Patents

Literature

856 results about "Direct printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of direct printing. : the process of printing textiles by passing them between a succession of rollers having different colors and different parts of the pattern.

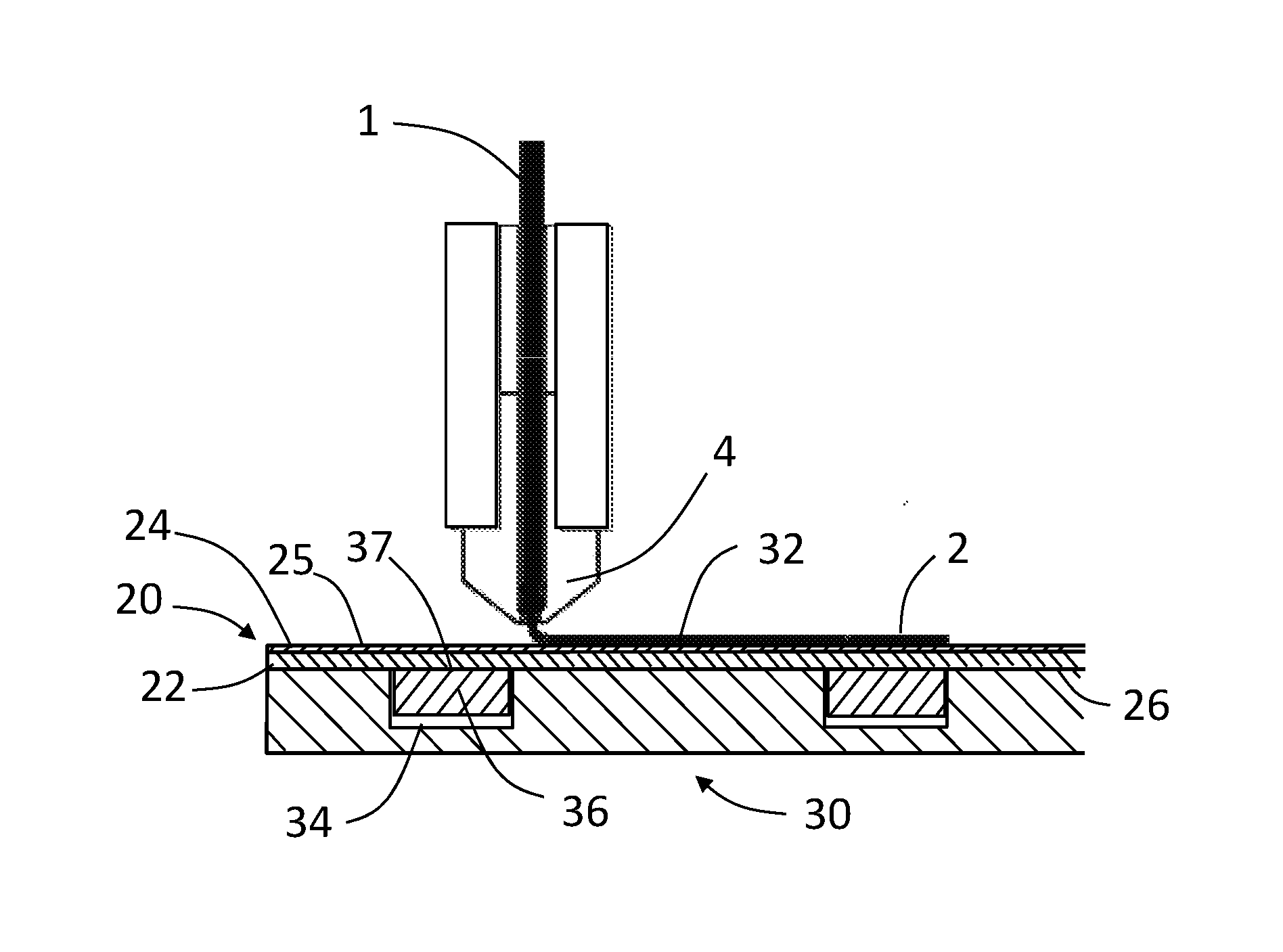

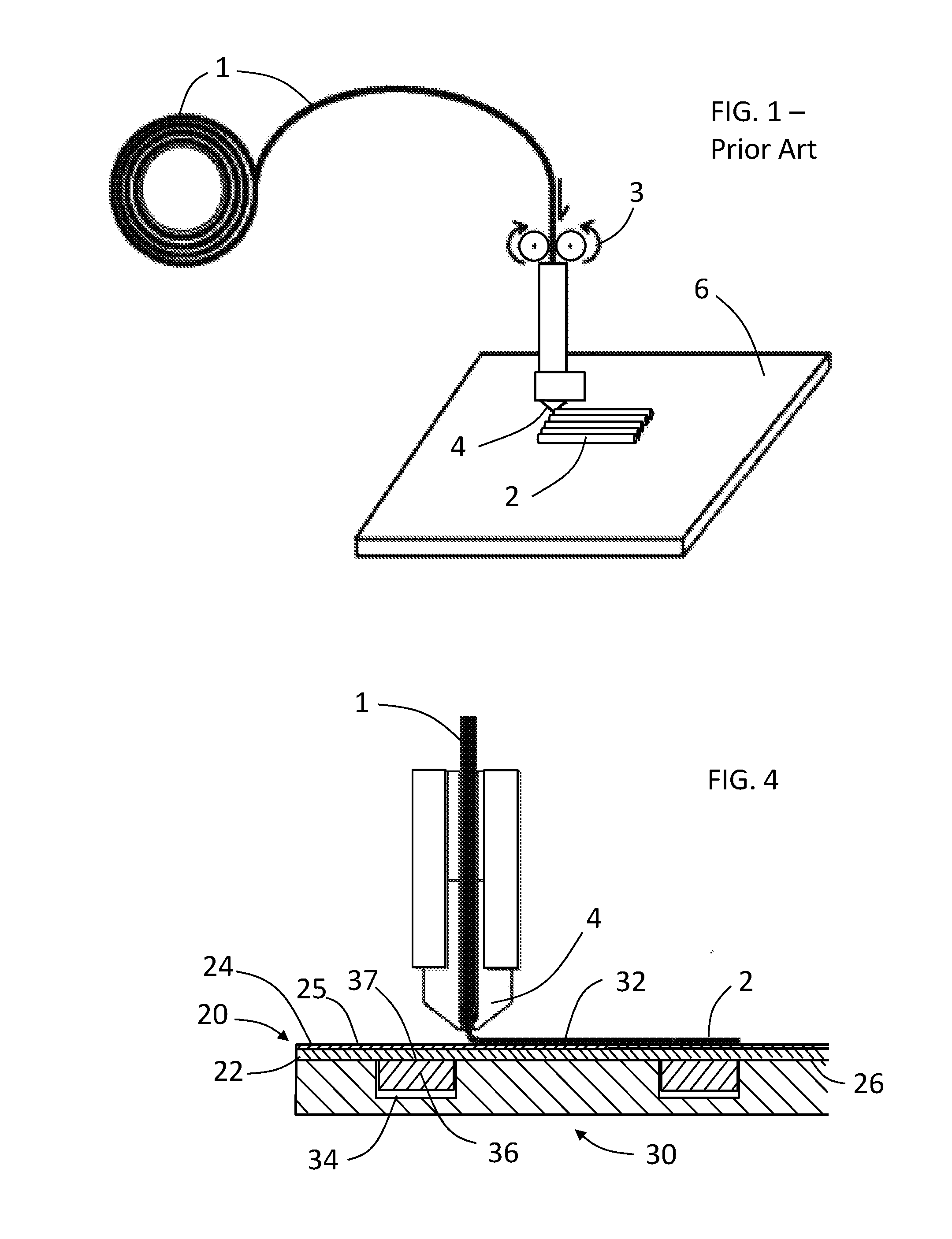

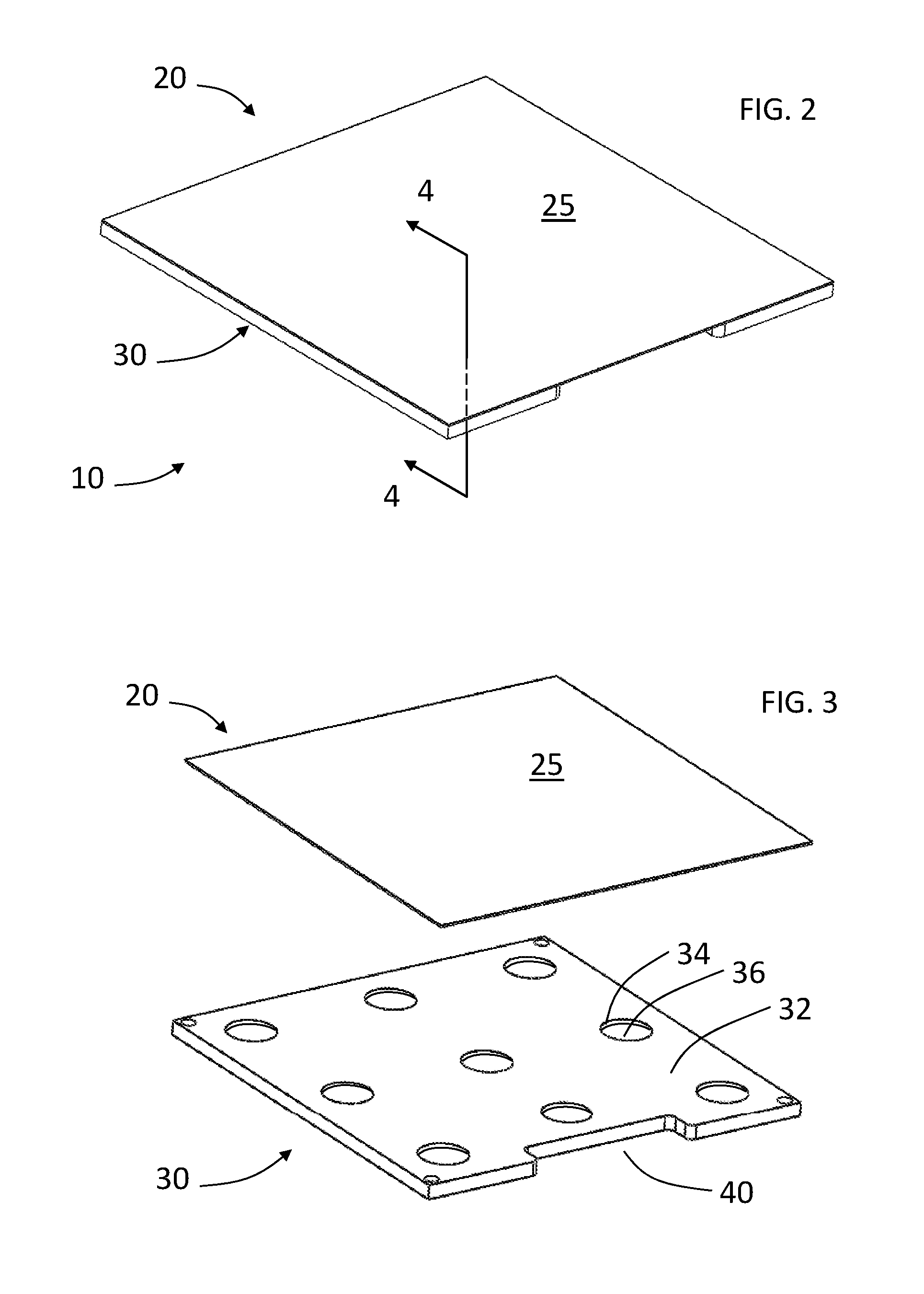

3D Print Bed Having Permanent Coating

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

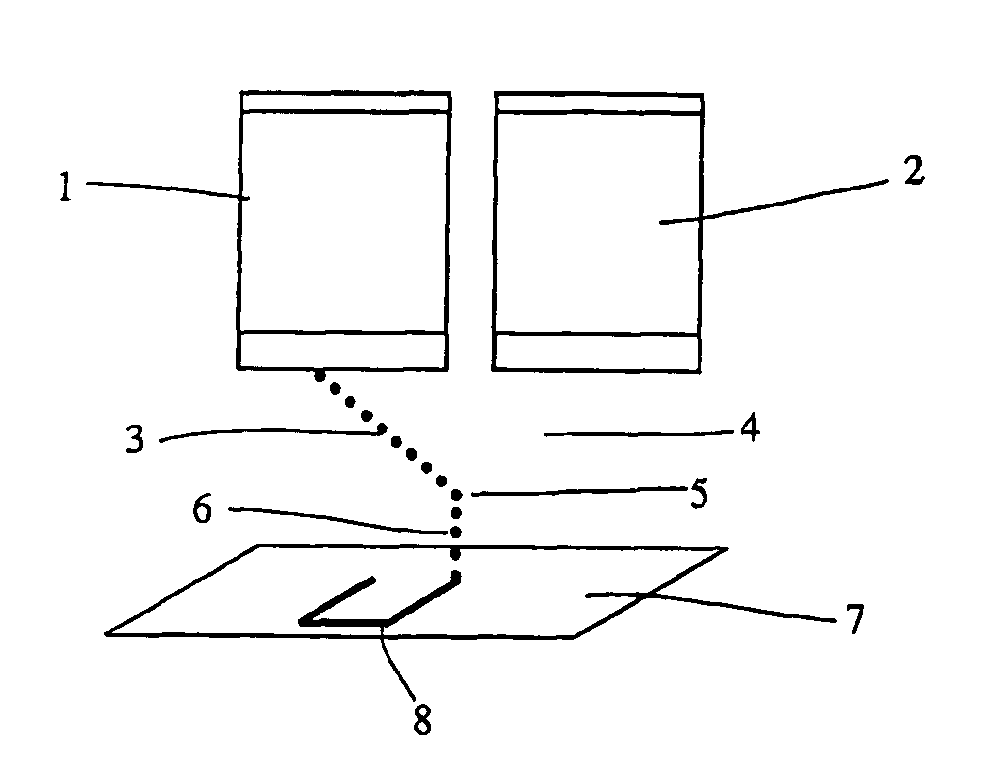

Depositing solid materials

InactiveUS20050174407A1High levelHigh yieldAdditive manufacturing apparatusLiquid surface applicatorsInk printerElectronic component

Material can be deposited directly onto a substrate by using a fluid applicator such as an inkjet printer to apply at least two fluids which react to give the desired material for a range of applications. Thus, multiples of a printing mechanism are used to deposit materials as reagents that react together to form products. The materials may also be advantageously deposited from multiple inkjet heads to prepare a wide range of reaction scenarios in the form of user-defined patterns which may be sequences of differing layers and possibly to build up thicker layers. Thus, a PCB could be printed by the inkjet printer by simply printing the metal salt and the reducing agent directly, instead of two colours from a conventional inkjet printer for example. To print a three dimensional article, a pair of fluids which react to give a precipate can be used instead. Repeated passes can then build up a desired shape. The two processes could be combined to produce composite devices such as electrical components.

Owner:QINETIQ LTD

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

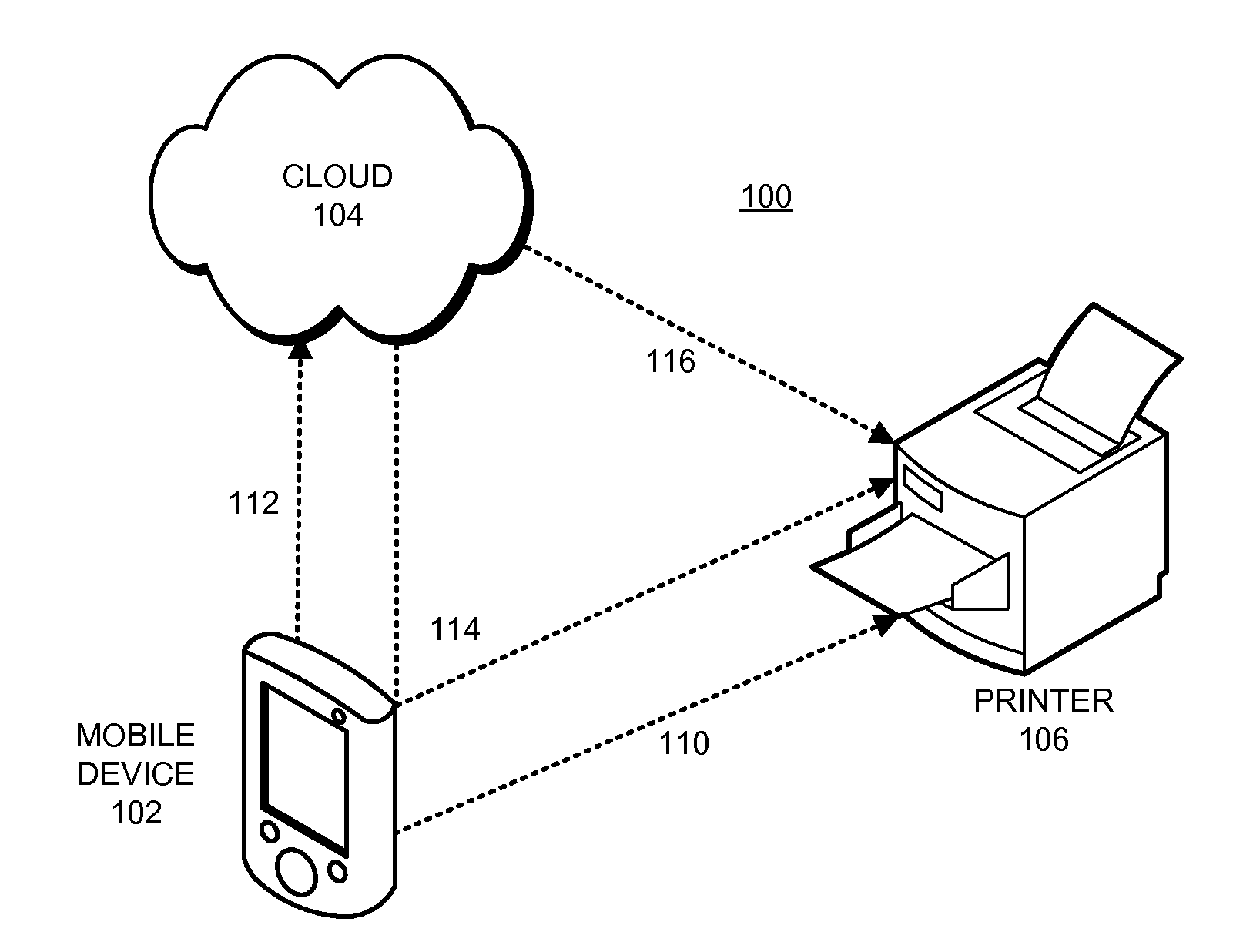

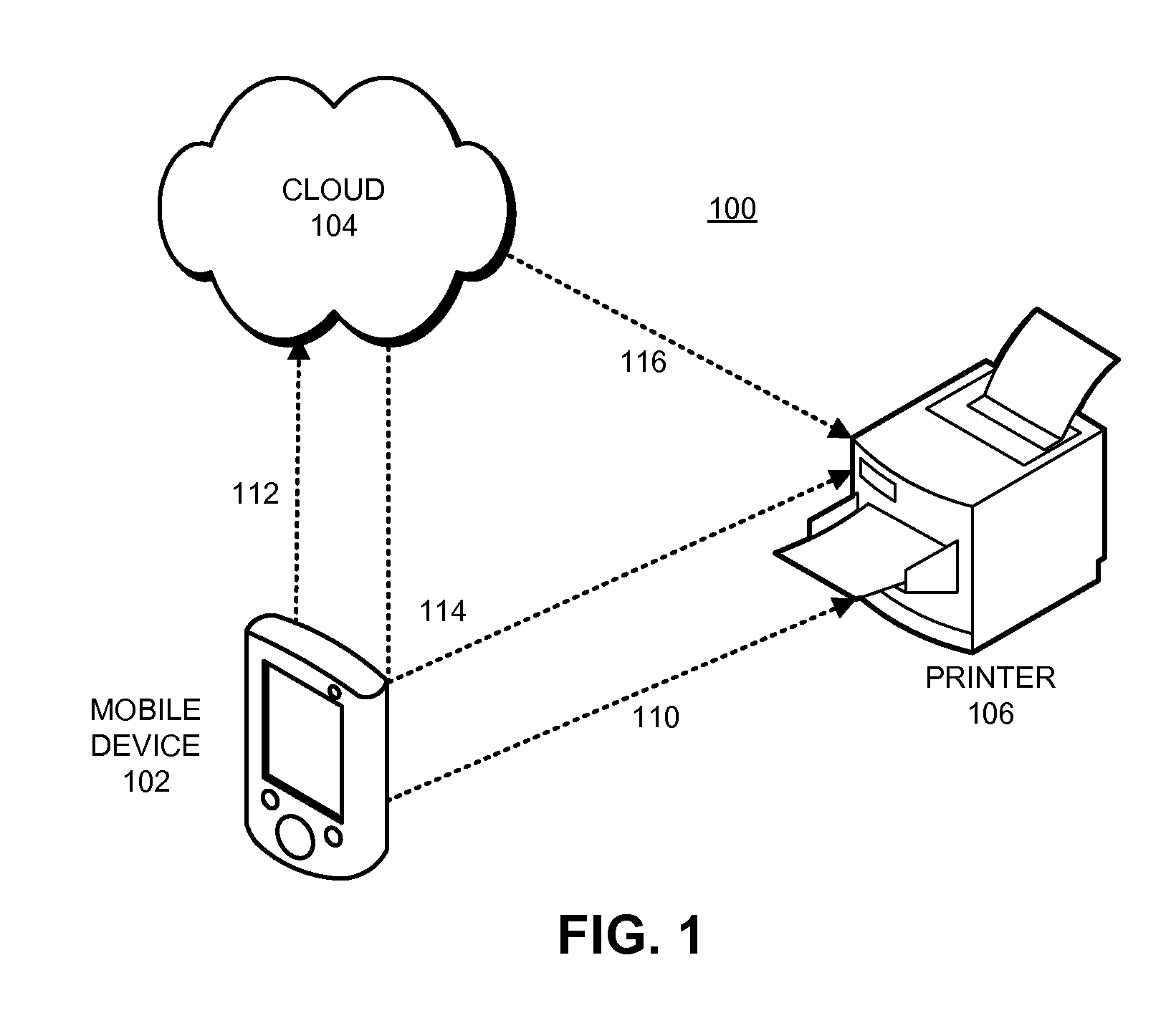

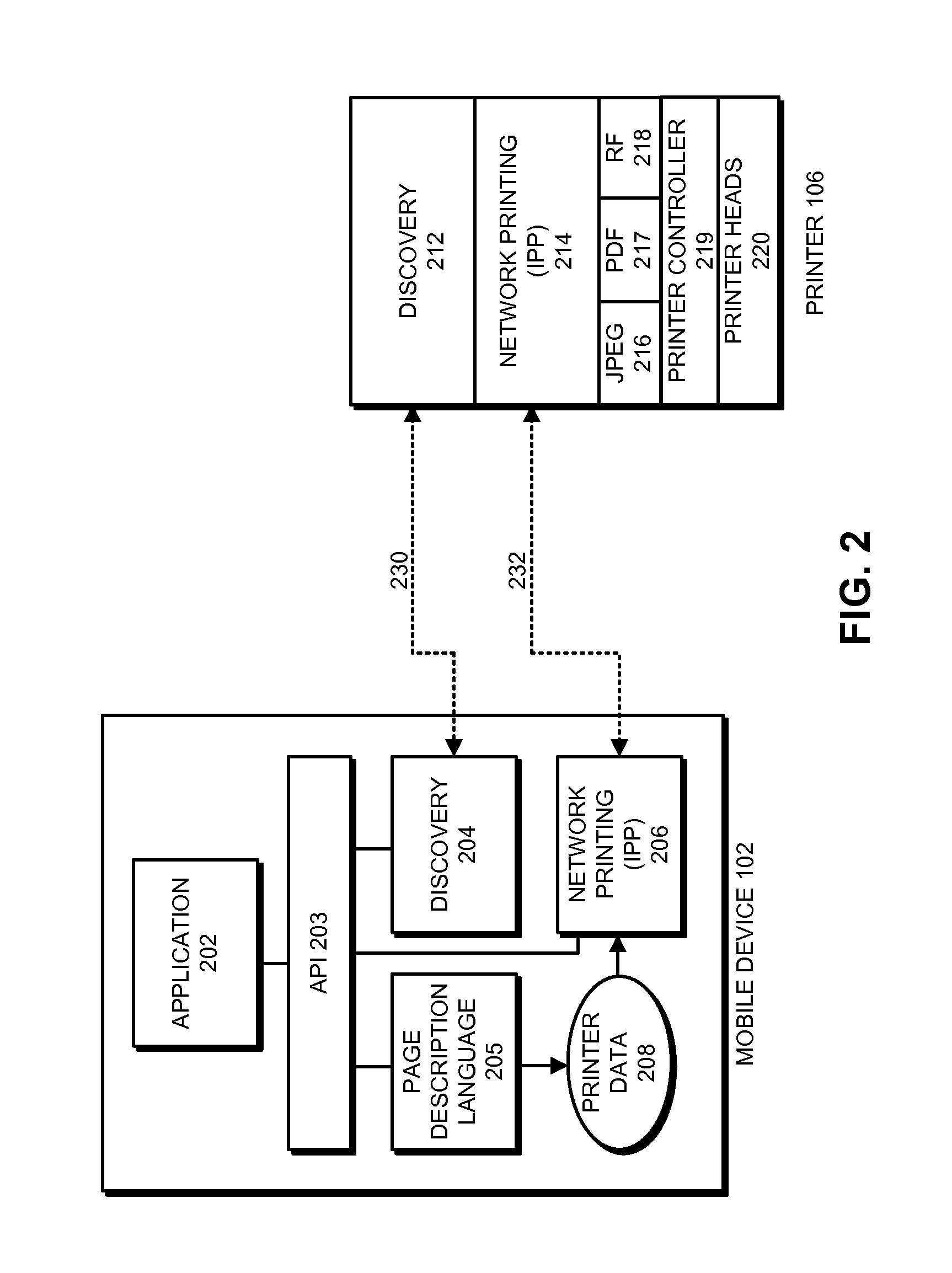

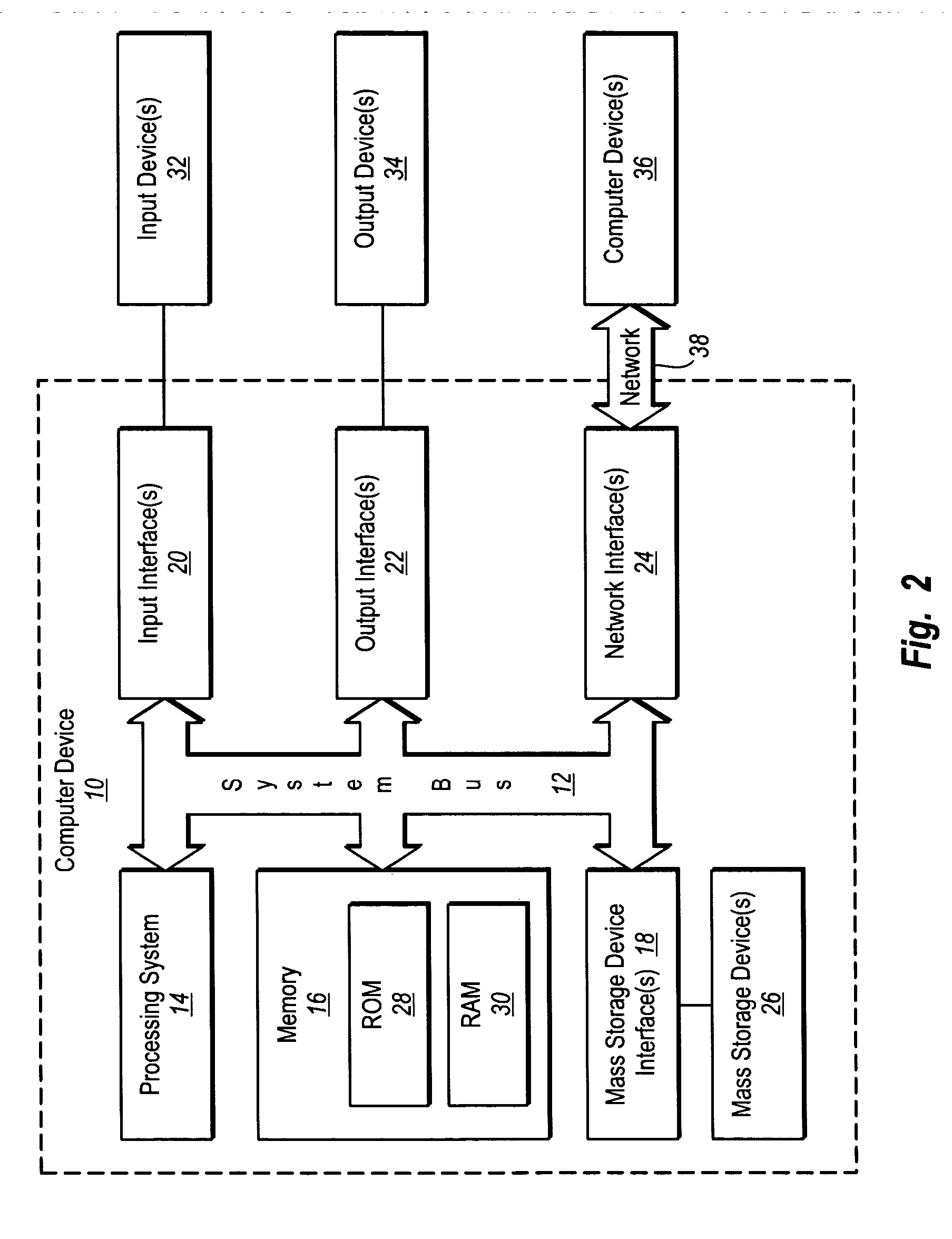

Walk-up printing without drivers

ActiveUS20110194140A1Reduce file sizeReduce in quantityDigitally marking record carriersVisual presentation using printersDistributed computingDirect printing

The disclosed embodiments provide a system that supports printing from a computing device. During operation, the system uses a discovery protocol to identify printers that can be accessed by the computing device. Next, the system receives a selection of a printer that can be accessed by the computing device. The system then generates printer data for the print job. This can be accomplished in a number of ways. The system can use a driverless printing technique, which involves obtaining printer capability information from the selected printer and generating printer data for the selected printer based on the printer capability information. Alternatively, the system can use a printer-specific driver for the selected printer to generate the printer data. The system can also send the print job to a cloud, which includes one or more servers that provide a printing service, so that the cloud can generate the printer data. Finally, the system sends the generated printer data to the printer.

Owner:APPLE INC

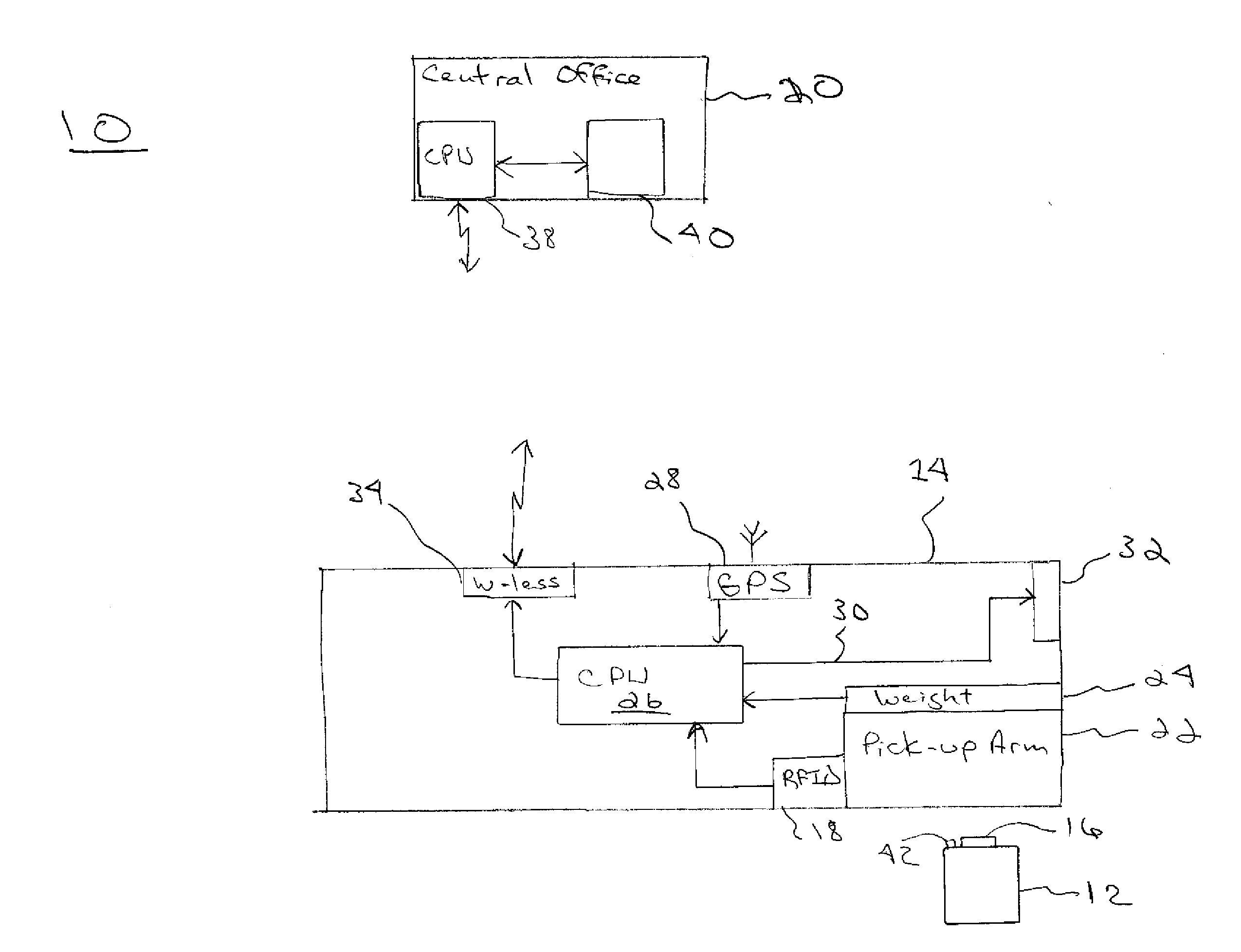

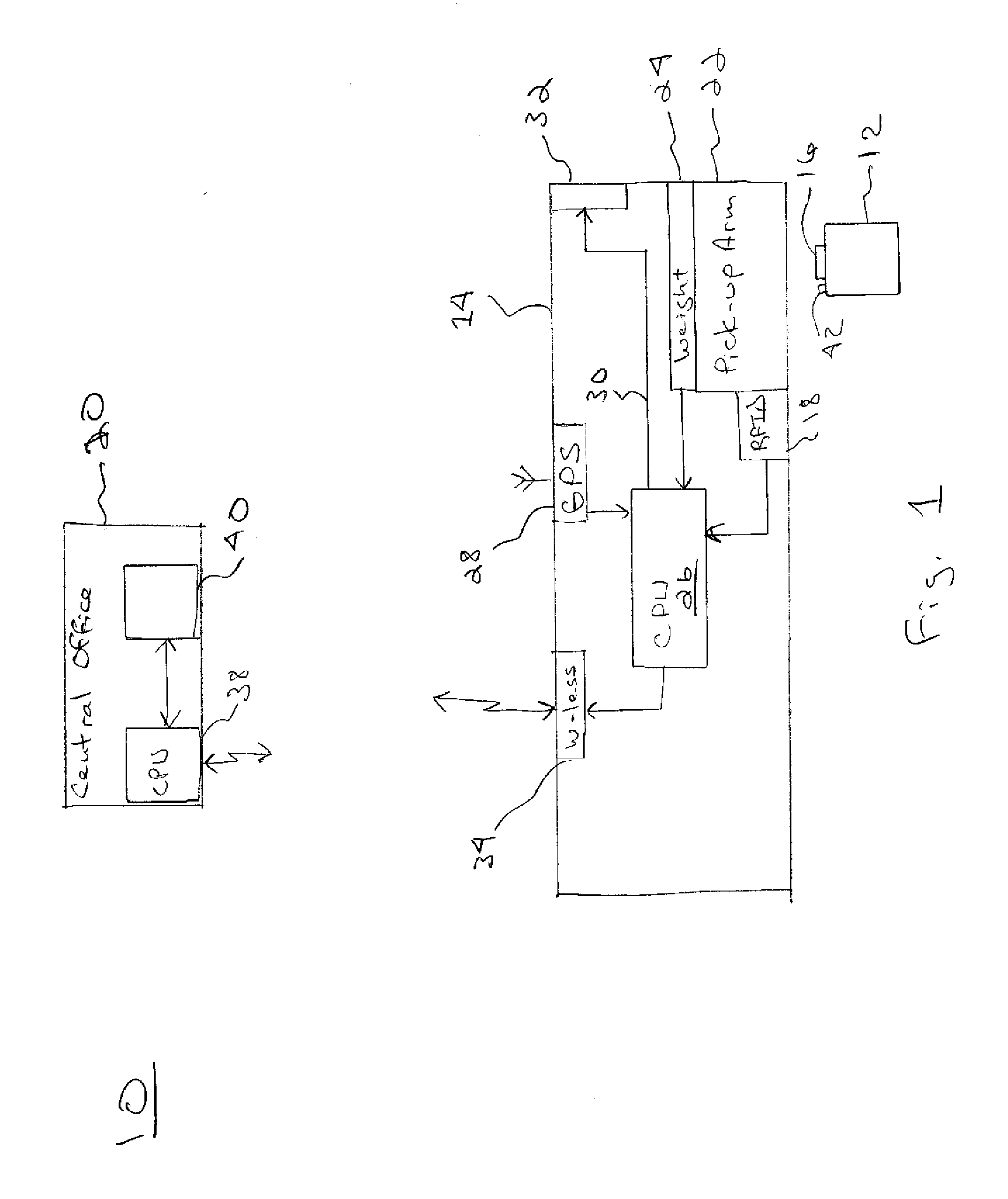

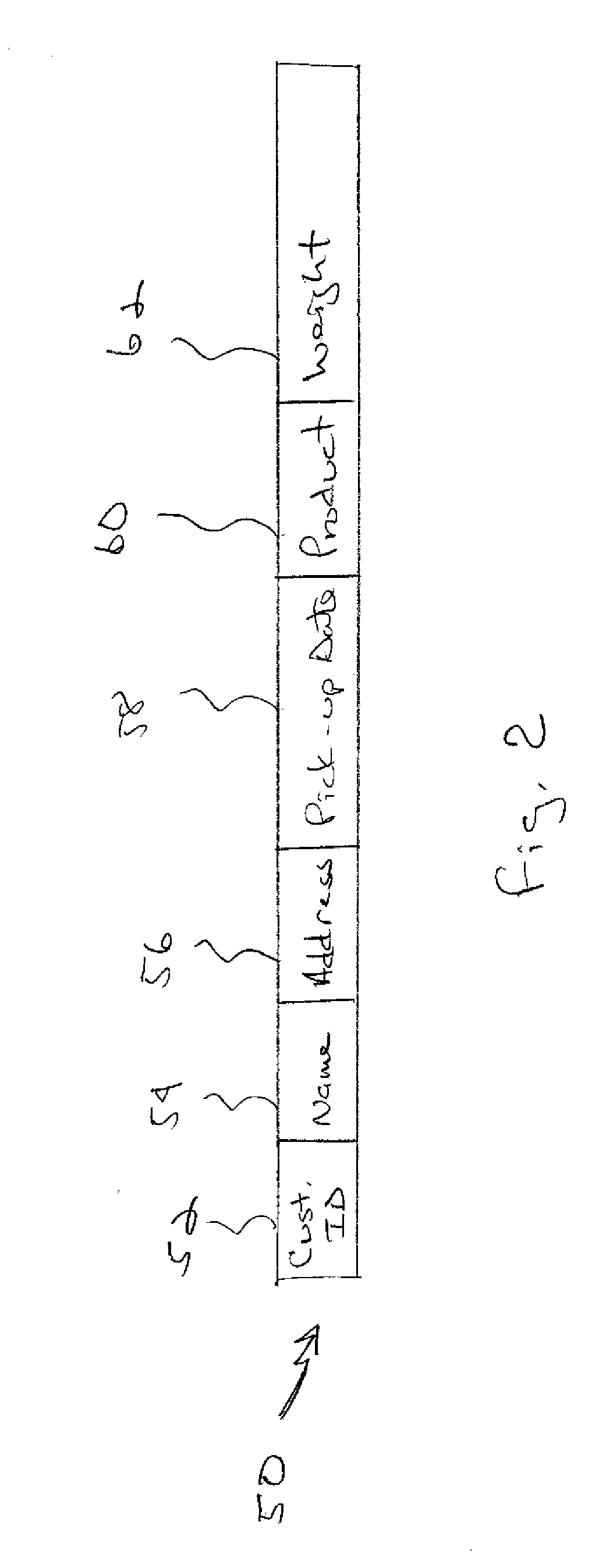

System and method for associating RFID smart labels with customer database records for use with automated tracking of waste and recyclable material

InactiveUS20110279245A1Quickly accurately associatingDigitally marking record carriersDigital computer detailsComputer printingHand held

A method of quickly and accurately associating a customer name and address with a unique RFID identification tag to be used on a waste or recyclable materials container by the customer. A self-adhesive RFID label including an embedded RFID identification tag is provided in an envelope. Using a hand-held RFID tag reader or more preferably, an RFID reader mounted in a printer coupled to a computer device, a customer name and address is selected from a database and printed on an envelope or directly on the RFID label. Using the RFID reader in the printer and while the customer name and address is being printed, the unique RFID identification number from the RFID identification tag is read, provided to the computer device and automatically inserted into the customer database record, thereby associating the unique RFID identification tag number with the customer record. The RFID label is then delivered (mailed) to or picked up by the customer, all without need to send someone to a customer site to read the RFID tag associated with a waste or recycle bin and associated with the customer record. The customer can then easily apply the self-adhesive label with the RFID tag to their appropriate waste or recycle container.

Owner:ADVANCED MFG CONTROL SYST

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

An environment-friendly digital ink-jet direct printing textile ink and method for preparing same

ActiveCN101531848ASolve problems such as easy to cause pollution to the environmentSolve problems such as pollutionInksDyeing processUltra fineEngineering

An environment-friendly digital ink-jet direct printing textile ink and method for preparing same, the digital ink-jet direct printing textile ink composed of components as follows: pigment paste, connection materials, cross-linking agent, softening agent, solvent, surfactant, bactericide, pH regulating agent, and deionized water. The pigment paste is a mixture of the following components: pigments, ultra-dispersing agent, wetting agent, and deionized water. The preparation method includes: a. mixing the pigments, ultra-dispersing agent, wetting agent, and deionized water into a pigment paste, mixing the pigment paste at high-speed and then grinding it in an ultra-fine nano-grinding machine, to obtain the nano stage ultrafine grain paste; b. mixing the proportioning mixture with the grinded nano stage ultrafine grain paste, high-speed stirring and then filtering to obtain a finished environment-friendly digital ink-jet direct printing textile ink. The inventive printing textile ink does not contain formaldehyde, can be direct digital printed wtihtout plate-making when in use, and has rich color, soft hand feeling, and capability of allowing the digital ink-jet printing textile materials to meet the high environmental and quality requirements.

Owner:深圳市墨库图文技术有限公司

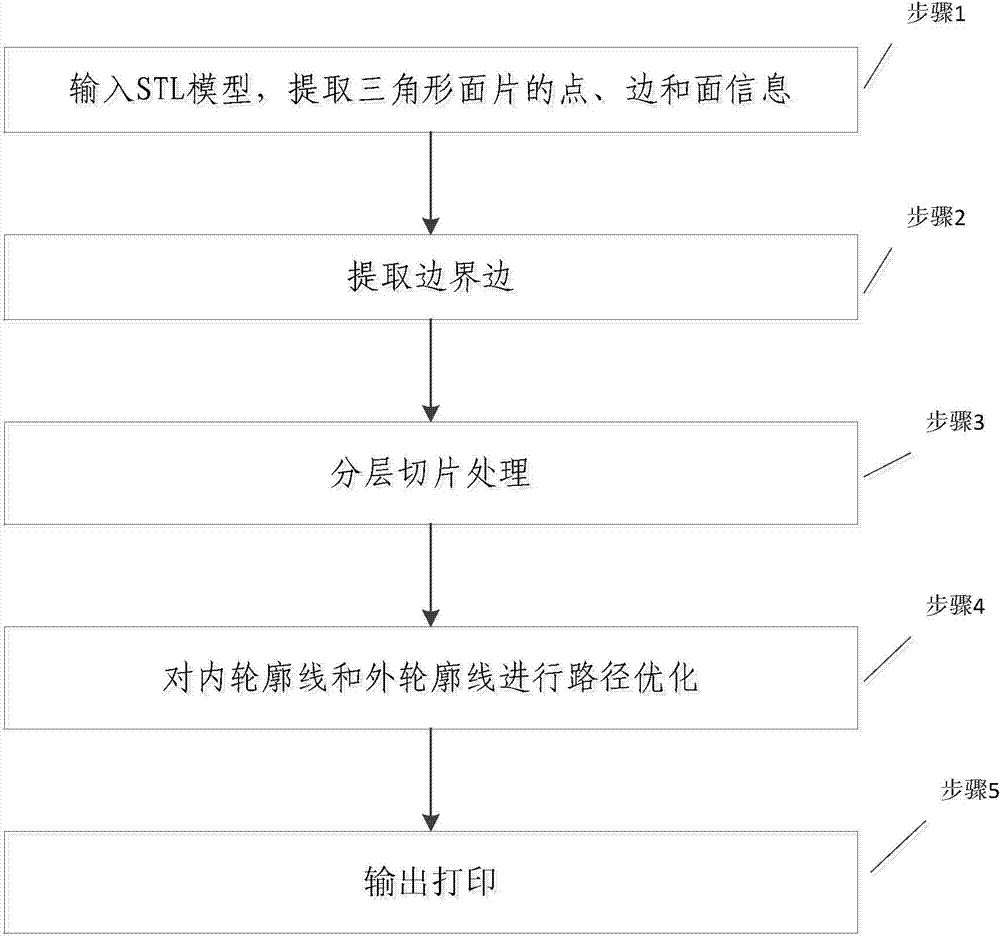

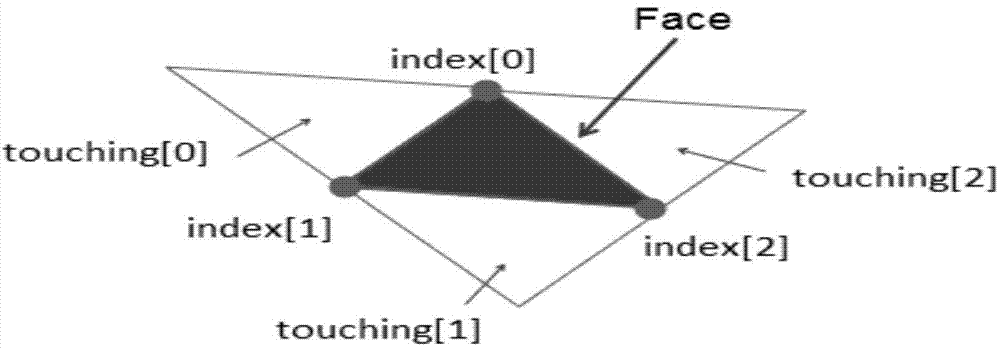

Slicing processing method aiming at non-closed STL model with boundaries

InactiveCN104331555ATroubleshoot slice handling issuesImprove molding efficiencySpecial data processing applicationsComputer graphics (images)3d printer

The invention discloses a slicing processing method aiming at a non-closed STL model with boundaries for a 3D (three-dimensional) printer. The method comprises the following steps that point, edge and surface information of triangles in an STL model are extracted, and in addition, the topology relationship among the point, edge and surface information is built; all boundary edges are extracted according to the boundary edge judging rule; lamination slicing processing is carried out on non-closed lattices to obtain non-closed 2D polygons; printable inner and outer contour lines obtained after the deflection processing on the polygons are subjected to path optimization for reducing idle strokes; a slicing file is used for outputting universal Gcode files which are read and printed by the 3D printer. The invention provides the slicing method aiming at non-closed STL model input from the boundary extraction aspect for the first time, and breaks through the limitation that the traditional 3D printer can only carry out the slicing processing on the closed STL model, and the slicing processing on the non-closed STL model with the boundaries is realized, so that the non-closed STL model can be directly printed and formed.

Owner:上海极臻三维设计有限公司

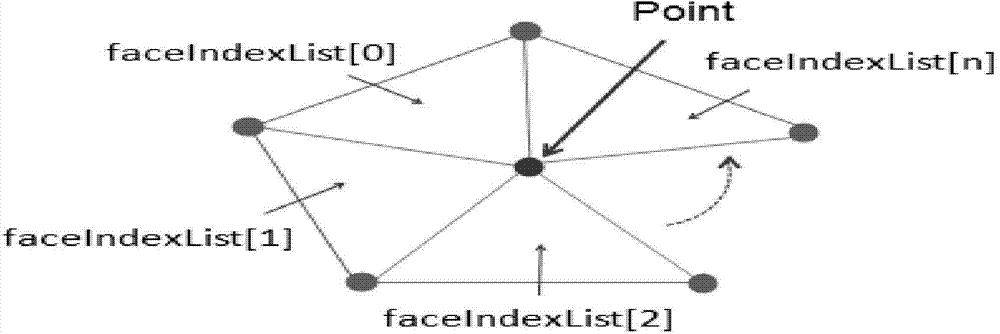

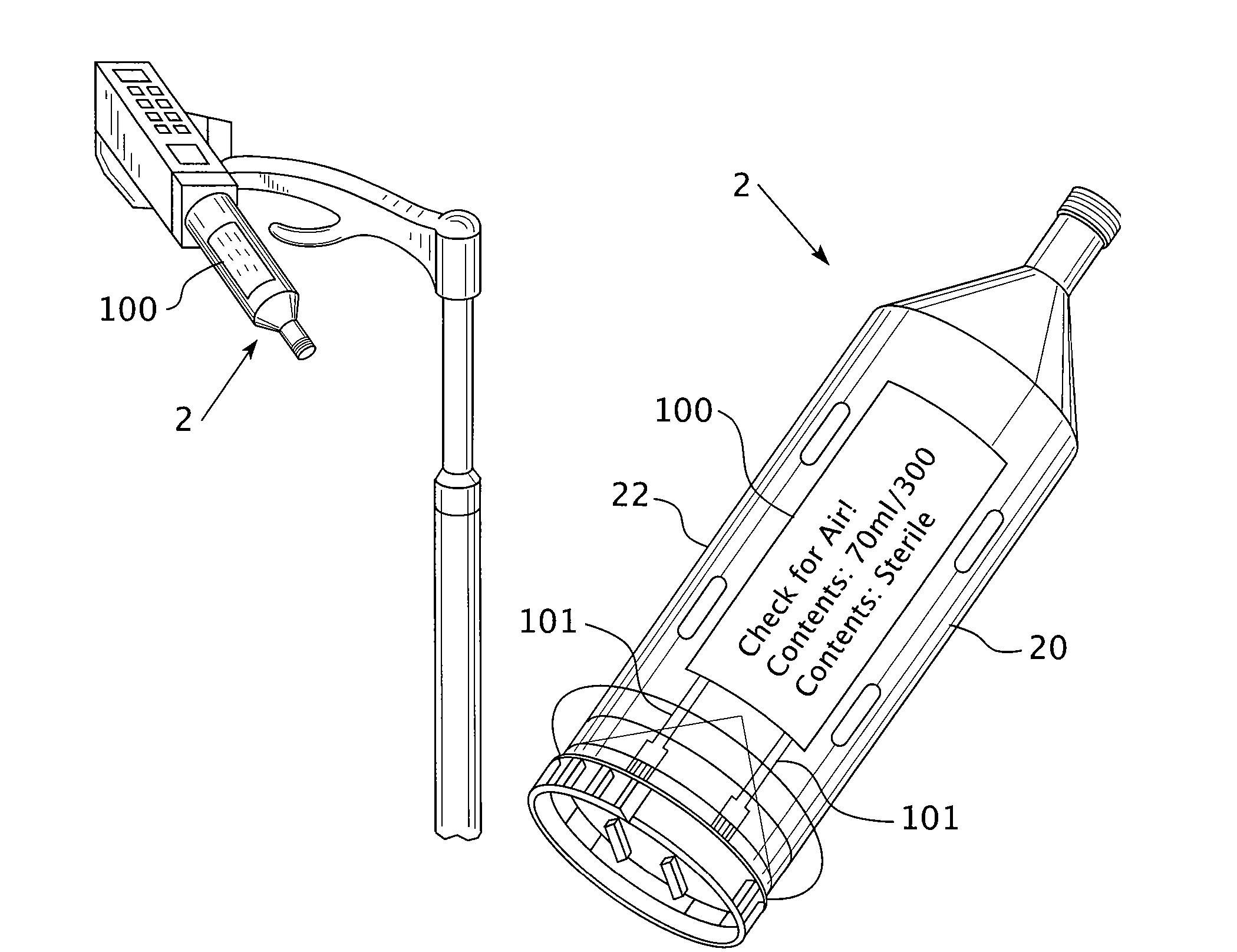

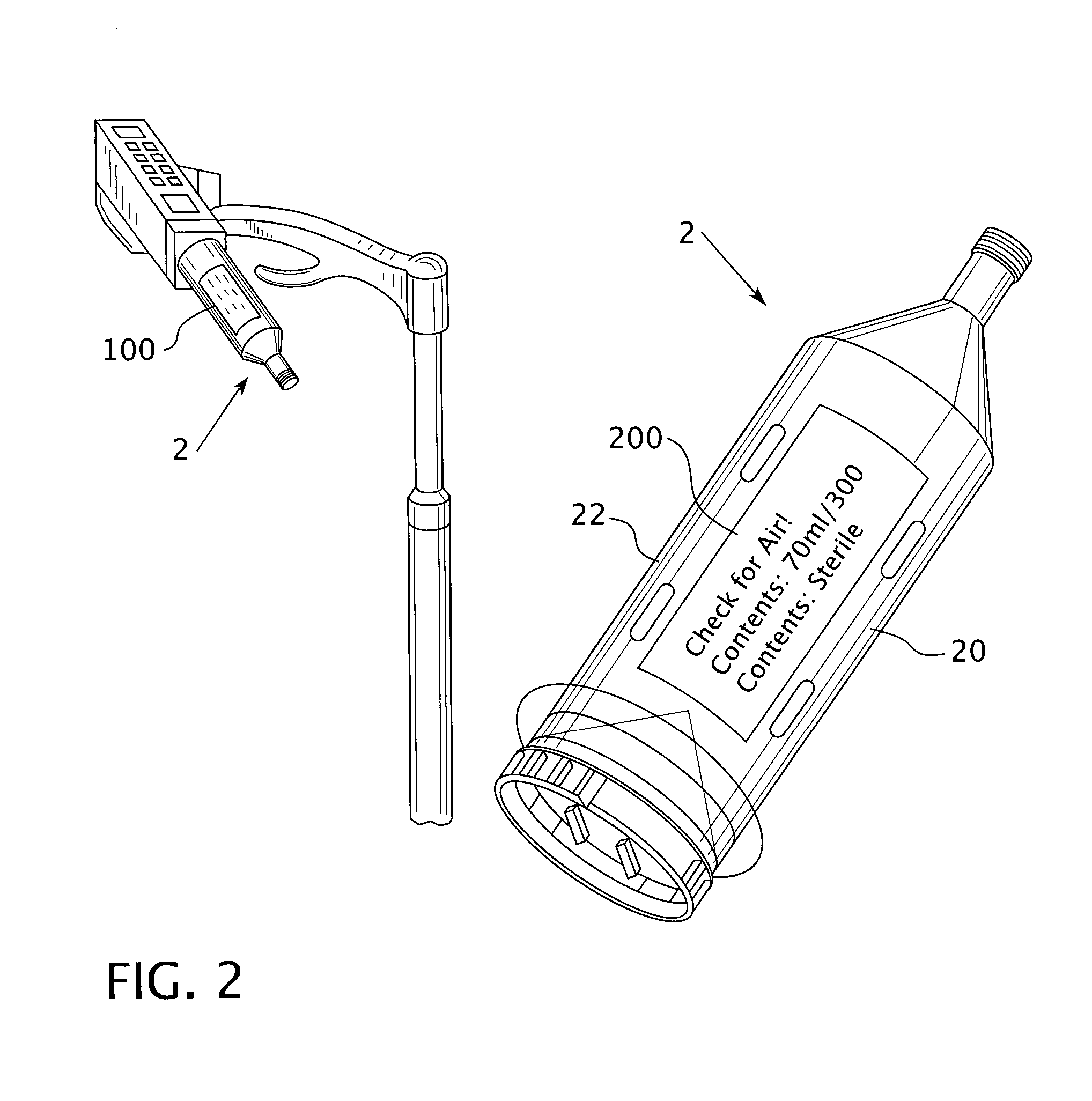

Devices, methods and applications for intelligent medical packaging

InactiveUS20070056871A1Easy to manufactureEnhanced information displayContainer decorationsLevel indicationsVisibilityCommunication interface

An intelligent package system for holding or delivering medical pharmaceuticals, controlled substances, or hazardous materials includes at least one integral active display, a controller and one or more of the following: a programmable memory; one or more sensors; a communication interface device; a power source; one or more user input devices; and an externally connected device in communication with the controller / display. The active display allows static as well as dynamic visual information to be presented, and may be printed or stamped directly onto the surface of the pharmaceutical container or packaging to provide for enhanced information display, access, and visibility.

Owner:MEDRAD INC.

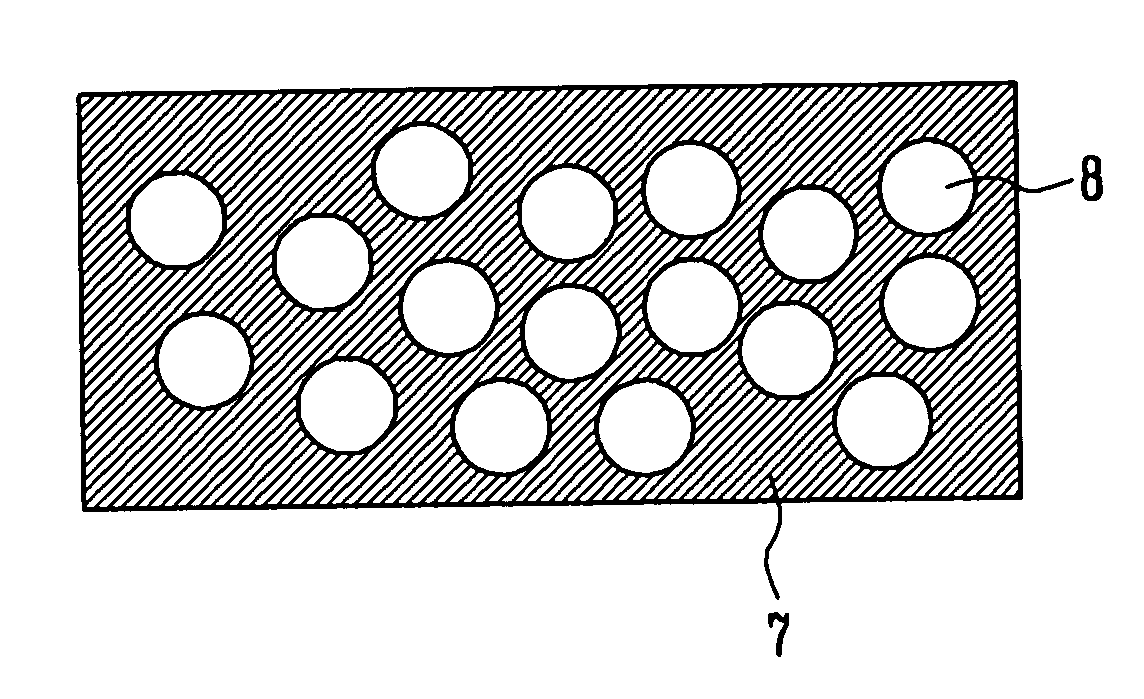

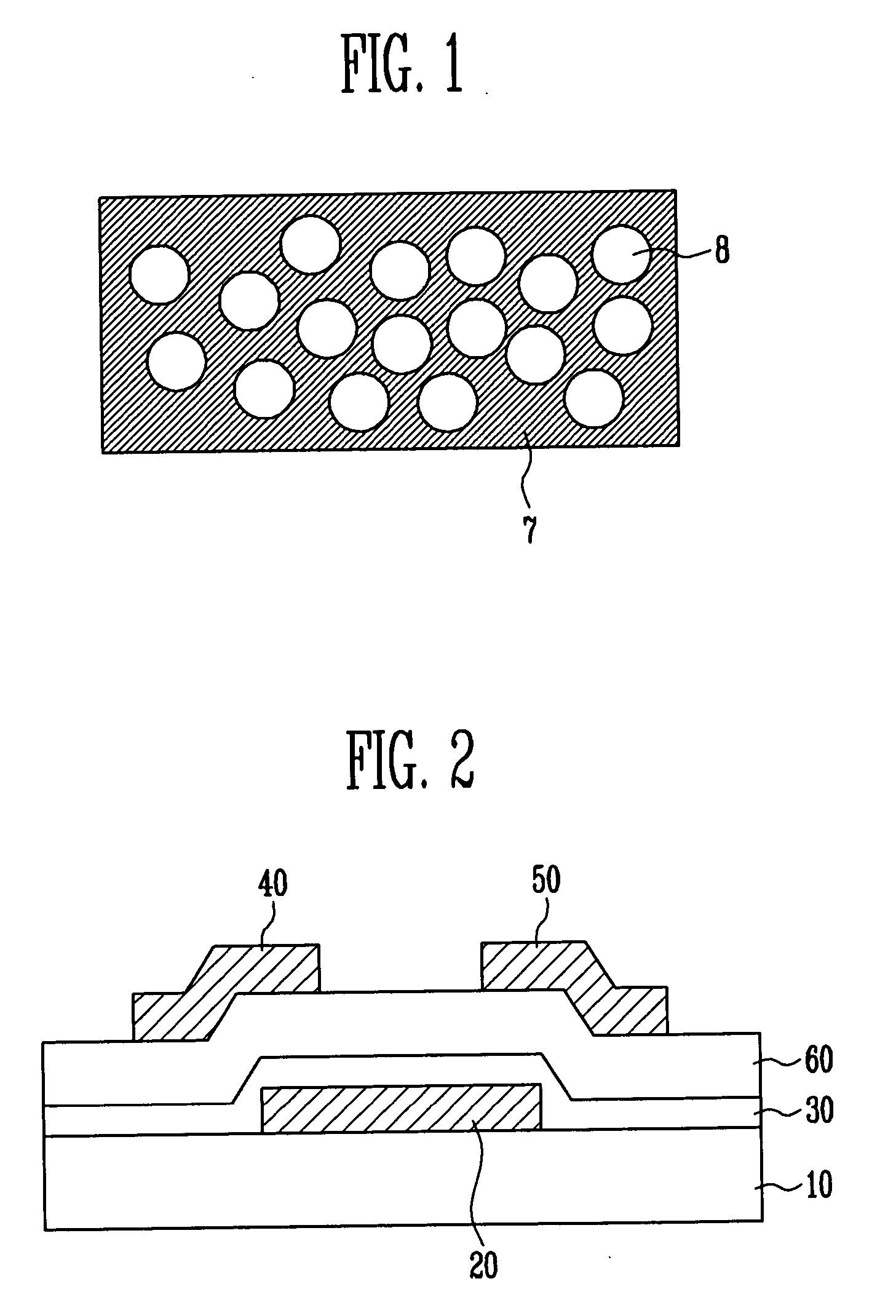

Conductive ink, organic semiconductor transistor using the conductive ink, and method of fabricating the transistor

InactiveUS20060124922A1Large work functionNot to damageMaterial nanotechnologySolid-state devicesConductive polymerEngineering

Provided are a conductive ink, organic semiconductor transistor using the conductive ink, and method of fabricating the transistor. The conductive ink is used to form electrodes on an organic semiconductor while minimizing the damage of the organic semiconductor. The conductive ink is formed by mixing metal nanoparticles with a conductive polymer and used as an electrode material during the fabrication of the organic semiconductor transistor using a direct printing process. By using the conductive ink as the electrode material, the production cost of the organic semiconductor transistor can be greatly reduced.

Owner:ELECTRONICS & TELECOMM RES INST

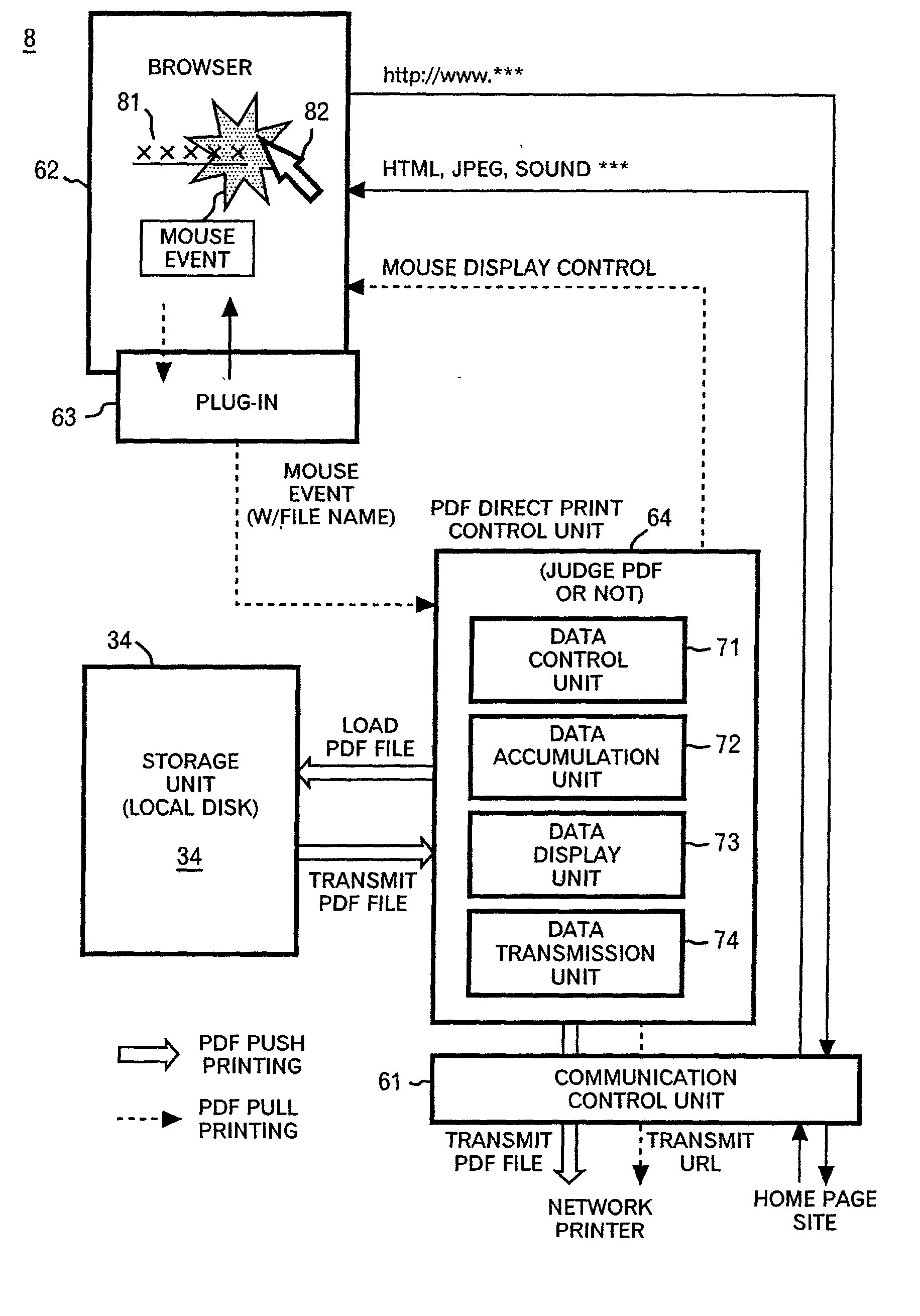

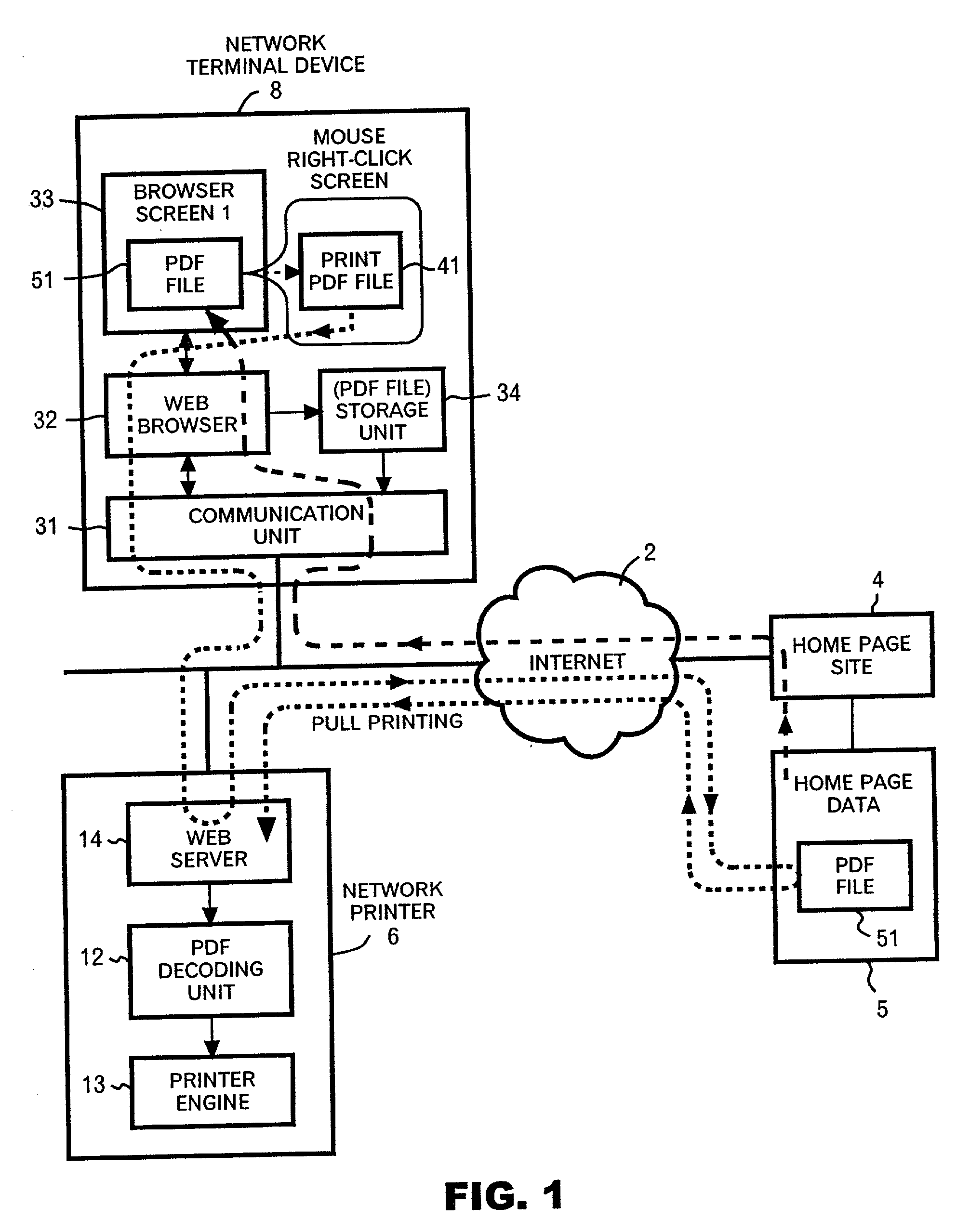

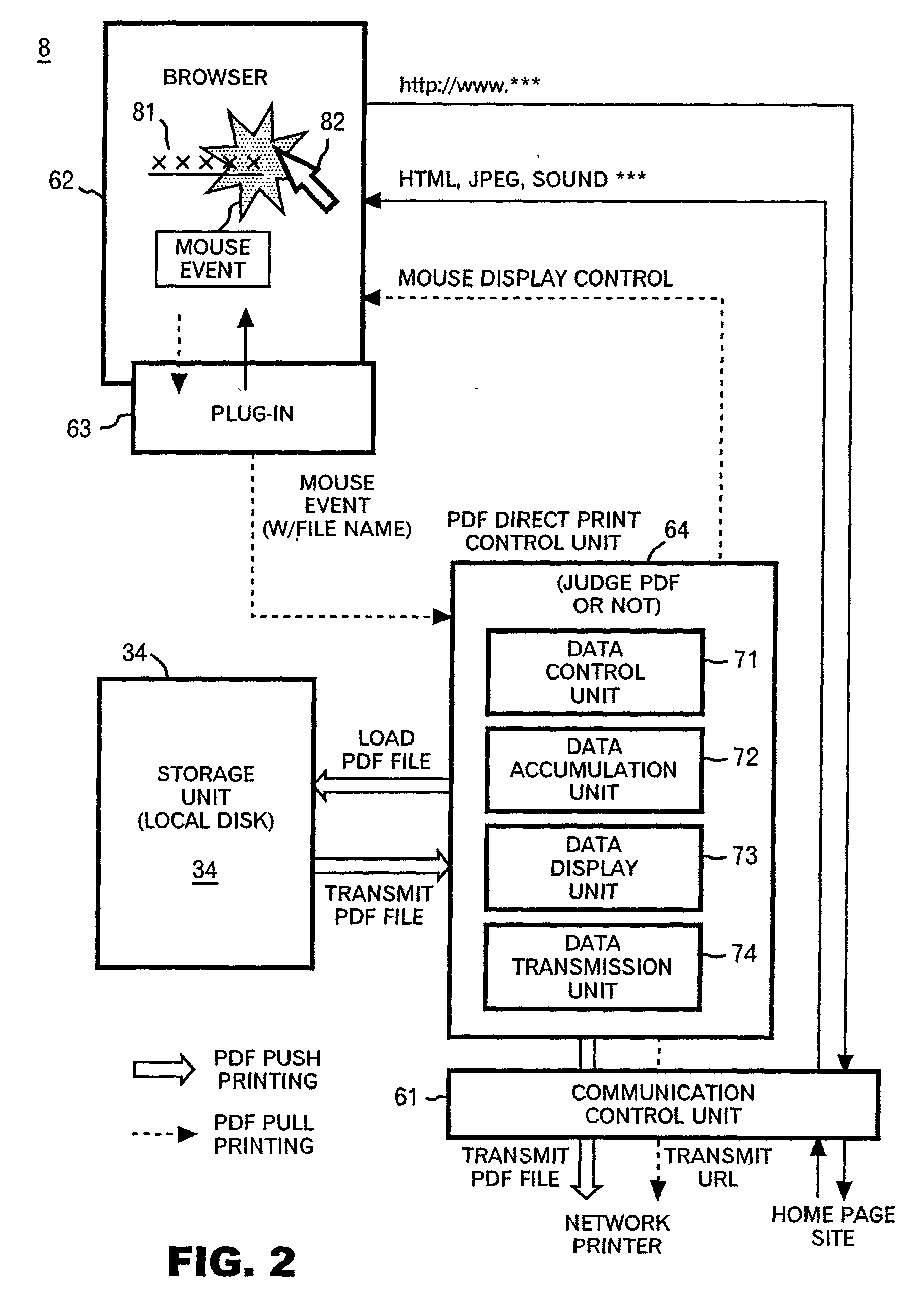

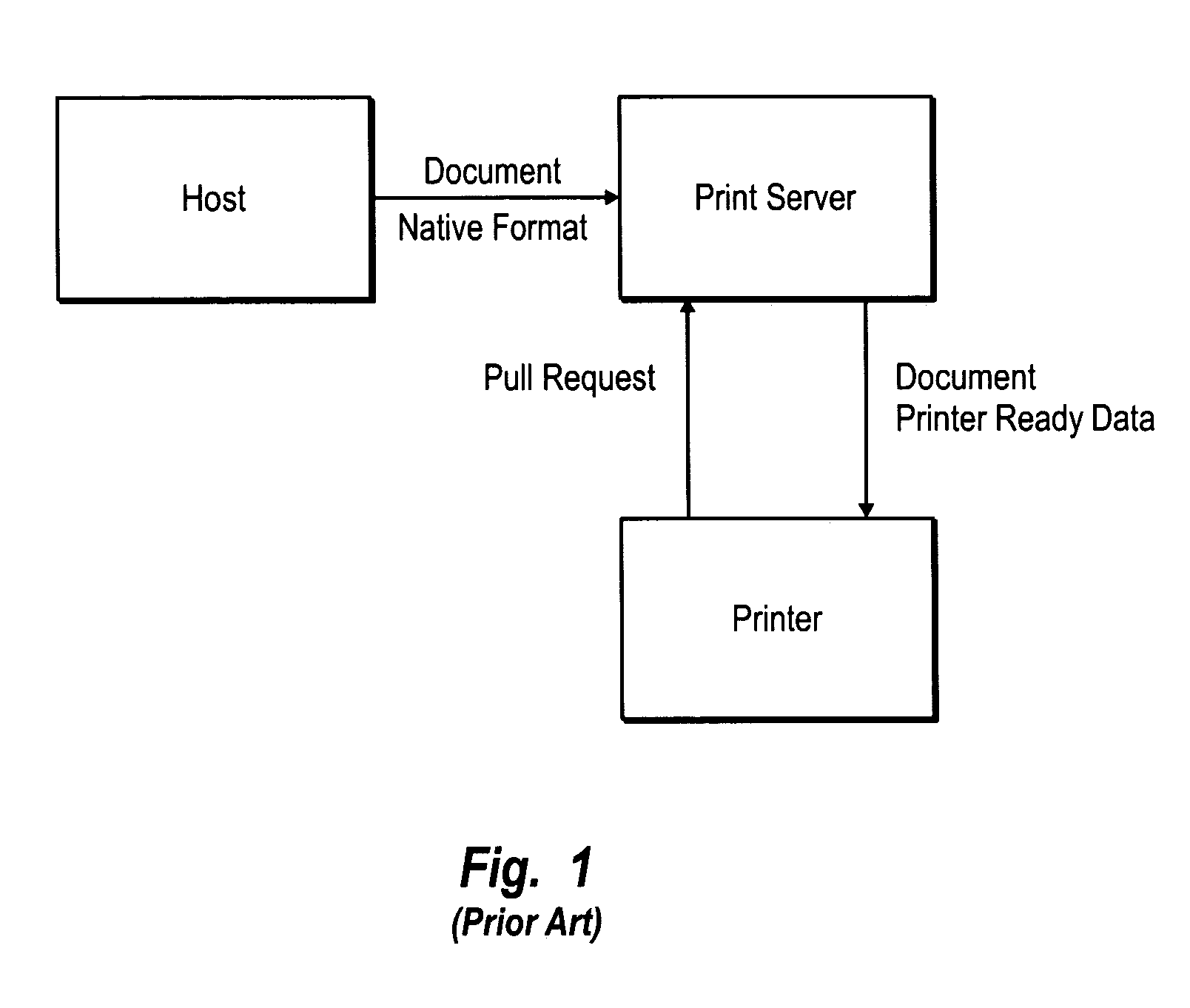

Program and method of print instruction for printer with PDF direct printing function

InactiveUS20020126306A1Easy for to instruct print operationEasy to operateData processing applicationsDigital computer detailsNetwork terminationWeb browser

A print instruction program and method for allowing a network terminal device to send print instructions to a PDF direct-printing printer in a communications network in an efficient and advantageous manner. The program and method includes the capability to obtain PDF file name and network address data from the location of a mouse pointer in a web browser screen. The file name and address data can be stored locally on the network terminal device, preferably in a list format. The program and method also provides for the display and operation of a direct print menu in association with a click on a control button of the mouse. The program and method allows the PDF file name and address data to be sent to the network-attached printer, either singly or as part of a list and either as a network address or as an actual file.

Owner:RICOH KK

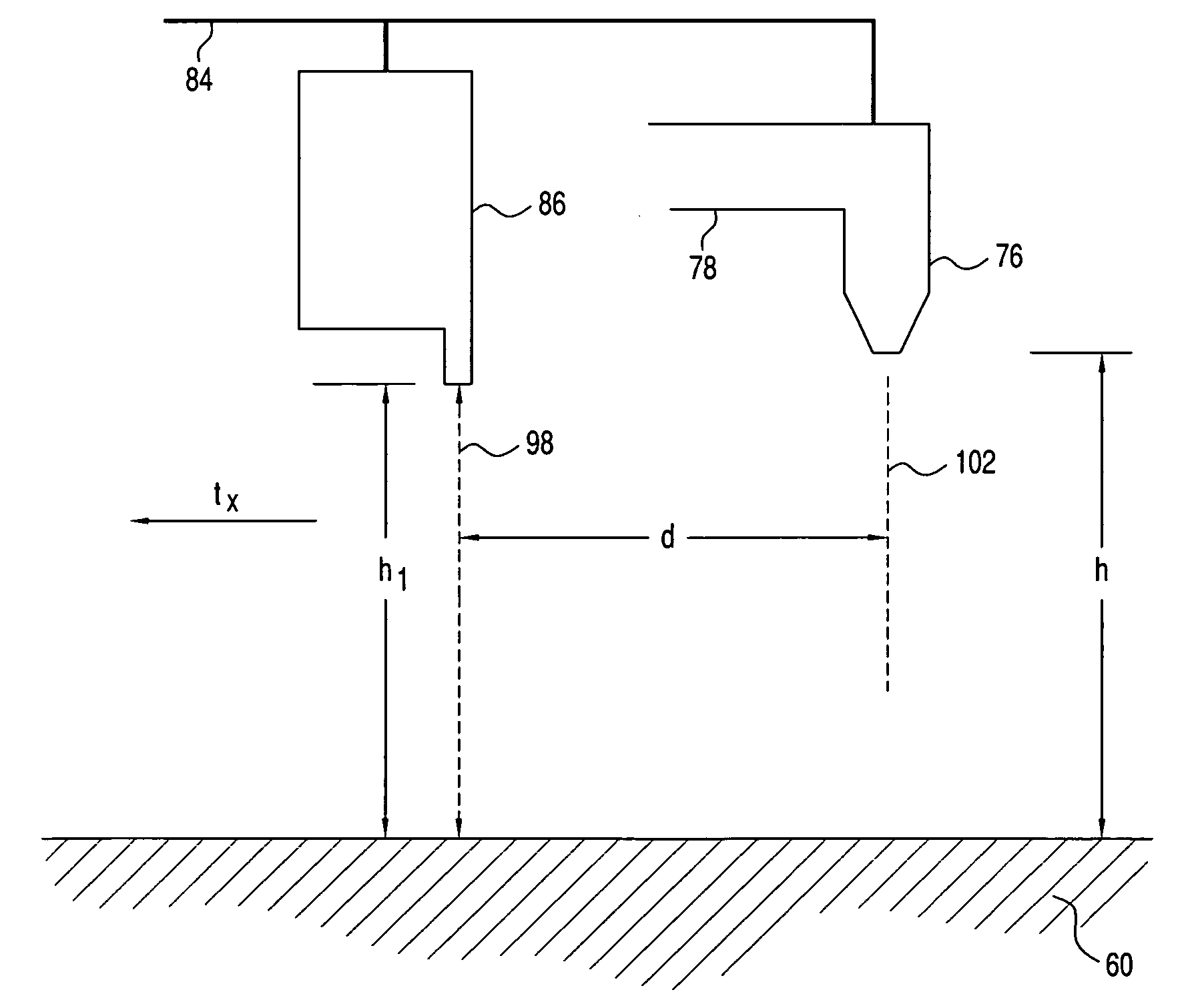

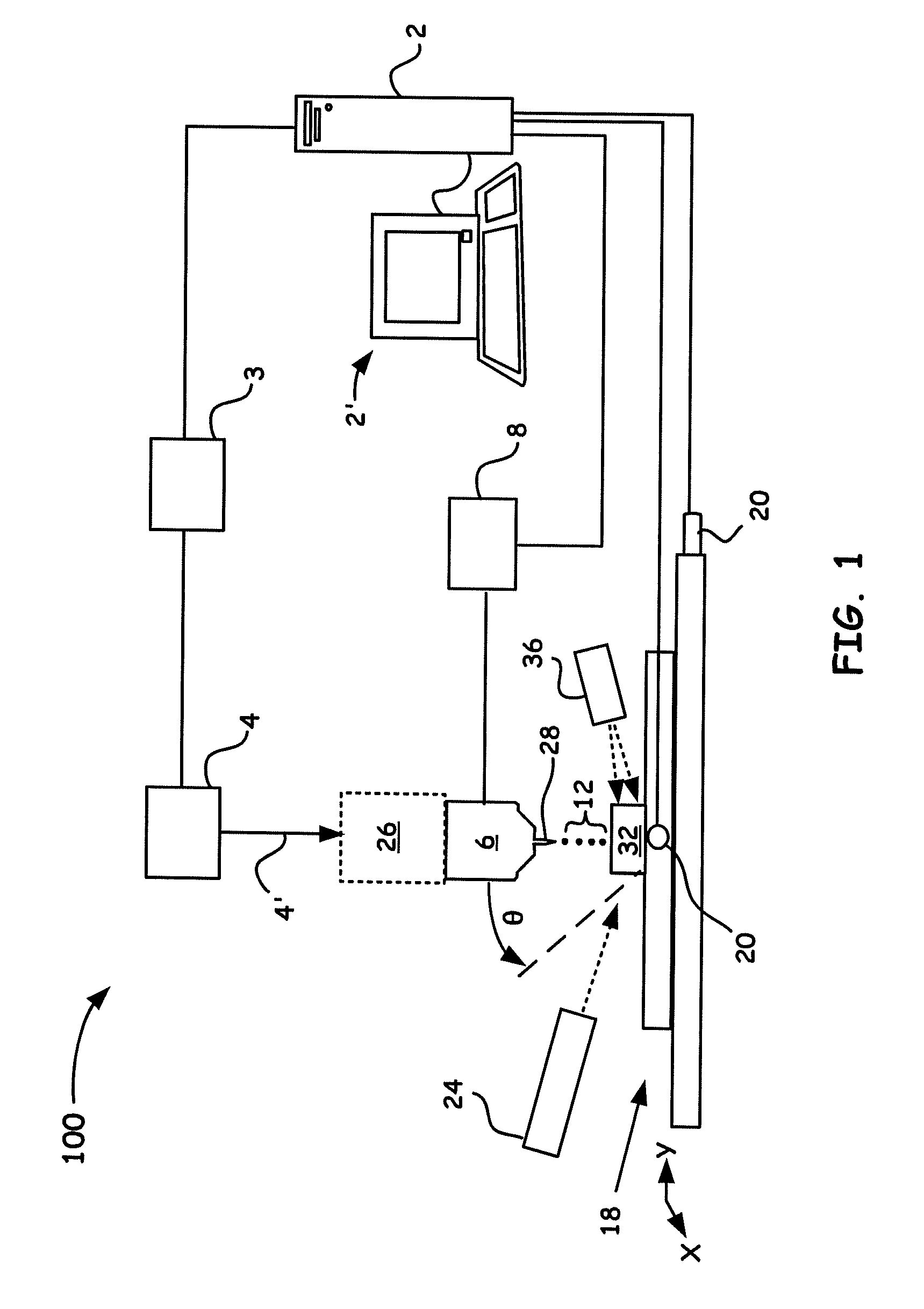

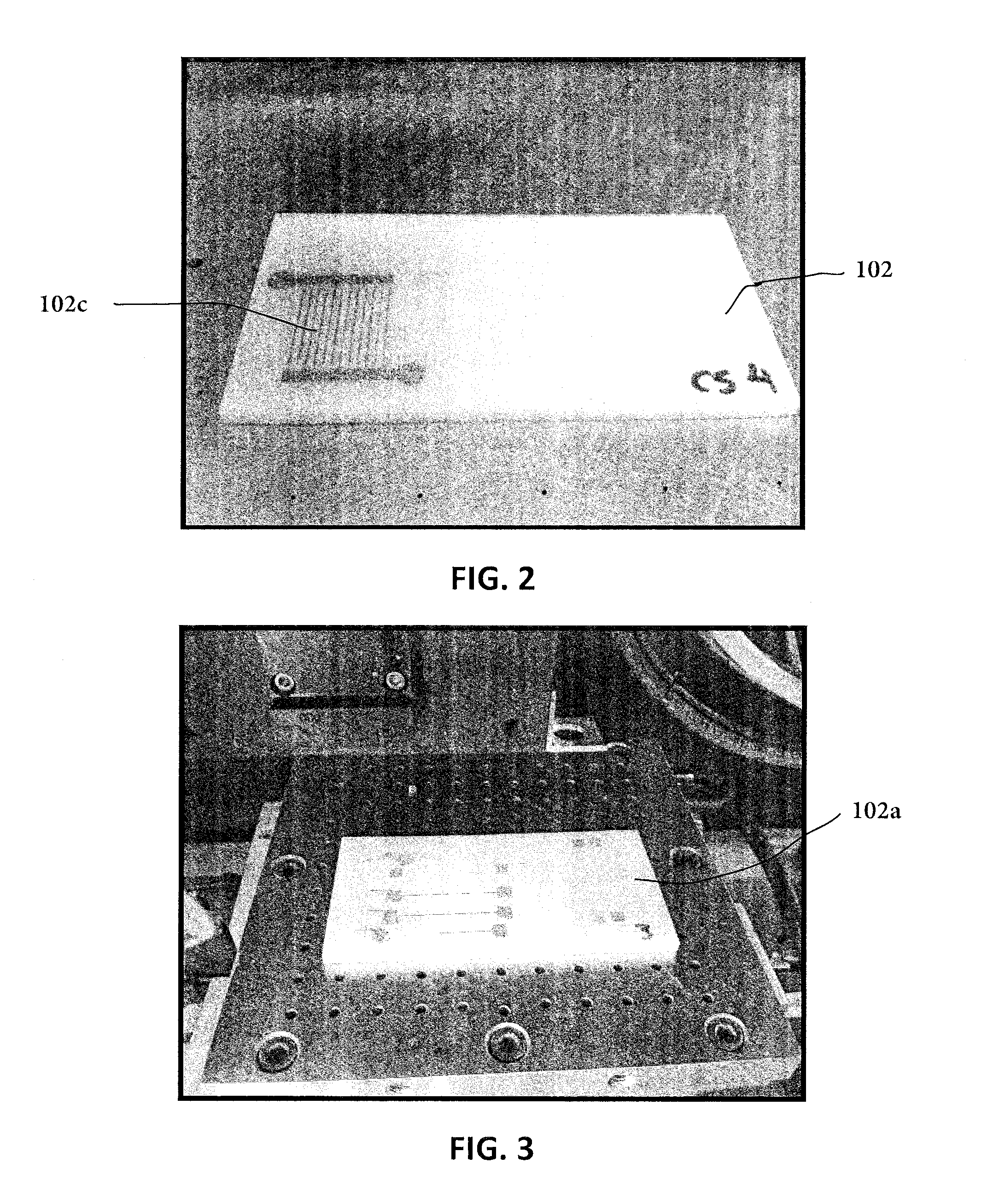

Printable electronic features on non-uniform substrate and processes for making same

A system and process for compensating for non-uniform surfaces of a substrate when direct printing traces is provided. The system and process provided herein measures the surface of a substrate and can determine whether the surface is substantially flat, rises or falls, or whether a mesa or valley is encountered. Depending on the surface feature (i.e., mesa, valley, falling or rising surface), the direct printing system can change the frequency of the printing timing signal, advance or retard the print timing signal, advance or retard the print data, or make repeated passes over certain areas. In addition, the process disclosed herein can determine whether two, three or all of the aforementioned steps for compensating for non-uniform substrates should be combined to most effectively and efficiently print on the non-uniform surface of the substrate as intended.

Owner:CABOT CORP

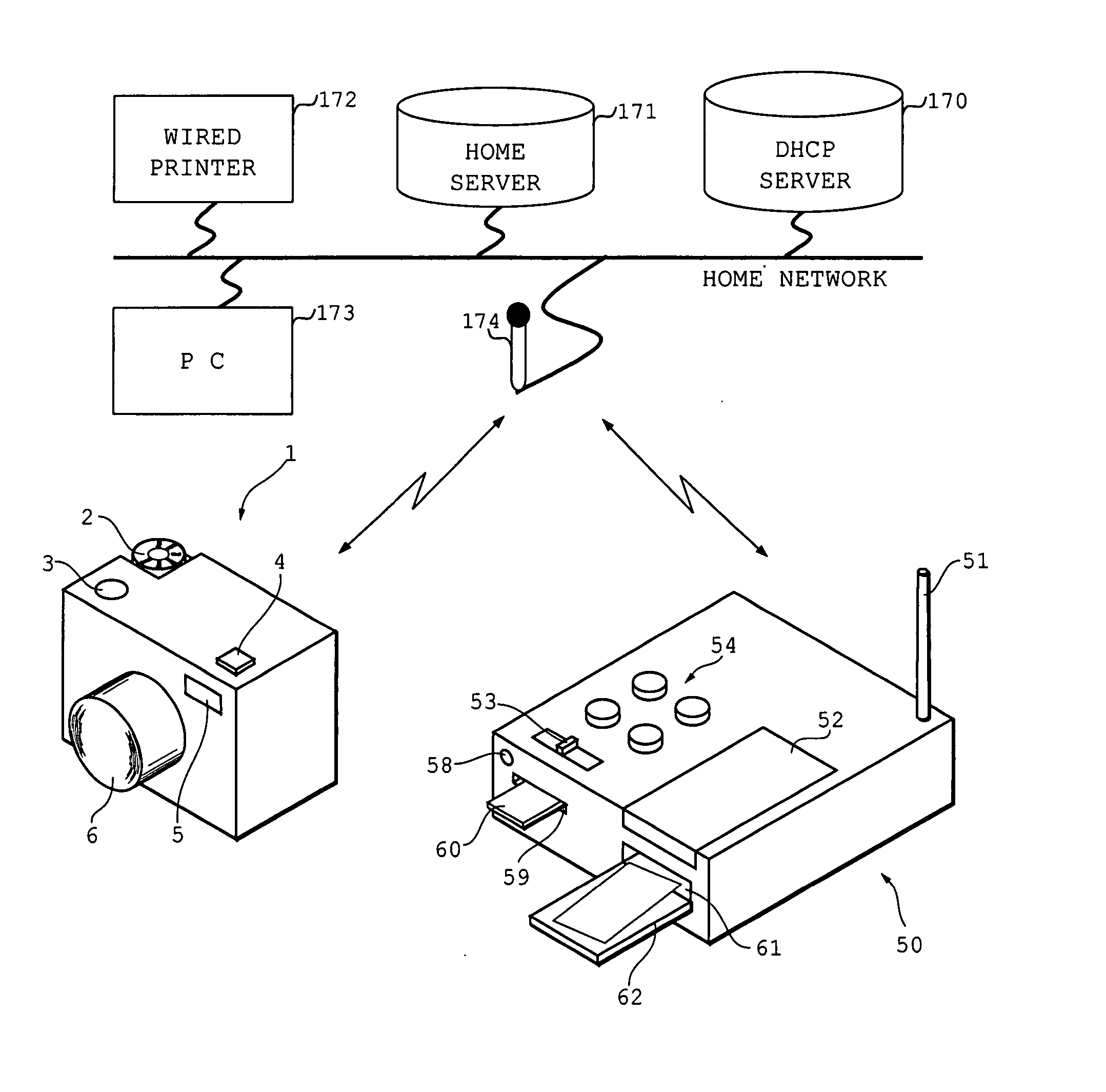

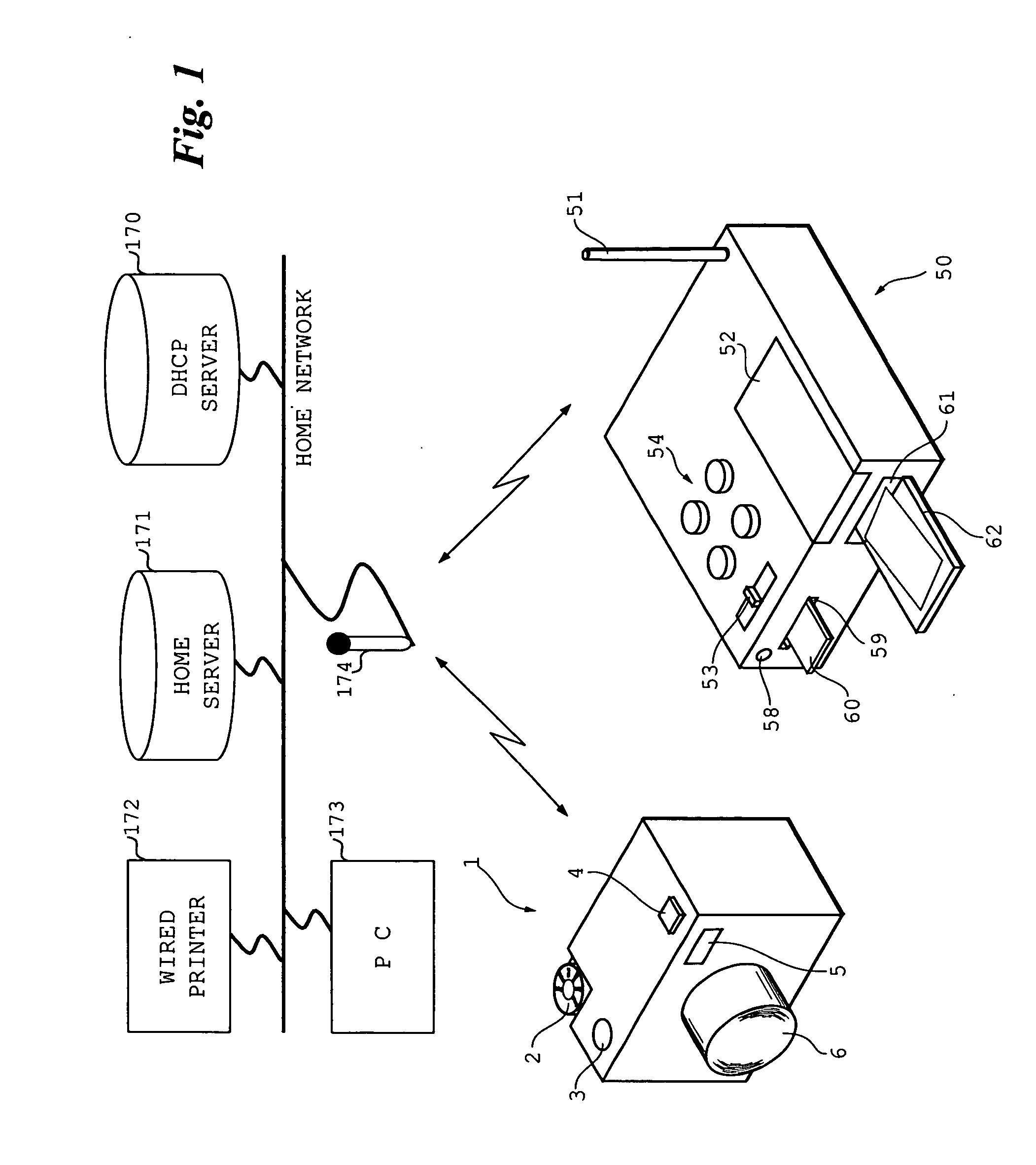

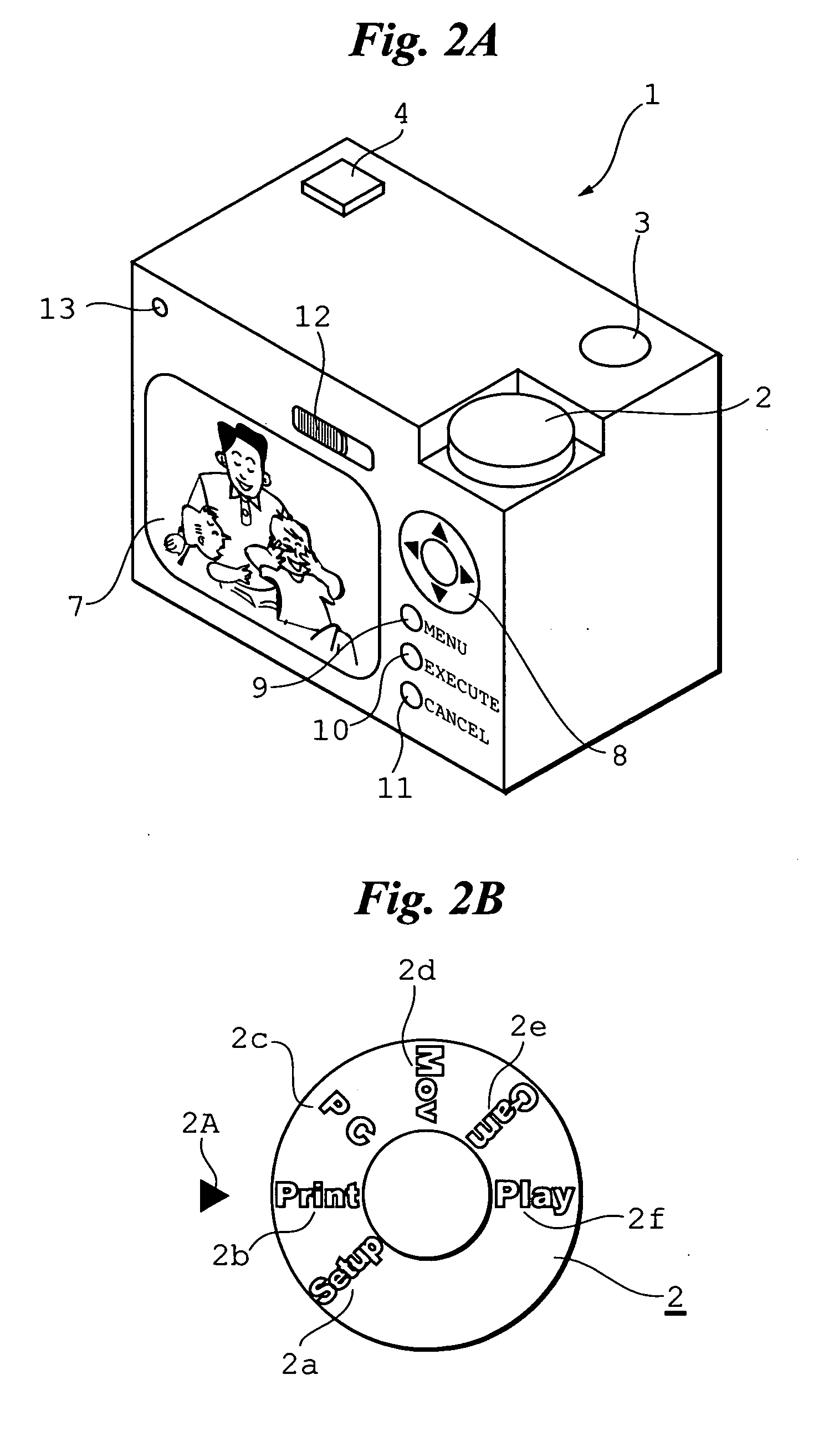

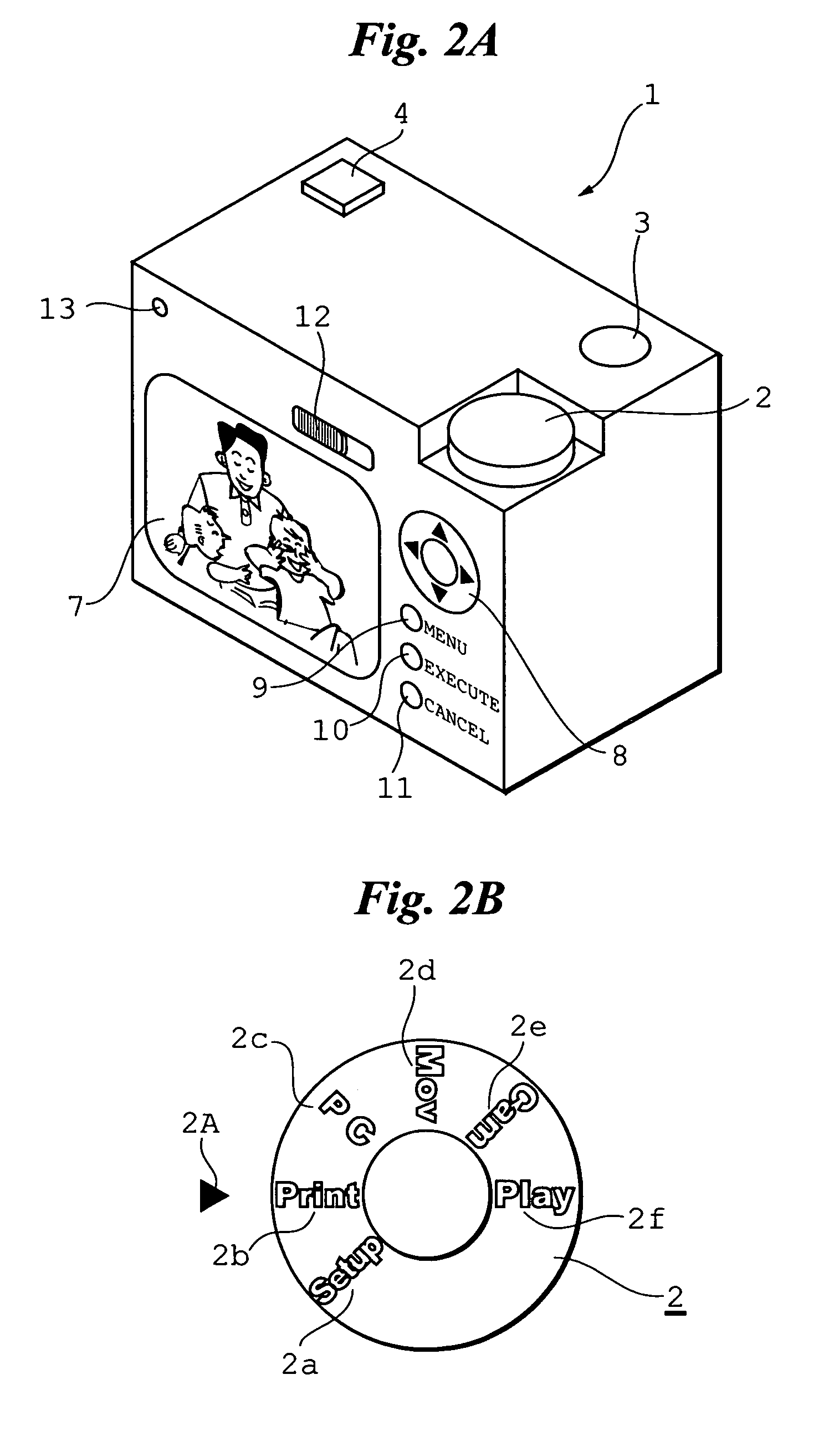

Direct print system

ActiveUS20050279833A1Simply performedCharacter and pattern recognitionSecret communicationComputer graphics (images)Ip address

Wireless-LAN information is set in a digital still camera in a comparatively simple manner. Specifically, if a digital still camera and a printer are to communicate utilizing a wireless LAN, the printer generates a two-dimensional bar code containing wireless-LAN setting information such as ESS-ID and WEP KEY, and printer setting information such as an IP address. The printer is used to generate a direct print setting sheet on which have been recorded the generated two-dimensional bar code as well as the wireless-LAN setting information and printer setting information. The digital still camera is used to take a picture of the two-dimensional bar code and read the wireless-LAN setting information and printer setting information from the two-dimensional bar code. The read wireless-LAN setting information and printer setting information is set in the digital still camera, and the printer and digital still camera cooperate to perform direct printing using the wireless LAN.

Owner:FUJIFILM CORP

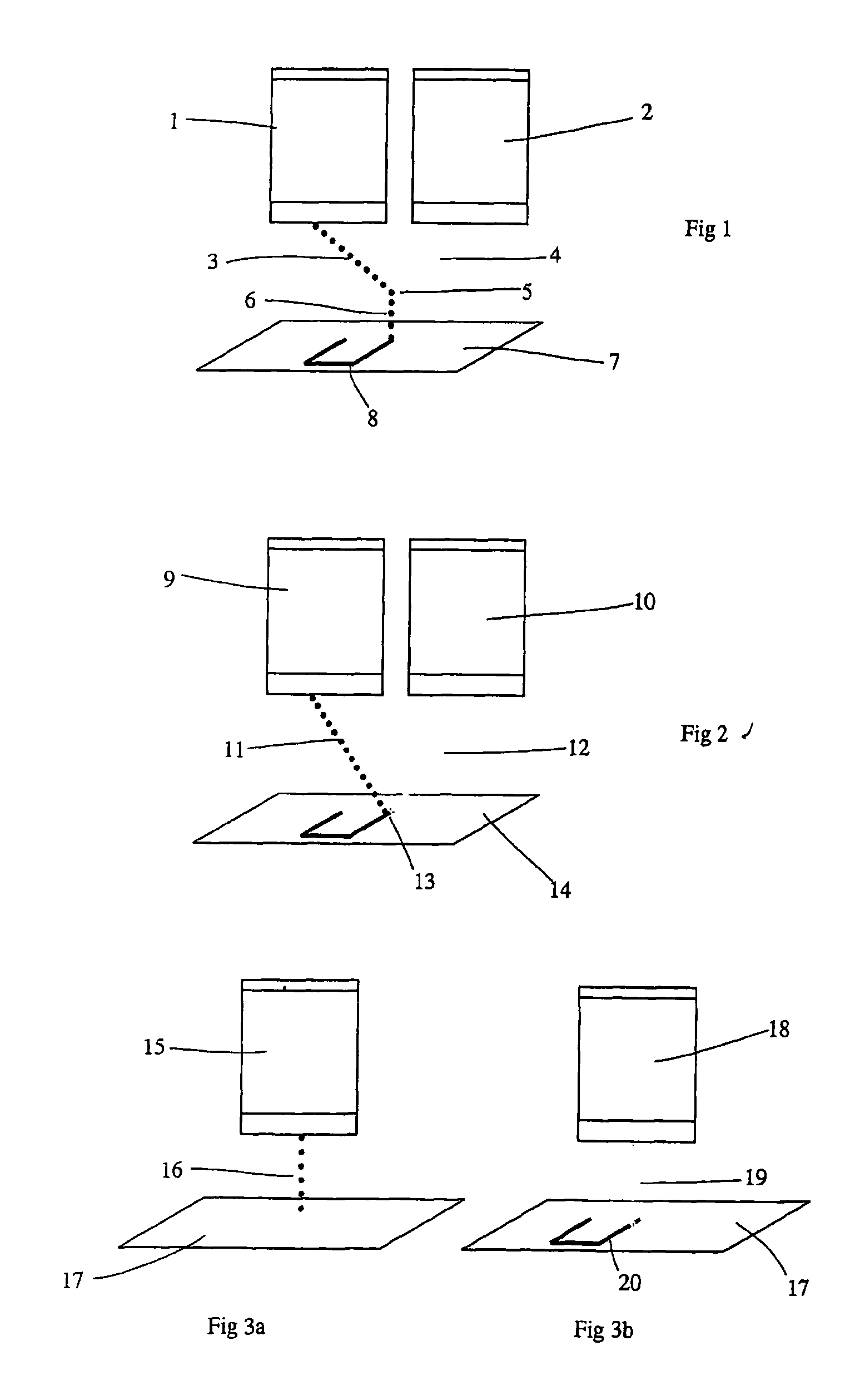

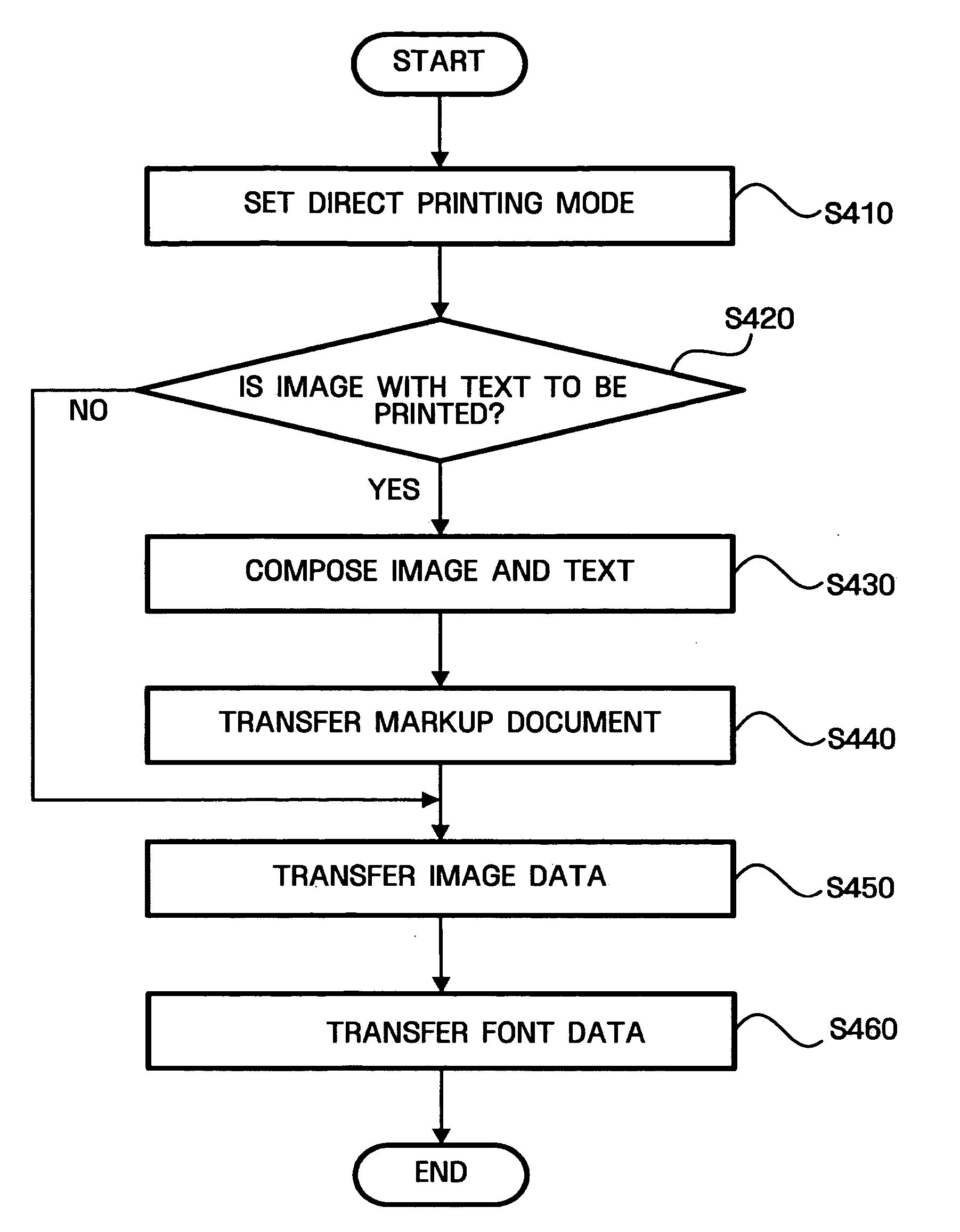

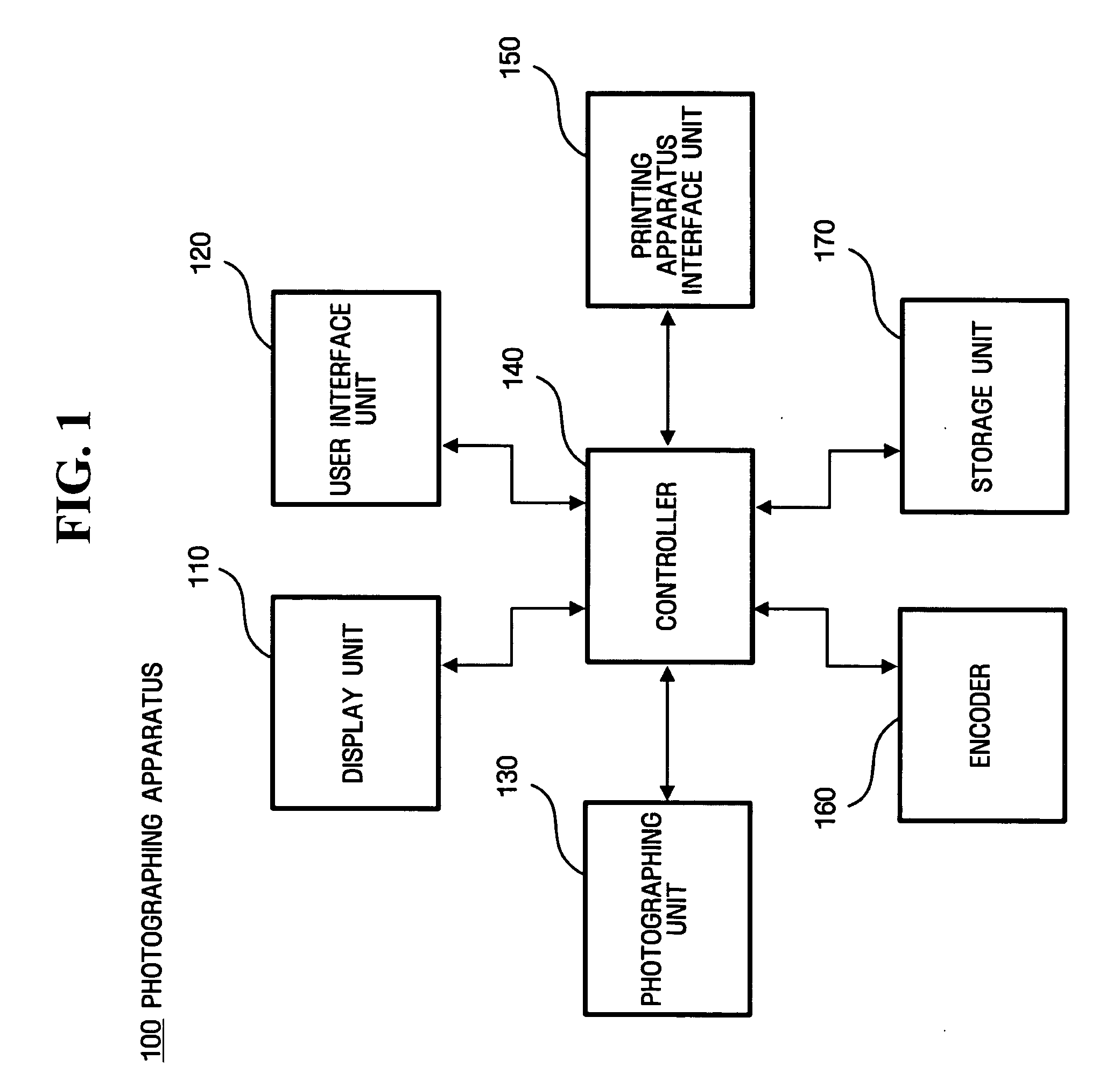

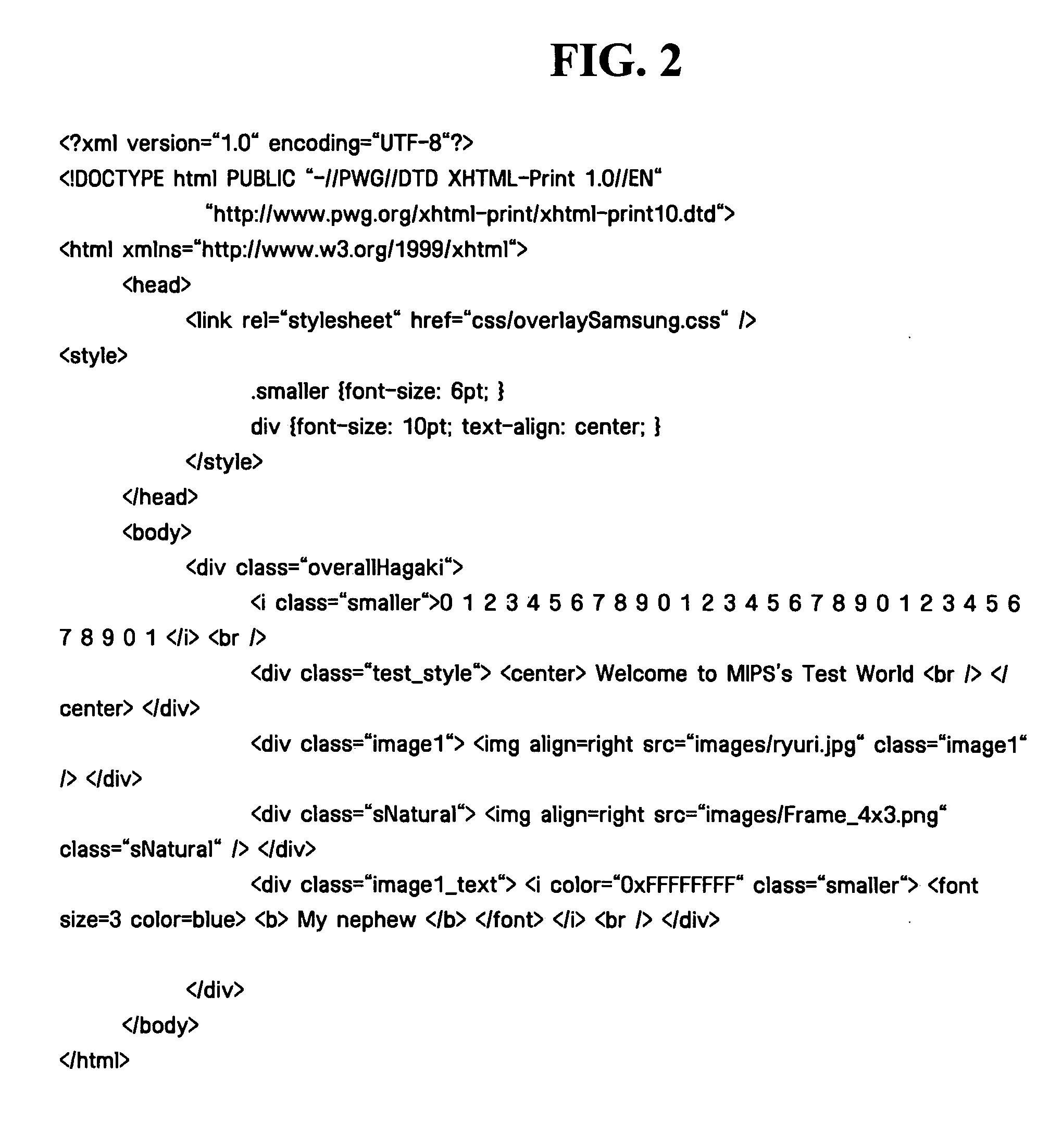

Direct printing method and apparatus

InactiveUS20050254081A1Digital computer detailsDigital output to print unitsHyperlinkComputer graphics (images)

A direct printing method and for printing multimedia data including an image and text are provided. The direct printing method includes composing hyperlink information on image data to be printed by an image supplying apparatus and text using a predetermined markup language, transferring the markup document resulting from the composing to a printing apparatus directly connected with the image supplying apparatus via a predetermined interface to perform a direct printing job, and transferring font data corresponding to the text data to the printing apparatus in response to a request from the printing apparatus. Multimedia data including text and an image can be printed by performing the direct printing job.

Owner:SAMSUNG ELECTRONICS CO LTD

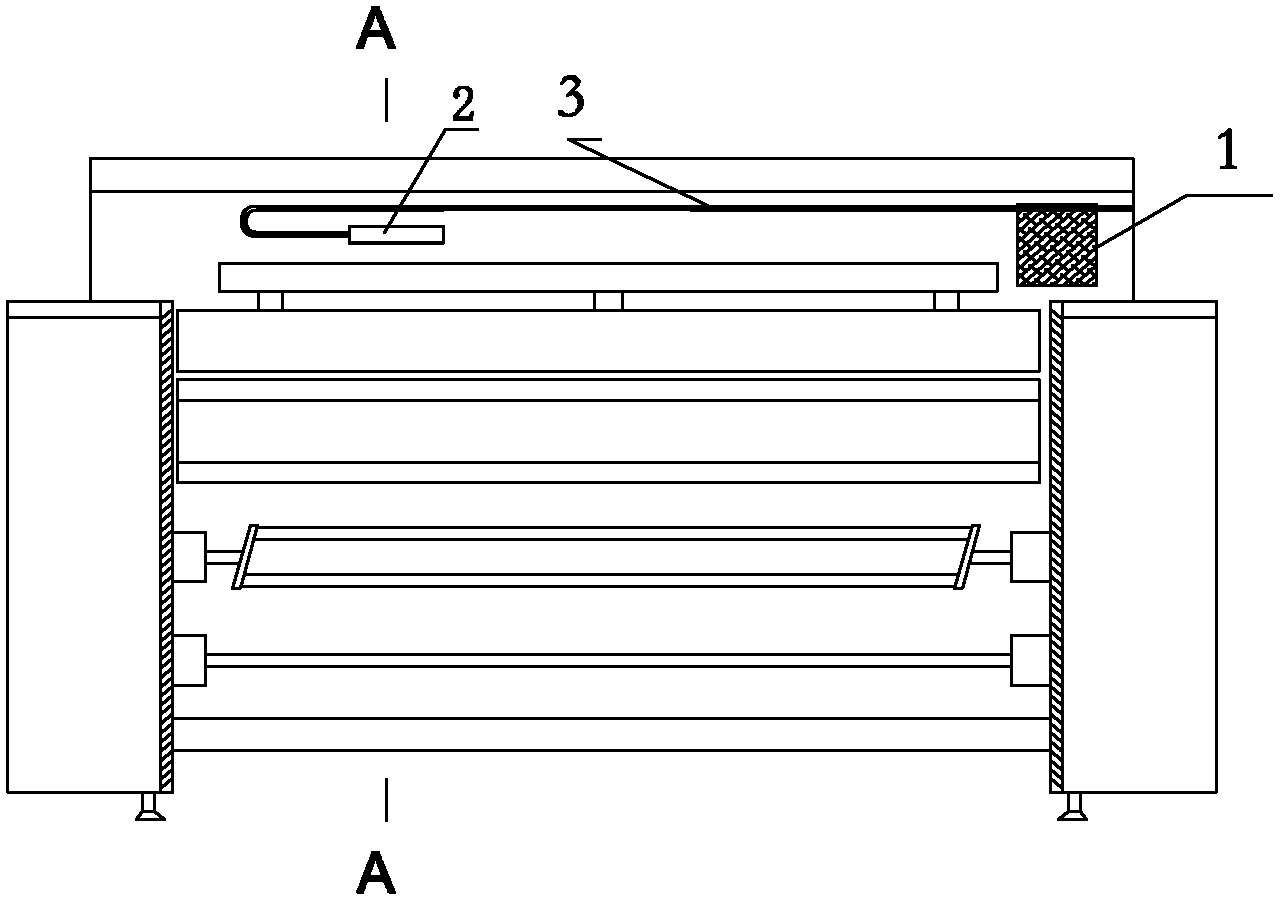

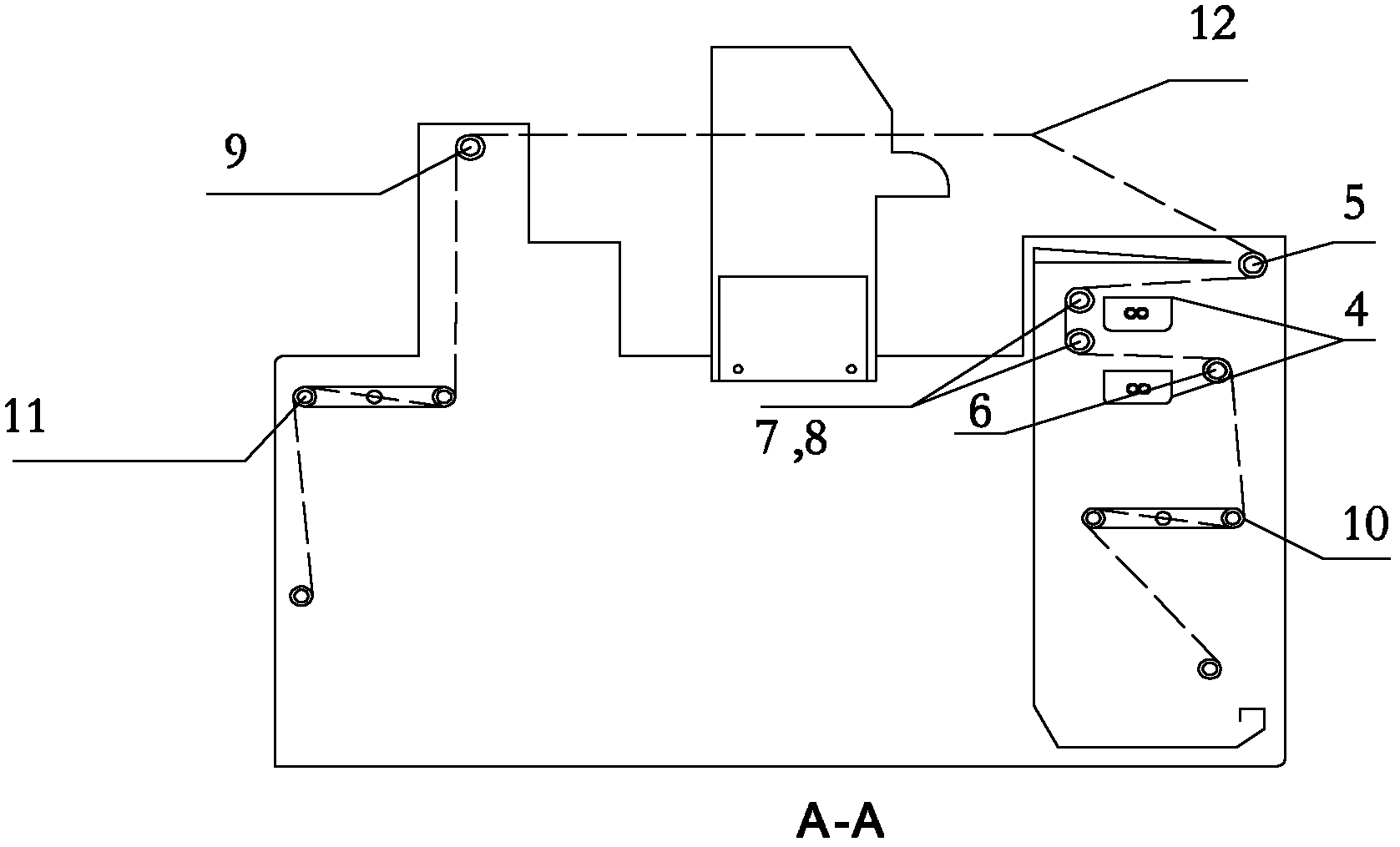

Flexographic plate CTP (computer to plate) direct printing method and equipment based on 3D rapid forming printing principle

ActiveCN103121323AEliminate complicated operation linksLow costPlate printingFoil printingComputer to plateEngineering

The invention discloses a flexographic plate CTP (computer to plate) direct printing method and equipment based on a 3D rapid forming printing principle and belongs to the technical field of printing flexographic plate manufacture. The equipment comprises a computer, a 3D rapid forming printer and one of photocuring equipment and heat drying equipment. The 3D rapid forming printer is utilized to spray a solidifiable forming material on the base surface of a flexographic plate so as to form a relieve image, the relieve image is subjected to light curing or thermocuring on-line drying so that the printing information is stabilized on the base surface of the flexographic plate, and then the printer can be used for printing; and the base of the flexographic plate is an organic polymer plate or an organic polymer-organic polymer compound plate. The method omits the middle process such as exposure and development, the plate manufacturing speed is greatly accelerated, the printing quality is improved, the printing cost is reduced, the flow is greatly shortened, the flexography environment friendliness is realized, and the application area is further expanded.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

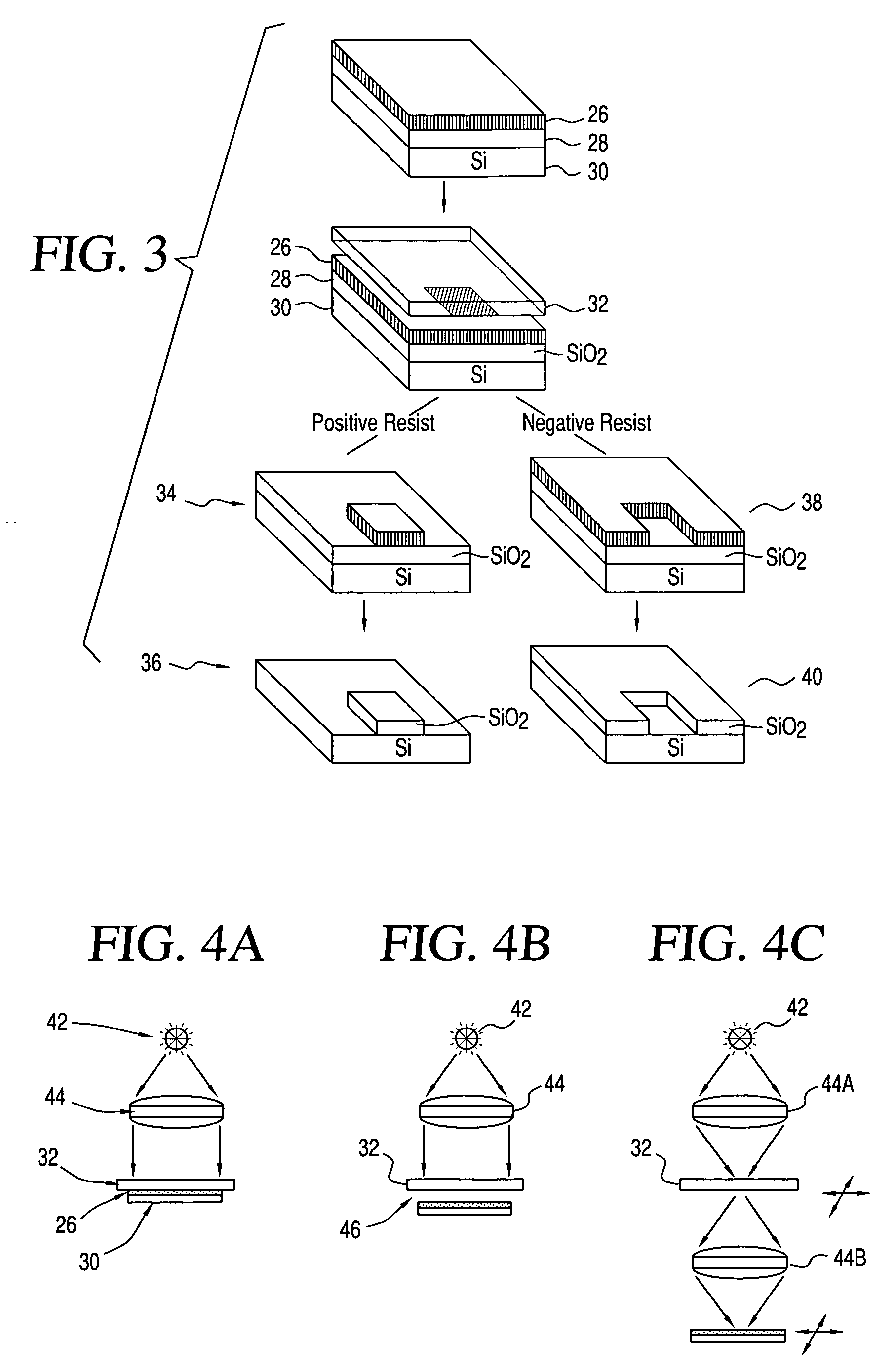

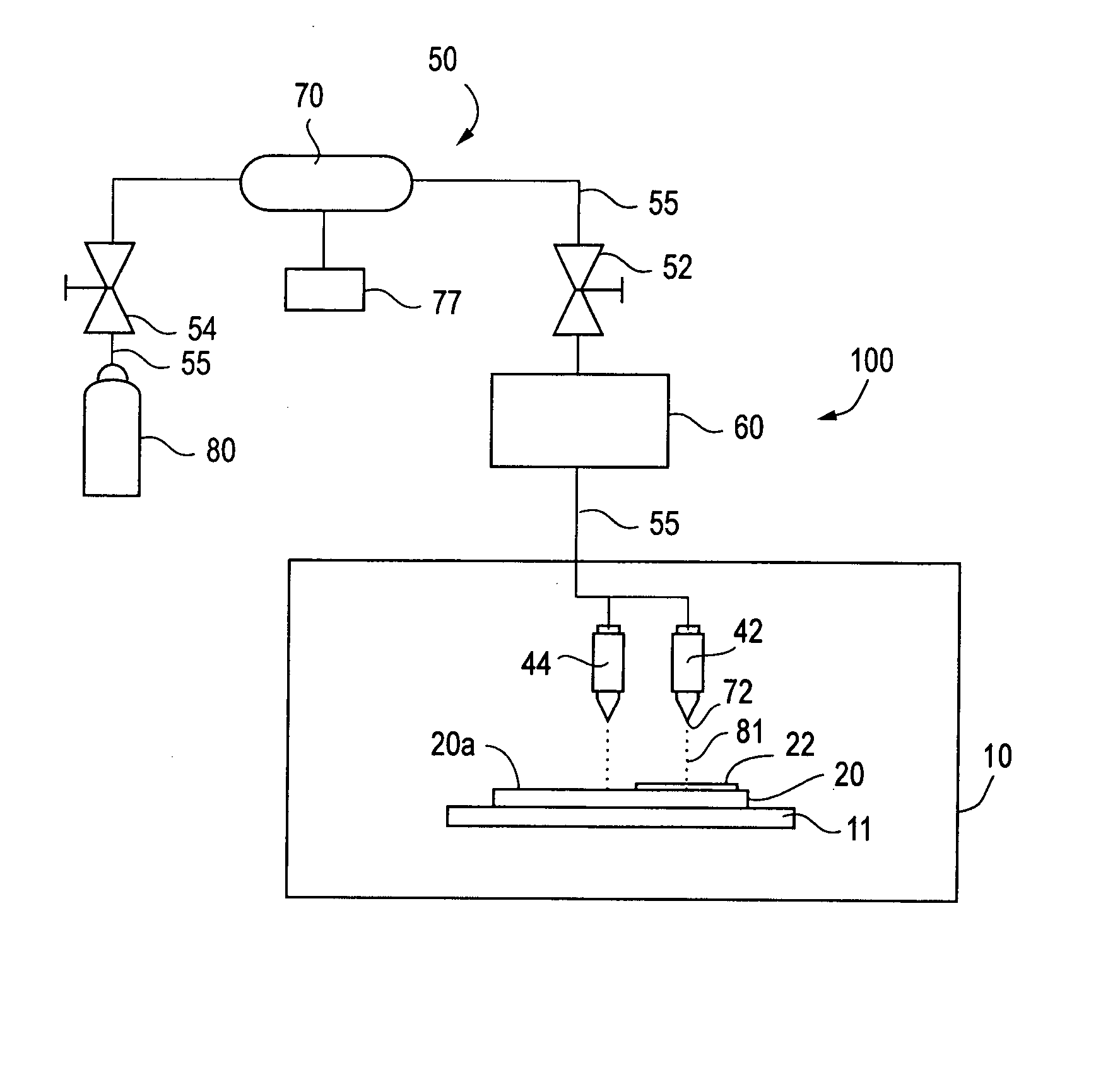

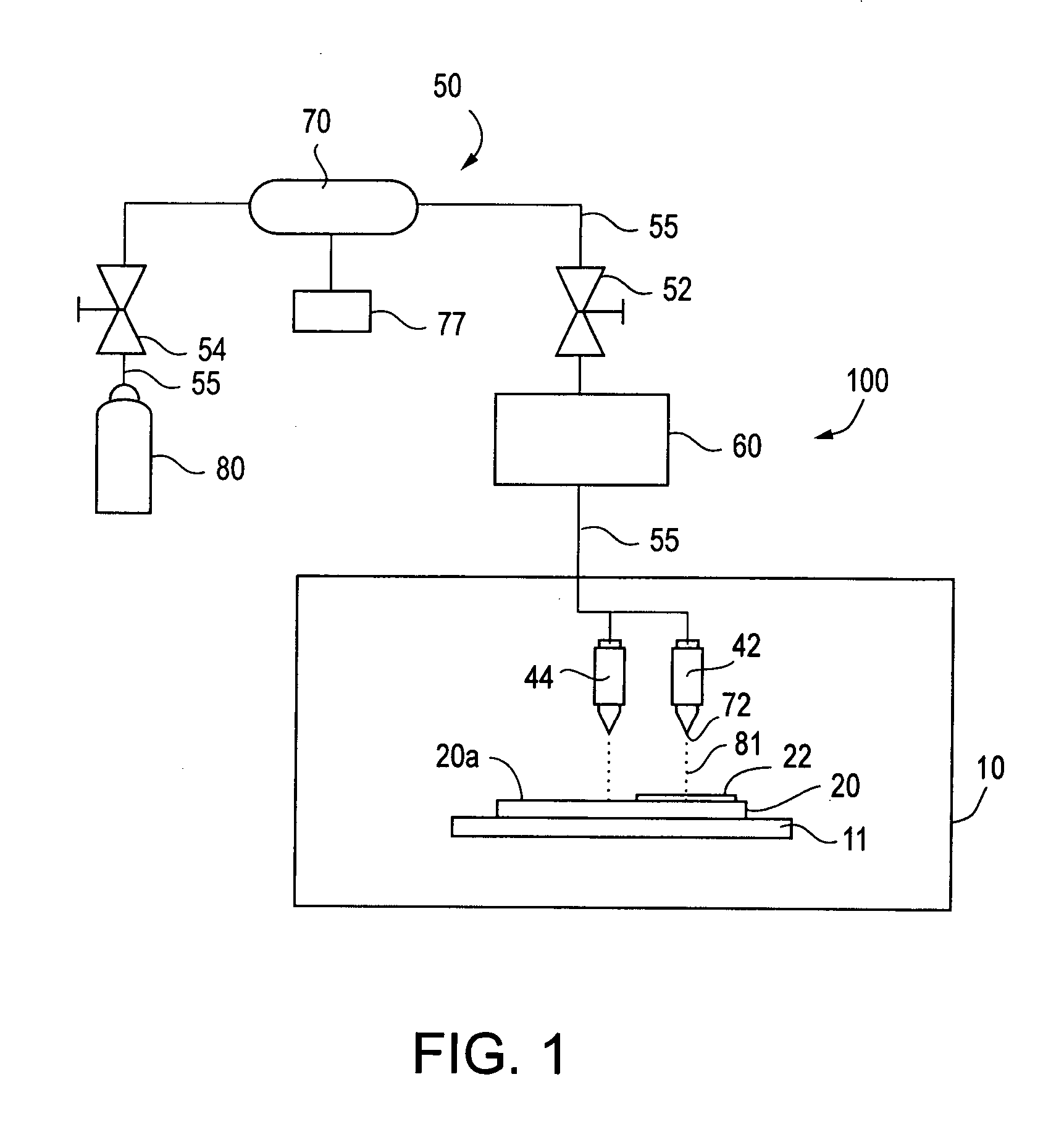

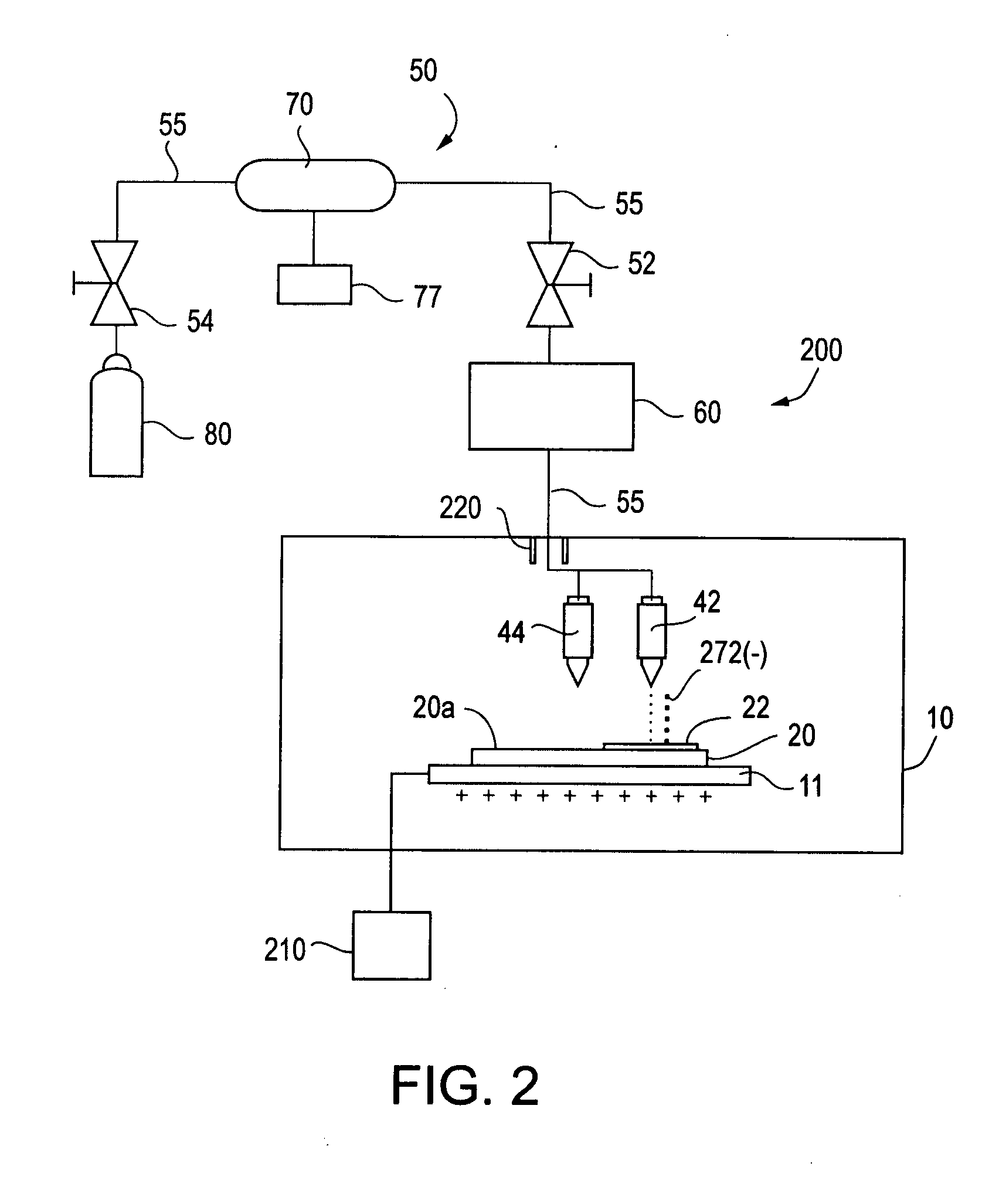

Supercritical fluid-assisted direct write for printing integrated circuits

InactiveUS20060266235A1High resolutionSemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

High resolution patterns provided on a surface of a semiconductor substrate and methods of direct printing of such high resolution patterns are disclosed. The high resolution patterns may have dimensions less than 0.1 micron and are formed by a direct writing method employing a supercritical fluid comprising nanometer-sized particles, which may be optionally electrically charged.

Owner:MICRON TECH INC

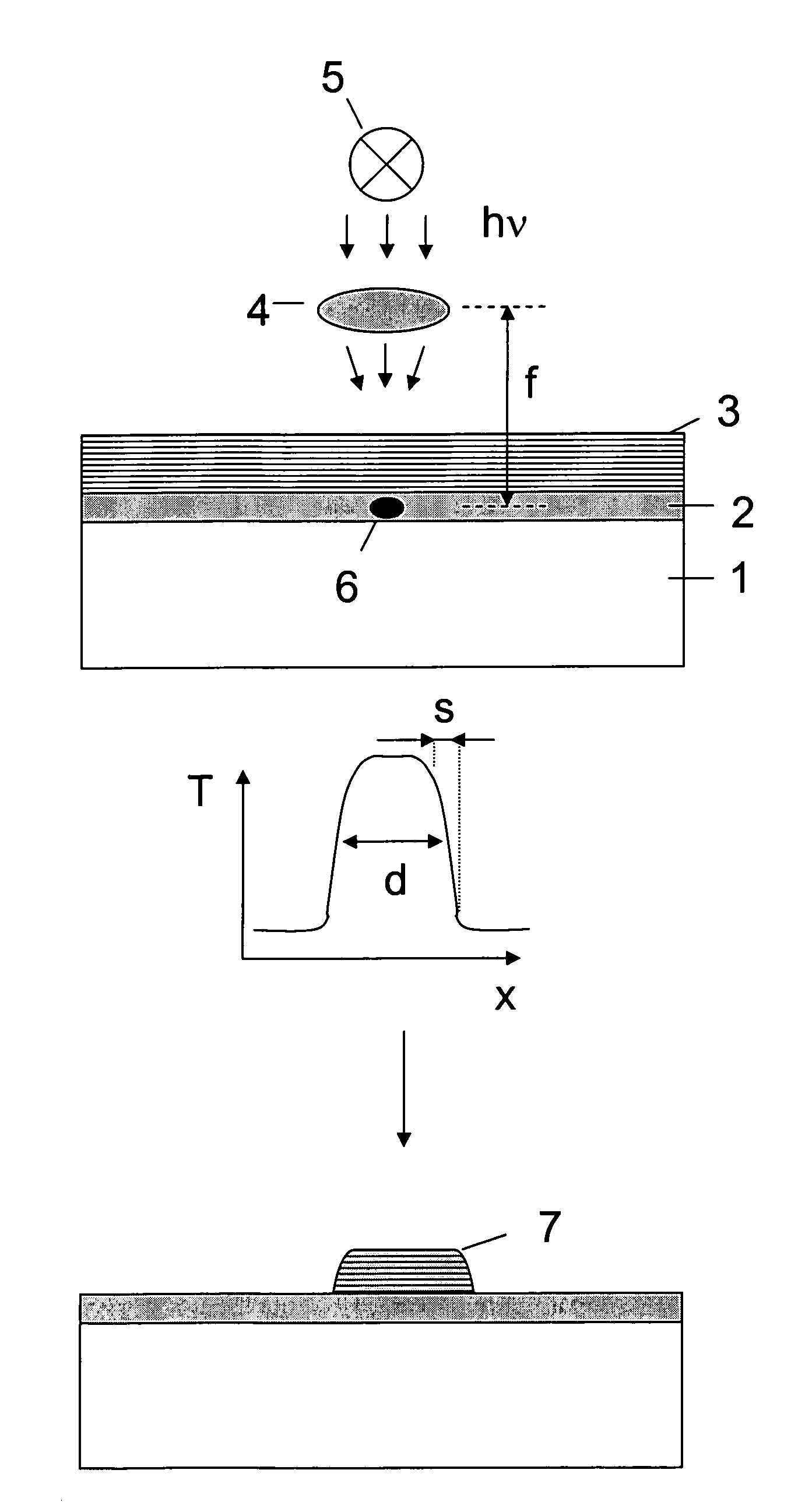

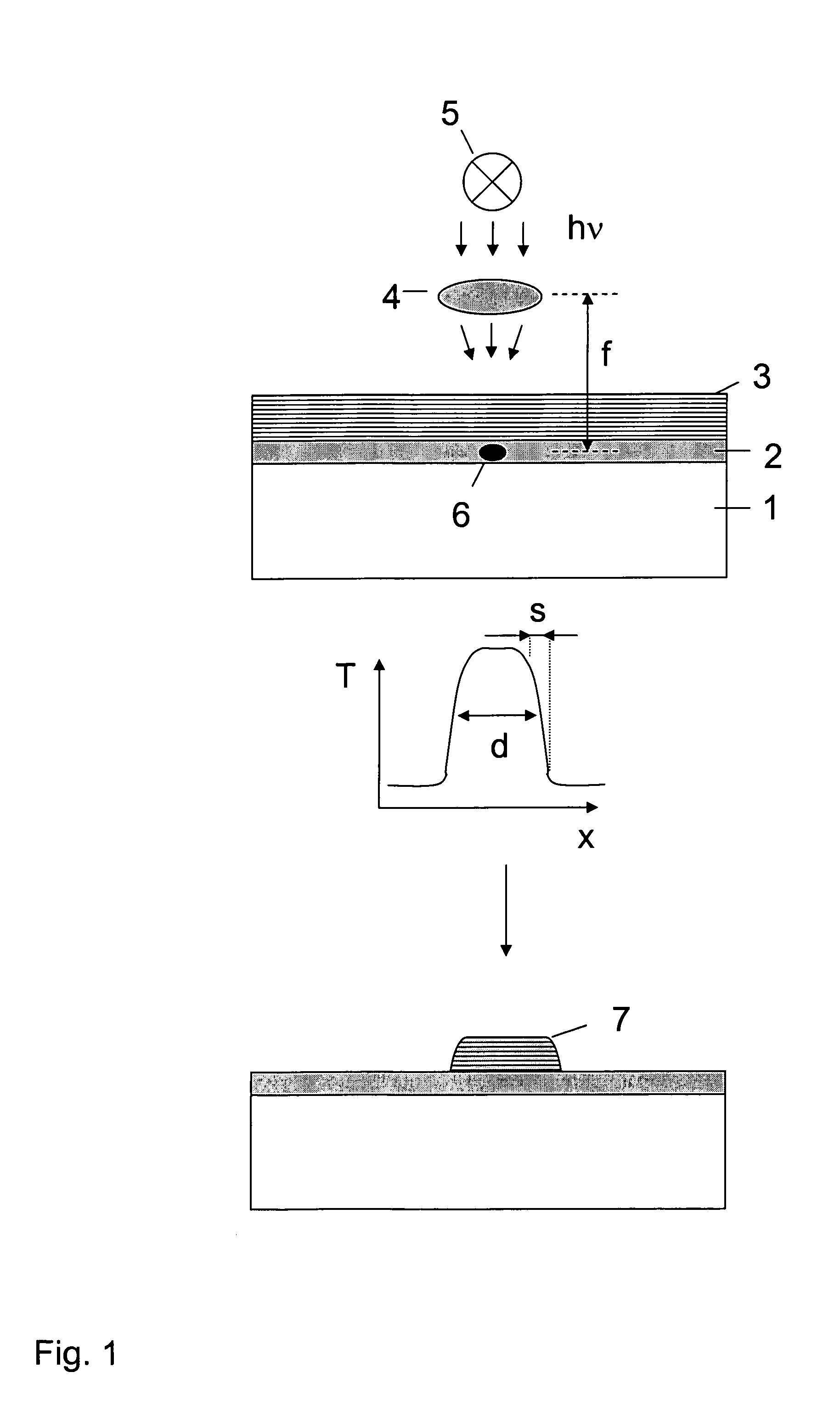

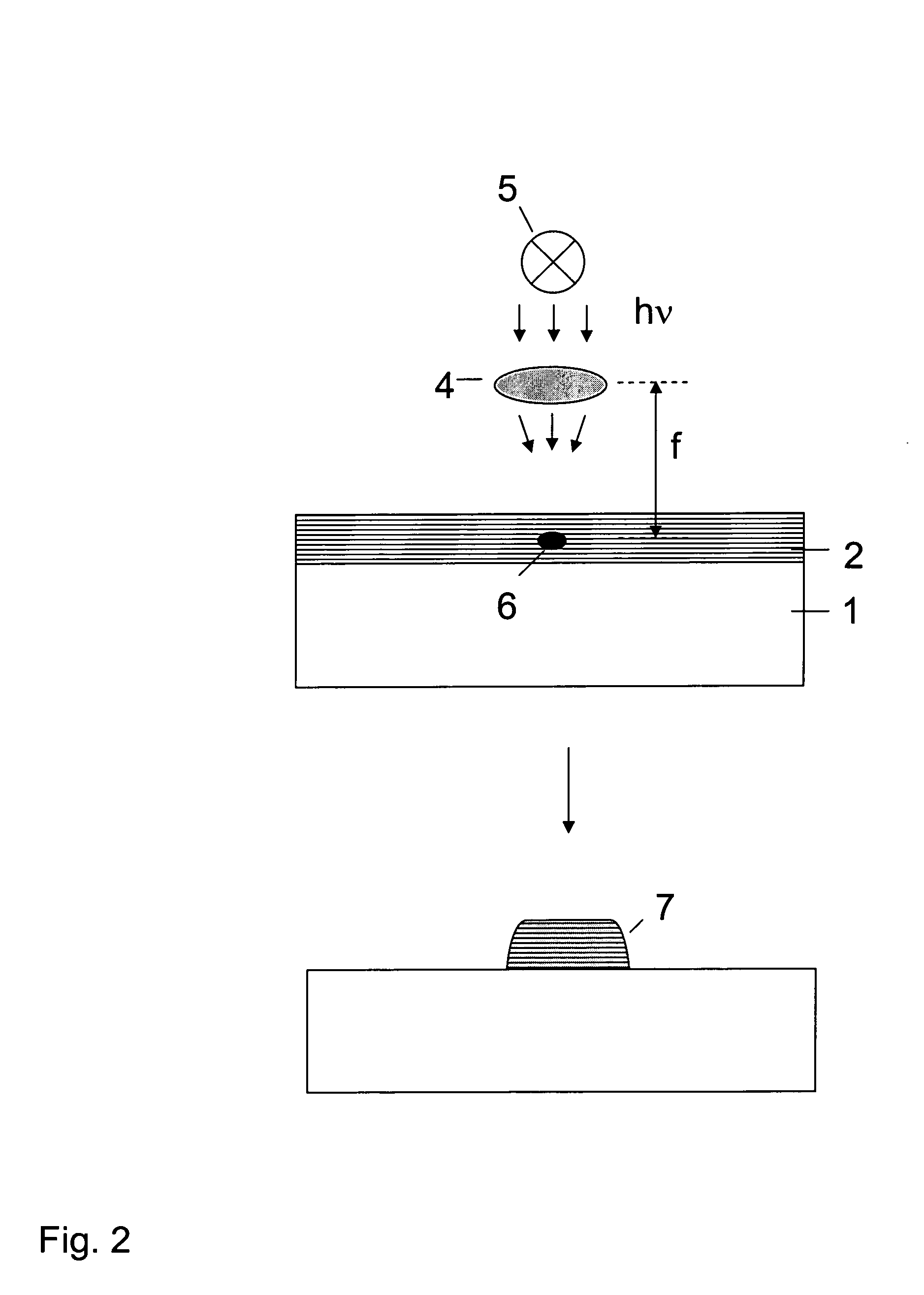

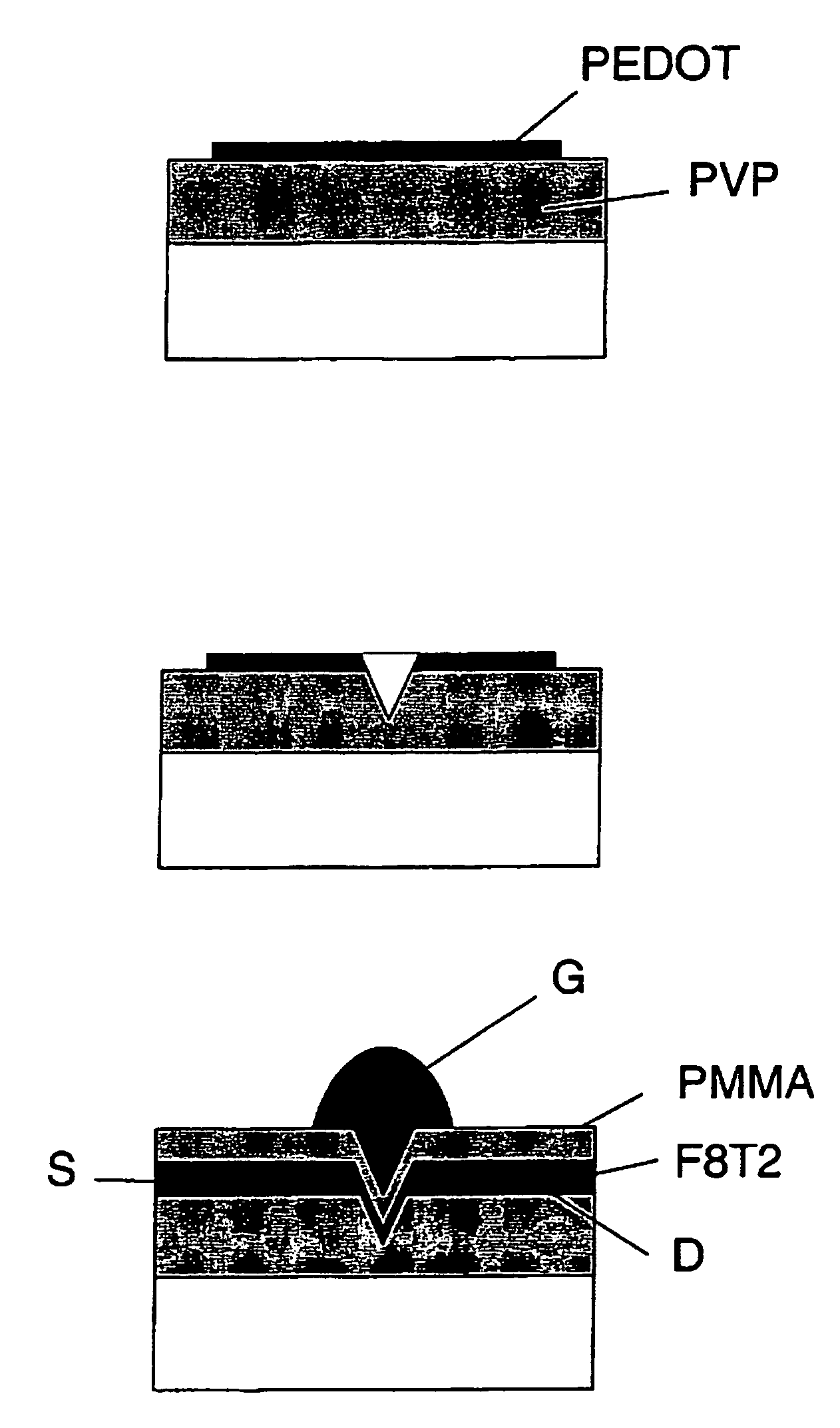

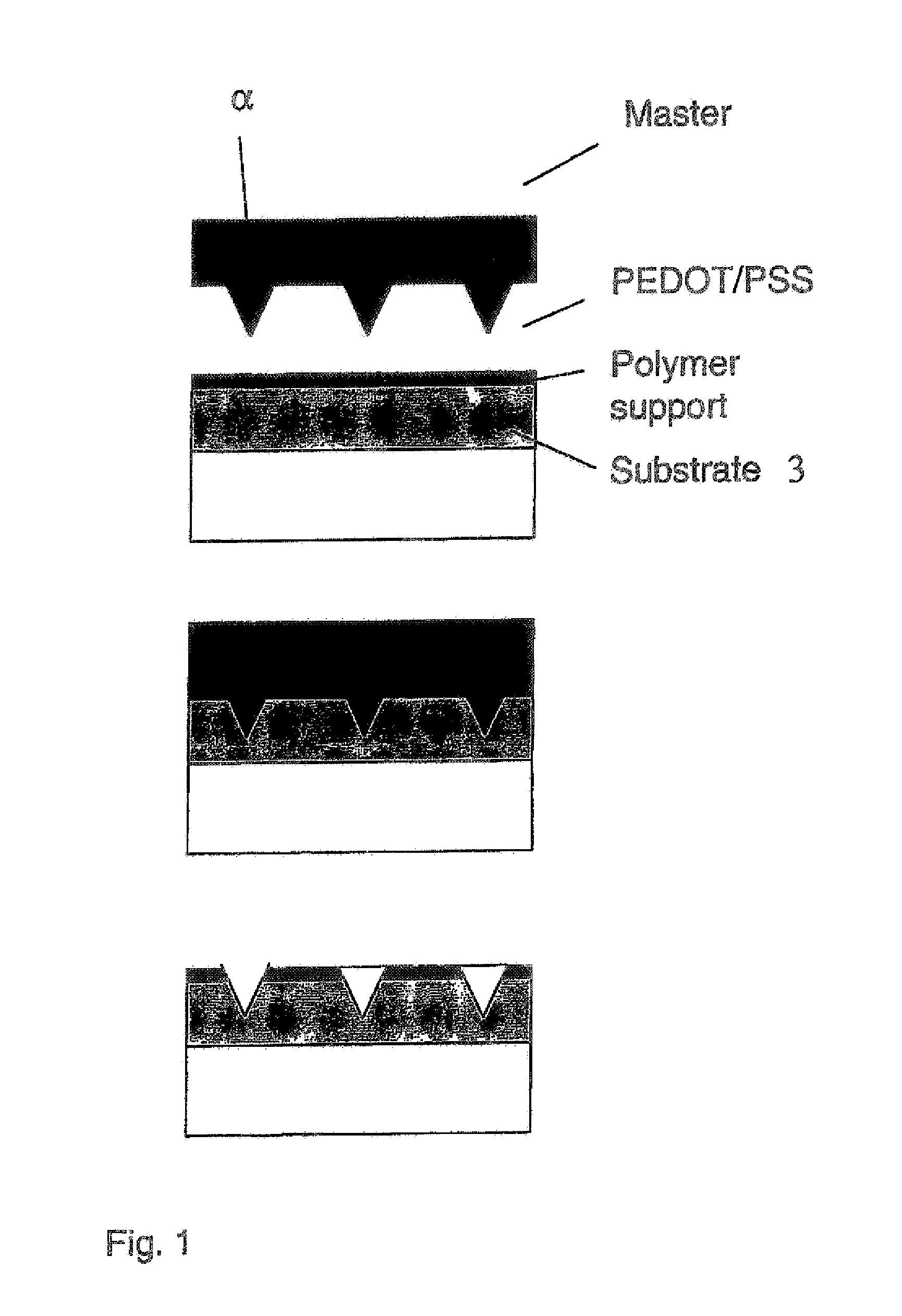

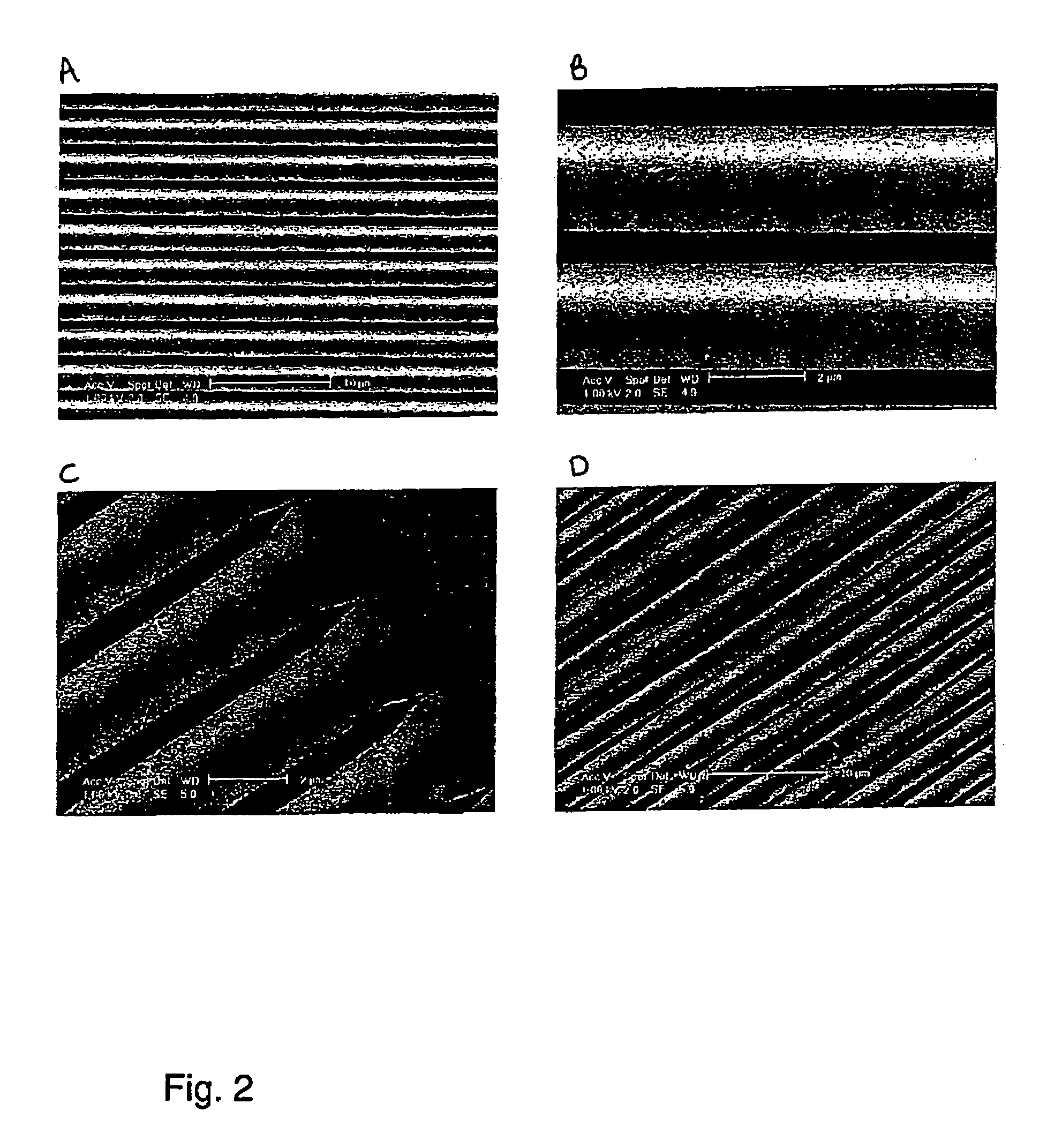

Patterning of devices

InactiveUS7244669B2Increase printing speedTransistorDuplicating/marking methodsOptoelectronicsLaser beams

A method for forming an organic or partly organic switching device, comprising: depositing layers of conducting, semiconducting, insulating, or surface modifying layers by solution processing and direct printing; and defining high-resolution patterns of these layers by exposure to a focused laser beam.

Owner:ETV CAPITAL

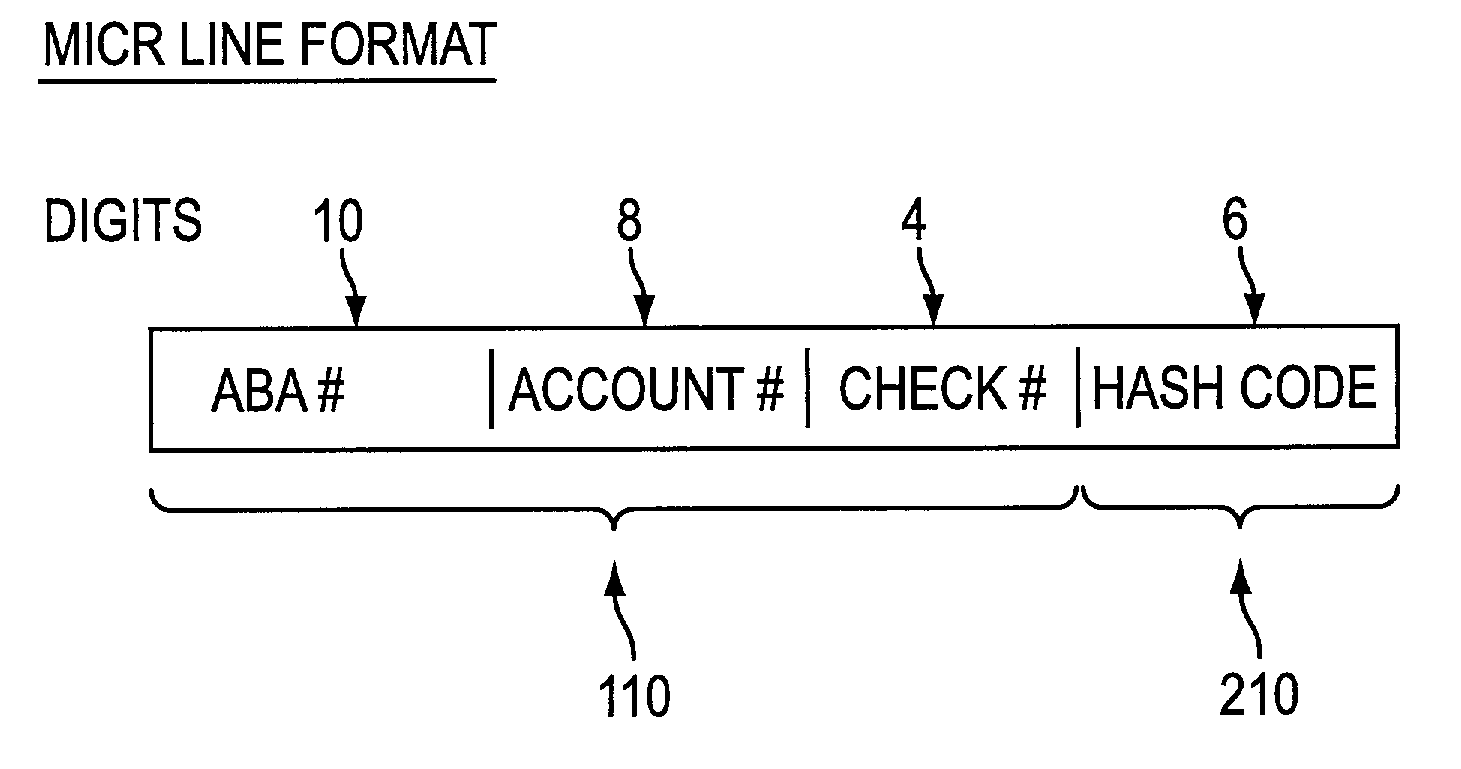

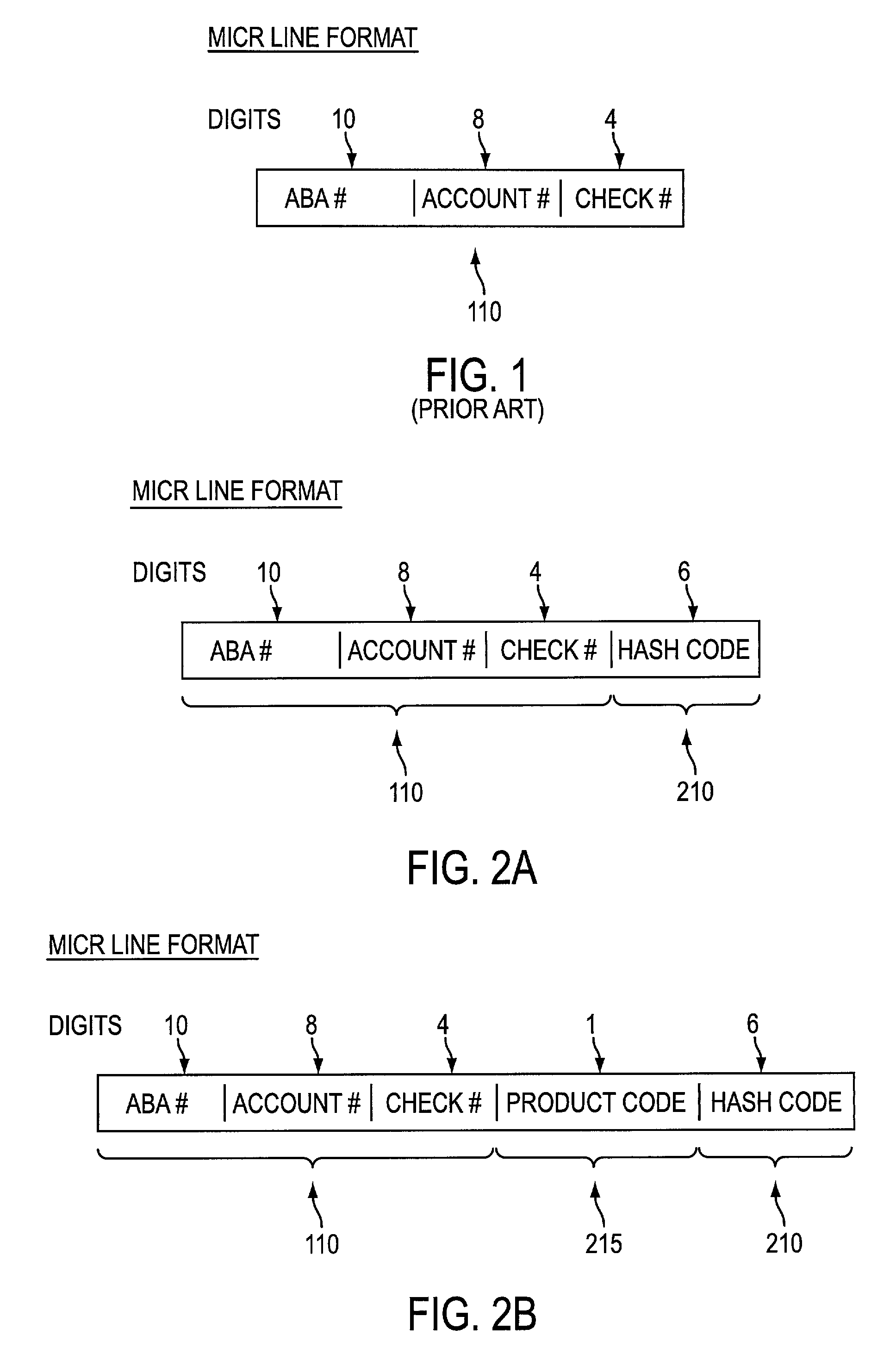

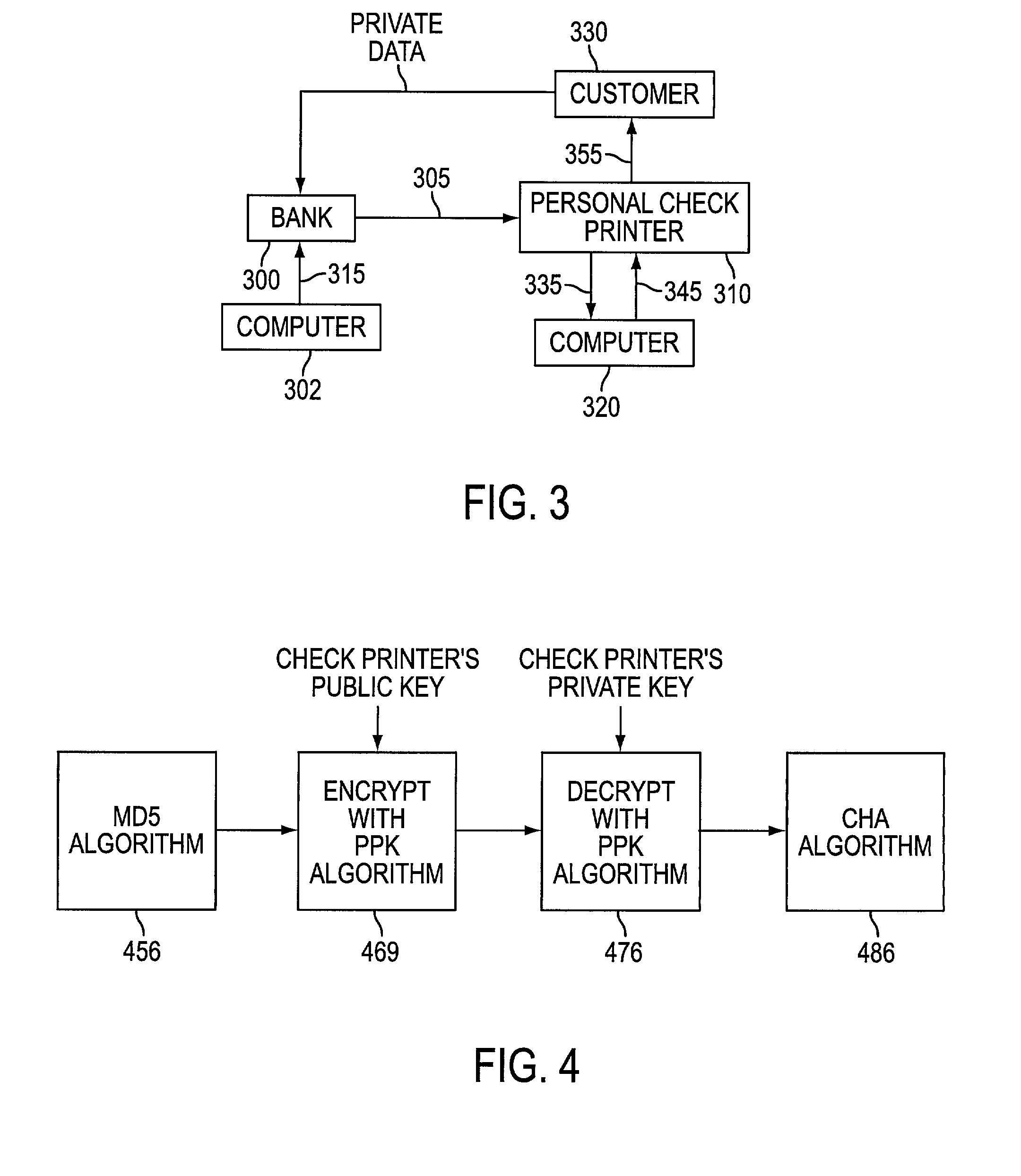

Check based online payment and verification system and method

A method and system for verifying a check that is being used for an on-line transaction, utilizes a hash code value either printed directly on the check, or obtained from an insert card provided by a check printer. To conduct an on-line transaction using a check, the customer enters in data obtained from a MICR line of the check, whereby the data includes a one-way hash value that is based on the data provided on the MICR line as well as private data not provided on the MICR line. A web server of an e-tailer for which the customer seeks to make the on-line transaction, receives the data entered by the customer. The web server of the e-tailer transmits, to a check verifier, the data entered by the customer. The check verifier verifies whether or not the check is valid, by comparing the hash code value entered in by the customer with a hash code value that is separately calculated by the check verifier, based on private data of the customer obtained by the check verifier from a database.

Owner:CUFER ASSET LTD LLC

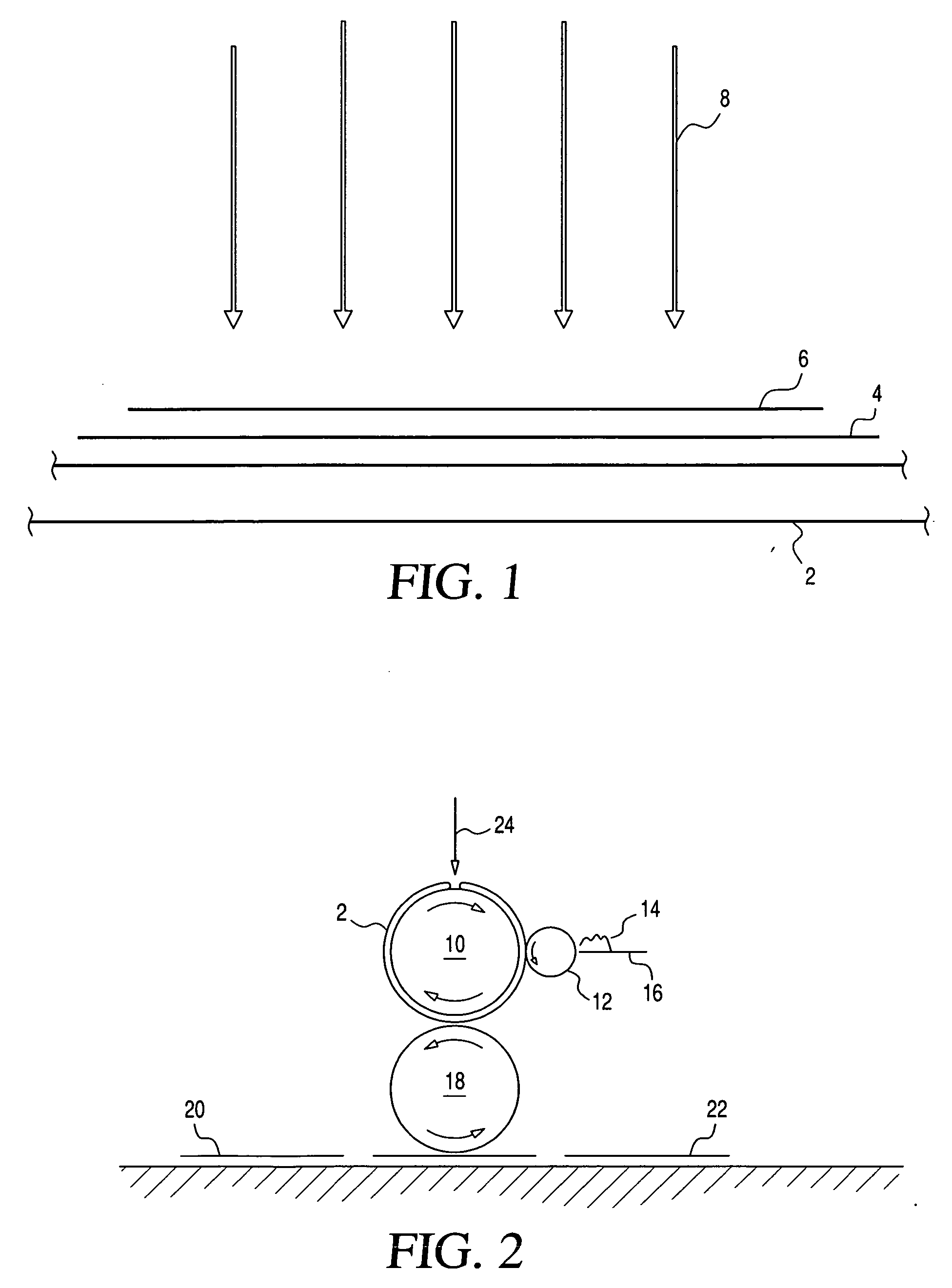

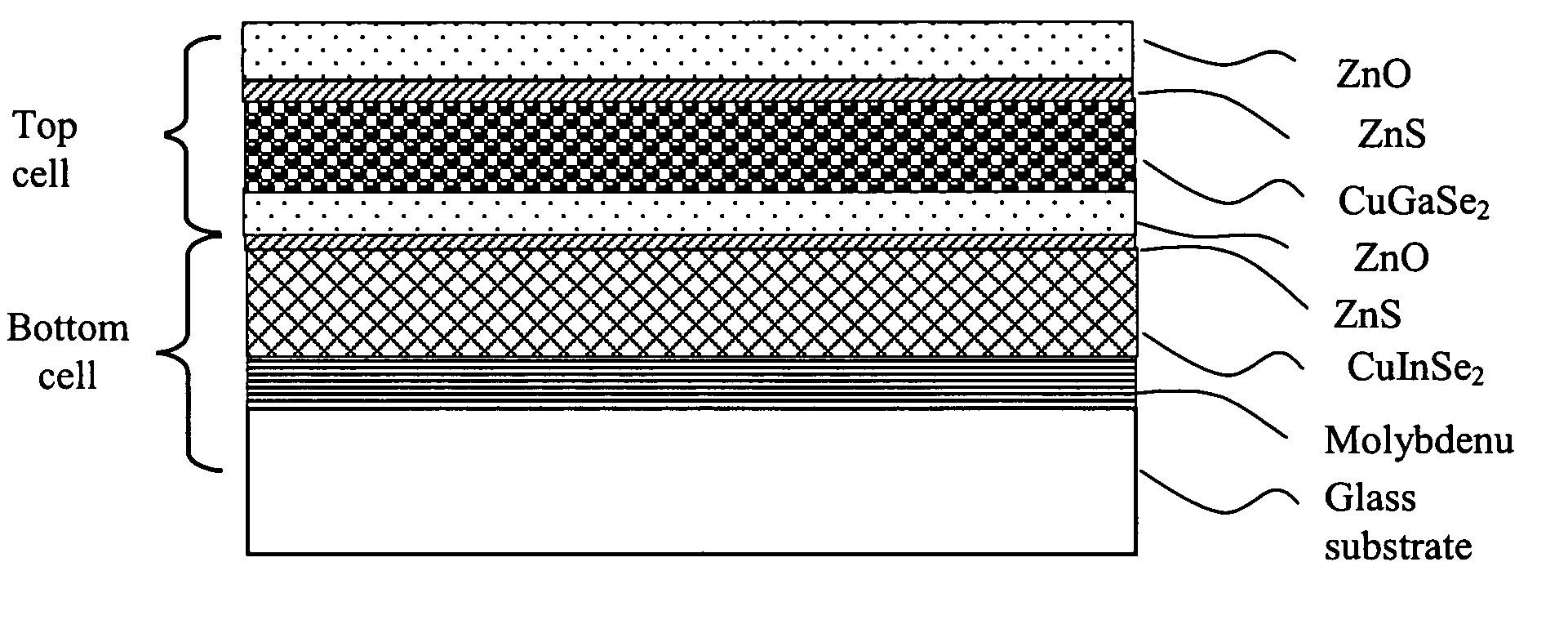

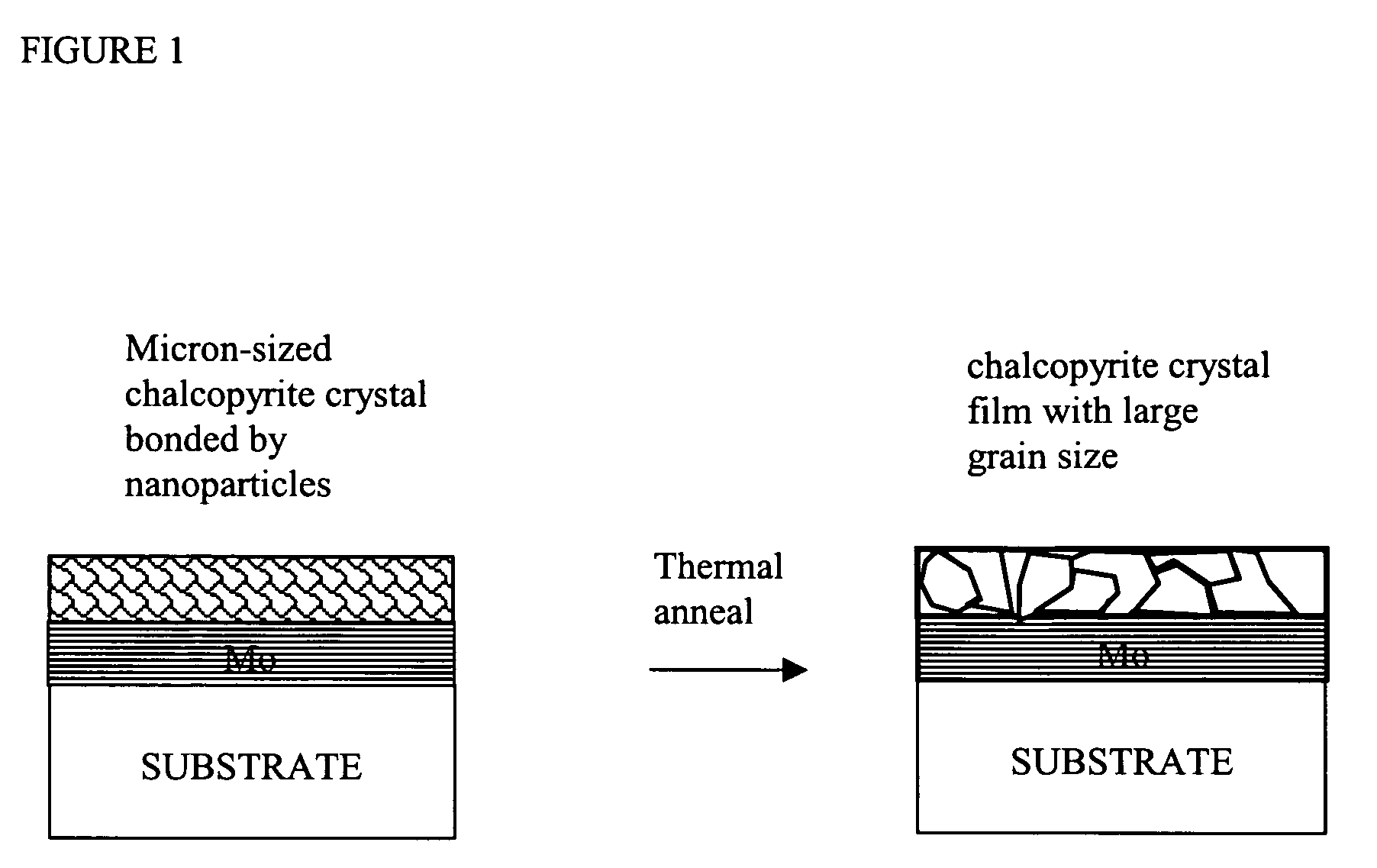

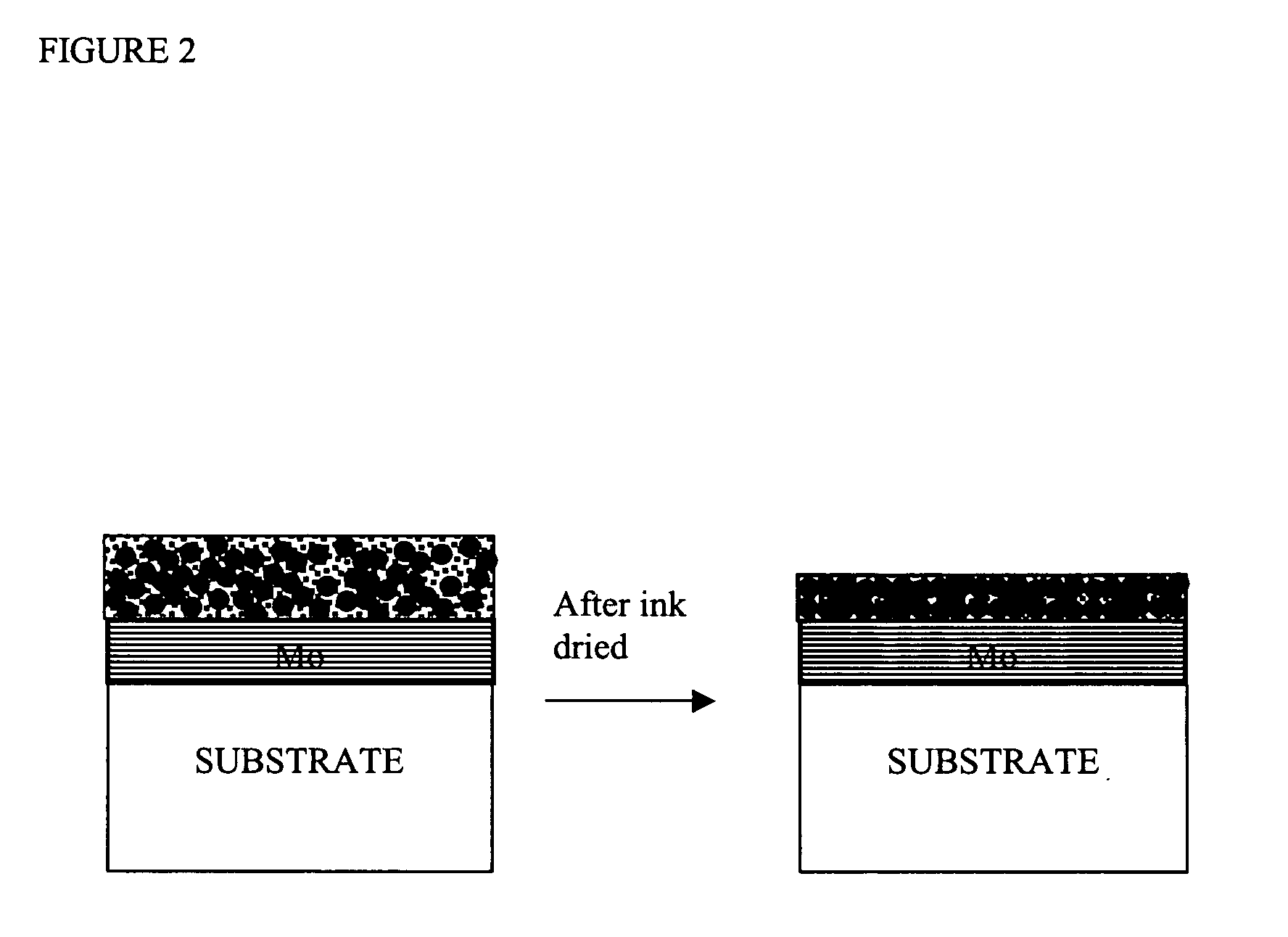

Manufacture of thin solar cells based on ink printing technology

ActiveUS20110065228A1Increase the open circuit voltageLoss can be compensatedFinal product manufactureSemiconductor/solid-state device manufacturingBrickTandem solar cell

Semiconductor ink is disclosed for use in printing thin film solar cell absorber layer. The semiconductor ink is particularly useful in fabricating multi junction tandem solar cell wherein a high bandgap absorber layer as the top cell and a lower band gap absorber layer as the bottom cell. The ink contains ingredients of IB-IIIA-VIA compound with micron-sized semiconductor as the main building “bricks” and nano-sized semiconductor as the binder to fulfill the formation of smooth semiconductive film with micron-sized crystal grain size. Thus formed ink can be used in direct printing for the fabrication of low cost high performance solar cells.

Owner:GUANMAT OPTOELECTRONIC MATERIALS (JIANGXI) INC

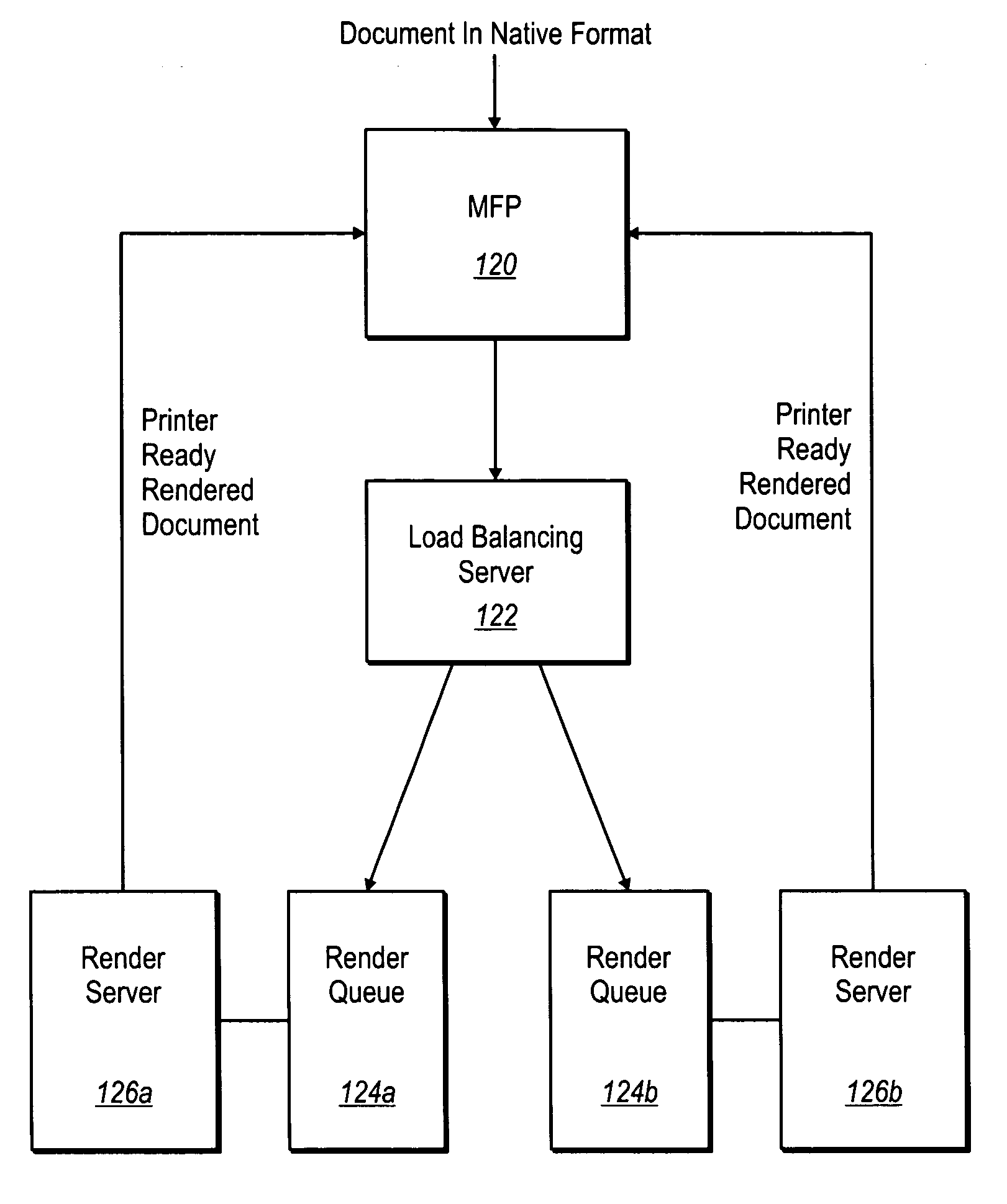

Systems and methods for providing load balance rendering for direct printing

InactiveUS20050206917A1Digitally marking record carriersVisual representation by matrix printersLoad SheddingComputer printing

Systems and methods for rendering a document in a native format at an imaging device using a host service for rendering into printer ready data. Documents / images are despooled to an imaging device in their native format for printing, wherein the imaging device includes the capability of discovering application / print server processes that render the document in its native format into a format compatible with the imaging device. The imaging device broadcasts job rendering requirements to one or more application / imaging servers, which in turn provide a response to the broadcast. One or more of the application / imaging servers are selectively chosen for use in rendering the document / print job, providing the device specific rendered job to the imaging device for rendering. In addition, when multiple compatible services are available, an optimal host service is determined and used for rendering into printer ready data.

Owner:SHARP KK

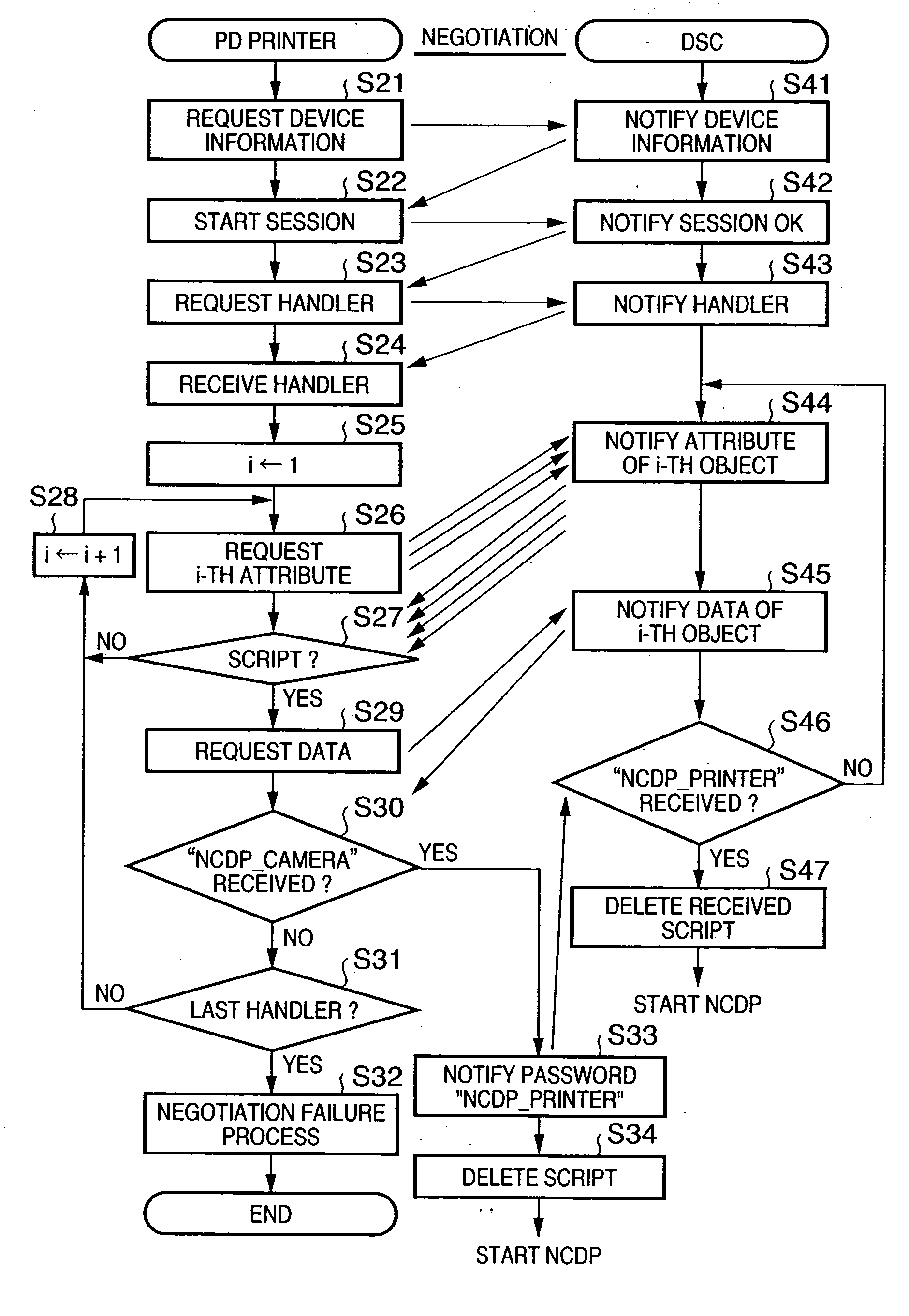

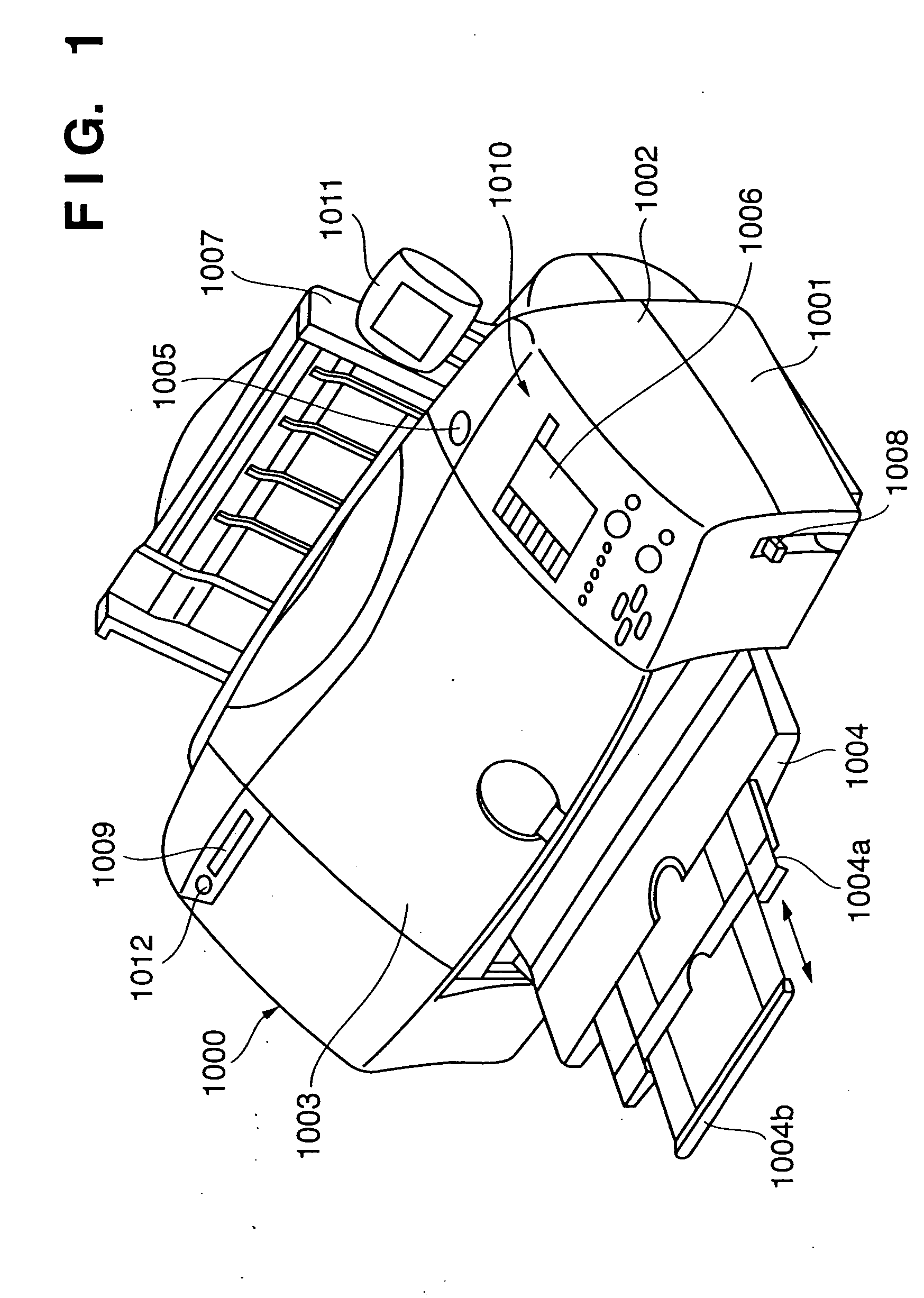

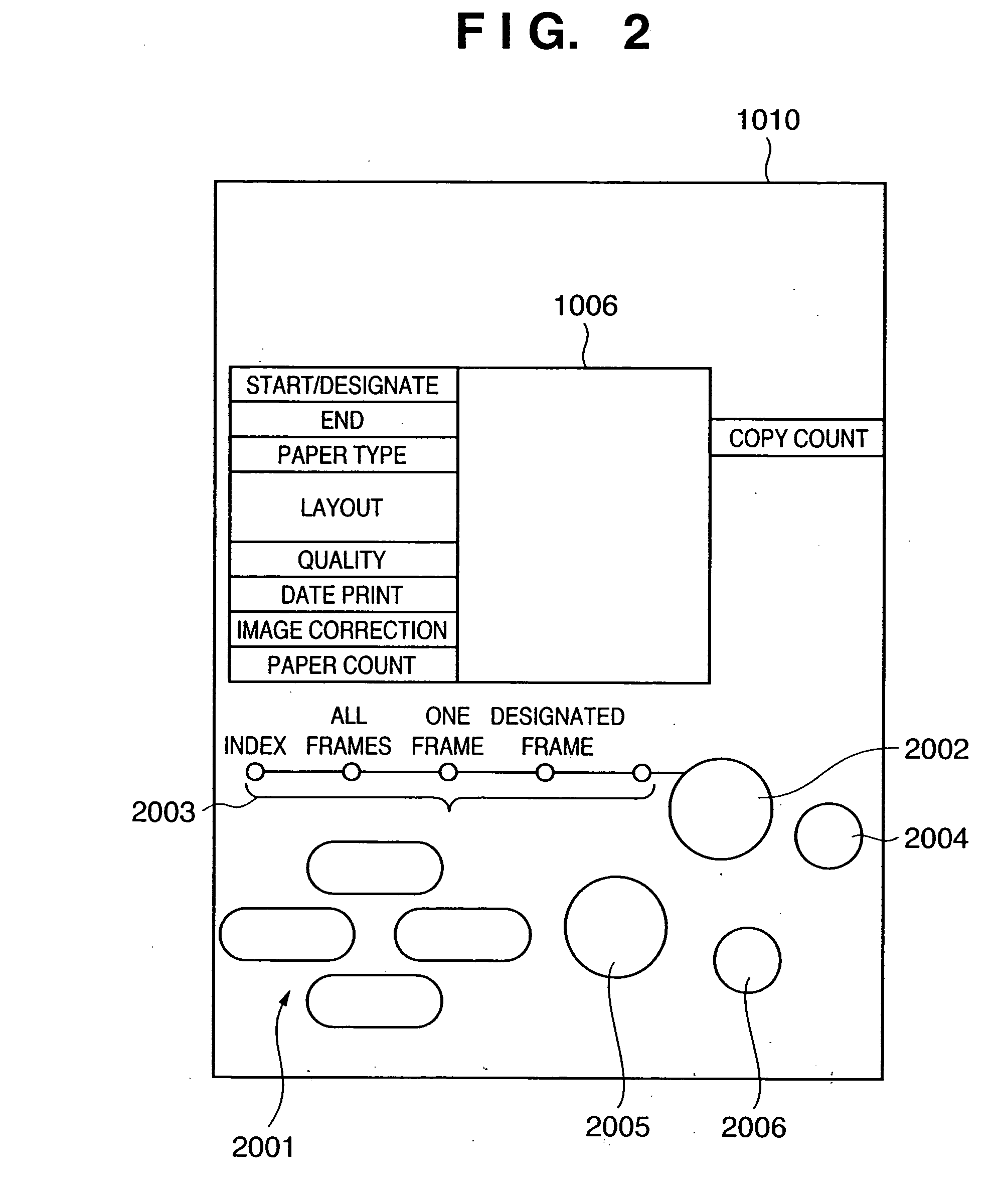

Printing apparatus and control method thereof, and printing system

ActiveUS20050088689A1Inhibition of informationImprove transmission efficiencyTelevision system detailsColor television detailsComputer hardwareComputer printing

This invention has as its object to allow an authentication process that avoids unnecessary information from being stored in a digital camera irrespective of whether or not a digital camera connected to the printer has a direct print function. To this end, in this invention, in an early stage of connection between a digital camera DSC and PD printer, the PD printer side requests an object which contains a keyword as authentication information of those which are stored and held by the DSC (S29). As a result, after it is determined the returned information contains authentication information, the printer notifies the DSC of its own authentication information (S33).

Owner:CANON KK

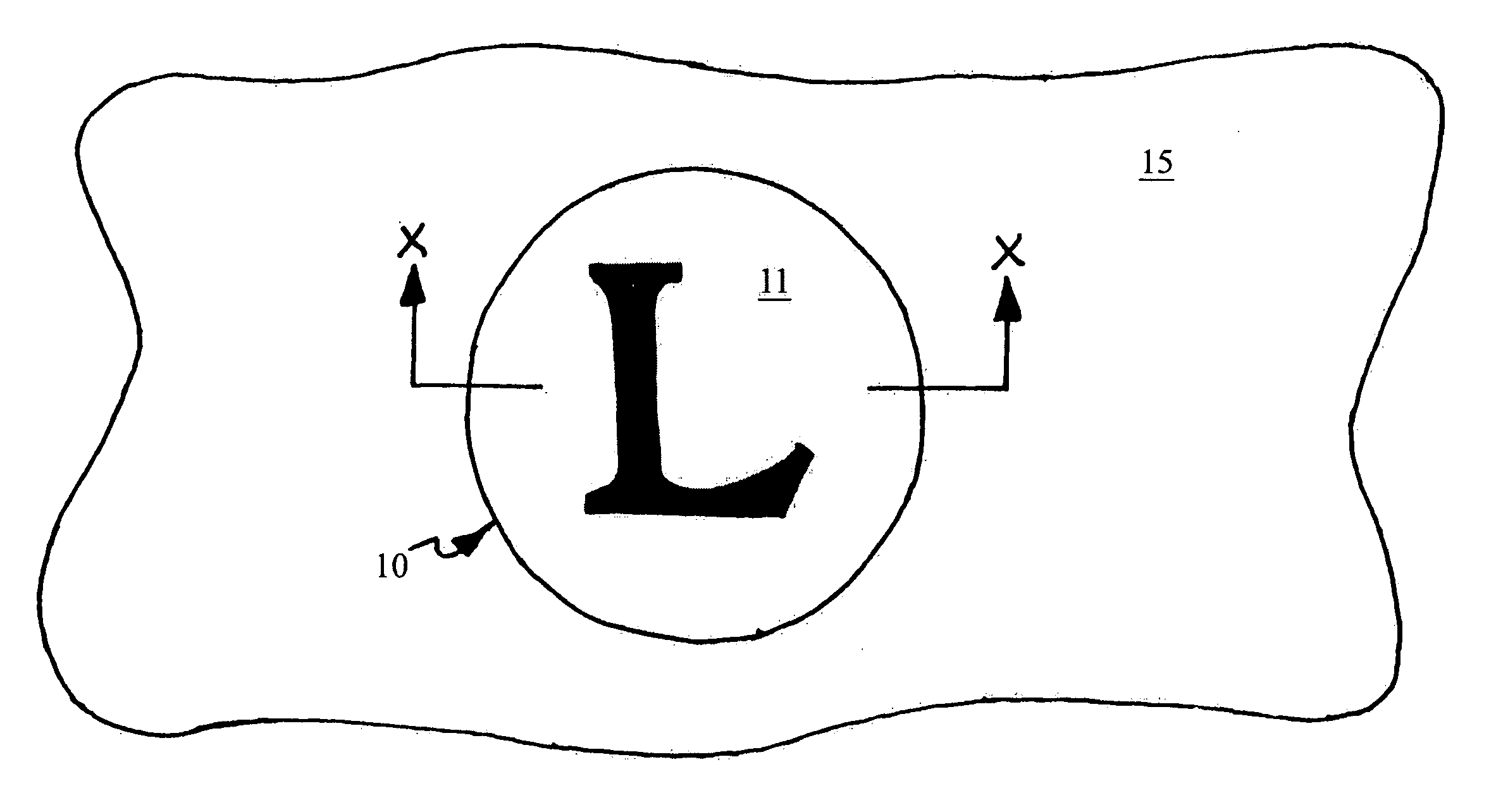

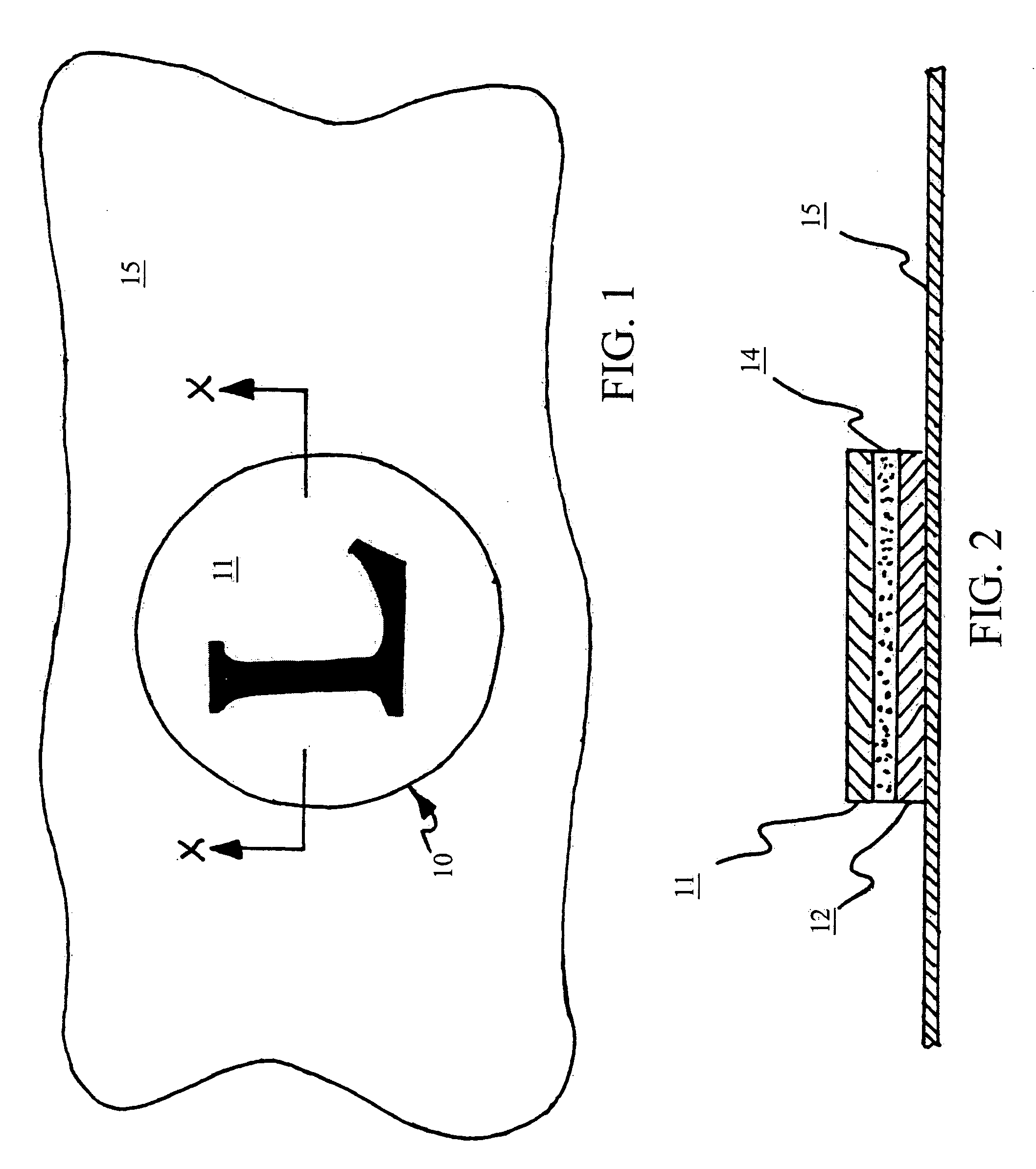

Heat activated applique with upper stretch fabric layer

ActiveUS20090280290A1Excellent heat activated appliquéEasy to cutDecorative surface effectsSynthetic resin layered productsYarnPolyester

The heat activated appliqué for providing in particular decorative elements providing contrast in texture or color including graphical images, logos, numbers and letters for apparel and other textile products, specifically but not limited to those made out of stretch fabrics (typically knit or woven fabrics) comprised of synthetic or natural fiber yarns constructed with spandex fibers and yarns. The appliqué includes an upper stretchable fabric layer bonded to a substrate by a thermoplastic adhesive. Preferably, the stretchable fabric layer is a knit or woven fabric comprised of at least 3% and preferably between 3% to 33% spandex and polyester or nylon threads and the thermoplastic adhesive is a urethane-based thermoplastic adhesive with suitable stretch and recovery characteristics. The appliqué can be layered to provide three-dimensional characteristics. The stretchable fabric layer can be embossed to provide surface characteristics to the heat activated appliqué, either prior to or during application. This is also suitable for applying additional indicia in the form of direct printing or sublimation dye heat transferred into the stretchable fabric layer.The above appliqué may bear a combination of digitally-printed elements such as letters, logo graphics and numbers or other indicia, and may include a simulated embroidery-stitched appearance from either said printing or laser-etching or some combination of both, all in a form that is easily heat-sealed to a garment or other textile.

Owner:LION BROS CO INC

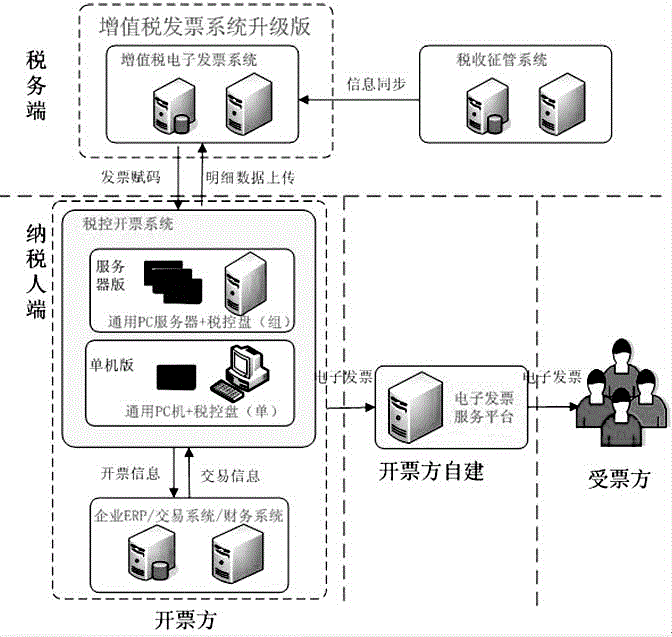

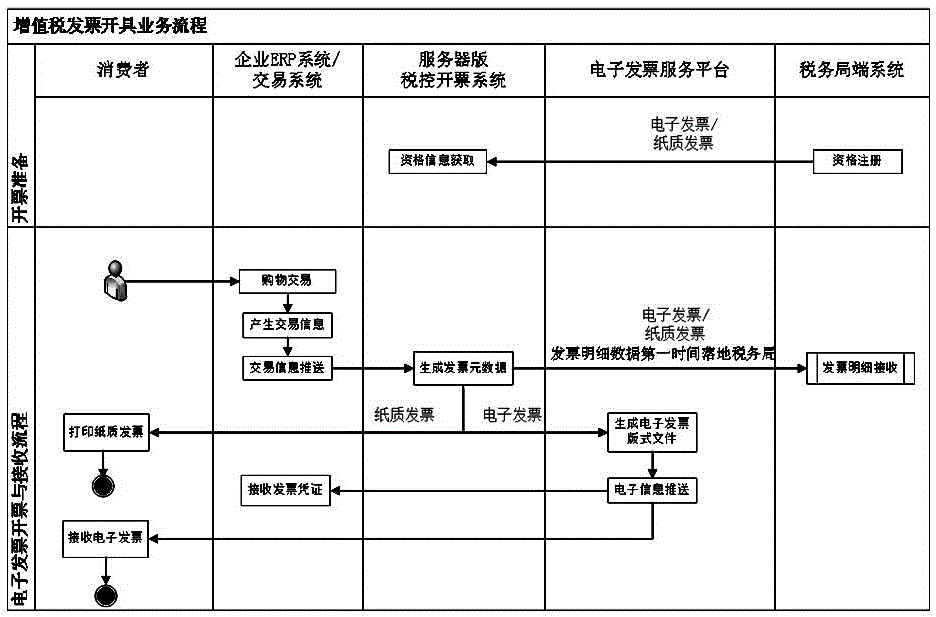

Electric power invoice issuing system and working method thereof

InactiveCN106127537ARealize extremely fast applicationRealize self-service maintenanceBilling/invoicingPaper invoiceElectric power system

The invention relates to an electric power invoice issuing system and a working method thereof. The existing value-added tax special invoice and named general machine-printing voice mode cannot meet requirements for electric power client demands. The invention comprises a value-added tax invoice management platform which is connected with an electric power marketing system. The electric power marketing system receives transaction information submitted by various channels and requests invoice issuing of the value-added tax invoice management platform. The value-added tax invoice management platform generates invoice information. If an electronic invoice needs to be issued, an electronic invoice seal service platform is called according to the invoice information, an electronic invoice layout file is generated, an invoice issuing result is returned to the electric power marketing system, and the electric power marketing system conducts invoice delivery and pushing. If a paper invoice needs to be issued, the paper invoice can be directly printed. The value-added tax invoice management platform is connected with a tax administration end system. The technical scheme achieves electric power electronic invoice application capable of all-weather client information self-service maintenance, business hall top-speed application, electronic invoice query and issuing, one-click reimbursement and one-stop declaration of dutiable goods.

Owner:HANGZHOU POWER SUPPLY COMPANY OF STATE GRID ZHENGJIANG ELECTRIC POWER +3

Method for forming an electronic device in multi-layer structure

A method for forming an organic or partly organic switching device, comprising: depositing layers of conducting, semiconducting and / or insulating layers by solution processing and direct printing; defining microgrooves in the multilayer structure by solid state embossing; and forming a switching device inside the microgroove.

Owner:CAMBRIDGE UNIV TECHNICAL SERCICES LTD +2

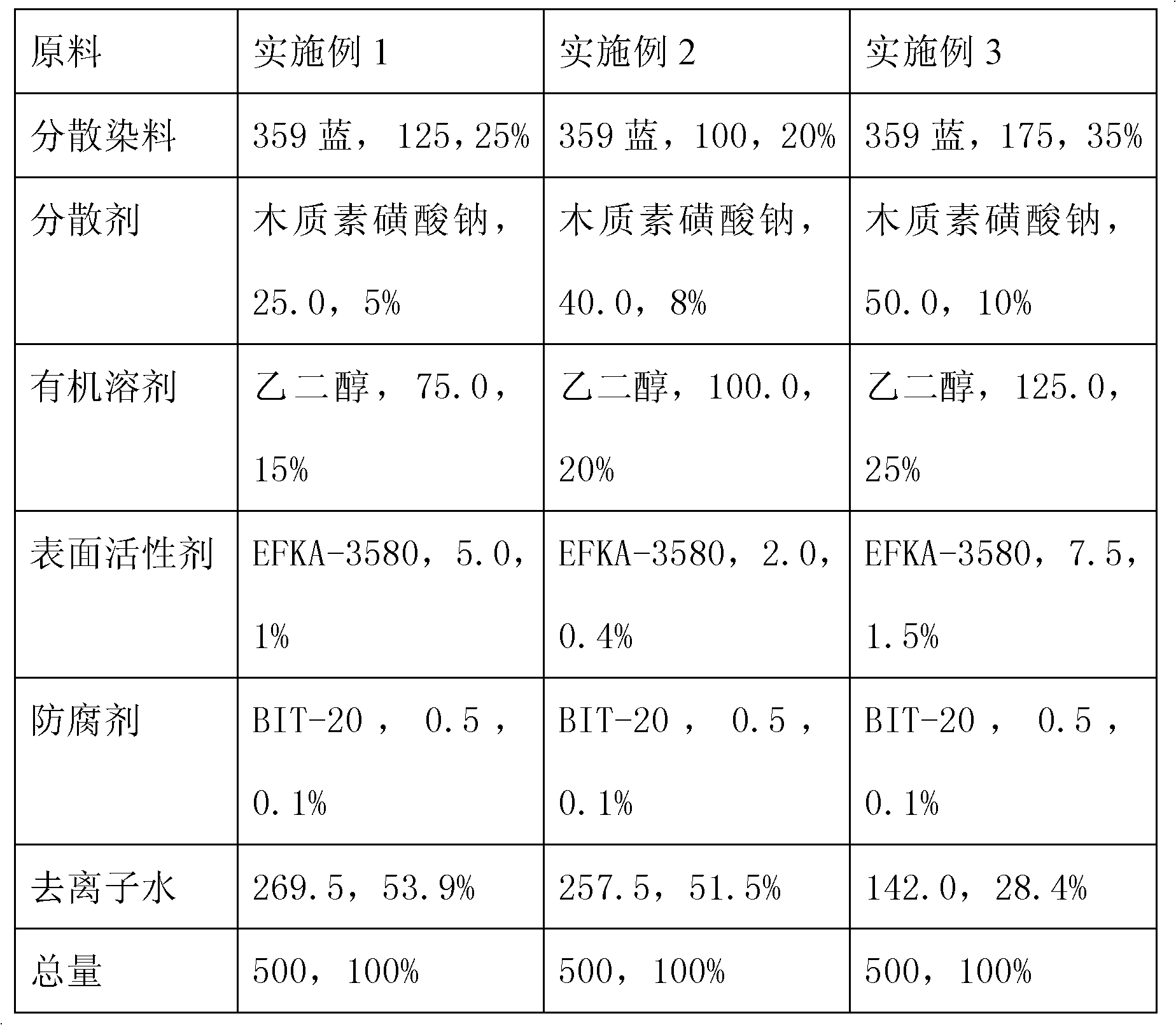

Thermal sublimation ink as well as direct printing technology and equipment

The invention discloses a thermal sublimation ink as well as a direct printing technology and equipment. The invention aims to solve the technical problem that the printing cost of polyester fiber cloth is lowered. The thermal sublimation ink comprises the following components in percentage by weight: 20-35% of dispersed dye, 5-10% of dispersing agent, 15-25% of organic solvent, 0.4-1.5% of surfactant, 0.1% of preservative and 40-59.5% of deionized water. The printing technology disclosed by the invention comprises the following steps: coating slurry on the polyester fiber cloth; and printing the thermal sublimation ink on the polyester fiber cloth by a printing machine. The equipment disclosed by the invention is characterized in that a printing system is composed of a printing head and an ink supply system connected to the printing head. Compared with the prior art, the thermal sublimation ink is characterized in that the thermal sublimation ink is directly printed on the sized polyester fiber cloth, the ink develops color on the cloth to form an image. The technical process is short, thus the production efficiency is greatly improved, and the production cost is reduced.

Owner:深圳市墨库图文技术有限公司

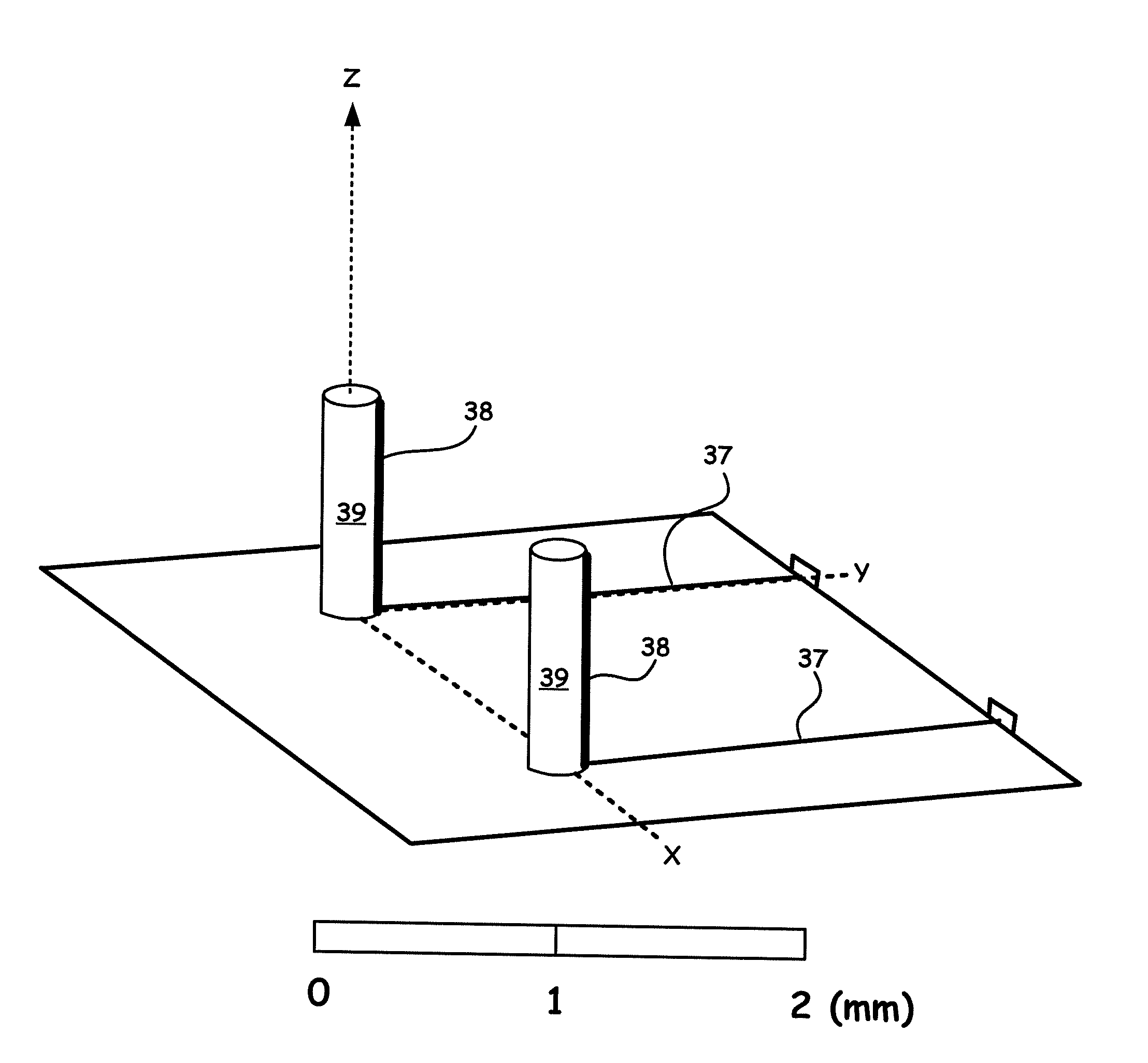

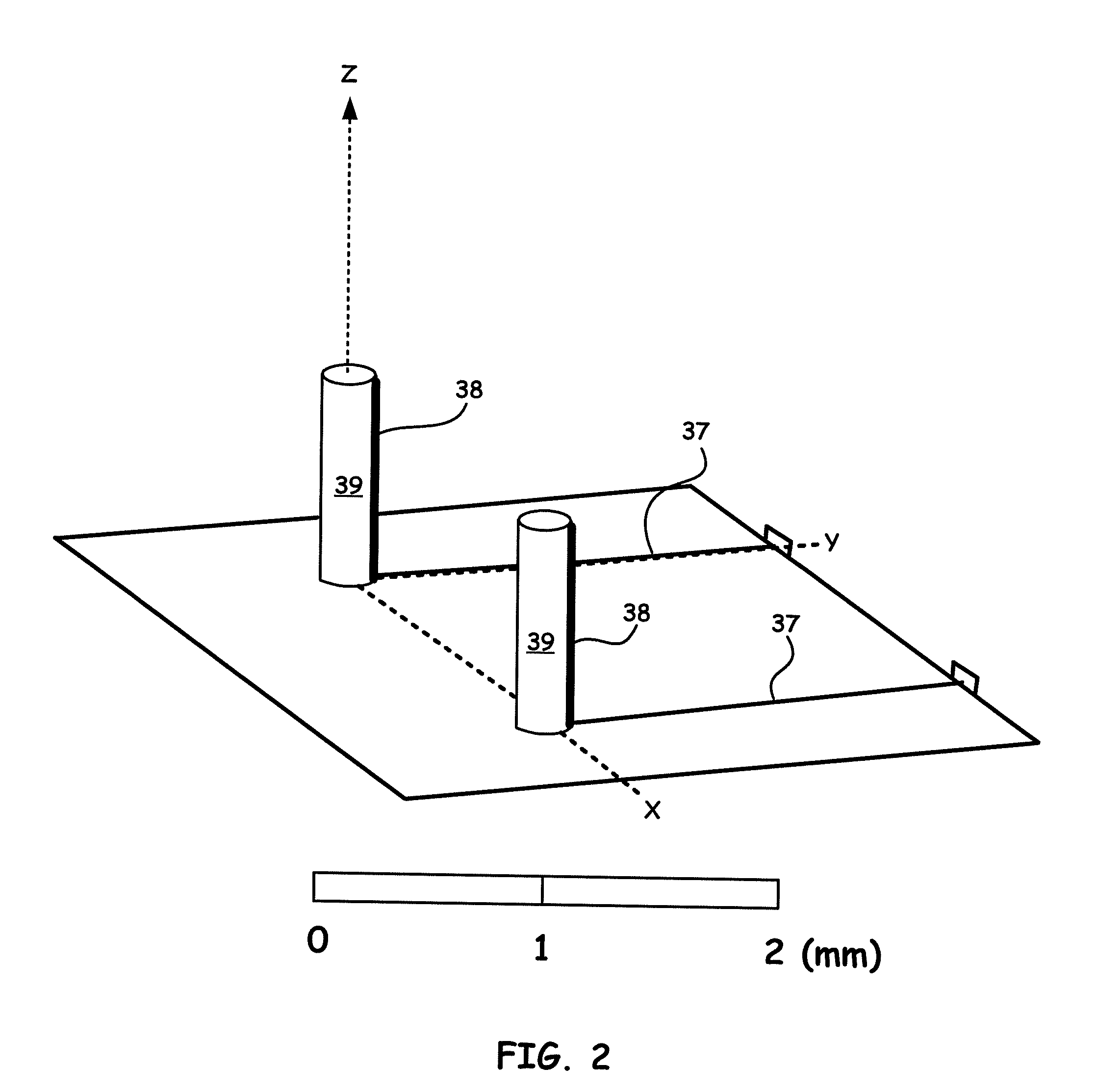

Three dimensional sub-mm wavelength sub-thz frequency antennas on flexible and uv-curable dielectric using printed electronic metal traces

ActiveUS20160172741A1High revenue streamCost-effective and versatile manufacturing processTransportation and packagingTransformers/inductances magnetic coresUltravioletLength wave

Novel methods for micro-additive manufacturing three dimensional sub-millimeter components are disclosed herein. The methods can include dispensing a dielectric at positions on a substrate so as to provide dielectric structures having an aspect ratio of up to 1:20. The methods can also include in-situ curing of the dielectric structure upon dispensing of the dielectric wherein the dispensing and curing steps provide for three dimensional configurations. Direct printing a metal nanoparticle solution on the dielectric to create conductive traces and thereafter sintering the printed nanoparticle solution so as to cure the conductive traces enables three dimensional conductive (antenna) elements having a length and width scale of down to 1 μm.

Owner:WASHINGTON STATE UNIVERSITY

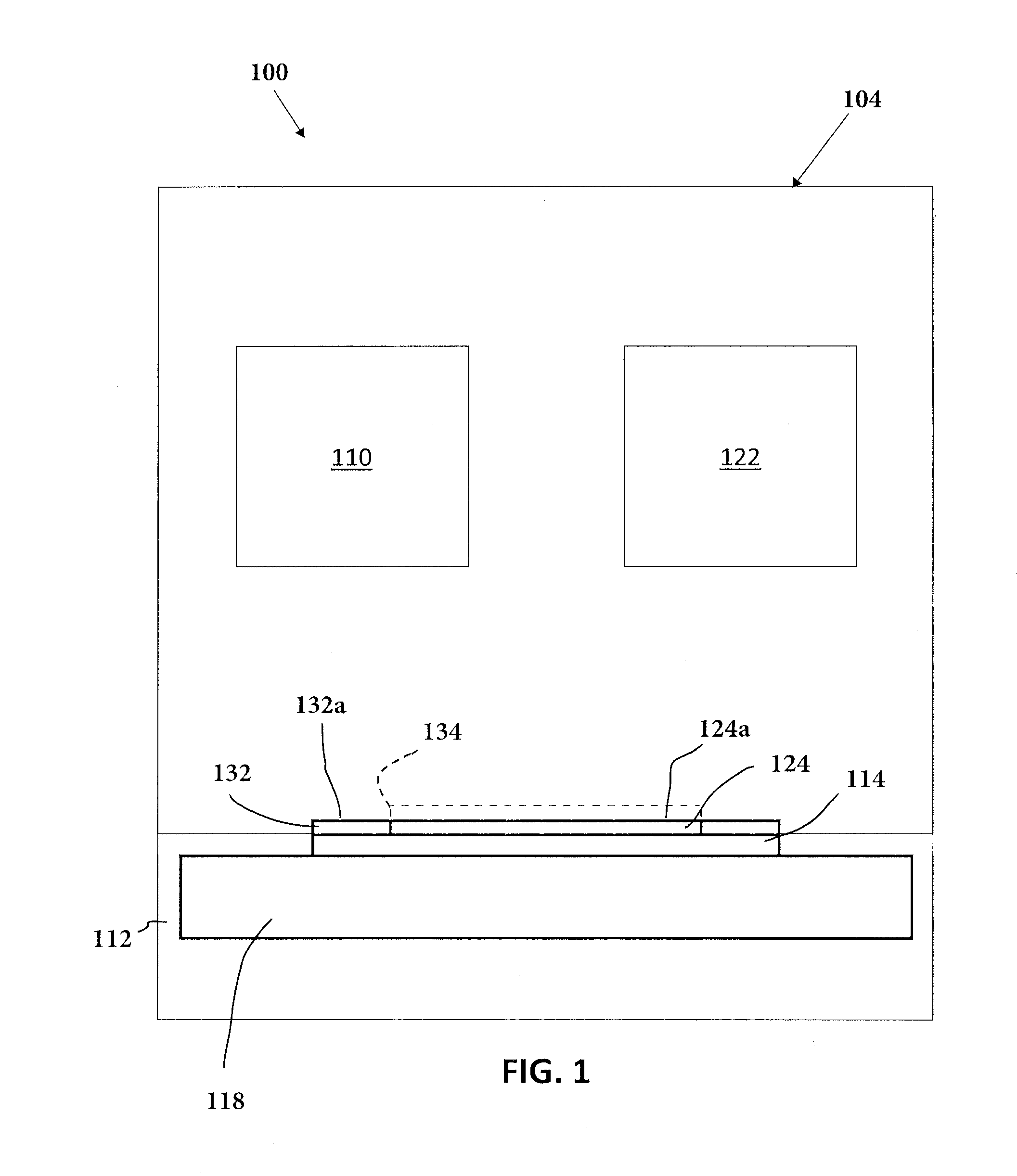

Direct Writing For Additive Manufacturing Systems

ActiveUS20150352785A1Reduce weightPreferable functionNon-insulated conductorsLayered productsElastomerMulti material

There are provided techniques for direct printing material into parts made by additive manufacturing, such as parts made by laser sintering. The direct printed material may be a metal, elastomer, ceramic, or any other material. Further, the direct printed material is typically different than the laser sintering material. Other aspects of the invention include using direct printed materials in the laser sintered parts to improve part strength, provide multi-materials, selectively provide electrical conductivity, and / or provide other desirable features to the parts.

Owner:3D SYST INC

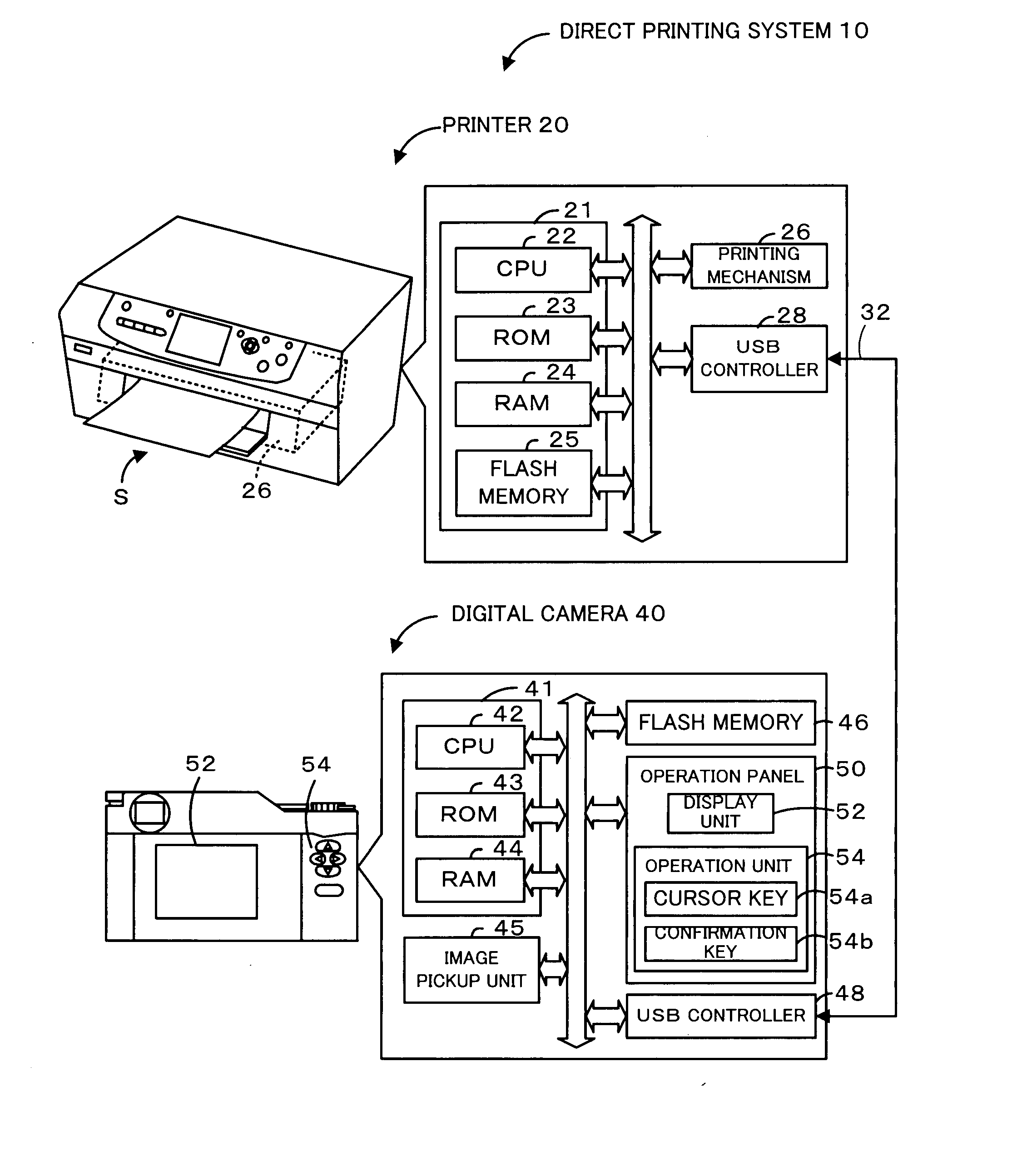

Image output device, image processing apparatus, image output and image processing system, and method therefore

ActiveUS20080106604A1Improve reliabilityTelevision system detailsDigitally marking record carriersImaging processingOutput device

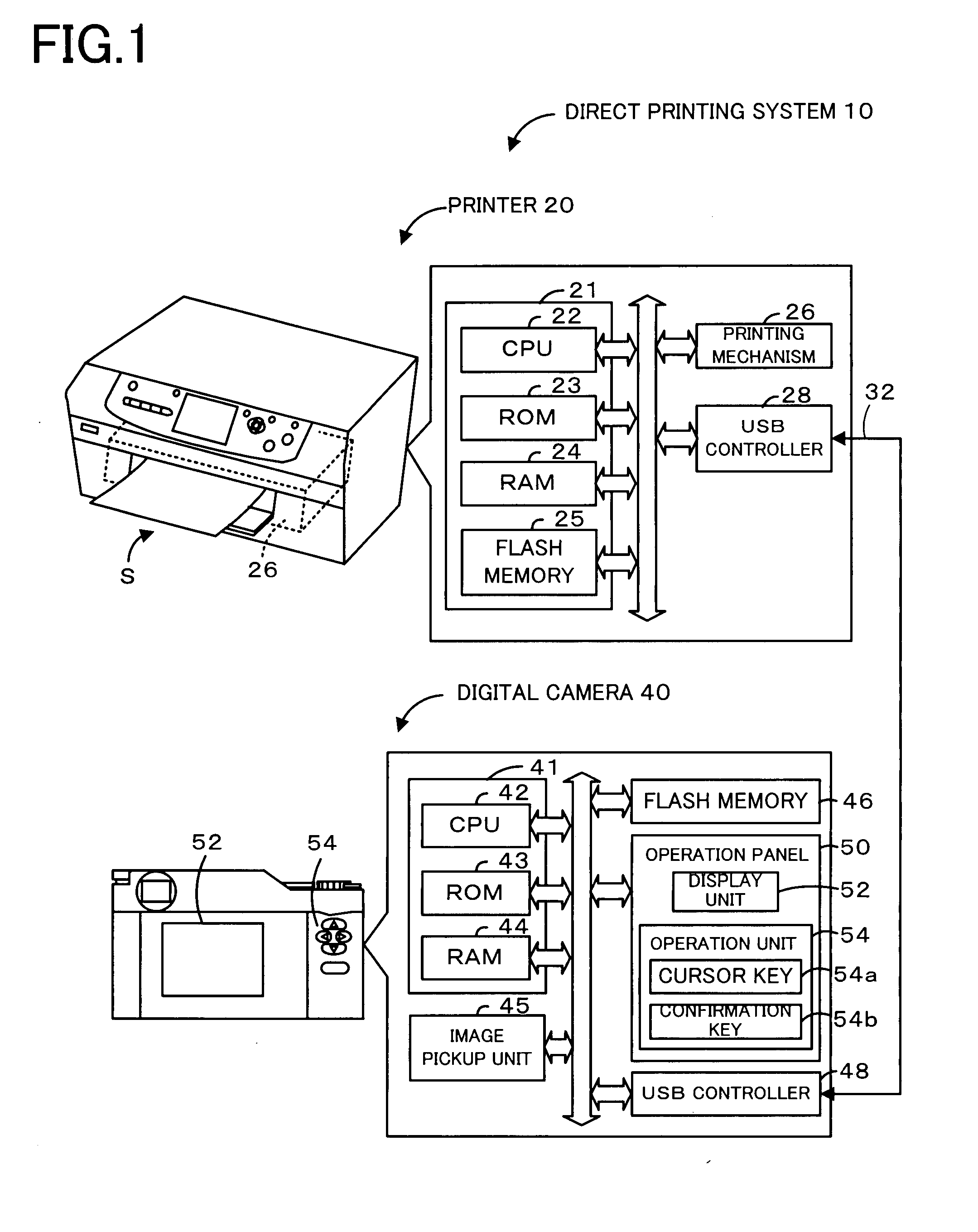

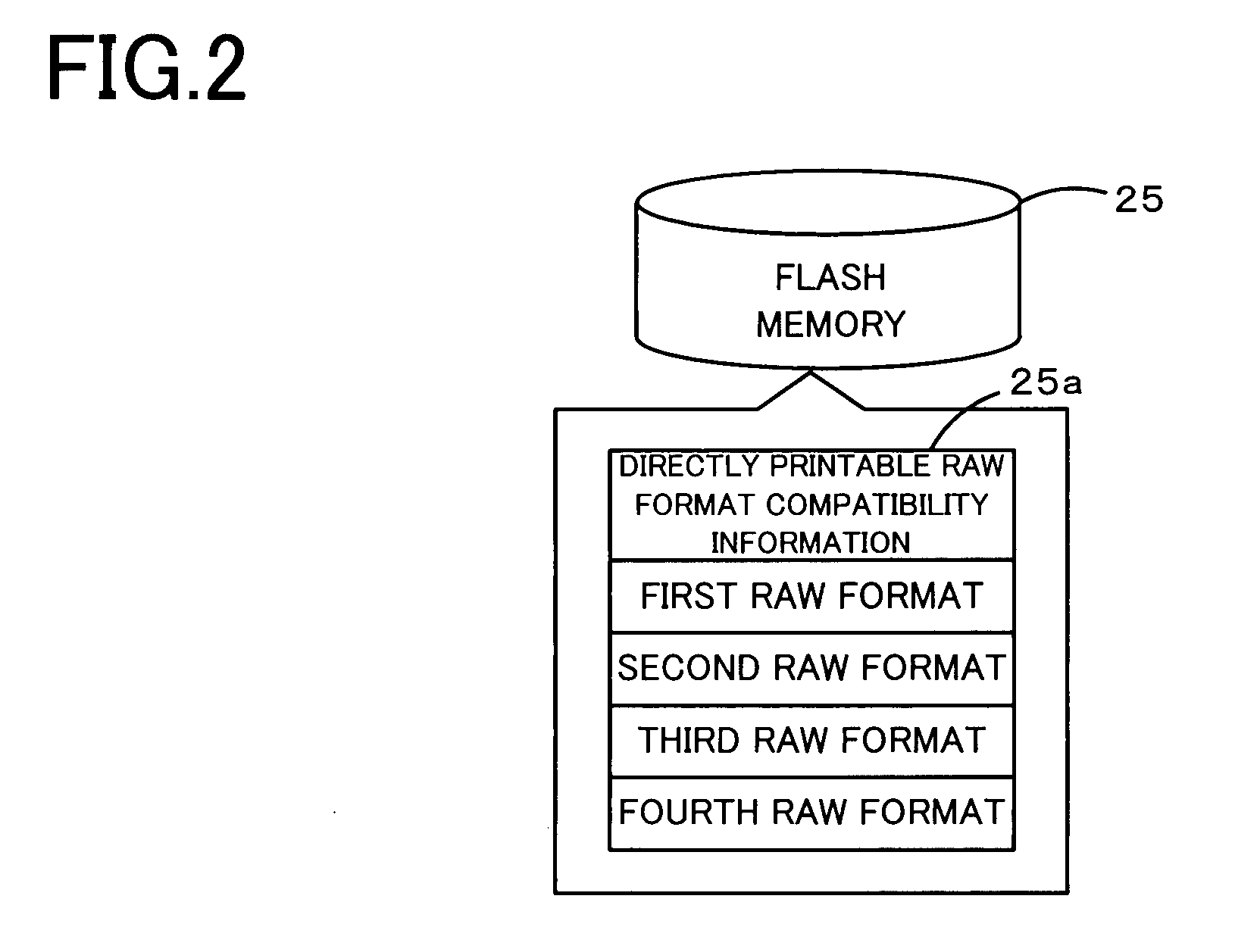

A digital camera 40 transmits to a printer 20 a command for transmitting RAW format compatibility information which is information of a RAW file format directly printable by the printer 20. Upon receipt of the RAW format compatibility information from the printer 20, the digital camera 40 determines, on the basis of the received RAW format compatibility information and the format of a RAW file stored in a flash memory 46 thereof, whether the RAW file can be directly printed by the printer 20. If the RAW file can be directly printed, the digital camera 40 transmits the RAW file to the printer 20. If the RAW file cannot be directly printed, the digital camera 40 transmits to the printer 20 the RAW file and a development enabling parameter which enables analysis of RAW data included in the RAW file as image data. The printer 20 prints the RAW file with the use of the development enabling parameter.

Owner:138 EAST LCD ADVANCEMENTS LTD

Method for printing patterns on finished product shoe in three-dimension way

InactiveCN102511975AThe purpose of expanding salesSimple processShoemaking devicesTypewritersEconomic benefitsEngineering

The invention relates to a method for printing patterns on a finished product shoe in a three-dimension way and belongs to the field of finished product shoe processing. The method comprises the following steps of: (1) carrying out computer treatment on electronic digital pictures to be printed; (2) spraying early-stage treatment liquid on vamp materials; (3) sheathing the finished product shoe onto a three-dimension manufacture tool, supporting the vamp printing part into a plane, fixing the plane and placing the sheathed finished product shoe in a position with a distance being 2 to 3cm under a printing spray head; (4) setting the parameters of a printing machine and calling out the pictures by machine operation software for printing; (5) directly printing the electronic digital pictures to be printed onto the finished product shoe through the printing machine; and (6) carrying out finished product baking, placing the finished product shoe printed with the electronic digital pictures into a baking oven to be baked, taking out the finished product shoe after the finished product shoe is baked, and obtaining the finished product shoe with the electronic digital pictures printed on the vamp. The method is used for printing the patterns on the finished product shoe in the three-dimension way, the patterns printed on the vamp are very stable and firm, the patterns are clear, the precision is high, the quality is good, the processing work procedures are few, and the economic benefits are good.

Owner:邓健

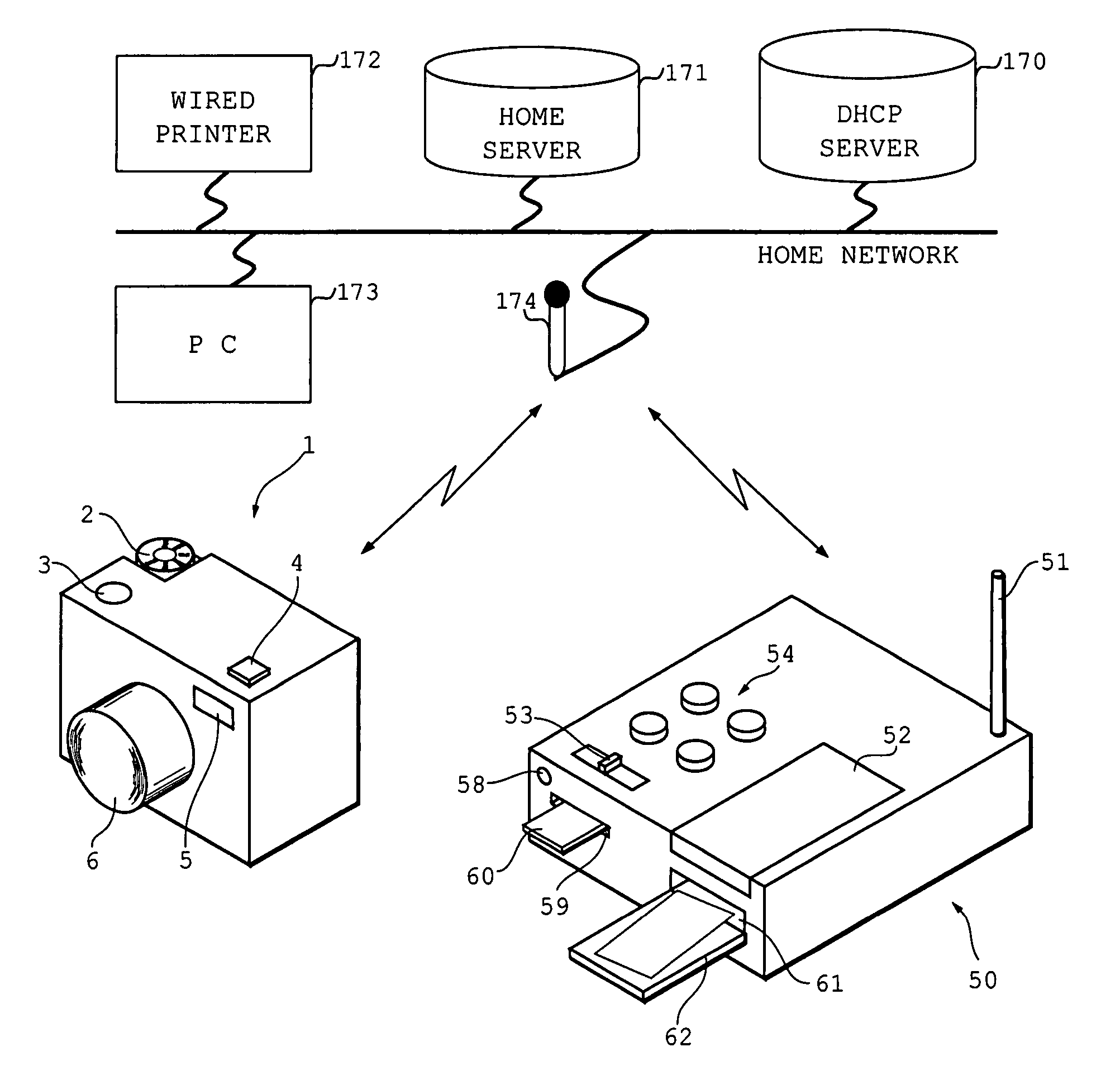

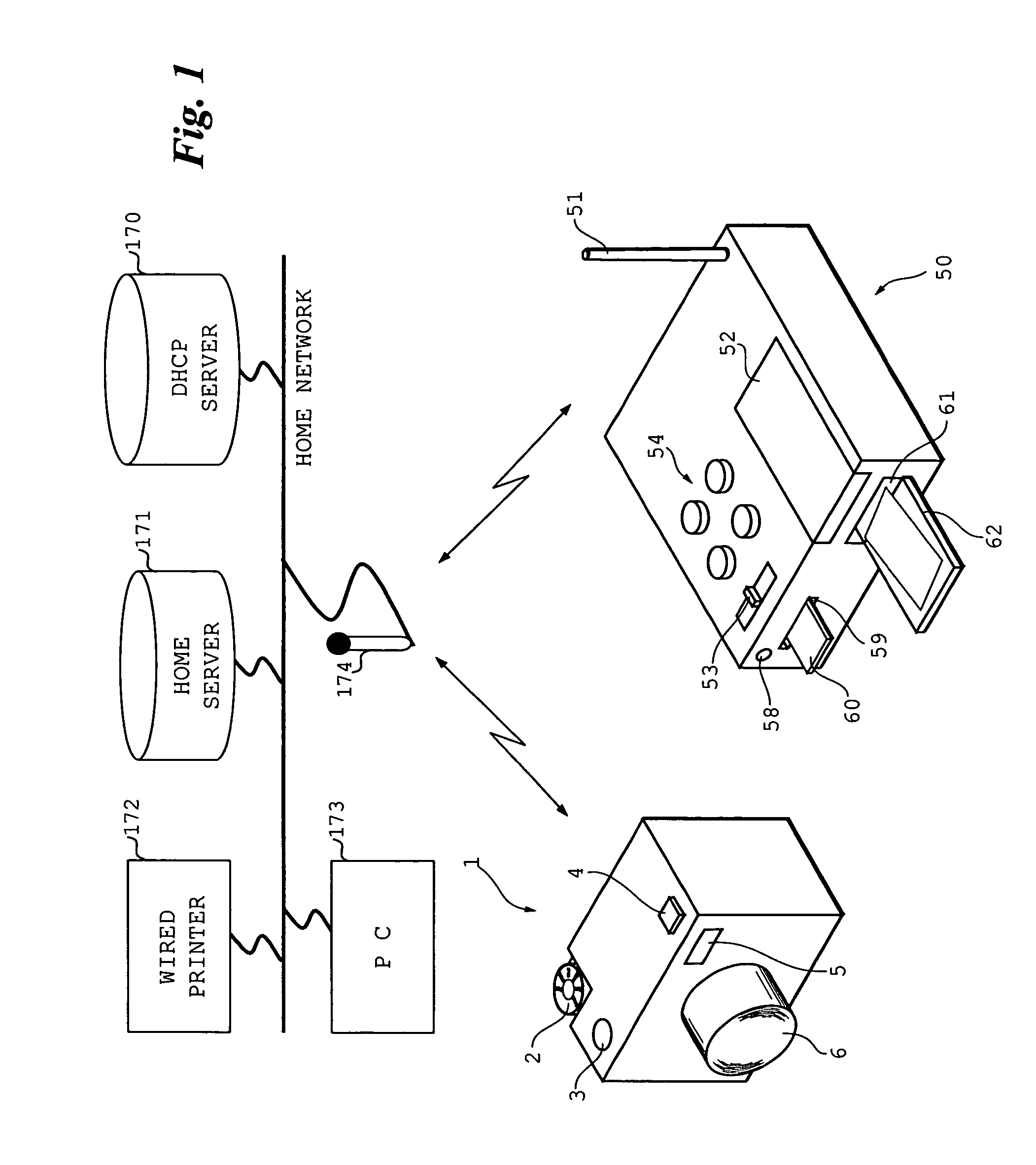

Direct print system

Wireless-LAN information is set in a digital still camera in a comparatively simple manner. Specifically, if a digital still camera and a printer are to communicate utilizing a wireless LAN, the printer generates a two-dimensional bar code containing wireless-LAN setting information such as ESS-ID and WEP KEY, and printer setting information such as an IP address. The printer is used to generate a direct print setting sheet on which have been recorded the generated two-dimensional bar code as well as the wireless-LAN setting information and printer setting information. The digital still camera is used to take a picture of the two-dimensional bar code and read the wireless-LAN setting information and printer setting information from the two-dimensional bar code. The read wireless-LAN setting information and printer setting information is set in the digital still camera, and the printer and digital still camera cooperate to perform direct printing using the wireless LAN.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com