Patents

Literature

191results about How to "Solve problems such as pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An environment-friendly digital ink-jet direct printing textile ink and method for preparing same

ActiveCN101531848ASolve problems such as easy to cause pollution to the environmentSolve problems such as pollutionInksDyeing processUltra fineEngineering

An environment-friendly digital ink-jet direct printing textile ink and method for preparing same, the digital ink-jet direct printing textile ink composed of components as follows: pigment paste, connection materials, cross-linking agent, softening agent, solvent, surfactant, bactericide, pH regulating agent, and deionized water. The pigment paste is a mixture of the following components: pigments, ultra-dispersing agent, wetting agent, and deionized water. The preparation method includes: a. mixing the pigments, ultra-dispersing agent, wetting agent, and deionized water into a pigment paste, mixing the pigment paste at high-speed and then grinding it in an ultra-fine nano-grinding machine, to obtain the nano stage ultrafine grain paste; b. mixing the proportioning mixture with the grinded nano stage ultrafine grain paste, high-speed stirring and then filtering to obtain a finished environment-friendly digital ink-jet direct printing textile ink. The inventive printing textile ink does not contain formaldehyde, can be direct digital printed wtihtout plate-making when in use, and has rich color, soft hand feeling, and capability of allowing the digital ink-jet printing textile materials to meet the high environmental and quality requirements.

Owner:深圳市墨库图文技术有限公司

Fruit tree special-purpose fertilizer and preparation method thereof

InactiveCN103524270AAvoid pollutionSolve problems such as pollutionFertilizer mixturesPhosphateAgricultural engineering

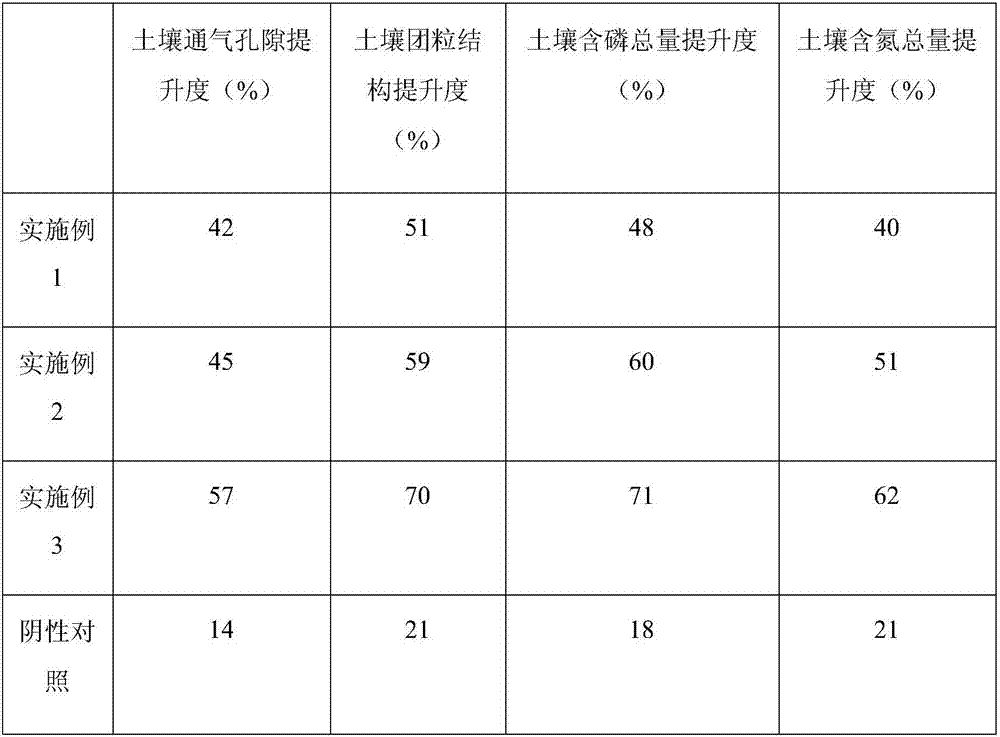

The invention discloses a fruit tree special-purpose fertilizer which is prepared from the raw materials of, by weight: 300-340 parts of live stock and poultry manure, 200-230 parts of soybean stalk, 100-120 parts of bagasse, 100-120 parts of air-dried sludge, 50-55 parts of beer grains, 30-35 parts of ox blood powder, 20-24 parts of cooked soybean, 60-65 parts of rock phosphate powder, 14-18 parts of bamboo charcoal, 10-12 parts of maifanite powder, 12-15 parts of zeolite powder, 30-35 parts of urea, 50-55 parts of mono-ammonium phosphate, 20-23 parts of ammonium sulfate, 6-9 parts of an EM inoculant, 10-15 parts of a soil conditioner, and proper amount of water. According to the fruit tree special-purpose fertilizer, wastes such as live stock and poultry manure, soybean stalk, bagasse, air-dried sludge, and the like are adopted as main raw materials, such that resource is saved, and problems such as environment pollution are solved. The raw materials are convenient to obtain, and are cheap, such that good environmental and economic benefits are provided. The fertilizer provided by the invention has the advantages that: with the fertilizer, beneficial microbe number and activity are improved, soil physiochemical traits are improved, soil nutrients are increased and balanced, and pesticide and chemical fertilizer residue and other harmful substances in soil can be degraded.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

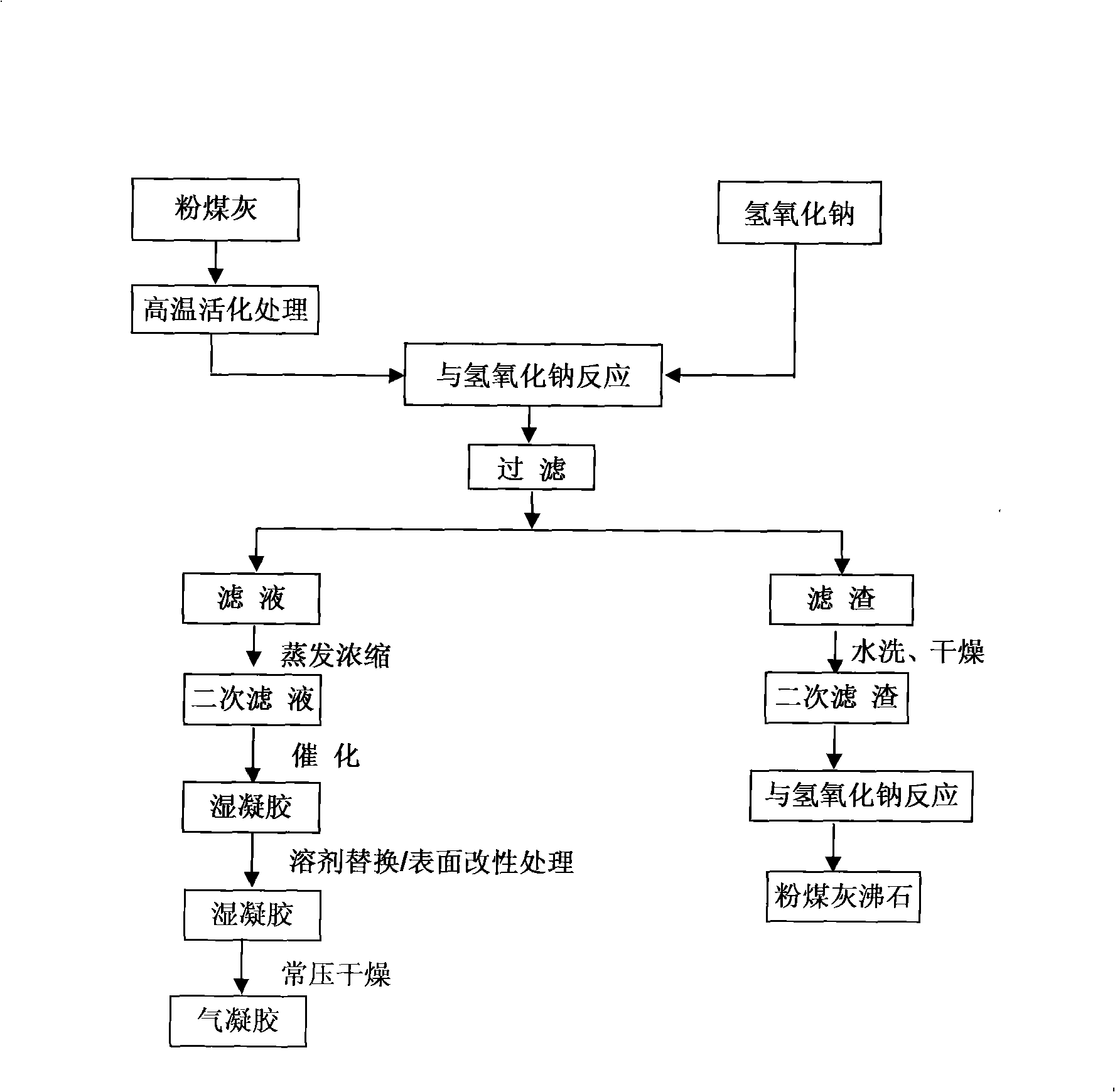

Method for simultaneously preparing SiO2 aerogel and zeolite by utilizing fly ash

InactiveCN101538046AGood workmanshipHigh porositySilicaCrystalline aluminosilicate zeolitesResource utilizationSoluble glass

The invention relates to a method for simultaneously preparing SiO2 aerogel and zeolite by utilizing fly ash, belonging to the technical field of the high-efficiency resource utilization of solid wastes and chemical material preparation. The method is as follows: the fly ash is firstly processed by high-temperature activation and then carries out hydro-thermal synthesis reaction with a sodium hydroxide water solution, soluble glass is catalyzed by a sulphuric acid with certain concentration, or the solution carries out cation exchange resin and is then processed by base catalysis to obtain SiO2 gel; aquagel is processed by solvent exchange / surface modification by utilizing a mixed solution of alcohols / alkanes solvent and trimethylchlorosilane, and the SiO2 aerogel is obtained under the condition of normal pressure and dryness; the fly ash is reacted with NaOH and then filtered to obtain filter residue, and the filter residue is further reacted with the NaOH so as to synthesize fly ash zeolite. The invention is not only a new way of the high-efficiency recycling of the solid wastes, but also a new technical method of the low-cost preparation of the SiO2 aerogel and the zeolite.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Production of alumina solid acid catalyst fixed carried on aluminum muriate

InactiveCN1939590ASolve problems such as pollutionEasy to separatePhysical/chemical process catalystsSolid acidSewage

An alumina carried AlCl3 solid acid catalyst with high activity, selectivity and stability for the oligomerizing reaction of isobutene on suspended bed is prepared through reaction between CCl4 and high-purity gamma-Al2O3 to generate AlCl3 vapor, reacting on the hydroxy groups on the surface of gamma-Al2O3 with both meso-porous and macroreticular structure, pulverizing and sieving by 10-400 meshes.

Owner:DALIAN UNIV OF TECH

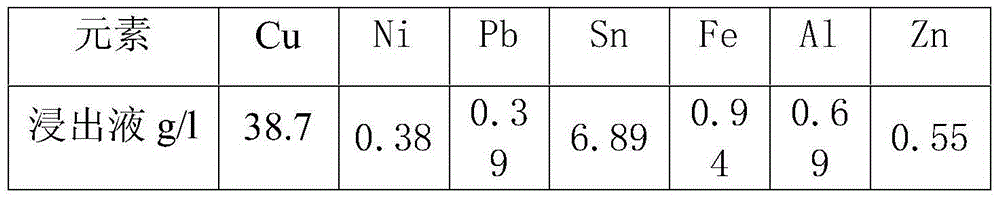

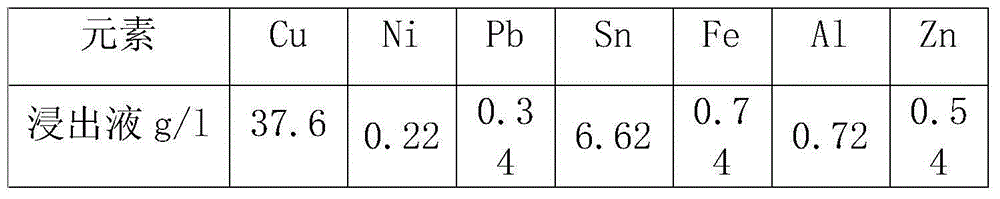

Resourceful comprehensive utilization method of waste printed circuit boards

ActiveCN104532005ARealize resource utilizationSolve problems such as pollutionProcess efficiency improvementElectrostatic separationSlag

The invention discloses a resourceful comprehensive utilization method of waste printed circuit boards. The method comprises the following steps: crushing waste printed circuit boards and carrying out magnetic separation to obtain ferrous raw materials and non-ferrous raw materials; carrying out high-voltage electrostatic separation on the non-ferrous raw materials to obtain metallic materials and non-metallic materials; and separating such metals as copper, gold and silver from the metallic materials. By adopting the method disclosed by the invention, such valuable metals as copper, tin, aluminum, iron, lead, gold and silver and metal slag containing nickel and zinc in the waste printed circuit boards can be recovered and the materials such as non-metallic resin can also be recovered. By adopting the resourceful comprehensive utilization method, the problems of environmental pollution caused by the waste printed circuit boards and the like are solved and the resourceful comprehensive utilization of the waste printed circuit boards is achieved. The method is simple in process and is economical and practical and industrialization is easy to implement.

Owner:清远市东江环保技术有限公司

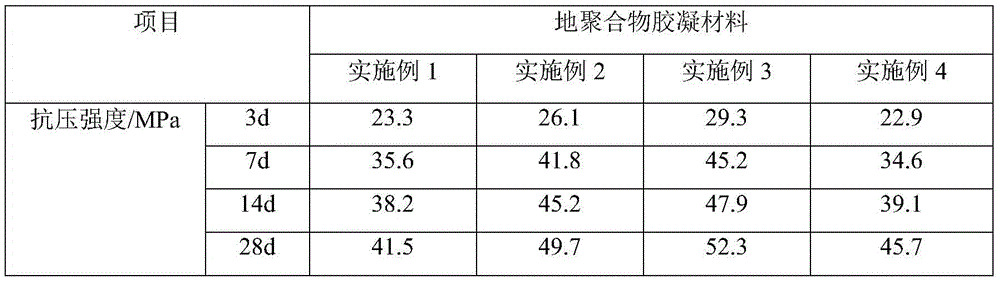

Lead-zinc smelting slag based geopolymer gelling material and preparation method thereof

The invention discloses a lead-zinc smelting slag based geopolymer gelling material and a preparation method thereof and belongs to the technical field of geopolymer. The material is composed of, by mass, 65-72 wt.% of lead-zinc smelting slag, 5-10 wt.% of coal ash, 8-15 wt.% of composite alkali activator, 3-6 wt.% of sulfate activator, 1-3 wt.% of aluminate activator and 10-14 wt.5 of deionized water. The preparation method includes: respectively drying and grinding lead-zinc smelting slag and coal ash, and mixing well with a sulfate activator and an aluminate activator before joint grinding to obtain a ball-milled mixture; adding a composite alkali activator solution into the ball-milled mixture, stirring well, forming, and maintaining to obtain the material. The preparation method is simple, low in energy consumption and free of pollution in the preparation process, and geopolymer has good gelling performance, mechanical performance, corrosion resistance, wear resistance and dry shrinkage resistance.

Owner:燕京理工学院

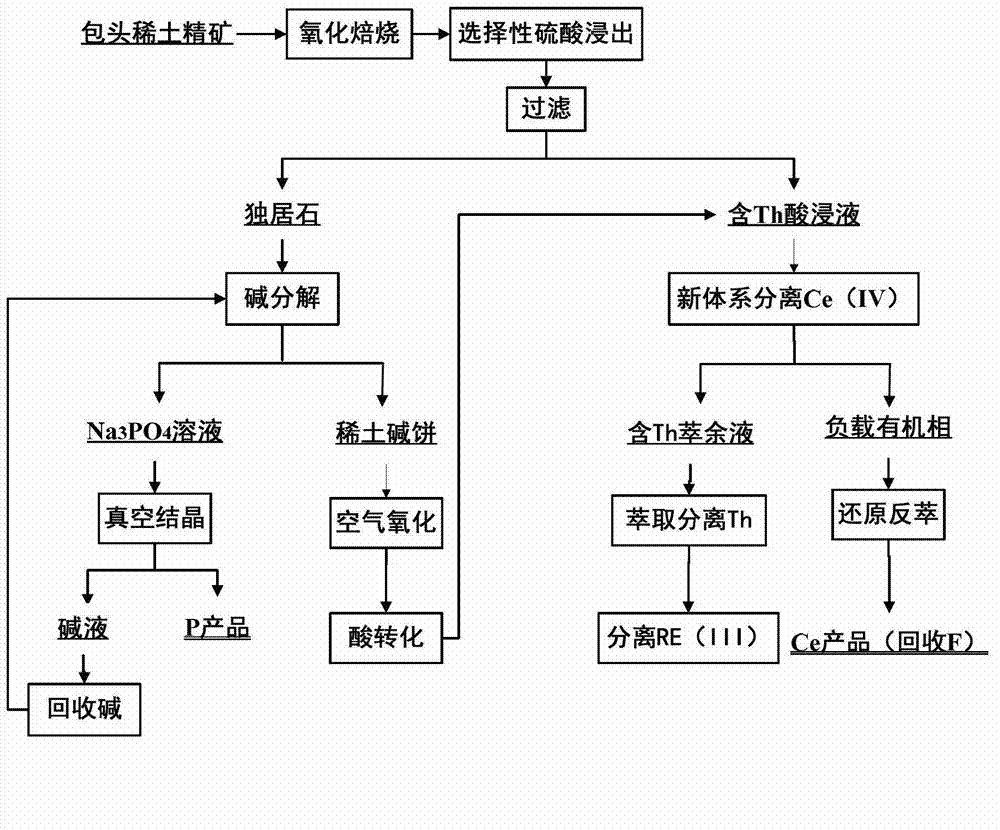

Technique for decomposing Baotou rare-earth ores

InactiveCN103045851AReduce stockpilesReduce processingProcess efficiency improvementPregnant leach solutionSodium phosphates

The invention relates to a technique for decomposing Baotou rare-earth ores. The invention solves the technical problems of environmental pollution and resource loss caused by the rare-earth ore separation technique in the prior art. The technique comprises the following steps: carrying out oxidizing roasting on mixed rare-earth concentrate; leaching the roasted ores with an H2SO4 solution to obtain a leach solution and urdite; extracting and separating Ce (IV), F and Th as well as single RE (III) from the sulfuric acid leach solution; and carrying out alkali conversion on the urdite to obtain a rare-earth alkali cake, carrying out size mixing, filtering, and crystallizing the alkaline solution to recover sodium phosphate, wherein the residual alkali liquor is used for cyclically leaching urdite slag. When being used for treating the mixed rare-earth concentrate, the technique provided by the invention can implement multi-step extraction of bastnaesite and urdite in the mixed ores. Besides, the invention is beneficial to further effectively recovering Th, F and P from baotite, thereby avoiding environmental pollution, enhancing the rare-earth yield, saving the cost and implementing clean production and comprehensive resource utilization in deed.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

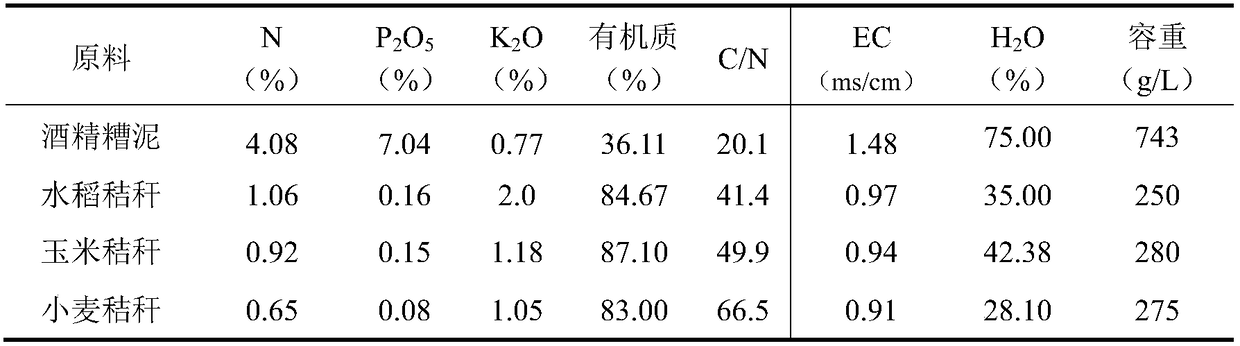

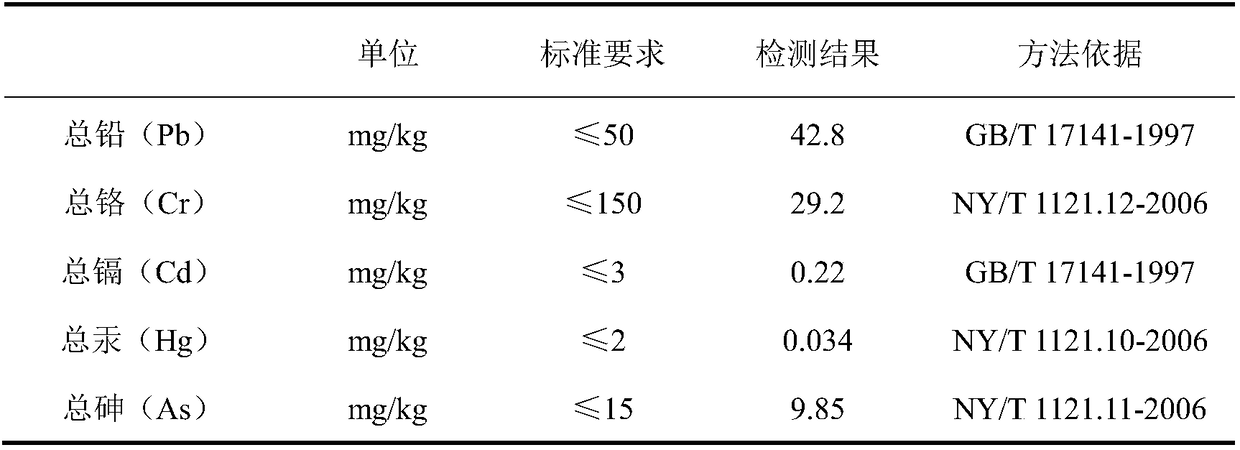

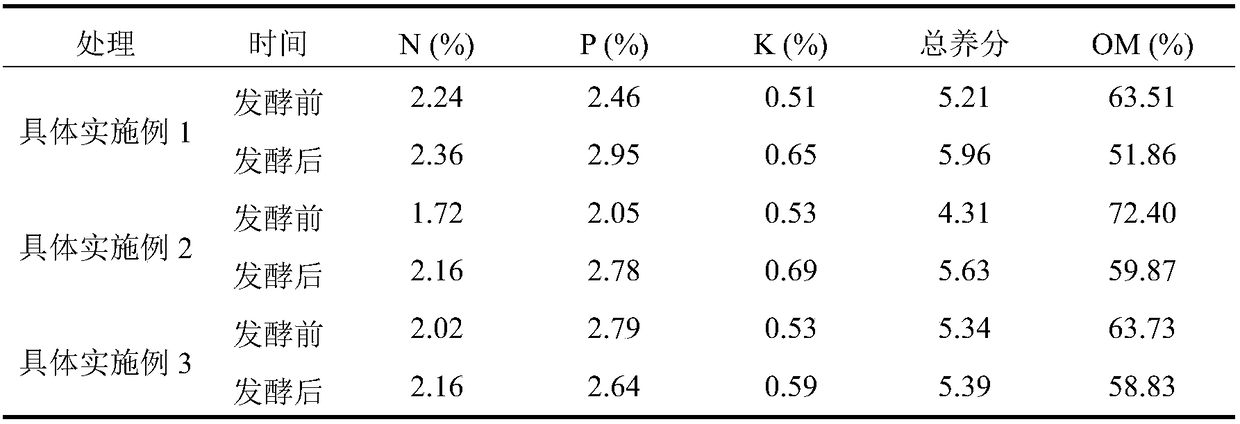

Sludge-derived saline-alkali soil remediation agent as well as preparation method and application thereof

InactiveCN106867545AImprove soil fertilityReduce salt contentAgriculture tools and machinesContaminated soil reclamationMunicipal sewageEnvironmental chemistry

The invention provides a sludge-derived soil remediation agent as well as a preparation method and application thereof in sludge digestion. According to the adopted technical scheme, pretreatment is carried out on urban sewage and sludge, and the sludge is treated by means of twice fermentation. Tests prove that after the sludge remediation agent is used for 20 days, the proportional effective removal rate of various pollutants in soil reaches 95% or more and is in line with national standards. Furthermore, a sulfuric acid substance can acidify the hardened saline-alkali soil and is also good organic fertilizer, thus beneficial to reduction of the use of chemical reagents and chemical fertilizer in agricultural production, and putting an end to pollution and secondary pollution from the source.

Owner:北京绿安创华环保科技有限公司

Method for recycling alumina and sodium oxide from bayer process red mud

ActiveCN103030160AHigh dissolution rateEfficient cycleAlkali metal oxidesAluminium oxides/hydroxidesBrickRed mud

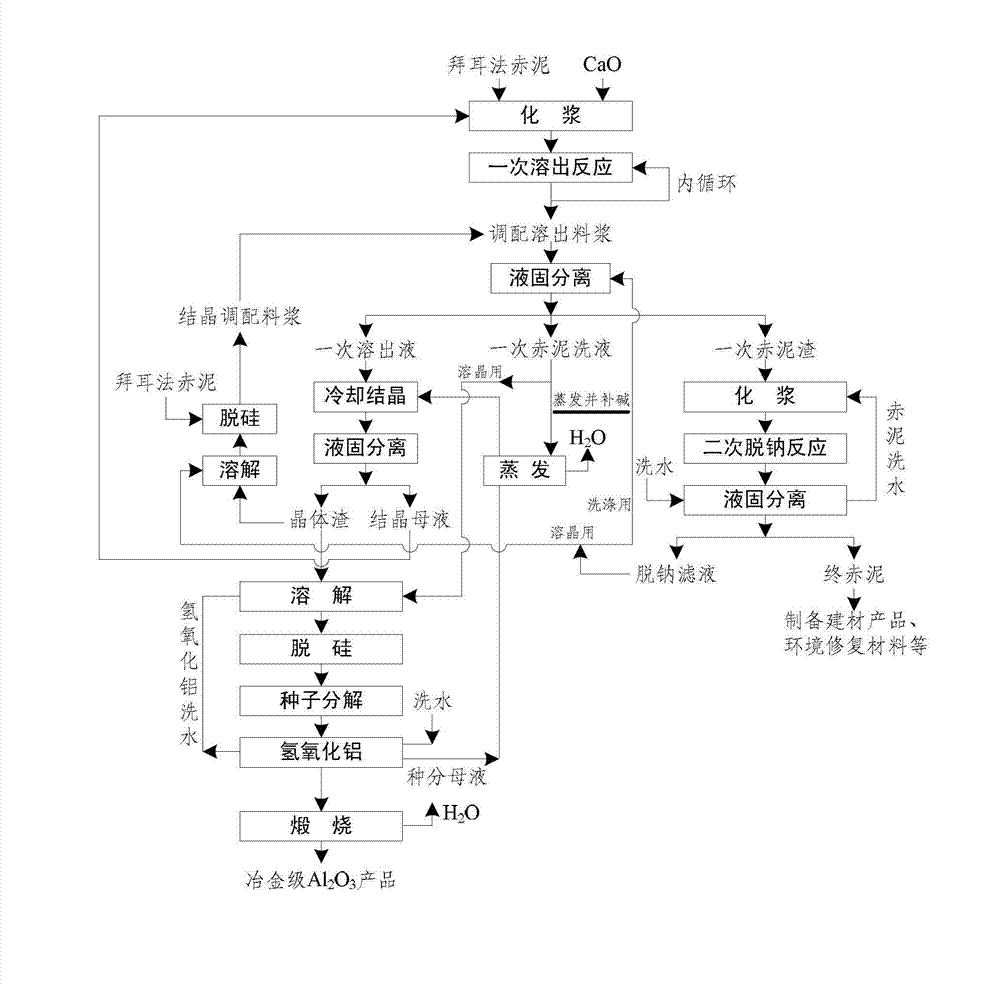

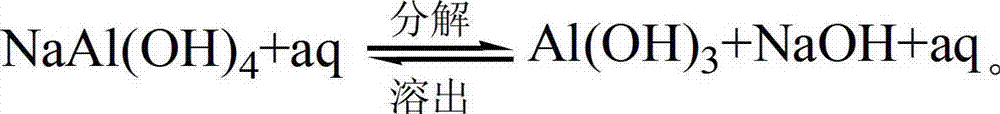

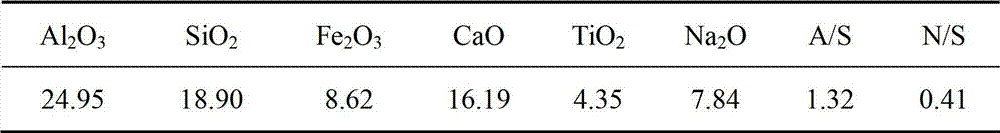

The invention relates to a method for recycling alumina and sodium oxide from bayer process red mud. In the method, by adopting a high molecular ratio and high alkali concentration sodium aluminate solution, aluminum extracting reaction can be rapidly carried out under mild operating conditions, so that the recovery rate of alumina in the red mud reaches more than 85%, and the defects, such as equipment scabbing and the like can be effectively prevented and even eliminated; by implementing an efficient crystallization process of an intermediate product of hydrated sodium aluminate, the cycle efficiency of a dissolution medium is greatly improved; due to complete transformation of a phase in the aluminum extracting reaction, a reaction process of recycling sodium oxide can be performed at low temperature and normal pressure; and after secondary sodium removal reaction, the sodium oxide content in final red mud is not more than 1% and is far less than 6-8% of the bayer process red mud. Therefore, the red mud can be doped in large proportion for preparing cement, brick and roadbed materials, concrete additives, environmental remediation materials and other fillers, and the problems such as resource utilization of the red mud, potential environment hazard and the like are hopefully solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

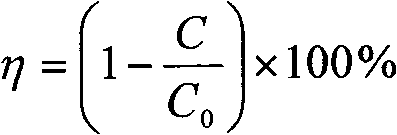

Method for preparing sewage treatment adsorbent by edible fungi residues

ActiveCN104107684AAvoid pollutionSolve problems such as pollutionOther chemical processesWater/sewage treatment by sorptionSuspended particlesSorbent

The invention relates to a method for preparing a sewage treatment adsorbent, and particularly relates to a method for preparing a sewage treatment adsorbent by edible fungi residues. The method comprises the steps of with the edible fungi residues as raw materials, crushing the raw materials, carrying out microwave-assisted alkali process degradation, washing, formaldehyde modification, washing, and drying. The sewage treatment adsorbent prepared by adopting the method not only solves the problem of waste of a fungi residue resource, and also can be used for adsorbing and settling suspended particles, organic dye, heavy metal ions and the like in the earlier-stage processing of sewage, thereby realizing a function of recycling the edible fungi residues.

Owner:NANJIANG HONGXIN BIOTECH

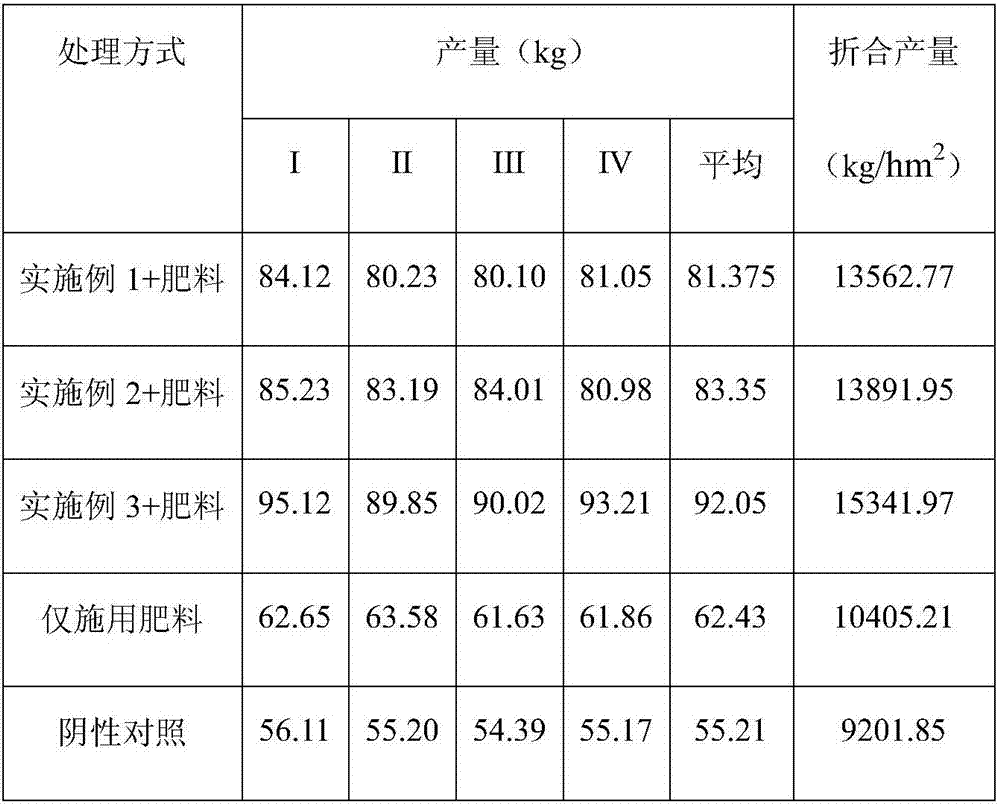

Environment-friendly fertilizer for lotus and preparation method thereof

ActiveCN104211537AControl plant diseasesPotassium-dissolving effect is obviousBio-organic fraction processingOrganic fertiliser preparationNutrientHumic acid

The invention discloses an environment-friendly fertilizer for lotus and a preparation method thereof. The environment-friendly lotus fertilizer is prepared from the following raw materials in parts by weight: 70-80 parts of organic fertilizer, 15-25 parts of inorganic fertilizer, 1-5 parts of microelement, 0.1-0.3 part of fermenting compound bacteria, 1-2 parts of enzyme microorganism, 2-7 parts of humic acid and 0.5-1 part of chitosan oligosaccharide. The preparation method comprises the following steps: evenly mixing the fermenting compound bacteria with water in the weight ratio of 1 to (5-50) to obtain a diluted bacterial liquid; adding the diluted bacterial liquid to the organic fertilizer, mixing evenly, piling, and turning over circularly to obtain a primary fermentation product; next, adding the enzyme microorganism for fermenting until thorough decomposition, drying at a low temperature and crushing to obtain a secondary fermentation product; finally, adding such components as inorganic fertilizer, microelement, humic acid, chitosan oligosaccharide and biological bacteria, mixing evenly, pelletizing and sorting to obtain the environment-friendly fertilizer for lotus. The environment-friendly fertilizer for lotus is prepared from husbandry waste materials as the major raw materials, so that the problem of nutrient supply to lotus and the heavy metal and organic matter pollution problem in the production process of lotus can be solved.

Owner:WUHAN RUIZE SOURCE BIOLOGICAL ENVIRONMENTAL PROTECTION TECH

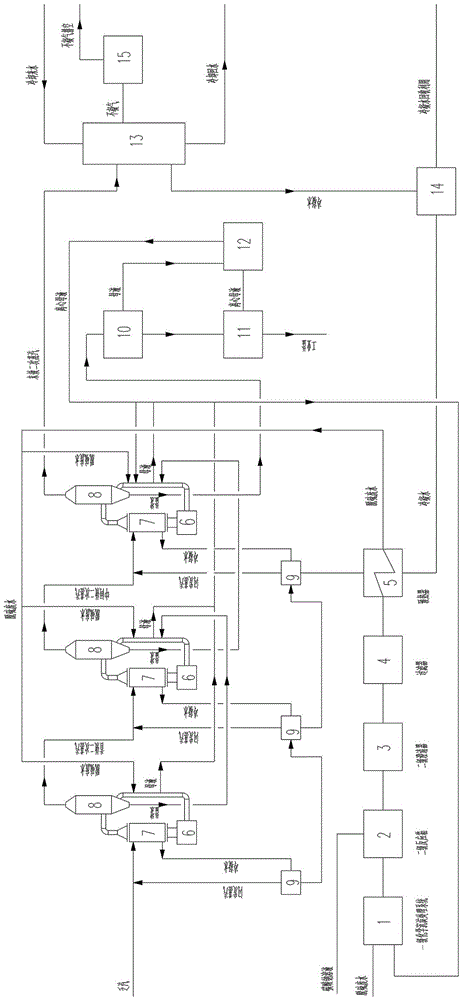

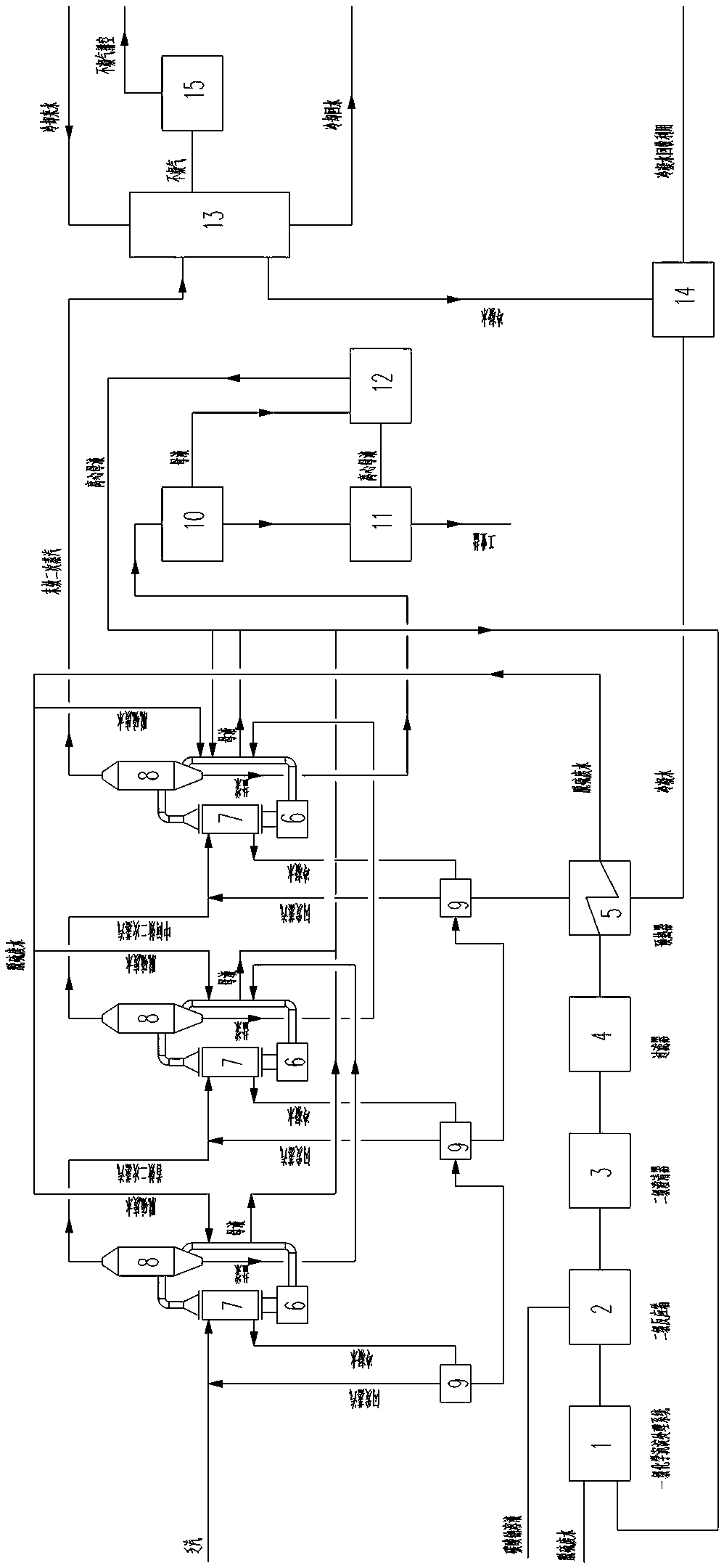

Treatment system capable of realizing zero discharge of desulfurization wastewater

ActiveCN105523677AReduce ion concentrationReduced fouling tendencyWaste water treatment from gaseous effluentsMultistage water/sewage treatmentEngineeringSolvent

The invention discloses a treatment system capable of realizing zero discharge of desulfurization wastewater. The treatment system comprises a primary chemical sedimentation treatment system (1), a secondary chemical sedimentation treatment system, a multi-effect evaporating device and a solid-liquid separating device which are arranged sequentially as well as a pipeline for guiding mother liquor in the multi-effect evaporating device into the primary chemical sedimentation treatment system (1). The treatment system has the benefits as follows: the scaling tendency of the desulfurization wastewater is reduced, and phenomena that heat transfer is affected by scaling, heat exchange tubes of evaporation chambers are corroded by corrosion ions and the like are avoided; meanwhile, the desulfurization wastewater is converted into a solution system with NaCl serving as a solvent mainly, multi-effect vacuum evaporation, concentration and crystallization are performed on the desulfurization wastewater by the aid of exhaust steam of coal-fired power plants, secondary industrial salt by-products are produced, and zero discharge of the desulfurization wastewater is realized.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD +1

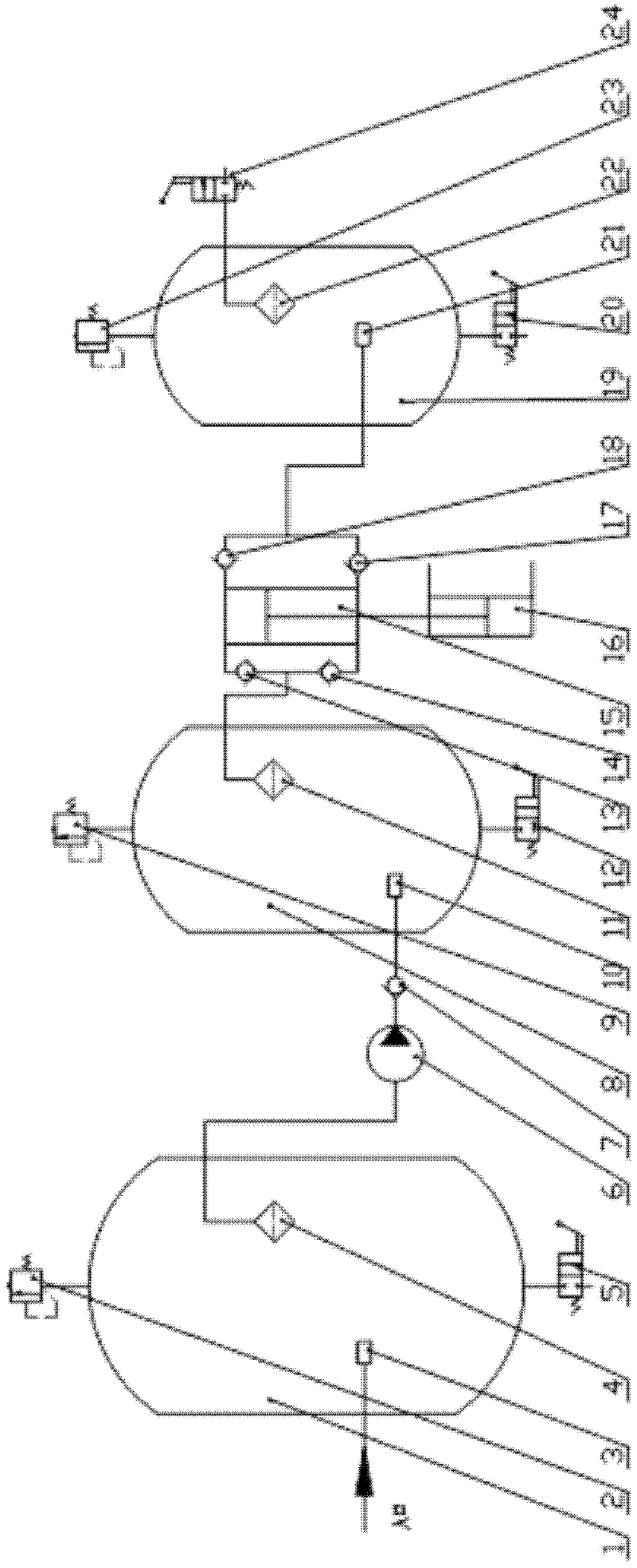

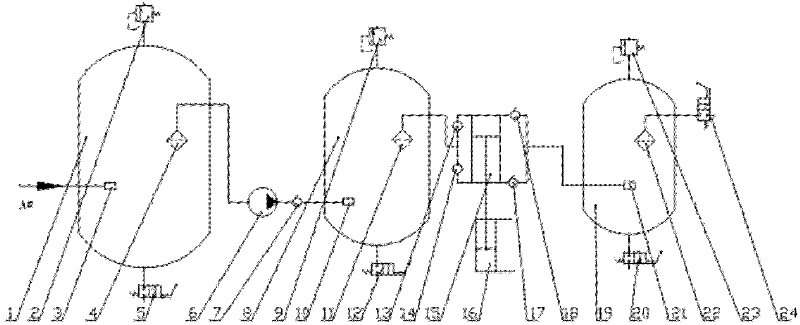

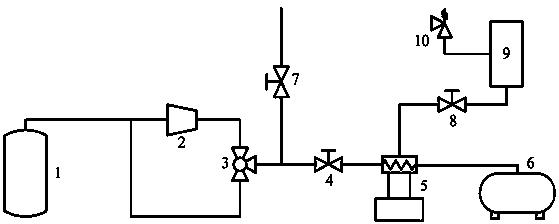

Oilfield oil well casing natural gas multi-stage compression recovery device

InactiveCN102297336ARealize automatic recovery of multi-stage compressionSolve problems such as pollutionPipeline systemsOil fieldGas holder

The invention discloses a multi-stage compression and recovery device for oil well casing natural gas in an oil field, which is characterized in that it comprises a natural gas collection tank, a medium-pressure gas storage tank and a high-pressure gas storage tank sequentially connected in series on the natural gas transmission pipeline; the natural gas collection tank A first-stage booster pump is installed on the natural gas transmission pipeline between the medium-pressure gas storage tank and the medium-pressure gas storage tank, and a second-stage booster pump is installed on the natural gas transmission pipeline between the medium-pressure gas storage tank and the high-pressure gas storage tank. The invention can realize multi-stage compression and automatic recovery of single well and multi-well casing natural gas, can effectively solve the problems of current oil field oil well casing natural gas waste and environmental pollution caused by burning natural gas, and also solve the problem of scattered oil wells with a large number , a problem that requires a large number of people on duty. Moreover, the manufacturing cost is low, the transportation and installation are convenient, the occupied space is small, and failures are not easy to occur, and the service life is long.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

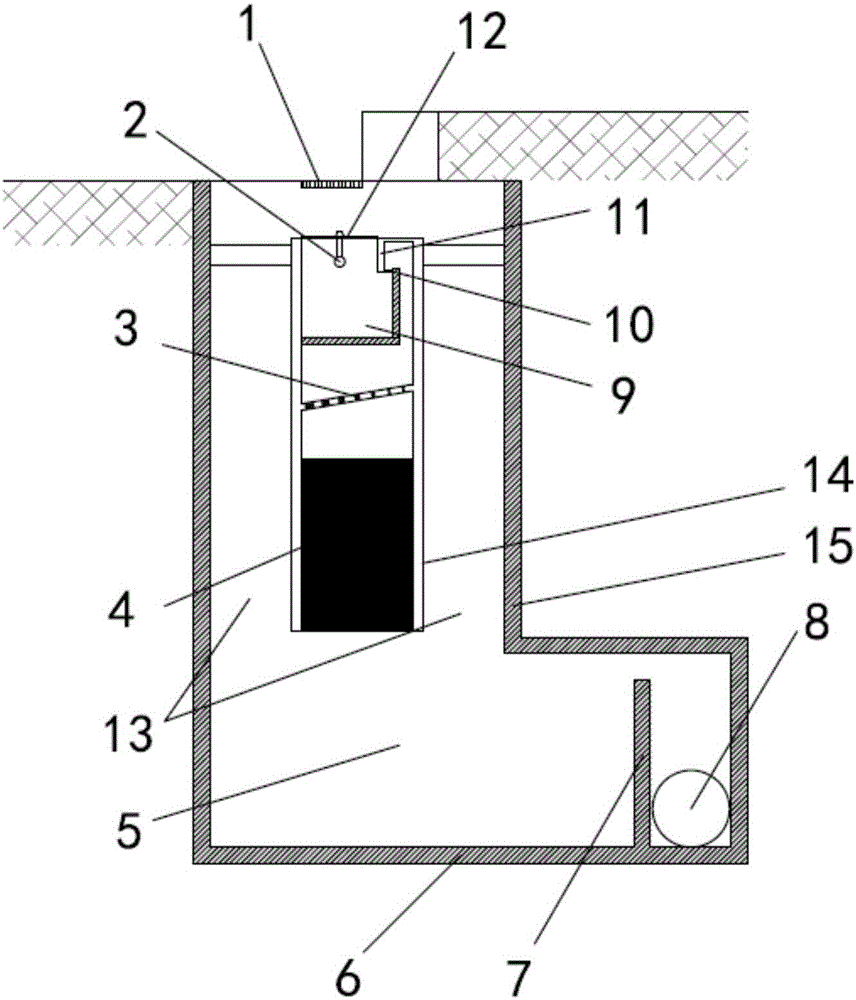

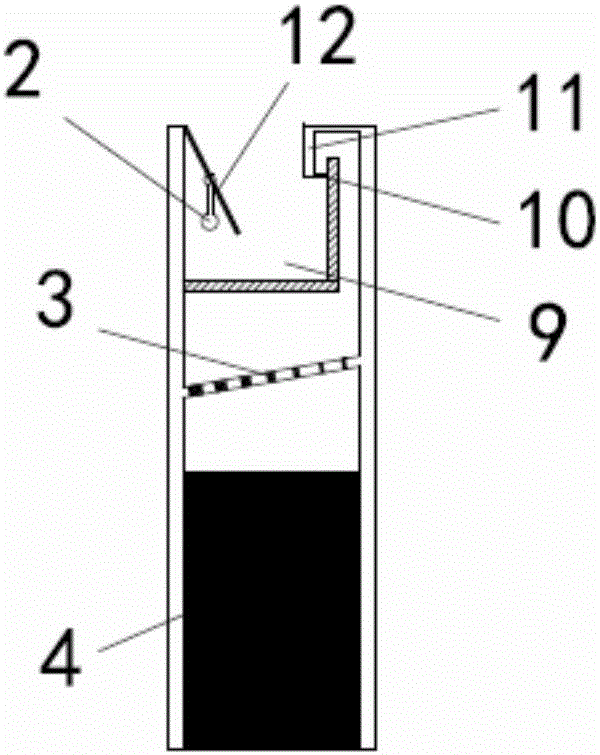

Rainwater well with purification and storage functions

ActiveCN107524223ASolve problems such as pollutionEasy to manufactureSewerage structuresGeneral water supply conservationBrickRain fall

The invention relates to a rainwater well with purification and storage functions. The top of an inner well is fixedly connected with a fine screen overturning plate with a floating ball valve; the floating ball valve drives the fine screen overturning plate to rotate; a weir plate is arranged between one side of the well mouth of the inner well and the fine screen overturning plate; a sedimentation groove is formed below the fine screen overturning plate; a filtering net is arranged between an outlet of the sedimentation groove and the weir plate; a water distribution plate with uneven gaps is arranged below the sedimentation groove; biological filler is arranged in a cavity formed by the water distribution plate with the uneven gaps and the bottom of the inner well; an outer well built by water permeable bricks and a reservoir are arranged outside the inner well; channels between the inner well and the outer well are arranged at the two sides of the exterior of the inner well; the reservoir is internally provided with an overflow wall; a drainage pipeline is arranged at one side of the bottom of the reservoir; a rainwater well coarse screen is arranged at the top of the outer well. At the initial period, rain falls into the sedimentation groove in the upper portion of the inner well, the water level rises to drive a floating ball to rise to make the fine screen overturning plate closed, during long-time rainfall, rainwater directly flows into the reservoir through the channels between the inner well and the outer well and is mixed with treated rainwater at the initial period, and mixed rainwater flows into the reservoir for storage.

Owner:SHENYANG JIANZHU UNIVERSITY

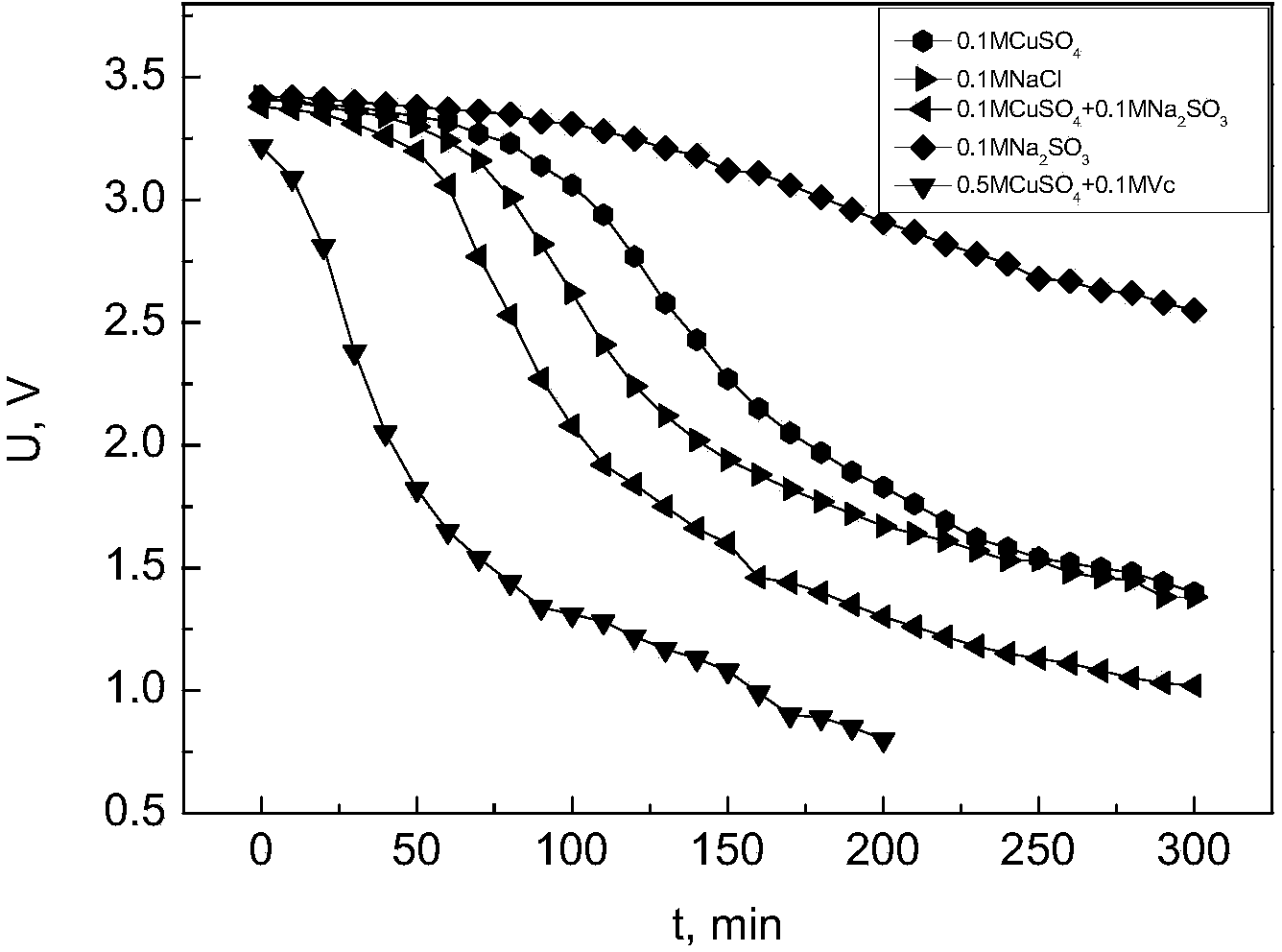

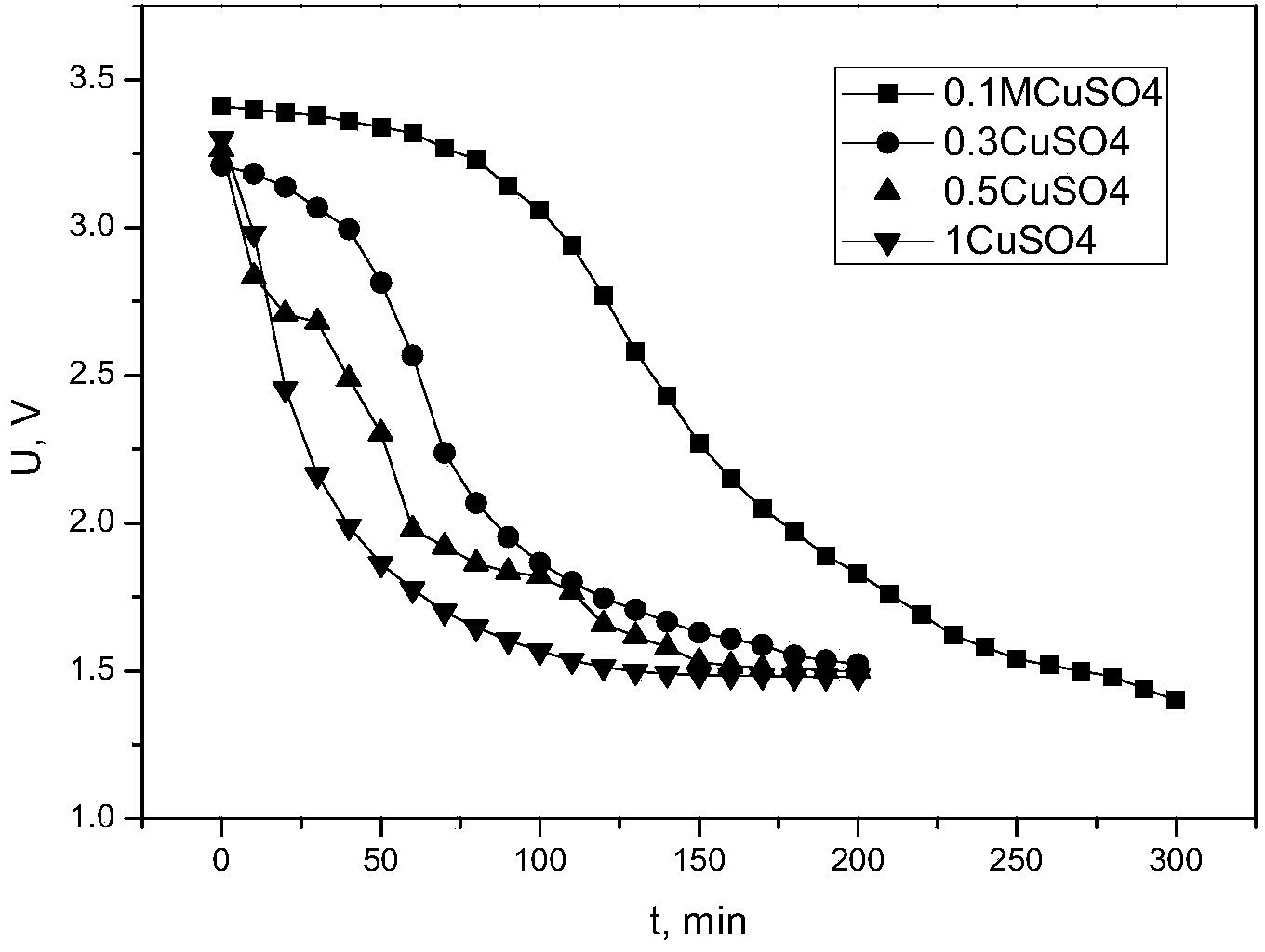

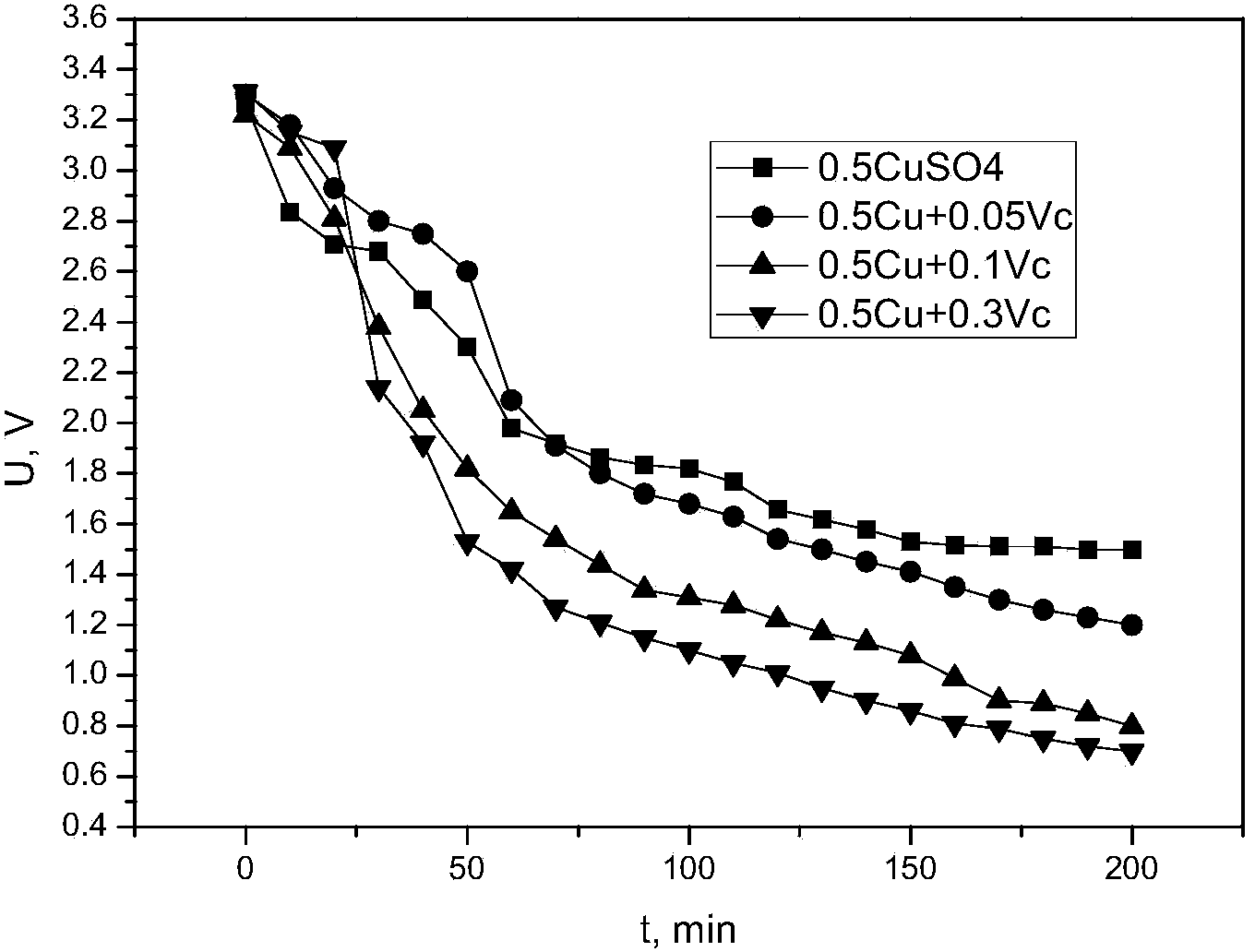

Electrolyte used for waste lithium battery discharge, and waste lithium battery discharge method

ActiveCN103682510AImprove reaction speedImprove discharge efficiencyWaste accumulators reclaimingSecondary cells charging/dischargingChemistryElectrical battery

The invention discloses an electrolyte used for waste lithium battery discharge, and a waste lithium battery discharge method. The electrolyte contains copper sulfate and the concentration of copper sulfate is 0.1-1mol / L; the electrolyte also contains ascorbic acid; and the discharge method comprises a step that a waste lithium battery is immersed in the electrolyte until the voltage tends toward stability. The electrolyte used for waste lithium battery discharge is obtained through a large amount of experiments and researches by the inventors of the invention, and has the advantages of safety, environmental protection, high discharge efficiency, no precipitation of the above solution in the discharge process, and no dissolving loss of the shell of the battery. The waste lithium ion battery discharge method has the advantages of simple technology, easy operation, and suitableness for the industrial application.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

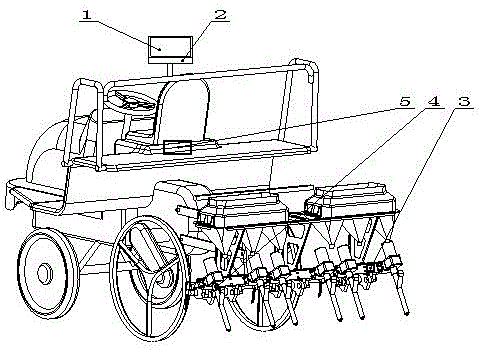

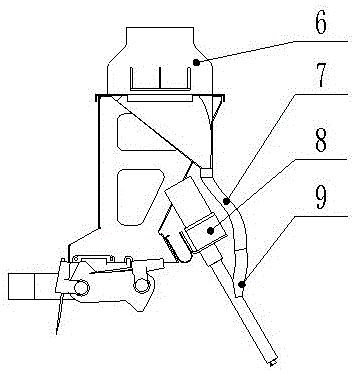

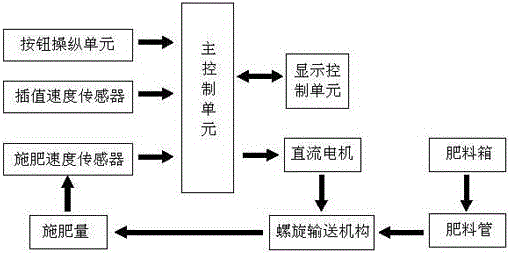

Precision fertilizer application control device of rice transplanter

InactiveCN105850315ASolve problems such as pollutionSolve the problem of uneven productionFertiliser distributersTransplantingMicrocontrollerMicrocomputer

The invention relates to a precision fertilization control device for a rice transplanter, which is characterized in that it includes: a button operation unit, an interpolation speed sensor, a fertilization speed sensor, a display control unit, a main control unit, a fertilizer box, a fertilizer pipe, a DC motor and a screw conveyor Mechanism; the main control unit includes a single-chip programmable logic controller and a DC motor driver. The switch input of the main control unit is connected to the interpolation speed sensor, the fertilization speed sensor and the button operation unit; the output of the main control unit is connected to the DC motor driver. The DC motor driver is connected to the DC motor; the DC motor is connected to the screw conveying mechanism; the screw conveying mechanism is connected to the fertilizer box through the fertilizer pipe; the display control unit includes a touch screen and a liquid crystal display; the display control unit and the main control unit Use serial port connection for data communication. The invention solves the problem of accurately controlling the amount of fertilization.

Owner:HUNAN LONGZHOU FARM EQUIP HLDG CO LTD

Zero-discharge treatment method of desulfurization waste water

ActiveCN105502792AReduce ion concentrationReduced fouling tendencyWater contaminantsMultistage water/sewage treatmentEvaporation chamberVacuum evaporation

The invention discloses a zero-discharge treatment method of desulfurization waste water. The method comprises the following steps that after the desulfurization waste water is treated through a primary chemical precipitation treatment system (1), sodium carbonate is added into the desulfurization waste water to conduct a reaction, and then the desulfurization waste water is sent into a multi-effect evaporating device for evaporation after being precipitated and filtered; partial mother solution in the multi-effect evaporating device is introduced into the primary chemical precipitation treatment system (1) to be treated before the concentration of scaling ions of a mother solution in the multi-effect evaporating device reaches the scaling concentration or before the concentration of corrosion ions reaches the concentration of corroding heat exchange tubes. The zero-discharge treatment method of the desulfurization waste water has the advantages that scaling tendency of the desulfurization waste water is reduced, and the phenomena that due to scaling, heat transfer is affected, and corrosion of the heat exchange tubes in an evaporation chamber is caused are avoided; meanwhile, the desulfurization waste water is converted into a solution system of which the solute is mainly NaCl, multi-effect vacuum evaporation concentration crystallization is conducted on the desulfurization waste water by means of waste steam of a coal-fired power plant, secondary industrial salt byproducts are generated, and zero discharge of the desulfurization waste water is achieved.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD +1

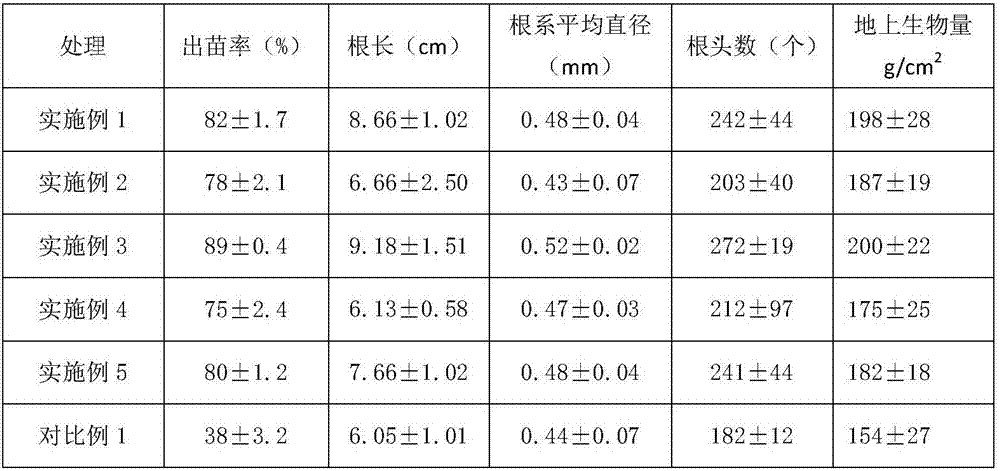

Vegetation particle for high and cold meadows and method for preparing vegetation particle

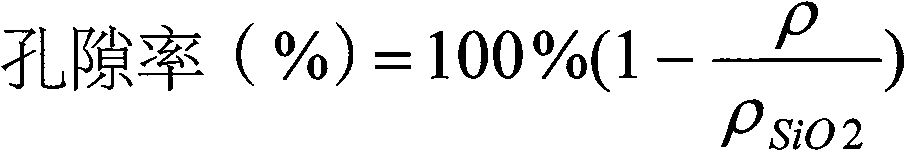

InactiveCN107417460APrevent mildewPrevent the situationSuperphosphatesMagnesium fertilisersVegetationGrassland

The invention provides a vegetation particle for high and cold meadows, and relates to the field of ecological restoration of grasslands. The vegetation particle is heavier than 0.8 g, and the porosity of the vegetation particle is 45%-50%. The vegetation particle comprises diversified pretreated grass seeds, substrate nutrition layers and water retention layers. The substrate nutrition layers wrap the surfaces of the grass seeds; the water retention layers are positioned between the grass seeds and the substrate nutrition layers. The vegetation particle has the advantages that the technical problems of difficulty in sowing seeds in high and clod grassland regions, high destructiveness, weak material selection pertinence of pelleting processes and the like can be solved by grass seed pelleting processes; the drifting properties of the seeds can be effectively lowered, the seed landing stability can be improved, the seed sowing accuracy can be enhanced, the germination percentage of the seeds can be increased, and the vegetation particle is suitable for near-natural reseeding restoration of high and cold grasslands.

Owner:LANZHOU UNIVERSITY

Polymer section and preparation method thereof

The invention discloses a polymer section and a preparation method thereof. The polymer section is prepared by mixing the following raw materials in parts by weight: 40-85 parts of recovered PU (polyurethane) / PVC (polyvinyl chloride) bag leather waste granule, 10-55 parts of plastic resin, 1.0-1.5 parts of coupling agent, 1.2-2.0 parts of EVA (ethylene vinyl-acetate copolymer), 1.5-2.0 parts of stearic acid and 1.5-2.0 parts of lubricant. The preparation method of the polymer section comprises the following steps: pulverizing the recovered PU / PVC bag leather waste, adding the plastic resin, evenly mixing, sequentially adding the coupling agent, EVA, stearic acid and lubricant, evenly mixing, granulating and extruding. The polymer section disclosed by the invention not only has the advantages of favorable water resistance and strength of plastics, but also has the advantages of favorable processability, no toxicity and environmental protection of wood. The polymer section has natural tactile sensation of wood, can not be easily damaged by mold or termites, has the characteristics of high weatherability and high compression strength, and can be used in the fields of building materials, packaging, transportation, decoration and the like.

Owner:河北泓之木环保科技股份有限公司

Cryogenic gas condensing and recycling system and method

ActiveCN104110574ASolving Recycling ProblemsSolve pollutionContainer filling methodsPressure vesselsNitrogenLiquid storage tank

The invention discloses a cryogenic gas condensing and recycling system and method. The cryogenic gas condensing and recycling system comprises a storage tank, a pump, a switching valve, a first valve, a cryogenic refrigerating machine, a liquid storage tank and a second valve, wherein the storage tank, the pump and a first inlet of the switching valve are connected with one another in sequence; an outlet of the switching valve, the first valve, the cryogenic refrigerating machine and the liquid storage tank are connected with one another in sequence; the storage tank is connected with a second inlet of the switching valve; the outlet of the switching valve is connected with the second valve. The system and the method are applicable to condensing and recycling of natural gas which is required to be emitted during an annual inspection or overhaul and maintenance process of a vehicle-mounted LNG (Liquefied Natural Gas) bottle, an LNG tank wagon, a storage tank and the like, and can also be used for recycling gas when storage tanks of corresponding cryogenic gases, such as nitrogen, oxygen and argon, are inspected, and thus the problems about safety, environmental pollution, resource waste and the like caused by directly exhausting a large quantity of dangerous gases are avoided.

Owner:JIANGSU CRYOTE CRYOGENIC TECH

Method for preparing high-strength lightweight aggregate by use of building waste residue, casting waste sand and sludge

InactiveCN102219419AHigh compressive strengthSolve problems such as pollutionConstruction waste recoverySludgeEconomic benefits

A method for preparing a high-strength lightweight aggregate by the use of building waste residue, casting waste sand and sludge comprises the following steps of: (1) taking the building waste residue, casting waste sand and sludge as raw materials; (2) drying the raw materials, followed by ball milling, and adding throughs into water with uniformly mixing; (3) extruding the raw materials for molding; (4) sintering: drying a blank material at the temperature of 105 DEG C for 5-6 hours, heating to the temperature of 450 DEG C, keeping warm for at least 10 minutes, heating up to the temperatureof 1125-1150 DEG C to roast for at least 10 minutes, and stopping heating; (5) naturally cooling to room temperature so as to obtain the high-strength lightweight aggregate. The produced high-strength lightweight aggregate in the invention completely meets the high-strength lightweight aggregate standard in Lightweight Aggregate and its Test Method GB / T17431.2-1998. According to the invention, building waste, industrial waste and waste generated from city or industrial sewage are taken as the raw materials to prepare the lightweight aggregate for buildings. By the adoption of the high-strength lightweight aggregate, problems such as the environmental pollution due to the difficulty of processing building waste residue, used sand regenerating dust and sludge are solved. In addition, the high-strength lightweight aggregate, which is prepared by using waste as the raw materials, replaces building materials prepared by natural raw materials to change waste into valuables, and has obvious environmental benefit and economic benefit.

Owner:云南华威废弃物资源化有限公司

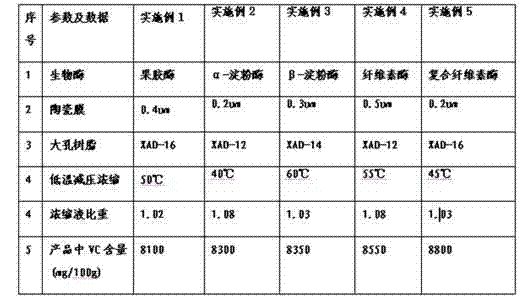

A kind of preparation method of porcine lung protein peptide

ActiveCN102286592ASolve problems such as pollutionPromote absorptionAnimal feeding stuffAccessory food factorsUltrafiltrationMedicine

The invention discloses a preparation method for pork lung protein peptide, which adopts waste liquid after the heparin sodium extraction from pork lungs as raw materials and comprises the steps of desalting, enzymolysis, ultrafiltration membrane separation and drying. The invention also discloses the pork lung protein peptide obtained by the method and an application of the pork lung protein peptide, which solve the problems of biological resource waste, environment pollution and the like of the waste liquid after the heparin sodium extraction from the pork lungs, in addition, the utilization value of products is greatly improved through the continuous processing process, the prepared pork lung protein peptide is easy to absorb and has special biological activity, the animal yield can be improved when the pork lung protein peptide is applied to high-grade feedstuff, and the pork lung protein peptide can also be used for preparing compounds for improving the immunity or can be used for preparing compounds for enhancing peripheral blood lymphocytes.

Owner:SHANGHAI TRANSGENIC RES CENT

Cultivating matrixes and application thereof

InactiveCN101215204AReduce manufacturing costImprove resource utilizationSuperphosphatesBio-organic fraction processingAdditive ingredientPhosphoric acid

The invention discloses a cultivation medium taking waste material of processing bamboo shoots as the main ingredient, which comprises the following components and contents (part by weight) that waste material of processing bamboo shoots taking 5000-7000, rice bran taking 1000-3000, corn meal taking 500-600, gypsum taking 100-200, lime taking 100-200, calcium superphosphate taking 100-200, carbamide taking 40-100, compound fertilizer taking 150-200, cake fertilizer taking 500-600, calcium carbonate taking 100-200, potassium chloride taking 40-50 and Mould free taking 10-15. The invention improves the comprehensive utilization of the bamboo shoot resource and solves the environmental pollution problem caused by bamboo shoot processing leavings and the leavings decaying. The invention further discloses the application and the method of the culture substrate cultivating the edible fungus.

Owner:CHONGQING NENGWEI EDIBLE FUNGUS DEV

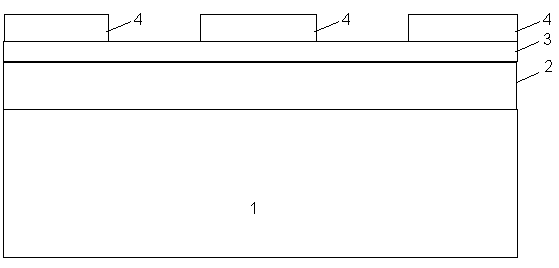

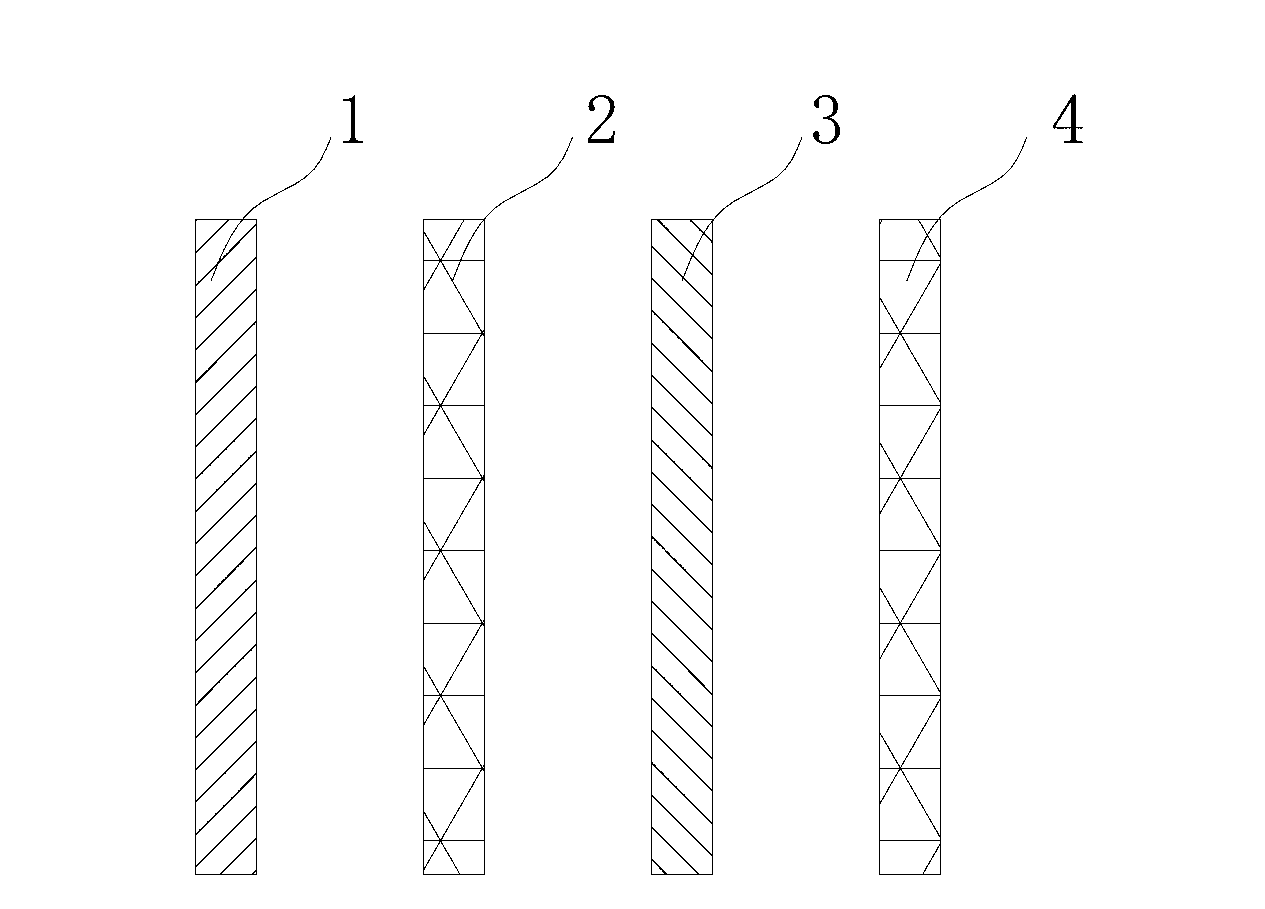

Etching method for improving bottom of silicon carbide table board

ActiveCN102915911ASolve the edge glitch problemGuaranteed injection protectionSemiconductor/solid-state device manufacturingDielectricSputtering

The invention relates to an etching method for improving the bottom of a silicon carbide table board. The technique comprises the following steps: 1, a layer of dielectric film is formed on an outward-extending silicon carbide layer; 2, photoresist is coated on the dielectric film, so as to form pattern transfer of the table board through a photolithography technique; 3, the photoresist serves as a barrier layer, and the dielectric film is etched by the dry method under a first condition; 4, the photoresist out of the etched dielectric film on the surface of silicon carbide can be removed at the same time; 5, the remaining dielectric film serves as a barrier layer, and the silicon carbide is etched by the dry method under a second condition to form the table board; and 6, after part of the processes, all dielectrics on the surface of the silicon carbide can be removed through wet etching. The etching method has the advantages that the problems of burrs at edges when a metal mask forms the silicon carbide table board, peaks caused by the slight sputtering of metal, metal ion pollution easily caused at high temperature and the like can be solved, and the injection protection for the silicon carbide table board as well as the exposure and the etching of the area out of the table board can be ensured through a self-alignment mode, so that the surface of the bottom area of the table board can be smooth, and the subsequent process operation can be convenient.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

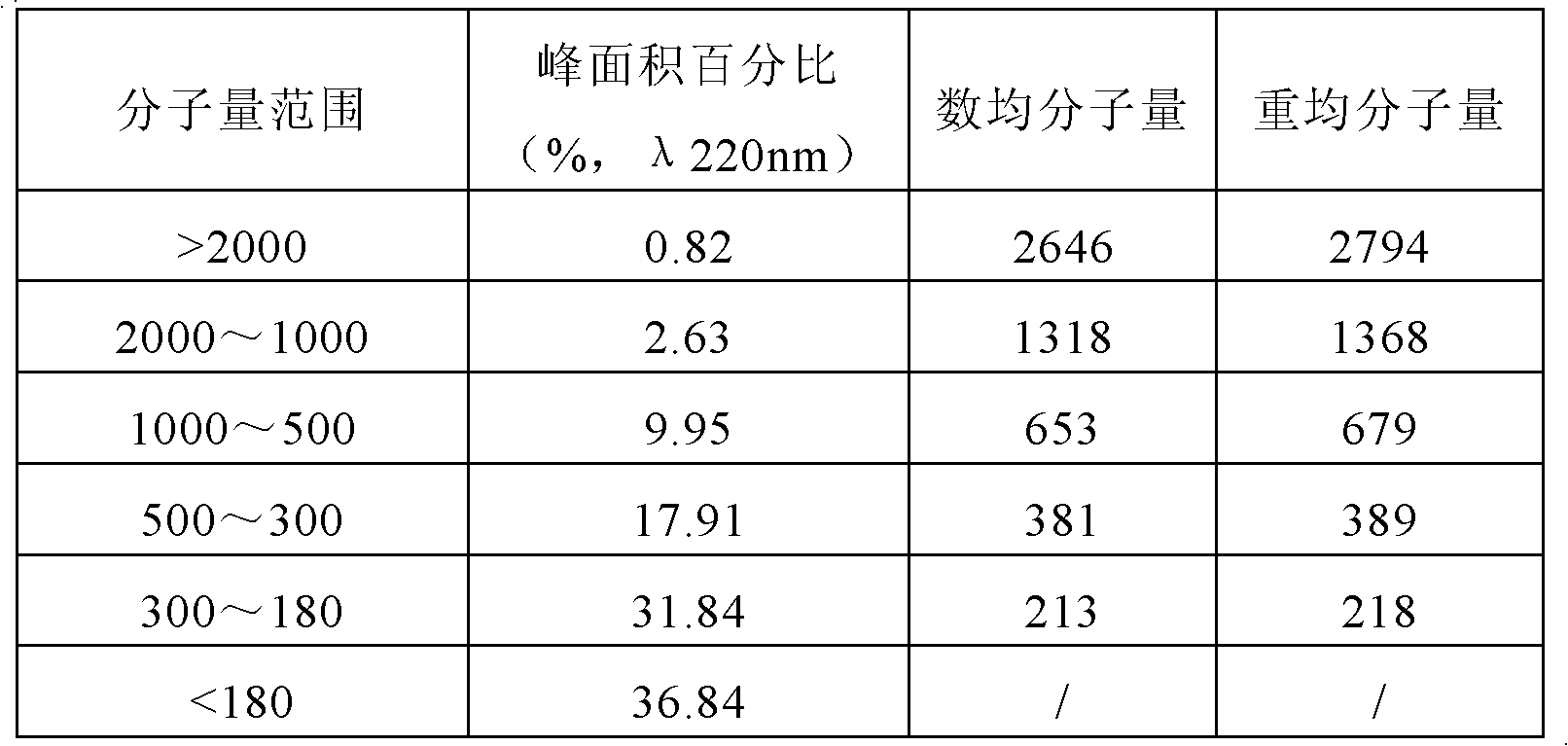

Nano silver modified polypropylene material for electrodialyzer clapboard network and preparation and application of nano silver modified polypropylene material

ActiveCN103012954AImprove toughnessHigh strengthGeneral water supply conservationDispersed particle separationDesalinationSludge

The invention relates to a preparation method of a nano silver modified polypropylene material for an electrodialyzer clapboard network. The preparation method comprises the following steps of: 1, modifying nano silver to obtain modified silver; 2, carrying out nano silver modification on polypropylene by using the modified nano silver obtained in the step 1. The nano silver modified polypropylene material clapboard network prepared by adopting the method has high flexibility and high strength as well as excellent bactericidal activity, thereby preventing microorganisms in an electrodialyzer from propagating, solving the problems of dirt blockage and the like of biological sludge of the electrodialyzer, improving desalination effect of the electrodialyzer, and prolonging service life.

Owner:BEIJING JINGRUN NEW TECH DEV

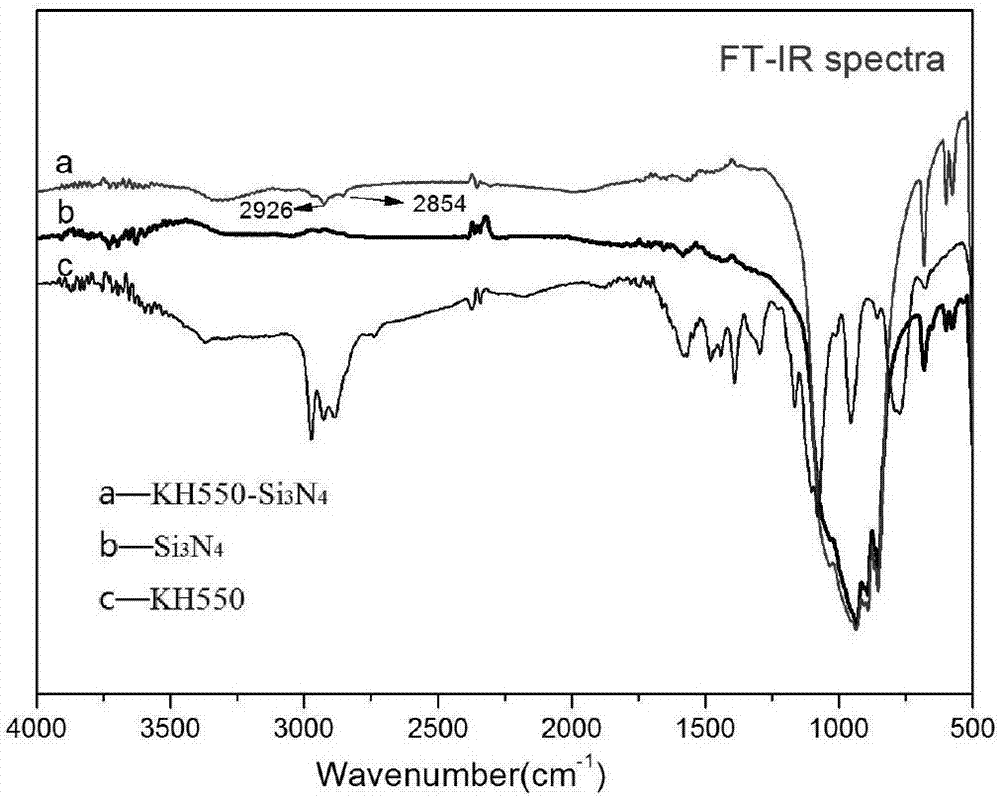

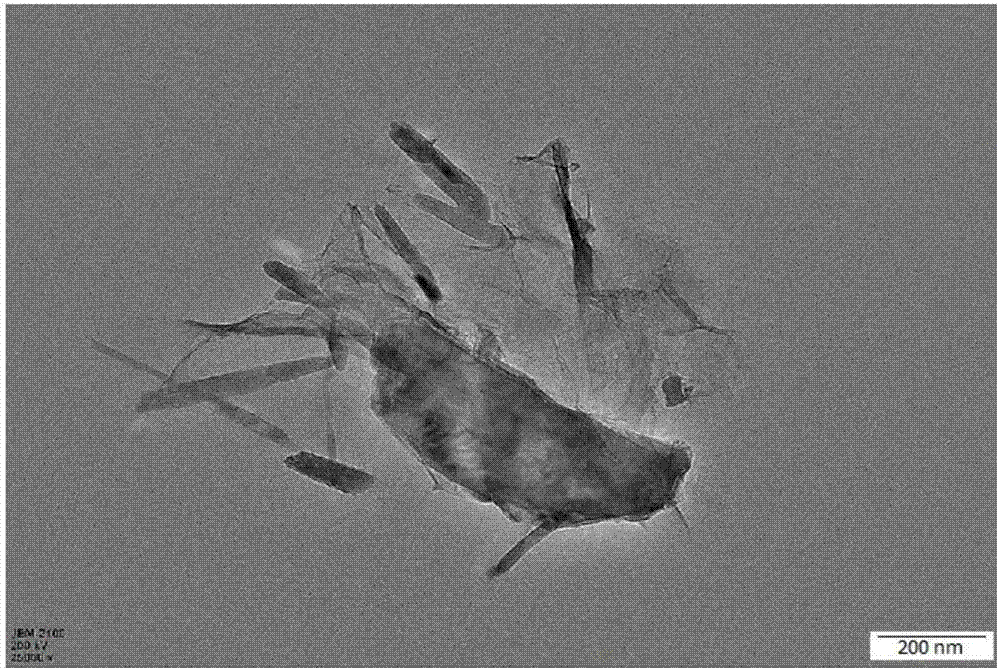

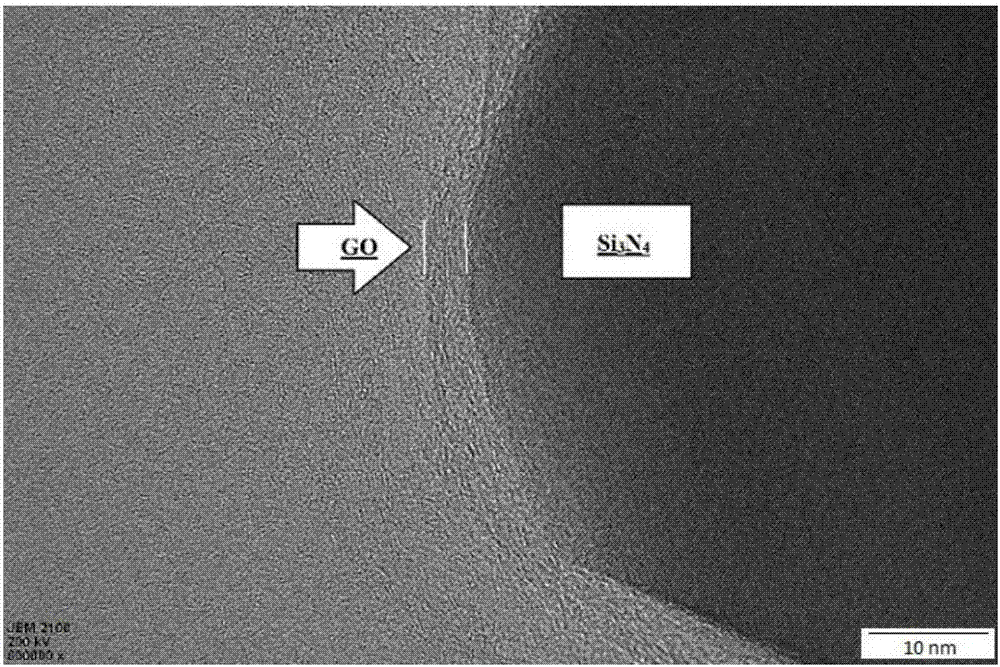

Method for preparing graphene oxide wrapped silicon nitride composite powder

The invention relates to a method for preparing graphene oxide wrapped silicon nitride composite powder. The method comprises the following steps: performing high-temperature surface oxidation on Si3N4 powder in hydrogen peroxide, putting a coupling agent hydrolysis solution into a surface oxidized Si3N4 suspension, and performing grafting modification treatment on the surface of Si3N4; and preparing a graphene oxide water dispersion, putting the Si3N4 suspension into the graphene oxide water dispersion, performing ultrasonic treatment, leaving to stand till wrapped particles completely settledown, removing supernate, and drying, thereby obtaining the graphene oxide wrapped silicon nitride composite powder. The graphene oxide wrapped silicon nitride composite powder prepared by using themethod is good in wrapping completeness, simple and convenient in process and high in efficiency. Application spaces of silicon nitride and graphene oxide are expanded, and after the graphene oxide wrapped silicon nitride composite powder is applied to a ceramic material, the mechanical properties of the ceramic material can be remarkably improved.

Owner:QILU UNIV OF TECH

Light-weight heat-insulating wall body material and preparation method thereof

The invention discloses a light-weight heat-insulating wall body material. The light-weight heat-insulating wall body material is prepared from the following raw materials in parts by weight: 10 to 20parts of ceramic waste mud, 20 to 30 parts of ordinary portland cement, 15 to 28 parts of aluminum electrolysis waste refractory material, 5 to 10 parts of wood sawdust, 12 to 18 parts of building waste muck, 18 to 27 parts of coal ash, 10 to 20 parts of yellow sand, 15 to 30 parts of vitrified micro bubbles, 20 to 40 parts of bentonite tailing meal, 13 to 21 parts of modified sepiolite, 8 to 14parts of kaolin, 5 to 10 parts of borax, 2 to 3 parts of a foaming agent, 1 to 2 parts of a dispersing agent and 40 to 60 parts of water. The light-weight heat-insulating wall body material disclosedby the invention is light in weight, high in strength, low in water absorption rate, small in heat conductivity coefficient and high in heat-insulating performance, and can meet actual application requirements of a building material well.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Domesticating cultivation medium for increasing survival rate of pinellia tissue culture seedlings and preparation method of domesticating cultivation medium

InactiveCN109479671AWide variety of sourcesGood homologySuperphosphatesBio-organic fraction processingDiseaseSeedling

The invention relates to the technical field of agricultural cultivation medium production, in particular to a domesticating cultivation medium for increasing the survival rate of pinellia tissue culture seedlings and a preparation method of the domesticating cultivation medium. The medium is prepared from, by mass, 80-90 parts of straw compost, 5-18 parts of an inorganic mineral material and 1-5parts of a compound conditioner. The medium is easy in formula material selection, simple in production process, reasonable in ratio, convenient and efficient in use, capable of giving full play to water retention, ventilation, rooting, disease resistance and nutrition effects required by domesticating cultivation of the pinellia tissue culture seedlings, extensive in material source, low in costand high in popularization value. The pinellia tissue culture seedlings cultivated with the domesticating cultivation medium are great in growth condition, robust and uniform, and developed roots androbust plants are realized. By adoption of the domesticating cultivation medium for pinellia domesticating cultivation, required seedling hardening time is short, the seedlings can be transplanted infields only after 1-2 months, the survival rate reaches 95% or above, low use cost is realized, and production benefits are greatly increased.

Owner:李金文

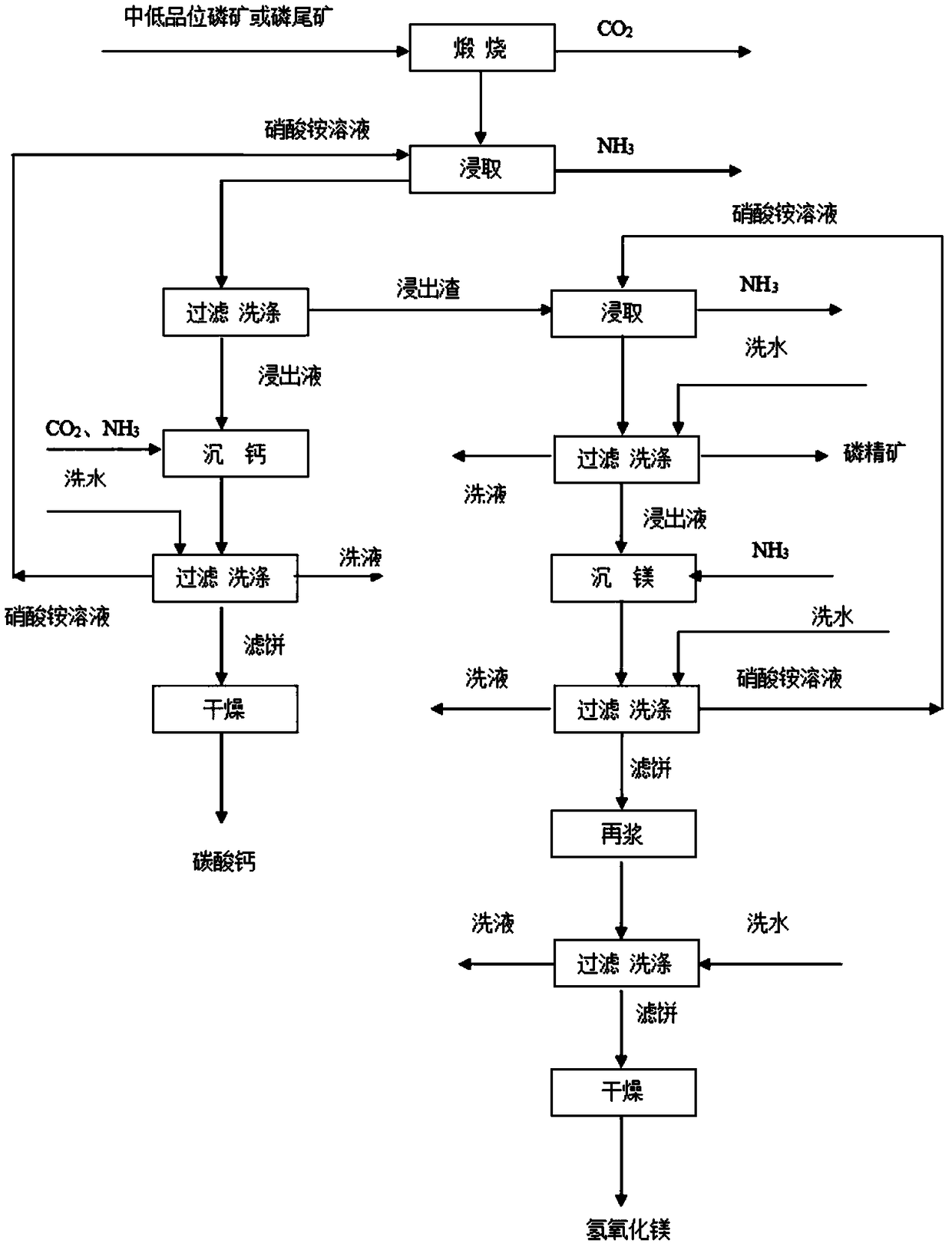

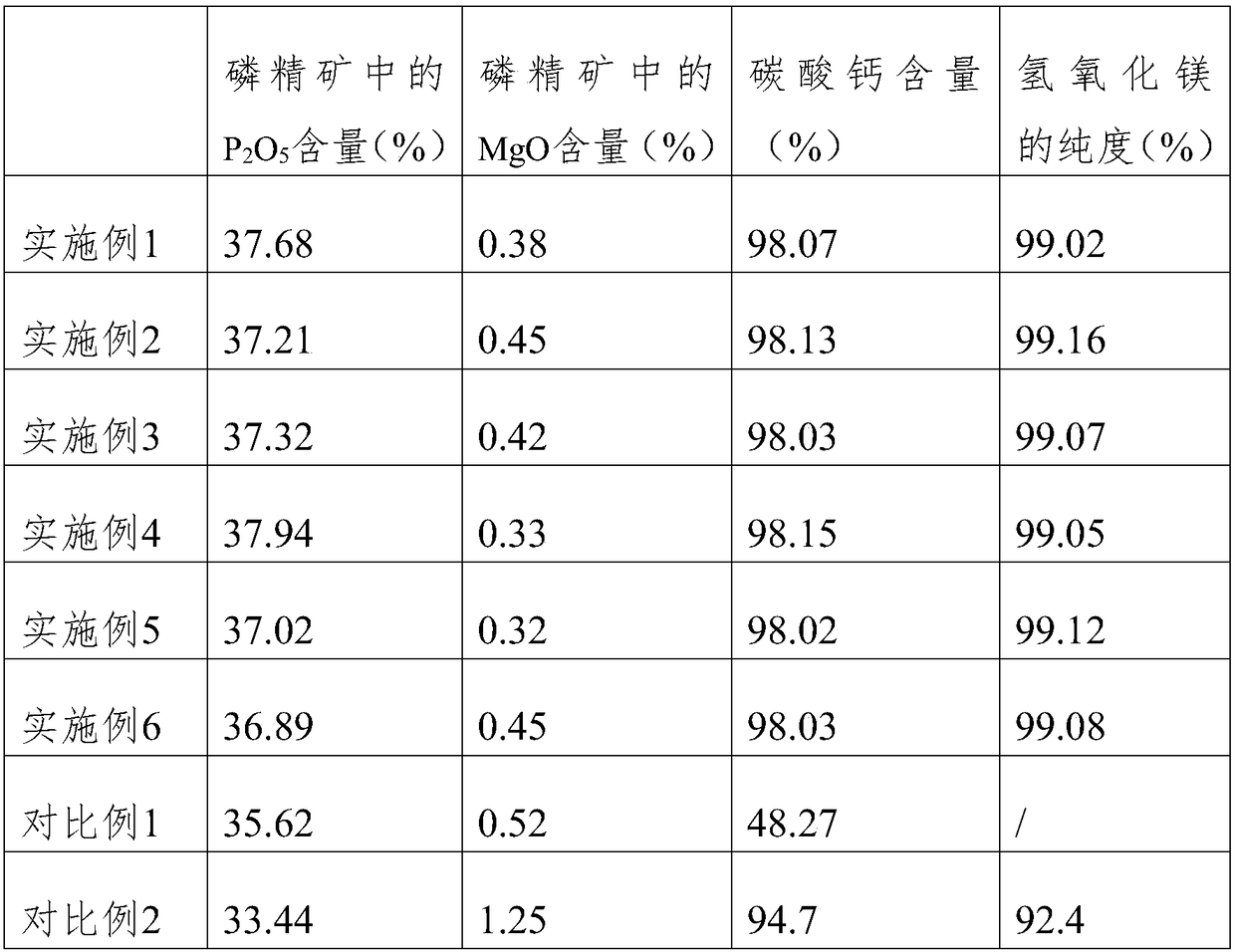

Technology for enriching phosphate concentrate and recycling calcium carbonate and magnesium hydroxide from middle-low grade phosphate rock or phosphate tailing simultaneously

ActiveCN109264686AGood separation effectSolve the low recovery rate of phosphorusCalcium/strontium/barium carbonatesRaw phosphate material treatmentMagnesium carbonate hydroxideChemistry

The invention relates to the technical field of inorganic chemical industry and specifically relates to a technology for enriching phosphate concentrate and recycling calcium carbonate and magnesium hydroxide from middle-low grade phosphate rock or phosphate tailing simultaneously. According to the technology disclosed by the invention, middle-low grade phosphate rock or phosphate tailing is utilized as a main raw material to enrich phosphate concentrate and recycle calcium carbonate and magnesium hydroxide simultaneously, so that the problems that an existing twice reverse-flotation phosphateconcentrate enriching technology for phosphate is low in phosphorus recovery rate and discharges a lot of tailing to bring environment-friendly risk. Phosphate or phosphate tailing is roasted at thetemperature of 700 to 1200 DEG C, so that calcite and dolomite are decomposed, and contained fluorapatite (Ca5F(PO4)3) is not decomposed; by means of twice ammonium nitrate leaching, phosphate concentrate, high-quality light calcium carbonate and high-purity magnesium hydroxide can be finally obtained; calcium and magnesium can be effectively recycled, and a good economic benefit is achieved; meanwhile, the method can prevent new tailing from generating, and the problems of a lot of land occupancy, environment pollution and the like caused by a lot of phosphate tailing accumulation are effectively solved.

Owner:贵州盛源新材料股份有限公司

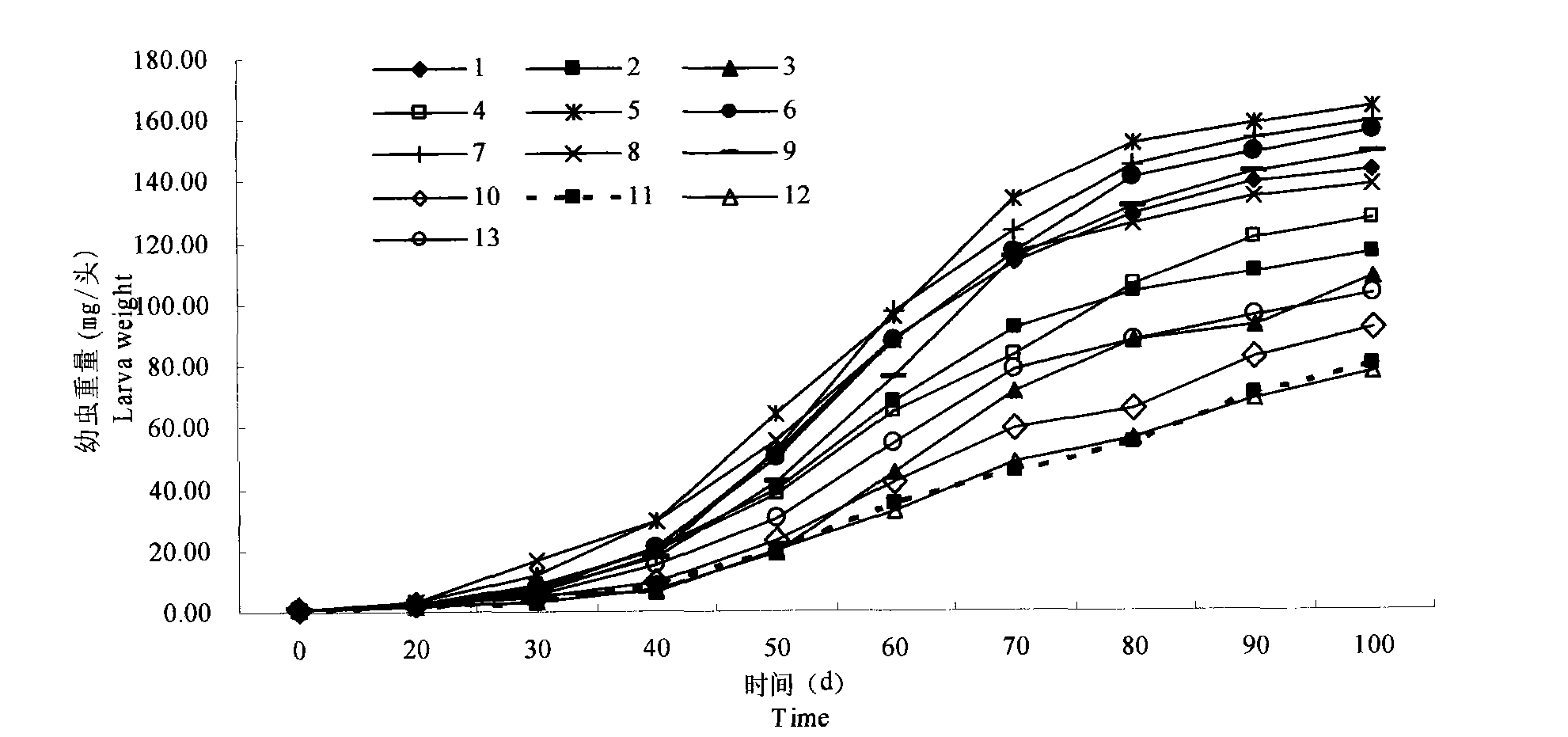

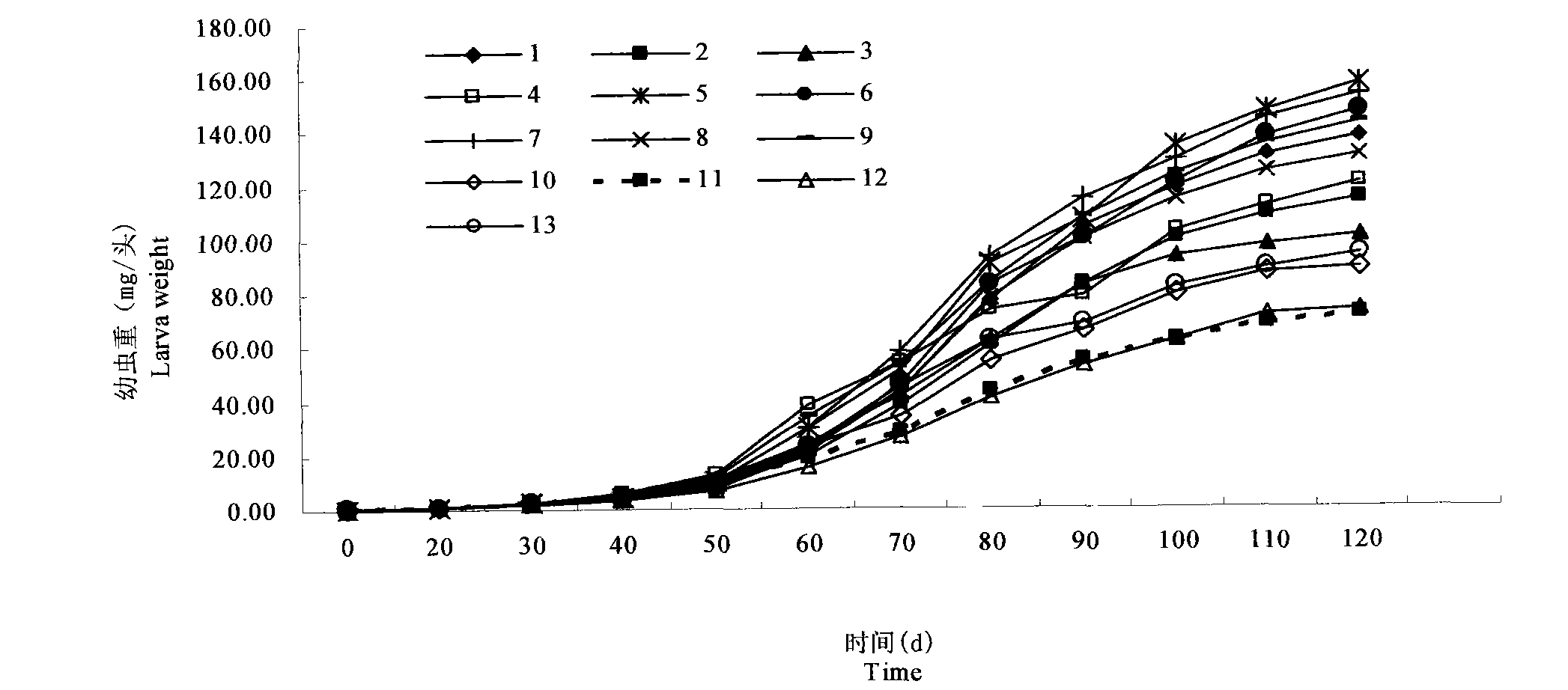

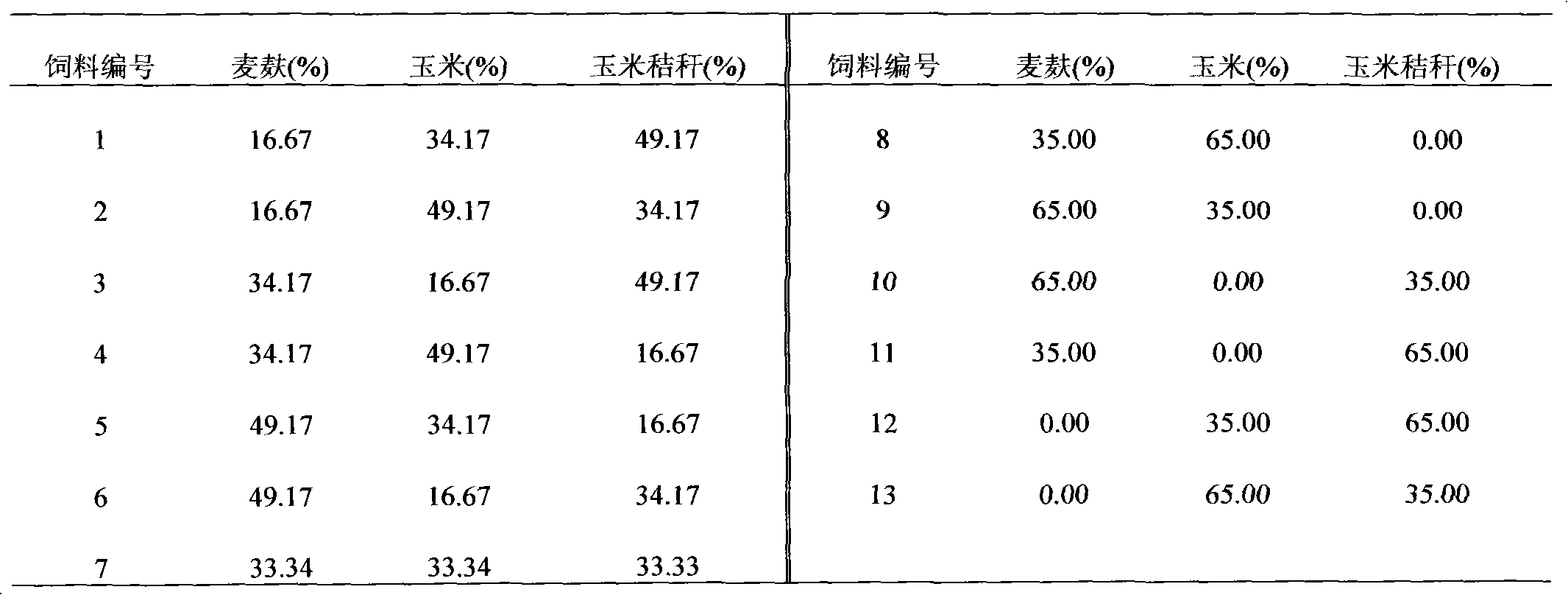

Mixed feed for feeding yellow mealworms

InactiveCN102835604AReduce the cost of farmingIncrease profitFood processingAnimal feeding stuffCorn stoverAgricultural science

The invention discloses mixed feed for feeding yellow mealworms. The mixed feed is formed by wheat bran, corn and corn straws through the mixing, wherein the corn straws are crushed in advance and are subjected to fermentation treatment. After the adoption of the scheme, the corn straws are fermented, wheat bran and corn are mixed for feeding the yellow mealworms, the culture cost is reduced, the cellulose can also be converted into protein for people to eat, the great effect is realized in the aspect of solving the problems of grain and environment pollution, and in addition, in the optimized embodiment, the corn straw utilization rate can also be improved by the feed.

Owner:YANAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com