Patents

Literature

347results about "Printing blankets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

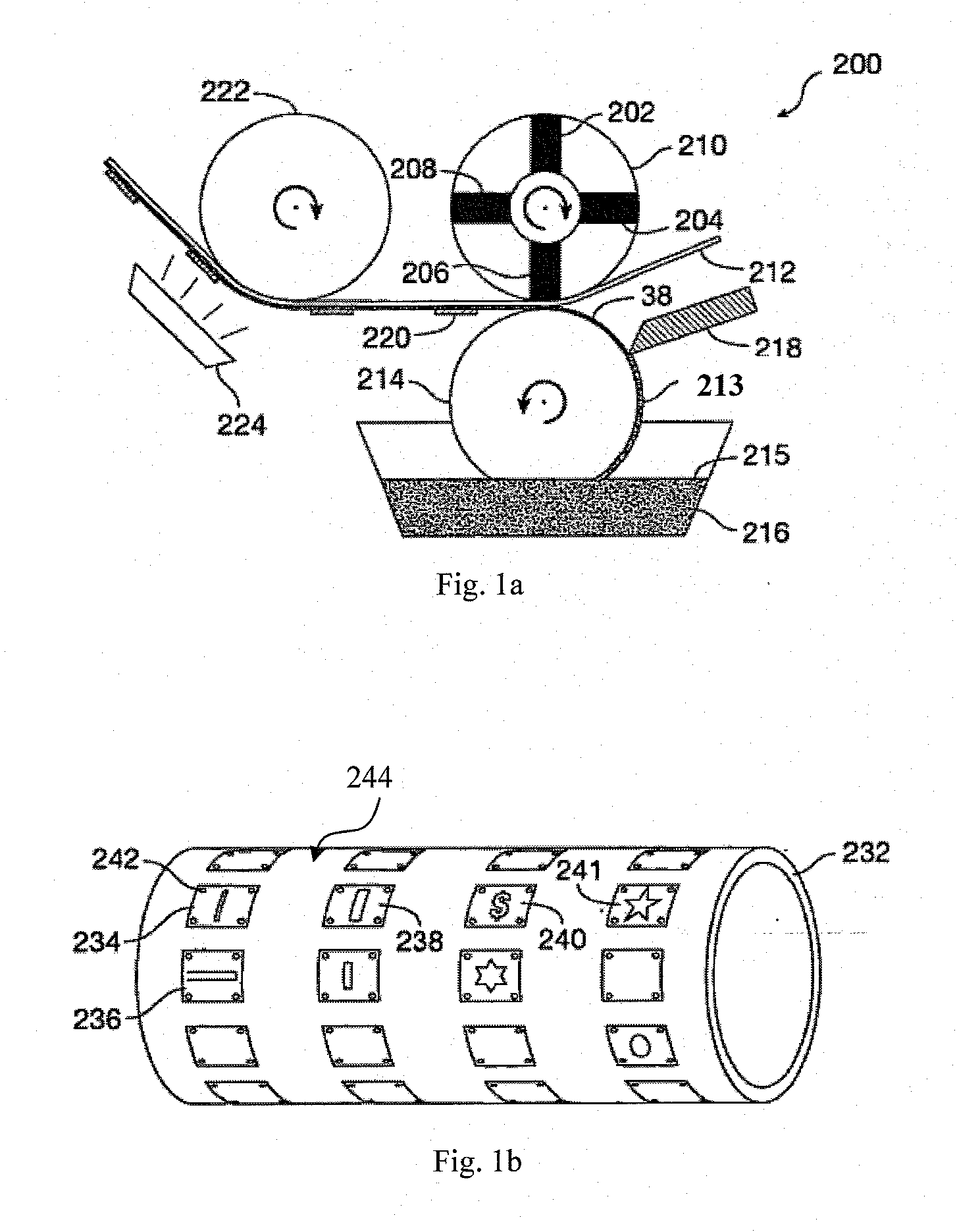

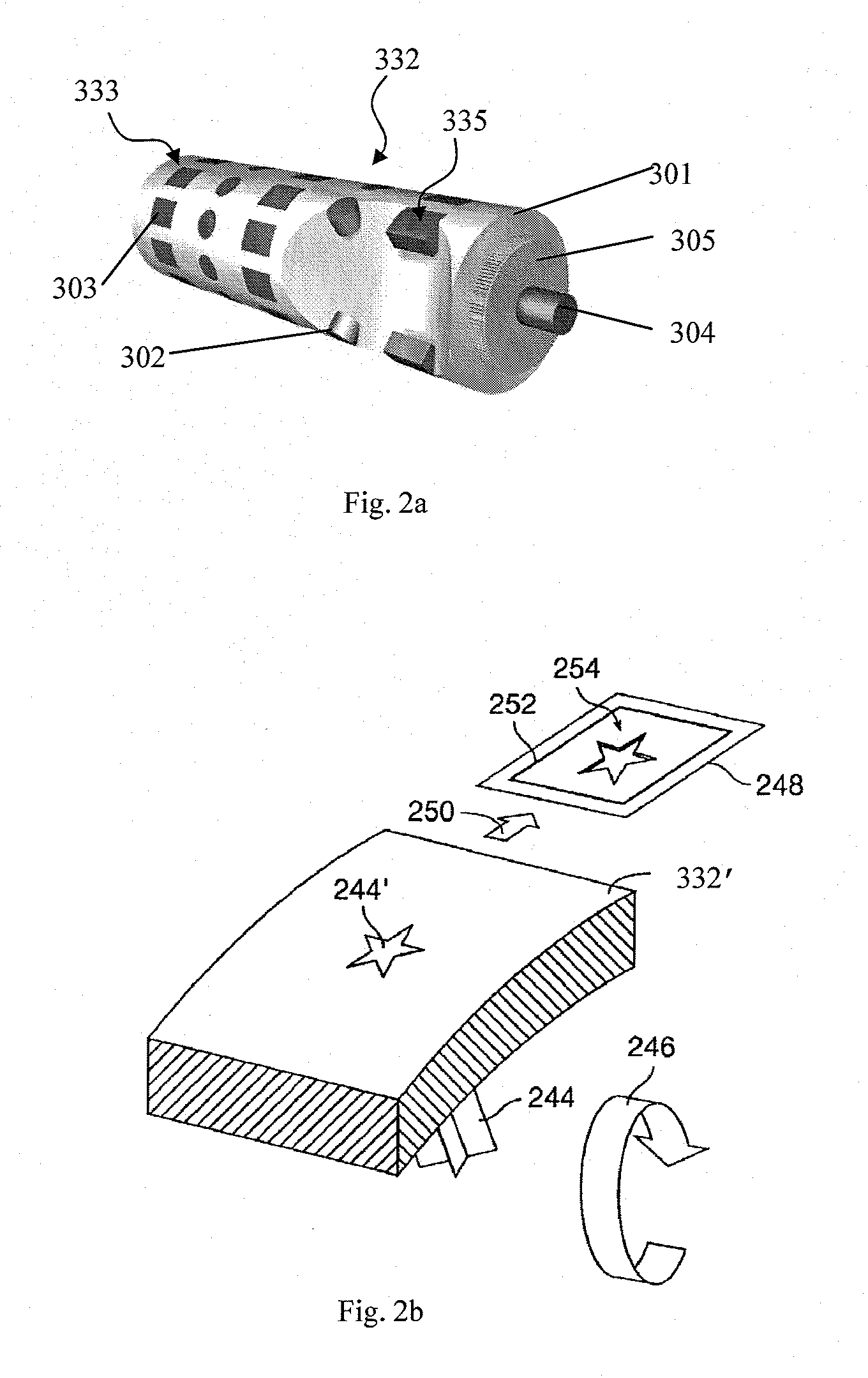

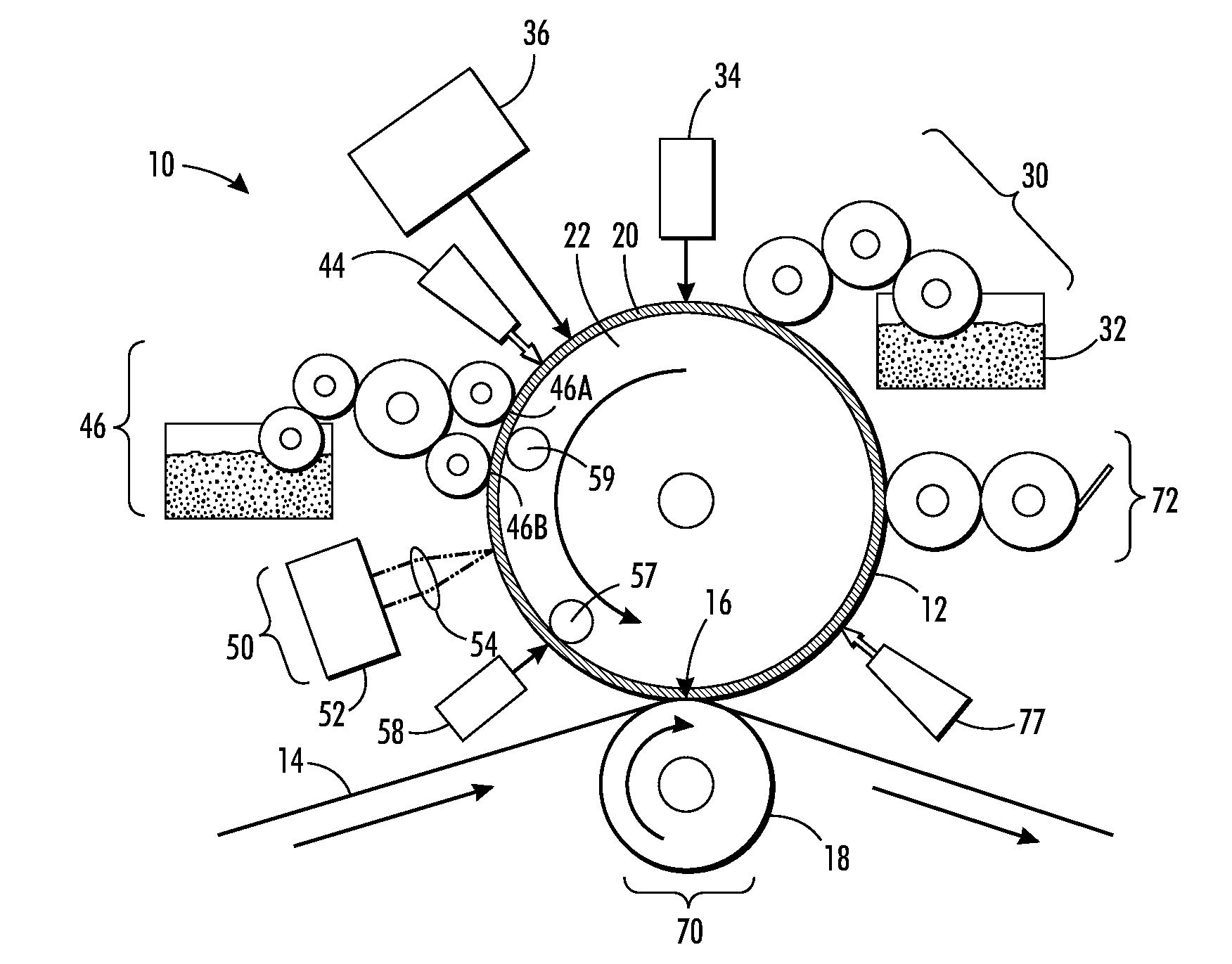

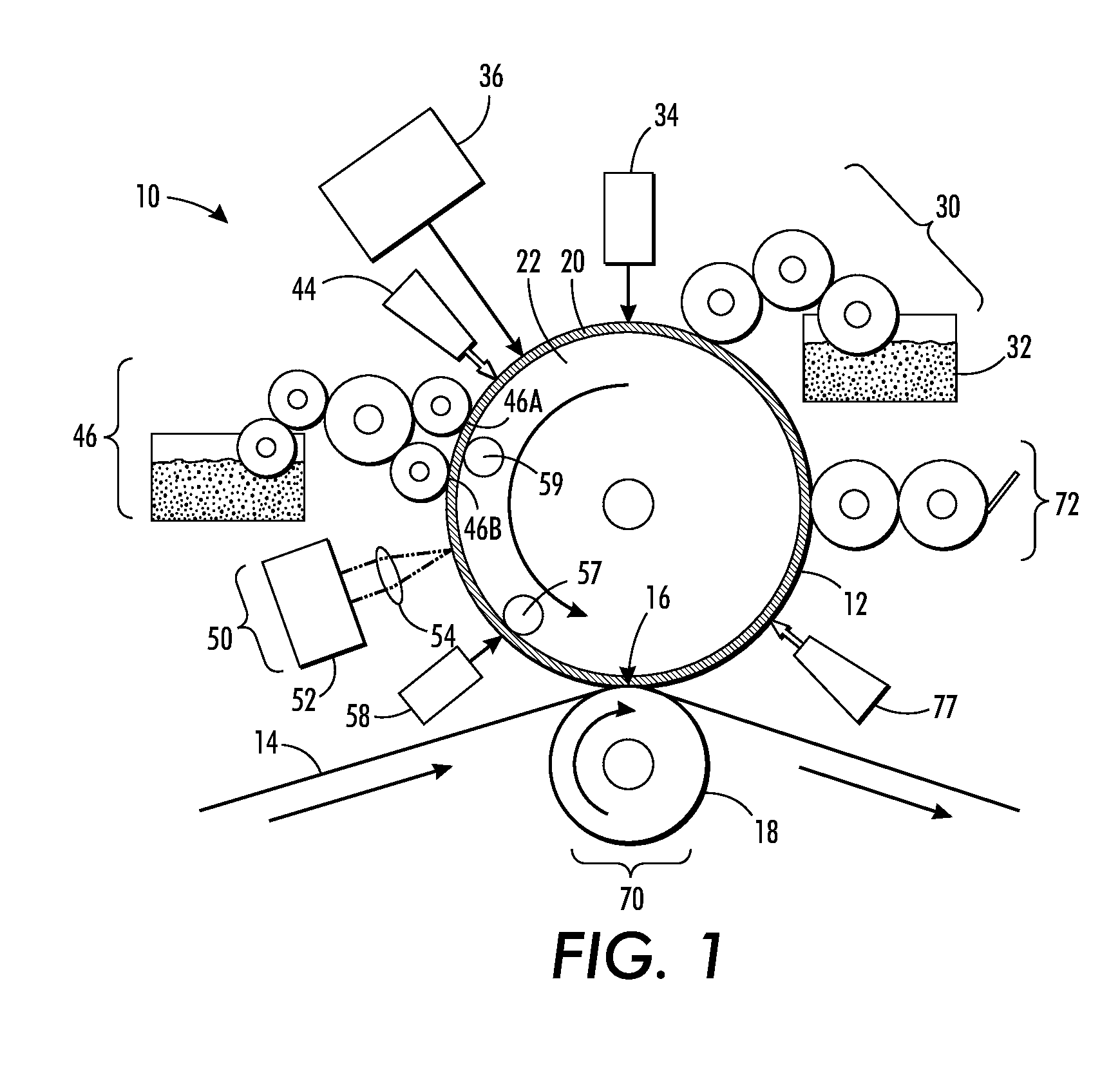

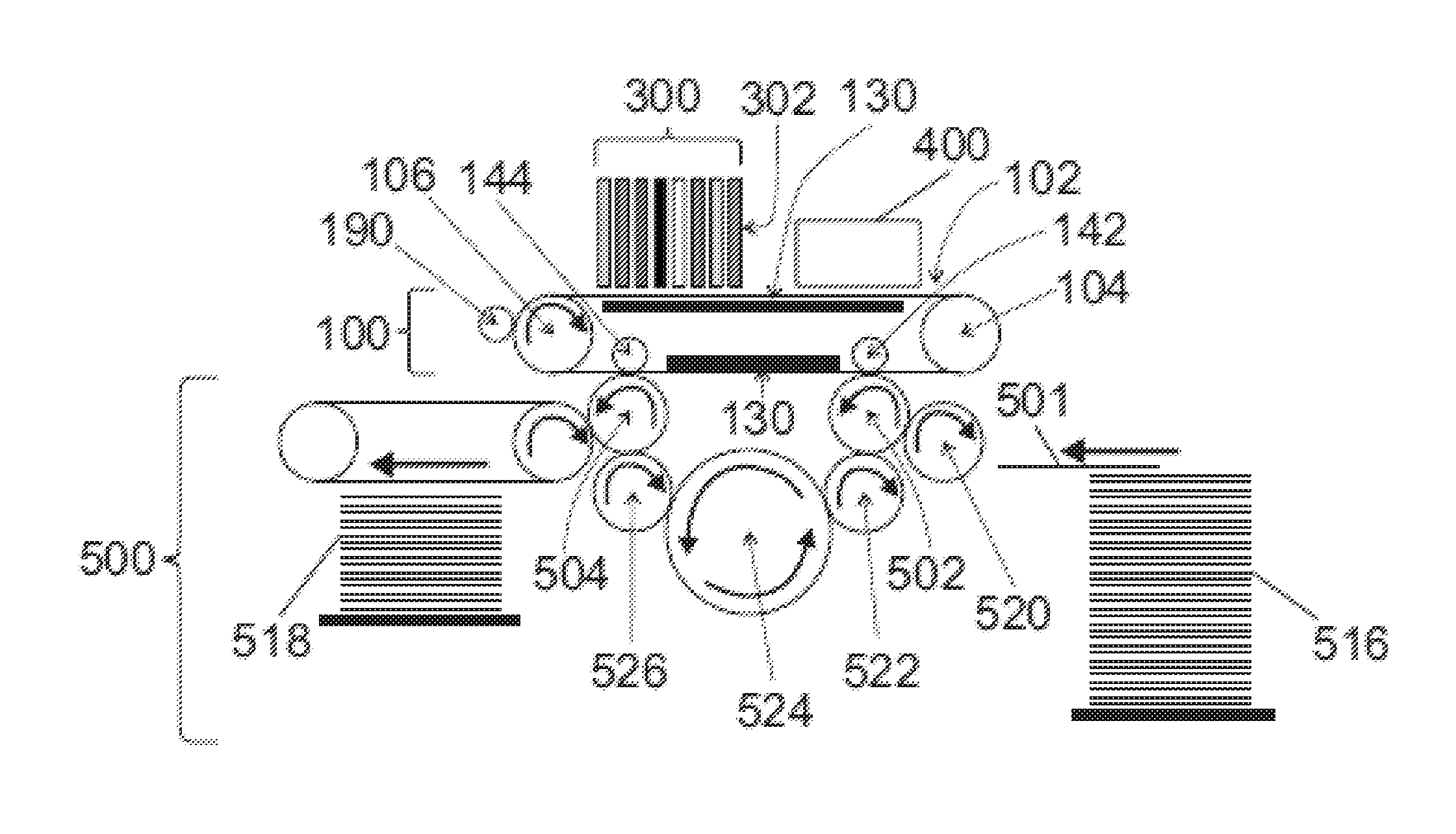

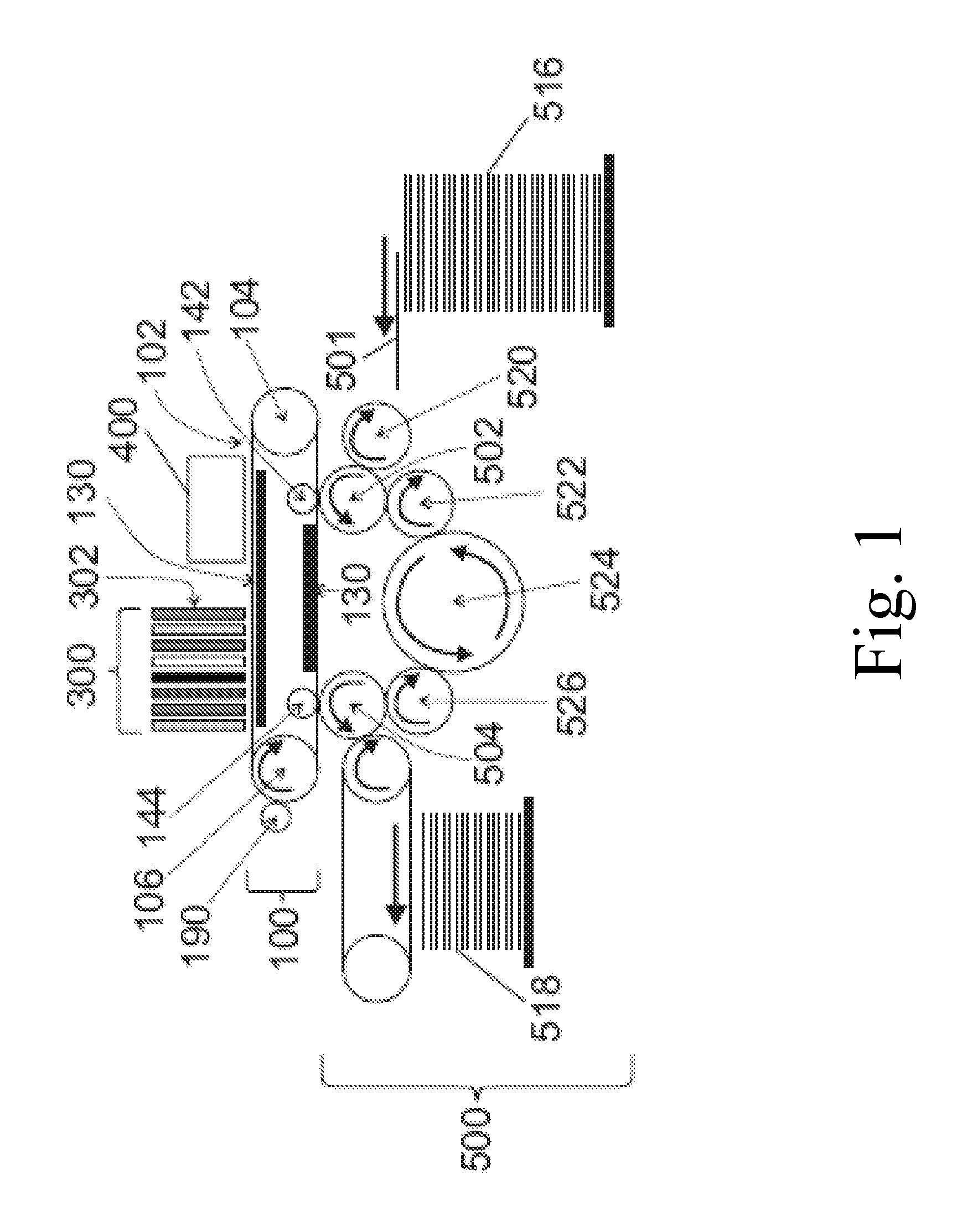

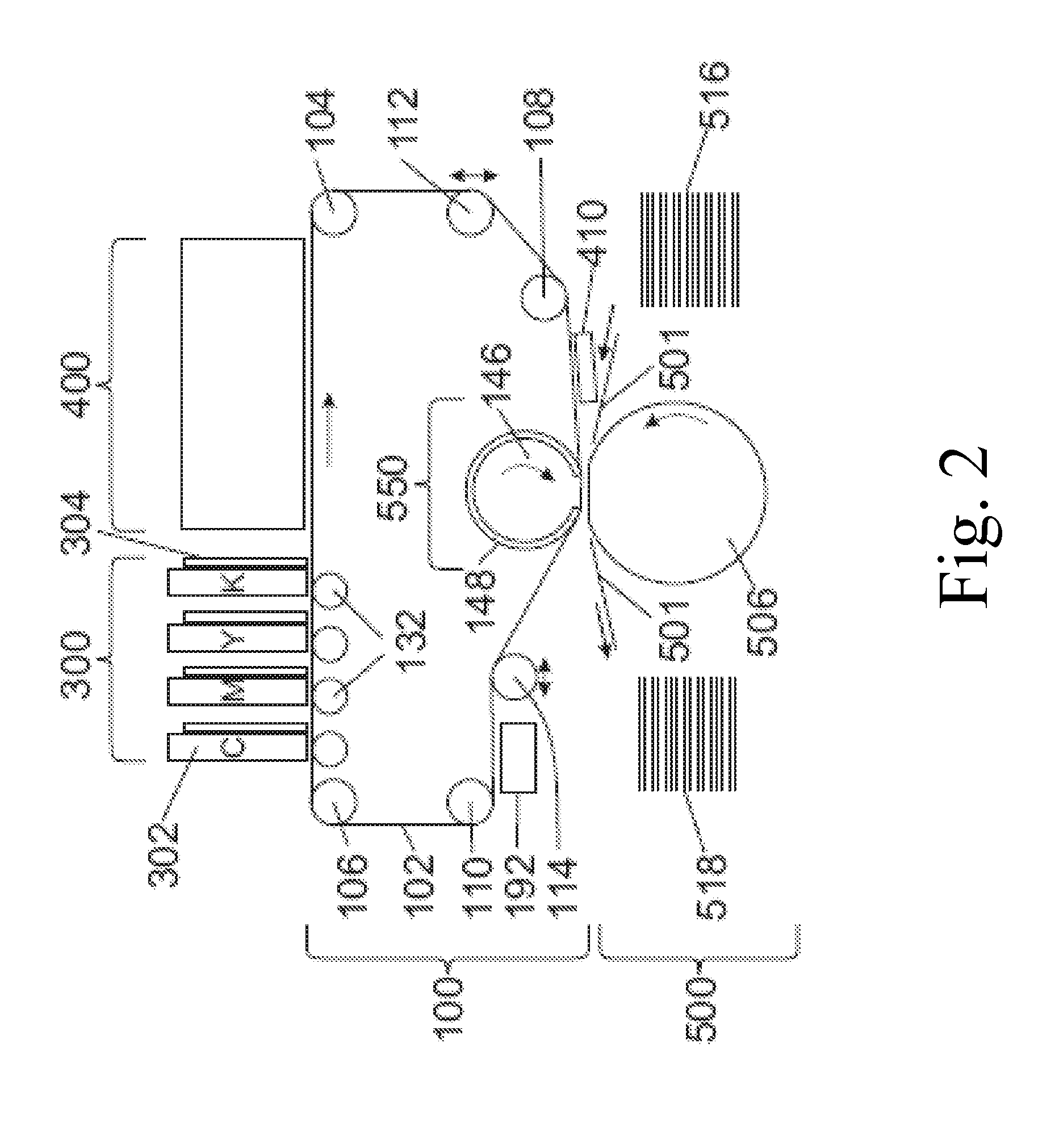

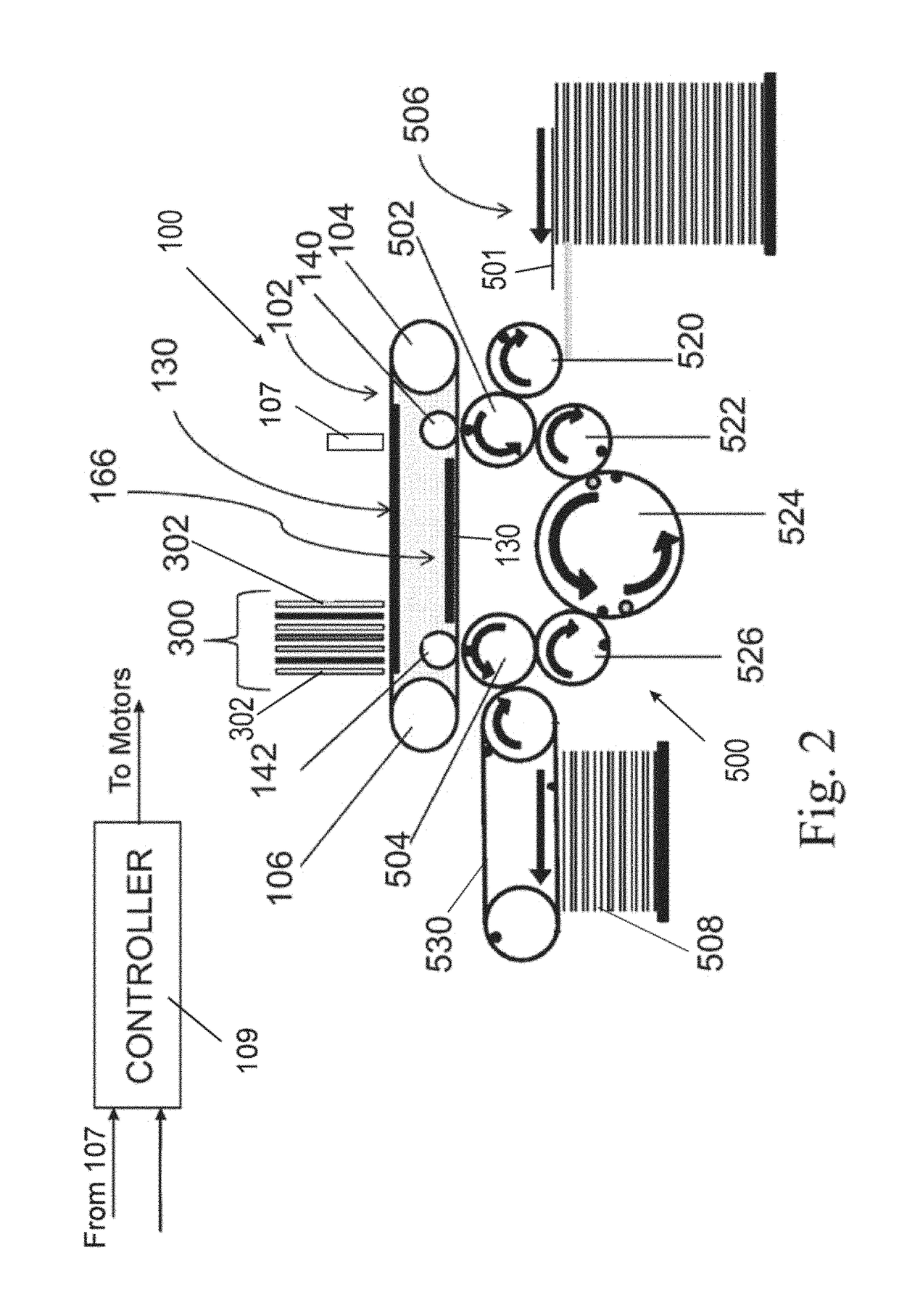

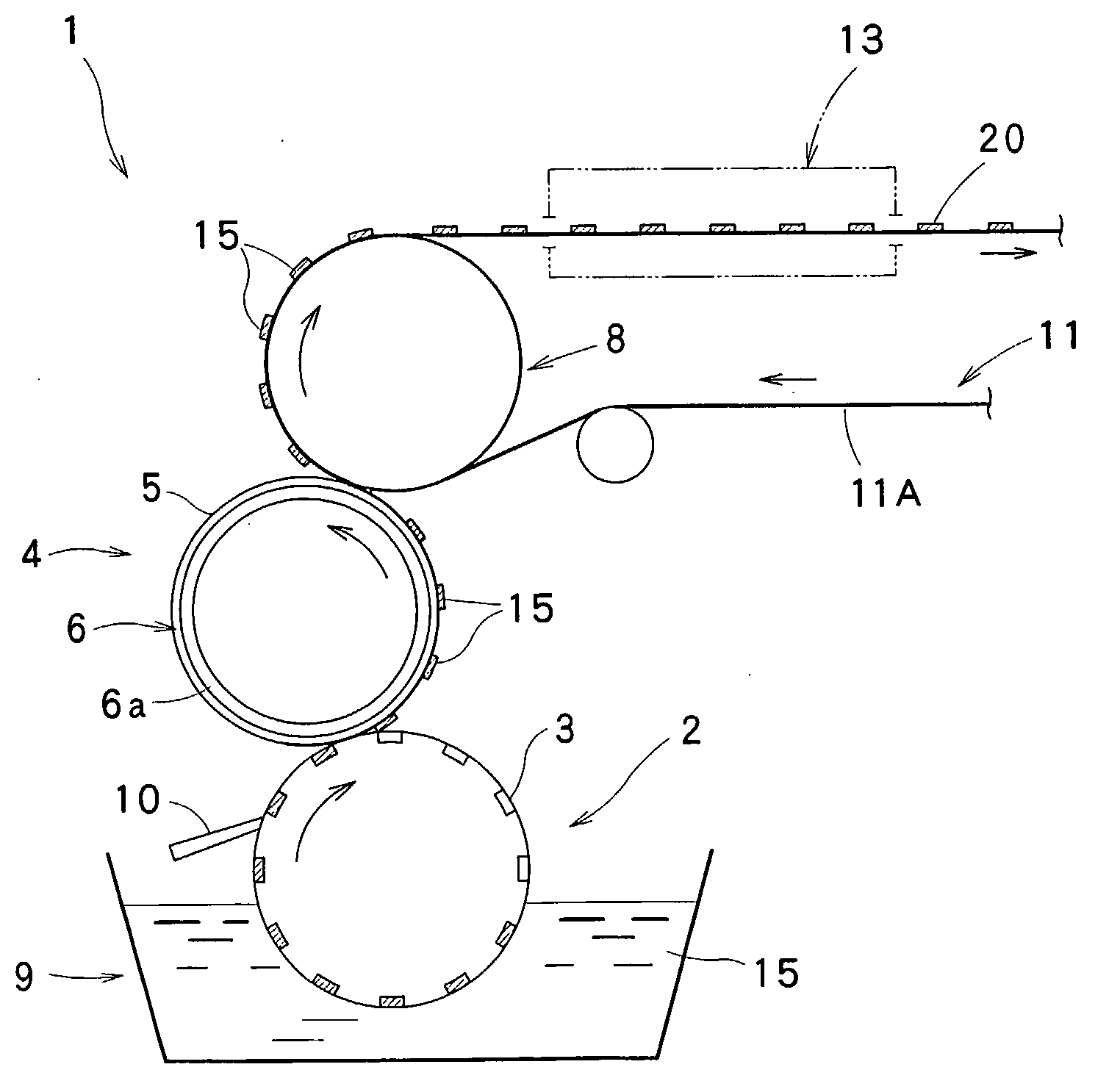

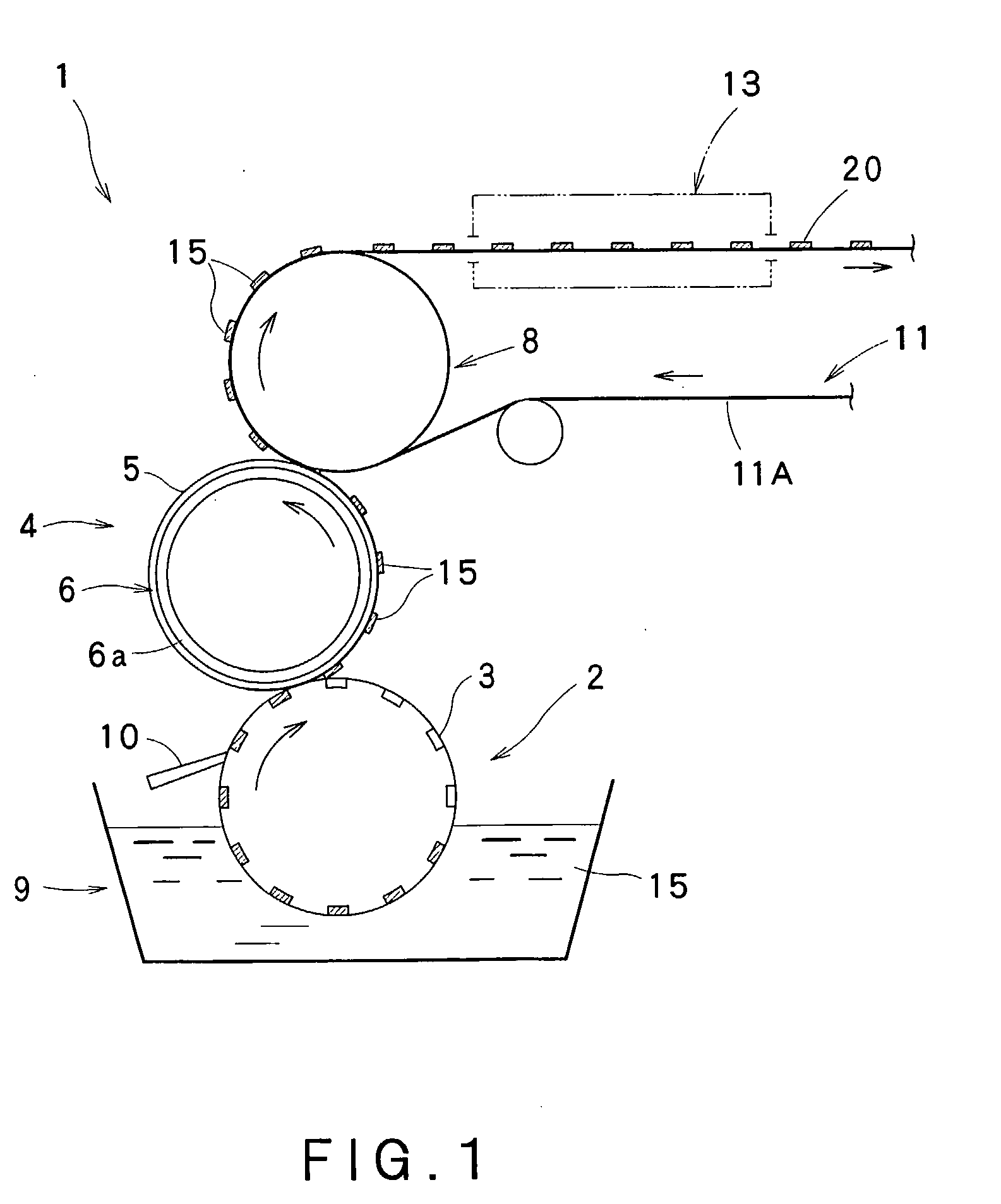

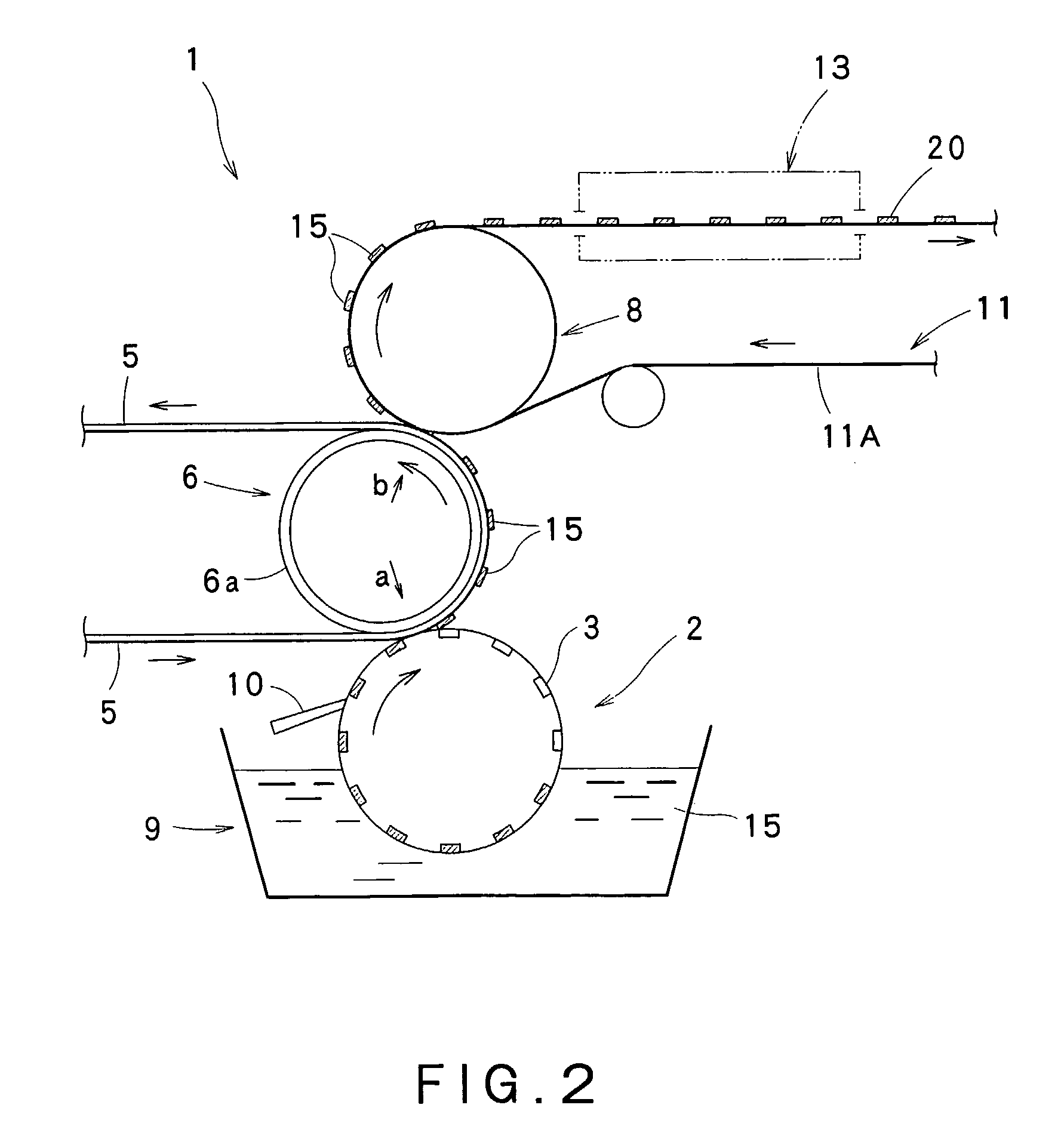

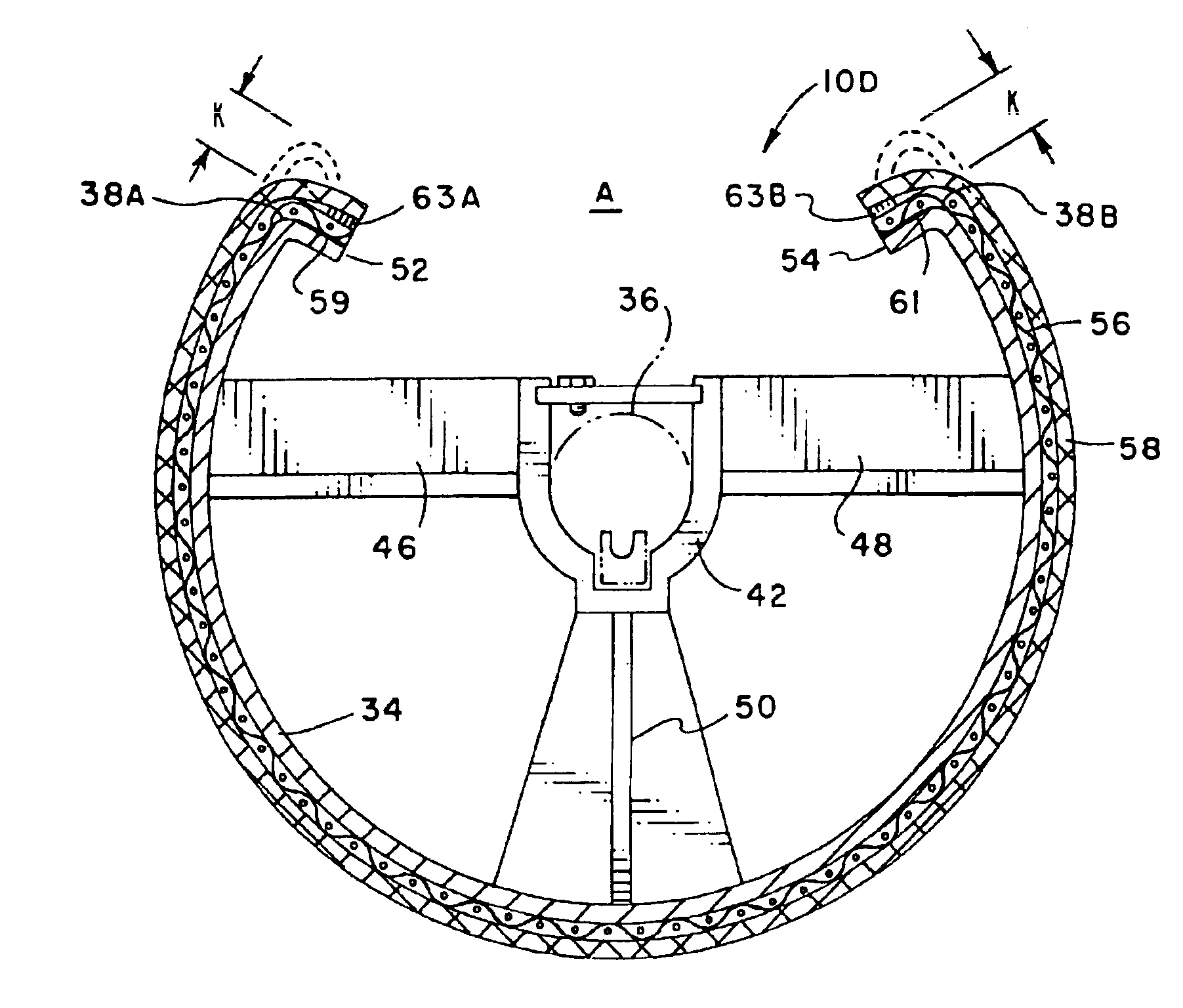

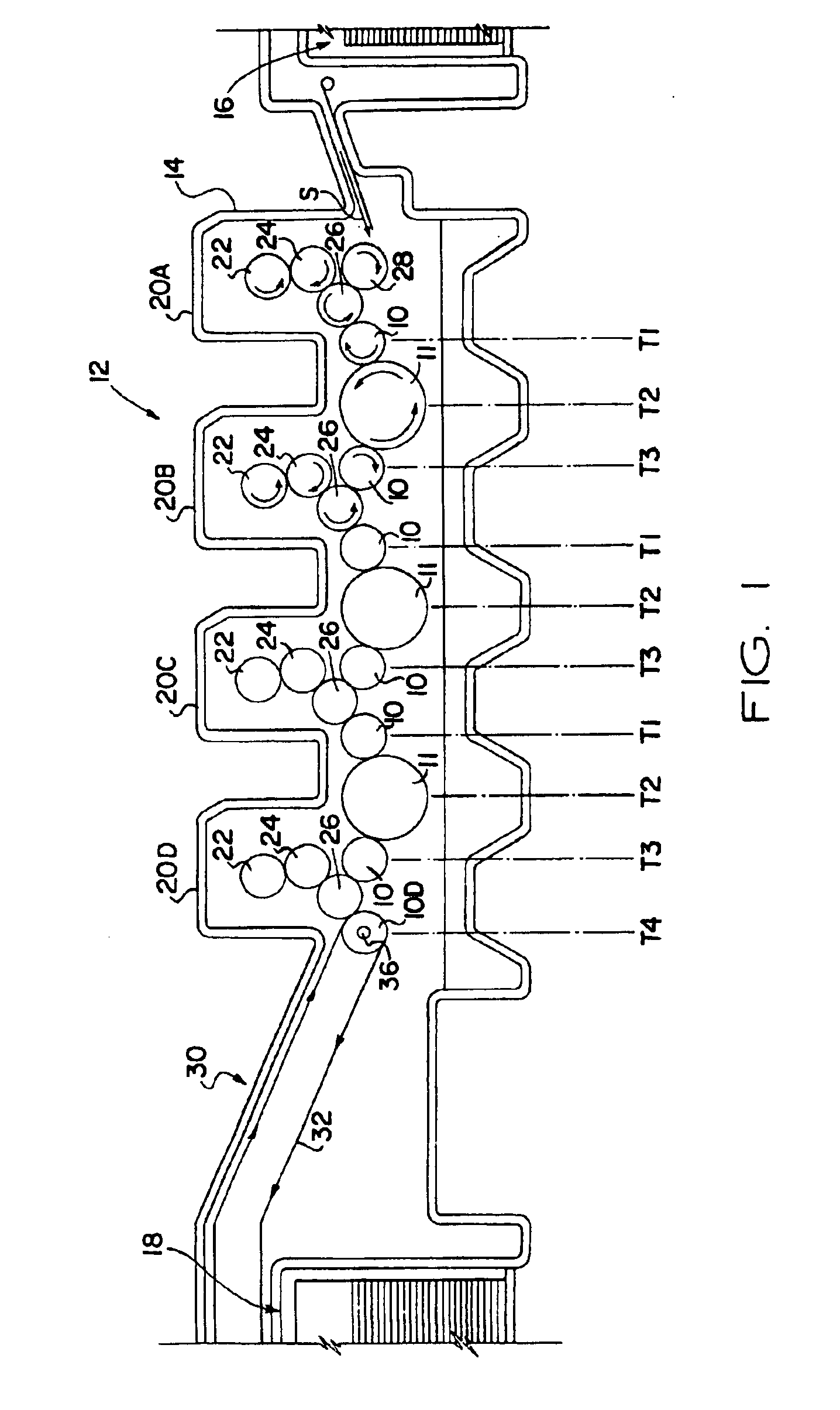

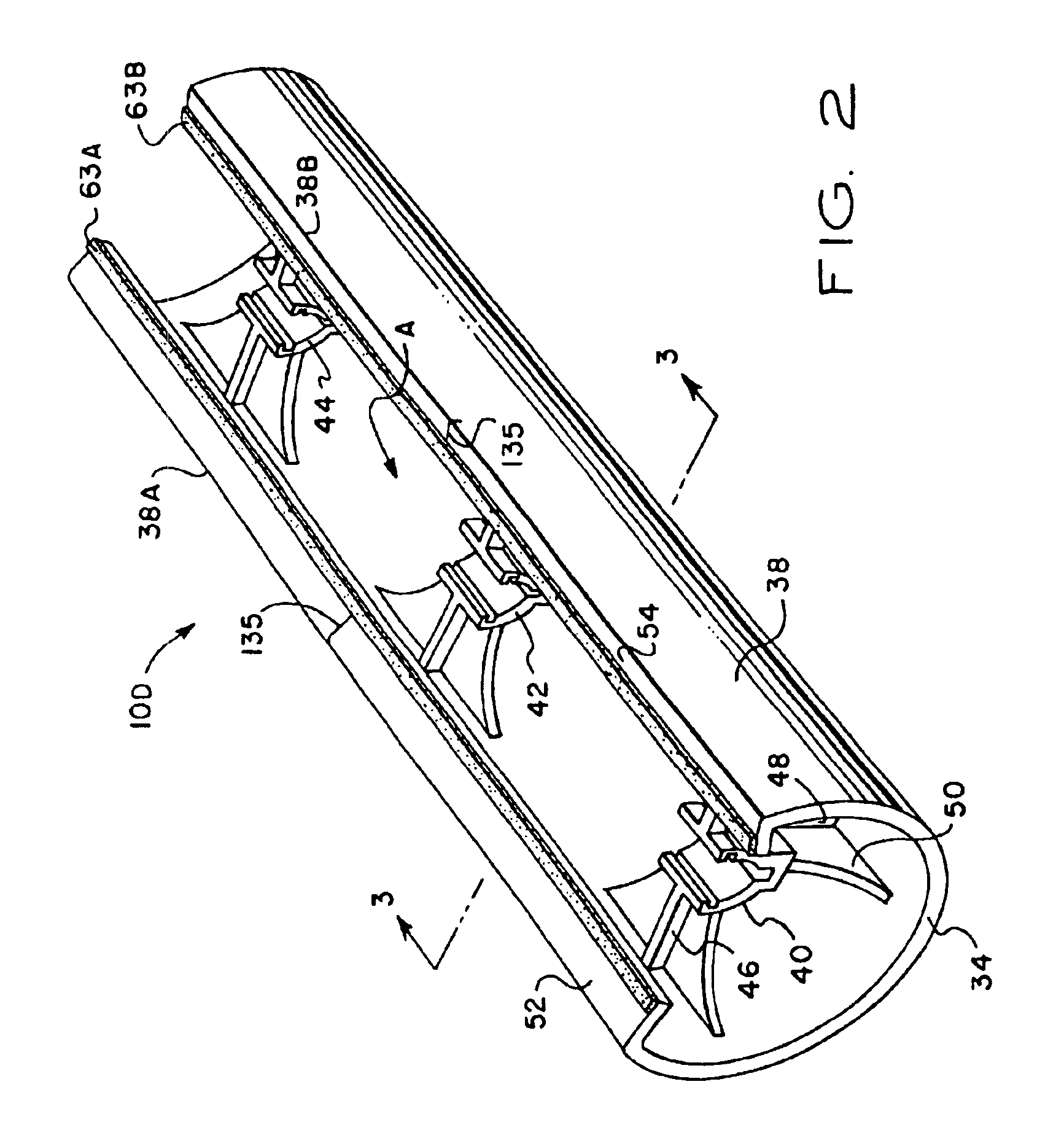

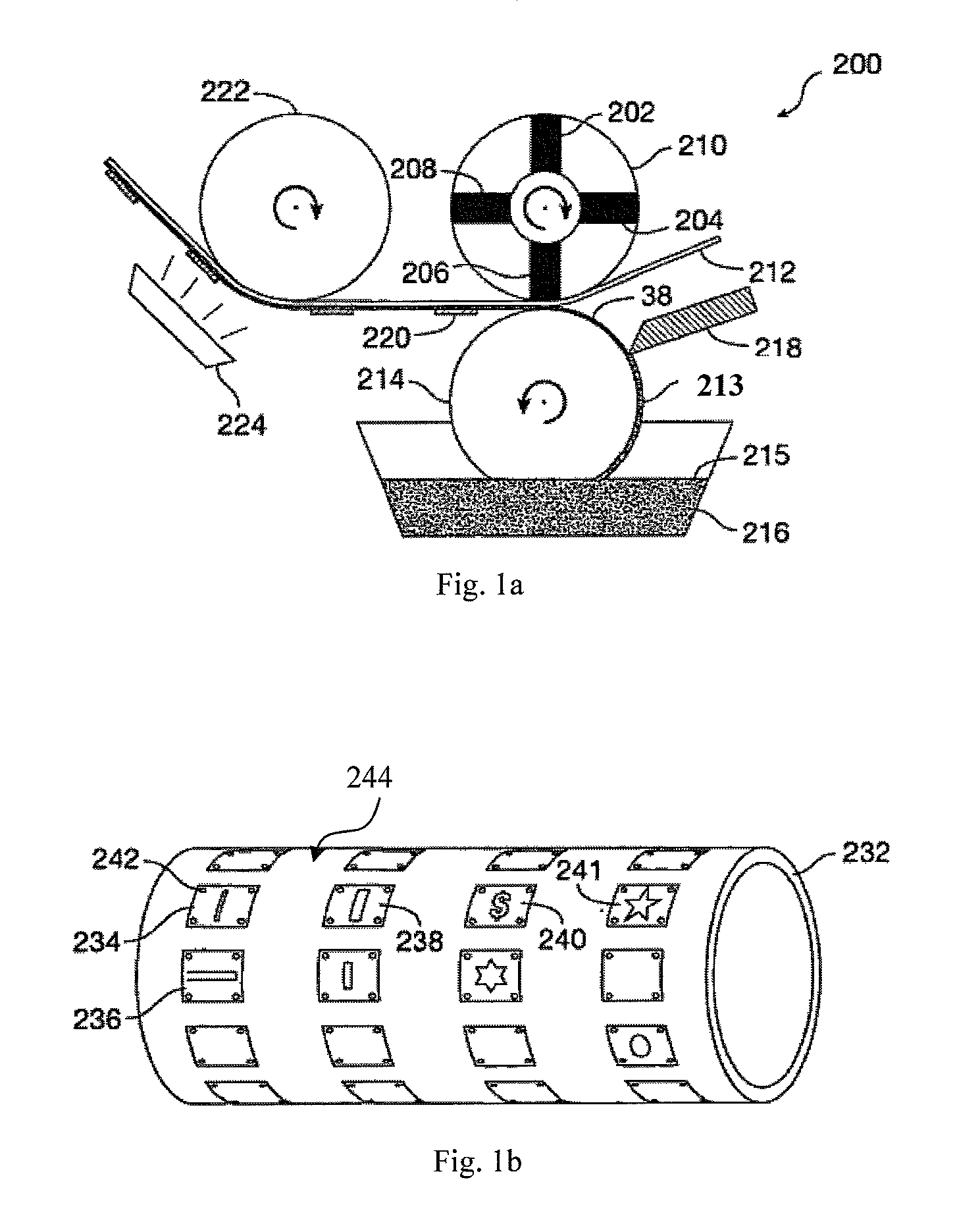

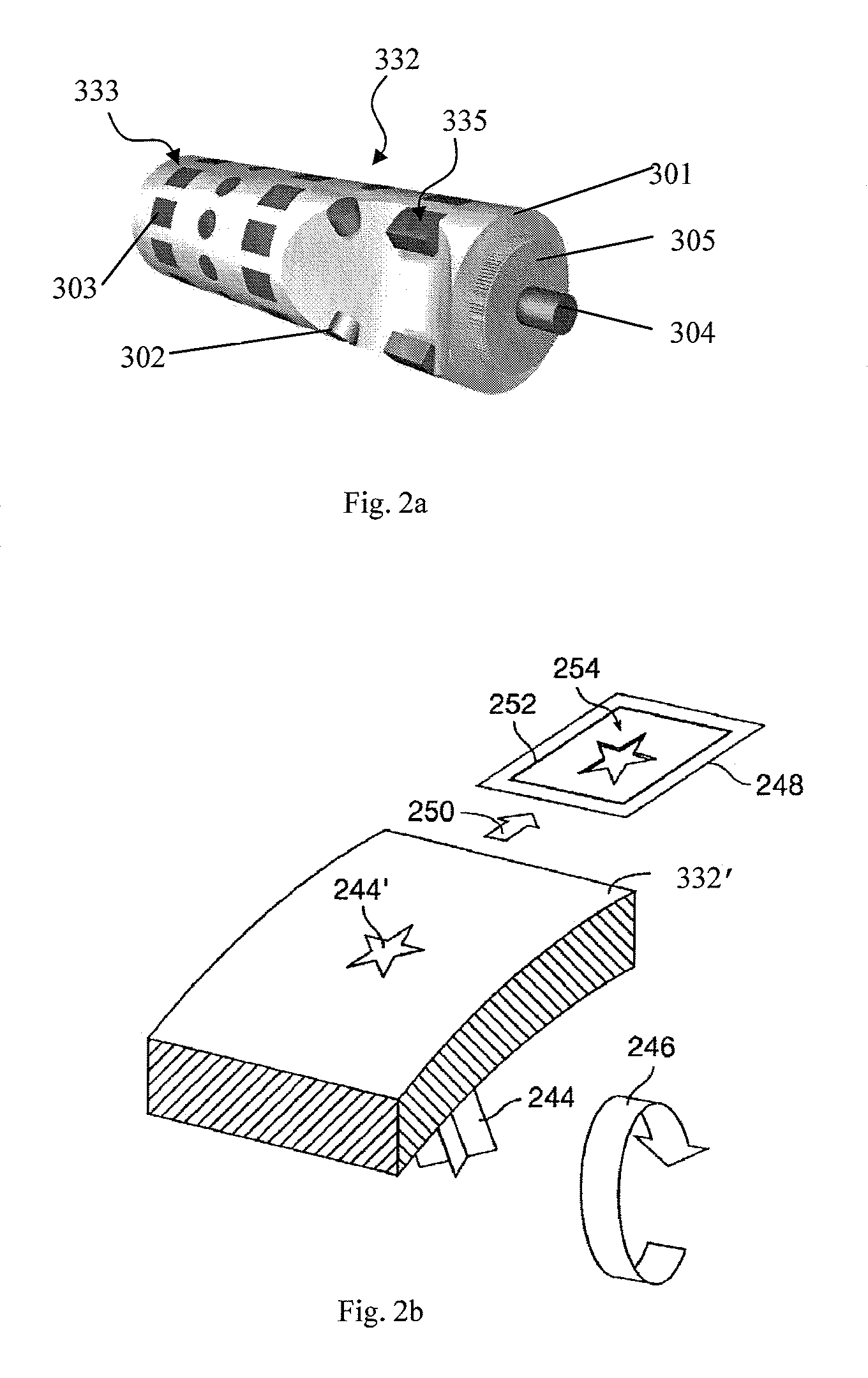

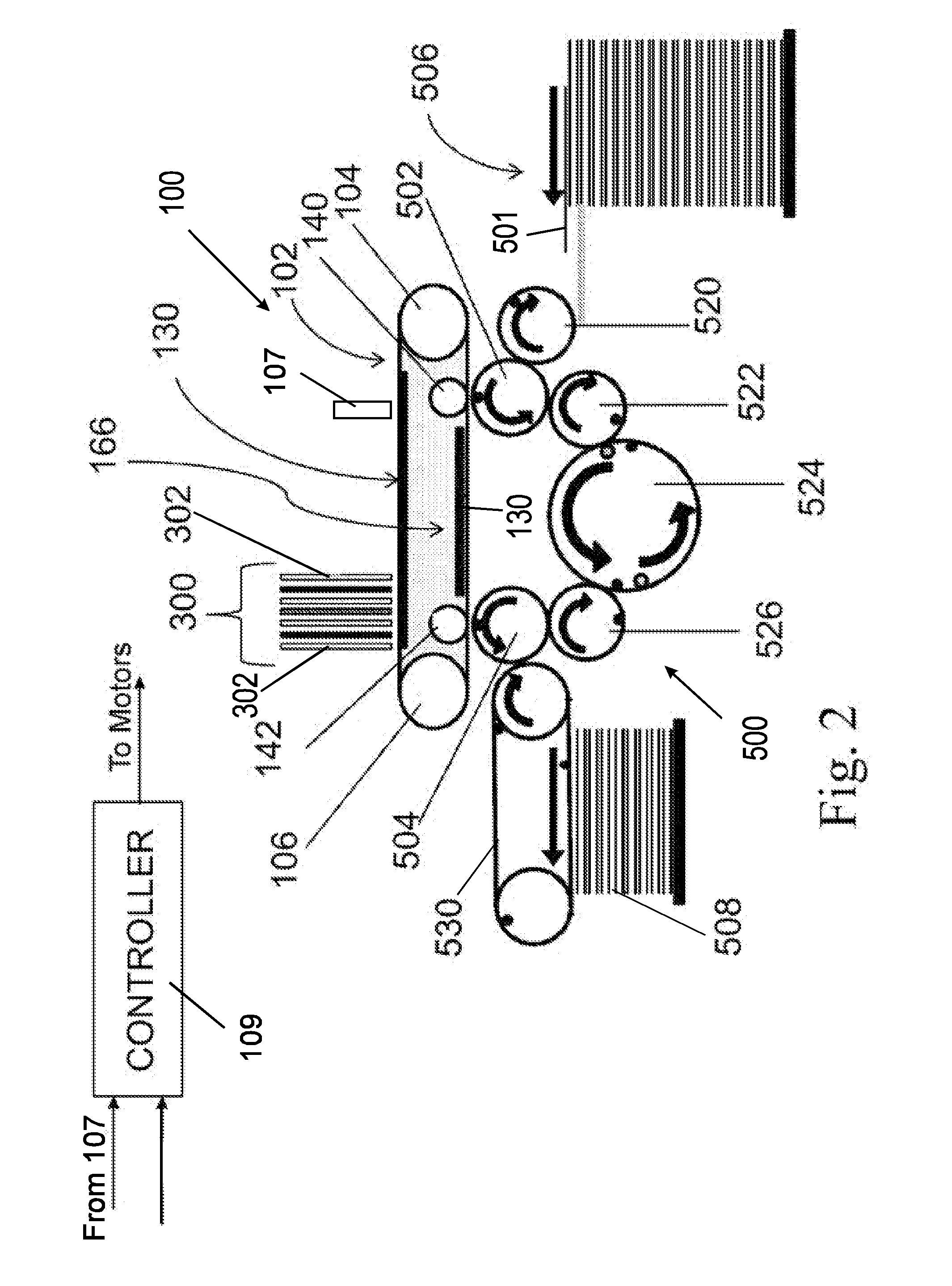

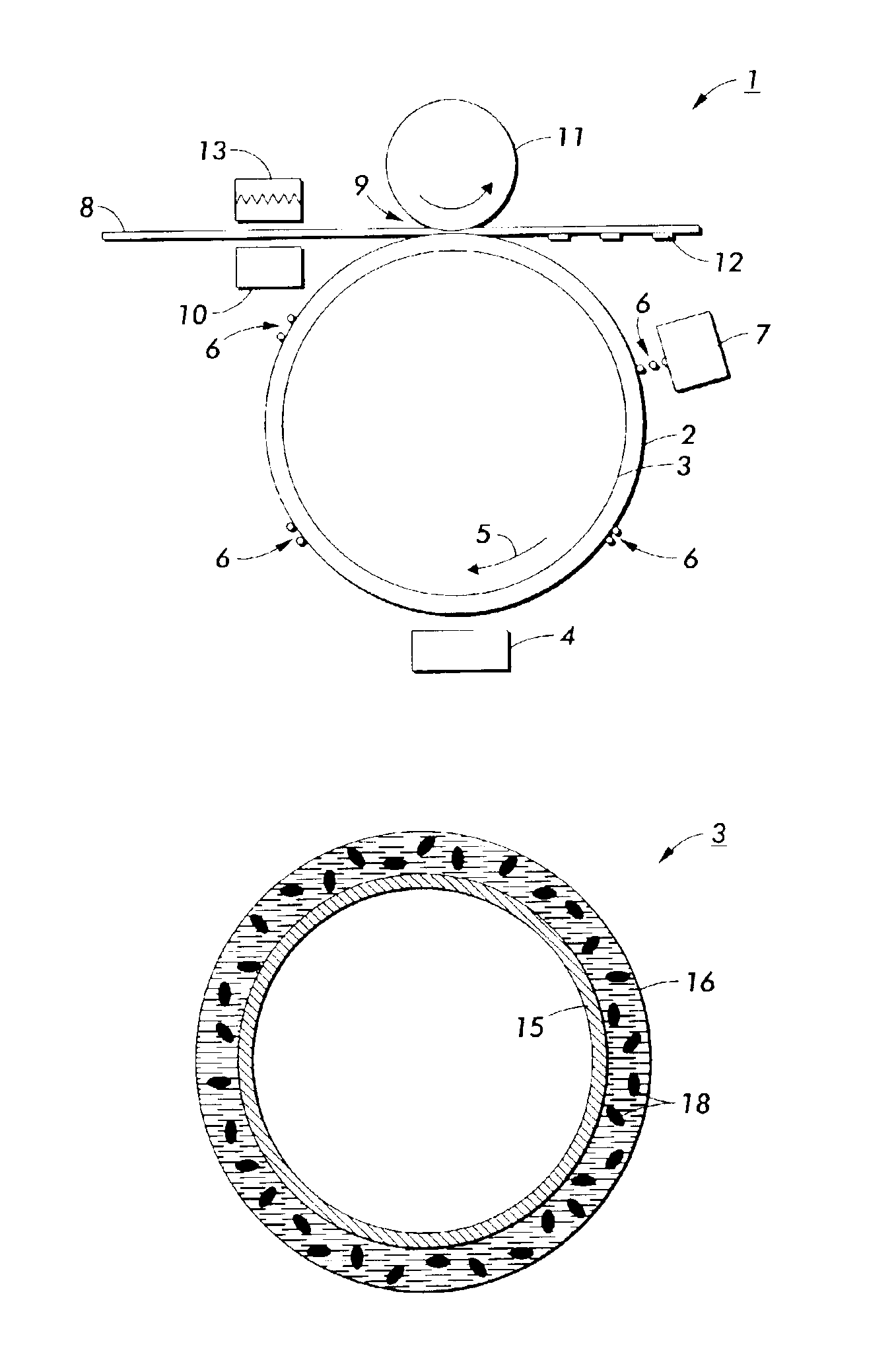

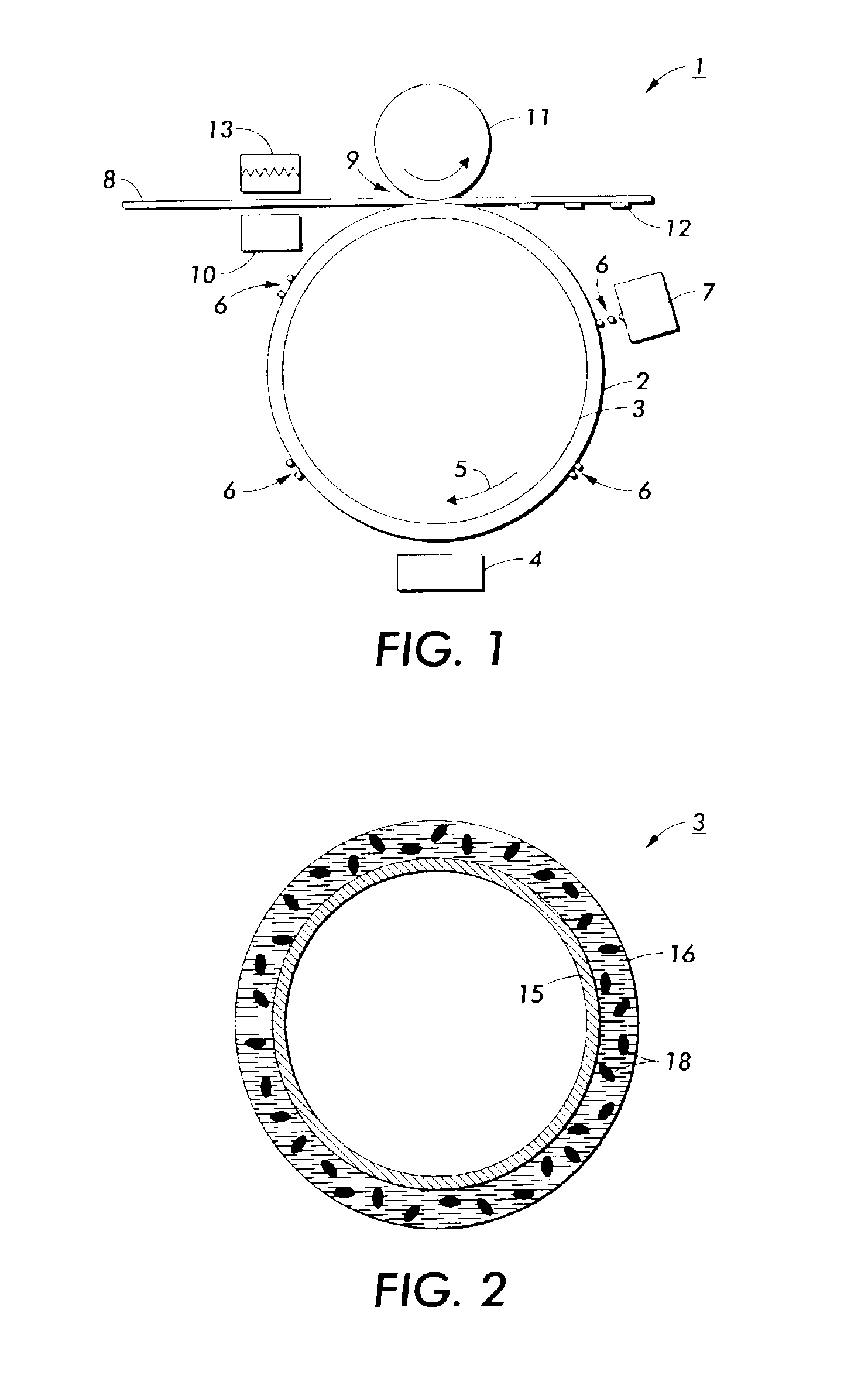

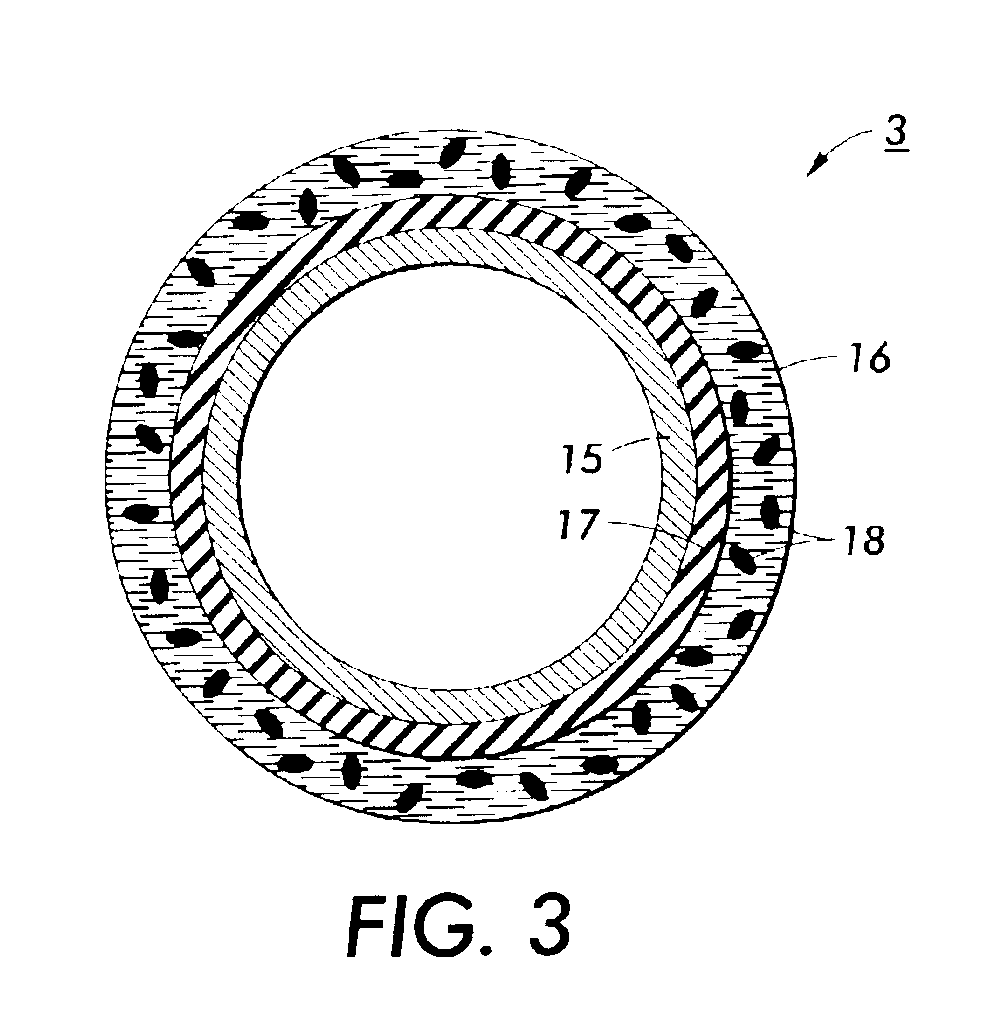

Apparatus For Orienting Magnetic Flakes

A printing apparatus includes a magnetic rotatable roller with a smooth even outer surface for aligning magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnetic portions of the roller, that can be formed by permanent magnets embedded in a non-magnetic roller body, or selectively magnetized portions of a flexible magnetic cover of the roller. In some embodiments, the roller is assembled for a plurality of interchangeable sections, which can include spinning magnets. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

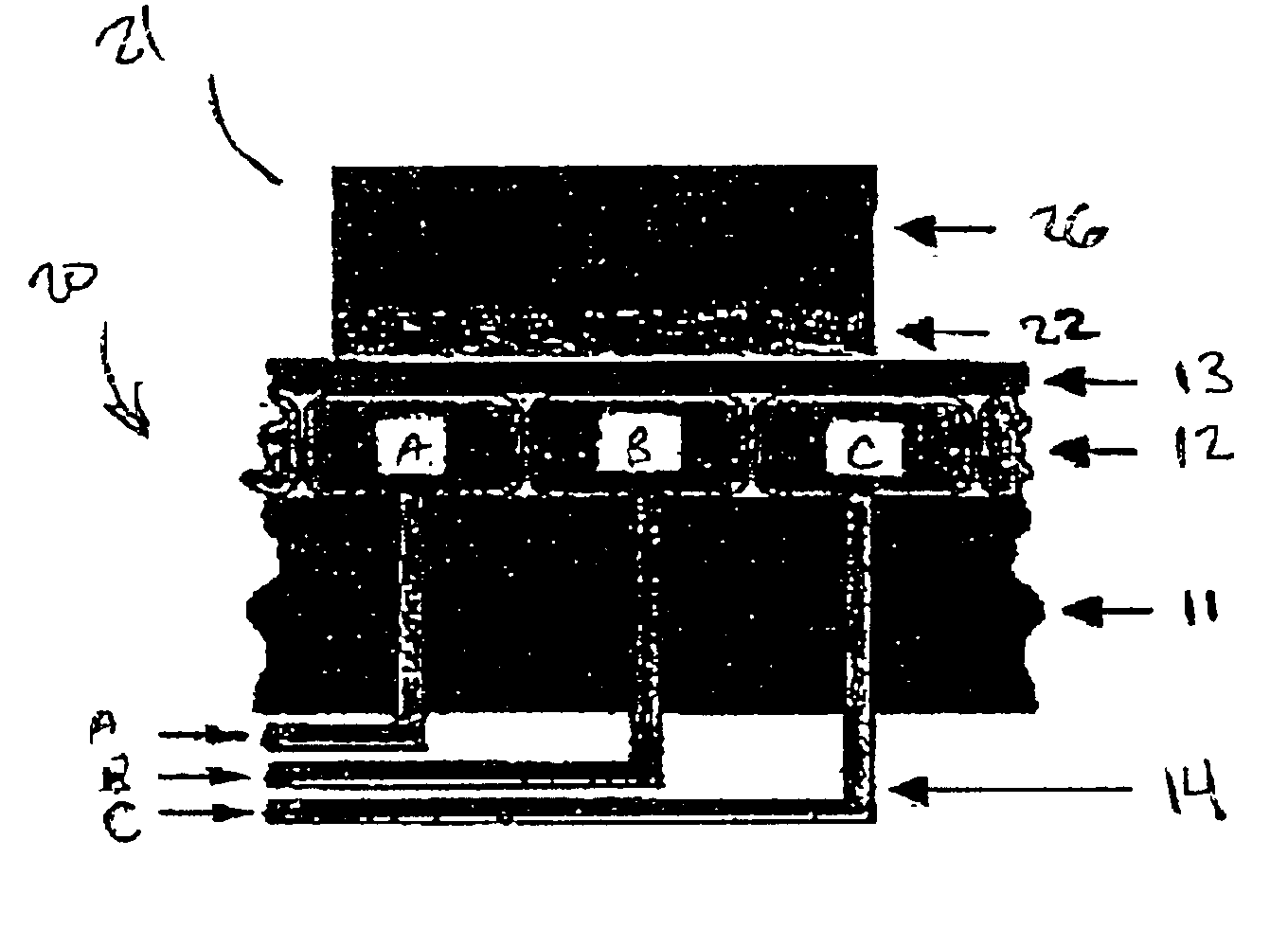

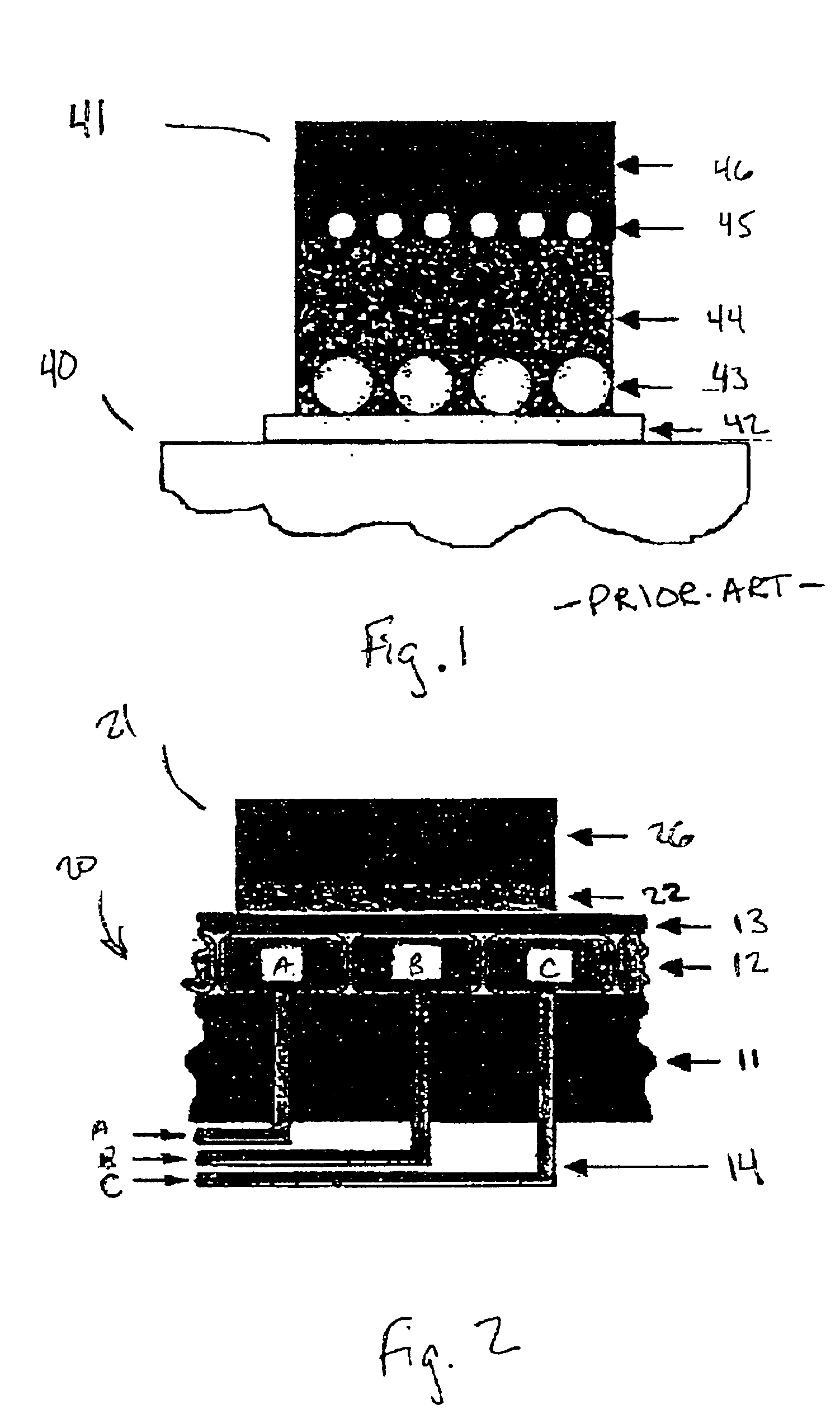

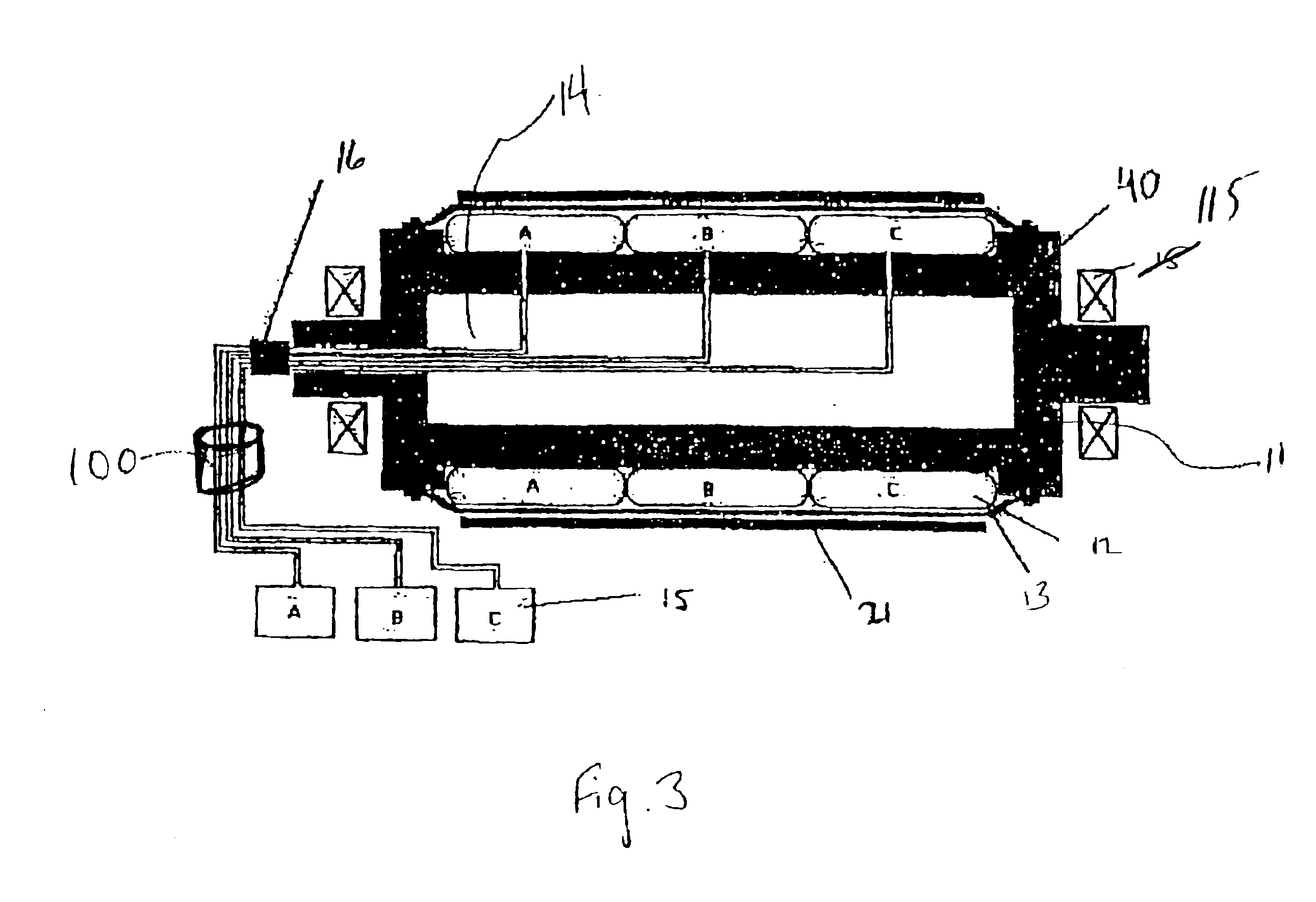

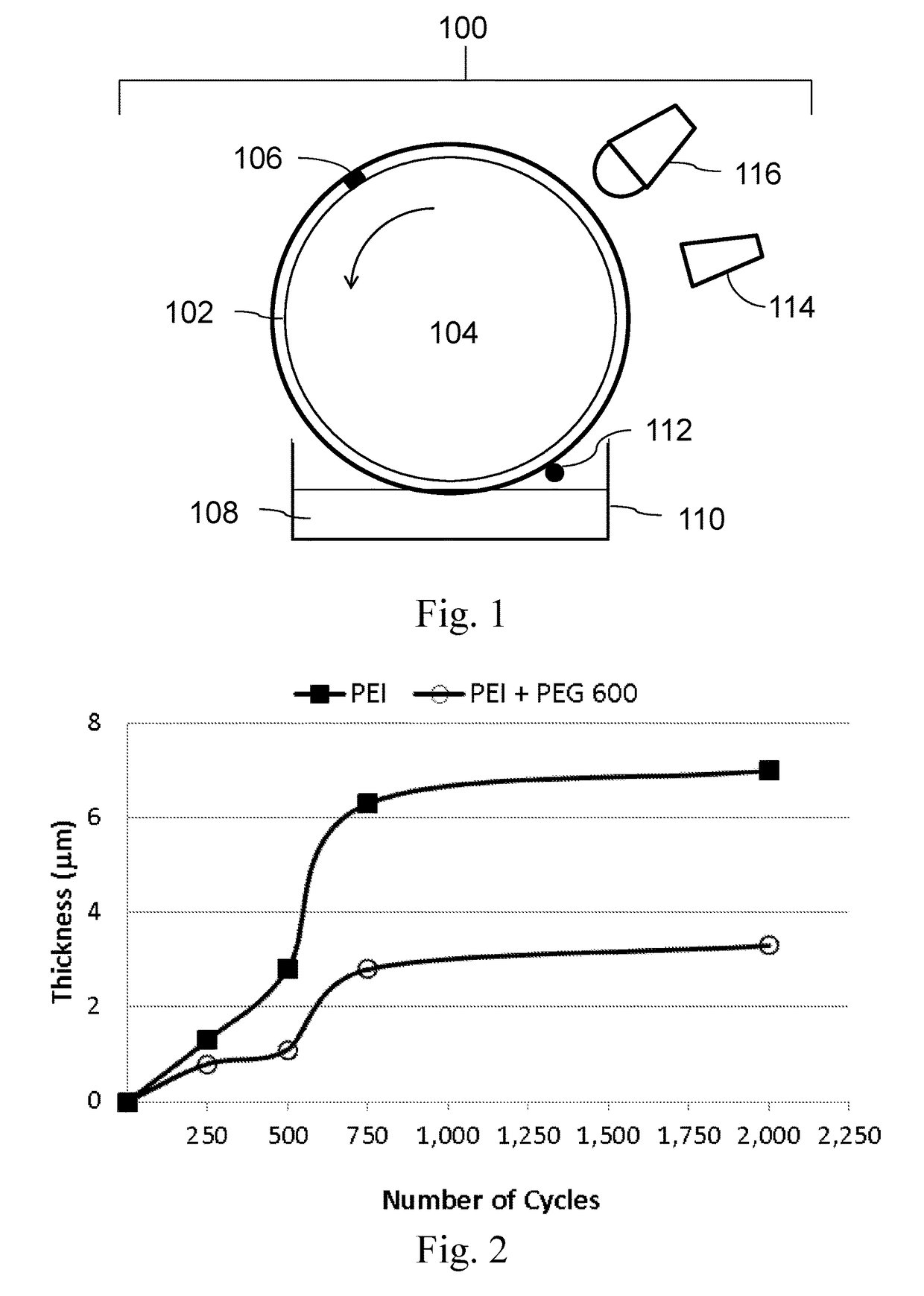

Blanket cylinder with integrated compressible layer

A printing unit including a rigid cylinder rotatable about an axis of rotation, a plurality of inflatable bladders disposed on a circumferential surface of the cylinder, and a first fluid supply regulation unit configured to supply a first fluid to a first set of inflatable bladders of the plurality of inflatable bladders and to regulate a first fluid pressure inside the first set inflatable bladders. In addition, a method for mounting a sleeve-shaped printing sock onto a blanket cylinder of an offset printing press, in which a set of inflatable bladders disposed at an outer region of the blanket cylinder are at least partially deflated. The sleeve-shaped printing sock is slid over one end of the blanket cylinder so that the printing sock at least partially surrounds a circumference of the blanket cylinder. The set of inflatable bladders are then inflated so that the printing sock fits tightly around the circumference of the blanket cylinder.

Owner:SHANGHAI ELECTRICGROUP CORP

Doctor blade

InactiveUS6431066B1Extended service lifeImprove productivityLiquid surface applicatorsRotary intaglio printing pressCeramic coatingHardness

A doctor blade for direct contact with a ceramic roll surface. The doctor blade includes a strip of metallic carrier material, which, along one edge section is provided with a ceramic coating. The ceramic coating on the blade has a hardness ranging from approximately 850 to 950 microvickers, thereby substantially increasing wear resistance of the blade without substantially increasing wear on the ceramic roll surface for which the blade is adapted for use.

Owner:BTG ECLEPENS

Surface treated doctor blade

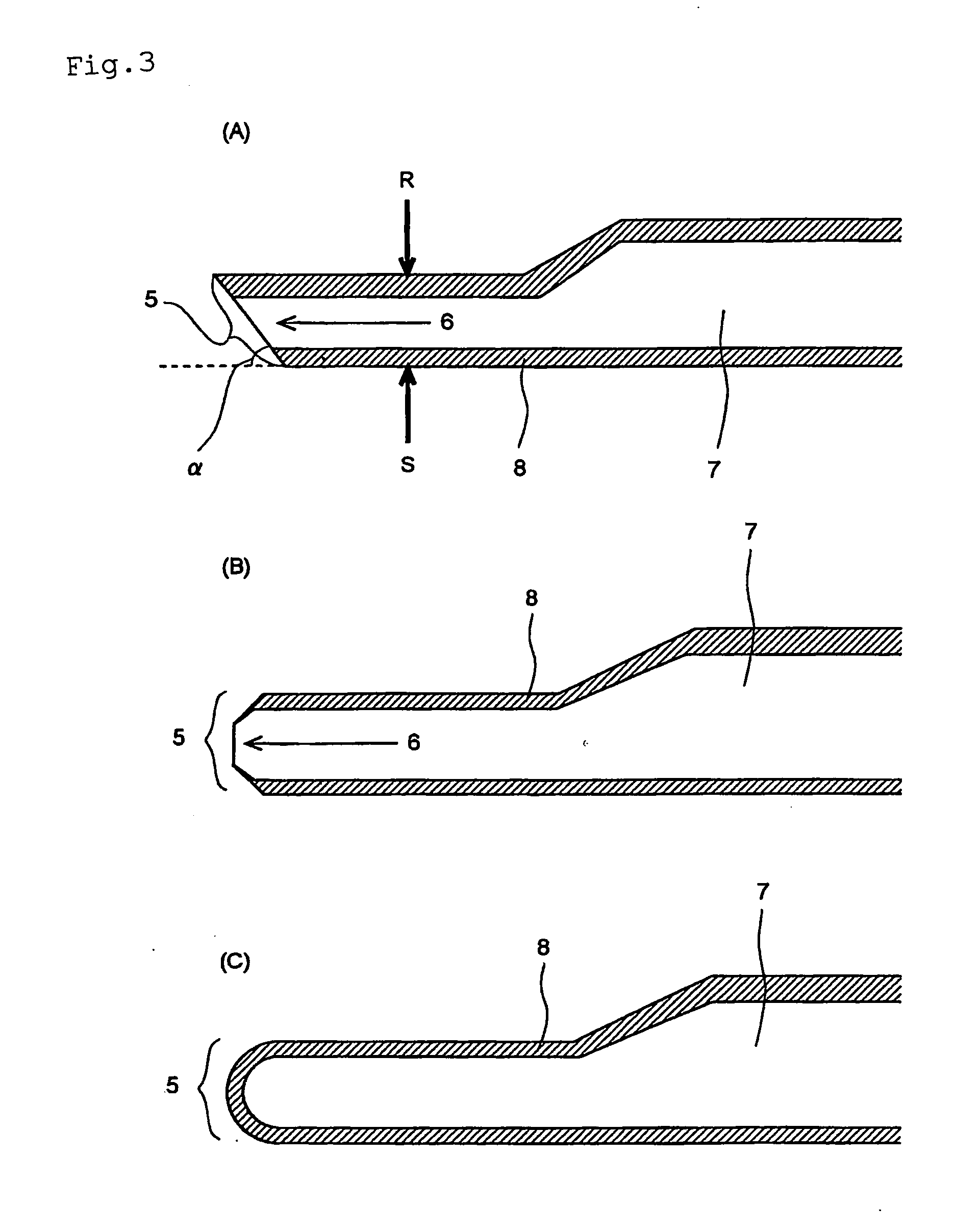

InactiveUS20050089706A1Improve consistencyReduce hardnessRotary intaglio printing pressBrushesEngineeringWear resistance

Disclosed is a surface treated doctor blade in which the surface of at least the blade edge portion thereof consists of a surface treatment coating film composed of a first layer consisting of a specific nickel-based plating and a second layer provided thereon which has low surface energy, and in which preferably at least a part of the blade edge end portion of the blade base material is exposed. In the surface treated doctor blade of the present invention, it is possible to improve wear resistance of the blade edge end and to suppress generation of printing failures during continuous printing. Further, in the mode in which at least a part of the blade base material is exposed, it is possible to reduce running-in time for adjustment of contact of the blade edge with the cylinder after replacement of the doctor blade.

Owner:NIHON NEW CHROME

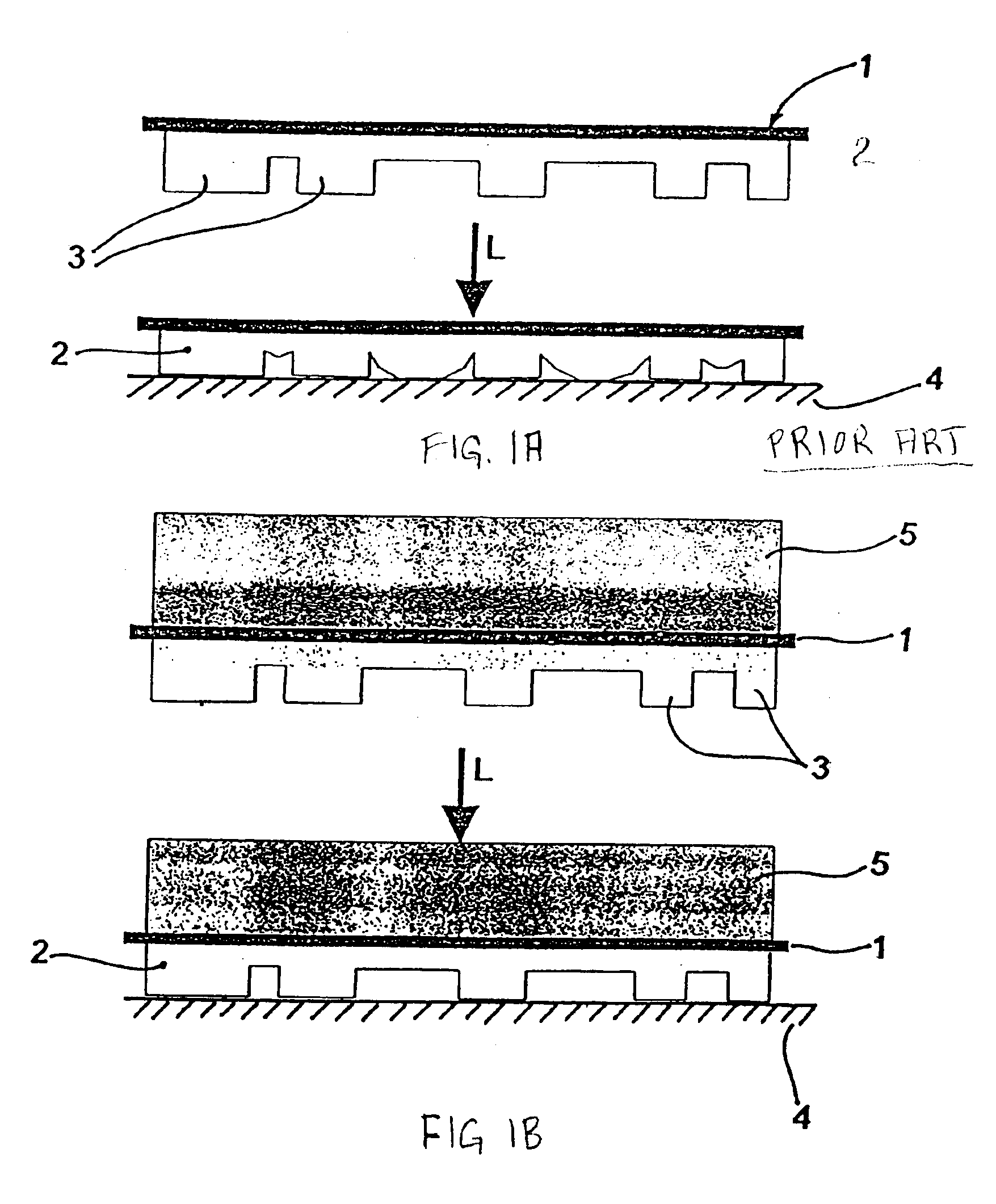

Digital printing process

A printing process is disclosed which comprises directing droplets of an ink onto an intermediate transfer member to form an ink image, the ink including an organic polymeric resin and a coloring agent in an aqueous carrier, and the transfer member having a hydrophobic outer surface so that each ink droplet in the ink image spreads on impinging upon the intermediate transfer member to form an ink film. The ink is dried while the ink image is being transported by the intermediate transfer member by evaporating the aqueous carrier from the ink image to leave a residue film of resin and coloring agent. The residue film is then transferred to a substrate. The chemical compositions of the ink and of the surface of the intermediate transfer member are selected such that attractive intermolecular forces between molecules in the outer skin of each droplet and on the surface of the intermediate transfer member counteract the tendency of the ink film produced by each droplet to bead under the action of the surface tension of the aqueous carrier, without causing each droplet to spread by wetting the surface of the intermediate transfer member.

Owner:LANDA

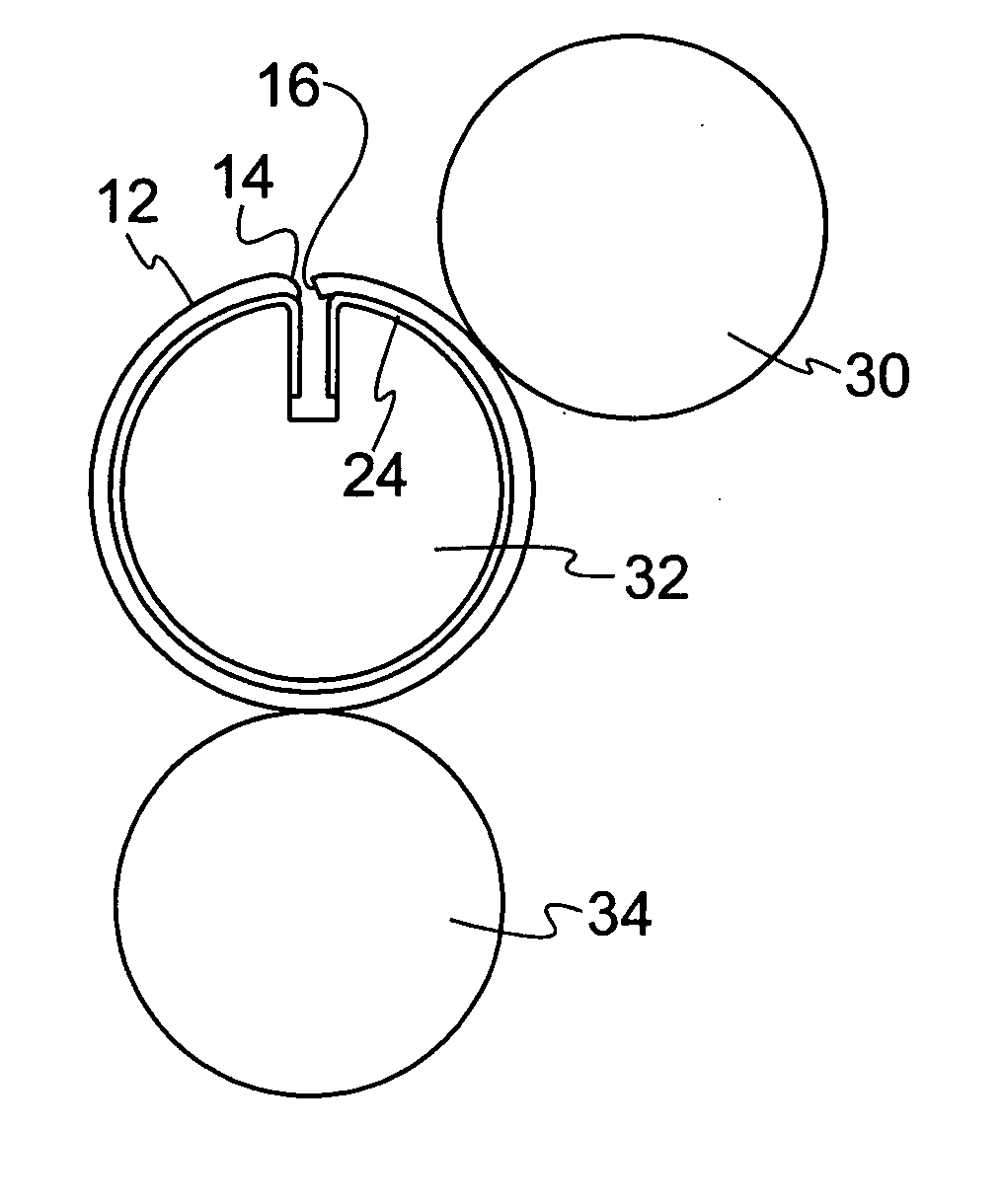

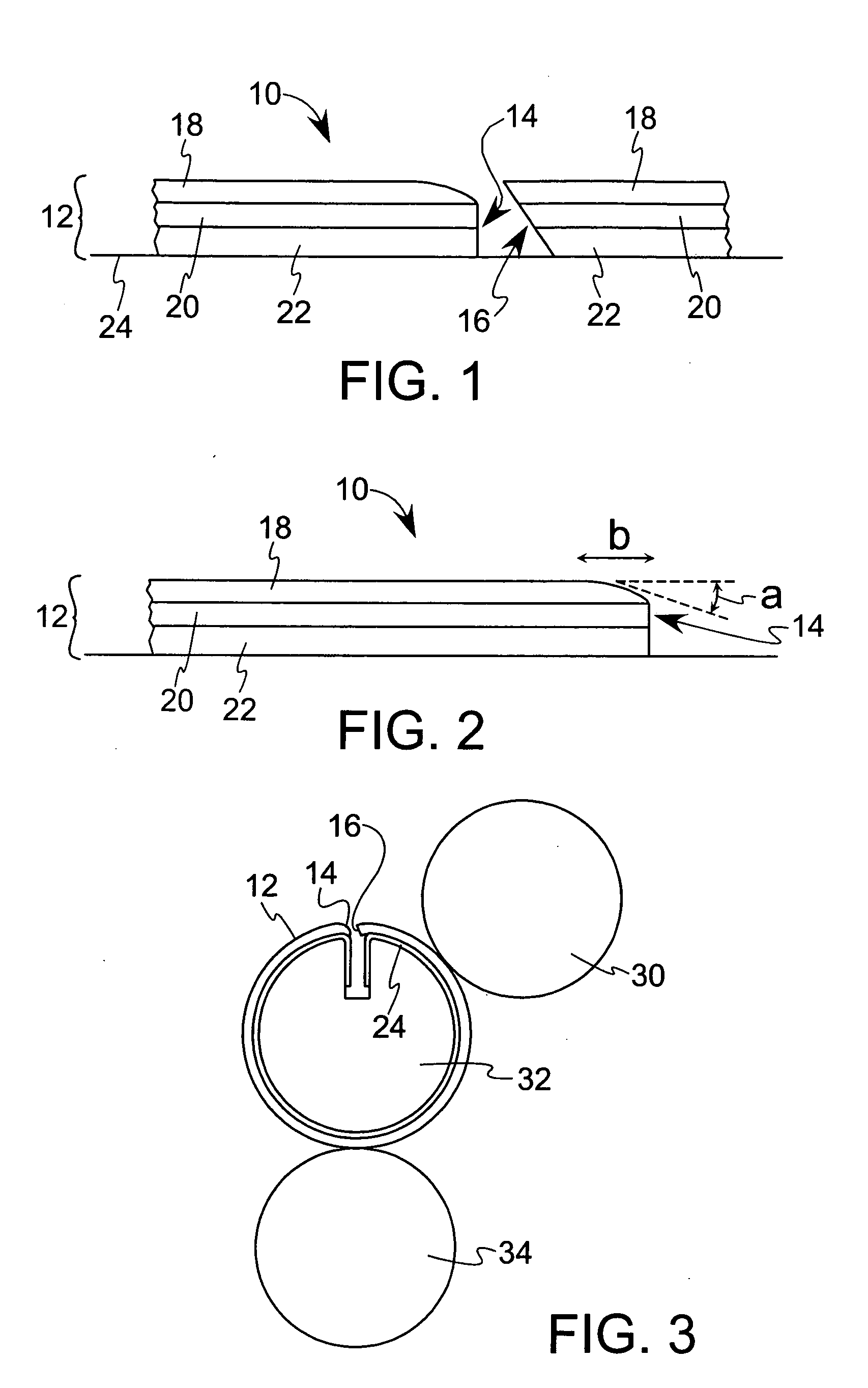

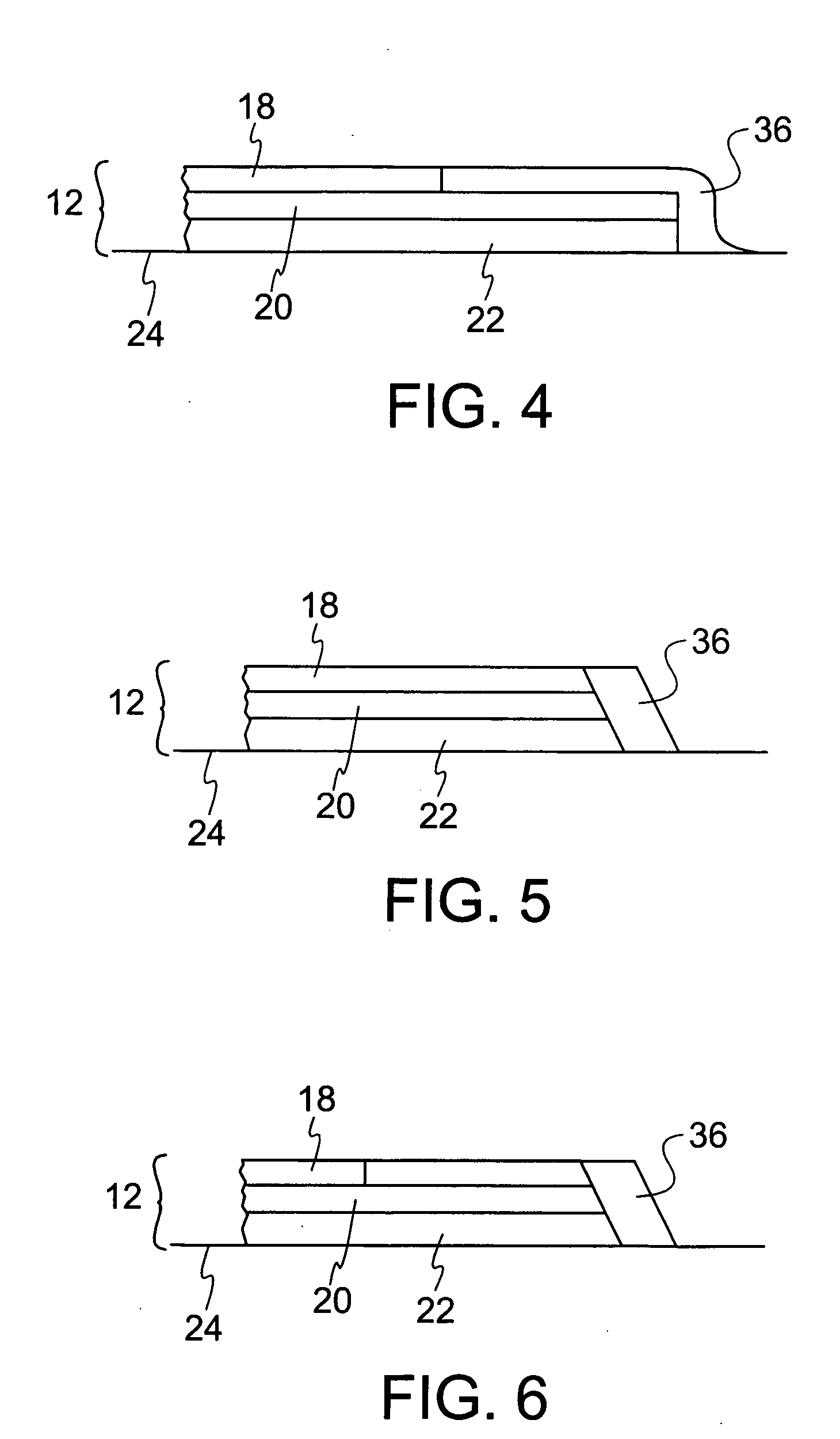

Printing blanket construction and method of making

ActiveUS20050098051A1Reduce shock effectsIncrease surface areaPrinting blanketsRotary lithographic machinesLeading edgeEngineering

An improved printing blanket construction is provided which includes at least a top ply, a bottom ply, and a non-extensible backing ply. The blanket includes leading and trailing edges which are secured directly to the backing ply, where at least a portion of the leading edge forms a contoured edge, a stair-stepped edge, a beveled edge, or a combination thereof. The printing blanket construction having such a shaped leading edge reduces printing gap, reduces the impact forces on the leading edge of the blanket, and protects the blanket from the penetration of ink, solvents, moisture and the like into the blanket plies during use.

Owner:DAY INT

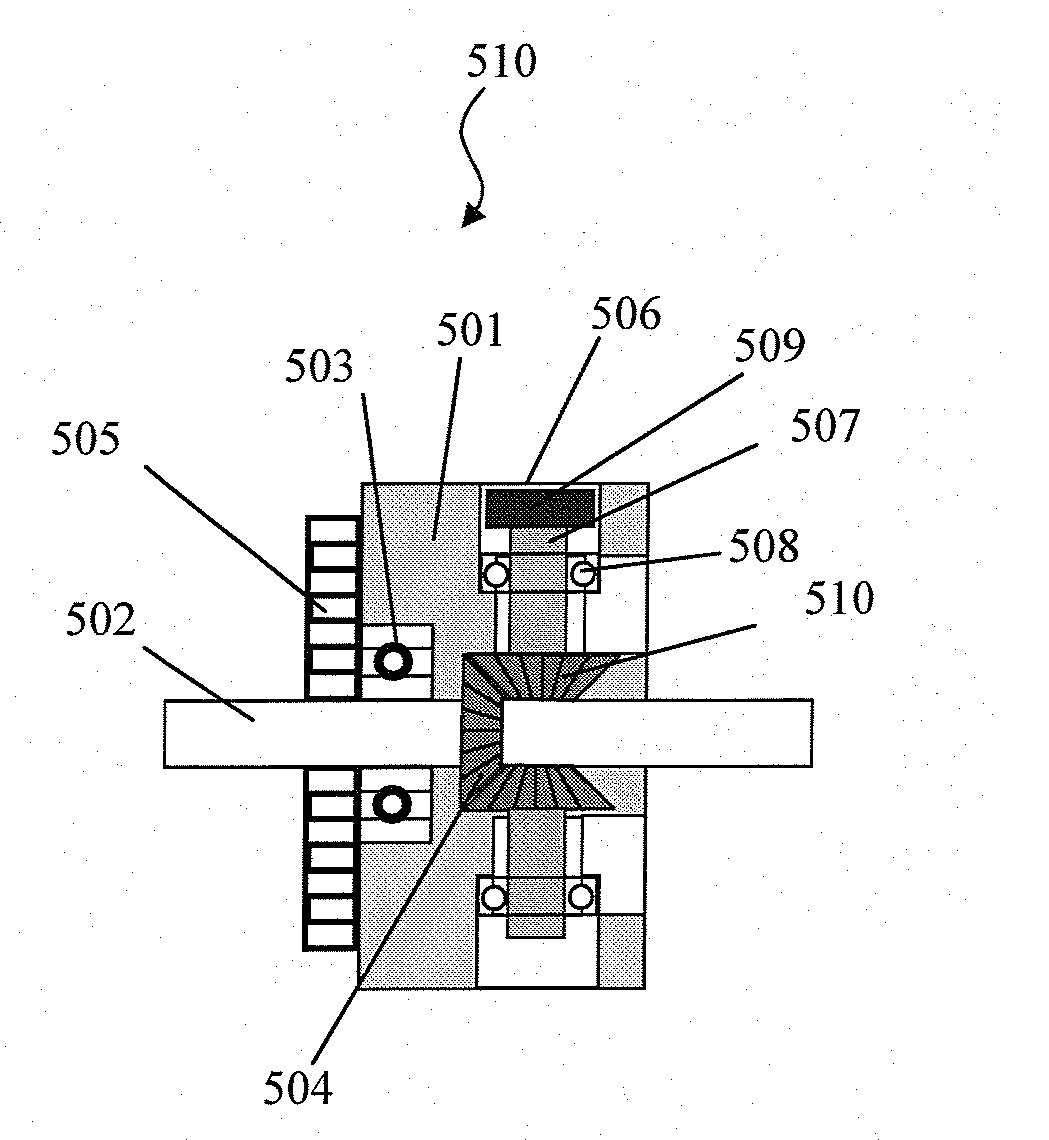

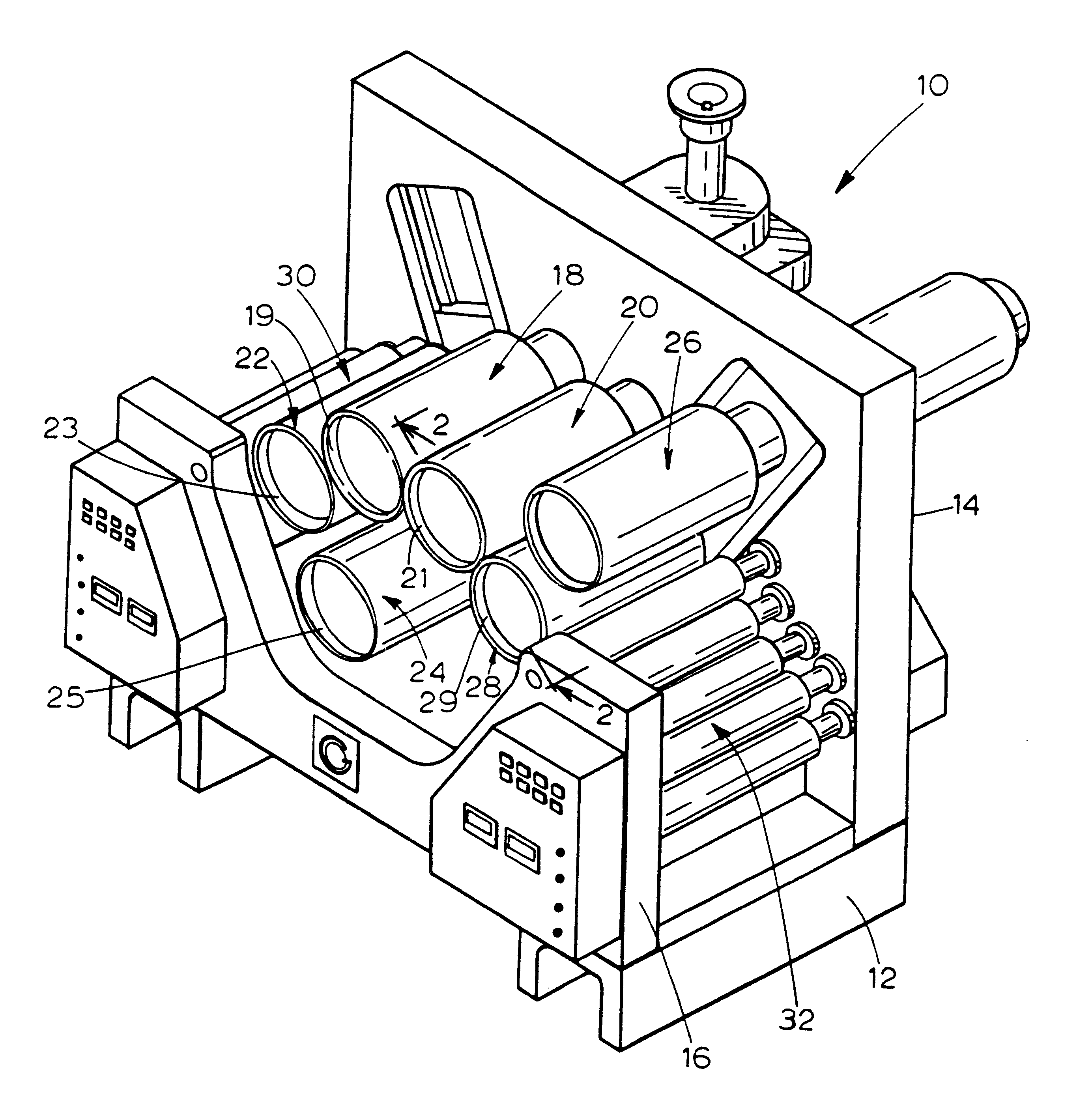

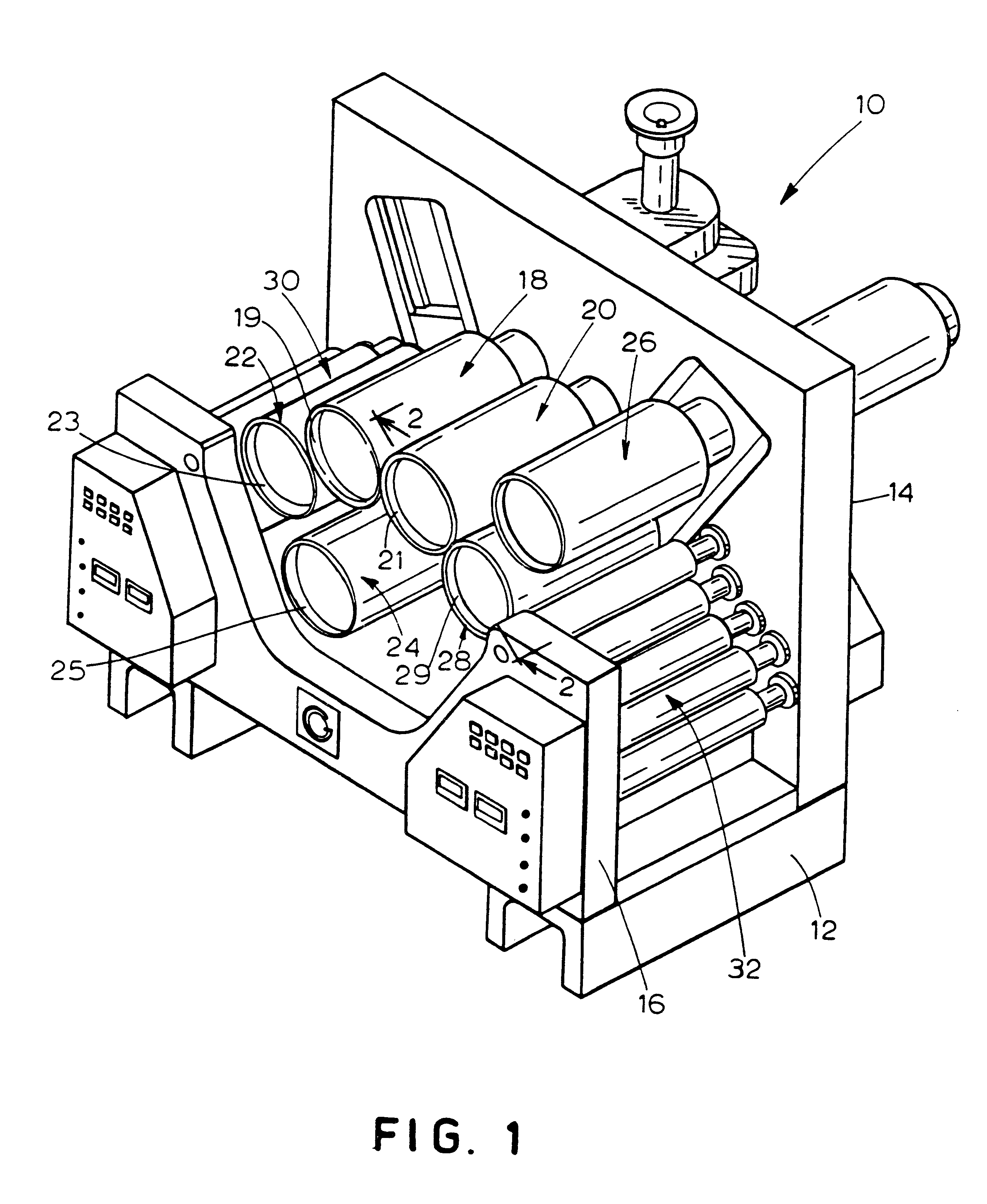

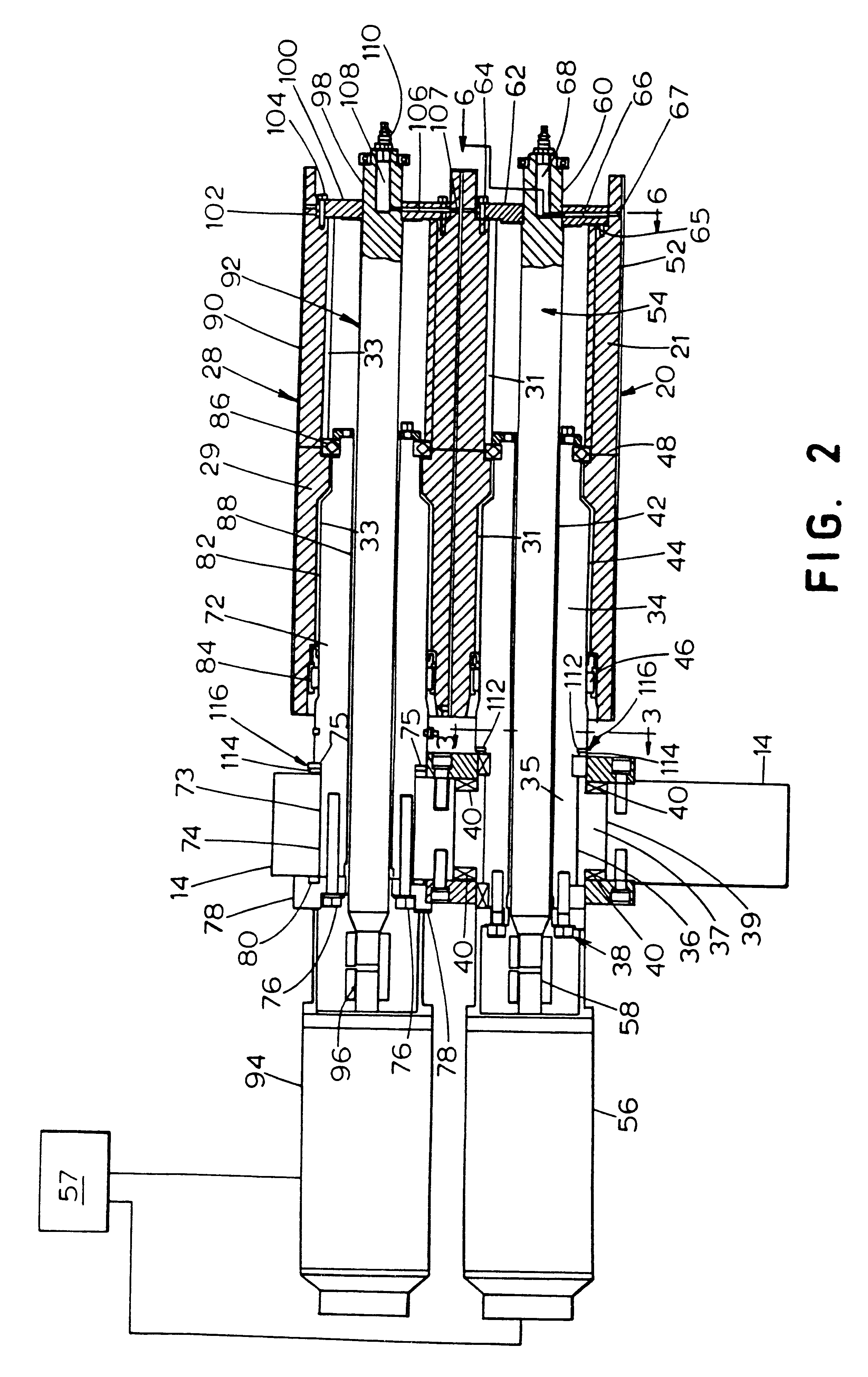

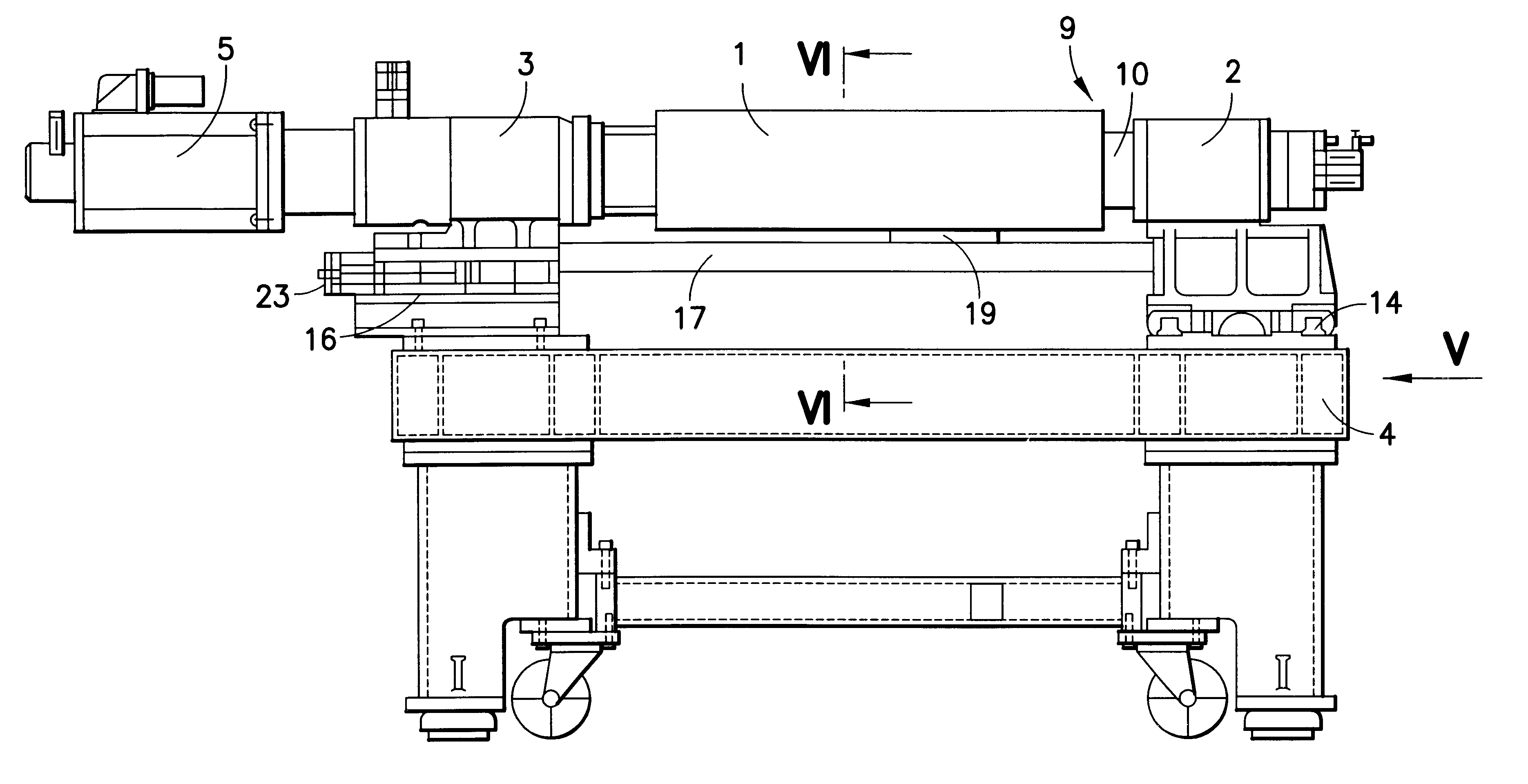

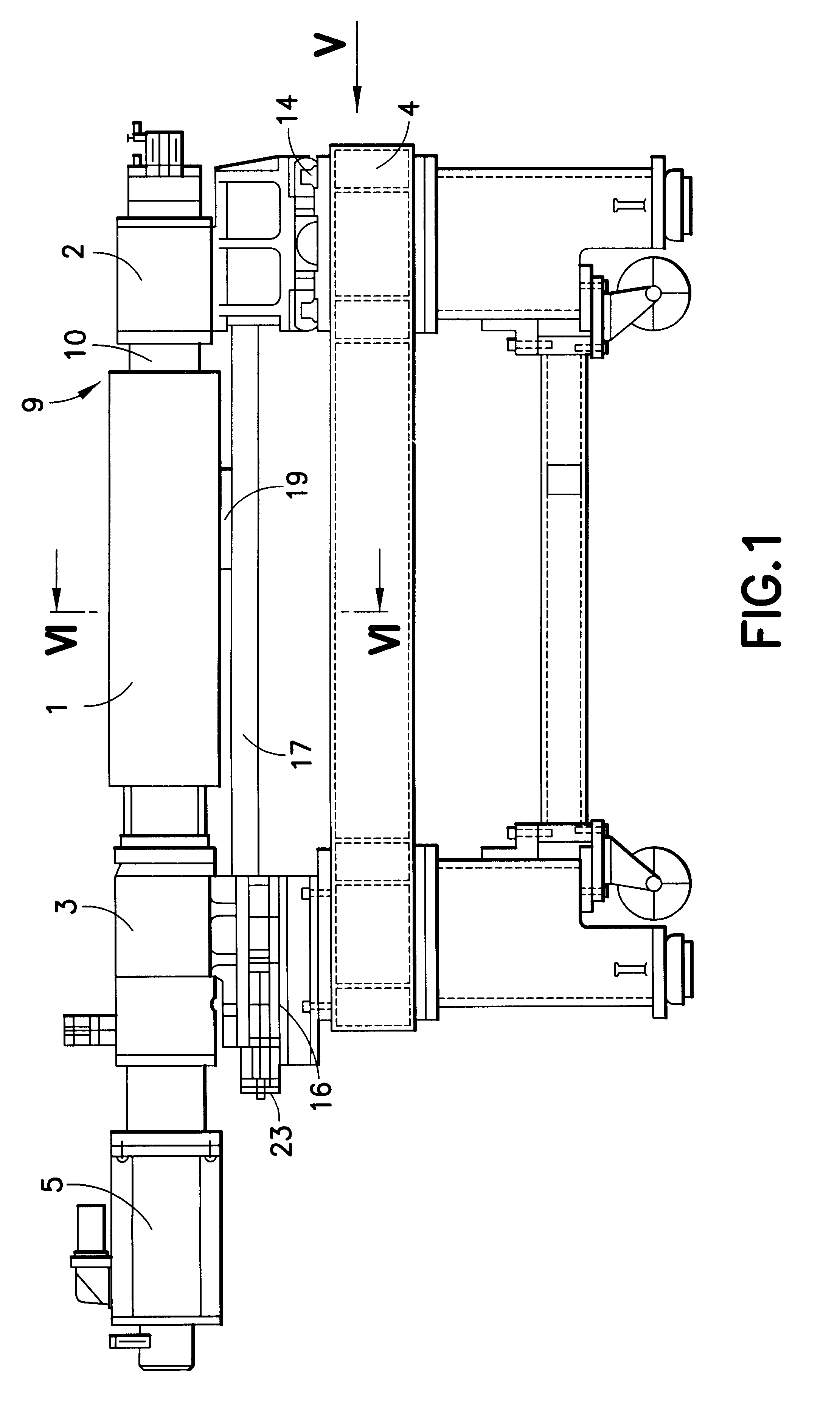

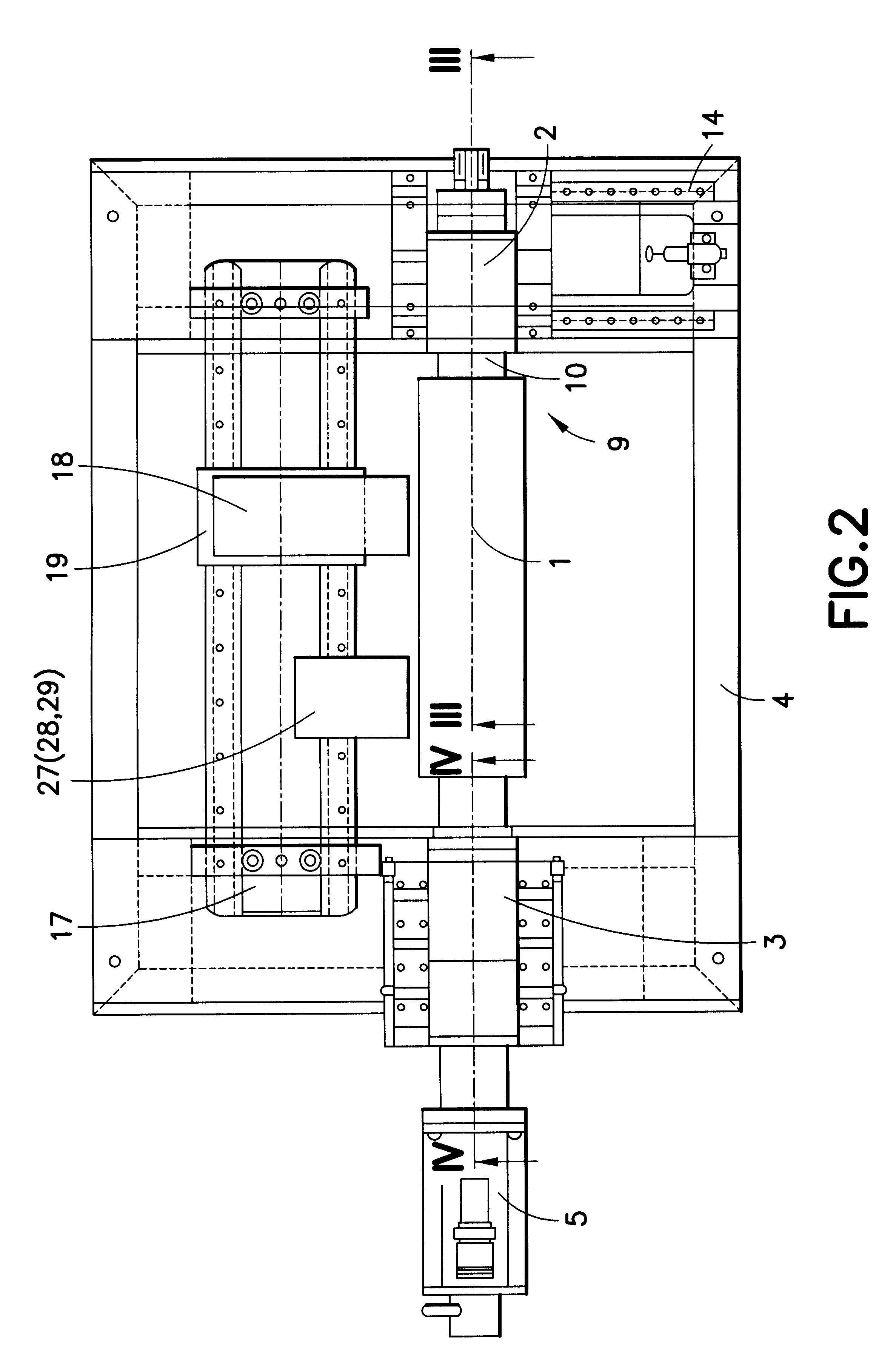

Bearing support system for a printing press having cantilevered cylinders

A bearing assembly for rotatably supporting the cylinder on a printing press is disclosed. The printing press comprises a frame, a support shaft, a cylinder, and the bearing assembly. The support shaft includes an inner fixed end attached to the frame, a free end disposed outwardly away from the frame, and an interconnecting central portion. The bearing assembly rotatably supports the cylinder on the support shaft The bearing assembly includes an inboard bearing set secured to the support shaft adjacent the central portion, and further includes an outboard bearing set secured to the support shaft adjacent the free end. A portion of the bearing assembly is adapted to permit angular adjustment of the cylinder about an axis perpendicular to the support shaft longitudinal axis.

Owner:SHANGHAI ELECTRICGROUP CORP

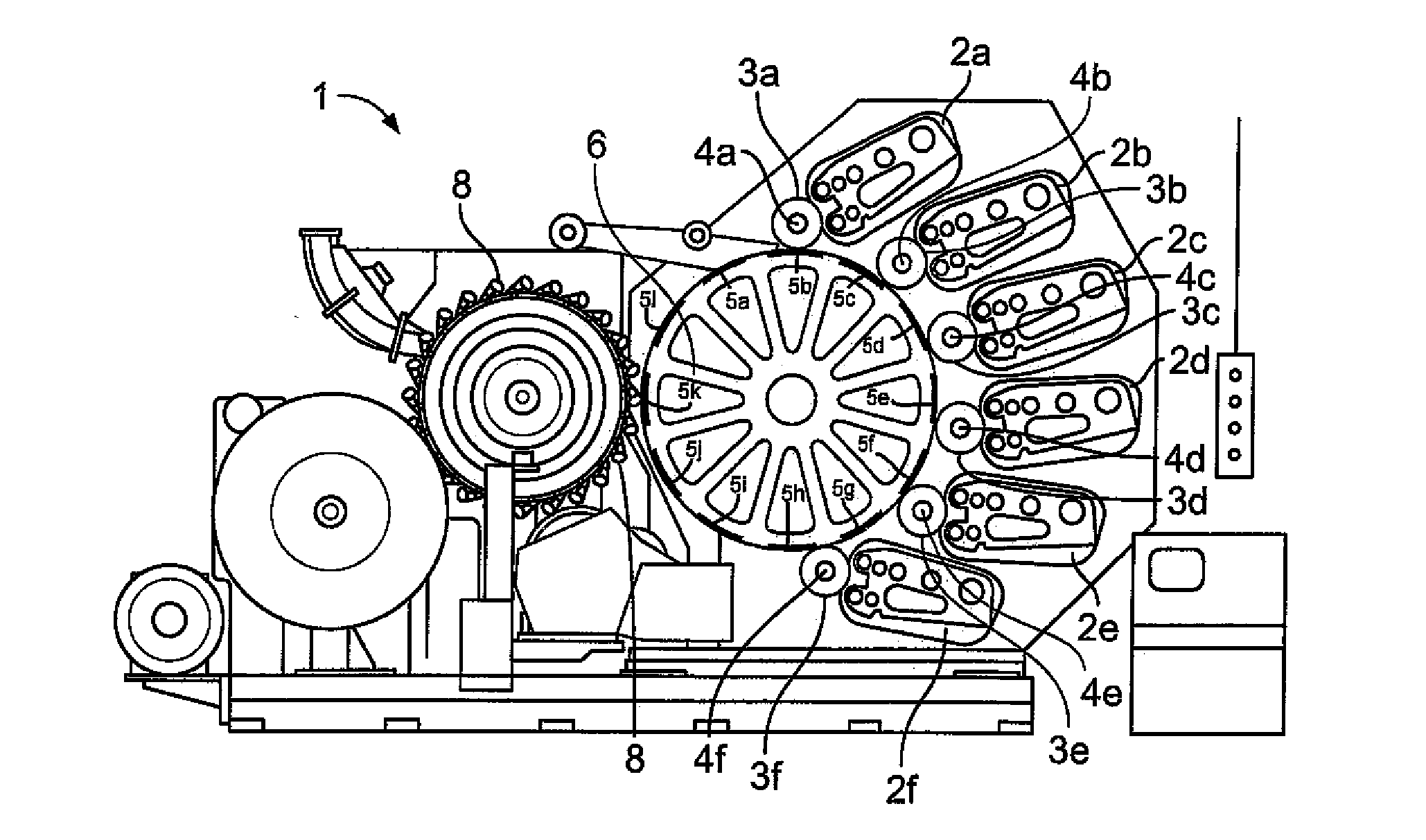

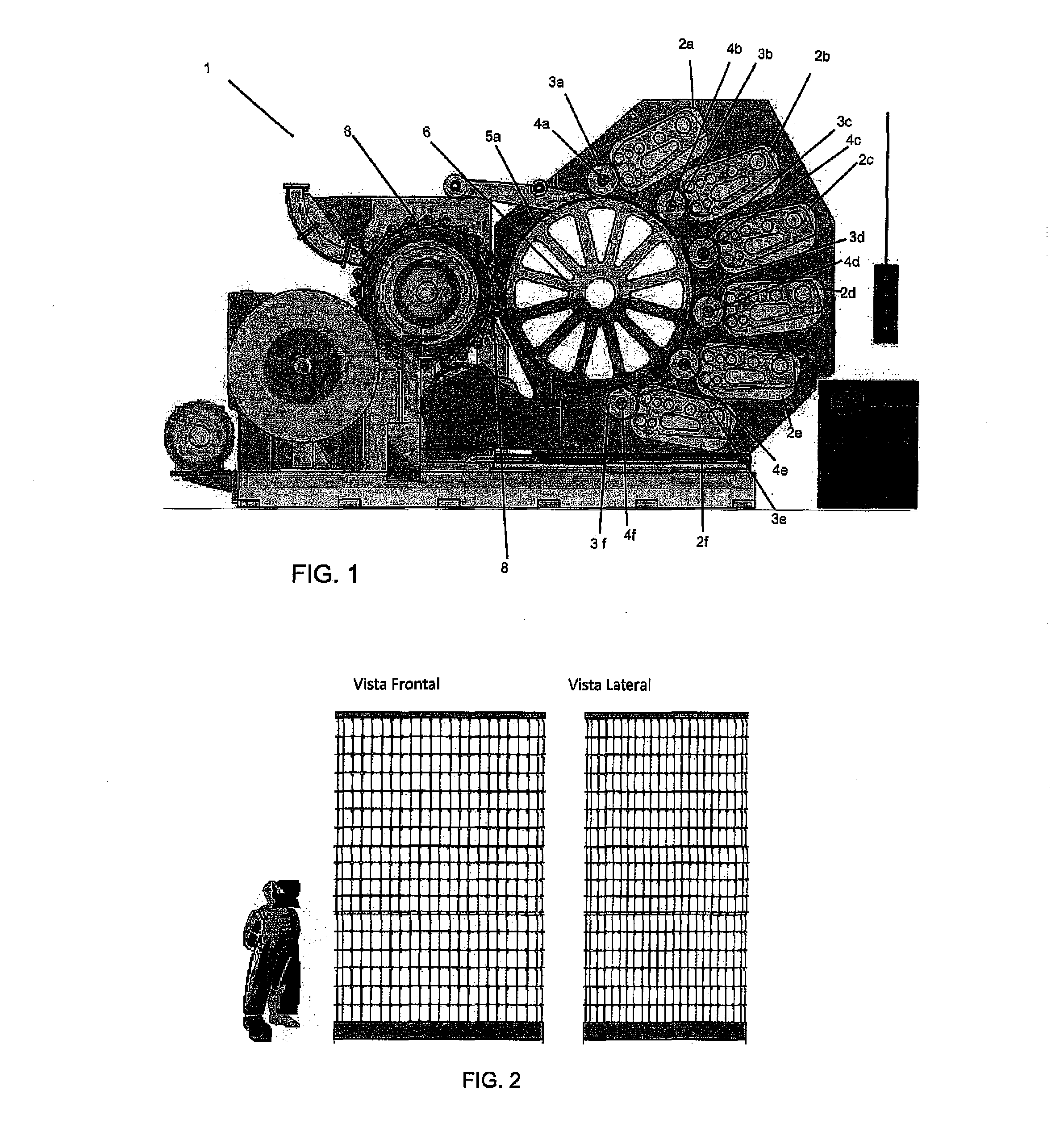

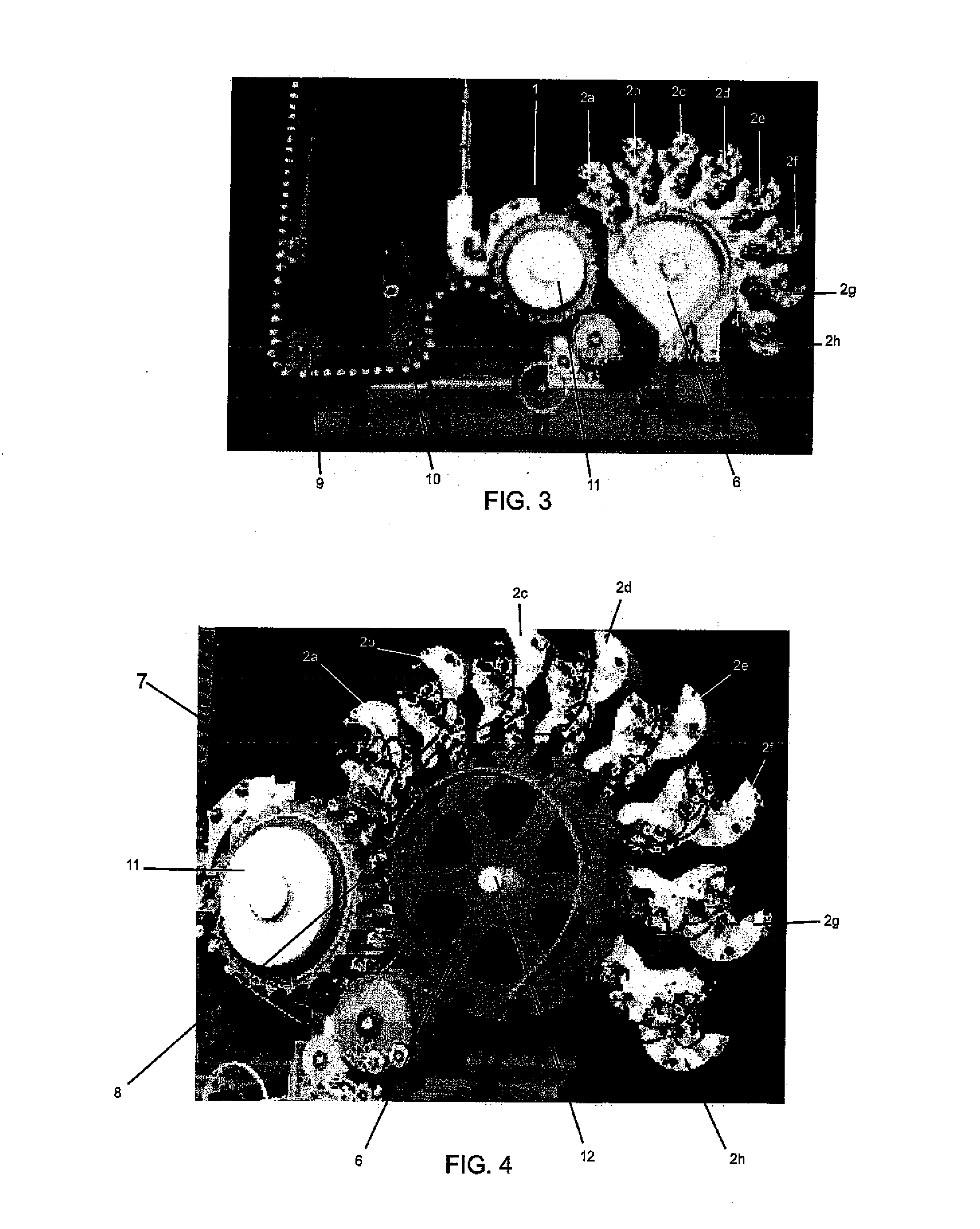

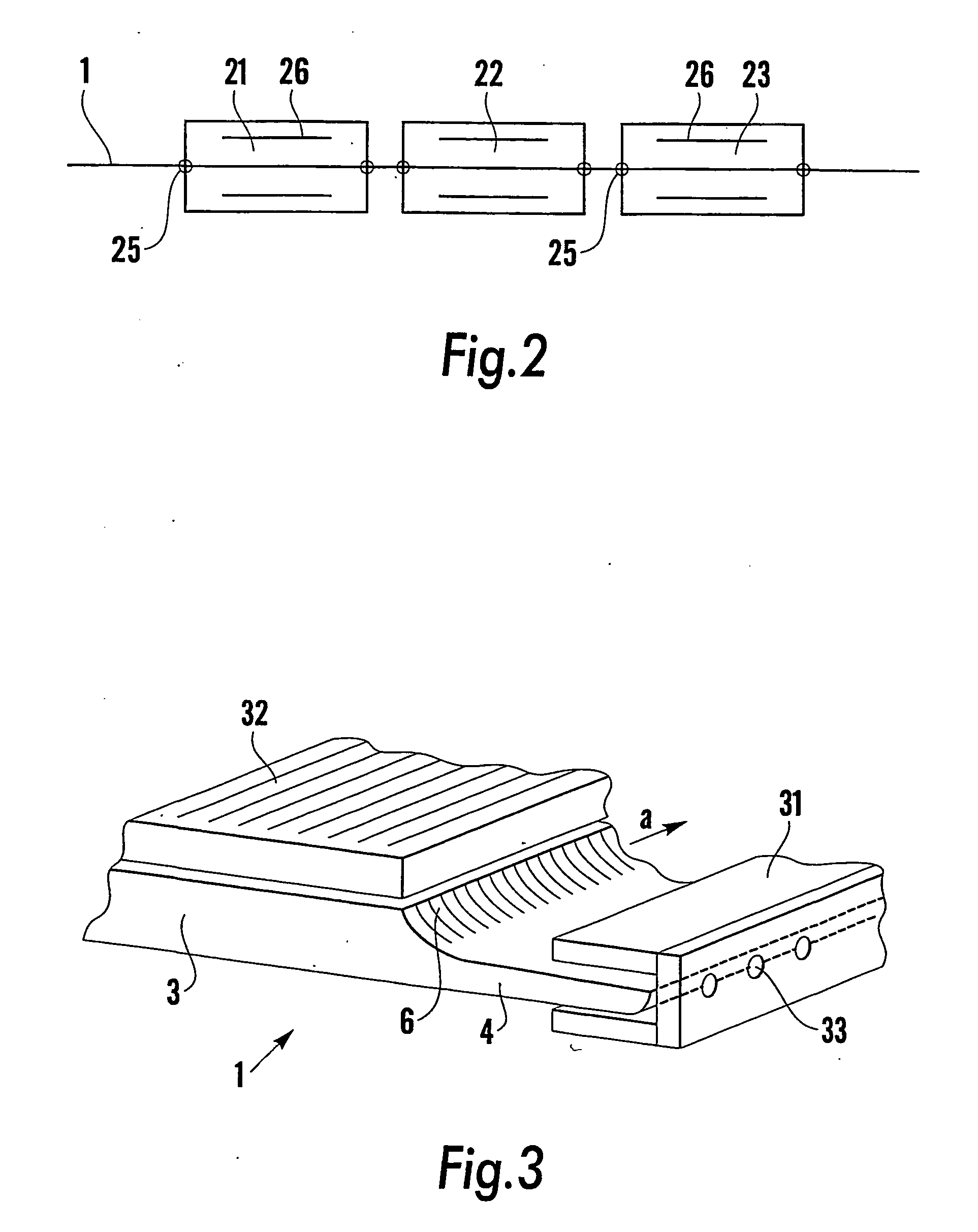

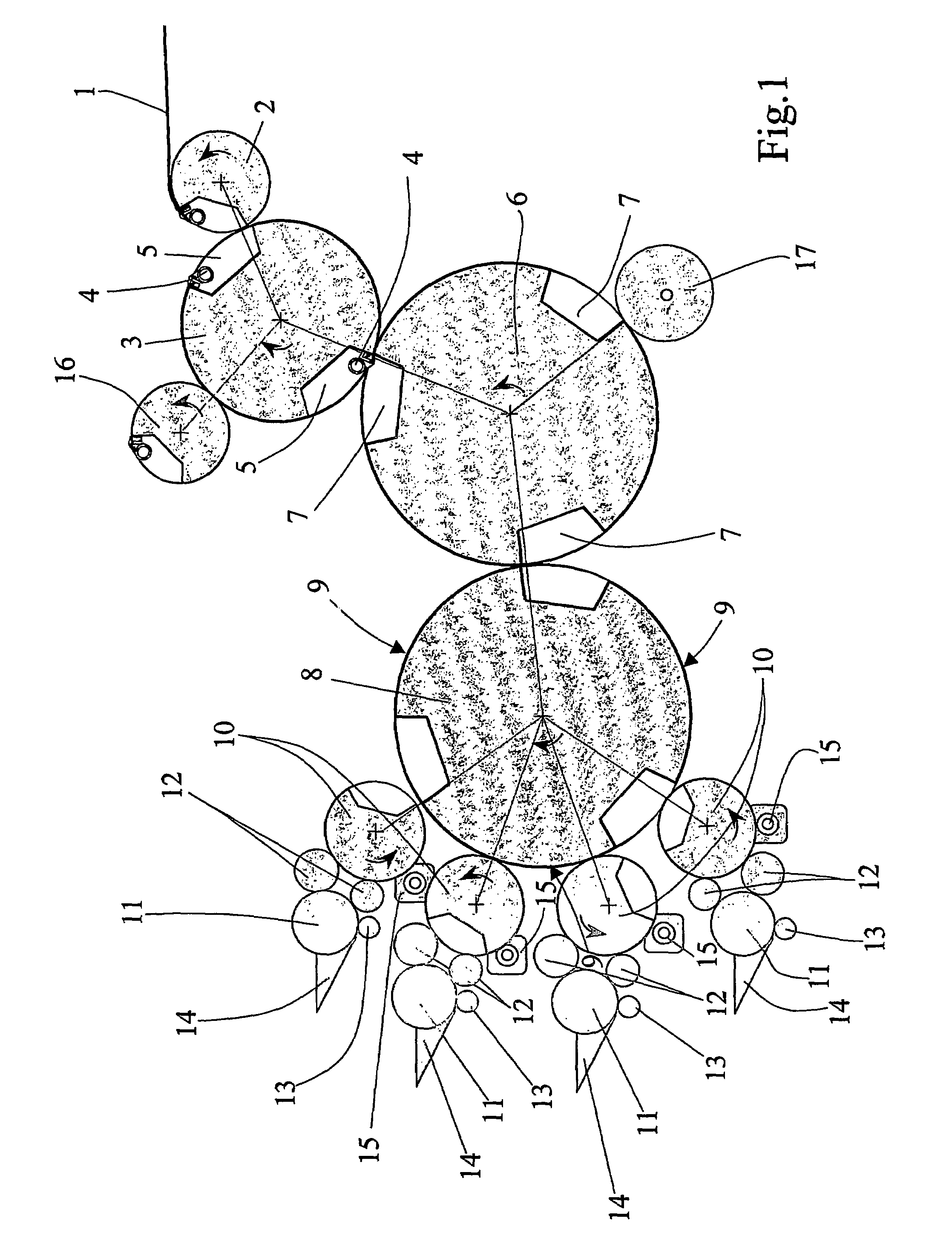

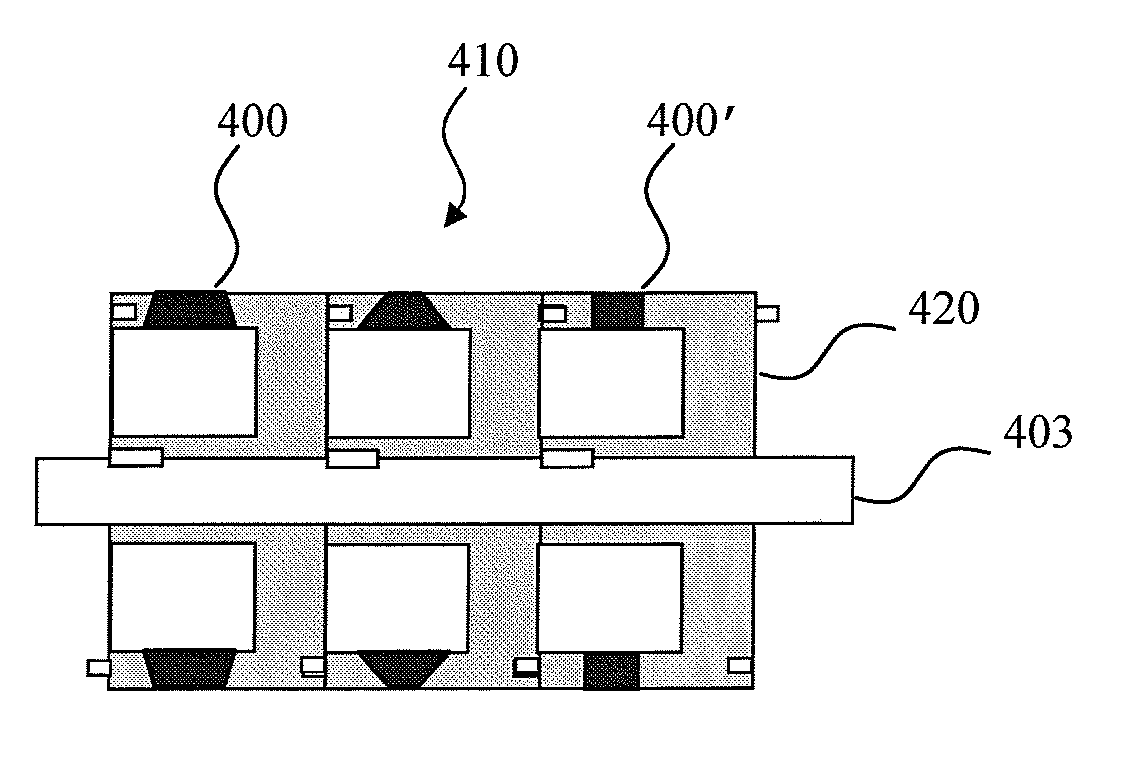

Device for Printing Cans, A Process for Printing Cans, A Printed Can and A Transfer Blanket

ActiveUS20150174891A1Other accessoriesContainer/bottle contructionElectrical and Electronics engineeringBlanket

The present invention relates to a device for printing cans with different print patterns in the same production sequence, without it being necessary to interrupt the production. Another objective of the present invention is to provide a process for producing cans, which uses a printing device, the can produced by the device and process, and a transfer blanket that is a graphic means that influences the final print patterns of the cans to be printed.

Owner:REXAM BEVERAGE CAN SOUTH AMERICA

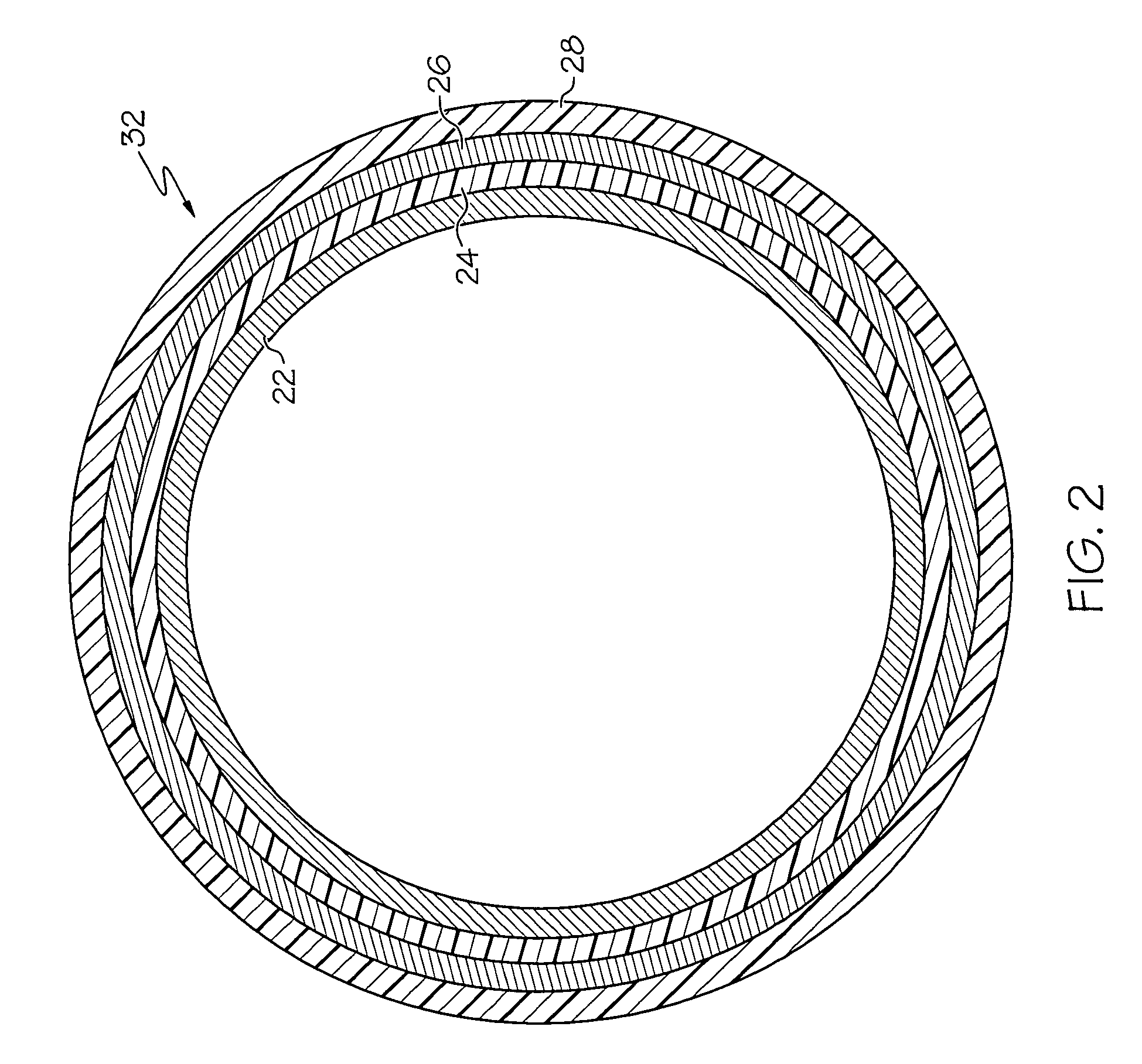

Rubber cylinder sleeve, especially for web-fed rotary offset printing machines

InactiveUS6484632B2Produced cost-effectivelyImprove printing qualityMounting boardsPrinting blanketsCompressible materialEngineering

A rubber cylinder sleeve for web-fed rotary offset printing machines has a covering layer which is a finite layer having a joint location, the joint location being filled with a compressible material.

Owner:MANROLANAD AG

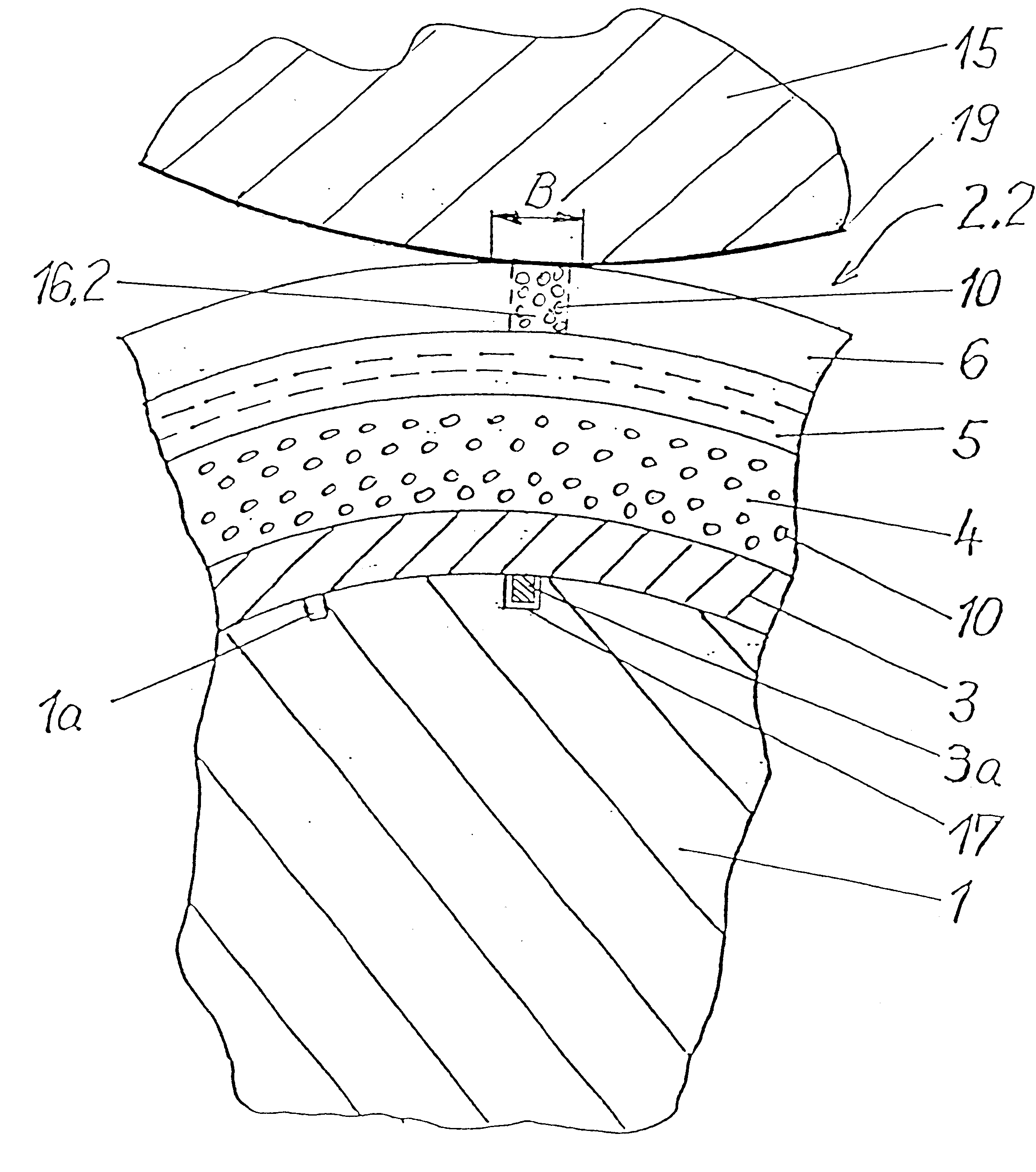

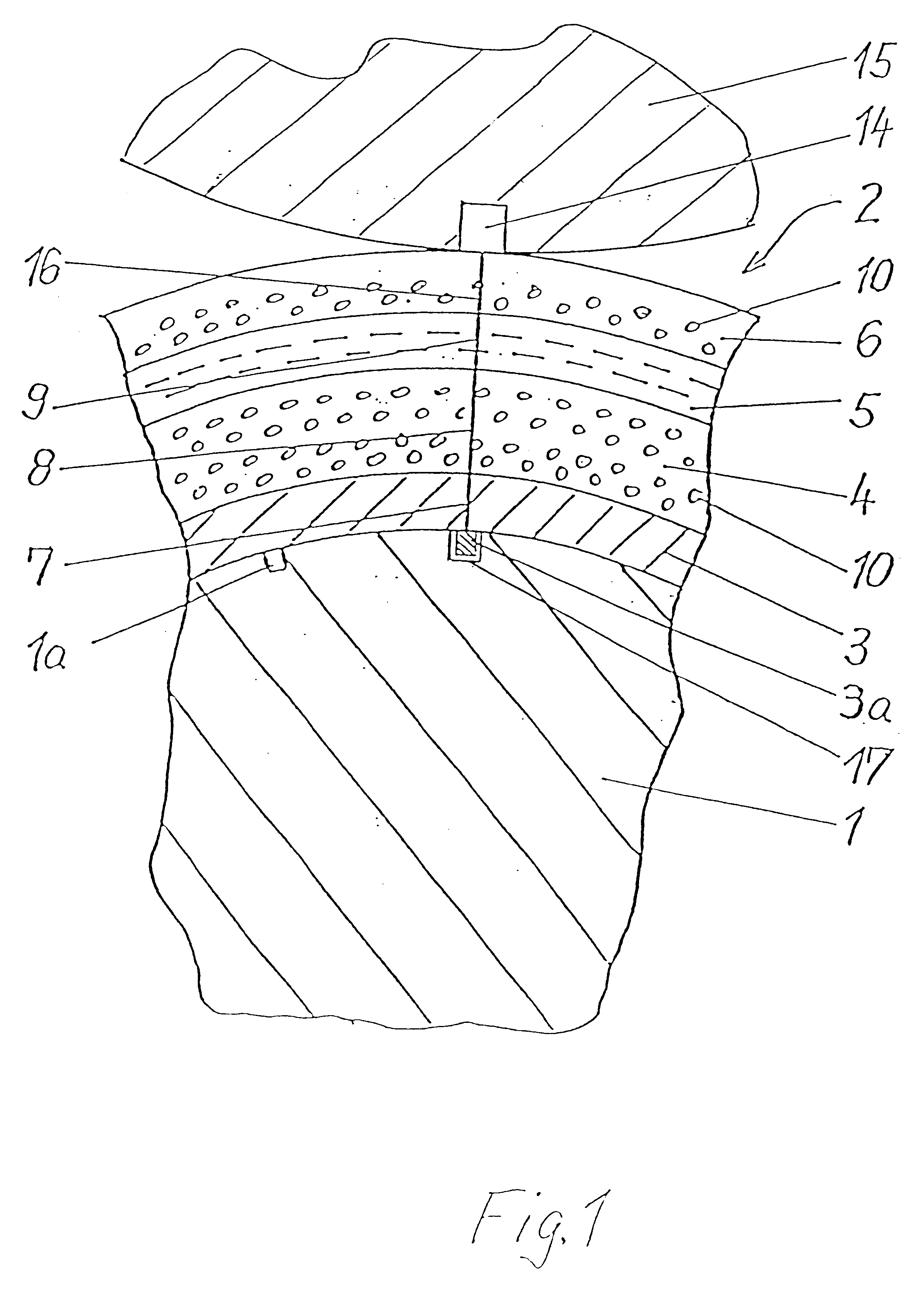

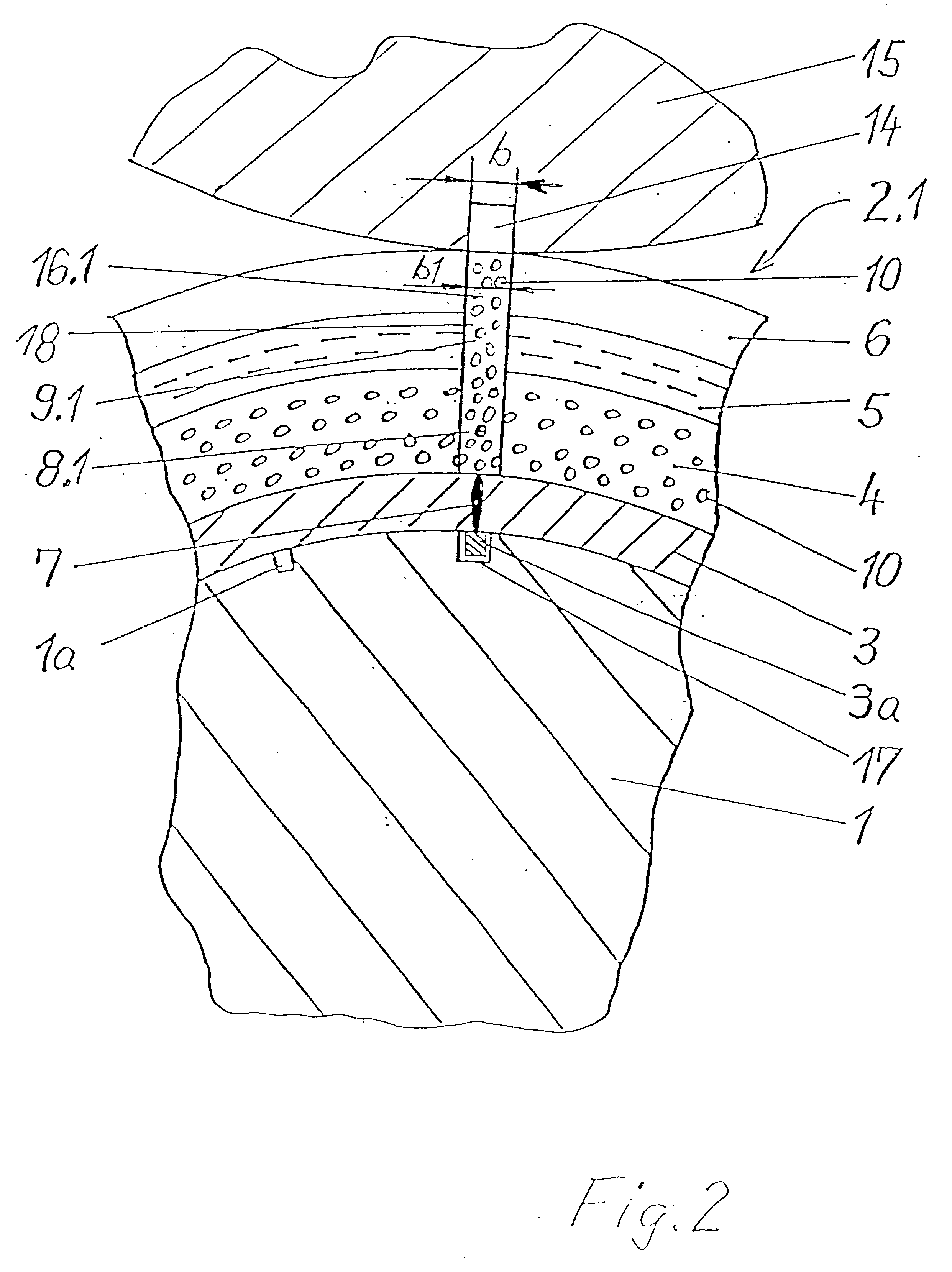

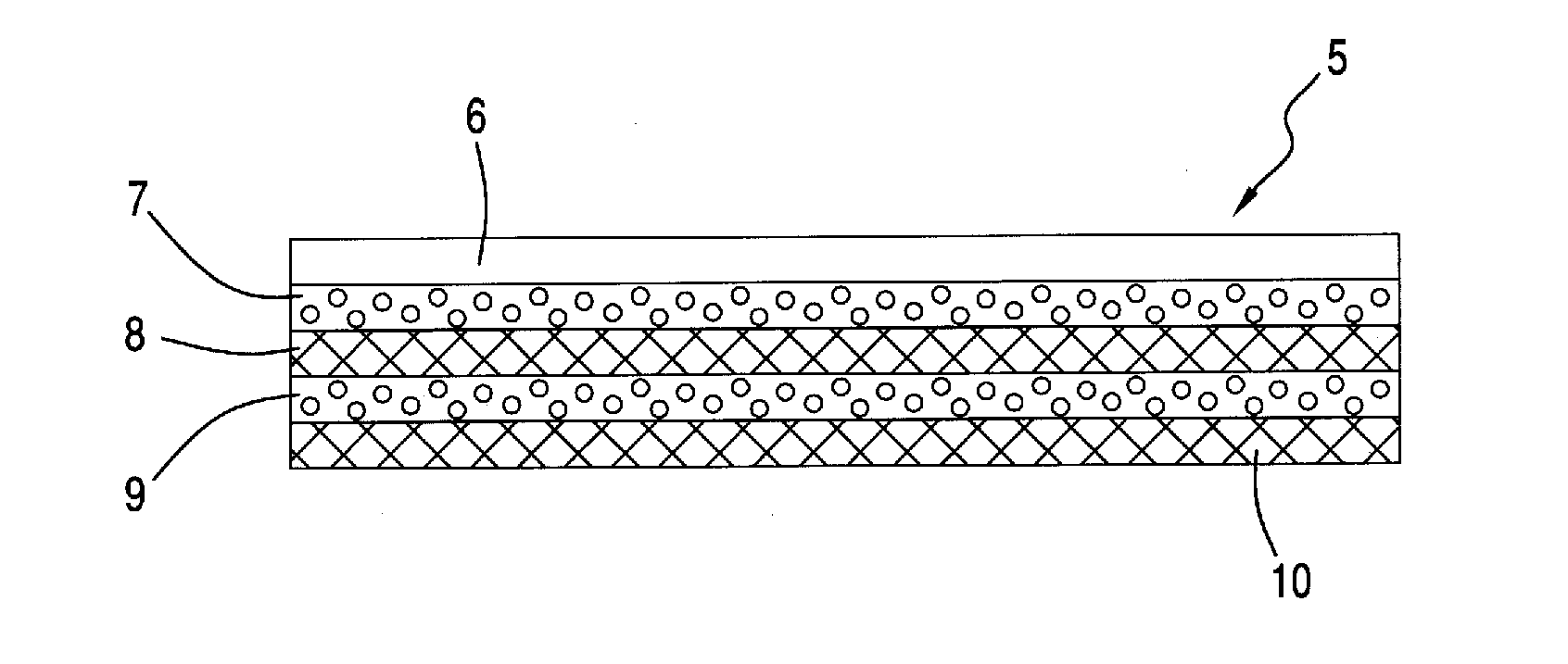

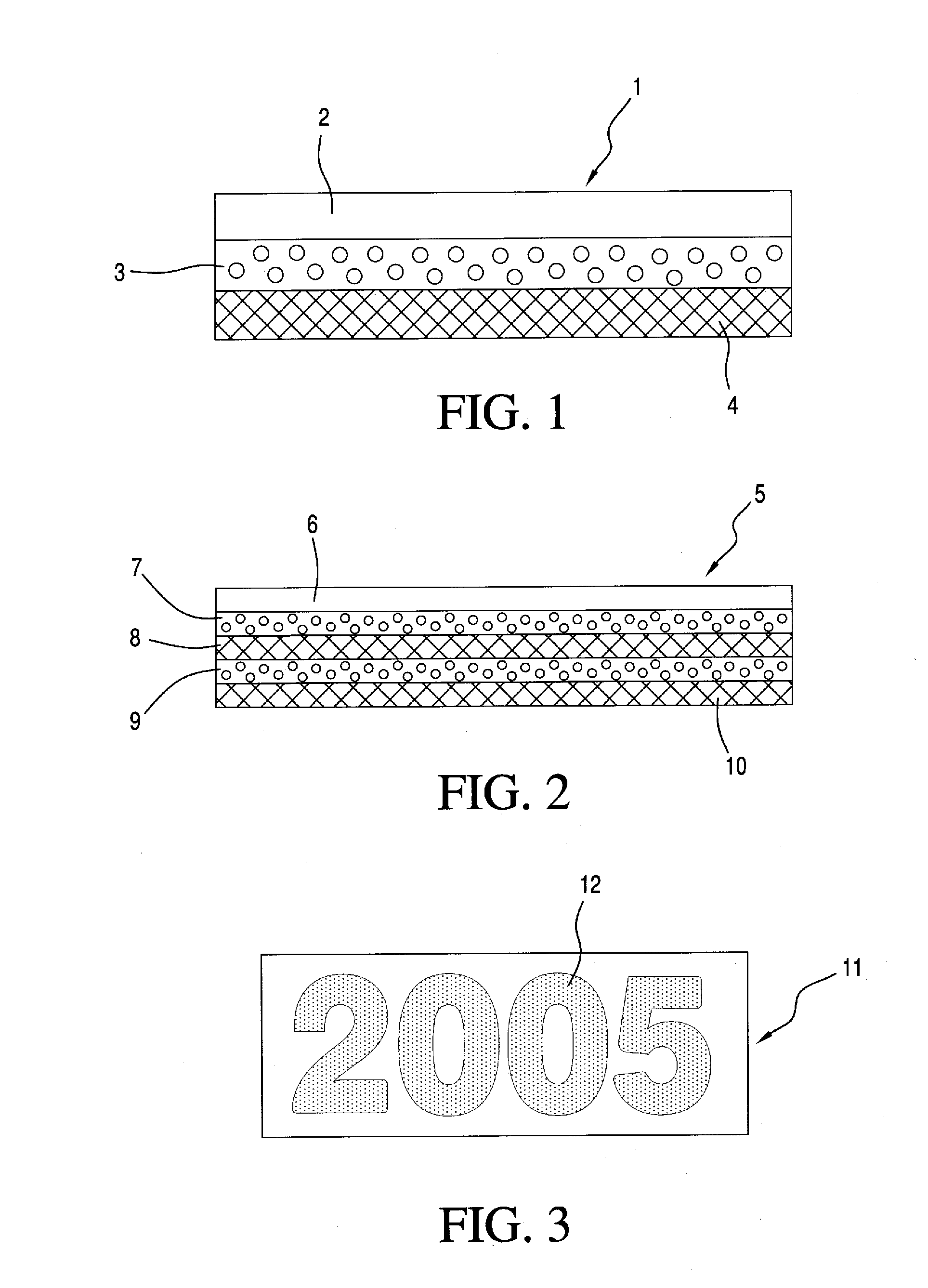

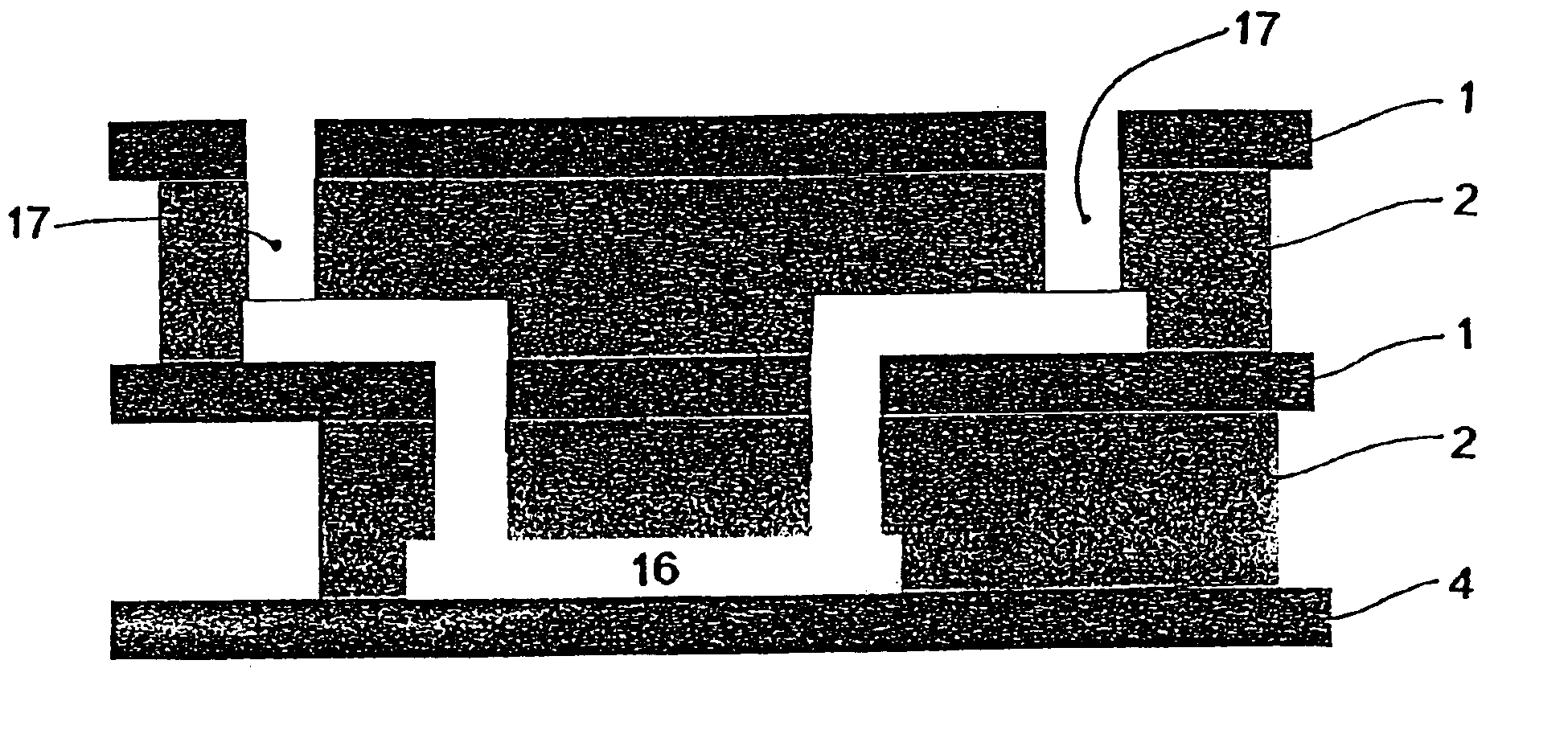

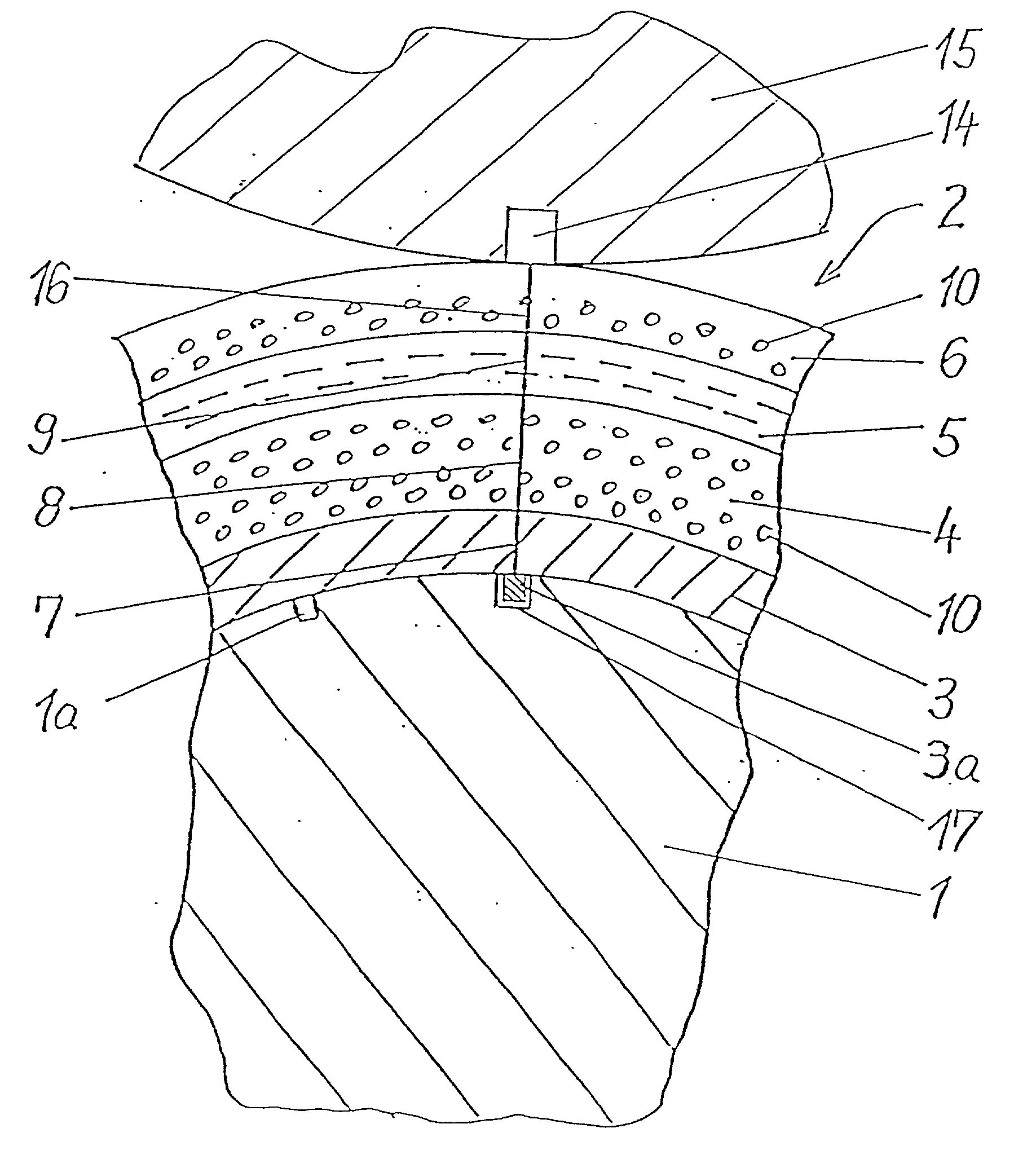

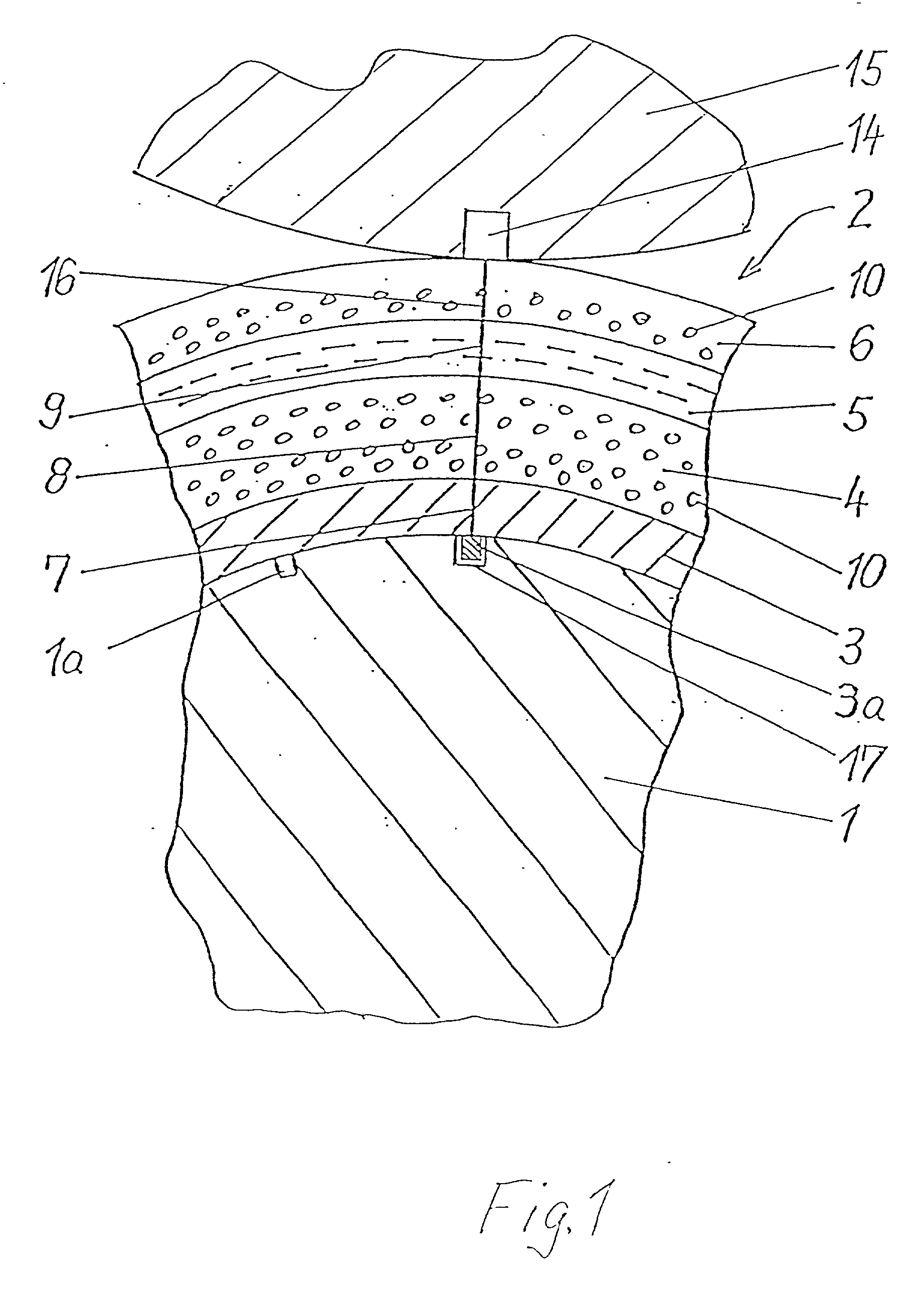

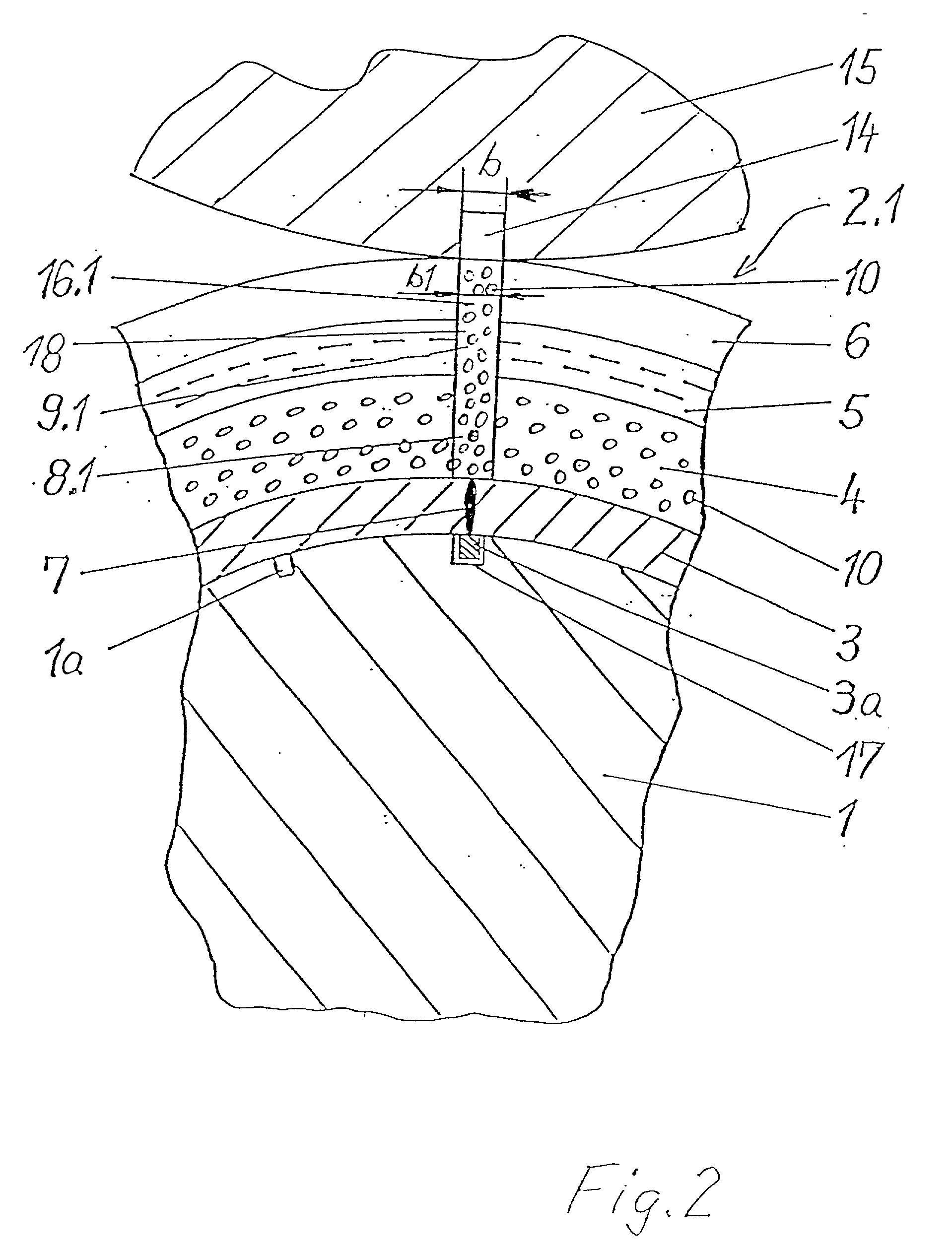

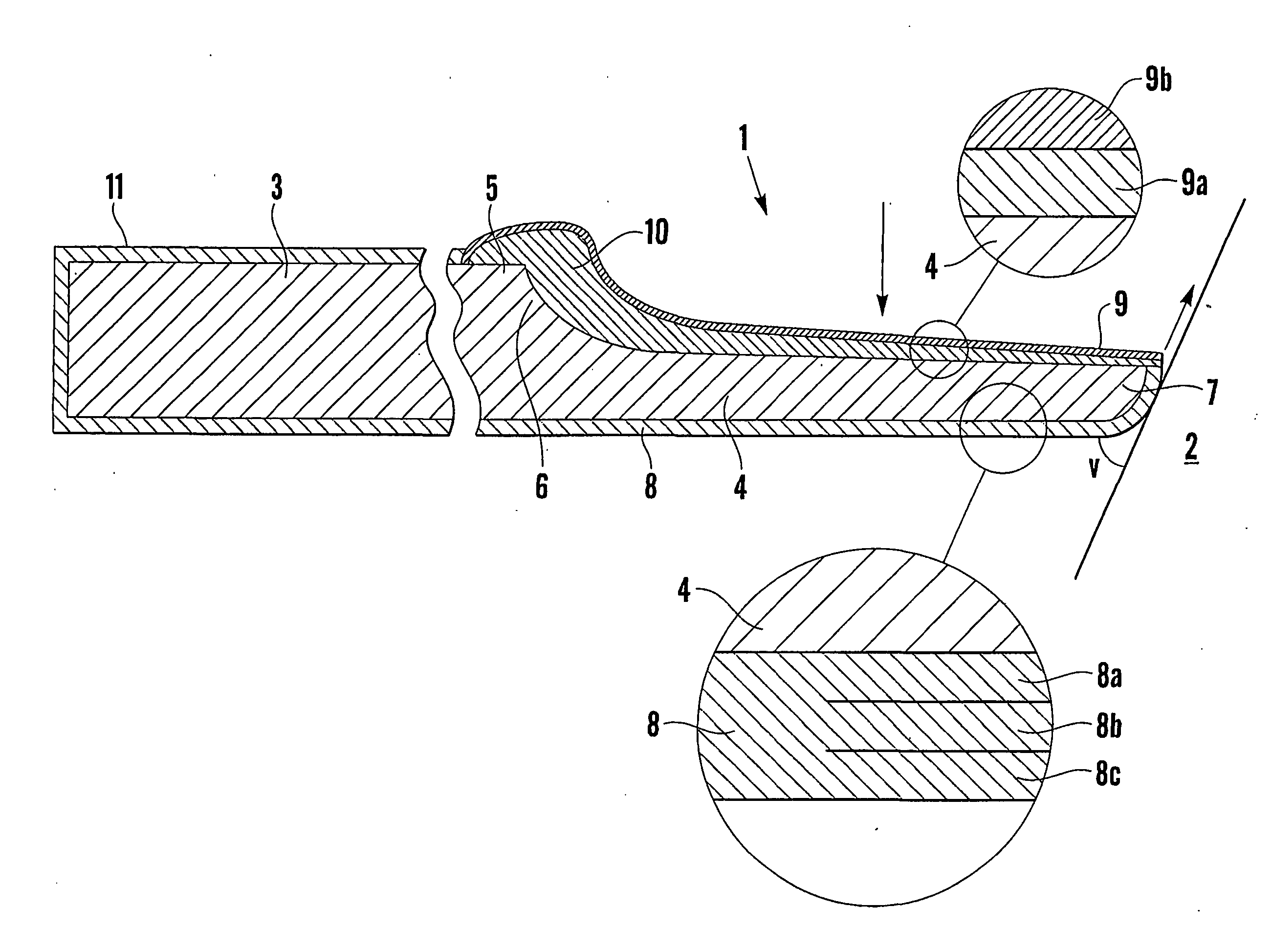

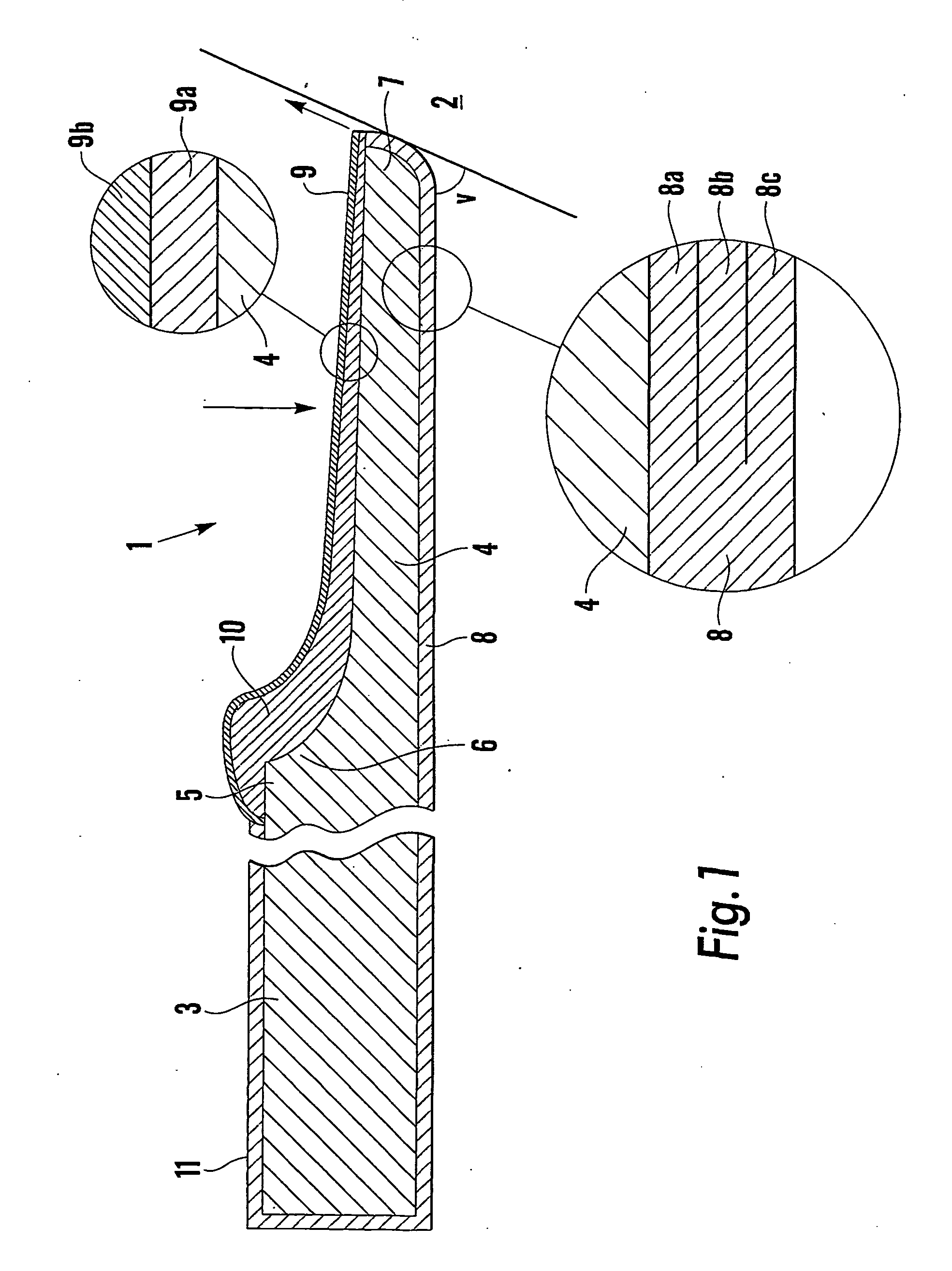

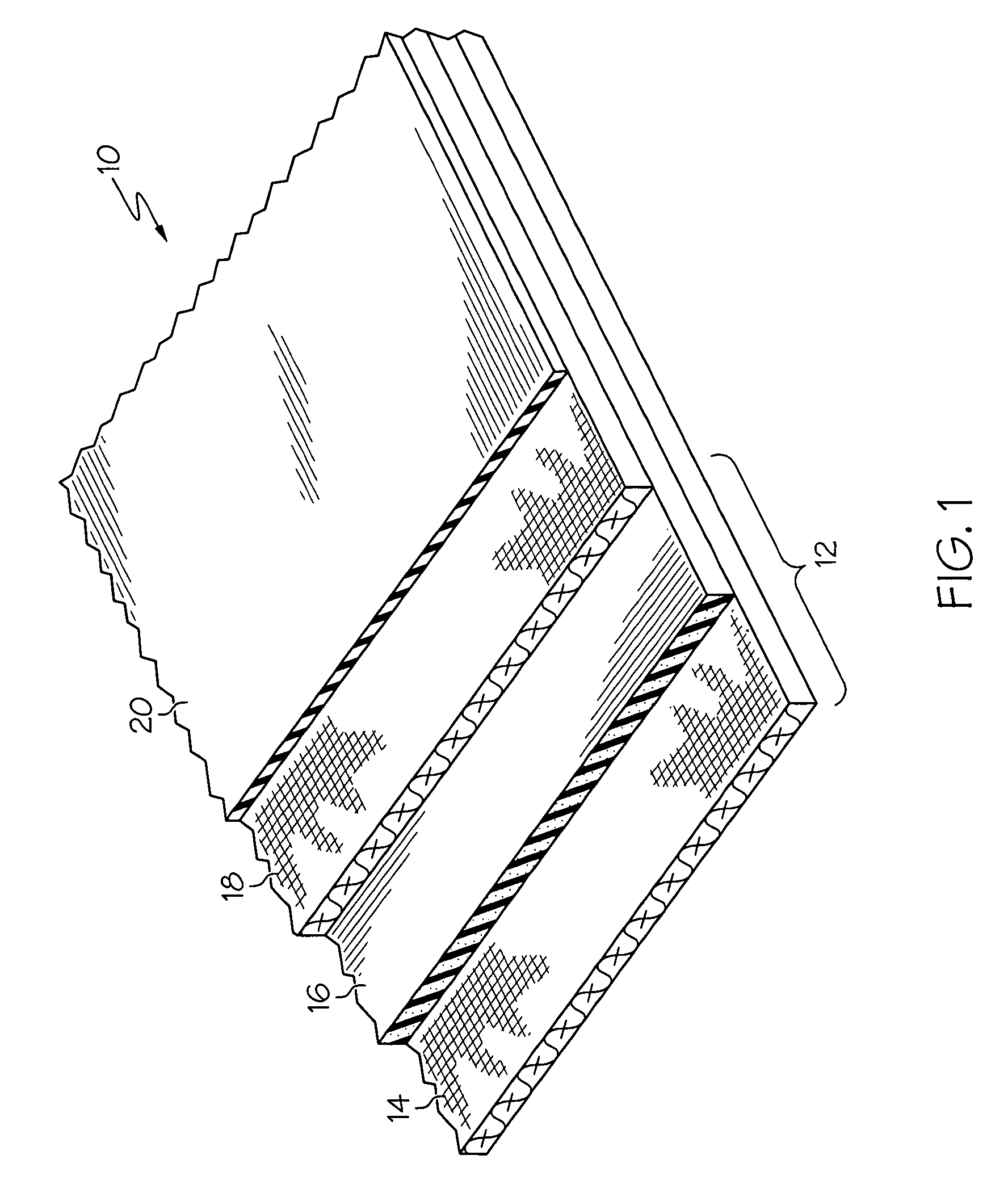

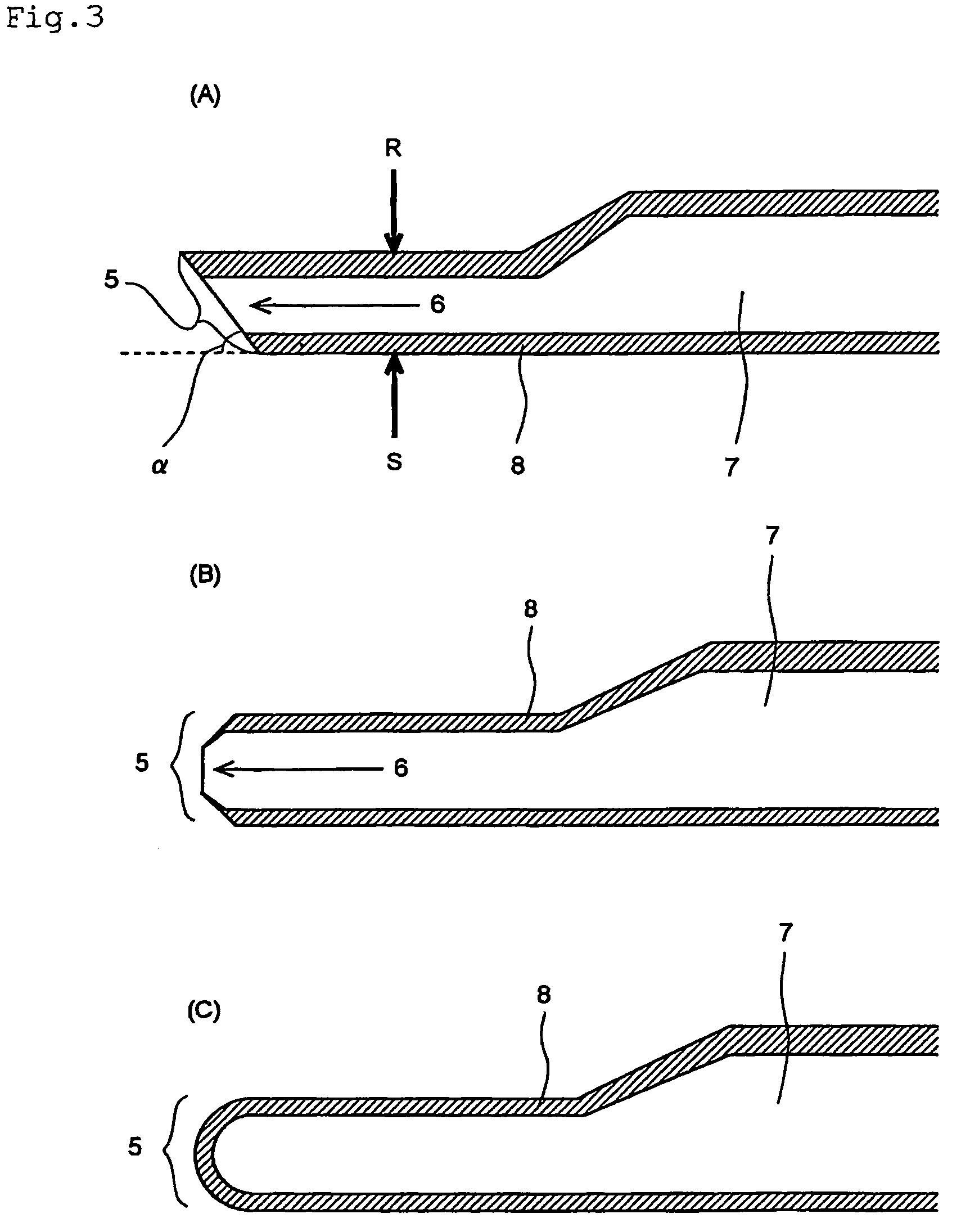

Multiple-layer flat structure in the form of a printing blanket or a printing plate for flexographic and letterpress printing with laser engraving

InactiveUS20120103216A1Quick clean upFast formingMounting boardsPlate printingLetterpress printingLaser engraving

The invention is directed to a multiple-layer flat structure (1) in the form of a printing blanket or a printing plate for flexographic and letterpress printing with: a printing layer (2) which is made from a polymeric material and is provided with laser engraving; at least one compressible layer (3); and, at least one strength-support layer (4); wherein the individual layers form an adhesive connection among one another. The multiple-layer flat structure (1) according to the invention is distinguished by the fact that the polymeric material of the printing layer (2) is a vulcanizate. Advantageous materials are proposed in this regard. The printing layer (2) expediently lies directly on a compressible layer (3). The compressible layer (3) is in turn in direct contact with a strength-support layer (4).

Owner:CONTITECH ELASTOMER BESCHICHTUNGEN

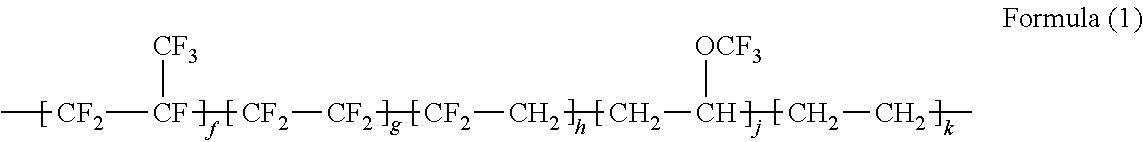

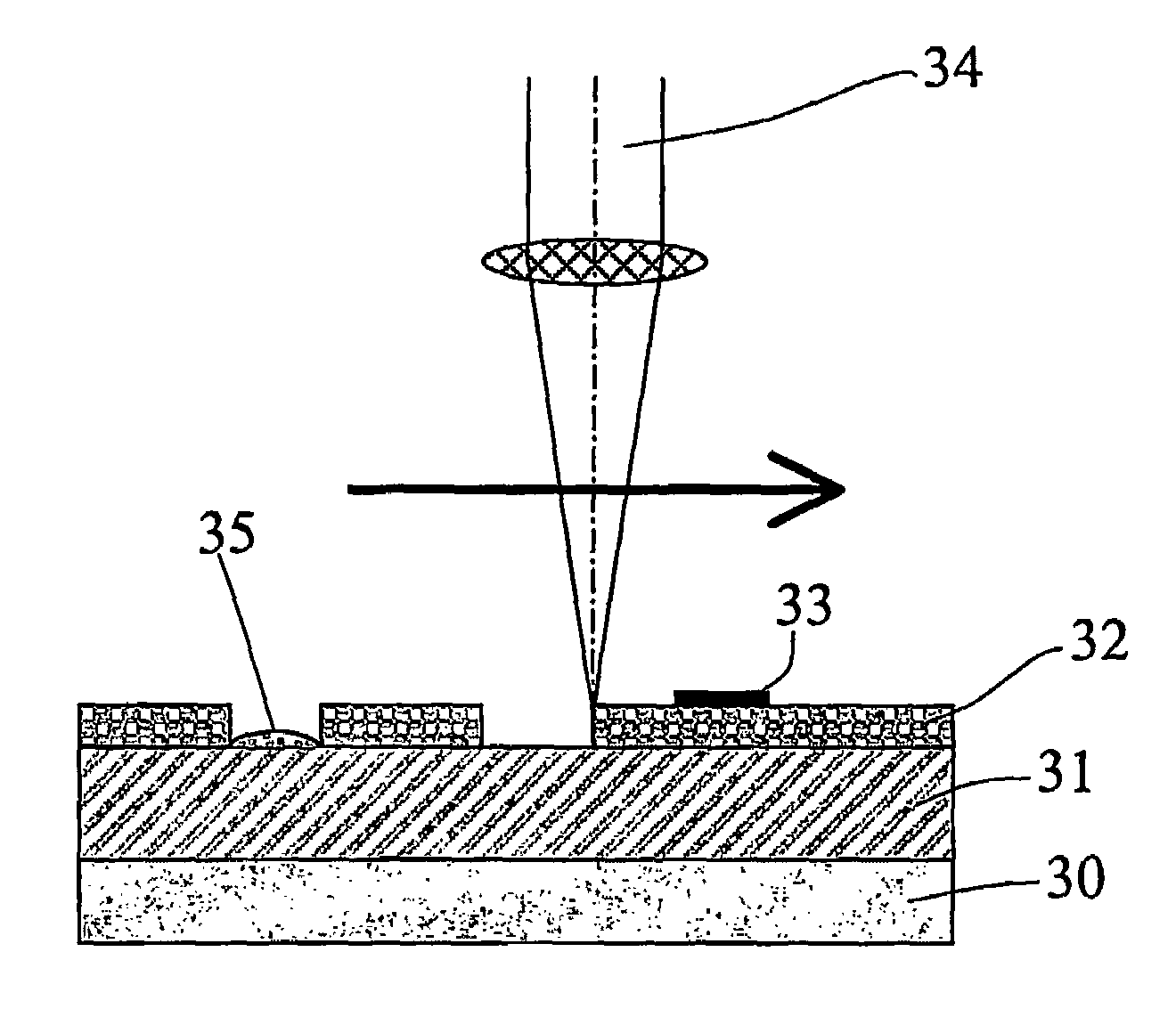

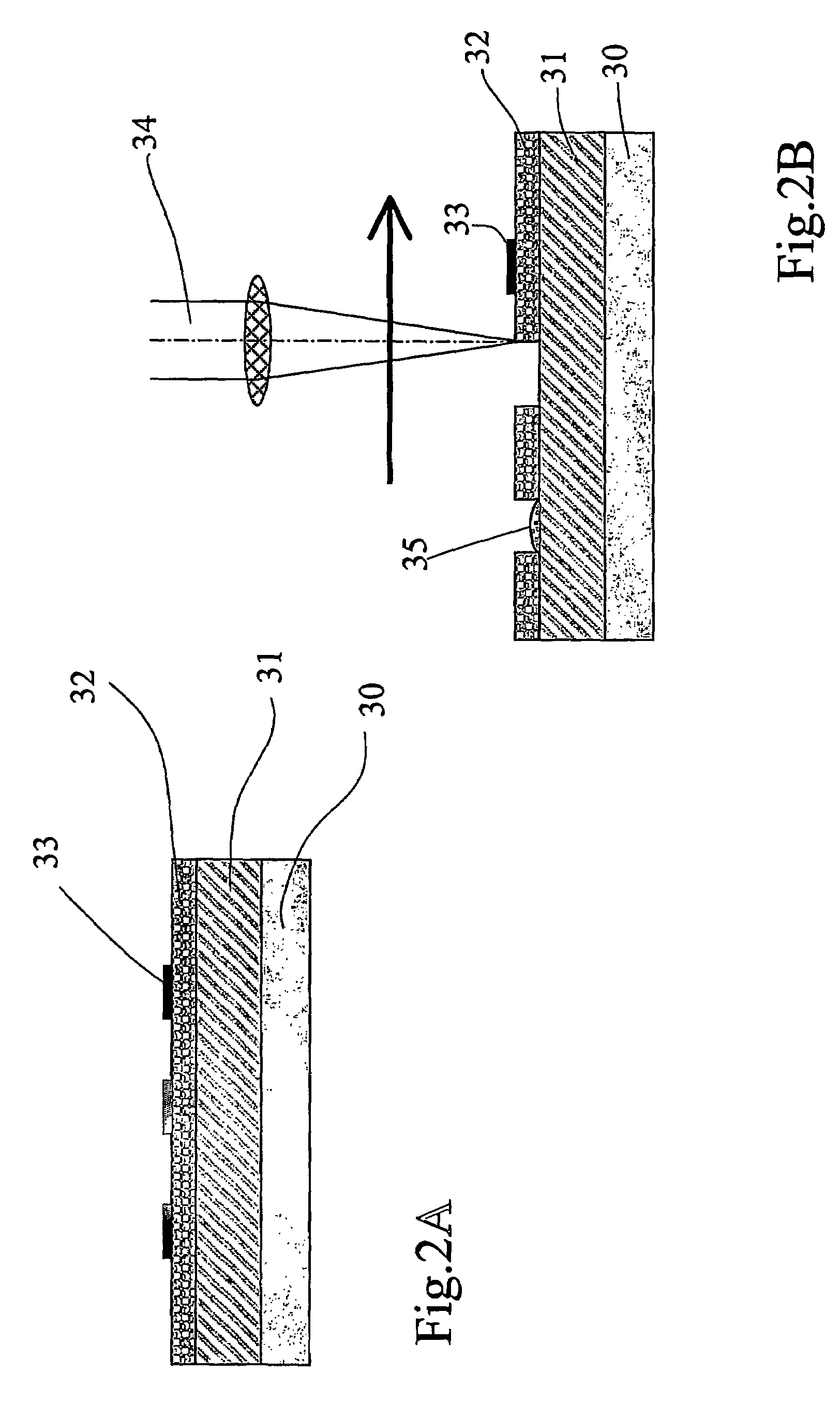

Imaging member for offset printing applications

ActiveUS20140060359A1Uniform layersFree from defectPlaten pressesElectrographic process apparatusSurface layerEngineering

An imaging member includes a surface layer comprising a fluorosilicone and an infrared-absorbing filler. At least 75% of the siloxane units in the fluorosilicone are fluorinated. Methods of manufacturing the imaging member and processes for variably lithographic printing using the imaging member are also disclosed.

Owner:XEROX CORP

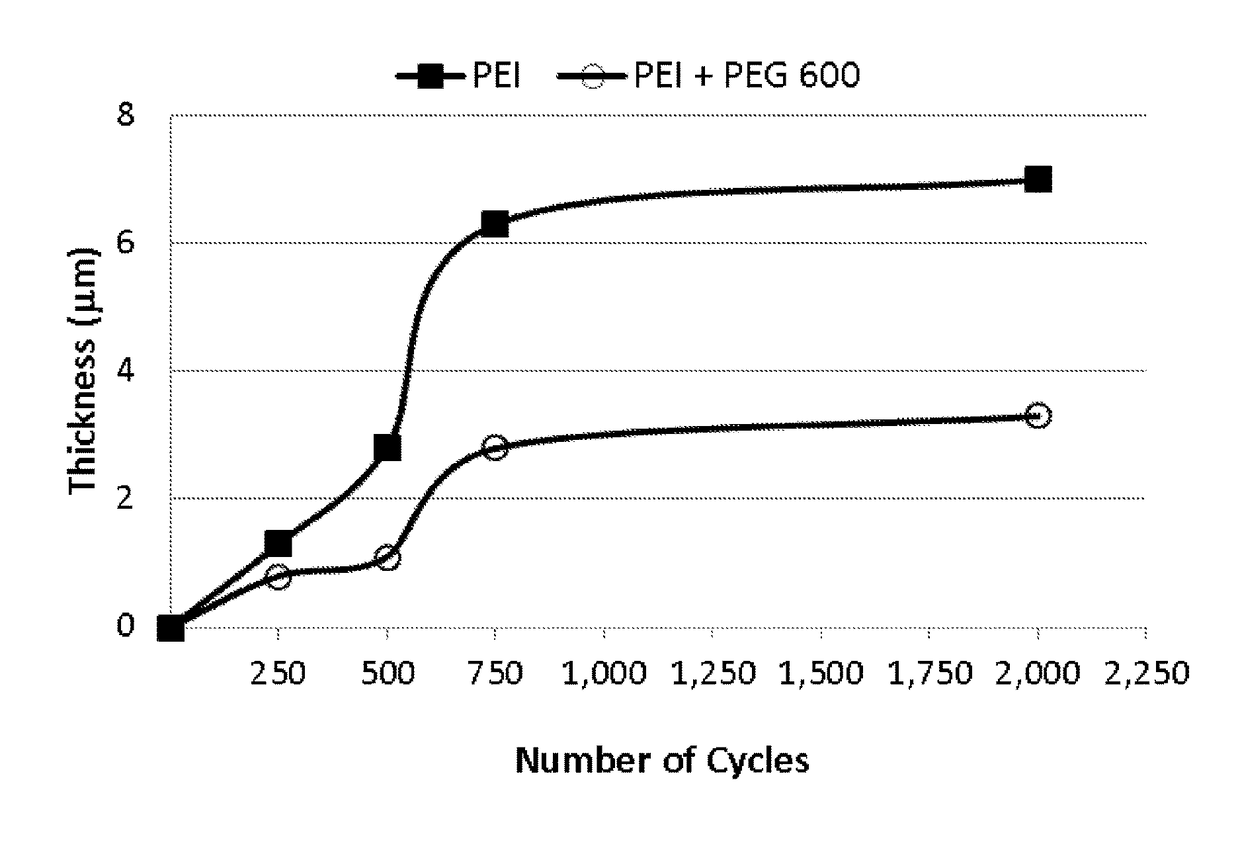

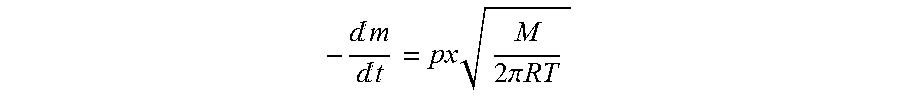

Release layer treatment formulations

There is disclosed a formulation for use with an intermediate transfer member of an indirect printing system, including: (a) a carrier liquid: (b) a positively chargeable polymeric chemical agent having amine functional groups; and (c) a resolubilizing agent selected to improve resolubilization of said chemical agent. Method of use thereof is also provided.

Owner:LANDA

Inkjet ink containing polystyren copolymer latex suitable for indirect printing

An aqueous latex ink comprising a polystyrene copolymer latex, a co-solvent; and a colorant, which is suitable for use in an indirect printing method.

Owner:XEROX CORP

Stamp device for printing a pattern on a surface of a substrate

InactiveUS6976424B2Thin layerIncrease frictionDecorative surface effectsNanoinformaticsSoft layerSoft materials

A stamp device for printing a pattern on a surface of a substrate having a two-sided rigid carrier layer providing on its first side a patterned layer made of a first material and being combined on its second side with a soft layer made of a softer material than that of the first material.

Owner:IBM CORP

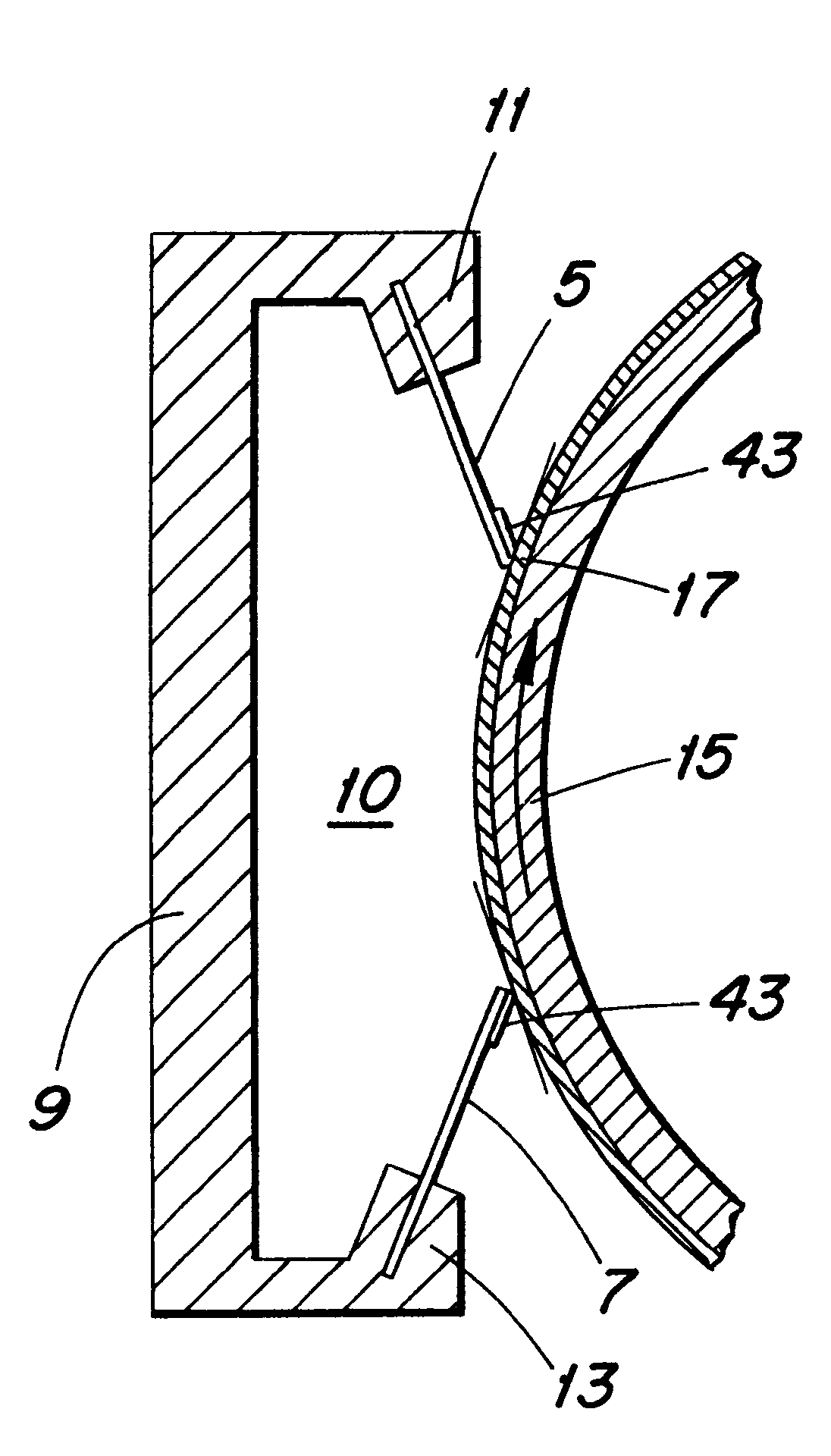

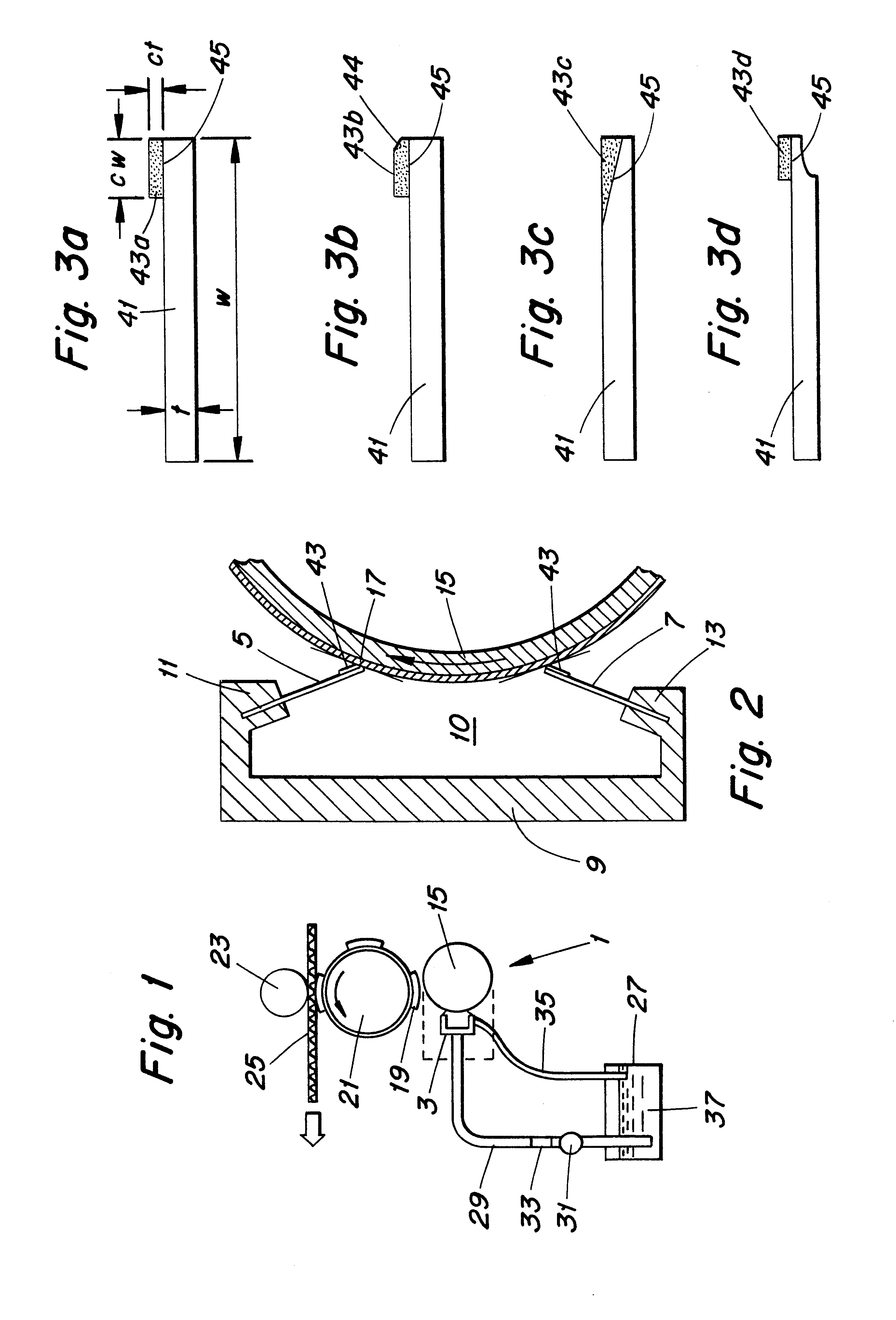

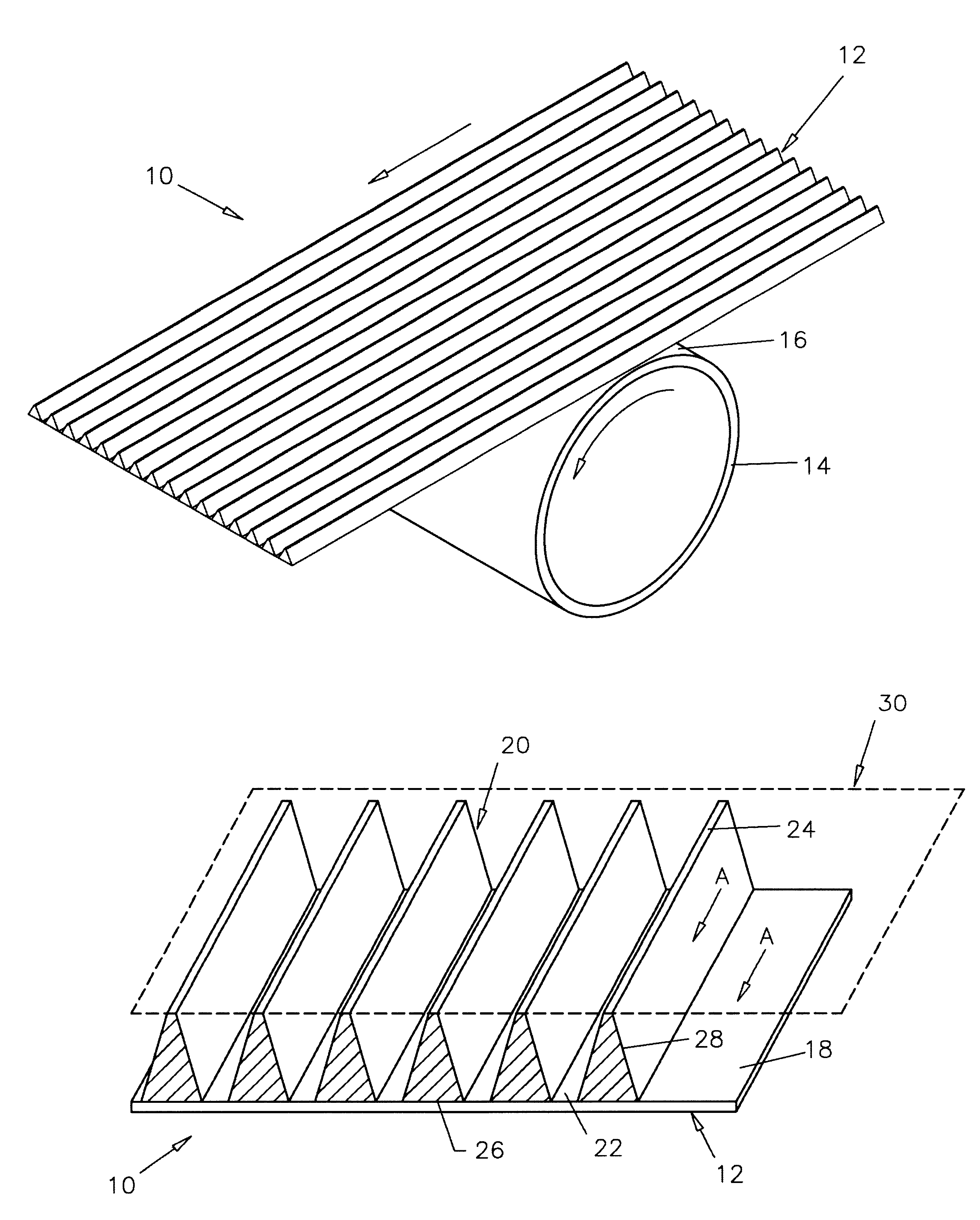

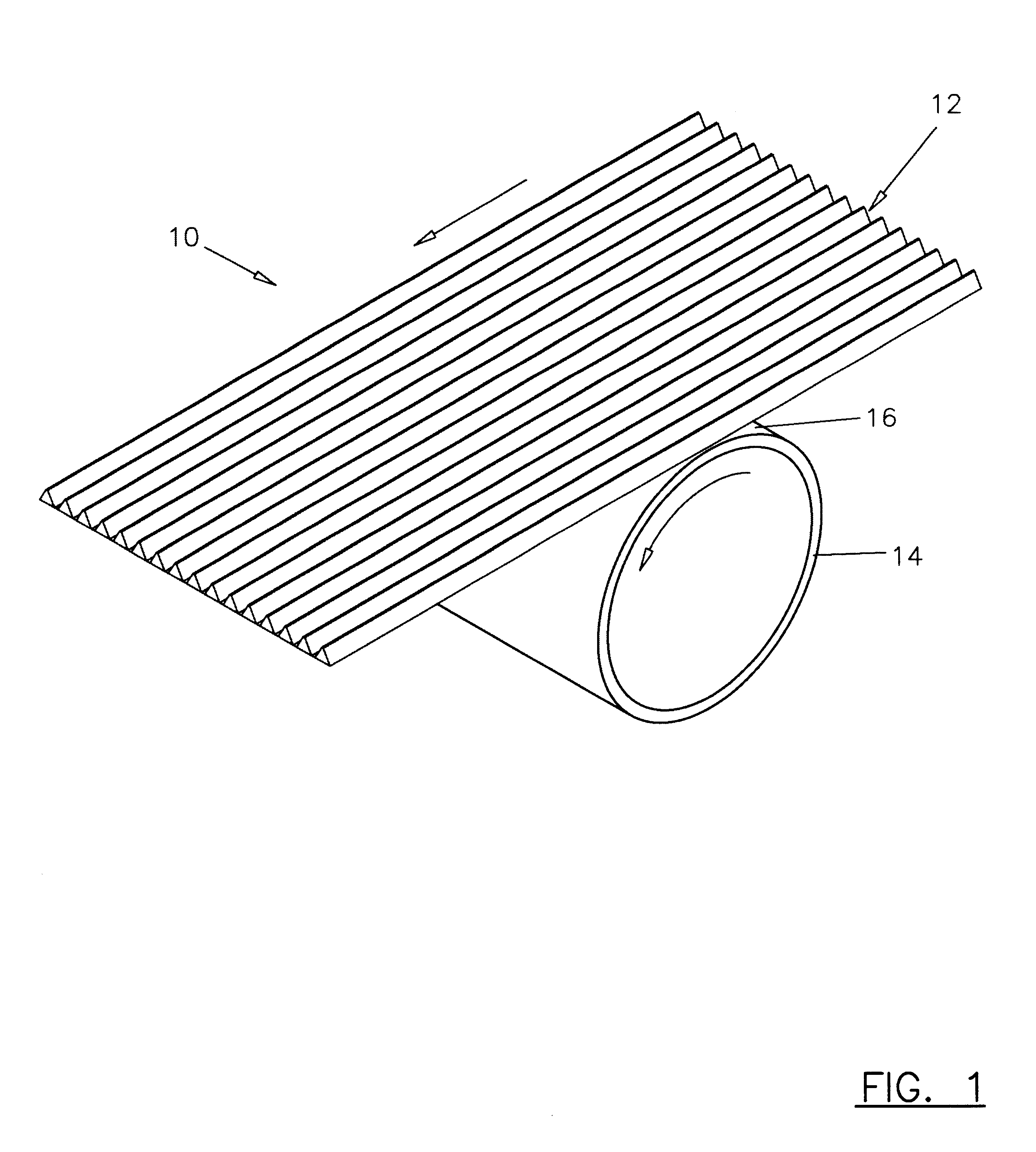

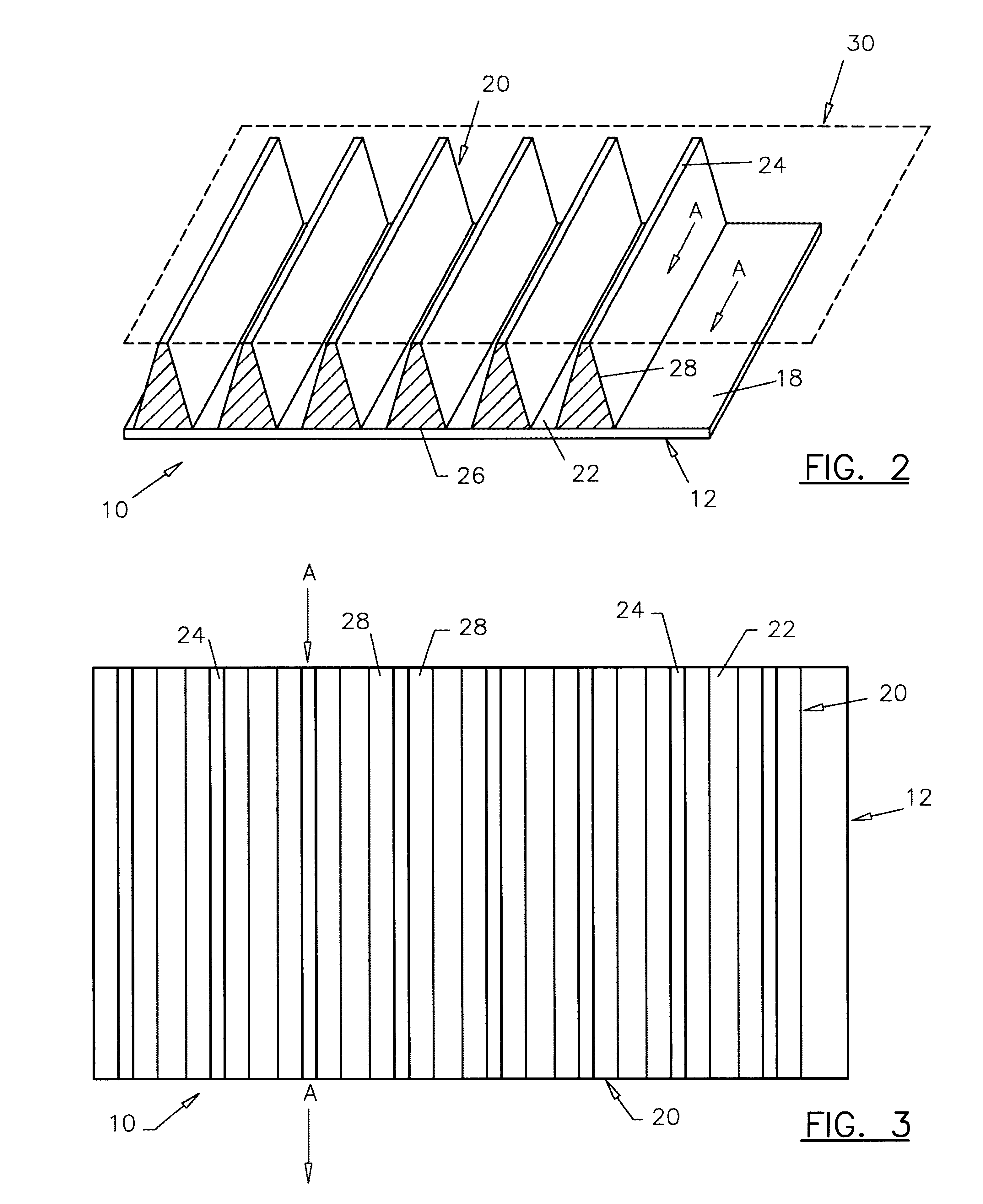

Shock absorber cushion for flexographic printing plate and method of use

InactiveUS6247403B1Increase pressureImprove efficiencyMounting boardsPlate printingElastomerEngineering

A sheet of elastomeric material that serves as a shock absorber and cushion for use between a flexographic printing plate and a printing cylinder during printing for compensating for variations in thickness, height and centricity of the printing cylinder and flexographic printing plate to prevent distortions in the image being printed that includes providing an elastomeric sheet having a longitudinal direction in the direction of circumferential travel of the cylinder circumference that includes a plurality or array of protrusions formed of the elastomeric material of predetermined cross-sectional shape and area and the material having a durometer to cushion the flexographic plate in such a way to provide the necessary compensation to ensure a high quality printed image at high speed. The cross-sectional shapes and the array of the longitudinal protrusions provide for material displacement zones that allows the elastomeric material to be compressed and return relatively instantaneously to its original height or near original height in sharing high quality printing compensating for tolerance errors between the drum size and the flexographic plate thicknesses.

Owner:RANDAZZO JEFFREY A

Imaging member for offset printing applications

An imaging member includes a surface layer comprising a fluoroelastomer-fluorosilicone composite. Methods of manufacturing the imaging member and processes for variable lithographic printing using the imaging member are also disclosed.

Owner:XEROX CORP

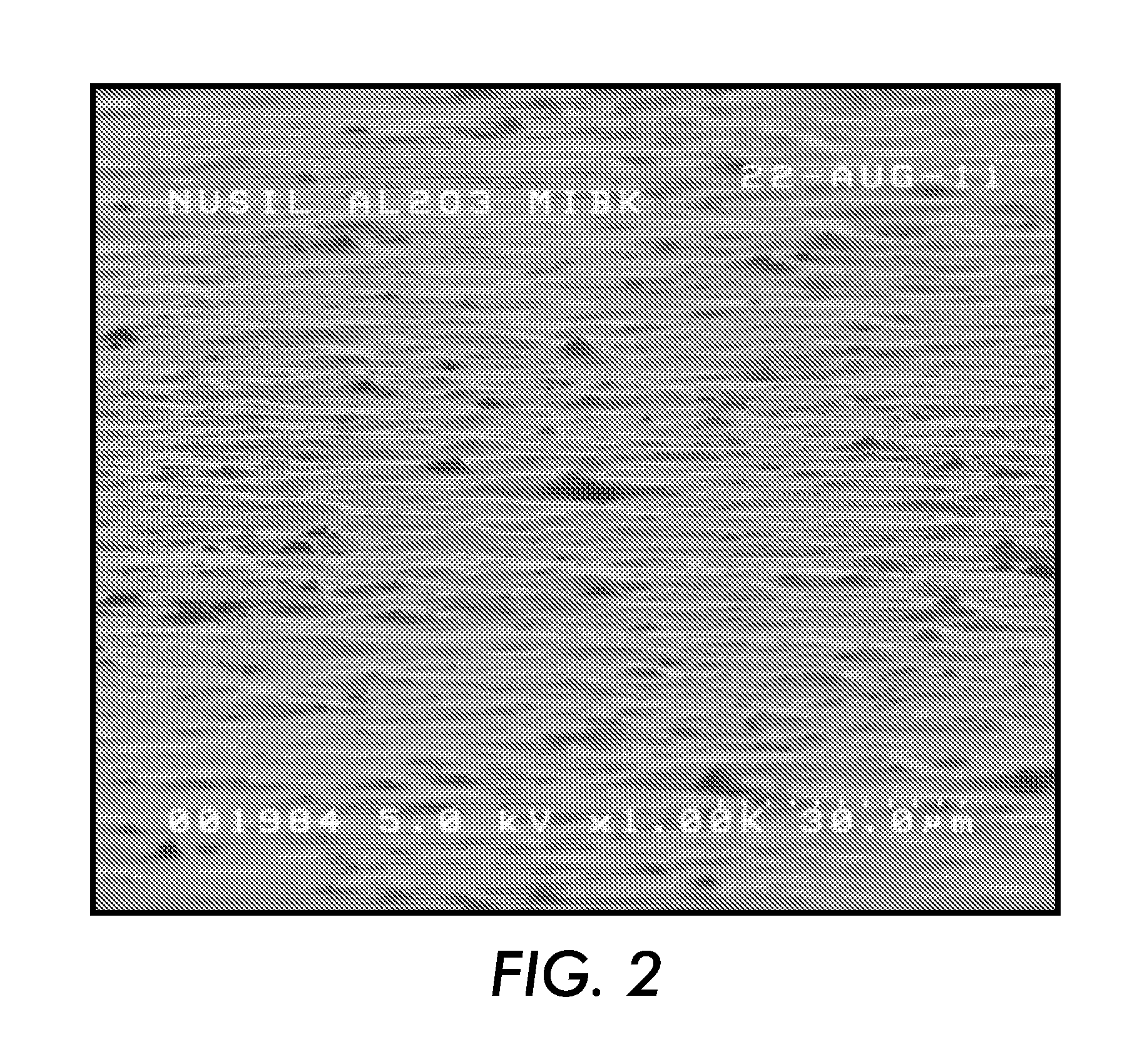

Treatment of release layer

ActiveUS9566780B2Less coverageSlim shapePrinting blanketsThermographyChemical agentMaterials science

A method for treating a hydrophobic release layer of an intermediate transfer member for use in a printing process in which a negatively charged aqueous inkjet ink is jetted onto the surface of this layer. The method comprises contacting the release layer with a chemical agent which is an amine functionalized silicone. Transfer members comprising such a treated release layer and images printed therefrom are also disclosed.

Owner:LANDA

Treatment of release layer

ActiveUS20160207306A1Effective treatmentLess coveragePrinting blanketsThermographyPolymer chemistrySilicone

A method for treating a hydrophobic release layer of an intermediate transfer member for use in a printing process in which a negatively charged aqueous inkjet ink is jetted onto the surface of this layer. The method comprises contacting the release layer with a chemical agent which is an amine functionalized silicone. Transfer members comprising such a treated release layer and images printed therefrom are also disclosed.

Owner:LANDA

Rubber cylinder sleeve, especially for web-fed rotary offset printing machines

InactiveUS20020002921A1Produced cost-effectivelyImprove printing qualityMounting boardsPrinting blanketsCompressible materialMechanical engineering

A rubber cylinder sleeve for web-fed rotary offset printing machines has a covering layer which is a finite layer having a joint location, the joint location being filled with a compressible material.

Owner:MANROLANAD AG

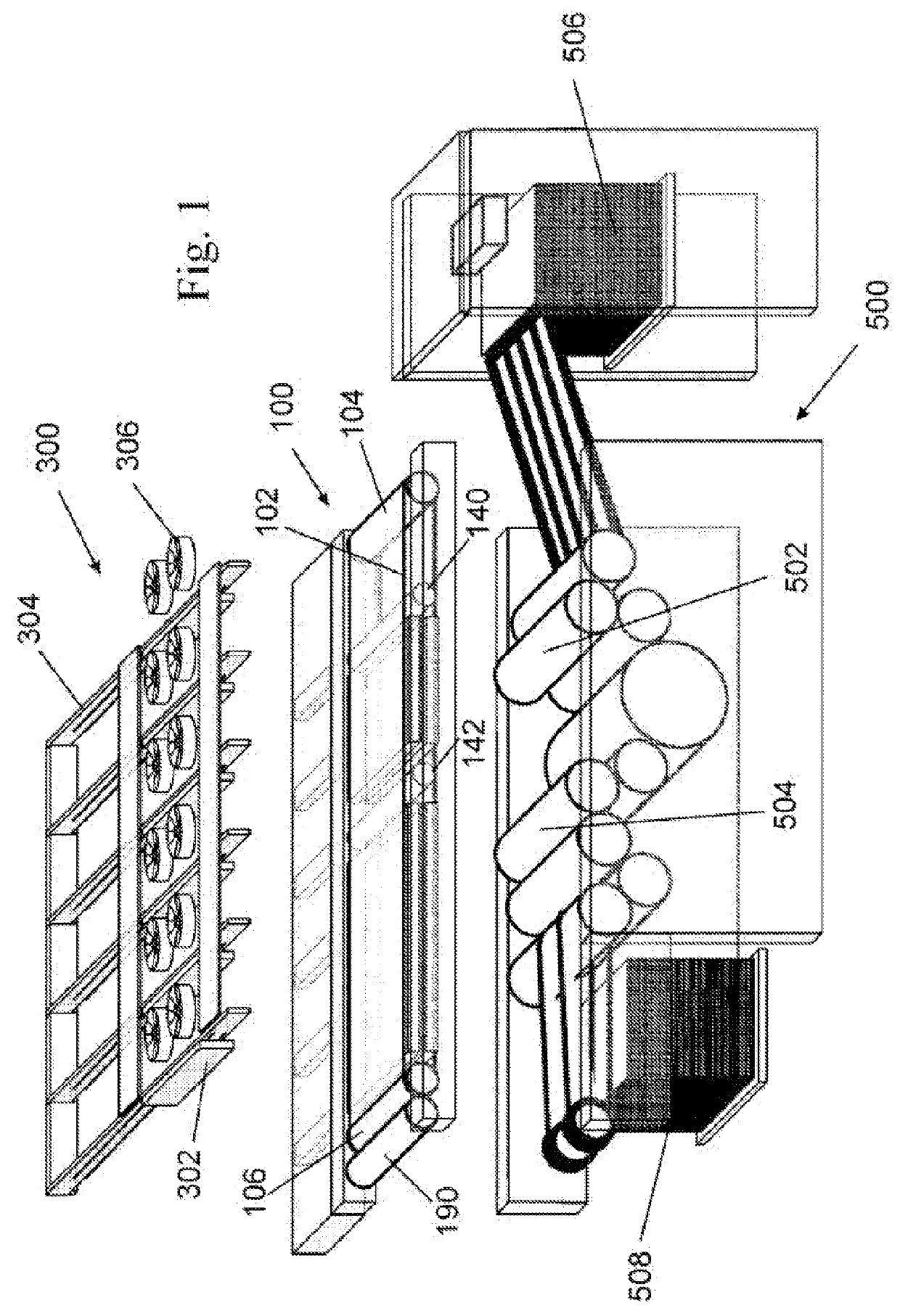

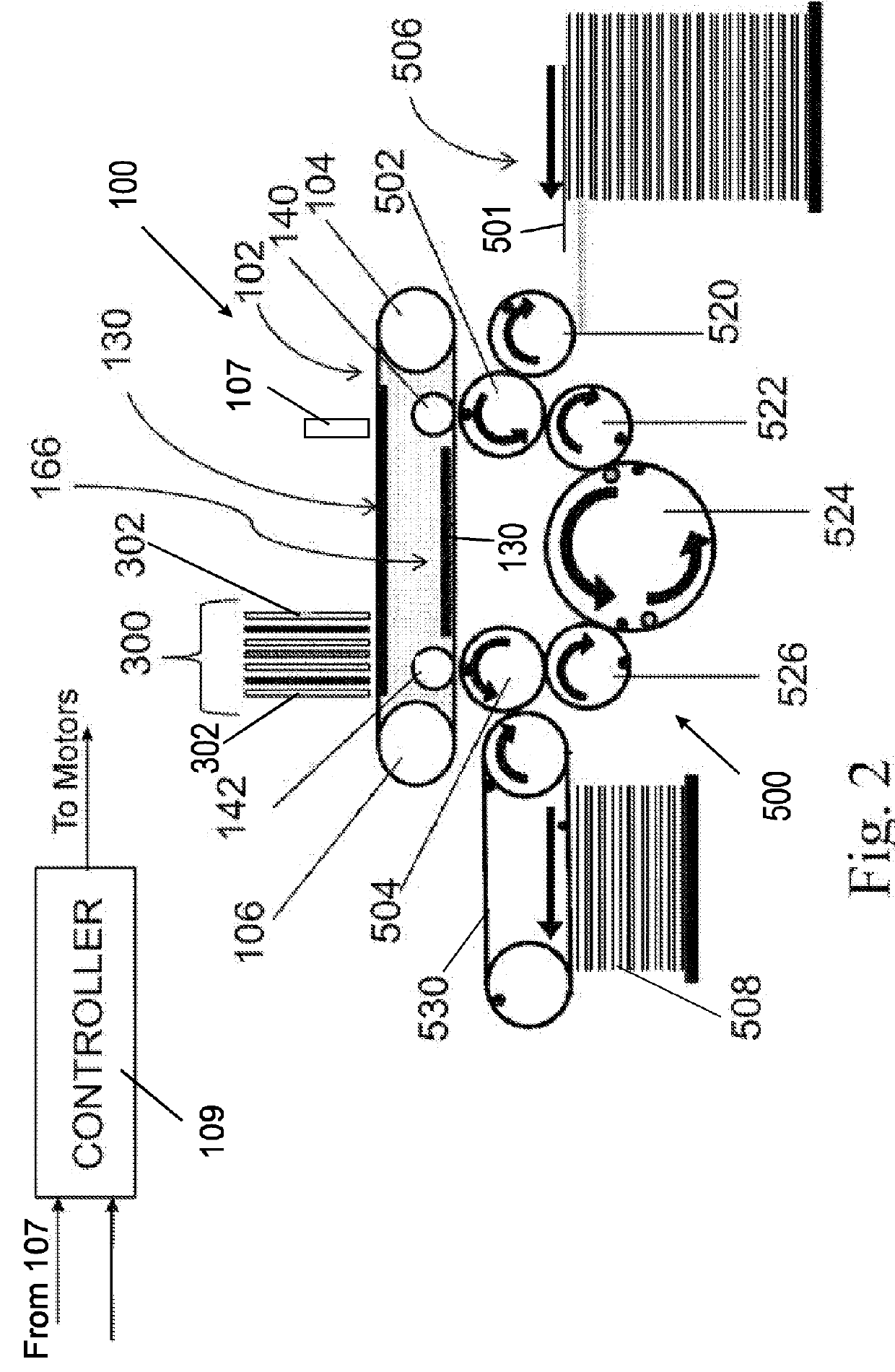

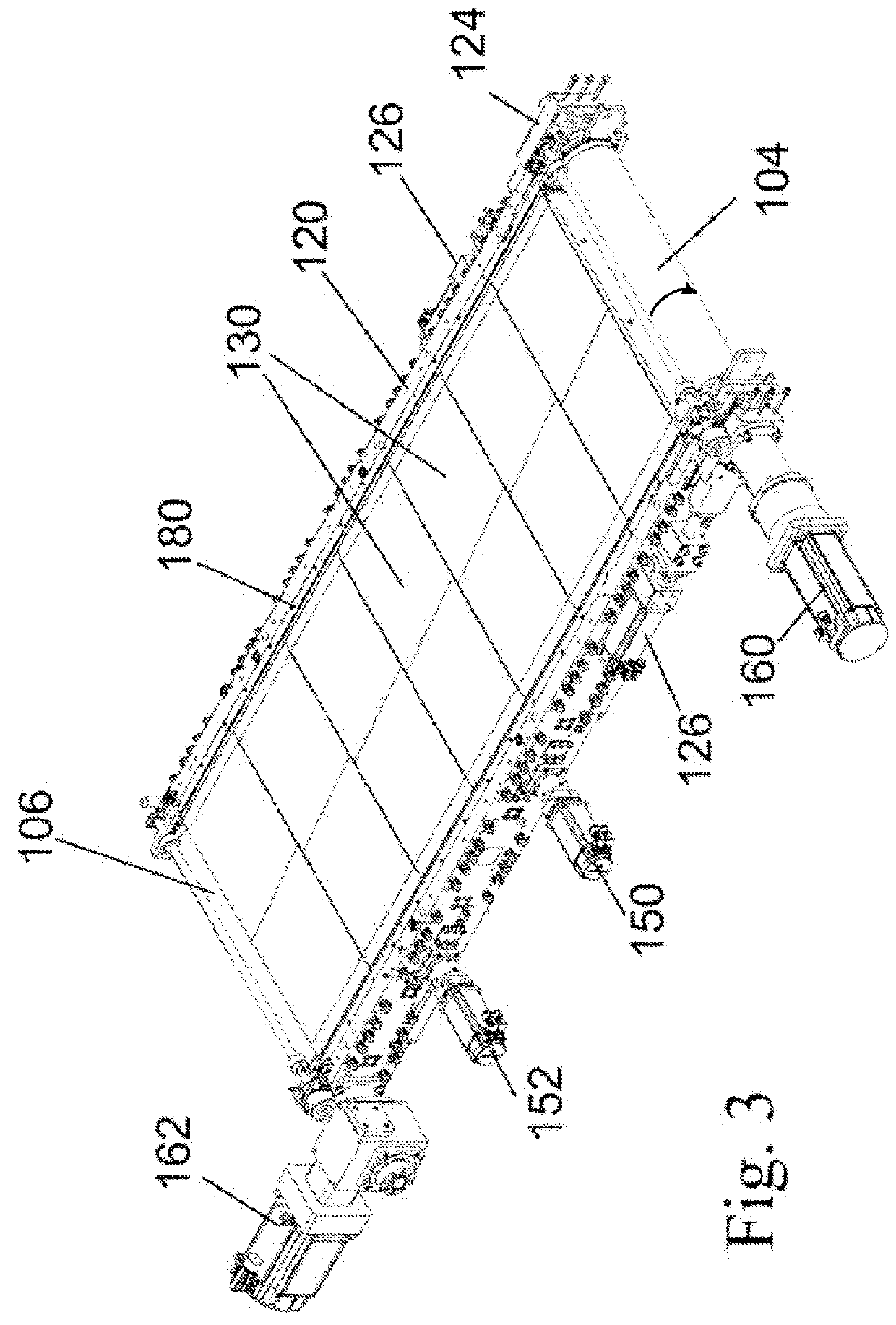

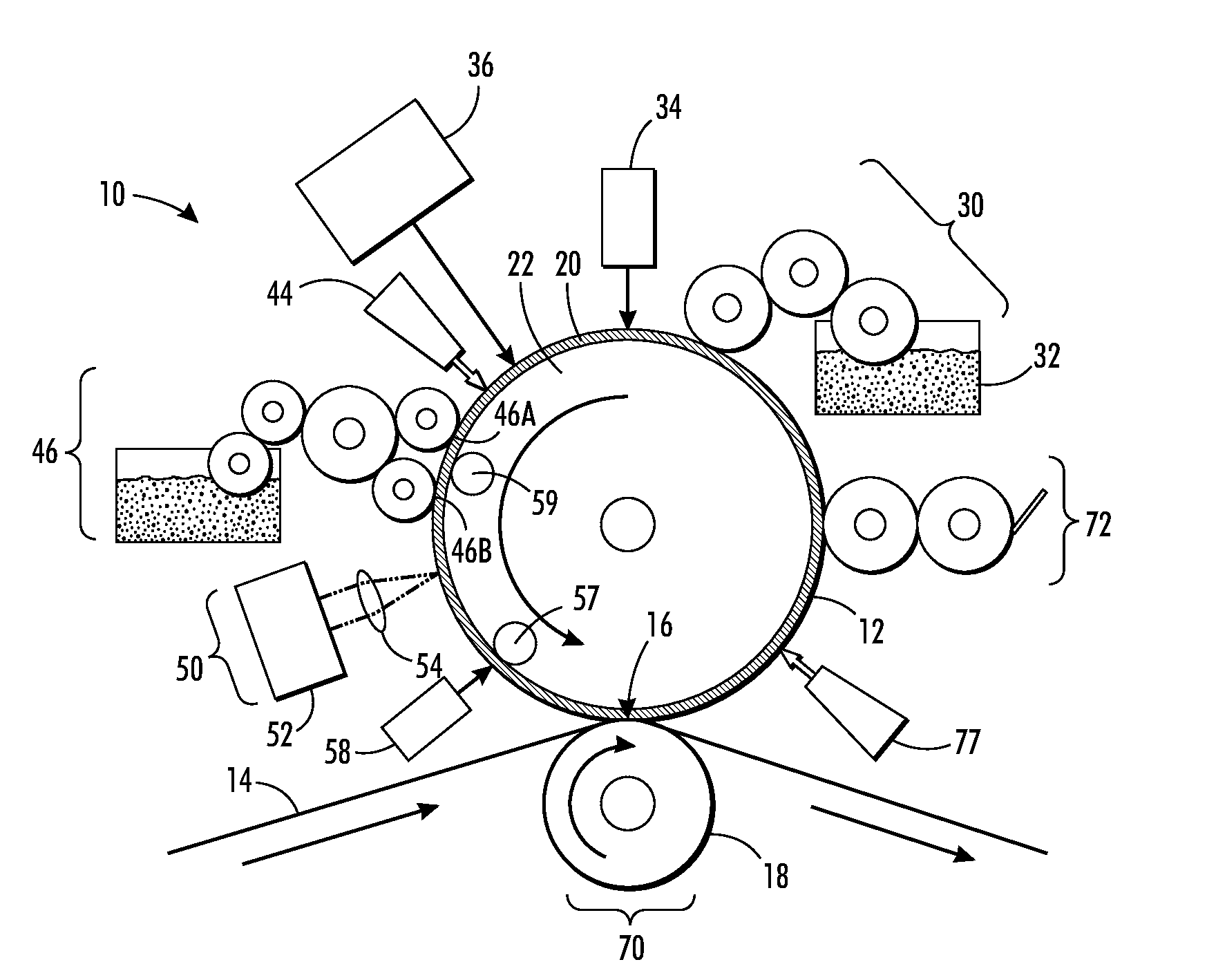

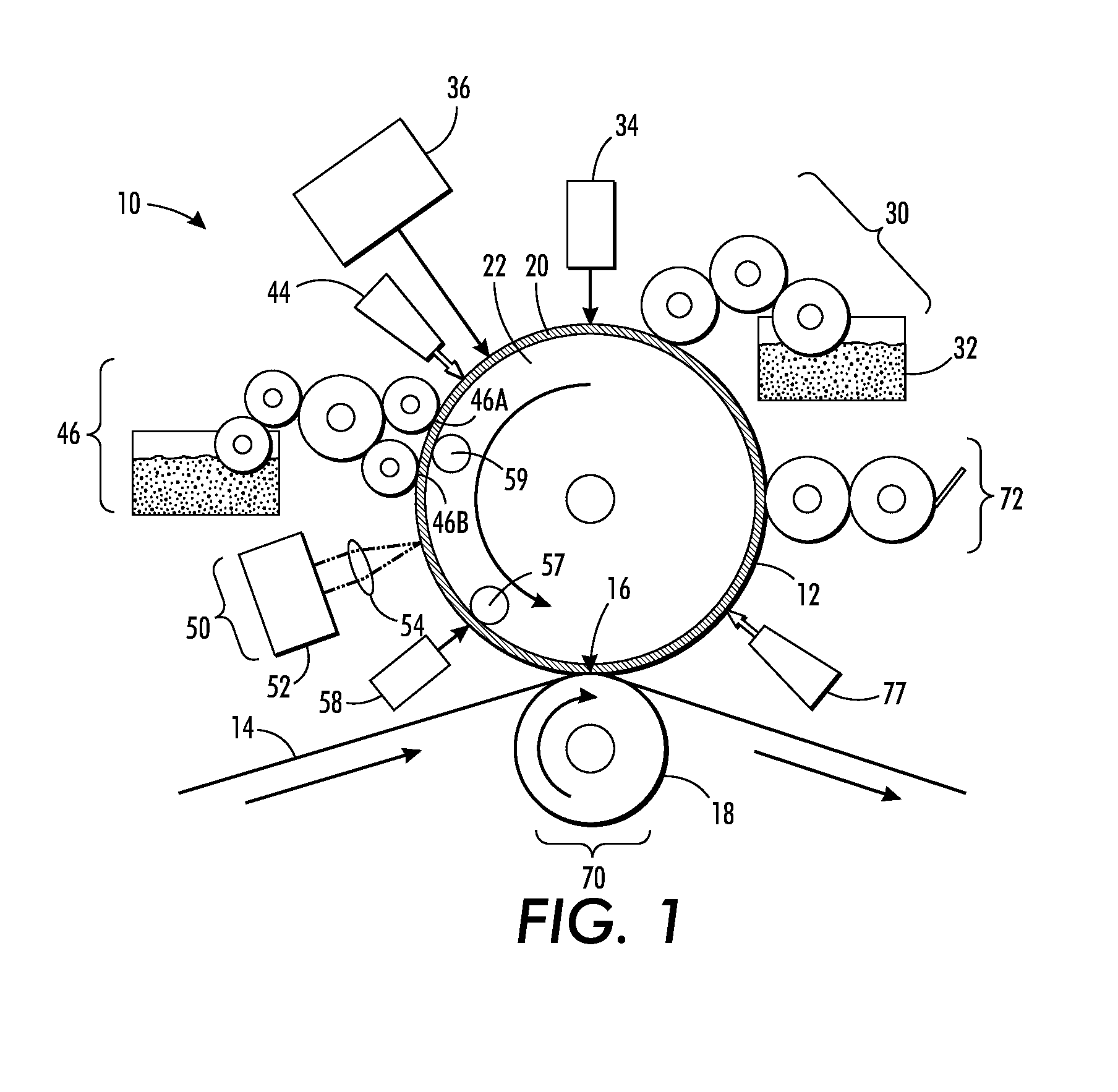

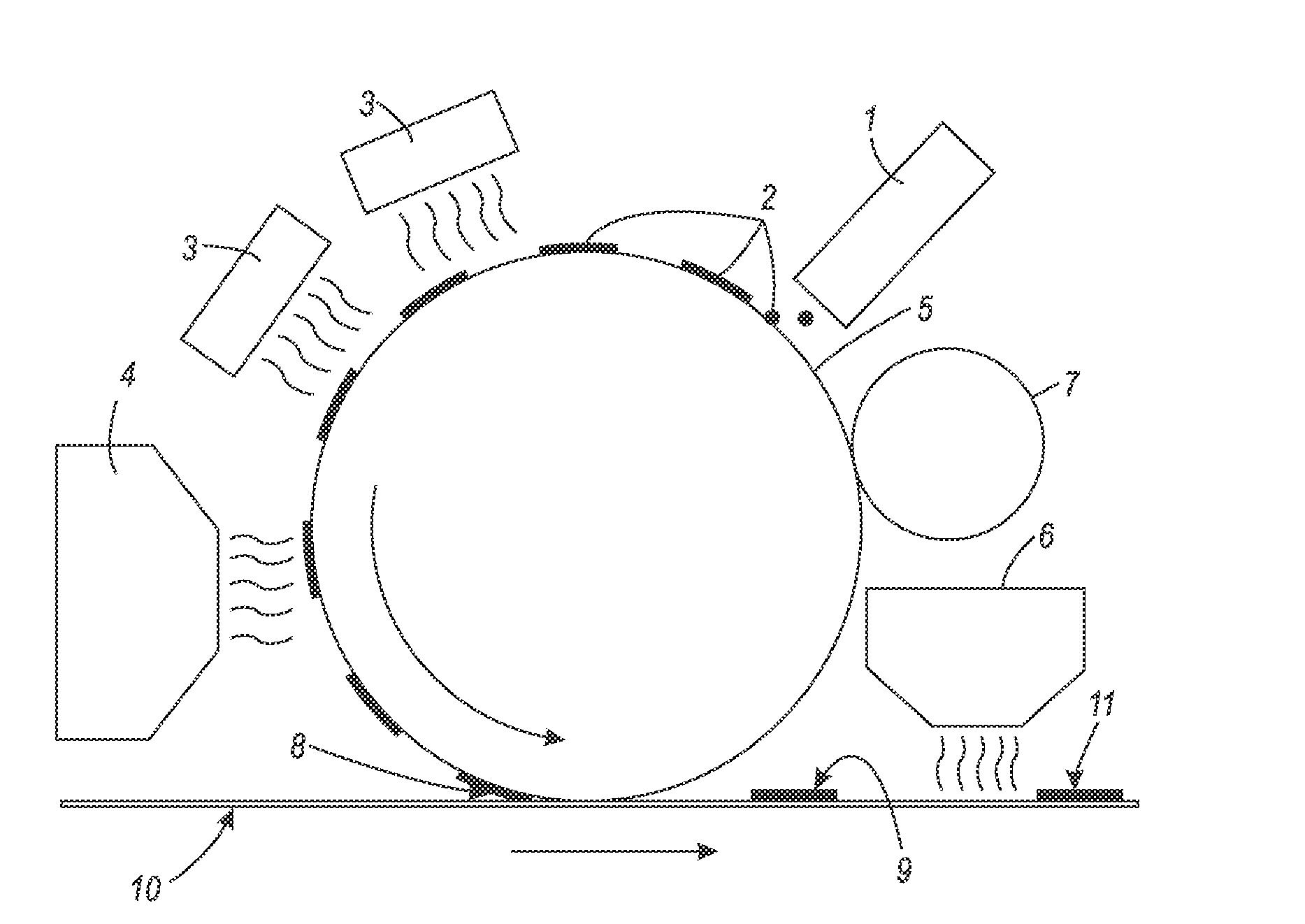

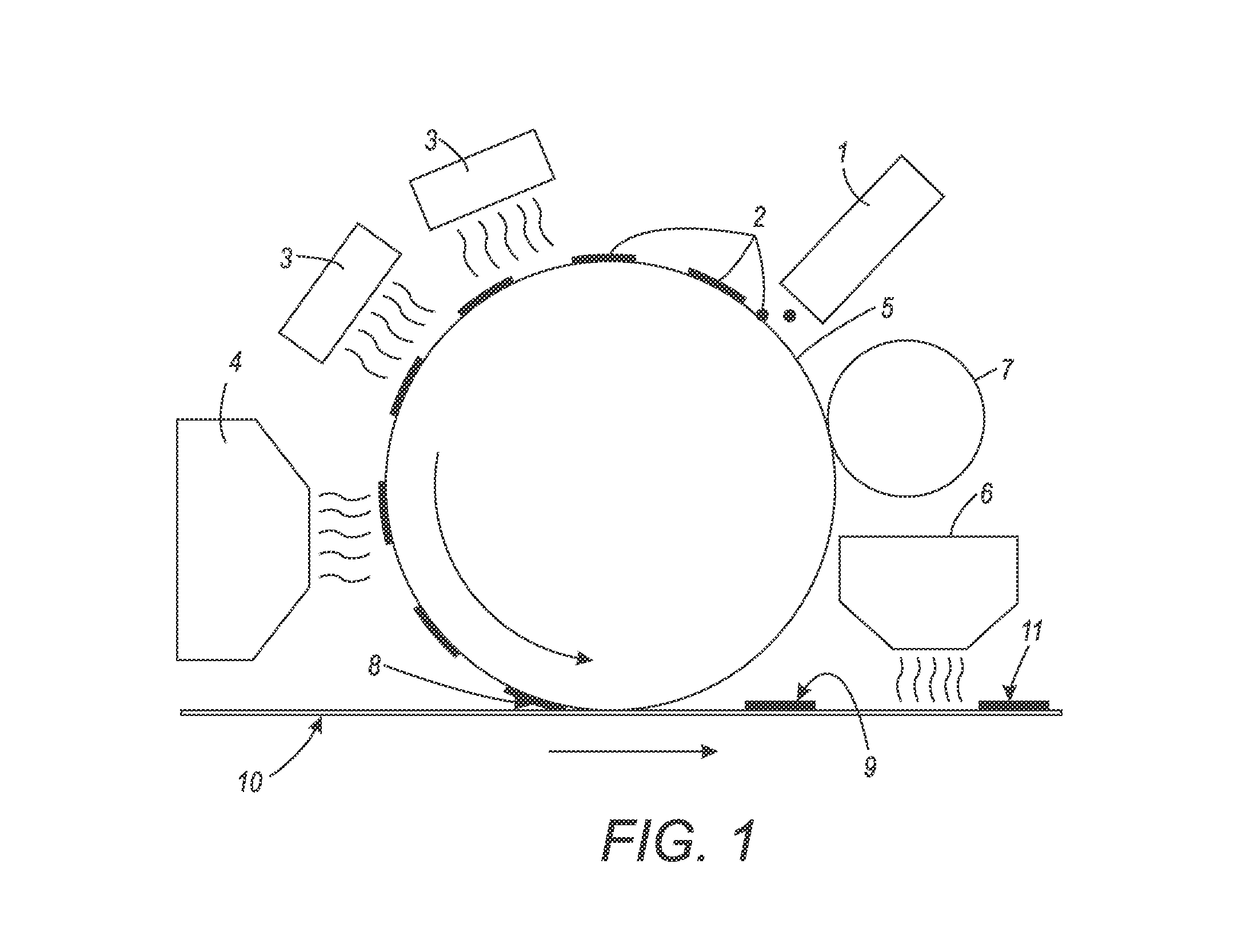

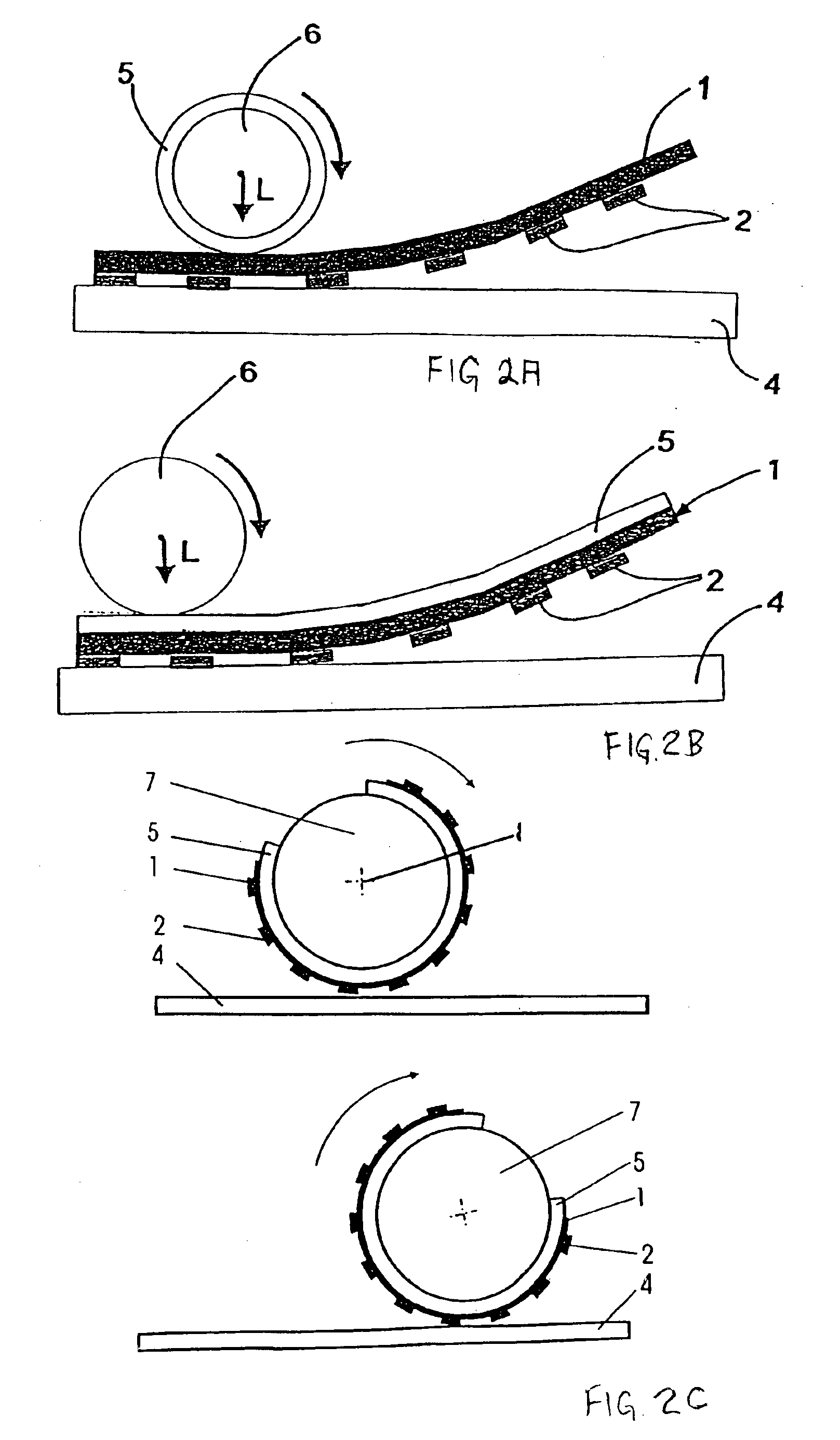

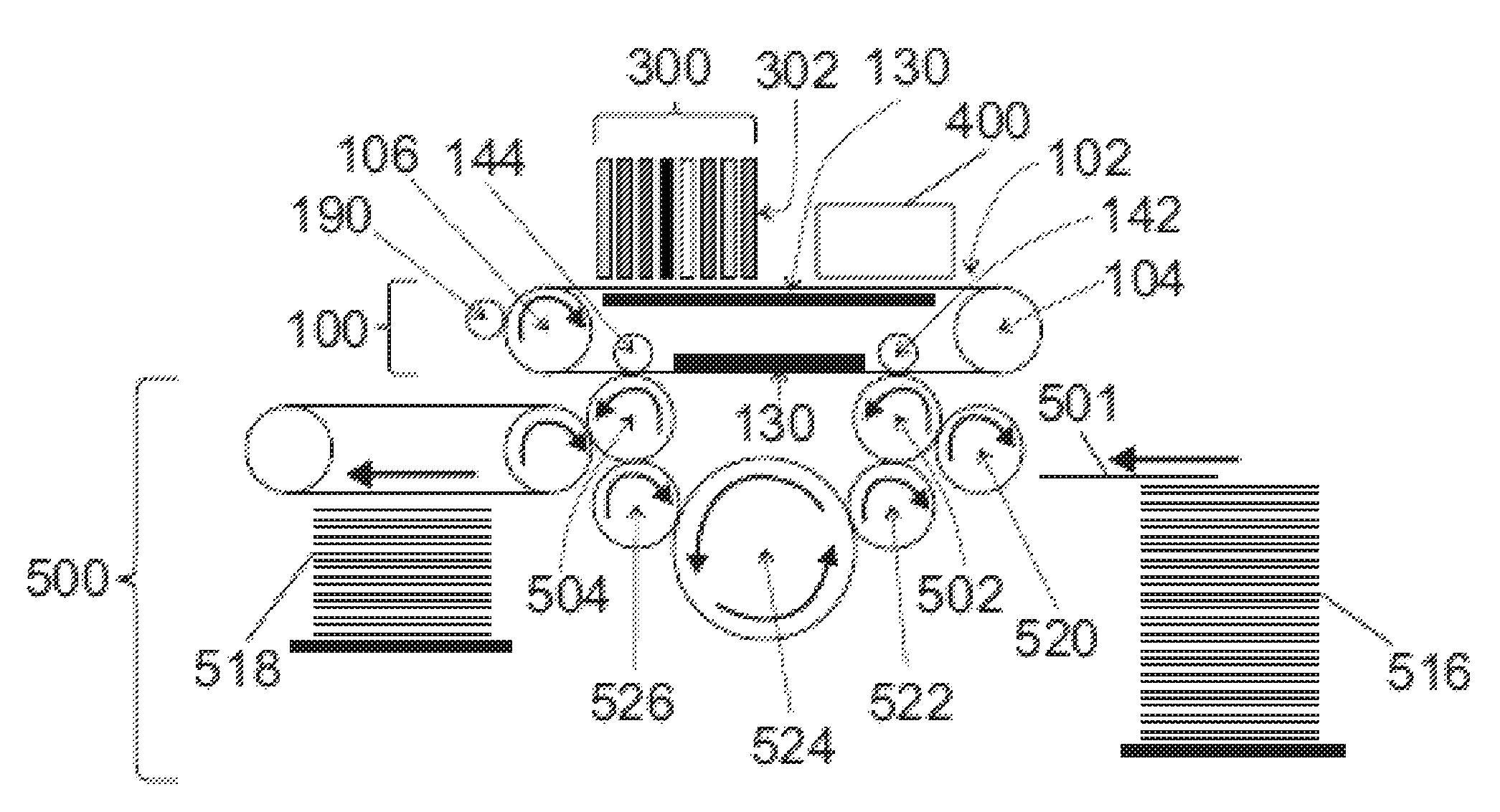

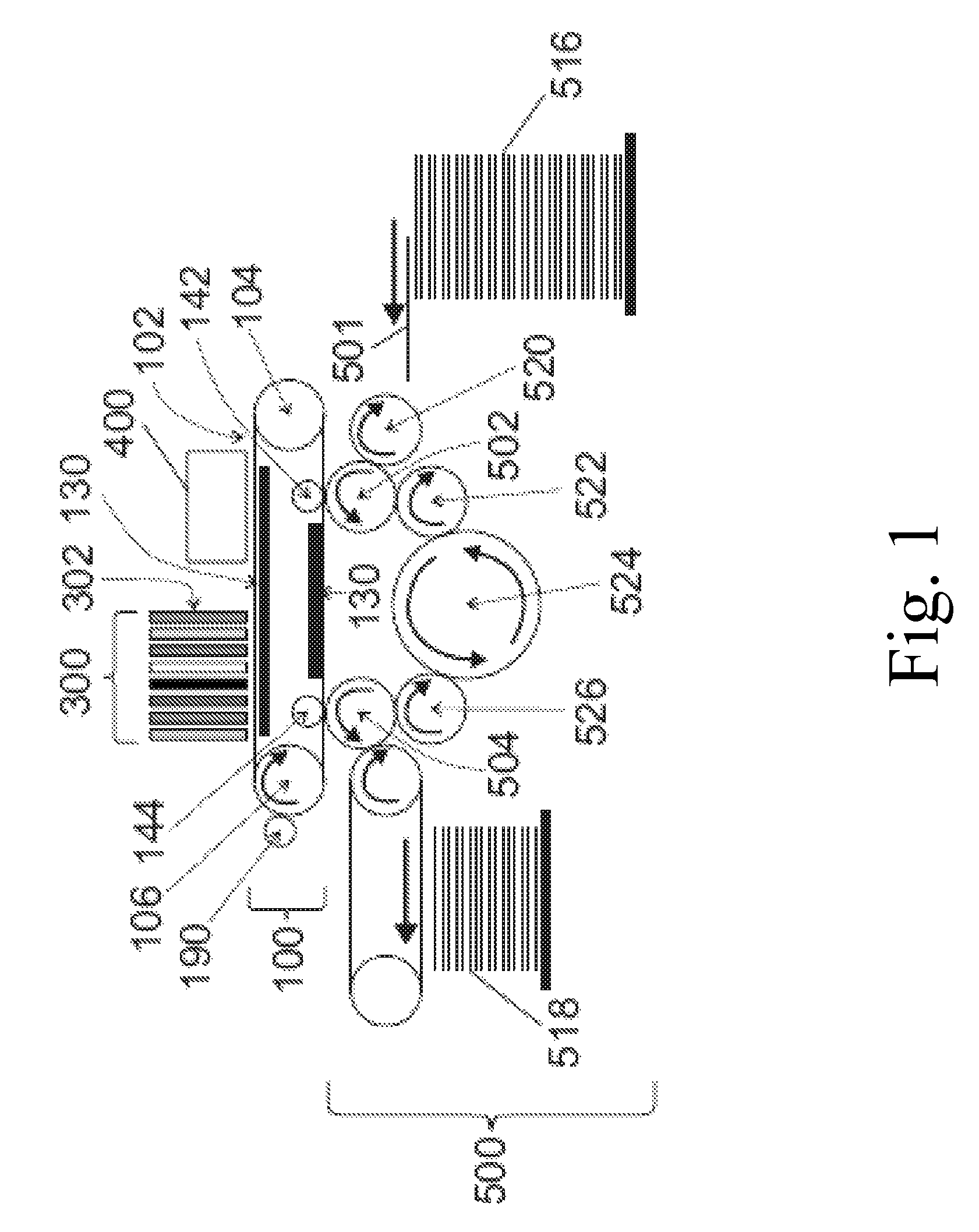

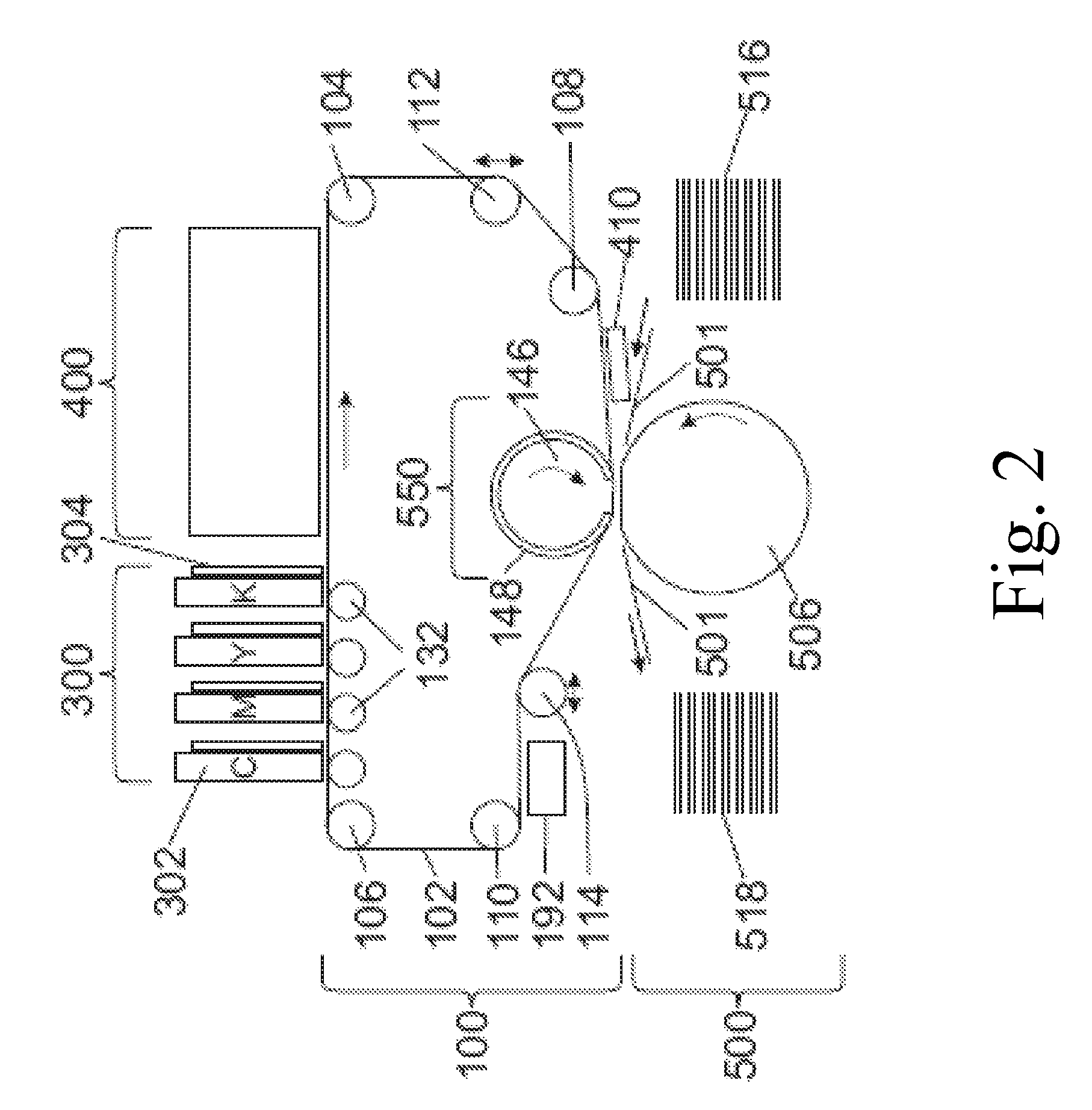

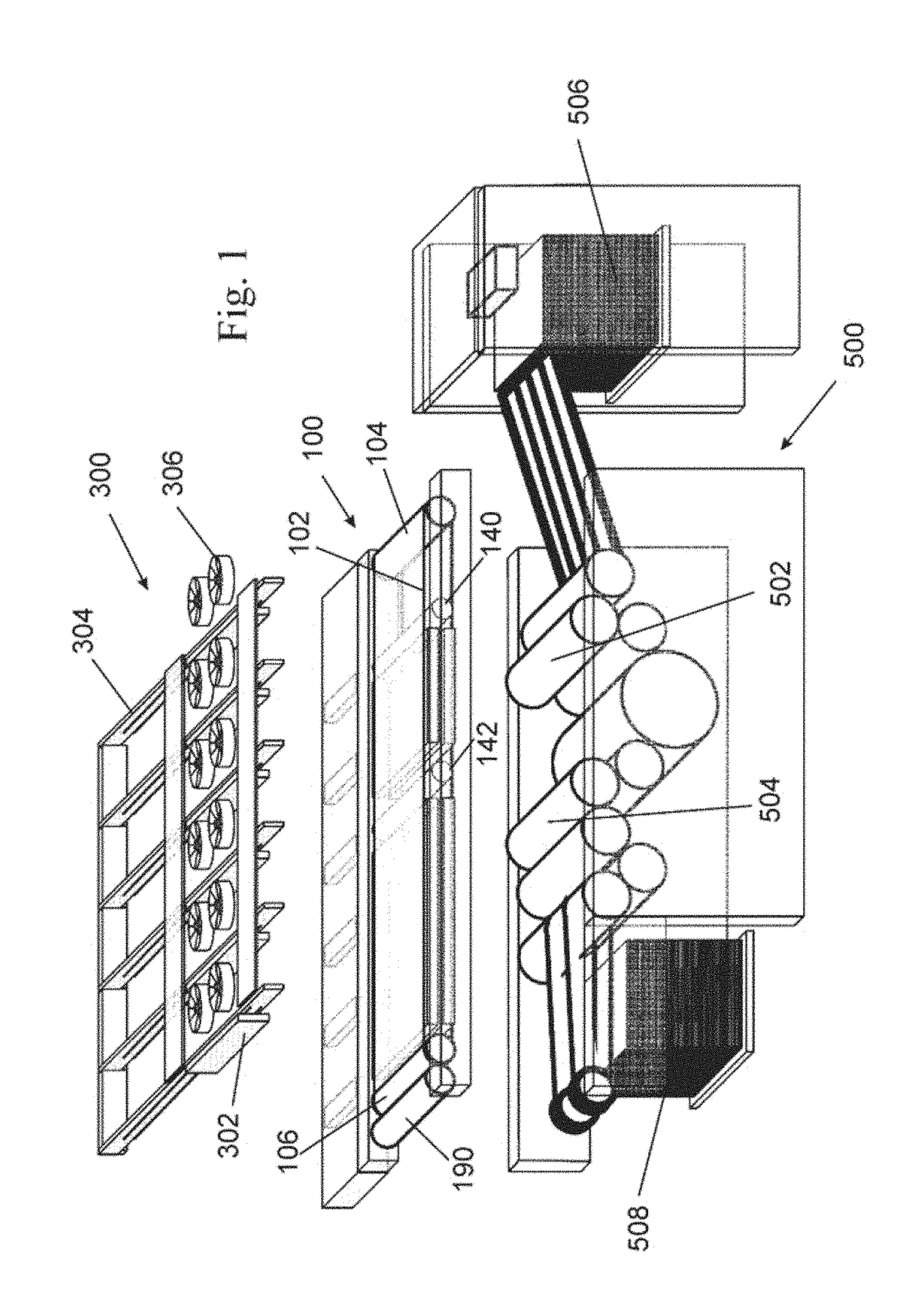

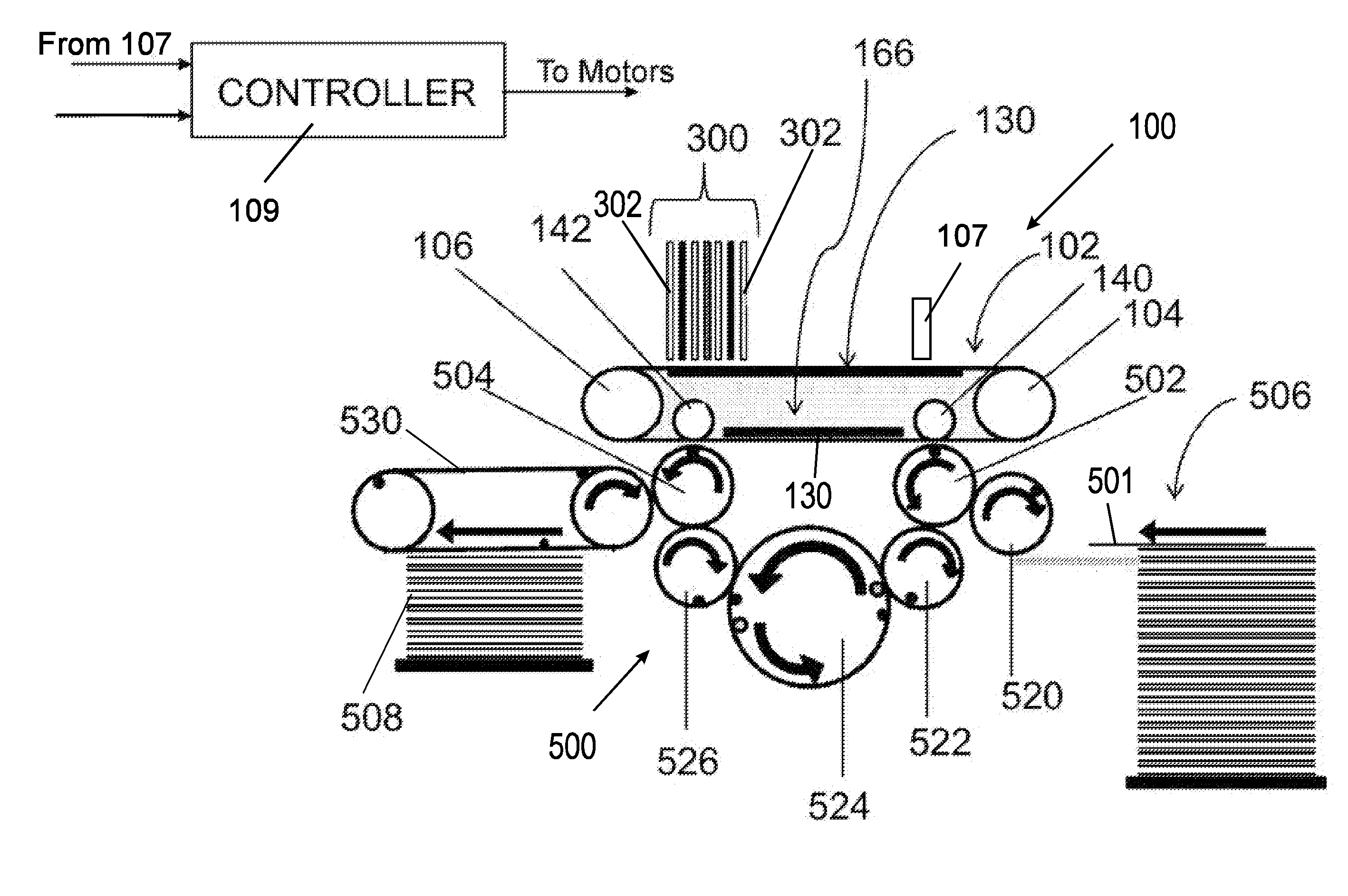

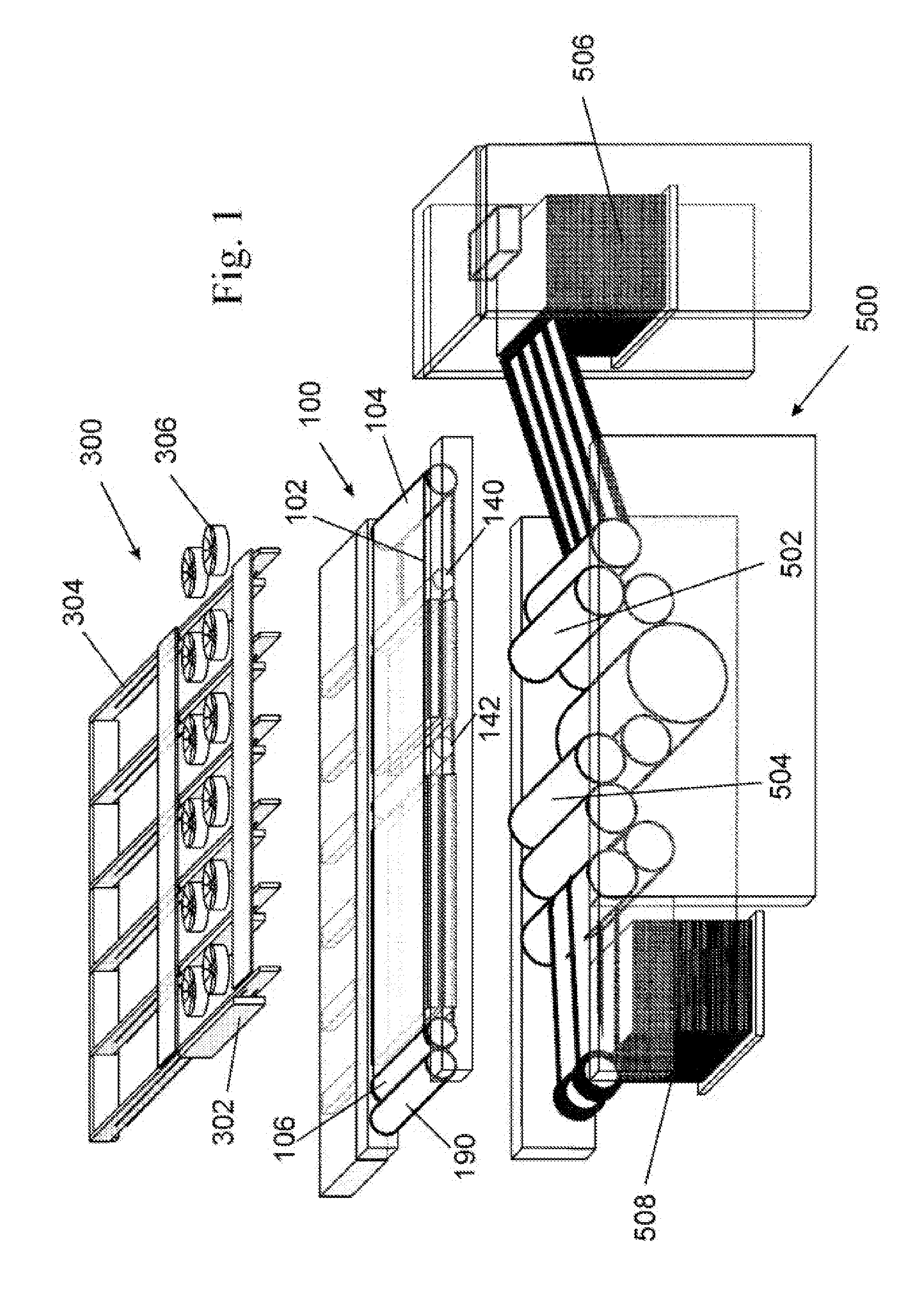

Digital Printing Process

A printing system is disclosed which includes a plurality of rollers configured to support and move a loop-shaped, flexible intermediate transfer member of at least 10 meters in length along a printing system path. The printing system further includes an image forming station configured to form an image on a portion of the intermediate transfer member, and an impression station configured to enable substantial transfer of the deposited image to a substrate. The printing system also includes at least one high-speed motor associated with the plurality of rollers and configured to move the loop-shaped flexible intermediate transfer member at a speed of at least about one meter per second. Moreover, the printing system includes guiding channels configured for exerting a lateral tensioning force on the loop-shaped intermediate transfer member as it is received within the guiding channels and circulates at the speed of at least about one meter per second.

Owner:LANDA

Doctor or coater blade and method in connection with its manufacturing

InactiveUS20040137261A1Improve wear resistanceEasy to wearLiquid surface applicatorsMechanical working/deformationNickel saltElectrolyte

The invention relates to a doctor or coater blade (1) of steel, having a nickel coating comprising abrasion resistant particles, said coating being constituted by an electrolytic nickel layer comprising abrasion resistant particles. The coating preferably comprises at least two electrolytic nickel layers having different composition, and may be formed differently in different sections of the blade. The invention also relates to a continuous process for electrolytic nickel coating in at least one electrolytic cell holding an electrolyte liquid comprising at least one nickel salt, and in at least one of these cells also comprising abrasion resistant particles.

Owner:SWEDEV

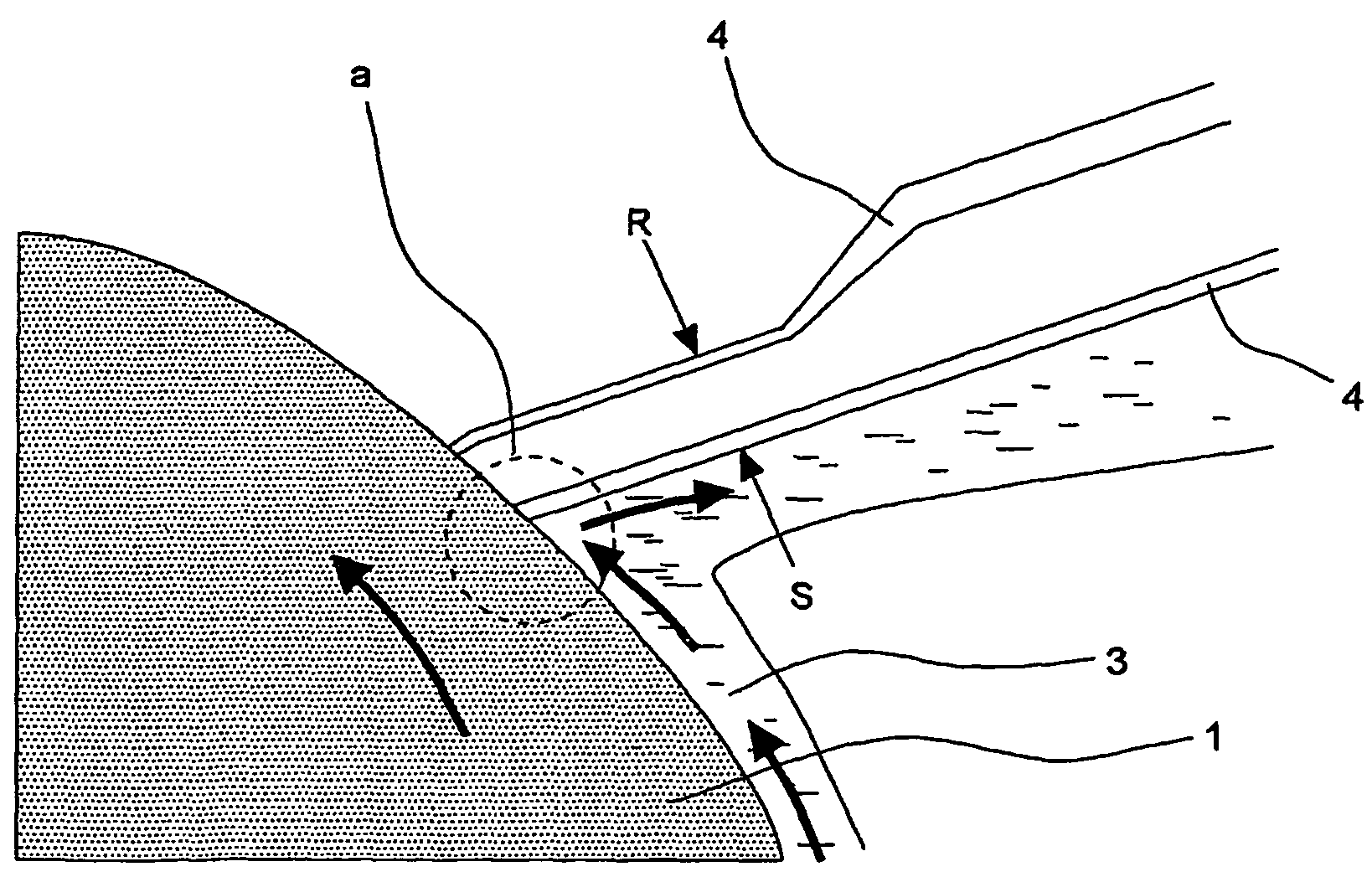

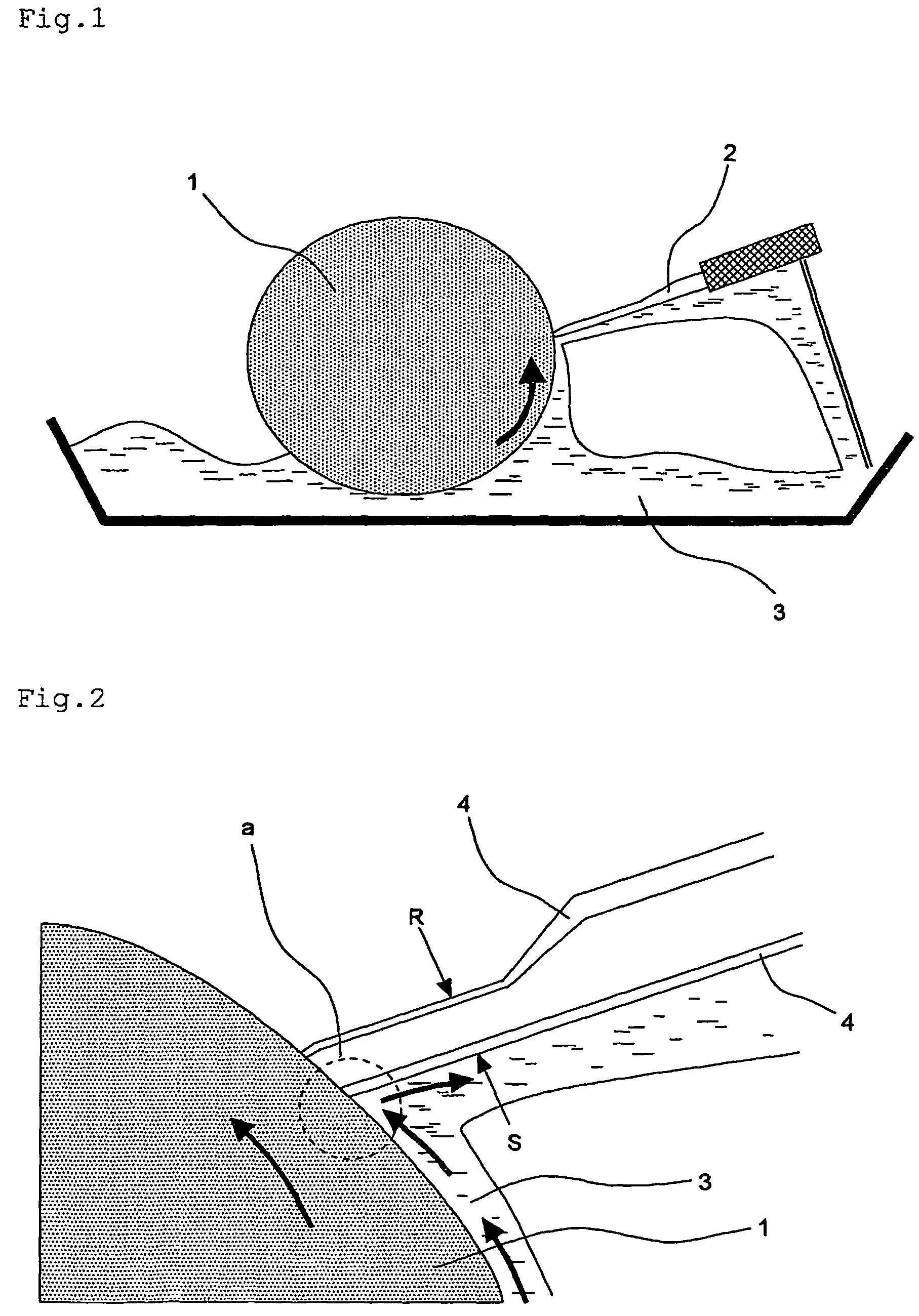

Method for luminescent layer formation and organic electroluminescent device

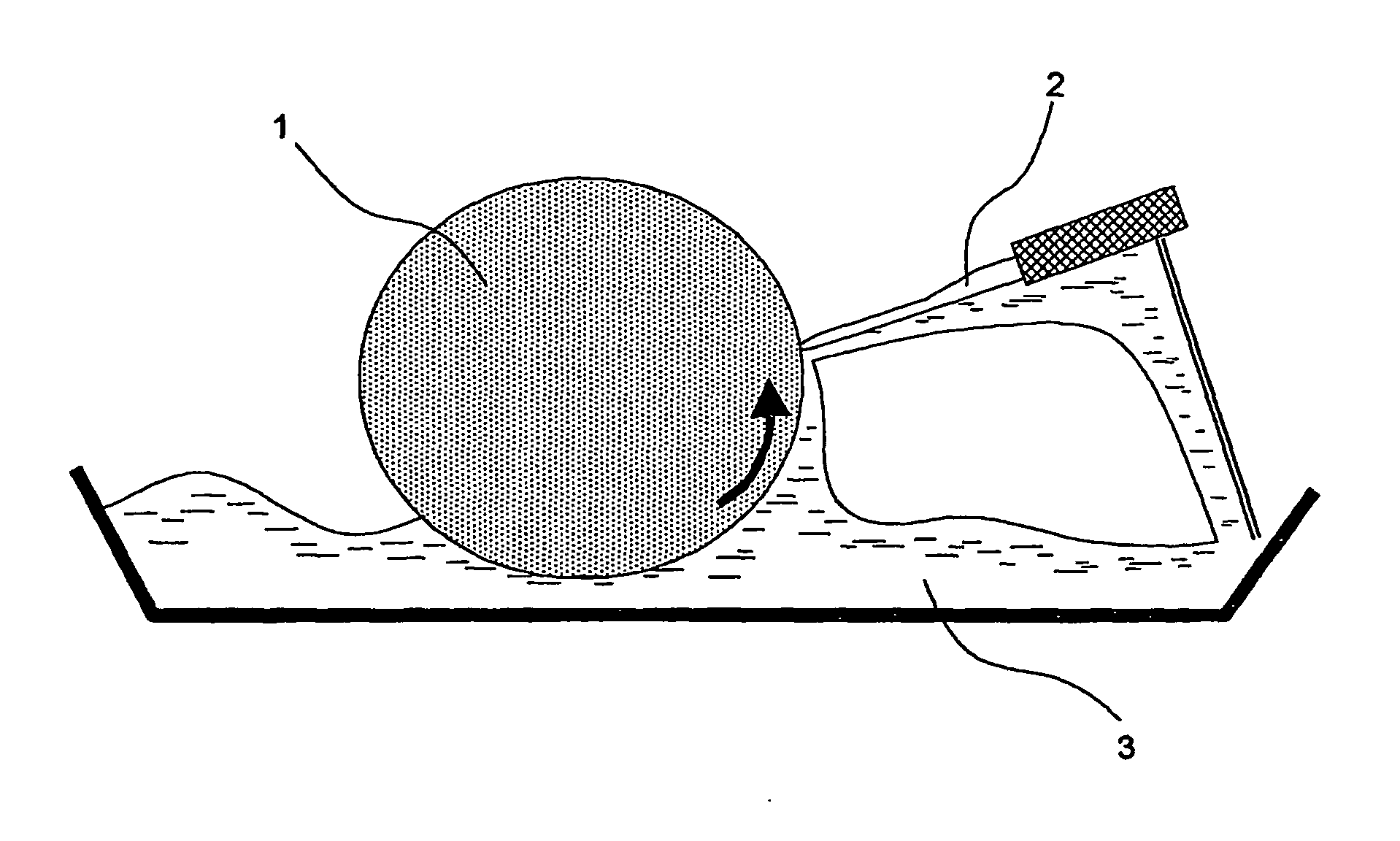

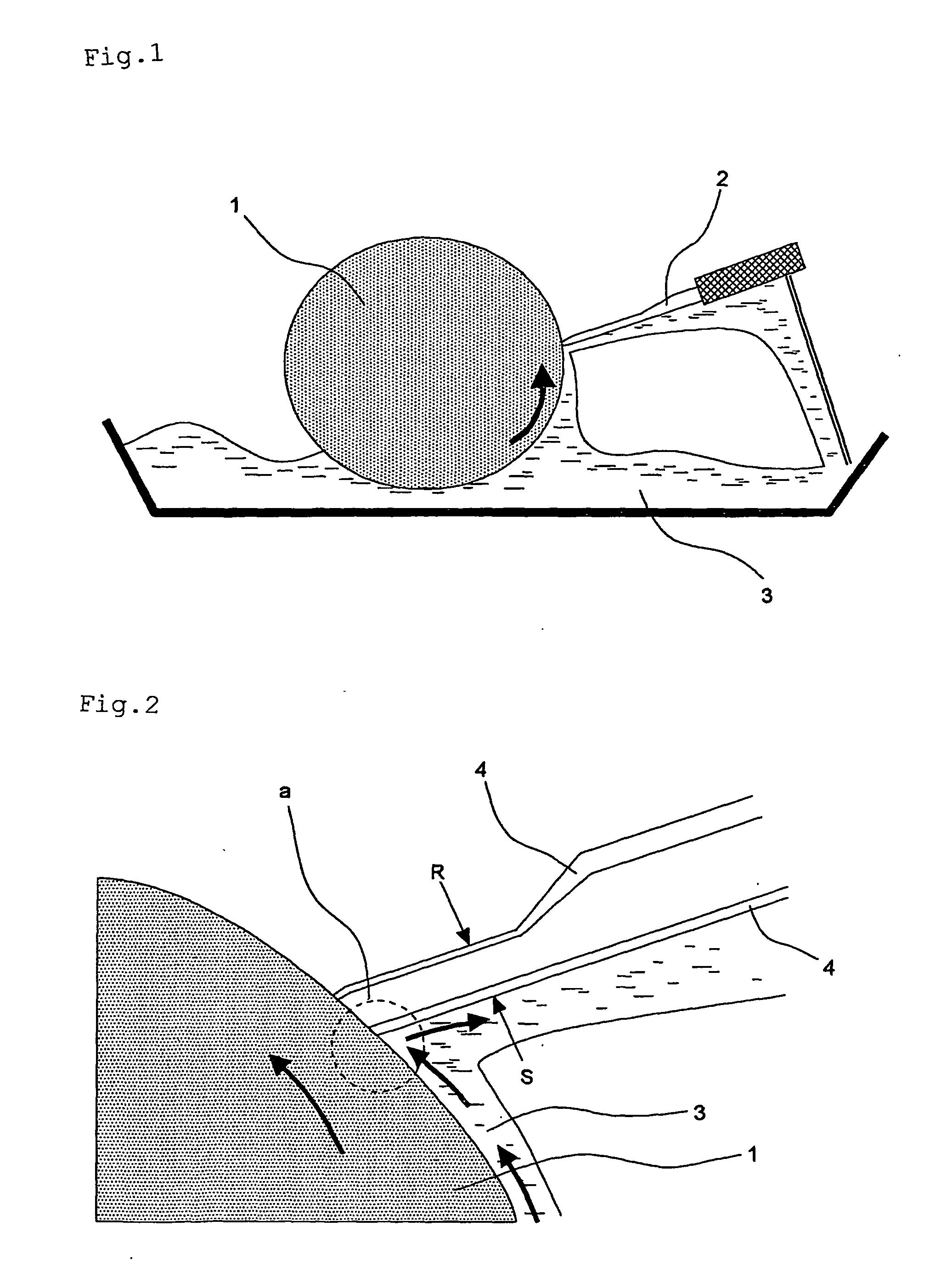

InactiveUS20090081480A1Excellent printing durabilityLow production costRotary intaglio printing pressElectroluminescent light sourcesForming faceSurface layer

A method for the formation of a luminescent layer having a uniform thickness in a desired pattern and an organic electroluminescent device that can realize high-quality display and is highly reliable. The luminescent layer is formed by providing a blanket having a resin film having a surface tension of not less than 35 dynes / cm as a surface layer and an ink for a luminescent layer, having a viscosity (ink temperature 23° C.) in the range of 5 to 200 cP as measured at a shear rate of 100 / sec, and containing a solvent having a surface tension of not more than 40 dynes / cm and a boiling temperature in the range of 150 to 250° C., filling the ink into cells in a gravure form, allowing the blanket to receive the ink from the cells, and transferring the ink on the blanket onto a luminescent layer forming face.

Owner:DAI NIPPON PRINTING CO LTD

Image transfer product including a thin printing surface layer

ActiveUS8409698B2Efficient preparationReduce the amount of solvent usedRecord information storageLight beam reproducingSurface layerImage transfer

An image transfer product such as an offset printing blanket or sleeve is provided which comprises a very thin printing surface layer in combination with a smooth image reinforcement layer comprising a polymeric film, a fabric, or a polymer-coated fabric. The thin printing surface layer has a thickness between about 0.001 to about 0.012 inches (about 0.025 to about 0.3 mm). The image transfer product is more efficiently manufactured due to reduced solvent usage and reduced number of coating passes, and in use, exhibits uniform feed, web control, and registration characteristics.

Owner:DAY INT

Blanket cylinder for an intaglio printing machine

InactiveUS7464642B2Reduce in quantityQuality improvementRotary intaglio printing pressMounting boardsEngravingPrinting press

The blanket cylinder for an intaglio printing machine comprising a plate cylinder carrying printing plates with engravings corresponding to a specific intaglio structure to be printed on a substrate, and cooperating with an impression cylinder, the blanket cylinder having at least one blanket on which the ink in the different colors is deposited by selector cylinders, each selector cylinder having reliefs with contours corresponding to the area of the intaglio structure to be inked with said color, the at least one blanket being made of several successive layers each with different properties.

Owner:KBA NOTASYS SA

Anti-static, anti-smearing pre-stretched and pressed flat, precision-cut striped flexible coverings for transfer cylinders

InactiveUSRE39305E1Build-up of electrostatic charges on the movable, flexible jacket covering is preventedAvoid chargingCylinder pressesPlaten pressesFrictional coefficientConductive materials

Freshly printed sheets are transferred from one printing unit to another by transfer cylinders each having an ink repellent, electrically conductive, striped flexible jacket covering that is movable relative to the sheet support surface of the transfer cylinder. The jacket covering is made of a flexible fabric material that is pre-stretched, pressed flat, cut to size and treated with an ink repellent compound and is also treated with an anti-static ionic compound or is otherwise rendered electrically conductive by one or more conductive strands. Electrostatic charges carried by the freshly printed sheets are discharged through the ink repellent, electrically conductive, flexible jacket covering into the grounded transfer cylinder. A low friction, electrically conductive cylinder base covering that includes center alignment marks is secured to the transfer cylinder for engaging the flexible jacket covering. The ink repellent, electrically conductive flexible jacket covering is provided with alignment center marks and alignment stripes so that the flexible jacket covering can be precisely aligned with ease and secured over the gripper edge, tail edge and side edges of the transfer cylinder. The low frictional coefficient of the conductive cylinder base covering is further reduced by nodes and / or openings.

Owner:DEMOORE HOWARD WARREN +1

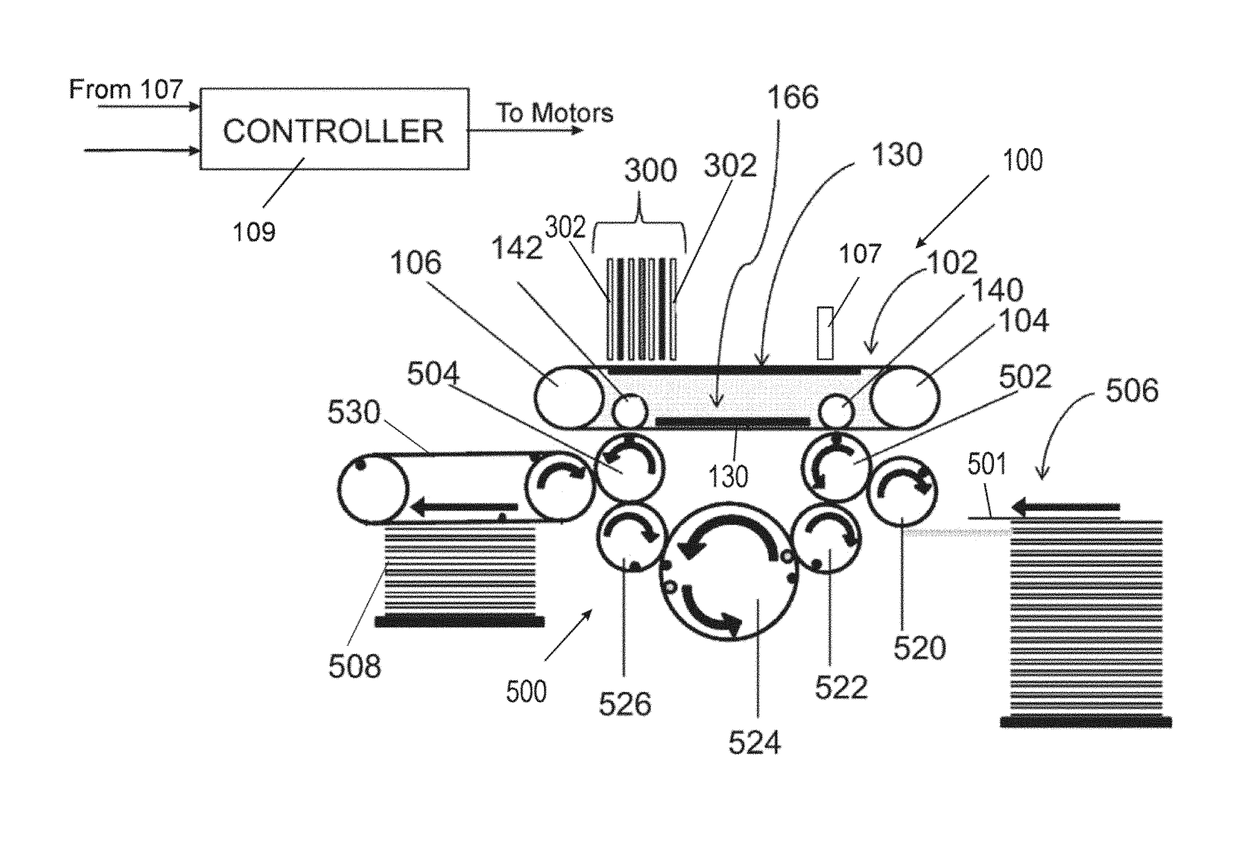

Apparatus for orienting magnetic flakes

A printing apparatus includes a magnetic rotatable roller with a smooth even outer surface for aligning magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnetic portions of the roller, that can be formed by permanent magnets embedded in a non-magnetic roller body, or selectively magnetized portions of a flexible magnetic cover of the roller. In some embodiments, the roller is assembled for a plurality of interchangeable sections, which can include spinning magnets. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

Digital printing process

A printing process is disclosed which comprises directing droplets of an ink onto an intermediate transfer member to form an ink image, the ink including an organic polymeric resin and a coloring agent in an aqueous carrier, and the transfer member having a hydrophobic outer surface so that each ink droplet in the ink image spreads on impinging upon the intermediate transfer member to form an ink film. The ink is dried while the ink image is being transported by the intermediate transfer member by evaporating the aqueous carrier from the ink image to leave a residue film of resin and coloring agent. The residue film is then transferred to a substrate. The chemical compositions of the ink and of the surface of the intermediate transfer member are selected such that attractive intermolecular forces between molecules in the outer skin of each droplet and on the surface of the intermediate transfer member counteract the tendency of the ink film produced by each droplet to bead under the action of the surface tension of the aqueous carrier, without causing each droplet to spread by wetting the surface of the intermediate transfer member.

Owner:LANDA

Surface treated doctor blade

InactiveUS7152526B2Lower surface energyAvoid failureRotary intaglio printing pressBrushesEngineeringKnife blades

Disclosed is a surface treated doctor blade in which the surface of at least the blade edge portion thereof consists of a surface treatment coating film composed of a first layer consisting of a specific nickel-based plating and a second layer provided thereon which has low surface energy, and in which preferably at least a part of the blade edge end portion of the blade base material is exposed. In the surface treated doctor blade of the present invention, it is possible to improve wear resistance of the blade edge end and to suppress generation of printing failures during continuous printing. Further, in the mode in which at least a part of the blade base material is exposed, it is possible to reduce running-in time for adjustment of contact of the blade edge with the cylinder after replacement of the doctor blade.

Owner:NIHON NEW CHROME

Phase change ink imaging component with nano-size filler

An offset printing apparatus having a coated imaging member for use with phase-change inks, has a substrate, an optional intermediate layer, and thereover an outer coating with a nano-size filler having an average particle size of from about 1 to about 250 nanometers, and an optional heating member associated with the offset printing apparatus.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com