Patents

Literature

36 results about "Dihydrate Calcium Sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

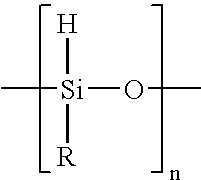

Siloxane polymerization in wallboard

ActiveUS20070022913A1Small expansionDimensional stabilitySolid waste managementWoven fabricsDihydrate Calcium SulfateSlurry

Polymerization of siloxane is improved using a gypsum-based slurry that includes stucco, Class C fly ash, magnesium oxide and an emulsion of siloxane and water. This slurry is used in a method of making water-resistant gypsum articles that includes making an emulsion of siloxane and water, then combining the slurry with a dry mixture of stucco, magnesium oxide and Class C fly ash. The slurry is then shaped as desired and the stucco is allowed to set and the siloxane polymerizes. The resulting product is useful for making a water-resistant gypsum panel having a core that includes interwoven matrices of calcium sulfate dihydrate crystals and a silicone resin, where the interwoven matrices have dispersed throughout them a catalyst comprising magnesium oxide and components from a Class C fly ash.

Owner:UNITED STATES GYPSUM CO

Fire-resistant gypsum

InactiveUS20050263925A1Point becomes highImprove fire resistanceConstruction materialWood working apparatusGlass fiberFiber

An improved, fire-resistant, set gypsum composition contains set calcium sulfate dihydrate as the major ingredient and a reinforcing ingredient of resilient, flexible, boron-free glass fibers. Continuous filament forming glass compositions with a softening point preferably greater than about 1580° F. (about 860° C.) and more preferably greater than about 1681° F. (about 916° C.) may be used. The fibers typically are distributed as their separate constituent individual glass filaments uniformly throughout the set calcium sulfate dihydrate.

Owner:OWENS CORNING FIBERGLAS TECH INC

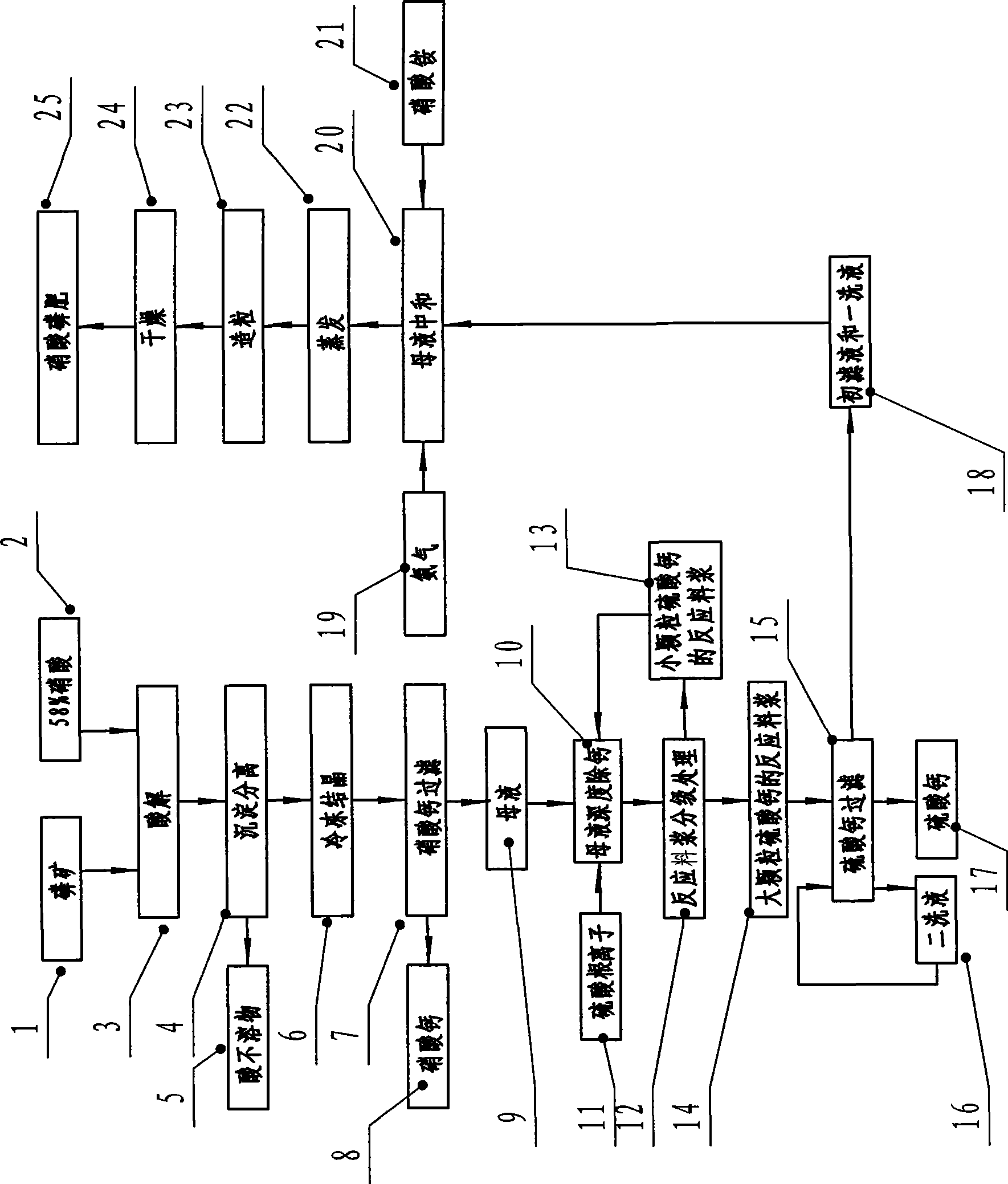

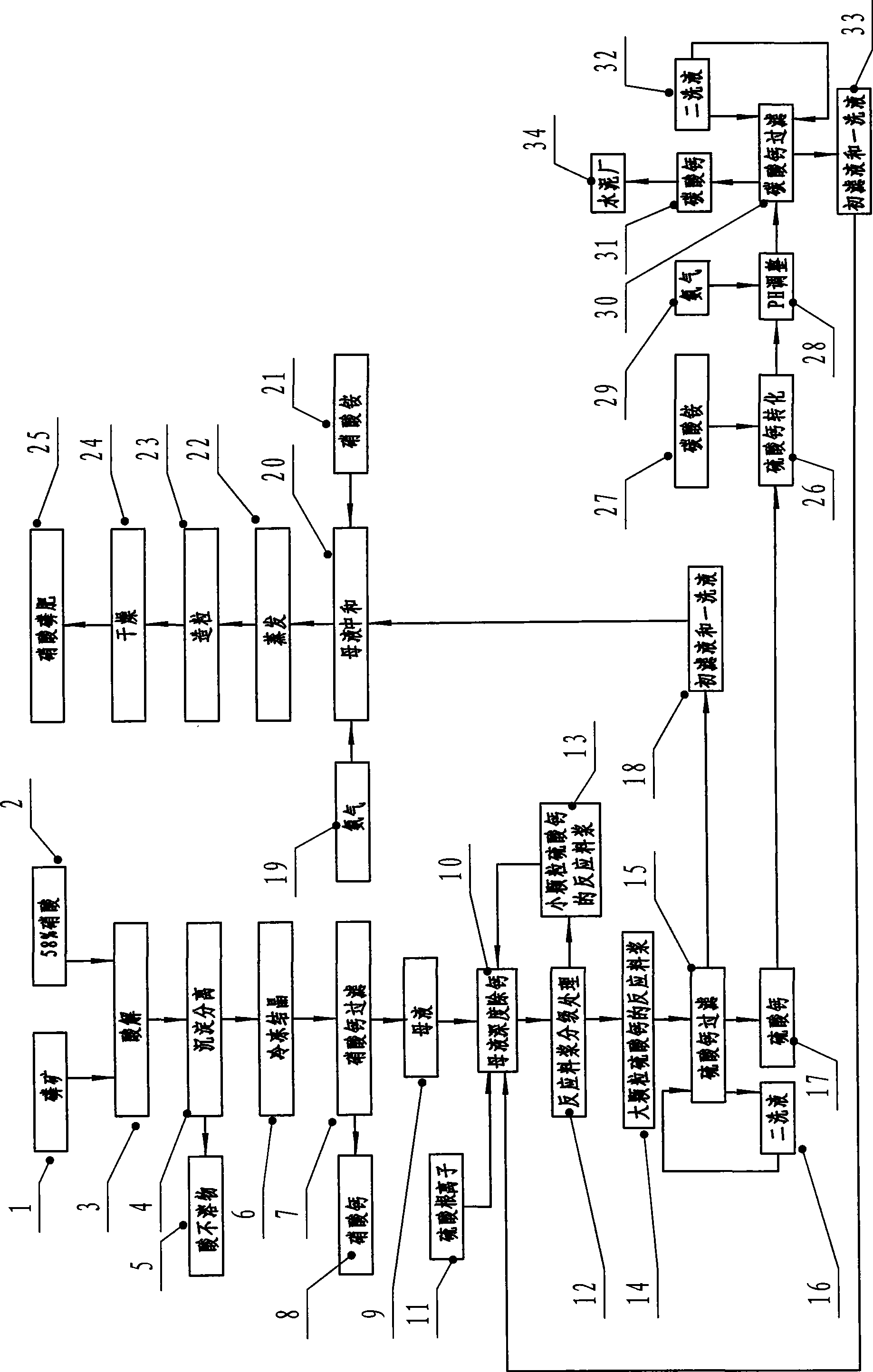

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

Alkaline land soil repair agent

InactiveCN101417286AReduce alkalinityImprove biological activityContaminated soil reclamationOrganic fertilisersNatural organic matterAlkali soil

The invention relates to a restoration agent for saline-alkali land soil, which consists of free gypsum dehydration, nature organic substance, microbial fertilizer and inorganic nutrient with weight ratio of 60-70:25-35:1-4:3-6; the content of dihydrate calcium sulfate in the free gypsum dehydration is over 80 percent; the nature organic substance consists of weathered coal and grass carbon with weight ratio of 1.0:0.93; the content of effective bacteria in the microbial fertilizer is 2.0 hundred millions / g; and the inorganic nutrient consists of urea, ordinary superphosphate and potassium chloride with weight ratio of 1.0:2.42:075. The restoration agent can utilize calcium ions in the free gypsum dehydration for replacing sodium ions in the soil so as to lower the alkalinity in the soil and provide calcium and sulfur elements for crops, while the nature organic substance can lower and regulate the slat content and the alkalinity in the soil. In addition, the nature organic substance, the microbial fertilizer and the inorganic nutrient can supply large amount of nutrient elements such as nitrogen, phosphorus, potassium and the like to the crop for normal growth, thereby being capable of improving the yield of the crop.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

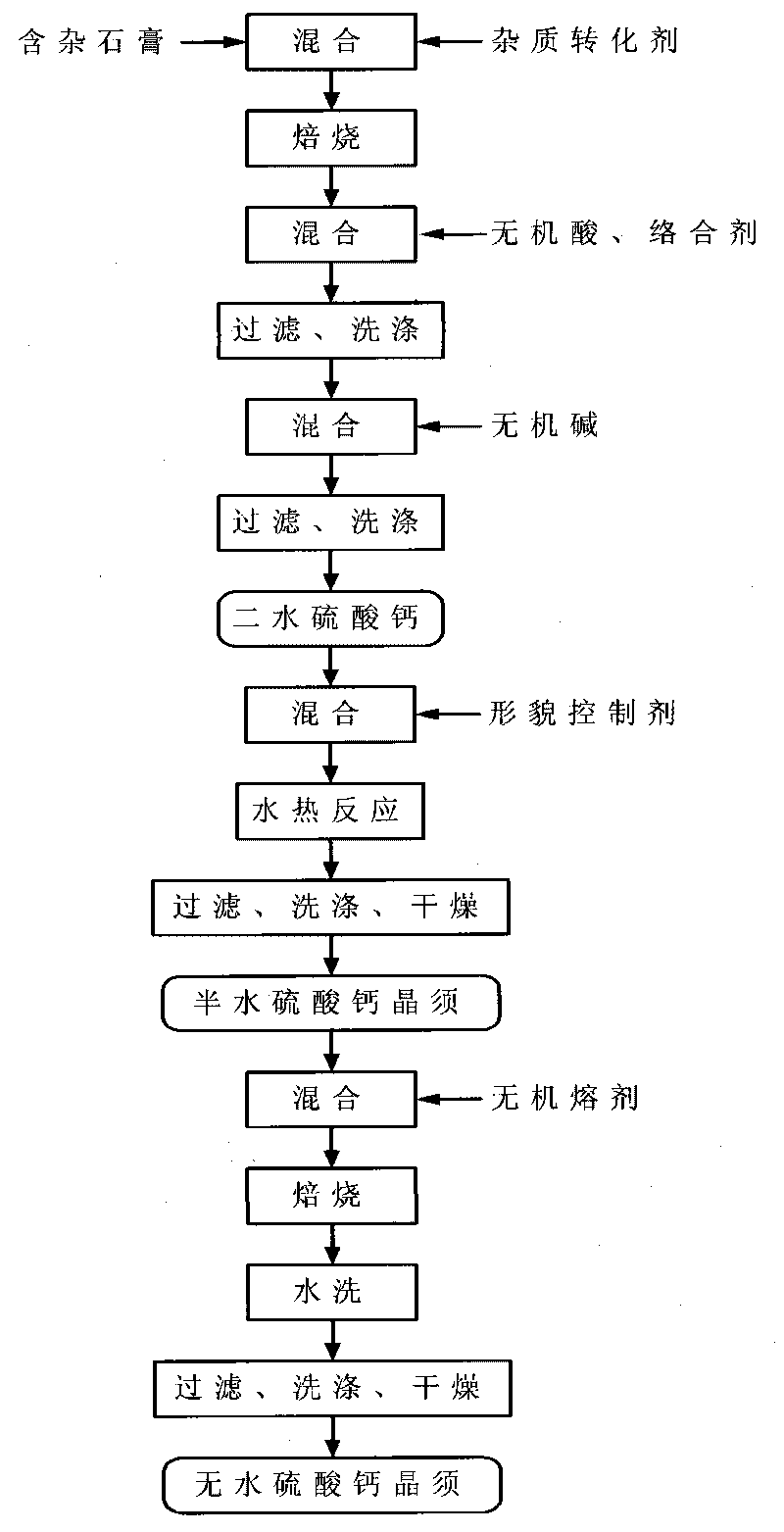

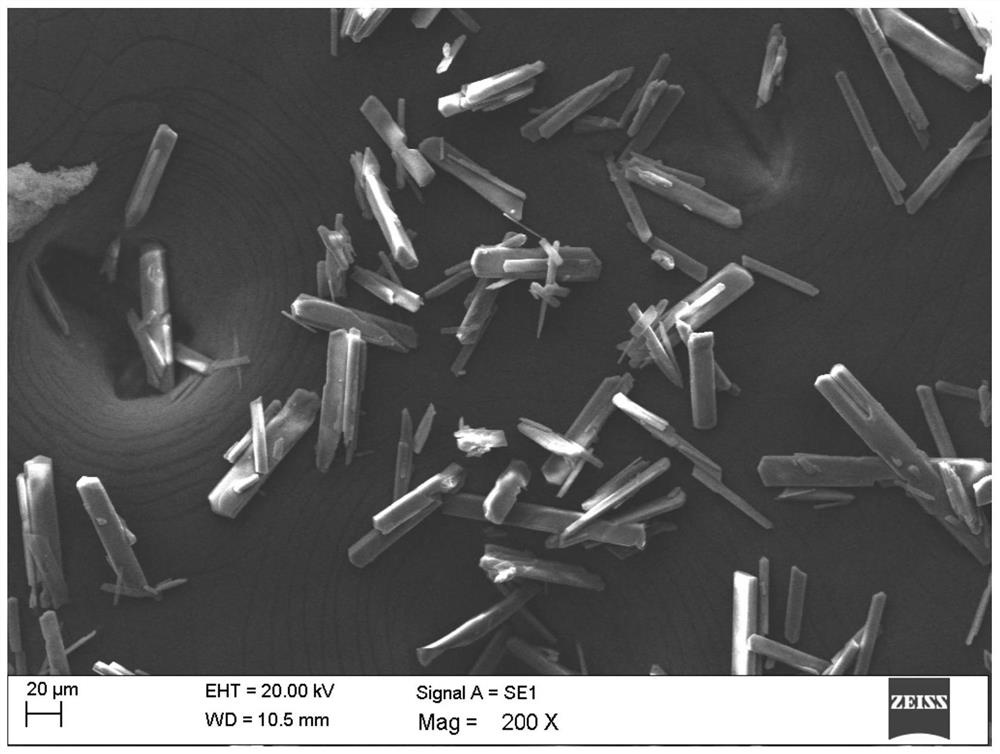

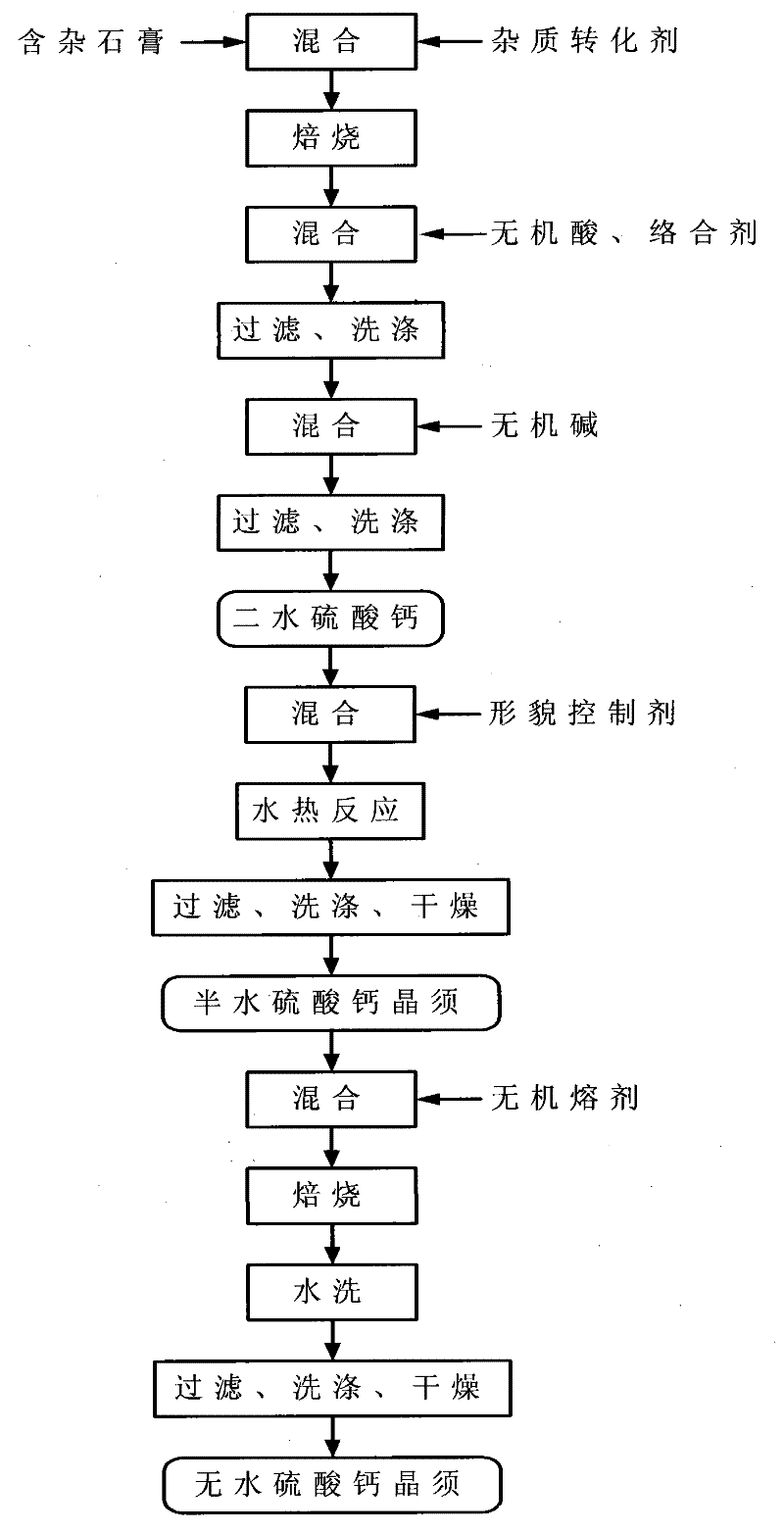

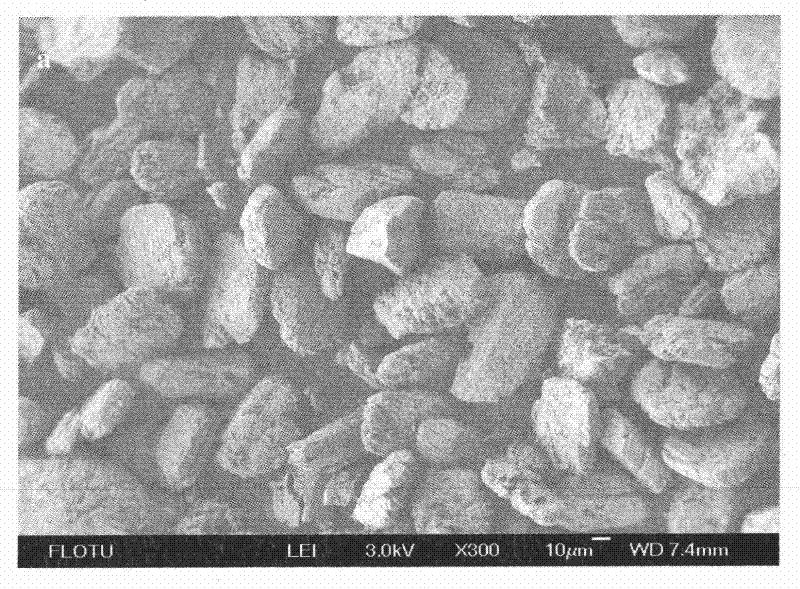

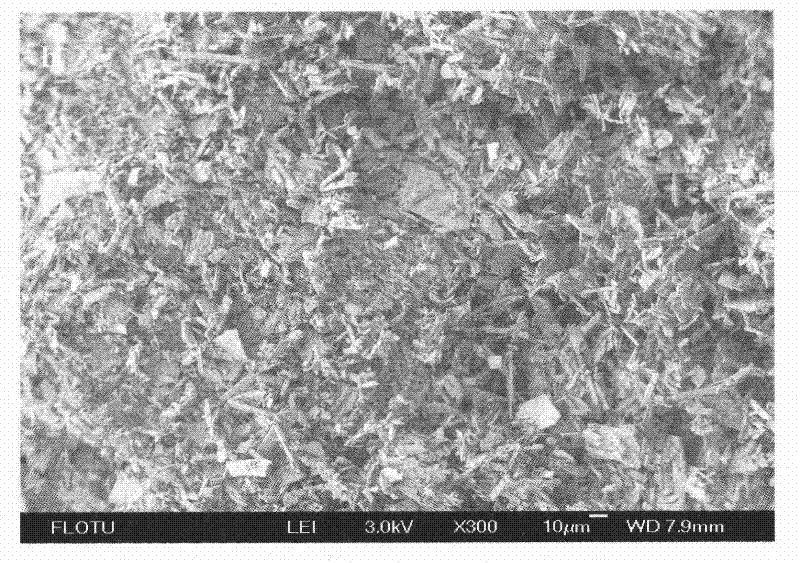

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

InactiveCN101736403AHigh purityGood dispersionPolycrystalline material growthCalcium/strontium/barium sulfatesAnhydrous Calcium SulfateDihydrate Calcium Sulfate

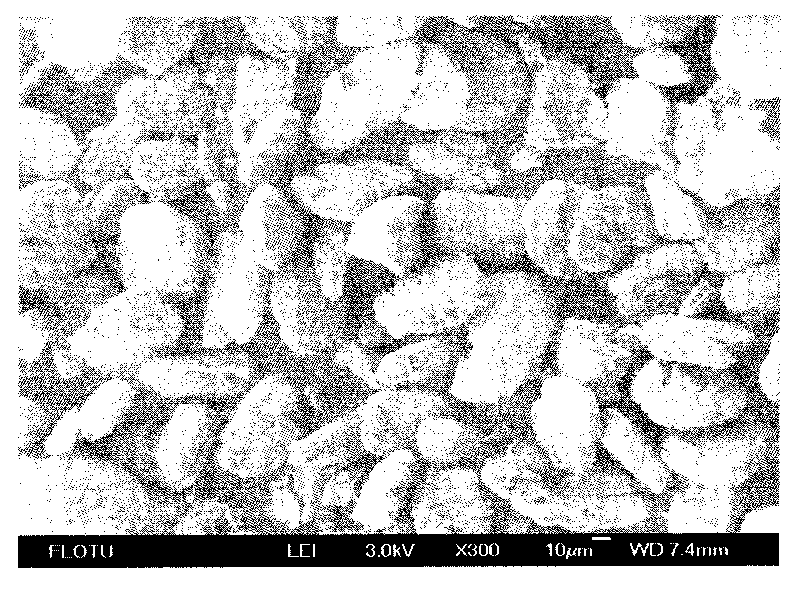

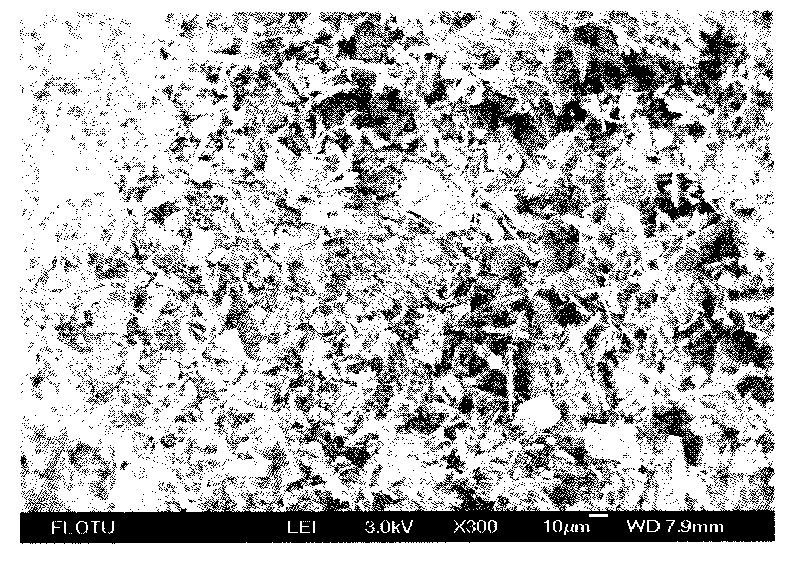

The invention relates to a method for preparing calcium sulfate crystal whiskers (CaSO4) by using impurity-containing gypsum as a raw material. The method comprises the following steps of: removing main impurities in the raw material which is the low-priced impurity-containing gypsum resource in a mode of roasting, acid-complex leaching and alkaline leaching and simultaneously thinning crystal grains to obtain a superfine dihydrate calcium sulfate precursor which is high in purity and dispersibility; and preparing the anhydrous calcium sulfate crystal whiskers with a length of 20 to 2,000mu m, a diameter of 0.5 to 20 mu m, a length-diameter ratio of 40 to 1,000 and a weight percent content of over 95 percent in a mode of hydrothermal conversion-roasting of a fluxing agent. The method has the advantages of low-priced and easily bought raw materials, simple process, wide application range, and high added value. The calcium sulfate crystal whiskers prepared by the method have a big length-diameter ratio and regular shape, and can be used as reinforcing, heat insulating or flame retardant materials in industries of plastics, rubbers, coatings, papermaking, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Gypsum products and method for their manufacture

ActiveUS20060283356A1Improve waterproof performanceReduced strengthSolid waste managementLaminationWaxEmulsion

A method is provided which uses an improved emulsion to imparting water-resistance to gypsum products. In one embodiment, gypsum products comprise calcium sulfate dihydrate and an emulsion which comprises a saponified wax, a nonsaponifiable wax, an alkyl phenol, a surfactant / dispersant salt of polynaphthalenesulfonic acid, and carboxymethylcellulose. Optionally, the emulsions may contain a preservative, e.g., a biocide (mildewcide, fungicide, etc.). These gypsum products resist the uptake of water and therefore resist biological infestation without addition of a preservative.

Owner:HEXION INC

Resource utilization method for titanium white by-product ferrous sulphate

InactiveCN102351231ASolve pollutionSolve the technical problem that the titanium dioxide by-product ferrous sulfate cannot be processed in large quantities at low costIron oxides/hydroxidesCalcium/strontium/barium sulfatesResource utilizationDihydrate Calcium Sulfate

The invention discloses a resource utilization method for titanium white by-product ferrous sulphate, which solves the technical problem of incomplete utilization of titanium white by-product ferrous sulphate with low cost in the prior art. The method of the invention comprises the following steps: a, purifying and processing titanium white by-product ferrous sulphate; b, introducing ammonia gas in a ferrous sulphate solution obtained by purifying and processing, fully reacting and filtering to obtain ferrous hydroxide deposition and an ammonium sulfate solution; c, adding calcium hydrate in the ammonium sulfate solution and fully reacting to obtain dihydrate calcium sulphate deposition and ammonia gas, recovering ammonia gas as a raw material of a step b, drying the dihydrate calcium sulfate deposition and processing to obtain the product gypsum. According to the invention, sulfur and iron resources in titanium white by-product ferrous sulphate are fully used for producing industrial grade gypsum and iron ore concentrate, the problem of titanium white by-product on environmental pollution is solved; The ammonia gas can be circularly used without consumption based on theory, the loss amount needs to be added in practical production, and the production cost is low.

Owner:攀枝花市尚亿科技有限责任公司

Modified landplaster as a wallboard filler

InactiveUS20070044687A1Improve performanceDelay exposureThin material handlingHemihydrate Calcium SulfateDihydrate Calcium Sulfate

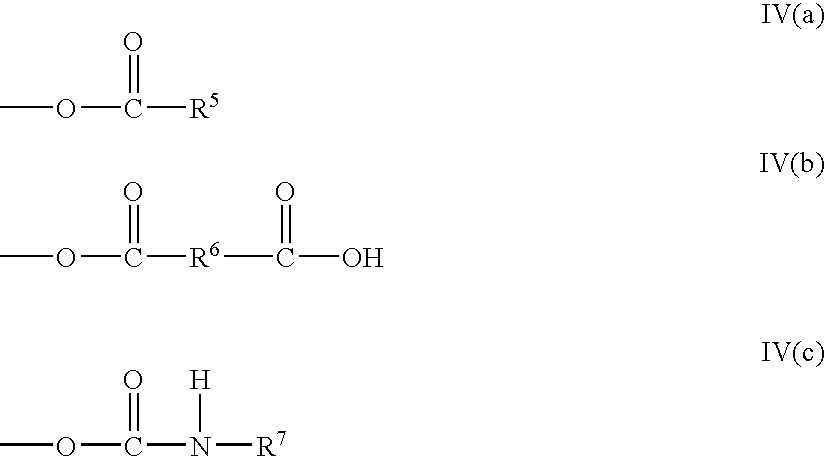

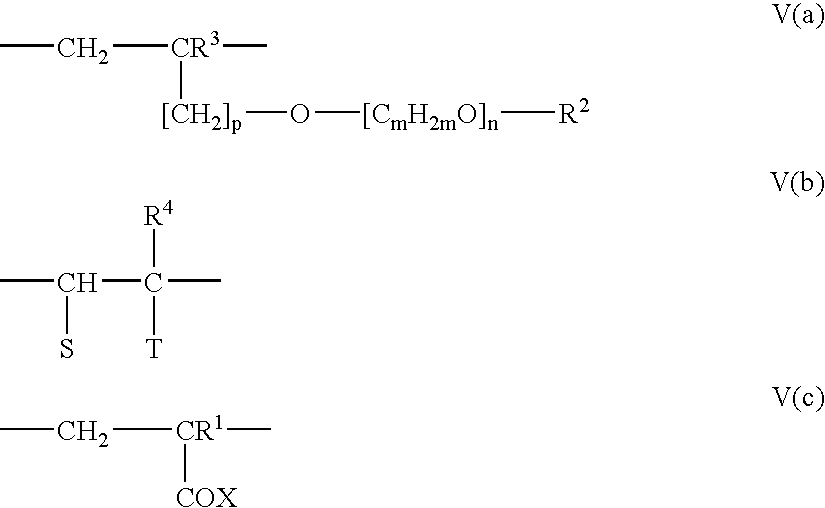

A gypsum slurry includes calcium sulfate hemihydrate, water and calcium sulfate dihydrate is coated with a hydrophilic, dispersible coating. The coating is less soluble than the calcium sulfate hemihydrate to delay exposure of the landplaster to the remainder of the slurry, preventing premature crystallization and the early stiffening that accompanies it. Another embodiment is a gypsum slurry that includes calcium sulfate hemihydrate, a polycarboxylate dispersant, water and coated calcium sulfate dihydrate. In this case, the hydrophilic, dispersible coating is selected to serve as a modifier to enhance the ability of the dispersant to fluidize the gypsum slurry.

Owner:UNITED STATES GYPSUM CO

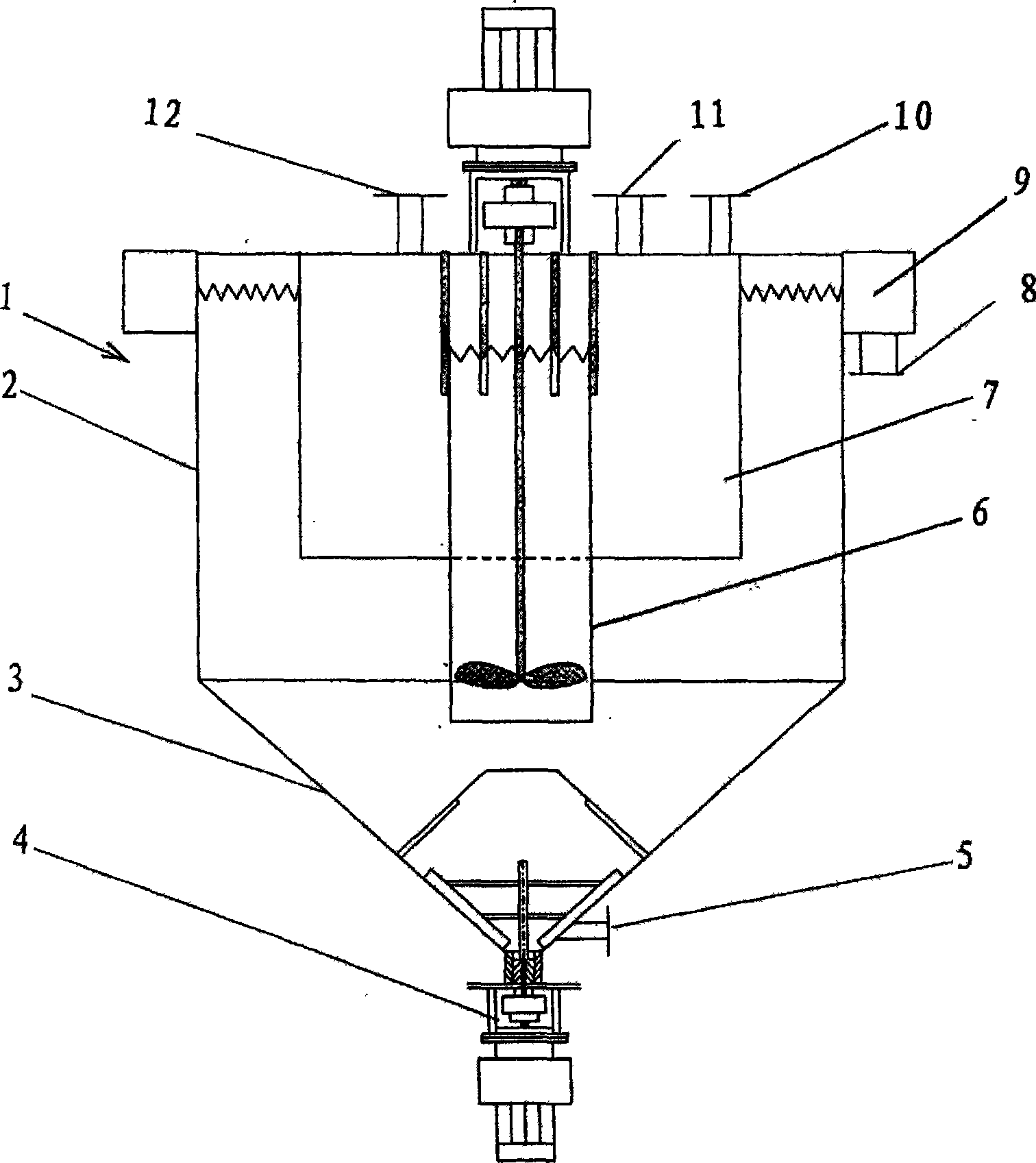

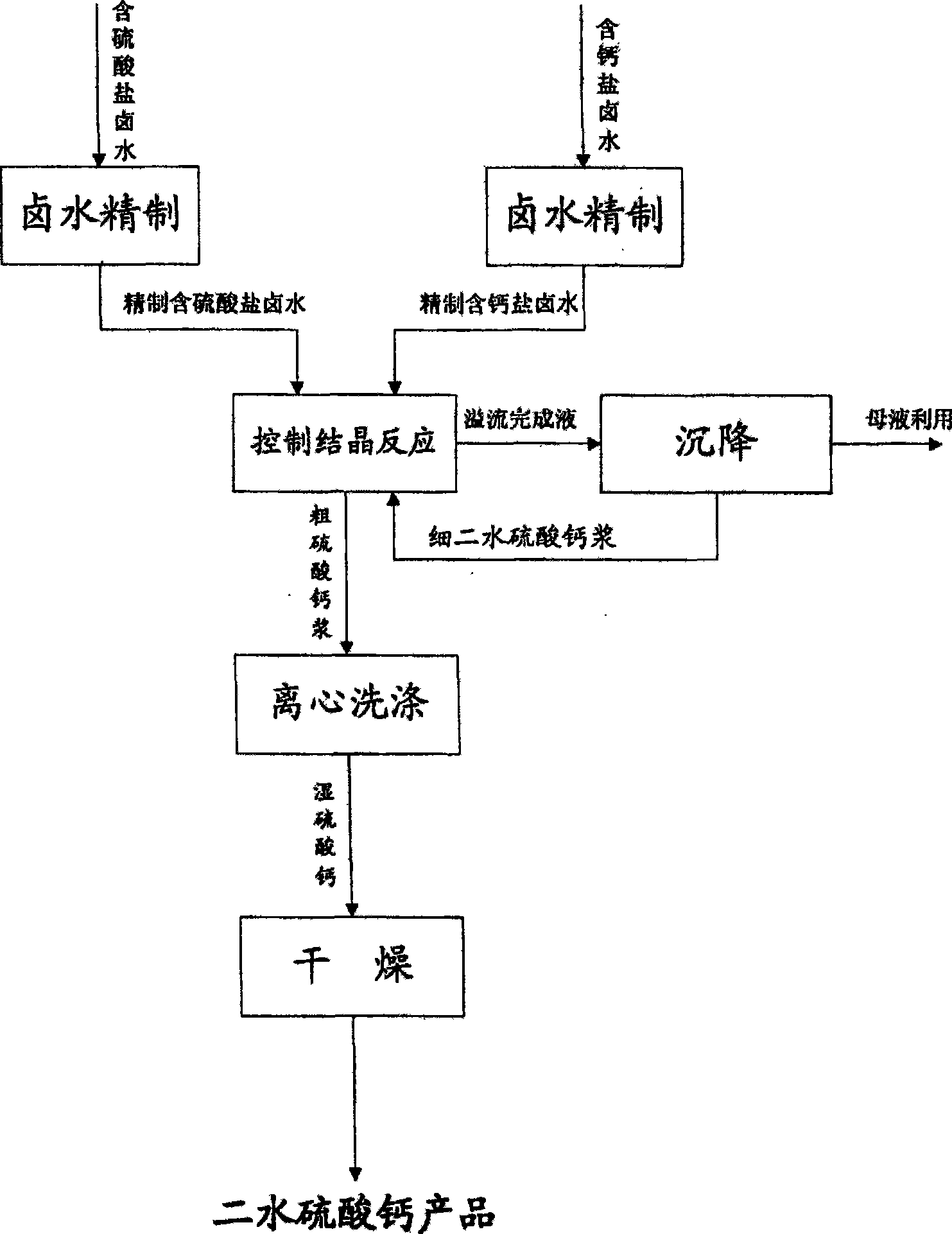

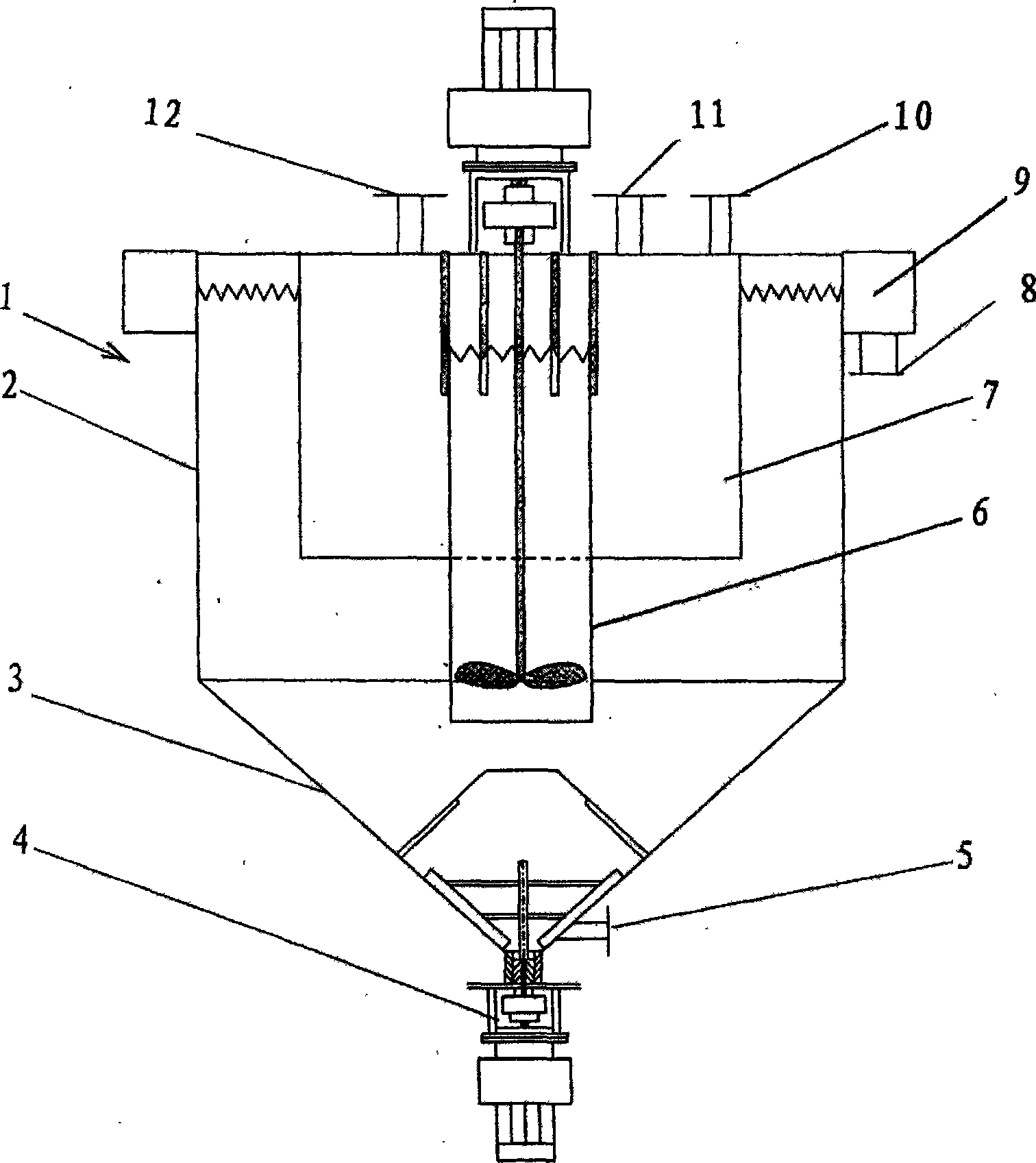

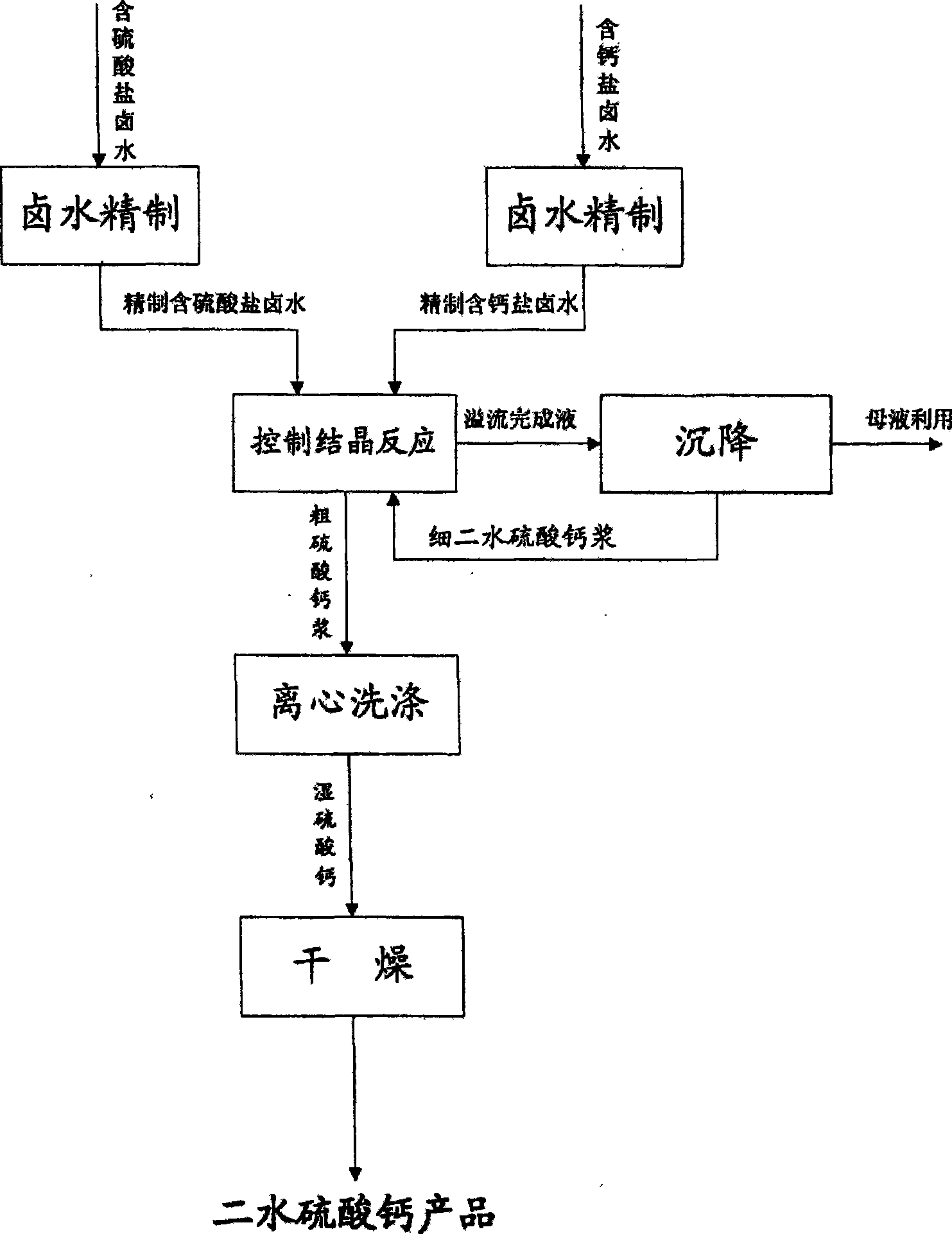

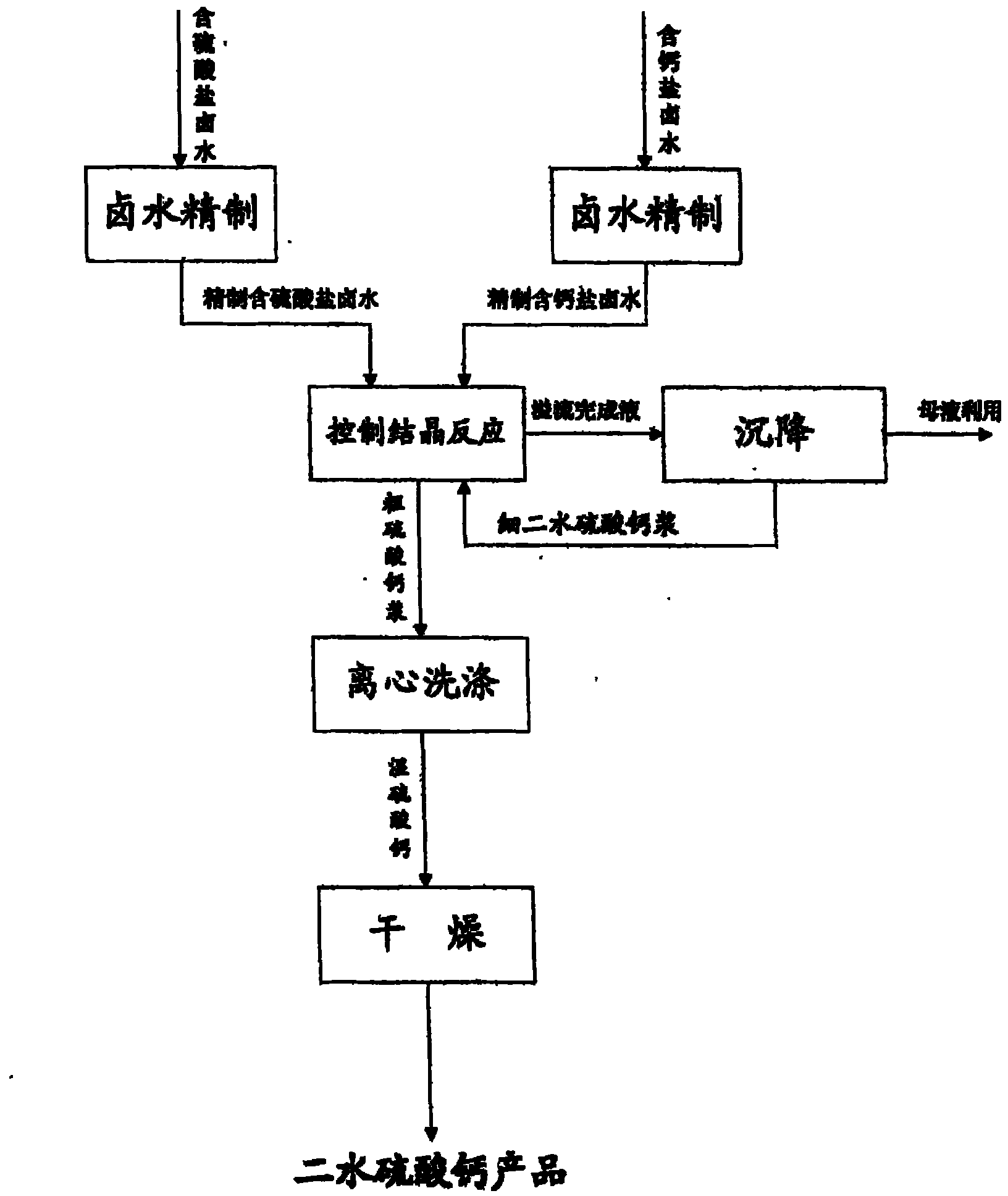

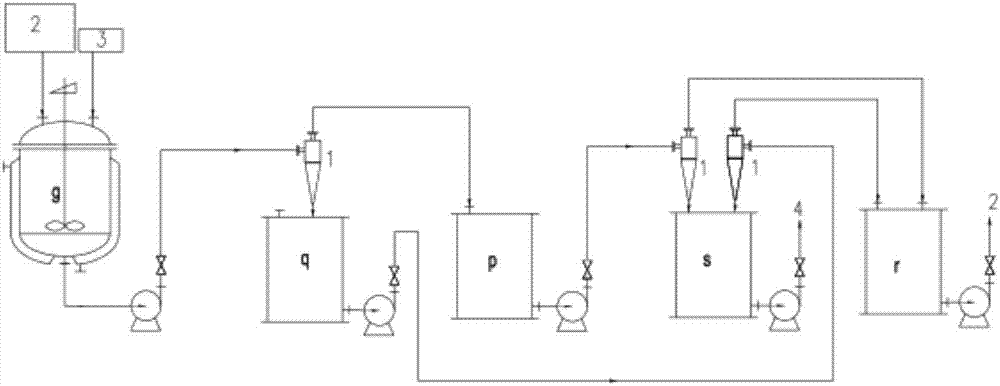

Method for preparing calcium sulphate with sulfate containing bittern and calcium containing bittern

ActiveCN101367538AReduce supersaturationLarge crystalsCalcium/strontium/barium sulfatesSulfate radicalsDihydrate Calcium Sulfate

The invention relates to a method for preparing the calcium sulfate with the sulfate-contained brine and the calcium-salt-contained brine; the two refined brines in a crystallization control reactor are uniformly and consecutively mixed with the cycling liquid inside a cycling lifting device to form dihydrate calcium sulfate crystal with large grain diameter; the dehydrate calcium sulfate crystal is centrifugally washed and dried to prepare the product of the high-purity dehydrate calcium sulfate. The flow rate of the refined sulfate-contained brine that is continuously added in a reaction crystallization barrel is determined according to the ratio between the flow rate of the refined sulfate-contained brine and the flow rate of the cycling liquid in the cycling lifting device in the reactor of 1:10 to 1:30. The flow rate of the refined calcium-salt-contained brine that is consecutively added is determined according to the mol ratio of 1:1 between the sulfate radical ion and the calcium ion in the refined sulfate-contained brine and the calcium-salt-contained brine.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Method for recovering high purity calcium hydrogen phosphate in sulfur acid-containing waste phosphoric acid

InactiveCN103738933AHarm reductionHigh purityPhosphorus compoundsPhosphoric acidDihydrate Calcium Sulfate

The invention discloses a method for recovering high purity calcium hydrogen phosphate in sulfur acid-containing waste phosphoric acid, which comprises the following processes: adding 0.5% of active carbon powder in the sulfur acid-containing waste phosphoric acid, filtering and adding excessive calcium carbonate suspending liquid or a calcium hydrate emulsion, filtering to obtain dihydrate calcium sulfate and aluminium phosphate, adding calcium with theoretical amount of 0.95-1.1 mole time required by phosphoric acid in the obtained filtrate with the forms of calcium carbonate suspending liquid and the calcium hydrate emulsion, filtering and drying to obtain high purity dihydrate calcium hydrogen phosphate; adding purified water in the obtained high purity dihydrate calcium hydrogen phosphate, beating, controlling the concentration of the solid content at 10-30%, heating a slurry to the temperature of 90-100 DEG C, stirring and aging for 0.5-1.5 hours, performing solid-liquid separation, and drying to obtain the high purity dicalicium phosphate anhydrous. The method has the advantages of simple process and low cost, and effectively uses sulfuric acid and phosphoric acid in waste acid, and reduces the harm on environment.

Owner:JIANGSU XIAOCHUN NEW MATERIAL CO LTD

Method for preparing active magnesium oxide by using reverse flotation of phosphate tailings

PendingCN109250736ALow costEmission reductionMagnesium carbonatesCalcium/strontium/barium sulfatesFiltrationDihydrate Calcium Sulfate

The invention discloses a method for preparing active magnesium oxide by using reverse flotation of phosphate tailings. The method comprises the following steps: dissolving phosphate ore reverse flotation demagnesium tailings in a hydrochloric acid solution, adding lime to adjust the pH value to 6-7, and filtering to obtain a filtration liquid; adding sulfuric acid to form a precipitate, filtering, washing and drying to obtain a dihydrate calcium sulfate whisker, and adding an oxidant into the filtration liquid; heating to 50-80 DEG C and adjusting pH to 6-7, filtering to obtain an filtrationliquid, adding ammonium carbonate for reaction to obtain basic magnesium carbonate crystals, and calcining to obtain active magnesium oxide powders. The method for preparing active magnesium oxide byusing reverse flotation of phosphate tailings achieves the purpose of comprehensively recycling and utilizing phosphate ore beneficiation tailings, prepares active magnesium oxide while preparing gypsum whiskers, and has the advantages of simple process and low energy consumption.

Owner:中化重庆涪陵化工有限公司

Modified landplaster as a wallboard filler

InactiveUS20070044688A1Improve performanceDelay exposureSynthetic resin layered productsCellulosic plastic layered productsHemihydrate Calcium SulfateDihydrate Calcium Sulfate

A gypsum slurry includes calcium sulfate hemihydrate, water and calcium sulfate dihydrate is coated with a hydrophilic, dispersible coating. The coating is less soluble than the calcium sulfate hemihydrate to delay exposure of the landplaster to the remainder of the slurry, preventing premature crystallization and the early stiffening that accompanies it. Another embodiment is a gypsum slurry that includes calcium sulfate hemihydrate, a polycarboxylate dispersant, water and coated calcium sulfate dihydrate. In this case, the hydrophilic, dispersible coating is selected to serve as a modifier to enhance the ability of the dispersant to fluidize the gypsum slurry.

Owner:UNITED STATES GYPSUM CO

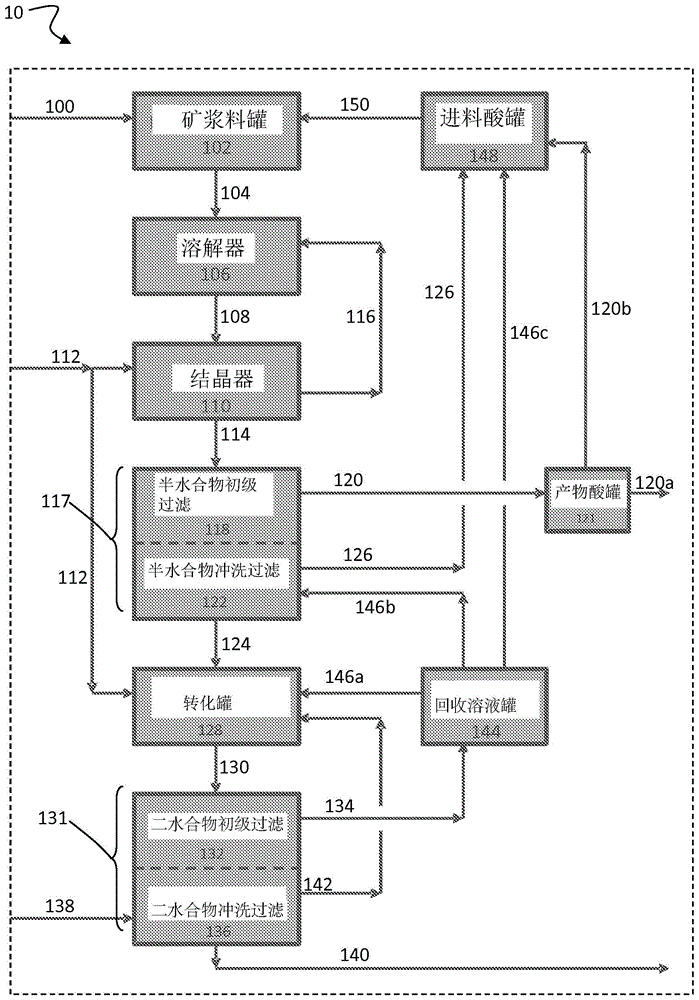

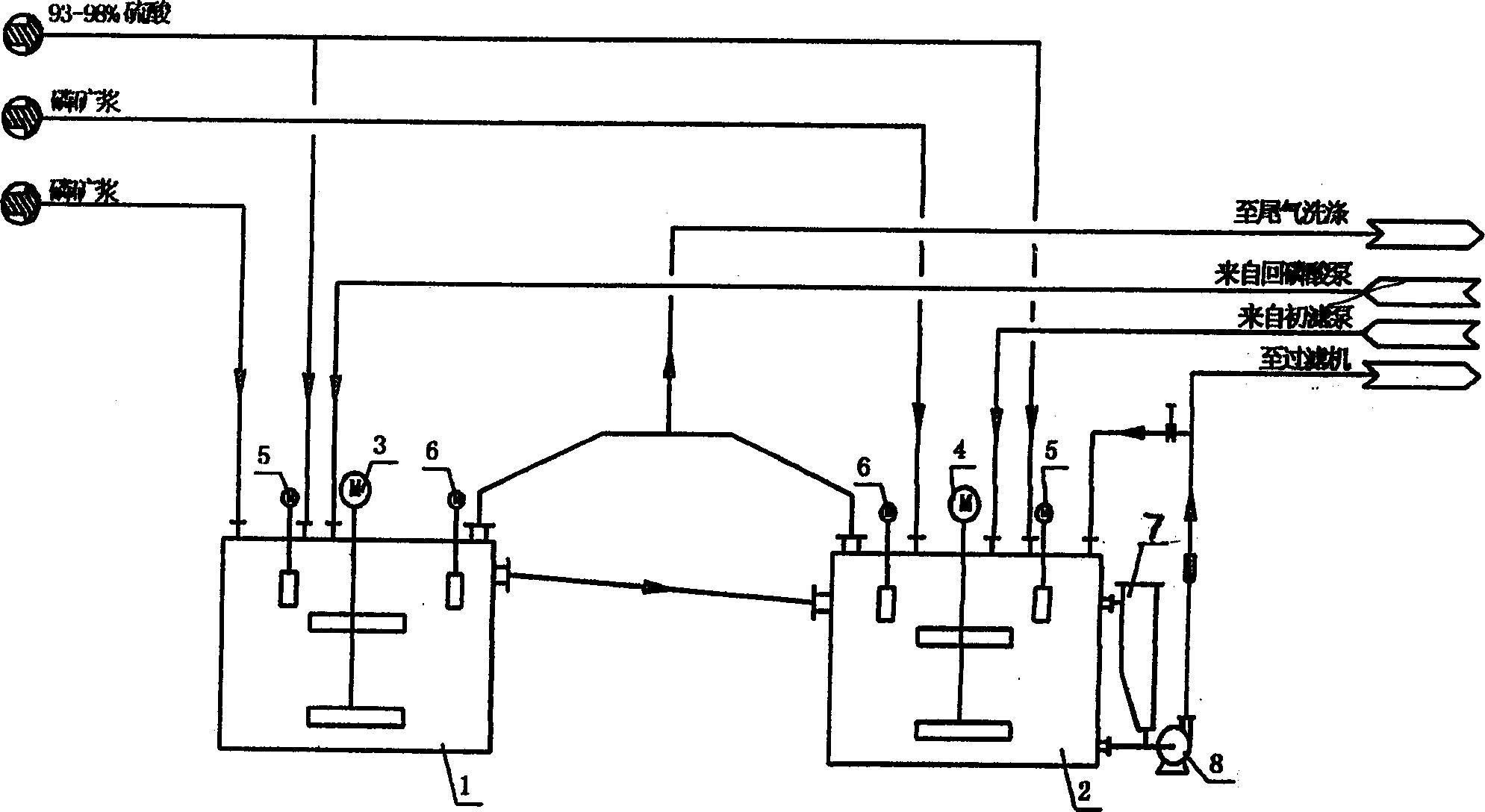

Production of phosphoric acid by a two-stage crystallization process

InactiveCN105008273AOrganic compounds purification/separation/stabilisationChemical recyclingO-Phosphoric AcidPhosphate

A process and system for producing phosphoric acid. Phosphate rock is dissolved in phosphoric acid in a reaction vessel to form a slurry. The slurry is then reacted in a first stage of crystallization with sulfuric acid to produce calcium sulfate hemihydrate and phosphoric acid. The product acid is separated from the hemihydrates via filtration, and the filter cake is then reacted, in a second crystallization step, with additional sulfuric acid to produce dihydrate calcium sulfate (gypsum) and recovery solution. The gypsum is separated from the recovery solution via filtration and removed as a by-product. The recovery solution is recycled back to the transformation tank and to the hemihydrate filtration step. A feed acid tank combines wash solution, recovery solution and product acid. Once adjusted to a target P2O5 concentration, it is fed to the initial reactor vessel to dissolve the phosphate ore.

Owner:THE MOSAIC COMPANY

Method for deeply extracting calcium sulfate from phosphorus ore acid hydrolysis liquid

PendingCN112624174ALow content requirementModerate crystal sizeCalcium/strontium/barium sulfatesHydration reactionDihydrate Calcium Sulfate

The invention relates to a method for deeply extracting calcium sulfate from phosphorus ore acid hydrolysis liquid, and belongs to the technical field of chemical production. The method comprises the following steps: (1) acid hydrolysis; (2) acid hydrolysis liquid purification; and (3) calcium removal and crystal transformation. The calcium removal purification comprises two crystallization processes, calcium sulfate hemi-hydrate is generated by primary crystallization, and secondary crystallization is to add a seed crystal into a primary crystallization reaction solution to prepare calcium sulfate dihydrate. According to the method, the optimal conditions in each process are controlled by adopting a mode of flocculating and then crystallizing twice, so that the production process is effectively shortened, the requirement on the content of the used raw material (phosphorus ores) is relatively low, the application range is wide, and the method is not limited by the quality of the phosphorus ores. The produced calcium sulfate dihydrate product is moderate in crystal form particle size, the phosphorus content can be as low as 0.2%, and further utilization of phosphogypsum is better facilitated.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

Method for preparing calcium sulphate with sulfate containing bittern and calcium containing bittern

ActiveCN101367538BReduce supersaturationLarge crystalsCalcium/strontium/barium sulfatesSulfate radicalsPhysical chemistry

The invention relates to a method for preparing the calcium sulfate with the sulfate-contained brine and the calcium-salt-contained brine; the two refined brines in a crystallization control reactor are uniformly and consecutively mixed with the cycling liquid inside a cycling lifting device to form dihydrate calcium sulfate crystal with large grain diameter; the dehydrate calcium sulfate crystalis centrifugally washed and dried to prepare the product of the high-purity dehydrate calcium sulfate. The flow rate of the refined sulfate-contained brine that is continuously added in a reaction crystallization barrel is determined according to the ratio between the flow rate of the refined sulfate-contained brine and the flow rate of the cycling liquid in the cycling lifting device in the reactor of 1:10 to 1:30. The flow rate of the refined calcium-salt-contained brine that is consecutively added is determined according to the mol ratio of 1:1 between the sulfate radical ion and the calcium ion in the refined sulfate-contained brine and the calcium-salt-contained brine.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Set accelerator for gypsum hydration

ActiveUS20120160133A1Low costMaintain efficacy of the productCeramic shaping apparatusDihydrate Calcium SulfateSlurry

In a first embodiment of the invention, aged brushite is combined with calcium sulfate hemihydrate and water to make a gypsum slurry. Aged brushite slurry behaves similarly to calcium sulfate dihydrate to act as a seed crystal and rapidly initiate crystallization. The brushite slurry does not require the addition of a coating to maintain its activity over time compared to calcium sulfate dihydrate set accelerators. A gypsum-based product made using brushite slurry as the set accelerator is a second embodiment. The product has the brushite molecules integrated as part of the calcium sulfate dihydrate matrix and is distributed throughout the matrix.

Owner:UNITED STATES GYPSUM CO

Method for preparing anhydrous calcium sulfate to co-produce industrial hydrochloric acid by using pure alkali distilled waste liquid

InactiveCN102070173AEfficient governanceEliminate chemical pollutionCalcium/strontium/barium sulfatesPreparation from chloridesChemical industryLiquid waste

The invention belongs to the technical field of treatment and utilization of three wastes in the chemical industry, and particularly discloses a method for preparing anhydrous calcium sulfate to co-produce industrial hydrochloric acid by using pure alkali distilled waste liquid. The invention has the main technical scheme that: the pure alkali distilled waste liquid reacts with the hydrochloric acid to obtain solution mainly containing calcium chloride, synthetic reaction and filtration are carried out on the obtained solution and sulfuric acid to obtain dihydrate calcium sulfate, calcination is carried out on the dihydrate calcium sulfate to obtain the anhydrous calcium sulfate, and filtrate is decompressed and distilled to obtain 25%-30% industrial hydrochloric acid. In the method, not only is the distilled waste liquid of the pure alkali industry effectively treated, industrial pollution is eliminated, but also the distilled waste liquid can be modified into anhydrous calcium sulfate and industrial hydrochloric acid products with economic value, the production technology and equipment thereof are simple and the cost is low.

Owner:汪晋强

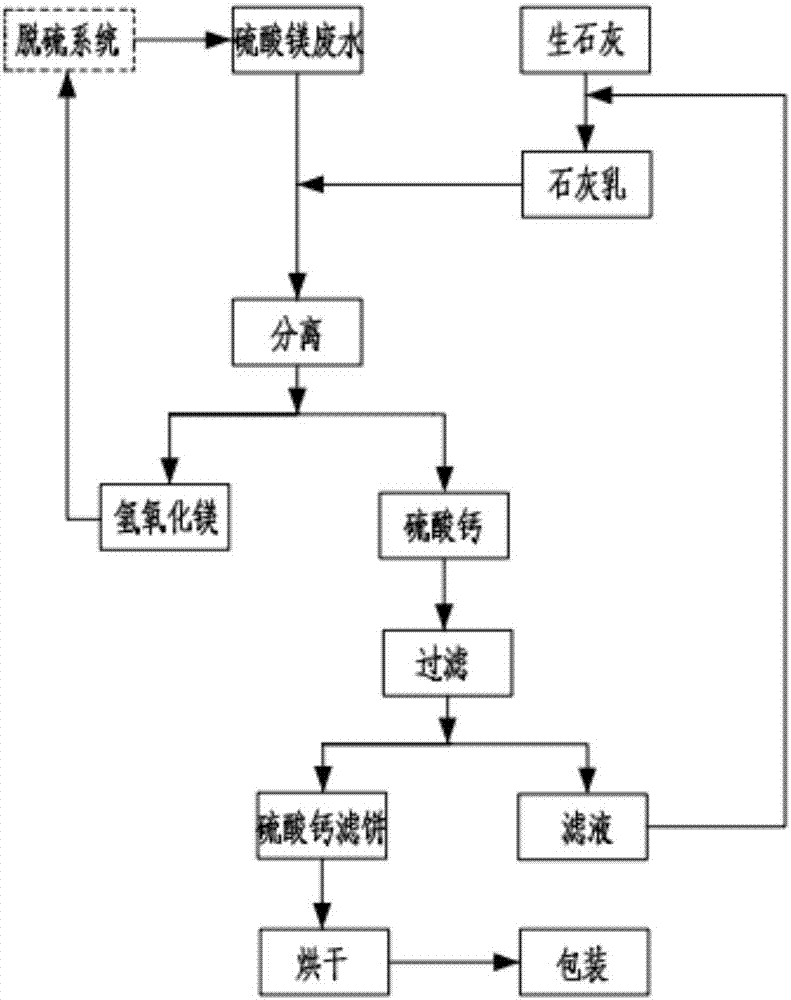

Method for treating magnesium sulfate wastewater by lime-base process

InactiveCN107445343ASolve processing problemsEfficient separationWater/sewage treatment by centrifugal separationWater contaminantsSulfateDihydrate Calcium Sulfate

The invention discloses a method for treating magnesium sulfate wastewater by a lime-base process and relates to the field of wastewater treatment. The method comprises the following steps: preparing lime milk into specified concentration, and reacting the lime milk with the magnesium sulfate wastewater under certain conditions; separating a reacted mixture of dihydrate calcium sulfate and magnesium hydroxide by a hydrocyclone; enabling the magnesium hydroxide to be effectively separated from the dihydrate calcium sulfate by two-stage separation; enabling the magnesium hydroxide to return to a desulfurization system for continuously desulfurizing; filtering and drying the dihydrate calcium sulfate to obtain a calcium sulfate product for selling. According to the whole treatment process, the difficult problem of the treatment of the magnesium sulfate wastewater generated by magnesium desulfurization can be thoroughly solved by only supplementing a small amount of primary water and preventing wastewater discharge. The method disclosed by the invention has the beneficial effects that compared with a distillation method, the method has the advantages that the problems of equipment scaling and long operation period are solved; in addition, the equipment is simple and less in investment, so that more energy is saved; compared with a flotation method, the process has the advantages that no various organic auxiliary materials are added in the process, so that the process is more environmentally friendly and lower in operation cost.

Owner:淄博美盛化工有限公司

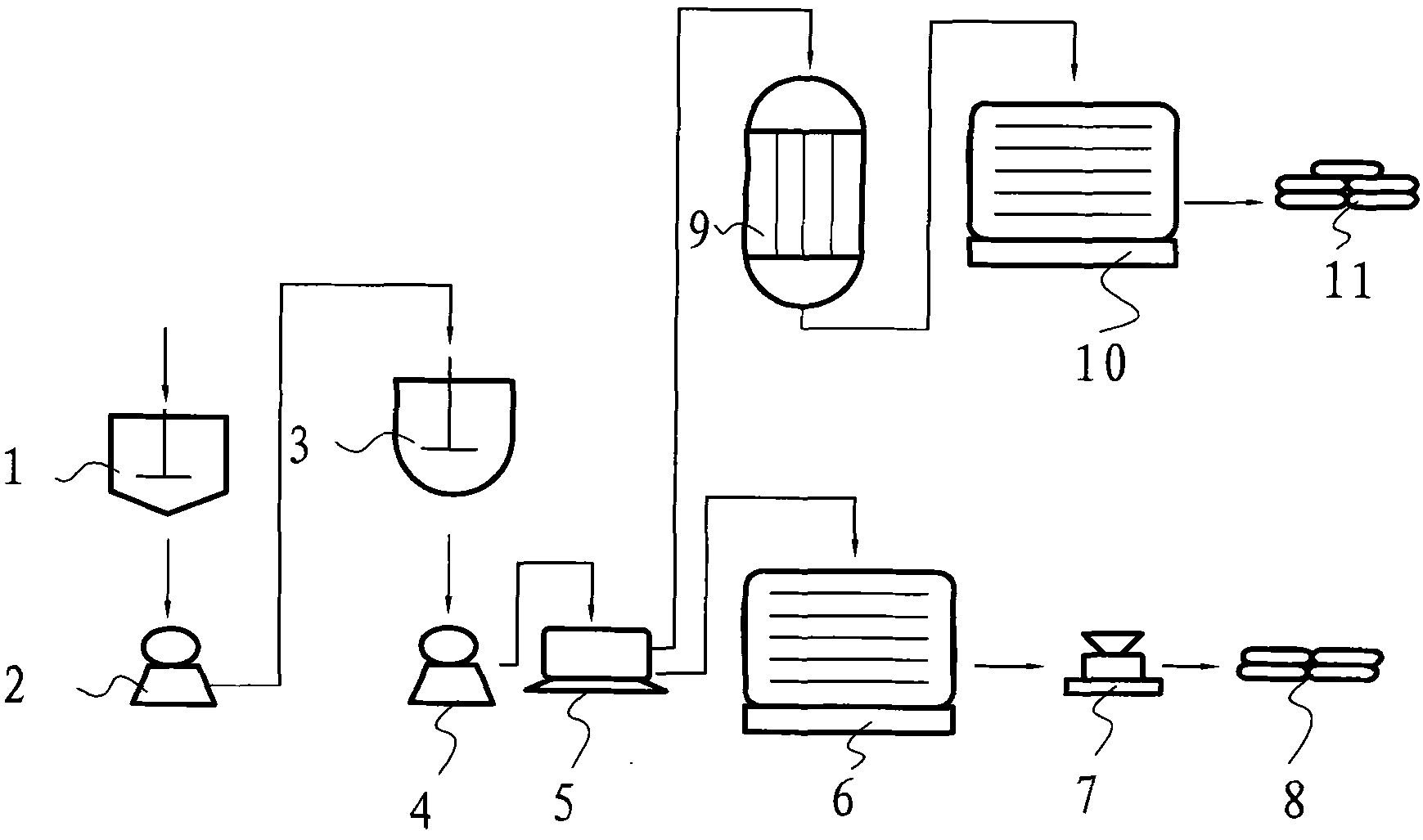

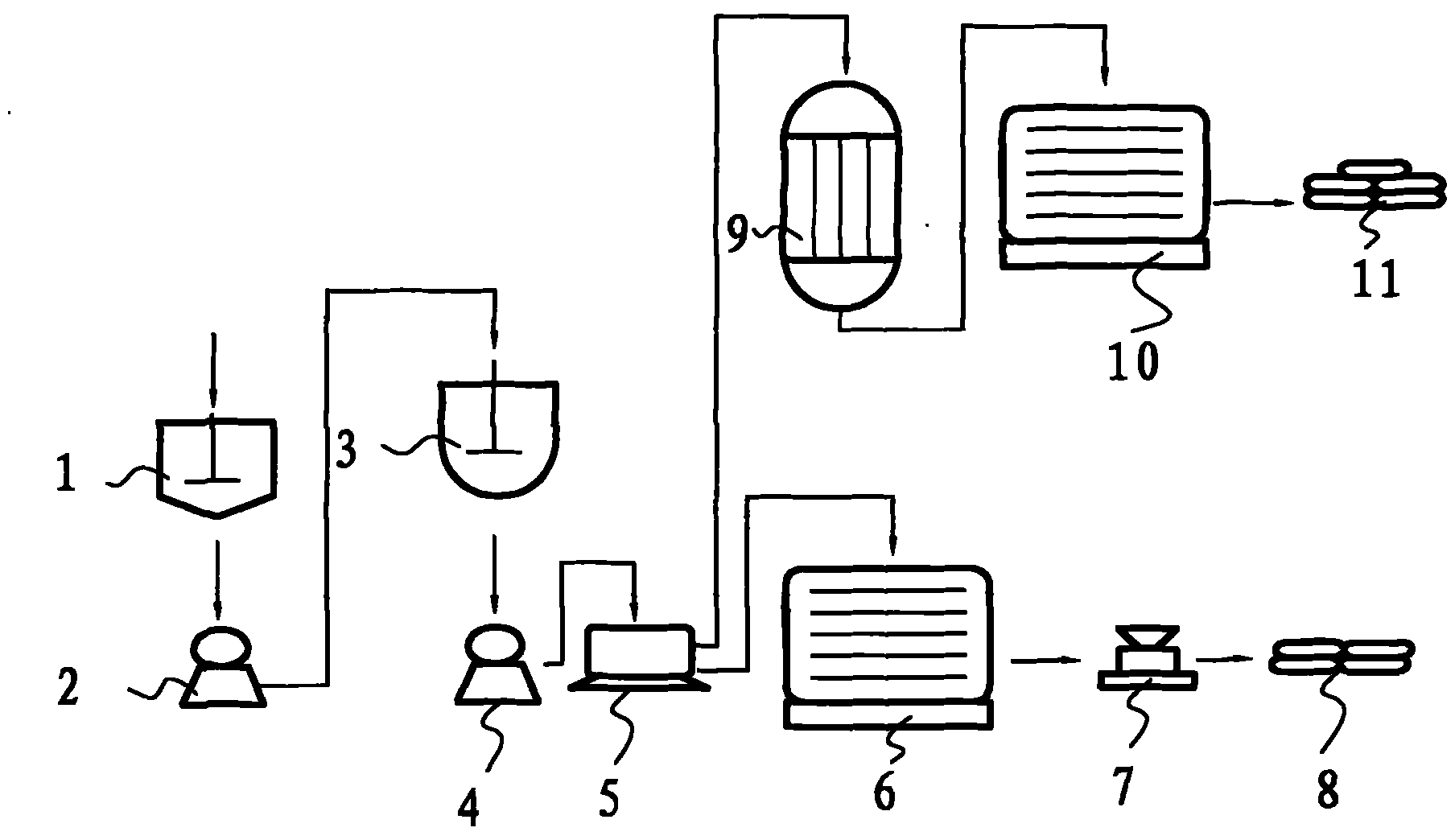

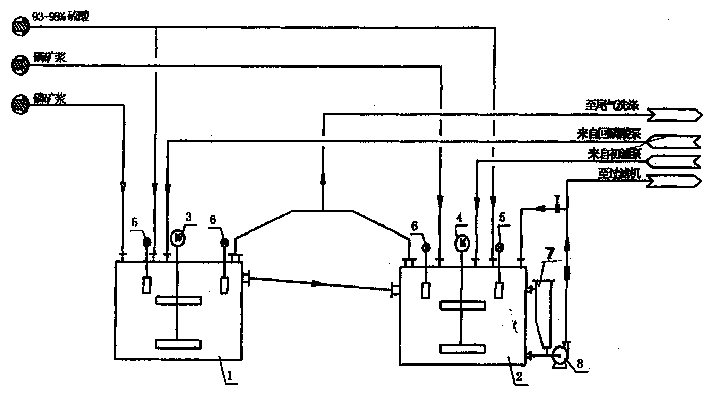

Method for producing phosphoric acid by using 93%-98% concentrated sulfuric acid to extract phosphate rock and its equipment

InactiveCN1460635ALess process equipmentLess investmentPhosphorus compoundsSurface coolingO-Phosphoric Acid

The present invention provides a method for producing phosphoric acid by using 93%-98% concentrated sulfuric acid to extract phosphorus ore and its equipment. The sulfuric acid and phosphorus ore pulp are respectively added into two series-connected cylindrical reactor tanks with identical volume, according to a certain proportion, every reactor tank is equipped with several sulfuric acid distributors, surface cooling device and central stirring poddle with large circulation quantity, and the extraction reaction can be implemented in two reactor-tanks at the same time, and the operation condition of every reactor tank can be respectively controlled. Said invention can effectively raise extraction rate of P2O5, improve dihydrated calcium sulfate crystal and can raise filtering strength.

Owner:EAST CHINA ENG SCI & TECH

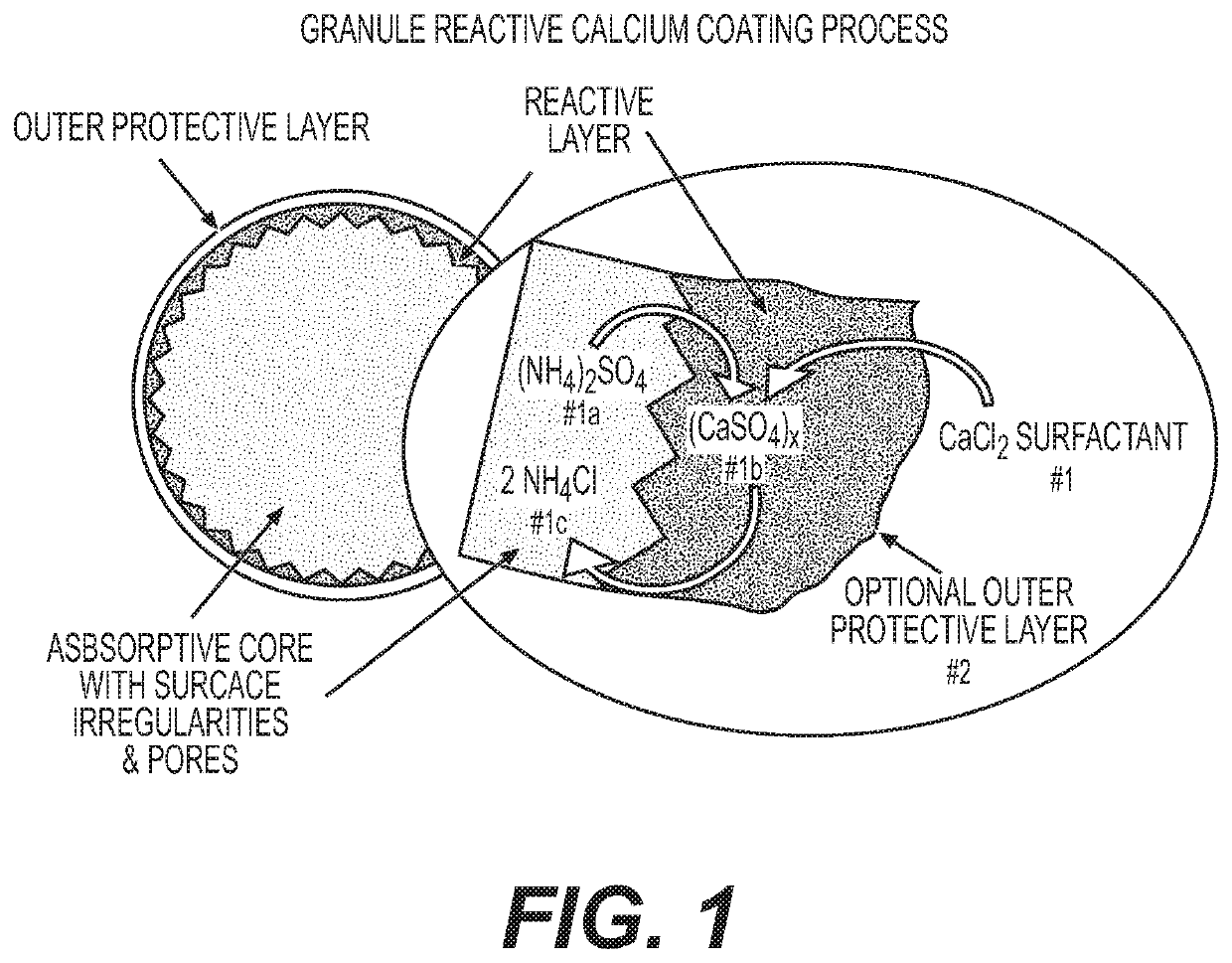

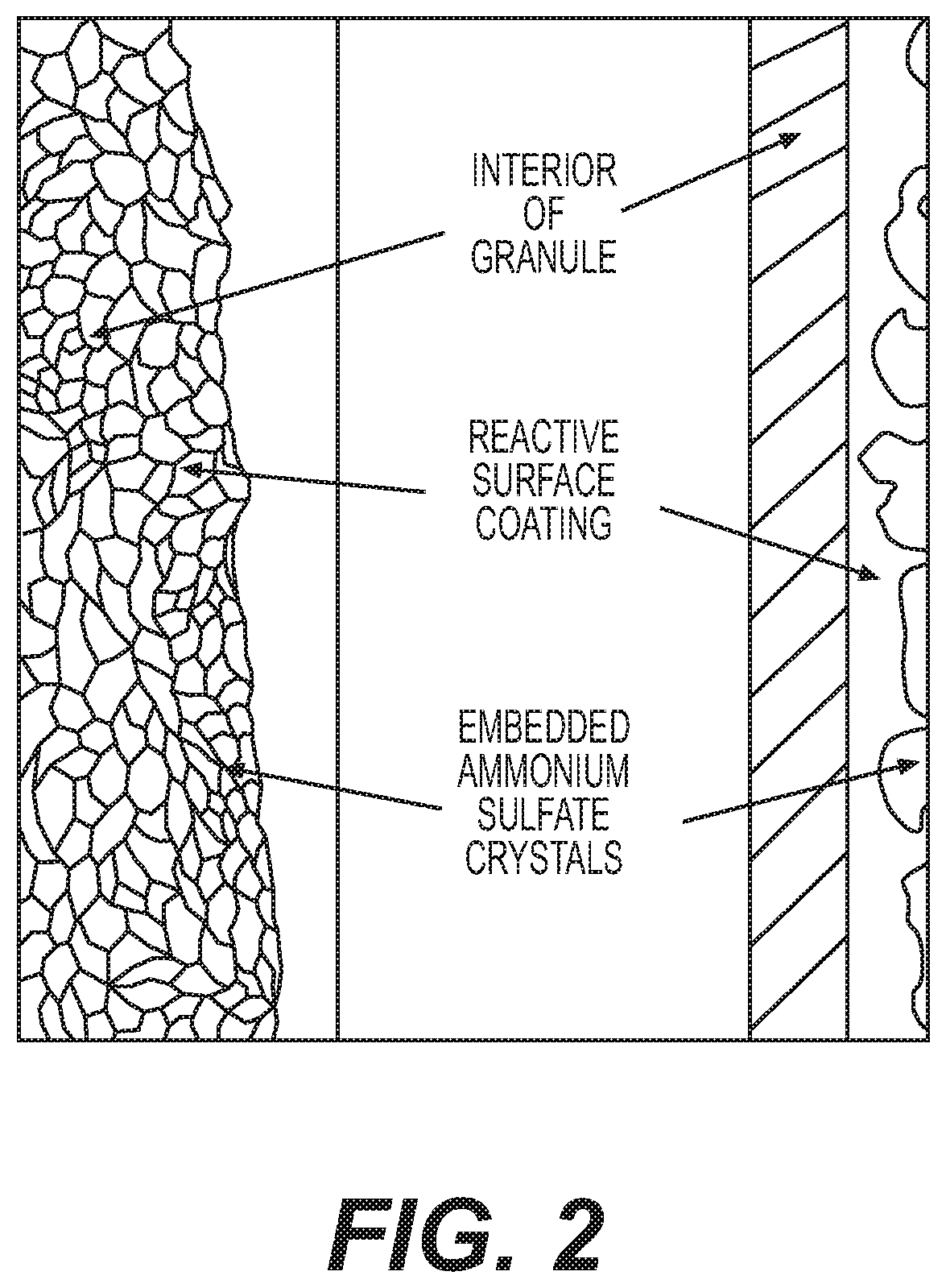

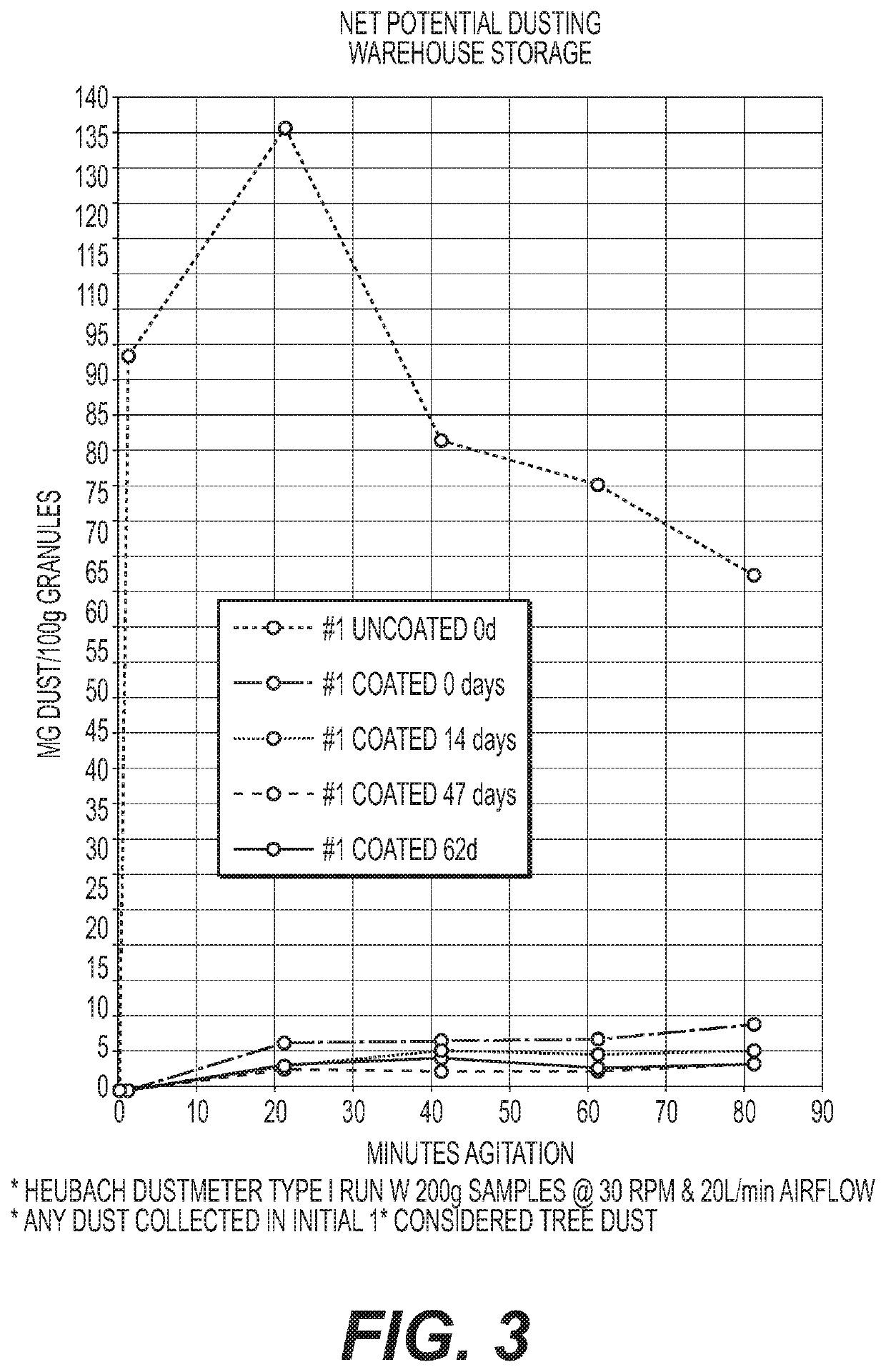

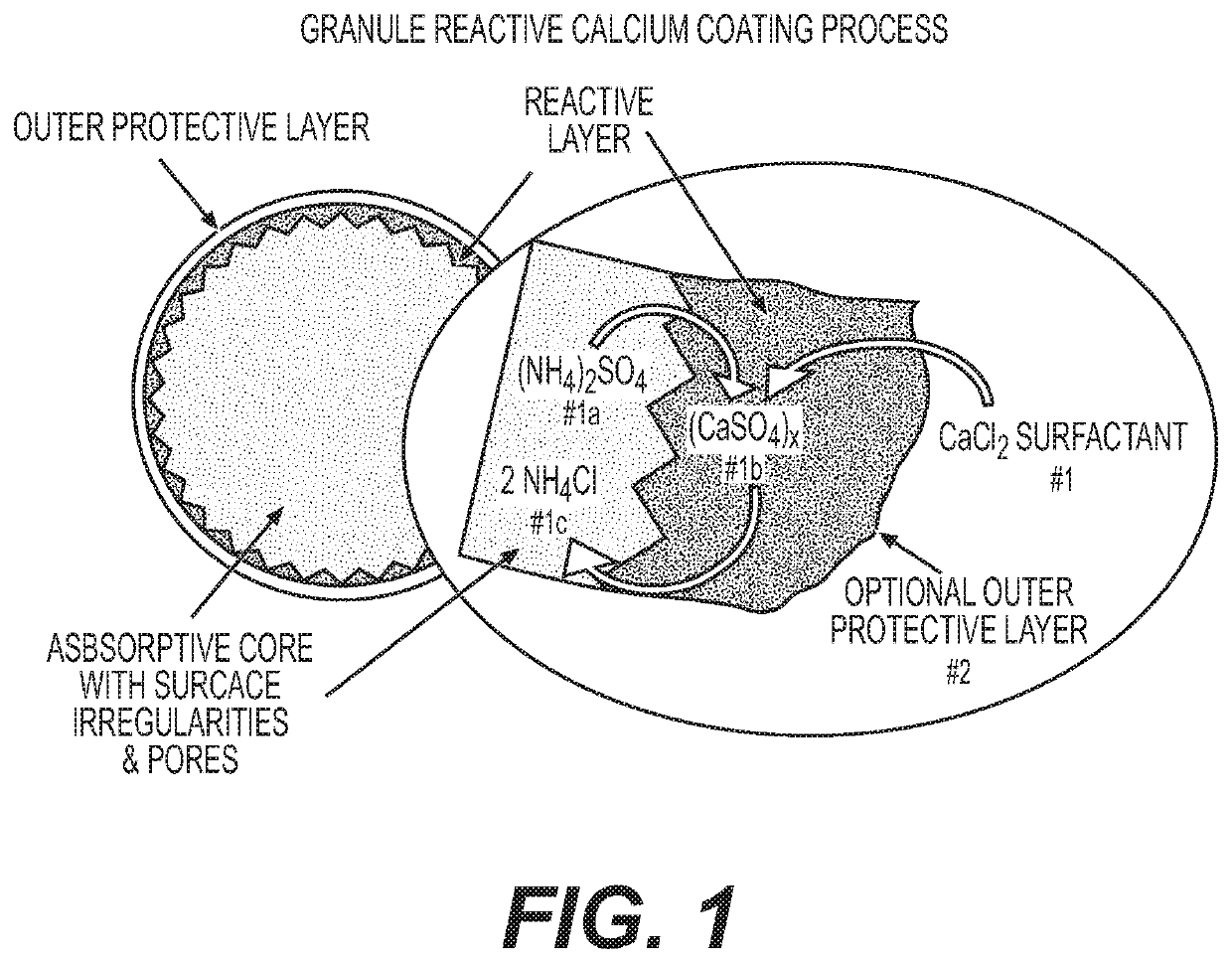

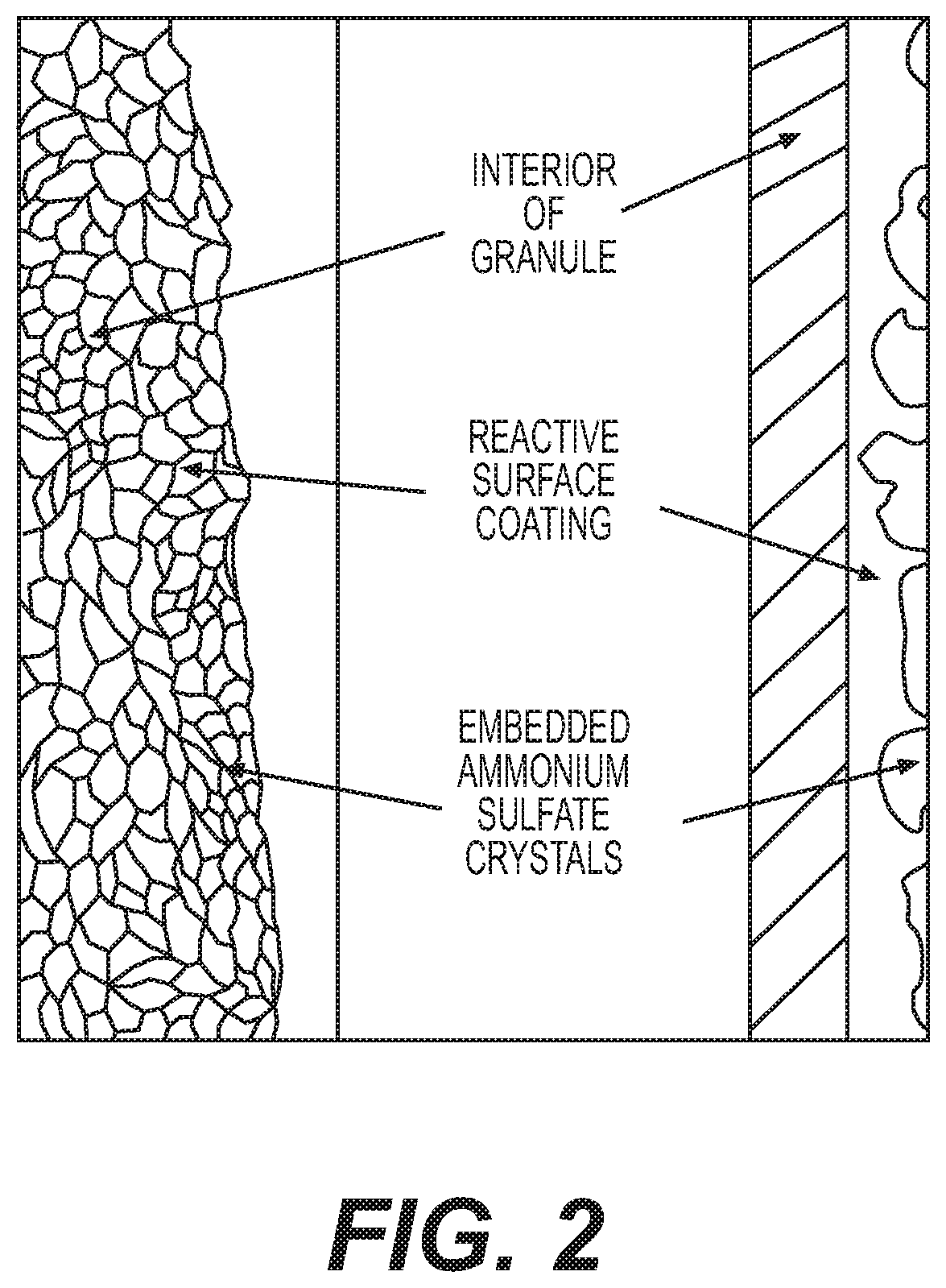

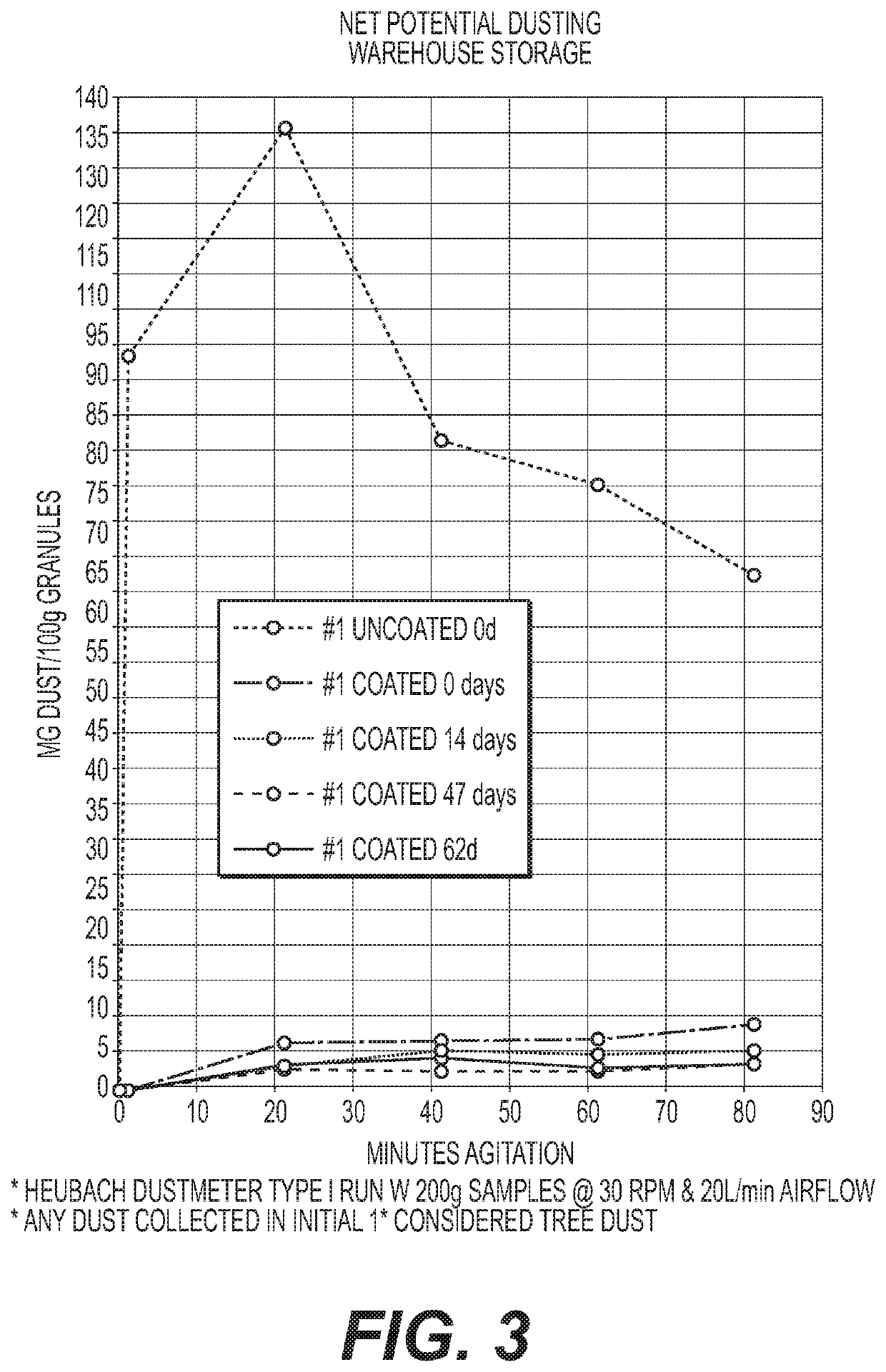

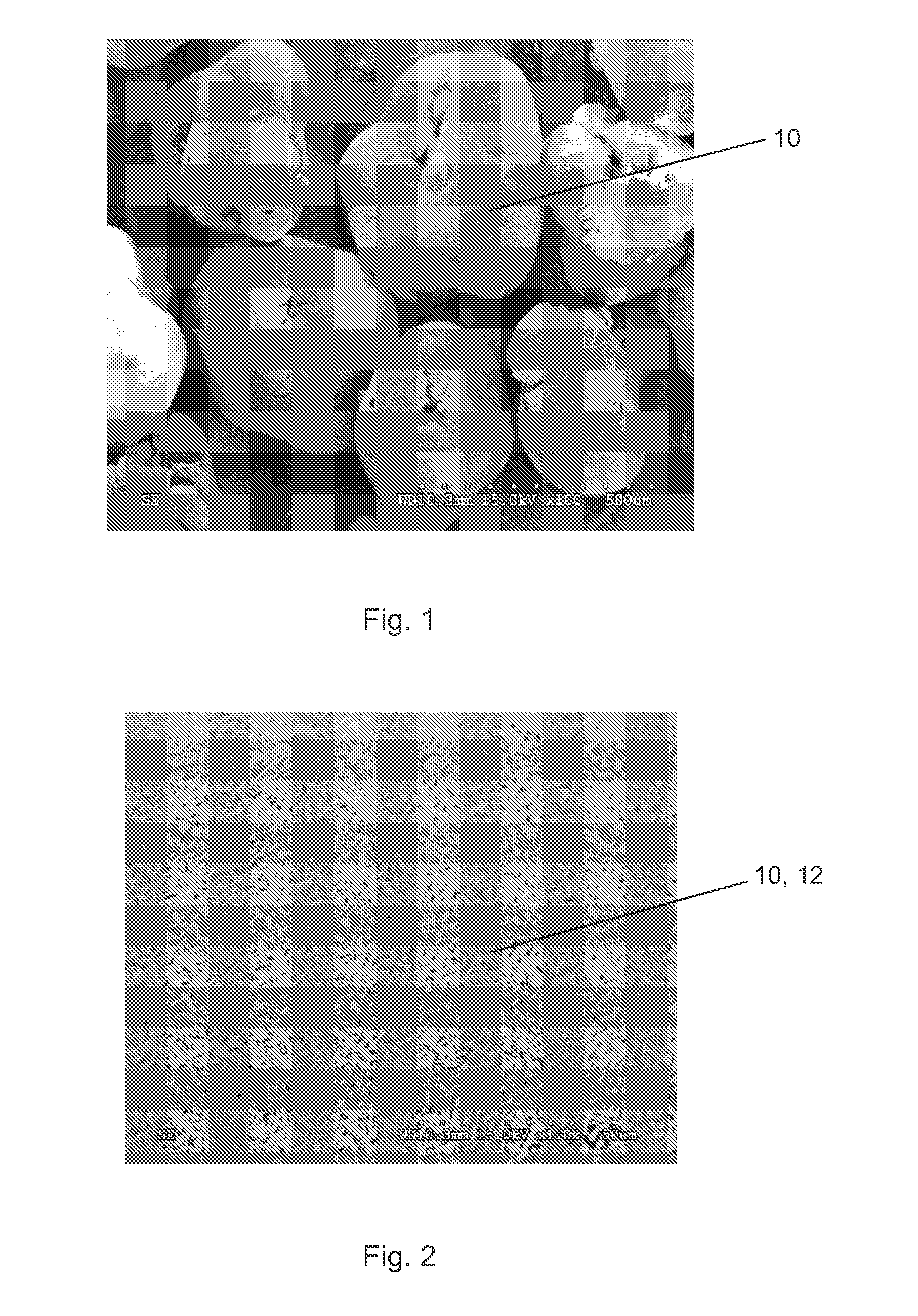

Reactive inorganic coatings for agricultural fertilizers

The invention relates to a coated granular fertilizer, preferably wherein granules are sulfate-based or phosphate-based. When sulfate based granules, as in ammonium sulfate, the coating substance is an inorganic salt of alkaline earth elements, preferably calcium, such that when applied to the surface of fertilizers, forms calcium sulfate, preferably a calcium sulfate-dihydrate, as a protective coating. For a reactive coating of a thiosulfate, free sulfuric acid present on the granule reacts to provide an elemental sulfur coating. For ammonium phosphate-based granules, coatings may comprise compounds of Ca++, Al+++ and / or Fe+++ salts thereby forming a calcium, an aluminum, an iron, or mixed cation phosphate protective coating. Thiosulfate is also effective with phosphate based granules which are manufactured with sulfuric acid. Granules coated according to the disclosure have advantageous properties as the coating can be applied in a specified and sparing manner due to its tendency to adhere to surfaces during the reaction. Coated fertilizer granules of the disclosure are also advantageous in that, with regard to the applied amount of coating, they provide increased resistance to dusting in long term warehouse storage, to moisture uptake and to oxidative heating. Coating components also add nutrients to plants that can provide nutrients over a longer period of time such as a slow-release characteristic.

Owner:GENERATE LENDING LLC +1

Method for preparing calcium sulfate crystal whiskers by using impurity-containing gypsum as raw material

InactiveCN101736403BHigh purityGood dispersionPolycrystalline material growthCalcium/strontium/barium sulfatesAnhydrous Calcium SulfateDihydrate Calcium Sulfate

The invention relates to a method for preparing calcium sulfate crystal whiskers (CaSO4) by using impurity-containing gypsum as a raw material. The method comprises the following steps of: removing main impurities in the raw material which is the low-priced impurity-containing gypsum resource in a mode of roasting, acid-complex leaching and alkaline leaching and simultaneously thinning crystal grains to obtain a superfine dihydrate calcium sulfate precursor which is high in purity and dispersibility; and preparing the anhydrous calcium sulfate crystal whiskers with a length of 20 to 2,000mu m, a diameter of 0.5 to 20 mu m, a length-diameter ratio of 40 to 1,000 and a weight percent content of over 95 percent in a mode of hydrothermal conversion-roasting of a fluxing agent. The method has the advantages of low-priced and easily bought raw materials, simple process, wide application range, and high added value. The calcium sulfate crystal whiskers prepared by the method have a big length-diameter ratio and regular shape, and can be used as reinforcing, heat insulating or flame retardant materials in industries of plastics, rubbers, coatings, papermaking, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Alkaline land soil repair agent

InactiveCN101417286BReduce alkalinityImprove biological activityContaminated soil reclamationOrganic fertilisersNatural organic matterAlkali soil

The invention relates to a restoration agent for saline-alkali land soil, which consists of free gypsum dehydration, nature organic substance, microbial fertilizer and inorganic nutrient with weight ratio of 60-70:25-35:1-4:3-6; the content of dihydrate calcium sulfate in the free gypsum dehydration is over 80 percent; the nature organic substance consists of weathered coal and grass carbon with weight ratio of 1.0:0.93; the content of effective bacteria in the microbial fertilizer is 2.0 hundred millions / g; and the inorganic nutrient consists of urea, ordinary superphosphate and potassium chloride with weight ratio of 1.0:2.42:075. The restoration agent can utilize calcium ions in the free gypsum dehydration for replacing sodium ions in the soil so as to lower the alkalinity in the soil and provide calcium and sulfur elements for crops, while the nature organic substance can lower and regulate the slat content and the alkalinity in the soil. In addition, the nature organic substance,the microbial fertilizer and the inorganic nutrient can supply large amount of nutrient elements such as nitrogen, phosphorus, potassium and the like to the crop for normal growth, thereby being capable of improving the yield of the crop.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

Reactive Inorganic Coatings for Agricultural Fertilizers

The invention relates to a coated granular fertilizer, preferably wherein granules are sulfate-based or phosphate-based. When sulfate based granules, as in ammonium sulfate, the coating substance is an inorganic salt of alkaline earth elements, preferably calcium, such that when applied to the surface of fertilizers, forms calcium sulfate, preferably a calcium sulfate-dihydrate, as a protective coating. For a reactive coating of a thiosulfate, free sulfuric acid present on the granule reacts to provide an elemental sulfur coating. For ammonium phosphate-based granules, coatings may comprise compounds of Ca++, Al+++ and / or Fe+++ salts thereby forming a calcium, an aluminum, an iron, or mixed cation phosphate protective coating. Thiosulfate is also effective with phosphate based granules which are manufactured with sulfuric acid. Granules coated according to the disclosure have advantageous properties as the coating can be applied in a specified and sparing manner due to its tendency to adhere to surfaces during the reaction. Coated fertilizer granules of the disclosure are also advantageous in that, with regard to the applied amount of coating, they provide increased resistance to dusting in long term warehouse storage, to moisture uptake and to oxidative heating. Coating components also add nutrients to plants that can provide nutrients over a longer period of time such as a slow-release characteristic.

Owner:GENERATE LENDING LLC

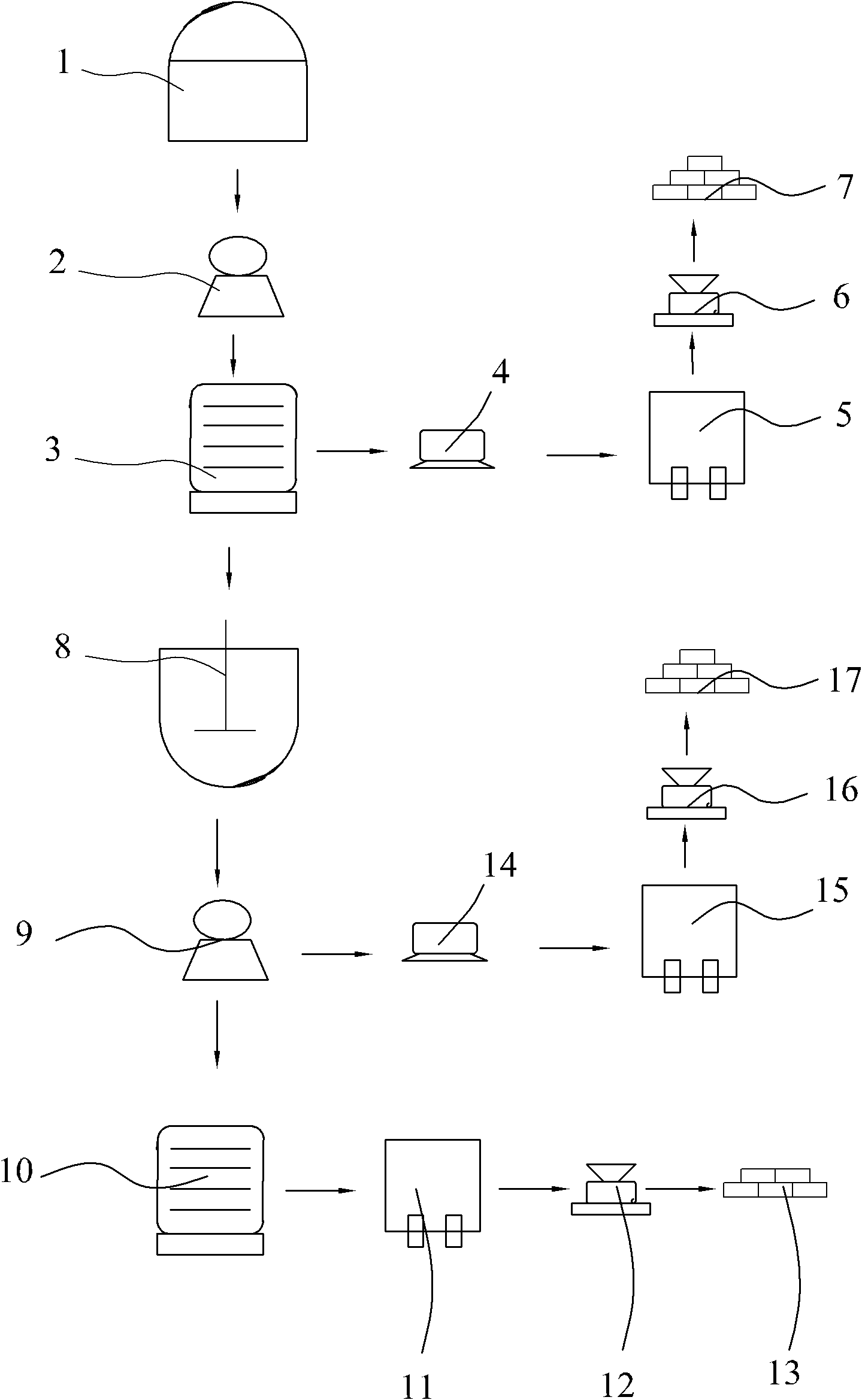

Calcium sulfate composite particles including aggregated calcium sulfate nanoparticles and method of use for bone augmentation

Calcium sulfate composite particles for bone augmentation are disclosed. The composite particles are composed of aggregated calcium sulfate nanoparticles of a diameter from about 50 to about 800 nm, which include a mixture of calcium sulfate dihydrate and calcium sulfate hemihydrate. The composite particles have a diameter from about 200 to about 1,200 μm, and a mean half-life no less than 18 days. Further disclosed is a bone grafting material for bone augmentation. The bone grafting material includes a mixture of the calcium sulfate composite particles and a second type of calcium sulfate particles having a particle diameter from about 2 to about 60 μm, at a ratio from 1:1 to 4:1. The method of using the composite particles and the bone grafting material for bone augmentation is also disclosed.

Owner:ORTHOGEN LLC

Gypsum board made using dry starch at an interface between the gypsum slurry and a facing material

PendingUS20220098108A1Surface layering apparatusCeramicwareDihydrate Calcium SulfatePhysical chemistry

The present invention is directed to an improved gypsum board and a method of making such gypsum board. For instance, the method comprises: providing a first facing material, depositing a gypsum slurry comprising at least stucco and water on the first facing material, providing a second facing material on the gypsum slurry, and allowing the stucco to convert to calcium sulfate dihydrate, wherein the method further comprises a step of providing a dry starch layer including a dry starch at an interface between the first facing material and the gypsum slurry, the second facing material and the gypsum slurry, or both.

Owner:GOLD BOND BUILDING PROD LLC

Method for preparing manganese sulfate, manganese hydroxide and calcium sulfate

InactiveCN102249335ANo secondary pollutionEasy to operateCalcium/strontium/barium sulfatesManganese oxides/hydroxidesCALCIUM HYDROXIDE SOLUTIONFiltration

The invention provides a method for preparing manganese sulfate, manganese hydroxide and calcium sulfate, which comprises the following steps: pulverizing manganosite into coarse powder, soaking with titanium dioxide produced by a sulfuric acid method at 60-80 DEG C for 8-15 hours, performing suction filtration to obtain a clarified filtrate, adding manganese hydroxide for impurity removal so as to obtain a pure manganese sulfate solution; performing reduced pressure distillation of the pure manganese sulfate solution to obtain a saturated manganese sulfate solution, cooling, precipitating manganese sulfate crystals with crystal water, drying and crushing the manganese sulfate crystals to obtain a manganese sulfate crystal product; allowing the pure manganese sulfate solution to react with a calcium hydroxide solution under stirring, filtering the reaction product to obtain a calcium sulfate filter cake and a manganese hydroxide filtrate, performing reduced pressure distillation of the manganese hydroxide filtrate to obtain a supersaturated manganese hydroxide solution, performing cooling and crystallization to obtain manganese hydroxide crystals, drying and crushing the manganese hydroxide crystals to obtain a manganese hydroxide product; washing, drying, crushing the calcium sulfate filter cake to obtain a dihydrate calcium sulfate product.

Owner:王莉

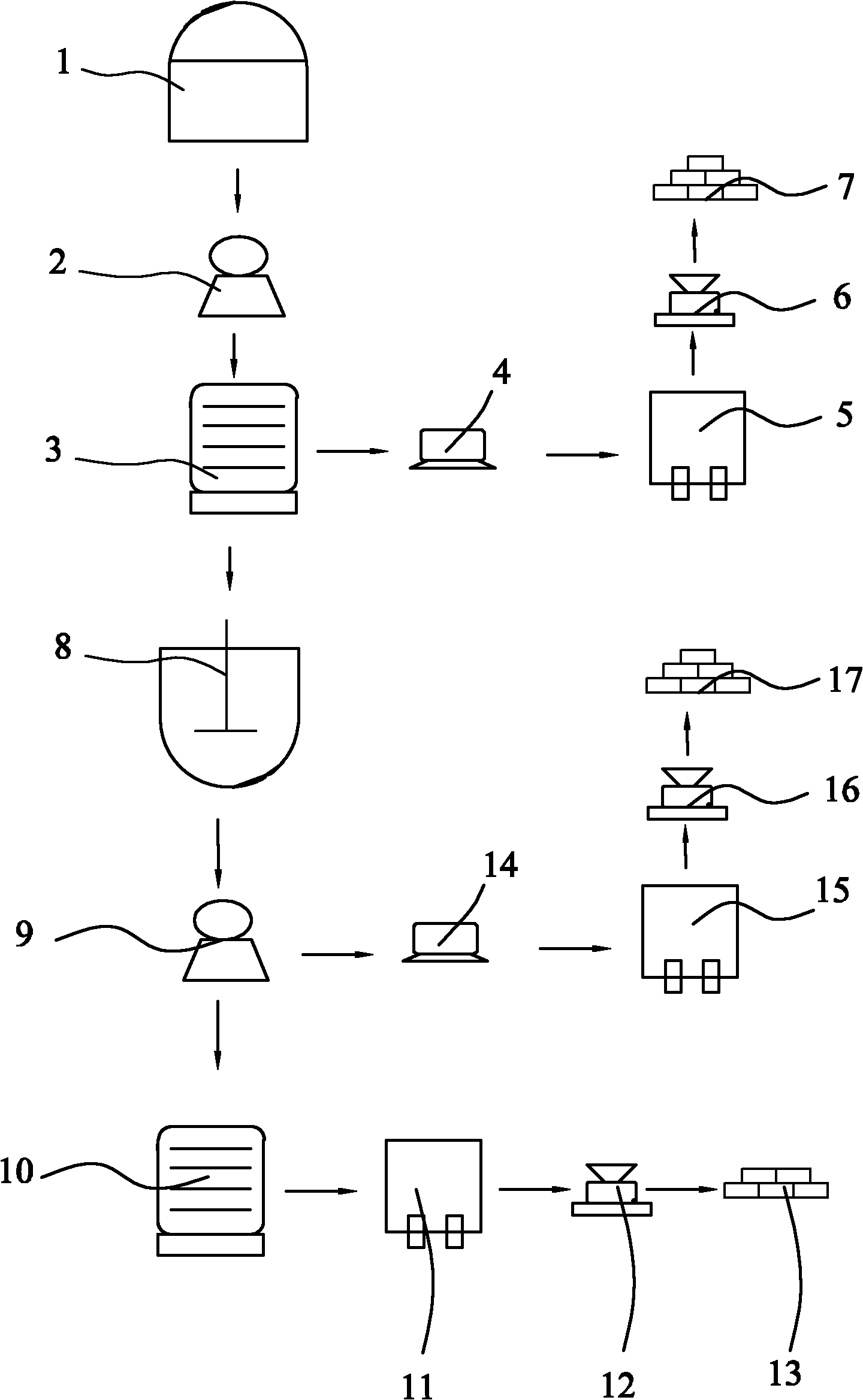

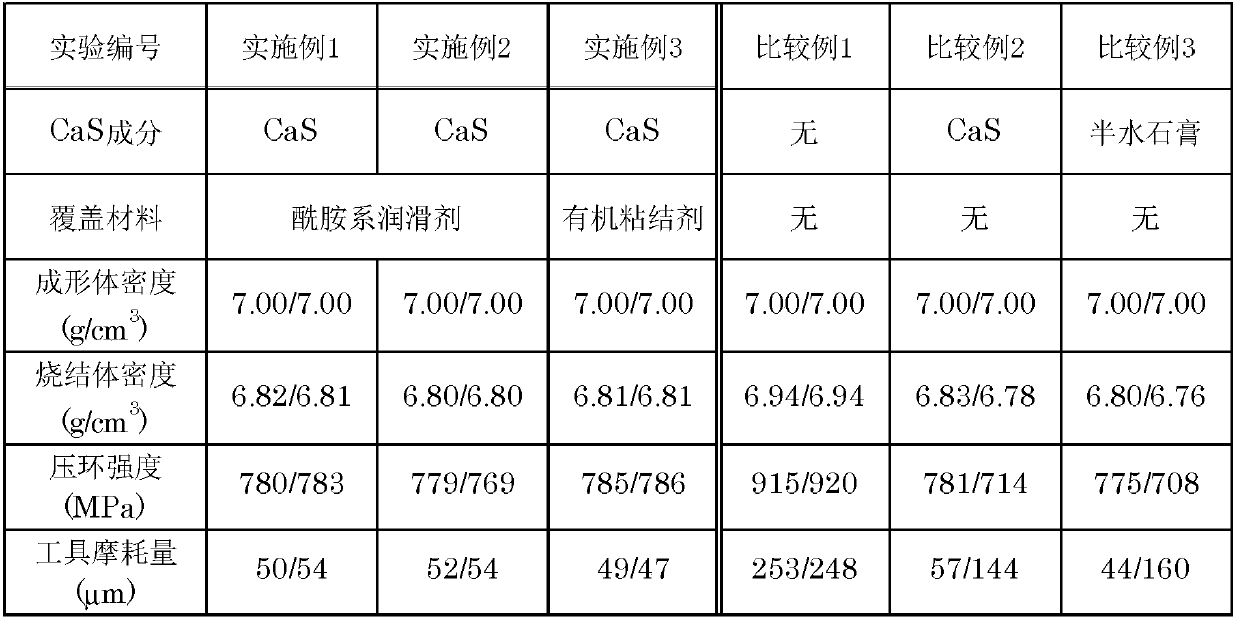

Mixed powder for iron-based powder metallurgy, method for producing same, sintered body produced using same, and method for producing sintered body

ActiveCN107614158ATransportation and packagingMetal-working apparatusCalcium sulphideAnhydrous Calcium Sulfate

This mixed powder for iron-based powder metallurgy comprises a metal-based powder and a CaS raw material powder containing one or more substances selected from the group consisting of anhydrite III, anhydrite II, dihydrate calcium sulfate, calcium sulfide, and calcium sulfate hemihydrate. The CaS raw material powder is coated with a lubricant and / or a binder.

Owner:KOBE STEEL LTD

Medicinal powder for stopping toothache and preparation method for medicinal powder

InactiveCN110680884ALow costEasy to makePowder deliveryHydroxy compound active ingredientsAnhydrous Calcium SulfateFlos chrysanthemi

The invention discloses medicinal powder for stopping toothache and a preparation method for the medicinal powder and relates to the field of traditional Chinese medicines. The medicine powder is prepared from the following components including menthol, calcium sulfate dihydrate, anhydrous calcium sulfate, honeysuckle, Japanese cinnamon fruits, radix rehmanniae, bamboo leaves and flos chrysanthemi, wherein the ratio of the menthol to the calcium sulfate dehydrate to the anhydrous calcium sulfate is 1 to 1 to 3; the ratio of the honeysuckle to the Japanese cinnamon fruits to the radix rehmanniae to the bamboo leaves to the flos chrysanthemi is 1 to 1 to 1 to 1; and the medicinal powder contains totally 5g of the trace honeysuckle, Japanese cinnamon fruits, radix rehmanniae, bamboo leaves and flos chrysanthemi per 100g. The medicinal powder is low in cost of the adopted raw materials, simple to prepare and remarkable in analgesic effect, is convenient for adults and children to use withmultiple use methods and does not have toxic or side effect.

Owner:高全良

A method for preparing low-magnesium calcium sulfate dihydrate by-product from rare earth sulfate solution

ActiveCN110106373BReduce manufacturing costHas economic valueCalcium/strontium/barium sulfatesProcess efficiency improvementChemical industryHydration reaction

The invention relates to a method for preparing low-magnesium calcium sulfate dihydrate by-product from a rare earth sulfate solution. The method uses the rare earth sulfate solution produced in the process of sulfuric acid smelting and separating rare earth concentrate as a raw material, and uses calcium hydroxide as a neutralizing agent. By controlling the concentration of calcium hydroxide slurry, REO concentration in rare earth sulfate solution, reaction time, reaction temperature, neutralization pH value, aging method and other conditions, the yield of rare earth will not be lost, and the supply for downstream rare earth smelting, that is, extraction and separation, will be qualified. Under the condition of rare earth sulfuric acid feed solution, CaSO can be prepared to meet the requirements of cement, building materials, chemical industry and other industries. 4 2H 2 O by-products. And its CaSO 4 2H 2 O quality achieved: m (CaO) ≥30.9%, m (MgO) ≤0.05%. The overall process realizes the lower cost of industrialized production, and lays a solid foundation for green production and circular economic utilization.

Owner:甘肃稀土新材料股份有限公司

Culture medium for promoting recombinant pichia pastoris to express xylanase and preparation method thereof

InactiveCN105420219AClear ingredientsEconomical priceFungiMicroorganism based processesPichia pastorisWater methanol

The invention provides a culture medium for promoting recombinant pichia pastoris to express xylanase and a preparation method of the culture medium, wherein the culture medium is prepared from the following components: 15.0-40.0 g of sodium glycerophosphate, 1.0-10.0 g of ammonium sulfate, 1.0-4.0 g of calcium sulfate dihydrate, 8.0-16.0 g of potassium sulfate, 7.0-15.0 g of magnesium sulfate heptahydrate, 0.5-6.0 mL of PTM1 trace element solution, 5.0-20.0 mL of absolute methanol and 1.0-3.0 g of Tween80; the preparation method comprises the following steps of dissolving the components in distilled water to 1000 mL, and adjusting the pH to be 5.5-7.5 by utilization of KOH. The culture medium for promoting the recombinant pichia pastoris to express the xylanase and the preparation method of the culture medium have the advantages that the components are specific, the price is economic, the recombinant pichia pastoris well grows in the culture medium, and the culture medium is suitable for expressing the xylanase in an industrialized large-scale manner.

Owner:XINXIANG MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com