Patents

Literature

1538results about How to "Turn waste into treasure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

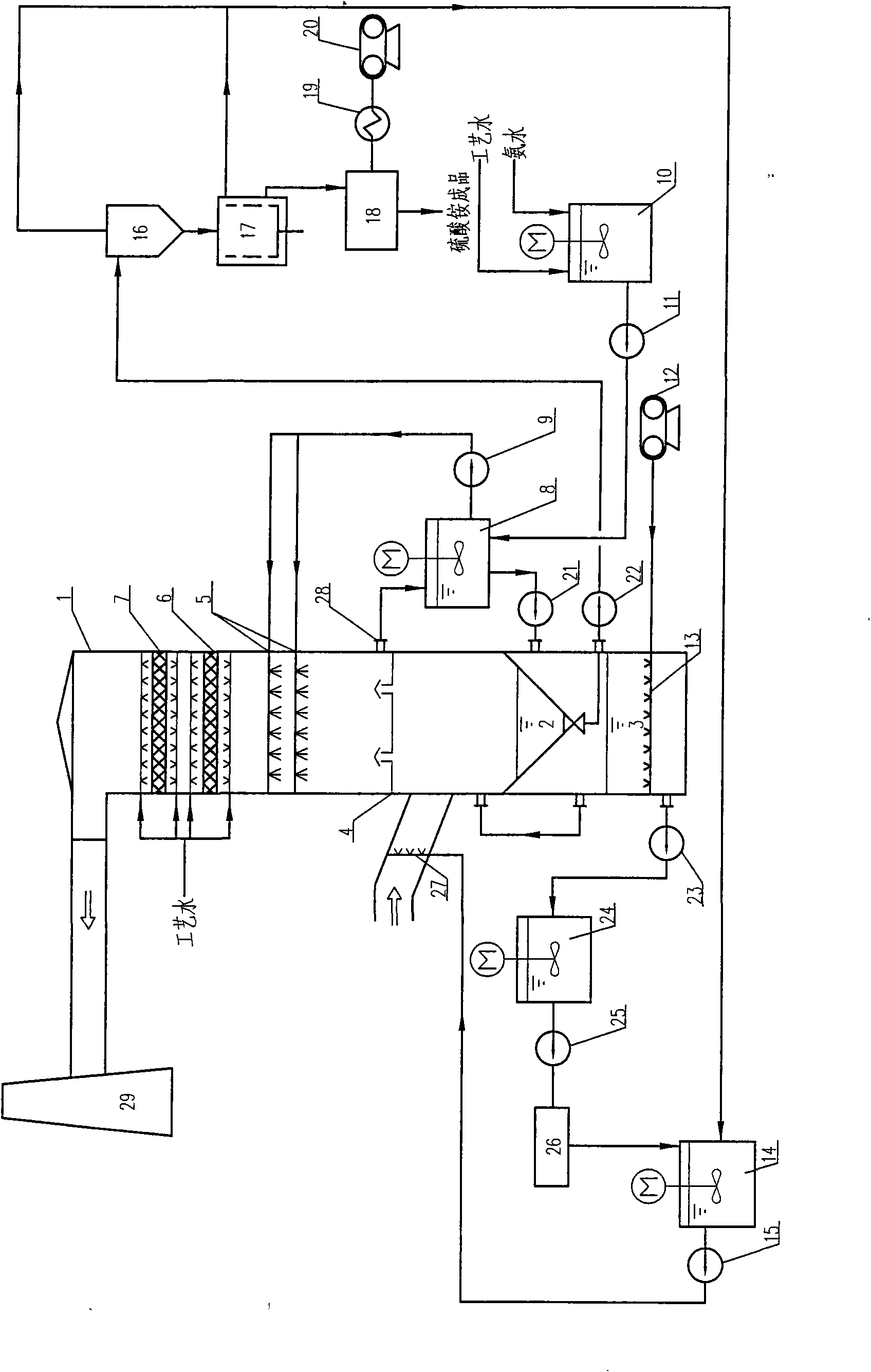

Energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery

InactiveCN101579602ALow recycling comprehensive operating costConsiderable "positive benefit"Dispersed particle separationThermal energySulfate

The invention belongs to flue gas desulphurization technology of the environmental protection field. To solve the problems of large energy consumption, lower product quality and large investment in recovering ammonia sulfate by an ammonia desulphurization technique, the invention provides an energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery. The process adopts ammonia water as a desulfurizer, ammonium sulfite is produced after the ammonia water and flue gas are decarbolized completely, and ammonia sulfate is produced after the ammonium sulfite is forcibly oxidized in a tower; impurities in the ammonia sulfate solution is removed by filtering, the filtrate is contacted with high-temperature flue gas in a desulfurizing tower for heat exchange, and when flue gas is cooled, the ammonia sulfate solution is heated and saturated; and then after crystallization of the saturated ammonia sulfate solution for a period of time, high-quality ammonia sulfate is produced after centrifugal drying. By adopting the technical proposal of the invention, not only thermal energy of an ammonia sulfate product which is produced by drying process can be greatly saved, high-quality ammonia sulfate fertilizer can be recovered, occupation area can be reduced and investment can be save, but also flue gas emission can meet the standard, without resulting in secondary pollution such as waste water and the like.

Owner:山西晋丰节能环保工程设计有限公司

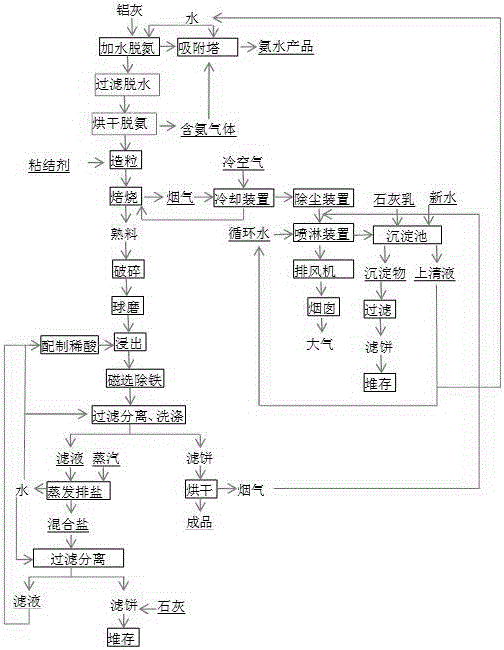

Resourceful treatment method for aluminum ash

ActiveCN106694514AIncrease profitImprove protectionSolid waste disposalTransportation and packagingMetallic aluminumResource utilization

The invention provides a resourceful treatment method for aluminum ash. Firstly, denitrification treatment, defluorination treatment and arsenic removal treatment are conducted so that nitrogen in the aluminum ash can be separated out in the form of ammonia gas to be recycled, harmful substances such as fluorine and arsenic are volatilized out, roasting is conducted, and aluminum ash clinker is obtained; and then metal impurity removing treatment is conducted, the roasted aluminum ash clinker is broken and finely ground and then is leached through diluted acid, metal impurities such as K2O, Na2O, CaO and MgO in the aluminum ash clinker are dissolved out, iron is removed through magnetic separation, and after pressure filtration separation, a finished aluminum oxide product is obtained through drying. According to the resourceful treatment method for the aluminum ash, aluminum oxide, metallic aluminum and the like in the aluminum ash can be recycled, byproducts such as ammonia water and iron are obtained, waste is turned into wealth, the social resource utilization rate is increased, meanwhile, components of fluorine and arsenic in the aluminum ash are removed, innocent treatment is done, and environment protection is facilitated.

Owner:三门峡华森新型材料有限公司 +1

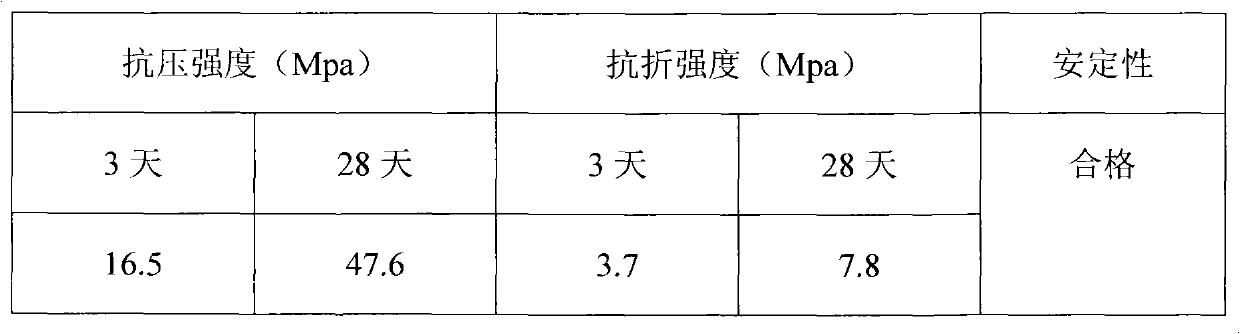

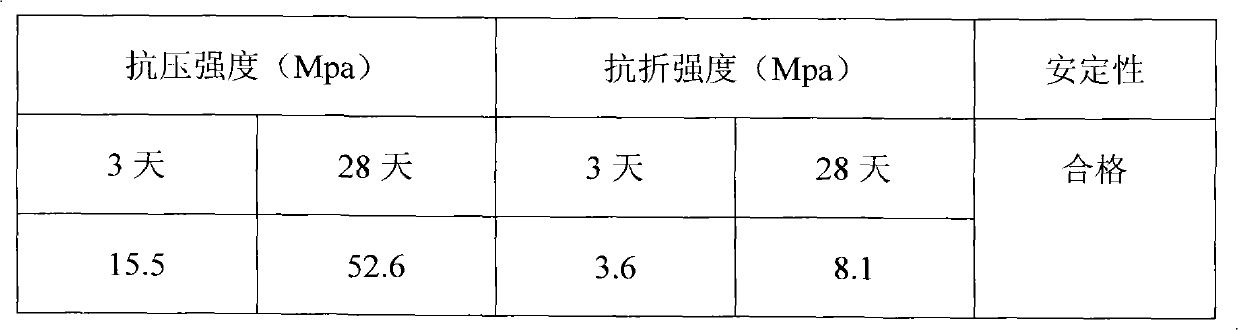

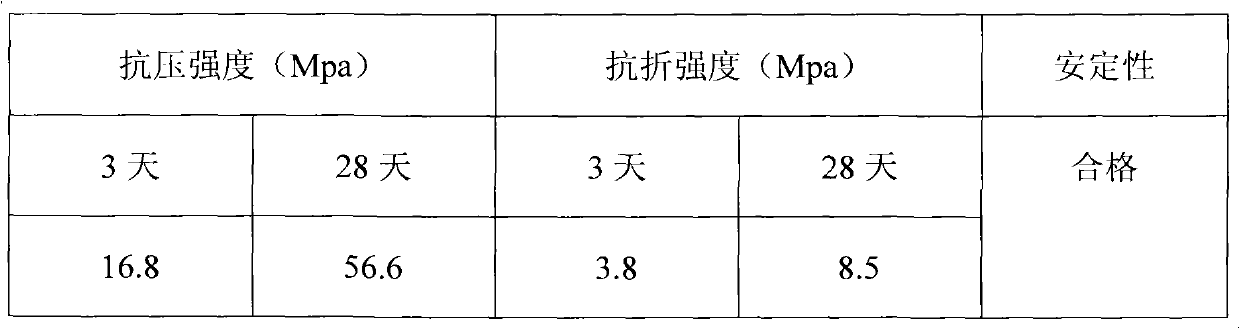

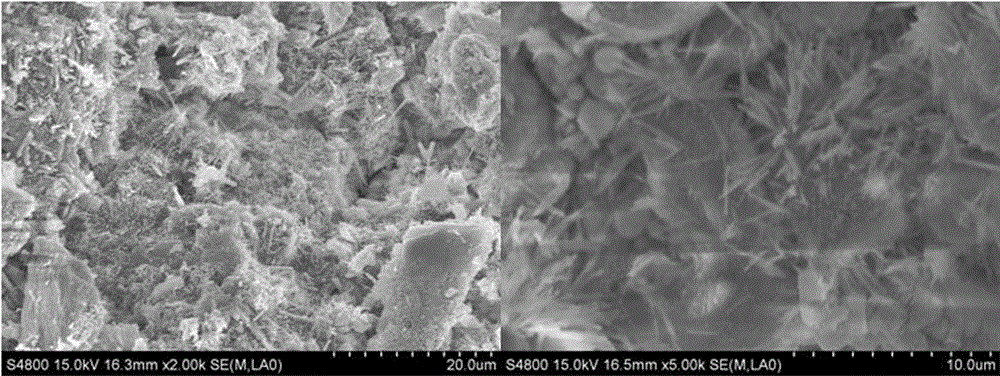

Method for preparing electrolytic manganese slag ecological cement

The invention discloses a method for preparing electrolytic manganese slag ecological cement, and belongs to the field of building materials and environment protection. The cement is characterized by consisting of calcined electrolytic manganese slag, blast furnace slag, a clinker, gypsum and an additive. The method comprises the following steps of: crushing the electrolytic manganese slag and then calcining the crushed slag at the temperature of between 500 and 900 DEG C, wherein the activity of the slag is increased to be close to that of fly ash from zero activity of volcanic ash; and grinding the blast furnace slag, the clinker, the fly ash or steel slag, the gypsum and the additive together or respectively according to a certain proportion and uniformly mixing the materials to prepare the electrolytic manganese slag ecological cement, wherein the amount of the calcined electrolytic manganese slag in the mixture is 10 to 50 percent. The method has the advantages of circularly utilizing a great amount of accumulated electrolytic manganese slag on a large scale and relieving serious damage of the electrolytic manganese slag to the environment, along with simple process, high product quality, low production cost and high economic, environmental and social benefit.

Owner:UNIV OF SCI & TECH BEIJING

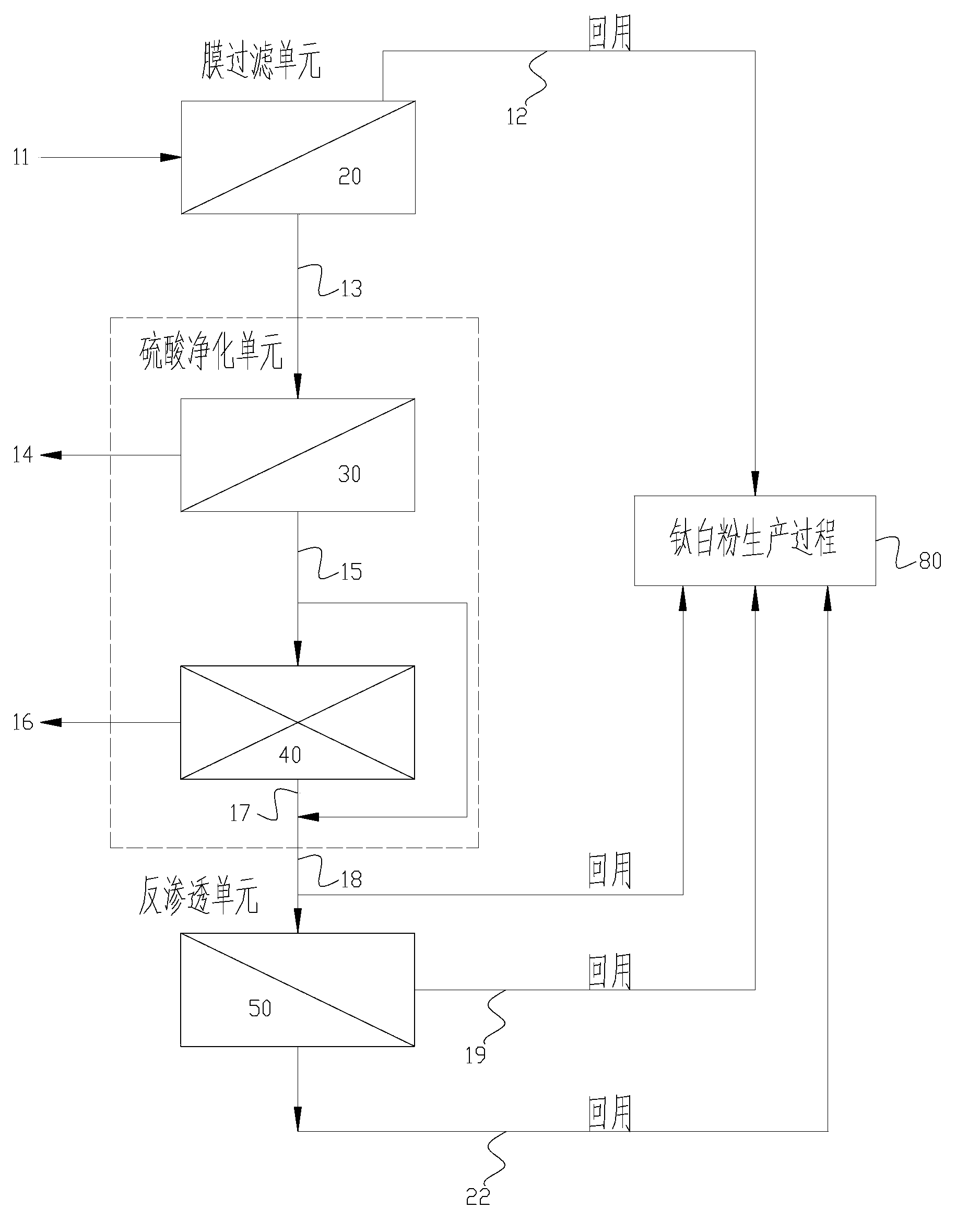

Treatment and recovery process of acid wastewater in titanium dioxide production process

ActiveCN103663547AEmission reductionEasy to meet environmental protection requirementsWater/sewage treatment bu osmosis/dialysisSulfur-trioxide/sulfuric-acidSludgeFiltration

The invention discloses a treatment and recovery process of an acid wastewater in a titanium dioxide production process. The treatment and recovery process mainly comprises the following steps: A, pumping the acid wastewater into a membrane filtration unit, filtering by using a filtering membrane, wherein a membrane intercept object is titanium dioxide particle concentrate, and is fed to the system to be reused, and membrane permeate is a crude sulphuric acid, and enters the next step to be treated; B, pumping the crude sulphuric acid obtained in the step A into a sulphuric acid purification unit, decontaminating and purifying the crude sulphuric acid to obtain pure dilute sulphuric acid, wherein a part of pure dilute sulphuric acid is directly reused, and the other part enters the next step to be treated; C, pumping the dilute sulphuric acid obtained in the step B into a reverse osmosis unit, filtering by a reverse osmosis membrane, wherein the intercept object is concentrated sulfuric acid and is fed to a titanium dioxide production system to be used, the permeate is water and can be directly reused as process water, and 99.9% of titanium dioxide particles, 80-90% of sulfuric acid and 60-80% of water can be recovered after the titanium dioxide acid wastewater is processed by the process disclosed by the invention, so that the production cost of an enterprise can be reduced, and the discharge amount of the wastewater and the sludge waste emission are greatly reduced.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

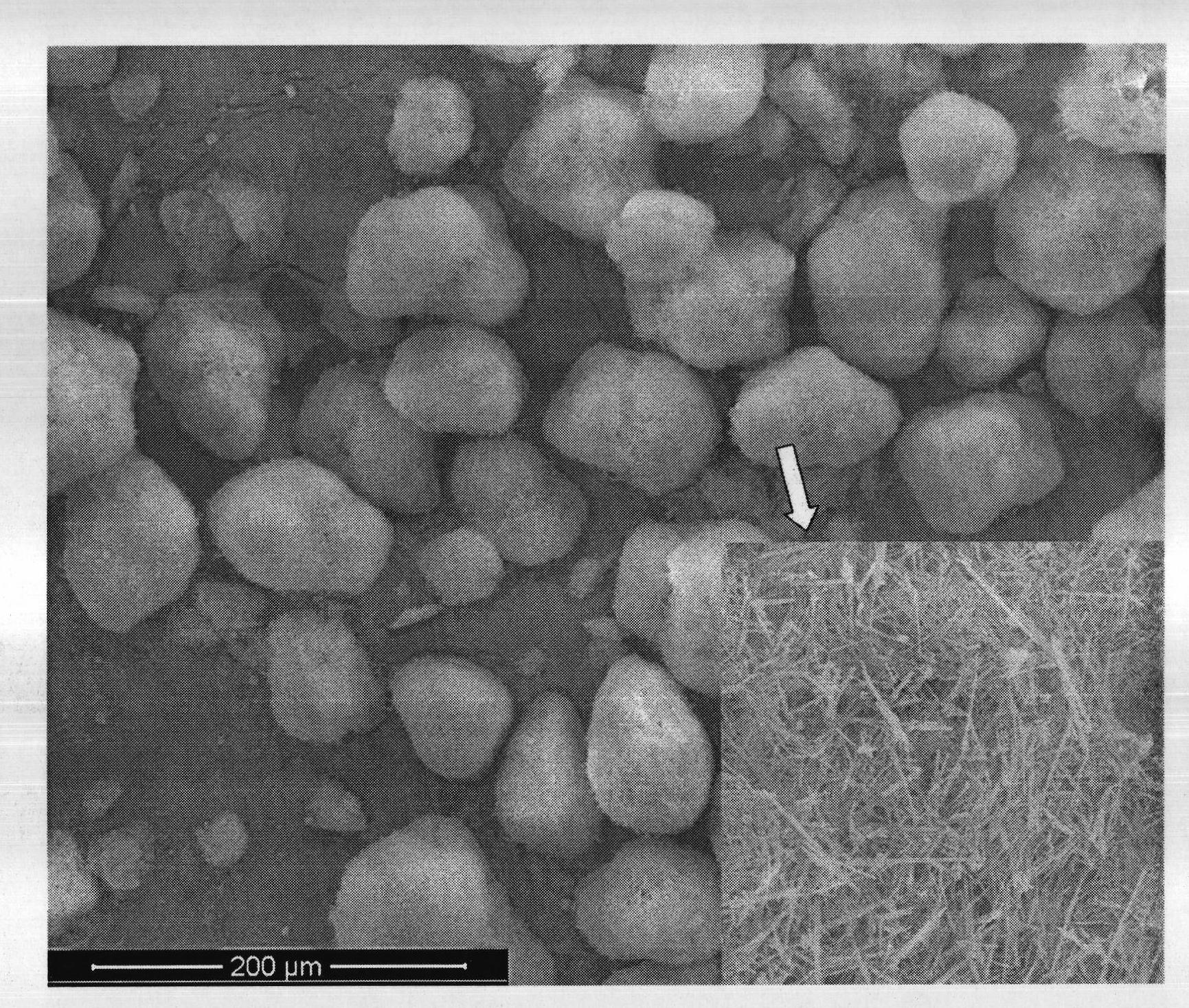

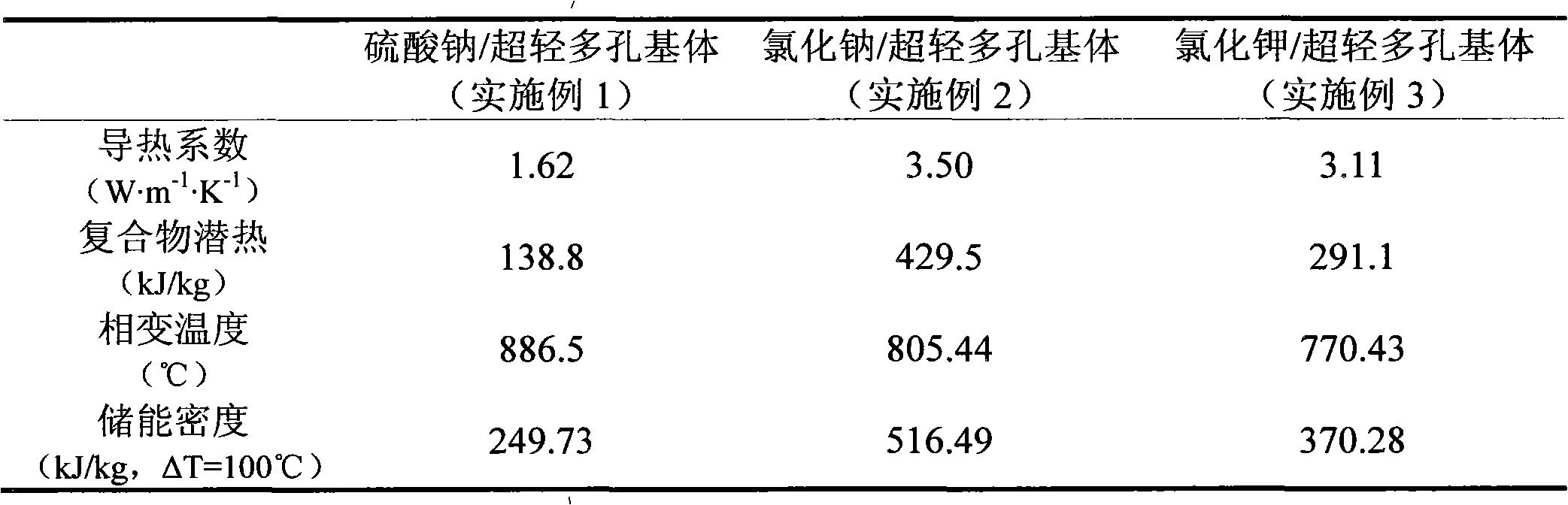

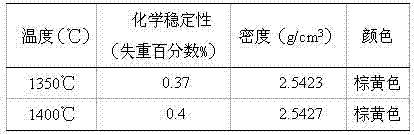

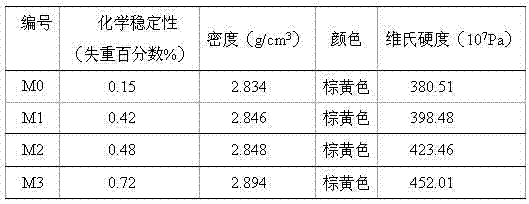

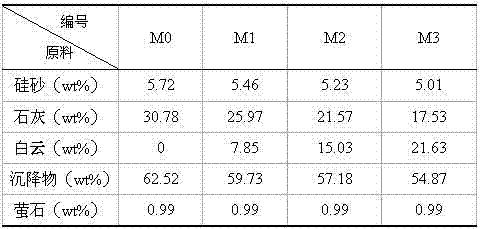

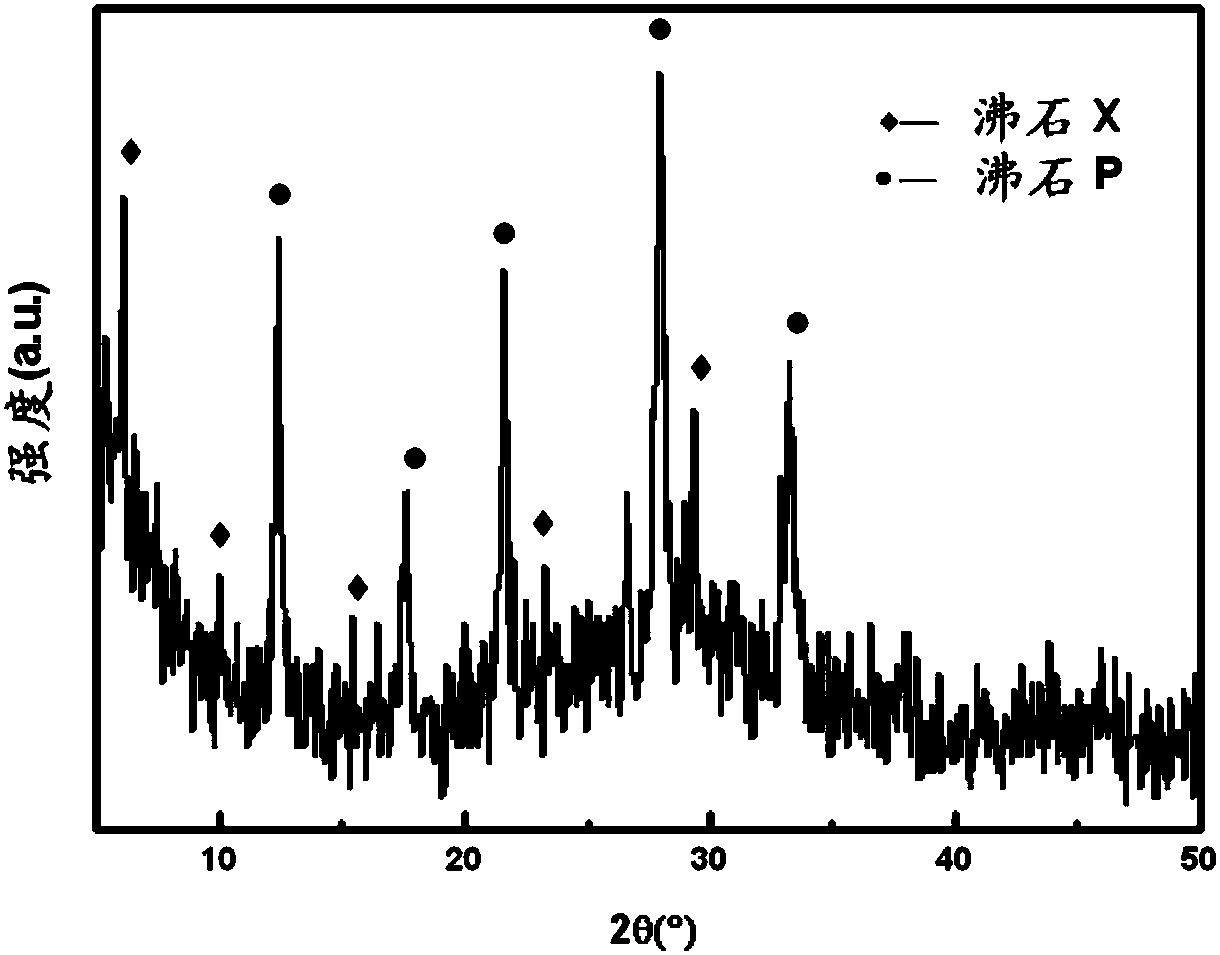

Porous material matrix and composite phase-change heat storage material and preparation methods thereof

InactiveCN102061403AIncrease contentImprove heat storage capacityHeat-exchange elementsCeramicwareWater basedHeat conducting

The invention provides a preparation method of a porous material matrix. The preparation method comprises the following steps: mixing a weighed calcium-containing raw material and a silicon-containing raw material at the mole ratio of Ca to Si of 1:(0.4-1), adding 20-40-times water based on the total weight of the raw materials, stirring and keeping the temperature of 180-320 DEG C for 4-12 hours, and obtaining porous material slurry; and adding 0%-5% of nano-metal powder after the slurry is cooled, drying and molding to obtain the porous material matrix. The preparation method of a composite phase-change heat storage material comprises the following steps: dipping the obtained porous material matrix into a fully fused inorganic salt phase-change material so that the phase-change material is completely infiltrated into a pore path of the porous material matrix; and blowing out for cooling, and then desalting the discharged sample to finally obtain the composite phase-change heat storage material. The obtained matrix material has the advantages of good infiltration property and excellent high-temperature chemical stability relative to inorganic salt; and the obtained composite phase-change heat storage material has the advantages of high heat storage density, good heat-conducting property and cheap raw material.

Owner:SOUTH CHINA UNIV OF TECH

Intensive processing method for stalk articles or agricultural castoff

InactiveCN101492700AEasily hydrolyzedCompletely hydrolyzedBiofuelsMicroorganism based processesFiltrationMonopotassium phosphate

The invention provides a method for intensive processing of straw-type materials or wastes of agriculture and forestry. The method has the following steps: the straw-type materials or the wastes of agriculture and forestry are first ground and then soaked in hot water; hydrolyzation is carried out by diluted acid or monopotassium phosphate solution, the hydrolyzate is used for producing furfural or xylose, solid content after the hydrolyzation is washed and added with alkali substances for neutralization, then cellulase and feruloyl esterase are added to synergetically hydrolyze cellulose in solid content, the cellulose is broken down into 6-carbon monosaccharide and exists in sugar liquor; adsorption filtration is carried out on the sugar liquor by activated carbon, then high-temperature sterilization and cooling are carried out on the sugar liquor before inoculation of fermentation strain to produce acetone, butanol and ethanol by fermentation; the method of the invention maximizes the application of the straw-type materials or the wastes of agriculture and forestry, thus turning existing wastes into the valuables while finding new raw material sources and a new method for producing acetone, butanol and ethanol and bringing more economic and social benefits to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

Efficient ecological waste water treating apparatus and method

InactiveCN1673122AGood hydraulic conductivityWide variety of sourcesTreatment using aerobic processesWater aerationPetroleumStreamflow

The present invention is efficient ecological waste water treating apparatus and method. The apparatus consists of grit contacting oxidizing area, vertical upstream flow artificial wet land area, aerating jet area and horizontal flow artificial wet land area connected serially. The present invention has the advantages of composite medium in new recipe resulting in excellent phosphate and organic matter eliminating effect, the grit contacting oxidizing resulting in the long term stable running of the system, the composite of vertical upstream flow artificial wet land and horizontal flow artificial wet land resulting in raised effective volume and the aerating jet creating condition for aerobic degrading of organic matter.

Owner:PEKING UNIV

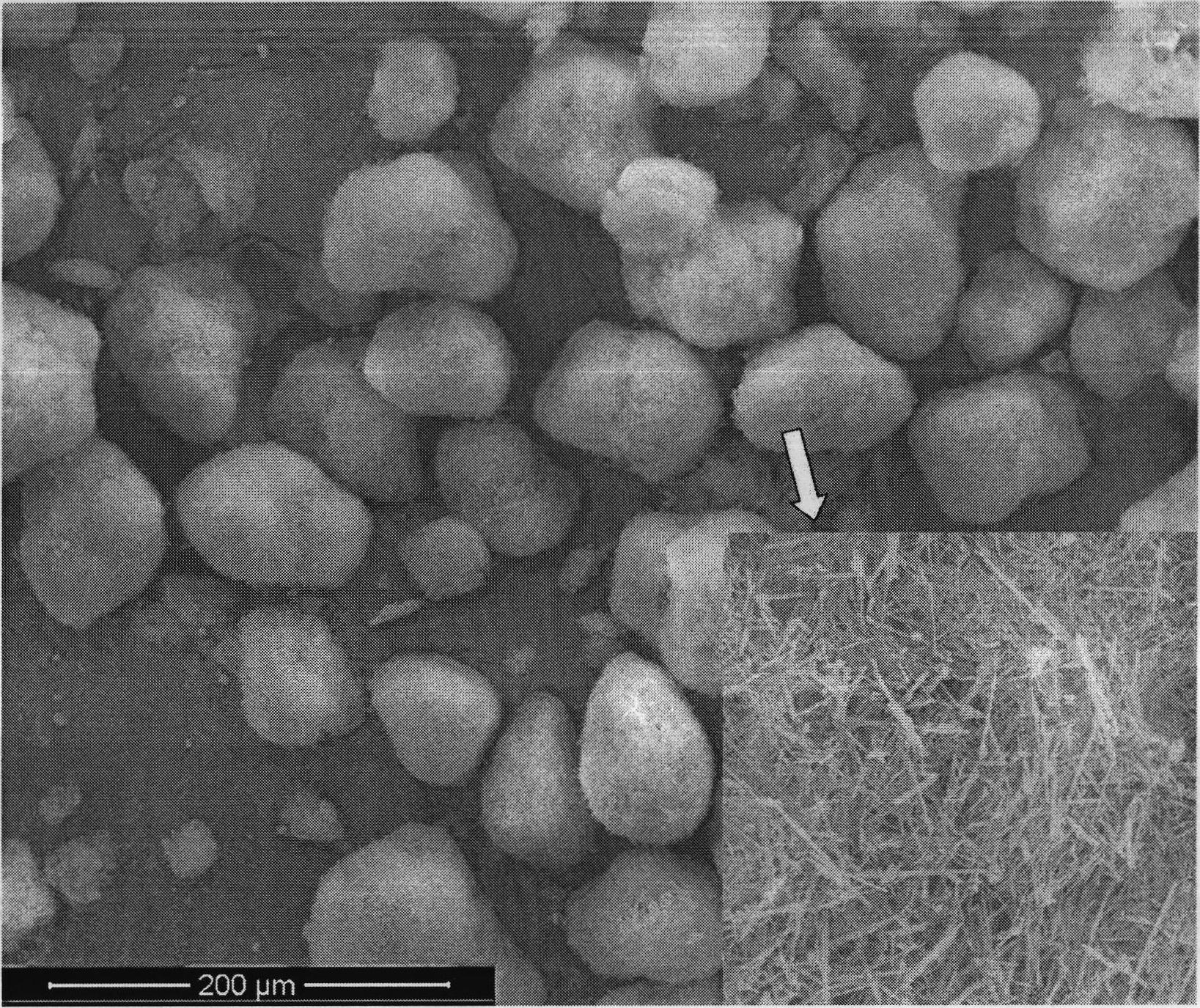

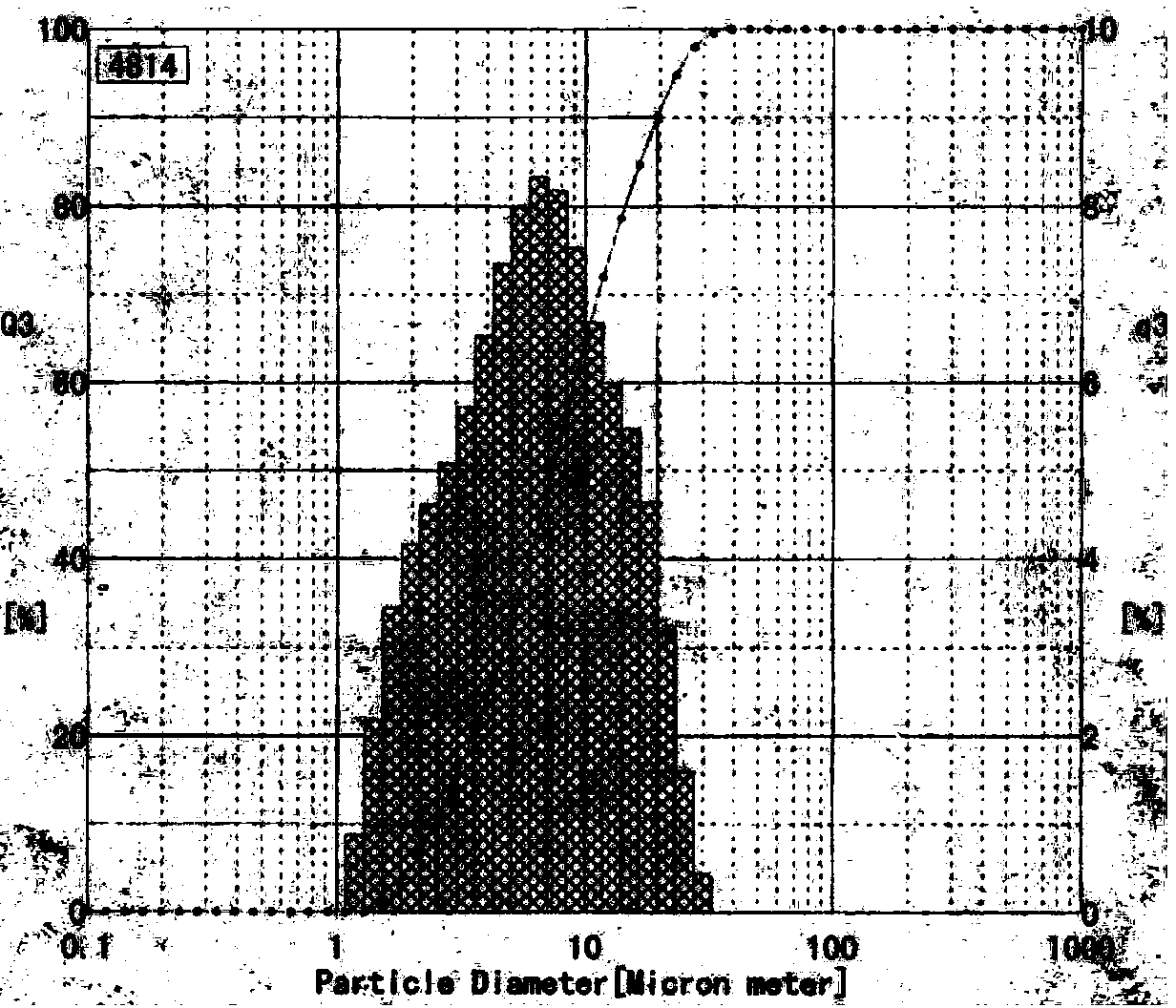

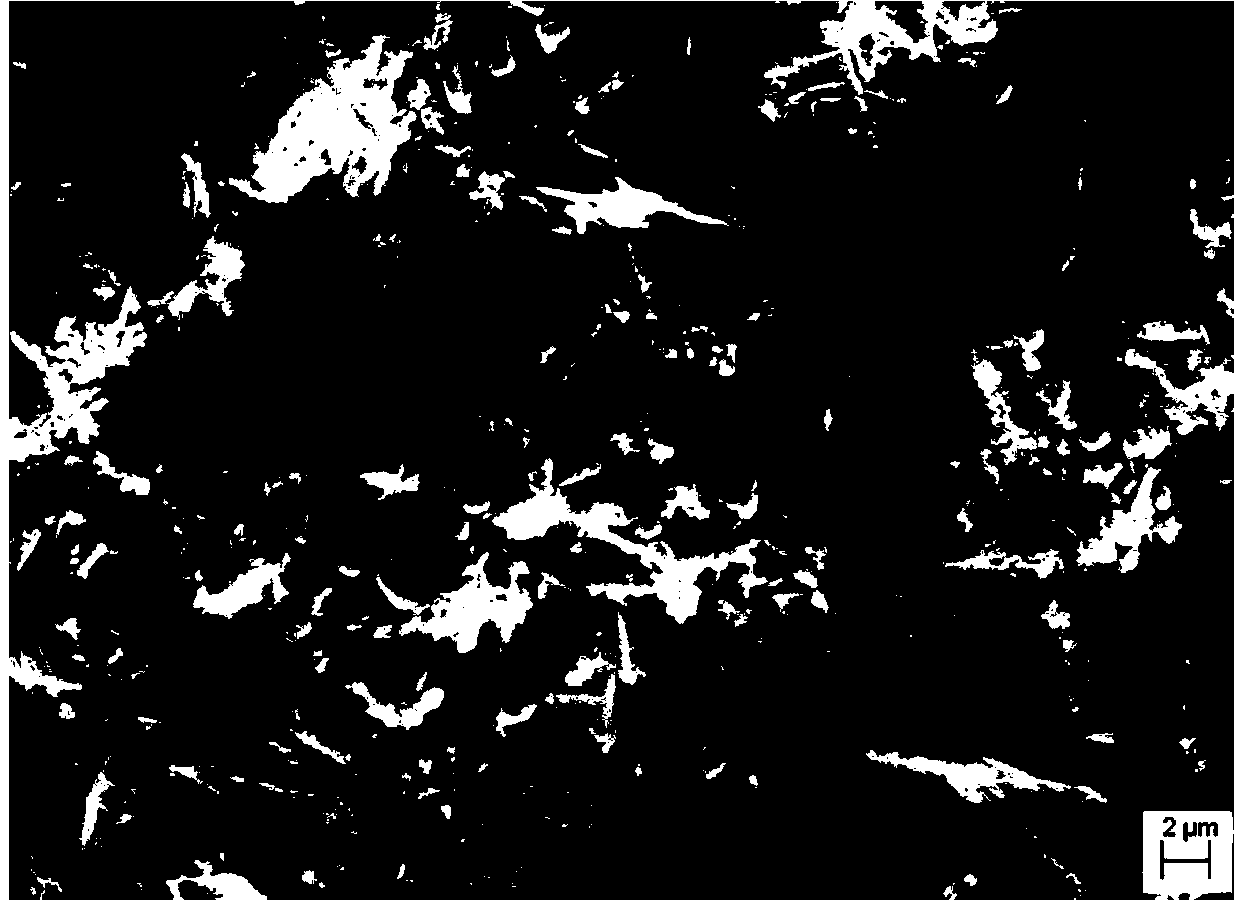

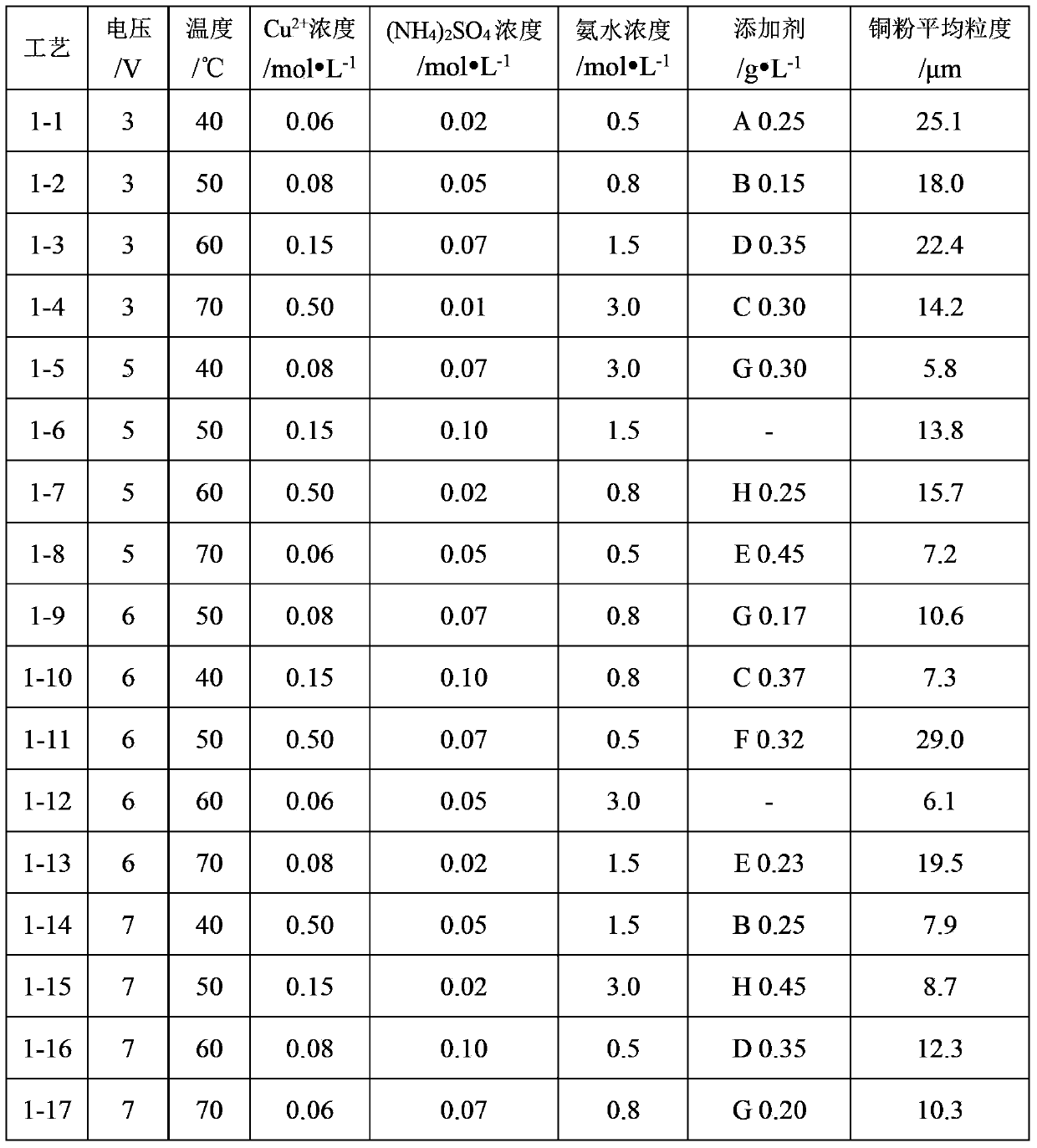

Method for preparation of ultrafine copper powder by waste circuit board copper dissolution-electrodeposition combined method

ActiveCN103388160AThe concentration of copper ions does not changeAchieve recyclingAmmonium sulfateElectronic waste recycling

The invention discloses a method for preparation of ultrafine copper powder by a waste circuit board copper dissolution-electrodeposition combined method and belongs to the technical field of electronic waste recycling. Each liter of a copper dissolution electrolyte comprises 0.06-0.8mol of copper sulfate, 0.02-0.1mol of ammonium sulfate, 0.3-3mol of ammonia water, 0-0.5g of an additive and the balance water. Direct voltage of an electrolytic bath is in a range of 2-8v. A cathode zone and an anode zone are separated by a cation exchange membrane. A waste circuit board without paint is put into the anode zone and nitrogen is fed into the cathode zone so that oxygen is removed. At a temperature of 30-70 DEG C, electrolysis is carried out under the condition of magnetic stirring. After electrolysis, copper powder is separated from a cathode by ultrasonic wave and then is subjected to washing, filtration and vacuum drying to form the ultrafine copper powder. Through the waste circuit board as a copper source, the ultrafine copper powder is obtained under the optimal conditions. The ultrafine copper powder has the average particle size of 5.8 microns, uniform particle size distribution, good dispersibility, high purity of 99.9% and a high application value. The method realizes recycle of the electrolyte and is environmentally friendly.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing xylose coupled cogeneration of propanone, butanol and ethanol using stalk

InactiveCN101358218AIncrease profitNot easy to useBiofuelsMicroorganism based processesSocial benefitsCellulose

The invention provides a method for producing xylose co-produced with acetone, butanol and ethanol by utilizing straws. The straws are hydrated by acid to be filtered to be divided into xylose hydrolysis fluid and xylose residue; the xylose residue is zymohydrolyzed, fermented and rectified to prepare the acetone, the butanol and the ethanol; the xylose hydrolysis fluid is used for preparing the xylose. The method of producing xylose co-produced with acetone, butanol and ethanol by utilizing straws of the invention realizes the maximization of the cellulose straw substances, not only the straw resources are fully utilized to realize changing waste into valuable and the added value of products is improved to realize the economic value of the straws, but also the new raw material source and methods for the production of the acetone and the ethanol are developed and more economic benefits and social benefits are brought to the enterprises and the society.

Owner:ZHENGZHOU DAYANG GREASE CHEM EQUIP

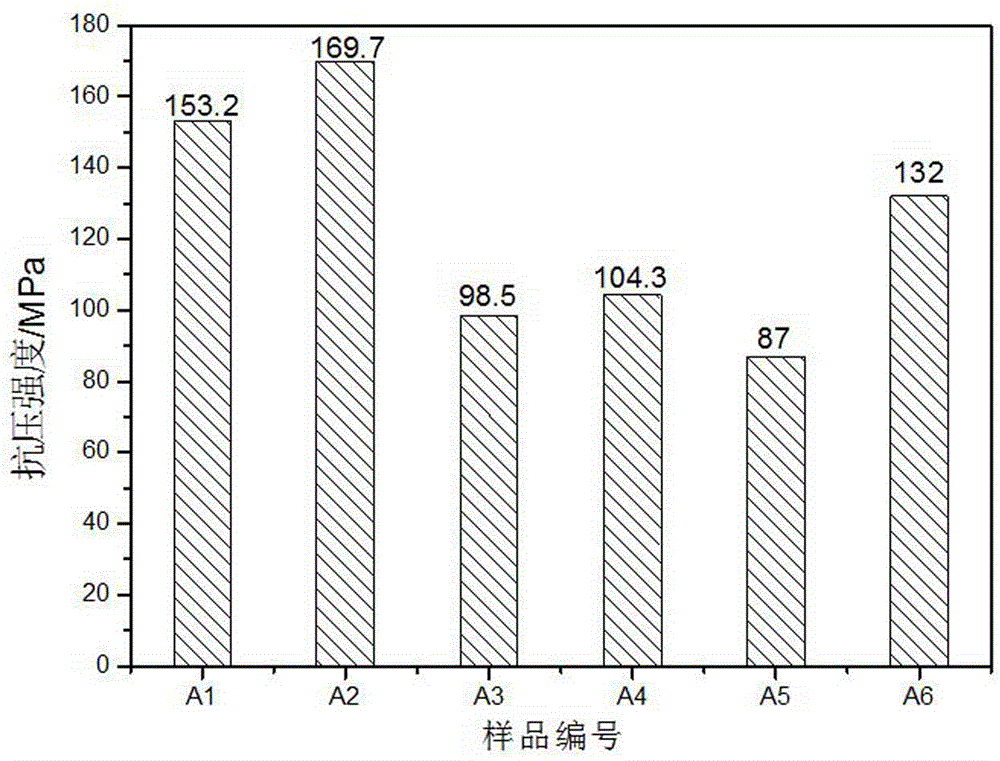

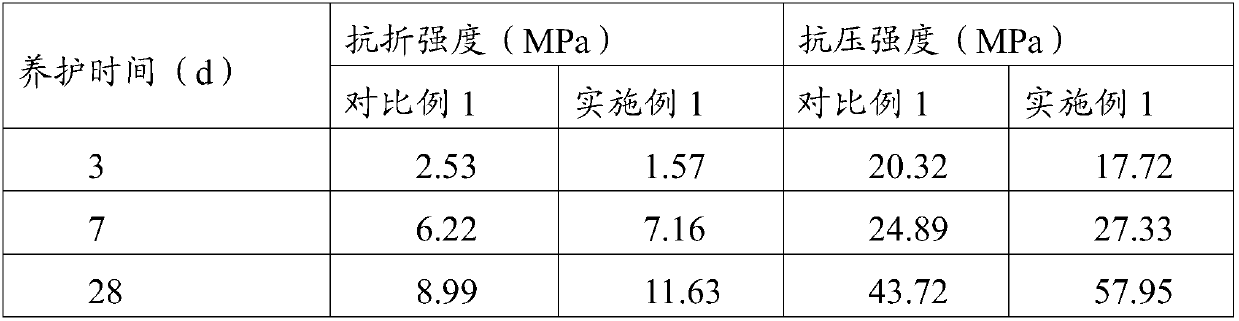

Method for preparing building material by using phosphogypsum

The invention relates to a method for preparing a building material by using phosphogypsum. The method comprises the steps of firstly, preparing a dry blend by using the phosphogypsum, aluminosilicate industrial residues, a calcium cementing material and aggregate, then adding water or water with a dissolved activator to obtain a wet mixture, standing, carrying out static pressure molding, and finally, carrying out natural or steam curing to obtain an ultrahigh strength material. The method solves the problems that the phosphogypsum has more impurities and is difficult to utilize, and can be used for preparing the ultrahigh strength building material with high compressive strength by enabling the phosphogypsum to be coupled with a great deal of aluminosilicate industrial residues. The ultrahigh strength building material can be used for preparing various high-strength and high-durability products such as high strength building bricks, high strength road bricks, high strength water permeable bricks, road edge stones and various decorative boards by changing a molding mould, and overcomes the defects that gypsum products are low in strength and poor in water resistance and durability. The method realizes functionalization, greenization and high value while consuming a great deal of phosphogypsum and aluminosilicate industrial residues, thus having good economic benefit and social benefit.

Owner:韩涛

Organic fertilizer and its manufacture method

The composition of ecological fertilizer comprises (by weight portion) straw powder 30-70, fungous preparation 1-20, coal humic acid 5-30, urea 5-25, ground phosphate rock 3-25, potassium mineral powder 3-30 and lime 0.3-15. It is made up by adopting biological method, and is low in production cost, and is an organic composite fertilizer applicable to grain crops, vegetables, fruit tree, tobacco and economic crops of acid soil, alkali soil and neutral soil, and its fertilizer effect is good.

Owner:王柏学

Preparation method for manufacturing building board by utilizing mine tailing residue

The invention discloses a preparation method for manufacturing building board by utilizing mine tailing residue. The following raw materials are used by weight ratio: 30-75% of tailing residue and 25-70% of additive; brine with the weight percent concentration of 25-28% is utilized to stir the material into paste, the paste is placed into a mould to be rolled and moulded, and the tailing residue is one or more than one of gold slag, copper slag and ferrum slag. The invention utilizes tailing residue to produce building board, massive tailing residue is consumed, pollution harm of tailing discharge is solved, the produced building board has low cost and high strength, tailing residue can be made into various building boards by utilizing the technology, and various building section bars, stone pillar, brick and lattice prism used for historic building restoration as well as modern city sculpture, roman column pendant, external decorative wall, leisure chair, rail and sidewalk lattice brick can be cast.

Owner:王琦 +3

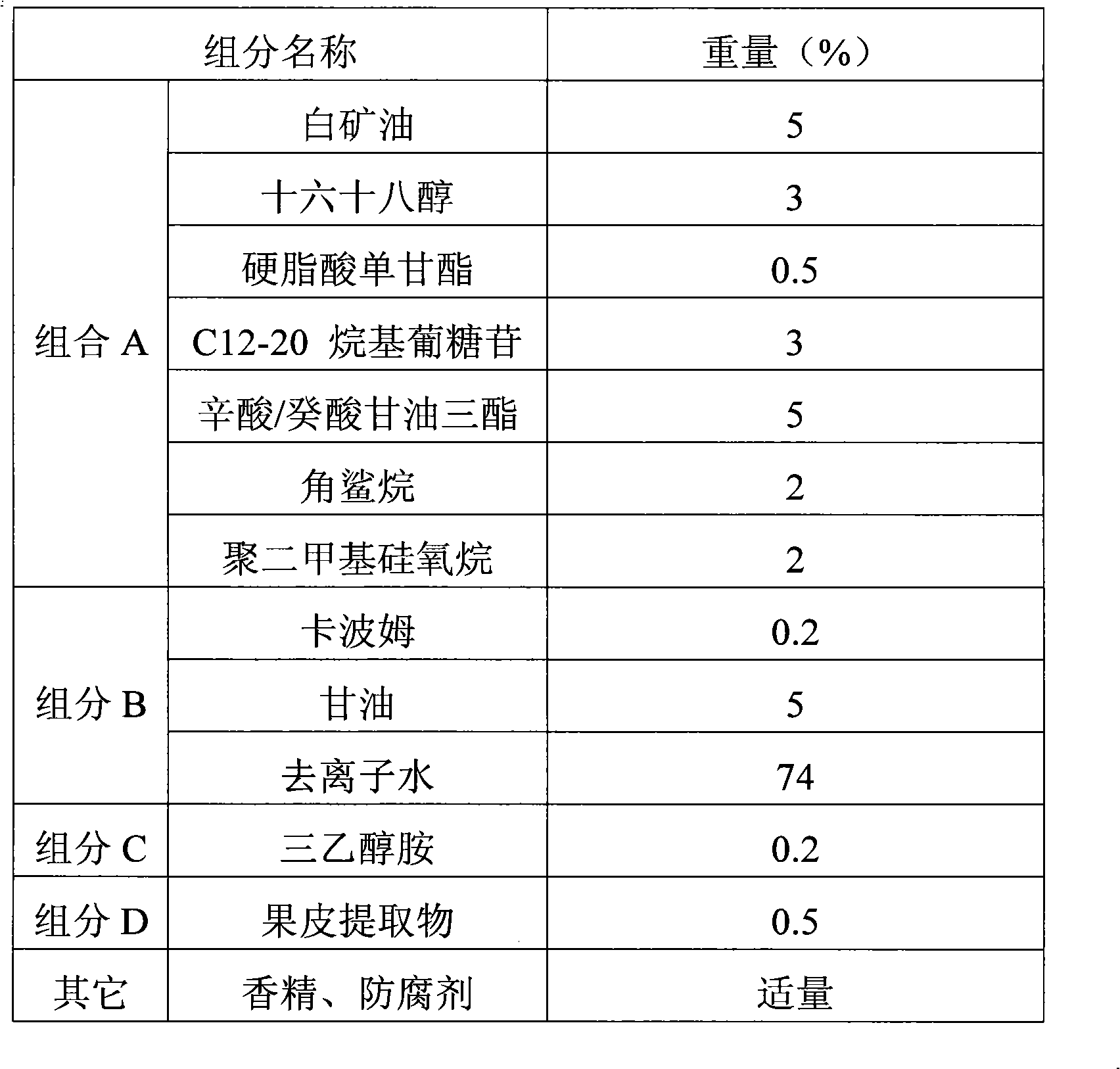

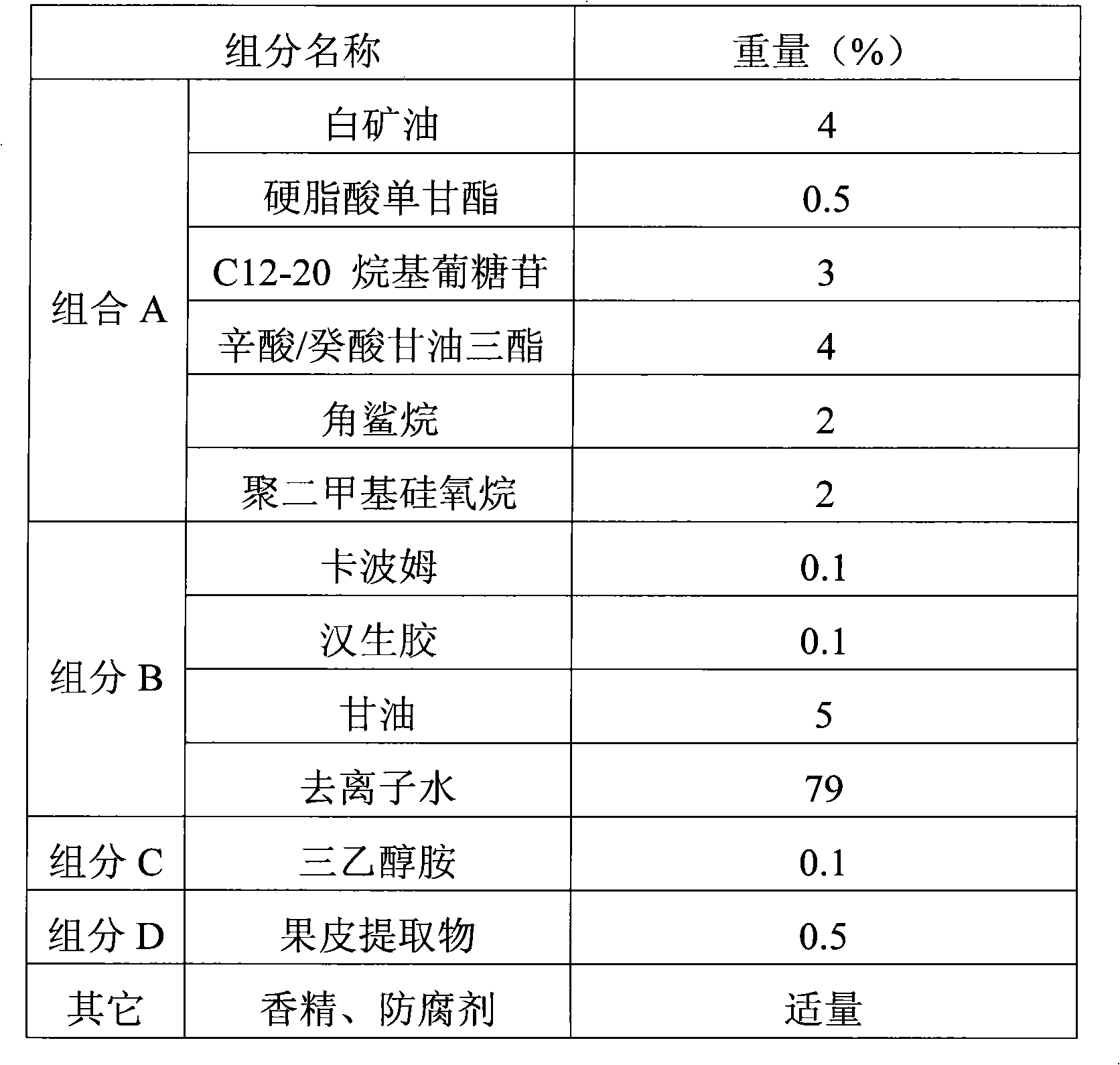

Water-solubility active extract in fruit skin, preparation method and use thereof

InactiveCN101336874AAbundant sourcesLow costCosmetic preparationsToilet preparationsSolubilityFlocculation

The invention relates to a water-soluble active extract derived from fruit peels, the preparation method and the application thereof. The fruit peel is treated by the steps of drying, pulverization, extraction, flocculation, separation and concentration, to prepare a water-soluble active extract. Then, the extract is added in cosmetic matrixes to allow a cosmetic to have skin-whitening and anti-skin ageing functions. The fruit peel extract is obtained after the screening of tyrosinase-inhibiting, antioxidant and free radical-scavenging activities in the water-soluble extracts of fruit peels such as Citrus peels, and has skin-whitening and anti-skin ageing effects. The water-soluble active extract has the advantages of easily-accessible raw materials, renewable resources and simple preparation method. The obtained extract has good stability and durable effect and serves as cosmetic additives in any stage of cosmetic production, without the risks of solvent residue and microbial contamination.

Owner:BEINONG BIOCHEM SUZHOU INDAL PARK

Method for baking ceramsite by using town sludge, river mud and bentonite

InactiveCN102173746ASolving difficult and costly problemsIncrease productionCeramic materials productionClaywaresSodium BentoniteSludge

The invention discloses a method for baking ceramsite by using town sludge, river mud and bentonite. The method comprises the following steps of: milling 30 to 35 weight percent of original sludge, 45 to 50 weight percent of river sludge, and 17 to 23 weight percent of bentonite by wheels, mixing and stirring to homogenize the materials; and aging, pelleting, screening, sintering and expanding, and performing air cooling. The bulk density of the obtained ceramsite is 400 to 500Kg / m<3>, the compression strength is 1 to 3.5Mpa, one-hour water absorption is 8 to 10 percent, and the grain size of the product is 1 to 26mm; and the original sludge, the river sludge and the bentonite are used as the raw materials, the ceramsite is directly baked by taking cavings as fuel, the treatment capacity of the sludge is large, the production cost is low, secondary pollution in the production process is avoided, and the performance of the obtained ceramsite product meets the standard requirement of GB / T17431.1-1998.

Owner:常州市金坛博大陶粒制品有限公司

Full-solid waste weak concrete material prepared with solid sulphur slag of fluidized bed fire coal

The invention discloses a concrete material which totally adopts industry solids waste to replace cement preparation, comprising a gelled material and a skeletal material. The gelled material is composed of the components with the following weight portions of 36 to 75 portions of fluidized bed burning coal solid sulfur clinker, 9 to 25 portions of acetylene sludge and 6 to 15 portions of phosphogypsum; because the cementing materials such as cement, lime, asphalt, and the like, are not needed at all, material costs are remarkably reduced, great amount of industry solids waste is used to produce building materials, especially the fluidized bed burning coal solid sulfur clinker is used to serve as raw material, environment pollution is avoided, and land resources are saved.

Owner:CHONGQING UNIV

Slab continuous casting mold covering slag and production method thereof

The invention discloses slab continuous casting mold covering slag, which comprises the following chemical components in percentage by mass (wt percent): 25-40 percent of SiO2, 0.1-10 percent of MgO, 21-41 percent of CaO, 0.2-2.5 percent of Fe2O3, 2.5-14 percent of Al2O3, 3-14 percent of Na2O, 2.5-10 percent of F, 0-1.5 percent of Li2O, 0-6 percent of MnO, 0.5-10 percent of volatile matter and 1-11 percent of Cfixed. A cheap electrolytic aluminum waste residue raw material is effectively added into the slab continuous casting mold covering slag formula for use, wherein the chemical elements of fluorine, carbon, sodium, aluminum and the like can be used for substituting or partially substituting one or more of raw materials of the chemical elements used in the continuous casting mold covering slag formula, and the quality performance of a product can reach and meet enterprise standard. In actual production, the skilled worker in the art tries to reduce the cost in various aspects; but since the covering slag production field is far different from the electrolytic aluminum production field, improvement cannot be performed in the electrolytic aluminum waste residue and the electrolytic aluminum waste residue cannot be changed into things of value.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

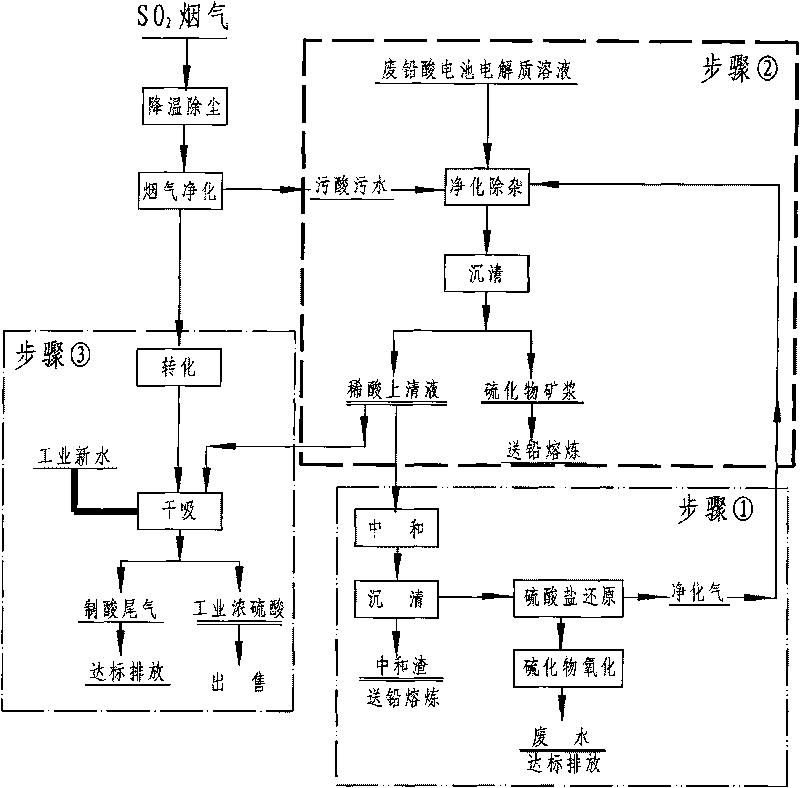

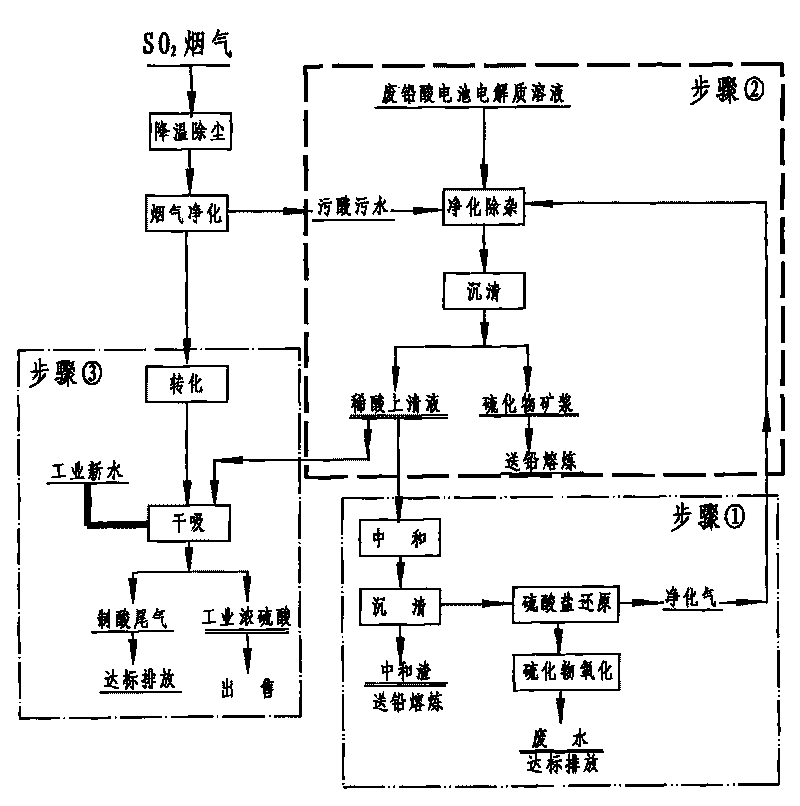

Method for regenerating and recovering sulfuric acid from waste acid

ActiveCN101759158AAvoid pollutionReduce processing costsWater contaminantsSulfur-trioxide/sulfuric-acidFlue gasNuclear chemistry

The invention relates to a method for regenerating and recovering sulfuric acid from waste acid generated in the production of the sulfuric acid or waste acid collected from waste lead-acid storage batteries, comprising the following steps of: firstly preparing purified gas containing H2S with volume percent of 2.5%-5%, CO2 with volume percent of 20%-45% and N2 with volume percent of 50%-77.5; supplying the purified gas to a waste acid solution with the flow rate of 10-20 m3 / h and the stirring speed of 300-400 rpm at the speed of 400-600 L / h so that heavy metal impurities in the waste acid solution and S2+ react to generate a sulfide; precipitating, filtering and separating the generated sulfide so that the sulfide is purified and removed from a dilute sulfuric acid solution; and replenishing the filtered dilute sulfuric acid solution which replaces new water into the dry-adsorbing procedure of a flue gas acid making systemso that the sulfuric acid in the waste acid solution is recovered into industrial sulfuric acid. The method has the advantages of low production cost, short flow, high cyclic utilization rate, low energy consumption, treatment of wastes by using wastes, small environmental pollution and high level of automation.

Owner:HENAN YUGUANG GOLD & LEAD

Preparation method of lignin-based electrostatic blended materials

The invention discloses a preparation method of lignin-based electrostatic blended materials. The method comprises the following steps: extracting lignin from a lignin raw material; or performing acetylation or acidifying modified treatment on the lignin; mixing the modified lignin with co-spinning materials according to the weight rate of 1 to 1-2, and dissolving in an organic solvent and proportioning into an electrostatic spinning solution with the solute content of 0.1-0.4g / mL; preparing the lignin-based electrostatic blended materials by using an electrostatic spinning process. The extracted or chemically-modified lignin is good in dissolubility in the organic solvent, and is mixed with high-molecular materials with high performance and dissolved in the organic solvent to be made into the spinning solution for performing electrostatic spinning, so that a compound fiber film material with security, non-toxicity, environmental protection property and degradability is prepared, and the current problems of resource shortage and environment crisis are solved. In addition, the raw materials are fully supplied, the equipment requirement is low, the preparation process is simple, and the industrial production is easy to realize.

Owner:NANJING TECH UNIV

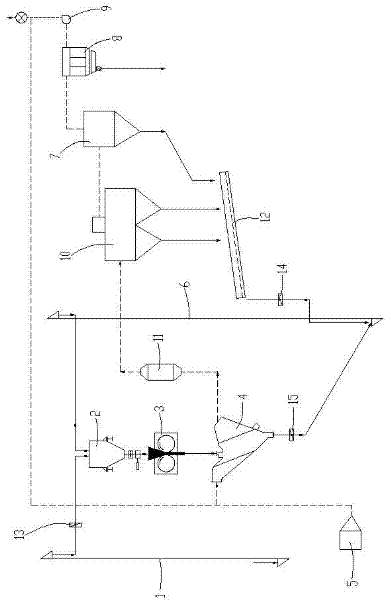

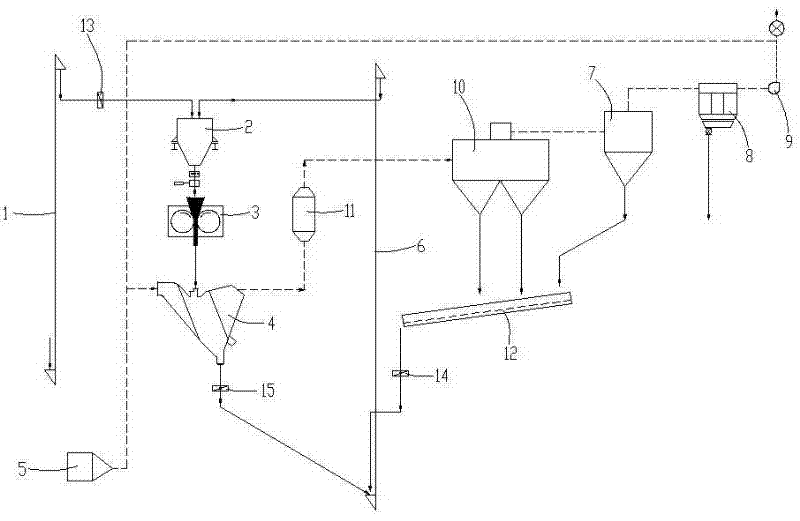

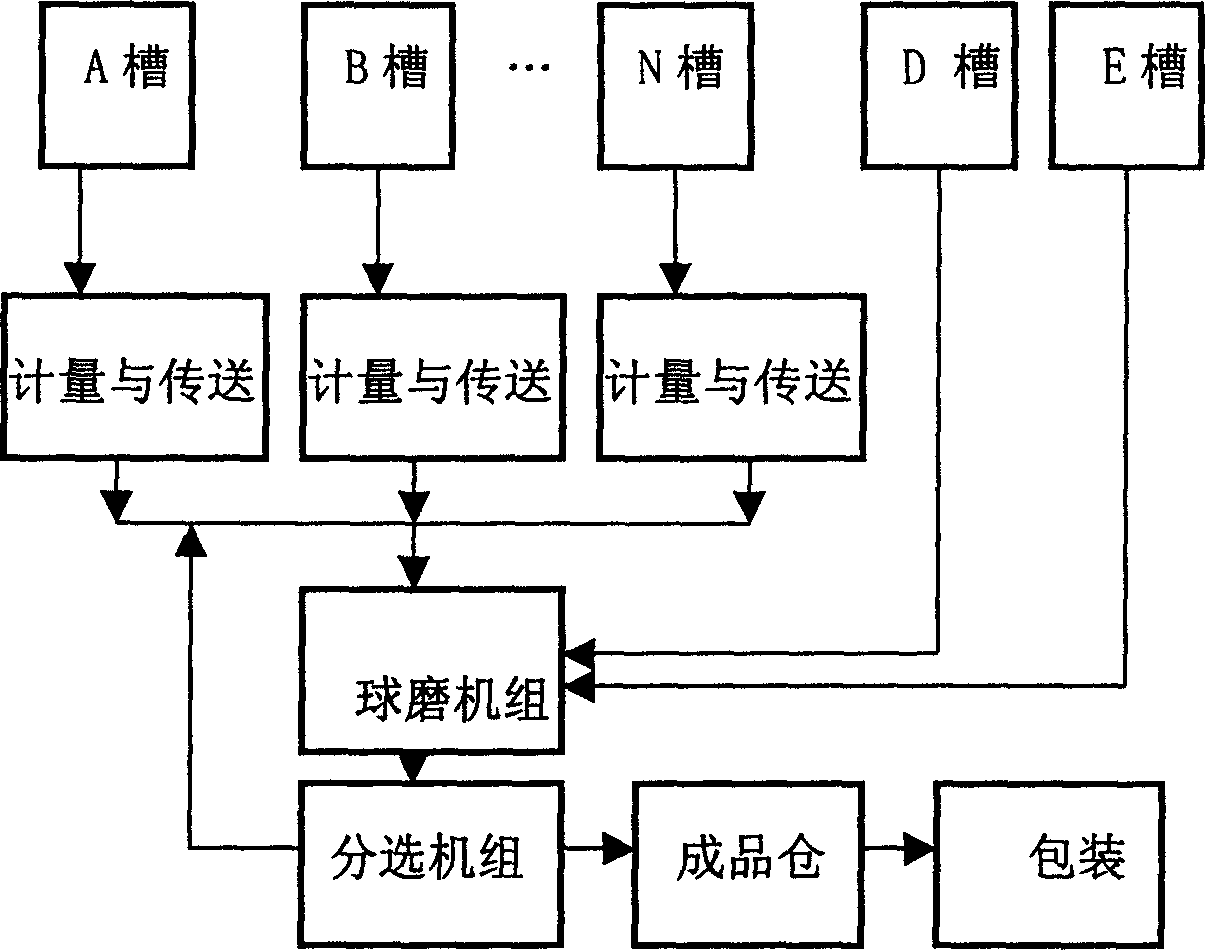

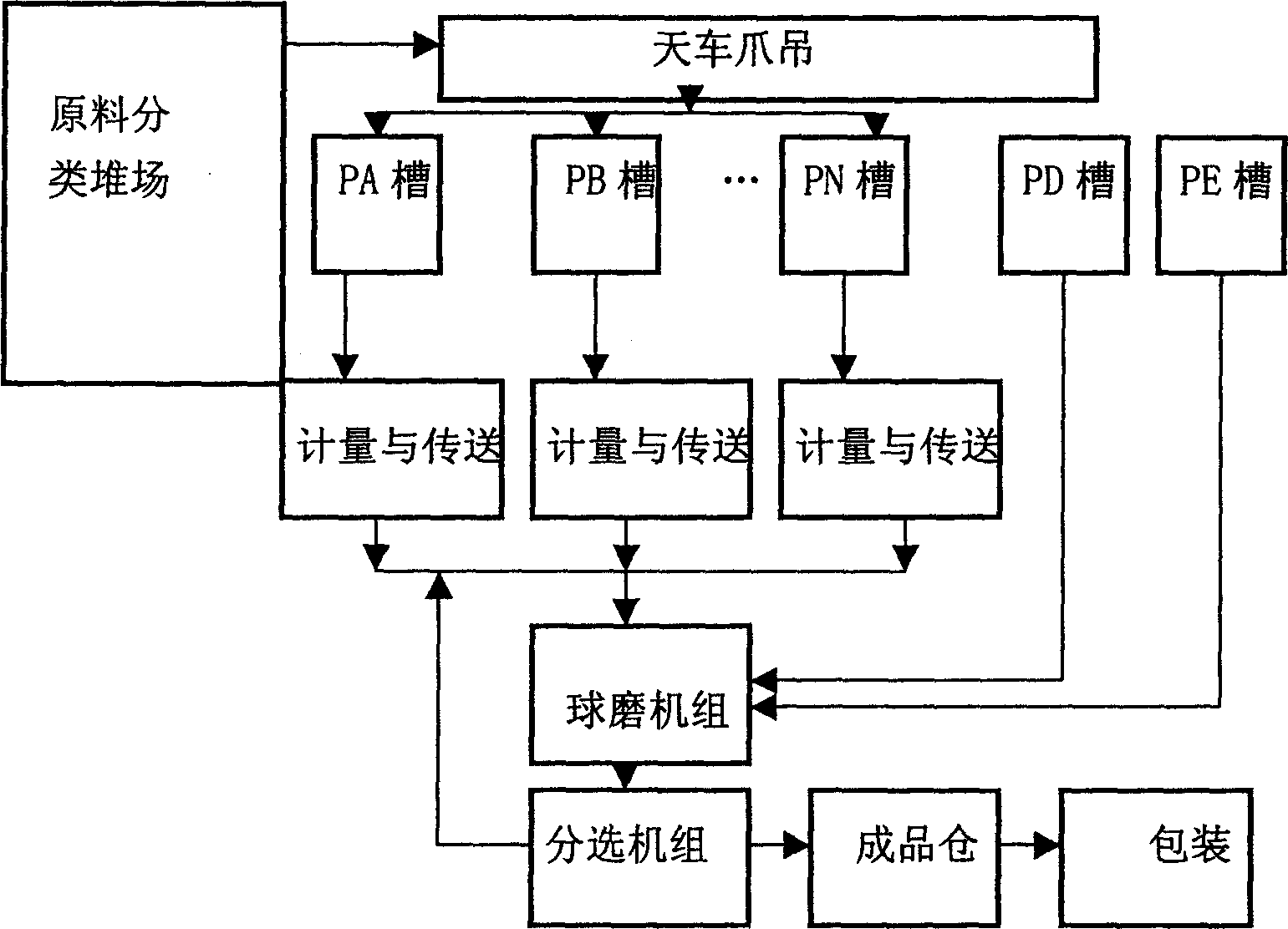

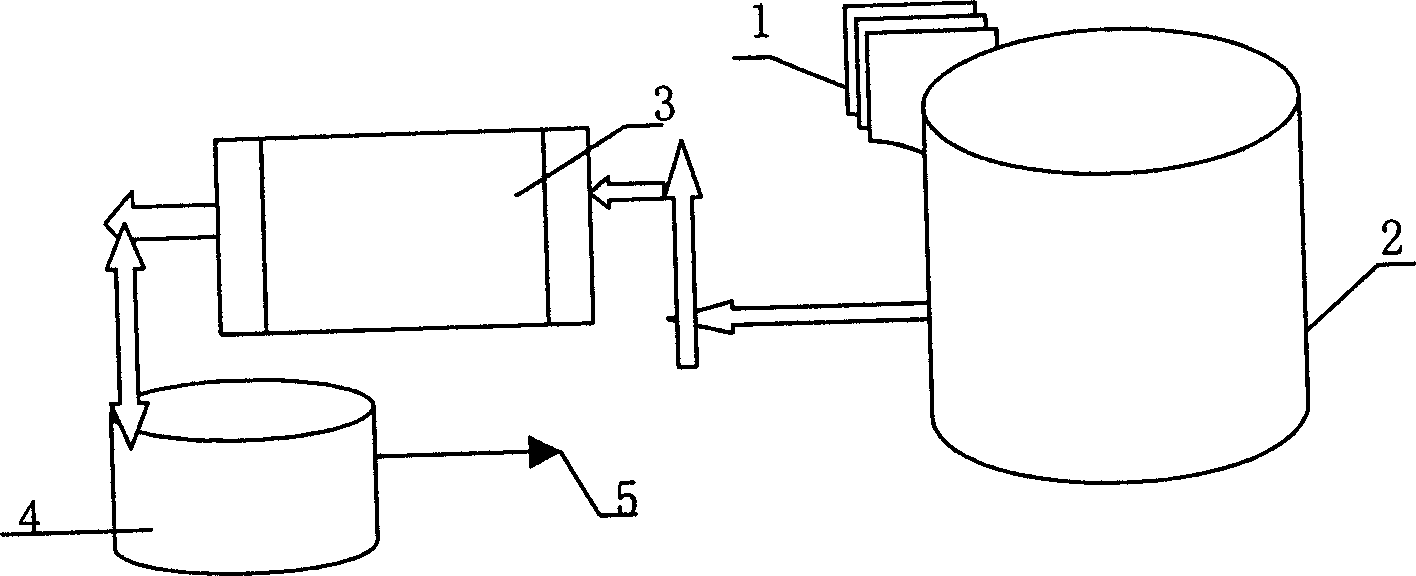

Final grinding system of rolling machine in steel slag and mineral slag micropowder production line

ActiveCN102179272ASolve the problem of waste reuseTurn waste into treasureGrain treatmentsSlagTuyere

The invention discloses a final grinding system of a rolling machine in a steel slag and mineral slag micropowder production line. A first hopper type lifting machine feeds materials to a steady-flow weighing bin, and the product of the rolling machine is dispersed and graded in a V-shaped powder concentrator; a high-temperature and high-speed fluidized bed furnace is connected with the air inletof the V-shaped powder concentrator; a drying tube and a rotoclone collector are arranged between the V-shaped powder concentrator and an ultrafine separator; the air outlet of the V-shaped powder concentrator is first connected with the drying tube in series and then connected with the air inlet of the rotoclone collector; the air outlet of the rotoclone collector is connected with the air inletof the ultrafine separator through a pipe; a chute is arranged below the rotoclone collector and the ultrafine separator; and the lowest end of the chute is positioned above the feeding hopper of thesecond hopper type lifting machine. In the invention, through the extruding and crushing of the steel slag and the mineral slag by the rolling machine, and the drying and three-stage powder concentration treatment, steel slag powder and mineral slag powder with a specific surface area of 400 to 550m<2> / kg are provided, the steel slag and mineral slag waste reutilization is realized, and the system has the advantages of changing waste materials into valuable materials, saving energy, reducing emission, protecting environment and the like.

Owner:CHONGQING JINGQING HEAVY MACHINERY

Phosphogypsum-base wall material for cast-in-place wall

The invention discloses a phosphogypsum-base wall material for a cast-in-place wall. The invention is characterized in that the material is prepared from the following raw materials in percentage by weight: 60-80% of beta-phosphogypsum, 10-20% of mineral admixture, 5-25% of cement, 0.25-0.5% of retarder, 0.05-0.15% of defoaming agent, 0.05-0.2% of thickener and 0.5-1% of water reducer. The raw materials are uniformly mixed to obtain the phosphogypsum-base cast-in-place wall material; and the material and water are mixed uniformly in a water / material ratio of 0.4-0.5 to obtain a slurry, and the slurry is cast in place and molded. The phosphogypsum-base wall material has the advantages of controllable setting time, low flowing loss rate, high utilization ratio of solid waste, low material cost and high strength, is convenient for construction, and can be widely used for frame-structure infilled internal walls of commercial and civil buildings.

Owner:WUHAN UNIV OF TECH

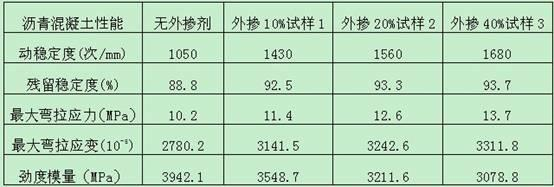

Paving asphalt concrete additive and preparation method thereof

InactiveCN101863637AImprove performanceSimple construction processPlasticizerArchitectural engineering

The invention provides a method for preparing a paving asphalt concrete additive through direct liquefaction of residues with coal. The paving asphalt concrete additive is prepared through the following steps: adding an appropriate amount of plasticizing agent, coupling agent and rubber powder during direct liquefaction of the residues with the coal, high-temperature melting, mixing and the like. When being added, the additive can substitute 10-40 percent of total asphalt in the paving asphalt concrete without changing the proportion of the components of the paving asphalt concrete, and can not affect the use performance of the road adopting the paving asphalt concrete, but can improve part of the performances of the road. Moreover, the invention can reduce the cost of the paving asphalt concrete, and realize the purposes of transforming the residues into valuable resources, saving the energy and reducing the emission.

Owner:CHANGAN UNIV

Method for extracting glucosamine from self-fermentation liquid

InactiveCN104788510AAccelerated settlementReduce dosageSugar derivativesSugar derivatives preparationFlocculationFiltration

The invention discloses a method for extracting glucosamine from a self-fermentation liquid, which comprises the following steps: fermentation liquid flocculation, filtration, double-effect concentration, crude product preparation, fine product preparation and the like. The technique is simple and convenient, and is high in yield.

Owner:江苏赛奥生化有限公司

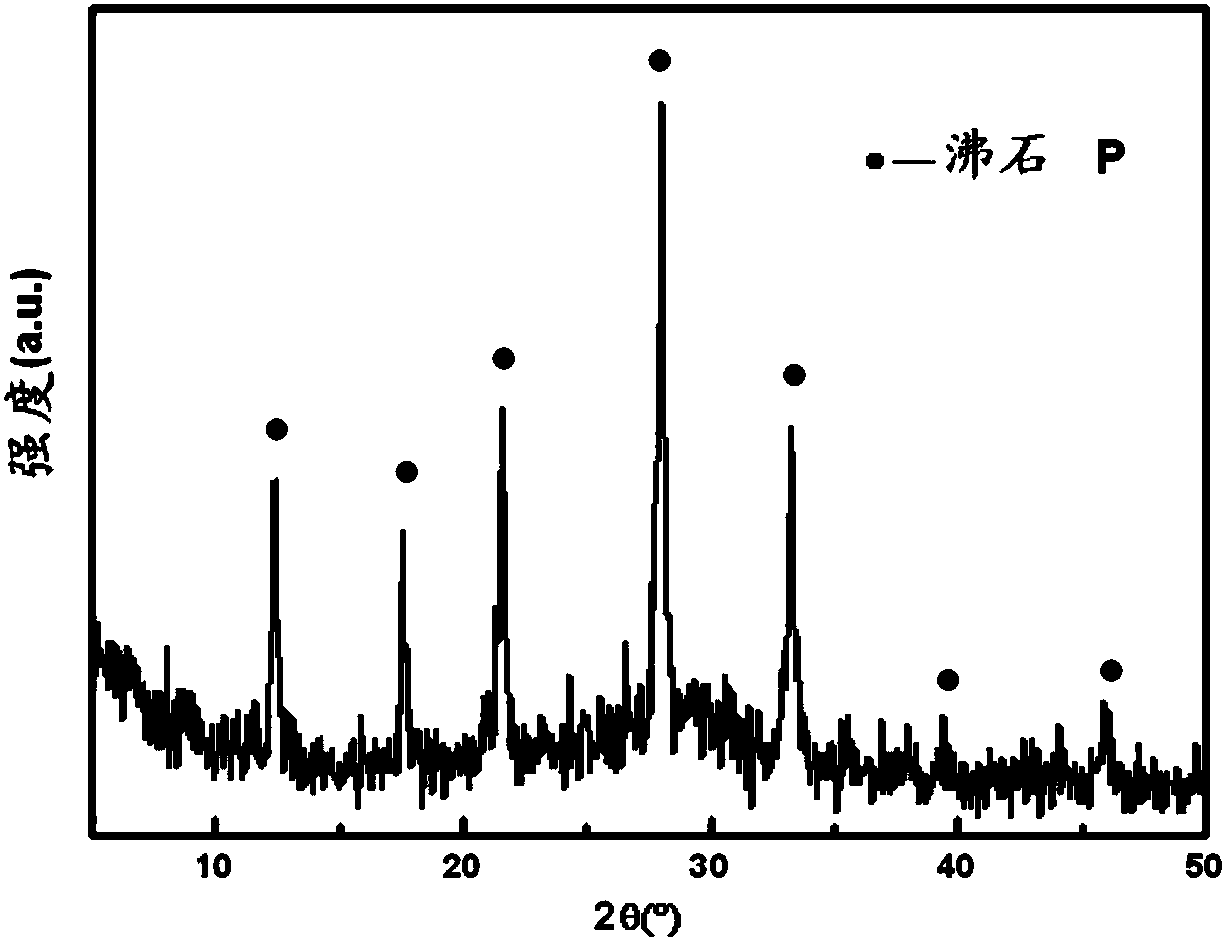

New type of ecological cement and its prepn and application

InactiveCN1609031AImprove corrosion resistanceHas gelling propertiesCement productionUltimate tensile strengthNatural mineral

The new type of ecological cement and its preparation and application belongs to the field of cementing material technology. The materials includes aluminum-rich material F, aluminum-poor material P and guide crystal seed D, and material F and material P are selected from various industrial wastes and natural minerals. Material F has the molar ratio of Si / Ca in 0.5-1.7 and Si / Al in 1.5-3.0, and material P has the molar ratio of Si / Ca in 0.3-1.0 and Si / Al in 1.0-2.6. During use, material F, material P and material D are mixed while adding water to form cementing matter with high strength. The present invention changes industrial wastes into useful material, and has no secondary environmental pollution.

Owner:张立省

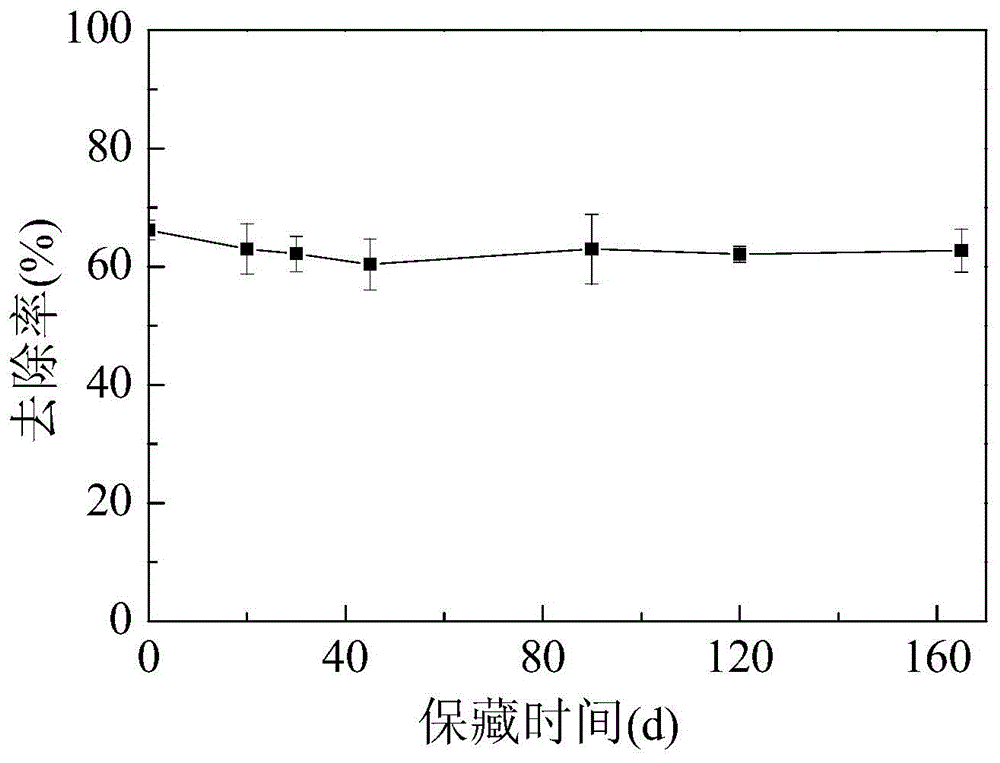

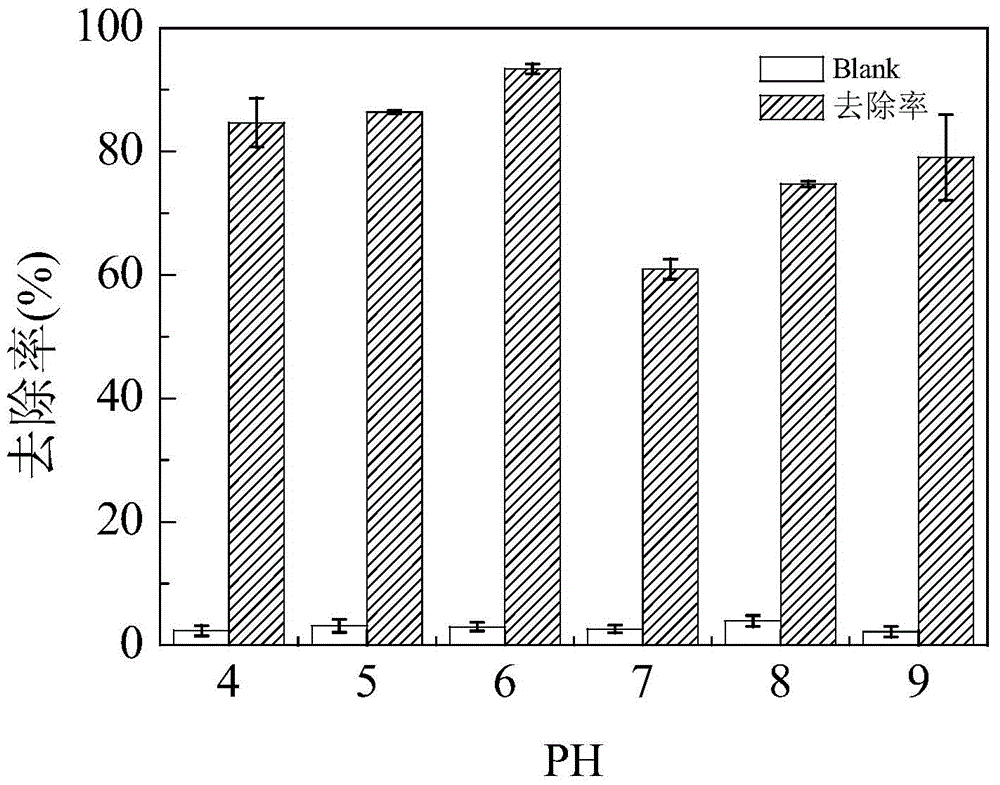

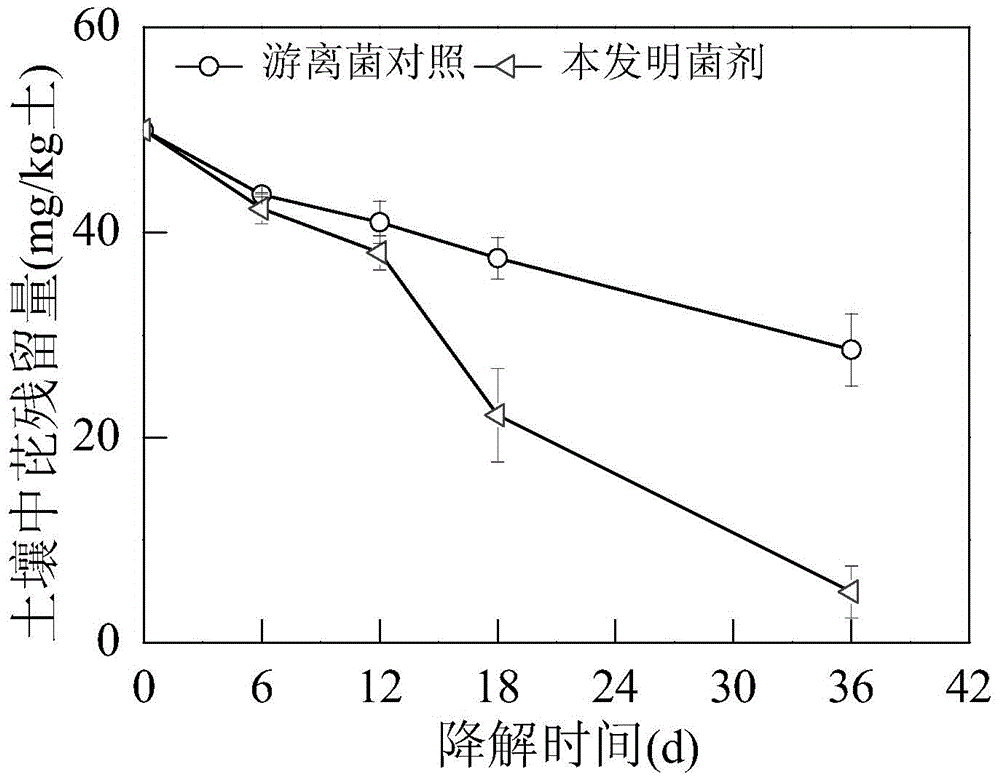

Microbial agent capable of degrading polycyclic aromatic hydrocarbons as well as preparation method and application of microbial agent

The invention relates to a microbial agent capable of degrading polycyclic aromatic hydrocarbons as well as a preparation method and an application of the microbial agent. The microbial agent comprises the following effective components: mycobacterium gilvum CP13, trichoderma viride and rhamnolipid. The preparation method comprises the following steps: mixing bacterial solutions obtained by respectively culturing mycobacterium gilvum CP13 and trichoderma viride, simultaneously adding a composite carrier of diatomaceous earth and modified peanut shells and rhamnolipid and carrying out microbial immobilization to prepare the microbial agent. The microbial agent has super strong polycyclic aromatic hydrocarbons removal capability and meanwhile has the advantages of low cost and long shelf life; and by virtue of the microbial agent, over 90% of polycyclic aromatic hydrocarbons, such as high-concentration (50mg / kg) pyrene contained in the vegetable garden soil can be removed under conditions of room temperature (20 + / -5 DEG C) and pH of 4-9 within 36 days.

Owner:SOUTH CHINA UNIV OF TECH

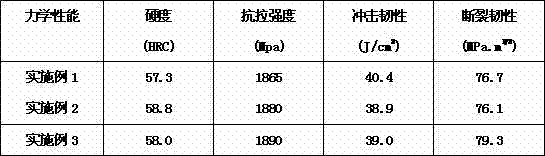

H13 die steel and preparation method thereof

The invention relates to H13 die steel and a preparation method thereof, and belongs to the technical field of wear-resistant materials. The H13 die steel comprises the following chemical elements in percentage by weight: 0.40 to 0.46 percent of C, 6.00 to 6.30 percent of Cr, 0.50 to 0.65 percent of V, 0.30 to 0.45 percent of Mo, 0.85 to 1.05 percent of Mn, 1.25 to 1.55 percent of Si, 0.12 to 0.25 percent of W, 0.008 to 0.018 percent of Nb, 0.008 to 0.015 percent of Ta, 0.08 to 0.12 percent of Ti, 0.003 to 0.006 percent of B, 0.08 to 0.15 percent of Al, 0.03 to 0.06 percent of N, 0.06 to 0.12 percent of Y, less than 0.025 percent of S, less than 0.030 percent of P and the balance of Fe. The H13 die steel has the advantages that: the content of precious alloy elements, namely molybdenum and vanadium is low, the H13 die steel is not required to be forged, and forging can be replaced by casting, so that the cost of the H13 steel is obviously reduced; the performance of the H13 steel can be obviously improved, and a tungsten slag iron alloy is recycled; a solidification structure can be obviously refined, and the mechanical property of the H13 steel is improved; and the H13 steel has high wear resistance and is used as a hot working die, and the service life is prolonged.

Owner:江苏环立板带轧辊有限公司

Method for recycling and reusing solid waste and glass prepared by using solid waste as raw material

The invention discloses a method for recycling and reusing solid waste. The solid waste comprises oxide of silicon, aluminum, calcium and sodium; the solid waste is directly made into glass or is made into glass with other raw materials. The invention further discloses glass prepared by using the solid waste as a raw material. The solid waste can be the solid waste belonging to any fields of the oxide of silicon, aluminum, calcium and sodium. The solid waste is directly verified or is mixed with other cheap minerals and then is verified; the utilization ratio of the solid waste is up to 100 percent and 60 percent respectively; the obtained products can meet the general requirements; the products can be recycled completely; and multiple aims of changing waste into treasures, protecting environment and realizing sustainable development can be fulfilled.

Owner:SHENZHEN GANGCHUANG BUILDING MATERIAL

Environment-friendly lightweight nutrition matrix for soilless cultivation and preparation method thereof

InactiveCN103992185ATurn waste into treasureGood synergyFertilizer mixturesMoisture retentionNutrient

The invention discloses an environment-friendly lightweight nutrition matrix for soilless cultivation and a preparation method thereof, belonging to the field of planting in agriculture, forestry and horticulture. According to the technical scheme, the preparation method is technically characterized by comprising the following steps: taking sawdust, coco peat, reed residue, bagasse, corn cob grains, rice hull, peanut shell, traditional Chinese medicine residue, perlite and fly ash, proportioning, performing ultraviolet disinfection, and mixing in a material mixing machine; completely dissolving potassium dihydrogen phosphate and urea in wate, then mixing with base material; covering the mixed base material with a film in a fermentation tank; after covering with the film, adding the base material into the material mixing machine, adding fermenting bacteria and mixing; then placing the base material into the fermentation tank again, stacking and covering with the film for biological fermentation, wherein the base material obtained after the fermentation is completed is the nutrition matrix; and finally drying by a dryer. The raw materials used in the nutrition matrix disclosed by the invention are basically agricultural or industrial wastes, low in cost and easily available and can be really turned into treasure; furthermore, the nutrition matrix has the advantages of long fertilizer effect, sufficient nutrients, good moisture retention, good air permeability and short production period and is suitable for large-area popularization and utilization in production.

Owner:HUNAN ZHIXIN ENVIRONMENTAL PROTECTION TECH

Method for comprehensively utilizing fine coal gasification slag

ActiveCN107857496AHigh activityImprove adsorption capacityOther chemical processesSolid waste managementCycloneSlag

The invention discloses a method for preparing an adsorption material from fine coal gasification slag. The method comprises the following steps: 1, taking a proper amount of the fine coal gasification slag, and adding water to prepare a fine coal gasification slag slurry with the solid content being 10-30 wt%; 2, fully stirring the slurry prepared in step 1, performing gravity cyclone separation,collecting the obtained heavy separation product to obtain a silicon-rich composite slurry, and collecting the obtained light separation product to obtain a carbon-rich composite slurry; and 3, carrying out solid-liquid separation and drying on the carbon-rich composite slurry to obtain the carbon-rich adsorption material, and further preparing other products from the remaining silicon-rich composite slurry. The method realizes the high-added value recycling of the fine coal gasification slag.

Owner:鄂尔多斯市慧恒科技有限责任公司

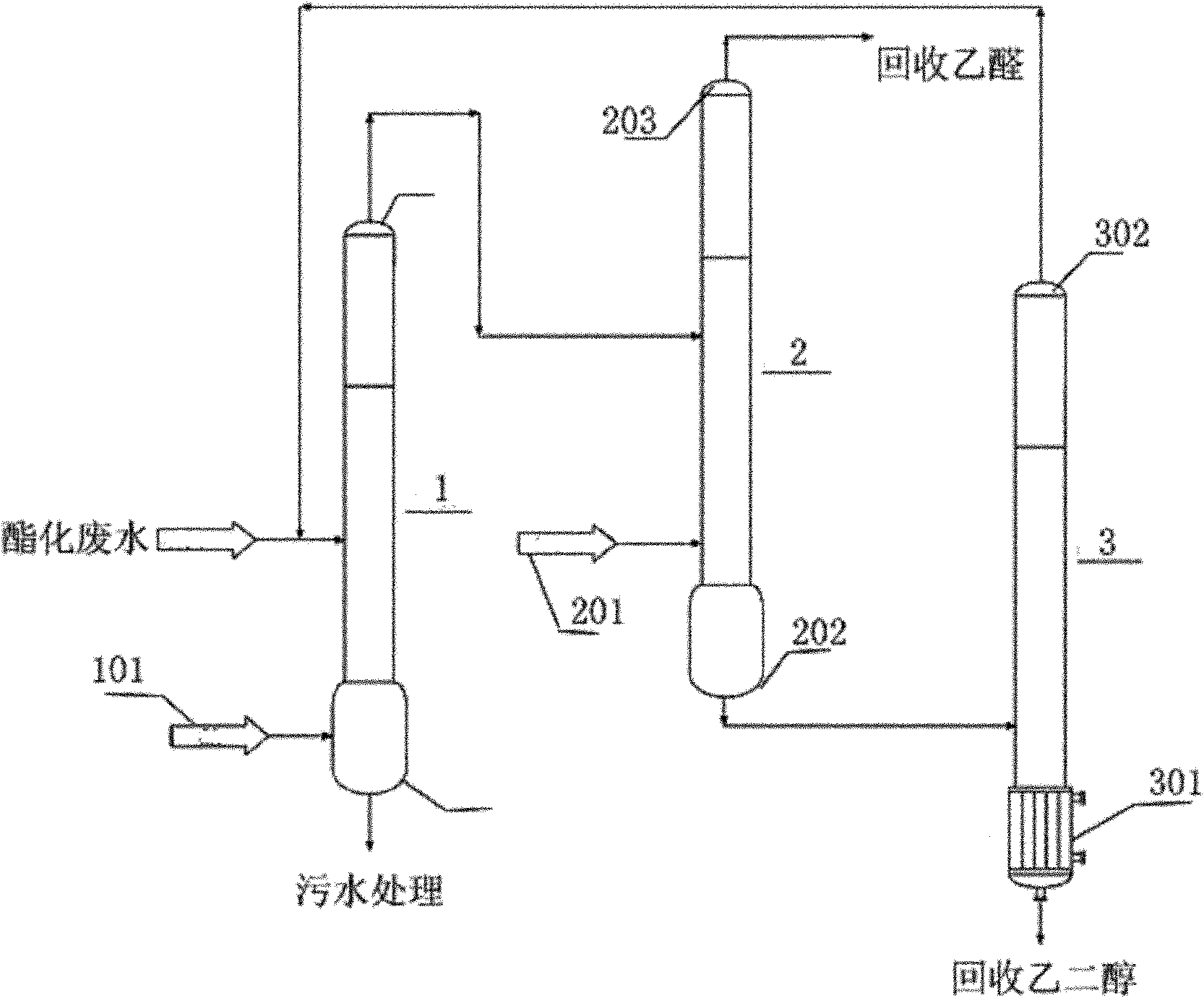

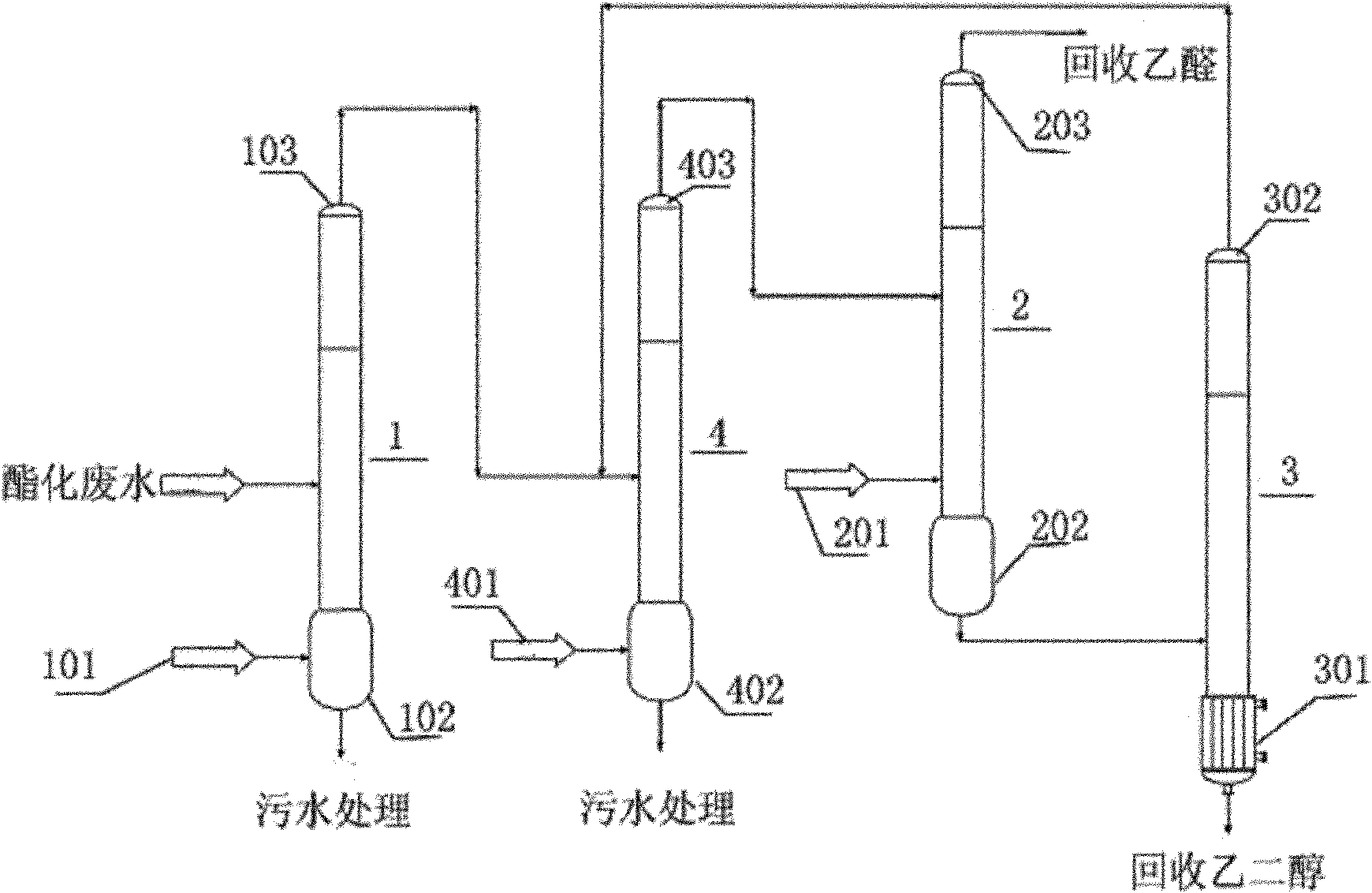

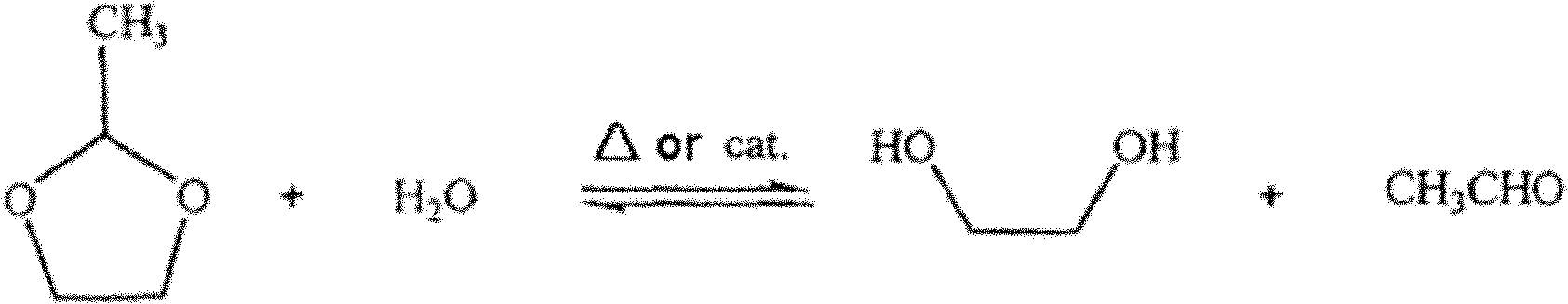

Method for recycling ethylene glycol and acetaldehyde from polyester waste water

ActiveCN102126926AReduce COD valueFix security issuesMultistage water/sewage treatmentWater/sewage treatment by degassingPolyesterDistillation

The invention discloses a method for recycling ethylene glycol and acetaldehyde from polyester waste water. The method is implemented by the following steps of: (1) introducing esterification waste water into a stripping tower for treating and directly introducing organic matter gas and water vapor collected from a tower top into an acetaldehyde rectifying tower; (2) treating in the acetaldehyde rectifying tower, collecting high-purity acetaldehyde from the tower top and introducing waste water collected from a tower bottom into an ethylene glycol distillation tower; and (3) treating in the ethylene glycol distillation tower, collecting a high-purity ethylene glycol solution from the tower bottom and introducing waste gas and water vapor produced on the tower top into the stripping tower for cyclic treatment. In the method, acetaldehyde and ethylene glycol are continuously collected, so that hydrolysis of byproduct of 2-methyl-1,3-dioxolane in the esterification waste water is continuously performed positively and negatively, acetaldehyde with the concentration of over 95 percent and ethylene glycol with the concentration of over 70 percent are obtained at the end of treatment, and the 2-methyl-1,3-dioxolane is fully hydrolyzed.

Owner:SHANGHAI JUYOU CHEM ENG +1

Nylon composite material and preparation method thereof

The invention discloses a nylon composite material and a preparation method thereof. The nylon composite material comprises the following components, by mass, 20-90% of nylon 66, 3-20% of high impact polystyrene, 5-50% of an inorganic filler, 0.1-3% of a chain extender, 0.1-1% of an antioxidant, 0.1-1% of a coupling agent, 0.2-3% of a lubricant, and 0.5-3% of functional assistants. The recycled nylon 66 which is adopted as a main raw material allows a case of changing wastes into valuables and the resource recycle to be realized; the high impact polystyrene which is used as a compatilizer allows the comprehensive performance and the impact toughness of the material to be improved, and balanced physical and mechanical properties to be obtained; and the adopted chain extender allows the molecular weight and the relative viscosity of nylon to be effectively improved, and an abuse of the decrease of the physical and mechanical properties caused by the molecular chain rupture in the nylon regeneration process to be effectively prevented. The preparation method which is a one-step method has the advantages of simple production technology and low processing cost.

Owner:洪伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com