Patents

Literature

406results about "Printing plates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

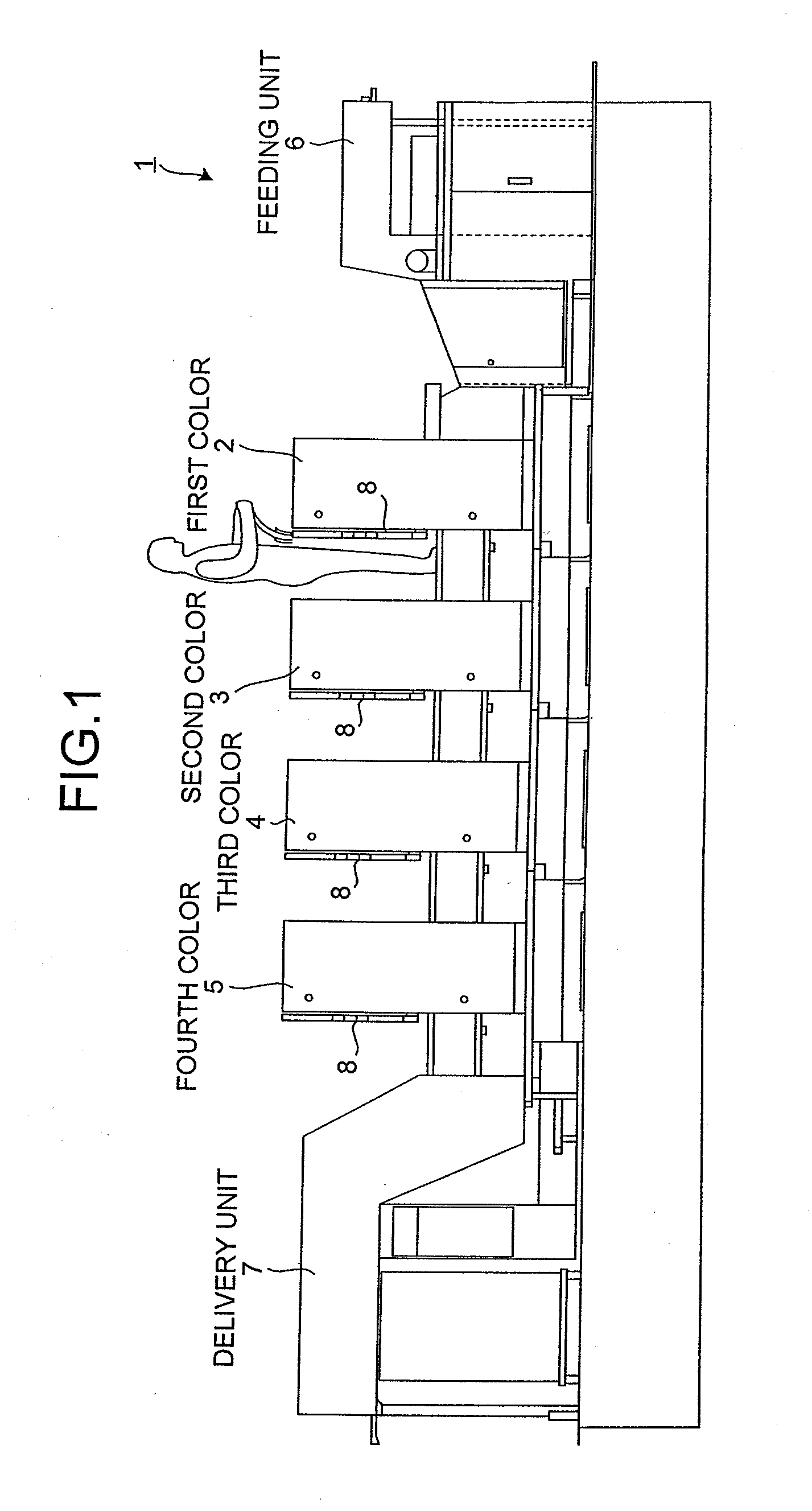

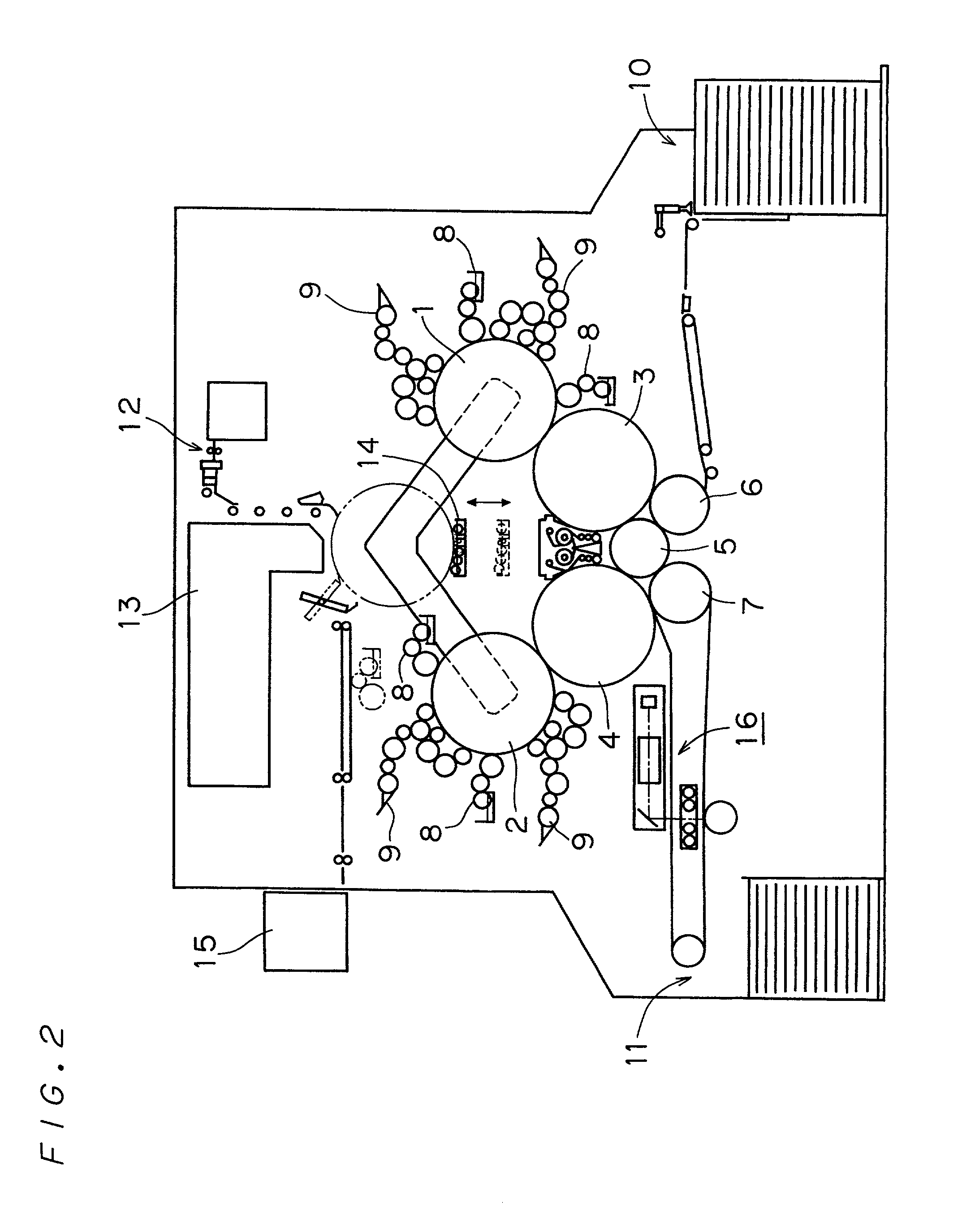

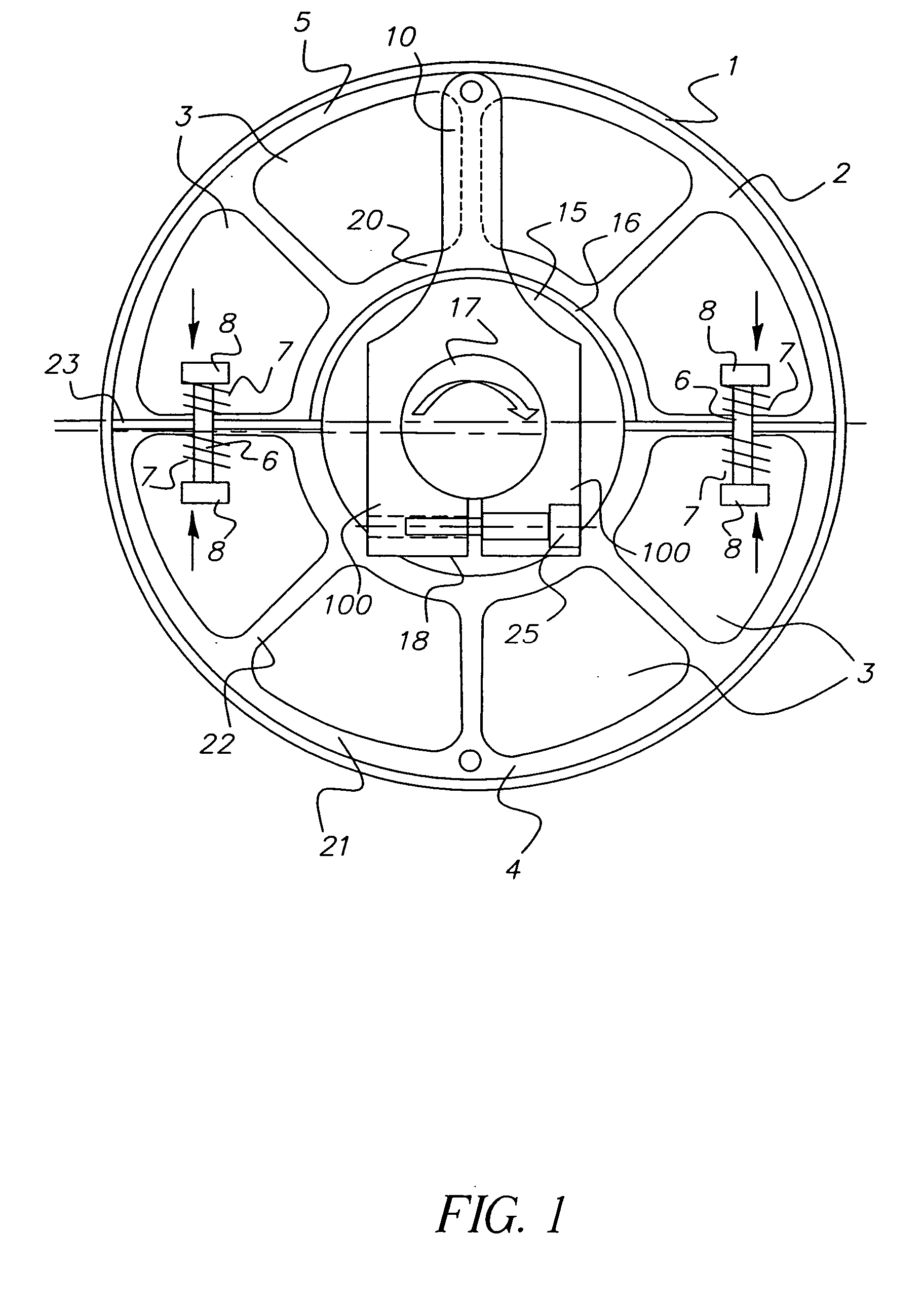

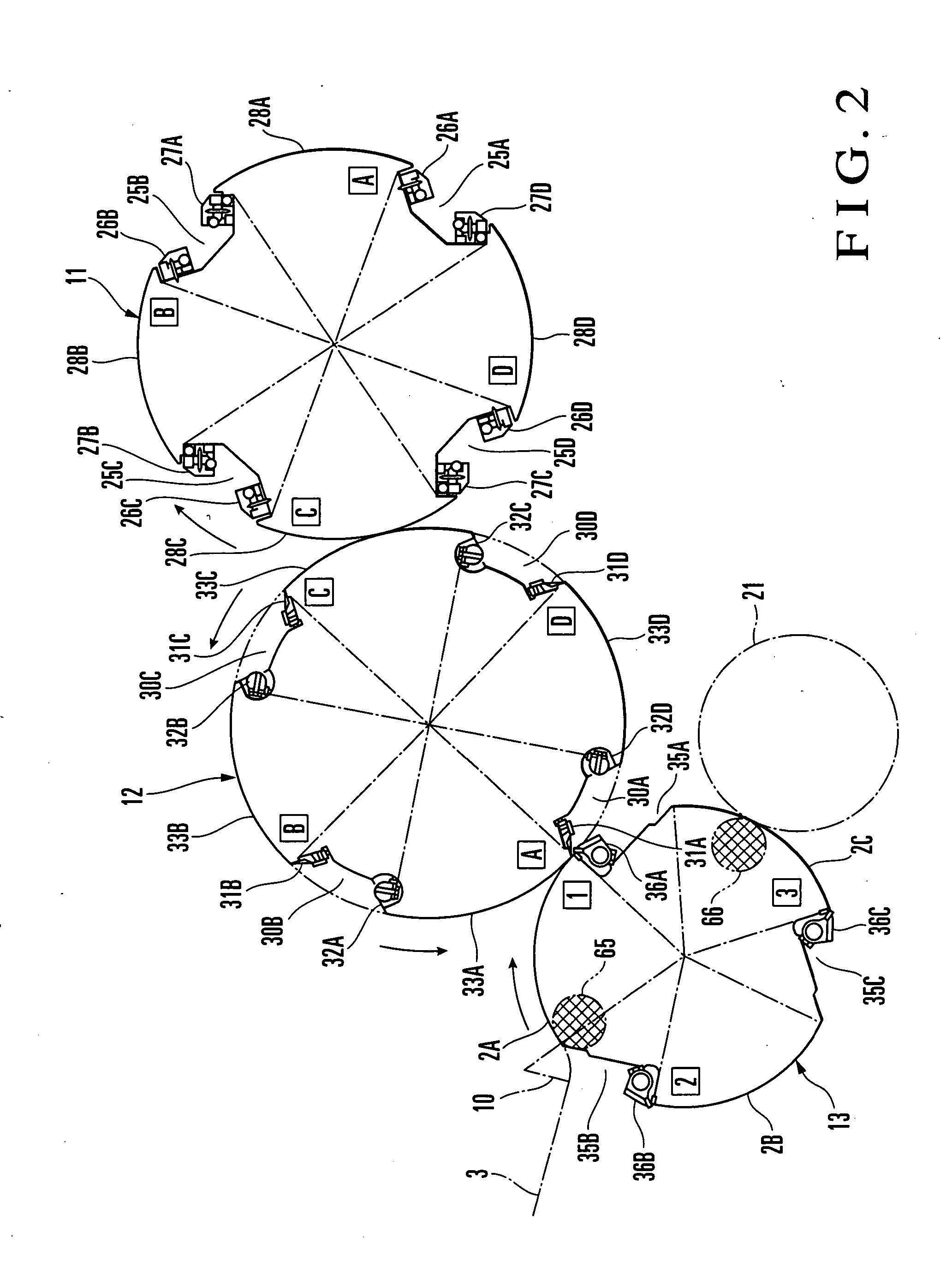

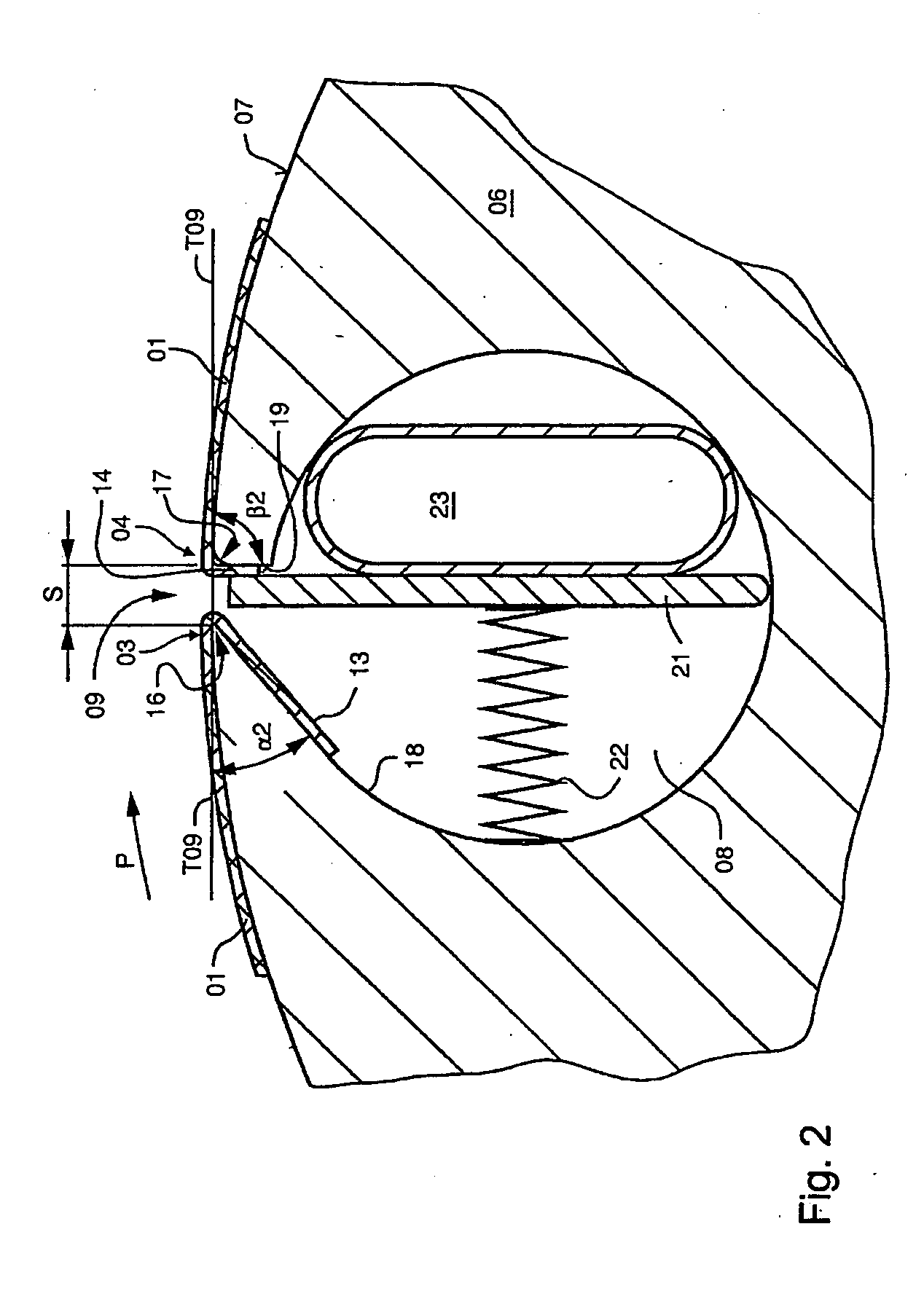

Web-fed rotary printing press for rapid change in production

InactiveUS6019039APrinting platesOther printing apparatusPrinting pressElectrical and Electronics engineering

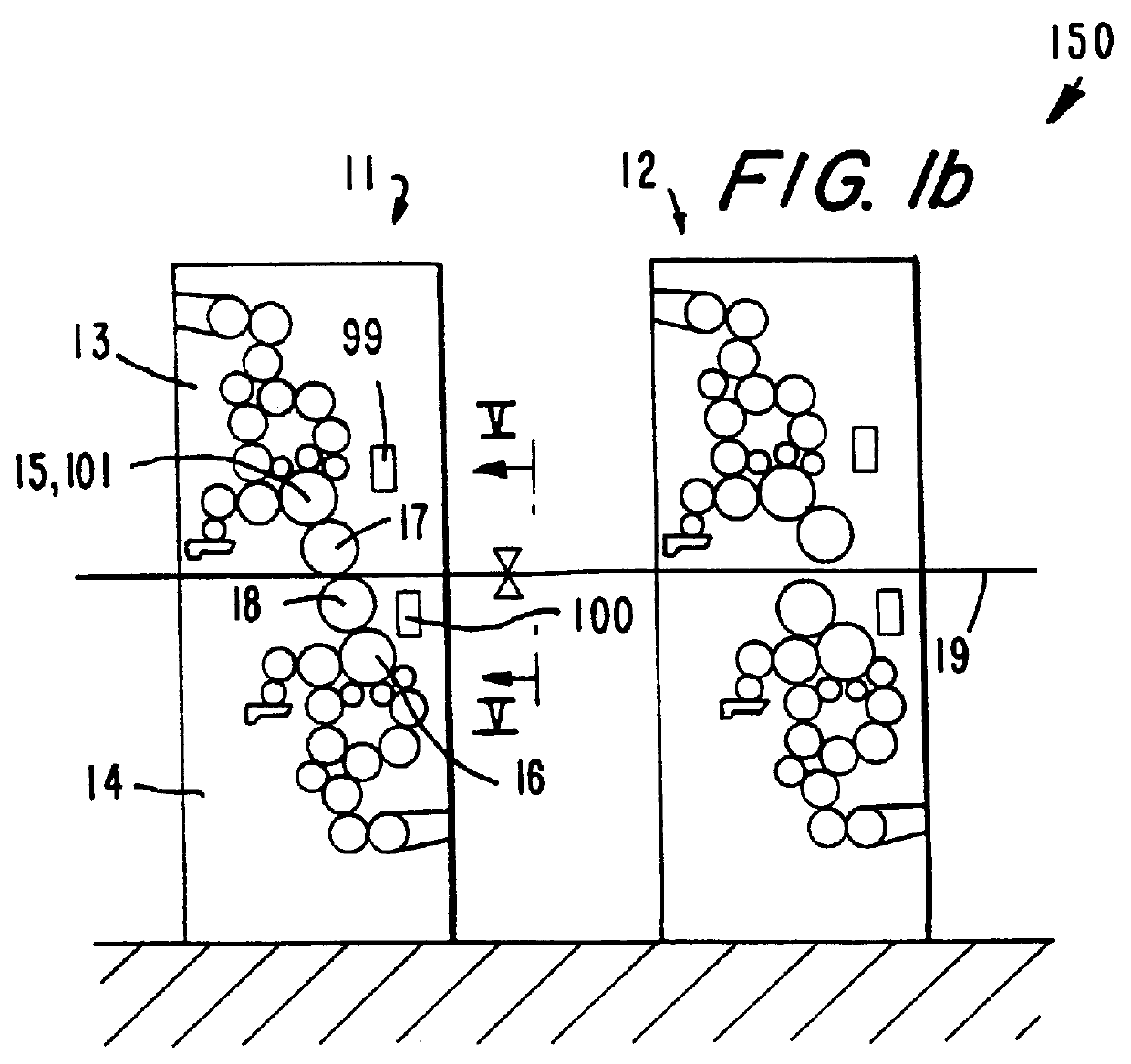

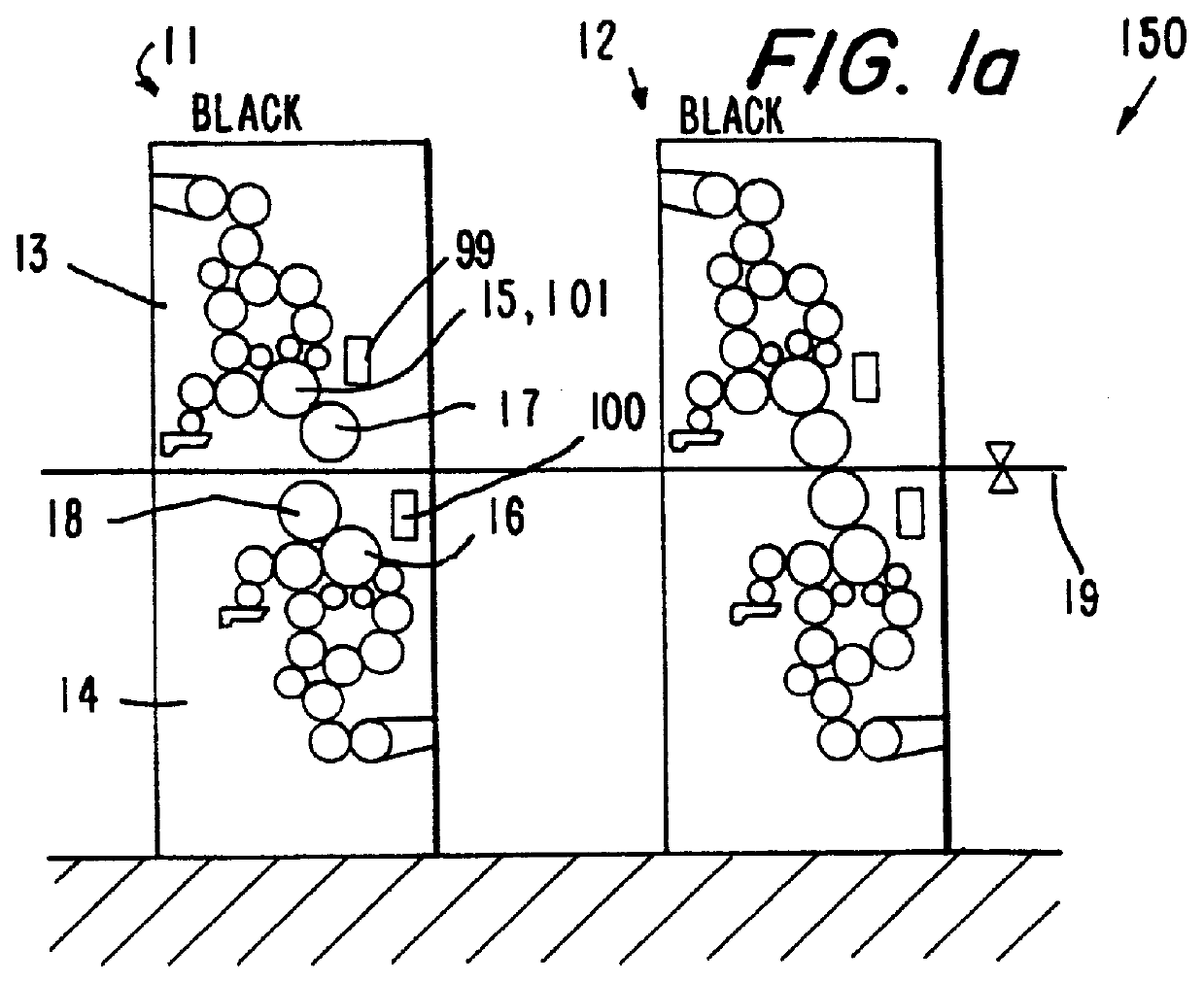

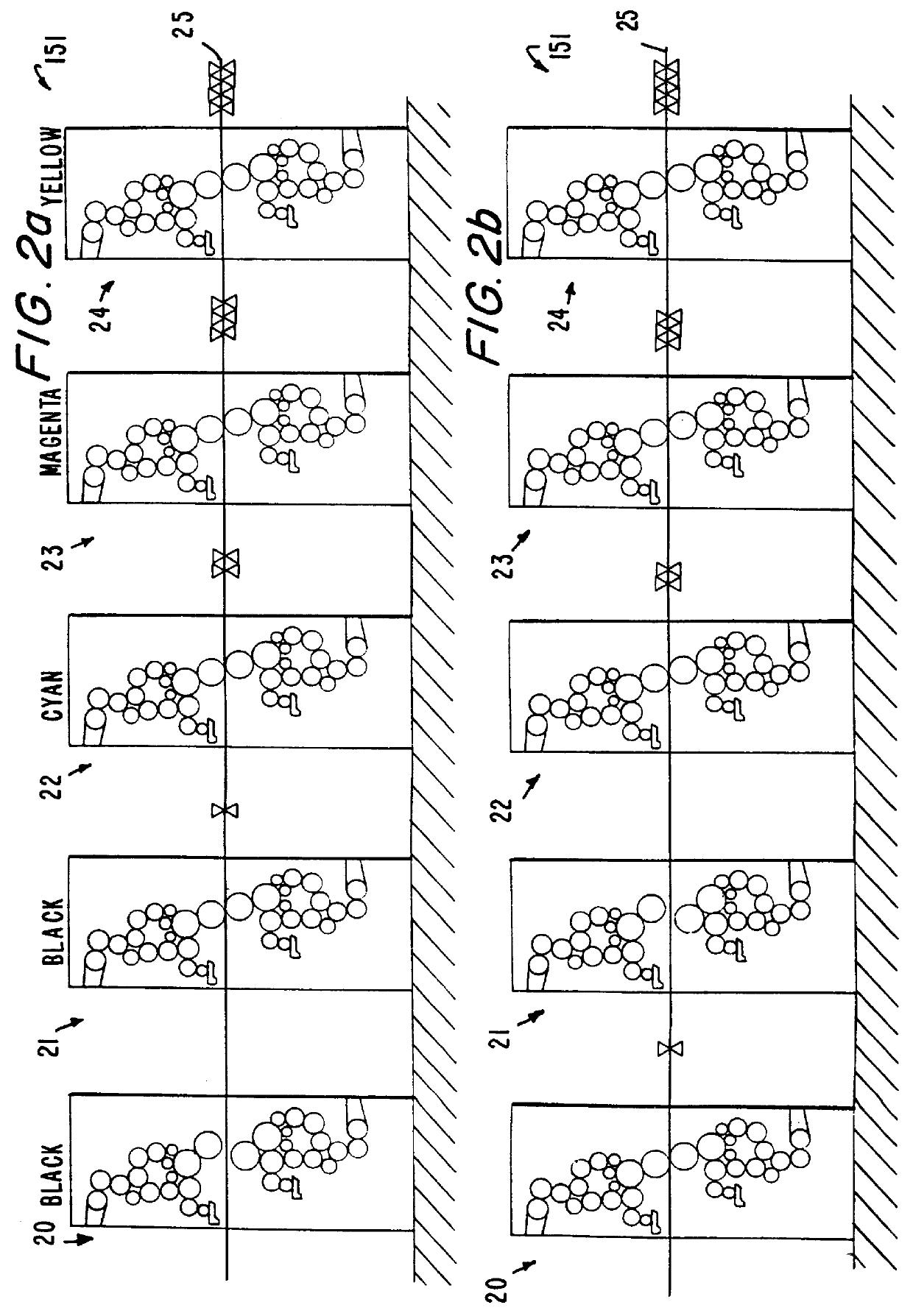

The invention relates to a web-fed rotary printing press having a plurality of double printing units in which each of the printing units of the double printing units work together in the blanket-blanket method and each has its own drive. Transfer cylinders of each printing unit are driven independently. To permit a rapid change in production, both upon recto and verso printing, the transfer cylinders of the disconnectable double printing units are separable by eccentric bushings or swingable levers such that a web which passes through the printing press is conducted between them without being printed.

Owner:MANROLAND WEB SYST

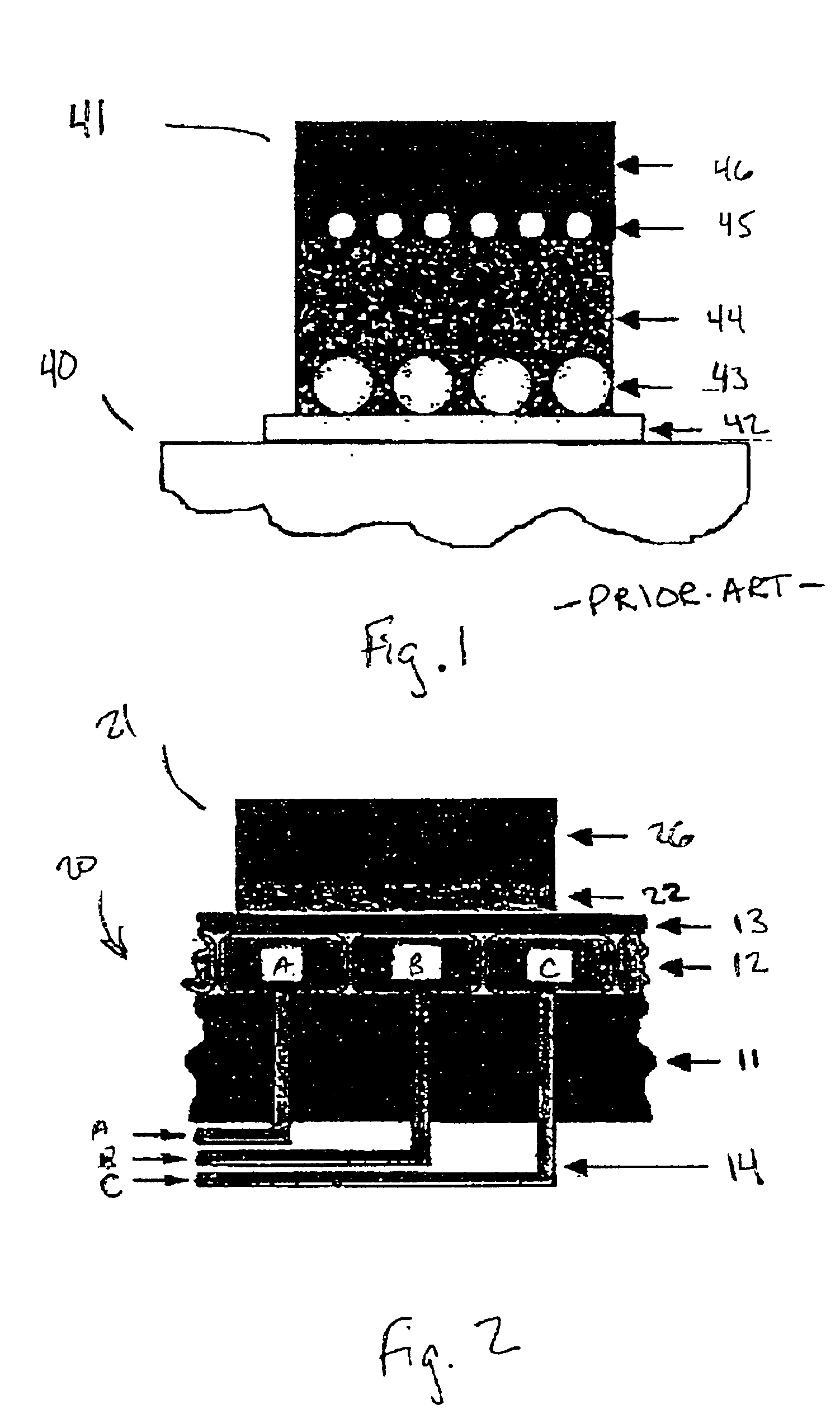

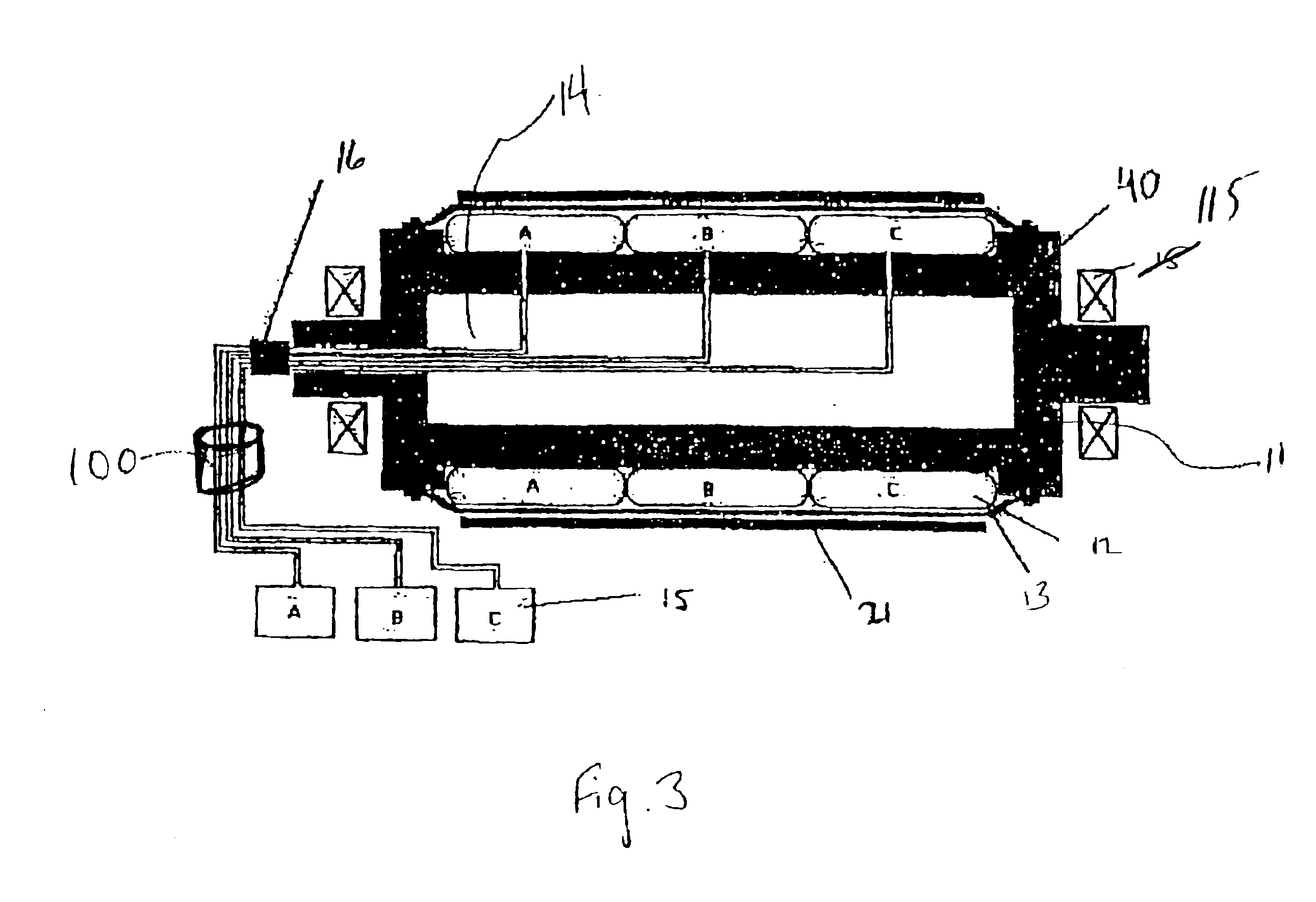

Blanket cylinder with integrated compressible layer

A printing unit including a rigid cylinder rotatable about an axis of rotation, a plurality of inflatable bladders disposed on a circumferential surface of the cylinder, and a first fluid supply regulation unit configured to supply a first fluid to a first set of inflatable bladders of the plurality of inflatable bladders and to regulate a first fluid pressure inside the first set inflatable bladders. In addition, a method for mounting a sleeve-shaped printing sock onto a blanket cylinder of an offset printing press, in which a set of inflatable bladders disposed at an outer region of the blanket cylinder are at least partially deflated. The sleeve-shaped printing sock is slid over one end of the blanket cylinder so that the printing sock at least partially surrounds a circumference of the blanket cylinder. The set of inflatable bladders are then inflated so that the printing sock fits tightly around the circumference of the blanket cylinder.

Owner:SHANGHAI ELECTRICGROUP CORP

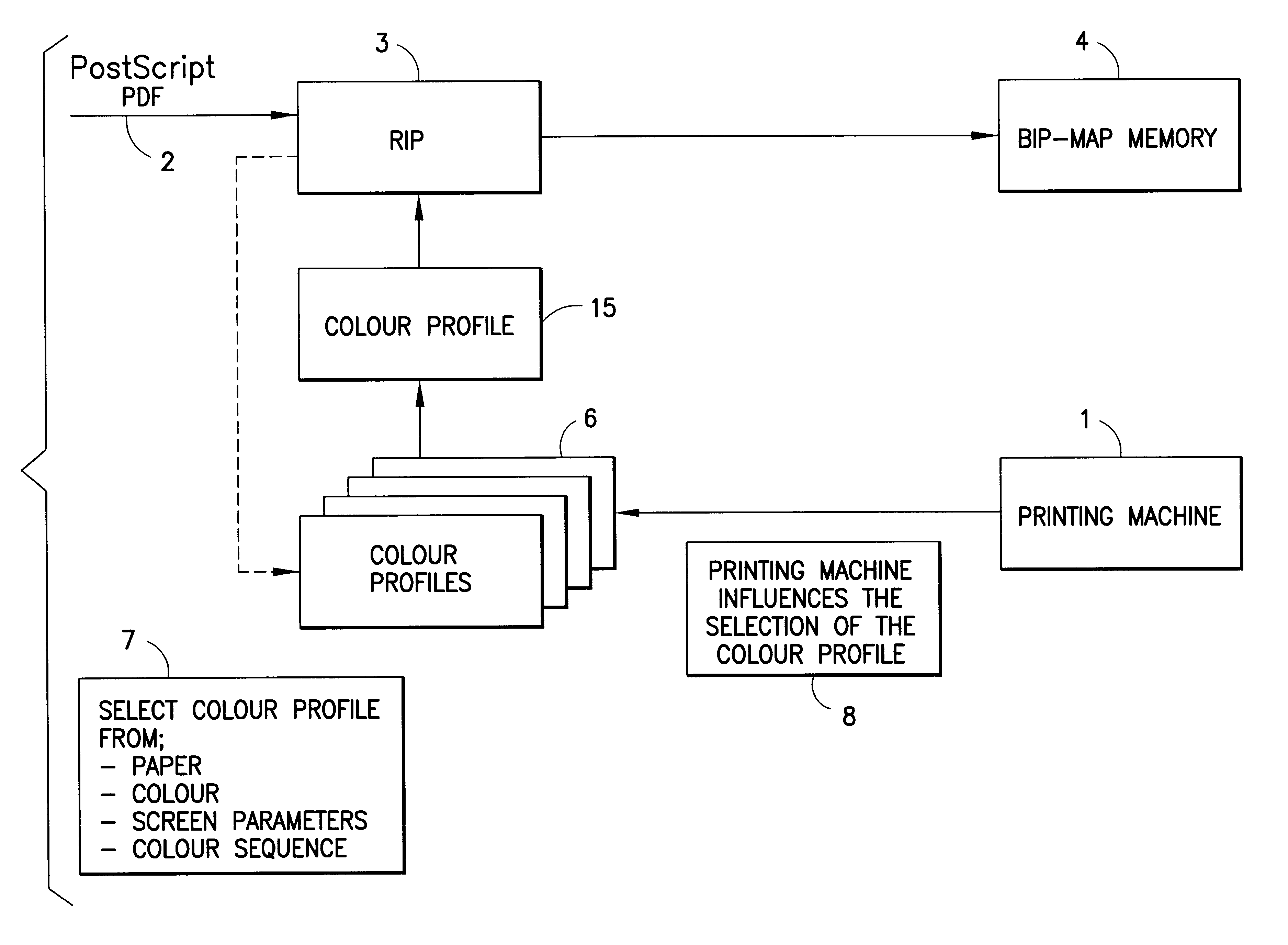

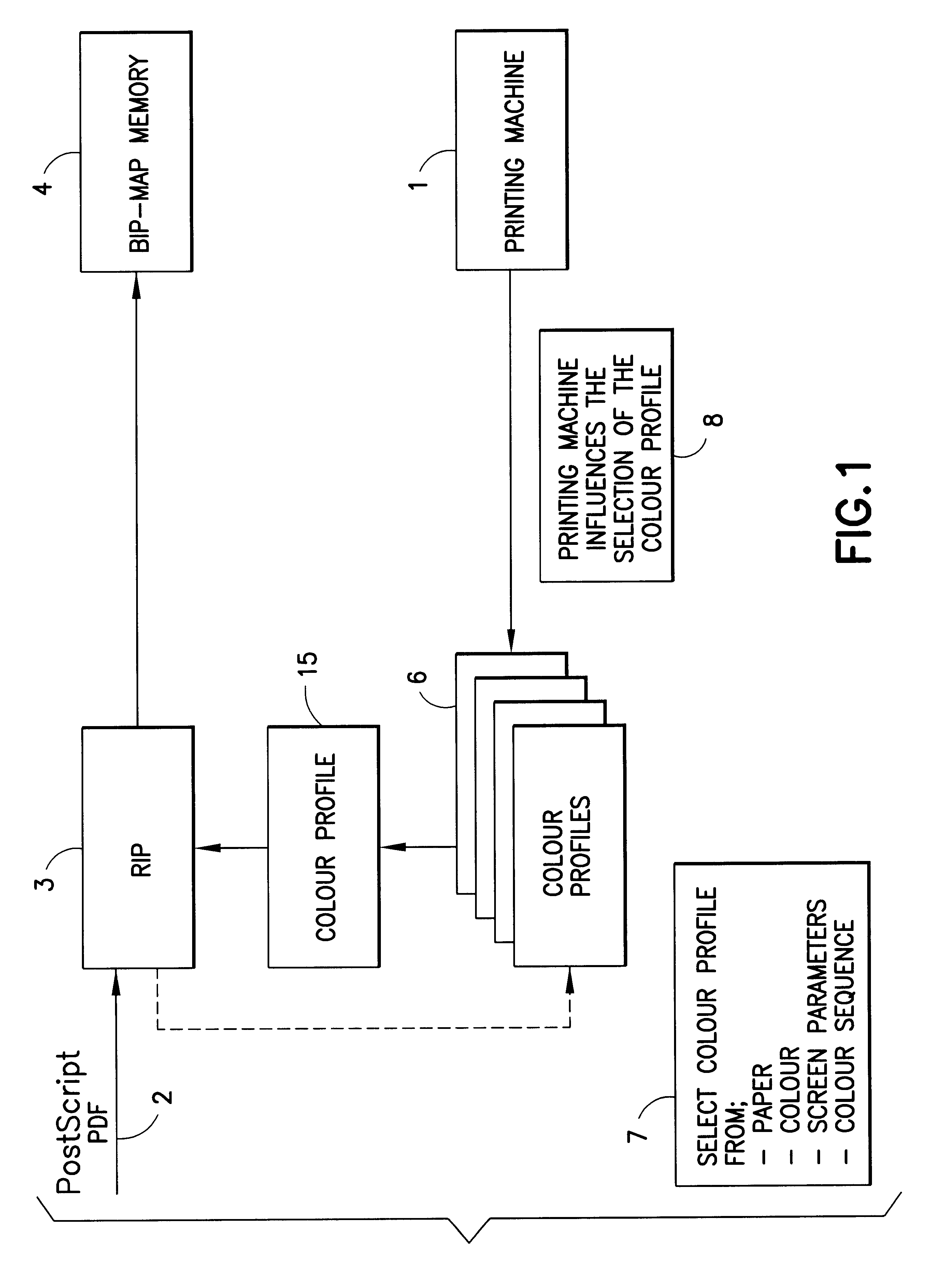

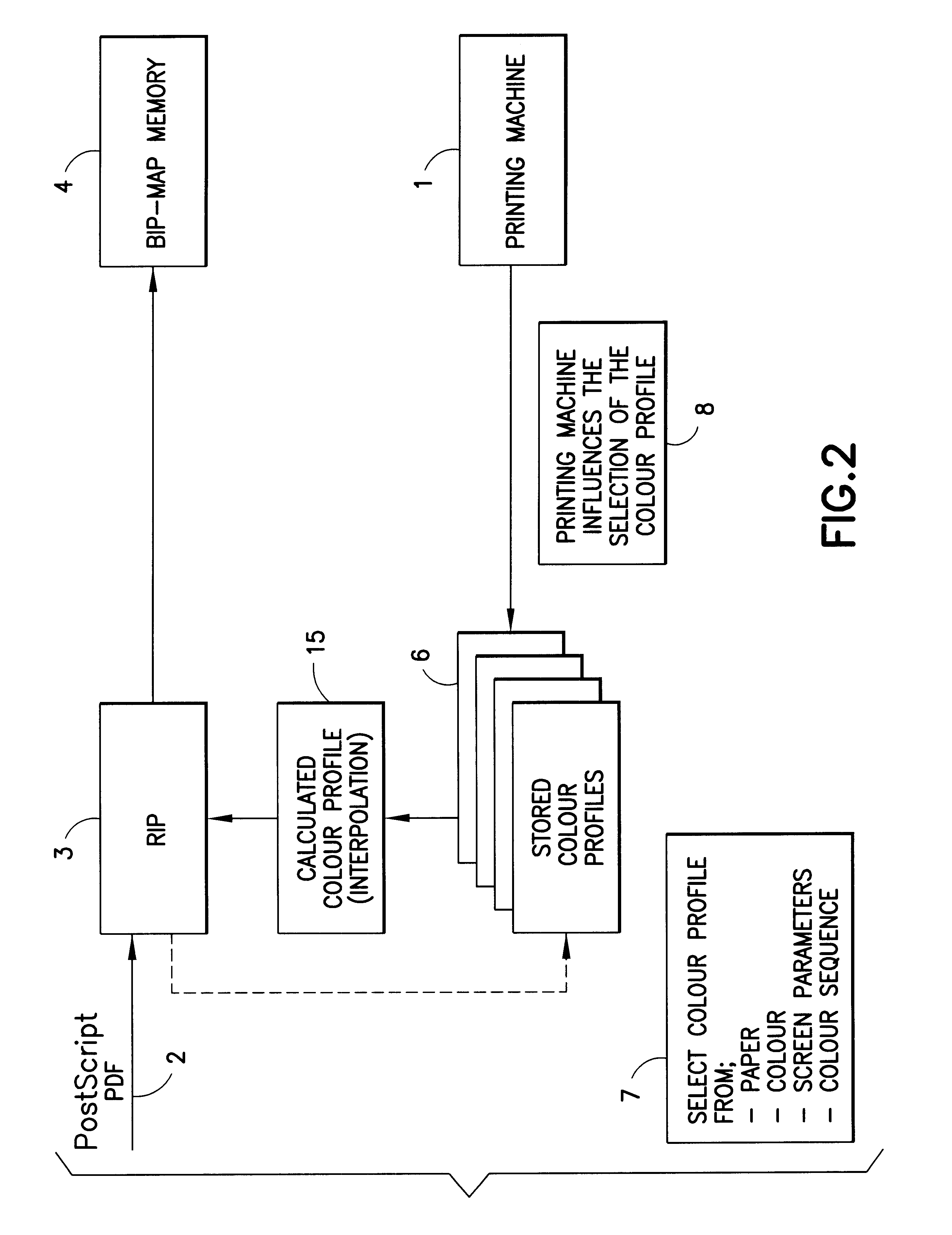

Method for profiling and calibrating a digitally controllable printing machine having a permanent printing plate

A method for calibrating a digitally controllable printing machine having a permanent printing plate, for which image data has been created in machine-independent format in a pre-press stage. The image data is prepared for the printing process by a data processing device and is fed in adapted form to the printing machine 1. The data processing device uses a profile which corresponds precisely with the current machine condition, for the final data preparation for printing. The profile can be addressed using the correct color-space conversion for the printing machine (i.e., calibrated). For this purpose, at the time at which the data is prepared for image setting, a machine condition forecast for the time of printing is called up and, from this, together with the knowledge of the operating materials, the machine profile which most closely approaches that for the print job is determined. This profile is then used for the data preparation.

Owner:MANROLANAD AG

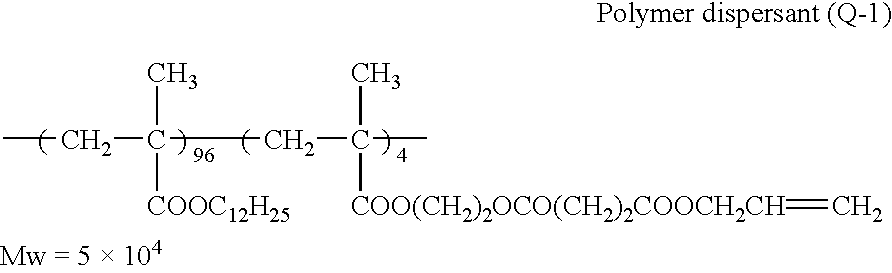

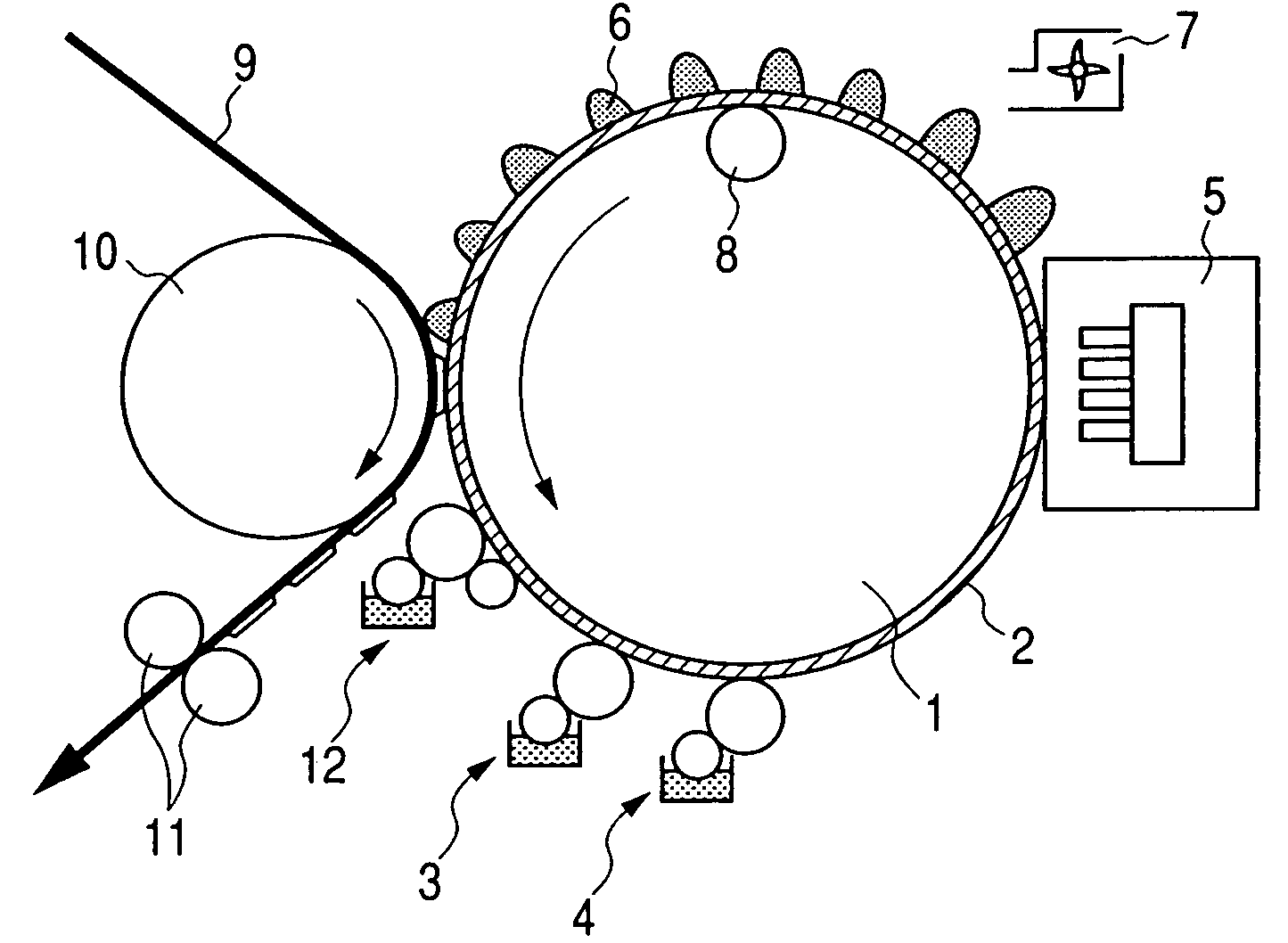

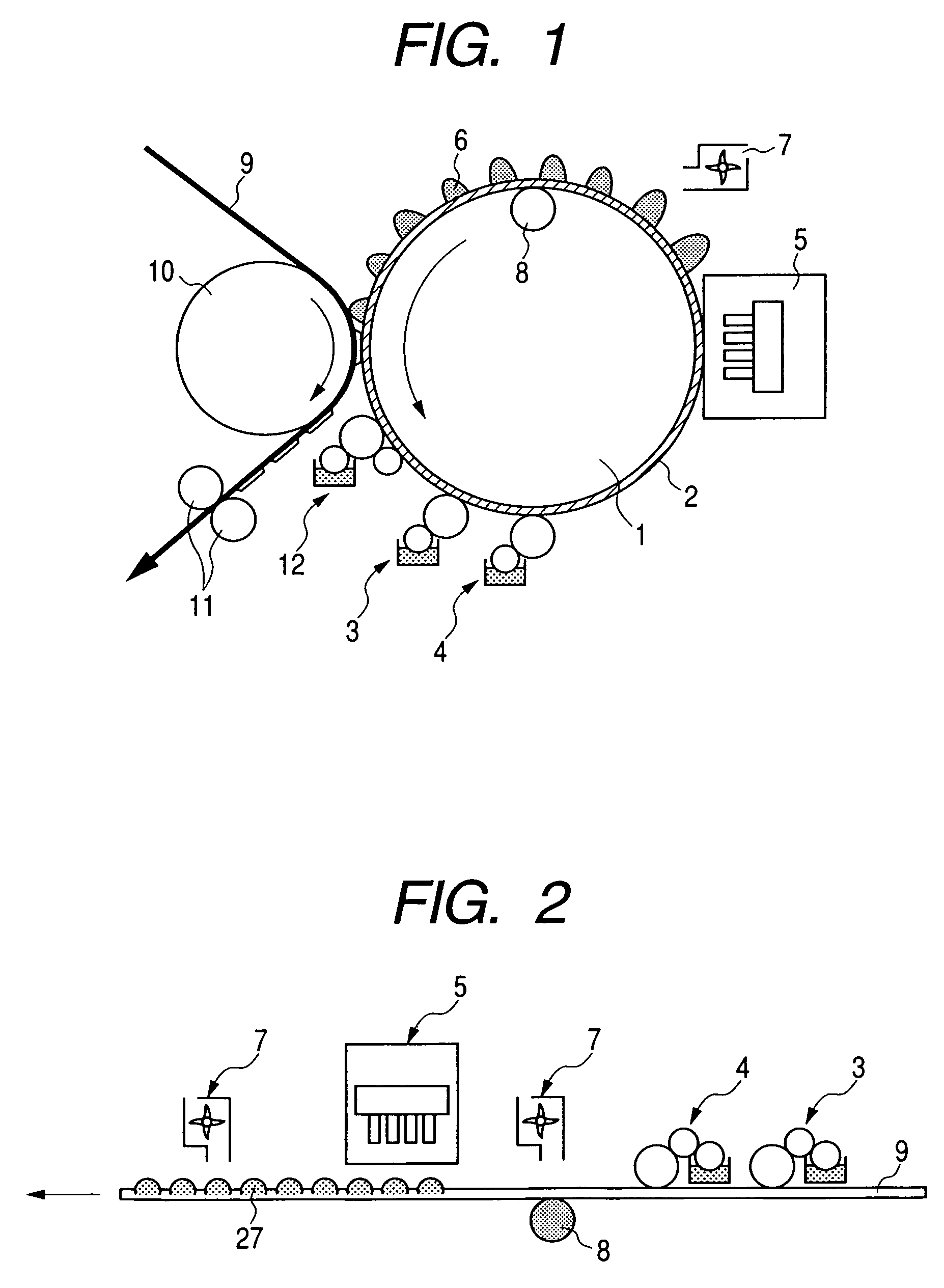

Image forming process and image forming apparatus

InactiveUS20060164488A1High recording flexibility of recordingImprove surface wettabilityMeasurement apparatus componentsDecorative surface effectsImage formationComputer science

Disclosed herein is an image forming process comprising the steps of applying a first material for improving the wettability of the surface of an intermediate transfer medium to the intermediate transfer medium, applying a second material for lowering the flowability of an ink to the intermediate transfer medium to which the first material has been applied, applying the ink to the intermediate transfer medium, to which the first material and second material have been applied, from an ink-jet recording head to form an image of the ink on the intermediate transfer medium, and transferring the ink image formed to a recording medium.

Owner:CANON KK

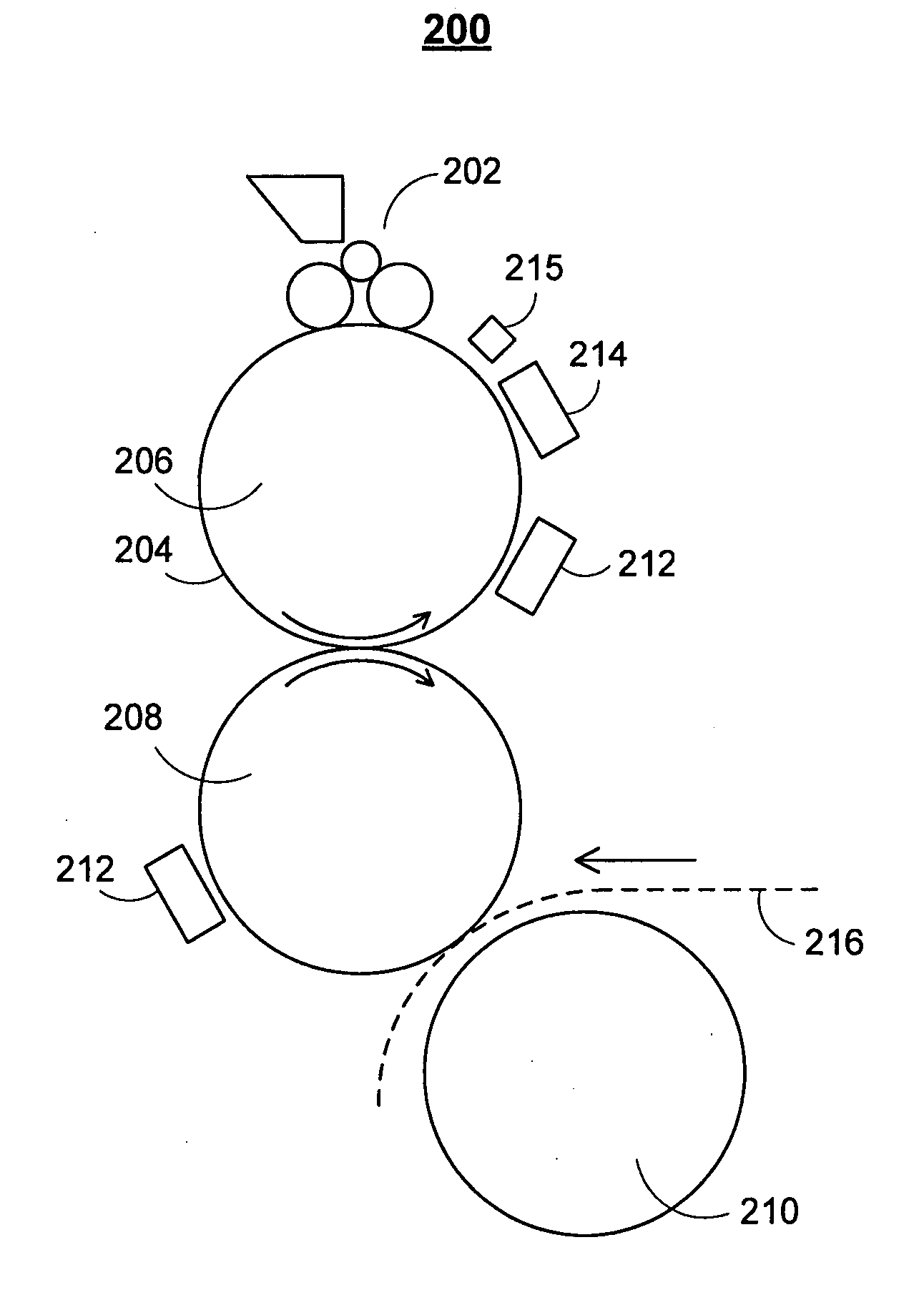

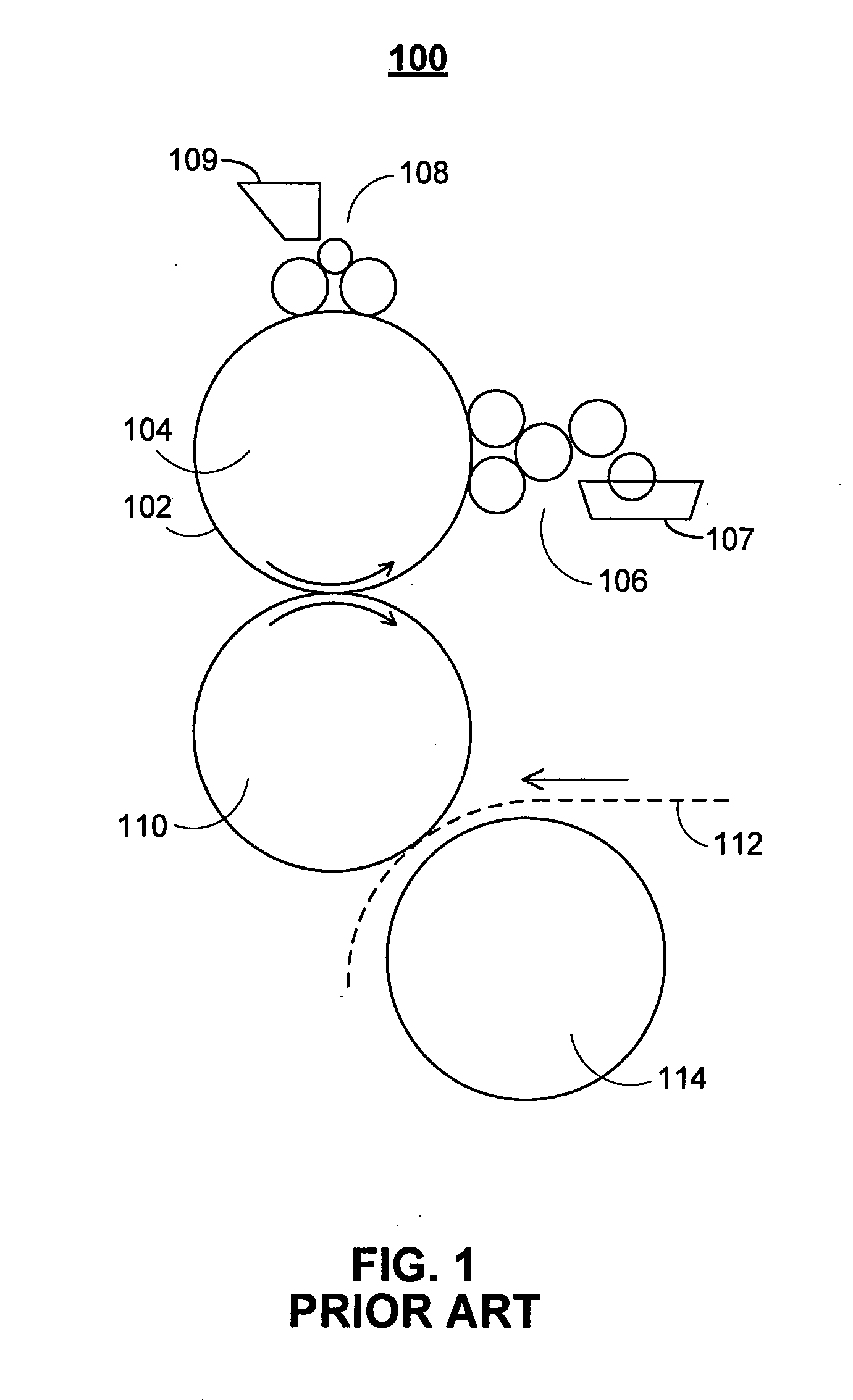

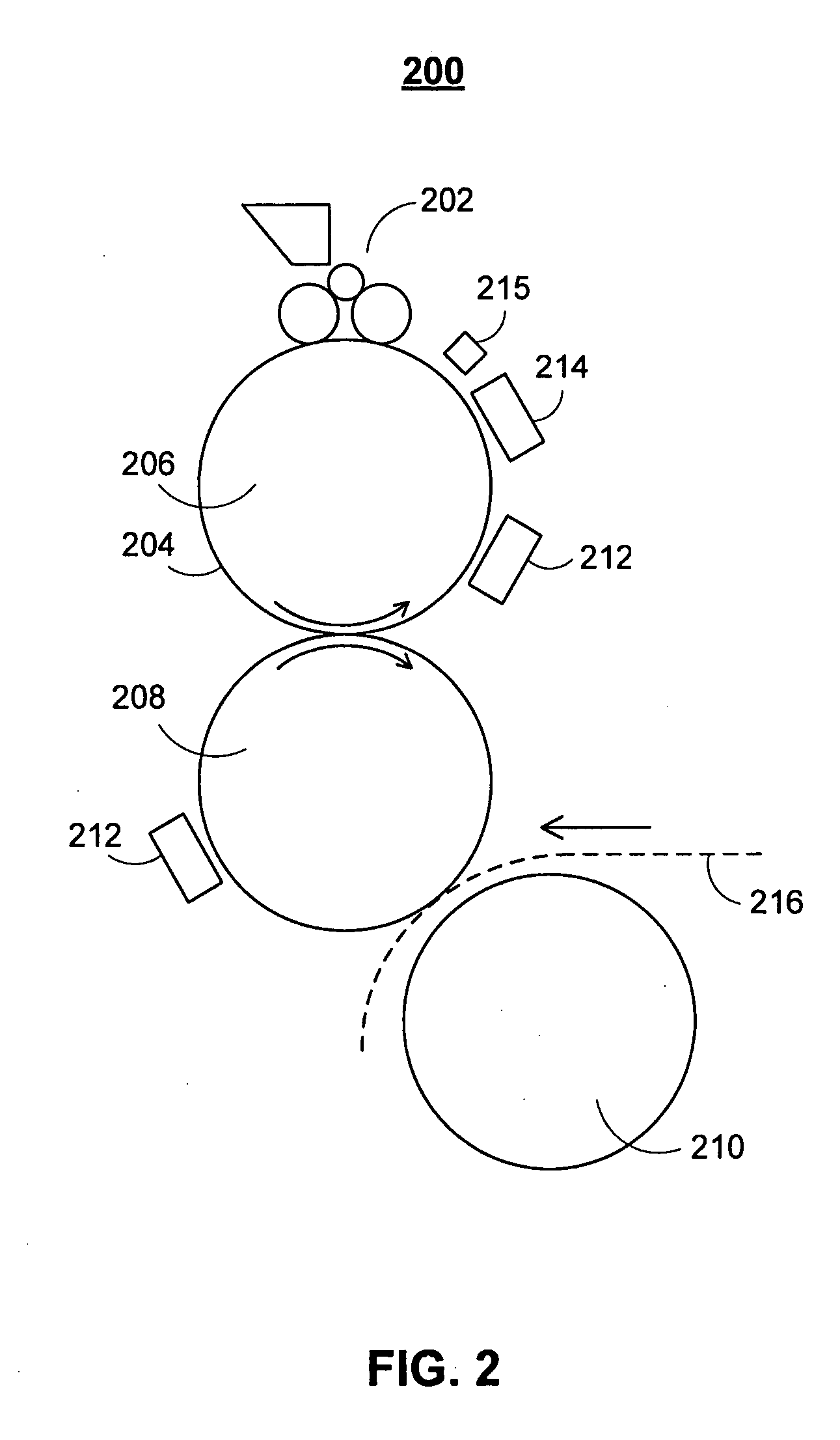

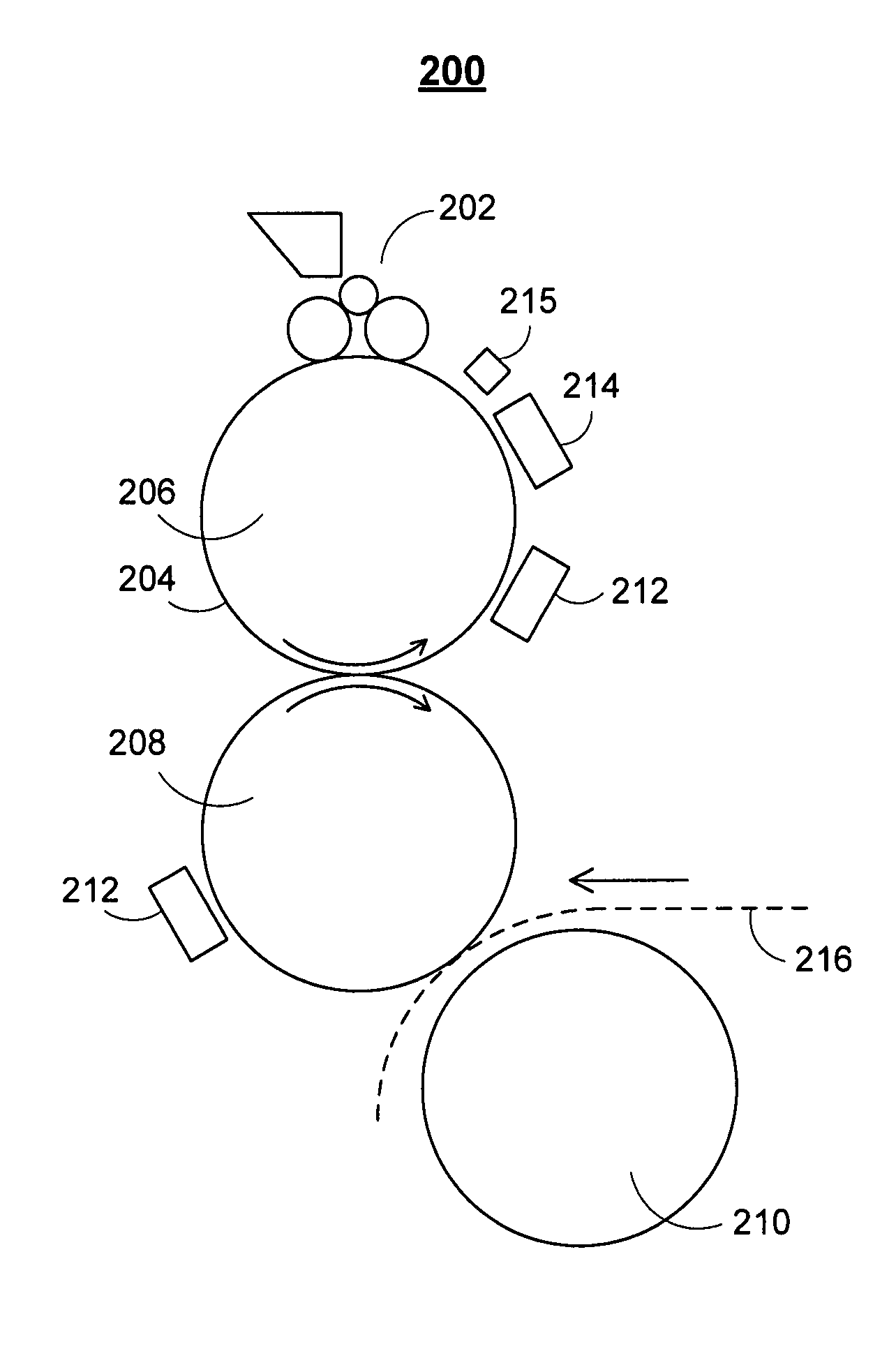

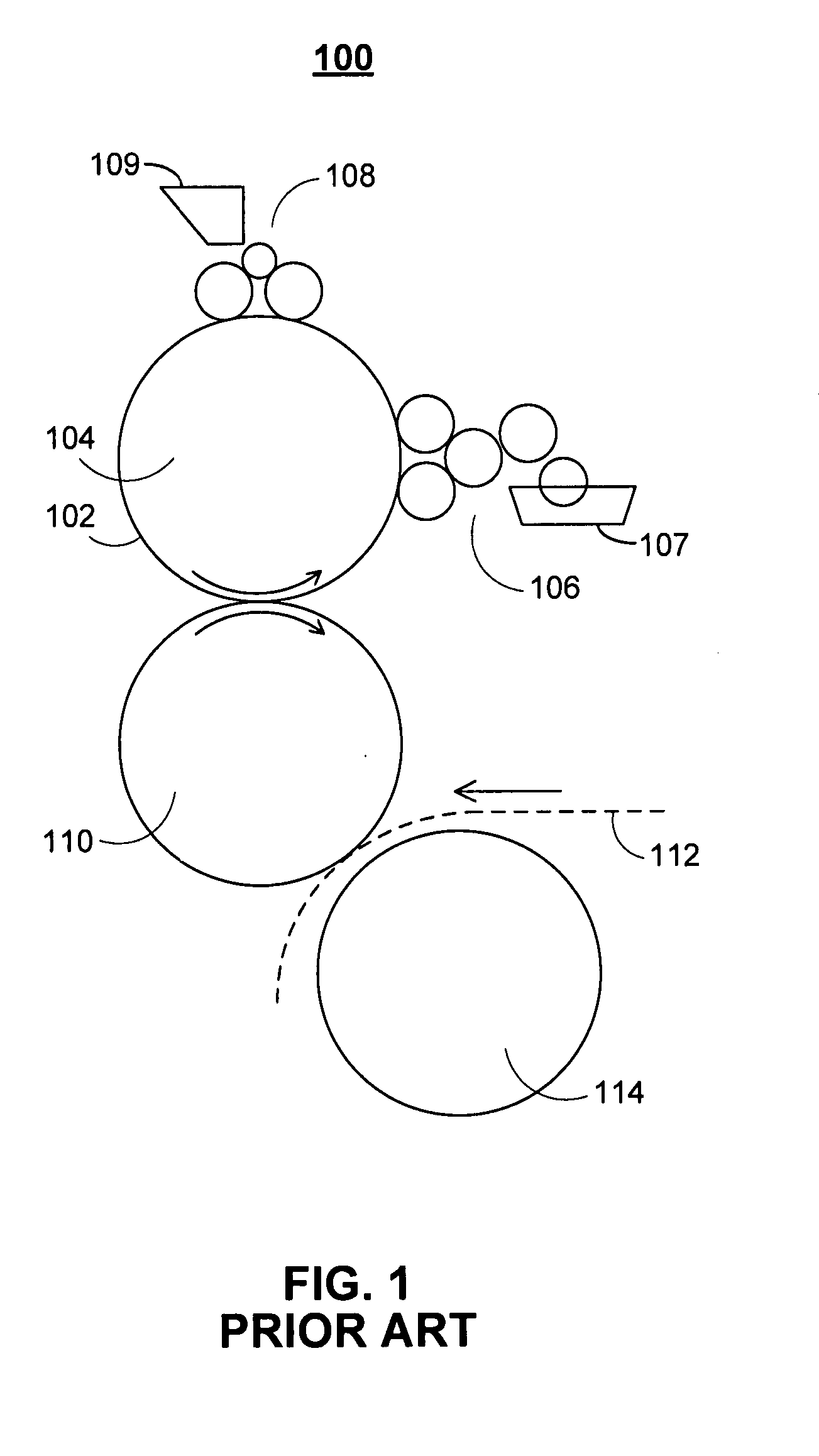

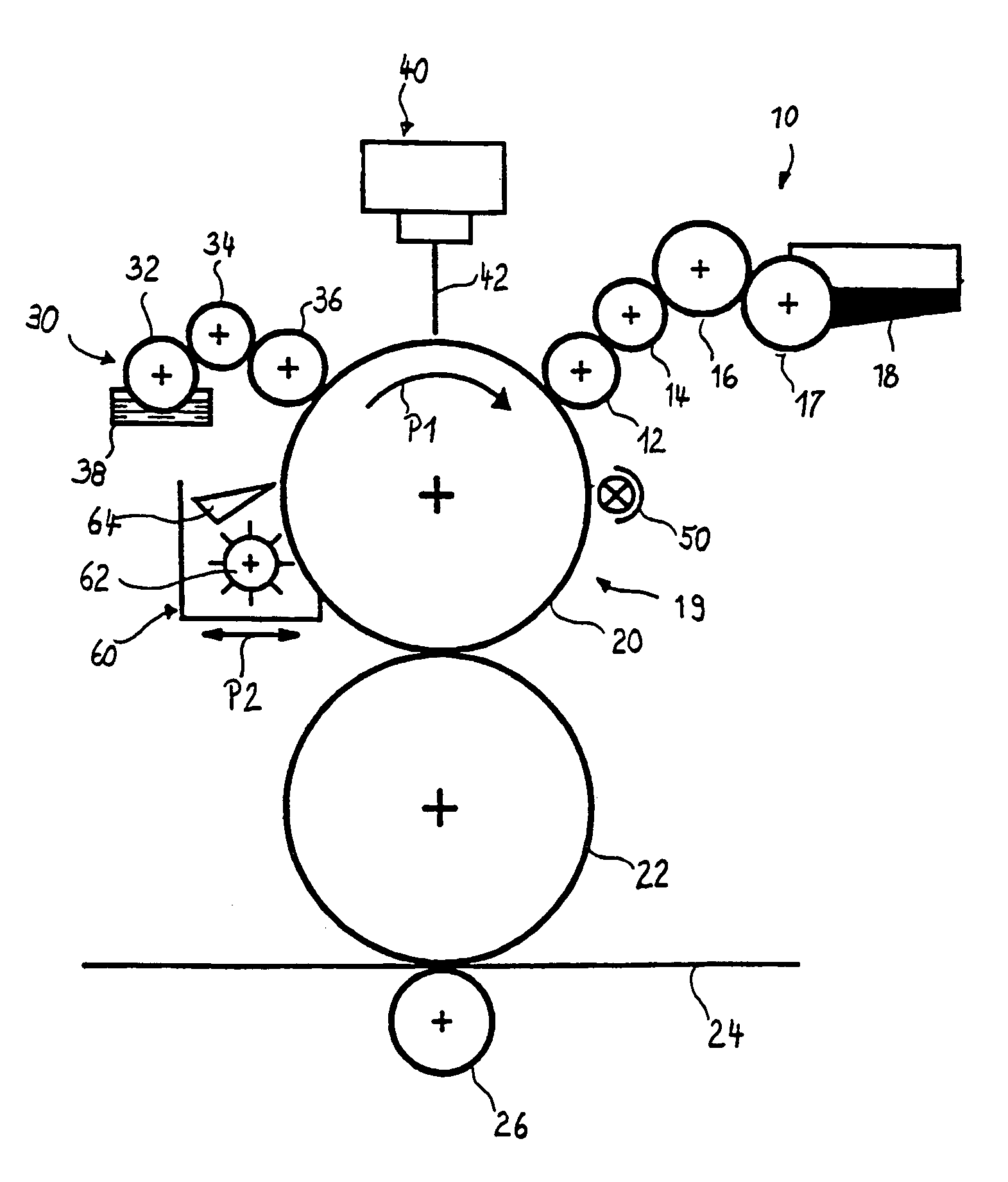

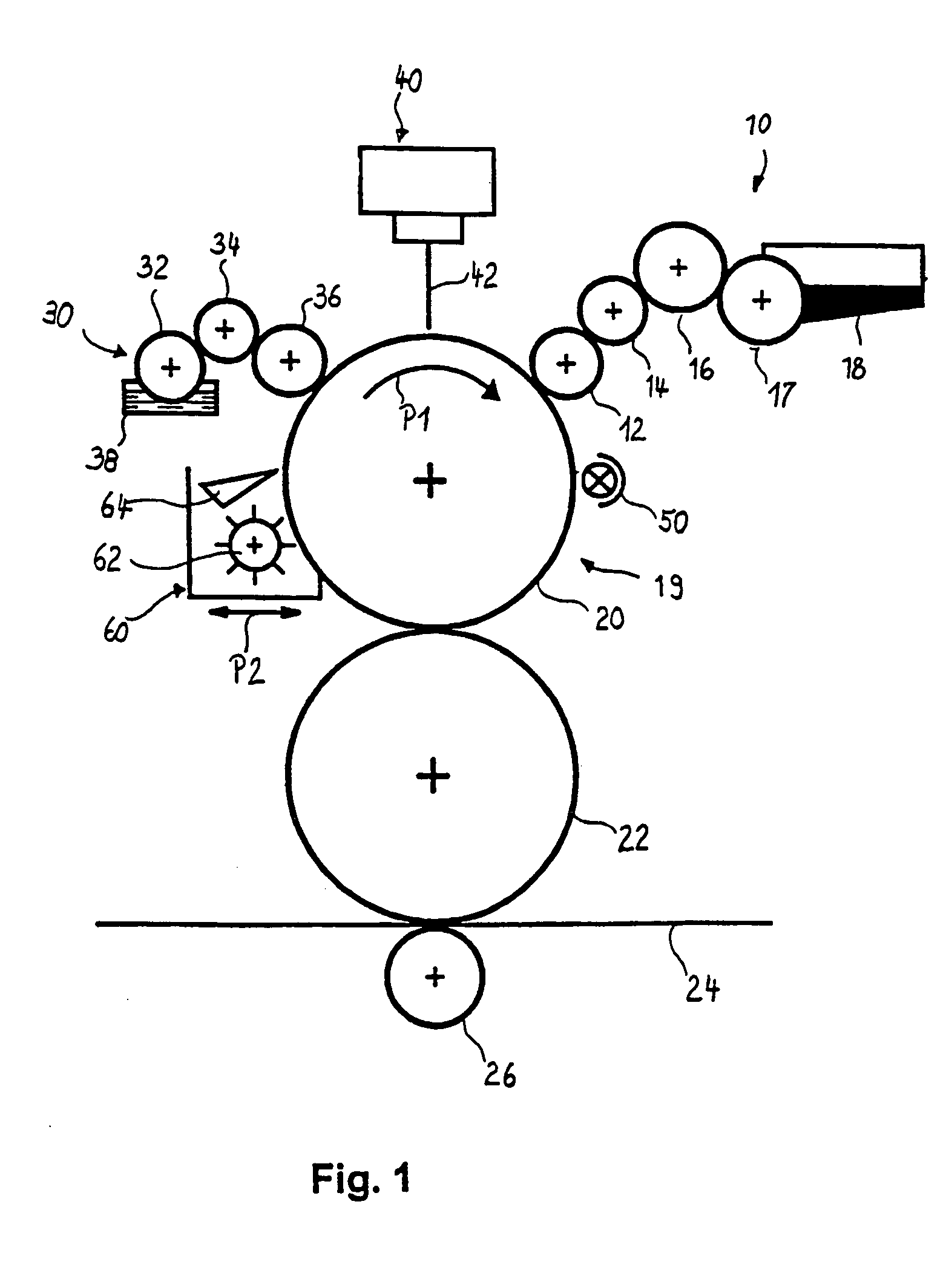

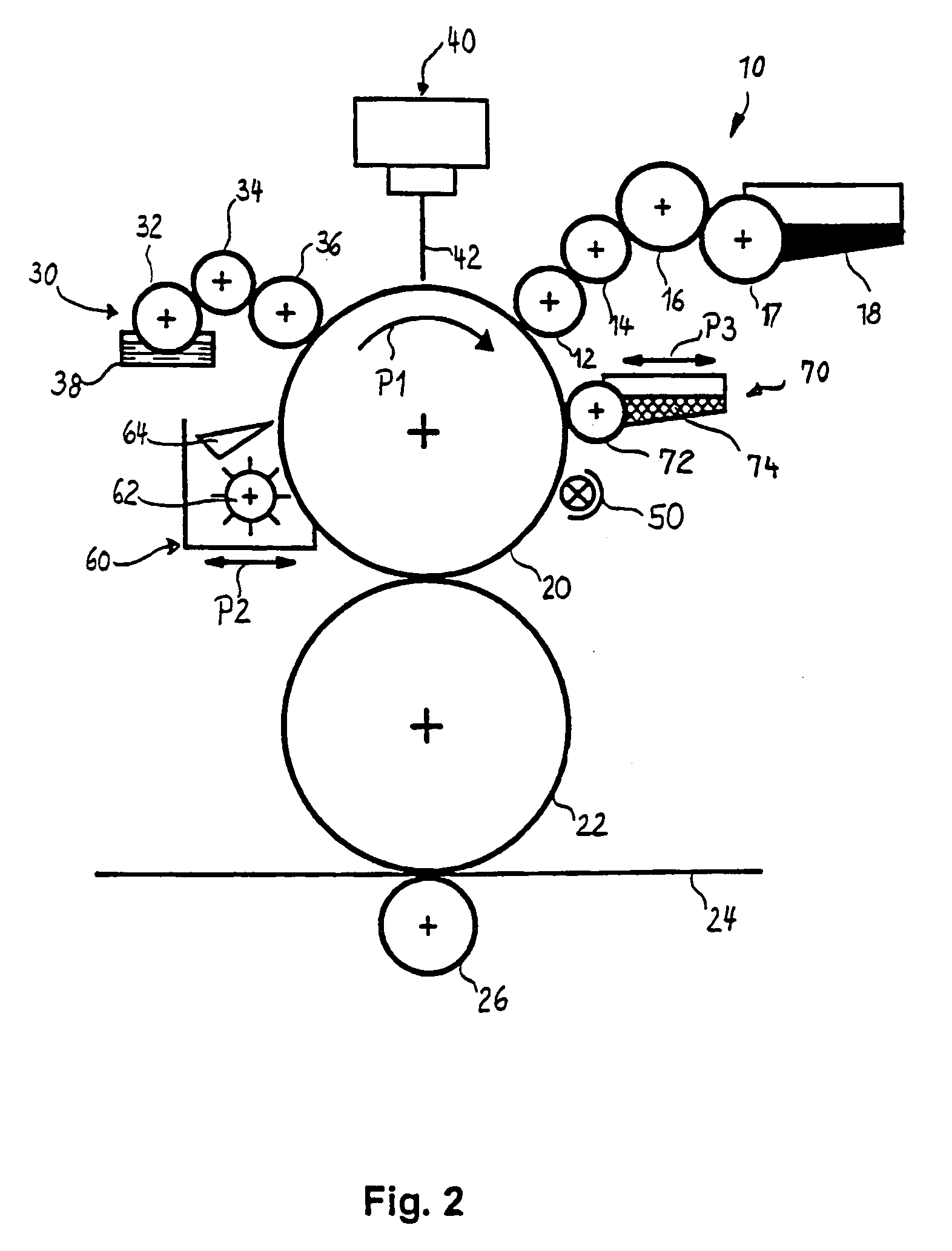

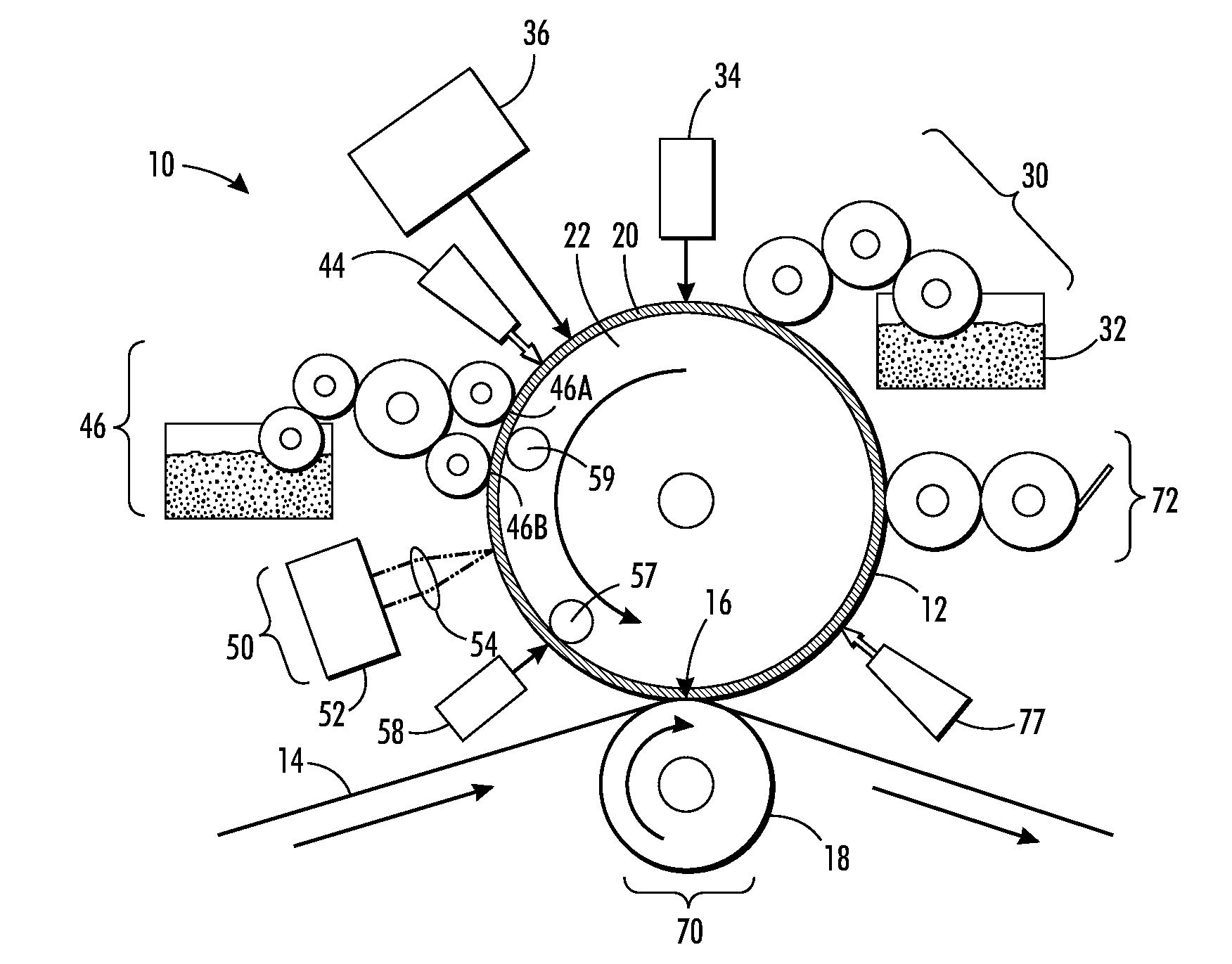

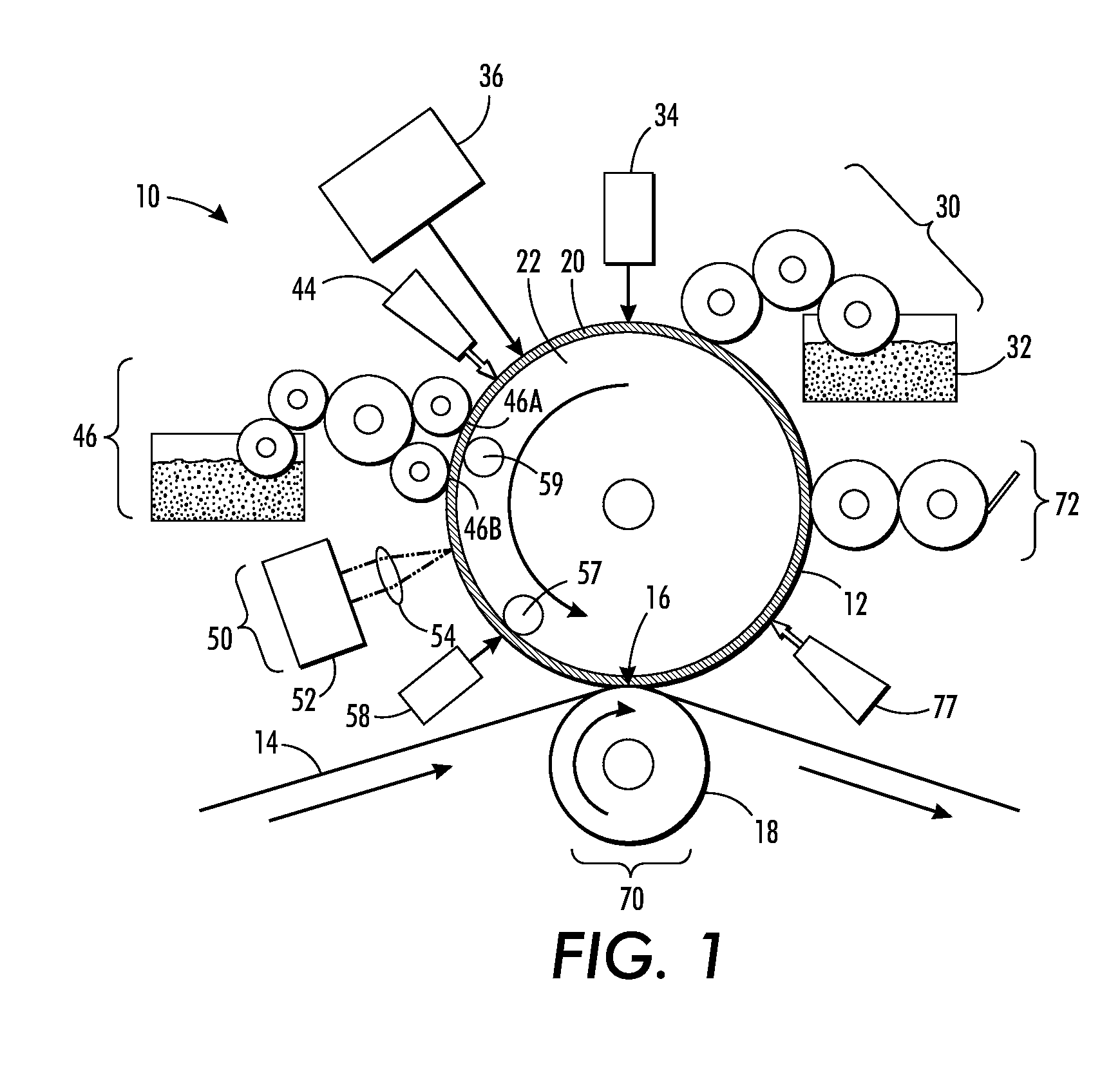

Systems and methods for high speed variable printing

Systems and methods for high-speed variable printing are provided. Ink jet technology and lithographic systems may be combined in such a way to create a fully variable and high-quality print system. An aqueous solution is applied to a cylinder to produce a negative image. The aqueous solution may comprise a block copolymer capable of physical bonding with the cylinder. Ink is then applied to the cylinder, and a positive image is transferred in ink to a print medium. The systems and methods described herein may be used to create high-quality one-to-one marketing applications.

Owner:R R DONNELLEY & SONS CO

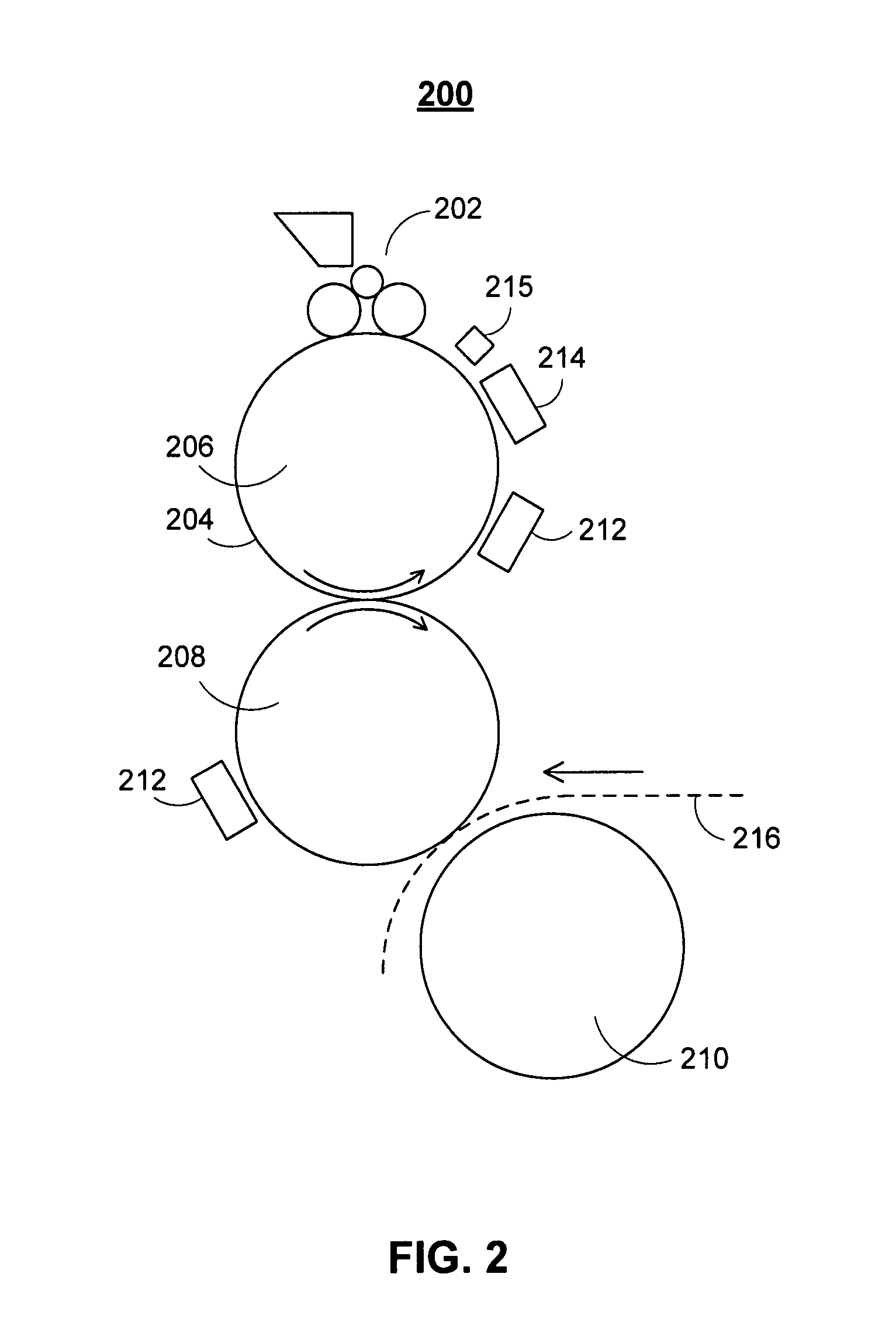

Systems and methods for high speed variable printing

Systems and methods for high-speed variable printing are provided. Ink jet technology and lithographic systems may be combined in such a way to create a fully variable and high-quality print system. An aqueous solution is applied to a cylinder to produce a first negative image. A positive image in ink is transferred to a print medium. Residue ink and aqueous solution is then cleaned from the cylinder and aqueous solution is applied to the cylinder to produce a second negative image. The systems and methods described herein may be used to create high-quality one-to-one marketing applications.

Owner:R R DONNELLEY & SONS CO

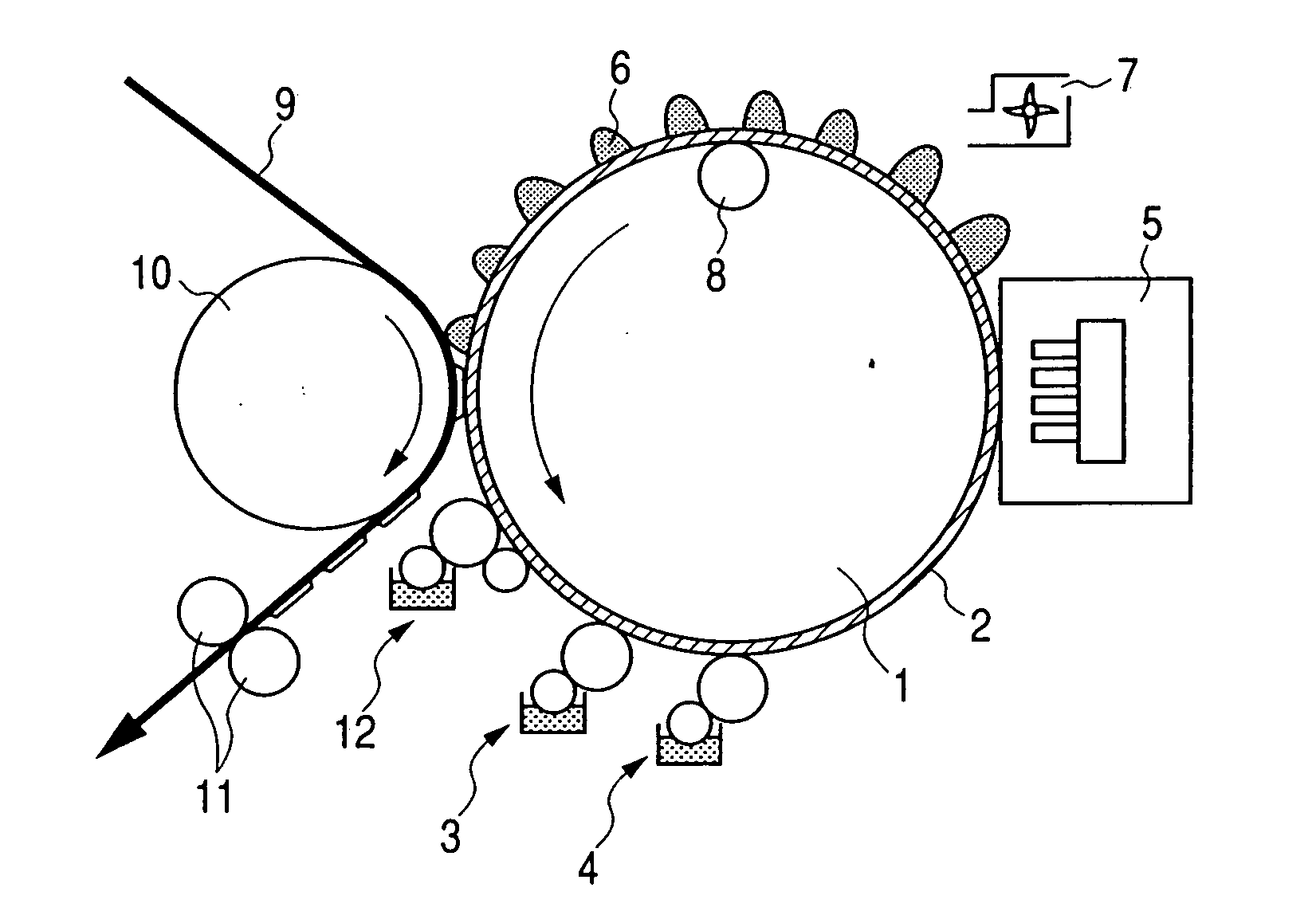

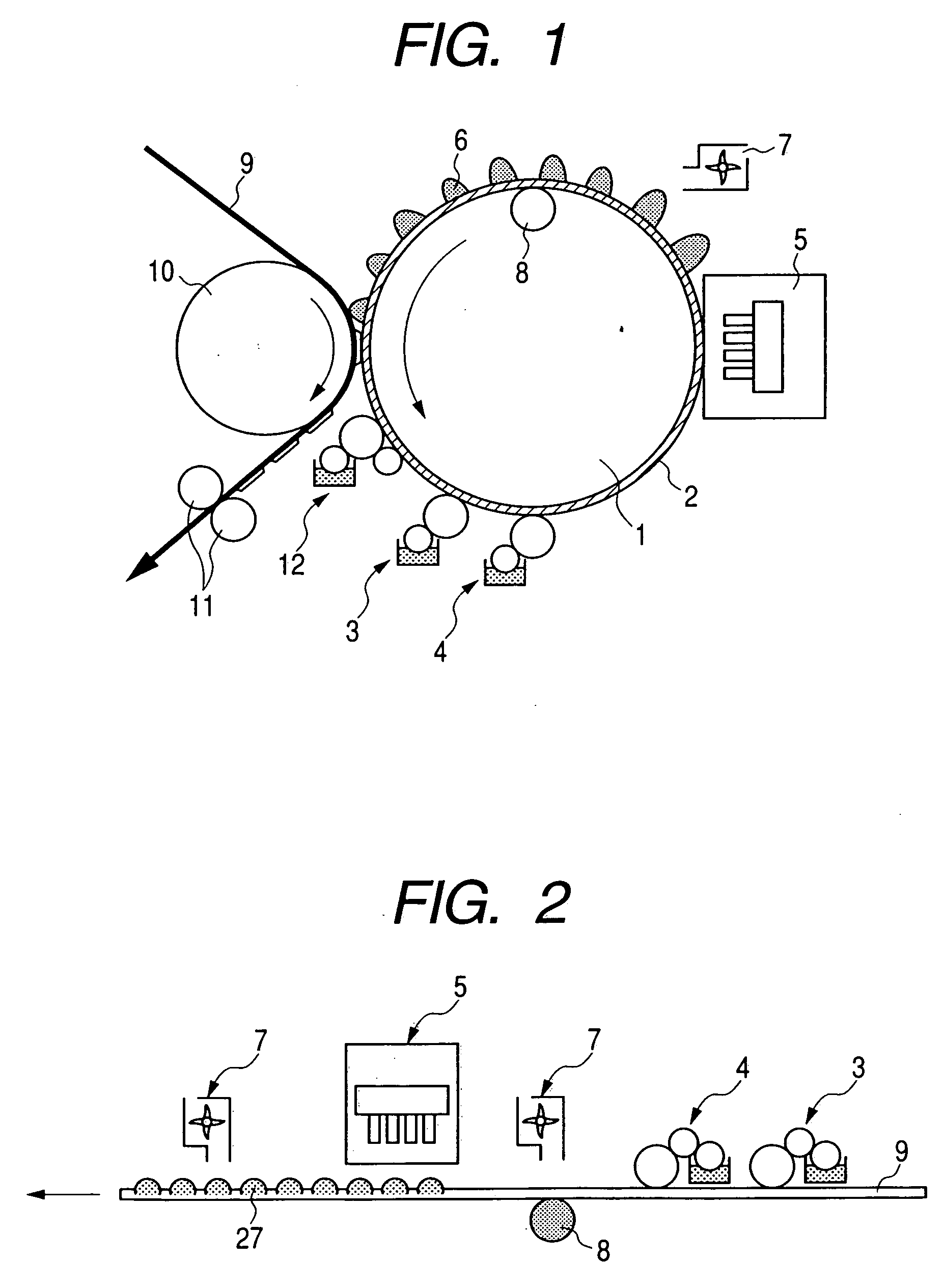

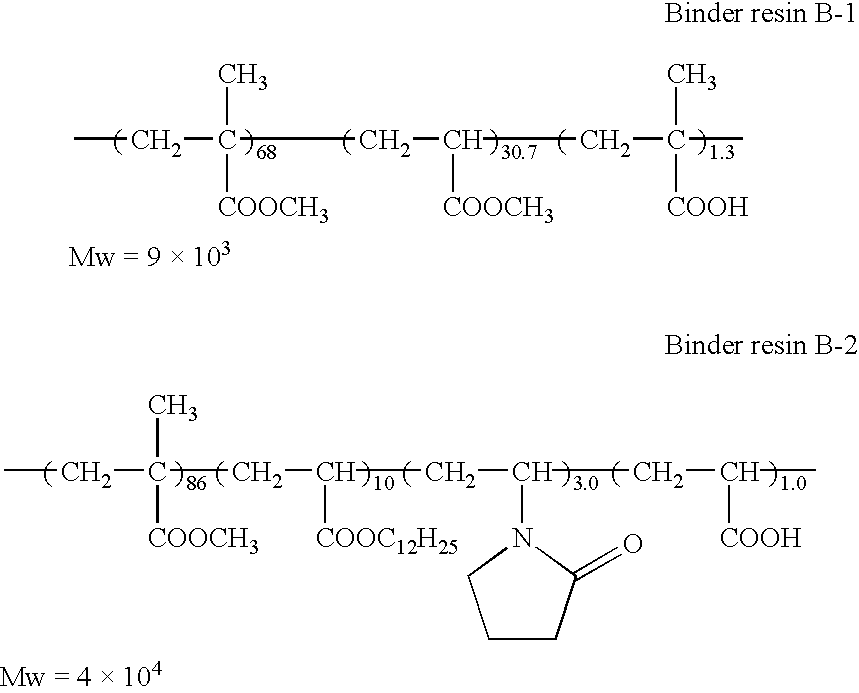

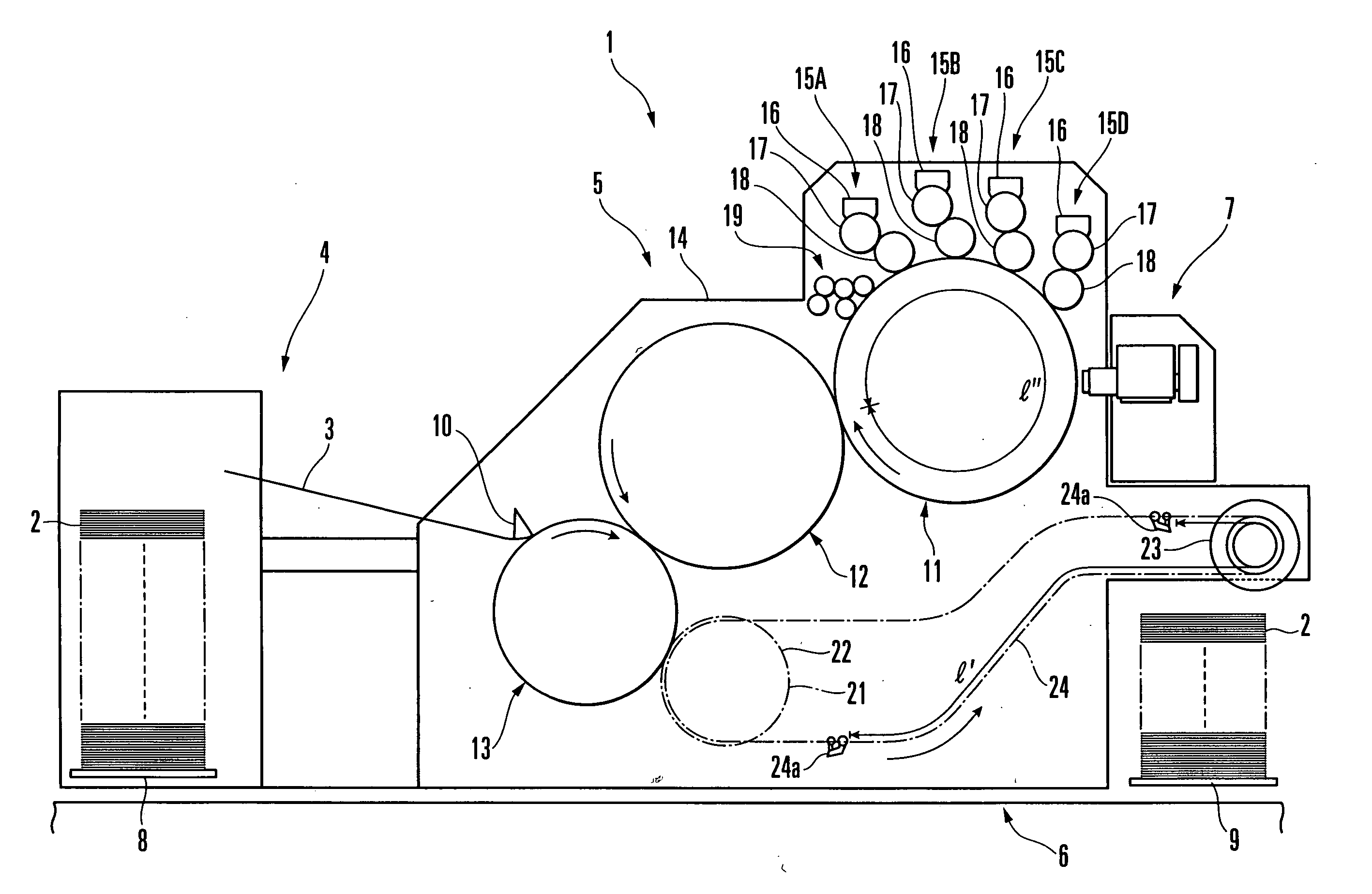

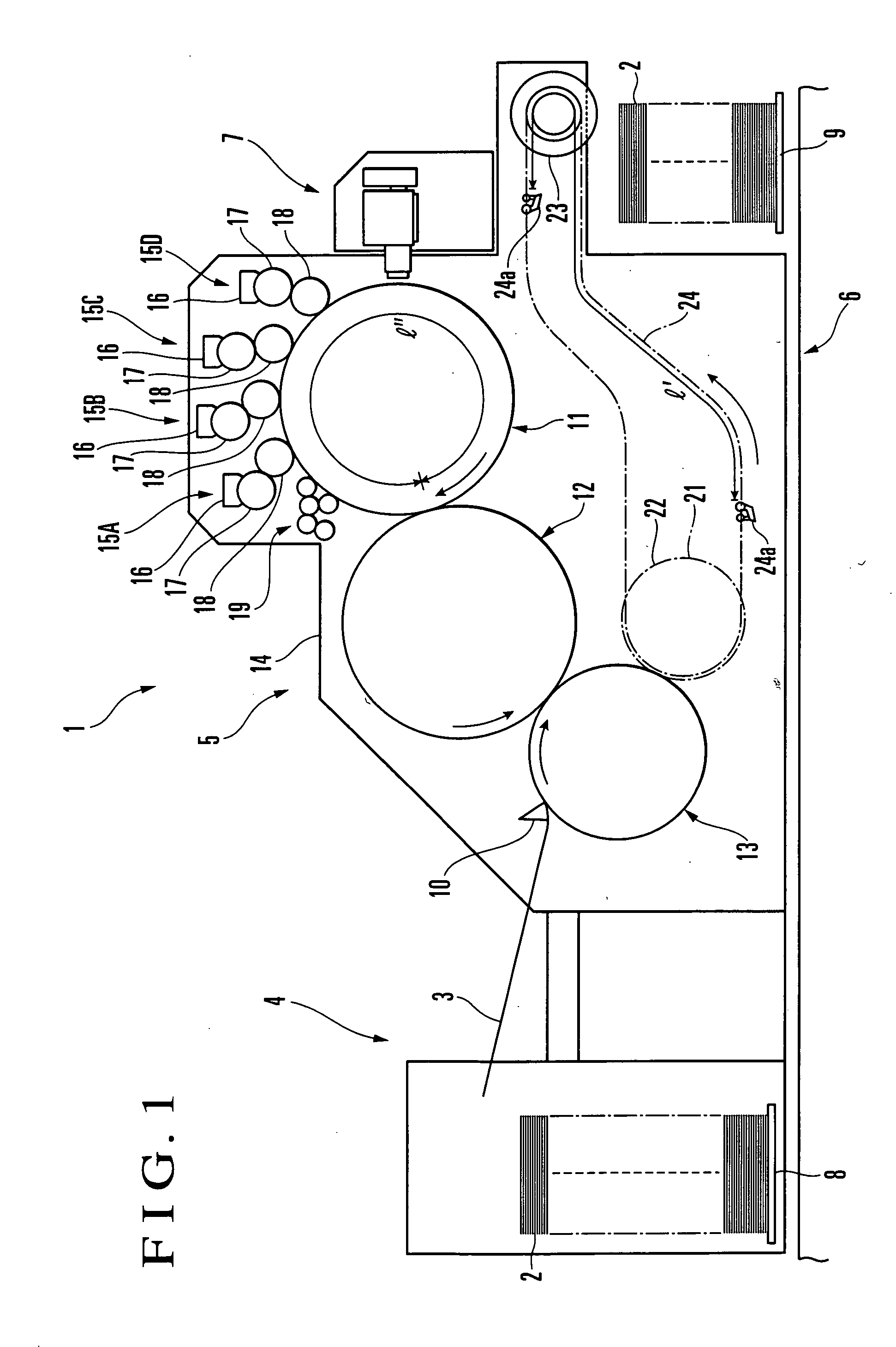

Computer-to-cylinder type lithographic printing method and apparatus

A method of computer-to-cylinder type lithographic printing comprising: loading a plate material on a plate cylinder of a printing apparatus; forming an image, based on image data signal, directly onto the plate material by an inkjet image-recording process comprising ejecting an oil-based ink from a recording head; heat-fixing the thus formed inkjet image to prepare a printing plate; and performing lithographic printing with the thus prepared printing plate, wherein said heat fixing step comprises heating with a heat roller. In a preferred embodiment, said heat-fixing step further comprises preliminary heating prior to said heating with the heat roller. Also disclosed are computer-to-cylinder type lithographic printing apparatuses for carrying out the printing methods.

Owner:FUJIFILM HLDG CORP +1

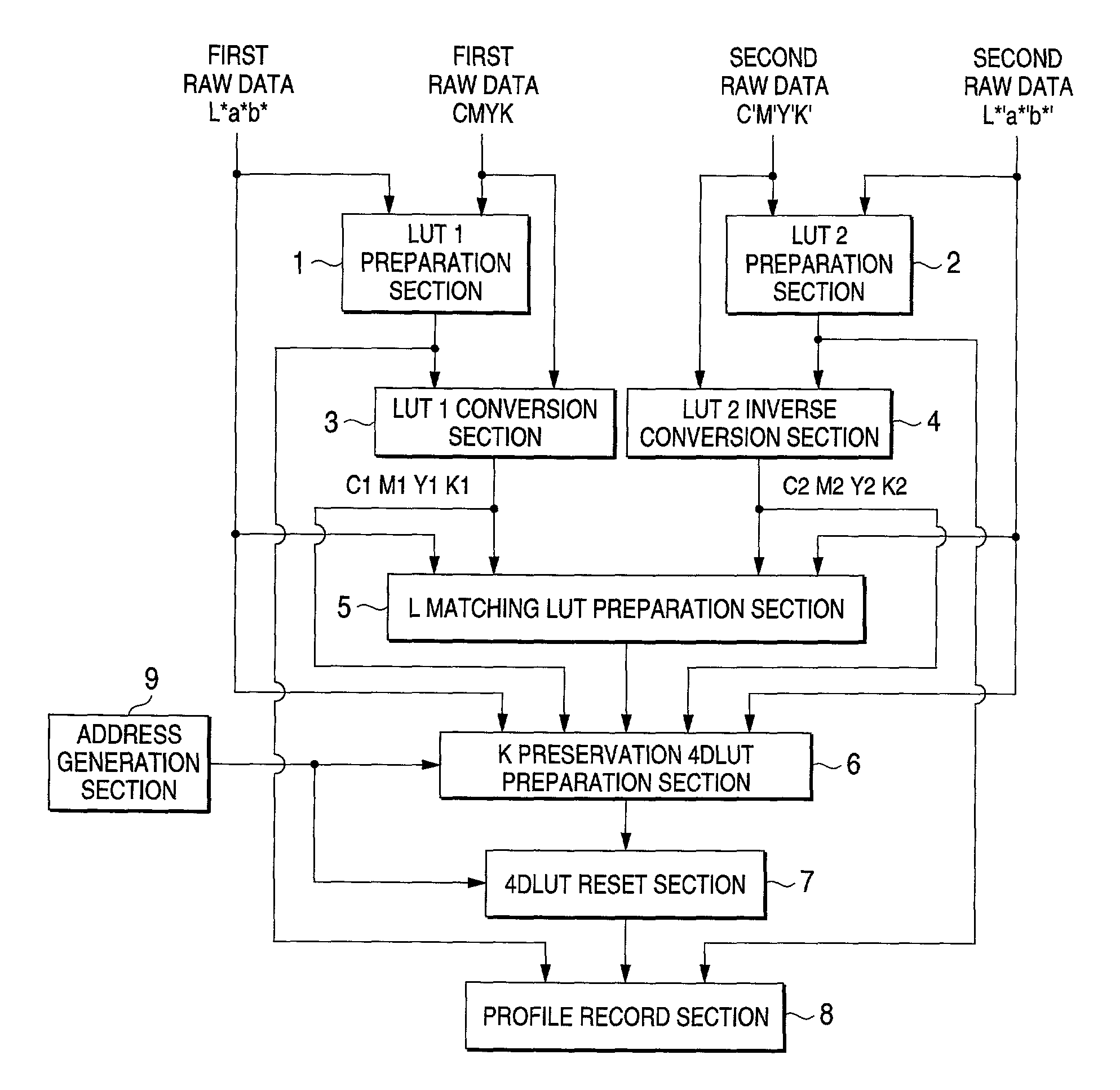

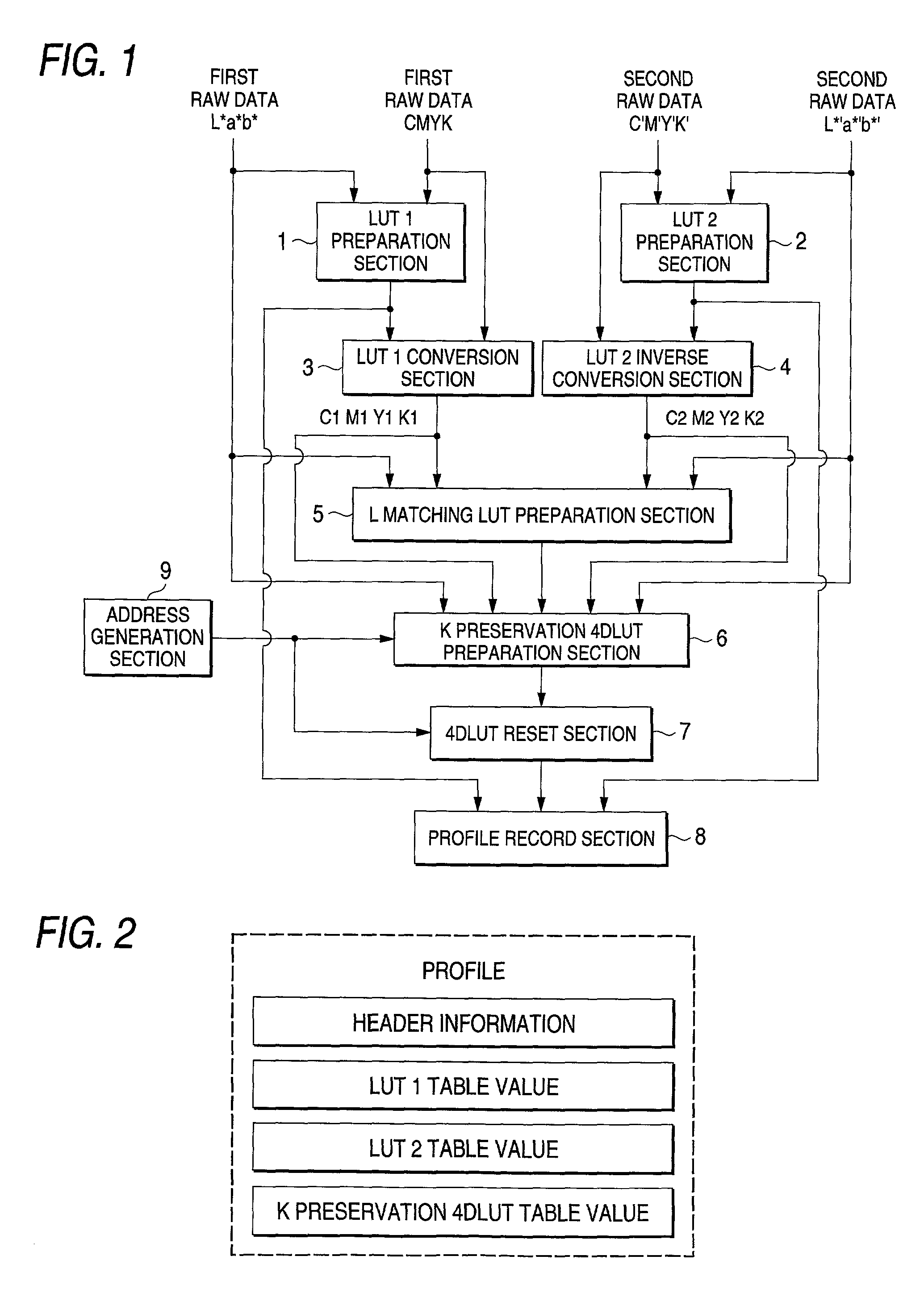

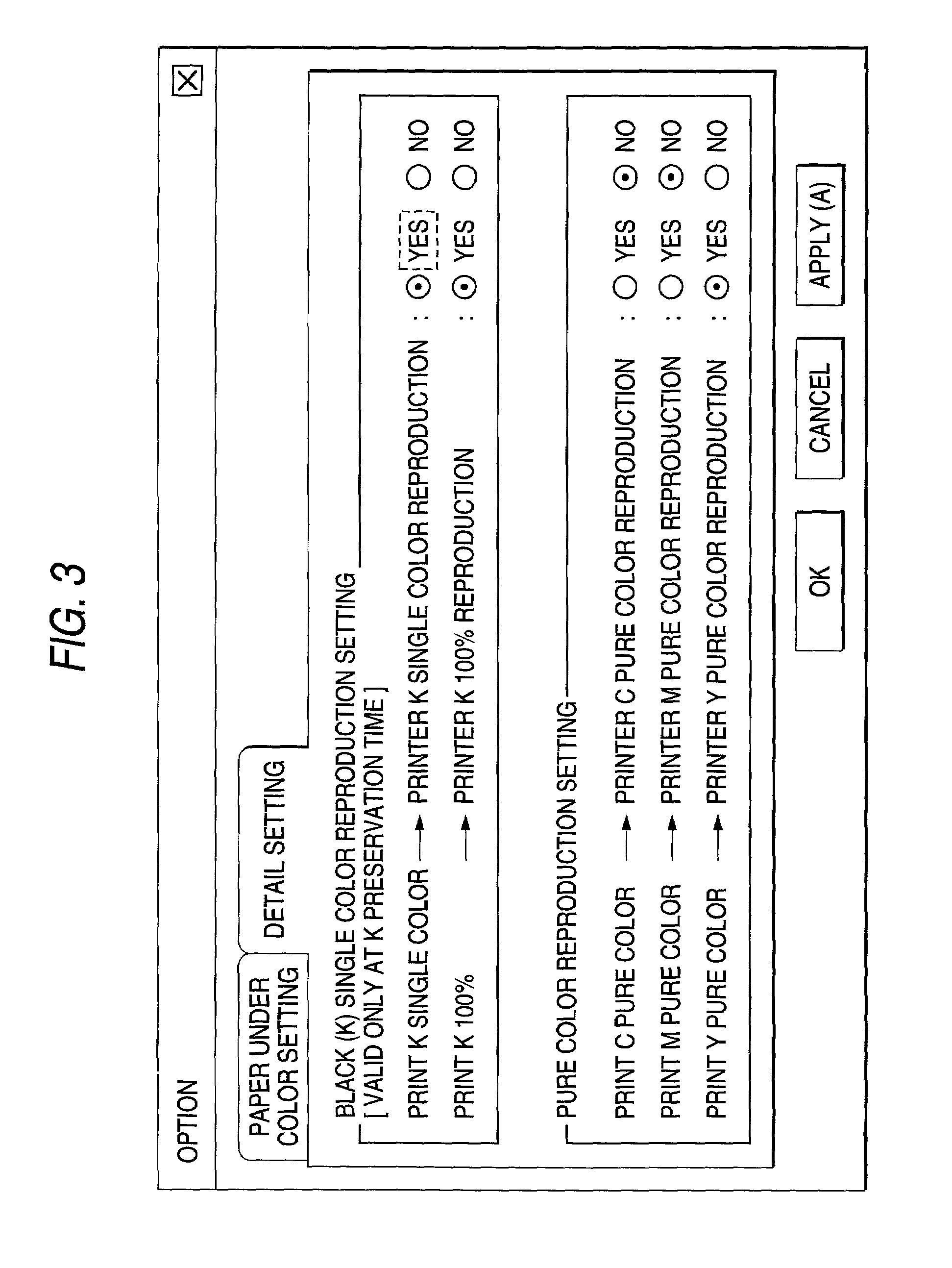

Color conversion coefficient preparation apparatus, color conversion coefficient preparation method, storage medium, and color conversion system

InactiveUS7199900B2Good reproducibilityPromote reproductionDigitally marking record carriersPrinting platesPattern recognitionColor transformation

An LUT1 preparation section 1 and an LUT2 preparation section 2 prepare an LUT1 and an LUT2 for producing linear output from first raw data or second raw data. Using the LUT1 and LUT2, an LUT1 conversion section 3 and an LUT2 inverse conversion section 4 convert CMYK of the first raw data and C′M′Y′K′ of the second raw data into four color values adjusted, and an L matching LUT preparation section 5 prepares an L matching LUT so that the K value of the four color values adjusted becomes equal. A K preservation 4DLUT preparation section 6 prepares a K preservation 4DLUT from the four color values adjusted, the L matching LUT, and the Lab value of the first and second raw data. A 4DLUT reset section 7 resets some of data in the prepared K preservation 4DLUT, whereby partial calorimetric match is intended.

Owner:FUJIFILM BUSINESS INNOVATION CORP

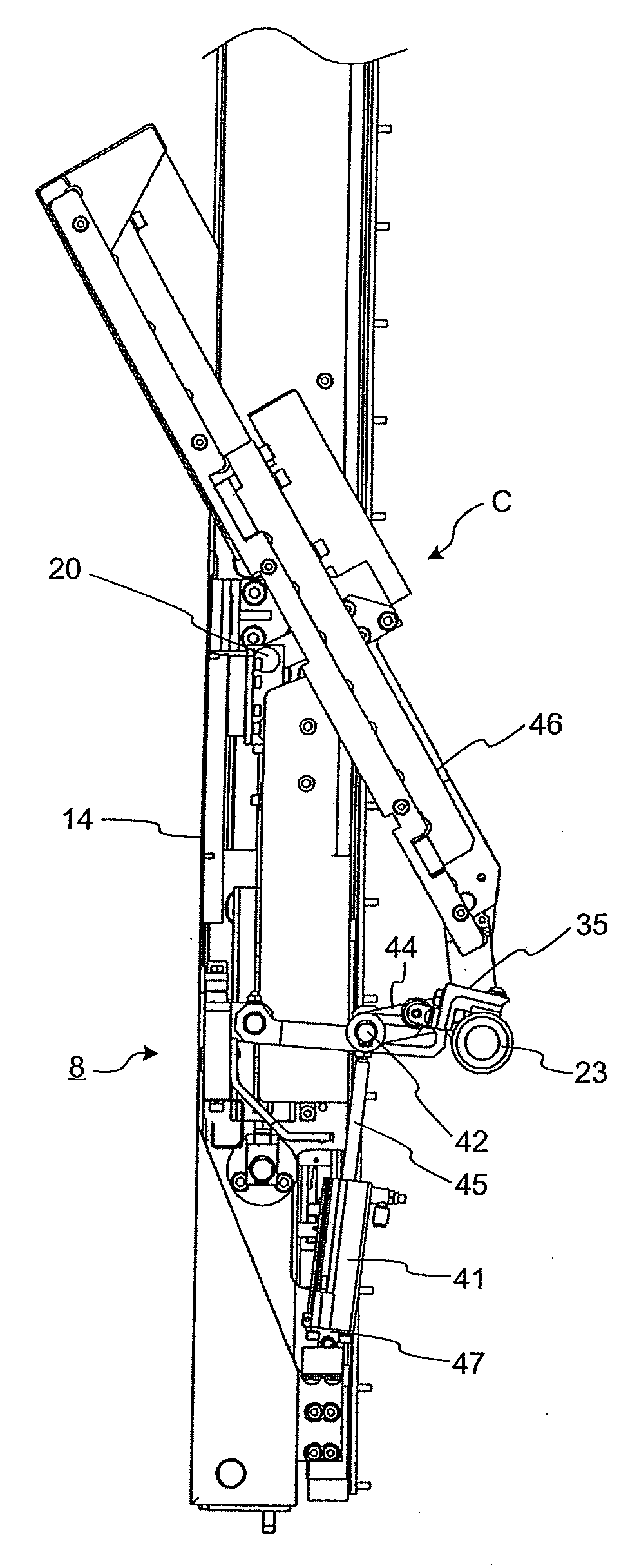

Plate replacing apparatus

A plate replacing apparatus includes a plate-winding support roller that presses a plate on a plate cylinder and a plate pressing unit that rotates around the plate-winding support roller and thereby pressing a trailing end of the plate in an edge portion of the plate pressing unit. The plate pressing unit presses the plate in a position in front of a lower tooth of a vice built in the plate cylinder.

Owner:MITSUBISHI HEAVY IND LTD

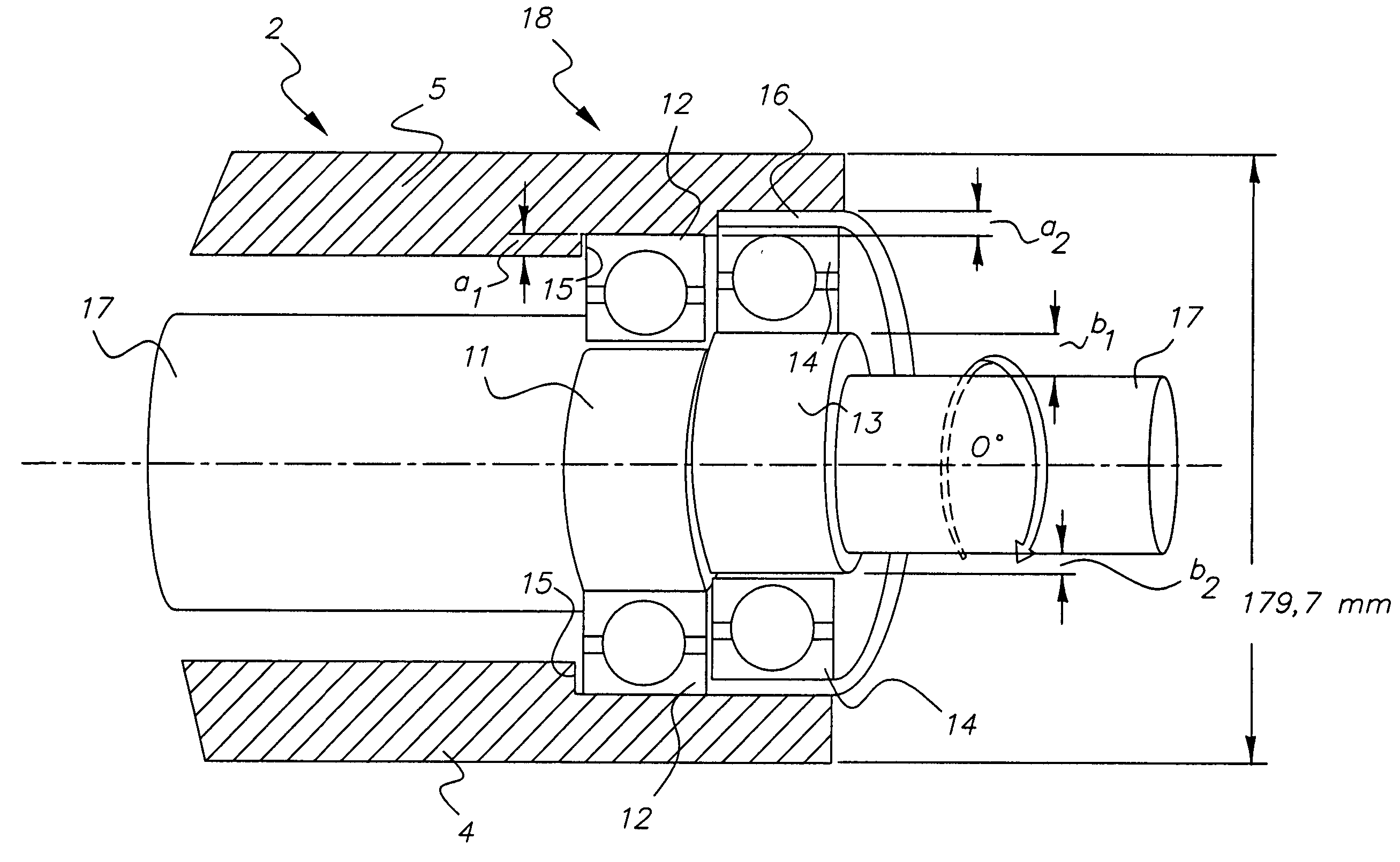

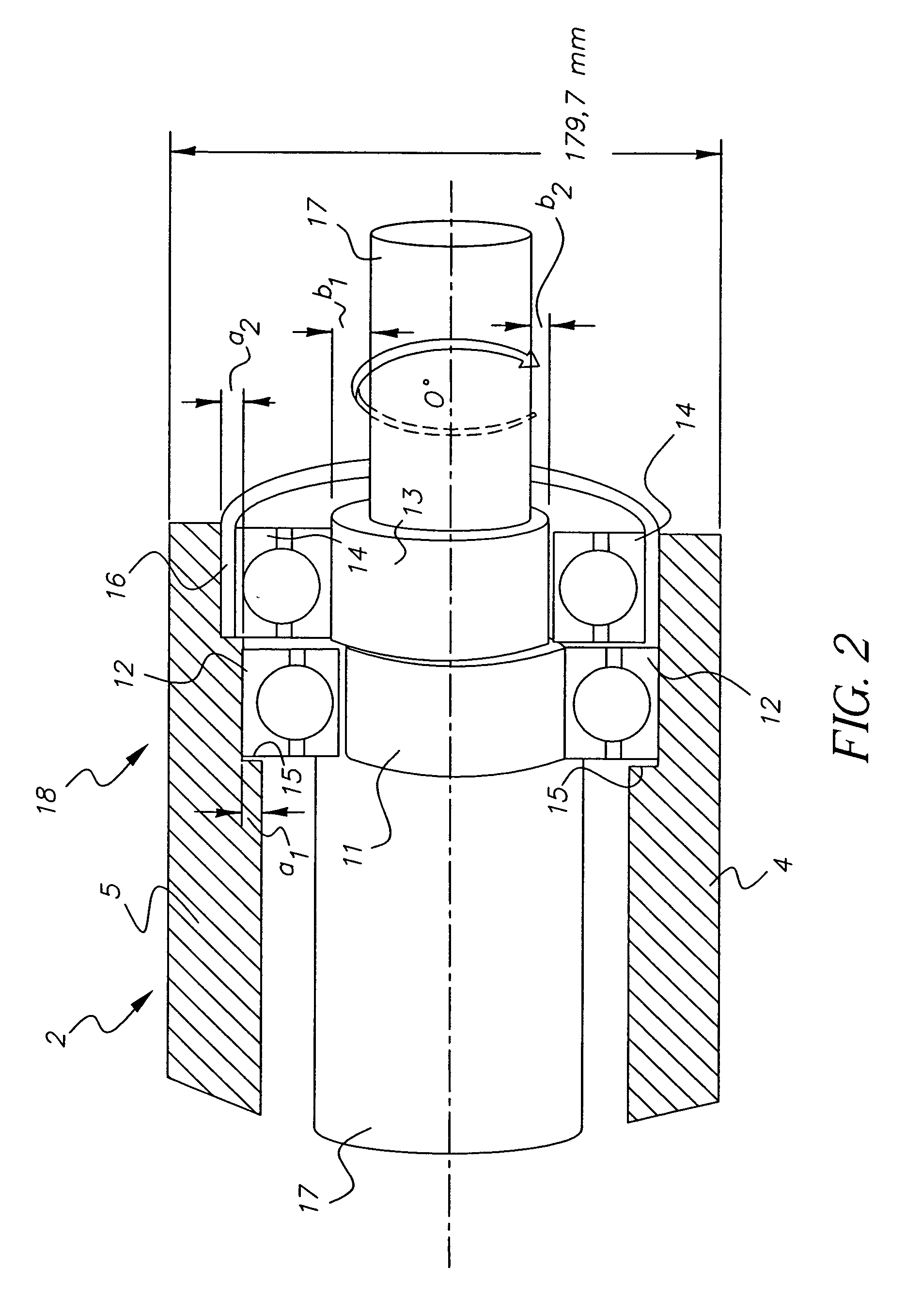

Bearing support system for a printing press having cantilevered cylinders

A bearing assembly for rotatably supporting the cylinder on a printing press is disclosed. The printing press comprises a frame, a support shaft, a cylinder, and the bearing assembly. The support shaft includes an inner fixed end attached to the frame, a free end disposed outwardly away from the frame, and an interconnecting central portion. The bearing assembly rotatably supports the cylinder on the support shaft The bearing assembly includes an inboard bearing set secured to the support shaft adjacent the central portion, and further includes an outboard bearing set secured to the support shaft adjacent the free end. A portion of the bearing assembly is adapted to permit angular adjustment of the cylinder about an axis perpendicular to the support shaft longitudinal axis.

Owner:SHANGHAI ELECTRICGROUP CORP

Method and device for producing different printed images on the same print substrate

InactiveUS7100503B2Less effortImprove printing qualityPlaten pressesDuplicating/marking methodsEngineeringSubstrate surface

In a method and system to generate a print image on a carrier material, the surface of a print substrate is covered with at least one of an ink-repelling and an ink-attracting layer. In a structuring process, ink-attracting regions and ink-repelling regions are generated corresponding to a structure of the print image to be printed. An ink-attracting carrier substance is applied which can be an ink or other carrier substance on the print substrate surface that adheres to the ink-attracting regions and is not accepted by the ink-repelling regions. The carrier substance is fixed and subsequently the fixed carrier substance is inked with ink at least once. The applied ink is transferred to the carrier material. Before a new structuring process, the print substrate surface is cleaned and newly covered.

Owner:OCE PRINTING SYST

Slip sheet removal

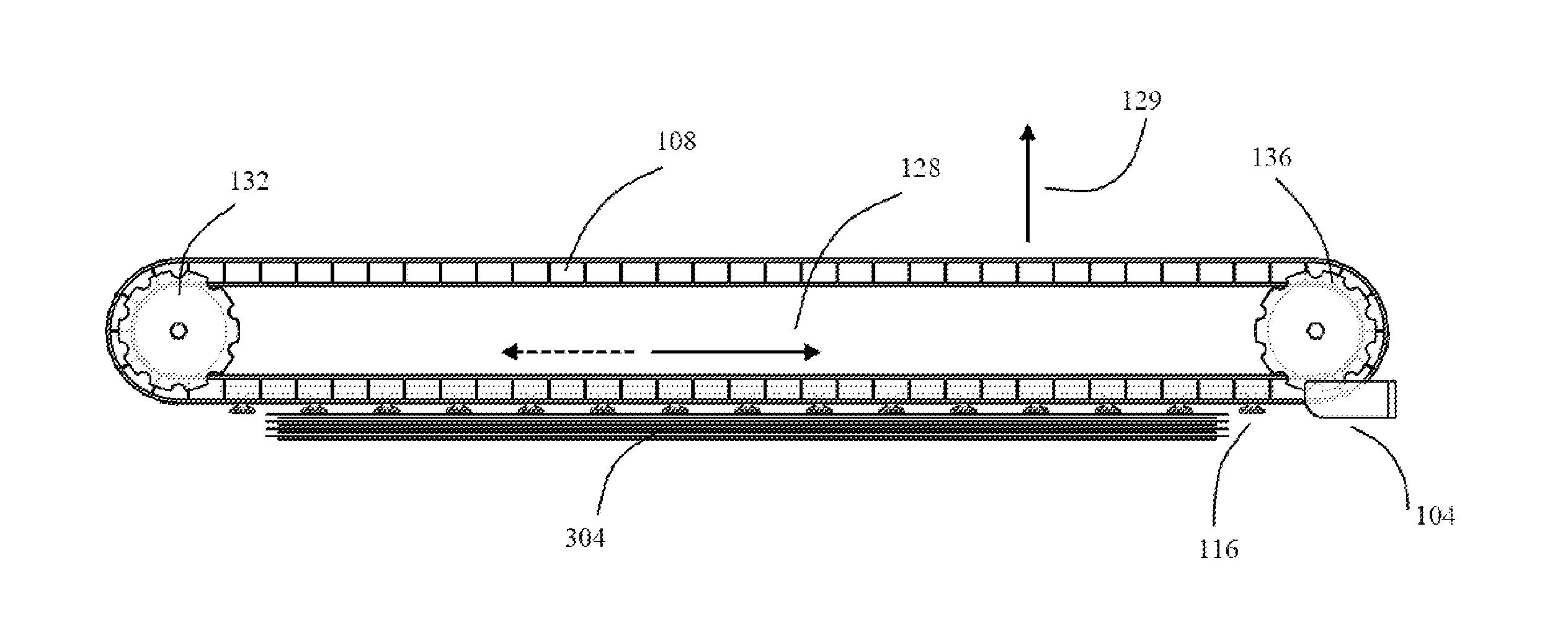

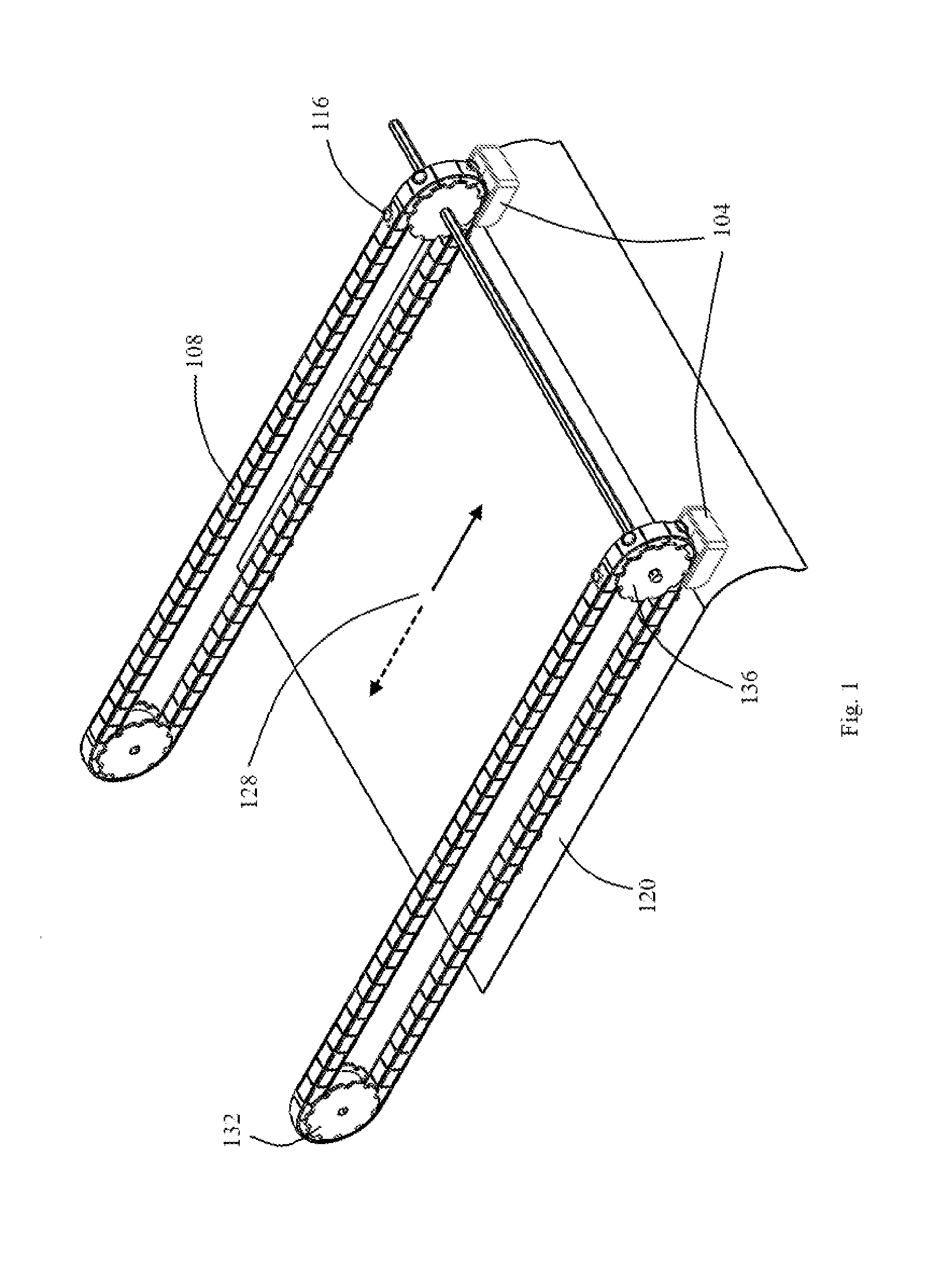

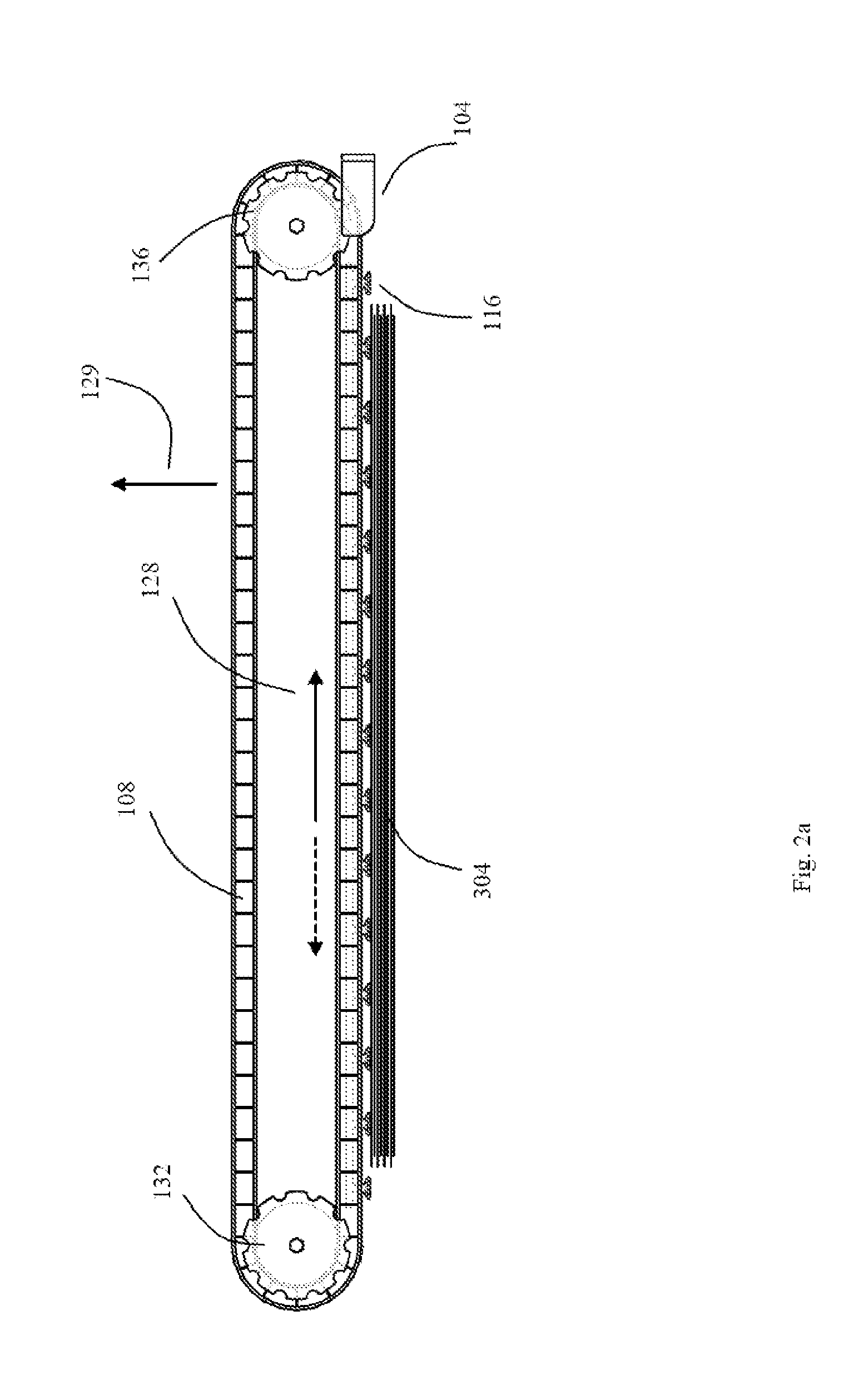

A method of removing slip sheets from a printing plates stack is disclosed, wherein the slip sheets are interspersed between the printing plates includes moving at least two parallel energy chains. Each of the energy chains carries a plurality of vacuum cups over the stack of printing plates. The vacuum cups are attached to a top slip sheet placed on top of the printing plates stack and peel off sheets while vacuum is maintained and transferring the top slip sheet into a slip sheet bin.

Owner:EASTMAN KODAK CO

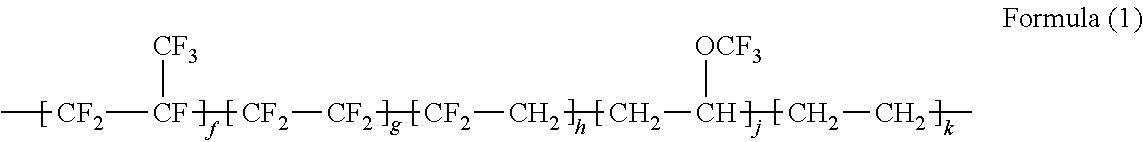

Imaging member for offset printing applications

An imaging member includes a surface layer comprising a fluoroelastomer-fluorosilicone composite. Methods of manufacturing the imaging member and processes for variable lithographic printing using the imaging member are also disclosed.

Owner:XEROX CORP

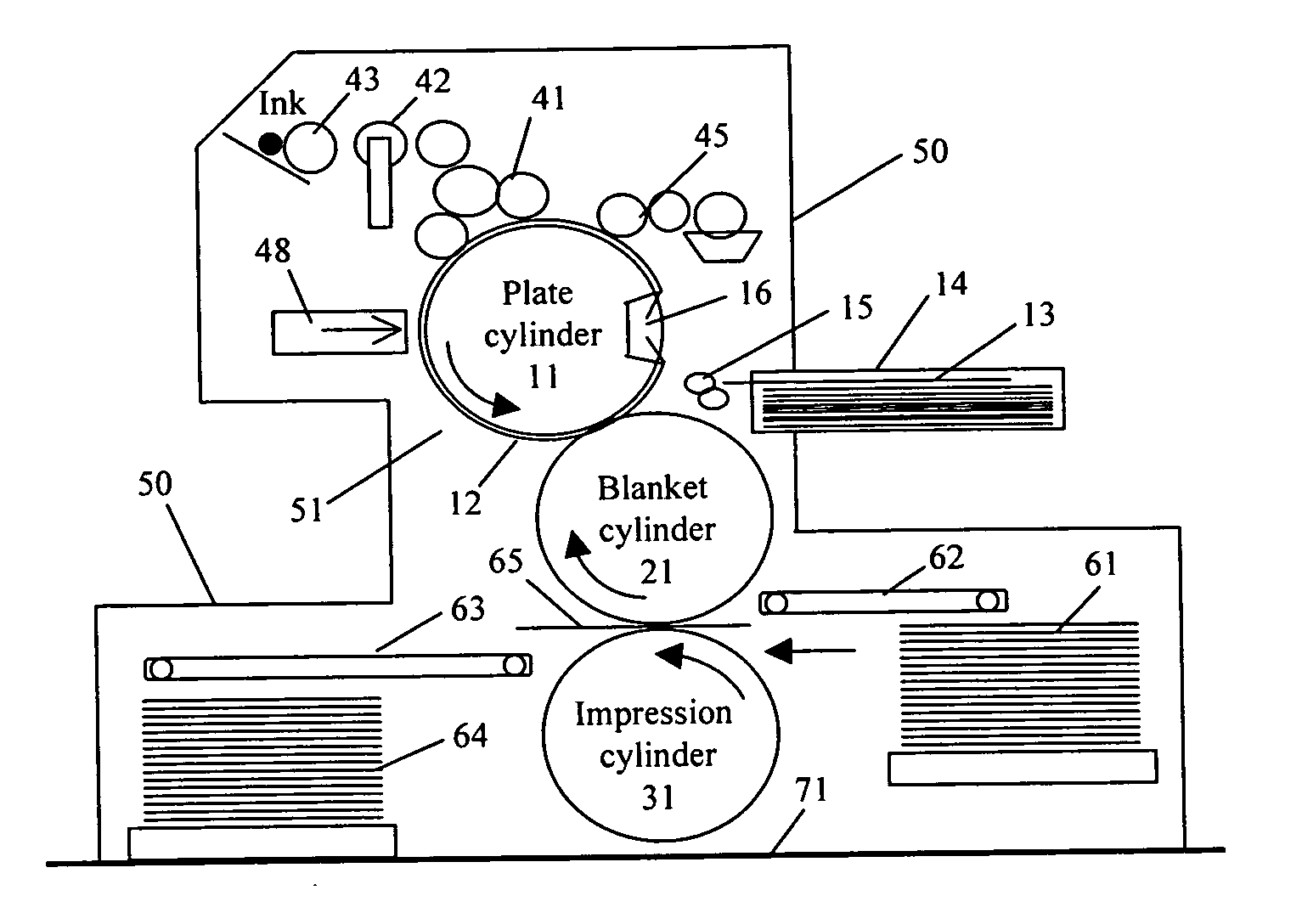

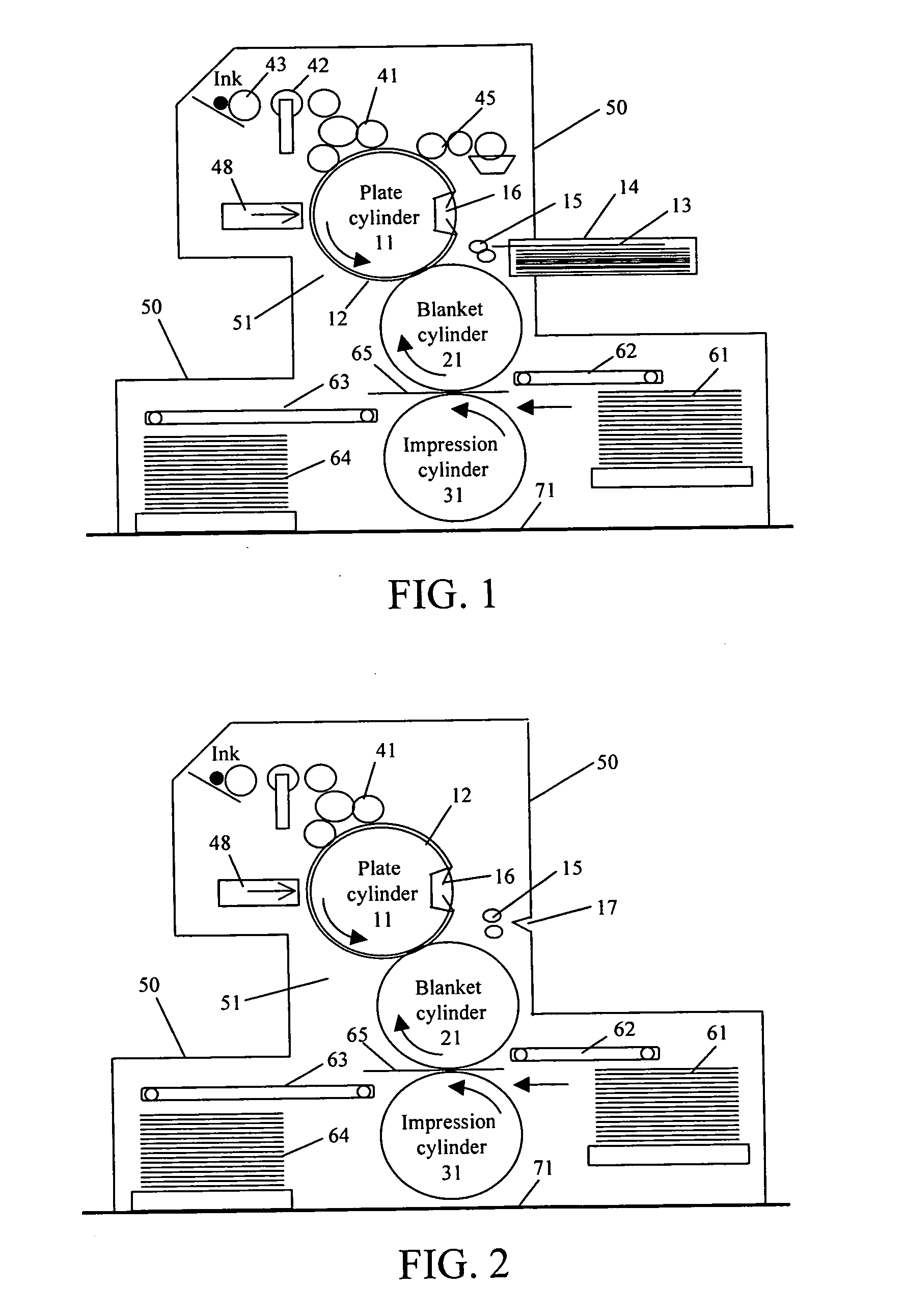

Lithographic printing press and method for on-press imaging lithographic printing plate

InactiveUS20070095232A1Undesired reactionPrinting platesPhotomechanical apparatusEngineeringPrinting ink

A lithographic printing press having a plate cylinder in a substantially light-tight compartment suitable for on-press imaging and developing a laser sensitive plate is described. The plate cylinder as well as certain other press parts is covered by non-transparent and / or safe-light-passing-only covers so that no or only limited amount of unsafe light passes onto the plate mounted on the plate cylinder during on-press imaging and development. The plate comprises on a substrate a photosensitive layer soluble or dispersible in ink and / or fountain solution and capable of hardening upon exposure to a laser having a wavelength selected from 200 to 1200 nm. The plate is on-press exposed with the laser, developed with ink and / or fountain solution, and then directly prints inked images to the receiving sheets.

Owner:TENG GARY GANGHUI

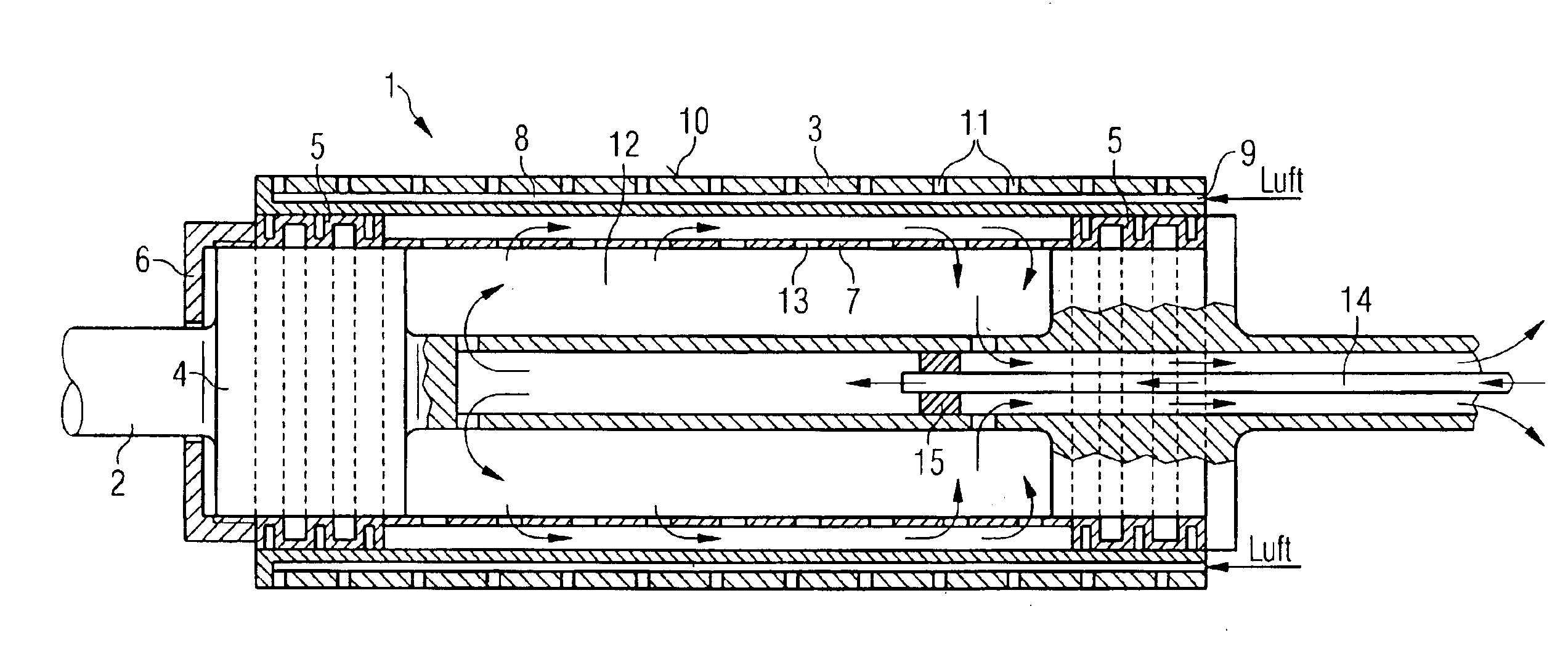

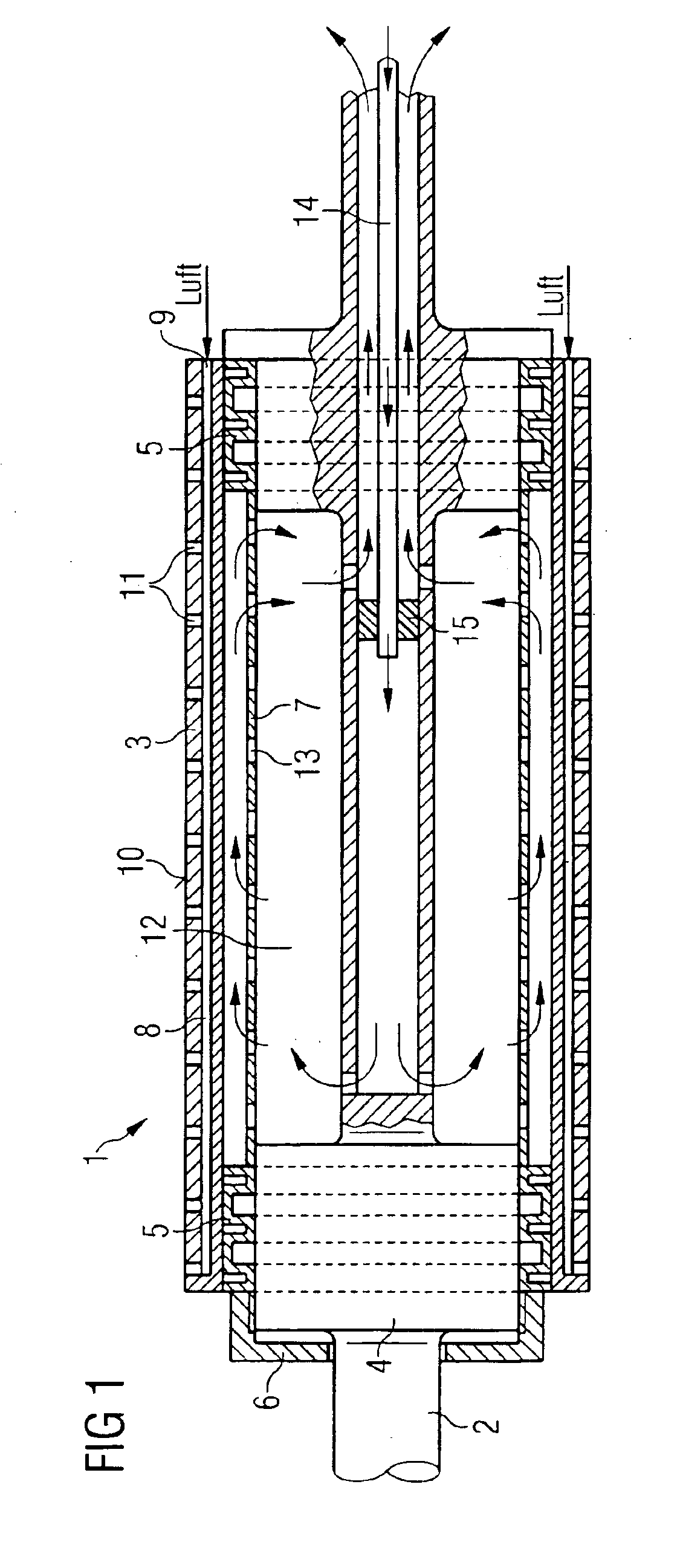

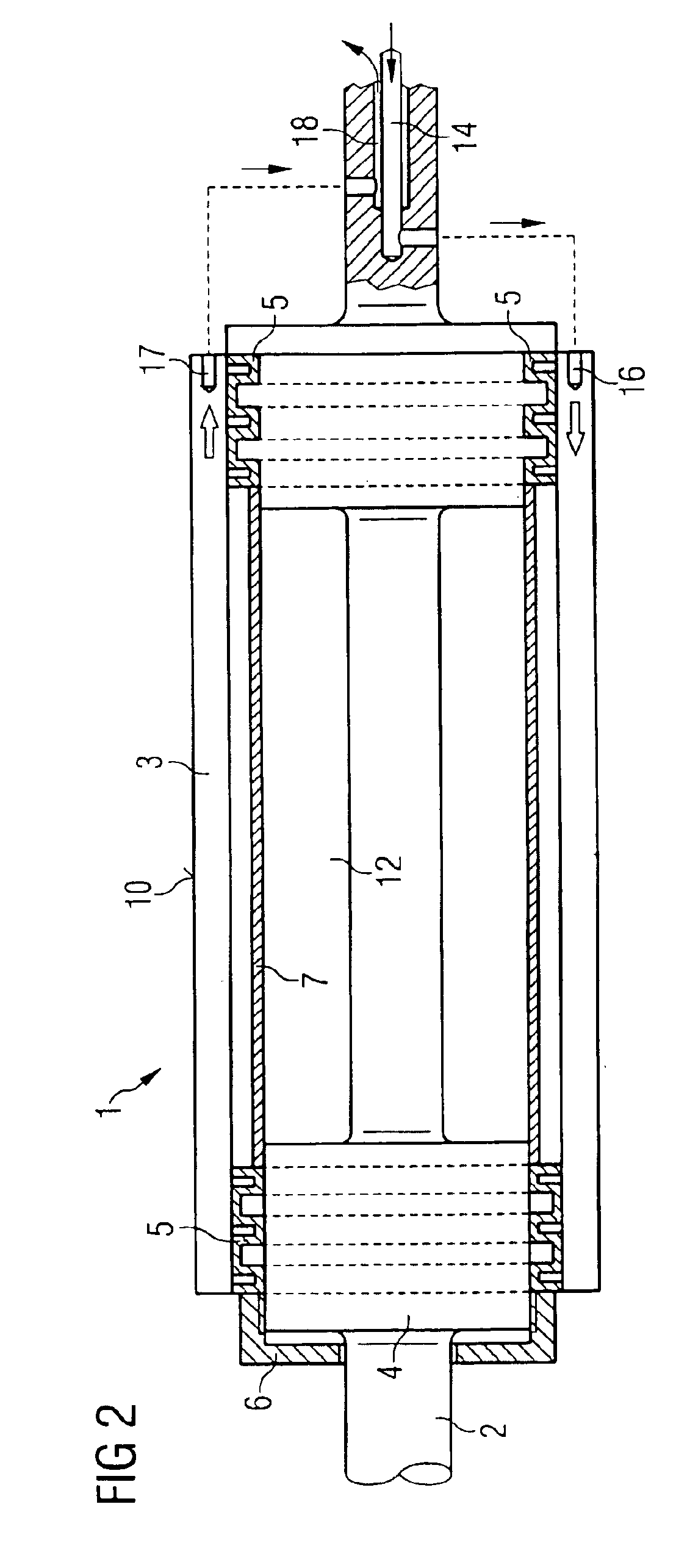

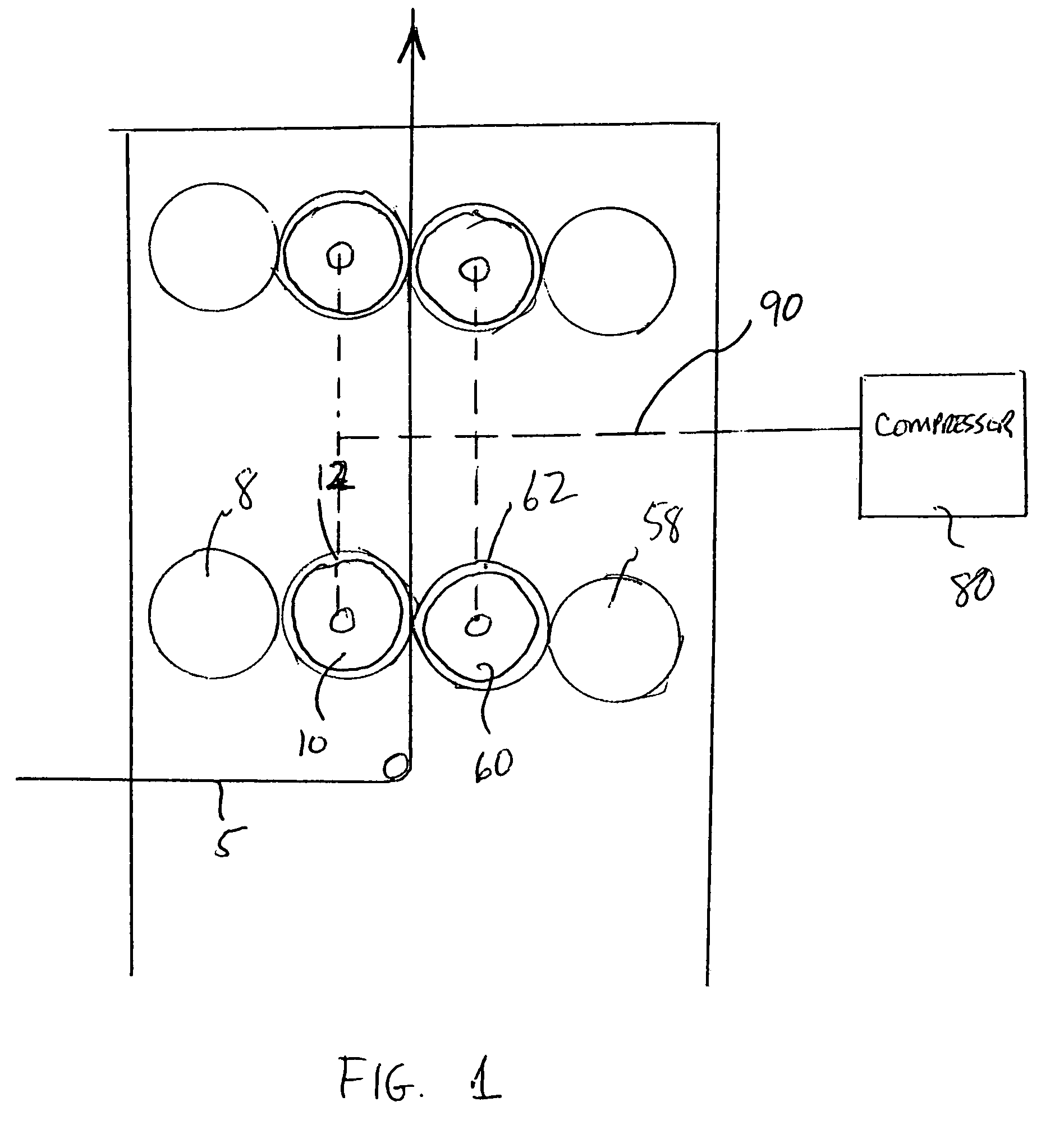

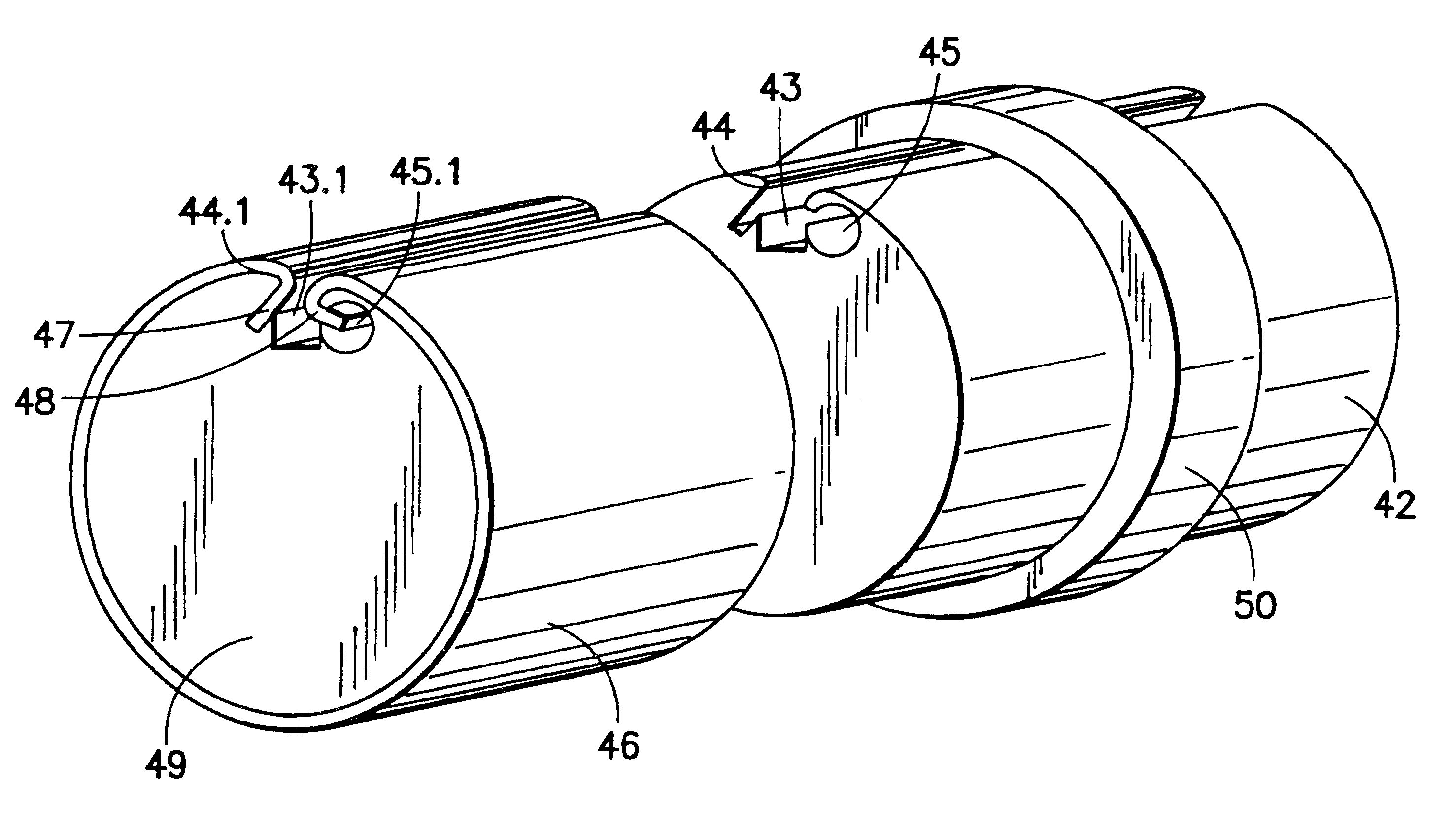

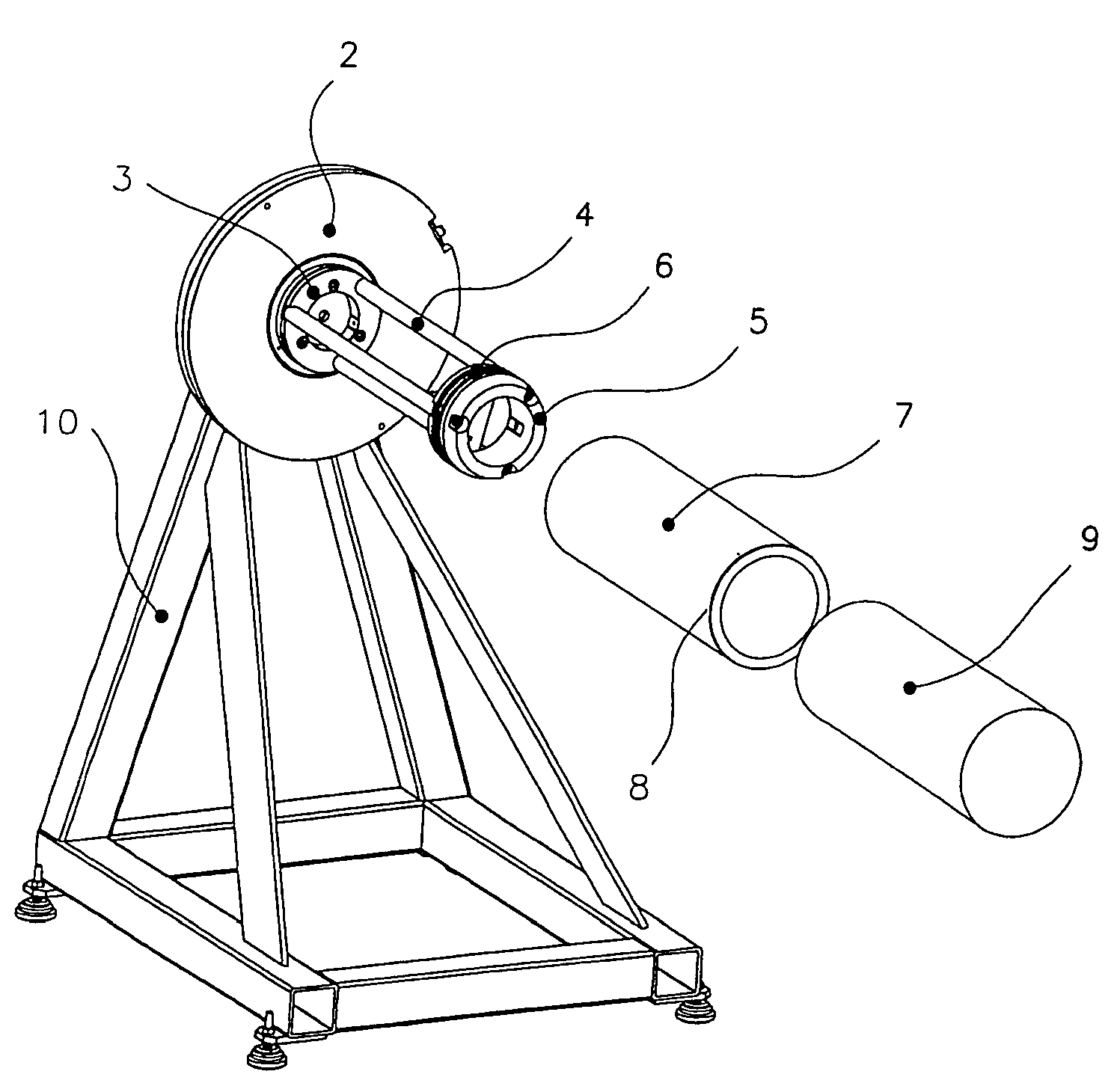

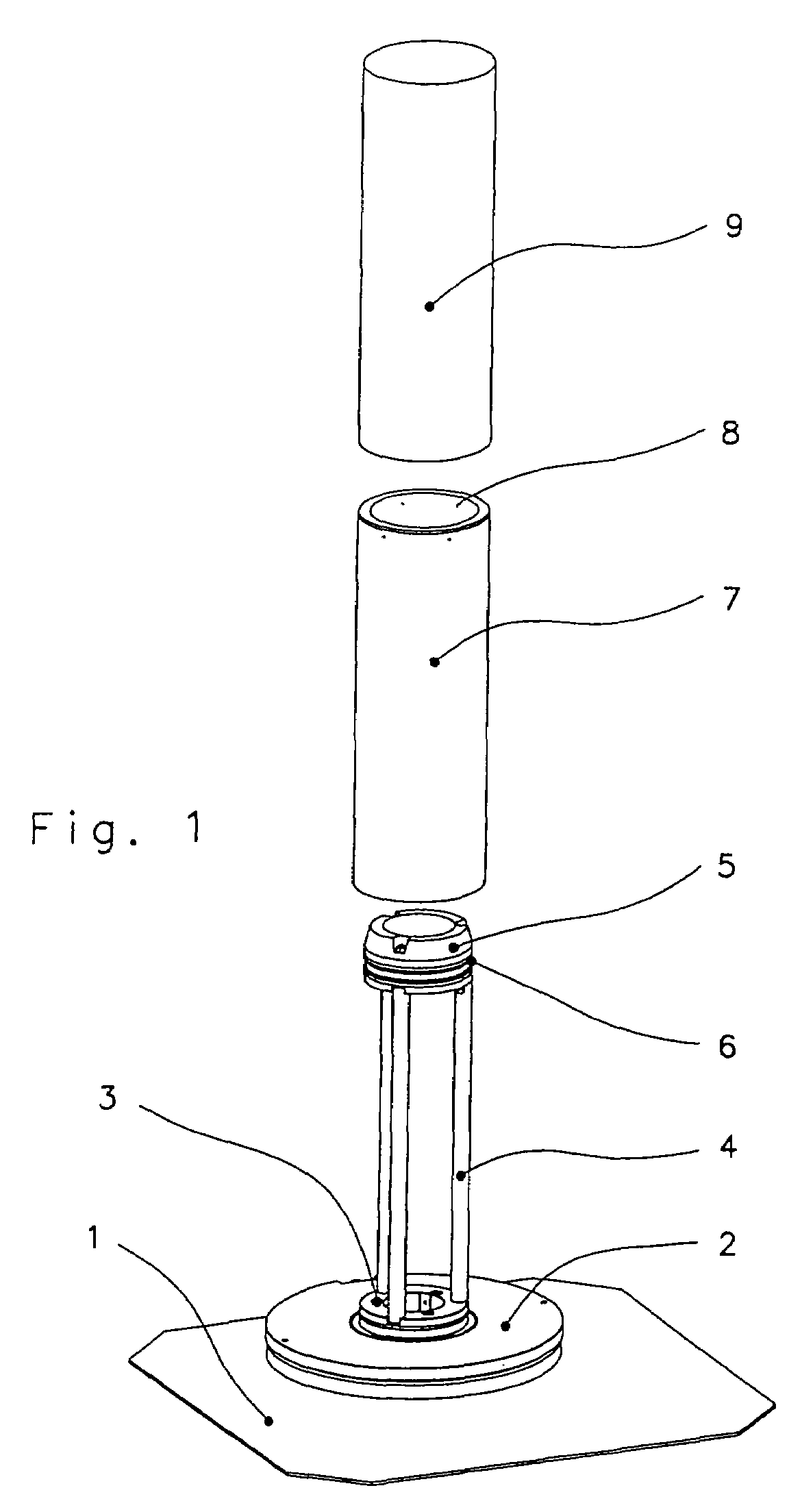

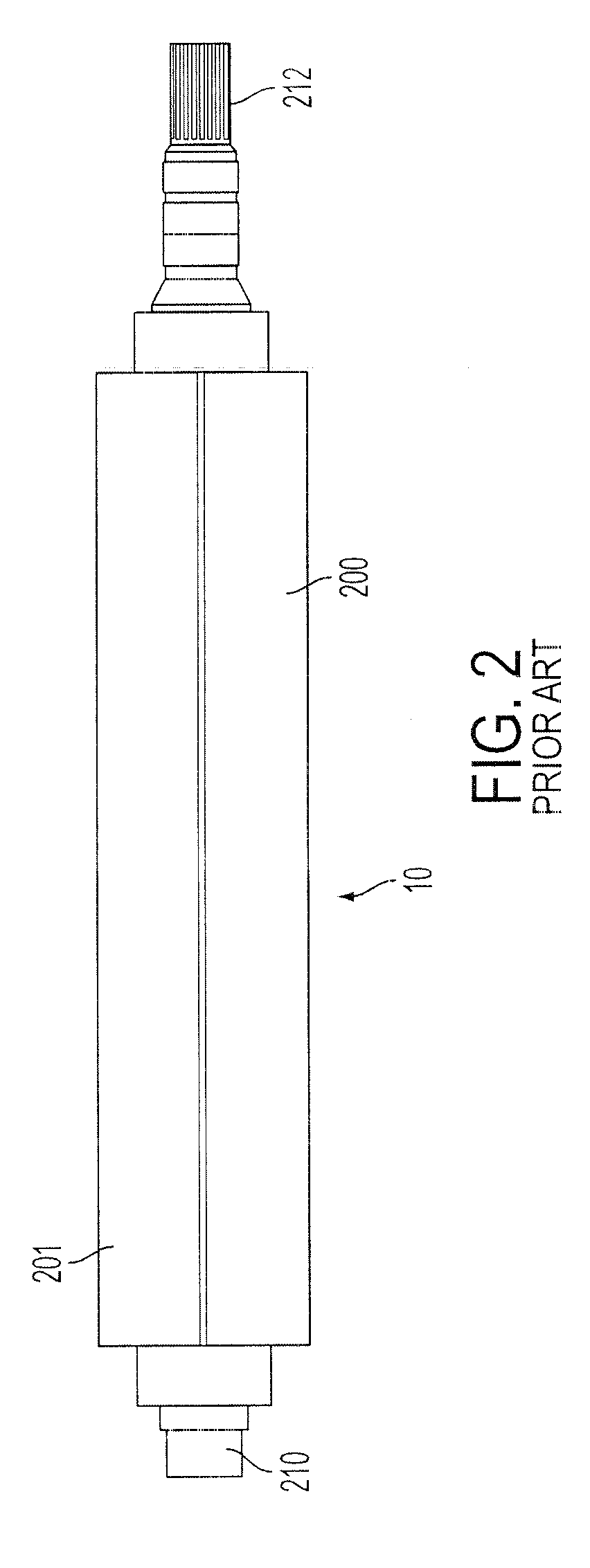

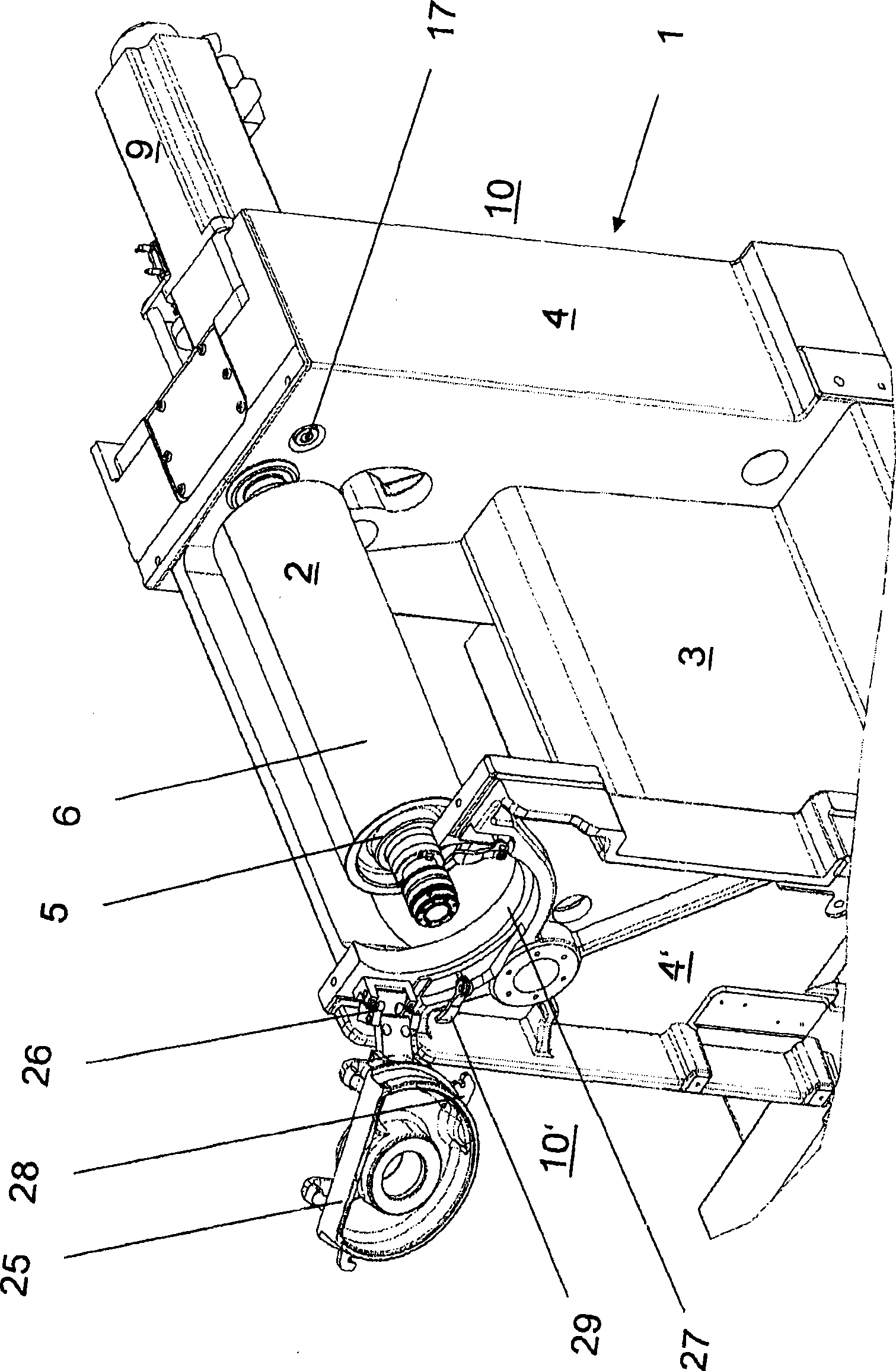

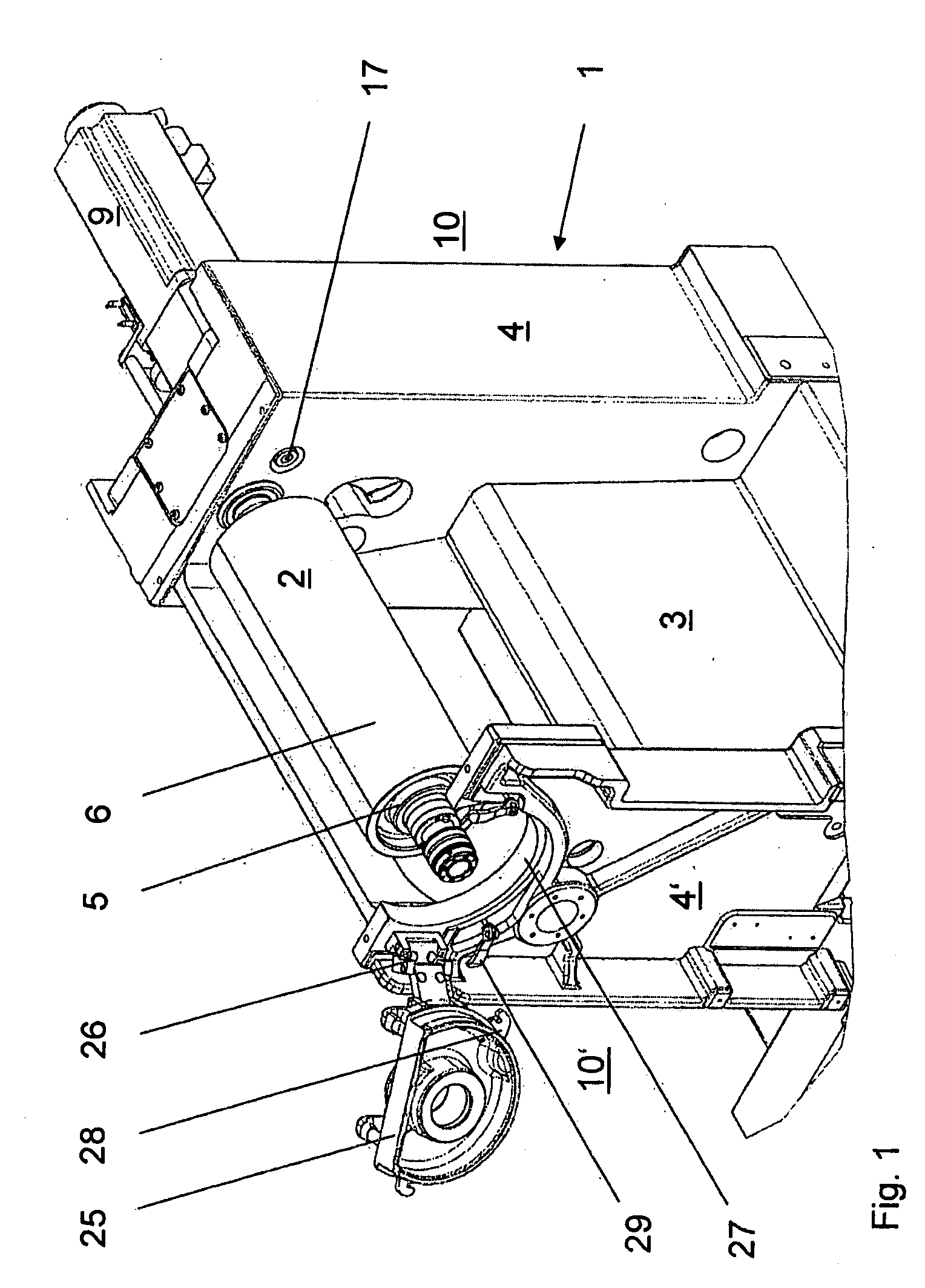

Mounting cylinder for mounting cylindrical embossing tools for embossing rolls

InactiveUS6874415B2Easy resetSimple structurePrinting platesHeat exchange apparatusEngineeringCompressed air

A mounting cylinder (1) for mounting cylindrical embossing tools for embossing rolls for embossing diffraction gratings or holograms includes a mounting shell (3) for mounting the embossing tool and a fixing device for fixing the mounting shell (3) on a shaft (2) and a tempering device for tempering the mounting shell. According to one variant, the embossing tool is expanded by compressed air in order to be slipped onto the mounting shell or removed therefrom, a compressed air channel system (8) with radial compressed air discharge openings (11) extending axially and / or tangentially within the mounting shell (3). According to another variant, the mounting shell is expanded mechanically in order to fix a embossing tool slipped over the mounting shell and simultaneously fix the mounting shell (3) on the shaft (2).

Owner:GIESECKE & DEVRIENT GMBH

Process for on-press developing overcoat-free lithographic printing plate

Owner:TENG GARY GANGHUI

Image forming process and image forming apparatus

InactiveUS7494213B2Increase flexibilityImprove surface wettabilityMeasurement apparatus componentsDecorative surface effectsImage formationEngineering

An image forming process comprises the steps of applying a first material for improving the wettability of the surface of an intermediate transfer medium to the intermediate transfer medium, applying a second material for lowering the flowability of an ink to the intermediate transfer medium to which the first material has been applied, applying the ink to the intermediate transfer medium, to which the first material and second material have been applied, from an ink-jet recording head to form an image of the ink on the intermediate transfer medium, and transferring the ink image formed to a recording medium.

Owner:CANON KK

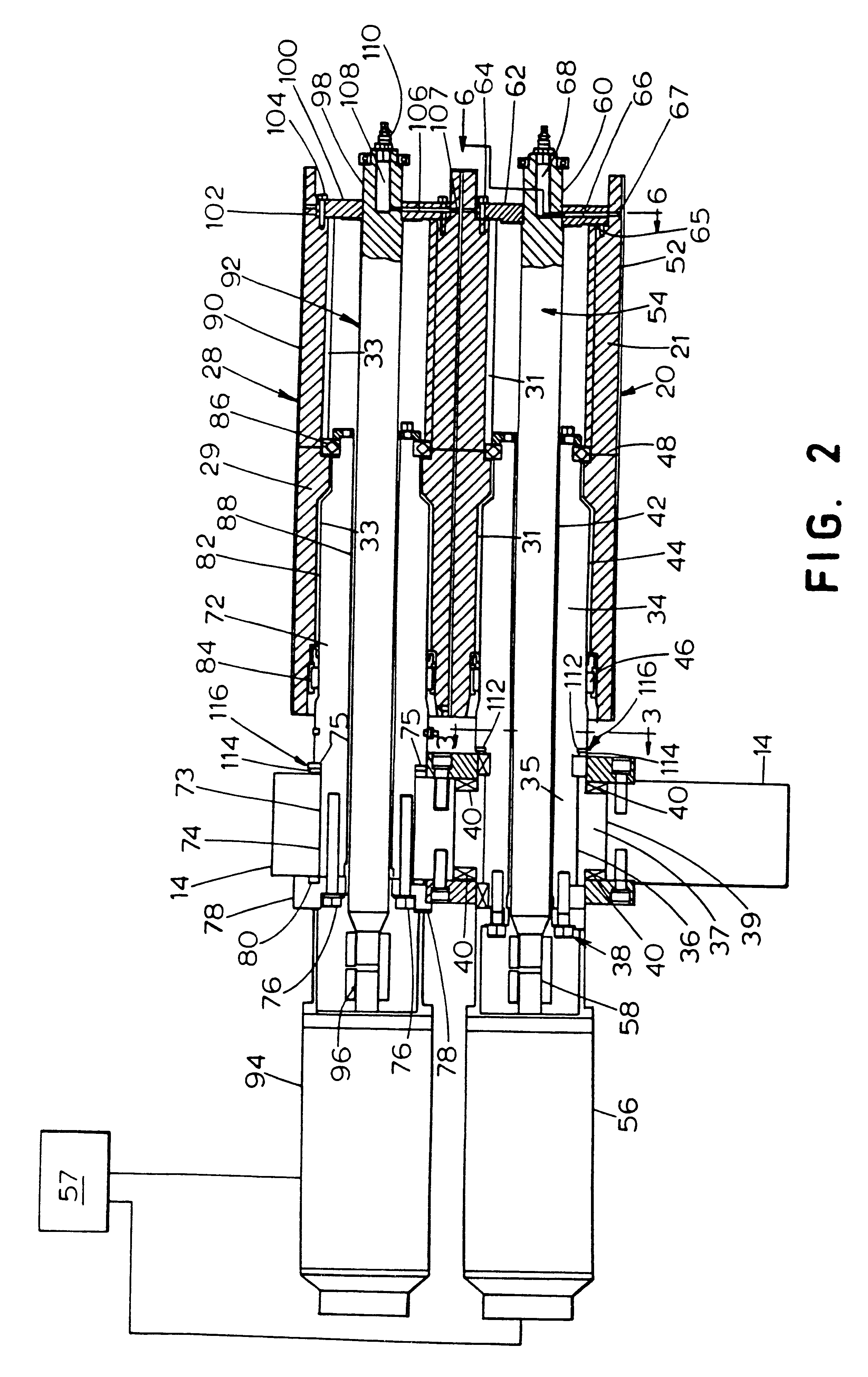

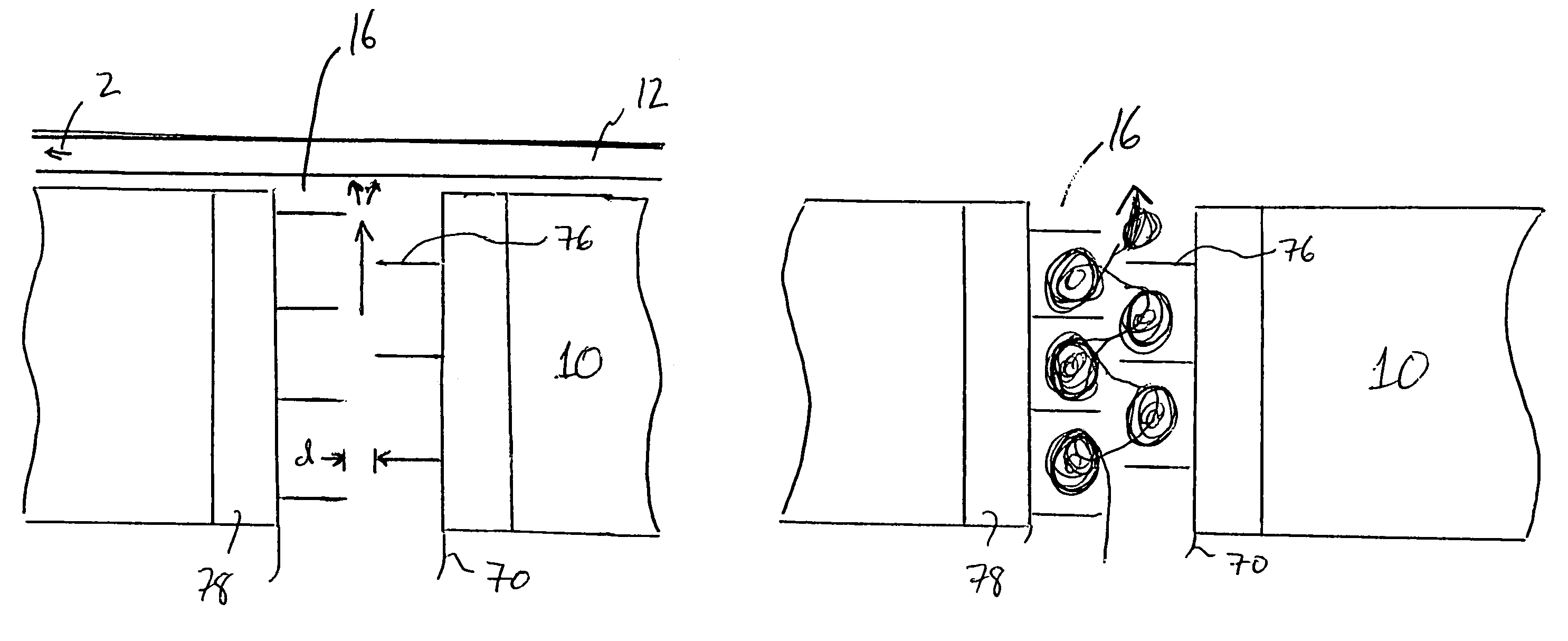

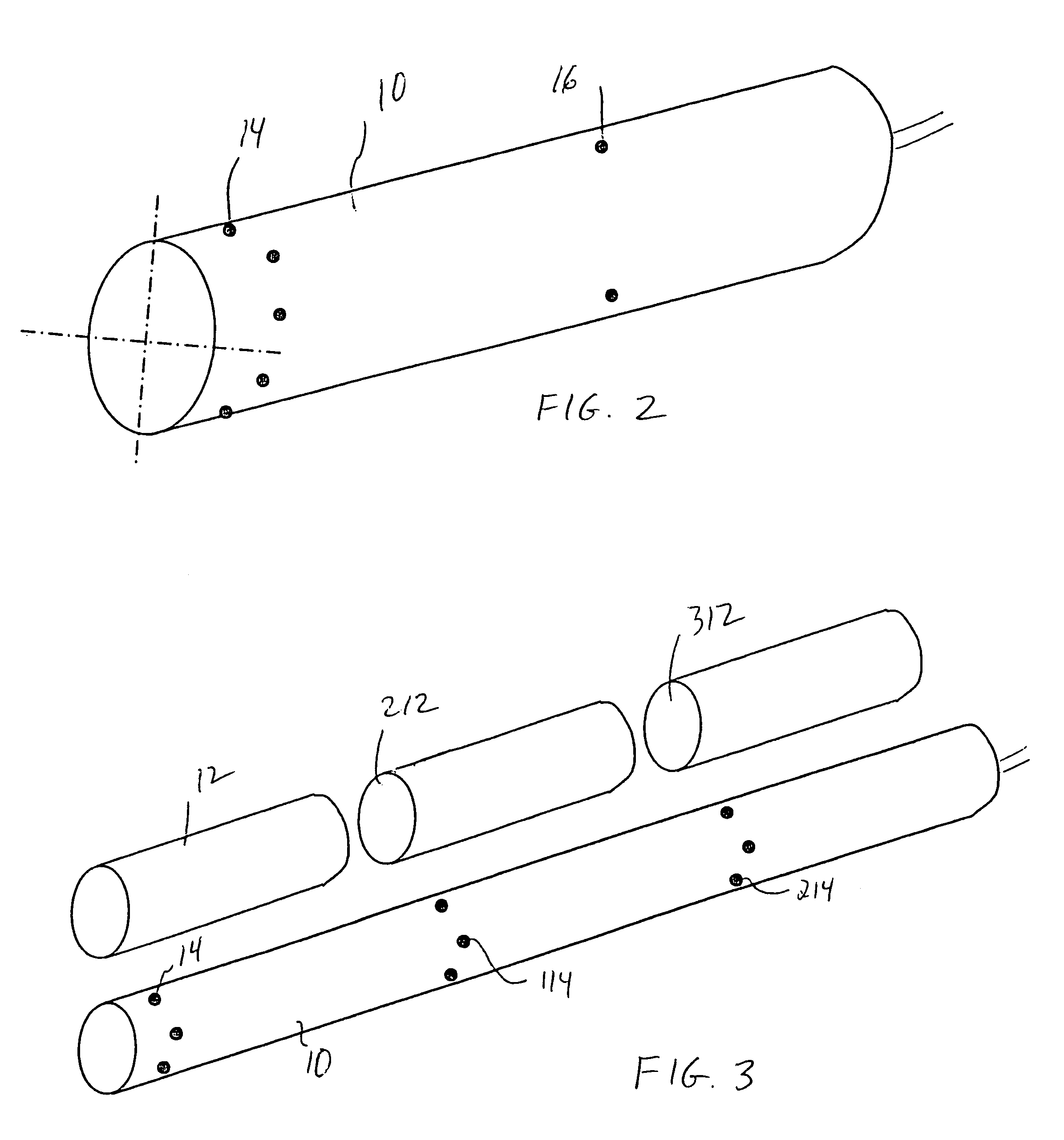

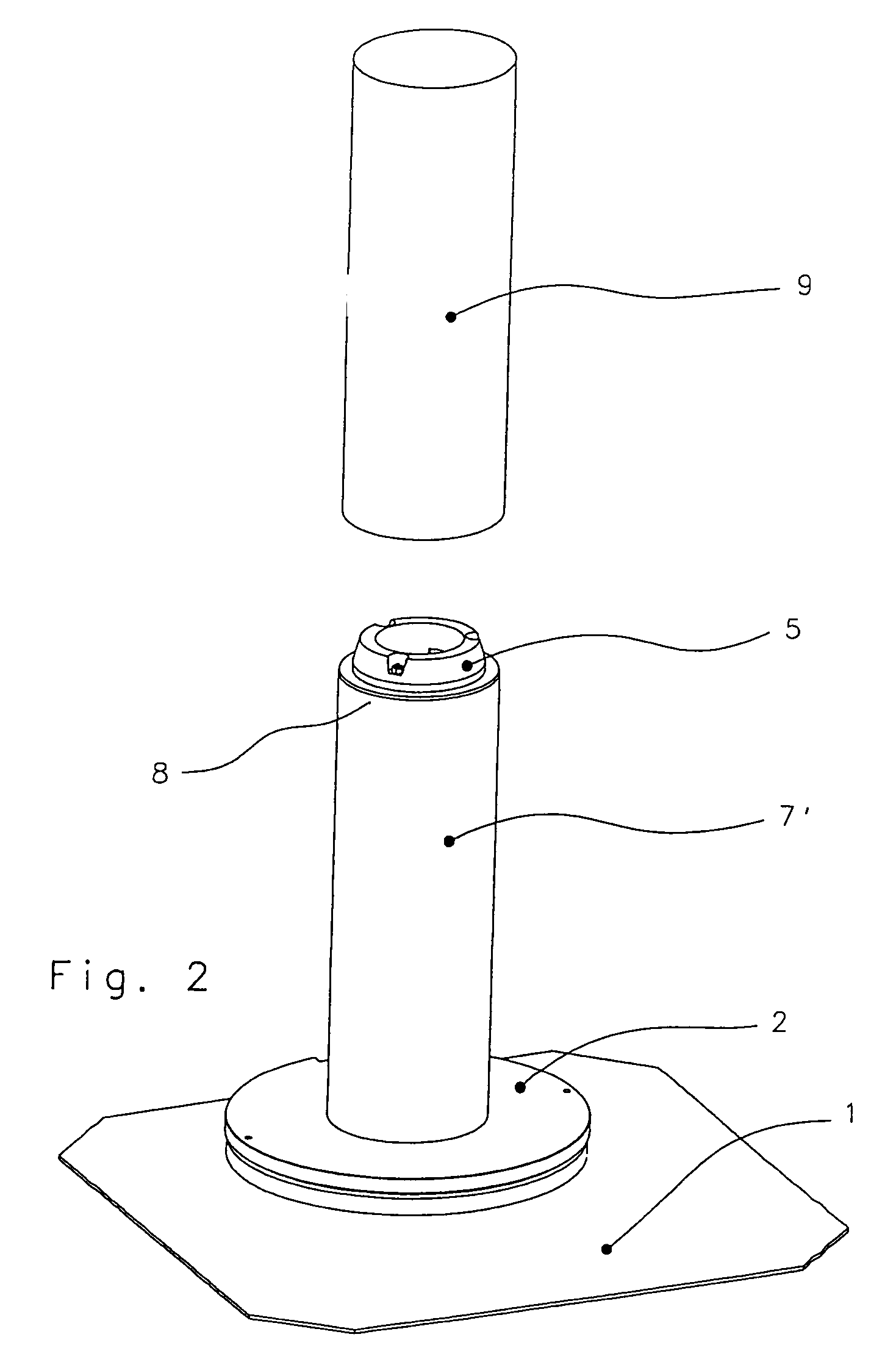

Flow-restricted printing cylinder for a removable printing sleeve

A printing cylinder for accepting an axially-removable printing sleeve includes a cylinder body having an outer surface, the outer surface having at least one hole and a supply line in the cylinder body for supplying fluid to the at least one hole. The supply line has at least one flow restrictor designed to alter fluid flow as a function of the at least one hole being covered by an axially-removable printing sleeve. Also provided is a printing press having two such cylinders and a common pressure source. A method for axially removing a printing sleeve over a printing cylinder includes the steps of applying fluid pressure to an inside of a printing sleeve located on a printing cylinder through holes at a work side end of the printing cylinder and through other holes between the holes at the work side end and a gear side end of the printing cylinder, sliding the printing sleeve in a direction of the work side end of the printing cylinder, and automatically restricting flow through the other holes when the printing sleeve no longer is located over the other holes.

Owner:GOSS INT AMERICAS

Method and apparatus for fitting a printing plate to a plate cylinder

Owner:MANROLANAD AG

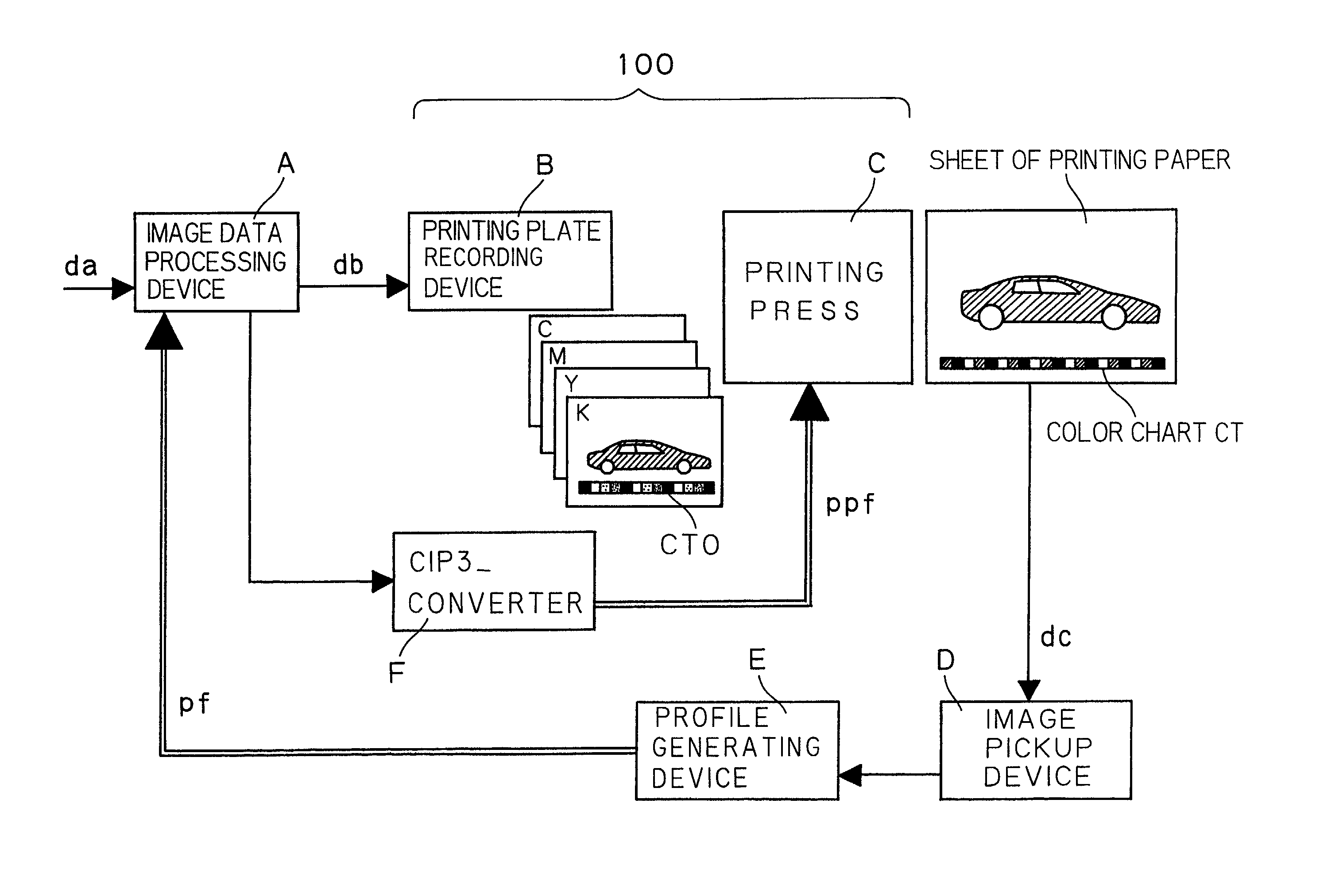

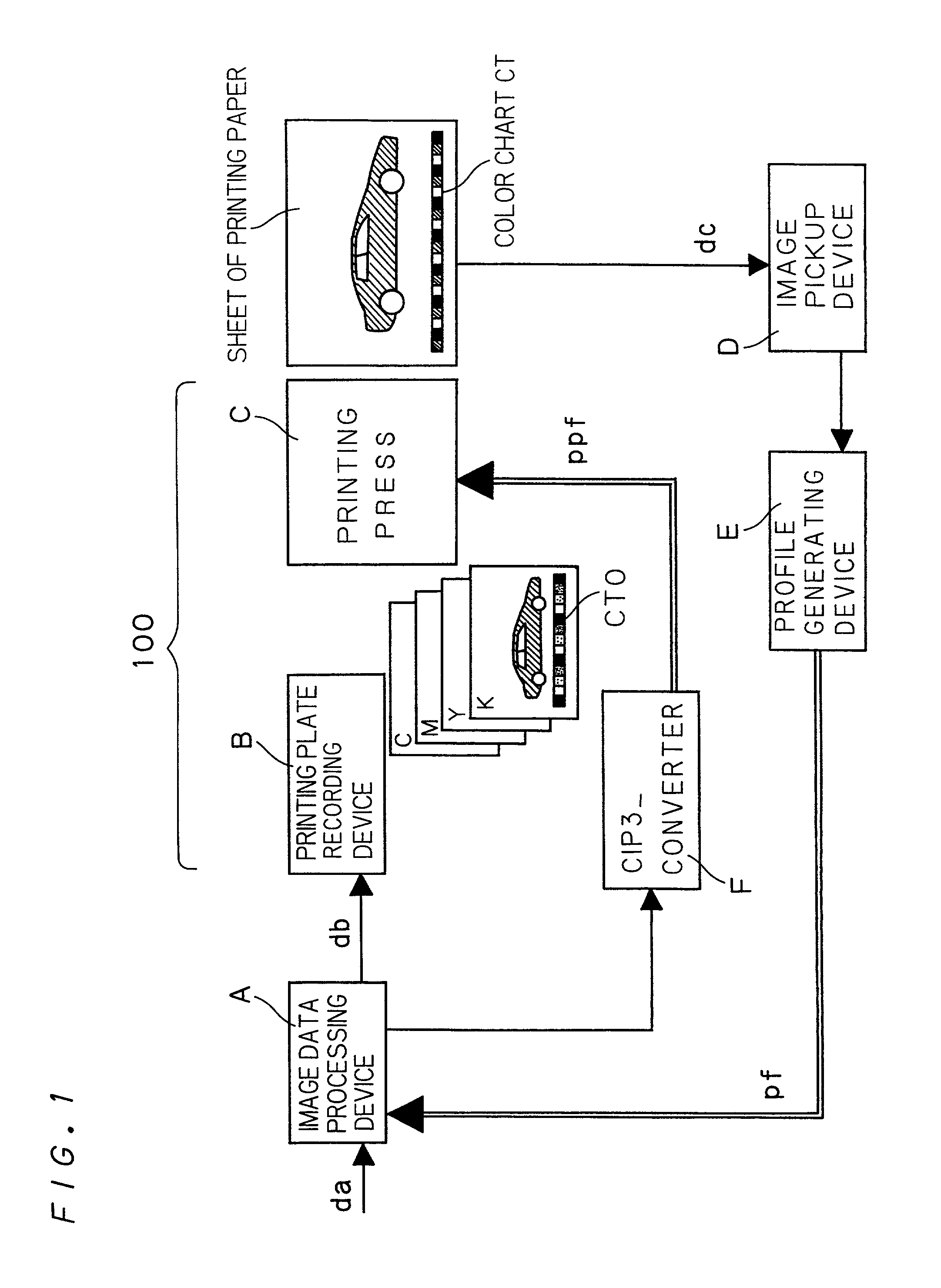

Method of and device for managing print colors, and image data processing device

InactiveUS6999200B2Easy to manageDigitally marking record carriersPlaten pressesEngineeringPrinting press

A plate-recording and printing system is provided with a printing plate recording device for recording an image on a printing plate based upon binary image data formed in an image data processing device, a printing press for carrying out a printing operation by using the printing plate, an image pickup device for picking up an image of a printed object and a profile forming device for forming profile data of the printing press from picked up image data. A printing operation is carried out under reference conditions by using predetermined ink and sheet of printing paper. An image of a color chart on the printed object is picked up by the image pickup. Print color of the color chart is determined in the Lab color system based upon image data. Printing press profile data is generated as a function of print color and predetermined reference color of the color chart. This profile data is stored in association with kinds of ink and sheets of printing paper used in the printing press. Prior to forming binary image data used in the printing plate recording device, the image data processing device specifies printing conditions of the ink and sheets of printing paper used in the printing press placed on the following stage, and reads profile data related to these printing conditions. Then, it carries out a color conversion on the image data by using the profile.

Owner:DAINIPPON SCREEN MTG CO LTD

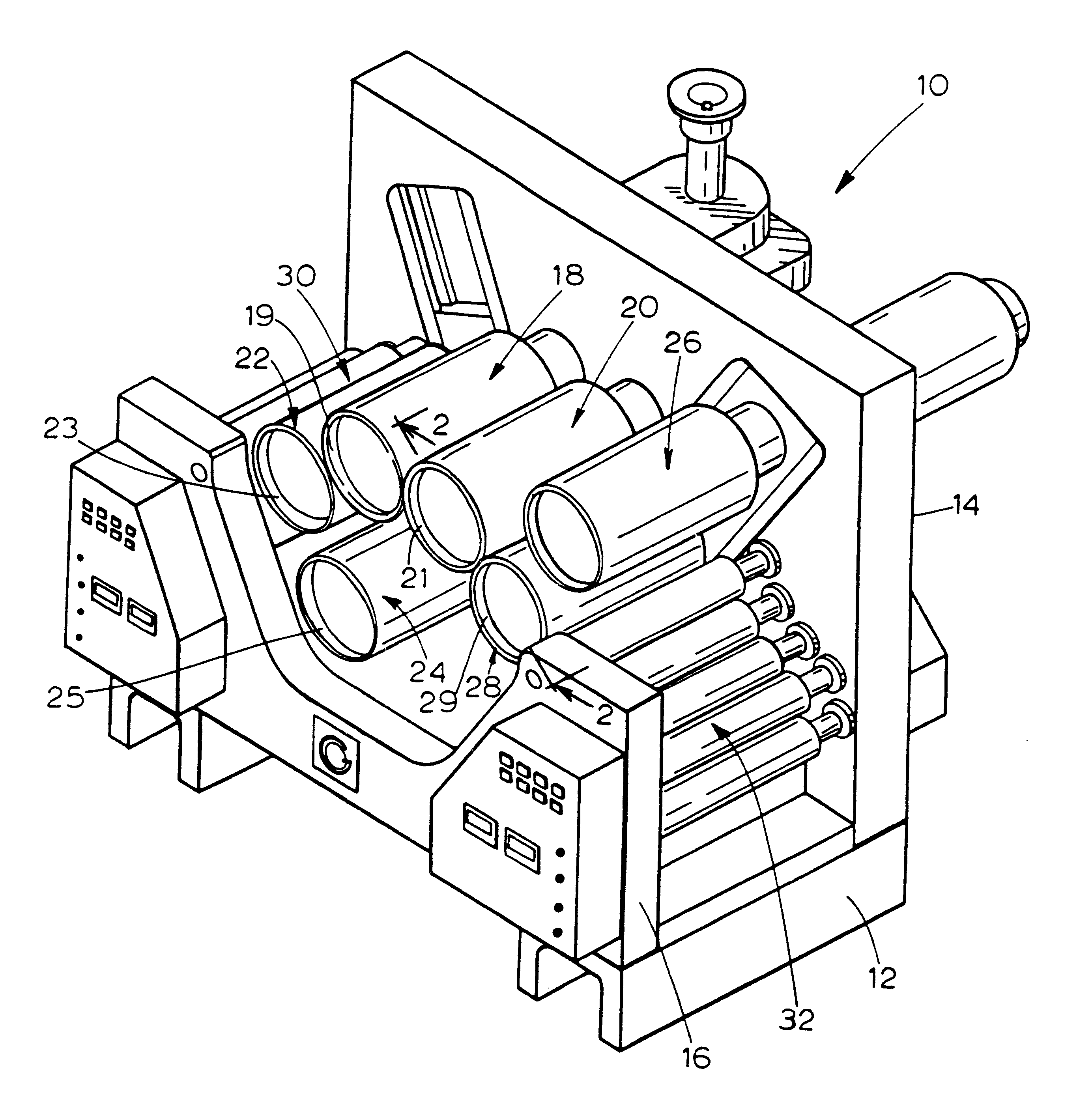

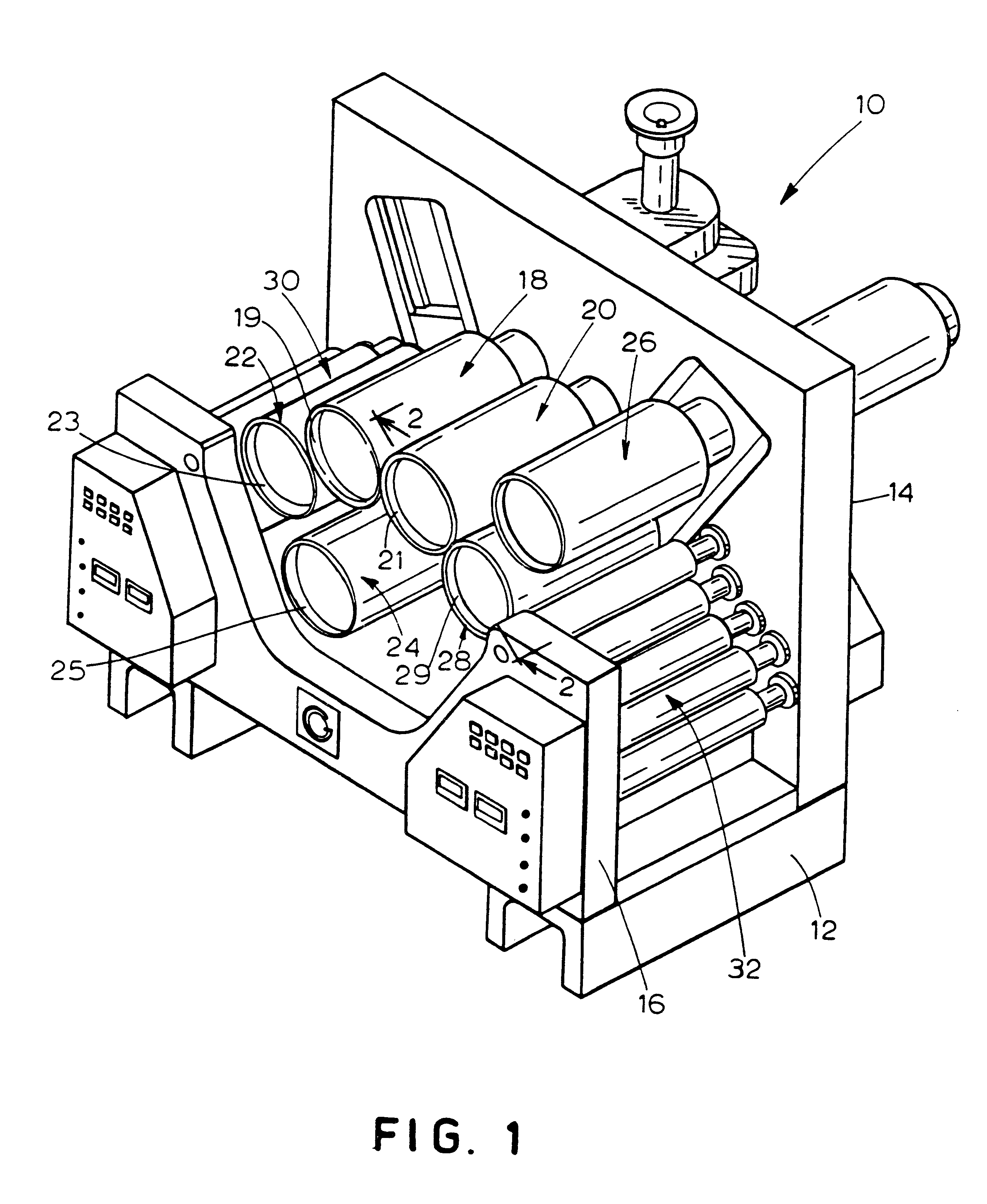

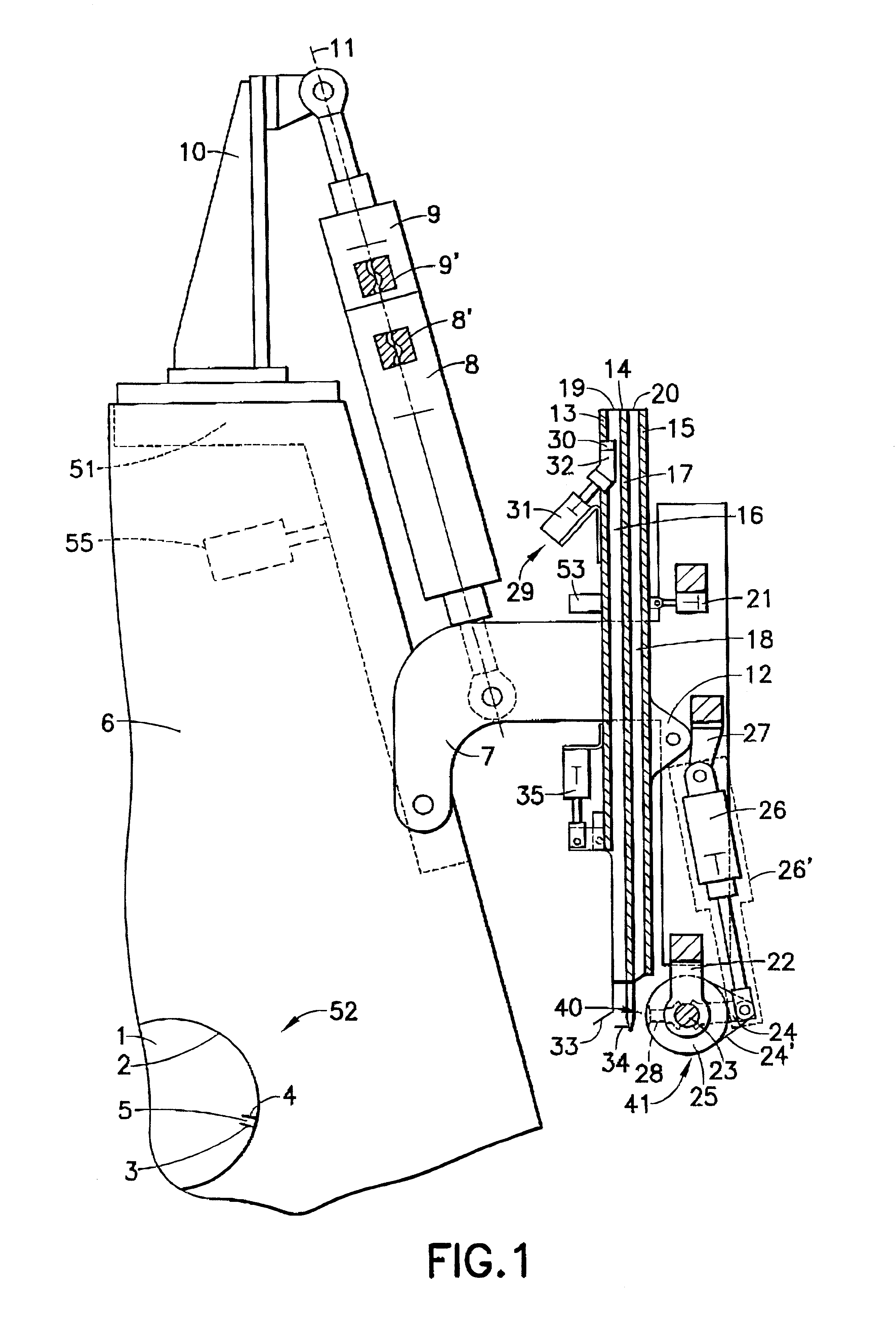

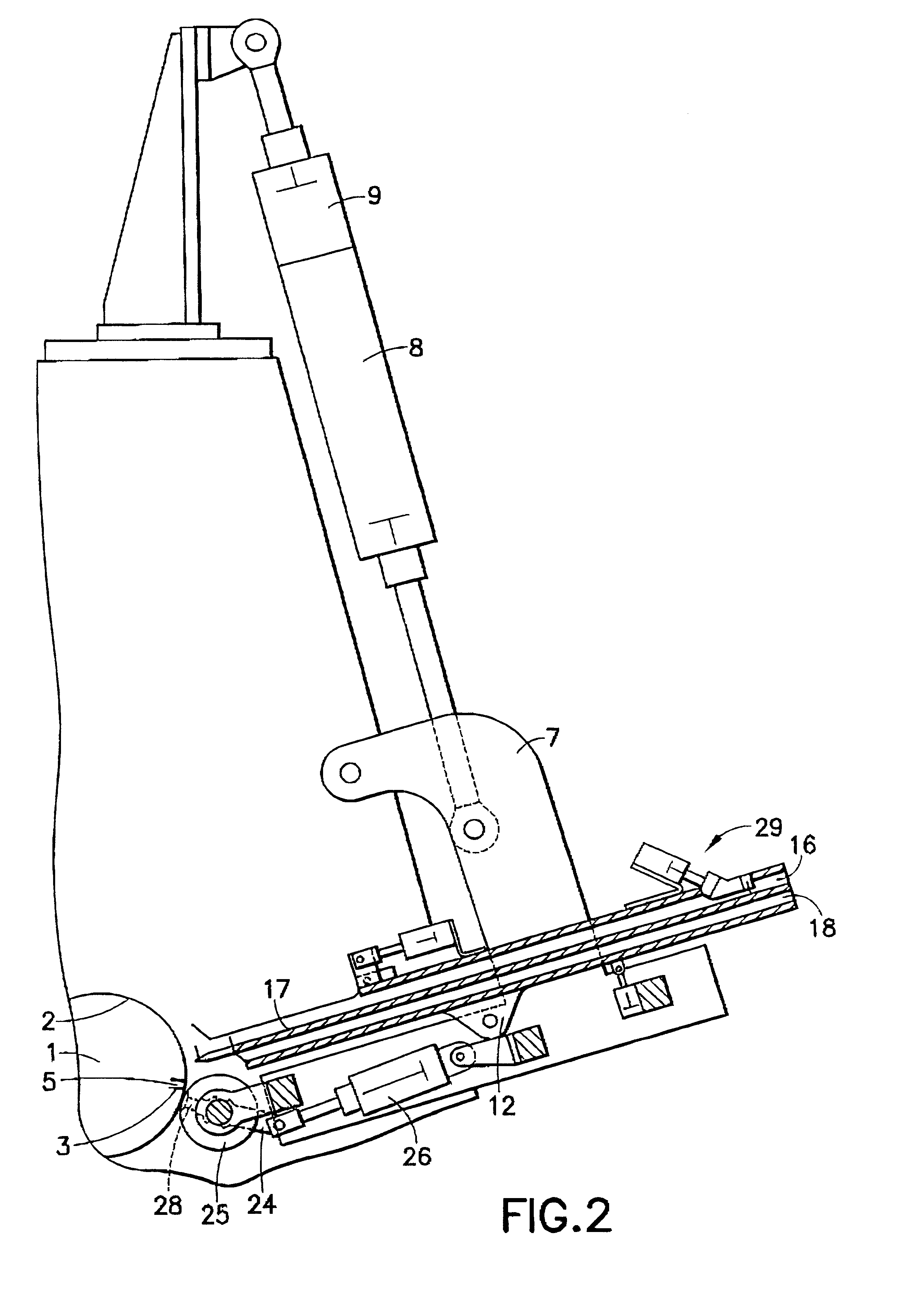

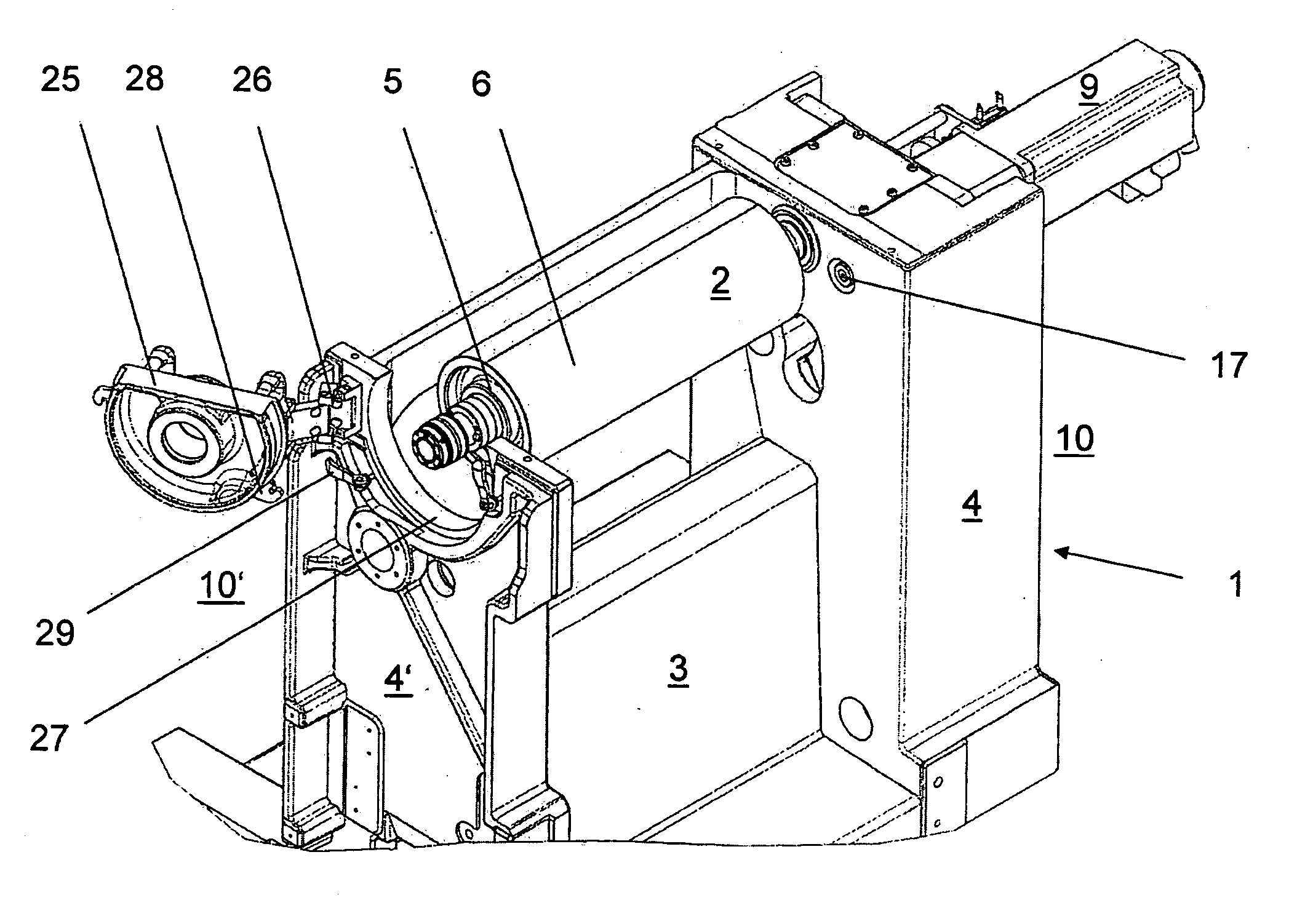

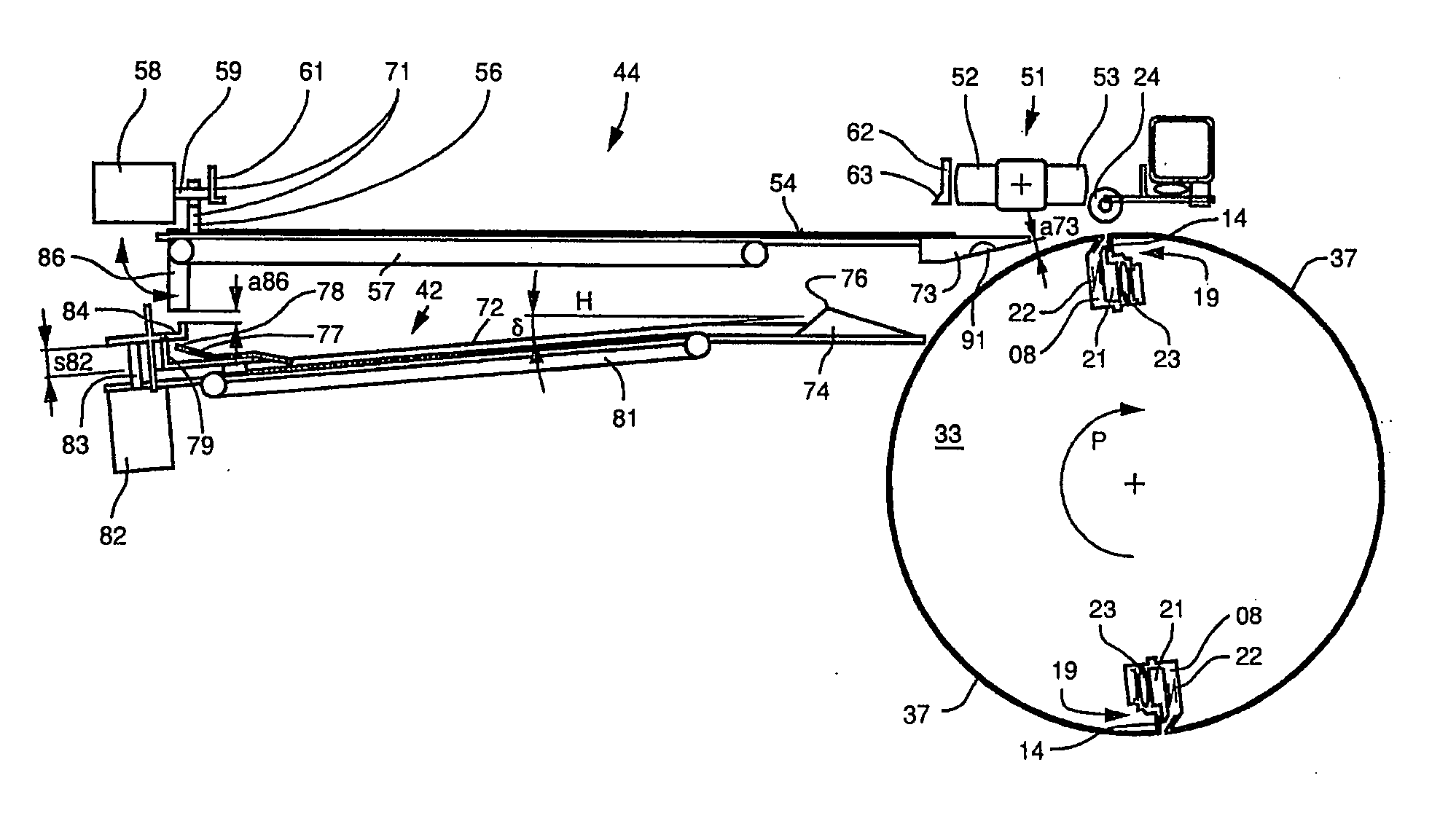

Apparatus and method for changing printing sleeves on a printing machine

InactiveUS7290488B2Pushed more easilyEasy to pushPrinting platesPlate printingPrinting pressComputer engineering

The invention provides an apparatus for the mounting and / or demounting of at least two printing sleeves outside a printing unit of a printing machine. The printing sleeves include an outer printing sleeve forming a printing surface and an inner printing sleeve providing diameter compensation between the outer printing sleeve and an impression cylinder of the printing machine. The apparatus having a reception device onto which an inner printing sleeve can be pushed for mounting the two printing sleeves. The apparatus having at least one compressed-air device for facilitating the fixing of the inner printing sleeve on the reception device and for conducting compressed air through orifices assigned to the inner printing sleeve in order thereby to make it possible for an outer printing sleeve to be pushed more easily onto the inner printing sleeve.

Owner:MANROLANAD AG

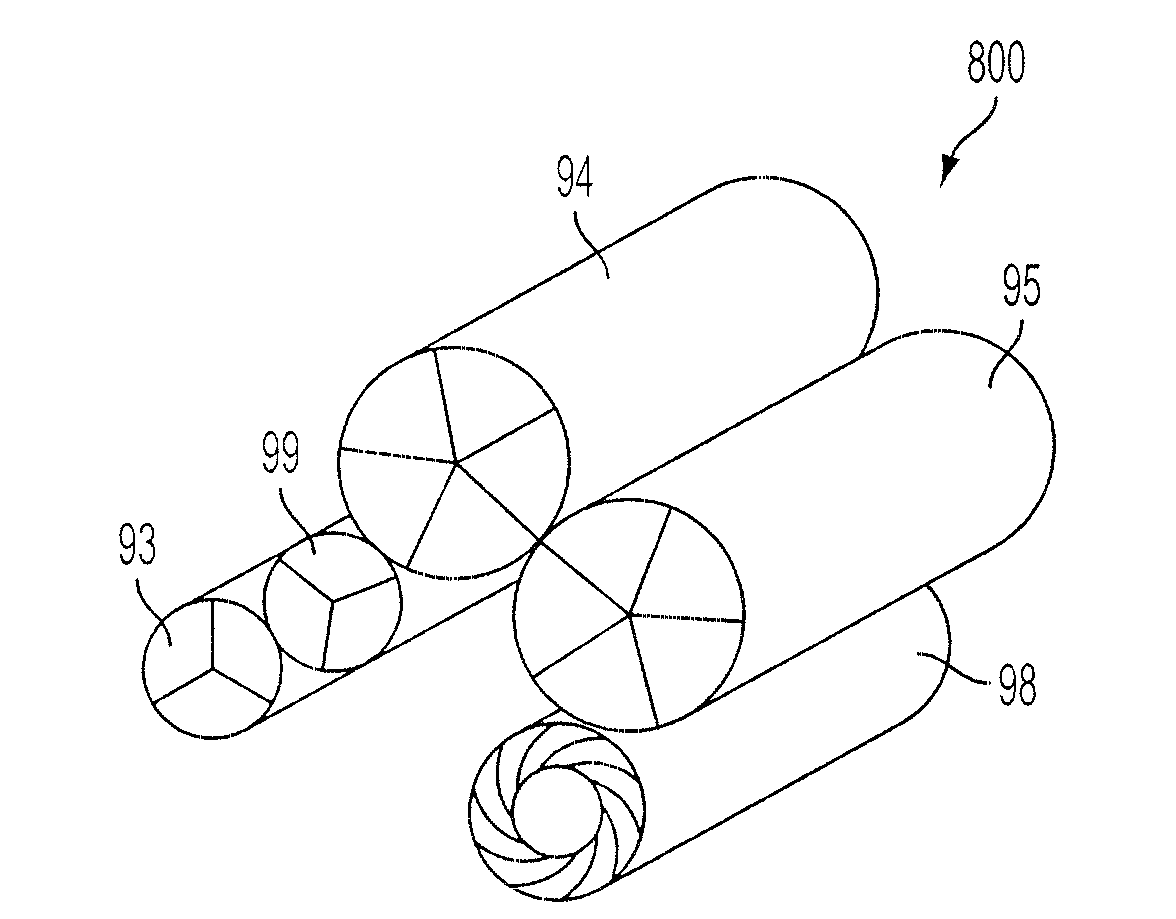

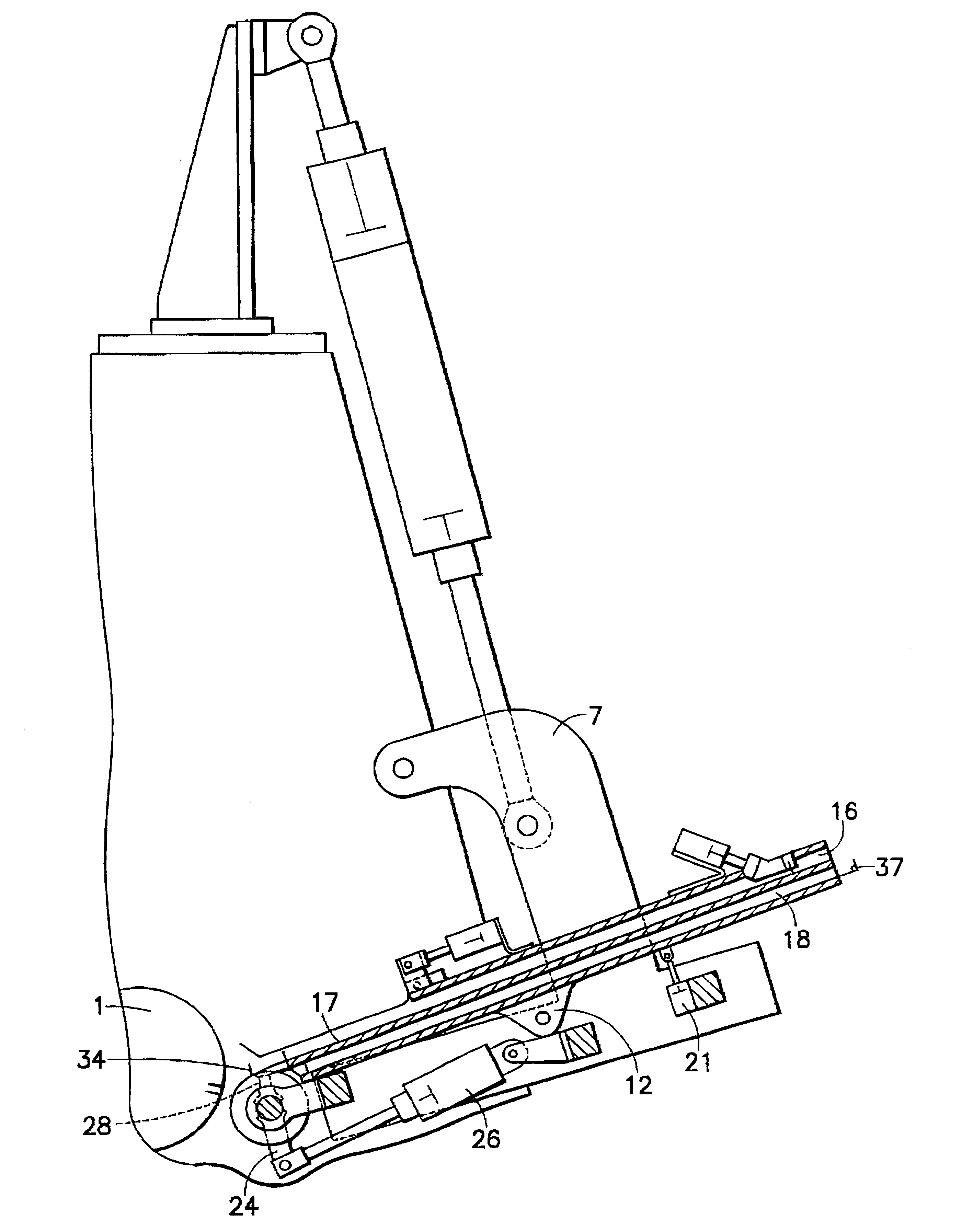

Printing Press, Folder, and Methods of Operation

InactiveUS20090241787A1Shorten the lengthPrinting platesFolding thin materialsEngineeringPrinting press

Systems and methods for allowing existing rotary printing press units to produce smaller pages at a faster rate of speed without having to replace the press unit. Specifically, the systems and methods relate to retrofitting an existing press unit to produce three pages of material in each full rotation instead of the traditional two pages.

Owner:PRESSLINE SERVICES

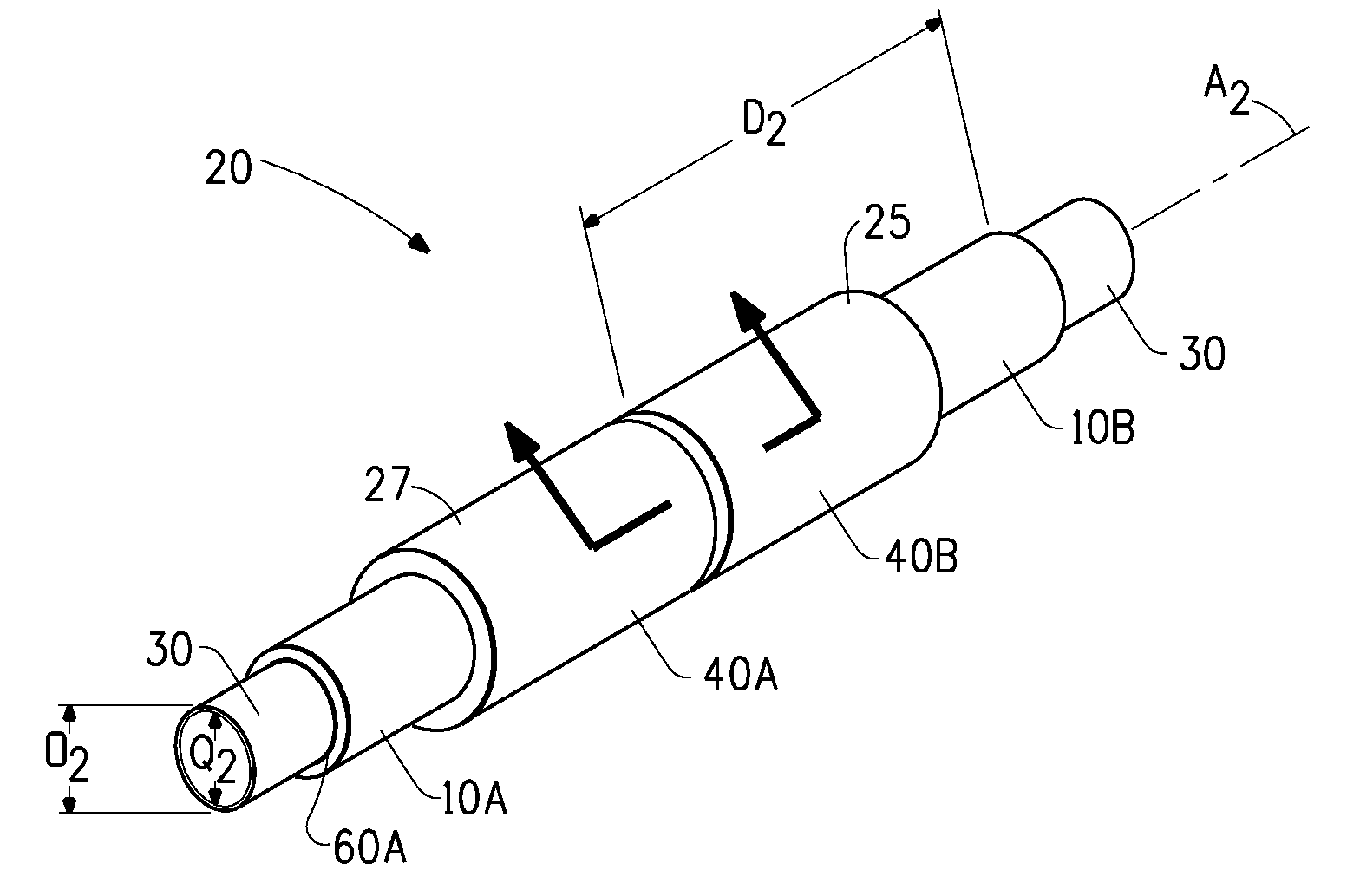

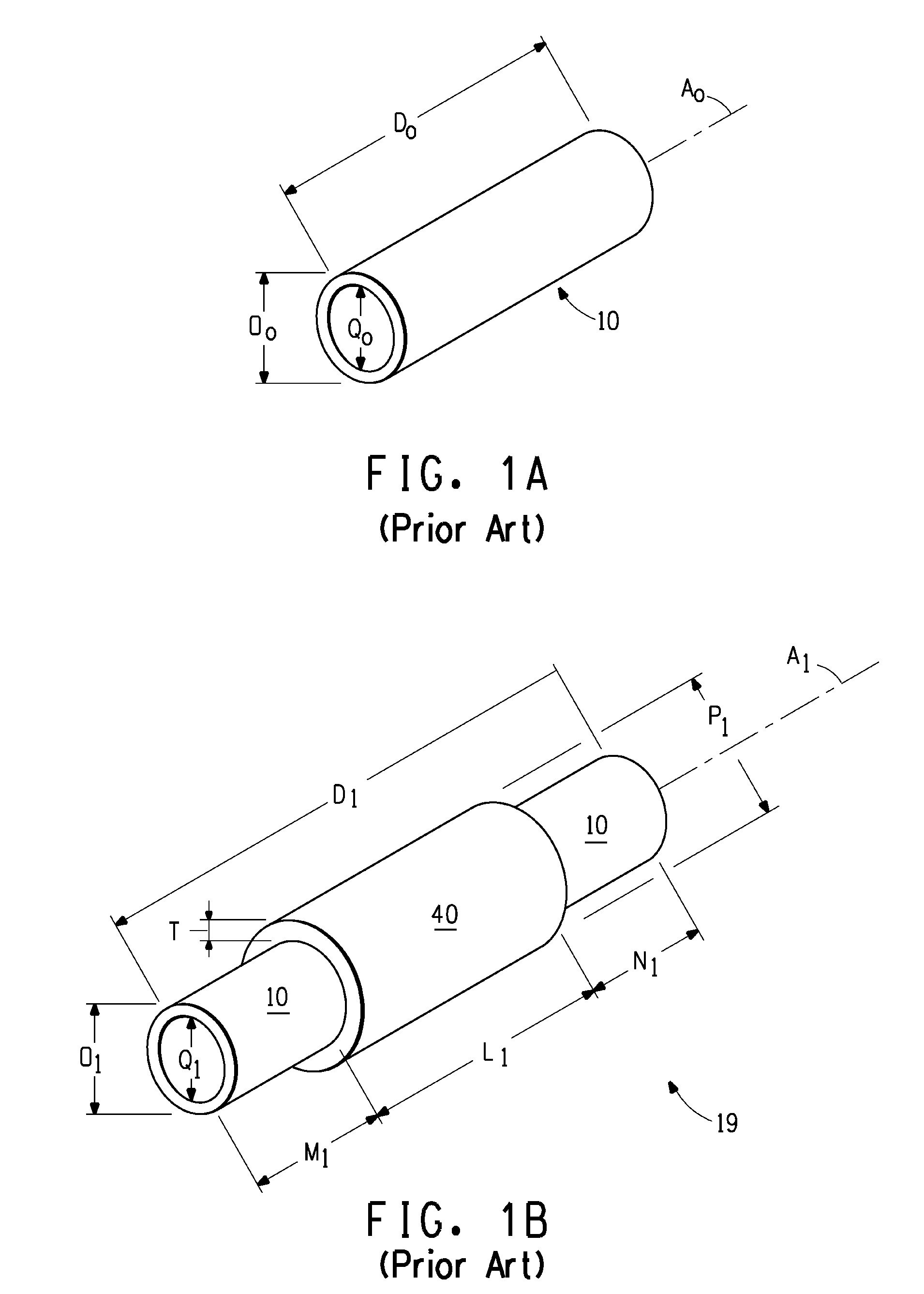

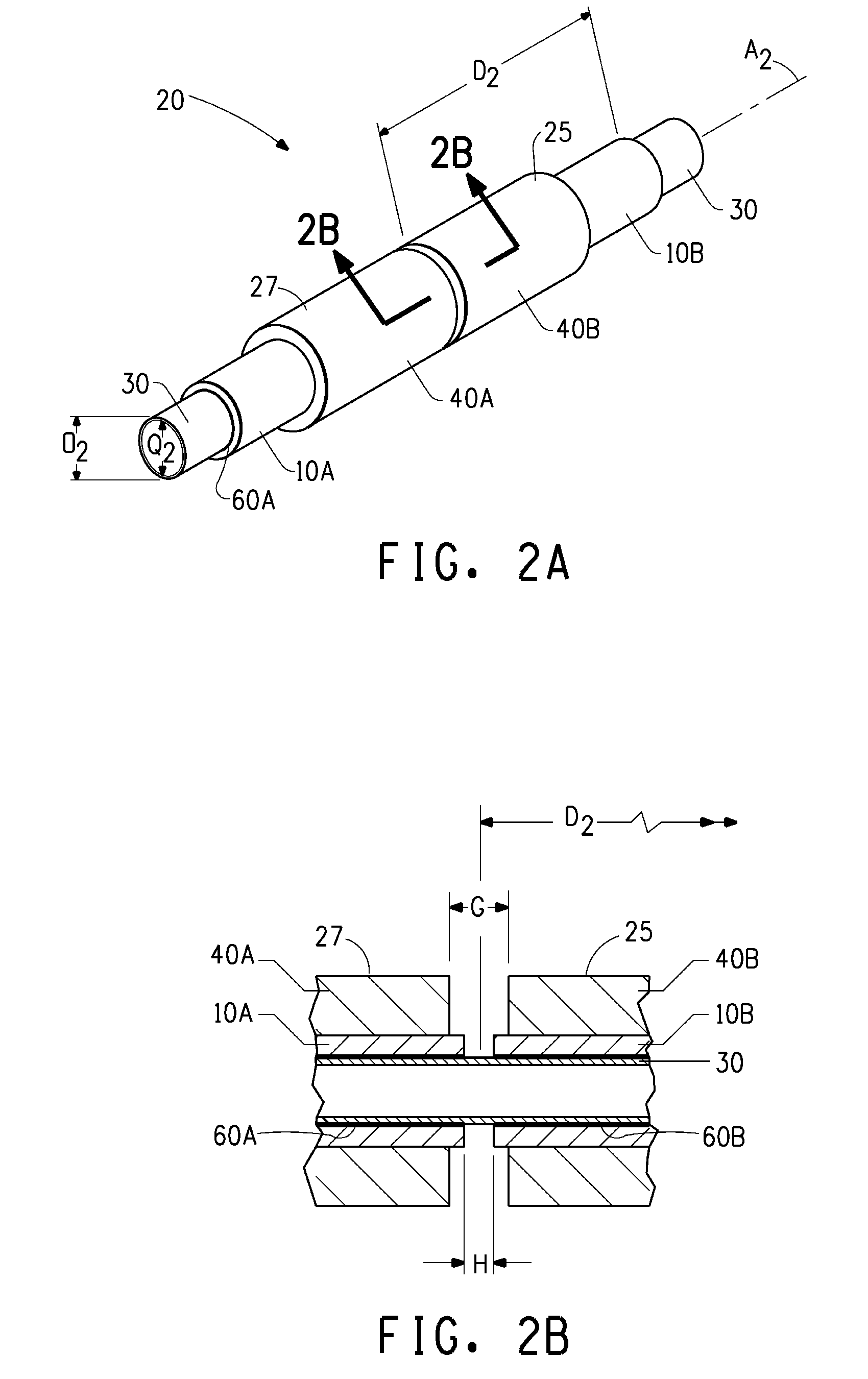

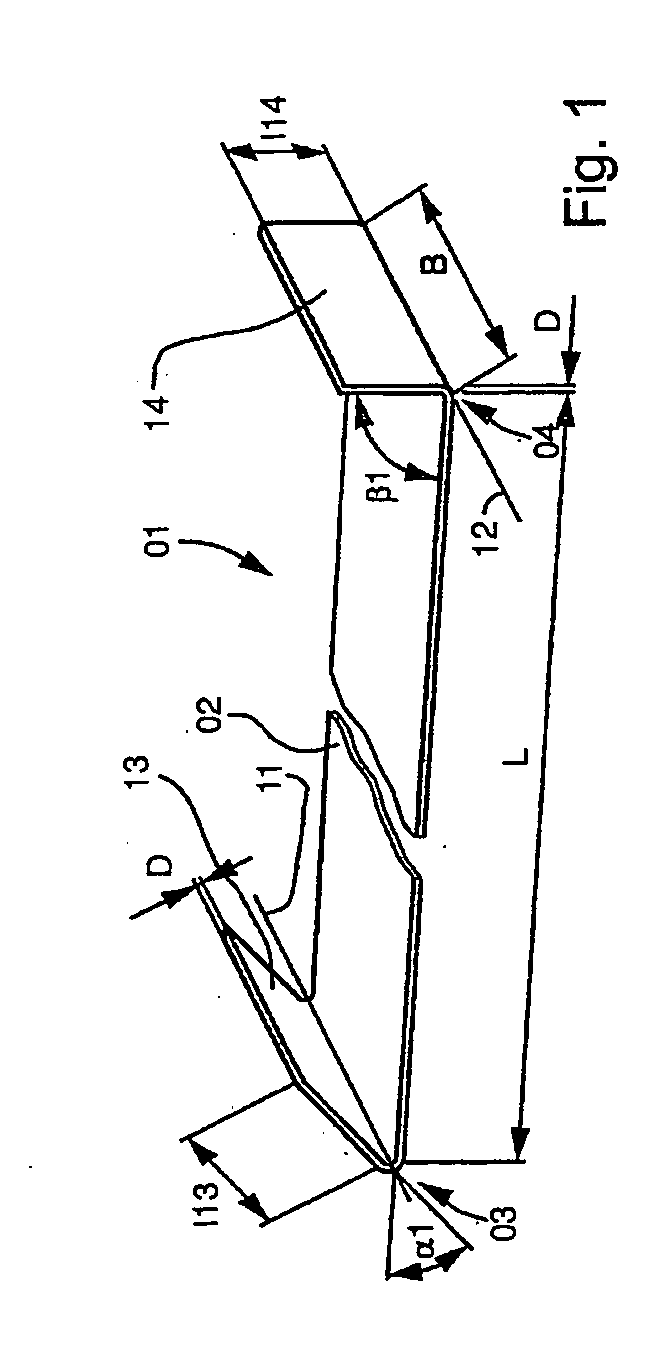

Extended print sleeve and method for preparing a printing form from the sleeve

The invention provides an extended print sleeve having a longitudinal axis and adapted to form a printing form having a circumferential seam with no printing surface disposed a distance D along said longitudinal axis from one end thereof, comprising: a first print element; and a second print element; wherein each print element comprises a separate cylindrically-shaped support having a photosensitive layer thereon and disposed at a fixed position along said longitudinal axis, and wherein said second print element has a length substantially equal to distance D.

Owner:EI DU PONT DE NEMOURS & CO

Sleeve on a drum and changing said sleeve

ActiveUS20050069353A1Good precisionEasy to replaceShaft and bearingsMetal-working apparatusMechanical engineeringEngineering

Owner:THE PROCTER & GAMBLE COMPANY +1

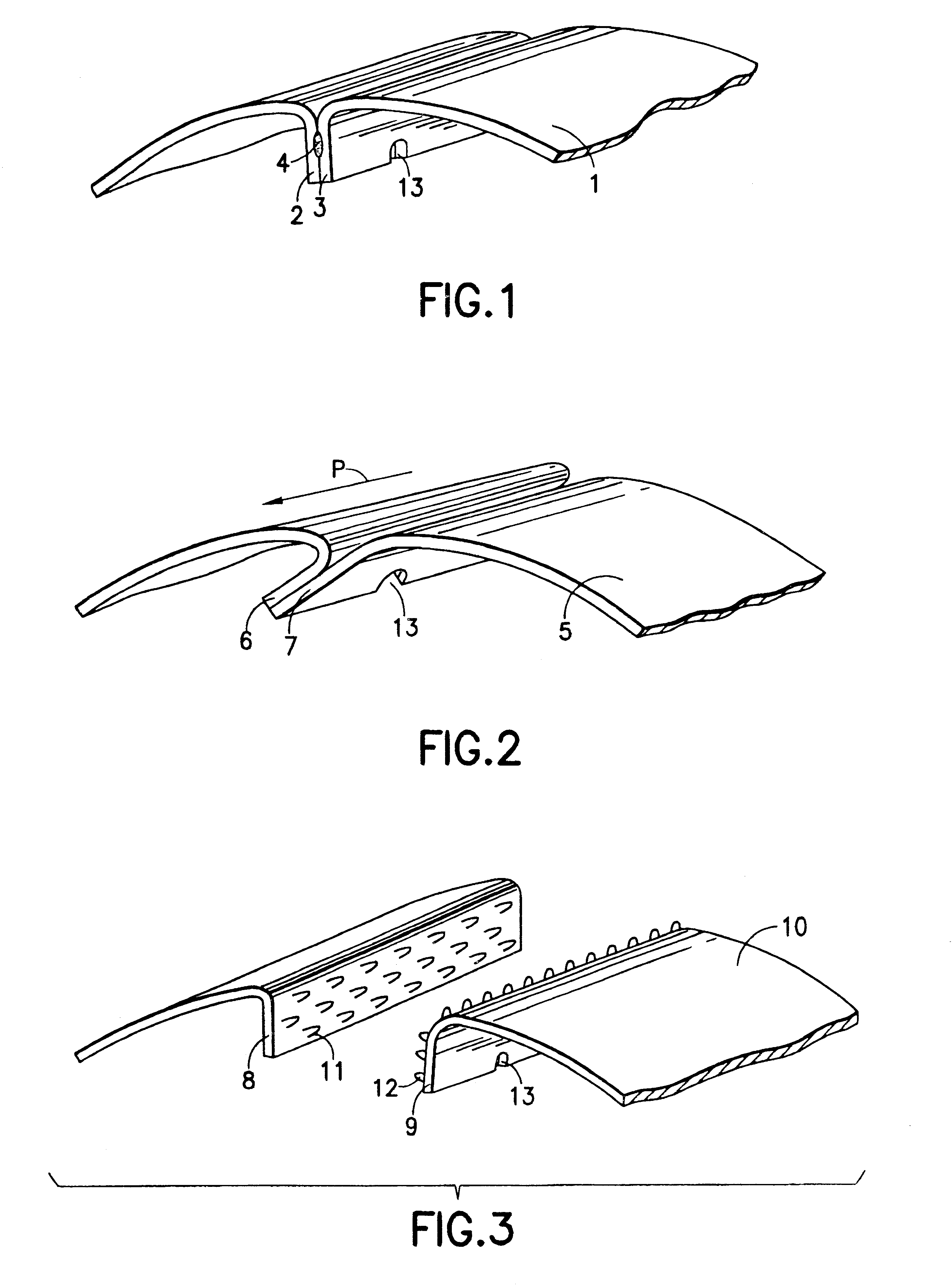

Apparatus and method for changing flexible printing plates

InactiveUS6450096B1Easy constructionEasy to handleAddressographsPlaten pressesEngineeringPrinting press

An apparatus for changing flexible printing plates on a plate cylinder of printing machines having a simple, compact and space-saving construction is provided. The apparatus includes two magazines arranged beside each other, to hold the printing plates to be inserted and removed. A transporting arrangement pivotably mounted on a shaft is beside the magazines. A holding arrangement which is on the transporting means is used both to grip and guide a printing plate to be inserted and to grip and guide a printing plate to be removed. The magazines and the transporting arrangement are mounted in a frame that can be pivoted towards and away from the plate cylinder. The invention further relates to a method of changing flexible printing plates on a plate cylinder of a printing machine.

Owner:MANROLANAD AG

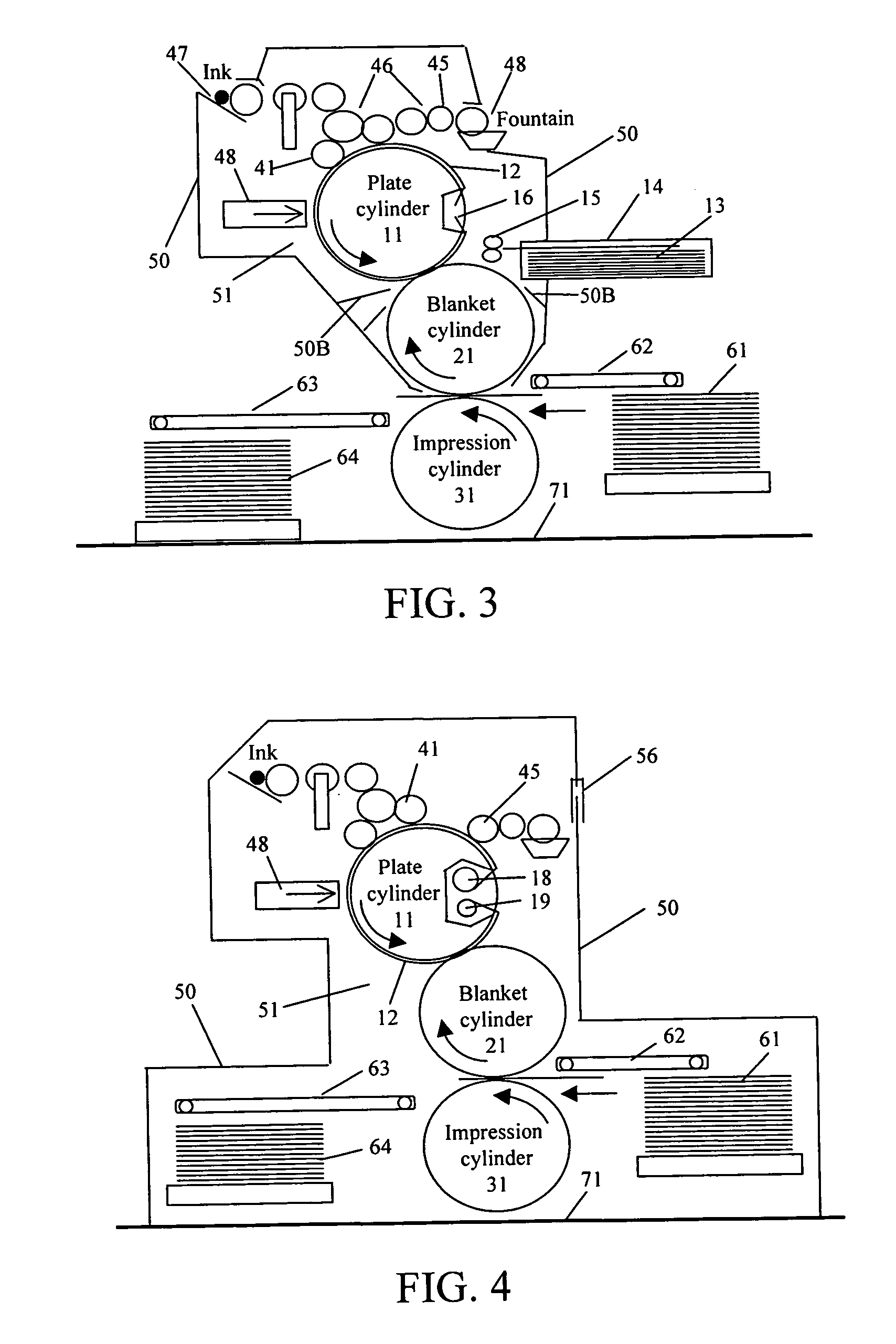

Sheet-fed offset rotary printing press

InactiveUS20050155503A1Improve printing qualityImprove productivityPrinting platesRotary letterpress machinesEngineeringPrinting press

A sheet-fed offset rotary printing press includes one plate cylinder, one blanket cylinder with the same size as that of the plate cylinder, one impression cylinder, one plate making device, four inking devices, four roller throw-on / throw-off devices, and a cylinder throw-on / throw-off device. At least one plate is mounted on an outer surface of the plate cylinder. The blanket cylinder opposes the plate cylinder, and at least one blanket is mounted its outer surface. The impression cylinder has at least one gripper device for holding a paper sheet. The plate making device can inscribe four printing patterns on four regions of the plate. The inking devices individually supply inks to the four printing patterns of the plate on the plate cylinder through four ink form rollers. The roller throw-on / throw-off devices throw on one ink form roller onto corresponding one printing pattern of the plate and throw off the remaining ink form rollers from the remaining printing patterns. The cylinder throw-on / throw-off device throws on the blanket cylinder supplied with the inks immediately before it opposes the paper sheet held by the gripper device, and throws it off before it opposes the impression cylinder while the gripper device does not hold a paper sheet.

Owner:KOMORI CORP

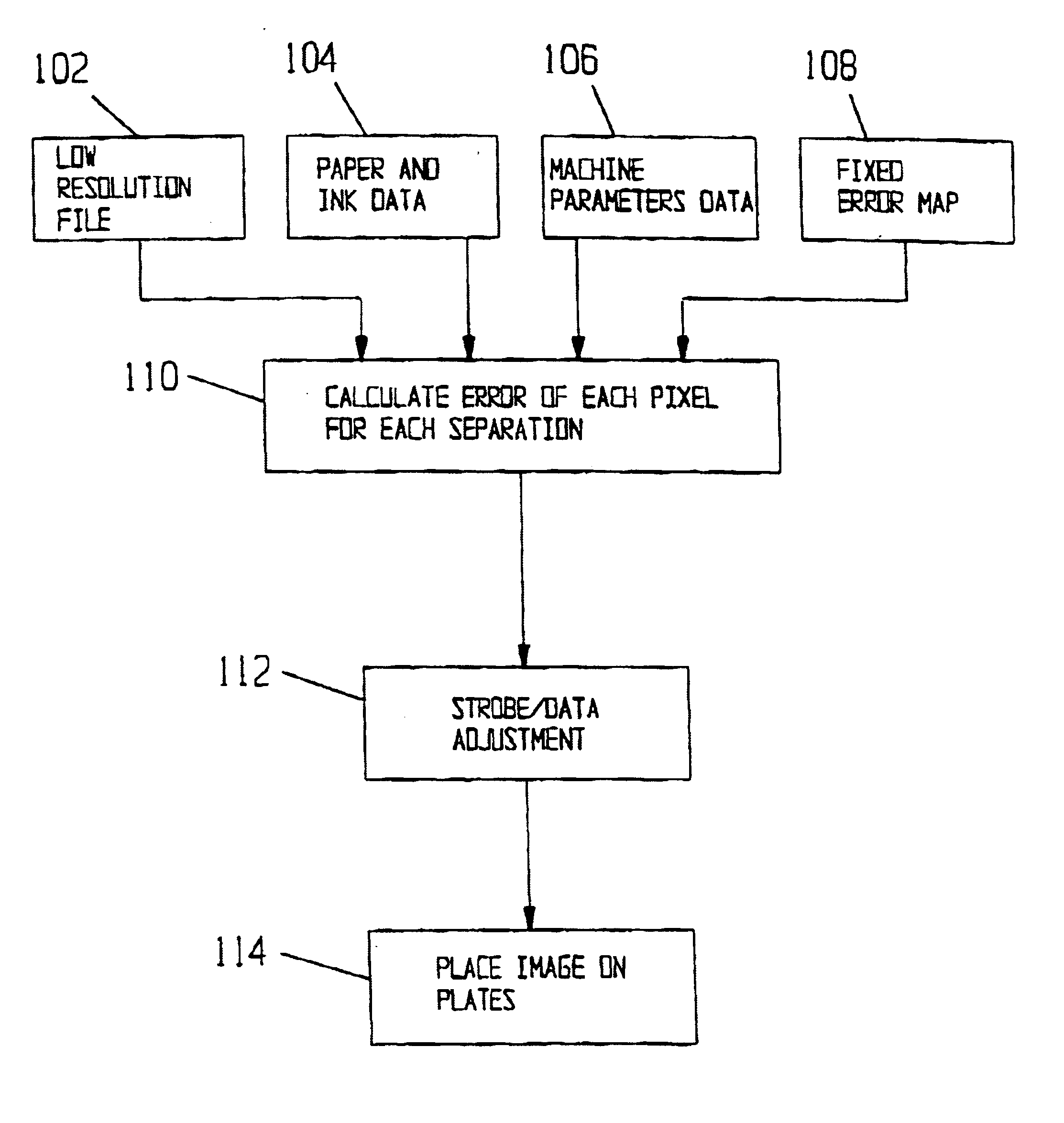

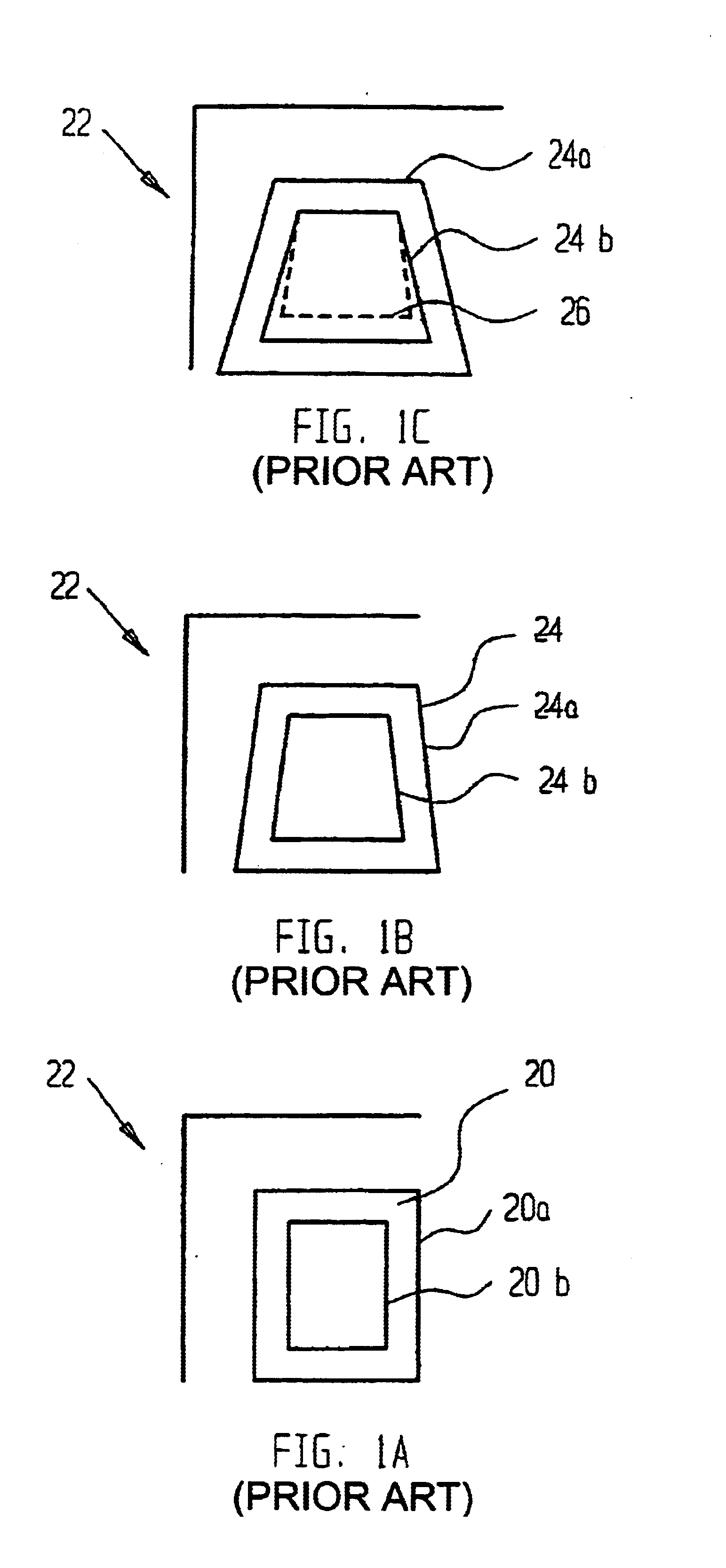

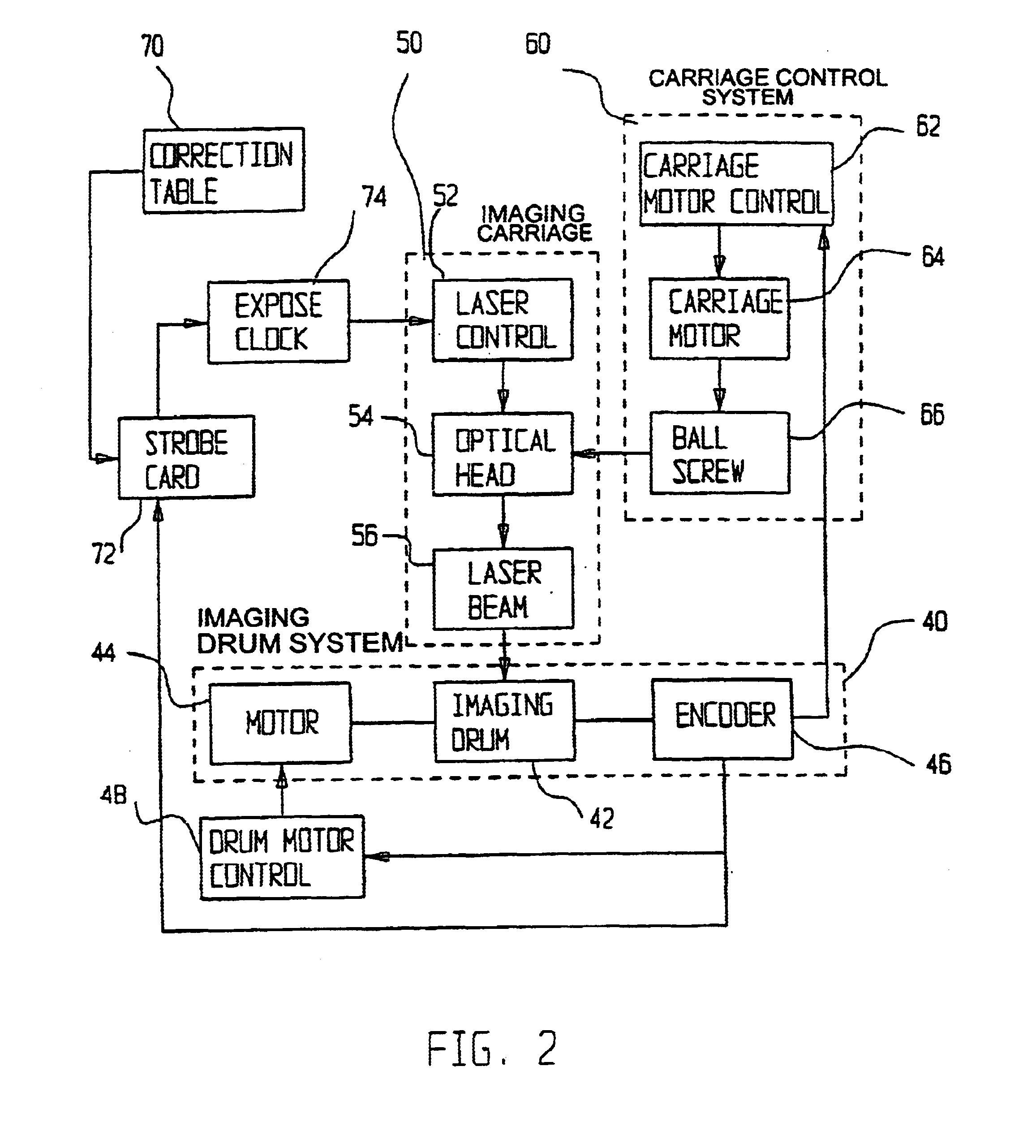

Digital offset printing registration

InactiveUS6895862B1Speed up the processAddressographsPlaten pressesComputer scienceOffset printing

There are disclosed methods and systems for the process of on-press plate imaging, including automatic processes for plate preparation, that compensate for registration and print-length errors (plate loading is performed before imaging). As a result of these processes, the position accuracy is determined by the imaging system. The system of the present invention creates deformed images on the plates during the imaging stage, these deformed images, being such that the separations will be in register (coordinated) after printing.

Owner:A I T ISRAEL - ADVANCED IMAGING TECH

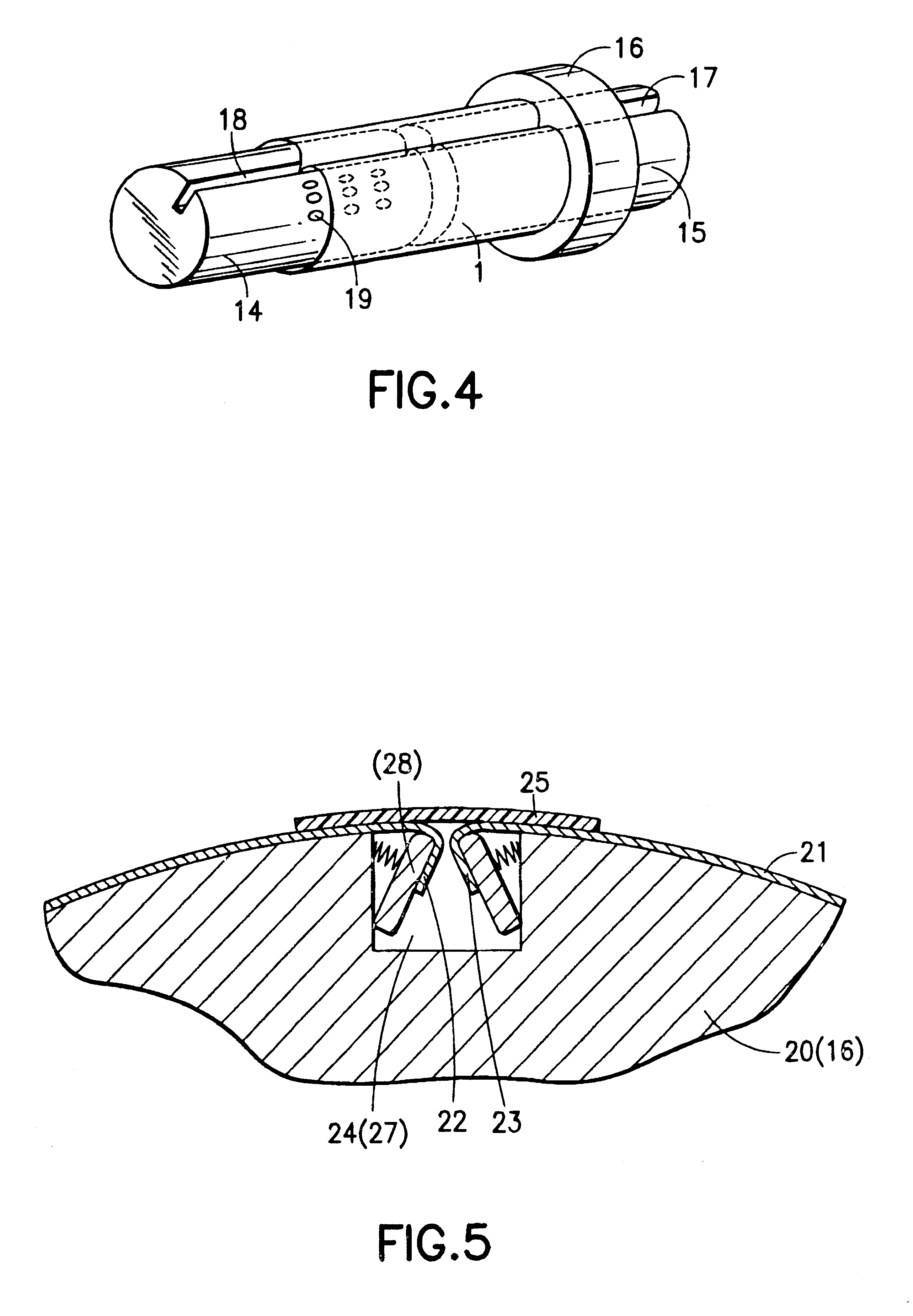

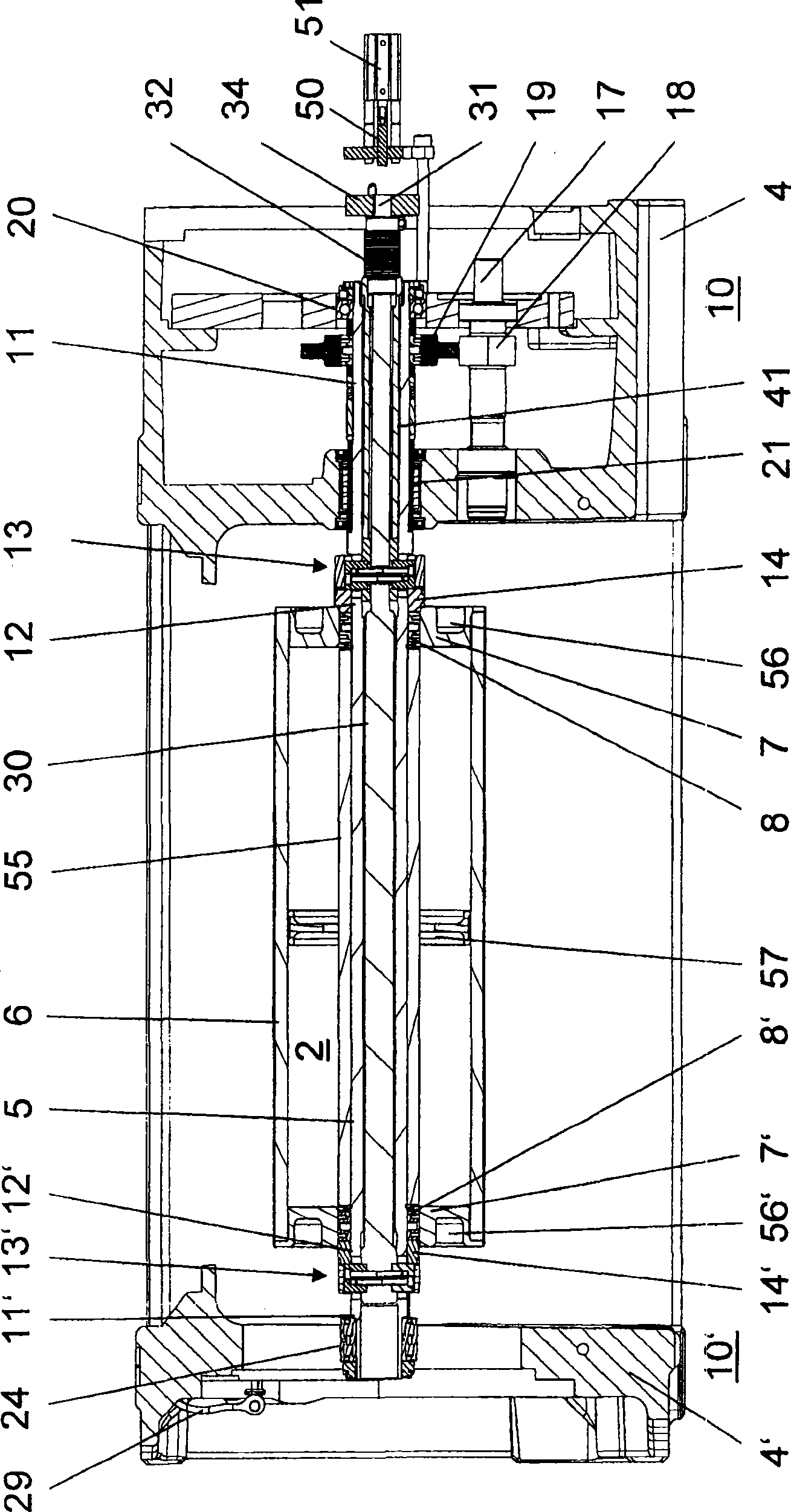

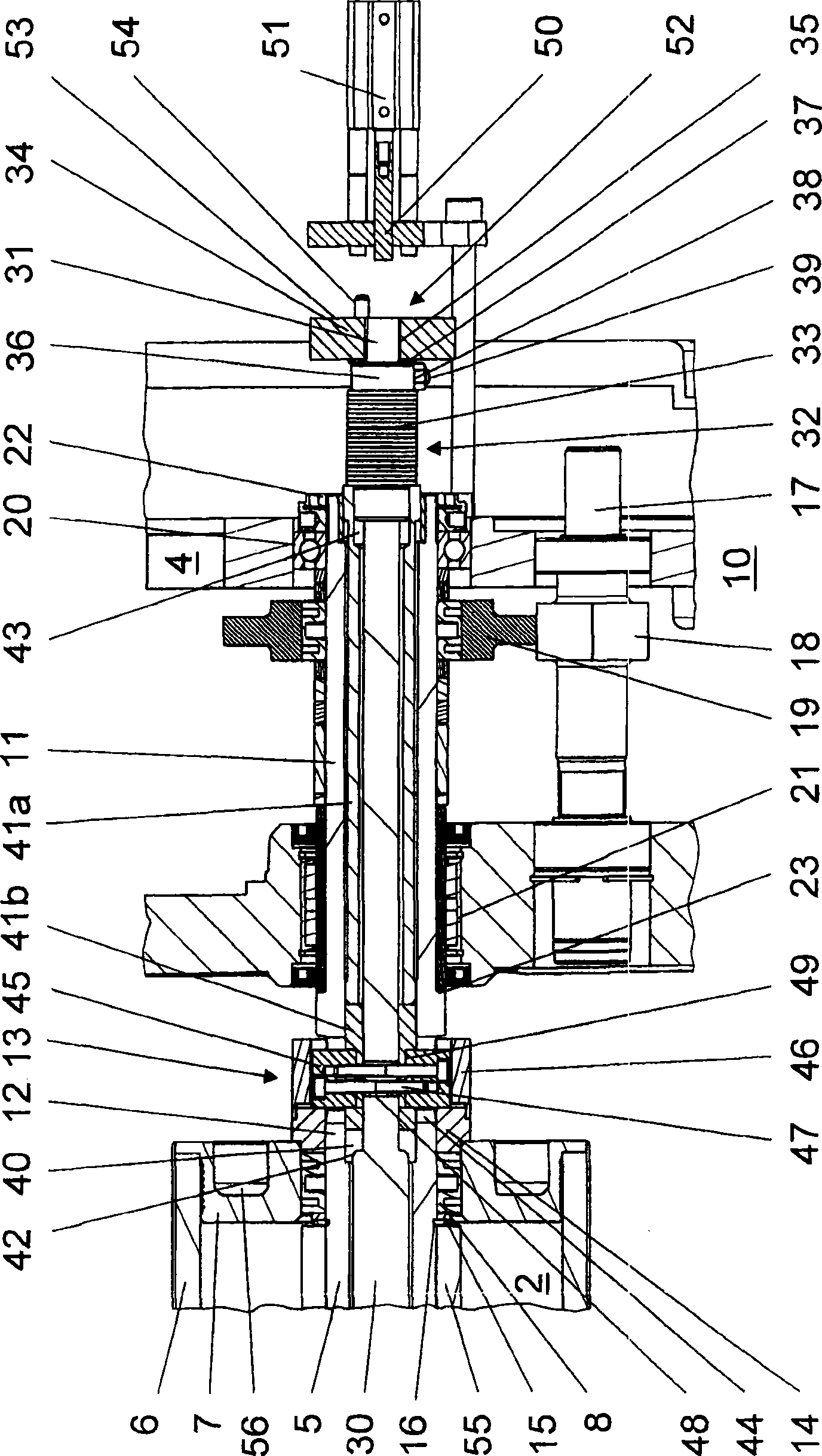

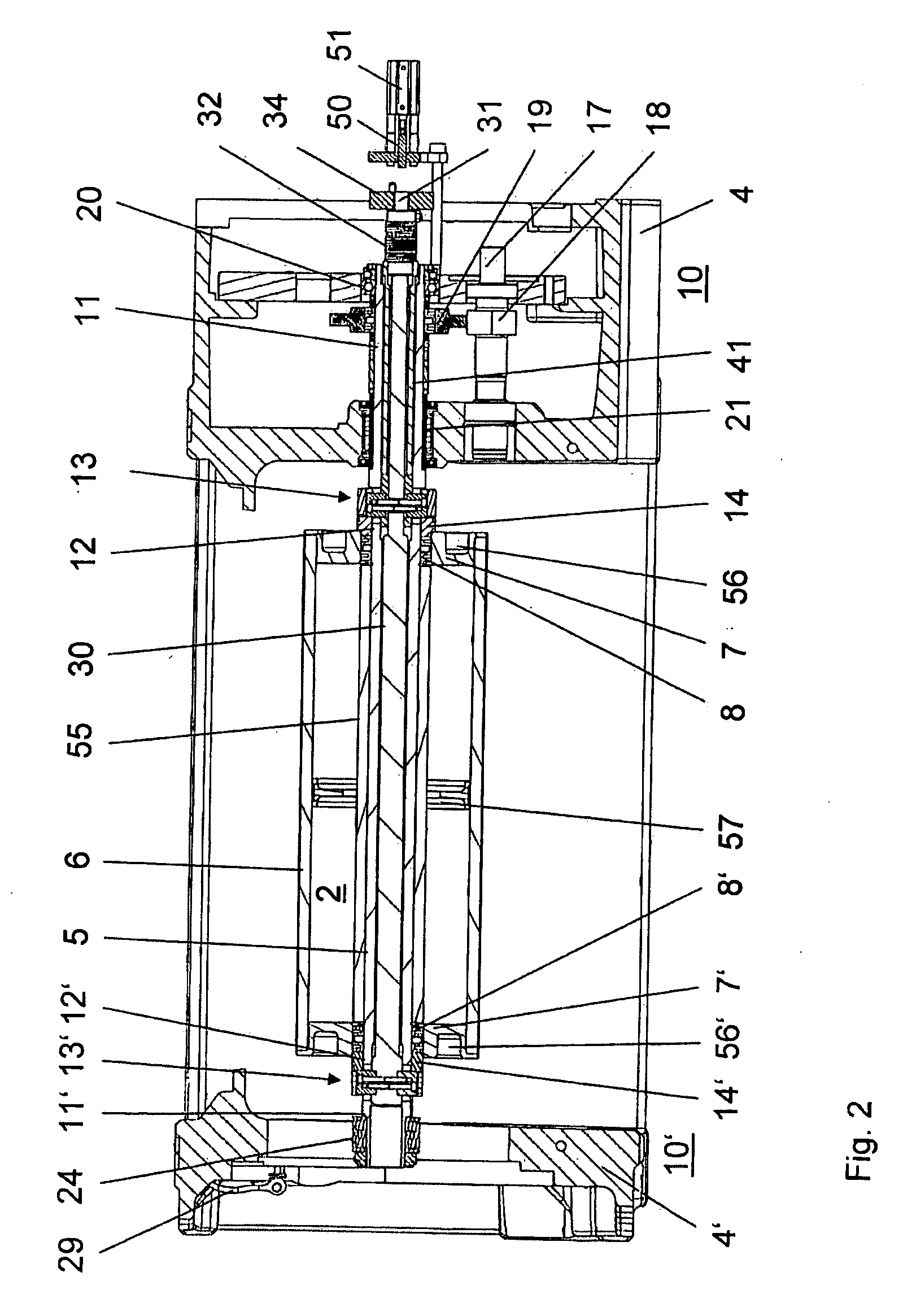

Cylinder for a printing unit of a printing machine and method for swapping out the printing sleeve of such a cylinder

InactiveCN101508195AClamp firmlyEasy to replacePrinting platesRotary pressesEngineeringPrinting press

A cylinder for a printing unit of a printing machine includes a hollow support shaft (5) with first and second tensioning elements (8, 8') arranged thereon at a distance to each other. A replaceable printing sleeve (6) is positioned on the support shaft. First and second force transfer elements (13, 13') respectively cooperate with the first and the second tensioning elements (8, 8') for clamping down and releasing the printing sleeve (6). An operating mechanism (30) is arranged on the inside of the hollow support shaft (5) and is operatively connected to the two force transfer elements (13, 13'). The operating mechanism includes at least one energy-storage element (32) for tightening and releasing the two tensioning elements (8, 8').

Owner:MULLER MARTINI HLDG

Cylinder for a printing unit of a printing machine and method for replacing a sleeve for such the cylinder

InactiveUS20090199732A1For quick replacementImprove printing qualityPrinting platesRotary pressesEngineeringPrinting press

A cylinder for a printing unit of a printing machine includes a hollow support shaft with first and second tensioning elements arranged thereon at a distance to each other. A replaceable printing sleeve is positioned on the support shaft. First and second force transfer elements respectively cooperate with the first and the second tensioning element for clamping down and releasing the printing sleeve. An operating mechanism is arranged on the inside of the hollow support shaft and is operatively connected to the two force transfer elements. The operating mechanism includes at least one energy-storage element for tightening and releasing the two tensioning elements.

Owner:MULLER MARTINI HLDG

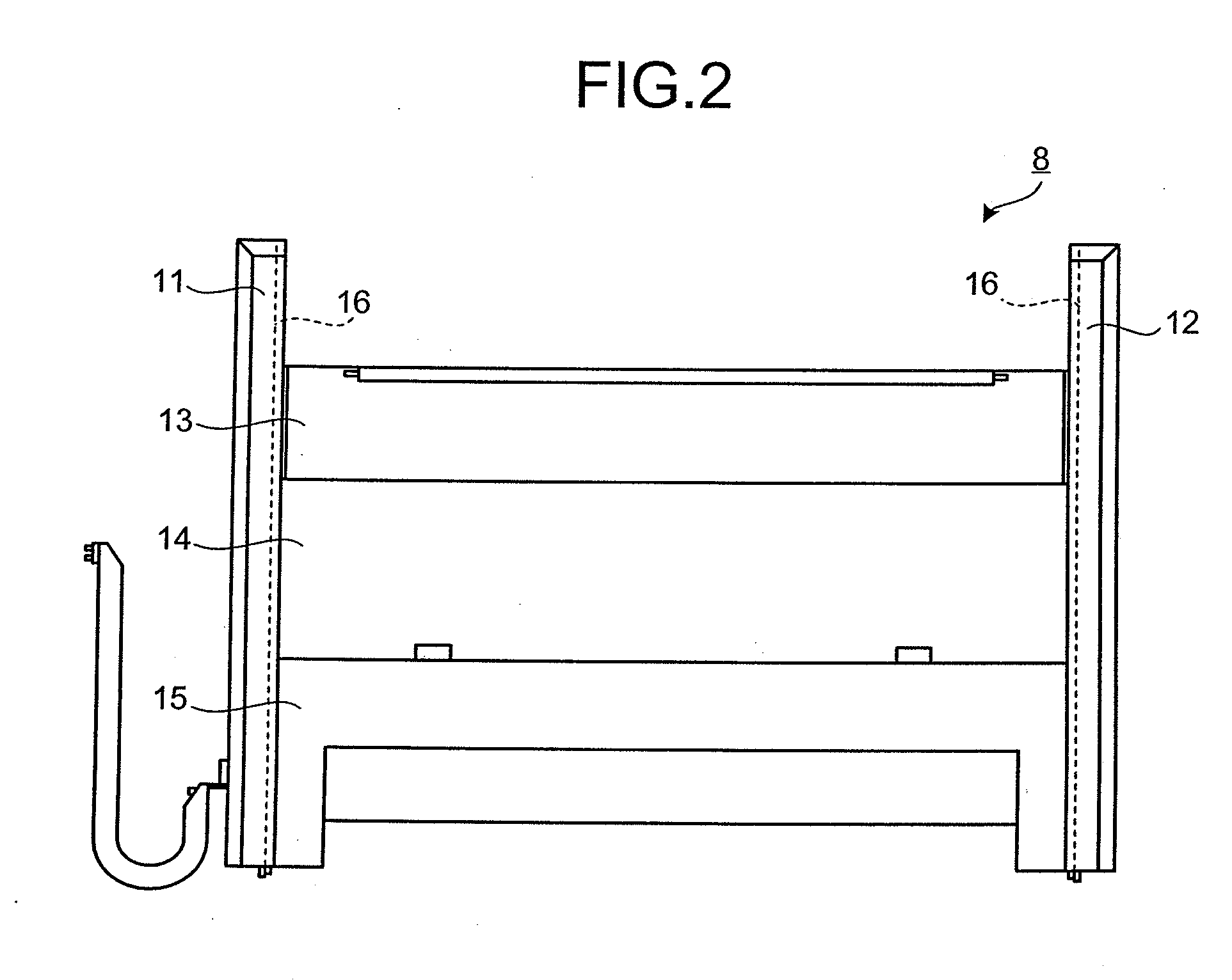

Devices for storing a blanket to be supplied to a cylinder of a printing machine

InactiveUS20050172846A1The overall height of the structure becomes lowerLow structural requirementsCylinder pressesAddressographsEngineeringPrinting press

A device is used to store blankets or dressings which are to be supplied to a cylinder of a printing machine. A plurality of such blankets or dressings, which are to be applied to the cylinder adjacent each other and axially spaced, are stored next to each other. These blankets or dressings are stored vertically above a supporting surface, in at least two vertically offset planes. The offset planes form a first storage position and the supporting surface forms a second storage position once at least one of the blankets or dressings has been stored in the different planes.

Owner:KOENIG & BAUER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com