Patents

Literature

2418 results about "Offset printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

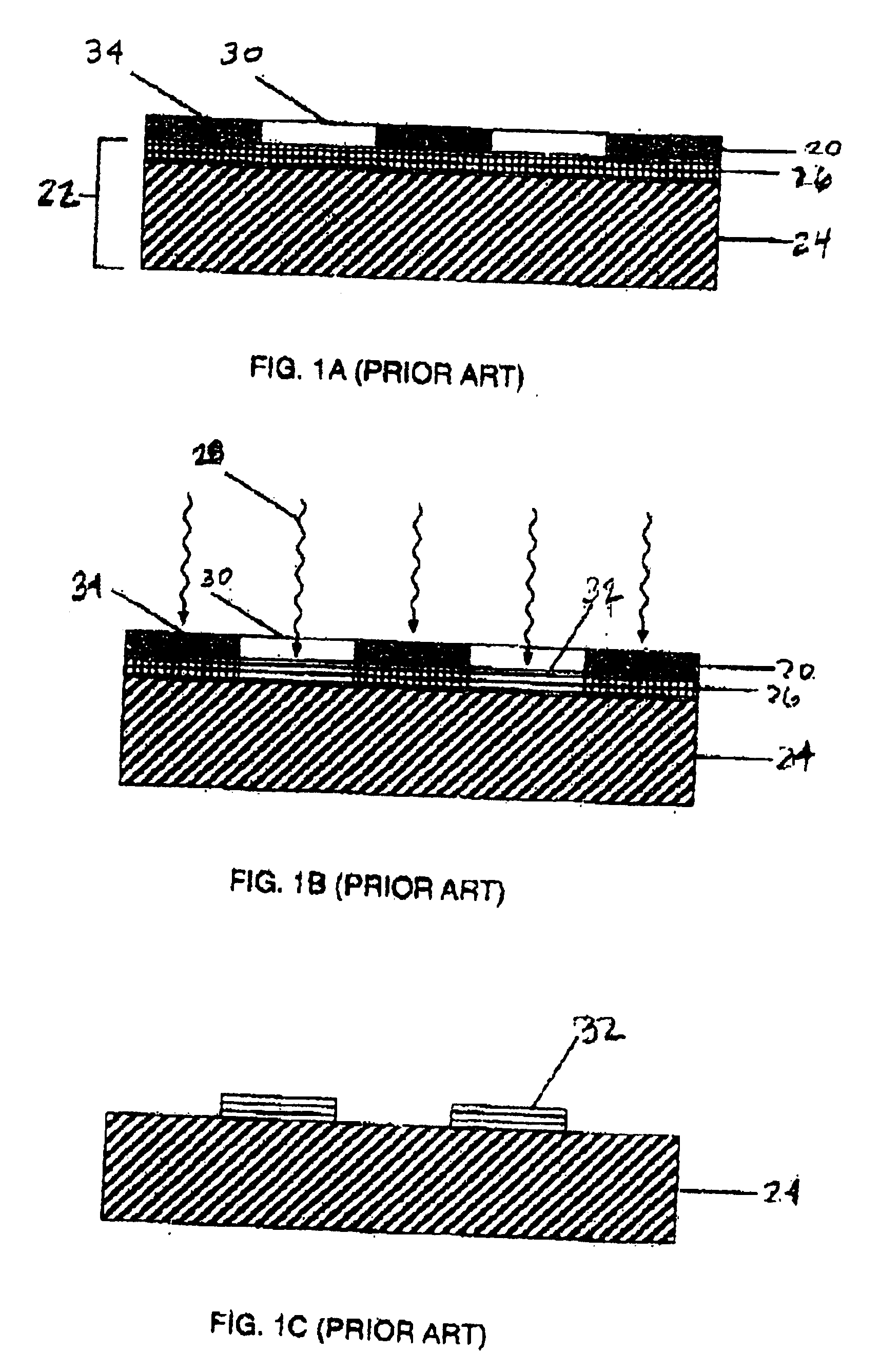

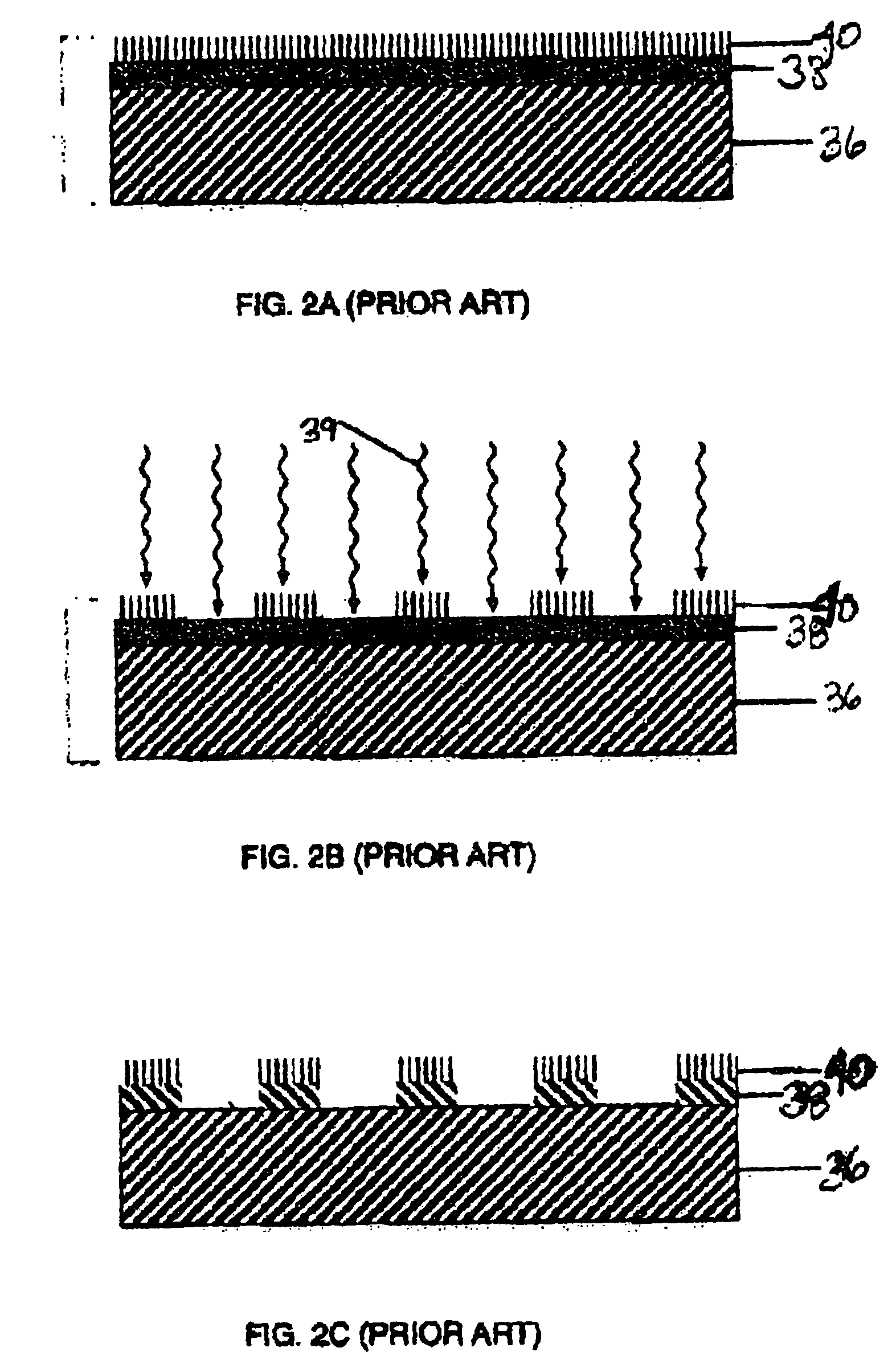

Offset printing is a commonly used printing technique in which the inked image is transferred (or "offset") from a plate to a rubber blanket, then to the printing surface. When used in combination with the lithographic process, which is based on the repulsion of oil and water, the offset technique employs a flat (planographic) image carrier. Ink rollers transfer ink to the image areas of the image carrier, while a water roller applies a water-based film to the non-image areas.

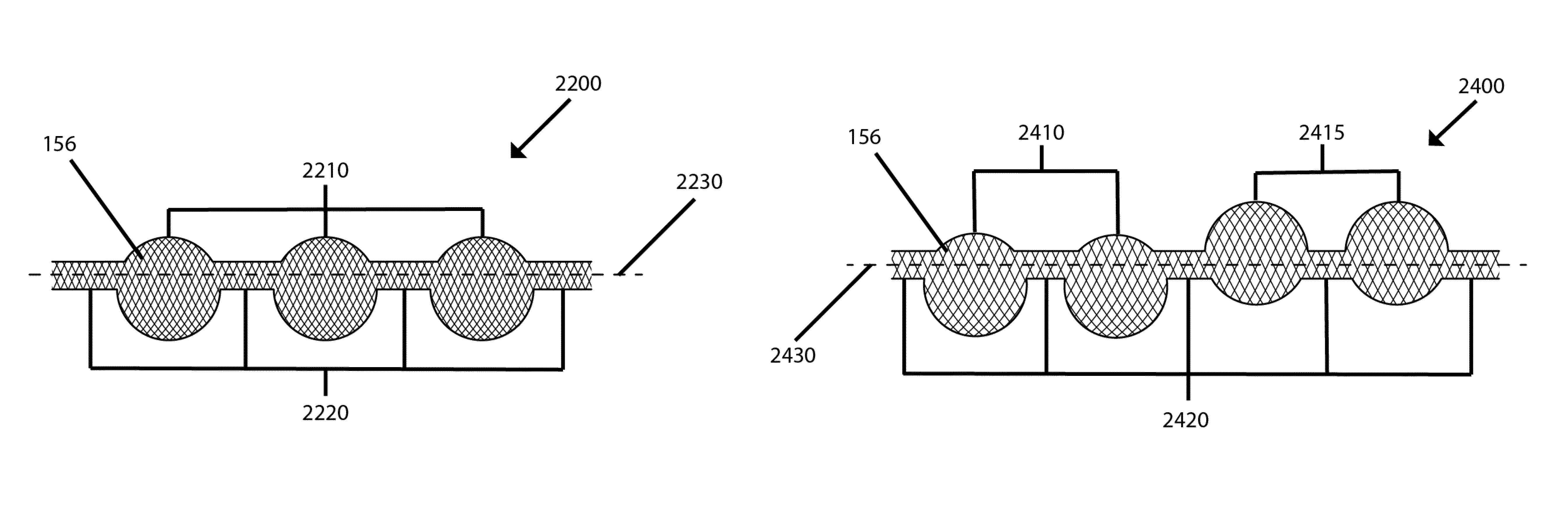

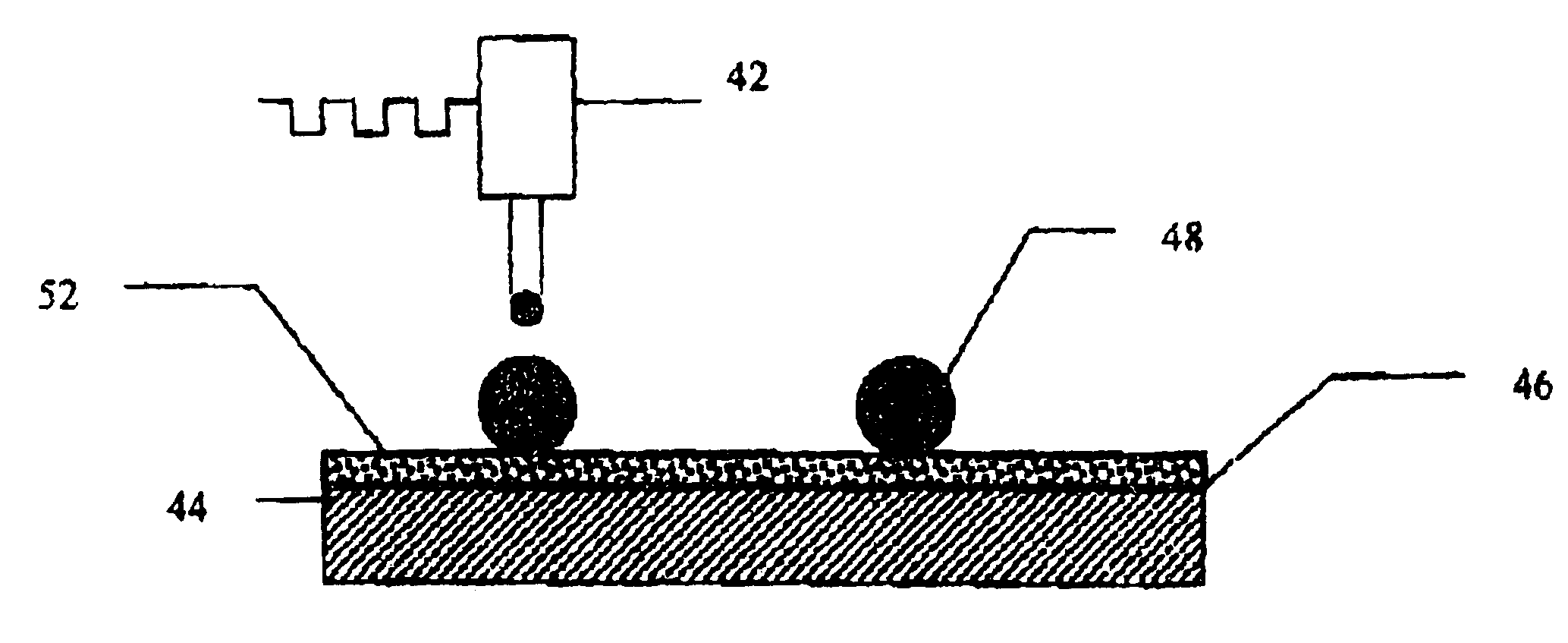

Printing semiconductor elements by shear-assisted elastomeric stamp transfer

ActiveUS8506867B2Sacrificing printing yield and accuracyIncrease chanceConfectionerySolid-state devicesEngineeringVertical displacement

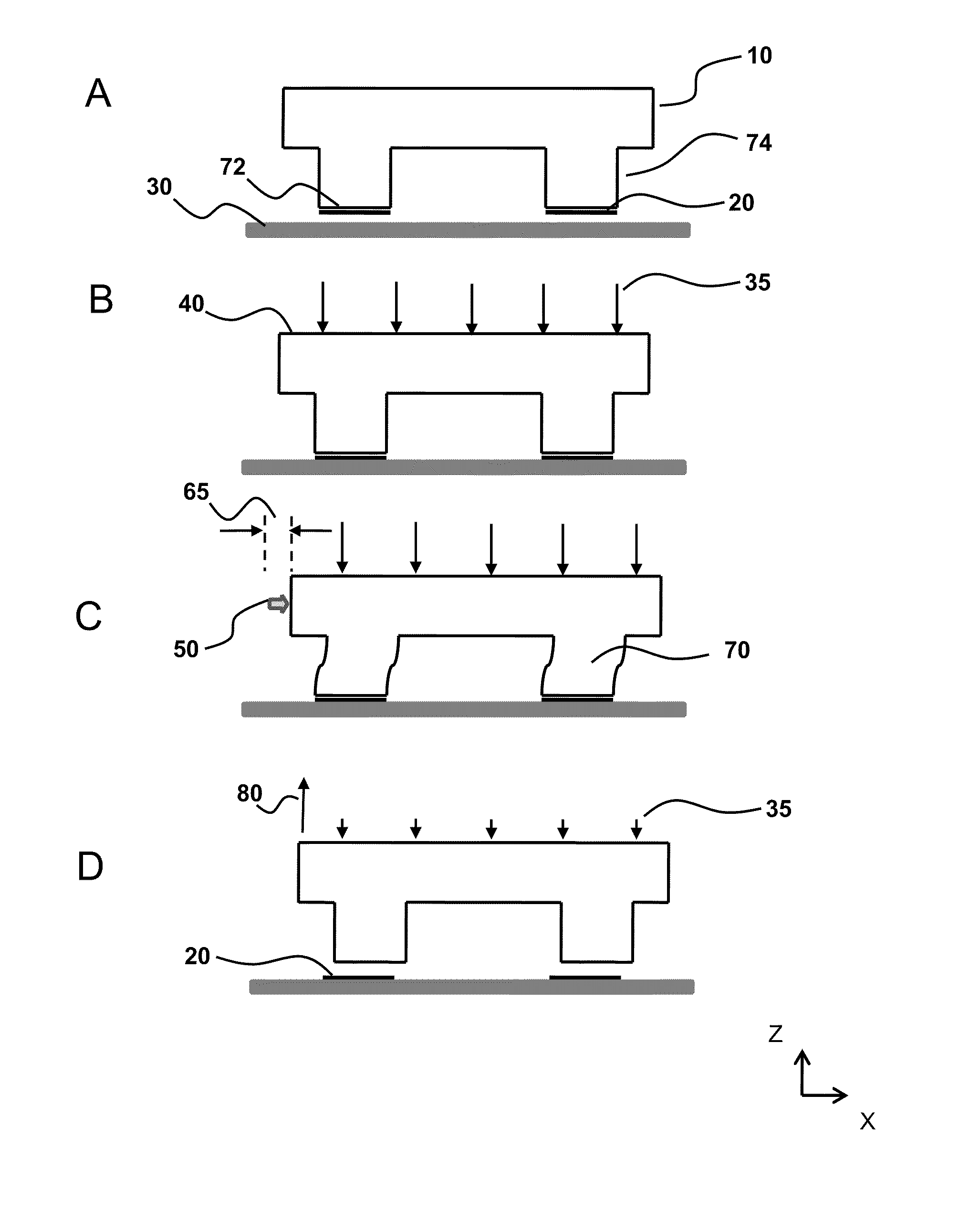

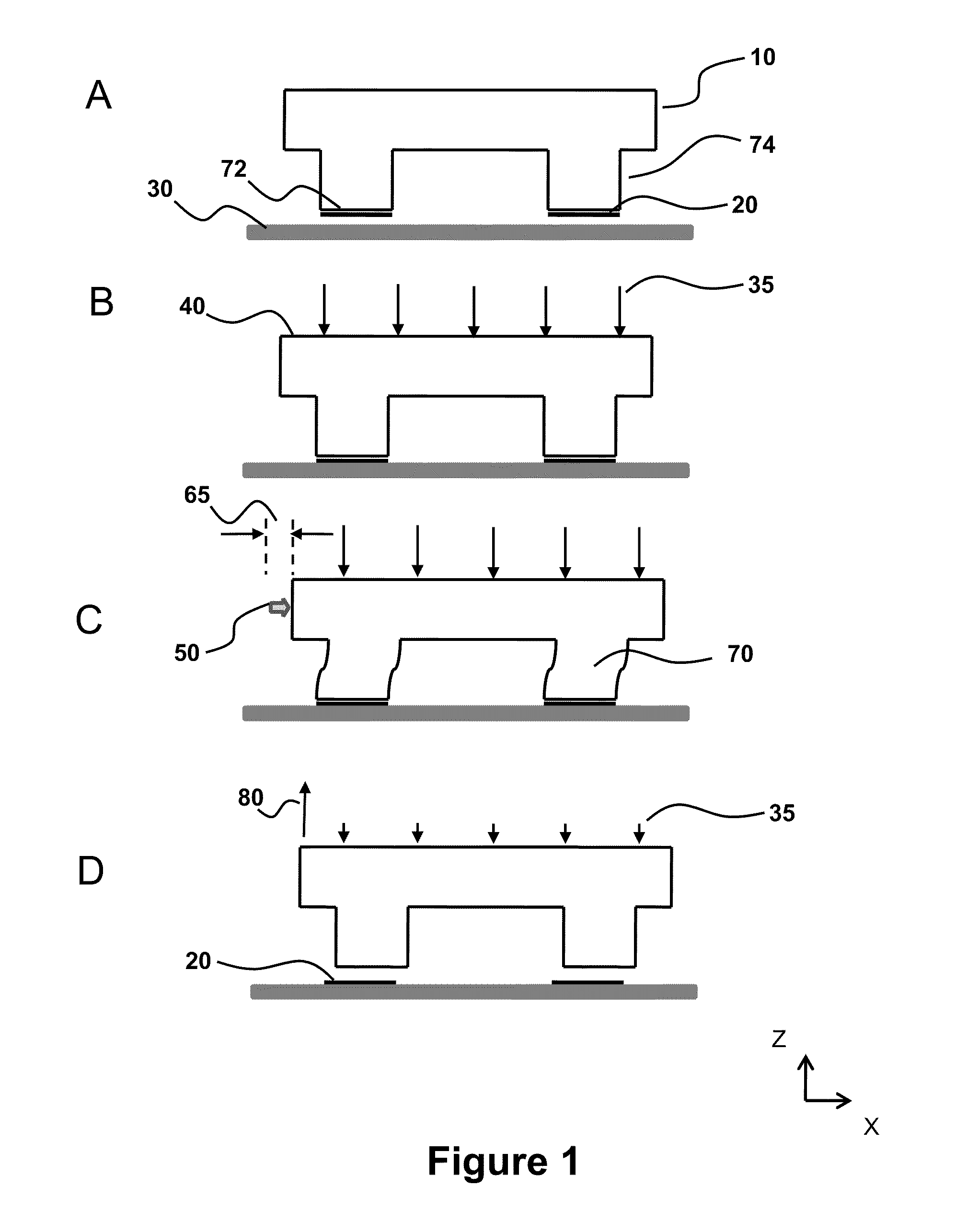

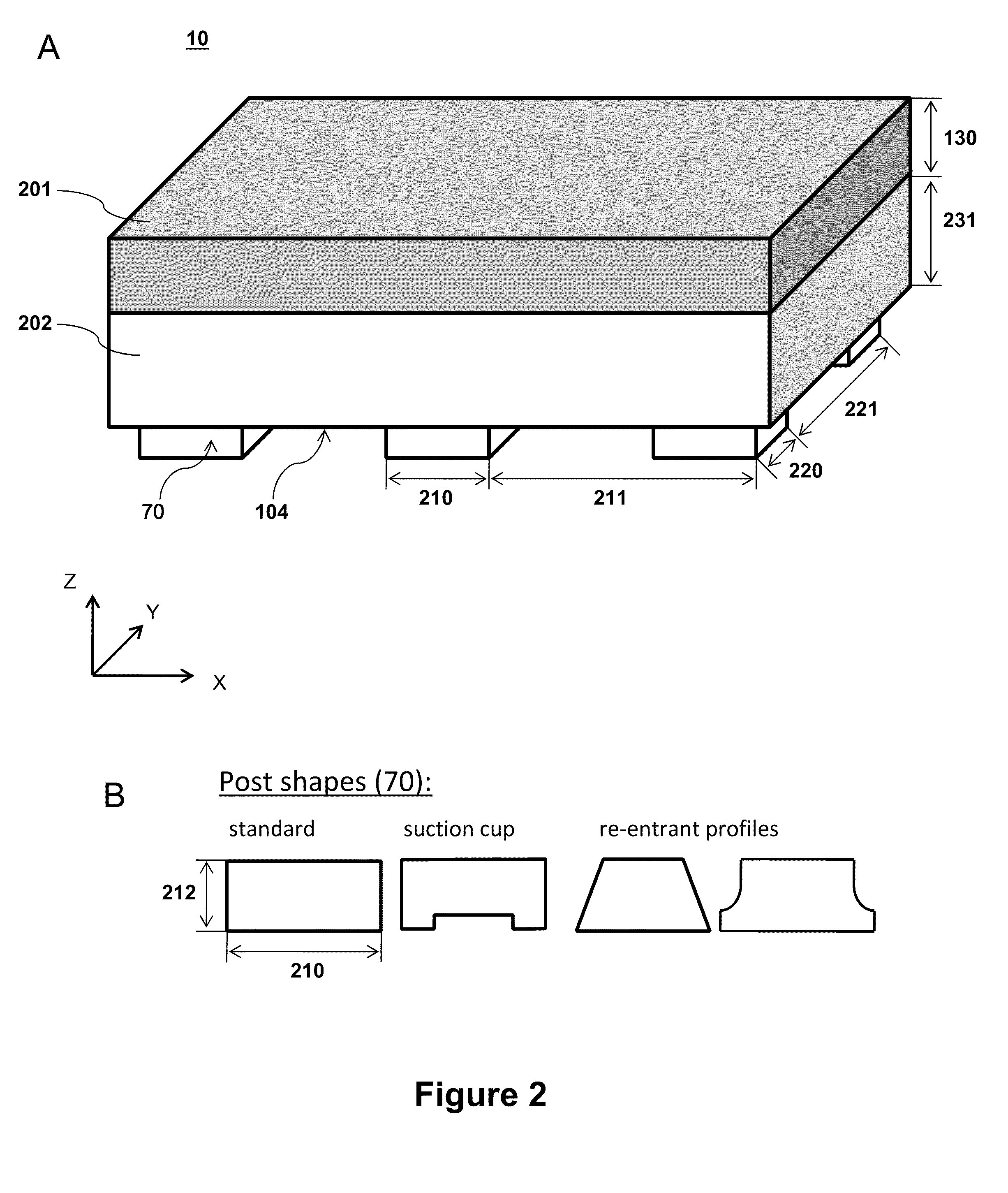

Provided are methods and devices for transfer printing of semiconductor elements to a receiving surface. In an aspect, the printing is by conformal contact between an elastomeric stamp inked with the semiconductor elements and a receiving surface, and during stamp removal, a shear offset is applied between the stamp and the receiving surface. The shear-offset printing process achieves high printing transfer yields with good placement accuracy. Process parameter selection during transfer printing, including time varying stamp-backing pressure application and vertical displacement, yields substantially constant delamination rates with attendant transfer printing improvement.

Owner:X DISPLAY CO TECH LTD

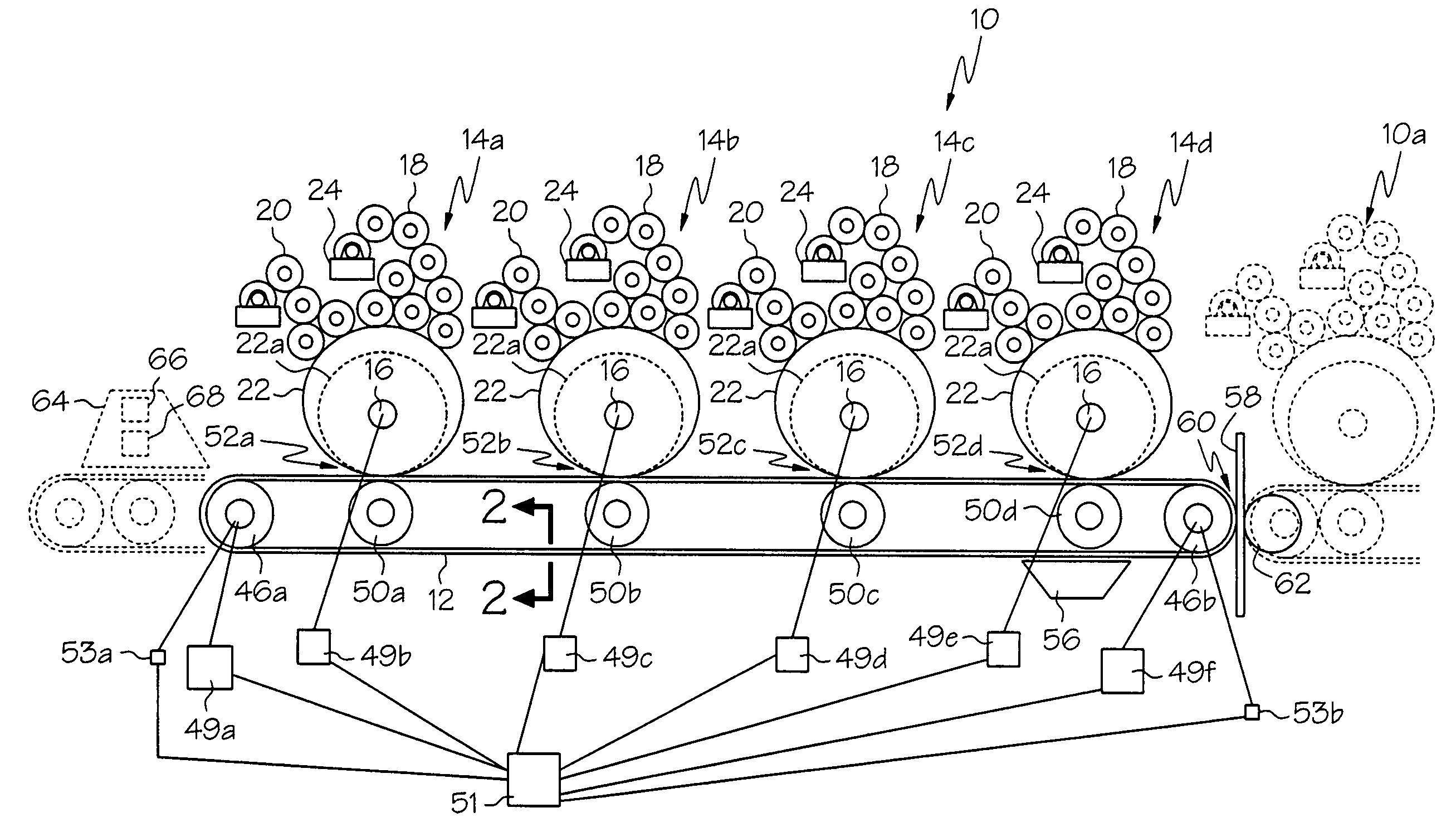

Low VOC web offset heatset inks

InactiveUS7018453B2Increasing drying and setting speedImprove stabilityInksEmulsion paintsPlasticizerPrinting ink

A web offset heatset printing ink composition having less than about 2 wt. % of volatile organic compounds containing an aqueous polymer latex dispersed in an ink base of a resin, a non-volatile plasticizer, and a pigment and method for preparing same.

Owner:SUN CHEM CORP

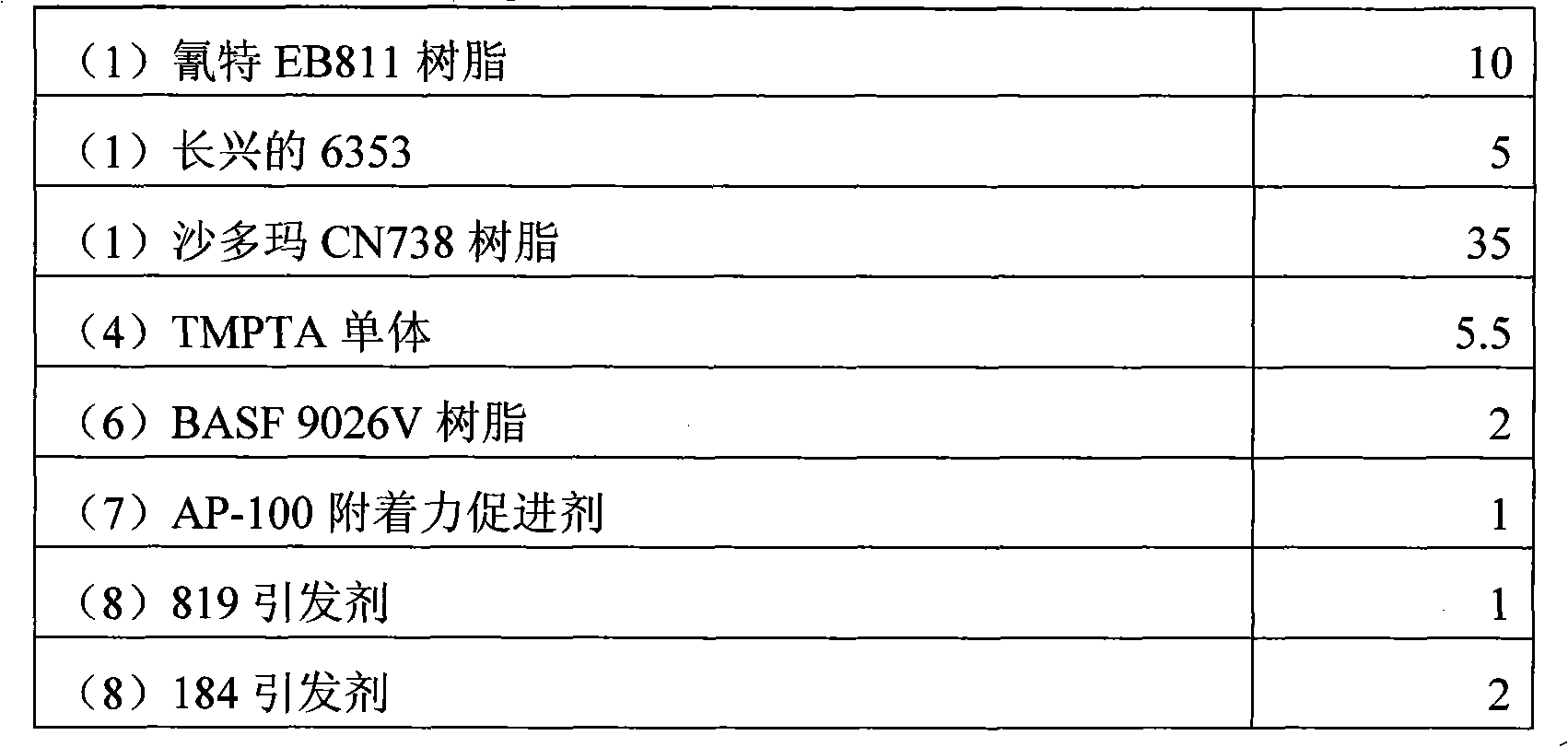

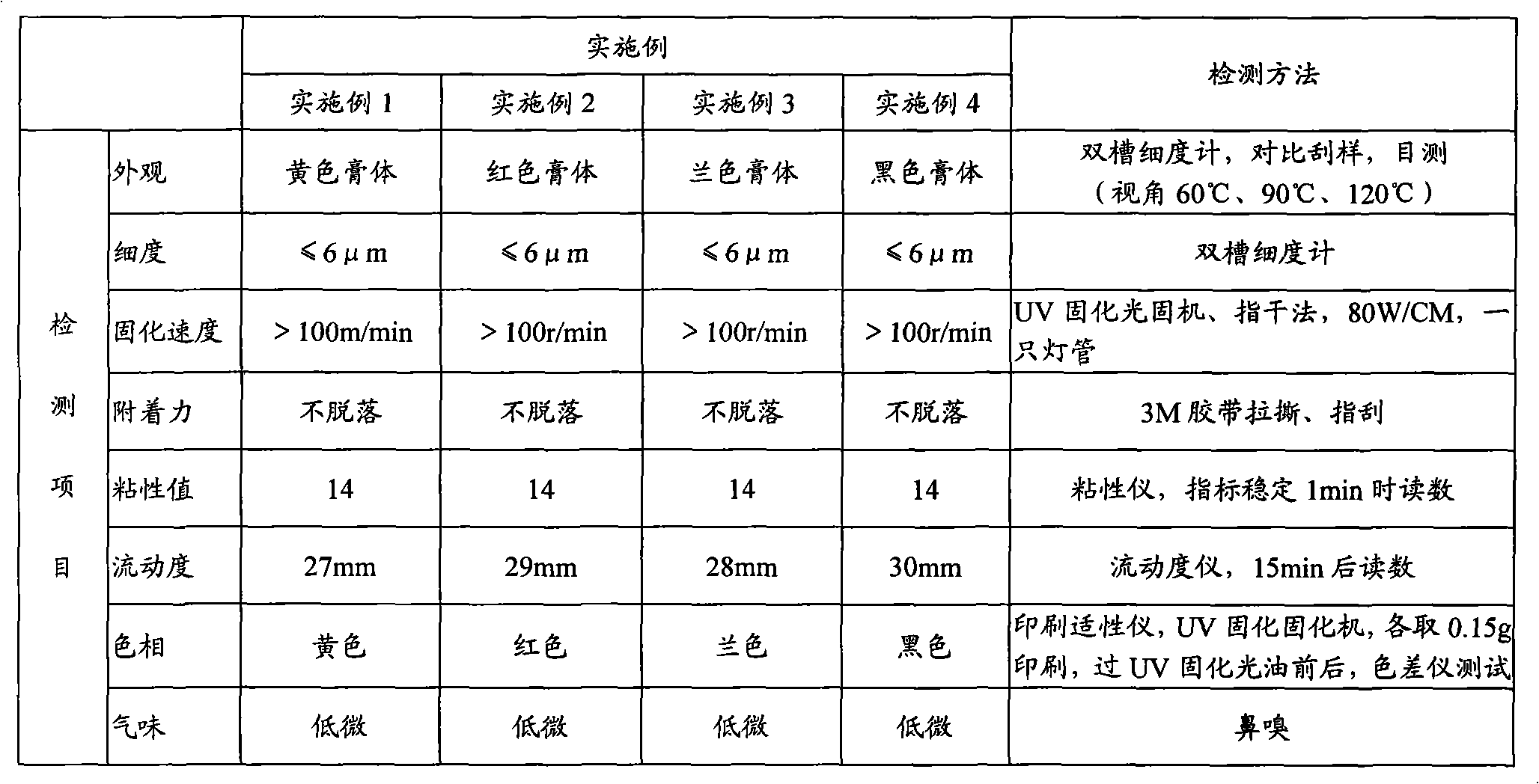

Ultraviolet light curing offset printing ink and preparation method thereof

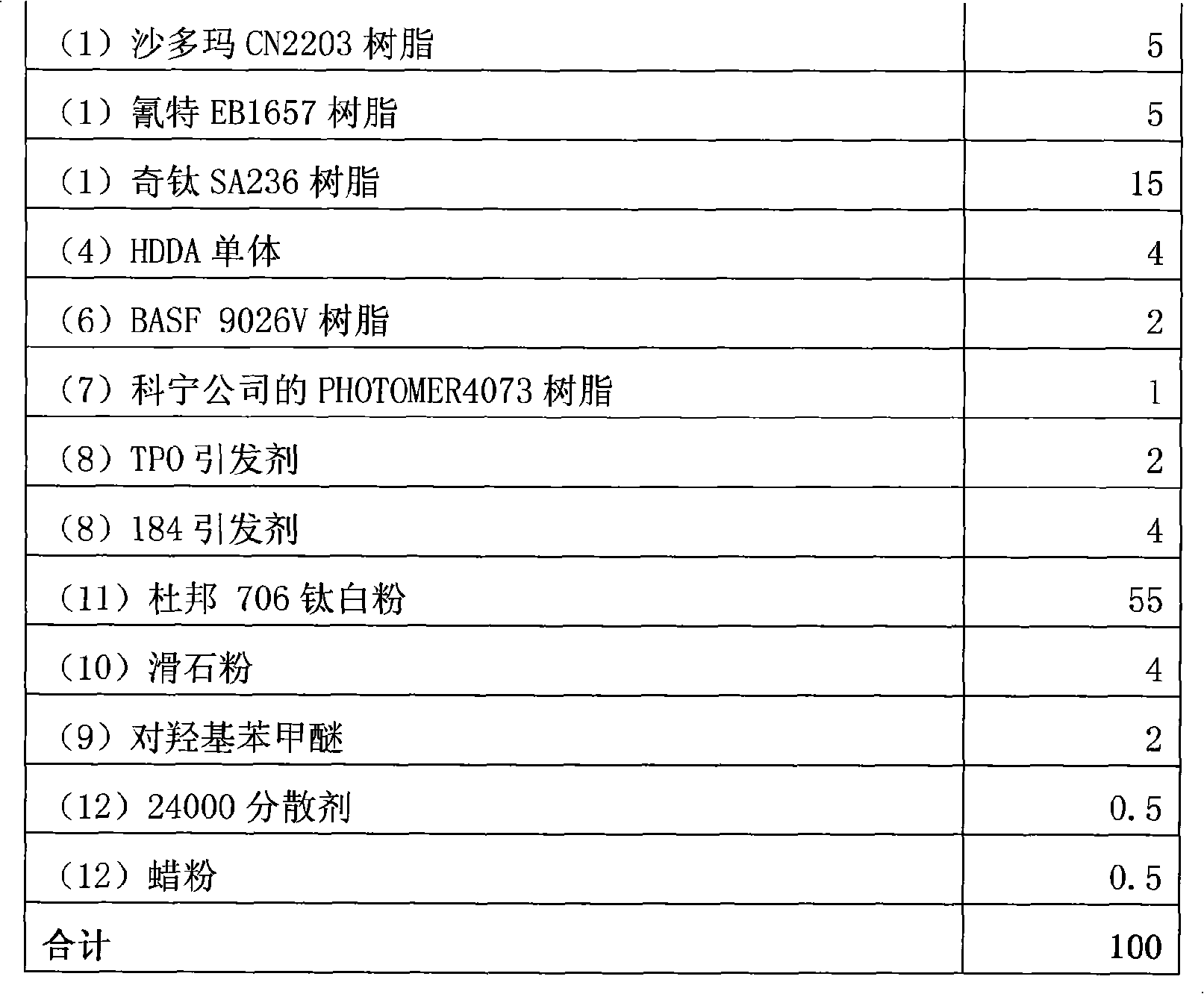

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

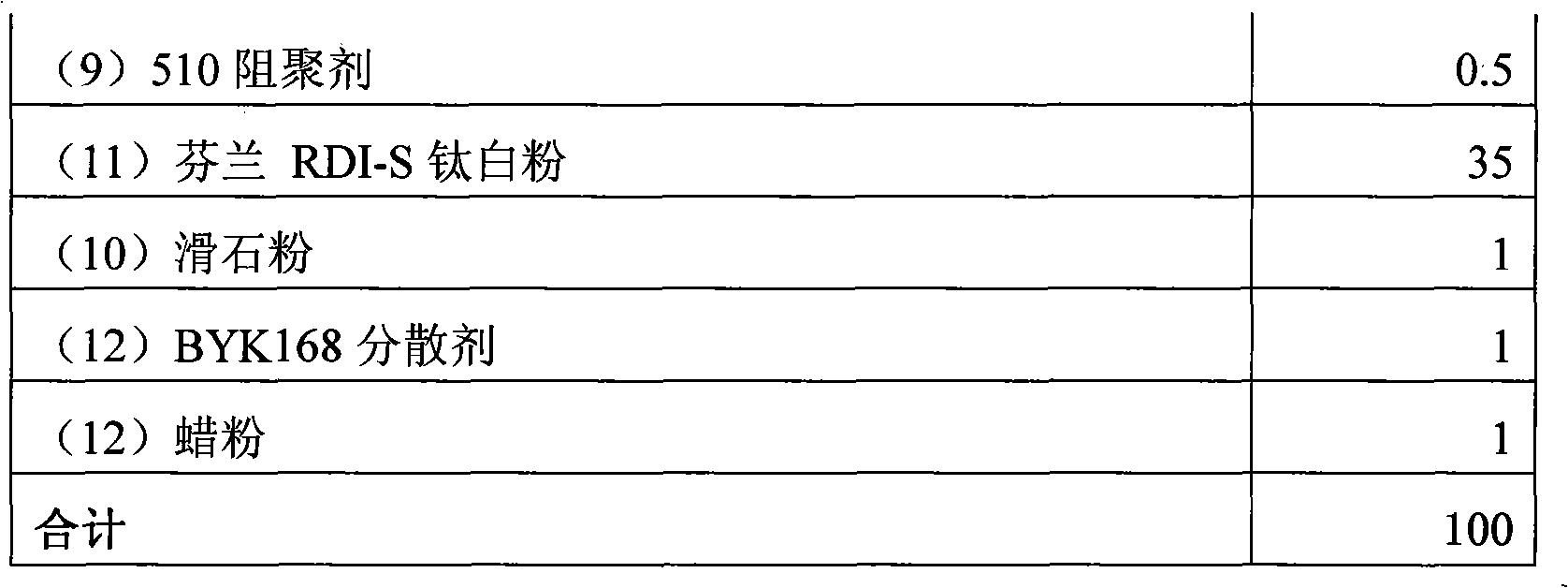

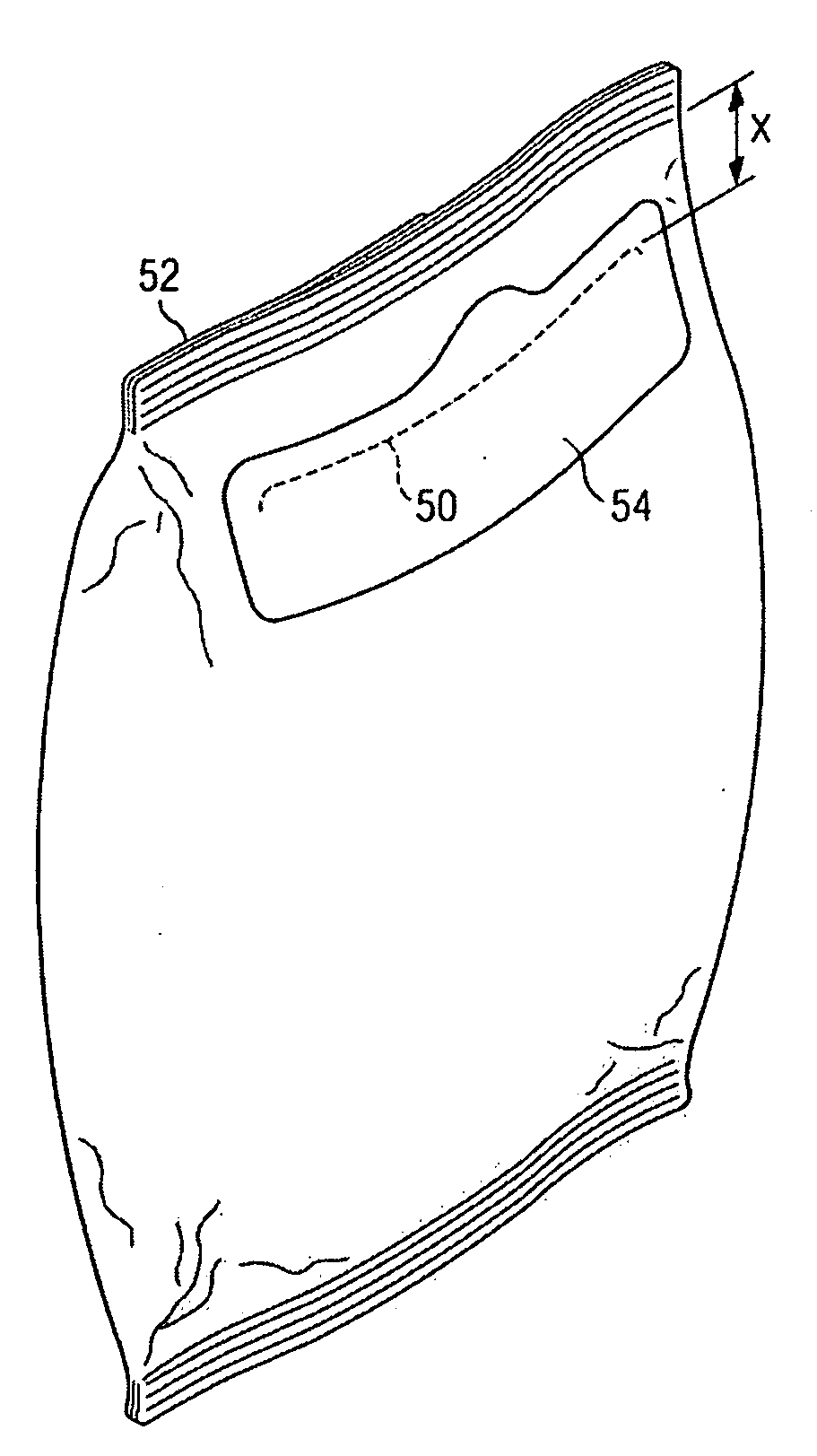

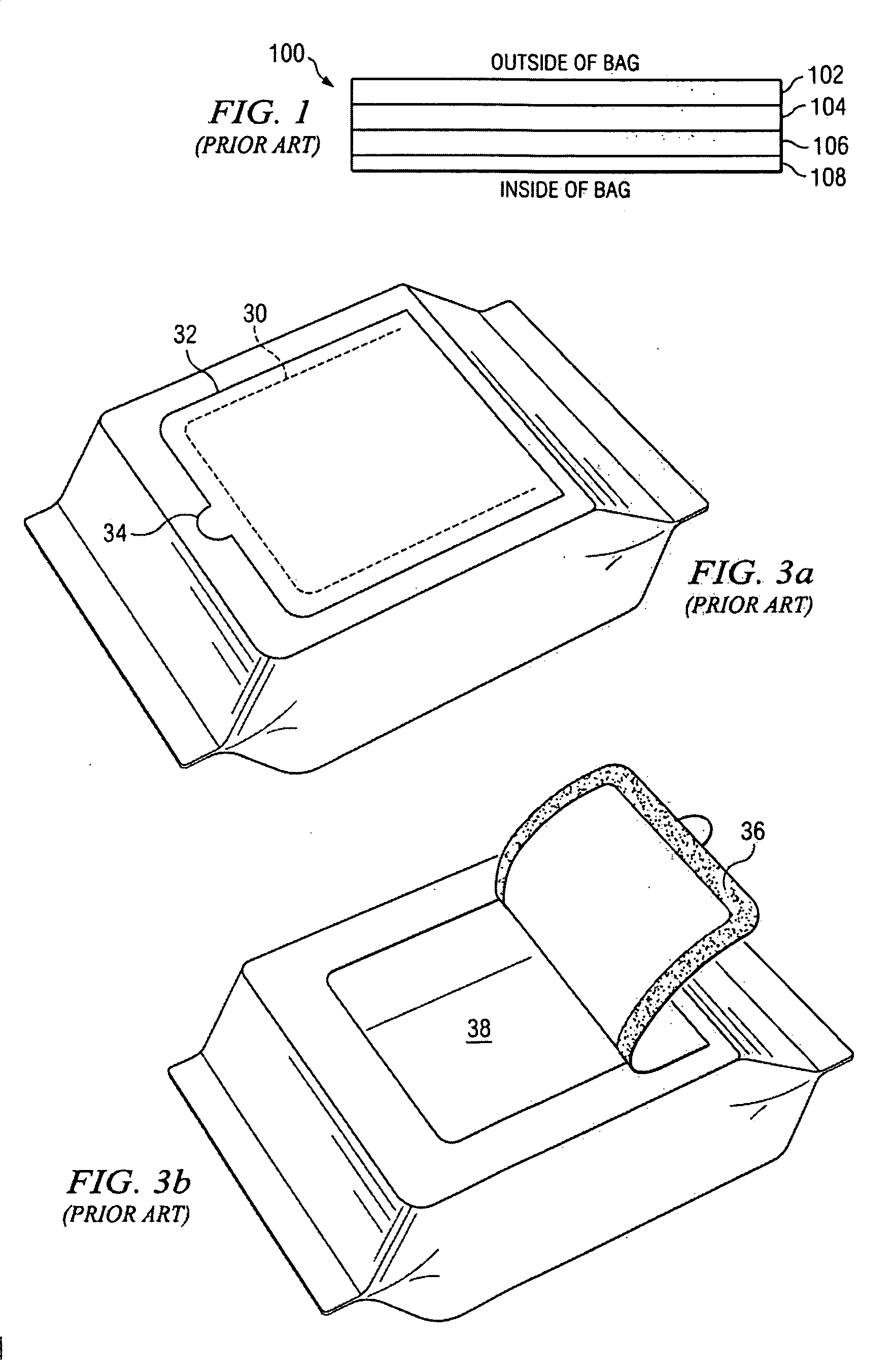

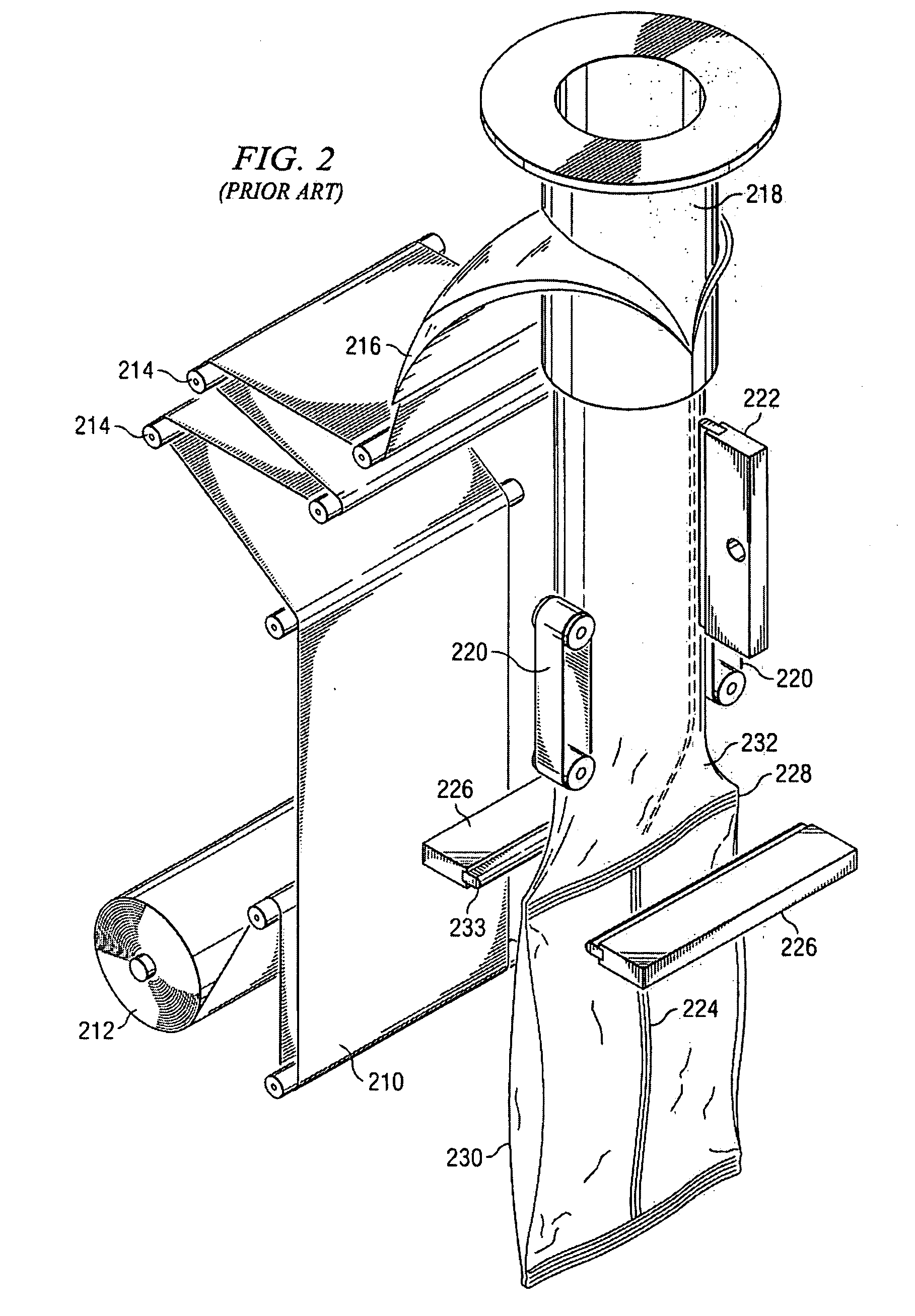

Two Side Cut Reseal With Pressure Sensitive Adhesive and the Method for Making Same

InactiveUS20100111453A1Prevent premature deterioration of qualityAvoid damageCapsDecorative coversSheet filmHermetic packaging

Two side cut reseal with pressure sensitive adhesive. A flexible package having a reseal integrated within the opposite layers of its film is constructed using existing vertical form fill and seal packaging machines. The invention involves a single sheet of flexible packaging film web having at least three layers. In a preferred embodiment, the reseal is comprised of two offsetting score lines on interior and exterior sides of the film and spaced apart by 0.5 to 1 inch. The scoring creates lines of weakness, which define an opening in the package. Upon opening, a pressure sensitive adhesive layer, which is pattern applied in between the offsetting score lines, is exposed from an interior side of the film. The adhesive releasably adheres the inner and outer layers of the film back together once separated by a consumer.

Owner:FRITO LAY NORTH AMERICA INC

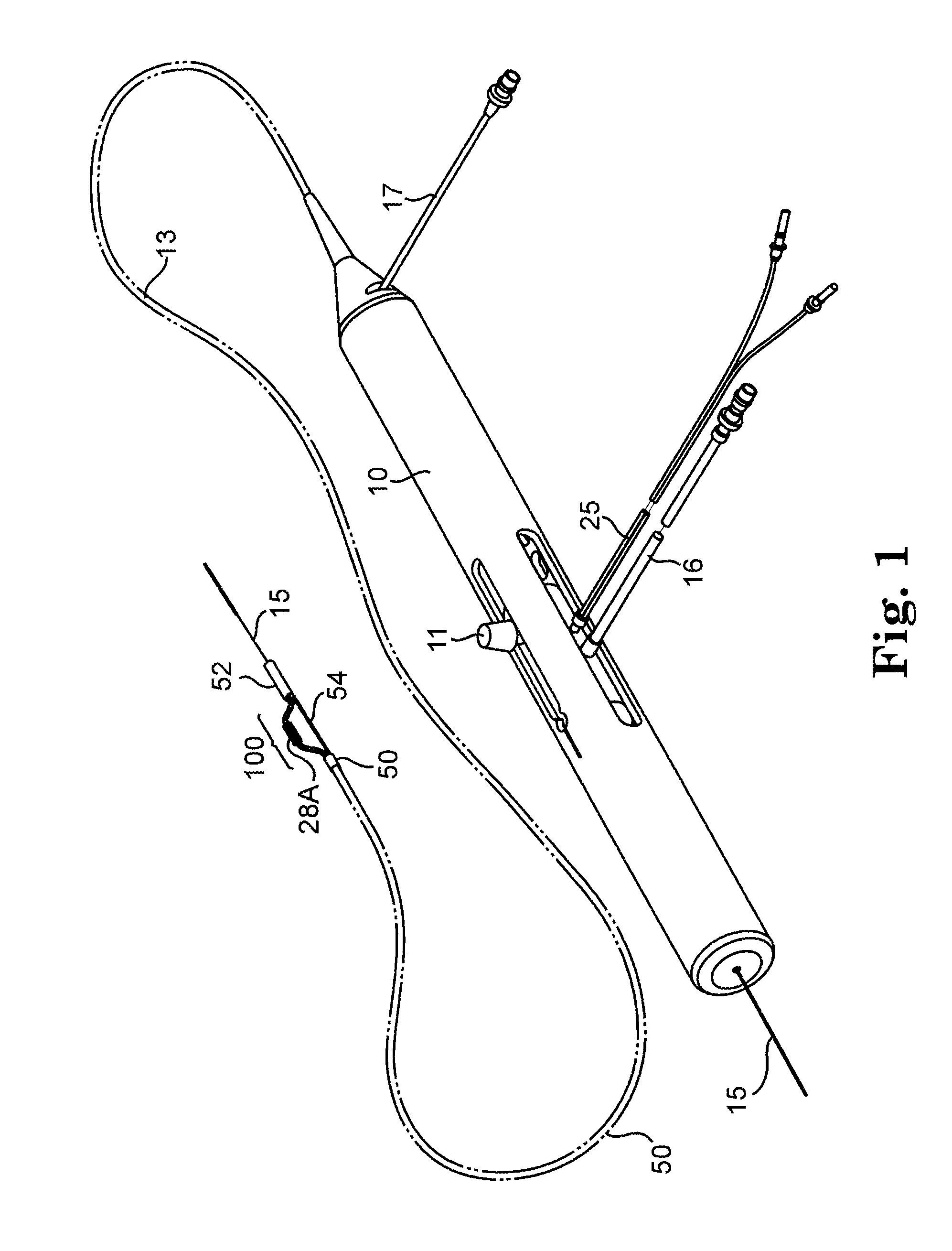

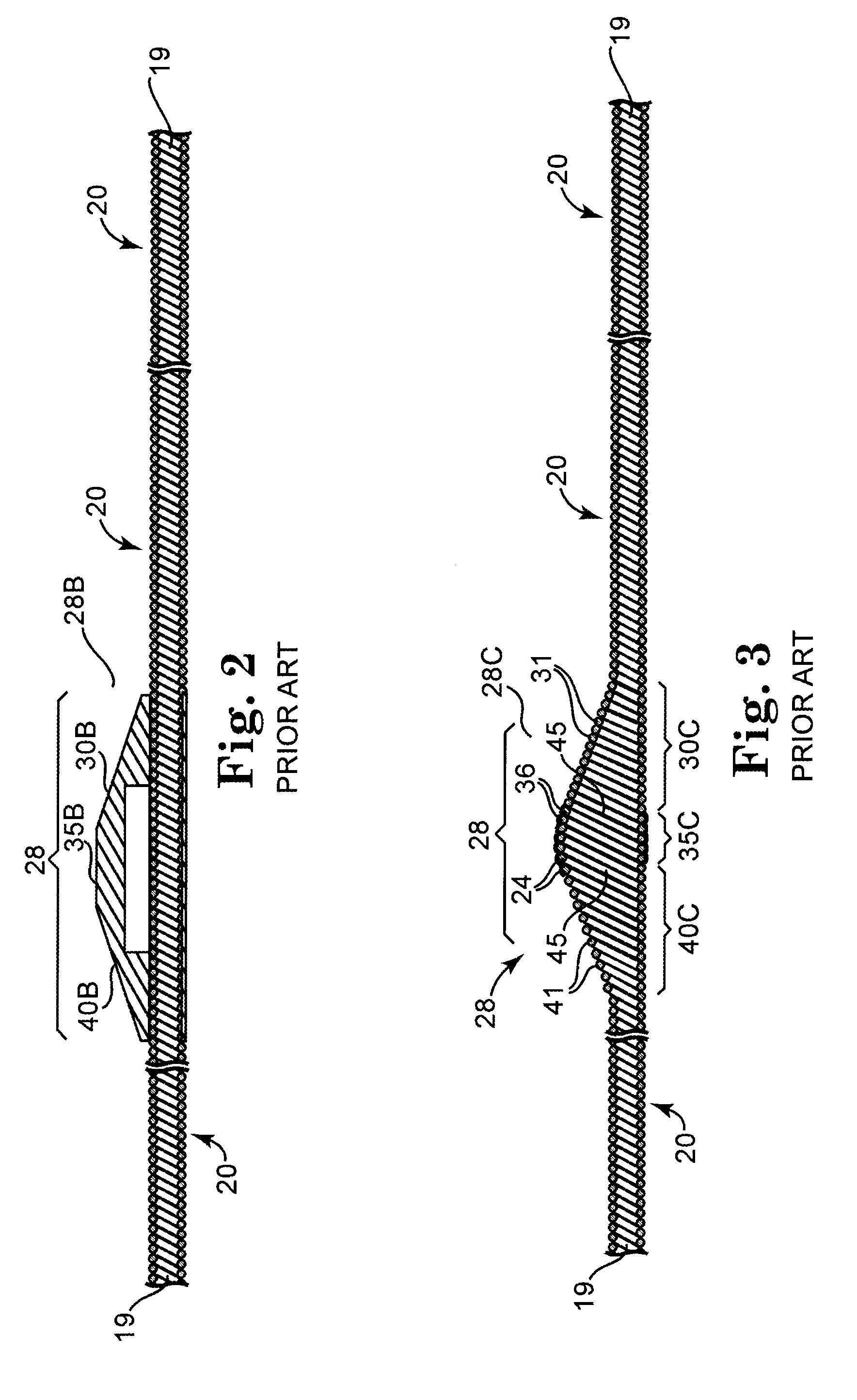

Offset vascular treatment devices

ActiveUS8715316B1Effectively and efficiently capturingIncrease awarenessLathesOrnamental textile articlesMedicineLaser cutting

Vascular treatment and methods include a plurality of self-expanding bulbs and a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Joints between woven structures and hypotubes include solder. Woven structures include patterns of radiopaque filaments measurable under x-ray. Structures are heat treated to include at least shapes at different temperatures. A catheter includes a hypotube including interspersed patterns of longitudinally spaced rows of kerfs. Heat treating systems include a detachable flange. Laser cutting systems include a fluid flow system.

Owner:INSERA THERAPEUTICS

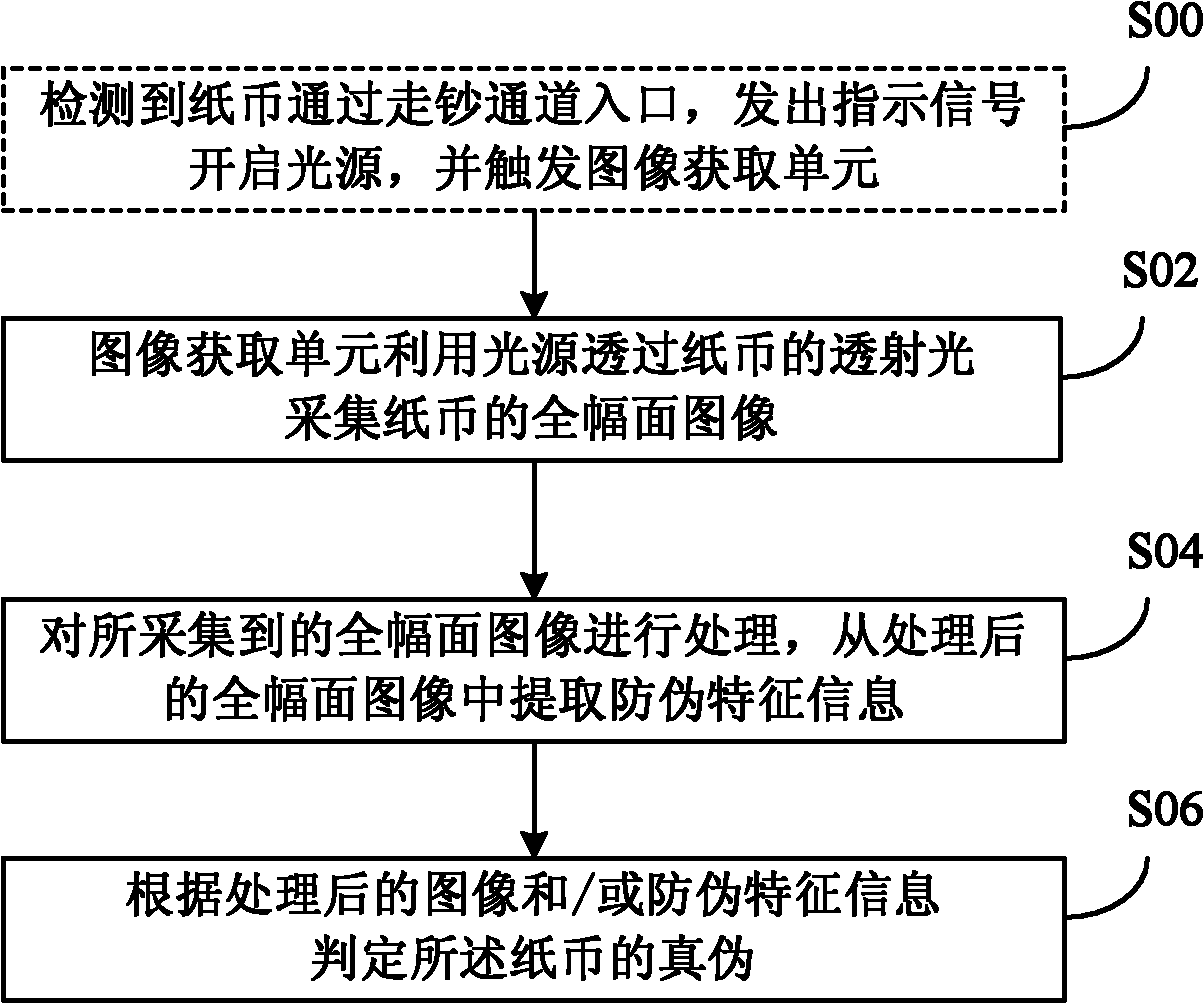

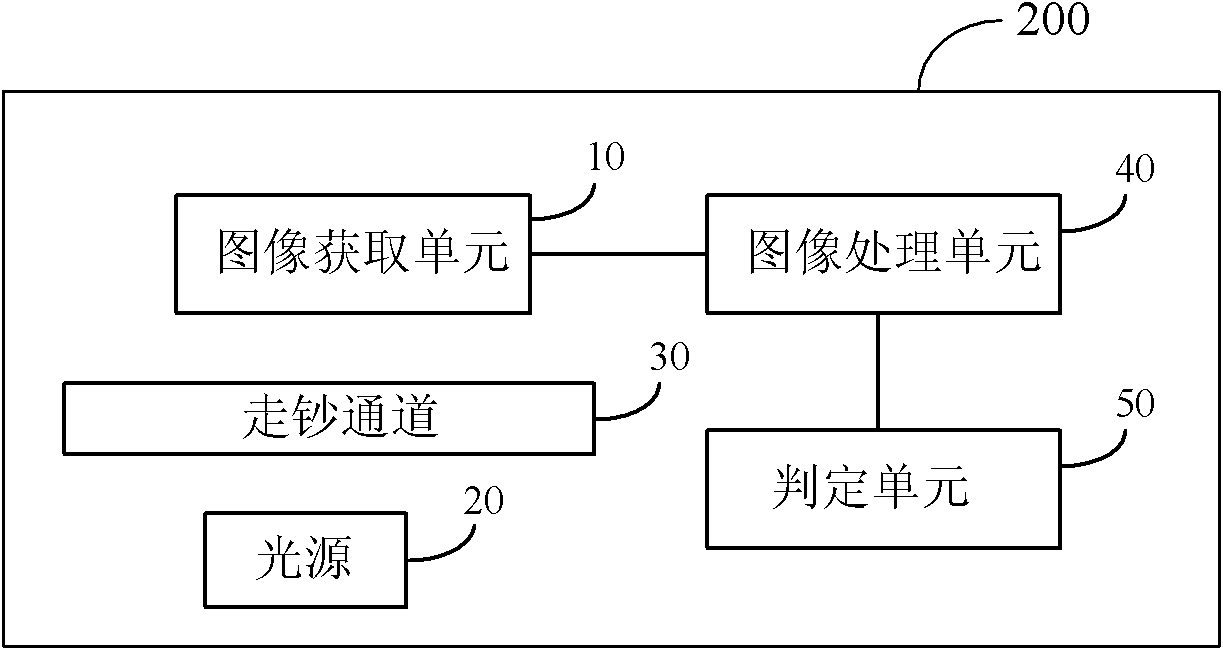

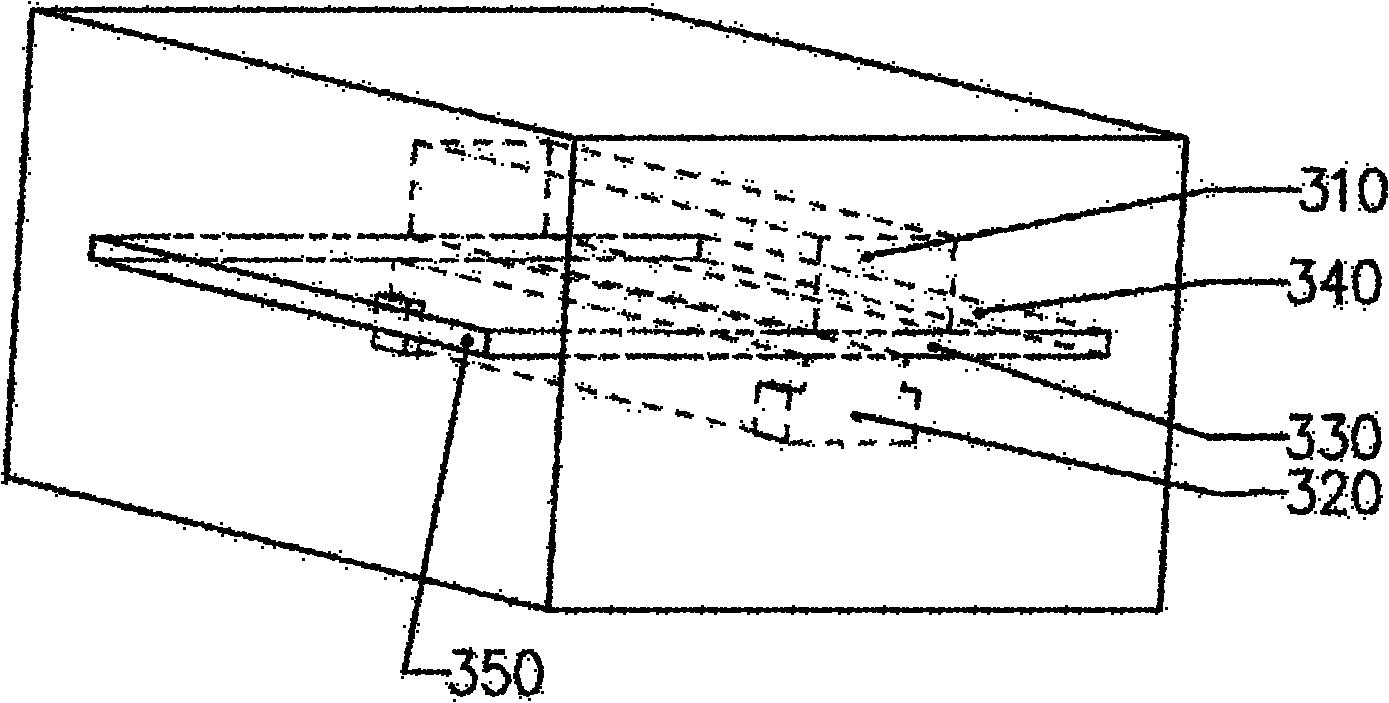

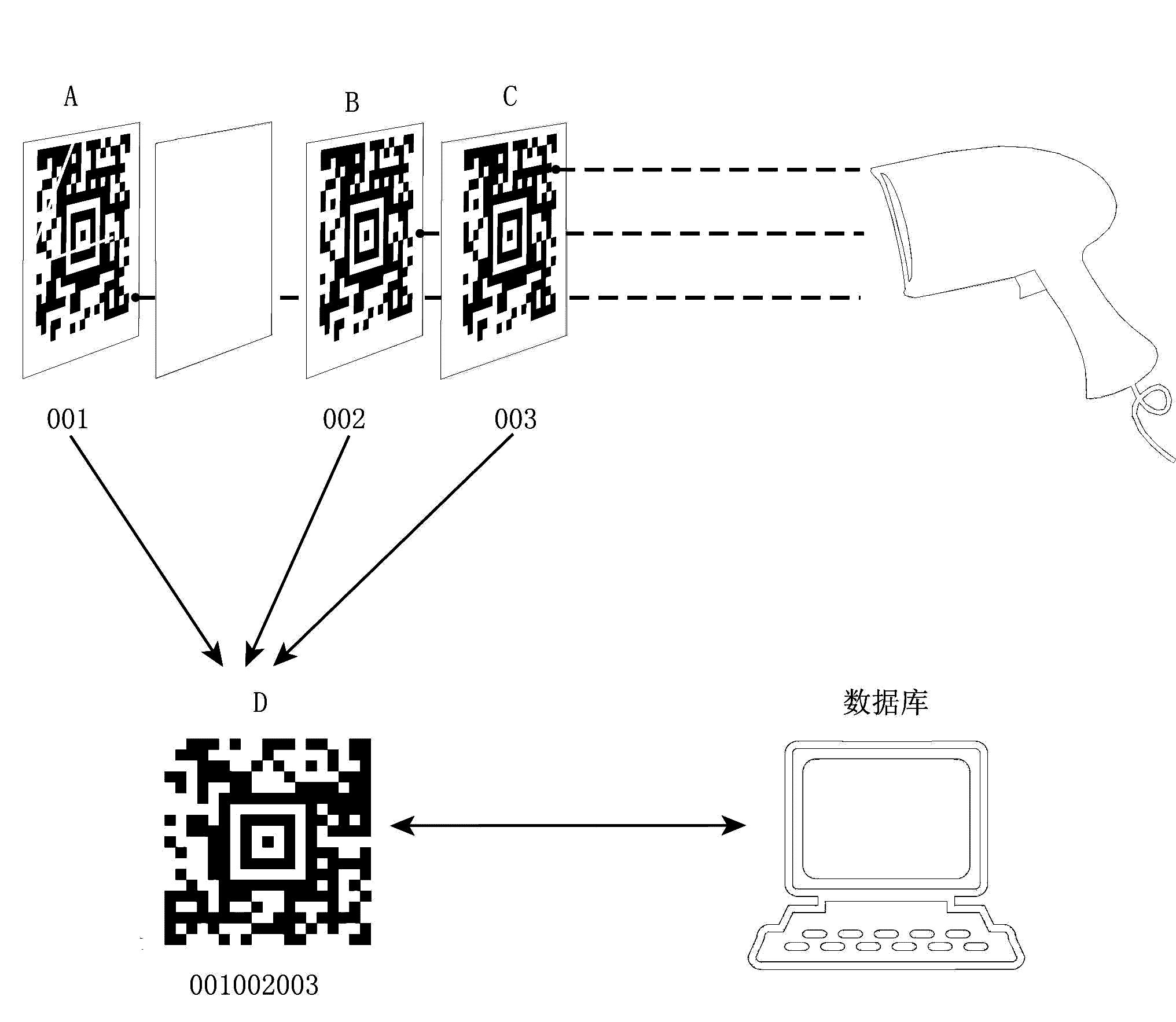

Paper currency detecting method and device

InactiveCN102096962AOvercoming Undetectable DefectsFalsification, the effect is obviousPaper-money testing devicesCharacter and pattern recognitionAlgorithmImaging algorithm

The invention discloses a paper currency detecting method. A paper currency recognition device is internally provided with an image acquisition unit, a light source and a currency delivering channel, wherein the image acquisition unit and the light source are respectively located on two sides of the currency delivering channel of the paper currency recognition device. The paper currency detecting method comprises the following steps: in a process for delivering a paper currency to be detected through the currency delivering channel, acquiring and processing the full-breadth image of the paper currency by the image acquisition unit through transmission light of the light source, transmitting through the paper currency; extracting anti-counterfeiting feature information from the processed full-breadth image; and judging the authenticity of the paper currency according to the processed image and / or the anti-counterfeiting feature information. The invention further provides a corresponding device. A paper currency detection scheme provided by the invention is beneficial to overcoming of the limitedness of processing with a reflection-type imaging algorithm, and is easy to realize with lower cost and fast and accurate detection, thus, false money can be accurately detected, and particularly, a more obvious effect on the false authentication can be achieved on a changed paper currency; and the paper currency detecting method and device can be used for accurately detecting complementary opposite printing type features of offset printing.

Owner:BEIJING NUFRONT SOFTWARE SCI TECH

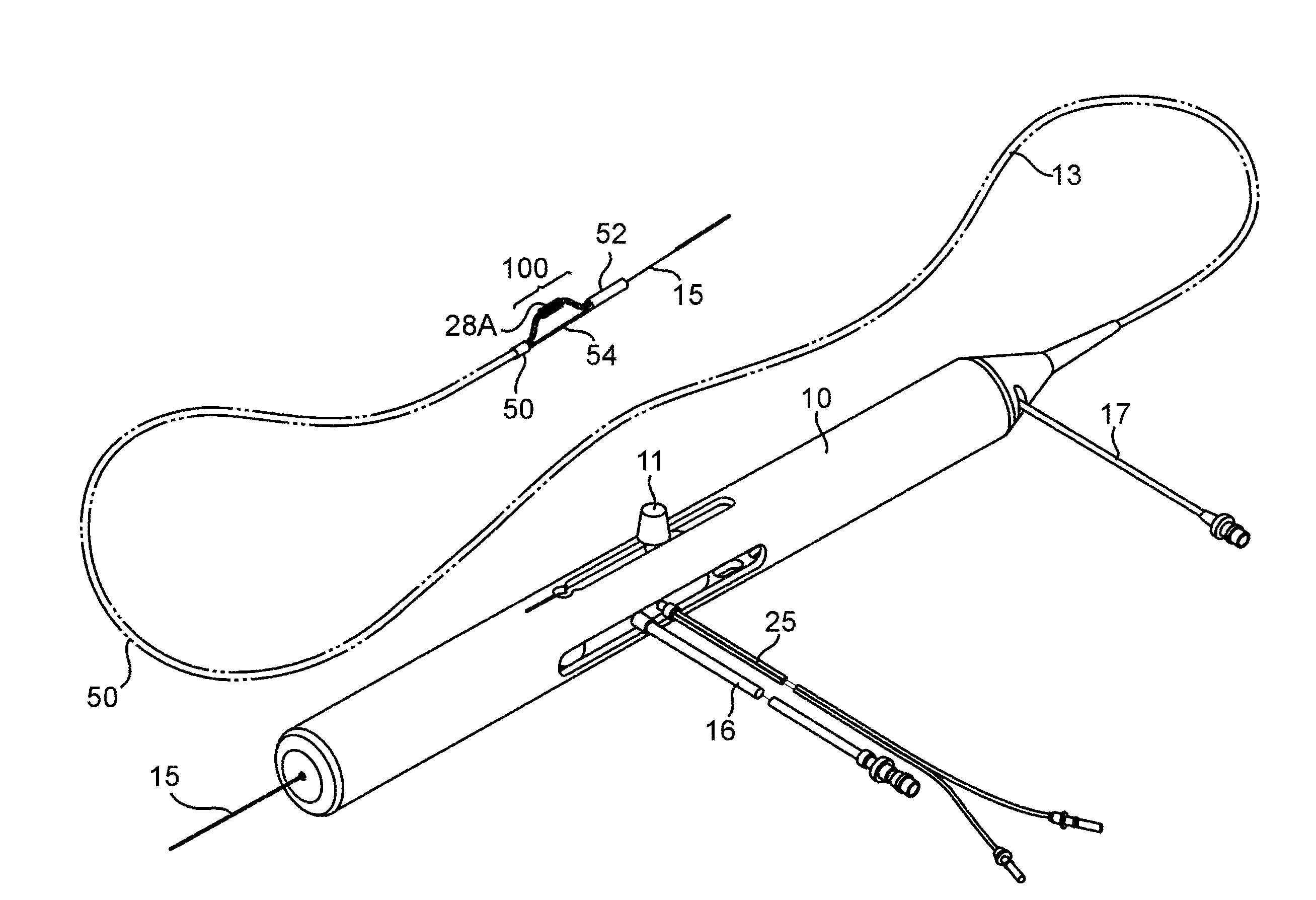

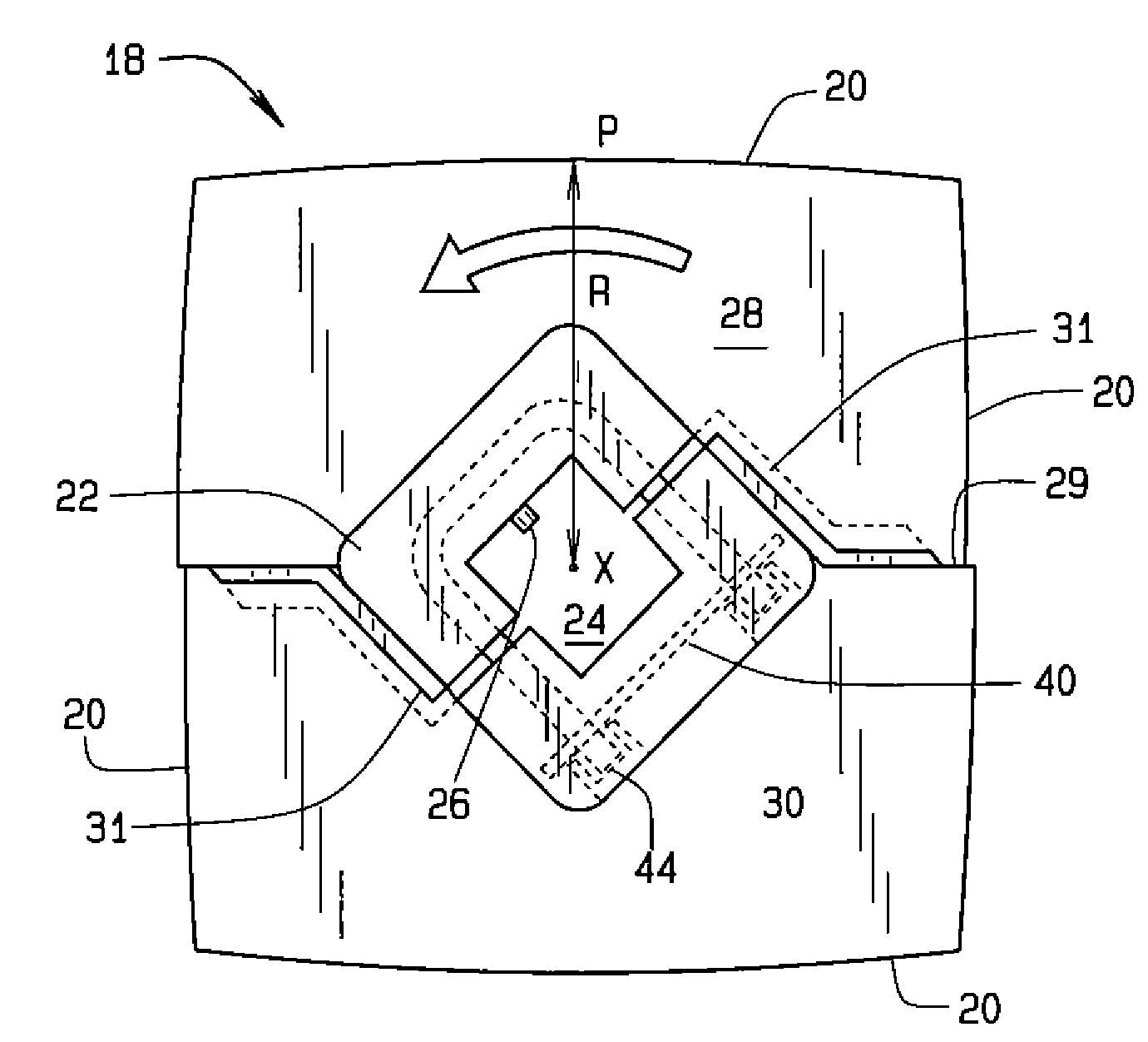

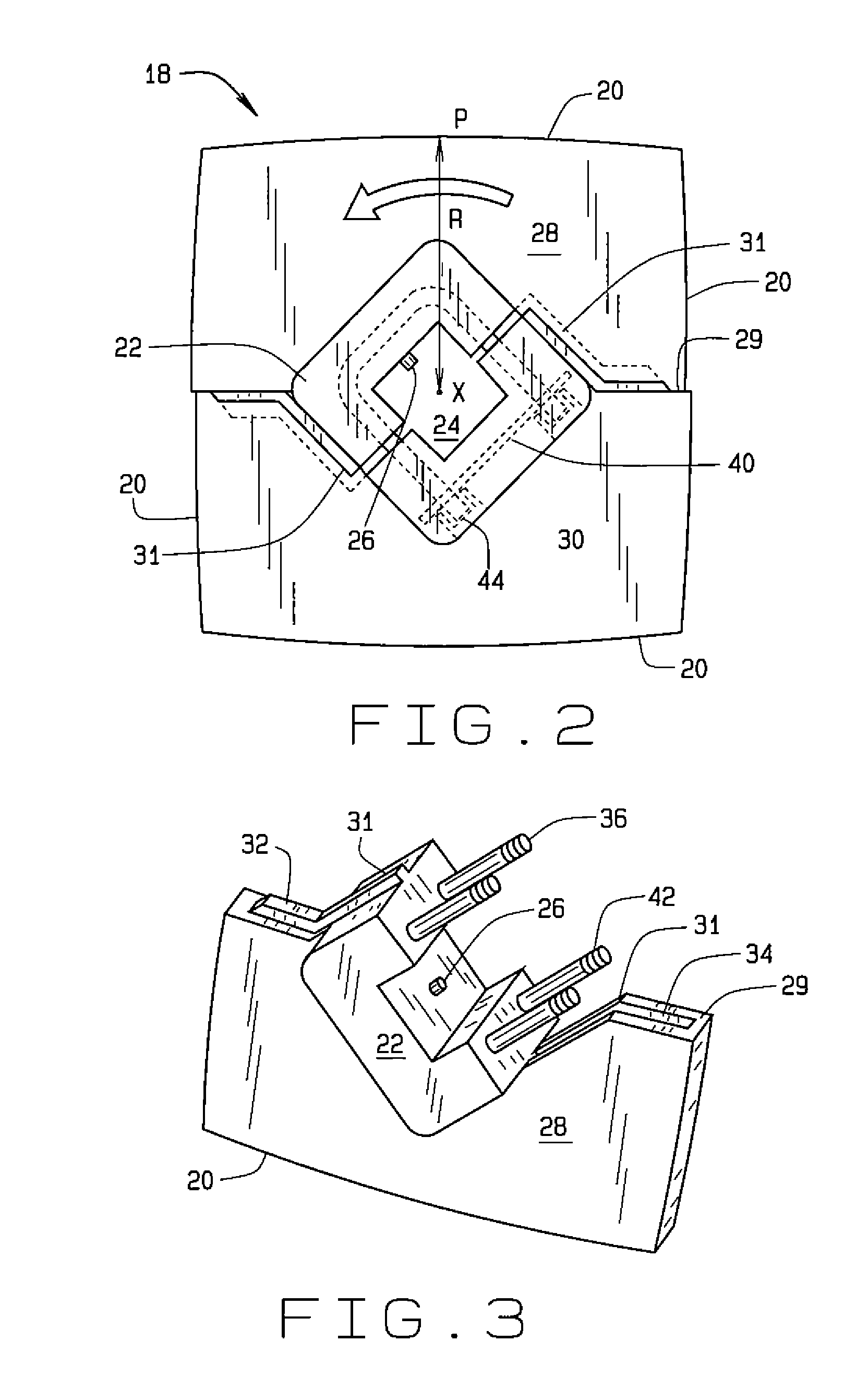

Directional rotational atherectomy device with offset spinning abrasive element

The invention provides a rotational atherectomy system, device and method comprising a flexible, elongated, rotatable drive shaft with a pre-curved abrasive section disposed within a catheter that deforms the abrasive section to a substantially straight profile and, when the abrasive section is moved distally out of the catheter, the abrasive section resumes its pre-curved profile. Directional ablation is achieved by rotation of the drive shaft along its pre-curved axis as the abrasive section is urged against a portion of the lumen wall.

Owner:CARDIOVASCULAR SYST INC

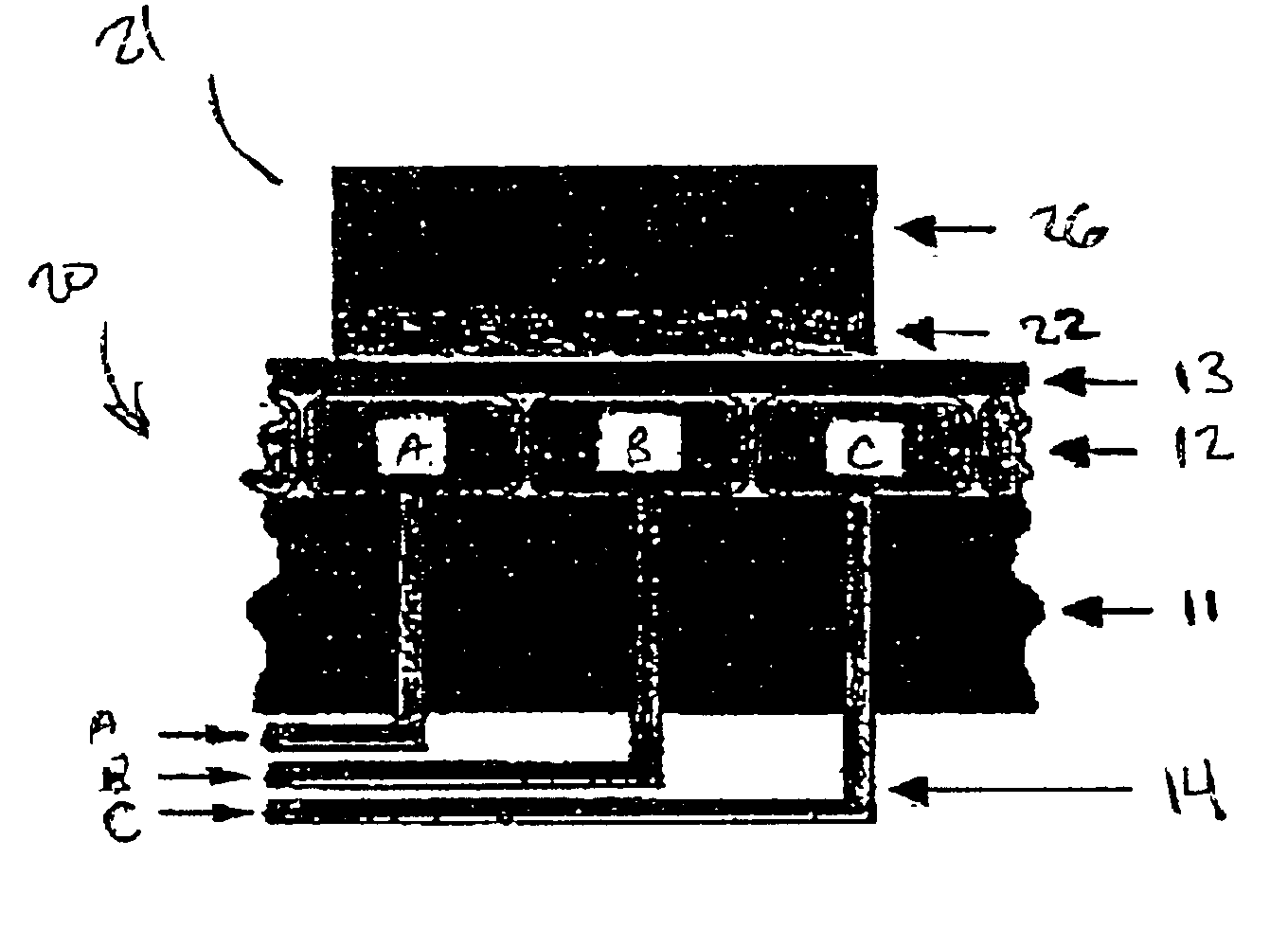

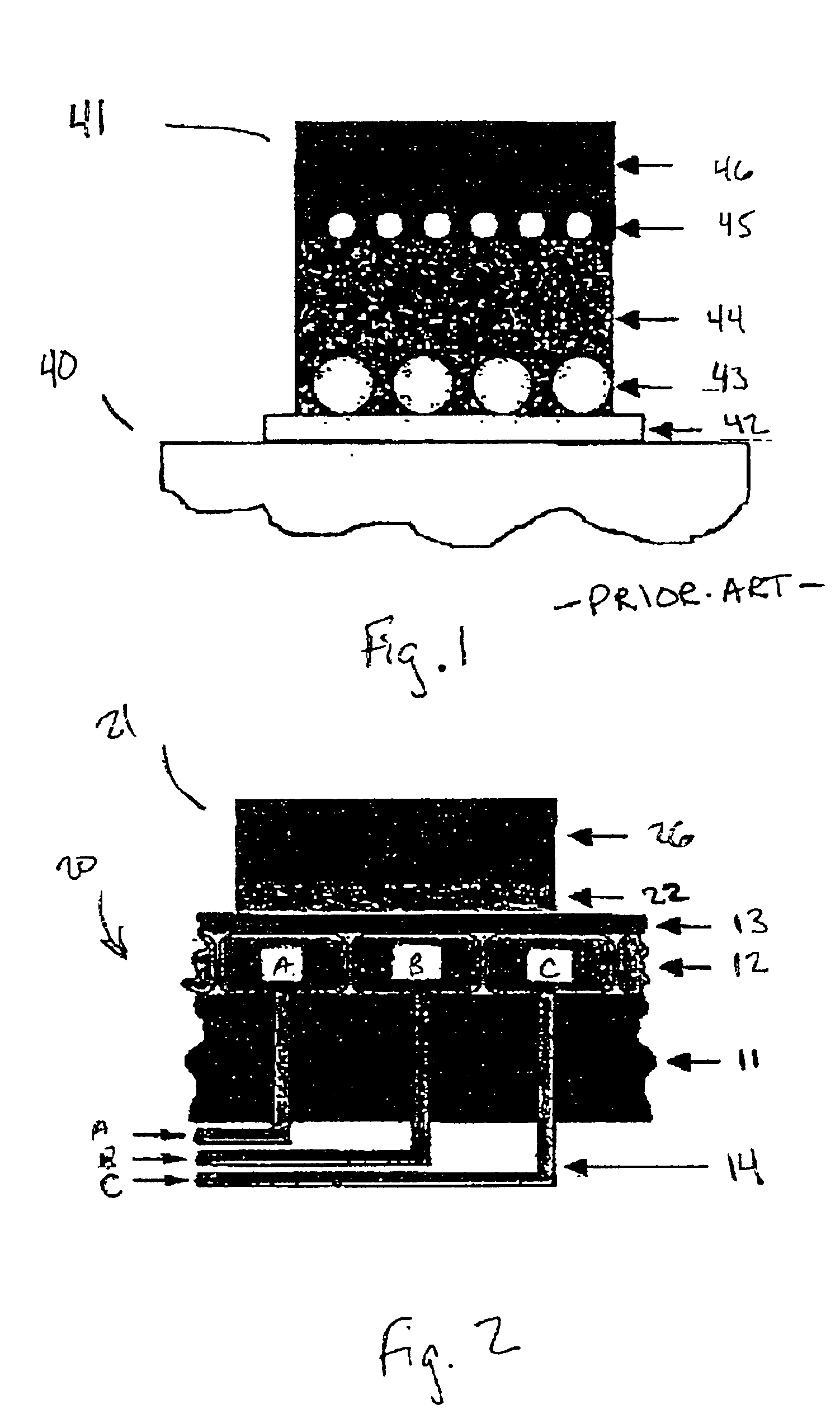

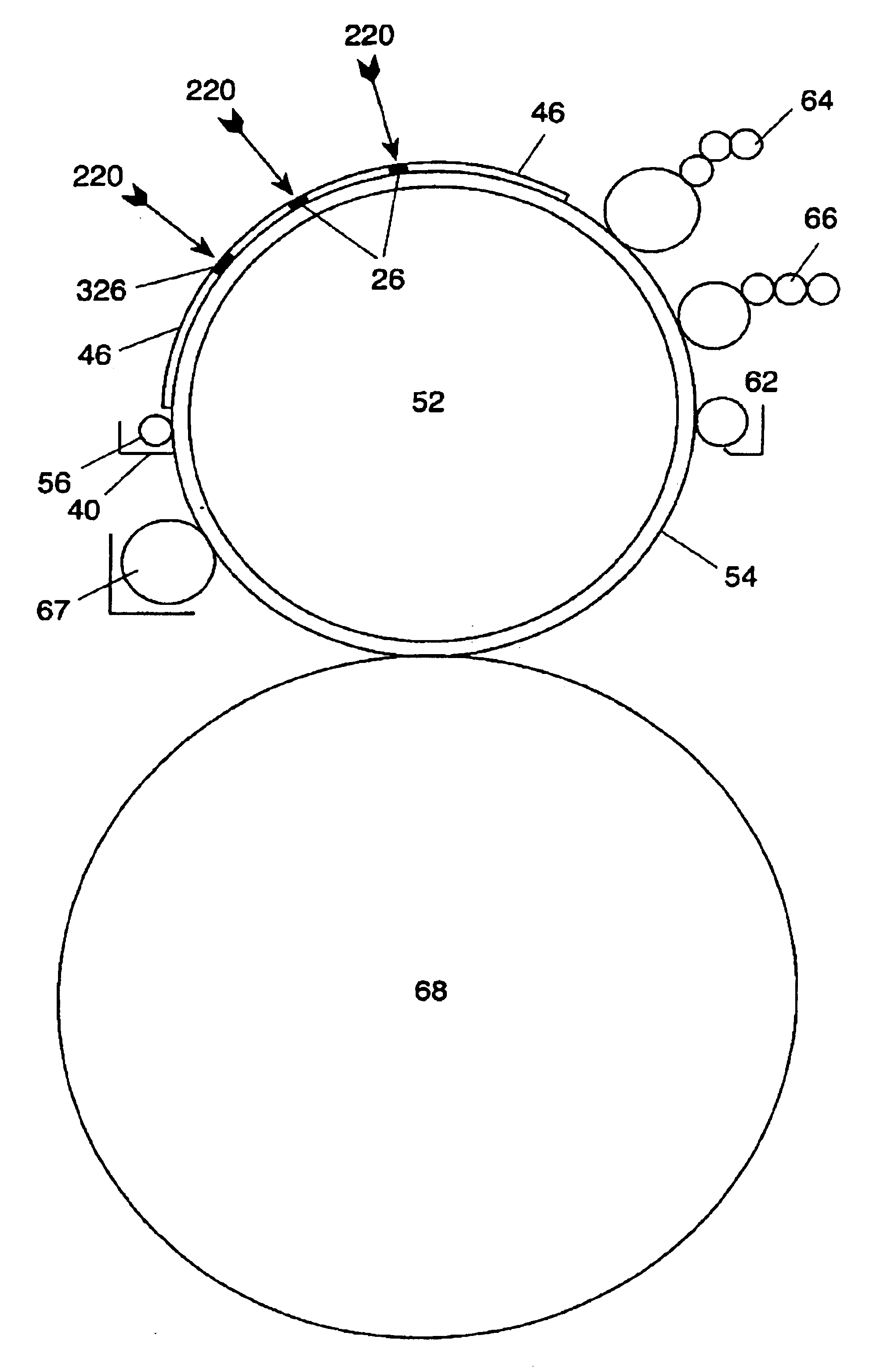

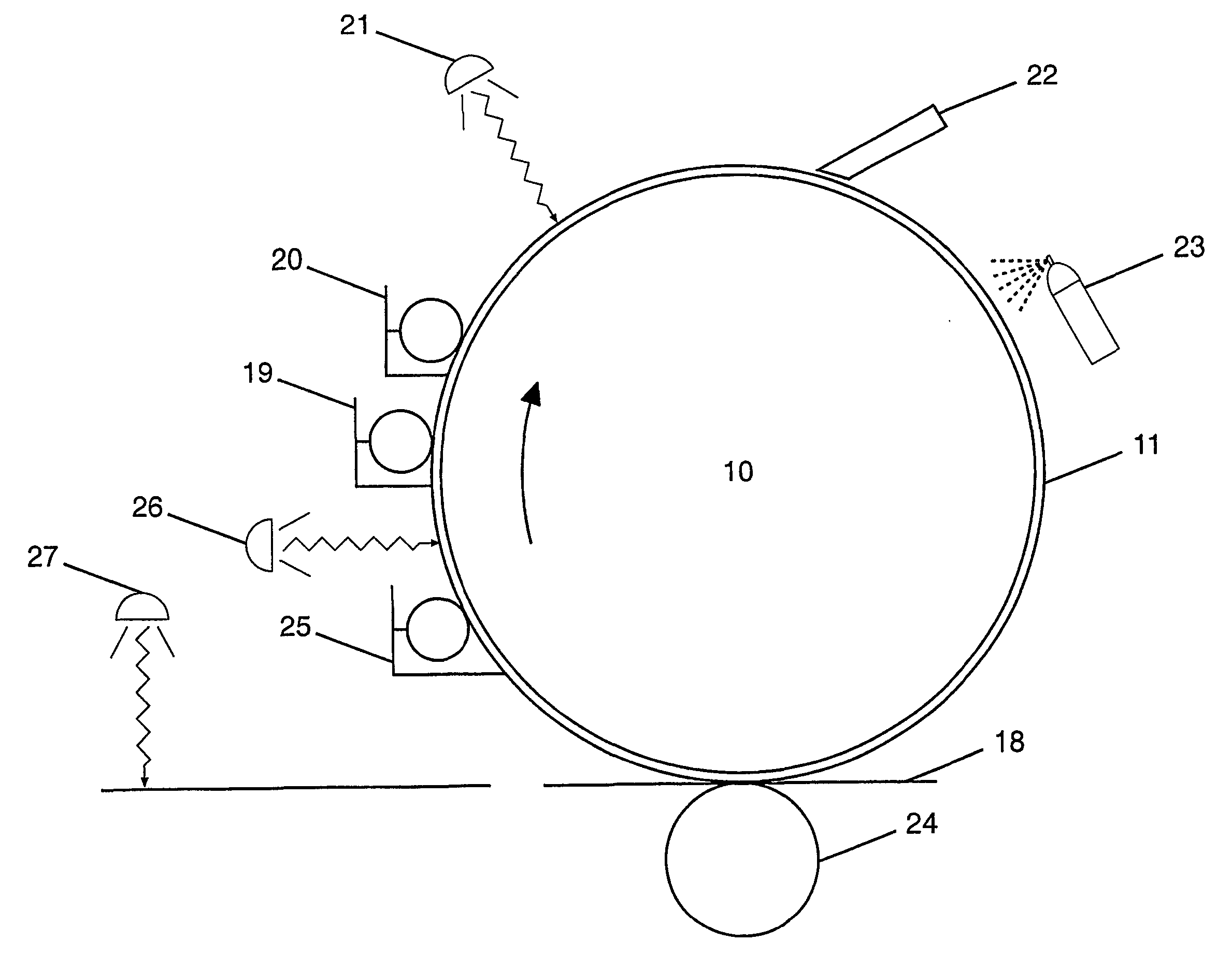

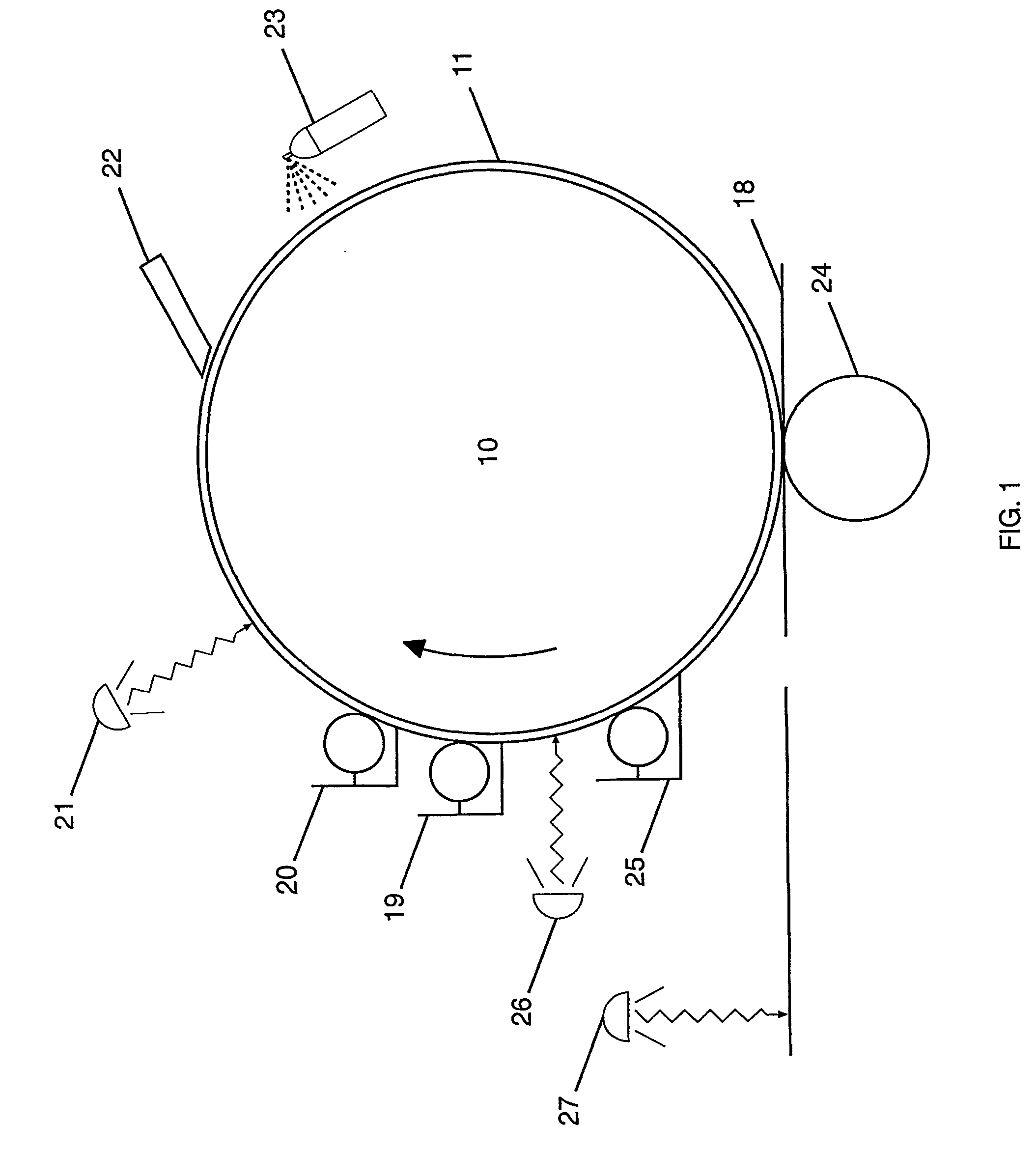

Blanket cylinder with integrated compressible layer

A printing unit including a rigid cylinder rotatable about an axis of rotation, a plurality of inflatable bladders disposed on a circumferential surface of the cylinder, and a first fluid supply regulation unit configured to supply a first fluid to a first set of inflatable bladders of the plurality of inflatable bladders and to regulate a first fluid pressure inside the first set inflatable bladders. In addition, a method for mounting a sleeve-shaped printing sock onto a blanket cylinder of an offset printing press, in which a set of inflatable bladders disposed at an outer region of the blanket cylinder are at least partially deflated. The sleeve-shaped printing sock is slid over one end of the blanket cylinder so that the printing sock at least partially surrounds a circumference of the blanket cylinder. The set of inflatable bladders are then inflated so that the printing sock fits tightly around the circumference of the blanket cylinder.

Owner:SHANGHAI ELECTRICGROUP CORP

Single Serving Reusable Brewing Material Holder With Offset Passage for Offset Bottom Needle

A single serving beverage filter cartridge is formed by placing a single serving portion of brewing material into a reusable coffee holder having a lid and a base. The reusable coffee holder includes an offset passage in the bottom of the base and is insertable into a cartridge housing of a single serving coffee maker having an offset bottom needle reaching up vertically from the base of the housing, the offset passage providing clearance for the offset bottom needle. The coffee holder defines a frustoconical exterior and includes mesh filtering material for retaining brewing material inside the reusable coffee holder. The mesh material may be a metal mesh or plastic mesh. The reusable coffee holder is configured for use in single serving coffee makers having the offset bottom needle and designed for single use cartridges.

Owner:ARM ENTERPRISES

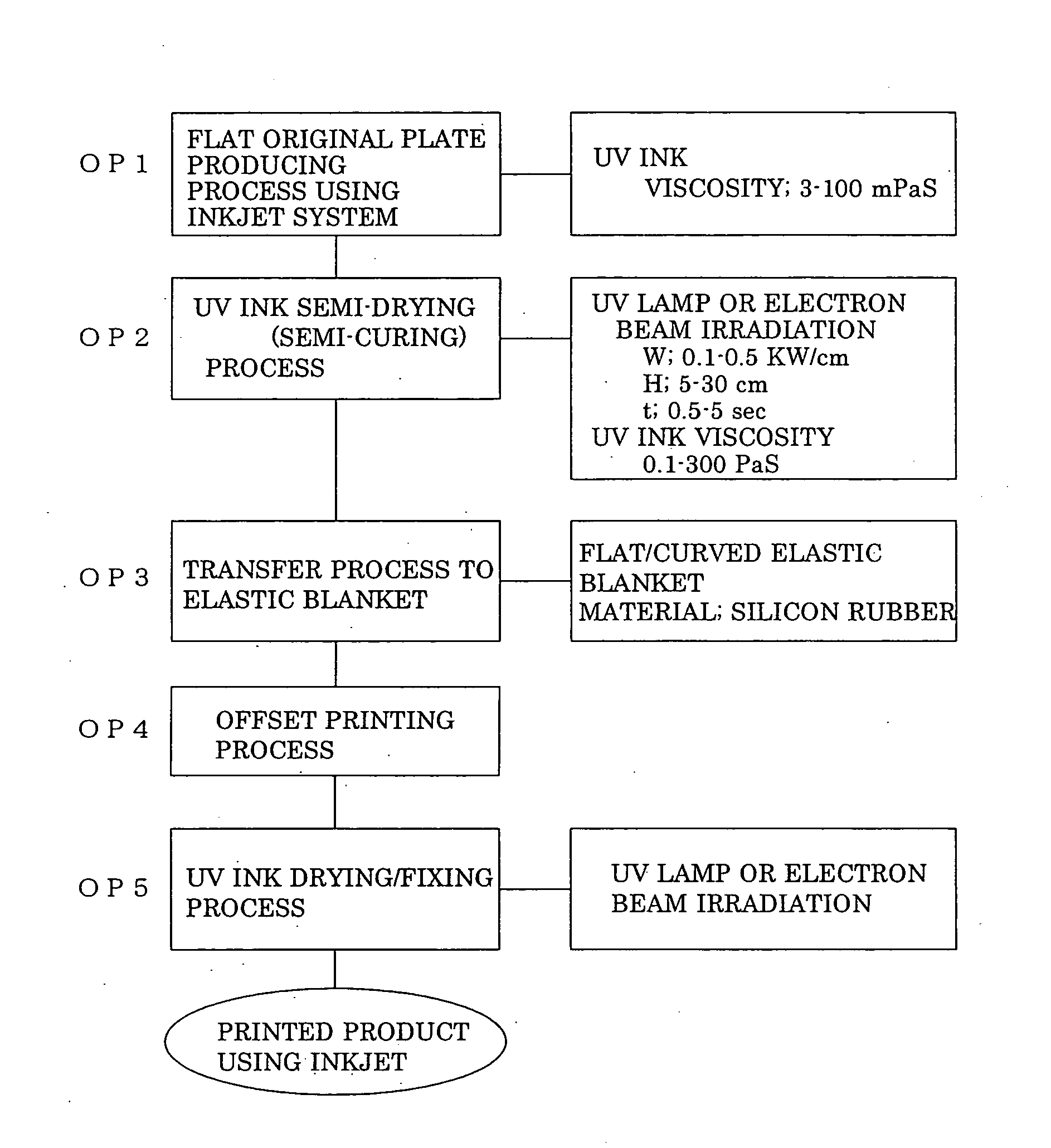

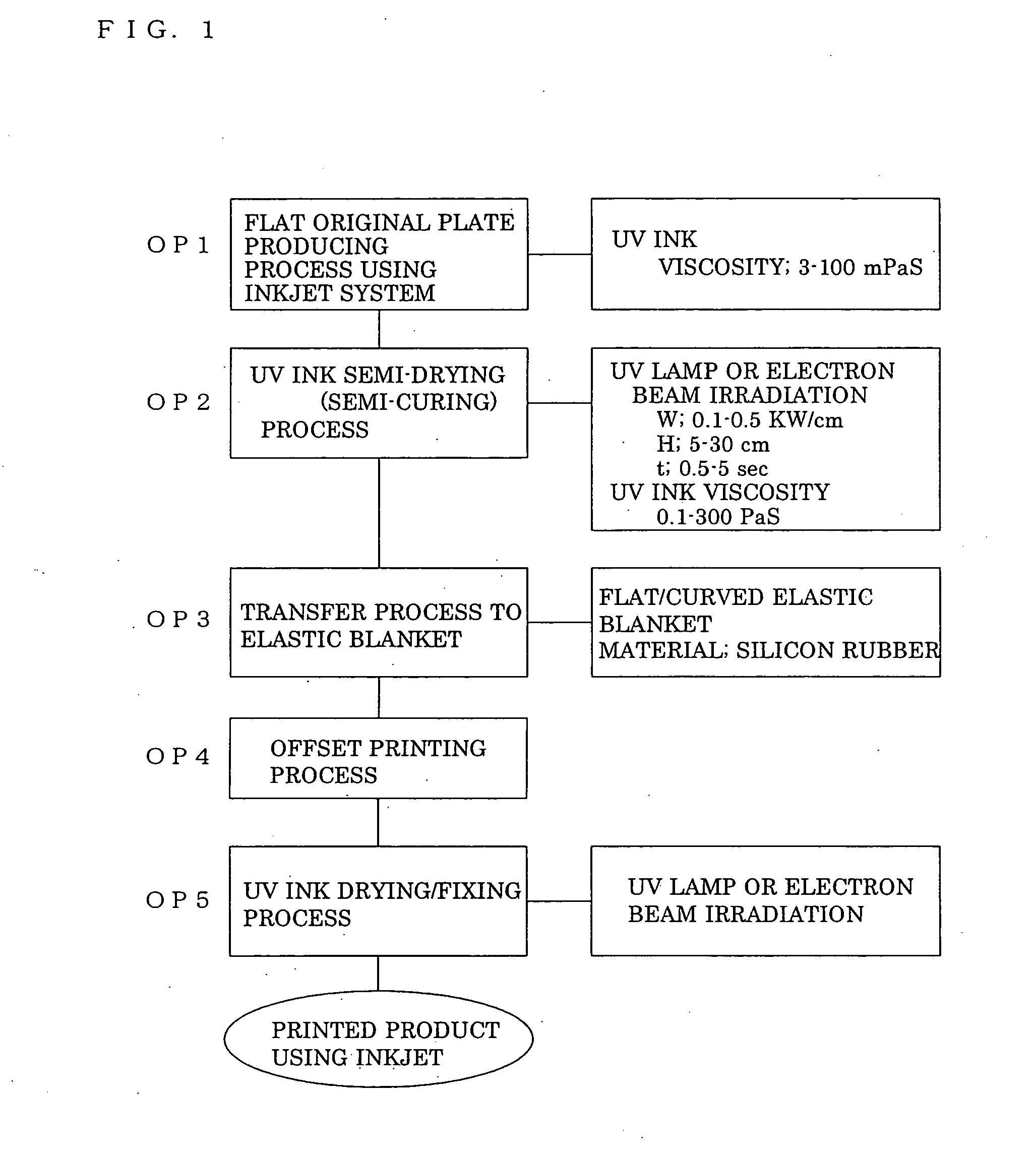

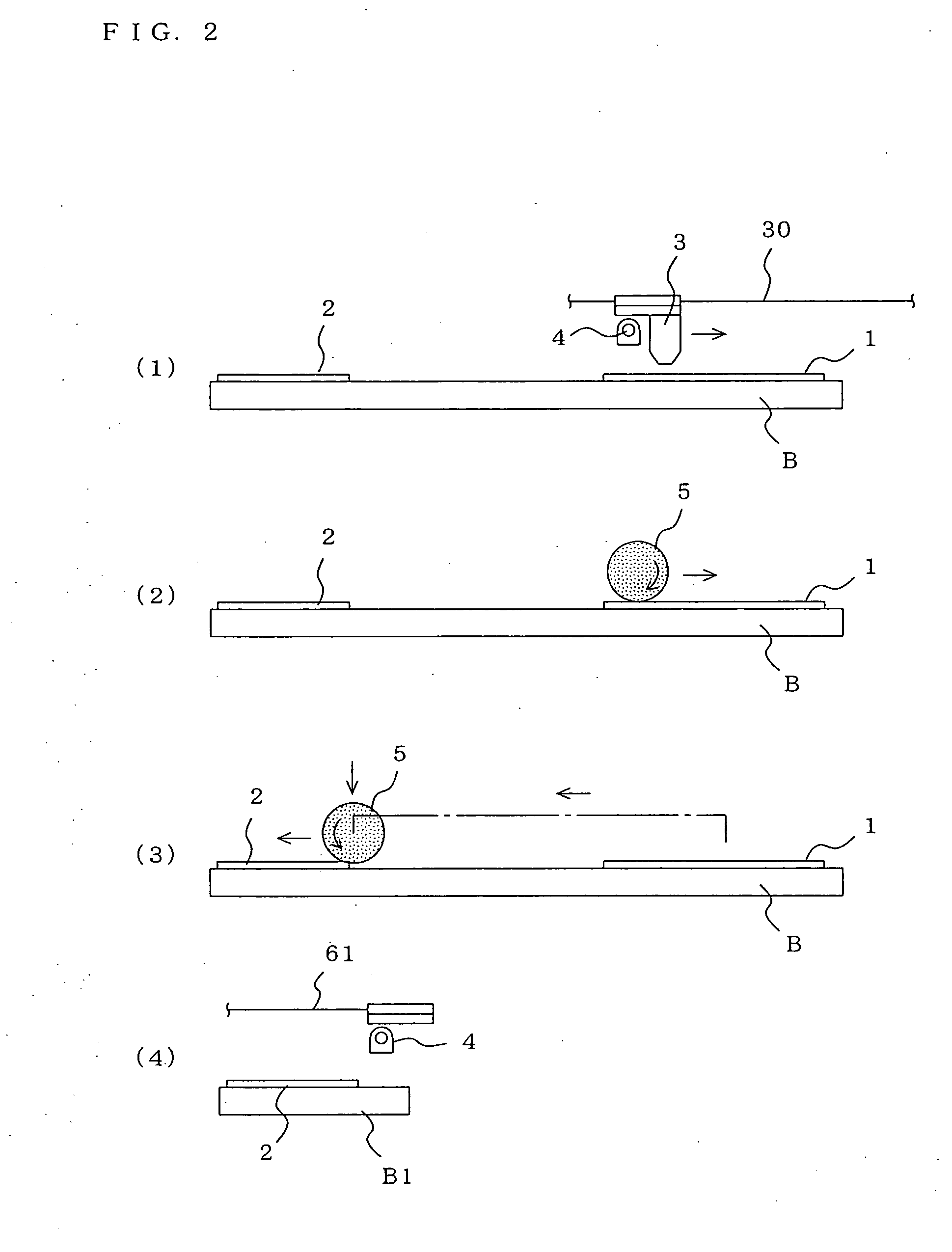

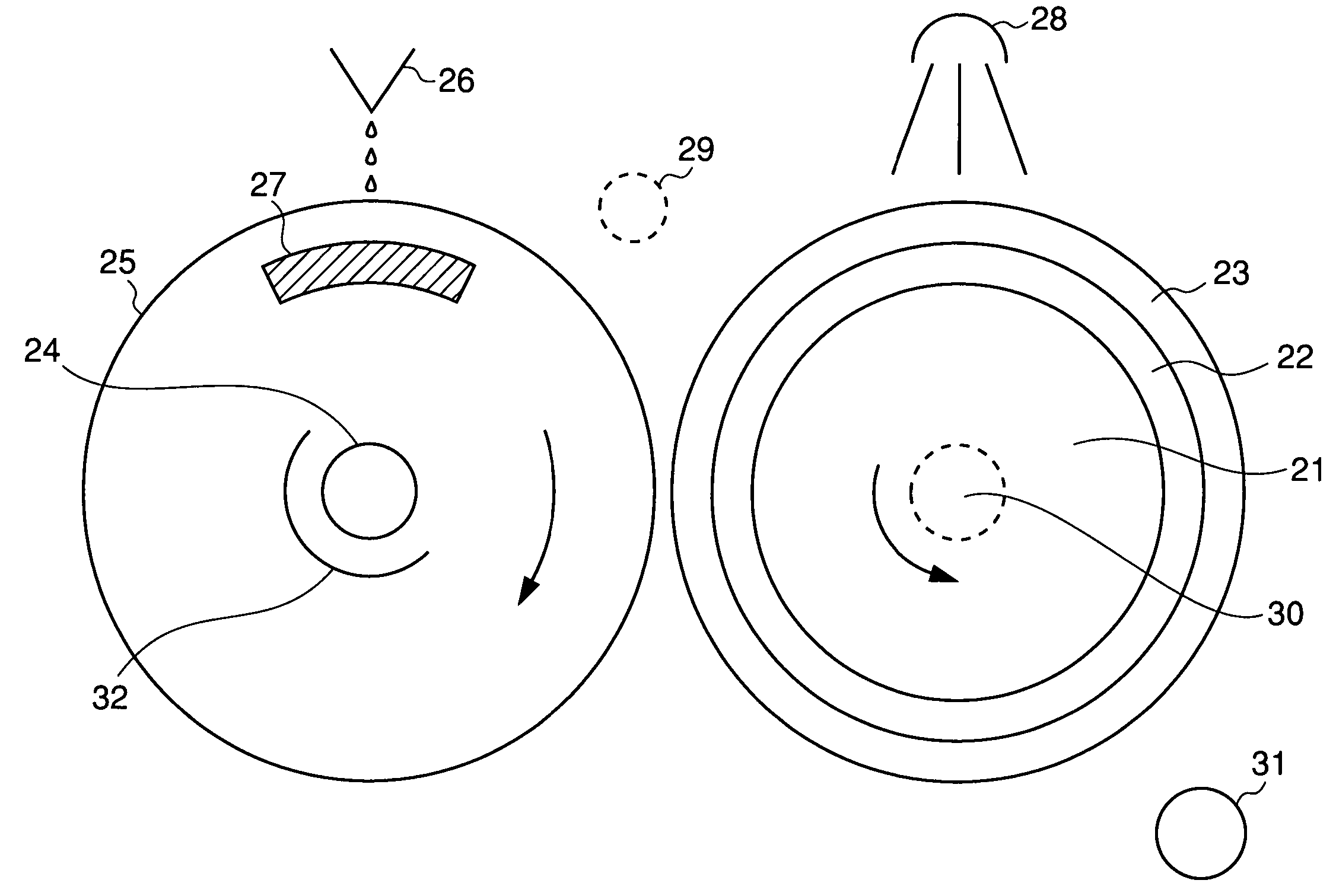

Offset printing method using inkjet system and product printed thereby

InactiveUS20090207198A1Correct printed imageAccurate imagingDuplicating/marking methodsRotary pressesImage transferEngineering

An offset printing method using an inkjet system, and a printed product printed thereby. The offset printing method includes a first step of printing a UV ink image on a flat original plate by inkjet using UV-ink, a second step of irradiating the UV ink image with a UV or an electron beam while or immediately after printing the UV ink image, so as to bring the UV ink image into a semi-dried state, a third step of transferring the semi-dried UV ink image to a surface of an elastic blanket, a fourth step of offset-printing the UV ink image transferred to the elastic blanket onto a to-be-printed product, and a step of drying and fixing the offset-printed UV ink image. Viscosity of the UV ink in the first step is set as 3-100 mPaS at 30° C., and viscosity of the UV ink in the second step is set as viscosity equivalent to 0.1-300 PaS at 25° C. in standard UV ink.

Owner:SHUHOU

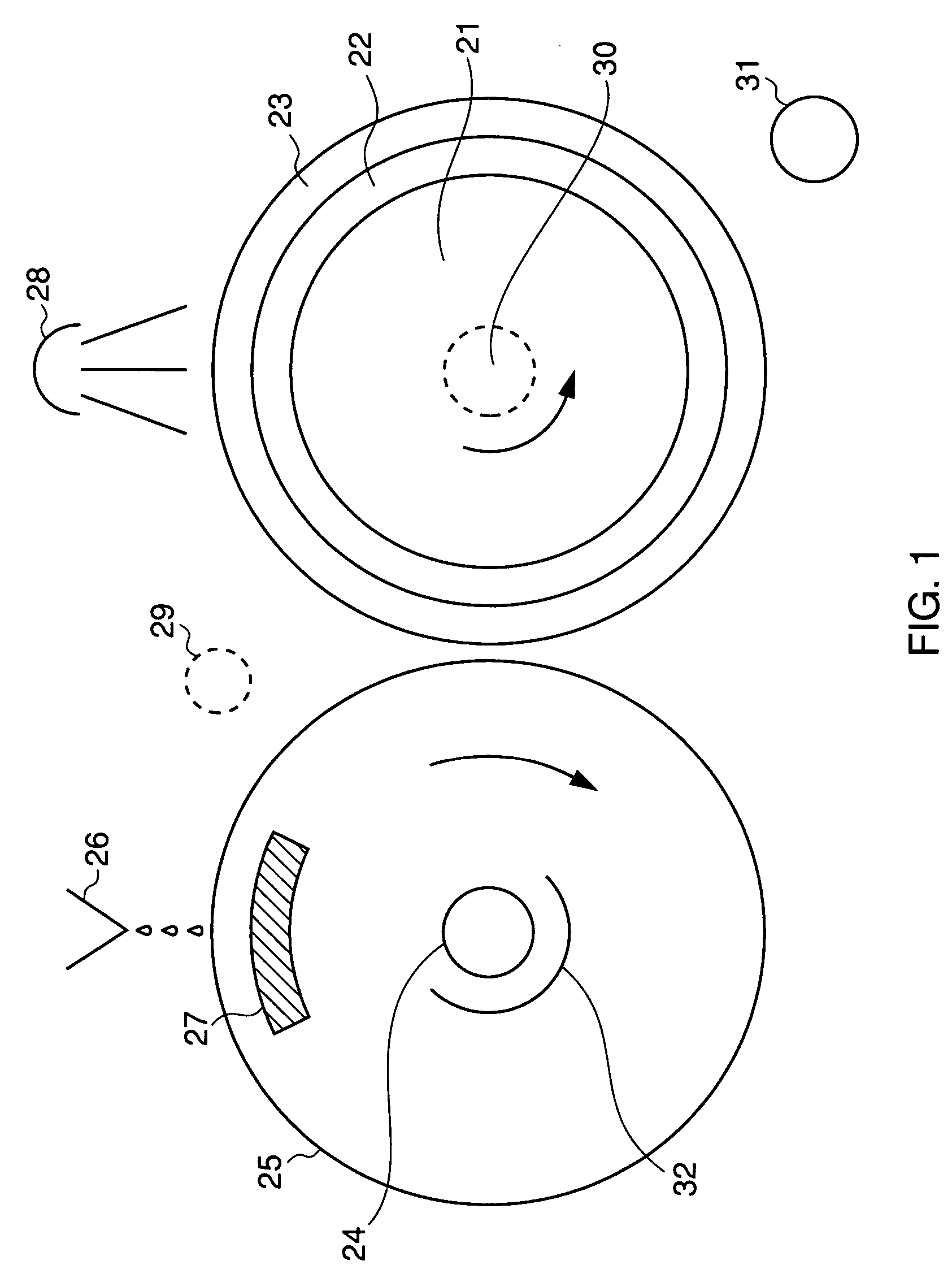

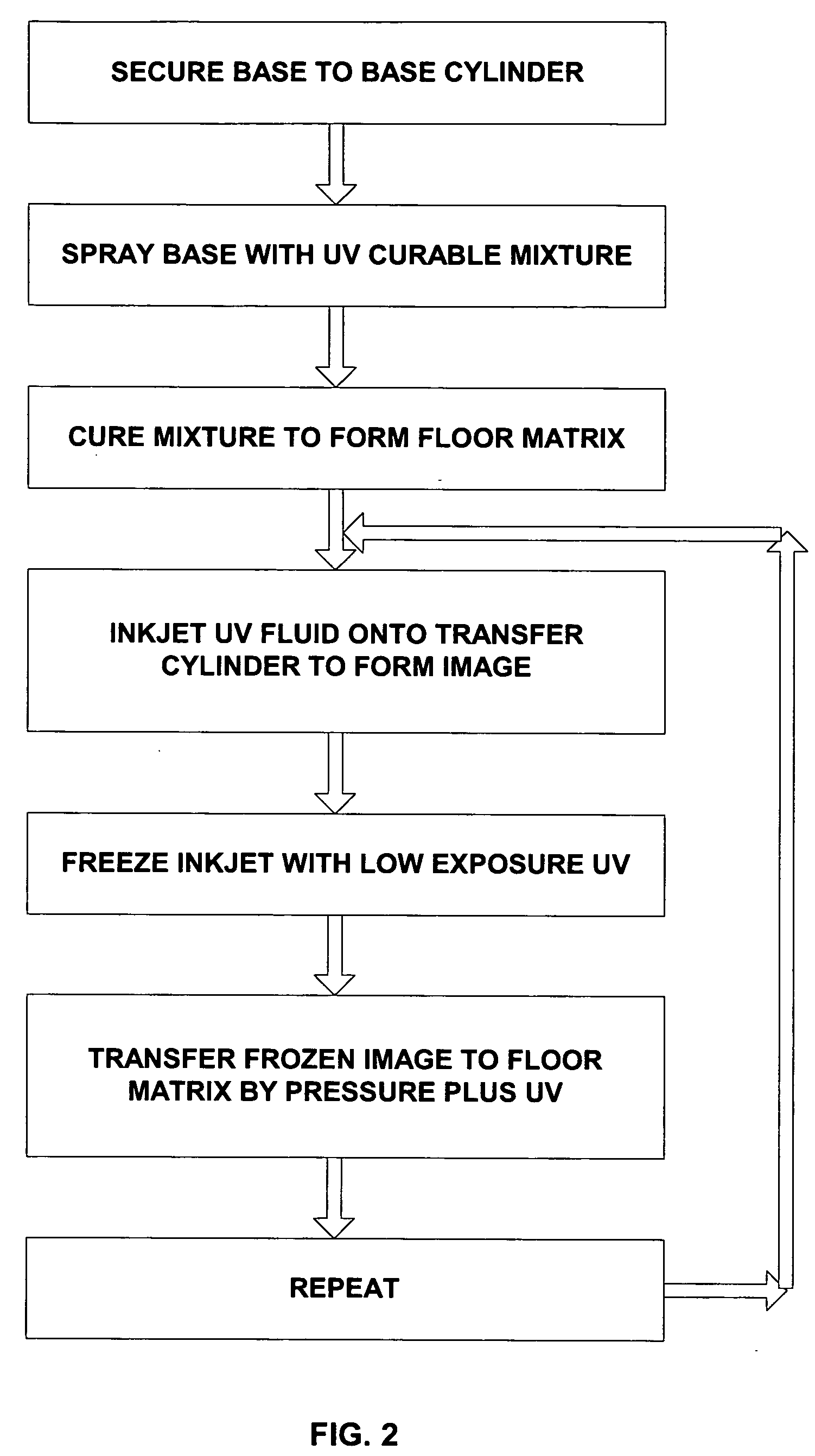

Method for producing a flexographic printing plate formed by inkjetted fluid

InactiveUS20040129158A1Rapid and inexpensive mannerDuplicating/marking methodsMounting boardsEngineeringElectrical and Electronics engineering

Owner:KODAK IL

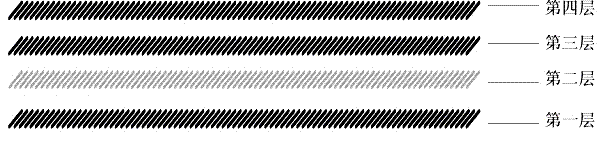

Anti-counterfeiting printing method by using invisible two-dimensional codes

InactiveCN101819647AEliminate the risk of imitationImprove use valuePattern printingRecord carriers used with machinesUltraviolet absorptionAbsorbent material

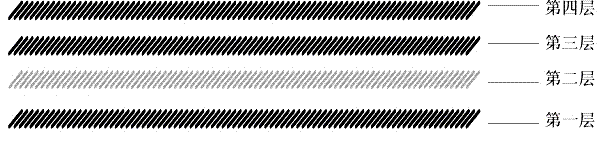

The invention relates to an anti-counterfeiting printing method by using invisible two-dimensional codes. The anti-counterfeiting printing method is characterized in that at least four printing layers for printing are adopted, and comprises the following steps of: firstly, providing a digital serial number and splitting the serial number into three fields of which information is assigned to three groups of two-dimensional codes; secondly, printing one group of two-dimensional codes on a first layer by using aqueous ink black materials; thirdly, overprinting a grey isolating layer on the first two-dimensional code layer by using infrared non-absorbent materials to form a second layer; fourthly, overprinting a second group of two-dimensional codes on the second layer of the grey isolating layer by using the infrared non-absorbent materials to form a third layer; and finally, overprinting a third group of two-dimensional codes on the third two-dimensional code layer by using ultraviolet absorption materials to form a fourth layer. The method has the advantages of eliminating the possibility of imitation by scanning the two-dimensional codes and achieving relatively higher use value because the overprinting is performed in the same area in an offset printing and digital jet printing way and the upper printing layer covers the lower layer naturally.

Owner:HONGBO CO LTD

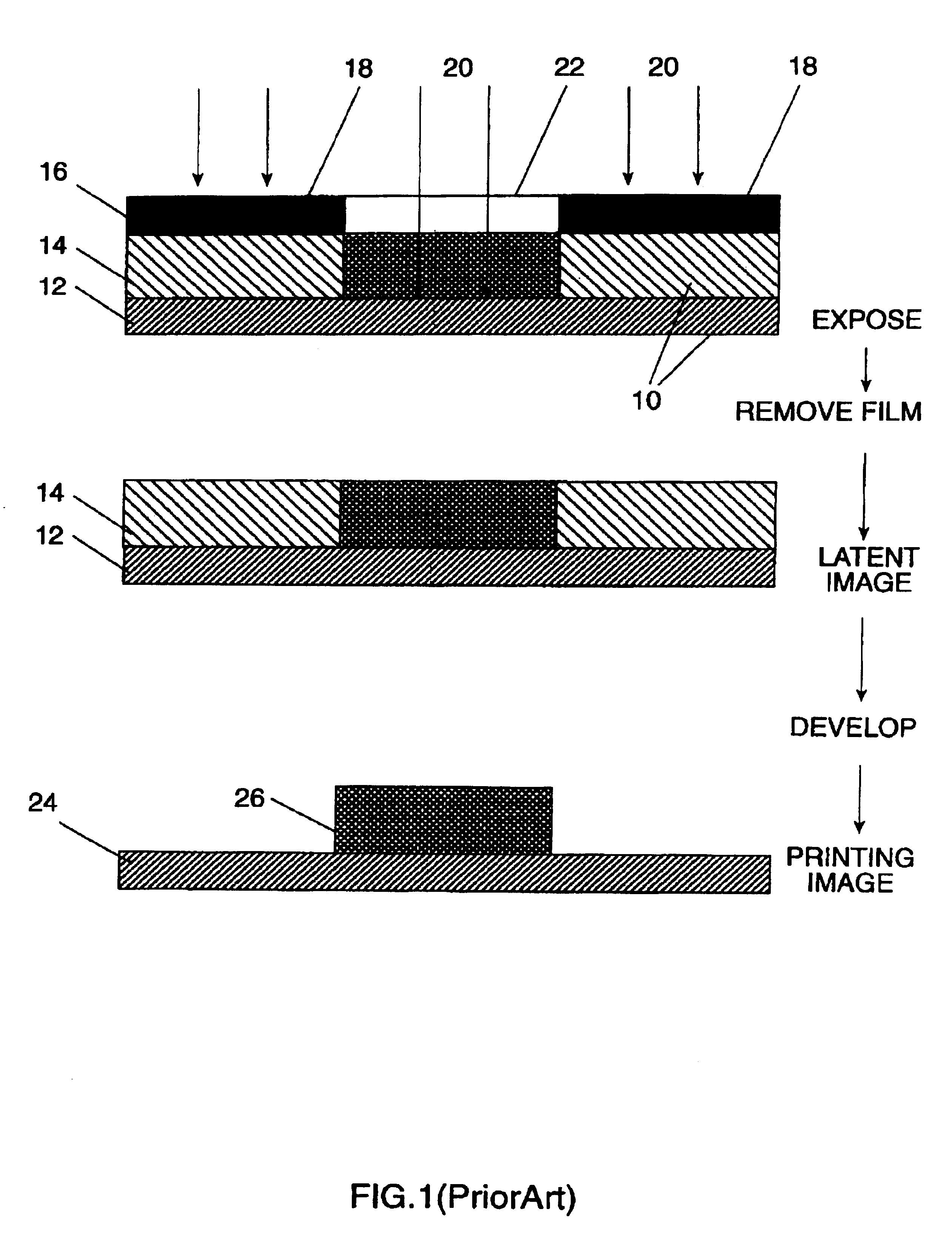

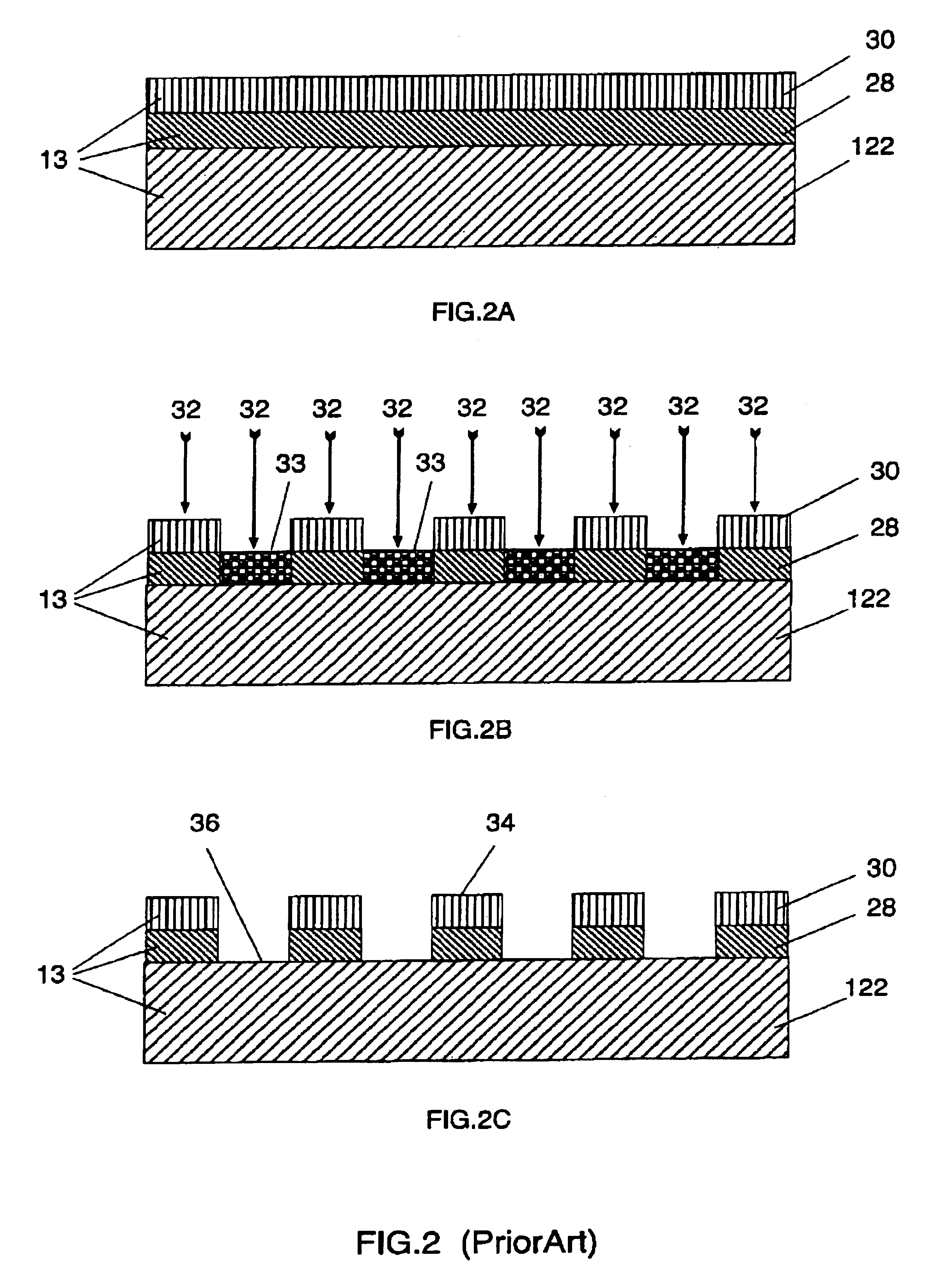

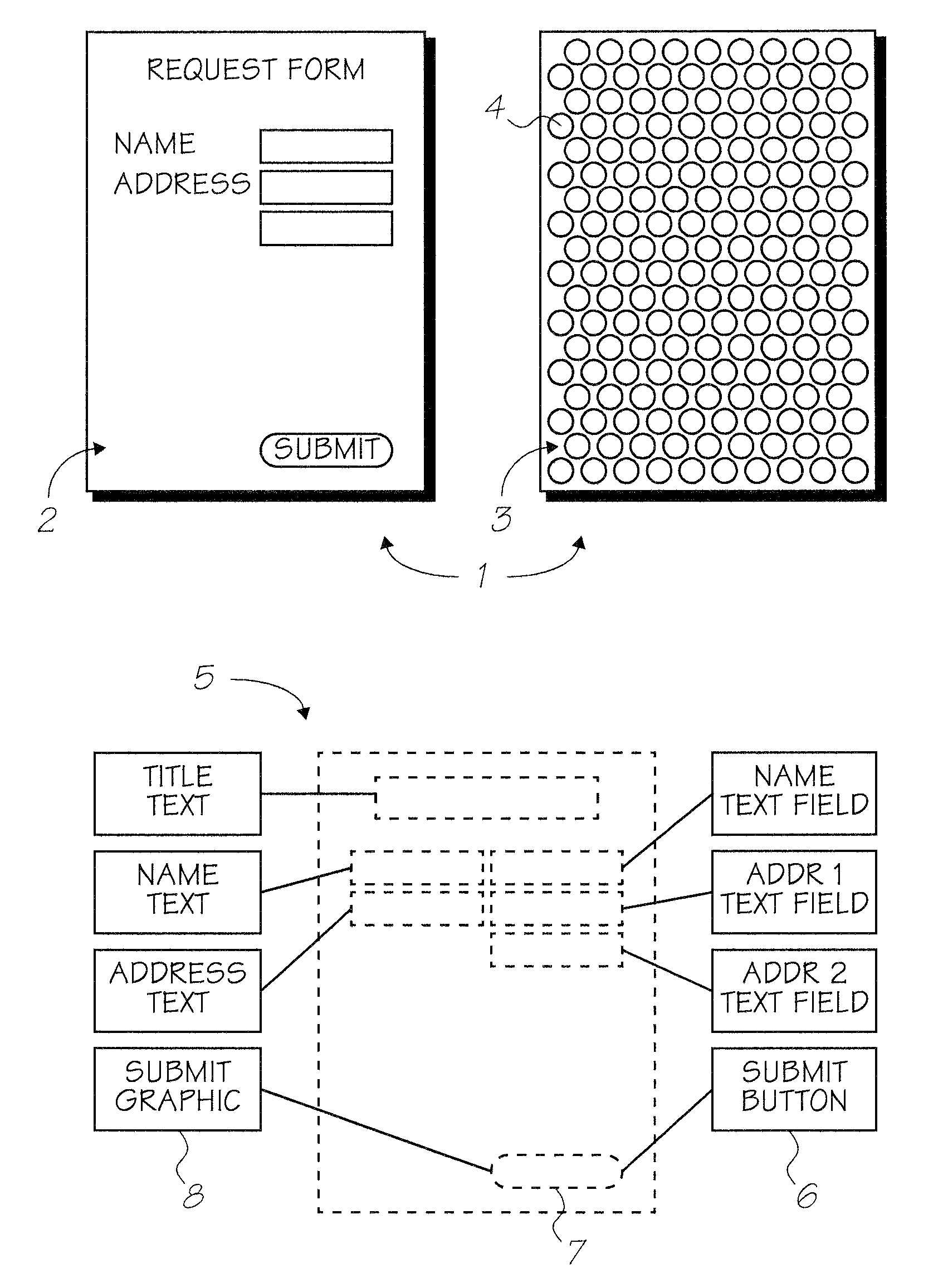

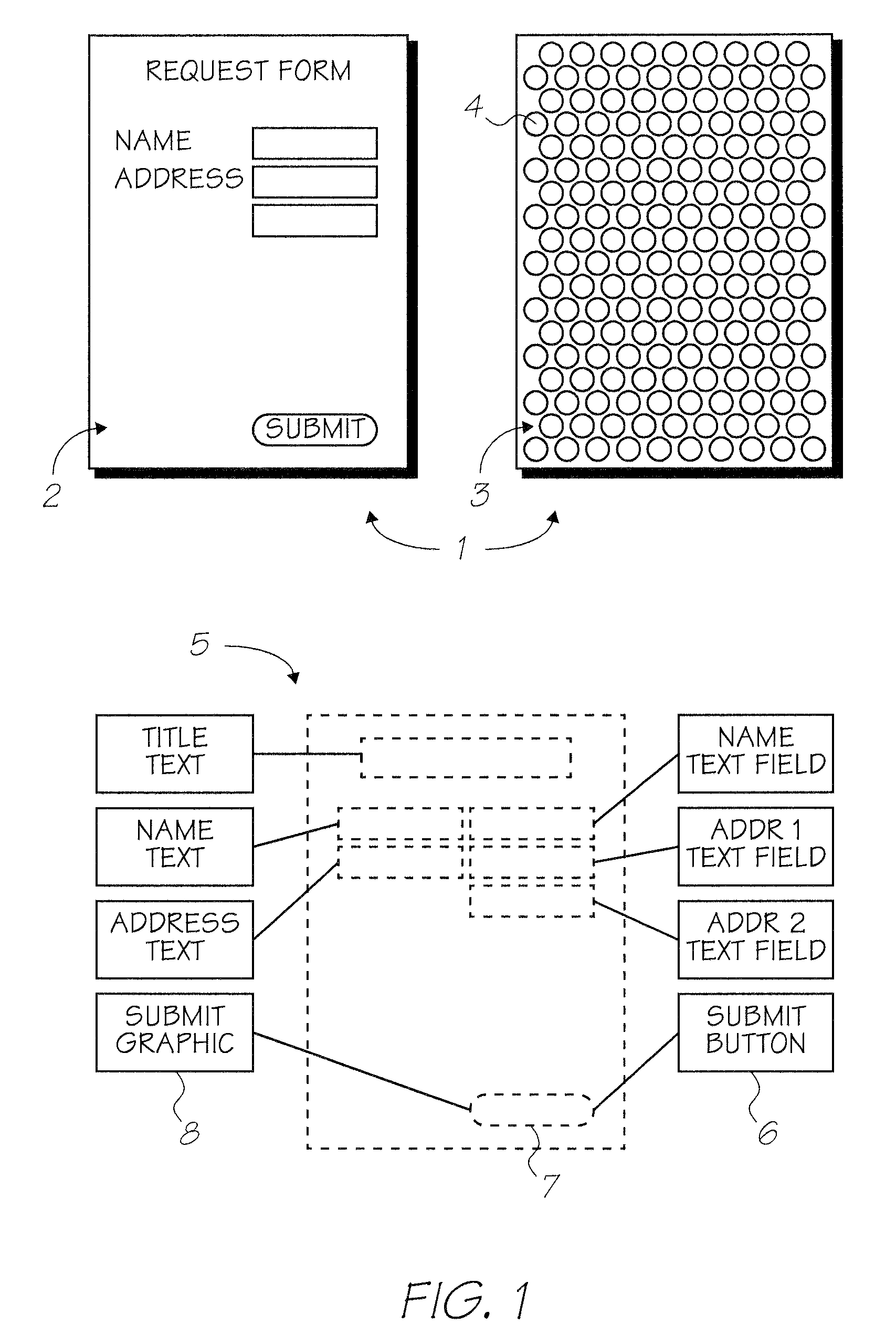

Method and a plate for digitally-imaged offset printing

InactiveUS6899998B2Simple and inexpensiveSimple wayX-ray/infra-red processesPhotosensitive materialsDigital imagingPhotopolymer

An offset plate sensitive to UV or visible light, prepared simply and imaged digitally therewith in a CTP method, and also processed in a simple manner. The plate is provided as a photopolymer plate with increased sensitivity, and is used in a simple imaging-on-press system, using the surface of a lithographic printing cylinder itself as a plate substrate. The method of preparing the printing plate begins by applying a photosensitive liquid coating to the substrate, digitally imaging the coated substrate, using an actinic light source to polymerize portions of the liquid coating in accordance with the imaging, and washing the liquid.

Owner:KODAK IL

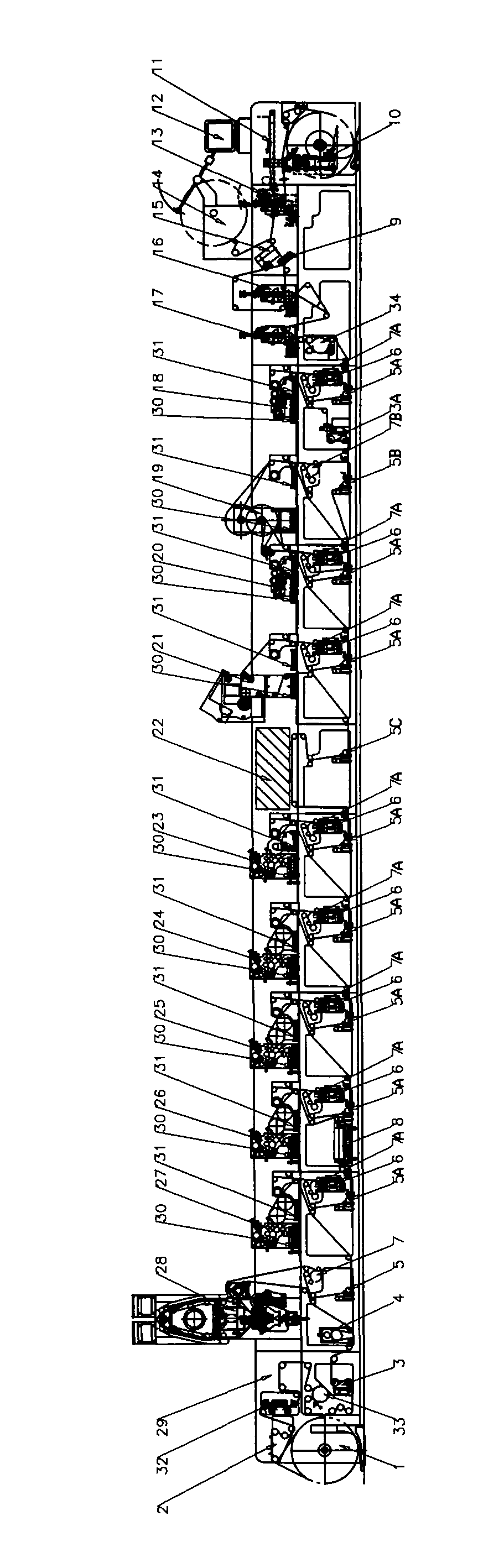

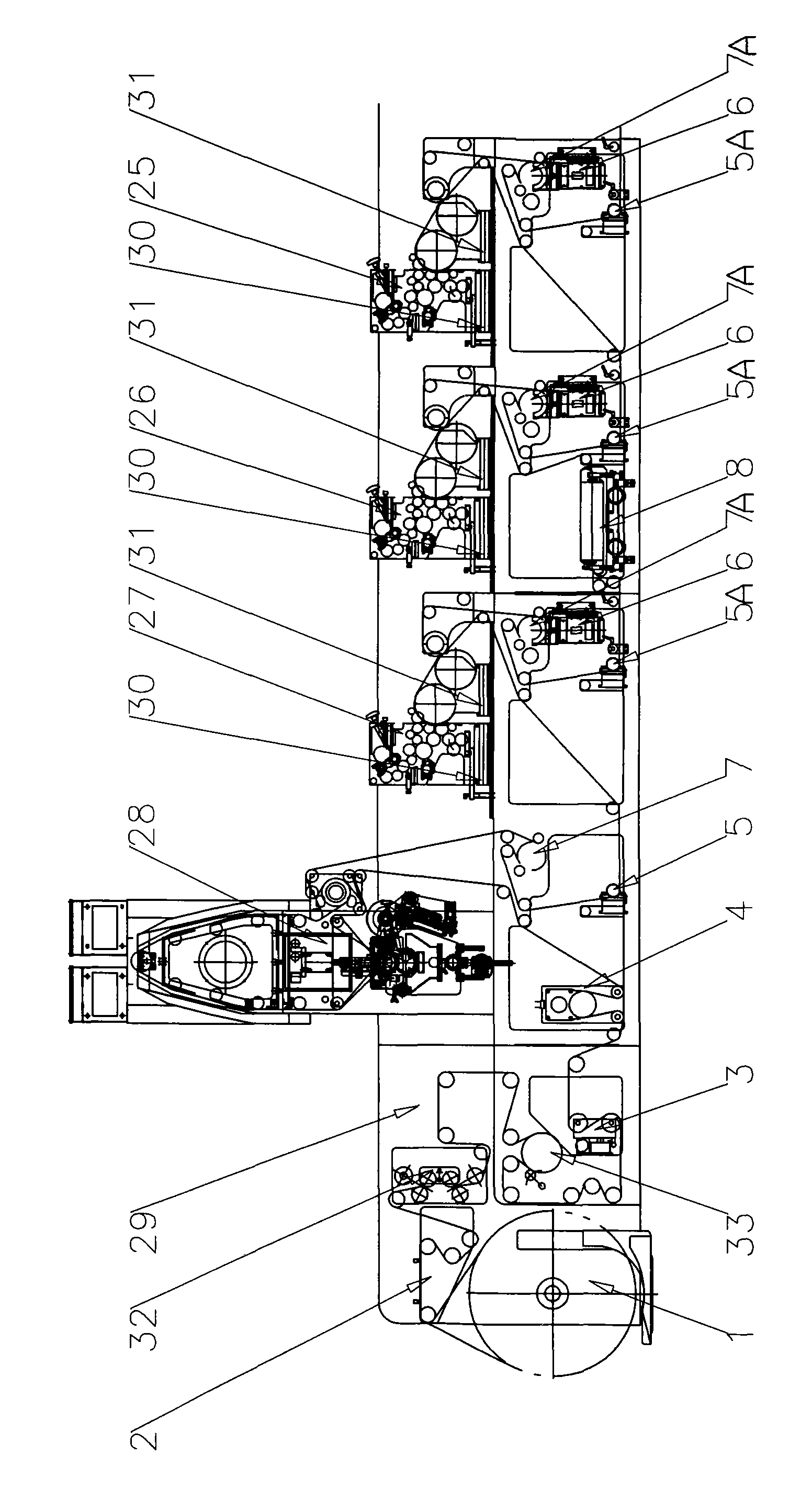

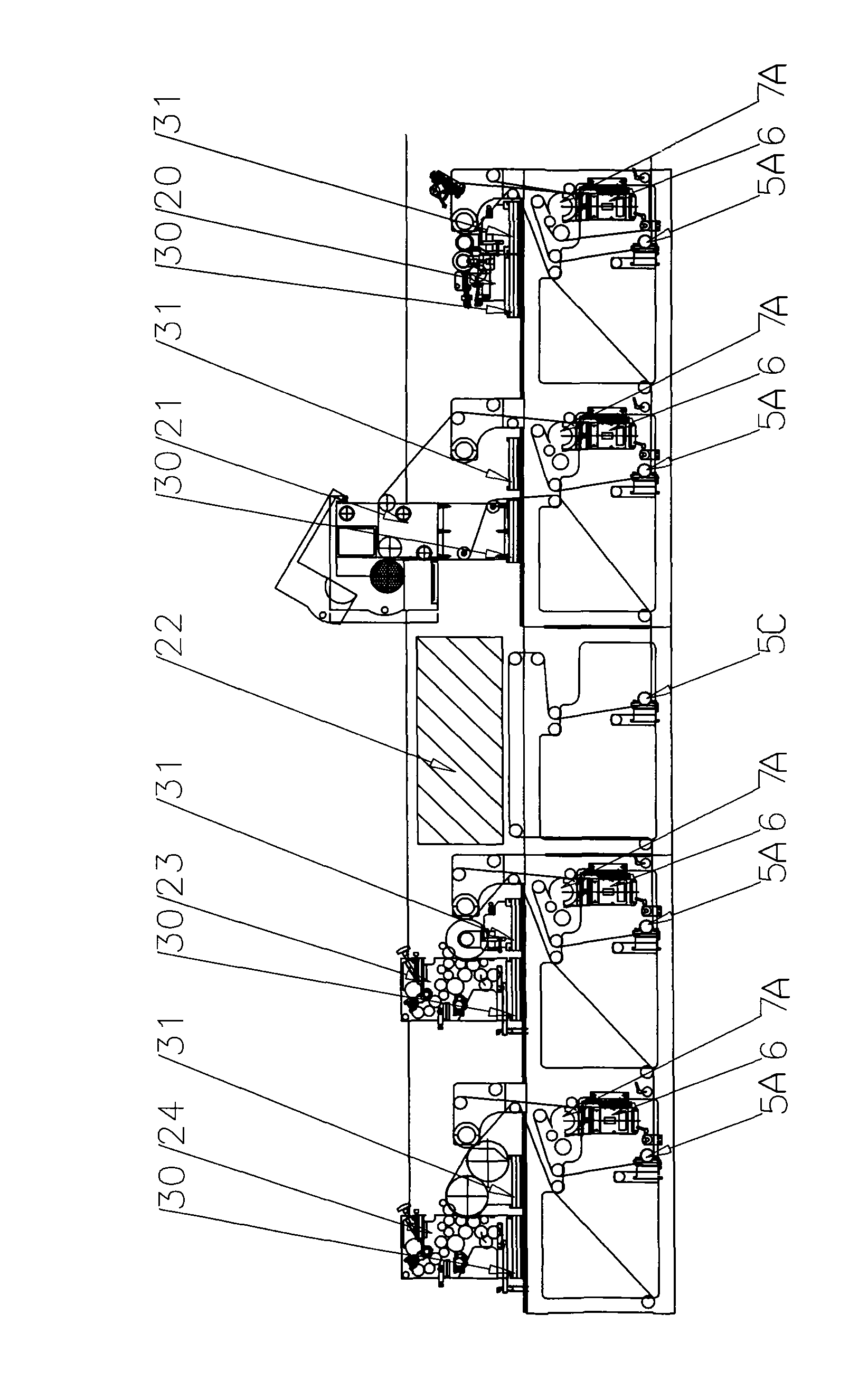

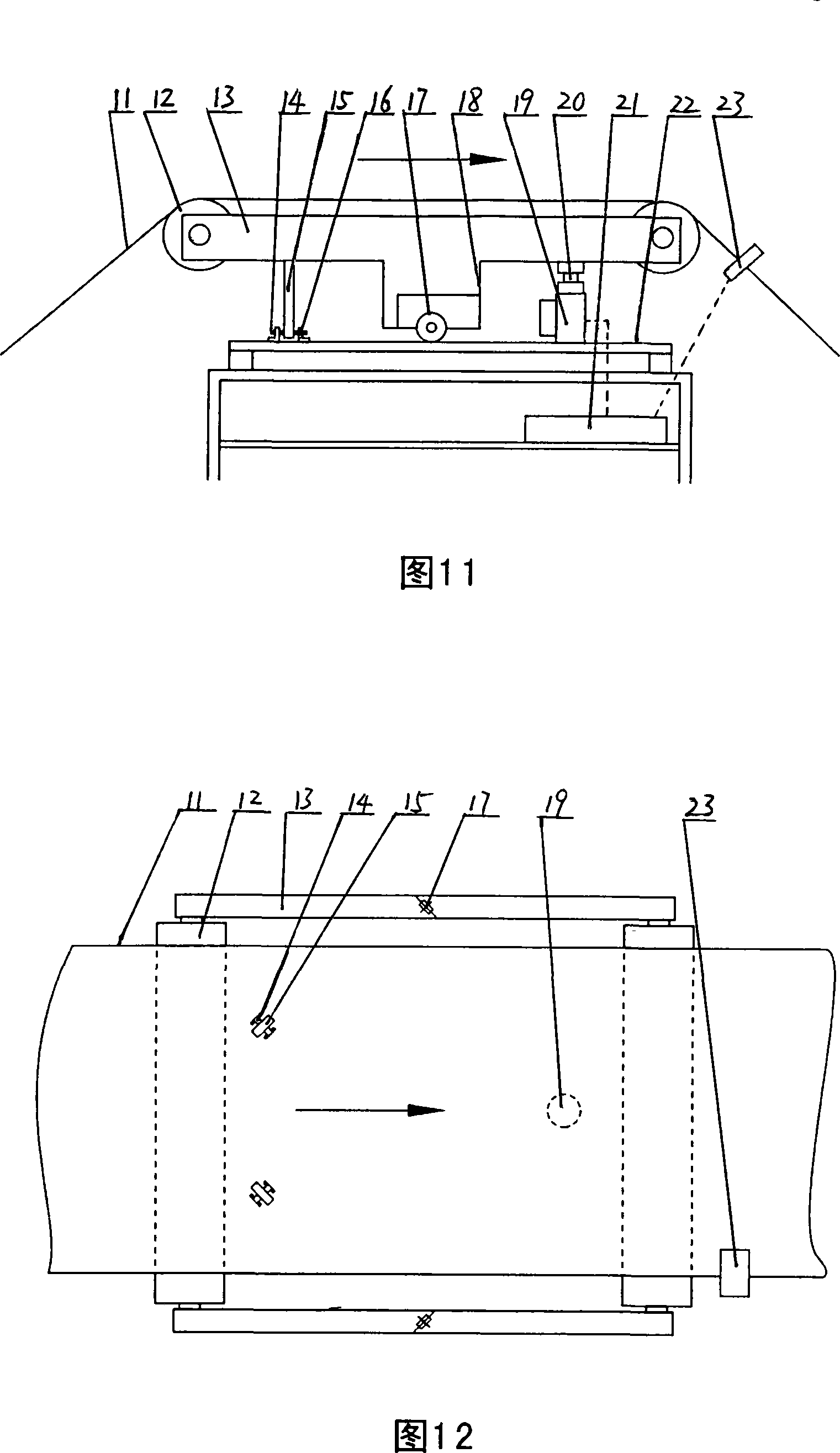

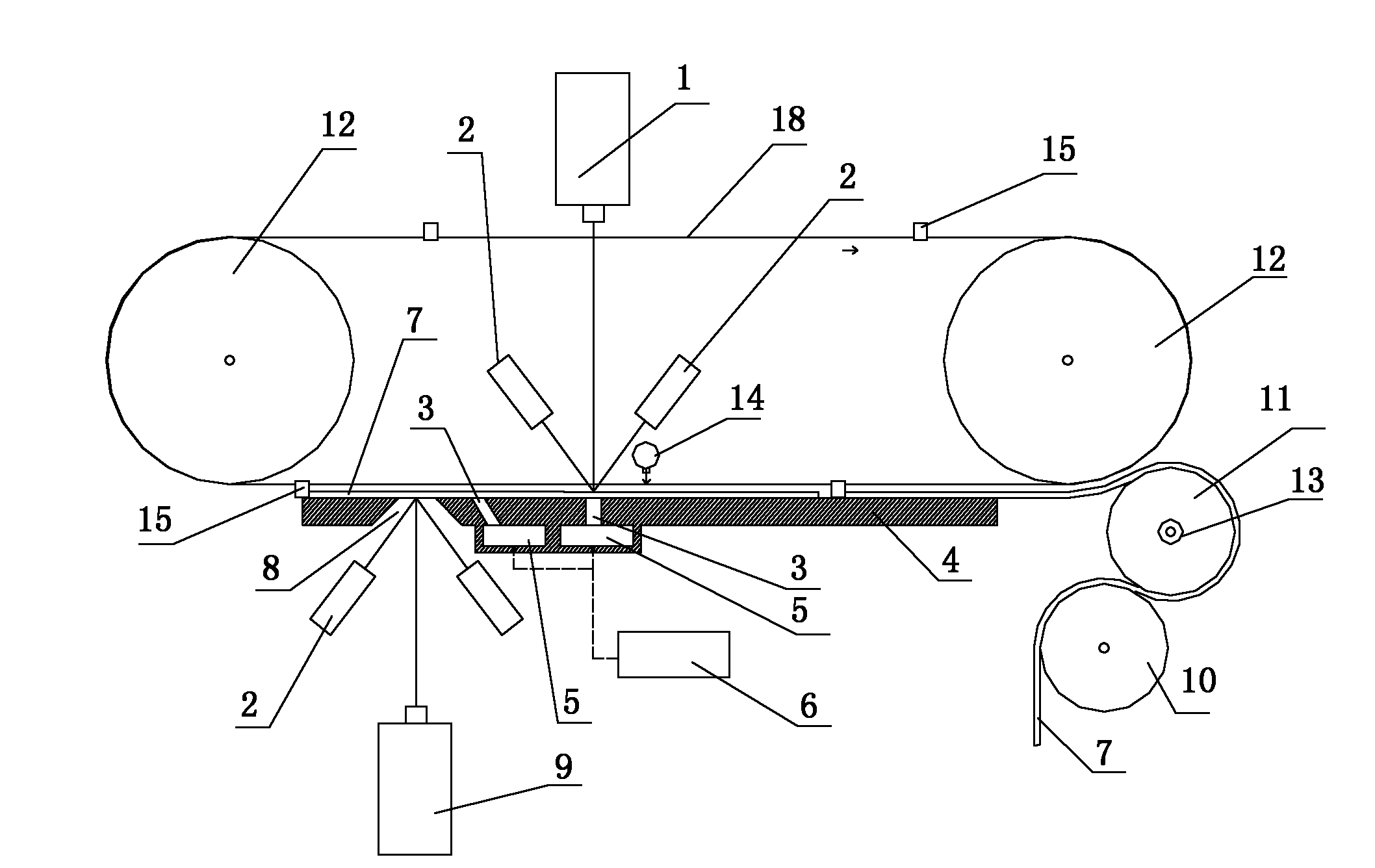

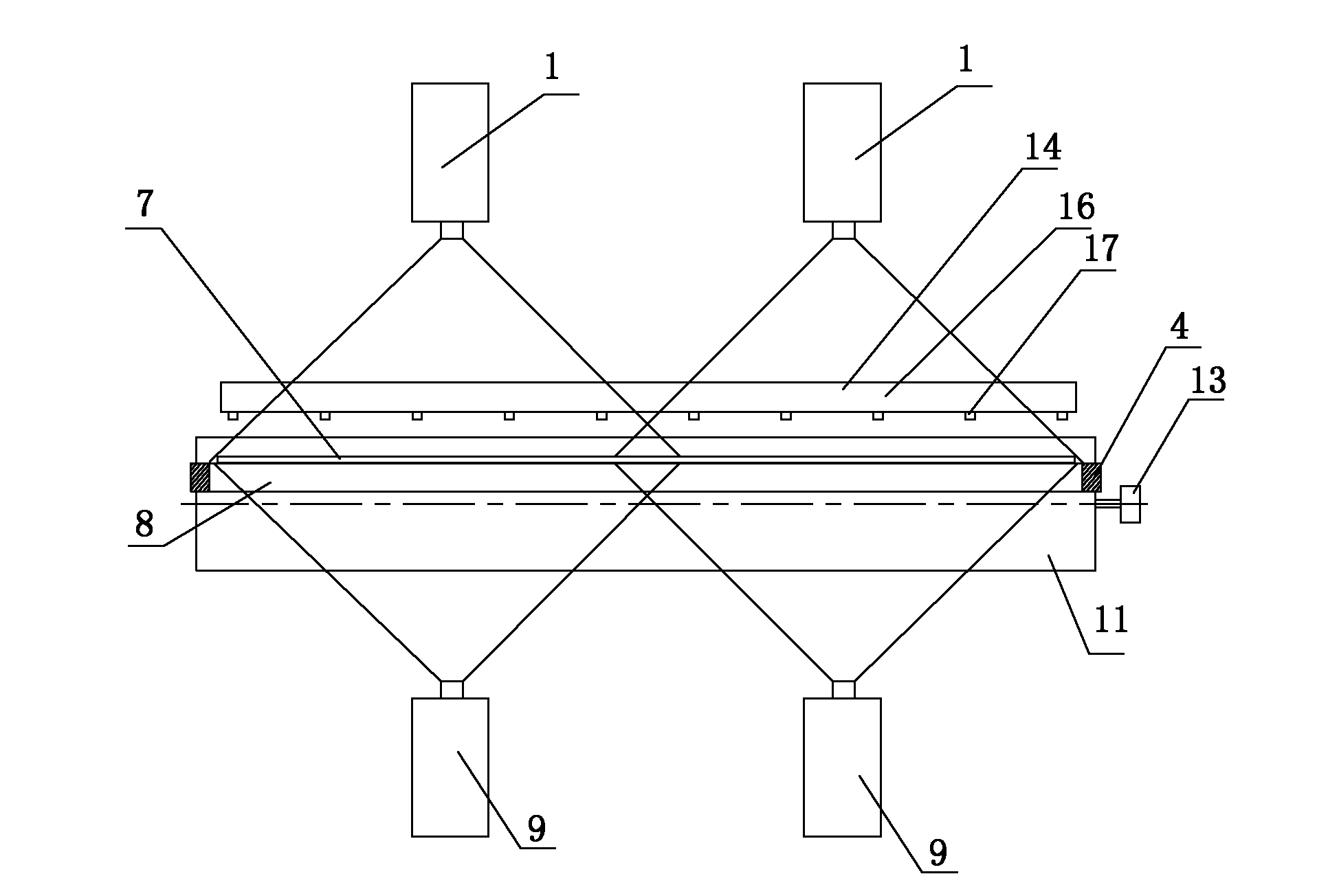

Multifunctional complex printer

InactiveCN101524912AControllable tensionHigh sensitivityTypewritersRotary pressesScreen printingLetterpress printing

The invention relates to a multifunctional complex printer. The multifunctional complex printer comprises a lifting device of a paper feed part. The multifunctional complex printer is characterized in that a corona device, a first AC servo tension detection device and a first cooling pull roll device are sequentially arranged at right side of a first deviation correction device, an intaglio printing unit is arranged above the corona device, the first AC servo tension detection device and the first cooling pull roll device, a first interchangeable hectograph unit, a second interchangeable hectograph unit, a third interchangeable hectograph unit, a fourth interchangeable hectograph unit, an interchangeable letterpress printing unit, an interchangeable screen printing unit and a first interchangeable flexography printing unit are sequentially arranged at the right side of the intaglio printing unit, a fourth AC servo tension detection device is arranged below a reserved platform of an inkjet device, and a second two-cylinder die cutting device, a back cutting device and a television monitoring camera are sequentially arranged at the right side of a first two-cylinder die cutting device. The multifunctional complex printer has the advantages of flexibly combining various printing modes according to pluralism of products and optionally exchanging printing modes of various color classes.

Owner:SHANGHAI XINMIN TAIYO KIKAI

Pre-treatment liquid for use in preparation of an offset printing plate using direct inkjet CTP

InactiveUS6906019B2Improve image qualityFast plating speedSurface-active detergent compositionsDuplicating/marking methodsPre treatmentSurface chemical

A method of making a printing plate in which the uncoated surface of a substrate is treated with a pre-treatment solution prior to the deposition of ink on the surface. The pre-treatment liquid comprises a polyvalent metal salt, and at least one of an organic swelling reagent and / or a coalescence reagent. The pre-treatment liquid is applied to form a thin, homogenous layer of approximately 4 μm to the entire upper surface of the recording plate. The swelling reagent and / or the coalescence reagent and the polyvalent metal cations are physically well localized in the porous structure of the plate's surface. After partial drying of the pretreated anodized aluminum plate, CTP liquid is deposited onto the surface to form an image. The CTP liquid solids react with the pre-treatment liquid and are, therefore, chemically bound to the surface. This allows all data to be deposited in a single pass of the inkjet head without the problem of clustering.

Owner:HEWLETT PACKARD IND PRINTING LTD

Alternative phthalocyanine dyes suitable for use in offset inks

A phthalocyanine phthalocyanine salt suitable for formulation in a solvent-based or oil-based ink vehicle is disclosed. The phthalocyanine comprises one or more sulfonate groups and a counterion of at least one sulfonate group is an ammonium cation comprising at least 15 carbon atoms. Ammonium salts of sulfonated gallium naphthalocyanines exemplify such phthalocyanine salts.

Owner:BASF SE

Method of printing variable information

The gel method of printing variable information of the present invention involves applying inks onto a substrate that is part of or attached to a cylinder of the printing machine. Imaging is by means of an energy source in the UV, visible or infrared regions, modulated to represent a digital image pattern that has been composed on a computer. The consequence of imaging is to gel the ink and increase its adhesion to the substrate of the printing cylinder. The non-gelled background ink with lower adhesion is then removed by a squeegee action and returned to an ink reservoir. The remaining image is transferred to an offset blanket or directly to print stock by pressure. The process does not use a master, but produces an image that is erased after printing with each cylinder rotation so that the next rotation producing the next print can have fresh information written upon it.

Owner:KODAK IL

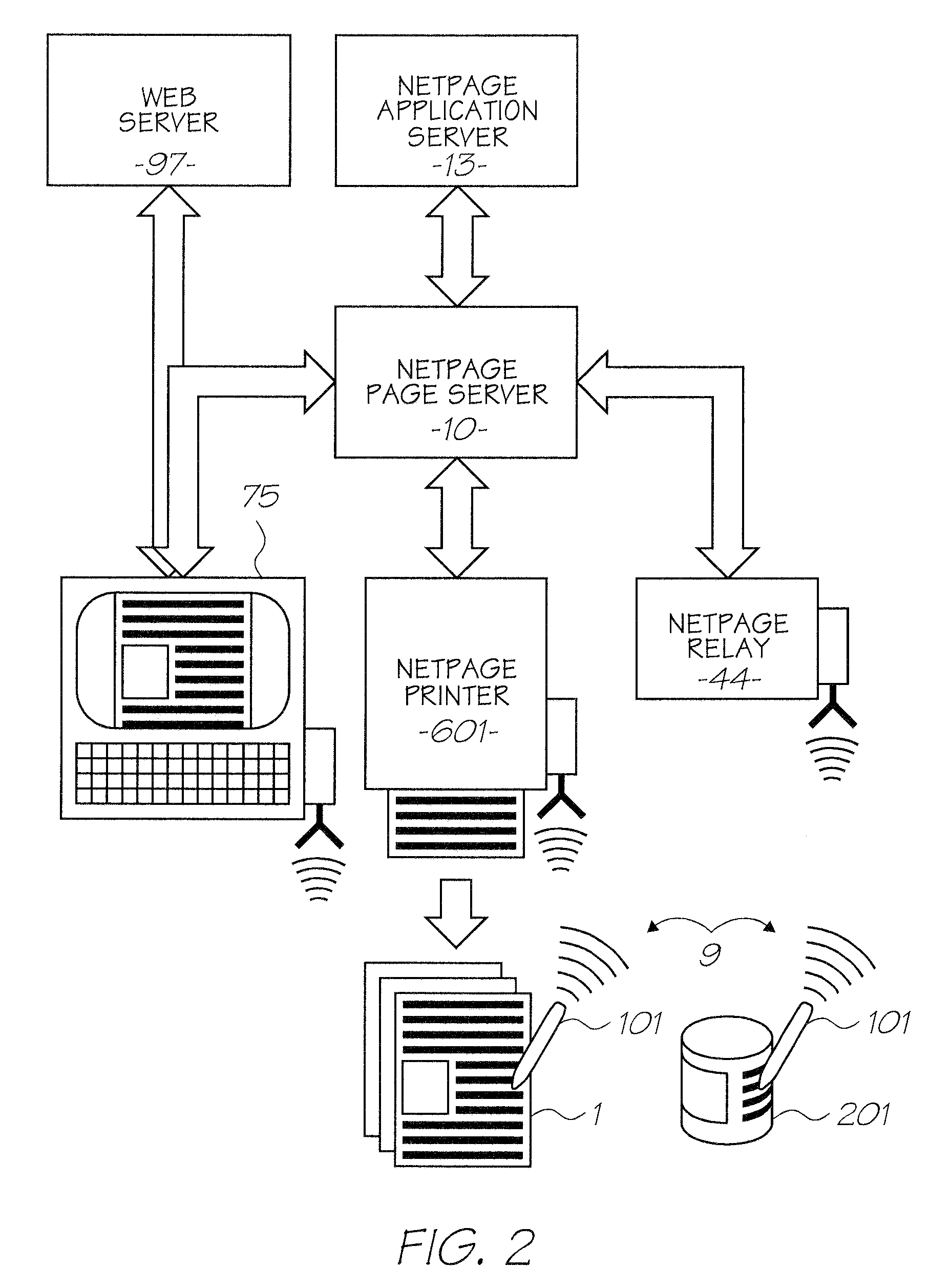

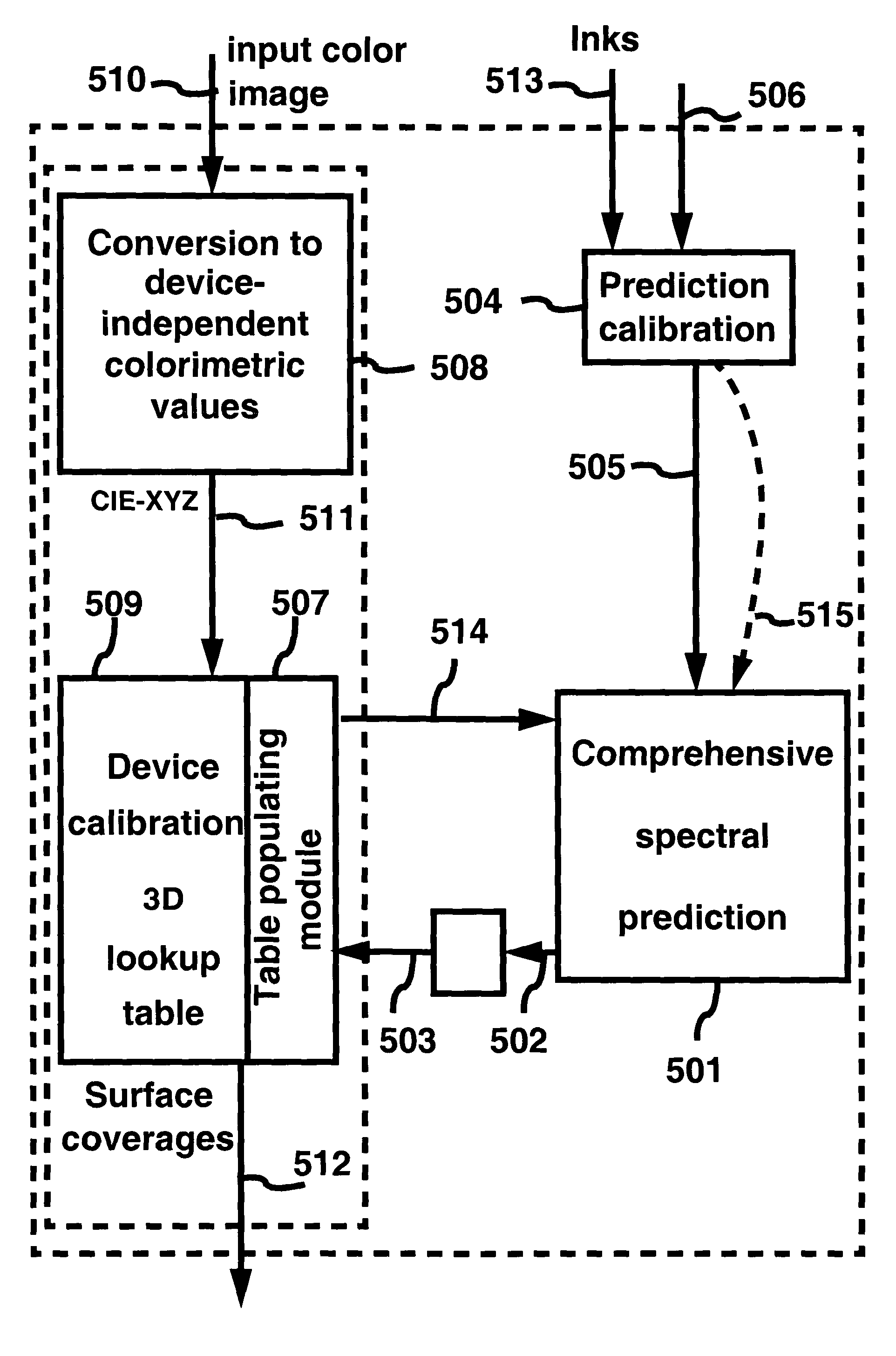

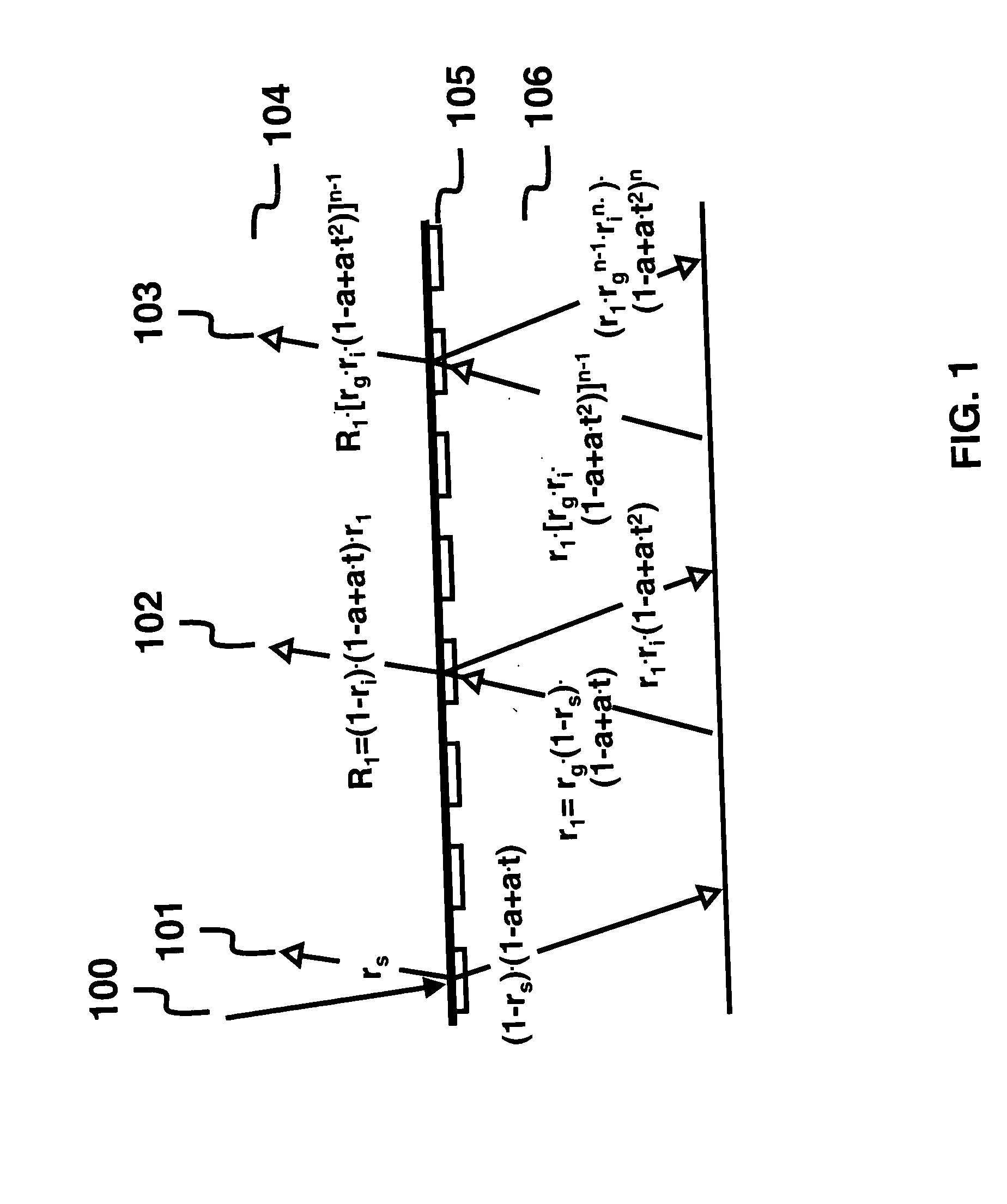

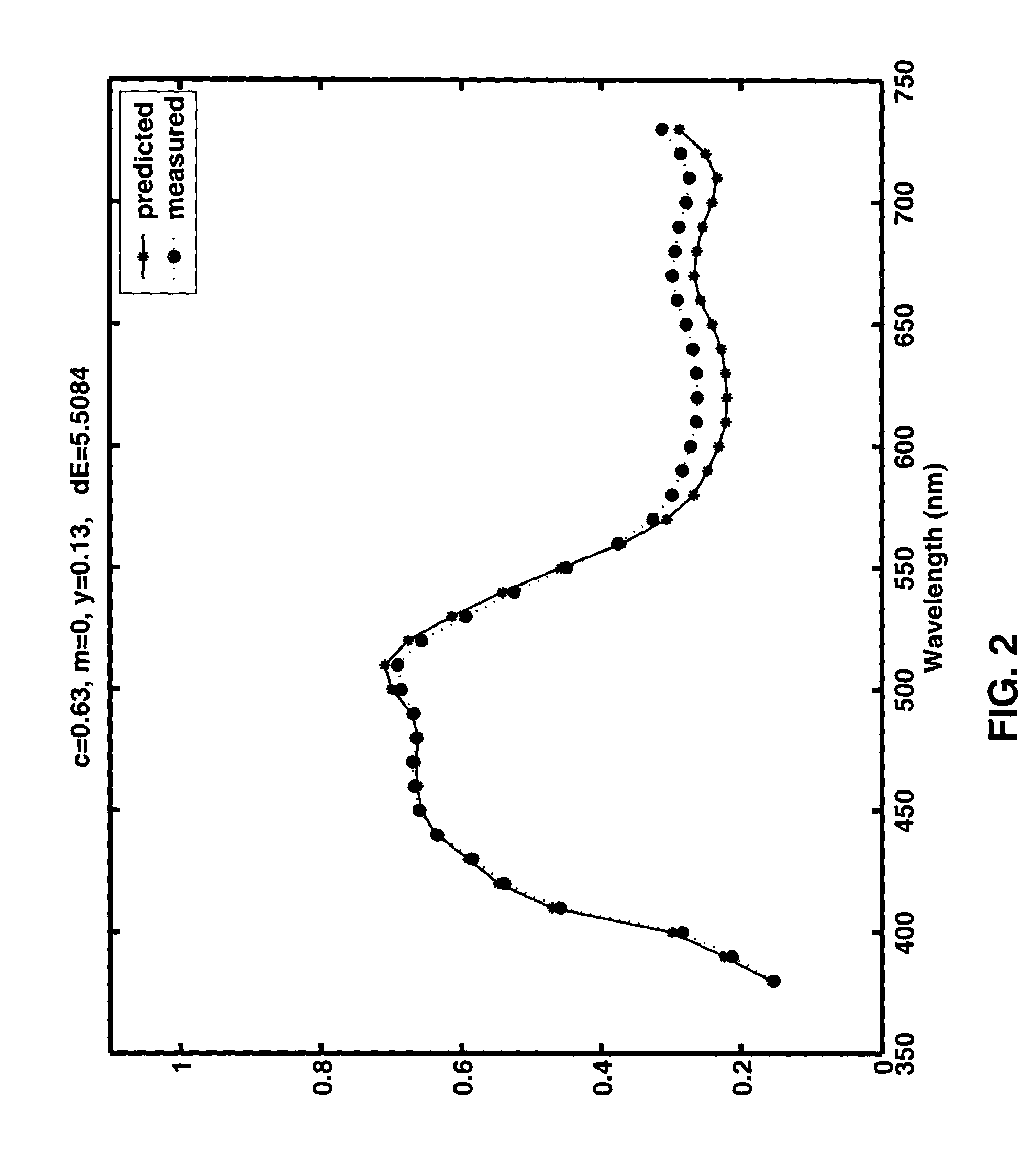

Prediction model for color separation, calibration and control of printers

InactiveUS20050083540A1Easy CalibrationImprove accuracyDigitally marking record carriersDigital computer detailsEffective surfaceHue

The present invention facilitates the calibration of printers and the color separation of input images into a set of inks by disclosing methods and systems for populating device-calibration lookup tables. The disclosed methods and systems rely on a comprehensive spectral prediction model which is capable of predicting at a high accuracy the reflectance spectra of halftone ink patches. The comprehensive spectral prediction model is composed of a first part predicting the reflection spectra as a function of physical (mechanical) surface coverages and of a second part comprising functions mapping nominal surface coverages to effective surface coverages. These mapping functions are calibrated by halftone patch wedges printed alone and by half-tone patch wedges printed in superposition with one or several solid inks. The part of the comprehensive spectral prediction model predicting the reflection spectra relies on a weighted average between one component behaving according to the Clapper-Yule model and another component behaving as the spectral Neugebauer model, extended to include multiple internal reflections at the paper-air boundary. The disclosed methods and systems can perform the color separation as well as the calibration of printers printing with standard cyan, magenta, and yellow inks as well as with inks comprising standard and non-standard inks such as Pantone inks (custom inks). They are also used for performing precise undercolour removal in order to carry out the color separation of images into cyan, magenta, yellow and black inks. They can further be used to carry out the color separation of images into cyan, magenta, yellow, black, light cyan and light magenta inks. In addition, the disclosed methods and systems can be used for printer control, i.e. to control printer actuation parameters in different types of printers e.g. liquid ink professional printers (offset, gravure, letterpress), electrophotographic printers, ink-jet printers, thermal transfer printers and in dye-sublimation printers.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

UV curing offset printing ink and use

The invention relates to UV cured lithographic ink and purposes thereof. The ink is a compound which comprises the following components by the weight percent: 30 to 50 of polyester acrylic ester, 0 to 15 of epoxy acrylic ester, 2 to 22 of high-viscosity monofunctional polyurethane acrylic ester, 0 to 10 of acrylic monomer, 10 to 15 of photoinitiator, 2 to 5 of filler and 16 to 22 of pigment. The UV curing glue printing ink of the invention can be cured at high speed, can meet the requirements of high-speed packaging, printing and environment protection, does not contain VOC, has little irritation to the human skin, and can be used as lithographic ink for the high-speed printing, and paper and plastic printing of packaging and printing.

Owner:深圳市美丽华科技股份有限公司

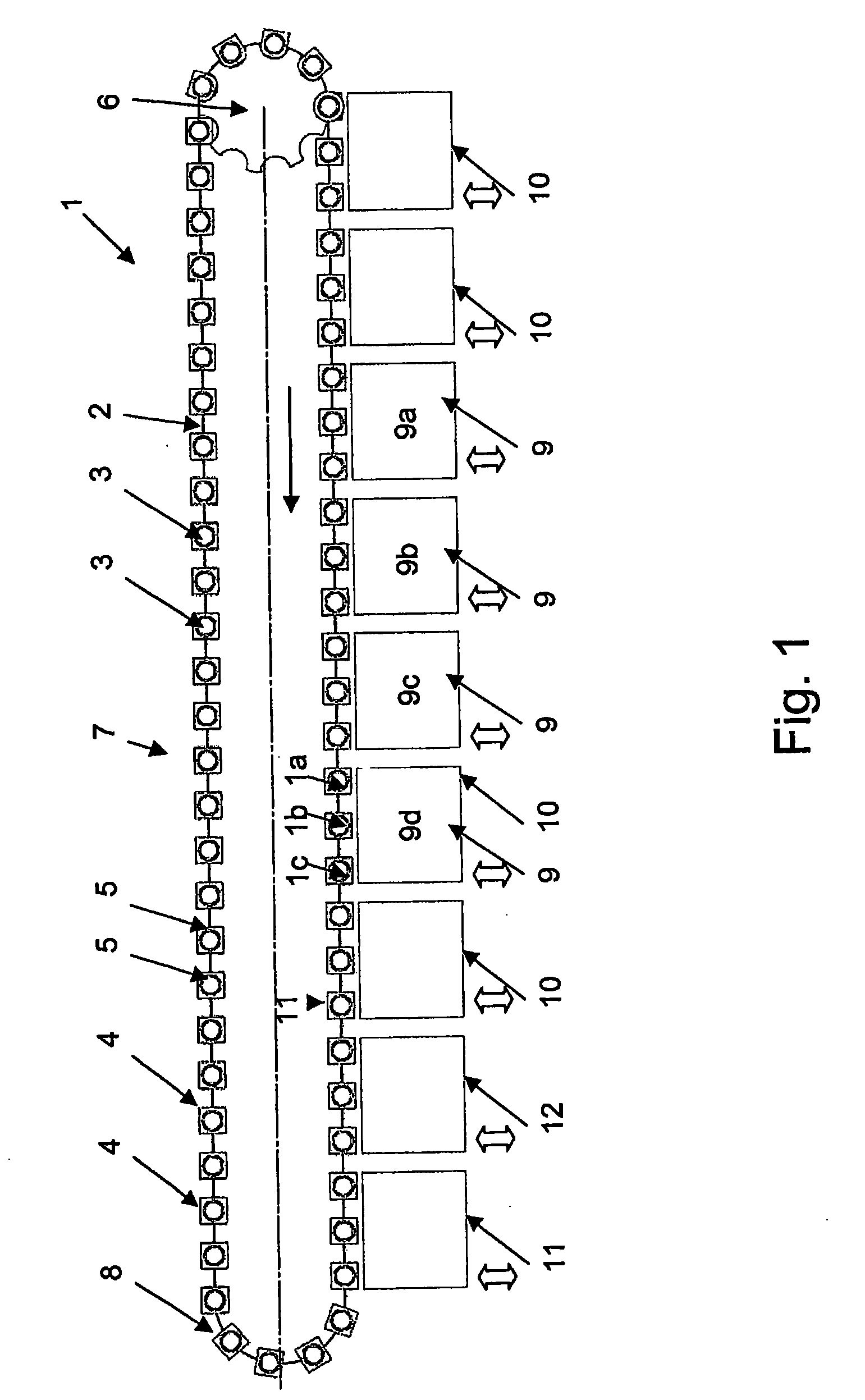

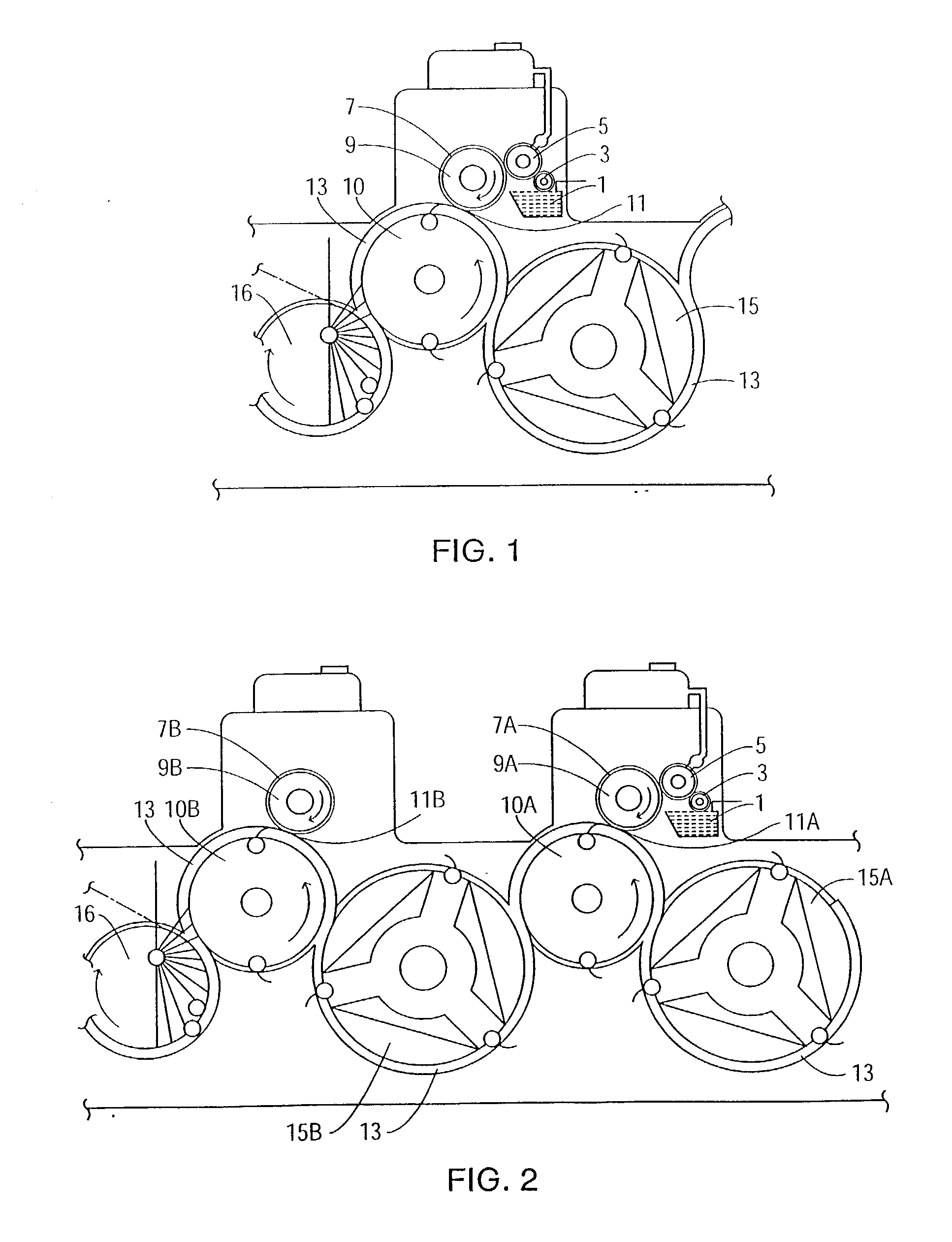

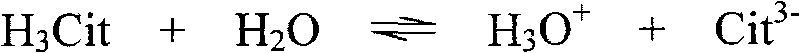

Modular linear printing press for printing hollow articles by means of different printing processes

InactiveUS20110067584A1Increase productionMethod is differentScreen printersTypewritersScreen printingTransport system

A linear printing machine with exchangeable printing modules for printing on hollow bodies. The machine includes a transport system including a drive, using which the hollow bodies to be printed on are transported through the linear printing machine and at least a first printing station and a second printing station which is arranged downstream of the first printing station in the conveying direction of the hollow bodies. At least one drying station dries the ink on the hollow bodies which have been printed on. A machine controller controls at least the transport of the hollow bodies through the linear printing machine, wherein each of the printing stations is prepared to accommodate a printing module comprising a drive of its own, and wherein the printing module can be connected to the machine controller via an interface, wherein the printing modules print on the hollow bodies using a printing method selected from screen printing and / or flexographic printing and / or offset printing and / or cold embossing and / or hot embossing and / or laser colour transfer and / or inkjet.

Owner:POLYTYPEAG

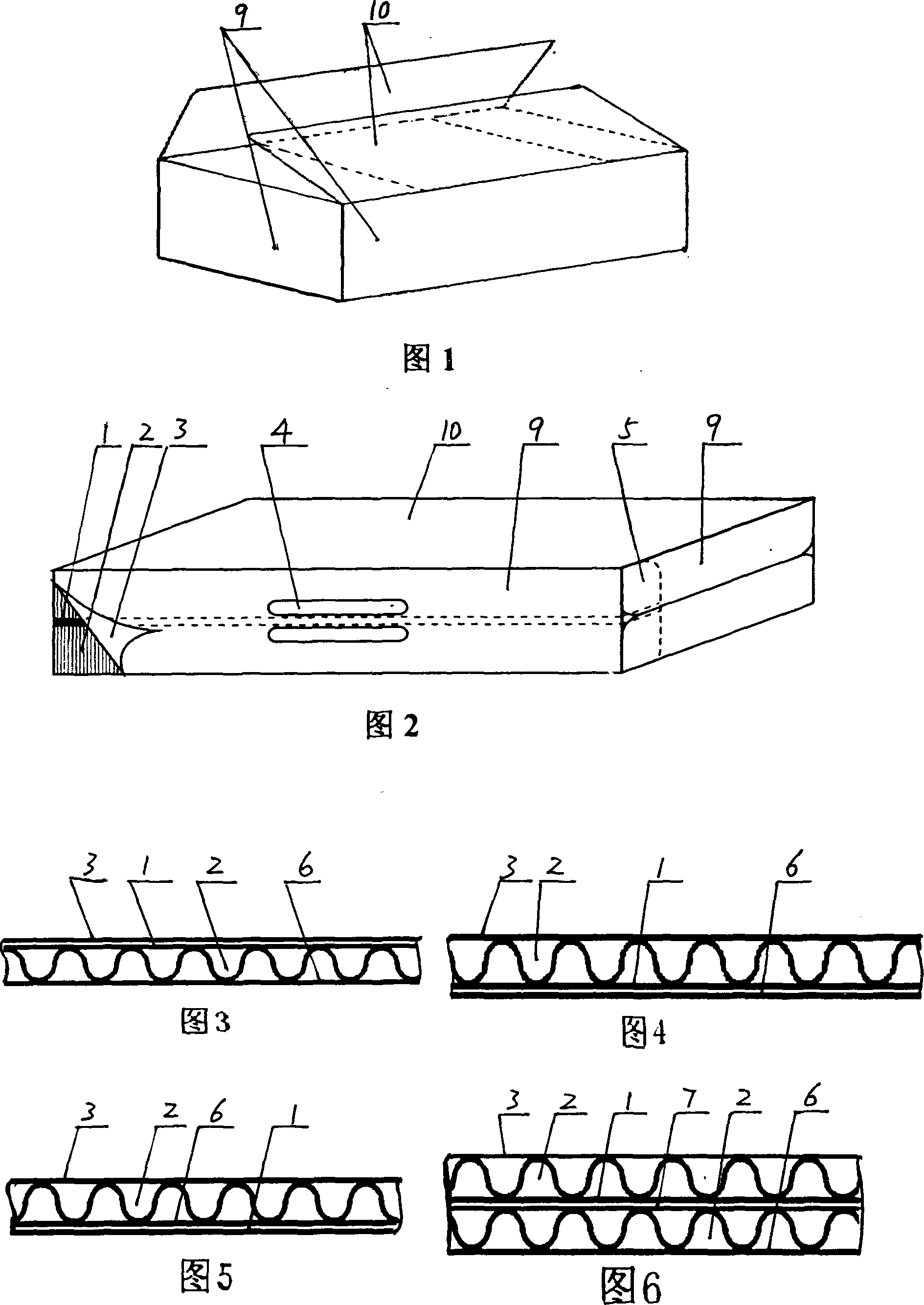

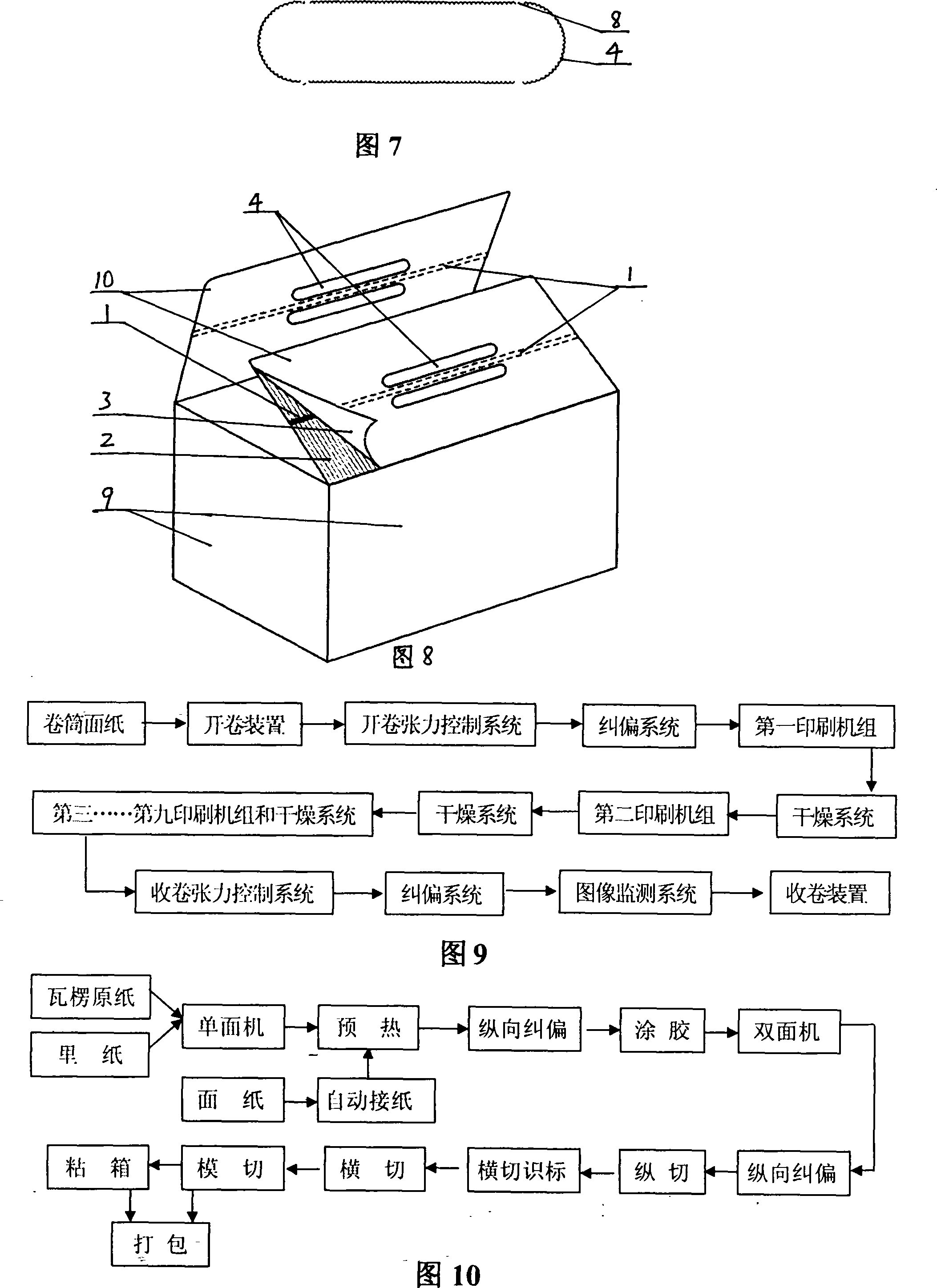

Flexible preprinting cardboard box, production method and production equipment thereof

The invention discloses a flexibly pre-printed paper box, a manufacture method and a manufacture equipment thereof; the paper box has a box body consisting of a printed sheet, corrugated paper, inner paper and in some cases core paper; color patterns on the printed sheet are flexibly printed on the printed sheet before the paper box is manufactured. The manufacture method consists of a manufacture method of flexibly printed paper sheet and a manufacture method of the paper box; firstly the color patterns are manufactured on the printed sheet with a rotary flexographic press; then bright oil is applied, and then the printed sheet, the corrugated paper and the inner paper are made into the paper box by adopting a corrugated paper manufacture device; some paper box also comprises the core paper. The manufacture device consists of the rotary flexoographic press, the corrugated paper manufacture equipment and a die-cutting machine. Adopting the method and the equipment of the invention, the manufactured paper box is green and environmental protective, nice in printed patterns, high in compressive strength, convenient in lifting and low in reject rate; compared with paper boxes which are printed with offset printing and directly with flexible plate of the same quality requirement, the paper box of the invention has lower cost.

Owner:保定中士达包装有限公司

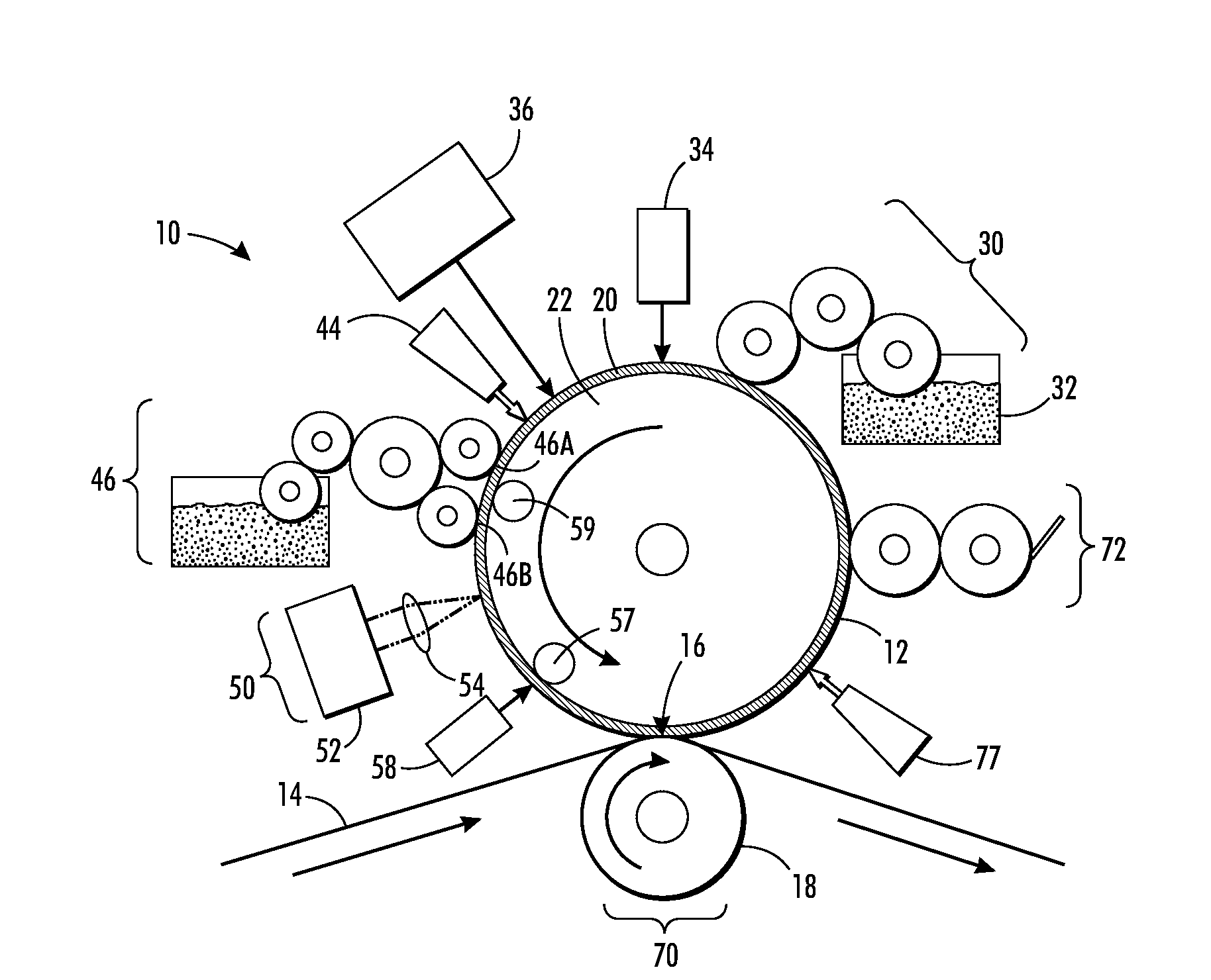

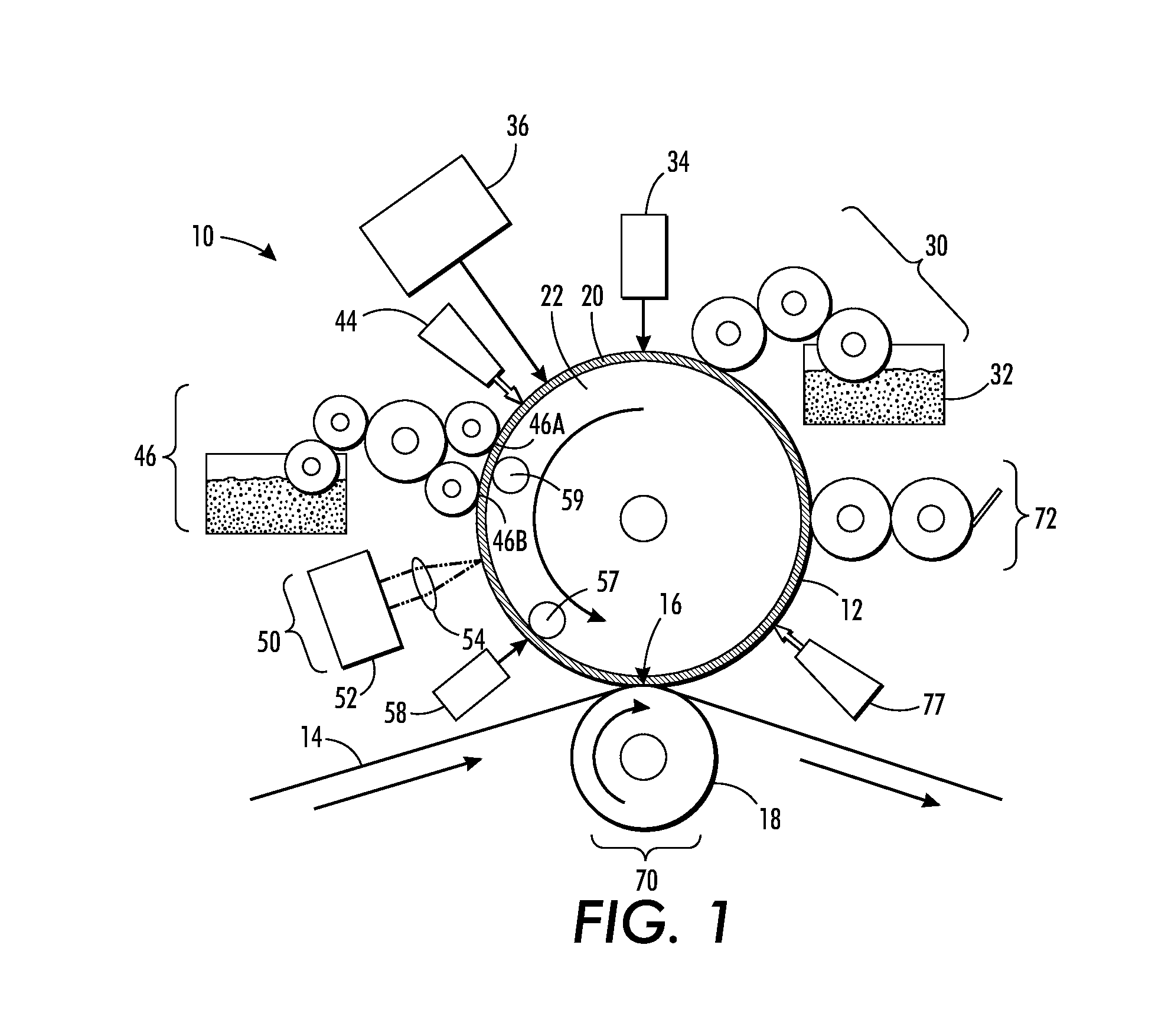

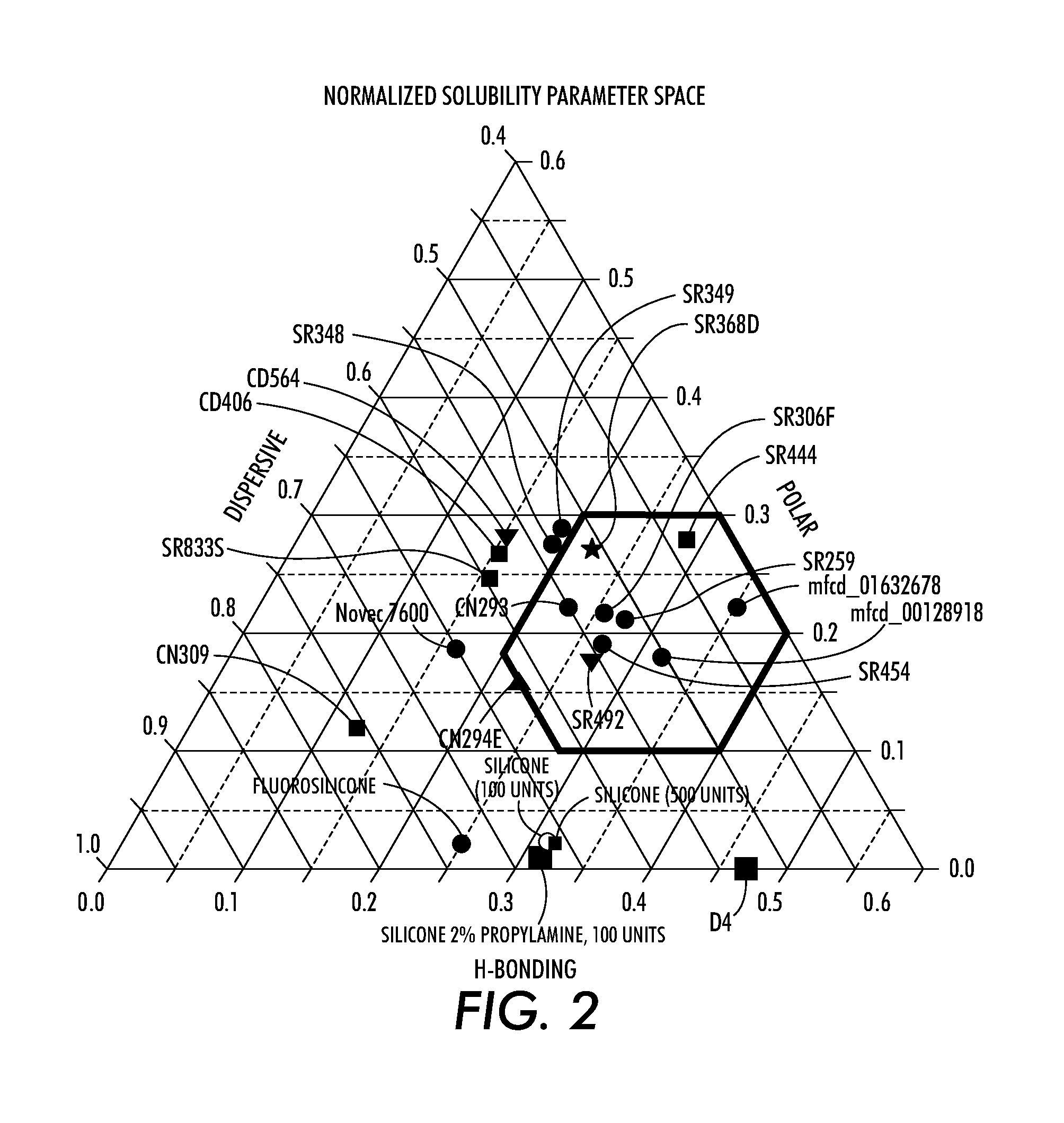

Photochromic security enabled ink for digital offset printing applications

An ink composition useful for digital offset printing applications comprises a photochromic material and a plurality of curable compounds. The compounds have Hansen solubility parameters as described herein, and the resulting ink composition is both compatible with certain dampening fluids and has certain rheological properties, including a low viscosity. The photochromic ink compositions are useful for providing security information in certain printing applications.

Owner:XEROX CORP

Direct drawing type waterless planographic original form plate

InactiveUS6096476AHigh nitrogen contentHigh degreePhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringHeat sensitive

PCT No. PCT / JP96 / 03296 Sec. 371 Date Oct. 27, 1997 Sec. 102(e) Date Oct. 27, 1997 PCT Filed Nov. 8, 1996 PCT Pub. No. WO97 / 17208 PCT Pub. Date May 15, 1997A directly imageable raw plate for waterless planographic printing plate, in which a heat insulating layer, heat sensitive layer and ink repellent layer are formed in this order on a substrate, comprising physical properties of 5 to 100 kgf / mm2 in initial elastic modulus and 0.05 to 5 kgf / mm2 in 5% stress as tensile properties of the heat sensitive layer or the heat insulating layer or the laminate consisting of both the layers. It can be suitably used also for large printing presses and web offset printing presses requiring high printing durability, and makes it possible to obtain an economically advantageous printing plate.

Owner:TORAY IND INC

Disc screen apparatus

Owner:HUSTLER CONVEYOR

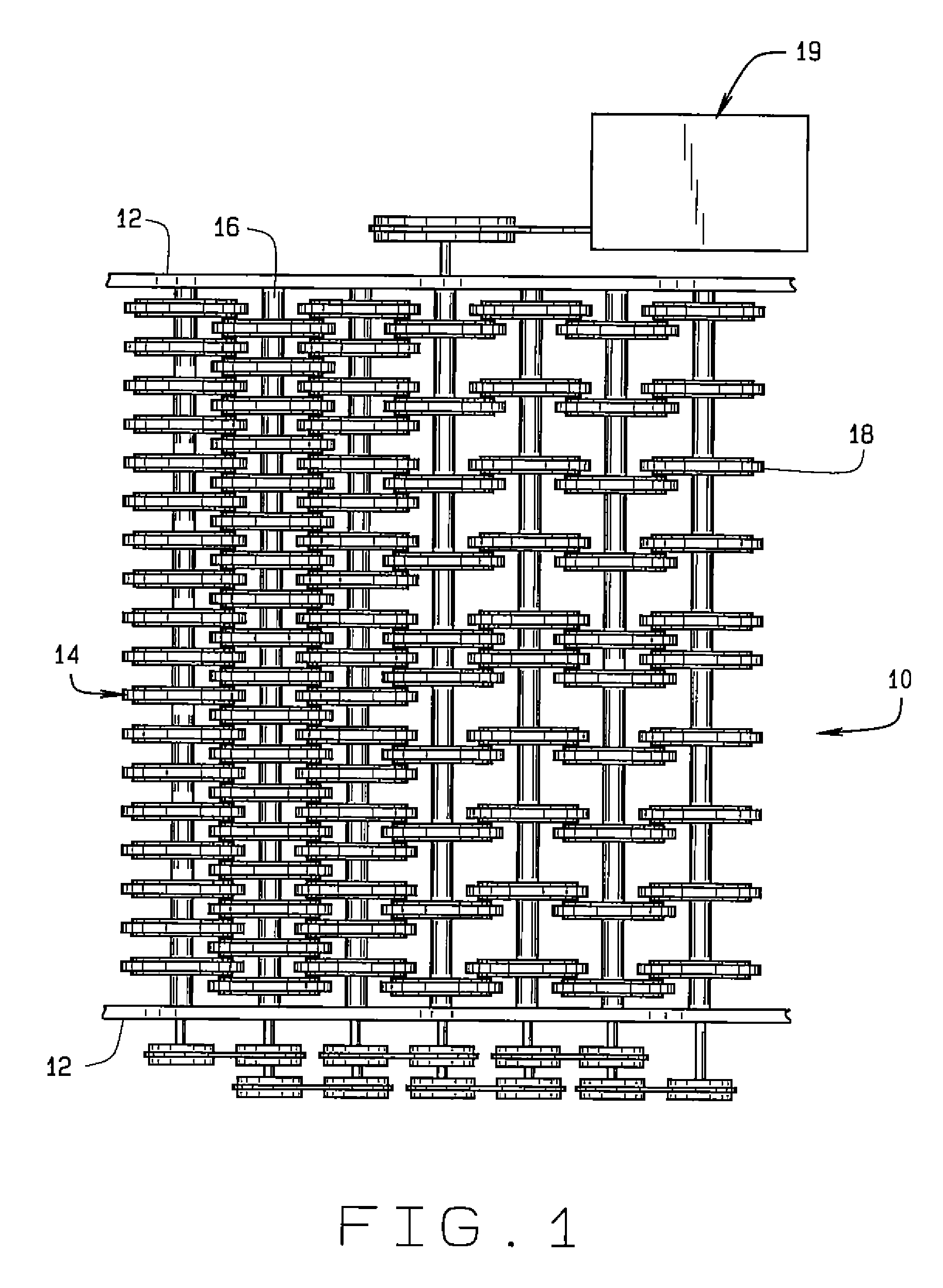

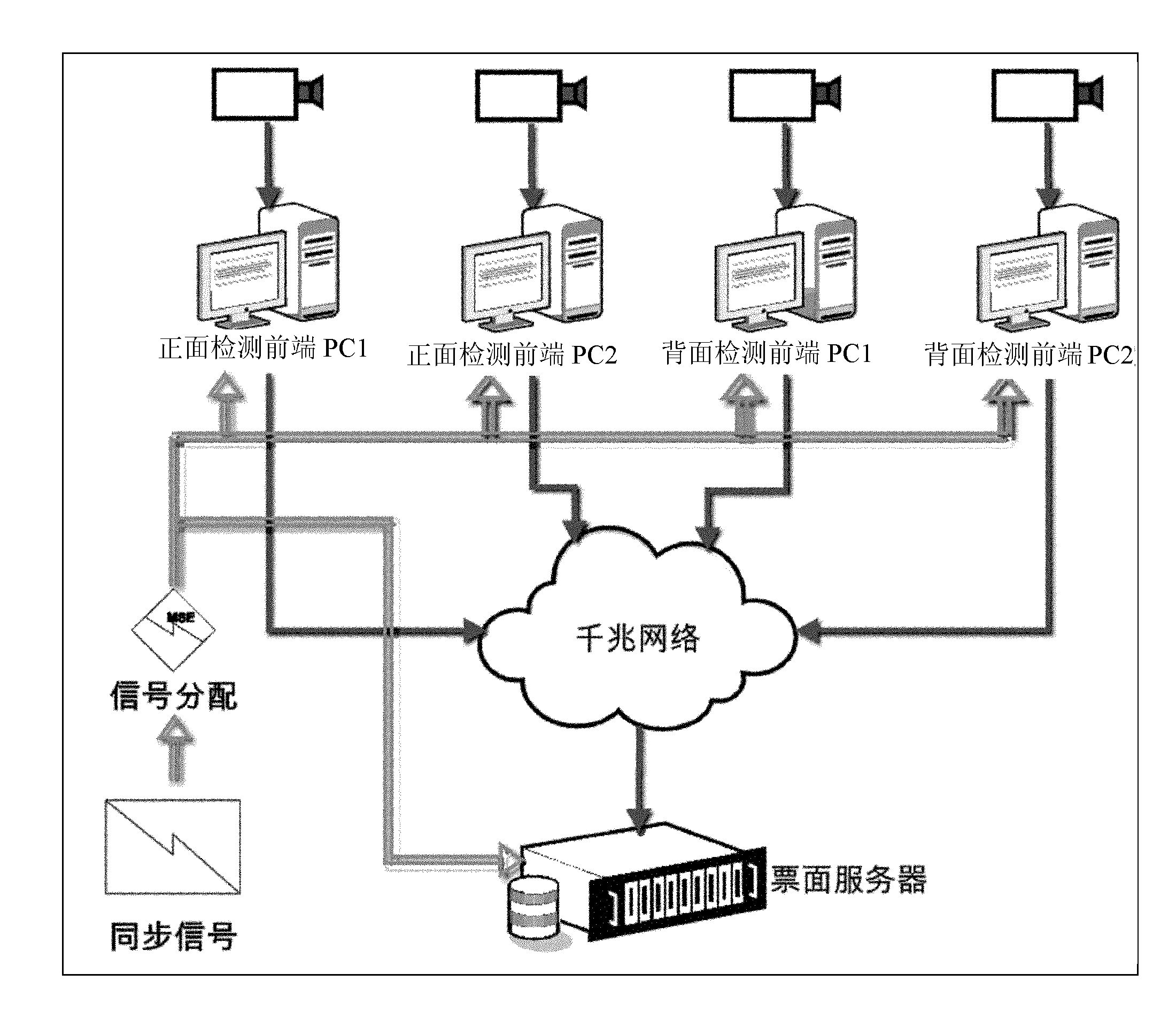

System and method for detecting front and back face qualities of imprinted Renminbi (RMB) large-page product

ActiveCN102136165AFactory quality and safetyReduce detection capacity dropCoin testingMaterial analysis by optical meansEngineeringQuality safety

The invention relates to a system and method for detecting front and back face qualities of an imprinted Renminbi (RMB) large-page product. The method comprises the following steps of: arranging a front face detecting unit and a back face detecting unit on a paper collecting part of an imprinter respectively; and transmitting a pulse signal by using an encoder which is synchronous to a system detection drum to trigger a colored linear array CCD (Charge Coupled Device) camera to acquire an image, wherein the reduction in the detection capability of the system, caused by paper fluctuation, can be reduced to the maximum extent by using a flattening device. By adopting the system and method, products with severe quality problems caused by an imprinting procedure per se and a series of products with continuous remarkable quality problems (such as paper holes, break angles, oil stains, number strike-through and the like) can be intercepted, and products with remarkable and severe quality problems in an offset printing procedure and a gravure procedure can be controlled according to a detection result, better technical supplements are provided for the conventional running computer retrieval process, and the front and back face qualities of the important imprinted RMB product can be checked, scraps can be positioned accurately, and the delivery quality safety of the product is ensured.

Owner:XIAN BANKNOTE PRINTING +1

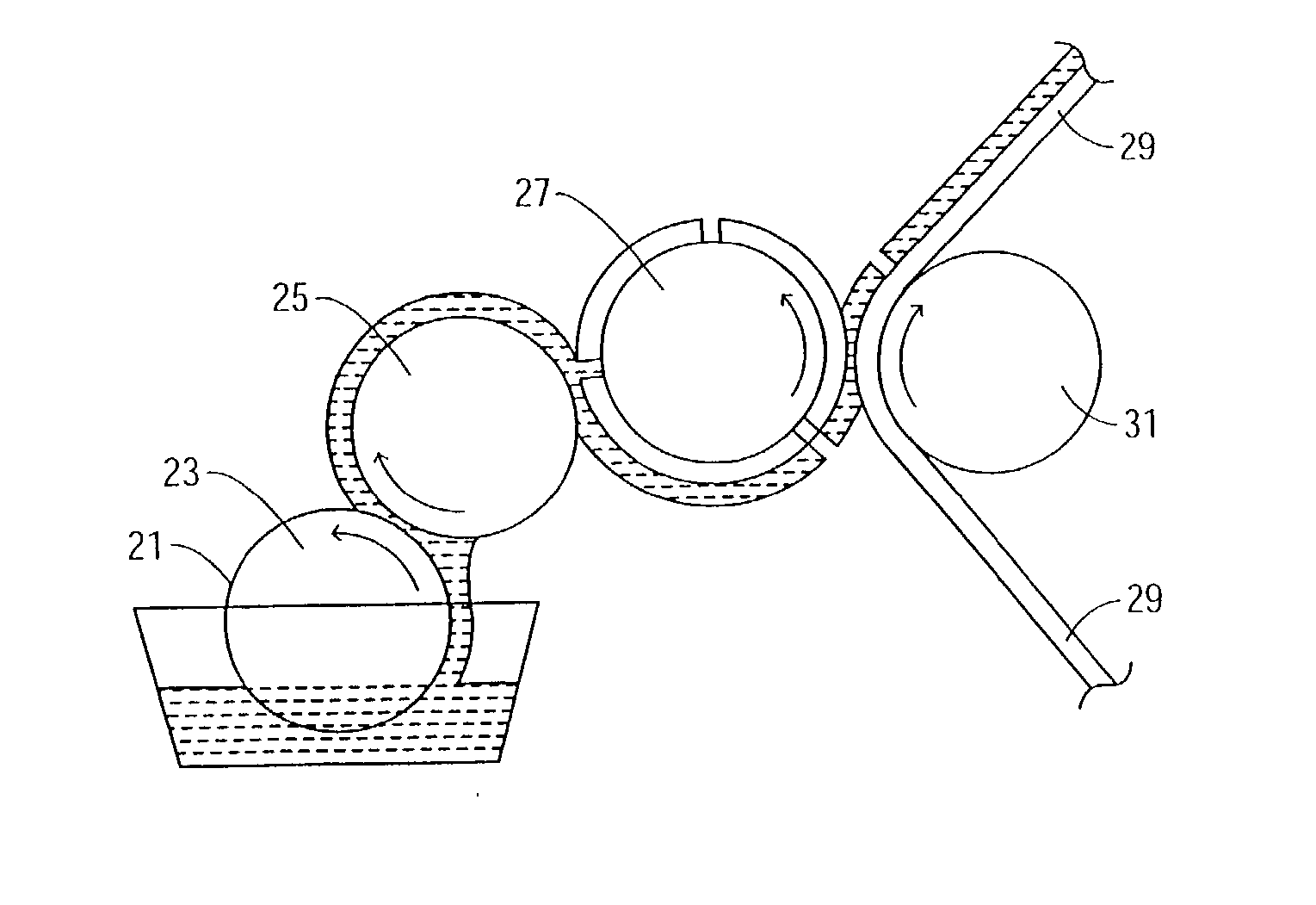

Method of producing a high gloss coating on a printed surface

InactiveUS20030113466A1High coatingLow production costCylinder pressesTransfer printingPresent methodPaper sheet

The present invention is directed to a method for producing a high gloss coating on a printed surface. In the present method, an aqueous coating composition is deposited onto a surface to be printed using a blanket roller coating face which is a low energy, non-stick, smooth surface profile. In the present method, simultaneous with the deposition of aqueous coating onto a substrate, or shortly thereafter, pressure either alone or in combination with heat may be applied to the coating in order to create a substantially tack-free surface conforming to the surface of the coating face. By using a highly polished coating face, high gloss coatings may be readily obtained using this methodology in a number of traditional printing techniques including wet trap inline sheet-fed printing, heat-set offset printing, dry trap inline flexographic printing, offset web-fed printing and gravure printing. Coatings which are produced utilizing the present invention have high gloss values heretofore unobtainable using aqueous coating compositions.

Owner:FRAZZITTA JOSEPH +1

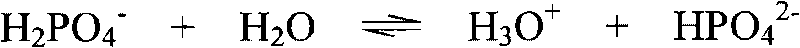

Offset printing fountain solution composition containing composite buffer system

InactiveCN101758680AAdapt to the needs of actual printingGood buffer tolerancePrinting pre-treatmentSodium citrateCitric acid

The invention relates to an offset printing fountain solution composition containing composite buffer system, which contains two buffer systems, wherein one of the buffer systems comprises citric acid and M2(I)HPO4, and in the molecular formula M2(I)HPO4, M is K plus, Na plus or NH4 plus ion; and the other buffer system comprises citric acid and potassium citrate, sodium citrate or ammonium citrate, components are as follows in percentage by weight: 1.0-10 percent of the citric acid, 1.0-10 percent of K2HPO4, Na2HPO4 or (NH4)2HPO4, 1.0-10 percent of the potassium citrate, the sodium citrate or the ammonium citrate, and the balance water. When 1 percent to 5 percent by weight of working solution prepared with the diluted fountain solution is used for printing, the change of pH value is less than 0.35, and when 1 percent to 2 percent of working solution is prepared, the change of pH value is less than 0.25. The ultrahigh buffering property of the fountain solution can significantly help to improve adaptability and tolerance during high-speed printing operation.

Owner:HUNAN NORMAL UNIVERSITY

Hydrophobic material and application thereof in preparation of offset print printing plates

ActiveCN103305078AAvoid pollutionImprove wear resistancePlate printingPolyamide coatingsMicro structureChemical treatment

The invention discloses a hydrophobic material and an application thereof in preparation of offset print printing plates, and belongs to the technical field of preparation of printing plates. The hydrophobic material comprises 0-30wt% of hydrophobic resin, 10-40wt% of film forming resin, 0.001-1wt% of a crosslinking agent, 0.001-5wt% of a surfactant, 0.001-5wt% of an assistant and the balance of a solvent. The hydrophobic material has the function of rejecting waterborne printing ink and excellent performance of preventing chemical solvents and resisting wear. According to the material applied to preparation of offset print printing plates, the plate base used is not electrochemically treated. The UV (Ultraviolet) curing bottom coating can better bind the metal substrate with a hydrophobic coating and no VOC (Volatile Organic Compound) is discharged. The hydrophobic coating can be used to construct a nano- or micro-structure and reject waterborne printing ink, and has better wear resistance. The plate provided by the invention avoids pollution of waste acids and waste alkalis caused by electrochemical treatment. The plate prepared by way of printing is free from light, and chemical treatment processes such as development and fixation are avoided. During printing, waterborne printing ink can be used to realize image-text transfer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

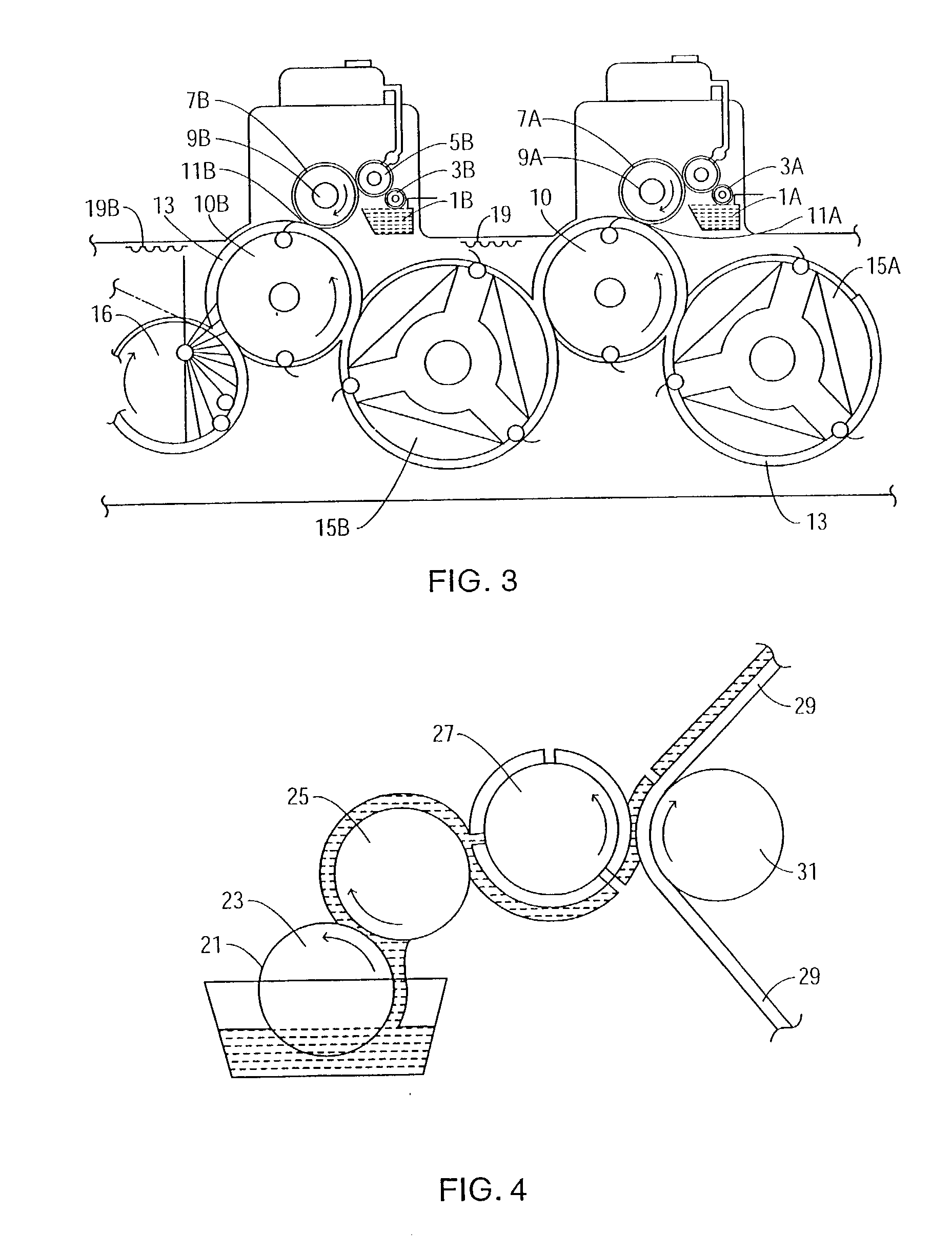

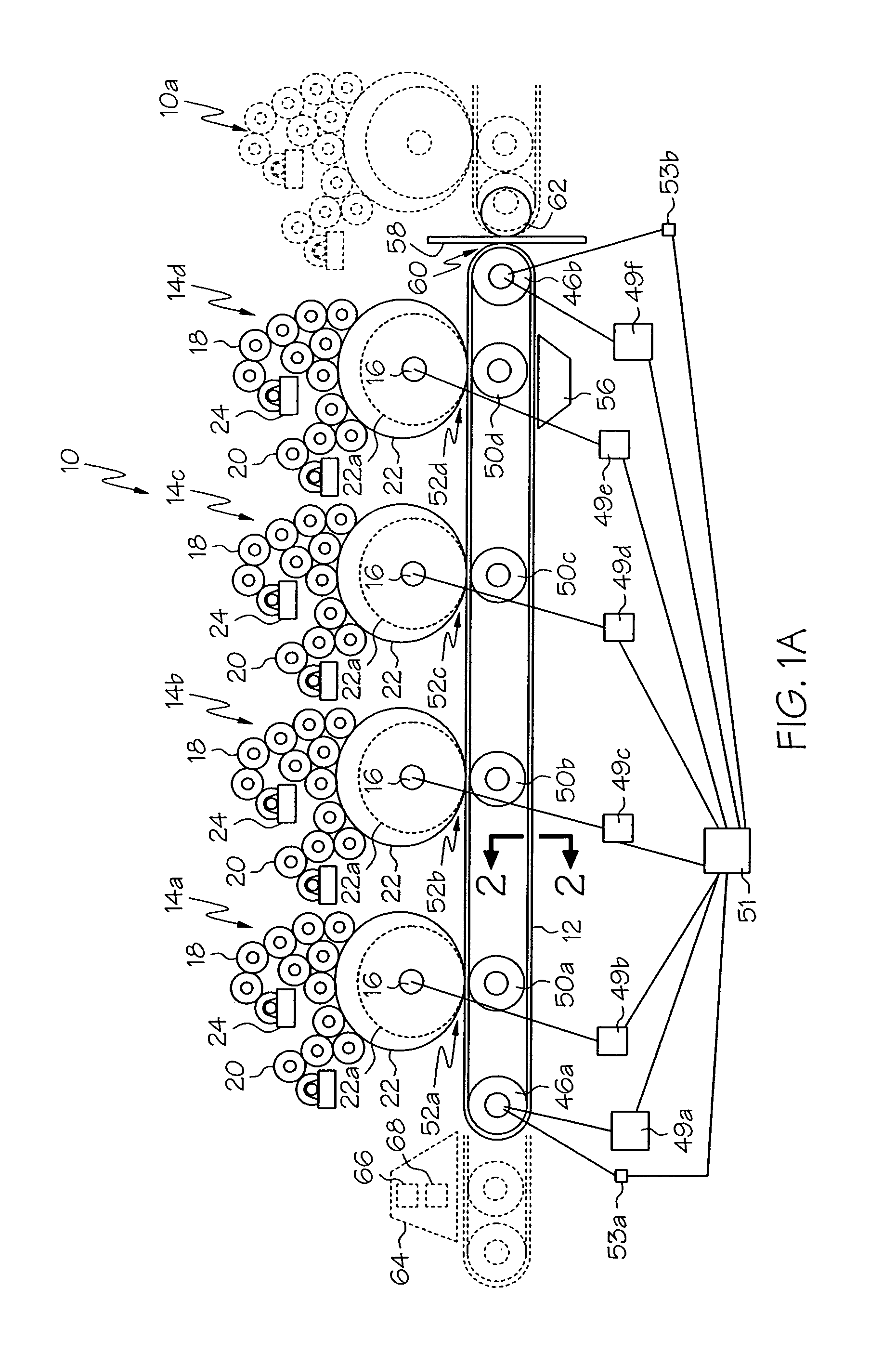

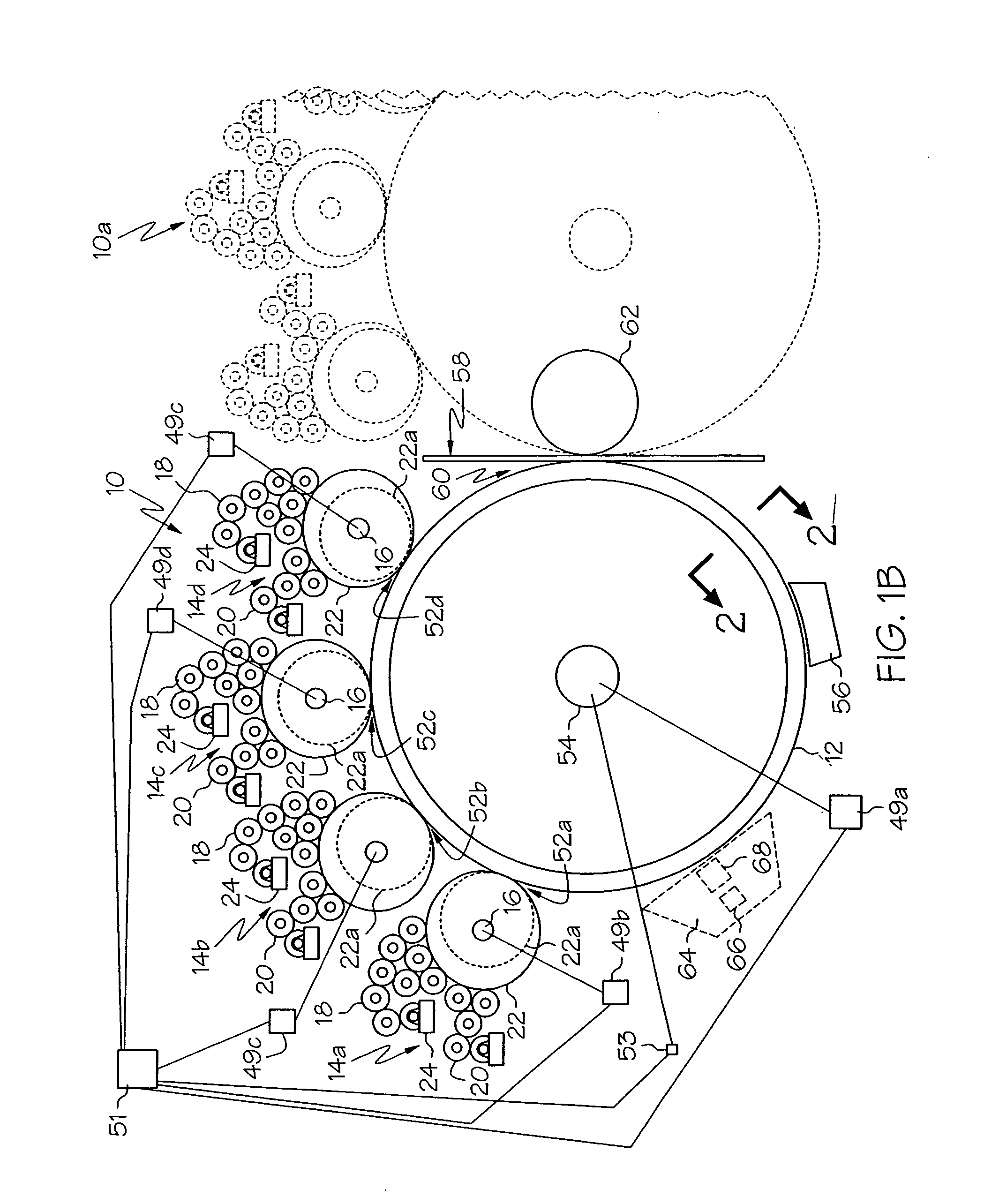

Variable cut-off offset press system and method of operation

InactiveUS7066088B2Aid in smooth operation of systemIncrease frictionCylinder pressesTransfer printingImage transferCleaning station

A variable cut-off offset press system and method of operation which utilizes a continuous image transfer belt is provided. The offset printing system comprises at least two plate cylinders adapted to have thereon respective printing sleeves. Each of the printing sleeves is adapted to receive colored ink from a respective ink source. An optional coating source may be provided to fully or partially coat the image transfer belt before inking. The system further comprises at least a impression cylinder, wherein the image transfer belt is positioned to contact each of the printing sleeves at respective nips formed between respective ones of the plate cylinders and the at least one impression cylinder. An image belt cleaning station adapted to remove residual ink or coating from the surface of the image transfer belt after image transfer of a multicolored image from the image transfer belt to a substrate is also provided.

Owner:DAY INT

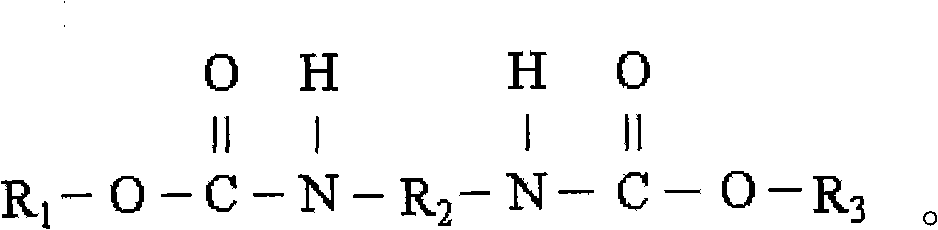

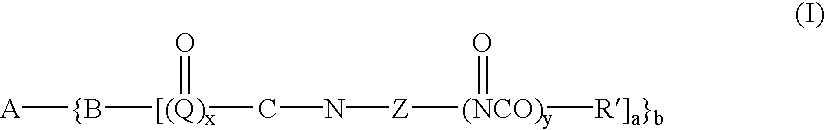

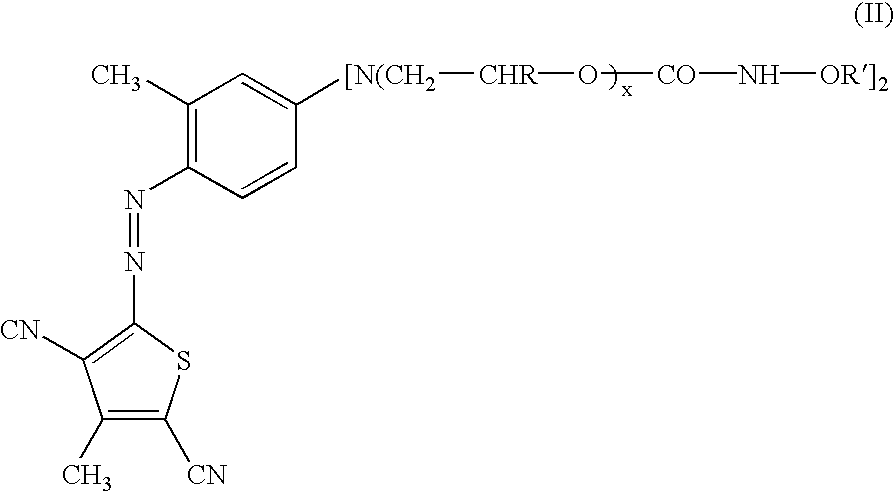

Novel toner compounds and compositions for black offset inks

InactiveUS20030110977A1Desired look of printed imageExcellent spectral strengthLayered productsPretreated surfacesSolubilityAlcohol

A novel colorant compound is provided which is the addition product of an organic chromophore having at least one reactive hydroxyl or amine substituent, a mono or polyisocyanate, and / or an alcohol. Such a compound provides solubility in oil-based ink compositions, complete water resistance and excellent oil based ink compositions. Furthermore, such colorants provide an easy and efficient way to tone shades of oil based inks. In addition, such colorants provide a way to tone carbon black based lithographic inks that gives the images a appearance of jet black on various types of printing substrates. A method for producing such a colorant is also provided, as well as offset ink compositions comprising such a colorant (including other colorants that provide the same toner performance within black pigment formulations).

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com