Patents

Literature

60results about How to "Wide operating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

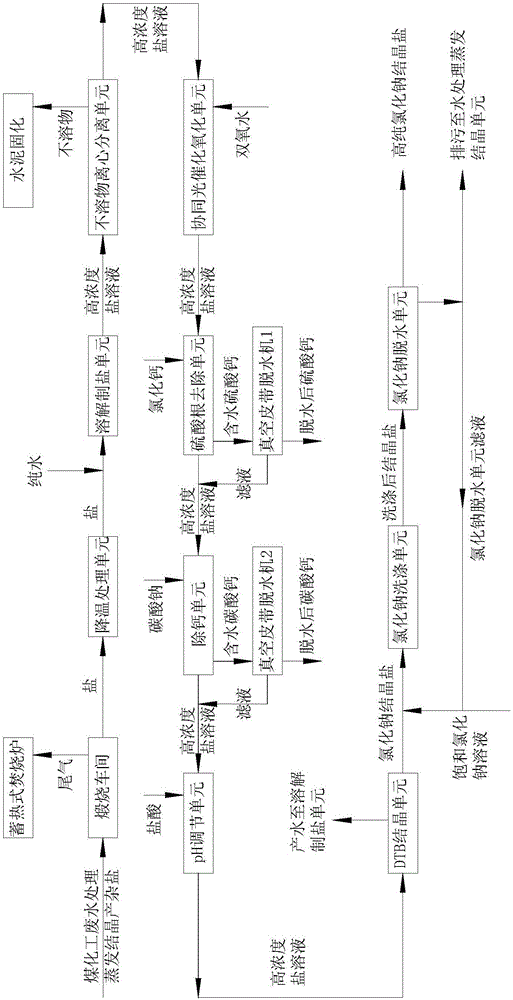

Method for recycling impurity salts generated in industrial wastewater treatment

ActiveCN106745076AEasy to handleWide operating conditionsCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesHigh concentrationSulfate radicals

The invention provides a method for recycling impurity salts generated in industrial wastewater treatment. The method comprises the following steps: (1) calcining impurity salts generated in an industrial wastewater treatment process, cooling, dissolving in pure water, and obtaining a high-concentration sodium chloride solution; (2) performing solid-liquid separation, and removing residual organisms in the solution; (3) successively removing sulfate radicals and calcium ions, adjusting the pH of the solution to neutral, and obtaining a high-purity sodium chloride solution; and (4) crystallizing the high-purity sodium chloride solution obtained in step (3), obtaining a sodium chloride crystal product, and washing to obtain the high-purity sodium chloride crystal product. By adopting the method, the effective treatment and recycling of impurity salts generated in the industrial wastewater zero emission process of electric power, petroleum chemistry, coal chemistry and the like; moreover, the method is simple in treatment process and moderate in operation conditions, and is a high-efficiency and stable impurity salt recycling method; and a final product sodium chloride is high in recycling rate and purity.

Owner:DATANG INT CHEM TECH RESINST

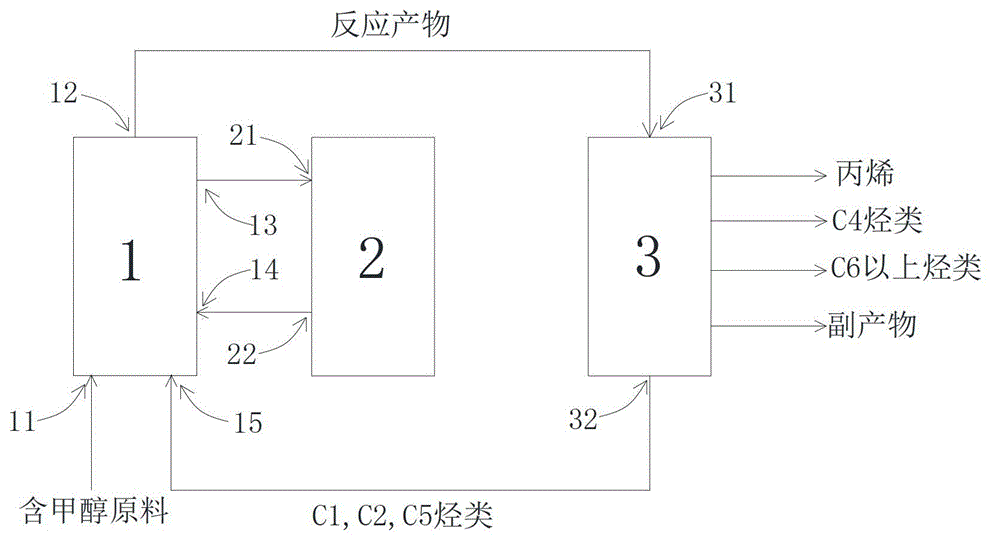

Method for utilizing circulating fluidized bed to prepare propylene and C4 hydrocarbons from methanol

InactiveCN104098429APromote regenerationLarge amount of processingCatalytic crackingMolecular sieve catalystsFluidized bedSeparation system

The invention provides a method for utilizing a circulating fluidized bed to prepare propylene and C4 hydrocarbons from methanol. The method comprises the following steps: 1) enabling a raw material containing methanol to enter a fluidized bed reactor, so as to generate a reaction product flow containing C1 hydrocarbon, C2 hydrocarbons, propylene, by-products, C4 hydrocarbons, C5 hydrocarbons, C6 hydrocarbons and hydrocarbons with more than six carbon atoms under the effect of a catalyst; and 2) enabling the reaction product flow obtained in the step 1) to enter a separation system to perform separation, so as to separate C1, C2 and C5 hydrocarbons, propylene, C4 hydrocarbons, C6 hydrocarbons, hydrocarbons with more than six carbon atoms and by products, returning C1, C2 and C5 hydrocarbons to the reactor to perform reaction, and recovering propylene, C4 hydrocarbons, C6 hydrocarbons, hydrocarbons with more than six carbon atoms and by-products as final products.

Owner:SHANGHAI BI KE CLEAN ENERGY TECH +1

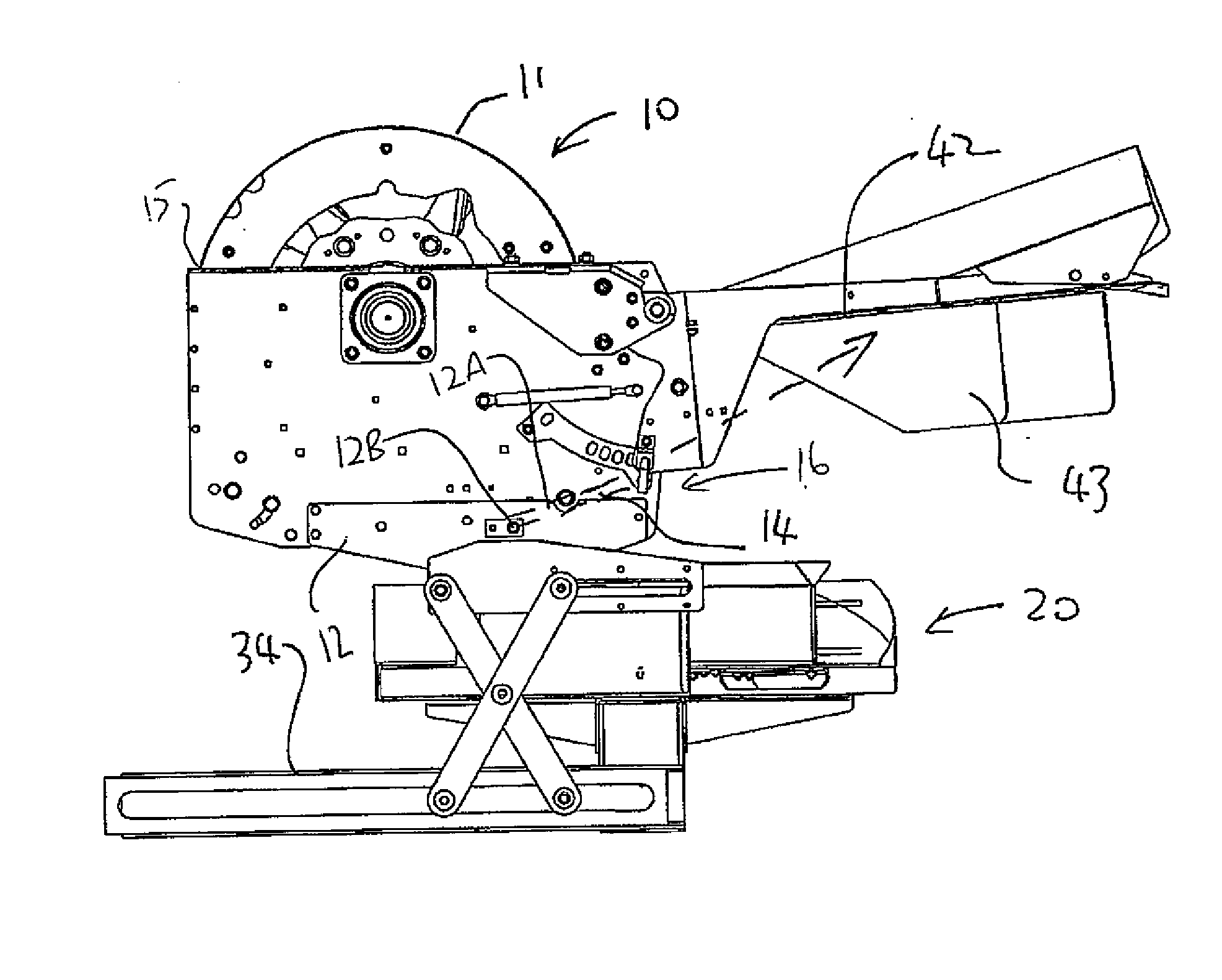

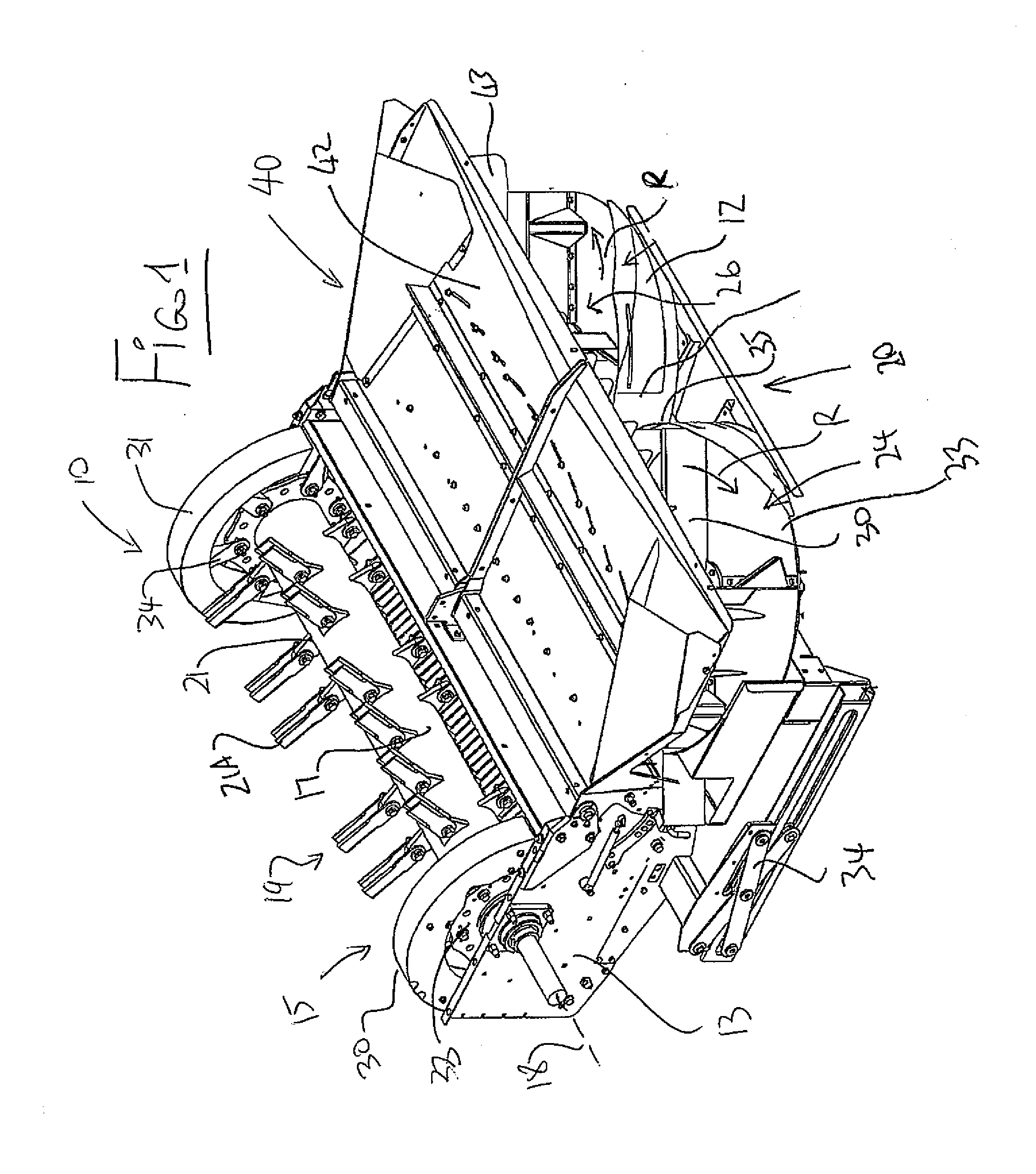

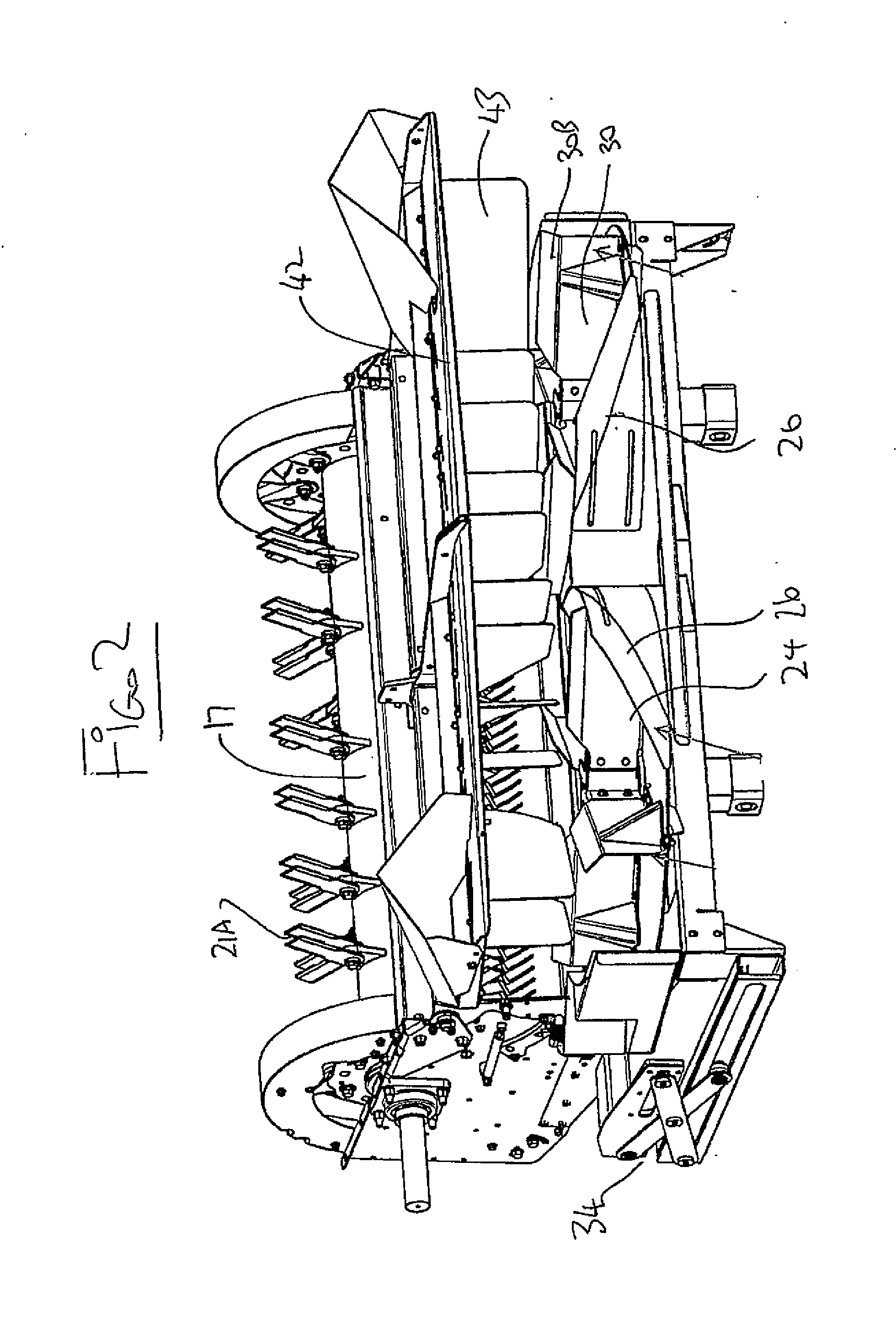

Apparatus for Chopping and Discharging Straw from a Combine Harvester

InactiveUS20160150727A1Wide operating conditionsSimple materialMowersThreshersChaffCombine harvester

A chopper for receiving the straw and / or chaff from a combine harvester includes a housing with a chopping rotor to transport the materials though a discharge opening onto a tailboard construction with downwardly facing guide surface and fins for spreading of the crop materials. A rotary spreader has a plurality of fan members with blades rotatable for discharge to a respective side of the rotary spreader. An arrangement is operable so that in a first mode the crop material is spread wholly by the tailboard and in a second mode the crop material is spread at least mainly by the rotary spreader. In the second mode the tailboard remains position above the rotary spreader which is therefore located underneath a guide surface with fins of the guide surface facing downwardly adjacent the blades. The movement to the second ode is provided by the rotary spreader being moved forwardly and downwardly.

Owner:TRITANA INTPROP LTD

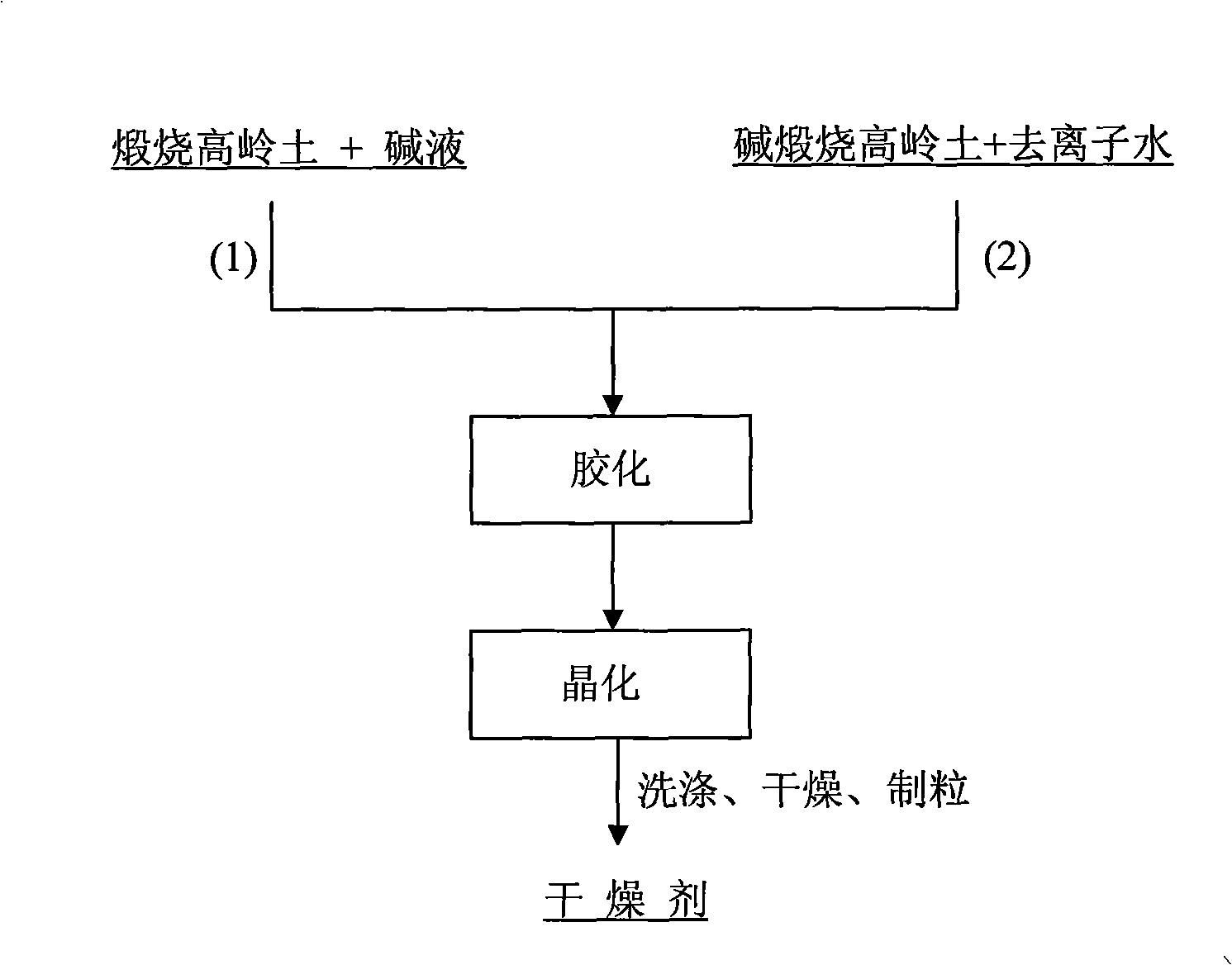

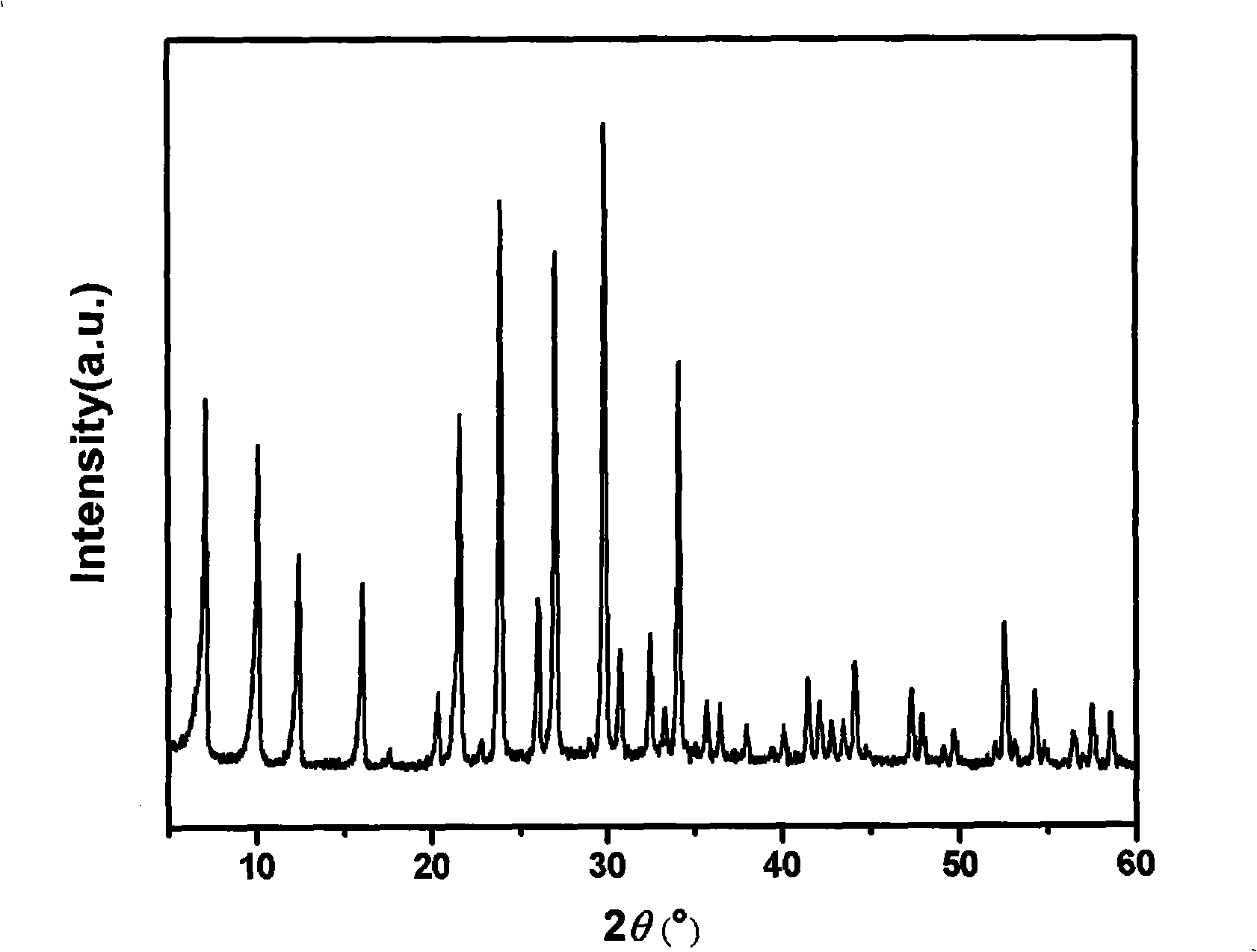

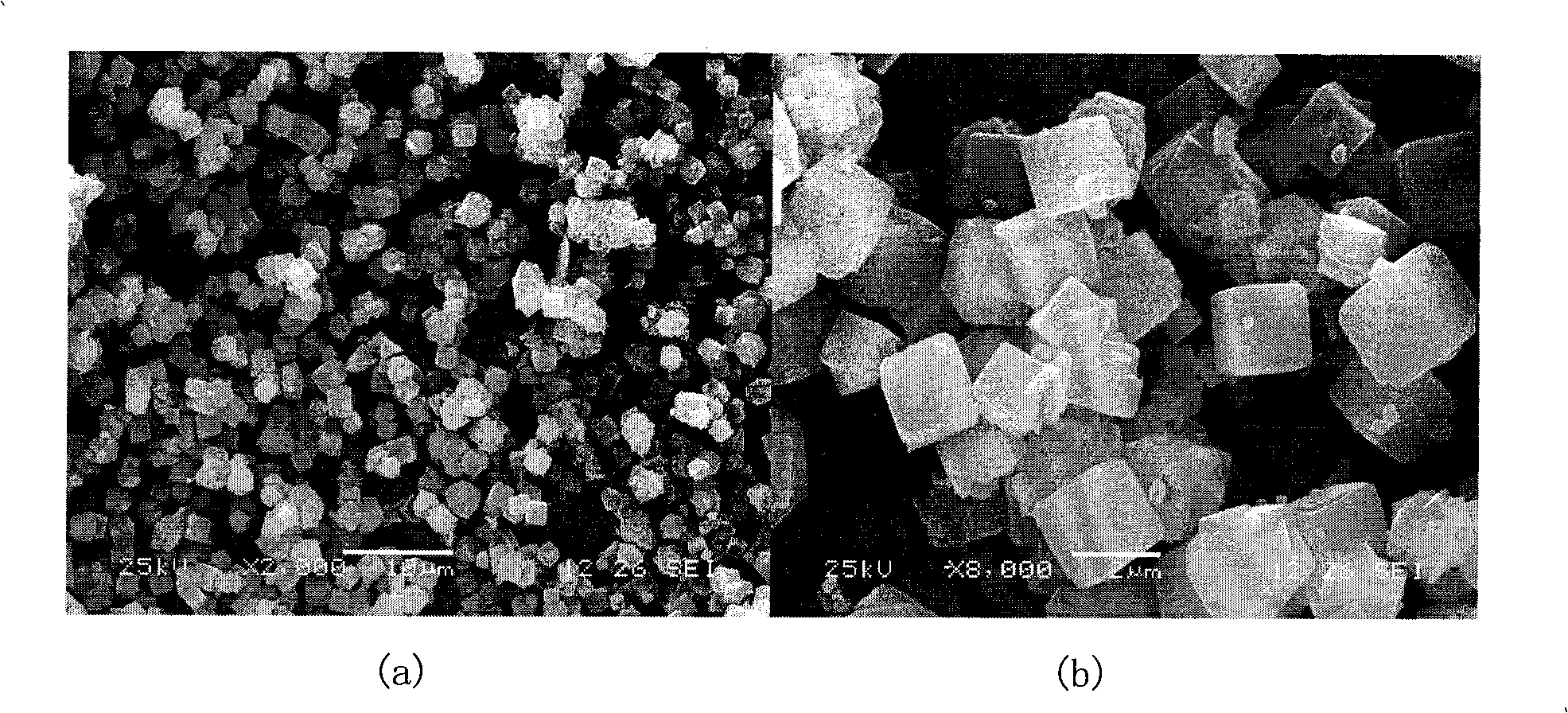

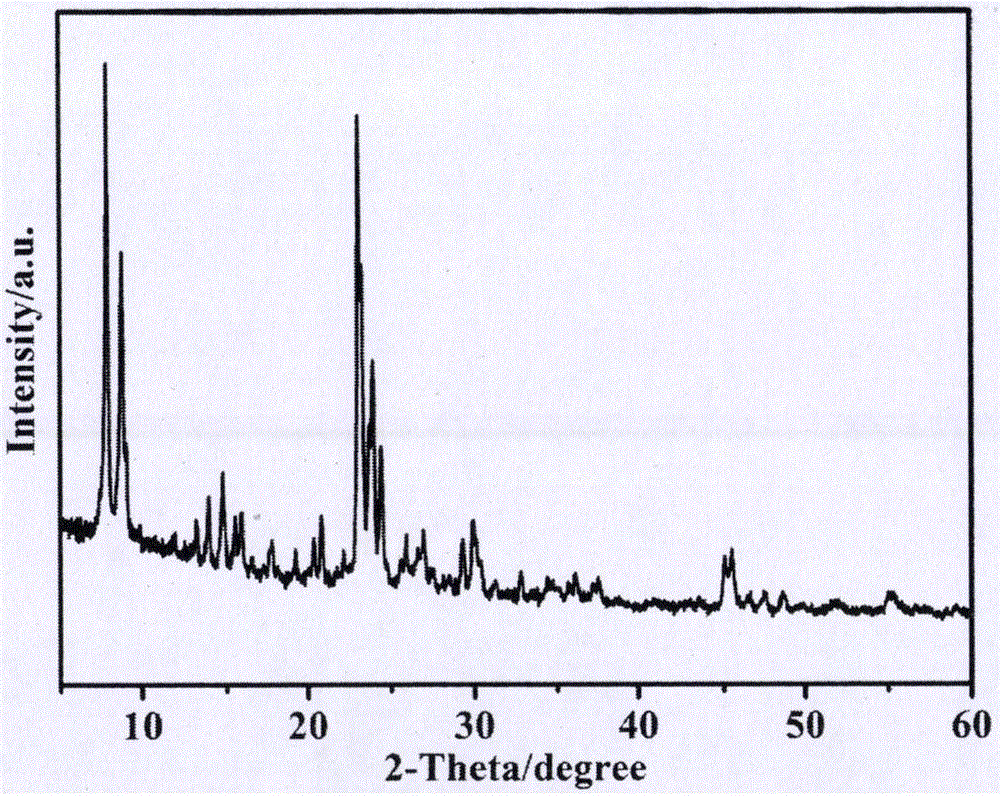

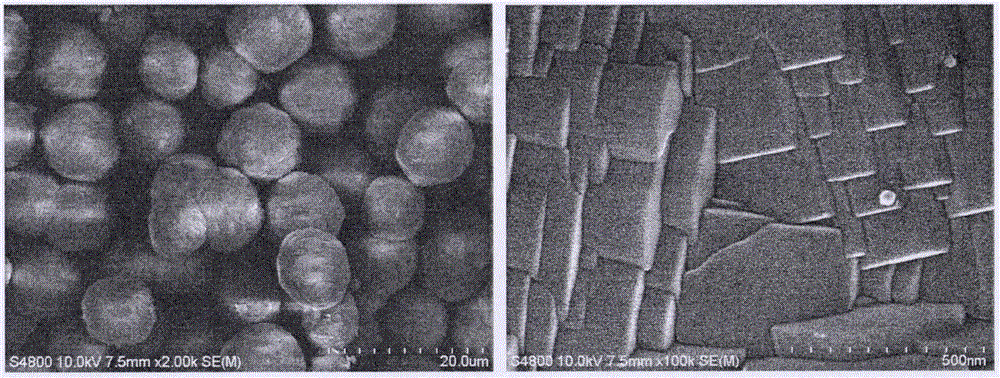

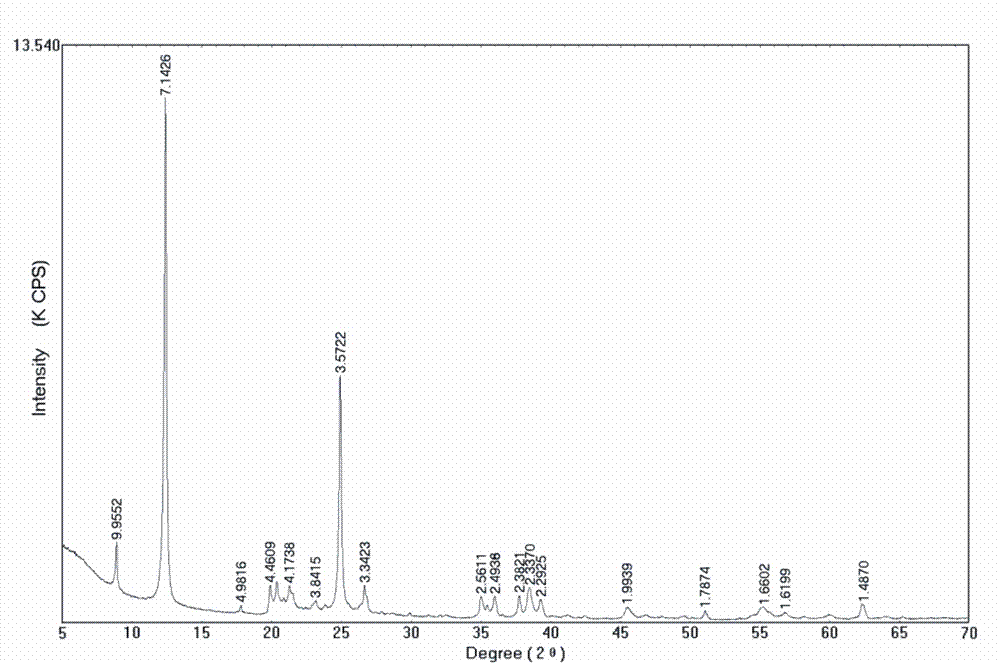

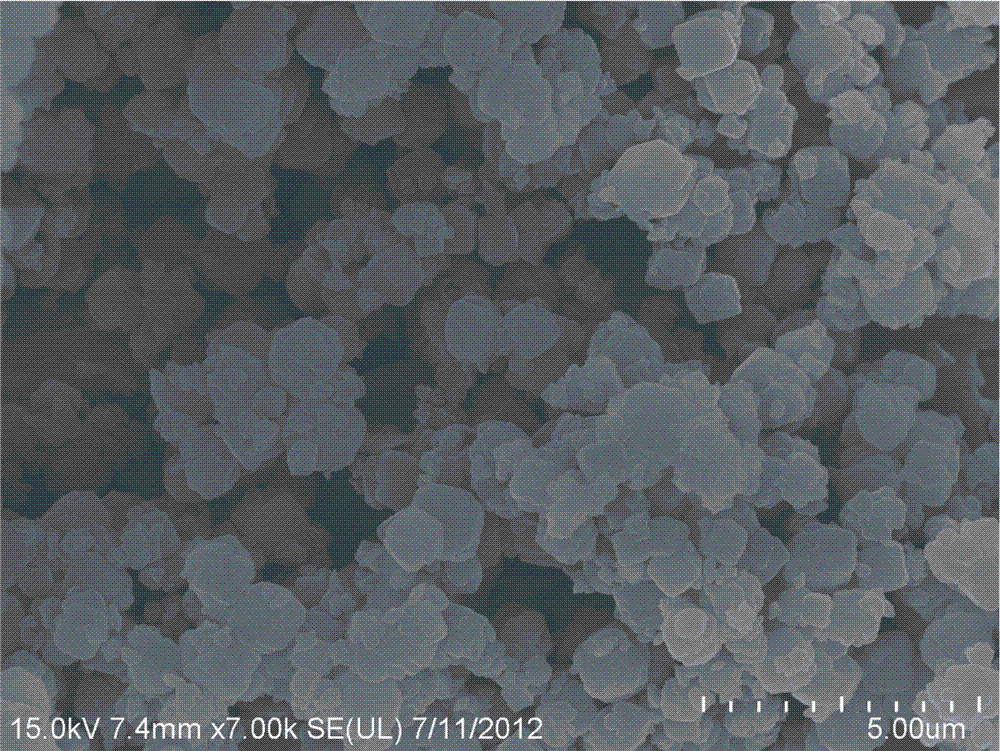

Method for synthesizing 4A molecular sieve drier using kaoline

InactiveCN101406825ASimple processRaw materials are easy to getOther chemical processesDispersed particle separationMolecular sieveChemical industry

The invention discloses a method for preparing a 4A zeolite molecular sieve desiccant with high crystallinity through a raw material of common natural kaolin. The method comprises the following steps: taking kaolin as the raw material, roasting the kaolin by a direct roasting method or a dry-process alkali roasting method, colloidizing, crystallizing, and suction filtrating and cleaning the kaolin through deionized water, and then drying the kaolin; and adding clay mineral bentonite or kaolin crude ore into the kaolin for granulation, and then obtaining the 4A zeolite molecular sieve desiccant after roasting. The method has the advantages that the method has a simple preparation process, raw material available, and loose operating conditions; and the synthesized 4A zeolite molecular sieve has the characteristics of high crystallinity, small particle size, good dispersibility, and high static water adsorption rate and high strength against crushing. The static water adsorption rate of the desiccant reaches 21.5 weight percent, and the strength against crushing reaches 62.1N / particle. The indexes reach the standards of the Department of Chemical Industry.

Owner:CENT SOUTH UNIV

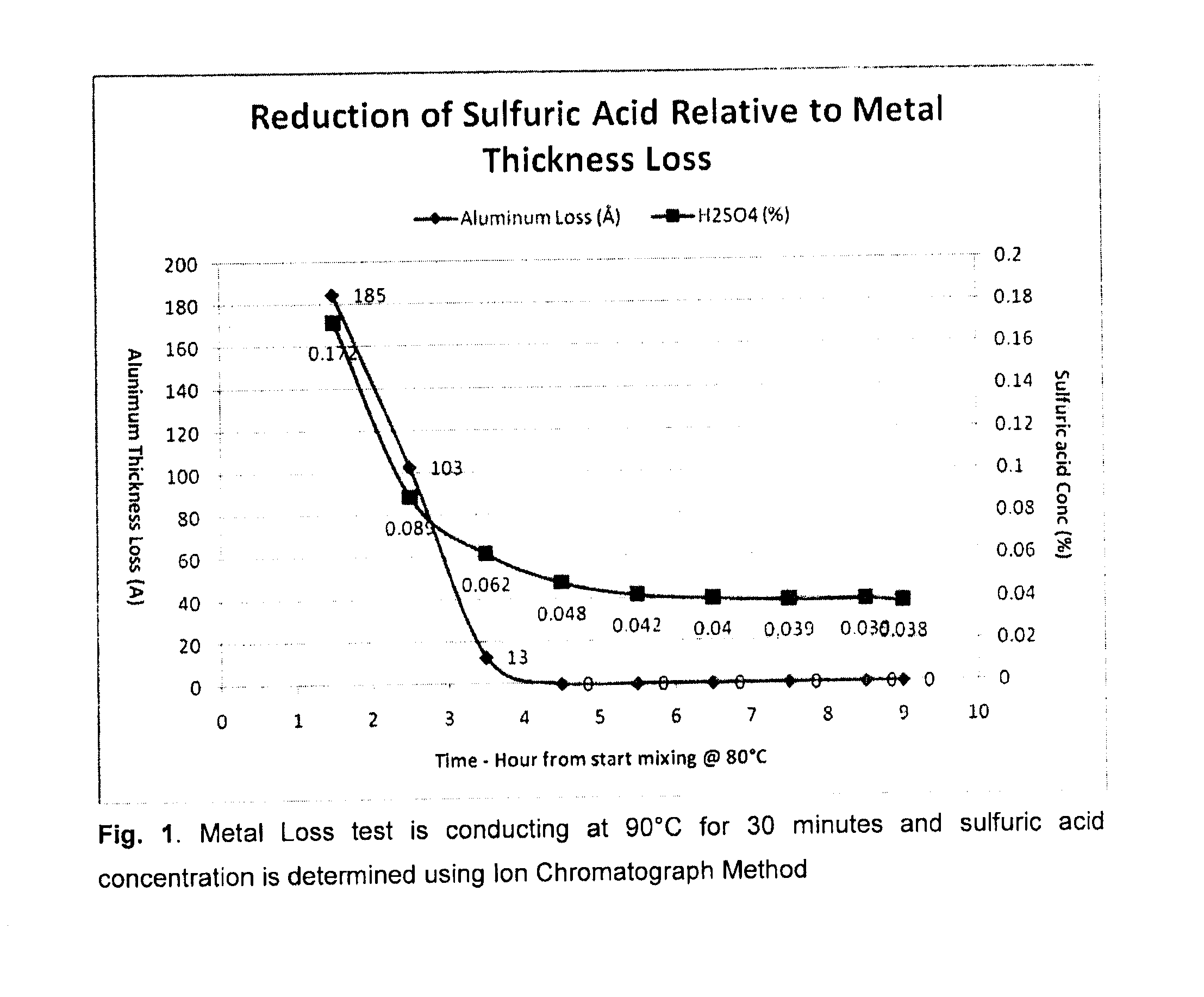

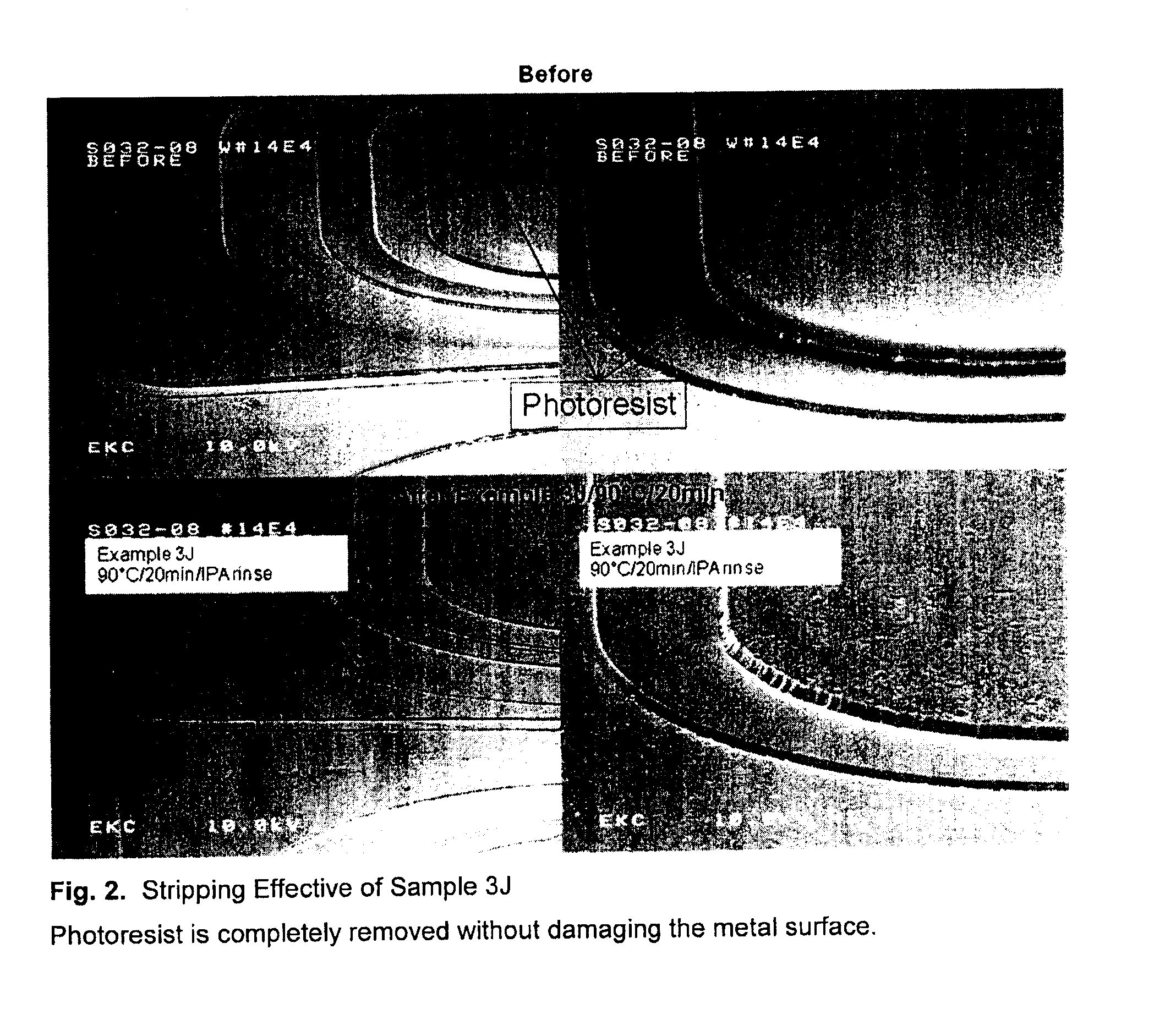

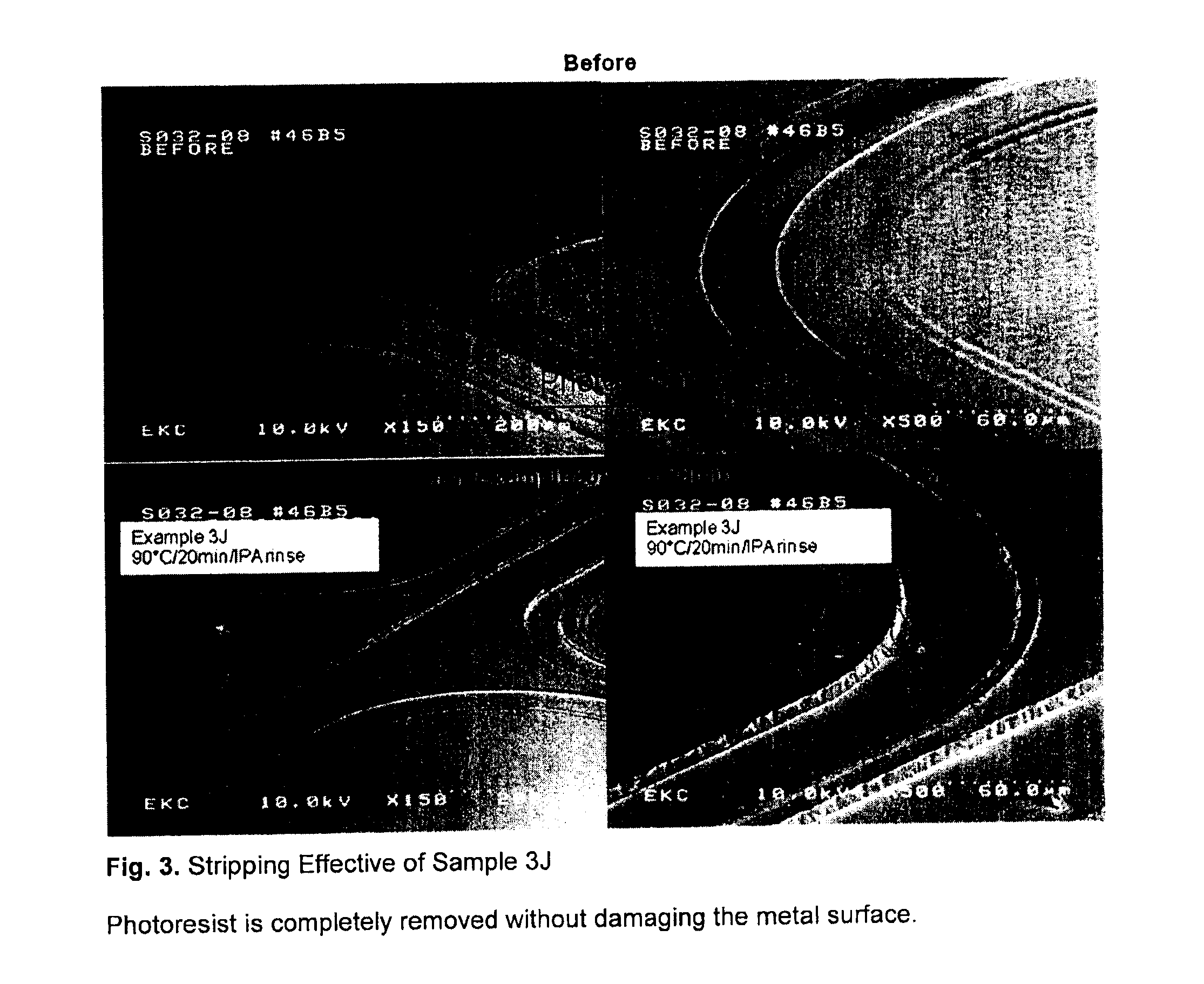

Method for making a photoresist stripping solution comprising an organic sulfonic acid and an organic hydrocarbon solvent

ActiveUS20100279910A1No corrosionWide operating conditionsOrganic detergent compounding agentsSurface-active detergent compositionsHydrocarbon solventsHalogen

An improved method for making a photoresist stripping solution for a metal-containing semi-conductor substrate where the stripping solution comprises a blend of at least one organic sulfonic acid with a halogen-free hydrocarbon solvent wherein concentrations of trace amounts of residual sulfuric acid and sulfur trioxide in the blend are reduced to very low levels.

Owner:EKC TECH

Method for preparing chromium based composite coating in environment protection type trivalent chromium plating bath

The invention discloses a method for preparing a chromium-based composite plating layer in an environment-friendly trivalent chromium plating bath. The method adds different particles in a basic electrolyte containing chromium chloride to prepare the chromium-based composite plating layer which has even surface and is firmly combined with a substrate by selecting appropriate process conditions. The method has the advantage that the thickness of the prepared chromium-based composite plating layer is more than 50mu m. The composite plating layer has the hardness higher than that of a hexavalent chrome electroplating layer and the tribological property equivalent to that of the hexavalent chrome electroplating layer, and can substitute the prior hexavalent chrome electroplating technology under various friction working conditions.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

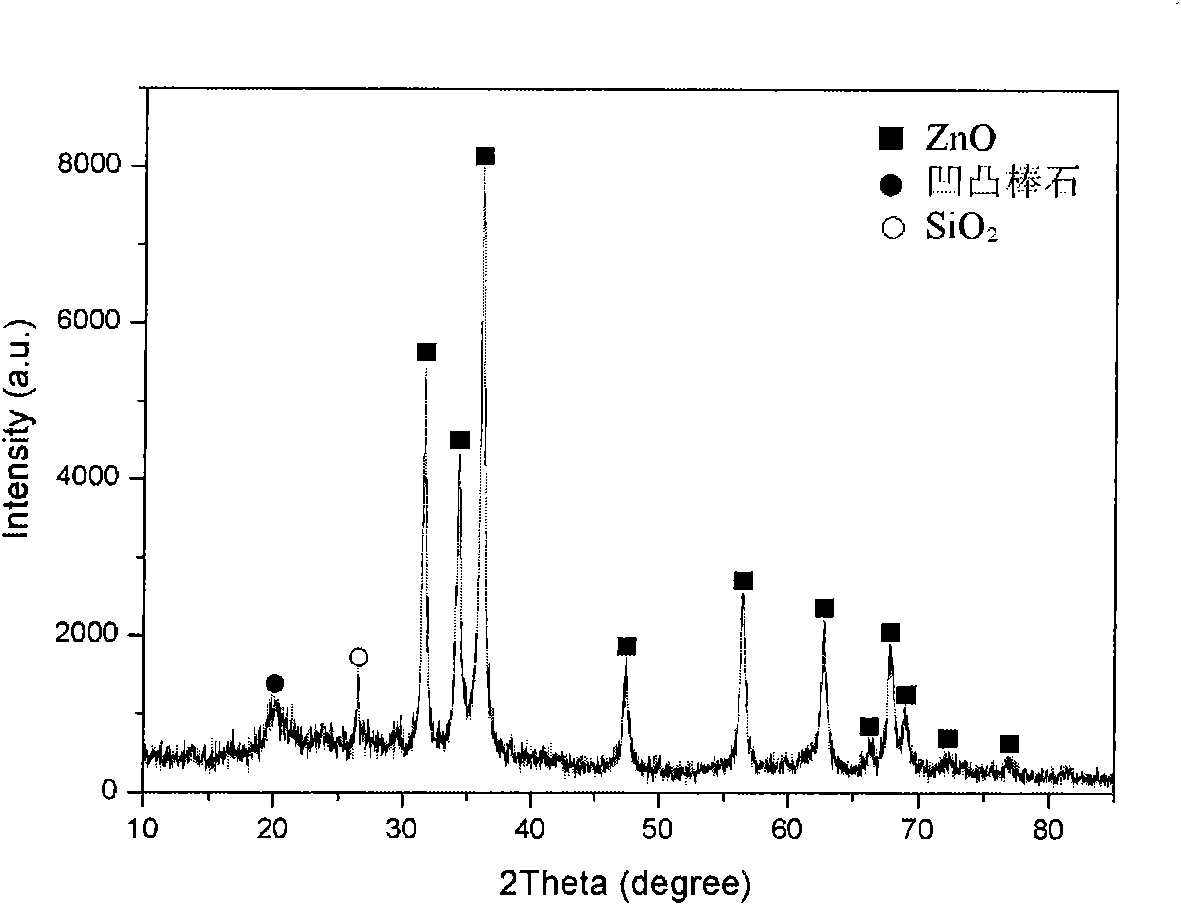

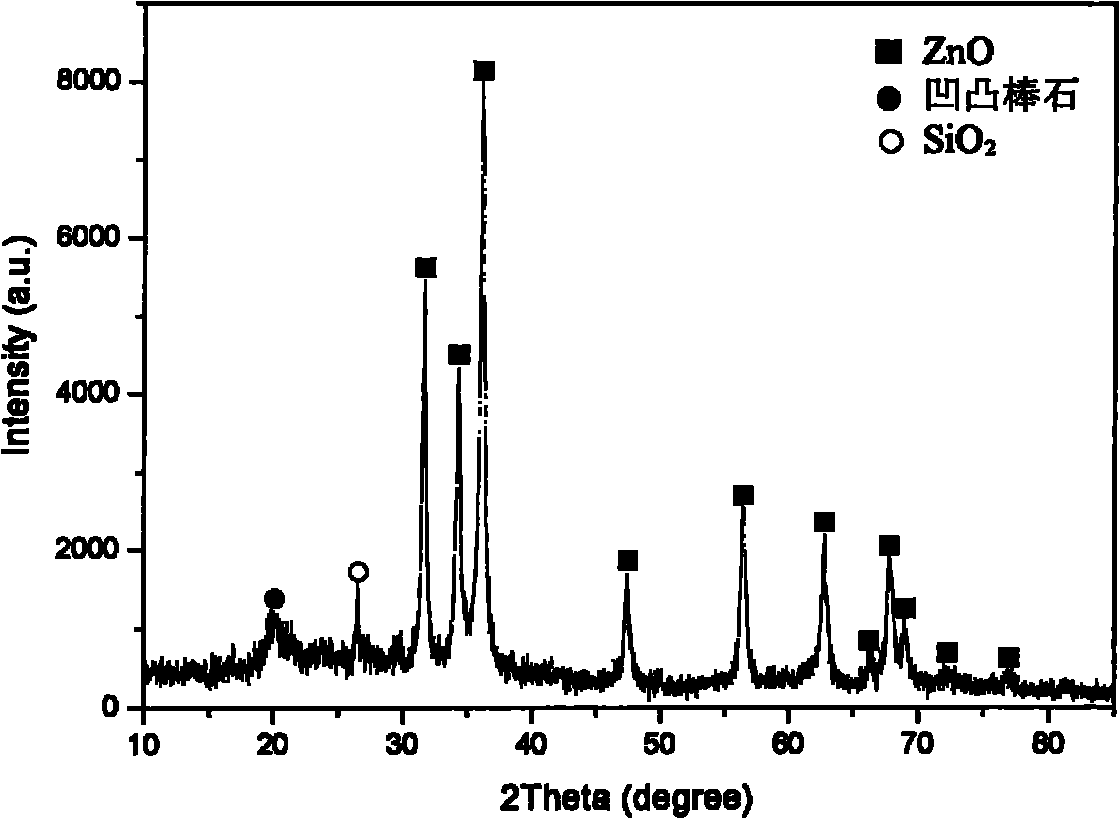

Method for preparing ZnO/attapulgite composite antibacterial agent

The invention discloses a method for preparing a ZnO / attapulgite composite antibacterial agent, comprising the following steps: dissolving water-soluble inorganic zinc salt in distilled water, adding attapulgite powder in the solution, stirring and dispersing for 15min by ultrasonic wave at the same time, and continuing stirring to obtain turbid liquid consisting of the attapulgite and the water-soluble inorganic zinc salt; and adding NaOH solution in the turbid liquid, stirring till fully mixing to obtain turbid liquid of zinc hydroxide and the attapulgite, filtering the turbid liquid, taking filter residue and drying, calcining, and naturally cooling to the room temperature to obtain the ZnO / attapulgite composite antibacterial agent. The invention has the advantages of simple preparation process, convenient operation and low cost, takes the attapulgite with larger specific surface area as a carrier to absorb a certain amount of ZnO, thus being capable of effectively improving the antibiosis property of ZnO; and the prepared material can be widely used in fields such as antibiotic plastics, antibiotic ceramics, cosmetics packaging materials and the like.

Owner:杨倩

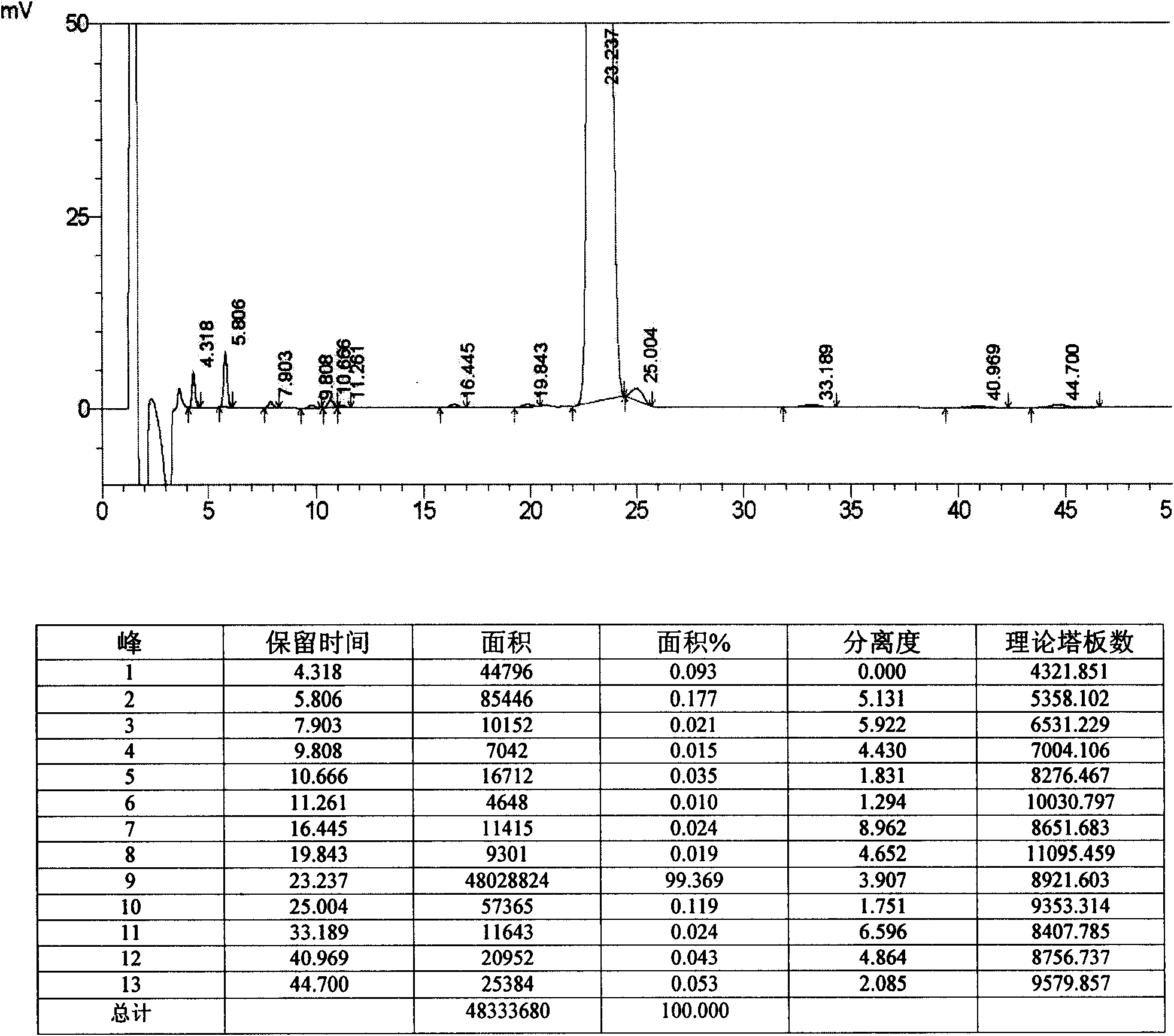

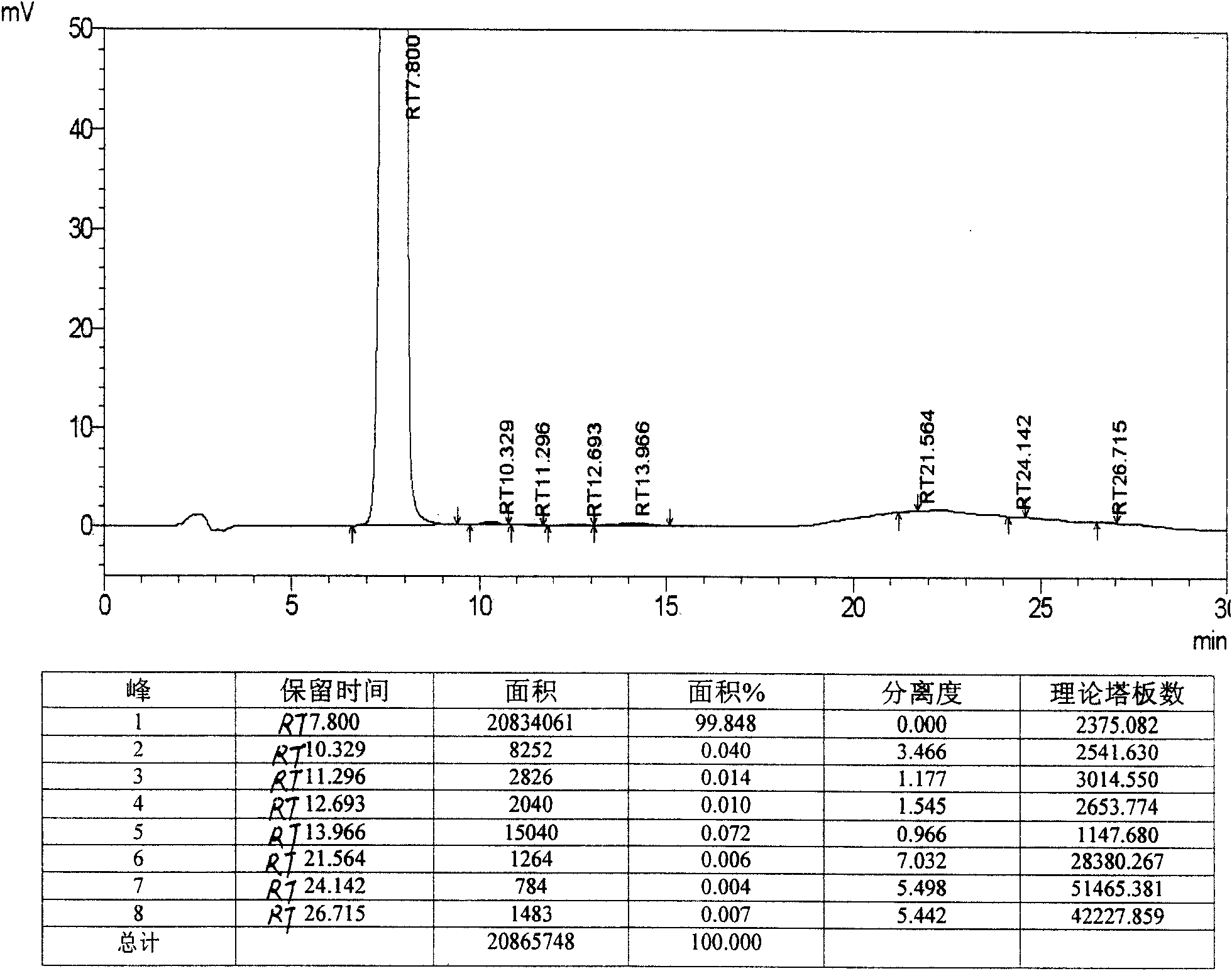

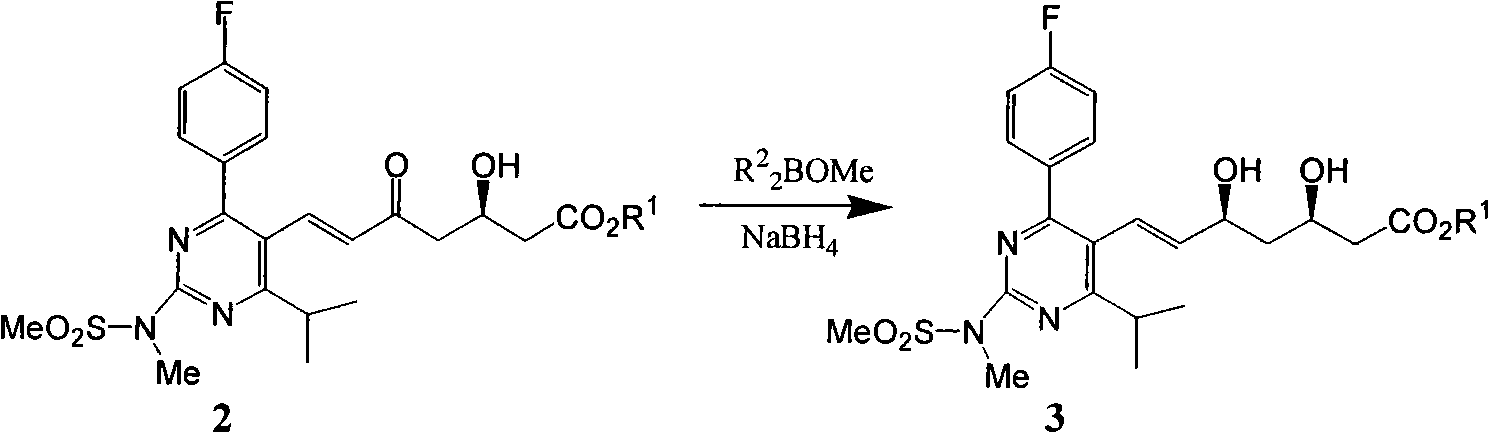

Preparation method of 3, 5-dihydroxy heptyl-6-gadoleic acid derivative

ActiveCN101591301AAddress impurity controlSolving Mass Manufacturing ProblemsOrganic chemistryCardiovascular disorderHydrolysisMedicinal chemistry

The invention improves a preparation method of 3, 5-dihydroxy heptyl-6-gadoleic acid derivative. Asymmetric reduction is performed on intermediate 3-hydroxy-5-oxo-6-heptenoic acid ester derivative, alkali hydrolysis is performed on the obtained 3, 5-dihydroxy heptyl-6-heptenoic acid ester derivative crude product which is treated by alkali hydrolysis to obtain 3, 5-dihydroxy heptyl-6-gadoleic acid sodium salt derivative which is extracted and purified to obtain 3, 5-dihydroxy heptyl-6-gadoleic acid sodium salt derivative solution, then 3, 5-dihydroxy heptyl-6-gadoleic acid sodium salt derivative is converted into 3, 5-dihydroxy heptyl-6-gadoleic acid derivative, and 3, 5-dihydroxy heptyl-6-gadoleic acid sodium salt derivative is again converted into 3, 5-dihydroxy heptyl-6-gadoleic acid ester derivative with high yield, and purification methods such as recrystallization are performed to obtain purified 3, 5-dihydroxy heptyl-6-gadoleic acid ester derivative. The purified 3, 5-dihydroxy heptyl-6-gadoleic acid ester derivative is then hydrolyzed into 3, 5-dihydroxy heptyl-6-gadoleic acid sodium salt derivative which is finally converted into 3, 5-dihydroxy heptyl-6-gadoleic acid calcium salt derivative. 3, 5-dihydroxy heptyl-6-gadoleic acid derivative with high quality is obtained.

Owner:CHANGZHOU PHARMA FACTORY

Cellulose and red alga polysaccharide plant empty capsule and raw material composition and preparation method thereof

InactiveCN102895215AOvercoming and Avoiding DefectsGuarantee long-term stabilityCapsule deliveryMaillard reactionCross-link

The invention discloses a raw material composition of a cellulose and red alga polysaccharide plant empty capsule. The raw material composition of the cellulose and red alga polysaccharide plant empty capsule comprises the following raw materials in parts by weight: 77.5-98.5 parts of component A, 1.5-22.5 parts of red alga polysaccharide and 0.5-12.5 parts of alcohol, wherein the component A is a cellulose derivative or resin. The invention also discloses the cellulose and red alga polysaccharide plant empty capsule prepared from the raw material composition and a preparation method for the cellulose and red alga polysaccharide plant empty capsule. The plant empty capsule does not deform or crisp in an environment of high temperature, high humidity or cold, is low in moisture content and high in stability, and can be conveniently stored for a long time. Moreover, the requirements on the storage condition are low. Meanwhile, the plant empty capsule is stable in chemical property and has no cross-linking reaction or Maillard reaction or condensation reaction. Various physicochemical indexes of the plant empty capsule, such as disintegration time limit, completely accord with the specifications of the Chinese pharmacopoeia or national standard, and therefore, all defects and potential safety hazards of a gelatin capsule are completely eliminated. The industrial production of the cellulose and red alga polysaccharide plant empty capsule can be realized.

Owner:GUANGXI NANNING HUIRUN BIO TECH

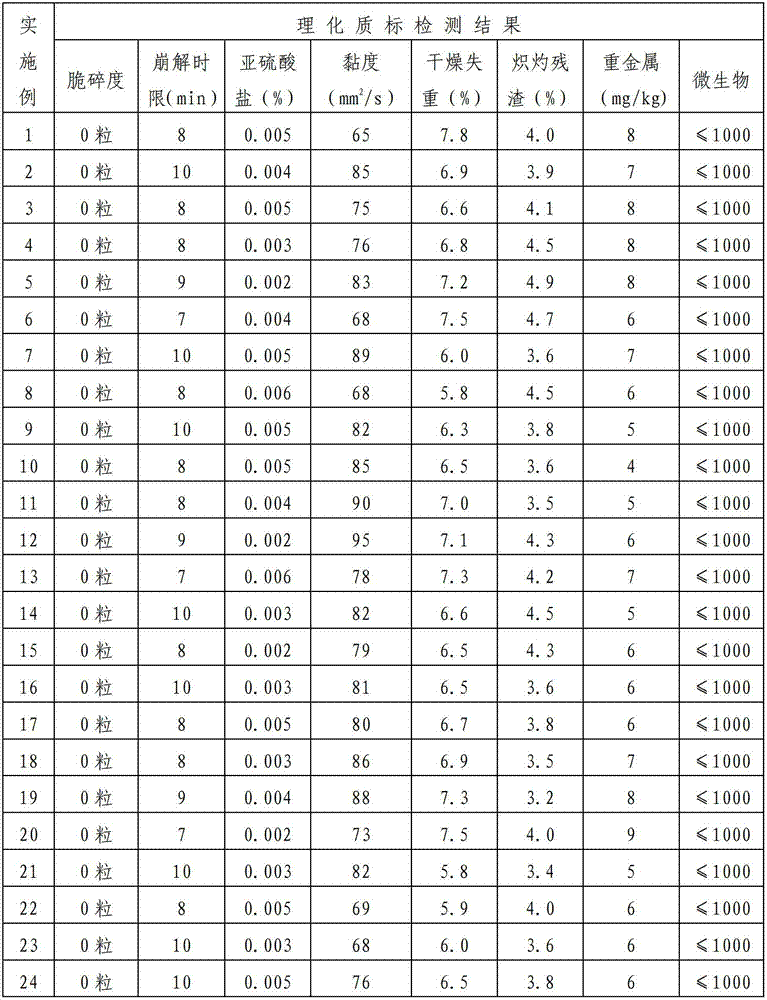

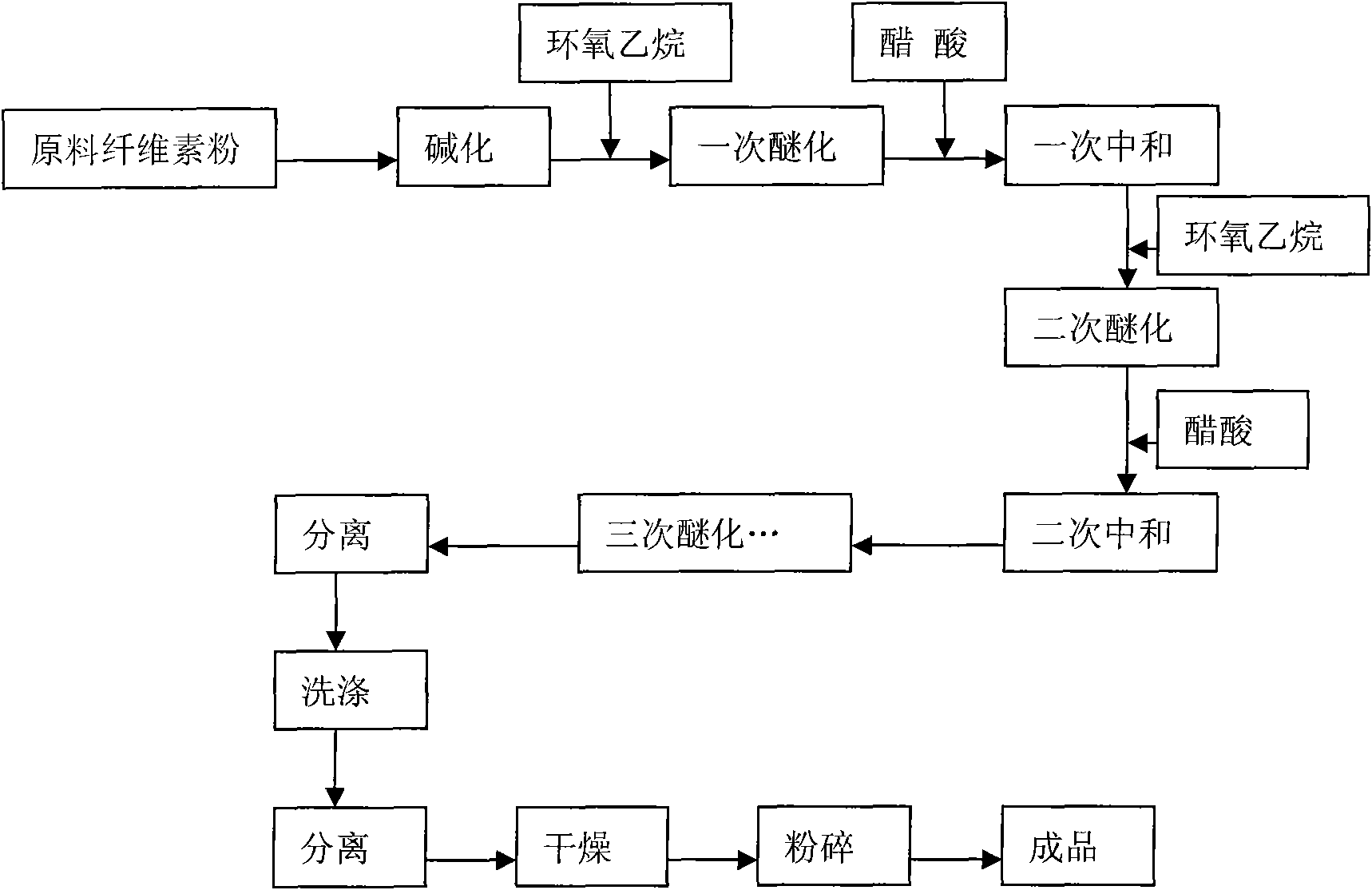

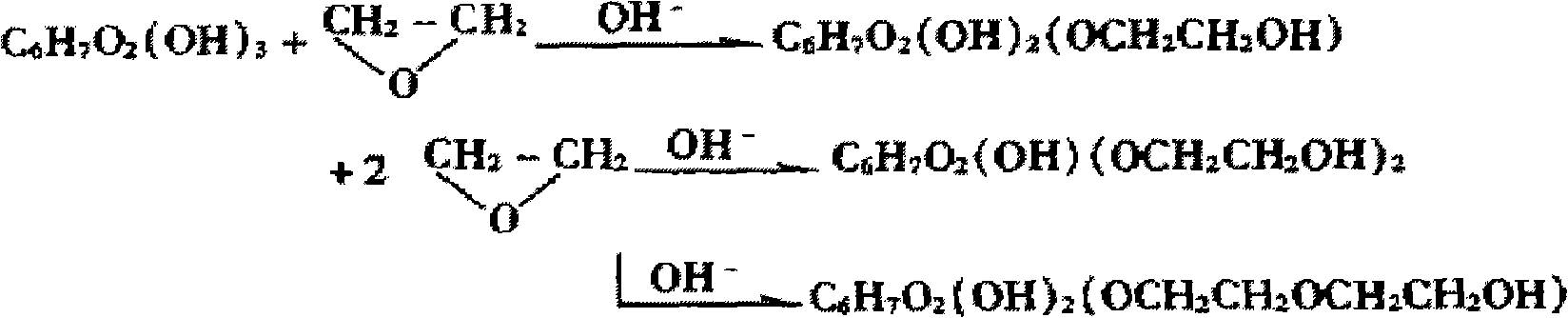

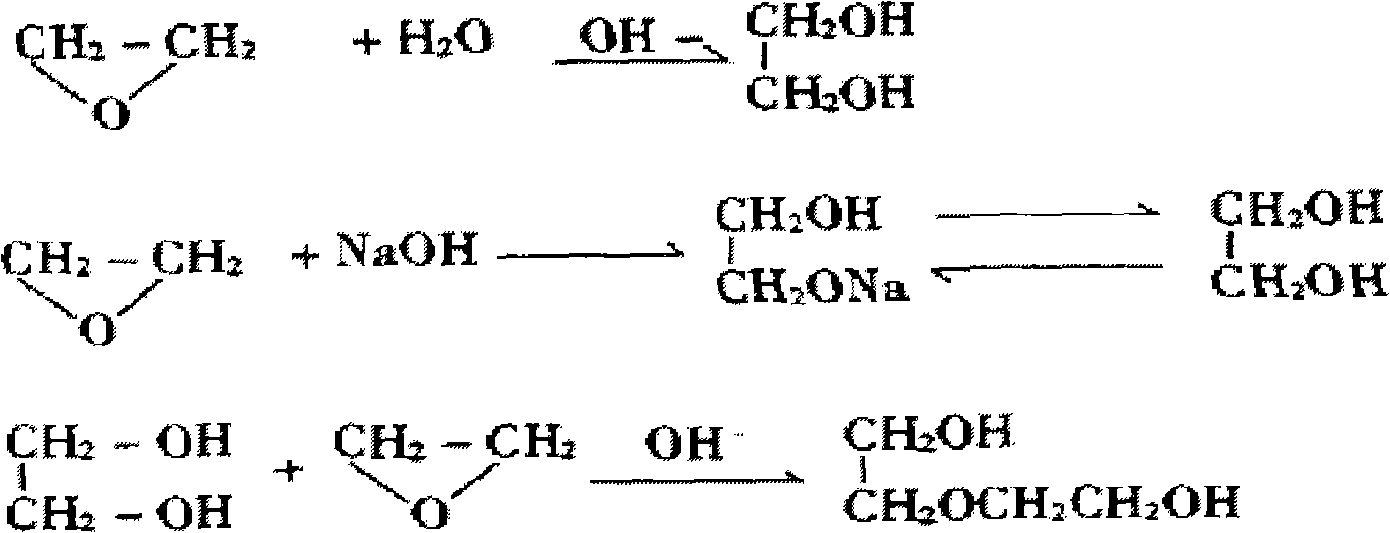

Method for preparing hydroxyethyl cellulose with high degree of substitution

InactiveCN101798353AHigh degree of substitutionEasy to operateDegree of substitutionHydroxyethyl cellulose

The invention relates to a method for preparing hydroxyethyl cellulose with high degree of substitution. The method prepares the hydroxyethyl cellulose by crushing, alkalifying, etherifying, neutralizing, separating, cleaning and drying a raw material cellulose. The method can produce the hydroxyethyl cellulose with high degree of substitution of between 2.2 and 3.5, and is applicable to production by universally adopted conventional vertical stirring reaction kettle without reforming the conventional equipment when put into production.

Owner:HENAN XIREN CELLULOSE

Method of using gangue to prepare high purity molecular sieve ZSM-5

InactiveCN106219568AHigh puritySimple processPentasil aluminosilicate zeoliteRoom temperatureHigh pressure

The invention discloses a method of using gangue to prepare a high purity molecular sieve ZSM-5. The method comprises the following steps: taking gangue as the raw material, burning gangue to activate gangue, soaking gangue in acid, then adding an alkali solution with a certain concentration, carrying out reactions under a high pressure at a high temperature to obtain a silicon-aluminum source, adjusting the pH value of the obtained silicon-aluminum source to a certain range, adding a surfactant (tetrapropyl ammonium bromide), stirring for a while at a room temperature, then carrying out reactions at a temperature of 120 to 180 DEG C for 12 to 48 hours under hydrothermal conditions, filtering, washing, drying, and burning to obtain the high purity molecular sieve ZSM-5. The solid waste gangue is taken as the raw material to synthesize the high purity molecular sieve ZSM-5, the raw material is cheap and easily available, the operation conditions are not strict, and the purity of the prepared molecular sieve ZSM-5 is high.

Owner:INNER MONGOLIA UNIVERSITY

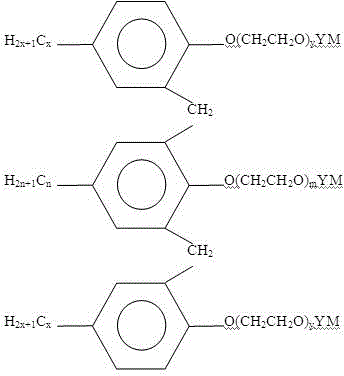

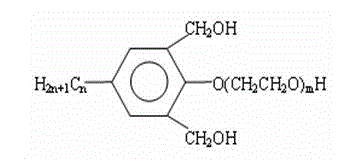

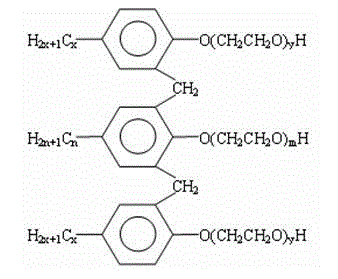

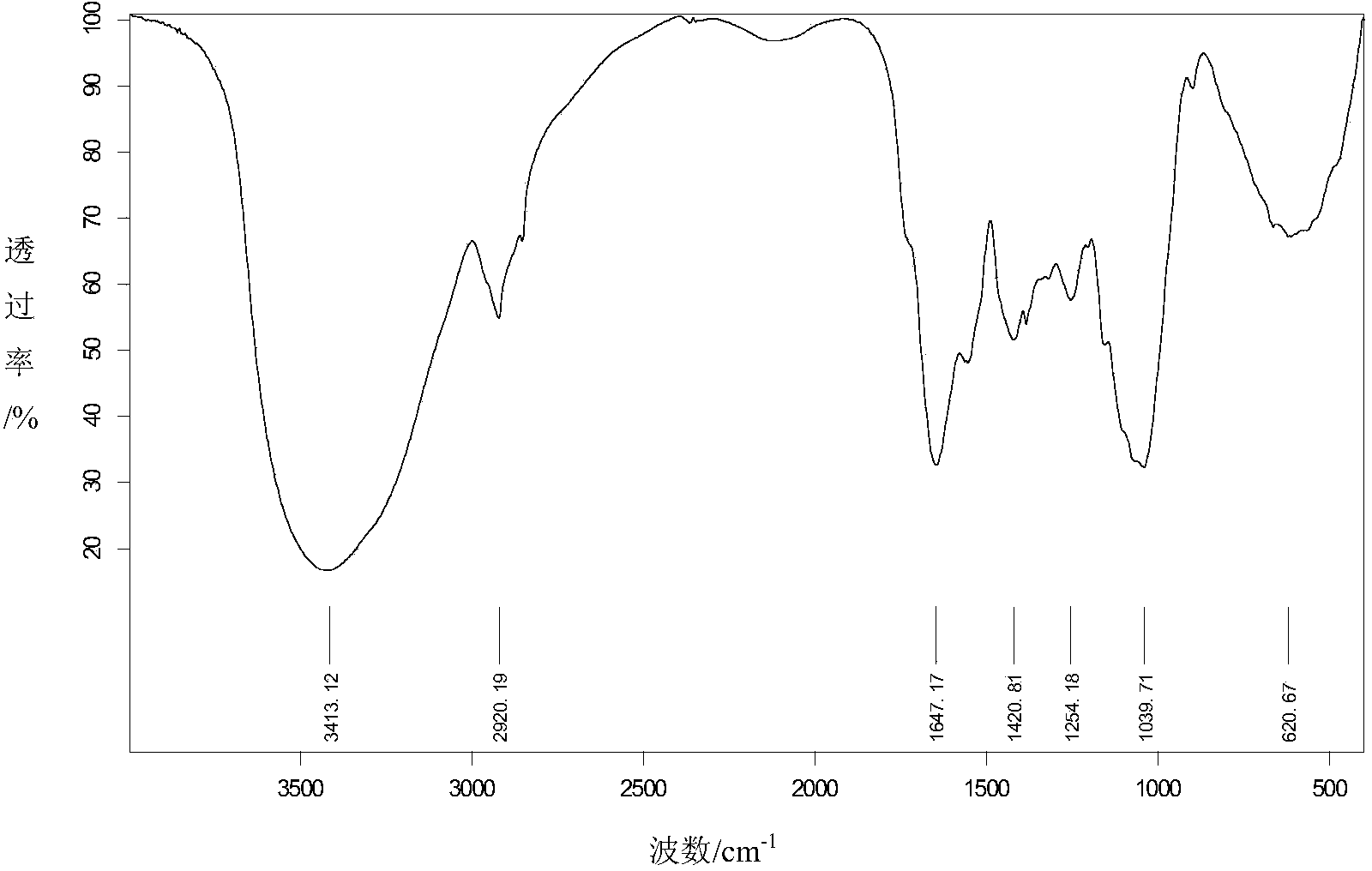

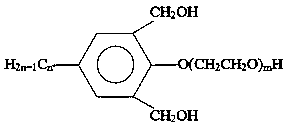

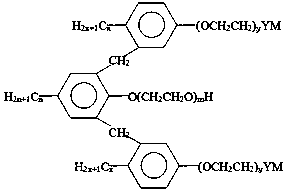

Tri-anionic-nonionic surfactant and preparation method thereof

ActiveCN105312008AImprove salt toleranceImprove high temperature resistanceTransportation and packagingMixingPolymer scienceDecomposition

A tri-anionic-nonionic surfactant has the following structure formula, wherein H<2x+1>C<x> and H<2n+1>C<n> are alkyl group chains, x is an integer of 8 to 24 and n is an integer of 8 to 24 and x can be equal to or different from n; O(CH2CH2O)y and (CH2CH2O)m are polyoxyethylene groups, wherein y is an integer of 1 to 30 and m is an integer of 1 to 30, and y can be equal to or different from m; Y is an anionic group; and M is Na<+>, K<+> or NH<4><+> ions. A preparation method includes the following steps: 1) preparing an alkylphenol polyoxyethylene ether hydroxymethyl intermediate; 2) preparing a tri-alkylphenol polyoxyethylene ether nonionic surfactant; and 3) preparing the tri-anionic-nonionic surfactant. The surfactant has excellent alkali resistance, salt resistance and high temperature resistance, is excellent in dispersing property and anti-decomposition capability, has excellent compatibility with a polymer and is suitable for the fields of development and exploitation of oil reservoir in severe conditions, such as high temperature, high slat, thick oil, low permeation and the like.

Owner:SHANDONG XINGANG CHEM

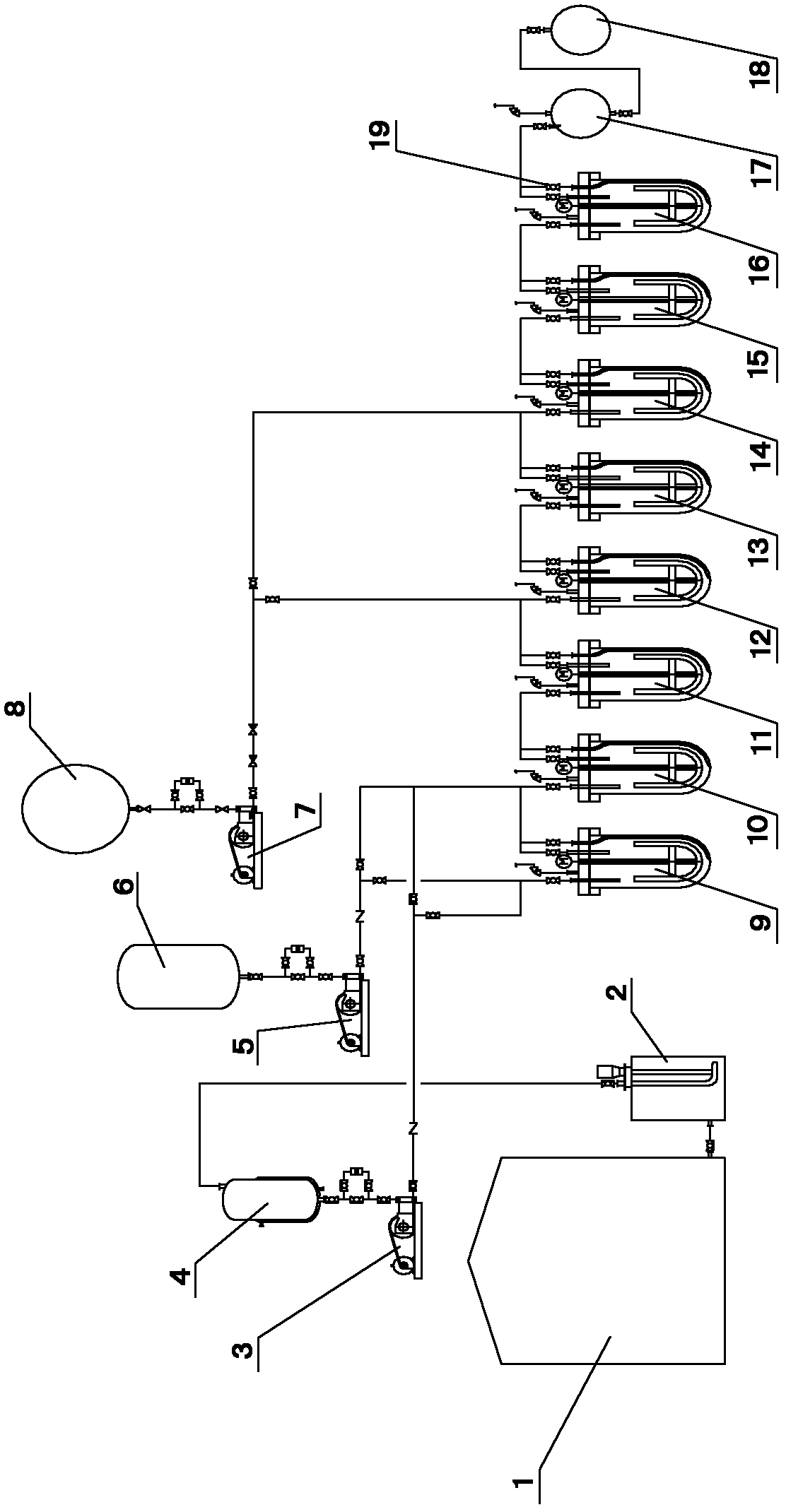

Method for producing o-nitroaniline by multiple series-connected kettles

ActiveCN102320982AShort stayImprove abilitiesOrganic compound preparationAmino compound preparationNitrobenzeneChemistry

The invention discloses a method for producing o-nitroaniline by multiple series-connected kettles. The method comprises the following steps of: adding ammonia water and o-chloro nitrobenzene to eight series-connected ammonification autoclaves, and carrying out ammonification reaction on materials when the content of the materials in each autoclave reaches 45-55%; adding ammonia water and o-chloro nitrobenzene to the first and second ammonification autoclaves when the temperature of each ammonification autoclave reaches 185-195 DEG C and the pressure reaches 4.0-4.4Mpa, and adding liquid ammonia to the fourth and sixth ammonification autoclaves at the same time; discharging the materials in the eighth ammonification autoclave to a discharge buffering tank, and then discharging to a flash distillation tank; washing the depressurized materials flash-distilled by the flash distillation tank with water to obtain an ammonified mixture; and pumping the ammonified mixture to a rectifying tower for rectifying, returning o-chloro nitrobenzene to the ammonification process from the tower top for continuing reaction, cooling o-nitroaniline in the tower kettle, and discharging to a finished product tank. In the invention, continuous kettle type ammonification and rectifying separation process are combined, thereby achieving the purposes of improving the productivity, saving the energy and reducing the consumption.

Owner:ANHUI BAYI CHEM IND

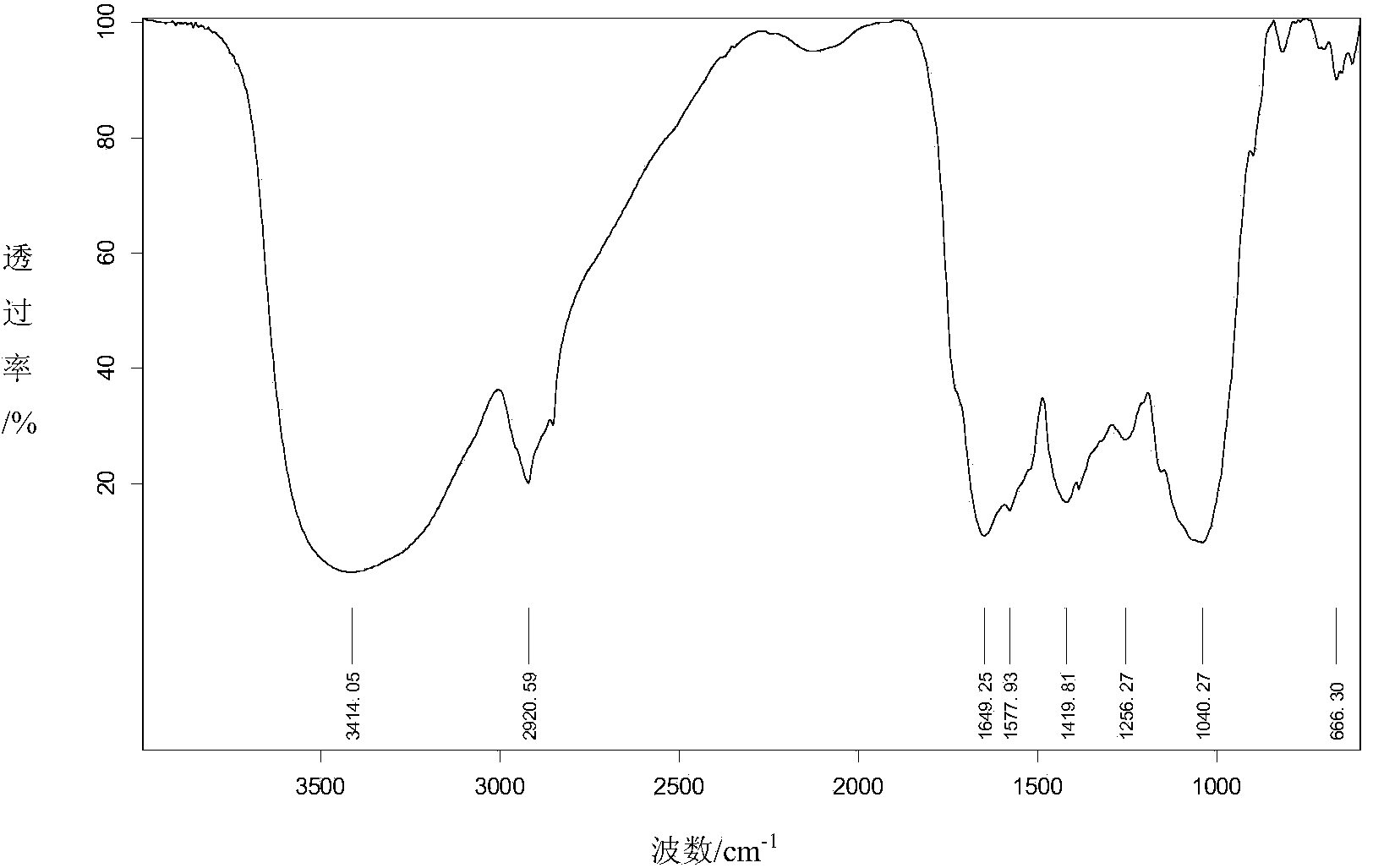

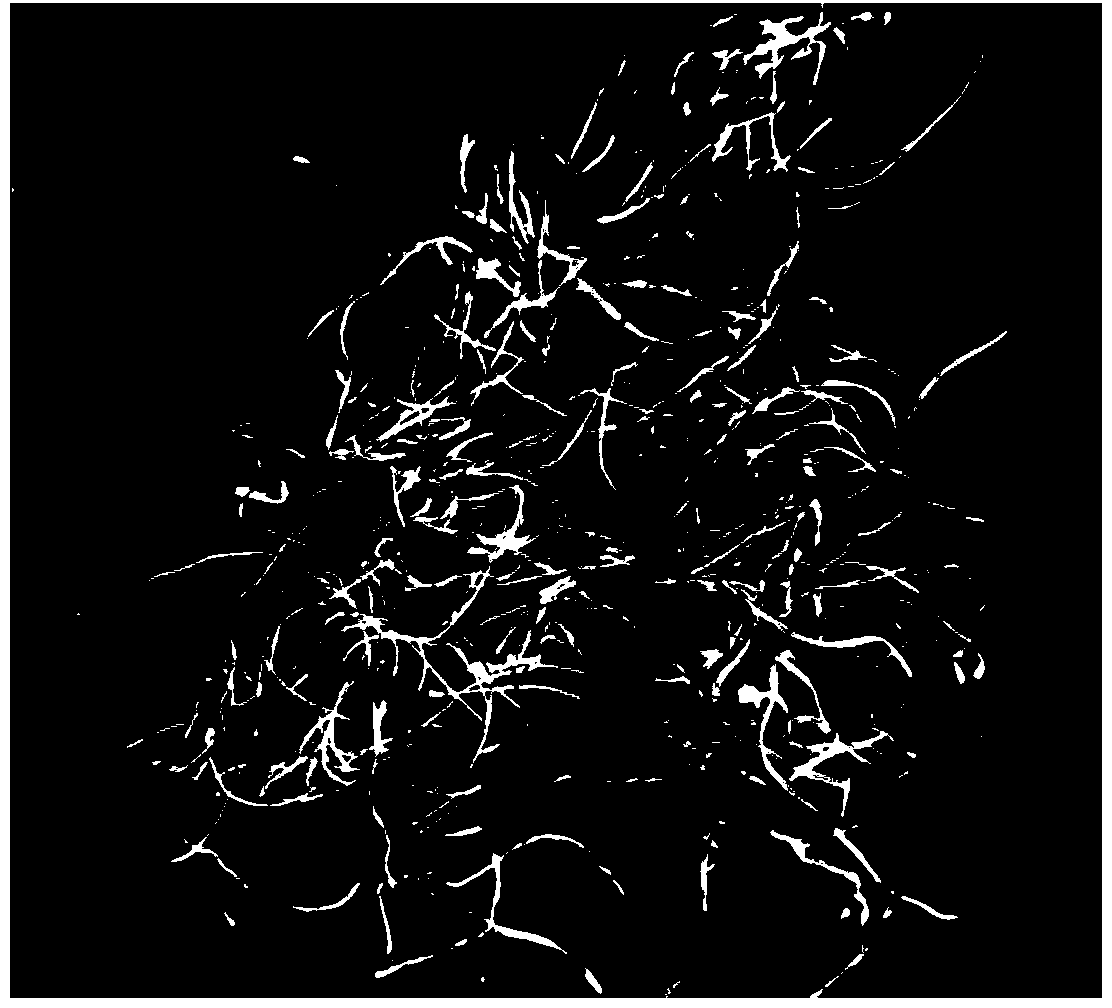

Method for treating lead-containing wastewater by using corn stigma as biomass adsorbent

ActiveCN103816873AFew stepsExtensive sources of raw materialsOther chemical processesWater contaminantsChemistryBiomass

The invention relates to a method for treating lead-containing wastewater by using corn stigma as a biomass adsorbent. The method comprises the steps as follows: (1) the corn stigmas is washed, dried and sheared, wherein the average length is 3-4 cm, so that corn stigmas biomass adsorbent is obtained;(2) the pH value of the lead-containing wastewater to be treated is regulated to 1.0-6.0, the above corn stigmas biomass adsorbent is added, and oscillation and adsorbing are performed, wherein the use amount ratio of the lead-containing wastewater and the corn stigmas biomass adsorbent is (30-50mL):(0.05-0.25g), the adsorption temperature is 20-30 DEG C, and the adsorption time is 0.5-10 h. According to the invention, compared with other biomass adsorbent, the biomass adsorbent adopted in the method has the advantages as follows: the preparation process is simpler, the steps are less, the raw materials of the adsorbent are wide in source, and cheap in price, and belong to agricultural wastes; the prepared corn stigma biomass adsorbent has a good treatment effect on heavy metal at low concentration, is over 95 percent in the adsorption rate, and the adsorption can be basically completed within 30 minutes.

Owner:DONGHUA UNIV

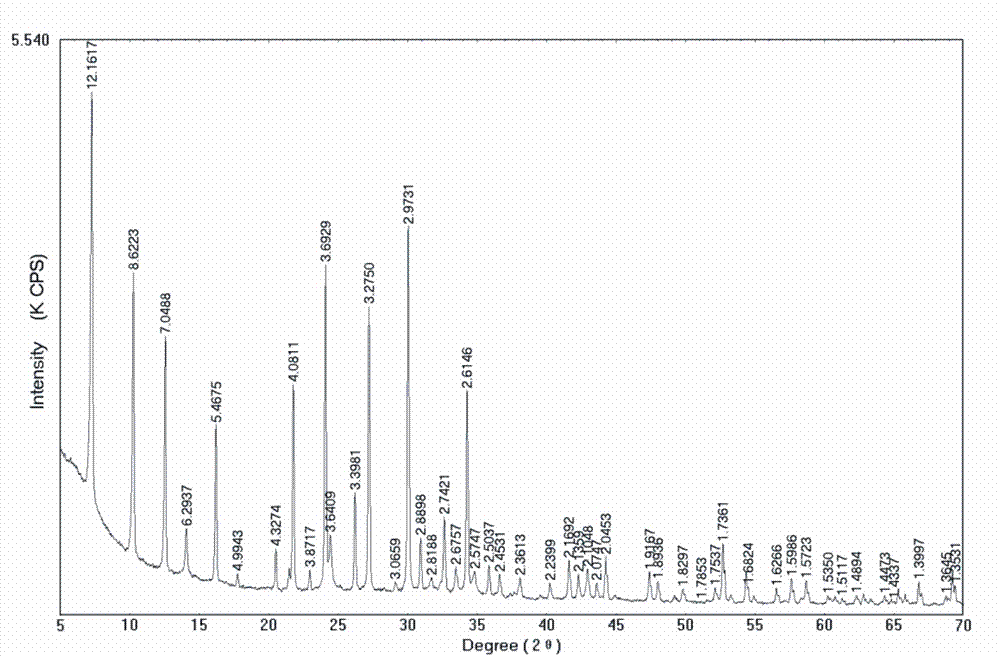

Method for preparing 4A zeolite molecular sieve with illite-containing kaolin

InactiveCN102807231AReduce energy consumptionReduce the impactAluminosilicate zeolite type-AMolecular sieveZeolite

The invention relates to a method for preparing a 4A zeolite molecular sieve with illite-containing kaolin. The method comprises the following steps of: (1) calcining illite-containing kaolin and NaOH particles together at the temperature of 250-400 DEG C for 2 hours, activating, cooling, grinding and smashing to obtain alkali-calcined kaolin; (2) mixing the alkali-calcined kaolin with a certain amount of distilled water, stirring at the temperature of 60 DEG C for 2-4 hours to obtain a gelatination product, and stirring the gelatination product at the temperature of 90 DEG C for 2-4 hours to obtain a crystallization product; and (3) leaching the crystallization product, washing and drying to obtain the 4A zeolite molecular sieve. The illite-containing kaolin is taken as a raw material, so that the adverse effect on a synthetic molecular sieve caused by incapability of activating illite serving as a difficultly-separable mineral in kaolin ore during low-temperature calcining is reduced effectively, the calcining temperature is low, and the energy consumption is low.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

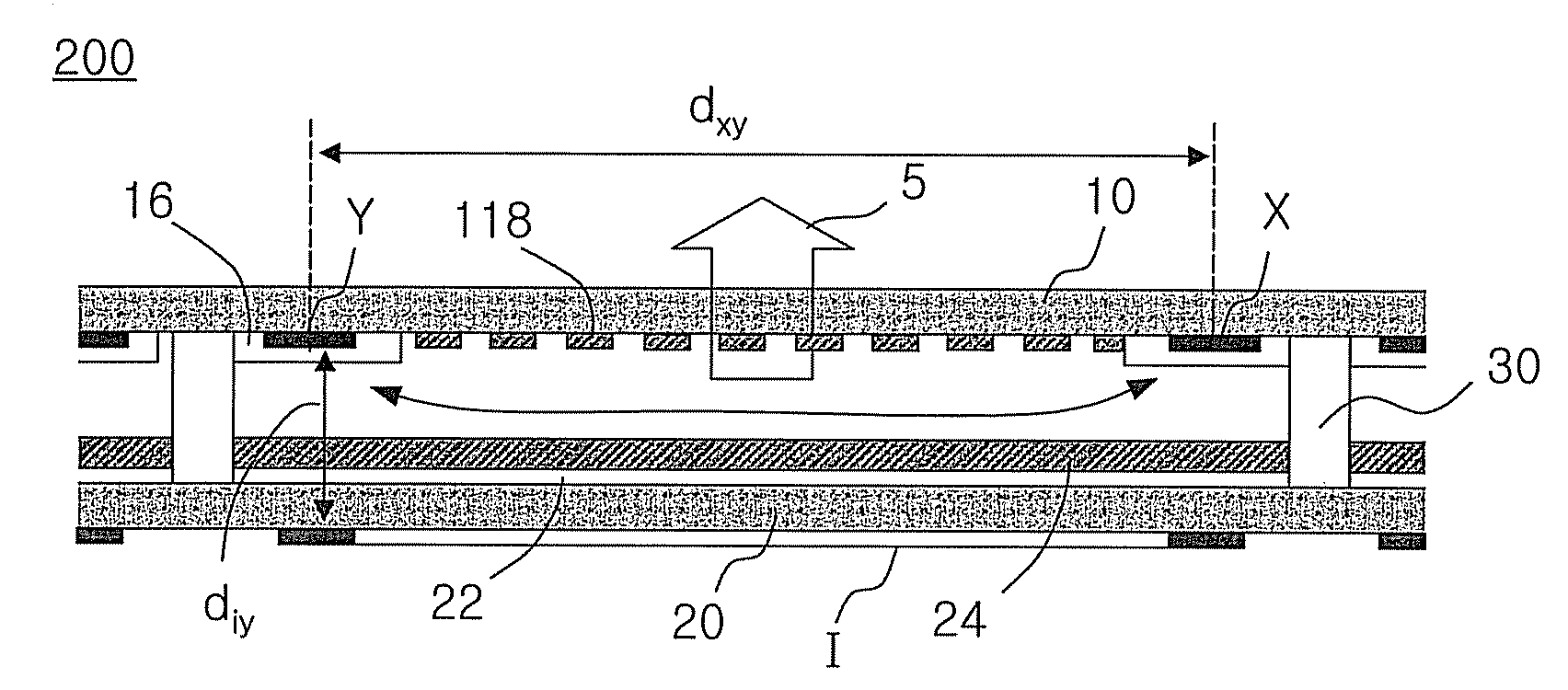

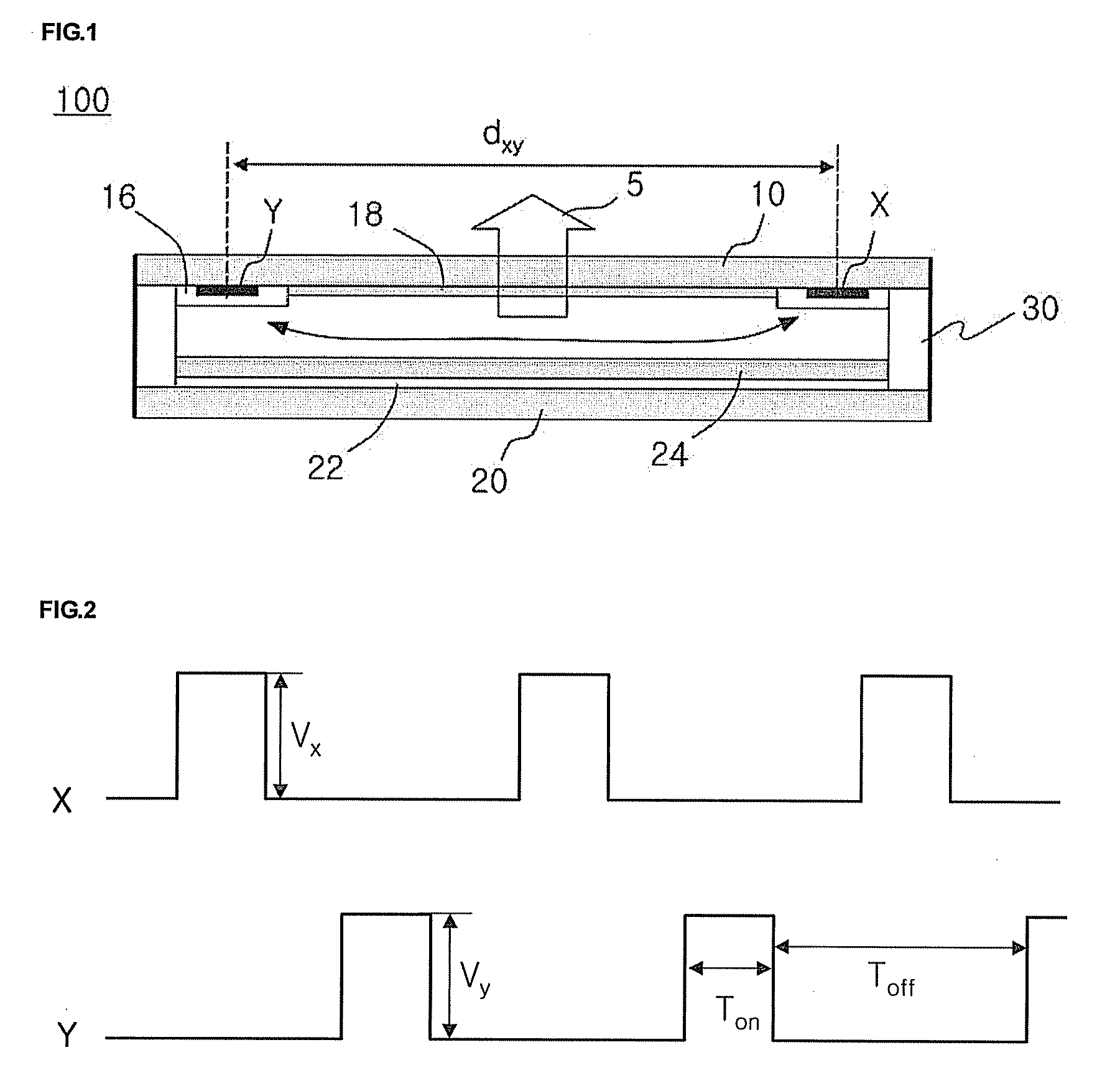

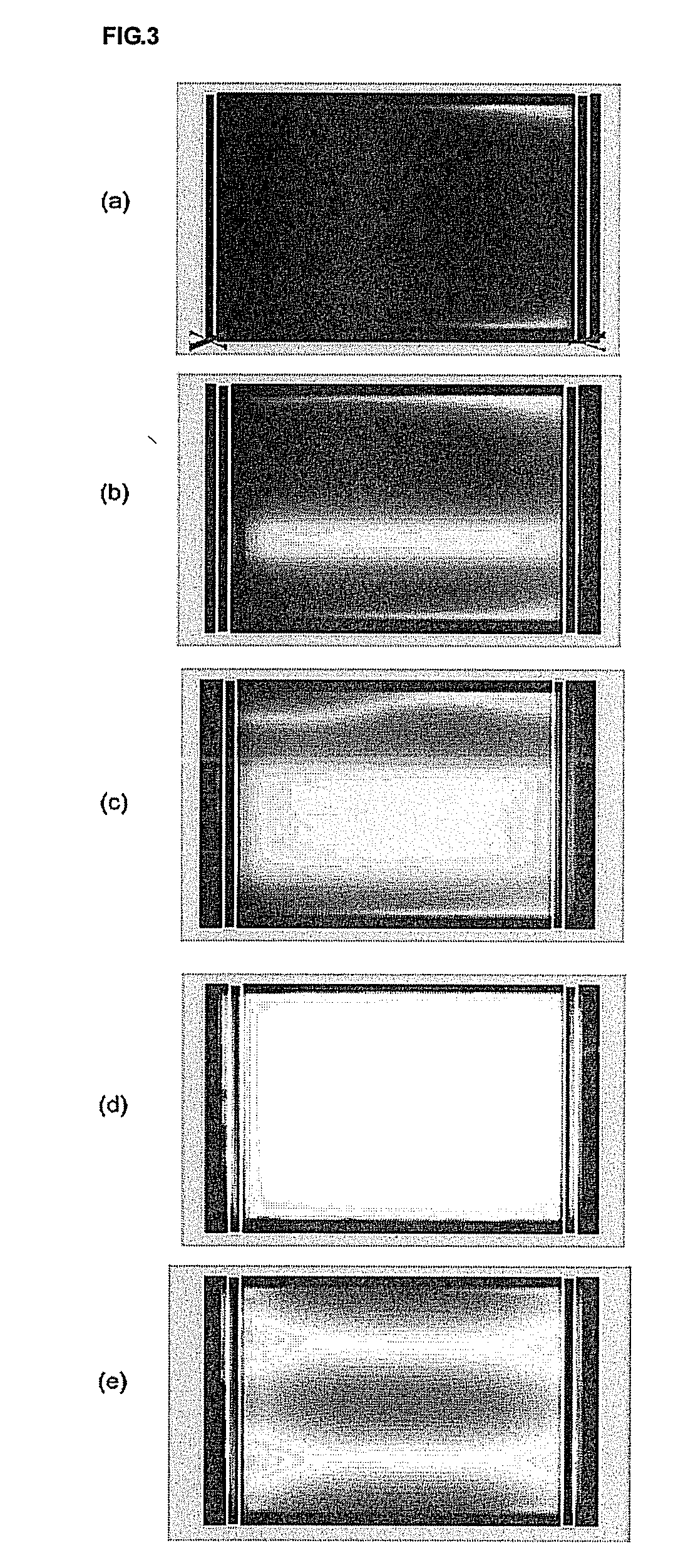

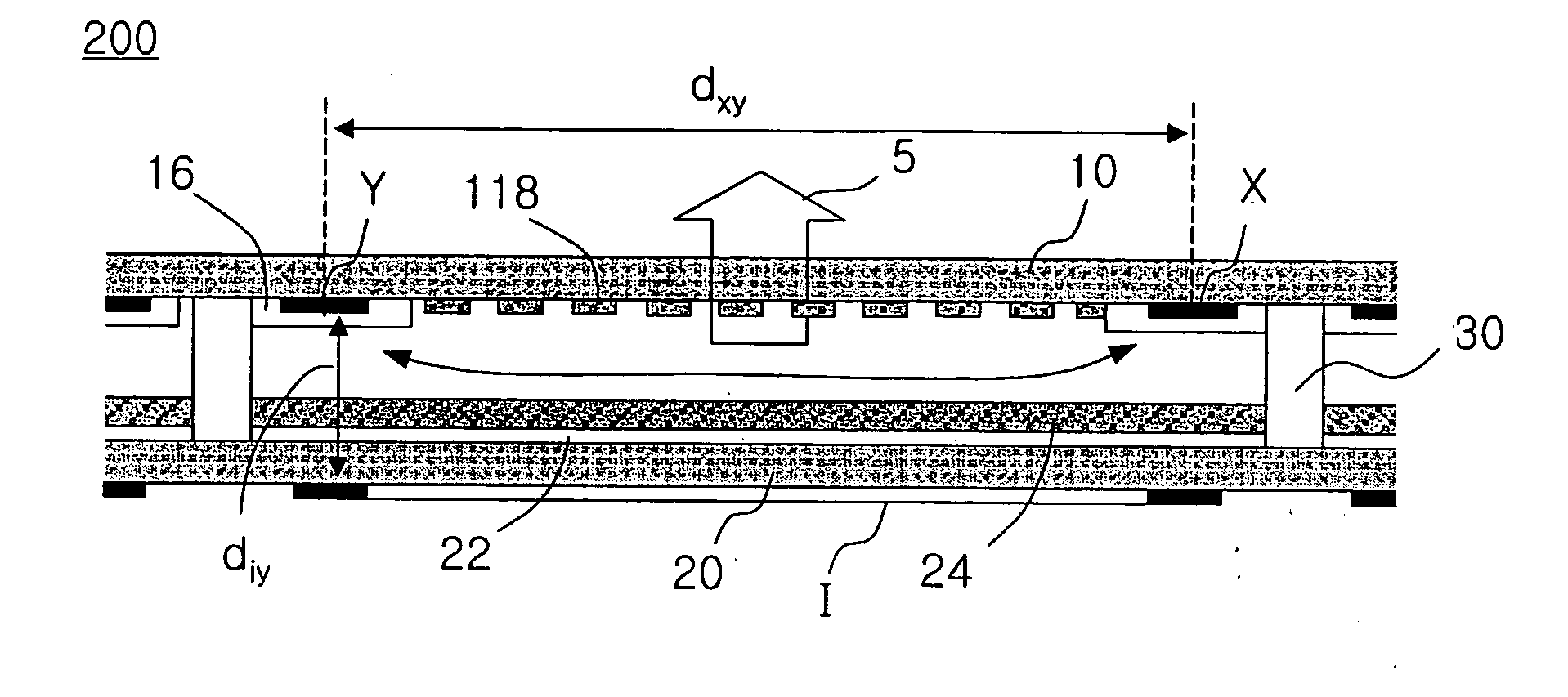

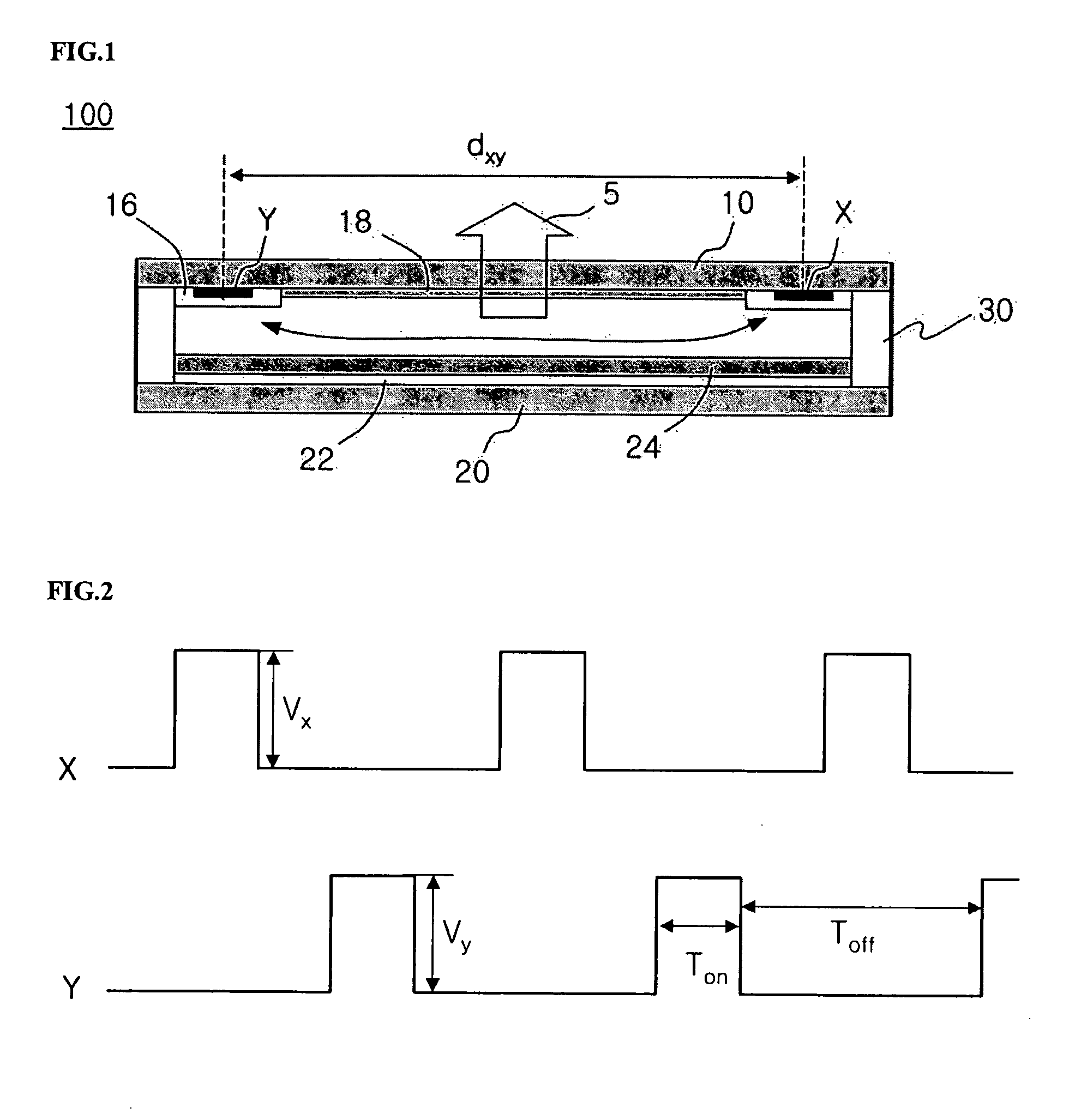

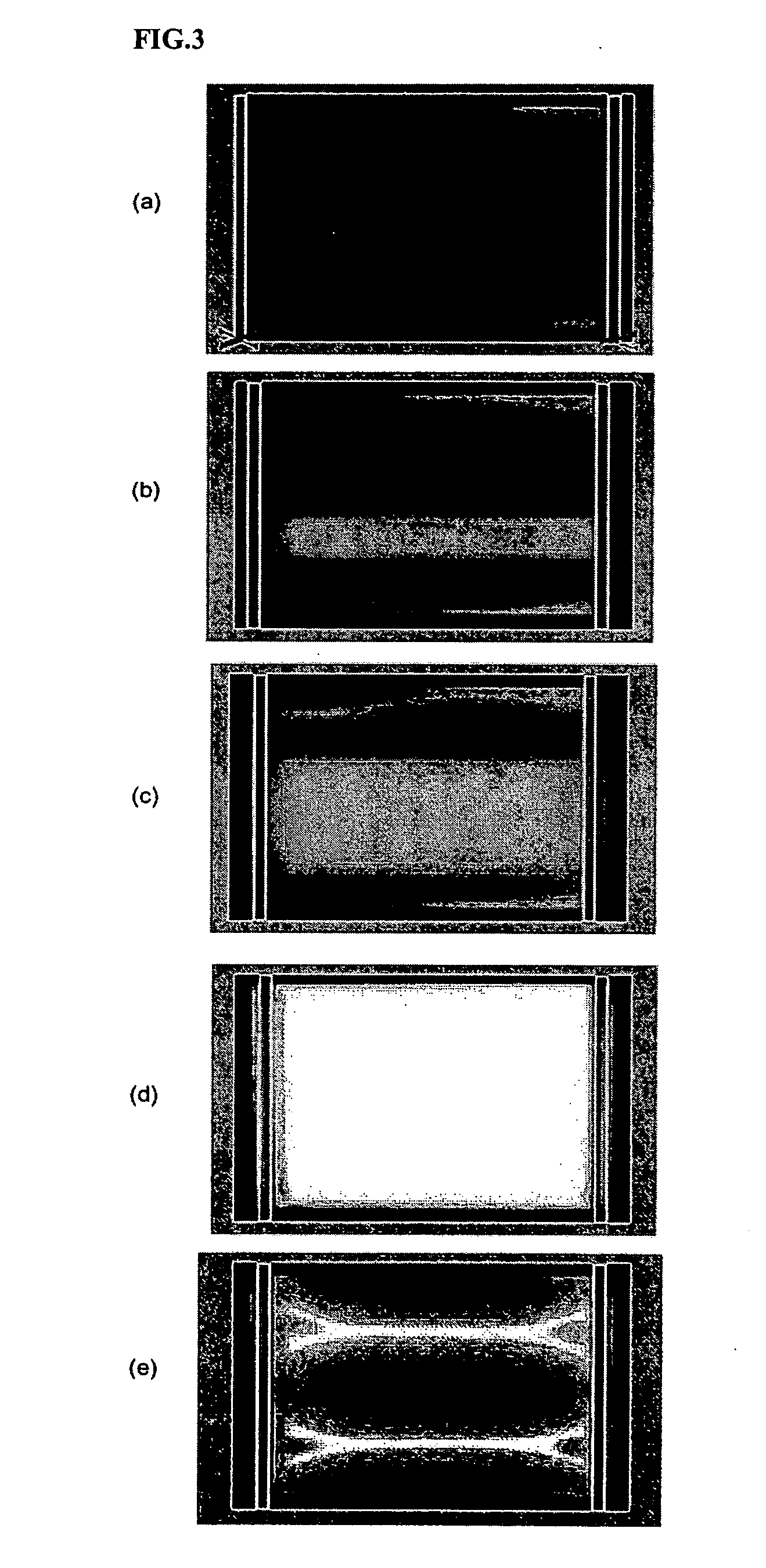

Driving Method for High Efficiency Mercury-Free Flat Light Source Structure, and Flat Light Source Apparatus

ActiveUS20100039040A1Improve luminous efficiencyShort timeStatic indicating devicesAlternating current plasma display panelsPhosphorAuxiliary electrode

Disclosed are a new Mercury-free flat light source structure capable of enhancing and adjusting brightness, maintaining stable and uniform discharge, and improving luminous efficiency, and a large flat light source apparatus using the same Mercury-free flat light source structure as a unit cell capable of adjusting the brightness and causing local discharges in selected areas, and a driving method thereof.The flat light source structure according to the present invention includes an upper substrate made of a light transmitting material; a lower substrate separated from the upper substrate by a distance; a barrier rib for maintaining the distance, thereby defining a discharge space filled with a discharge gas with a predetermined pressure; a phosphor coated on at least one of the inner surfaces of the upper substrate and the lower substrate, respectively; a pair of main electrodes disposed at predetermined positions on the surface of the upper or lower substrate and applied with a predetermined driving voltage, frequency and duty ratio to excite the phosphor by plasma generated due to electric field induced in the discharge space; an auxiliary electrode formed at a predetermined position on the lower and / or upper substrate(s) to have a parallel component which is parallel with any one of the main electrodes when viewing the discharge space from the upper substrate and a perpendicular component which traverses the electrodes across the pair of main electrodes.

Owner:SEOUL NAT UNIV R&DB FOUND

High efficiency mercury-free flat light source structure, flat light source apparatus and driving method thereof

ActiveUS20060290267A1Improve luminous efficiencyShort timeDischarge tube luminescnet screensStatic indicating devicesAuxiliary electrodeElectric field

Disclosed are a new Mercury-free flat light source structure capable of enhancing and adjusting brightness, maintaining stable and uniform discharge, and improving luminous efficiency, and a large flat light source apparatus using the same Mercury-free flat light source structure as a unit cell capable of adjusting the brightness and causing local discharges in selected areas, and a driving method thereof. The flat light source structure according to the present invention includes an upper substrate made of a light transmitting material; a lower substrate separated from the upper substrate by a distance; a barrier rib for maintaining the distance, thereby defining a discharge space filled with a discharge gas with a predetermined pressure; a phosphor coated on at least one of the inner surfaces of the upper substrate and the lower substrate, respectively; a pair of main electrodes disposed at predetermined positions on the surface of the upper or lower substrate and applied with a predetermined driving voltage, frequency and duty ratio to excite the phosphor by plasma generated due to electric field induced in the discharge space; an auxiliary electrode formed at a predetermined position on the lower and / or upper substrate(s) to have a parallel component which is parallel with any one of the main electrodes when viewing the discharge space from the upper substrate and a perpendicular component which traverses the electrodes across the pair of main electrodes.

Owner:SEOUL NAT UNIV R&DB FOUND

Triple anionic-nonionic surfactant, and preparation method and application thereof

ActiveCN110229050AIncrease contentGood alkali resistanceOrganic compound preparationTransportation and packagingTwo stepSurface-active agents

The invention provides a triple anionic-nonionic surfactant, and a preparation method and application thereof, belonging to the technical field of surfactants. The preparation method of the inventioncan overcome the technical problems of generation of inorganic salts, randomness of products, low yield and the like in conventional preparation methods. According to a technical scheme in the invention, the preparation method comprises the following two steps: preparation of a hydroxymethyl alkyl phenol polyoxyethylene ether intermediate; and preparation of the triple anionic-nonionic surfactant.The triple anionic-nonionic surfactant is applicable to exploitation of high-temperature high-salt petroleum reservoirs.

Owner:SHANDONG XINGANG CHEM

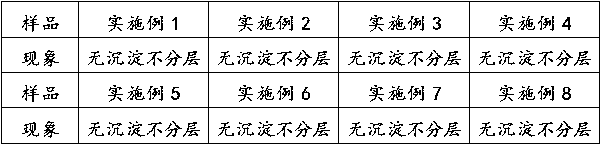

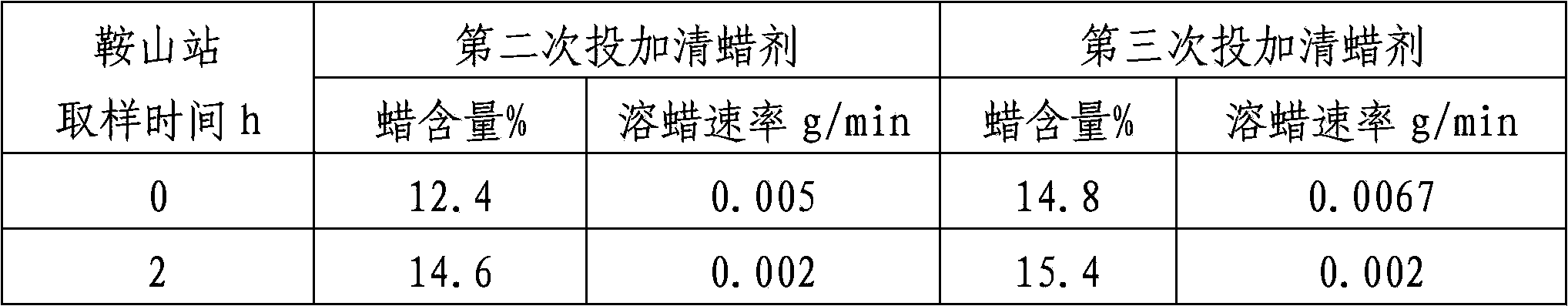

Long-distance pipeline wax-cleaning agent and wax-cleaning conveying technology method

ActiveCN103421625AEasy operating conditionsImprove wax removal effectHollow article cleaningNon-surface-active detergent solventsSolventWax

The invention discloses a long-distance pipeline wax-cleaning agent and a wax-cleaning conveying technology method. The wax-cleaning agent is prepared by complex formulation of crude oil, 0 # diesel oil and solvent oil 90 #, wherein the crude oil comprises lower than 6% of wax and has a solubility parameter of 7.0-8.0, and the weight ratio of crude oil: 0 # diesel oil: solvent oil 90 # is 6-8:3-1:1. The wax-cleaning conveying technology method comprises the following steps: 1) estimating the effective volume of a pipeline for wax cleaning; 2) mixing the 0 # diesel oil and the solvent oil 90 # in a weight ratio of 3-1:1, and then mixing the crude oil and a diesel oil and solvent oil mixed solution in a weight ratio of 6-8:1; 3) heating to enable the output temperature to be 50-70 DEG C; 4) pumping a wax-cleaning agent mixed solution into the pipeline from a first station in three times with the dosage for each time being the effective pipeline volume, when oil head arrives a terminal station, testing the wax content of the wax-cleaning agent, and stopping pipeline conveying for 3 days; 5) in sixth and ninth day later, repeating the steps of 2) to 4), and performing the second and third addition of the wax cleaning agent, testing the wax content of the wax-cleaning agent at the terminal station in every 2 hours, and calculating the wax dissolving rate; and 6) outputting from the terminal station.

Owner:PIPECHINA SOUTH CHINA CO

Electrode capable of reversing polarity, and application thereof

PendingCN113337845AImprove corrosion resistanceImprove bindingWater/sewage treatmentElectrodialysisElectrolysisElectrical polarity

The invention discloses an electrode capable of reversing polarity, and application thereof. The electrode comprises a substrate, a middle layer and a catalyst layer, wherein the substrate comprises metal or alloy thereof; the middle layer is arranged on the substrate and comprises platinum group metal and platinum group metal oxide; and the catalyst layer is disposed on the middle layer, and the catalyst layer includes a mixed metal oxide. The electrode can be used as an electrode for electrolysis, electrodialysis or electroplating. The electrode can meet the working environment requirements of the cathode and the anode at the same time, the environmental tolerance is improved, and the protection of the substrate is realized; and polarity reversal can be carried out, and sediments on the surface of the electrode can be quickly and efficiently cleaned.

Owner:MAGNETO SPECIAL ANODES SUZHOU CO LTD

Preparation of potassium tellurite

InactiveCN101348241AThe preparation process is simple and environmentally friendlySimple stepsSelenium/tellurium compundsHazardous substanceEvaporation

The invention relates to a method for preparing a composition, in particular to a method for preparing potassium tellurite. The method for preparing potassium tellurite comprises the following steps that: (1) tellurium dioxide is added in water and evenly stirred to obtain the solution(I); (2) potassium hydroxide is gradually added and dissolved in the solution(I) to obtain the solution(II); (3)the solution(II) is subjected to evaporation, condensation and crystallization to obtain a potassium tellurite crystal; and (4) the potassium tellurite crystal is dried to obtain the potassium tellurite product. The method for preparing potassium tellurite is a preparation process which is safe, highly efficient and environment friendly. The preparation method of the invention takes tellurium dioxide, water and potassium hydroxide as materials, the product is potassium tellurite and water, and the target product can be obtained by removing water out of the product; moreover, the preparation method of the invention has the advantages of no generation of other harmful substances in the preparation process, simple procedure, flexible operating conditions and easy industrialized promotion and application.

Owner:FIRST RARE MATERIALS CO LTD

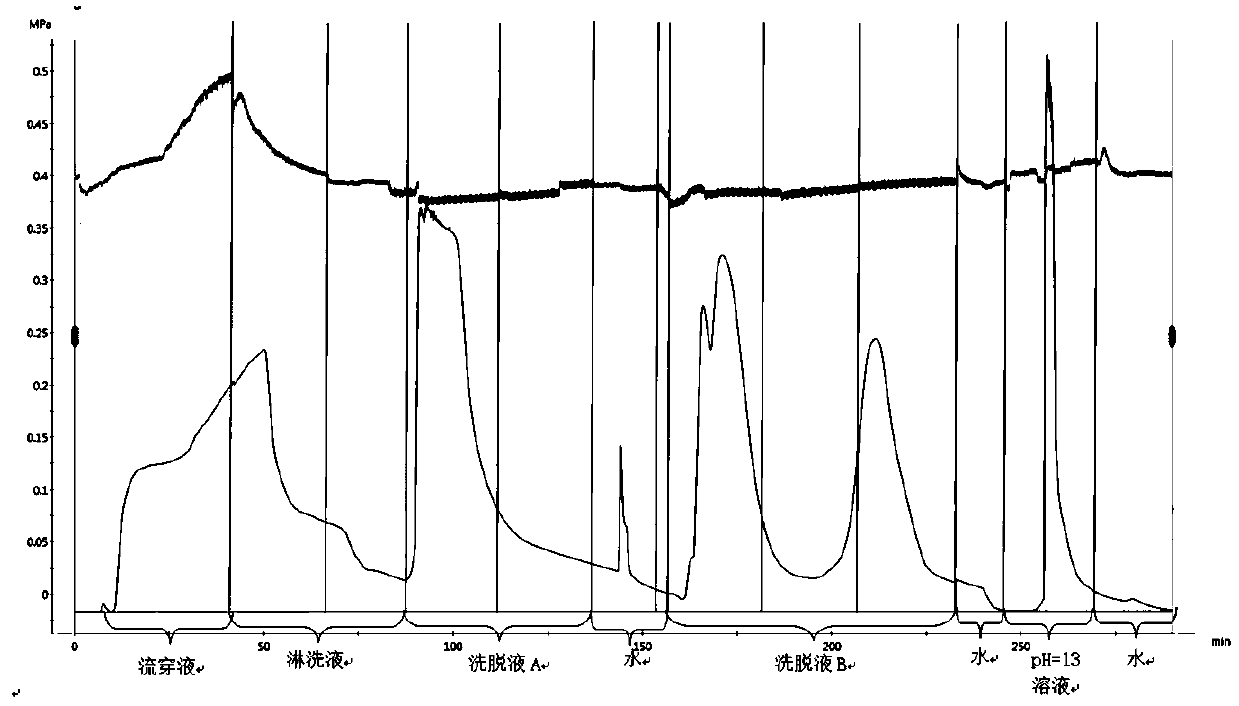

Method for capturing and separating effective components in liquorice by utilizing mixed-mode agarose gel medium

ActiveCN111001189AExtend engagement and criticalityWide operating conditionsIon-exchange process apparatusIon-exchanger regenerationNatural productIon exchange

The invention relates to a method for capturing and separating effective components in liquorice by utilizing a mixed-mode agarose gel medium. The method is characterized in that the mixed-mode agarose gel medium with ion exchange and hydrophobic ligands is used for capturing and separating acidic saponin substances and flavonoid substances in liquorice; the two substances are effectively adsorbedin the agarose gel medium in an adsorption mode, and effective separation of the acidic saponin substances and the flavonoid substances is realized by changing the pH value of an eluent. According tothe method for capturing and separating liquiritin and glycyrrhizic acid substances in liquorice, the result can approximately reach that the purity of the liquiritin substances is 65%-95%, and the yield is 80%-98% (calculated by taking the liquiritin as a standard substance); the purity of glycyrrhizic acid substances is 60-95%, the yield is 75-95% (calculated by taking ammonium glycyrrhizinateas a standard substance), the purity and the yield are relatively high, and the method has important significance for a component separation process of natural products and a traditional Chinese medicine extraction and purification process.

Owner:TAIZHOU GUOKEHUAWU BIOMEDICAL TECH CO LTD

Method for preparing sodium hydrogen selenite

InactiveCN101343048ASimple stepsWide operating conditionsSelenium/tellurium compundsSource materialHazardous substance

The invention relates to a sodium hydrogen selenite preparation method which includes the steps that: (1) the selenium dioxide is dissolved in water to generate solution I; (2) the sodium hydroxide is added to the solution I; the PH is adjusted to equal to 2-9, so as to obtain the solution II; (3) the solution II is evaporated, condensed and crystallized to obtain crystal water sodium hydrogen selenite; (4) the crystal water sodium hydrogen selenite is dried to obtain the sodium hydrogen selenite product. The sodium hydrogen selenite preparation method is a safe, efficient and environmental protection preparation process; the preparation adopts the selenium dioxide, water and sodium hydrate as the source materials to generate the sodium hydrogen selenite and water; and then the water is removed to obtain the target product. The sodium hydrogen selenite preparation method has the advantages of generating no other hazardous substance in the production process, simple steps, convenient operation condition, easy industrial popularization and application.

Owner:FIRST RARE MATERIALS CO LTD

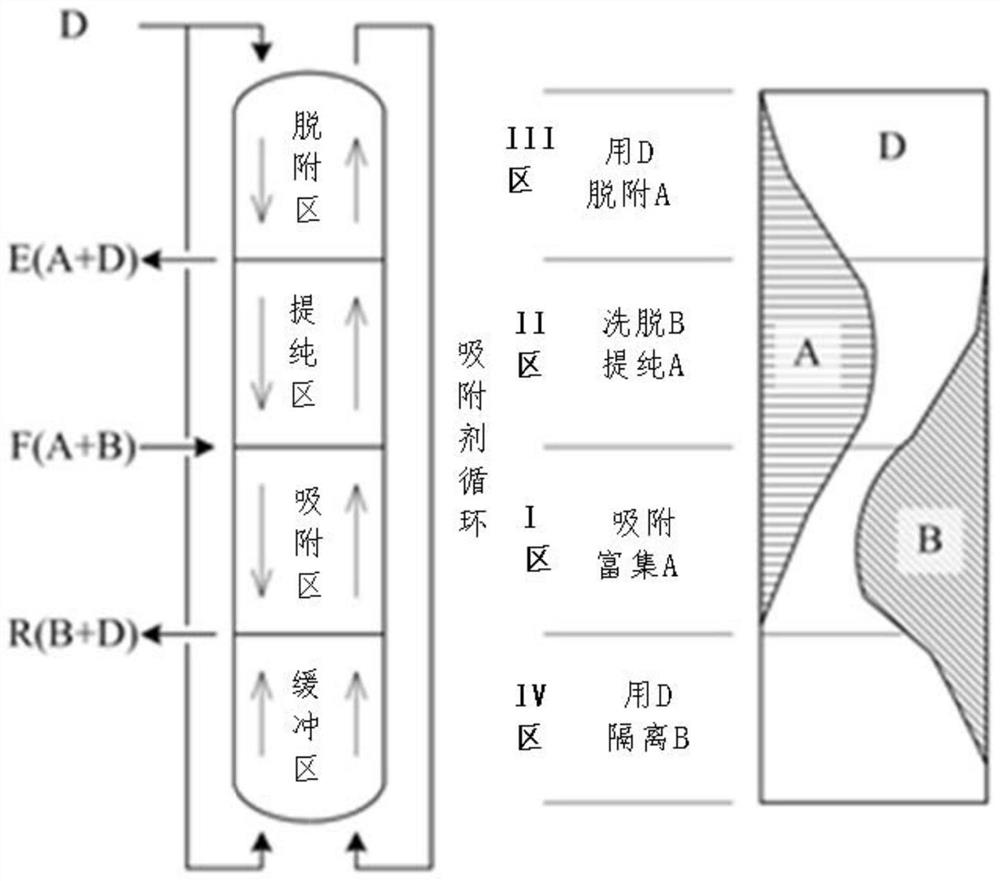

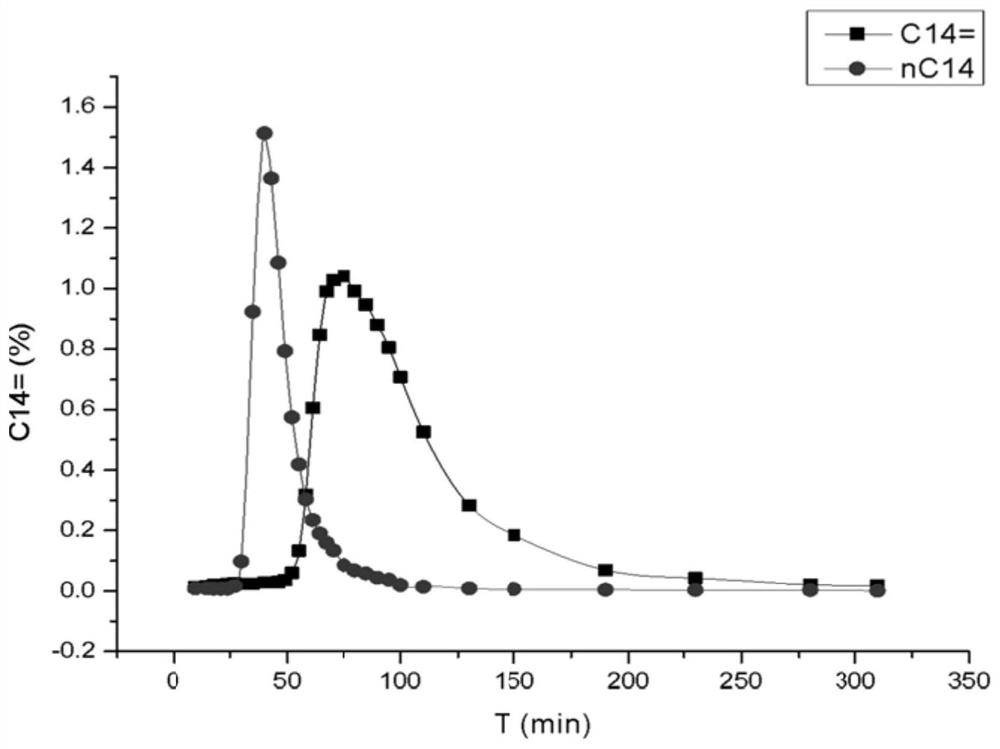

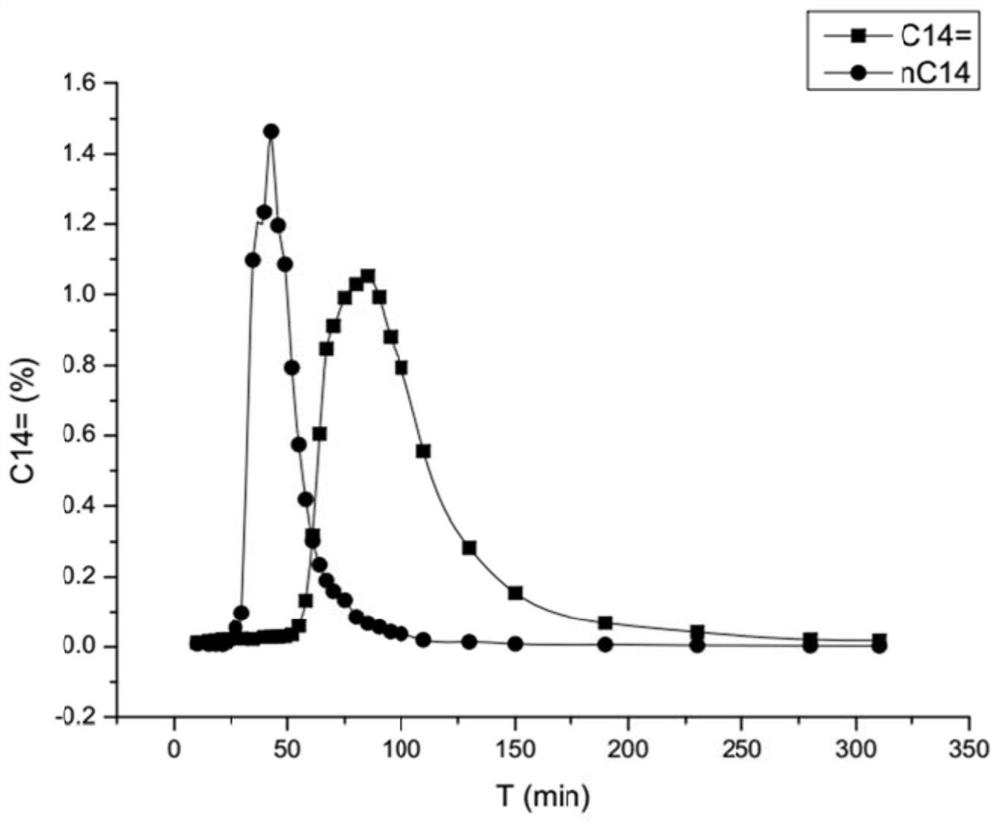

Method for separating alkane and olefin by using simulated moving bed

PendingCN113087587AFlexible ratioCheap and easy to getAdsorption purification/separationAlkaneCarbon number

The invention provides a method for separating alkane and olefin by using a simulated moving bed. The method comprises the following steps: eluting by using an eluent, wherein the eluent is n-alkanes, and the difference between the carbon number of the n-alkanes and the carbon number of olefins in a raw material to be separated is greater than 1 and less than 7 (e.g., 2, 3, 4, 5 or 6), preferably greater than 1 and less than 5 (e.g., 2, 3 or 4). The eluent can reduce the cost and improve the product recovery rate.

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

Method for pretreatment of sulfur-containing wastewater after refinery gas extraction by using activated refinery coke

InactiveCN101434422AReduce processing costsMild activation treatmentWater/sewage treatment by sorptionPretreatment methodAlkaline activation

The invention provides an activation and regeneration method of petroleum coke, and a pre-treatment method for applying active petroleum coke to refinery waste water, particularly a method for reducing COD in sulfur-bearing waste water after the air lift of the refinery. The method comprises the following steps: carrying out alkaline activation treatment to petroleum coke in an alkaline aqueous solution, roasting the petroleum coke at 200-350 DEG C to prepare the active petroleum coke, using the prepared active petroleum coke to absorb organic containments in the water, and oxidizing the absorbed petroleum coke material at 200-350 DEG C so as to regenerate the active petroleum coke to be reused. The method provided by the invention can reduce the COD of waste water after the air-lift of the refinery by 60-90 percent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

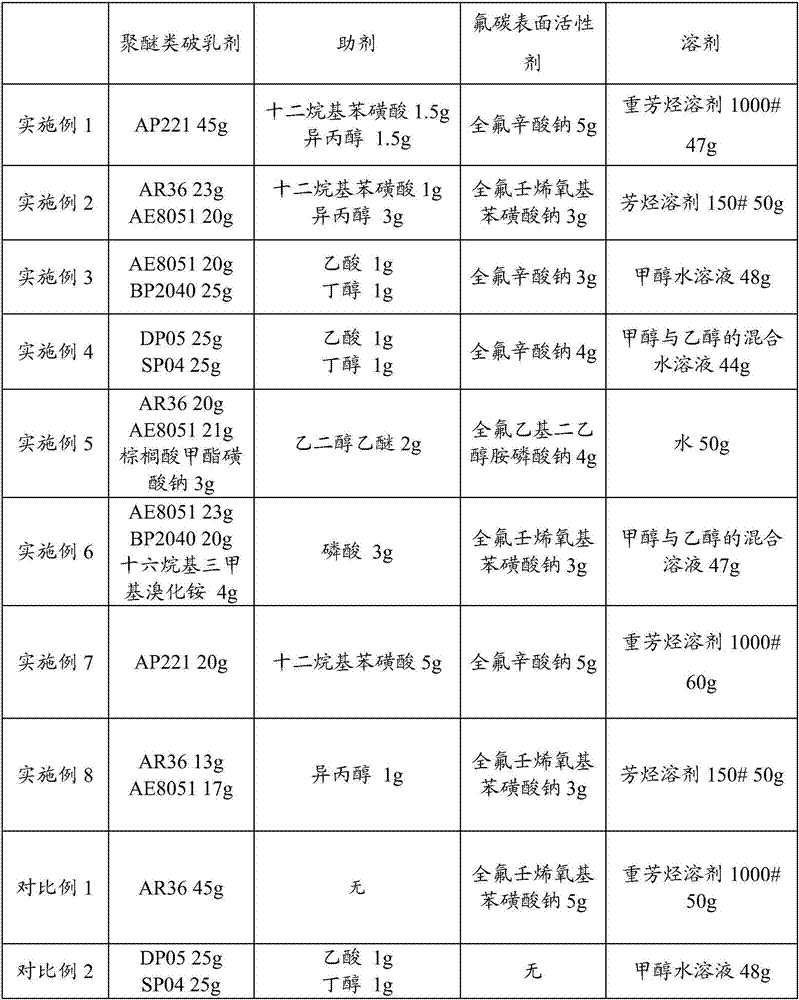

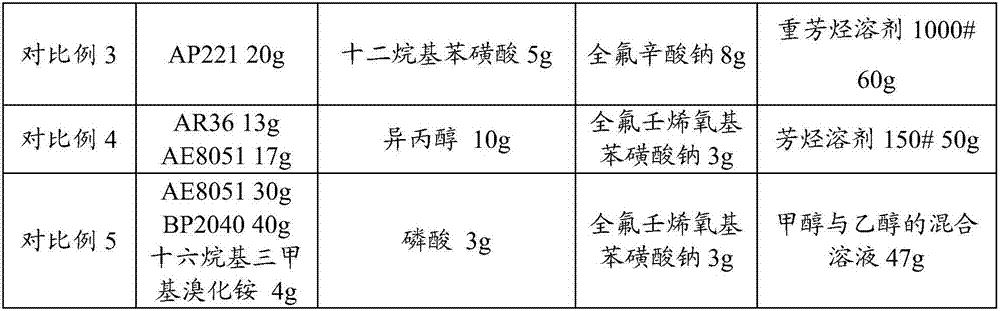

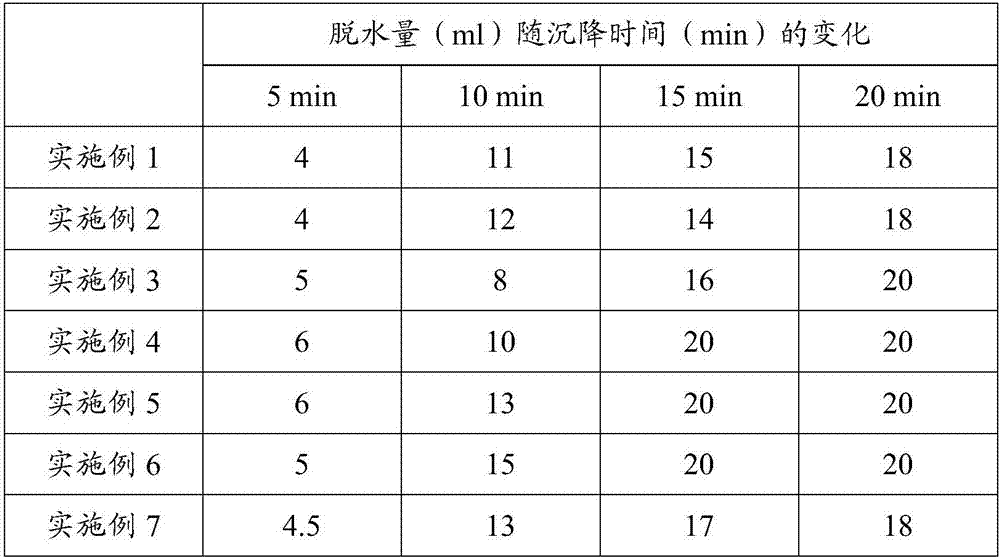

Compound demulsifying agent for wood tar dehydration

InactiveCN108003909AImprove solubilityReduce interface strengthTar working-up by water removalAdjuvantCarbonization

The invention relates to the technical field of biomass energy, in particular to a dehydration technology applicable to biomass pyrolysis and carbonization products. For wood tar, a novel compound demulsifying agent is firstly researched and developed, and can be applicable to dehydration of the wood tar. By adding of an adjuvant, effects of solubilization, dispersion and pH value adjustment can be achieved; other acid and alkali adjusters are not required to be added; demulsifying and dehydrating effects are achieved through the synergistic effect among a polyether demulsifying agent, a fluorocarbon surfactant and the adjuvant. The compound demulsifying agent provided by the invention can be applied to the wood tar obtained by carbonization and pyrolysis of various biomasses, and is goodin broad spectrum; furthermore, a demulsified interface is clear, and the demulsifying effect is good; the wood tar subjected to the dehydration treatment is low in moisture content. Reagents used forcompounding are all known or available substances, so that the cost required for synthesis of a large number of new products is reduced; efficient and low-cost production of the demulsifying agent isrealized.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

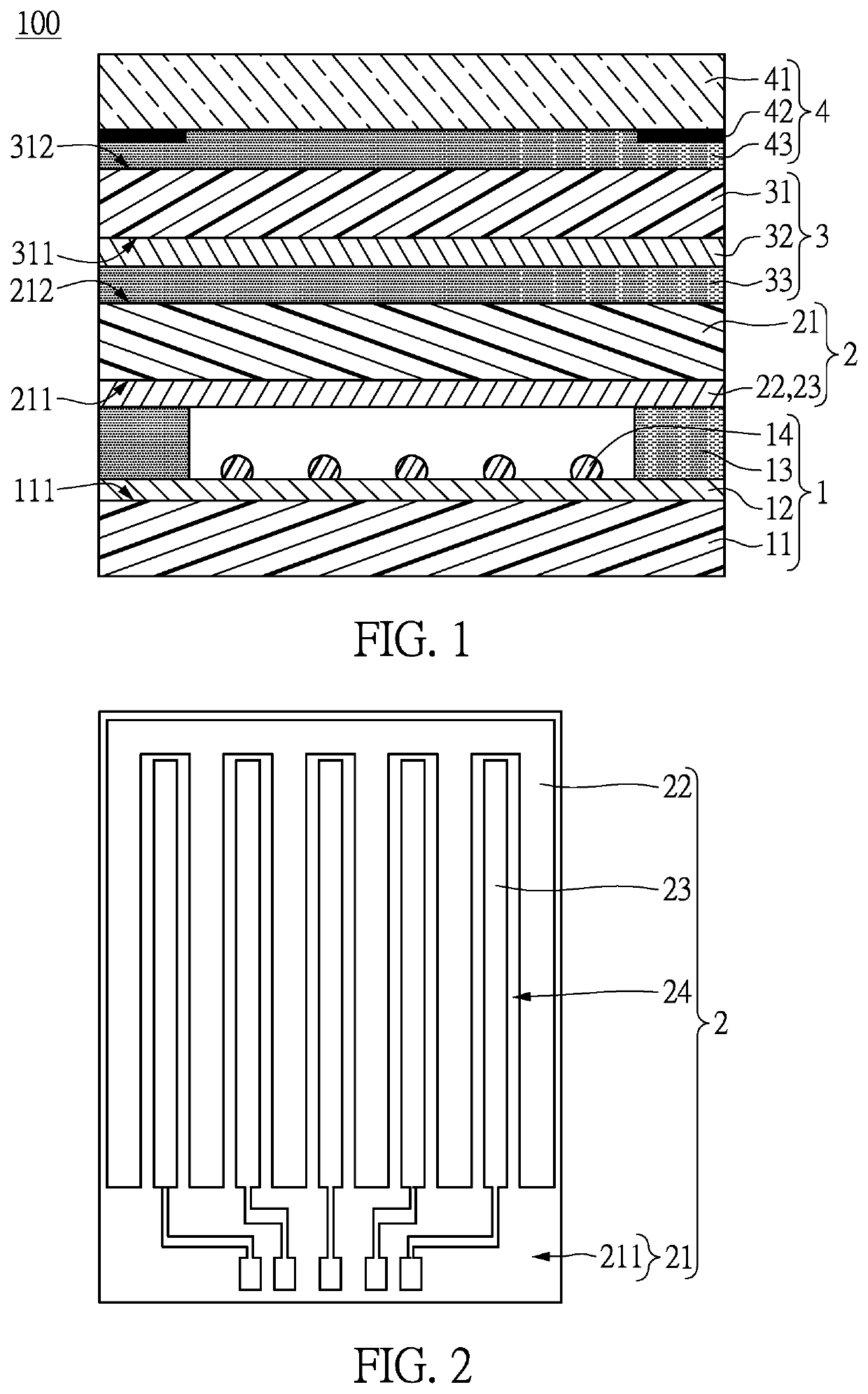

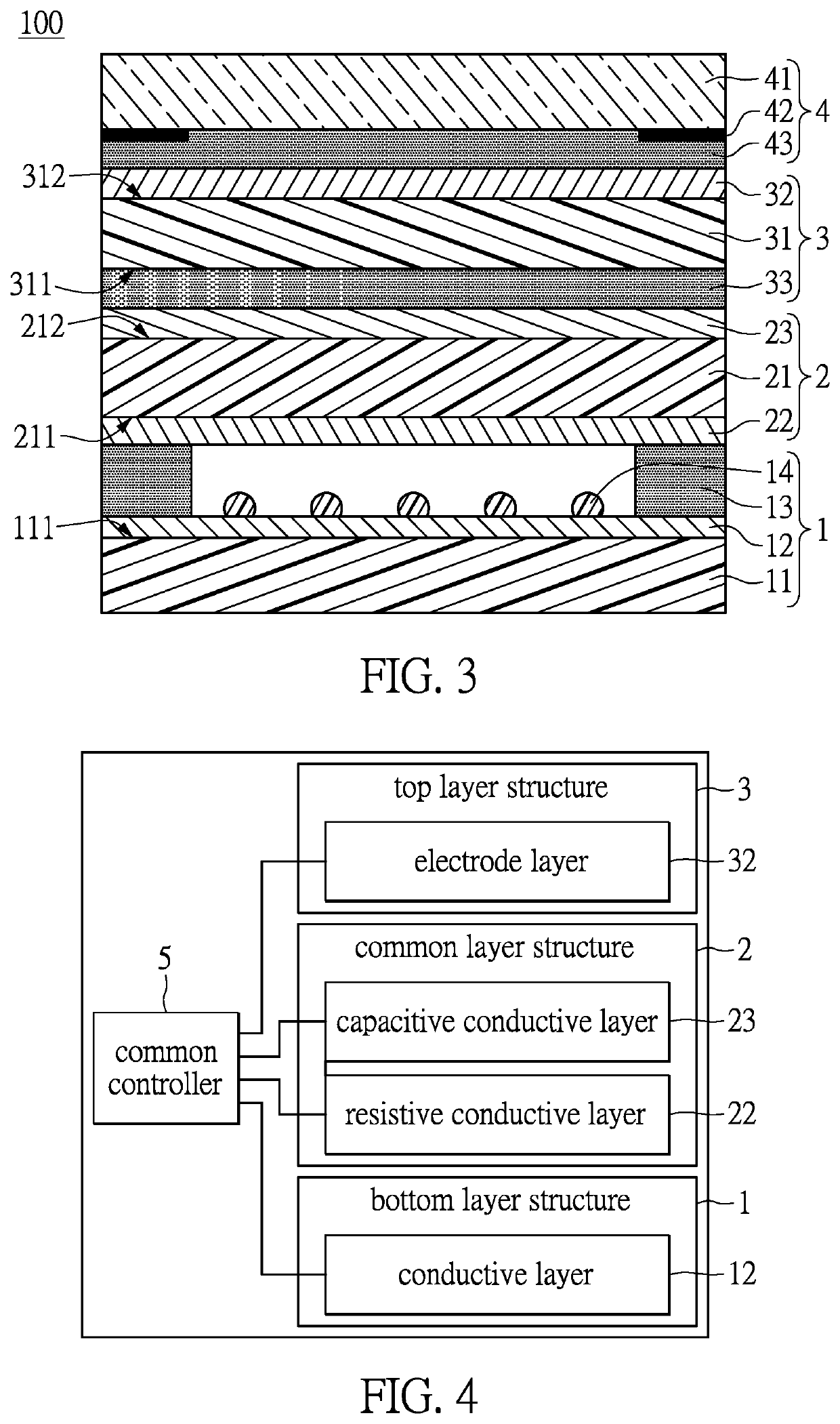

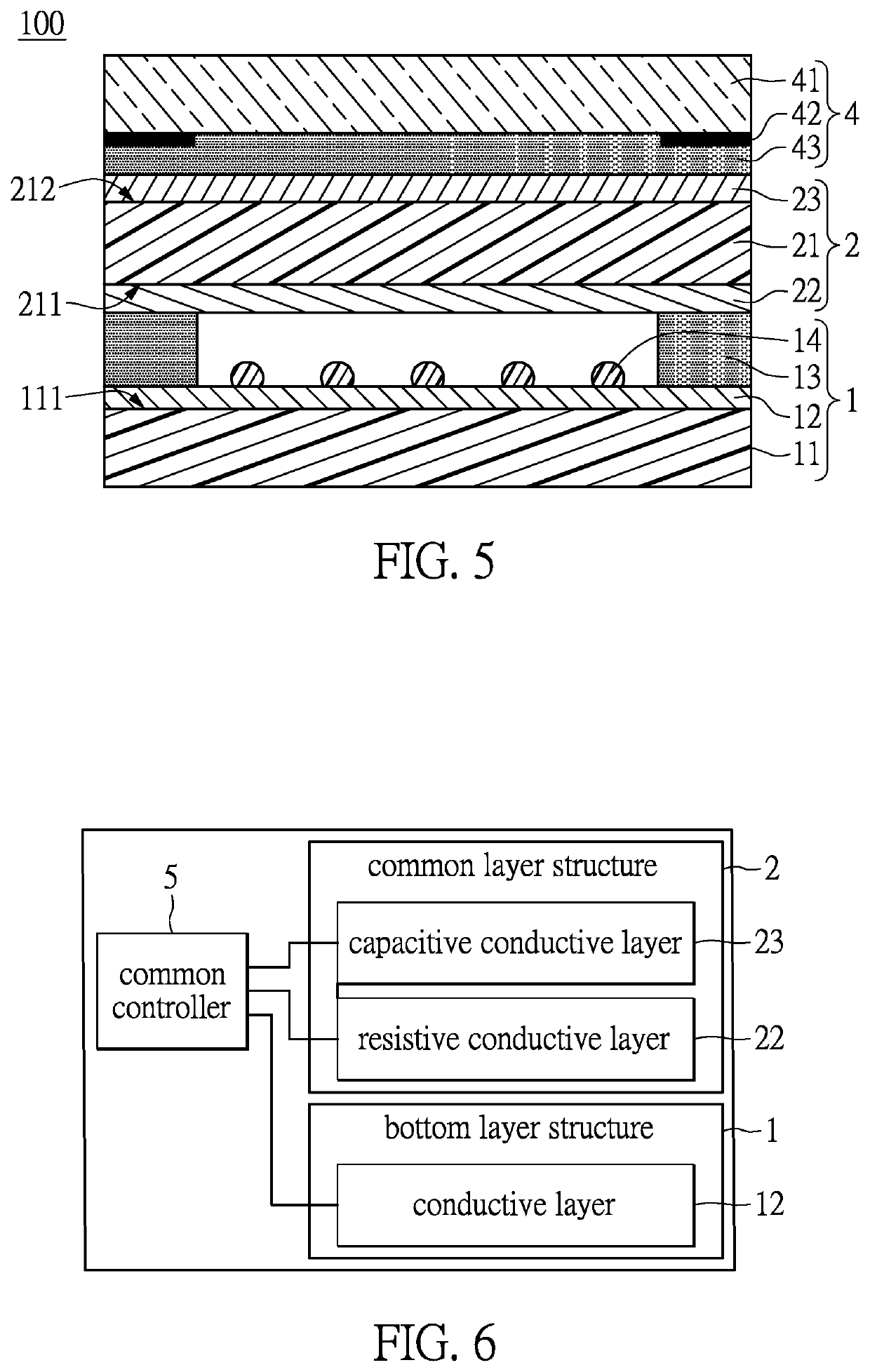

Hybrid touch module

ActiveUS10572061B2Wide operating conditionsGuaranteed uptimeInput/output processes for data processingCapacitanceEngineering

A hybrid touch module includes a bottom layer structure, a common layer structure, and a top layer structure. The bottom layer structure includes a conductive layer, and a bezel disposed on the conductive layer. The common layer structure is disposed on the bezel. The common layer structure includes a common film, a resistive conductive layer, and a capacitive conductive layer. The resistive conductive layer and the capacitive conductive layer are disposed on a first surface of the common film. The top layer structure is attached to the common layer structure, and the top layer structure includes an insulation film and an electrode layer disposed on the insulation film. The common layer structure can be cooperated with the bottom layer structure to provide a resistive touch function, and the common layer structure can be cooperated with the top layer structure to provide a capacitive touch function.

Owner:HIGGSTEC

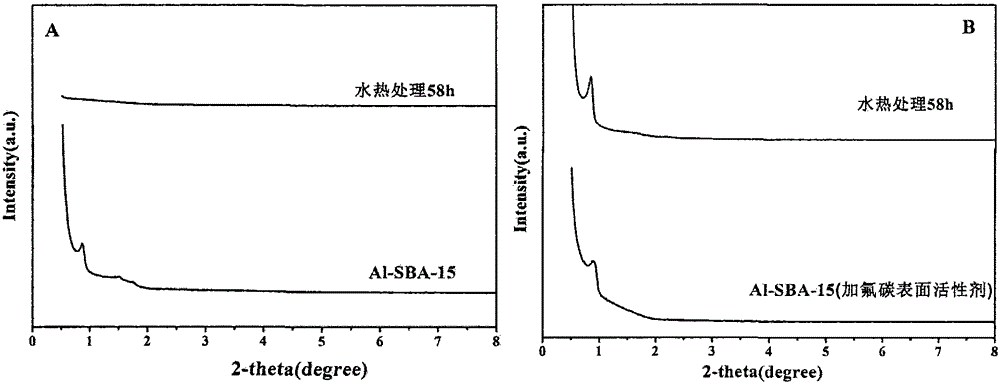

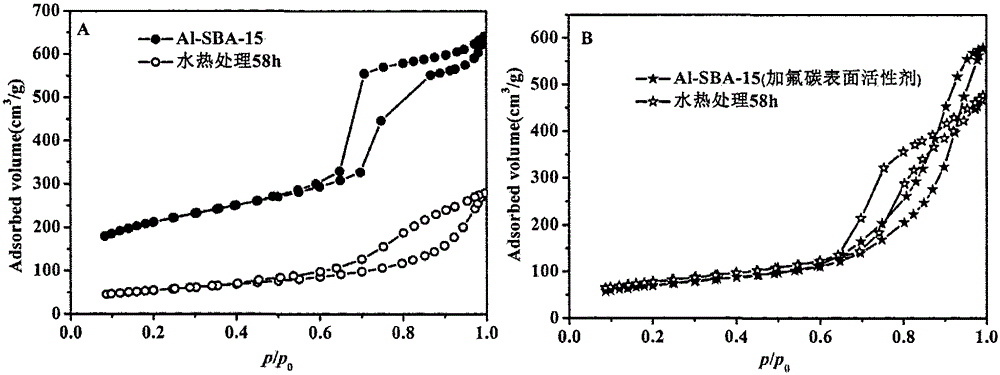

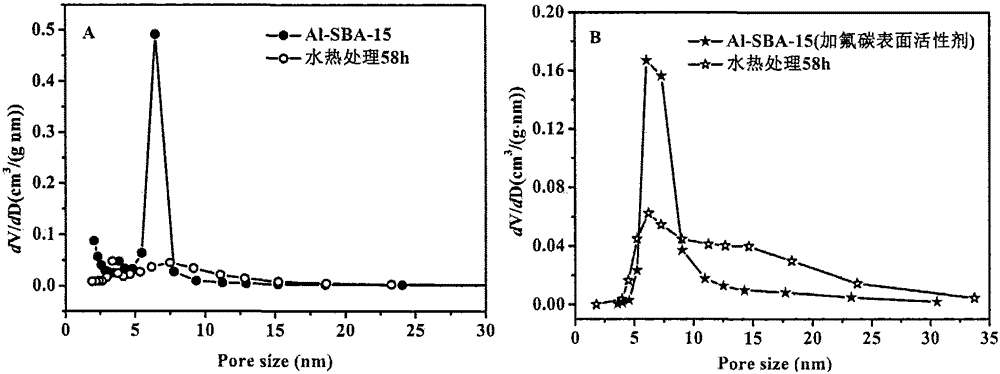

A kind of method utilizing kaolin to synthesize highly stable ordered mesoporous material al-sba-15

InactiveCN104016369BImprove thermal stabilityHigh hydrothermal stabilityMolecular-sieve and base-exchange compoundsMolecular-sieve compoundsSynthesis methodsMesoporous material

The invention discloses a method for synthesizing a high-stability ordered mesoporous material A1-SBA-15 by use of kaoline. The method comprises the following steps: by taking kaoline as a raw material, performing roasting and acid leaching treatment on kaoline, and then adding an alkaline solution with a certain concentration to the treated kaoline to have a reaction, thereby obtain silicon and aluminum sources; adjusting the pH value of the obtained silicon-aluminum source solution to a certain value, and then adding the silicon-aluminum source solution to a mixed solution of a triblock copolymer (P123), a fluorocarbon surfactant (FSO-100 or FS-31) and hydrochloric acid, stirring at 40 DEG C, then carrying out reaction under a hydrothermal condition for 12-72 hours, and finally, filtering, washing, drying and roasting to obtain the high-stability ordered mesoporous material A1-SBA-15. The ordered mesoporous material A1-SBA-15 is synthesized by use of the cheap natural mineral kaoline as the raw material; the preparation process is simple, the raw material is easy to get, and the operation conditions are lenient; the synthesized ordered mesoporous material has excellent hydrothermal stability and catalytic activity.

Owner:INNER MONGOLIA UNIVERSITY

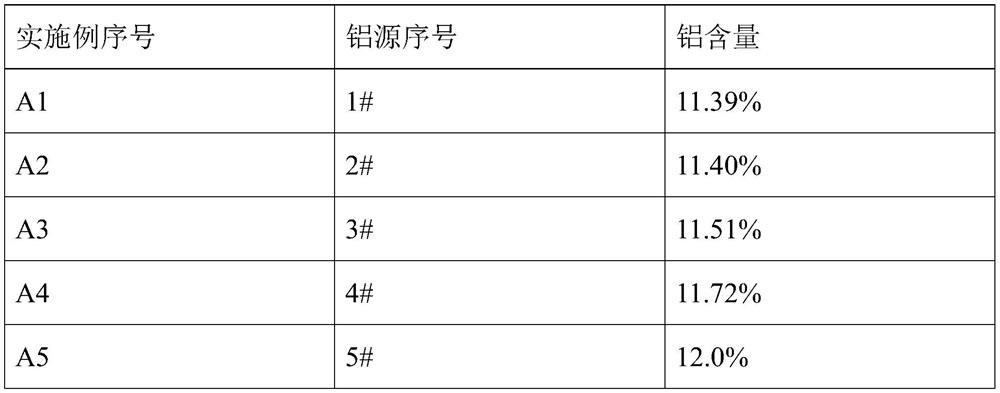

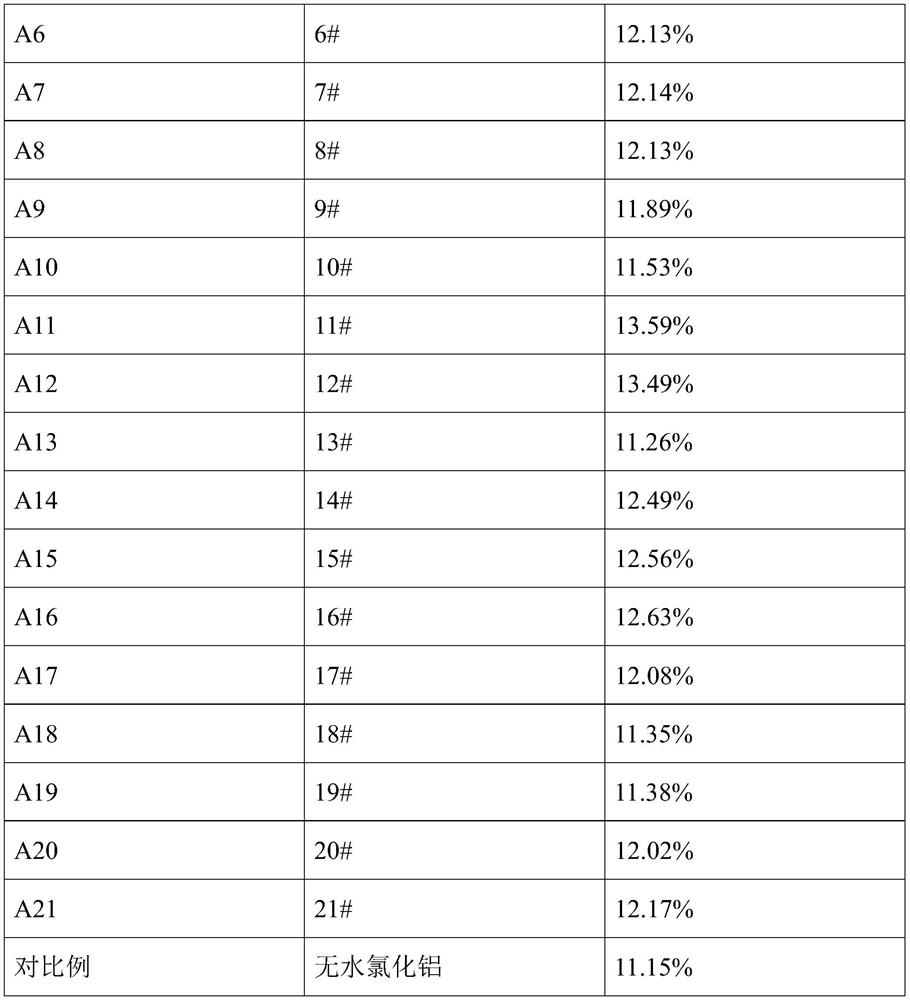

Aluminum source for electrolytic preparation of aluminum alloy, preparation method and method for preparing aluminum alloy using same

The invention provides an aluminum source for electrolytic preparation of an aluminum-containing aluminum alloy. The aluminum source comprises complex salt which is formed by aluminum halide and alkali metal halides. The aluminum source comprises problems of easy water absorbing of aluminum halide at a normal temperature, easy sublimation at a high temperature, and high difficulty for controllingthe actual adding amount of the aluminum source. Furthermore the aluminum source has advantages of settling environment harm caused by sublimation of an aluminum halide aluminum source, settling a problem of aluminum hydroxide deposition generation caused by water absorbing of the aluminum halide aluminum source, and prolonging slag removal period of an electrolytic cell and service life of the electrolytic cell. The aluminum source is used for preparing the aluminum-containing alloy and can realize advantages of controlling the content of the aluminum element which enters electrolyte, furtherrealizing element proportion controllability of the aluminum-containing alloy, realizing high stability of element proportions in different batches of aluminum-containing alloy, and saving secondarymelting in preparing a workpiece through the aluminum-containing alloy material. Furthermore the aluminum source according to the invention can reduce sublimation of the aluminum element and reduces environment harm.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

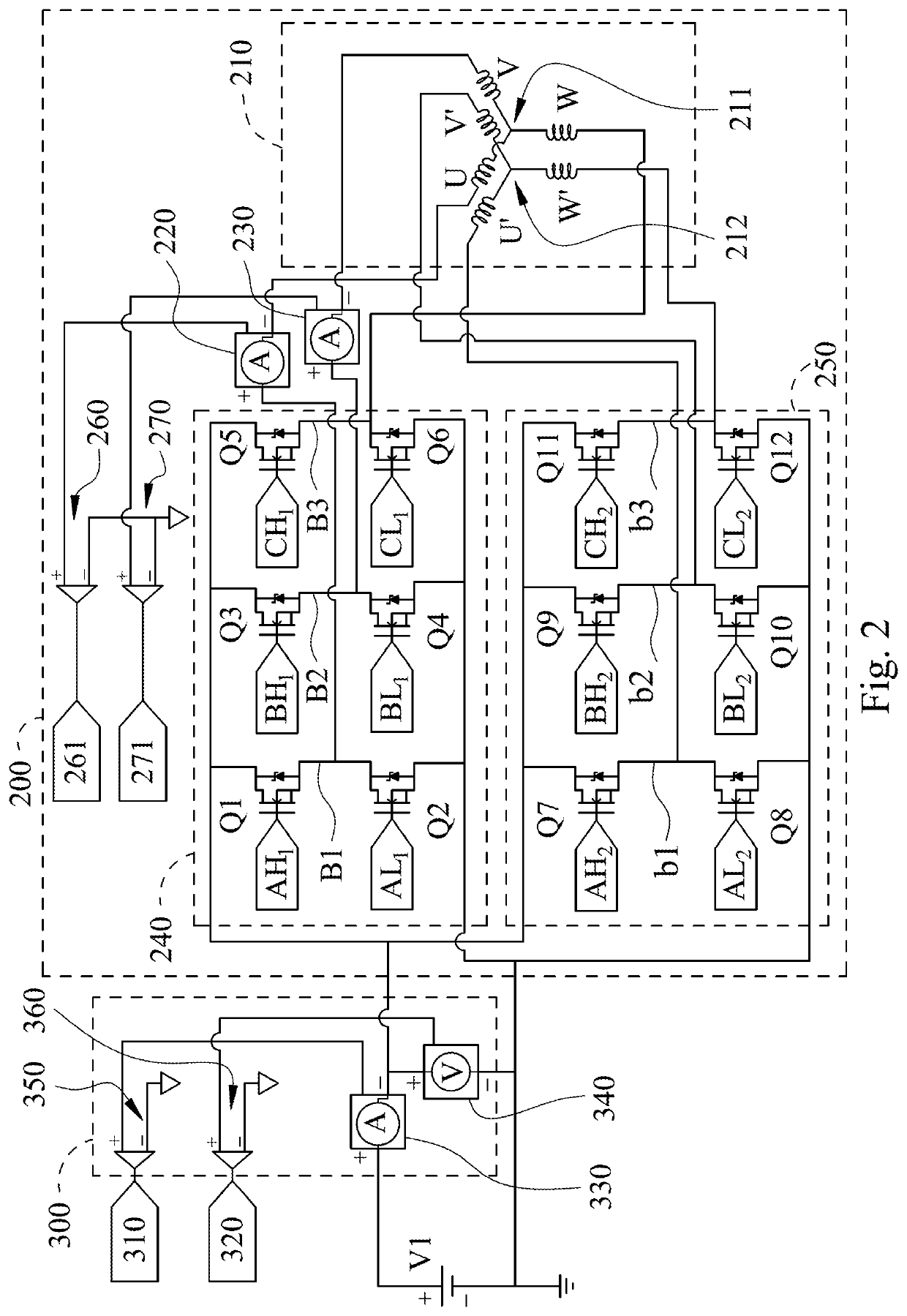

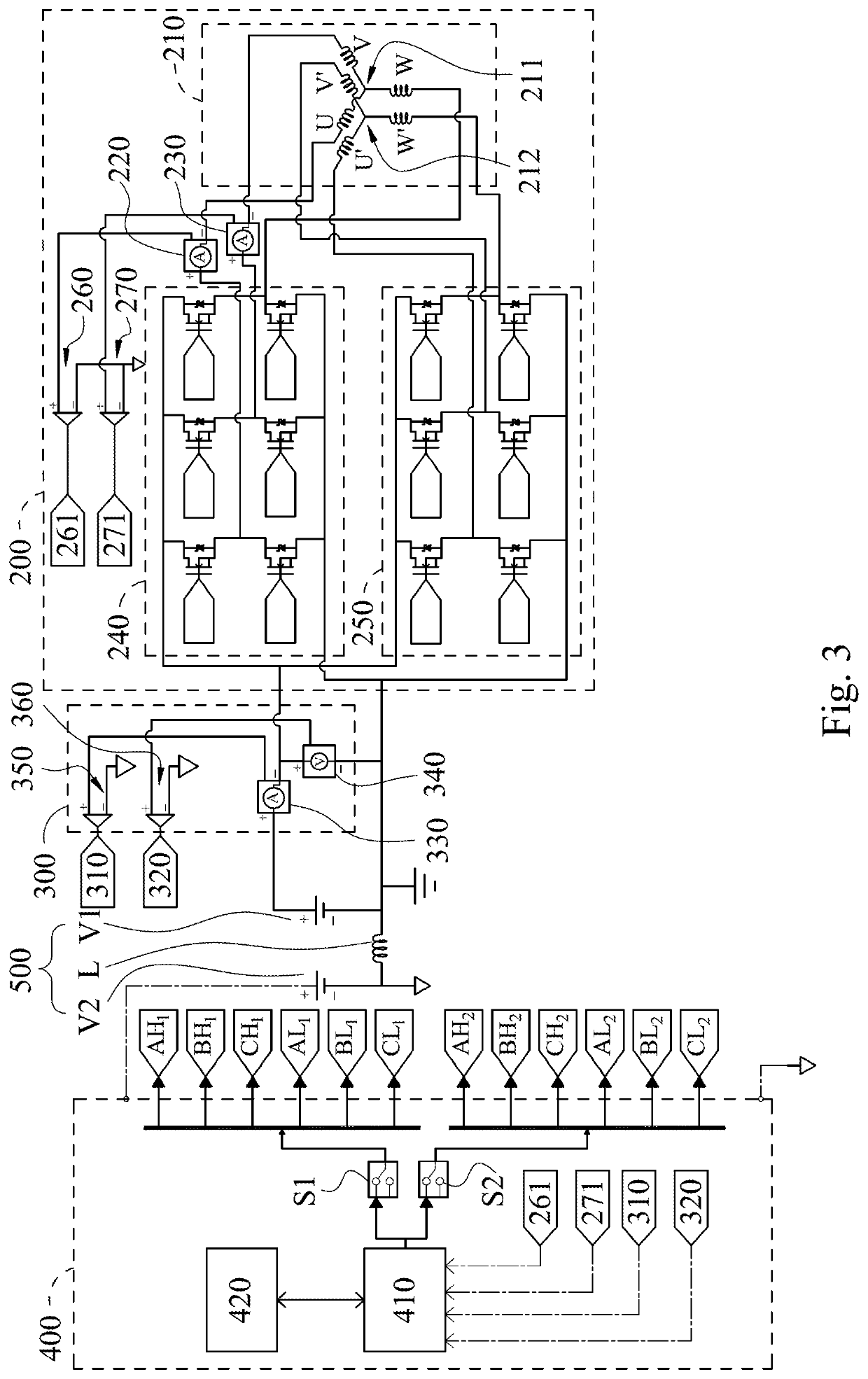

Power detecting device and method thereof

ActiveUS20220103105A1Improve efficiencyIncrease powerAC motor controlVector control systemsPhase currentsCurrent sensor

A power detecting device includes a vehicle driving system, a battery detecting module and a controlling module. A first stator winding and a second stator winding are synchronized and connected in parallel with each other. A first end of a first current sensor is coupled to a first-phase winding end of the first stator winding for measuring a first-phase current. A first end of a second current sensor is coupled to a second-phase winding end of the first stator winding for measuring a second-phase current. The battery detecting module is coupled to a first power supply for measuring a current signal and a voltage signal. A controller generates a first power according to the current signal and the voltage signal and generates a second power according to a plurality of data from a database. The controller compares the first power with the second power to generate a detecting result.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com