Compound demulsifying agent for wood tar dehydration

A demulsifier and composite technology, which is applied in the field of dehydration of biomass pyrolysis and carbonization products, can solve the problems of inability to break demulsification of wood tar, improve the speed and quality of pretreatment, reduce interfacial tension, and achieve good demulsification effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

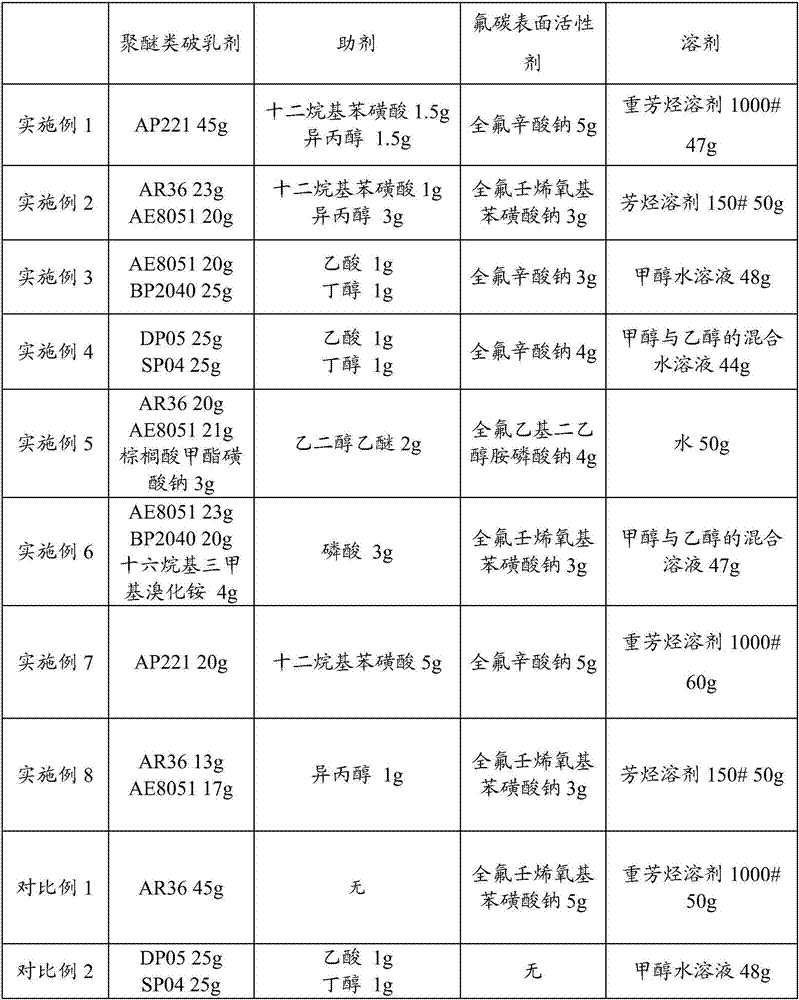

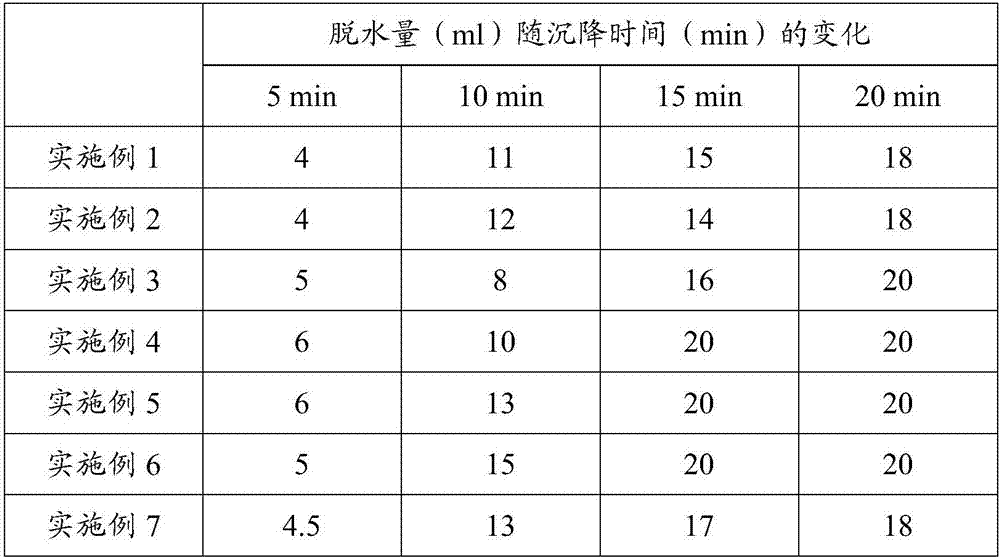

Embodiment 1

[0042] The oil-soluble composite demulsifier for wood tar dehydration provided in this example is composed of: 45 g of block polyether demulsifier AP221 with amine as the initiator, 5 g of sodium perfluorooctanoate, and dodecylbenzenesulfonic acid Mixture with isopropanol 3g, heavy aromatic hydrocarbon solvent 1000 # 47g.

Embodiment 2

[0044] The oil-soluble composite demulsifier for wood tar dehydration provided in this example is composed of: 23g of block polyether demulsifier AR36 with alkyl phenolic resin as the initiator, block polyether demulsifier AR36 with amine as the initiator Segment polyether demulsifier AE805 120g, sodium perfluorononenyloxybenzene sulfonate 3g, mixture of dodecylbenzenesulfonic acid and isopropanol 4g, aromatic solvent 150g # 50g.

Embodiment 3

[0046] The water-soluble composite demulsifier for wood tar dehydration provided in this example is composed of: 20 g of block polyether demulsifier AE8051 with amine as the initiator, and block polyether with alcohol as the initiator Demulsifier BP2040 25g, sodium perfluorooctanoate 3g, mixture of acetic acid and butanol 2g, 20wt% methanol aqueous solution 48g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com