Patents

Literature

283 results about "Alclad" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

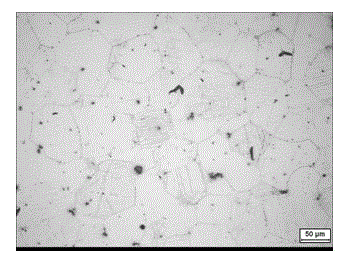

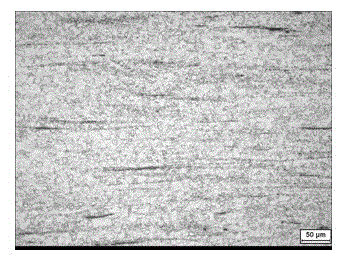

Alclad is a corrosion-resistant aluminium sheet formed from high-purity aluminium surface layers metallurgically bonded (rolled onto) to high-strength aluminium alloy core material. Alclad has a melting point of about 500 degrees celsius, or 932 degrees Fahrenheit. These sheets are commonly used by the aircraft industry. The first aircraft to be constructed from Alclad was the all-metal US Navy airship ZMC-2, constructed in 1927 at Naval Air Station Grosse Ile. Alclad is a trademark of Alcoa but the term is also used generically.

Enhanced alumina layer produced by CVD

Owner:SECO TOOLS AB

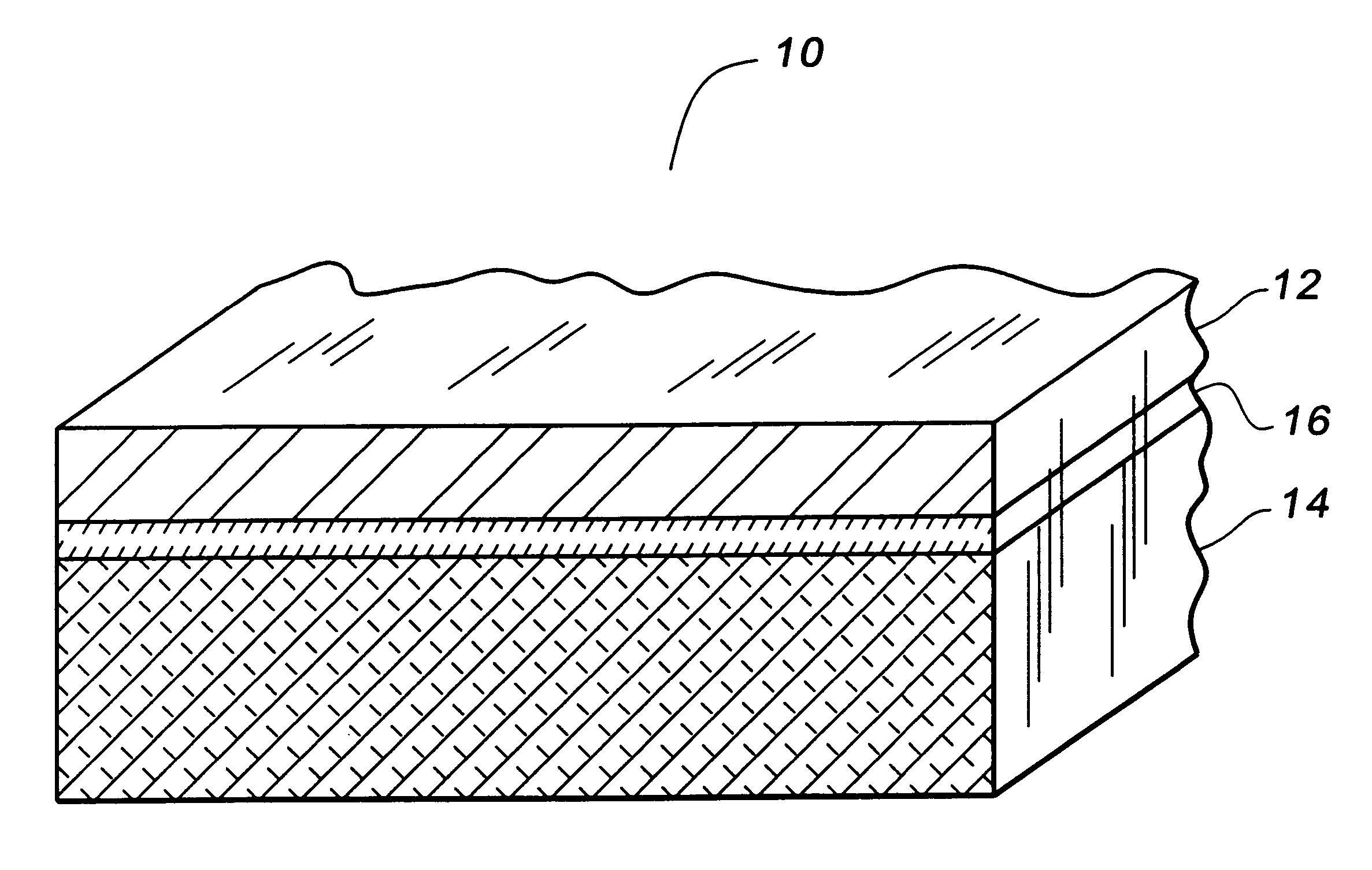

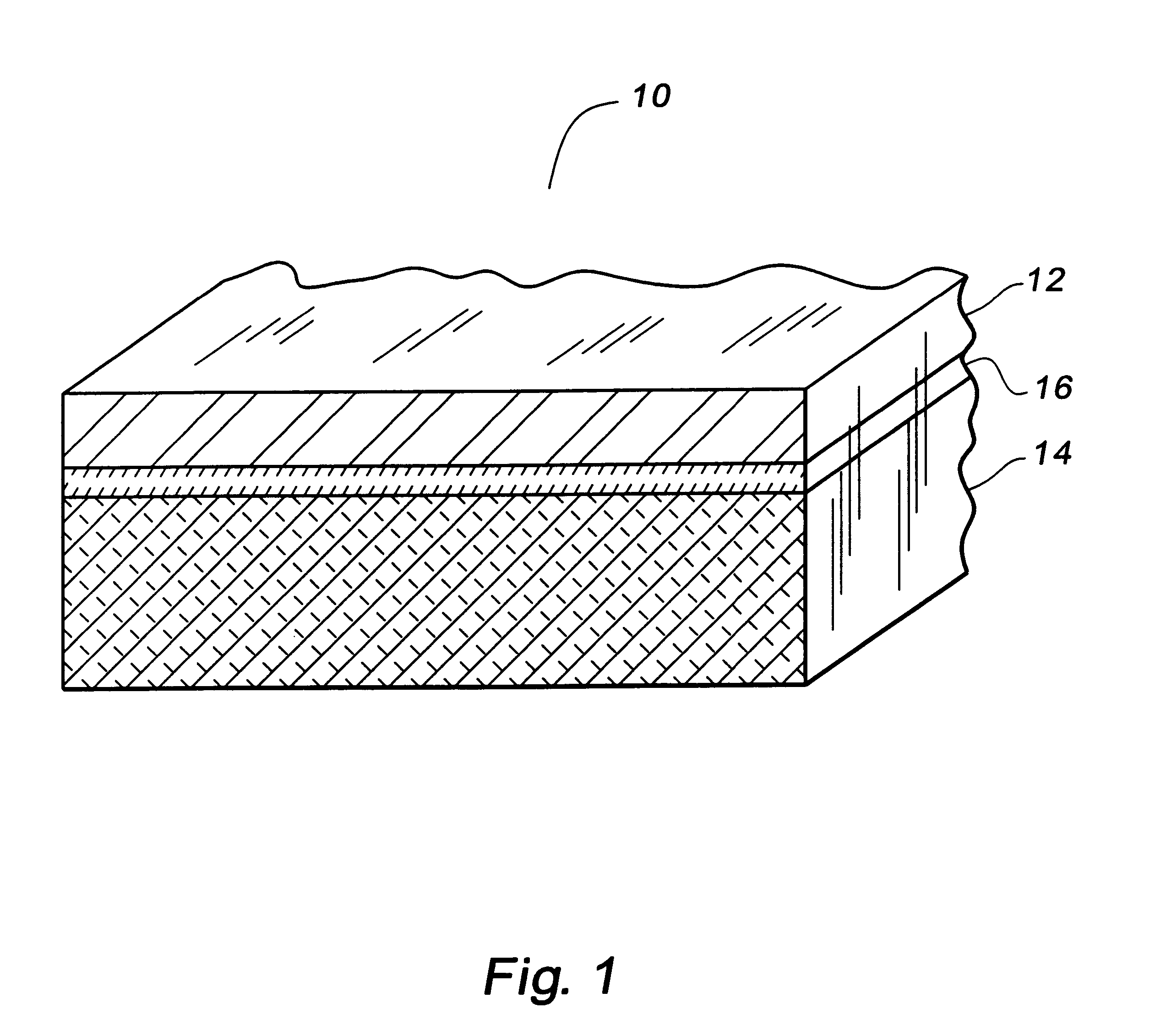

Aluminum laminate

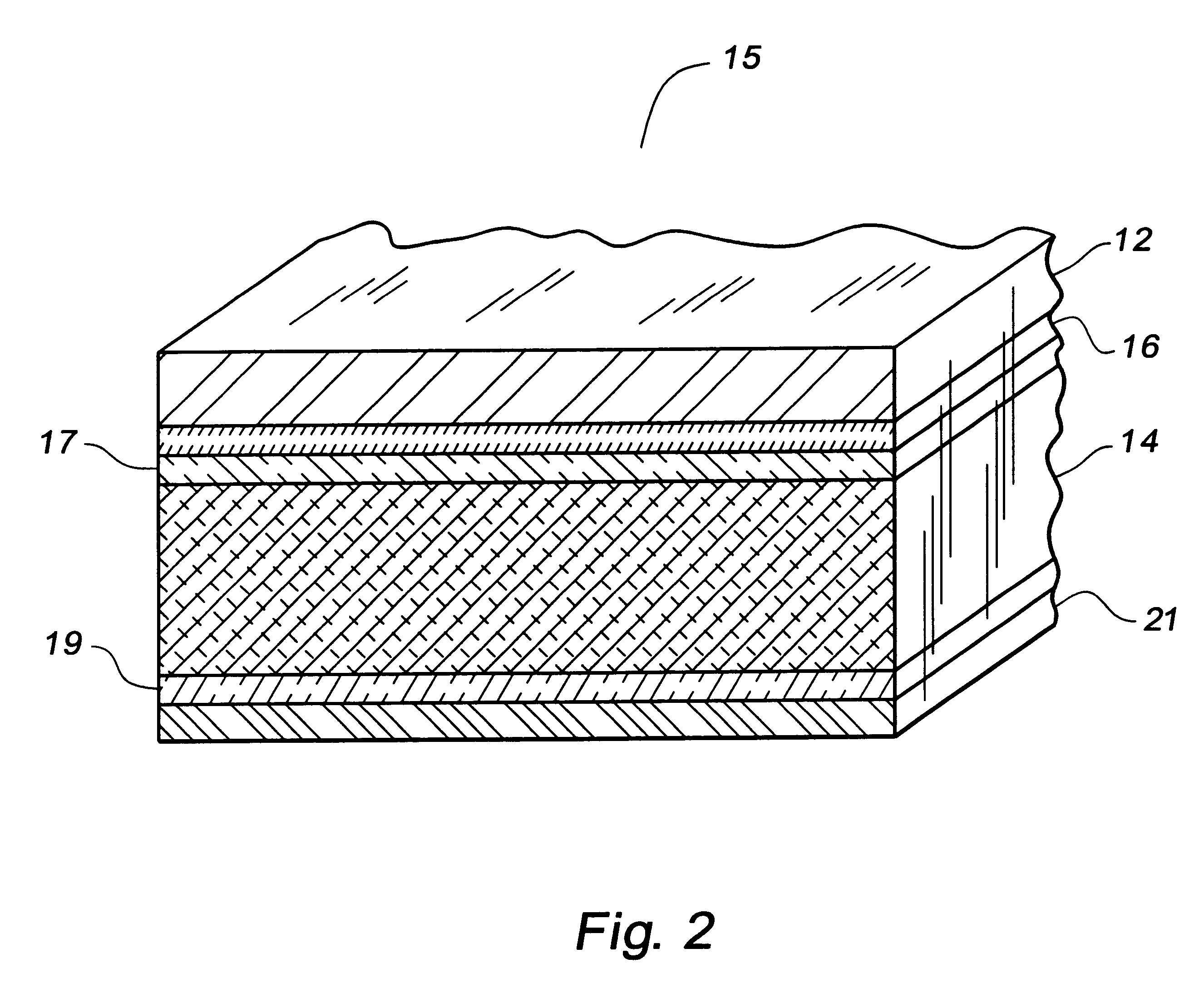

InactiveUS6235409B1Light weightHigh strengthHot-dipping/immersion processesAdhesive processesAlloy substrateAlclad

A bright finish aluminum alloy on high strength aluminum or aluminum alloy lamination is disclosed including a bright finish top sheet, a high strength aluminum or aluminum alloy substrate, and an adhesive bonding the bright finish metal top sheet to the high strength aluminum or aluminum alloy substrate to provide a bright finish aluminum on high strength aluminum or aluminum alloy lamination product having brighter finish than a sheet product of said high strength aluminum or aluminum alloy and higher strength than a sheet product of said bright finish aluminum of the same thickness as said lamination product, wherein said lamination product withstands galvanic corrosion. In one aspect, the bright finish metal top sheet is 5657 aluminum foil. In one aspect, the high strength aluminum alloy is 5182 alloy sheet.

Owner:ARCONIC INC

Adhesive bonding process for aluminium and/or aluminium alloy

InactiveUS6319351B1Group 4/14 element organic compoundsAdhesive processes with surface pretreatmentTriethoxysilaneAlclad

The durability of a bonded aluminium alloy and / or Alclad (Trade Mark) material joint can be improved by a two stage pre-treatment process in which after the surfaces to be joined have been degreased, a first solution BTESE and / or BTMSE in water, with or without methanol and / or ethanol, is applied to the degreased surfaces dried and coated with a second solution of gamma-glycidoxypropyltrimethoxysilane, an amino silane, gamma-aminopropyltriethoxysilane and / or trimethoxyvinylsilane in water with or without methanol and / or ethanol and drying prior to the application of an epoxy adhesive coating to the dried second solution surfaces, bonding and curing.

Owner:BAE SYSTEMS PLC

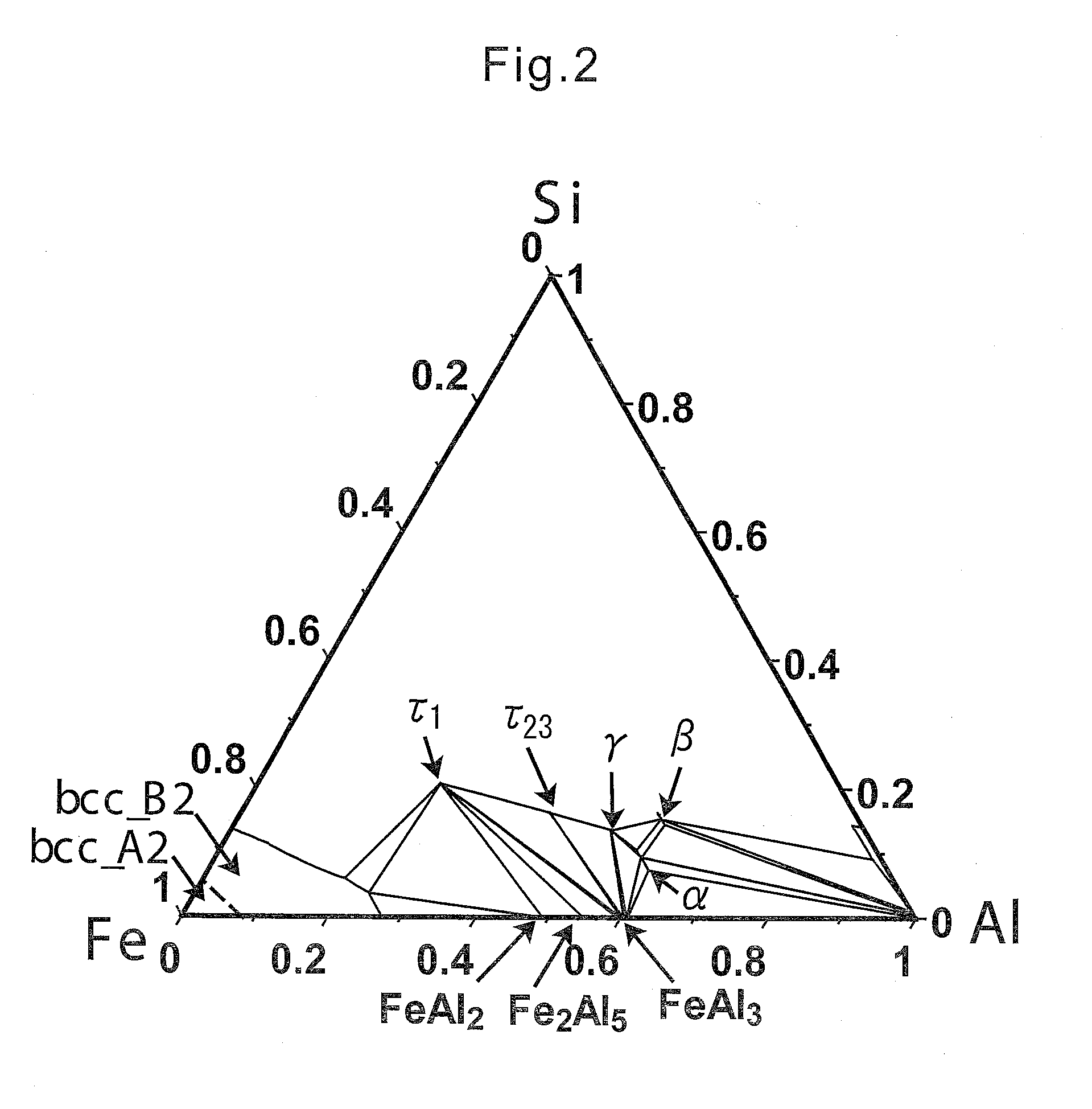

Hot-dip aluminized steel sheet, method of manufacturing the same and alloy-layer control apparatus

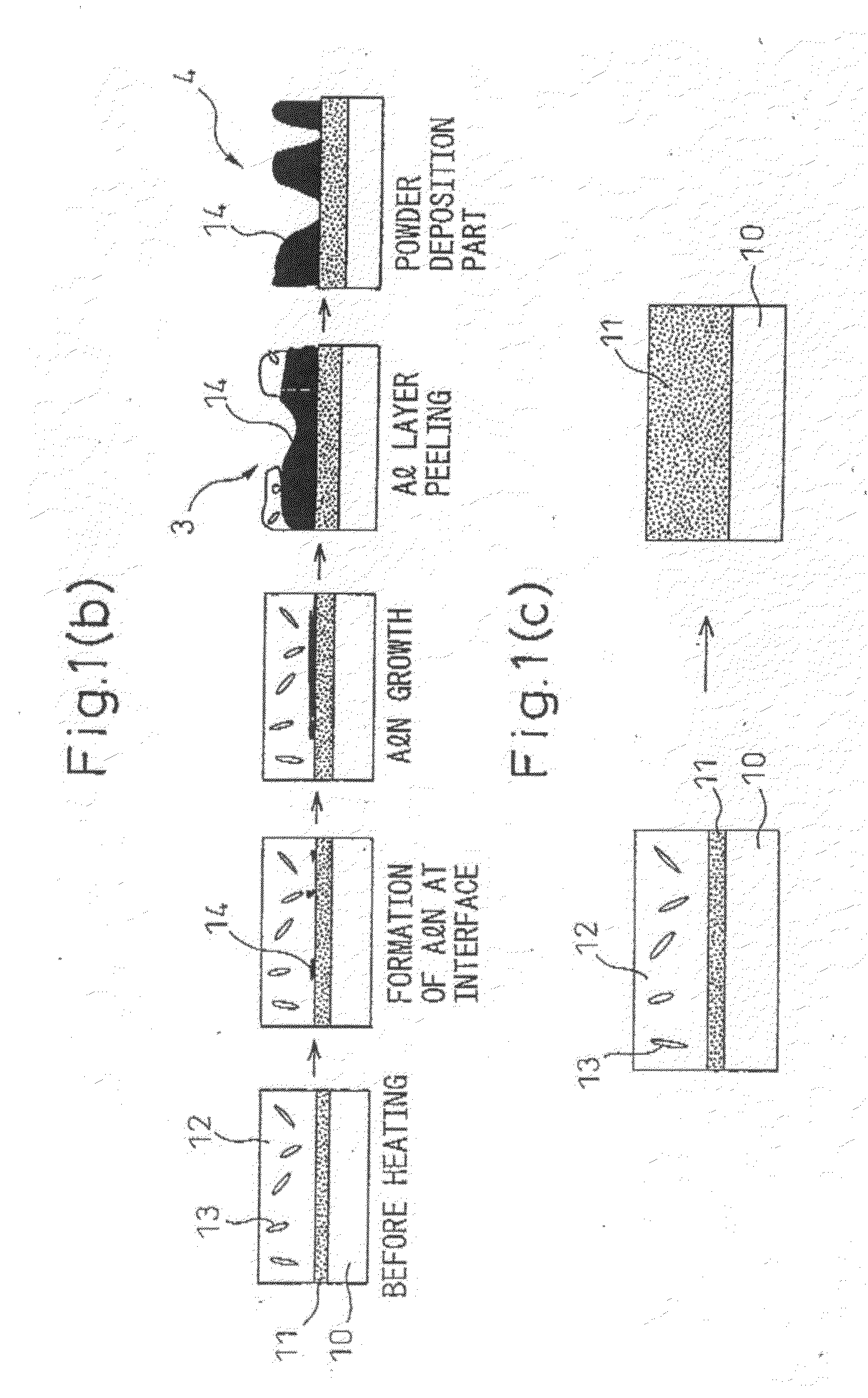

InactiveUS6017643AEasy to peelPrevent peelingHot-dipping/immersion processesRadiation pyrometrySheet steelMetal

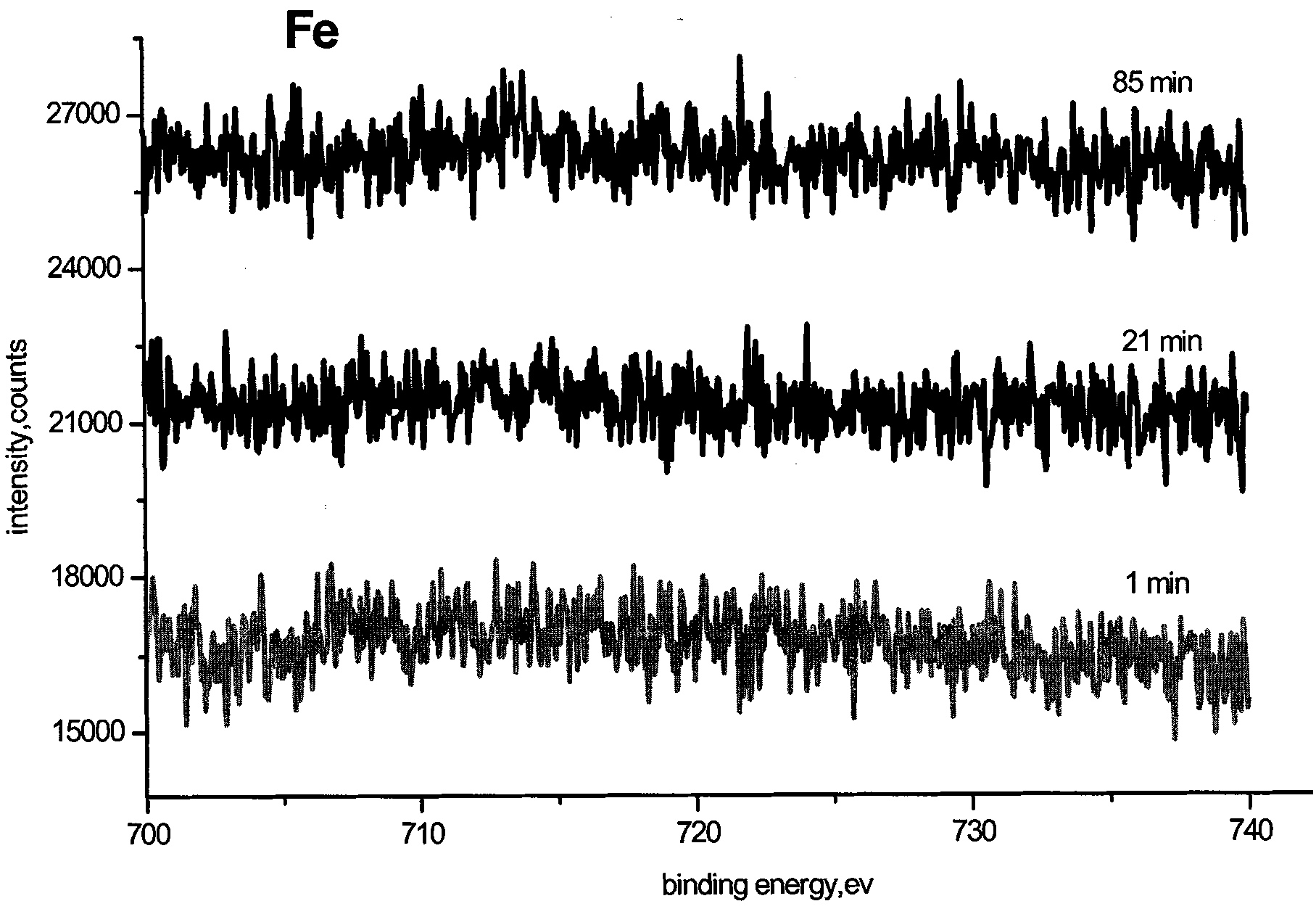

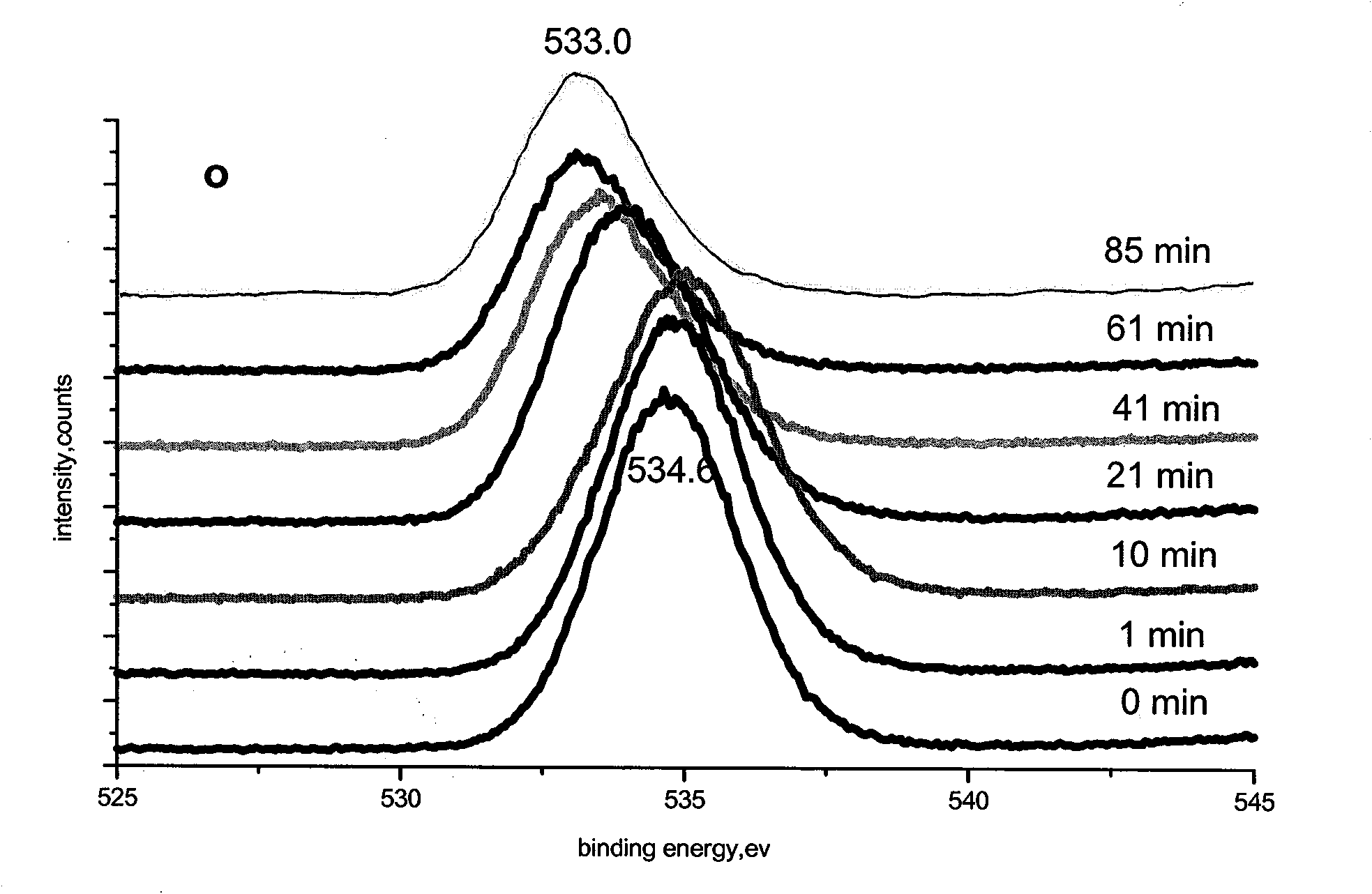

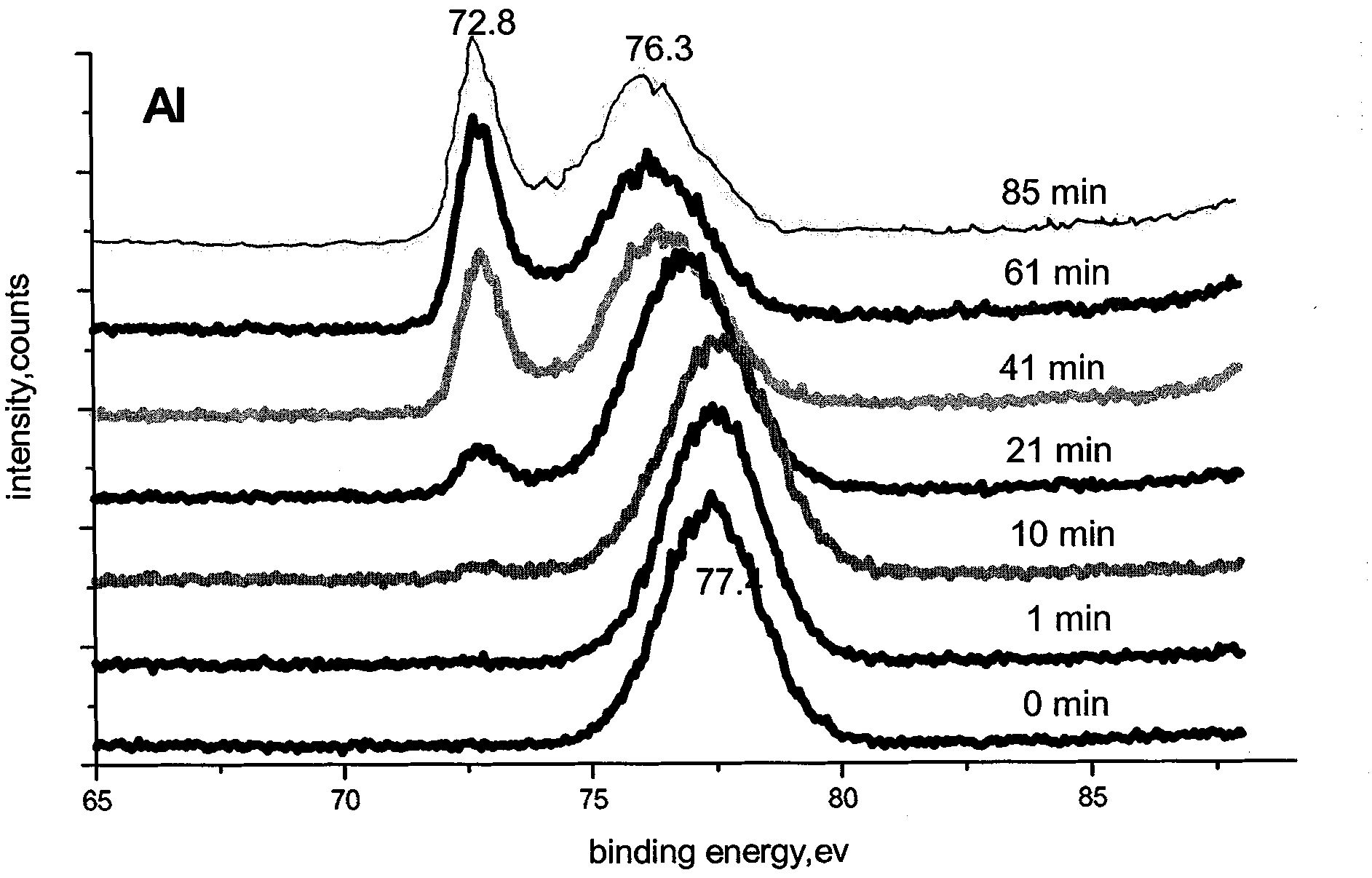

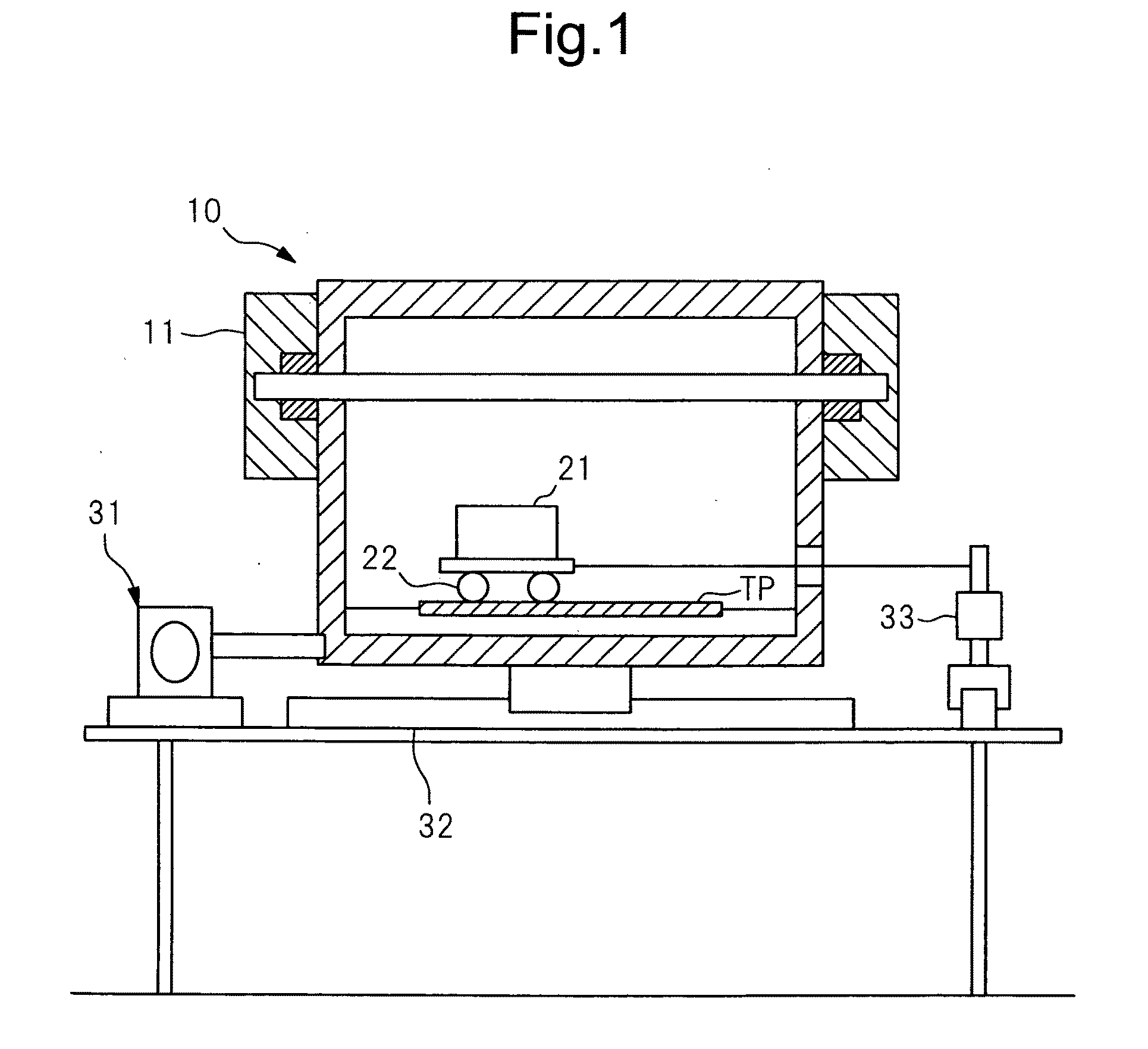

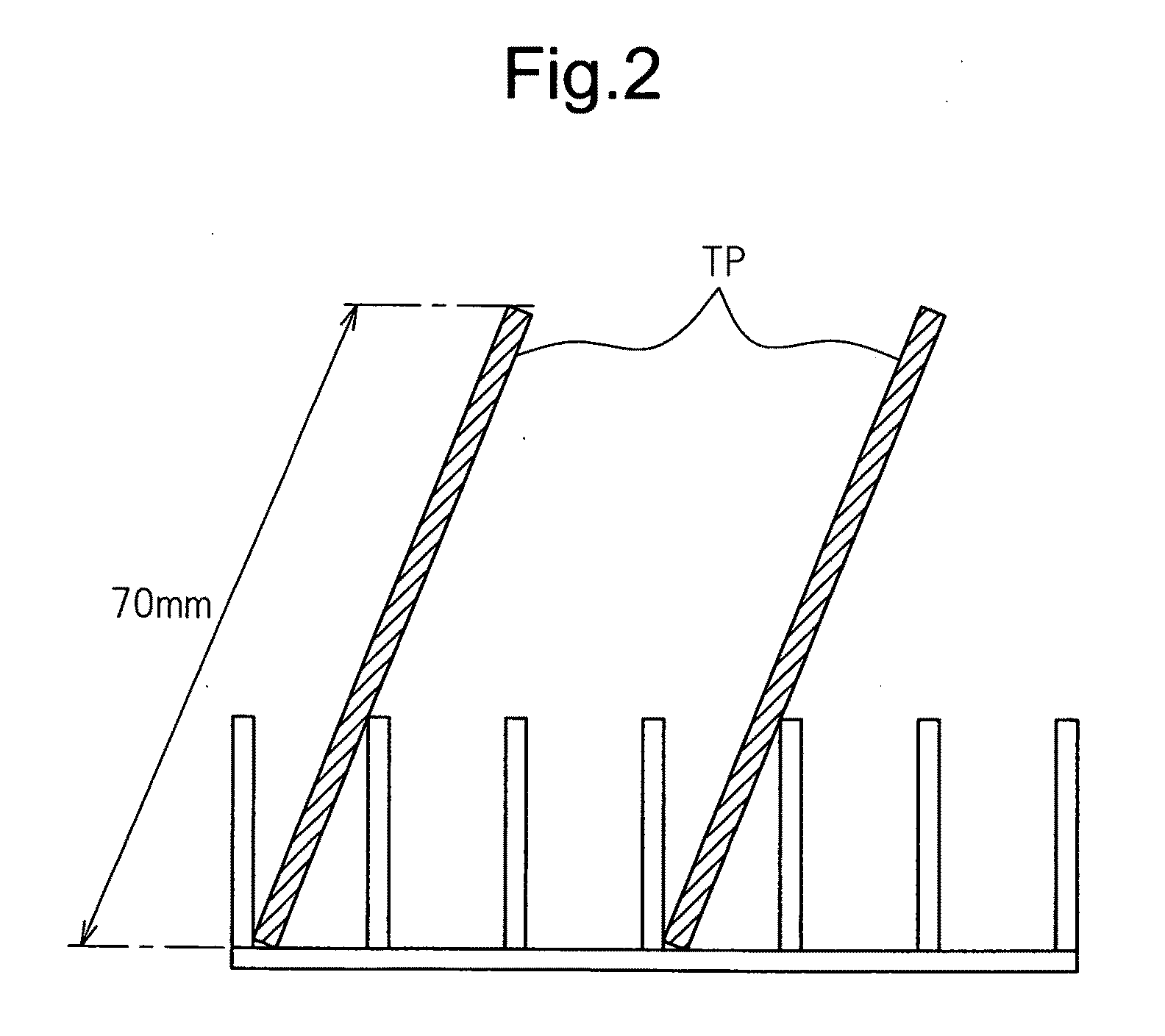

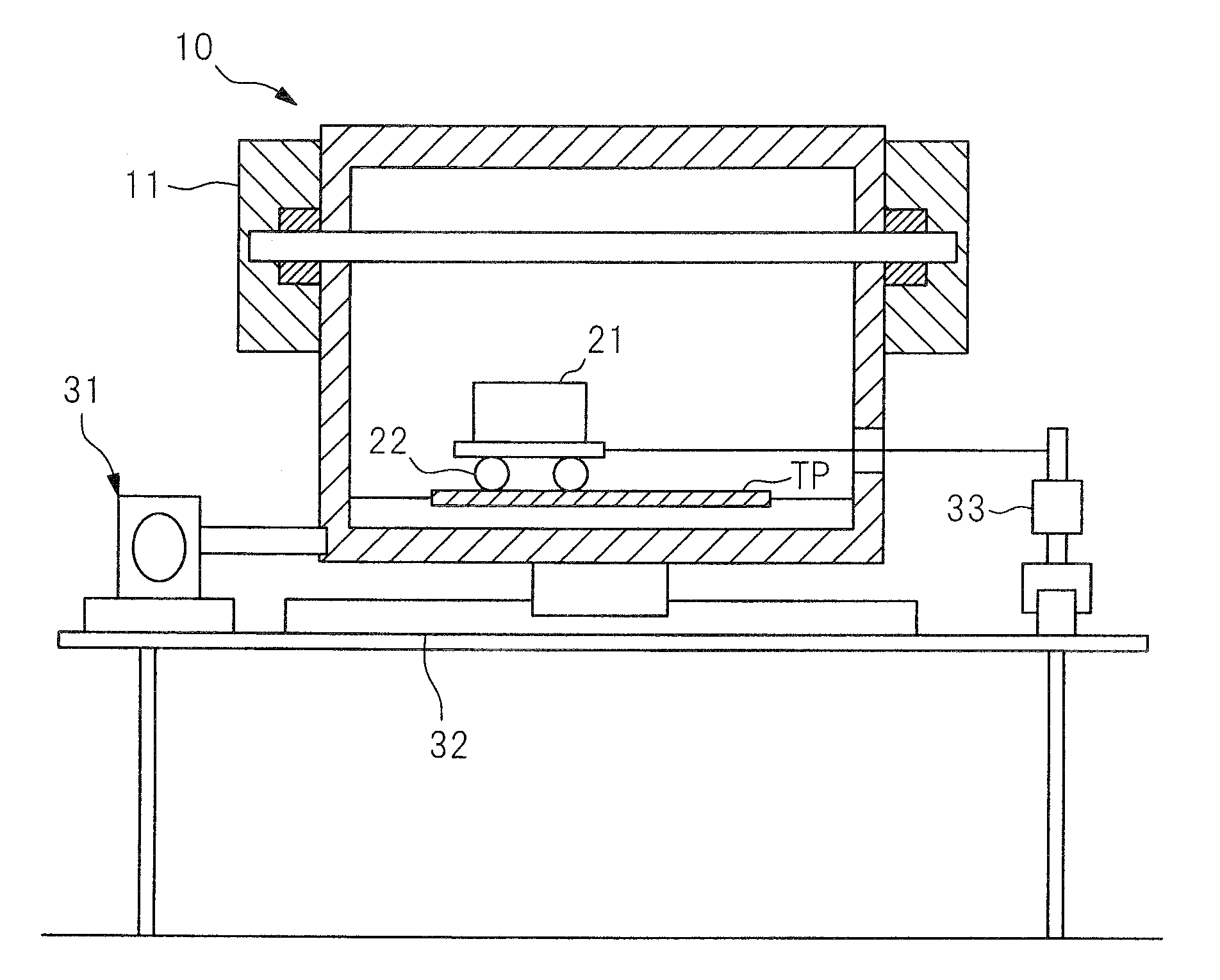

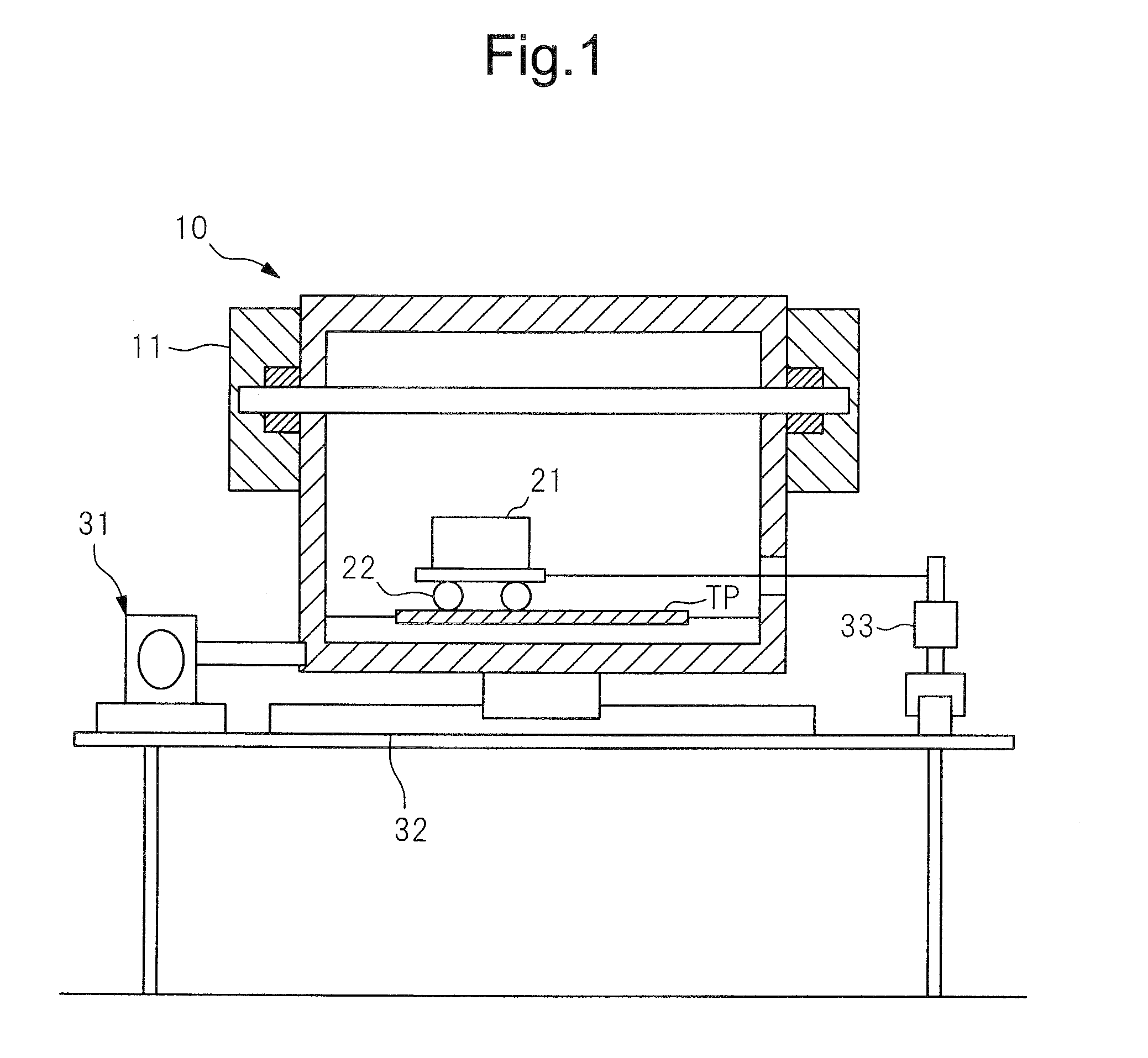

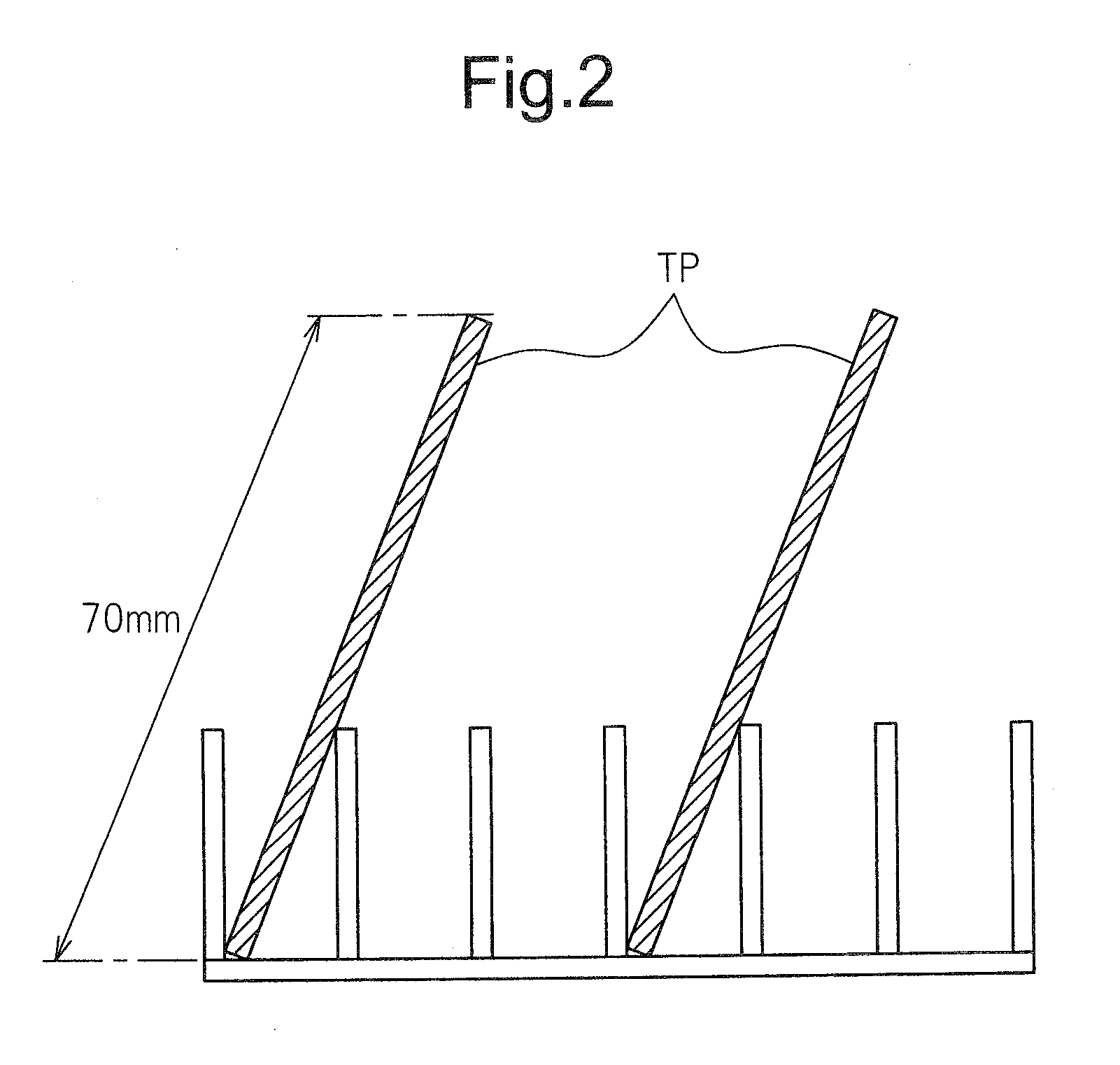

PCT No. PCT / JP96 / 00307 Sec. 371 Date Oct. 23, 1996 Sec. 102(e) Date Oct. 23, 1996 PCT Filed Feb. 9, 1996 PCT Pub. No. WO96 / 26301 PCT Pub. Date Aug. 29, 1996In order to provide a hot-dip aluminized steel sheet with increased peeling resistance of the coating layer, the thickness of the Fe-Al-Si alloy-layer is set to be 1-5 mu m, while the maximum differential unevenness of thickness of the Fe-Al-Si alloy layer is set to be 0.5-5 mu m. The hot-dip aluminized steel sheet is manufactured by controlling an elapsed time from the beginning of immersion of the basemetal steel sheet into the aluminizing bath to the completion of solidification of the coating-metal layer which has passed through the bath. In addition another elapsed time is controlled from the time after the base-metal steel sheet has been guided out over the bath to the completion of solidification of the coating-metal layer.

Owner:NISSHIN STEEL CO LTD

Copper conductor with anodized aluminum dielectric layer

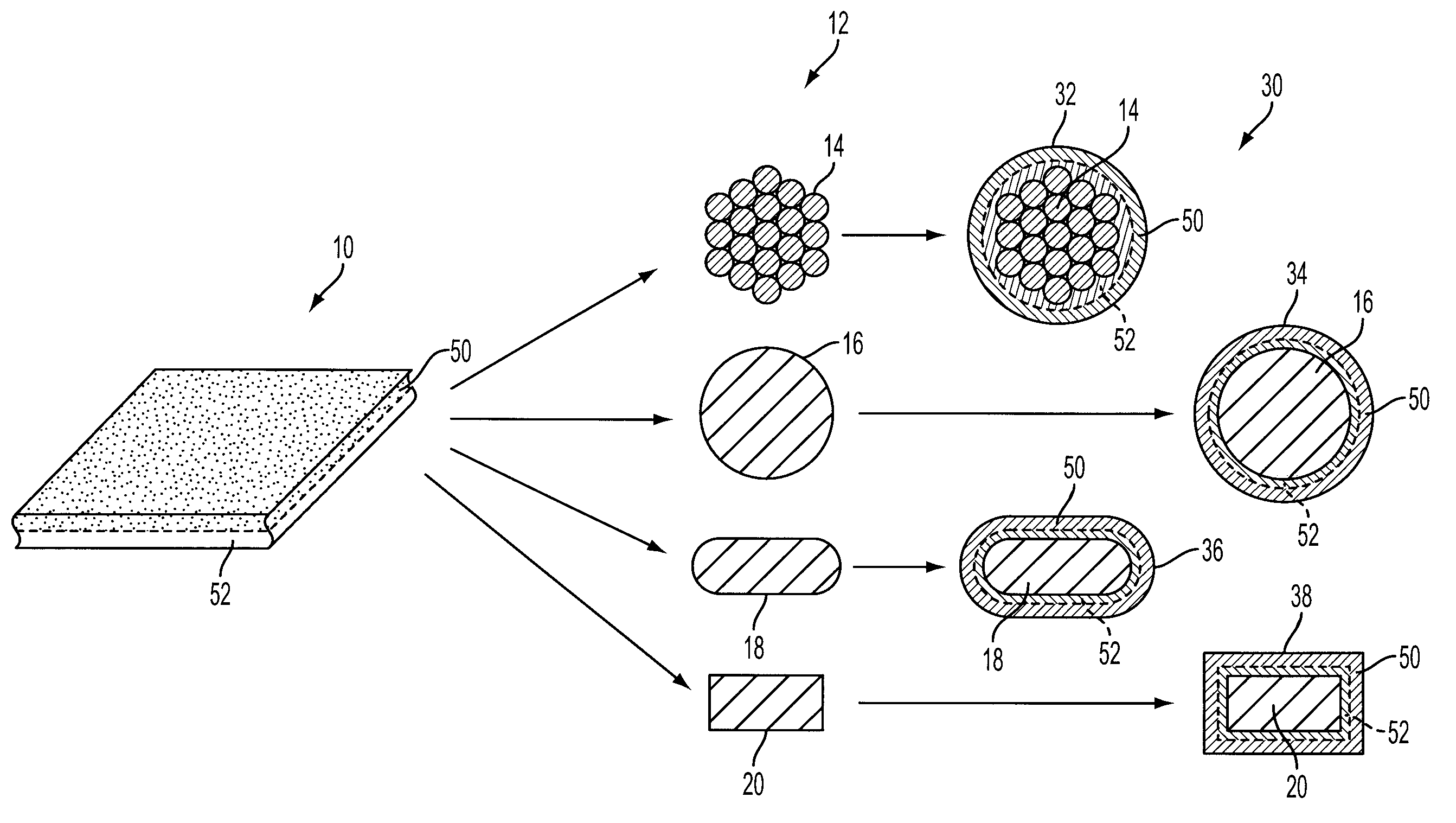

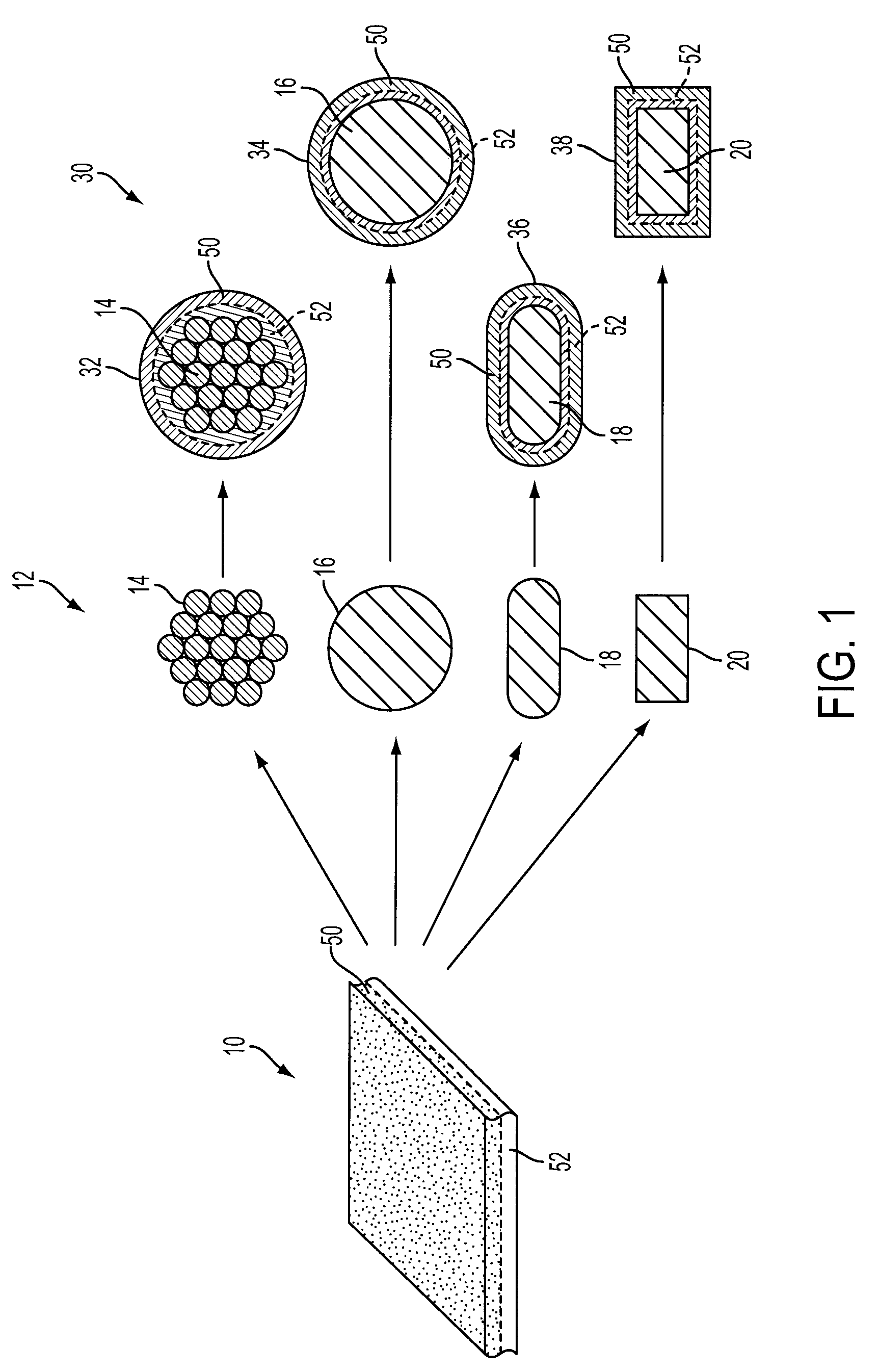

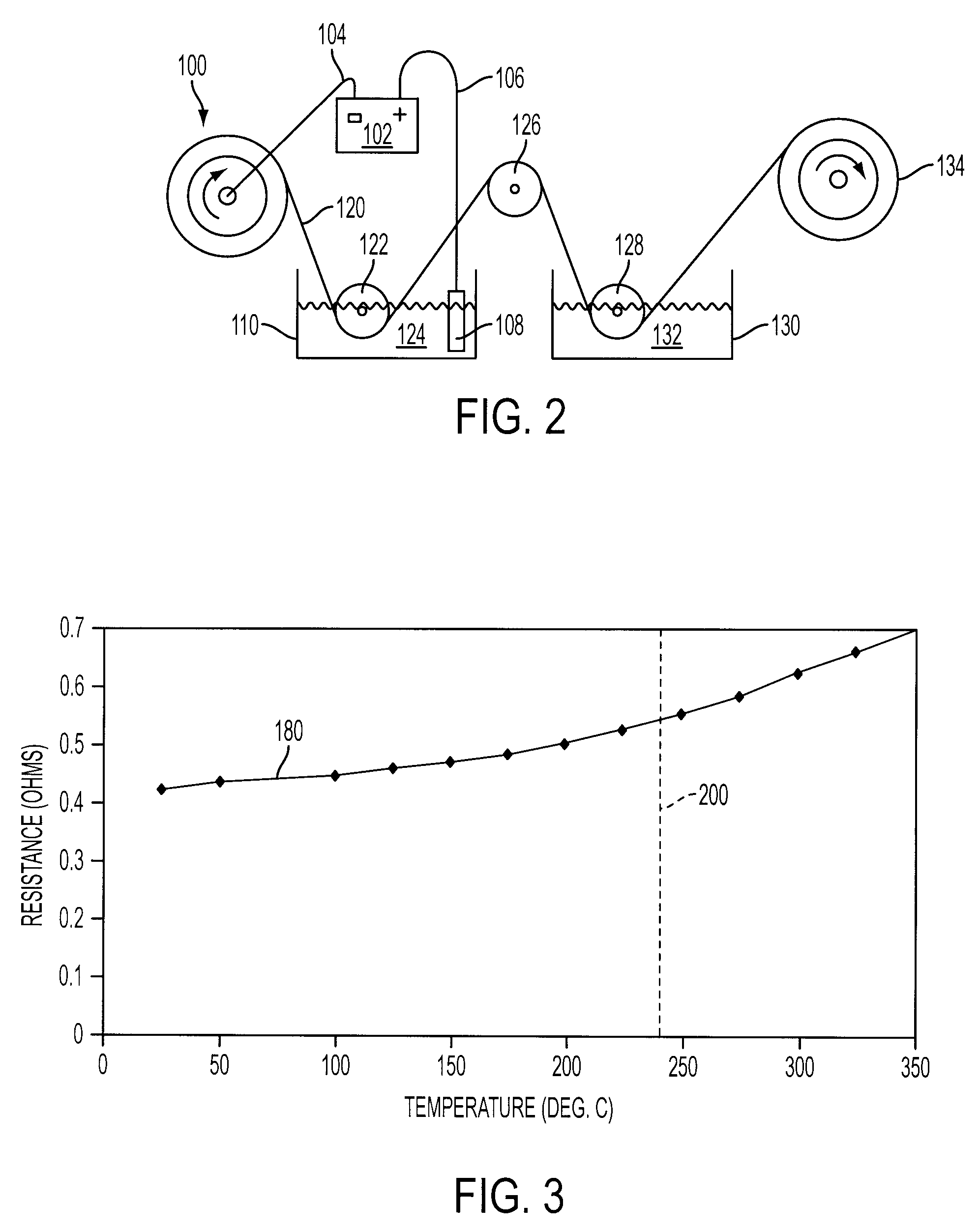

ActiveUS7572980B2Reduce and eliminate any internal stressEconomically viable to produce in large quantities and long continuous lengthsInsulated cablesMetallic oxidesCopper conductorAlclad

An electrically insulated conductor for carrying signals or current includes a solid or stranded copper core of various geometries with only a single electrically insulating and thermally conductive layer of anodized aluminum (aluminum oxide). The device is made by forming a uniform thickness thin sheet or foil of aluminum to envelop the copper or copper alloy core. The aluminum has its outer surface partially anodized either before or after forming to the core in an electrolytic process to form a single layer of aluminum oxide.

Owner:FORD GLOBAL TECH LLC

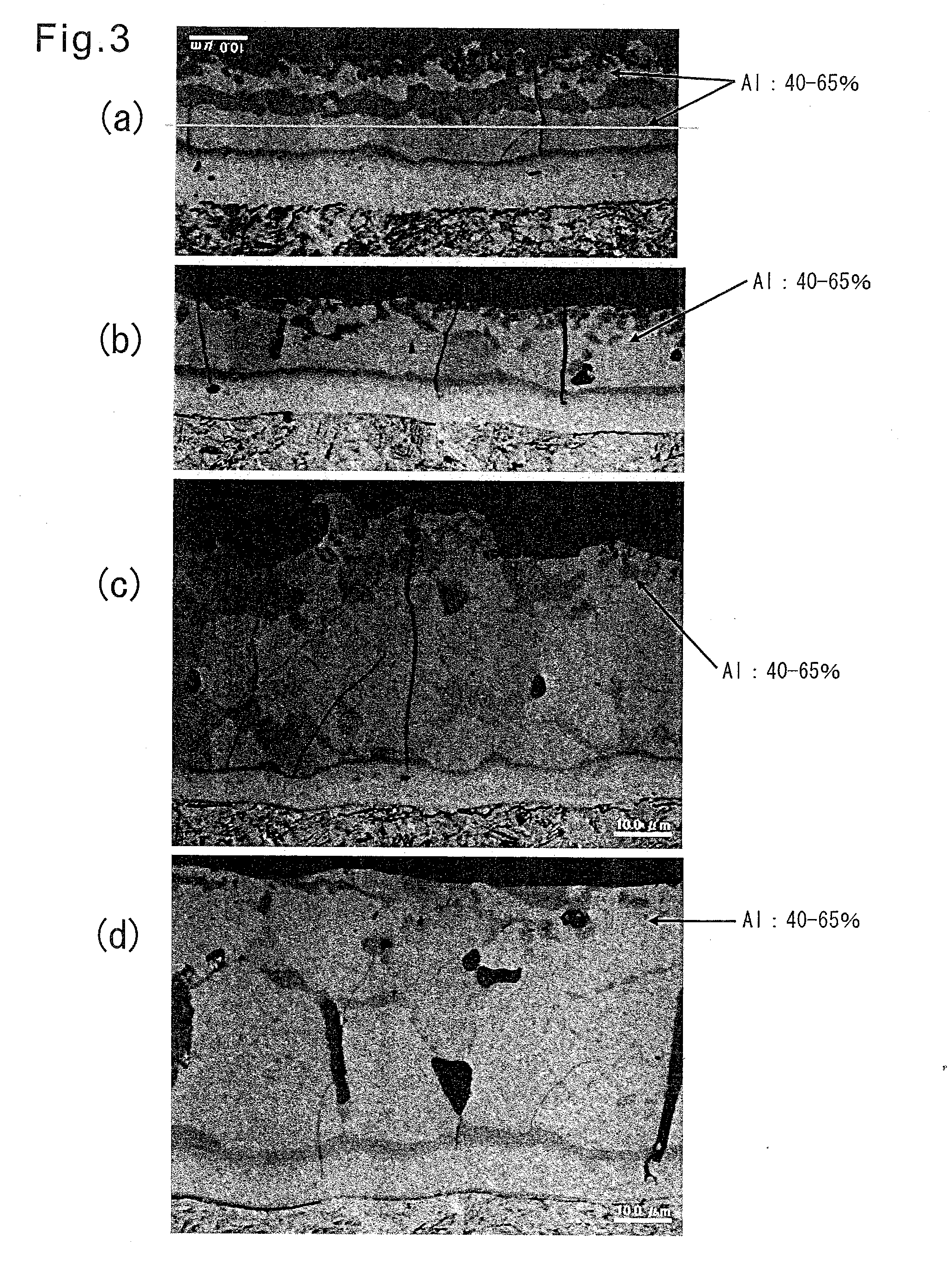

Hot stamped high strength part excellent in post painting anticorrosion property and method of production of same

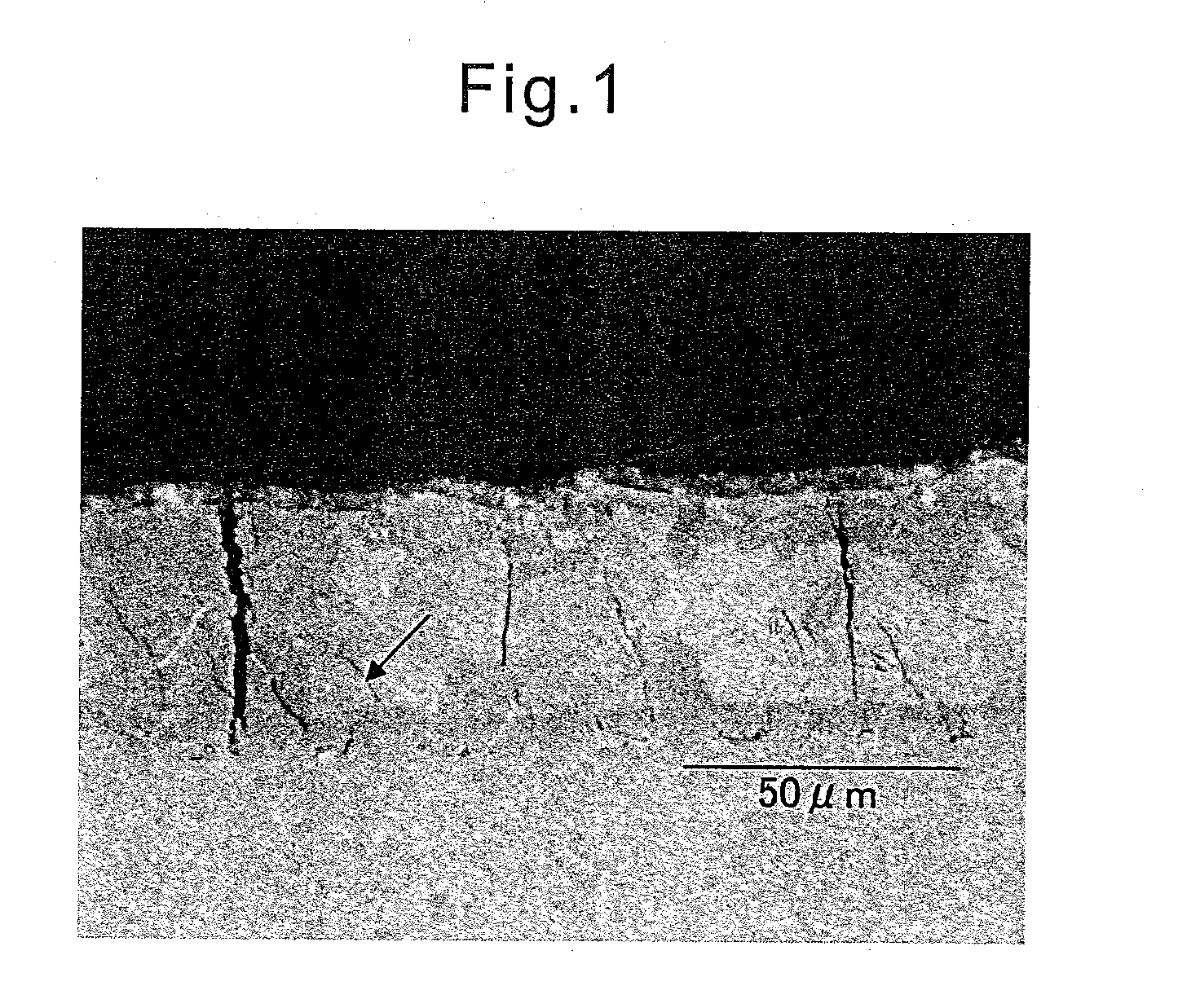

ActiveUS20140030544A1Inhibits the formation of cracksHigh strengthHot-dipping/immersion processesFurnace typesHot stampingCrazing

A hot stamped high strength part in which the propagation of cracks which form at the plating layer at the time of hot stamping when hot stamping aluminum plated steel sheet is suppressed and the post painting anticorrosion property is excellent even without adding special ingredient elements which suppress formation of cracks in an aluminum plating layer is provided.A hot stamped high strength part which is excellent in post painting anticorrosion property, which hot stamped high strength part has an alloy plating layer which includes an Al—Fe intermetallic compound phase on the surface of the steel sheet, wherein the alloy plating layer is comprised from phases of a plurality of intermetallic compounds, a mean linear intercept length of crystal grains of a phase containing Al: 40 to 65 mass % among the phases of the plurality of intermetallic compounds is 3 to 20 μm, an average value of thickness of the Al—Fe alloy plating layer is 10 to 50 μm, and a ratio of the average value of thickness to the standard deviation of thickness of the Al—Fe alloy plating layer satisfies the following relationship:0<standard deviation of thickness / average value of thickness≦0.15.

Owner:NIPPON STEEL CORP

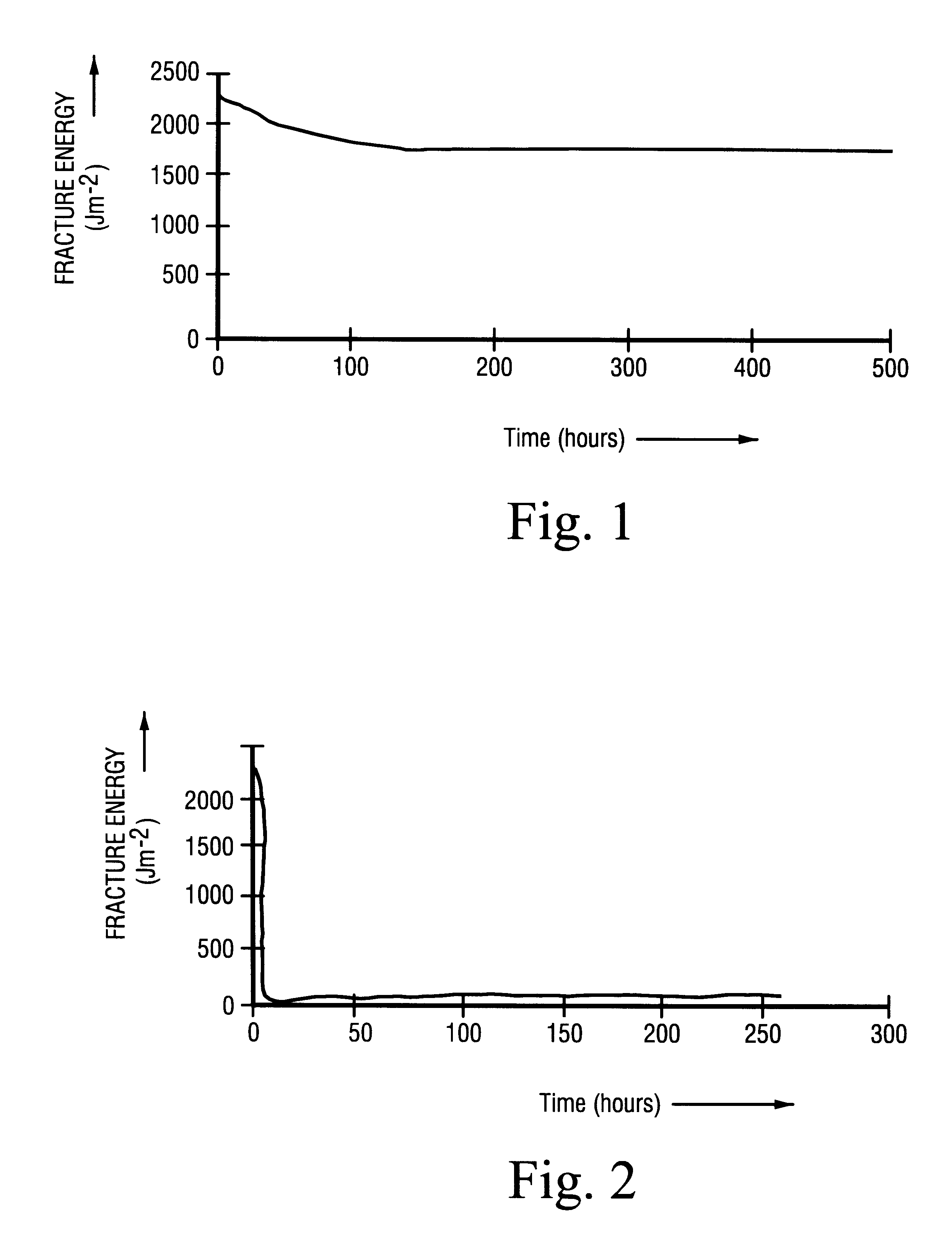

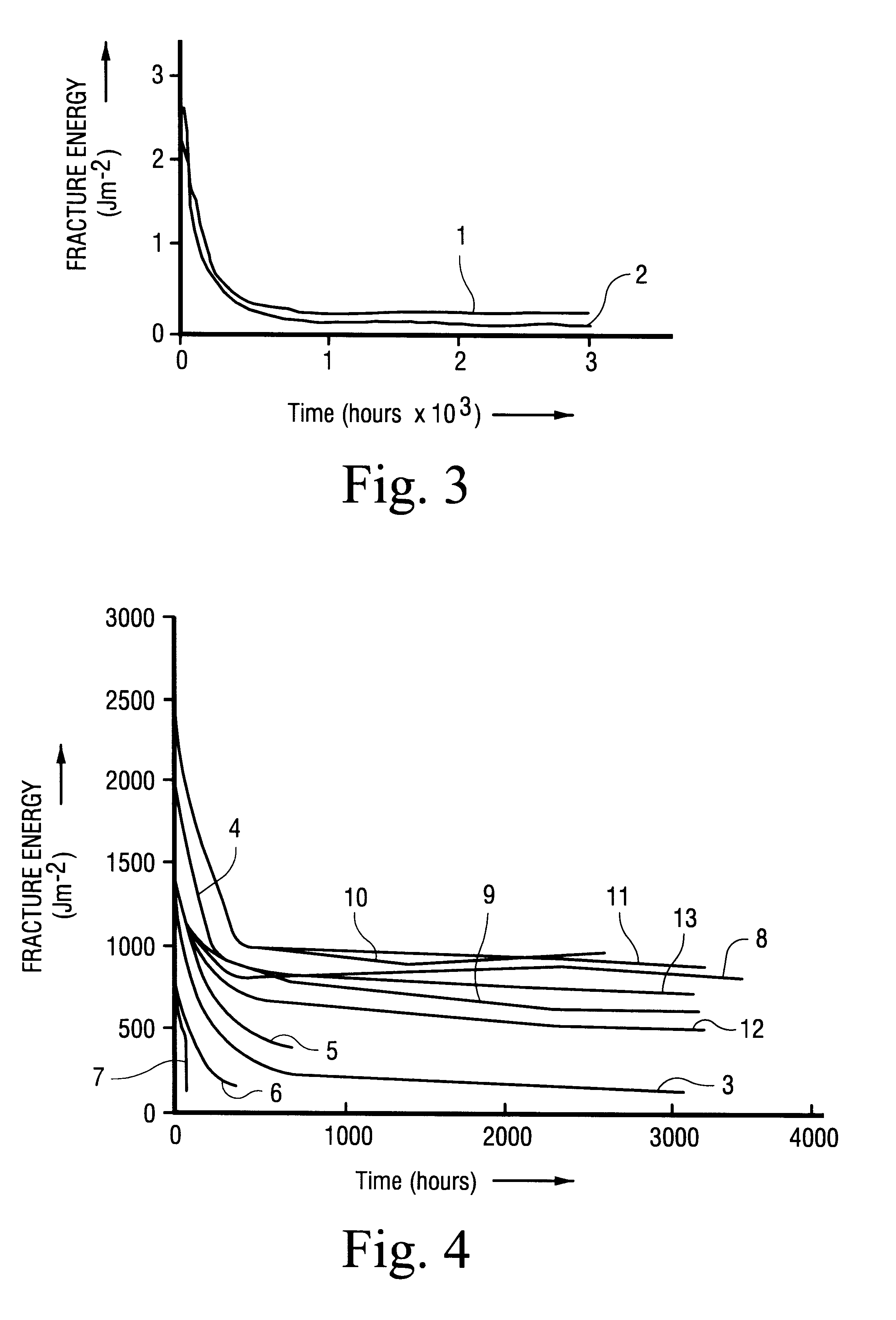

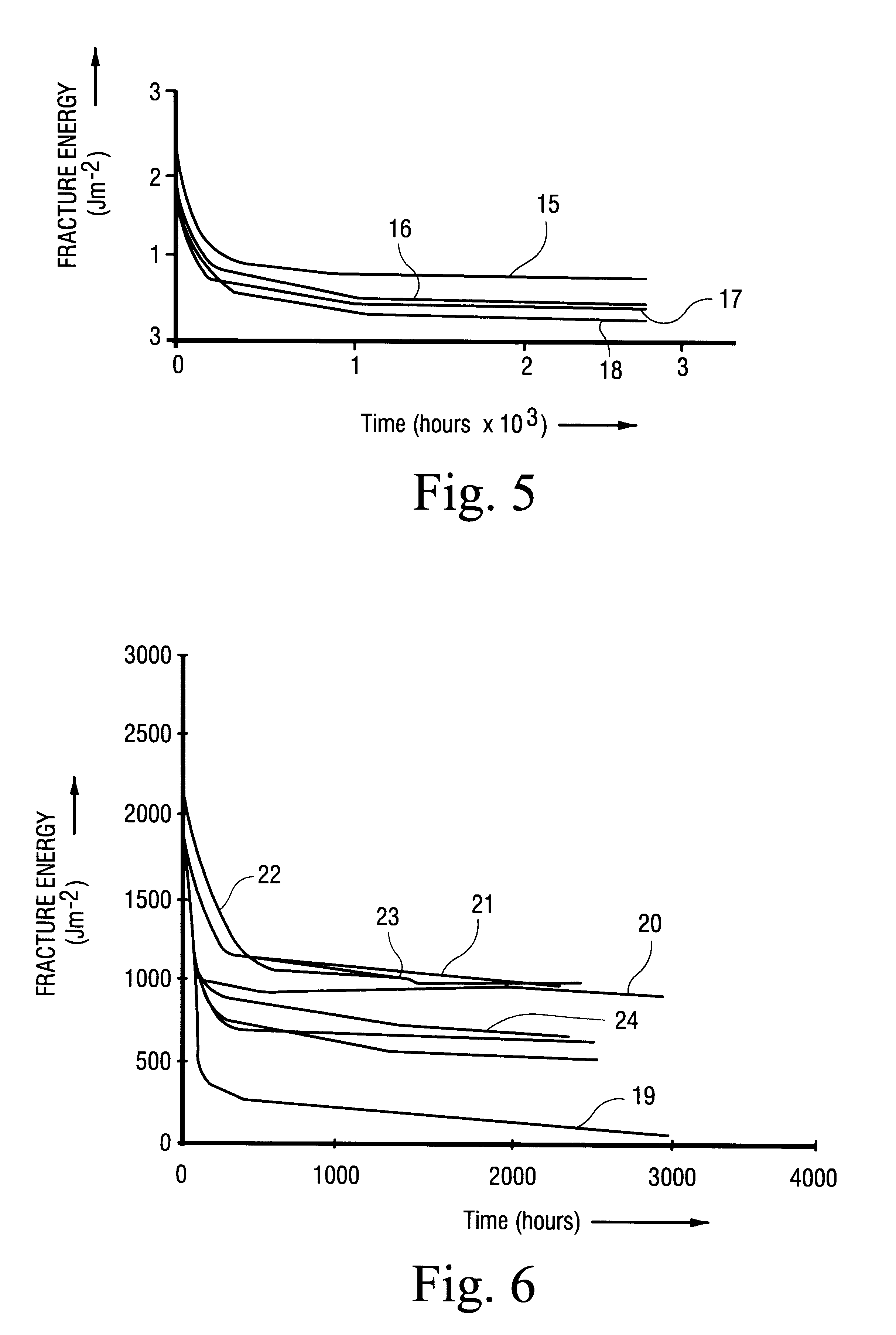

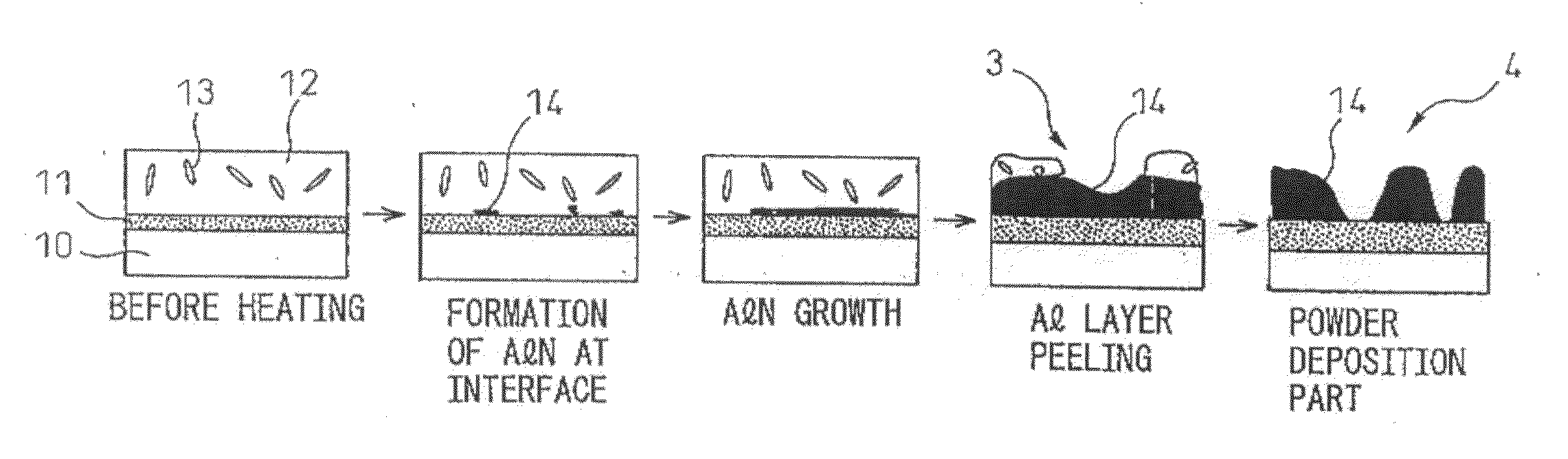

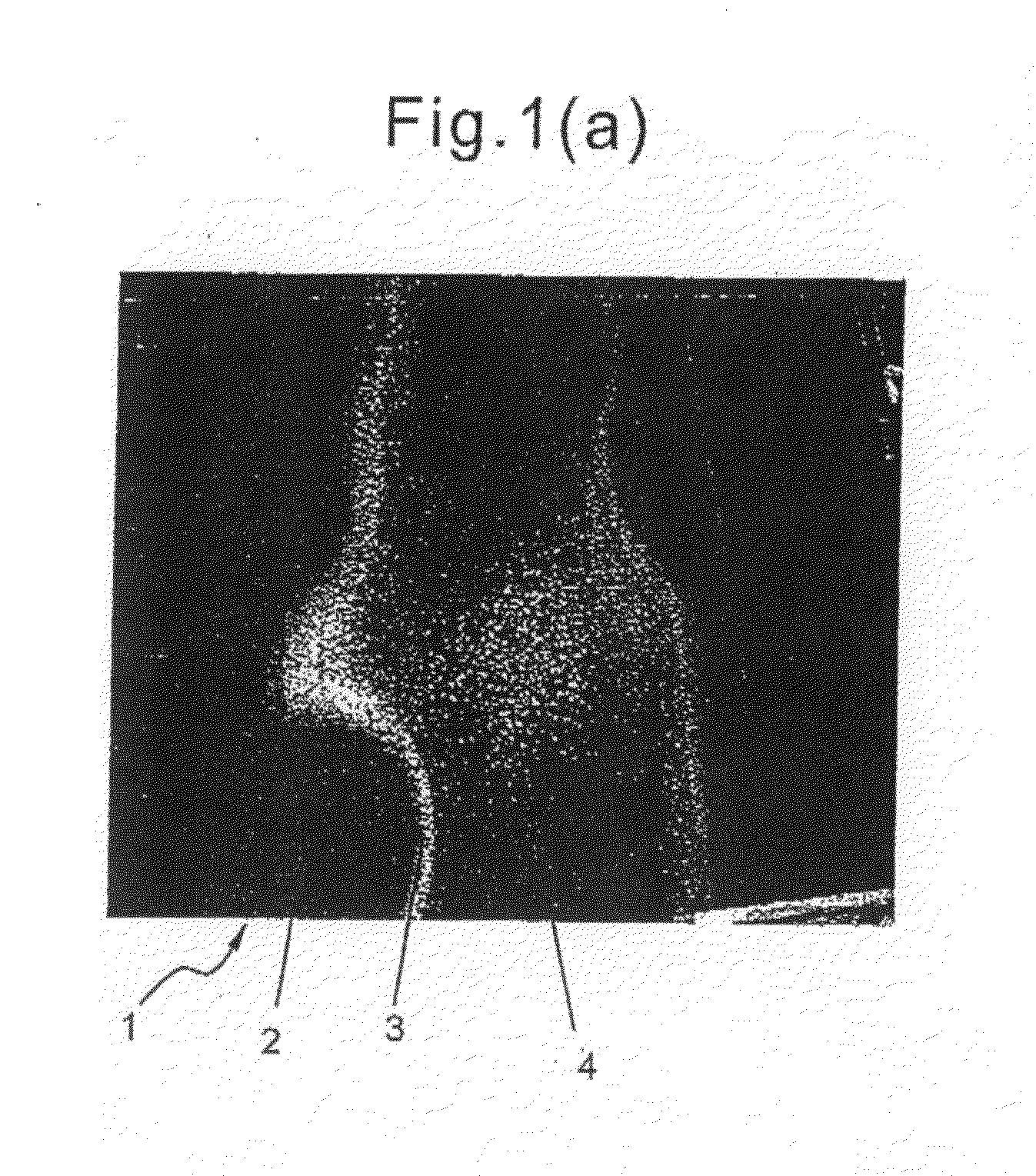

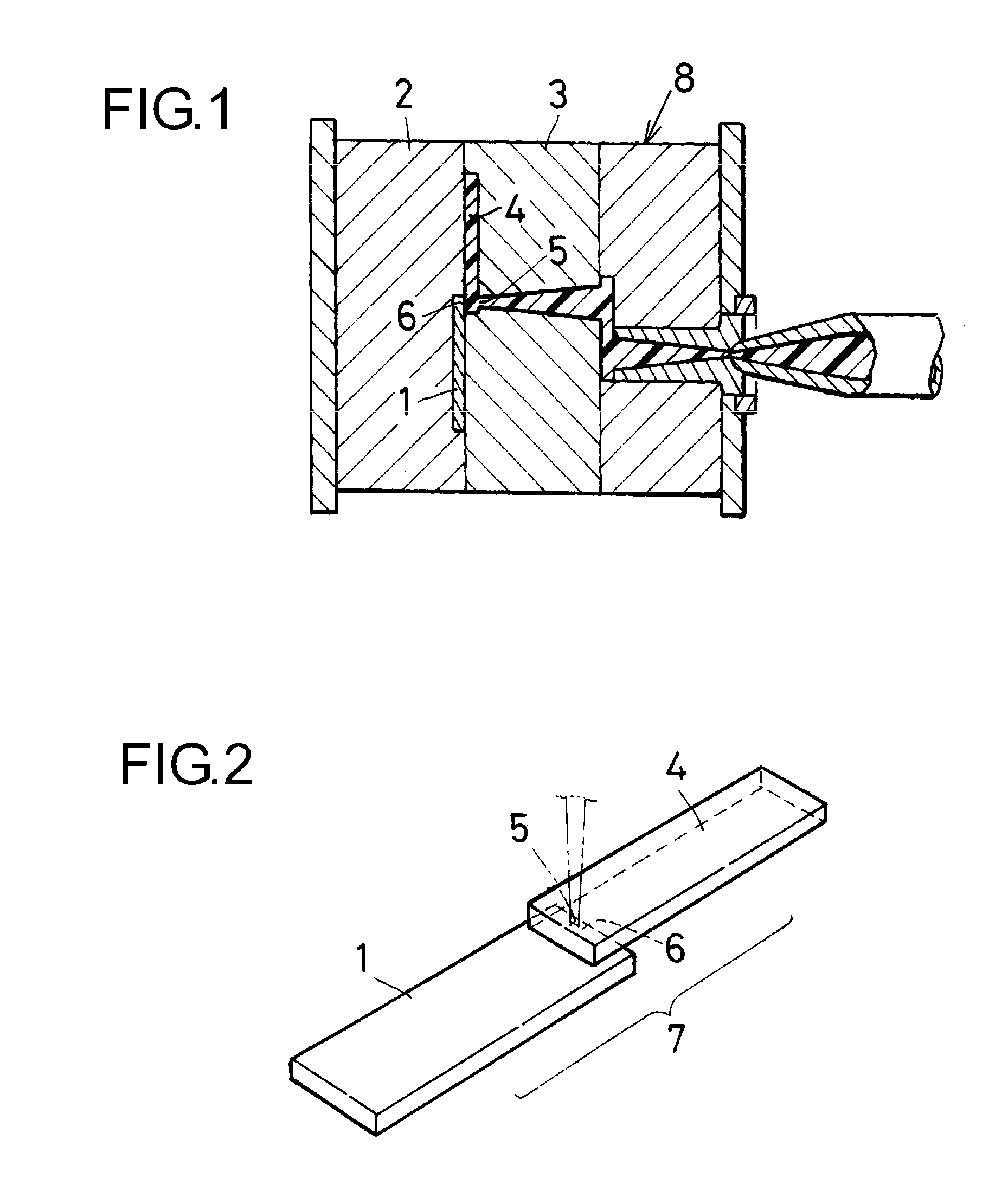

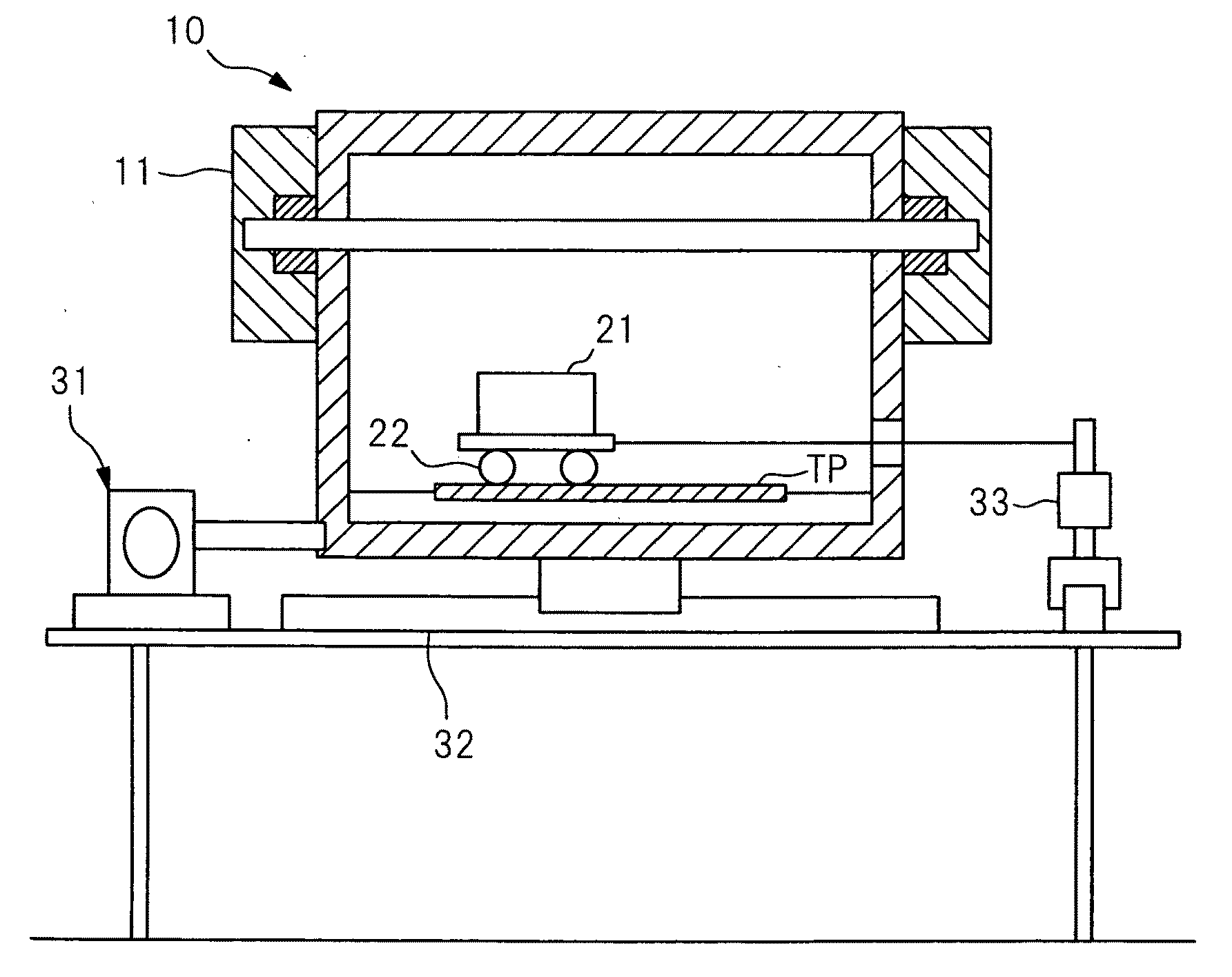

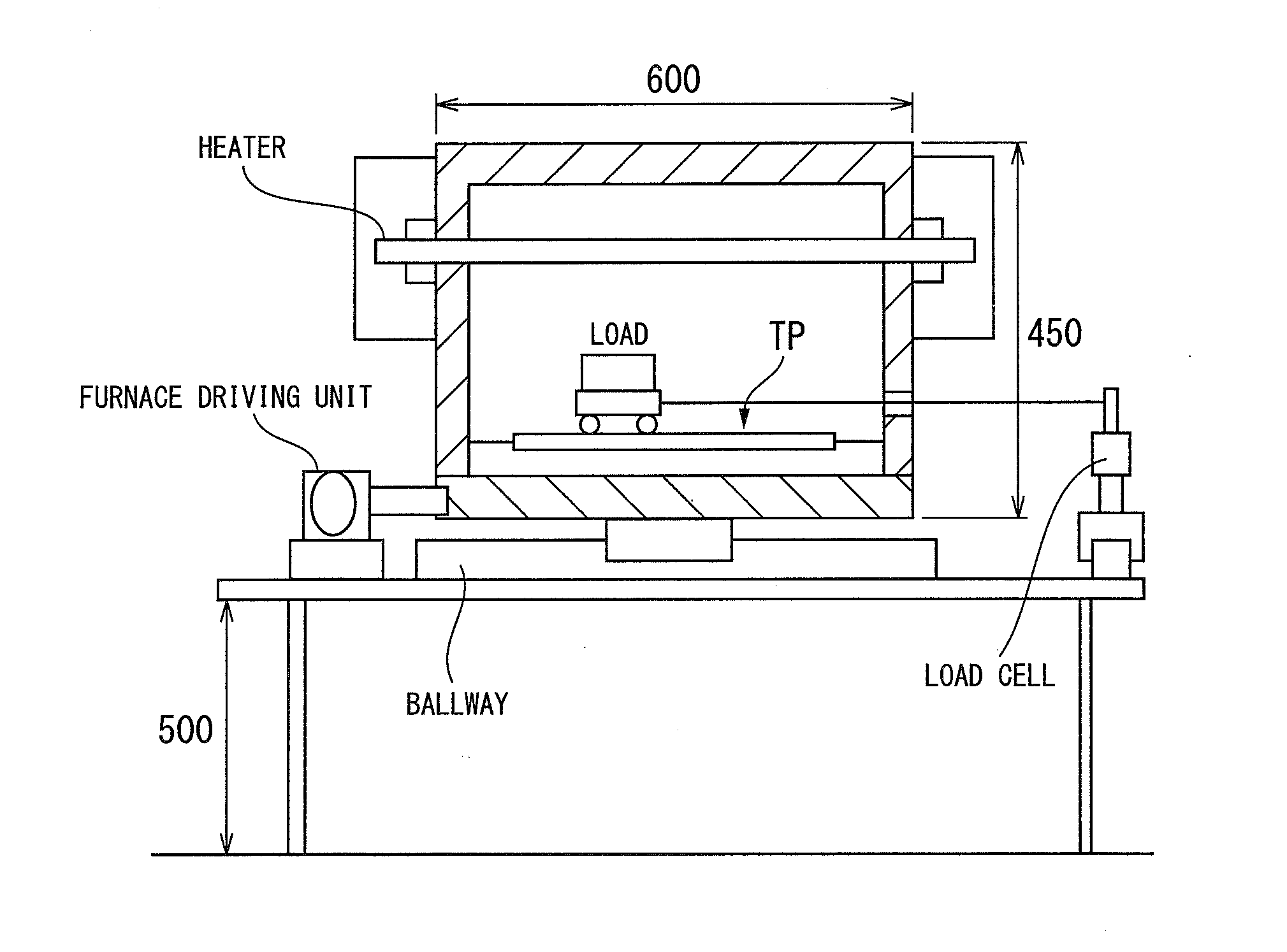

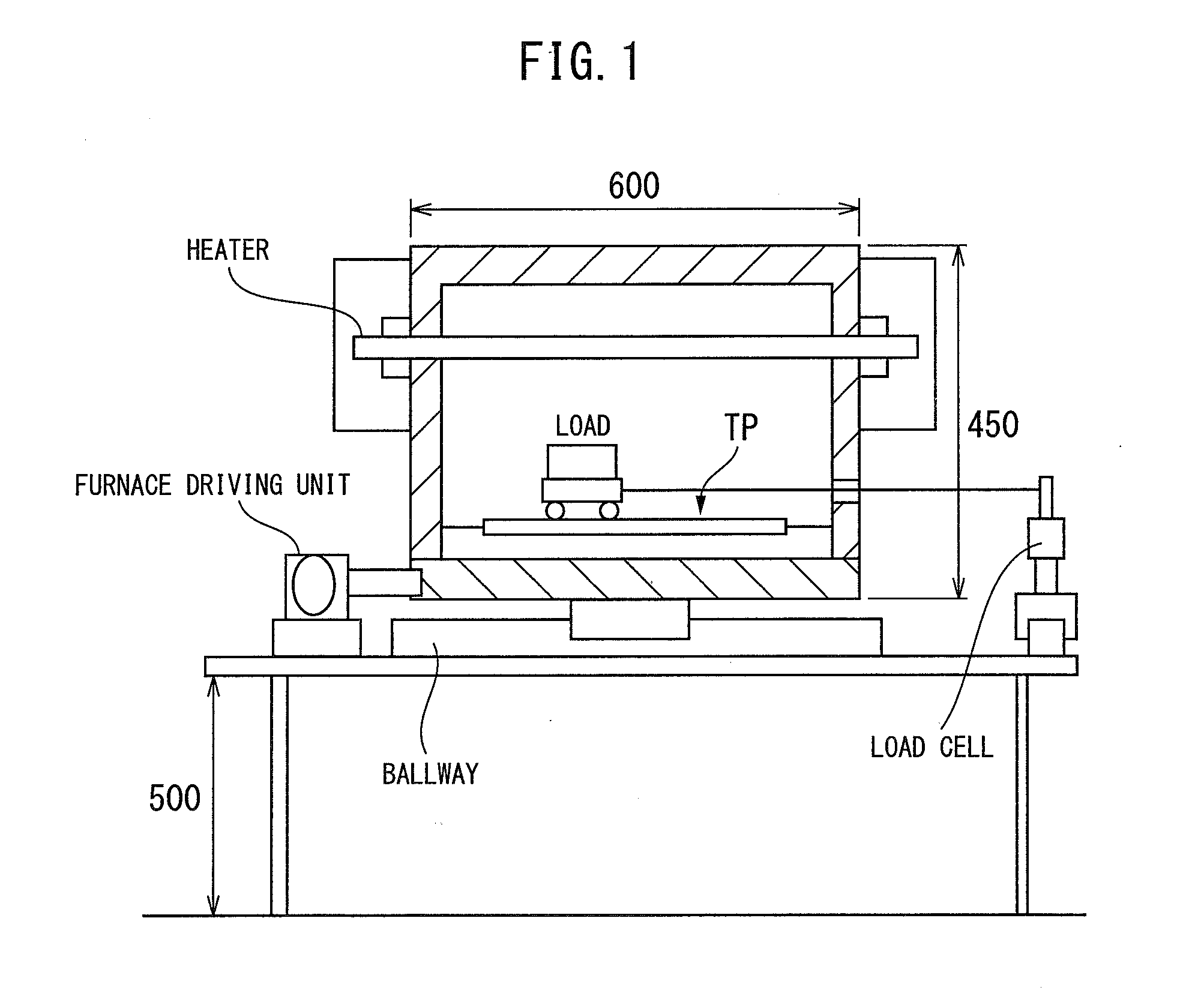

Aluminum plated steel sheet for rapid heating hot-stamping, production method of the same and rapid heating hot-stamping method by using this steel sheet

ActiveUS20110174418A1Eliminate generationReduce riskShaping toolsHot-dipping/immersion processesHot stampingHydrogen

The present invention solves the problem of melting of Al in heating before hot-stamping, which had been a problem in the past in applying hot-stamping to Al-plated steel sheet, and provides Al-plated steel sheet for hot-stamping and a method of hot-stamping using that Al-plated steel sheet to solve the problem of delayed fracture due to residual hydrogen, and, furthermore, a method of a rapid heating hot-stamping using that Al-plated steel sheet.The Al-plated steel sheet of the present invention is produced by annealing the Al-plated steel sheet as coiled in a box-anneal furnace for the time and at the temperature indicated in FIG. 5, and alloying of a plated Al and a steel sheet.Further, a method of rapid heating hot-stamping in the present invention is characterized by cutting out a stamping blank of an Al-plated steel sheet, and heating that blank in heating before hot-stamping by an average temperature with a rising rate of 40° C. / sec or more and a time of exposure to an environment of 700° C. or more of 20 seconds or less, and then hot-stamping it.

Owner:NIPPON STEEL CORP

Composite of steel and resin and method for manufacturing same

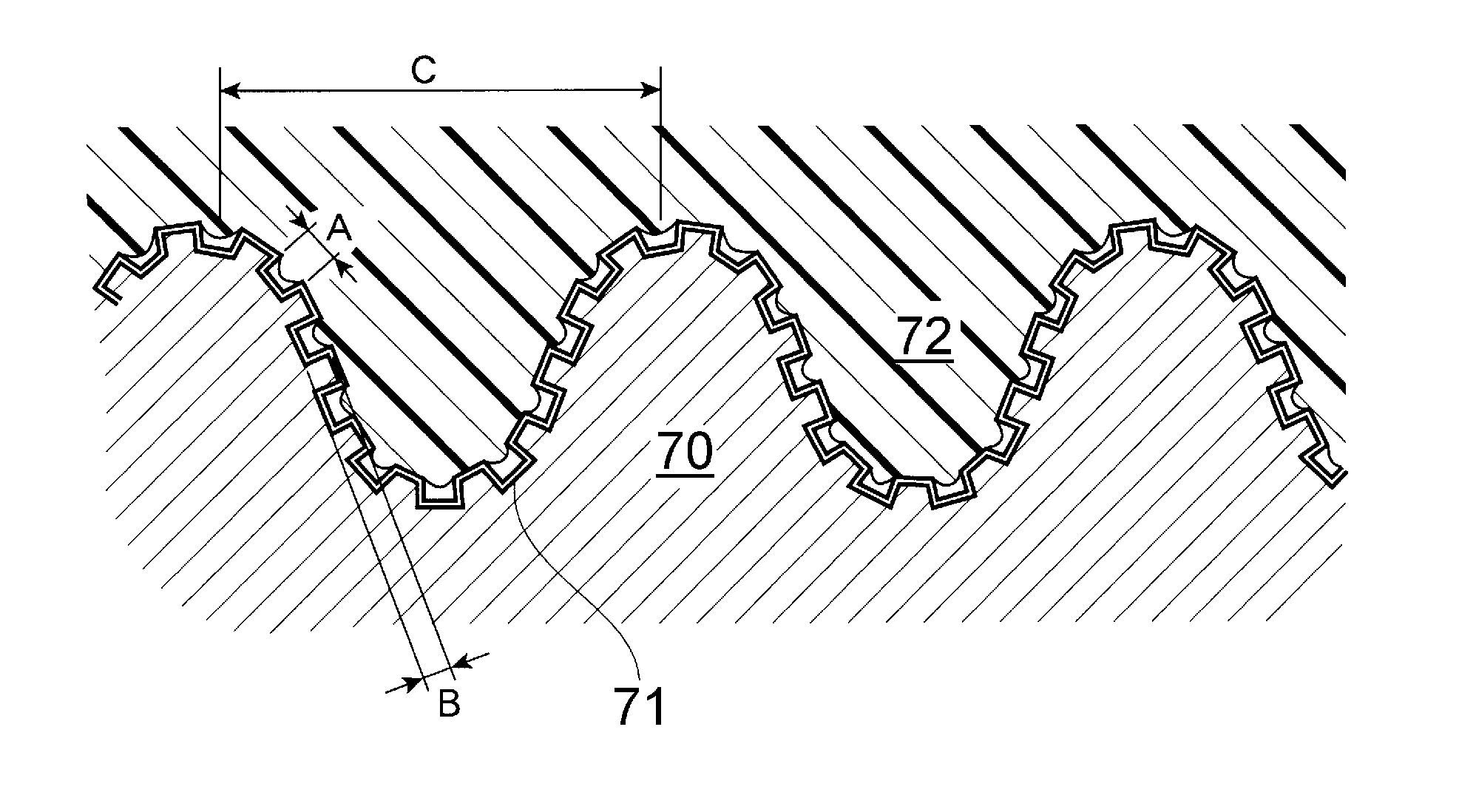

ActiveUS20100279120A1Improve corrosion resistanceImprove performanceMetal rolling stand detailsSynthetic resin layered productsSheet steelAdhesive

Disclosed is a composite in which an aluminum-plated steel sheet and a resin are securely and integrally joined together, as well as a corrosion resistant steel sheet. Through chemical etching the aluminum-plated steel sheet is caused to have a surface configuration, in which three-dimensional protrusions having pebble-like shapes with a diameter of at least about 0.3 μm or having irregular shapes with a minor diameter of at least 0.3 μm and a major diameter of at least several microns are scattered over a plain-like part, where 30 to 50% of the surface area of the plain-like part is accounted for by a portion covered with shallow recesses having a diameter of 20 to 50 nm in a state of being distributed adjacent to each other. The surface of the three-dimensional protrusions is mainly ceramic containing silicon and the flat part is mainly a ceramic containing aluminum. The steel is heated and welded under pressure to a resin composition, injection joining is performed or adhesion joining with another adherend is performed with a resin-based adhesive. Coating with a corrosion resistant material can also be performed.

Owner:TAISEI PLAS CO LTD

Process for hot immersion plating iron and steel with aluminium-zinc alloy

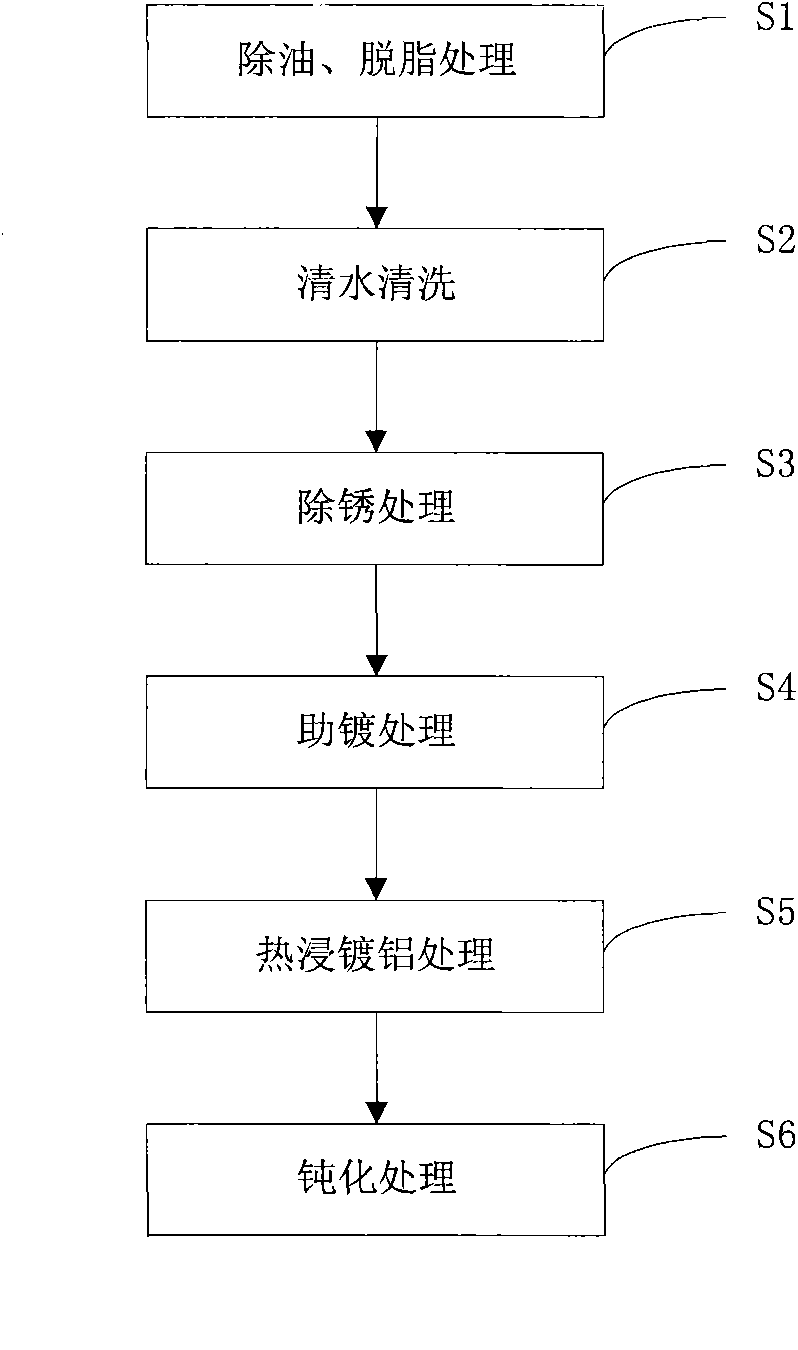

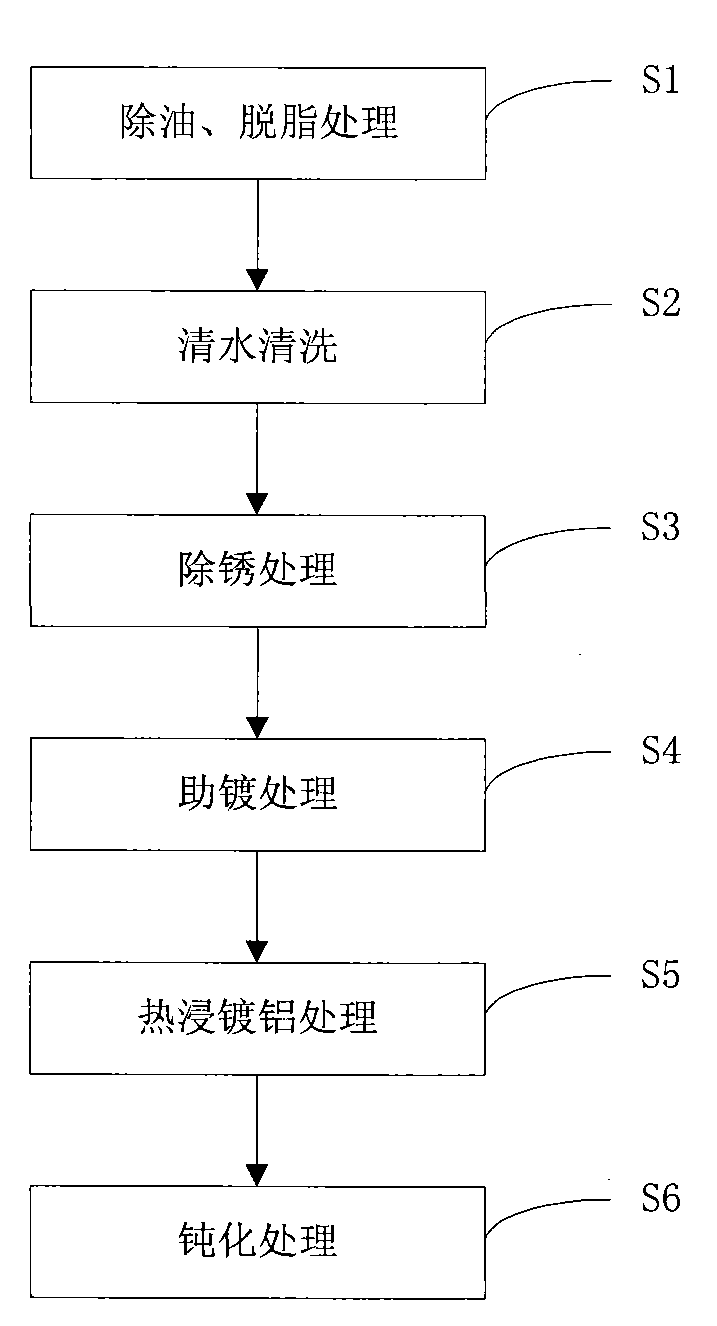

InactiveCN1392284ANo polluting emissionsImprove working conditionsHot-dipping/immersion processesRare earthZinc alloys

The present invention belongs to the field of hot immersion plating of iron and steel with aluminium-zinc alloy. The iron and steel after being pretreated with inactivation solution, compounded by using CrO3 0.2-5 wt%, K2MnO4 0.05-3 wt%, NaNO2 0.05-6 wt% and water, is hot immersion plated with aluminium-zinc alloy plating liquid with small amount of antioxidant alloy. The antioxidant alloy consists of Al 70-80 wt%, mixed RE 4-10 wt%, Si 8-10 wt%, Ni 3-5 wt%. The technological process can obtain high-quality smooth and bright coating without leakage, false plating, pinhole, color difference and other defects, and has low cost, simple operation and no drainage pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing hydrogen permeation preventing coating by aluminizing by adopting room temperature fused salt

The invention discloses a method for preparing a hydrogen permeation preventing coating by aluminizing by adopting room temperature fused salt, comprising the following steps of: firstly, carrying out surface treatment of degreasing and oxidation film removing on strain steel matrix with a conventional method; secondly, aluminizing by adopting room temperature fused salt, wherein the room temperature fused salt for aluminizing is a system formed by AlCl3 and organic salt, the organic salt is one of alkyl pyridine halide, alkyl imidazole halide and alkaryl chloration ammonium salt, the mole ratio of the AlCl3 to the organic salt is larger than 1.0 and smaller than or equal to 2.0, the technical parameter for aluminizing by adopting room temperature fused salt is as follows: an aluminum wire as the anode has the temperature of 25-60 DEG C and the current density of 5-30mA / cm<2>, and the plating time is 30-200min; and thirdly, heat treatment to obtain an Fe-Al alloy layer, wherein the technical parameter for heat treatment is as follows: the temperature is 670-750 DEG C, and the time is 30min to 24h; fourthly, oxidation, wherein the technical parameter for oxidation is as follows: the temperature is 670-1050 DEG C, the time is 1-200h, and the oxygen partial pressure is 1.0*10-2 Pa to 2.1*104 Pa. The invention is suitable for preparing tritium permeation preventing coatings on surfaces of special-shaped pieces such as the inner wall of a pipeline, and the like, is suitable for the requirement of large-scale industrialized production, and has a self-healing function.

Owner:ZHEJIANG UNIV +1

Plated steel sheet and method of hot-stamping plated steel sheet

ActiveUS20110030441A1Improve the lubrication effectGood in post-painting corrosion resistanceHot-dipping/immersion processesShaping toolsHot stampingWurtzite crystal structure

In a plated steel sheet having an aluminum-plating layer comprising at least Al formed on one side or both sides of the steel sheet, there is provided a plated steel sheet which, owing to the presence of a surface coating layer containing a compound having wurtzite crystal structure on the aluminum-plating layer, has excellent lubricity, prevents the plating thickness from becoming uneven during heating, and can improve formability and productivity in hot stamping, and a method of hot-stamping the plated steel sheet.

Owner:NIPPON STEEL CORP

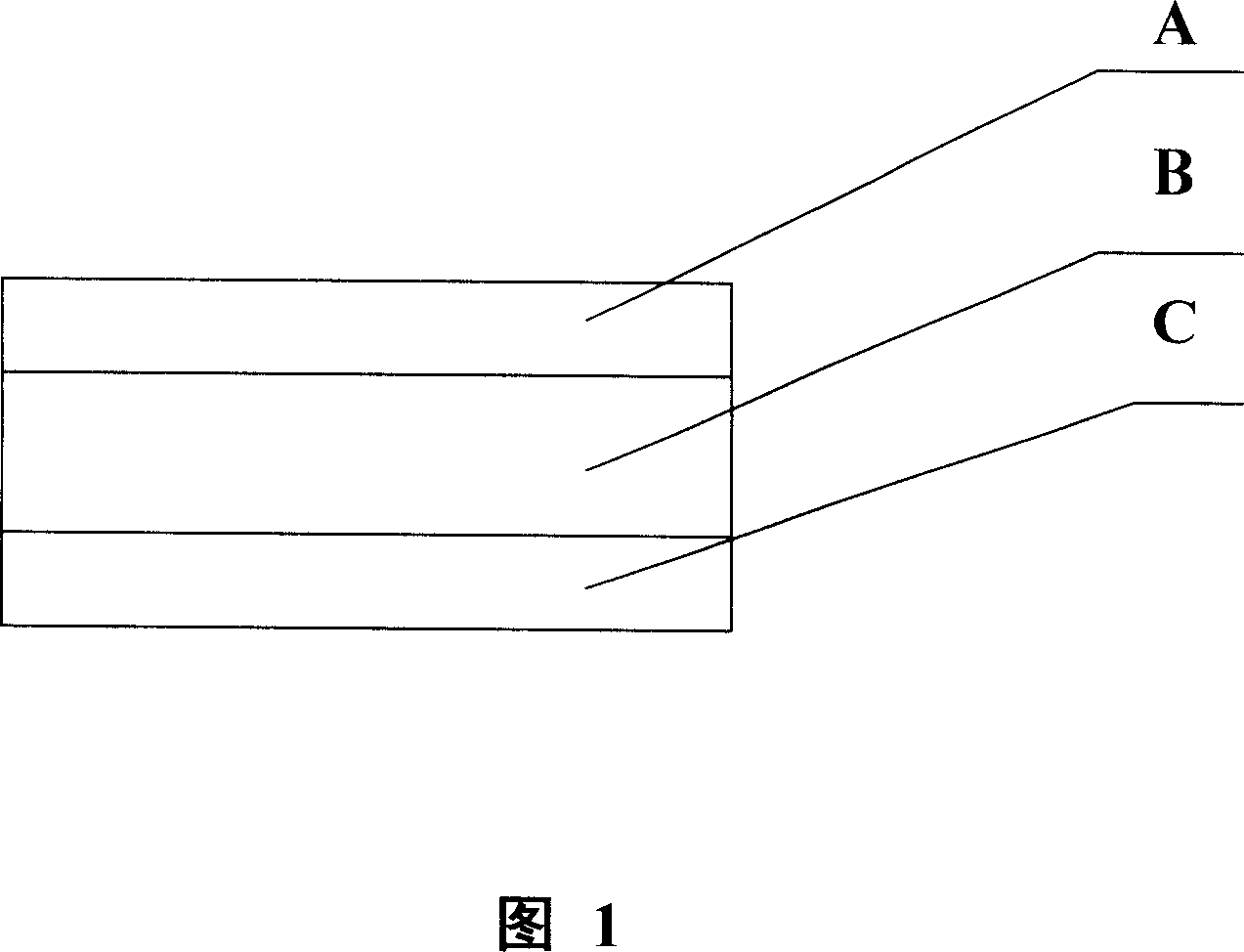

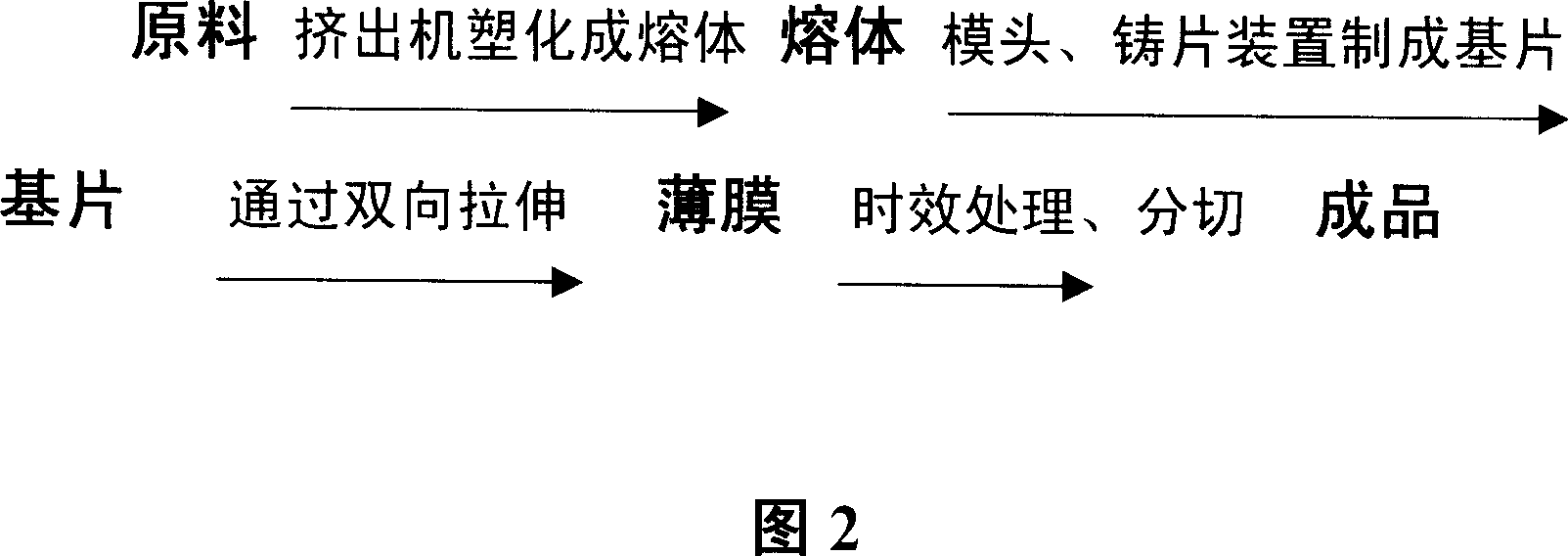

Vacuum aluminium coating laser bidirection drawed BOPP film and its production method

InactiveCN1948000ALow market priceIncrease productivitySynthetic resin layered productsSurface layerOptoelectronics

A bidirectionally stretched polypropene film substrate with high aluminum-plating effect, transfer effect and laser effect is composed of upper surface layer, core layer and lower surface layer, which are combined through heat fusing and co-extruding. It is prepared from cheap homopolypropene. Its preparing process is also disclosed.

Owner:DAQING PETROLEUM ADMINISTRATION

Plated steel sheet and method of hot-stamping plated steel sheet

ActiveUS20120073351A1Improve the lubrication effectGood in post-painting corrosion resistanceHot-dipping/immersion processesSuperimposed coating processHot stampingWurtzite crystal structure

Owner:NIPPON STEEL CORP

Cold spray-coating method for composite solder of conduit and fin of aluminium alloy heat exchanger

InactiveCN1962941AIncrease productivityQuality improvementWelding/cutting media/materialsHeat exchange apparatusSpray coatingAlclad

The invention discloses a preparing method of automobile aluminium alloy exchanger, which comprises the following steps: 1. blending Al-Si and Zn powder and brazing flux with weight rate at 9: 3-4: 0.5-4; drying; preparing cold spraying powder; 2. cleaning the conductor and fin surface; drying to make cold spraying powder; adopting cold-spraying method to sediment powder on the surface of conductor and fin; 3. assembling the base conductor; brazing according to NOCOLOK technique to obtain the product.

Owner:HARBIN INST OF TECH

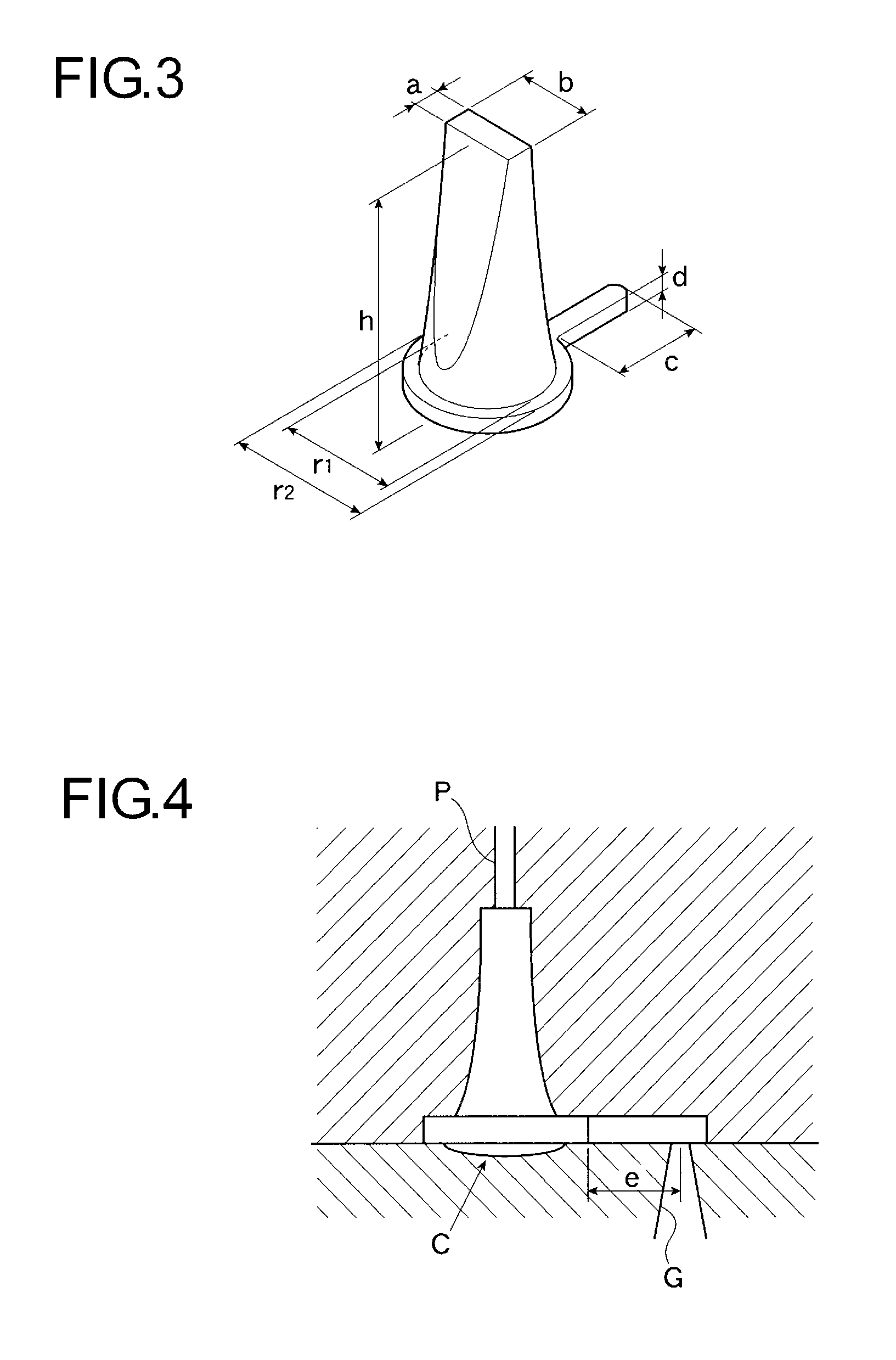

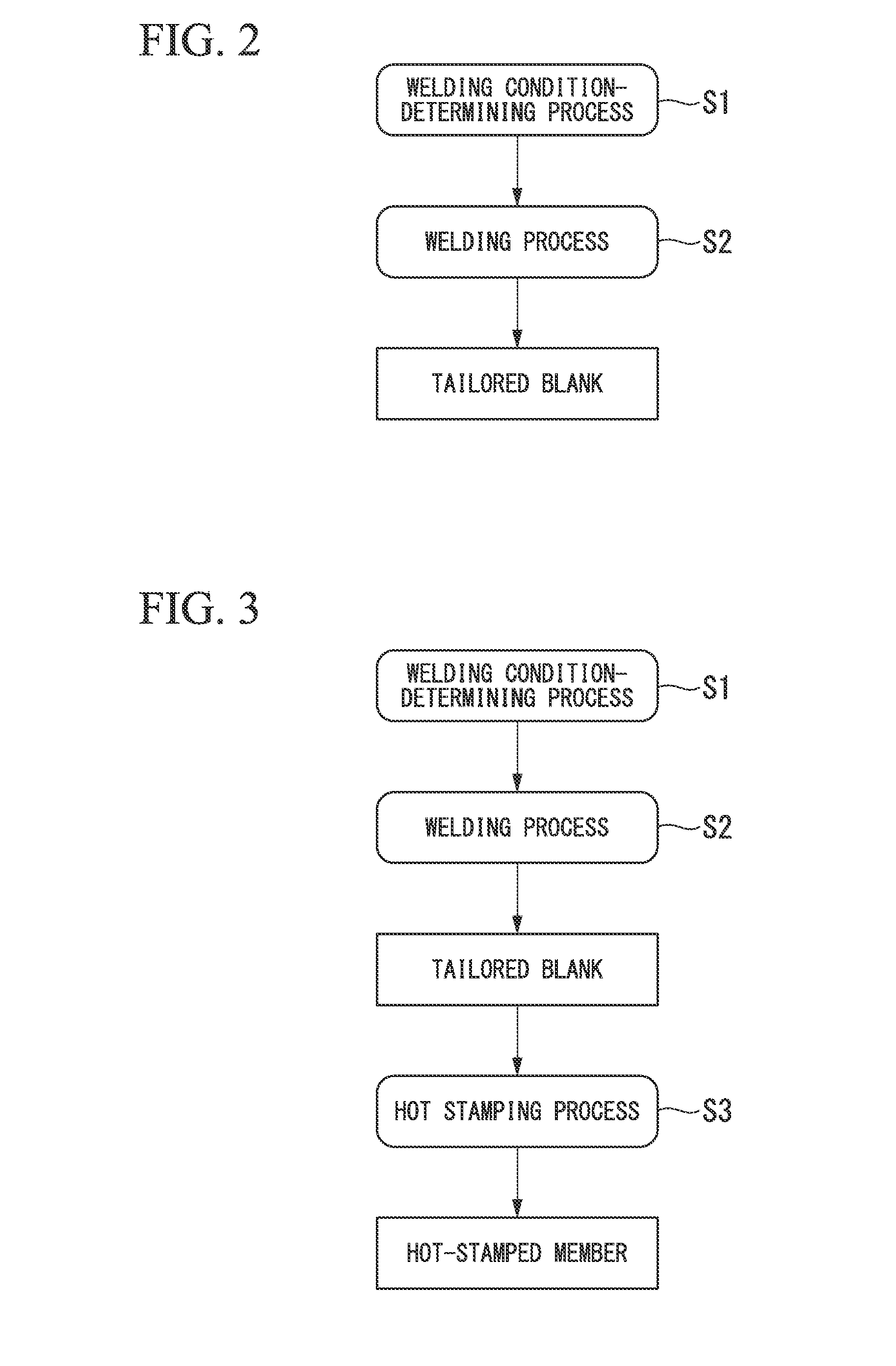

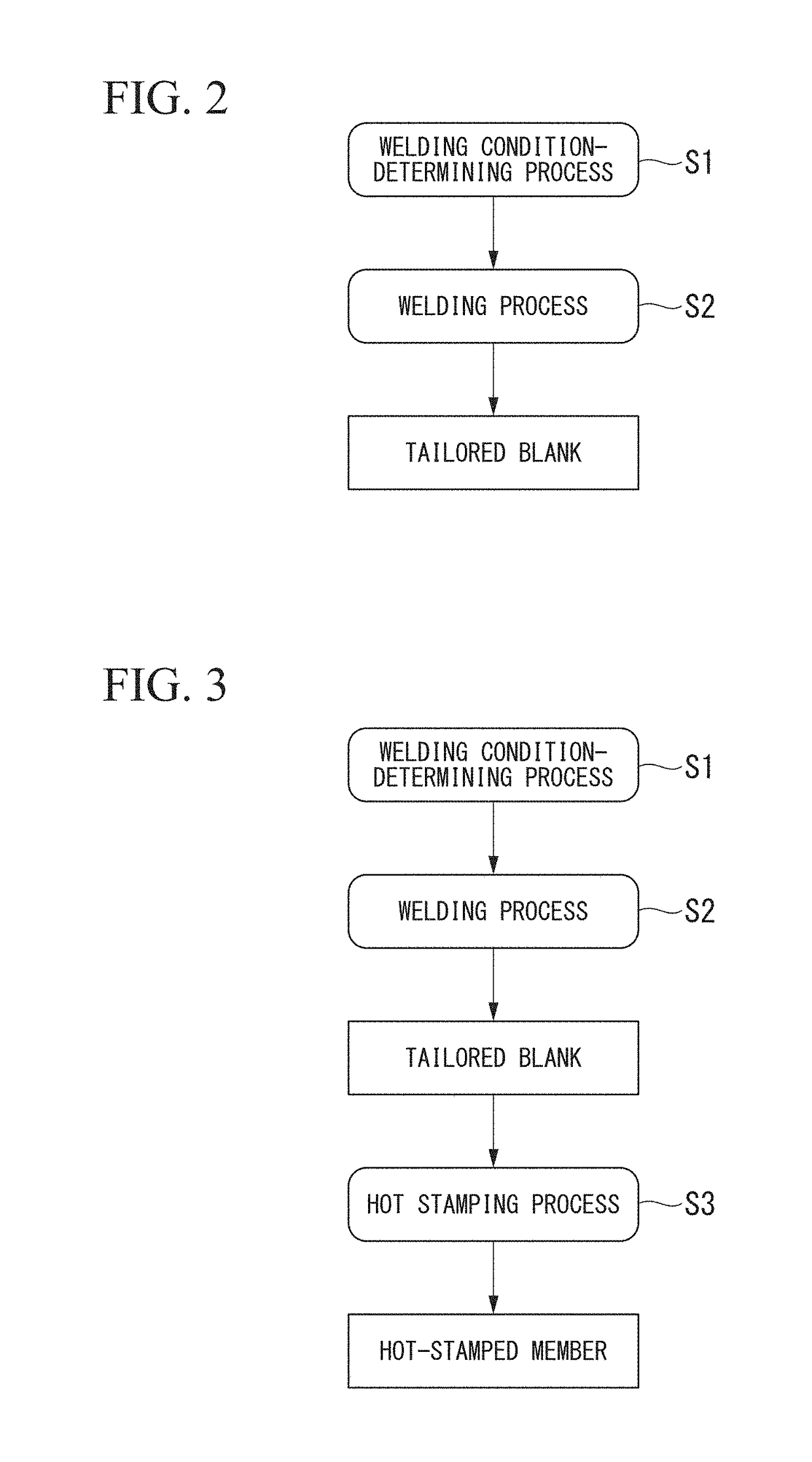

Tailored blank for hot stamping, hot stamped member, and methods for manufacturing same

ActiveUS20150043962A1Improve joint strengthPoor corrosion resistanceArc welding apparatusFurnace typesHot stampingAlclad

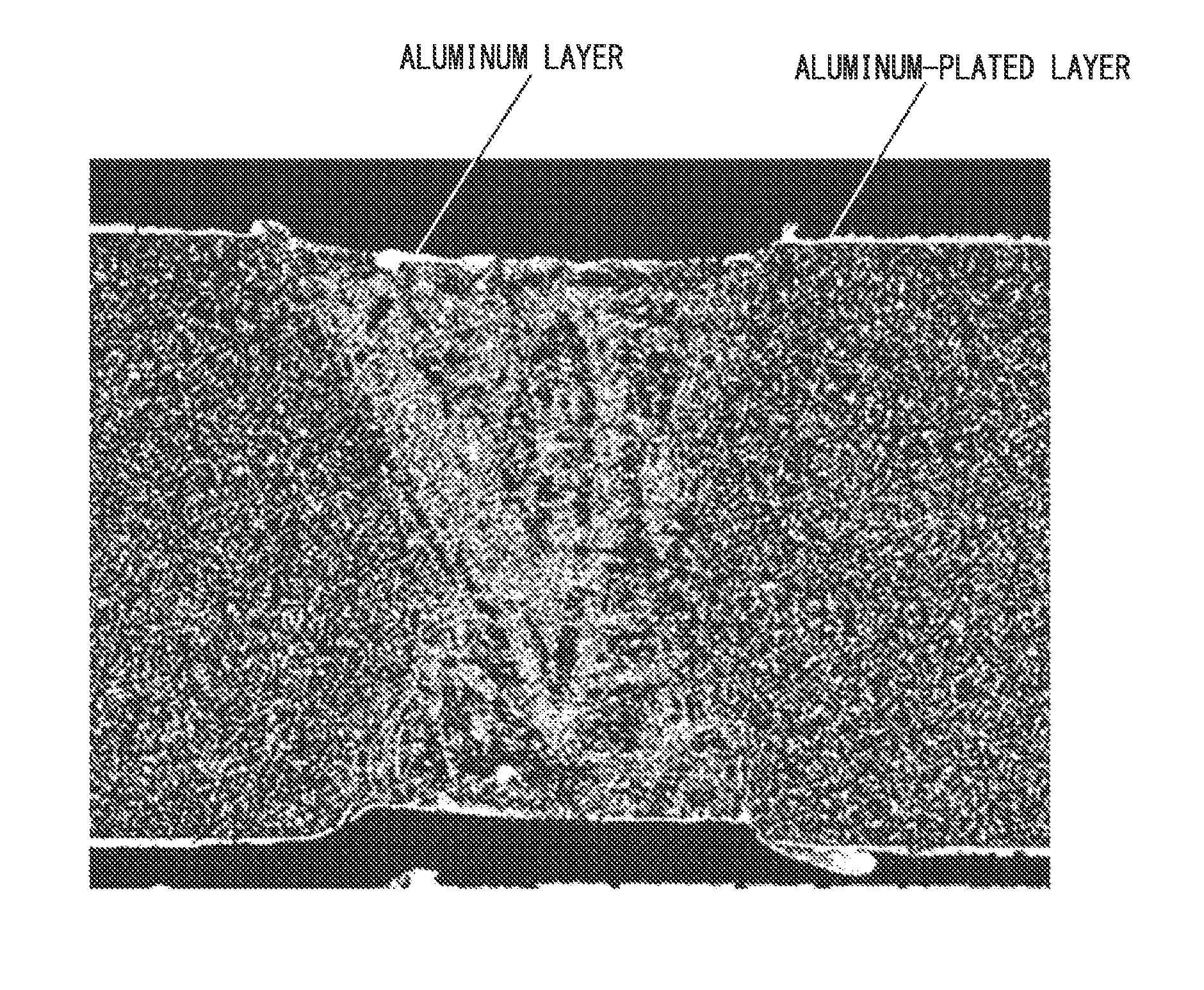

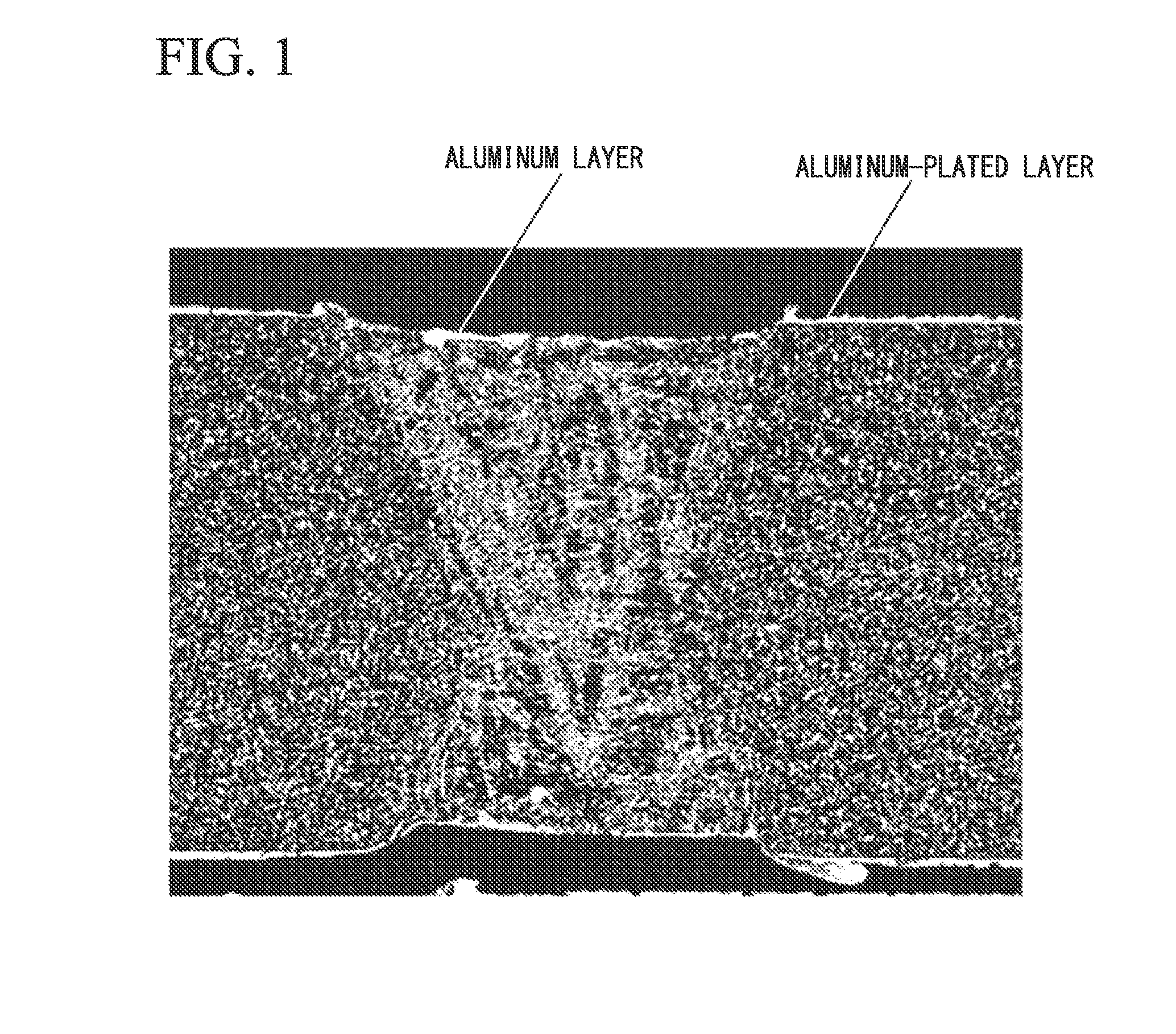

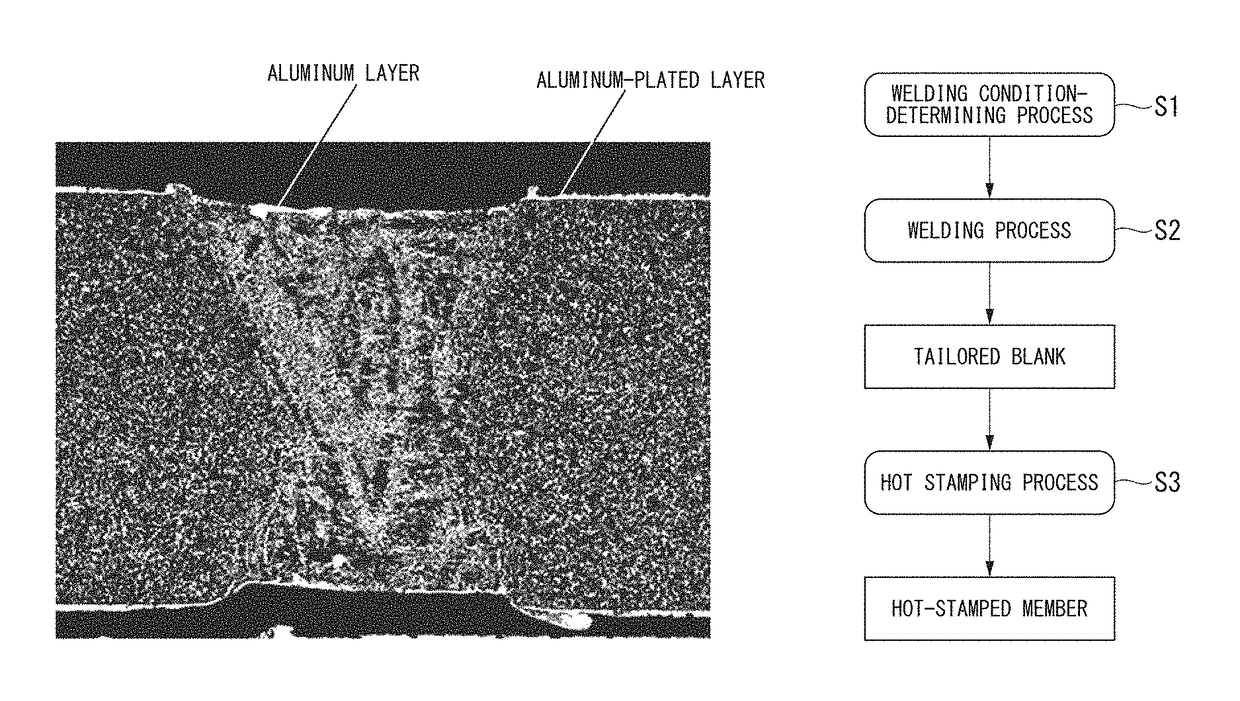

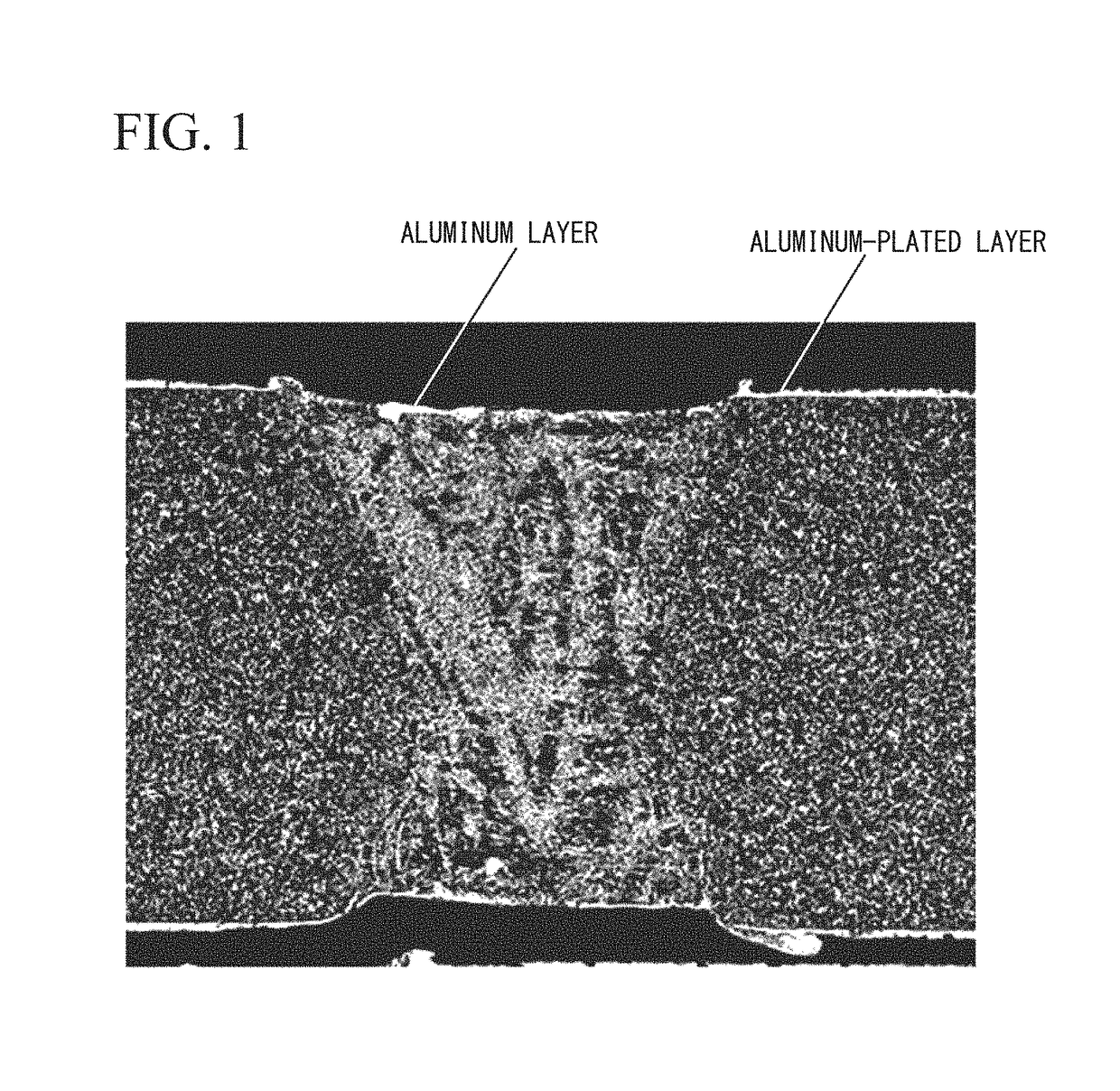

A tailored blank for hot stamping includes a welded portion formed by butt-welding a first aluminum-plated steel sheet and a second aluminum-plated steel sheet, an Average Al concentration of a weld metal in the welded portion is in a range of 0.3 mass % to 1.5 mass %, an Ac3 point of the weld metal is 1250° C. or lower, and furthermore, an aluminum layer formed during the butt-welding is present on a surface of the welded portion.

Owner:NIPPON STEEL CORP

Aluminum-zinc hot plating deep drawing steel with thick gauge of more than 1.2 mm, and manufacturing method thereof

InactiveCN103320689AGuaranteed ultra-low yield performanceExcellent deep drawing performanceTemperature control deviceMetal rolling arrangementsSteelmakingAlclad

The present invention relates to an aluminum-zinc plating deep drawing steel and a manufacturing method thereof. In the prior art, annealing rate reduction is adopted to ensure a deep drawing performance, such that the surface quality can not meet household appliance plate requirements, and a yield is low. With the present invention, the technical problems in the prior art are mainly solved. The manufacturing method comprises: smelting according to components, sequentially carrying out hot metal desulphurization, converter top and bottom composite blowing, steel ladle bottom argon blowing, RH furnace refining, protection casting through blowing Ar to low carbon steel protection slag, heating with a slab heating furnace, descaling, rough rolling, fine rolling, controlled cooling on the rear segment, and coiling to obtain a hot rolling slab, carrying out re-uncoiling, and carrying out acid washing, cold rolling and continuous annealing to obtain the finished product, wherein a continuous casting slab heating temperature is 1180-1220 DEG C, an intermediate billet after rough rolling is subjected to coiling through a hot coiling box, uncoiled, and then enters a first pass stand of the fine rolling, a fine rolling starting temperature is 990-1030 DEG C, a fine rolling end temperature is 890-??930 DEG C, a coiling temperature after fine rolling is 690-730 DEG C, a cold rolling reduction rate is 65-85%, an annealing temperature of the cold-rolled hard state strip steel at the soaking segment of the continuous annealing furnace is 840-880 DEG C, and a time of the strip steel at the soaking segment is 40-90 s.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Full-hard aluminum-zinc coated steel sheet and method for producing same

ActiveCN100529141CReduce intensityGuaranteed temperatureMetallic material coating processesReduction rateChemical composition

The invention discloses a fully hard galvanized steel plate and a production method thereof. The chemical composition of the substrate is: (weight percentage) C: 0.02% to 0.16%, Mn: 0.15% to 1.50%, Si≤0.05%, Ti and Nb is added alone or at the same time, the total content of Ti and Nb is 0.015% to 0.100%, and the rest is iron and unavoidable impurities. The characteristics of its production process are: hot rolling heating temperature 1150 ~ 1260 ℃, finishing rolling temperature 900 ~ 1100 ℃, The cooling rate after rolling is 30-60°C / s, the coiling temperature is 550-650°C, the reduction rate of cold rolling is 50%-80%, the annealing temperature is 630-710°C during galvanizing, and the hot-dip galvanizing line with open flame furnace or Produced on a hot-dip galvanizing line with full radiant tubes. The cooling section of the annealing furnace does not need to be reheated, and the yield strength of the steel plate reaches more than 600MPa, which solves the problem that the cooling section of the annealing furnace must be equipped with heating for the production of full-hard galvanized steel sheets, saves procedures and funds, and has broad application prospects. .

Owner:ANSC TKS GALVANIZING

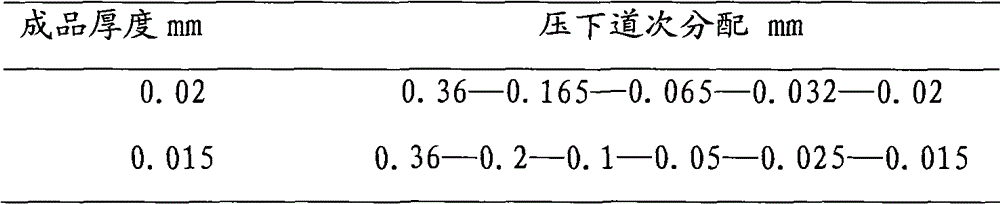

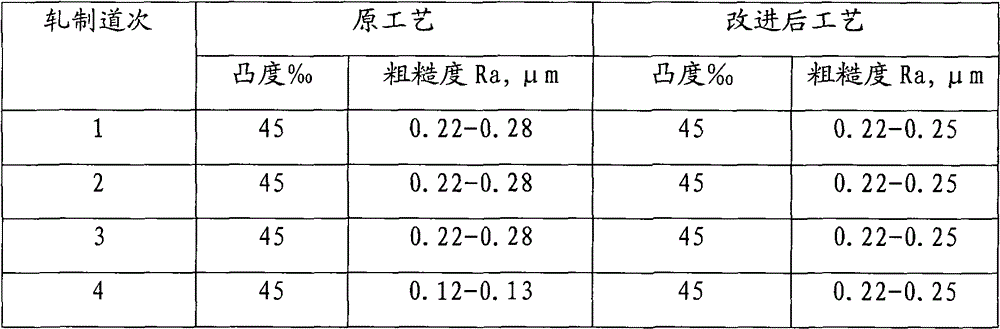

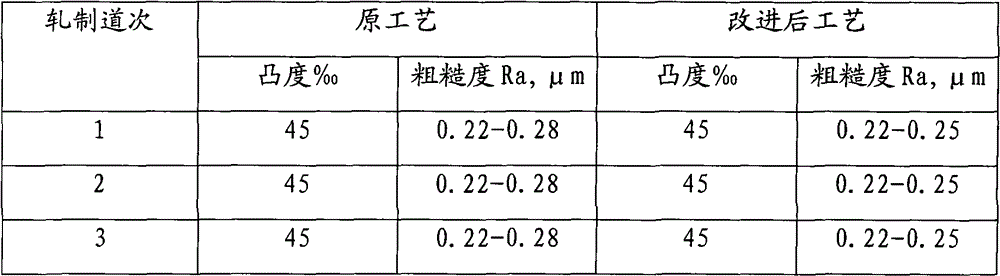

Process for producing battery aluminium foil

ActiveCN102744255AIncrease work hardeningImprove uniformityMetal rolling arrangementsElectrical batteryAlclad

The invention discloses a process for producing a battery aluminium foil. The process comprises the following steps of: (1), carrying out casting and rolling production by selecting 1070 alloyed scrap of which the scrap ratio is not more than 35%, and the rest of pure aluminium ingot to obtain a casting-rolling blank; (2), coldly rolling the casting-rolling blank to obtain an aluminium alloy belt material; (3), carrying out heat preservation on the aluminium alloy belt material at 500-560 DEG C for 8.5-9.5 hours, and intermediately annealing at 400-440 DEG C for 1.5-2.5 hours, wherein the thickness of the aluminium alloy belt material during intermediate annealing is 1.8 millimeters; and (4), rolling the intermediately annealed aluminium alloy belt material into a product with the thickness of a finished product. According to the process, the total processing rate after the intermediate annealing is increased; the work-hardening capacity of the material is enhanced; and therefore, the intensity index of the product is increased; in addition, because the annealing and temperature-increasing time is prolonged, the uniformity of the internal organization of the material is beneficial to being increased; and the process is relatively beneficial to processing of subsequent processes and the stability of the product quality.

Owner:NORTH CHINA ALUMINUM +1

Rare-earth and Zr reinforced Mg-Li based wrought magnesium alloy and preparation method thereof

ActiveCN102978492AImprove plastic deformation abilityHigh tensile mechanical properties at room temperatureRare-earth elementIngot casting

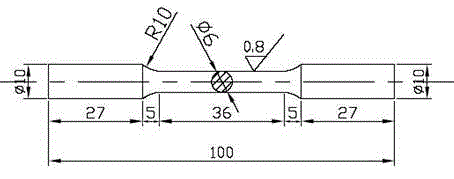

The invention belongs to the technical field of metal materials and metallurgy, and particularly relates to a rare-earth and Zr reinforced Mg-Li based wrought magnesium alloy and a preparation method thereof. The magnesium alloy adopts Mg-Li based magnesium alloy as the basis; the rare elements and Zr are adopted to be used as the alloying elements; and the Mg-Li based wrought magnesium alloy comprises the following components in percentage by weight: 1.5 to 5.5% of Li, 1% of rare earth element, 0.2 to 0.6% of Zr, and the balance of Mg. The preparation method comprises the following steps in sequence: melting the alloy; casting to an iron crucible which is pre-heated to reach 200 DEG C, thus obtaining an ingot casting; transferring the ingot casting wrapped by the aluminum foil into an iron container; completely covering the ingot casting by fine sand; placing the container into a heat treatment furnace for heat treating; turning; processing into an alloy bar of Phi 46mm; processing the alloy bar by a reverse extruding device so as to obtain a magnesium alloy extruding bar; and carrying out T6 heat treatment on the bar. By adopting the preparation method, the performances of the Mg-Li alloy can be reinforced, and the high plastic deformation capacity of the Mg-Li alloy can be remained; and the tensile mechanical properties of the Mg-Li alloy at room temperature can reach the following levels: the tensile strength Rm is 210MPa, the yield strength Rp 0.2 is 142MPa, and the elongation percentage A is of 23.5%.

Owner:NORTHEASTERN UNIV

Manufacturing method for composite aluminium plastic decorative buckles

InactiveCN1456436AImprove flatnessFriction-resistantMetal layered productsTectorial membraneSurface oxidation

A decorative fastening aluminium-plastic plate is prepared through preparing plastic substrate from engineering plastics, filler, stabilizer, plasticizer, lubricant and assistant through mixing, granulating, extruding out, fixing shape, and cutting, preparing the coated aluminium foil through washing, removing oil, oxidizing surface, baking, painting, baking and coiling, combining said plastic substrate with aluminium foil, covering adhesive protecting film on the surface of aluminium foil, and cutting. Its advantages are high abrasion compression, fire and water resistance, good thermal and acoustic insulation, no poison and beautiful appearance.

Owner:无锡市中德装饰新材料有限公司

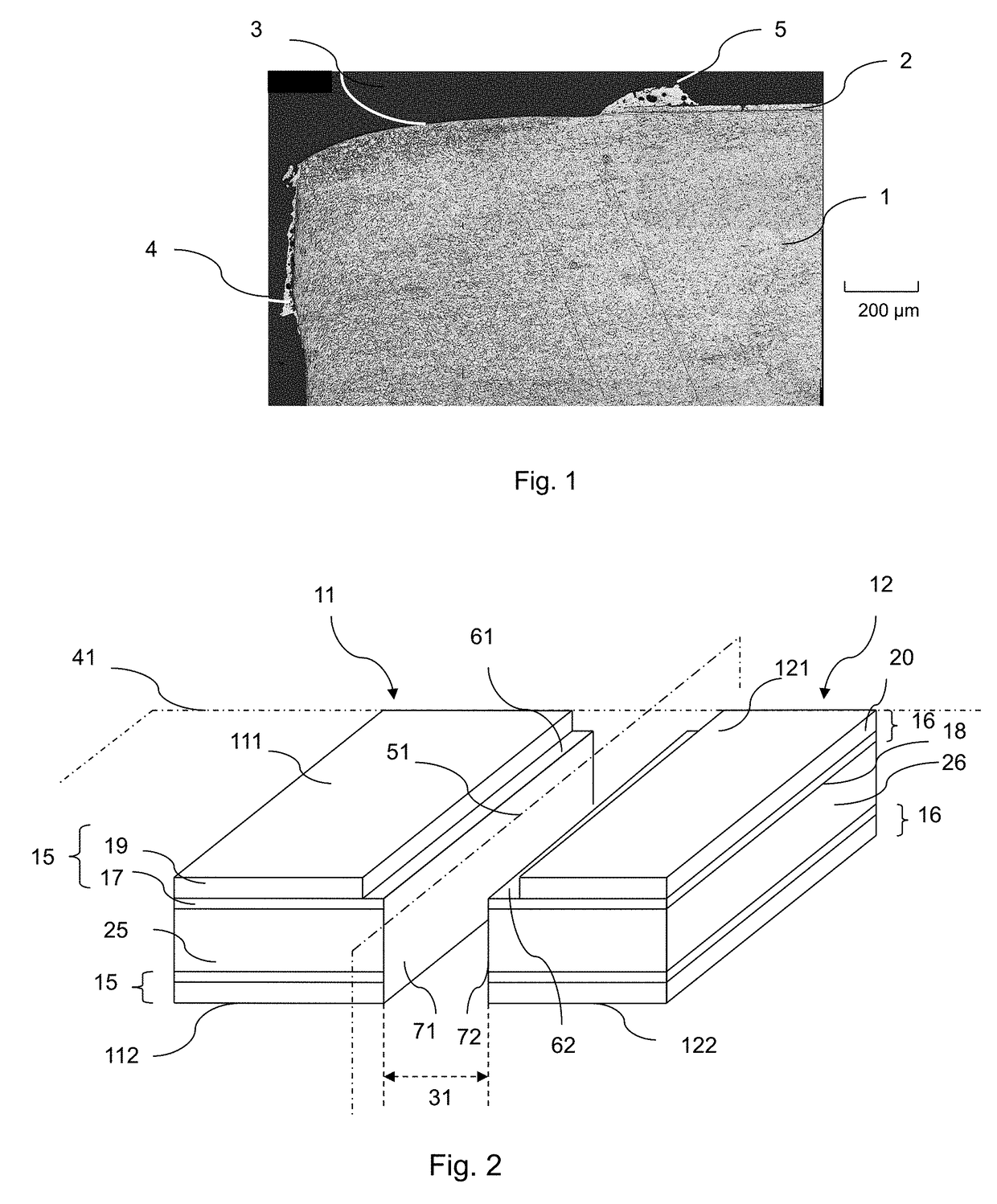

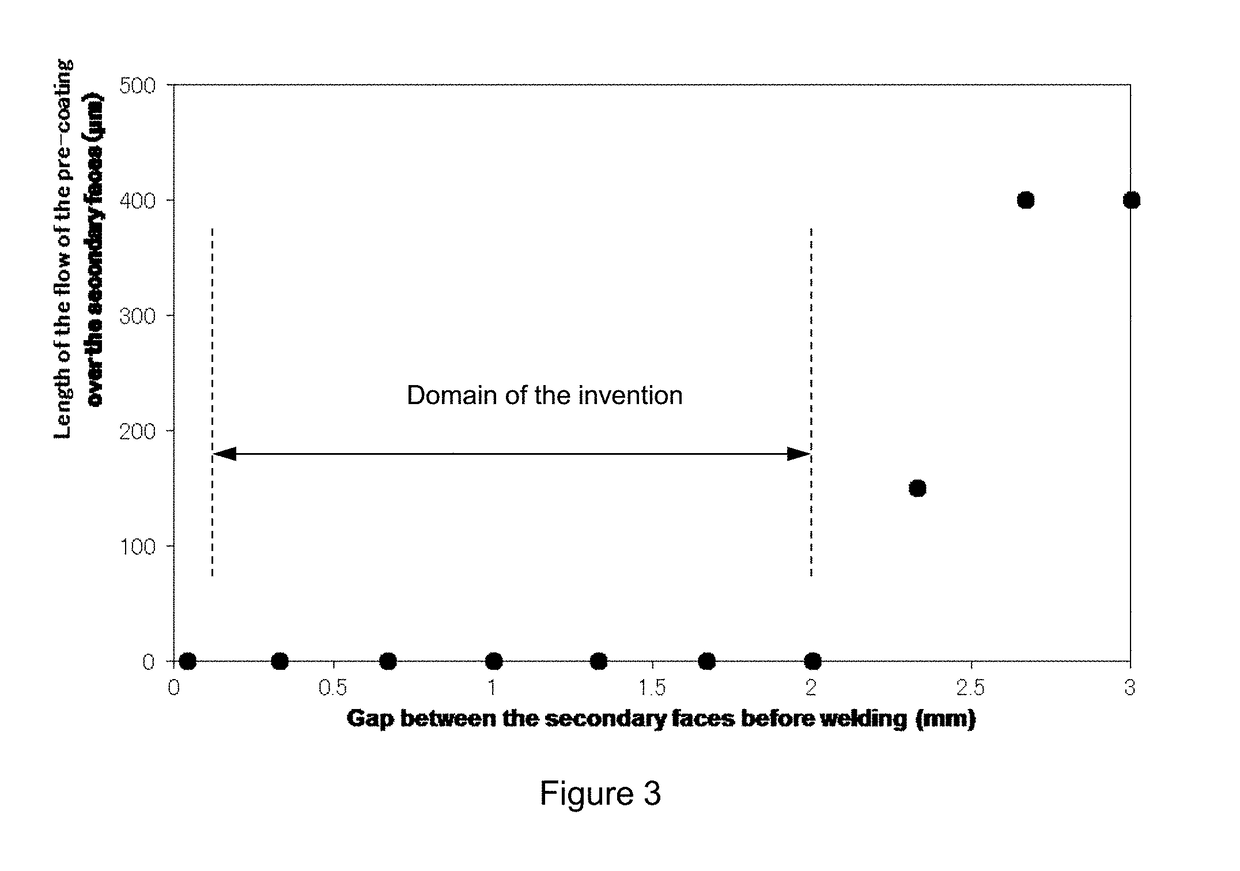

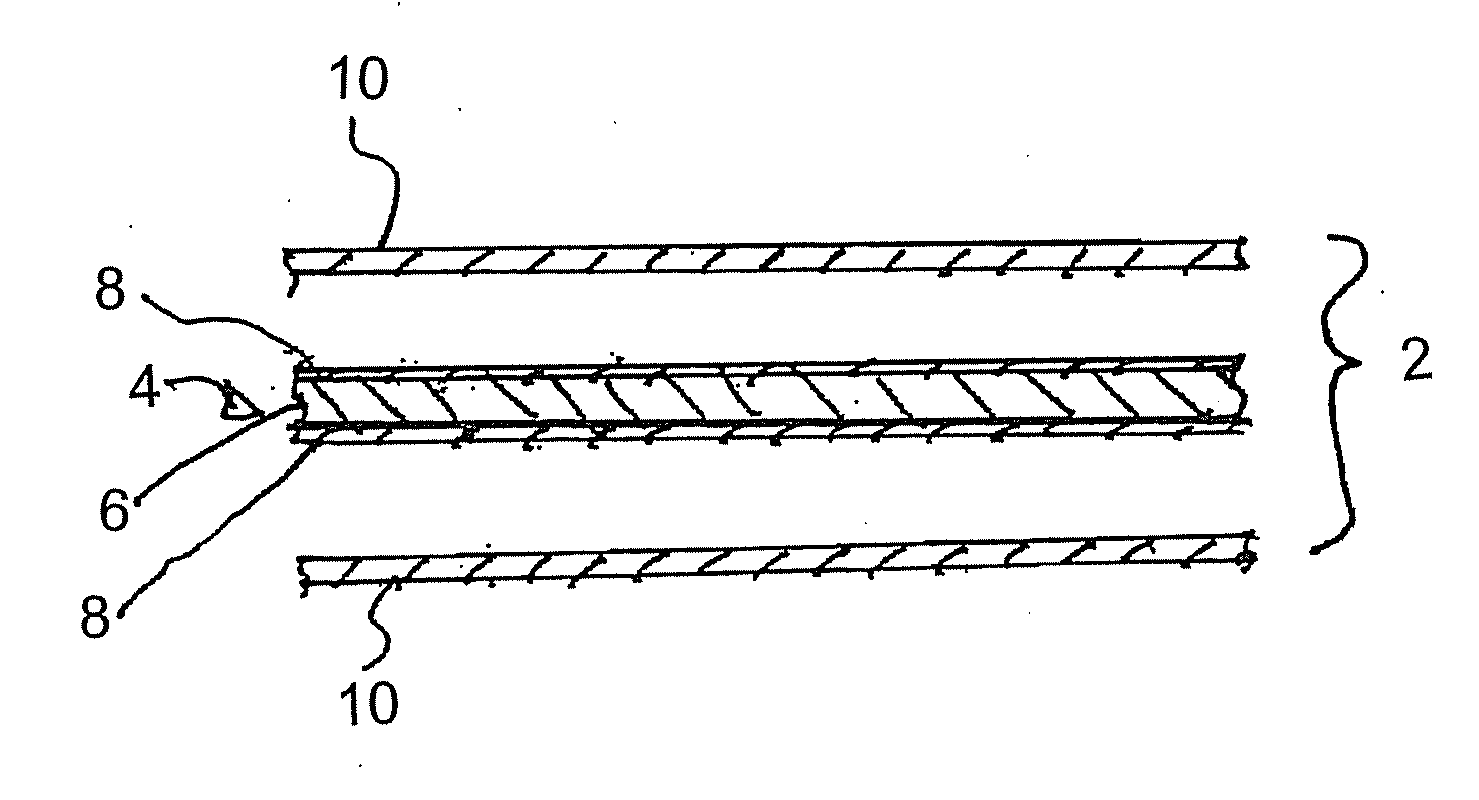

Method for the preparation of aluminized steel sheets to be welded and then press hardened

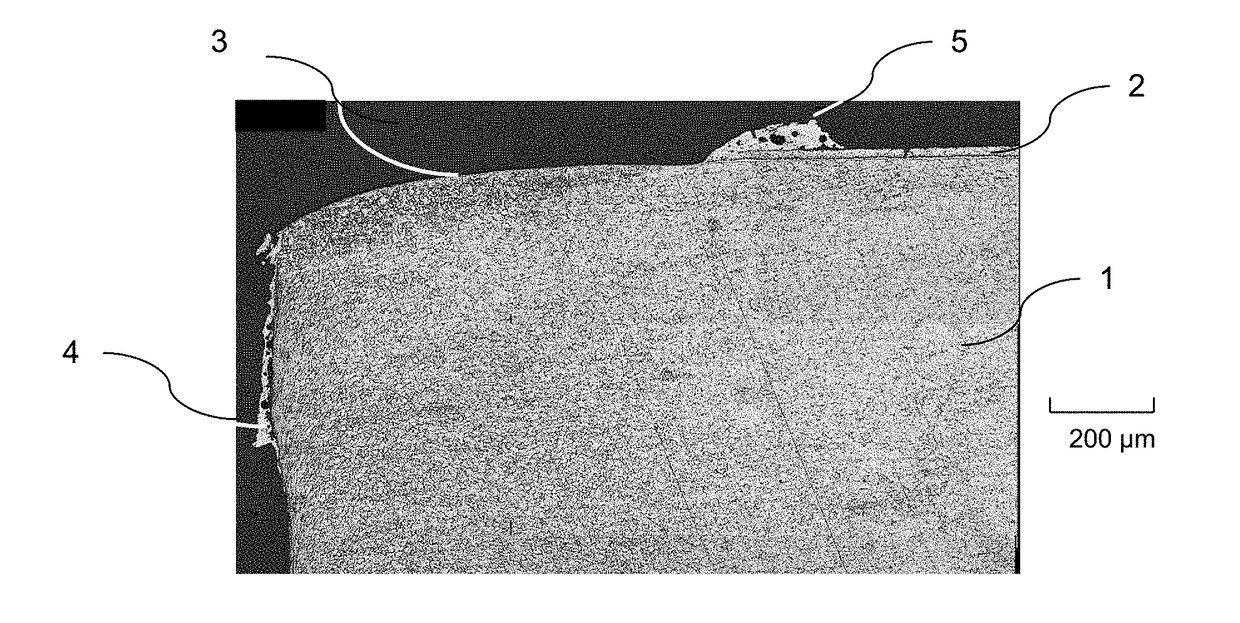

ActiveUS20170266761A1Eliminate expensiveTime-consuming to eliminateArc welding apparatusVehicle componentsSheet steelMetal alloy

A method for the preparation of steel sheets for fabricating a welded steel blank is provided. The method includes procuring at least two pre-coated steel sheets, each having a pre-coating of an intermetallic alloy layer, topped by a layer of aluminum metal or aluminum alloy or aluminum-based alloy. The sheets have a principal face, an opposite principal face, and at least one secondary face. The sheets are positioned so a gap between 0.02 and 2 mm exists between the secondary faces. The secondary faces face each other. The positioning of the first and second sheets defines a median plane perpendicular to the principal faces. Layers of metal alloy are removed by melting and vaporization simultaneously on the principal faces, in a peripheral zone of the sheets, the peripheral zones being the zones of the principal faces closest in relation to the median plane.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Low-temperature welding material

InactiveCN1712175ANo damageSmall loss tangentWelding/cutting media/materialsSoldering mediaAlcladZinc

A low-temp solder for soldering electric capacitors contains Sn (60-64 wt.%), Zn (35.891-39.891 wt.%) and the Cu, Pb, Fe, Sb, As, Al, Bi, Ni and Cd (rest). Its advantages are low smelting temp, no damage to polypropene film, and high adhesion to Al foil.

Owner:上海上电电容器有限公司

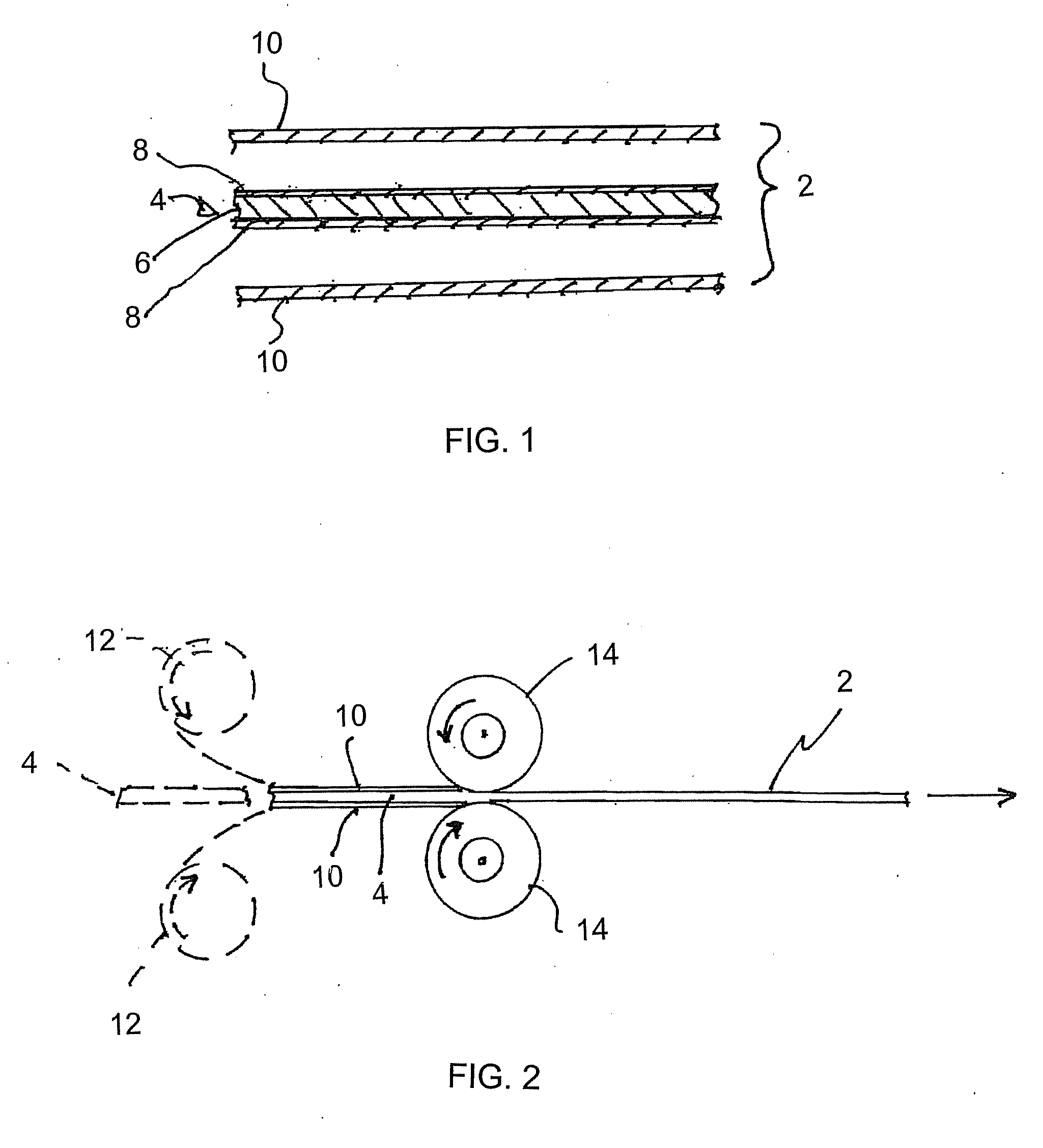

Aluminum Clad Steel Composite for Heat Exchanger Tubes and Manifolds

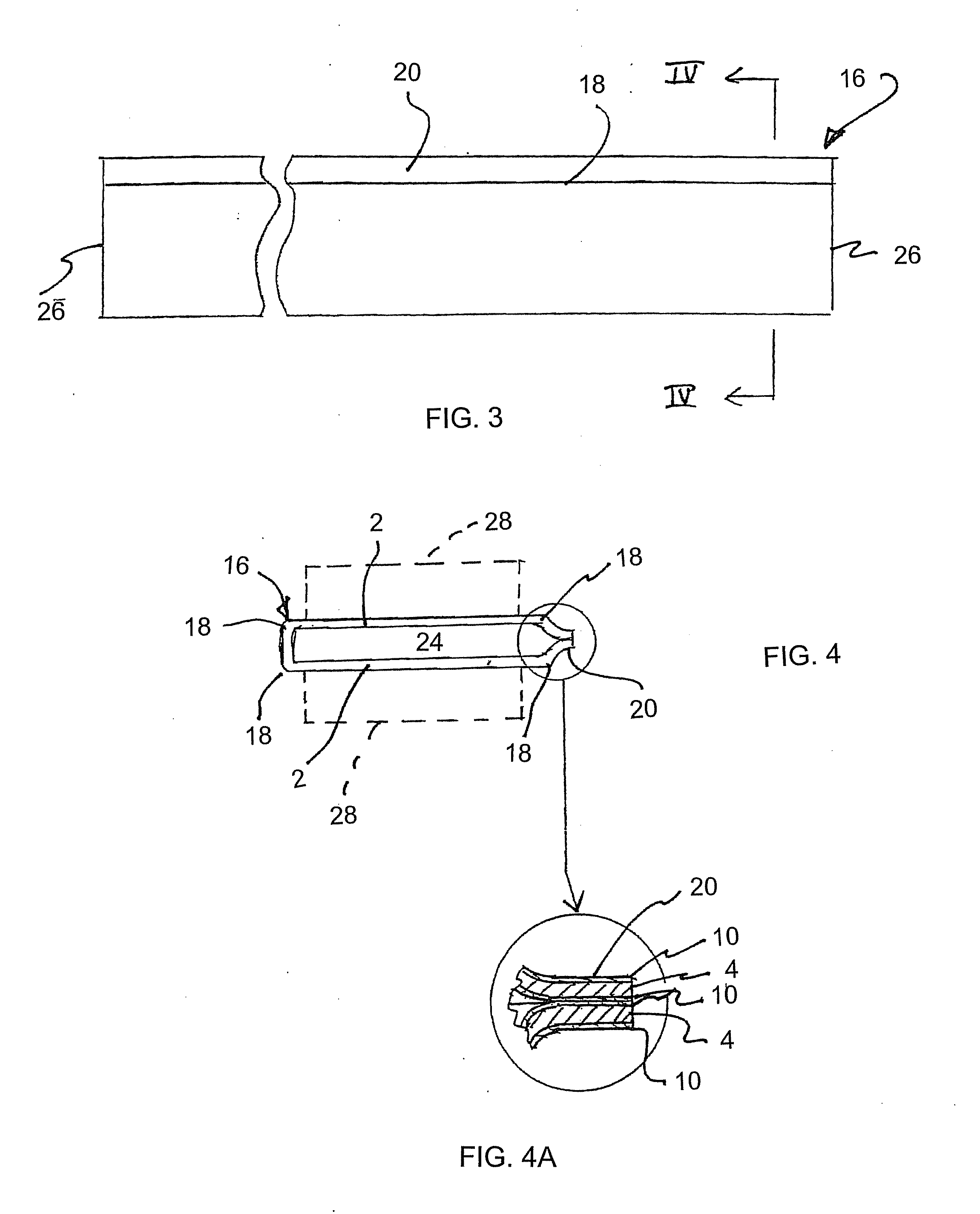

InactiveUS20080099183A1Well formedEasy to joinReinforcing meansMetal-working apparatusCarbon steelSteel belt

A brazable composite metal material for a heat exchanger tube or manifold, a method of making the tube or manifold, and a heat exchanger made therefrom. The composite metal suitable for making the heat exchanger tube or manifold has one of an aluminized carbon steel, galvanized carbon steel, or steel wire mesh core roll bonded to at least one outer layer of a brazable aluminum alloy, such as type 3003 aluminum alloy. The method of making the heat exchanger tube includes the steps of (a) providing a core of one of an aluminized carbon steel, galvanized carbon steel, or steel wire mesh sheet or strip material; (b) placing at least one sheet or strip of brazable aluminum alloy material on the steel core; (c) roll bonding the aluminum alloy material to the aluminized surface of the steel core to form a roll bonded composite sheet or strip material; (d) forming the composite material to a desired configuration; and (e) joining abutting aluminum edges of the formed composite to form a fluid tight joined edge defining a shape having an open interior.

Owner:CLAD METALS

Aluminizing liquid, hot dip aluminum plating method and metal device prepared by method

ActiveCN102337488AImprove liquidityImprove adhesionHot-dipping/immersion processesRare-earth elementMischmetal

The invention discloses an aluminizing liquid as well as a preparation method and application thereof. The aluminizing liquid comprises the following components by mass percent: 2-6% of Si and 2-4% of RE and the balance of Al, wherein the RE is a mixture of 25-30% of La, 55-65% of Ce and 5-10% of Pr. According to the invention, Si and rare earth elements are added in the aluminizing liquid, thereby improving the flowability of the aluminizing liquid, reducing the temperature of hot dip aluminum plating and reducing the content of oxide impurities in the aluminizing liquid; and the aluminizingliquid is used for a hot dip aluminum plating process so that the adhesion between a plated workpiece and a plating is improved, and the corrosion-resisting property of the workpiece is enhanced.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Cold-printing process

InactiveCN103231595AGood coloring effectShiny metallic effectDuplicating/marking methodsOther printing apparatusCardboardAdhesive

The invention discloses a cold-printing process. The cold-printing process comprises the following steps of: step 1, coating an UV (ultraviolet) curing adhesive at the part needing to be cold-printed on a printing stock by an offset printing plate; step 2, causing the UV curing adhesive coated on the printing stock to be adhesive via an UV curing device; step 3, adjusting the tone and hue of an easily-stripped metal foil film according to the tone needed by a product, and drying the easily-stripped metal foil film via an ultraviolet drying device until the water content is 0; step 4, clamping the printing stock between a rubber cylinder and an impression cylinder, compounding the easily-stripped metal foil film on the printing stock, and tightly adhering the easily-stripped metal foil film by the UV curing adhesive under the pressure of the impression cylinder; and step 5, curing the cold-printed part via an UV curing lamp, and stripping the bottom film, so as to realize the whole cold-printing process. The product can show an extremely abundant colour effects, and is bright in metal effect; the process is simple, and the printing speed is high up to 300 fpm; and the process is suitable for common copper plate paper, coated duplex board with grey back, coated duplex board with white back, white cardboard, aluminium-foil paper and the like, and capable of saving energy, reducing energy consumption, and greatly decreasing printing cost, thus being capable of being widely used.

Owner:苏州凹凸彩印厂

Processing method for welding of high-tension aluminum silicon coating plated steel plate and splicing structure thereof

InactiveCN106363301AReduce maintenance costsReduced precision requirementsLaser beam welding apparatusWorkpiece edge portionsSheet steelSilicon alloy

The invention discloses a processing method for welding of a high-tension aluminum silicon coating plated steel plate. The surface of a to-be-welded steel plate is coated with an aluminum silicon alloy layer. The processing method is characterized in that a part of the aluminum silicon alloy layer on the surface of the to-be-welded steel plate is peeled along a welding edge through laser beams; and the removed part of the aluminum silicon alloy layer takes up 90% to 95% of the original aluminum silicon alloy layer. According to the processing method, through maintaining a part of the aluminum silicon alloy layer, the production cost and daily maintenance cost are greatly reduced under the condition that the performance of a base material is not influenced, the processing difficulty is reduced, and the processing efficiency is improved.

Owner:昆山信杰汽车部件有限公司

Method for making copper dural alclad bus-bar row continuously through coating, welding and rolling

InactiveCN101465171AEasy to handleImprove productivitySingle bars/rods/wires/strips conductorsCable/conductor manufactureProduction rateElectrical conductor

The invention relates to a method for manufacturing copper clad aluminum bus bar through clad welding and rolling, which is characterized in that a process of copper strips cladding copper bar is continuously performed under gas shielding, the specific method comprises the following steps: cleaning; bus bar blank manufacturing; diameter reducing by cold drawing; stretching by heating and roll compacting and annealing. The invention has the advantages that conductors for securing metallurgical combined entirety are formed on the two metal interfaces through diffusing heat treatment of two materials and one or two elongating rolling. By adopting clad welding, diameter reducing, heating and roll compacting continuous finishing process, the production rate is improved greatly, the process time is shortened; and the quality is ensured. Because preprocessing mechanical scrubbing is finished during clad welding, the brush graining process is simplified, thereby facilitating dust treatment. By adopting the continuous production, the requirements of users for long line can be met.

Owner:徐志超 +1

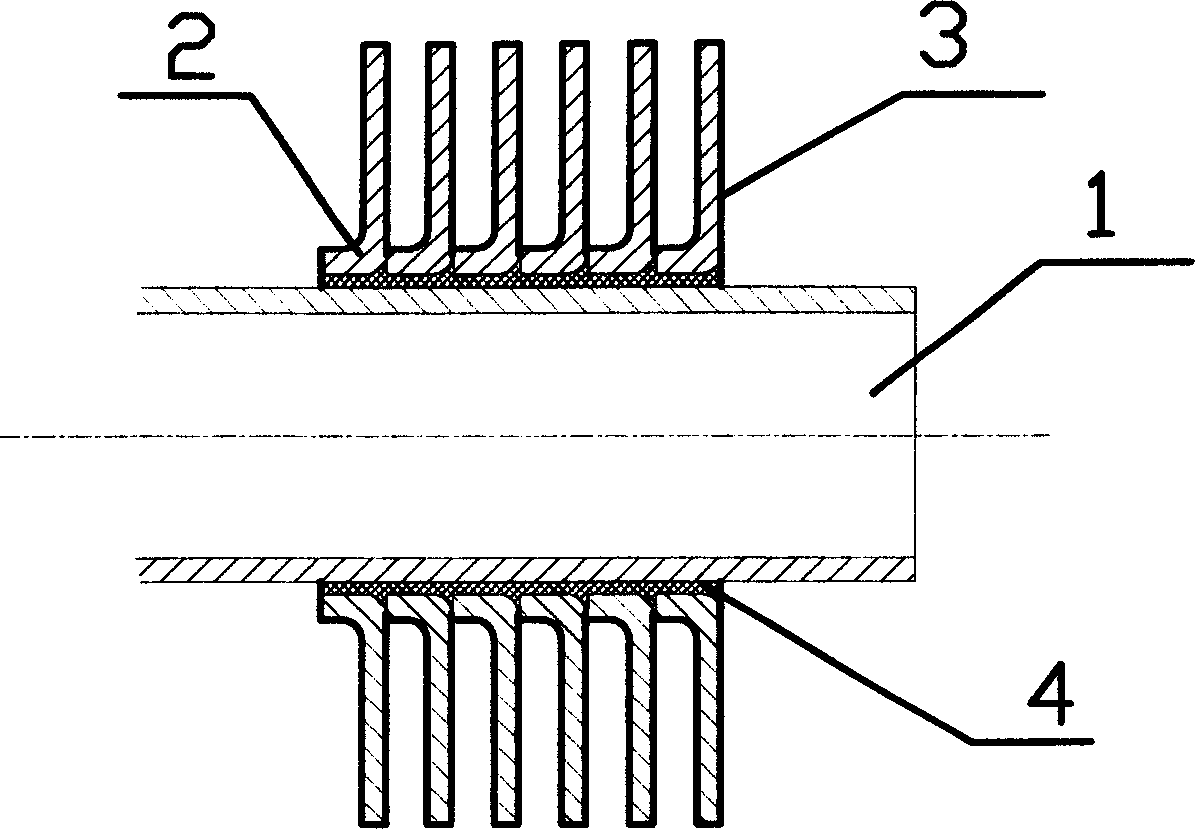

Fin heat exchange pipe and and its manufacturing method

InactiveCN1904539AAlleviate the contradiction between supply and demand of resource shortageLow market priceMetallic material coating processesTubular elementsCorrosion resistantMetal

The invention relates to a kind of fin heat exchanging tube and its producing method. It is used in the electric station air cooling condenser and the petrifaction air cooler. It is composed of a base tube (1) and a fin or a rib (2).Between the base tube and the fin filters the aluminium or aluminium alloy plating liquid with the method of hot dipping aluminium or aluminium alloy. After cooling, the base tube and the fin are jointed together. At the same time, the corrosion resistant aluminium or aluminium alloy film (3) forms on the fin surface. Compared with the current method of hot dipping zinc, the invention finds the substituting material of zinc relaxes the conflict of the zinc resource in short supply and reduces sharply the production cost of the heat exchanging component.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Tailored blank for hot stamping, hot stamped member, and methods for manufacturing same

ActiveUS9901969B2Improve joint strengthFurnace typesElectron beam welding apparatusHot stampingSheet steel

A tailored blank for hot stamping includes a welded portion formed by butt-welding a first aluminum-plated steel sheet and a second aluminum-plated steel sheet, an Average Al concentration of a weld metal in the welded portion is in a range of 0.3 mass % to 1.5 mass %, an Ac3 point of the weld metal is 1250° C. or lower, and furthermore, an aluminum layer formed during the butt-welding is present on a surface of the welded portion.

Owner:NIPPON STEEL CORP

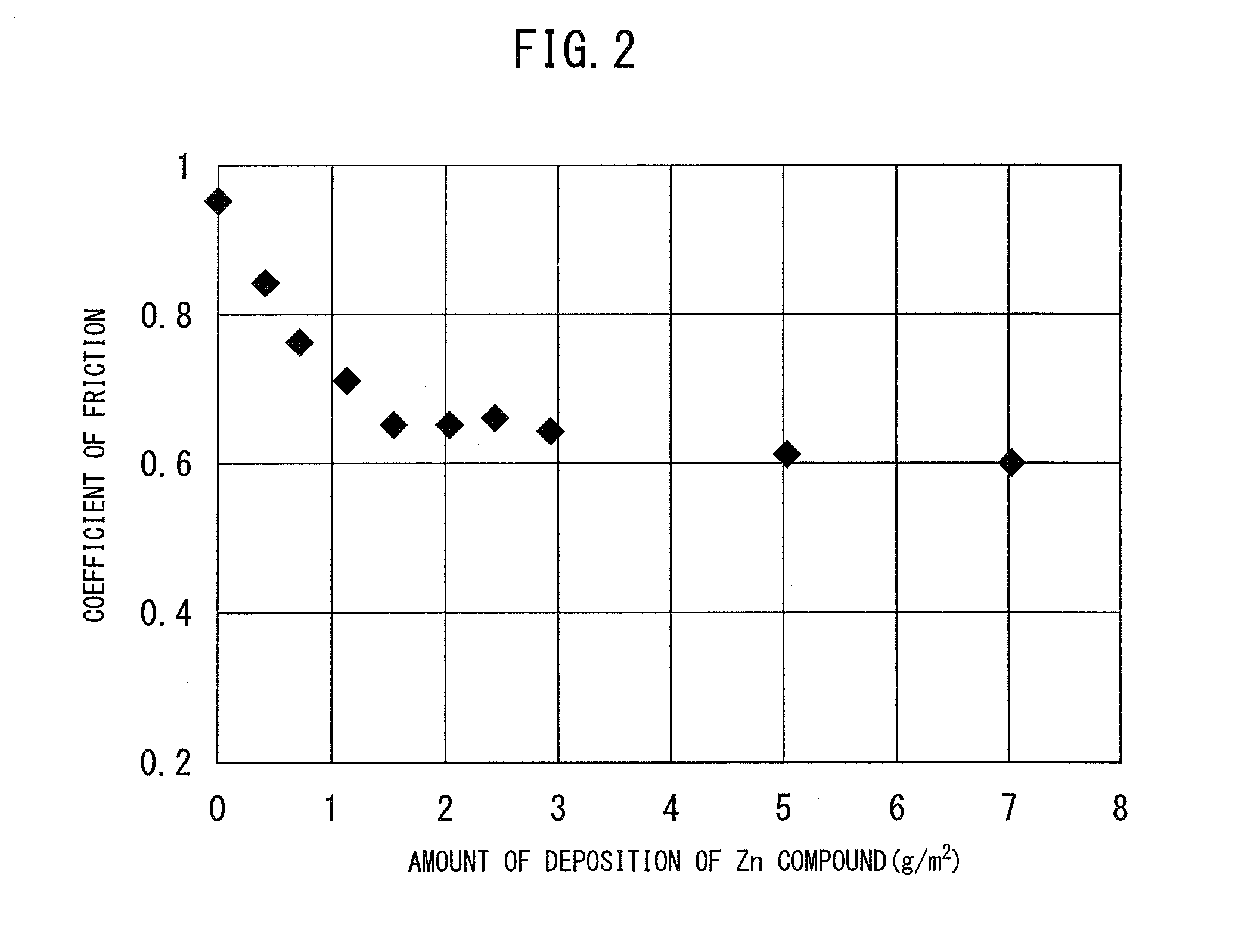

Plated steel plate for hot pressing and hot pressing method of plated steel plate

ActiveUS20150020562A1Improve productivityImprove adhesionHot-dipping/immersion processesWork treatment devicesZinc hydroxidePhosphate

The present invention provides plated steel sheet for hot press use which is excellent in hot lubricity, coating adhesion, spot weldability, and coated corrosion resistance and a method of hot pressing plated steel sheet. The present invention is Plated steel sheet for hot press use and a method of hot pressing plated steel sheet characterized by being plated steel sheet for hot press use which contains an Al plating layer which is formed on one surface or both surfaces of said steel sheet, and a surface coating layer which is formed on said Al plating layer, said surface coating layer containing at least one Zn compound which is selected from a group comprised of Zn hydroxide, Zn phosphate, and a Zn organic acid.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com