Method for preparing high-strength lightweight aggregate by use of building waste residue, casting waste sand and sludge

A technology of construction waste slag and foundry waste sand, which is applied in the direction of construction waste recycling, recycling technology, solid waste management, etc., can solve problems such as environmental degradation and resource shortage, and achieve high compressive strength, significant environmental benefits and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

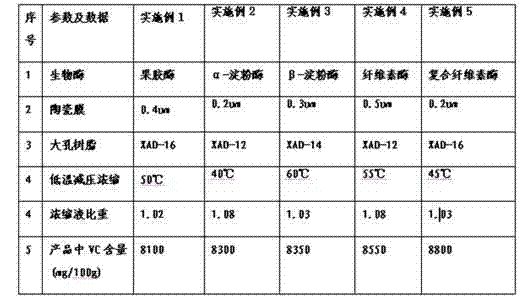

[0017] In each embodiment, the mass percentage of each component is: construction waste ash 50%-80%, foundry waste sand 10%-30%, sludge 10%-20%, among which, each component in construction waste ash The percentage by mass is: 35-45% of waste concrete slag, 25-35% of waste brick slag, 8-12% of waste dry mortar slag, 8-12% of sandy soil, and other impurities 5- 10%, the specific technical parameters of each embodiment are shown in Table 2. The specific method steps are as follows:

[0018] (1) Material preparation, construction waste is sorted, impurity removed, crushed and sieved, and made into various renewable building materials according to the different particle diameters. The remaining fine slag ash is screened into construction waste ash, and its composition is tested and prepared In order to meet the above requirements of construction waste ash; collect foundry waste sand to remove metal and other impurities; dehydrated sludge is dried and dried at 105°C for 6 hours in an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com