Patents

Literature

1208 results about "Sulfate radical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

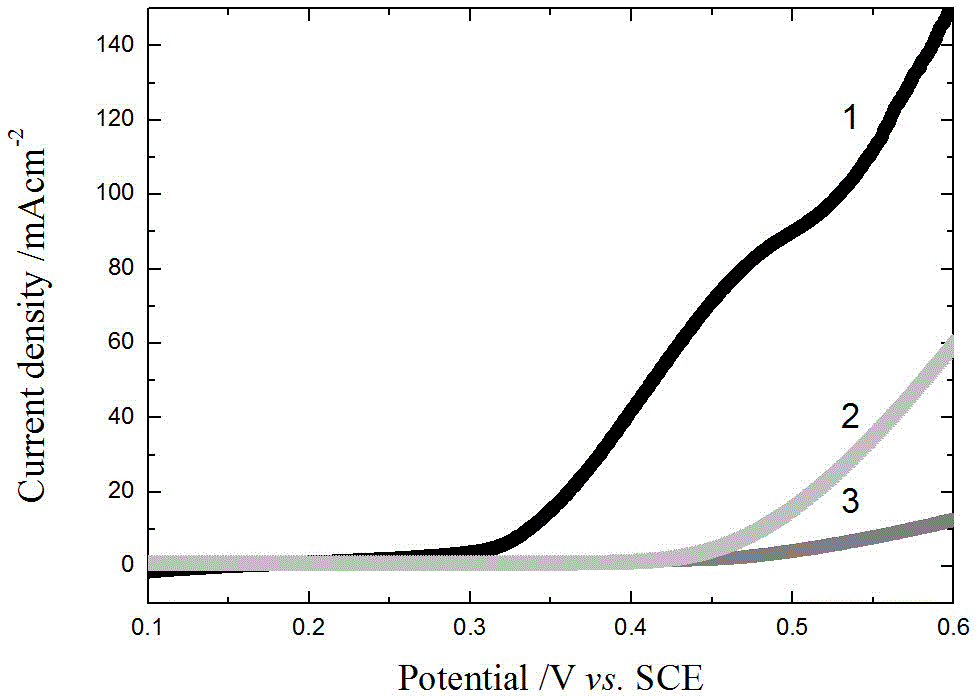

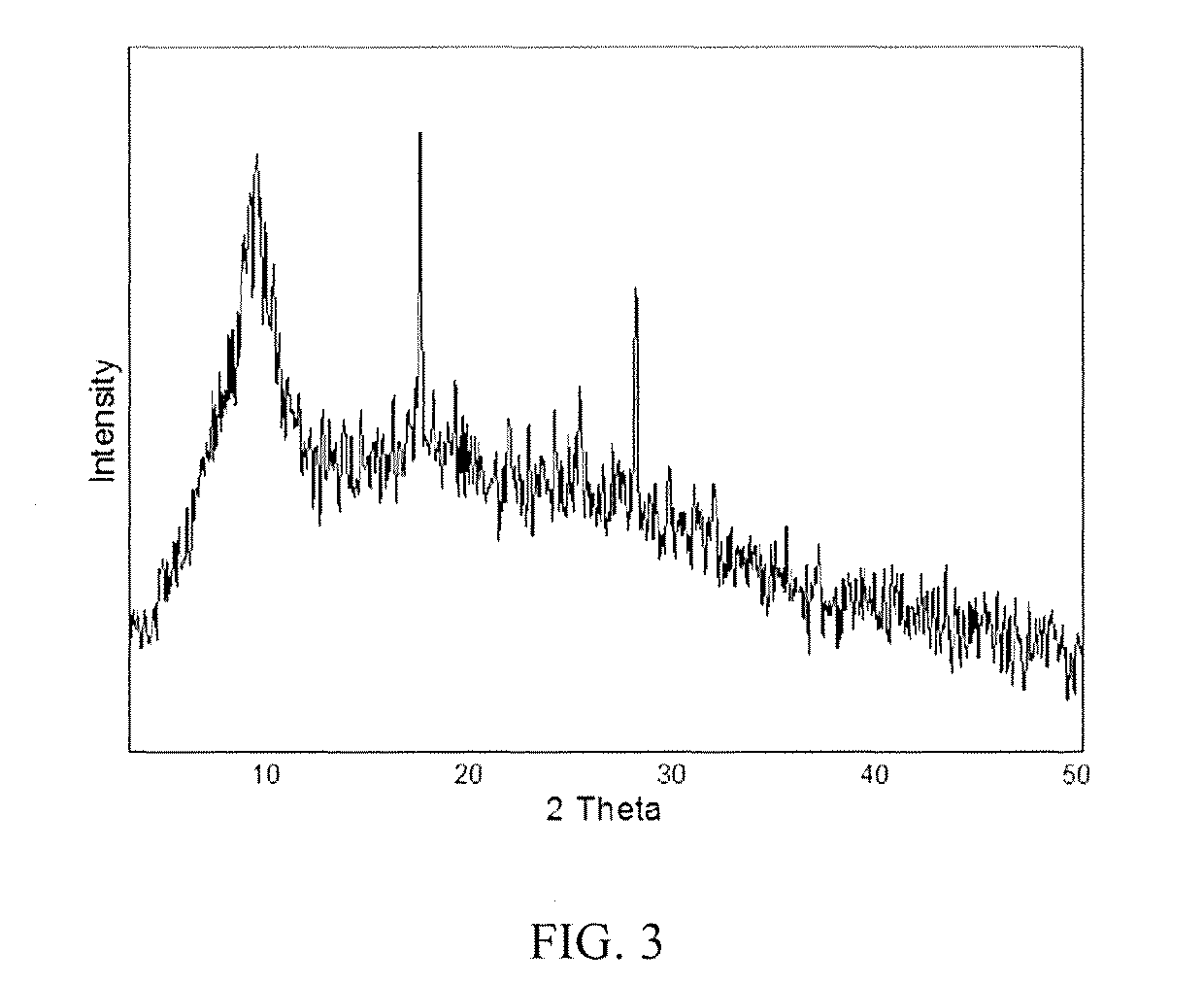

In this work, simultaneous generation of hydroxyl radical (• OH) and sulfate radical (SO 4 •–) by the reaction of ozone (O 3) with peroxymonosulfate (PMS; HSO 5 –) has been proposed and experimentally verified.We demonstrate that the reaction between the anion of PMS (i.e., SO 5 2–) and O 3 is primarily responsible for driving O 3 consumption with a measured second order rate ...

Method for continuously preparing regenerated cellulose fibre

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

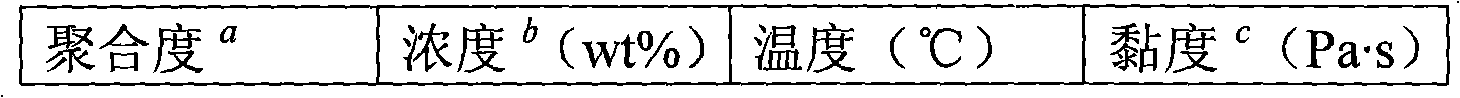

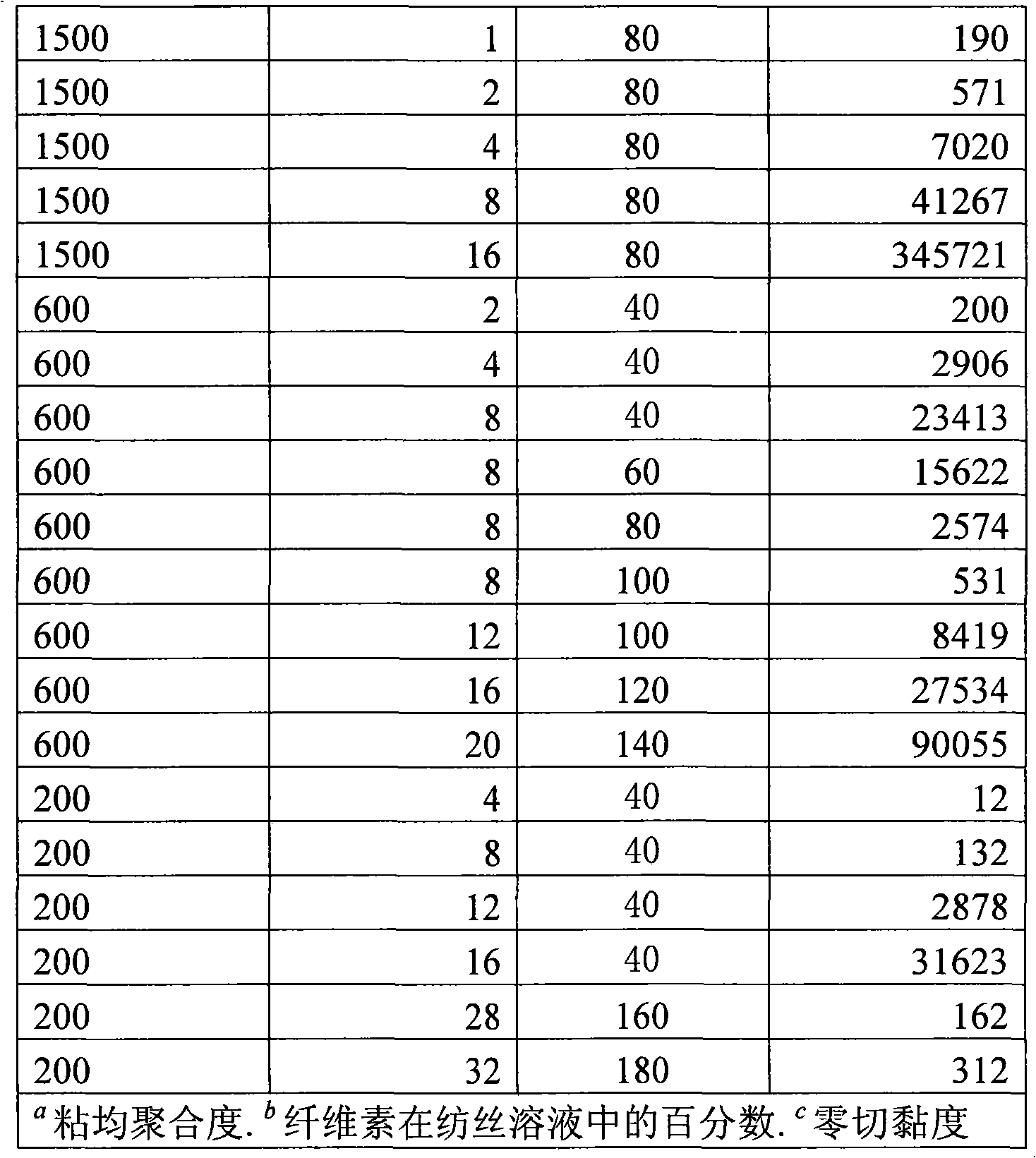

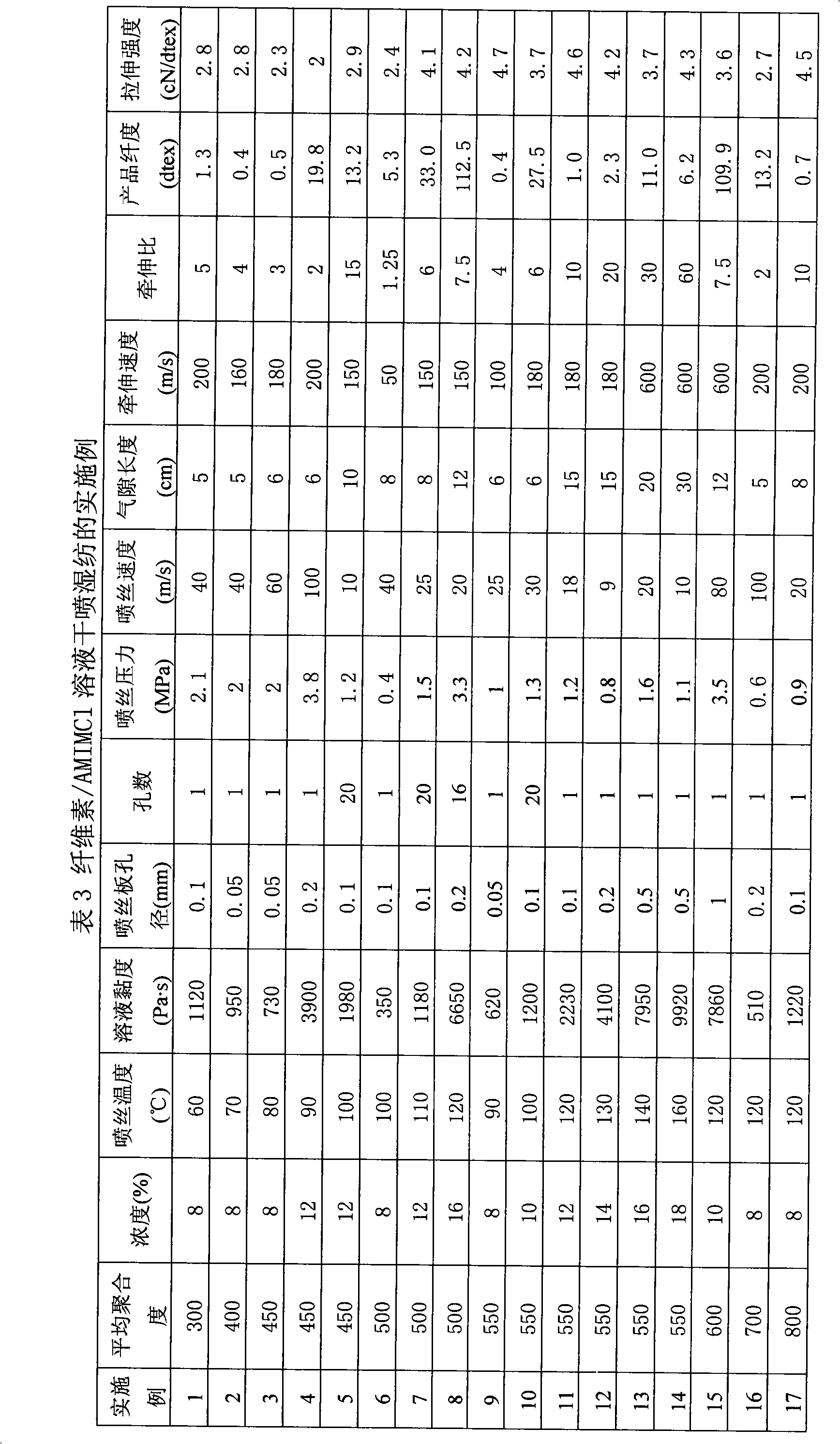

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Room temperature ionic liquid containing unsaturated double bond and its prepn and application

InactiveCN1417407AGroup 5/15 element organic compoundsPulping with organic solventsSulfate radicalsTriflic acid

The room temperature ionic liquid containing unsaturated double bond has the general expressino of A+B-, where A+ contains R1 being hydroxyl with 1-4 carbon atoms and R2 containing 2-20 carbon atoms and at least one double bond; and B- is one of anions, including chlorate radical, bromate radical, iodate radical, acetate radical, sulfate radical, nitrate radical, tetrafluorobromate radical, etc. Its preparation is to mixture and react olefin halide R1X and N-alkyl imidazole to obtain ionic liquid dialkyl imidazolium halide. The present invention also relates to the application of the ionic liquid in dissolving cellulose and preparing cellulose derivative.

Owner:山东中科恒联生物基材料有限公司

Nano-filtration method for separating magnesium and enriching lithium from salt lake brine

InactiveCN1542147AEfficient recyclingSimple processSemi-permeable membranesLithium compoundsIon contentLithium chloride

The nanofiltration process is suitable for Mg-Li separation and Li enriching of Li containing bittern or Li containing solution from salt lake to prepare lithium carbonate or lithium chloride with the Li enriching bittern. Nanofiltration membrane is used in separating and enriching lithium from lithium containing bittern, which contains Mg, Ca and other cations and sulfate radical and other anions and has Li ion concentration of 0.1-11.5 g / L and Mg / Li ion weight ratio 1-200, to obtain lithium enriched bittern suitable for preparing lithium carbonate or lithium chloride. The said process is effective, and can obtain lithium enriched bittern with Mg / Li ion weight ratio 0.6-5 and Li ion content of 0.6-20 g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

FeS and Fe0 composite and preparation method and application thereof

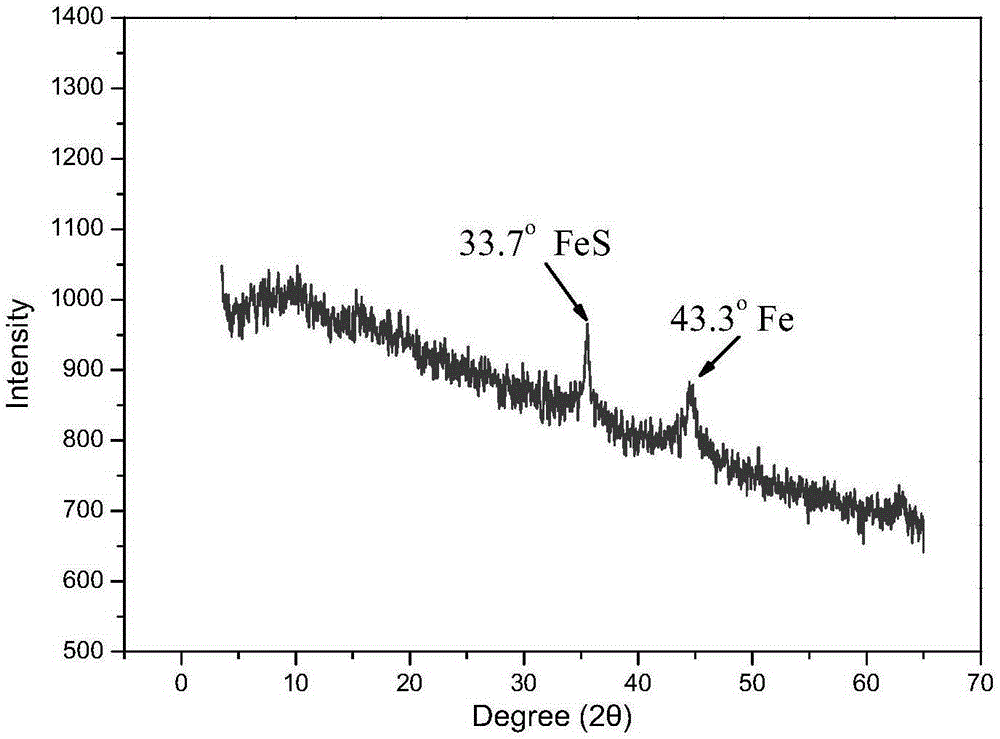

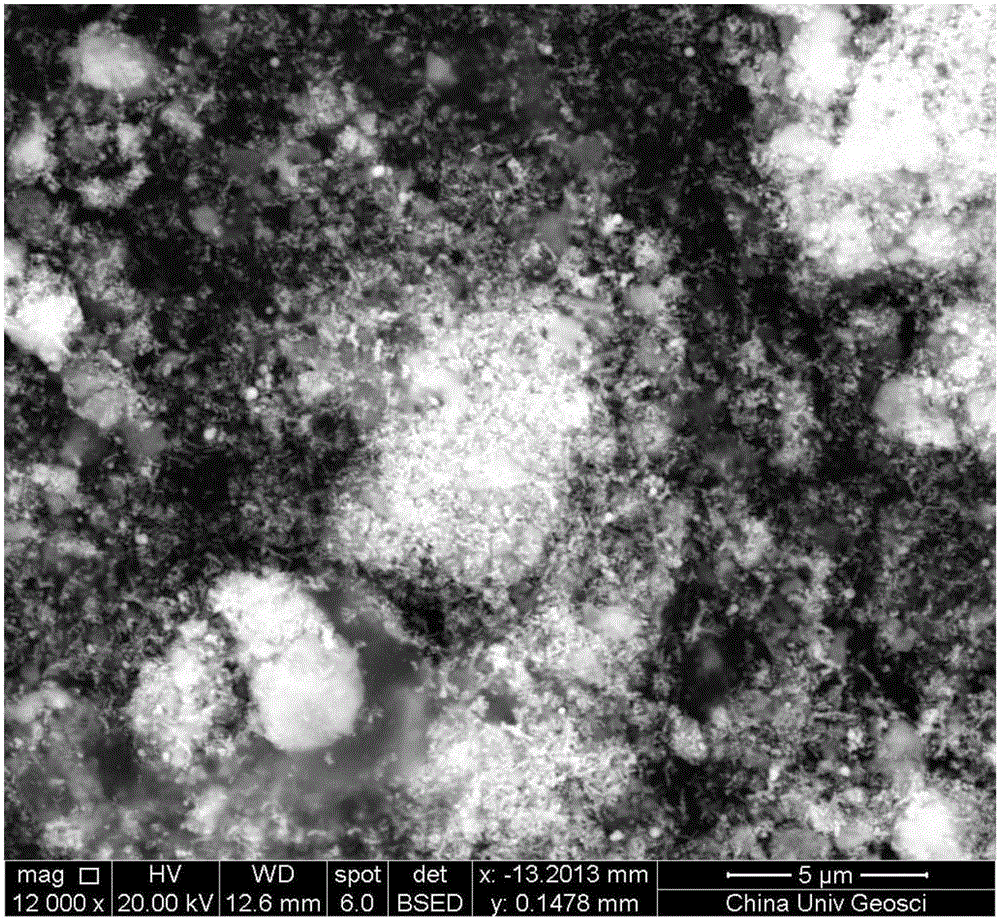

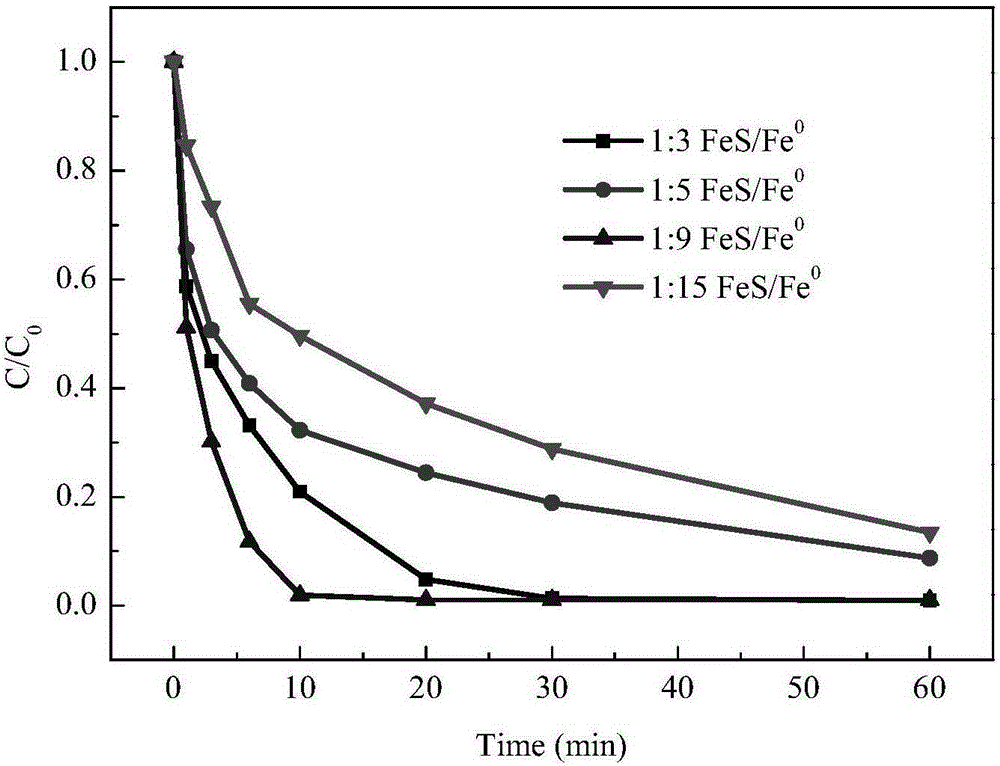

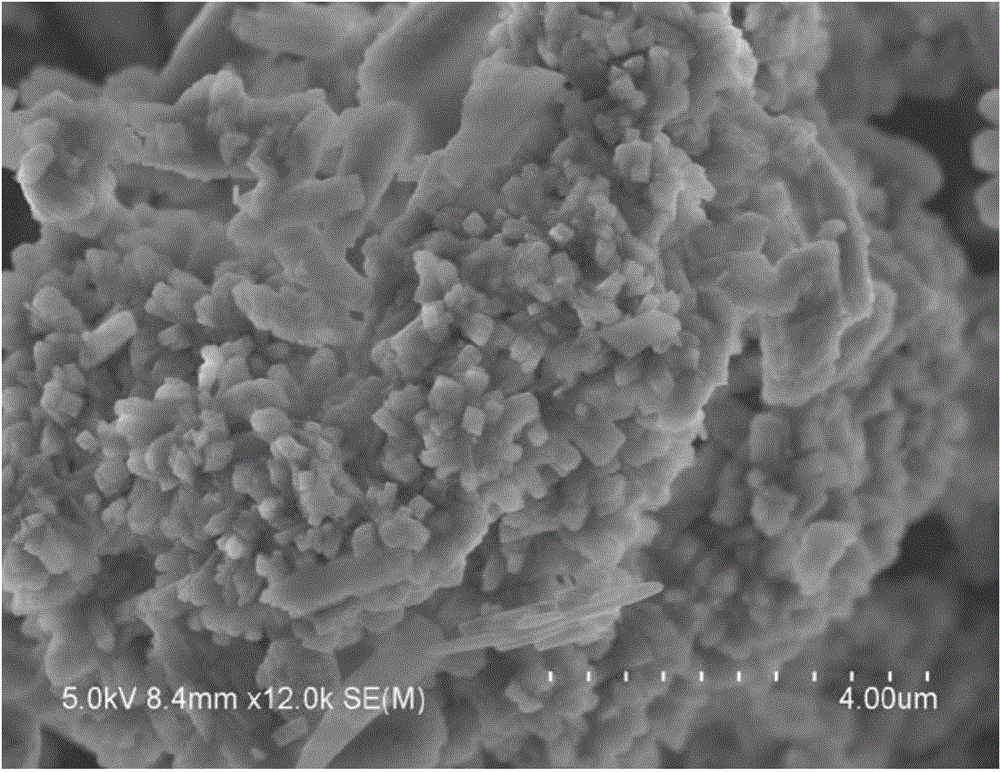

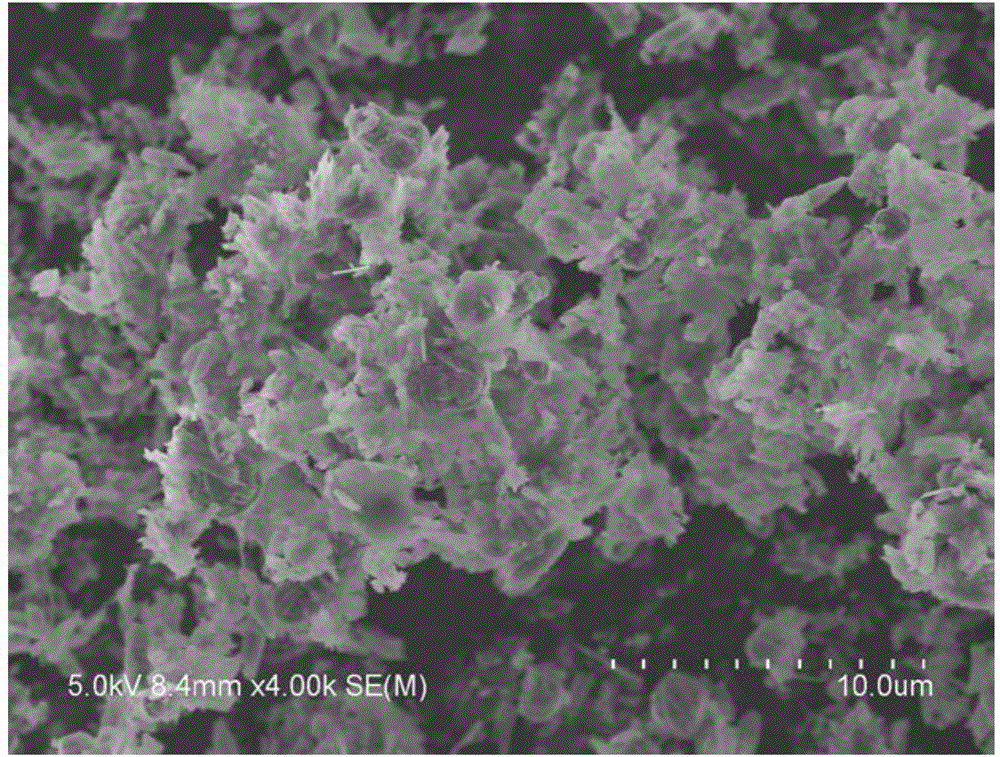

InactiveCN105174414AEfficient degradationHigh reactivityIron sulfidesWater/sewage treatment by reductionWastewaterSurface water

The invention belongs to the field of chemical materials, and particularly relates to a FeS and Fe0 composite and a preparation method and application thereof. The FeS and Fe0 composite is formed by compositing nano FeS and nano Fe0, the surface of the nano Fe0 is coated with the nano FeS, and the molar ratio of the nano FeS to the nano Fe0 is 2:1 to 15:1. According to the FeS and Fe0 composite and the preparation method and application thereof, the preparation process is simple, convenient, environmentally friendly and feasible, the prepared FeS and Fe0 composite is high in reaction activity, capable of efficiently and rapidly reducing and adsorbing heavy metal ions in waste water within a wider temperature range, a pH value range and a dissolved oxygen content range and further capable of rapidly and efficiently activating hydrogen peroxide and persulfate to make a system generate hydroxyl free radicals and sulfate free radicals to degrade and mineralize organic pollutants, and therefore the FeS and Fe0 composite can be widely applied to degradation of the organic pollutants in surface water and underground water.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

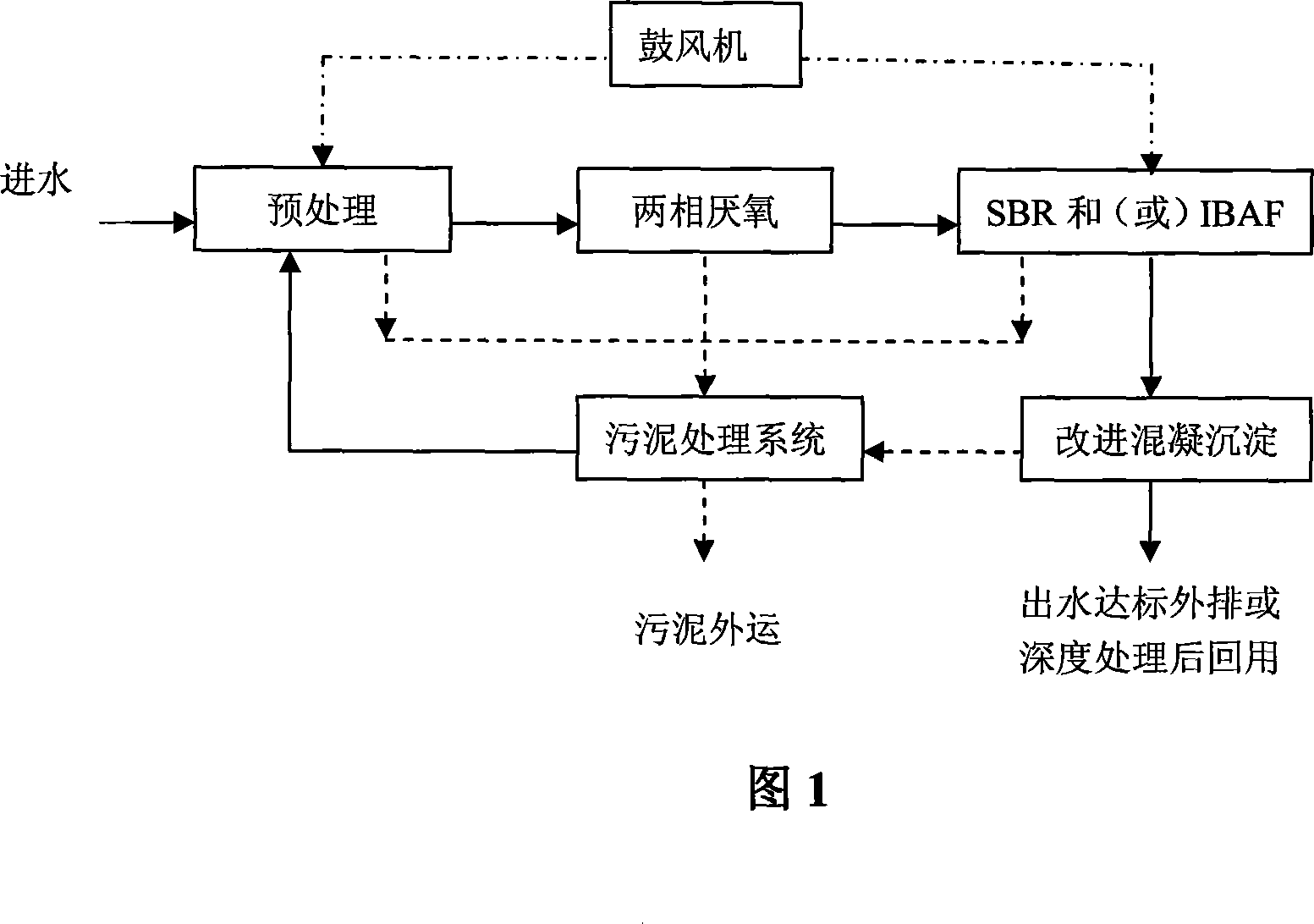

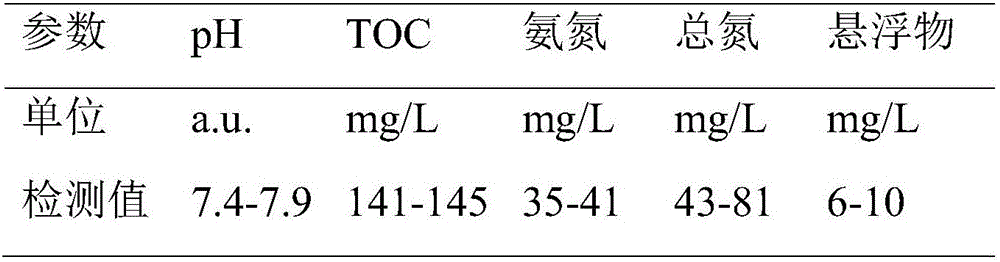

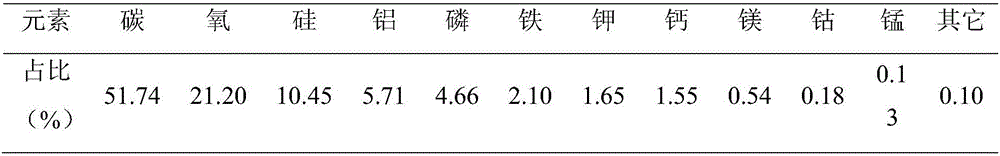

Process for treating antibiotic waste water and usage thereof

InactiveCN101157510AEliminate negative effectsGood effectTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSulfate radicals

The invention provides a processing technique of waste water containing antibiotic and the purpose thereof, wherein, the technique adopts the following steps: pretreatment, two-phase anaerobic, improving SBR, immobilized microorganism-aeration biological filter, and improving the coagulating sedimentation combination technique. The detailed technique is introduced in the specification. The invention has the advantages that the industrial waste water is pretreated and the two-phase anaerobic technique is adopted, the great mass of sulfate radical is eliminated, the treatment effect for producing firedamp anaerobic phase and the stability of operation are improved, the energy is recycled and the operating cost is lowered; through the immobilized microorganism-aeration biological filter, the biological treatment effect is improved, and the operating cost for back end processing is lowered; the deep processing can ensure that the waste water is discharged by reaching the standard, and can meet the requirement to the upgrade and reorganization of sewage treatment plants when the environment protection standard is improved in the future. The invention has the purpose that the processing technique not only is applicable to the treatment for the waster water containing antibiotic and the upgrade and reorganization of the prior engineering of sewage disposal, but also is applicable to the engineering of sewage disposal and other sewage disposals with high salt content, high sulfate radical content, high ammonia and nitrogen content, high COD content and higher concentration organic matter which is hard to be degraded.

Owner:北京盖雅环境科技有限公司

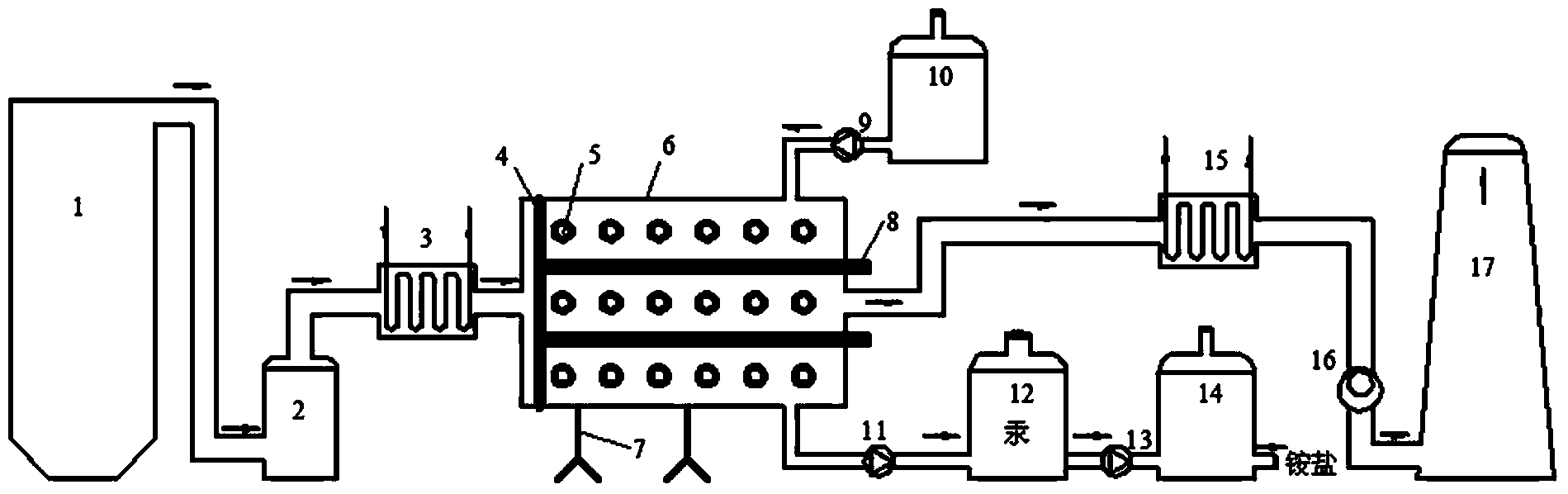

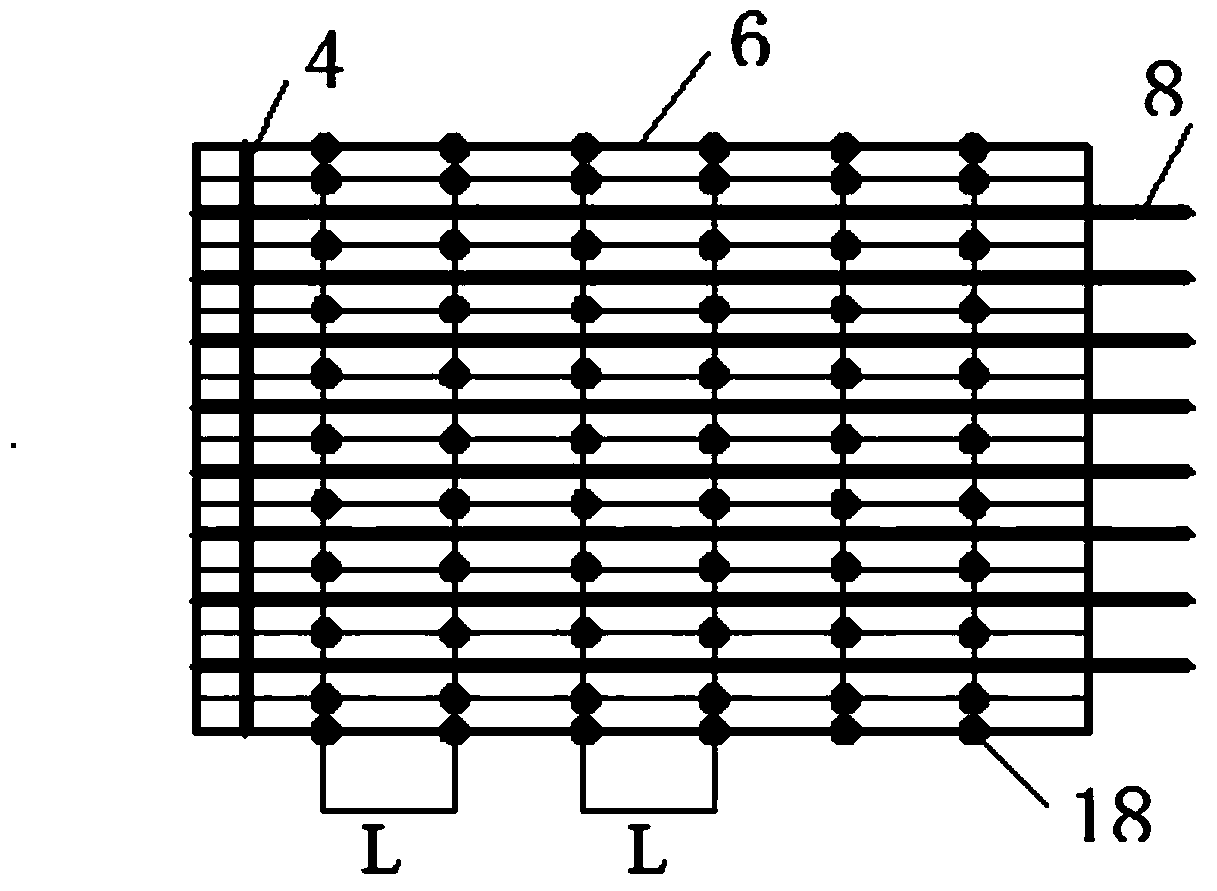

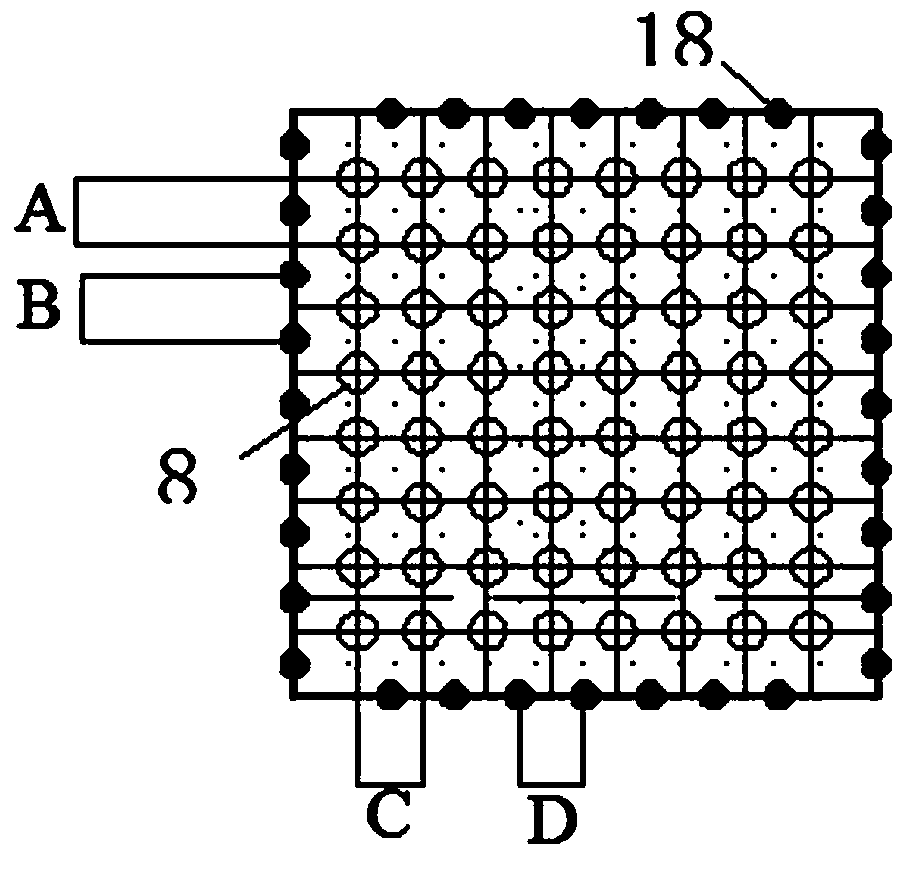

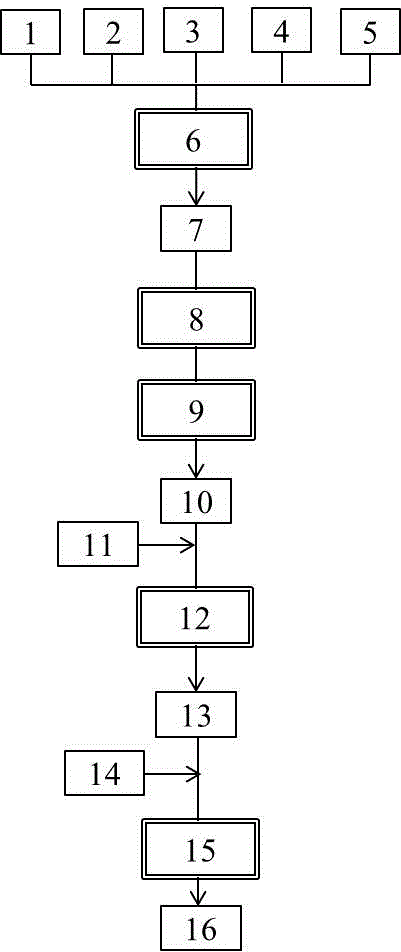

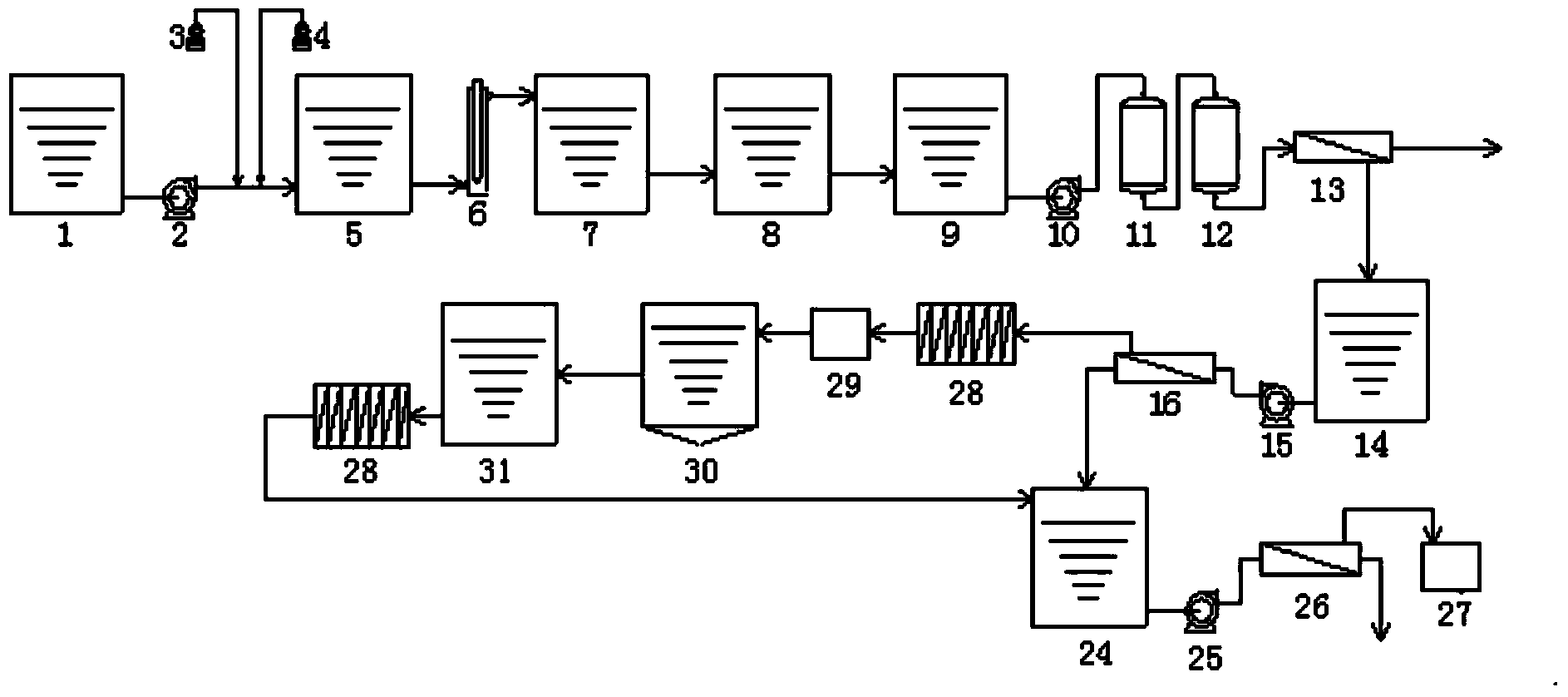

System and method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate

ActiveCN103638796ALow investment costLow running costDispersed particle separationAir quality improvementSulfate radicalsResource utilization

The invention discloses a system and a method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate. The system is mainly provided with a boiler or kiln, a deduster, a flue gas temperature regulator, a photochemistry reactor, a liquid spraying system as well as a byproduct post-processing system. Flue gas discharged from the boiler or kiln enters the photochemistry reactor arranged on a flue channel after being subjected to dedusting and temperature regulation, and an ammonium persulfate solution from the liquid spraying system is sprayed into the photochemistry reactor in a mist form; an UV (ultraviolet) lamp in the photochemistry reactor emits UV light to perform catalytic decomposition on ammonium persulfate, releases sulfate radical free radicals with high oxidizing property (SO4-.), and meanwhile oxidizes and removes SO2, NOx and mercury in the flue gas. Oxidized products are subjected to resource utilization after being processed by the byproduct post-processing system. The method has the prominent advantages that the method can be used for removing multiple pollutants in coal burned flue gas synchronously, has no secondary pollution during removing, and can be used for transforming aging units and the like, and the system is a novel flue gas purifying system with a wide application prospect.

Owner:JIANGSU UNIV

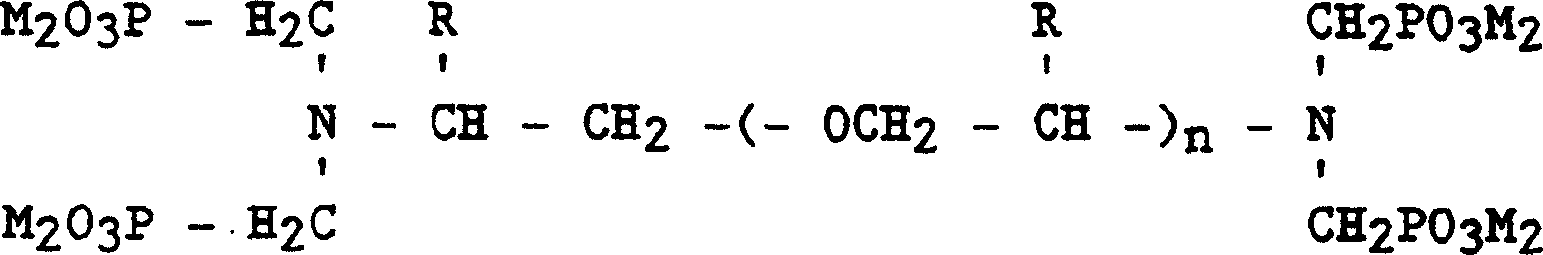

Antisludging agent and application of the same in water treatment

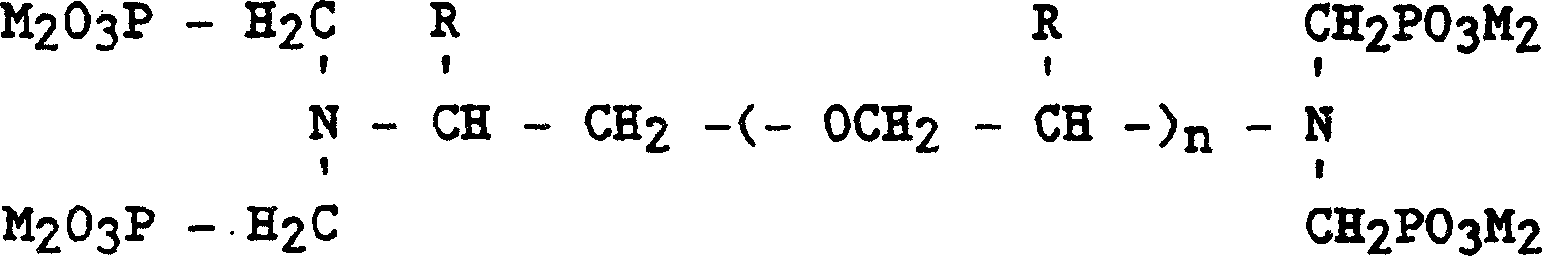

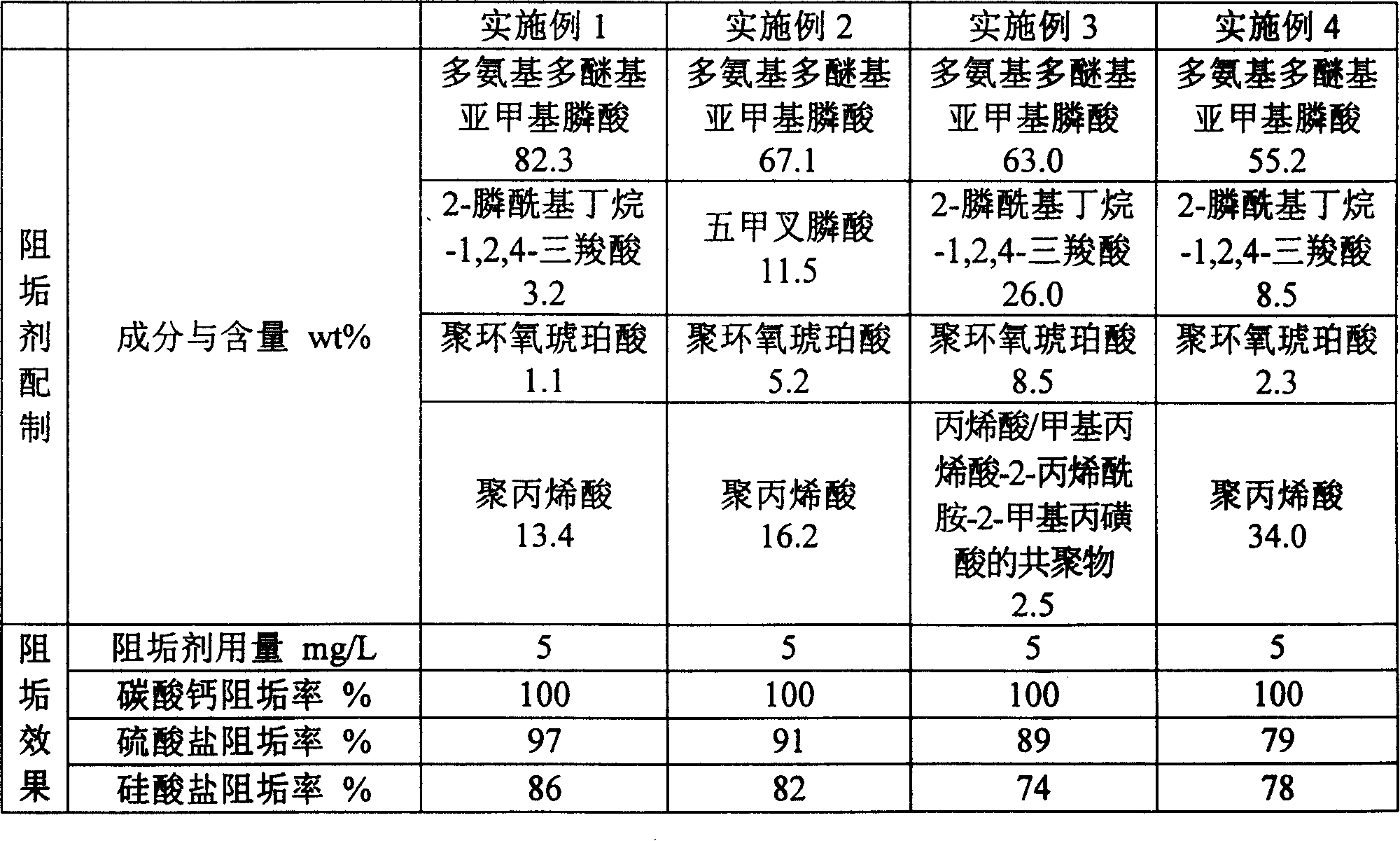

ActiveCN101172718AGood scale resistanceExtended cleaning cycleScale removal and water softeningInorganic saltsSulfate radicals

The invention provides antisludging agent and the application method thereof. The antisluding agent comprises polyether polyamino methylene phosphonates, polyepoxysuccinic acid, Aroset and organic phosphonic acid. The antisludging agent is applicable in the water quality with dense calcium, dense sulfate radical and soluble silica, and has great antisludging and dispersing effect. The antisludgingagent which is led into the high-density reverse osmosis water treatment system is added to effectively restrict polcard, sulfate, silicate and other inorganic salts from being deposited and foulingon the film surface, thereby prolonging the cleaning period of the reverse osmosis film.

Owner:CHINA PETROLEUM & CHEM CORP +1

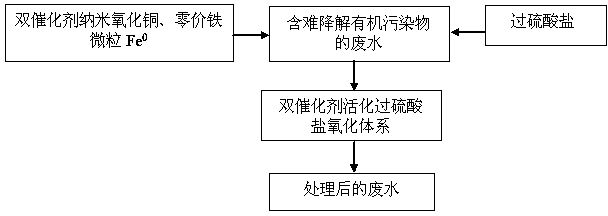

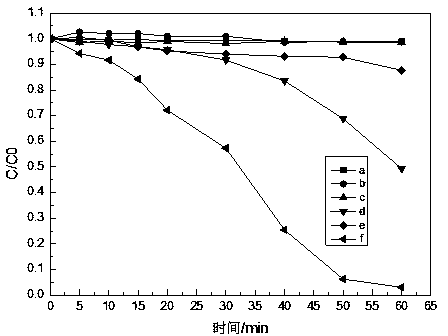

Method for treating organic wastewater by using double catalysts to heterogeneously activate persulfates

ActiveCN103896388AHigh catalytic activityIncrease profitWater/sewage treatment by oxidationSulfate radicalsBiological activation

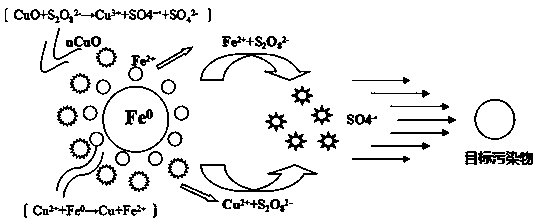

The invention discloses a method for treating organic wastewater by using double catalysts to heterogeneously activate persulfates, belonging to the technical field of water pollution control. According to the method, nano copper oxide and zero-valent iron particles are used as a combined catalyst to activate the persulfates to generate free sulfate radicals with strong oxidizing property, so that refractory organics are removed from the wastewater. Compared with a homogeneous persulfate water treatment technology, the method has the advantage that the heterogeneous catalysts can efficiently and continuously activate the persulfates to achieve a heterogeneous activation effect due to the properties of relatively large specific surface area, relatively high catalytic activity and the like. The double-catalyst heterogeneous persulfate activation water treatment technology established by the method disclosed by the invention is applicable to treatment of various kinds of organic wastewater, is high in efficiency, good in durability and convenient in operation, can efficiently remove toxic and harmful pollutants from the wastewater within a relatively wide pH range, provides a broad prospect for treating toxic, harmful and non-biodegradable organic wastewater, and has a great application potential in the field of environmental pollution treatment.

Owner:SOUTH CHINA UNIV OF TECH

Granular solid super strong acid catalyst and its preparing method

InactiveCN1425500AHigh catalytic activityHigh purityCatalyst activation/preparationSulfate radicalsStrong acids

The present invention provides a granular solid super strong acid catalyst and its preparation process. The active carrier is carried by granular basic carrier and contains oxide capable of binding with sulfate radical ion to form active catalyst layer; and the granular basic carrier contains porous oxide supporting the active catalyst layer and with certain strength and shape. During the preparation, granular basic carrier is first soaked into the salt solution of active carrier, ammonia water is added to regulate pH value greater than 8, the water solution is filtered out and filtered matter is washed and dried; and after soaking the dried granular carrier in sulfuric acid solution and filtering to eliminate sulfuric acid solution, the filtered matter is dried and roasted at 550-650 deg.c to obtain the catalyst.

Owner:曲阜市圣泉催化应用科技有限公司

A method for resource processing non-ferro metals processing wastewater containing ammonia and sulfate radical

ActiveCN101161596AHigh practical valueEliminate pollutionWater contaminantsWaste water treatment from metallurgical processSulfate radicalsSodium sulfate

The invention relates to a novel process for recycling treatment for waste water which contains ammonia and sulfate radicals and is produced in the process of non-ferrous metal processing. The invention is characterized in that: sodium hydroxide is added into the waste water to convert ammonium ions in the waste water into molecular ammonia; then the waste water is heated by heat resource in a rectification tower; the ammonia in the waste water enters into a condenser in the form of gas from the top of the tower to be cooled into liquid ammonia and partial liquid ammonia returns, thus the remainder becomes the product; the water removed of ammonia exchanges heat with the waste water to be treated and then continues to be cooled, thus sodium sulfate crystals are obtained; the water removed of sodium sulfate removed is removed also sulfate radicals and ammonia, and can directly return to a production plant. The invention has a combined process of ammonia rectification recycle and sodium sulfate cooling crystallization, ensures the recycling use of the water as the ammonia in the water is reclaimed in the form of liquid ammonia or ammonia water as well as the sulfate radicals are reclaimed in the form of sodium sulfate, retains valuable metal ions in the water, and improves the recycling rate of the resource. In a word, the process can realize the recycling utilization of ammonia-nitrogen waste water produced by non-ferrous metal processing, has a simple process flow, is suitable for large-scale industrial production, and has both economic and environmental benefits.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

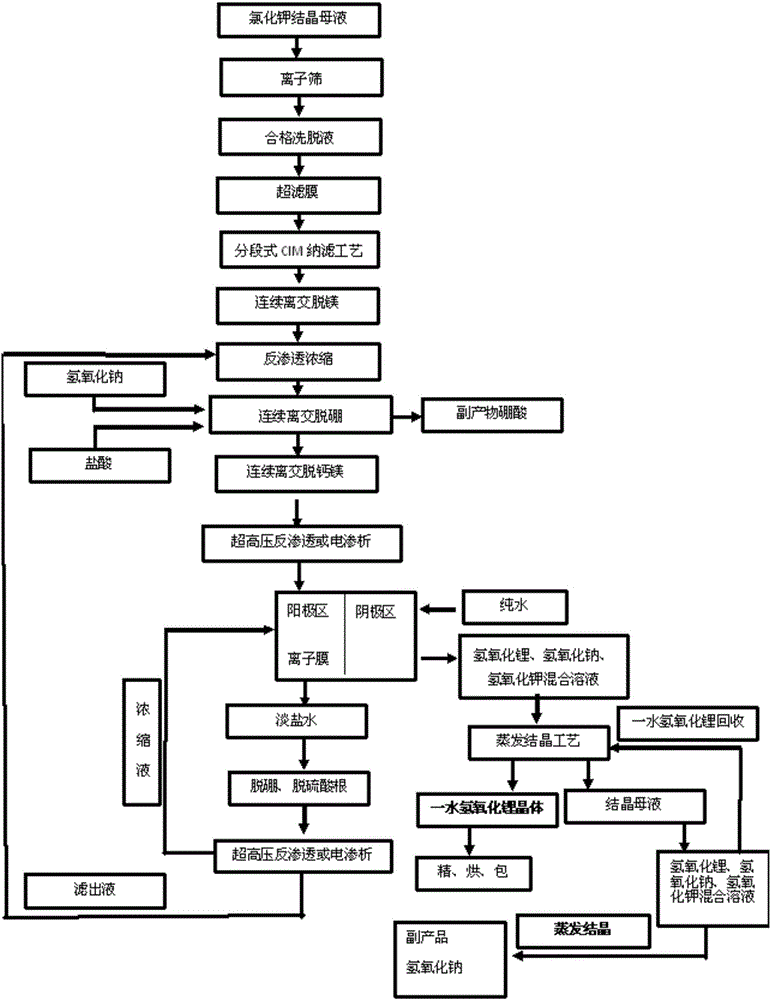

Production method of high-purity lithium hydroxide

ActiveCN106011917AHigh yieldReduce consumptionCellsBoron-oxygen compoundsLithium hydroxideUltrafiltration

The present invention relates to a production method of high-purity lithium hydroxide. A crystallization mother liquor waste water is obtained after production of potassium chloride by using a salt lake bittern as the raw material, a magnesium-lithium ratio of the crystallization mother liquor waste water is 200-500:1, an eligible eluant is obtained through ion sieve adsorption and elution of the crystallization mother liquor waste water, and after treatment of the eluant through the ultrafiltration membrane technology, the sectional type nanofiltration technology, the external regeneration continuous hybridization technology and the reverse osmosis technology, a reverse osmosis concentrated solution is obtained. In the reverse osmosis concentrated solution, the content of magnesium ions is <=300 ppm, the content of lithium ions is 4-6 g / L, the content of sodium ions is 3-5 g / L, the content of calcium ions is <=5 ppm, the content of sulfate ions is 1-30 ppm and the content of boron is <=400 ppm. According to the production method provided by the present invention, the reverse osmosis concentrated solution is used as the raw material, the process comprises ultrahigh pressure reverse osmosis continuous hybridization for boron-removing, continuous hybridization for sulfate radical removing, ion-exchange membrane electrolysis, and crystallizing evaporation, and by using the hybridization boron-removing technology, the ion-exchange membrane electrolysis technology and the crystallizing evaporation technology, the high-purity lithium hydroxide is obtained, with the byproducts being the boric acid and sodium hydroxide. The process is continuous, controllable, high in extraction rate, low in production cost and easy to industrialize.

Owner:启迪清源(上海)新材料科技有限公司

Supported nickel-iron composite hydroxide oxygen evolution electrode for alkaline water electrolysis and preparation method for supported nickel-iron composite hydroxide oxygen evolution electrode

The invention discloses supported nickel-iron composite hydroxide oxygen evolution electrode for alkaline water electrolysis and a preparation method for the supported nickel-iron composite hydroxide oxygen evolution electrode. The preparation method comprises the following steps: performing easy physical mixing-rolling on nickel and iron salt solutions, a conductive carrier and a binder to directly obtain a metal salt / carbon film; and performing low-temperature thermal treatment, in-situ precipitation and metal current collector pressing to obtain the supported nickel-iron composite hydroxide oxygen evolution electrode. Through the in-situ precipitation reaction of a metal salt pre-absorbed in the carrier, the dimension of a nickel-iron composite hydroxide catalyst is controlled, and an active site is improved; and secondly, through the in-situ precipitation reaction process, negative ions of a nitrate radical, a sulfate radical and the like are easily inserted into a nickel-iron composite hydroxide lattice, so that the oxygen evolution activity of the electrode is further regulated; moreover, the resistance loss is reduced through an internal structure constructed by the conductive carrier with a high specific surface area. The preparation method for an electrode material has the advantages of being simple, gentle in condition and high in raw material utilization rate, so that the good industrial prospect and a high economic value are shown.

Owner:BEIJING UNIV OF CHEM TECH

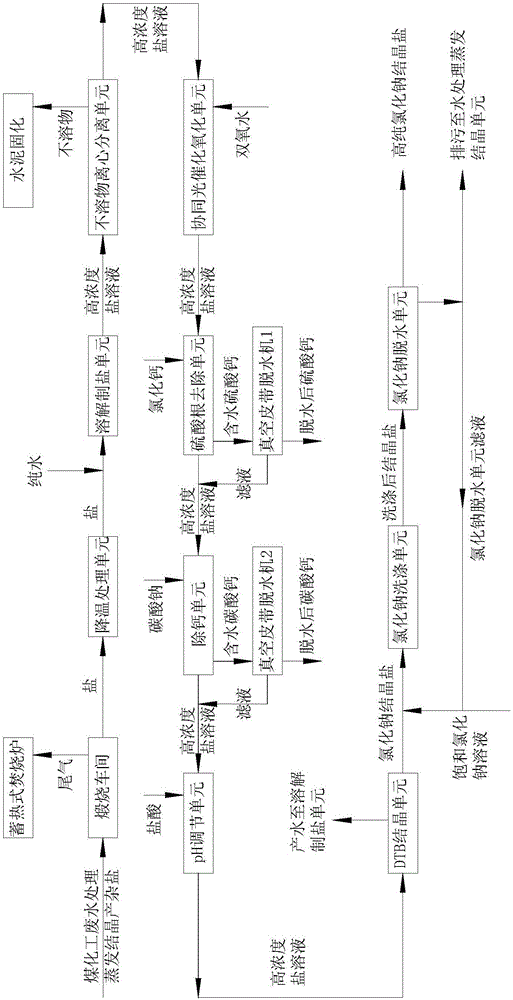

Method for recycling impurity salts generated in industrial wastewater treatment

ActiveCN106745076AEasy to handleWide operating conditionsCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesHigh concentrationSulfate radicals

The invention provides a method for recycling impurity salts generated in industrial wastewater treatment. The method comprises the following steps: (1) calcining impurity salts generated in an industrial wastewater treatment process, cooling, dissolving in pure water, and obtaining a high-concentration sodium chloride solution; (2) performing solid-liquid separation, and removing residual organisms in the solution; (3) successively removing sulfate radicals and calcium ions, adjusting the pH of the solution to neutral, and obtaining a high-purity sodium chloride solution; and (4) crystallizing the high-purity sodium chloride solution obtained in step (3), obtaining a sodium chloride crystal product, and washing to obtain the high-purity sodium chloride crystal product. By adopting the method, the effective treatment and recycling of impurity salts generated in the industrial wastewater zero emission process of electric power, petroleum chemistry, coal chemistry and the like; moreover, the method is simple in treatment process and moderate in operation conditions, and is a high-efficiency and stable impurity salt recycling method; and a final product sodium chloride is high in recycling rate and purity.

Owner:DATANG INT CHEM TECH RESINST

Method for treating organic waste water by using electrochemistry under assistance of persulfate

InactiveCN102249378AReduce dosageLess side effectsWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationElectrochemical responseSulfate radicals

The invention relates to a method for treating organic waste water by using electrochemistry under the assistance of persulfate. The method comprises the following steps of: putting sulfate, a divalent or tervalent ferric salt and organic waste water into an electrochemical reactor consisting of a DSA (Dimensional Stable Anode) and an anti-corrosive cathode; adjusting the pH value of a reaction liquid to 3-9; stirring; and switching on a power supply for reacting. The method is characterized in that: special requirement on the ferric salt is not made, the ferric salt can be divalent or tervalent, generated free sulfate radicals can be used for effectively treating organic pollutants in water; meanwhile, in the electrochemical reactor, reutilization of divalent ferric ions can be realized under the reducing action of the cathode, so that the adding amount of the ferric salt is reduced, side reactions between an excessive amount of ferric salt and free sulfate radicals are reduced, ineffective consumption of free sulfate radicals is avoided, and the generation of iron sludge is reduced simultaneously.

Owner:WUHAN UNIV

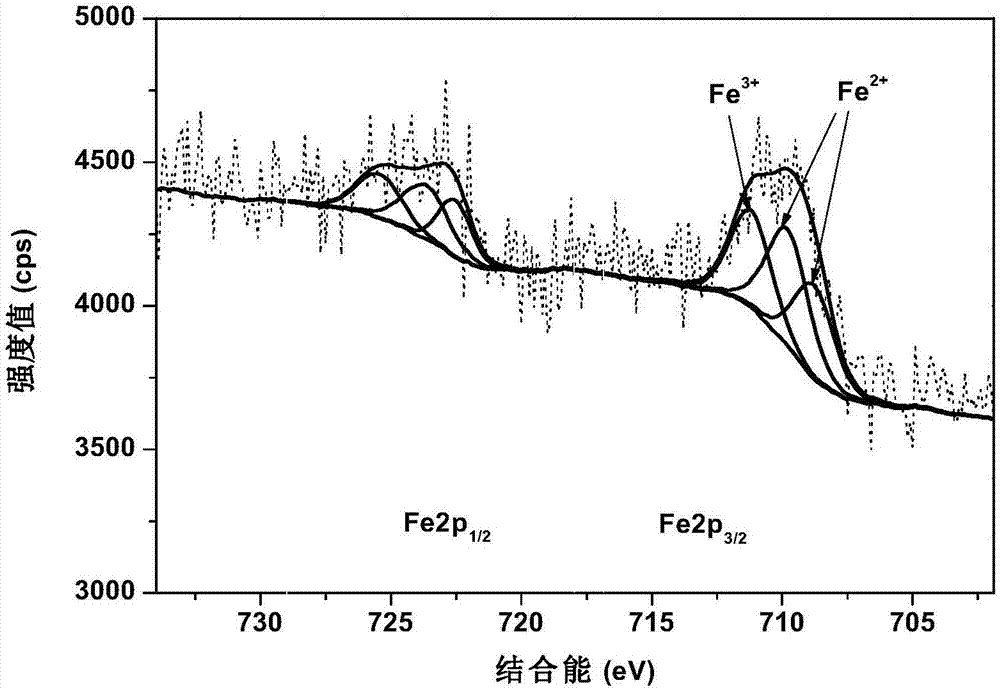

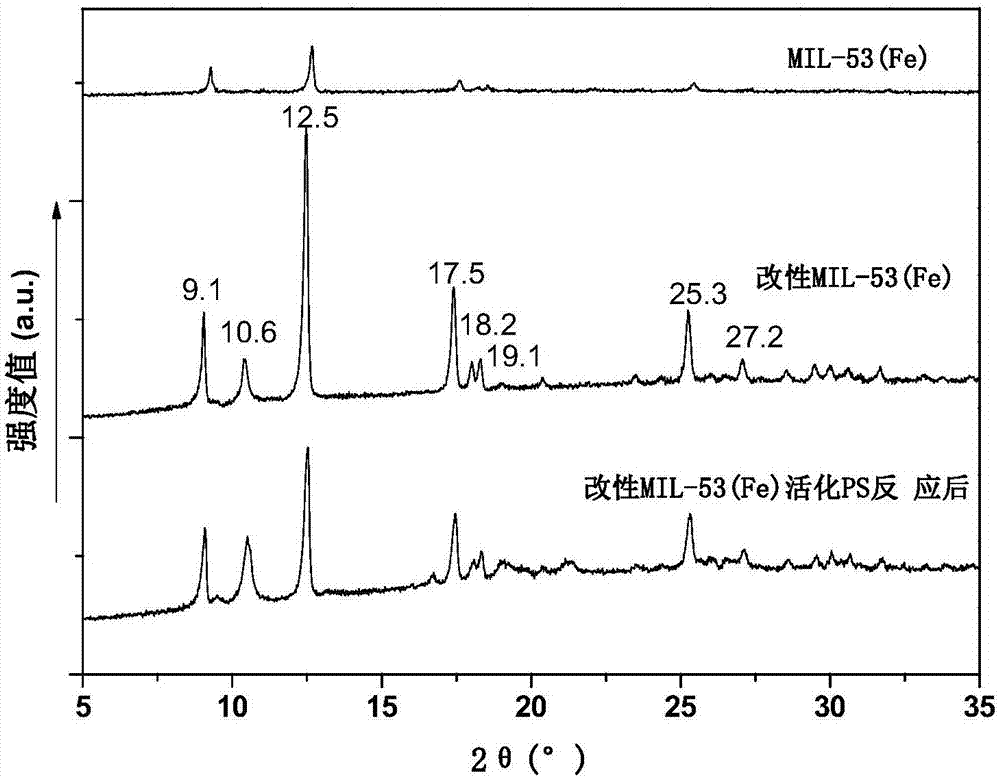

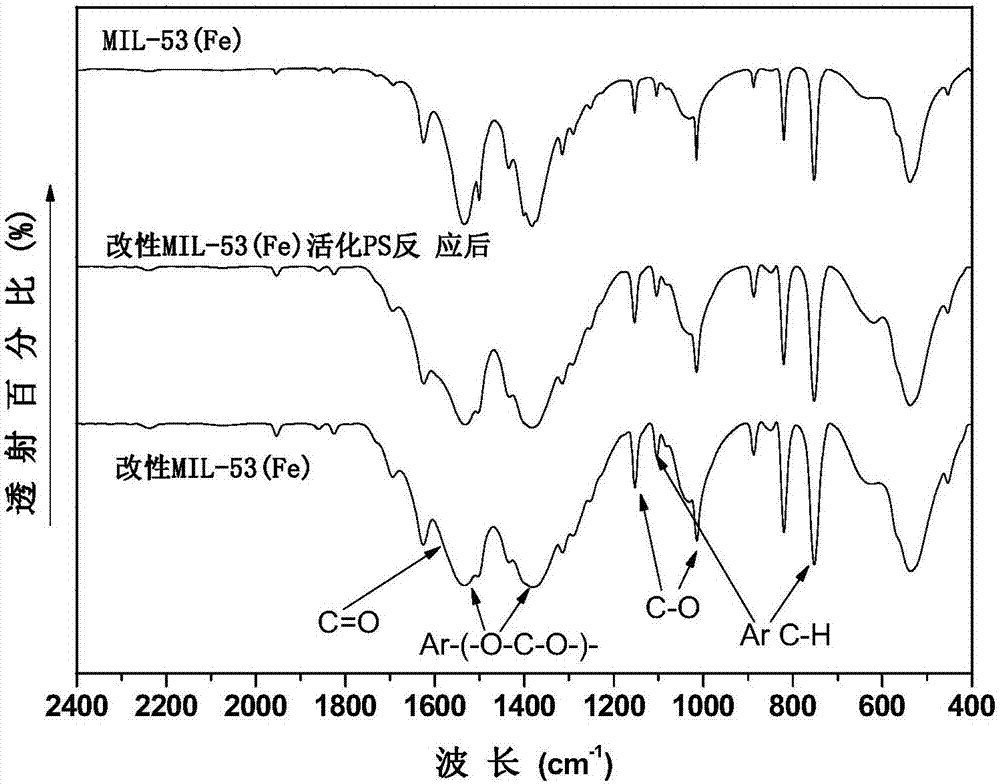

Method of treating organic wastewater based on Fenton-like reaction of iron-based organic-framework material

InactiveCN104310565AIncrease the areaLarge apertureWater treatment compoundsWater contaminantsSulfate radicalsPtru catalyst

The invention discloses a method of treating organic wastewater based on Fenton-like reaction of an iron-based organic-framework material. The method comprises the following steps: by taking the iron-based organic-framework material as a catalyst and taking persulfate or hydrogen persulfate as an oxidant, degrading organic pollutants by virtue of sulfate radicals formed in a reaction process. The iron-based organic-framework material has a relatively great specific surface area and a relatively great bore diameter, is regular in metal ion spatial arrangement, uniform in distribution, high in active point location density, high in catalytic activity, environmentally friendly, easy to recycle and capable of being recycled. And moreover, the method is simple in equipment, convenient to operate, capable of efficiently degrading organic pollutants in water within a relatively wide pH value range, and very great in application prospect.

Owner:UNIV OF JINAN

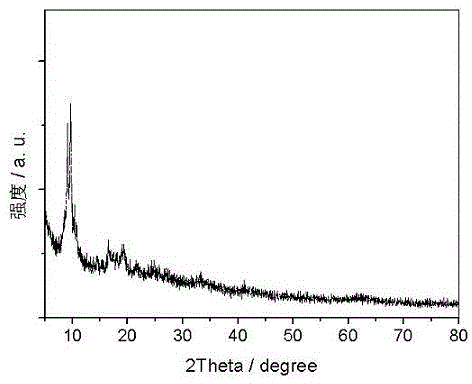

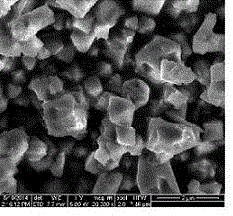

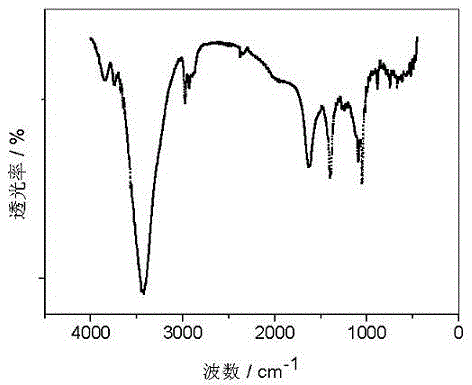

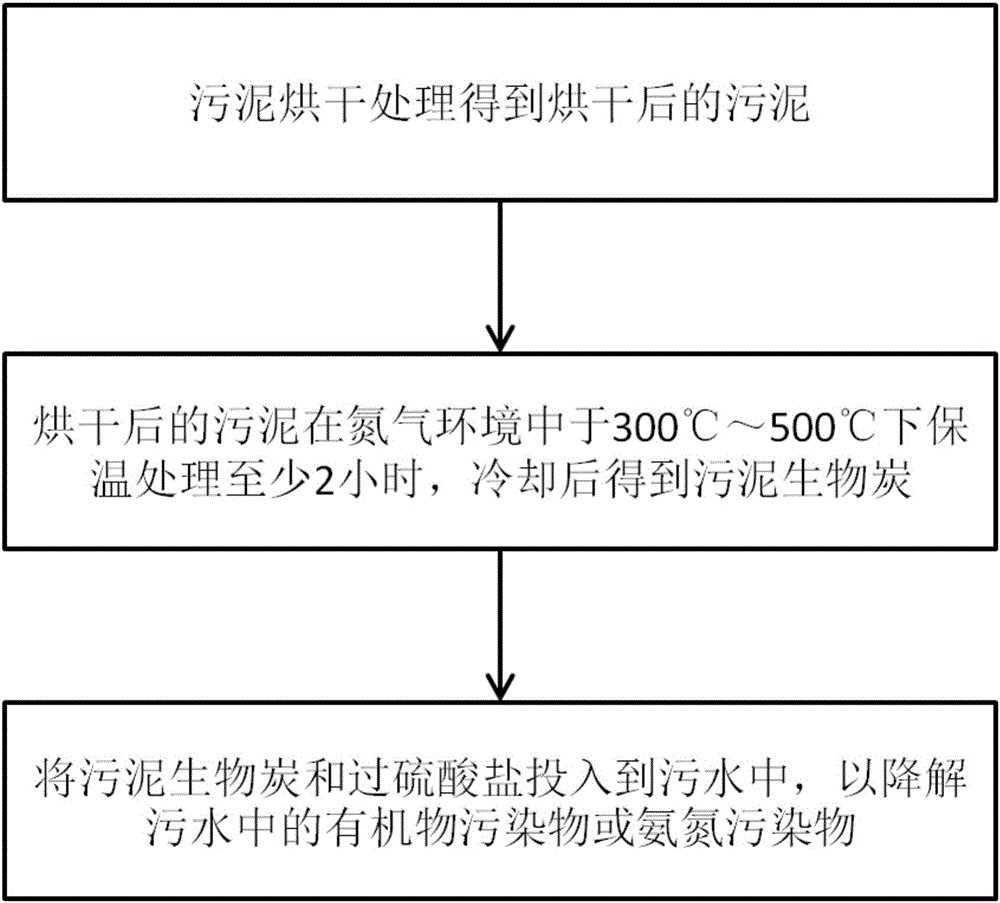

Method for degrading organic substances or ammonia nitrogen by catalyzing persulfate through sludge biochar

ActiveCN106045002AEfficient degradationEasy to prepareWater/sewage treatment by oxidationPersulfateSludge

The invention discloses a method for degrading organic substances or ammonia nitrogen by catalyzing persulfate through sludge biochar. The method includes the following steps that firstly, sludge is dried to obtain dried sludge, then the dried sludge is subjected to pyrolysis treatment for at least 2 h in the ammonia environment at 300-500 DEG C, and then sludge biochar is obtained after cooling; secondly, the sludge biochar and persulfate are put into sewage to degrade the organic substances or ammonia nitrogen in the sewage. By improving key preparation conditions of sludge biochar and increasing the application ratio of the sludge biochar and persulfate, under the catalytic function of the sludge biochar, persulfate can efficiently degrade the organic substances and ammonia nitrogen in sewage on the basis of catalysis and oxidization of sulfate free radicals, the problem of organic pollutant and the ammonia nitrogen pollution problem in sewage are effectively solved, and the degradation effect is good.

Owner:HUAZHONG UNIV OF SCI & TECH

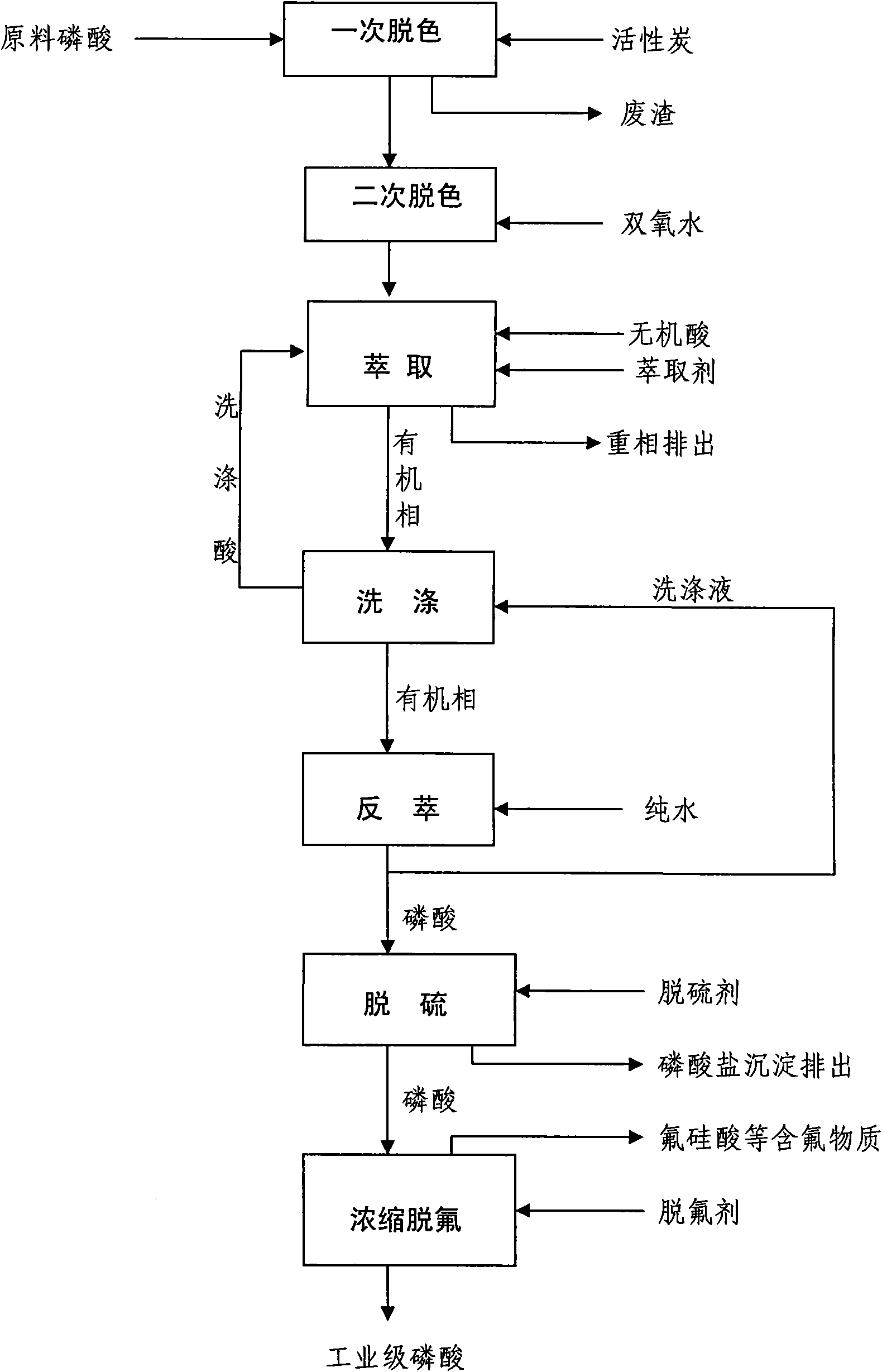

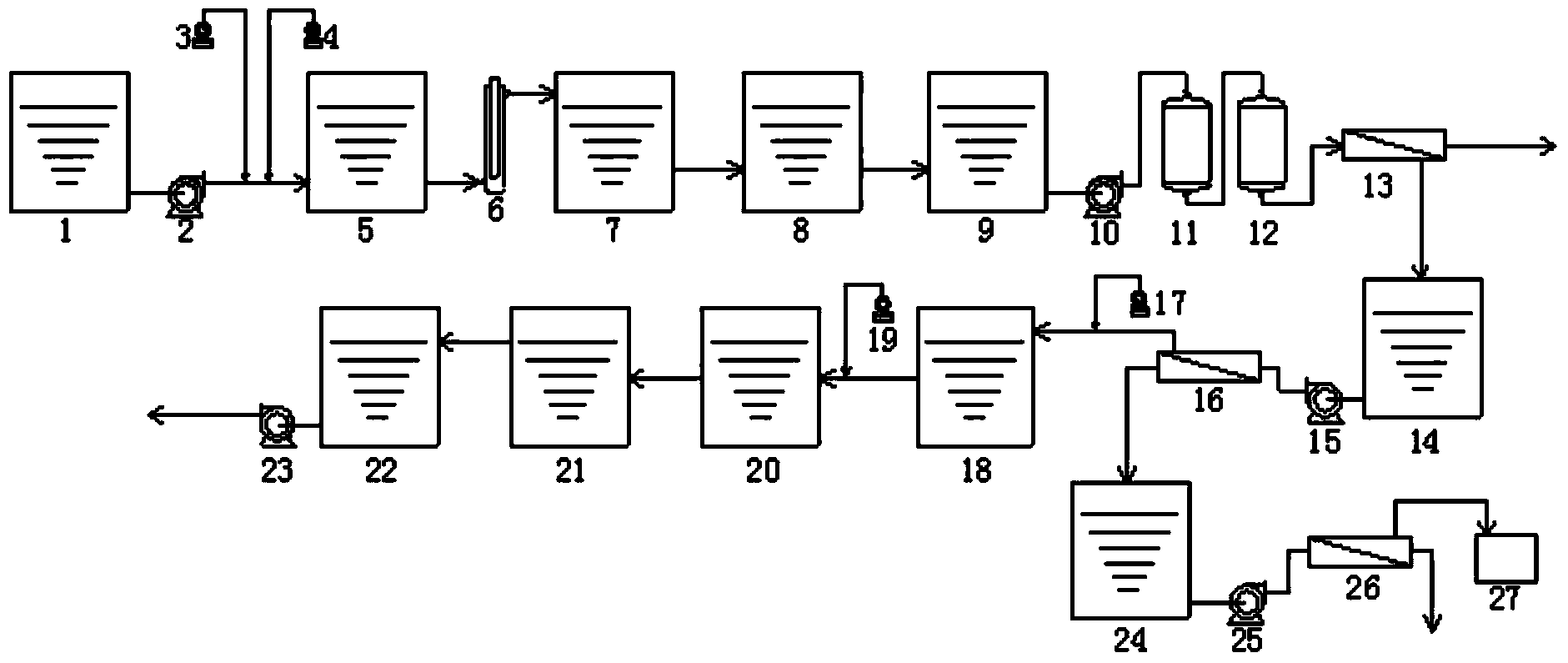

Method for extracting and purifying wet-process phosphorous acid to produce industrial-grade phosphorous acid

ActiveCN101857216AIncreased concentration of hydrogen ionsHigh partition coefficientPhosphorus compoundsPhosphorous acidSulfate radicals

The invention discloses a method for extracting and purifying wet-process phosphorous acid to produce industrial-grade phosphorous acid, which comprises the following steps: step 1, decoloration: utilizing active carbon and hydrogen peroxide to decolorize the phosphorous in two steps; step 2, extraction: utilizing extracting agent to extract phosphorous; step 3, washing: utilizing cleaning solution to washing organic phase; step 4, backextraction: utilizing pure water to extract the phosphorous acid in the organic phase; step 5, desulphurization: utilizing desulphurization agent to remove sulfate radical in the phosphorous acid; and step 6, concentration: improving the concentration of phosphorous acid, defluoridating through vacuum concentration to obtain the industrial-grade phosphorous acid. The method has the advantages that: (1) segmented decoloration is adopted, so the pretreatment process is simplified; (2) the used turntable tower is stable, the continuity is strong, and the maintenance expense is low; (3) sulfuric acid is compensated from the middle part of the extraction tower, so the yield of the industrial product is improved, the extraction rate can reach more than 95 percent, and the yield of the industrial product can reach more than 90 percent; (4) a plate-type heat exchanger is adopted, so the land occupation area is small; and (5) and the side-product barium sulfate is washed and dried to be used as an industrial product.

Owner:GUIZHOU CHANHEN CHEM CO LTD

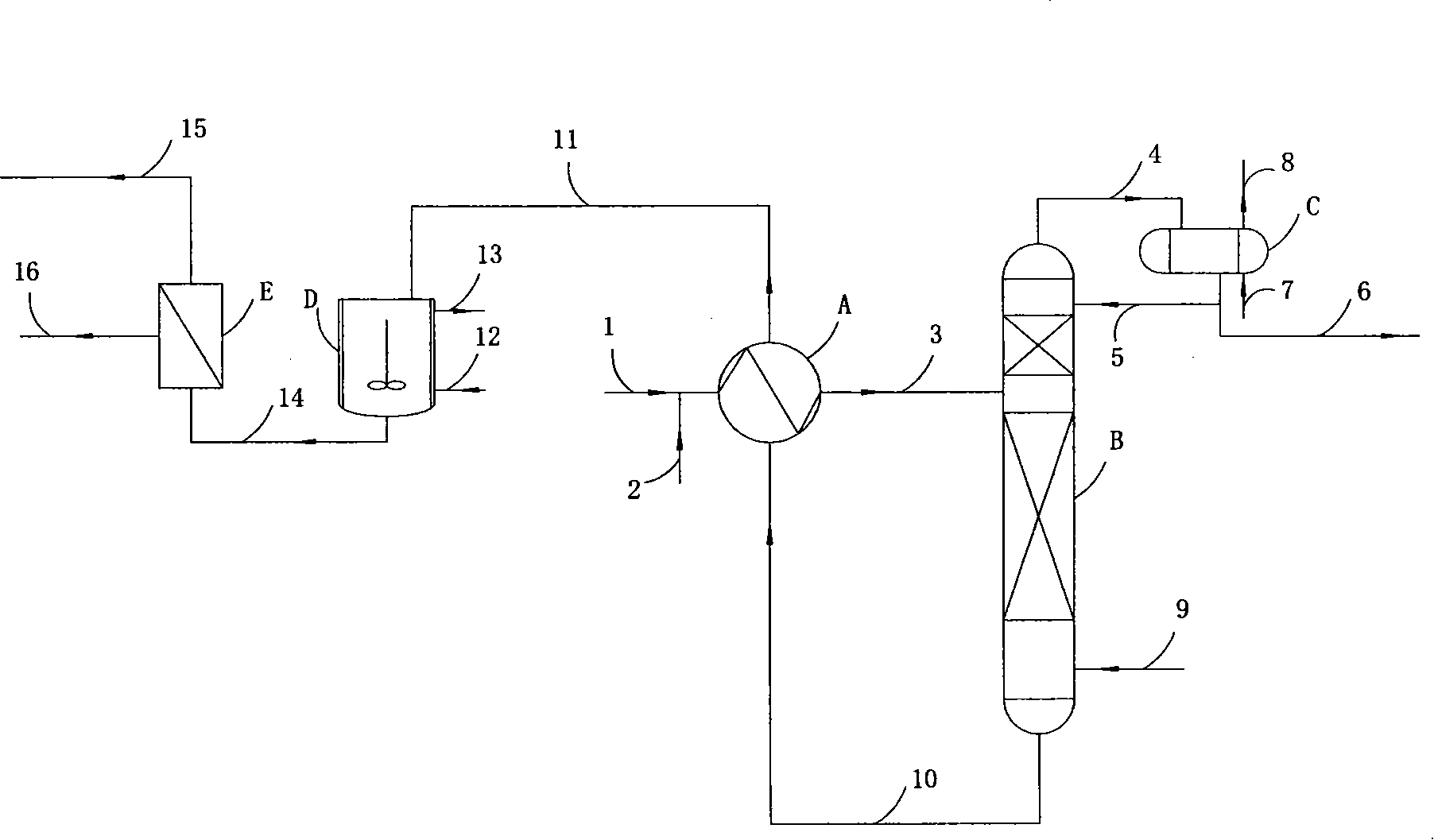

Method and device for zero-emission treatment of high-hardness waste water containing sulfate

ActiveCN104291511AIncrease the concentration factorSave investmentWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentSulfate radicalsIon exchange

The invention belongs to the field of waste water treatment and reclaimed water reuse, in particular to a method and a device for the zero-emission treatment of high-hardness waste water containing sulfate. The method for the zero-emission treatment of high-hardness waste water containing sulfate comprises the following steps: 1) sequentially substituting calcium and magnesium ions in waste water into sodium ions by a double-alkali process and an ion exchange process and simultaneously removing most alkalinity so as to promote sulfate radicals and chlorine ions to be the main components of rest anions in water and promote sodium ions to be the main component of cations; 2) concentrating waste water obtained in step 1) through reverse osmosis and reclaiming produced water; 3) separating and concentrating concentrated water treated by reverse osmosis in step 2) through nanofiltration so as to obtain nanofiltered concentrated water of which the main component is sodium sulfate and nanofiltered produced water of which the main component is sodium chloride; 4) after concentrating the produced water nanofiltered in step 3) through reverse osmosis or positive osmosis, evaporating and concentrating; 5) removing sulfate radicals from the concentrated water nanofiltered in step 3). The concentrating times of waste water is increased as much as possible, and the evaporating quantity of waste water is reduced.

Owner:山东泰禾环保科技股份有限公司

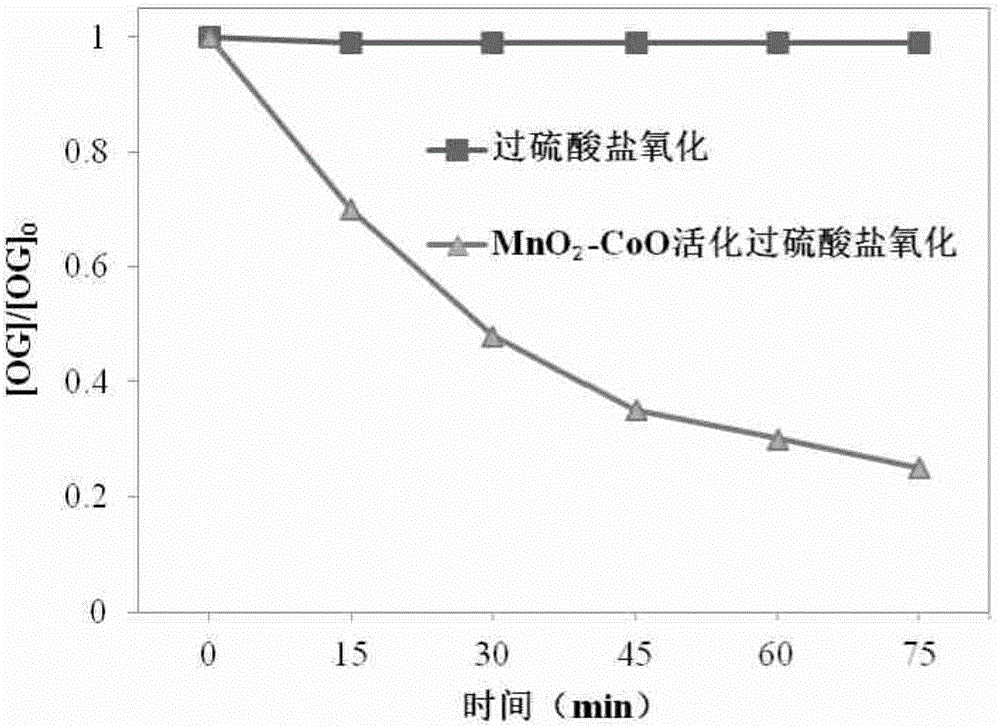

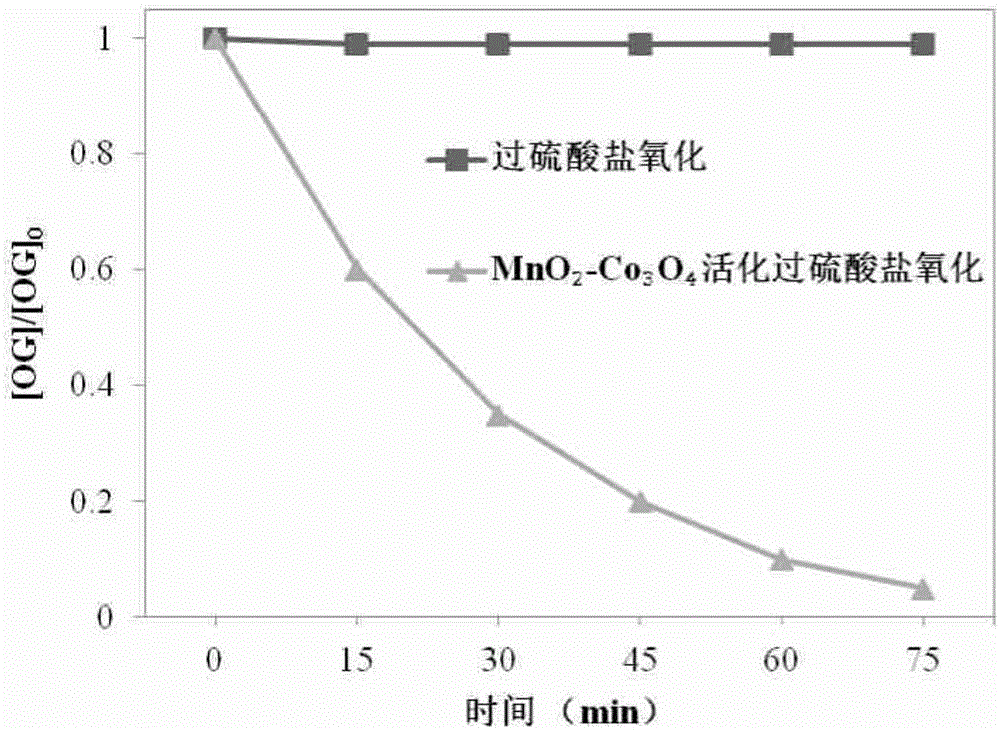

Method for degrading organic waste water by activating persulfate through manganese-cobalt composite oxide

InactiveCN105084511ALow toxicityLow priceWater/sewage treatment by oxidationManganese oxideComposite oxide

The invention discloses a method for degrading organic waste water by activating persulfate through manganese-cobalt composite oxide. The method includes the following steps that under the normal temperature condition, the persulfate with the concentration of 0.5-5.0 mM and the manganese-cobalt composite oxide with the concentration of 0.1-2.0 g / L are added into the waste water containing organic pollutants, the water sample is treated for 20 min-3 h, then solid-liquid separation is carried out, and the treatment process is completed. The heterogeneous manganese-cobalt oxide is adopted as a catalyst and can efficiently and continuously activate the persulfate to generate sulfate free radicals and hydroxyl free radicals to degrade the organic pollutants. Serving as an environment-friendly material, the manganese oxide can effectively reduce leakage of cobalt ions and reduce secondary pollution and biotoxicity. The method is suitable for treatment on various kinds of organic waste water, high in efficiency and persistence, capable of being used repeatedly and convenient to operate and provides wide prospects for treatment on the degradation-resistant organic waste water.

Owner:HOHAI UNIV

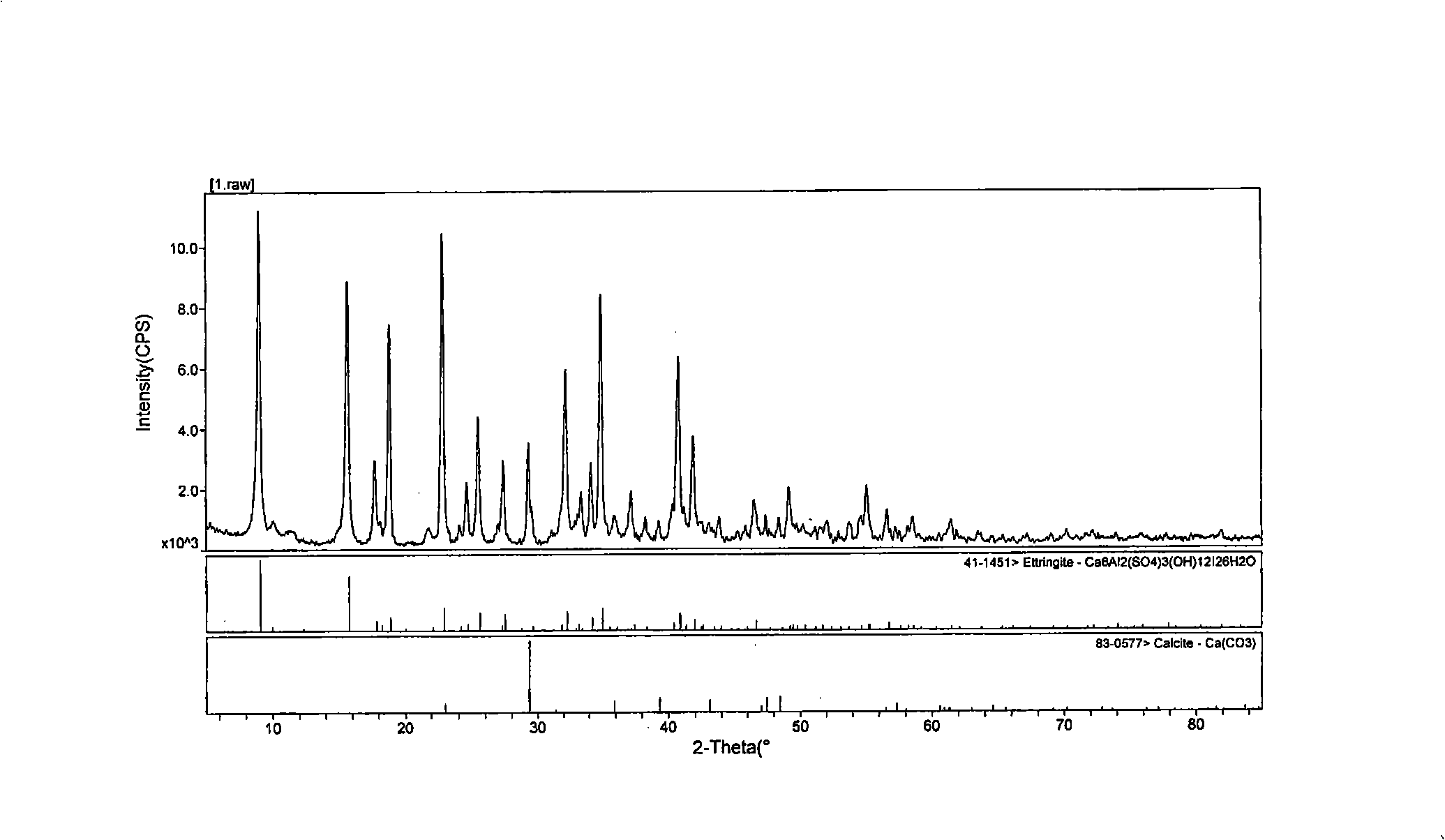

Method for removing sulfate radical in waste water

The invention discloses a sulfate radical wastewater treatment method by using a complex salt method, proposing that hydration aluminum nitrate and calcium hydroxide are taken as removing agents to remove the sulfate radical ions in the wastewater. Al (NO3)3 question mark 9H2O is added into metallurgy and mining industry sulfate radical wastewater with the initial concentration of 1300 to 2000mg / L according to the mol ratio of 0.8-1.1:1 of SO4<2-> / Al<3+>, reaction temperature is controlled at 20-40 DEG C, the pH value of the calcium hydroxide regulation system is 9-12, stirring reaction is carried out for 30-90min, SO4<2-> in the system, Ca<2+> and Al<3+> form compound Ca6Al2(SO4)3(OH)12 question mark 26H2O (ettringite) precipitation, then solid-liquid separation is carried out, and purifying water with water sulfate radical ion concentration of less than 100mg / L is obtained. The invention has the advantages of simple operation, high reaction speed, small temperature affect, highly-efficient treatment and the like.

Owner:CENT SOUTH UNIV

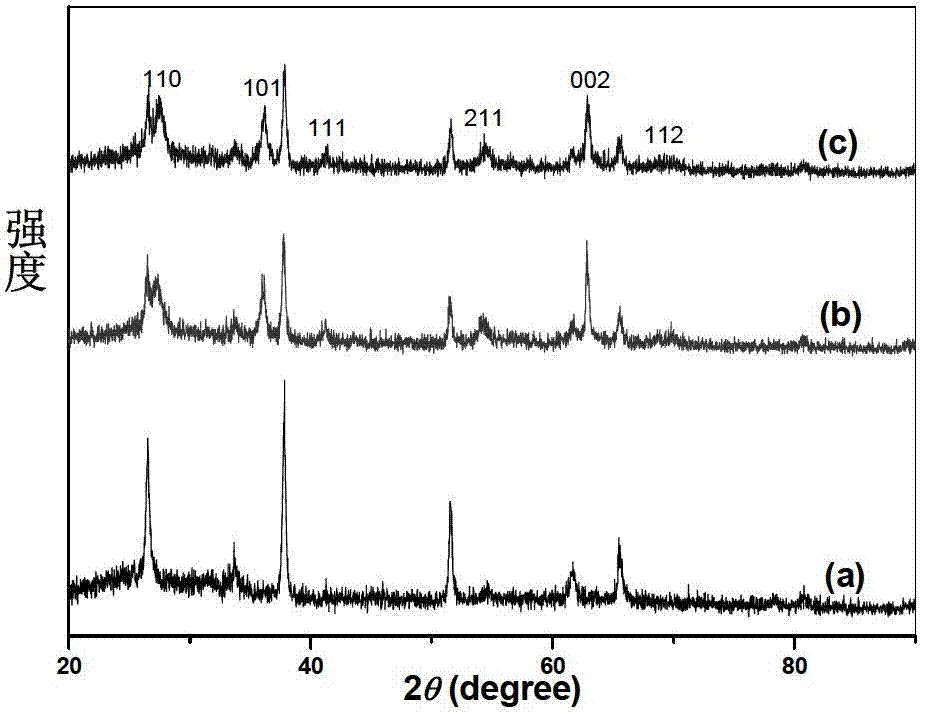

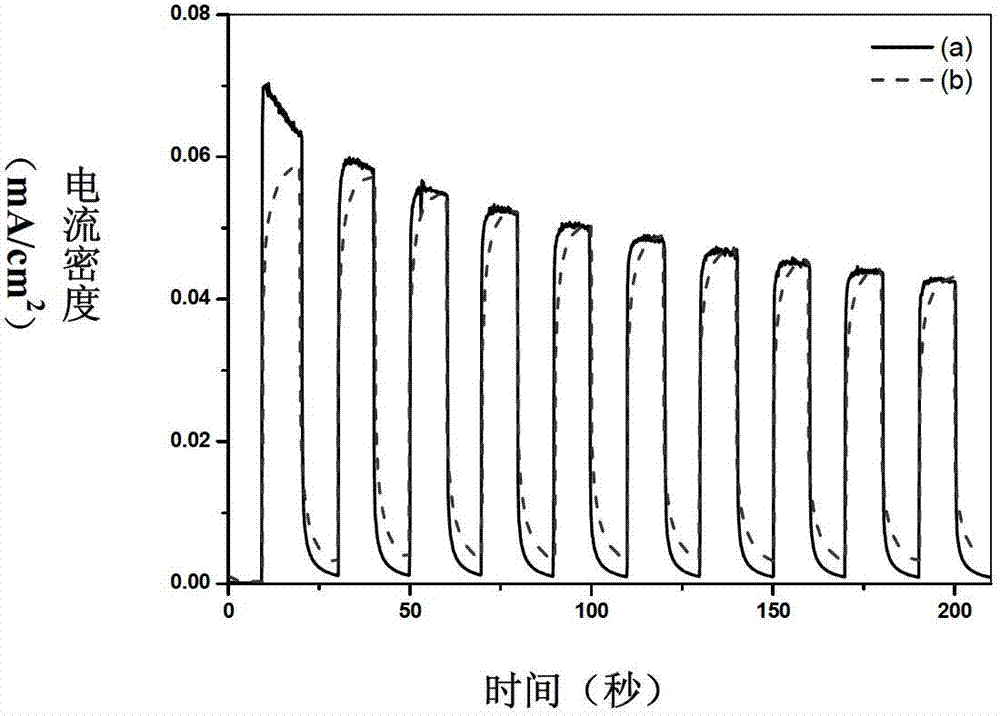

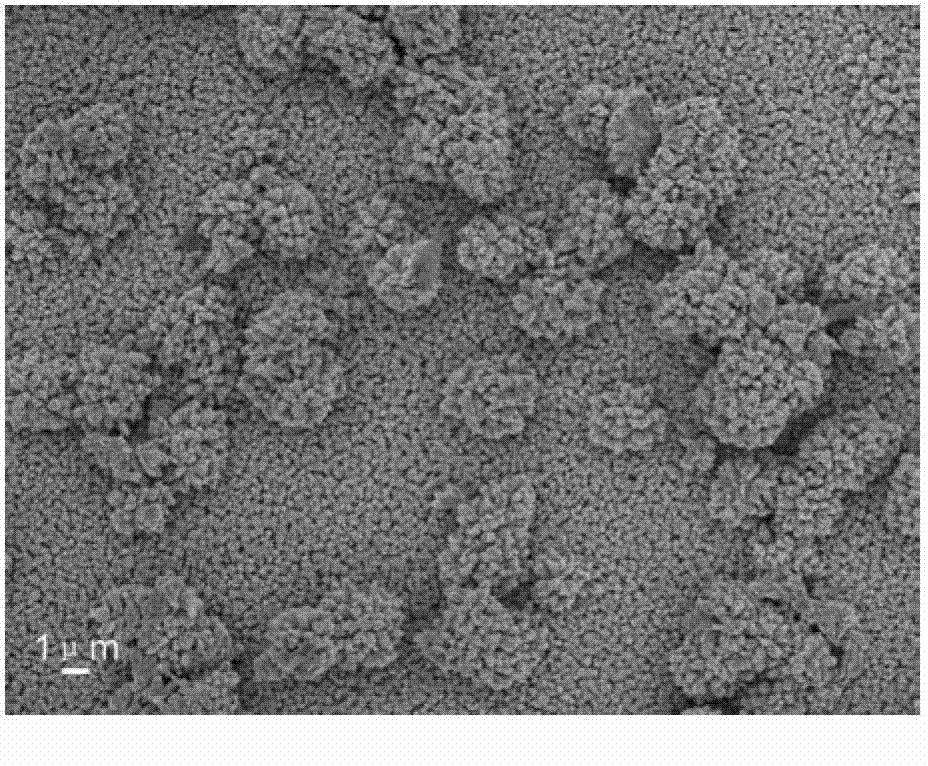

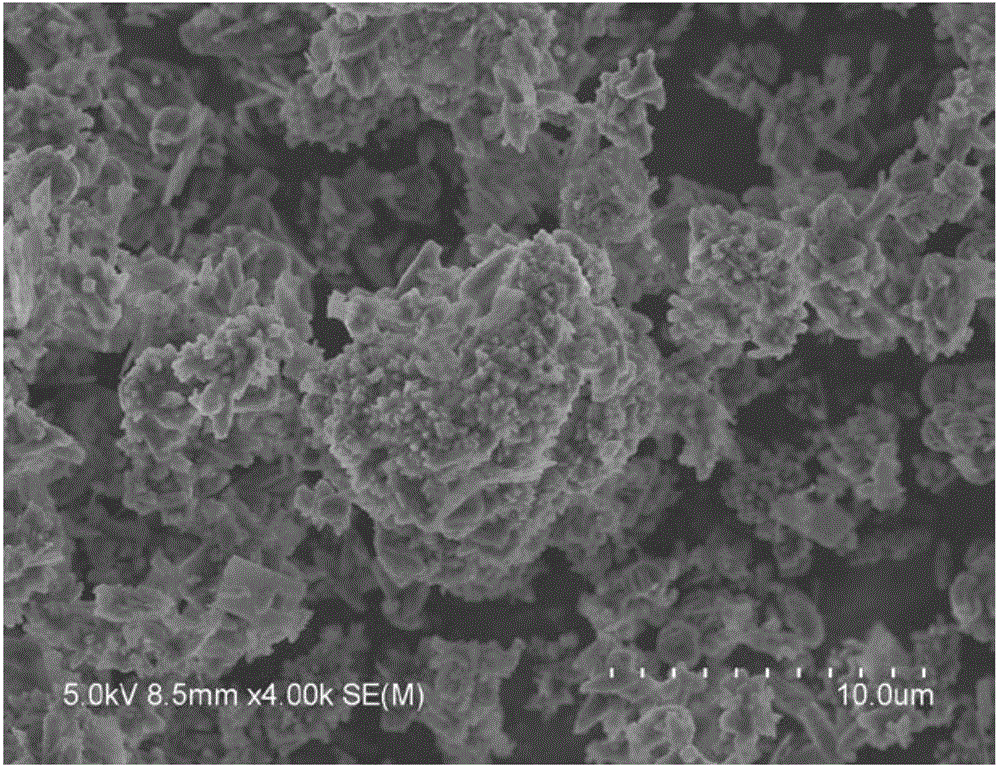

Rutile type titanium dioxide nanowire film and preparation method and applications thereof

InactiveCN102774883ASolve the difficult preparation of rutile phaseSolve conductivity problemsPhysical/chemical process catalystsElectrolytic capacitorsSulfate radicalsTithonia longiradiata

The invention relates to a rutile type titanium dioxide nanowire film and a preparation method and applications thereof. The preparation method of the film comprises the steps of directly growing rutile phase titanium dioxide nanowire array on a conductive glass substrate, and evenly distributing titanium dioxide nanowire clusters on the surface of the top end of the array; and regulating the proportion of various reactants, reaction time, temperature and other factors by taking sulfate radical-containing titanium slat as precursor for preparing the film. The invention further provides applications of the film, and the film can be used as anode materials to assemble a solar cell, or as photocatalyst to carry out water photolysis or organic matter degradation treatment. The method is simple, and has strong controllability, the problems that therutile phase is difficult to be prepared by using the sulfate radical-containing titanium slat and the titanium dioxide nanowire array grows on the conductive substrate in situ are solved, and the change on the diameter and length of the nanowire can be realized while the no change on crystallinity of a sample can be ensured through a calcination method.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for photocatalyst for treating nitrophenol wastewater and treatment method for nitrophenol wastewater

InactiveCN104399516AEnlarging hole diameterImprove performanceMolecular sieve catalystsWater/sewage treatment by irradiationMolecular sieveSulfate radicals

The invention provides a preparation method for a photocatalyst for treating nitrophenol wastewater and a treatment method for the nitrophenol wastewater. Compared with the prior art, the preparation method and the treatment method have the advantages that by modification of ZSM-5, the hole diameter of a molecular sieve is enlarged, more mesoporouses are provided, and the specific surface area and the hole capacity are enlarged; a secondary mesoporous molecular sieve (ZSM5) is prepared; nano TiO2 is synthesized by a sol-gel method and is loaded on the ZSM5 to prepare a composite catalyst with high performance; meanwhile, peroxysulphate is added in order to solve the problem that independent UV / TiO2 is low in oxidization capacity, so that a sulfate radical anion is generated by peroxysulphate under UV excitation and can develop higher oxidization capacity under cooperation with -OH. According to the preparation method and the treatment method, the photocatalysis action of nano TiO2 / mesoporous ZSM-5 and the advanced oxidation action of the sulfate radical anion are combined, so that the photocatalysis treatment efficiency is improved, the treatment cost is reduced, and the characteristics of repeated use and green high efficiency are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

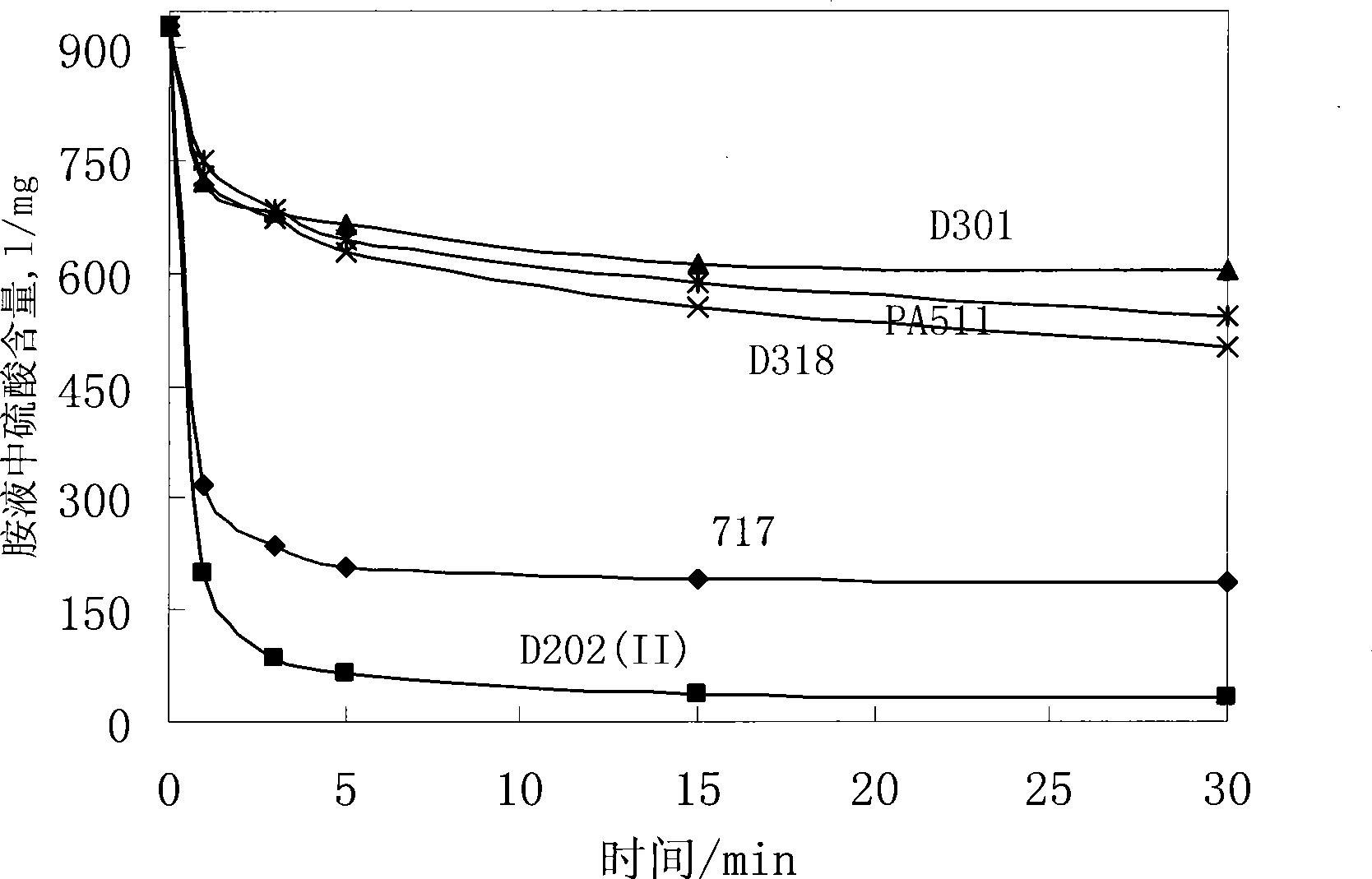

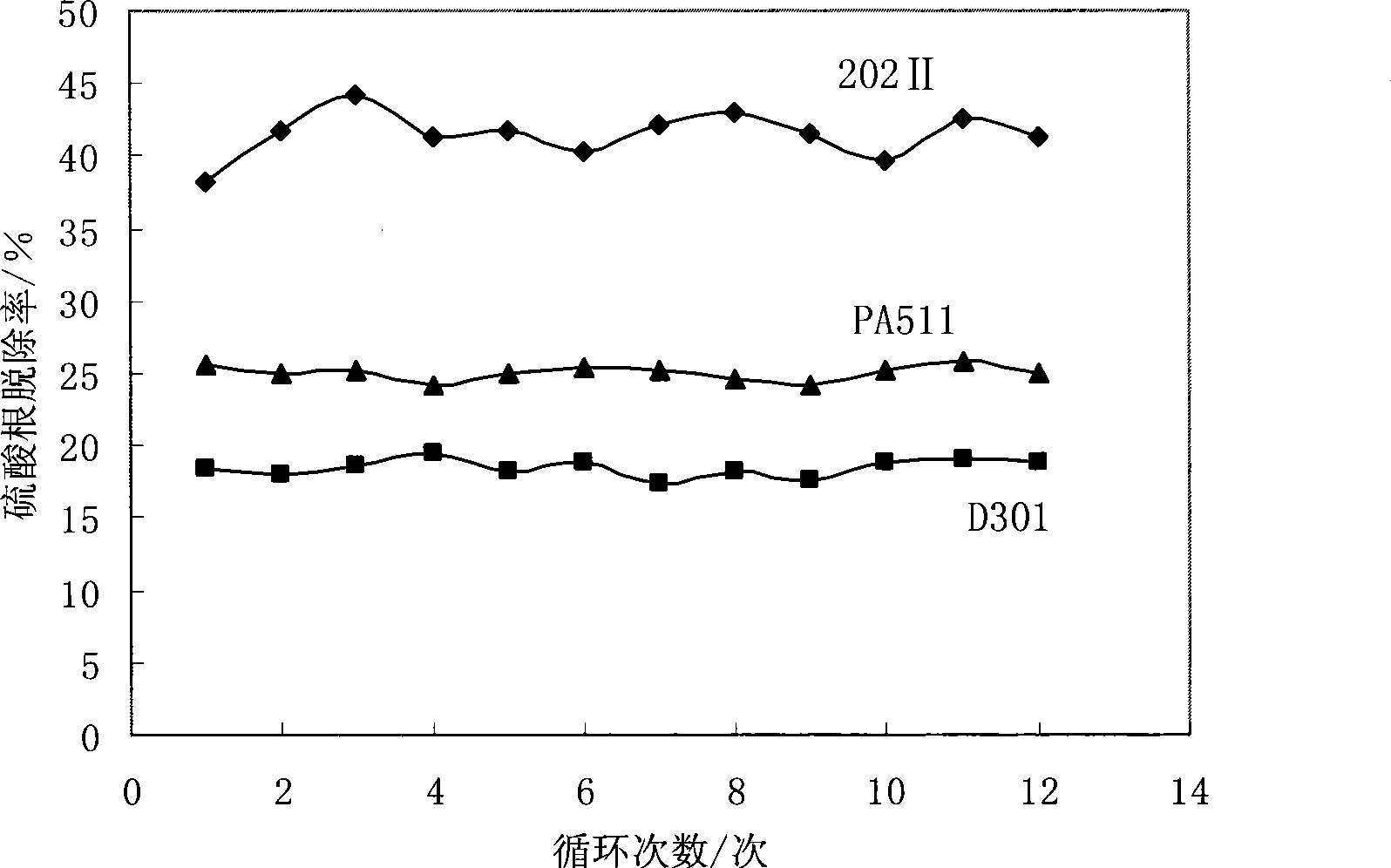

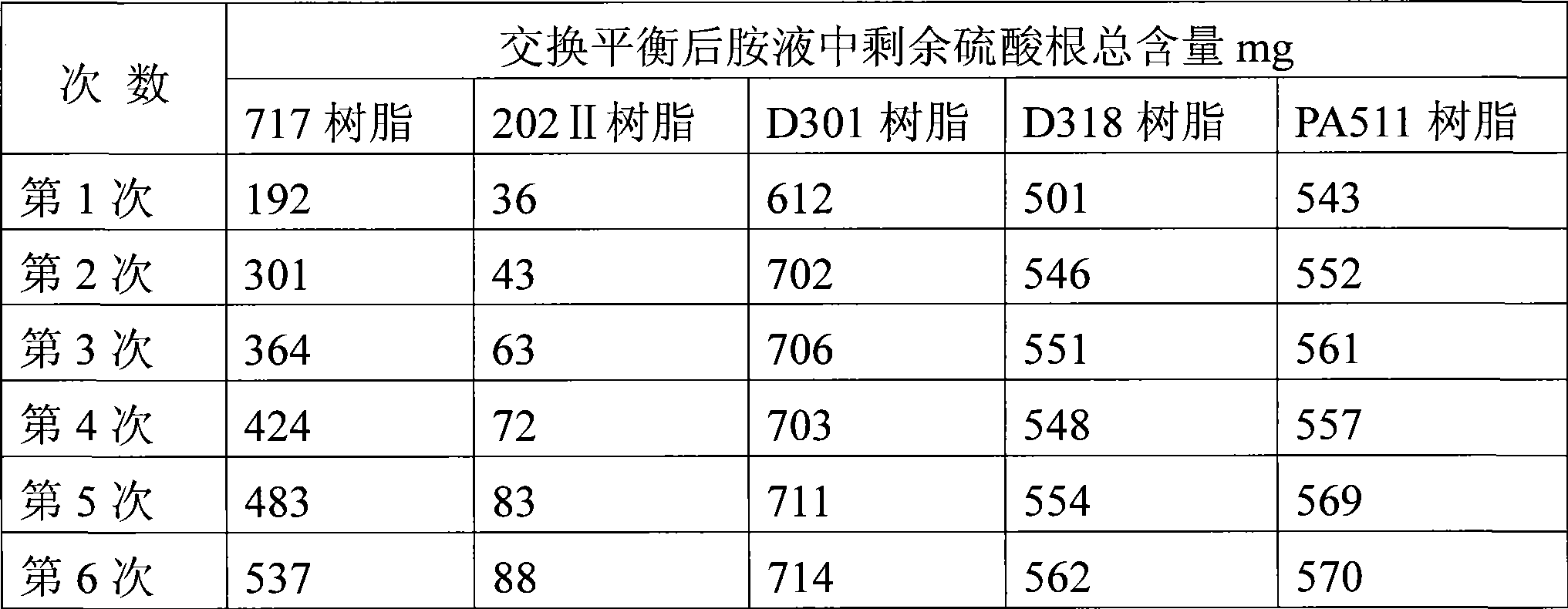

Method for removing thermostable salt in amine liquid for desulphurization

ActiveCN101502742AQuick releaseSolve the speed problemIon-exchange column/bed processesOrganic compound preparationSulfate radicalsFlue gas

The invention discloses a method for removing heat-stable salts in amine desulphurization, aiming at solving the problem that the prior art has difficulty in treating desulphurizer with high content of sulfate radical. The method is as follows: strong base type II anion exchange resin with particle size of 0.5-1.5mm is filled in an ion exchange resin tower with height-diameter ratio of 1:1-3:1, the desulphurized amine solution with PH value less than 5.4 passes through the ion exchange resin tower at the airspeed of 30h-50h to experience purifying treatment, when the PH value of the desulphurized amine solution at the exit of the resin tower is equal to that at the entrance of the resin tower, sodium hydroxide solution is used to carry out upflow regeneration on the ion exchange resin, and the regenerated ion exchange resin is recycled. The method can solve the problems of rapid cumulative rate and large total content of the sulfate radical in reproducible wet method flue gas desulphurization system.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Process for producing high purity magnesia

InactiveCN1704337ANo pollutionShort technical routeChlorine/hydrogen-chlorideMagnesium chloridesSulfate radicalsPhysical chemistry

The invention discloses a process for preparing high purity magnesium oxide products, which consists of using brine containing magnesium chloride from sea, lakes or crude magnesium chloride hexahydrate as raw material, purifying the brine through vacuum crystallization method, removing boron, sulfate radicals, calcium ions and soluble impurity substance in the raw material, finally carrying out dynamic calcinations.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

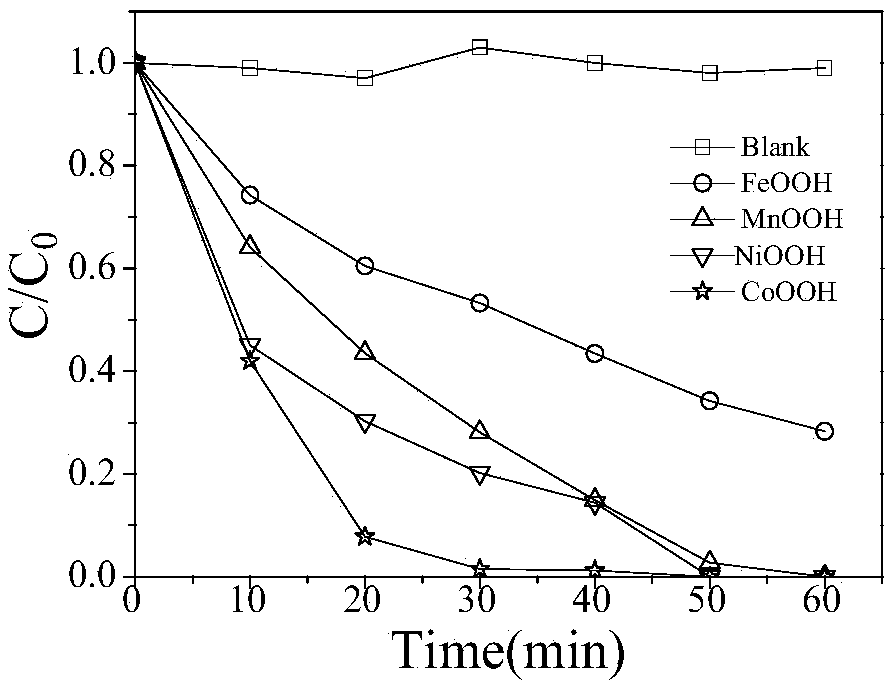

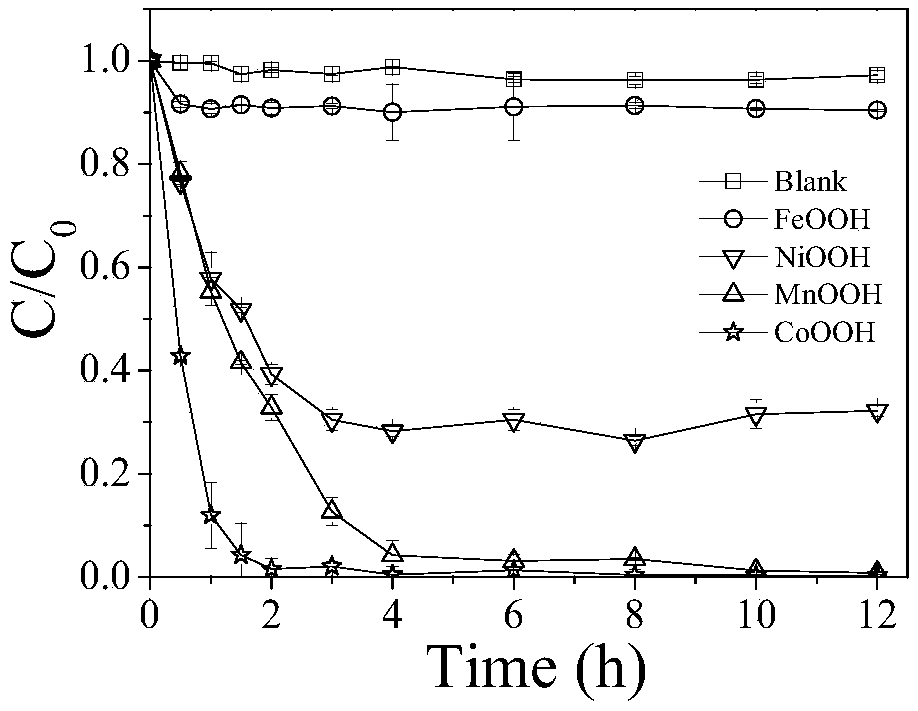

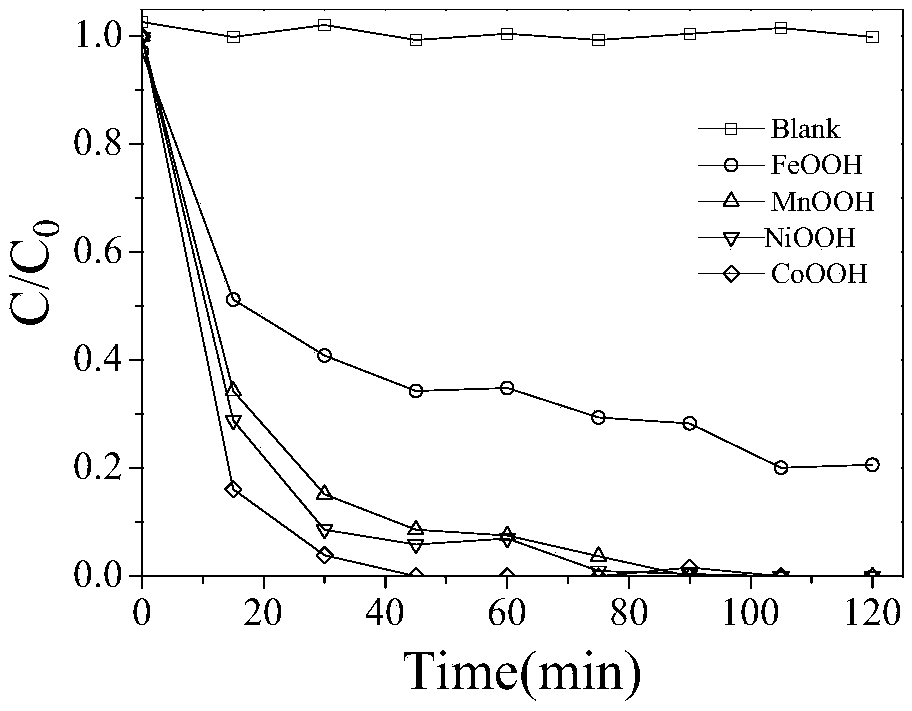

Catalytic method for generating sulfate radicals and active oxygen species as well as advanced oxidation method of organic pollutants difficult to biodegrade

ActiveCN108675430AStable structureImprove removal efficiencyWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsCatalytic methodSulfate radicals

The invention provides a catalytic method for generating sulfate radicals and active oxygen species as well as an advanced oxidation method of organic pollutants difficult to biodegrade. The problemsof low degradation efficiency of organic pollutants and high cost in the prior art are solved. According to the catalytic method for generating sulfate radicals and active oxygen species, a transitionmetal oxyhydroxide-based material serves as a catalyst, and the sulfate radicals, hydroxyl radicals, superoxide radicals and singlet oxygen non-radicals are generated, so that the organic pollutantsdifficult to biodegrade are efficiently oxidized. The transition metal oxyhydroxide-based material serves as the catalyst, the activation efficiency of perosulfate is improved and various radicals andactive oxygen species are generated, so that the oxidative degradation rate of the organic pollutants is increased; and the catalyst has a stable structure, is low in heavy metal dissolution rate inthe catalytic process, avoids secondary pollution, and can be widely applied to treatment of industrial production waste water, treatment of domestic sewage, purification treatment of polluted underground water and surface water as well as treatment of polluted soil.

Owner:JILIN UNIV

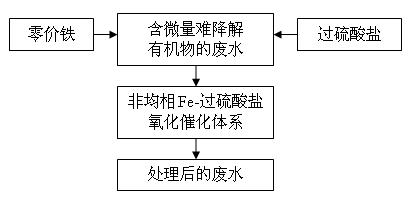

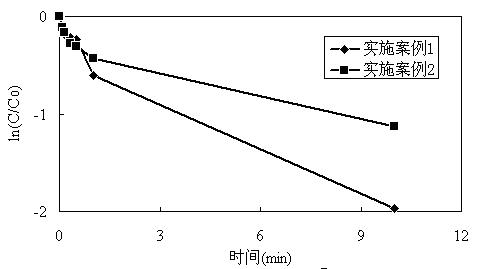

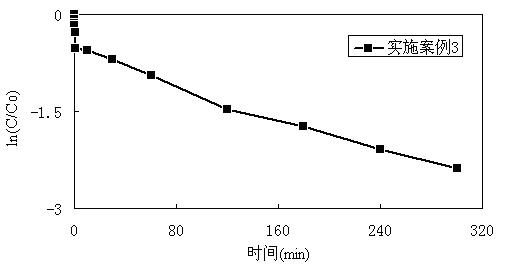

Method for treating track non-degradable organisms in water by aid of heterogenous sulfate radical oxidation

InactiveCN102633349AApplicable to a wide range of pHGood effectWater contaminantsWater/sewage treatment by oxidationSulfate radicalsBiochemical engineering

The invention discloses a method for treating trace non-degradable organisms in water by the aid of heterogenous sulfate radical oxidation. The method includes feeding zero-valent iron into the water to be used as a stable Fe2+ source; generating high-oxidability sulfate radicals by means of activating persulfate; leading the sulfate radicals to oxidize and degrade the track non-degradable organisms in the water; and accordingly achieving the purpose of removing target pollutants. The method is wide in applicable pH (potential of hydrogen) range and can realize an excellent effect in acidic water and neutral water. In addition, the added zero-valent iron can be slowly and continuously converted into Fe2+, and accordingly the sulfate radicals can be obtained by means of continuously and efficiently activating the persulfate. Besides, the method is low in cost, high in treatment efficiency and flexible in operation method, and has a high potential in the technical field of treatment of micro-polluted water.

Owner:SOUTH CHINA UNIV OF TECH

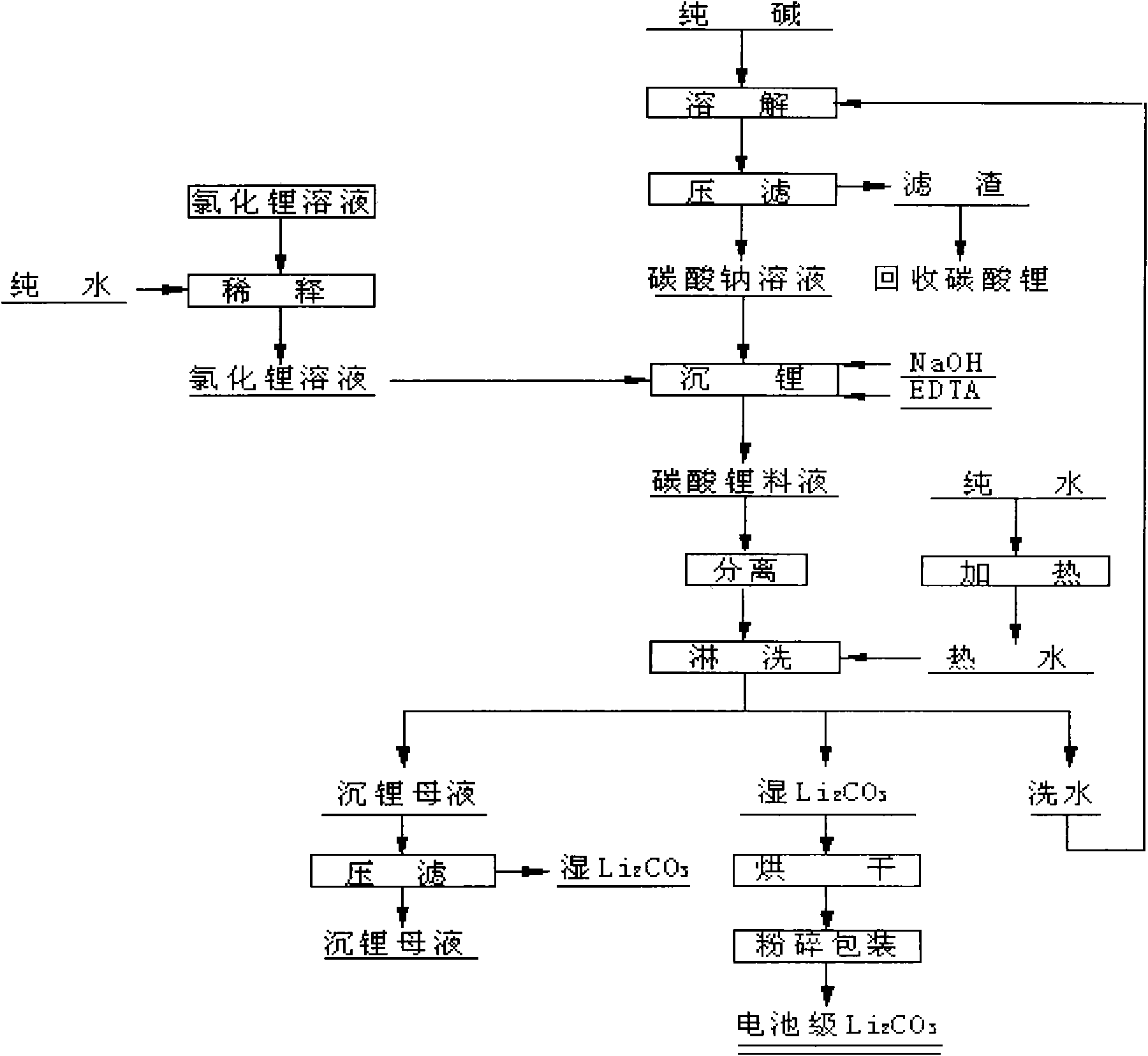

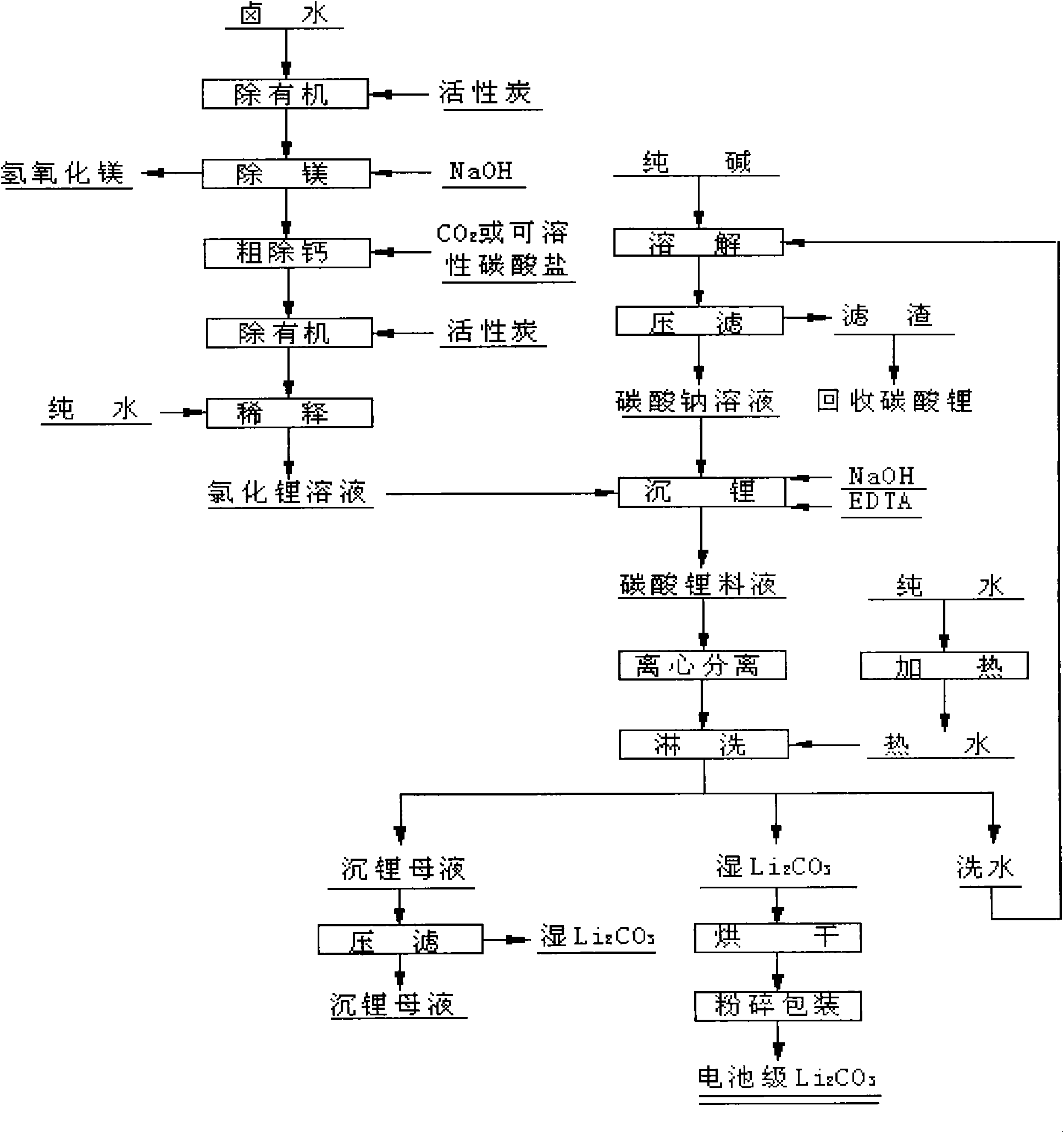

Method for preparing battery level lithium carbonate by using lithium chloride solution

ActiveCN101609888ALow Sulfate ContentQuality improvementElectrode manufacturing processesLithium carbonates/bicarbonatesLithium chlorideSulfate radicals

The invention provides a method for preparing battery level lithium carbonate by using lithium chloride solution. The method includes the steps of the dilution of lithium chloride solution, lithium sedimentation in sodium carbonate, the separation of lithium carbonate, washing, drying, grinding and packing. The method is simple in technology, easy in operation and low in production cost, and the obtained product, namely, battery level lithium carbonate, has the advantages of low sulfate radical content, stable quality, high utilization rate of resources and suitability for the production and application of lithium ion battery raw materials, and has extensive market prospect, as well as favorable economic and social benefit.

Owner:GANFENG LITHIUM CO LTD

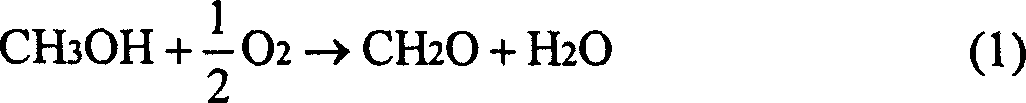

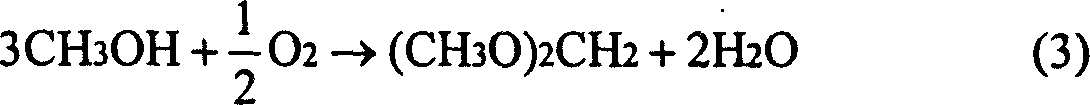

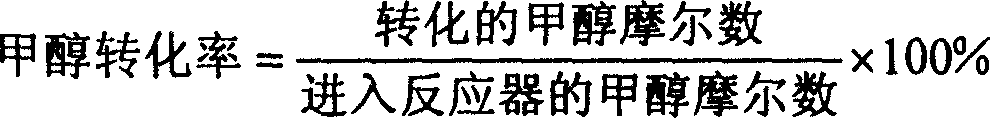

Catalyst for producing methylal by selective oxidation of methanol and preparation method and use thereof

InactiveCN1634655ASimple manufacturing methodLow costOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsSulfate radicalsDirect production

This invention relates to carbinol selection oxidation to process dimethoxym ethane catalyzer, which is loaded with vanadium on the modified titania with sulfur in acid environment, wherein the modified titania sulfur content is countered as the sulfate radical mass of 1.0-4.5 úÑ, and the vanadium load is countered as vanadic anhydride mass of 5-20 úÑ. The catalyzer in this invention has the conversion rate as 17.6-62.8 úÑ and the dimethoxym ethane selection rate as 67.8-97.9 úÑ.

Owner:NANJING UNIV

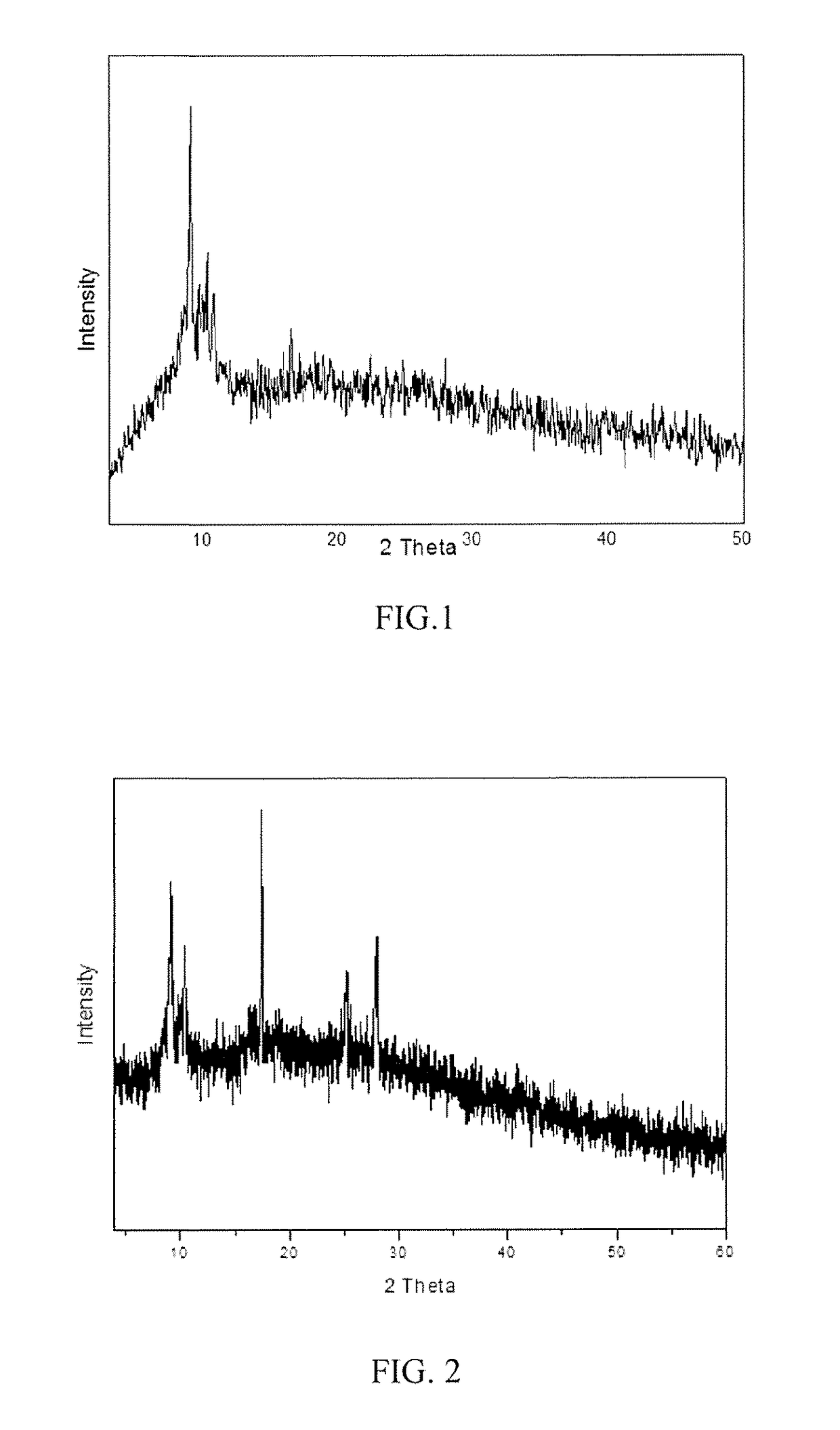

Preparation for modified MIL-53(Fe) metal organic framework and method for treating organic wastewater with activated persulfate thereof

ActiveCN106957438AIncrease contentImprove degradation efficiencyWater contaminantsChemical recyclingMetal-organic frameworkBiological activation

The invention discloses a preparation for a modified MIL-53(Fe) metal organic framework and a method for treating organic wastewater with activated persulfate thereof. Compared with unmodified MIL-53(Fe), the modified MIL-53(Fe) metal organic framework compounded according to the invention contains more ferrous reactive metal centers. The modified MIL-53(Fe) metal organic framework used as a catalytic active site can enhance the effective contact between the metal organic framework material and the persulfate so as to generate free radicals of sulfate with strong oxidizing property, so that the refractory pollutants in wastewater can be effectively removed. The modified MIL-53(Fe) metal organic framework has higher material stability, can maintain the stability of the crystal structure after the catalytic activation reaction of persulfate and can still maintain higher catalytic activity after repeated cyclic utilization. The method for treating organic wastewater according to the invention has the advantages of environmental protection, simple and convenient operation, low cost, high catalyst activity, high reusability, and the like. Besides, the method is also suitable for the treatment of various organic wastewaters.

Owner:SOUTH CHINA UNIV OF TECH

Copper-doped iron metal-organic framework, preparation method thereof, and application method for activation of persulfate to treat organic wastewater

InactiveUS20180185828A1Easy to operateGood repeatabilityWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSulfate radicalsMetal-organic framework

The present invention discloses a copper-doped iron metal-organic framework, a preparation method thereof, and an application method for activation of persulfate to treat organic wastewater. The copper-doped iron metal-organic framework is prepared by solution impregnation method, using relatively large specific surface area and more hollow structures of the iron metal-organic framework to effectively load copper ion. This method uses the unsaturated-coordinate iron active center on the iron metal-organic framework and copper ions on the load as a catalyst body, utilizing catalytic synergies of both to efficiently and continuously activate persulfate to produce sulfate radical anion for degradation of organic pollutants. This method is suitable for various organic wastewater, with high catalytic activity, good durability, easy operation and easy recovery, and activation effect of this heterogeneous catalyst is still high even after being used repeatedly, having a great application prospect in degradation of organic pollutants in water.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com