Method for recovering cobalt from lithium battery anode material

A cathode material and lithium battery technology, which is applied in the field of waste power battery recycling, can solve the problems of unsuitable industrial recycling, high requirements for incineration equipment, and difficult disposal of waste liquid, and achieves the effects of small particles, easy operation and high recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

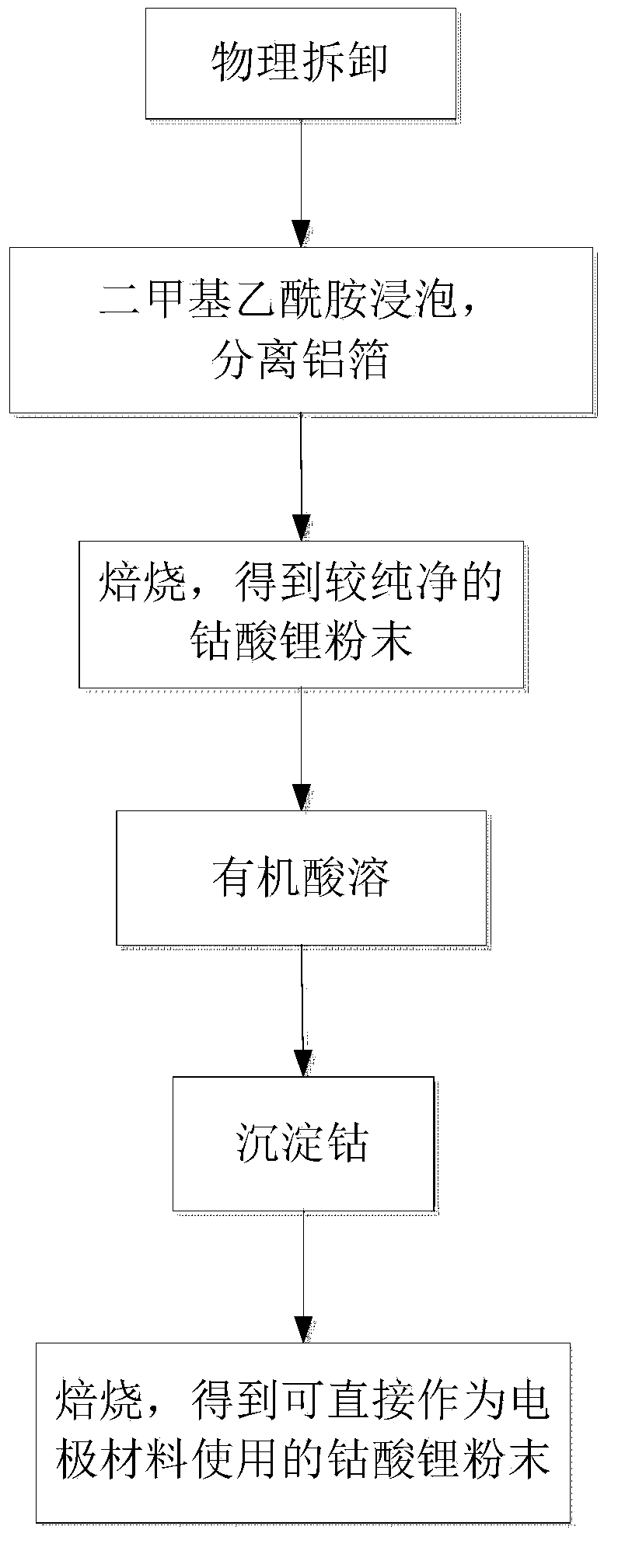

[0031] A method for reclaiming cobalt from lithium battery cathode materials, comprising the following steps:

[0032] (1) Pretreatment. Include the following steps:

[0033] (1-1) Physical dismantling: Discharge the waste lithium battery and perform physical disassembly to obtain the positive electrode material loaded with lithium cobalt oxide on the aluminum foil.

[0034] (1-2) Organic solvent immersion: Take the positive electrode material loaded with lithium cobaltate on the aluminum foil in (1-1) and add dimethylacetamide at a solid-to-liquid ratio of 1:10g / ml, soak at 30°C for 15min, take out The supernatant was used as a secondary solvent, the remaining solution was filtered, and the aluminum foil was removed to obtain a black solid substance containing lithium cobaltate.

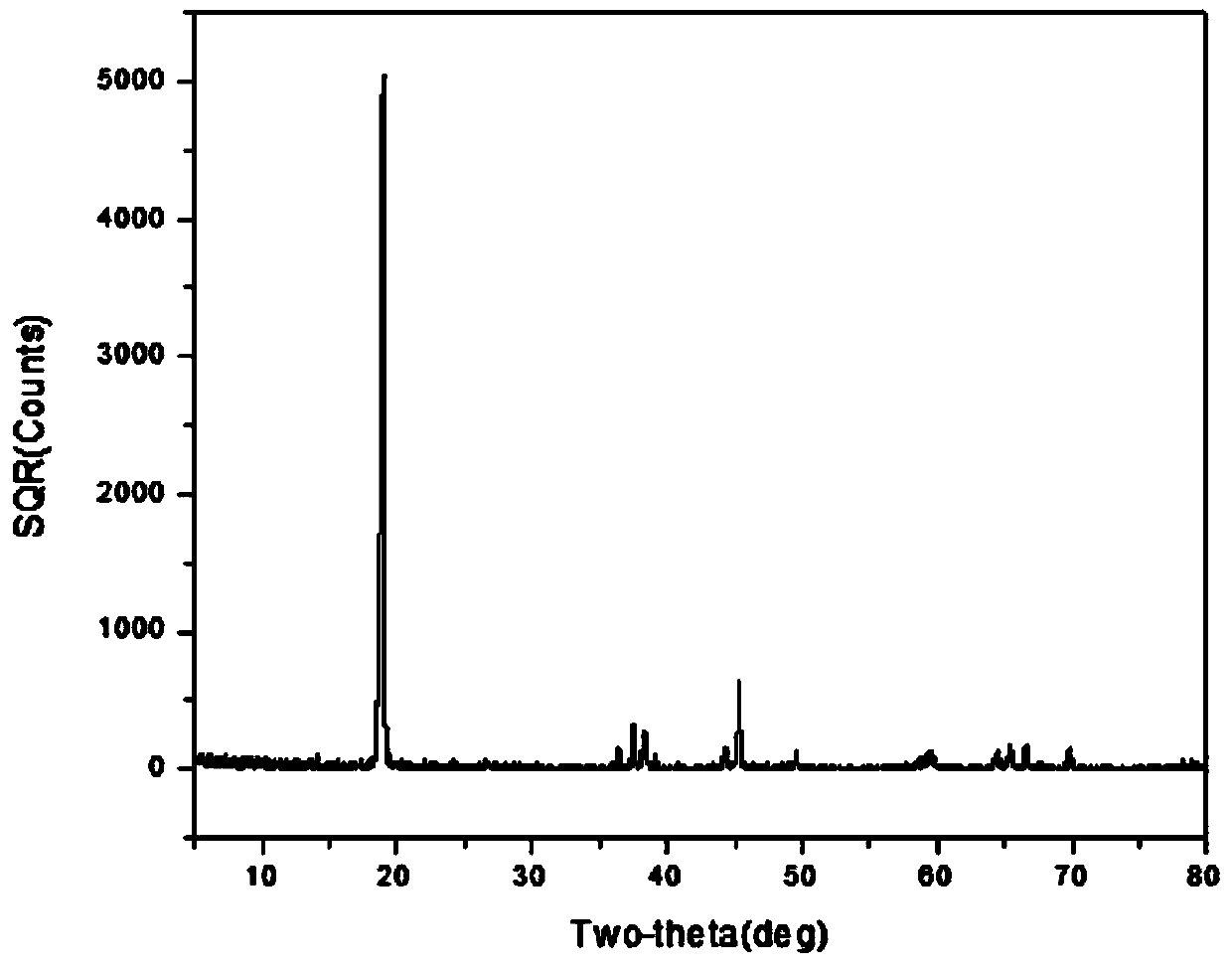

[0035] (1-3) Calcination: Calcinate the black solid substance containing lithium cobaltate in (1-2) at 600°C for 2 hours, and grind to obtain relatively pure lithium cobaltate powder. Such as f...

Embodiment 2

[0041] A method for reclaiming cobalt from lithium battery cathode materials, comprising the following steps:

[0042] (1) Pretreatment. Include the following steps:

[0043] (1-1) Physical disassembly: Discharge the waste lithium battery, and perform physical disassembly to obtain the positive electrode material loaded with lithium cobalt oxide on the aluminum foil.

[0044] (1-2) Organic solvent immersion: Take the positive electrode material loaded with lithium cobaltate on the aluminum foil in (1-1) and add dimethylacetamide at a solid-to-liquid ratio of 1:20g / ml, soak at 60°C for 5min, take out The supernatant was used as a secondary solvent, the remaining solution was filtered, and the aluminum foil was removed to obtain a black solid substance containing lithium cobaltate.

[0045] (1-3) Calcination: Calcinate the black solid substance containing lithium cobaltate in (1-2) at 700°C for 1 hour, and grind to obtain relatively pure lithium cobaltate powder.

[0046] (2) O...

Embodiment 3

[0051] A method for reclaiming cobalt from lithium battery cathode materials, comprising the following steps:

[0052] (1) Pretreatment. Include the following steps:

[0053] (1-1) Physical disassembly: Discharge the waste lithium battery, and perform physical disassembly to obtain the positive electrode material loaded with lithium cobalt oxide on the aluminum foil.

[0054] (1-2) Organic solvent immersion: Take the positive electrode material loaded with lithium cobaltate on the aluminum foil in (1-1) and add dimethylacetamide at a solid-to-liquid ratio of 1:15g / ml, soak at 45°C for 10min, take out The supernatant was used as a secondary solvent, the remaining solution was filtered, and the aluminum foil was removed to obtain a black solid substance containing lithium cobaltate.

[0055] (1-3) Calcination: Calcinate the black solid material containing lithium cobaltate in (1-2) at 650°C for 1.5h, and grind to obtain relatively pure lithium cobaltate powder.

[0056] (2) O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com