Method for removing sulfate radical in waste water

A sulfate radical and waste water technology, applied in the field of environmental engineering, can solve the problems of few applied research reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

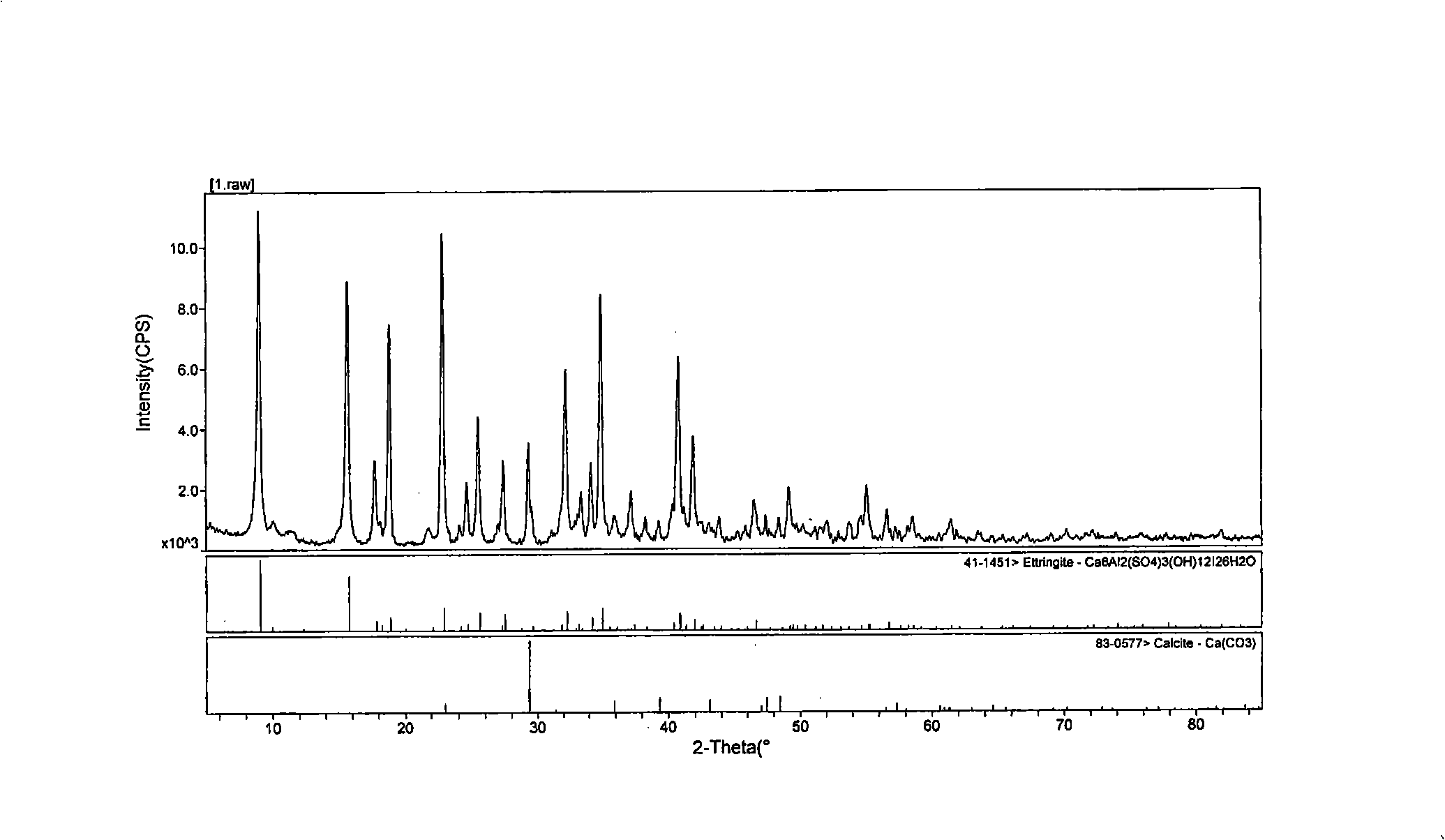

Image

Examples

Embodiment 1

[0015] with CaSO 4 ·2H 2 O, Na 2 SO 4 Simulated industrial SO with a concentration of 1720mg / L prepared with other reagents 4 2- waste water. take SO 4 2- The solution volume was 200ml, the reaction temperature was 25°C, and 1.24g Al(NO) was added. 3 ) 3 ·9H 2 O, adjust the pH of the solution to 10.5 with calcium hydroxide, stir for 90min, precipitate, filter, take the filtrate for analysis, SO 4 2- The concentration is 75.6 mg / L.

Embodiment 2

[0017] with CaSO 4 ·2H 2 O, Na 2 SO 4 Simulated industrial SO with a concentration of 1290mg / L prepared with other reagents 4 2- waste water. take SO 4 2- The solution volume was 200ml, the reaction temperature was 25°C, and 0.93g Al(NO) was added. 3 ) 3 ·9H 2 O, adjust the pH of the solution to 12.0 with calcium hydroxide, stir for 60 min, precipitate, filter, take the filtrate for analysis, SO 4 2- The concentration is 80.3 mg / L.

Embodiment 3

[0019] Take 5 L of lead and zinc smelting industrial wastewater of Zhuzhou Smelter Group with a sulfate ion concentration of 1720 mg / L, the reaction temperature is 30 ° C, and 31 g of Al (NO 3 ) 3 ·9H 2 O, adjust the pH of the solution to 11.0 with calcium hydroxide, stir for 60min, precipitate, take the supernatant for analysis, SO 4 2- The concentration is 82.7mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com