Patents

Literature

1577results about "Rotary lithographic machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative-acting no-process printing plates

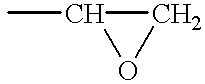

InactiveUS6171735B1Platen pressesSemiconductor/solid-state device manufacturingFunctional monomerOligomer

Owner:3M INNOVATIVE PROPERTIES CO

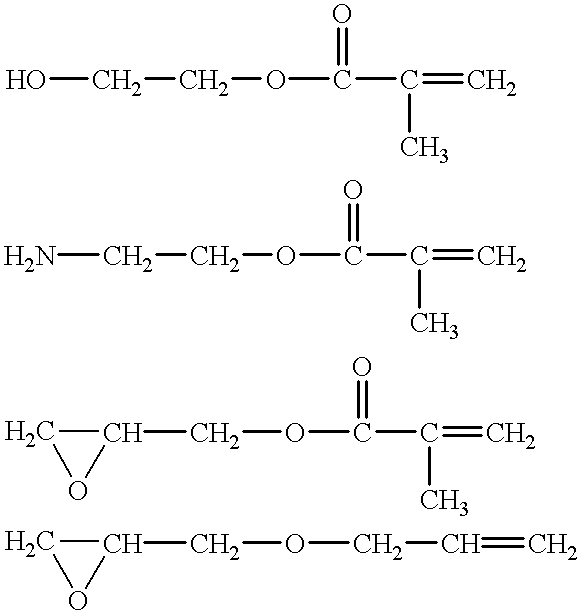

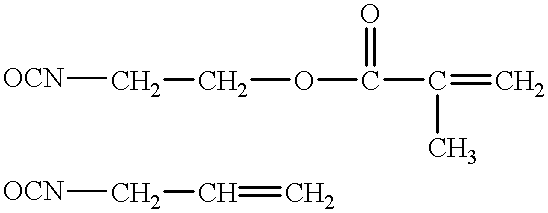

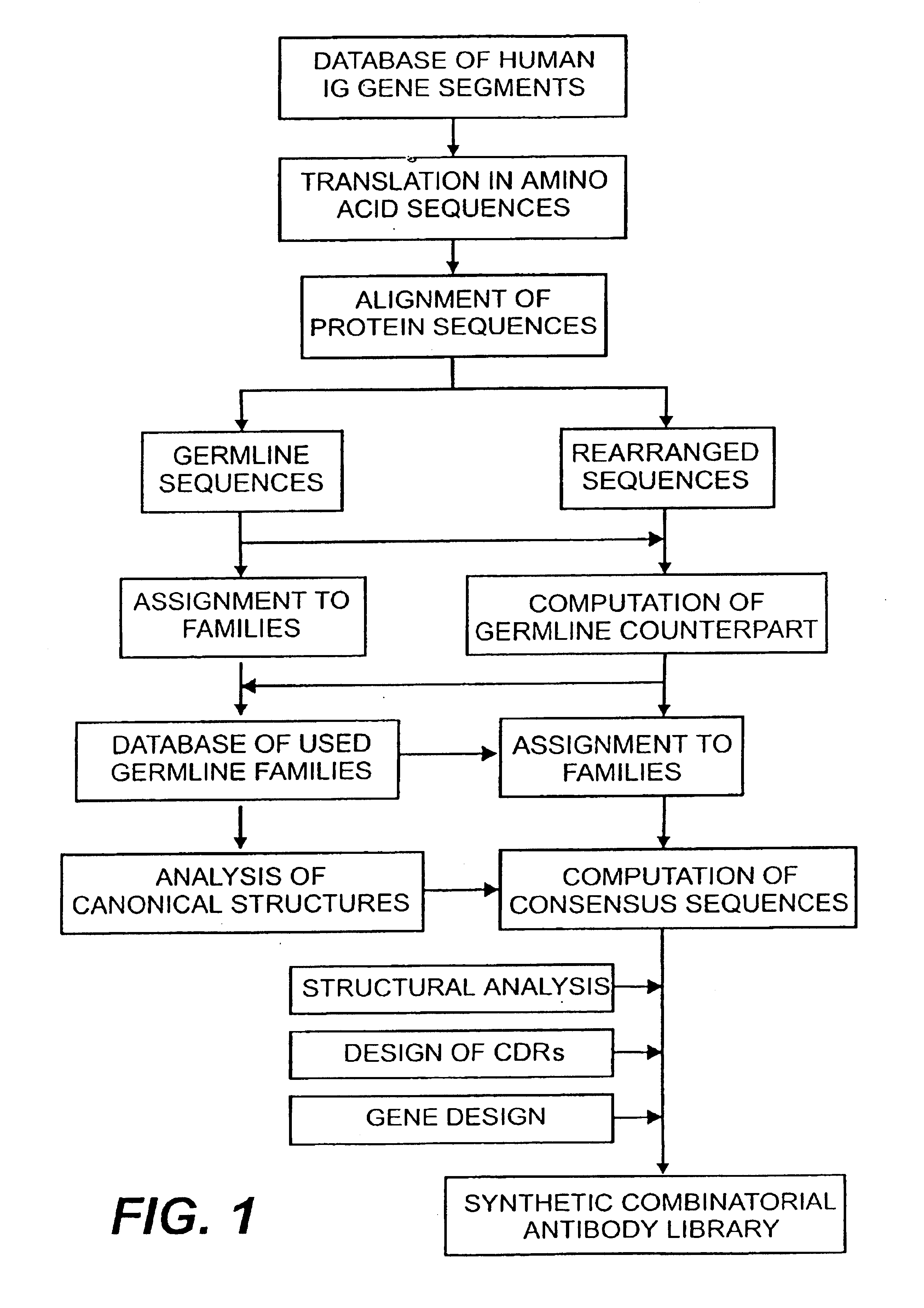

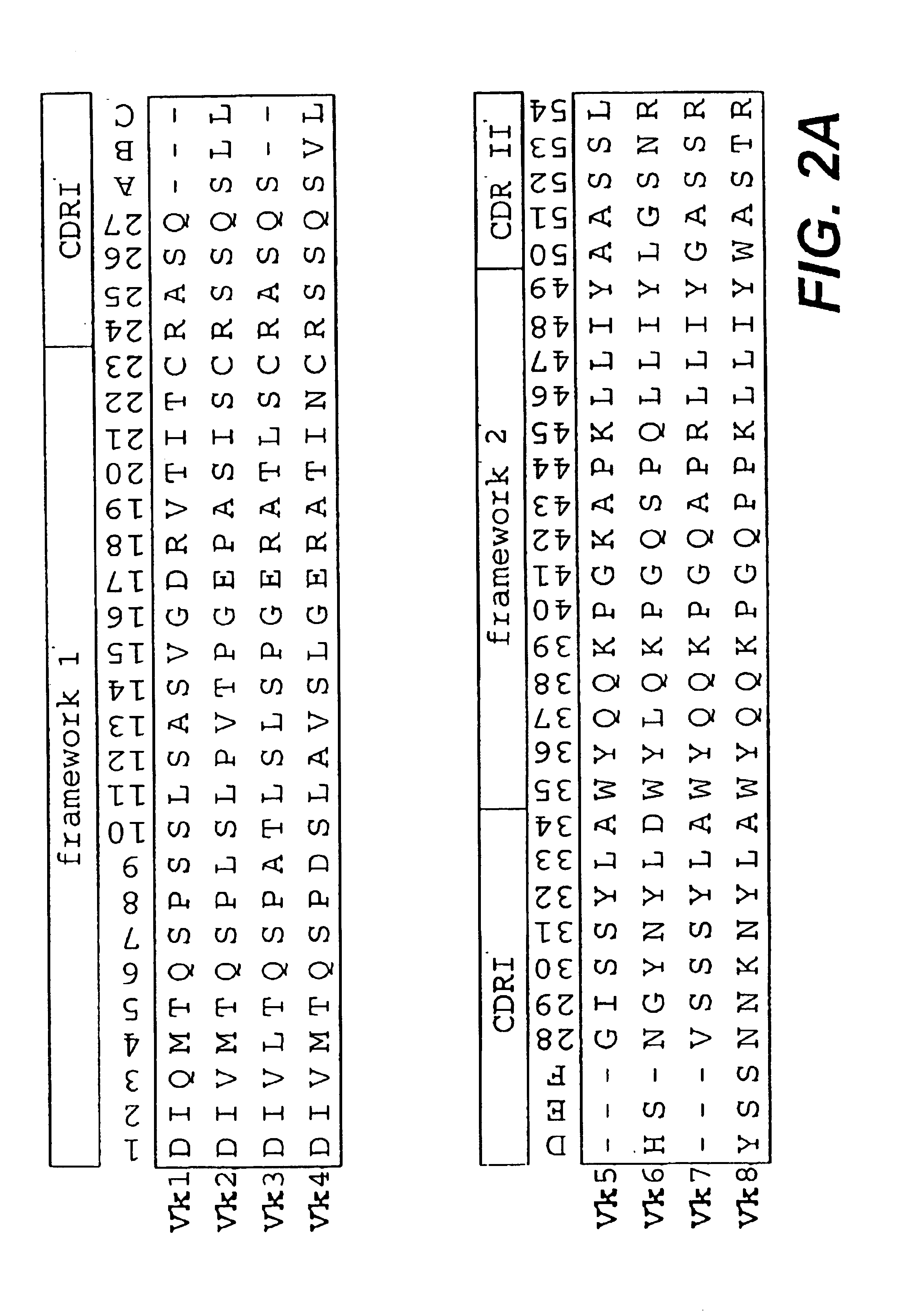

Protein/(poly)peptide libraries

InactiveUS6828422B1Reduce in quantityRemoving unwanted cleavages sitesPeptide/protein ingredientsAntibody mimetics/scaffoldsHuman DNA sequencingSynthetic DNA

The present invention relates to synthetic DNA sequences which encode one or more collections of homologous proteins / (poly)peptides, and methods for generating and applying libraries of these DNA sequences. In particular, the invention relates to the preparation of a library of human-derived antibody genes by the use of synthetic consensus sequences which cover the structural repertoire of antibodies encoded in the human genome. Furthermore, the invention relates to the use of a single consensus antibody gene as a universal framework for highly diverse antibody libraries.

Owner:MORFOZIS AG

Method of making a lithographic printing plate

ActiveUS8232043B2High degree of polymerizationQuality improvementPlaten pressesPhotosensitive materialsInter layerEngineering

A method of making a lithographic printing plate includes the steps of a) providing a lithographic printing plate precursor including (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a coating on the support including a photopolymerizable layer, and, optionally, an intermediate layer between the photopolymerizable layer and the support, b) image-wise exposing the coating in a plate setter, c) optionally, heating the precursor in a preheating unit, and d) developing the precursor off-press in a gumming unit by treating the coating of the precursor with a gum solution, thereby removing the non-exposed areas of the coating from the support, wherein the coating further includes a compound capable of interacting with the support, the compound being present in the photopolymerizable layer and / or in the intermediate layer.

Owner:AGFA OFFSET BV

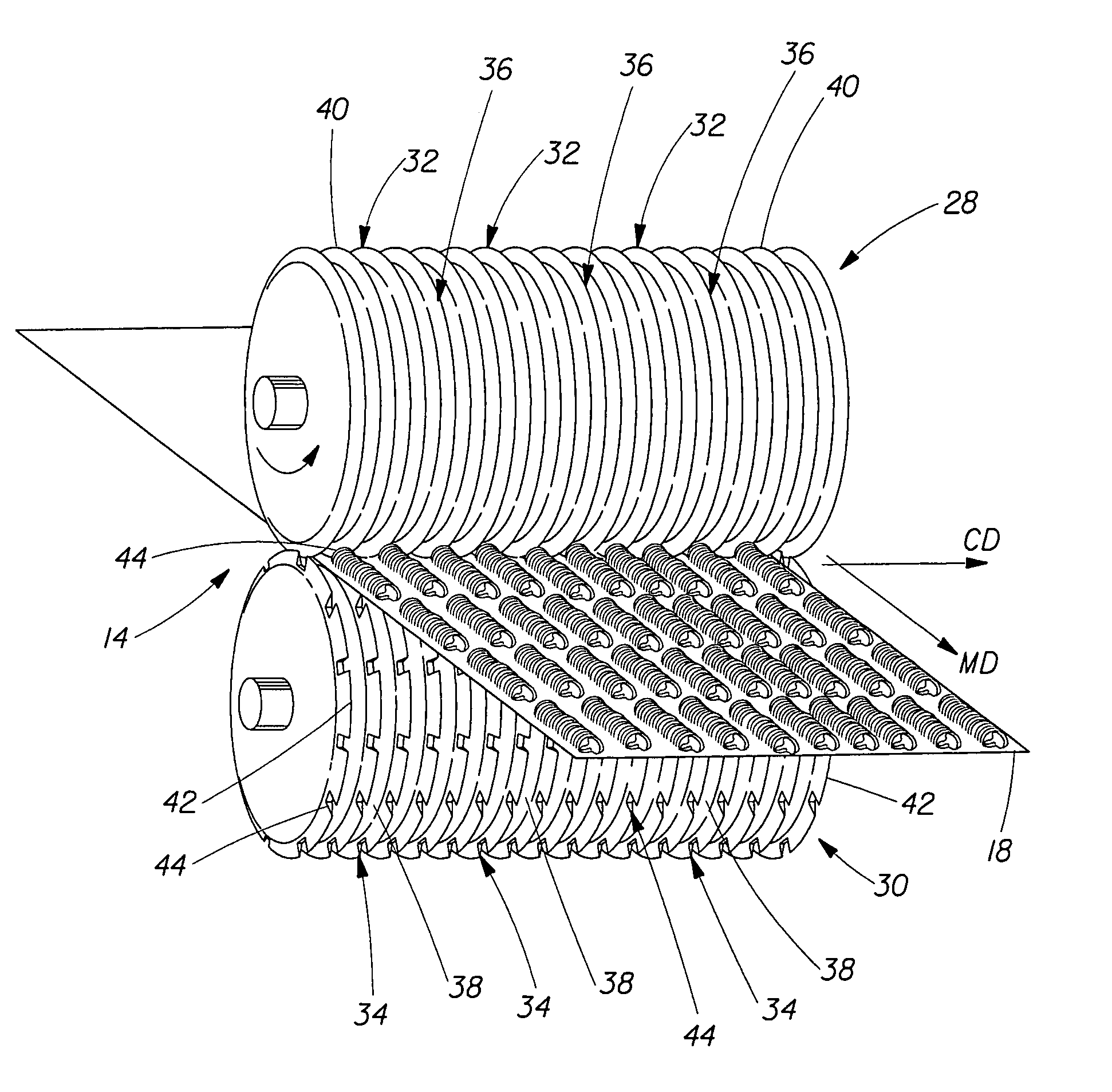

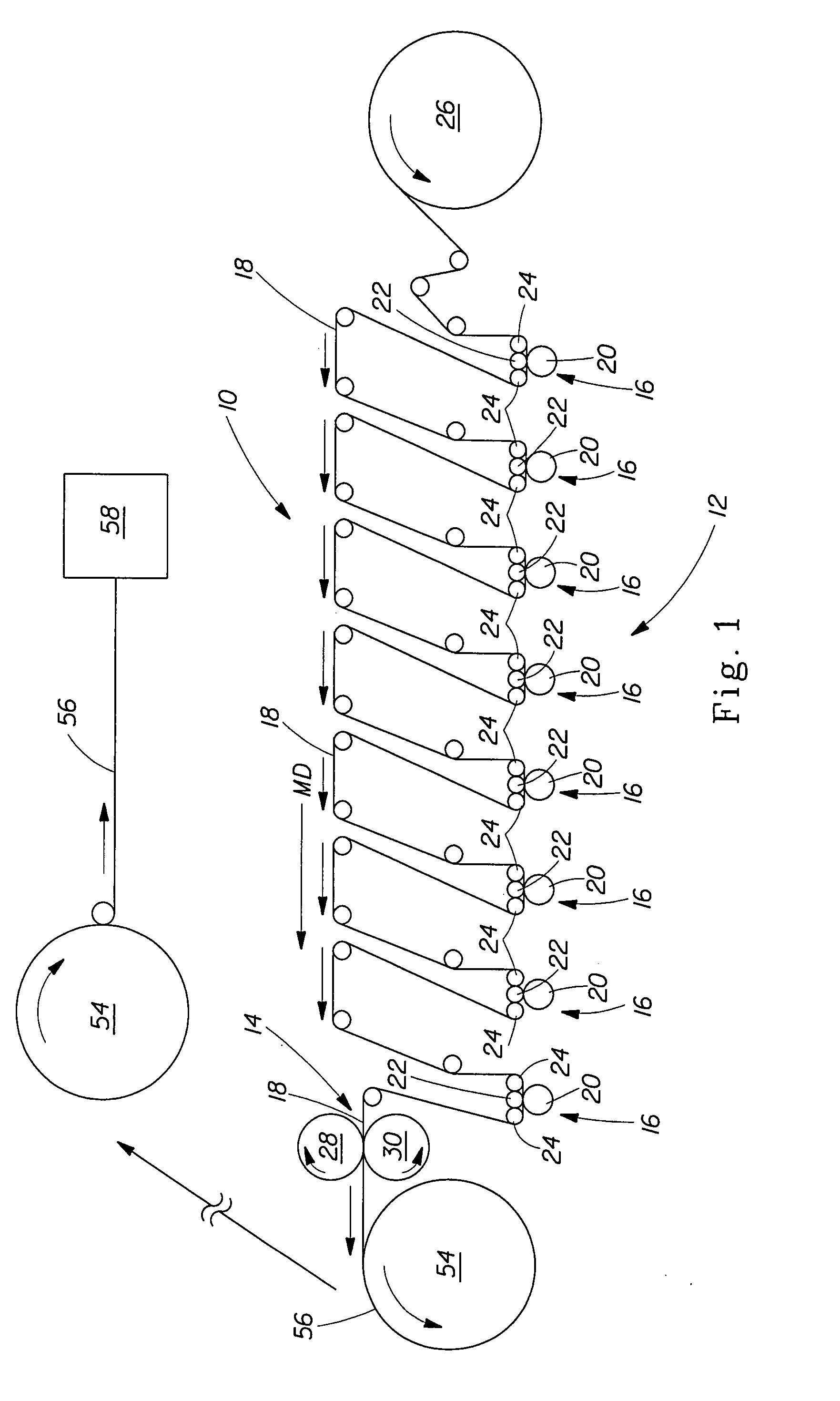

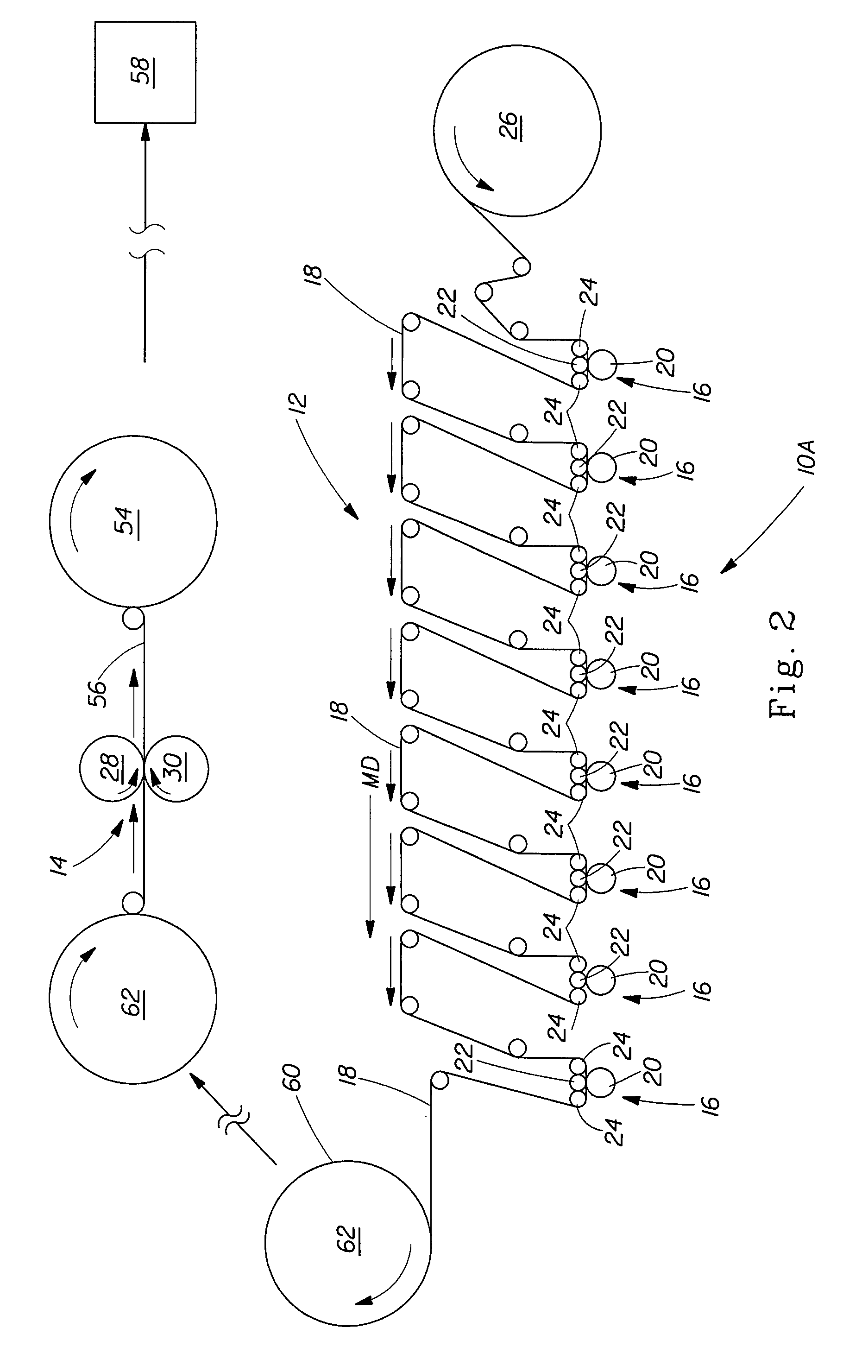

Apparatus and process for producing a web substrate having indicia disposed thereon and elastic-like behavior imparted thereto

Owner:THE PROCTER & GAMBLE COMPANY

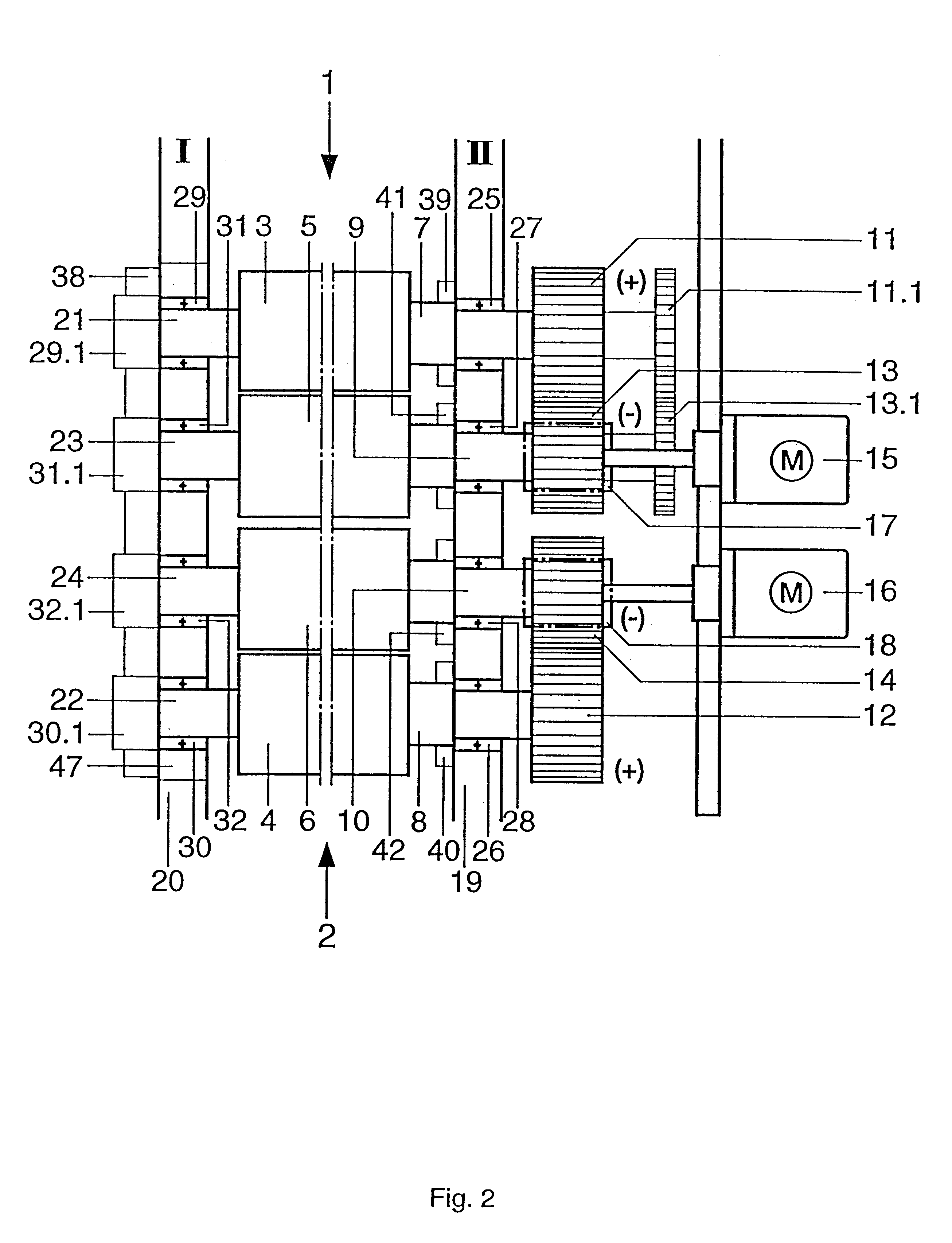

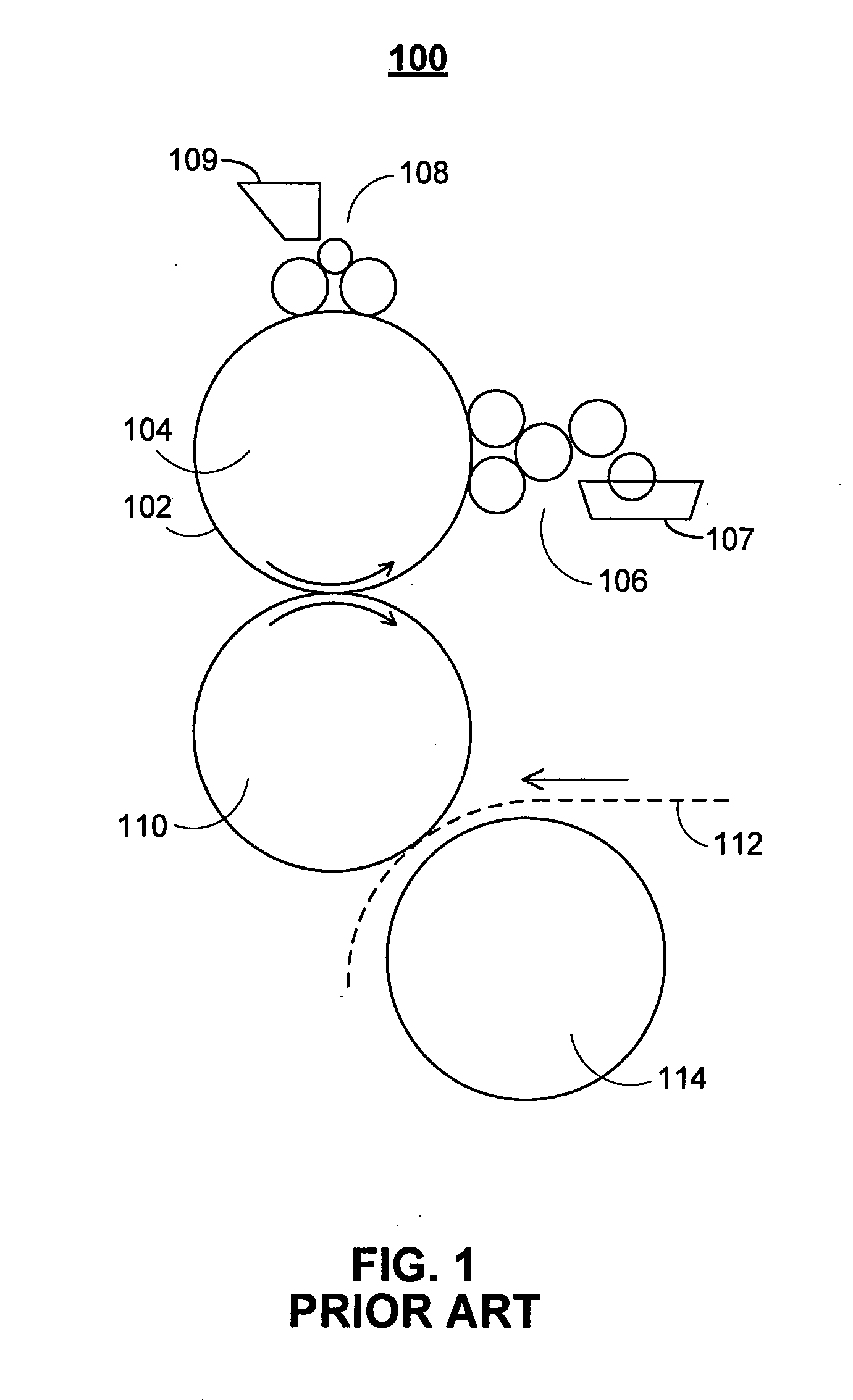

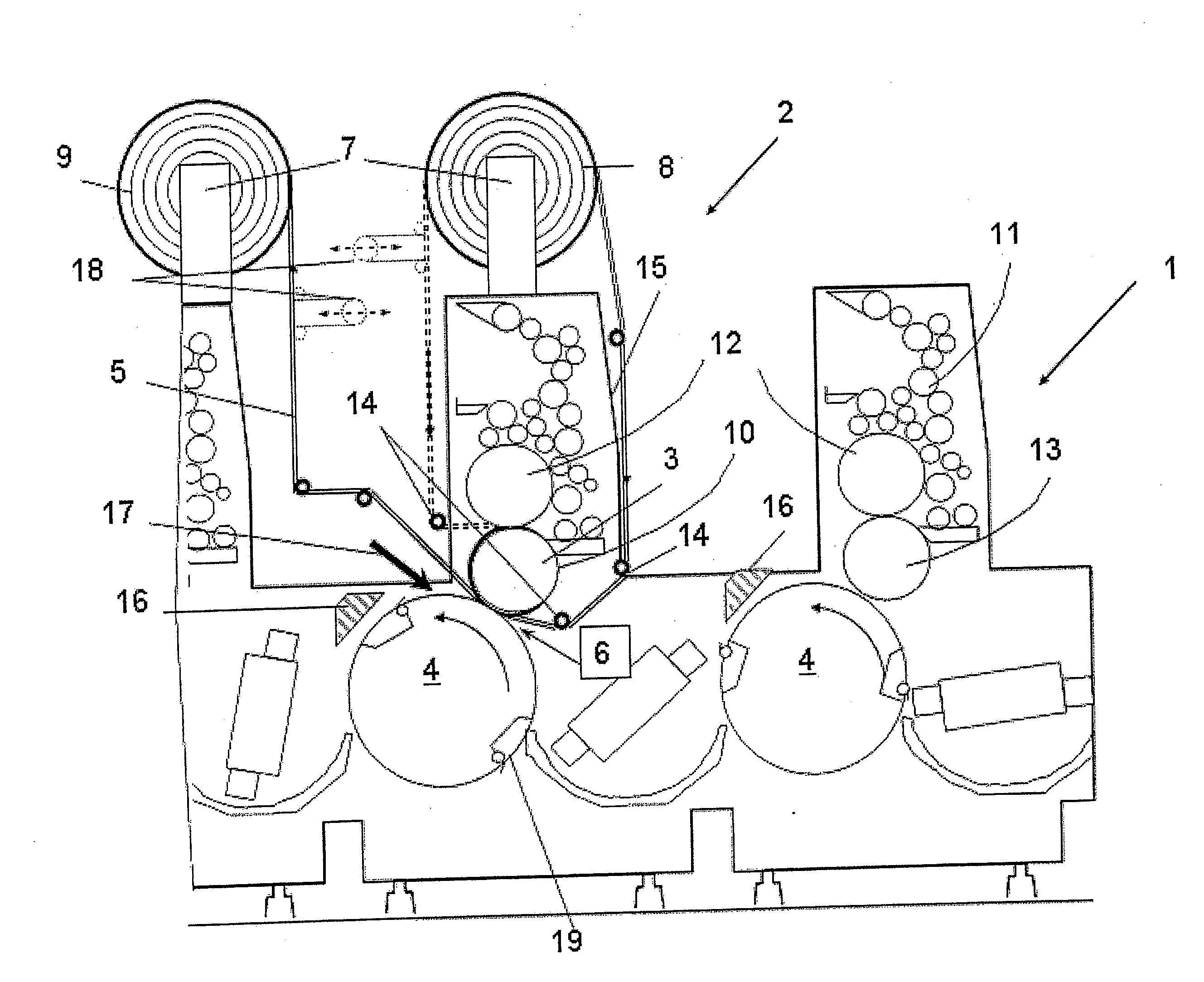

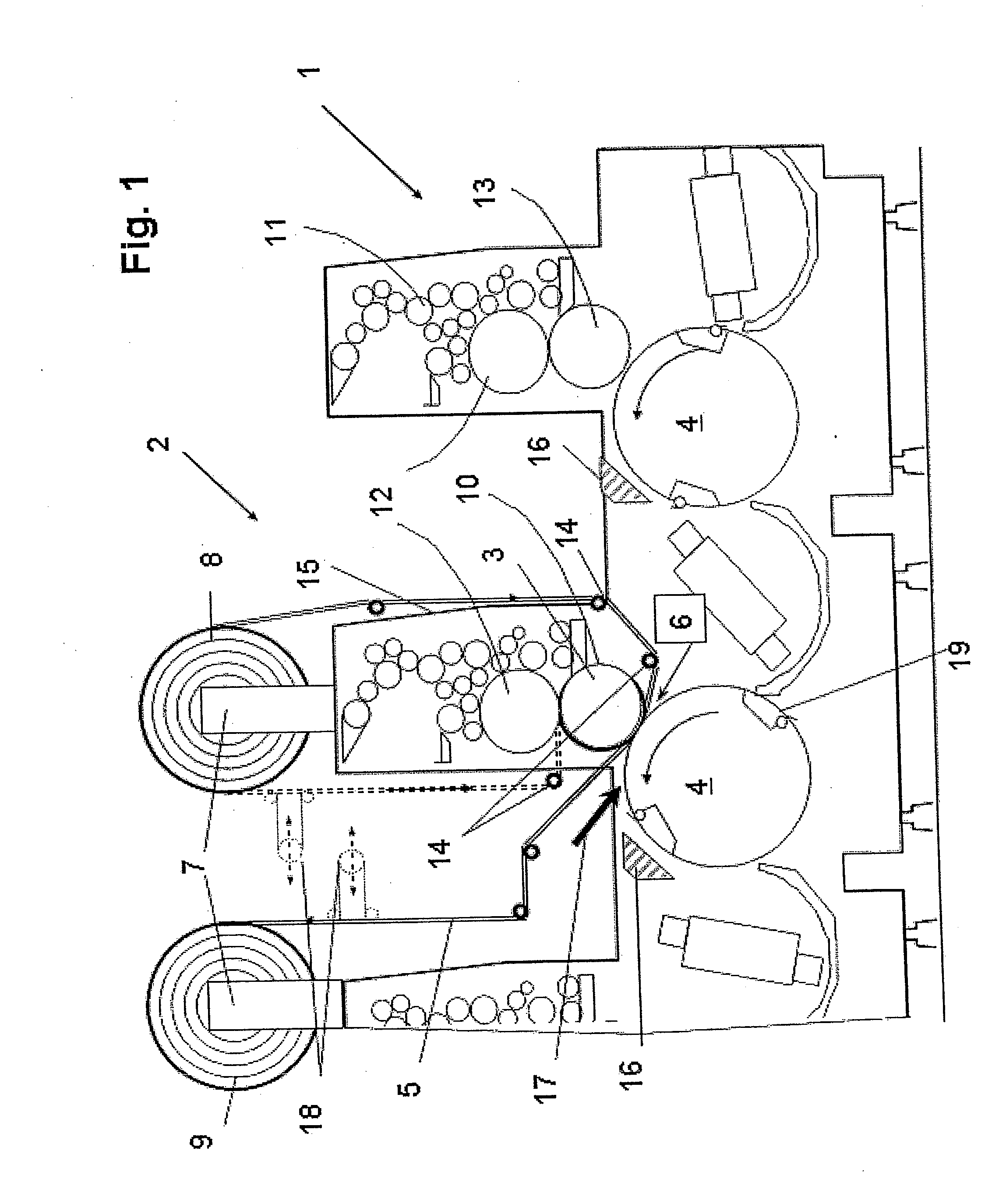

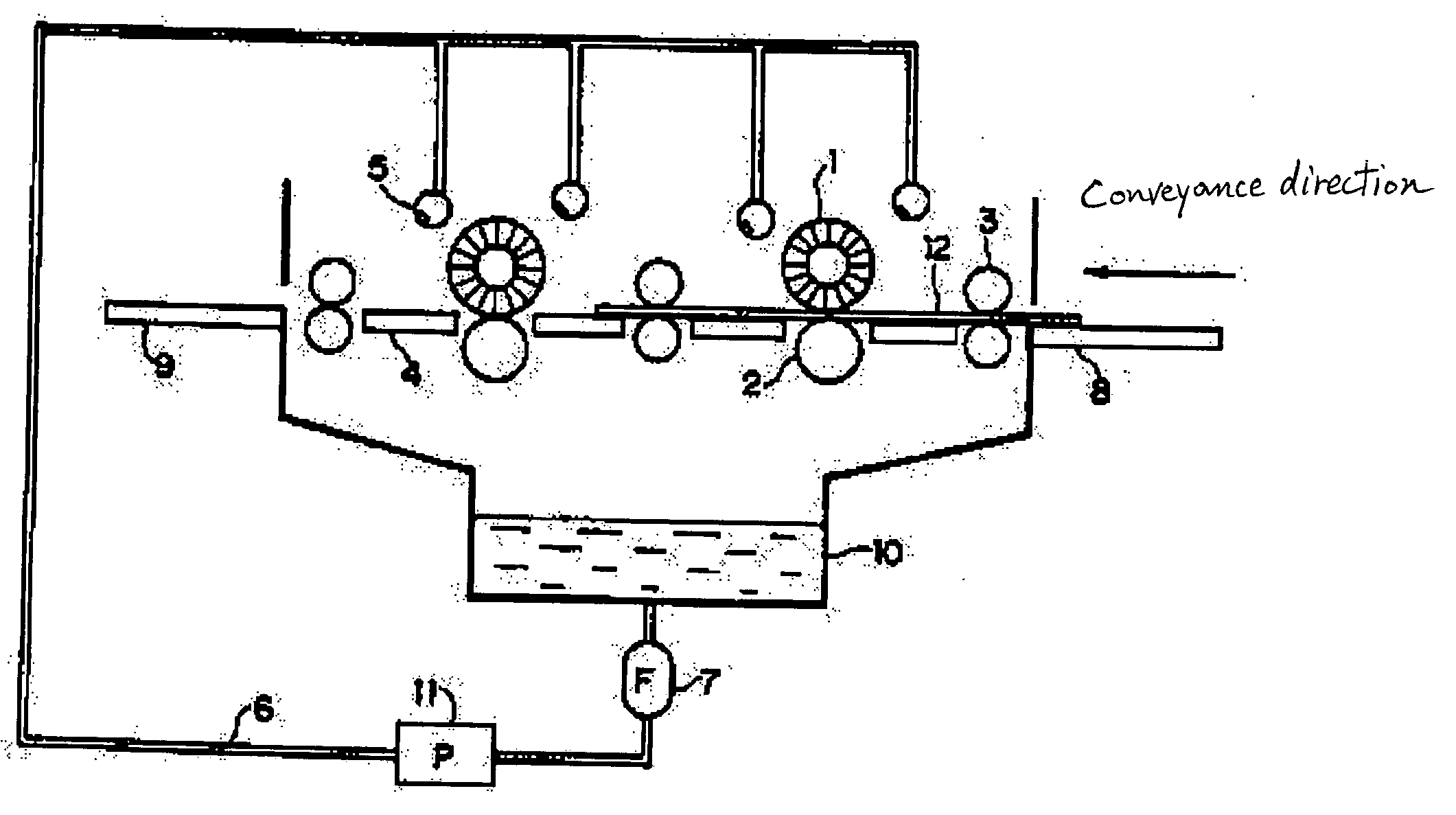

Web-fed rotary printing press for rapid change in production

InactiveUS6019039APrinting platesOther printing apparatusPrinting pressElectrical and Electronics engineering

The invention relates to a web-fed rotary printing press having a plurality of double printing units in which each of the printing units of the double printing units work together in the blanket-blanket method and each has its own drive. Transfer cylinders of each printing unit are driven independently. To permit a rapid change in production, both upon recto and verso printing, the transfer cylinders of the disconnectable double printing units are separable by eccentric bushings or swingable levers such that a web which passes through the printing press is conducted between them without being printed.

Owner:MANROLAND WEB SYST

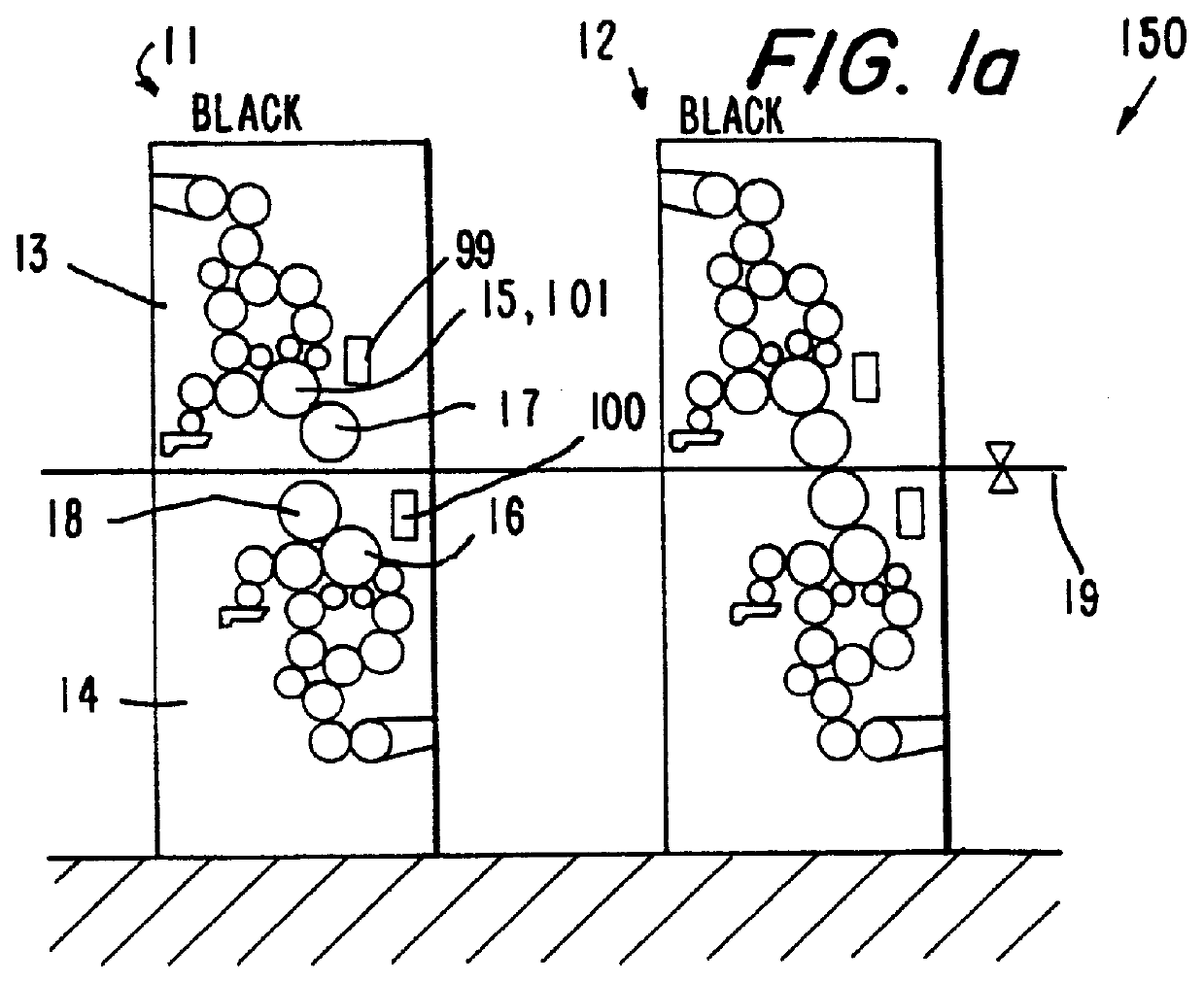

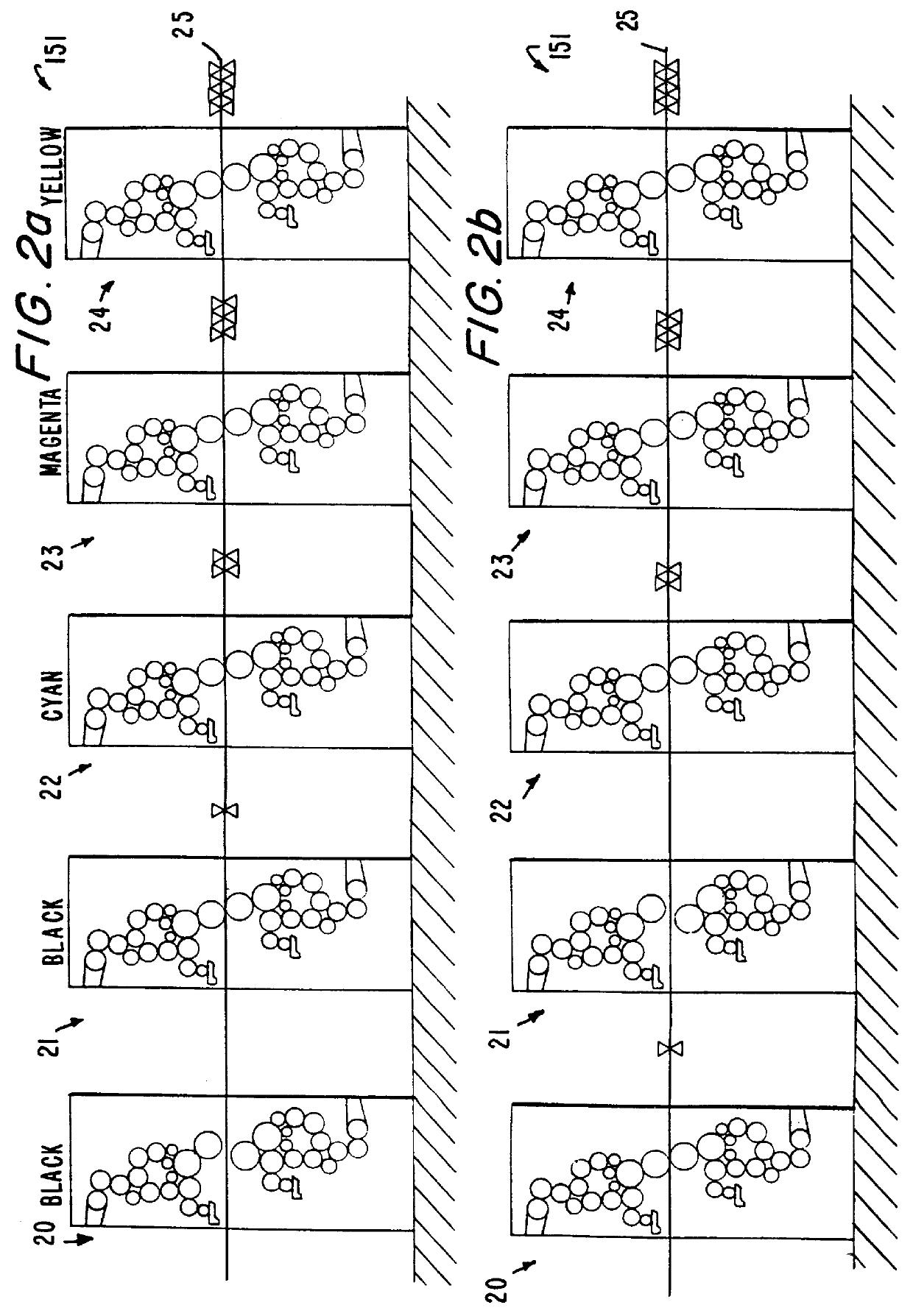

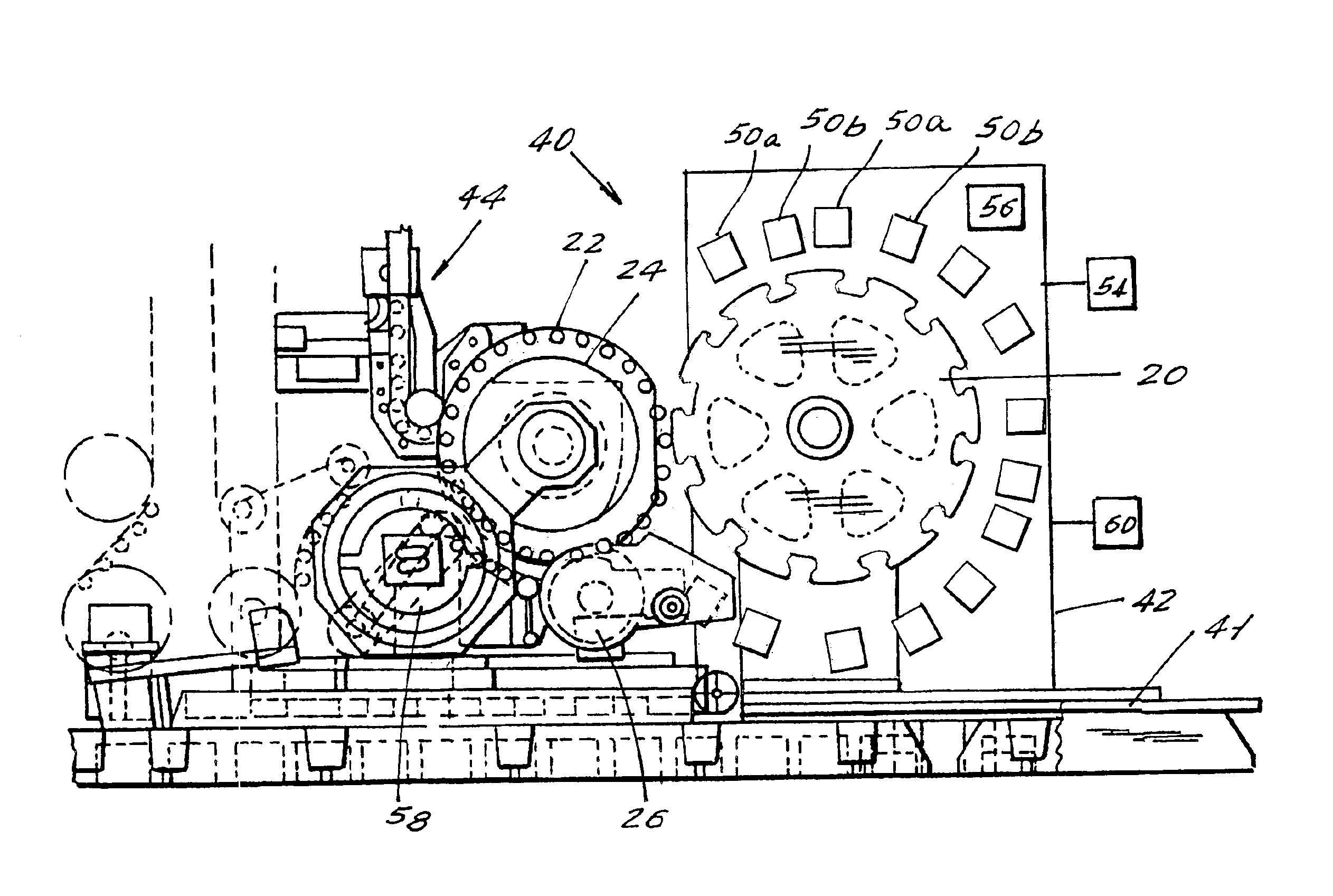

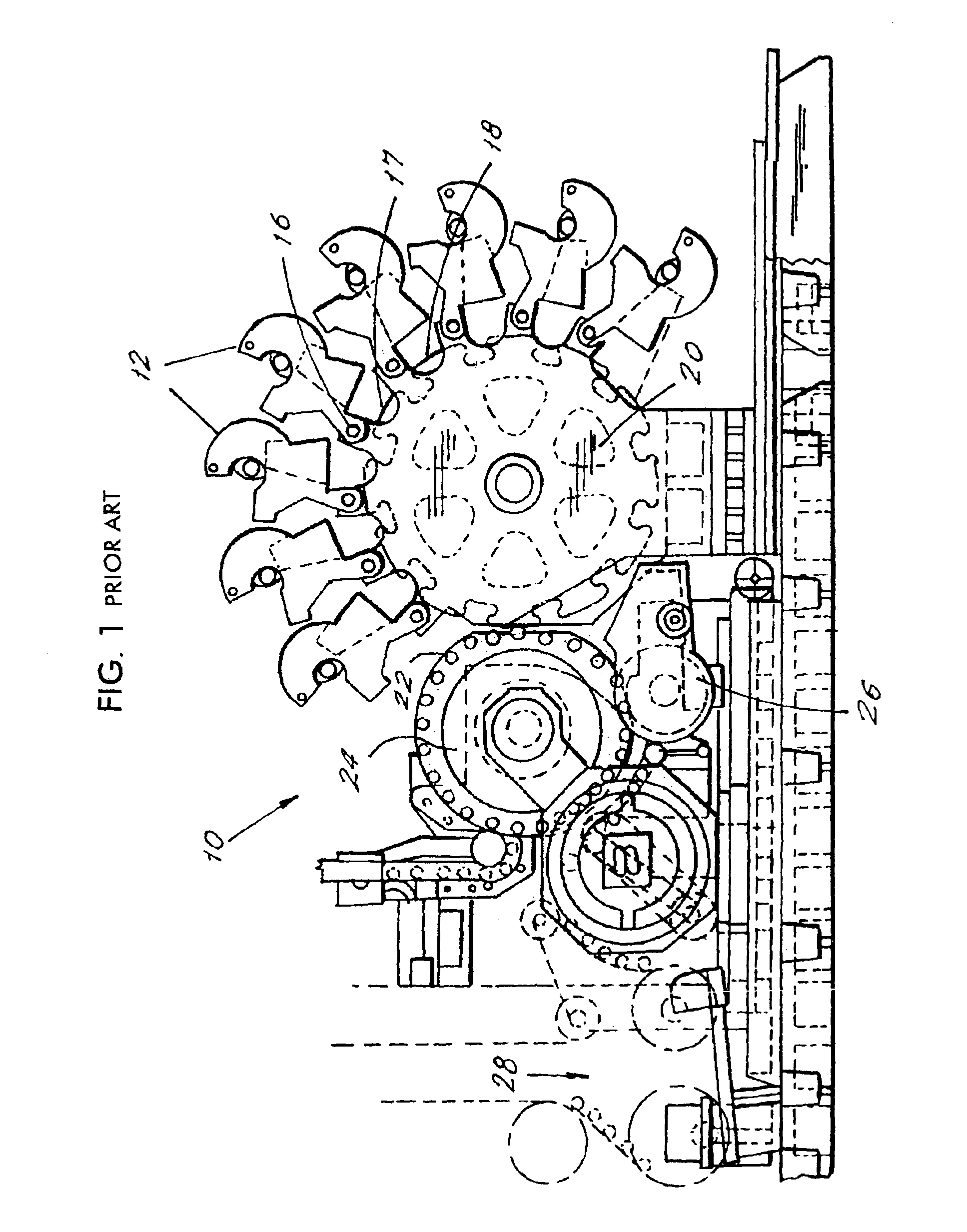

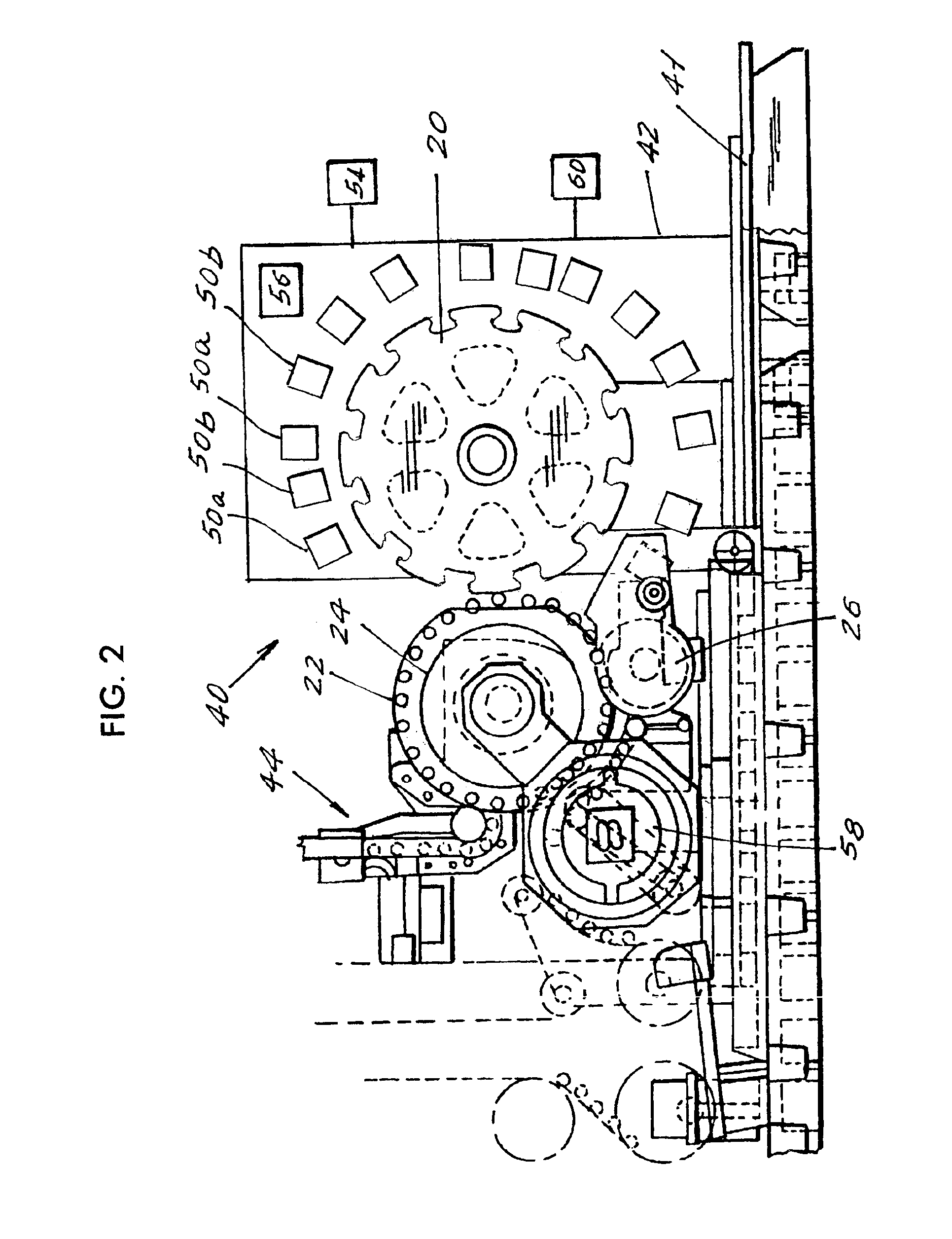

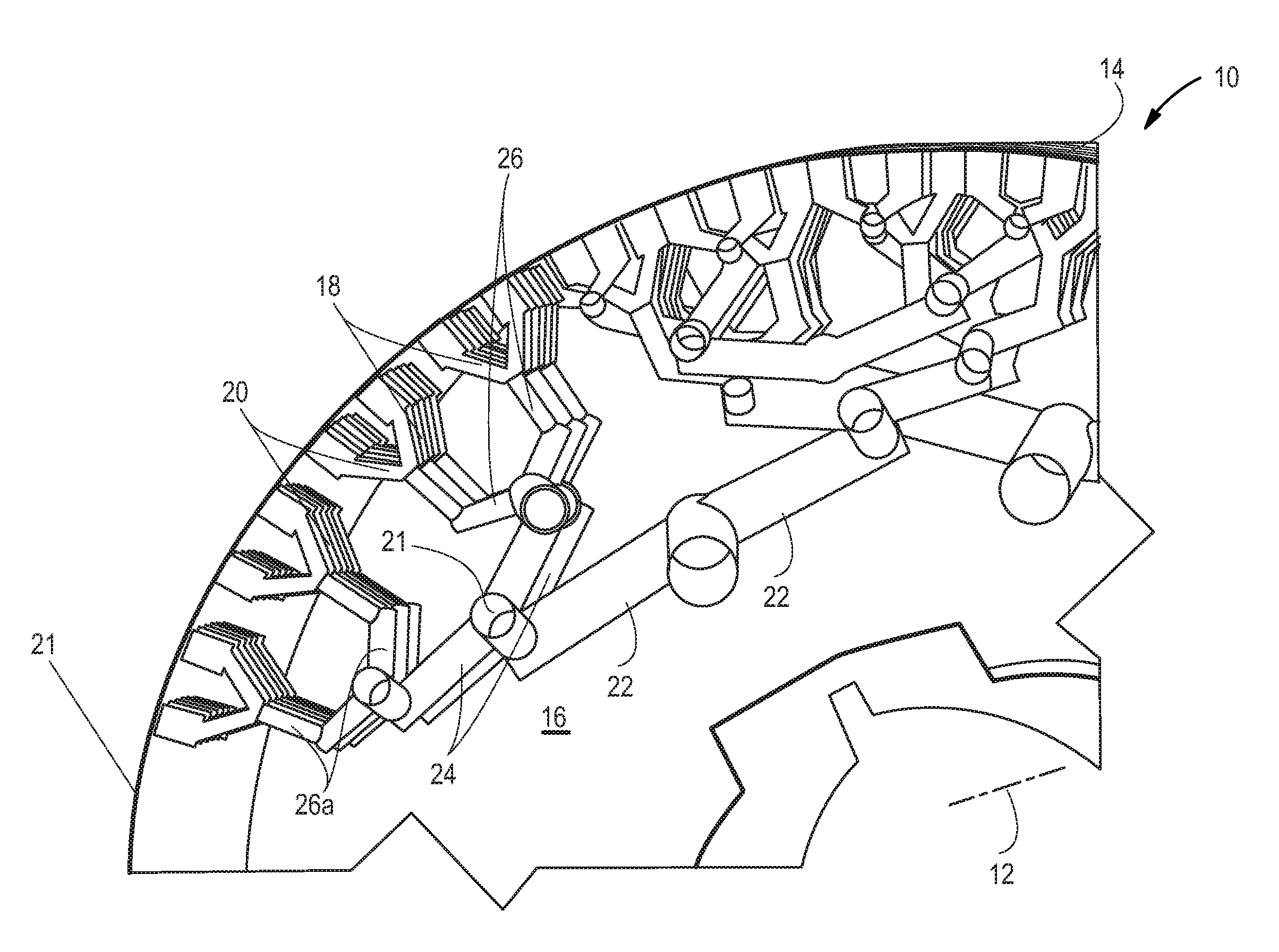

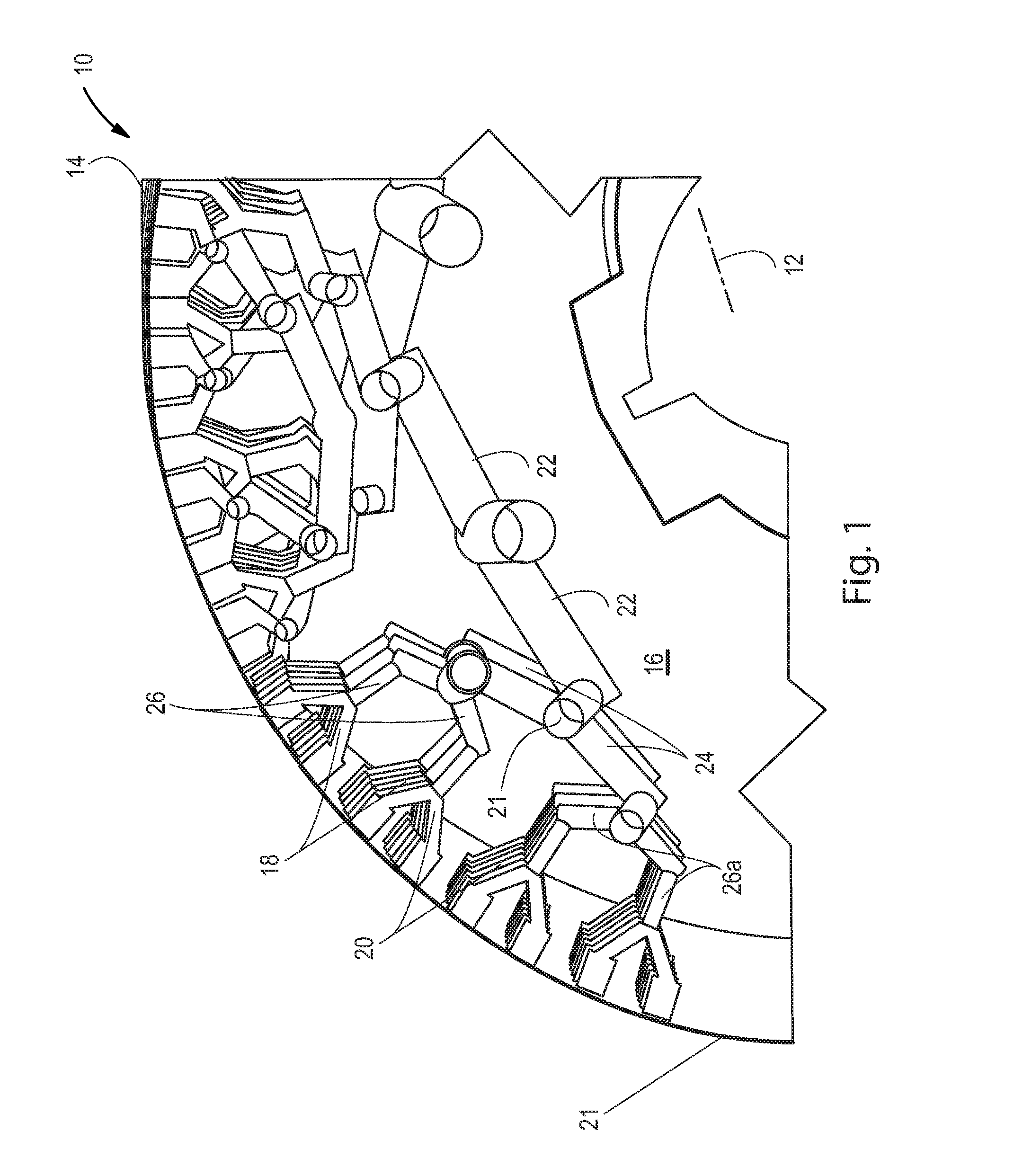

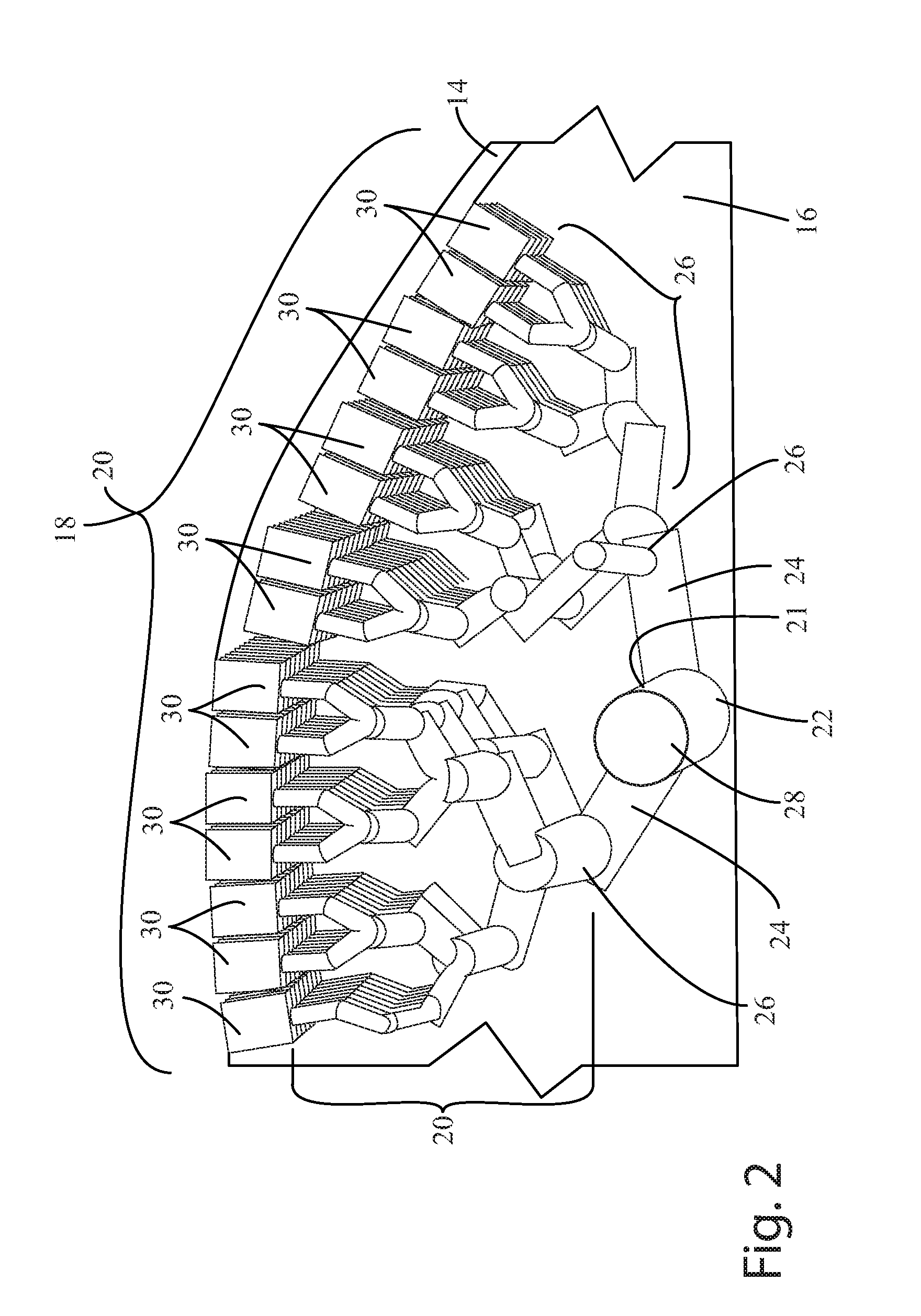

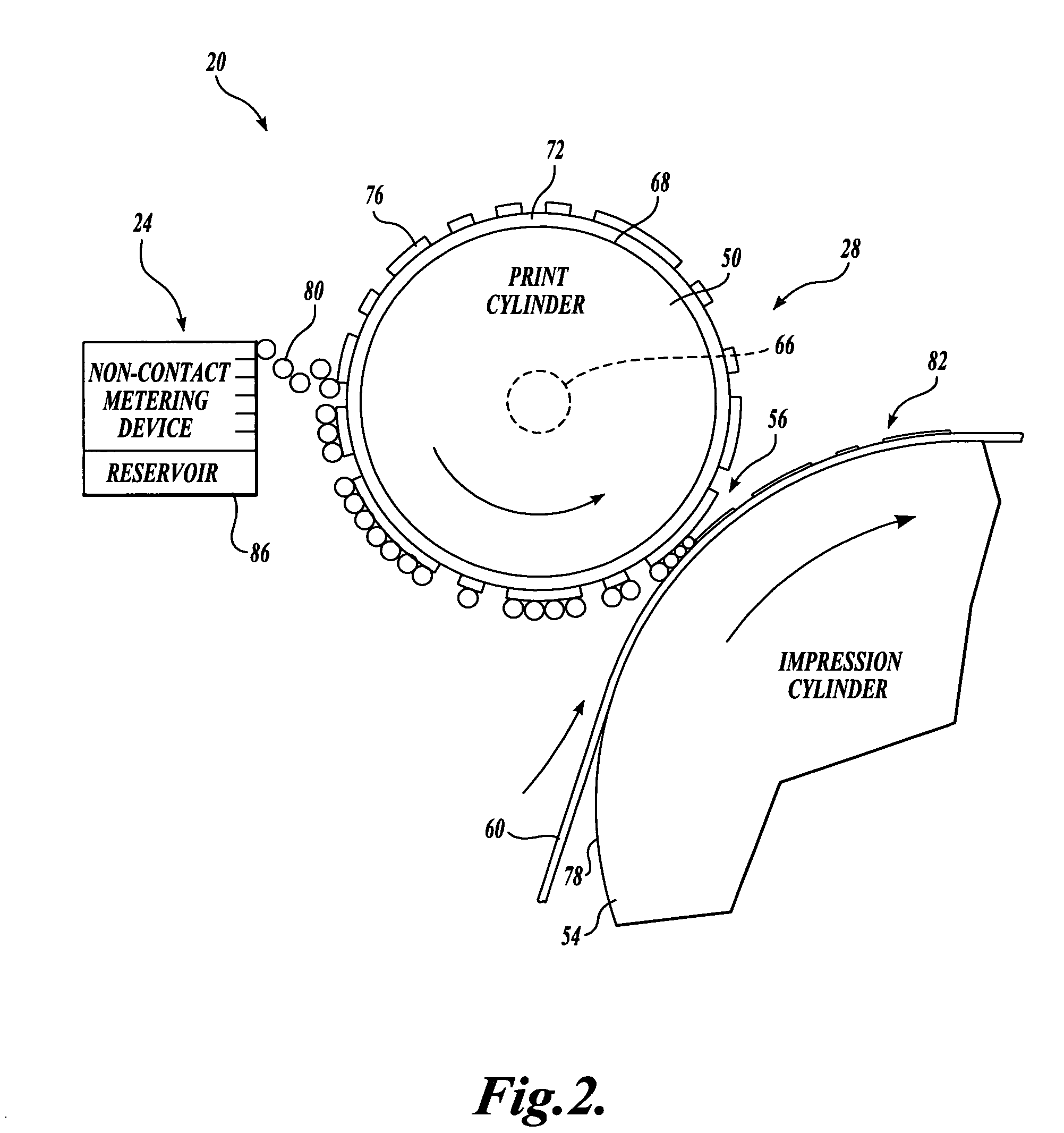

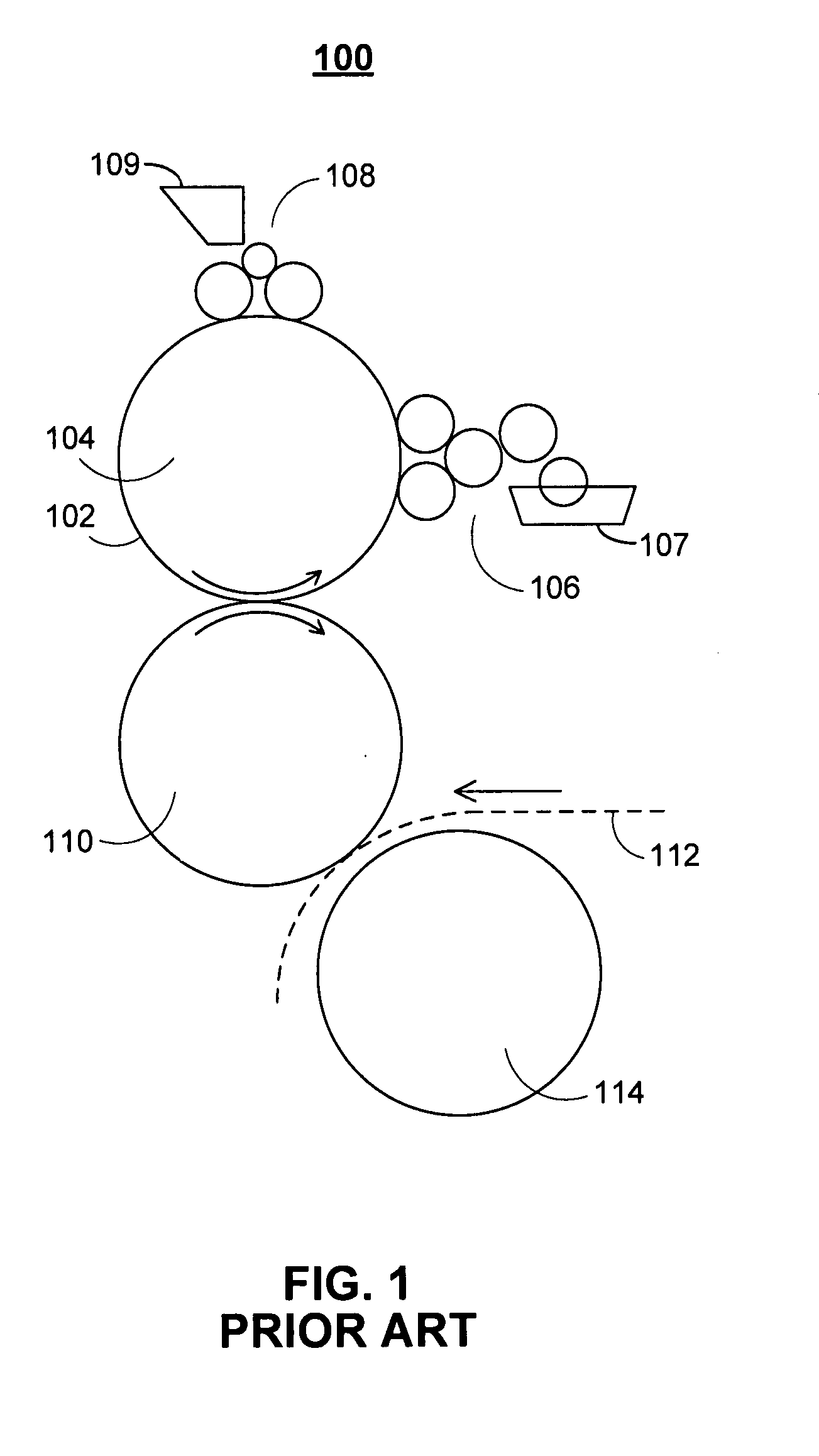

Digital can decorating apparatus

InactiveUS6920822B2Few partsTypewritersRotary lithographic machinesElectrical and Electronics engineeringBlanket

A digitally controlled can decorating apparatus including digitally controlled print heads arrayed around the blanket cylinder of an offset type decorating apparatus for delivering ink in a selected pattern from each print head to each blanket section of the blanket cylinder, and the blanket cylinder sections thereafter transferring the ink to the cans being decorated.

Owner:BALL BEVERAGE PACKAGING EUROPE LIMITED

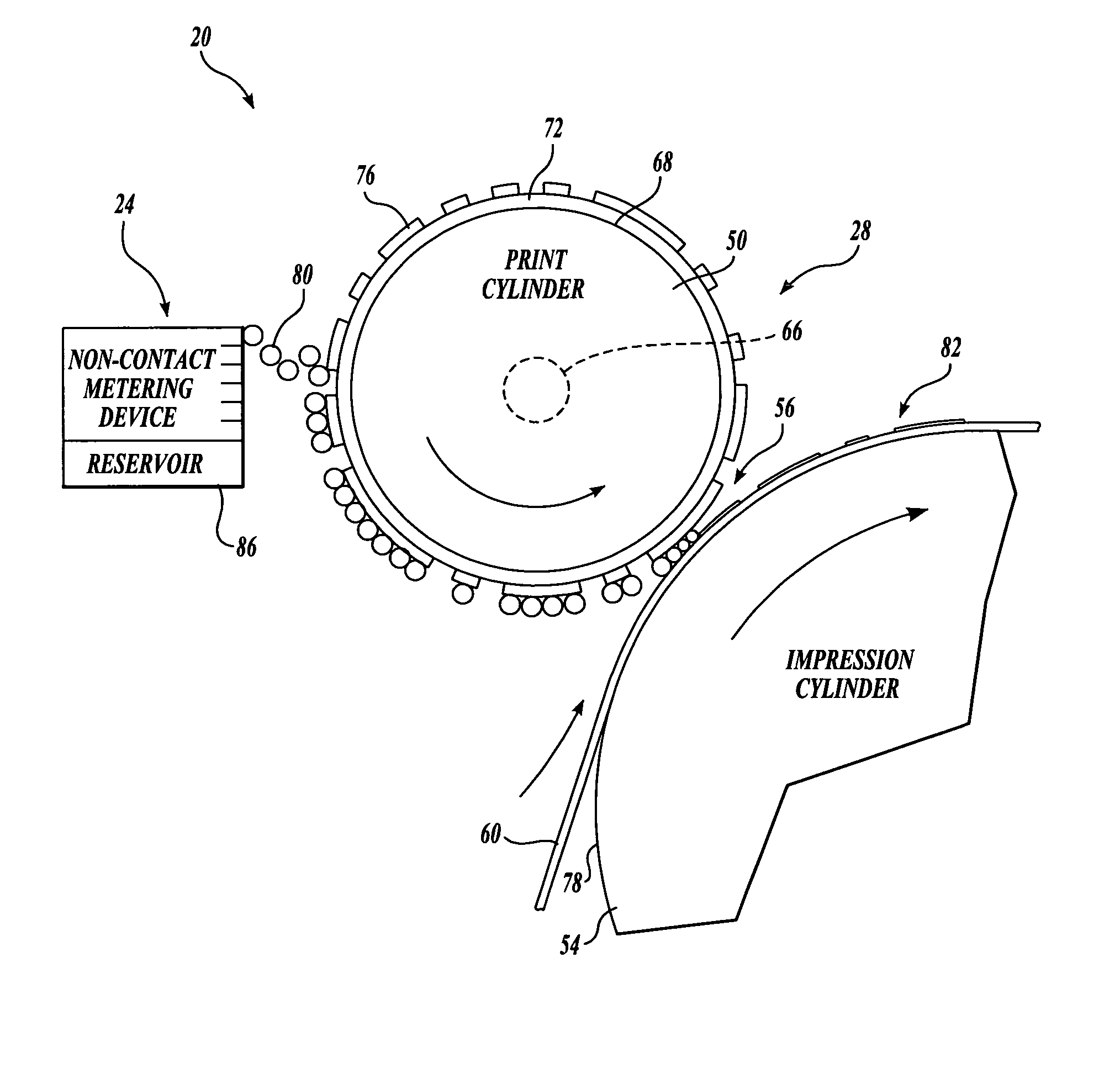

Apparatus and method for the transfer of a fluid to a moving web material

An apparatus and method for enabling the transfer of a fluid to a web material, the apparatus comprising a fluid transfer component having a first surface, a second surface, and a non-random pattern of distinct pores. The pores connect the first surface and the second surface and are disposed at preselected locations to provide a desired pattern of permeability. The apparatus also comprises a fluid receiving component comprising a fluid receiving surface, a fluid supply adapted to provide a fluid in contact with the first surface of the fluid transfer component, and a fluid motivating component adapted to facilitate transport of the fluid from the first surface through the pores to the second surface. The method comprises steps of providing the apparatus, motivating a fluid through the pores and bringing the fluid receiving component into contact with the motivated fluid.

Owner:PROCTER & GAMBLE CO

All printed solar cell array

The present invention relates to a method for producing a photovoltaic novelty item. Conductive polymer solutions and semiconductive oxide dispersions are formulated into inks that are laid down on top of one another to produce voltage and current when exposed to light. In addition, these inks may be printed on novelty items, such as magazine advertisements or greeting cards, connecting to printed light emitting graphics.

Owner:ZEIRA EITAN C

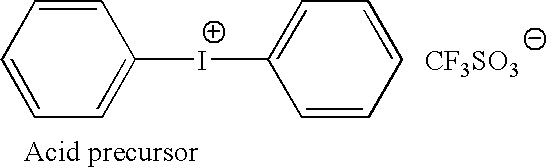

Positive-working radiation-sensitive imageable elements

InactiveUS20110059399A1High sensitivityHigh image resolutionPlaten pressesPhotosensitive materialsImideAryl

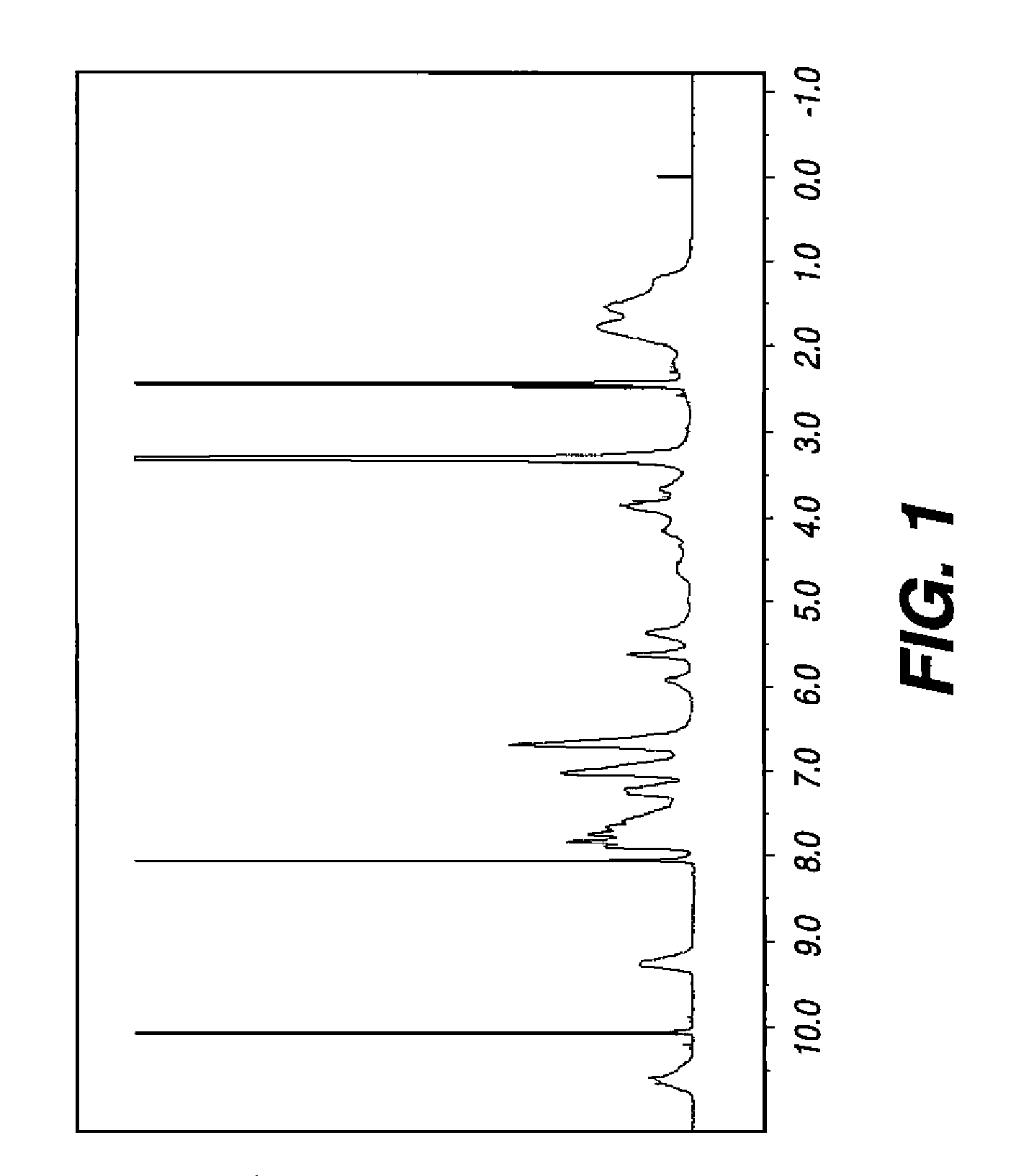

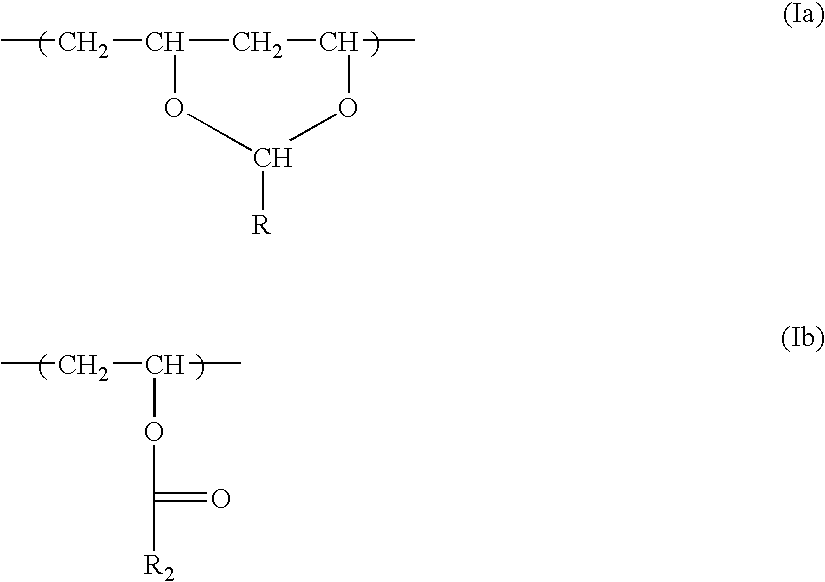

Positive-working imageable elements having improved sensitivity, high resolution, and solvent resistance are prepared using a water-insoluble polymeric binder comprising vinyl acetal recurring units that have pendant hydroxyaryl groups, and recurring units comprising carboxylic acid aryl ester groups that are substituted with a cyclic imide group. These imageable elements can be imaged and developed to provide various types of elements including lithographic printing plates.

Owner:EASTMAN KODAK CO

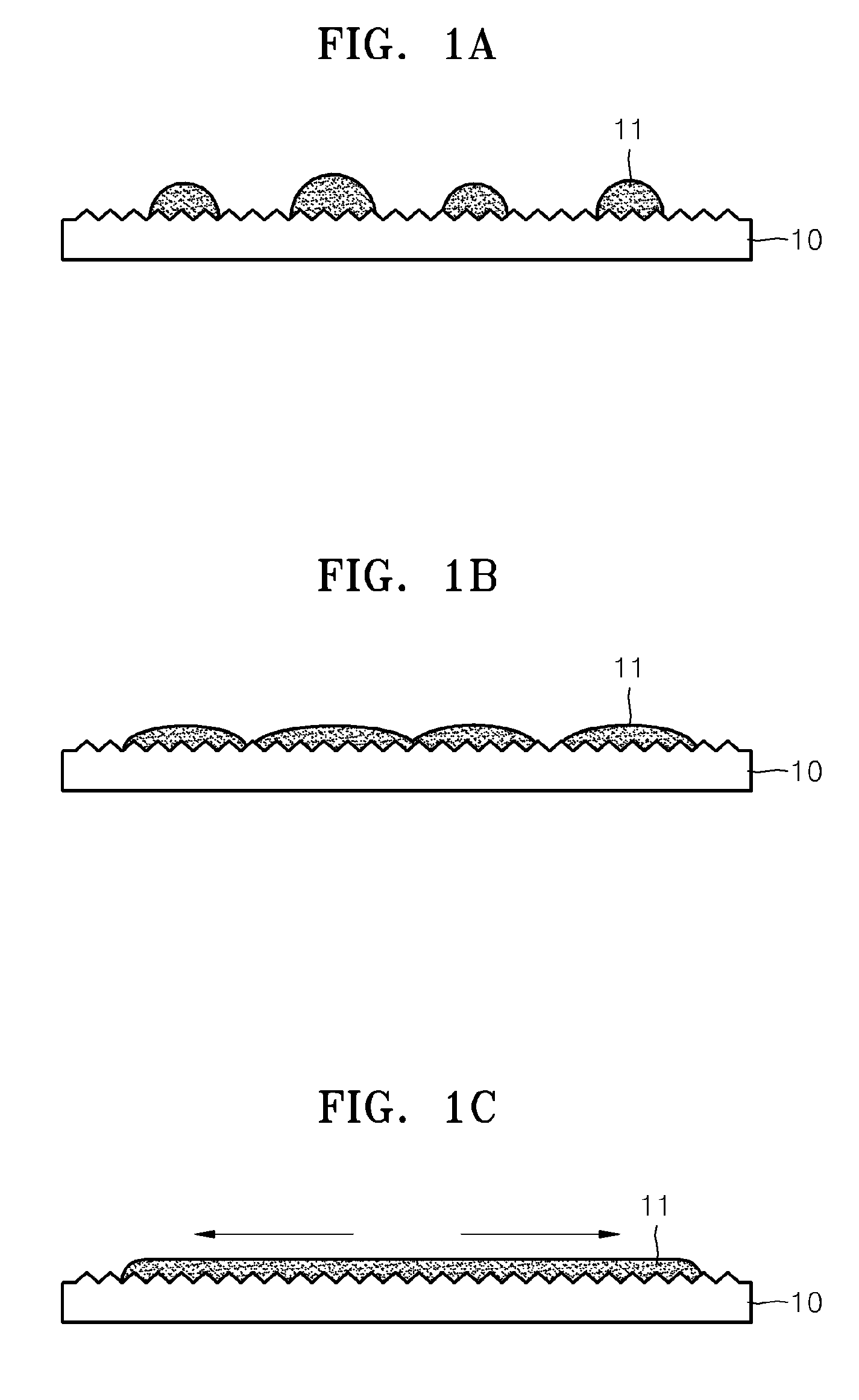

Electrode for secondary battery, manufacturing method thereof and secondary battery employing the same

InactiveUS20090098457A1Improve thickness uniformityIncrease electrode capacityCylinder pressesPlaten pressesElectrical batterySurface roughness

Provided are an electrode for a secondary battery employing an active material layer having improved thickness uniformity by printing low-viscosity ink on the active material layer, a manufacturing method of the electrode, and a secondary battery having improved electrode capacity due to the employing of the electrode. The electrode includes a current collector, and an active material layer formed by printing ink having a viscosity not exceeding 500 mPa·s on the current collector and drying the current collector, wherein the current collector has a surface roughness (Ra) in a range from about 0.025 to 1.0 μm.

Owner:SAMSUNG ELECTRONICS CO LTD

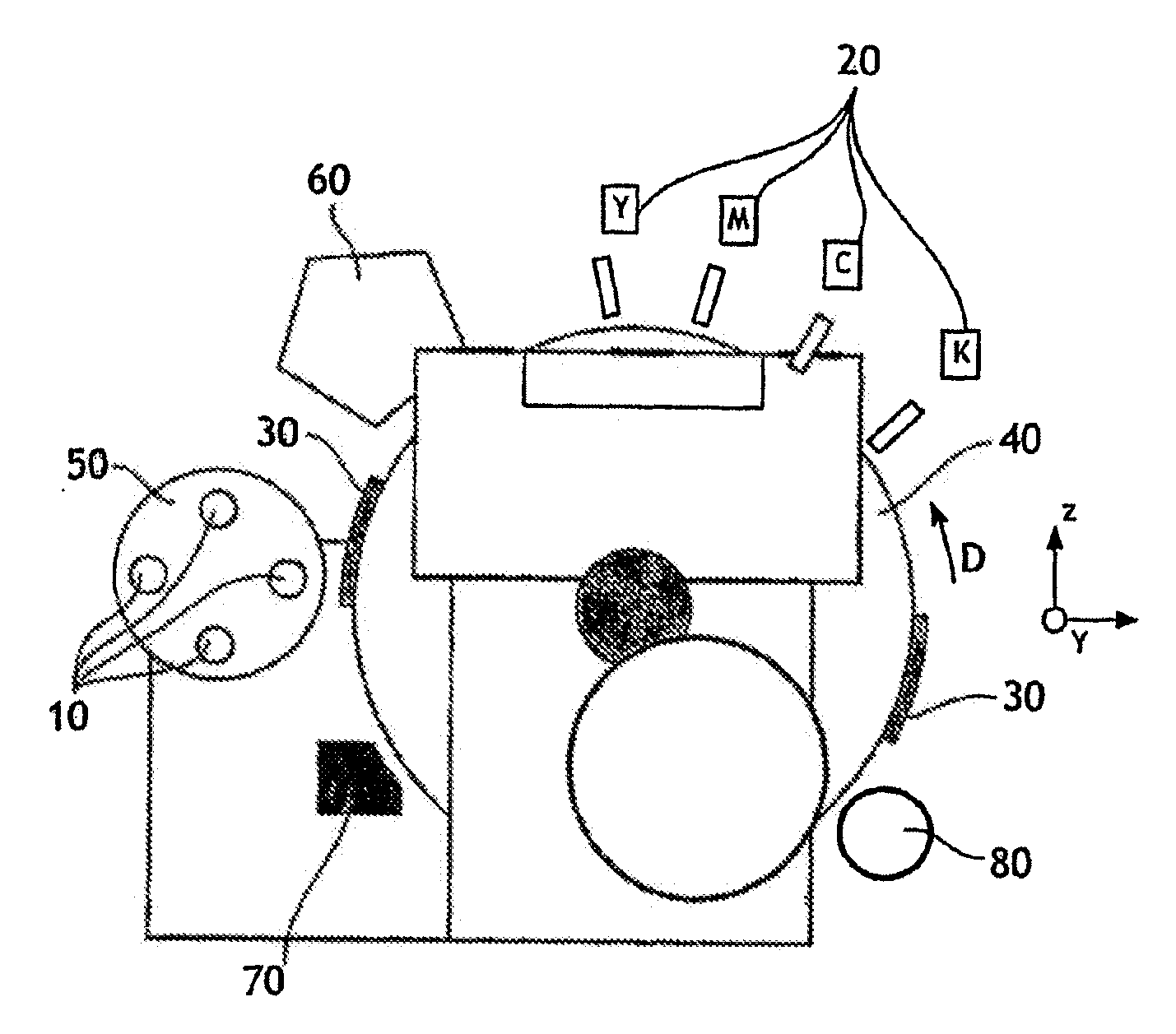

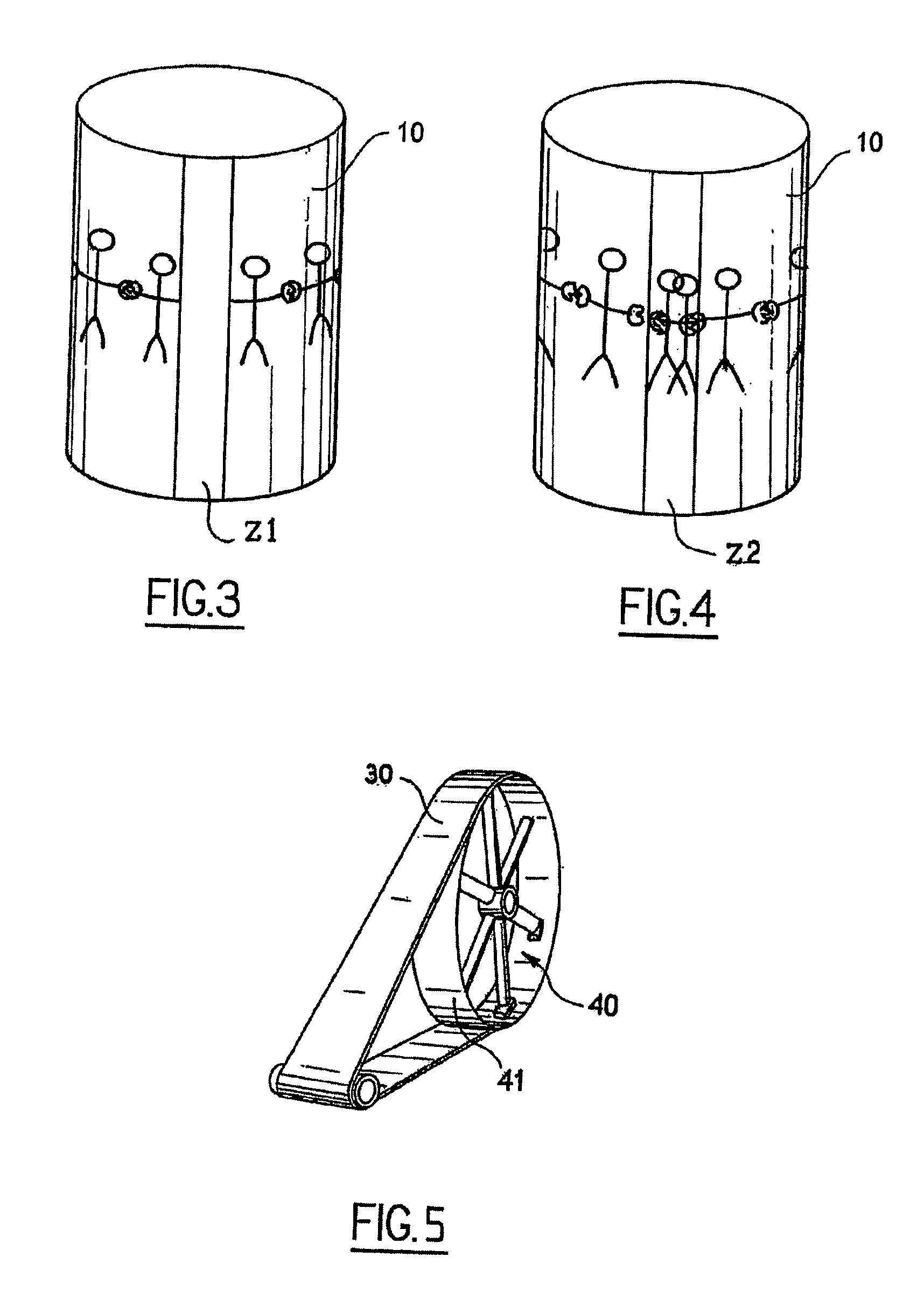

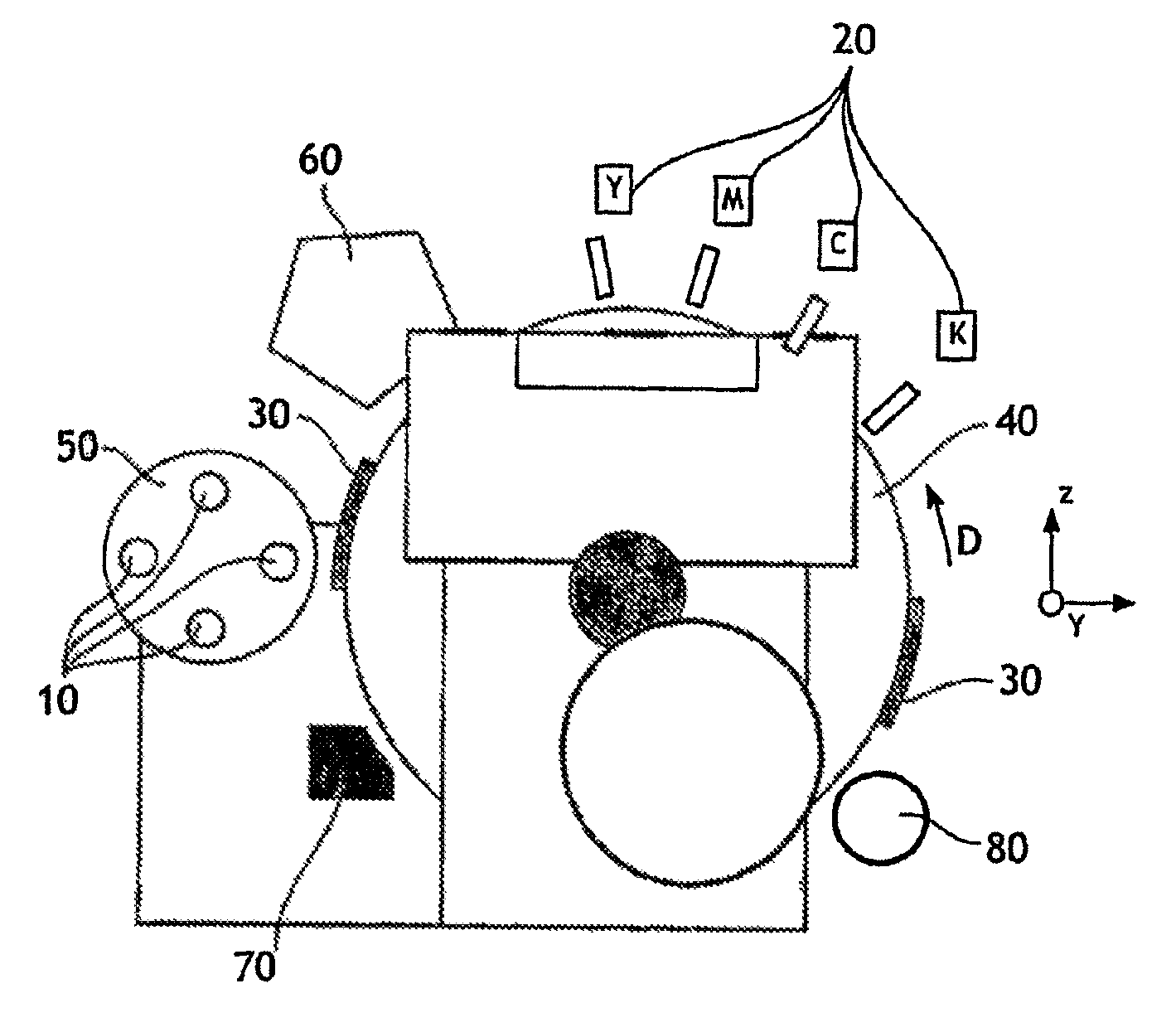

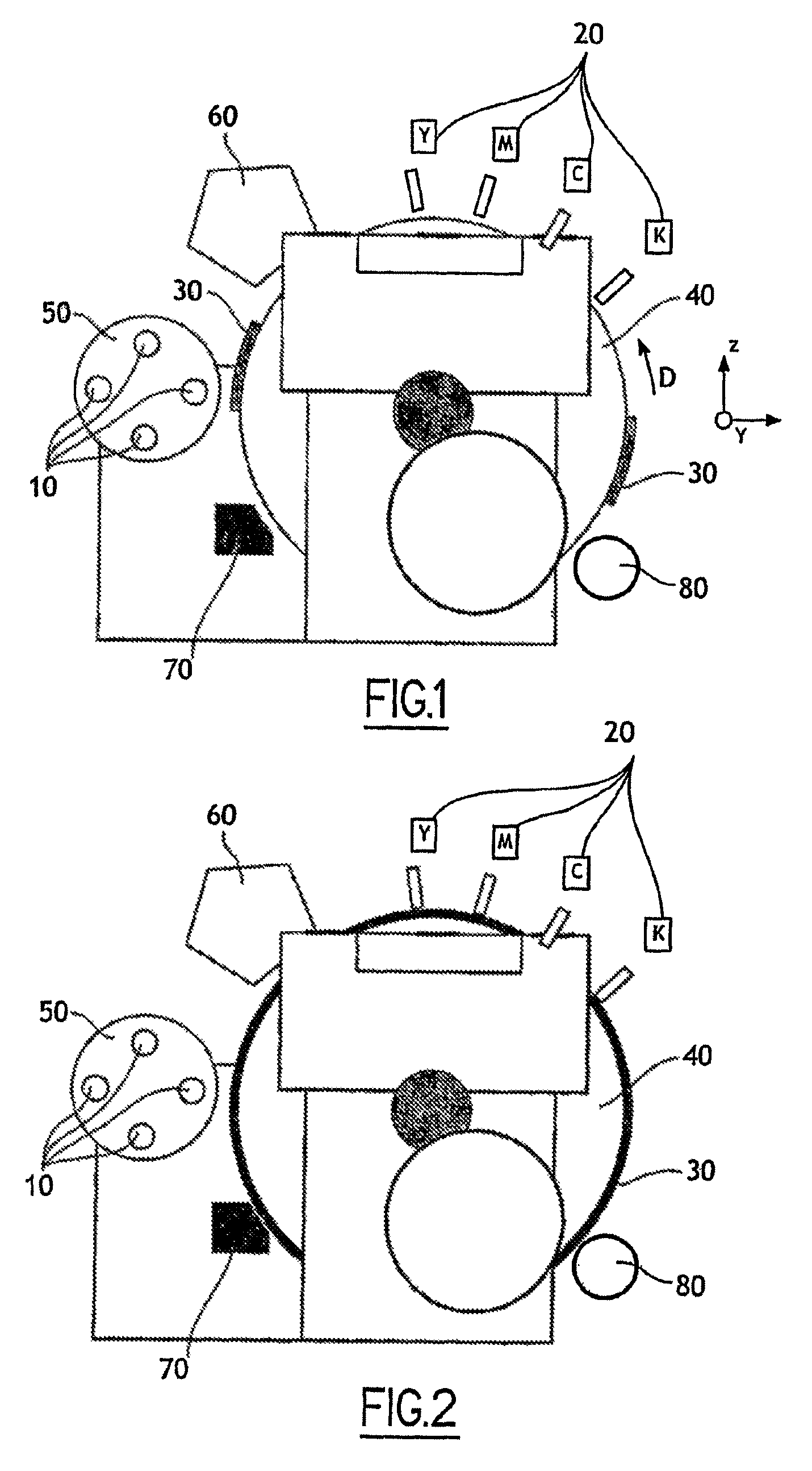

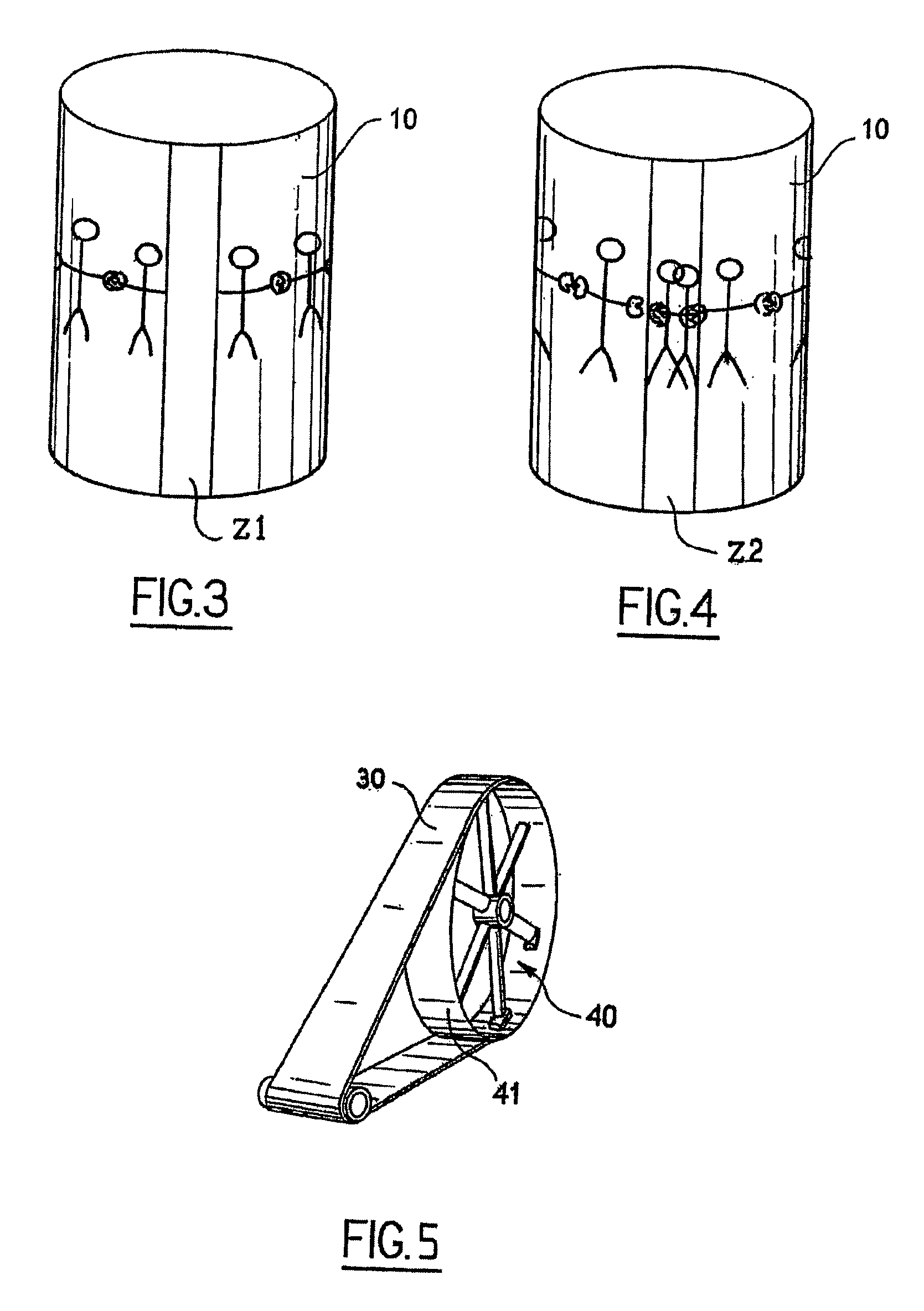

Device for printing by transfer onto a cylindrical printing medium

The invention relates to a device for printing by transfer onto a print support (10) comprising at least one blanket (30) driven in a sequential relative movement past a magazine (50) conveying the print supports (10), in which device the blanket (30) has a surface area greater than that of the print support (10), the device further comprising digital printing means (20) which print by spraying ink onto this blanket (30) over a variable area equal to that of the print support (10).

Owner:IMPIKA +1

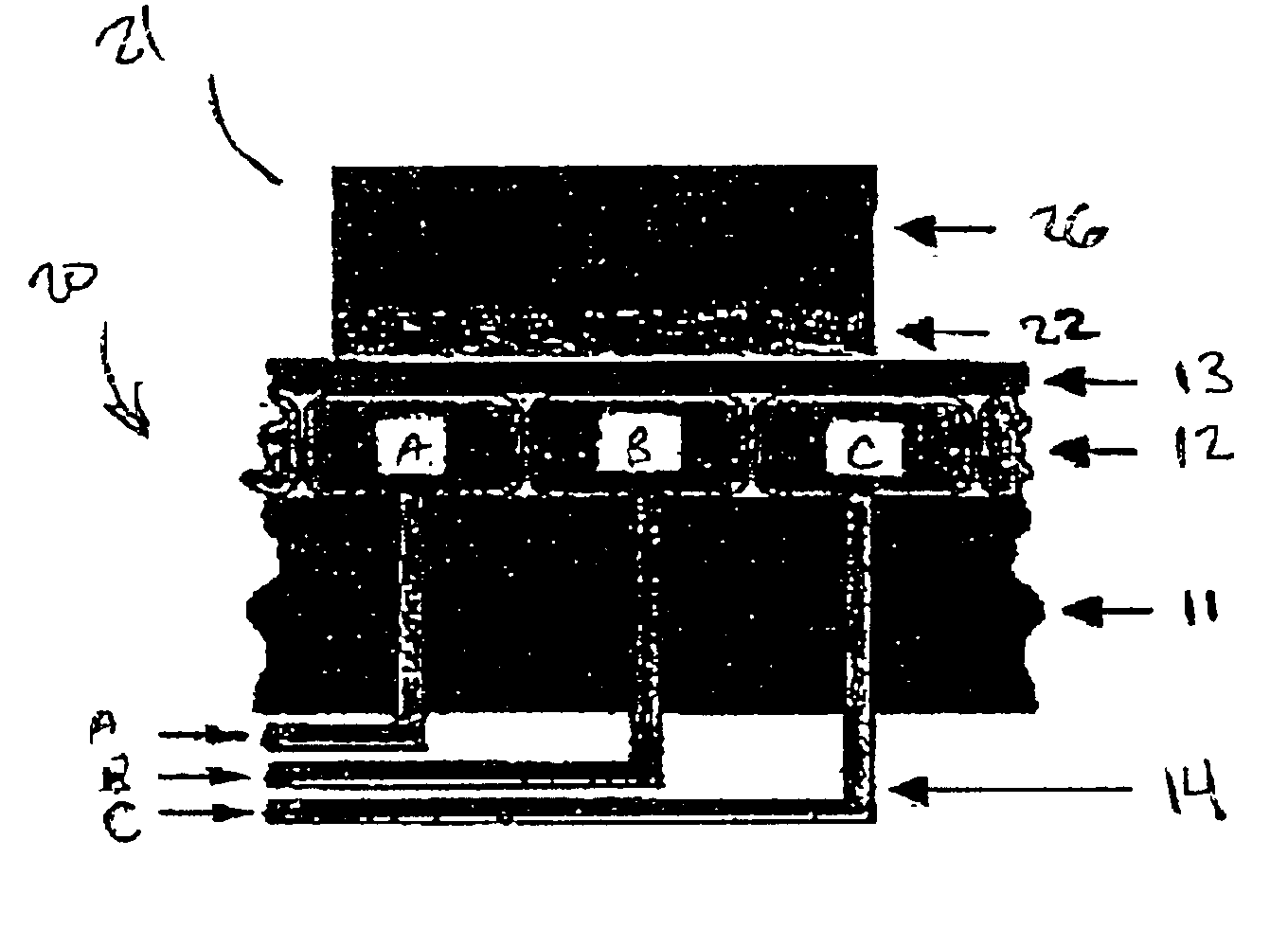

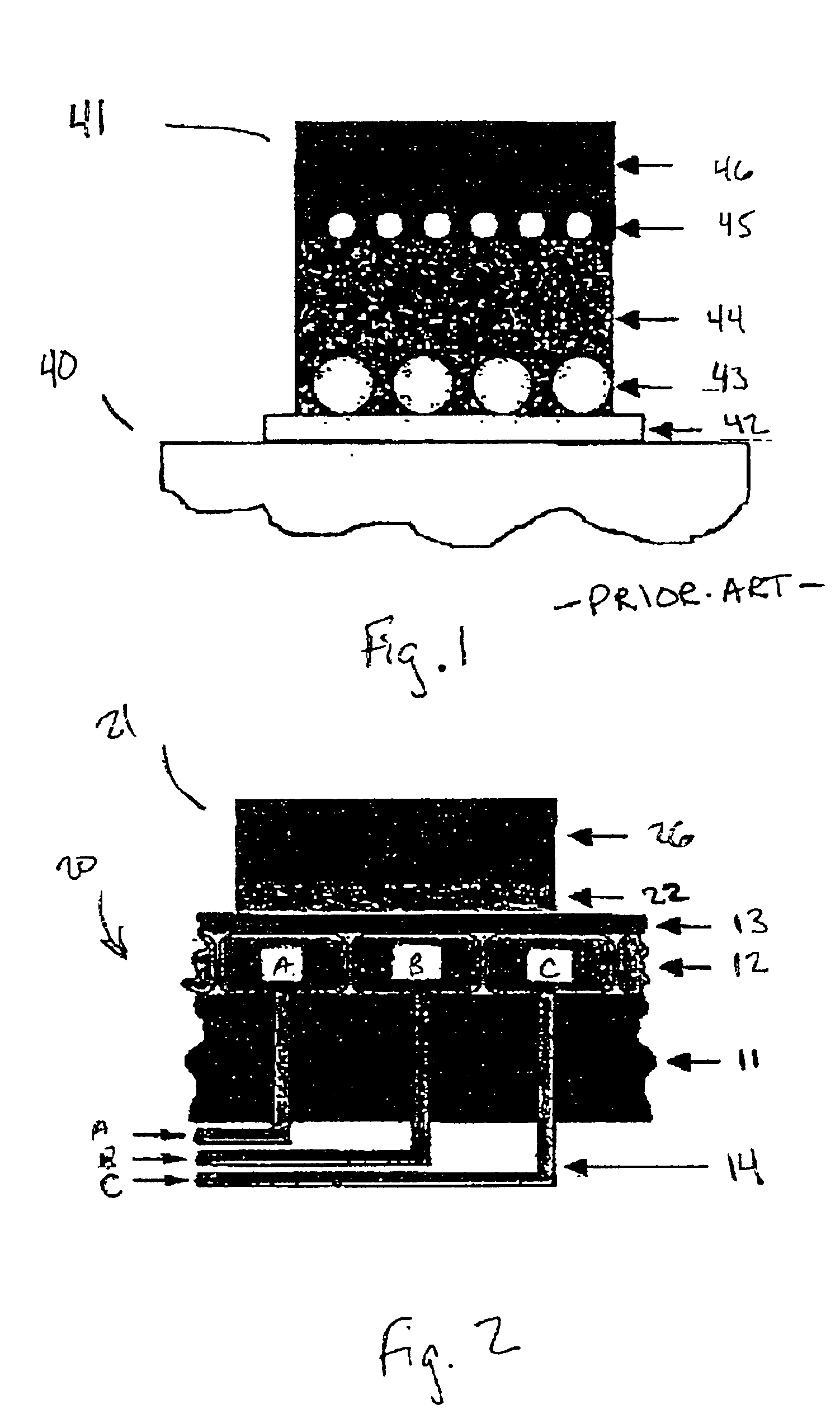

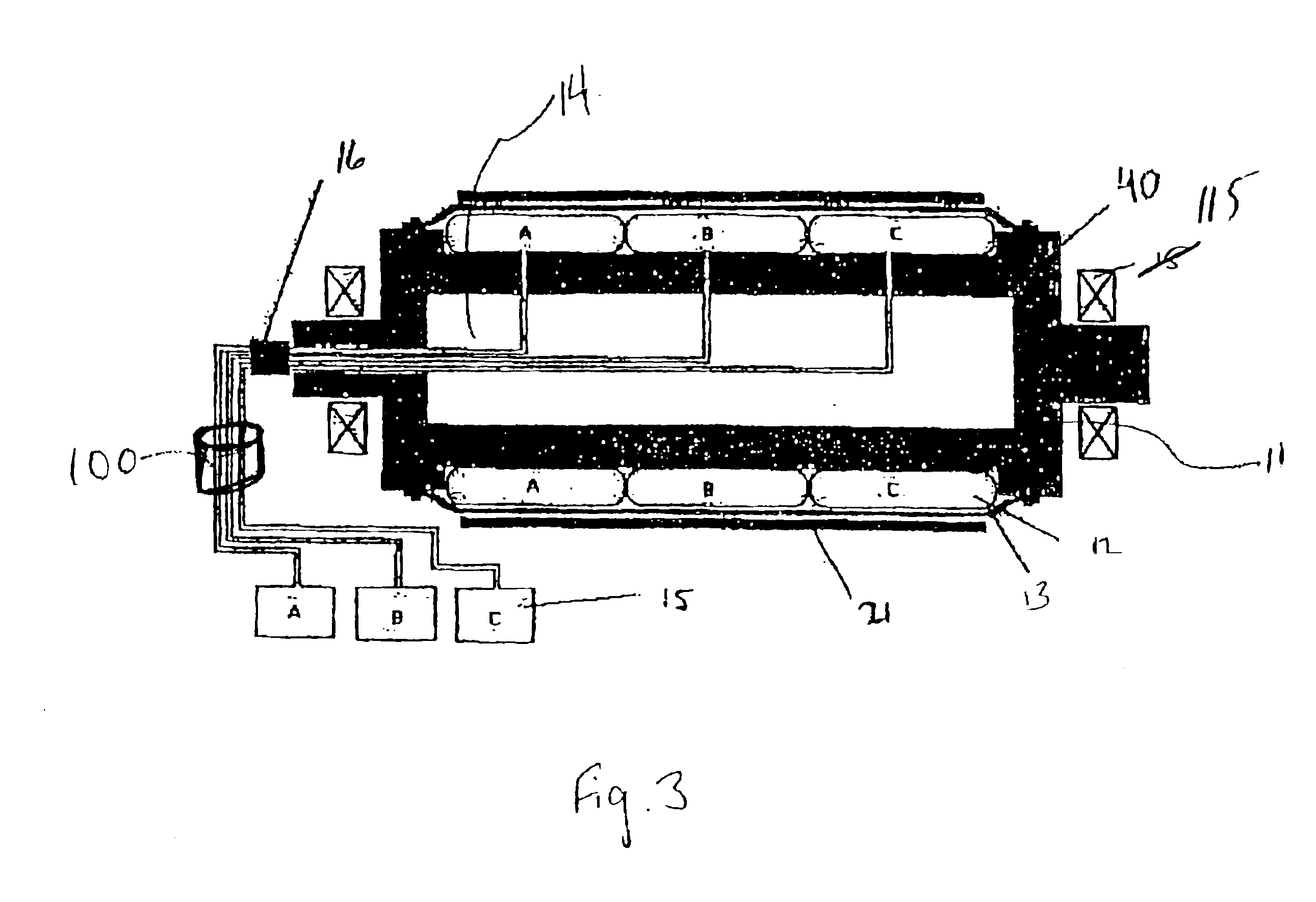

Blanket cylinder with integrated compressible layer

A printing unit including a rigid cylinder rotatable about an axis of rotation, a plurality of inflatable bladders disposed on a circumferential surface of the cylinder, and a first fluid supply regulation unit configured to supply a first fluid to a first set of inflatable bladders of the plurality of inflatable bladders and to regulate a first fluid pressure inside the first set inflatable bladders. In addition, a method for mounting a sleeve-shaped printing sock onto a blanket cylinder of an offset printing press, in which a set of inflatable bladders disposed at an outer region of the blanket cylinder are at least partially deflated. The sleeve-shaped printing sock is slid over one end of the blanket cylinder so that the printing sock at least partially surrounds a circumference of the blanket cylinder. The set of inflatable bladders are then inflated so that the printing sock fits tightly around the circumference of the blanket cylinder.

Owner:SHANGHAI ELECTRICGROUP CORP

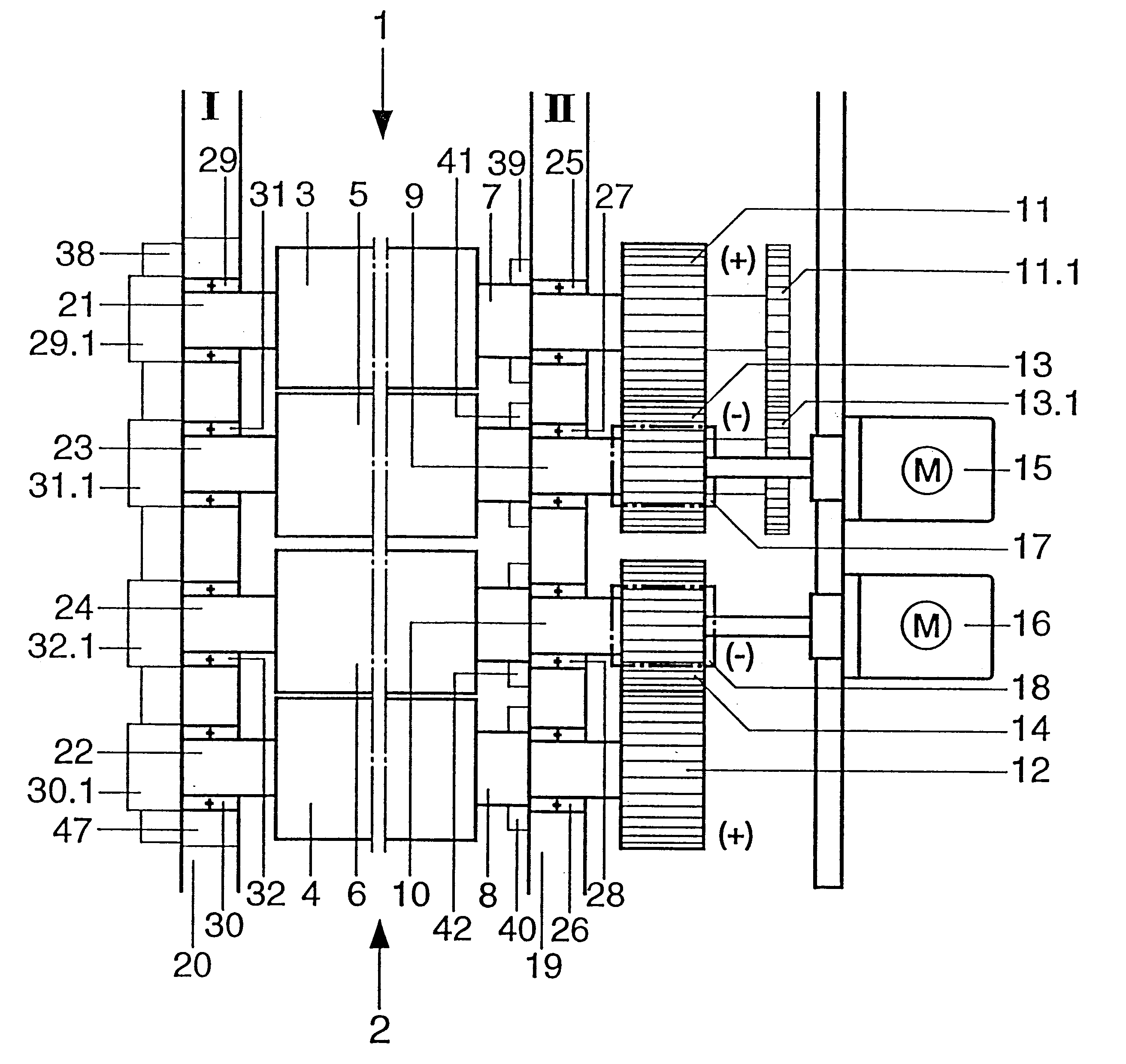

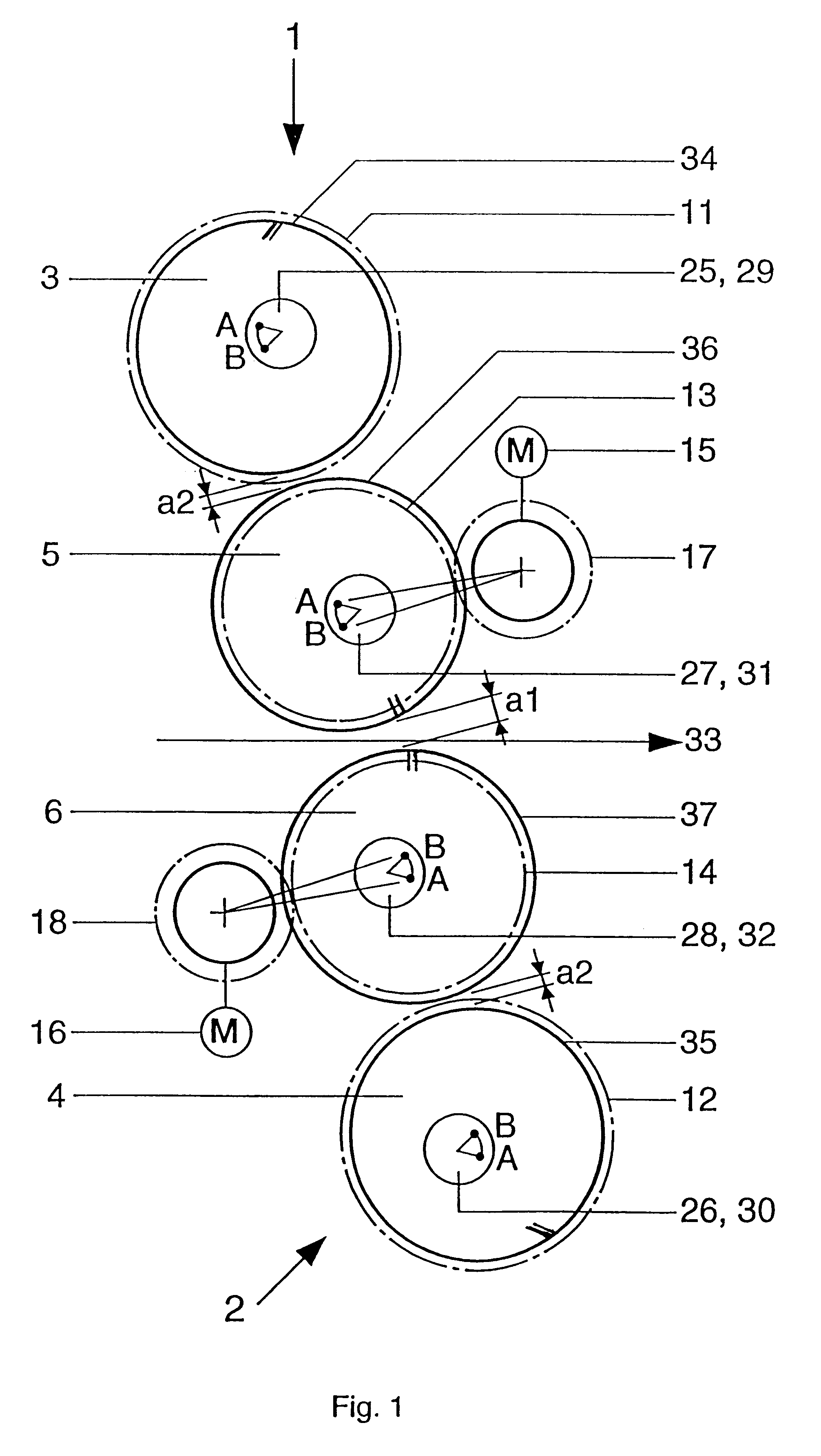

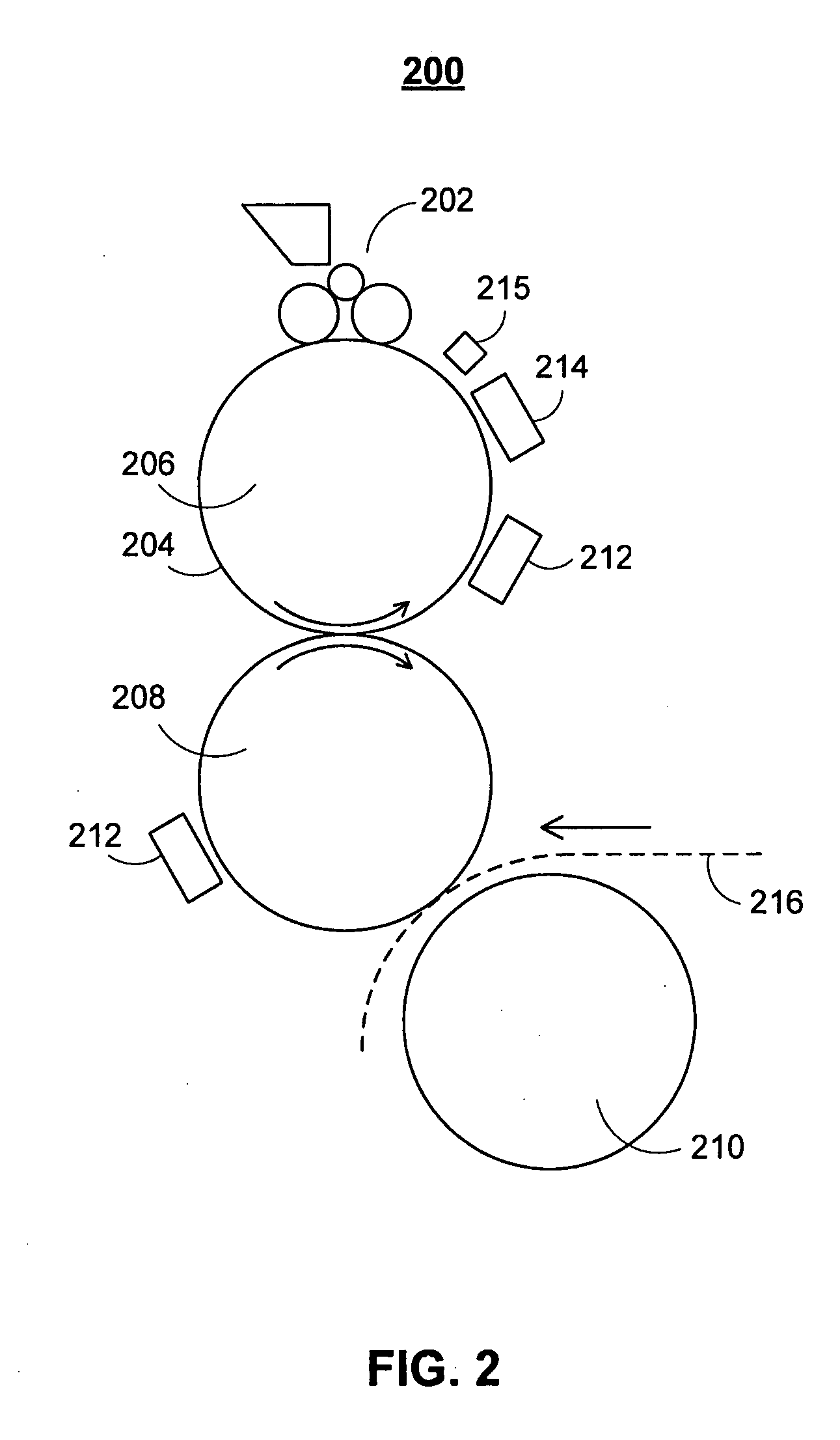

Double printing unit of a rotary printing machine

Large throw-off distances of the transfer cylinders in a double printing unit of a rotary printing machine operating on the rubber / rubber principle are achieved by enabling the two transfer cylinders to be set away from each other, and enabling the two form cylinders to be set away from the respective transfer cylinder. The form cylinder and the transfer cylinder of each printing unit have a drive connection via spur gears, the transfer cylinders are not in tooth engagement via their spur gears, and each printing unit has its own electric motor.

Owner:MANROLAND WEB SYST

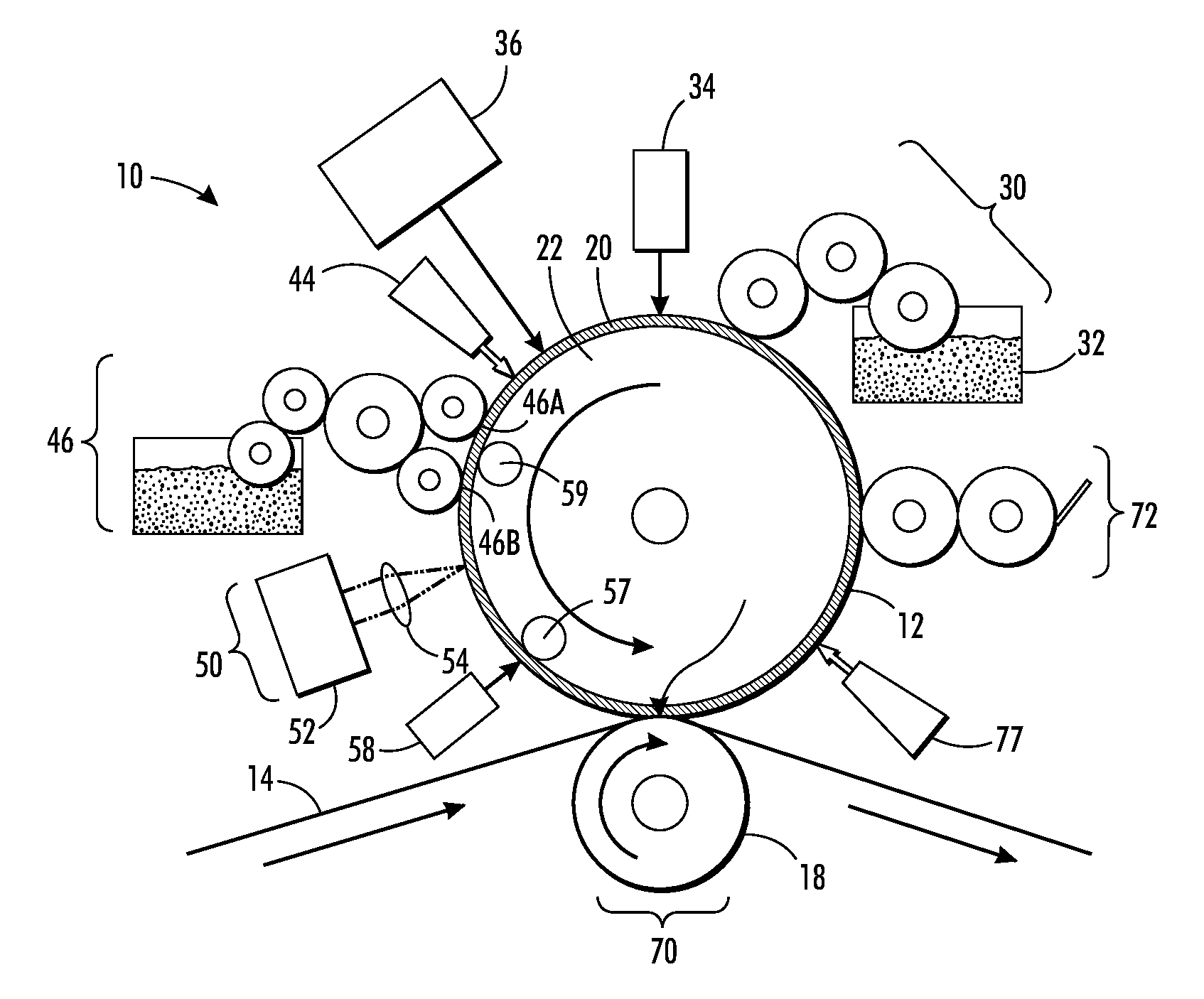

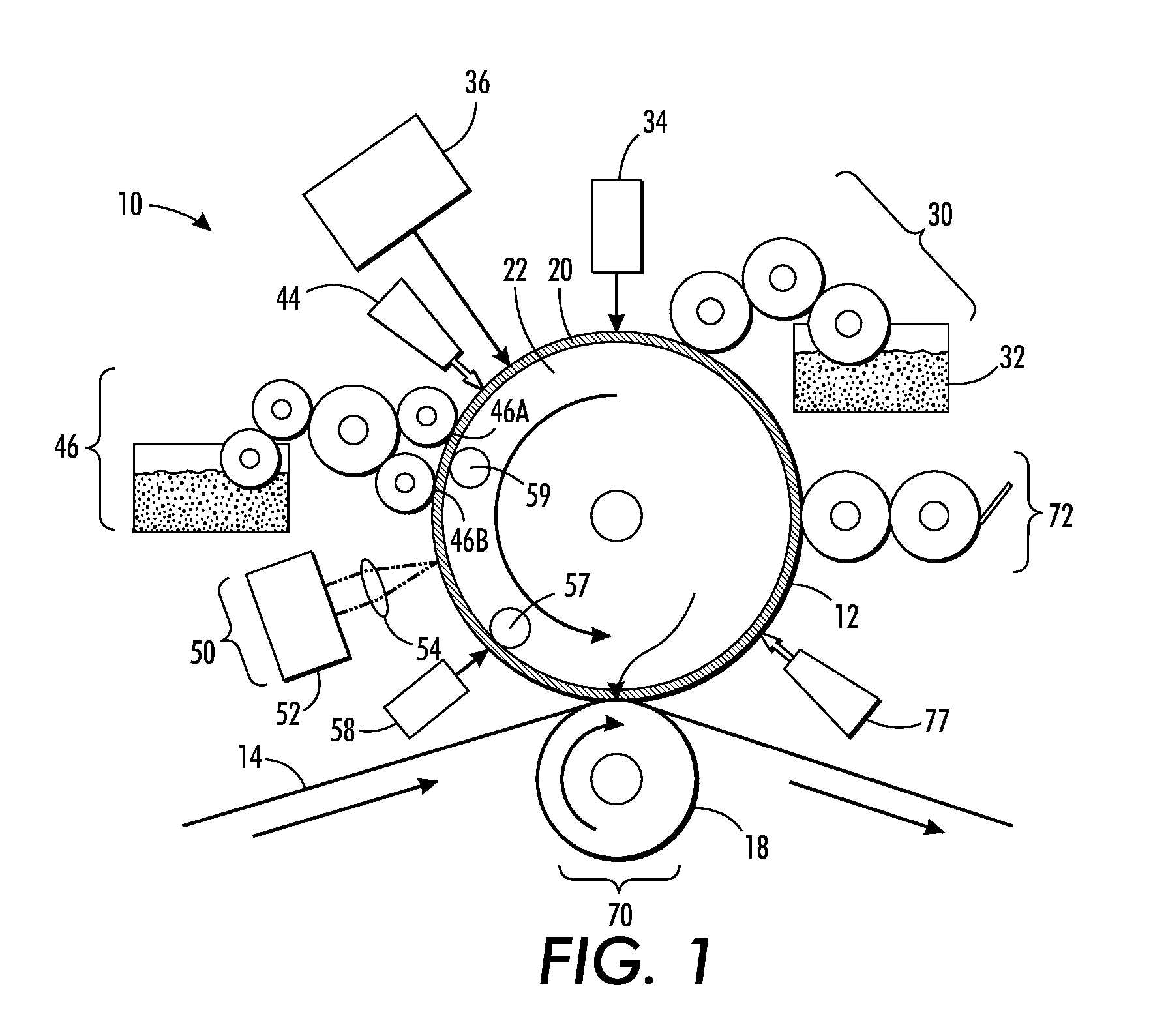

Systems and methods for high speed variable printing

Systems and methods for high-speed variable printing are provided. Ink jet technology and lithographic systems may be combined in such a way to create a fully variable and high-quality print system. An aqueous solution is applied to a cylinder to produce a negative image. The aqueous solution may comprise a block copolymer capable of physical bonding with the cylinder. Ink is then applied to the cylinder, and a positive image is transferred in ink to a print medium. The systems and methods described herein may be used to create high-quality one-to-one marketing applications.

Owner:R R DONNELLEY & SONS CO

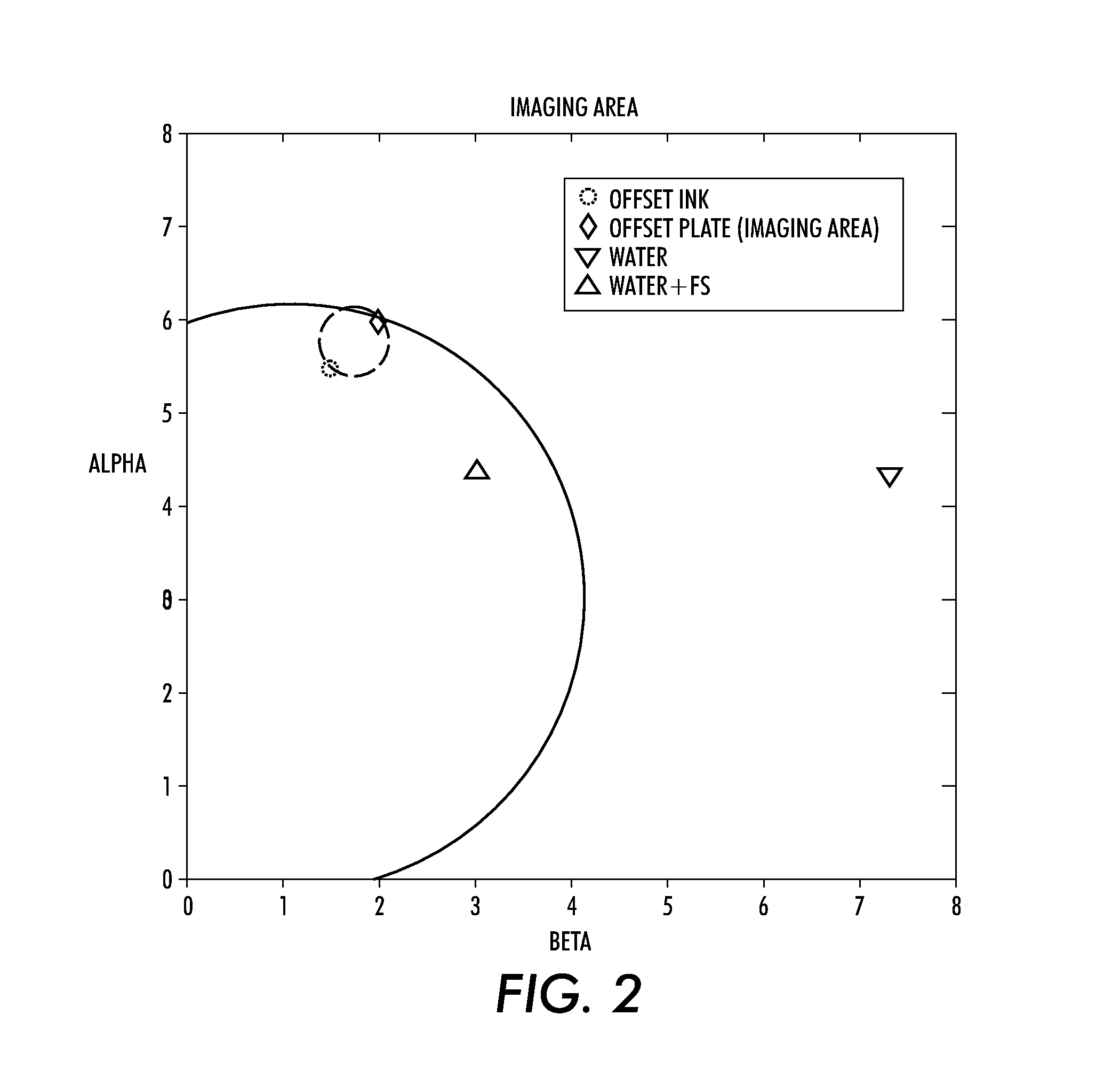

Dampening fluid for digital lithographic printing

ActiveUS20130104756A1Less residueSilicon organic compoundsPlaten pressesElectrical polarityVaporization

Different solvents for a dampening fluid are disclosed. The solvent is a volatile hydrofluoroether liquid or a volatile silicone liquid. Such liquids have a lower heat of vaporization, a lower surface tension, and better kinematic viscosity compared to water, which is the conventional solvent used in dampening fluids. The dampening fluids, which are relatively nonpolar, can be used in a combination with polar inks to form a new type of digital lithographic printing system.

Owner:XEROX CORP

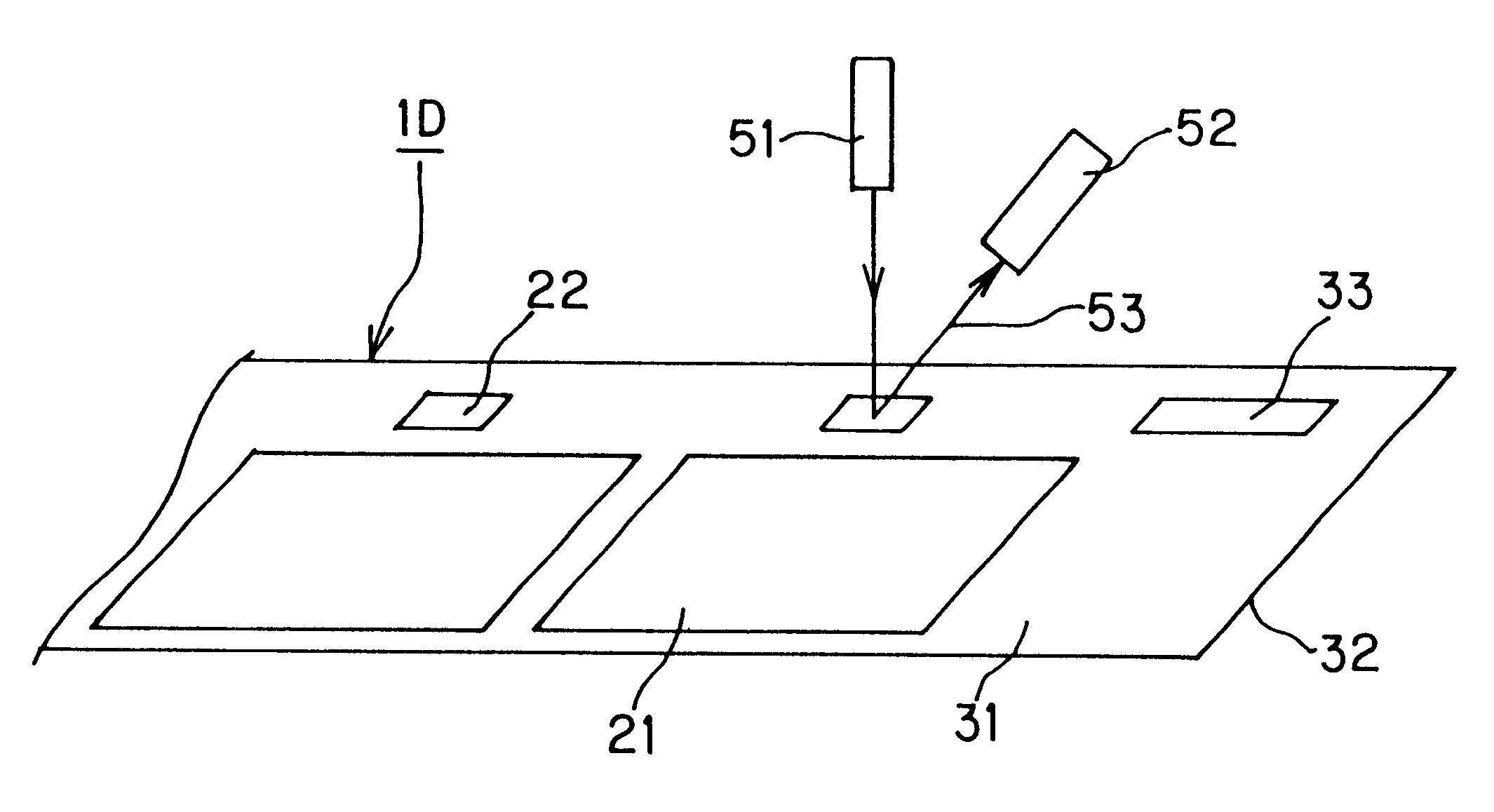

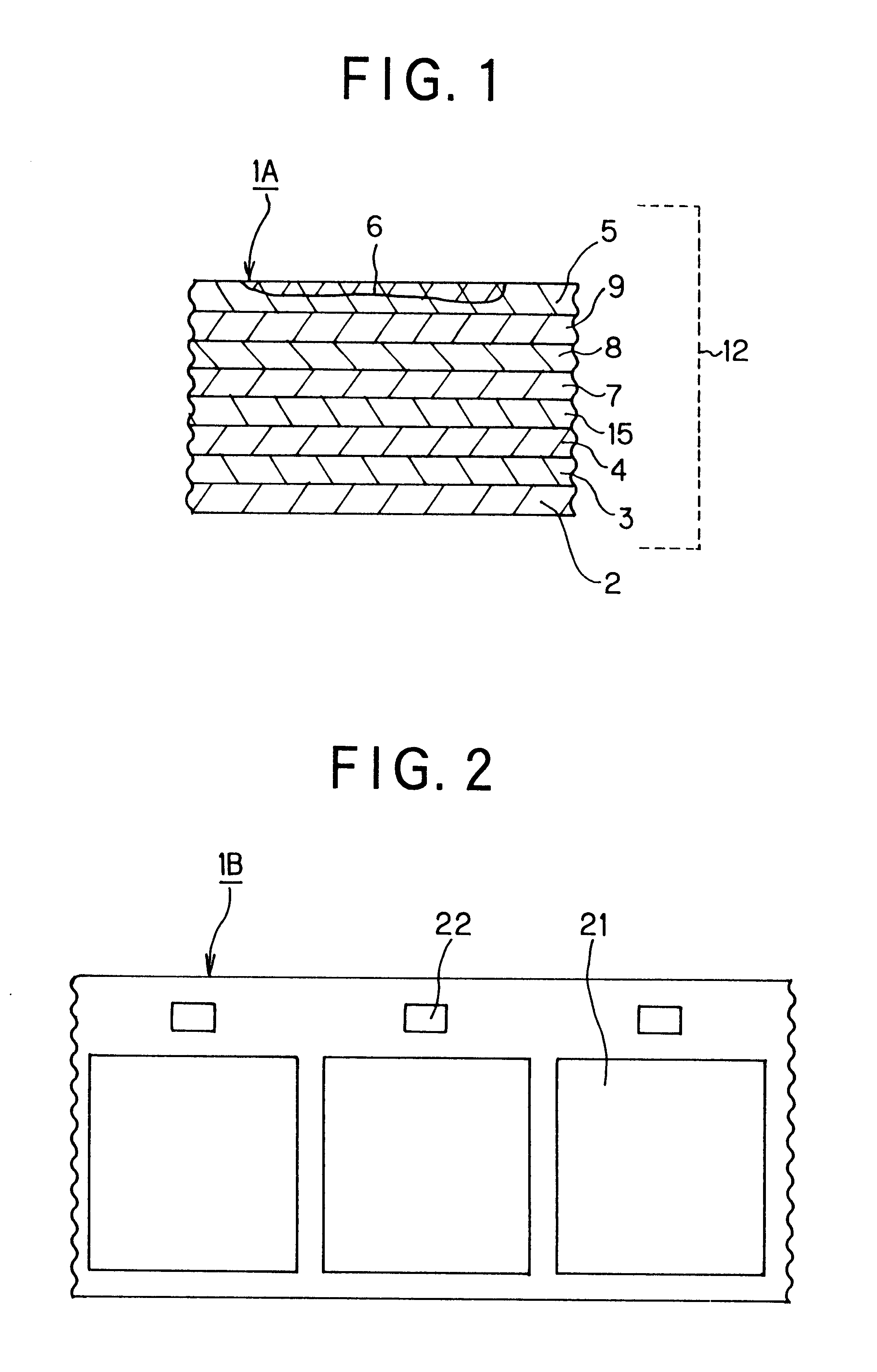

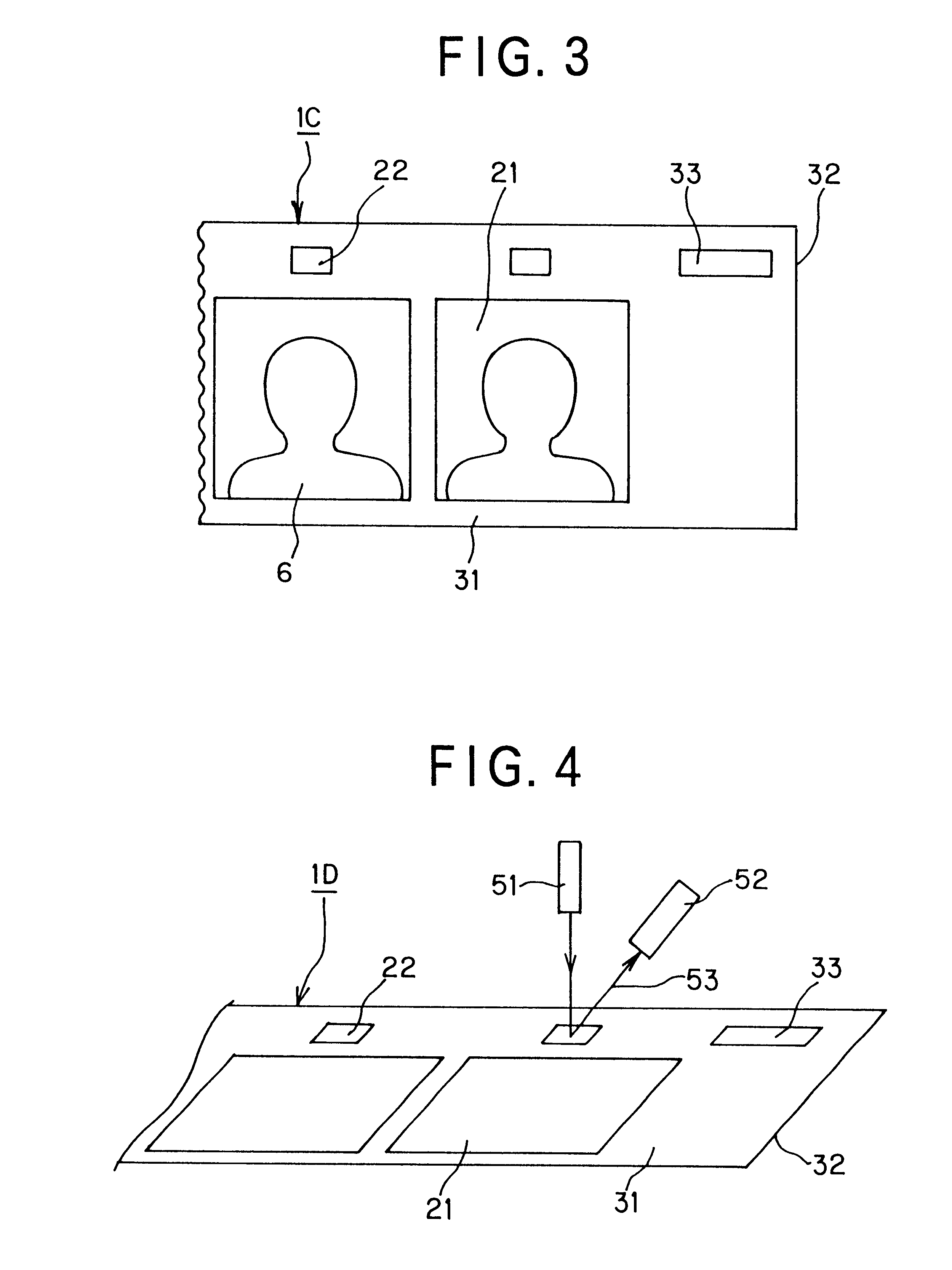

Intermediate transfer recording medium, method of forming print, and print

InactiveUS6308630B1Quality improvementSimple formatCylinder pressesPlaten pressesComputer scienceRecording media

An intermediate transfer recording medium is comprised by providing a transfer portion having a receptor layer on a substrate film. The transfer portion is printed with the image and thereafter transferred on a surface of a transfer-receiving material. In the first aspect of the intermediate transfer recording medium, the transfer portion is provided with plural hologram patterns 21 with a hologram mark 22 allocated to each the hologram pattern. According to the first aspect of the invention, since an image is formed on the receptor layer through positioning process using the hologram mark and then the transfer portion is transferred to the surface of the transfer-receiving material, no joint of a print plate appears in the hologram pattern and accuracy of transfer is remarkably excellent. On the other hand, In the second aspect of the intermediate transfer recording medium, peeling strength required to peel the transfer portion from the substrate film at the time when transferring the transfer portion to the transfer-receiving material is controlled in the range of 10 to 150 gf / inch. According to the second aspect of the invention, any transfer failure such as tail-extension or chip of the transfer portion is not caused.

Owner:DAI NIPPON PRINTING CO LTD

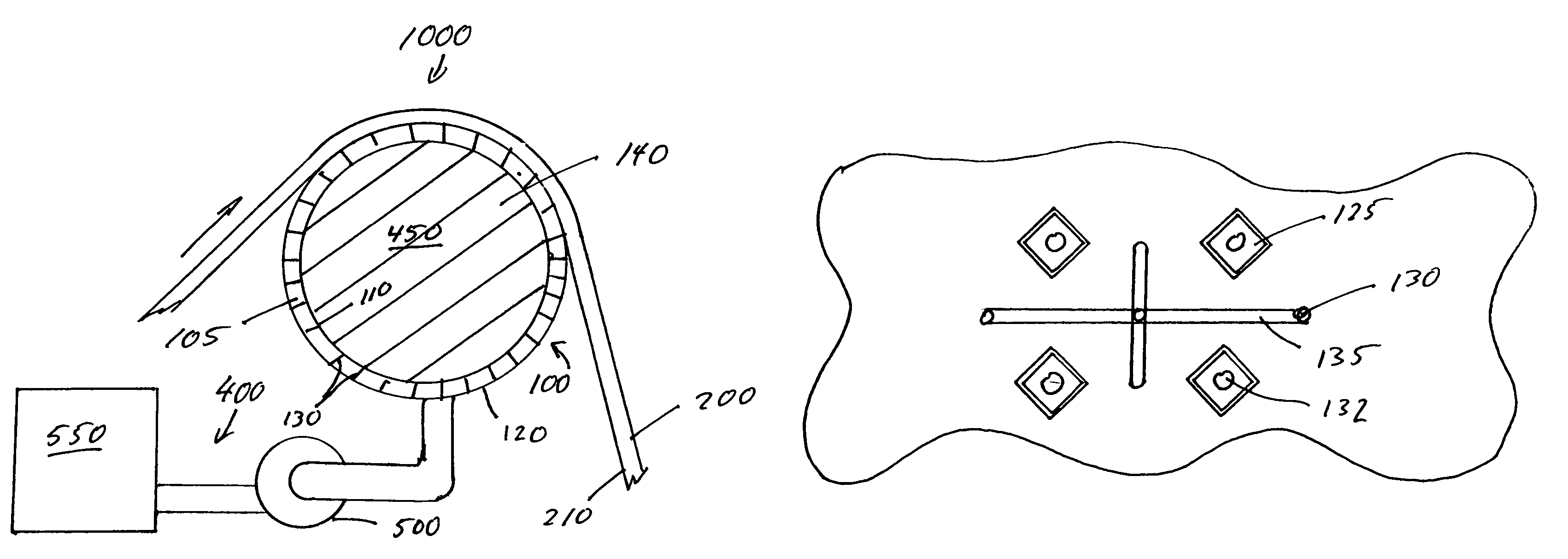

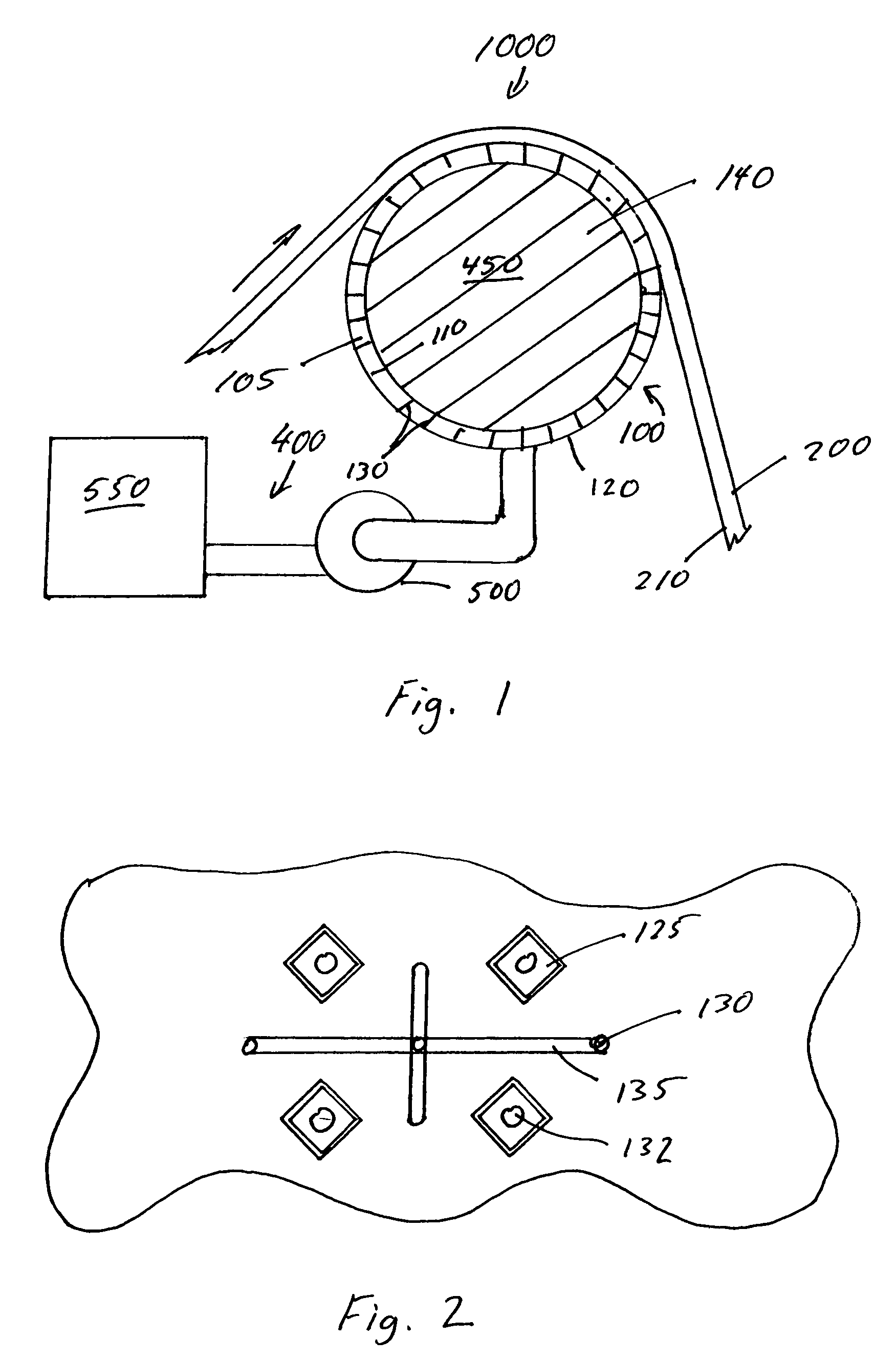

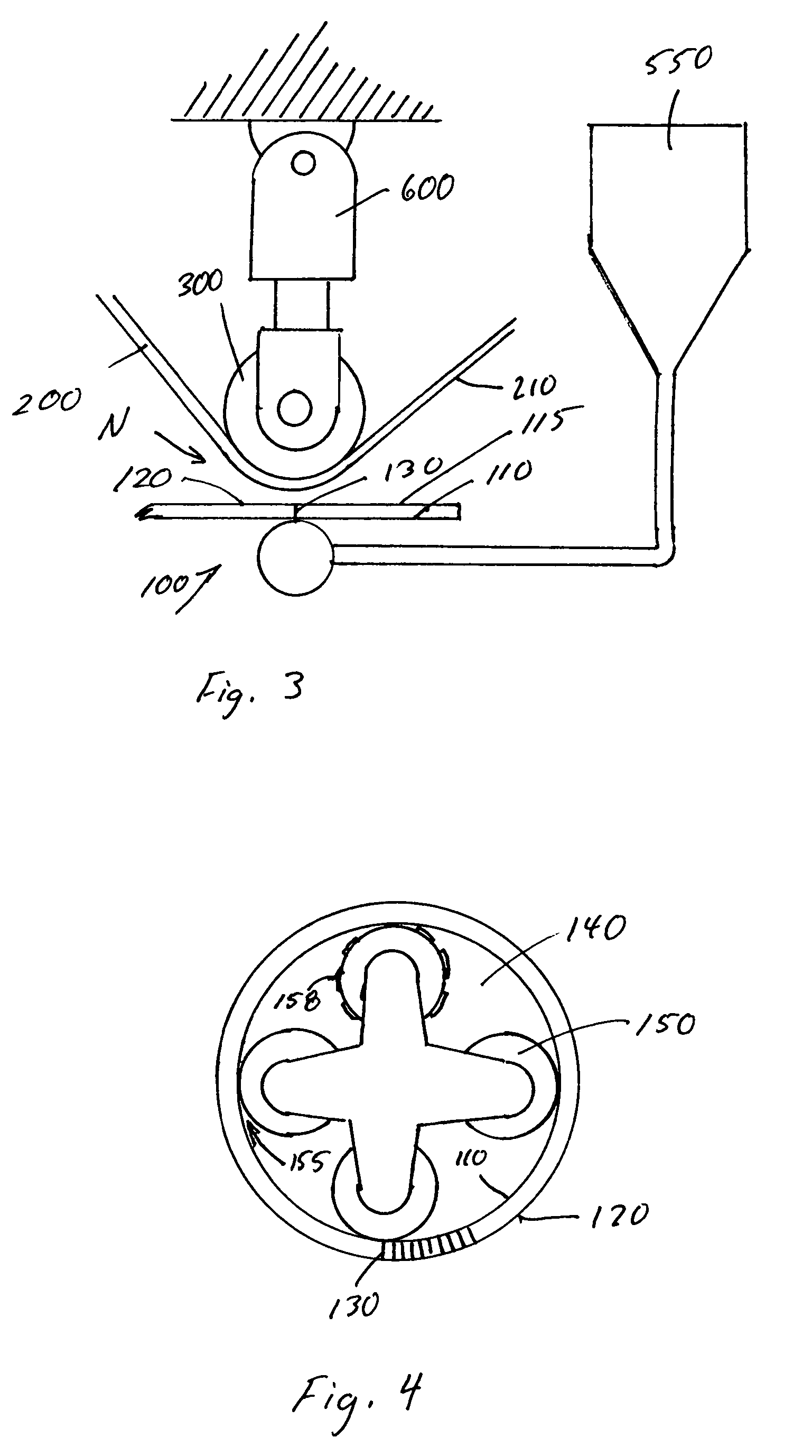

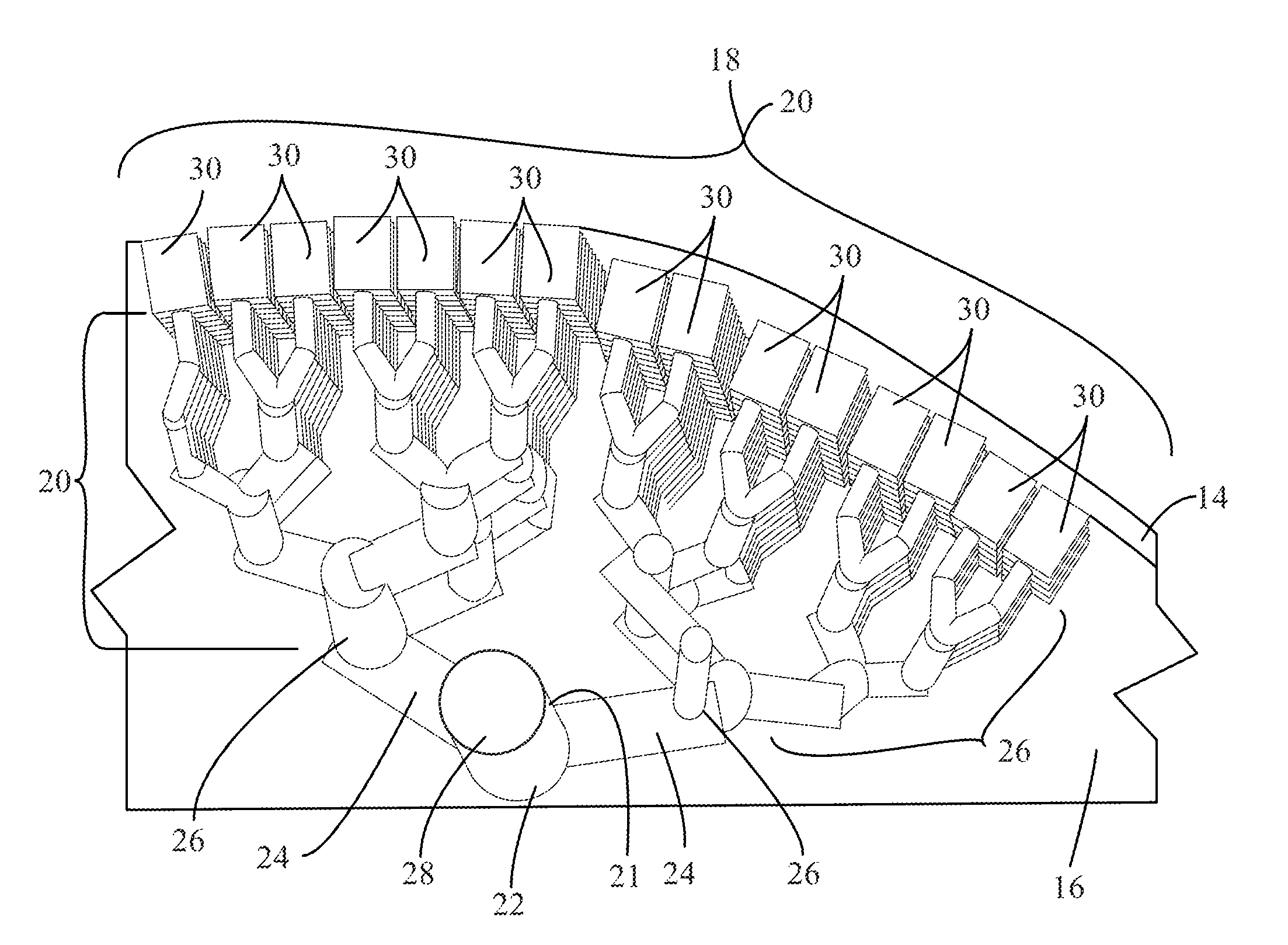

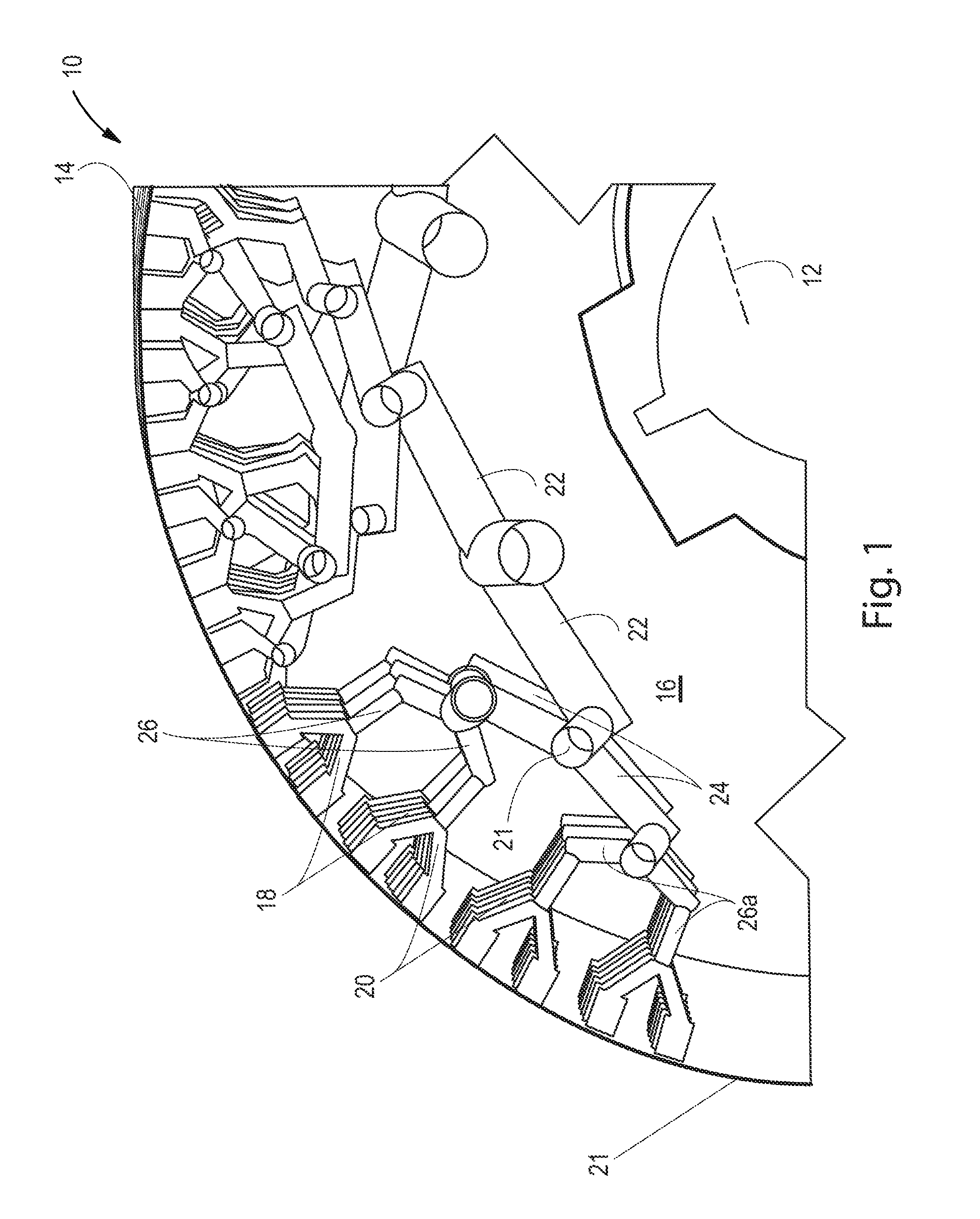

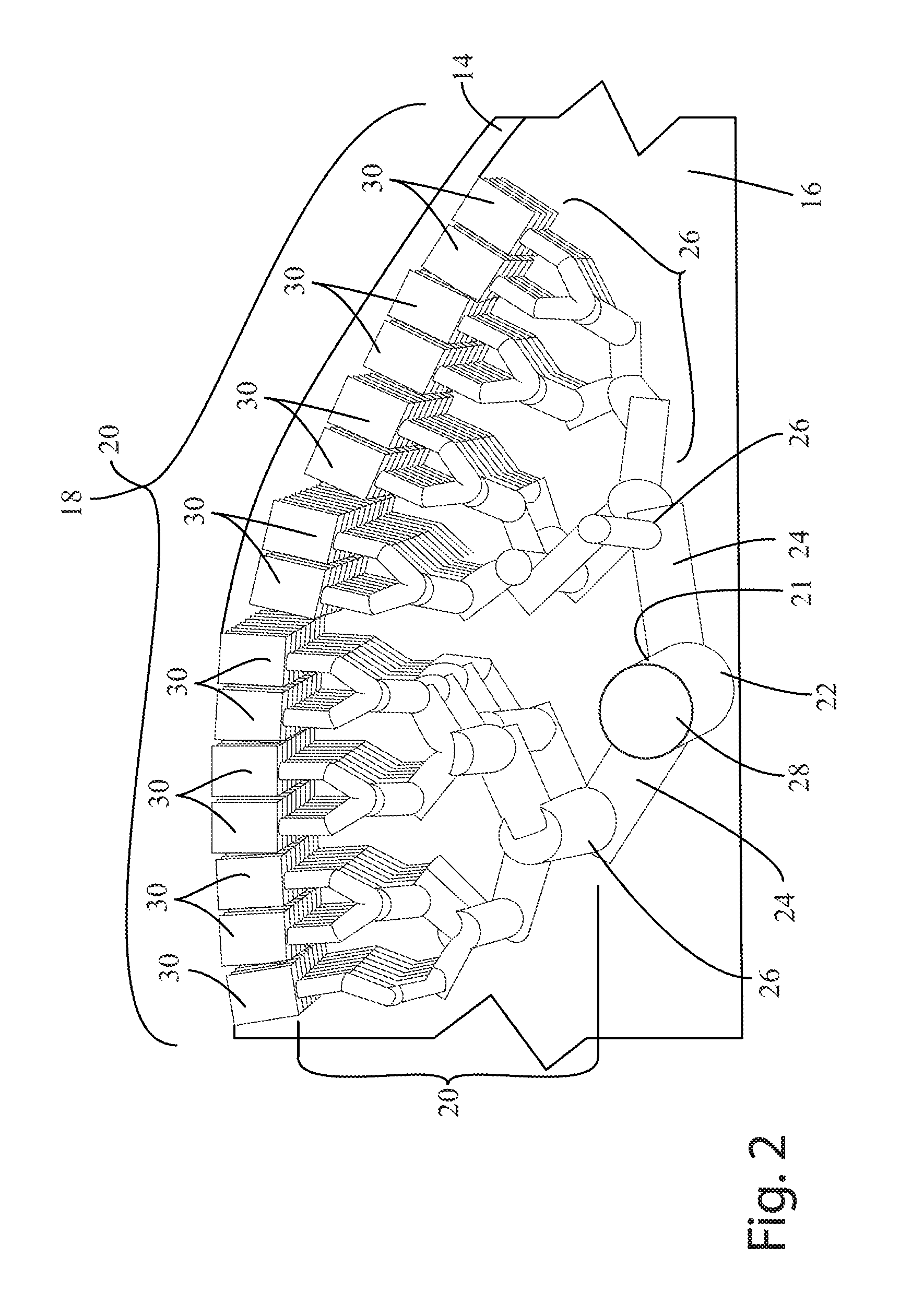

Customizable apparatus and method for transporting and depositing fluids

A system for dosing one or more fluids on a substrate, the system comprising a rotating roll. The rotating roll has a central longitudinal axis, wherein the rotating roll rotates about the central longitudinal axis; an exterior surface defining an interior region and substantially surrounding the central longitudinal axis; and a vascular network configured for transporting the one or more fluids in a predetermined path from the interior region to the exterior surface of the rotating roll.

Owner:THE PROCTER & GAMBLE COMPANY

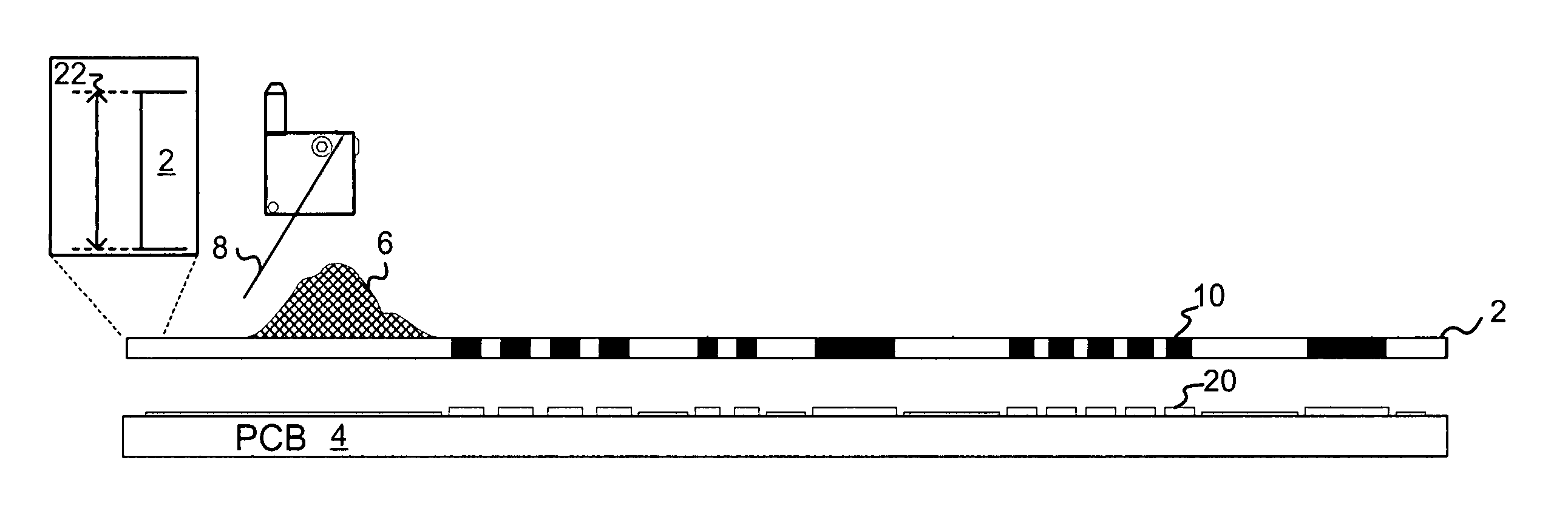

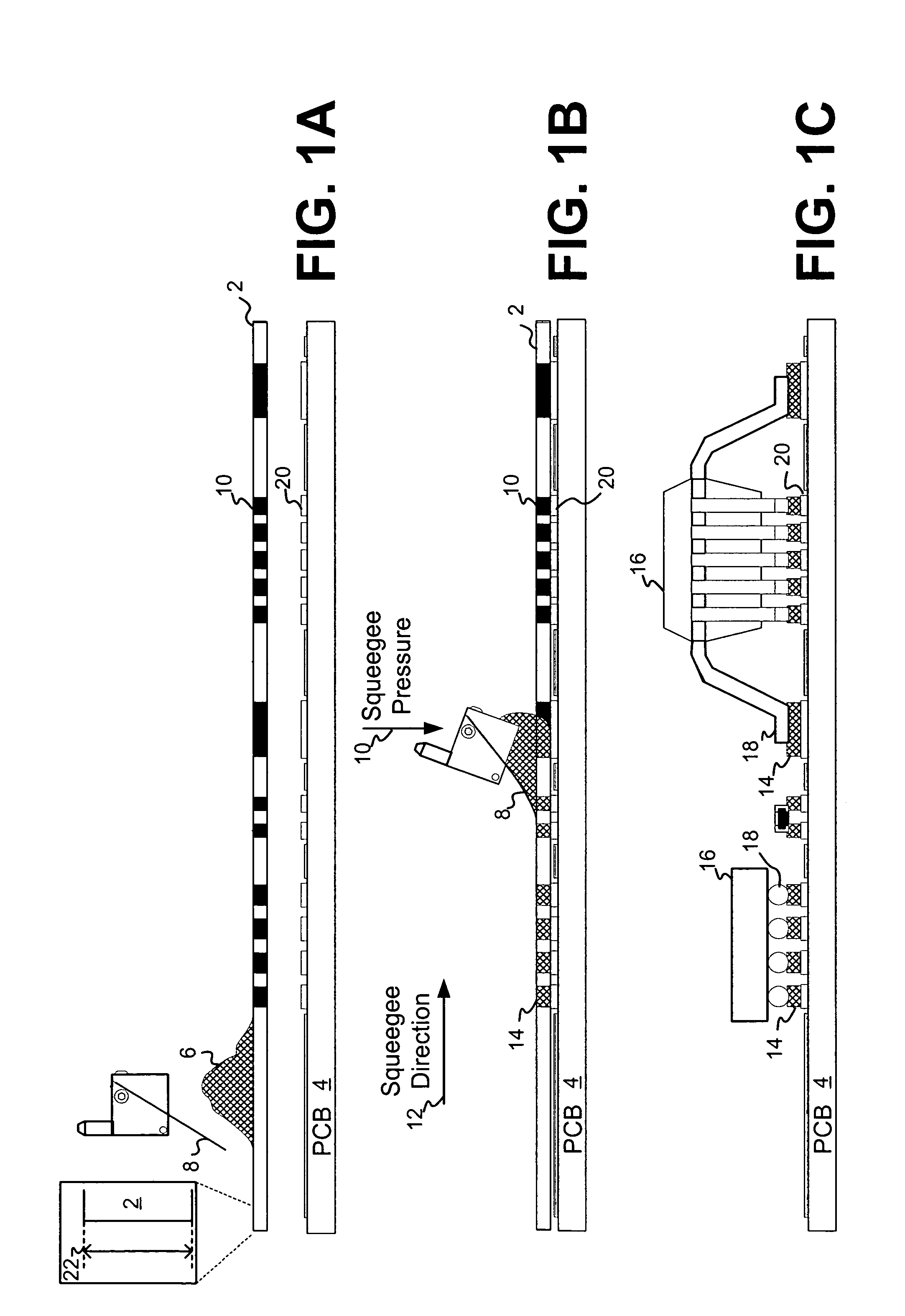

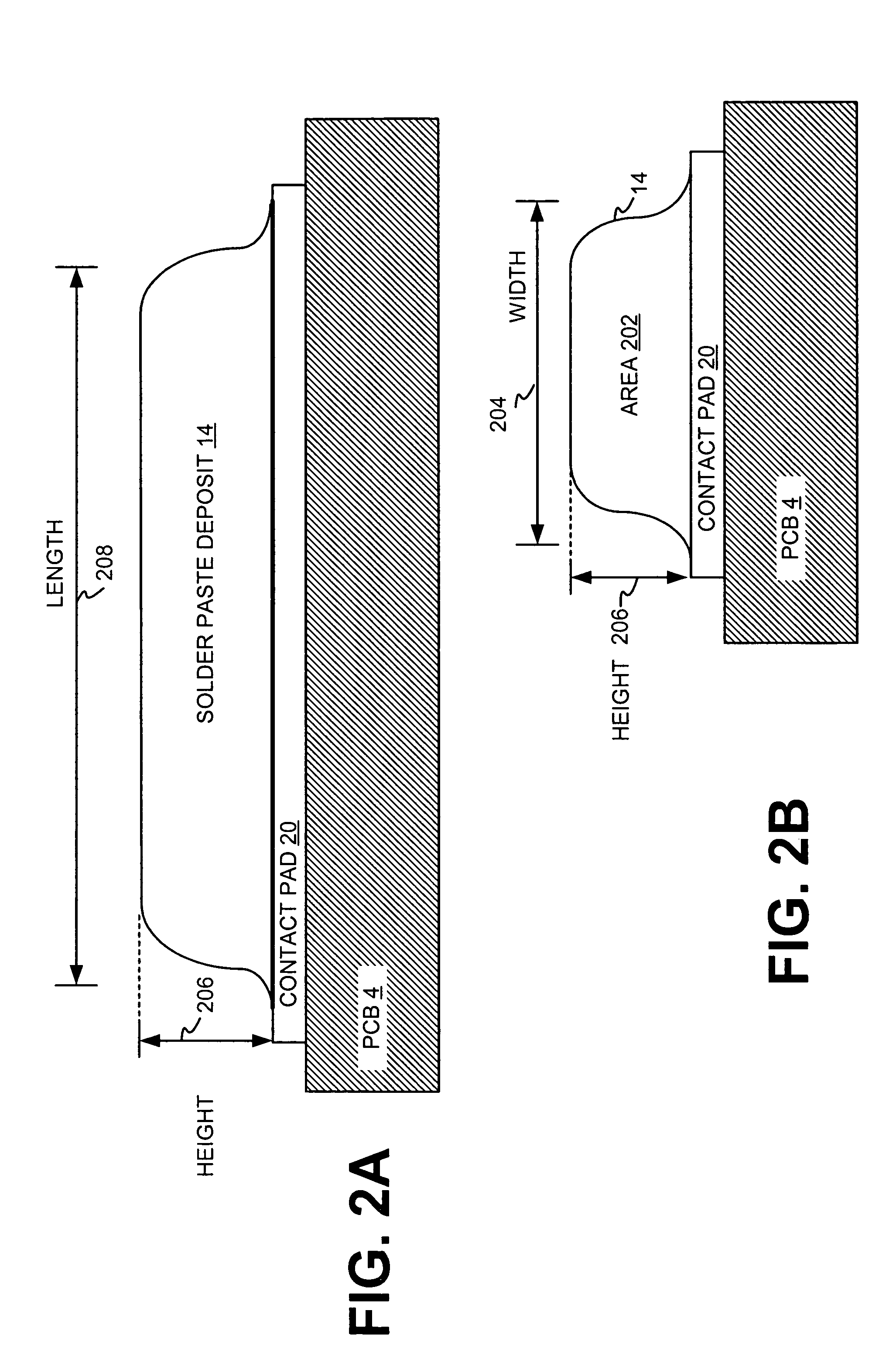

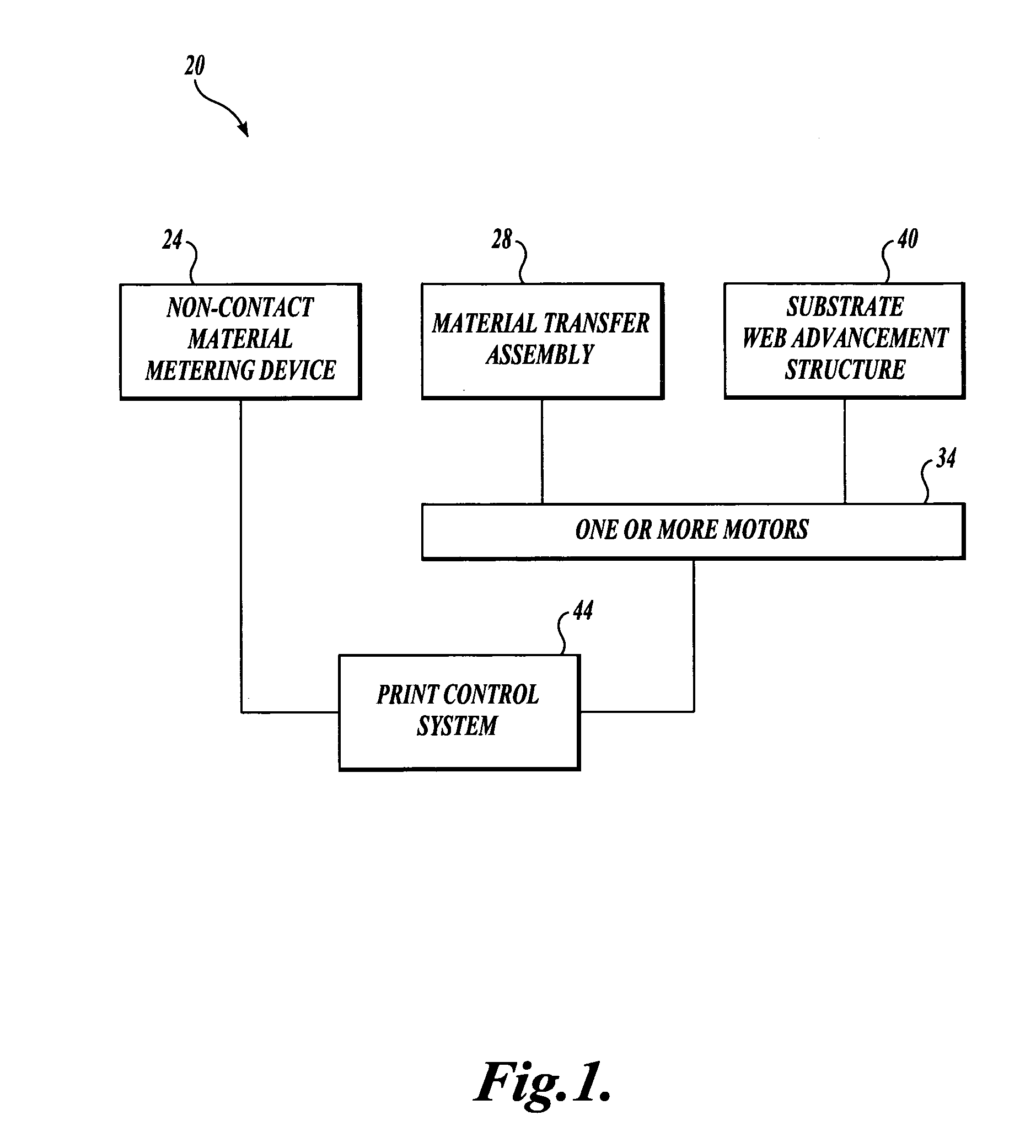

System and methods for data-driven control of manufacturing processes

Systems and methods for implementing hybrid, closed-loop control that generates control values for processes defined by a limited number of function evaluations and large amounts of process and measurement noise. The described control system is applied to a stencil printing process for applying solder paste to an electronic medium such as a printed circuit board or semiconductor wafer. The control system is defined by a hybrid approach. A first, coarse algorithm is used to rapidly produce the value of a stencil printer control value resulting in a solder paste deposit having a volume within predetermined acceptable limits. After the coarse algorithm no longer produces solder paste deposits closer to a desired volume, a second, more refined estimator is used to fine tune the process. An additional transitional algorithm may be added between the coarse algorithm and refined estimator. The coarse algorithm may be implemented with a constrained-conjugated gradient search, and the refined search may be a implemented using a least-squares affine estimator or a quadratic estimator. The transitional algorithm may be implemented using a block version of a least-squares affine estimator.

Owner:GEORGIA TECH RES CORP

Compatibilized blend of fluoroelastomer and polysiloxane useful for printing machine component

InactiveUS6035780AShaft and bearingsSynthetic resin layered productsPrinting pressFree-radical reaction

A process including: forming a first mixture of a first fluoroelastomer, and a first polymeric siloxane containing free radical reactive functional groups; and forming a second mixture of the resulting product with a mixture of a second fluoroelastomer and a second polysiloxane compound, and wherein the resulting product of the dissimilar polymeric materials is a phase compatible blend. The phase compatible blend is useful as a component of electrostatographic and liquid ink printing machines, including long-life fuser rolls, backing rolls, transfer and transfuse belts and rolls and bias charging and bias transfer rolls.

Owner:XEROX CORP

Systems and methods for additive deposition of materials onto a substrate

InactiveUS20070068404A1Sharp and accurate featureLevel of redundancySolid-state devicesRotary letterpress machinesEngineering

Owner:WEYERHAEUSER CO

Customizable apparatus and method for transporting and depositing fluids

ActiveUS20160375458A1Liquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingEngineeringMechanical engineering

A method for delivering a High Internal Phase Emulsion to a substrate. The method includes providing a rotating roll, The rotating roll has a central longitudinal axis, wherein the rotating roll rotates about the central longitudinal axis, an exterior surface defining an interior region and substantially surrounding the central longitudinal axis, and a vascular network configured for transporting the one or more fluids in a predetermined path from the interior region to the exterior surface of the rotating roll. The method further includes providing a High Internal Phase Emulsion to the rotating roll vascular network. The method further includes contacting a substrate with the rotating roll and contacting the substrate with the High Internal Phase Emulsion.

Owner:THE PROCTER & GAMBLE COMPANY

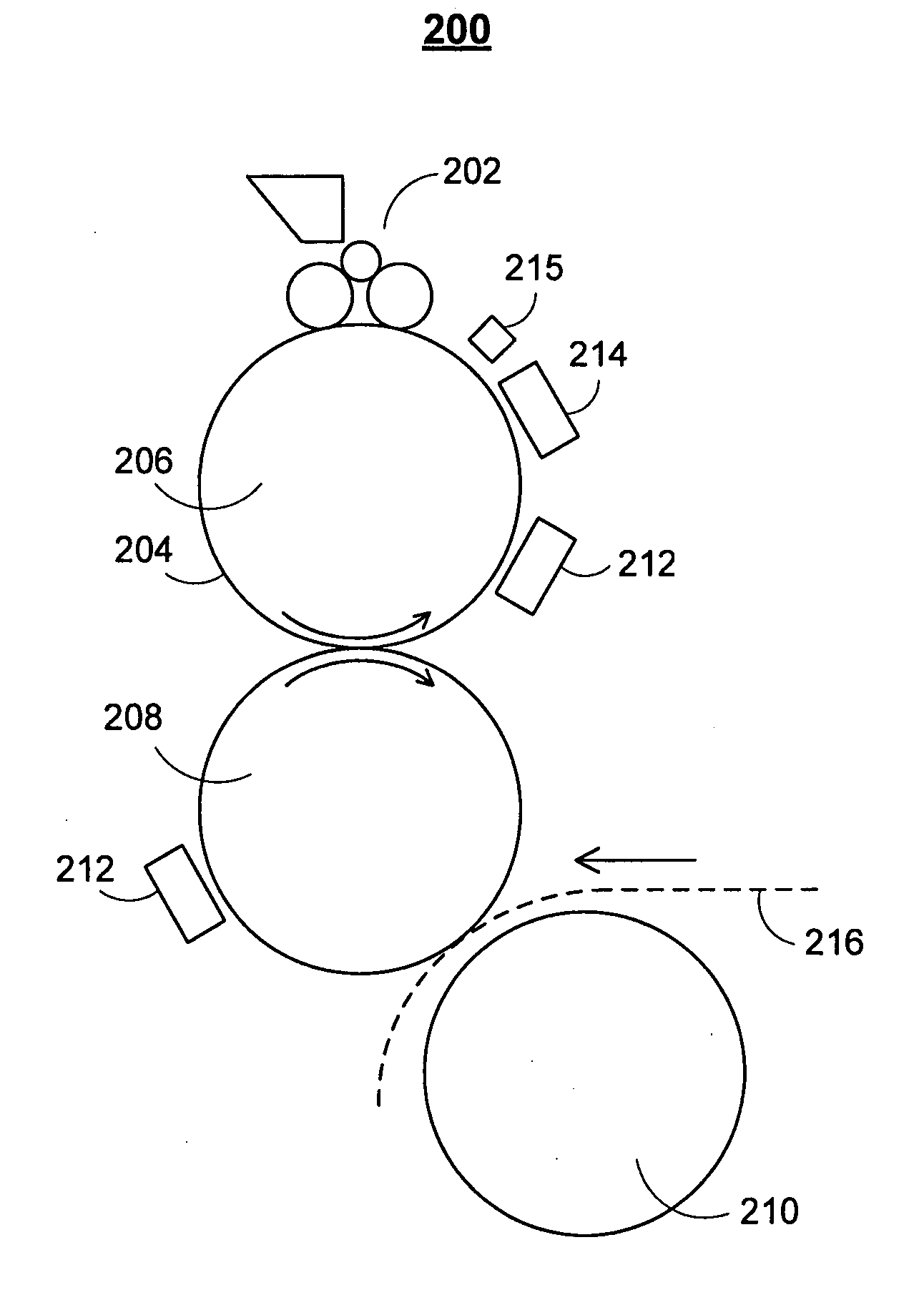

Systems and methods for high speed variable printing

Systems and methods for high-speed variable printing are provided. Ink jet technology and lithographic systems may be combined in such a way to create a fully variable and high-quality print system. An aqueous solution is applied to a cylinder to produce a first negative image. A positive image in ink is transferred to a print medium. Residue ink and aqueous solution is then cleaned from the cylinder and aqueous solution is applied to the cylinder to produce a second negative image. The systems and methods described herein may be used to create high-quality one-to-one marketing applications.

Owner:R R DONNELLEY & SONS CO

Device and method for printing by transfer onto a cylindrical printing medium

The invention relates to a device for printing by transfer onto a print support (10) comprising at least one blanket (30) driven in a sequential relative movement past a magazine (50) conveying the print supports (10), in which device the blanket (30) has a surface area greater than that of the print support (10), the device further comprising digital printing means (20) which print by spraying ink onto this blanket (30) over a variable area equal to that of the print support (10).

Owner:IMPIKA +1

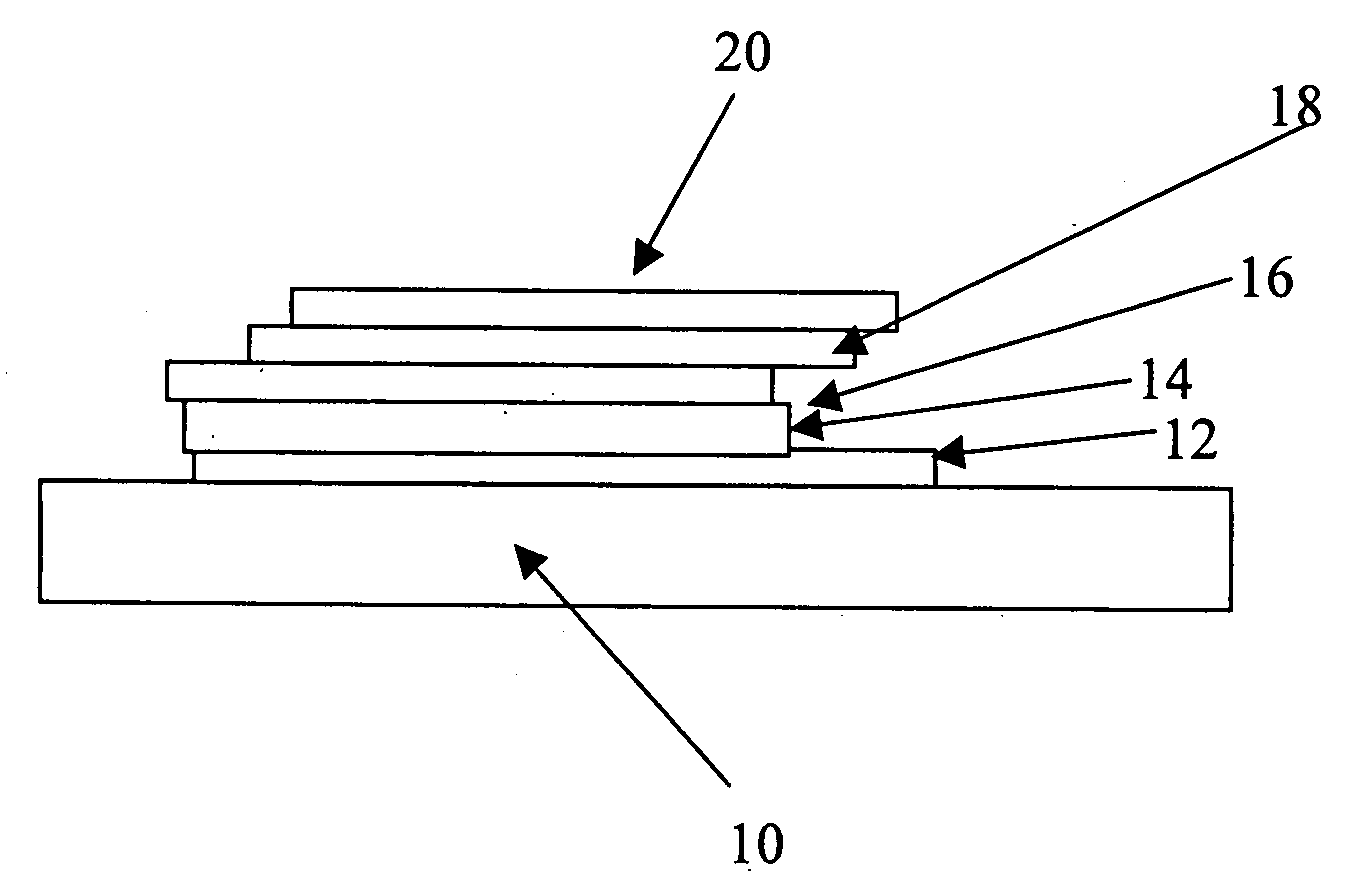

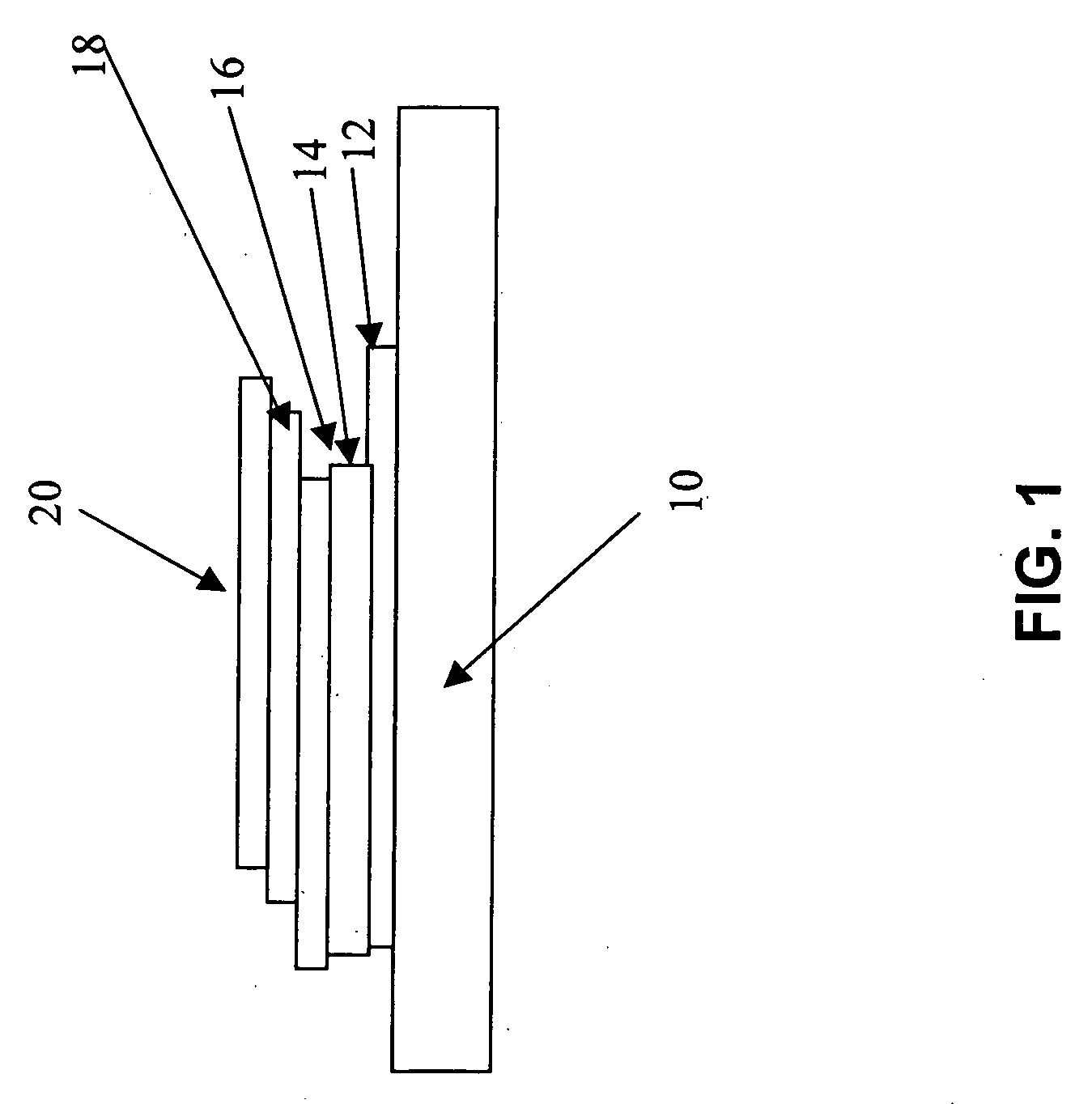

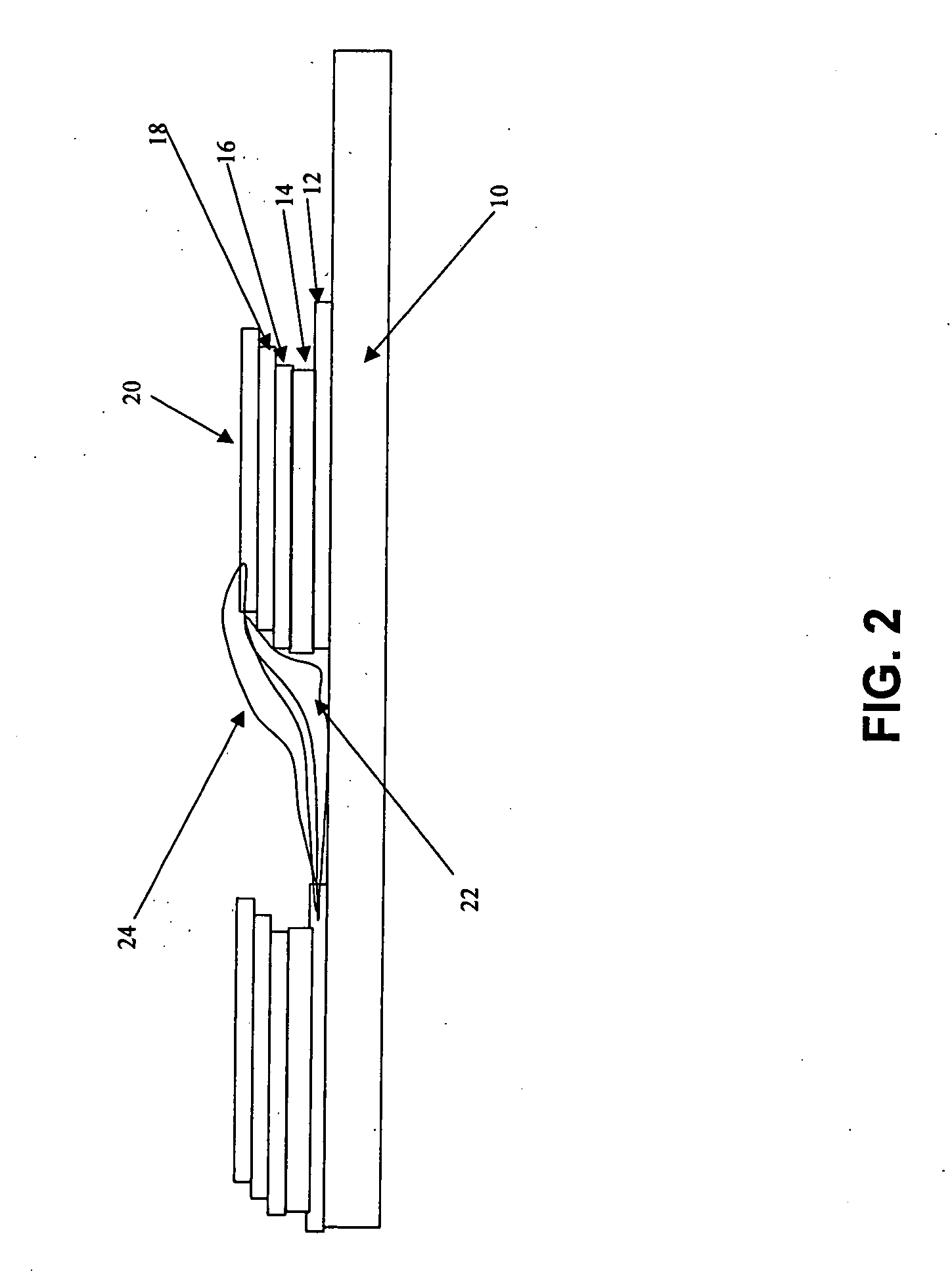

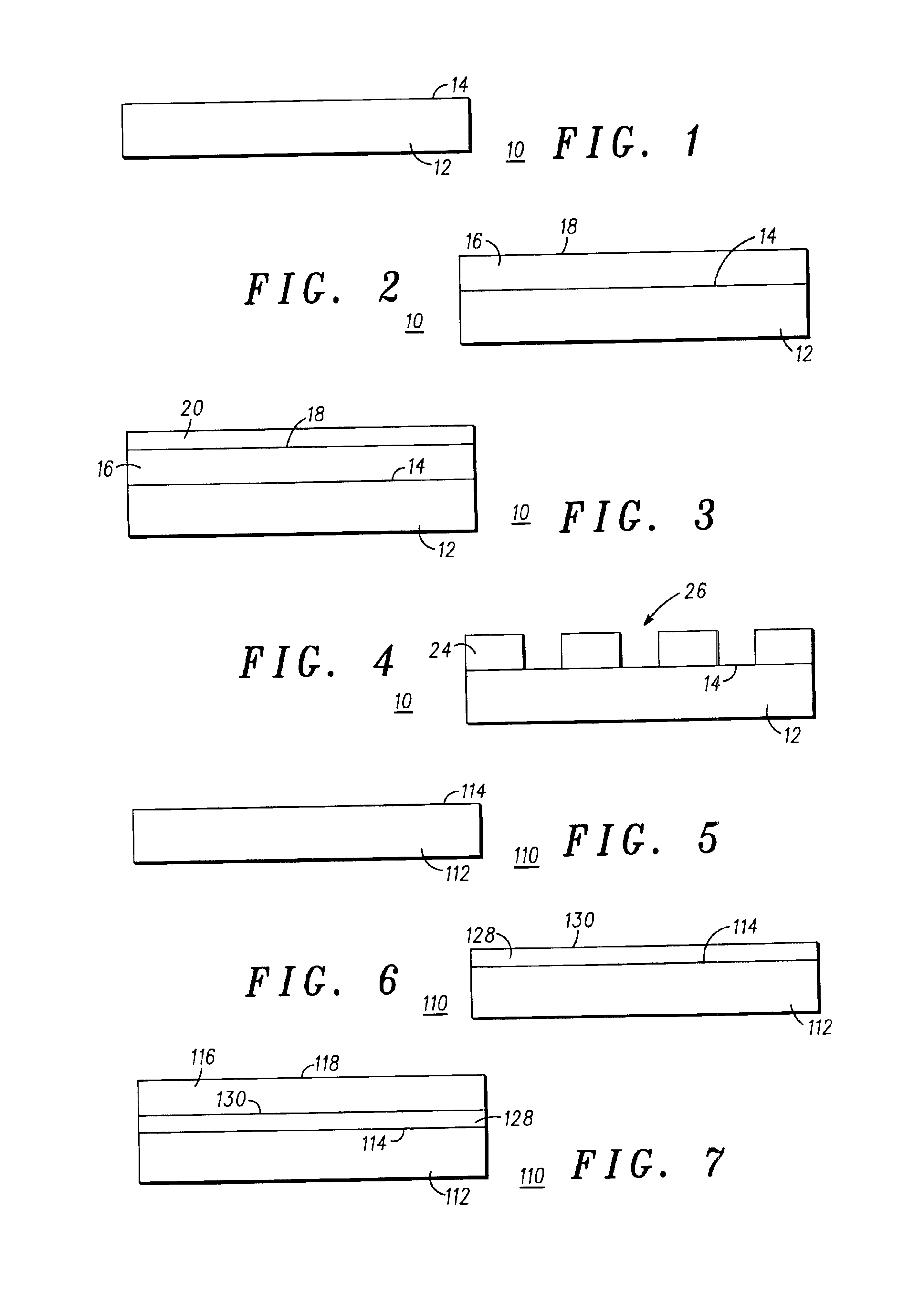

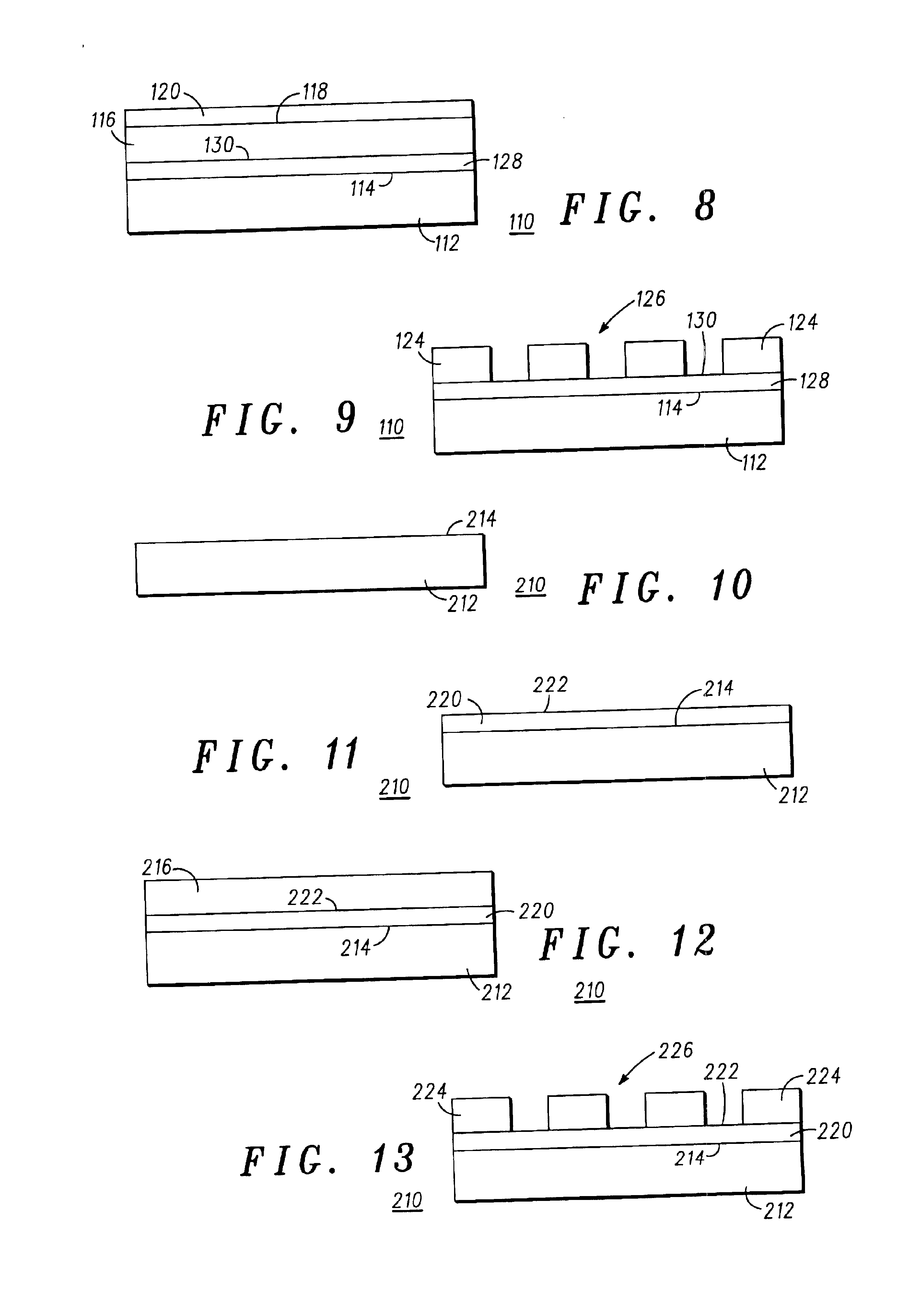

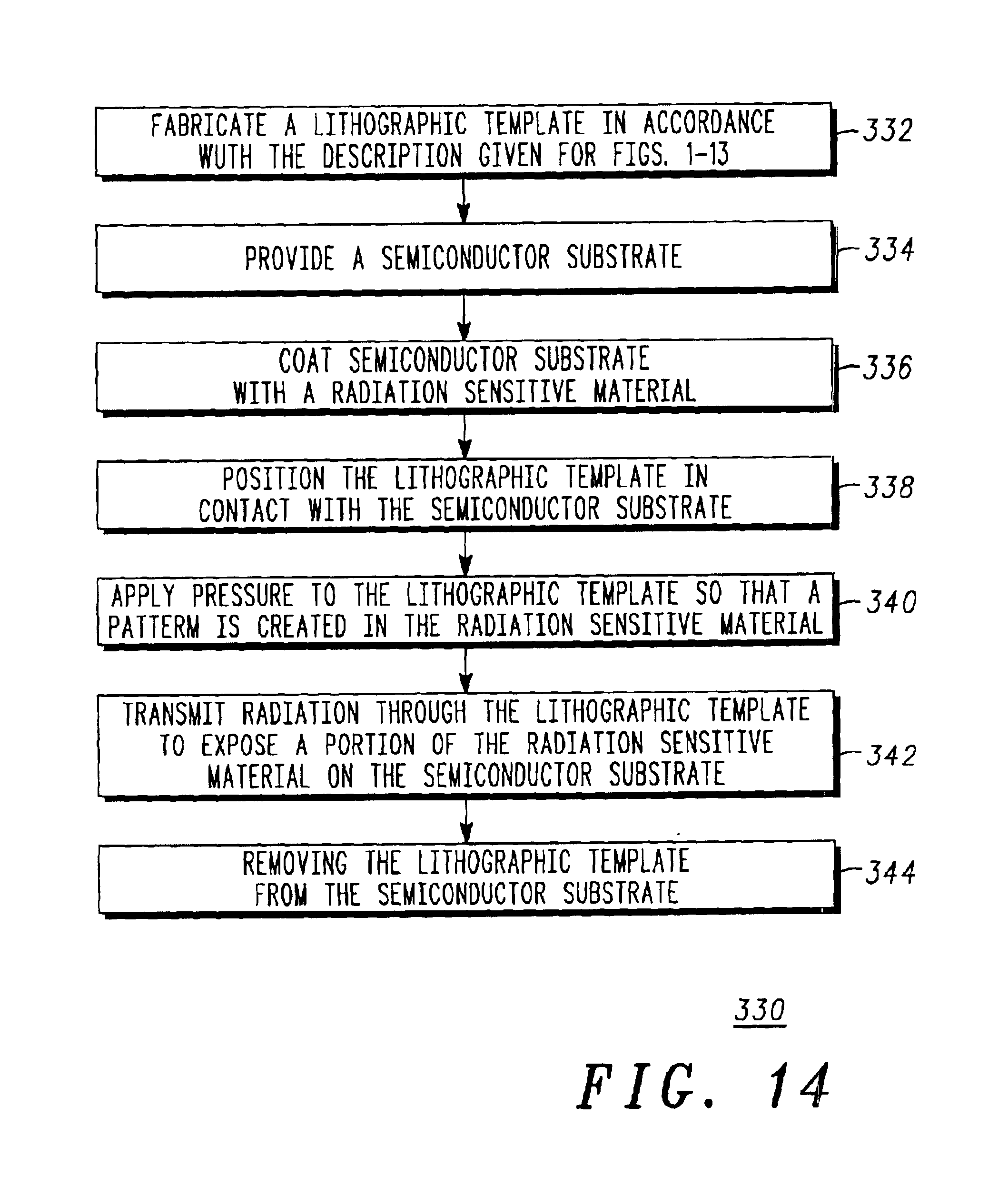

Lithographic template and method of formation and use

This invention relates to a lithographic template, a method of forming the lithographic template and a method for forming devices with the lithographic template. The lithographic template (10, 110, 210) is formed having a substrate (12, 112, 212) and a charge dissipation layer (20, 120, 220), and a patterned imageable relief layer, (16, 116, 216) formed on a surface (14, 114, 214) of the substrate (10, 110, 210) using radiation. The template (10, 110, 210) is used in the fabrication of a semiconductor device (344) for affecting a pattern in the device (344) by positioning (338) the template (10, 11, 210) in close proximity to semiconductor device (344) having a radiation sensitive material (334) formed thereon and applying a pressure (340) to cause the radiation sensitive material to flow into the relief image present on the template (10, 110, 210). Radiation (342) is then applied through the template (10, 110, 210) to cure portions of the radiation sensitive material and define the pattern in the radiation sensitive material. The template (10, 110, 210) is then removed to complete fabrication of semiconductor device (344).

Owner:NXP USA INC +1

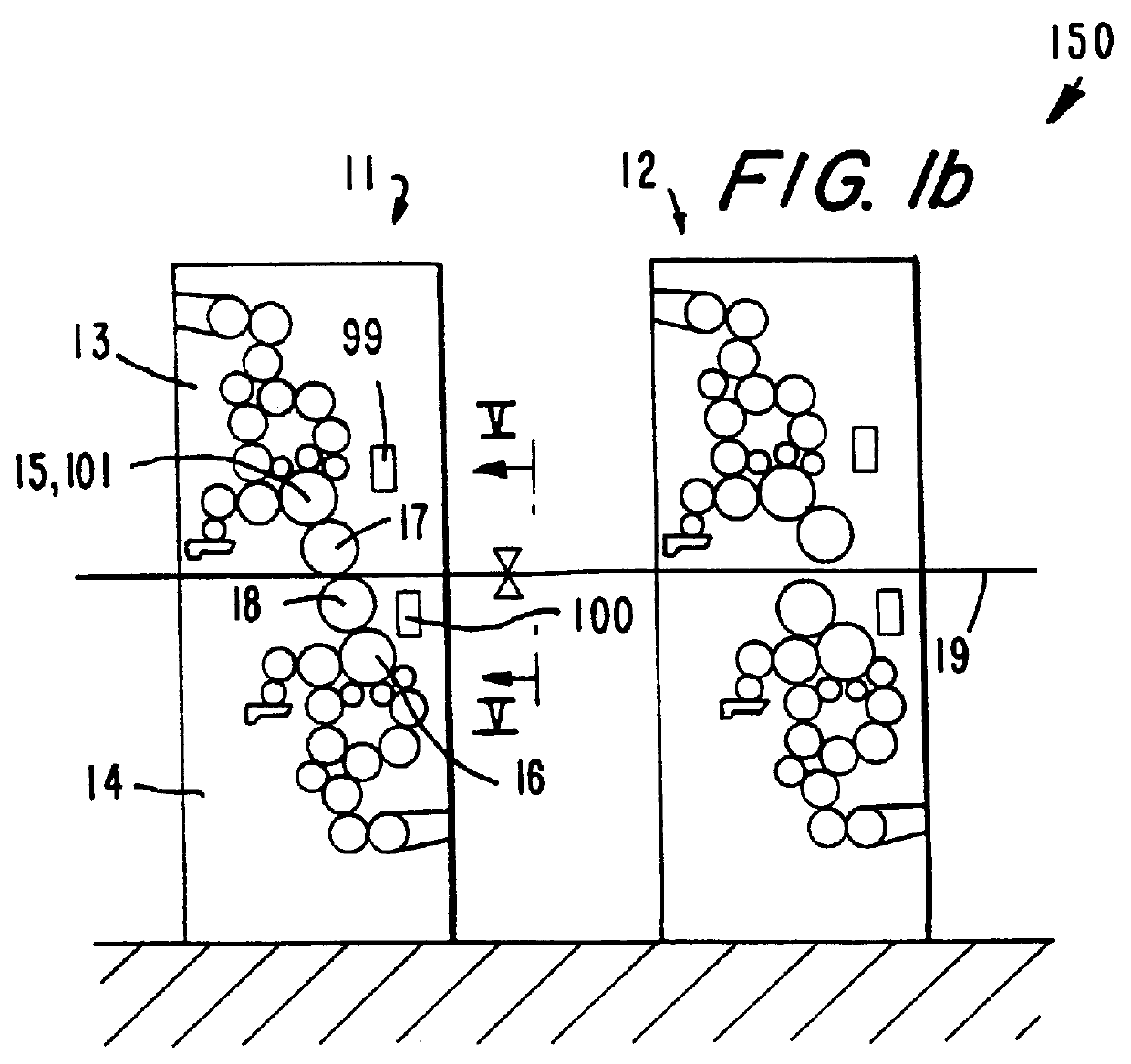

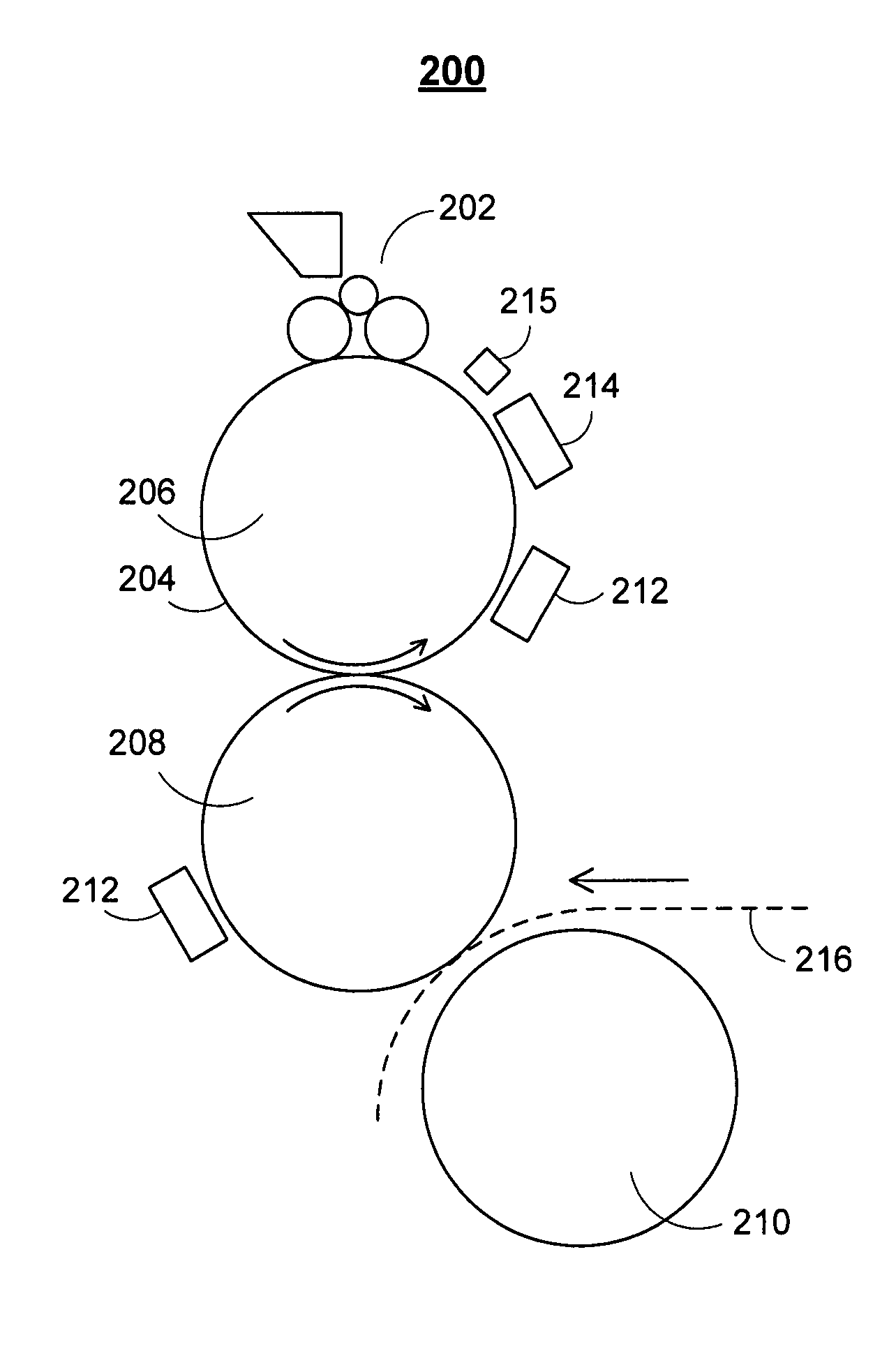

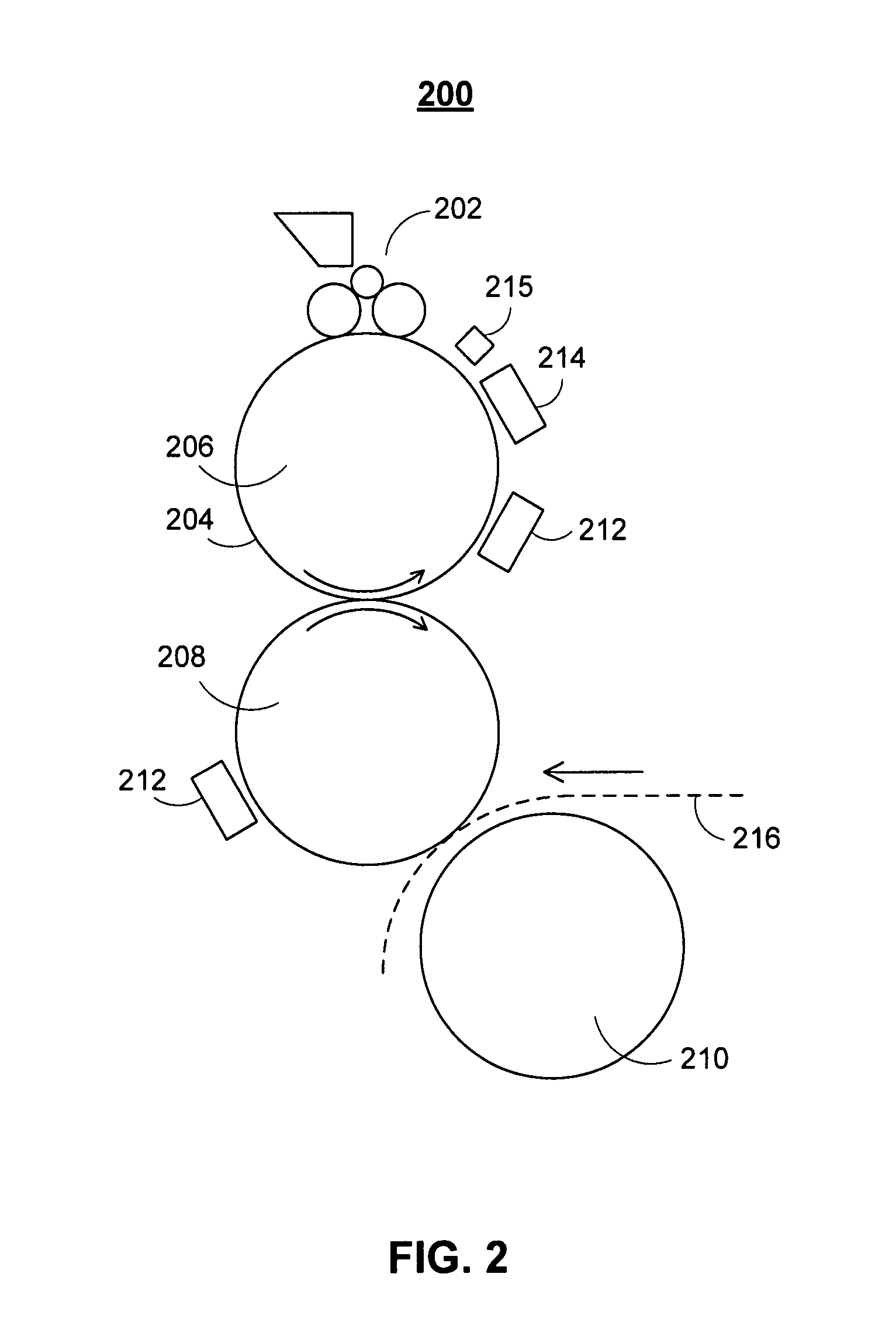

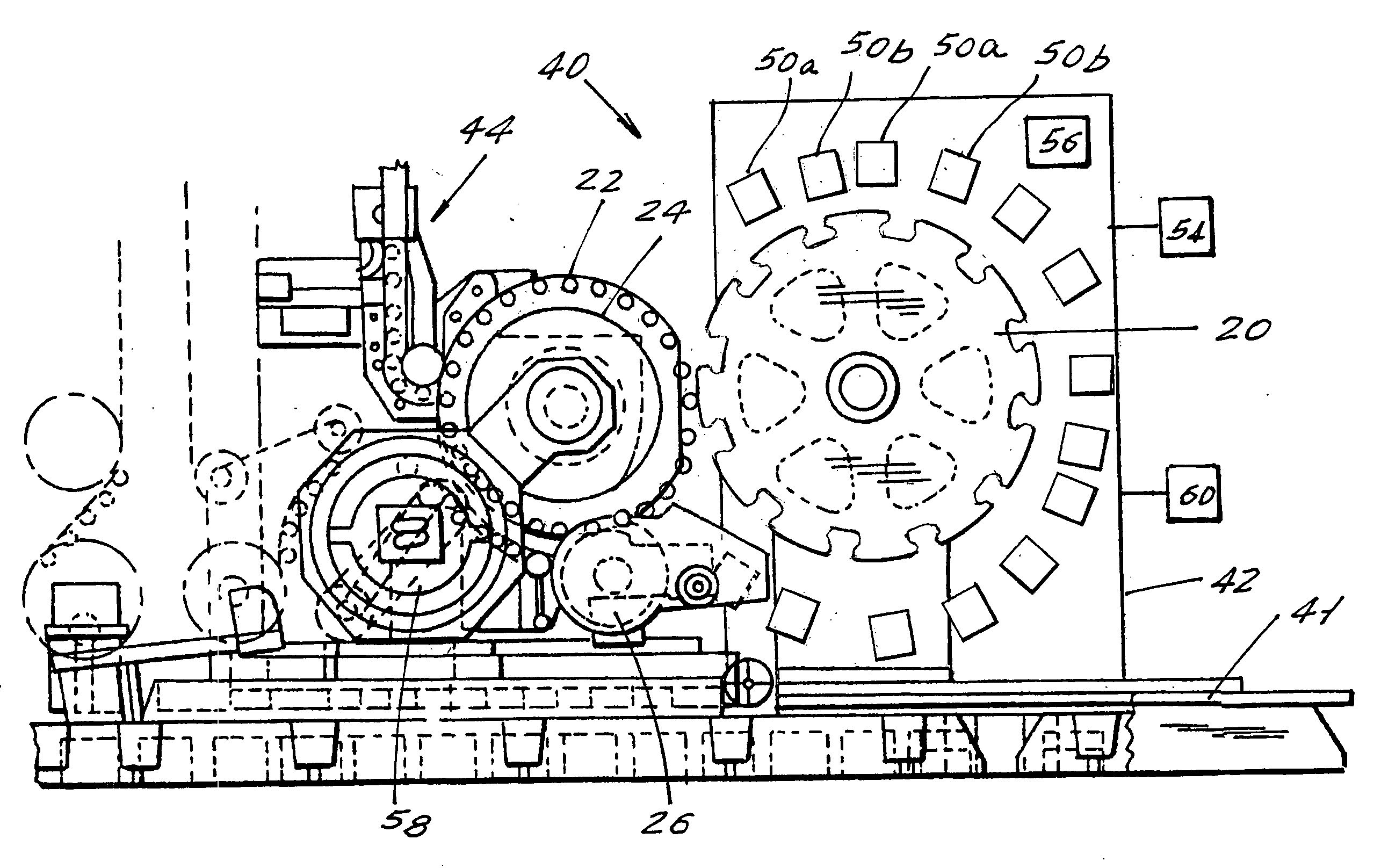

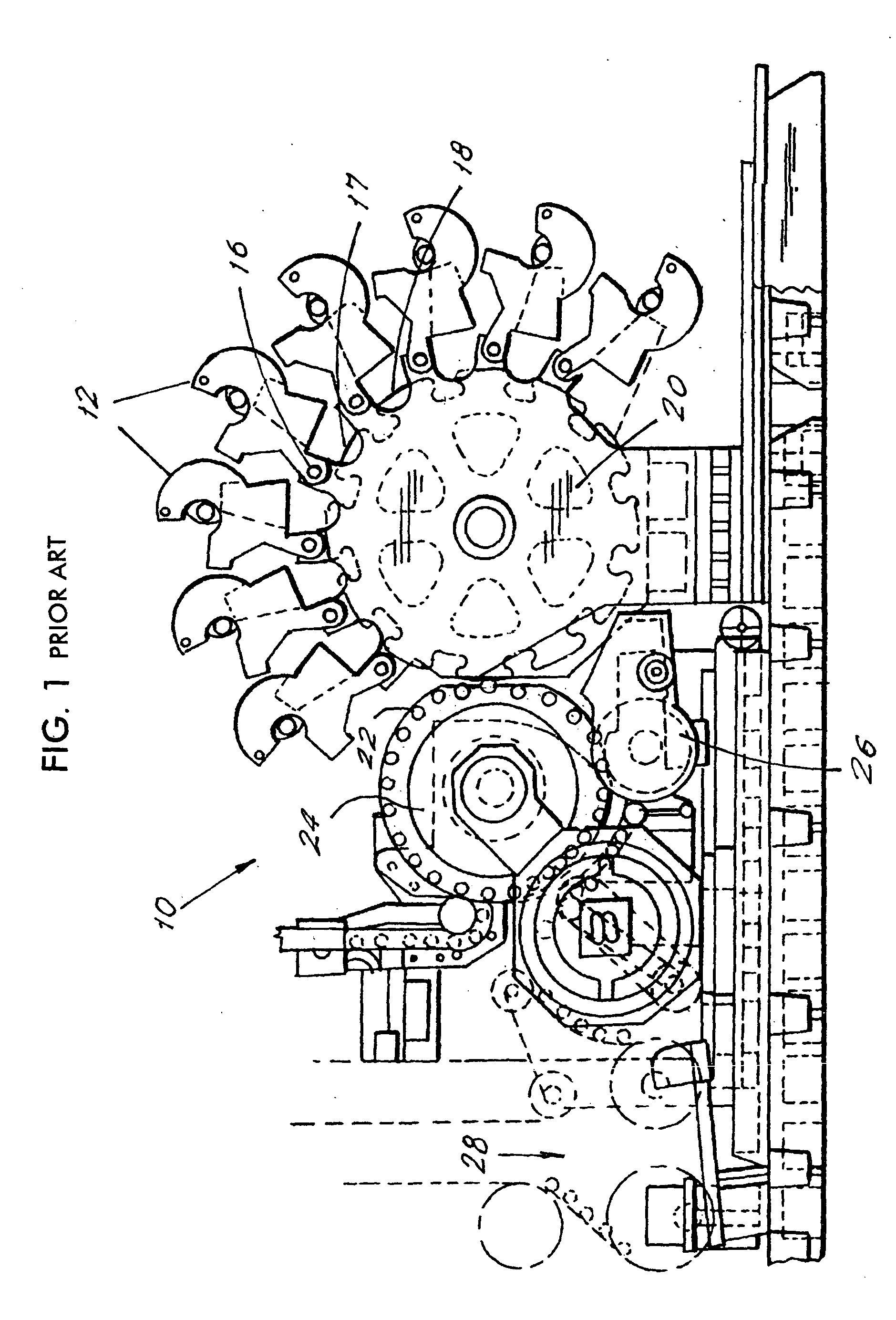

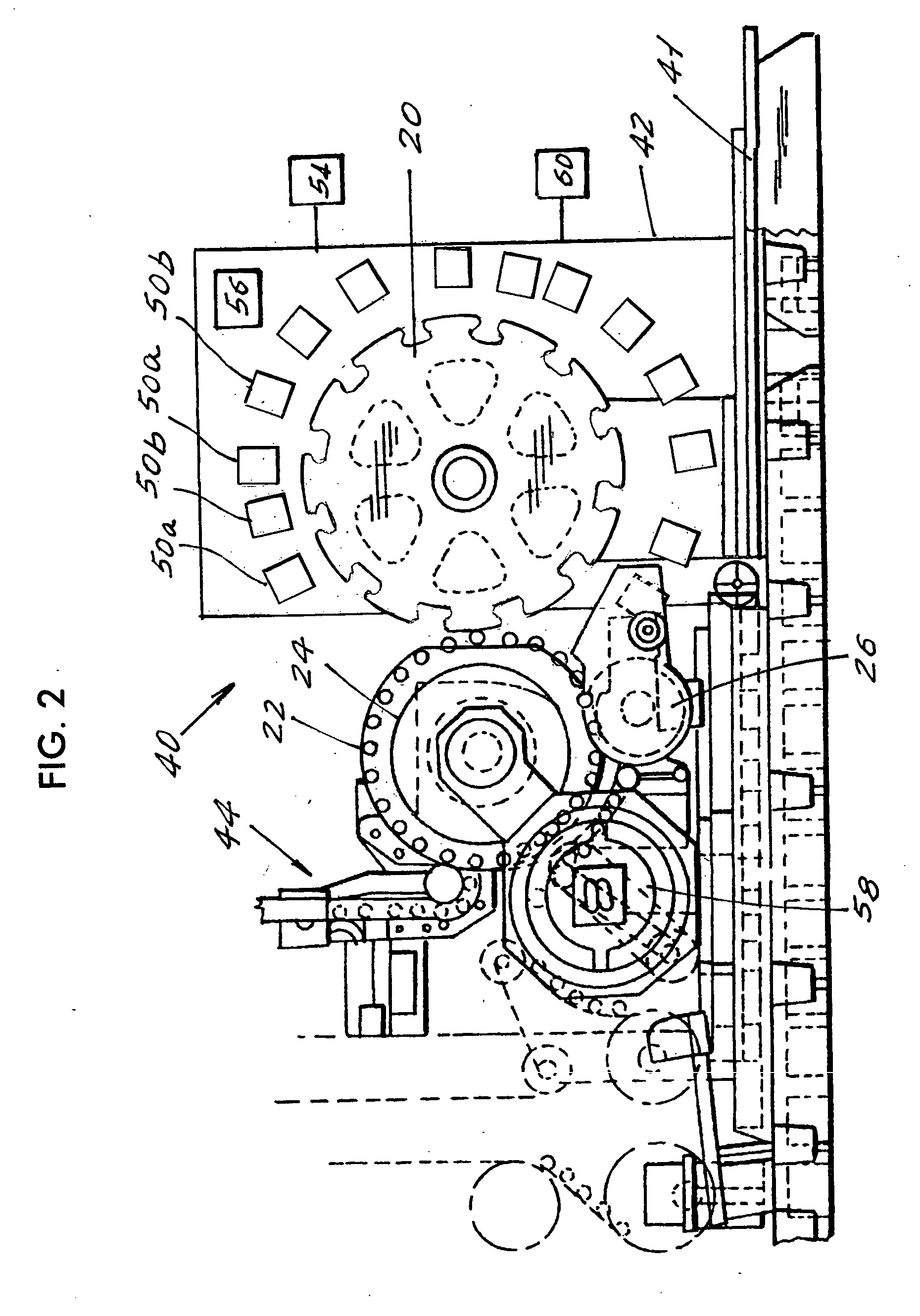

Digital can decorating apparatus

ActiveUS20050045053A1Allow flexibilityFew partsTypewritersRotary lithographic machinesEngineeringElectrical and Electronics engineering

A digitally controlled can decorating apparatus including digitally controlled print heads arrayed around the blanket cylinder of an offset type decorating apparatus for delivering ink in a selected pattern from each print head to each blanket section of the blanket cylinder, and the blanket cylinder sections thereafter transferring the ink to the cans being decorated.

Owner:BALL BEVERAGE PACKAGING EUROPE LIMITED

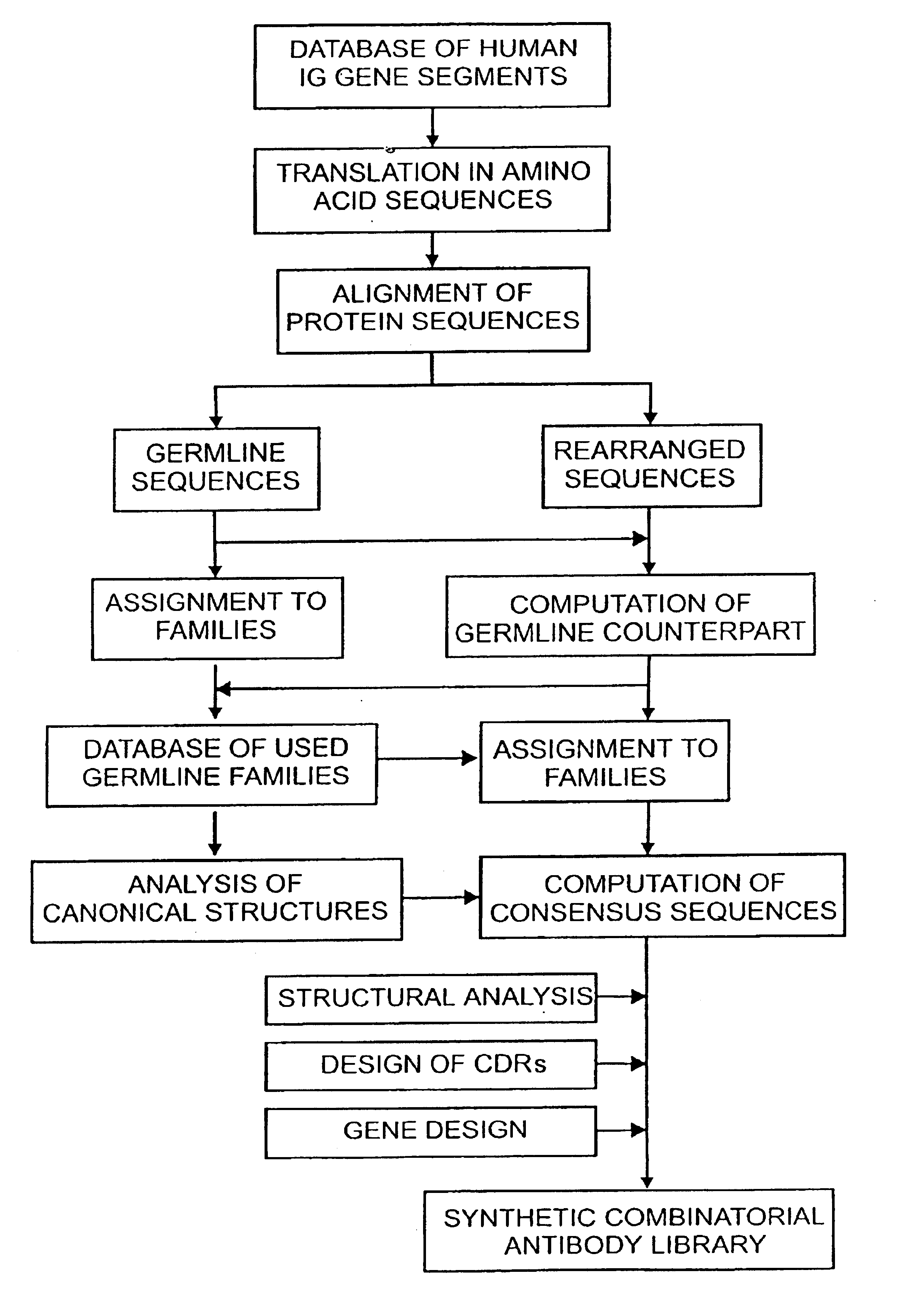

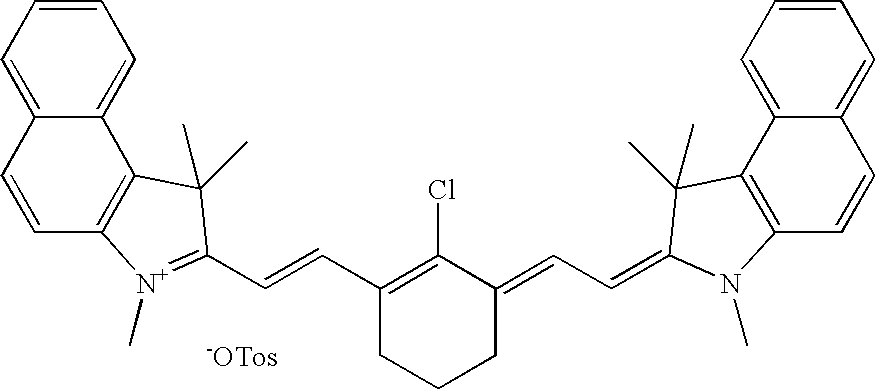

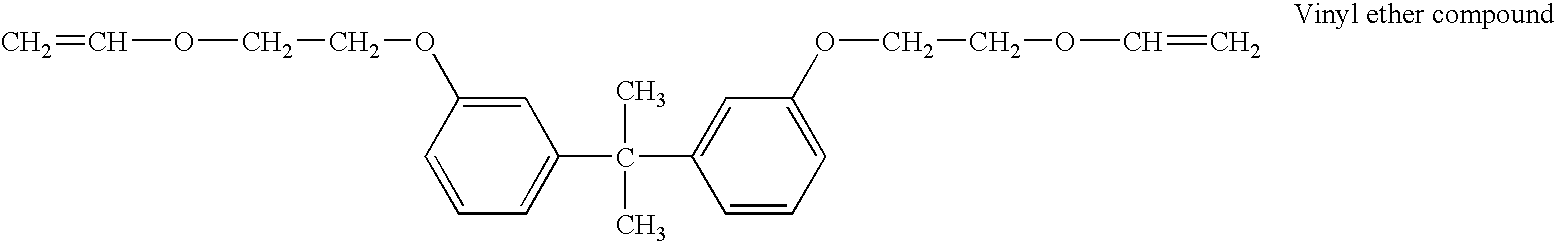

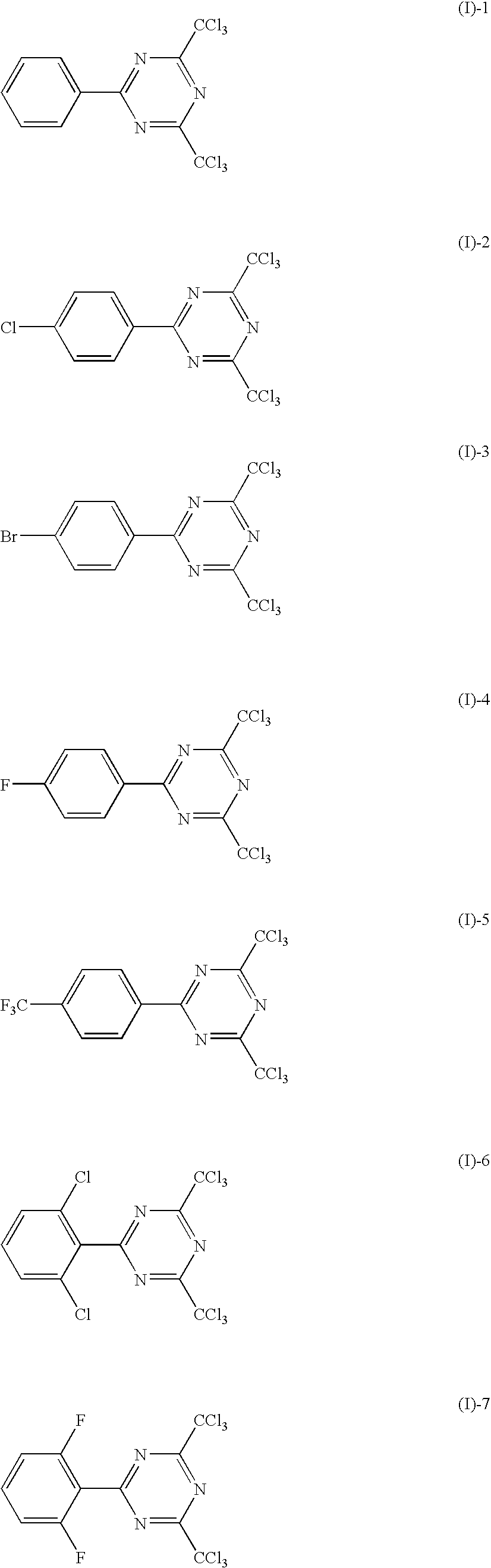

Radiation-curable polymerizable composition, ink composition, inkjet recording method, printed material, planographic printing plate, and method for forming planographic printing plate

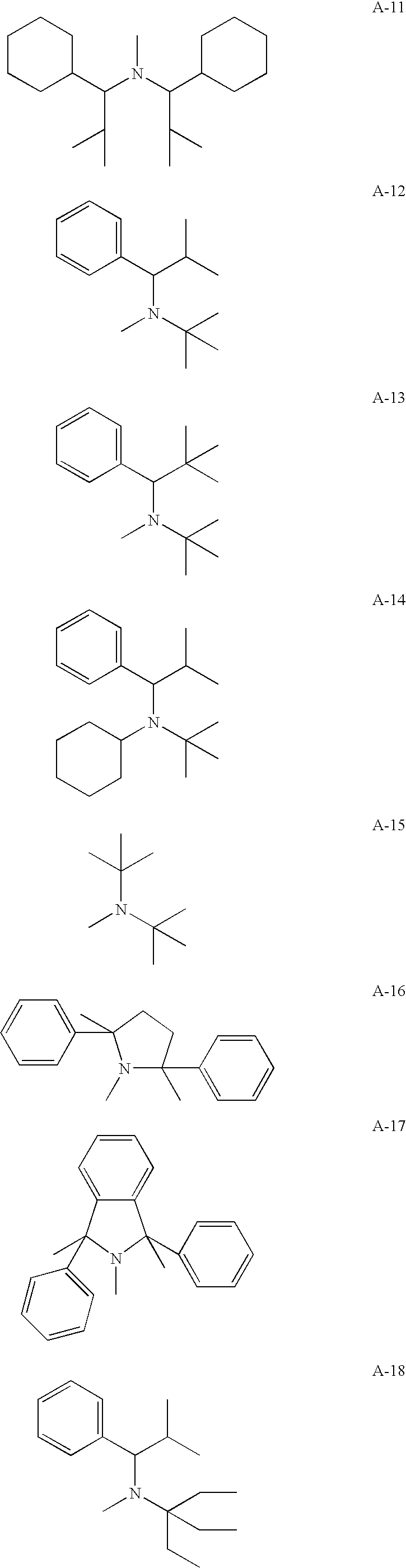

InactiveUS7900558B2Cylinder pressesLiquid surface applicatorsPolymer scienceHindered amine light stabilizers

Owner:FUJIFILM CORP

Manufacturing method for packaging and advertising means

InactiveUS20090301649A1Reliably, economically, and preciselyGood effectTransfer printingDecorative surface effectsPrinting pressMechanical engineering

The purpose is to improve the usability of the film coating in a coating module for the transfer of image-forming layers from a transfer film to a printing material. A film transfer module is, for that purpose, arranged in a printing machine for the single-color or multicolor printing of printed sheets. Moreover, one or more coating installations, in the form of varnishing modules, are arranged before and / or after the printing machine. By the application of layers, a subject consisting of a film image and a printed image is coated over part of the surface or over the entire surface. The additional coats serve the function of providing protection, drying, or generating optical effects.

Owner:M A N ROLAND DRUCKMASCHINEN AG

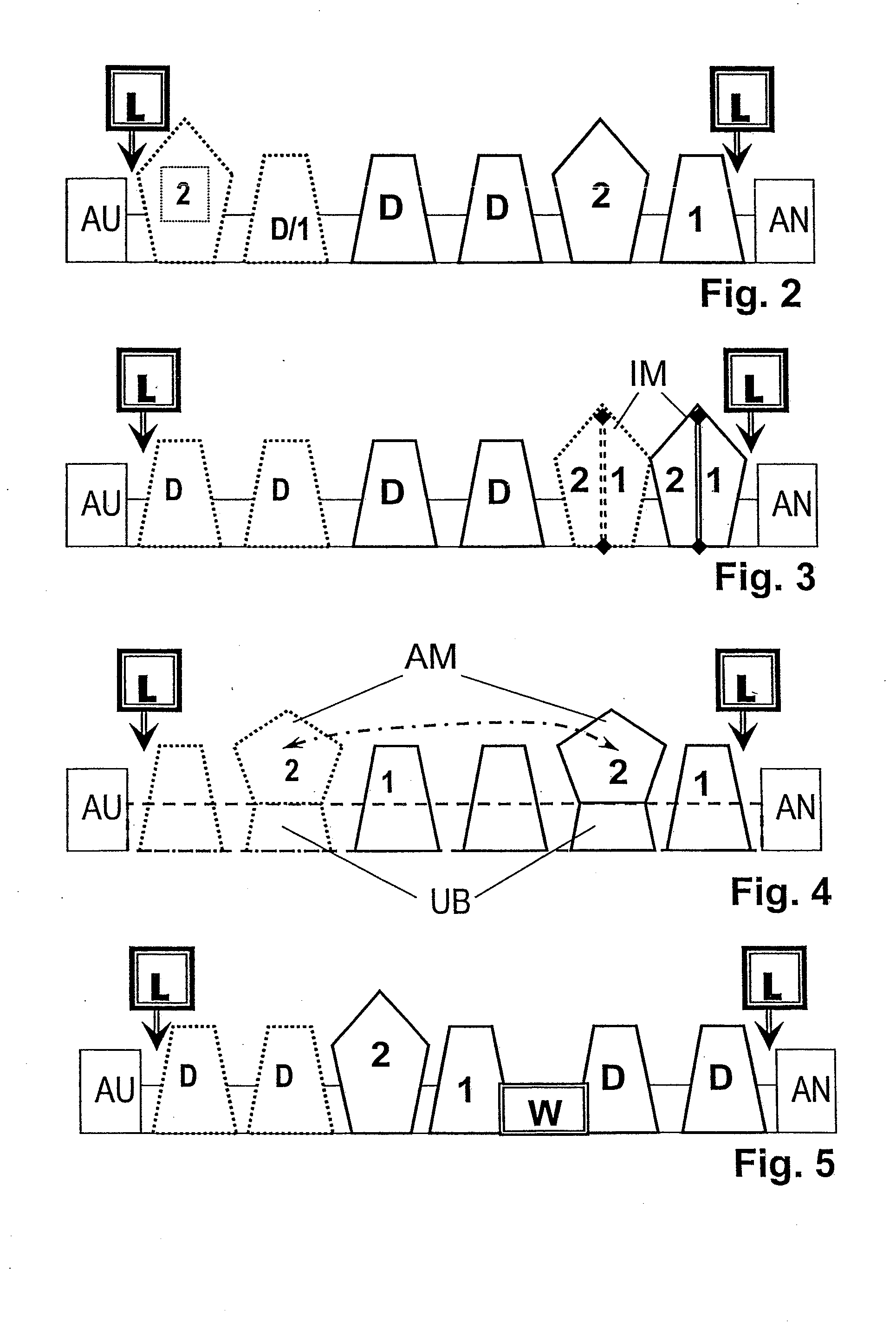

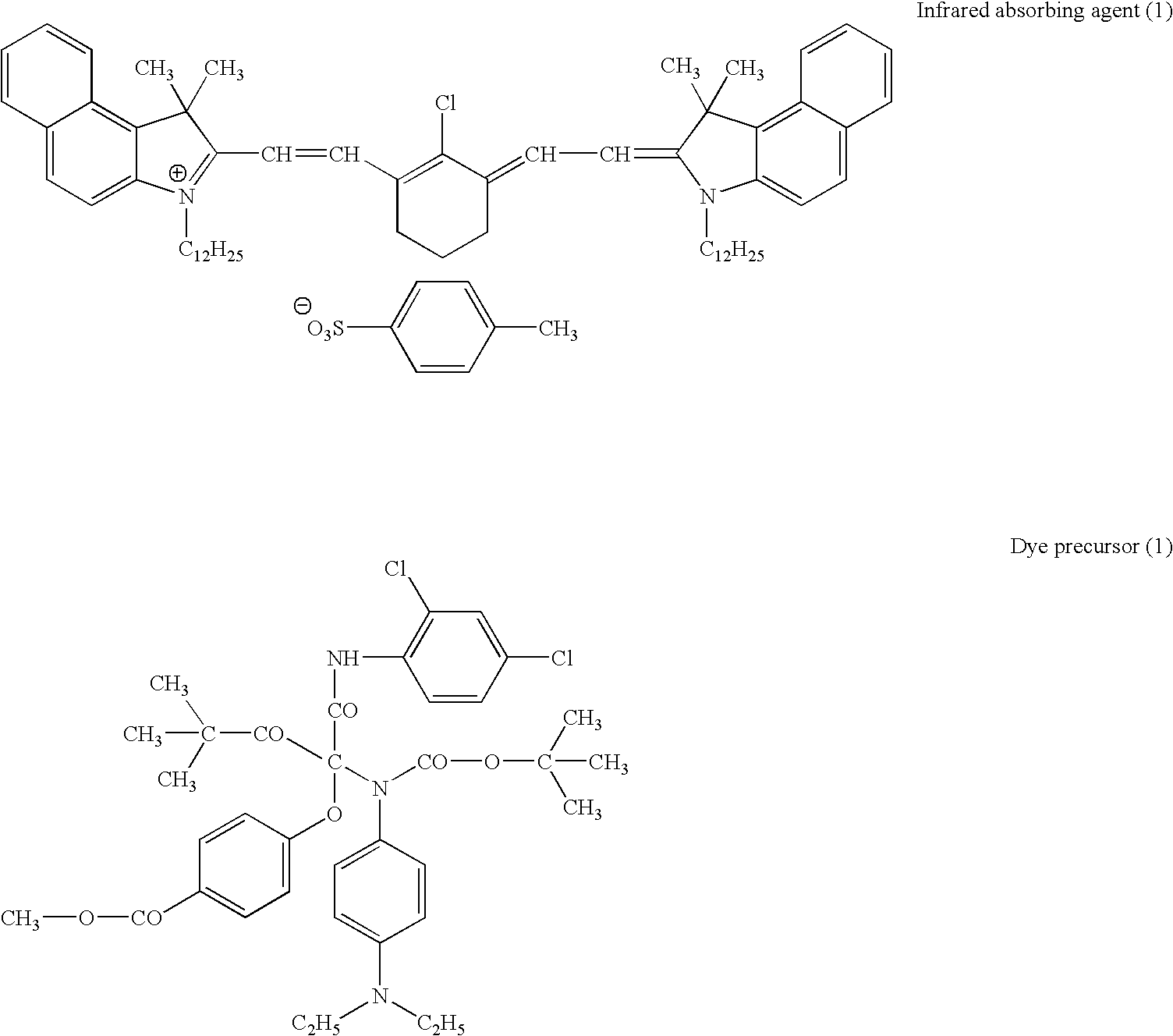

Lithographic printing process

A lithographic printing process which comprises the steps of: imagewise exposing to infrared light a presensitized lithographic plate which comprises a hydrophilic support and a removable image-forming layer containing an infrared absorbing agent having the absorption maximum within an infrared region and a dye precursor having substantially no absorption within a visible region to change the dye precursor to a visible dye having an absorption within a visible region within the exposed area, and to make the image-forming layer irremovable within the exposed area; removing the image-forming layer within the unexposed area of the lithographic plate mounted on a cylinder of a printing press; and then printing an image with the lithographic plate mounted on the cylinder of the printing press. The other processes are also disclosed.

Owner:FUJIFILM HLDG CORP +1

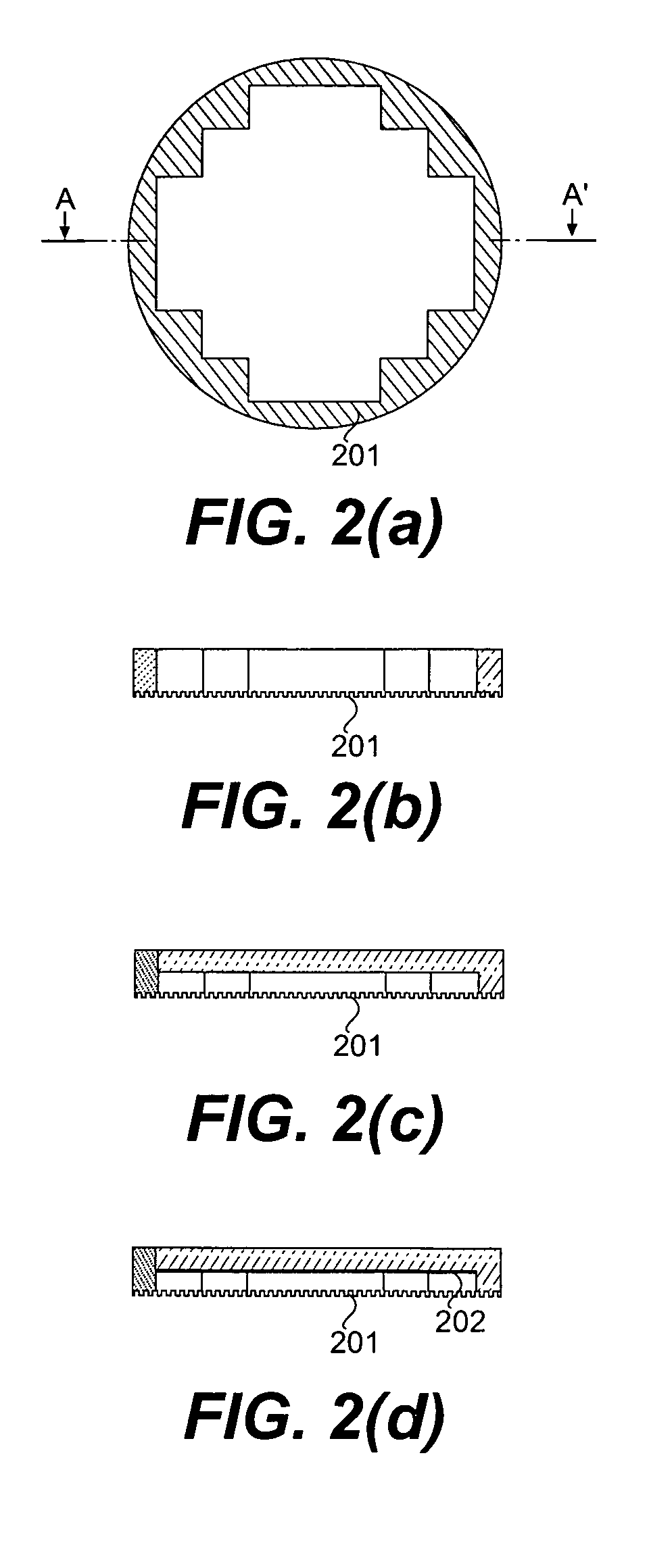

Process for producing member having pattern, pattern transfer apparatus, and mold

A pattern transfer apparatus is constituted by a first mold holding portion for holding a first mold for forming a pattern inside a peripheral area of a member and a second mold holding portion for holding a second mold for forming a pattern in the peripheral area of the member.

Owner:CANON KK

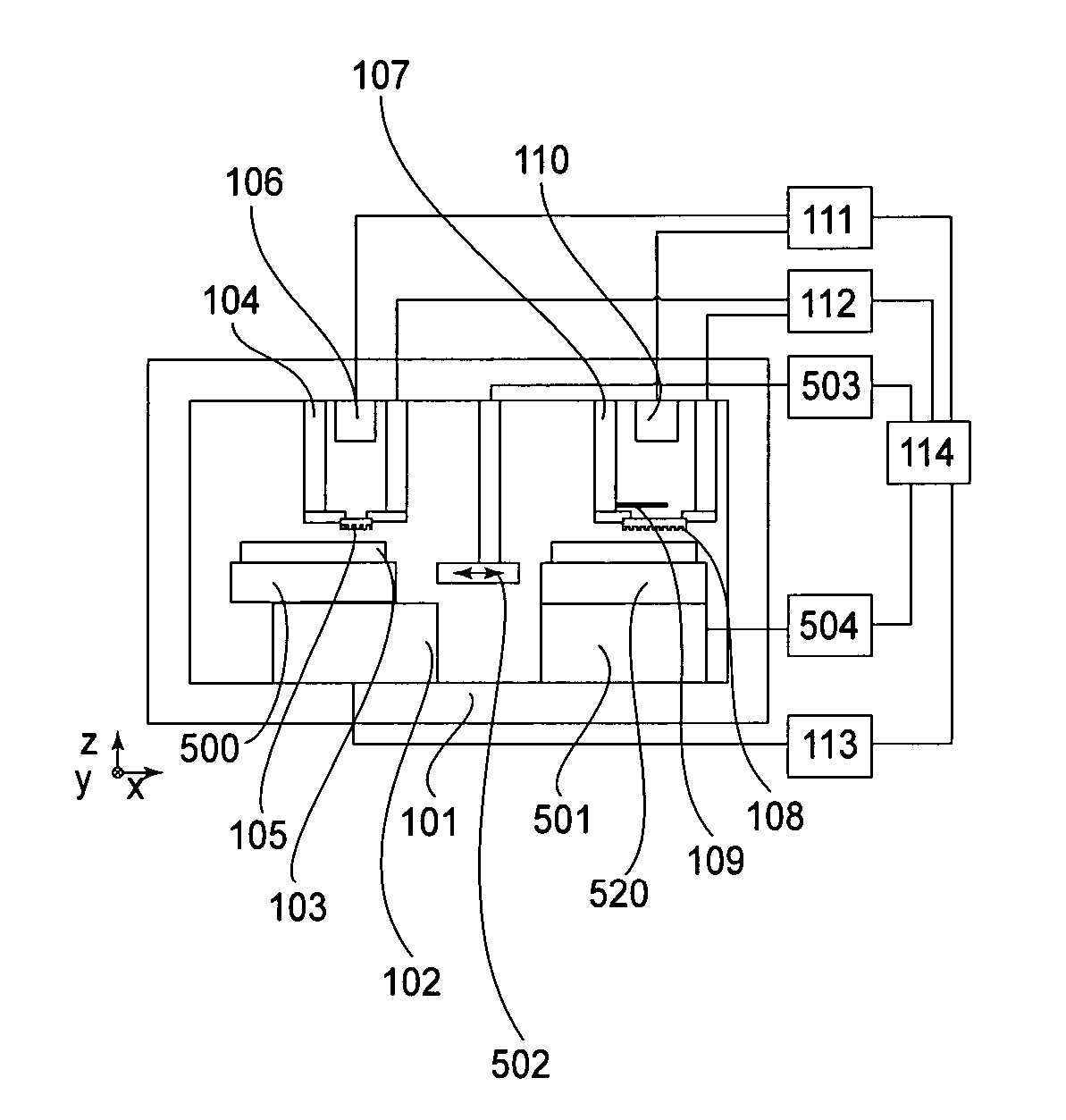

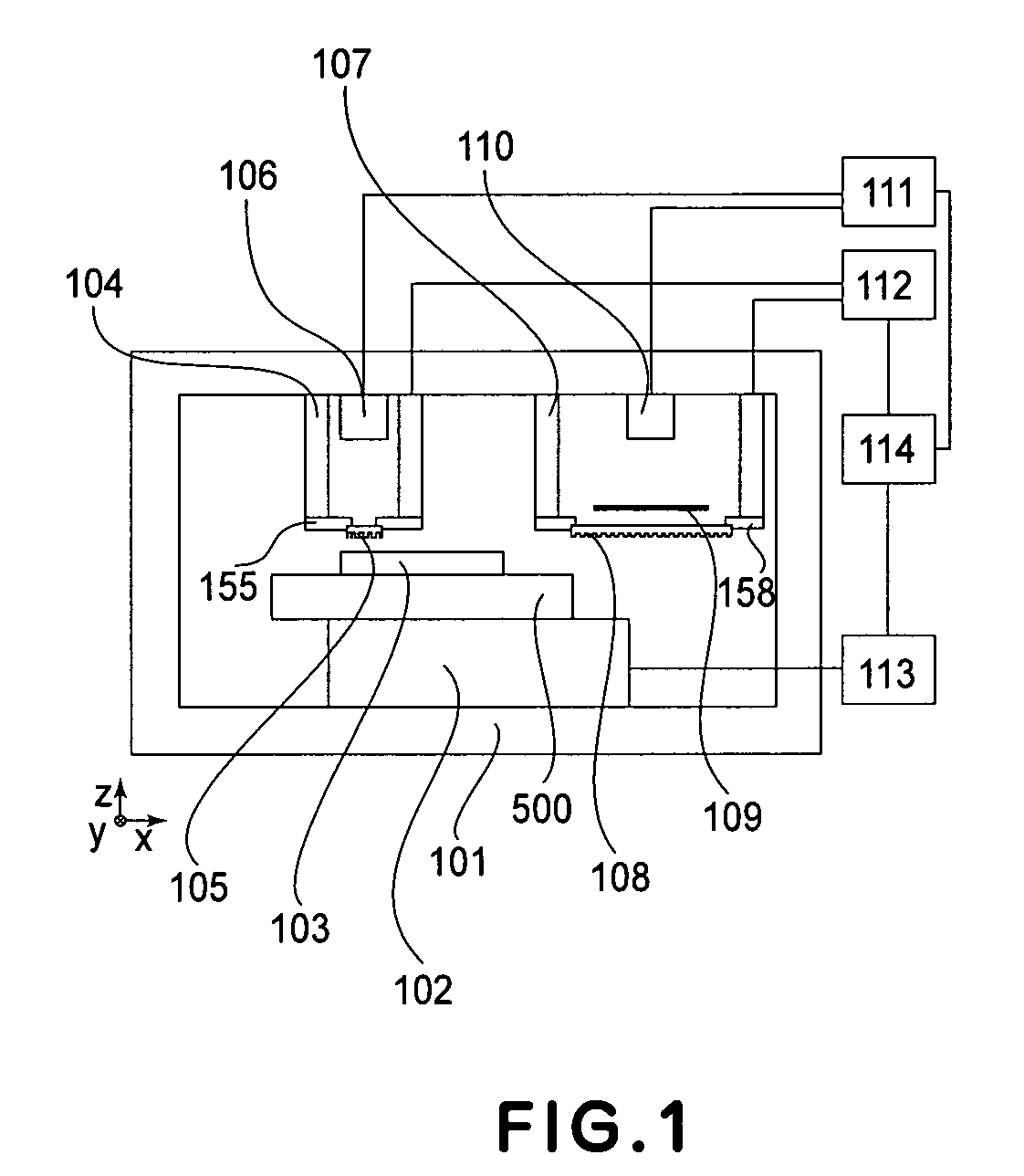

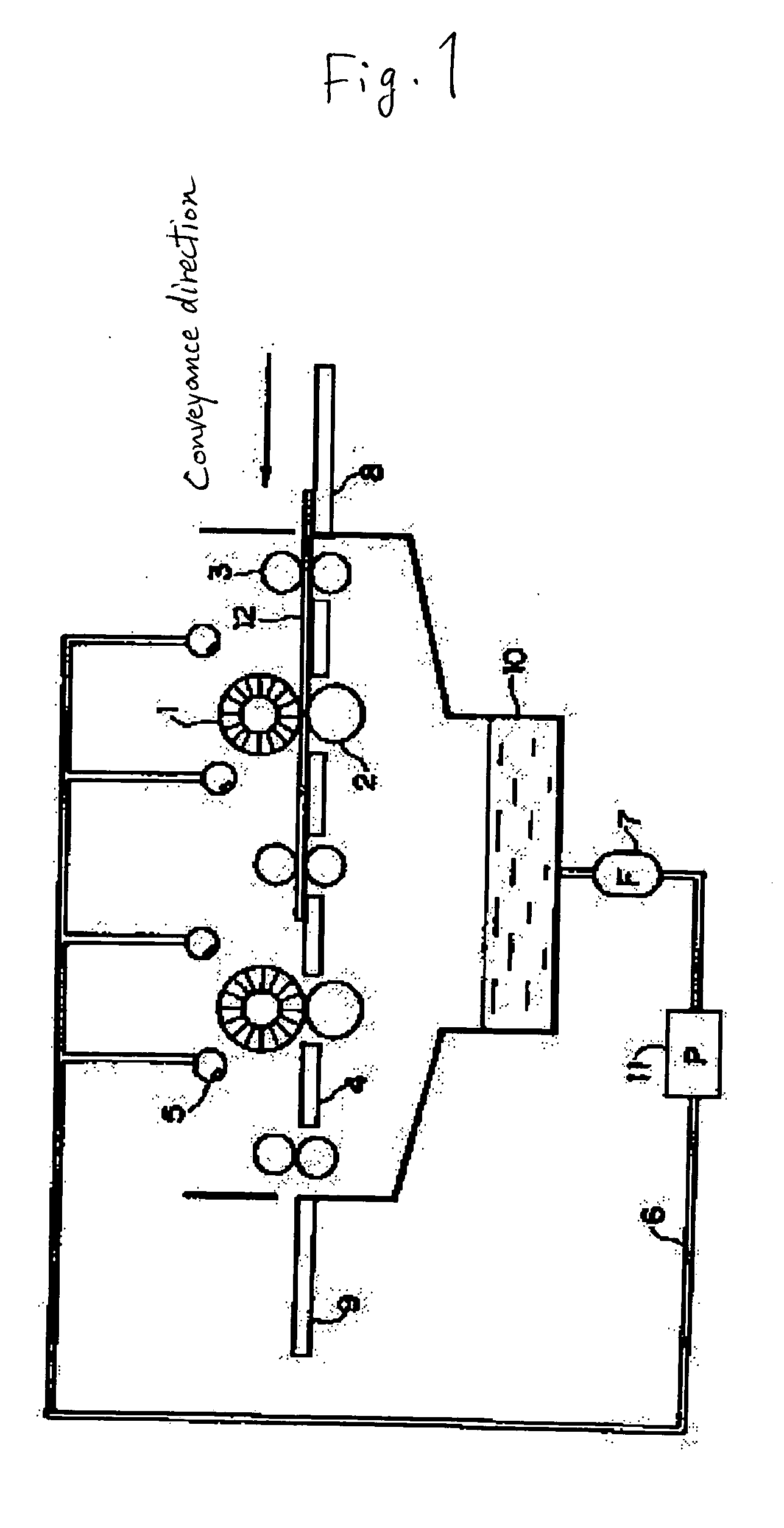

Production method of lithographic printing plate, lithographic printing plate precursor and lithographic printing method

ActiveUS20060046199A1Reduction in development removabilityGeneration can be inhibitedPlaten pressesPhotosensitive materialsPolyvinyl alcoholImage recording

A method for producing a lithographic printing plate is provided, wherein, in the non-alkaline development of a lithographic printing plate precursor having a protective layer, even if the protective layer components are mingled into the developer, the reduction in development removability of the image recording layer and the generation of development scum can be inhibited; an on-press development type lithographic printing plate precursor with excellent inking property, high scratch resistance, satisfied on-press developability and good fine line reproducibility is provided; and a lithographic printing method is provided, each of which is a method for producing a lithographic printing plate, comprising: imagewise exposing a lithographic printing plate precursor comprising a support, an image recording layer and a protective layer, and rubbing the plate surface by a rubbing member of an automatic processor in the presence of a developer at a pH of 2 to 10 to remove the protective layer and the image recording layer in the unexposed area; a lithographic printing plate precursor comprising a support, an image recording layer removable with a printing ink and / or a fountain solution, and a protective layer containing a polyvinyl alcohol having a carboxyl group and / or a sulfonic acid group within the molecule; and a lithographic printing method comprising on-press development.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com