Patents

Literature

1286results about "Rotary letterpress machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

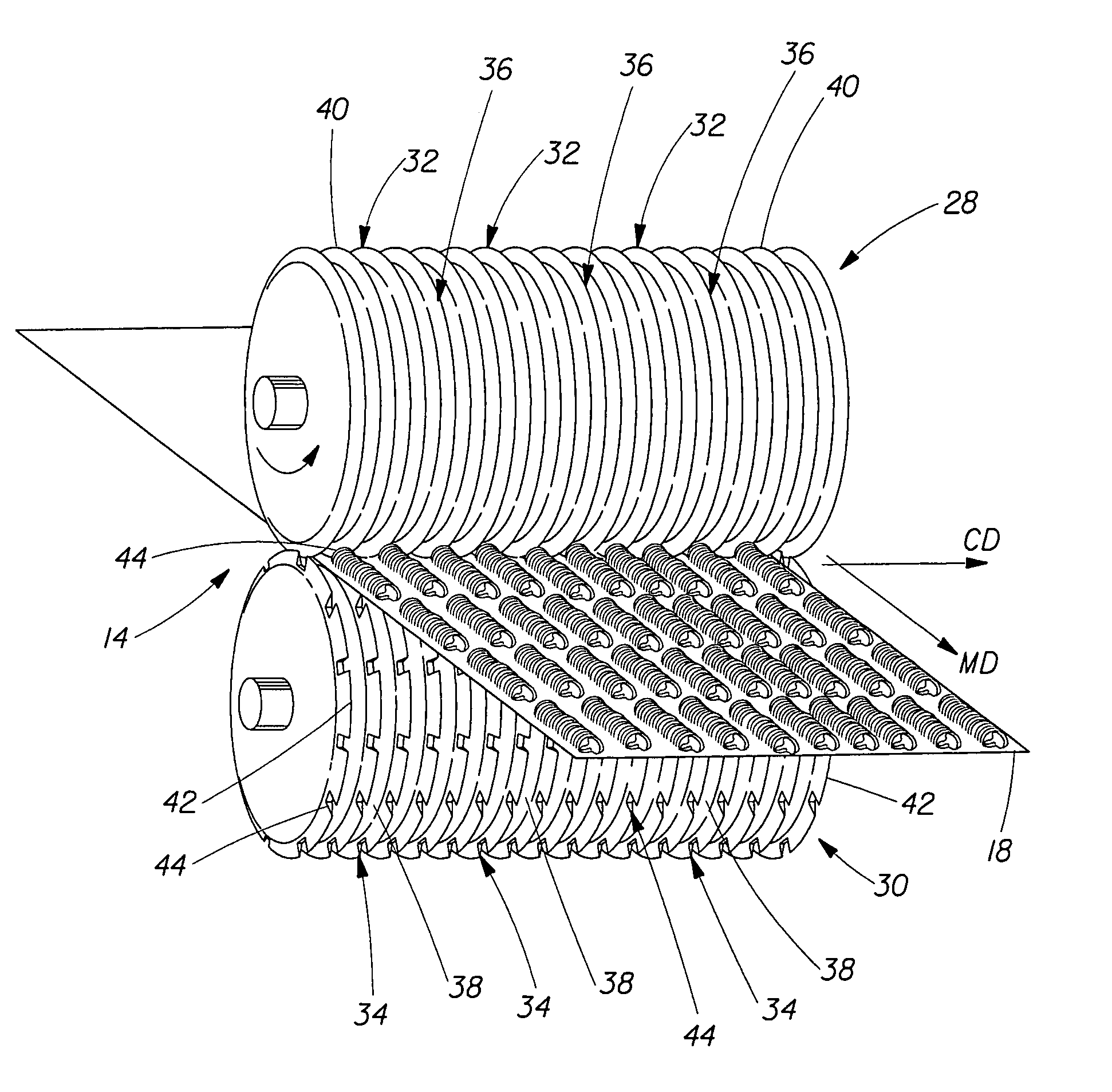

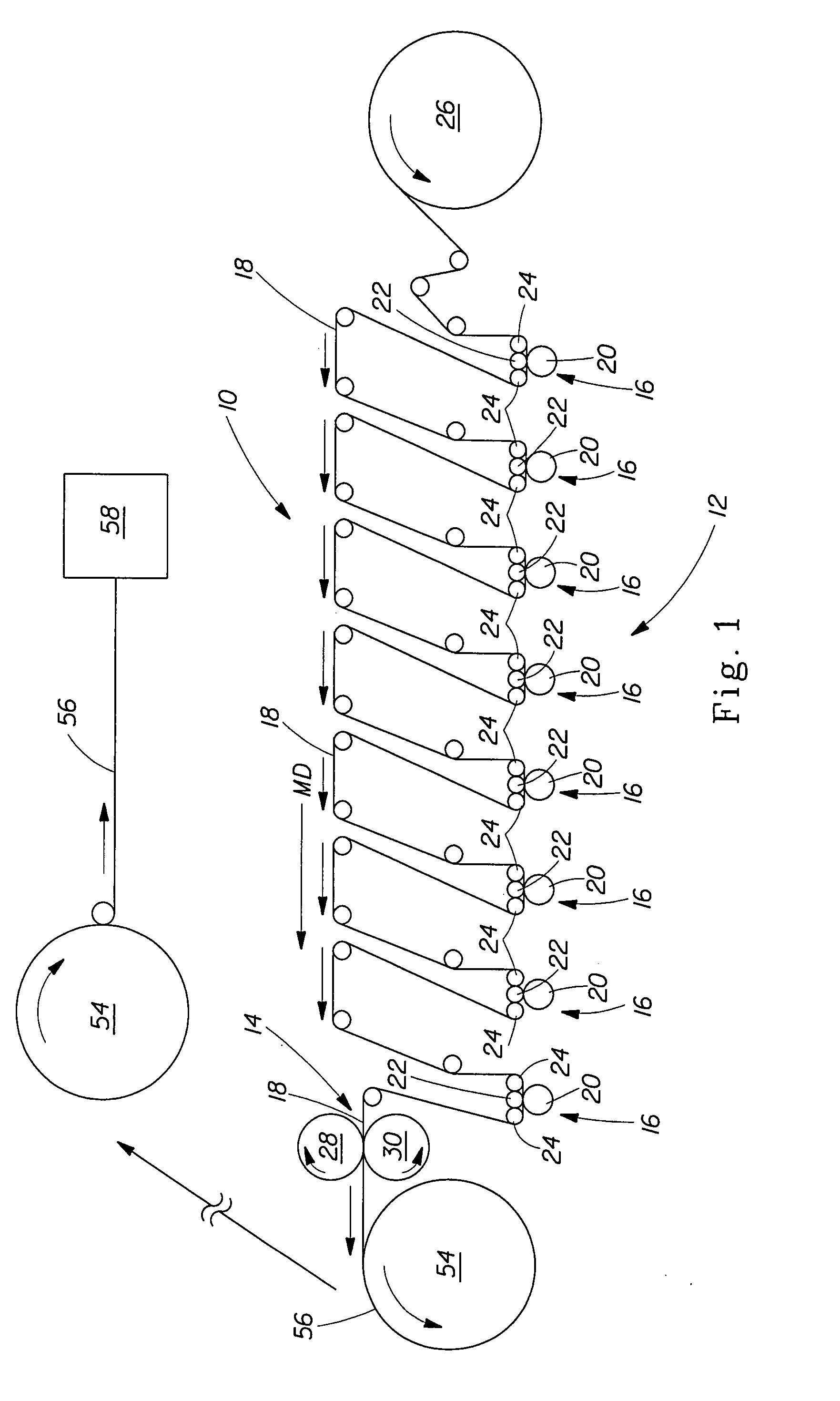

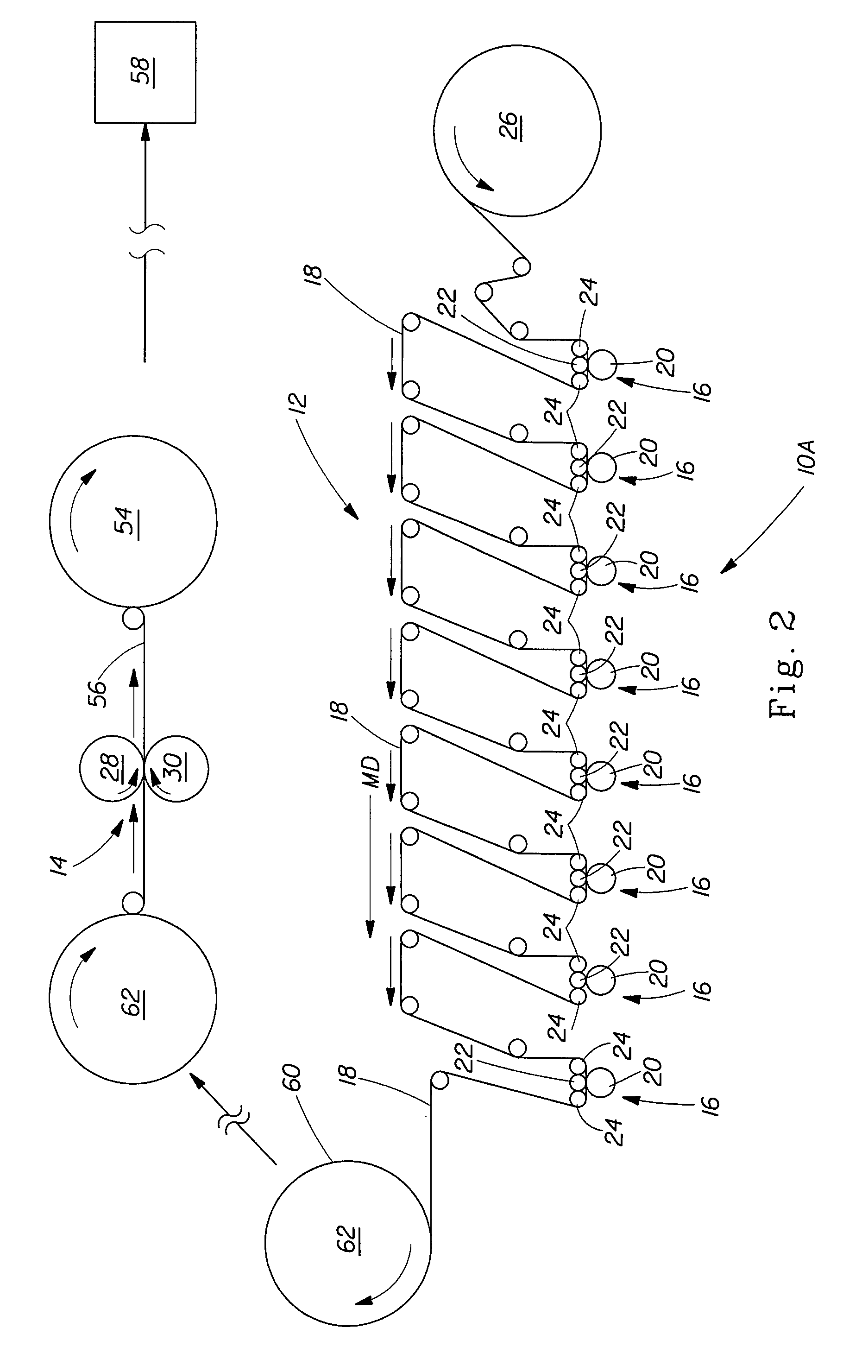

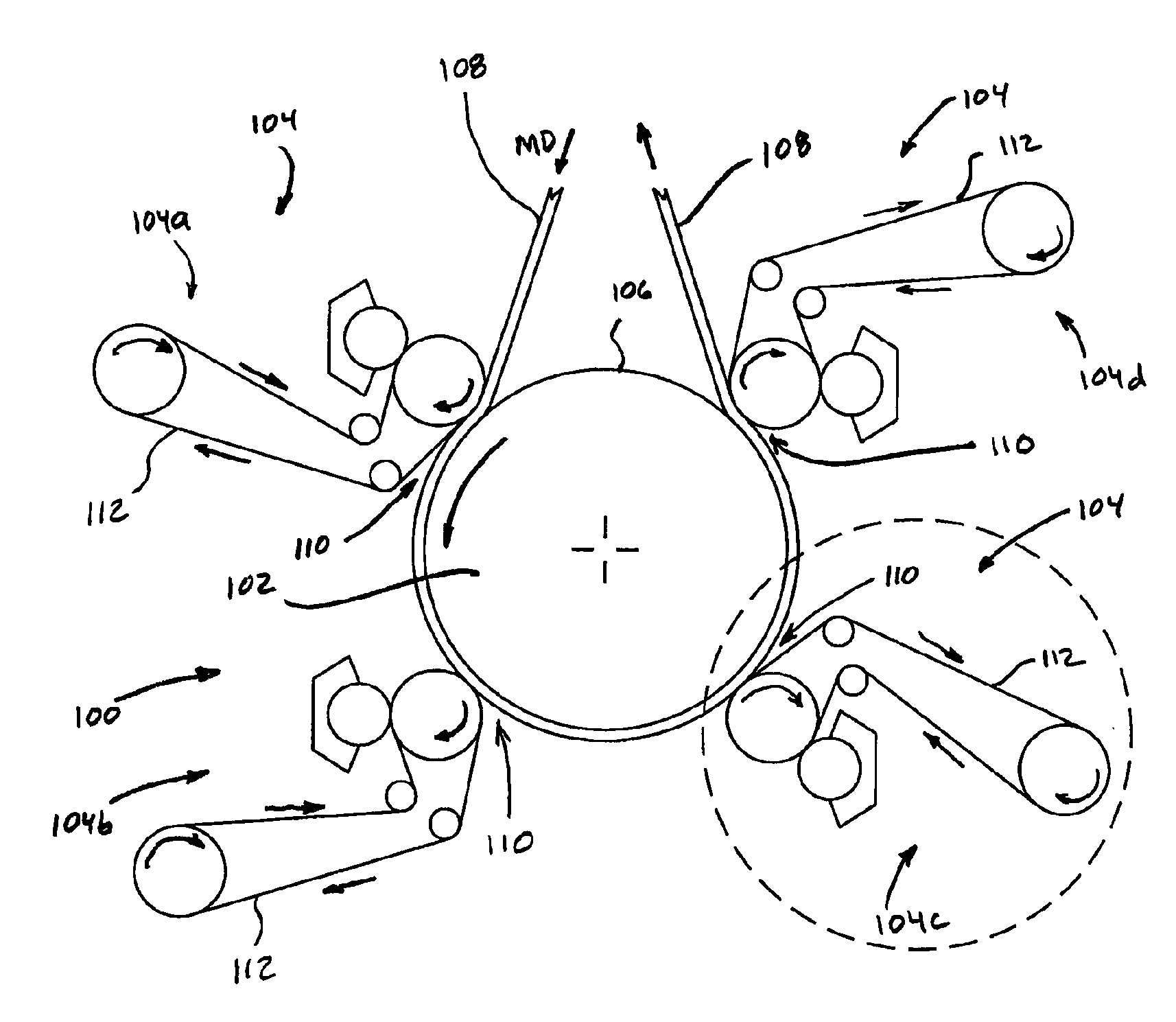

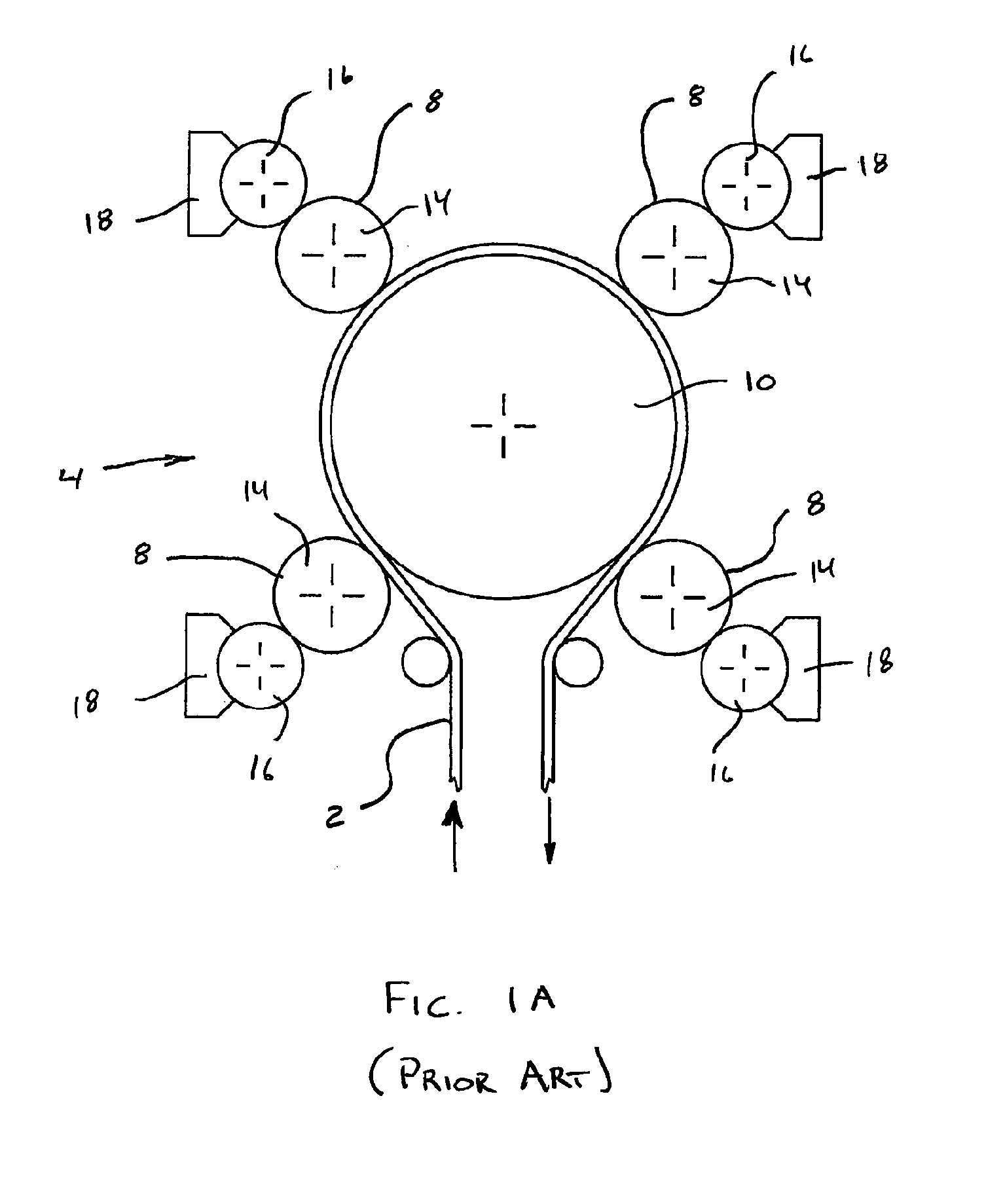

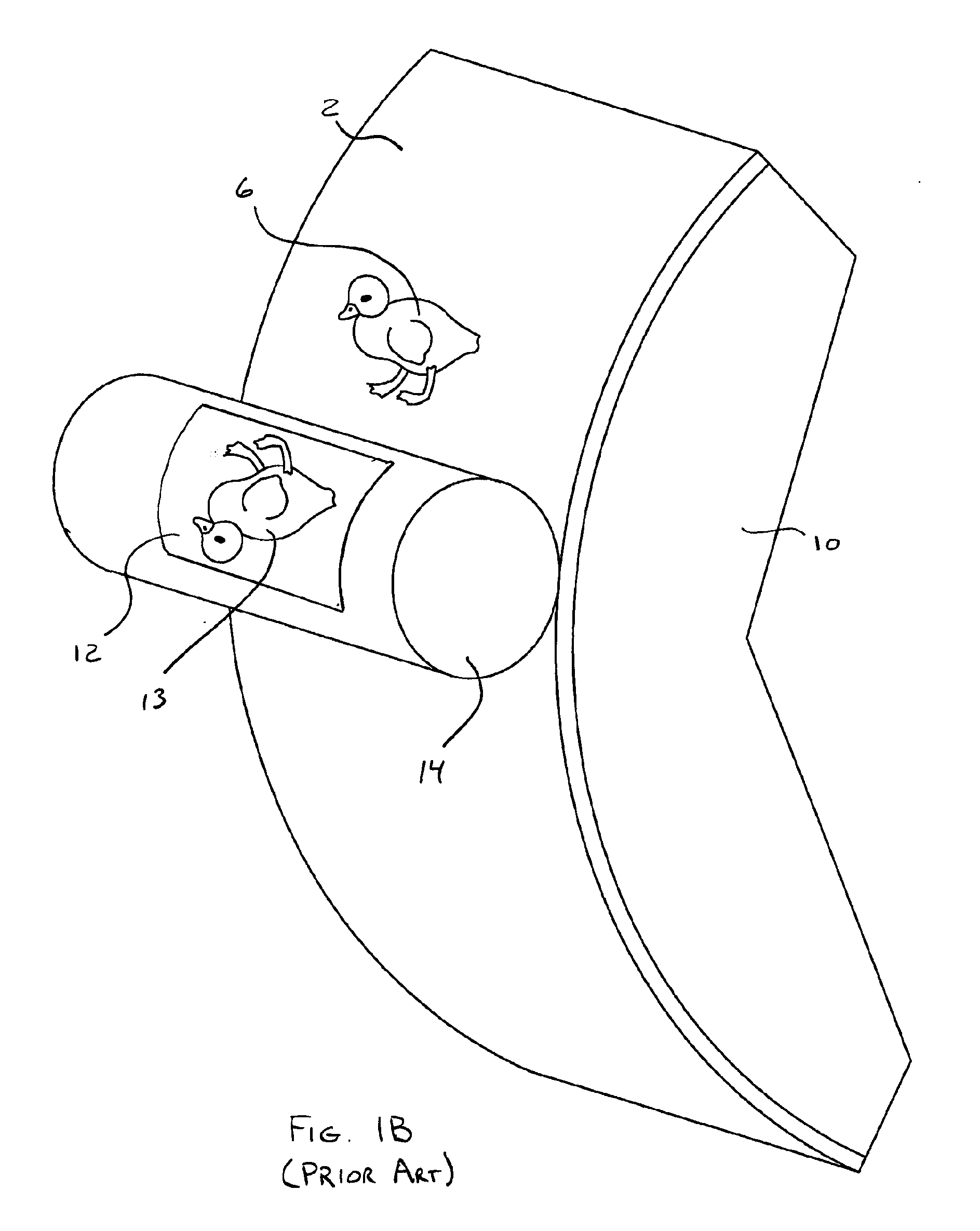

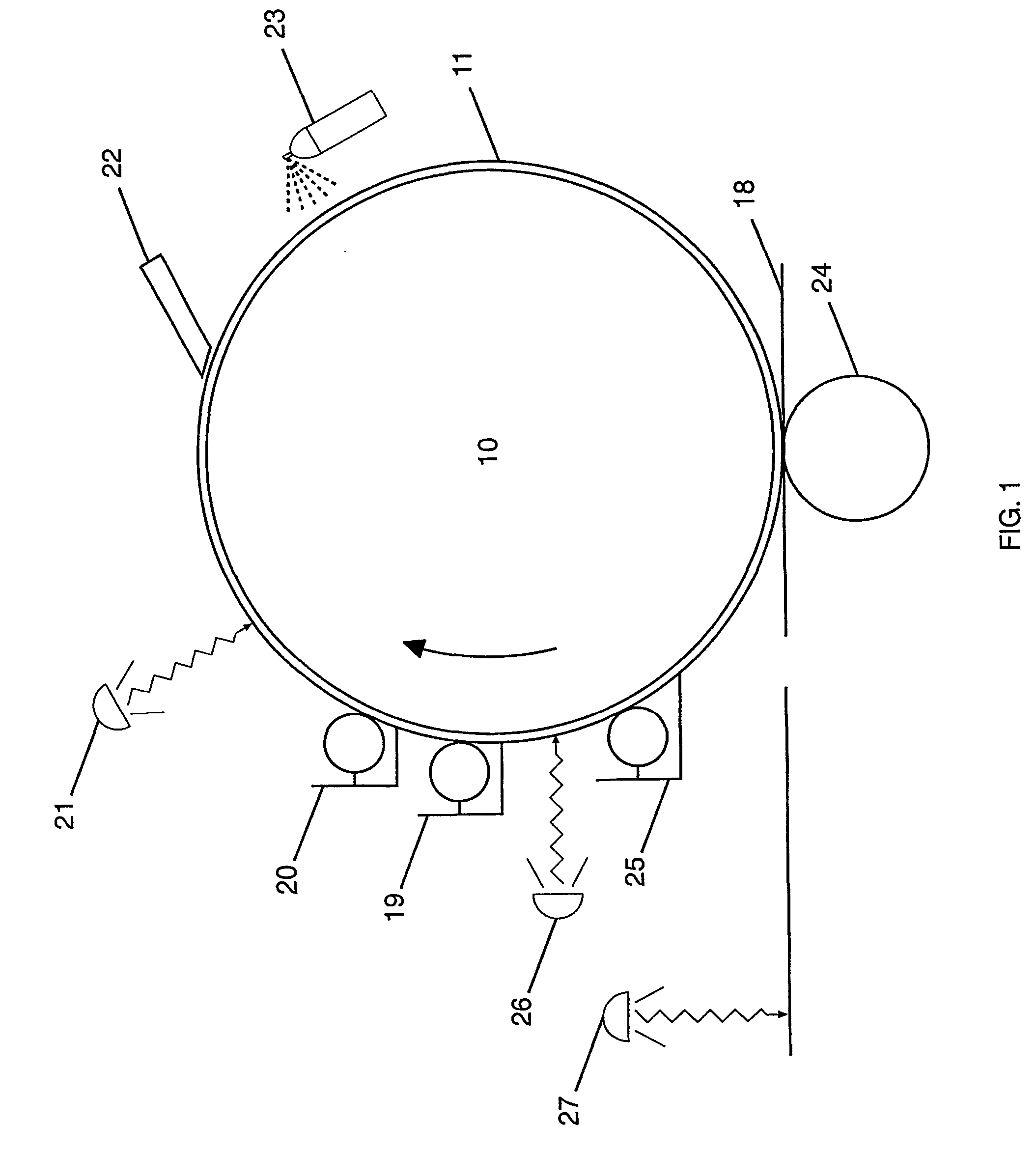

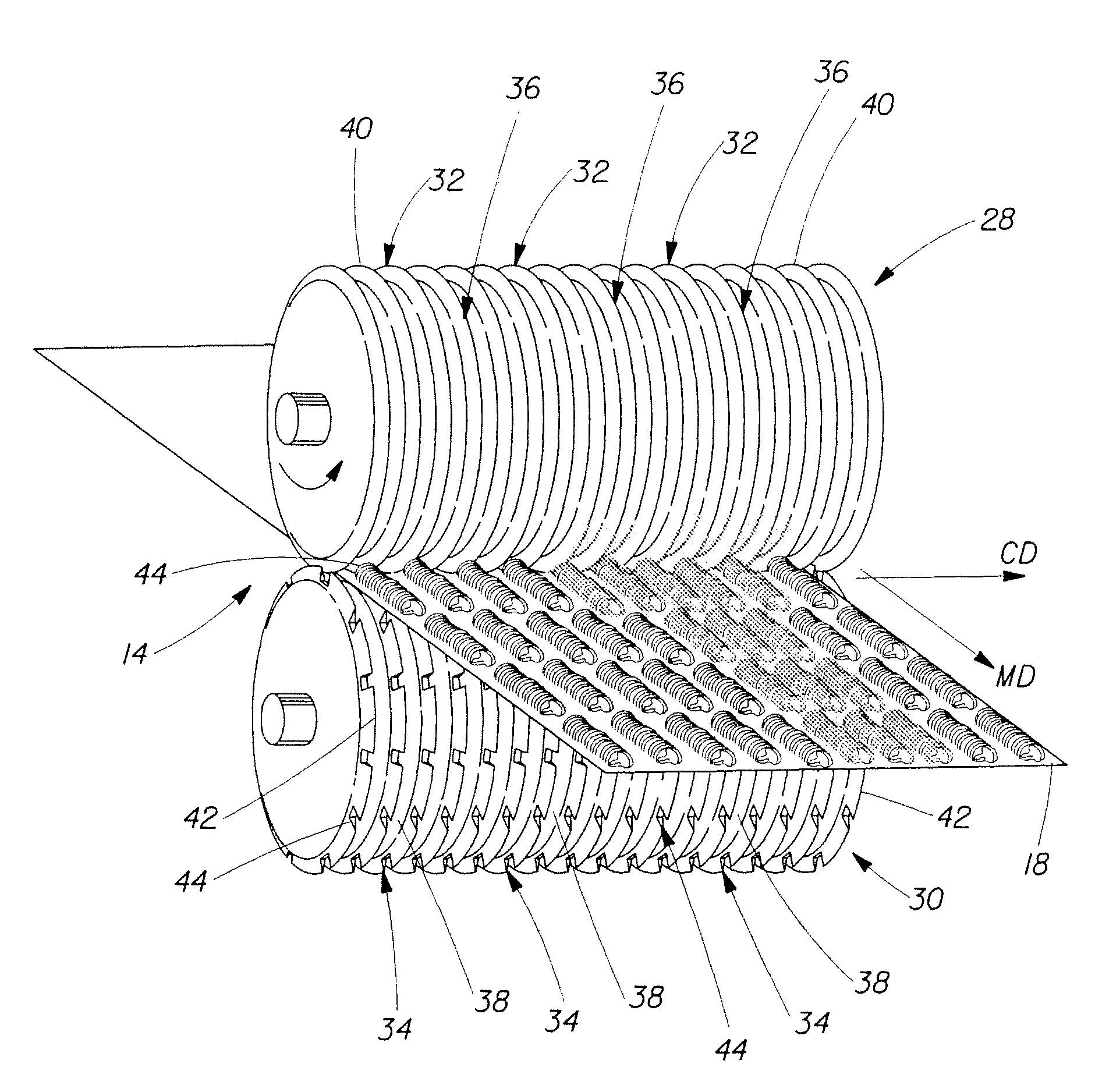

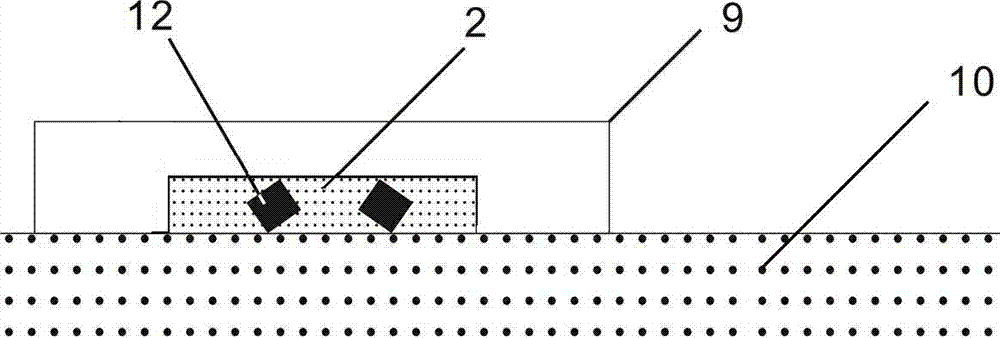

Apparatus and process for producing a web substrate having indicia disposed thereon and elastic-like behavior imparted thereto

Owner:THE PROCTER & GAMBLE COMPANY

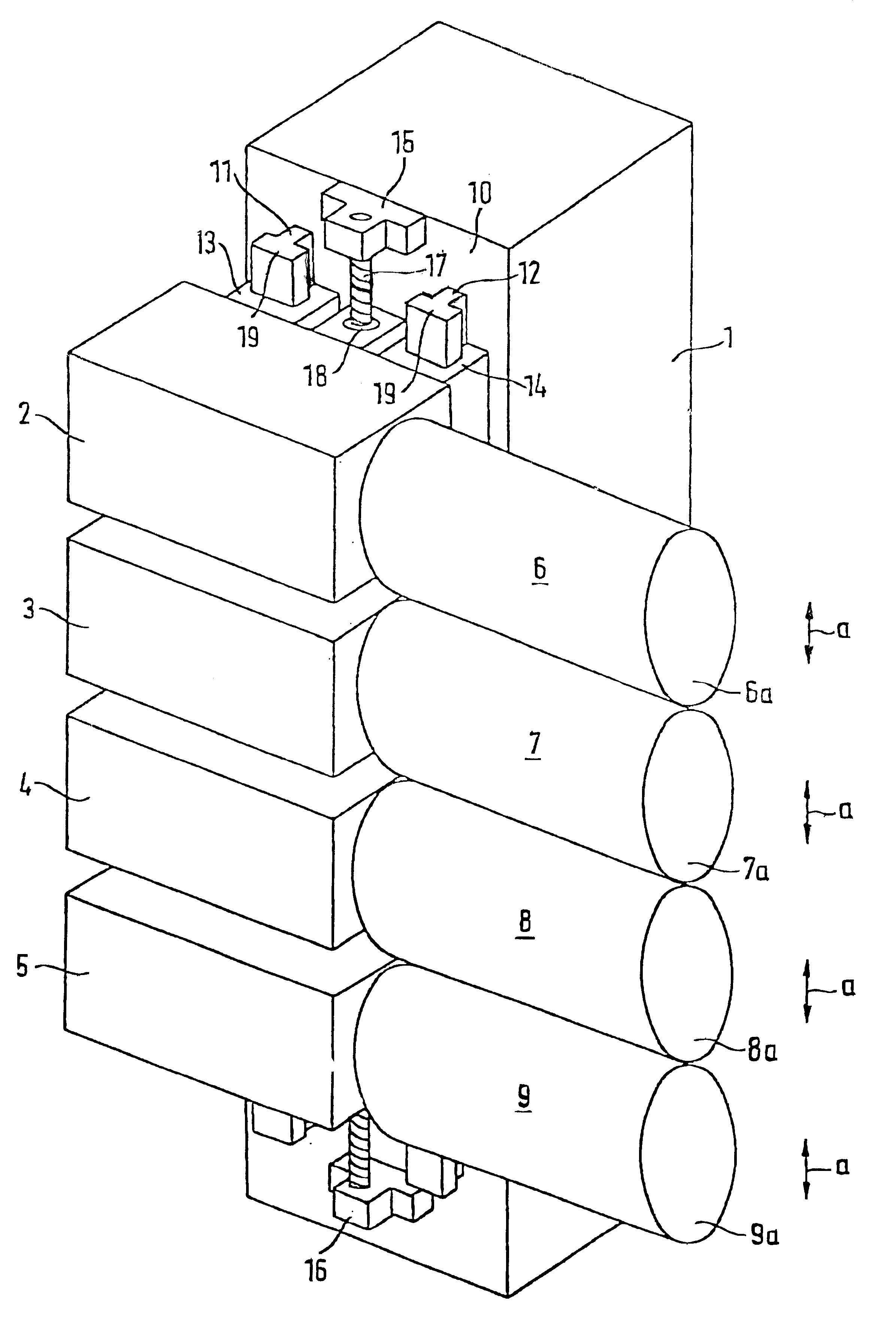

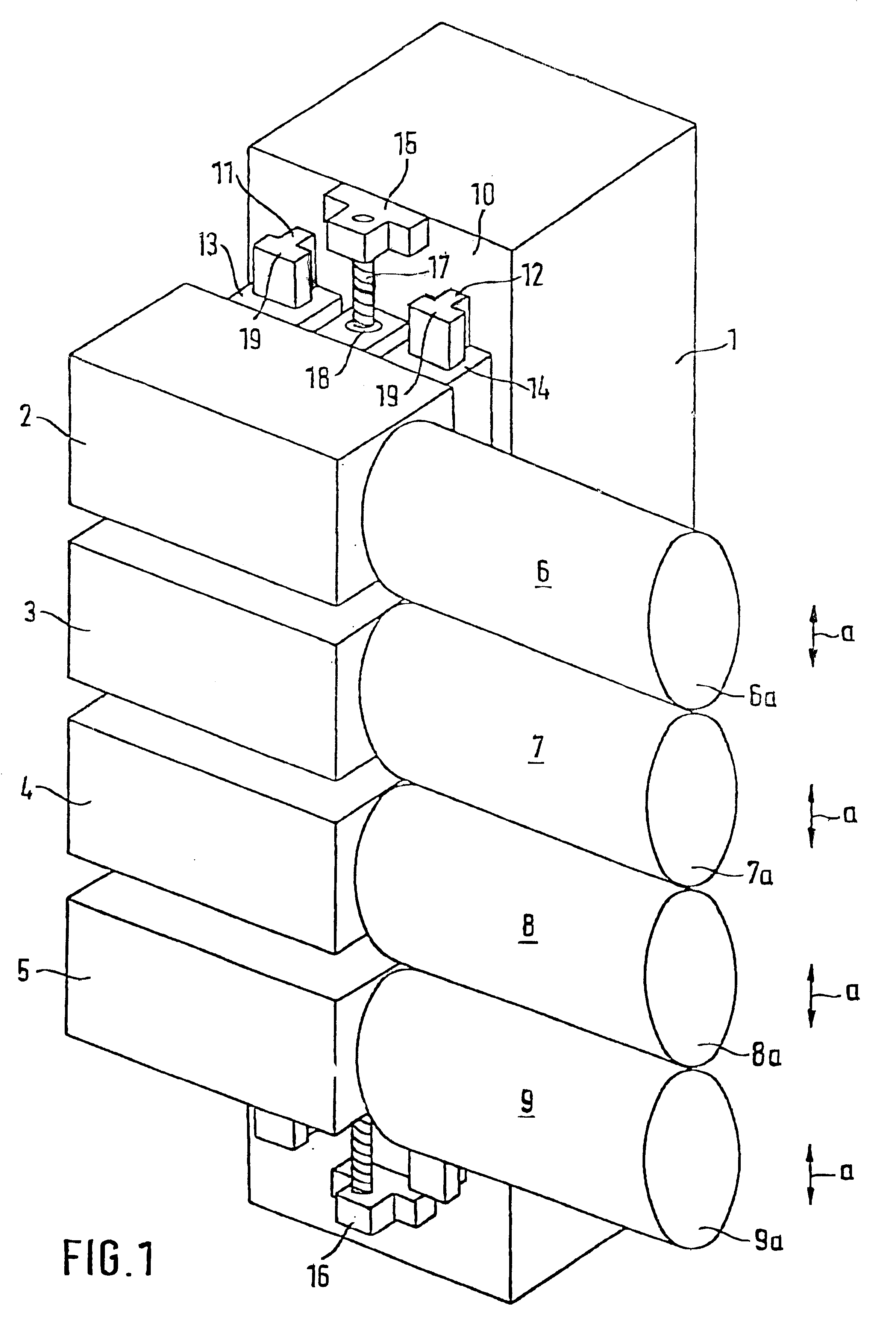

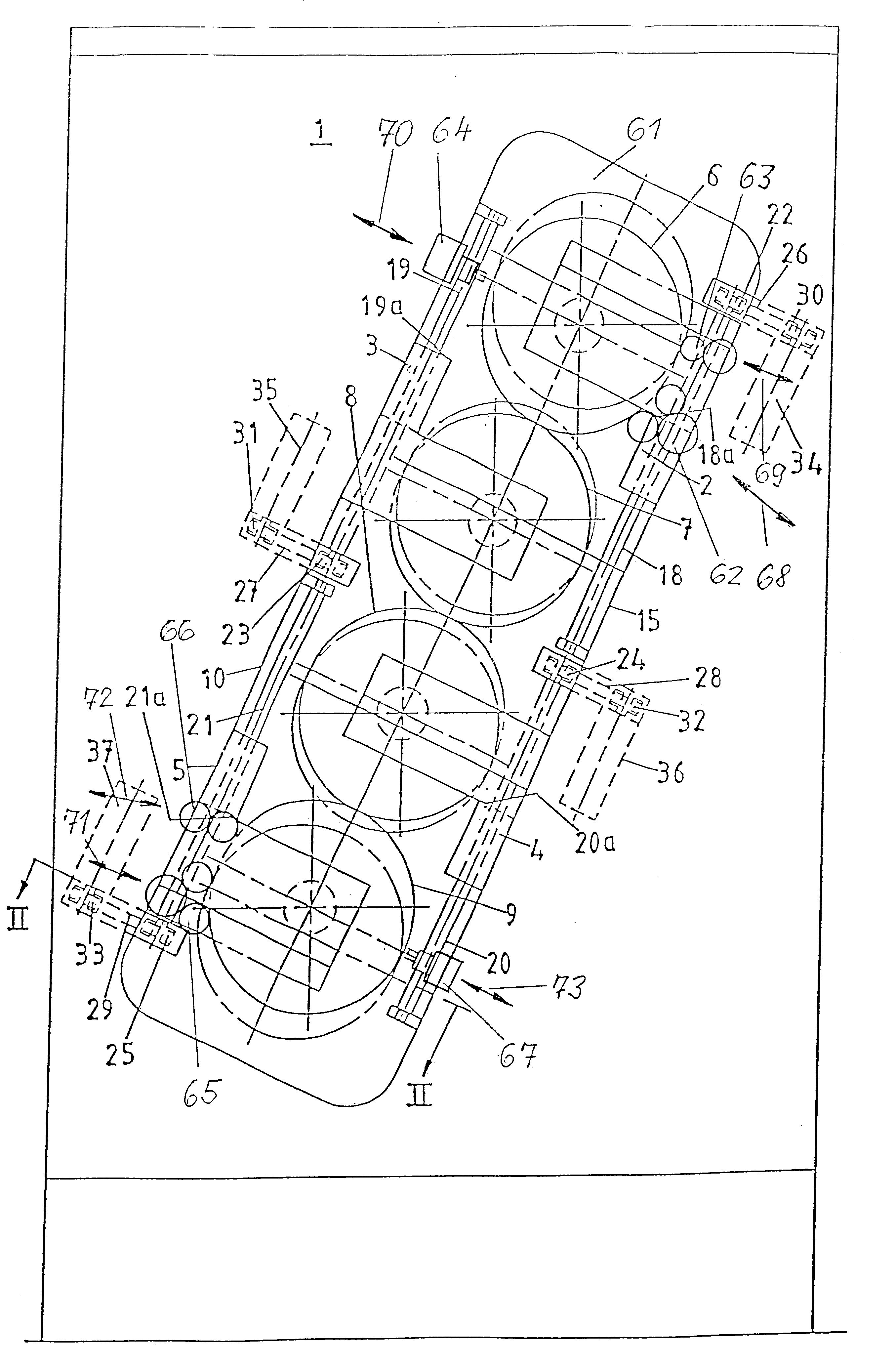

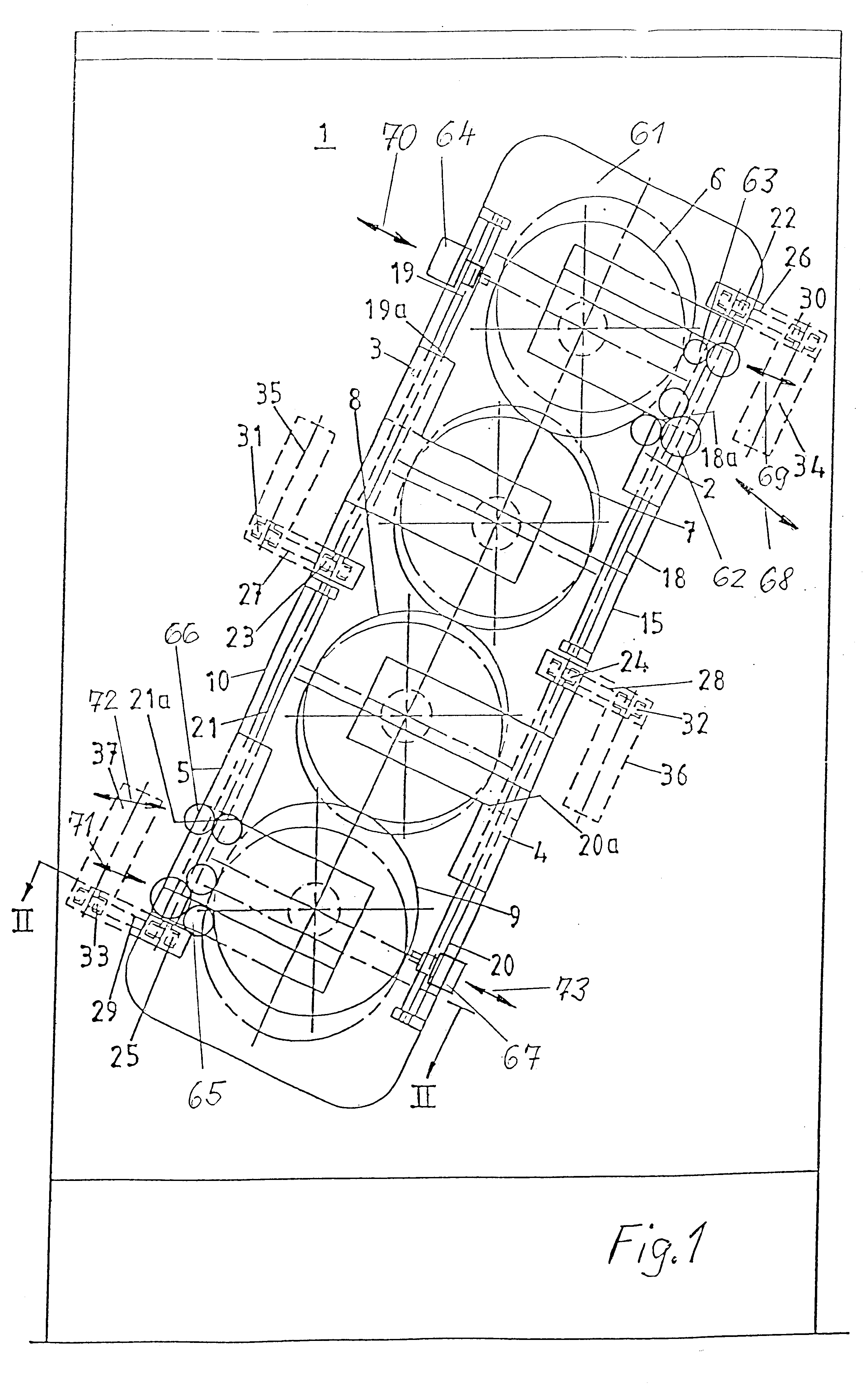

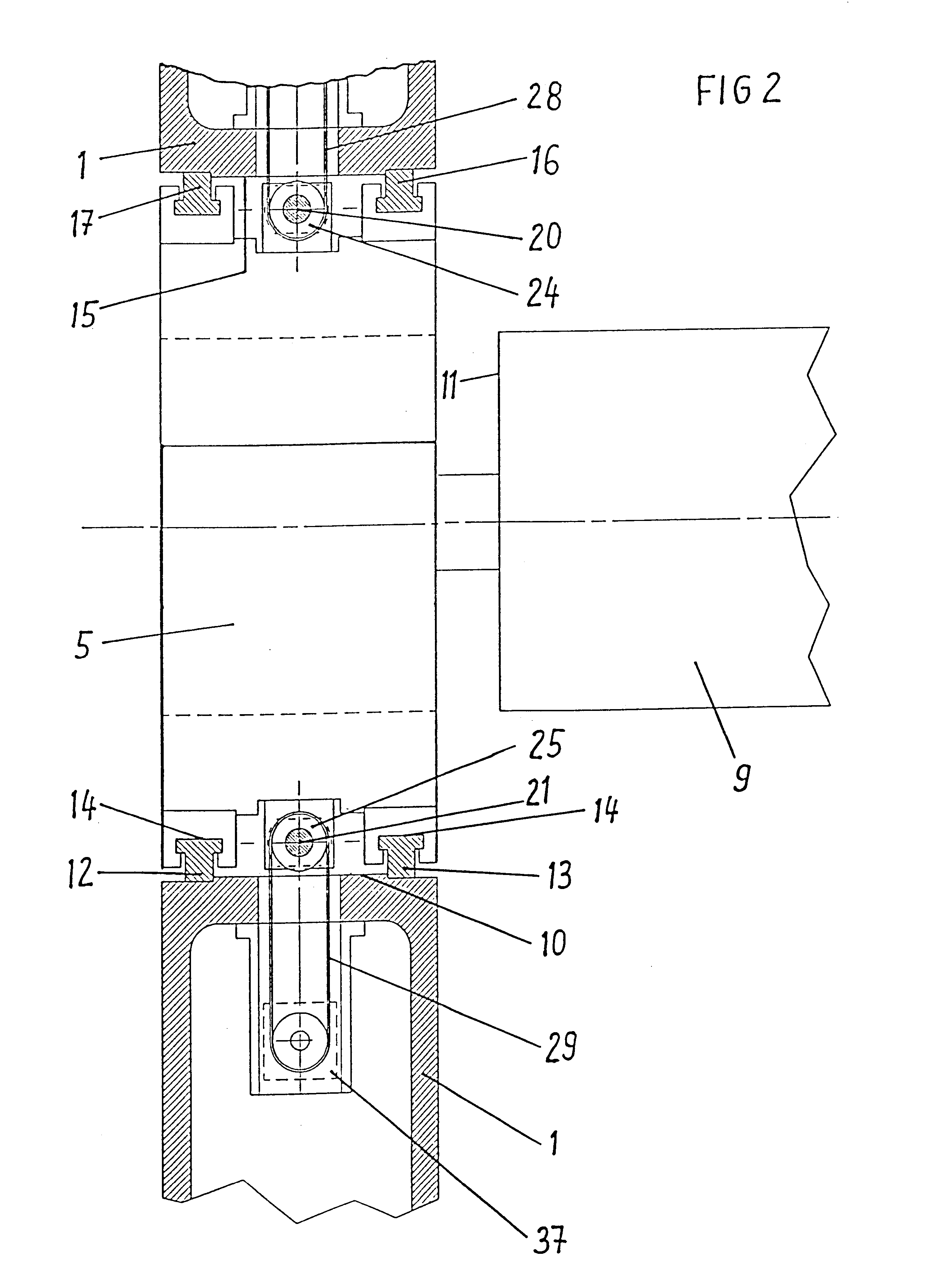

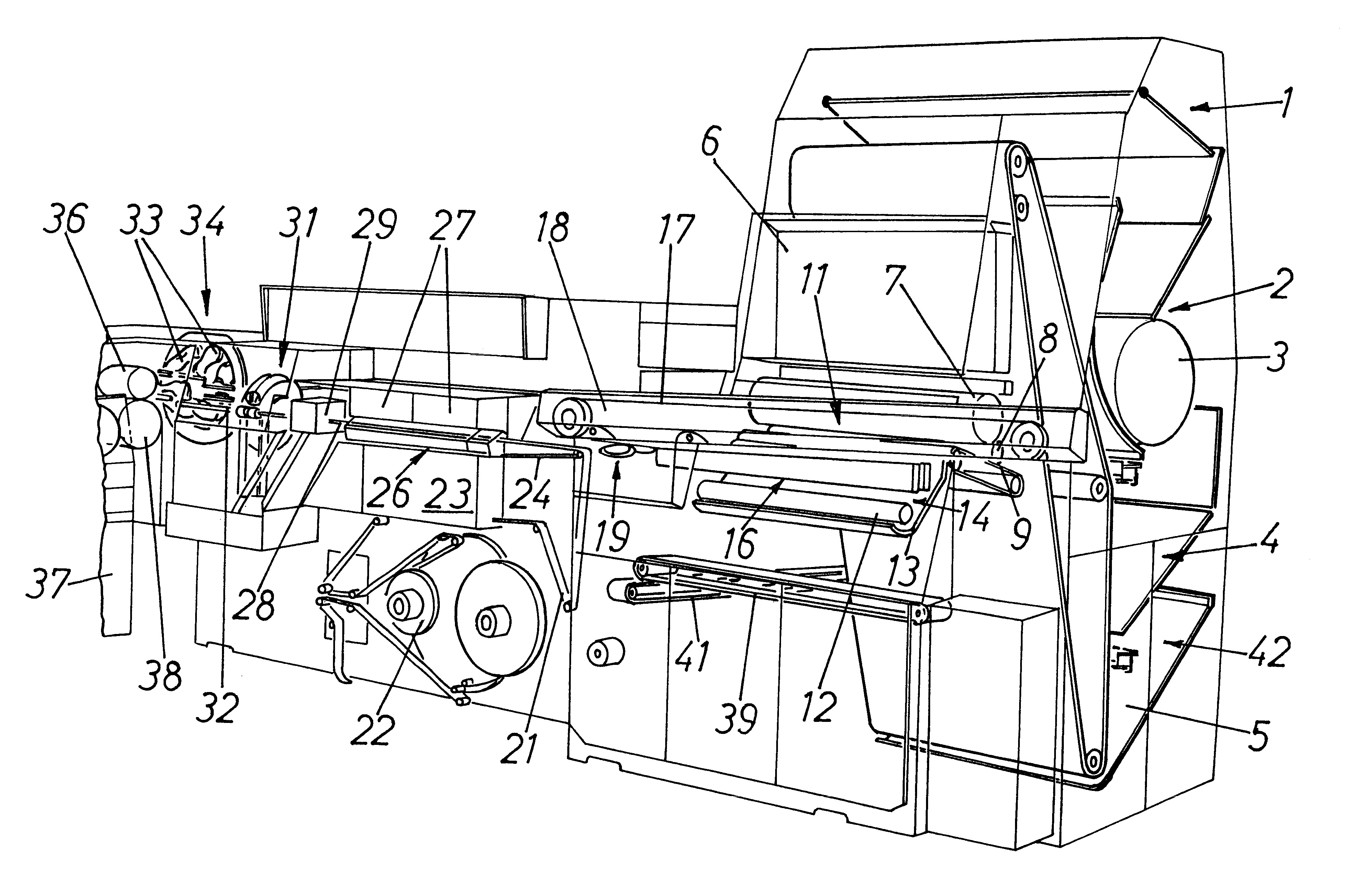

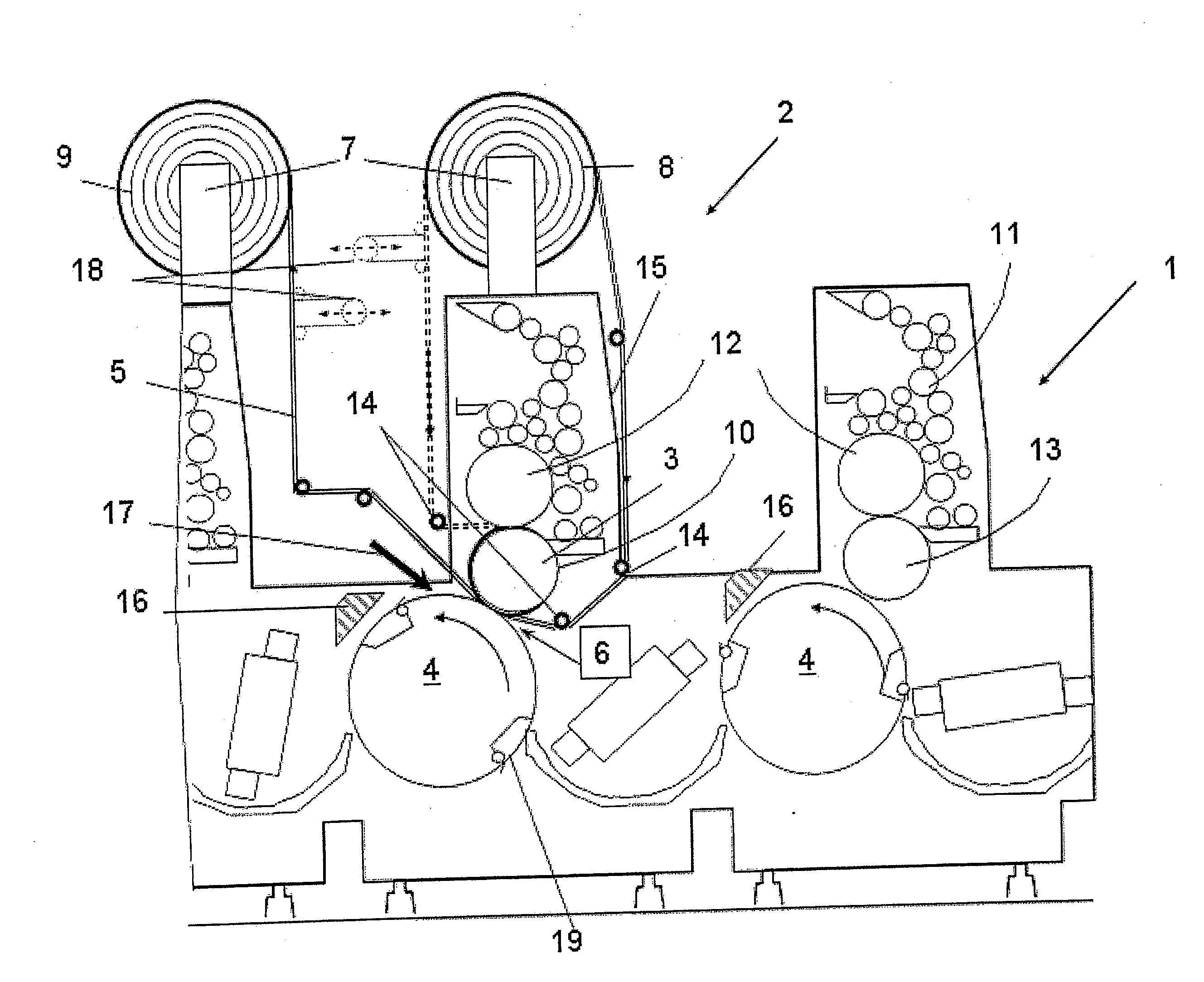

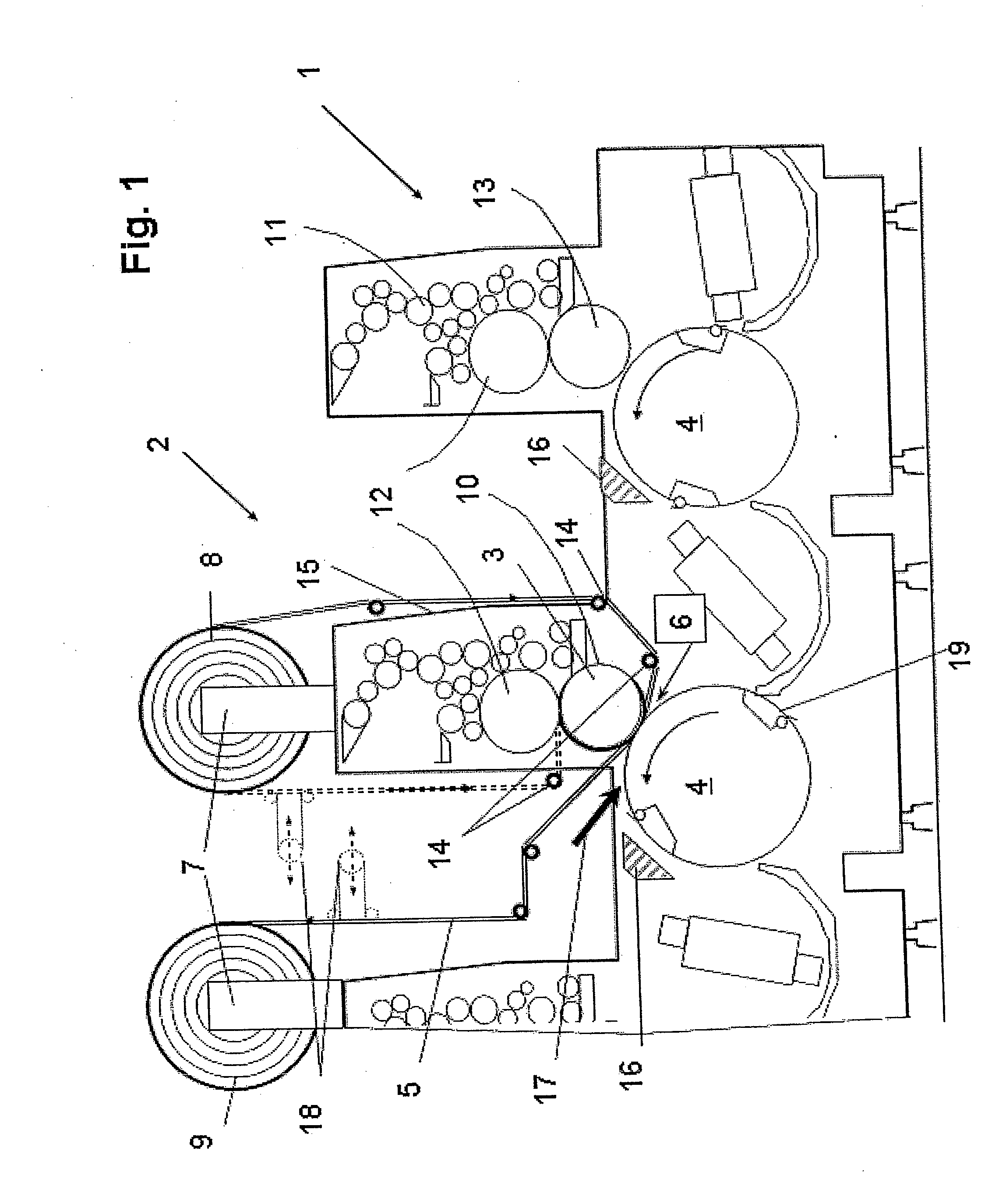

Web-fed rotary printing press for rapid change in production

InactiveUS6019039APrinting platesOther printing apparatusPrinting pressElectrical and Electronics engineering

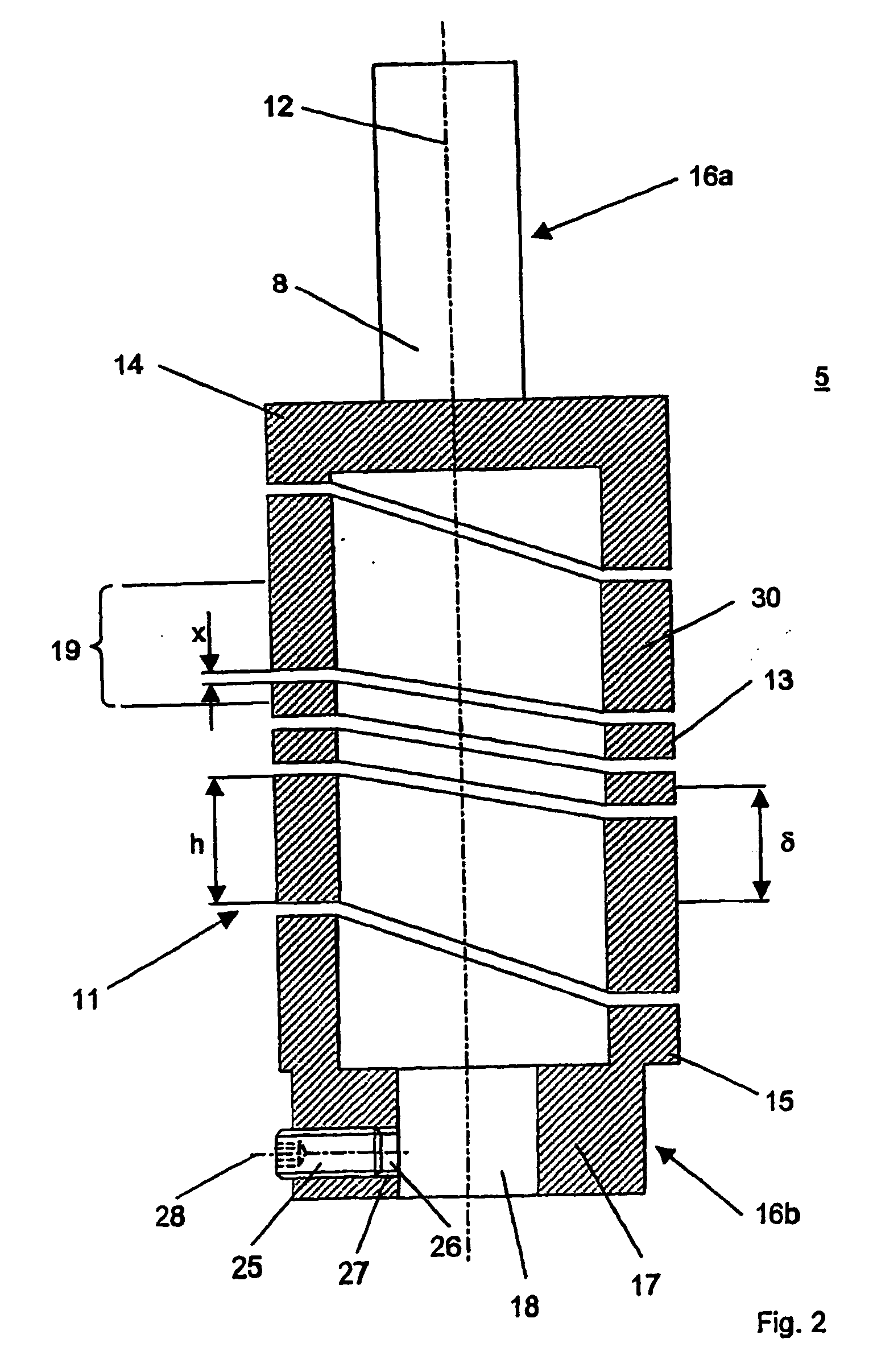

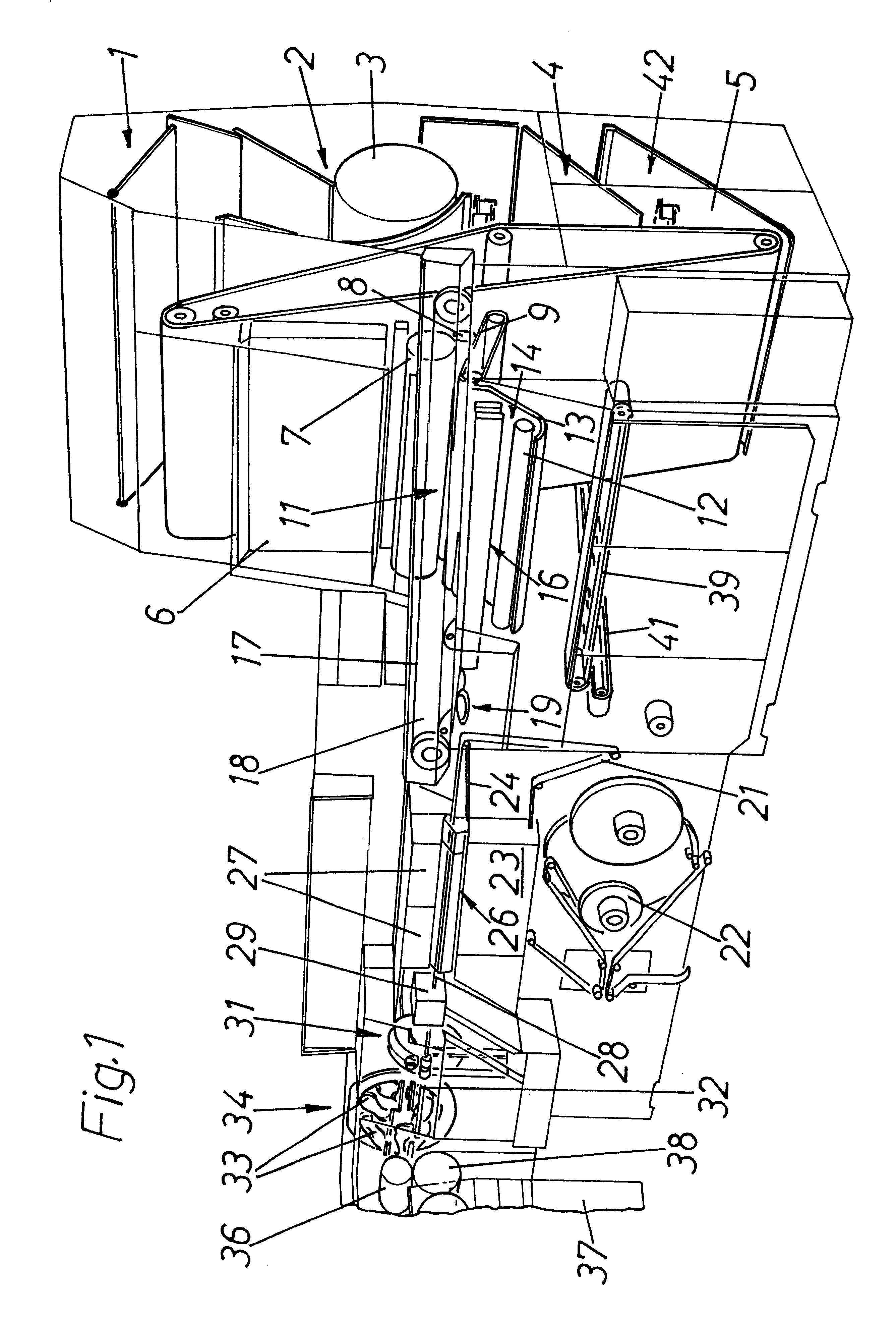

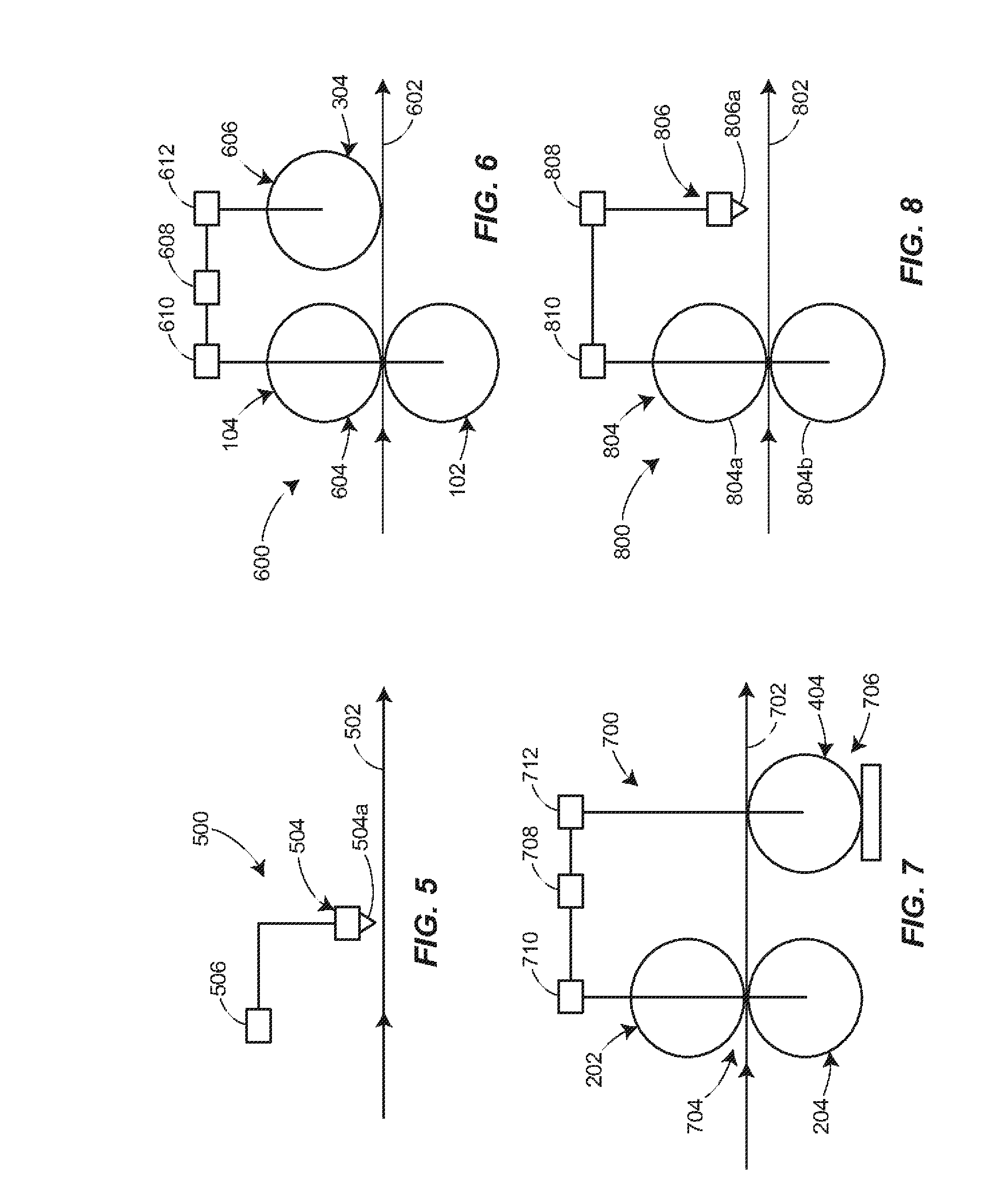

The invention relates to a web-fed rotary printing press having a plurality of double printing units in which each of the printing units of the double printing units work together in the blanket-blanket method and each has its own drive. Transfer cylinders of each printing unit are driven independently. To permit a rapid change in production, both upon recto and verso printing, the transfer cylinders of the disconnectable double printing units are separable by eccentric bushings or swingable levers such that a web which passes through the printing press is conducted between them without being printed.

Owner:MANROLAND WEB SYST

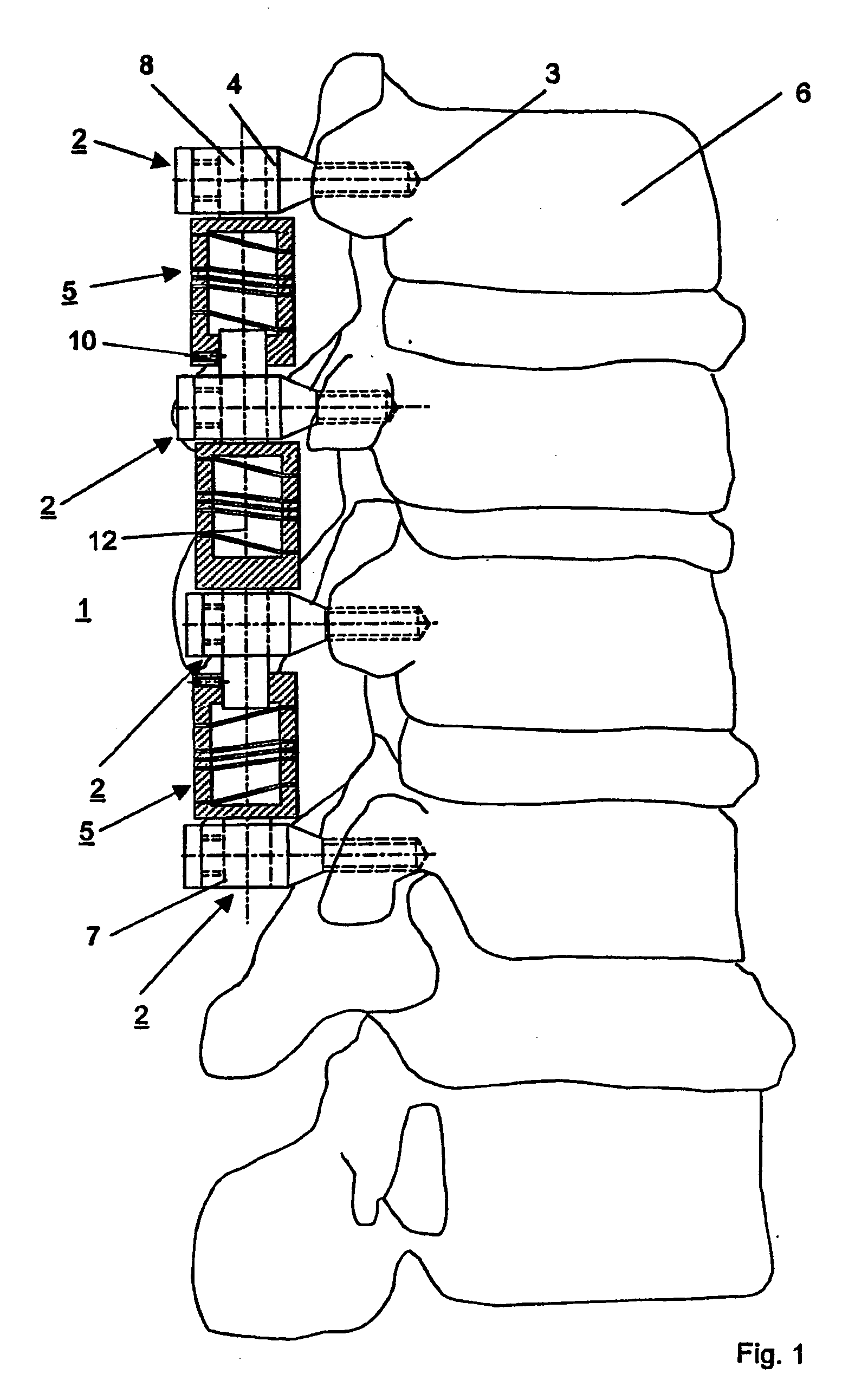

Device for elastically stabilizing vertebral bodies

ActiveUS20060260483A1Great elastic yieldingIncrease dampingInternal osteosythesisJoint implantsMetallic materialsEngineering

Owner:SYNTHES USA

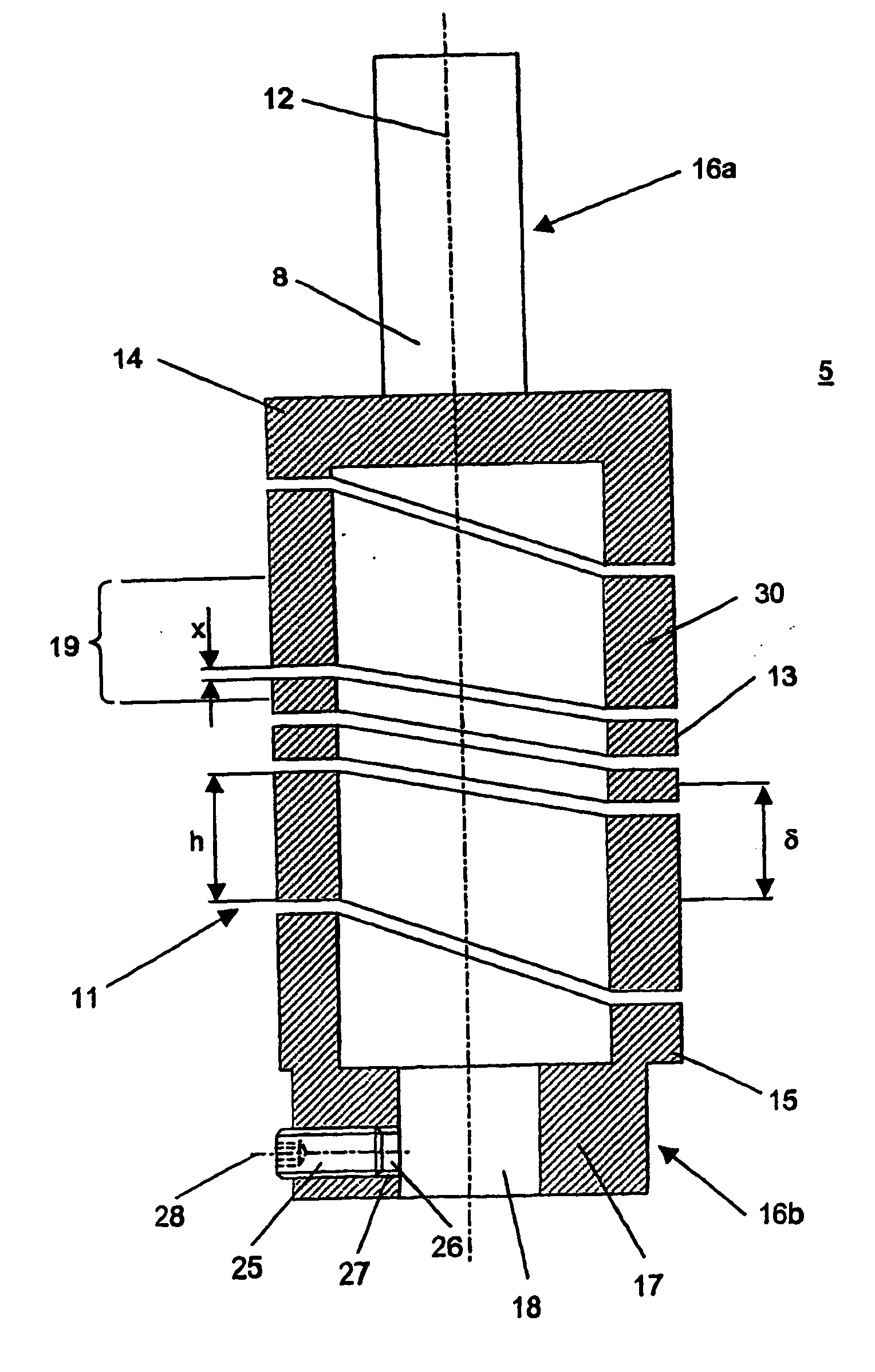

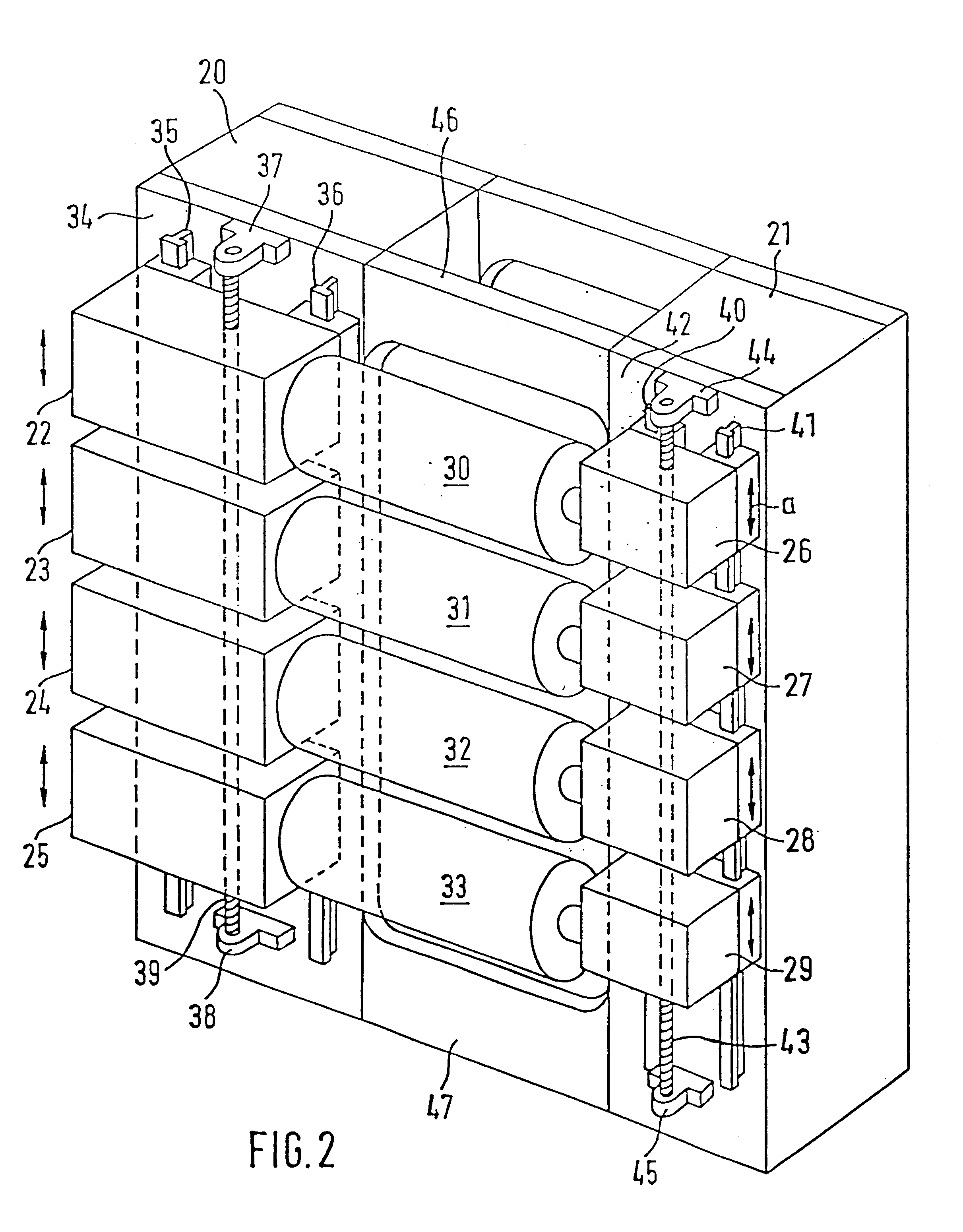

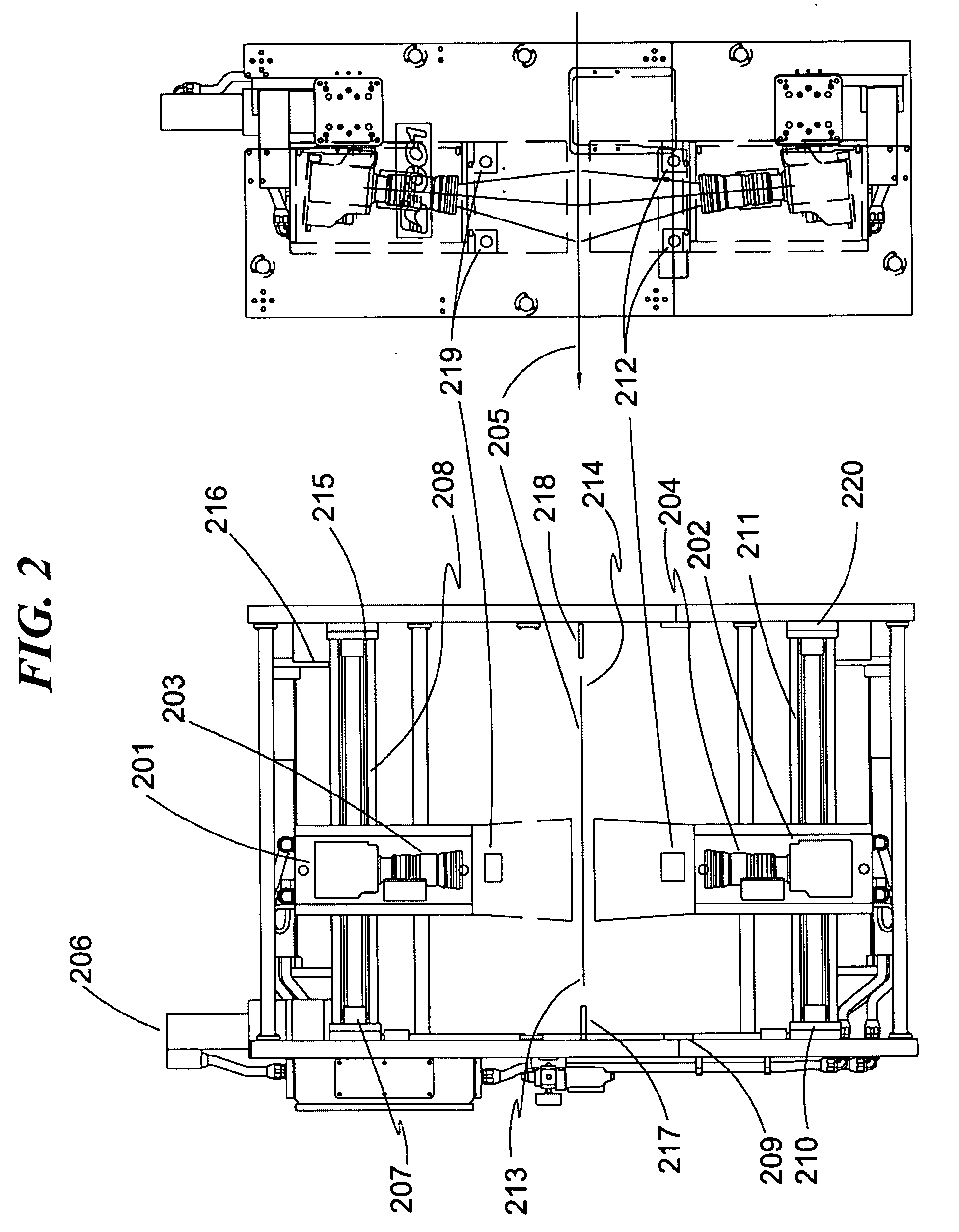

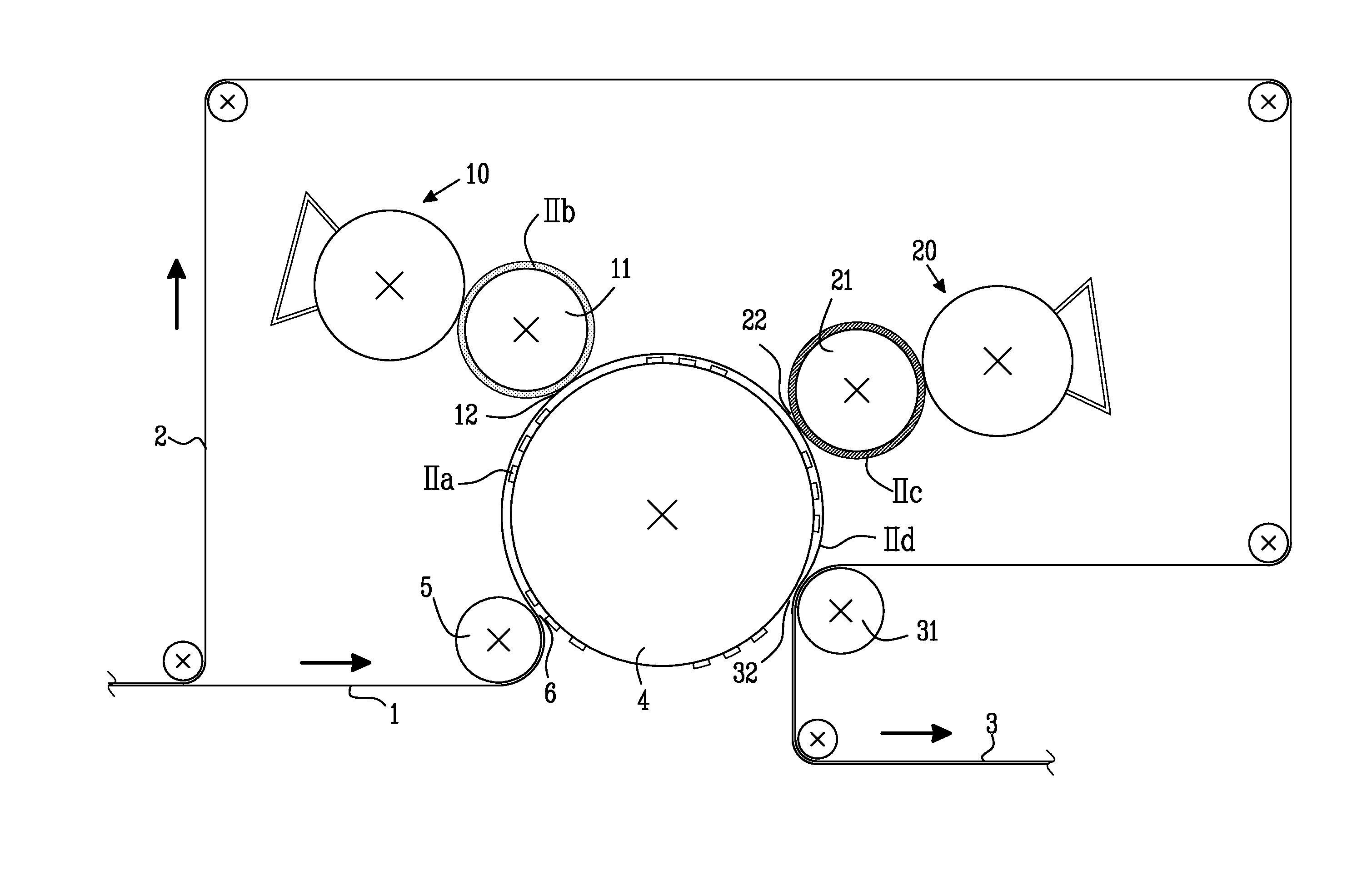

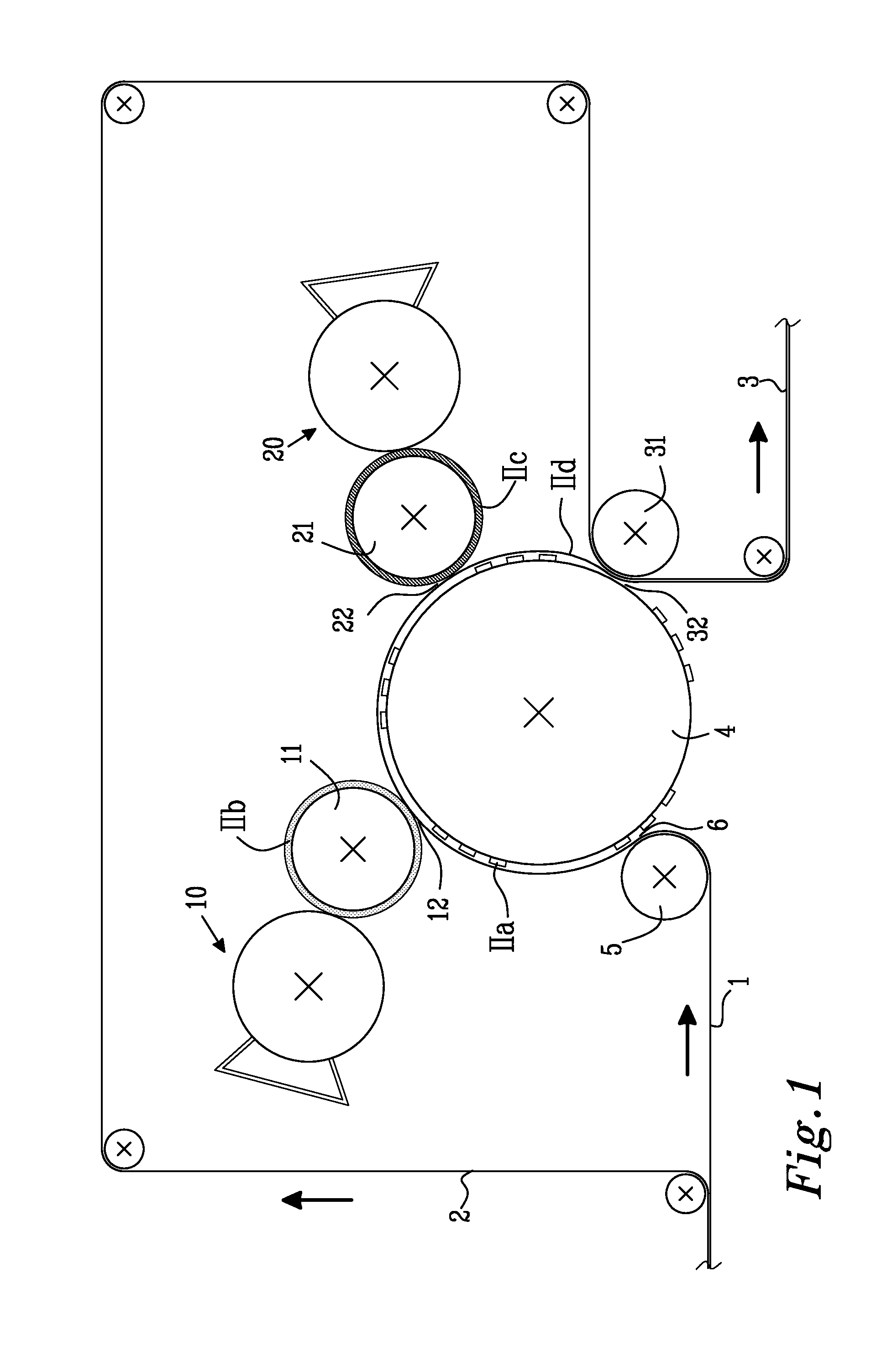

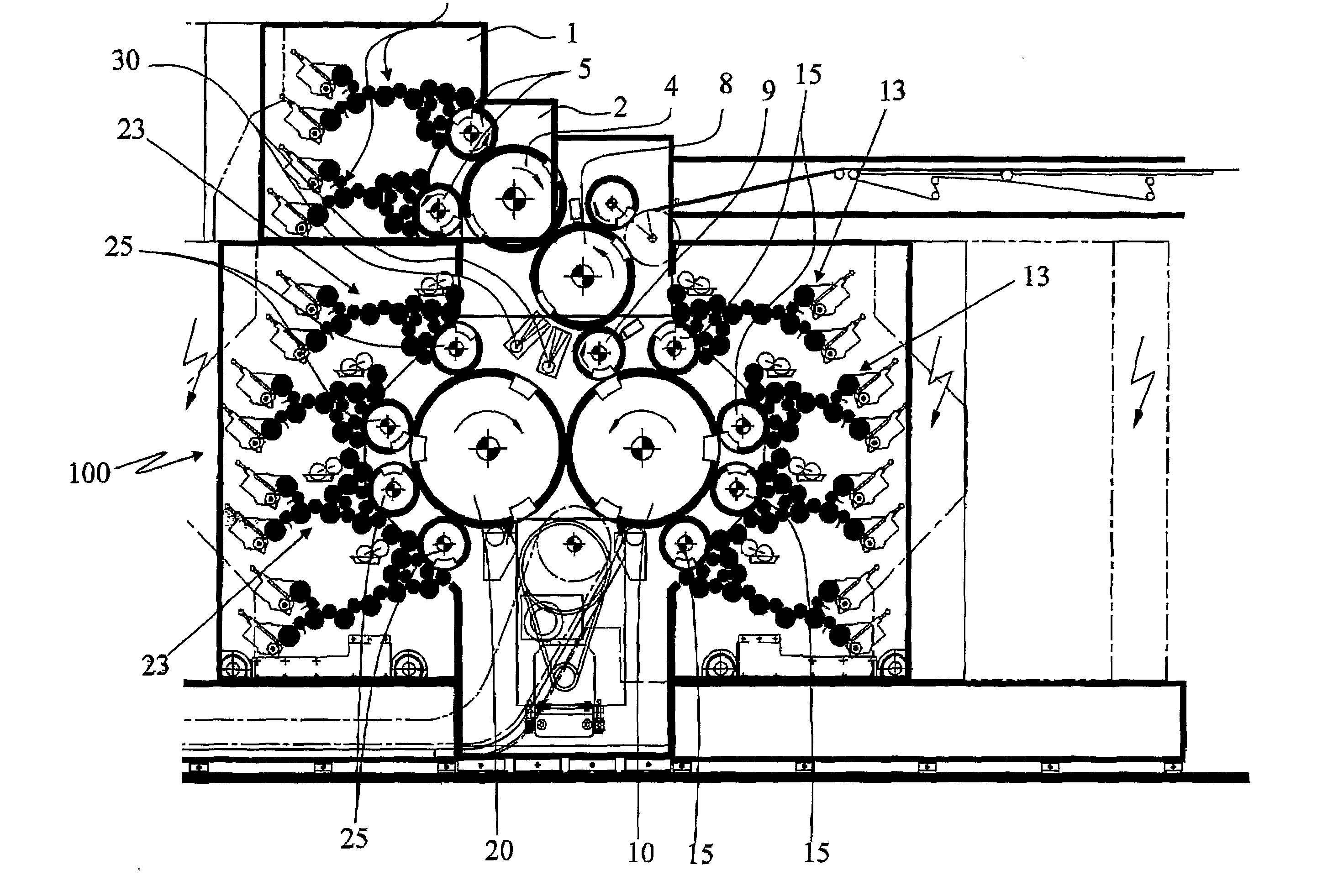

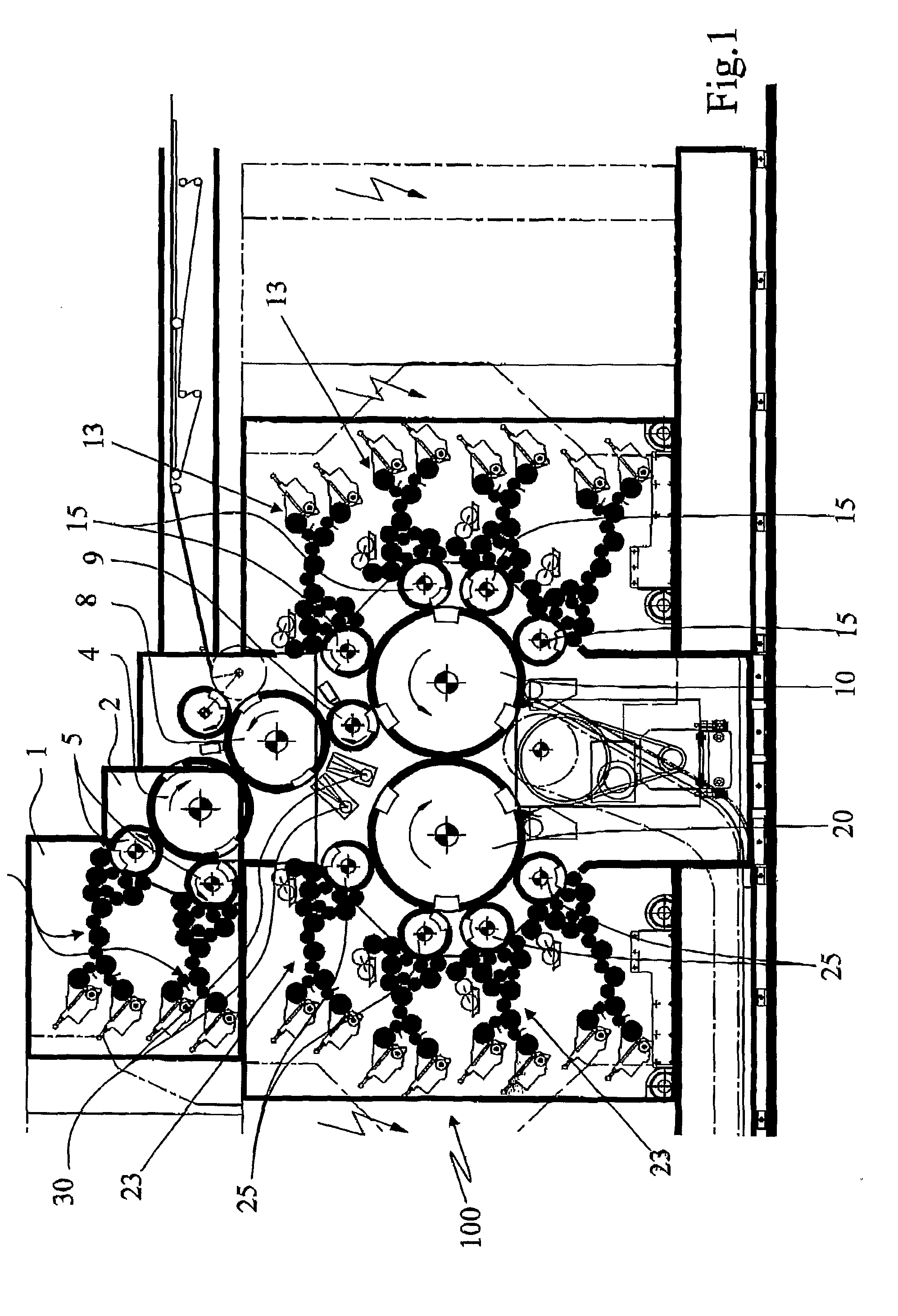

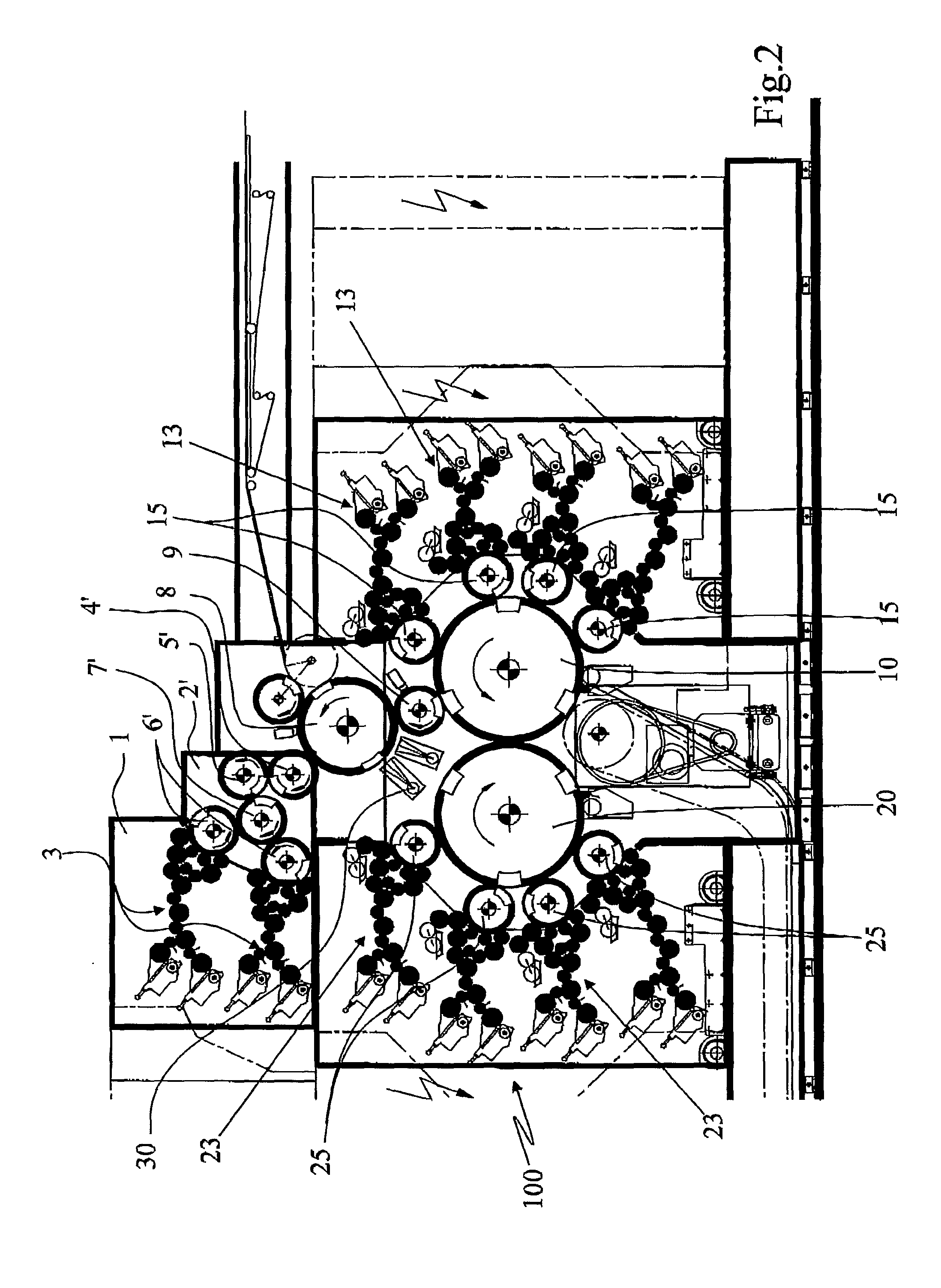

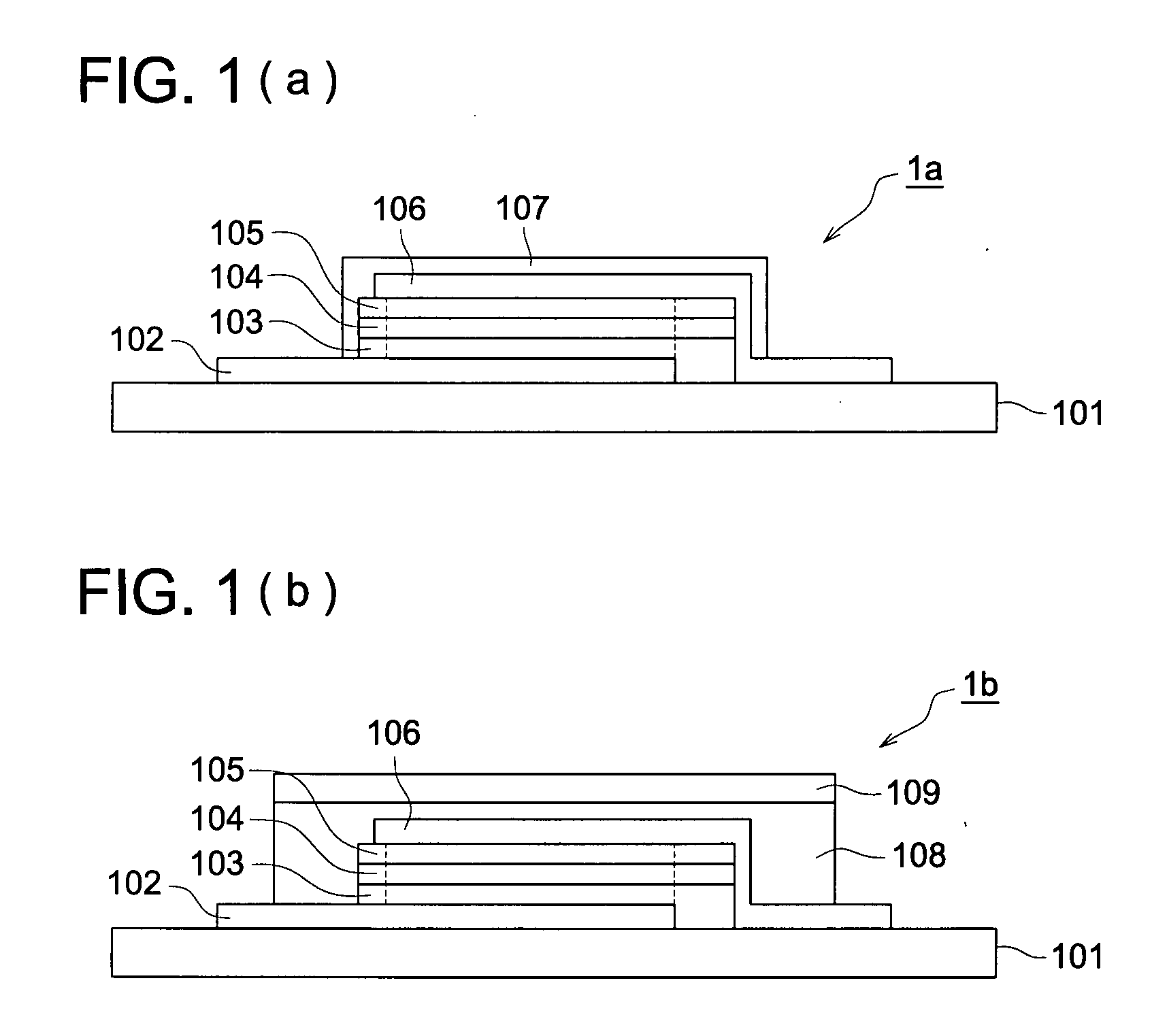

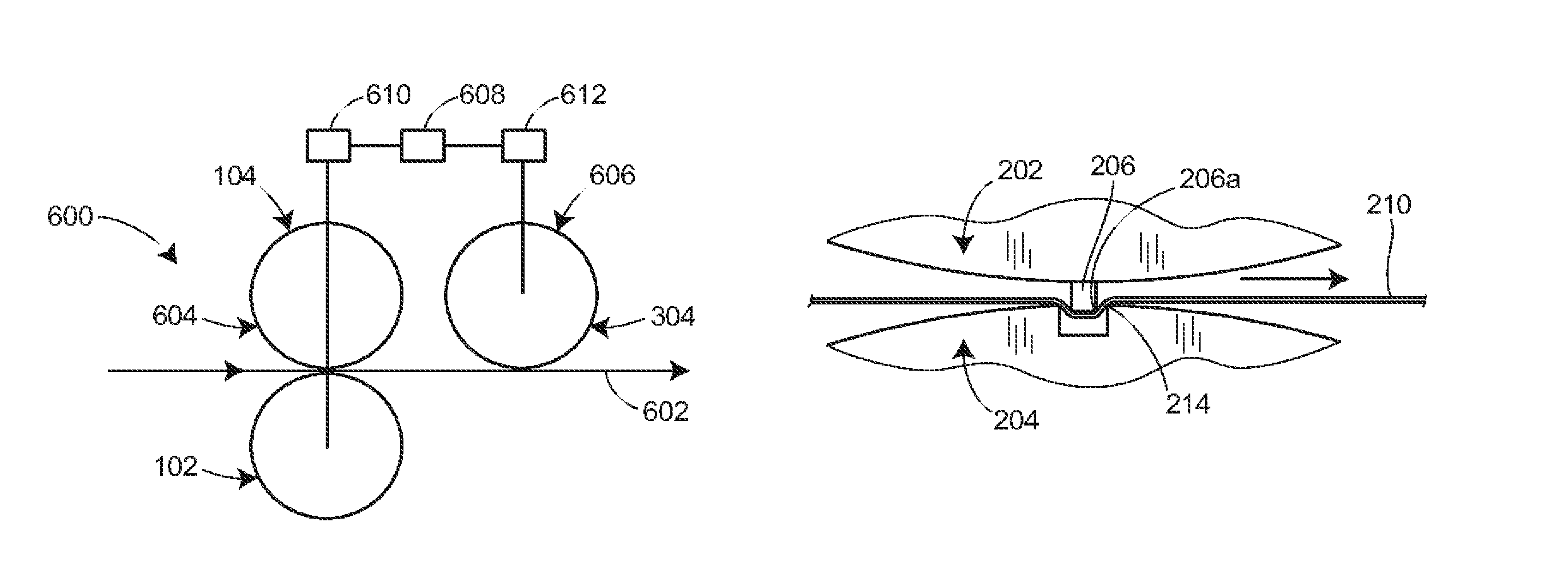

Printing unit

A printing unit is provided for a web fed printing machine having at least two cylinders where at least one of the cylinders is adjustable with respect to another of the cylinders; a machine frame having at least one load bearing wall arranged laterally beside an end of the cylinders; a drive motor corresponding to each cylinder; at least one guide element operably attached to the load bearing wall at a surface of the load bearing wall that runs perpendicular to a plane through the end faces of the cylinders; and a plurality of carriages attached to the guide element. At least one of the cylinders is connected to the carriages so that a distance from another of the cylinders can be adjusted.

Owner:MANROLAND WEB SYST

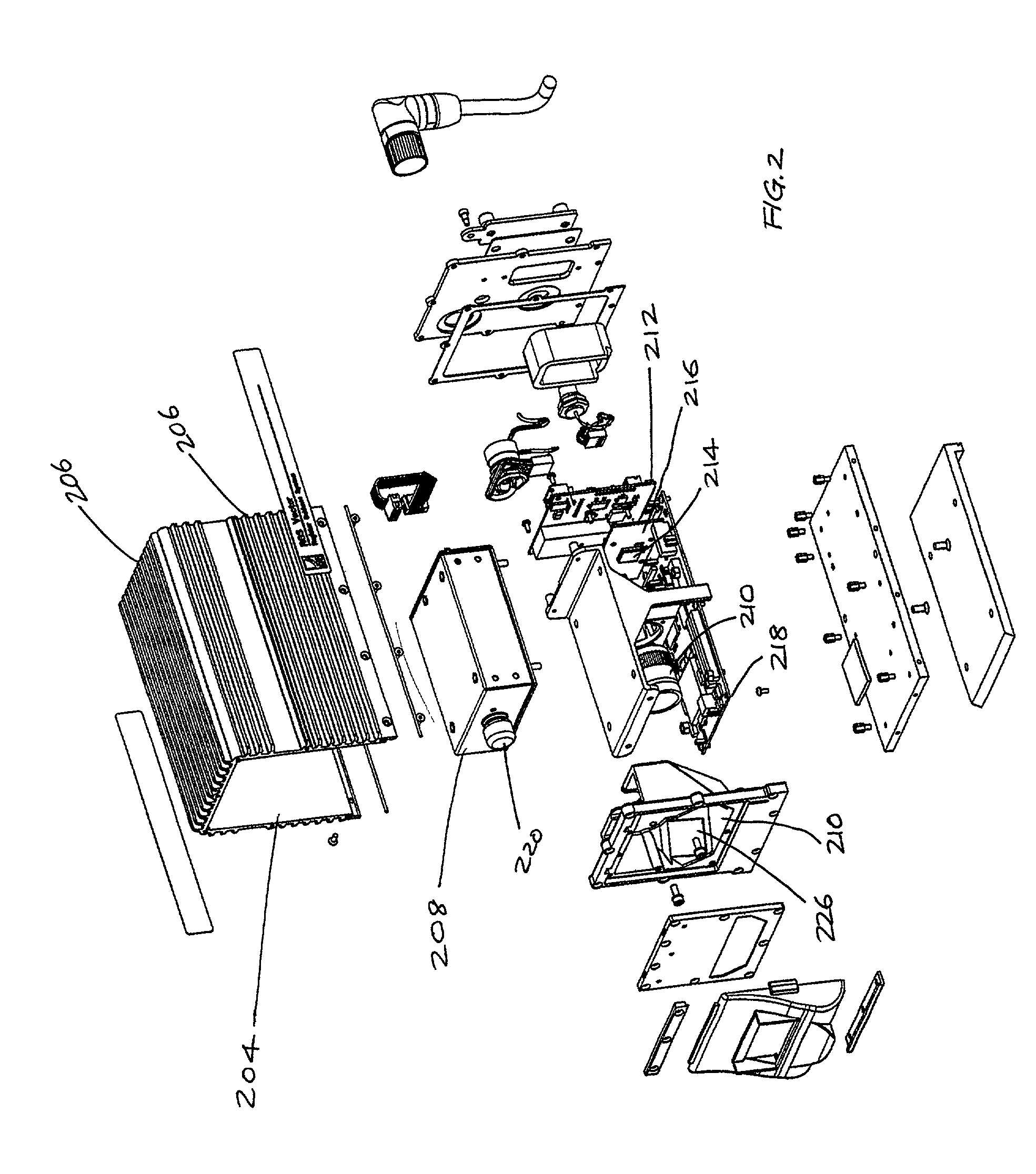

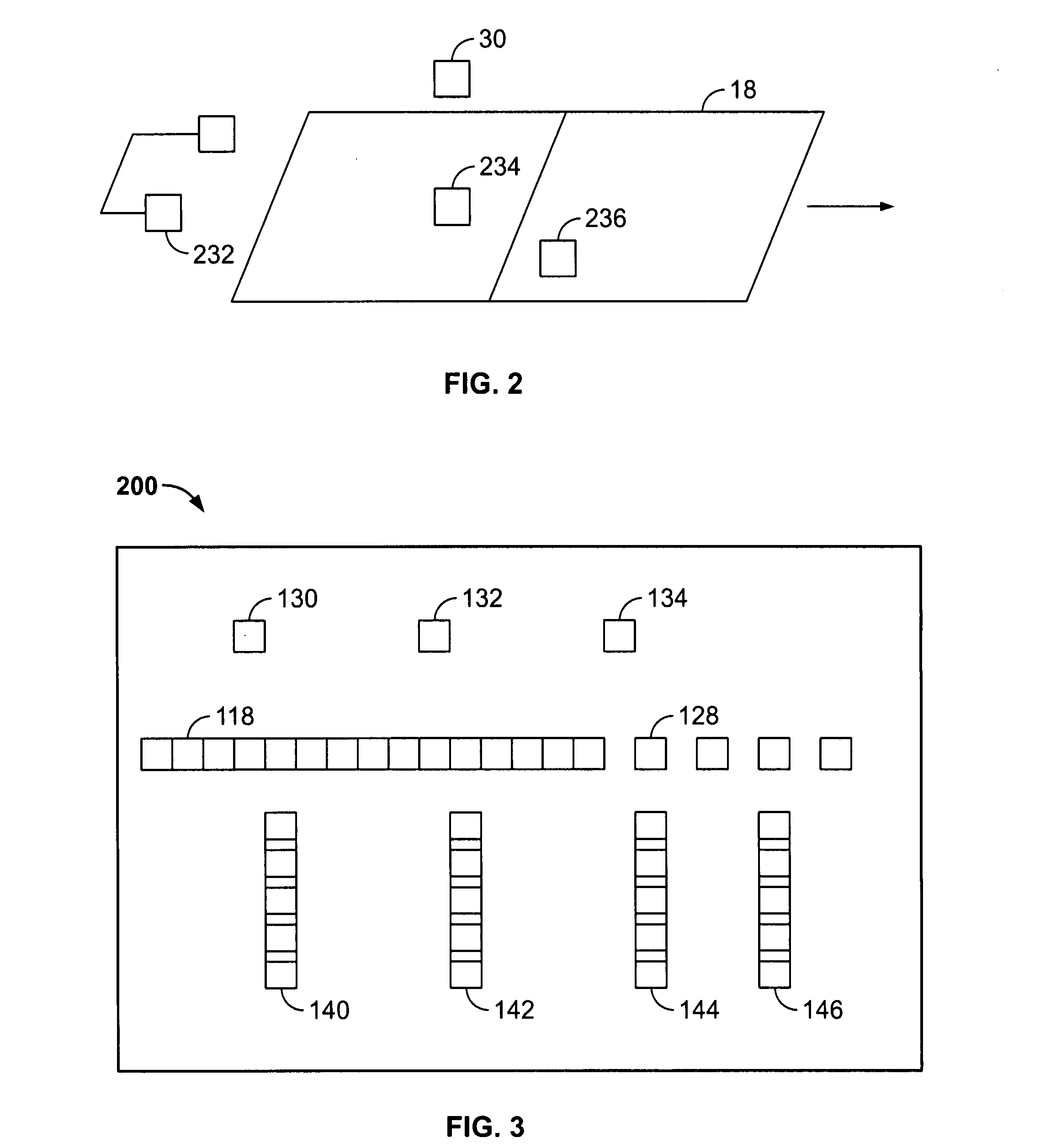

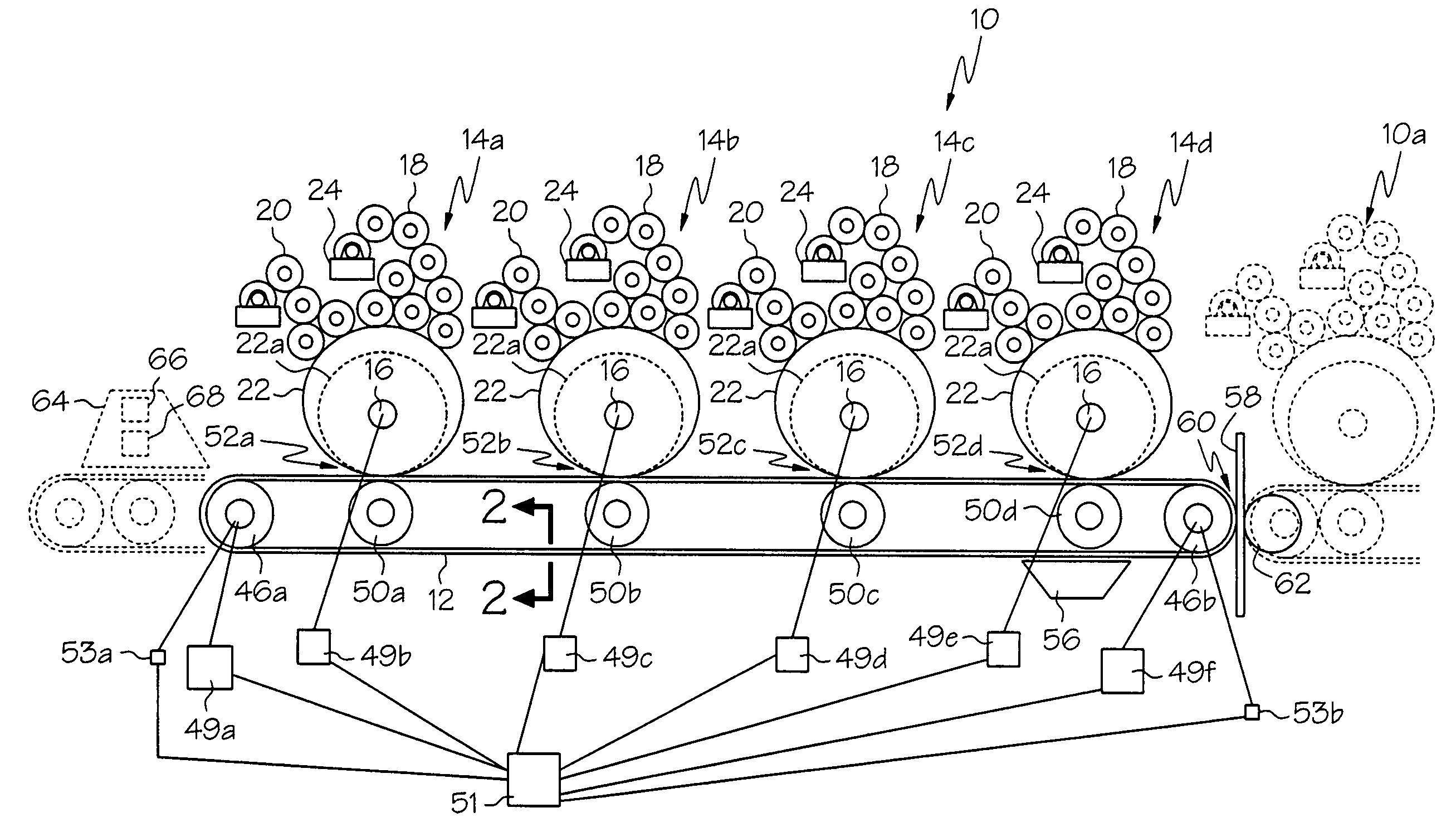

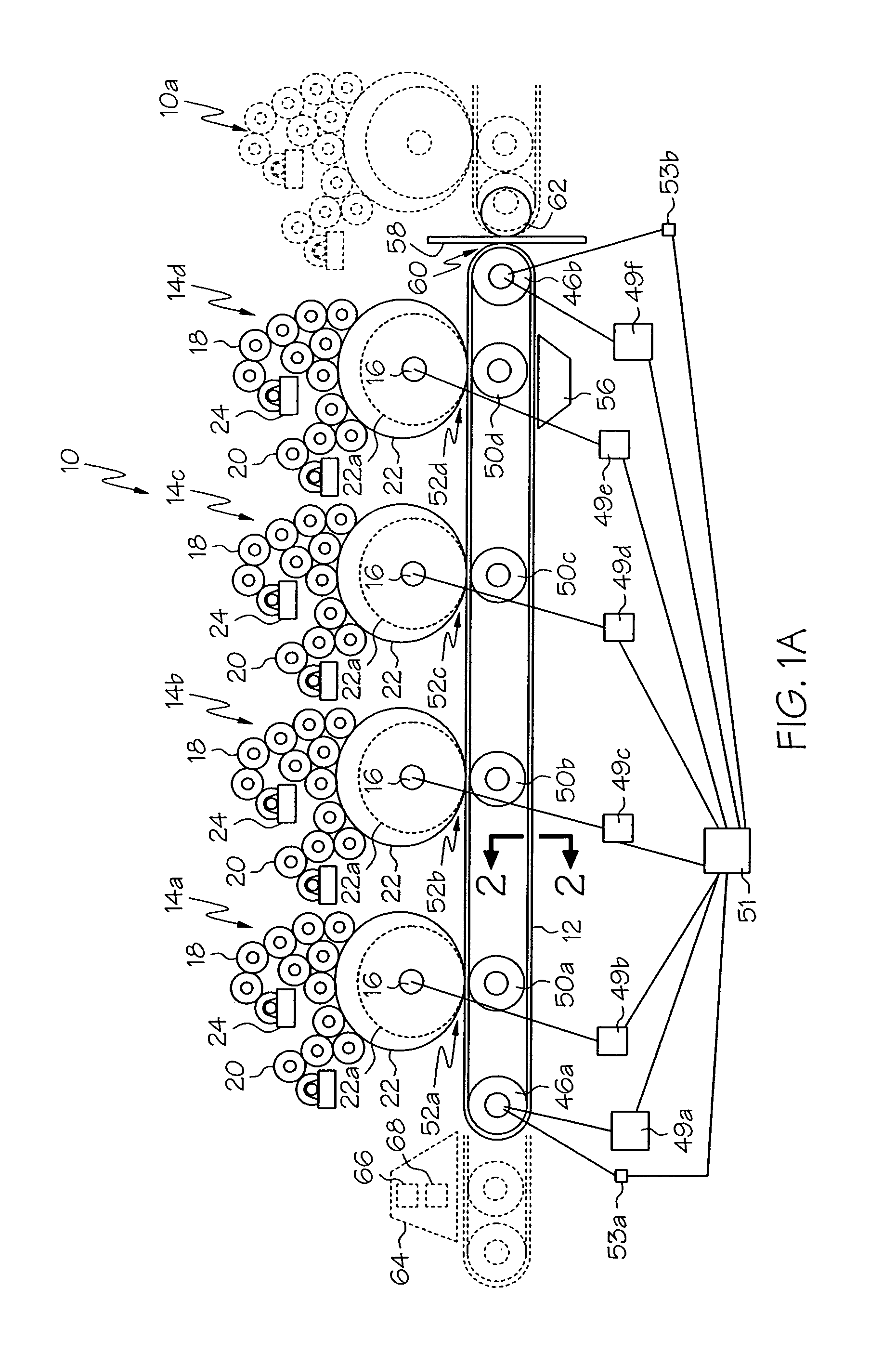

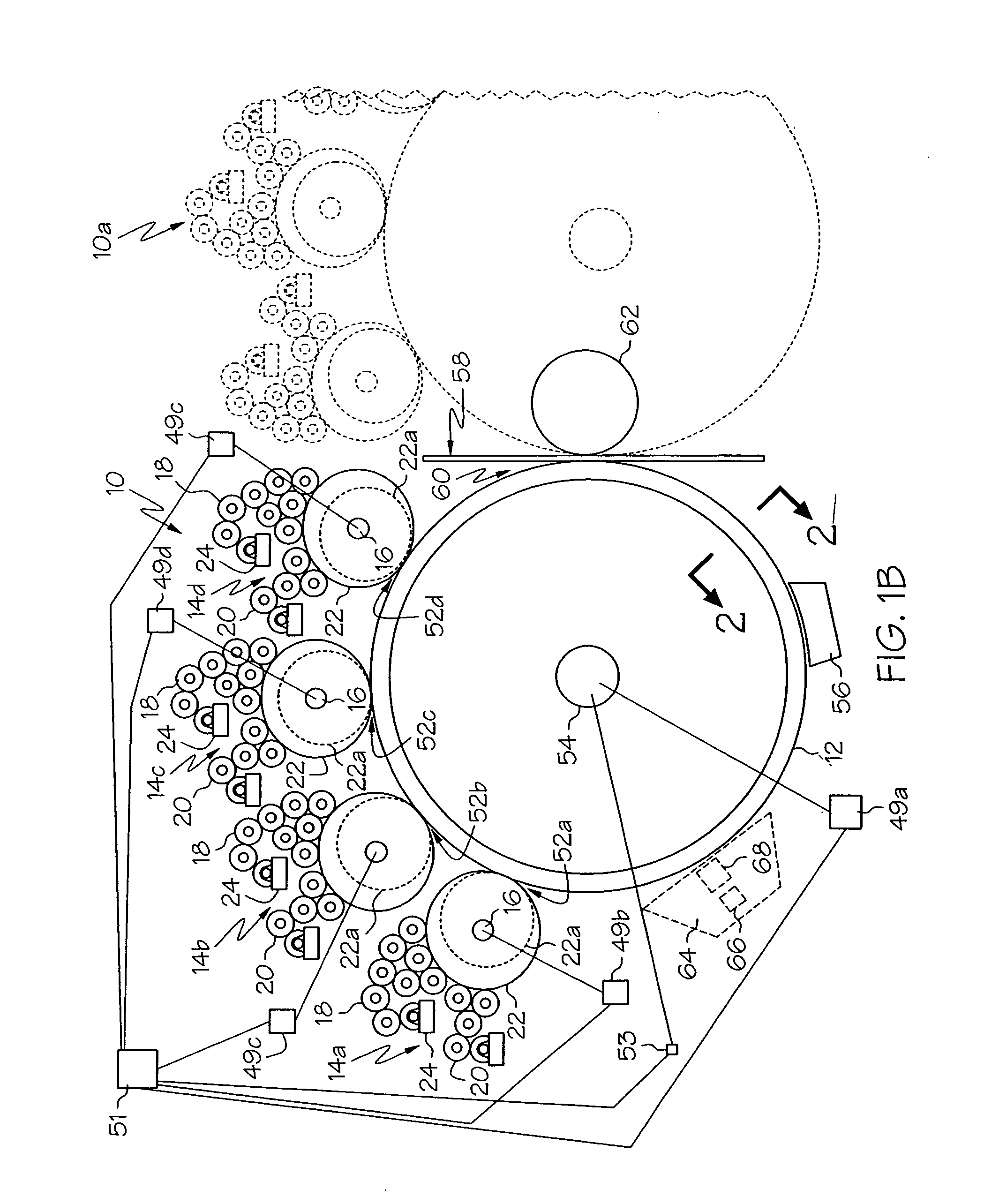

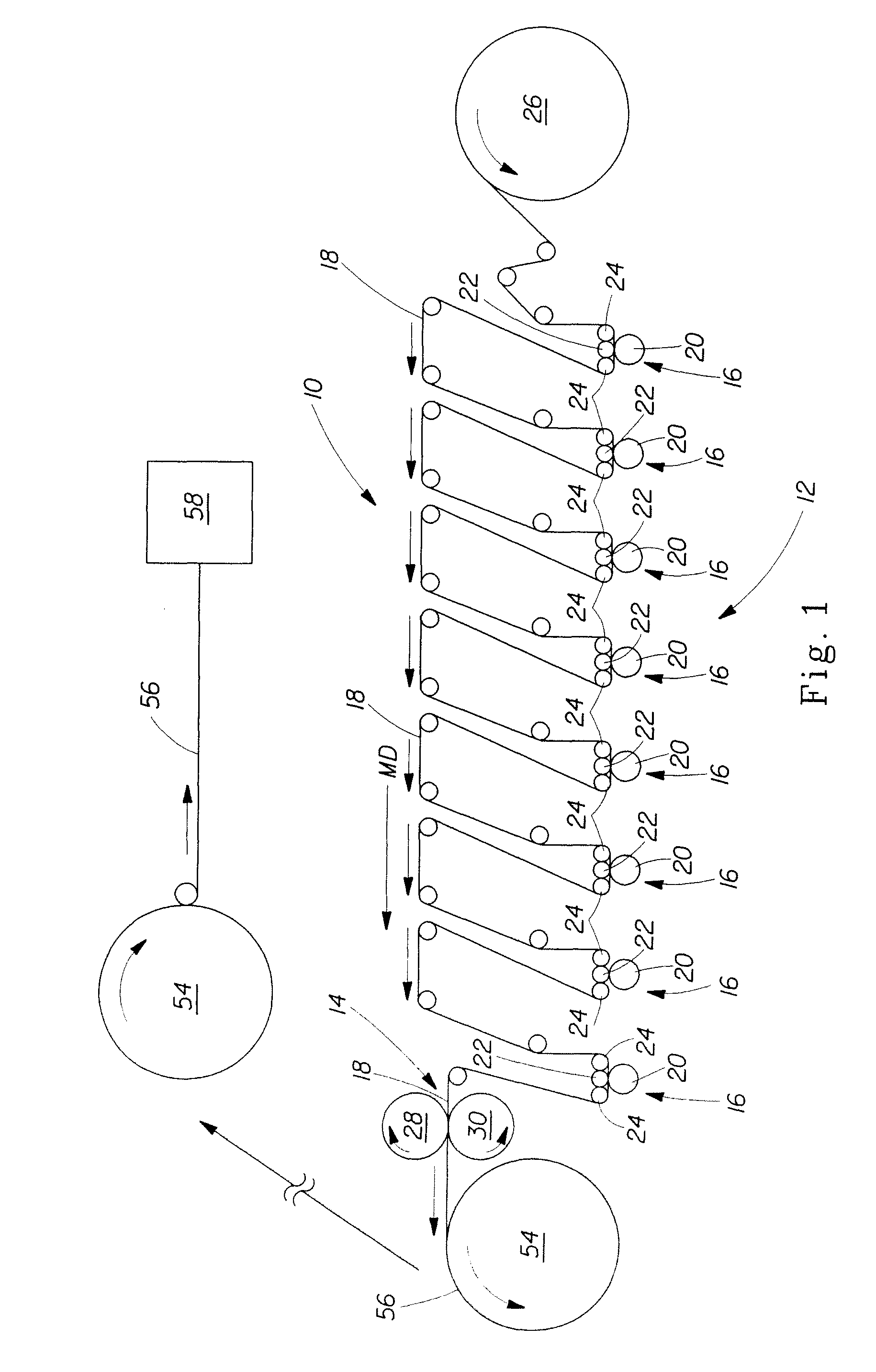

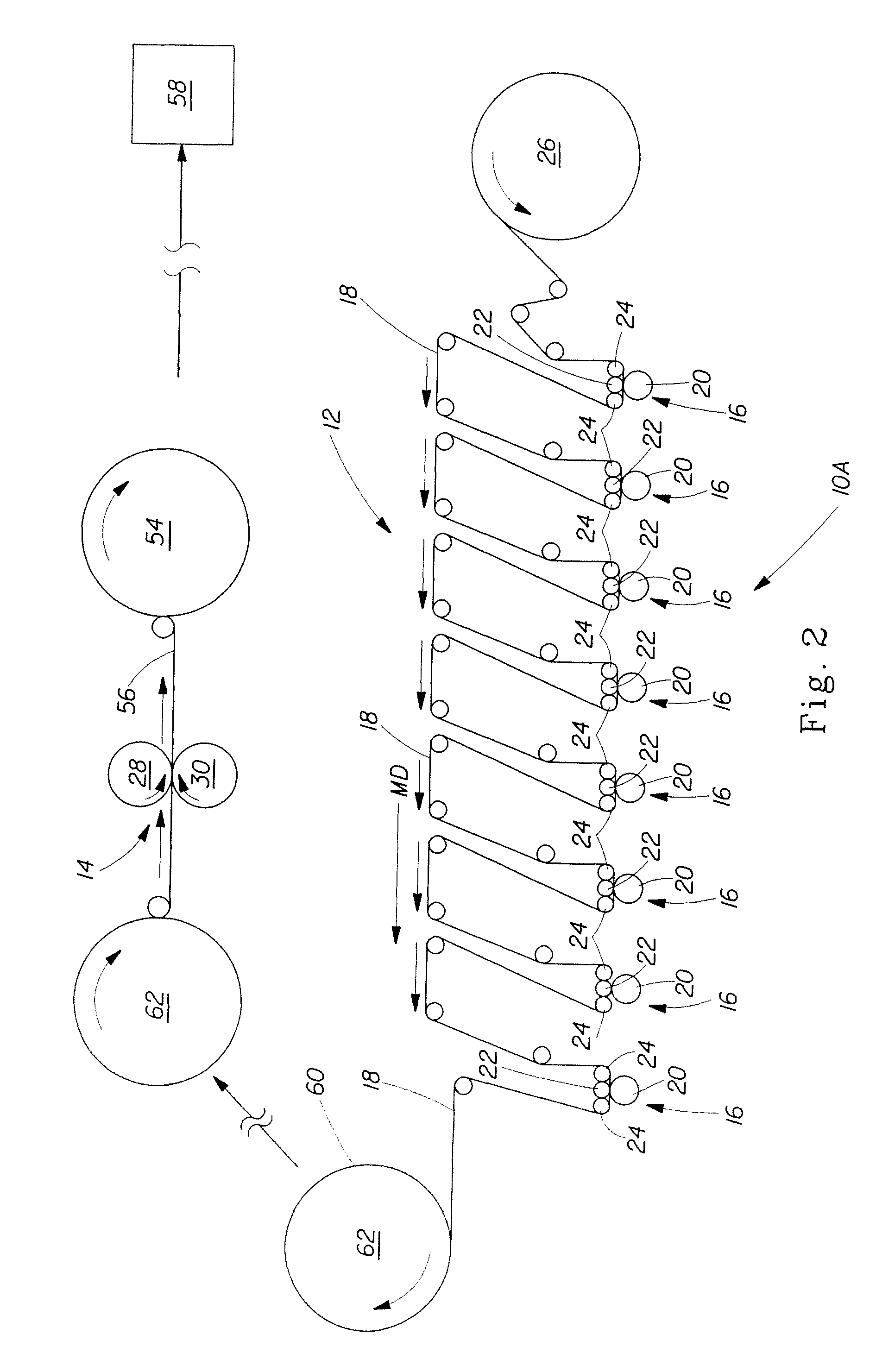

Absorbent Articles Having Distinct Graphics And Apparatus And Method For Printing Such Absorbent Articles

The present disclosure provides embodiments of processes and apparatuses for printing series of different graphics on substrates used in the manufacture of absorbent articles. Such printed substrates can be used, for example, in the manufacture of printed diaper components, such as backsheets, topsheets, landing zones, fasteners, ears, absorbent cores, and acquisition layers. Embodiments of the apparatuses and methods disclosed herein utilize flexographic printing to provide for a sequential manufacture of a series of n absorbent articles having different graphics printed thereon, wherein n can be a number of 2 or greater. In addition, an absorbent product may be produced by placing one or more, or a portion, of the series of n absorbent articles in a package.

Owner:FUSEPROJECT +1

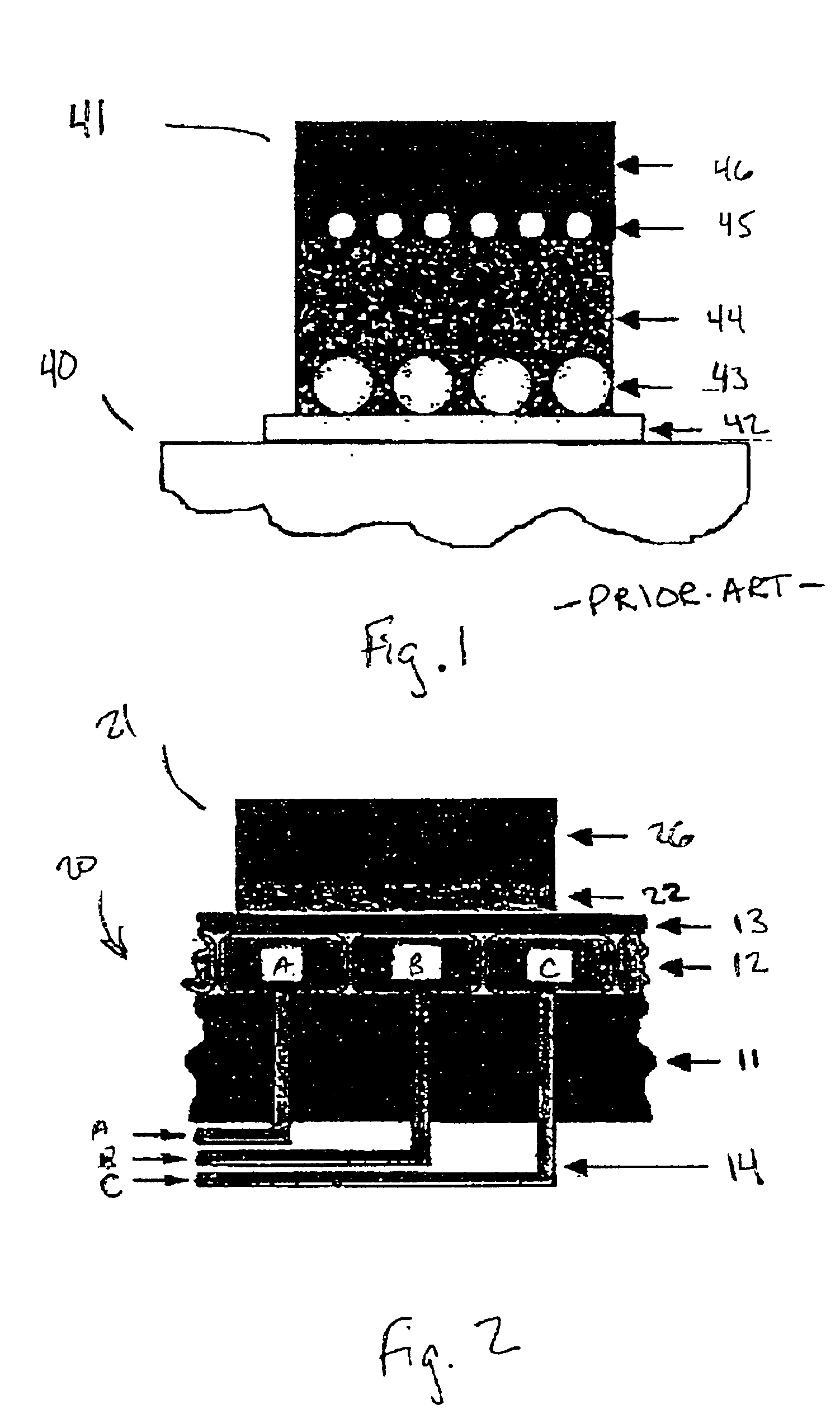

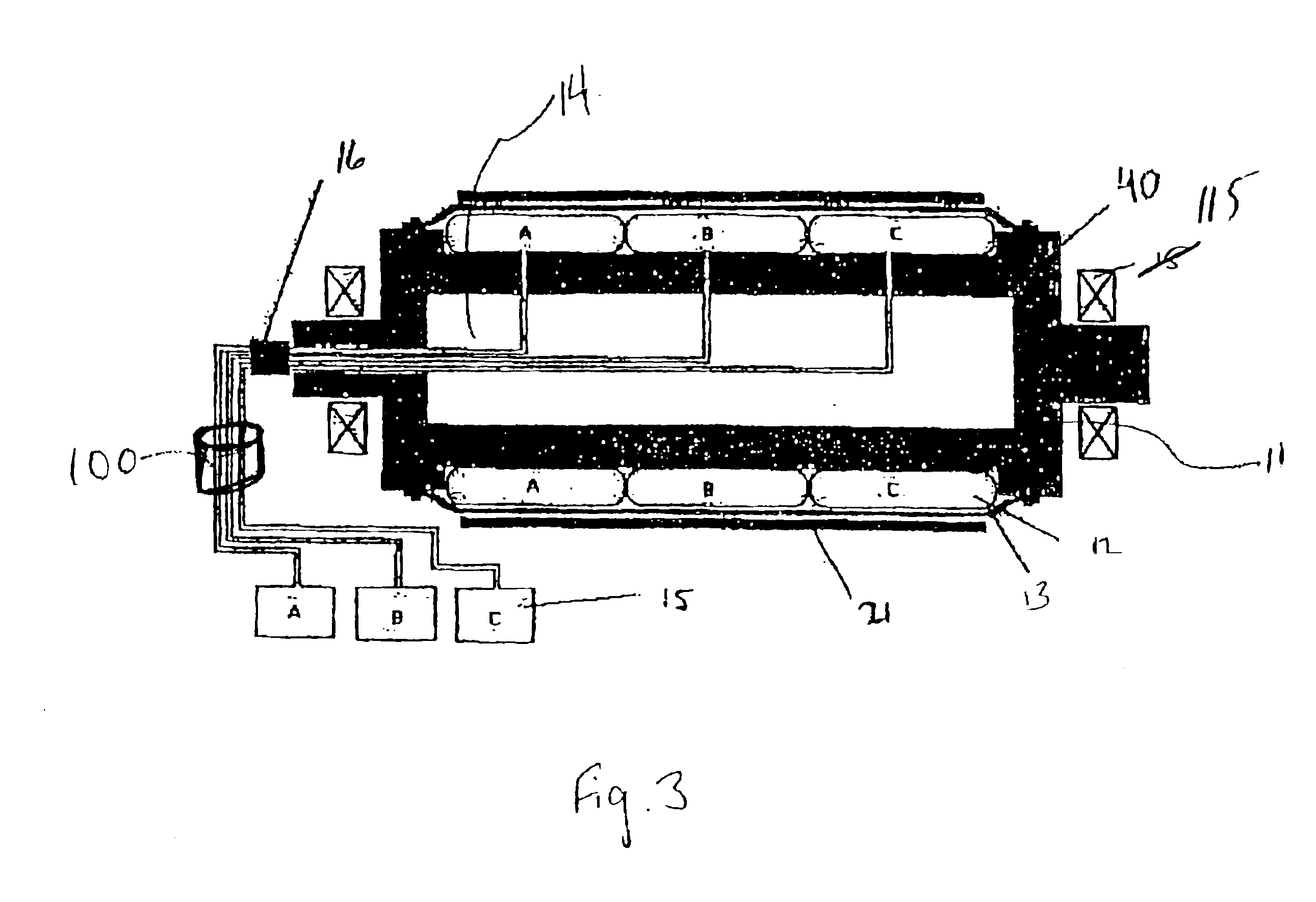

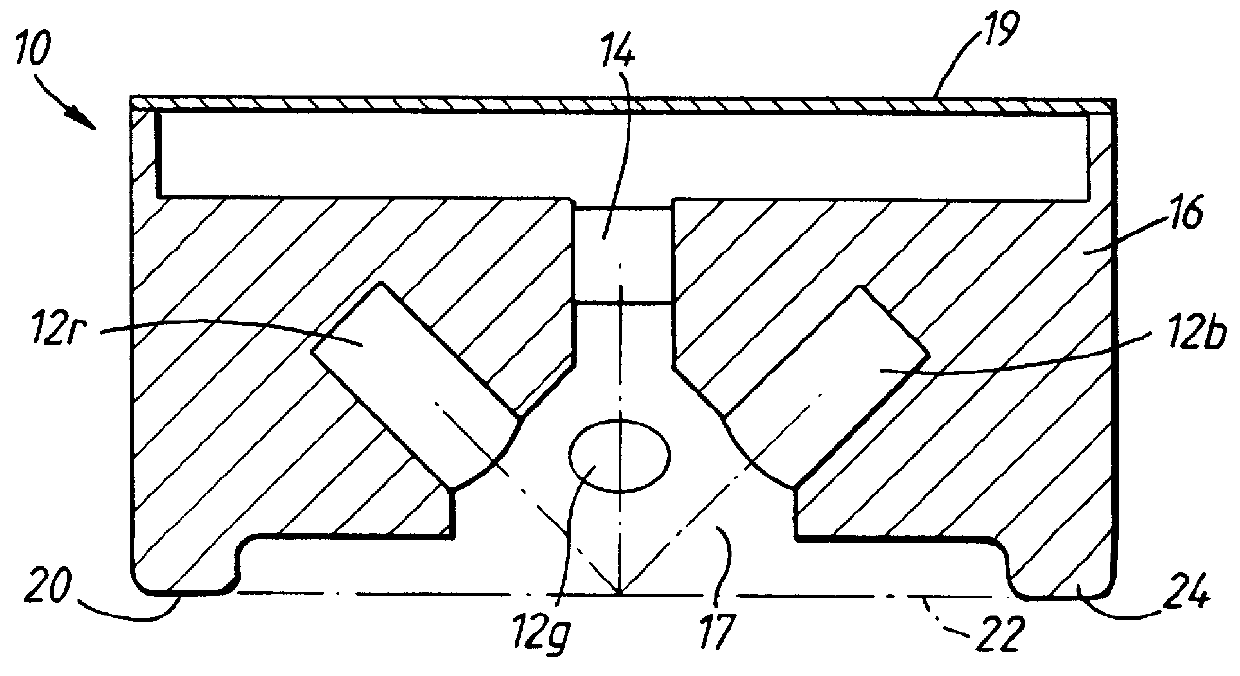

Blanket cylinder with integrated compressible layer

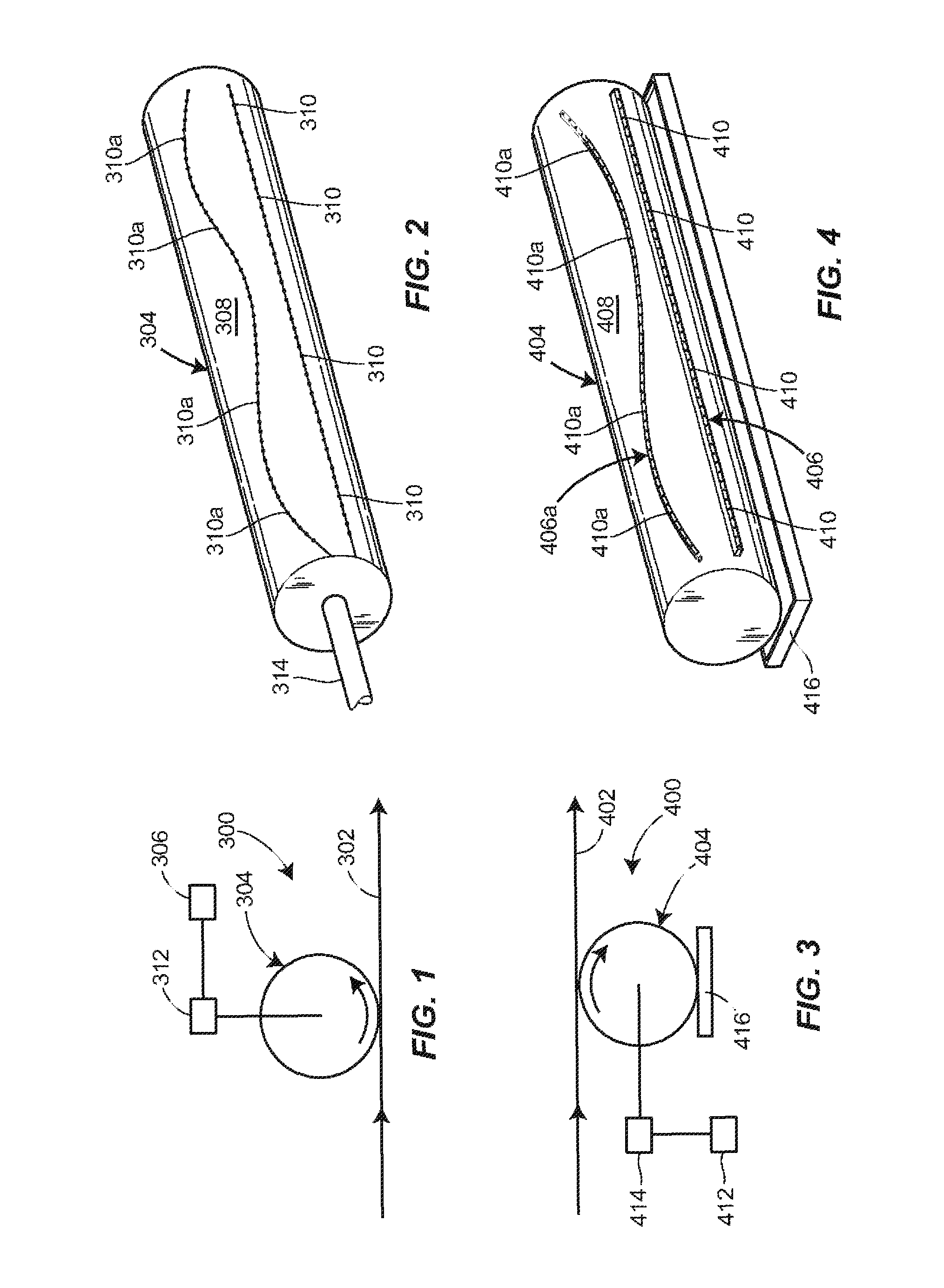

A printing unit including a rigid cylinder rotatable about an axis of rotation, a plurality of inflatable bladders disposed on a circumferential surface of the cylinder, and a first fluid supply regulation unit configured to supply a first fluid to a first set of inflatable bladders of the plurality of inflatable bladders and to regulate a first fluid pressure inside the first set inflatable bladders. In addition, a method for mounting a sleeve-shaped printing sock onto a blanket cylinder of an offset printing press, in which a set of inflatable bladders disposed at an outer region of the blanket cylinder are at least partially deflated. The sleeve-shaped printing sock is slid over one end of the blanket cylinder so that the printing sock at least partially surrounds a circumference of the blanket cylinder. The set of inflatable bladders are then inflated so that the printing sock fits tightly around the circumference of the blanket cylinder.

Owner:SHANGHAI ELECTRICGROUP CORP

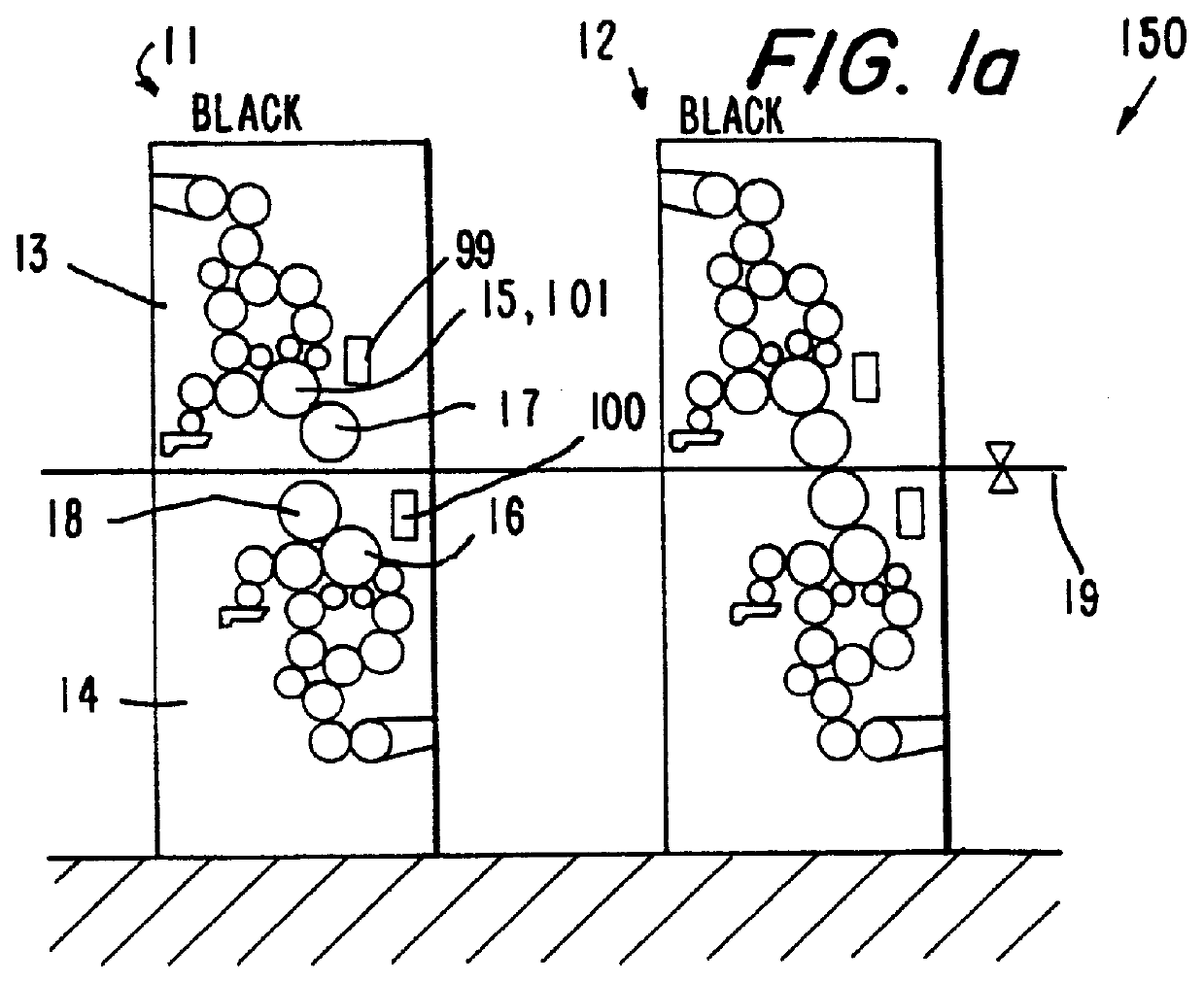

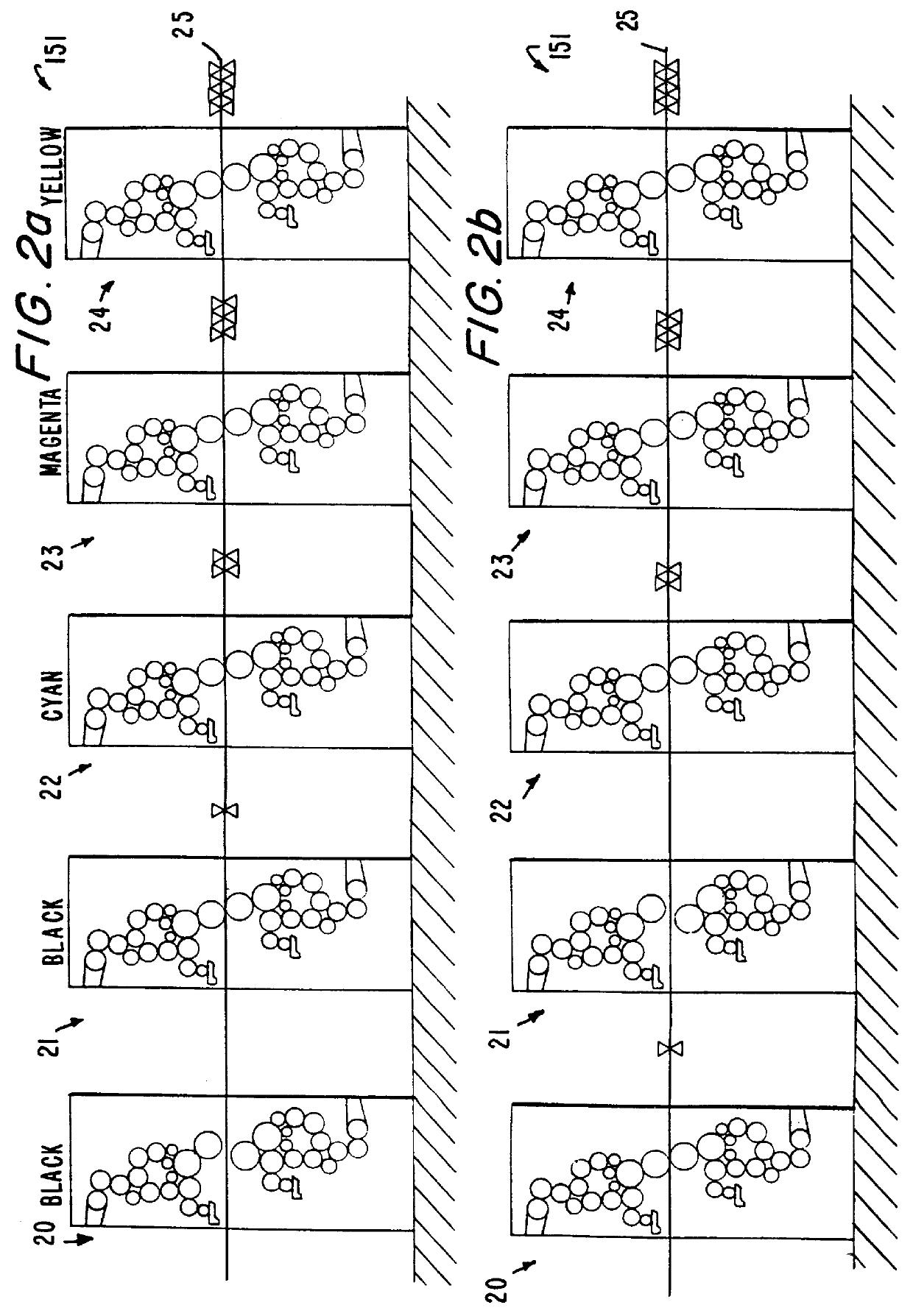

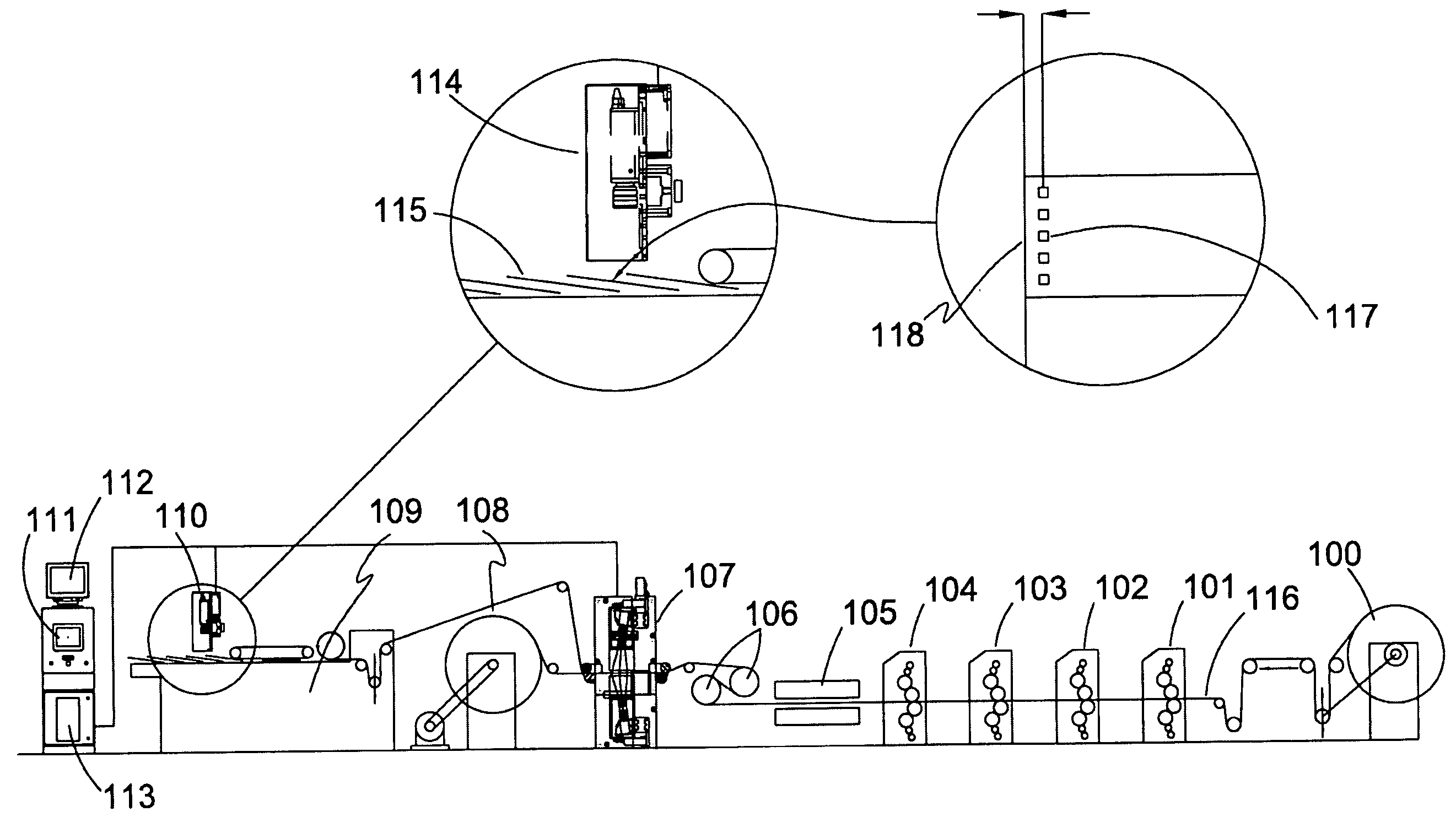

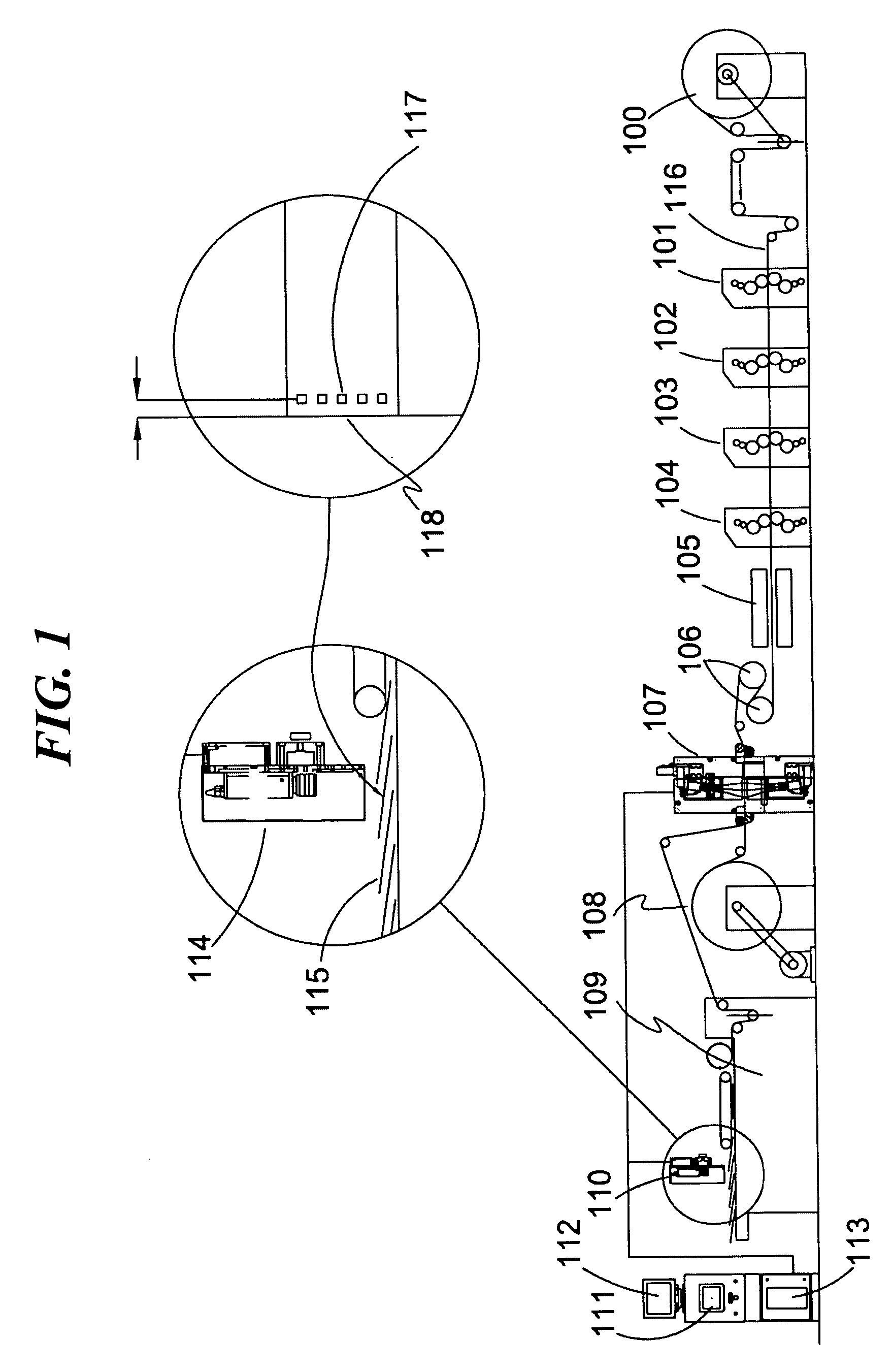

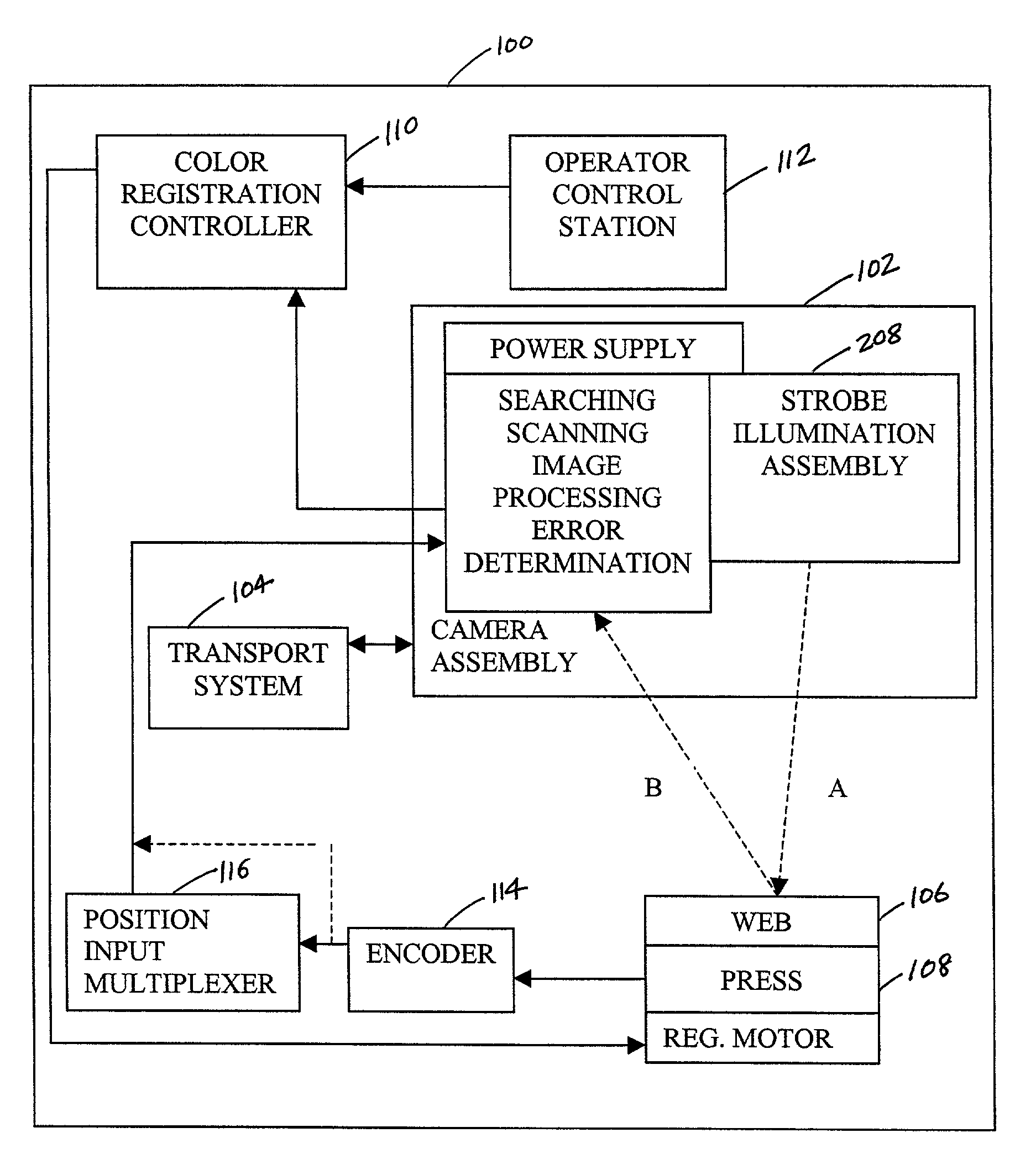

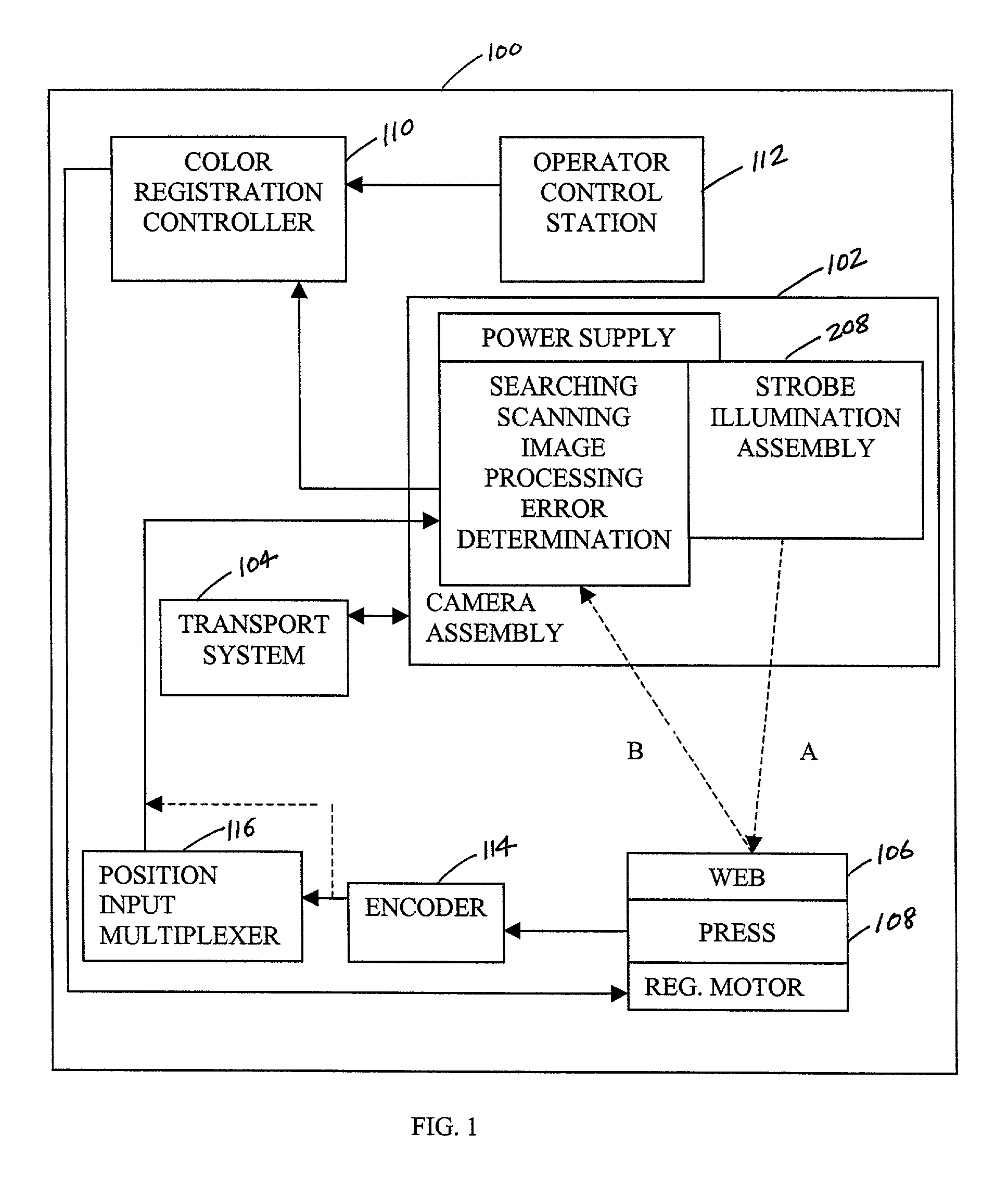

System and method for register mark recognition

InactiveUS20040163562A1Minimize timeReduce material wastePlaten pressesInvestigating moving sheetsOperator interfacePunching

A system, method, and process that determine and automatically correct registration errors between printed objects and mechanically produced objects using advanced image processing techniques is disclosed. Means are also presented for maintaining all registered functions to within very close tolerances during normal running, with other means for rapidly obtaining initial registration with substantial savings in material waste. The disclosed system and method / process are compatible with the printing and converting industry in which rolls of material are processed by printing a number of colors that require close registration especially in pictorial representation. These roll-fed printing machines are quite versatile and in addition to the printing of any number of colors on both front and back can perform any number of additional operations on the printed web at the same time. Some of these additional operations can be the punching of line holes, scoring, perforation and die cutting all of which impart a specific shape mechanically on the printed web. All of these functions must be initially registered to each other and maintained within close tolerances during normal running conditions. The presently disclosed registration system permits these initial registration procedures to be performed with high accuracy, speed, and across a wide variety of web materials and colors. The system generally applies to any web material (5701) on which register marks (5702) are applied, wherein images of the web are obtained (5703) and image processed (5704) under optional control of an operator interface display (5705), resulting in web press motor control (5706) to affect improved print registration on the web material (5701).

Owner:CC1

Printing unit

A printing unit for a web-fed rotary printing machine is provided having at least one carrying wall, a plurality of cylinders mounted on the carrying wall, a drive motor corresponding to each cylinder and a slide corresponding to each cylinder. Each slide carries its corresponding cylinder and receives the corresponding drive motor. A drive means is provided for driving the slides and a plurality of guide elements are mounted on the carrying wall and arranged laterally next to the adjacent end faces of the cylinders for guiding the slides along the wall. The guide elements are arranged opposite and parallel to one another on the carrying wall. Optionally, the carrying wall includes panels defining an orifice to allow cylinders, journals and sleeves of the printing machine of varying sizes to be changed readily.

Owner:MANROLANAD AG

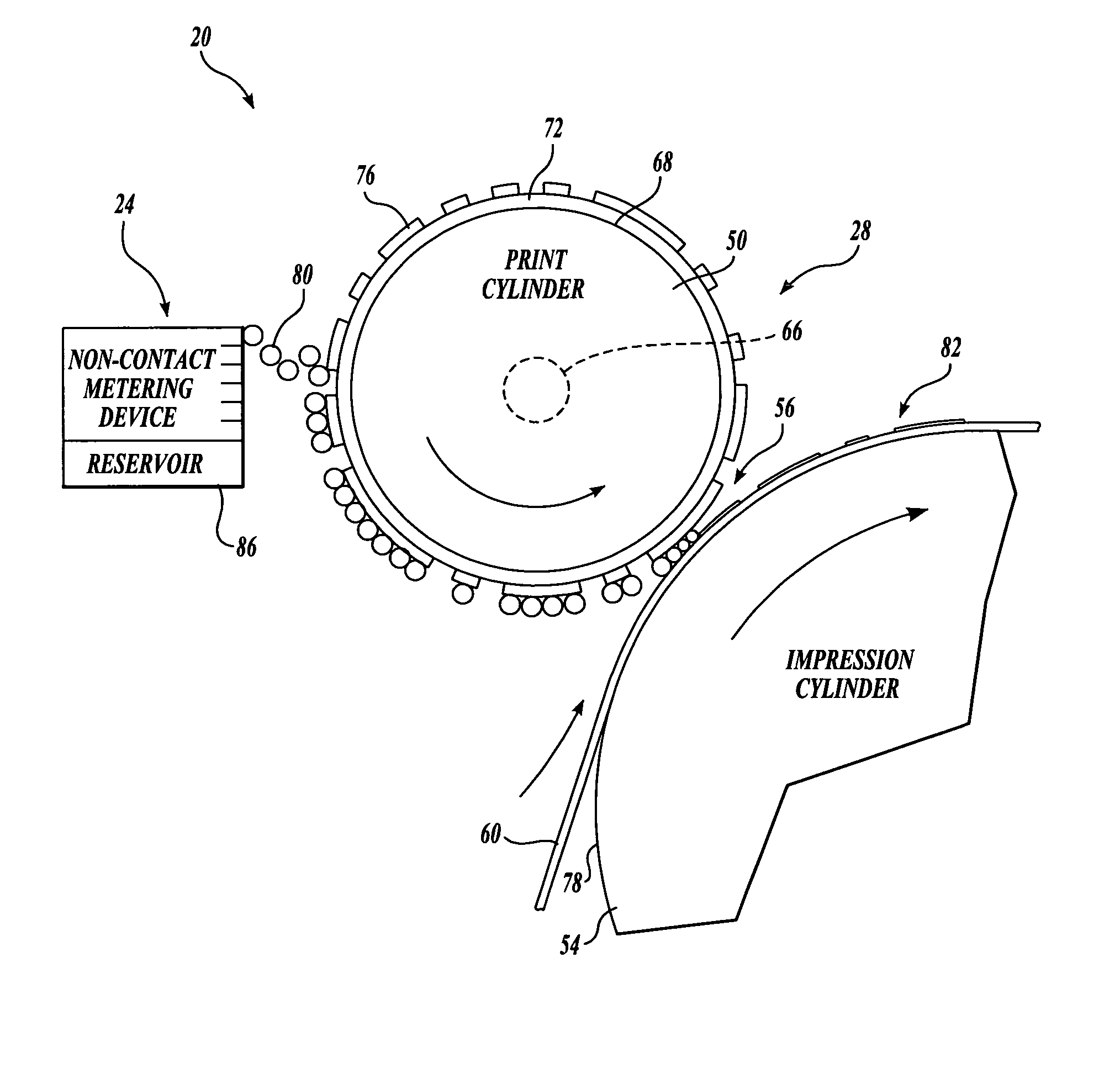

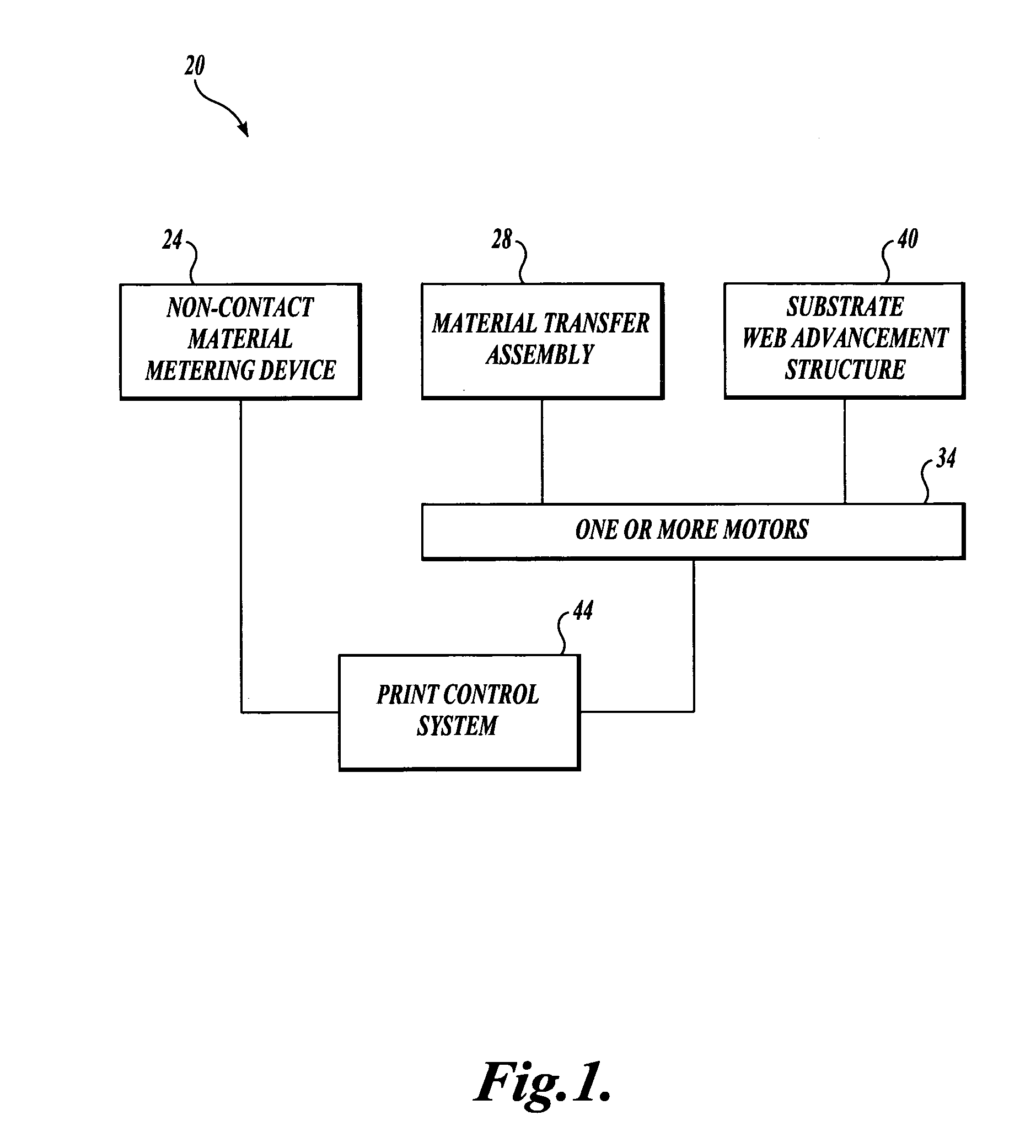

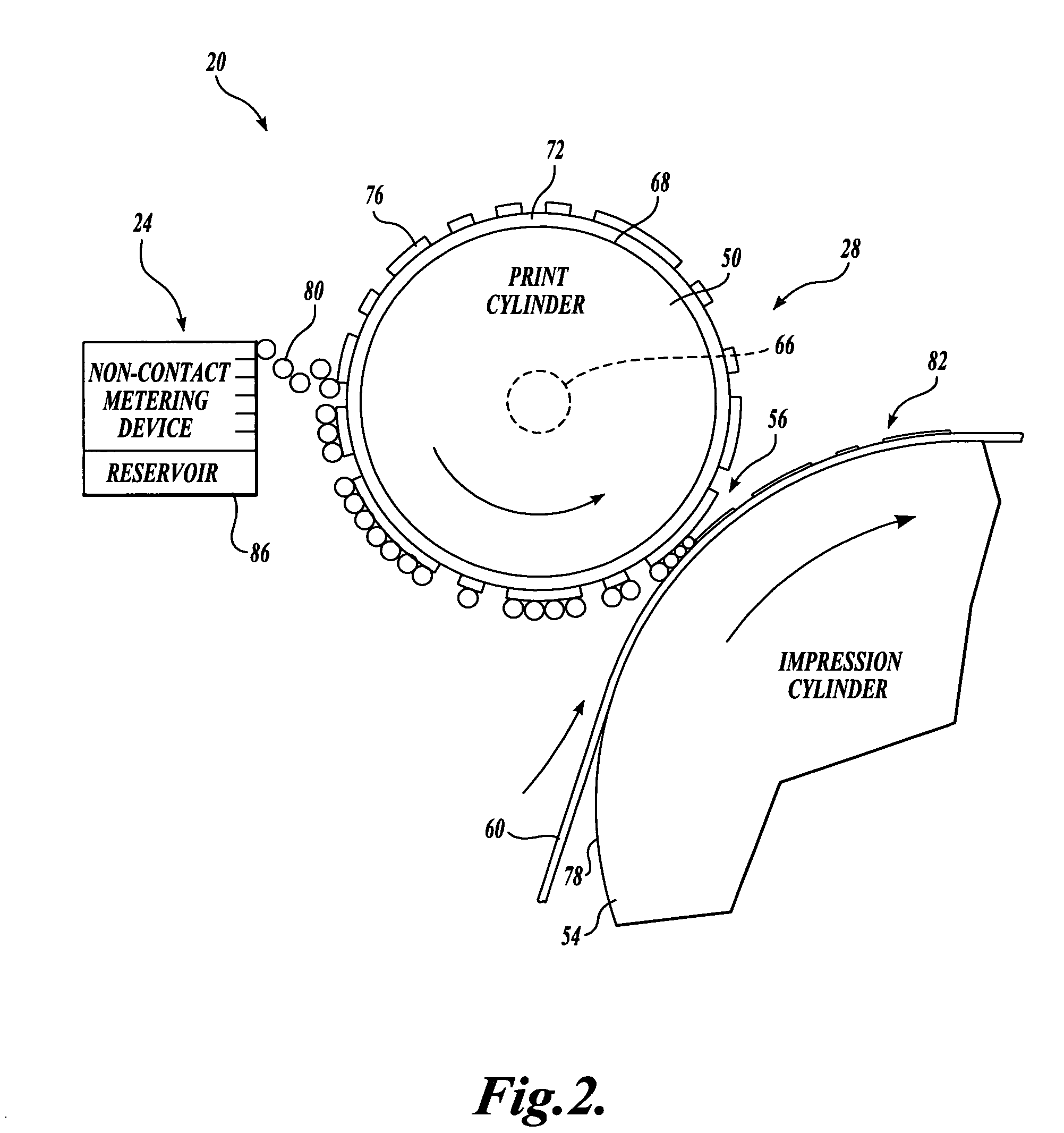

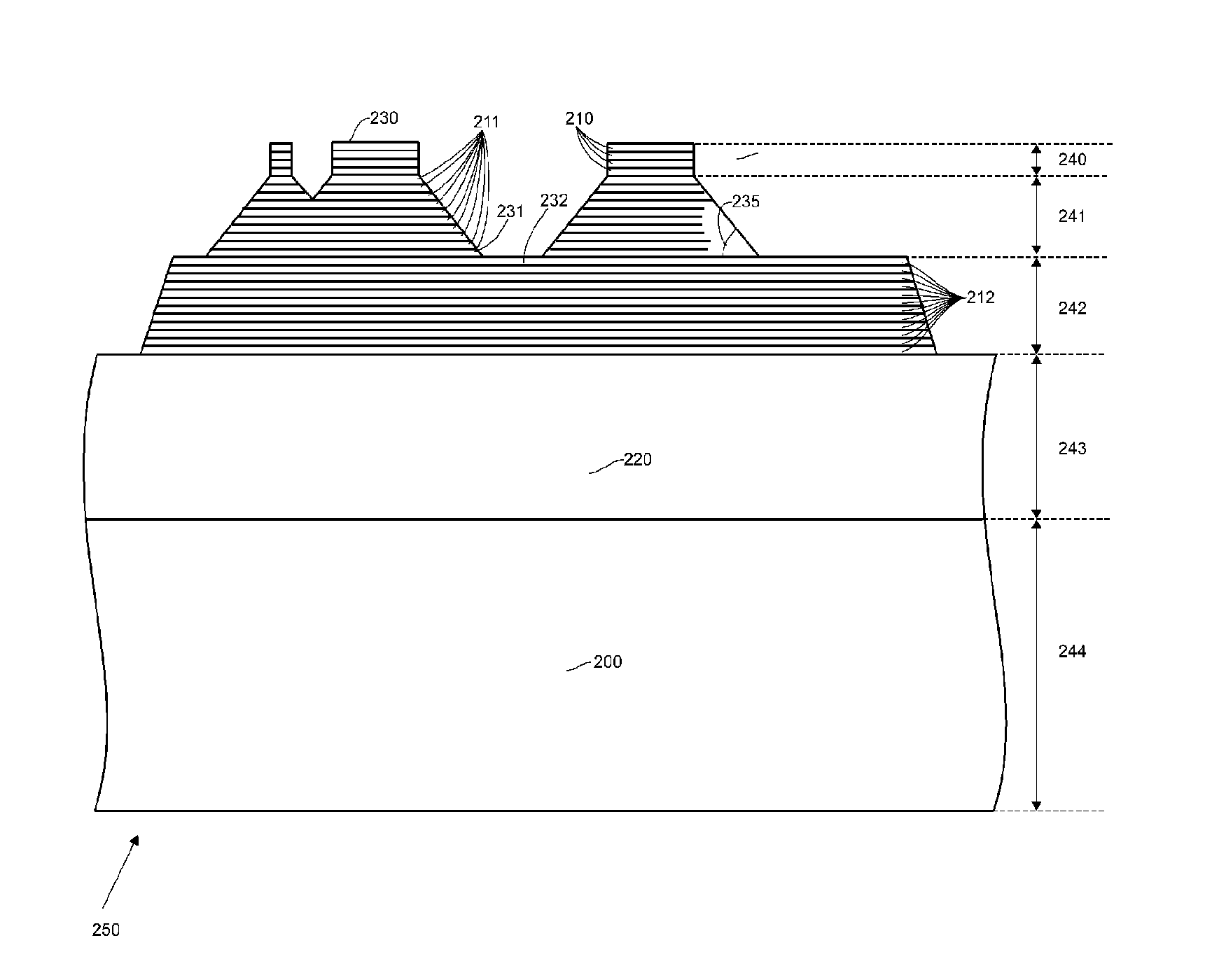

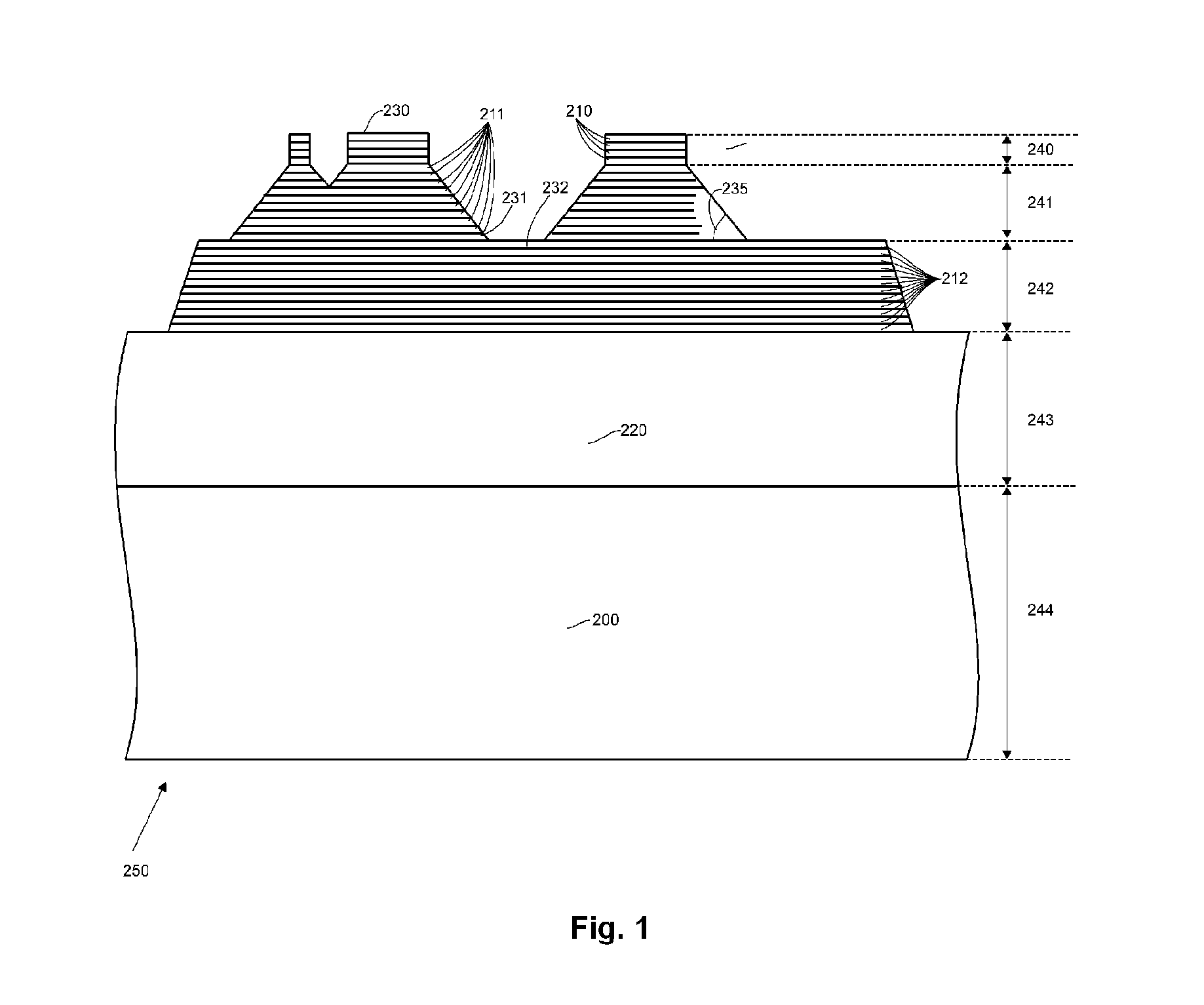

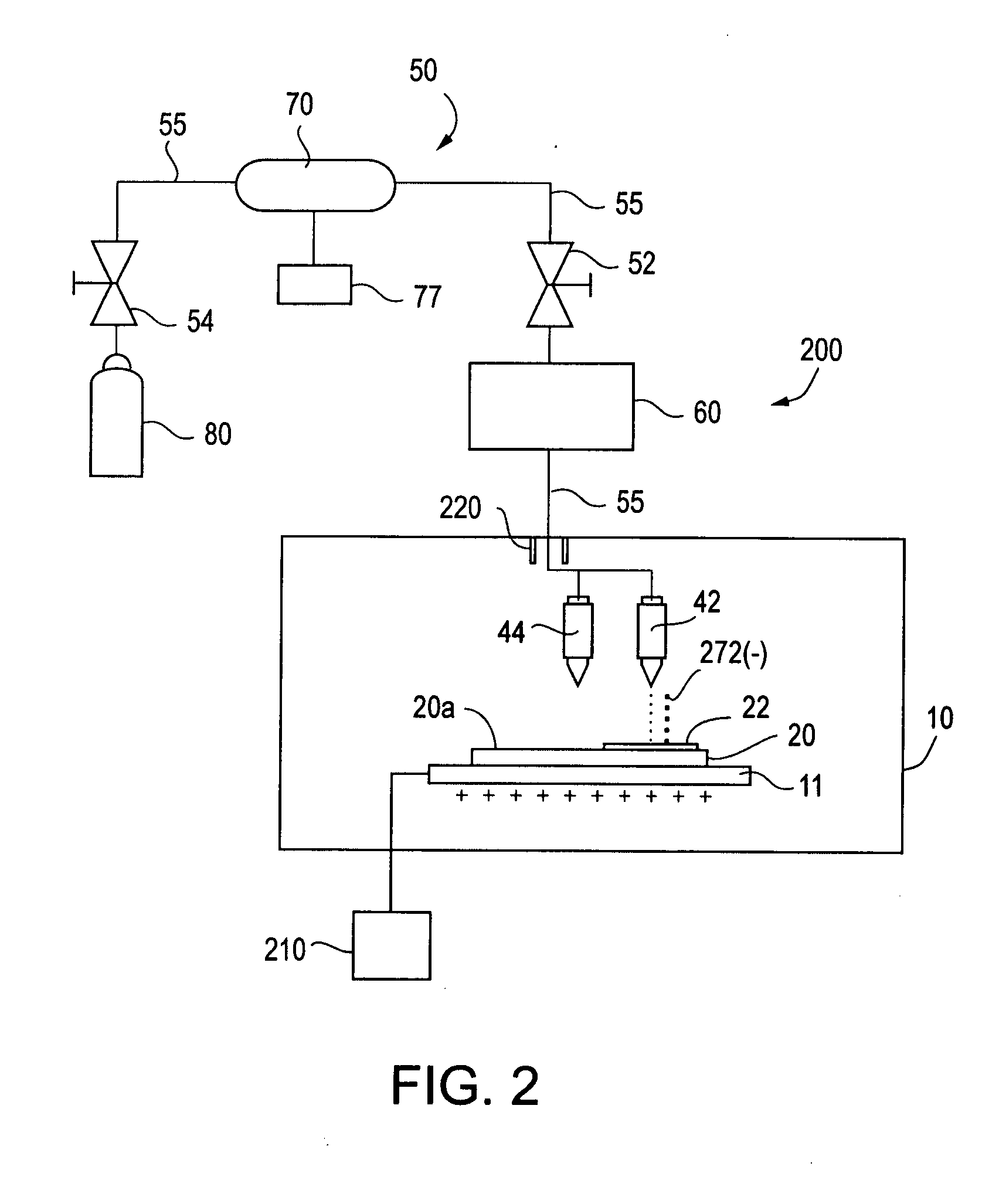

Systems and methods for additive deposition of materials onto a substrate

InactiveUS20070068404A1Sharp and accurate featureLevel of redundancySolid-state devicesRotary letterpress machinesEngineering

Owner:WEYERHAEUSER CO

Apparatus for applying printed matter to webs of wrapping material for smokers' products

Owner:HAUNI MASCHINENBAU AG

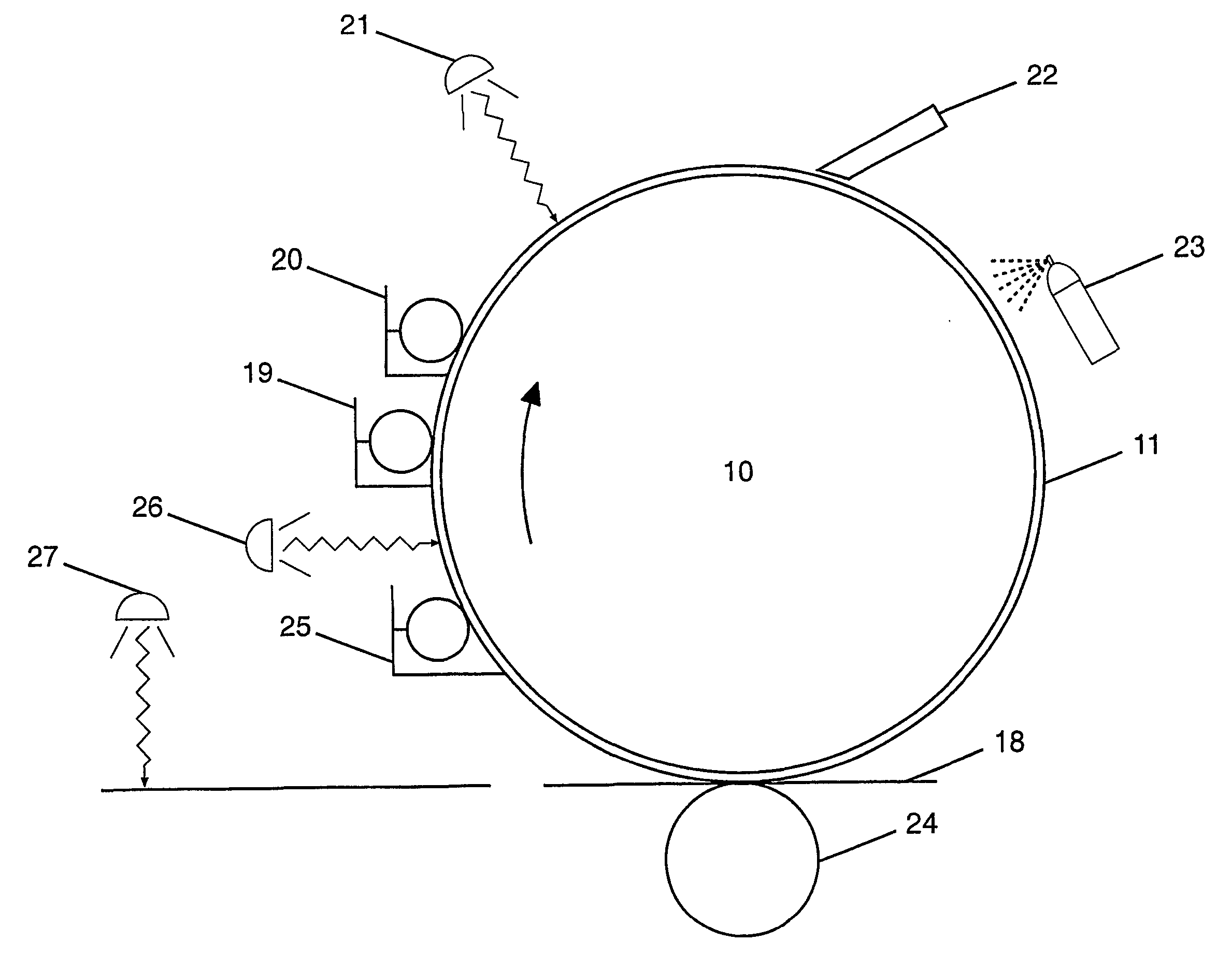

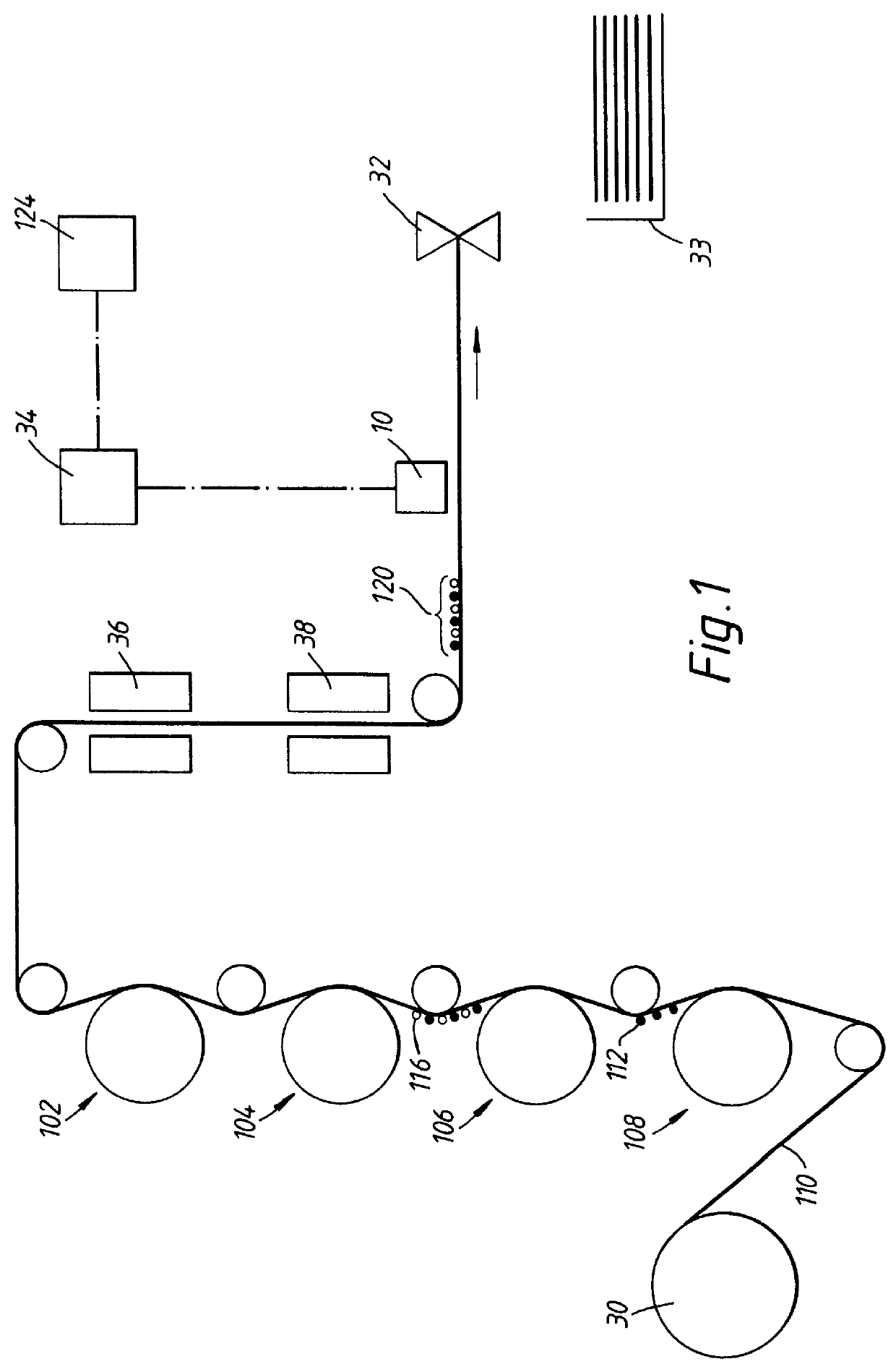

Method and device for producing a printed and embossed web

InactiveUS20100272965A1Good lookingIncrease impressionMechanical working/deformationLayered productsAdhesiveNonwoven fabric

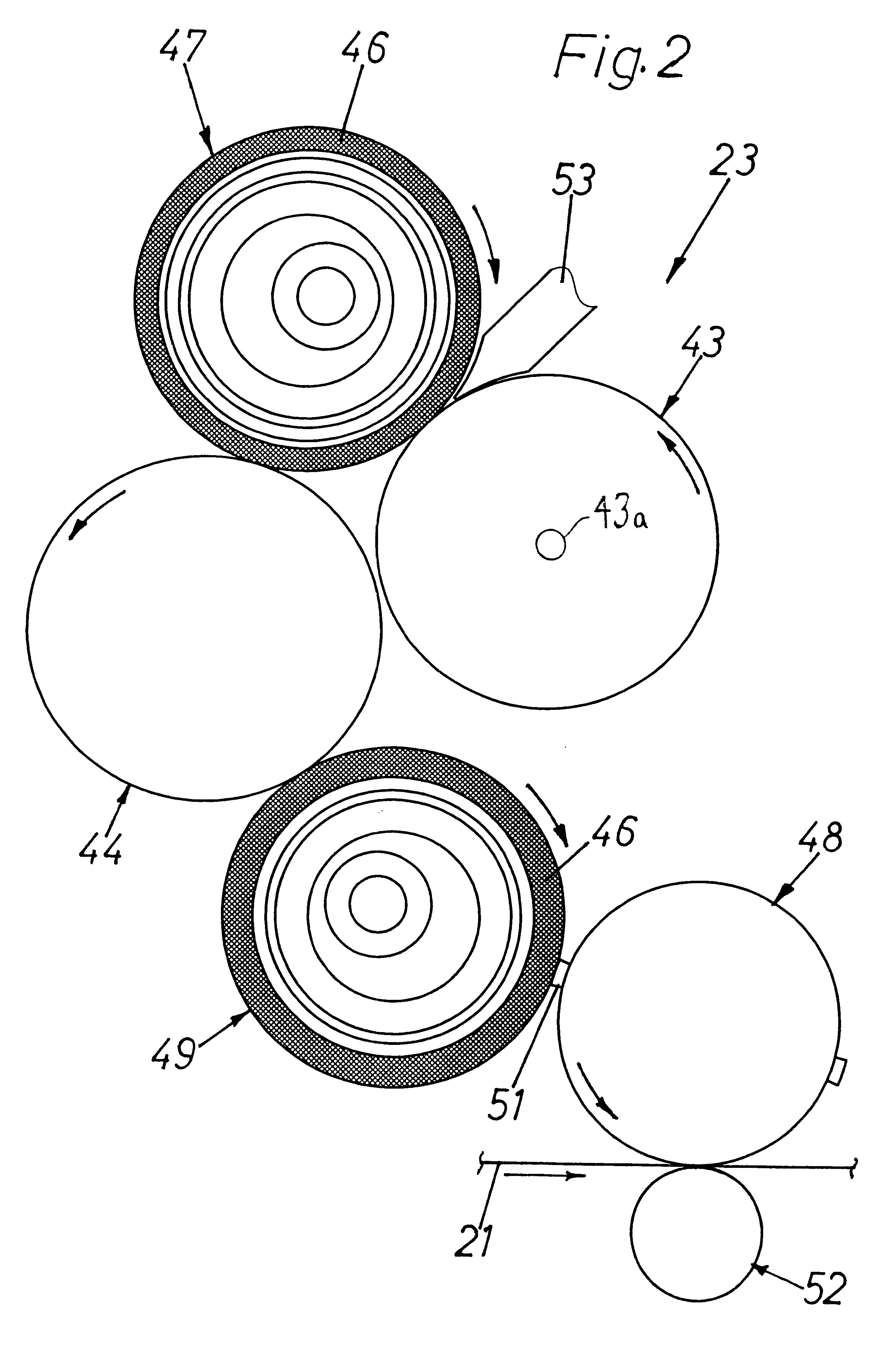

Method and device for producing a printed and embossed multi-ply web (3) of tissue paper or nonwoven having a good visual appearance. A first web-shaped material (1) is embossed in a nip (6) between a first embossing roll (4) and a counter roll (5), thereby creating a set of embossments. A first ink with a first colour is applied to a first subset of the set of embossments of the first web-shaped material while the material still resides on the first embossing roll. Thereafter an adhesive is applied to a second subset of the set of embossments of the first web-shaped material (1) while the material still resides on the first embossing roll (4). After that, the first web-shaped material is combined with a second web-shaped material (2) to form a multi-ply web (3). There is also provided a printed and embossed multi-ply web (3).

Owner:SCA HYGIENE PROD AB

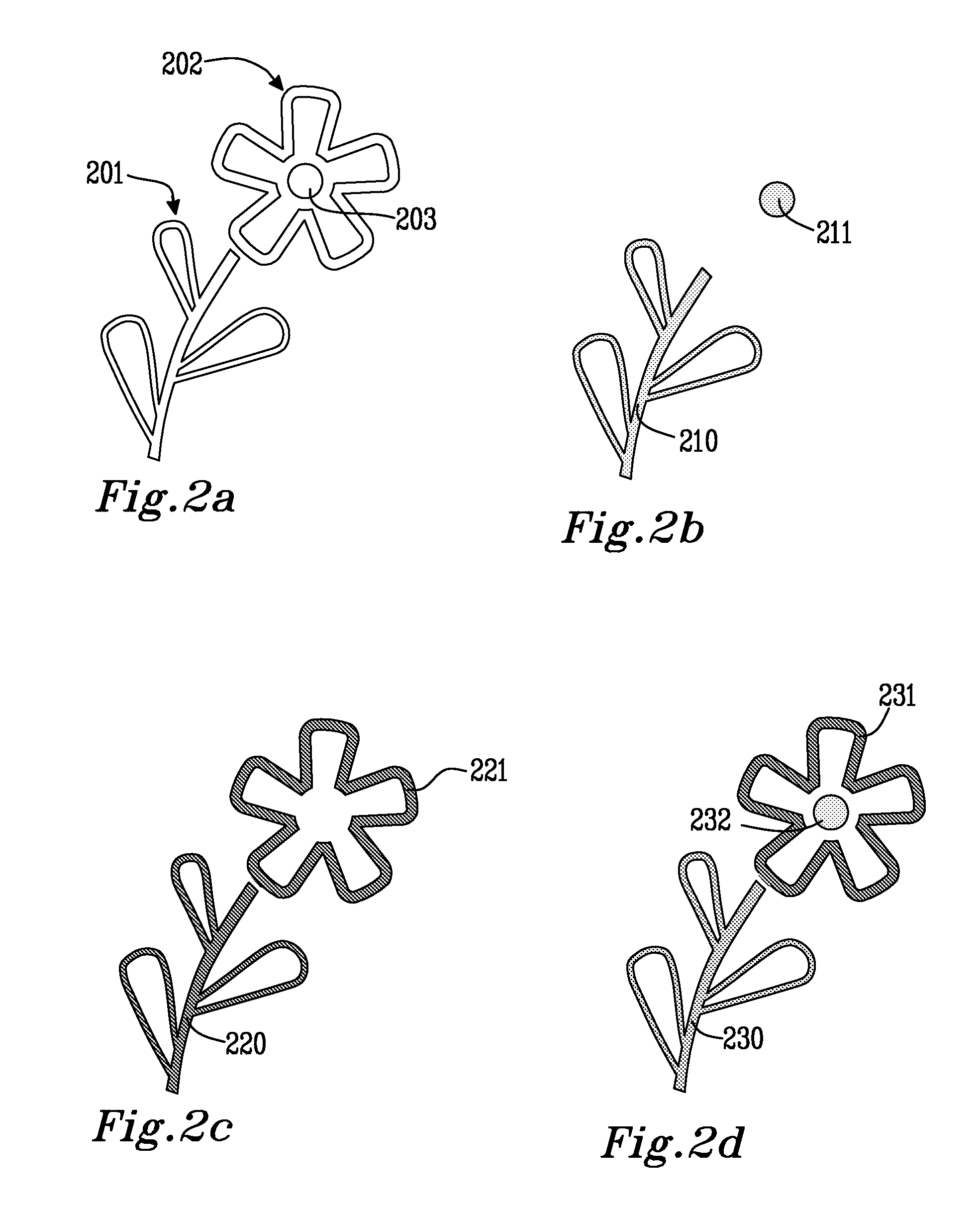

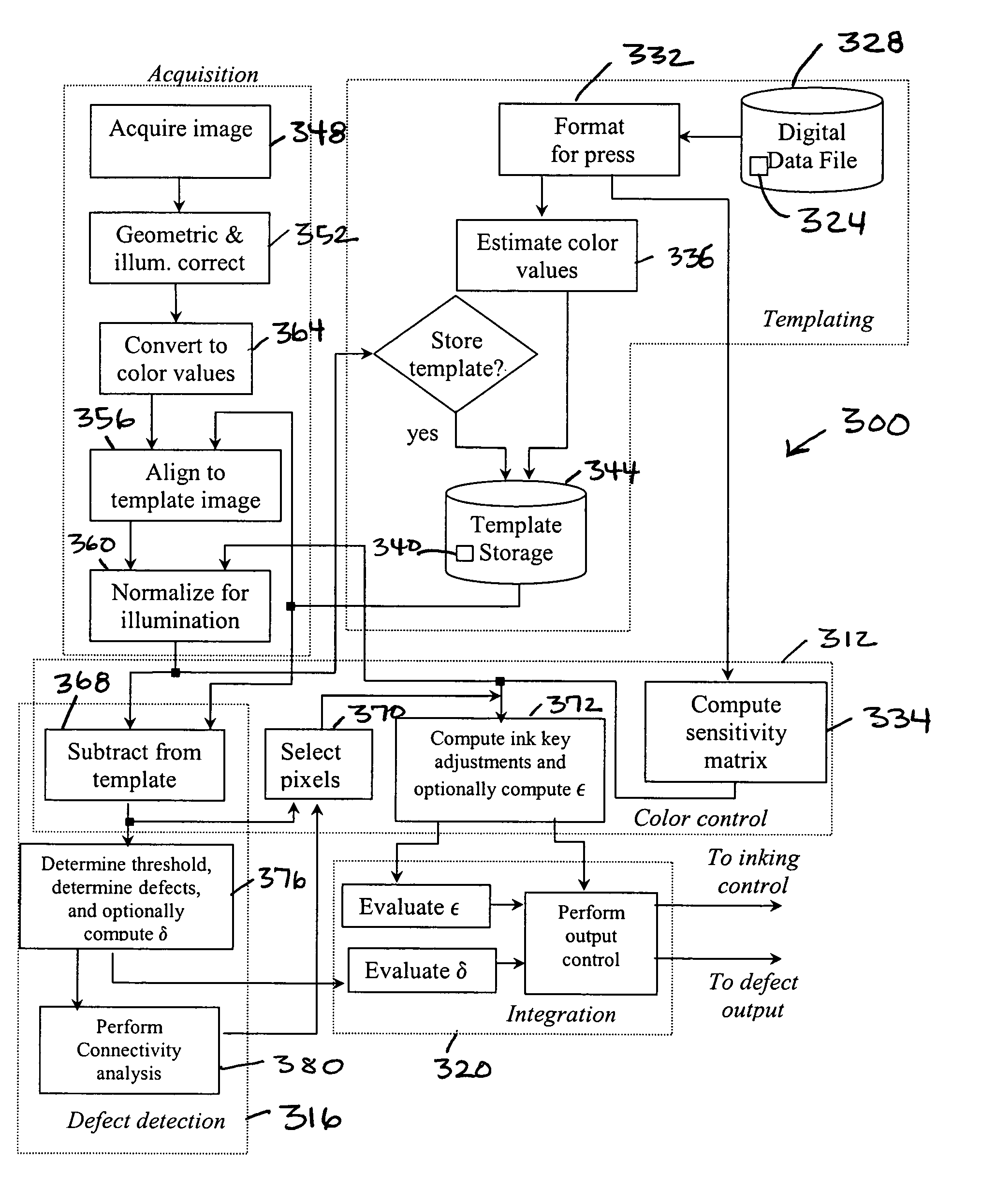

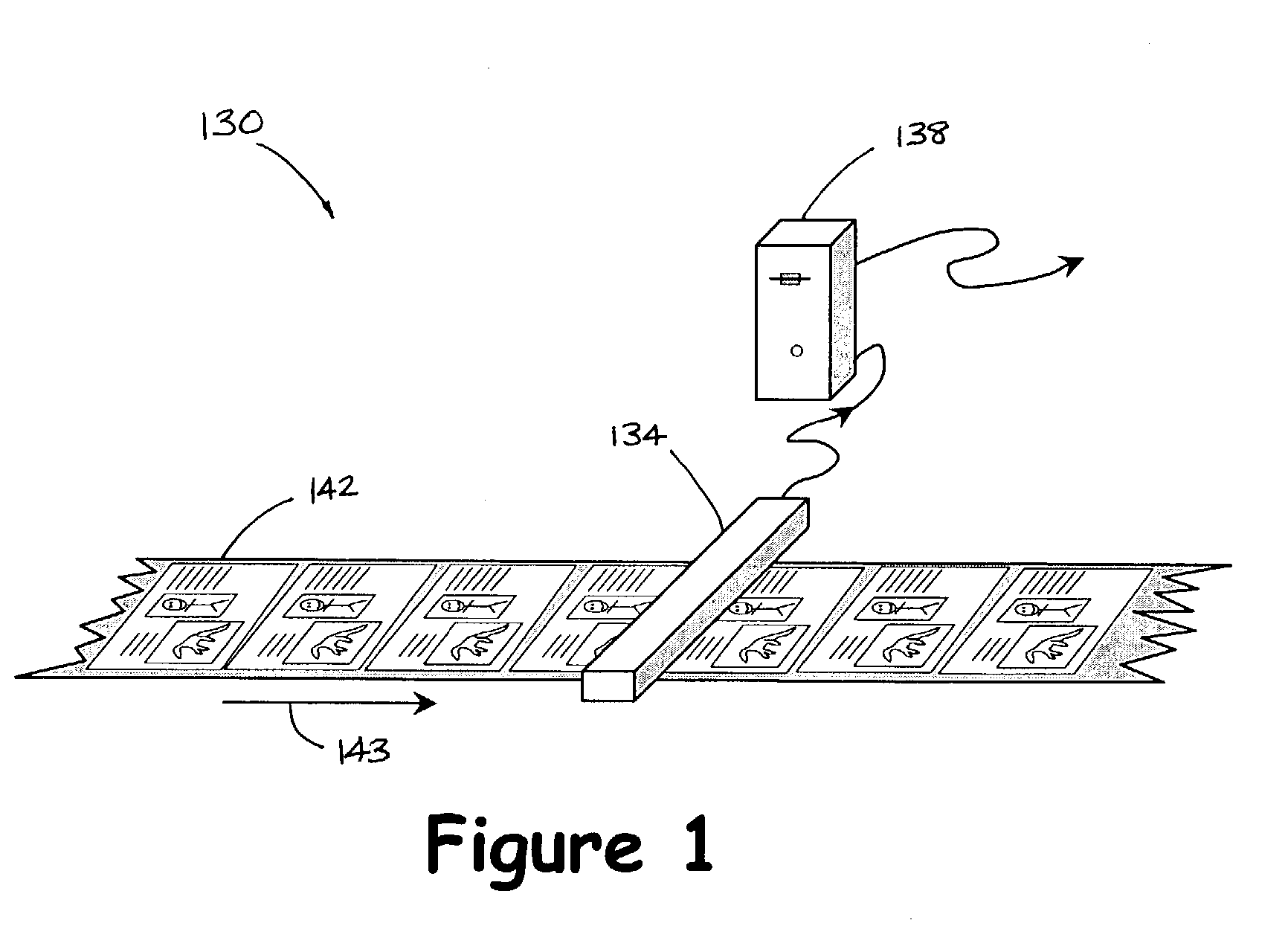

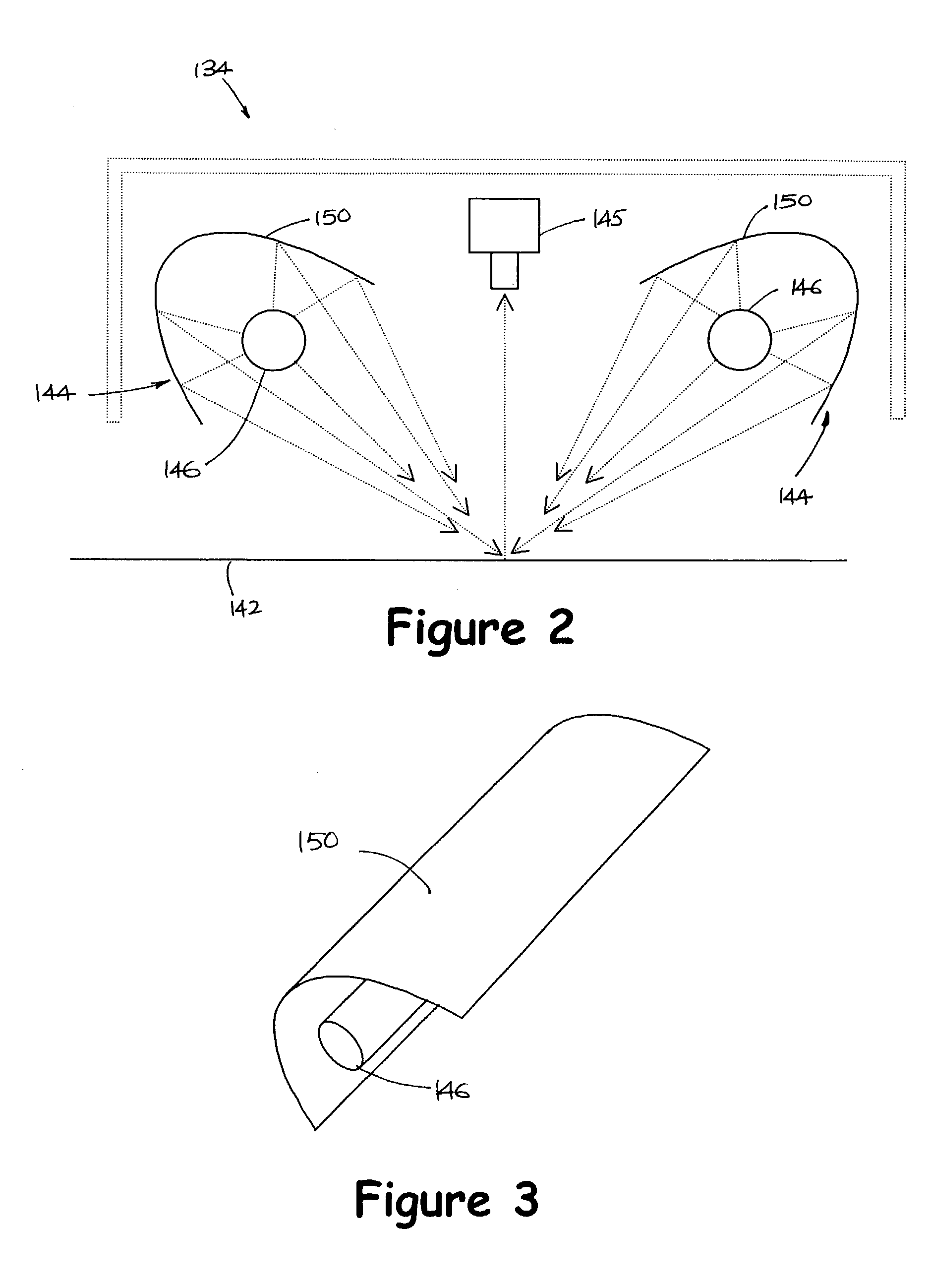

Coordinating the functioning of a color control system and a defect detection system for a printing press

A method of coordinating the utilization of a color control system and a defect detection system on a printing press includes acquiring image data and processing the data by a comparison to template image data and the generation of color error data and print defect data. The method further includes the steps of selectively enabling and disabling the color control system and selectively enabling and disabling the defect detection system based upon the color error data and the print defect data.

Owner:BALDWIN AMERICAS CORP

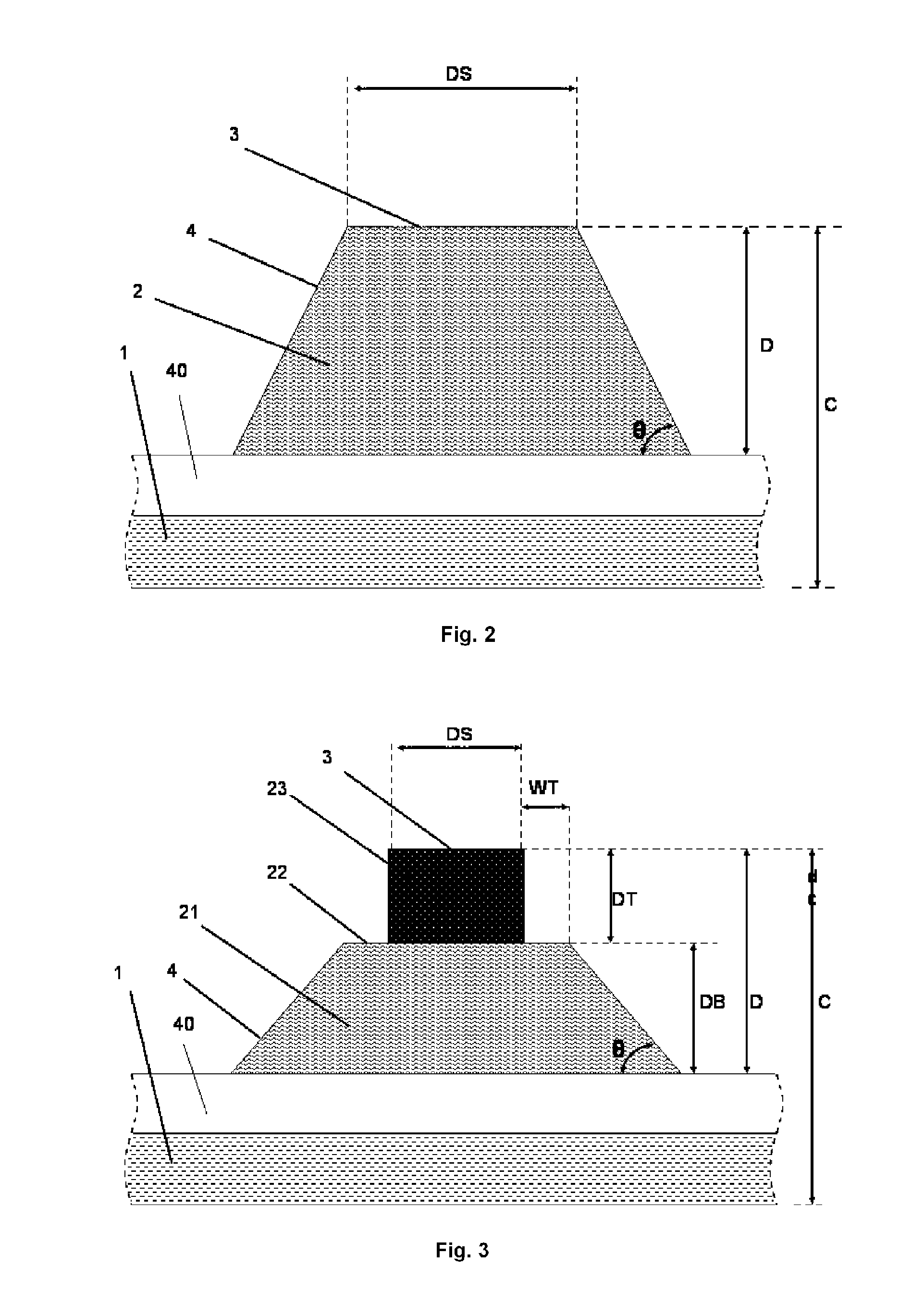

Imaging apparatus and method for making flexographic printing masters

InactiveUS20110219973A1Short manufacturing timeMounting boardsPlate printingEngineeringInkjet printing

A method for making a flexographic printing master includes the steps of providing a flexographic printing support; providing an inkjet printing device; applying a mesa relief on the flexographic printing support with the inkjet printing device; and applying an image relief with the inkjet printing device on the mesa relief. A method for making a flexographic printing master includes the imaging apparatus.

Owner:AGFA NV

Method of printing variable information

The gel method of printing variable information of the present invention involves applying inks onto a substrate that is part of or attached to a cylinder of the printing machine. Imaging is by means of an energy source in the UV, visible or infrared regions, modulated to represent a digital image pattern that has been composed on a computer. The consequence of imaging is to gel the ink and increase its adhesion to the substrate of the printing cylinder. The non-gelled background ink with lower adhesion is then removed by a squeegee action and returned to an ink reservoir. The remaining image is transferred to an offset blanket or directly to print stock by pressure. The process does not use a master, but produces an image that is erased after printing with each cylinder rotation so that the next rotation producing the next print can have fresh information written upon it.

Owner:KODAK IL

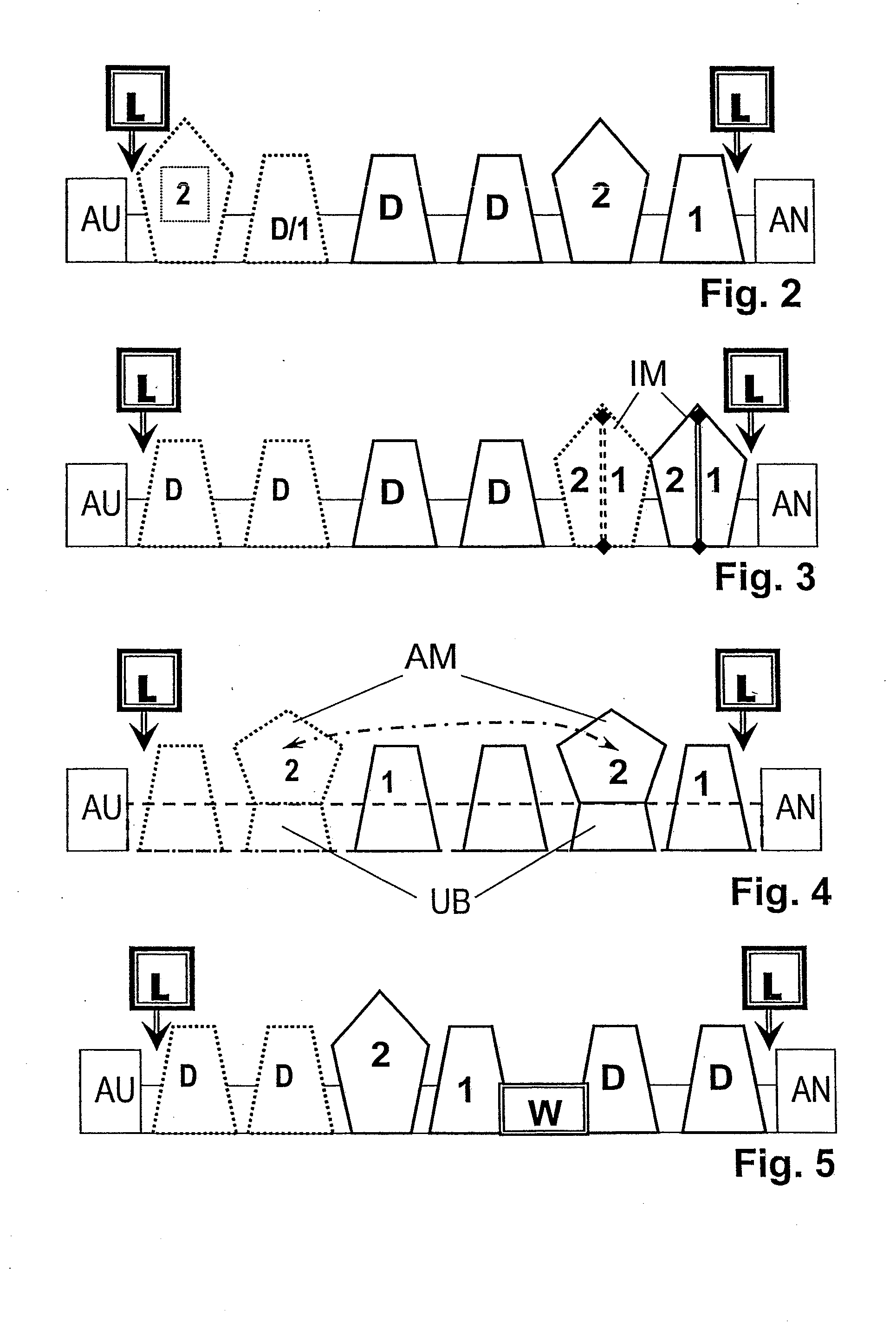

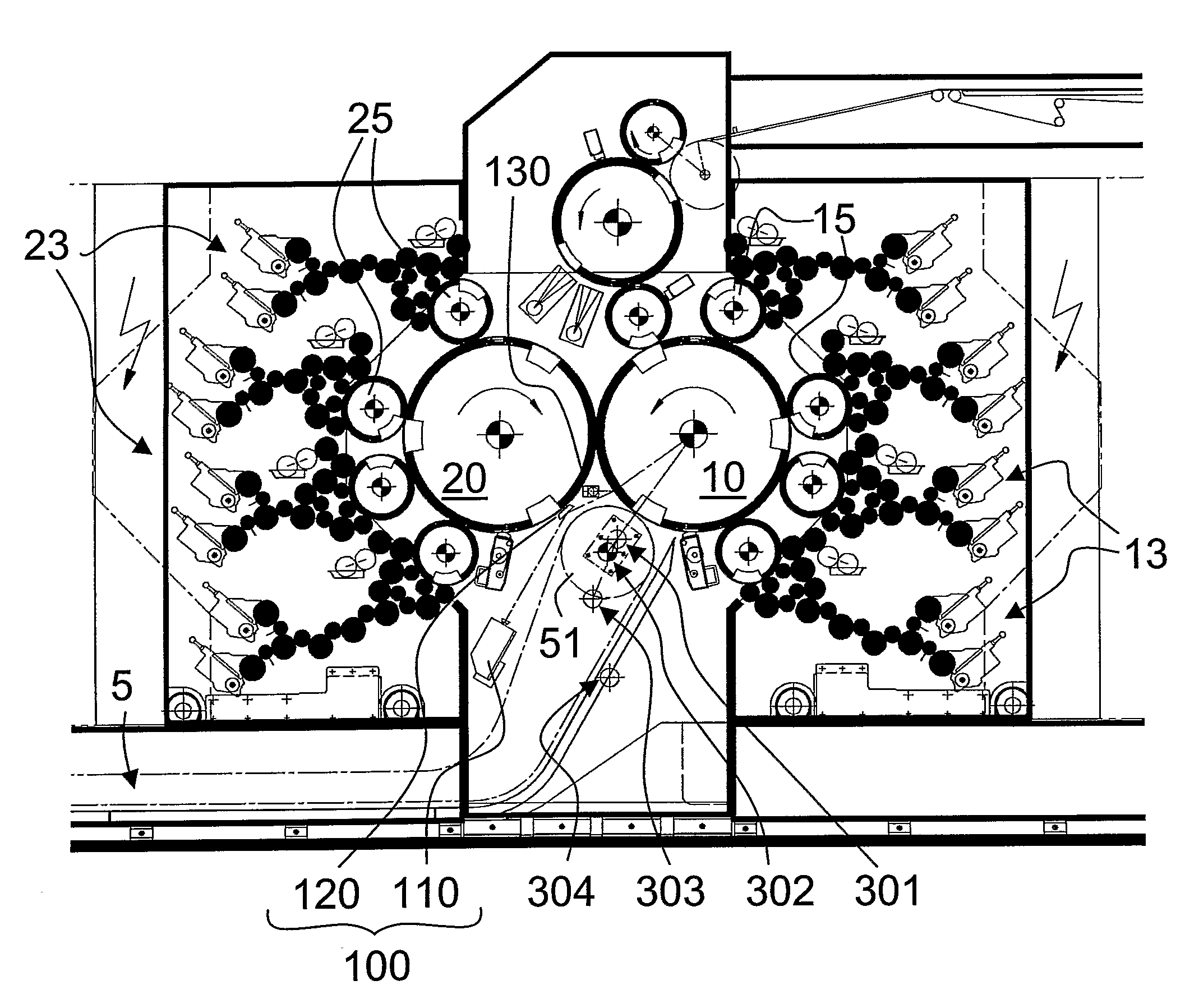

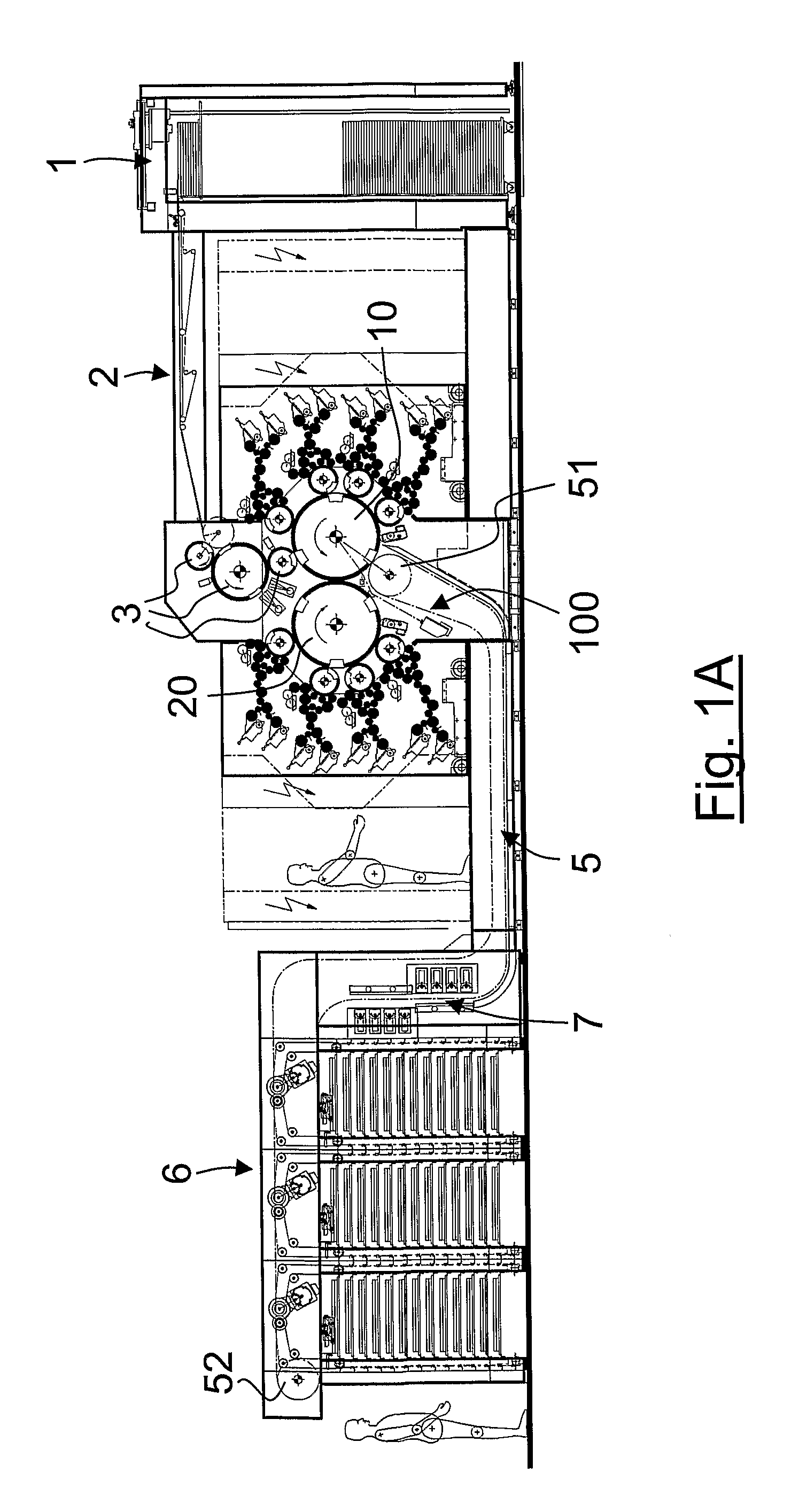

Printing Machine with Modular Additional Printing Group

InactiveUS20080271620A1Improve abilitiesIncrease flexibilityOther printing apparatusRotary letterpress machinesEngineeringPrinting press

There is described a web-fed or sheet-fed printing machine for security papers, in particular banknotes, comprising a machine frame in which is located a main printing group, the printing machine further comprising an additional printing group, independent of the main printing group, placed upstream of the main printing group with respect to a direction of displacement of the web or sheets for performing additional printing of the security papers prior to printing by said main printing group. The additional printing group comprises an inking module containing at least one inking device, and a printing module comprising a cylinder arrangement including a plurality of cylinders, the printing module being interposed between the inking module and the machine frame of the printing machine. The additional printing group is constructed in such a manner that the printing module can be decoupled from the inking module and the machine frame for replacement by another printing module without this requiring removal of said inking module from the printing machine.

Owner:KBA NOTASYS SA

Manufacturing method for packaging and advertising means

InactiveUS20090301649A1Reliably, economically, and preciselyGood effectTransfer printingDecorative surface effectsPrinting pressMechanical engineering

The purpose is to improve the usability of the film coating in a coating module for the transfer of image-forming layers from a transfer film to a printing material. A film transfer module is, for that purpose, arranged in a printing machine for the single-color or multicolor printing of printed sheets. Moreover, one or more coating installations, in the form of varnishing modules, are arranged before and / or after the printing machine. By the application of layers, a subject consisting of a film image and a printed image is coated over part of the surface or over the entire surface. The additional coats serve the function of providing protection, drying, or generating optical effects.

Owner:M A N ROLAND DRUCKMASCHINEN AG

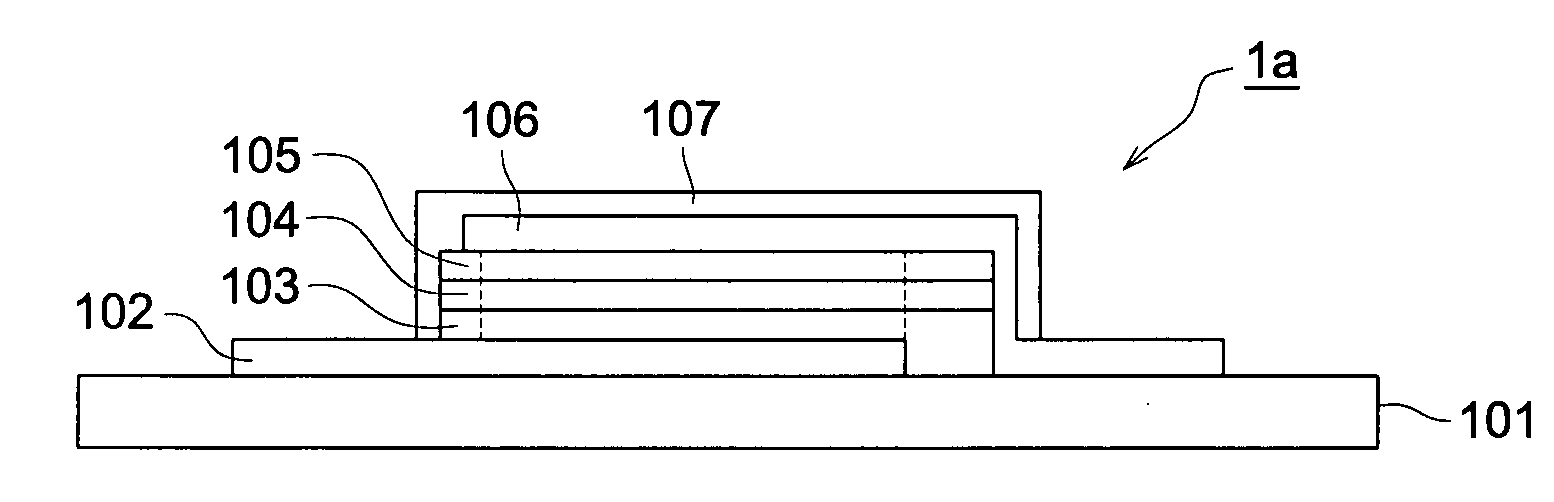

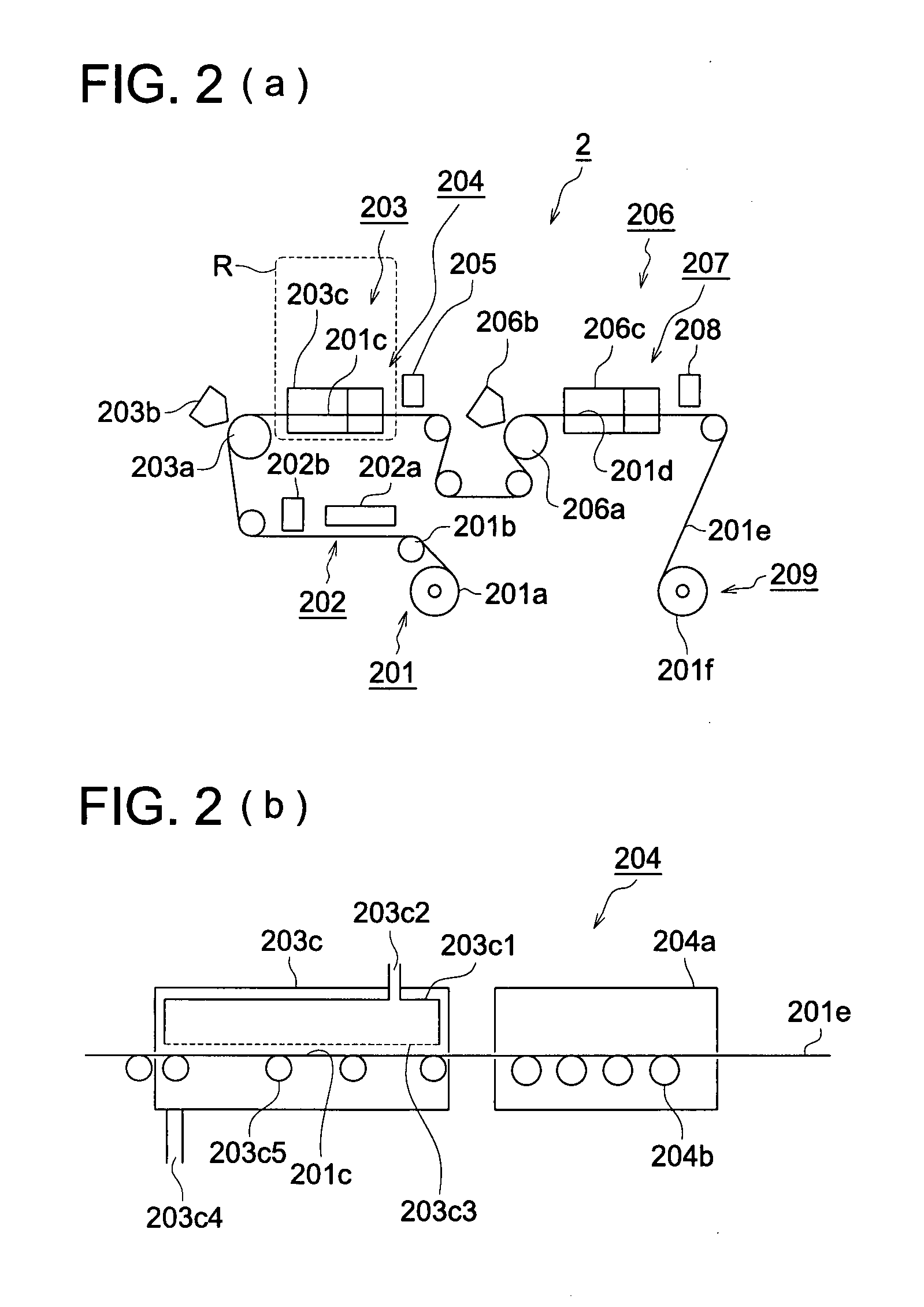

Method of Forming Organic Compound Layer, Method of Manufacturing Organic El Element and Organic El Element

ActiveUS20080213621A1Quality improvementIncrease costElectrical apparatusFibre treatmentProduction rateAtmospheric pressure

A method of forming an organic compound layer for producing organic EL element exhibiting high quality and high productivity without increasing cost; a relevant process for producing an organic EL element. There is provided a method of forming an organic compound layer of organic EL element using production apparatus including supply section, coating•drying section and recovery section, characterized in that flexible band substrate (A) having an anode layer in roll form is fed to the supply section; the production apparatus has at least one unit coating•drying section, the unit containing coating section capable of forming coating film for formation of organic compound later under atmospheric pressure by wet applicator and drying section; and at least one organic compound layer is formed on the anode layer to obtain flexible band substrate (B), which is wound on a core to form a roll in the recovery section.

Owner:MERCK PATENT GMBH

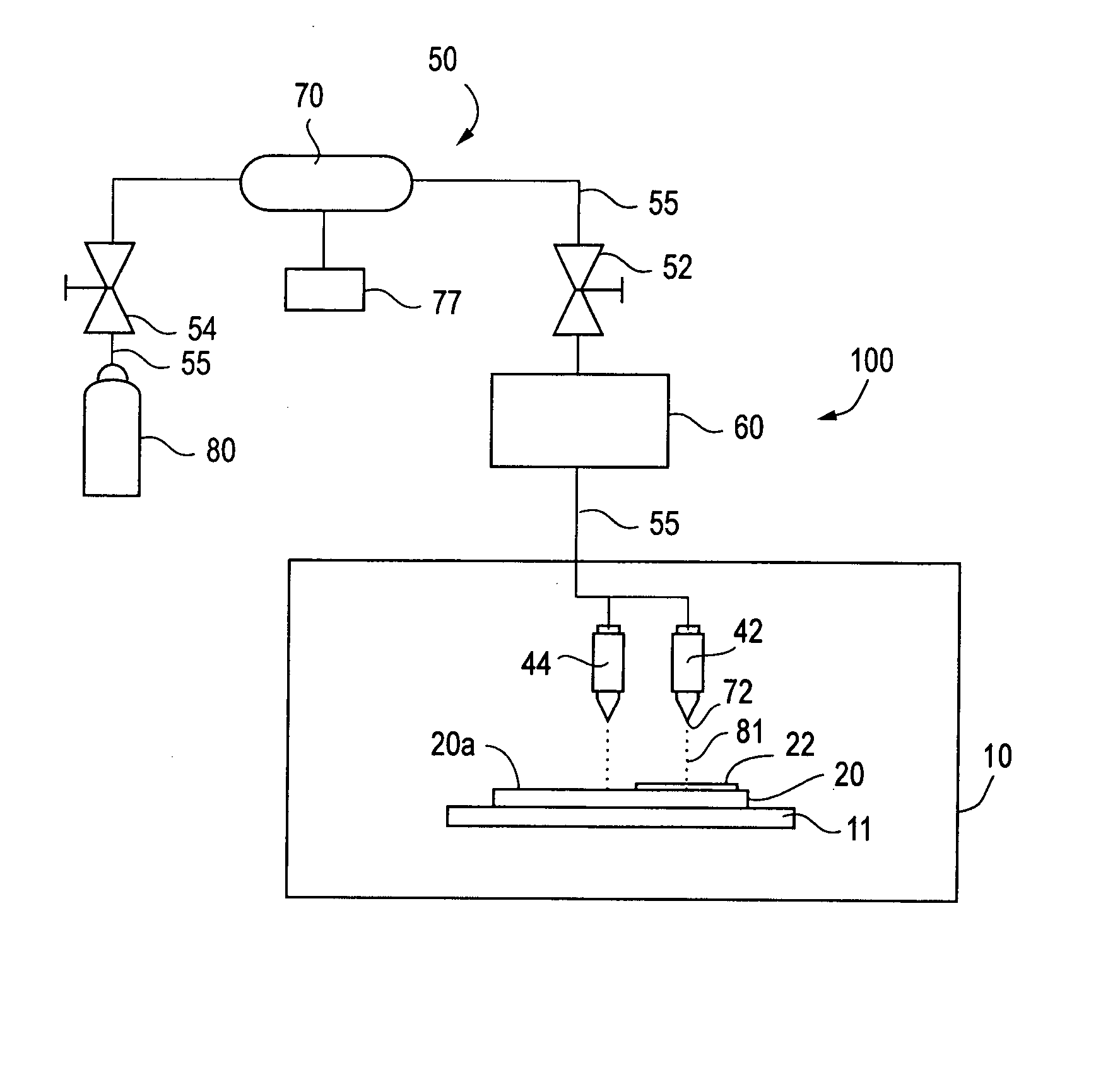

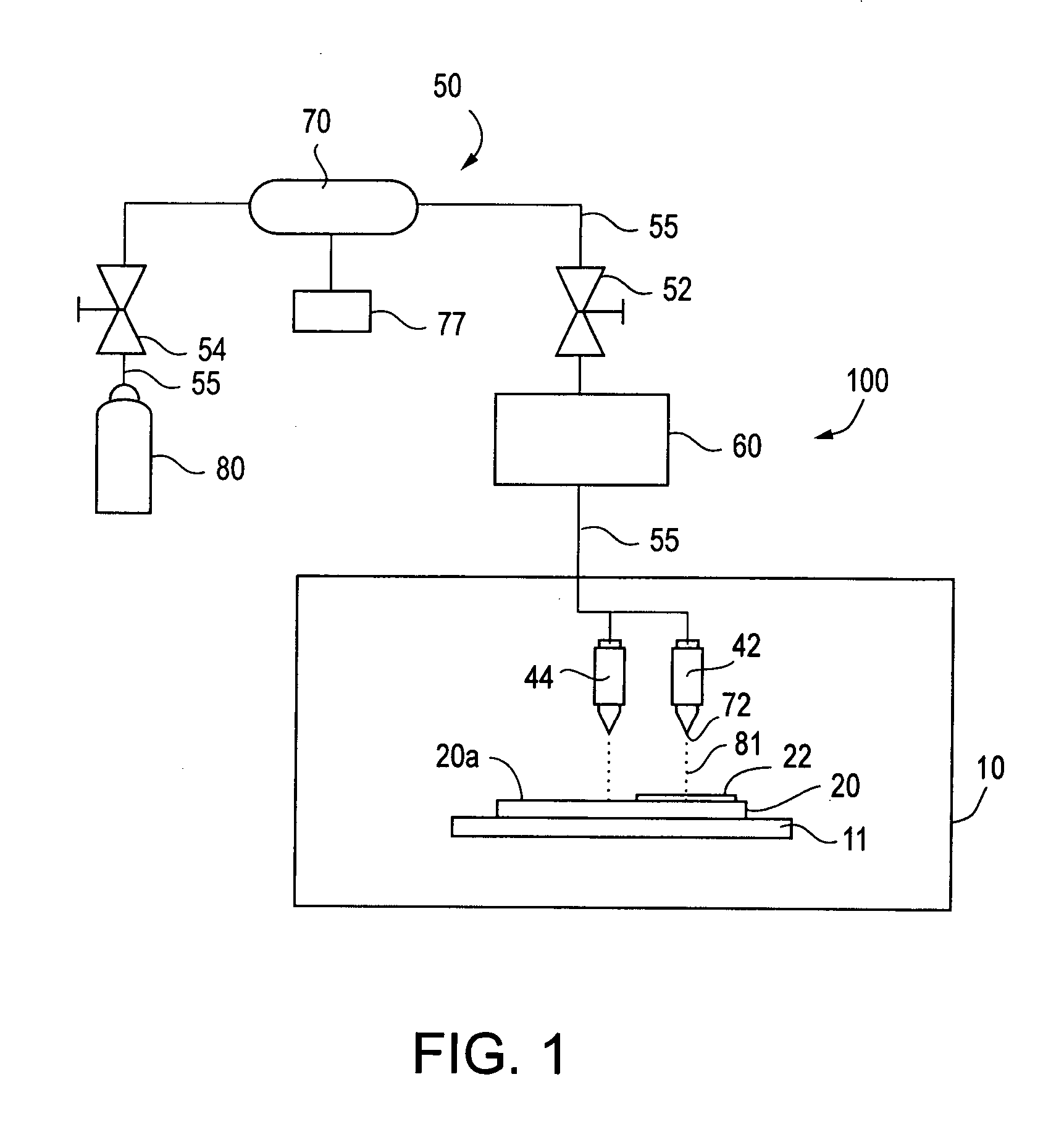

Supercritical fluid-assisted direct write for printing integrated circuits

InactiveUS20060266235A1High resolutionSemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

High resolution patterns provided on a surface of a semiconductor substrate and methods of direct printing of such high resolution patterns are disclosed. The high resolution patterns may have dimensions less than 0.1 micron and are formed by a direct writing method employing a supercritical fluid comprising nanometer-sized particles, which may be optionally electrically charged.

Owner:MICRON TECH INC

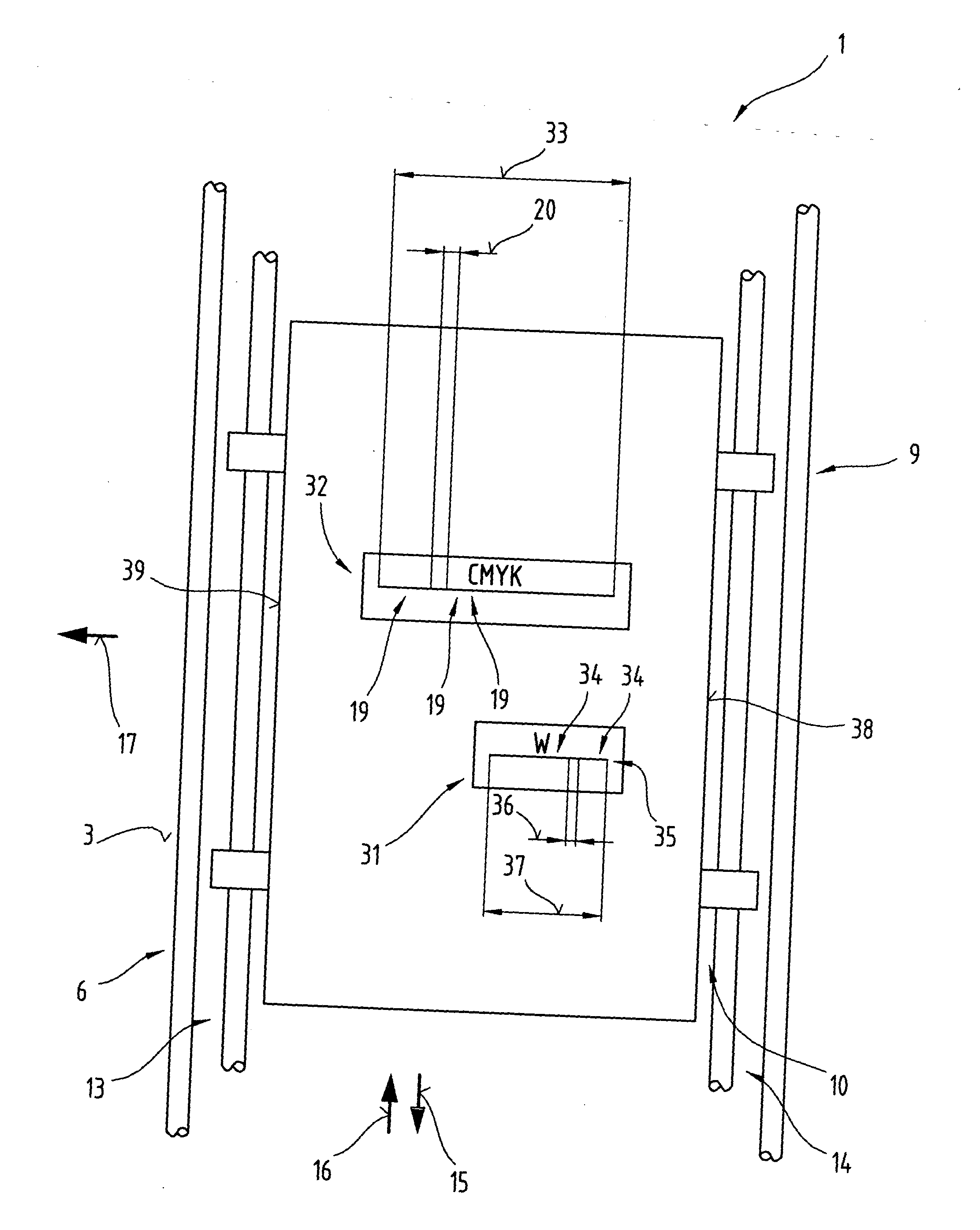

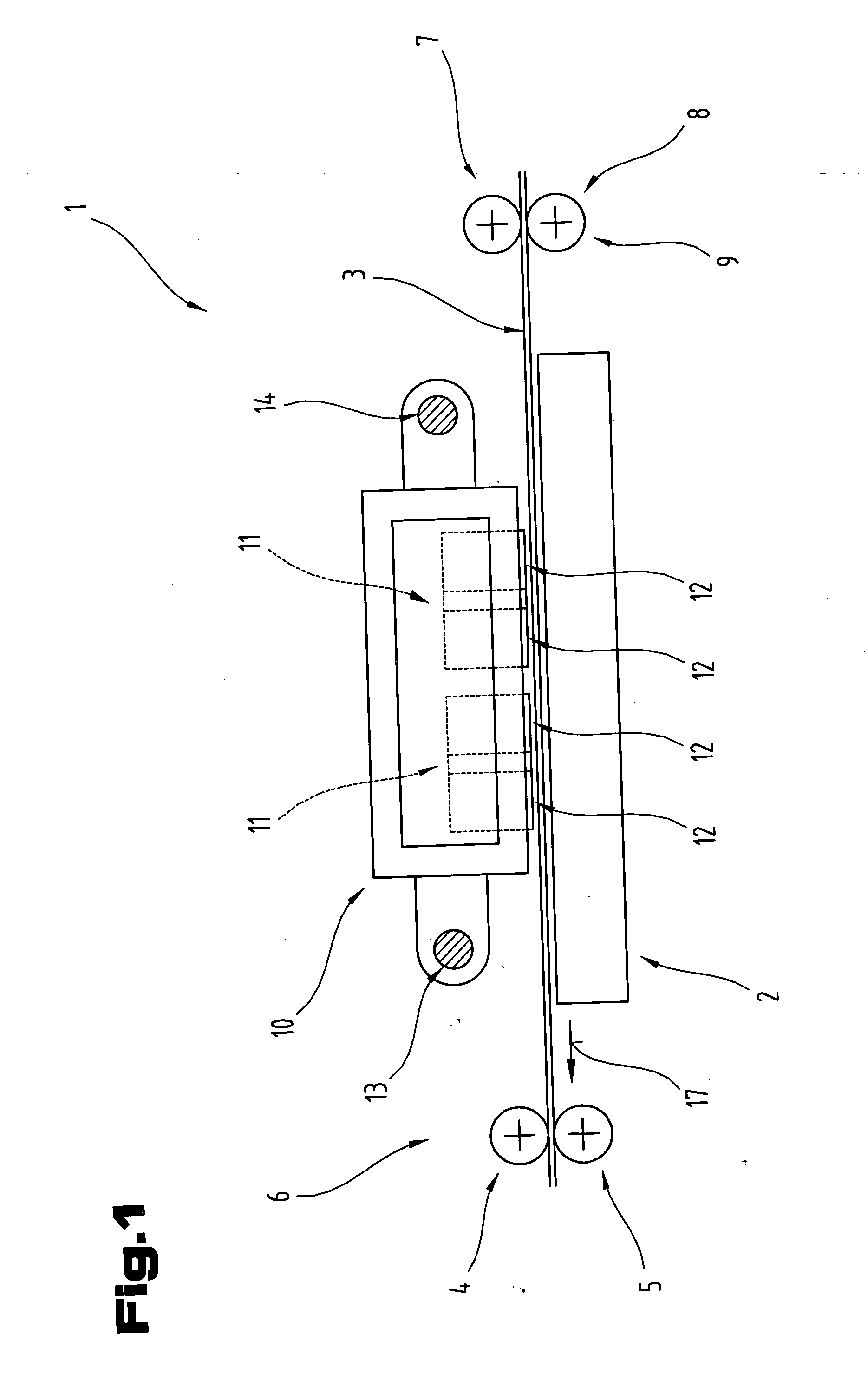

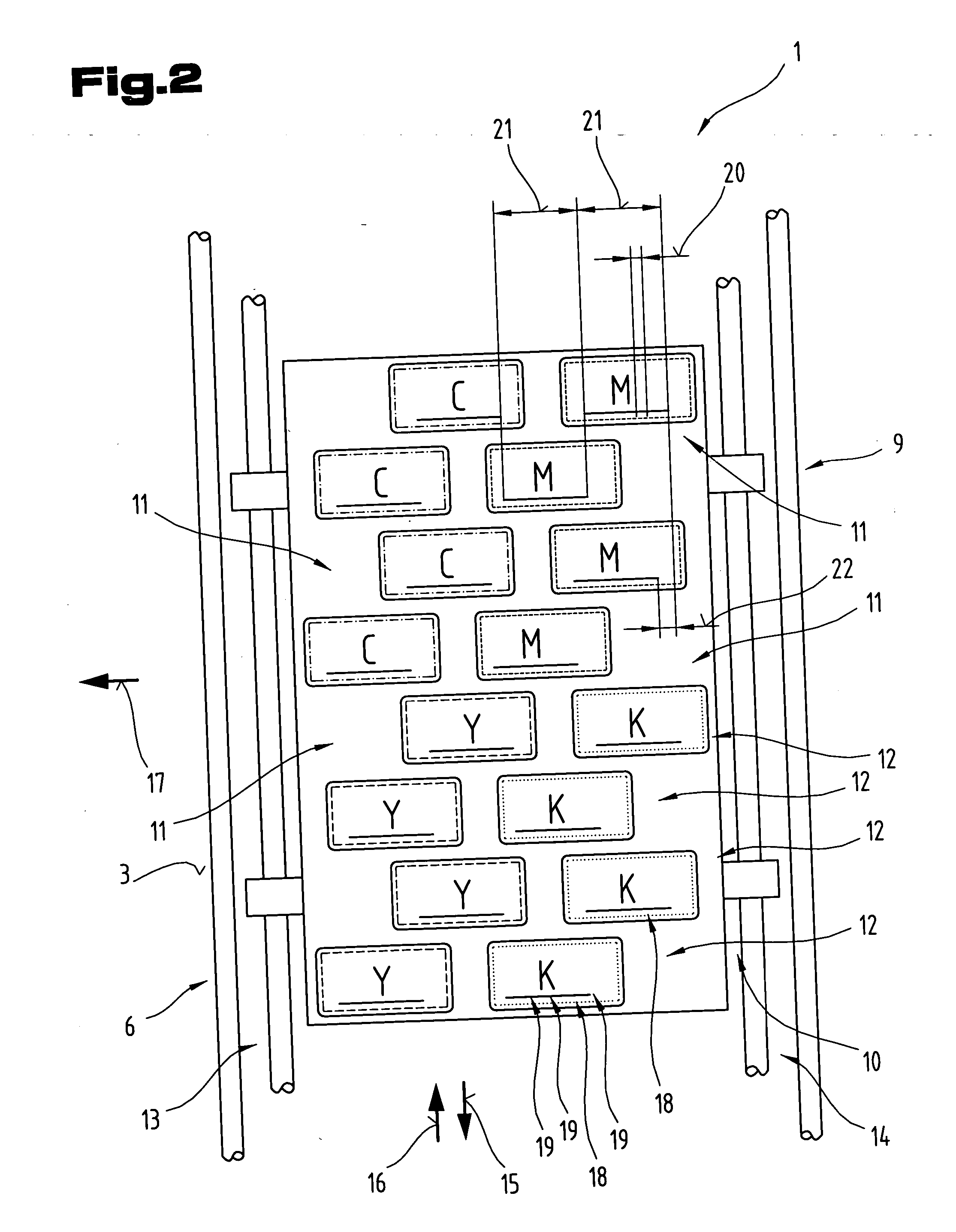

Inkjet printer

The invention describes an inkjet printer (1) with a printing bed (2) for displacing a print medium (3) in a forward feed direction (17) and a print head carriage (10) disposed above the printing bed (2) for displacing at least one print head unit (11, 32) in a transverse feed direction (15, 16), a print head unit (11, 32) with at least one print head (12) being provided for every colour to be printed, each print head (12) having at least one nozzle row (18) oriented in the forward feed direction (17) of the print medium (3). The nozzles (19) of the at least one nozzle row (18) of the print head unit (11, 32) are disposed offset from one another by a nozzle distance D (20) by reference to the forward feed direction (17). Another print head unit (31, 40, 41, 71) is provided, which has nozzles (34, 73) in at least one nozzle row (35, 72) disposed offset from one another by a second nozzle distance d (36) by reference to the forward feed direction (17) of the print medium (3), the ratio derived from the nozzle distance D (20) and the second nozzle distance d (36) being a ration al number and greater than 1.

Owner:DURST PHOTOTECHN DIGITAL TECH

Color registration control system for a printing press

InactiveUS7013803B2Shorten the timeEasy to set upOther printing apparatusPhotographic printingImaging processingControl system

A color registration control system for a printing press including an area scanner for acquiring an image of a paper substrate and an image processing system adapted to receive the image and process the image to determine any color register error.

Owner:QUADTECH

Real-time print product status

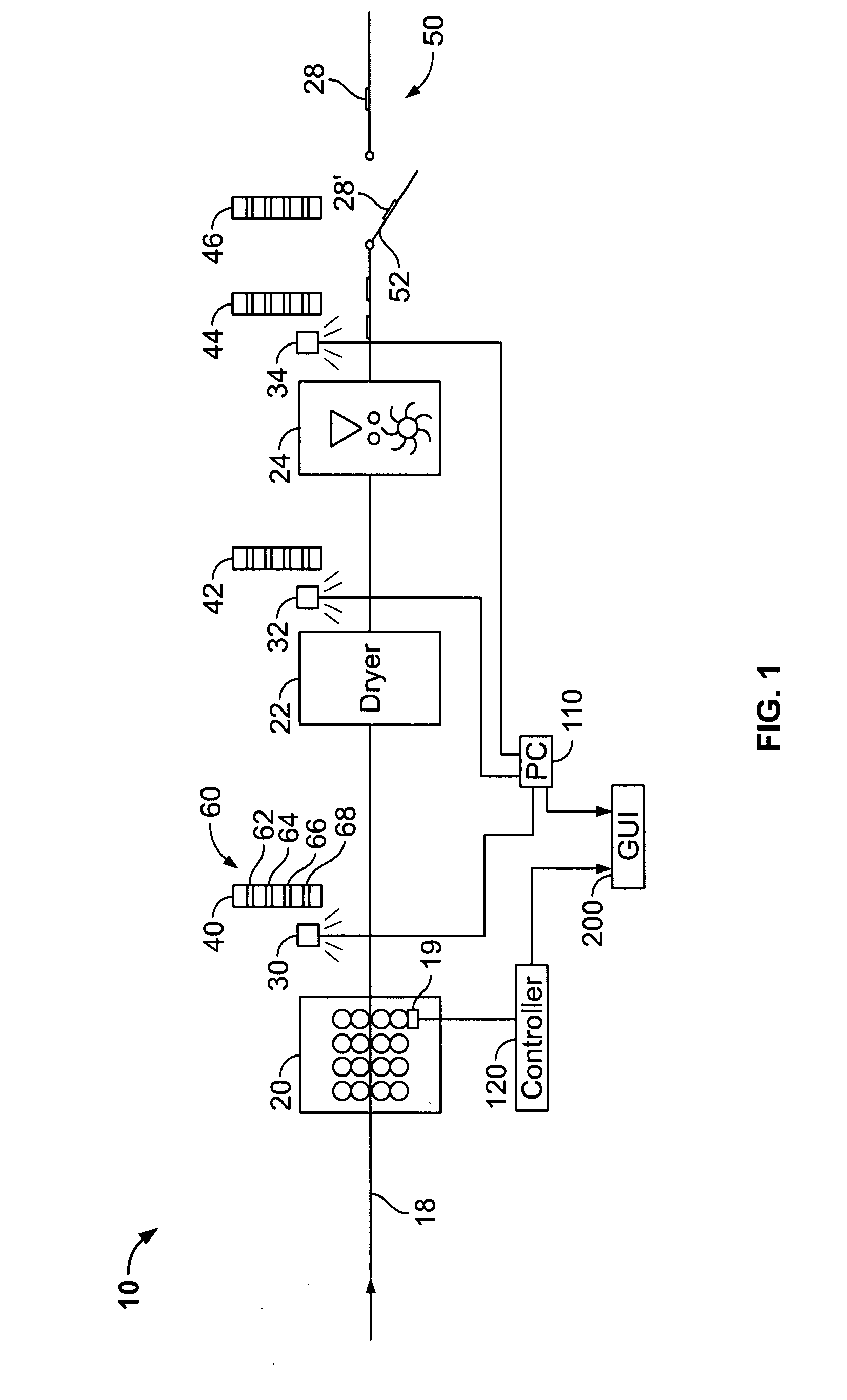

InactiveUS20080196612A1Realize automatic adjustmentRotary letterpress machinesPrinting press partsEngineeringPrinting press

A web printing press is provided including a printing unit for printing a web, a delivery for printed products formed from the web, the web and printed products defining a printed product stream, a first sensor sensing a first characteristic of the web or printed products, a controller connected to the first sensor, and an indicator indicating in real-time a print defect in the printed product stream as a function of the first sensor. A method is also provided.

Owner:MANROLAND GOSS WEB SYST AMERICAS LLC

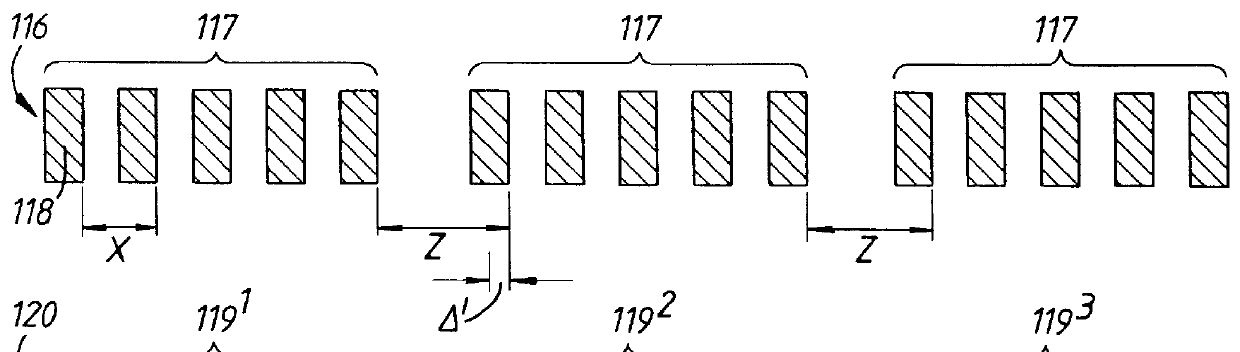

Method for monitoring registration of images printed by a printer

InactiveUS6065400AFacilitate web handlingPrecise positioningPlaten pressesOther printing apparatusComposite patternEngineering

The printer has at least two printing stations which cause images to be printed on a substrate. The printer is capable of registration adjustment. First and second patterns of spaced registration marks are printed onto the substrate by operation of the printing stations. The second pattern partially overlaps the first pattern to form a composite pattern of registration marks. The composite pattern is illuminated and the reflectivity thereof is examined at wavelengths complementary to the colors of the first and second patterns to obtain a reflectivity signature for the composite pattern. The reflectivity signature of the composite pattern (120) is compared with a predetermined signature to determine an adjustment factor for the printer.

Owner:PUNCH GRAPHIX INT

Variable cut-off offset press system and method of operation

InactiveUS7066088B2Aid in smooth operation of systemIncrease frictionCylinder pressesTransfer printingImage transferCleaning station

A variable cut-off offset press system and method of operation which utilizes a continuous image transfer belt is provided. The offset printing system comprises at least two plate cylinders adapted to have thereon respective printing sleeves. Each of the printing sleeves is adapted to receive colored ink from a respective ink source. An optional coating source may be provided to fully or partially coat the image transfer belt before inking. The system further comprises at least a impression cylinder, wherein the image transfer belt is positioned to contact each of the printing sleeves at respective nips formed between respective ones of the plate cylinders and the at least one impression cylinder. An image belt cleaning station adapted to remove residual ink or coating from the surface of the image transfer belt after image transfer of a multicolored image from the image transfer belt to a substrate is also provided.

Owner:DAY INT

Apparatus for producing a web substrate having indicia disposed thereon and elastic-like behavior imparted thereto

Owner:THE PROCTER & GAMBLE COMPANY

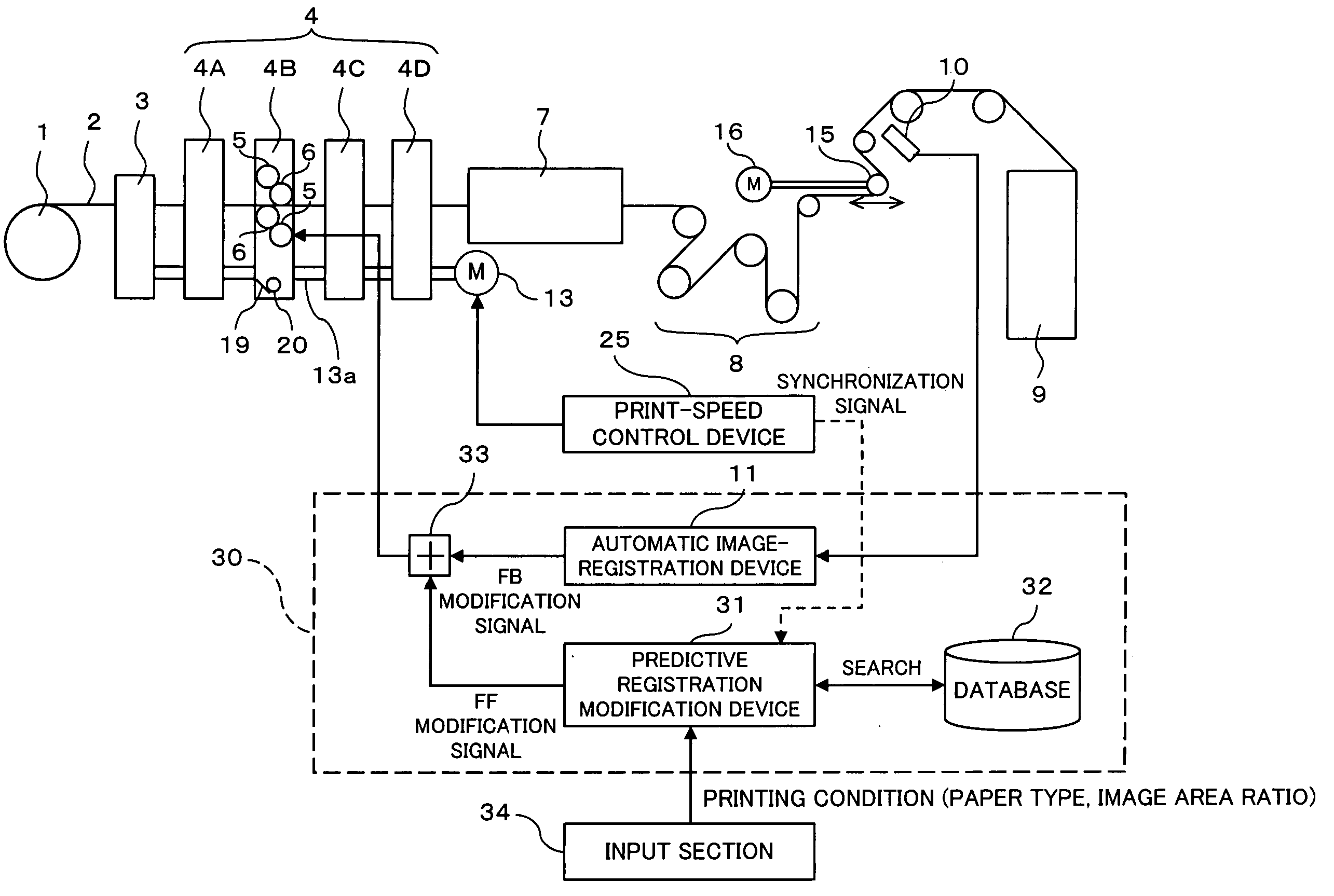

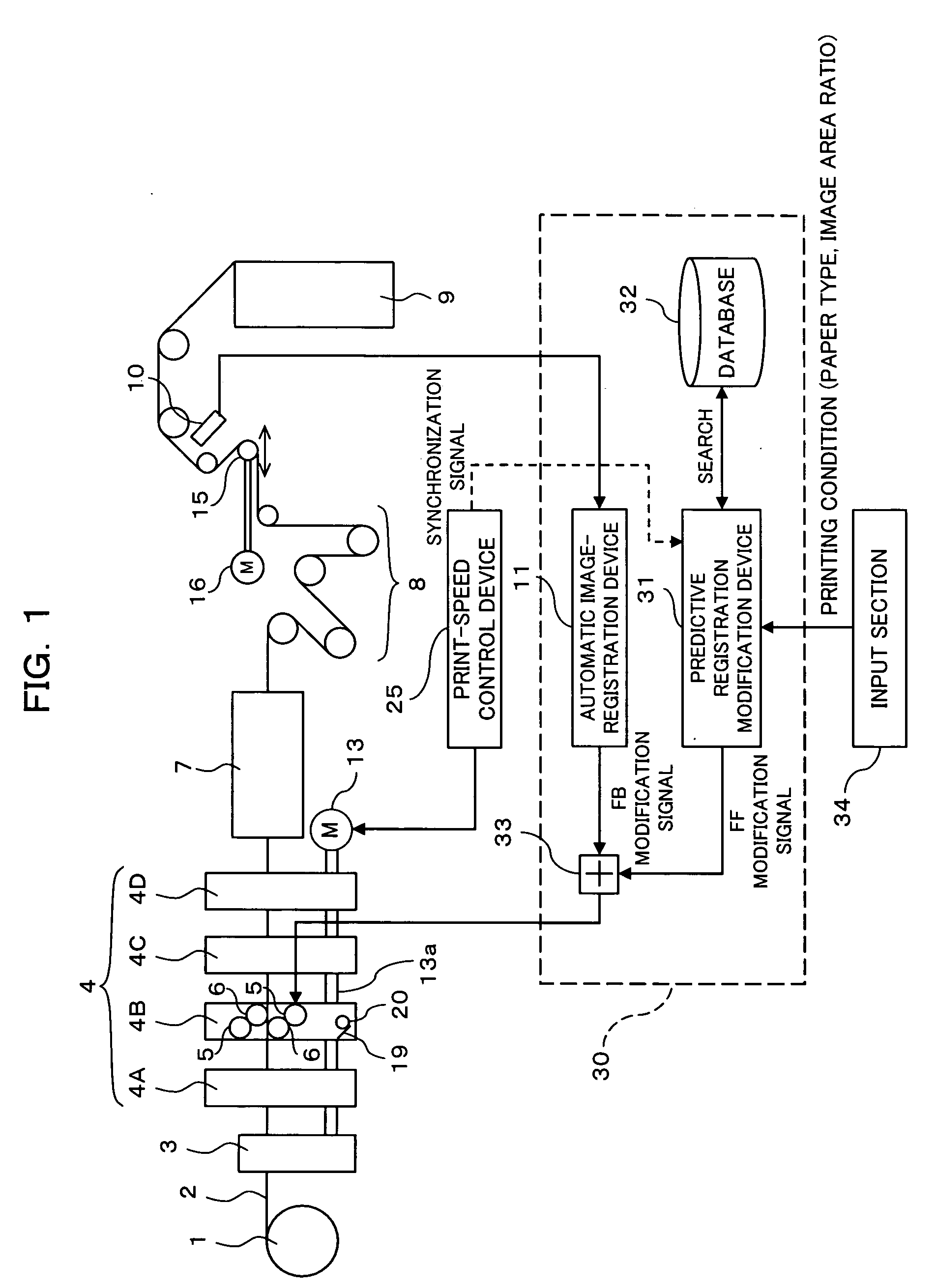

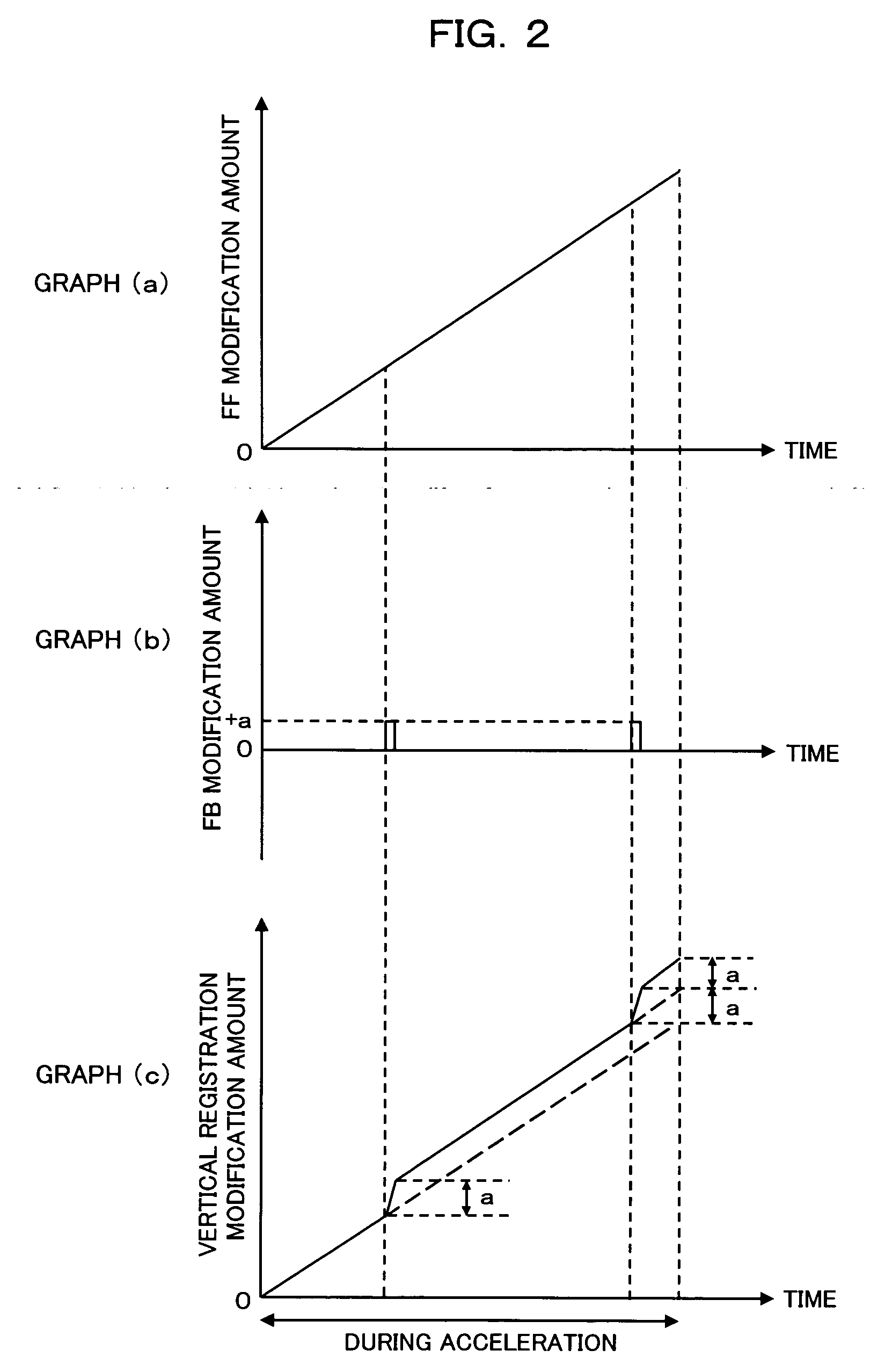

Misregistration when printing speed is changed, cutting misregistration, or pinter in which variation of printing density can be controlled

InactiveUS20060005722A1Suppress fluctuationsAvoid it happening againRotary letterpress machinesEngineeringPhase control

A fluctuation characteristic of registration between images printed by individual printing units (4A, 4B, 4C, 4D) while changing print speed is predicted for each of particular printing conditions that affect the registration fluctuation characteristic. Based on the predicted fluctuation characteristic of registration, a control characteristic of the phase between plate cylinders (5, 5, 5, 5) of the individual printing units (4A, 4B, 4C, 4D) is preliminarily set so as to compensate for vertical image misregistration between images printed by the individual printing units (4A, 4B, 4C, 4D), and is stored in a database (32). Then, when the print speed is being changed, from among the plural phase control characteristics thus preliminarily stored in the database (32), a phase control characteristic that corresponds to a printing condition concerning the current printing is selected, and the phase relation between the plate cylinders (5, 5, 5, 5) of the individual printing units (4A, 4B, 4C, 4D) is being modified according to the selected phase control characteristic. Thereby vertical image misregistration can be suppressed and the occurrence of brokes due to the change of print speed can be prevented.

Owner:MITSUBISHI HEAVY IND LTD

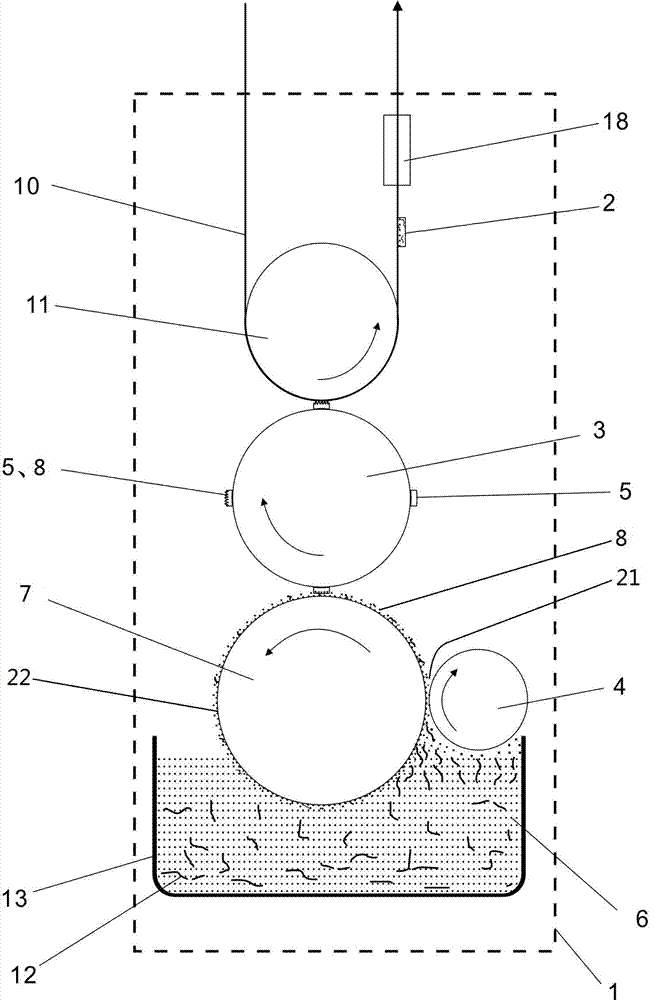

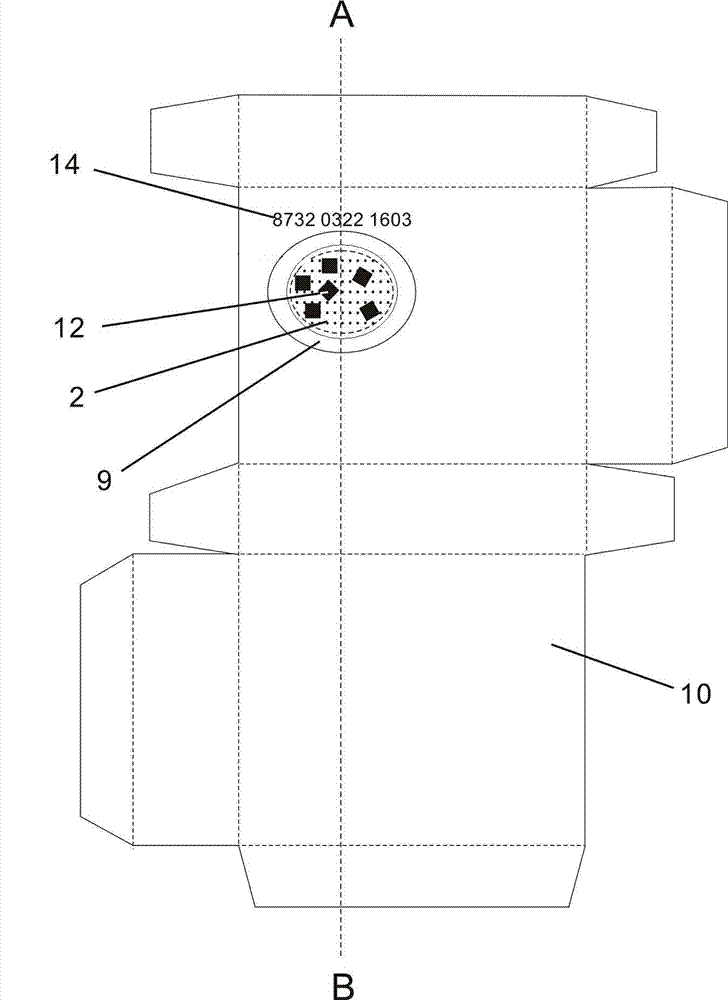

Local large-size fiber letterpress printing system and printed matter thereof

The invention provides a local large-size fiber letterpress printing system and a printed matter thereof. The system comprises a fiber ink letterpress printing unit which comprises a letterpress printing roller, an ink roller and a round roller scraper; the system also comprises an ink tank for containing fiber ink; the fiber ink penetrates through the gap between the ink roller and the round roller scraper to form a fiber ink layer; and the fiber ink layer is transferred to a printing material by a bulk boss to form a local fiber ink block. Through the invention, the limit that the existing printer cannot adopt large-size fiber ink is broken through, and a local large-size fiber printed matter is printed and produced.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

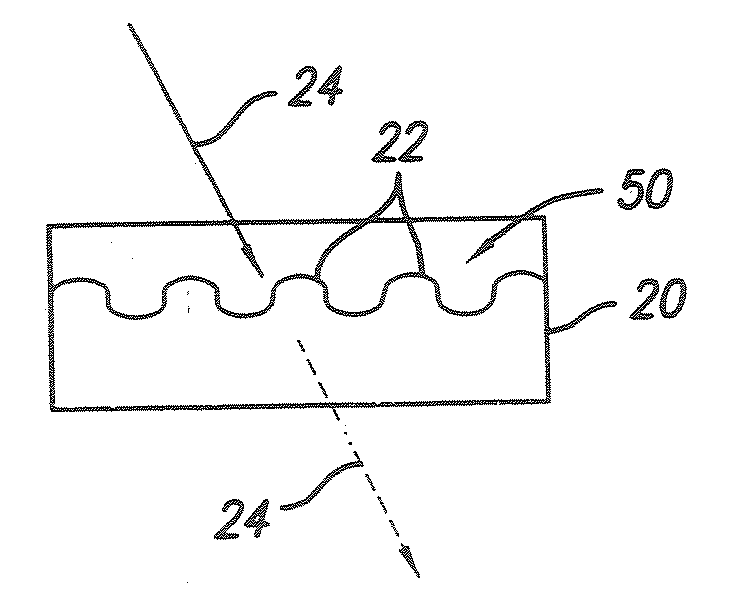

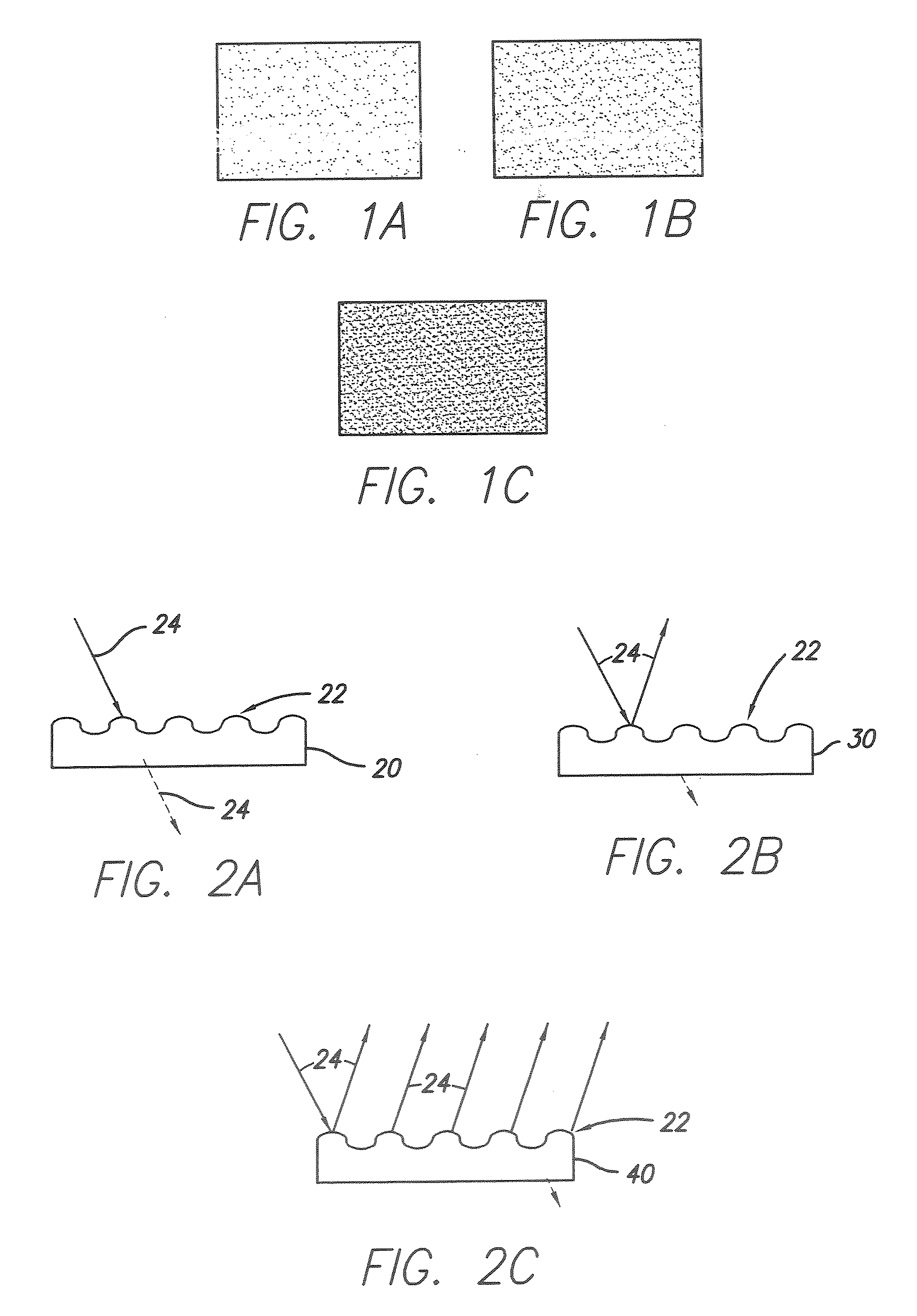

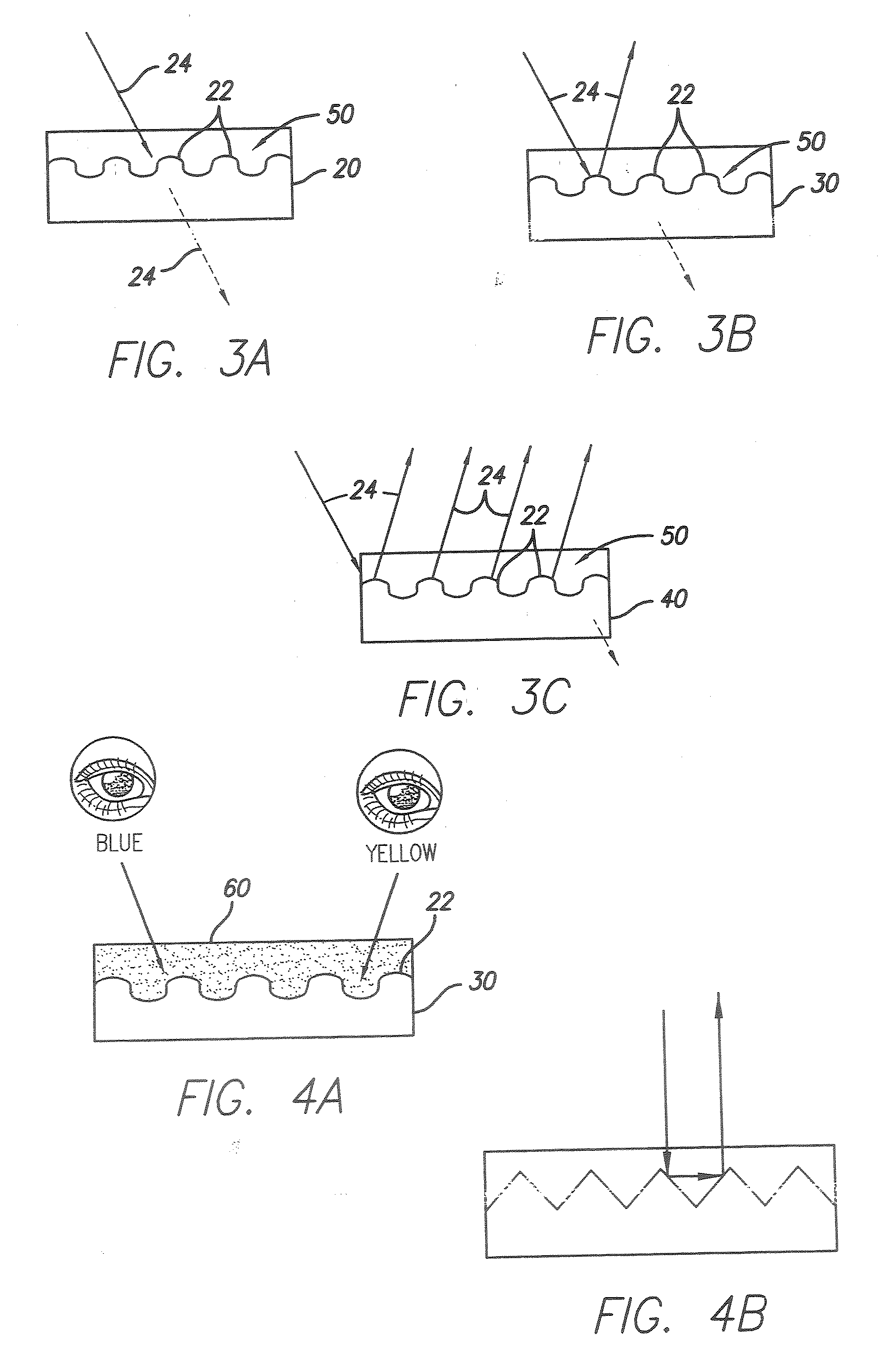

Substrates and articles having selective printed surface reliefs

The present invention provides articles comprising a substrate, a coating that is applied to the substrate, and surface reliefs that are cast or embossed onto the coating at substantially the same speeds and widths of conventional printing, and in substantially perfect register to conventional printing, wherein the coating is selected from the group consisting of HRISR coatings, LRISR coatings, water-based coatings, solvent-based coatings, UV / EB based coatings, sol-gel based coatings, conductive coatings, silver reduction based coatings and metallic coatings. A protective or printed layer may (or may not) be applied on top of the coating. Specifically, if the coating is an HRISR or LRISR coating, then it is unnecessary to apply a special high refractive layer because HRISR and LRISR coatings inherently contain the refractive index properties that are necessary to keep the surface reliefs viewable despite any printing on top of the coating. Otherwise, if the coating does not comprise an HRISR or LRISR coating, then a high refractive protective layer is applied on top of the coating, wherein the protective layer follows a topography of the surface reliefs such that a thickness of the protective coating is substantially uniform.

Owner:HOLOINKS

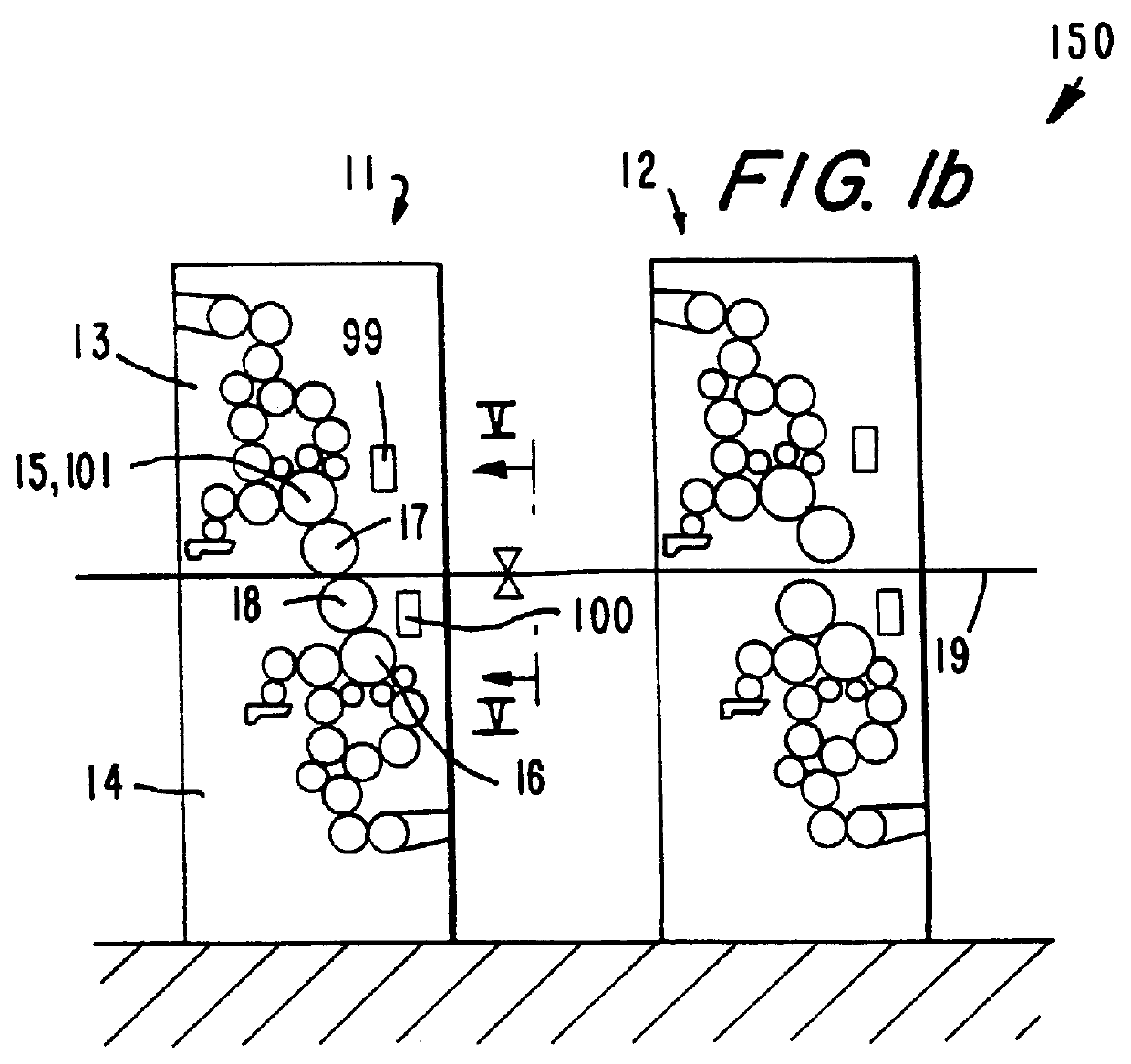

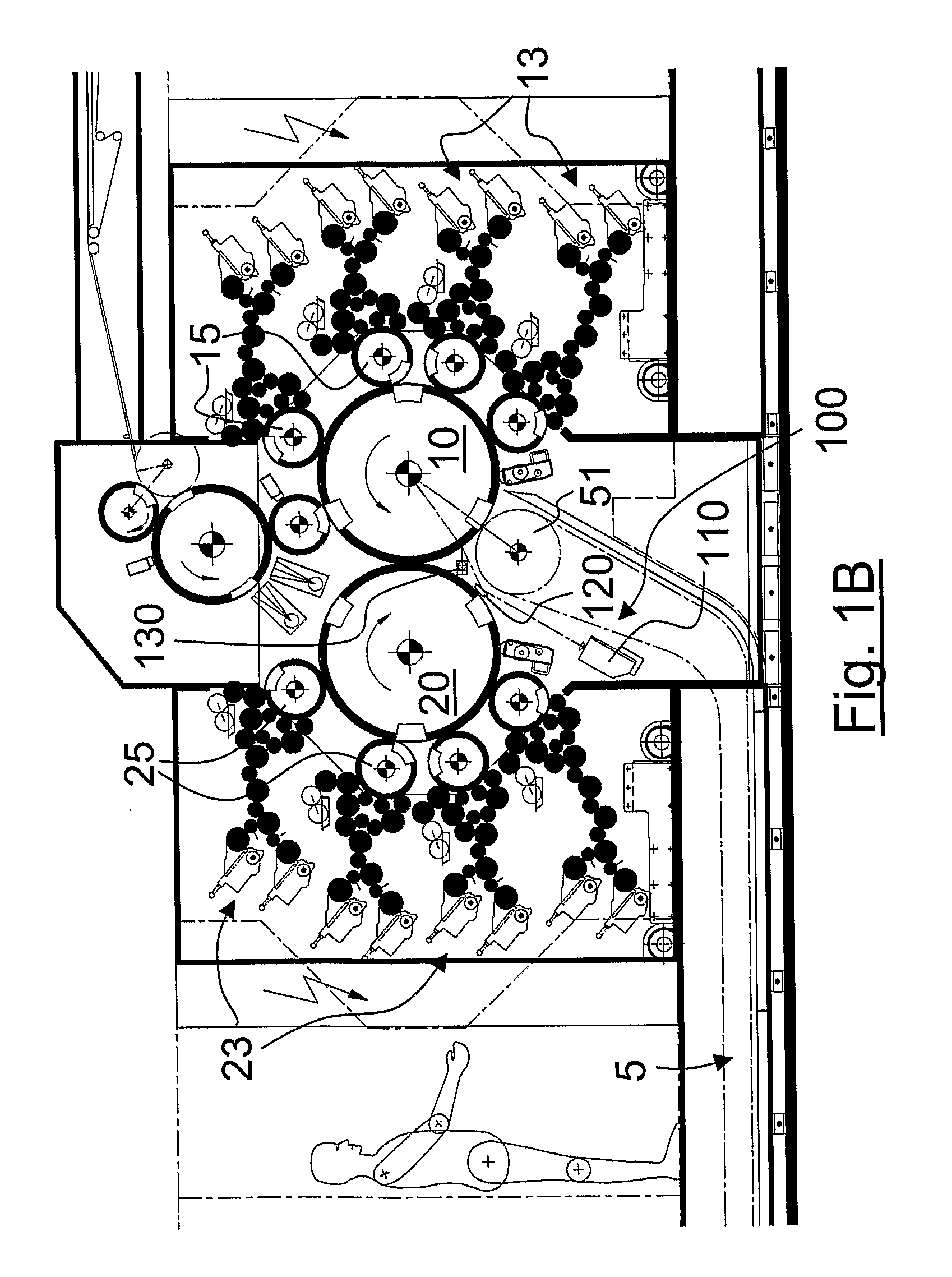

Inspection System for a Sheet-Fed Recto-Verso Printing Press

ActiveUS20090007807A1Increased complexityIncrease the lengthAddressographsLetterpress printingEngineeringPrinting press

There is described a sheet inspection system for a sheet-fed recto-verso printing press of the type comprising two printing cylinders (10, 20) for carrying out simultaneous recto-verso printing of the sheets, said sheet inspection system comprising at least a first inspection device (100) for taking an image of a first side of the printed sheets. The first inspection device (100) comprises a first line image sensor (110) for performing line-scanning image acquisition of the first side of the printed sheets, and the first inspection device (100) is disposed in such a way that the first line image sensor visually acquires an image of a printed sheet while the said printed sheet is still adhering onto the surface of a first one (10) of the two printing cylinders (10, 20) of the printing press and immediately before the said printed sheet is transferred to a chain gripper system (5) of the printing press. Also described is a printing press equipped with the inspection system.

Owner:KBA NOTASYS SA

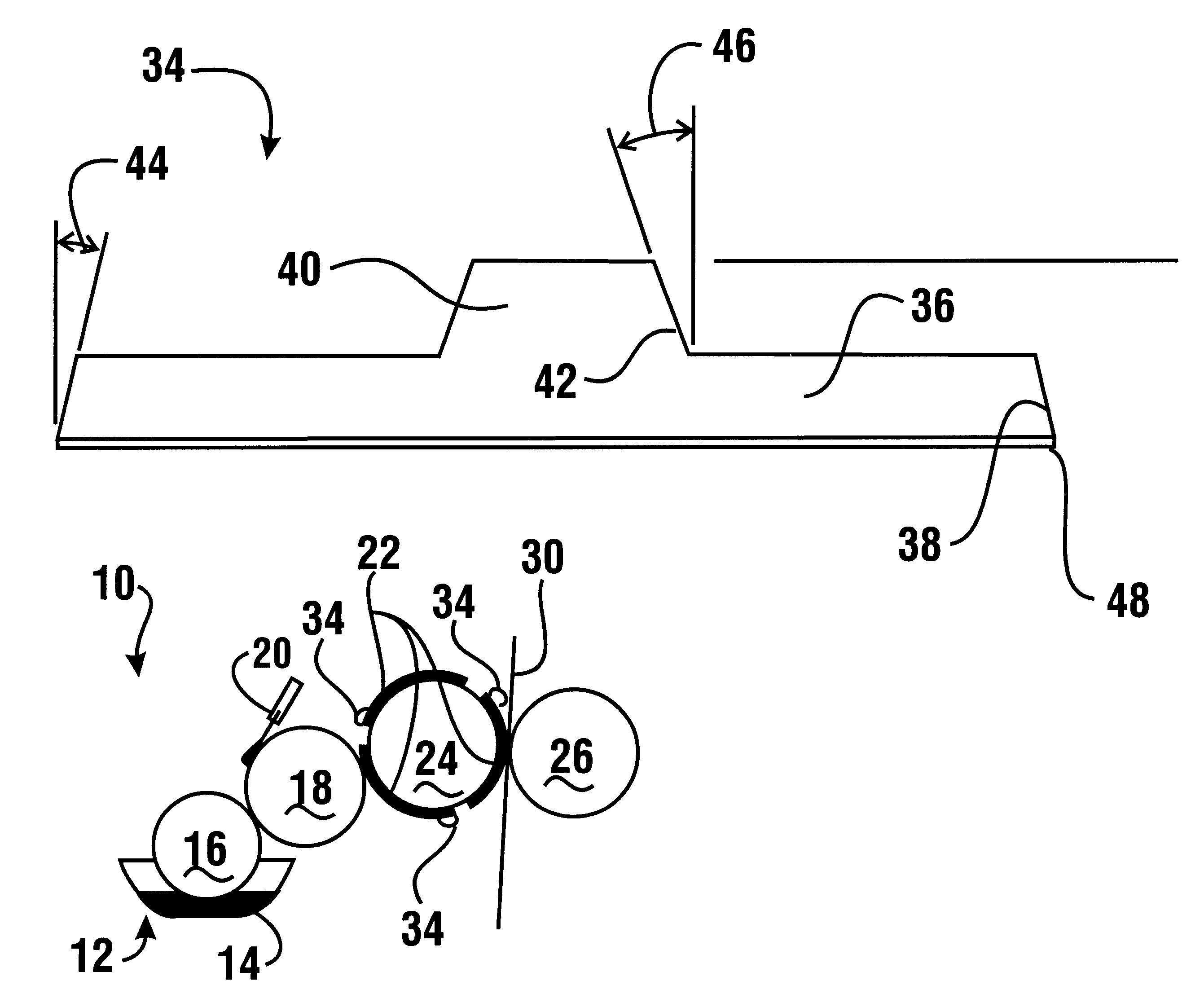

Flexographic printing apparatus and method

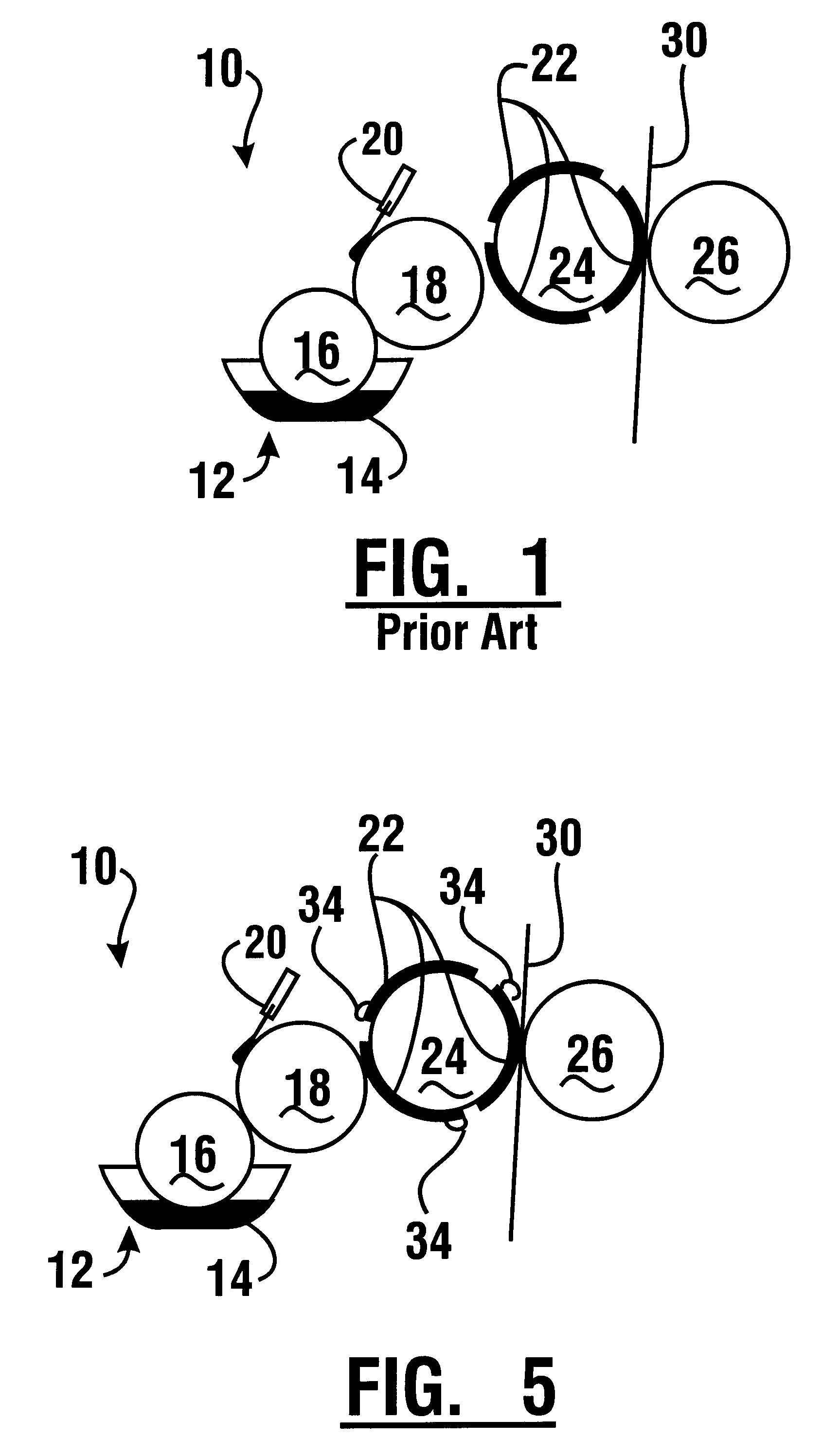

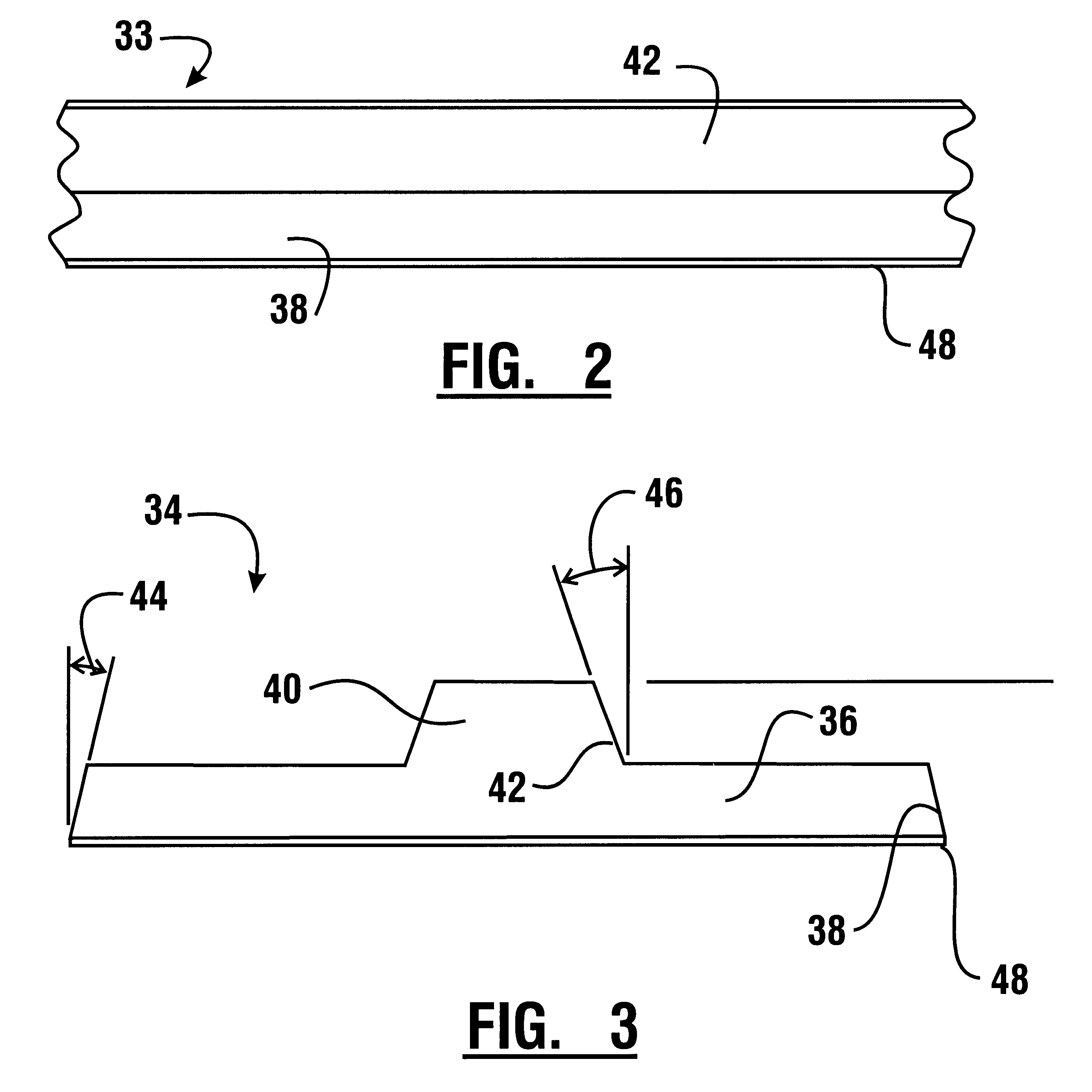

A pull band (34) is attached to a printing plate (22) in a flexographic printing operation to hold a flexible substrate (30) in a selected orientation for transfer of ink in a selected pattern. The pull band overcomes differences in friction between the printing plate and the substrate in areas of different amounts of ink to maintain the selected orientation. A specific length pull band may be selected and cut from a roll of pull band material. Pull bands may be attached parallel and perpendicular to the direction of rotation of the printing plate.

Owner:FEESLER DOUGLAS W

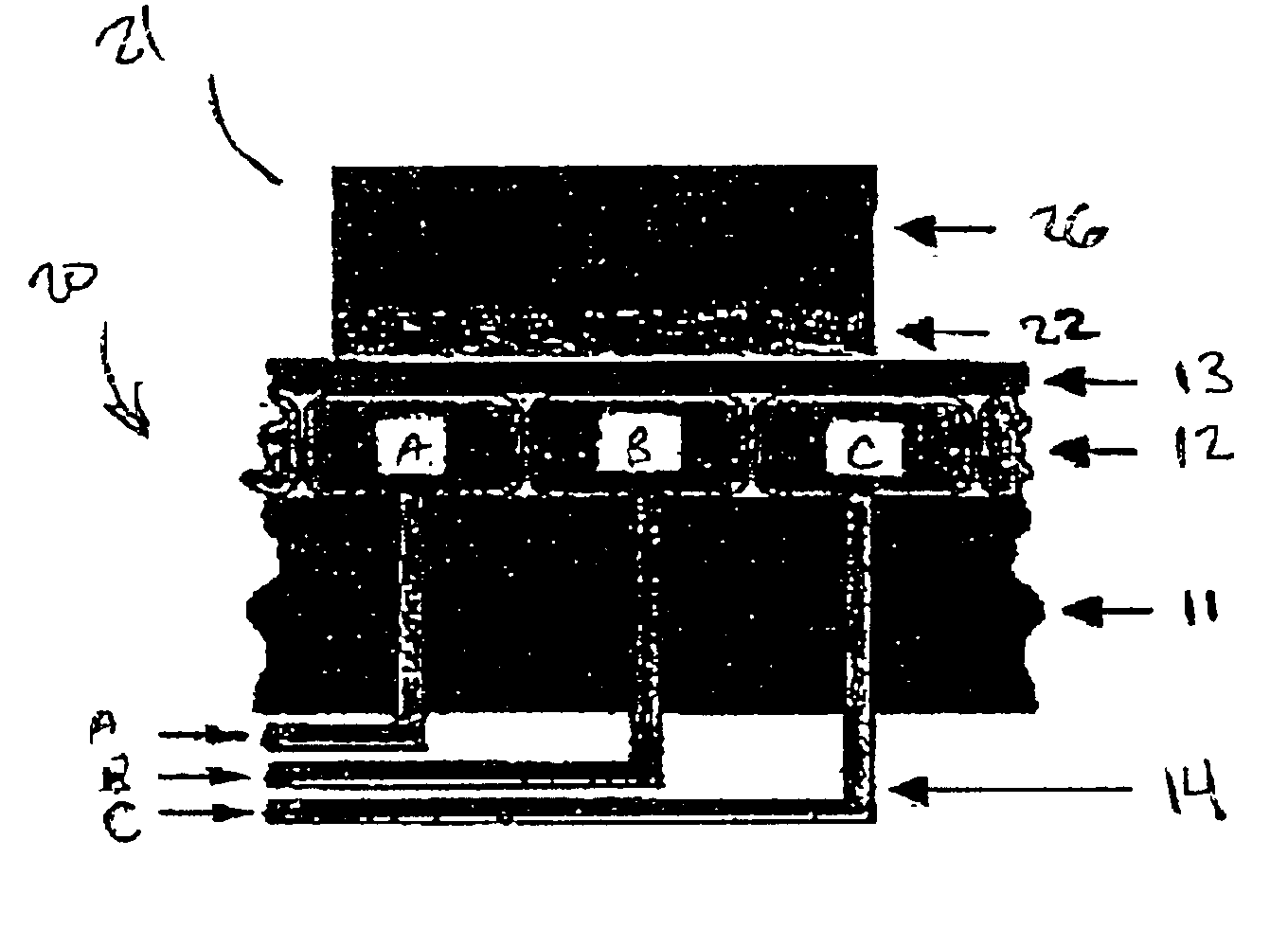

Apparatus for perforating a web material

ActiveUS8763526B2Easy to disassembleIncrease attractivenessNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringLinearity

Apparatuses are disclosed that include forming selected perforation designs and patterns. The perforation designs and patterns can be formed in linear or nonlinear fashion, can extend in the cross direction or the machine direction and can be formed to complement or match an embossed or printed design on the web. The perforation designs and patterns can be formed utilizing various mechanical perforating techniques.

Owner:PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com