Patents

Literature

44 results about "Electronic waste recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer recycling, electronic recycling or e-waste recycling is the disassembly and separation of components and raw materials of waste electronics. Although the procedures of re-use, donation and repair are not strictly recycling, there are other common sustainable ways to dispose of IT waste.

Method for preparing battery-grade lithium carbonate and iron phosphate by recycling lithium iron phosphate anode waste

ActiveCN112142077AImprove qualityImprove product qualityCell electrodesWaste accumulators reclaimingO-Phosphoric AcidPhosphate

The invention relates to a method for preparing battery-grade lithium carbonate and iron phosphate by recycling lithium iron phosphate cathode waste, and belongs to the fields of electronic waste recycling and resourcing. According to the method, air is adopted as an oxidizing agent to oxidize lithium iron phosphate into iron phosphate, so that lithium is removed and enters a solution, and leaching of other impurity elements is little. A lithium solution is neutralized and precipitated to remove impurities, and saturated sodium carbonate is added to obtain a lithium carbonate product; and water leaching residues are mixed with iron powder and a small amount of phosphoric acid, ball-milling is implemented for activation reduction, a solid product obtained after activation is stirred and dissolved out by using a phosphoric acid solution, and an iron and phosphorus solution is obtained by filtering. The characteristic that ferric phosphate is low in solubility at high temperature is utilized, ferric phosphate sediment is obtained through a high-temperature evaporative crystallization method, and the ferric phosphate for the battery is obtained after aging, washing and calcining. The method has the advantages of cheap reagent, low acid consumption, high valuable element recovery rate, environmental friendliness and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

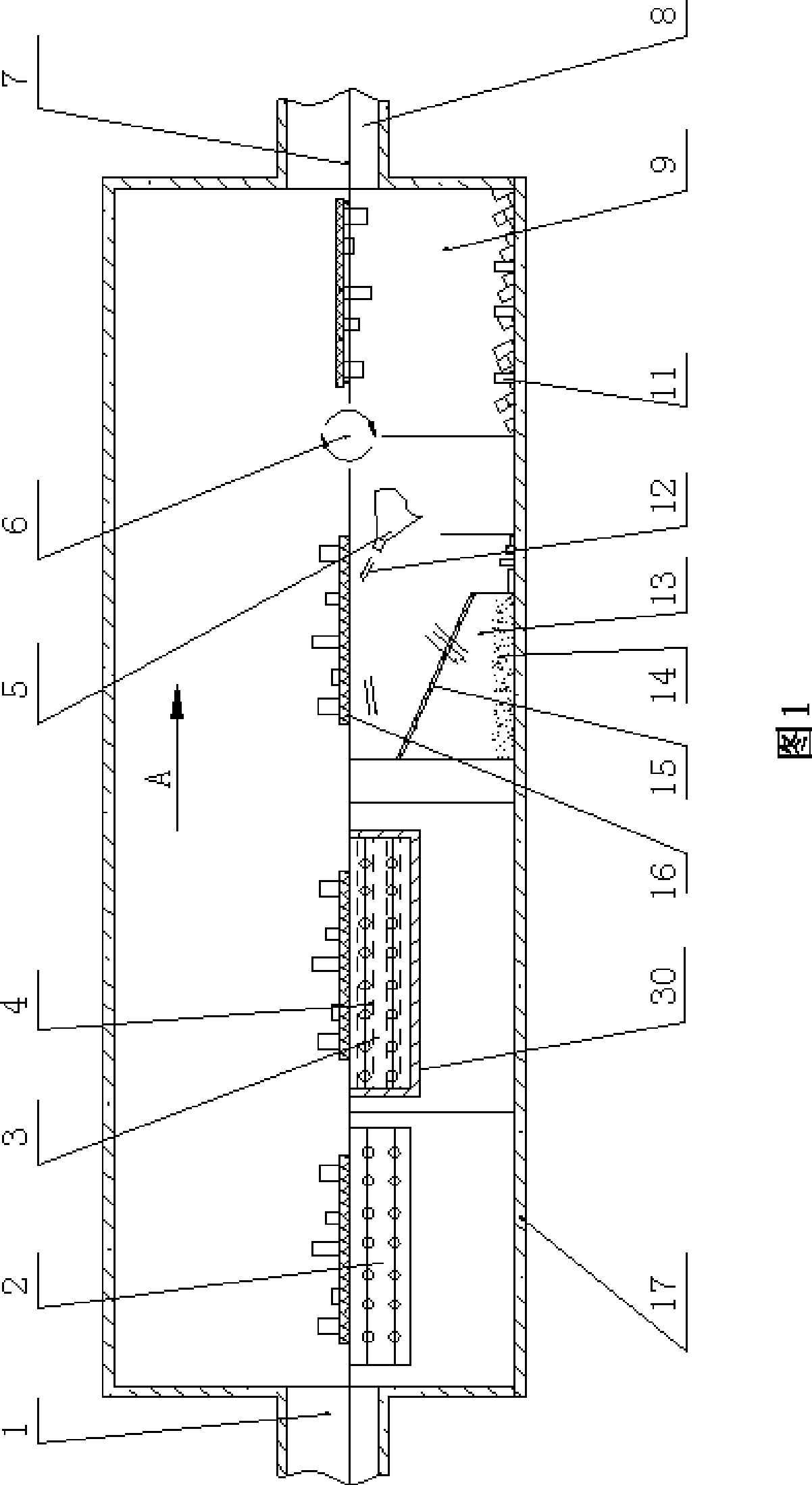

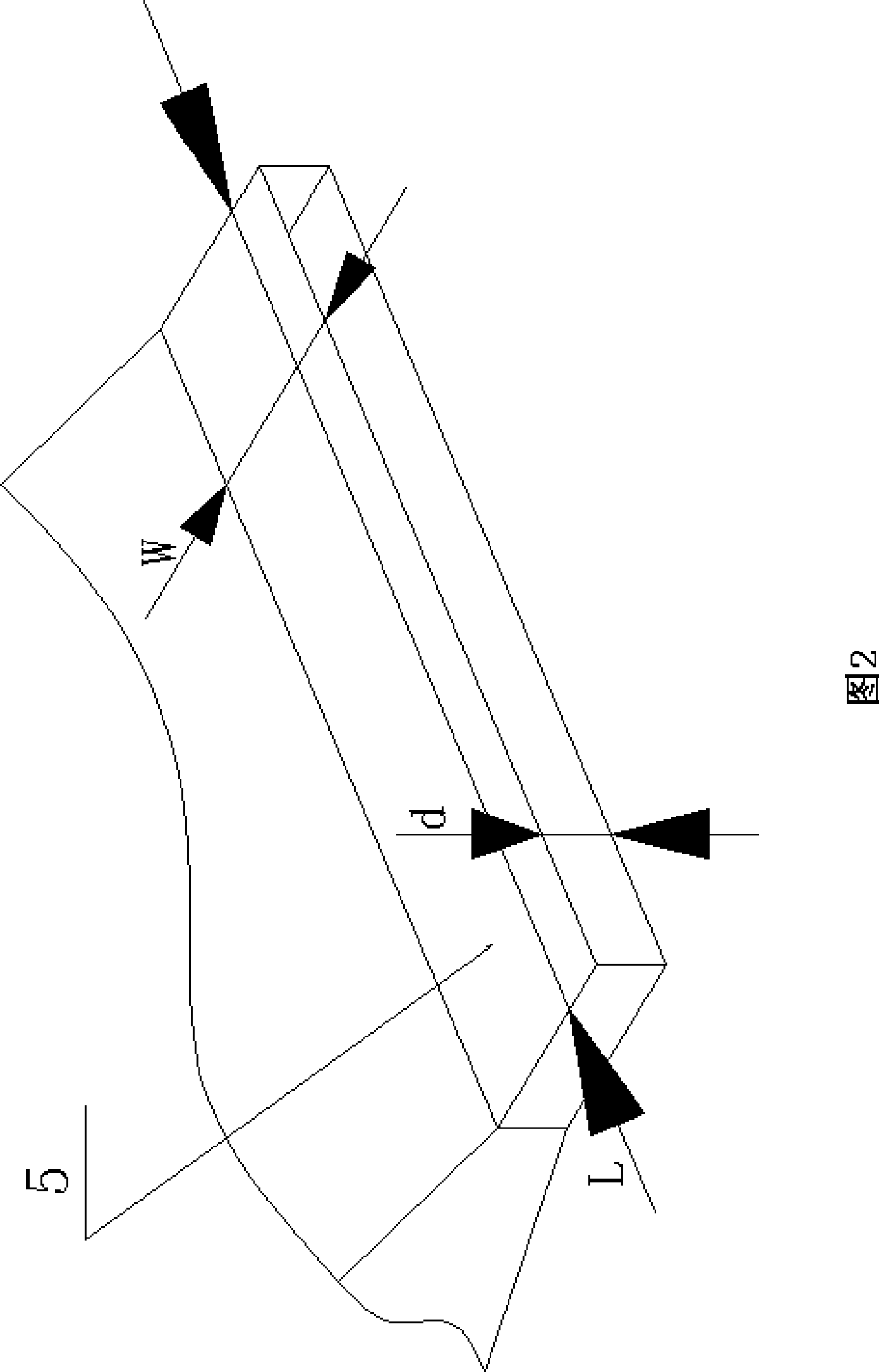

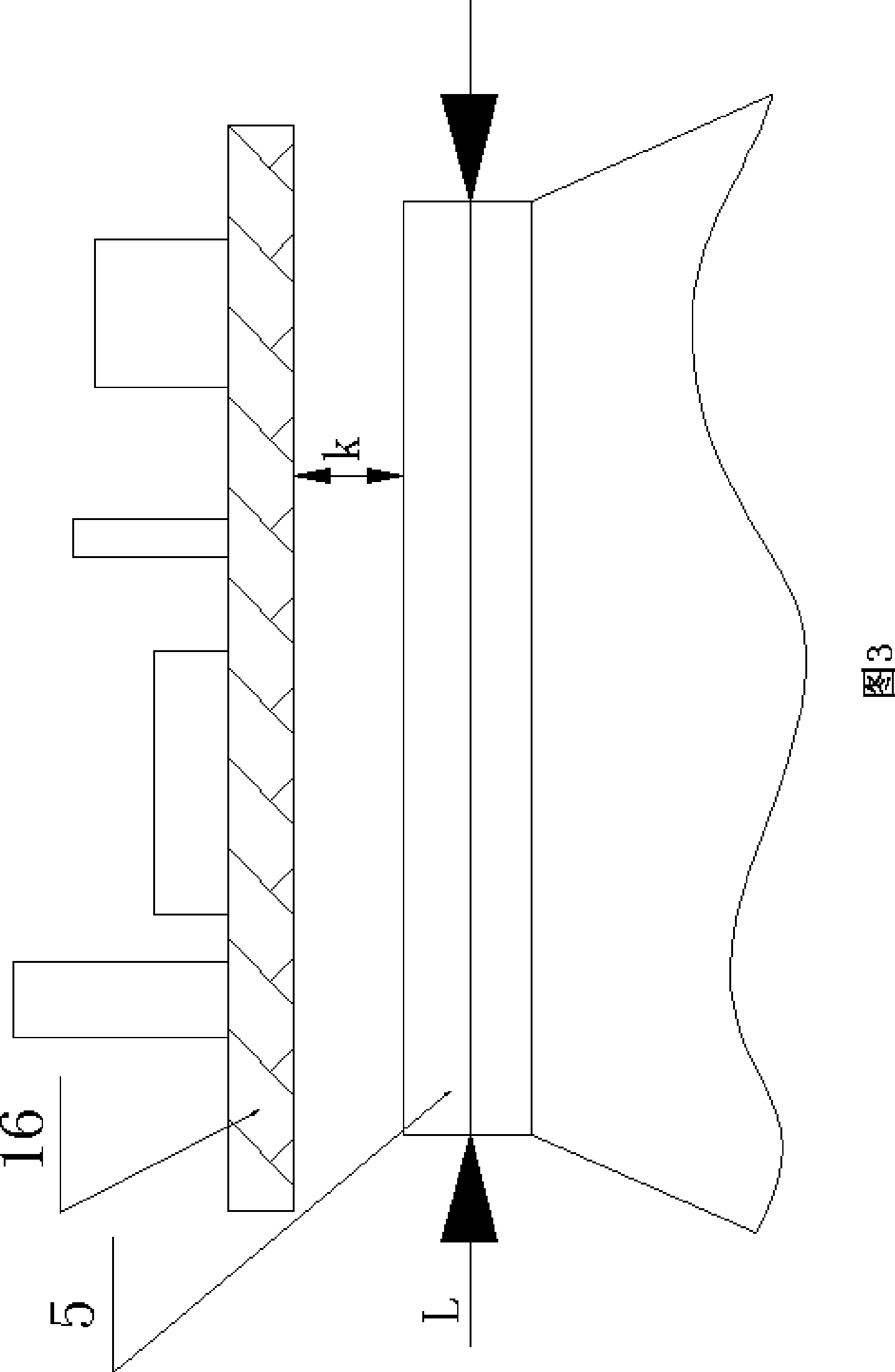

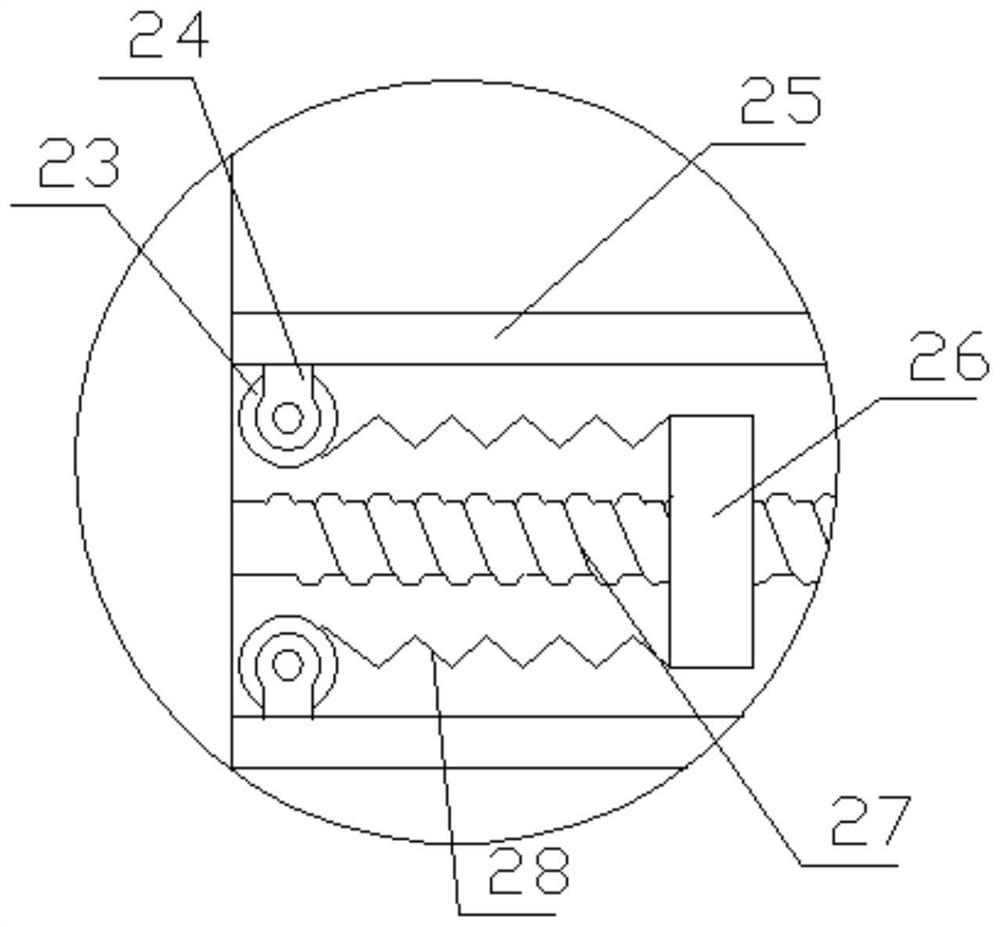

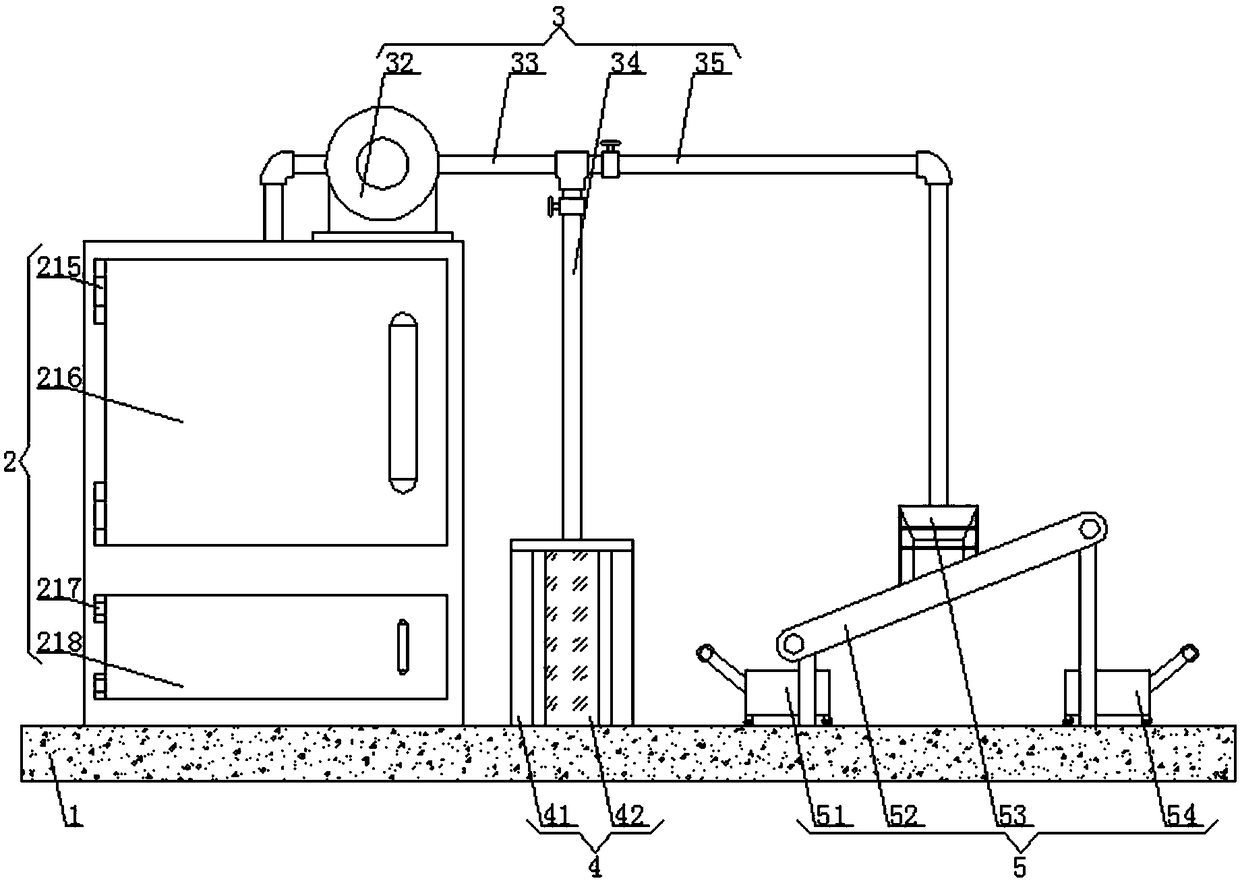

Circuit board element dismounting device

InactiveCN101417358AHigh demolition rateEasy to separateHeating appliancesSoldering auxillary devicesProduct gasHigh pressure

The invention relates to an electronic waste recycling technology, in particular to equipment which disassembles components and separates soldering flux from a circuit board. The invention discloses disassembling equipment for circuit board components. The technical proposal adopted by the invention is that the disassembling equipment for the circuit board components comprises desoldering equipment consisting of a slit nozzle used for injecting high-temperature and high-pressure gas to the circuit board so as to lead the soldering flux to be separated from the circuit board; and the disassembling equipment is characterized in that the slit width of the slit nozzle is more than 0.8mm and less than or equal to 2mm. The disassembling equipment is used for disassembling waste circuit boards, can reduce the energy consumption and improve the efficiency.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Method for efficient separation and recycling of precious metals in waste circuit board

ActiveCN104328281AAlleviate shortagesEasy to separateProcess efficiency improvementEcological environmentHigh pressure

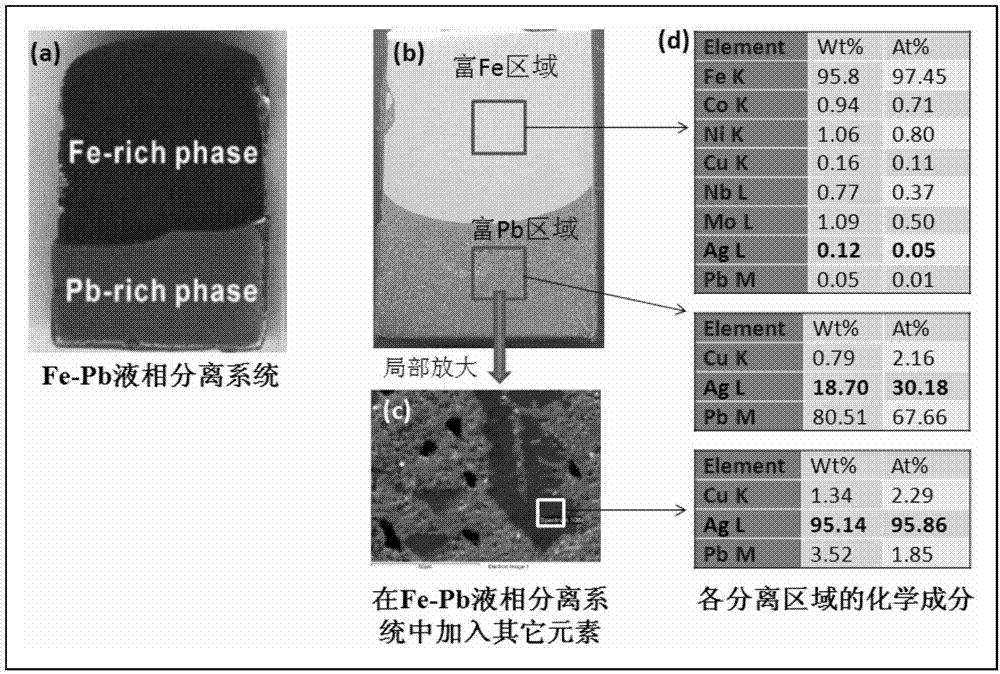

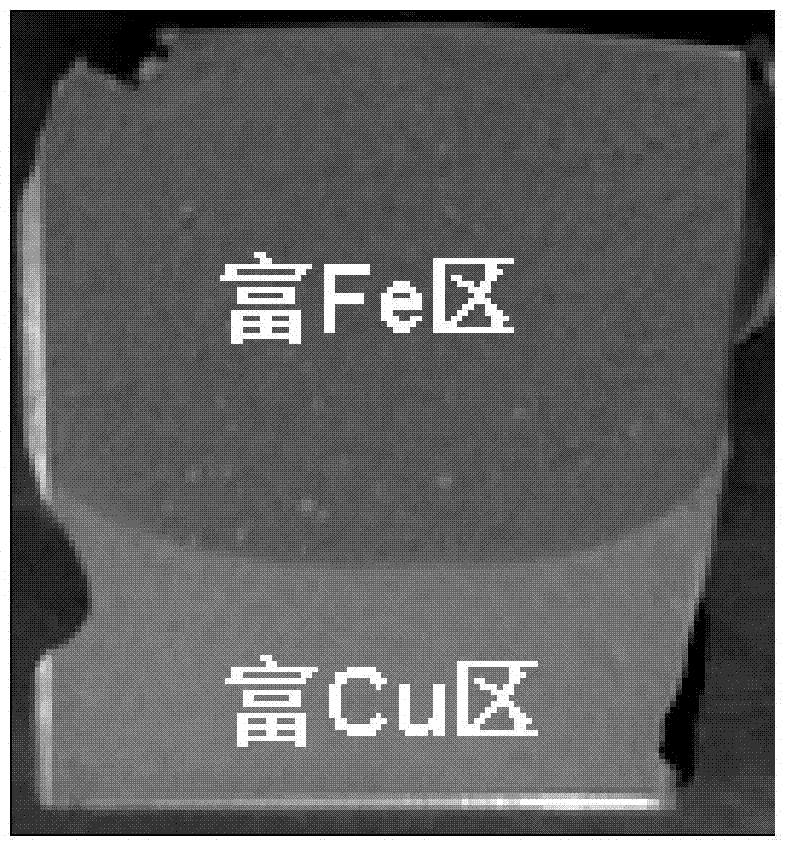

The invention belongs to the metal resources recycling technology, in particular relates to a method for efficient separation and recycling of precious metals in a waste circuit board, and achieves economic and environmental benefit win-win situation and other issues in electronic waste recycling. First of all, the waste circuit board is crushed into particles by mechanical processing technology, the particles are separated into metal and non-metal materials under high voltage electrostatic effect, then a Fe-Cu high temperature liquid phase separation system and a Cu-Pb relatively-low temperature liquid phase separation system are successively built; base metals and nonferrous metals are efficiently separated by use of rule of selective distribution of metal material components in the waste circuit board in a liquid phase separation system, almost all precious metals are enriched into a Cu-rich phase; by combination of hydrometallurgical technology, the precious metals are separated and extracted from a small amount of Cu-rich material enriched with the precious metals, the use amount of chemical reagents in metal multi-component separation and recovery process can be significantly reduced, and the harm of electronic waste on the ecological environment can be reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

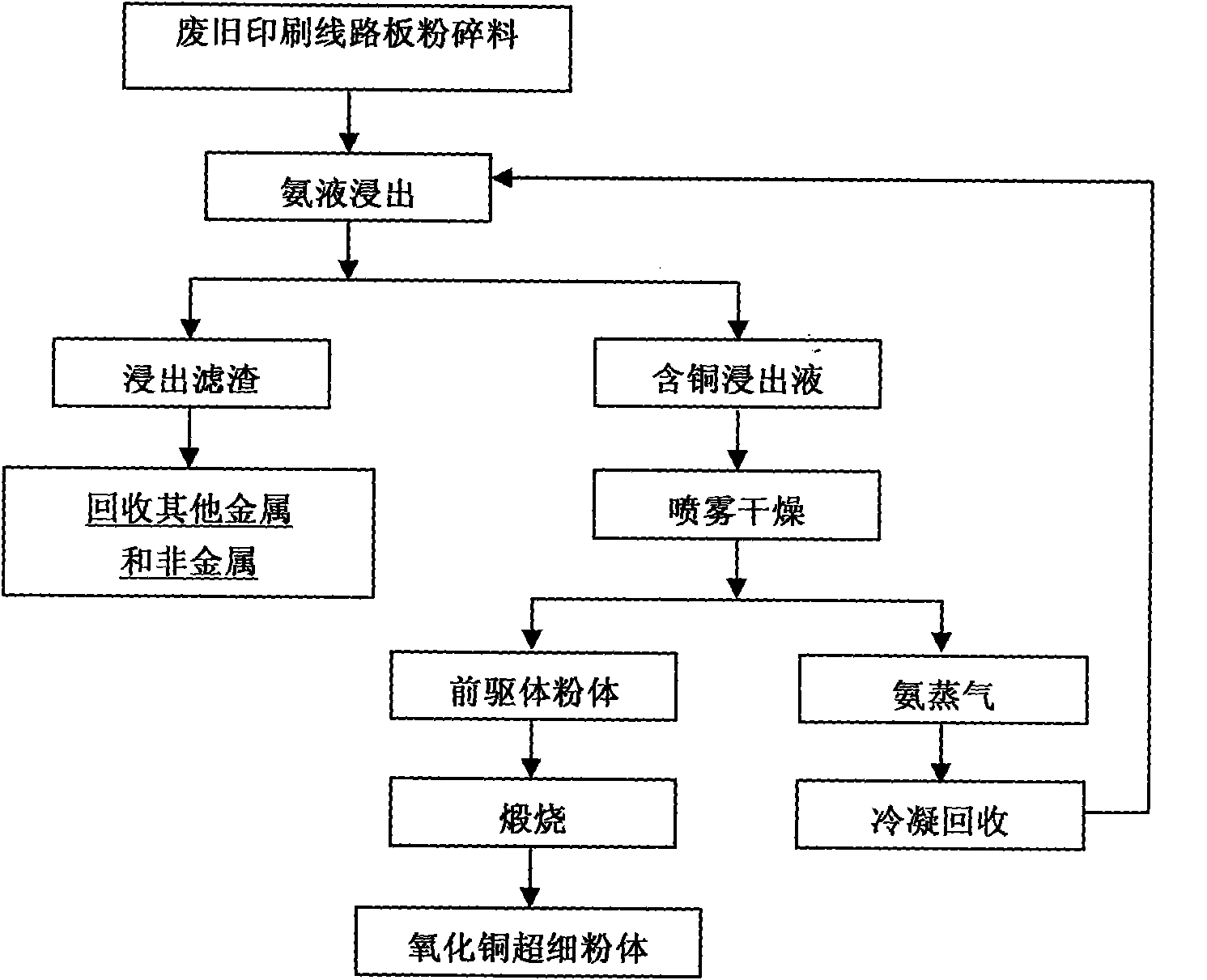

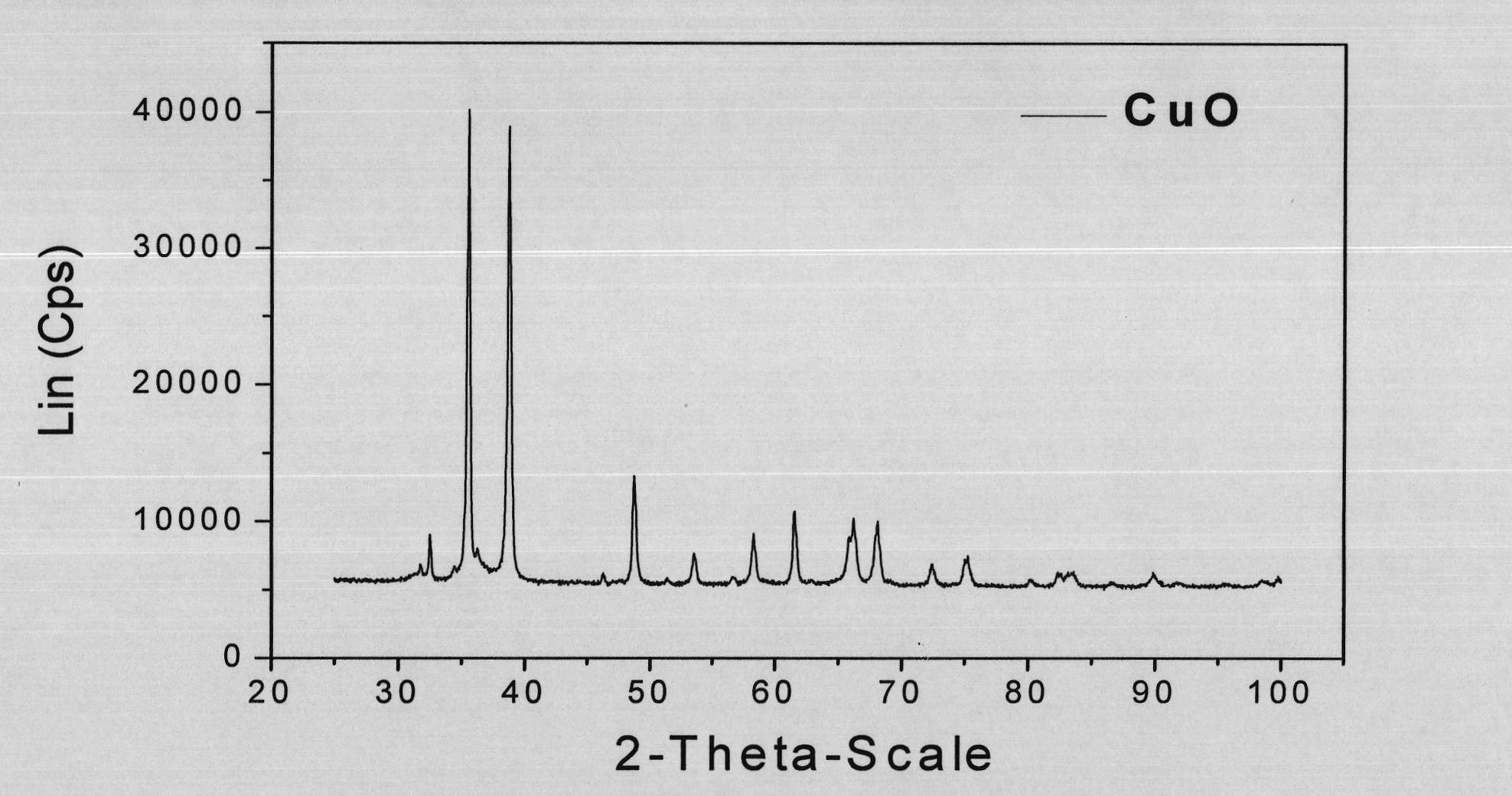

Method for preparing high-purity copper oxide superfine powder from waste printed circuit boards

InactiveCN102011008AWon't happenHigh purityCopper oxides/halidesProcess efficiency improvementStrong acidsHydrometallurgy

The invention belongs to the technical field of electronic waste recycling, and relates to a method for preparing high-purity copper oxide superfine powder from waste printed circuit boards. The method is mainly characterized in that: mechanical pretreatment-wet-process metallurgy-spray drying joint treatment technology is adopted, and comprises the following main steps of: performing mechanical crushing treatment on the waste printed circuit boards, selectively leaching metal copper from the waste printed circuit board crushed material by using ammonia water and hydrogen peroxide, and filtering to obtain copper-containing leachate; putting the copper-containing leachate into a reaction container of a spray drier, and preparing precursor powder by adopting a spray drying method; and calcining the precursor powder into a muffle furnace to obtain the high-purity copper oxide superfine powder. In the method, the ammonia water is adopted to replace strong acid or strong base solution to selectively leach the metal copper from the waste printed circuit board crushed material, so that the high purity of the copper oxide superfine powder is ensured; and the method is simple in process without pollution; and the aim of recycling electronic wastes can be fulfilled.

Owner:BEIJING UNIV OF TECH

Method for degrading polybrominated diphenyl ethers using surface active agent solubilization combined with UV technique

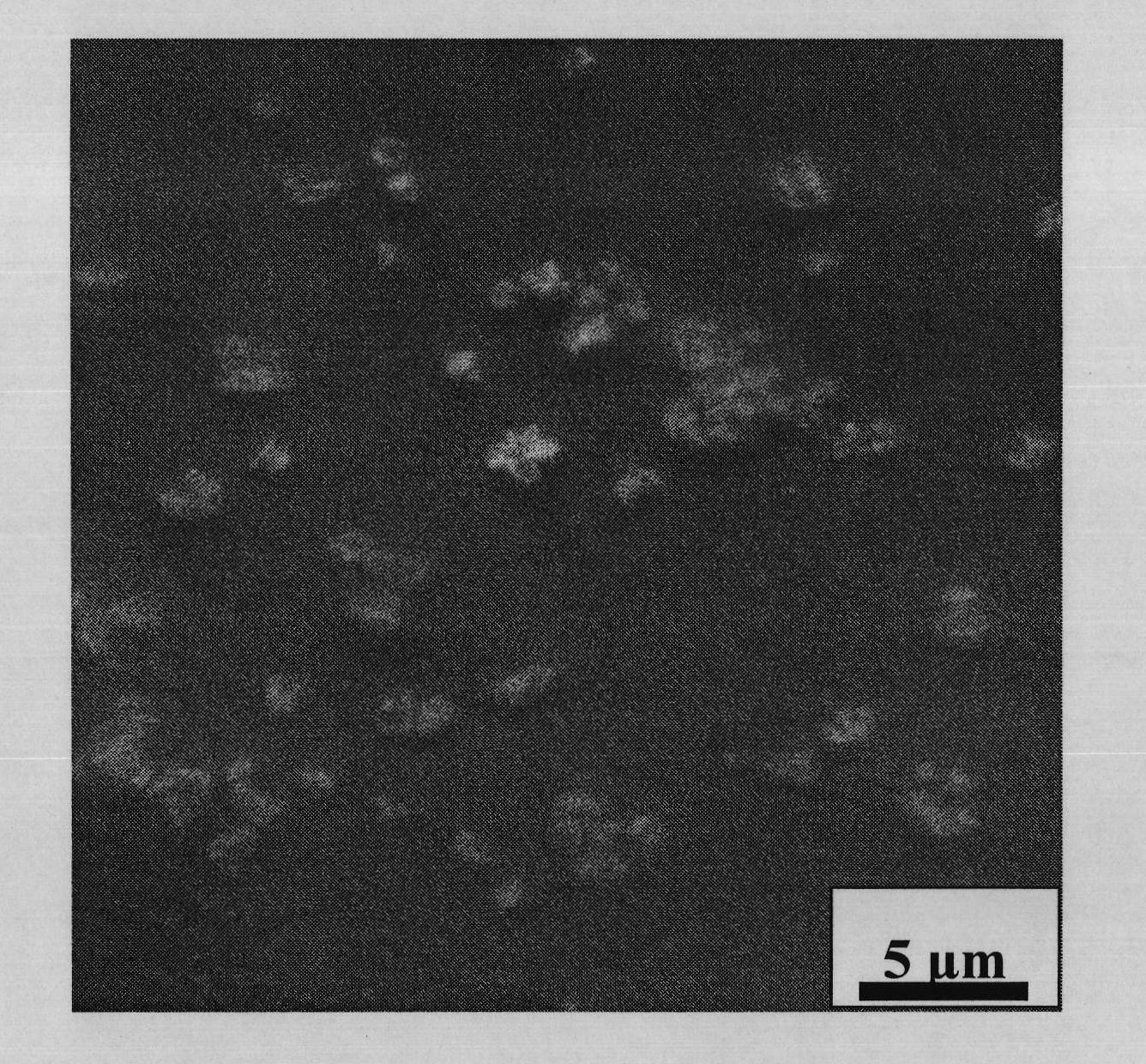

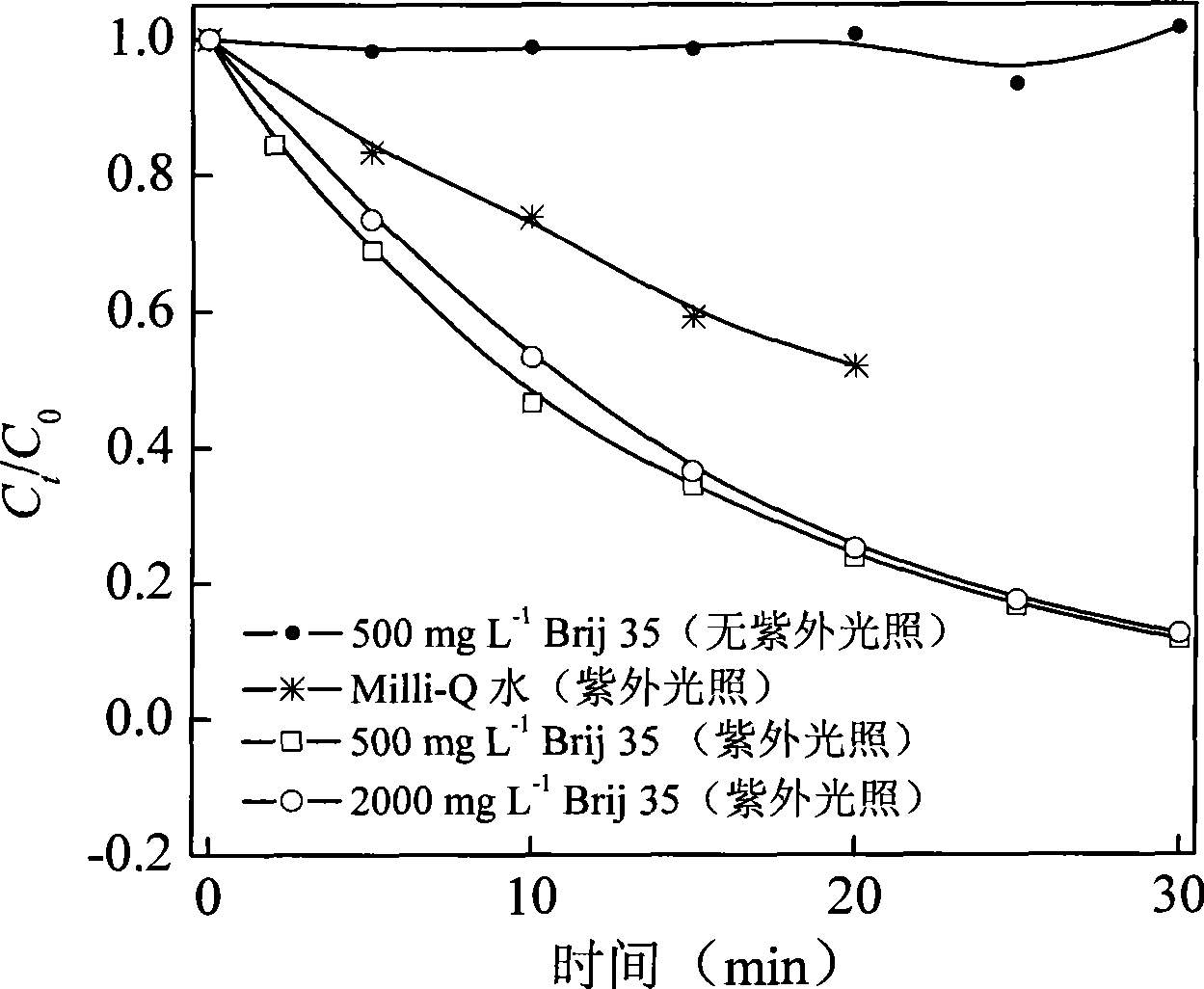

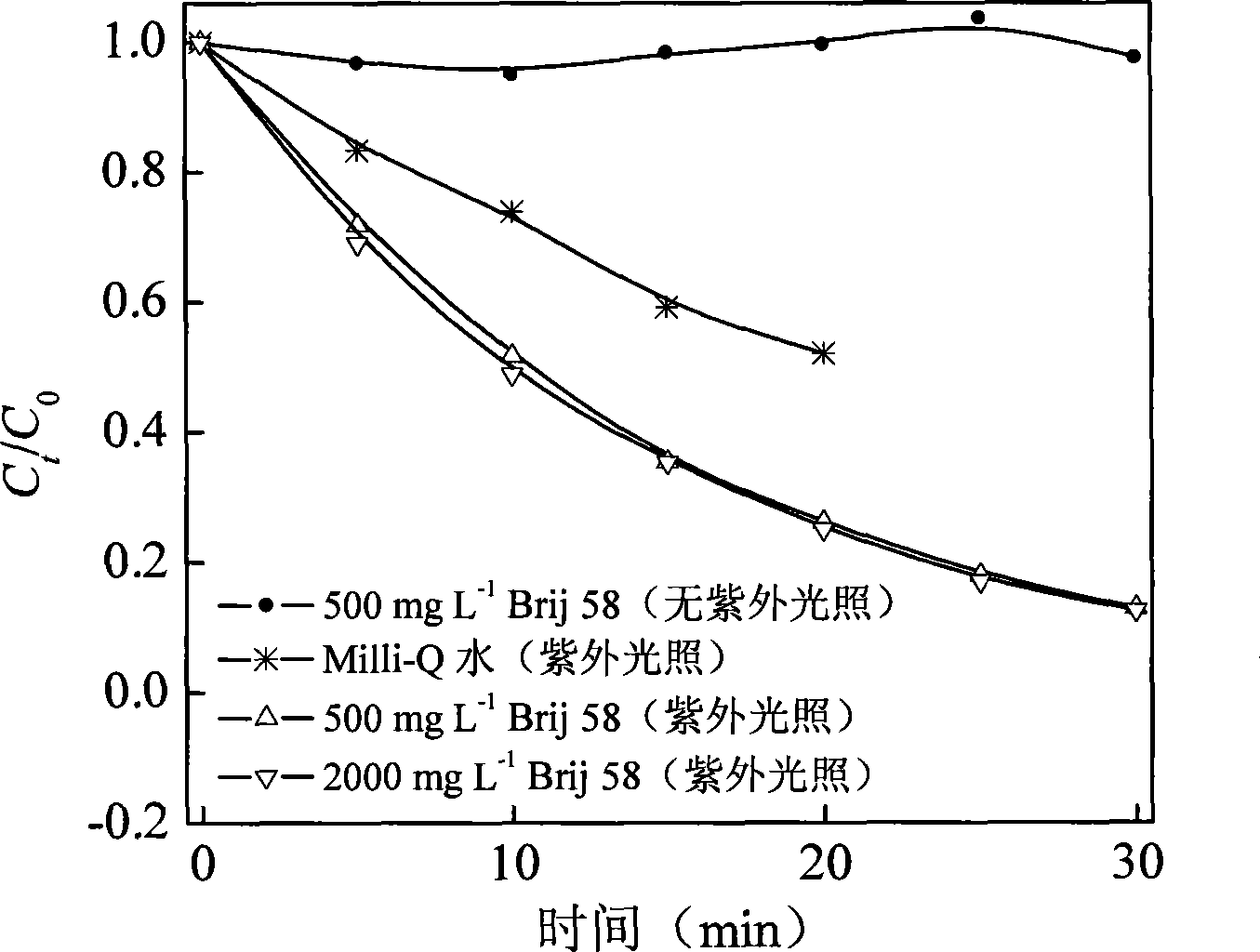

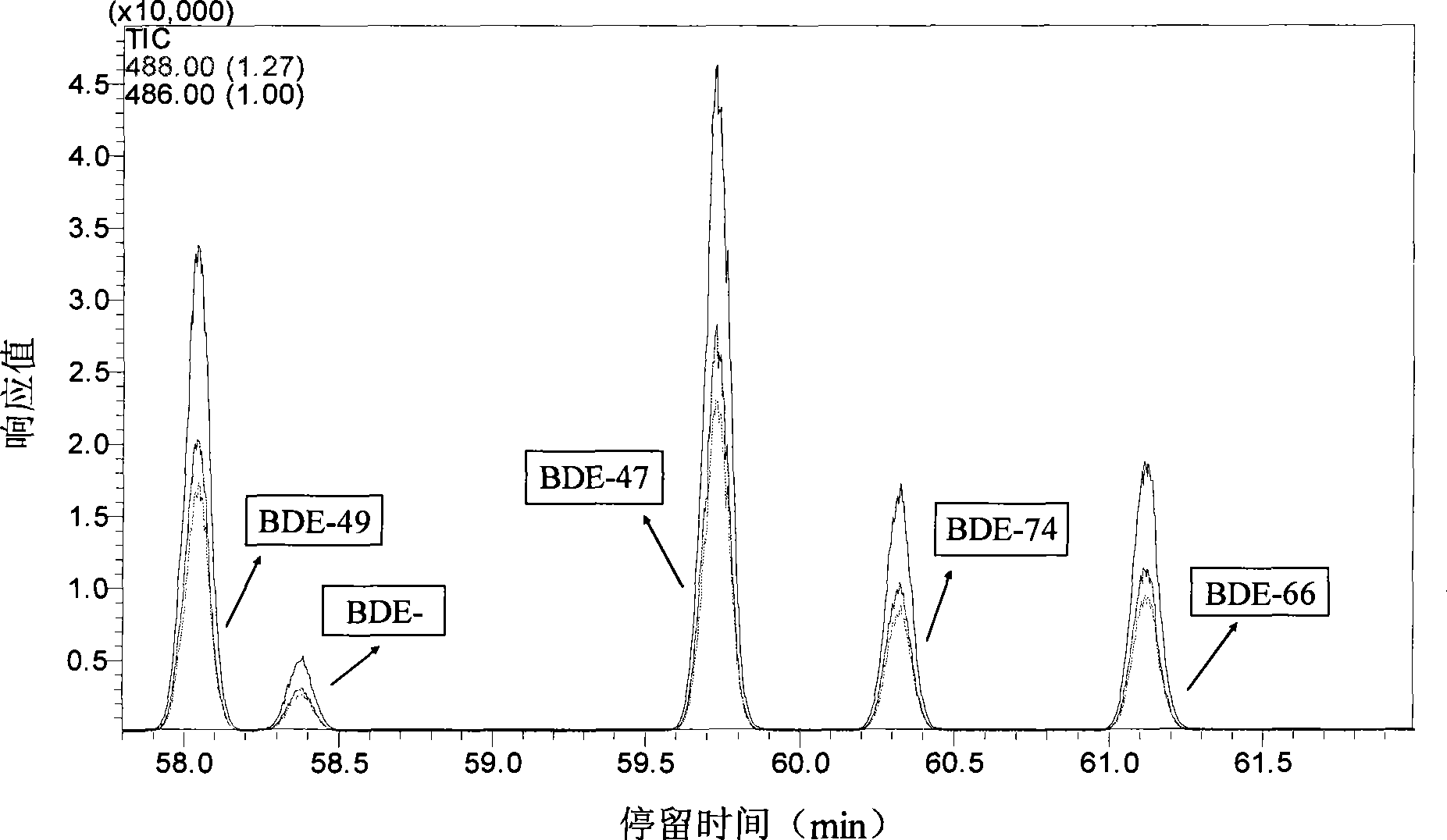

InactiveCN101461989AShort reaction timeImprove efficiencyChemical protectionWater bathsSelective degradation

The invention discloses a method for degrading polybrominated diphenyl ether by combining surfactant solubilization and UV technology, which belongs to the technical field of environment-friendly halogenated aryl hydrocarbon organic pollutant treatment. The method adopts the technical proposal that surfactant solubilization of 2,2',4,4',5-pentabromated diphenyl ether is improved in a hydrophobic environment provided by nonionic surfactant micelle (Brij 35 or Brij 38) under the conditions of normal temperature and pressure, water bath and ultrasonic sound; and the 2,2',4,4',5-pentabromated diphenyl ether which is dissolved in a surfactant solution is subjected to UV advanced treatment at normal temperature and pressure and then subjected to stepwise debromination reaction or intermolecular elimination and annulation reaction to generate intermediate products, namely PBDEs from monobromo to tetrabromo and polybrominated dibenzofuran (PBDFs) from monobromo to tetrabromo. The whole technology has short time consumption and high efficiency, and the method can selectively degrade target pollutant without damaging a surfactant, provides convenience for recycling of the surfactant, and has good application prospect in the aspect of remediation of soil polluted by the PBDEs in electronic waste recycling sites.

Owner:TSINGHUA UNIV

Method of recycling valuable elements from waste lithium ion battery

PendingCN110311186ASimple recycling processWide applicabilityCarbon compoundsWaste accumulators reclaimingResource utilizationElectrical battery

The invention relates to the technical field of electronic waste recycling treatment and resource utilization, and particularly relates to a method of recycling valuable elements from a waste lithiumion battery. The method performs discharge dismantling on the battery in advance and recycles a positive electrode piece and a negative electrode piece. The positive electrode piece recycling processcomprises steps of crushing, reacting, separating, recycling and the like. The negative electrode piece recycling process comprises steps of heat treatment, vibration, and the like. The positive electrode material and the negative electrode material of the waste lithium ion battery can be realized, the material has wide applicability, reduction of transition metal elements and conversion of lithium are simultaneously completed without additional addition of a reducing agent, subsequent separation and recycling are facilitated, the separation process of a positive active material and a currentcollector is also avoided, and the valuable element recycling process is greatly simplified.

Owner:TSINGHUA UNIV

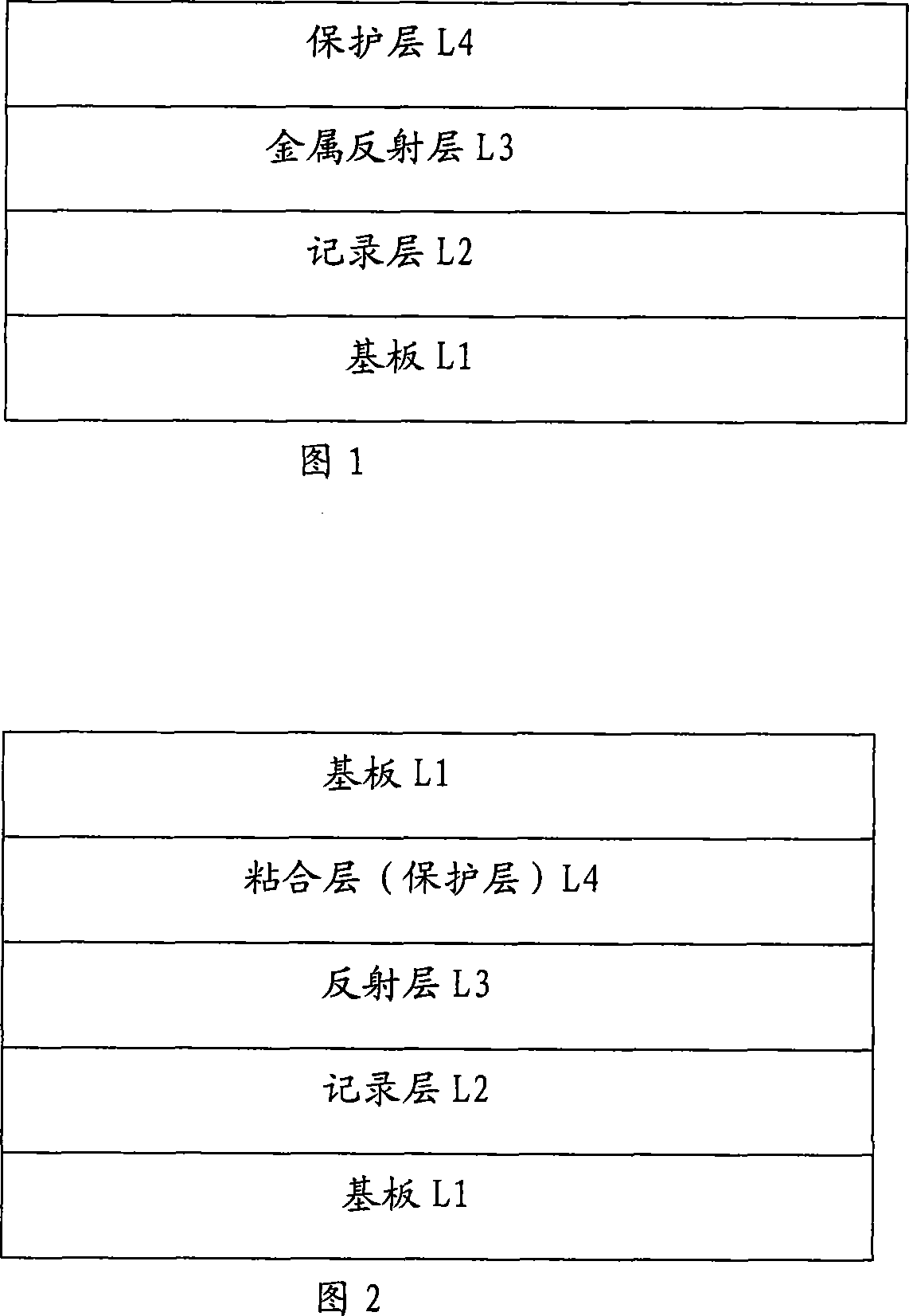

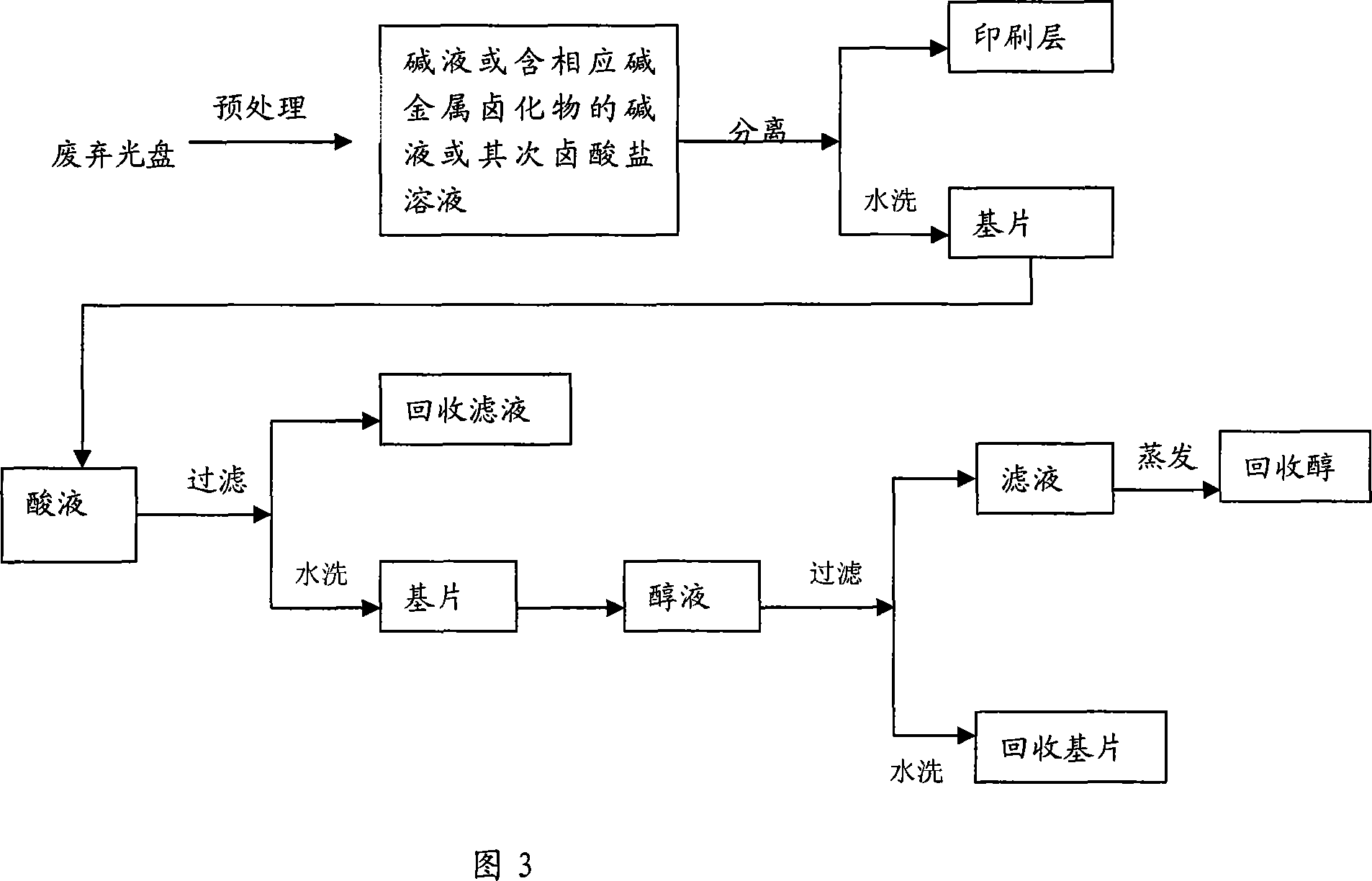

Method for reclaiming optical disk substrate from abandon optical disk

InactiveCN101157257AProcess environmental protectionCraft economyRecord carriersSolid waste disposalSaline waterHalogen

A method of recycling a compact disk substrate from waste discs pertains to the field of the electronic waste recycling technology. The invention has the following techniques: stripping treatment: the disc is put in alkali solution, alkaline salt solution, alkali solution including corresponding halide, or hypo-halogen acid salt solution one by one to isolate a printing layer and an aluminum layer from the CD. After being washed, other metals of the CD can be further separated by pouring acid liquor, and the CD is washed again and then put into the ethanol solution to strip the dye layer; separation and recovery: The CD substrate is taken out of the ethanol solution, and is washed in water to recycle plastic substrate. In the end, the ethanol is evaporated and recovered. The method has the advantages of realizing the recycle and the utilization of resources while reducing the environmental pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

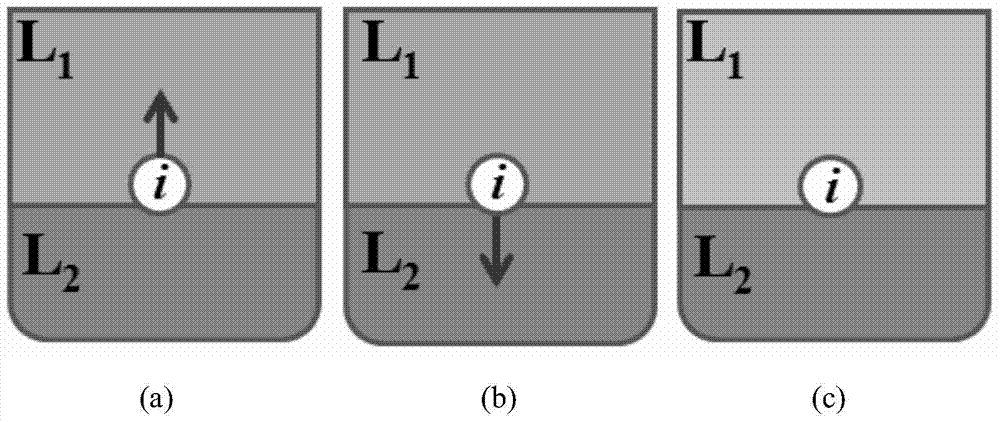

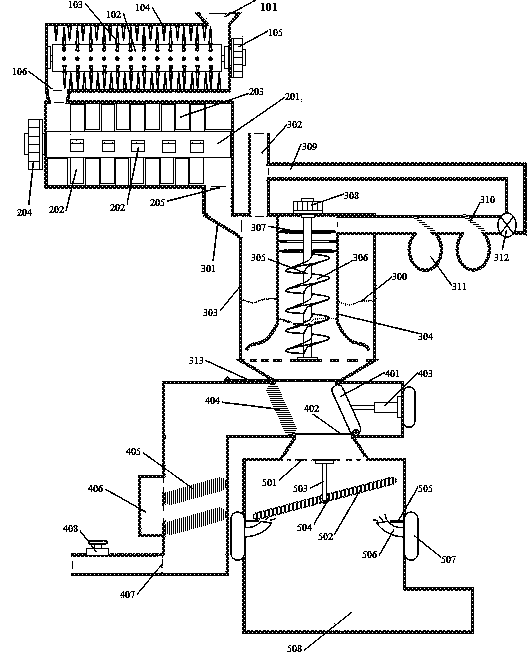

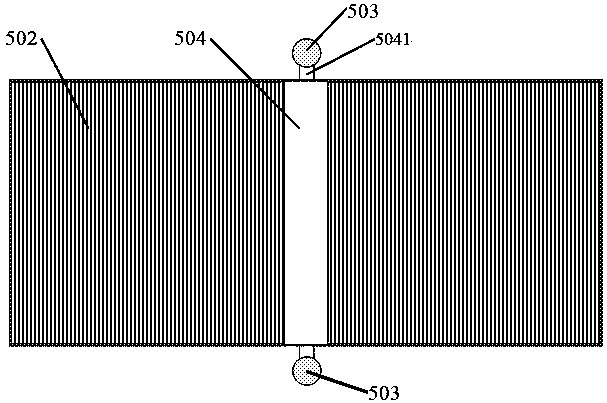

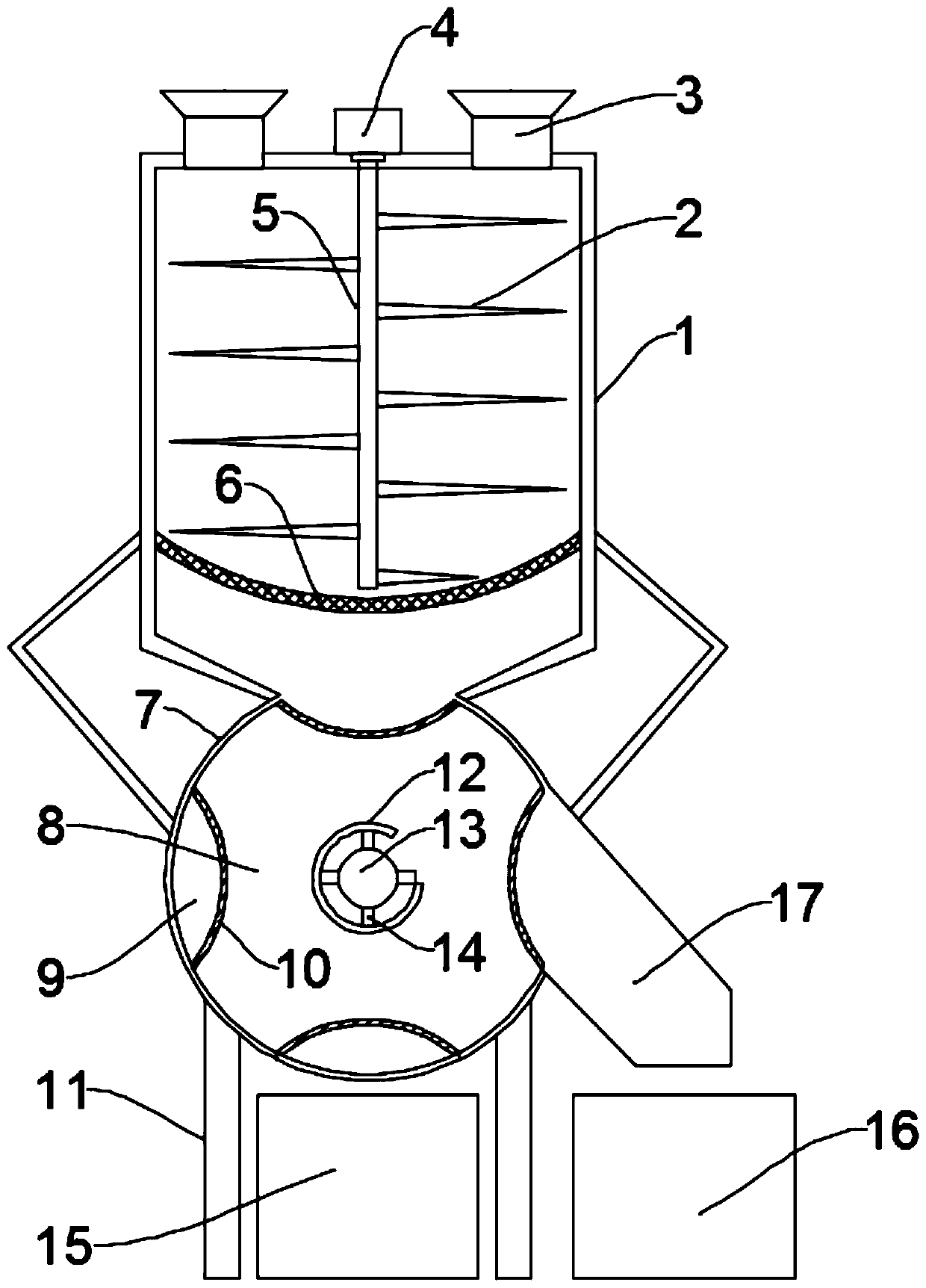

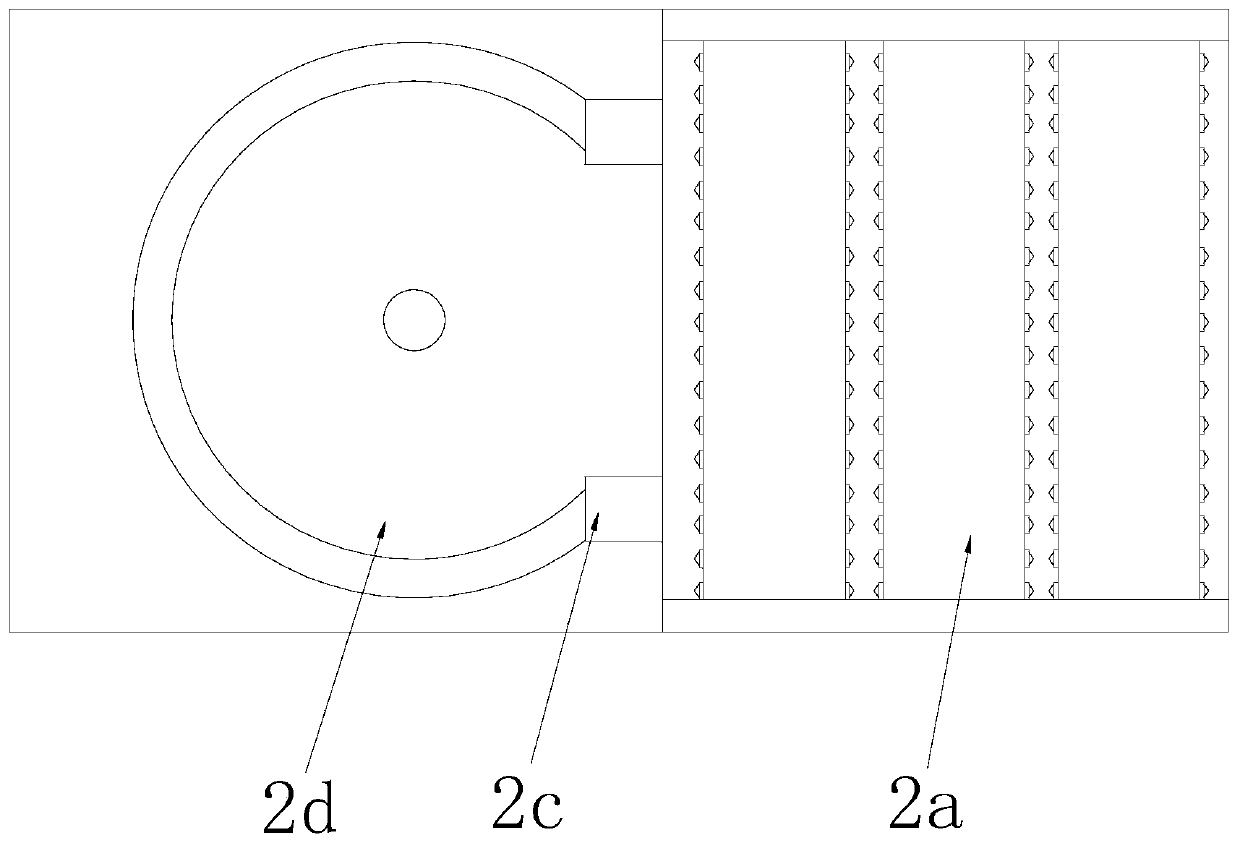

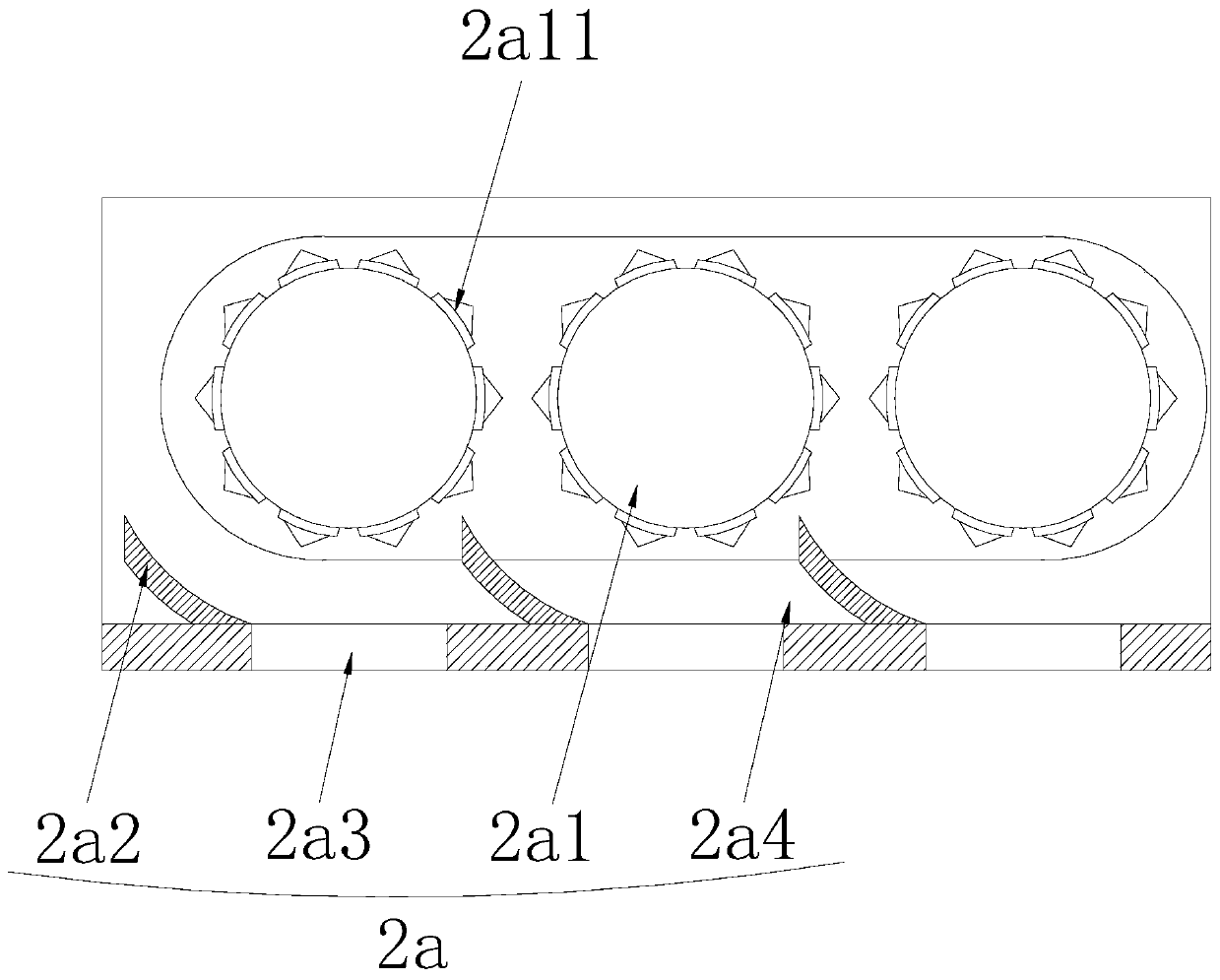

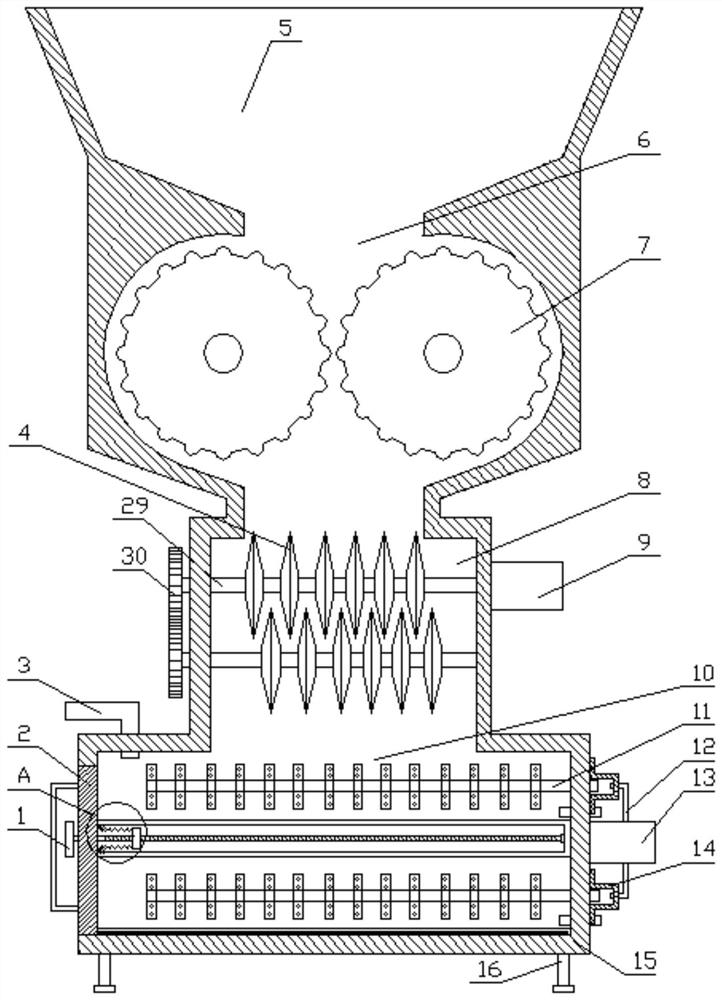

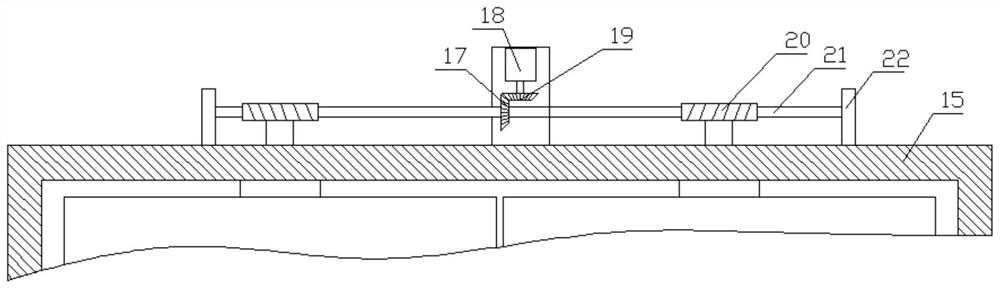

Electronic waste recycling treatment device and treatment method

InactiveCN111299304AEasy to separateBlow offTransportation and packagingSolid waste disposalSpiral bladeEnvironmental engineering

The invention relates to an electronic waste recycling treatment device and a treatment method using the device to recycle electronic waste. The device comprises a primary crushing cavity, a fine crushing cavity, a density separating device, an extruding water-removing part and a drying room. The density separating device is arranged, and a single spiral blade can rotate, so that water and crushedmaterials are integrally lifted and then are released, and therefore, materials with density much greater than that of water are separated from materials with density close to that of water or smaller than that of water, and solid-solution separation is realized through an extrusion and filtration way; and a drying plate with a special structure is arranged, so that the solid materials are storedafter being dried, and therefore, relative fine recycling efficiency of electronic waste is greatly improved.

Owner:高琦彬

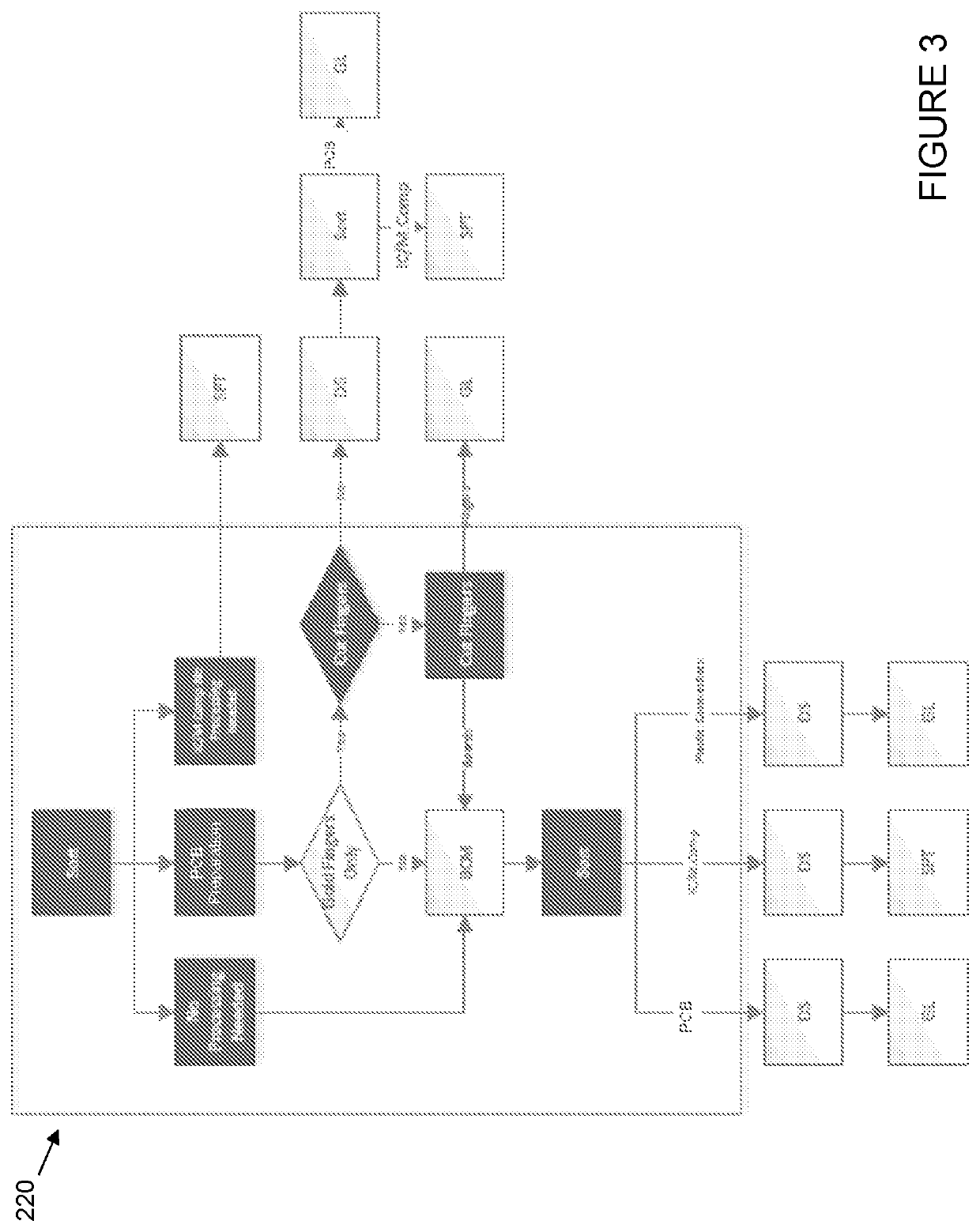

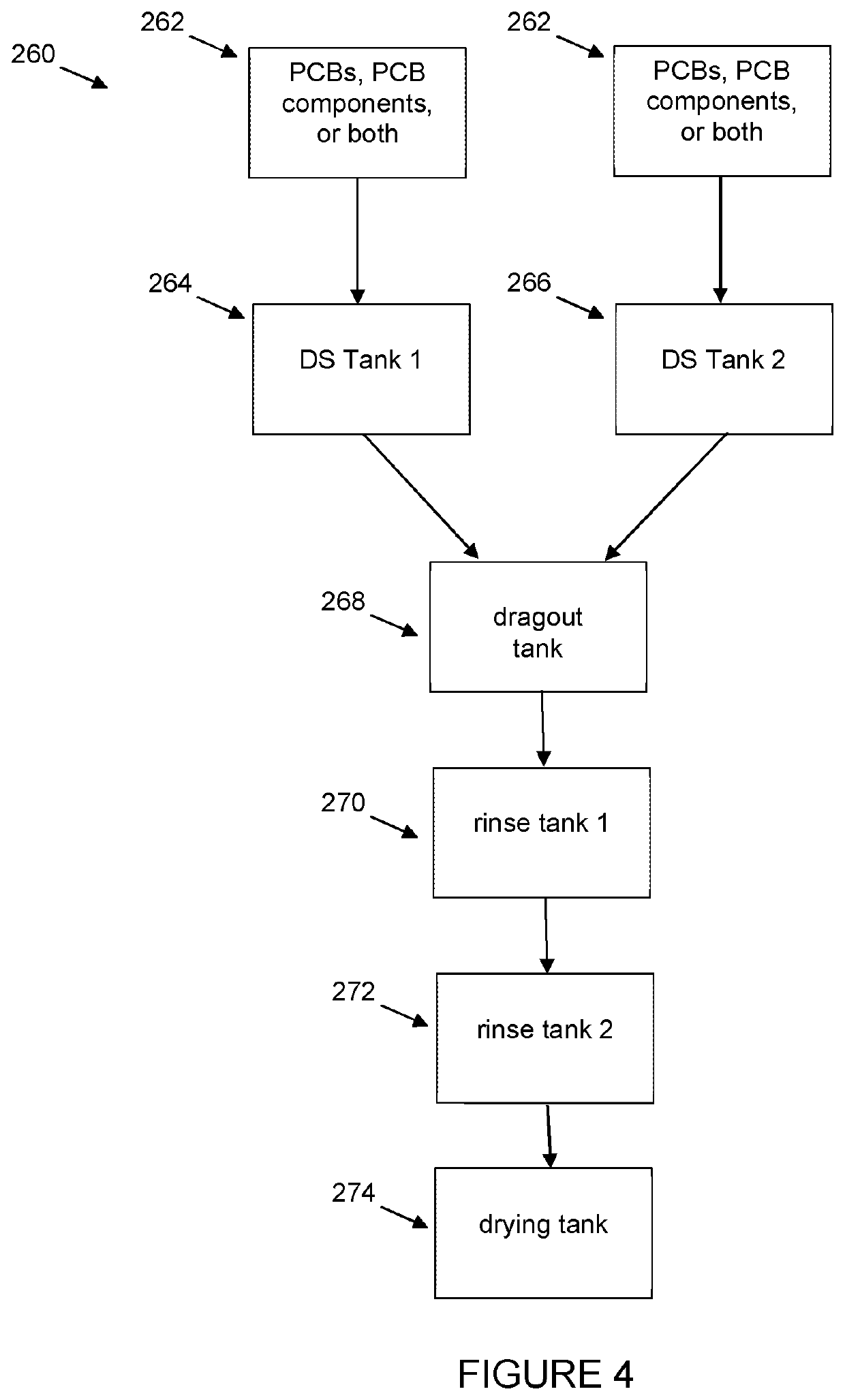

Integrated electronic waste recycling and recovery system and process of using same

Owner:ENTEGRIS INC

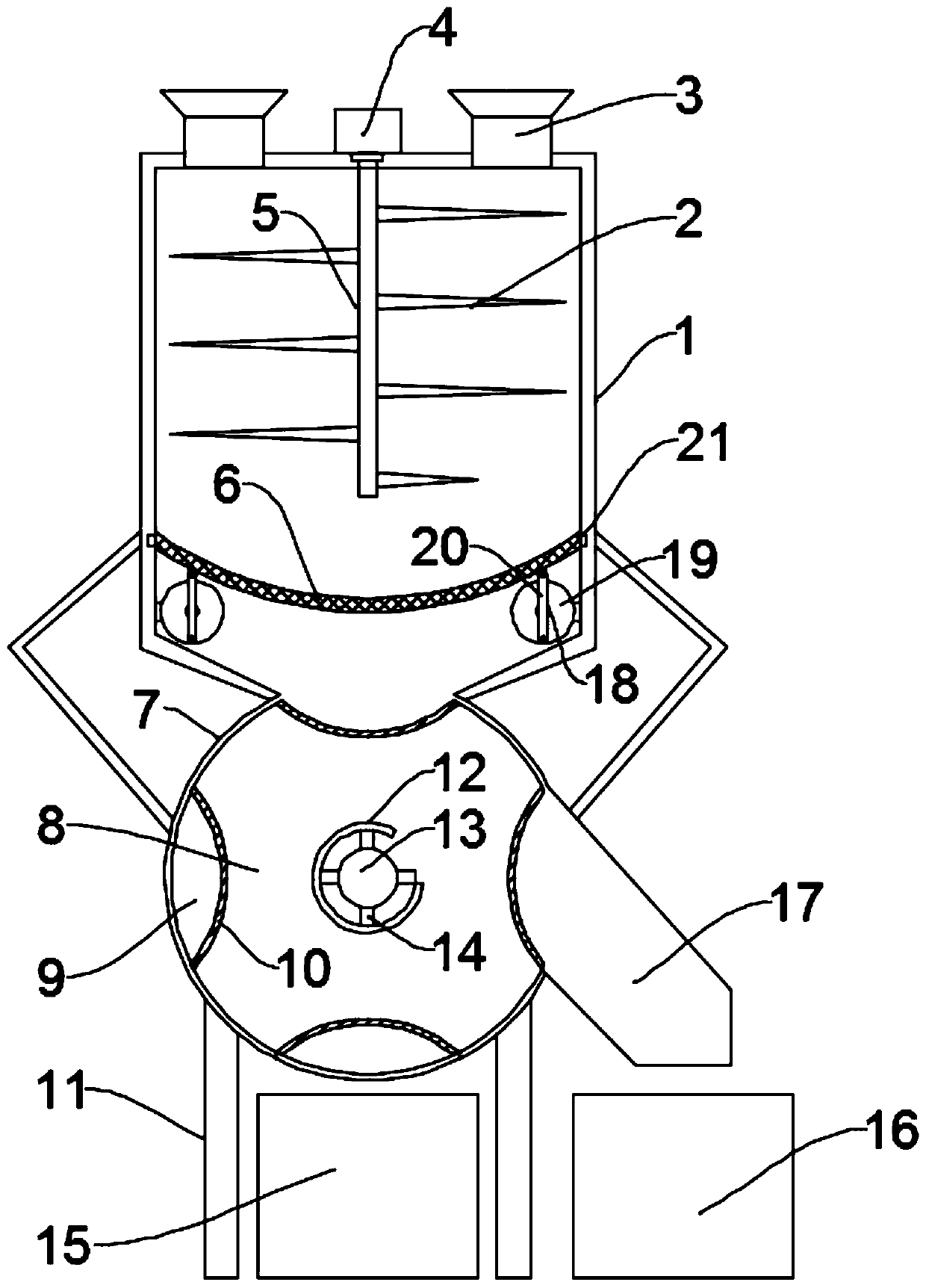

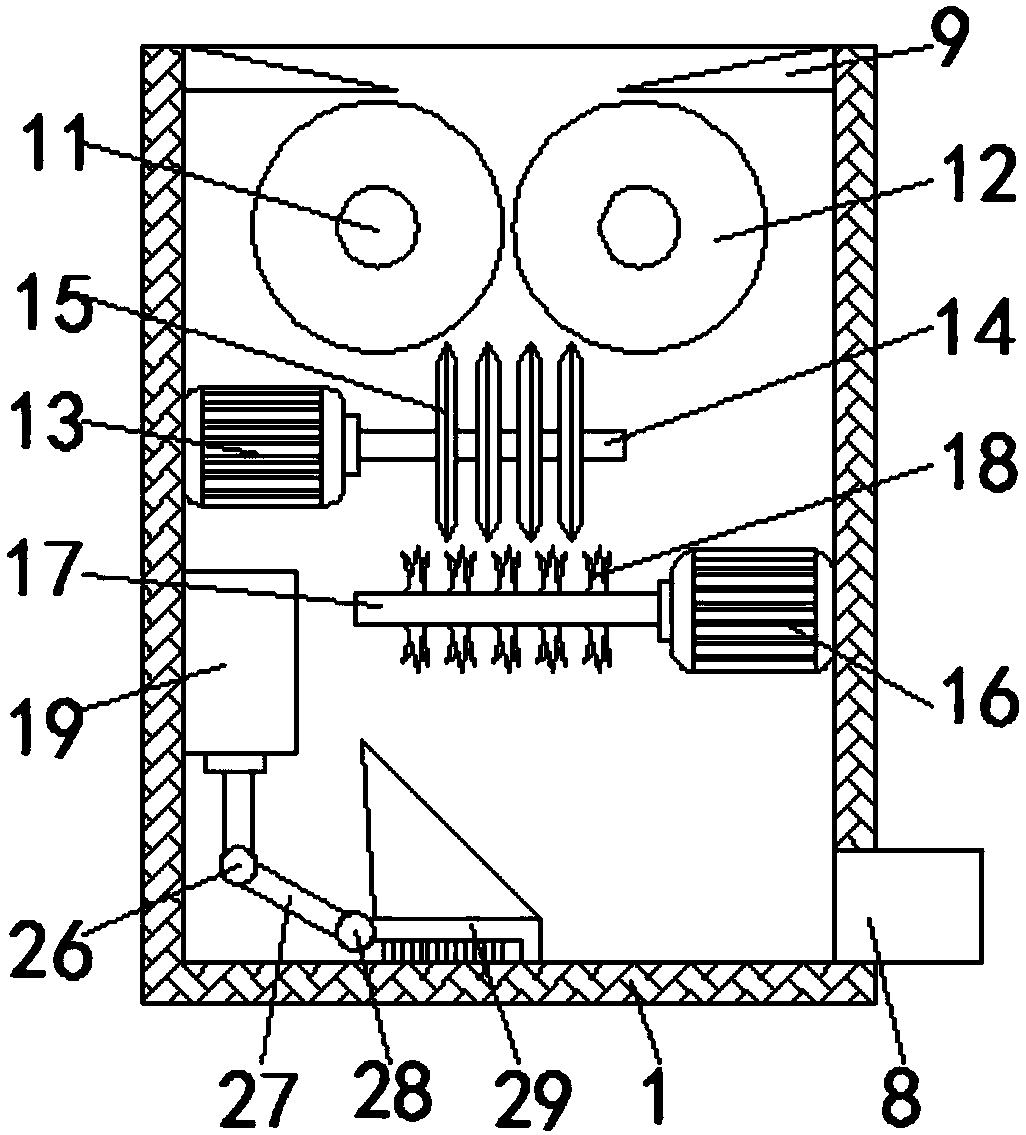

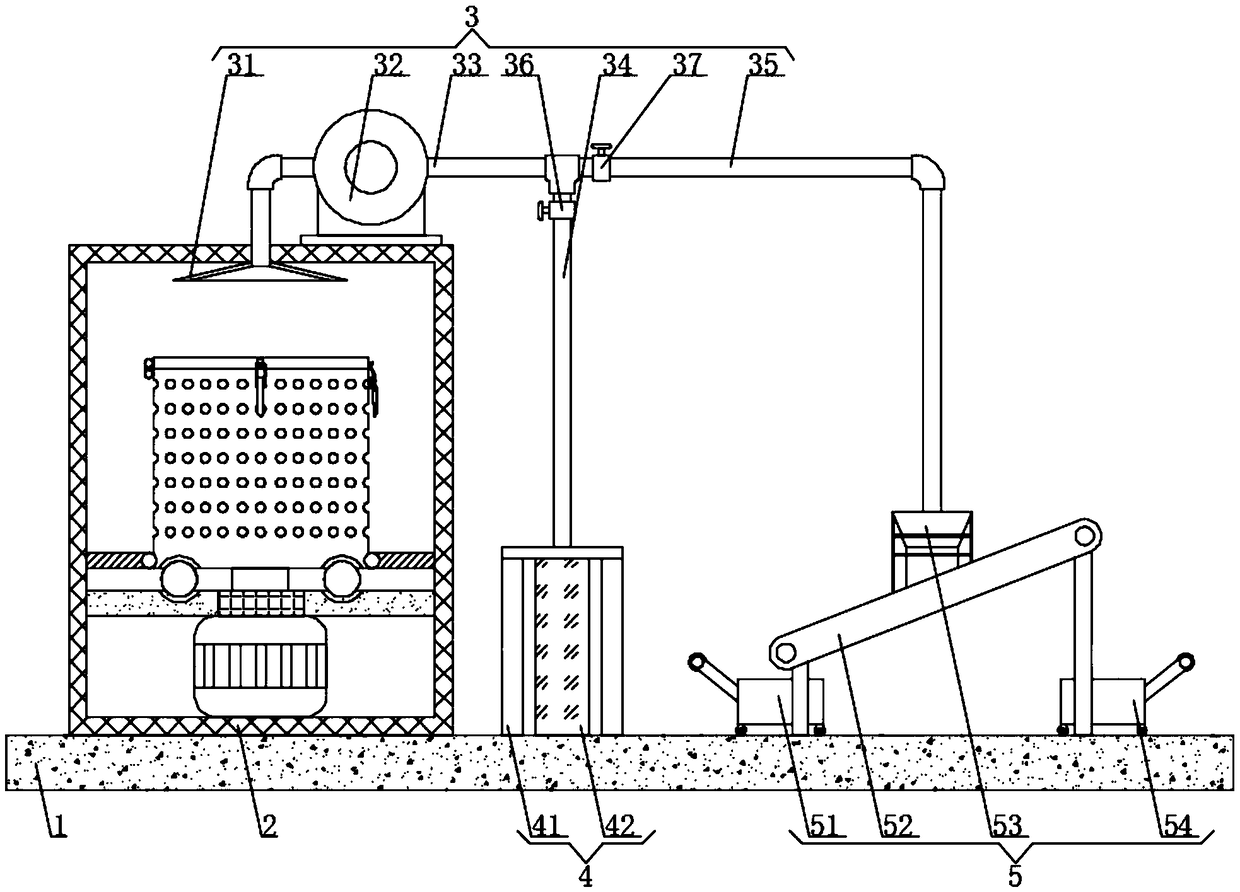

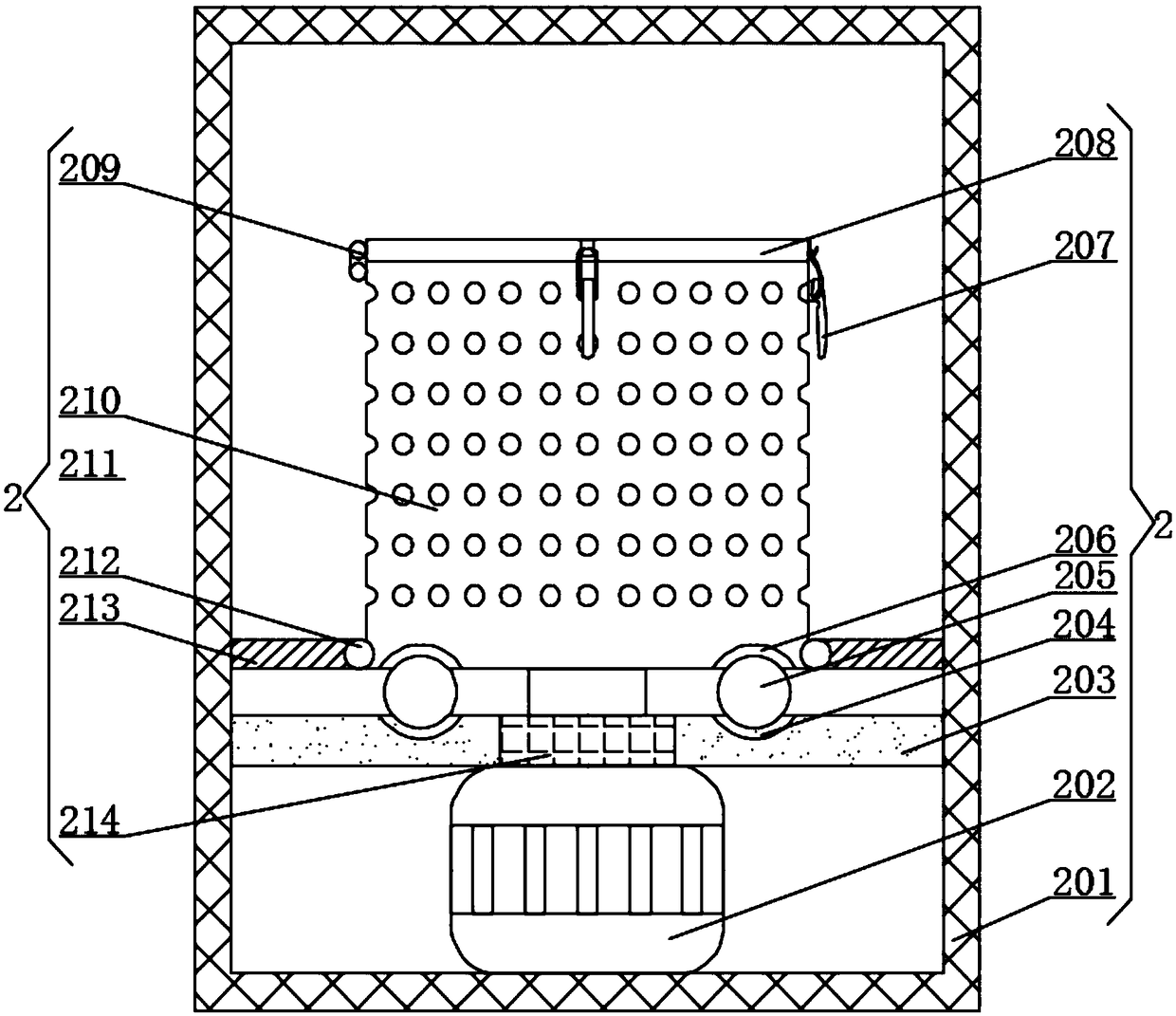

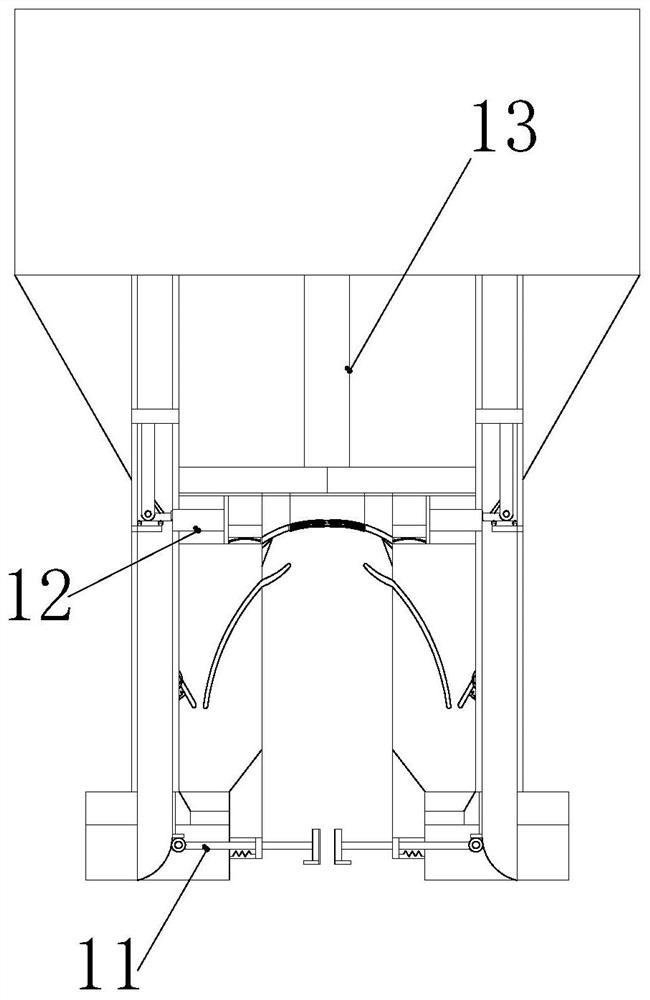

Crushing and sorting device for electronic waste recycling

InactiveCN109718915AHigh degree of automationImprove work efficiencySievingScreeningDrive motorEngineering

The invention discloses a crushing and sorting device for electronic waste recycling, and relates to the technical field of electronic waste disposal. The crushing and sorting device is mainly used for solving the problem of low manual sorting efficiency, and comprises a crushing mechanism and a sorting mechanism. The crushing mechanism is located above the sorting mechanism. The crushing mechanism comprises a crushing cylinder, a first motor, a rotating shaft, crushing knives and a metal sieve, and the sorting mechanism comprises a sorting cylinder, a sorting roller and electromagnets. Driving motors are installed on both sides of the bottom of the metal sieve, and discs are mounted on the end parts of output shafts of the driving motors. Connecting rods are hinged to the outer sides of the front end surfaces of the discs, and the other ends of the connecting rods are hinged to the bottom of the metal sieve. The crushing and sorting device is provided with the sorting mechanism, is capable of automatically completing continuous sorting work, has a high degree of automation, and improves the work efficiency; the driving motors, the discs and the connecting rods are arranged to drive the metal sieve to move up and down to enable electronic waste to be in fully contact with the crushing knives, the crushing efficiency is improved, and the up-down movement of the metal sieve can improve the screening efficiency.

Owner:江西工业贸易职业技术学院

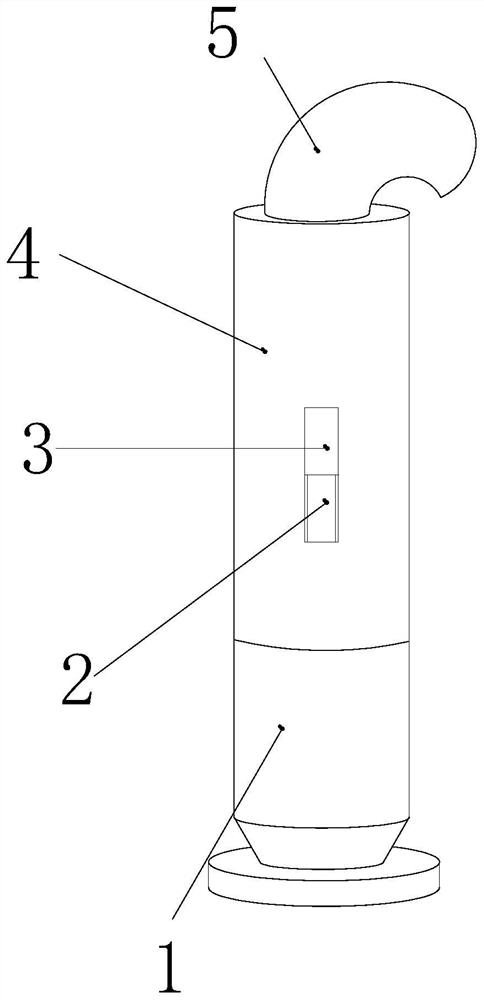

Electronic waste recycling treatment equipment with thorough element stripping function

InactiveCN110523747AAchieve separationImprove recycling efficiencySolid waste disposalScratchingMetal

The invention discloses electronic waste recycling treatment equipment with a thorough element stripping function. The electronic waste recycling treatment equipment structurally comprises an equipment body, a separation device, a control panel, a smashing shaft, a feeding hopper and a discharging opening. Beneficial effects are as follows: the stripping structure is used; the conical thorns rotate along with the stripping shaft; the conical thorns are used as a magnetic structure to adsorb a metal part; under the action of rotation, the metal piece and the plastic on the surface of the metalpiece are stripped in a scratching manner through friction; therefore, the separation of plastic and metal is realized; therefore, the garbage recycling treatment efficiency of workers is effectivelyimproved; by means of the arranged sweeping structure, under the interaction of the magnetic attraction plate and the swing plate, falling metal pieces are attracted, falling plastic falls under the action of the rectangular frame arranged on the surface of the plastic, and therefore metal and the plastic are thoroughly separated, and the attracted metal pieces are swept to the inner side of the round hopper under the action of the swing plate.

Owner:泉州骆贵贸易有限公司

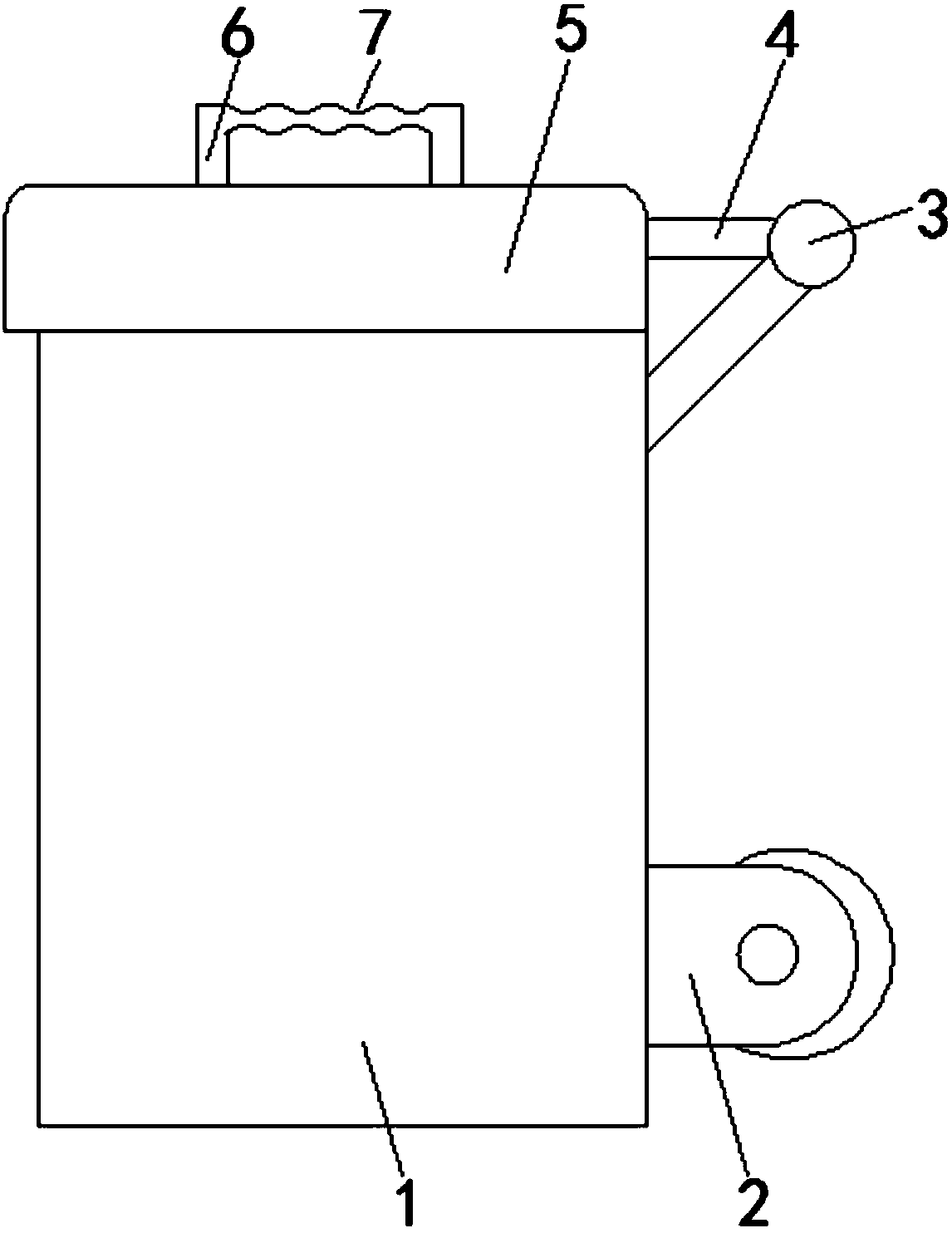

Electronic waste recycling device

The invention relates to the technical field of electronic waste and discloses an electronic waste recycling device comprising a machine body. A universal wheel is fixedly connected to the right sideof the machine body. A push rod located above the universal wheel is fixedly connected to the right side of the machine body. The outer surface of the push rod is sleeved with a connecting rod. A cover plate is fixedly connected to the left end of the connecting rod. A discharge pipeline located on the back face of the universal wheel is fixedly connected to the right side of the machine body. Theinner walls of the left side and the right side of the machine body are each fixedly connected with a limiting plate. The electronic waste recycling device is provided with the limiting plates, a driving motor, an extrusion roller, an asynchronous motor, a cutting blade, a synchronous motor and a smashing rod, thus the effects of step-by-step extrusion, cutting and smashing on electronic waste are achieved, the electronic waste is processed reasonably step by step, thus the size of the electronic waste is reduced to a great extent, then efficient recycling of more electronic waste is ensured,and the effect that the recycling efficiency of the electronic waste is improved is achieved accordingly.

Owner:梁玉燕

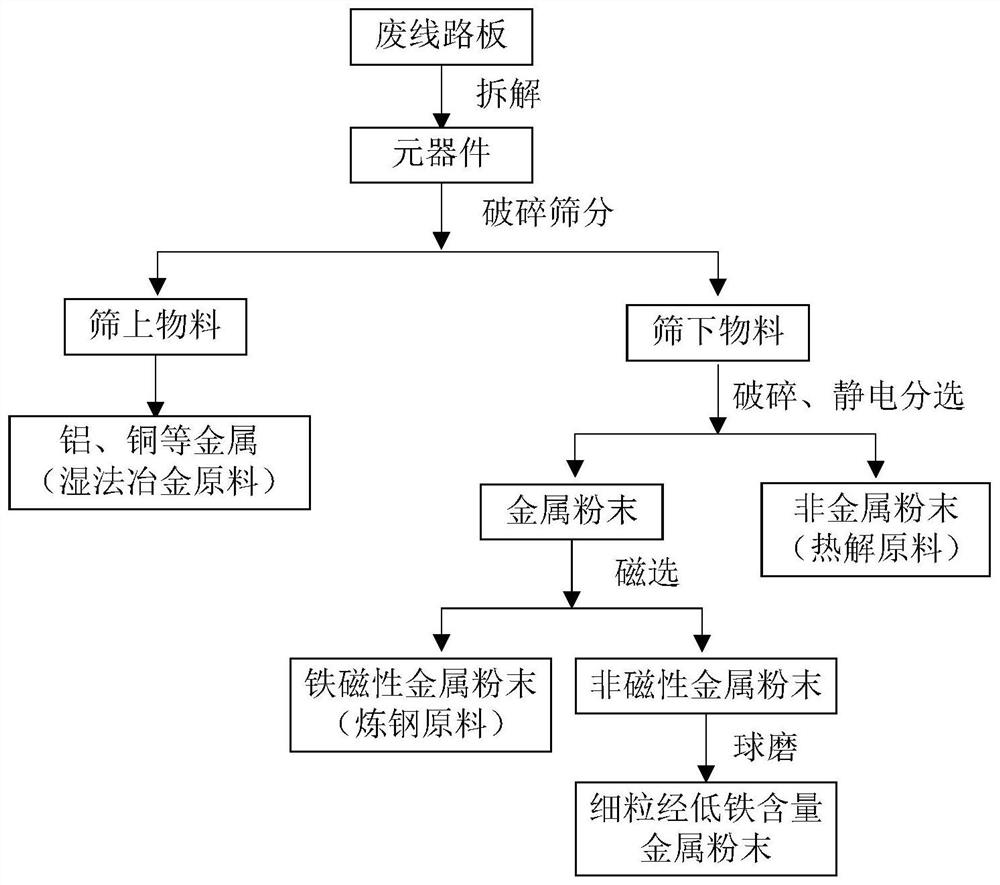

Method for preparing metal powder with low iron content by treating a waste circuit board component through mechanical physical method

InactiveCN113020219AEasy to separateEfficient separationSolid waste disposalElectronic waste recyclingElectrostatic separationCopper

The invention discloses a method for preparing metal powder with low iron content by treating a waste circuit board component through a mechanical physical method, and belongs to the technical field of electronic waste recycling. According to the method, firstly, a heat gun is used for disassembling the component, a small part of nonmetal is carbonized in the process, and therefore a part of metal and nonmetal in the component are separated to facilitate subsequent metal dissociation; then, primary crushing and screening are carried out by utilizing the metal ductility difference, and a part of copper with high ductility and most aluminum are separated from iron with low ductility; next, secondary crushing and screening are conducted on materials obtained through primary crushing and screening, and therefore metal is completely dissociated; high-grade metal powder and non-metal powder are efficiently separated through electrostatic separation; then, ferromagnetic metal and non-magnetic metal are separated from the metal powder with high iron content through a magnetic separation process; and finally, the ferromagnetic metal powder is ball-milled to obtain fine-grained metal powder with low iron content (mainly containing copper and precious metal).

Owner:BEIJING UNIV OF TECH

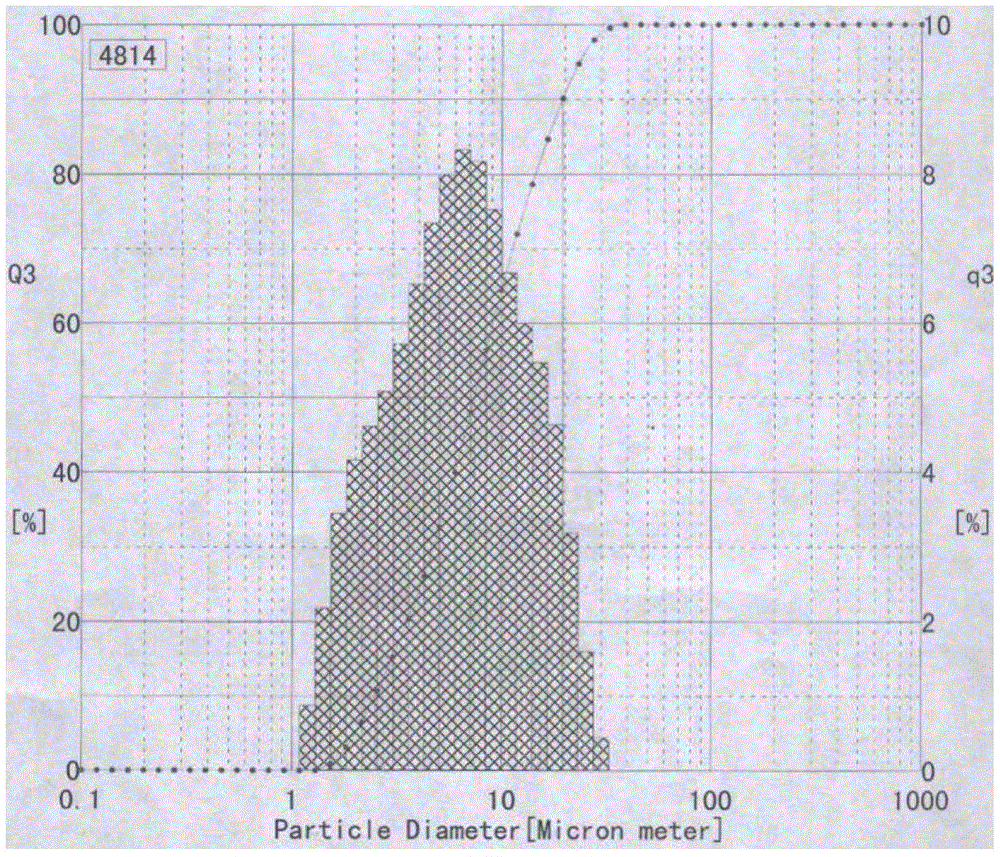

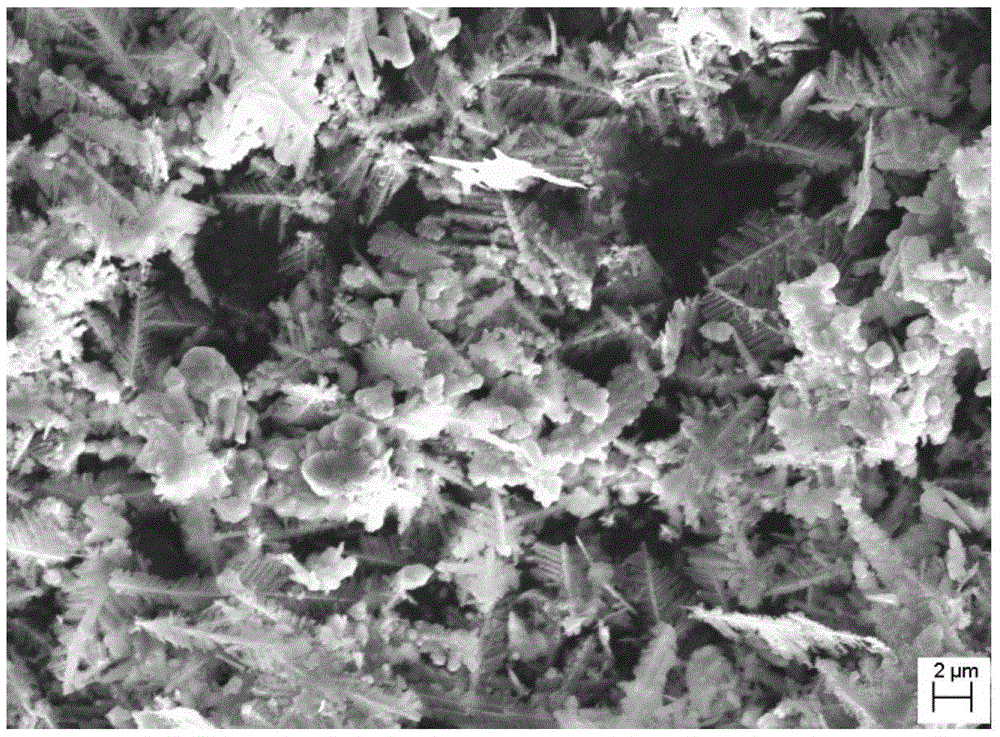

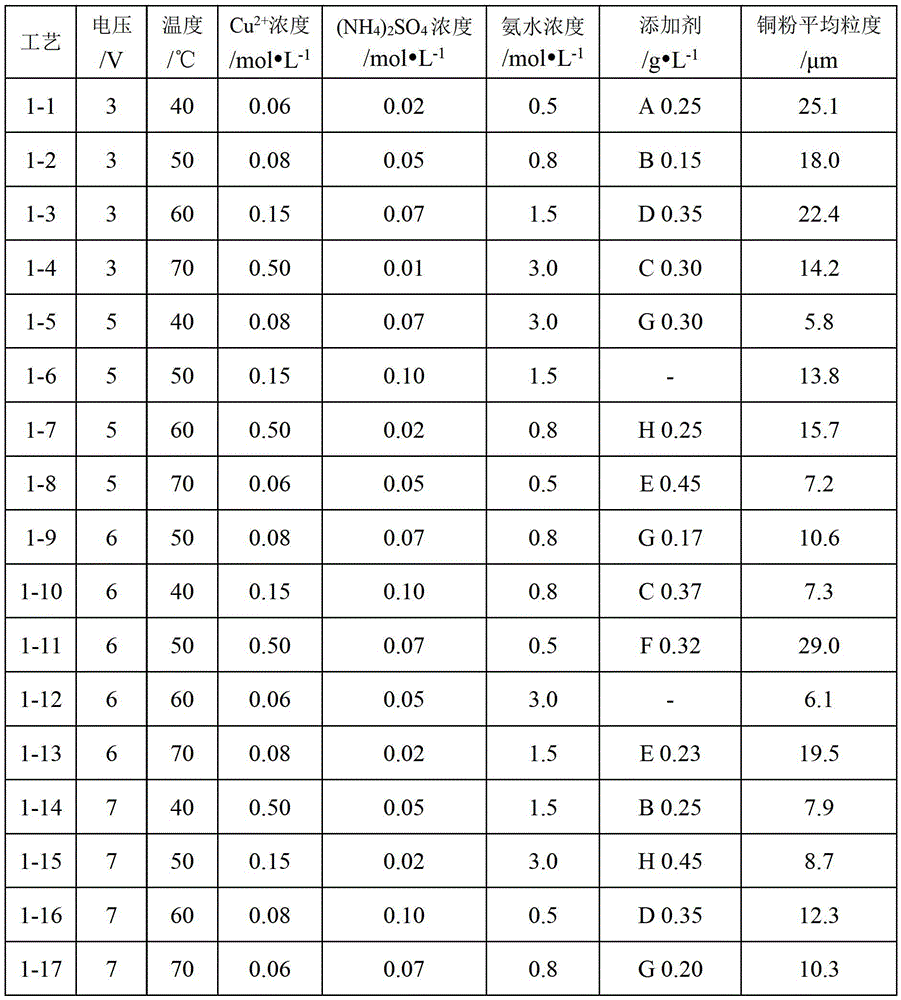

Method for preparing superfine copper powder by using waste circuit board dissolving copper-electrodeposition combined method

ActiveCN103388160BThe concentration of copper ions does not changeAchieve recyclingElectrolysisFiltration

The invention discloses a method for preparation of ultrafine copper powder by a waste circuit board copper dissolution-electrodeposition combined method and belongs to the technical field of electronic waste recycling. Each liter of a copper dissolution electrolyte comprises 0.06-0.8mol of copper sulfate, 0.02-0.1mol of ammonium sulfate, 0.3-3mol of ammonia water, 0-0.5g of an additive and the balance water. Direct voltage of an electrolytic bath is in a range of 2-8v. A cathode zone and an anode zone are separated by a cation exchange membrane. A waste circuit board without paint is put into the anode zone and nitrogen is fed into the cathode zone so that oxygen is removed. At a temperature of 30-70 DEG C, electrolysis is carried out under the condition of magnetic stirring. After electrolysis, copper powder is separated from a cathode by ultrasonic wave and then is subjected to washing, filtration and vacuum drying to form the ultrafine copper powder. Through the waste circuit board as a copper source, the ultrafine copper powder is obtained under the optimal conditions. The ultrafine copper powder has the average particle size of 5.8 microns, uniform particle size distribution, good dispersibility, high purity of 99.9% and a high application value. The method realizes recycle of the electrolyte and is environmentally friendly.

Owner:UNIV OF SCI & TECH BEIJING

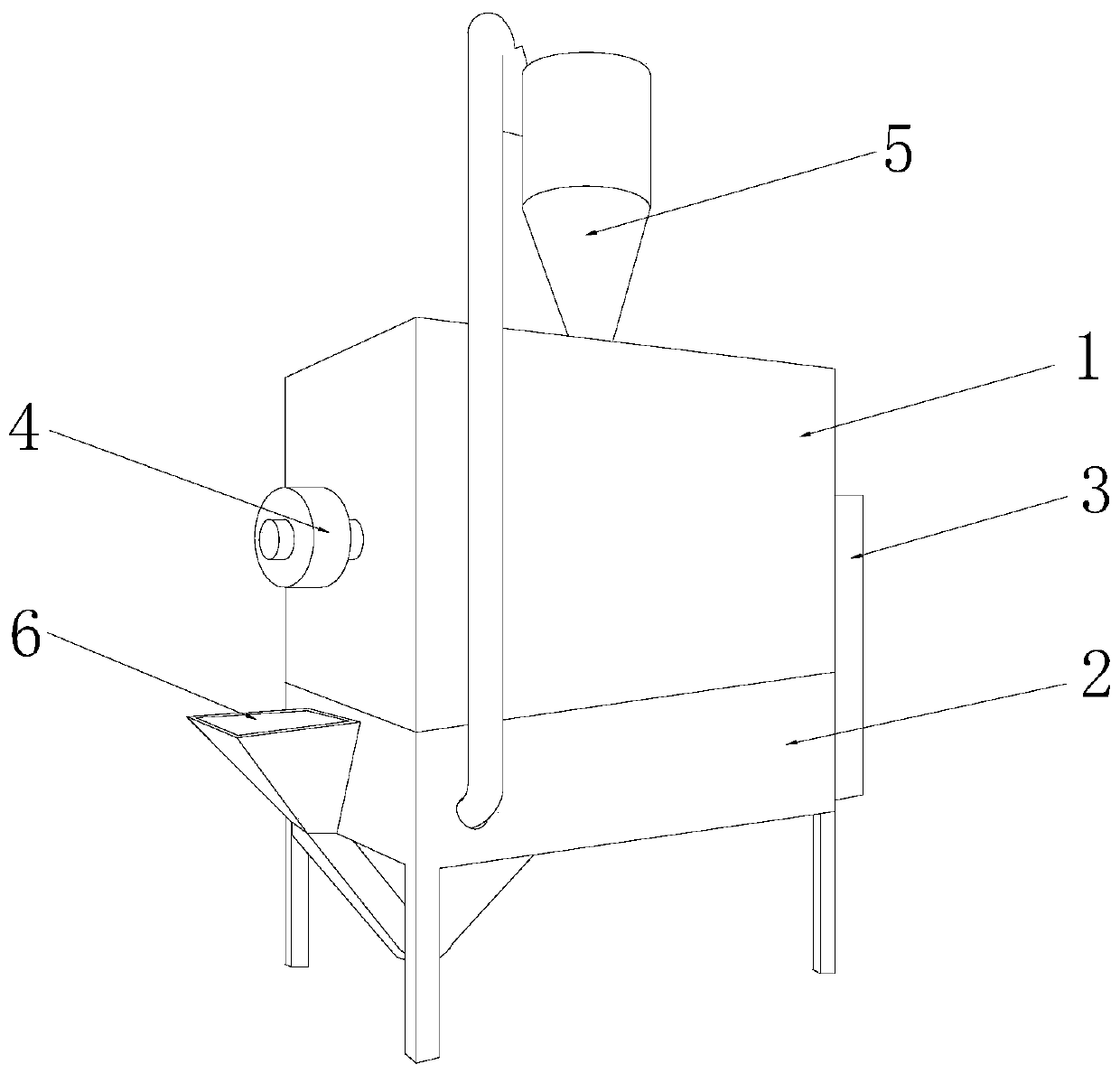

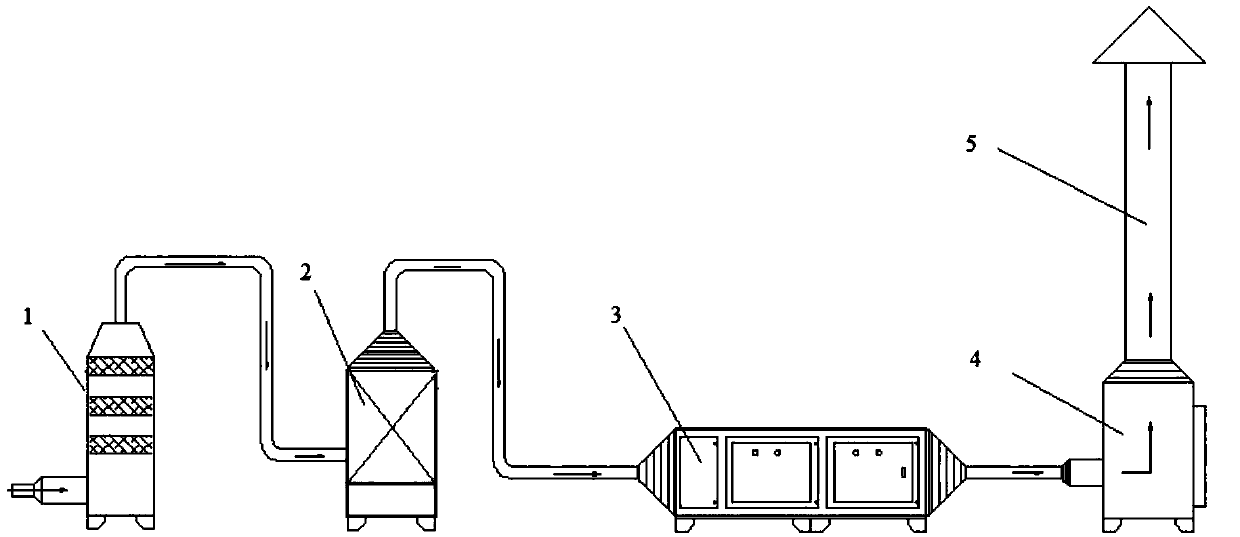

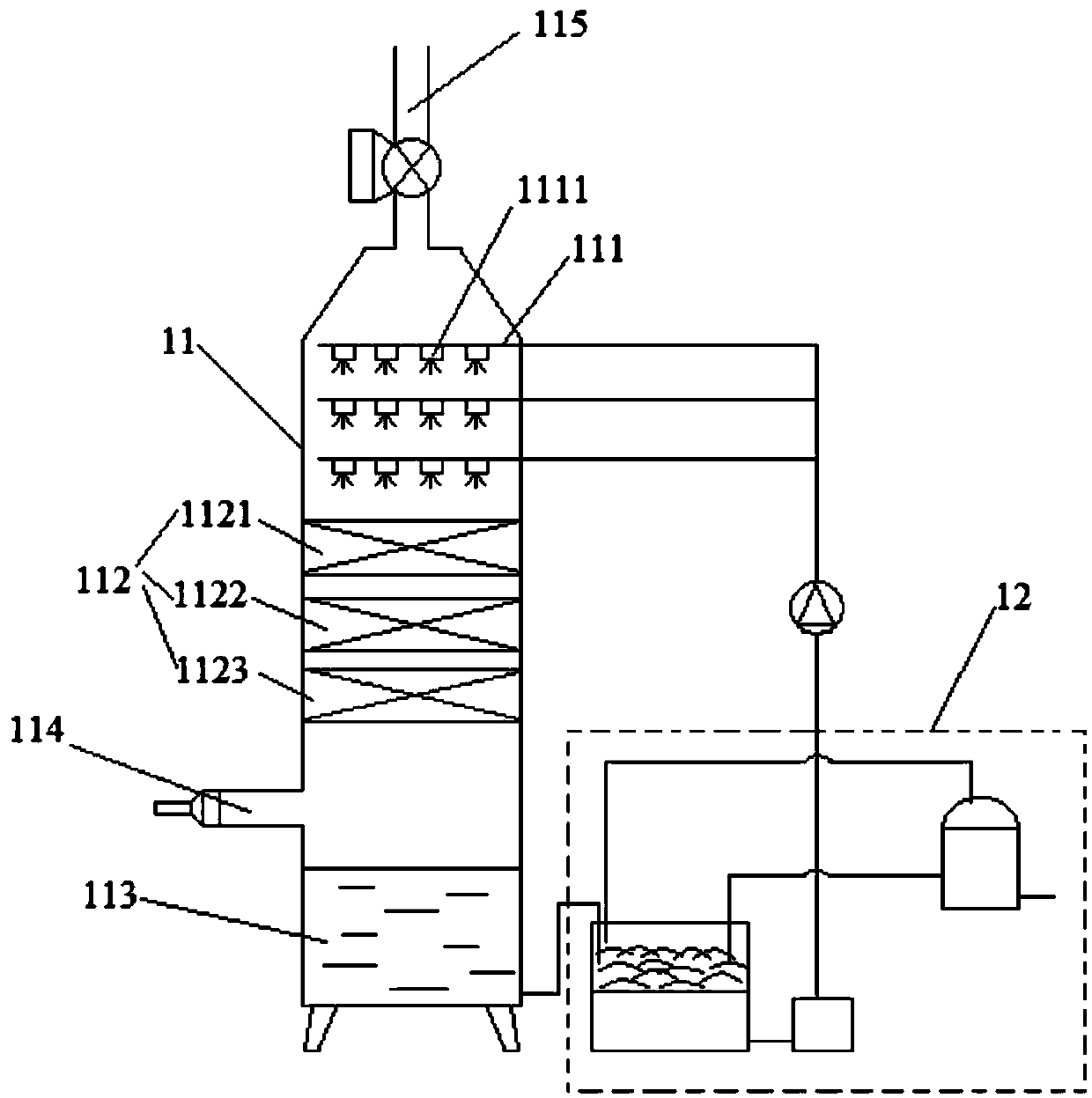

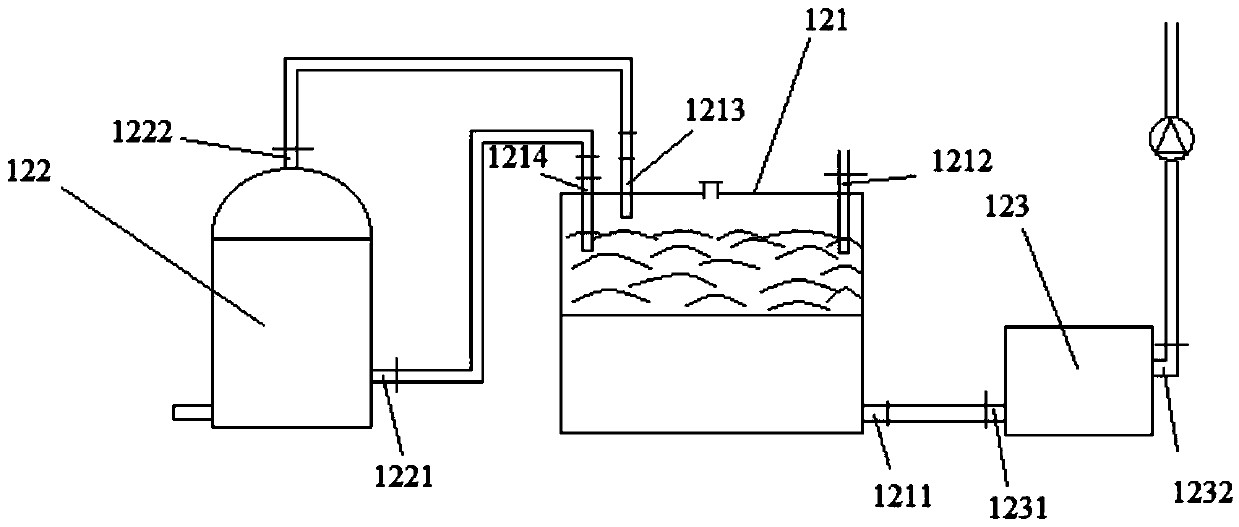

Treatment system for electronic waste and application of system

The invention discloses a treatment system for waste gas during electronic waste recycling. The system includes a spray absorption device, a degreaser, a photocatalytic decomposer and a fan; and the spray absorption tower, the degreaser, the photocatalytic decomposer and the fan are connected in sequence through pipelines. The invention develops a combined waste-gas treatment process of hot alkaliliquid spray absorption + high-efficiency removal of oil components by the degreaser + photocatalytic decomposition aiming at the characteristics that the waste gas generated in the electronic wasterecycling process contains low-boiling-point components and high-boiling-point oil components to realize more effective treatment of volatile organic compounds in the waste gas generated in the electronic waste recycling process; and at the same time, the system has the characteristics of a simple structure, low equipment costs, and low operating costs.

Owner:荆门格林循环电子废弃物处置有限公司 +1

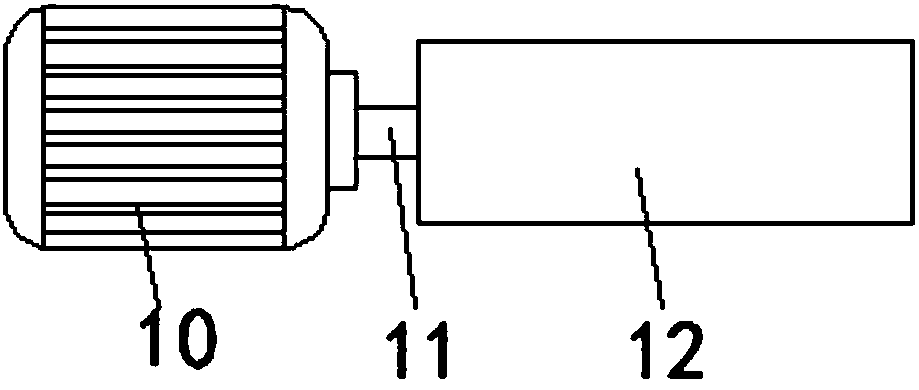

Efficient and environment-friendly electronic waste recycling device

InactiveCN112844737AAchieve separationEasy to cleanDrying gas arrangementsMagnetic separationProcess engineeringAir heater

The invention relates to the technical field of electronic product recycling, and discloses an efficient and environment-friendly electronic waste recycling device. The efficient and environment-friendly electronic waste recycling device comprises an air heater, a first motor, a second motor, a cloth roll and a box body, wherein the lower end of the box body is fixedly connected with a plurality of supporting legs, the box body is sequentially provided with a material grinding cavity, a material crushing cavity and a material distributing cavity from top to bottom, the upper end of the box is provided with a feeding hopper, the material grinding cavity is formed at the lower side of the feeding hopper, a material grinding mechanism is arranged inside the material grinding cavity, the material crushing cavity is formed at the lower side of the material grinding cavity, a material cutting mechanism is arranged inside the material crushing cavity, the material distributing cavity is formed in the lower side of the material crushing cavity, a sealing door is embedded into the left side of the material distributing cavity, a screw rod is rotationally connected to the center of the sealing door, a rotary handle is arranged at the left end of the screw rod, and a locking frame is rotationally connected to the right end of the screw rod. According to the efficient and environment-friendly electronic waste recycling device, the structure is simple, fine crushing treatment can be carried out on electronic products, and meanwhile simple classification can be carried out according to materials, so that recycling is facilitated, use is rapid and convenient, and the materials can be cleaned simply, so that the cleanliness of the materials is improved, and the efficient and environment-friendly electronic waste recycling device has the available value in the technical field of electronic product recycling.

Owner:江苏恒强环境工程有限公司

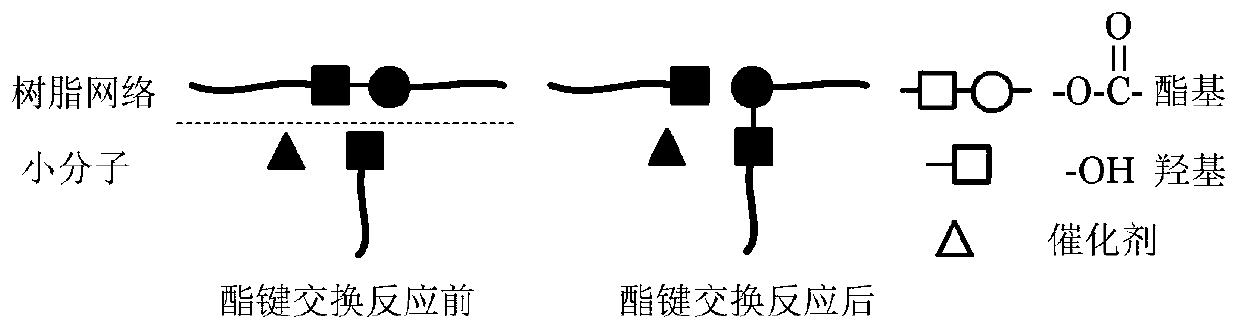

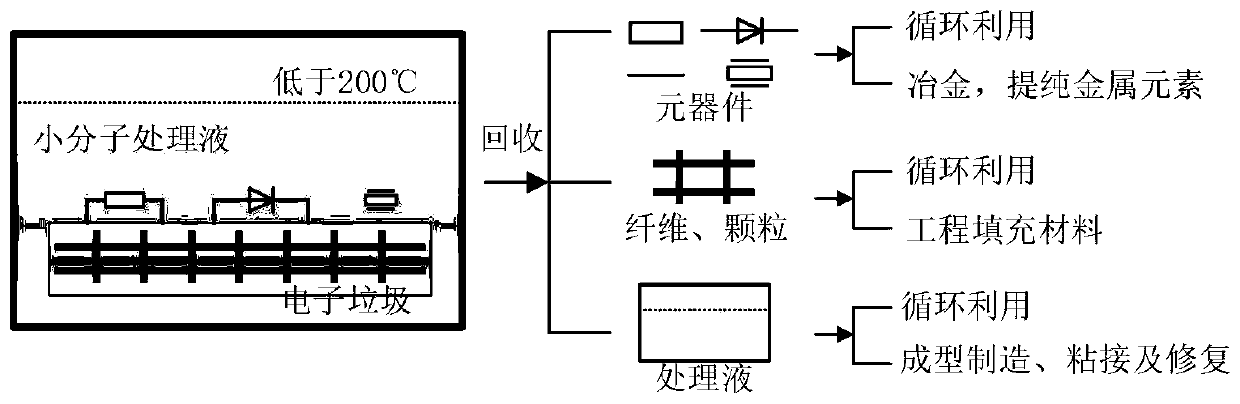

Small-molecule auxiliary electronic waste recycling method based on ester bond exchange reaction

The invention discloses a small-molecule auxiliary electronic waste recycling method based on an ester bond exchange reaction. The small-molecule auxiliary electronic waste recycling method includes the following steps that waste electronic waste is immersed into small molecule treatment liquid, and the mixture is placed into a heatable vessel; the small molecule treatment liquid is slowly heatedto 120 DEG C to 200 DEG C, and heat preservation is conducted for 0.5 hours to 8 hours; then substrate resin containing ester bond functional groups is degraded, electronic components and substrates are separated, and full recovery and recycling of various materials in the electronic waste are achieved. According to the small-molecule auxiliary electronic waste recycling method, it is realized that the substrate resin containing the ester bond functional groups is degraded at a low temperature, the electronic components and the substrates are separated, and therefore complete recovery and recycling of various materials including the electronic components, the resin, glass fibers and the like can be achieved accordingly.

Owner:XI AN JIAOTONG UNIV

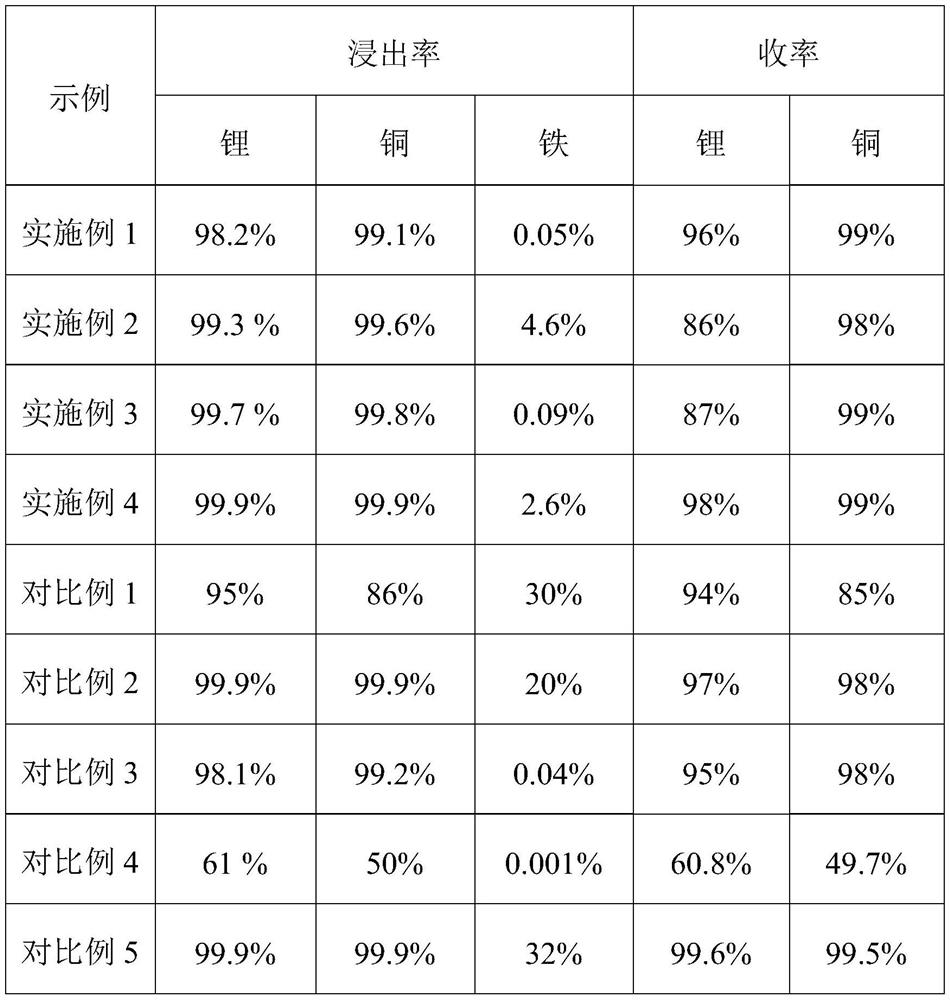

A method for selectively reclaiming lithium and copper in waste lithium iron phosphate batteries

ActiveCN111187913BEfficient leachingAvoid leachingWaste accumulators reclaimingProcess efficiency improvementPhosphateSeparating agent

The invention discloses a method for selectively recovering lithium and copper in waste lithium iron phosphate batteries, and relates to the technical field of electronic waste recovery and treatment. The method comprises: mixing waste lithium iron phosphate batteries, inorganic acid and oxygen, reacting at 96-150°C, and separating solid and liquid after the reaction to obtain leaching solution and iron phosphate leaching residue; mixing the leaching solution with a separating agent To separate the copper in the leaching solution, and then add alkaline substances to adjust the pH to remove impurity iron and impurity aluminum to obtain a purified solution; precipitate the purified solution and sodium salt to obtain a lithium product. In this application, the destruction of the structure of the waste lithium iron phosphate electrode material is achieved in a high-temperature oxidative acidic environment, especially at a temperature of 96-150°C, and only a small amount of inorganic acid is needed to achieve efficient leaching of lithium and copper. However, Fe is almost not leached, and high-value lithium and copper can be recovered; the process is short, the equipment is simple, and the cost of reagents is low.

Owner:GUANGDONG INST OF RARE METALS

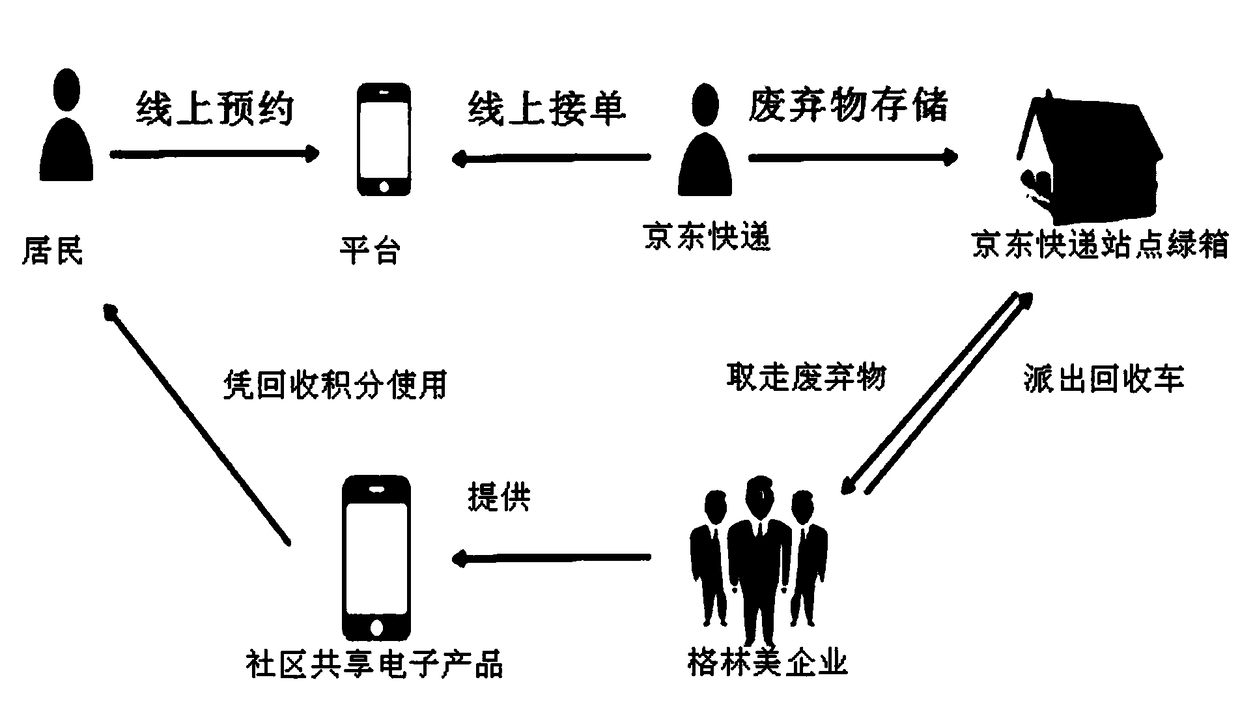

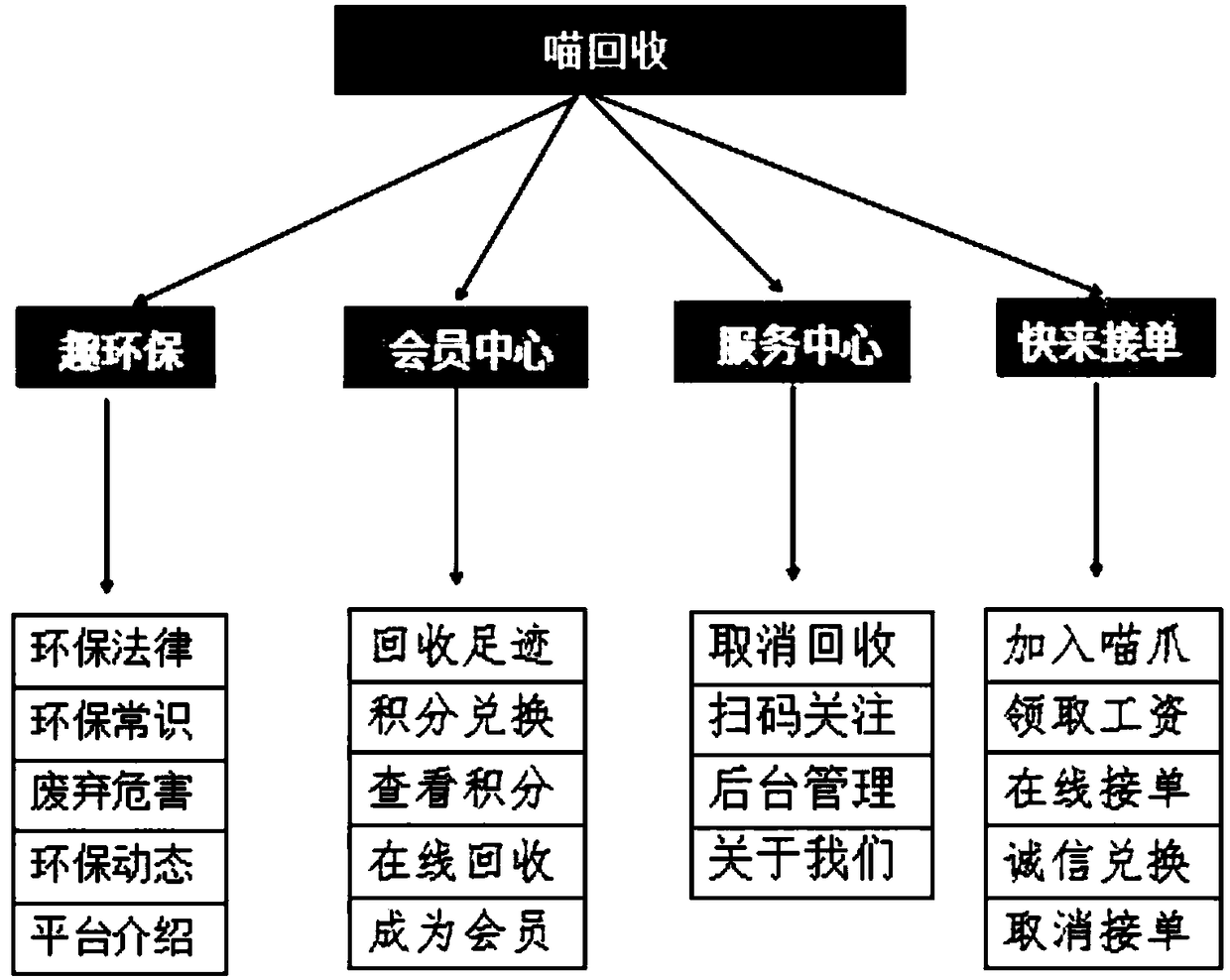

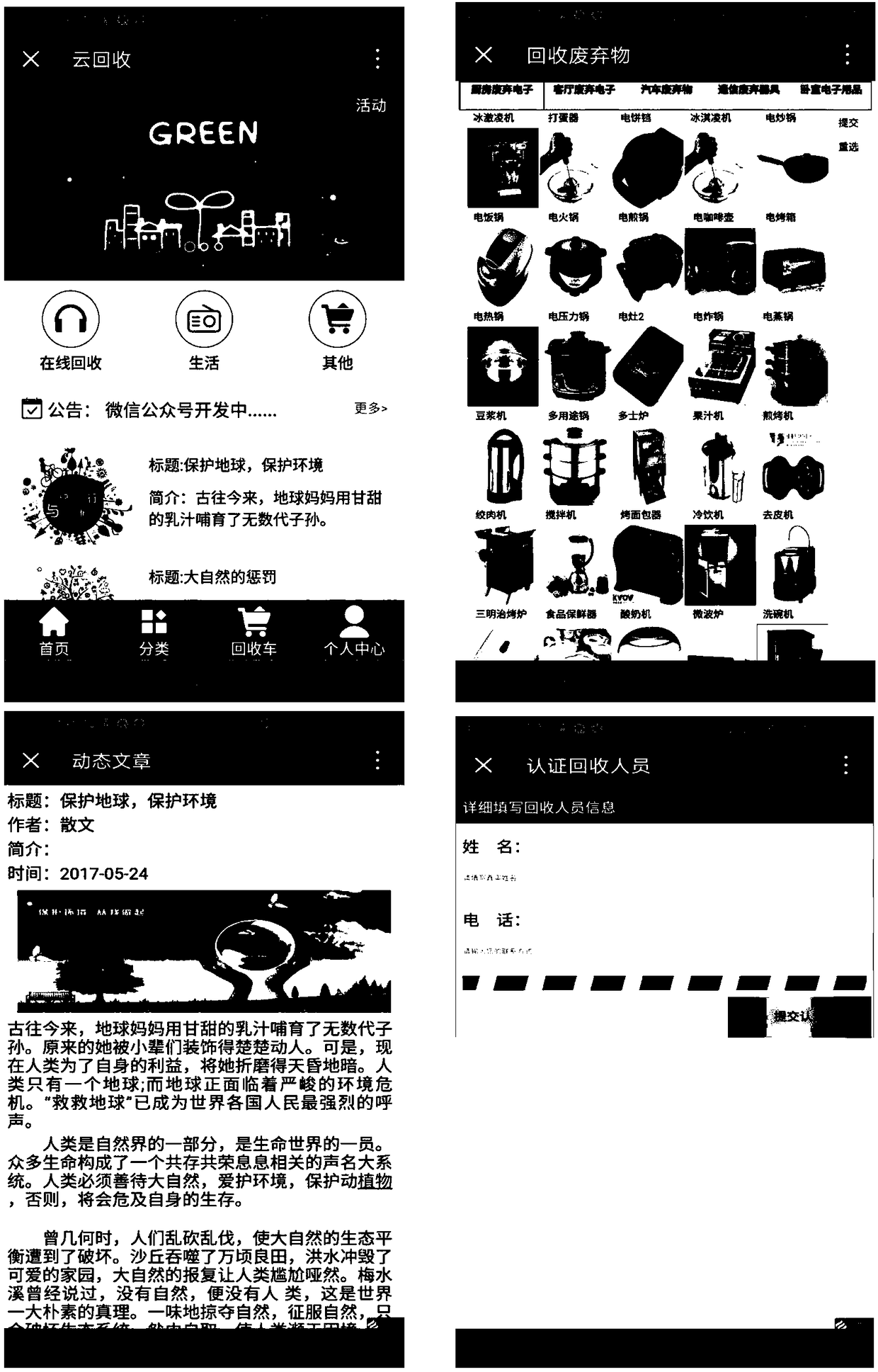

Online public benefit recycling method for electronic wastes

InactiveCN108126975AEnhance interestSustainable waste treatmentSolid waste disposalRecovery methodComputer science

The invention relates to an online public benefit recycling method for electronic wastes. The online public benefit recycling method is characterized by comprising the following steps of S1, classifying the electronic wastes into five classes, wherein each piece of electronic waste corresponds to a corresponding recycling credit value; S2, enabling a user to log in an online recycling APP (application) of a mobile phone to place an electronic waste recycling order, and enabling a platform to automatically inform a courier to recycle by self; S3, after the courier recycles by self, putting theelectronic wastes into a public benefit recycling green box at an expression point, sending a confirming notice via a recycling platform, and increasing the corresponding credit for the user; S4, enabling a recycling company to dispatch a recycling vehicle to arrive at the public benefit recycling green box to recycle; S5, enabling the user to convert the community benefits according to the received recycling credit. The online public benefit recycling method has the advantages that the public benefit and the environment protection are combined, the recycling of the electronic wastes is furthest applied to all recycling types of the electronic wastes, and the recycling is developed to the maximum benefit and public benefit effects.

Owner:TIANJIN UNIV OF SCI & TECH

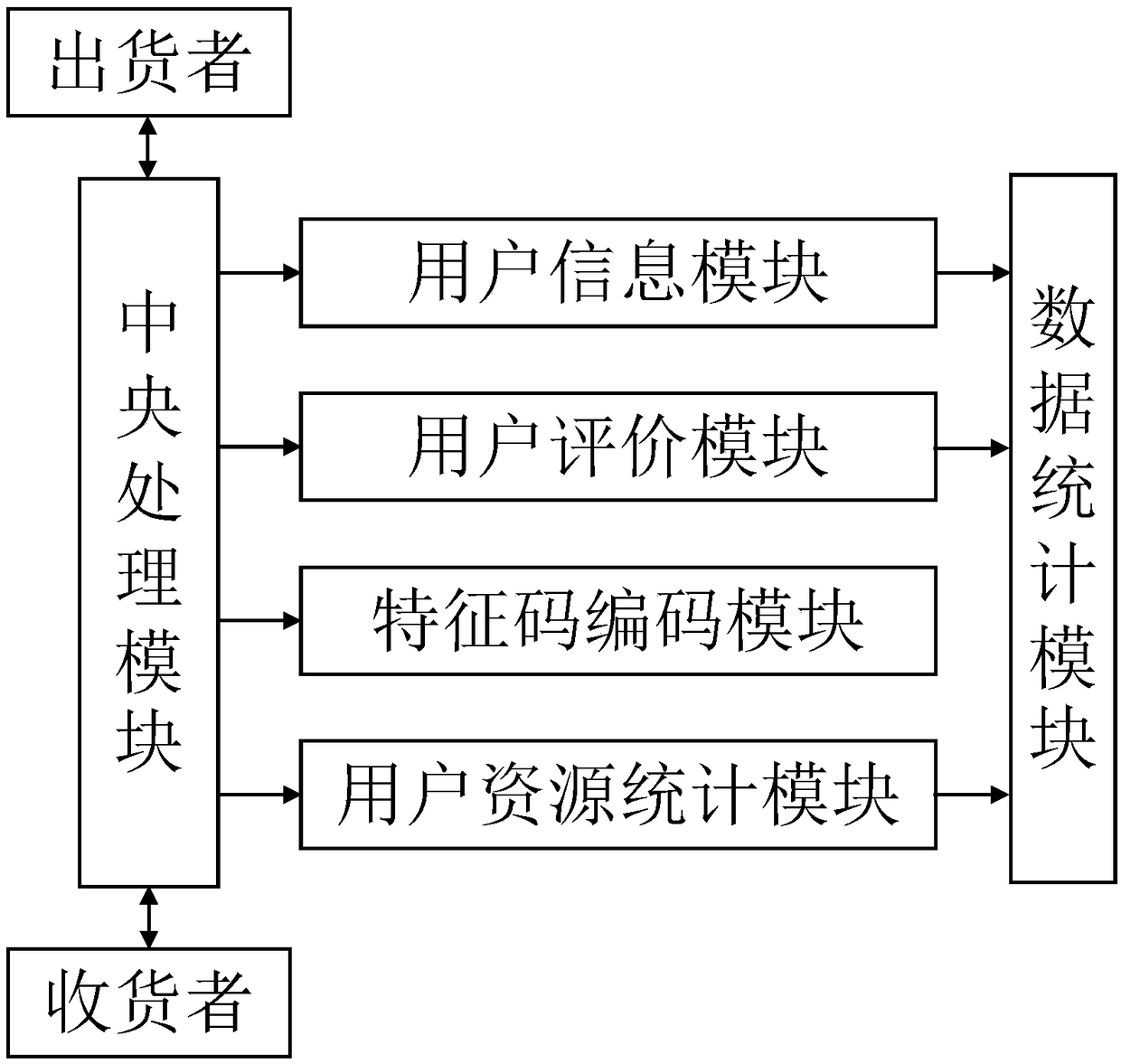

Electronic waste recycling and monitoring system and method

InactiveCN108898530AFlow monitoringMonitor transactions throughout the processData processing applicationsMonitoring systemLibrary science

The invention relates to an electronic waste recycling and monitoring system and method. The system includes a central processing module, a user information module, a user evaluation module, a featurecode encoding module, a user resource statistical module and a data statistical module. The user information module receives and saves personal information input from the user, wherein the personal information includes personal feature information and recycling information. The user evaluation module is used for evaluating the level of the user according to the content of the personal informationin the user information module. The feature code encoding module is used for generating a unique feature code corresponding to the feature code information of each electronic waste. The user resourcestatistical module is used for counting the feature codes corresponding to all the electronic waste under the user name. The data statistical module is used for classifying and counting the information of the users. The electronic waste recycling and monitoring system and method realize the monitoring of the recycling capacity and the flow direction of electronic waste receivers, and are convenient for the government and enterprises to supervise each relevant link of the electronic waste.

Owner:XIAMEN UNIV OF TECH

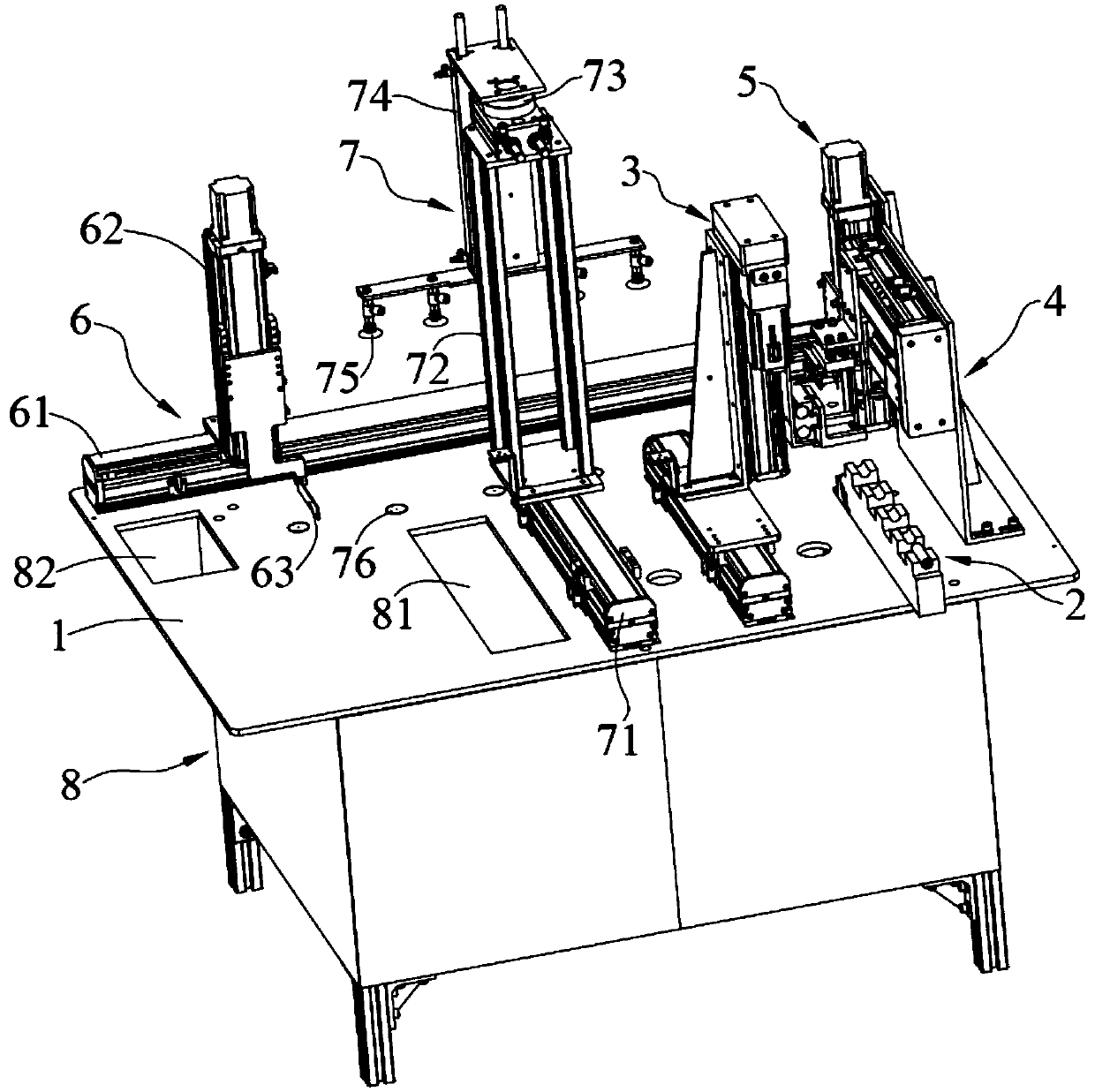

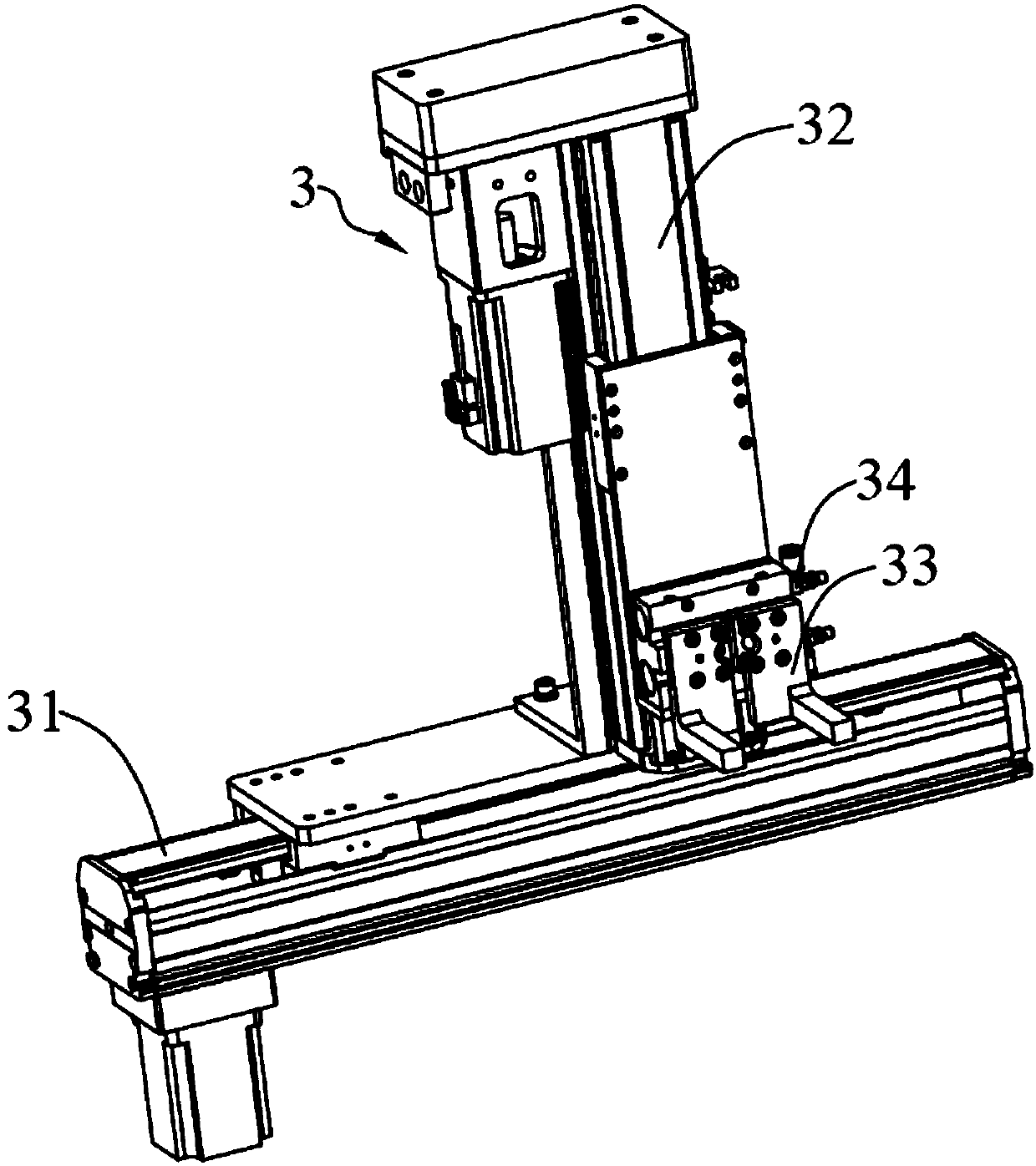

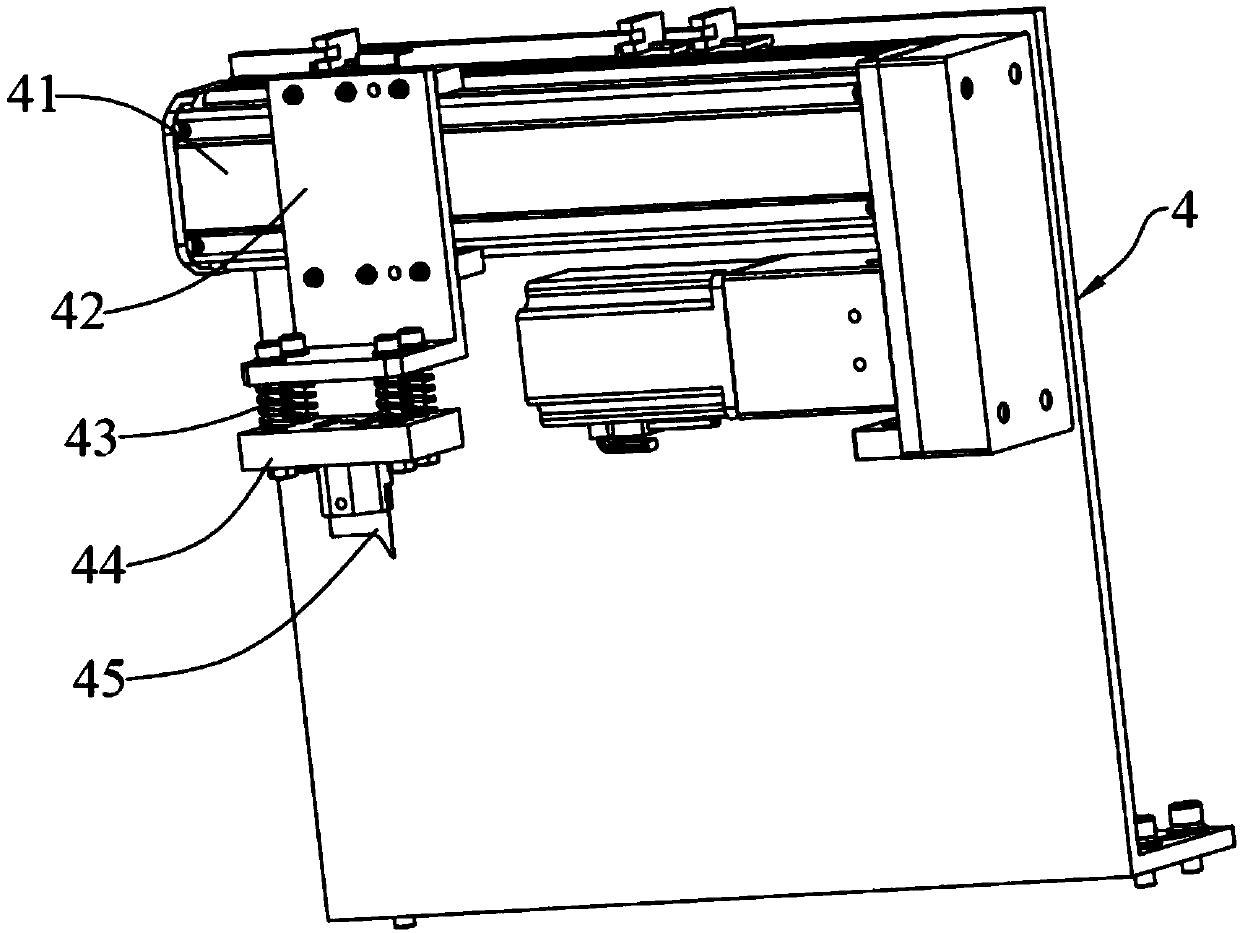

Lithium battery core package decomposition device and method

PendingCN111200172ARealize separate disassemblyAutomated separate disassemblyWaste accumulators reclaimingBattery recyclingProcess engineeringPole piece

The invention belongs to the technical field of electronic waste recycling, and discloses a lithium battery core package decomposition device and method. The lithium battery core package decompositiondevice comprises a clamping mechanism for clamping a core package, a cutting mechanism for cutting off a pole piece, a pressing mechanism for pressing one end of the cut-off pole piece, a reverse winding mechanism for unfolding and pressing the other end of the pole piece, and a separation mechanism for adsorbing and separating the unfolded pole piece. Through mutual cooperation of the clamping mechanism, the cutting mechanism, the pressing mechanism, the reverse winding mechanism and the separation mechanism, the lithium battery core package can be automatically and independently disassembled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing battery-grade lithium carbonate and iron phosphate by recycling lithium iron phosphate cathode waste

ActiveCN112142077BImprove qualityImprove product qualityCell electrodesWaste accumulators reclaimingO-Phosphoric AcidLithium iron phosphate

Owner:UNIV OF SCI & TECH BEIJING +1

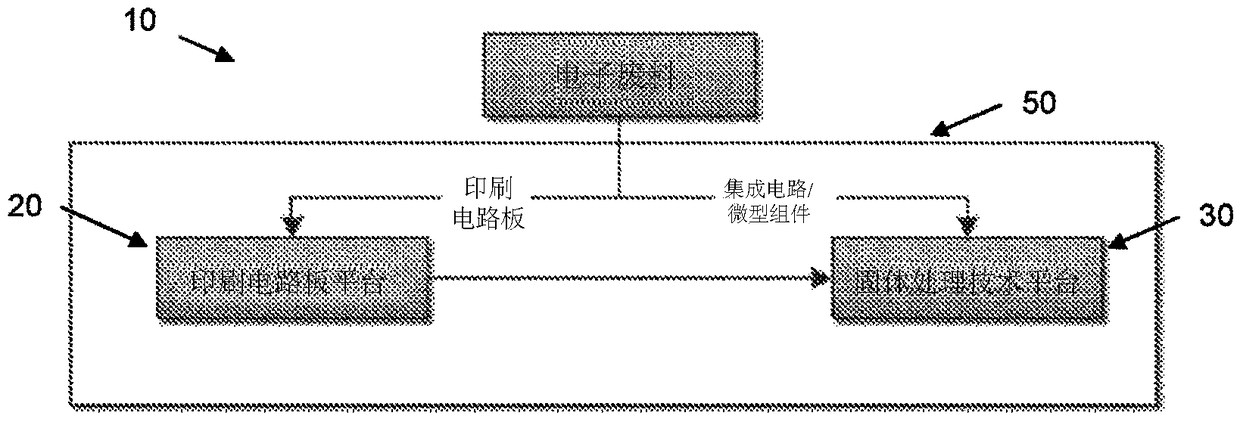

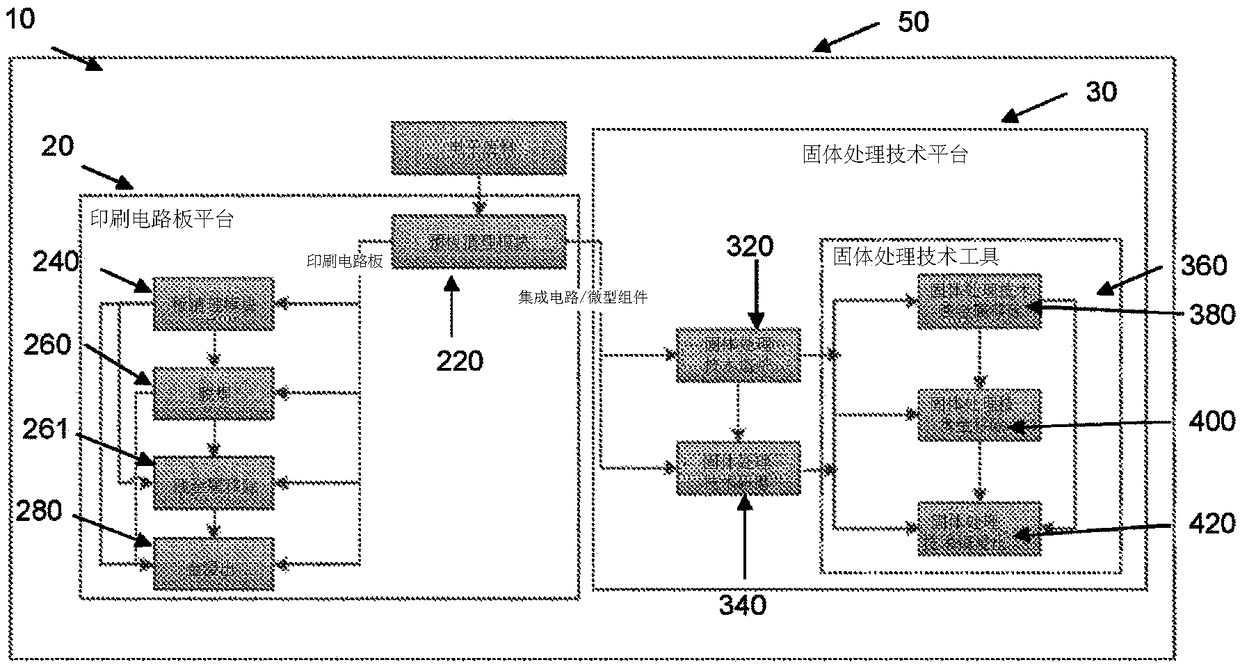

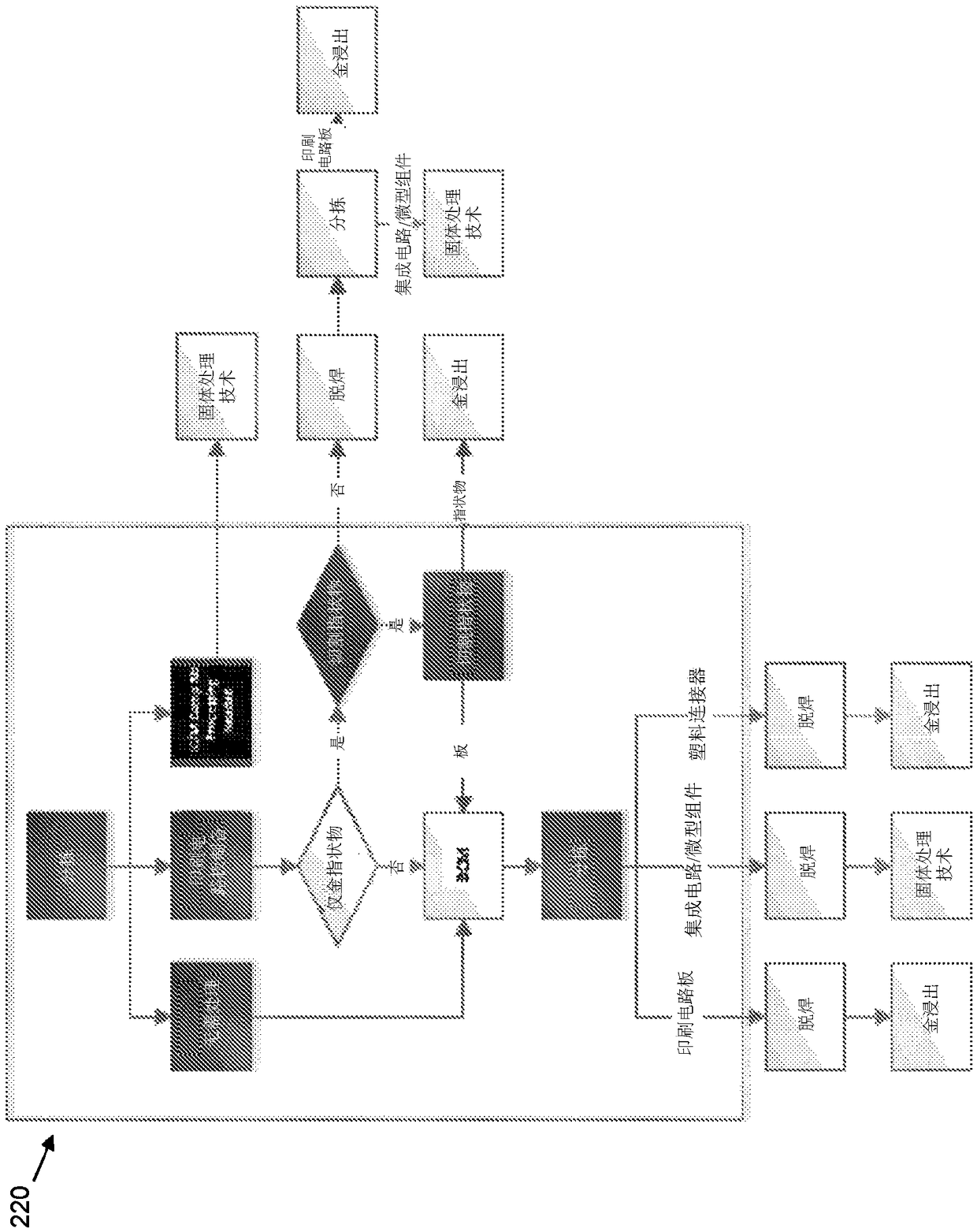

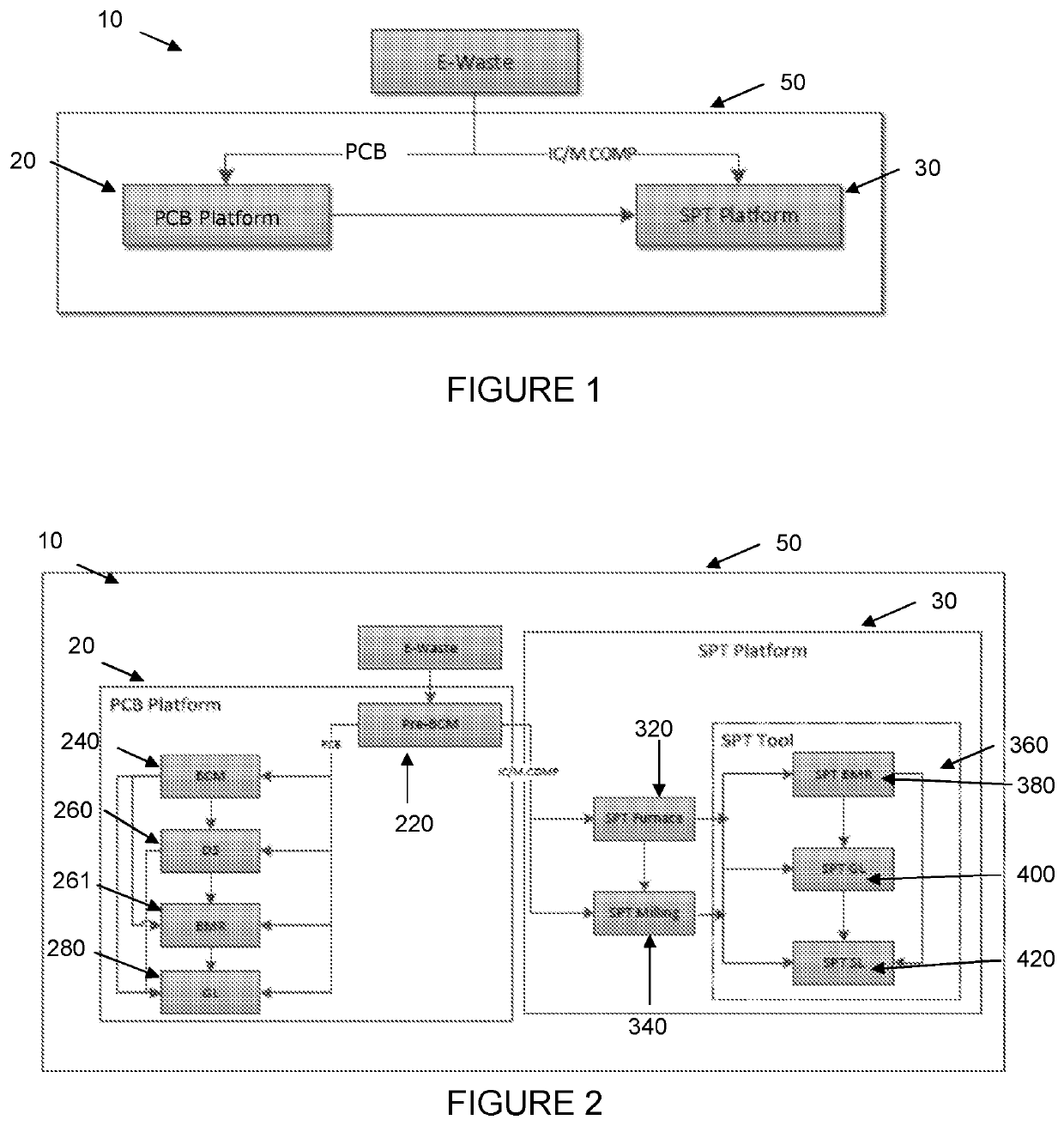

Integrated electronic waste recycling and recovery system and process of using same

InactiveUS20210040581A1Effective recoveryQuantity minimizationSolid waste disposalTransportation and packagingProcess engineeringElectronic waste recycling

Systems and processes for recycling printed circuit boards, wherein precious metals may be reclaimed. The system generally includes a number of modules to systematically remove materials from the printed circuit boards and to separate the precious metals from the materials.

Owner:ENTEGRIS INC

Electronic product sorting system and method

InactiveCN109454000APrevent flying cheapIncrease the burdenGas current separationCapacitanceEngineering

The invention discloses an electronic product sorting system and method and relates to the technical field of electronic waste recycling. A base is included, and the left side of the upper surface ofthe base is fixedly connected with a centrifugal mechanism; an attracting force mechanism is fixedly connected above the centrifugal mechanism; the middle portion of the upper surface of the base is fixedly connected with a storing mechanism which is located on the right side of the centrifugal mechanism; and the right side of the upper surface of the base is fixedly connected with a screening mechanism which is located on the right side of the storing mechanism. Due to the electronic product sorting system, impurities, particle materials and small electronic components doped in electronic products can be effectively removed; under the effects of a belt conveyor and an induced draught fan, the purpose that cylindrical capacitors and square chip resistors can be fast sorted and stored separately can be achieved; and due to the equipment, the manual labor is effectively reduced, the work efficiency of sorting is improved, and the equipment is low in manufacturing cost and suitable for medium and small type enterprises for production and use.

Owner:南京福禄源电子科技有限公司

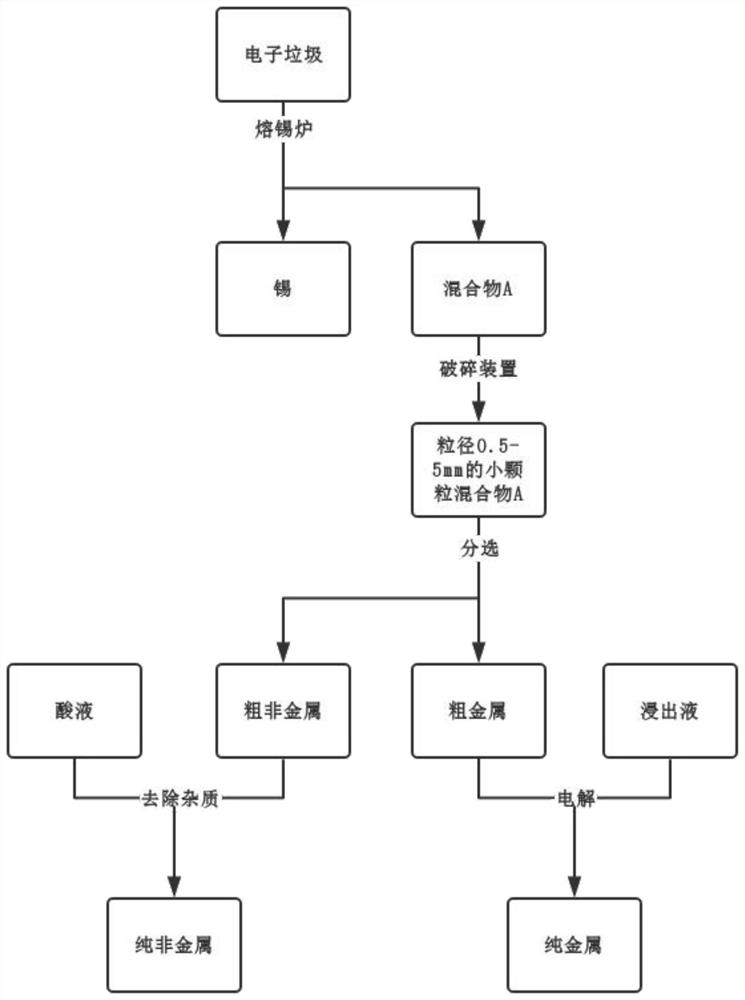

Electronic waste recycling method

PendingCN112410563AEasy to operateHigh strengthPhotography auxillary processesProcess efficiency improvementElectrolysisSeparation technology

The invention belongs to the field of electronic waste recycling, and provides an electronic waste recycling method. The method comprises the following steps: disassembling a large element into electronic waste, firstly melting low-melting-point metallic tin through a tin melting furnace, enabling the separated electronic waste to pass through a crushing device to realize metal and nonmetal dissociation, separating dissociated metal components by using a certain separation technology, obtaining most of nonmetal and metal components which are separated, leaching the metal components through a leaching agent, performing electrolytic separation on the leached metal through the leaching agent in an electrolytic mode, regenerating the leaching agent at an anode and recycling; and performing acid leaching on the nonmetal components obtained through sorting to remove mingled metal, and washing the nonmetal components with water to be used for manufacturing composite materials or building materials.

Owner:HUIZHOU ZHENDING ENVIRONMENTAL PROTECTION TECH CO LTD

Process for recycling valuable elements from positive electrode material of lithium ion battery

PendingCN110323509AWide adaptabilityAvoid separationWaste accumulators reclaimingProcess efficiency improvementResource utilizationElectrical battery

The invention relates to the technical field of electronic waste recycling treatment and resource utilization, in particular to a process for recycling valuable elements from the positive electrode material of the lithium ion battery. According to the process, through the crushing, reacting, separating and recycling of a positive electrode plate of the lithium ion battery and the adding of alkalisalt in the reaction process, the temperature required by the reaction is effectively reduced and the efficient recycling of the valuable elements in the positive electrode material of the lithium ionbattery is achieved. According to the process disclosed by the invention, the reduction of transition metal elements and conversion of lithium are synchronously completed under the condition of not additionally adding a reducing agent, and the efficient recycling of valuable elements is realized; and moreover, the separation process of a positive electrode active substance and a current collectoris avoided, and the recycling process of valuable elements is greatly simplified. On the basis of simple and reasonable flow, the process is economic and environment-friendly, the raw material applicability is wide, and the method has remarkable economic and environment-friendly benefits.

Owner:TSINGHUA UNIV

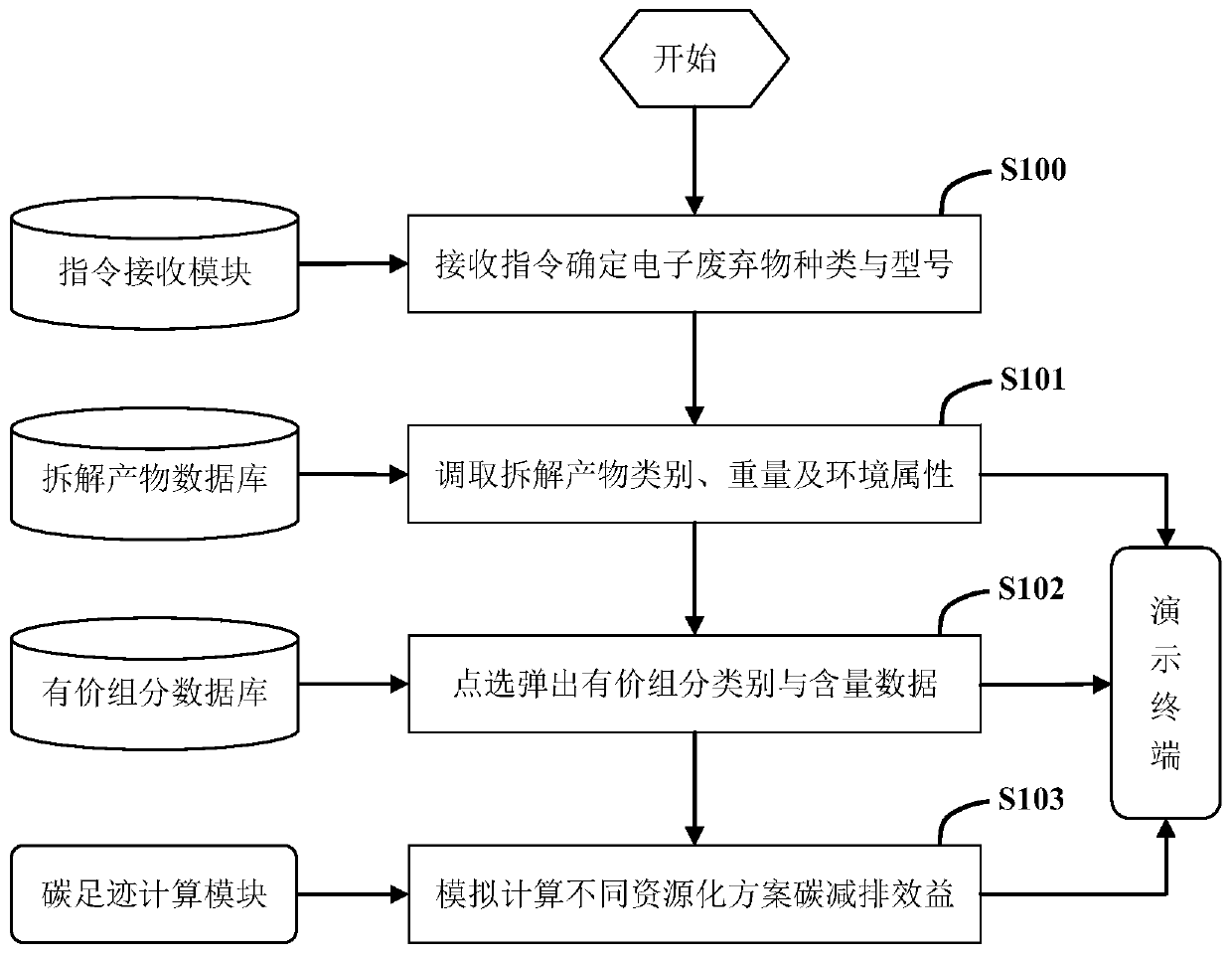

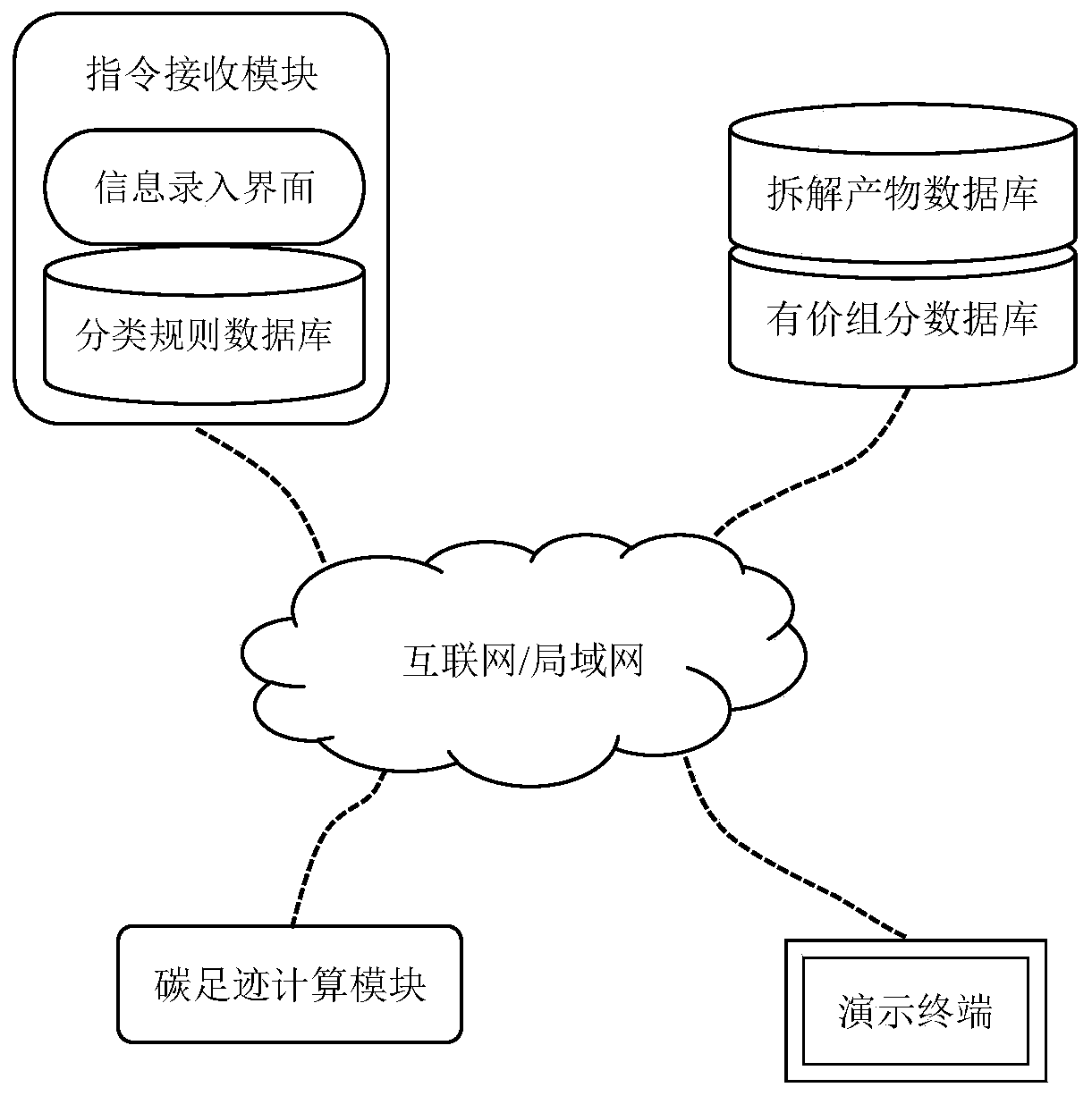

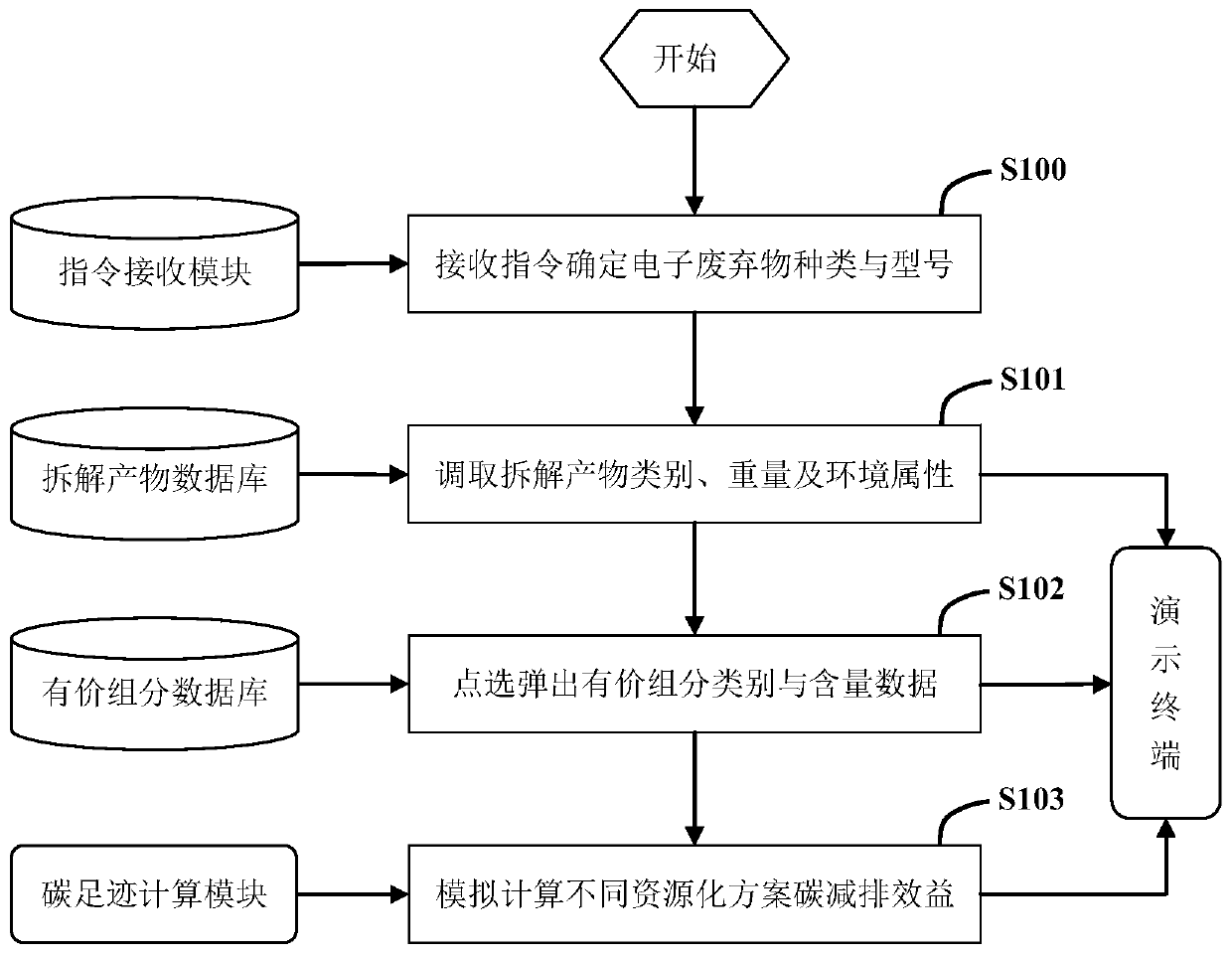

Electronic waste recycling characteristic information demonstration method and system

ActiveCN110046197ASpread quicklyImprove understandingDatabase management systemsVisual data miningCarbon footprintMulti dimensional

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

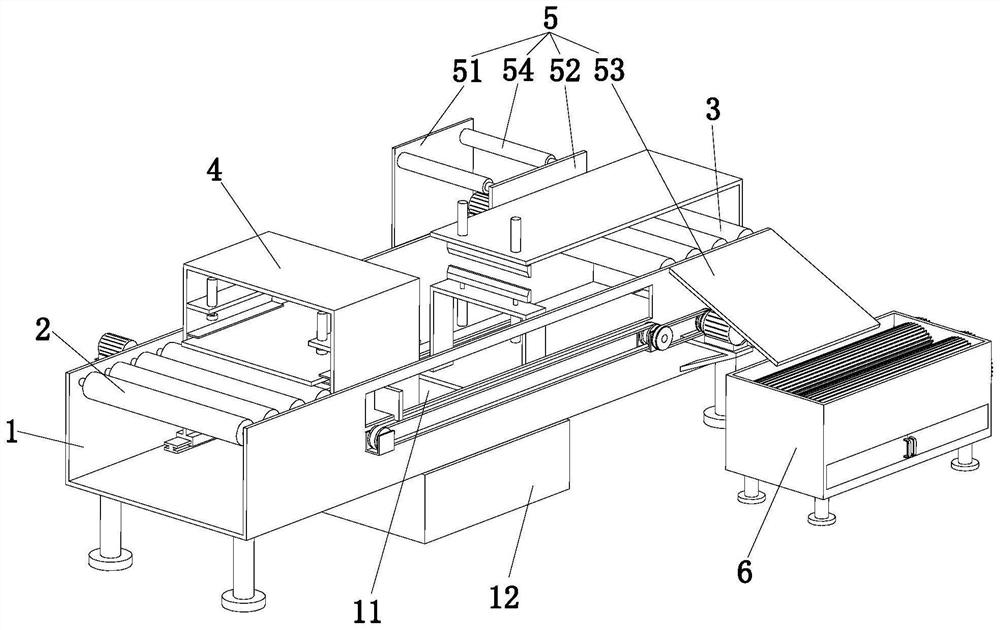

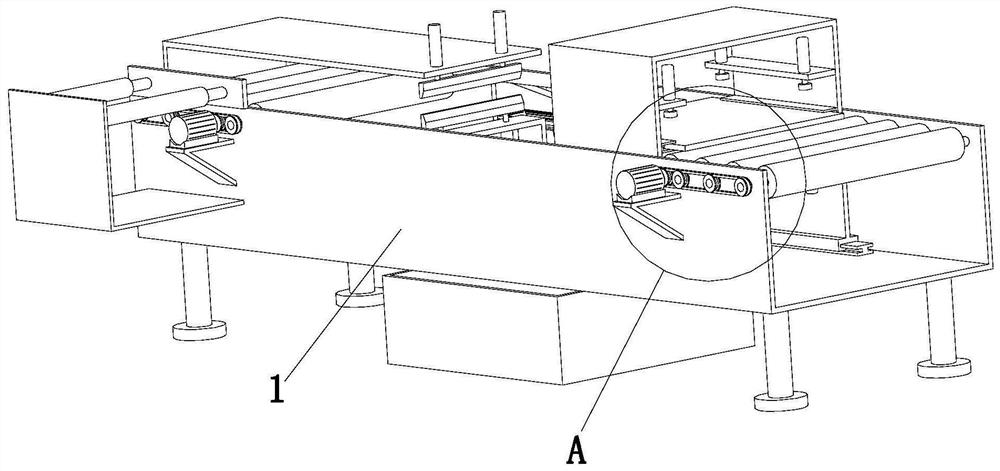

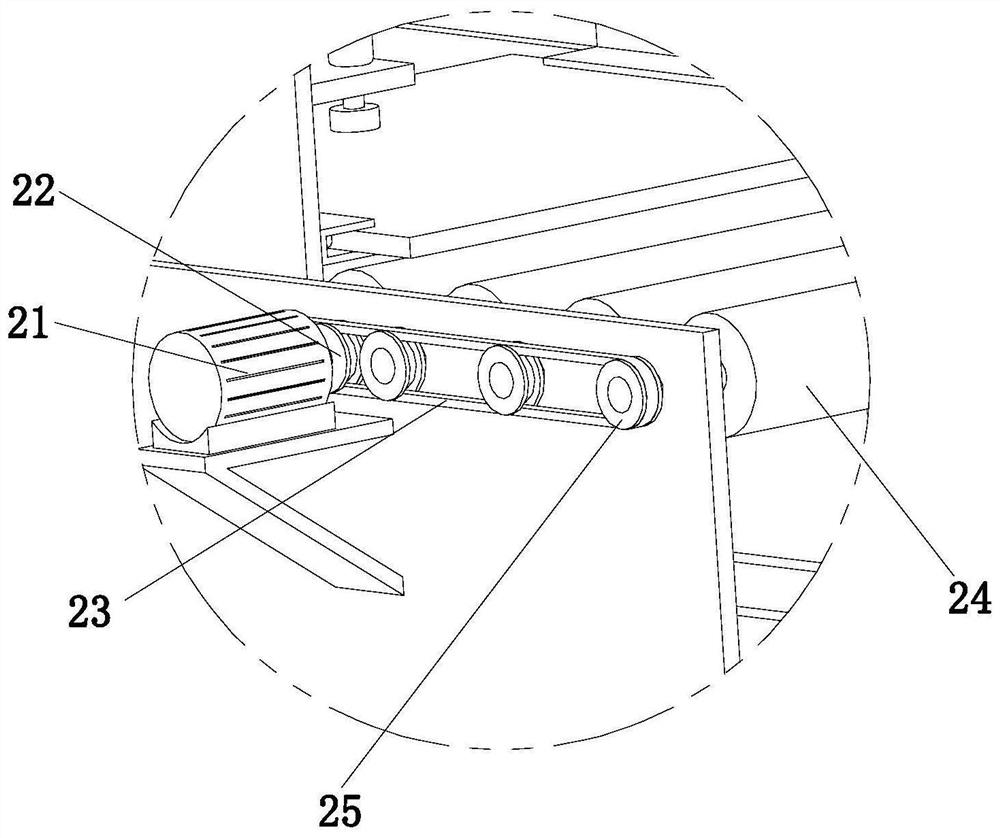

A device for separating and recycling waste copper clad laminates

ActiveCN110921193BTo achieve the purpose of sorting and recyclingNo wasteSolid waste disposalGrain treatmentsEnvironmental engineeringCopper

The invention discloses a waste copper-clad laminate separation and recovery device, which belongs to the technical field of electronic waste recovery, and includes a mounting frame, a feeding and conveying assembly, a feeding and conveying assembly, a clamping and scraping assembly, a feeding and pushing assembly, and a crushing assembly. The mounting frame is arranged on the ground, the feeding and conveying assembly and the unloading conveying assembly are symmetrically arranged at both ends of the mounting frame, the clamping and scraping off assembly is arranged in the mounting frame, and the The clamping and scraping assembly is located between the loading and conveying assembly and the unloading conveying assembly, the unloading pushing assembly is arranged on the mounting frame, and the unloading pushing assembly is located between the unloading and conveying assembly On the side of the assembly, the crushing assembly is arranged on the side of the installation frame. The invention solves the problems in the prior art that waste copper clad laminates are usually directly crushed and then sorted to recover the metal copper therein, and the remaining resin substrate fragments are directly buried, which seriously wastes resources and at the same time has the risk of polluting the soil.

Owner:义乌市昕闵日用品有限公司

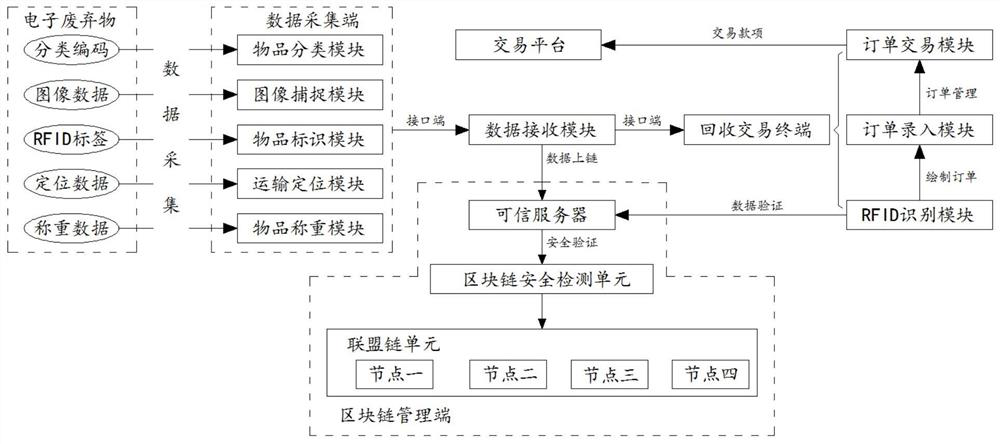

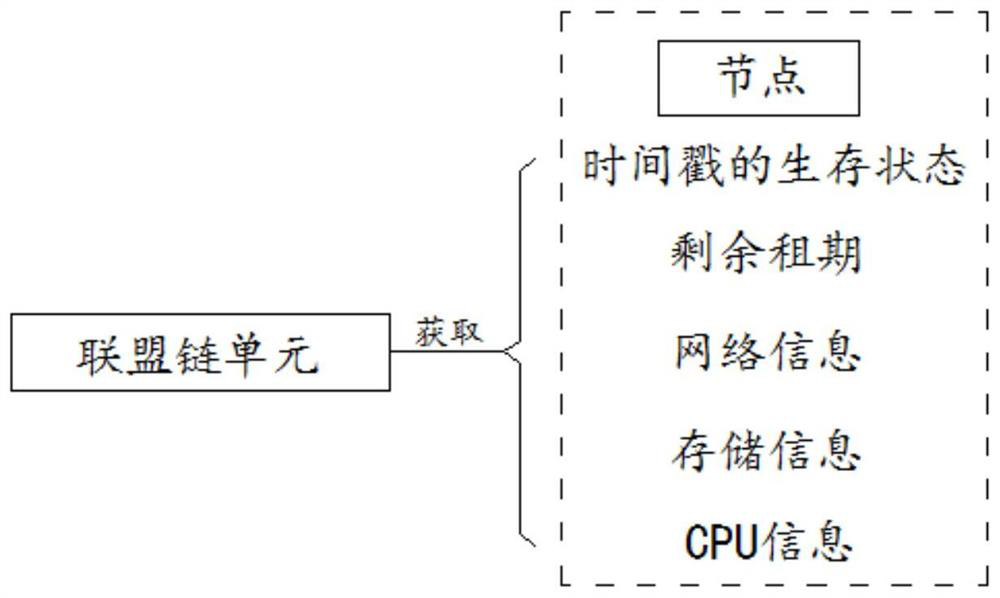

Electronic waste recycling transaction system based on block chain technology

ActiveCN113922950AAchieve decentralizationRealize immutableSustainable waste treatmentFinanceIllegal dumpingResource recovery

The invention discloses an electronic waste recycling transaction system based on a block chain technology, and belongs to the technical field of resource recycling, the electronic waste recycling transaction system comprises a data acquisition end, a block chain management end, a recycling transaction terminal and a transaction platform, the interface end of the data acquisition end is in signal connection with the interface end of a data receiving module; and the interface end of the data receiving module is in signal connection with the interface end of the block chain management end for data communication. According to the electronic waste recycling transaction system based on the block chain technology, uplink management is carried out on various data of electronic waste in the whole recovery transaction process, and the various data can be checked and traced in real time in nodes of the alliance chain unit; according to the invention, efficient and safe data acquisition can be carried out on each link of processes such as recovery classification, transportation, order transaction and the like, decentralization and non-tampering of electronic waste recovery transaction information storage are realized, and the effects of accurate recovery and illegal dumping prevention are achieved.

Owner:江苏环迈数字科技有限公司

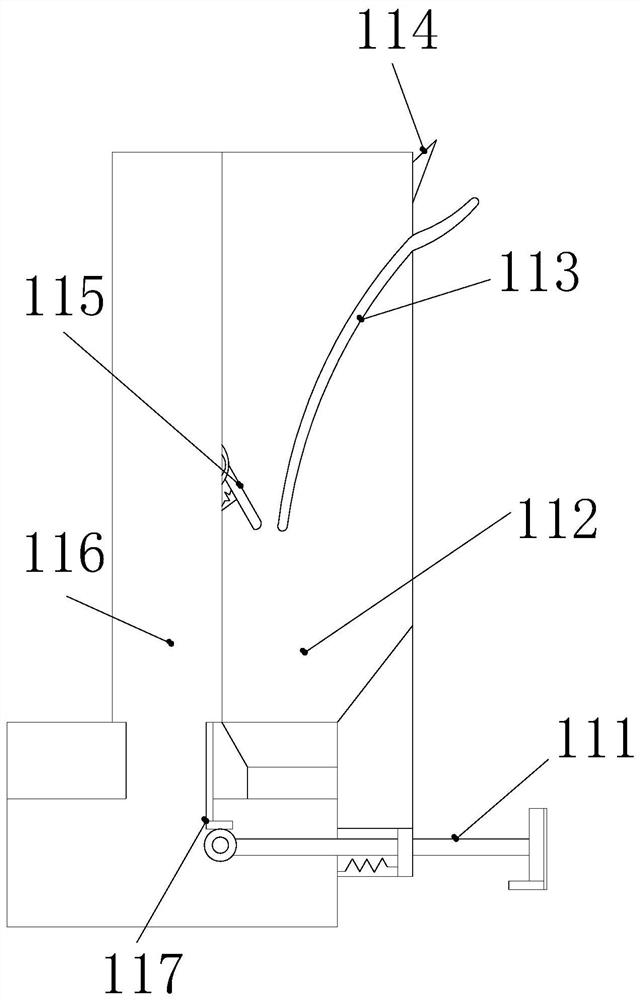

An e-waste recycling device that prevents sucked-out solder from reflowing through the bracket limit

InactiveCN109647847BAvoid cloggingPrevent secondary solidificationTransportation and packagingSolid waste disposalProcess engineeringMechanical engineering

The invention discloses an electronic waste recovery device that prevents sucked-out solder from reflowing through the limit of a bracket. The side end surface is flexibly connected with the device housing at the same time, and the card slot is located inside the device housing and is movably connected with the device housing. After the solder is melted by high temperature, the upper rod is pressed down, so that the lower special-shaped rod continues to press down. Therefore, the rollers are used to move the special-shaped rod to make the front push rod frame move forward, and the internal filaments are fixed by the push rod frame through the inward joint of both ends without manual manipulation. At the same time, it is absorbed by the negative pressure tube and soldered at the same time. It is sucked out and clamped on the matching frame, and the solder is cooled under the cooling of the gas flow, and is recycled to the interior of the disconnected collection chamber through the scraper and the inclined plate, thereby preventing the secondary solidification of the solder.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com