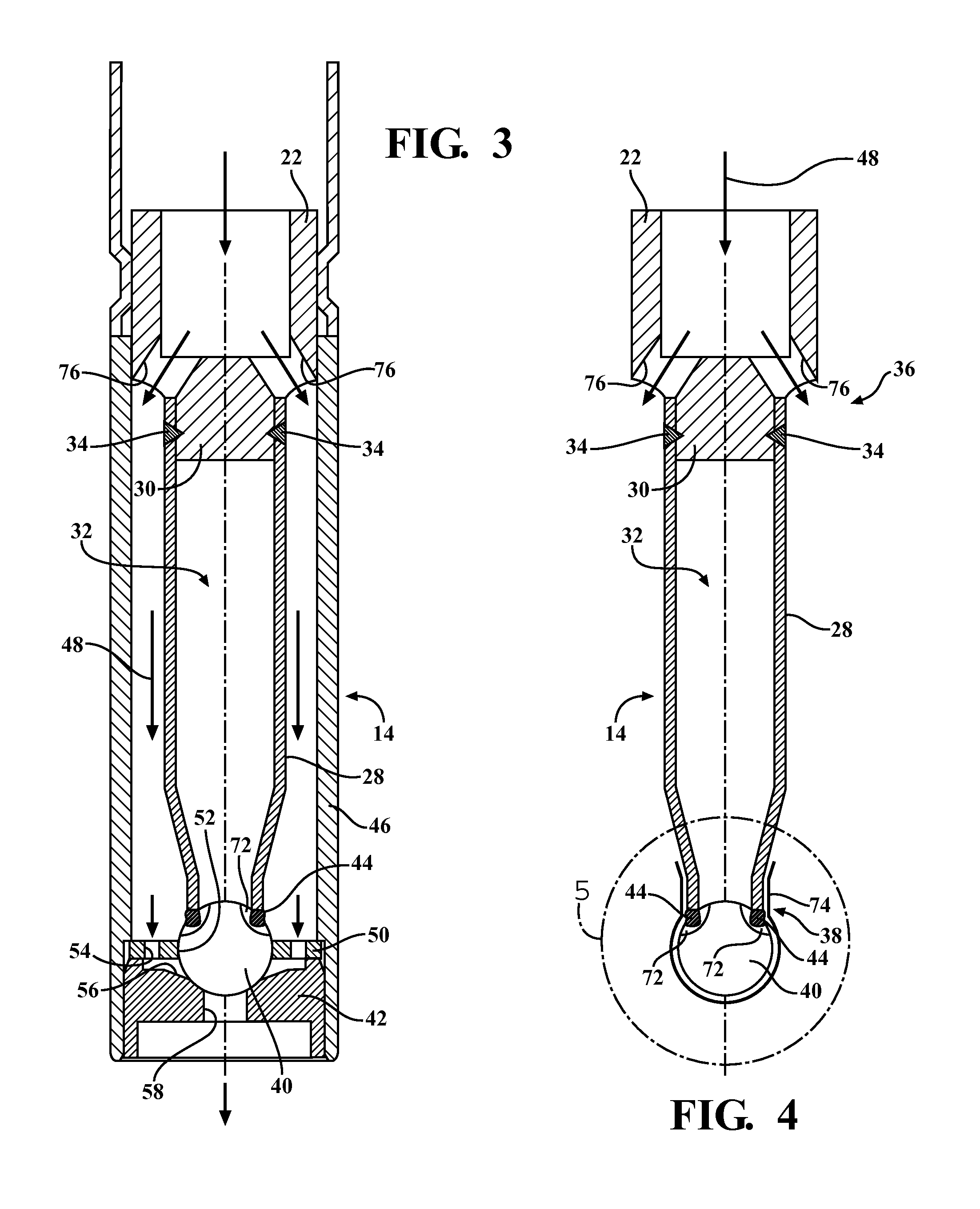

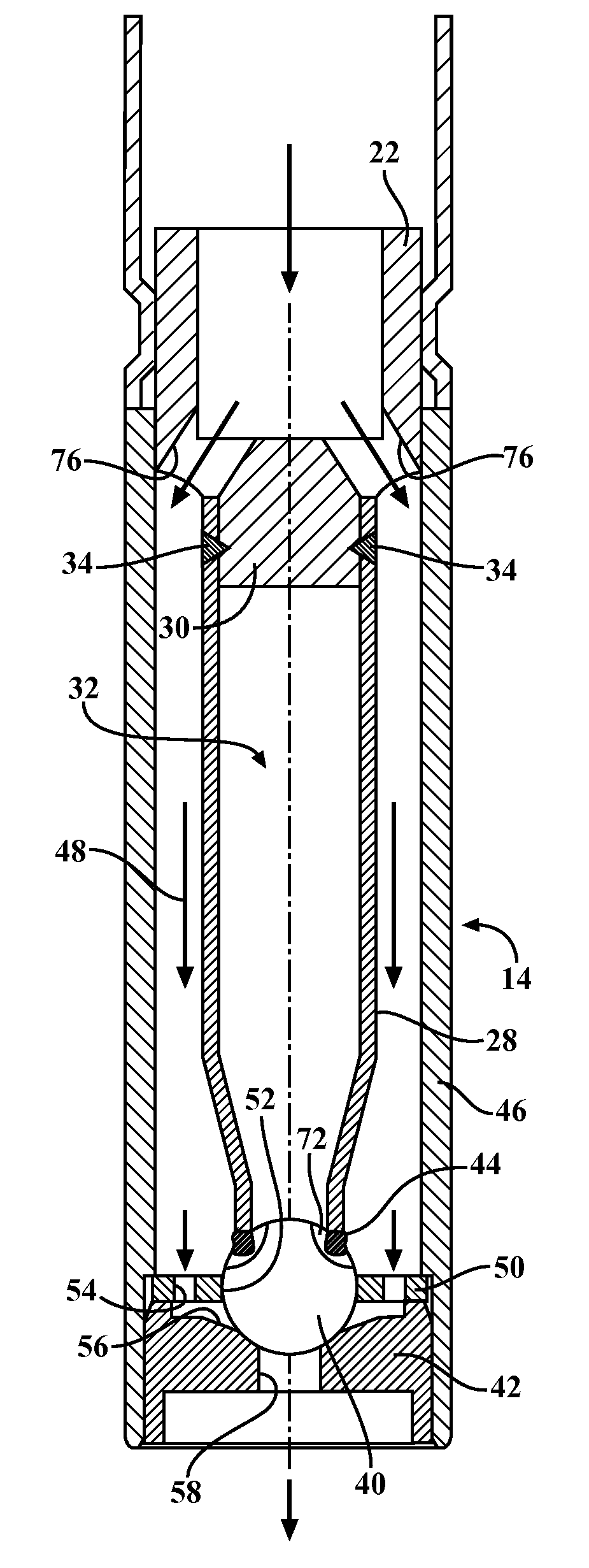

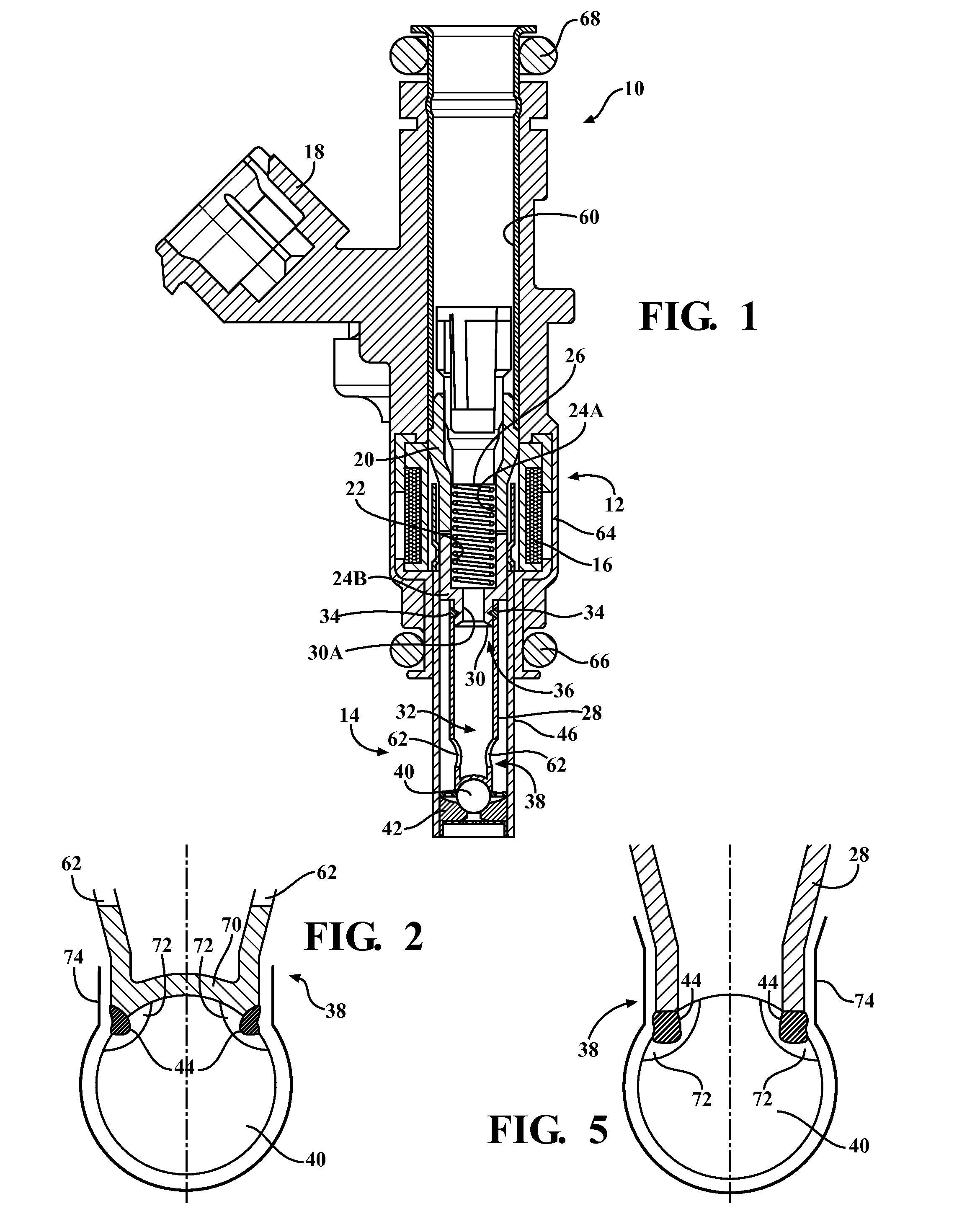

ActiveUS9366355B2Reduce the possibilityCorrosion protectionOperating means/releasing devices for valvesMachines/enginesHeat-affected zoneThermal impact

An injector having a tube attached to an armature. The injector includes a solenoid portion and a valve portion controlled by the solenoid portion. The armature includes a small diameter portion. Also included is a tube having a cavity, a first end of the tube is connected to the small diameter portion, and a ball is connected to a second end of the tube, such that the ball is selectively in contact with a valve seat. A hermetic weld connects the ball to the second end, and at least one heat affected zone is located in proximity to the hermetic weld. A coating substantially surrounds the heat affected zone and at least a portion of the ball, such that the coating prevents the heat affected zone from being exposed to diesel exhaust fluid and thus subsequent corrosion.

Owner:VITESCO TECH USA LLC

Sealed armature ball tube assembly

ActiveUS20140048629A1Mitigate possibilityCorrosion protectionOperating means/releasing devices for valvesSpray nozzlesInjectorCorrosion

An injector having a tube attached to an armature. The injector includes a solenoid portion and a valve portion controlled by the solenoid portion. The armature includes a small diameter portion. Also included is a tube having a cavity, a first end of the tube is connected to the small diameter portion, and a ball is connected to a second end of the tube, such that the ball is selectively in contact with a valve seat. A hermetic weld connects the ball to the second end, and at least one heat affected zone is located in proximity to the hermetic weld. A coating substantially surrounds the heat affected zone and at least a portion of the ball, such that the coating prevents the heat affected zone from being exposed to diesel exhaust fluid and thus subsequent corrosion.

Owner:VITESCO TECH USA LLC

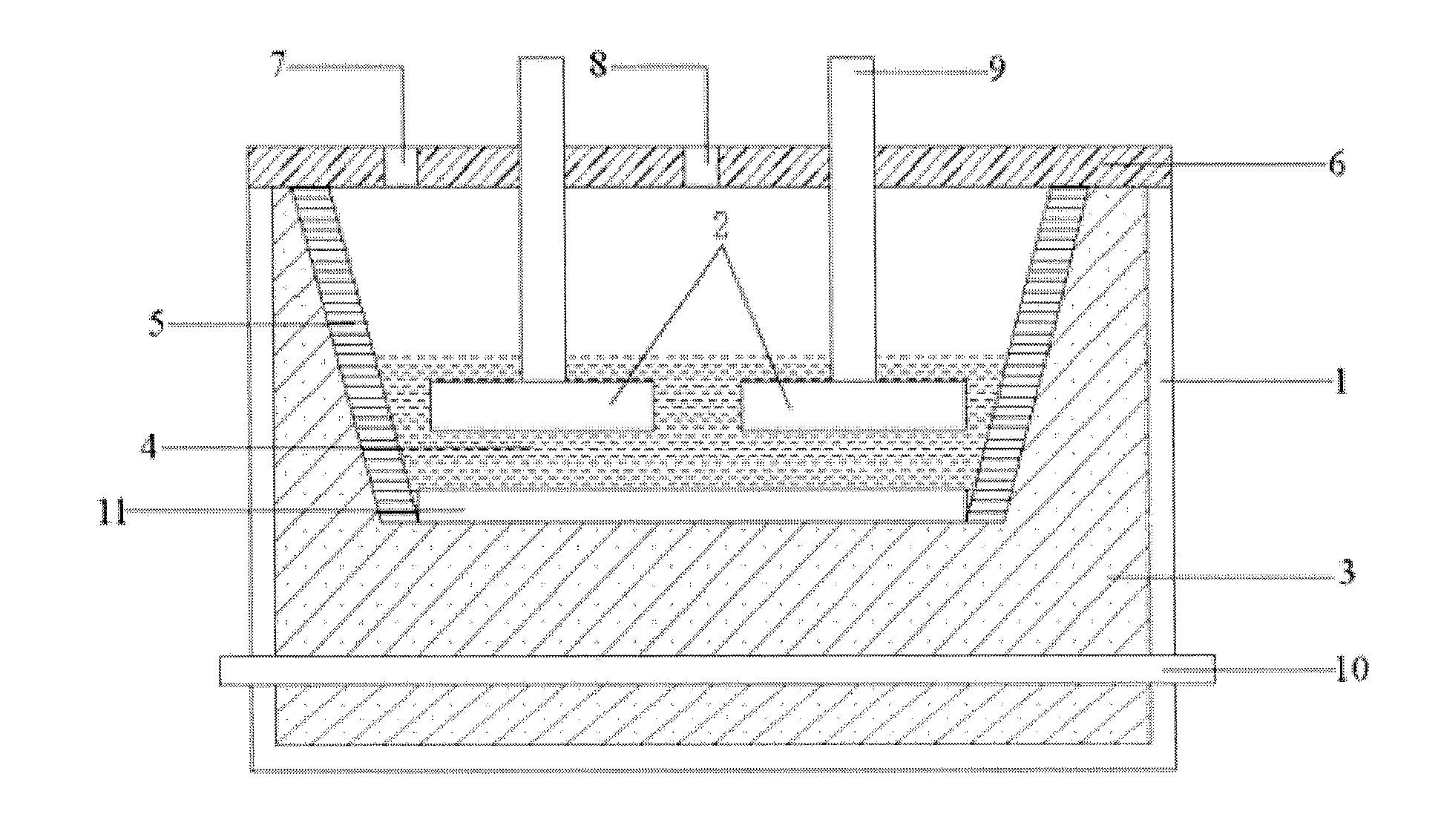

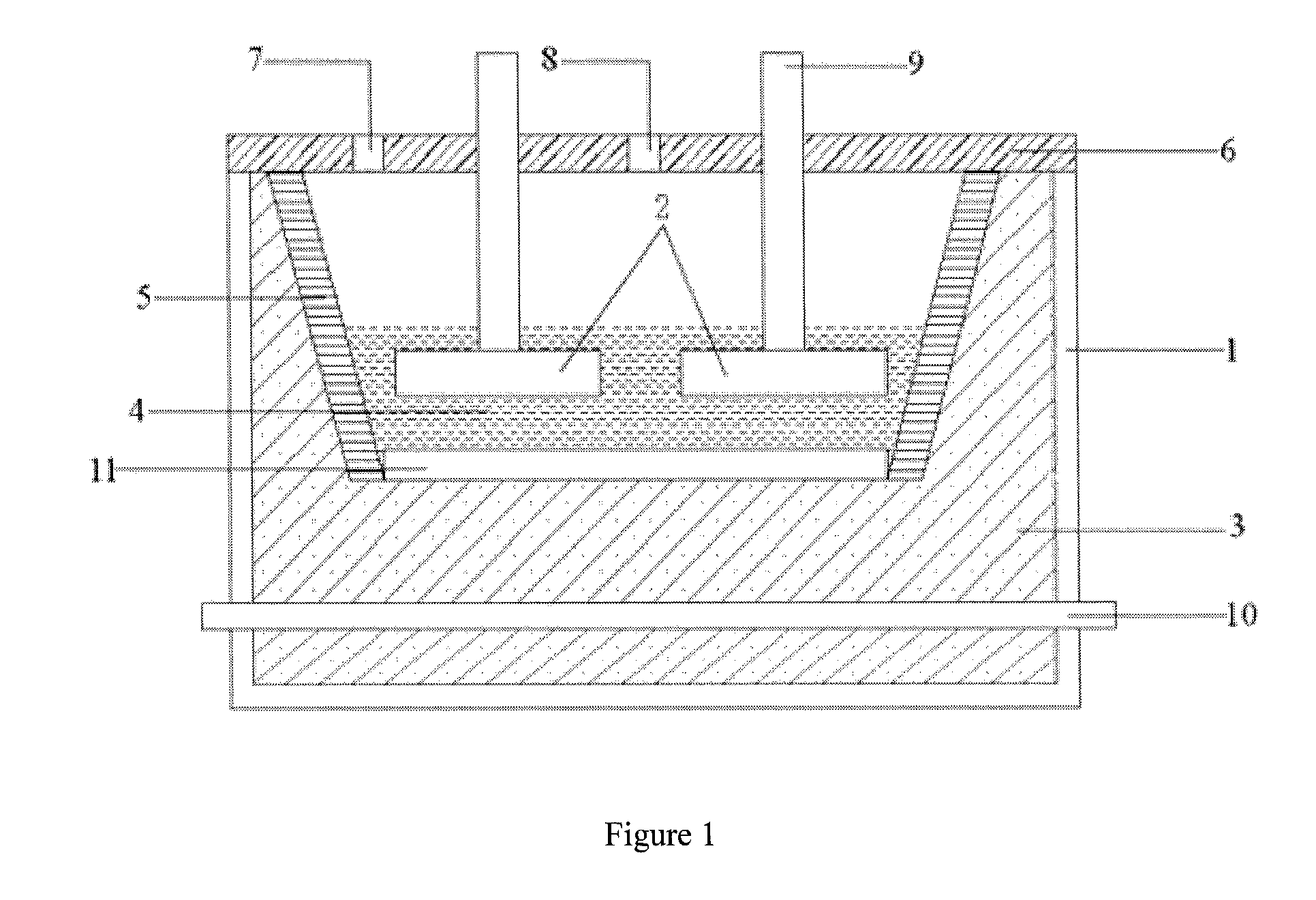

Electrolysis tank used for aluminum electrolysis and electrolysis process using the electrolyzer

InactiveUS20150122664A1Improve conductivityReduce overvoltageIsotope separationOxygenMaterials science

An electrolytic cell for aluminum electrolysis includes a cell body, in which an anode and a cathode are arranged inside the cell body, the cell body is filled with an electrolyte, and at least a part of the anode is immersed in the electrolyte; the anode is arranged above the cell body, the cathode is arranged at the bottom of the electrolytic cell and is covered by aluminum liquid, the electrolyte is located between the anode and the cathode and covers the aluminum liquid; and an insulating layer is arranged on the inner sidewall of the cell body for isolating oxygen or the electrolyte from a carbon block. The anode contains Fe and Cu as primary components; and the electrolyte is composed of 30-38 wt % of NaF, 49-60 wt % of AlF3, 1-5 wt % of LiF, 1-6 wt % of KF and 3-6 wt % of Al2O3, and the molar ratio of NaF to AlF3 is 1.0-1.52.

Owner:INNER MONGOLIA UNITED IND

Wallboard binder and preparation method thereof

The invention discloses wallboard binder and a preparation method thereof. The wallboard binder comprises cellulose ether, water and cement, wherein the weight ratio of the cellulose ether to the water to the cement is (0.1-3):(610-640):1000. The preparation method includes: loading the water into a stirring barrel according to the weight, placing the cellulose ether into the stirring barrel, and stirring with a stirrer for 150-180 seconds until liquid is thick; adding the cement, and stirring with an electric stirrer for 150-180 seconds to obtain the wallboard binder. The wallboard binder and the preparation method thereof have the advantages that the wallboard binder only comprises three components, the cellulose ether and the cement are powdered and do not form granules after mixing, the binder is fine and smooth and lubricating in surface and good in binding performance, the preparation method can replace a tradition method which needs multiple components to jointly prepare the binder, unevenness during binder smearing can be avoided, and manpower cost increasing can be avoided.

Owner:ZUNYI HENGRUIDE TECH CO LTD

Processing process of aluminum veneer

PendingCN112024339AUniform thicknessImprove corrosion resistancePretreated surfacesMetallic material coating processesCorrosion resistantVarnish

The invention discloses a processing process of an aluminum veneer. The processing process comprises the following steps of pretreatment: carrying out primary rough grinding and secondary fine grinding on the aluminum veneer through sand paper, washing the aluminum veneer completely, spraying an oil removing agent after the aluminum veneer is drained, washing and drying the aluminum veneer after removing oil, soaking the aluminum veneer in a pickling solution, and washing and draining the aluminum veneer after pickling; chromium-free passivation: putting the drained aluminum veneer into a passivation solution, washing with water, dipping in a solution containing phytic acid, cleaning with deionized water, and drying; and spraying: spraying a fluorocarbon coating primer on the surface of the passivated aluminum veneer by using a high-voltage electrostatic spray gun, placing at a low temperature for leveling, continuously uniformly spraying a fluorocarbon coating finish paint by using the high-voltage electrostatic spray gun, placing at a low temperature for leveling, continuously uniformly spraying a fluorocarbon coating varnish by using the high-voltage electrostatic spray gun, placing at a low temperature for leveling, and then drying to finish processing. The processing process of the aluminum veneer has the advantages of better corrosion resistance and higher stability.

Owner:江苏佰大幕墙科技有限公司

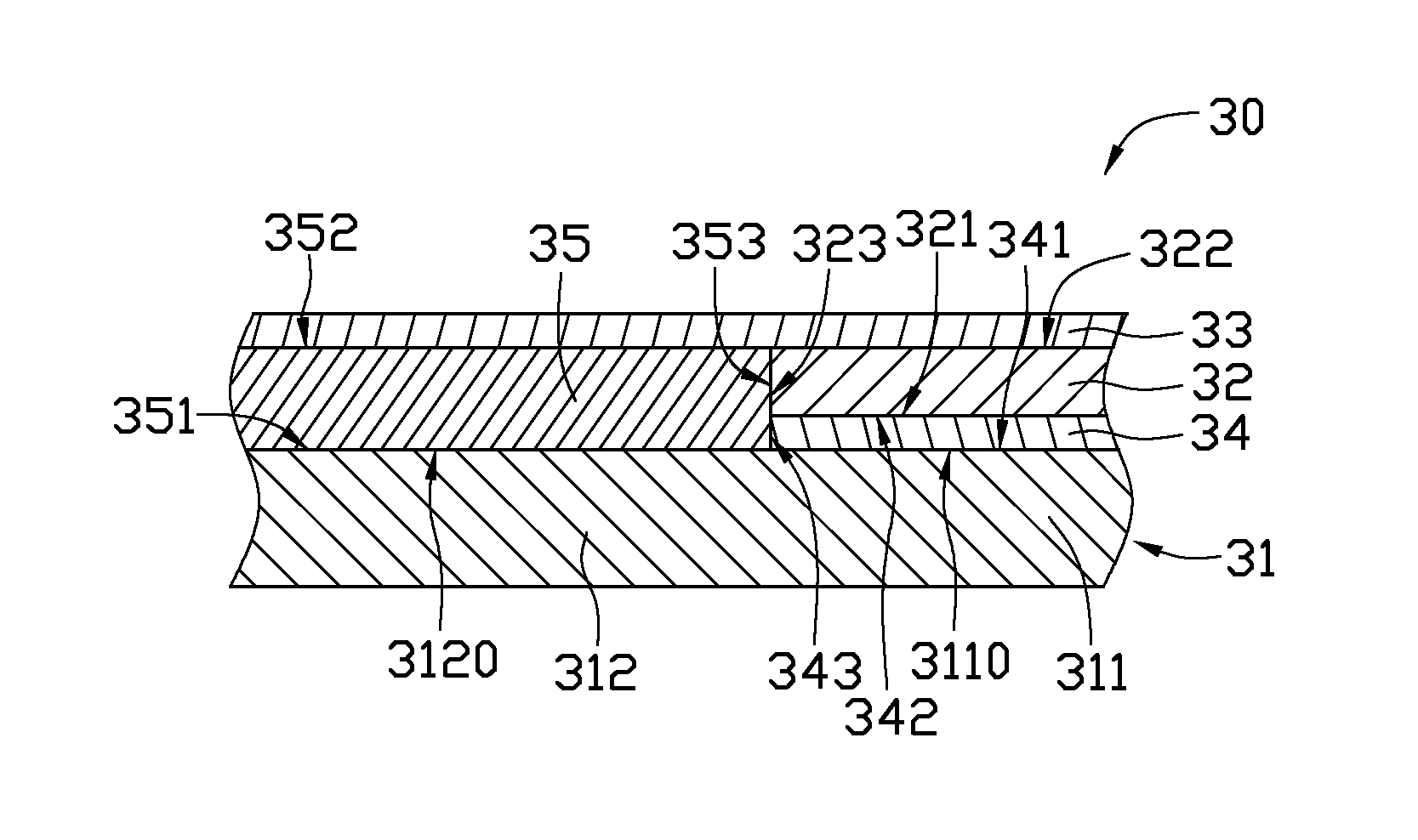

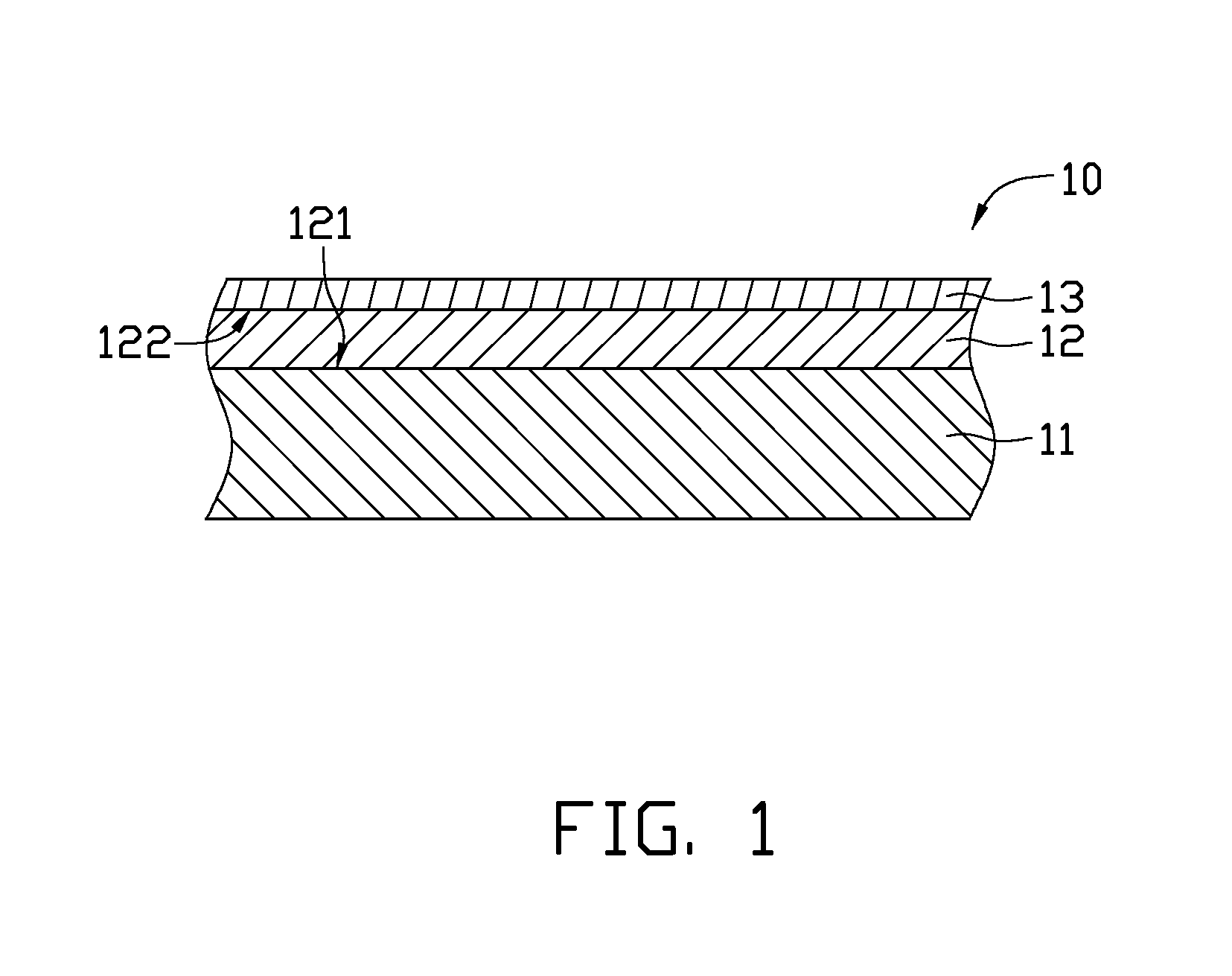

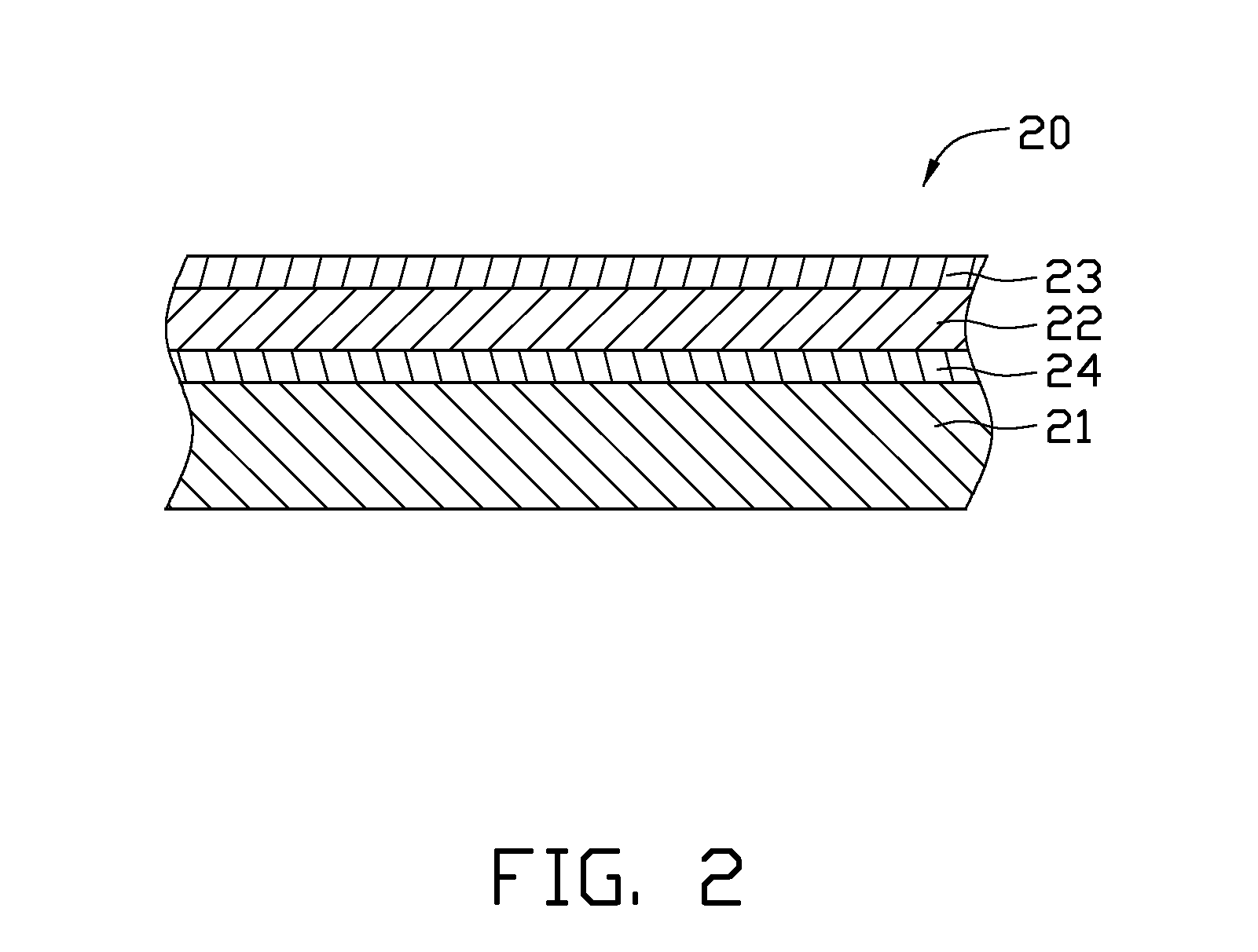

Plastic component with diamond-like carbon layer

InactiveUS20100297412A1Poor corrosion resistanceLayered productsRecord information storageCarbon layerDiamond-like carbon

An exemplary plastic component includes a polymer base, a metallic luster layer formed on the polymer base, and a diamond-like carbon layer formed on the metallic luster layer. The metallic luster layer is comprised of a material selected from the group consisting of silicon nitride, silicon carbide, titanium carbide, and a combination thereof. A thickness of the metallic luster layer is in the range from 50 nm to 1000 nm. The diamond-like carbon layer has a thickness in the range from 5 nanometers to 50 nanometers.

Owner:HON HAI PRECISION IND CO LTD

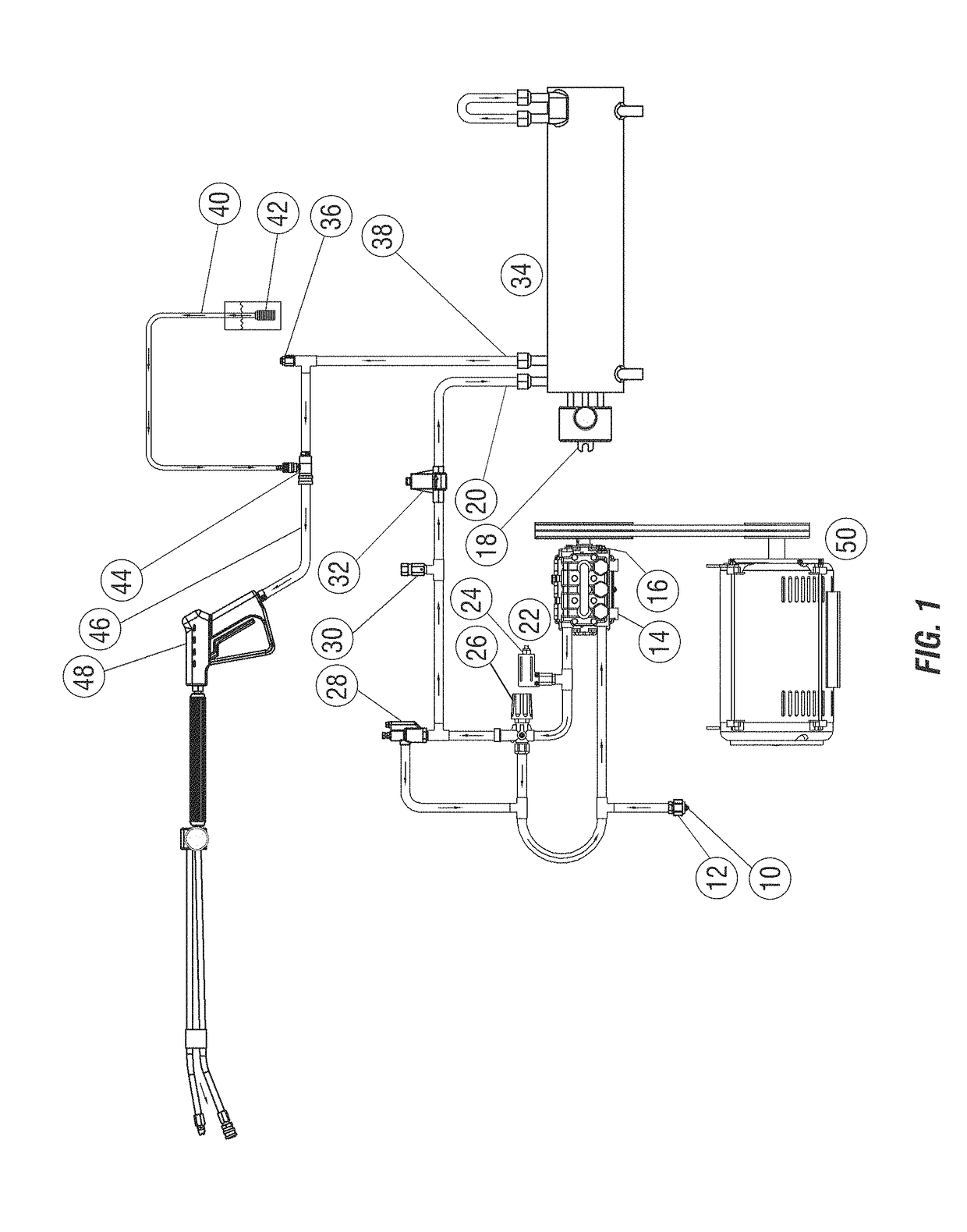

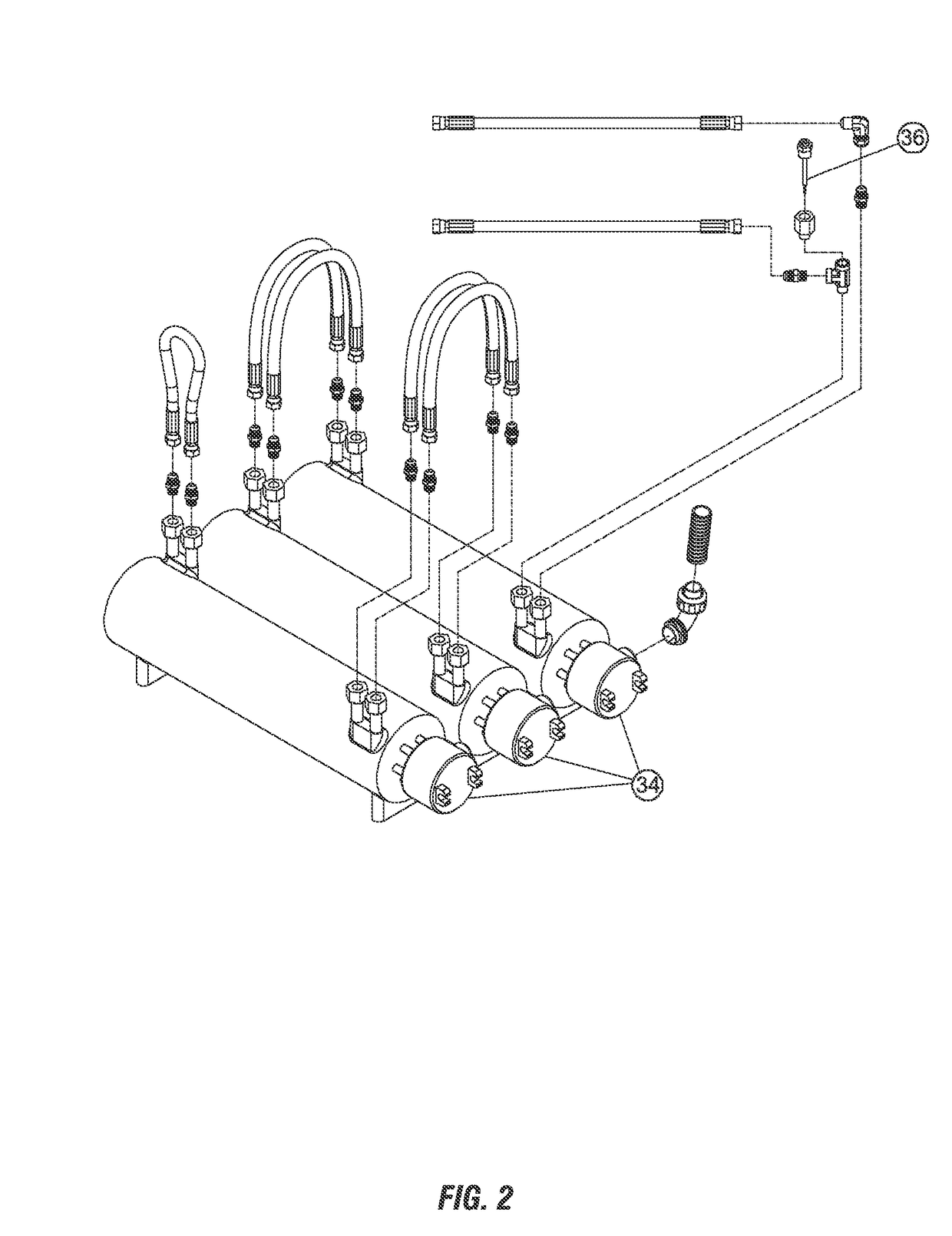

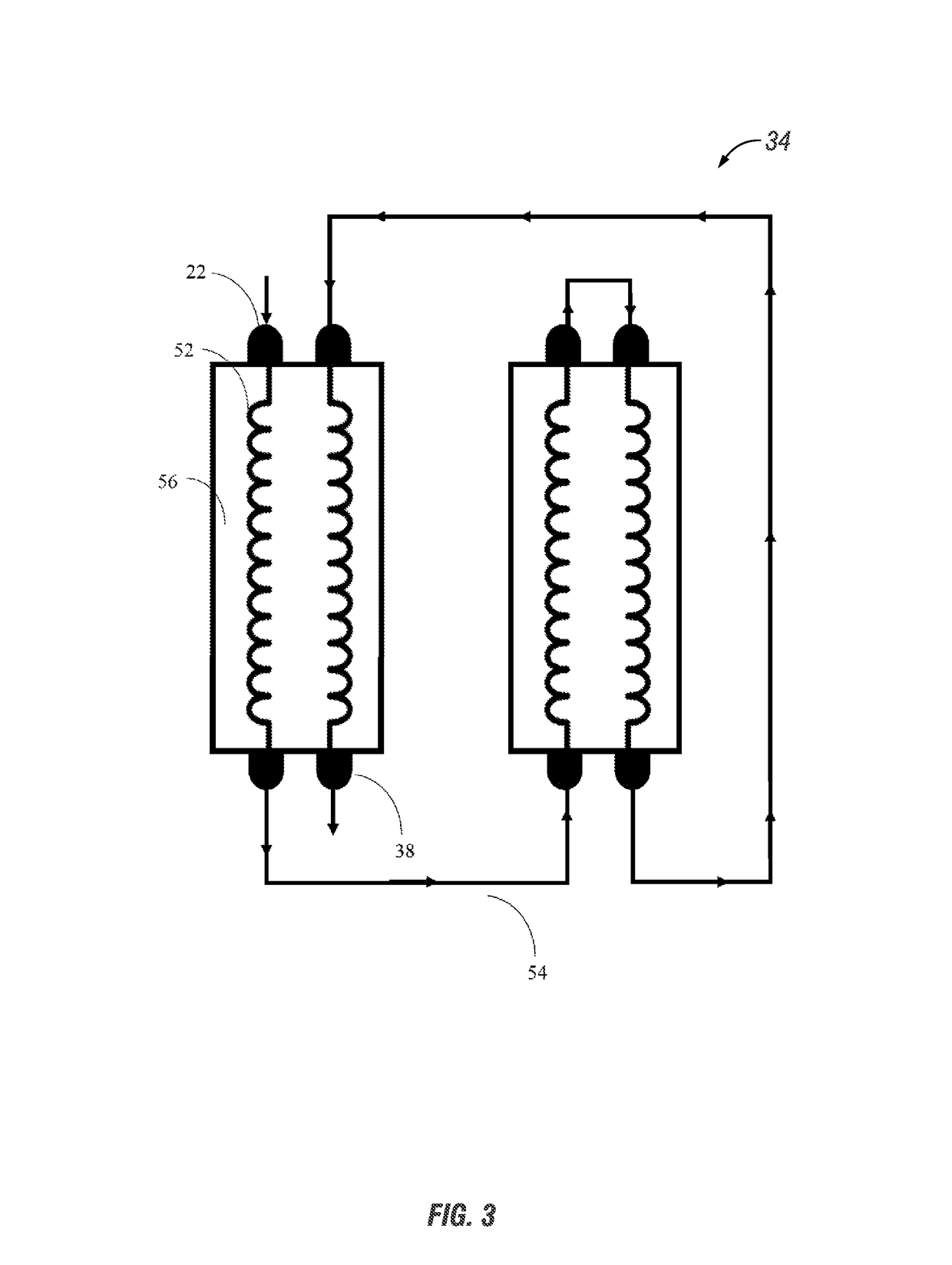

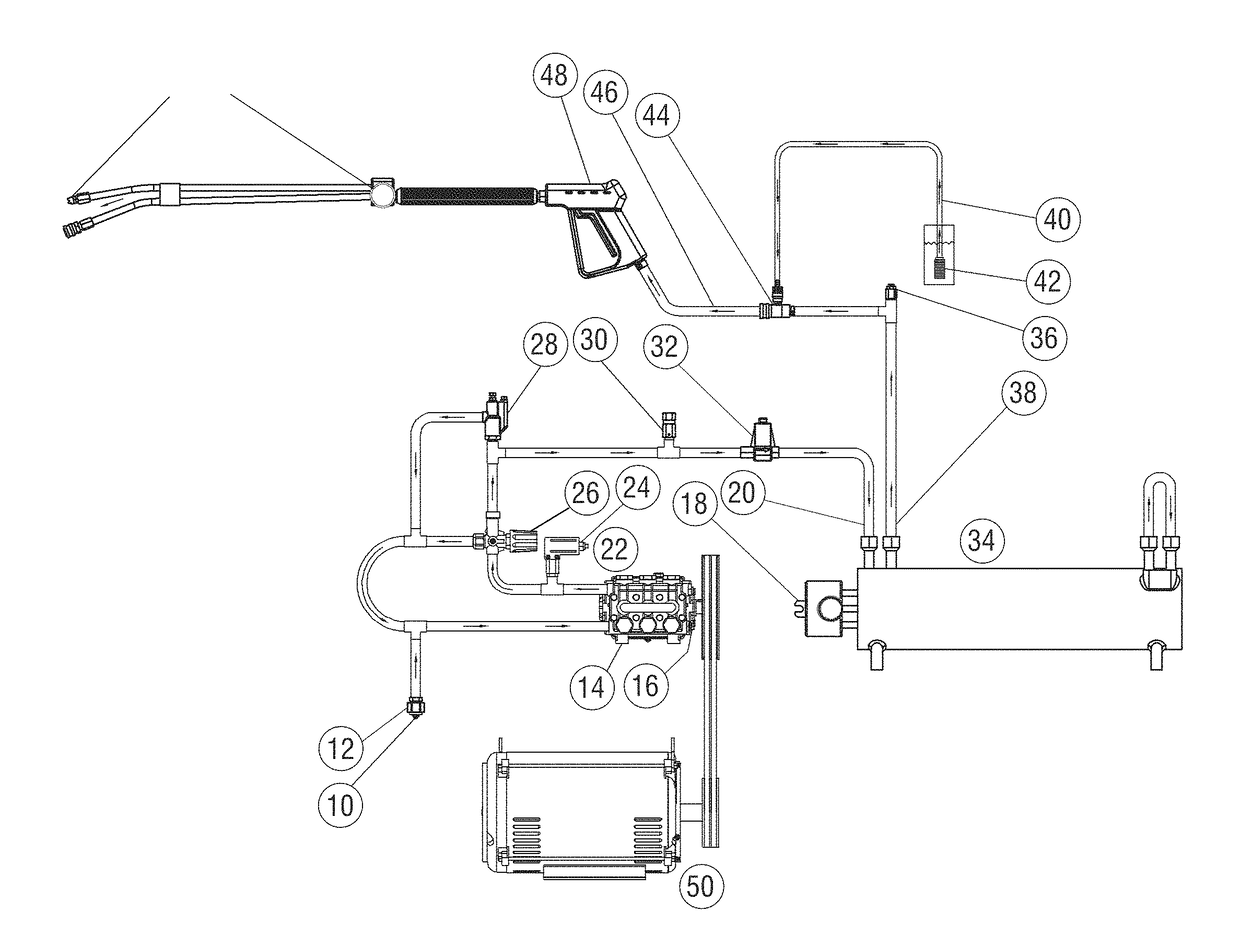

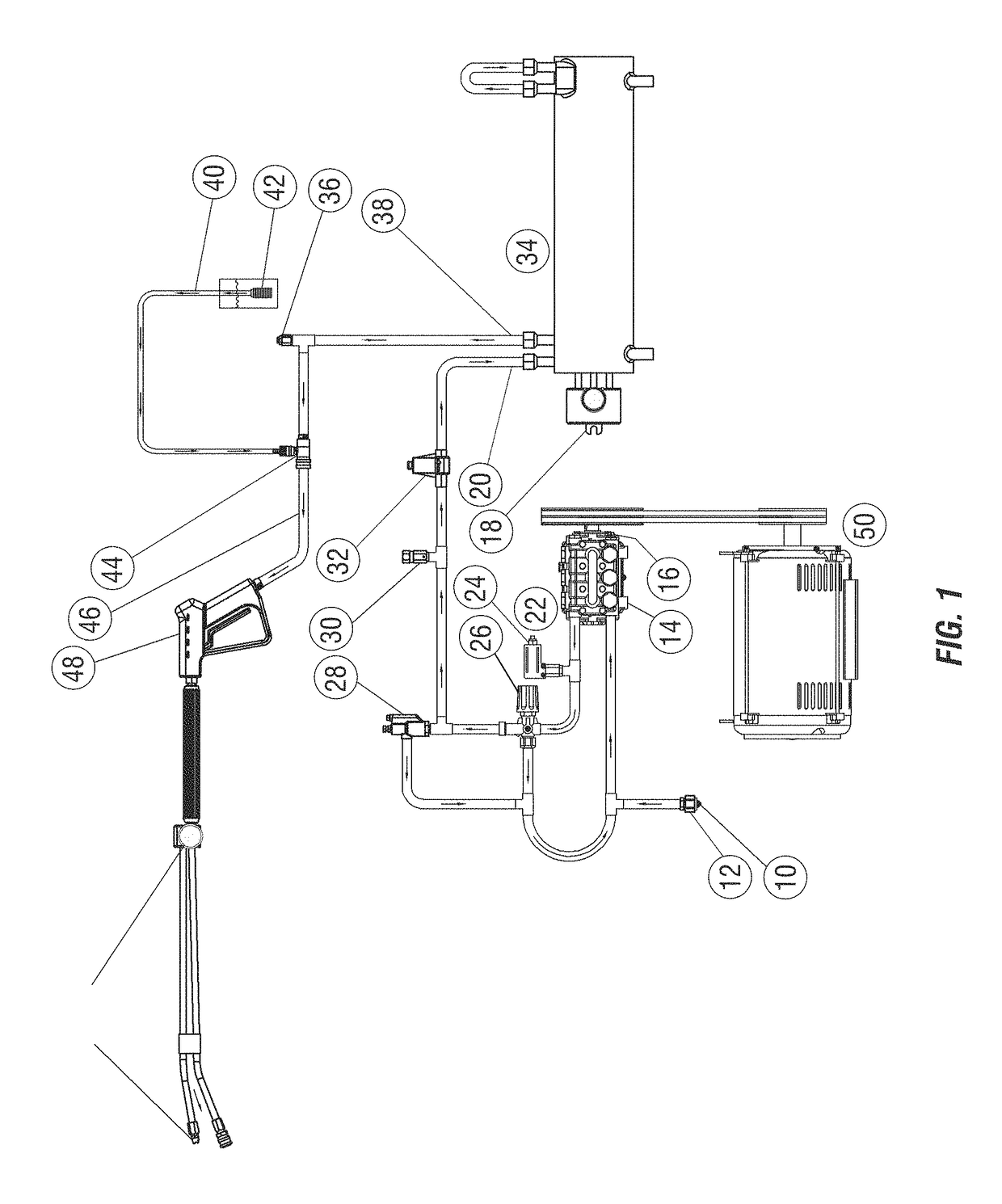

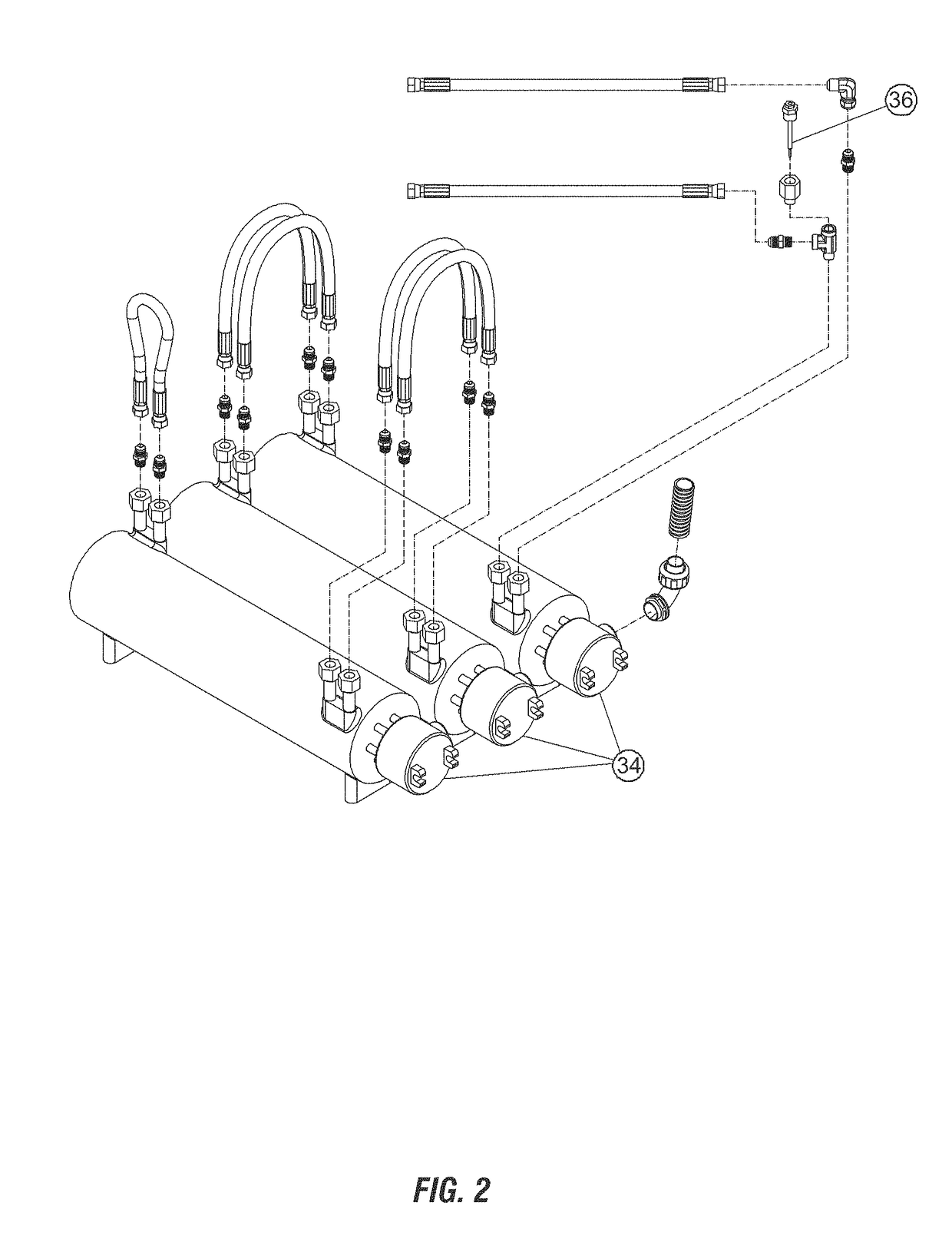

Electric cartridge style pressure washer heater module

ActiveUS10189036B2Efficient heatingPoor corrosion resistanceBeverage vesselsLiquid spraying apparatusEngineeringVoltage

An all-electric pressure washer heater module having a heating coil and a heating element is disclosed. A system for all-electric pressure washing is further disclosure. In particular, the all-electric pressure washer heater module contains the heating element from exposure to corrosion and fouling.

Owner:MI T M CORP

Method for coating aluminum wheel, and aluminum wheel

ActiveUS9259963B2Good cosmetic effectReduce degradationMaterial nanotechnologyLiquid surface applicatorsEpoxyAcrylic resin

The present invention provides a method for coating an aluminum wheel using a coating composition capable of forming a coating film having a superior cosmetic property as well as an anticorrosive property much enough for preventing corrosion even in the use in an area where the coating film is susceptible to salt damage, and an aluminum wheel obtained by the method. A method for coating an aluminum wheel including applying an anticorrosive coating composition onto the aluminum wheel, and thereafter applying a clear coating composition to form a transparent multilayer coating film, wherein the anticorrosive coating composition contains an acrylic resin (1) having a weight average molecular weight of 50,000 to 140,000, a glass transition point of 20 to 50° C., a hydroxyl value of 10 to 50 mgKOH / g, and an acid value of 10 to 40 mgKOH / g, and an epoxy resin (2) having an epoxy equivalent of 210 to 1,000 g / eq and contains the epoxy resin (2) in an amount of 5 to 20 parts by weight on the solid matter basis to 100 parts by weight of the solid matter of the acrylic resin (1).

Owner:TOPY INDUSTRIES +1

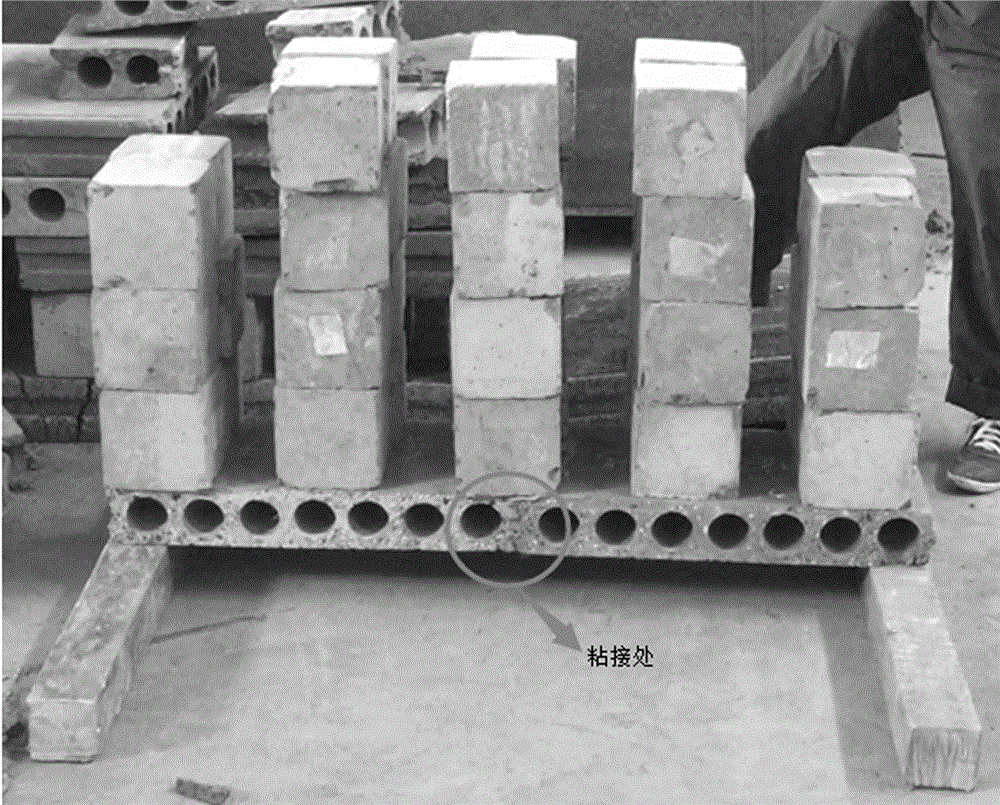

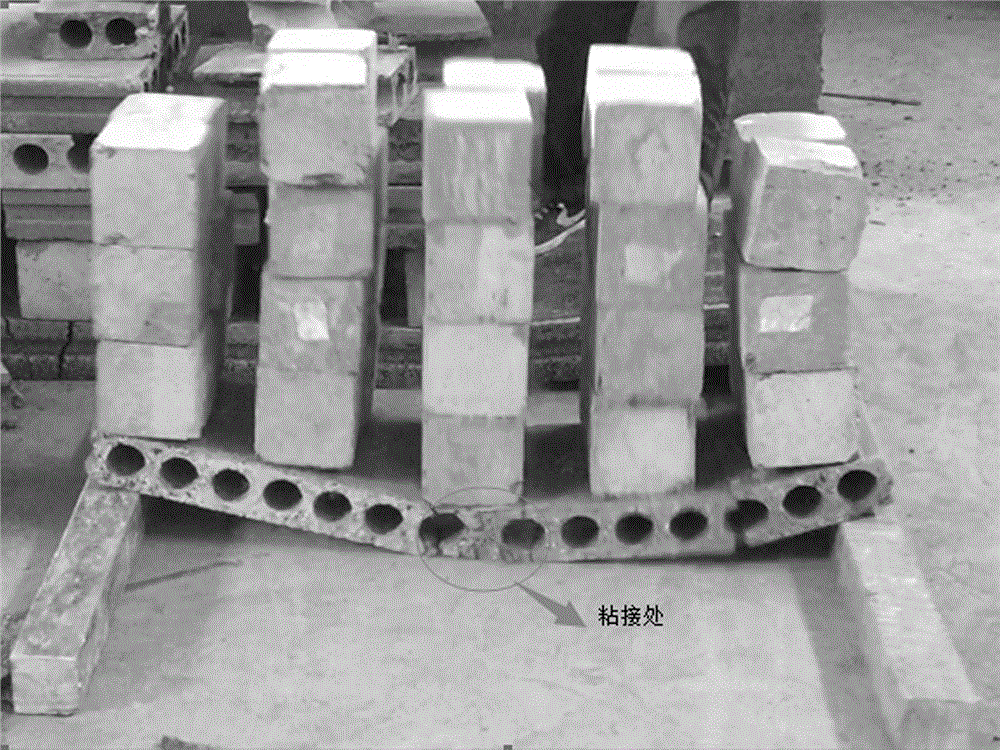

Non-cement-based sandy arsenic rock unburned brick and preparation method thereof

The invention relates to the field of building materials, in particular to a non-cement-based sandy arsenic rock unburned brick effectively utilizing arsenic rock and used for controlling water and soil loss of the arsenic rock and a preparation method thereof. The brick is prepared from the arsenic rock, an active blending material, an activator and water, a main material, the active blending material and the activator are weighed by weight and put into a cement paste mixer to be mixed and stirred uniformly, then water is added, stirring is carried out for 90 seconds, pressure molding is carried out after uniform stirring is carried out, the wet density of a molded module after forming and demolding is no less than 1950 kilograms per cubic meter, maintenance is carried out for 28 days ina natural state, and the non-cement-based sandy arsenic rock unburned brick of which the compressive strength is 10-20 MPa is obtained.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

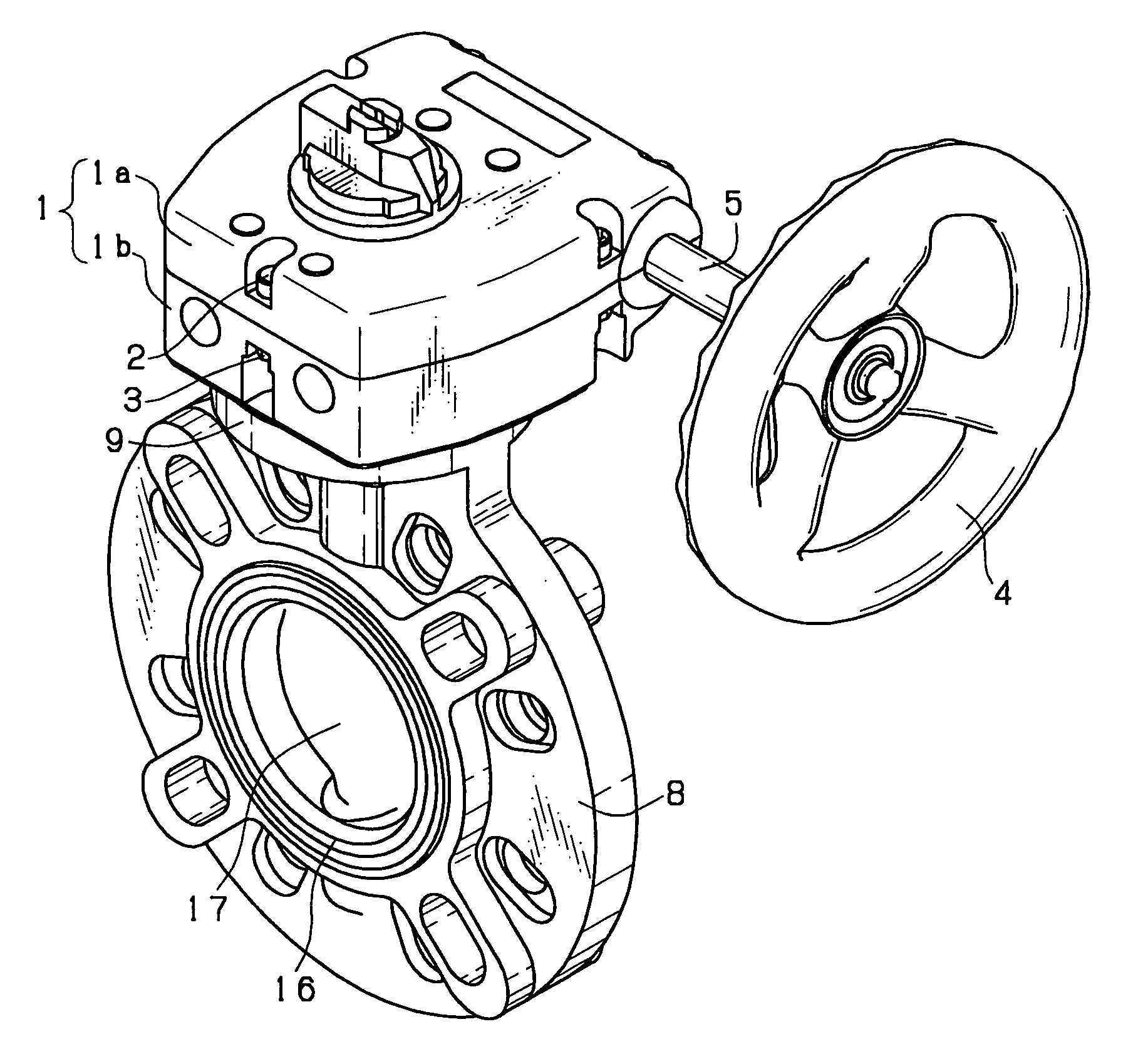

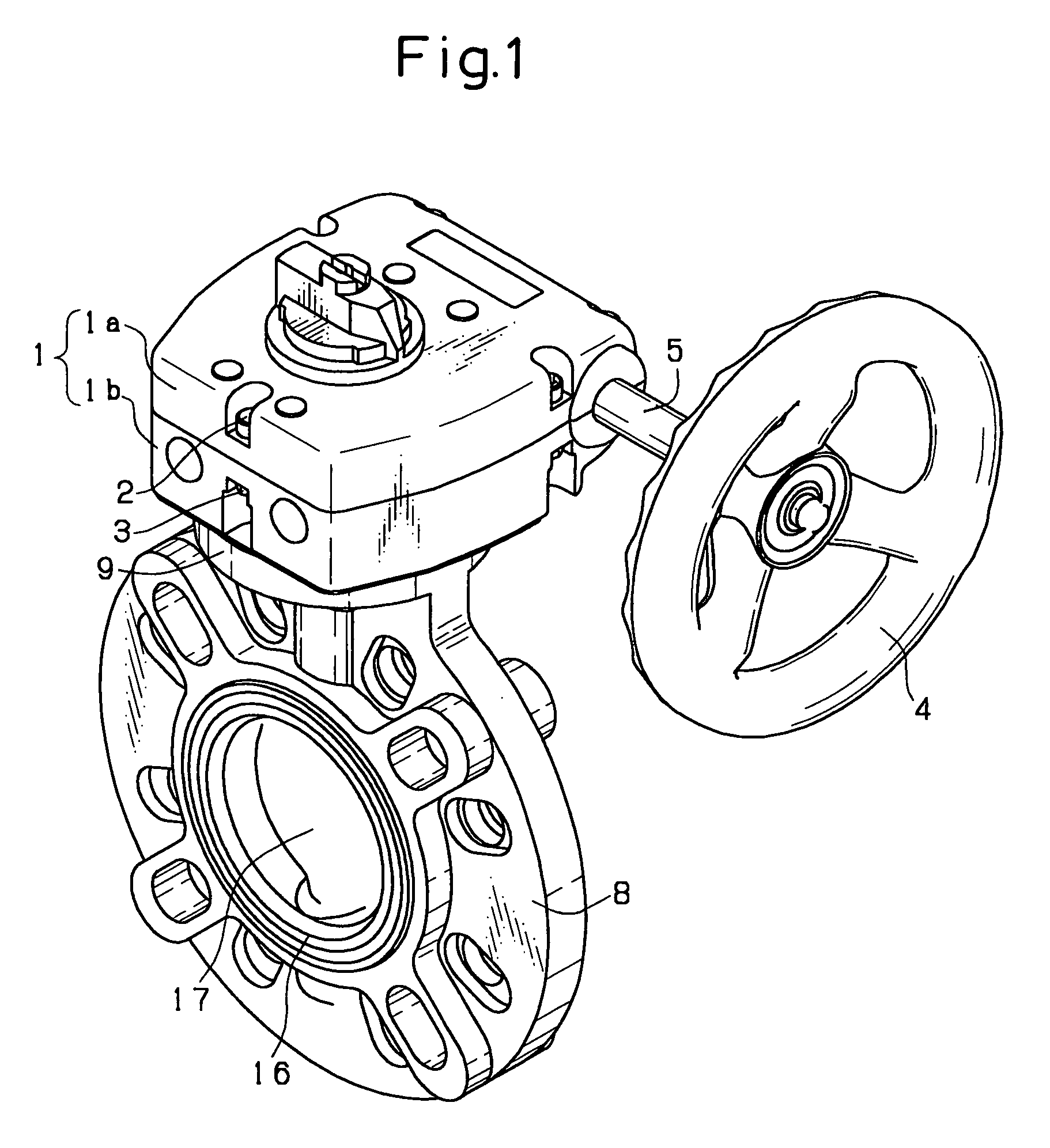

Resin member for valve

ActiveUS8366073B2Reduced strengthGood chemical resistanceDomestic articlesLift valveFiberHigh intensity

To provide a light-weight resin member, for a valve, which has high strength and can be used in a high-temperature atmosphere, and is also excellent in chemical resistance and corrosion resistance.A resin member for a valve, which is produced by molding a molding material having a tensile strength of 80 to 400 MPa at normal temperature, and a resin member for a valve, which is produced by molding a molding material having a tensile strength of 75 to 350 MPa at 120° C. are disclosed. There is also disclosed a resin member for a valve, which is produced by molding a molding material comprising a resin composition containing an epoxy acrylate resin (A) having a hydroxyl value of 60 to 100, a polyisocyanate compound (B) having 0.1 to 1.5 isocyanate groups per one hydroxyl group of the epoxy acrylate resin (A), a curing agent (C) and an internal mold release agent (D), and 20 to 70% by weight of a fiber reinforcing material (E).

Owner:ASAHI YUKIZAI KOGYO CO LTD

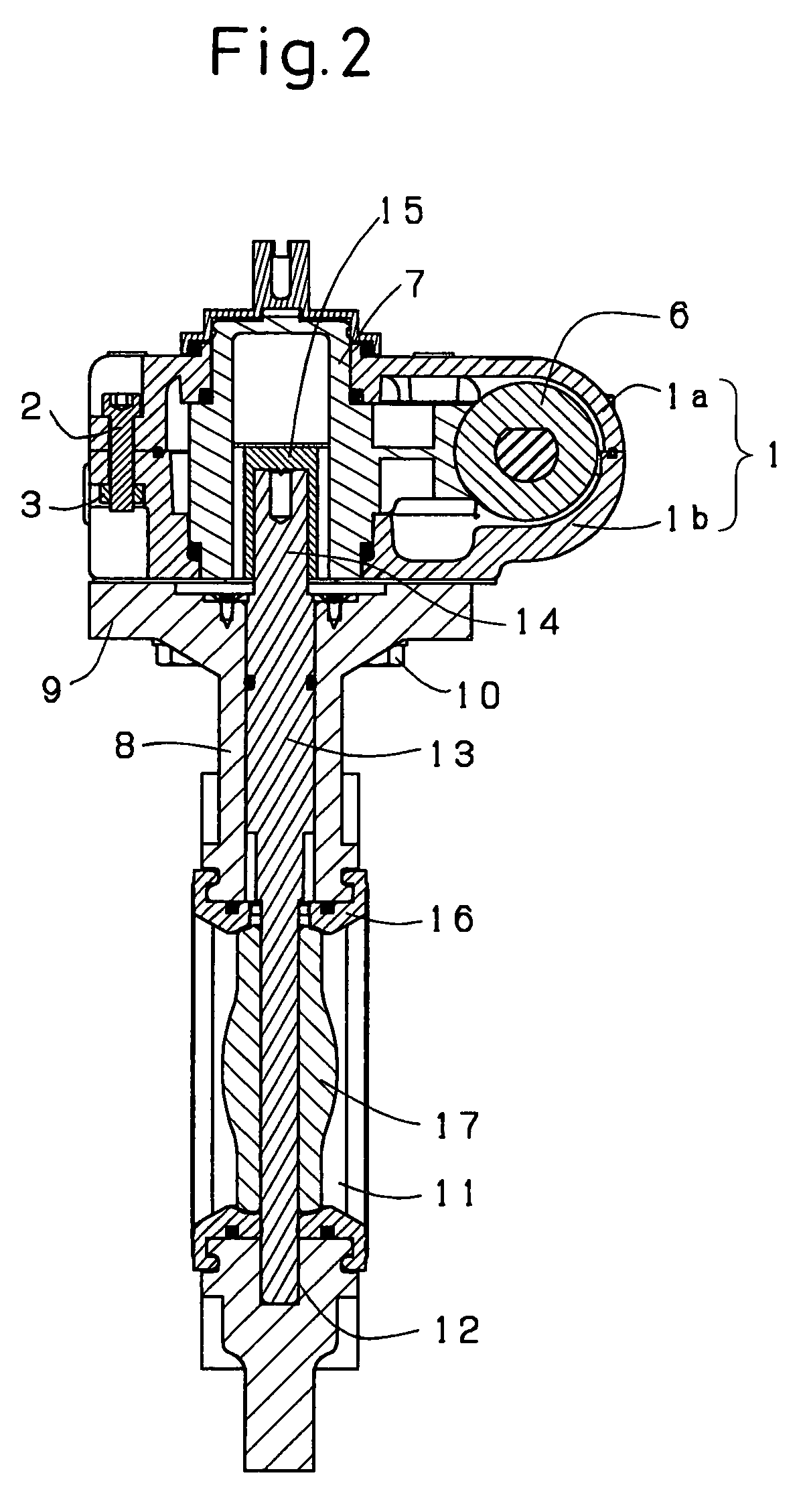

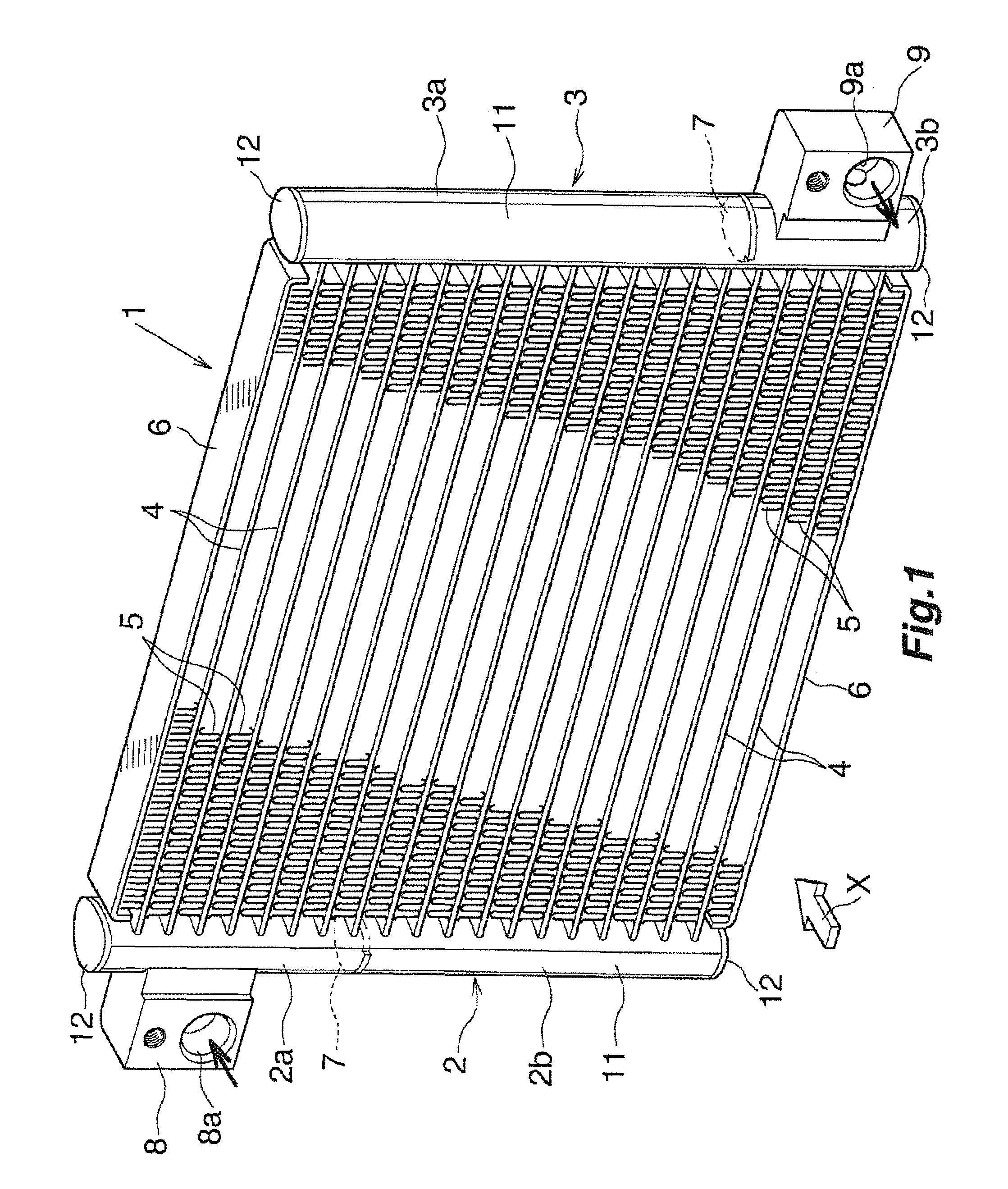

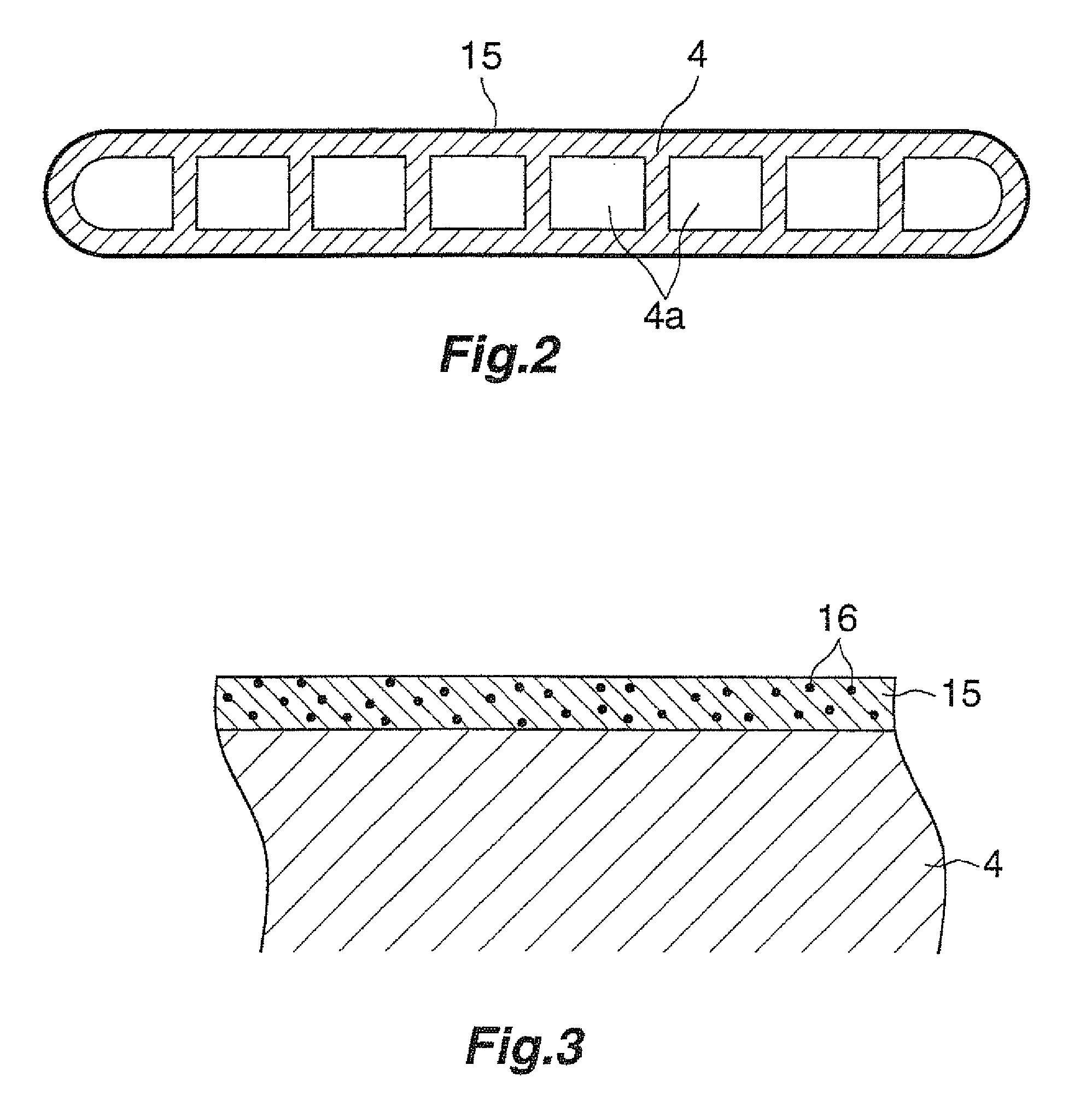

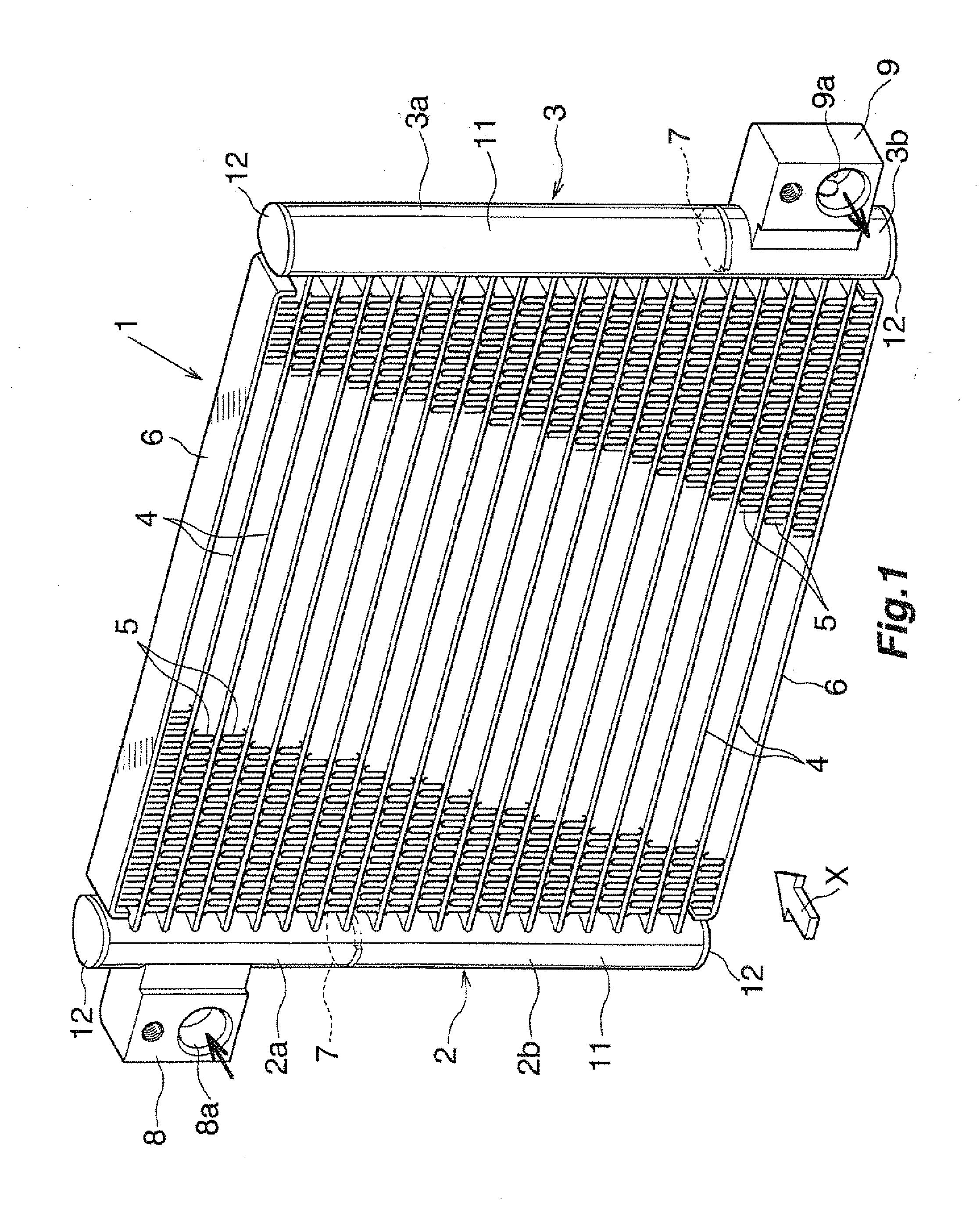

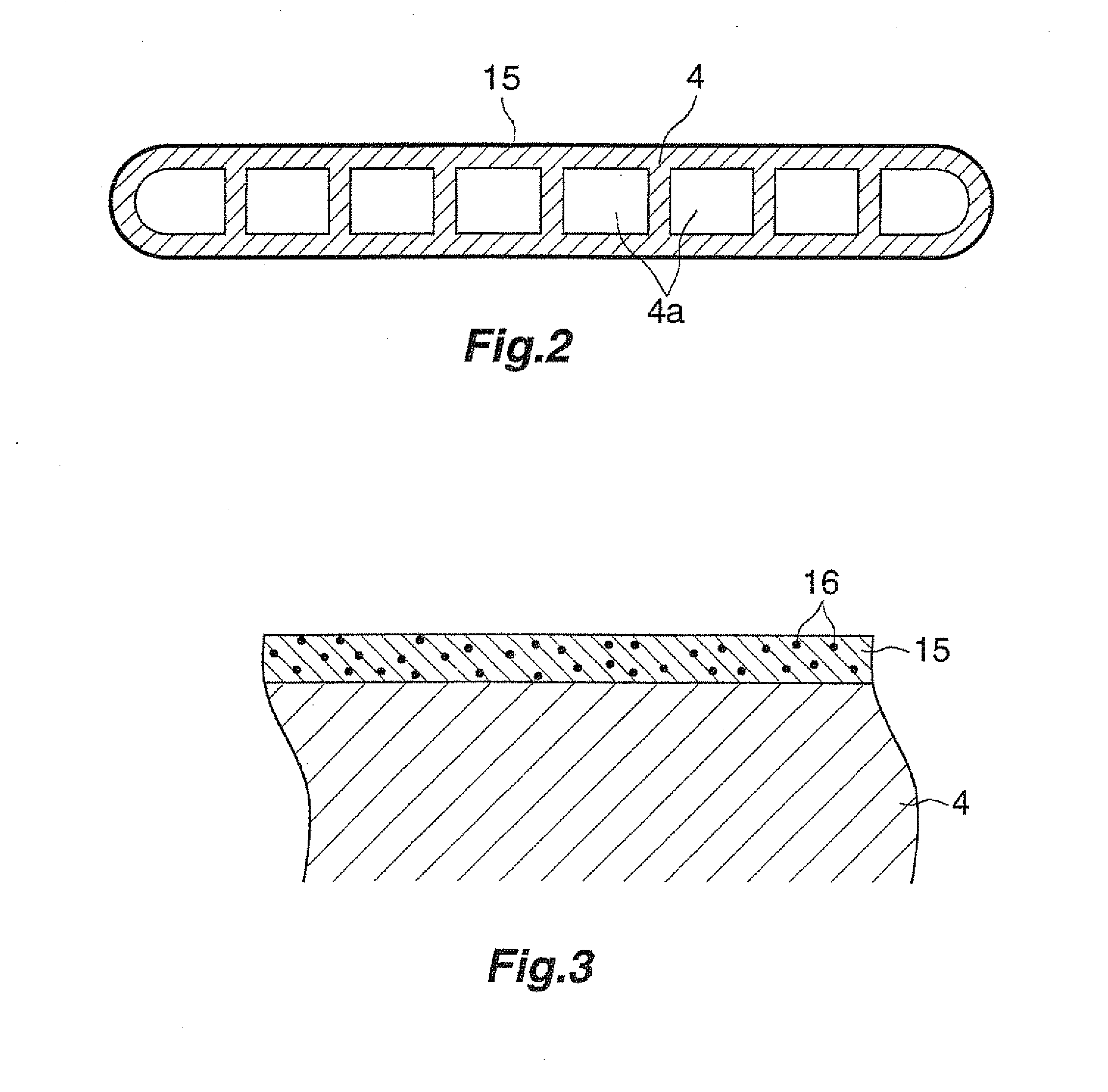

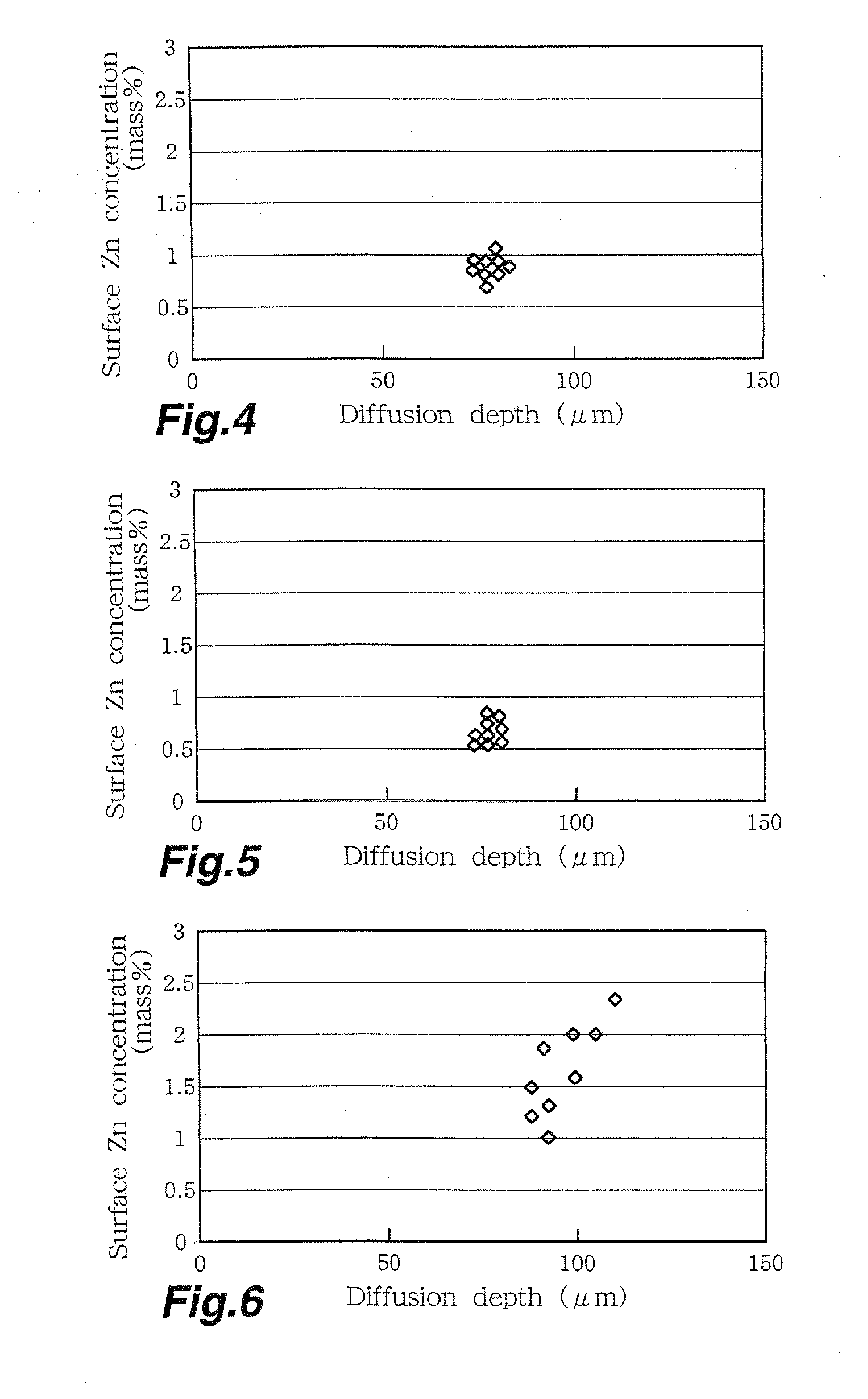

Method for anticorrosion treatment of outer surface of heat exchange tube made of aluminum extrusion and method for producing heat exchanger

ActiveUS9534851B2Improve corrosion resistanceHigh strengthLiquid surface applicatorsSoldering apparatusAlloyAluminum extrusion

The anticorrosion treatment method of the invention is carried out on the outer surface of an aluminum extruded heat exchange tube which is formed of an Al alloy containing Mn 0.2 to 0.3 mass %, Cu 0.05 mass % or less, and Fe 0.2 mass % or less, and which has a wall thickness of 200 μm or less. The anticorrosion treatment method includes applying a specific dispersion of a flux powder and a Zn powder onto the outer surface of the heat exchange tube, and vaporizing a liquid component of the dispersion, to thereby deposit the Zn powder and the flux powder on the outer surface of the heat exchange tube, such that the Zn powder deposition amount, the flux powder deposition amount, and the ratio of the flux powder deposition amount to the Zn powder deposition amount are adjusted to specific values.

Owner:MAHLE INT GMBH

Steel tube machining method with high yield

InactiveCN107138533AQuality improvementHigh yieldMetal rolling arrangementsWaste productSaponification

The invention relates to the field of steel pipe preparation, and discloses a steel pipe processing method with a high yield. The continuous casting billet is used as a raw material, and the following steps are followed in sequence: heating, piercing, surface machining, annealing, pickling, phosphating, and saponification , Rolling preheating, rolling, cooling, the steel pipe produced will not crack, the quality is high, the yield is high, and the production cost is low; the piercing temperature is related to the piercing rate and the cracking degree of the steel pipe, and the appropriate piercing temperature can ensure the piercing efficiency. Avoid cracking of the steel pipe, and also avoid the production of waste products. The annealing process of the present invention can overcome the defect that the inner or outer surface of the steel pipe is easy to crack. Since the steel pipe billet is first put into the furnace and kept at 750-760°C, the steel pipe and The temperature in the furnace is consistent, and then staged annealing treatment and cooling are performed to stabilize the performance of the tube billet.

Owner:射洪县才伦建材有限责任公司

Electric cartridge style pressure washer heater module

ActiveUS20180071759A1Efficient heatingImprove foulingLiquid spraying apparatusCleaning using liquidsCorrosionFouling

An all-electric pressure washer heater module having a heating coil and a heating element is disclosed. A system for all-electric pressure washing is further disclosure. In particular, the all-electric pressure washer heater module contains the heating element from exposure to corrosion and fouling.

Owner:MI T M CORP

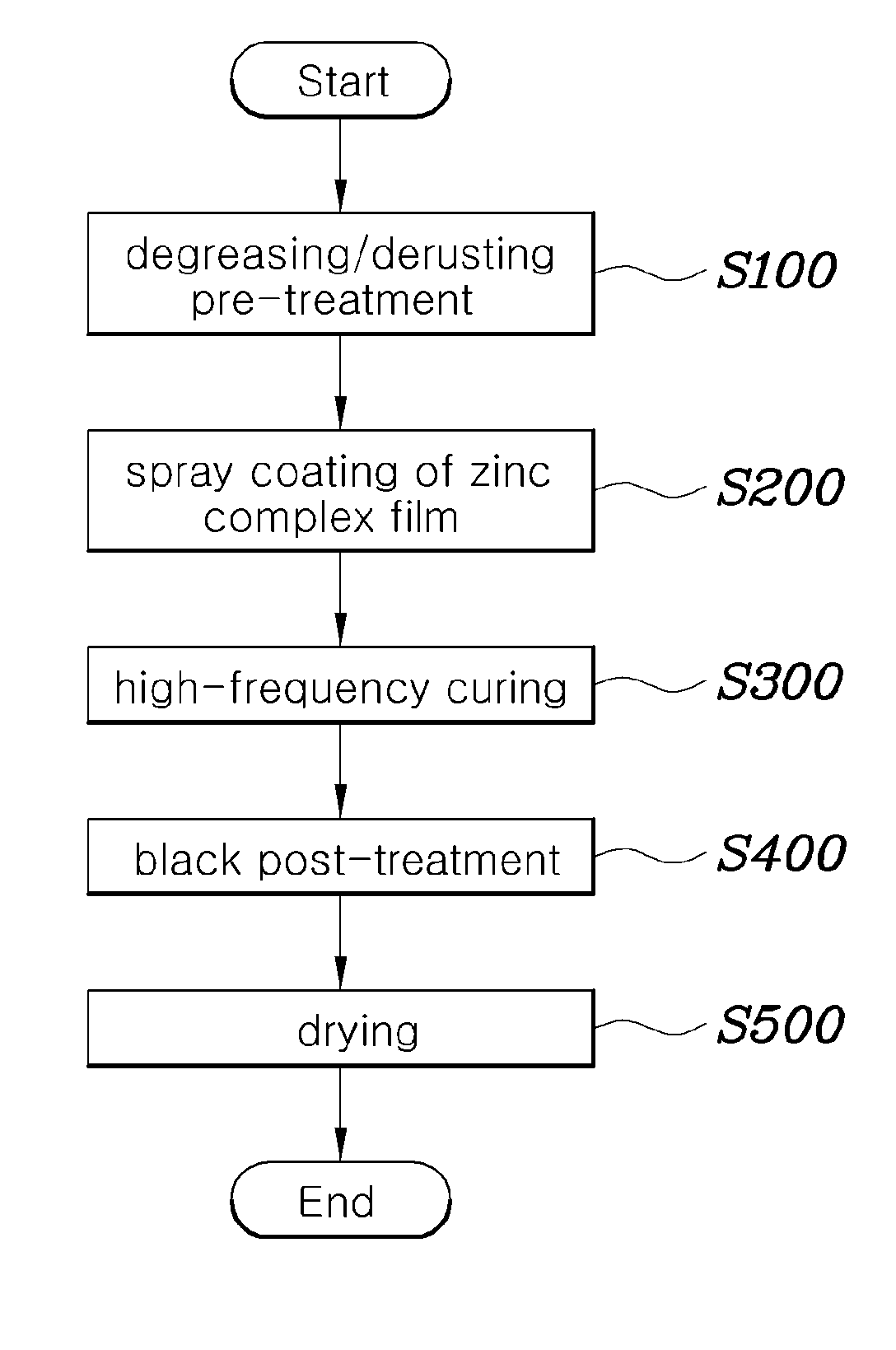

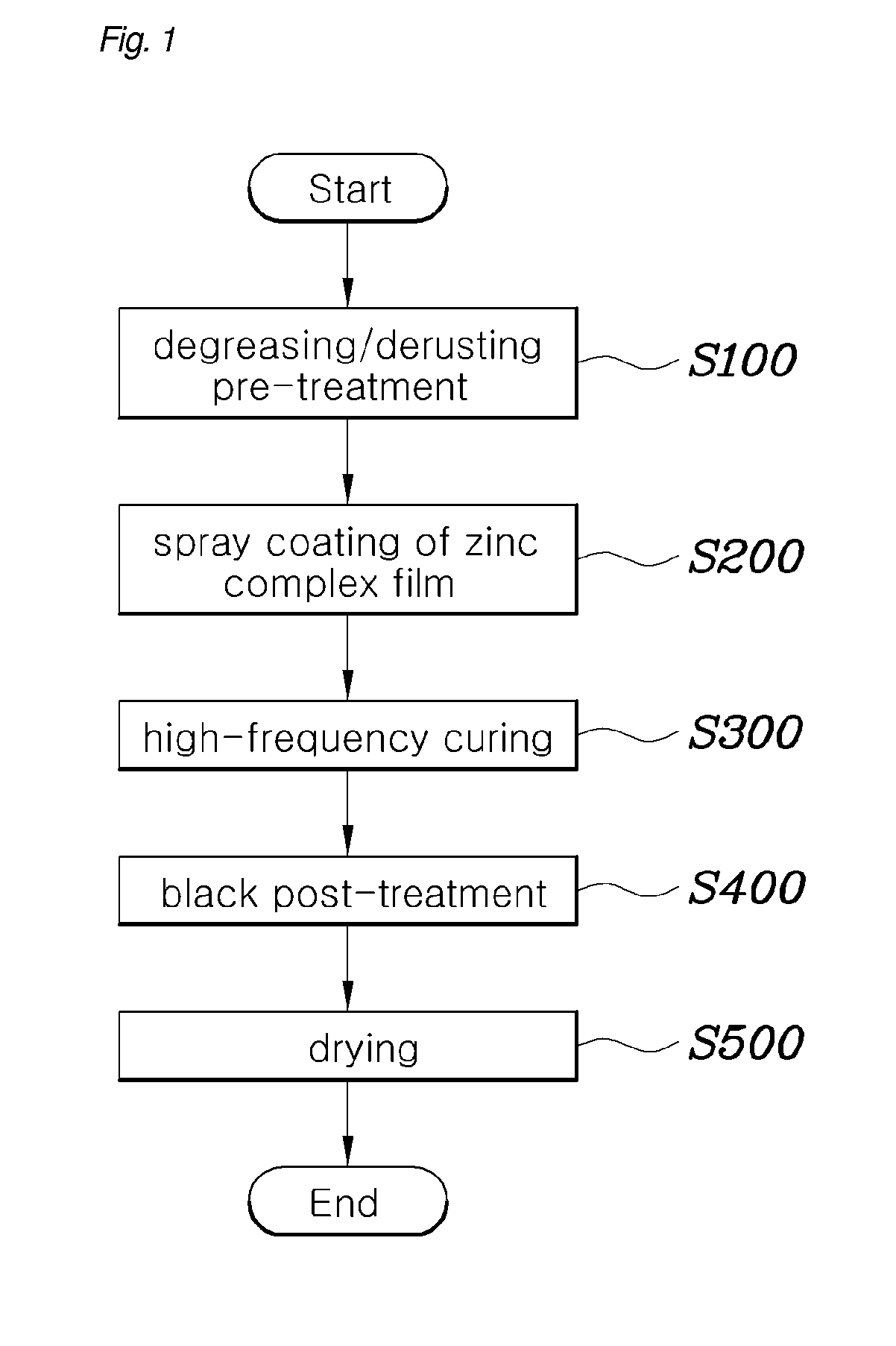

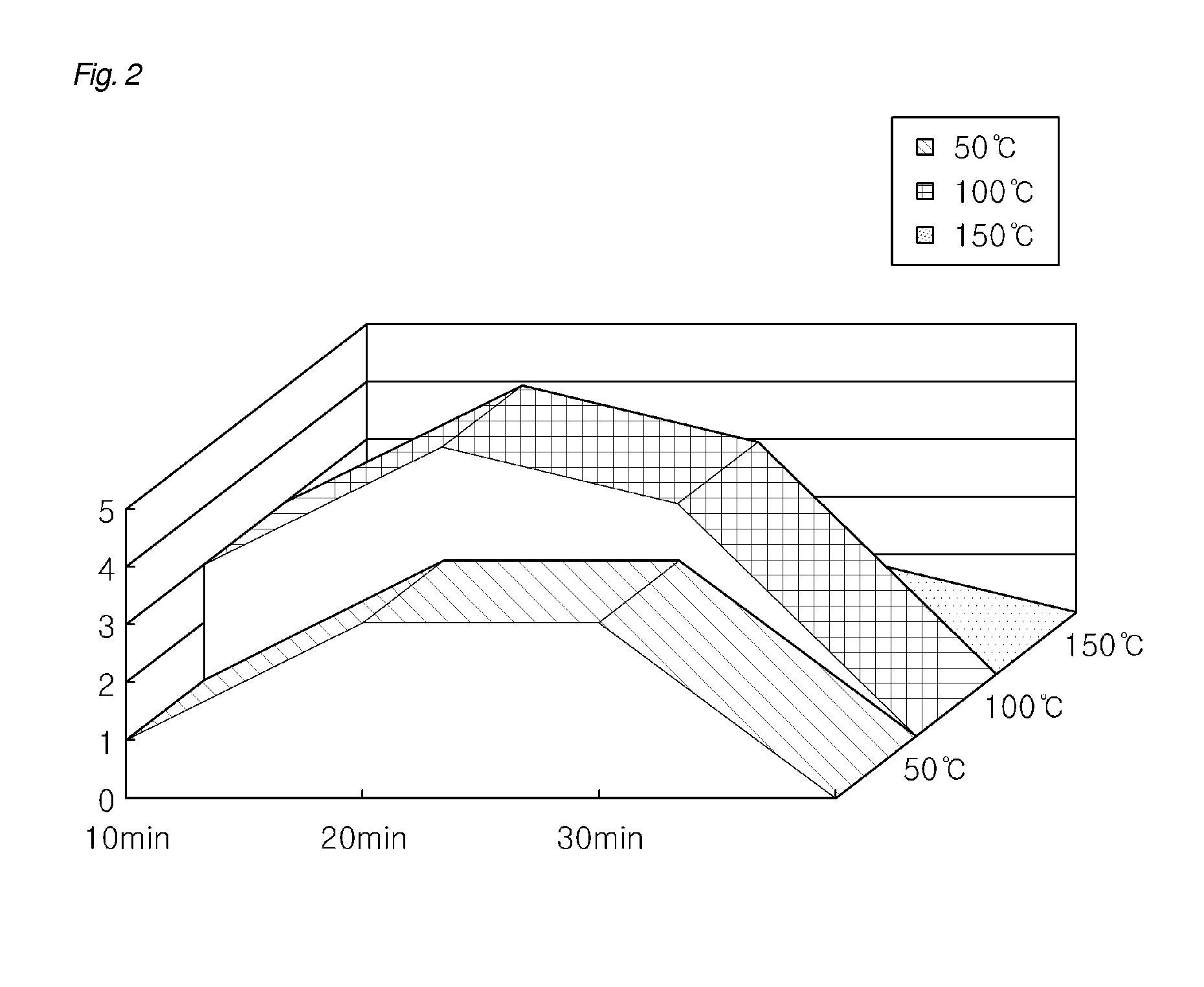

Method of applying zinc complex film, method of coating a brake caliper, and brake caliper thus formed

InactiveUS20140170437A1Poor corrosion resistanceHot-dipping/immersion processesAxially engaging brakesEngineeringCalipers

Disclosed is a method of applying a zinc complex film, including forming a zinc complex film on a surface of a substrate, performing high-frequency curing at about 90˜110° C. for about 18˜22 min, and performing painting and drying as post-treatment. Further disclosed are a method of coating a brake caliper using the zinc complex film, and to a brake caliper thus coated.

Owner:HYUNDAI MOTOR CO LTD

Method for anticorrosion treatment of outer surface of heat exchange tube made of aluminum extrusion and method for producing heat exchanger

ActiveUS20140360017A1Improve heat resistanceImprove corrosion resistanceSoldering apparatusPretreated surfacesAlloyAluminum extrusion

The anticorrosion treatment method of the invention is carried out on the outer surface of an aluminum extruded heat exchange tube which is formed of an Al alloy containing Mn 0.2 to 0.3 mass %, Cu 0.05 mass % or less, and Fe 0.2 mass % or less, and which has a wall thickness of 200 μm or less. The anticorrosion treatment method includes applying a specific dispersion of a flux powder and a Zn powder onto the outer surface of the heat exchange tube, and vaporizing a liquid component of the dispersion, to thereby deposit the Zn powder and the flux powder on the outer surface of the heat exchange tube, such that the Zn powder deposition amount, the flux powder deposition amount, and the ratio of the flux powder deposition amount to the Zn powder deposition amount are adjusted to specific values.

Owner:MAHLE INT GMBH

Inert alloy anode used for aluminum electrolysis and preparation method therefor

InactiveUS20150159287A1Increase processing costLow conductivityAngiosperms/flowering plantsElectrodesAlloyInert

An inert alloy anode for aluminum electrolysis contains Fe and Cu as primary components and further contains Sn; addition of the metal Sn contributes to formation of an oxide film with strong oxidization resistance and stable structure on the surface of the inert alloy anode and to improvement of the corrosion resistance of the anode; on this basis, the inert alloy anode further contains Ni, Al and Y, addition of the metal Al can prevent the primary metal components from being oxidized, and addition of the metal Y can control alloy to present a desired crystal form in the preparation process to achieve oxidization resistance.

Owner:INNER MONGOLIA UNITED IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com