Patents

Literature

675results about How to "Simple recycling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

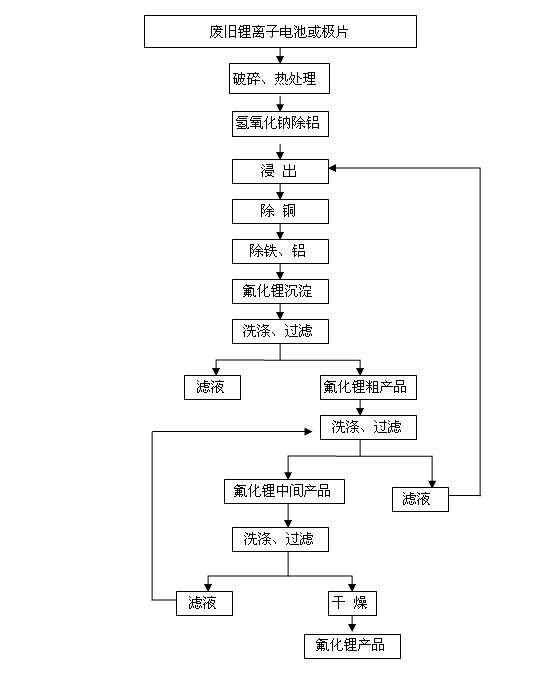

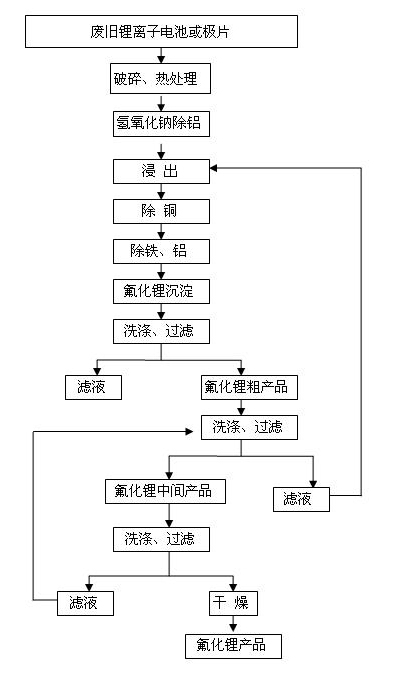

Method for recovering lithium from waste lithium ion battery and waste pole piece

ActiveCN101942569AHigh recovery rateEffectively realize comprehensive recyclingProcess efficiency improvementPhysical chemistryLithium-ion battery

The invention discloses a method for recovering lithium from a waste lithium ion battery and a waste pole piece. The method comprises the following steps of: (1) crushing the waste lithium ion battery or the waste pole piece by using a crusher, placing the crushed material in a high-temperature furnace and removing an adhesive from the crushed material by thermal processing to obtain powder; (2) removing aluminum from the powder by dissolving the aluminum in sodium hydroxide solution and filtering the solution to obtain low-aluminum filter mud; (3) leaching the low-aluminum filter mud with acid and a reducing agent to obtain lixivium; (4) removing impurities such as iron, copper, aluminum and the like from the lixivium by a chemical method; (5) precipitating lithium in the lixivium with fluorine salt to obtain a lithium fluoride rough product; (6) washing the lithium fluoride rough product, filtering and drying to obtain a lithium fluoride product; and (7) returning filtrate obtained after the lithium fluoride rough product is washed to the step (3) for processing. By the method of the invention, the lithium fluoride product has purity of over 98.0 percent and the primary recoveryrate of lithium is between 75 and 92 percent; and the method of the invention has the advantages of simple process, low cost, easy industrial production and high economic benefit.

Owner:HUNAN BRUNP RECYCLING TECH

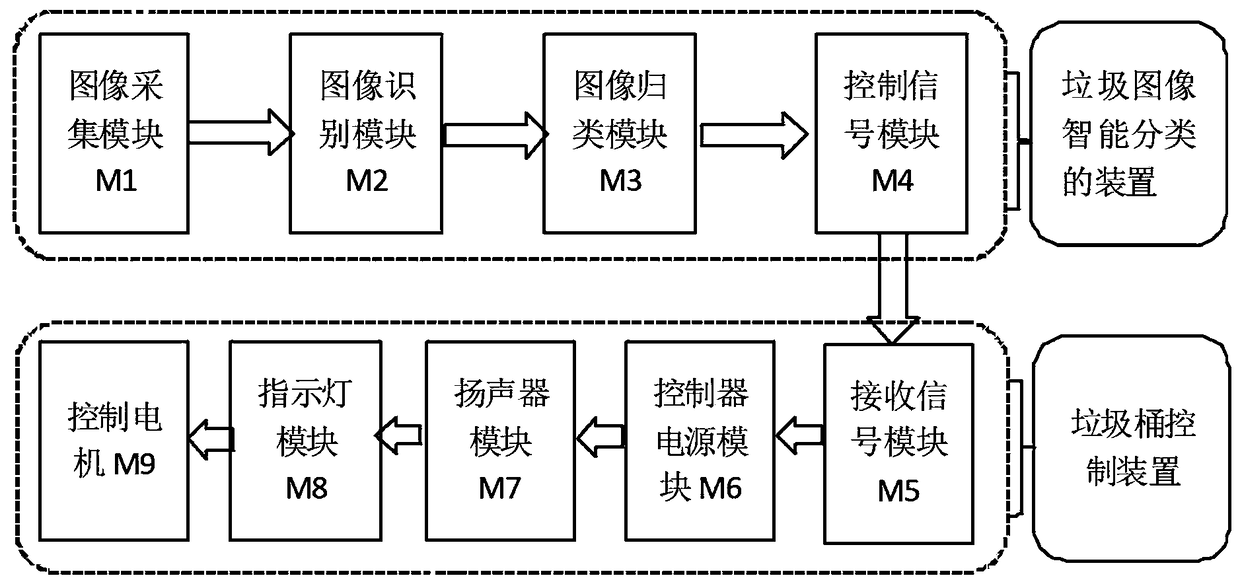

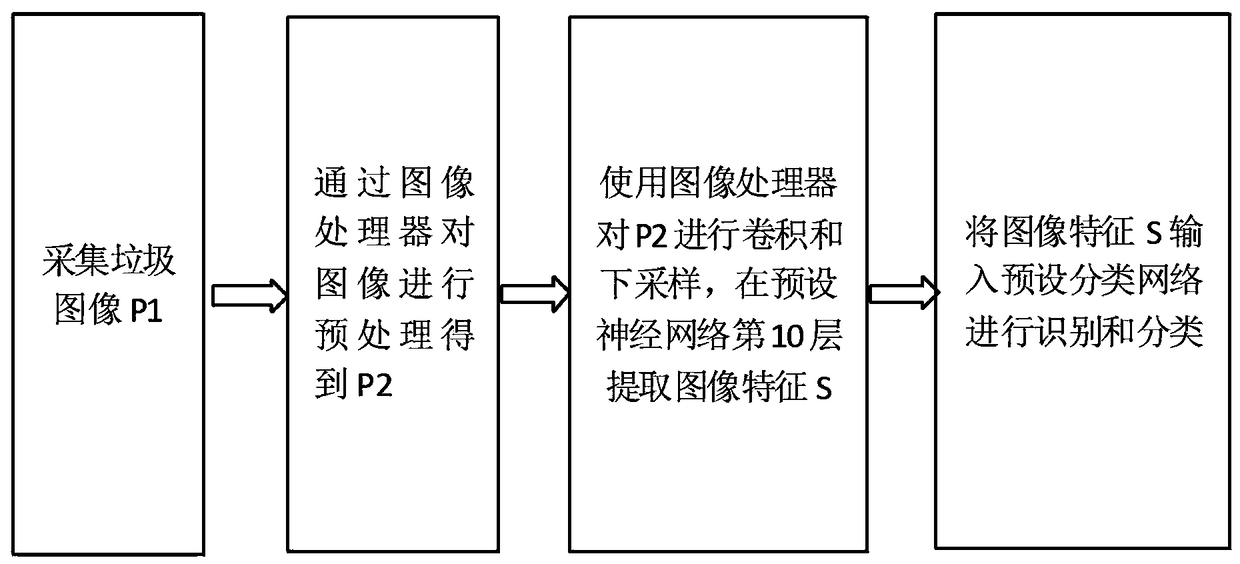

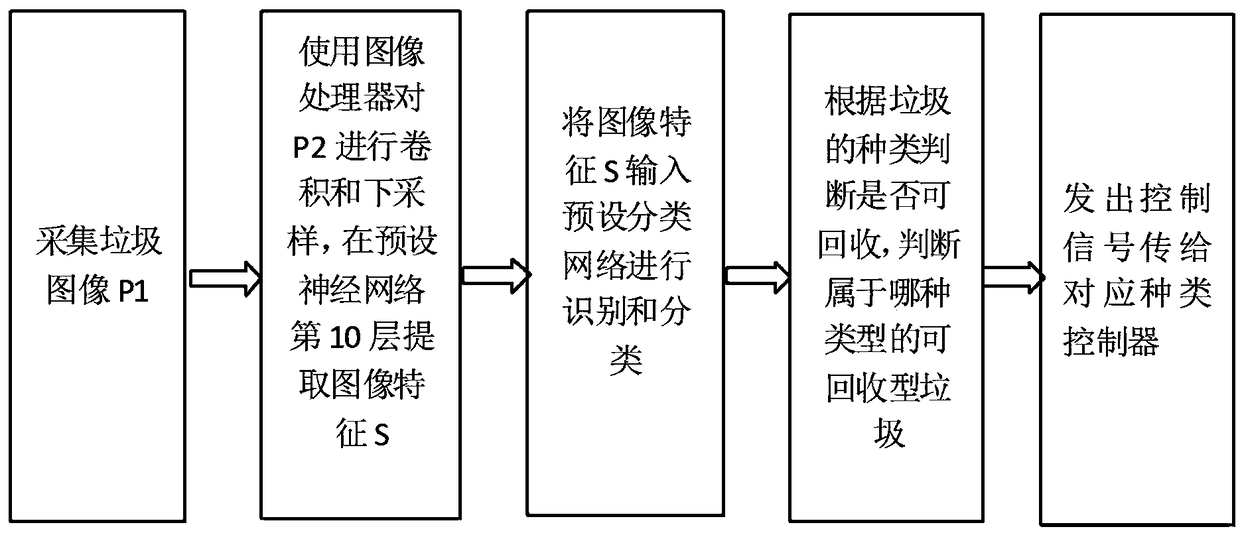

Method for intelligent classification of garbage images

InactiveCN108182455ASimple recycling processReduce pollutionWaste collection and transferCharacter and pattern recognitionImage extractionClassification methods

The invention discloses a method for intelligent classification of garbage images. The method is implemented as follows: a high-definition collecting device including a camera collects a garbage image; the collected garbage image is preprocessed; convolution and pooling processing are carried out on the pre-processed garbage image, feature image extraction is carried out, and then a feature imageis identified; and according to an identification result, whether the garbage type is a recyclable garbage type is determined. Compared with the prior art, the intelligent classification method has the following beneficial effects: identification and classification are carried out on the collected garbage images by using the camera, an image identification processor, and a controller to determinewhether the garbage is recyclable, so that manual garbage classification is not needed, the environmental awareness of people is strengthened, the waste pollution is reduced, and thus sustainable development is promoted. The intelligent classification method having advantages of high practicability and wide application range is easy to promote.

Owner:QILU UNIV OF TECH

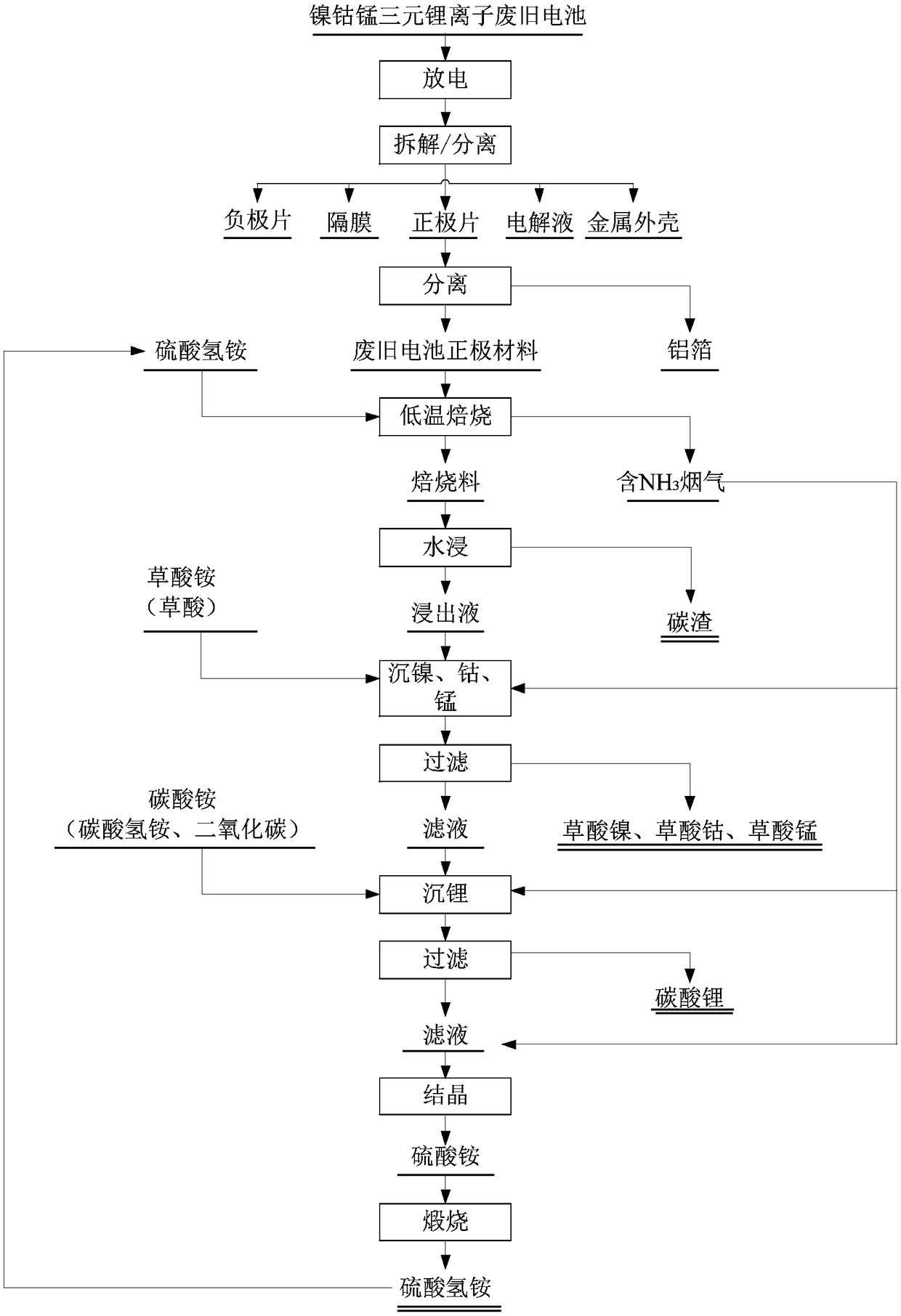

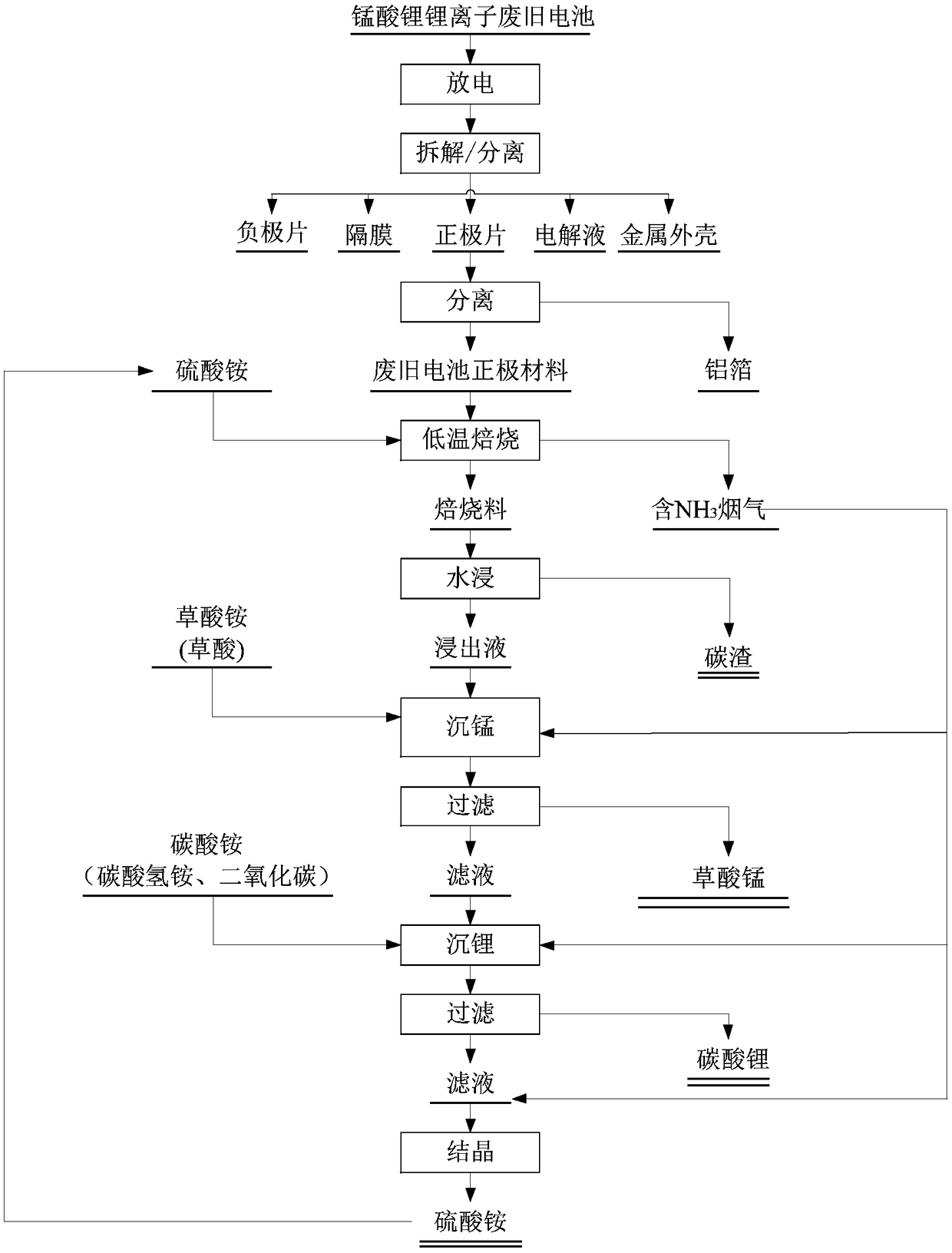

Method for recovering valuable metals from positive electrode material of waste lithium ion battery

ActiveCN108767354AHigh recovery rateAvoid it happening againWaste accumulators reclaimingProcess efficiency improvementLithium-ion batteryMaterials science

The invention provides a simple, efficient and environment-friendly method for recovering valuable metals from a positive electrode material of a waste lithium ion battery; the method comprises the following steps of performing discharging of a salt solution; performing disassembling to separate a positive plate; performing smashing on the positive plate to separate a positive electrode material and an aluminum foil; performing mixed low-temperature roasting on the positive electrode material and a roasting agent ammonium sulfate and / or ammonium bisulfate; performing leaching on the roasted material and separating to obtain carbon and a lixivium; adding a precipitant into the lixivium, and regulating the pH value by using NH<3>-containing flue gas, performing deposition on other metals except Li, and carrying out solid-liquid separation; regulating the pH value of a filtrate by using the NH3-containing flue gas, adding ammonium carbonate or ammonium bicarbonate or pumping CO<2> gas, and carrying out lithium precipitation to obtain a lithium carbonate product. The preparation process is simple, the process conditions are mild, the time required by the process is short, a large amount of acid and alkali do not need to be consumed, and the cost is low; and in addition, recovery of the valuable metals and carbon from the positive electrode material can be effectively realized, themethod is green and environment-friendly, and a large amount of solid waste and wastewater cannot be generated.

Owner:CENT SOUTH UNIV

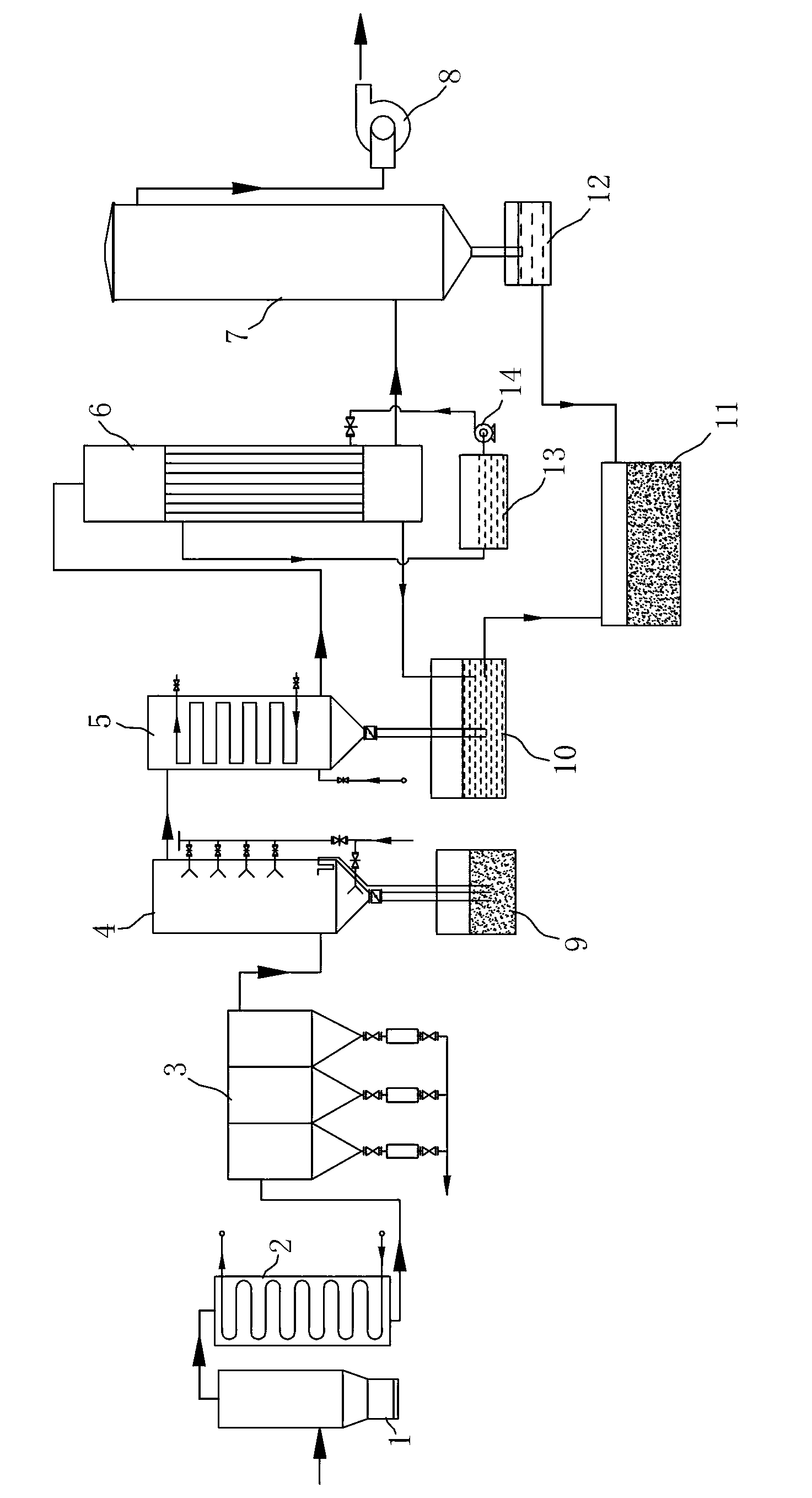

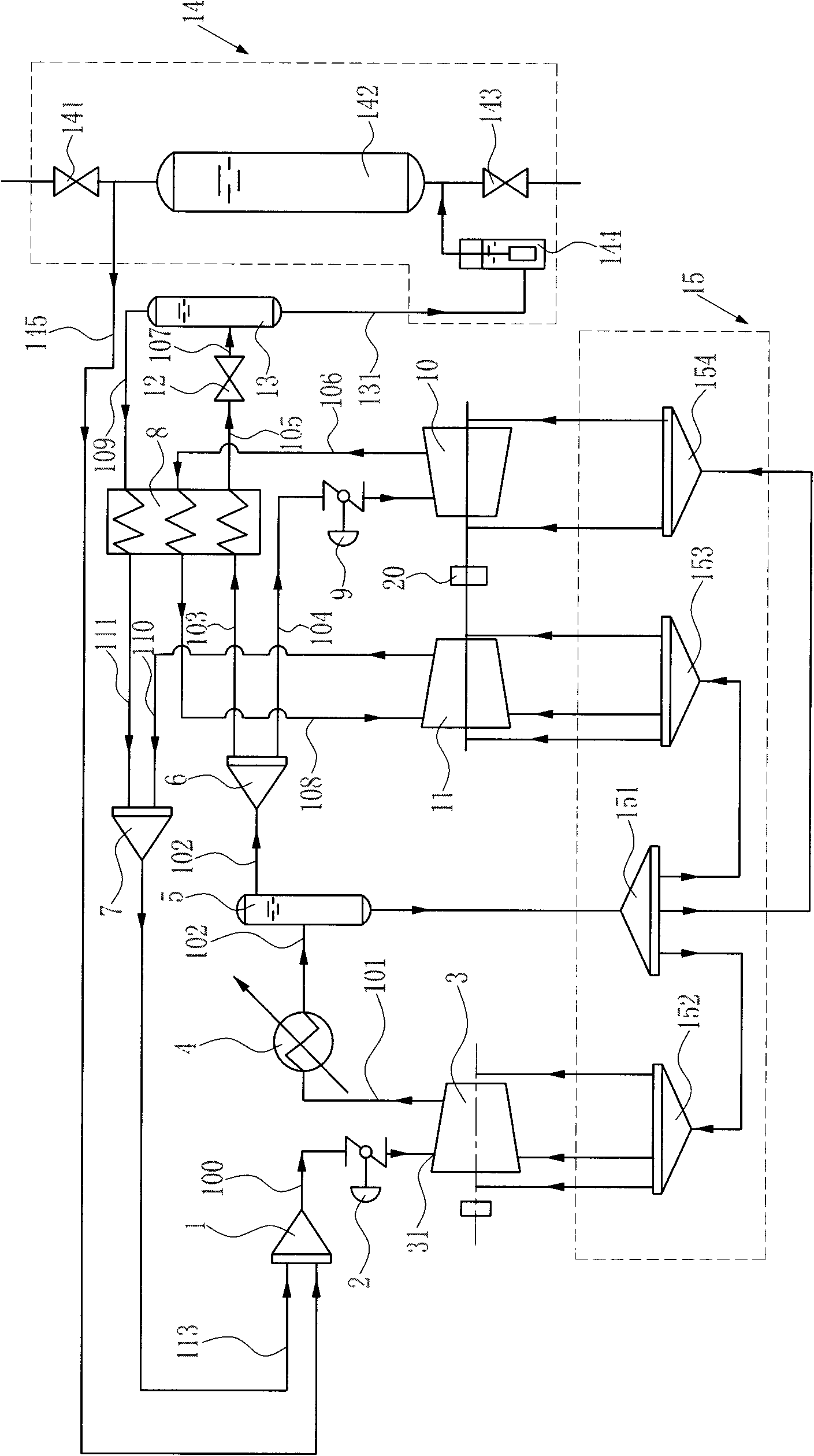

Process for dust removing, cooling and tar oil recovering of pyrolysis coal gas

The invention discloses a process for dust removing, cooling and tar oil recovering of pyrolysis coal gas. The process adopts an overheater, a high-temperature dust remover, an accident quench tower, a waste heat recovering boiler, an indirect cooling device and an electrical tar precipitator which are connected in sequence, and comprises the following steps: pyrolysis coal gas is fed into the overheater to be cooled to 400-700 DEG C, fed into the high-temperature dust remover to be subjected to dust removing, fed into the waste heat recovering boiler to be cooled to 50-100 DEG C and condensed to separate out water and tar oil, fed into the indirect cooling device to be cooled to 10-30 DEG C and further condensed to separate out water and tar oil, and finally fed into the electrical tar precipitator, so that the carried tar oil mist and water mist are recovered. According to the process, dust particles in the coal gas are removed by high-performance dust removing equipment before condensing of tar oil, so as to prevent tar oil and dust separated out through condensation in the coal gas cooling process from being mixed together, improve the quality of tar oil and avoid the problems of equipment blockage and high dust content of tar oil.

Owner:ZHEJIANG UNIV

Solvent recovery method for cellulose fiber preparation with ion liquid as solvent

InactiveCN1804161AImprove protectionGood for healthArtificial filament recoveryTextile/flexible product manufactureRecovery methodFiltration

The invention provides a solvent recovery method in the cellulose fiber preparation process by using ionic liquid as the solvent, which comprises subjecting coagulating bath components to precipitation, filtration, vacuum distillation and normal atmosphere distillation.

Owner:DONGHUA UNIV

Method for preparing rare earth oxide from rare earth polishing powder waste

ActiveCN103103361ASimple recycling processLow costProcess efficiency improvementHydrogen fluorideAfter treatment

The invention relates to a method for preparing rare earth oxide from rare earth polishing powder waste. The method is characterized in that the rare earth polishing powder waste is subjected to alkali roasting and washed acidification for decontaminating and is precipitated, filtered, washed and dried to obtain a rare earth oxide finished product. Acidified filtrate is precipitated and filtered for decontaminating and is burnt to obtain the rare earth oxide finished product. The method has the advantages that acids, such as hydrogen fluoride and nitric acid great harm to the environment are not used, the recycling process is pollution-free, the rare earth polishing powder waste is reasonably utilized comprehensively, the rare earth recovery ratio achieves more than 90%, and the rare earth oxide finished product with the purity of more than 95% can be prepared. Alkali and acid wastewater can be recycled after treatment, the rare earth polishing powder waste is utilized comprehensively, and the entire recovery process is environmentally-friendly and pollution-free.

Owner:BAOTOU RES INST OF RARE EARTHS

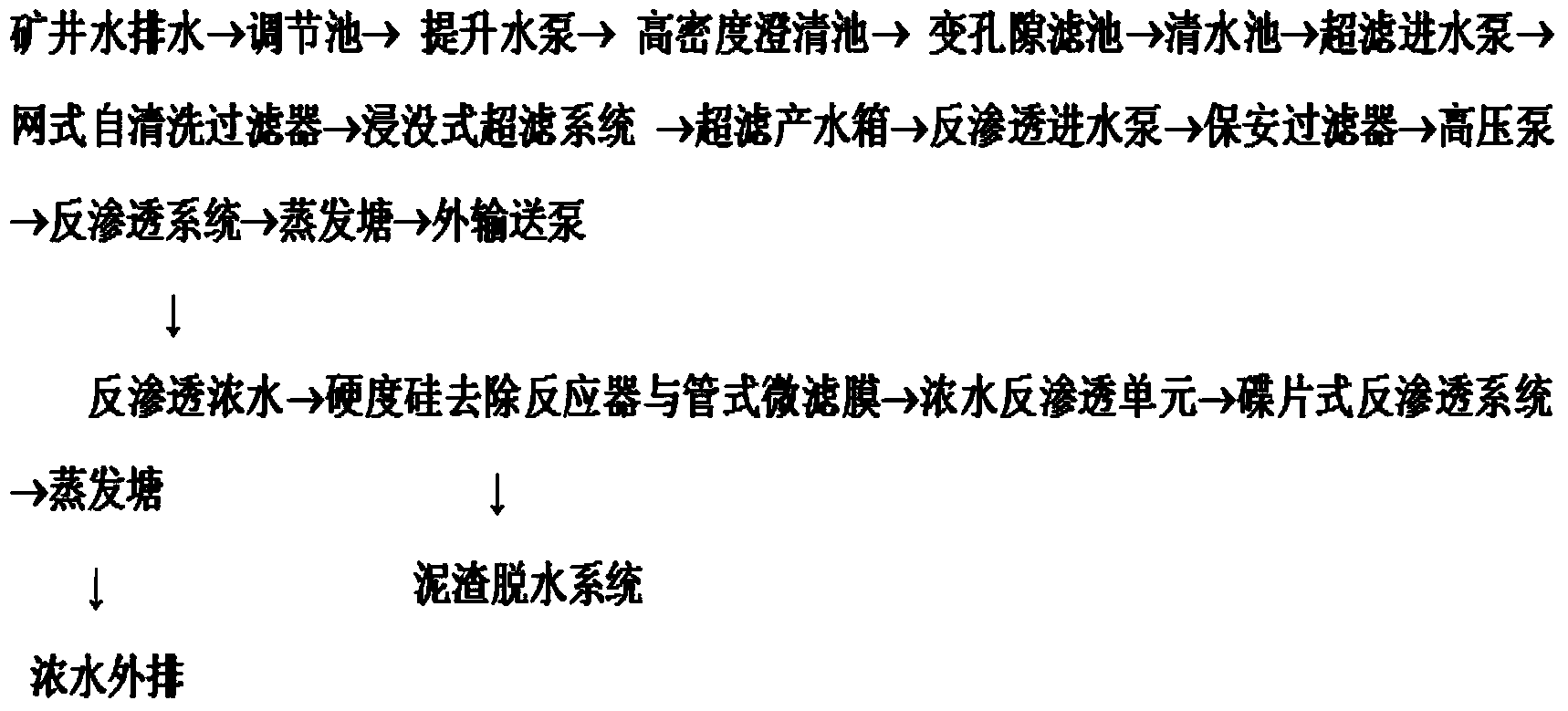

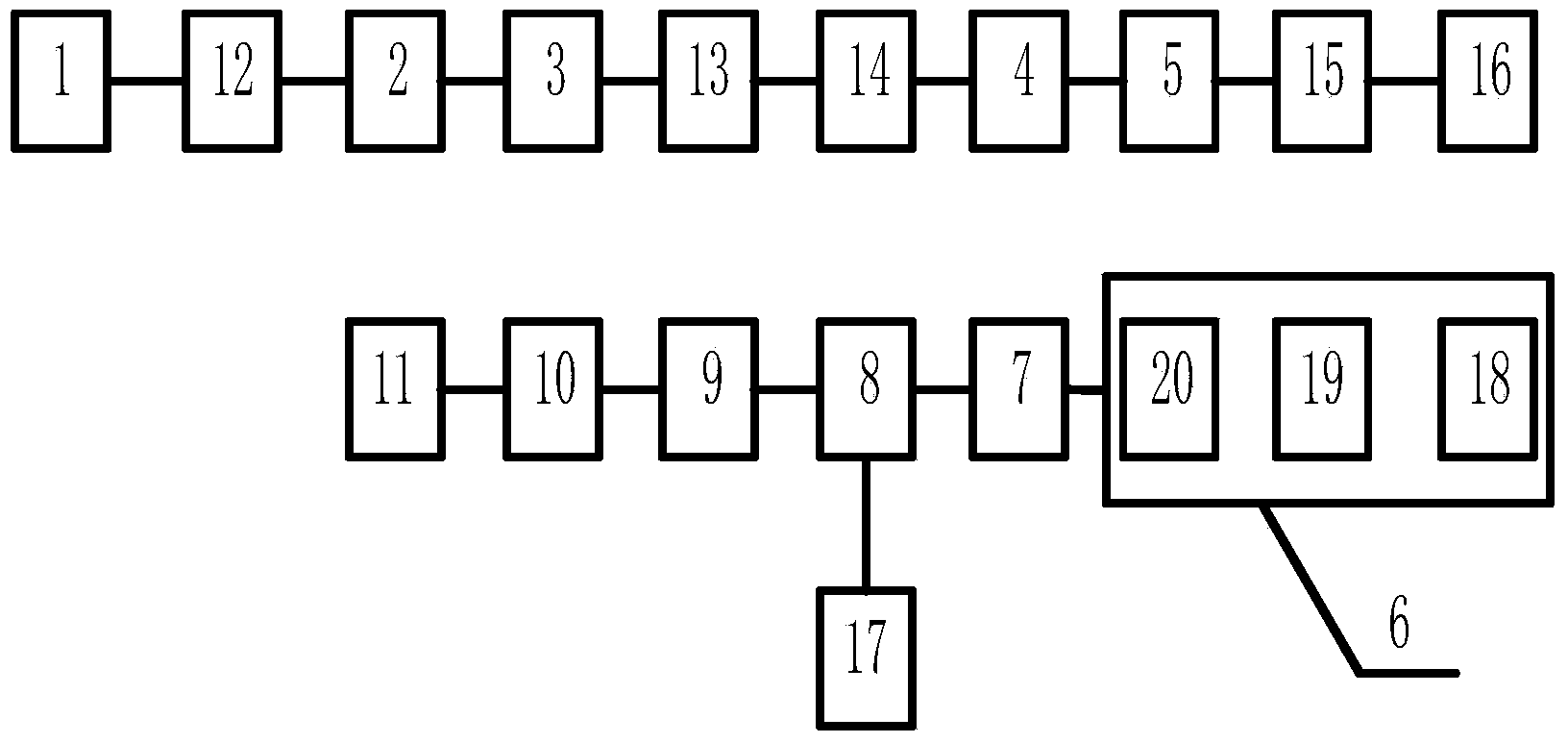

Method and system for high-efficiency recovery of high-salinity mine water

ActiveCN103523980ANo lossHigh strengthWaste water treatment from quariesScale removal and water softeningFiltration membraneReverse osmosis

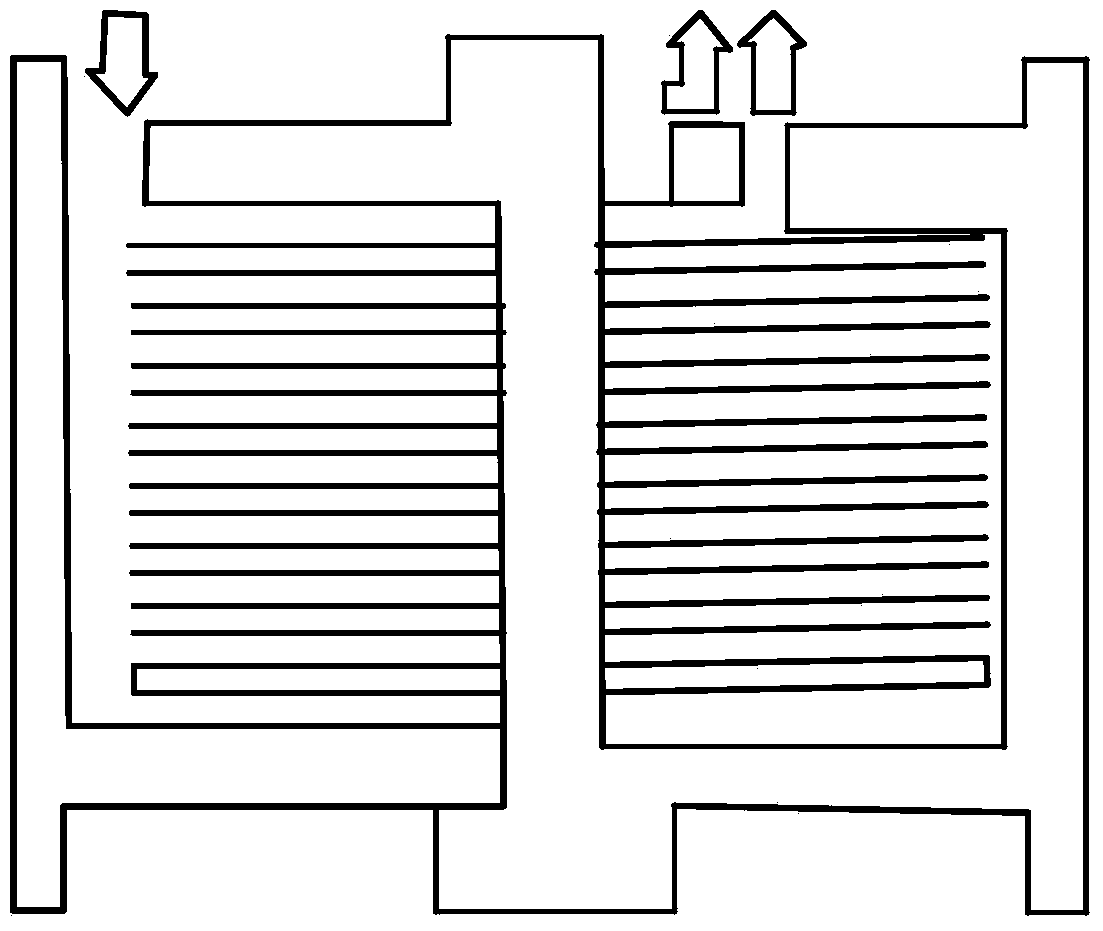

The invention discloses a method and system for high-efficiency recovery of high-salinity mine water. The method comprises the following steps: removing colemanite, bicarbonate radicals and suspended solids by using a high-density clarifying pond to reduce reverse osmosis structure tendency; subjecting concentrated reverse osmosis water to chemical softening pretreatment to remove easily fouling components; and carrying out solid-liquid separation by using a tubular micro-filtration membrane and allowing separated liquid to enter into a concentrated water reverse osmosis unit. According to the invention, the concentrated reverse osmosis water undergoes chemical softening pretreatment to remove the easily fouling components, the tubular micro-filtration membrane is employed for solid-liquid separation, the separated liquid directly enters into the concentrated water reverse osmosis unit without treatment by other filtering units, so operation process flow is simplified, a land occupation area is reduced, designed flux is great, and a good effluent effect is obtained. The tubular micro-filtration membrane used in the invention is different from other micro-filtration or ultra-filtration membranes; the tubular micro-filtration membrane runs in a cross flow mode, water flow tangentially flows through the surface of the membrane at a high speed, thereby realizing scouring and cleaning of the membrane surface while carrying out filtering, and the membrane surface is hardly contaminated.

Owner:华电水务工程有限公司

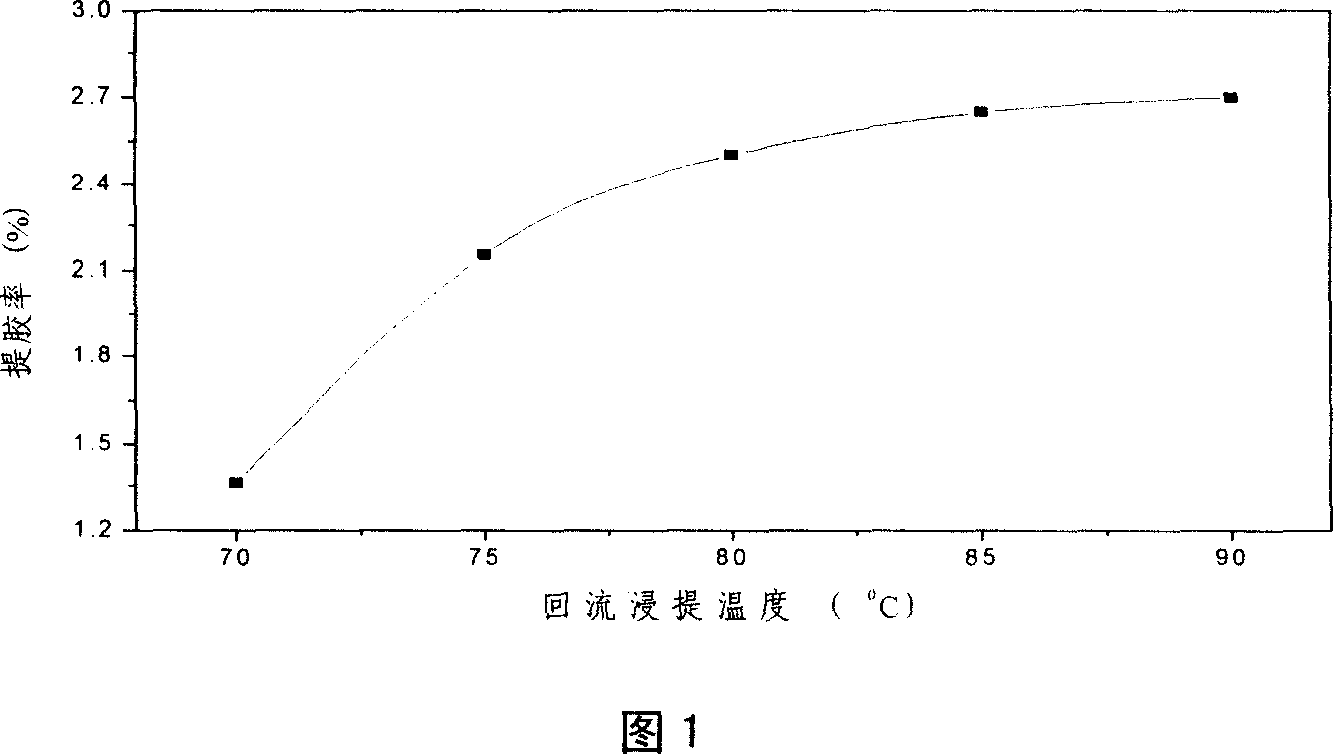

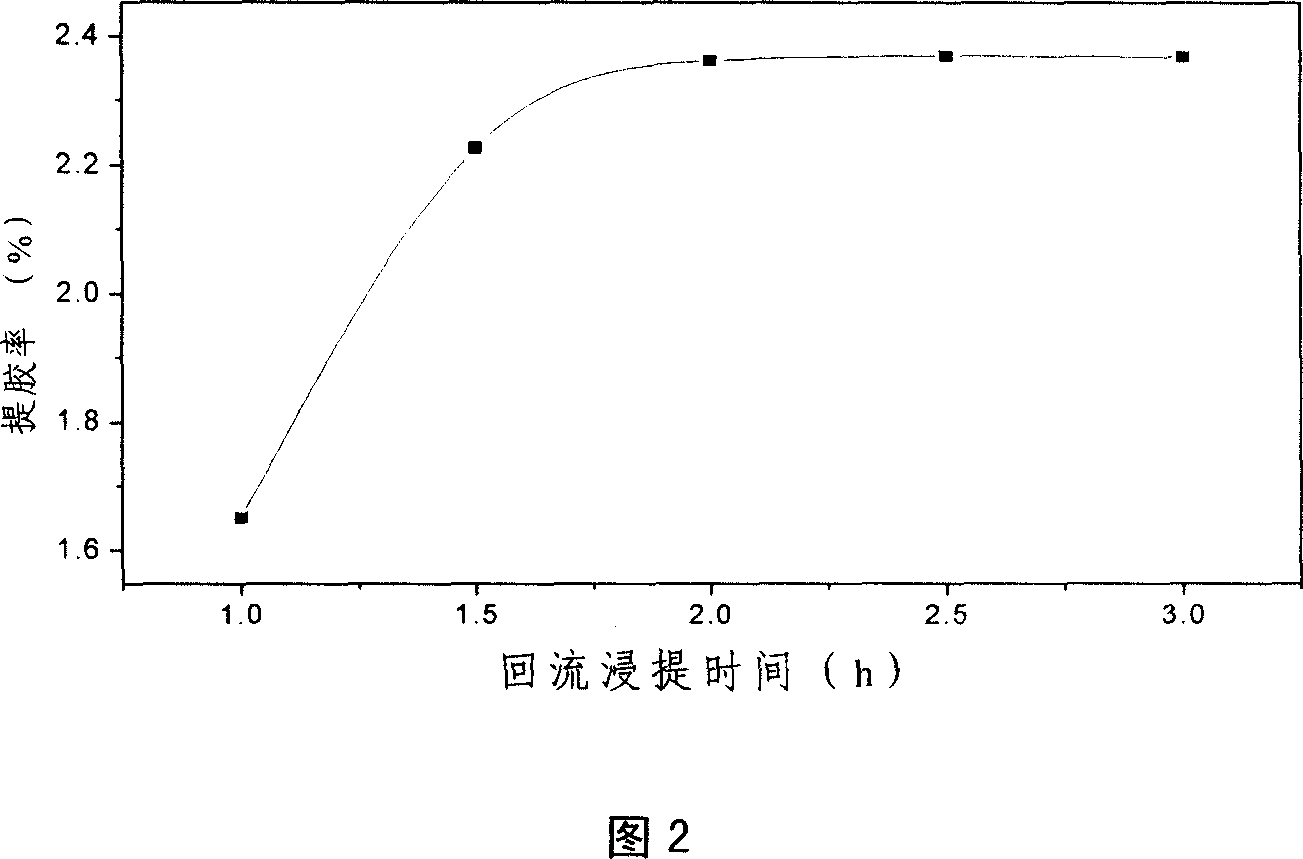

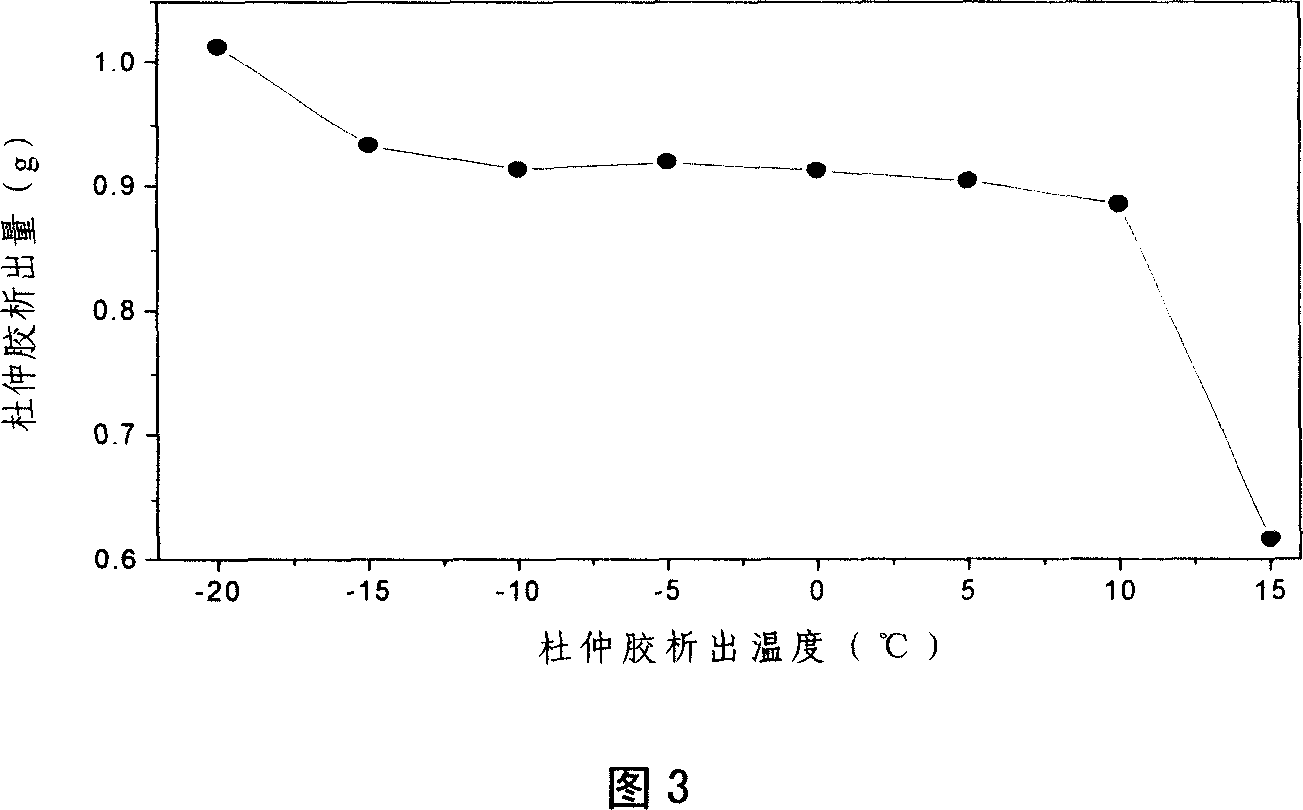

Method of extracting gutta percha by solvent circulation

This invention provides a solvent circulate extraction of gutta percha, and the ligarine is used for extraction of gutta percha from folium eucommiae or skin eucommiae. Its craft includes: (1)The raw material is through circulation drying in baking oven, and then shatterred by crusher, cribration. (2)The ligarine is added in accordance with dosage liquor ratio, refluxing in hot bath water. (3)Filtering as hot as possible, segregating its dregs and collecting the filtrate. (4)The filtrate is filtered after water cooling and hypothermy cold storage to reclaim gutta percha solid and filtrate separately. (5)The filtrate degelatinized mixes again with dregs, and then refluxing. (6)Crude product is obtained by combining gutta percha after conducting repetitive operation twice. (7)The ligarine reclaimed still can be used for extraction of gutta percha.

Owner:GUIZHOU UNIV

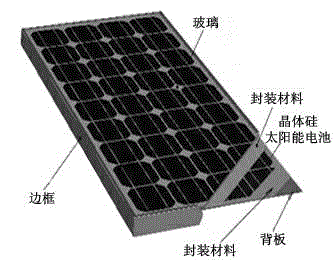

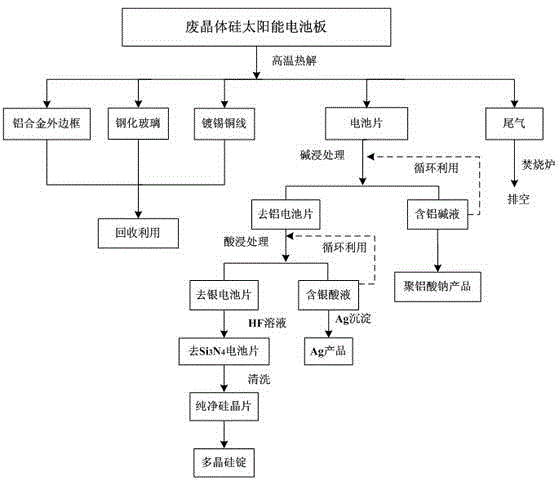

Waste crystalline silicon solar cell panel disassembling and recovering method

ActiveCN103978021AIncrease added valueRealize sorting and recyclingWaste processingSolid waste disposalWaferingPhysical chemistry

The invention discloses a waste crystalline silicon solar cell panel disassembling and recovering method. The method can realize the classification recovery of aluminum frames, toughened glass, silicon wafers, aluminum, silver and copper of waste crystalline silicon solar cell panels. The method adopts a heat treatment technology and a chemical technology combination technique to realize the frame and glass recovery of the waste crystalline silicon solar cell panels, the silicon wafer separation, and the valuable metal and silicon wafer recovery. The method has the advantages of recovery treatment difficulty reduction, tail gas harmlessness realization, secondary pollution control and environment protection; and an alkali dipping treatment and acid dipping treatment solution can be recycled, so the reagent consumption is reduced, the waste acid and waste alkali generation amount is reduced, and the final waste treatment cost is reduced.

Owner:刘景洋

Method for recycling positive material of waste lithium iron phosphate battery

InactiveCN102709620ASimple recycling processReduce equipment investmentWaste accumulators reclaimingBattery recyclingPre treatmentScrap

The invention discloses a simple and easy method for recycling positive material of a waste lithium iron phosphate battery, and the method can be used for the industrial production. The method comprises the following steps: firstly, carrying out total discharge (0.05V) on the waste lithium iron phosphate battery, then mechanically disassembling the battery in a fume hood and screening a positive plate; and placing the positive material into water to carry out ultrasonic stirring, sieving out an aluminium foil, drying the residual solution and material, carrying out ball milling, carrying out elemental analysis, matching the obtained material with a novel raw material and carrying out sintering to obtain the lithium iron phosphate positive material with superior performances. The method has the significance that according to the simple method for recycling the lithium iron phosphate positive material which can be used for the industrial production, the positive material with the superior performances can be obtained by utilizing additives in wastes, such as acetylene black and the like, without carrying out the pretreatment.

Owner:ZHEJIANG UNIV

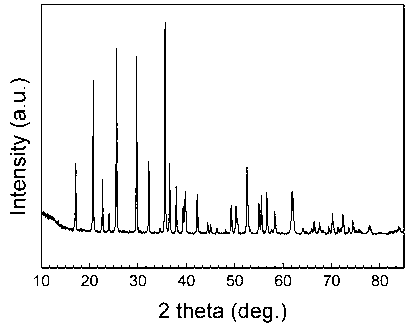

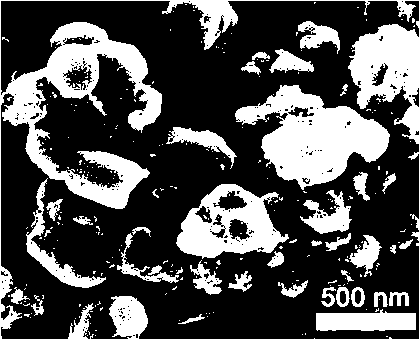

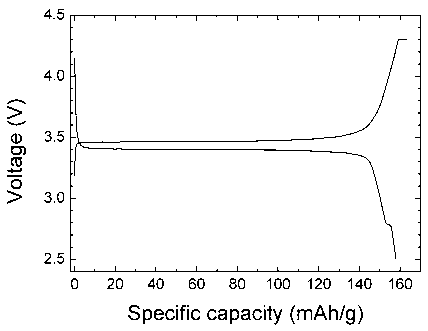

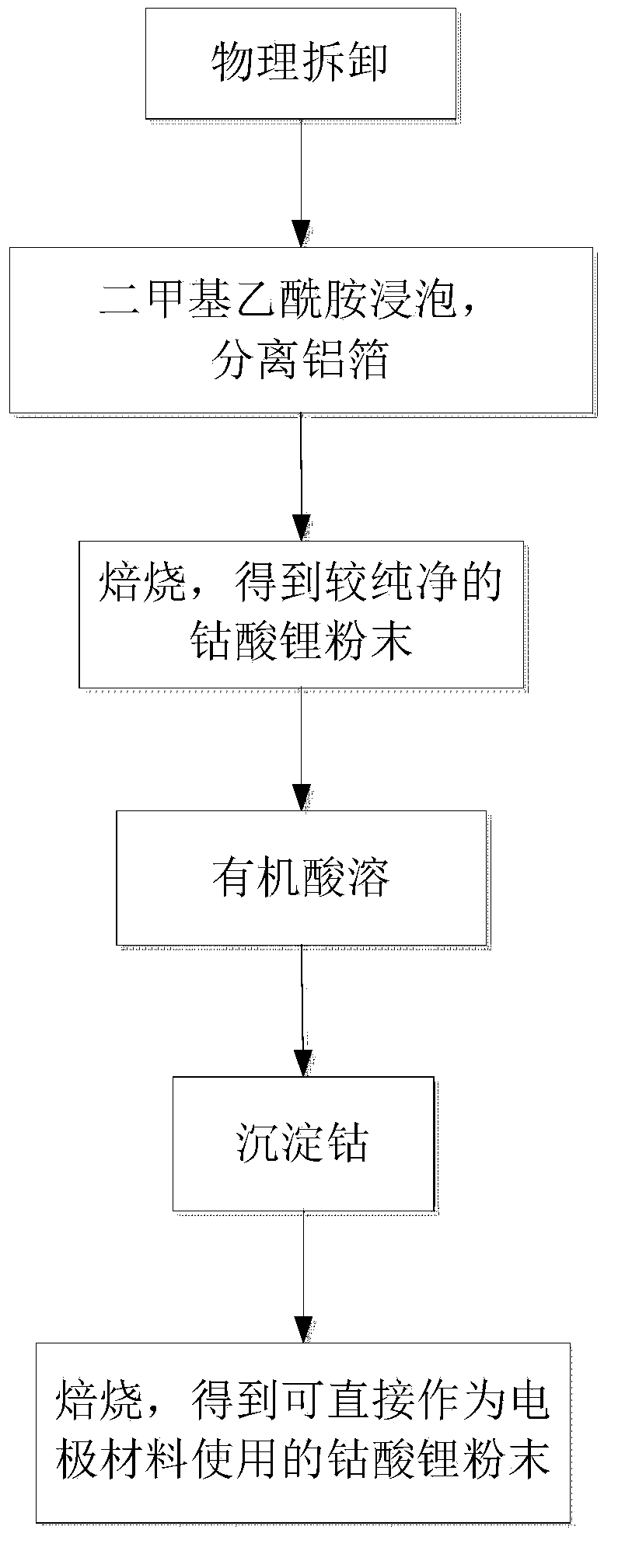

Method for recovering cobalt from lithium battery anode material

ActiveCN103474718AHigh recovery rateLow powder impurity contentWaste accumulators reclaimingBattery recyclingSolid matterAmmonium oxalate

The invention discloses a method for recovering cobalt from a lithium battery anode material. The method is characterized by comprising the following steps of: (1) removing aluminum foil from the anode material, obtaining a black solid matter containing lithium cobalt oxide, roasting the black solid matter to form lithium cobalt oxide powder, (2) weighing and adding the lithium cobalt oxide powder into 119-240g / L of citric acid according to a solid-to-liquid ratio of (20-30):1g / L, adding hydrogen peroxide at a mass fraction of 30% according to a mole ratio of 2:(1-1.05), performing stirring leaching for 5-7h at 80-90 DEG C, filtering to form filtrate containing the cobalt, (3) adding an ammonium oxalate solution into the filtrate to form a cobalt oxalate precipitate, and (4) after drying the cobalt oxalate precipitate, adding lithium carbonate powder according to a mole ratio (1:(1-1.05)) of the cobalt to lithium, grinding uniformly, roasting for 6-8h at 800-850 DEG C, and obtaining lithium cobalt oxide powder capable of directly serving as the electrode material. The method is easy to operate and high in recovery rate, equipment is simple, waste liquid is easy to treat, and the pollution of waste lithium batteries to an environment can be effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH WUCHANG BRANCH

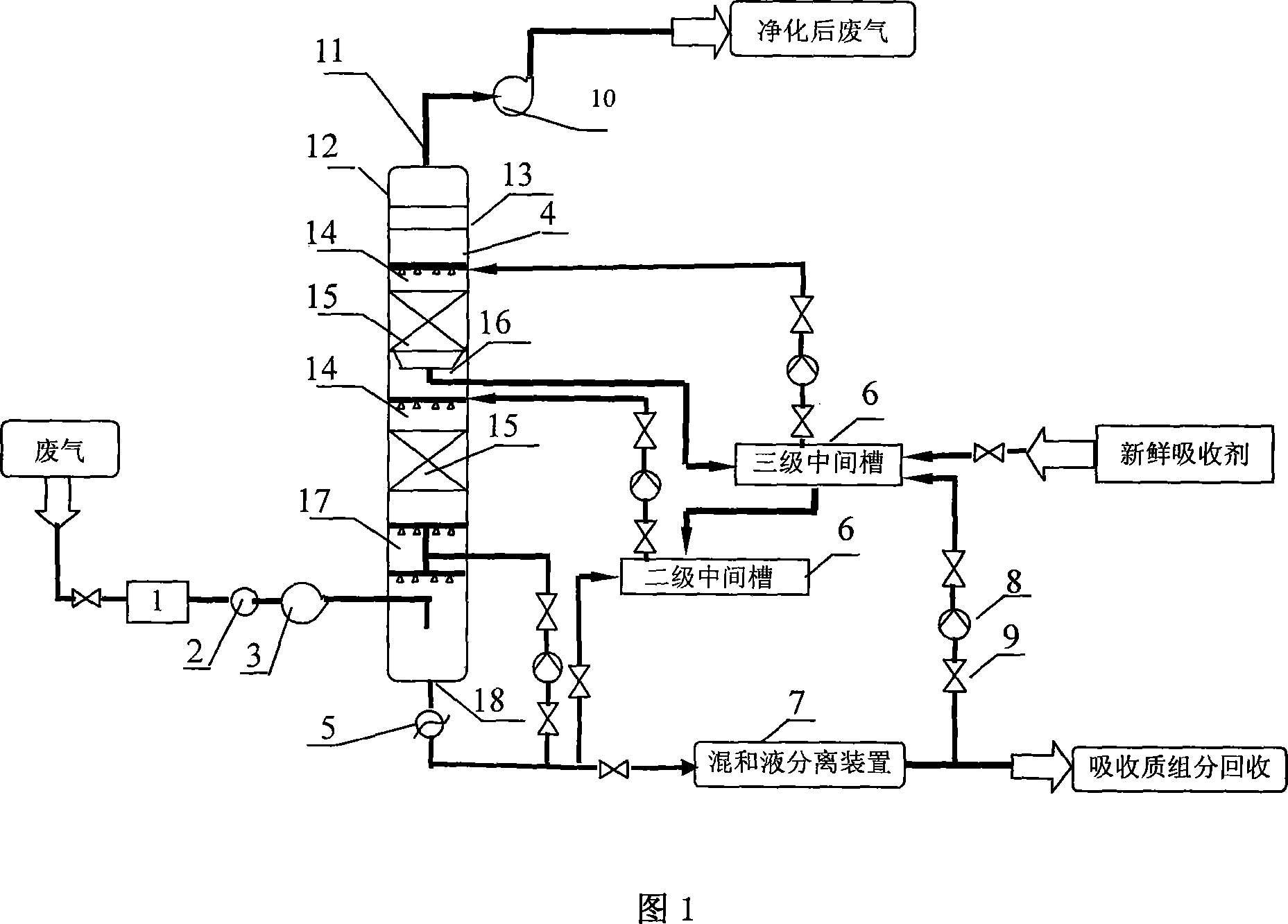

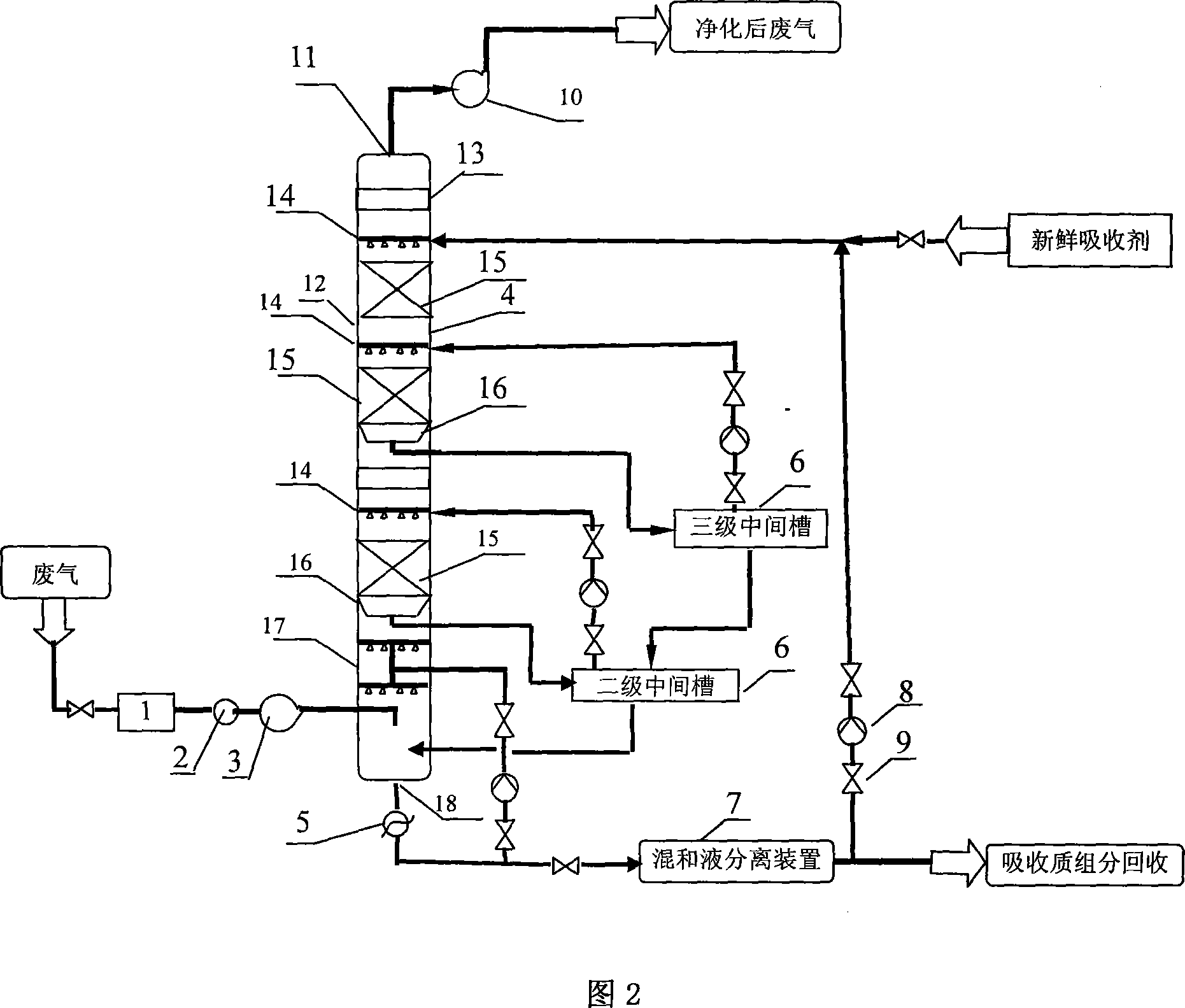

Process method of purifying and recycling mixed organic waste gas

InactiveCN101108296APromote absorptionHigh flash pointDispersed particle separationChemical industryOrganic solvent

The invention belongs to chemical industry and waste gas process field, in particular providing a process method which mixes organic waste gas purifying and resource recovery. The specific procedure is that: make the mixed waste gas pass through a filter to be filtered, and then enters into a single-seat multilevel absorption tower and contacts with a packing layer and a liquid distribution device; when the series of the single-seat tower is 3, the second-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising the mixing liquid which is pumped in after cooled by a heat interchanger at the bottom of the adsorption tower and the mixing liquid which generates in the middle groove of the third-grade; the third-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising fresh absorbent, the regenerating liquid recycled by a mixing liquid separation device and the collecting liquid collected by a collecting hopper of third-grade; when the series of the single-seat tower is N and is larger than 3, all grades of absorbent from the second grade to the N minus 2 is a mixing liquid comprising a mixing liquid generated in the middle groove of the next grade and a collecting liquid collected by the collecting hopper on the same grade, the absorbent of the N minus grade is the colleting liquid collected by the collecting hopper of the N minus 1 grade, the absorbent of the N grade is a mixing liquid comprising of pumped fresh absorbent and the regenerating liquid recycled by the mixing liquid separation device. The fresh absorbent is an environment-protected organic solvent with high boiling point, strong lipophilicity and low volatility. The invention can recycle a plurality of organic infectant in waste gas, the technics procedure is simple, practical, and the operation cost is low.

Owner:上海同济华康环境科技有限公司

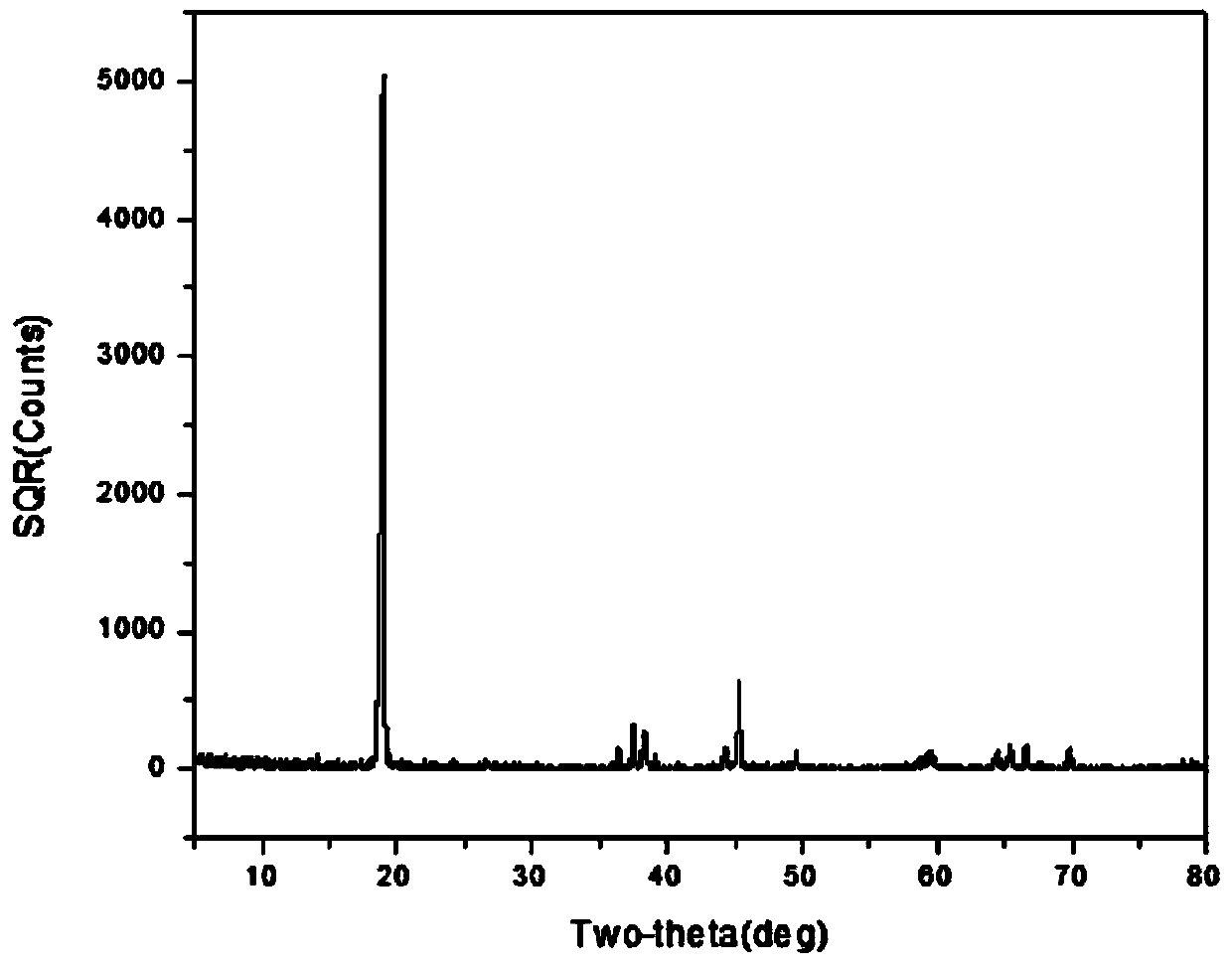

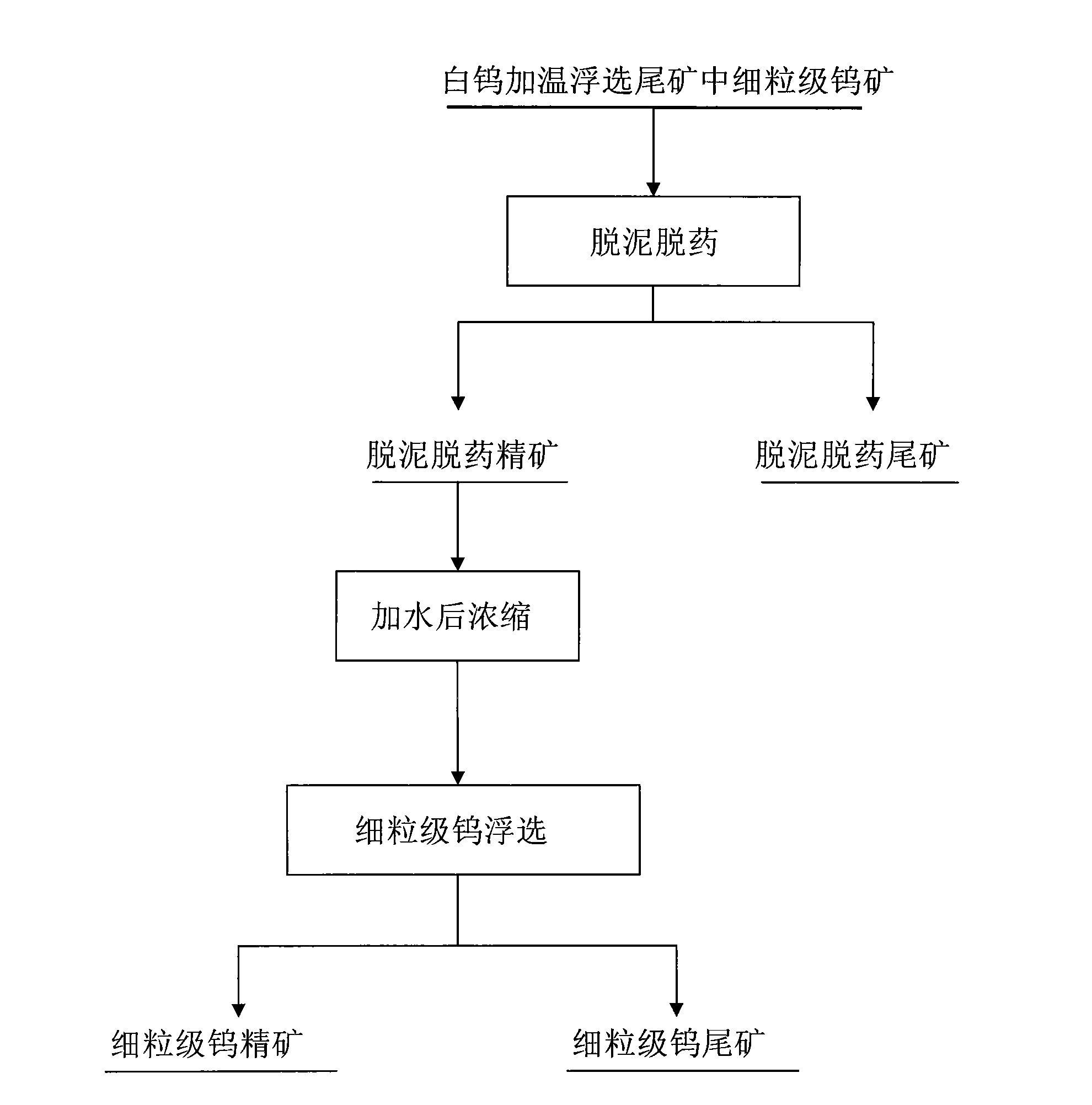

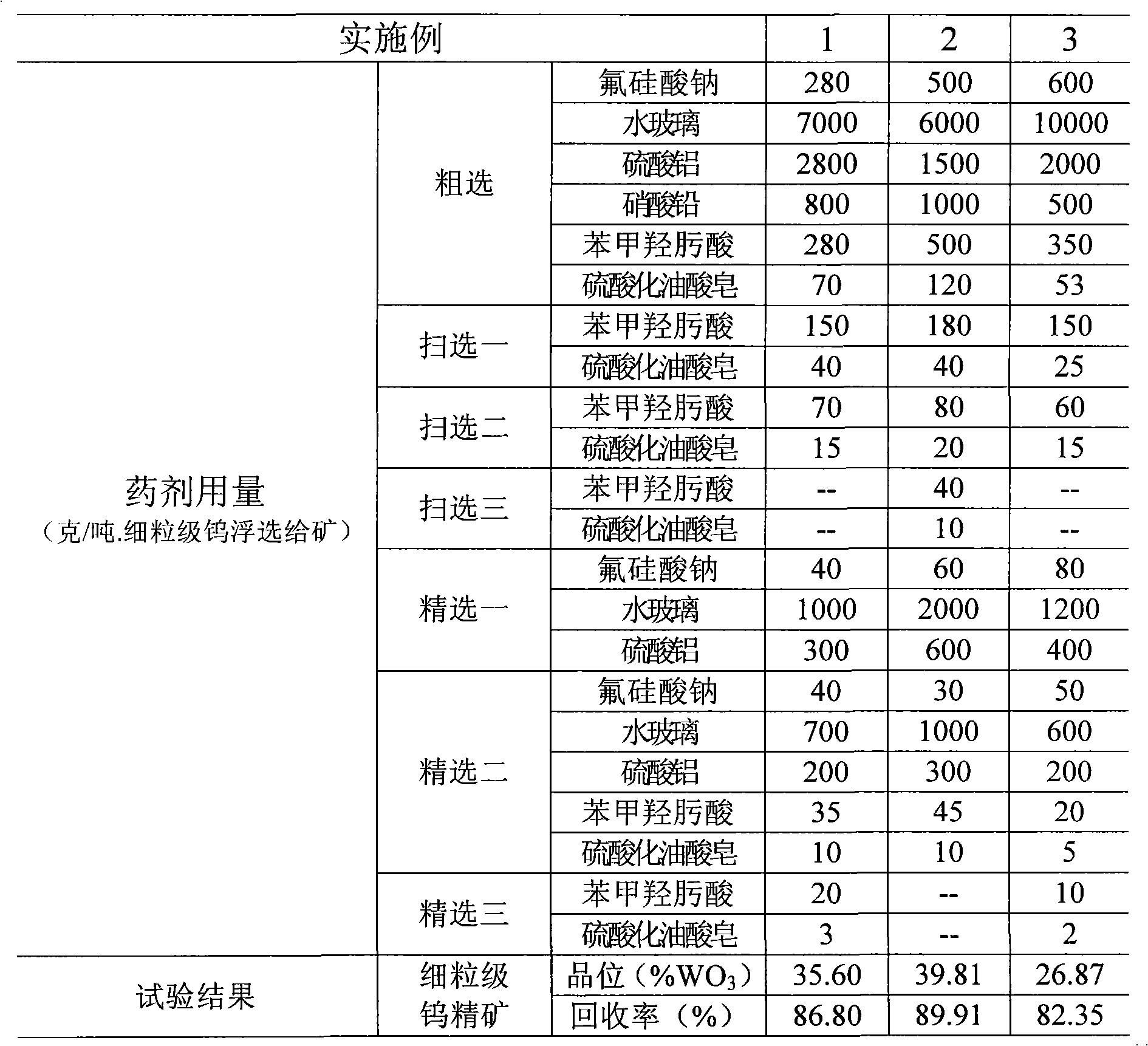

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Solid phase regeneration method of waste ternary lithium ion battery positive electrode material

InactiveCN107706477AEase vacanciesLarge repair regenerationWaste accumulators reclaimingBattery recyclingAir atmosphereElectrical battery

The invention discloses a solid phase regeneration method of a waste ternary lithium ion battery positive electrode material. The solid phase regeneration method comprises the following steps of (1) performing battery refined dismantling, taking out a positive electrode plate, and performing washing and drying on the positive electrode plate; (2) performing heat treatment on the positive electrodeplate at a temperature of 300-500 DEG C to realize screening and separating of a ternary positive electrode material and an aluminum foil or a conductive agent; (3) performing elemental analysis on the ternary positive electrode material and then matching with a lithium source, a cobalt source, a nickel source and a manganese source to adjust the element molar ratio; (4) performing mixing and ball milling on the added lithium source, cobalt source, nickel source and manganese source, and performing high-temperature sintering in an inert atmosphere or vacuum atmosphere to obtain a pre-sinteredsolid body; and (5) next, adding the conductive agent and doped metal ions, and performing secondary sintering in the air atmosphere to obtain the battery positive electrode material. The solid phaseregeneration method of the waste ternary lithium ion battery positive electrode material provided by the invention has the characteristics of simple operation, economic and reasonable property, highcycle recovery rate and environment friendliness.

Owner:长沙佳纳锂业科技有限公司 +1

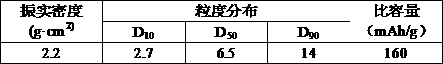

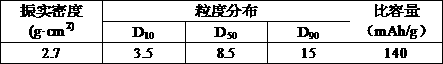

Method for preparing lithium carbonate by employing discarded lithium iron phosphate battery

InactiveCN106129519AHigh purityImprove extraction efficiencyWaste accumulators reclaimingLithium carbonates/bicarbonatesLithium vanadium phosphate batteryLithium iron phosphate

The invention discloses a method for preparing lithium carbonate by employing a discarded lithium iron phosphate battery. The method comprises the steps of crushing a discarded positive pole piece into blocks; calcining the massive positive pole piece in a high temperature furnace into which nitrogen is introduced; carrying out vibrating separation on the calcined positive pole piece through a vibrating screen; grinding a positive pole material which is obtained through vibrating separation; carrying out mixing and stirring reaction on the ground positive pole material and an acid liquid at a certain ratio; adding a TOPO-kerosene extracting agent to an acid leaching liquid to extract lithium and then carrying out reverse extraction through a stripping agent to obtain a lithium solution; and adding a sodium carbonate solution to the lithium solution and carrying out precipitation to prepare lithium carbonate. By the method for preparing the lithium carbonate by employing the discarded lithium iron phosphate battery, the recovery technology is simple; the equipment investment is low; the environmental pollution is small; the lithium loss is small; the extraction efficiency on lithium is high; the prepared lithium carbonate is high in purity; and the method is suitable for large-scale industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

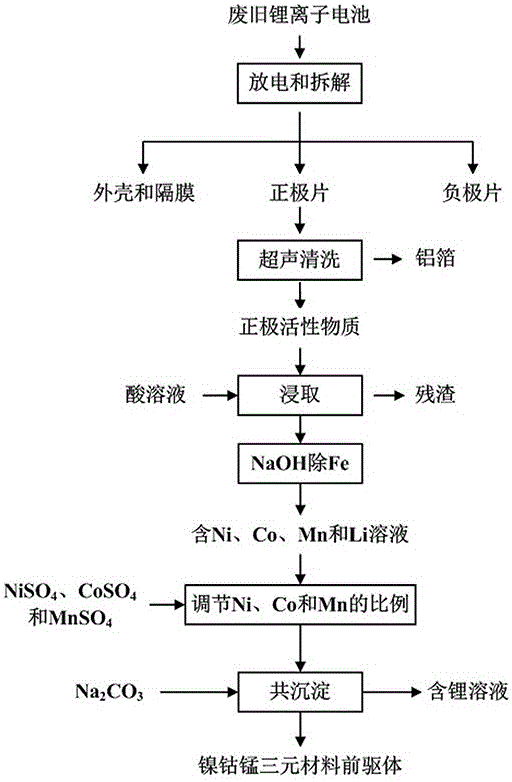

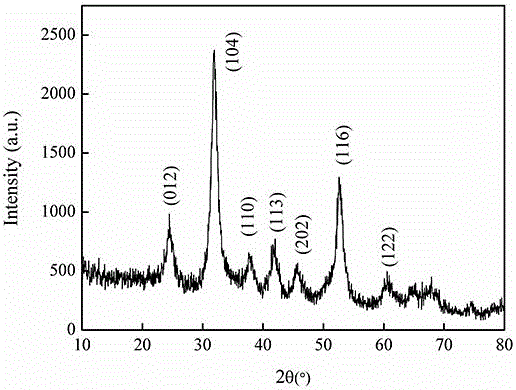

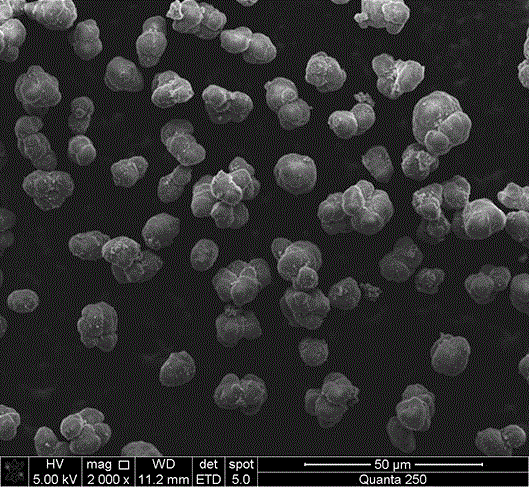

Method for preparing nickel-cobalt-manganese ternary material precursor from waste lithium ion battery

InactiveCN105789726AAvoid cross contaminationSimplify the subsequent impurity removal processWaste accumulators reclaimingBattery recyclingNickel saltFiltration

The invention discloses a method for preparing a nickel-cobalt-manganese ternary material precursor from a waste lithium ion battery. The method comprises the following steps: (1) physically disassembling the waste lithium ion battery which is fully discharged, and taking out a positive plate; (2) putting the separated positive plate into an ultrasonic cleaning machine for ultrasonic cleaning to let a positive active material fall off from a current collector aluminum foil, and directly recycling the aluminum foil after the aluminum foil is dried; (3) dissolving the positive active material obtained in the step (2) into acid, and adding sodium hydroxide to remove ferric; (4) measuring the concentration of metal ions in a leaching solution subjected to ferric removal, adding soluble nickel salt, cobalt salt and manganese salt to adjust the mole ratio of nickel, cobalt and manganese in the solution to be (1-3):(0.5-1):1; (5) adding a sodium carbonate precipitator to enable the three metal elements of nickel, cobalt and manganese to be precipitated at the same time, and performing filtration and drying to obtain the nickel-cobalt-manganese ternary material precursor. The process of the method is simple and flexible; the method is low in recycling cost, and recycled products have great value.

Owner:SUZHOU JUZHI TONGCHUANG ENVIRONMENTAL PROTECTION TECH

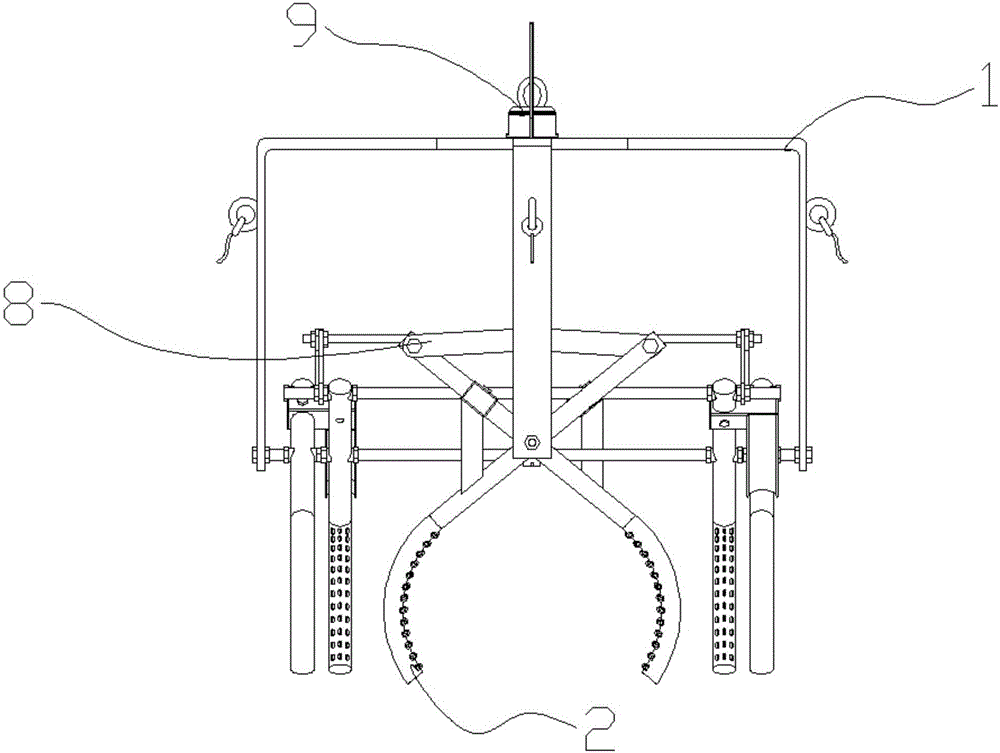

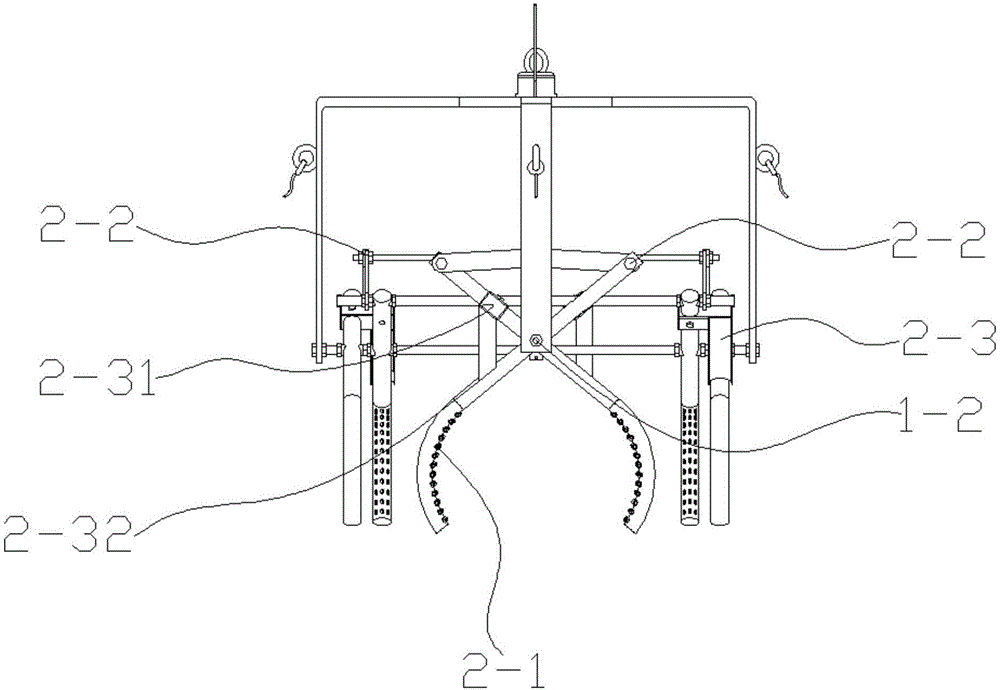

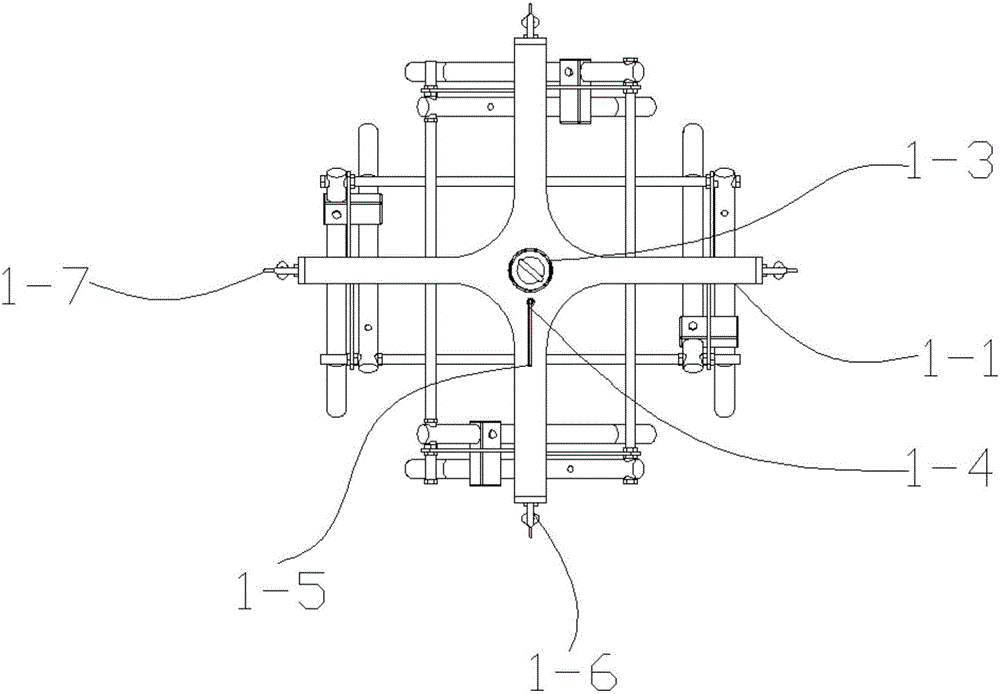

Two-dimensional omnibearing launching and retrieval device of underwater glider and launching and retrieval method

ActiveCN106275286AEasy to deployEasy to recycleCargo handling apparatusGripping headsHoopingRecovery method

The invention relates to the technical field of launching and retrieval of underwater gliders, underwater and surface aircrafts and the like, and relates to a two-dimensional omnibearing launching and retrieval device of an underwater glider and a launching and retrieval method. The corresponding pure mechanical structure comprises a main support, hooping jaw pairs, synchronous cross shafts, synchronous tensile shafts, connecting rods, a spring tensioning mechanism, a movable block stretching mechanism, jaw vice arms and a force removal swivel. The two-dimensional omnibearing launching and retrieval device fulfills the hooping and releasing functions on the underwater glider in a manner that the hooping jaw pairs are matched with the synchronous cross shafts, the synchronous tensile shafts, the connecting rods, the spring tensioning mechanism, the movable block stretching mechanism and the like, so that the underwater glider is launched and retrieved simply quickly. According to the invention, the launching and retrieval functions on the underwater glider are fulfilled through the mechanical structure, the structure is simple and ingenious, maintenance is convenient, operation is simple, the underwater glider is launched and retrieved extremely simply, the risk in the launching and retrieval processes is decreased, and the problems of high costs and high risks in the launching and retrieval processes are solved.

Owner:OCEAN UNIV OF CHINA

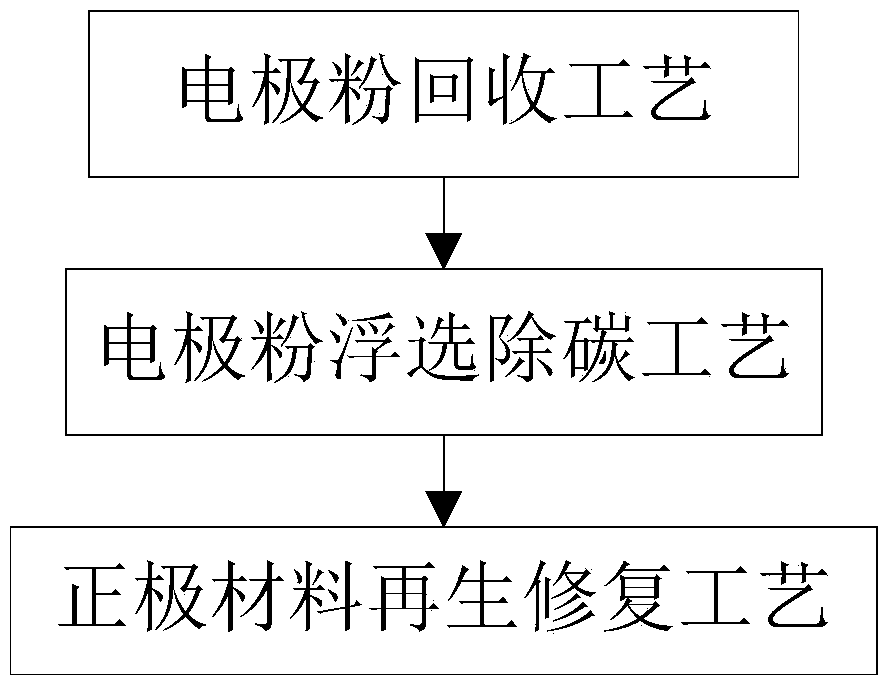

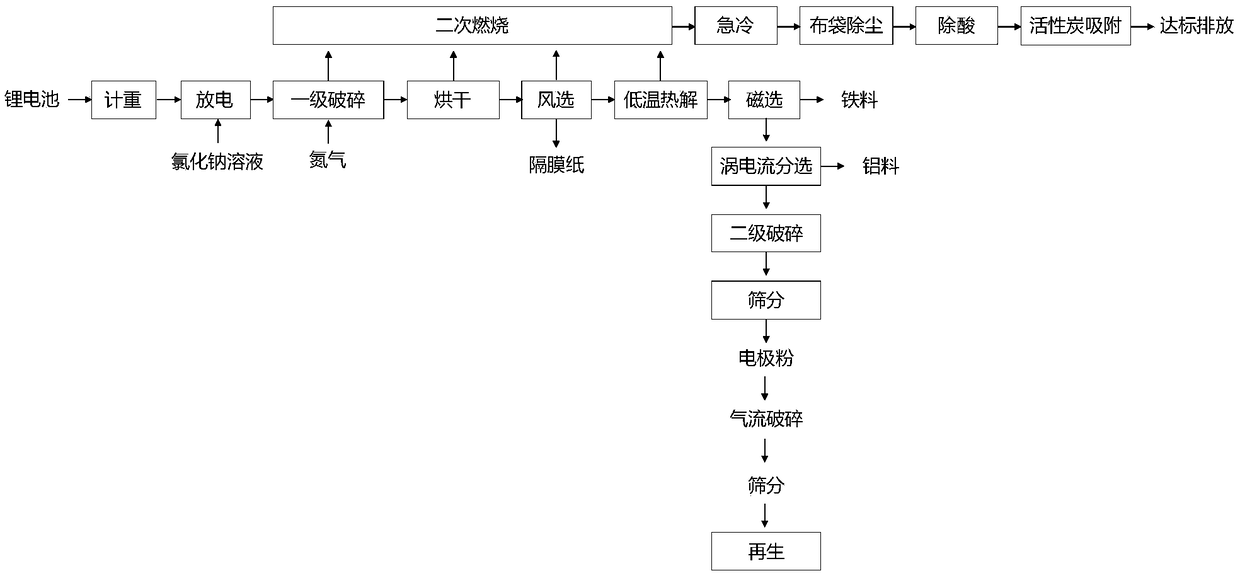

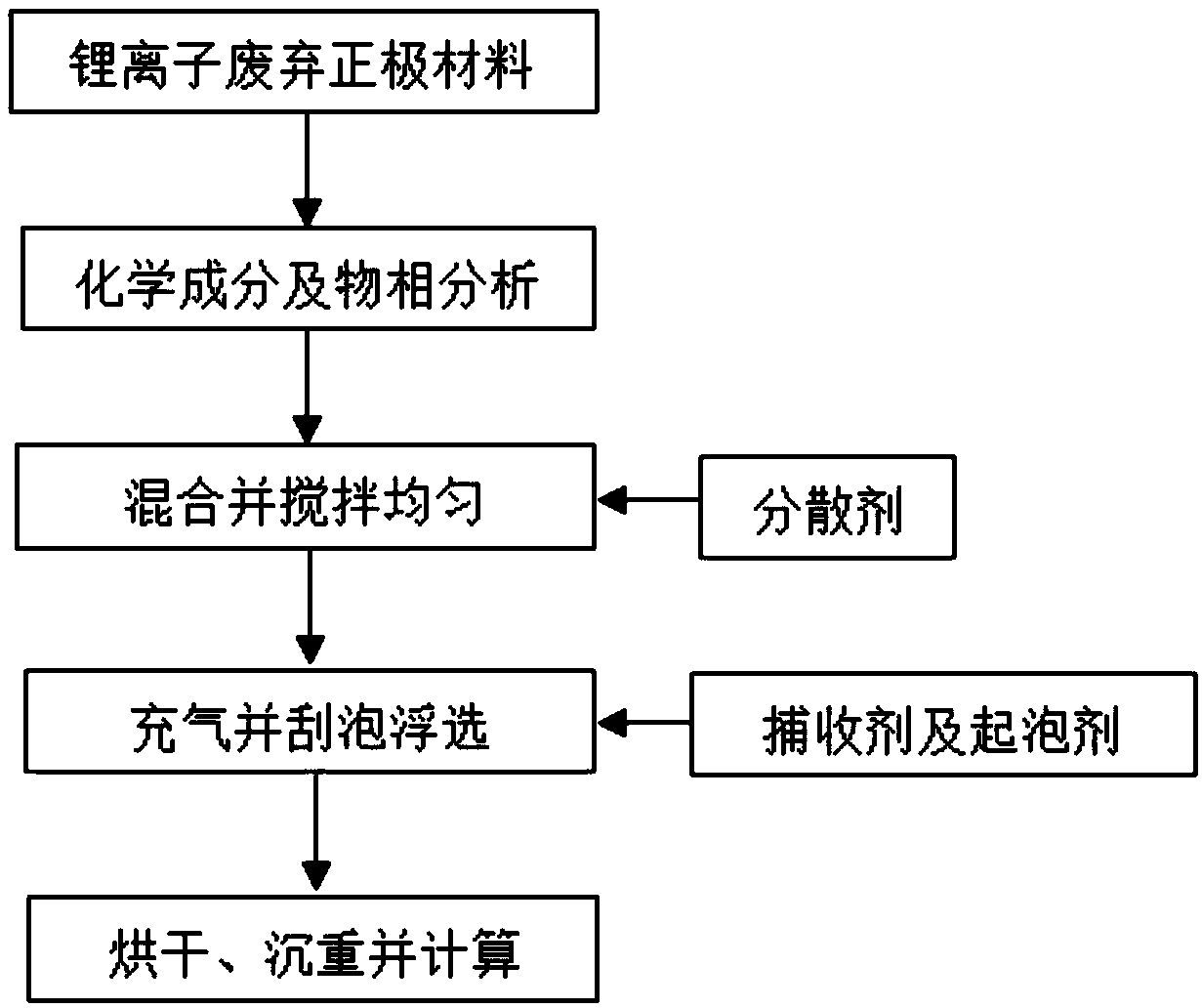

Recycling process of positive electrode materials of waste batteries

ActiveCN109326843ASimple recycling processHarmless treatmentWaste accumulators reclaimingFlotationEngineeringBiological activation

The invention discloses a recycling process of positive electrode materials of waste batteries. The recycling process includes the steps of completely discharging the waste lithium batteries, subjecting the waste lithium batteries to primary crushing under inert gas protection, removing diaphragm paper through air classification after crushing, performing low-temperature pyrolysis, respectively removing iron materials and aluminum materials through sorting, performing re-pulverization to obtain electrode powder, determining a flotation reagent system according to the phase composition of the electrode powder, performing flotation in a flotation tank, and filtering and drying products at the bottom of the flotation tank to obtain the positive electrode materials; according to the Li / M ratioof the positive electrode materials, calculating the lithium source powder to be added, and mixing water-soluble dispersants and the lithium source powder with water to form a mixed solution; addingthe positive electrode materials to be repaired into the mixed solution, performing cooking activation at a high temperature and under high pressure, continuing to dry the product under normal pressure to obtain uniform mixture powder, and calcining the mixture powder under an aerobic condition to obtain the regenerated and repaired lithium ion battery positive electrode materials. The recycling process has the advantages of low repair cost, high activity after repair, and higher promotion and application value.

Owner:荆门动力电池再生技术有限公司

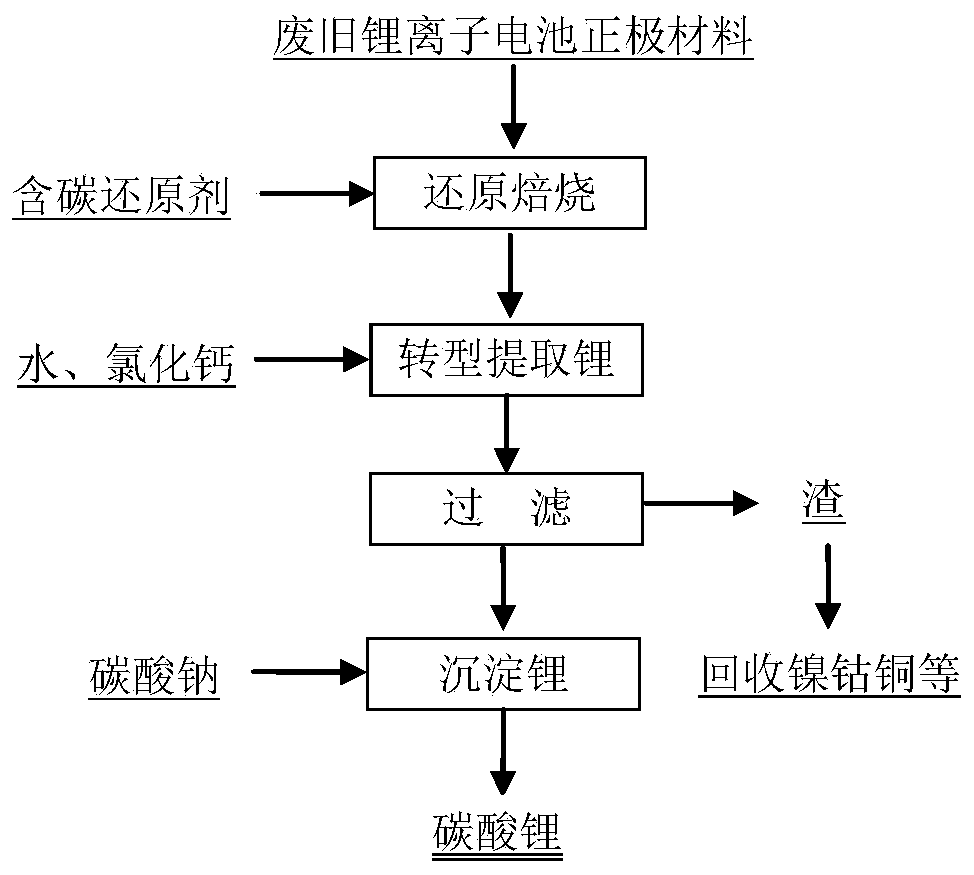

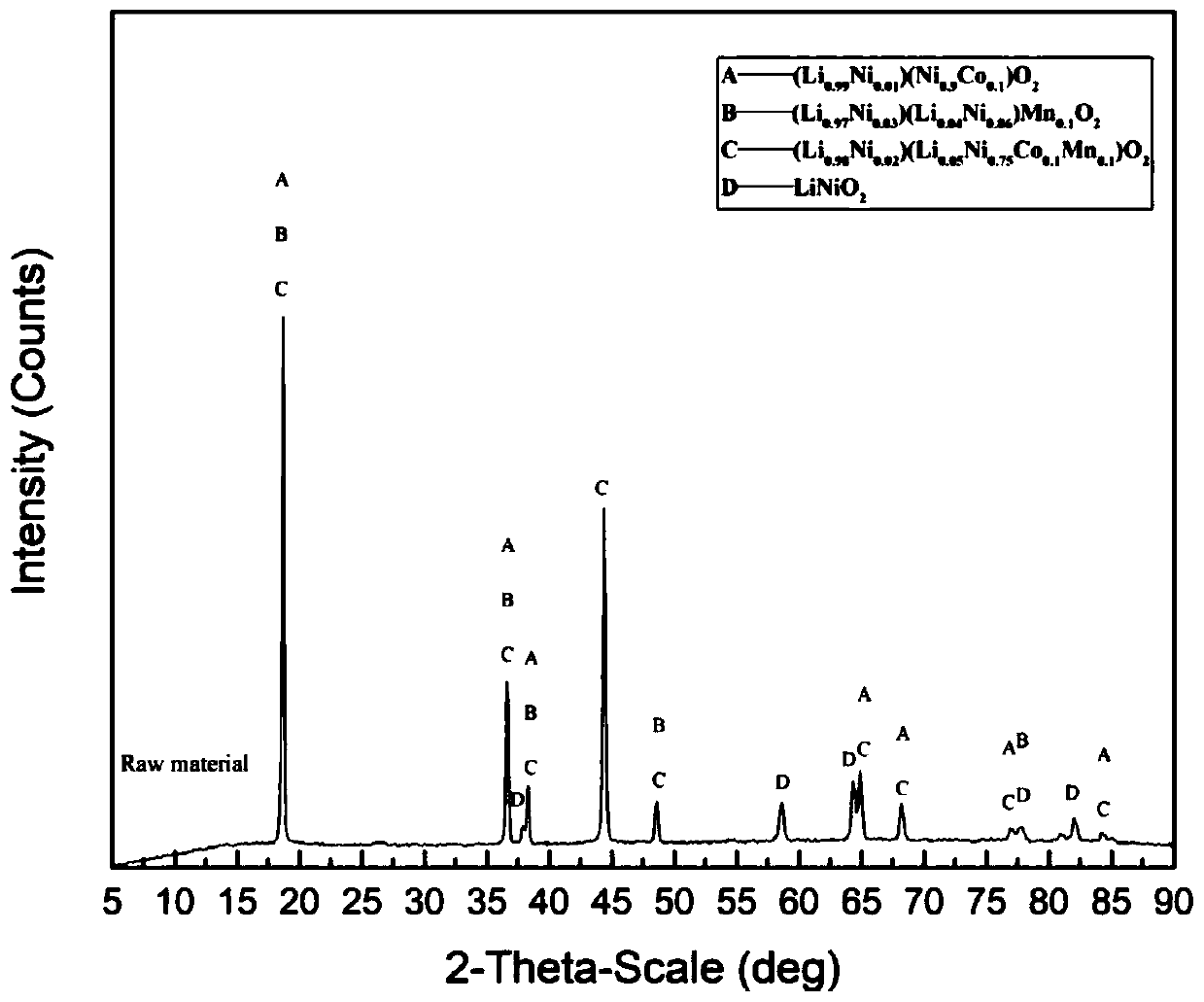

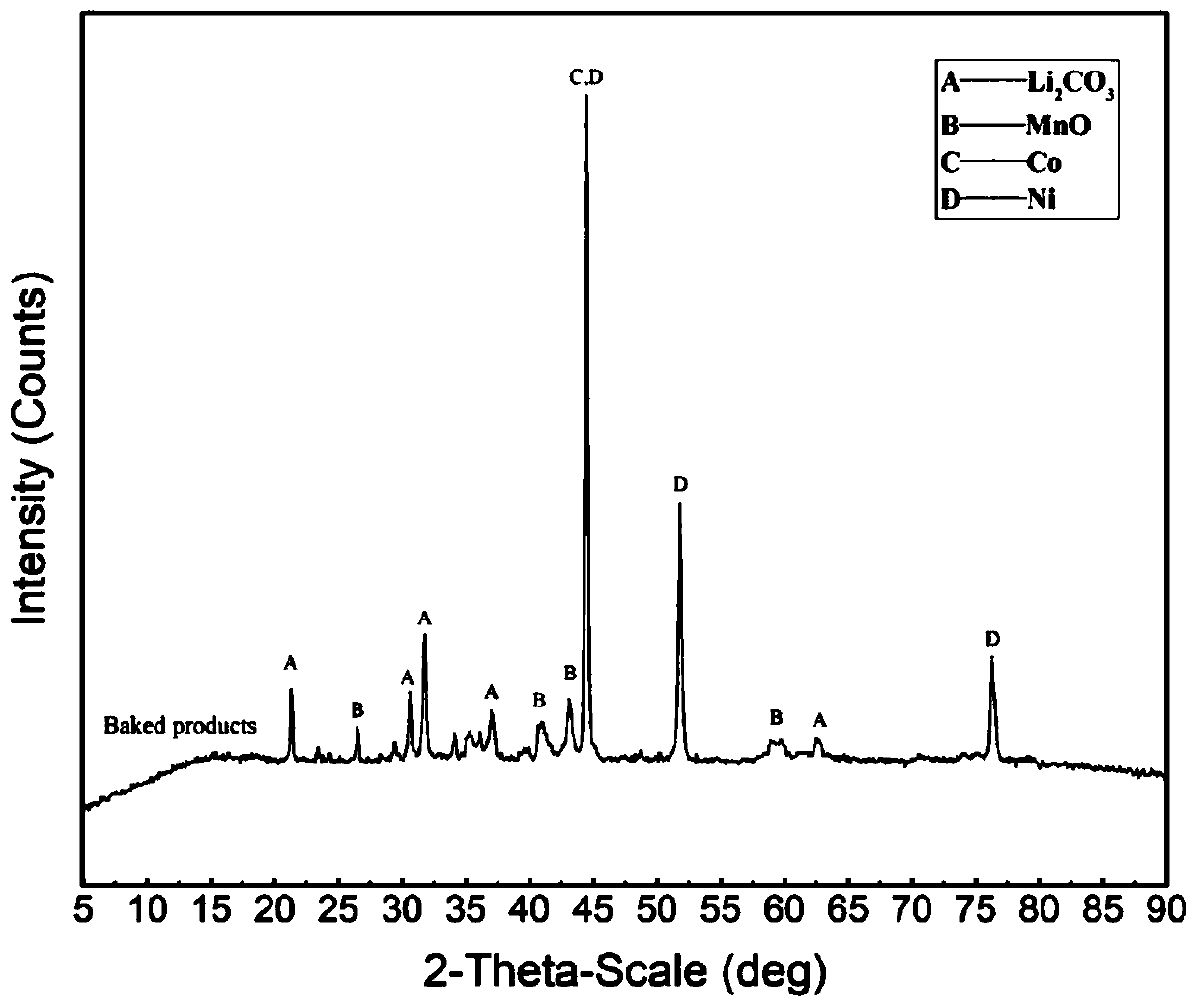

Method for extracting lithium and nickel cobalt from waste lithium ion battery step by step

ActiveCN110938743ASimplify the recycling processHigh selectivityProcess efficiency improvementBattery recyclingLithium carbonateLithium electrode

The invention discloses a method for extracting lithium and nickel cobalt from a waste lithium ion battery step by step, and belongs to the technical field of comprehensive recovery of lithium ion battery materials. The method comprises the following steps of splitting, crushing and screening a waste lithium ion battery to obtain a positive electrode material powder, carrying out reduction roasting on the positive electrode material powder with a carbon-containing reducing agent, size mixing the obtained calcine with water, adding a proper amount of calcium chloride or lime milk solution for reaction transformation, selecting lithium carbonate in the calcine to be extracted into the solution, thereby realizing separation with nickel, cobalt, manganese, iron, aluminum and phosphorus. The method can realize the preferential selective extraction of lithium, the obtained lithium solution is high in purity and lithium concentration, the extraction and impurity removal, evaporation and concentration processes are not needed, the recovery of lithium and the product preparation process are simple, the recovery rate is high, the energy consumption is low, and the environmental problem of high-concentration sodium salt wastewater is not present```.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

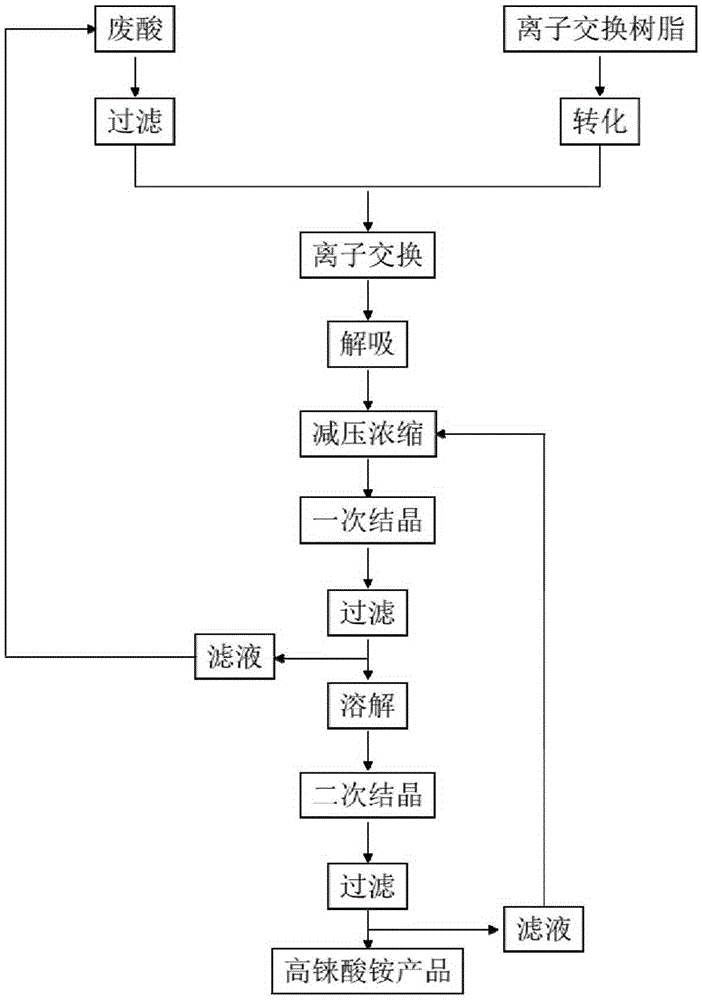

Method for recovering rhenium from molybdenum smelting waste acid

ActiveCN105384195ASimple recycling processSimple and efficient operationRhenium compounds preparationIon exchangeAmmonium sulfate

The invention discloses a method for recovering rhenium from molybdenum smelting waste acid and belongs to the technical field of metal rhenium recovery and recycle. The method comprises 1, filtering molybdenum smelting waste acid, and treating the filtrate by a composite aminoethylene weak basic anion exchange resin column for adsorption until adsorption is saturated, and 2, carrying out desorption on the saturated anion exchange resin column, collecting the desorption liquid and carrying out evaporation crystallization to obtain ammonium perrhenate. The composite aminoethylene weak basic anion exchange resin has large saturation adsorption quantity. The desorption liquid has rhenium content 100 times or more that of waste acid. Compared with the existing extraction method and ion exchange method, the method provided by the invention has a high rhenium recovery rate of 98% or more. Through use of solubility difference of ammonium perrhenate, ammonium molybdate and ammonium sulfate, ammonium perrhenate is purified by evaporation crystallization and ammonium perrhenate purity is 99.9% or more. The method has a simple rhenium recovery process, is environmentally friendly, is convenient for operation and is suitable for large scale production.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

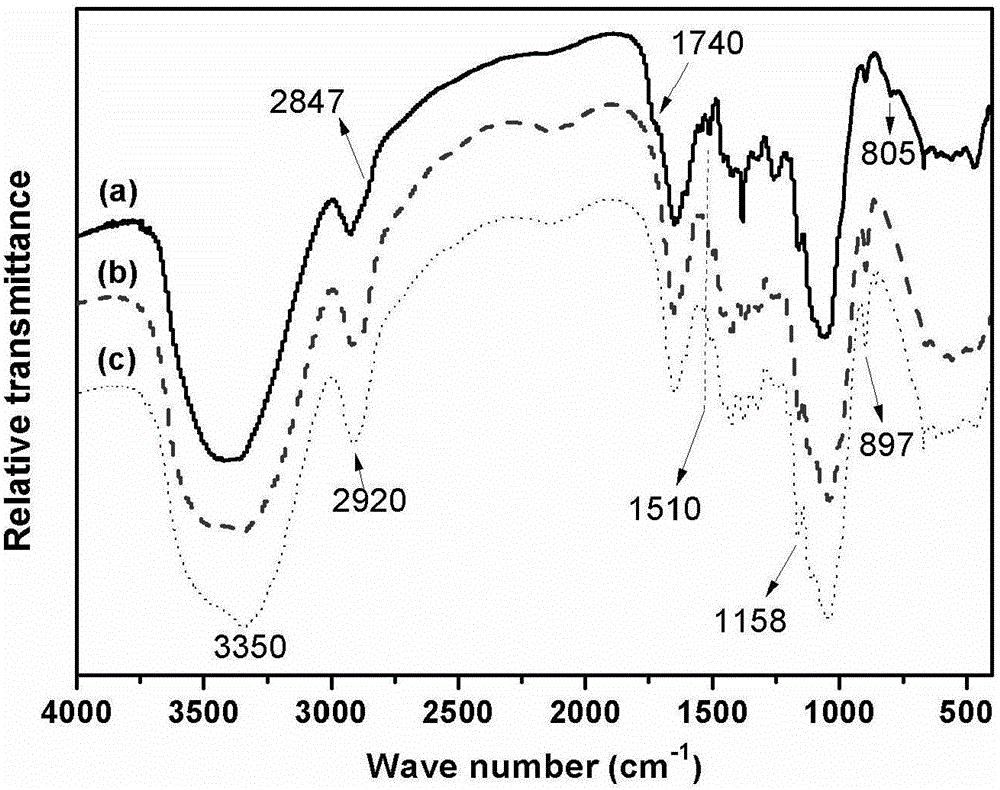

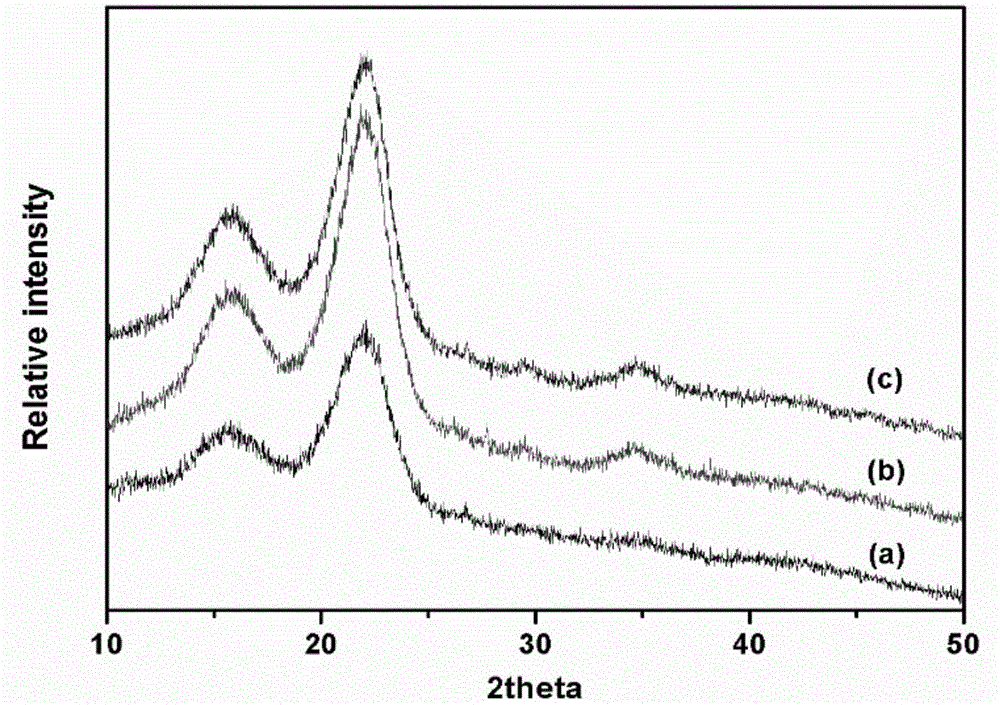

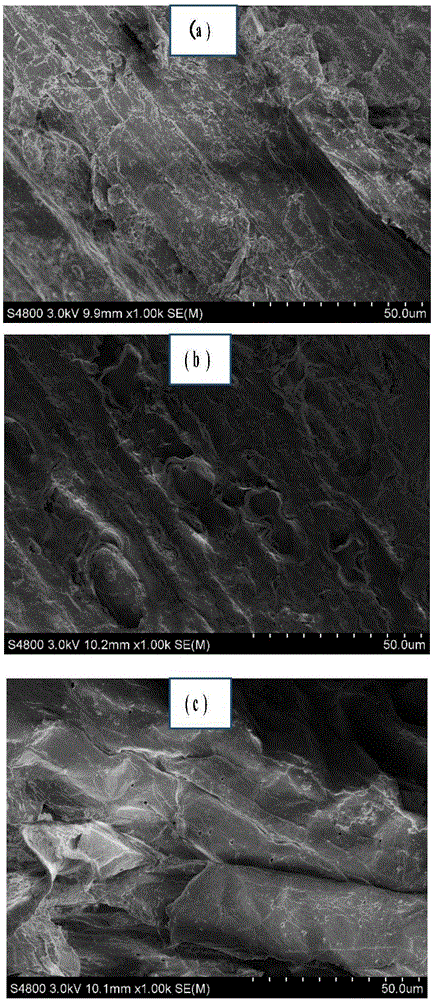

Method for preprocessing lignocellulose biomasses by virtue of carbonate and hydrogen peroxide

ActiveCN105154493AHigh retention rateReduce energy consumptionFermentationCelluloseFermentable sugar

The invention belongs to the fields of efficient conversion and utilization of biomasses and particularly relates to a method for preprocessing lignocellulose biomasses by virtue of carbonate and hydrogen peroxide. According to the method, the lignocellulose biomasses are preprocessed at a relatively low temperature by virtue of a combined solution of carbonate and hydrogen peroxide; an adopted alkali reagent is carbonate and is easier to recycle as compared with common hydroxide (such as sodium hydroxide), furthermore, hydrogen peroxide is an environmental-friendly oxidant and is combined with carbonate for use, so that the removal rate of lignin can be increased, the structure of lignin can be changed, more celluloses can be exposed, and the relatively high yield of fermentable sugars is achieved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

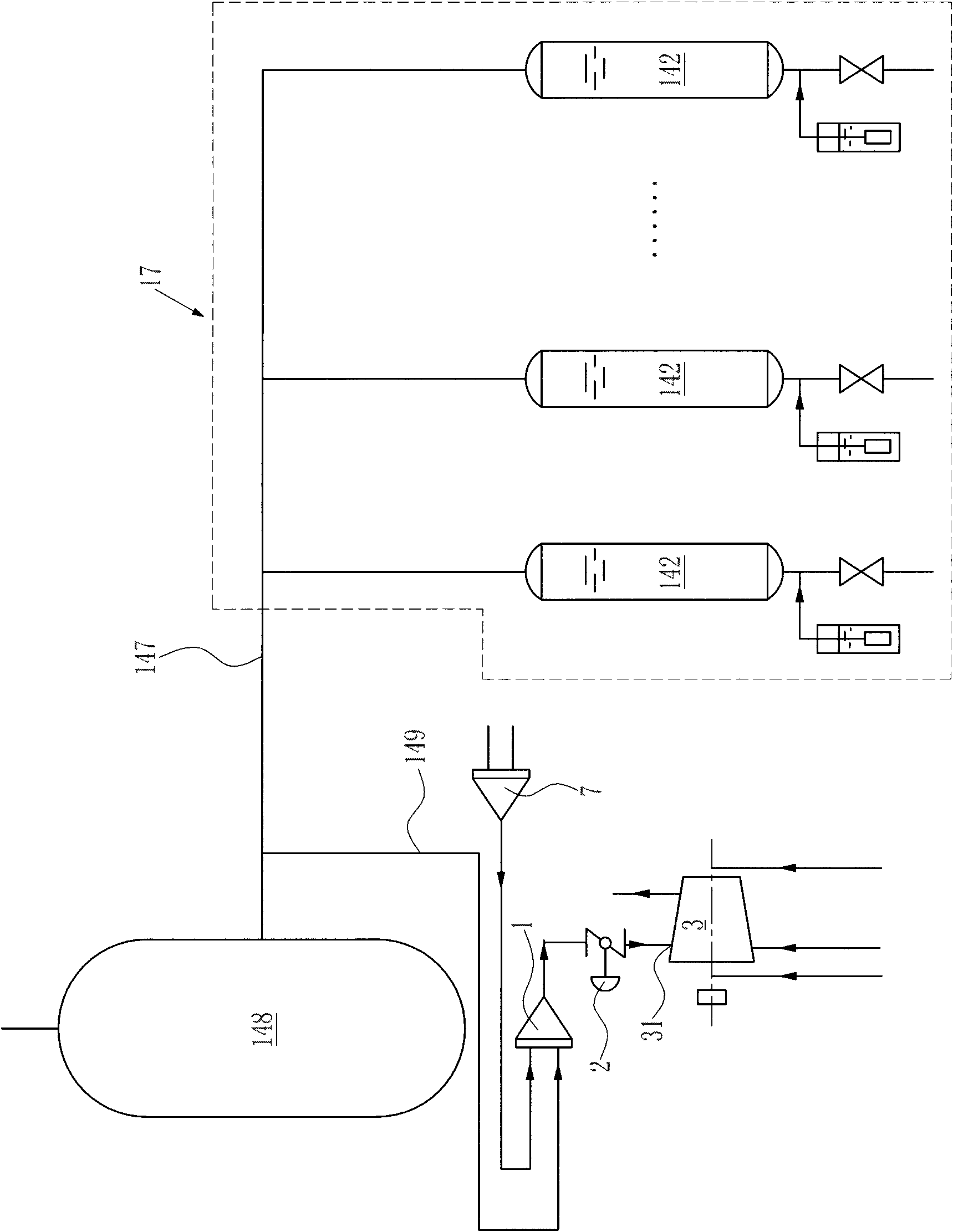

Device and method for recovery and reliquefaction of boil-off gas of liquefied natural gas

ActiveCN102182919ASimple recycling processSimplify liquefaction system processPipeline systemsEngineeringDistributor

The invention relates to a device for the recovery and reliquefaction of boil-off gas of liquefied natural gas, which comprises a storage tank with a safety valve and a low-temperature pump, wherein a first interface is formed between the storage tank and the safety valve and is connected with a recovery pipe; the low-temperature pump is provided with a second interface; the other end of the recovery pipe is communicated with a recovery compressor; an outlet of the recovery compressor is connected with a cooler, an oil-gas separator and a boil-off gas distributor, and first boil-off gas and second boil-off gas are respectively discharged from the boil-off gas distributor; the first boil-off gas is communicated with a screw expansion machine and enters a heat exchanger and a second screw compressor; the second boil-off gas is connected with the second interface of the low-temperature pump by the heat exchanger, a throttling valve and a gas-liquid separator; and the liquefied natural gas enters the storage tank. The device has the advantages that by using a screw expansion-compressor set refrigerating reliquefaction method of recovering the boil-off gas directly by the screw compressors and taking the boil-off gas as a refrigerant directly, system flow equipment is simplified, energy waste is avoided, and peripheral environmental pollution and potential safety hazards are avoided, so obvious economic and social benefits are created; and a system runs automatically, continuously and circularly, and has the excellent running work condition and high using efficiency and runningreliability.

Owner:NINGBO BAOSI ENERGY EQUIP

Method for collaborative treatment of positive and negative active materials of waste lithium-ion batteries

ActiveCN110835682AHigh reactivityAchieving auto-redoxWaste accumulators reclaimingBattery recyclingPhysical chemistryManganese

The invention discloses a method for collaborative treatment of positive and negative active materials of waste lithium-ion batteries, and belongs to the technical field of lithium-ion battery material recovery. Appropriate amount of concentrated sulfuric acids are added into a mixture of positive active materials and negative active materials obtained by crushing and separating the waste lithium-ion batteries for reaction and maturation to obtain solidified clinker, the obtained solidified clinker is leached with water or dilute acids, a leached solution containing cobalt, lithium, nickel, titanium and other useful metal elements is obtained from leached pulp through sedimentation and separation, high-quality graphite and residues are obtained from leached residues through centrifugal classification to achieve collaborative intensified treatment of the positive and negative active materials of the waste lithium-ion batteries, nickel, cobalt, manganese, lithium, graphite powder and other components can be recovered comprehensively, the recovery process of active materials in waste batteries is conducive to simplifying, the recovery rate of useful elements is high, and the purity ofrecovered graphite products is high. Main consumption agents of the method are sulfuric acids, and the cost is low.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

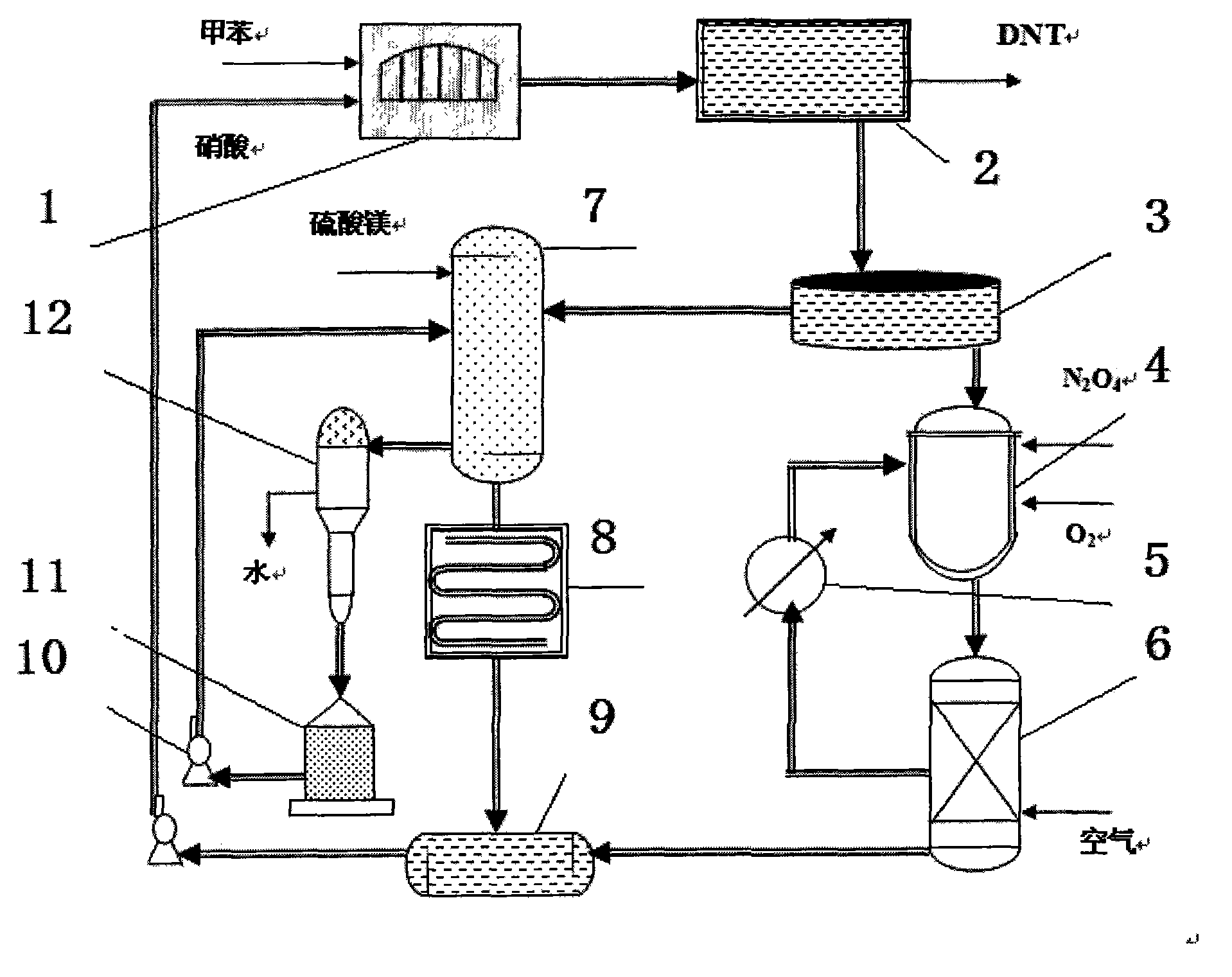

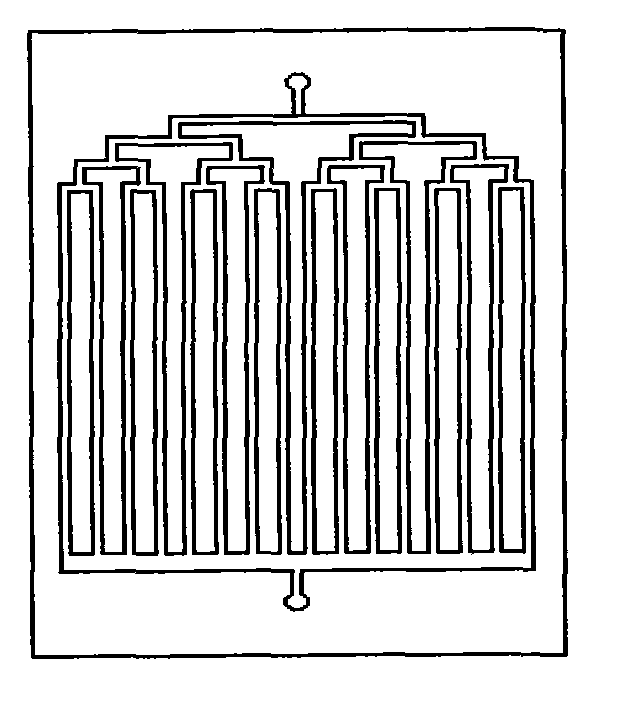

Clean production method and device of dinitrotoluene

InactiveCN102838489ASave resourcesSimple recycling processChemical industryNitro compound preparationChemistryEvaporator

The invention relates to a clean production method and a clean production device of dinitrotoluene, belonging to the field of chemical processes. The clean production method for preparing dinitrotoluene is realized through a methylbenzene micro-reactor nitration process, a fiber bed liquid-liquid separator separation process of nitric acid and dinitrotoluene mixture, and a dilute nitric acid thickening and concentration process. The clean production device of dinitrotoluene comprises a micro-reactor, a fiber bed separator, a mixing tank, a high-pressure kettle, a cooler, a bleaching tower, a concentrating tower, a condenser, a nitric acid storage tank, a delivery pump, a magnesium sulfate storage tank and an evaporator. Since nitration reaction is completed by using the micro-reactor, the micro-reactor consists of many micro-tubes which are connected in parallel, the specific surface area is very large and continuous production processes are formed, the heat exchange efficiency and the mixing efficiency are good, the reaction temperature can be accurately controlled, reaction materials can be accurately controlled to be instantly mixed according to accurate proportions, the yield, the selectivity and the safety are improved, and the reaction time is reduced.

Owner:LIAONING QINGYANG SPECIAL CHEM

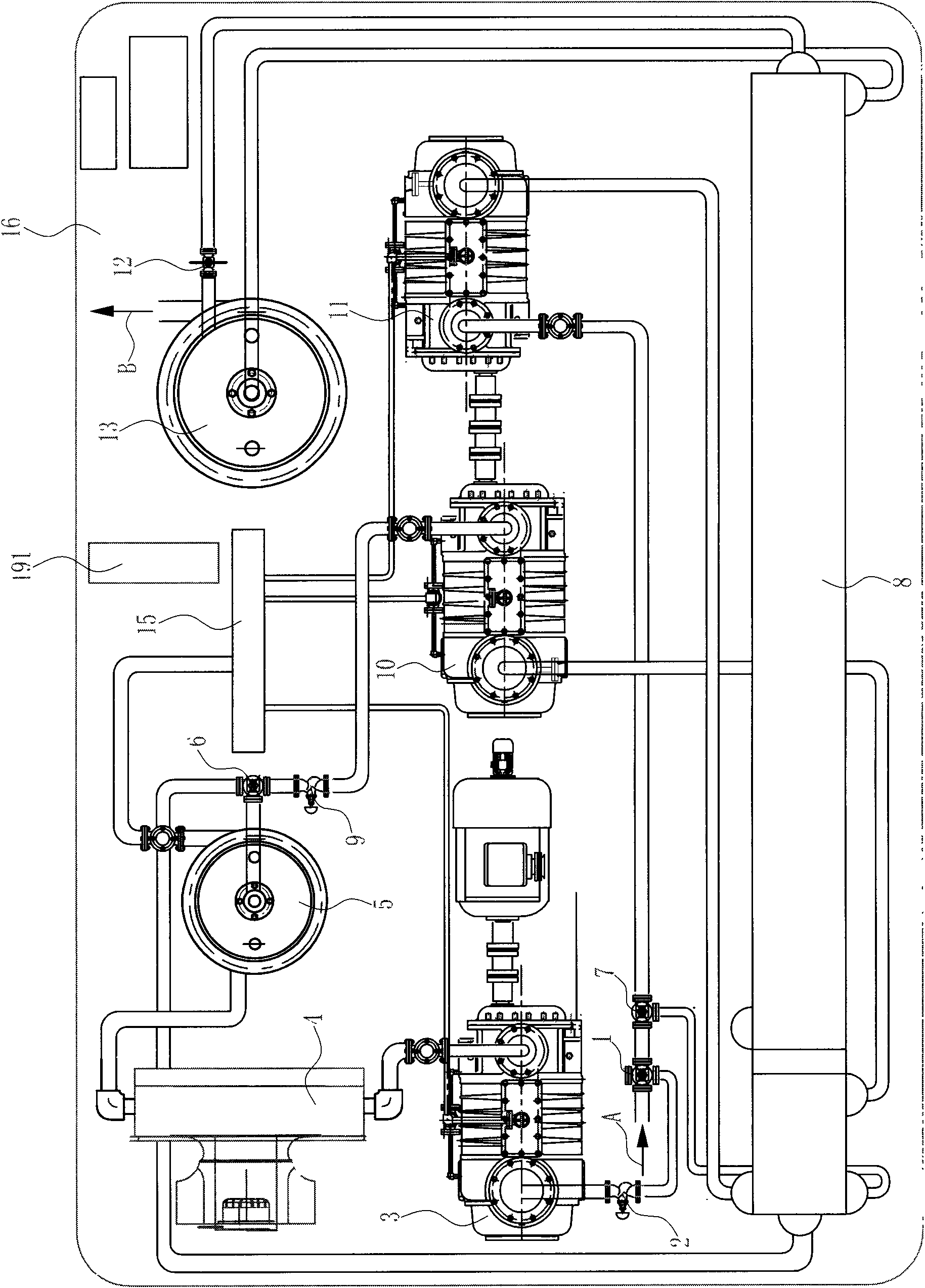

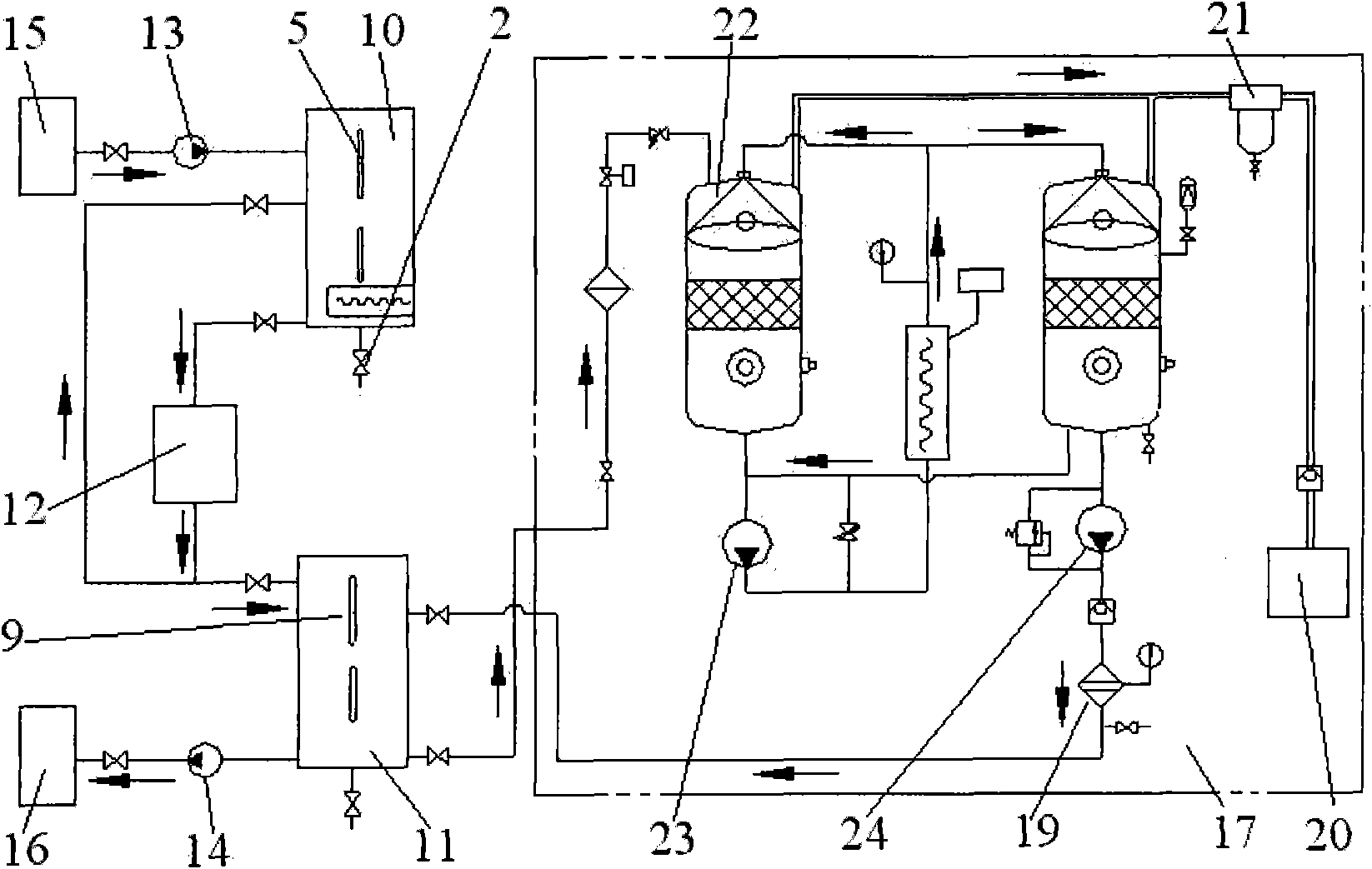

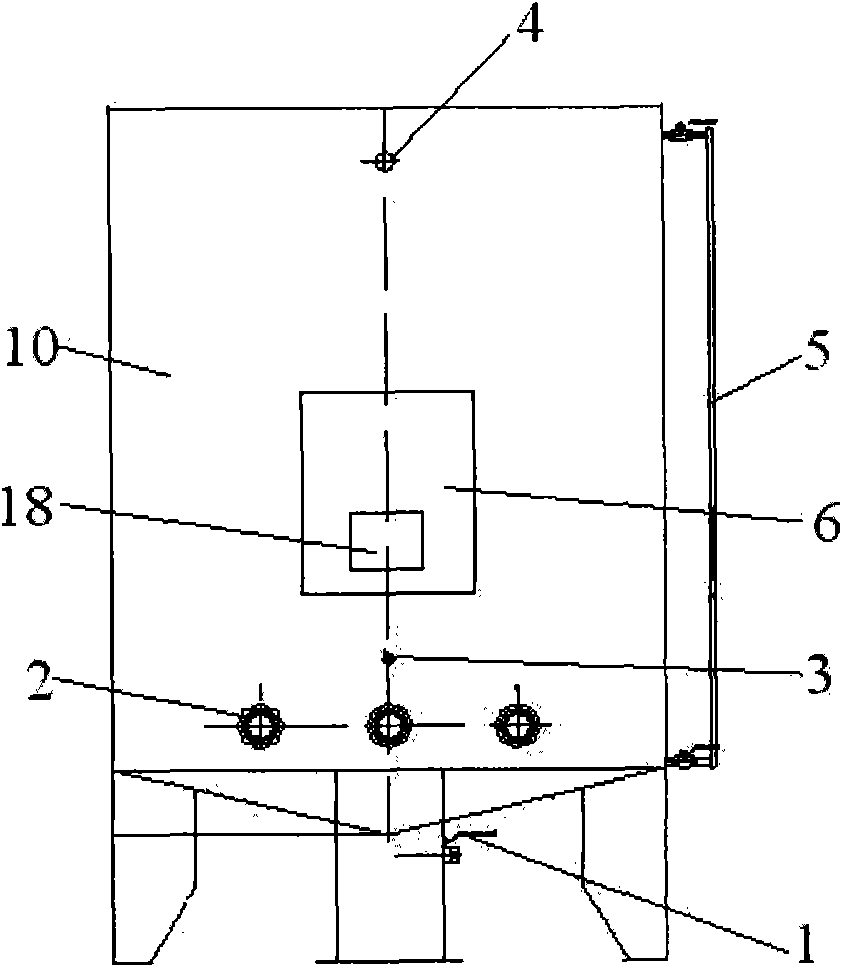

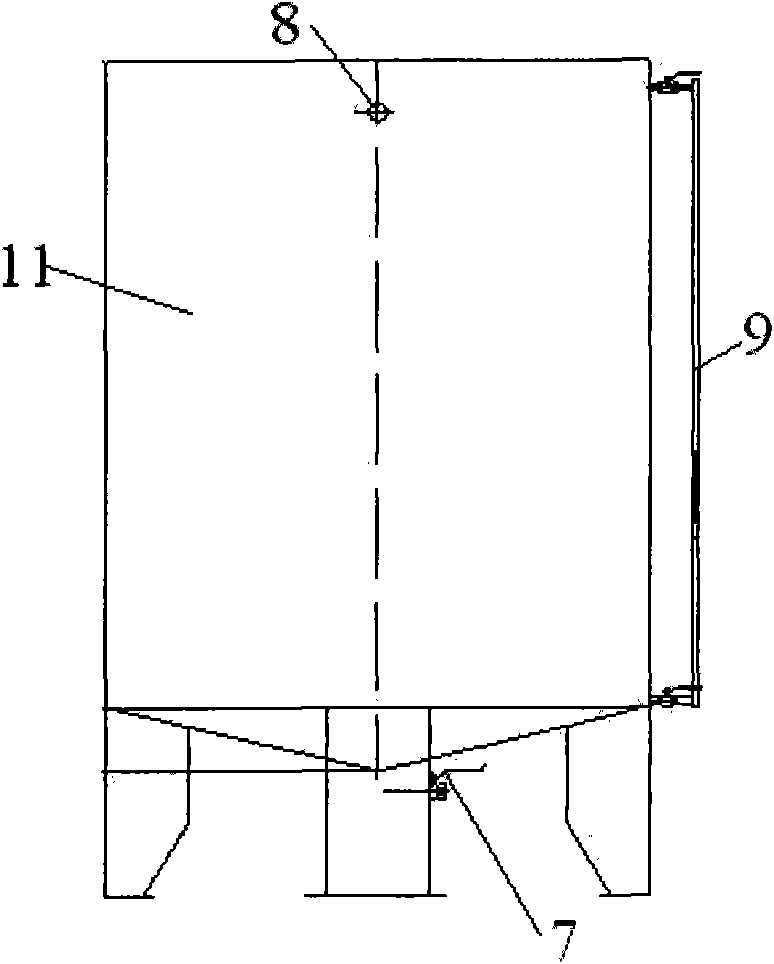

Waste lubricating oil treatment equipment and treatment method thereof

ActiveCN102010784ARestores viscosity and demulsibilityThe recovery process and equipment are simple and easyLubricant compositionDeep levelFuel tank

The invention discloses waste lubricating oil treatment equipment which comprises a waste oil barrel (15), a recovered engine oil barrel (16), a waste oil tank (10), an oil purification tank (11) and a plate type oil filter (12), wherein the waste oil barrel (15) is communicated with the waste oil tank (10) through an oil pump (13), and the oil purification tank (11) is communicated with the recovered engine oil barrel (16) through an oil pump (14). The invention also discloses a treatment method adopted by the waste lubricating oil treatment equipment. Based on the technical scheme, through pretreatment and step by step filtration, the waste lubricating oil treatment equipment fulfills the function of deep filtration on oil, efficiently removes impurities and moisture, restores the viscosity and the demulsibility of the oil, enhances the quality of recovered oil, enables a recovery process and equipment of waste lubricating oil to be convenient and feasible and is beneficial to environmental protection.

Owner:WUHU XINXING DUCTILE IRON PIPES

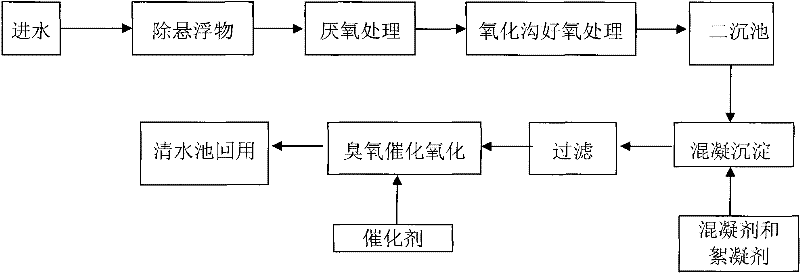

Treatment process for recycling water in pulping and papermaking wastewater

ActiveCN102531275AEasy to handleEmission reductionMultistage water/sewage treatmentWaste water treatment from plant processingReclaimed waterCatalytic oxidation

The invention discloses a treatment process for recycling water in pulping and papermaking wastewater. The treatment process comprises the following steps of: removing suspended matters of the pulping and papermaking wastewater and carrying out anaerobic treatment; and then, carrying out aerobic treatment through an oxidation ditch and inputting the wastewater into a secondary sedimentation basin to precipitate and carry out mud-water separation; and then, carrying out coagulating sedimentation and filtering; and finally, carrying out ozone catalytic oxidation treatment to obtain the water. The treatment process provided by the invention has the advantages of simple process flow, lower construction and operation cost and simplicity in management, and can effectively treat the pulping and papermaking wastewater and realize reuse of reclaimed water, so that the treatment process has an extremely good application prospect.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH +1

Method for extracting high-purity manganese dioxide from manganese slag

The invention discloses a method for extracting high-purity manganese dioxide from manganese slag, which comprises the following steps of: at normal temperature, adding dilute sulfuric acid in an amount 1.1-1.5 times the theoretical amount into the manganese slag and leaching metal impurity ions in the manganese slag; filtering to obtain an acid solution with the pH of 1.0-2.0, adding a sodium chlorate or potassium chlorate solution in an amount 1.1-1.5 times the theoretical amount into the acid solution, carrying out hydro-thermal reaction for 1-3 hours at the temperature of 120-150 DEG C, filtering manganese dioxide precipitates generated by the reaction, carrying out acid washing with 0.05-0.15mol / L-1 of dilute sulfuric acid, drying at the temperature of 60-120 DEG C after water washing, and calcining for 1-2 hours at the temperature of 350-450 DEG C to obtain the manganese dioxide with the product purity of larger than 98 percent. In the invention, the extraction ratio of the manganese in the manganese slag can reach more than 93 percent, the purity of the obtained manganese dioxide can reach more than 98 percent, the economic value of products is high, and the method has short process flow and simple operation.

Owner:BOHAI UNIV

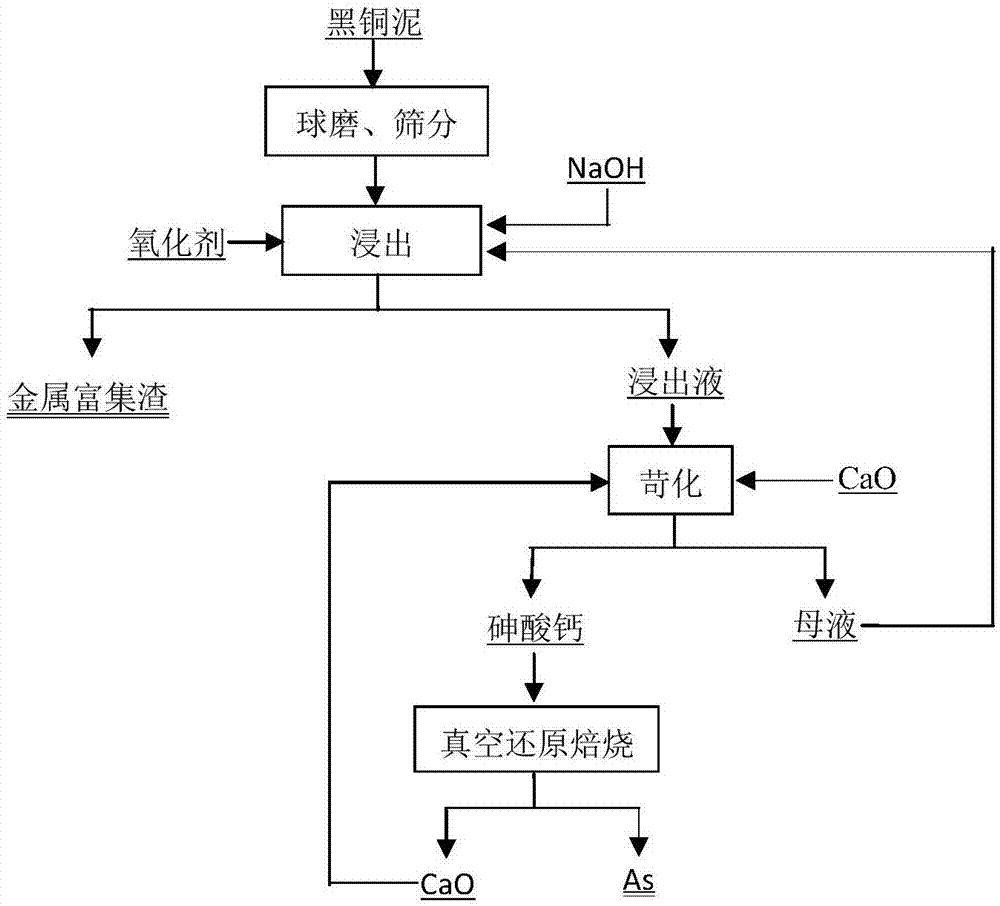

Method for recovering arsenic from black copper sludge

ActiveCN106893864AEfficient extraction and separationLow costProcess efficiency improvementCalcium arsenateCopper

The invention discloses a method for recovering arsenic from black copper sludge. The method comprises the following steps: carrying out alkaline leaching on a black copper sludge powder under an oxidation condition, causticizing a leaching solution through lime to obtain calcium arsenate, and regenerating an alkaline leaching agent during the causticizing process and returning the alkaline leaching agent to the alkaline leaching; and carrying out vacuum reduction roasting on calcium arsenate to obtain metallic arsenic and calcium oxide, wherein metallic arsenic can be directly sold, and calcium oxide is returned to the causticizing process. The method realizes the open loop of arsenic during a black copper sludge treatment process, and obtains non-toxic metallic arsenic with an economic value, and meanwhile, alkali and calcium oxide are circulated in the flow, so that alkali consumption is furthest reduced; and the method is simple in process, low in cost, environment-friendly, and great in application prospect.

Owner:CENT SOUTH UNIV +1

In-situ fibril method of recovering waste thermoplastic plastics

The present invention is in-situ fibrillation method of recovering waste thermoplastic plastics. Washed and dried waste thermoplastic engineering plastics and waste thermoplastic common plastics are mixed in certain ratio; the mixture is molten, extruded and stretched in selected technological conditions; and the stretched material strips are forced cooled in cooling water tank and pelletized to obtain the in-situ reinforced and toughened plastic alloy with excellent comprehensive performance. The said production process has low cost and high production efficiency, solves the environmental pollution caused by waste plastics and utilizes the resource of waste plastics in high additional value.

Owner:SICHUAN UNIV

Method for preparing N-type Bi2Te3 based thermoelectric materials by refrigeration crystal bar processing waste

ActiveCN103311426ASimple recycling processShort cycleThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsIngot

The invention relates to a method for preparing N-type Bi2Te3 based thermoelectric materials by refrigeration crystal bar processing waste. The technical scheme includes that firstly, the refrigeration crystal bar processing waste is grinded, washed and dried, secondly, dried powder is placed into a gas reduction furnace, mixed gas of reducing gas and inert gas is led in, the gas reduction furnace is heated up to reach 200-550 DEG C, the temperature is kept for 1.0-5.0h and is reduced to room temperature, and the refrigeration crystal bar processing waste with impurities removed is obtained. The refrigeration crystal bar processing waste with the impurities removed is placed into a quartz tube, and according to the chemical formula (BixSb2-xTe3-ySey, wherein 1.5<=x<=2.0 and 0.1<=y<=0.7) of the N-type Bi2Te3 based thermoelectric materials, Bi, Te, Sb and Se raw materials with purity higher than 99.9wt% are added. Finally, the quartz tube is packaged in an evacuated manner and is smelted in a heating furnace at the temperature of 580-850 DEG C, the temperature is kept for 0.5-5.0h, the quartz tube is cooled along with the furnace, and an alloy ingot in the quartz tube is taken out, so that the N-type Bi2Te3 based thermoelectric materials are obtained. The method has the advantages of simple process, short recovery cycle, less environmental pollution and low cost.

Owner:湖北赛格瑞新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com