Patents

Literature

181 results about "Letterpress printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Letterpress printing is a technique of relief printing using a printing press, a process by which many copies are produced by repeated direct impression of an inked, raised surface against sheets or a continuous roll of paper. A worker composes and locks movable type into the "bed" or "chase" of a press, inks it, and presses paper against it to transfer the ink from the type which creates an impression on the paper.

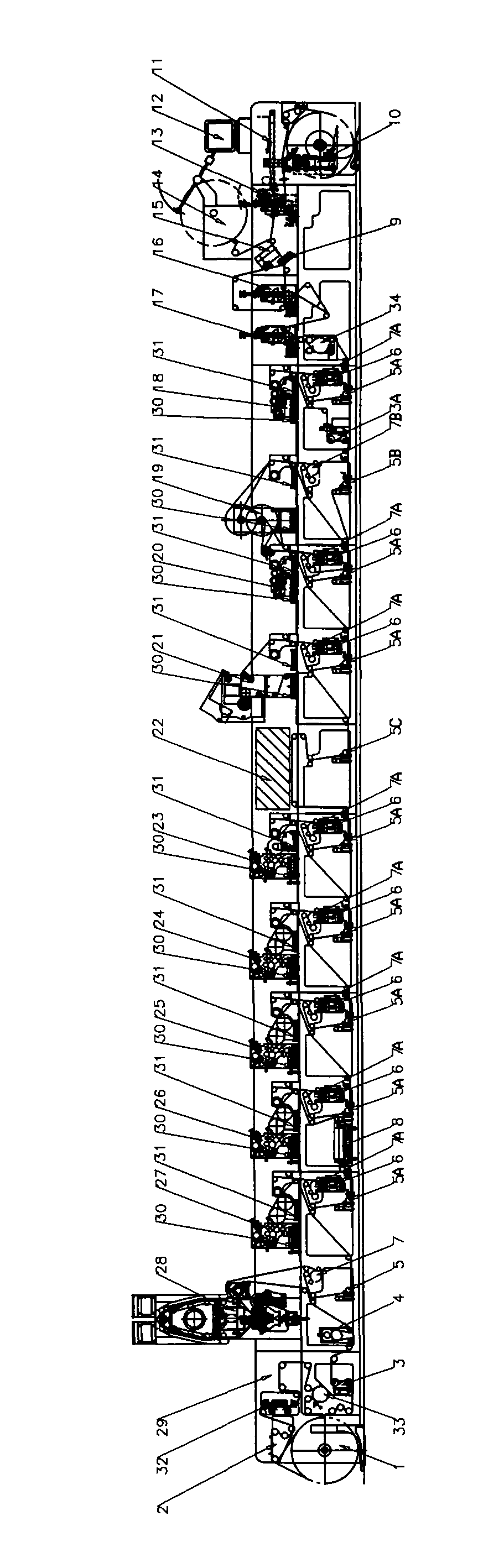

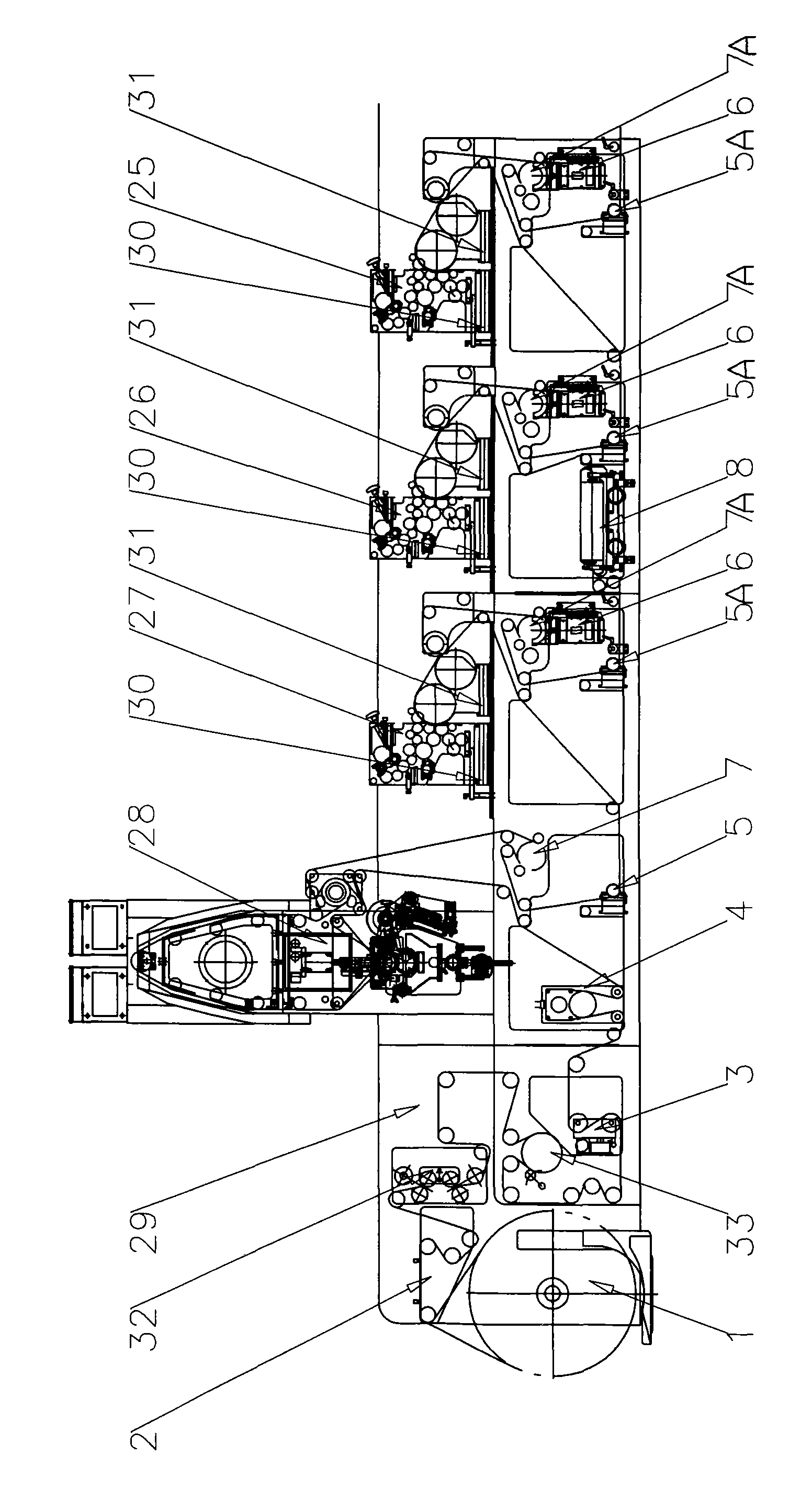

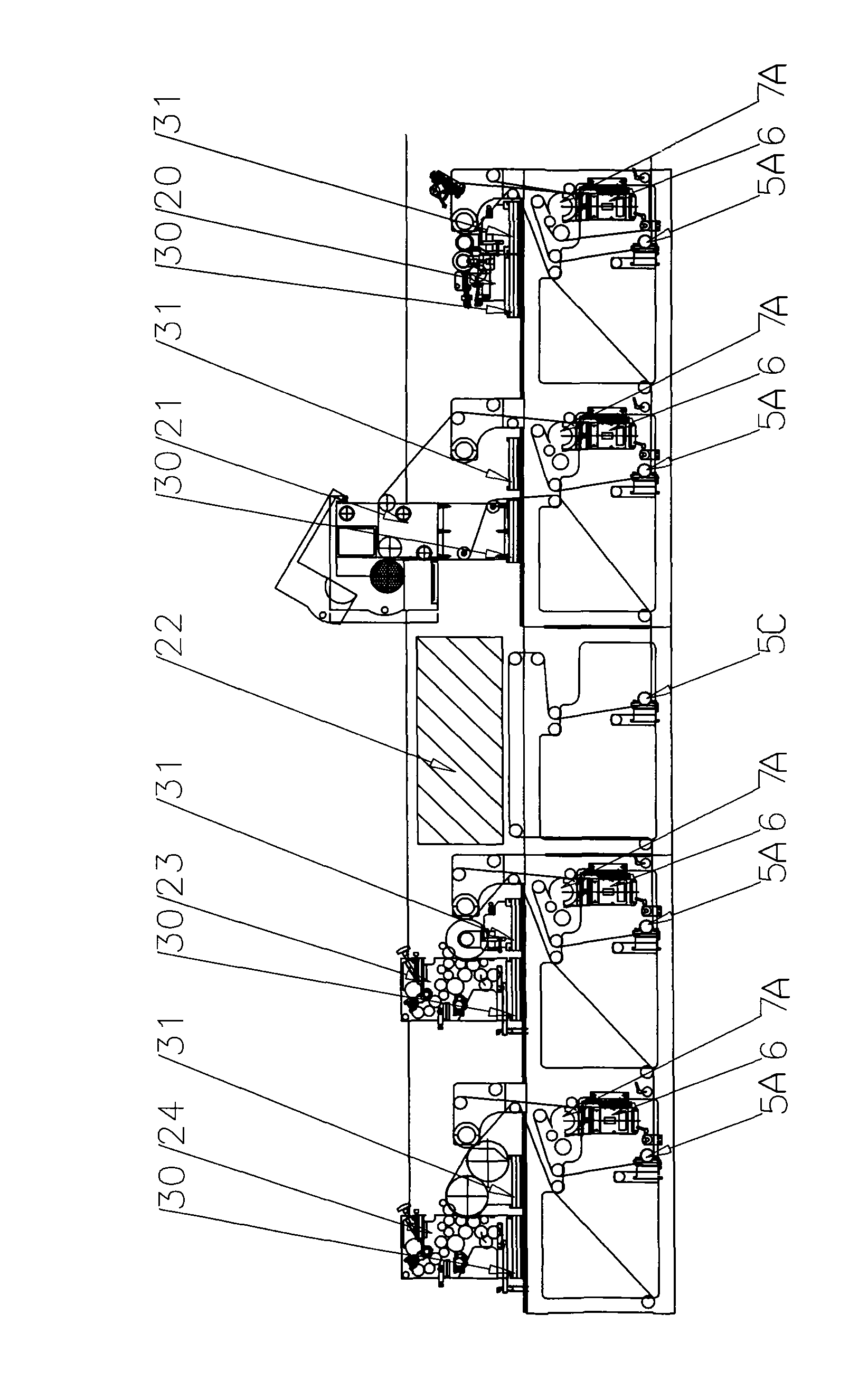

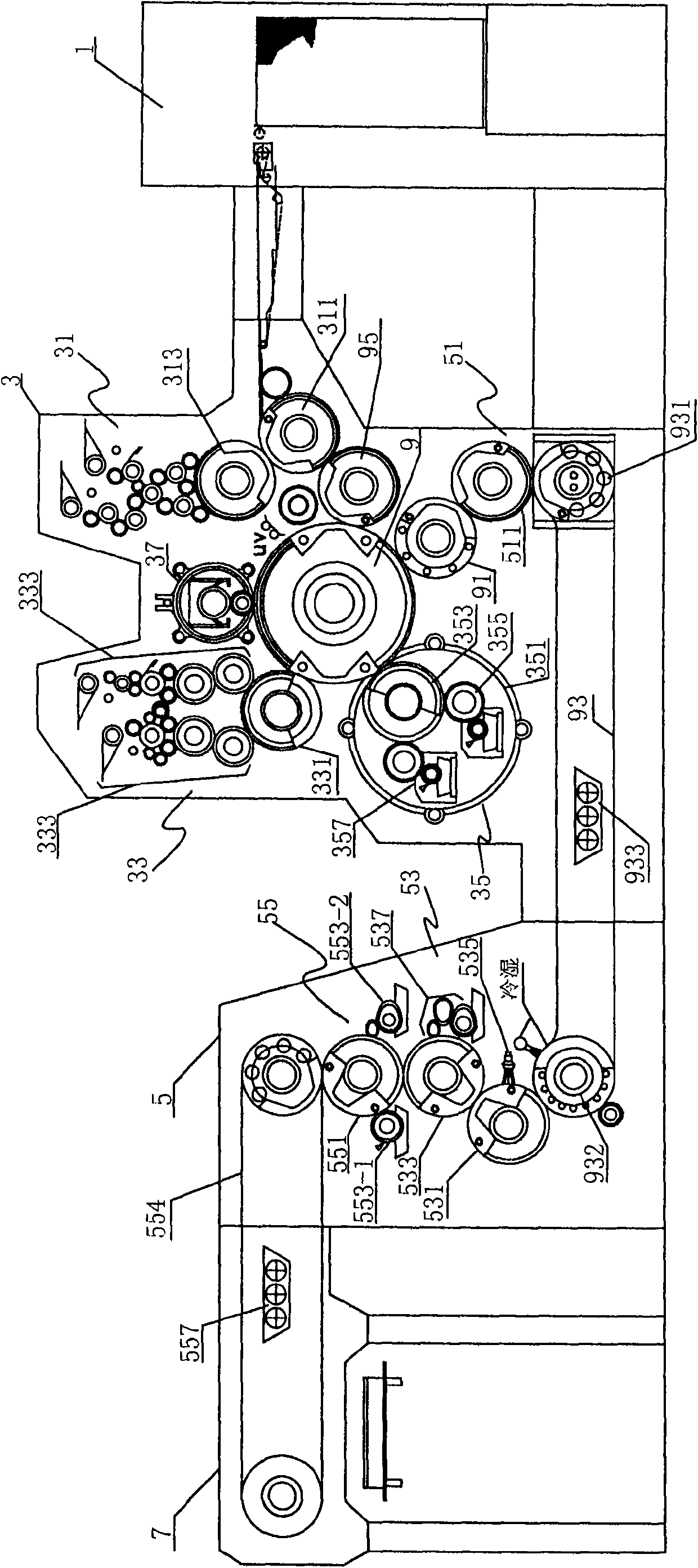

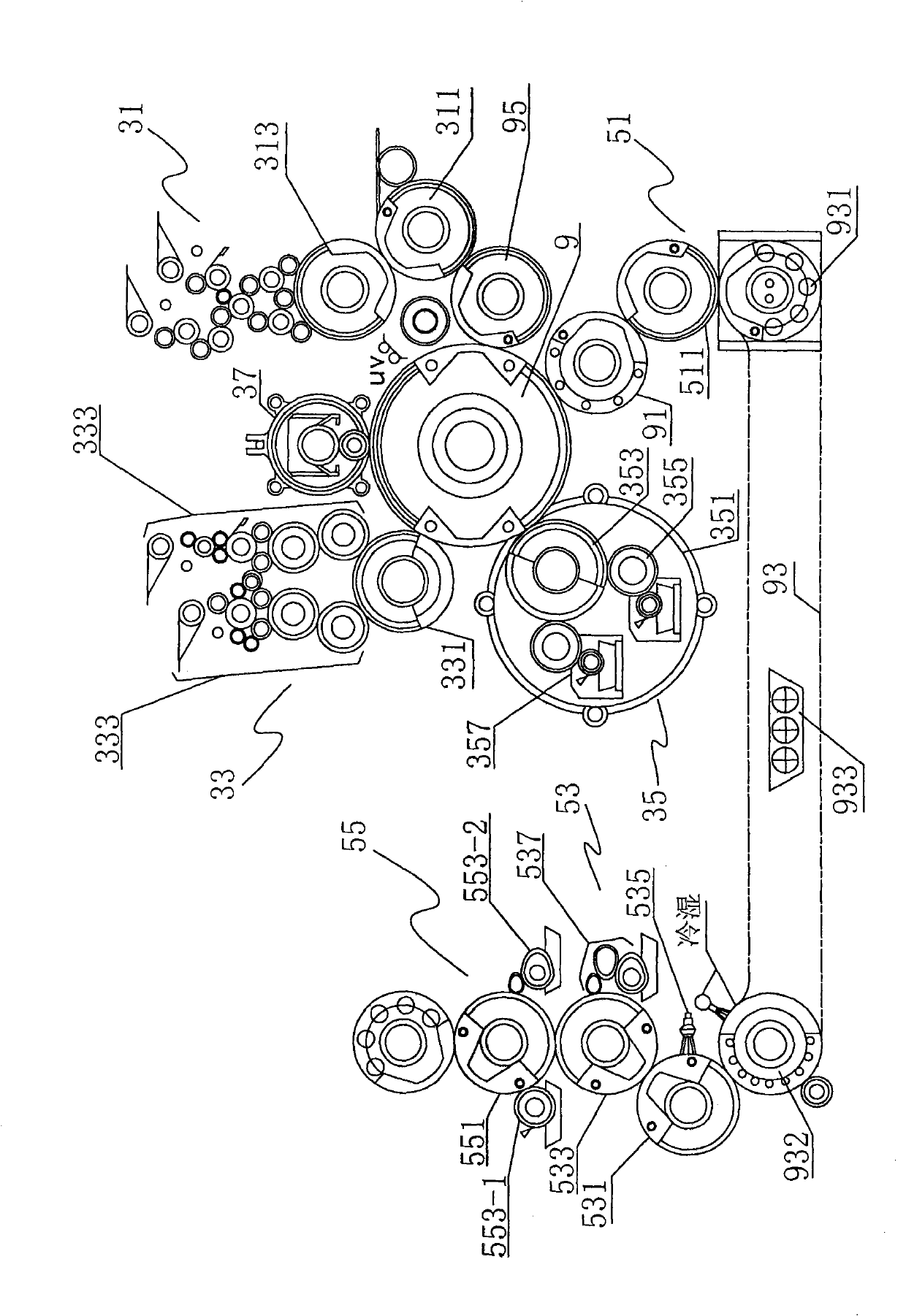

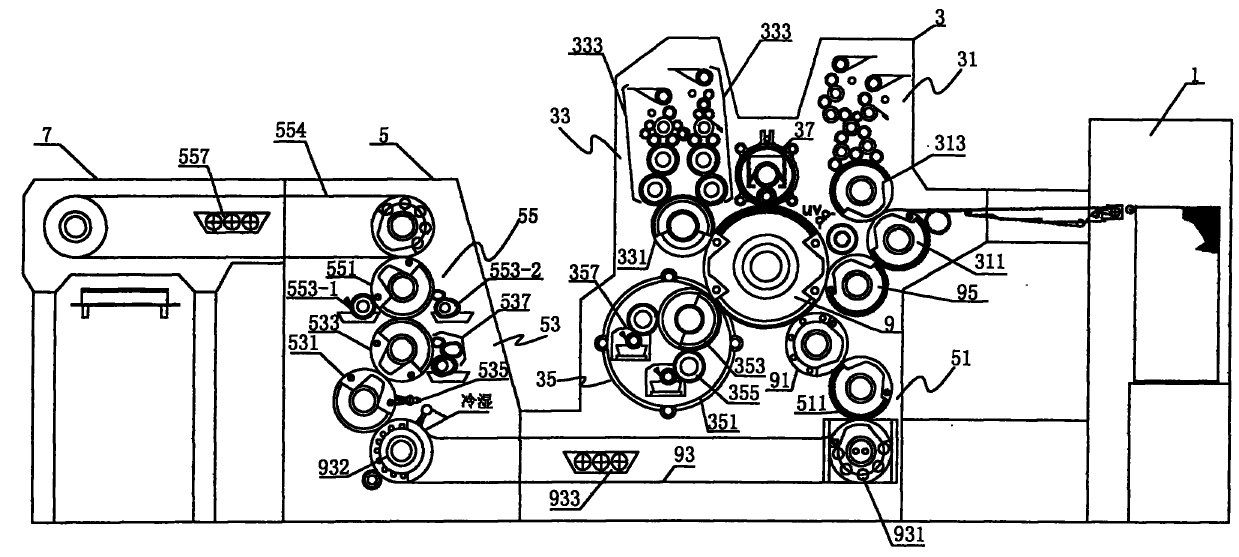

Multifunctional complex printer

InactiveCN101524912AControllable tensionHigh sensitivityTypewritersRotary pressesScreen printingLetterpress printing

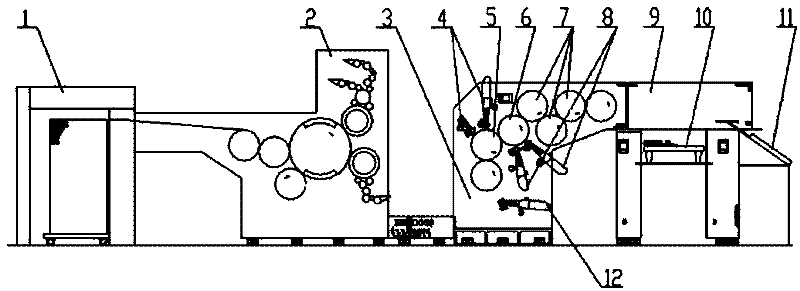

The invention relates to a multifunctional complex printer. The multifunctional complex printer comprises a lifting device of a paper feed part. The multifunctional complex printer is characterized in that a corona device, a first AC servo tension detection device and a first cooling pull roll device are sequentially arranged at right side of a first deviation correction device, an intaglio printing unit is arranged above the corona device, the first AC servo tension detection device and the first cooling pull roll device, a first interchangeable hectograph unit, a second interchangeable hectograph unit, a third interchangeable hectograph unit, a fourth interchangeable hectograph unit, an interchangeable letterpress printing unit, an interchangeable screen printing unit and a first interchangeable flexography printing unit are sequentially arranged at the right side of the intaglio printing unit, a fourth AC servo tension detection device is arranged below a reserved platform of an inkjet device, and a second two-cylinder die cutting device, a back cutting device and a television monitoring camera are sequentially arranged at the right side of a first two-cylinder die cutting device. The multifunctional complex printer has the advantages of flexibly combining various printing modes according to pluralism of products and optionally exchanging printing modes of various color classes.

Owner:SHANGHAI XINMIN TAIYO KIKAI

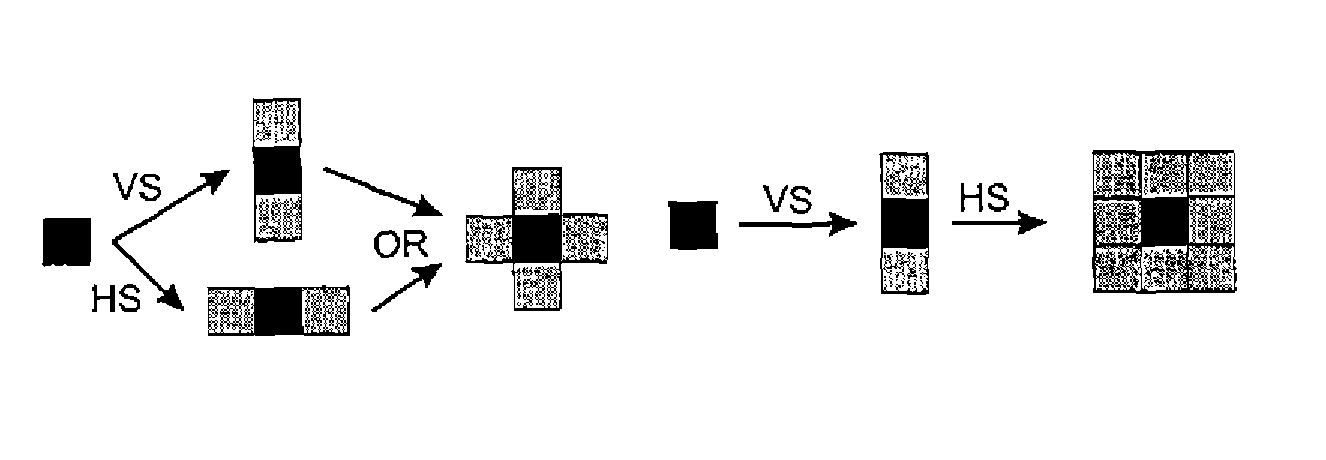

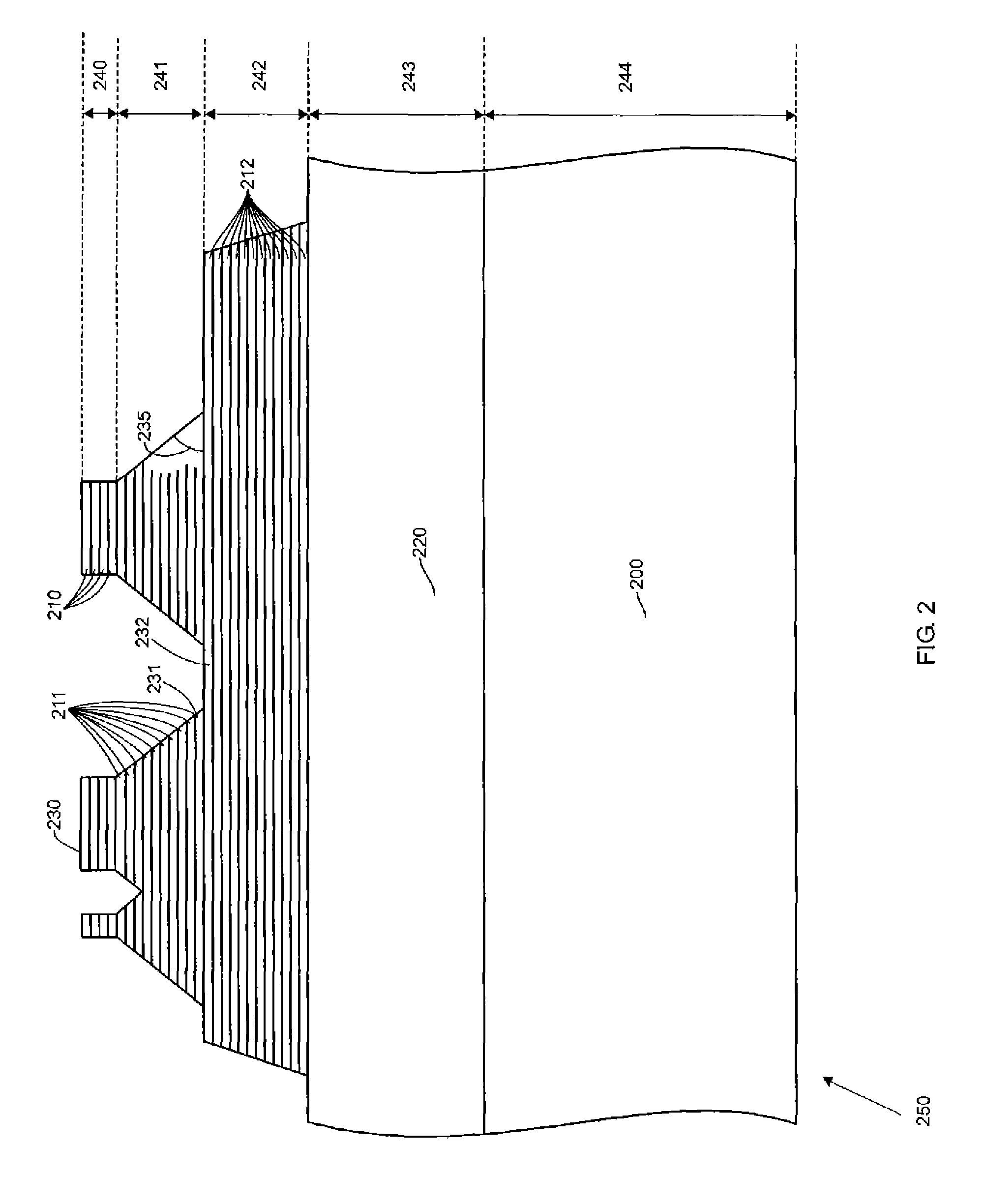

Image processing method for three-dimensional printing

InactiveUS8705144B2Efficient implementationDigitally marking record carriersAdditive manufacturing apparatusImaging processingInter layer

A relief print master is created by printing a sequence of layers on top of each other by an inkjet printing system. The top layer corresponds with the binary halftoned image that is to be printed by the print master and the lower intermediate layers are supporting layers. The features in a lower supporting layer have an area that is larger than the corresponding features in a higher supporting layer. A circular spread function is applied on the features of a higher intermediate layer to increase the area of the features in a lower intermediate layer. By using a sequence of two non-circular spread functions, the circular spread function is approximated and the number of required calculations can be reduced.

Owner:AGFA NV

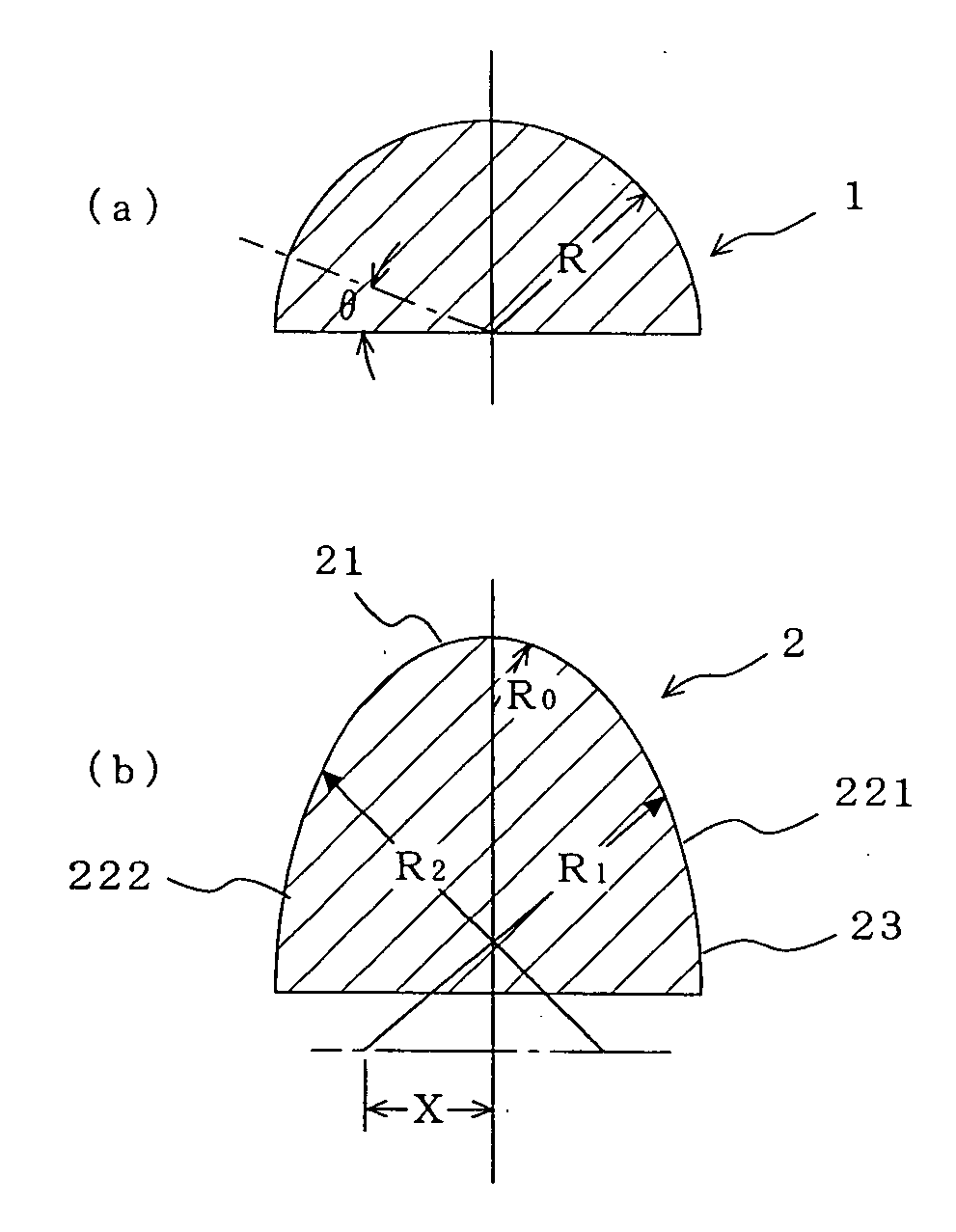

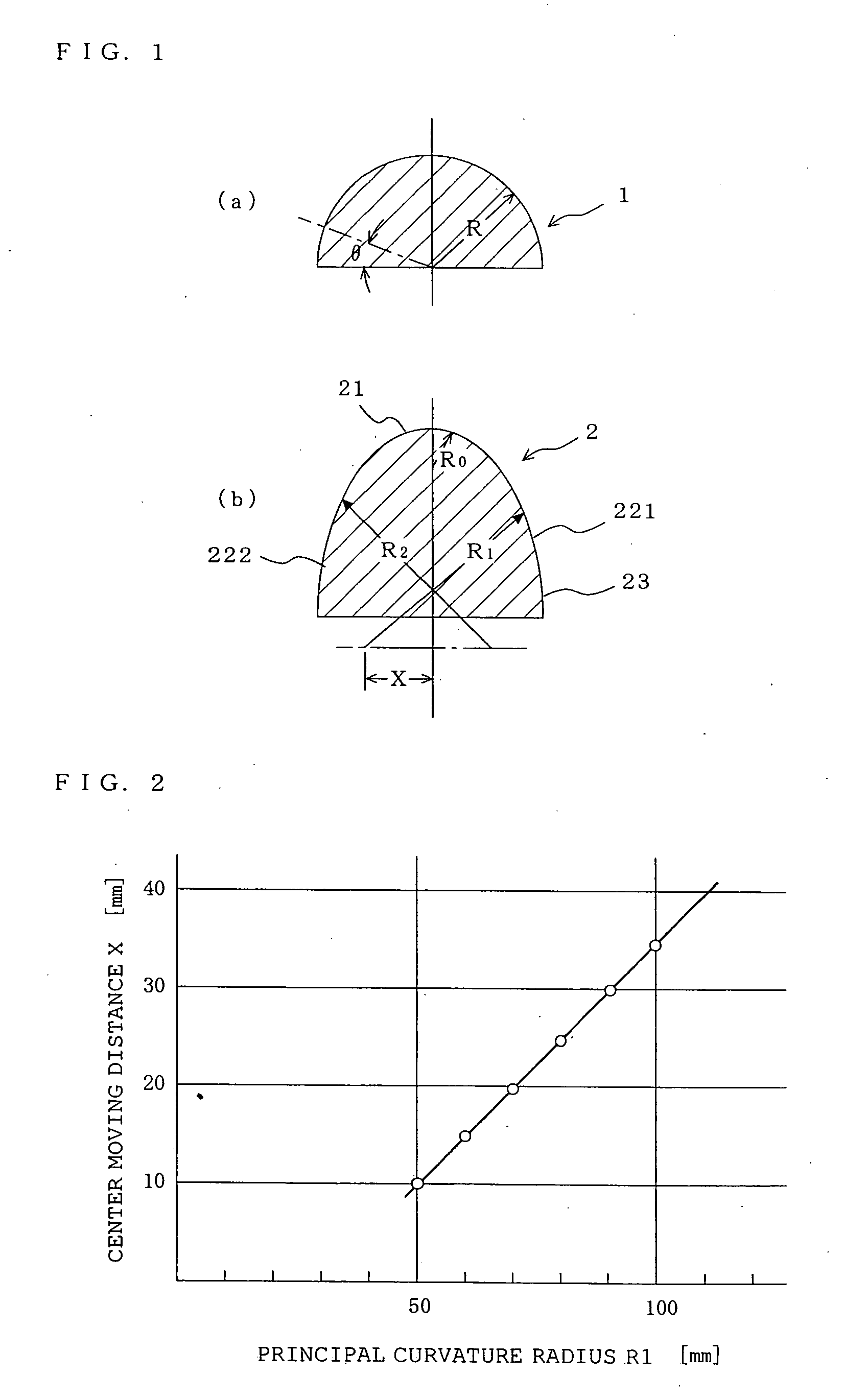

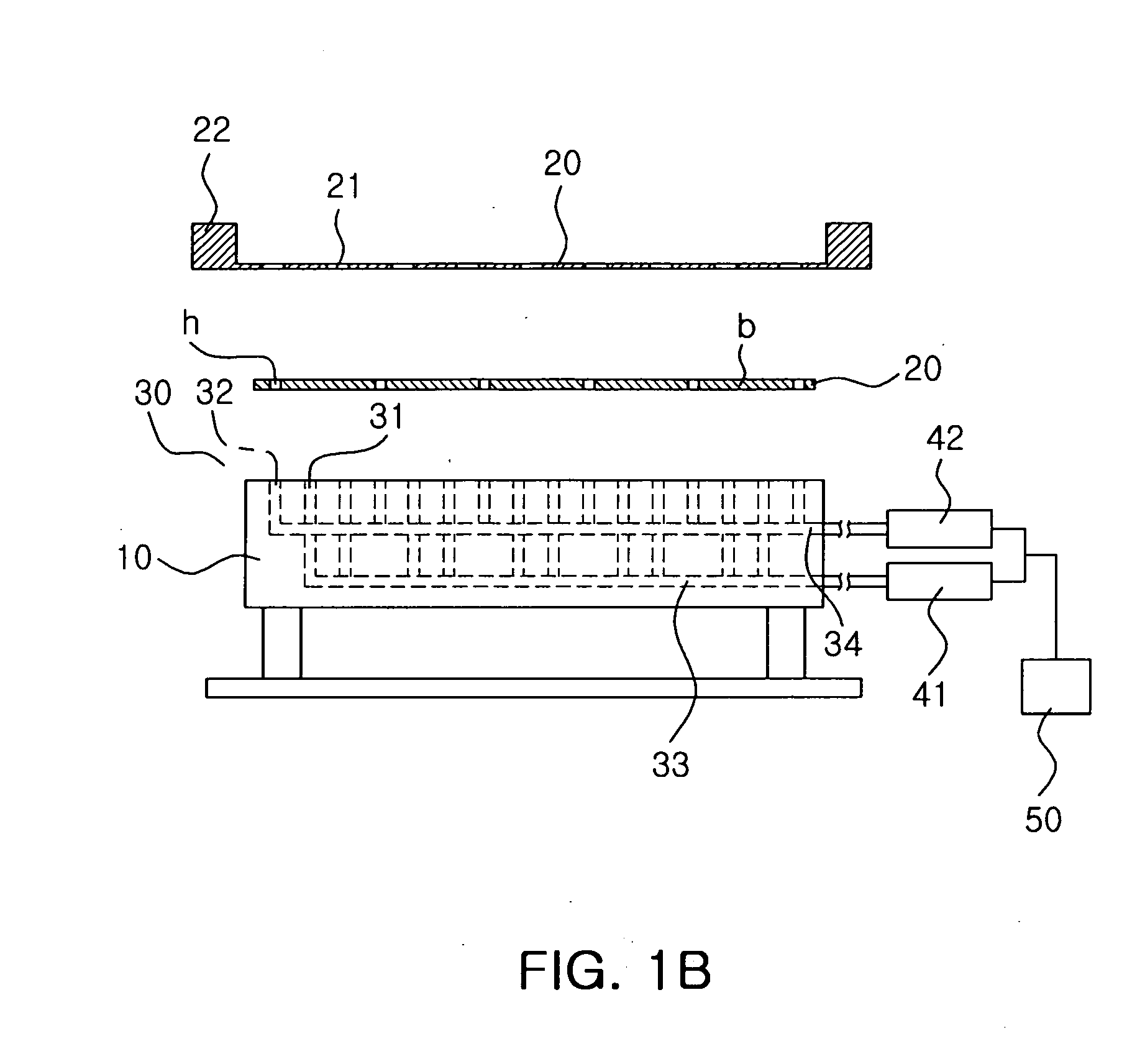

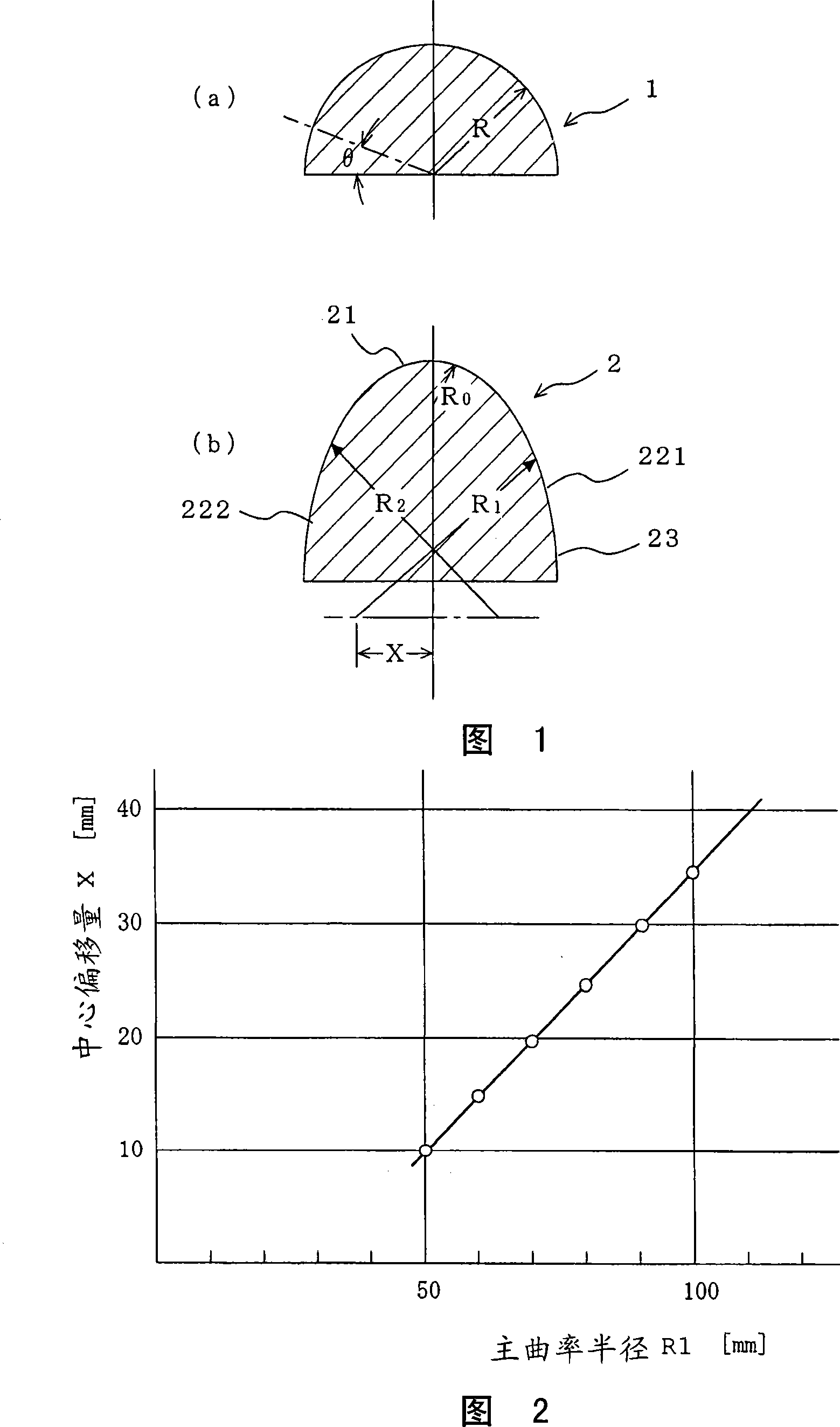

Method of Printing Curved Surface and Curved Surface Body Printed by Using Same

InactiveUS20080011177A1Accurate printingCylinder pressesPlaten pressesLetterpress printingEngineering

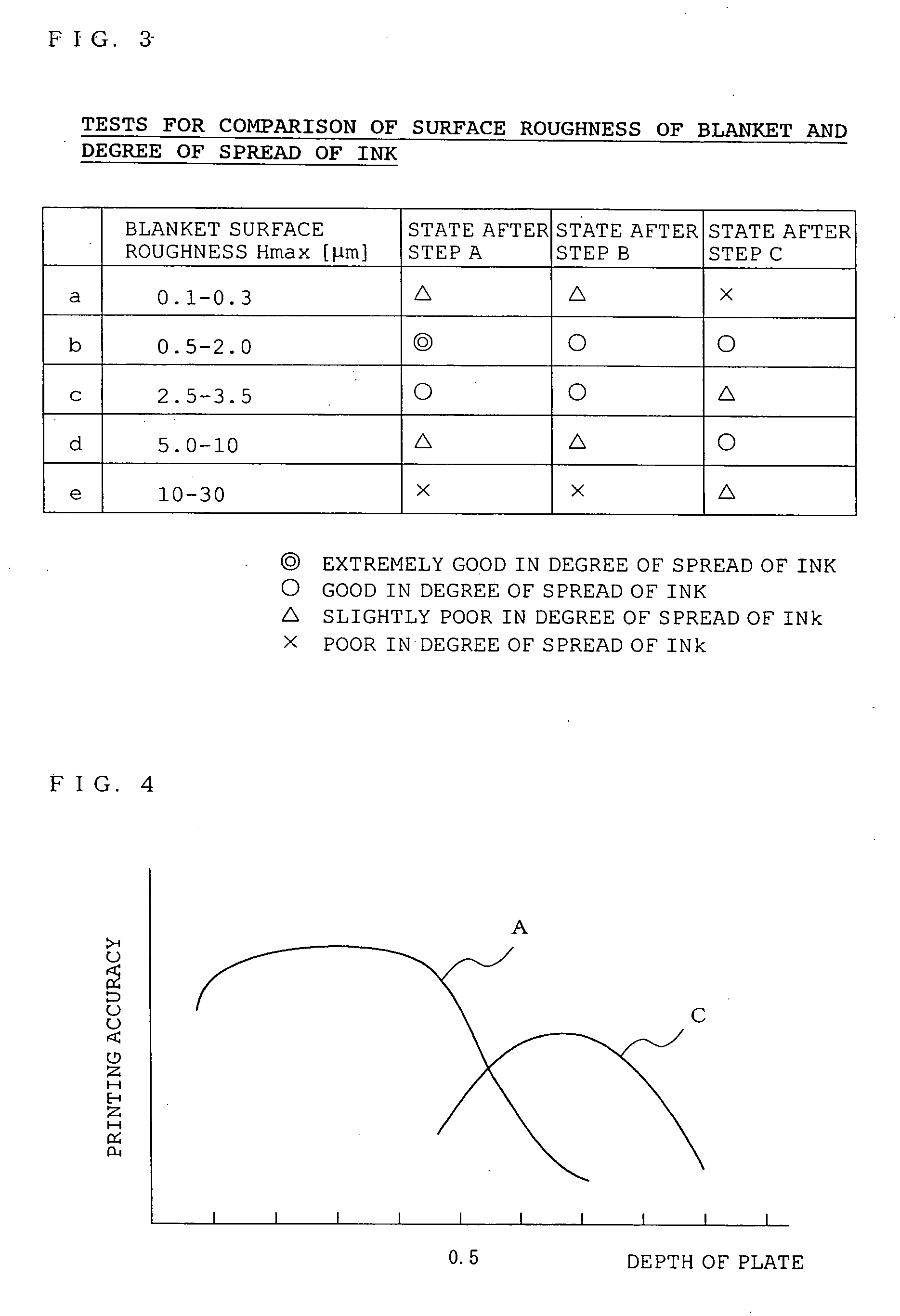

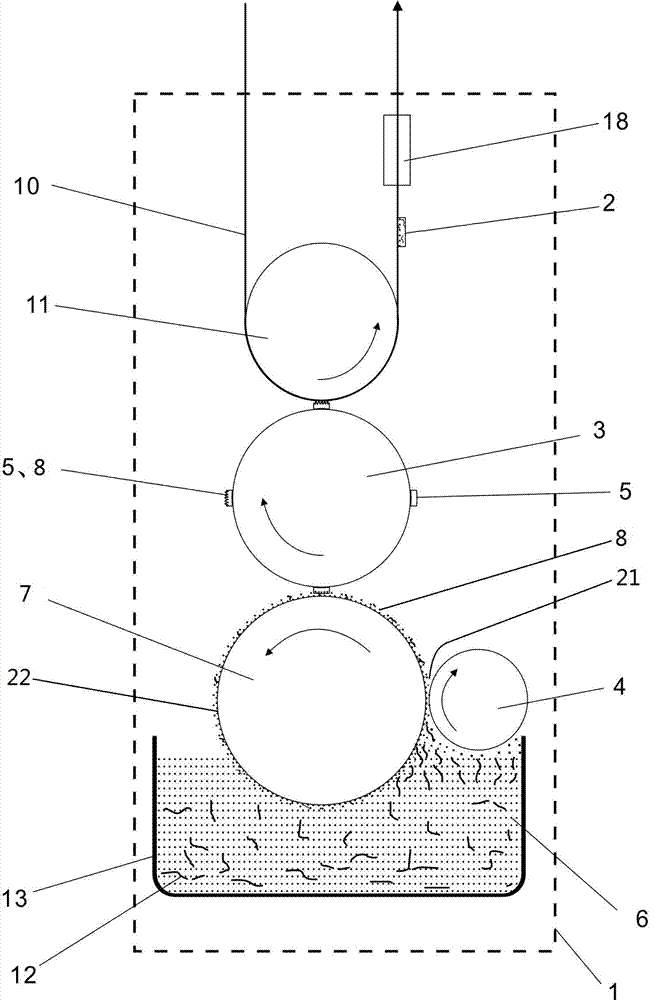

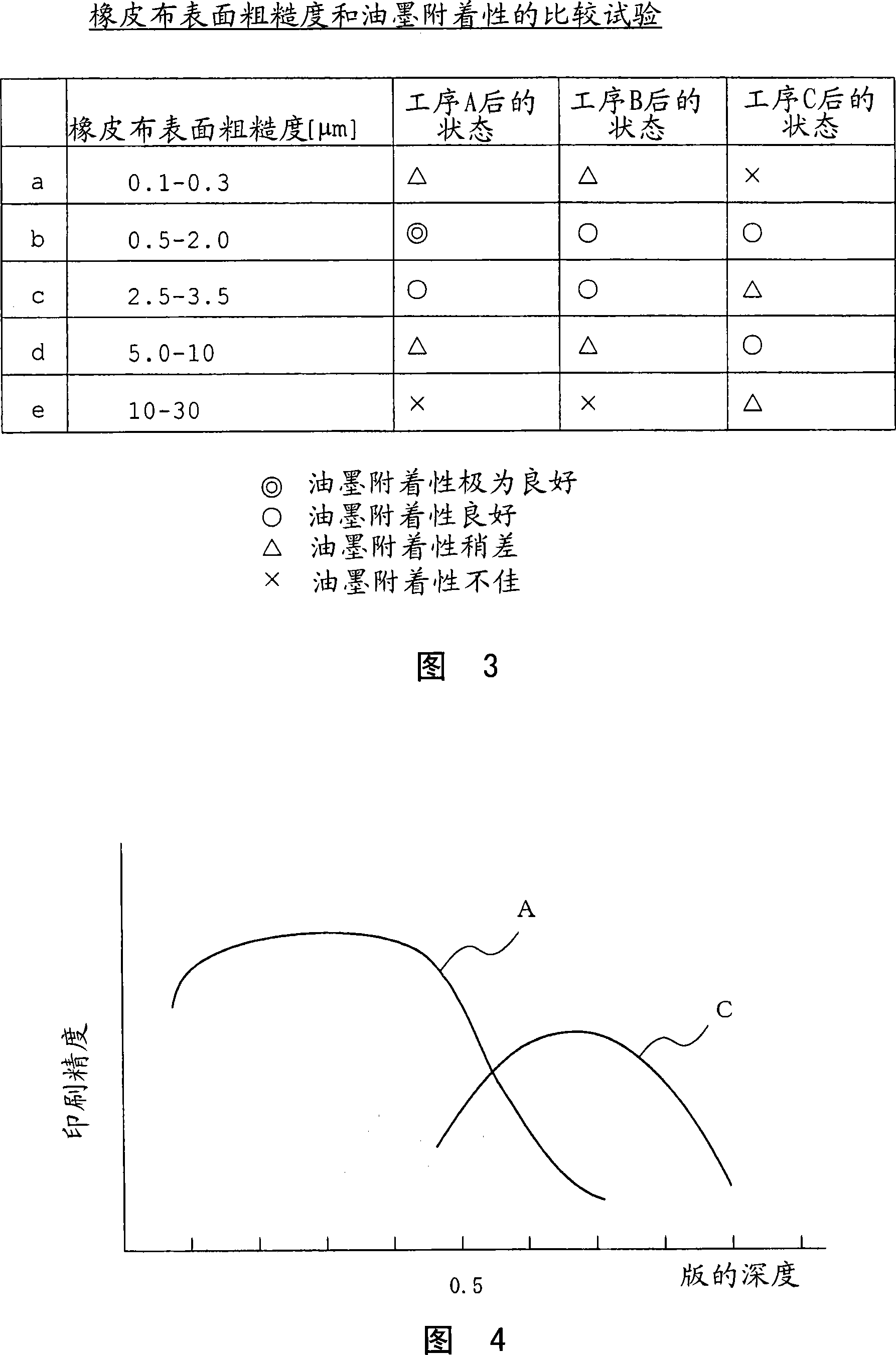

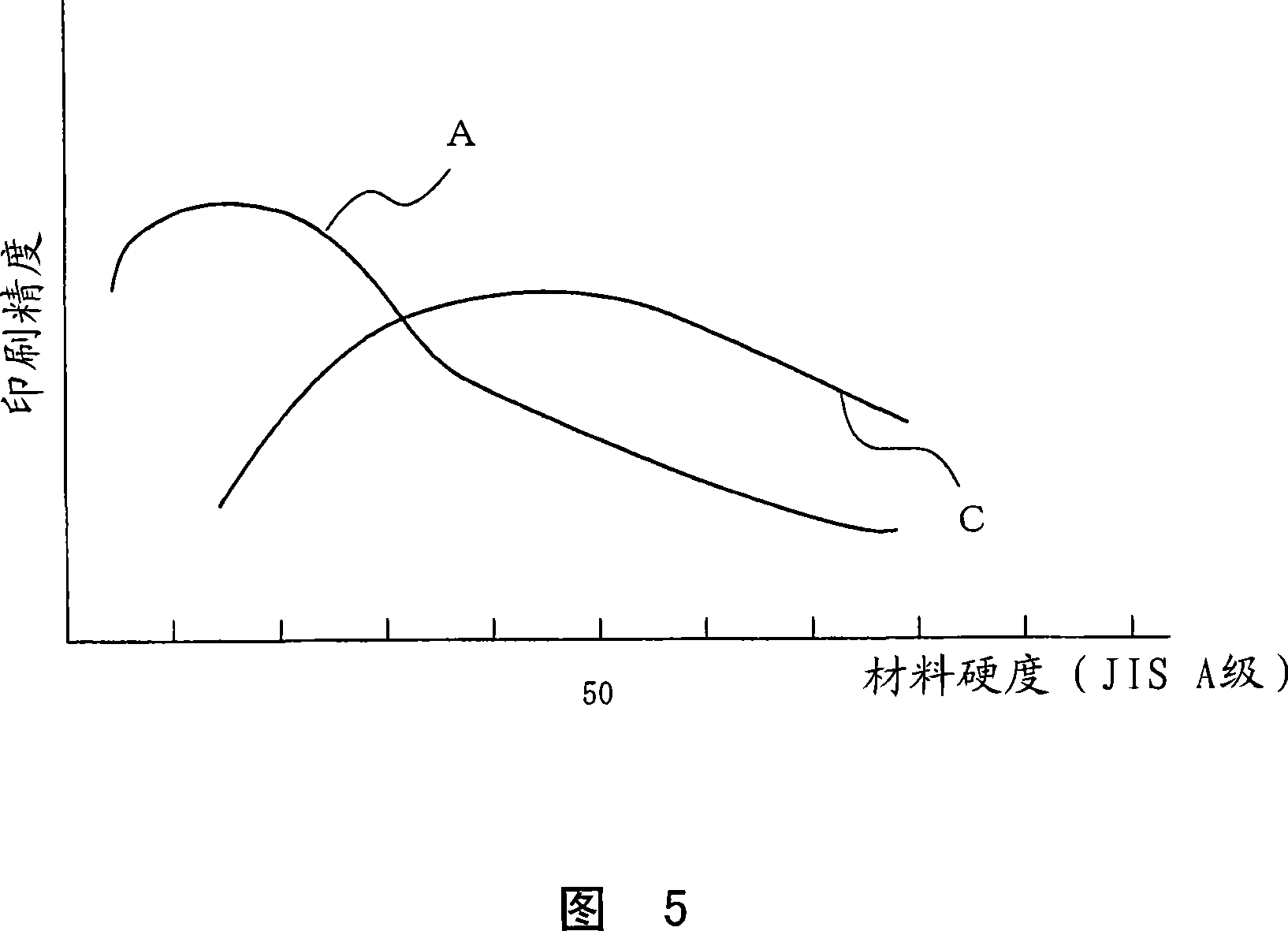

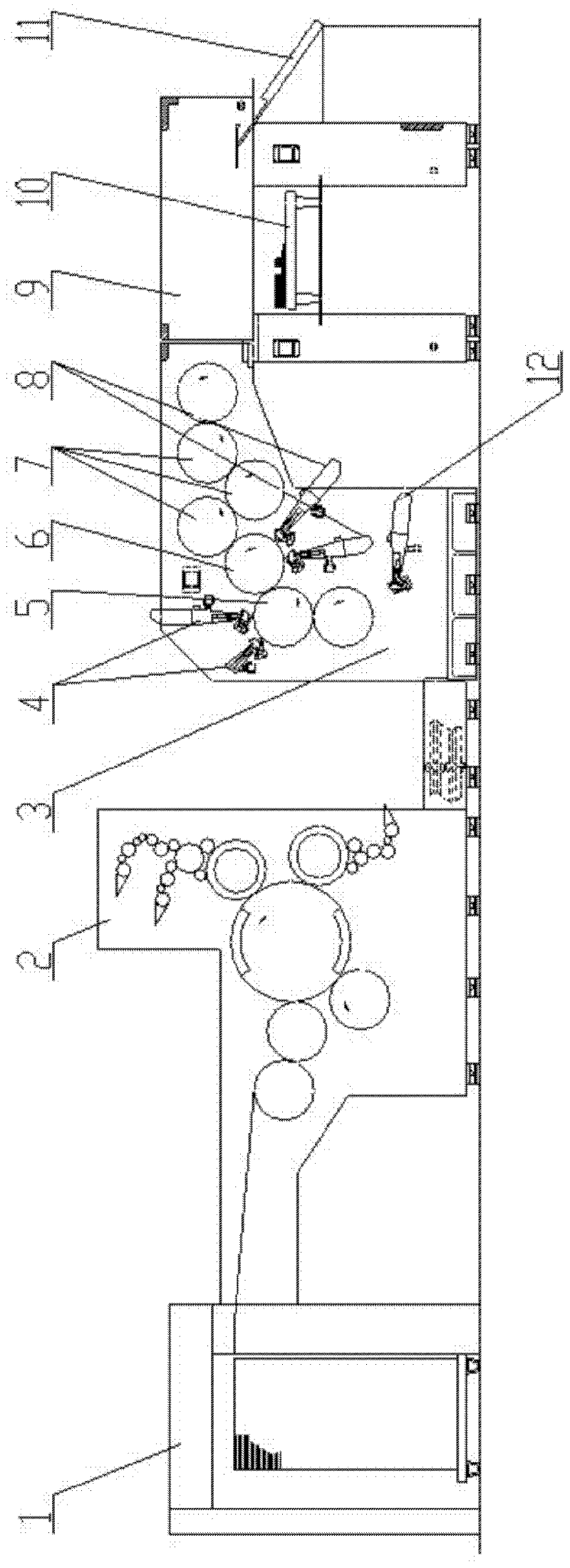

A curved surface printing method comprises a step of applying a printing ink to a raised portion of a letterpress printing original plate which is a planographic plate the raised portion of which is 0.1 to 50 μm high, a step in which an elastic blanket (2) of rubber or rubberish material having a curved surface (221, 222, 21) of a predetermined shape formed on a convex or concave surface of an object (1) to be printed and set in the same polarity direction as that of the convex or concave surface of the object (1) is pressed to the letterpress printing original plate placed in a fixed position and coated with the printing ink, and the printing ink is transferred to the curved surface (221, 222, 21) of the predetermined shape, and a step of moving the elastic blanket (2) to which the printing ink is transferred and which has curved surface (221, 222, 21) of the predetermined shape, bringing the elastic blanket (2) into contact with the curved surface of the object (1), and thus printing the object. A curved surface body printed by this method is also disclosed.

Owner:SHUHOU

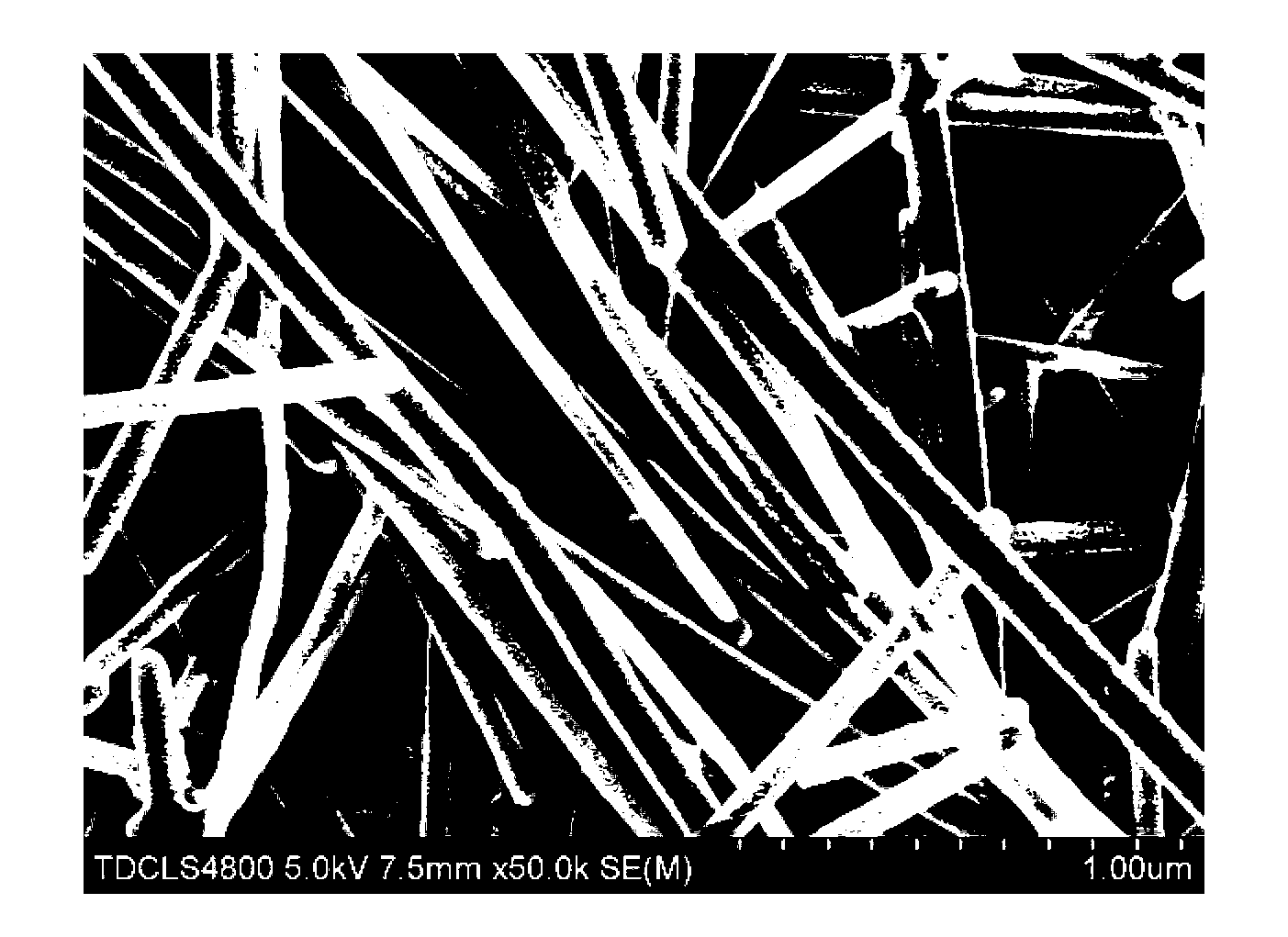

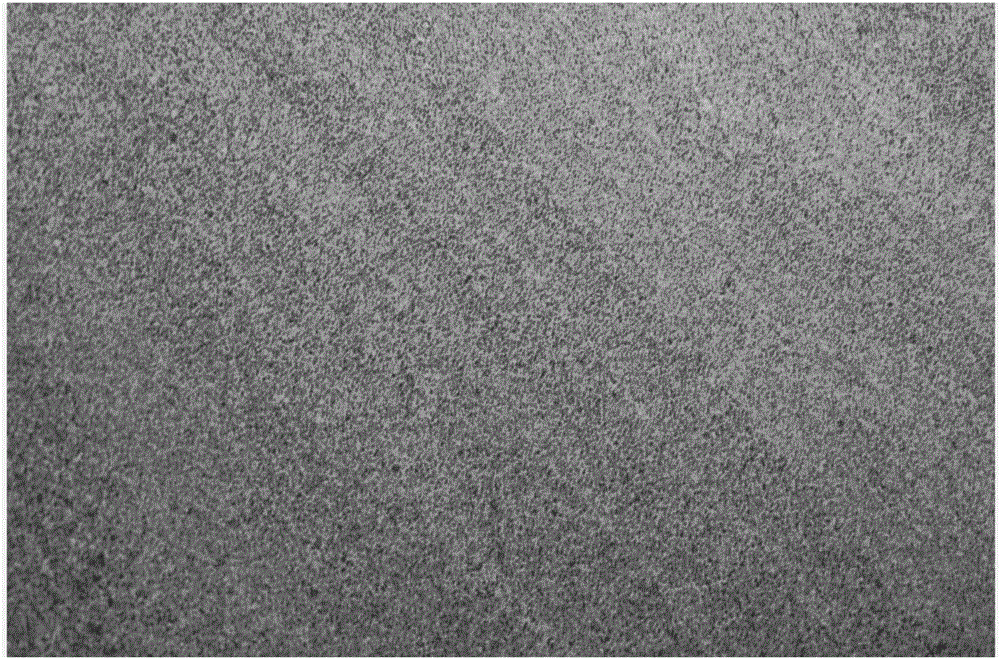

Local large-size fiber letterpress printing system and printed matter thereof

The invention provides a local large-size fiber letterpress printing system and a printed matter thereof. The system comprises a fiber ink letterpress printing unit which comprises a letterpress printing roller, an ink roller and a round roller scraper; the system also comprises an ink tank for containing fiber ink; the fiber ink penetrates through the gap between the ink roller and the round roller scraper to form a fiber ink layer; and the fiber ink layer is transferred to a printing material by a bulk boss to form a local fiber ink block. Through the invention, the limit that the existing printer cannot adopt large-size fiber ink is broken through, and a local large-size fiber printed matter is printed and produced.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

Method for preparing nano-silver particle and nano-silver wire mixed conductive ink

The invention discloses a method for preparing nano-silver particle and nano-silver wire mixed conductive ink. In the method, nano-silver particles and nano-silver wires are uniformly dispersed in a solvent. In the prepared nano-silver mixed conductive ink, the mass percentage of the nano-silver particles is 6-10 percent of the total mass of the conductive ink, and the mass percentage of the nano-silver wires is 2-5 percent of the total mass of the conductive ink. The solvent is a mixed solution which comprises the components by volume percentage of 40-50 percent of ethanol, 50-60 percent of ethylene glycol and 5-10 percent of glycerin. The mixed conductive ink has low content of silver, low cost and high electrical conductivity and is specially suitable for printing ways such as intaglio printing, letterpress printing and the like.

Owner:TIANJIN UNIV

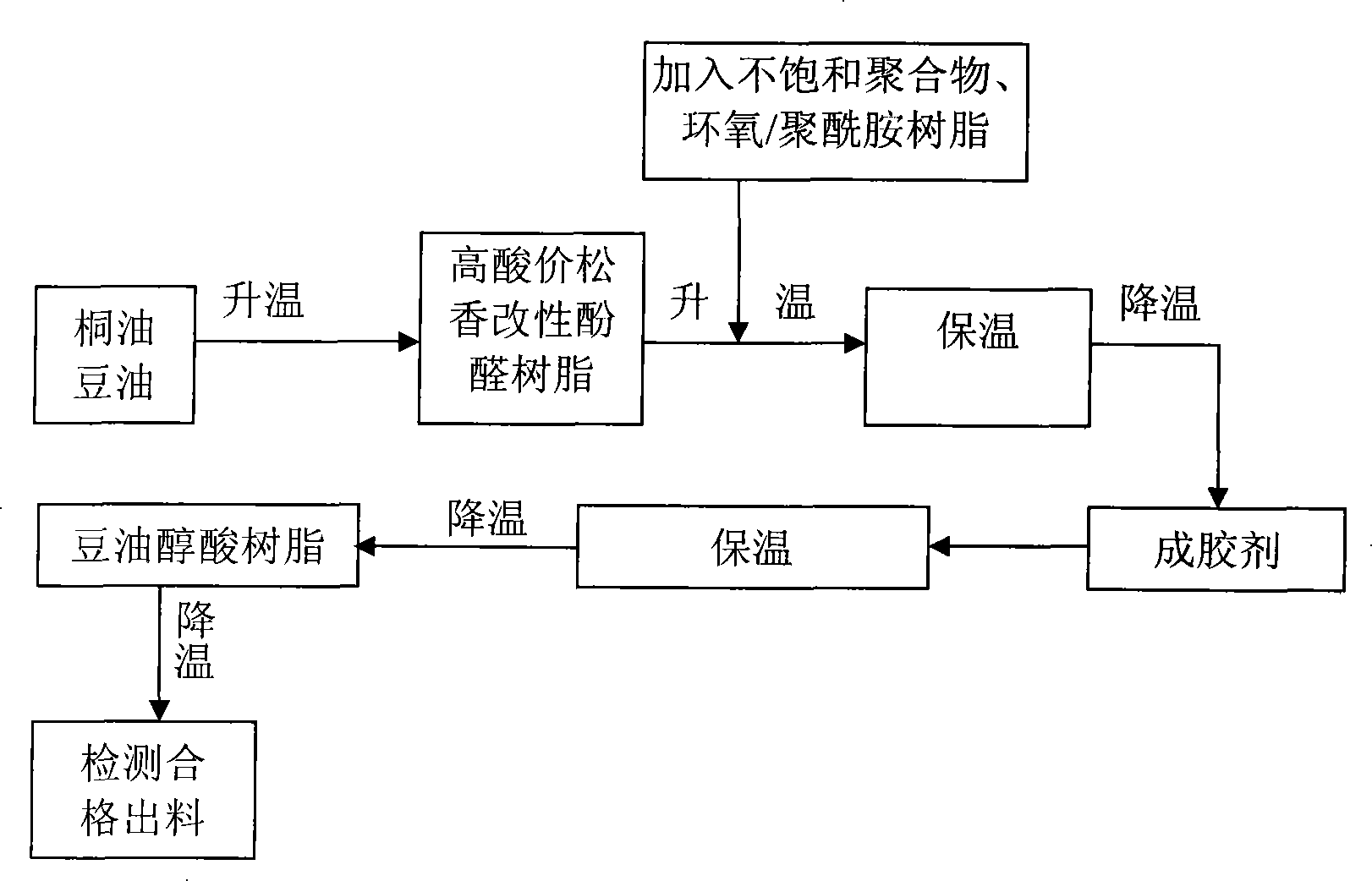

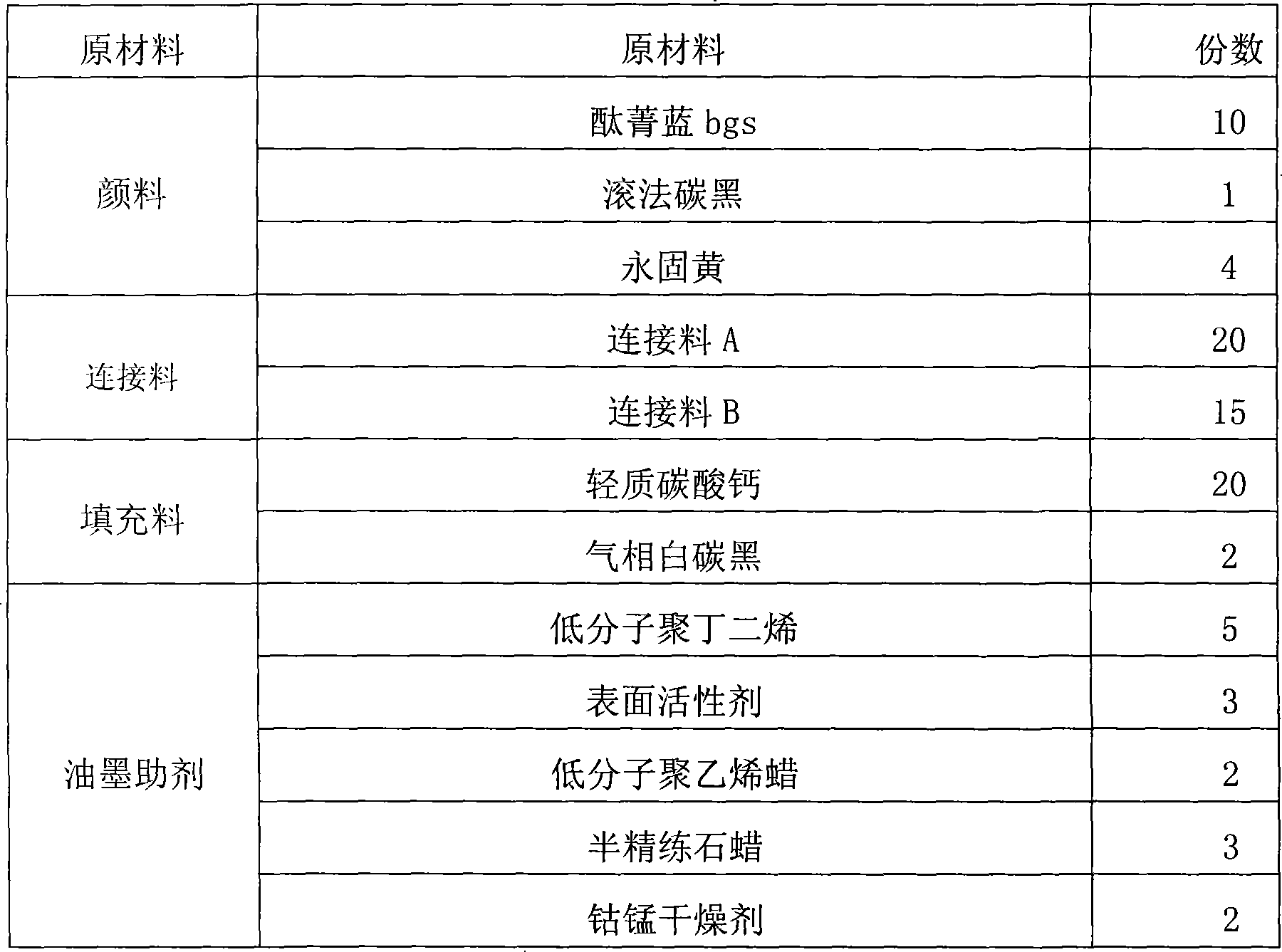

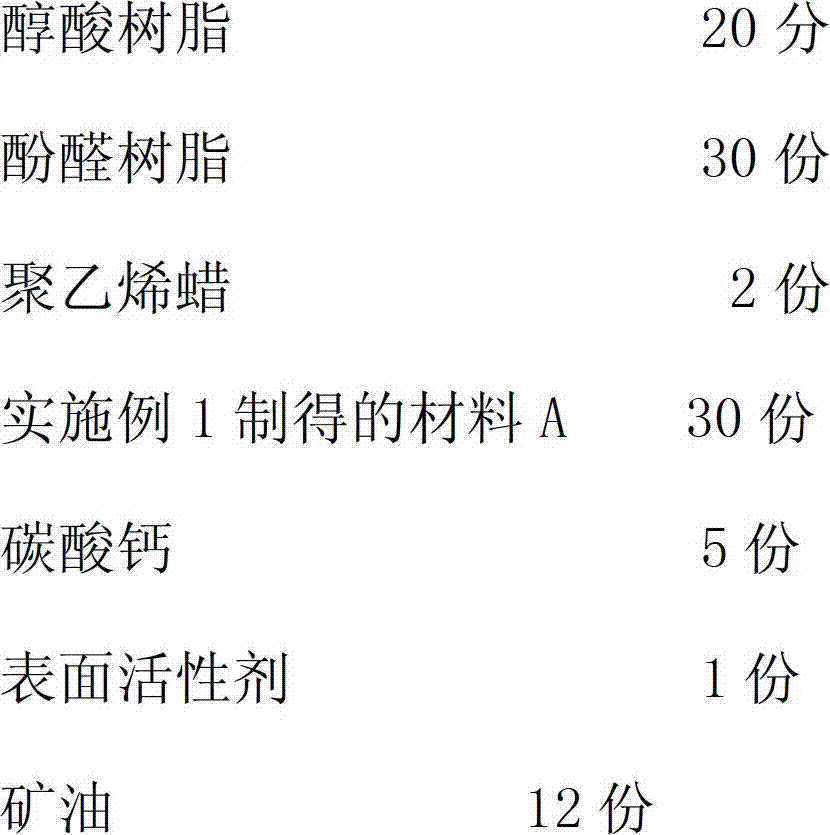

Soybean oil based protruding printing ink

ActiveCN101250350AImprove rheologyIncrease elasticityInksOther printing apparatusVegetable oilLetterpress printing

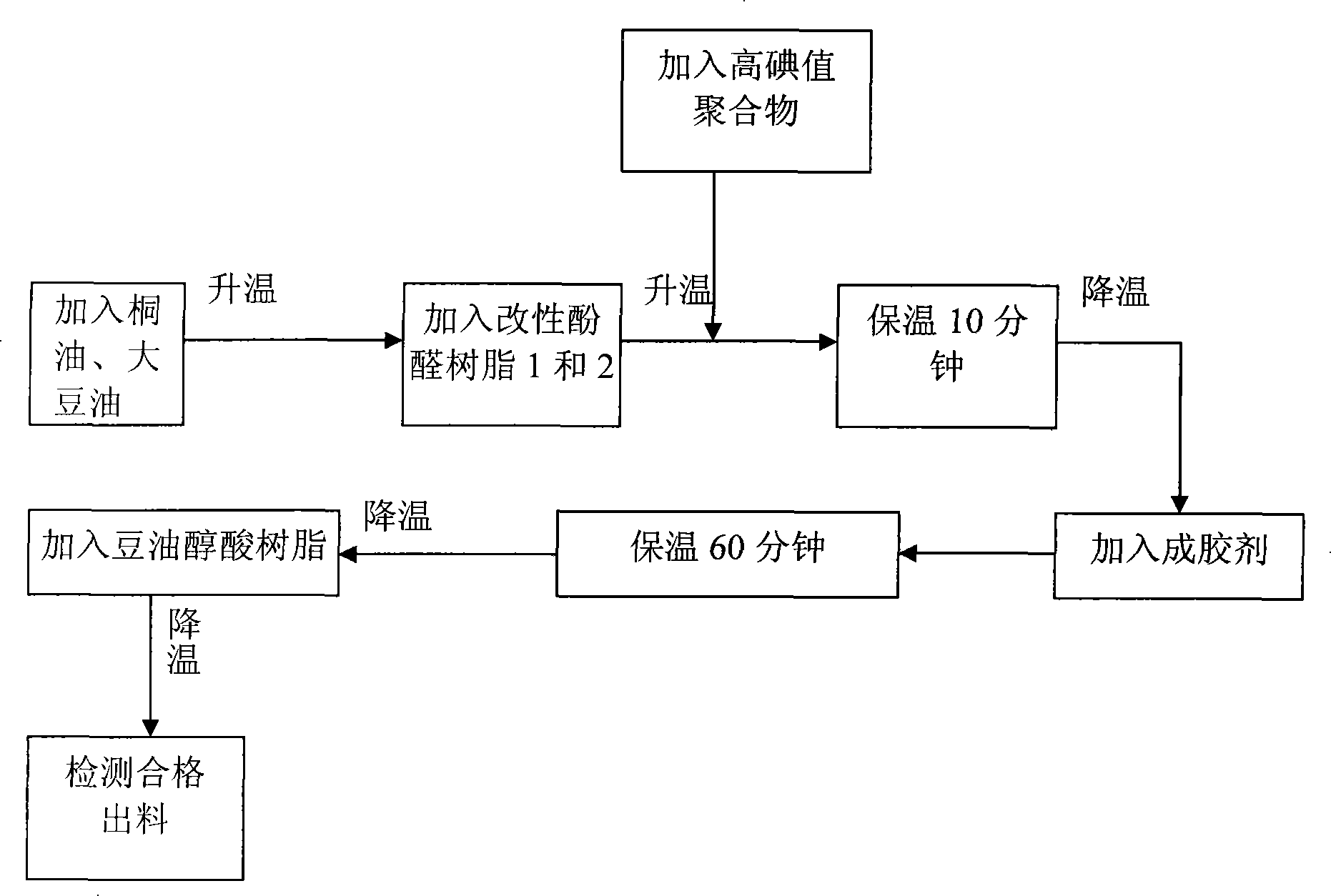

The invention relates to soybean oil base letterpress printing ink, which adopts modified phenolic with high viscosity and high dissolving ability, prepares resin oil through matching soybean oil with Chinese wood oil, regulates acid value with alkyd resin to improve appropriate hydrophilicity, uses gelatinizing agent to improve the rheological property of resin oil and increase elasticity, uses unsaturated polymer which can dissolve with vegetable oil to provide extra drying property as bonding material of printing ink. The printing ink solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, and has the advantages of small VOC content, low heavy metal content, excellent printability, set stability and processability after printed.

Owner:CHINA BANKNOTE PRINTING & MINTING

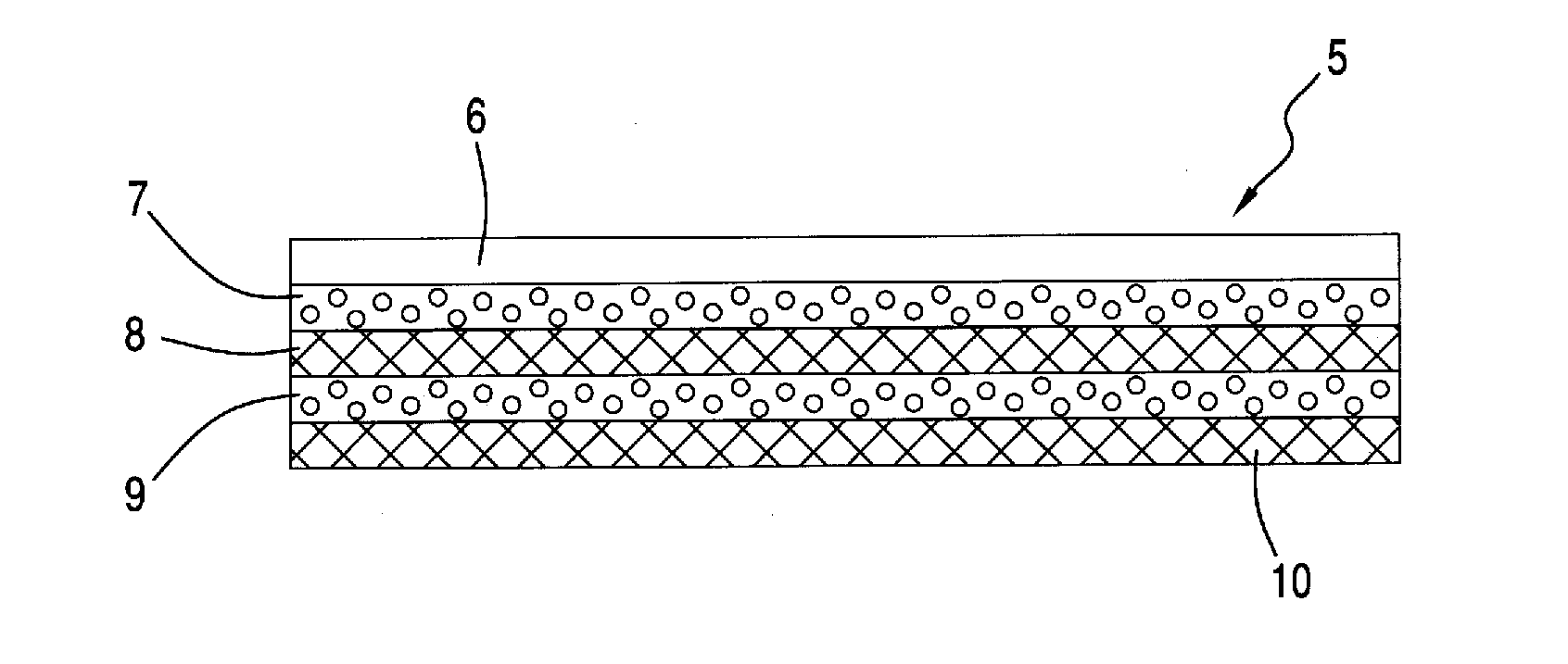

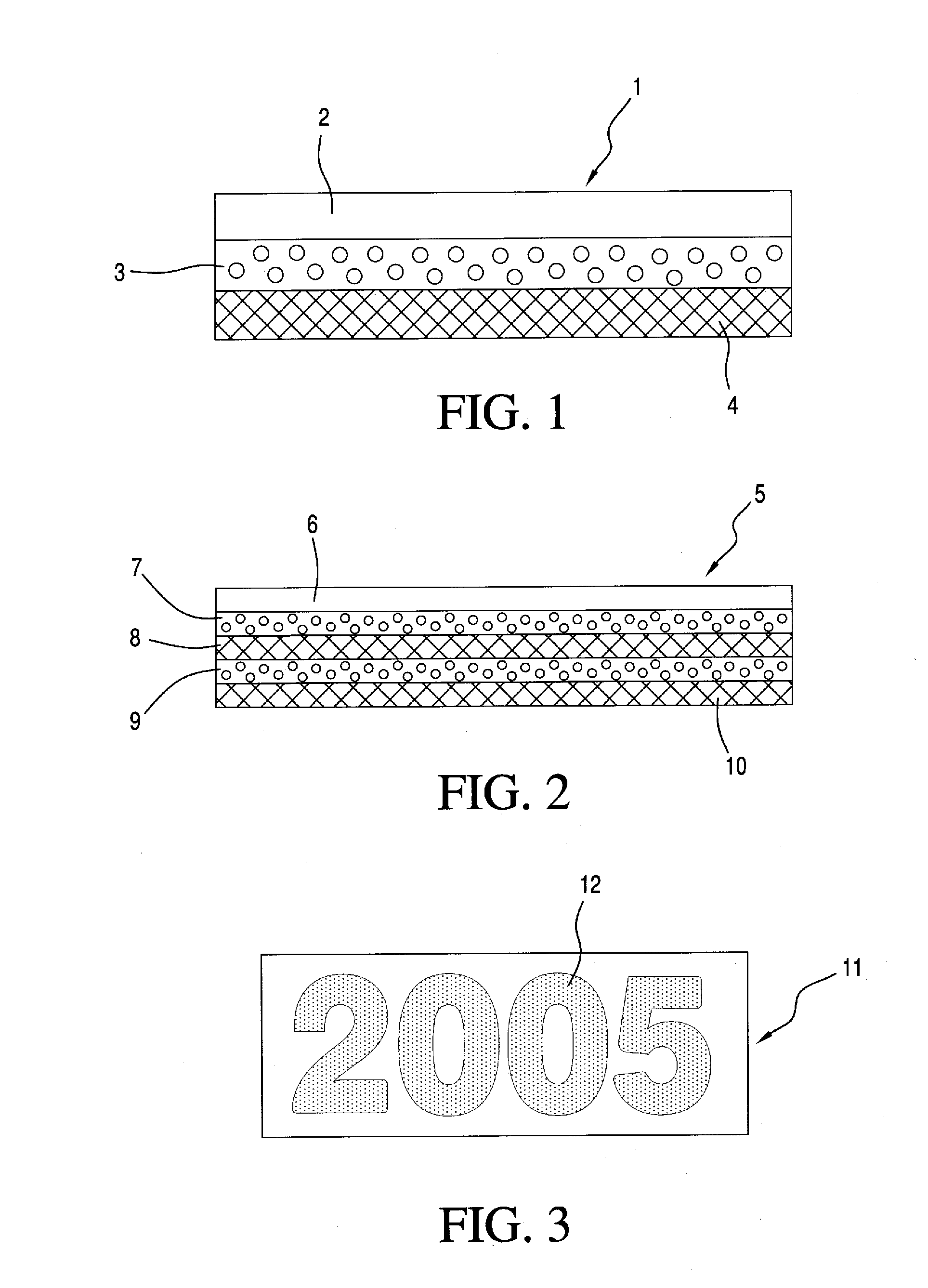

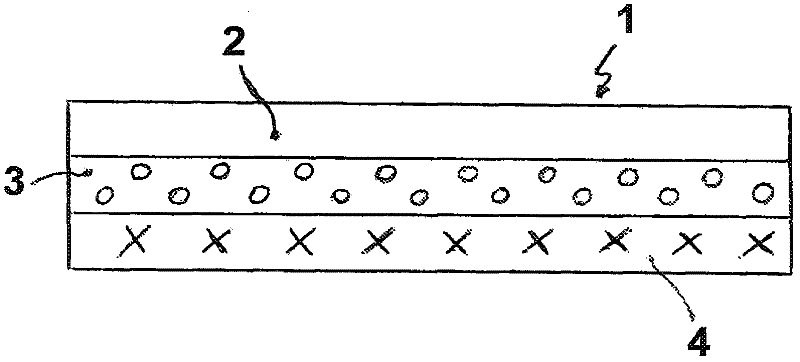

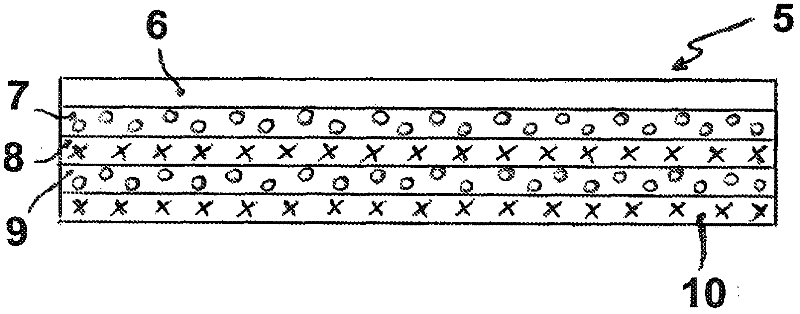

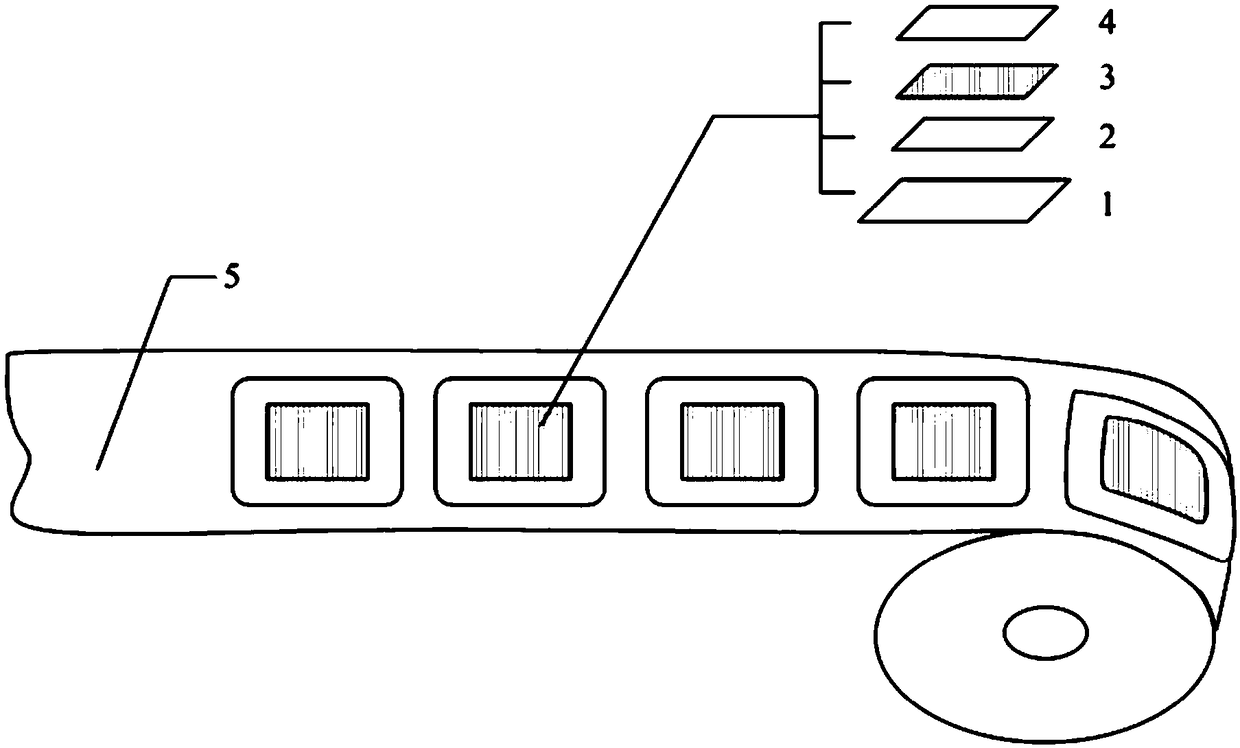

Multiple-layer flat structure in the form of a printing blanket or a printing plate for flexographic and letterpress printing with laser engraving

InactiveUS20120103216A1Quick clean upFast formingMounting boardsPlate printingLetterpress printingLaser engraving

The invention is directed to a multiple-layer flat structure (1) in the form of a printing blanket or a printing plate for flexographic and letterpress printing with: a printing layer (2) which is made from a polymeric material and is provided with laser engraving; at least one compressible layer (3); and, at least one strength-support layer (4); wherein the individual layers form an adhesive connection among one another. The multiple-layer flat structure (1) according to the invention is distinguished by the fact that the polymeric material of the printing layer (2) is a vulcanizate. Advantageous materials are proposed in this regard. The printing layer (2) expediently lies directly on a compressible layer (3). The compressible layer (3) is in turn in direct contact with a strength-support layer (4).

Owner:CONTITECH ELASTOMER BESCHICHTUNGEN

Note printing device

ActiveCN102085747AGuaranteed persistenceGuarantee anti-counterfeitingRotary pressesPrinting press partsLetterpress printingMagnetization

The invention discloses a note printing device, which comprises a paper feeding part, a printing part, a post-printing processing part and a paper discharge part, wherein the printing part comprises a letterpress unit, a color combined number printing unit and a through printing unit, wherein the post-printing processing part comprises a magnetically direction-finding unit, an ink-free belling unit and a dual-face coating unit; and all printing units of the printing parts are arranged around a central impression cylinder at intervals. The note printing device provided by the invention combines letterpress printing, porous plate printing, horizontal code arrangement, vertical code arrangement, magnetization, belling, coating and optical drying together, which means the eight flows are carried by one machine which is not bigger than a gravure press; several sets of paper feed and discharge parts are removed from the structure, so the manufacturing cost is further reduced; and compared with the single machine production, the note printing device occupies a small area and the production process is short.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

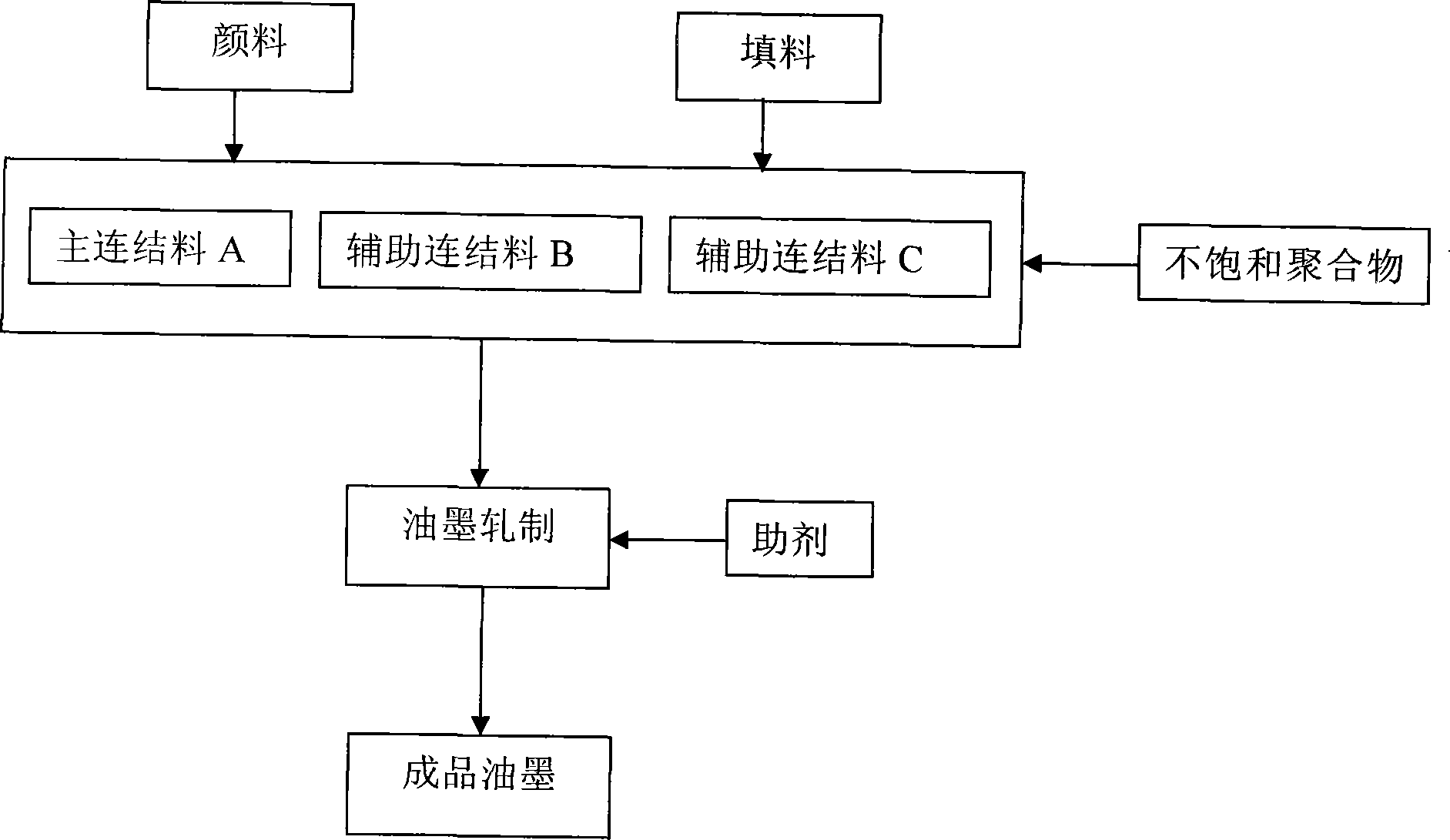

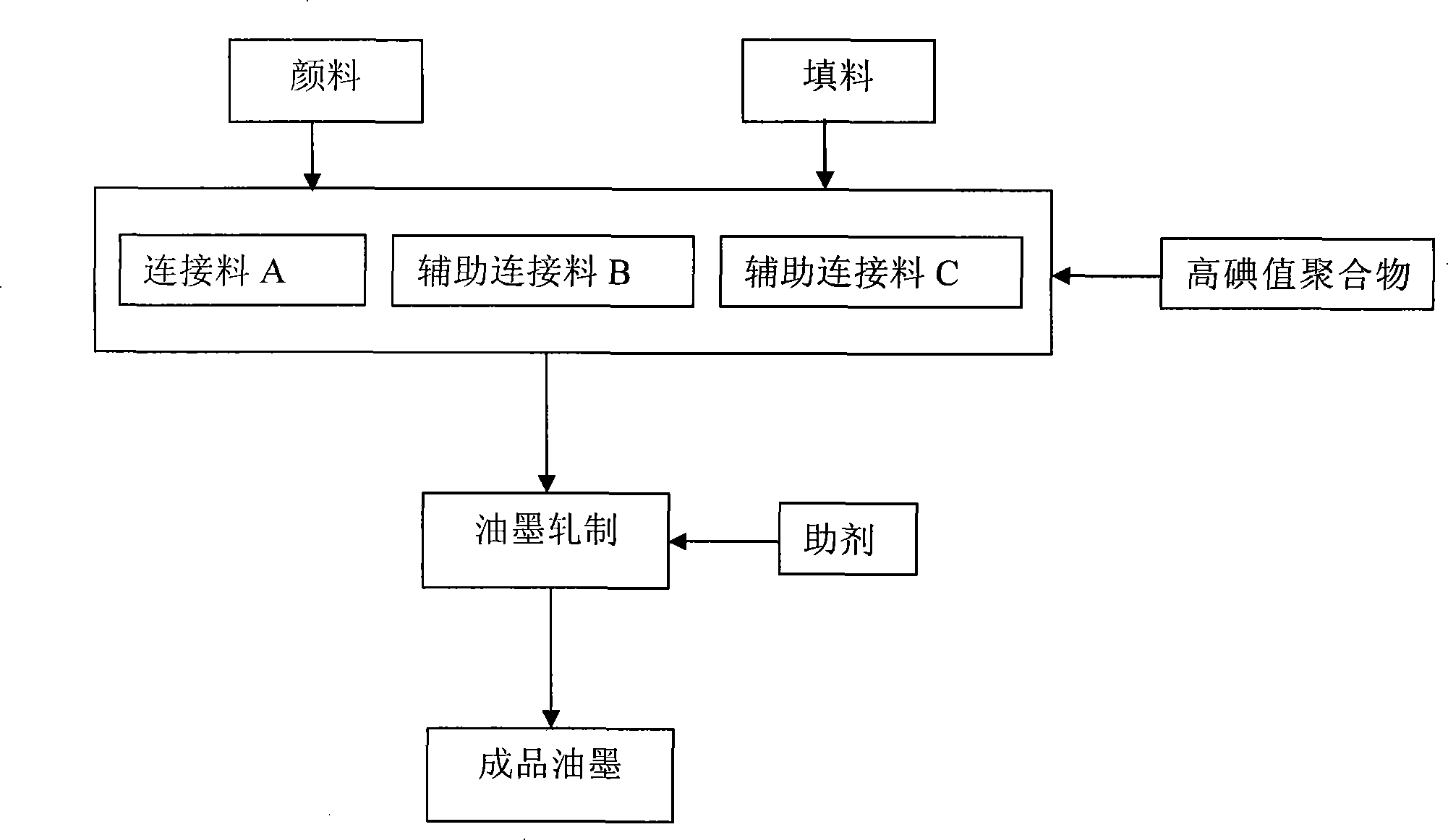

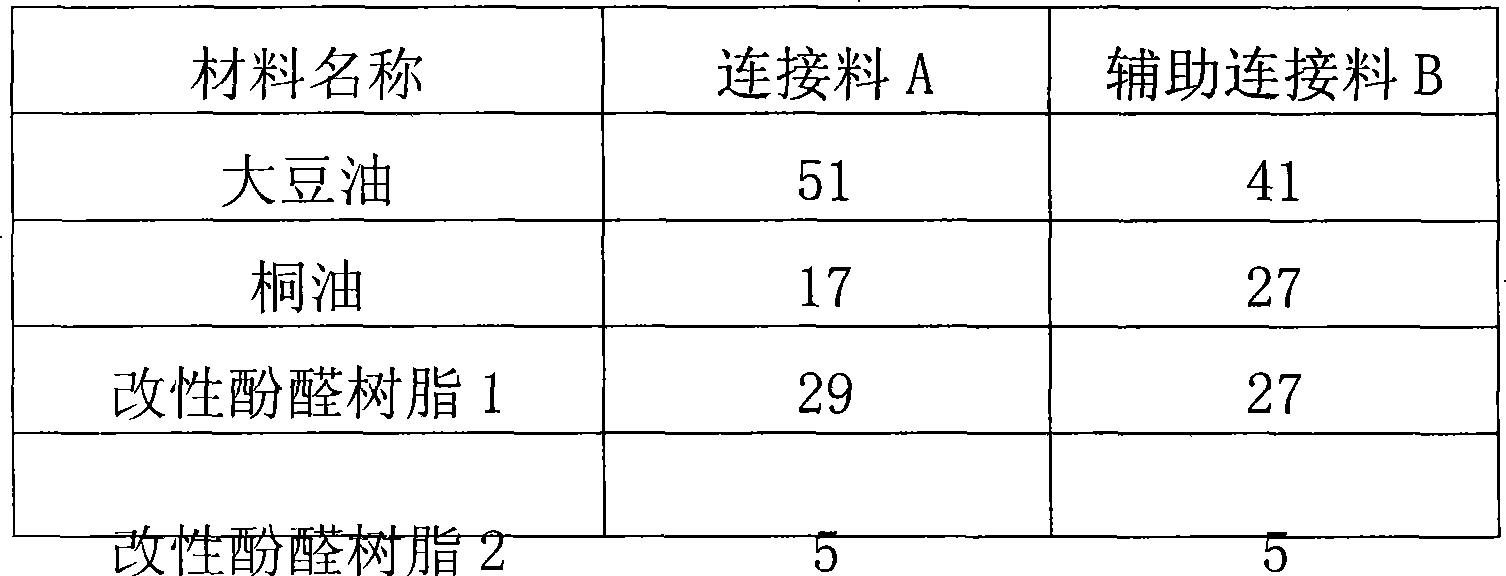

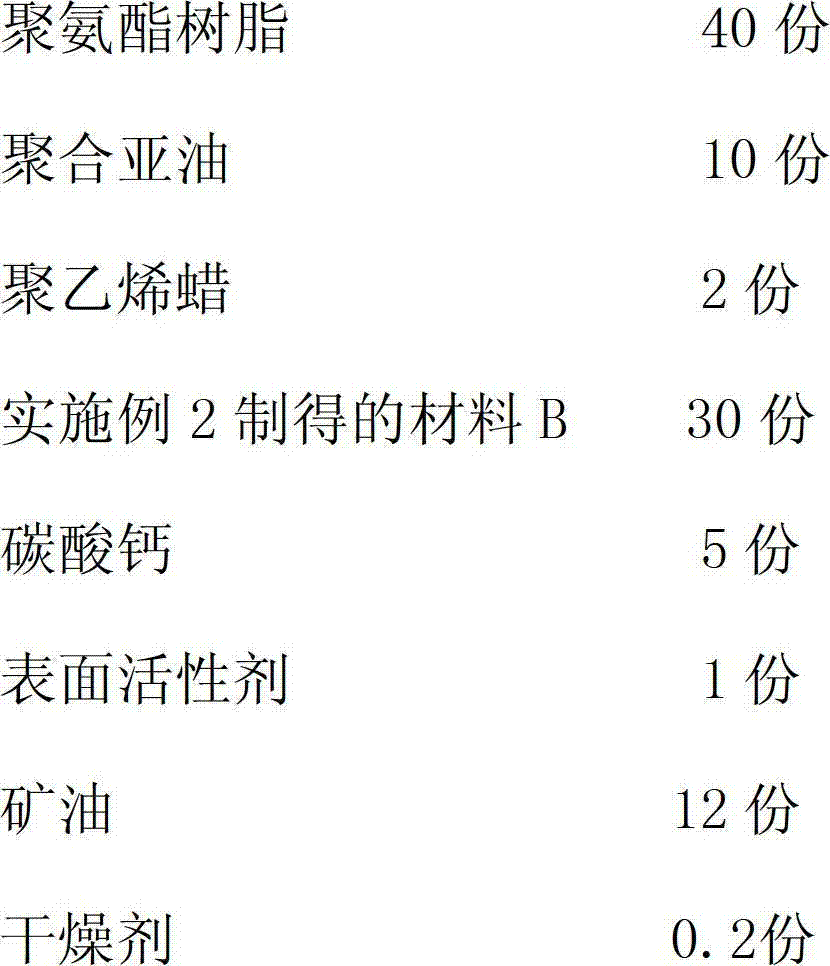

Soybean oil based hectographic ink and bonding material thereof

Soybean oil base offset printing ink and bonding material comprises bonding material A, auxiliary bonding material B and auxiliary bonding material C. The invention replaces most part or total petroleum mineral oil in printing ink with soybean oil, belonging to environment-friendly printing ink bonding material without significant petroleum components. The printing ink solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, has the advantages of environment-friendly, safety, extensive application range, excellent printability and prominent materialization index.

Owner:CHINA BANKNOTE PRINTING & MINTING

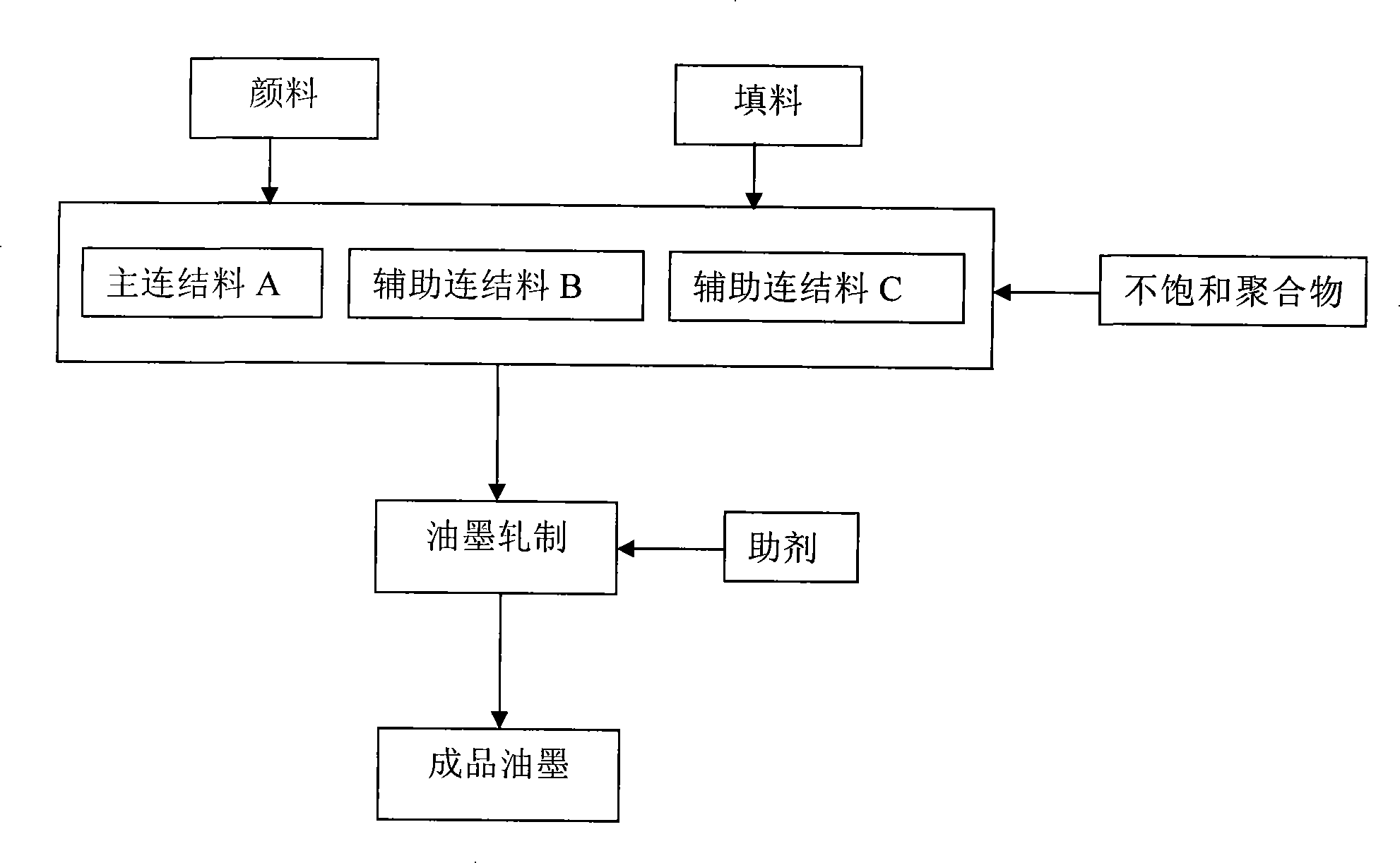

Soybean oil based silk-screen ink

ActiveCN101250351AEasy to identifyReduce harmful effectsInksOther printing apparatusScreen printingLetterpress printing

The invention relates to soybean oil base silk screen printing ink, which is formed by bonding material A, auxiliary bonding material B and auxiliary bonding material C, which have different effects. Printing ink proportion can be randomly regulated when in use, the auxiliary bonding material B and auxiliary bonding material C can be used to regulate ink property, and silk screen printing ink which meets the requirements can be produced through singly adding or adding by mixing in bonding material according to different printers. The printing ink replaces petroleum solvent with soybean oil, solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, and has the advantages of anti-counterfeiting, environment-friendly, excellent printability, extensive application range and prominent materialization index.

Owner:CHINA BANKNOTE PRINTING & MINTING

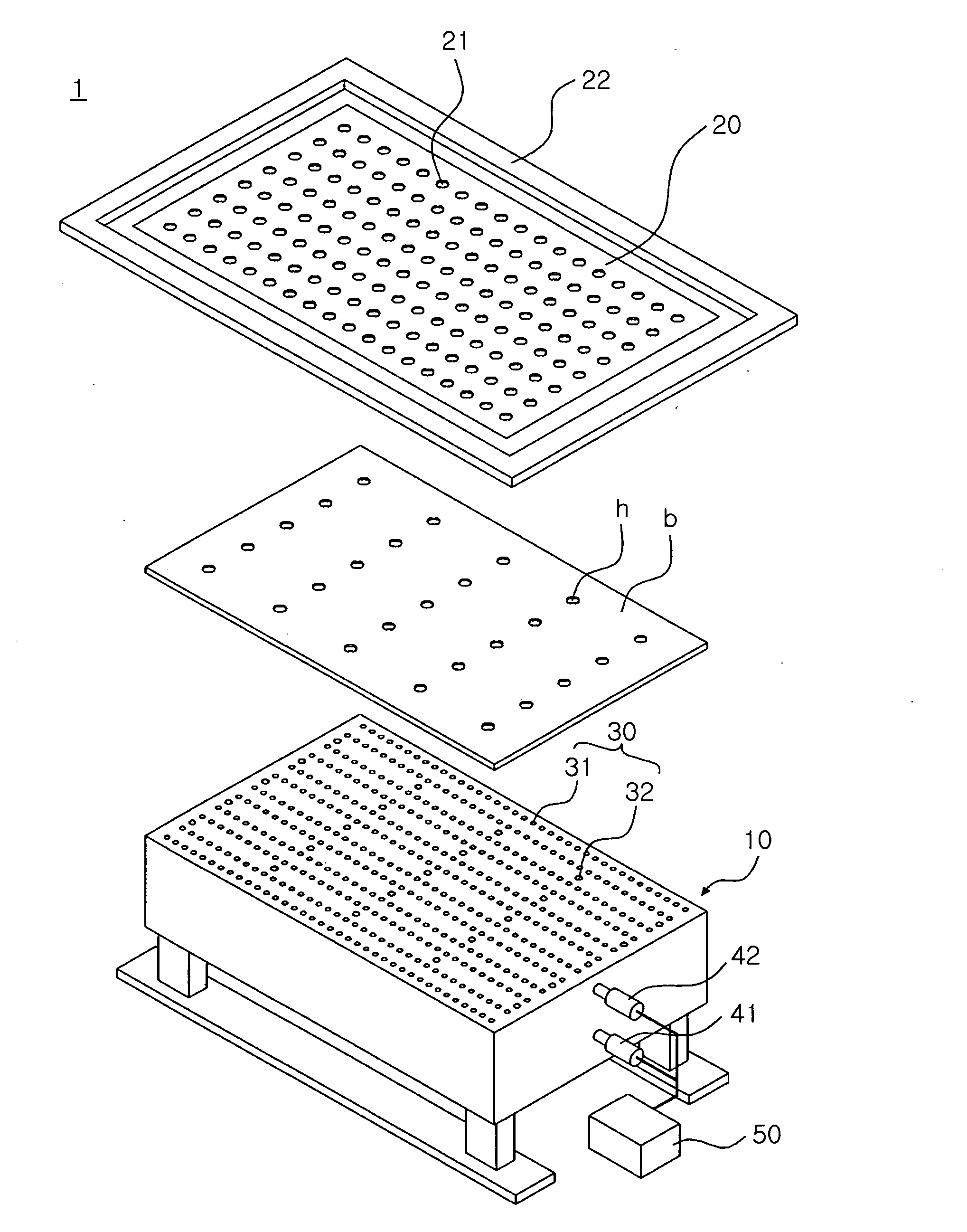

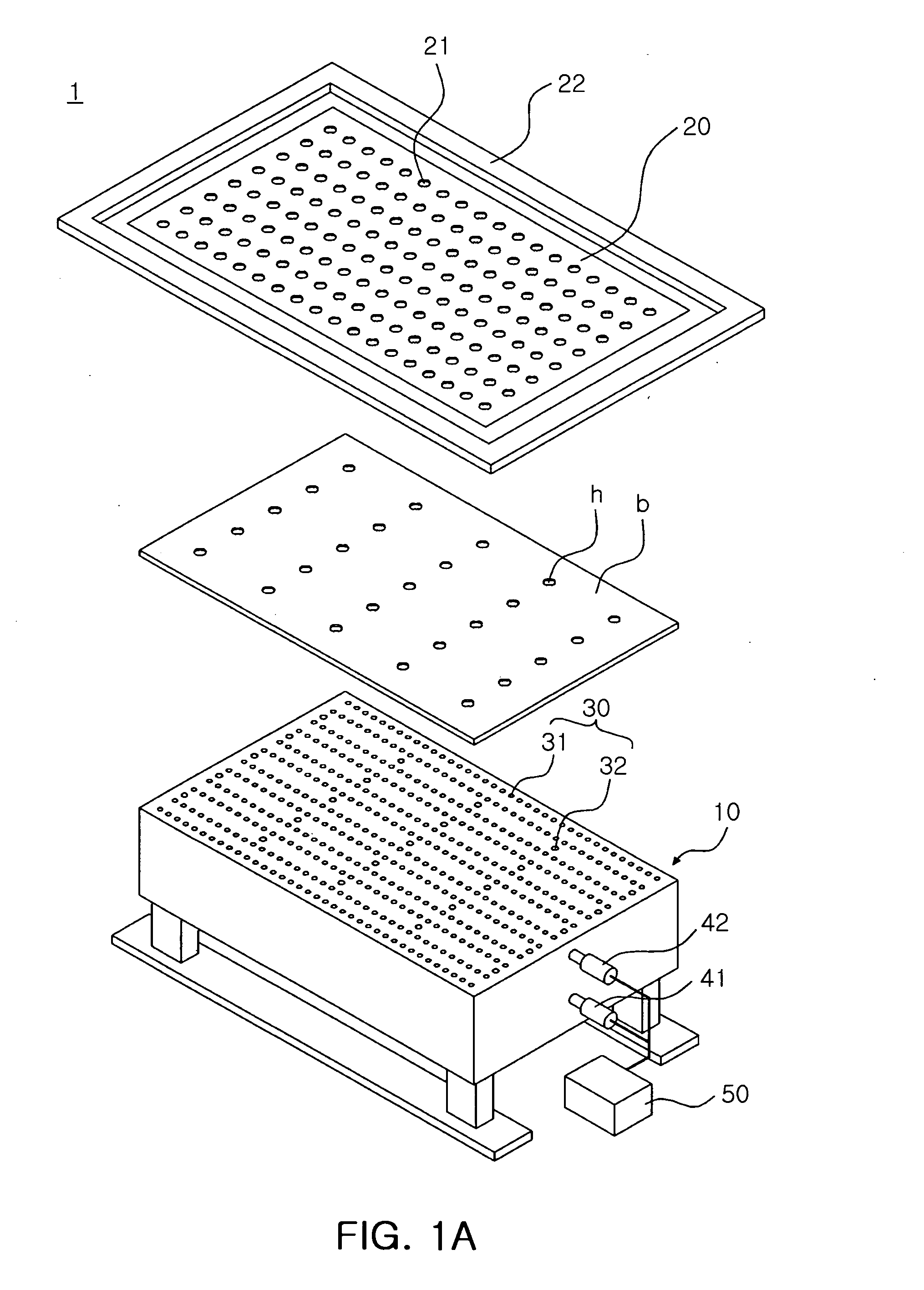

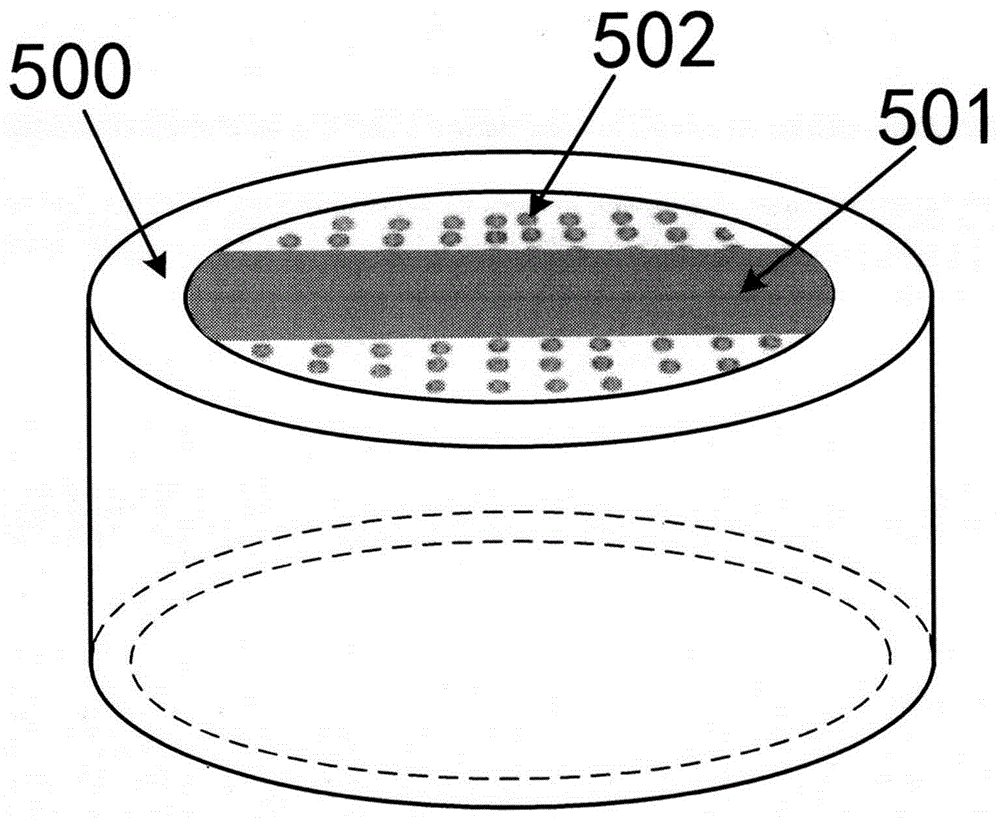

Bump printing apparatus and method of controlling the same

InactiveUS20100291289A1Good printabilityImprove reliabilitySpraying apparatusWelding/cutting auxillary devicesEngineeringClose contact

There is provided a bump printing apparatus and a method of controlling the same that can increase the printability of solder bumps being printed on a board. The bump printing apparatus may include a printing table onto which a board is mounted; a mask making close contact with the board and printing solder bumps on the board by separating the mask from the board after a printing operation; and air nozzles provided within the printing table and providing air suction to bring the board into close contact with the printing table and spraying air to separate the mask from the board.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

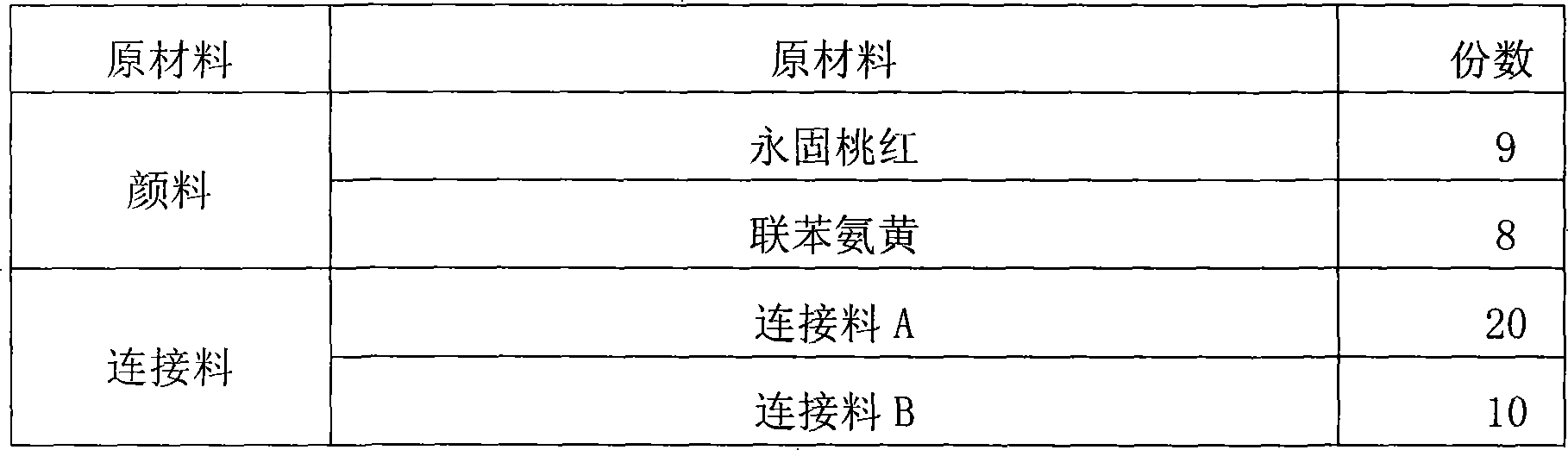

Letterpress-printing dark red ink and preparation method thereof

The invention discloses letterpress-printing dark red ink. The letterpress-printing dark red ink comprises the following components in parts by weight: 4.5-6 parts of pigment permanent red, 3-5 parts of ever-bright fast red BBN, 4-5 parts of 107 molybdate red, 10-60 parts of polyamide resin liquor, 7.6-8.4 parts of nitro-cotton liquor, 8-10 parts of alcohol, 0.5-0.8 part of polyethylene microcrystalline wax and 1.8-2.8 parts of dispersing dustproof agent. According to the letterpress-printing dark red ink and the preparation method thereof, the ink is colorful in color and luster, high in glossiness, capable of being completely dried within one second, excellent in rheological behavior and convenient for a printer to grasp and operate.

Owner:苏州凹凸彩印厂

Method of printing curved surface and curved surface body printed by using same

A curved surface printing method comprises a step of applying a printing ink to a raised portion of a letterpress printing original plate which is a planographic plate the raised portion of which is 0.1 to 50 mum high, a step in which an elastic blanket (2) of rubber or rubberish material having a curved surface (221, 222, 21) of a predetermined shape formed on a convex or concave surface of an object (1) to be printed and set in the same polarity direction as that of the convex or concave surface of the object (1) is pressed to the letterpress printing original plate placed in a fixed position and coated with the printing ink, and the printing ink is transferred to the curved surface (221, 222, 21) of the predetermined shape, and a step of moving the elastic blanket (2) to which the printing ink is transferred and which has curved surface (221, 222, 21) of the predetermined shape, bringing the elastic blanket (2) into contact with the curved surface of the object (1), and thus printing the object. A curved surface body printed by this method is also disclosed.

Owner:SHUHOU

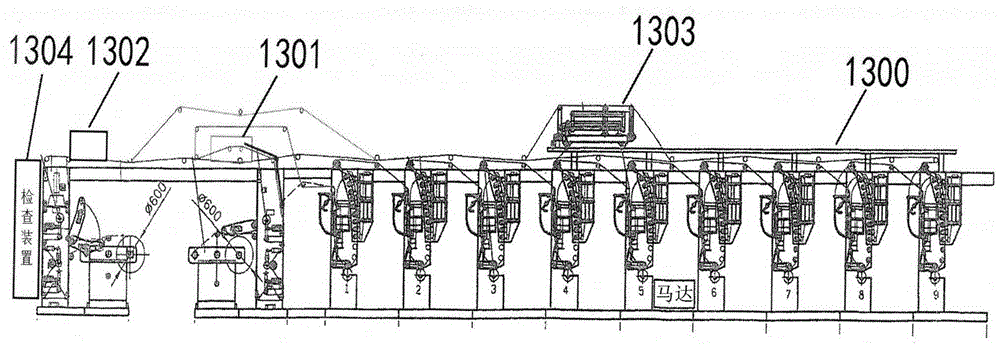

Letterpress printing and large-piece product quality inspection combination machine

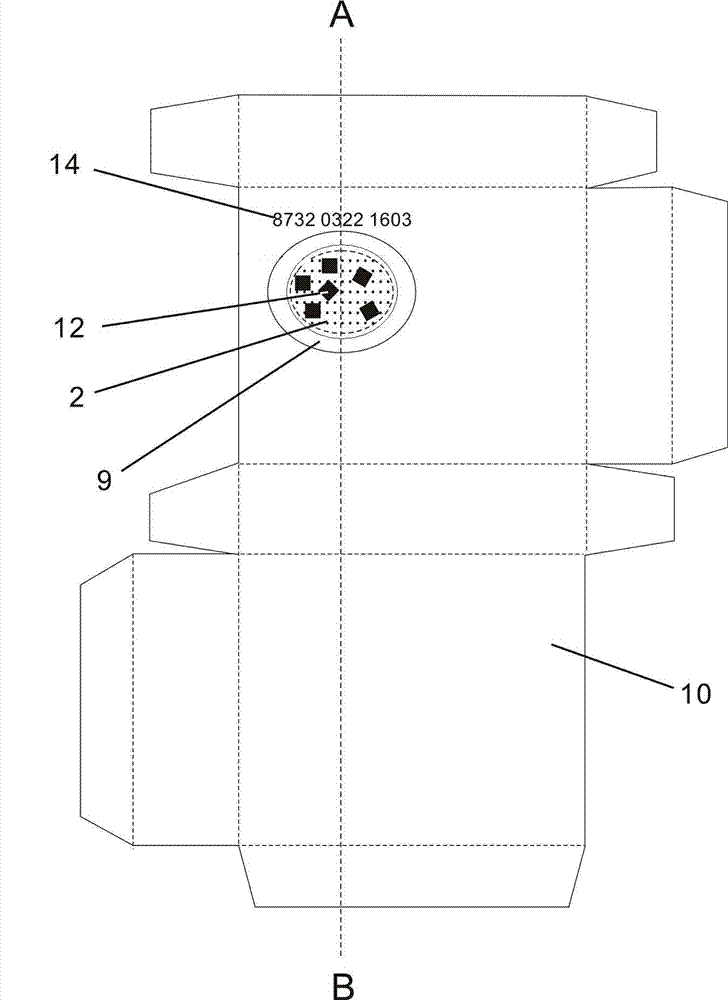

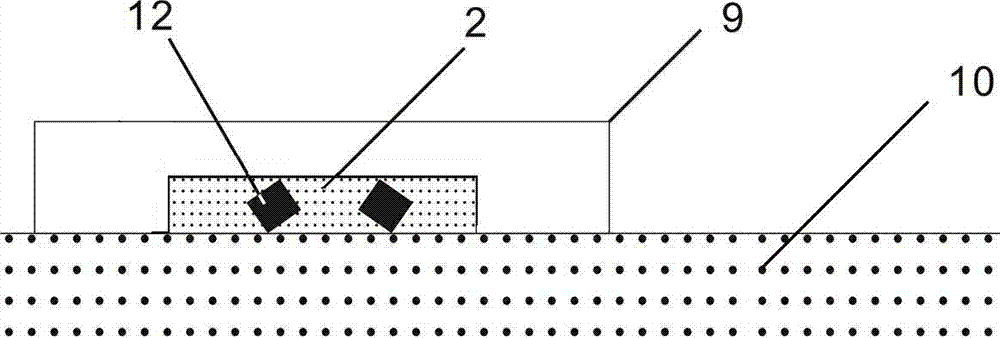

ActiveCN102350863AGuaranteed uptimeHigh precisionOptically investigating flaws/contaminationRotary pressesProduct inspectionInformation transmission

The invention discloses an imprinting and large-piece product quality inspection combination machine, which is characterized in that: an original paper feeding part (1) and an original imprinting part (2) of an original multifunctional imprinter are adopted, and watermark quality is examined by a fluoroscopic inspection device (12) after the watermark is completed; a product is returned to a front-surface inspection device (4) so as to examine the front surface of the product; then the product is conveyed to a back-surface inspection device (8) so as to examine the back surface of the product; and finally the product is conveyed to a paper collecting chain (9), so that the final quality of the large-piece product is comprehensively judged by an inspection system, and the product is respectively sent into a main paper collection cabin (10) or an auxiliary paper collection cabin (11) according to the judgment result. The present watermark procedure and the final quality inspection procedure of the large-piece product are integrated into a whole by the combination machine, so the production process can be simplified, the production field and the labor cost can be saved, the product flow process of the product can be shortened, the present large-piece product inspection procedure can also be shortened, the restraining of the previous procedure and the next procedure can be reduced, the production efficiency can be improved, the information transmission flow can be shortened, and the inspection process is simple and stable.

Owner:SHANGHAI BANKNOTE PRINTING +1

A multiple-layer flat structure in the form of a printing blanket or a printing plate for flexographic and letterpress printing with laser engraving

The invention relates to a multiple-layer flat structure (1) in the form of a printing blanket or a printing plate for flexographic and letterpress printing with: - a printing layer (2) which is made from a polymeric material and is provided with laser engraving; - at least one compressible layer (3), and - at least one strength-support layer (4); wherein the individual layers form an adhesive connection among one another. The multiple-layer flat structure (1) according to the invention is distinguished by the fact that the polymeric material of the printing layer (2) is a vulcanisate. Advantageous materials are proposed in this regard. The printing layer (2) expediently lies directly on a compressible layer (3). The compressible layer (3) is in turn in direct contact with a strength-support layer (4).

Owner:CONTITECH ELASTOMER BESCHICHTUNGEN

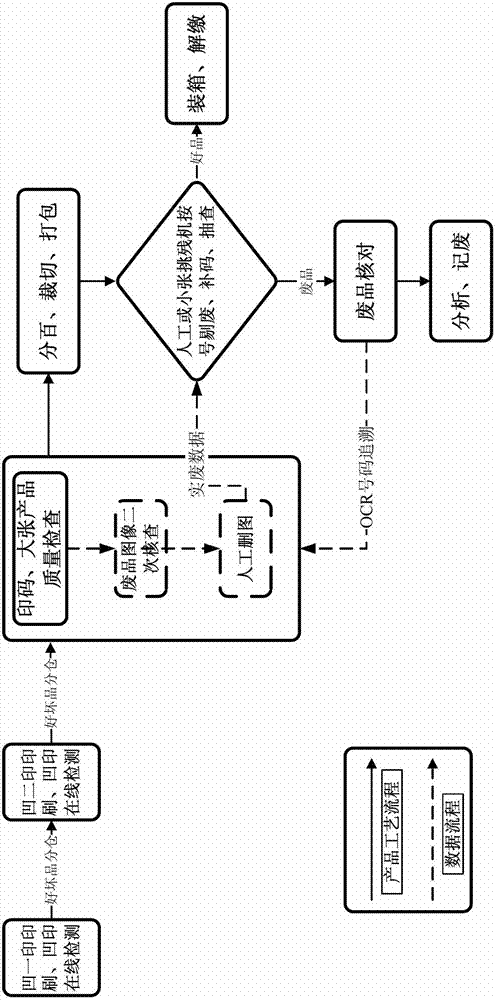

Quality control device and method for banknote product

ActiveCN102831703ARealize abolitionAvoid situations where retrospective work is difficultCoin/paper handlersRisk ControlMachine vision

The invention discloses a quality control device and method for a banknote product. According to the quality control method, two sets of online gravure secondary checking equipment, letterpress printing and large piece combining machine, one set of small piece RMB inspection rejecting equipment according to serial number for a waste picking machine and data collecting analysis and form forming equipment are at least comprised; a relatively-mature imprinting three-in-one online detection system is improved into the letterpress printing and large piece combining machine, so that quality full inspection of large-piece note surface after the banknote product is imprinted is realized by using a machine vision detection technology, data are transmitted to the small piece RMB inspection rejecting equipment according to the serial number for the waste picking machine and further automatic rejection of waste banknote products is realized. The quality control device and method disclosed by the invention have the advantages that due to the adoption of the device, a novel banknote production process with the advantages of concise flow, high efficiency, strong control force of quality risk and high automatic degree can be formed.

Owner:SHANGHAI BANKNOTE PRINTING +1

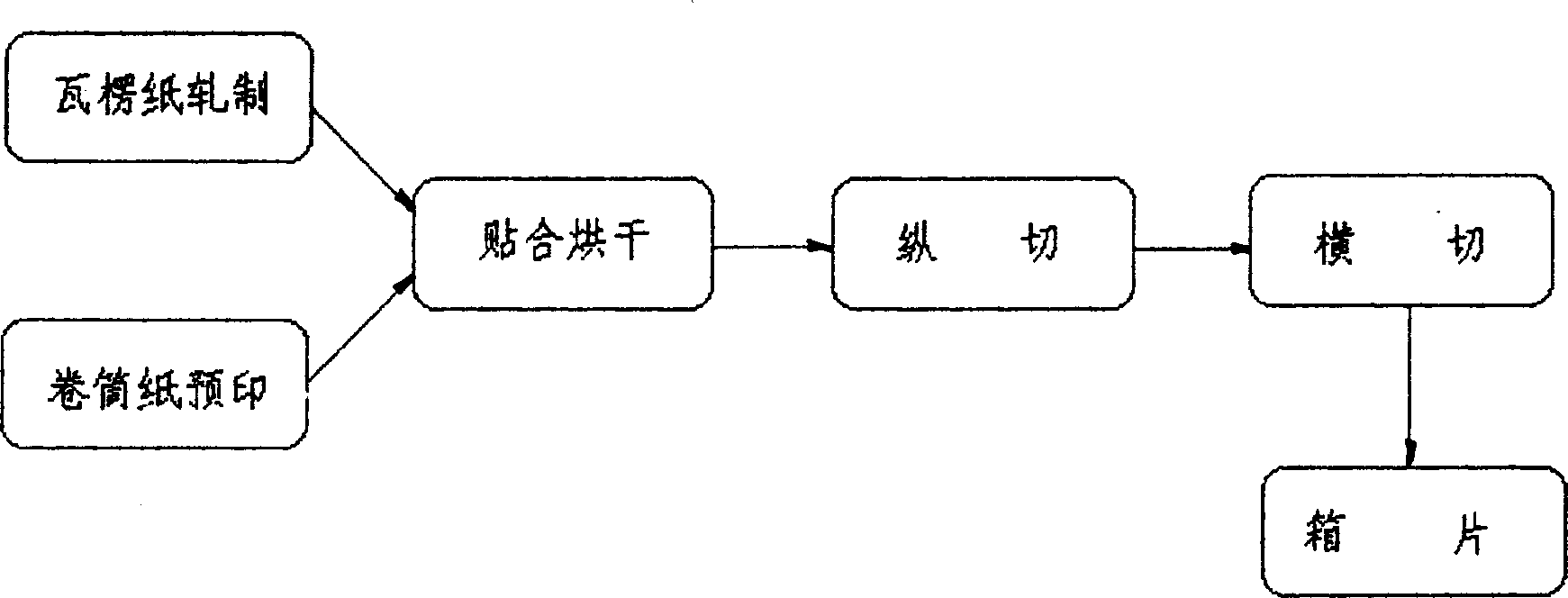

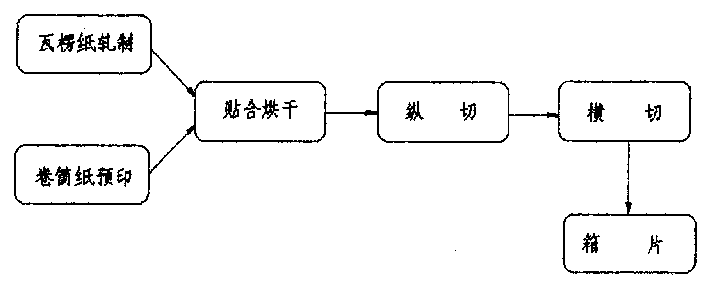

Method for producing corrugated box sheet

InactiveCN1408539AReduce intensityMechanical working/deformationPaper/cardboard layered productsRolling paperLetterpress printing

The production process of corrugated box sheet includes th technological steps of: preprinting of rolled paper, rolling corrugated paper, adhering and stoving, longitudinal cutting and transverse cutting to form box sheet. The said technological process is superior to available process and has high production efficiency, high paper utilization, high corrugation strength and beautiful corrugated box product.

Owner:浙江通天星集团股份有限公司

Soybean oil based intaglio printing ink and bonding material thereof

ActiveCN101250352AEnvironmental performanceHigh physical and chemical resistanceInksOther printing apparatusLetterpress printingPrinting ink

Soybean oil base gravure printing ink and bonding material comprises bonding material A with high washing property and bonding material B with high materialization resistant property. The invention replaces partial petroleum solvent in petroleum base printing ink, belonging to environment-friendly printing ink bonding material. The printing ink solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, has the advantages of environment-friendly, safety, excellent printability and set ability, and can meet special printings such as money bonds, and value added tax invoices and the like.

Owner:CHINA BANKNOTE PRINTING & MINTING

Letterpress printing original plate for laser engraving and a letterpress printing plate obtained therefrom

ActiveUS20100269721A1Maintain good propertiesEasy to disassemblePhotosensitive materialsSemiconductor/solid-state device manufacturingMeth-Letterpress printing

To provide a photosensitive resin composition which is a material for a printing original plate for laser engraving which generates no printing deficiencies and from which a printing plate with a satisfactory resolution can be produced. A printing original plate for laser engraving where image is formed by irradiation of laser beam to form a printing plate, characterized in that the photosensitive resin composition layer consists of a photosensitive resin composition in which soluble polyamide or soluble polyether urethane urea, ethylenic unsaturated monomer and photopolymerization initiator are essential ingredients and the amount of (meth)acryloyl group in the photosensitive resin composition is 0.25 to 0.40 mol per 100 g of the photosensitive resin composition.

Owner:TOYOBO MC CORP

Anti-counterfeiting ink containing electrophoresis microcapsule, and print product manufactured thereby

InactiveCN101831213ADetection means safetyEnhance color contrastOther printing matterInksScreen printingLetterpress printing

The invention provides an anti-counterfeiting ink containing electrophoresis microcapsule, and the ink contains 10-90% of electrophoresis microcapsule based on the total weight of the ink. The anti-counterfeiting ink is screen printing ink, gravure ink, litho printing ink, letterpress printing or the like. The anti-counterfeiting ink is used for printing characteristic information on articles which need anti-counterfeiting authentication; after electric field is applied, color change effect is generated on the impress of the anti-counterfeiting ink and can be maintained for a period of time; after reversed electric field is applied, the color of the impress is recovered immediately; after the reversed electric field is continuously applied for a period of time, the color of the impress is changed again and is different from the initial color. By utilizing the change of the specific color, the anti-counterfeiting ink can be used for identifying the authenticity of a print product; and the phenomenon can be identified by a simple instrument by the people, and the testing method is safe. The invention also provides the print product which is printed by the anti-counterfeiting ink and has the anti-counterfeiting identification characteristic.

Owner:SECURITY PRINTING INST OF PEOPLES BANK OF CHINA +1

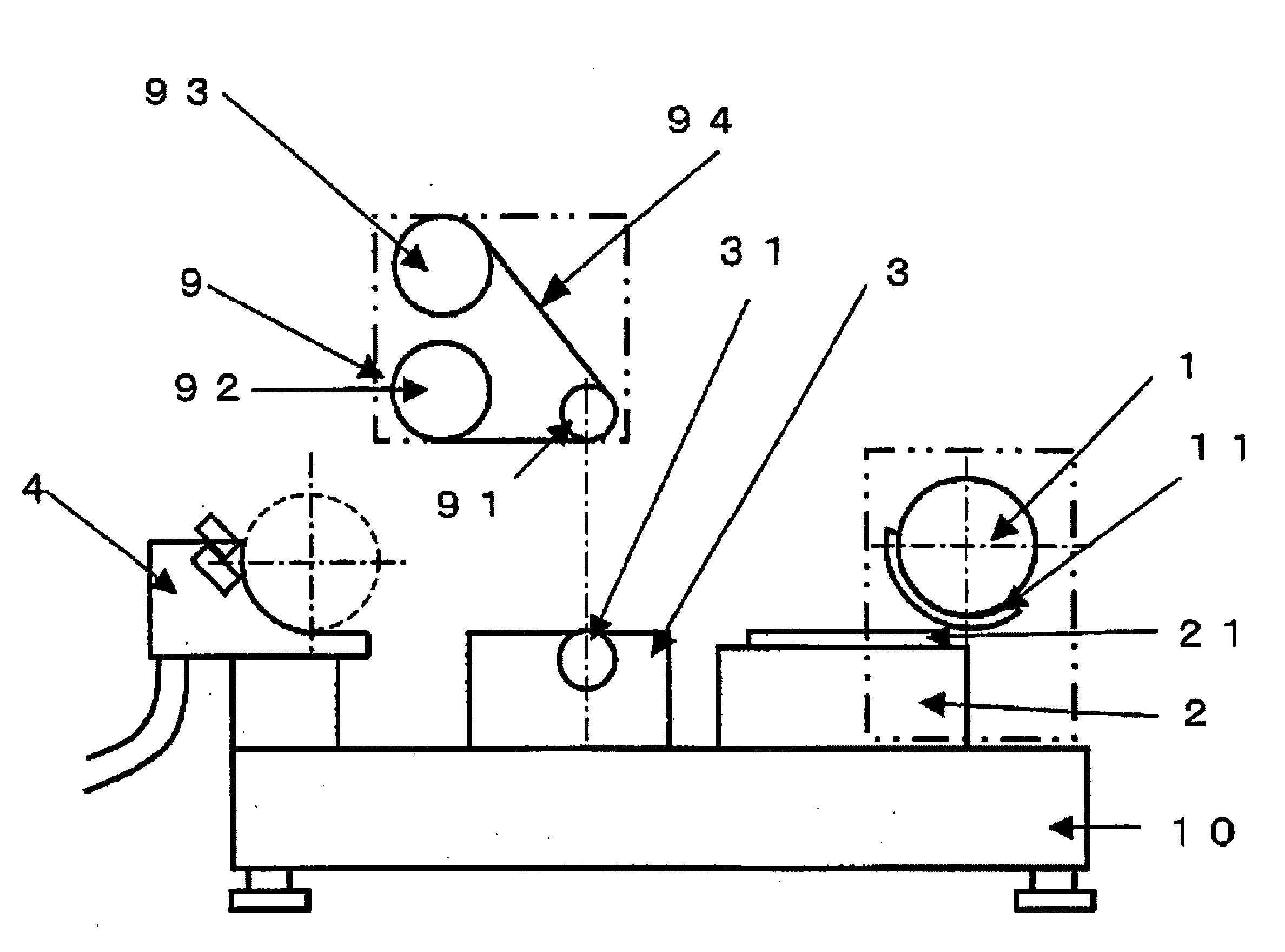

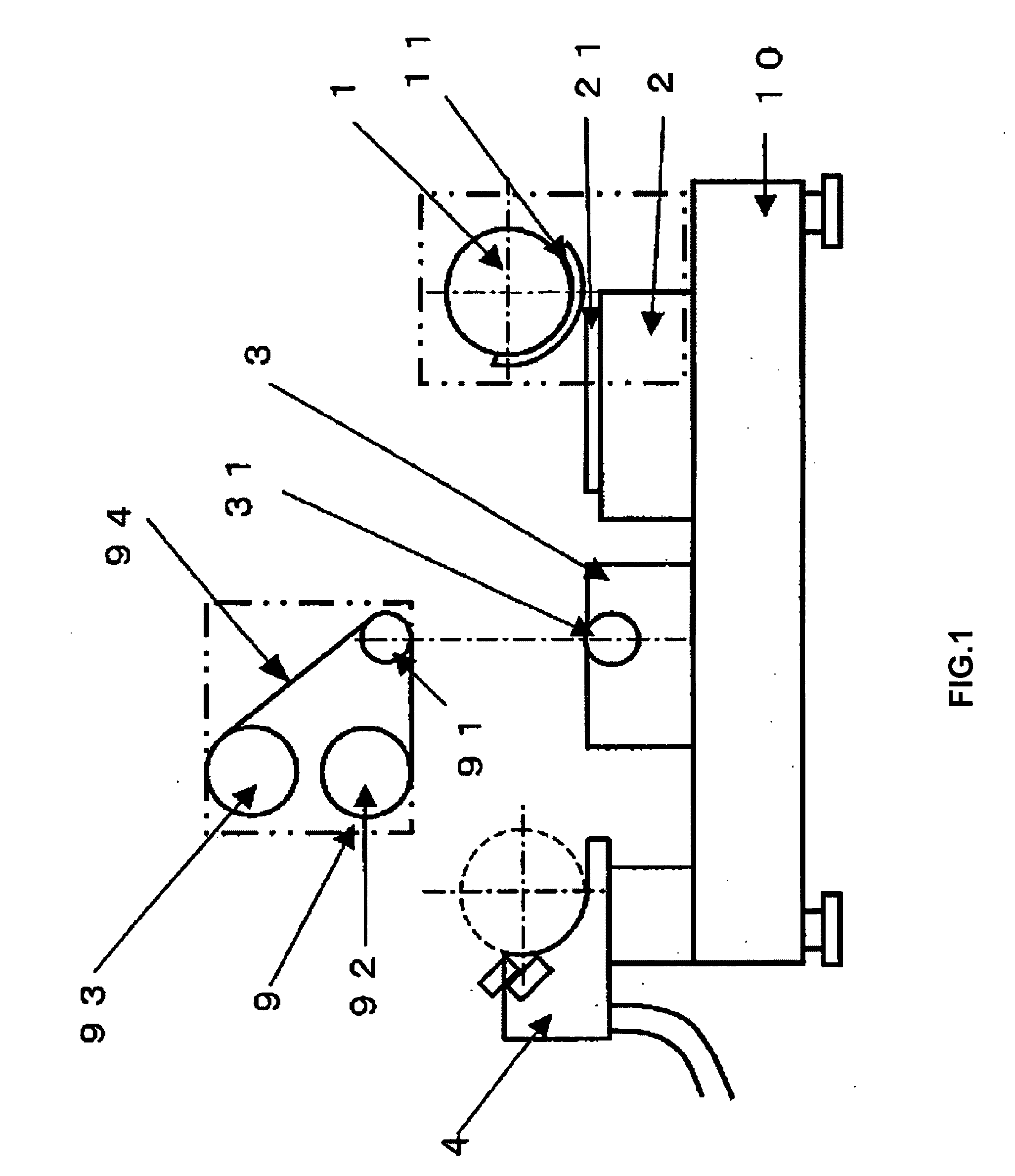

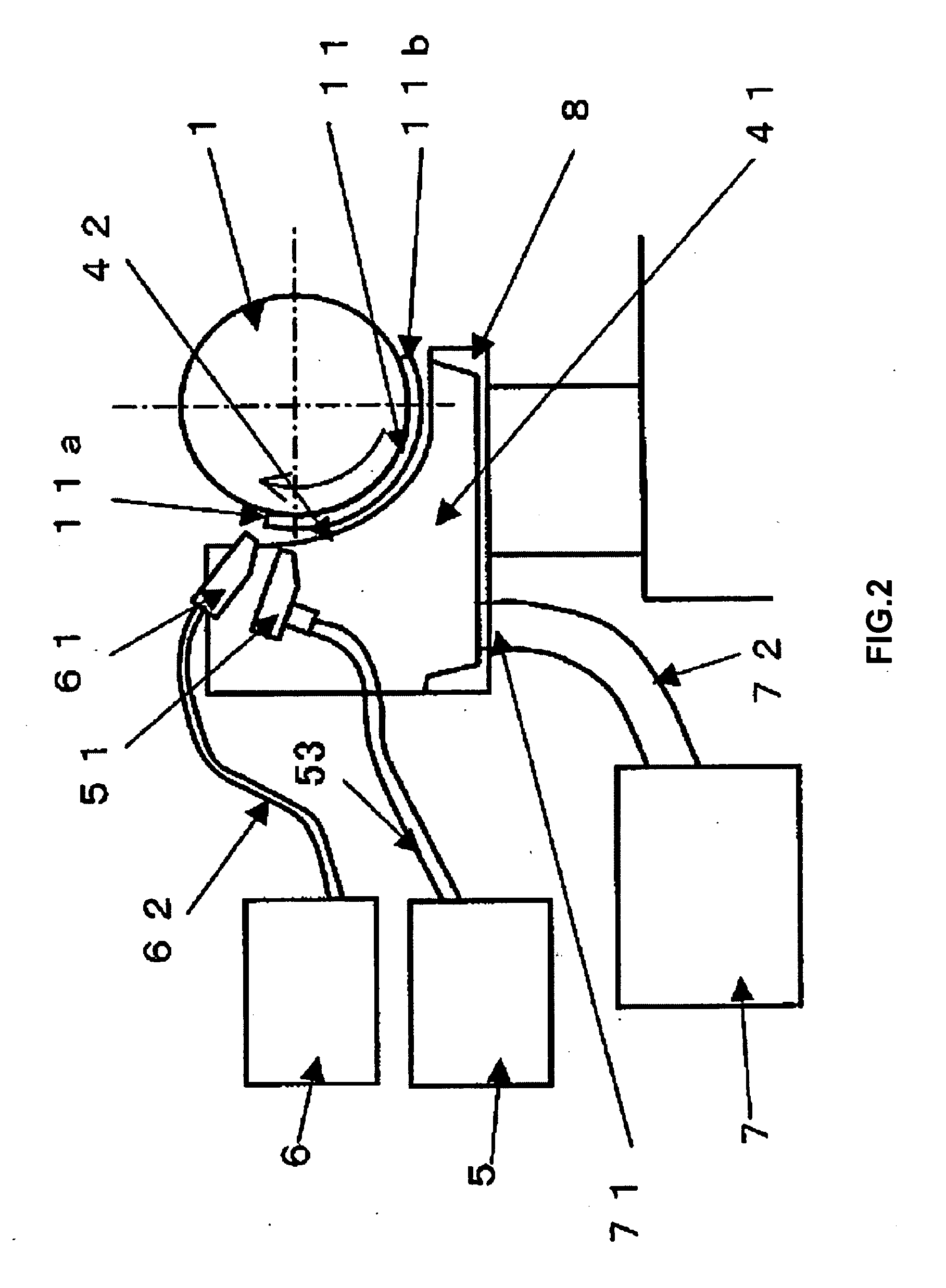

Letterpress printing machine

ActiveUS20070175349A1Easy to printImprove wettabilityOffice printingPrinting press partsLetterpress printingPrinting press

A letterpress printing machine is disclosed including a rotary printing cylinder in which a relief printing plate is installed, a substrate surface plate on which a substrate is placed, an ink supply device supplying ink on the relief printing plate, a relief printing plate washing equipment washing the surface of the relief printing plate, and a wiper for a plate. The relief printing plate washing equipment can include a washing liquid supplying unit, an air blasting unit jetting pressurized gas to the relief printing plate, a suction unit sucking the washing liquid scattered by air blasting unit, and a washing liquid recovery unit.

Owner:TOPPAN PRINTING CO LTD

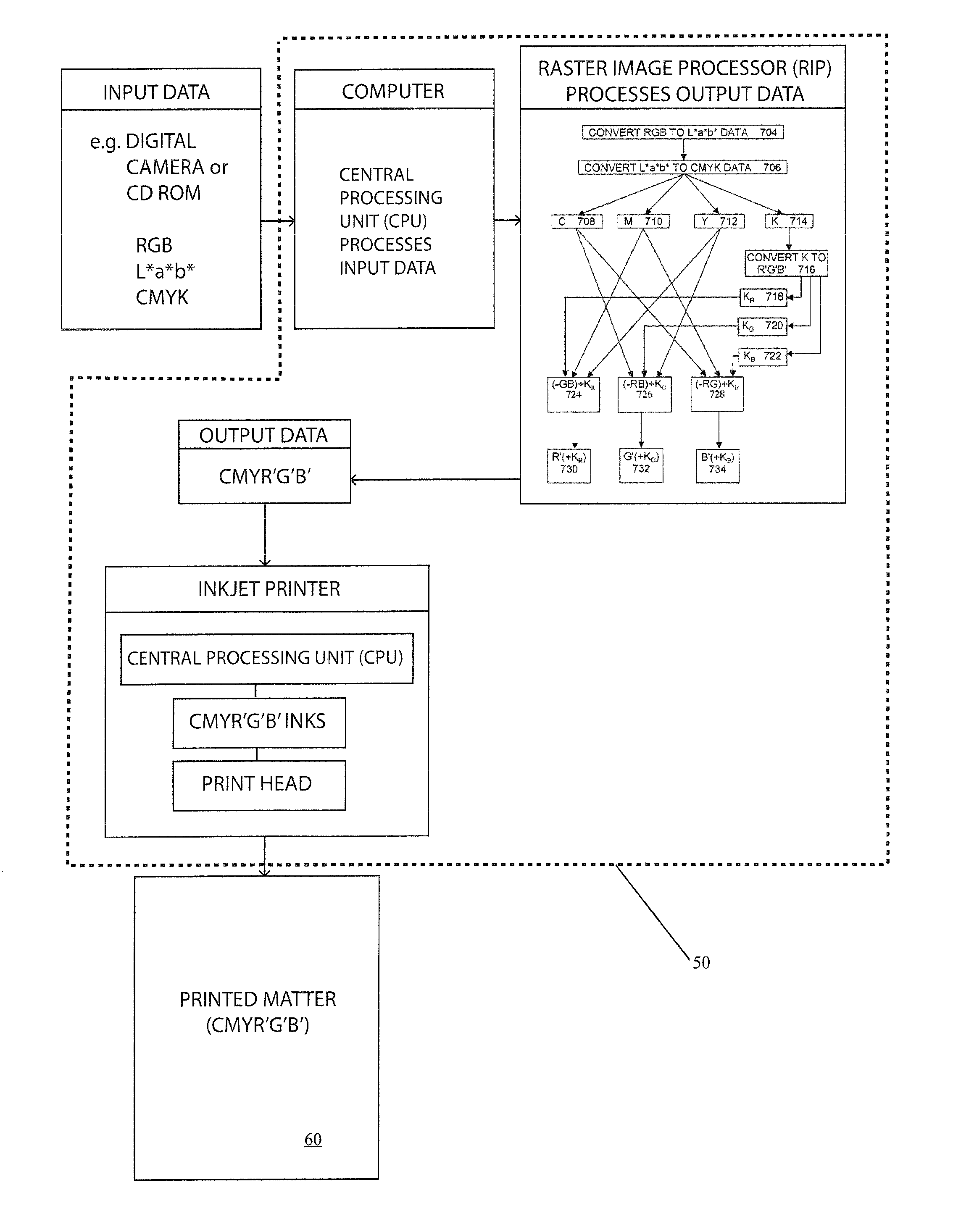

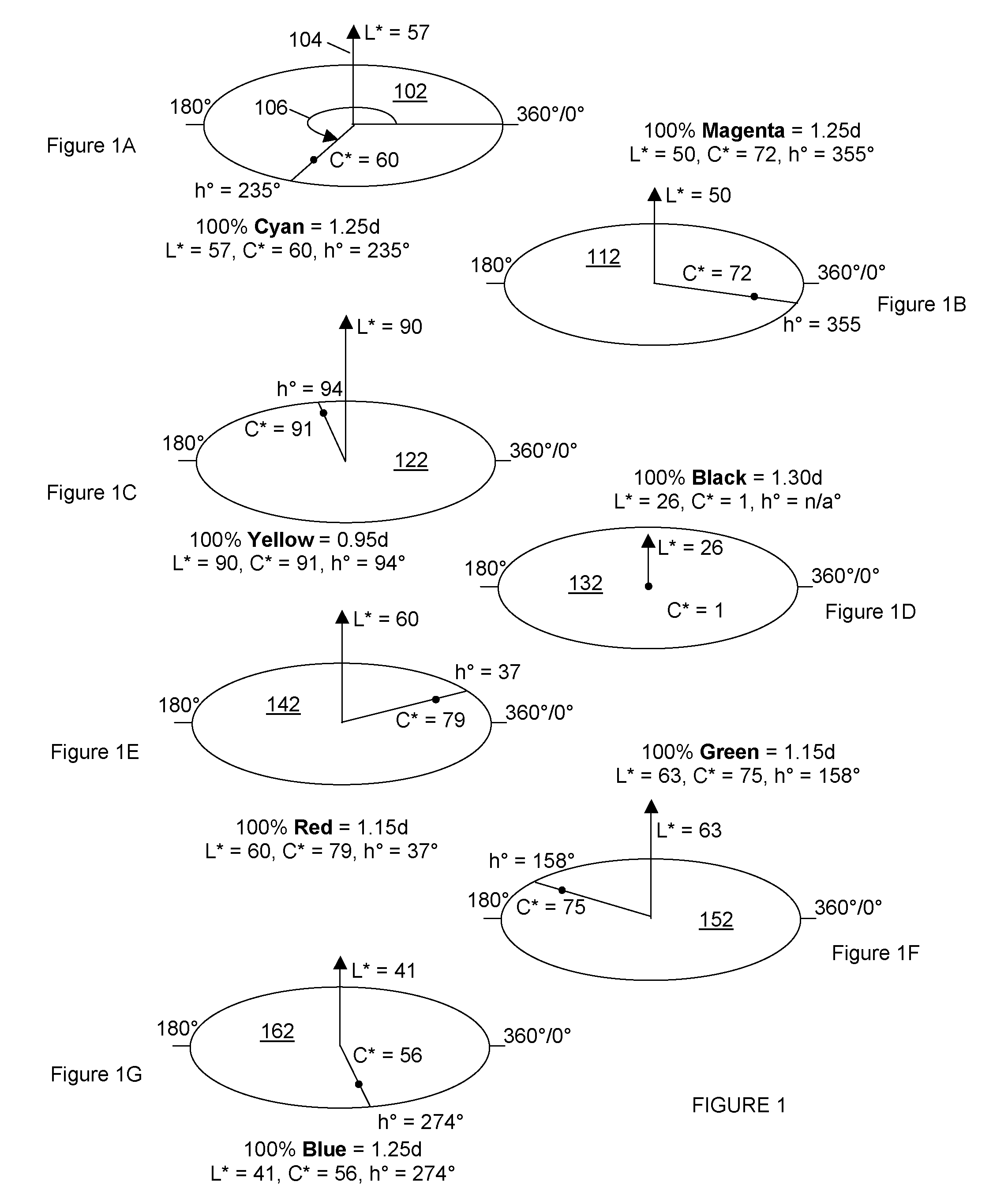

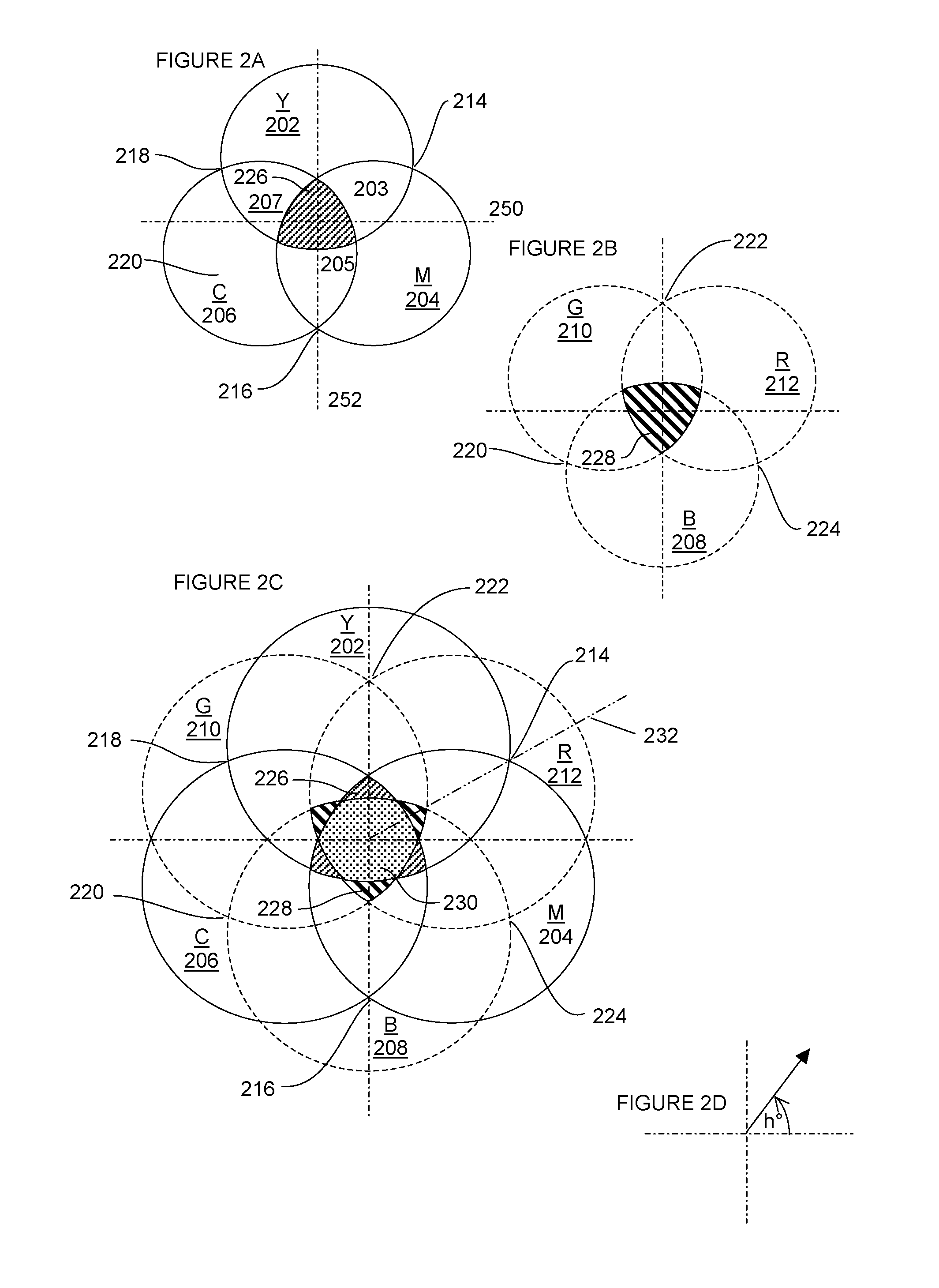

Color separation and reproduction method to control a printing process

InactiveUS8064112B1Process knownRecording apparatusDigitally marking record carriersComputer printingLetterpress printing

A computerized printer utilizes a color separation and printing process that adds brightness, saturation and ink density to traditional CMYK printing processes and optionally eliminates the need for Black (K) color separation data and Black ink in the printer. The process includes the creation of Red, Green, and Blue (R′G′B′) color separation data channels for use by a computer processor to complement the dynamic range of traditional Cyan, Magenta, and Yellow (CMY) color separation data channels. Accordingly, the process gives printers the capacity to utilize a six-color separation process with Cyan, Magenta, Yellow, Red, Green, and Blue (CMYR′G′B′) color separation data channels. The standard Black (K) separation data can be combined within the R′G′B′ separation data to optically simulate Black ink in print. The process can be applied to printing processes including: digital, flexography, inkjet, lithography, rotary gravure, rotary letterpress and screen-printing.

Owner:BERNASCONI MATTHEW JAMES

Conductive ink for letterpress reverse printing

InactiveUS20100148131A1Stable formationImprove conductivityConductive materialSolid-state devicesBoiling pointLetterpress printing

The present invention provides a conductive ink for forming a fine conductive pattern on a substrate by letterpress reverse printing. In particular, the conductive ink enables the pattern to be formed stably without the occurrence of transfer failures and is able to impart superior conductivity by low-temperature baking. The conductive ink, which contains substantially no binder component, comprises as essential components thereof conductive particles having a volume average particle diameter (Mv) of 10 to 700 nm, a release agent, a surface energy regulator and a solvent component, the solvent component being a mixture of a solvent having a surface energy at 25° C. of 27 mN / m or more (high surface energy solvent) and a volatile solvent having a boiling point at atmospheric pressure of 120° C. or lower (low boiling point solvent), and the surface energy of the ink at 25° C. is 10 to 21 mN / m.

Owner:DAINIPPON INK & CHEM INC

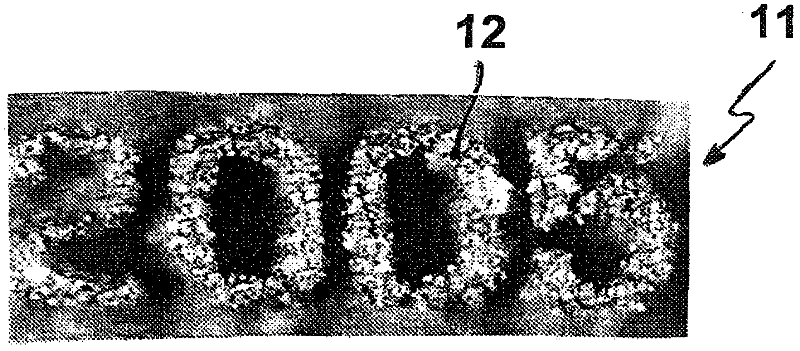

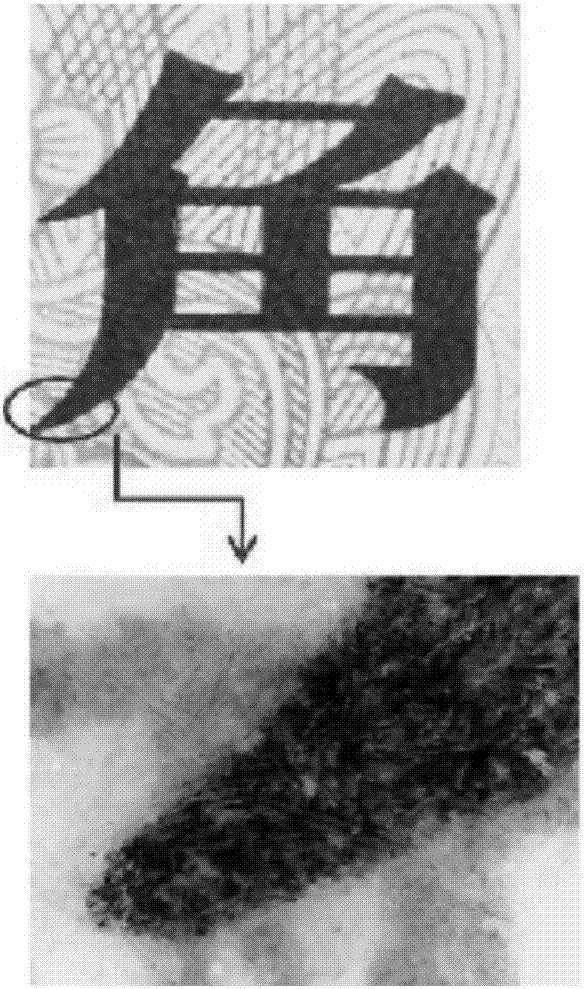

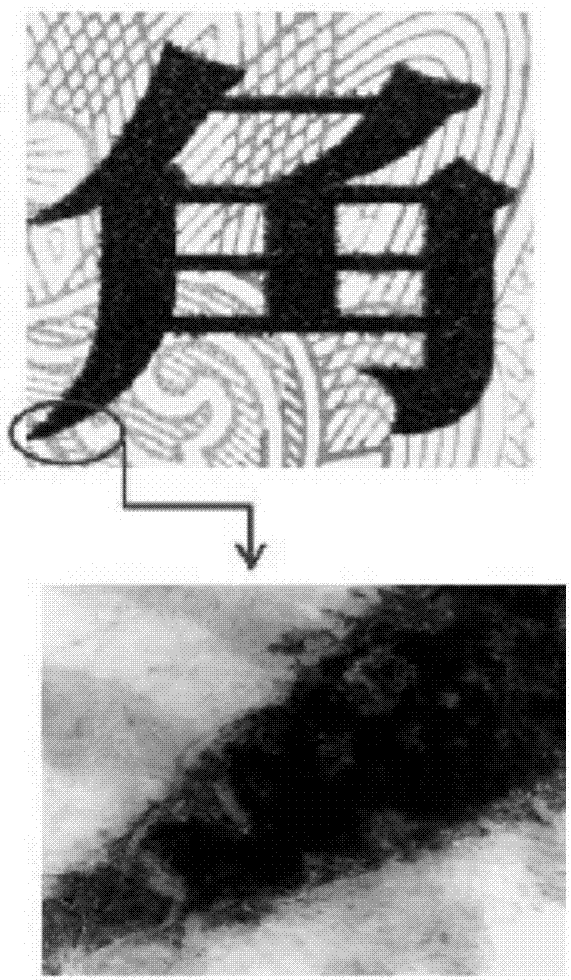

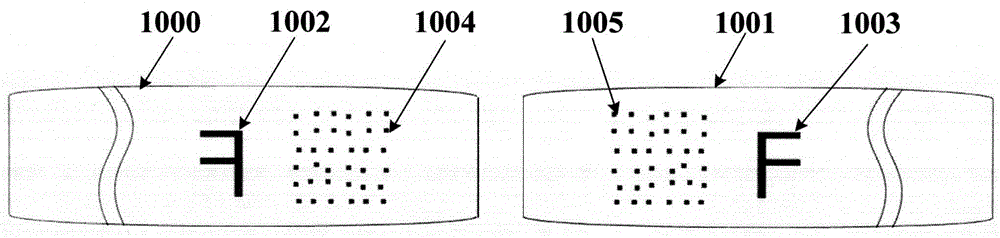

Method for identifying seal and print formation mode based on microcosmic trace point characteristics

InactiveCN107345922AImprove accuracyEasy to operateMaterial analysis by optical meansLetterpress printingComputer science

The invention relates to a method for identifying a seal and print formation mode based on microscopic trace point characteristics and belongs to the technical field of document examination. The method mainly comprises the following steps: (1) carrying out macroscopic examination on seal and print based on objective facts and living knowledge; and (2) deeply analyzing the seal and print by utilizing the microscopic trace point characteristics, wherein the microscopic trace point characteristics includes ink mark characteristics, ink point characteristics and dot characteristics; the seal and non-plate-making printing print are identified by adopting the ink mark characteristics and the ink point characteristics, and the plate-making printing print is identified by adopting the dot characteristics; and when no dot characteristic exists, whether the seal and print are sealed or printed in a non-plate-making way or formed by a woodblock and a metal plate in letterpress printing is judged, and when the dot characteristic exists, whether the seal and print are formed by the plate-making printing print is judged. The method provided by the invention has the beneficial effects that print production method identification utilizing the trace point characteristics is high in examination accuracy and convenient in operation and thus is a nondestructive and fast identification method.

Owner:韩伟

Preparation method of electroluminescent anti-counterfeiting trademark structure

InactiveCN108777110AImprove featuresImprove anti-counterfeiting performanceStampsInksLetterpress printingTrademark

The invention relates to a preparation method of an electroluminescent anti-counterfeiting trademark structure. The method includes the steps that electroluminescent nano-particles are dispersed in amixed solvent of water, ethylene glycol and a polymer through ultrasonic or mechanical stirring so as to be prepared into printing ink for printing an electroluminescent layer; then, a first conductive ink layer, an electroluminescent layer and a second conductive ink layer are printed on release paper layer by layer through the silk-screen printing technology or the letterpress printing technology to form the electroluminescent anti-counterfeiting trademark structure; the prepared electroluminescent anti-counterfeiting trademark structure is detected through a detector with a commercial button cell as a power source, and an electroluminescent anti-counterfeiting trademark is stimulated through physical contact to emit light and serve as the anti-counterfeiting basis. Characteristics are excellent, the formula of printing ink is difficult to copy, and the anti-counterfeiting performance of a printed product is greatly improved; a color pattern can be displayed only under the excitationof detection equipment, so that higher invisibility and anti-counterfeiting performance are achieved.

Owner:INST FOR PROCESS MODELING & OPTIMIZATION JITRI

Ceramic tile made of simulated sandstone and preparation process of ceramic tile

The invention discloses a ceramic tile made of simulated sandstone and a preparation process of the ceramic tile. The ceramic tile comprises a ceramic tile green body and an enamel layer on the surface of the ceramic tile green body. The ceramic tile is characterized in that stone-shaped stripes and ink jet coarse sandstone patterns are printed on the surface of the enamel layer, the enamel layer sequentially comprises a bottom enamel layer, a surface enamel layer, a first-time dot enamel layer, a second-time dot enamel layer, a protection enamel layer and a dry granular enamel layer, an area of the first-time dot enamel layer accounts for 95-99.9% that of the surface of the ceramic tile, and an area of the second-time dot enamel layer accounts for 70-90% of that of the ceramic tile. Processes of repeated enameling and distributing, drum, ink jet, dry granule distributing and single-roller letterpress printing are adopted, multilayer texture and multilayer enamel color are formed, and an effect like natural real sandstone formed by nature is completely realized.

Owner:白刚

Novel secure file

ActiveCN102806794ANot easy to imitateStrong concealmentOther printing matterInformation cardsSurface layerLetterpress printing

The invention discloses a novel secure file, which comprises two layers or three layers of patterns. When the secure file comprises two layers of patterns, the bottom layer is subjected to offset printing, and the surface layer is subjected to letterpress printing; the bottom layer of the secure file gives out monochromatic light with the same color as that of the bottom layer under the excitation of infrared laser, while the surface layer gives out light visible to human eyes under the excitation of the infrared laser. When the secure file comprises three layers of patterns, both the bottom layer and the surface layer are subjected to offset printing, and the middle layer is subjected to letterpress printing; and the bottom layer or the surface layer of the secure file gives out monochromatic light with the same color as that of the bottom layer or the surface layer correspondingly under the excitation of the infrared laser. The novel secure file implements an infrared up-conversion fluorescent material by combining the offset printing and letterpress printing ways with the light-emitting characteristics of infrared up-conversion composite white light, gives out two kinds of different visible lights recognizable by human eyes under the excitation of the infrared light, and is difficult to imitate, strongly elusive and easy to distinguish anti-counterfeiting effects.

Owner:SHANGHAI BANKNOTE PRINTING +1

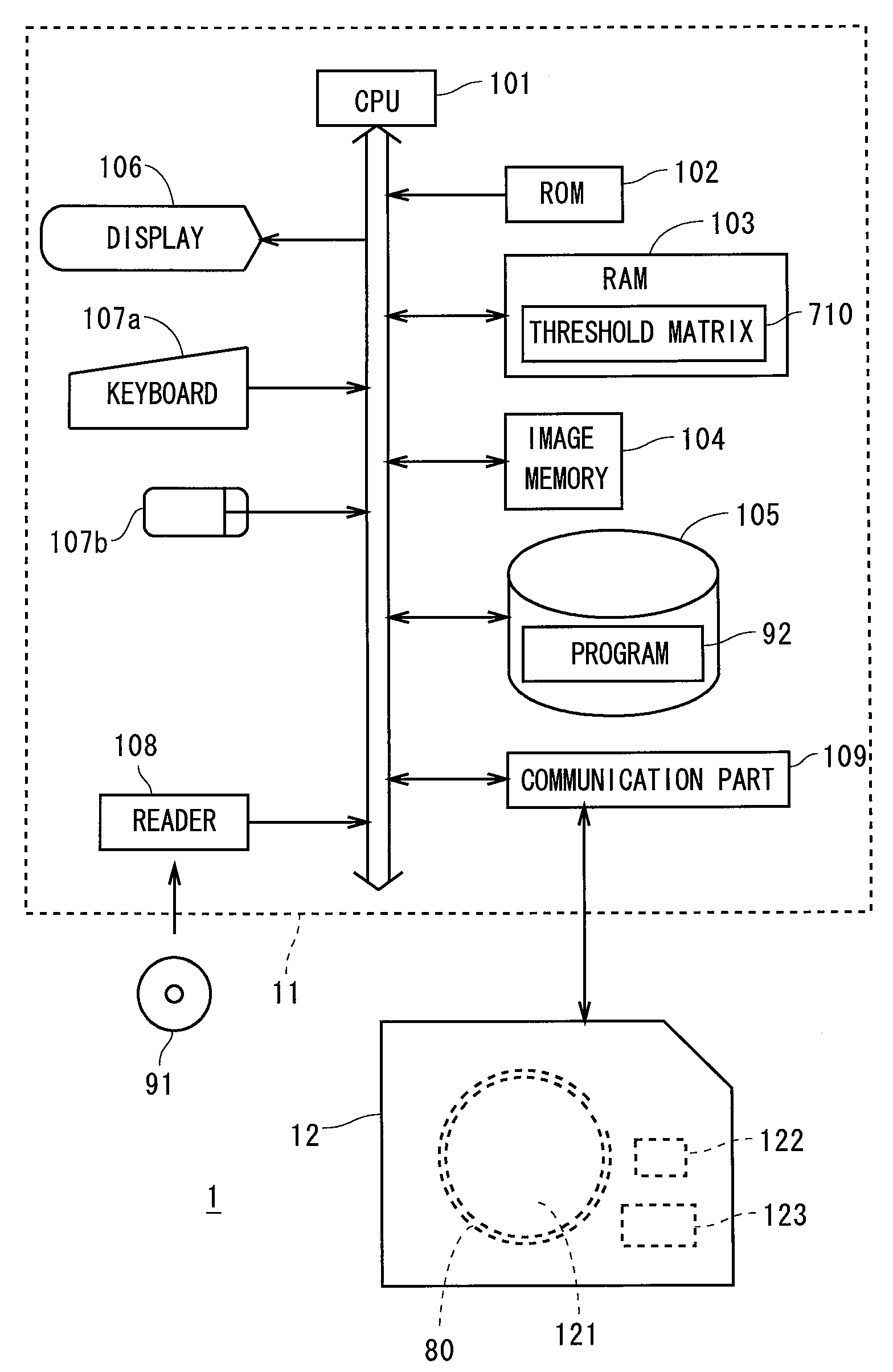

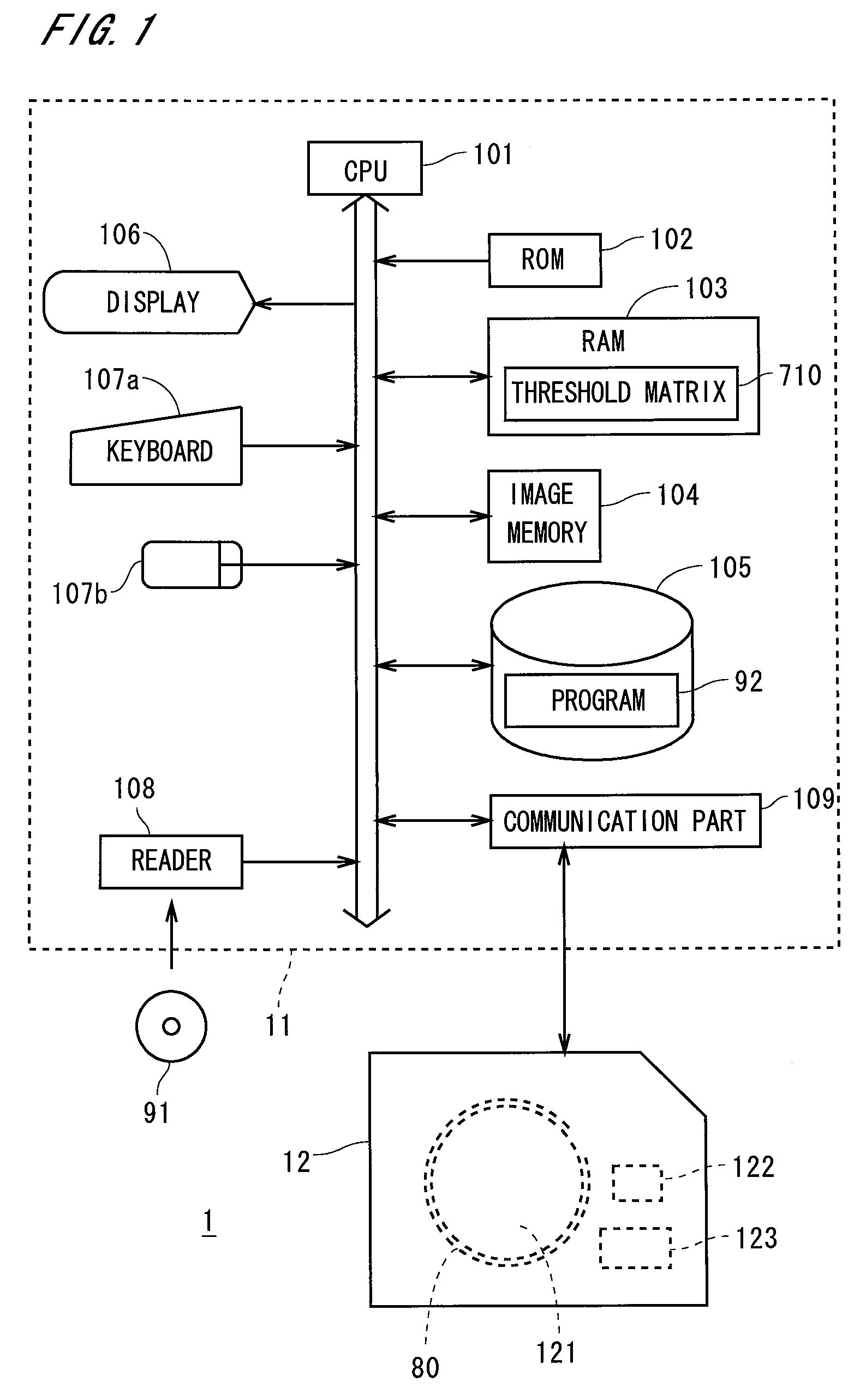

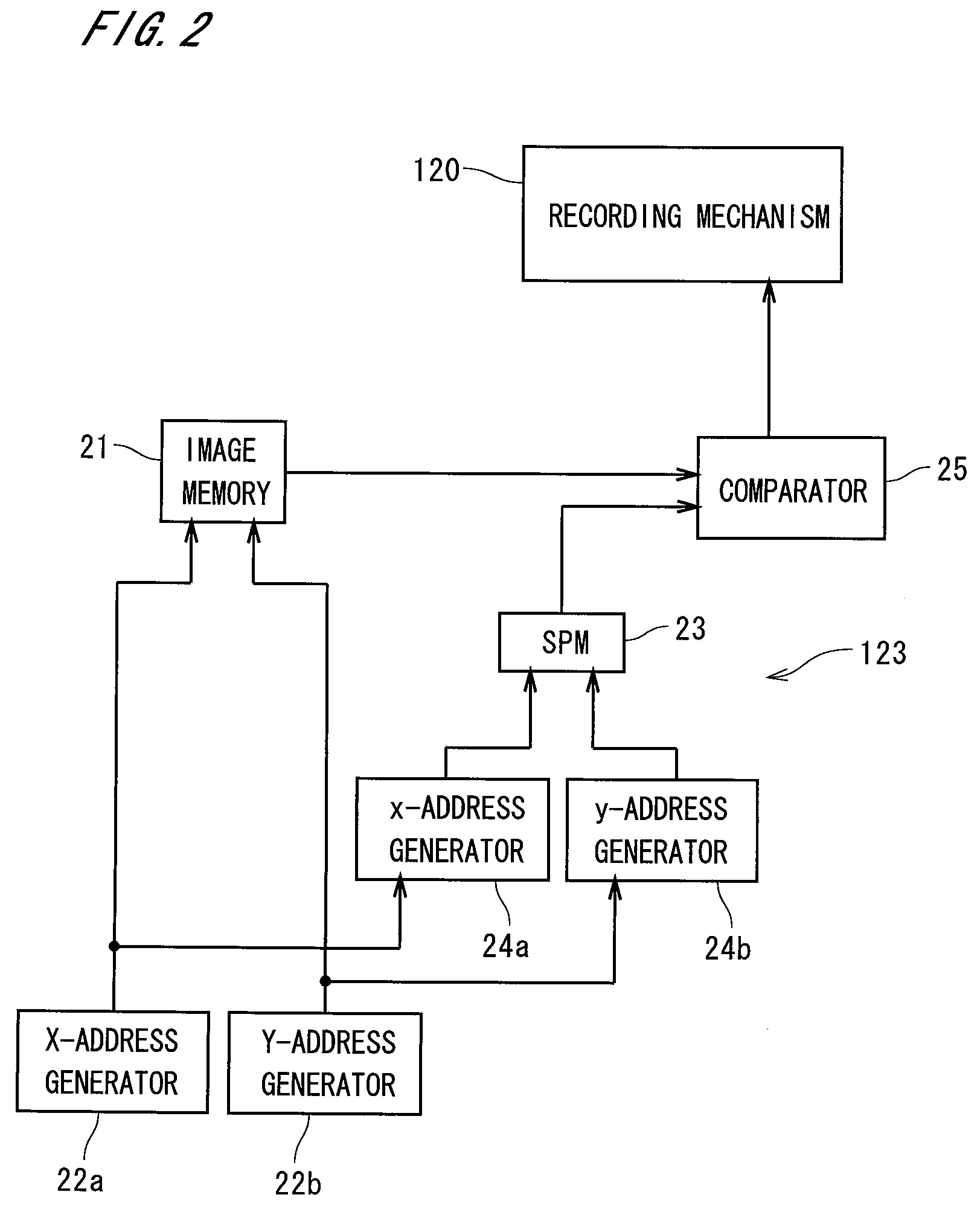

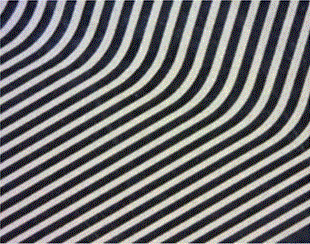

Halftone image generation method, threshold matrix generation method, threshold matrix, prinitng plate manufacturing method, and printing plate

ActiveUS20090262398A1Improve reproduction in printingHigh strengthVisual presentationOriginals for photomechanical treatmentLetterpress printingEngineering

In a halftone image formed on a printing plate for letterpress printing, a minimum halftone dot has a square main cluster consisting of 9 pixels and four sub-clusters located around the main cluster radially, each of which is one pixel. Each sub-cluster contacts with only a vertex of the main cluster. Convex portions corresponding to the minimum halftone dots in the halftone image are formed on the printing plate. A convex portion corresponding to the main cluster is supported by convex portions corresponding to the sub-clusters to increase the strength of relief corresponding to the minimum halftone dot. Reliefs corresponding to the minimum halftone dots are normally formed regardless of a dot area rate of highlight area to thereby improve reproduction in printing of the halftone image.

Owner:DAINIPPON SCREEN MTG CO LTD

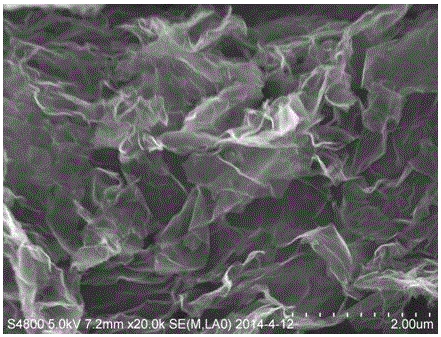

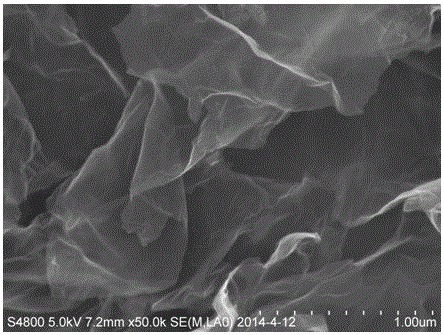

Graphene/nano-silver light-sensitive conductive composite paste and preparation method therefor

InactiveCN105869705AUniform dispersionLarge particle sizeMaterial nanotechnologyNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention discloses graphene / nano-silver light-sensitive conductive composite paste and a preparation method therefor. The composite paste comprises the following raw materials based on weight: graphene and spherical nano-silver, wherein the weight ratio of graphene to spherical nano-silver is 1 to 2.0-3.5; and the preparation process comprises the steps of drying graphene and then mixing the raw materials under yellow light to obtain the composite paste. Due to the reasonable formula of the graphene and nano-silver and the new technological method, the light-sensitive silver paste obtains the characteristics of clear image development, high resolution, extremely high conductivity, high coating film strength and the like; the paste is subjected to silk-screen printing, letterpress printing, surface drying, exposing and developing to obtain a pattern with the required high resolution (L / S is greater than 30 / 30[mu]m); and in addition, the composite paste has excellent printing performance, high storage stability, excellent conductivity, high resolution, and high adhesive force.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Tagging method of online variable information

InactiveCN106394043AImprove curing effectDuplicating/marking methodsPrinting after-treatmentLetterpress printingEngineering

The invention relates to a tagging method of gravure online variable information. The tagging method is characterized in that a nozzle is additionally arranged on any traditional printing machine including a gravure printing machine, an offset press, a letterpress printing machine and a rotary flexo press, so that an online variable information printing system is formed. A marking image or a packaging image is still printed in any mode including the gravure printing machine, the offset press, the letterpress printing machine and the rotary flexo press, and the variable information of an explicit two-dimensional code or an invisible two-dimensional code is realized in a code spraying mode. The marking image or the packaging image and the variable information of the explicit two-dimensional code or the invisible two-dimensional code are performed on line on the same printing line. When the transformed printing machine is used for printing variable information markers or packages, the marking image or the packaging image is printed, and additionally, the variable information of the explicit two-dimensional code or the invisible two-dimensional code can be loaded; and the tagging method has the characteristics of low introduction cost, high printing efficiency and high printing precision of the marking image or the packaging image and is suitable for wide popularization, and one tag with one code can be realized.

Owner:天津市阿波罗信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com