A multiple-layer flat structure in the form of a printing blanket or a printing plate for flexographic and letterpress printing with laser engraving

A technology of flexographic printing and letterpress printing, which is applied in printing, printing process, printing plate, etc., and can solve problems such as design restrictions on the form of roll products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

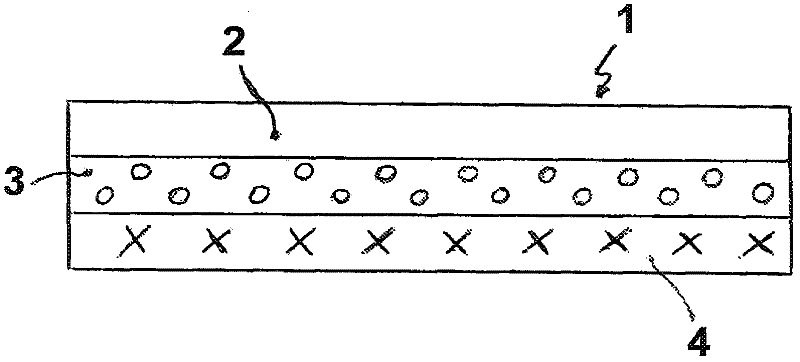

[0099] figure 1 Shown is a three-layer sheet 1 in the form of a printing blanket or printing plate having a printing layer 2 made of a vulcanized rubber, for example based on EPDM, where the printing layer is combined with a compressible layer 3 in direct contact, the compressible layer is for example in the form of microbeads made of plastic in a rubber mixture. The compressible layer then in turn has direct contact with a reinforcement layer 4, for example made of a textile material.

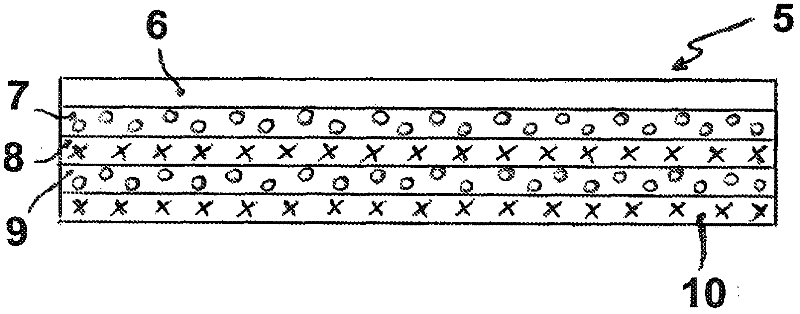

[0100] figure 2 A five-layer sheet 5 is shown with the following layer sequence:

[0101] - printing layer 6, which layer is made of a vulcanized rubber;

[0102] - a first compressible layer 7, for example in the form of microbeads made of plastic in a rubber mixture;

[0103] - a first reinforcement layer 8, for example made of a textile material;

[0104] - a second compressible layer 9, for example again in the form of microbeads made of plastic in a rubber mixture;

[0105] - A se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com