Patents

Literature

64 results about "Creosote" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Creosote is a category of carbonaceous chemicals formed by the distillation of various tars and pyrolysis of plant-derived material, such as wood or fossil fuel. They are typically used as preservatives or antiseptics.

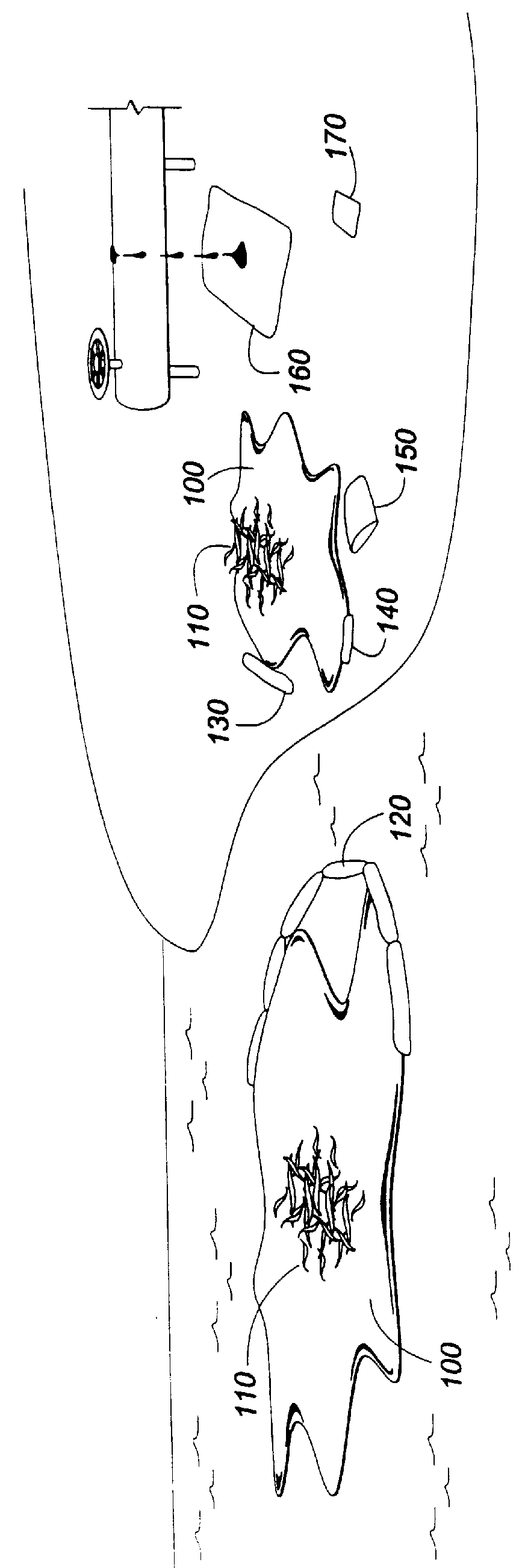

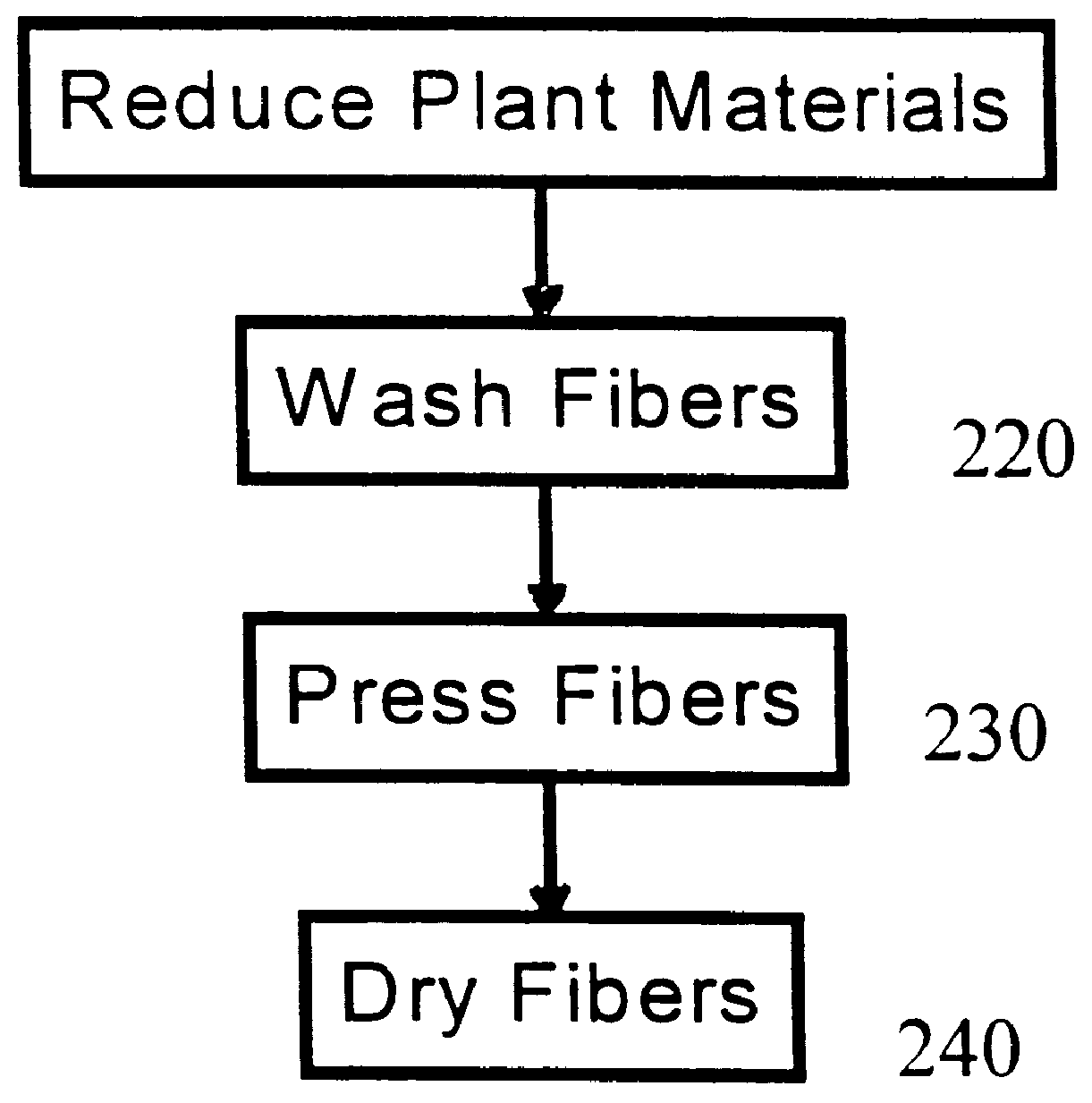

Process for sorbing liquids using tropical fibers

A process is described for using tropical fibers to recover spilled oil, gasoline, kerosene, hydrocarbons, pentachlorophenol, creosote or other hazardous liquids from land or water. The sorbent fiber material is produced from agricultural byproducts from cultivation of banana, plantain, cavendish plant, pineapple, coconut, palm, or other tropical fruit bearing plants. The sorbent fibers are produced by separating the raw plant materials; washing the separated fibers in a solution of 1% alum; pressing the fibers to extract liquids and natural juices; further separating the fibers by beating or agitating; and drying the fibers. The sorbent fibers have a water and natural liquid content of less than 10% by weight and may be applied to the surface or periphery of an oil or chemical spill, whereupon they will sorb the oil or chemical. Once the oil or chemical is sorbed the fibers may be collected and the oil or chemical may be partially recovered by compressing the fibers. The fibers may be disposed of by landfilling or may be thermally treated. When thermally treated in a boiler or furnace, the liquid laden fibers may also be a valuable source of fuel.

Owner:KEMRON ENVIRONMENTAL SERVICES INC +1

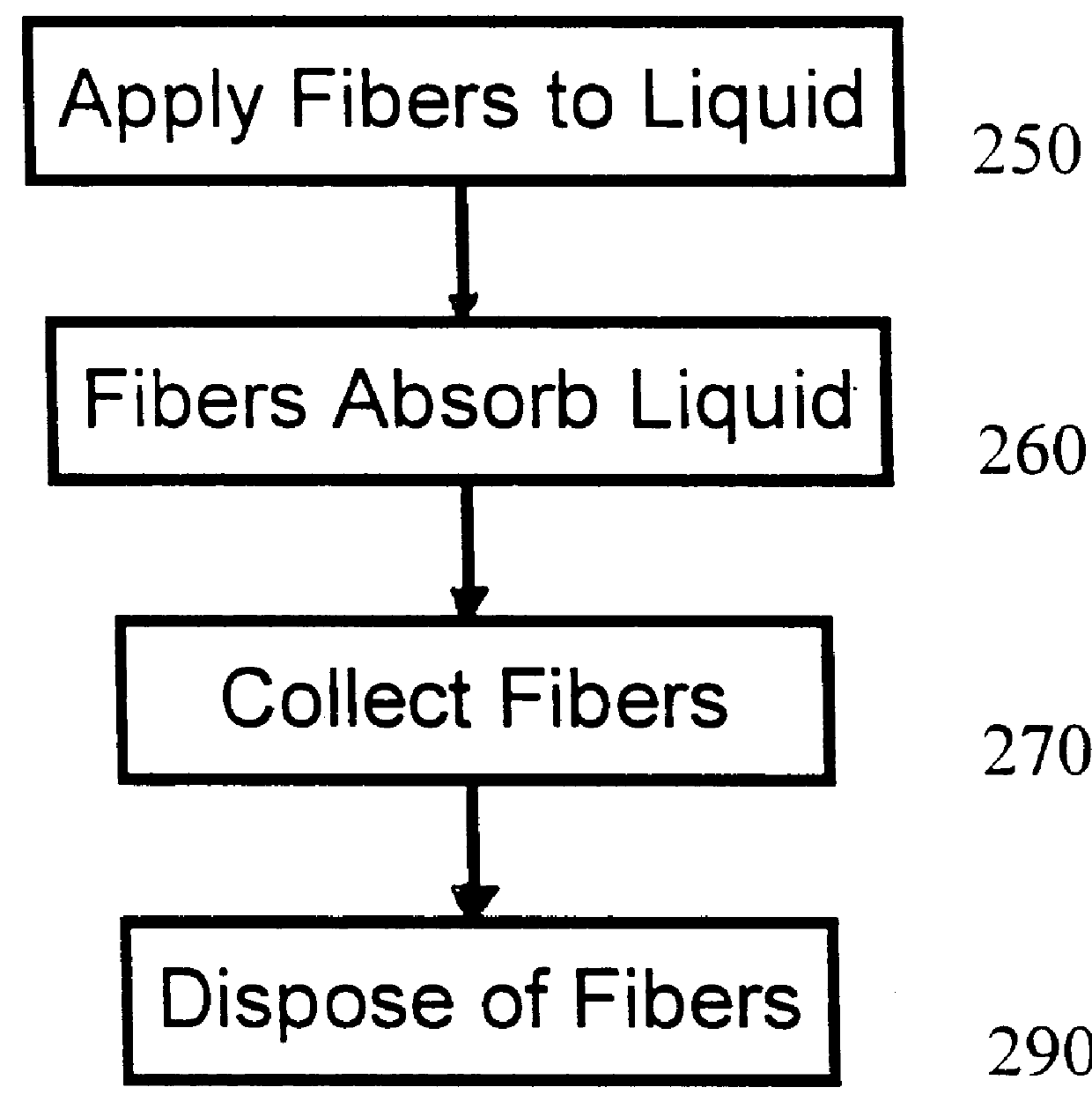

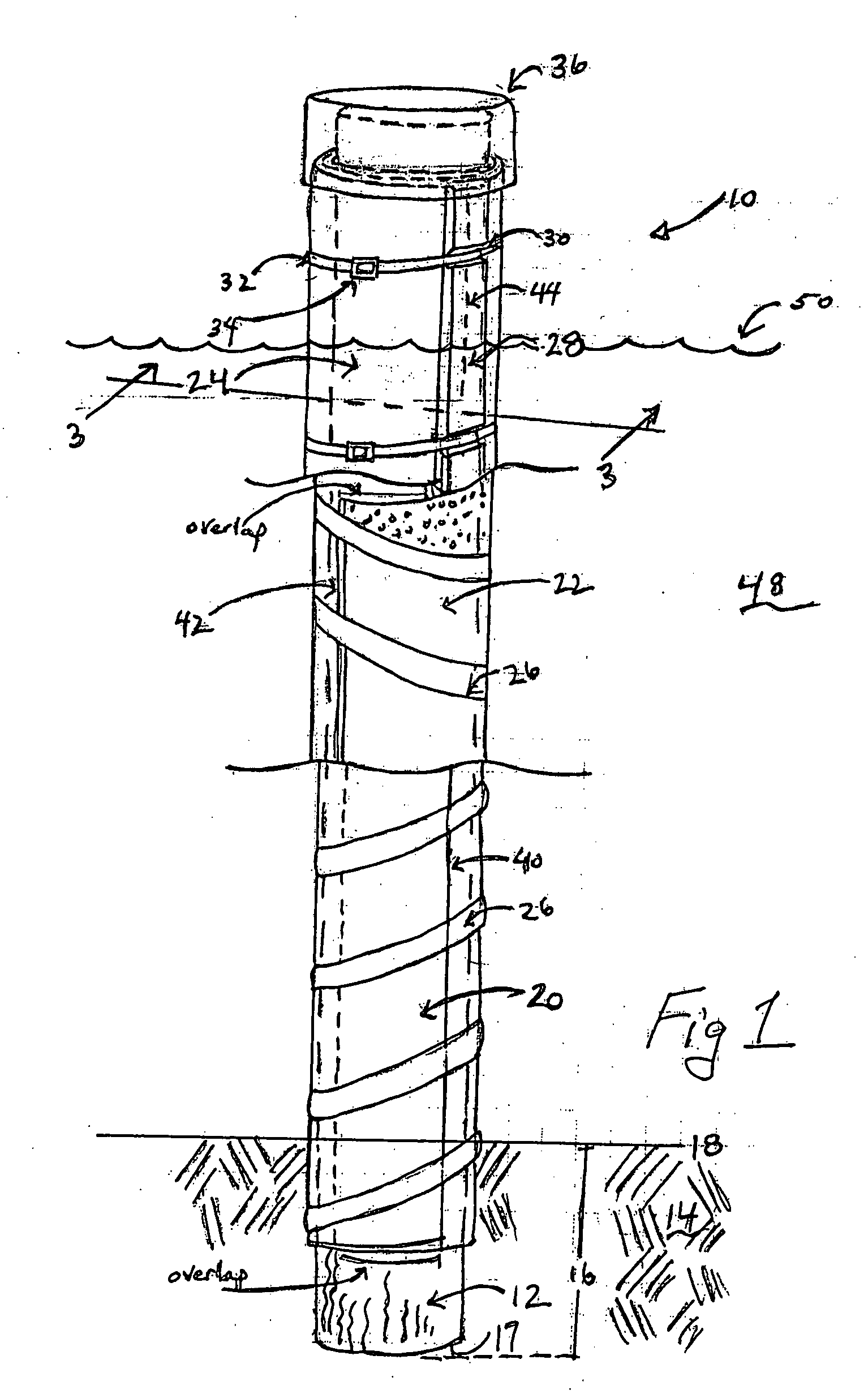

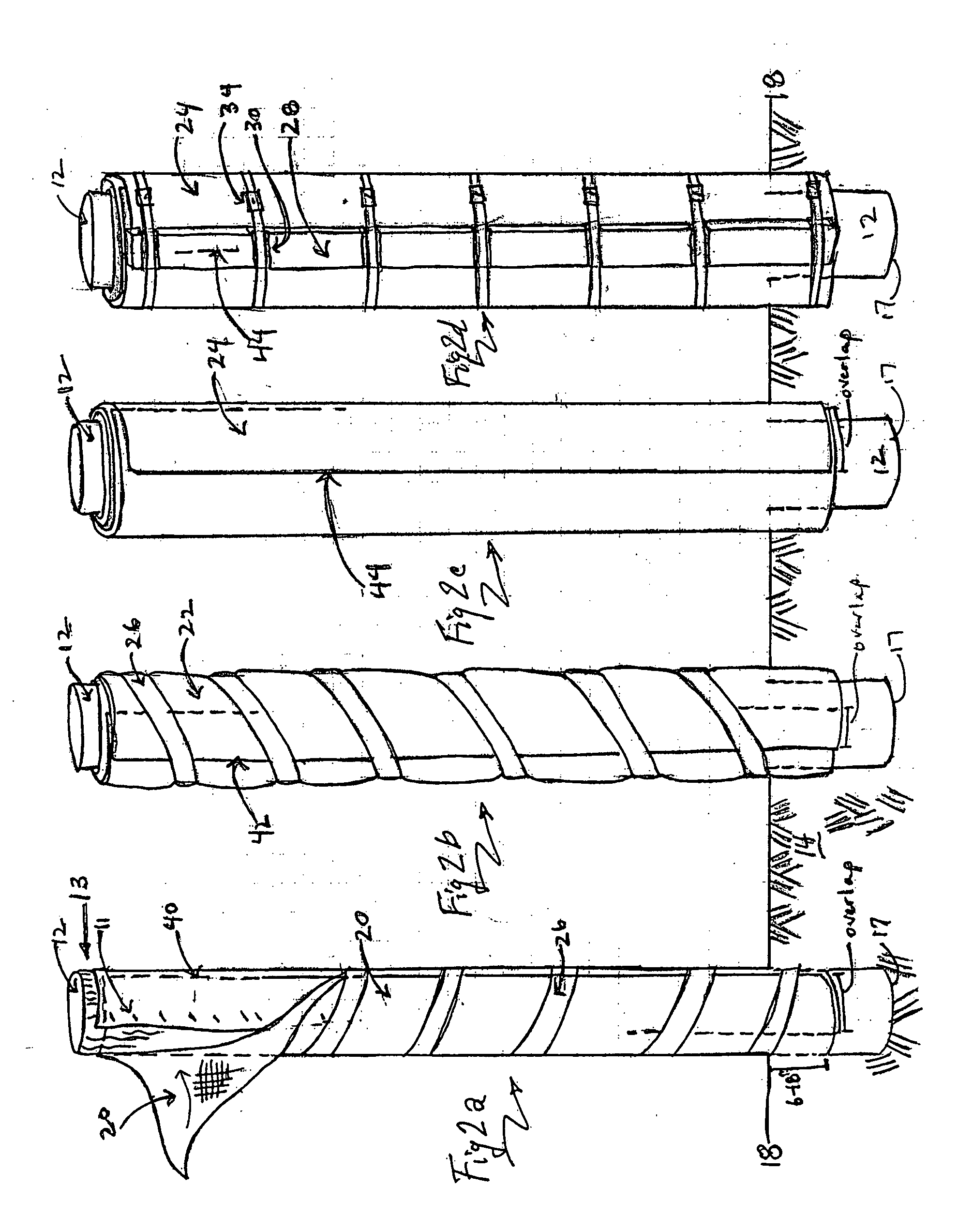

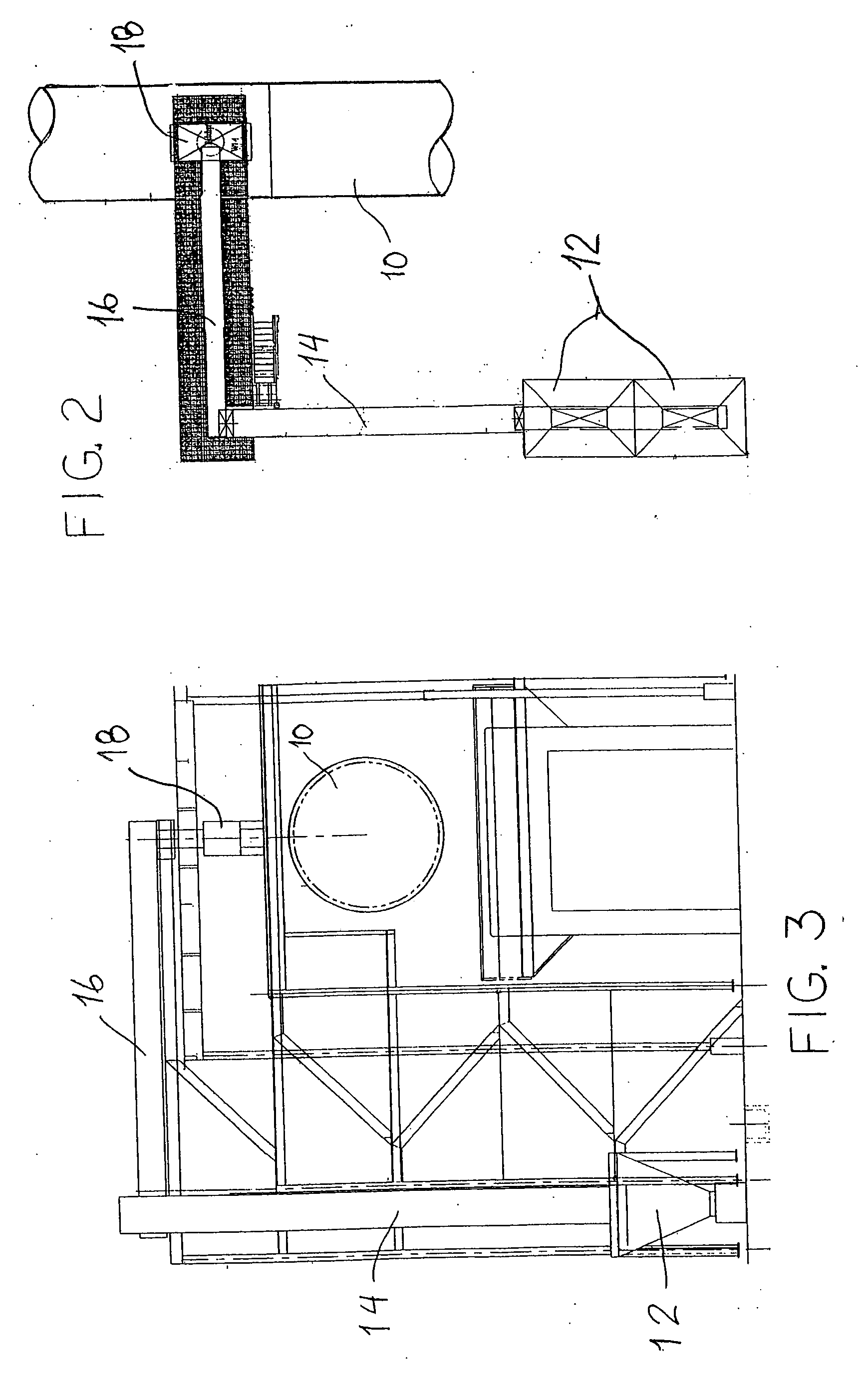

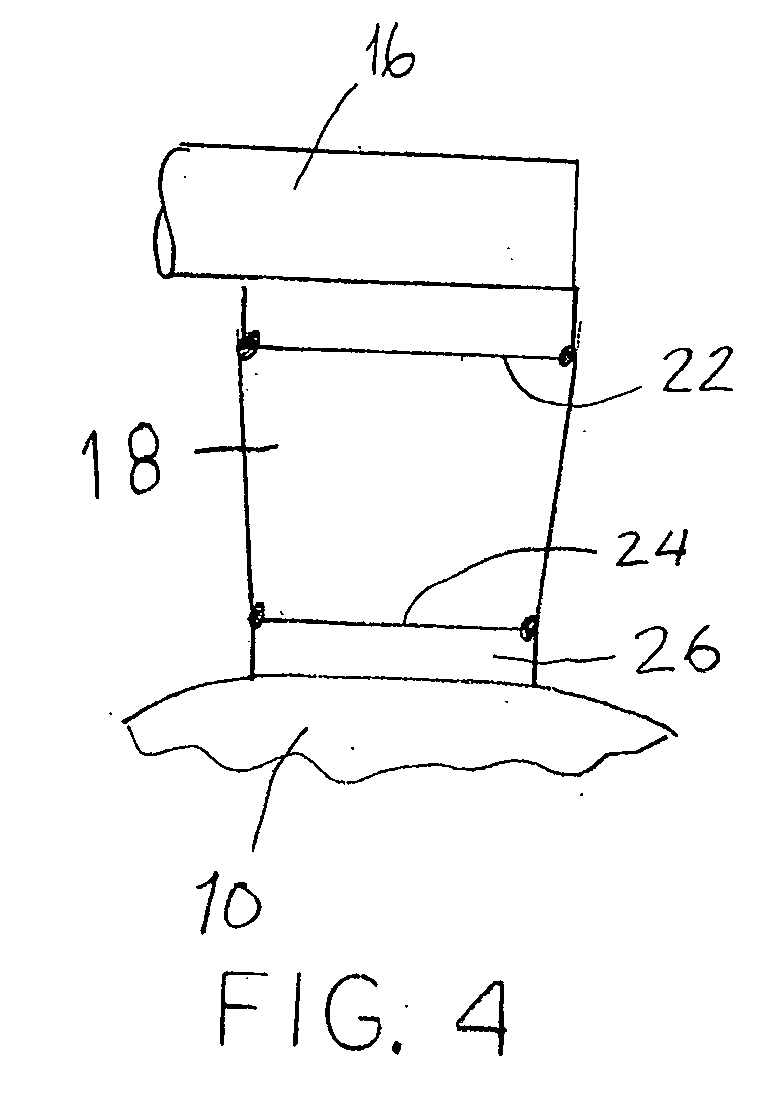

Piling and pole protective wrap system

InactiveUS20060088386A1Eliminate any undesirable bunching of materialFlat surfaceProtective foundationBulkheads/pilesBiological bodyCreosote

A multi-layer protective wrap system for wood or metal pilings and poles comprising multiple organic polymer layers (an inner seal wrap, an optional foam conformation layer, and an outer compression shell) secured to the pilings by a bar-and-band system provides resistance to decay, thereby extending the life of pilings / poles in both new and retrofit installations. The 2- or 3-layer wrap system not only extends the life of pilings / poles by protecting them from new infestation by organisms, but also starves existing organisms of the oxygen they require to survive. In addition, because the inventive wrap system seals the piling / poles, it prevents leaching of creosote or other protective coating materials into the environment, reducing the threat of toxicity. This permits industry current standard practice of impregnating pilings with creosote to act as a third or fourth layer inside the 2-3 layers of the inventive wrap system.

Owner:ELLIS WILLIAM

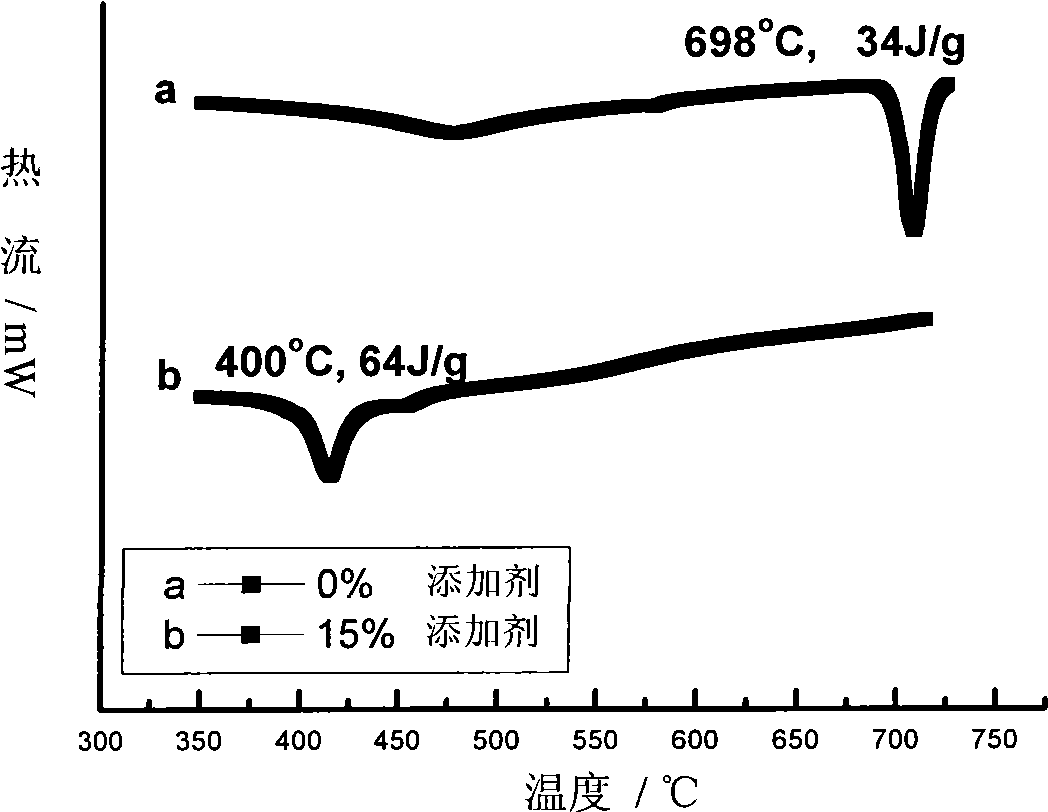

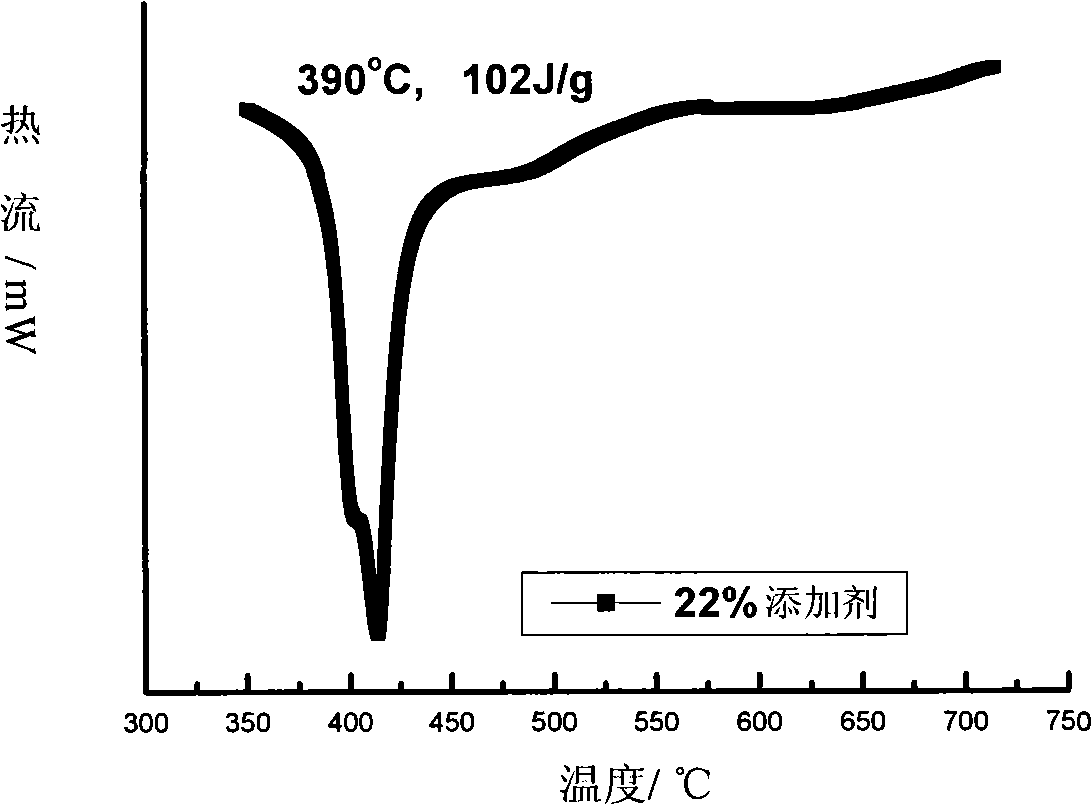

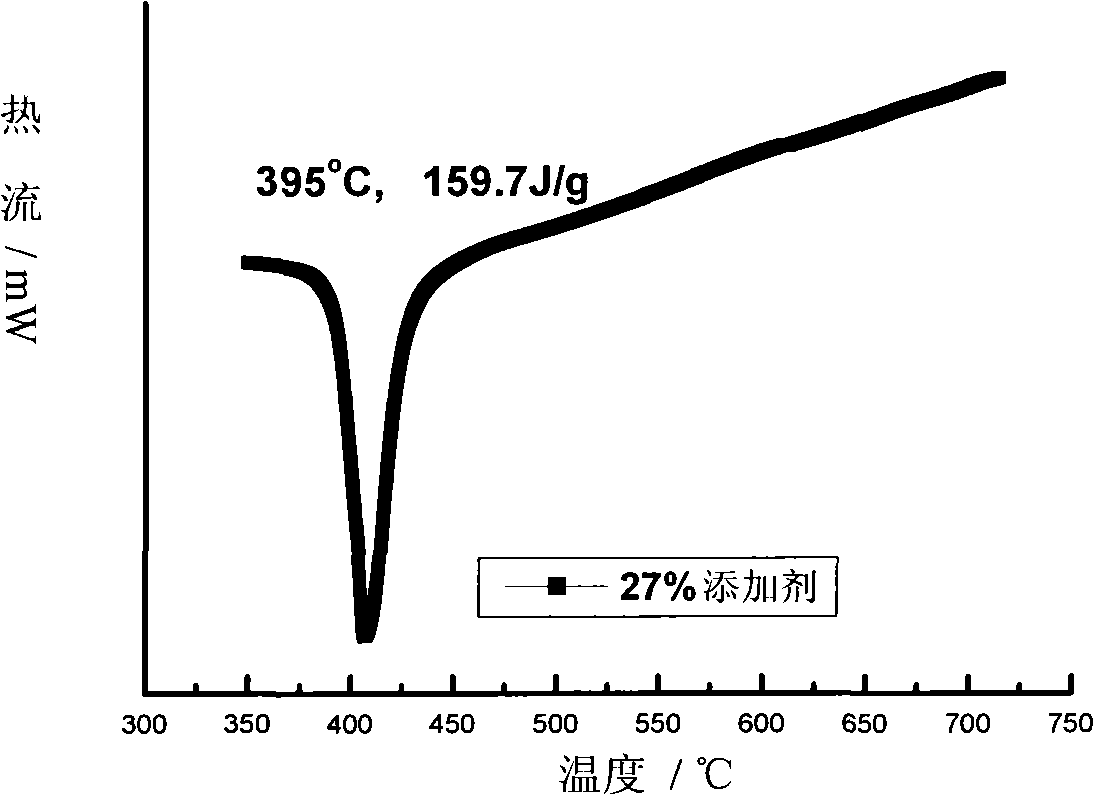

Lithium-containing molten salt creosote thermal transmission heat storage medium, preparation and uses thereof

InactiveCN101508888AImprove thermal stabilityGuaranteed safe use temperature upper limitSolar heat devicesEnergy inputChemical reactionCreosote

The invention discloses a lithium containing molten carbonate heat transmission and storage medium, a preparation method and the application thereof. The lithium containing molten carbonate heat transmission and storage medium comprises potassium carbonate, sodium carbonate and additive, wherein, the additive consists of sodium chloride and lithium carbonate. The lithium containing molten carbonate heat transmission and storage medium can meet the need of high temperature heat utilization of solar energy, more particularly, the operating temperature range required by using solar energy to produce hydrogen and reforming methane through solar energy supercritical heat power generation and solar energy thermal chemical reaction. The heat transmission and storage medium has good thermal stability, more latent heat of phase change, low lower limit of usage temperature, lower requirements for the size and energy of the system, high energy utilization rate and good effects.

Owner:SUN YAT SEN UNIV +1

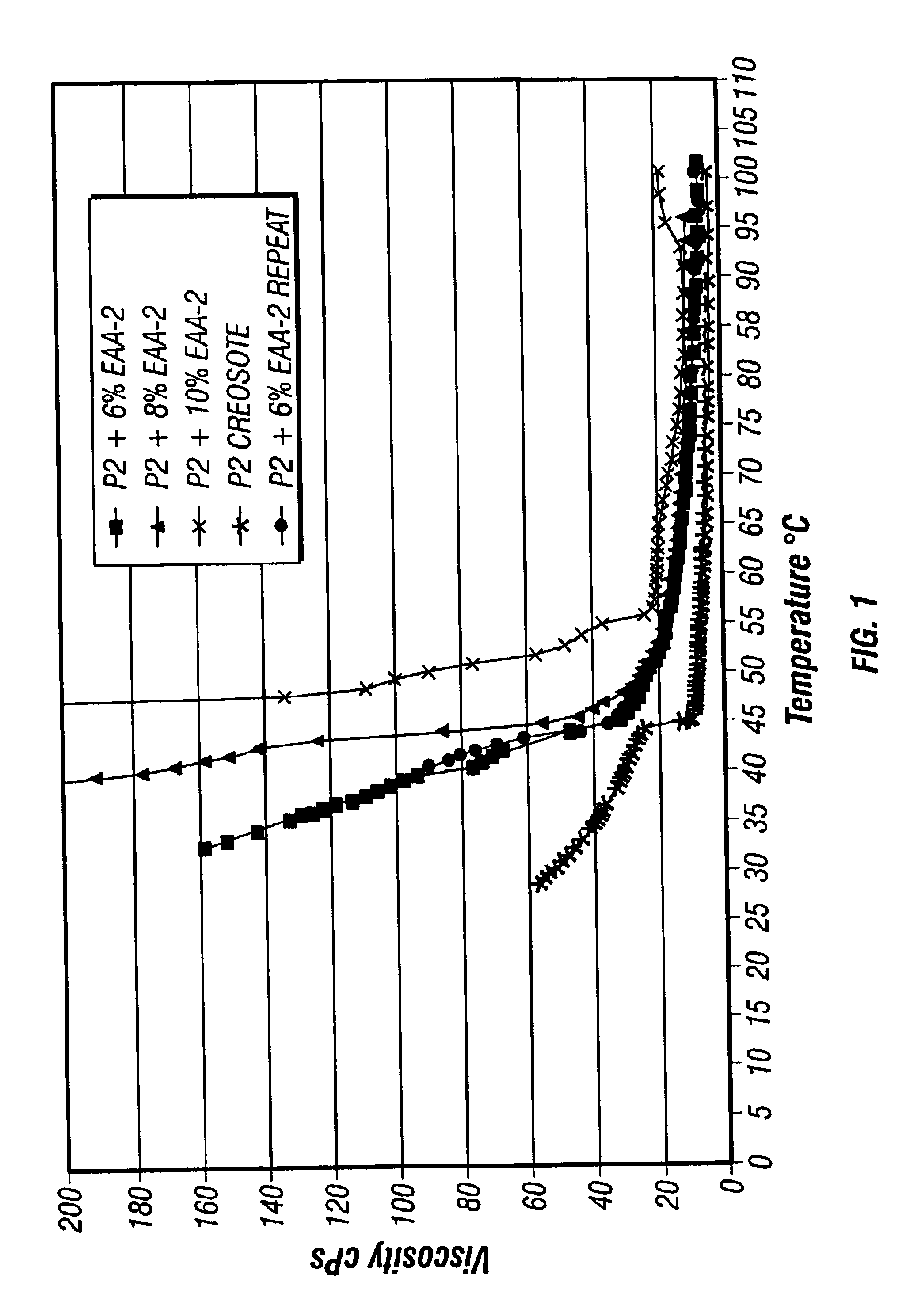

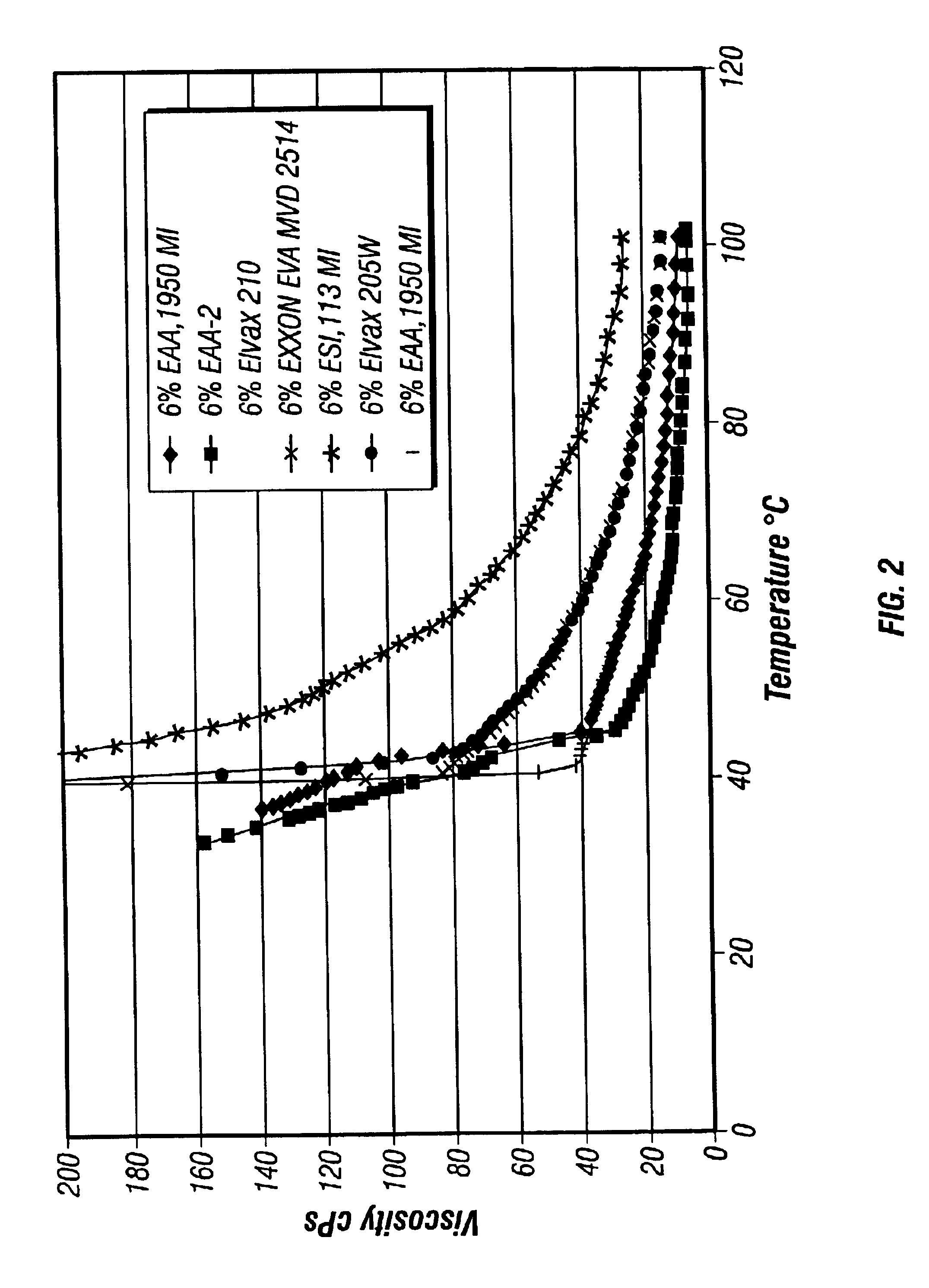

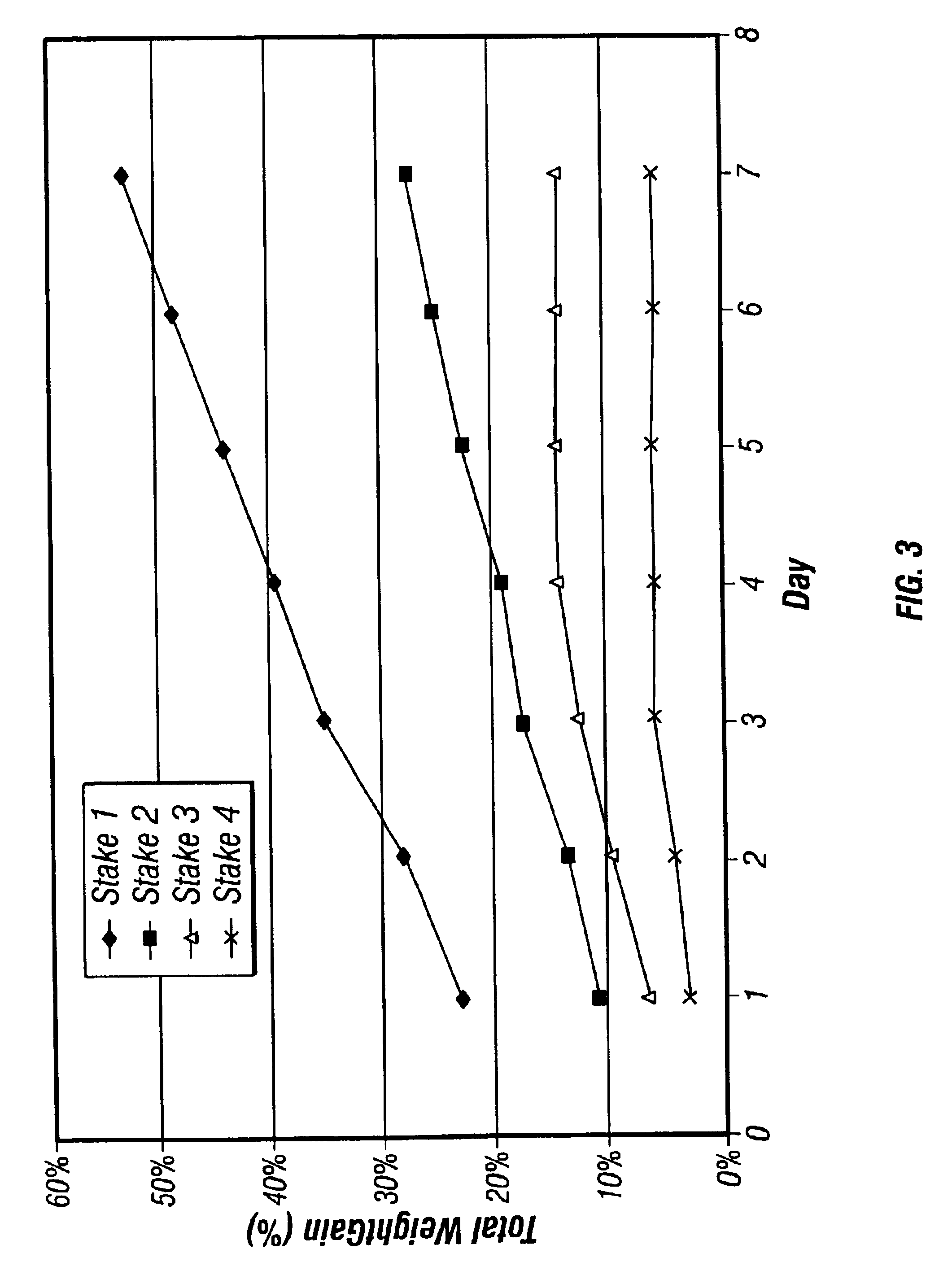

Wood treatment composition and method of use

A wood treatment composition for the preservation of wood comprises a mixture of creosote and a polymer which is miscible with the creosote at about 200° F. and does not substantially phase-separate when the wood treatment composition is under ambient conditions. The polymer may include, but is not limited to, ethylene vinyl acetate copolymers, ethylene methyl acrylate copolymers, ethylene ethyl acrylate copolymers, ethylene butyl acrylate copolymers, ethylene acrylic acid copolymers, ethylene methacrylic acid copolymers, ethylene methyl methacrylic acid copolymers, ethylene styrene interpolymers, styrene acrylic acid copolymers, styrene methacrylic acid copolymers, styrene methyl acrylate copolymers, styrene butadiene styrene block copolymers, styrene ethylene butylene styrene block copolymers, or a blend thereof. Preferably, the creosote is present in an amount of at least 50 percent by weight of the composition. Such compositions can be used to treat wood surfaces to prolong the service life of the wood.

Owner:DOW GLOBAL TECH LLC

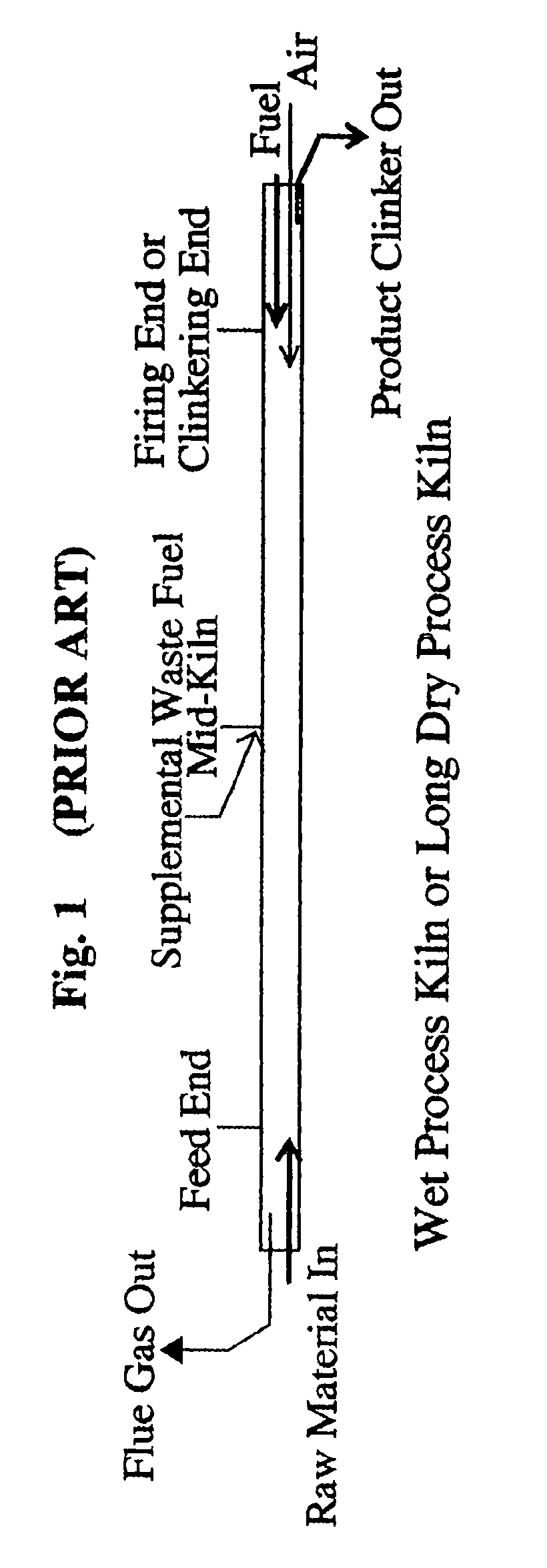

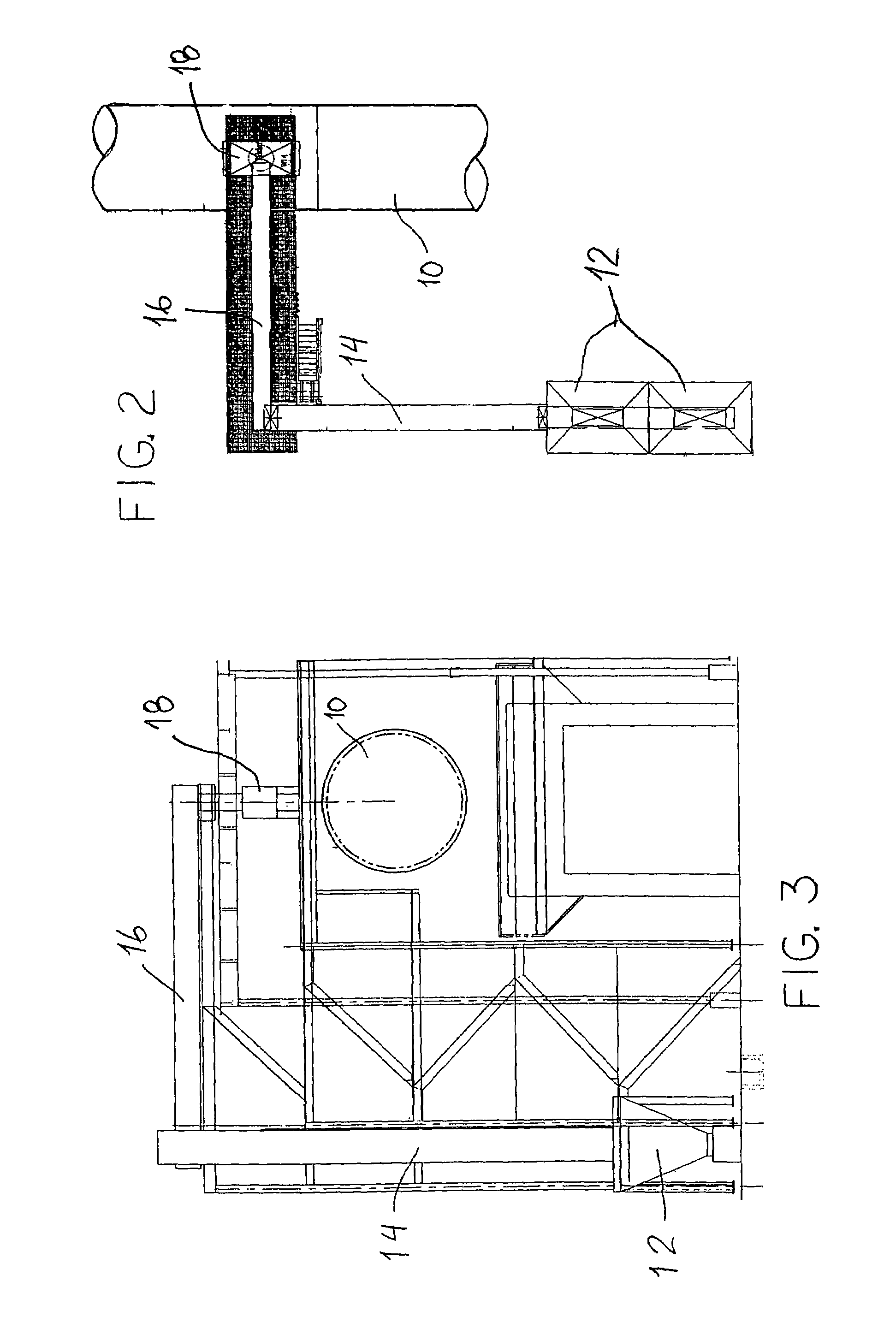

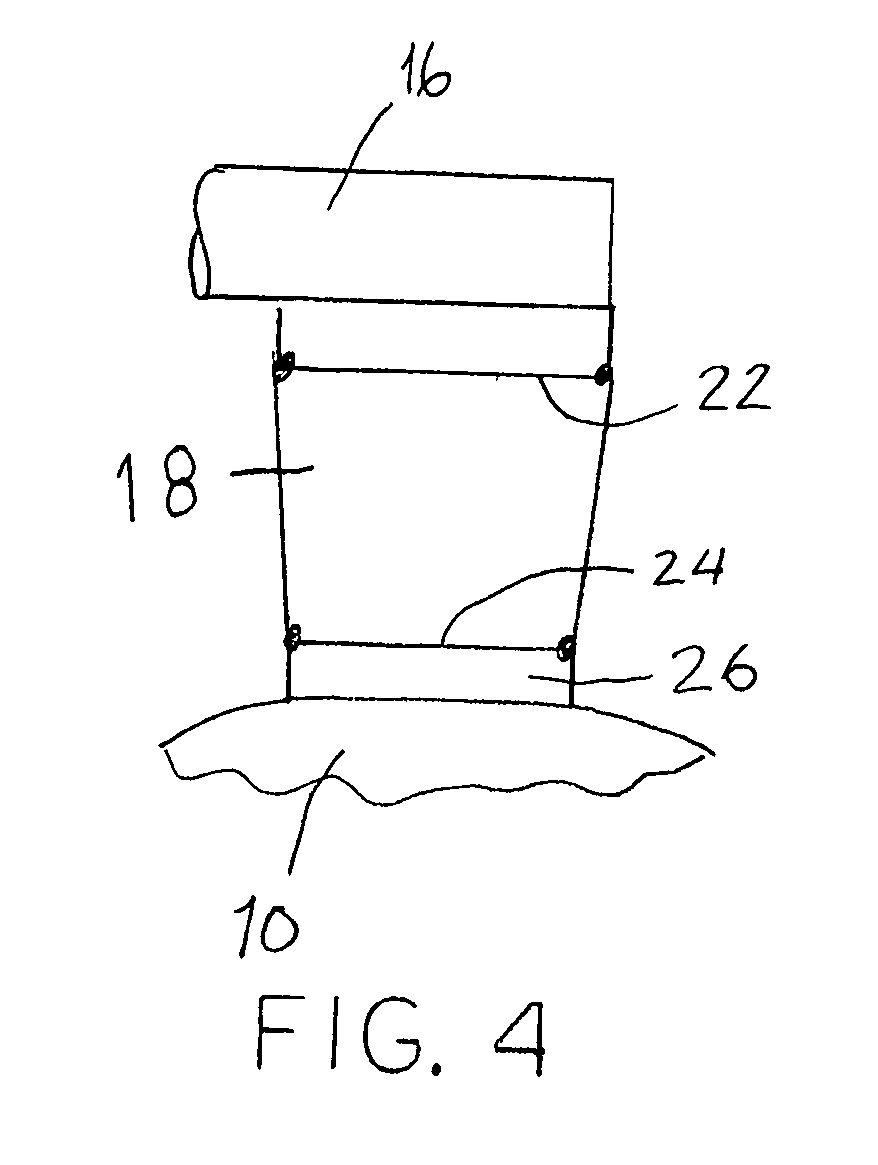

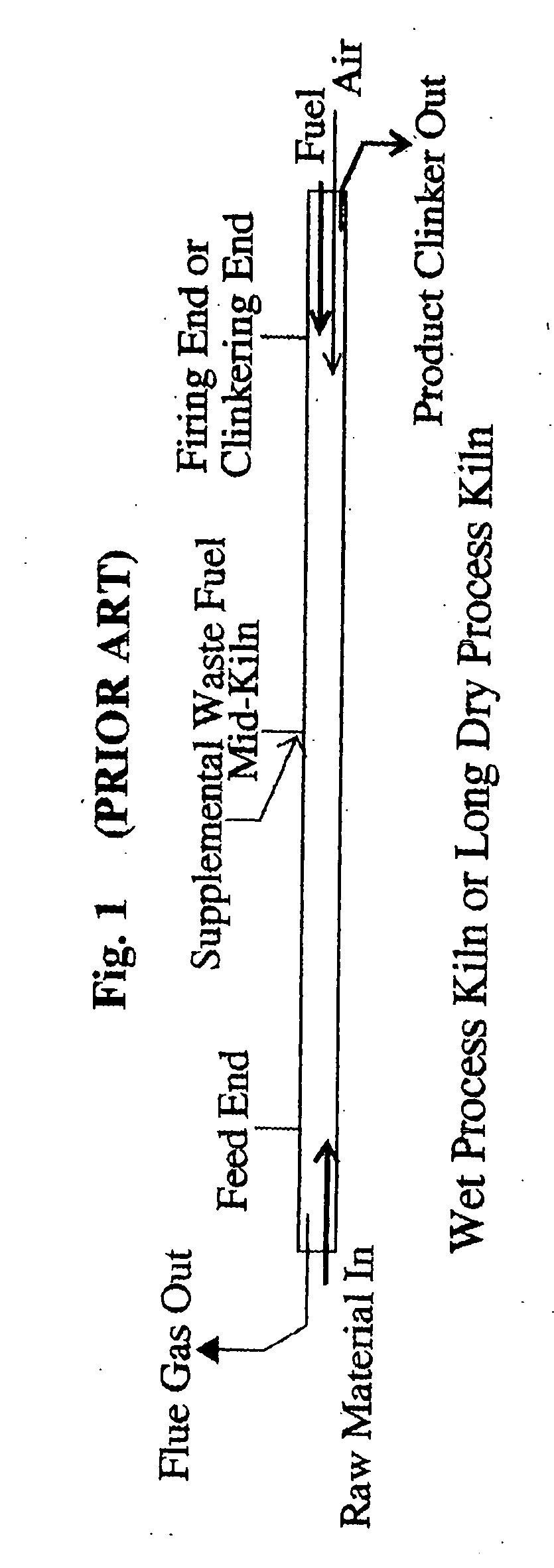

Mid-kiln injection of waste-derived materials

InactiveUS7037368B2Augments clinker productionReduces certain noxious emissionCement productionCreosoteMaterials science

A method for the production of cement clinker comprises the introduction of non-traditional materials into the kiln, preferably at a mid-kiln locations. The non-traditional materials are materials that are difficult, expensive or environmentally challenging for disposal. In one embodiment, weathered clinker is introduced into the kiln to admix with the raw material mix to augment clinker production. In another embodiment, bird, animal or human manure is added to the kiln so that gaseous reducing agents can be released by the manure and combine with certain noxious gases generated during the clinker production, to thereby reduce the noxious gas output. In other embodiments, other non-traditional waste-derived fuels are added to the kiln during clinker production, including railroad ties coated with creosote, industrial, commercial and consumer rubber components, such as rubber hoses, unshredded plastics, and organic materials, such as bird and animal meal.

Owner:LONE STAR INDS

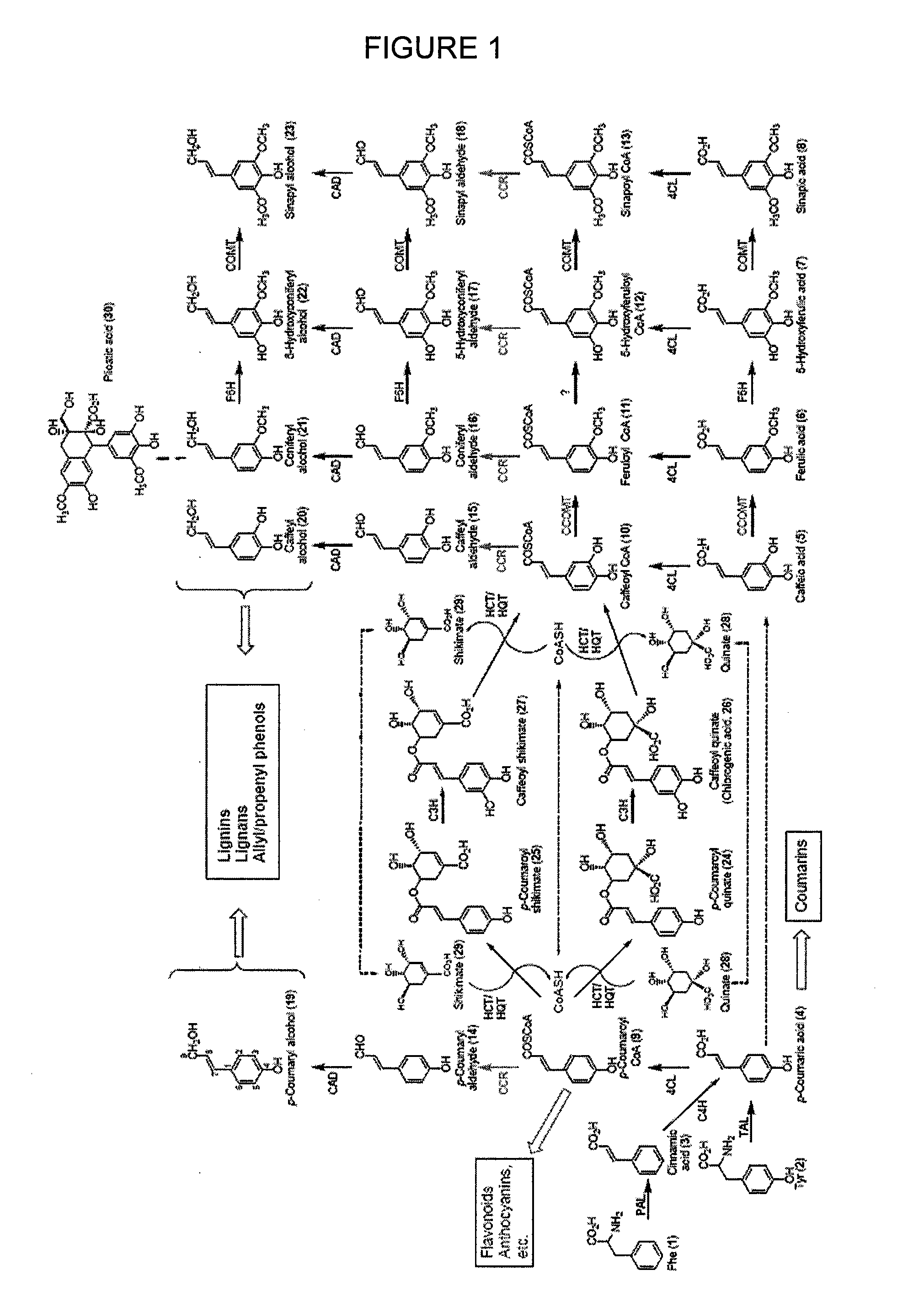

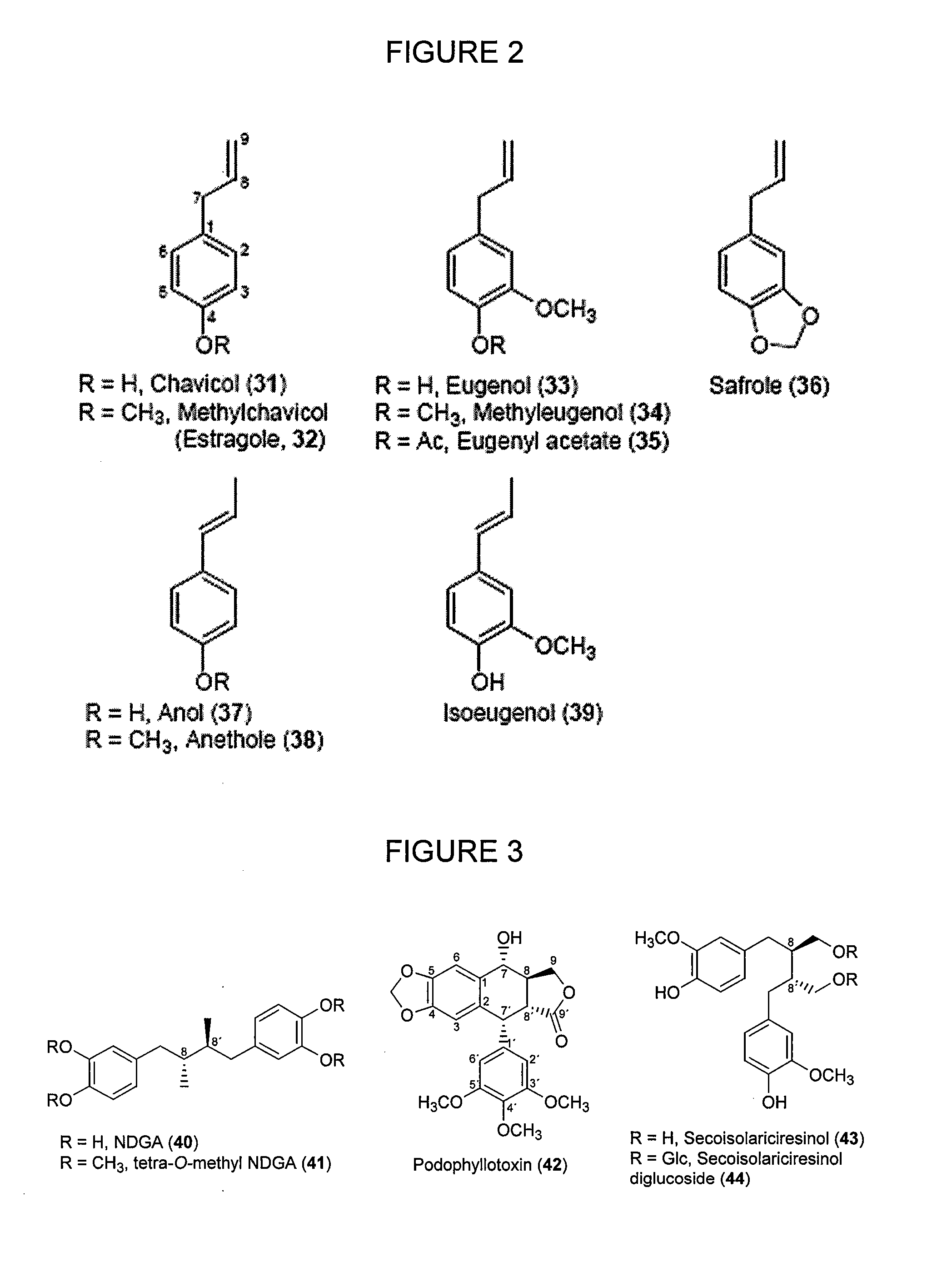

Genes encoding chavicol/eugenol synthase from the creosote bush larrea tridentata

Particular aspects provide novel methods for redirecting carbon allocation in plants or cell culture from lignification to inherently more useful and tractable materials, and to facilitate the generation of, e.g., biofuels from the remaining plant roculture biomass. Particular aspects provided novel methods for converting monolignols into allyl / propenyl phenols, and for chavicol / eugenol formation or production. Additional aspects relate to the discovery of novel chavicol / eugenol synthases that convert p-coumaryl / coniferyl alcohol esters into chavicol / eugenol, and to novel compositions (e.g., novel proteins and nucleic acids encoding same), and novel methods using same for producing or forming chavicol / eugenol and other derivatives in cell culture and / or genetically modified plants, and for re-engineering the composition of plant biomass. Particular aspects provide novel methods for generation in culture or in planta of liquid / combustible allyl / propenyl phenols, and these phenolic products are utilized for (non-ethanol) biofuel / bioenergy purposes, while the remaining plant biomass facilitates the generation of other biofuels.

Owner:WASHINGTON STATE UNIVERSITY

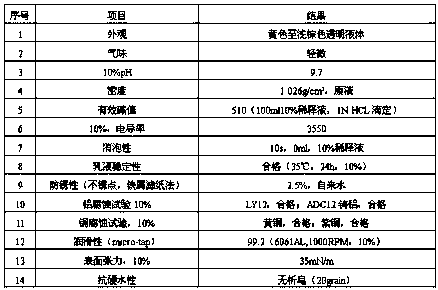

Universal cutting and grinding micro-emulsion without mineral oil

The invention discloses a universal cutting and grinding micro-emulsion without mineral oil. The micro-emulsion comprises organic amine, an antirust agent, macromolecular self-emulsifying ester, a lubricating agent, a coupling agent, an extreme pressure agent, an corrosion inhibitor, a surface active agent, an anti-bacteria sterilizing agent, an antifoaming agent and water. The universal cutting and grinding micro-emulsion without mineral oil meets requirements for machining universalities, no mineral oil is contained, the micro-emulsion is high in cleanliness, super-high in creosote resistance, good in wettability, excellent in wear resistance and extreme pressure resistance and long in service life, and EHS requirements are met.

Owner:TIANJIN RUNJIE INNOVATION ENVIRONMENTAL PROTECTION TECH

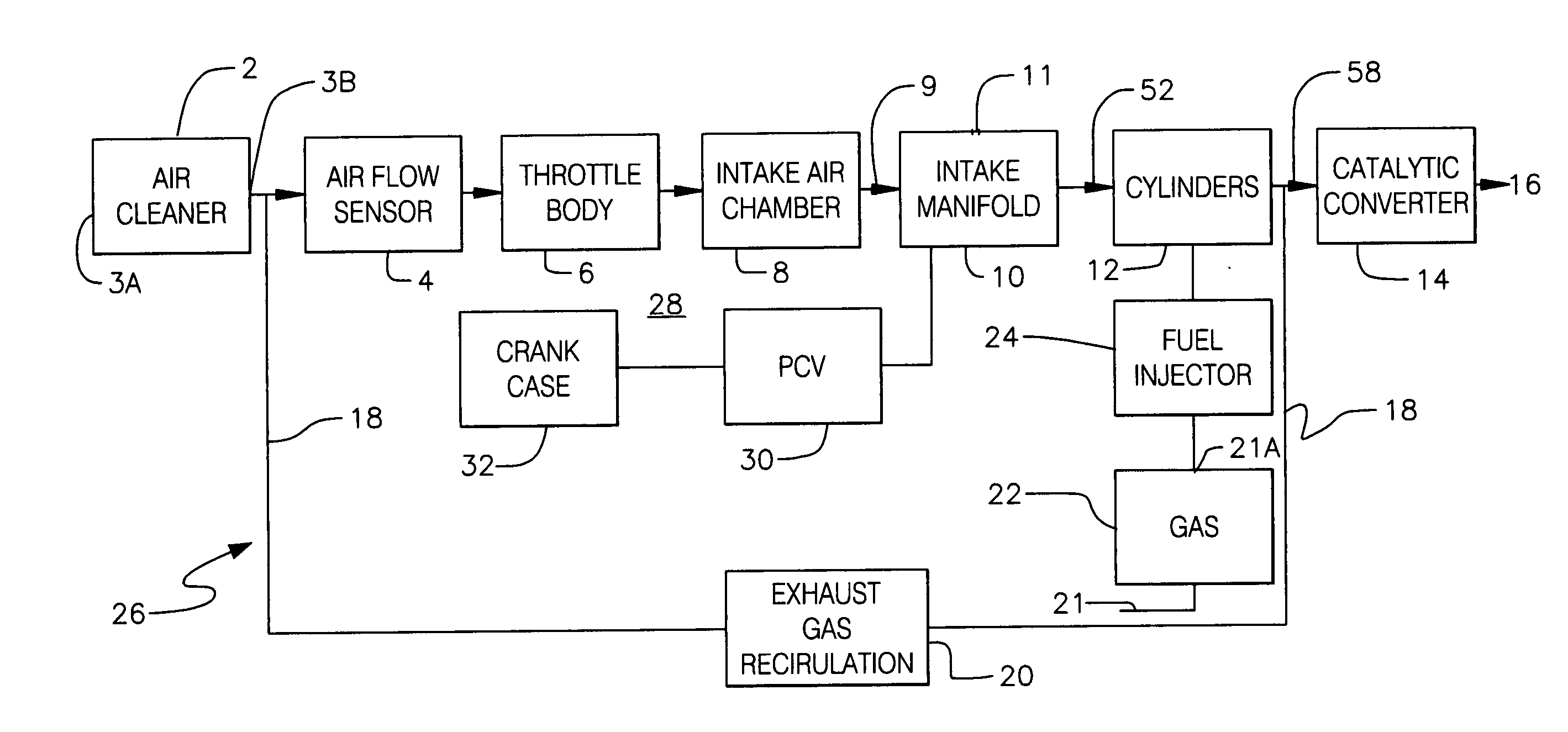

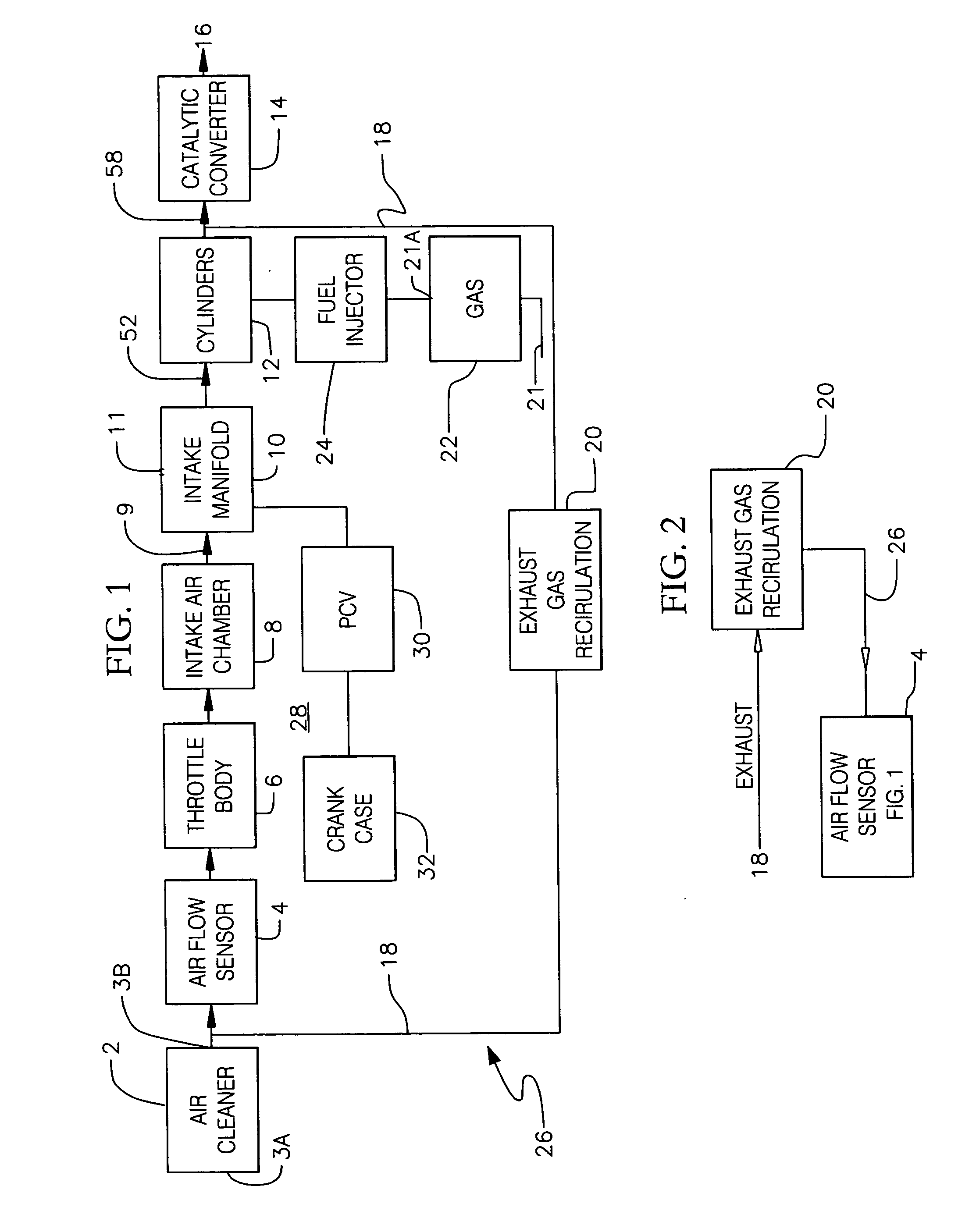

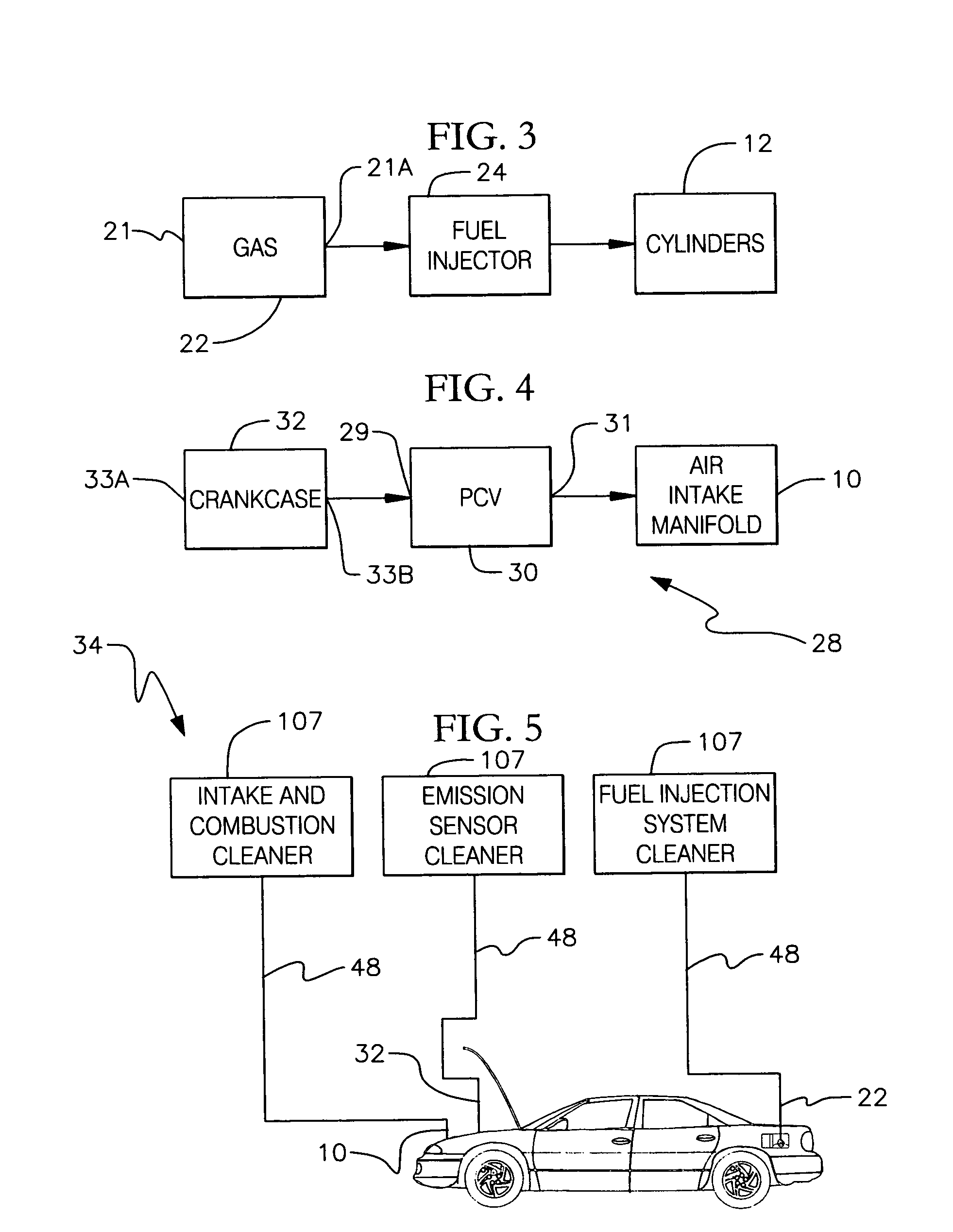

Bulk supply apparatus and method for cleaning a combustion engine system

InactiveUS20080060680A1High trafficHollow article cleaningElectrostatic cleaningCreosoteCombustion chamber

A method and apparatus for cleaning a combustion engine having, an intake and combustion chamber having a fuel injector injection device, an oil lubrication system, a catalytic converter and a fuel supply tank. Various solvents are introduced from bulk supply sources into the crank case and into the combustion chamber and into the fuel supply to clean an engine by the introduction of predetermined solvents in a predetermined sequence to clean the engine, the fuel supply tank, the oil lubrication system and the catalytic converter. As chemicals gasify and pass through the catalytic converter, clogging creosote deposits are released thus improving the flow of exhaust through the system improving efficiency and gas mileage.

Owner:ESTERLINE OLEN C

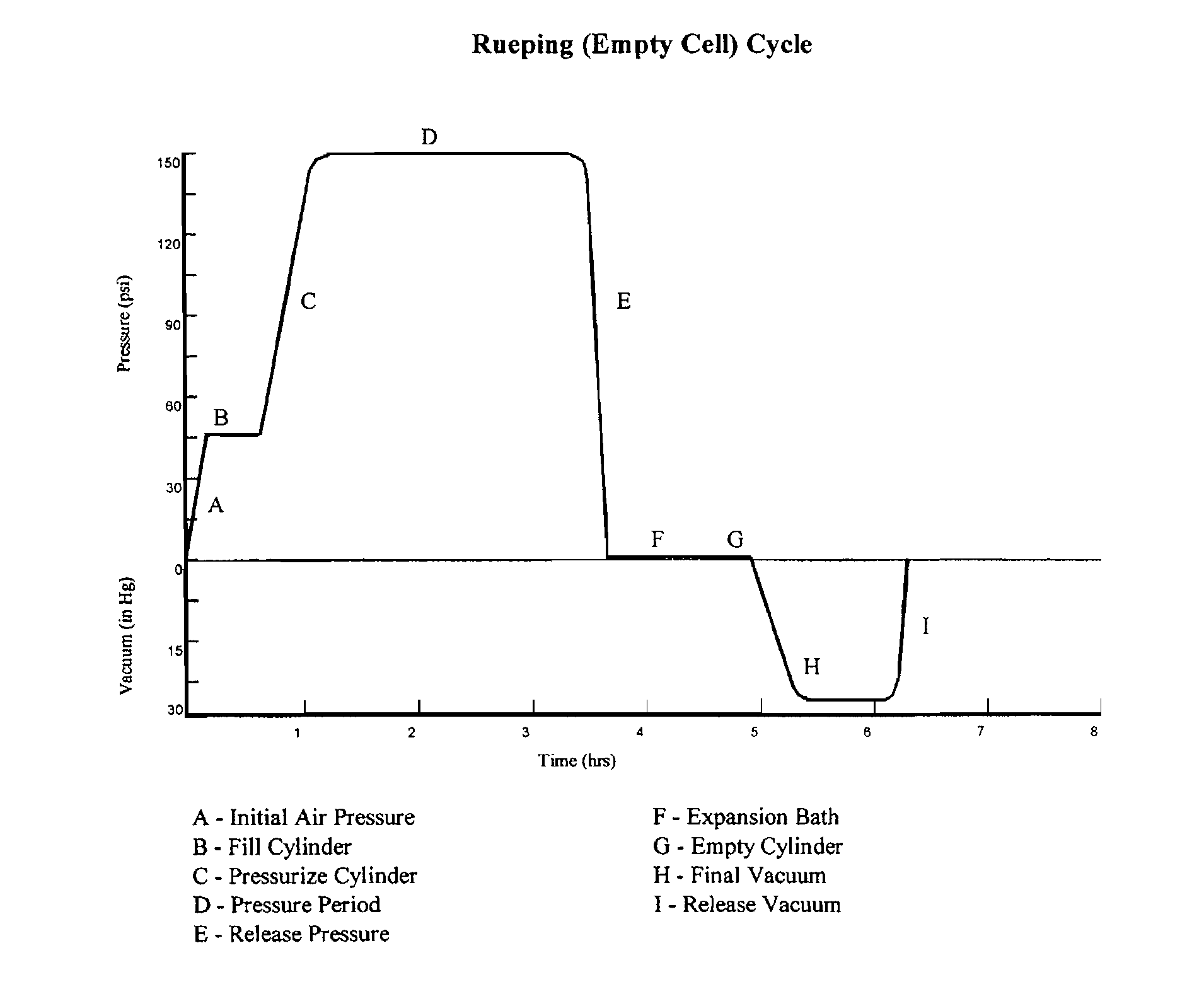

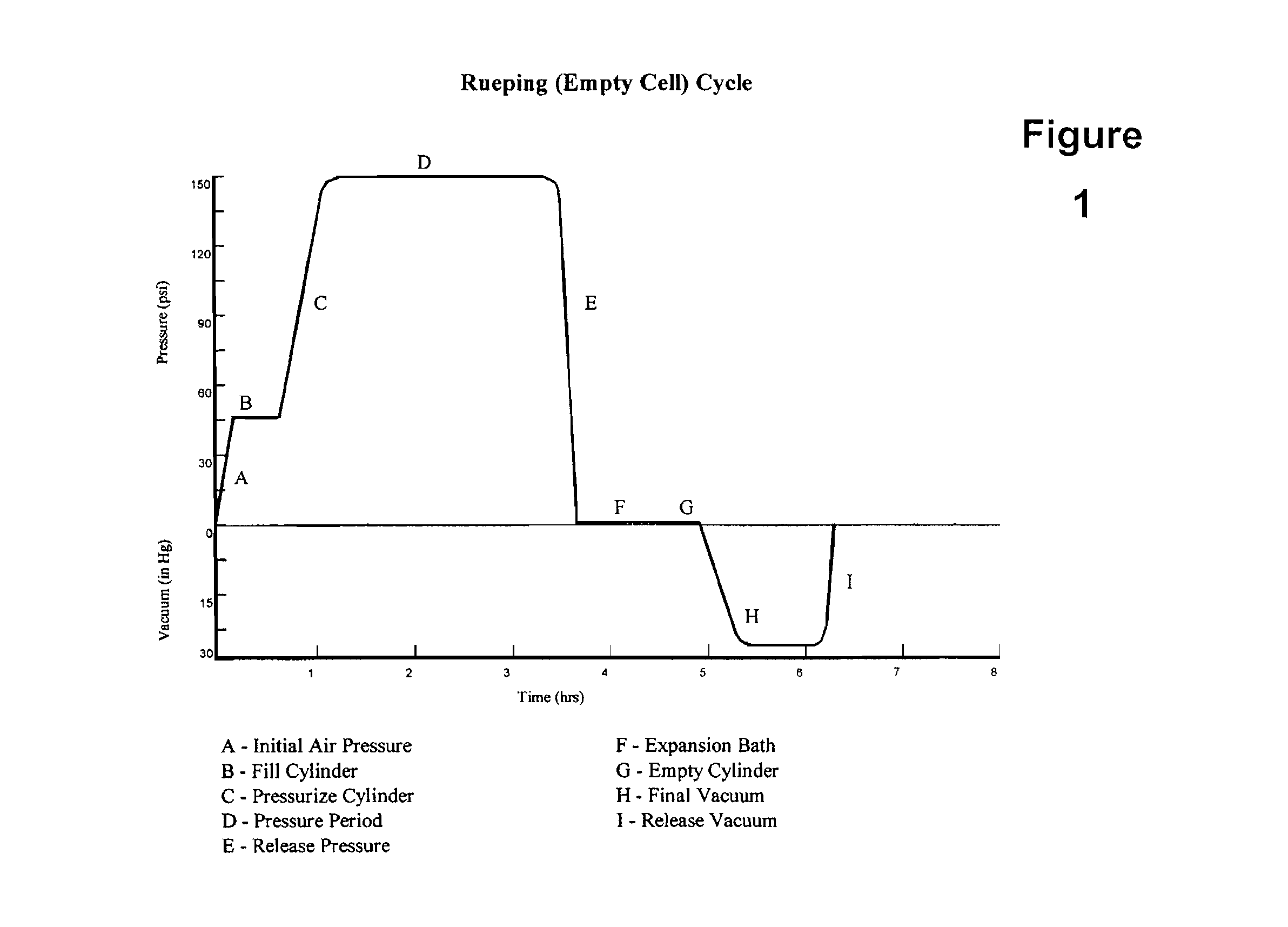

Single step creosote/borate wood treatment

ActiveUS20120171504A1Increase moisture contentEliminate stepsBiocideBoron compound active ingredientsMicroorganismCreosote

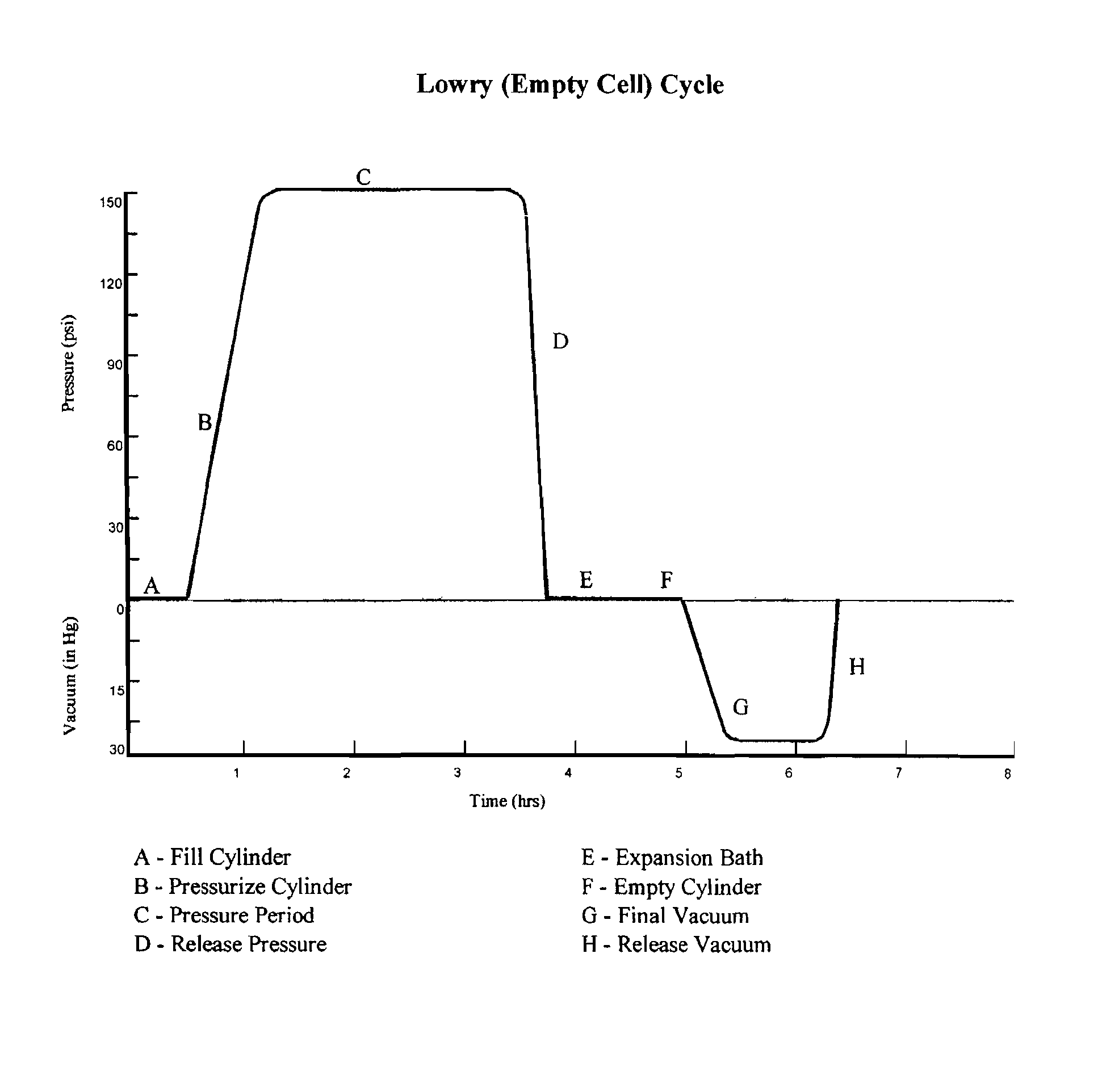

Disclosed is a method of reducing insect and microbial decay in wood. The method comprises the steps of:a) immersing the wood in a treatment solution comprising i) a C1-C6monoalkanolamine ester of boric acid (e.g., monoethanolamine ester of boric acid) and ii) creosote; andb) exposing the immersed wood from step a) to conditions which cause the release of boron from the C1-C6 monoalkanolamine ester of boric acid (monoethanolamine ester of boric acid) and which cause the boron to migrate into the interior of the wood.

Owner:STELLA JONES INC

Creosote and soot destroying fire log

Owner:SCHAEFER CLARK

Asphalt modifier

InactiveCN1931912AReduce manufacturing costGood high and low temperature performanceBuilding insulationsCreosoteAsphalt

The present invention is one kind of asphalt modifier, and belongs to the field of asphalt modifying assistant. The asphalt modifier is compounded with rubber powder, softening agent, activating agent, composite Al-Ti coupling agent, ammonium fluosilicate, creosote oil and light calcium carbonate in certain weight proportion. When used, it is mixed to asphalt and can improve the high and low temperature performance of asphalt obviously and make asphalt no melting down in the temperature up to 80 deg.c and no cracking in the temperature as low as -35 deg.c.

Owner:周立成

Creosote and soot destroying fire log

InactiveUS20040168366A1Reduce corrosionImproved creosote and soot removing compositionBiofuelsSolid fuelsCreosoteSolid fuel

A processed solid fuel composition incorporating agents for destroying creosote and soot within flue ducts and chimneys of fireplaces, solid fuel stoves and other heating devices is disclosed, along with a method for its manufacture and a method for its use. The composition is made up of a combination of compressed cellulosic particulate material and a chemical and / or catalytic creosote and soot removing agent, and is molded in the form of a fire log in the preferred embodiment. The composition may be used alone, but is ideally applied to an active fire to treat a chimney flue by combined heating and chemical disaggregation of accumulated creosote and soot deposits.

Owner:SCHAEFER CLARK

Mid-kiln injection of waste-derived materials

InactiveUS20060107875A1Augments clinker productionReduces certain noxious emissionCement productionCreosoteMaterials science

A method for the production of cement clinker comprises the introduction of non-traditional materials into the kiln, preferably at a mid-kiln locations. The non-traditional materials are materials that are difficult, expensive or environmentally challenging for disposal. In one embodiment, weathered clinker is introduced into the kiln to admix with the raw material mix to augment clinker production. In another embodiment, bird, animal or human manure is added to the kiln so that gaseous reducing agents can be released by the manure and combine with certain noxious gases generated during the clinker production, to thereby reduce the noxious gas output. In other embodiments, other non-traditional waste-derived fuels are added to the kiln during clinker production, including railroad ties coated with creosote, industrial, commercial and consumer rubber components, such as rubber hoses, unshredded plastics, and organic materials, such as bird and animal meal.

Owner:LONE STAR INDS

Fungal degradation and bioremediation system for creosote-treated wood

InactiveUS6664102B2Stimulating rapid and extensive fungal growthReadily storableFungiProductsCelluloseCreosote

A method for degrading and / or bioremediating waste wood containing creosote using a fungal inoculum is disclosed. The fungal inoculum comprises of at least one creosote-tolerant fungi, a lignocellulosic substrate and a nutrient supplement. The fungal inoculum is applied to the waste wood and maintained in an aerated and hydrated environment having temperature conditions sufficient to allow the inoculum to grow and metabolize the creosote. The inoculum and the waste wood are combined until an end product is achieved that is at least partially remediated or of a reduced volume.

Owner:US SEC AGRI

Decay resistant wooden railroad crosstie and method for making same

InactiveUS20070042161A1Improve the immunityMinimizing decayLiquid surface applicatorsCellulosic plastic layered productsCreosoteChemistry

Protection of wooden articles, such as railroad crossties, against decay or rot is improved through incorporation of borate compounds, such as sodium borate, and a protective coating such as creosote or a resin. Such protection is achieved by placement of a dry borate compound into a hole formed in the wooden article. The hole is then covered, and the borate compound then permitted to migrate and become distributed throughout the wooden article to provide the desired protection. Coating of the thus treated wooden article is conducted either shortly following placement of the borate compound in the hole or at a later convenient time.

Owner:GIBBS GROUP HLDG

Sequestering polycyclic aromatic hydrocarbons in asphalt

ActiveUS8852424B1Lower Level RequirementsReduce riskOrganic chemistryWorking-up pitch/asphalt/bitumen by chemical meansPolycyclic aromatic hydrocarbonActivated carbon

This invention is based upon the discovery that activated carbon can be used to sequester polycyclic aromatic hydrocarbons that may be present in asphalt and creosote compositions. The treatment of asphalt and creosote compositions with activated carbon accordingly reduces the level of free polycyclic aromatic hydrocarbons in such compositions by sequestering them therein or removing them from the composition. After being sequestered the polycyclic aromatic hydrocarbons remain trapped in the asphalt or creosote composition, and are not available to the environment during normal processing into useful industrial products. This sequestration reduces the risk of exposing humans and the environment to the polycyclic aromatic hydrocarbons which would otherwise be free to migrate from the asphalt or creosote product during manufacturing and the service life of the product. In other words, the polycyclic aromatic hydrocarbons are absorbed onto the activated carbon and are not available for bioaccumulation from the environment.

Owner:FLOW POLYMERS

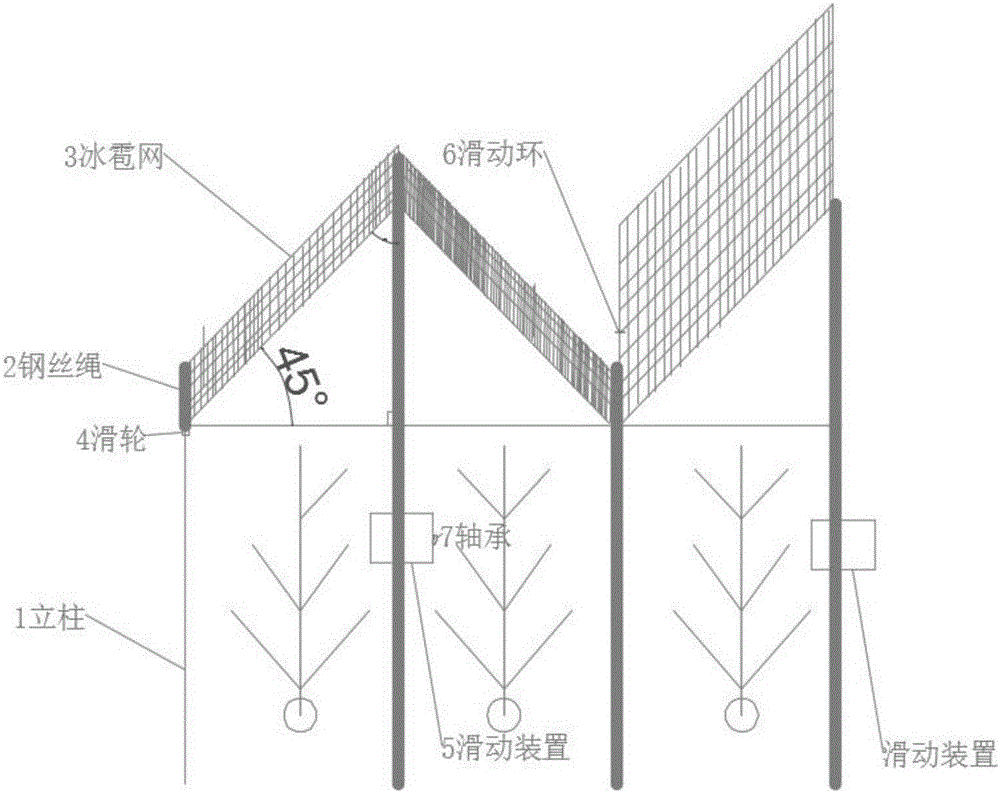

Inverted V-shaped intelligent telescopic fruit tree hail-proof design mechanism

The invention aims to provide an inverted V-shaped intelligent telescopic fruit tree hail-proof design mechanism which prevents collapse caused by heavy snow in winter, is effort-saving in stretch and retraction, is long in service life and can intelligently stretch and retract in summer and winter. The mechanism comprises stand columns, a steel wire rope, a polyethylene hail net, an agitating apparatus, pulleys, sliding rings, and bearings. The stand columns can be cement electric poles or creosote impregnated poles; the soil is dug downwards for 1.5-2m for fixing the stand columns; the diameter of each stand column is 100-300mm; the steel wire rope fixes and supports the hail net; steel pipes are connected with the bearings and are fixed and supported by angle steel to form sliding apparatuses; the sliding apparatuses rotate forwards and reversely for stretching and retracting the hail net; the agitating apparatus manually or electrically stretches and retracts the hail net; the sliding rings sleeve the meshes of the hail net and are connected with the steel wire rope to pull the steel wire rope back and forth; the pulleys change the direction of stretching and retracting the steel wire rope to lower the difficulty in stretching and retracting the hail net; the hail net is stretched to be in an inverted V shape; when hail falls down, the inverted V shape enables the hail to slide down from two sides according to a gravity principle, so that fruit trees are prevented from suffering from hail disaster in summer; the hail net is retracted in an effort-saving manner in winter, so that the hail net is prevented from being collapsed by large-area accumulated snow; and therefore, the service life is long.

Owner:BEIJING ROC THEURGY TECH

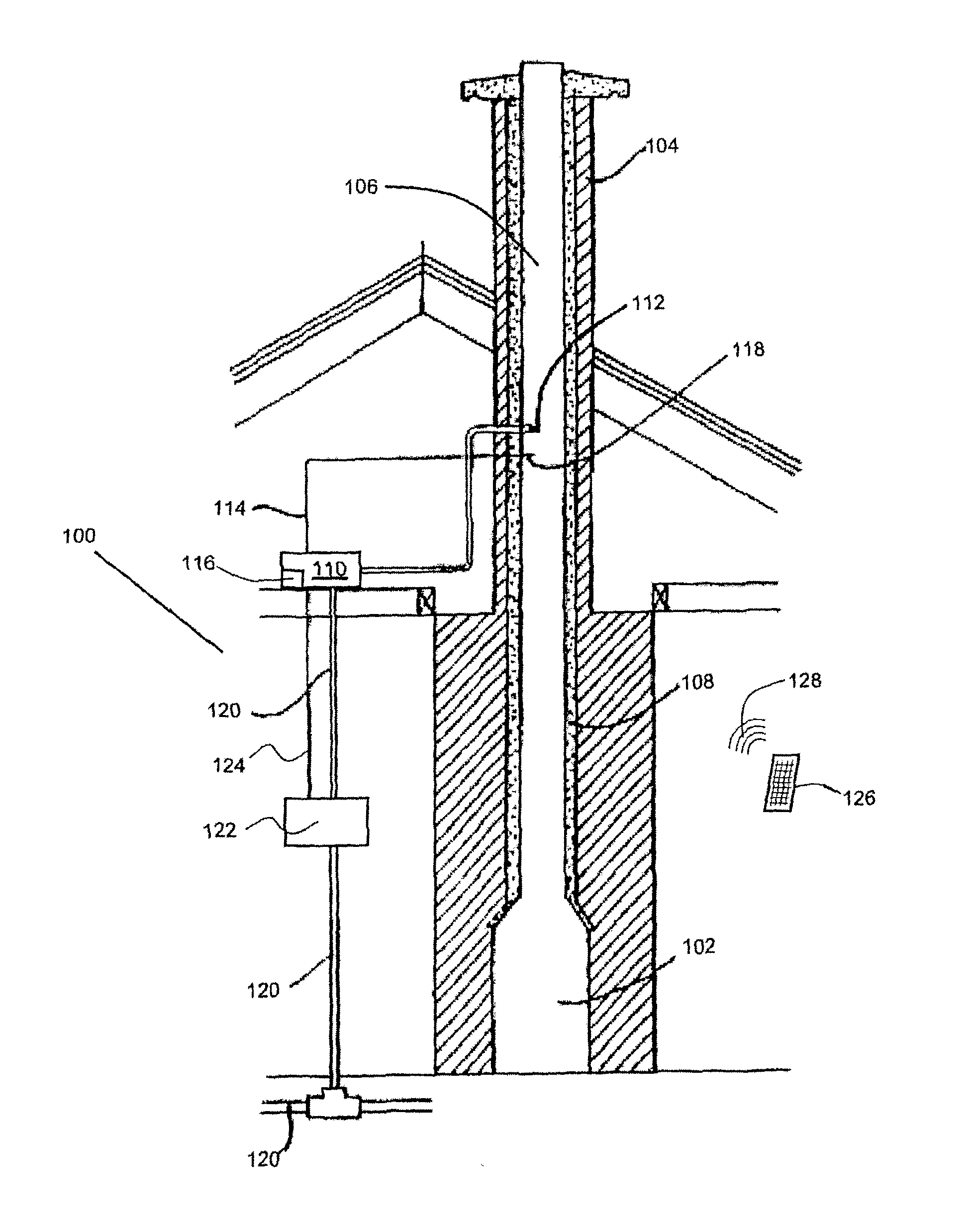

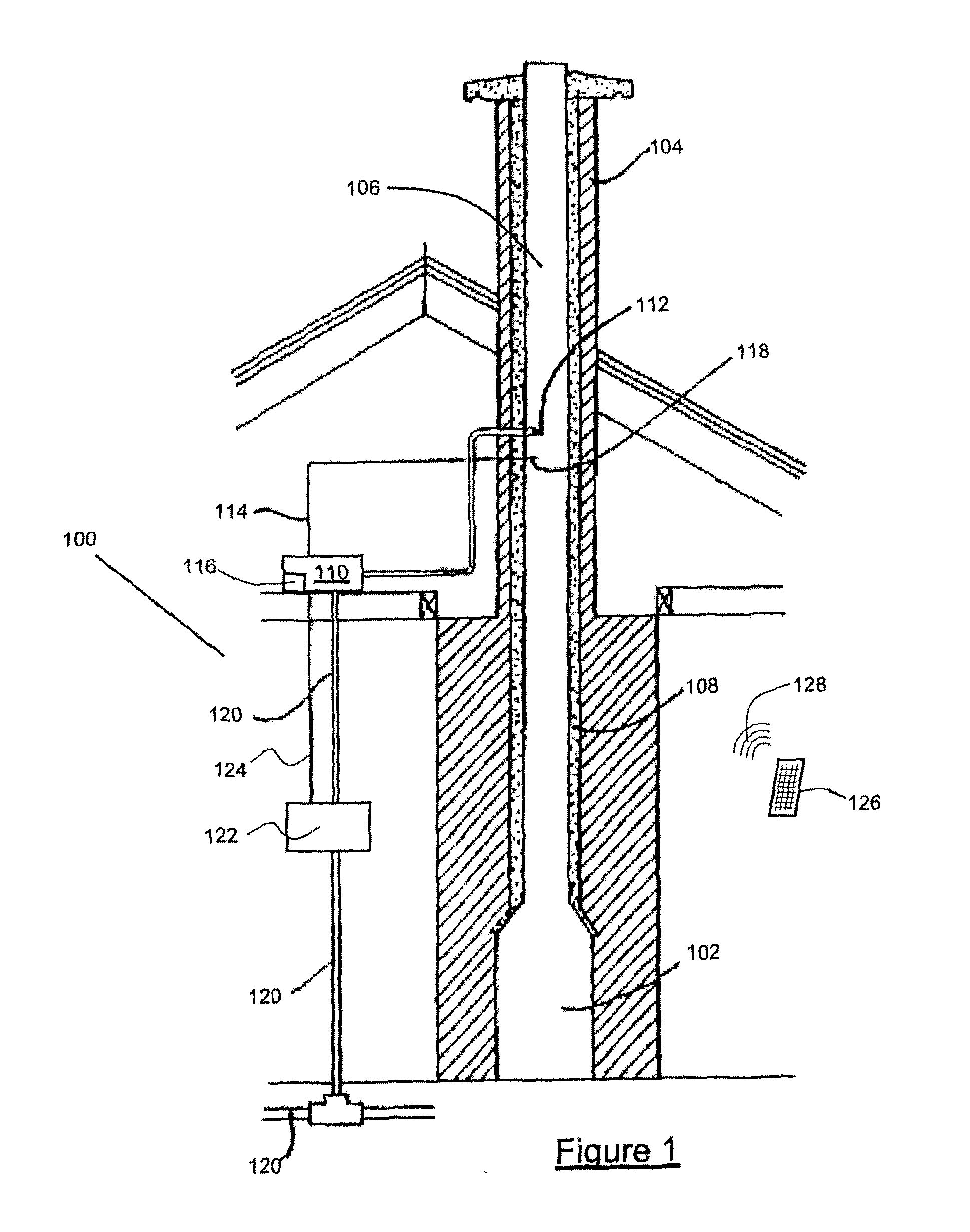

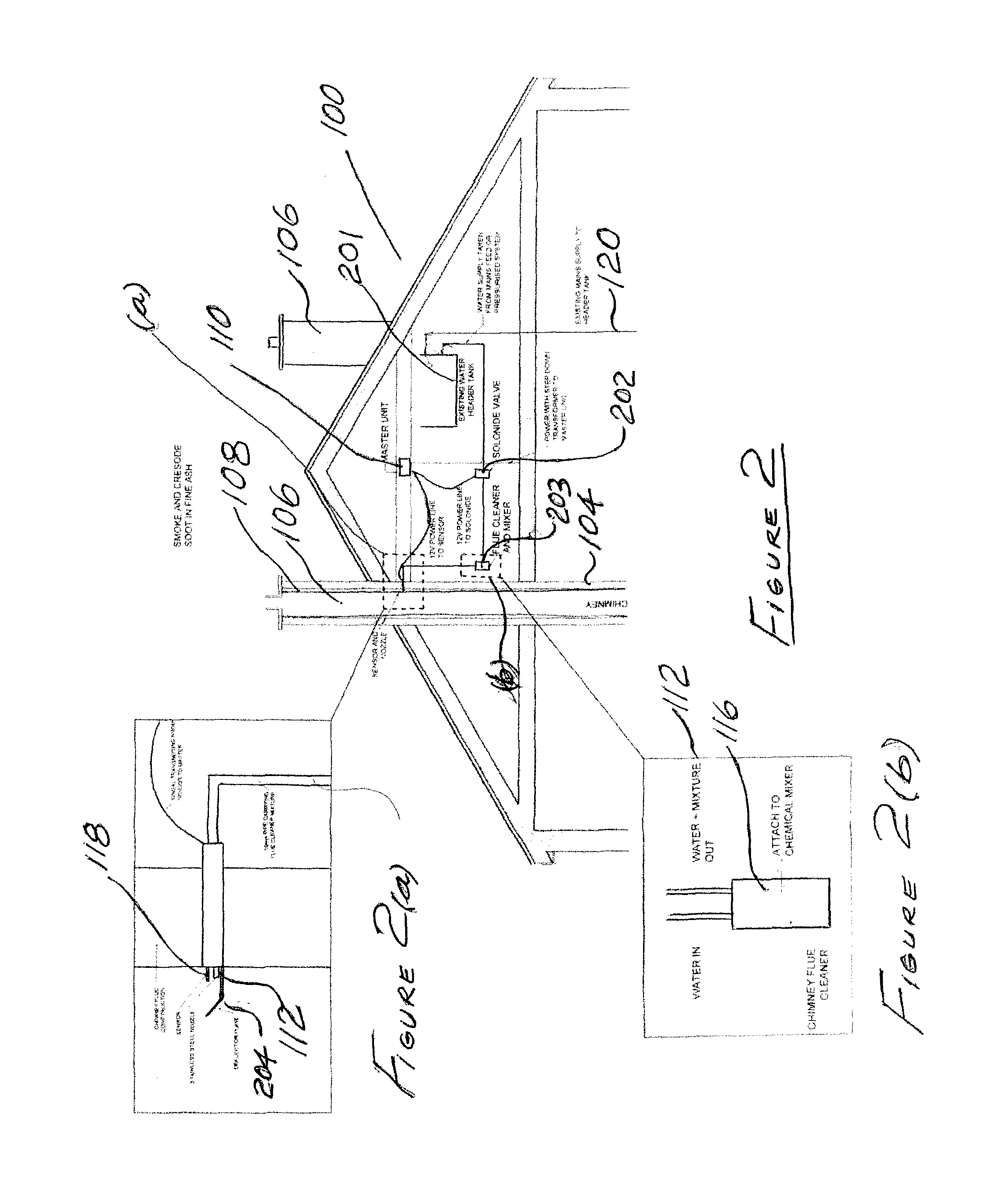

Chimney flue fire prevention system

A system (100) for fire prevention having a central control unit (110) controlling a flu cleaning dispenser (112) terminating within a chimney flue (106) for removal of creosote (108) is provided. At least one flue condition sensor (118) such as a temperature sensor, a flow sensor or a carbon monoxide sensor to name but a few is provided to record chimney status and on a chimney status alerting event occurring requiring one of a chimney flu cleaning operation or a fire extinguisher operation to take place automatically.

Owner:FDS HLDG

Method for improving creosote content in biomass molding fuel tar

InactiveCN104312604AThe total relative content increasedHigh synthesis reaction efficiencyCarbon compoundsBiofuelsAir atmosphereCreosote

The invention discloses a method for improving creosote content in biomass molding fuel tar and is suitable for a production technology for preparing molding charcoal through the pyrolysis of a rodlike fuel briquetted by the raw materials of pine chips, fir chips and hard mixed wood chips under the condition of an oxygen containing environment. The biomass molding fuel is pyrolyzed under an alkaline air atmosphere (VNH3: V air = (1-3): 100), and ammonia gas is produced in a mode of heating ammonia water. The constituents of the tar pyrolyzed by the biomass molding fuel can be obviously changed by the pyrolysis method. The total creosote relative content can be improved from less than 80wt% to 85-92wt%, the substitution ratio of the tar byproduct in the reaction of substituting part of phenol and synthesizing a phenolic resin adhesive is increased from 25% to 30-50%, the pollution of the tar byproduct to the environment in the production process of the biomass molding fuel can be reduced, and the preparing cost of the phenolic resin adhesive is reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

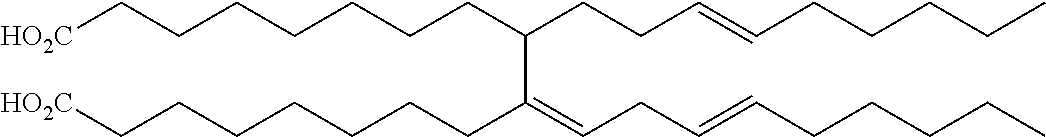

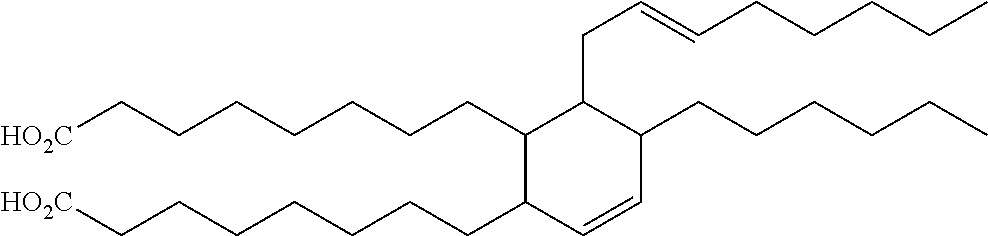

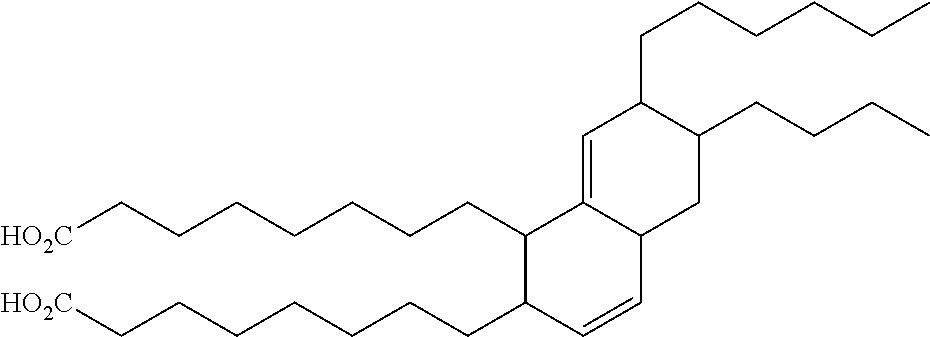

Compositions comprising unsaturated fatty esters and uses thereof

Disclosed is a wood preservative composition comprising creosote and / or pentachlorophenol (PCP) and one or more unsaturated fatty esters. The composition is useful for reducing insect and microbial decay in wood. Further disclosed are methods of making and using such a composition and wood treated with such a composition.

Owner:STELLA JONES INC

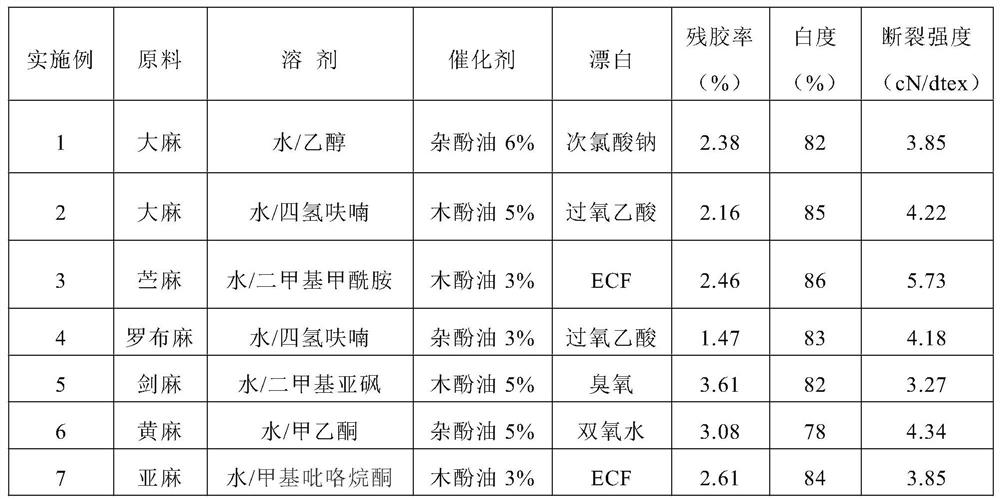

Method for degumming hemp

The invention relates to a method for degumming hemp. According to the method, an organic solvent is used as an extraction solvent, catalysts are adopted to degum hemp raw materials and remove lignin,the extraction process comprises four steps of catalytic cooking, solvent washing, water washing and bleaching, and the catalysts are selected from creosote, crosol, kreosote and / or creosote oil. According to the method, the technical problems of high energy consumption, large amount of waste water and high damage to the fiber strength of a conventional method for degumming hemp are avoided, andthe method has the advantages of high degumming efficiency, high product whiteness, high utilization ratio of raw materials, low equipment requirement, low cost, cleanness, energy conservation, environmental friendliness and safety and is suitable for large-scale industrial production.

Owner:湖南国麻新材料科技有限责任公司

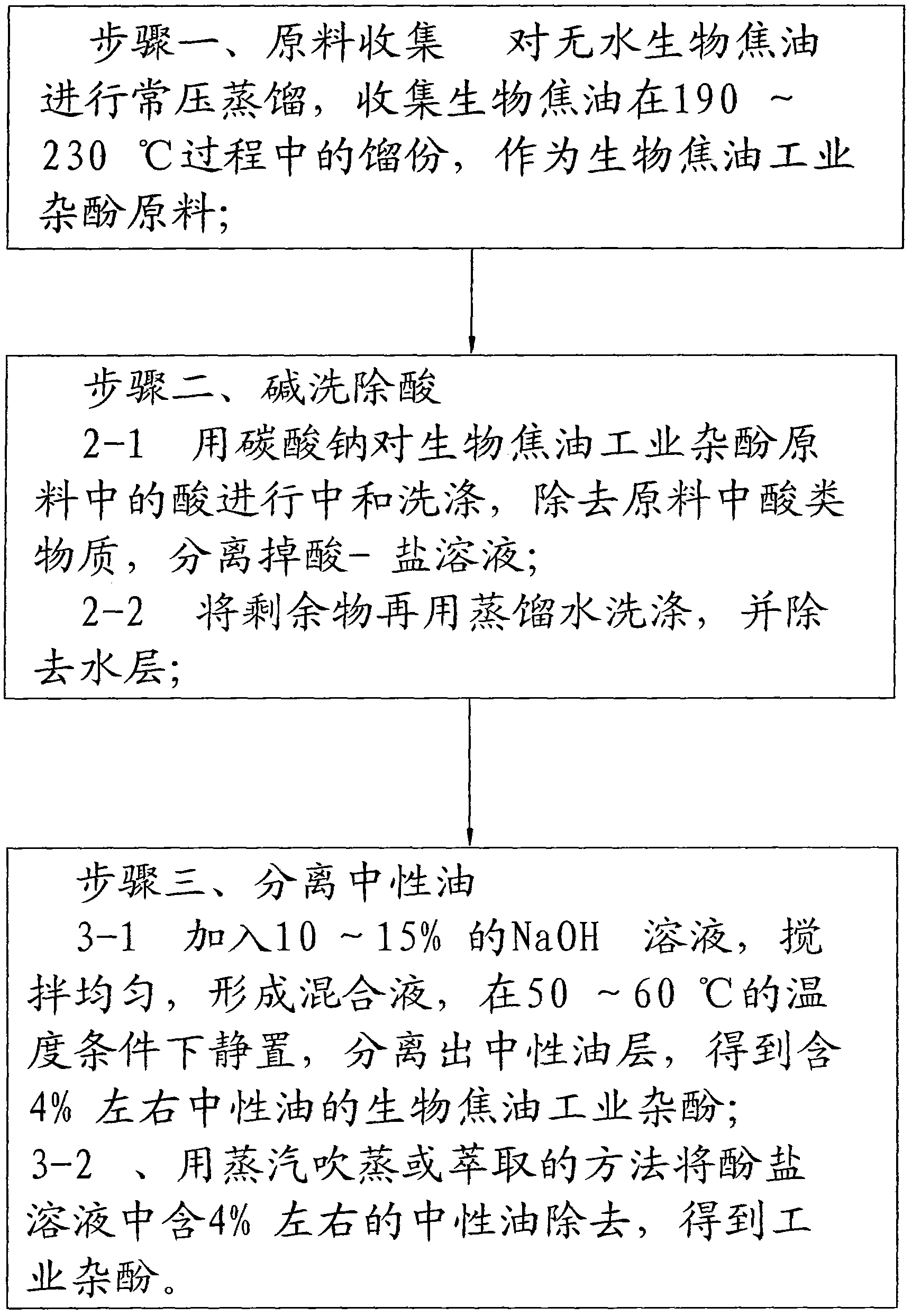

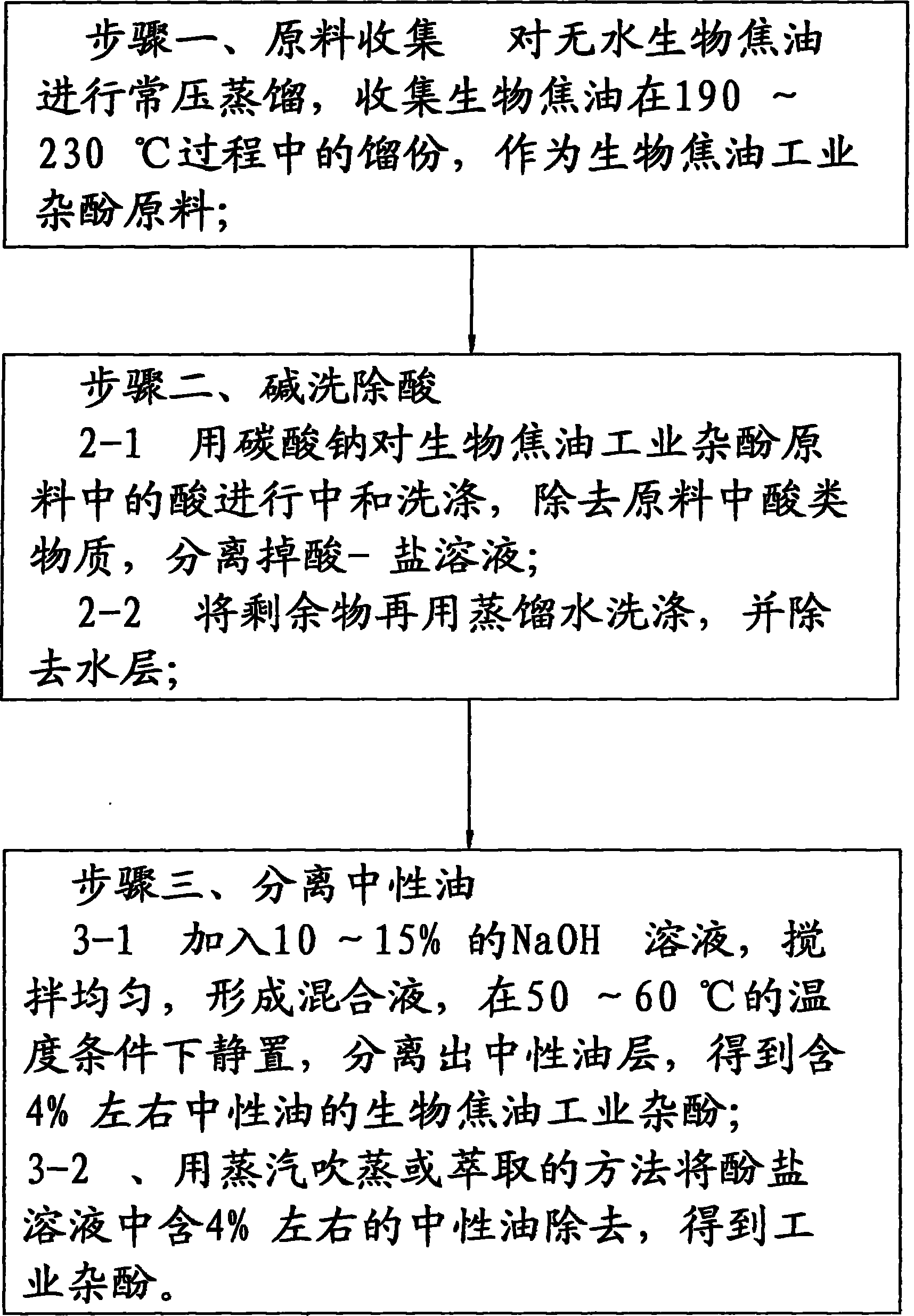

Preparation method of biomass tar industrial creosote

InactiveCN102485836AEfficient use ofSolve secondary pollutionOrganic chemistryOrganic compound preparationCreosoteDistillation

The invention relates to a comprehensive utilization technology of agricultural wastes, especially a preparation method of biomass tar industrial creosote. The method comprises: step 1. colleting raw materials: conducting atmospheric distillation to waterless biomass tar, and collecting distillates of the biomass tar ranging from a temperature of 190 to 230DEG C; step 2. conducting alkali washing to remove acid; step 3. separating neutral oil to obtain industrial creosote. By making effective use of biomass tar, the method of the invention solves the secondary pollution problem of biomass tar during utilizing carbonization and gasification technologies of agricultural wastes, changes waste materials into things of value, and improves the economic benefits of utilizing carbonization and gasification technologies of agricultural wastes.

Owner:周仁福 +2

Quality improving treatment method of tar

ActiveCN109749758ASimple processEfficient treatment processTar working-up by chemical refiningAlkaneCreosote

The invention provides a quality improving treatment method of tar. The quality improving treatment method of the tar comprises the following steps: tar raw materials and small molecule alcohols are introduced into a solid acid catalyst after being mixed; and aromatic hydrocarbon and phenol components in the tar raw materials have high temperature gas phase catalytic conversion reaction with the small molecule alcohols under a catalytic effect of the solid acid catalyst to obtain a gas phase product. According to the quality improving treatment method of the tar, high temperature gas phase catalytic conversion is carried out on the tar and the small molecule alcohols after mixing; by using the solid acid catalyst, the aromatic hydrocarbon and creosote components in the tar are enabled to react with the small molecule alcohols; and the aromatic hydrocarbons and the phenol in the tar are converted into a high-value product with pentamethylbenzene, hexamethylbenzene, pentaethylbenzene orhexaethylbenzene as a main component; moreover, a small quantity of small molecule oxygen-containing components contained in the tar are deoxygenated to be converted to obtain products, such as low boiling point alkanes and condensed ring hydrocarbon, and a gas product with higher heat value. The quality improving treatment method of the tar, provided by the invention, has the advantages that thetar raw materials and the catalyst are cheap, the tar treatment process is simple and efficient, industrial production is easy to realize, and the technological process is pollution-free.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

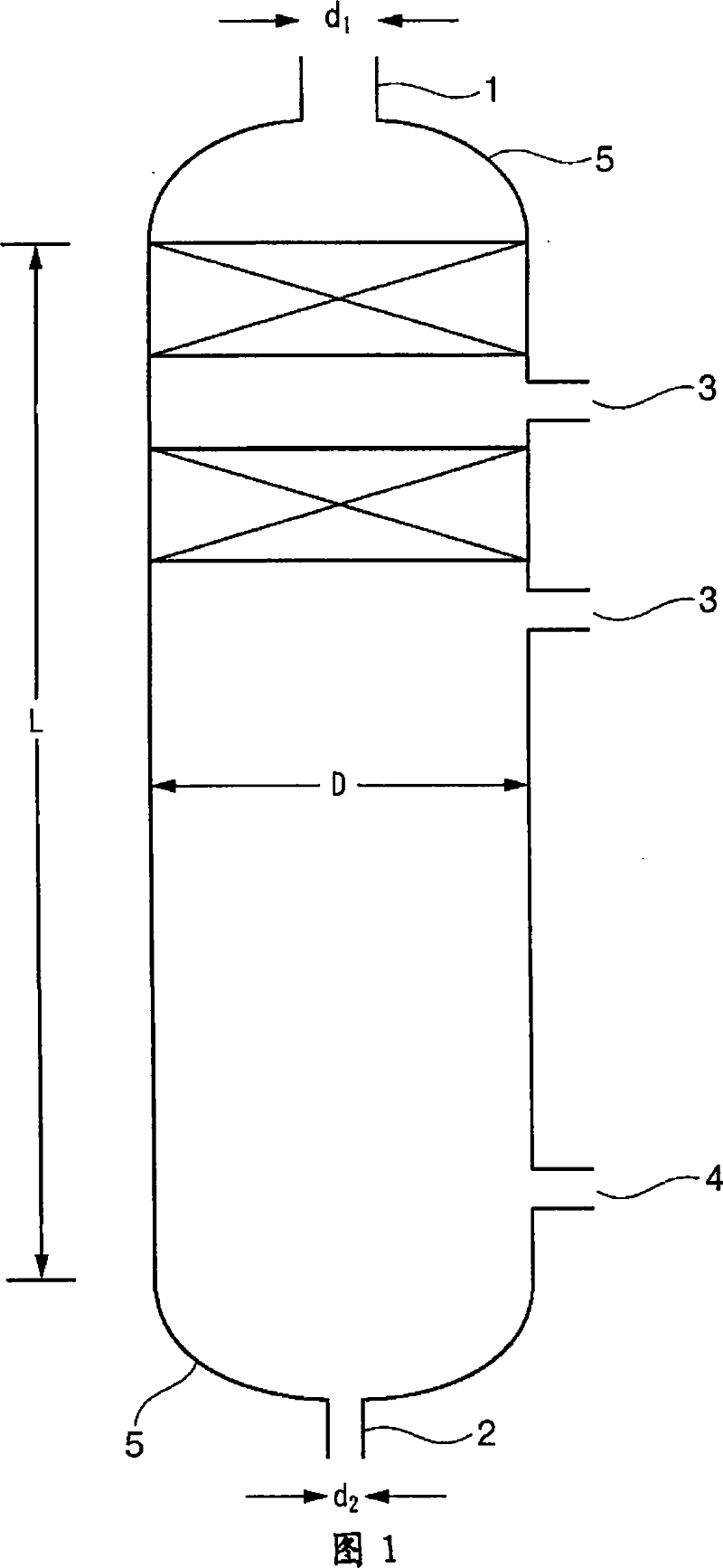

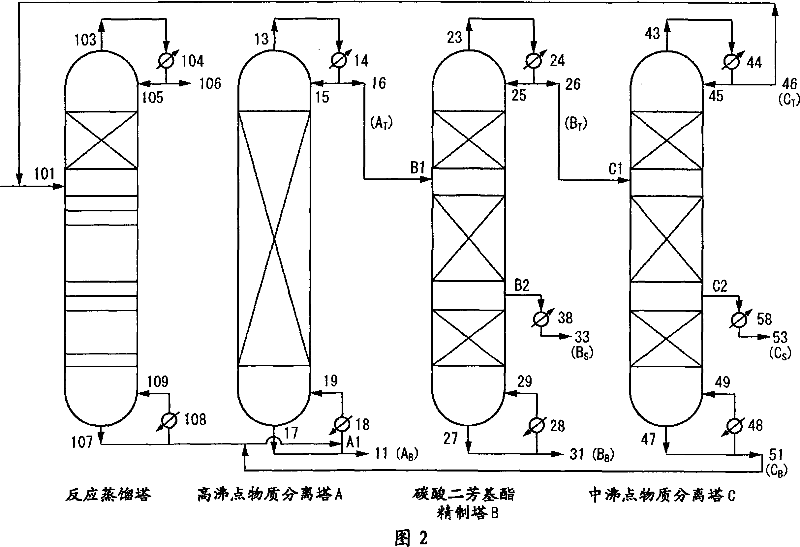

Industrial process for production of high-purity diaryl carbonate

ActiveCN101044109AStable manufacturingImprove qualityOrganic compound preparationChemical recyclingCreosoteNaphtha

The invention provides a specific method to provide a raw material of a reaction mixture containing creosote alkylaryl aster through the ester interchange reaction of creosote dialkyl ester and aromatic single hydroxyl compound and to steadily produce high-purity creosote diaryl aster used for preparing high-quality and high-purity polycarbonate material. The invention makes the materials get into the ester interchange reaction with a reaction distillation tower. The reaction compound with high boiling point from the bottom of the tower is continuously and orderly passed three specific continuous multistage distillation towers, saying a high boiling point material separating tower A, a creosote dialkyl ester treating tower B and a mid-boiling point material separating tower C, so as to steadily and permanently produce, in the industrial scale of more than 1t per hour, the high-purity creosote dialkyl ester which is taken as a sidedraw naphtha of the treating tower B and does not contain mid and high boiling point off-products substantially.

Owner:ASAHI KASEI KK

Method for treating high-COD (Chemical Oxygen Demand) components in phenoxyalkanoic acid production wastewater

ActiveCN103112968ALow costSolve processingOrganic compound preparationCarboxylic acid esters preparationCreosoteChemical oxygen demand

The invention discloses a method for treating high-COD (Chemical Oxygen Demand) components in phenoxyalkanoic acid production wastewater. The method comprises the following steps: separating the high-COD components from the phenoxyalkanoic acid production wastewater; carrying out esterification reaction on the high-COD components and the alcohol, so as to obtain the ester product. According to the method, the wastewater generated in the production process of phenoxyalkanoic acid products is simply treated by extracting and separating and the like in order to separate the high-COD components such as phenoxy carboxylic acid and creosote from the wastewater, and then the way of generating the esters is carried out on the high-COD components; the produced ester product is high in mobility and free from crystallizing at normal temperature, and can be used as the fuel for combusting, and the heat of combustion is about 4800 to 5000 kilocalories per kilograms, and therefore, the problems that in the prior art, the high-COD components separated from the wastewater cannot be treated and bring high pollution to the environment can be solved, a certain economic efficiency is brought, and the cost of treating the wastewater is decreased.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Dental pulp capping and pulp retaining paste, method for using pulp capping and pulp retaining paste for dental filling and application of pulp capping and pulp retaining paste

InactiveCN105125414AStable return to normal physiological function stateReduce the number of referralsImpression capsDentistry preparationsCreosoteAdditive ingredient

The invention relates to dental pulp capping and pulp retaining paste, which is prepared from iodine glycerin, iodophor, phenocamphor, creosote and zinc oxide powder, wherein the volume ratio of the iodine glycerin: the iodophor: the phenocamphor: the creosote is (3 to 4):(1 to 2):(1 to 2):(3 to 4); the ratio of the creosote(mL): the zinc oxide powder (g) is 1:(4 to 6); all ingredients are mixed and are prepared into the paste, and thus the dental pulp capping and pulp retaining paste is obtained. The paste has the advantages that after dental pulp is exposed, the nerve burnt killing, the nerve removal and the root canal therapy are not needed; the whole tooth body with the tooth root becomes a dead tooth; the dental pulp capping and pulp retaining paste is directly smeared on the exposed surface of the dental pulp, hard hulls can be formed on the surfaces of dental pulp active body cells; the normal physiological function state of the tooth body is stably recovered; in addition, the treatment process time is shorter; the subsequent consultation times of a patient are fewer; the work intensity of oral doctors is reduced. The pulp capping and pulp retaining paste can be applied to the protection of tooth body dental pulp exposure positions.

Owner:周建洲

Method for improving quality of phenolic materials in tar

ActiveCN106947507AHigh yieldHigh calorific valueTar working-up by chemical refiningSolubilityCreosote

The invention provides a method for improving quality of phenolic materials in tar. The method is characterized by finally converting the phenolic materials into aromatic ethers through a two-stage conversion process. The method comprises the following steps: firstly mixing the tar with alkylation reagents and carrying out first-stage reaction under the action of a solid acid catalyst modified by alkali metal salt or alkali metal oxide to obtain a first-stage product; mixing the first-stage product or alkylphenol obtained by separating the first-stage product with the alkylation reagents, and carrying out second-stage reaction by taking solid acid modified by alkali metal salt or alkali metal oxide as a catalyst to obtain a second-stage product. Through the method, the phenolic materials are converted into the aromatic ethers, the heat value and oil-phase solubility of the tar and / or creosote oil can be effectively improved; the acidity and the corrosivity of the tar and / or the creosote oil can be reduced; the quality of the tar and / or the creosote oil is improved; the process is simple and efficient; the costs of raw materials are low; the operation cost is low; the industrial production is easy to implement; the raw materials used by the method are pollution-free; the treatment process is pollution-free; the method is an environment-friendly green process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

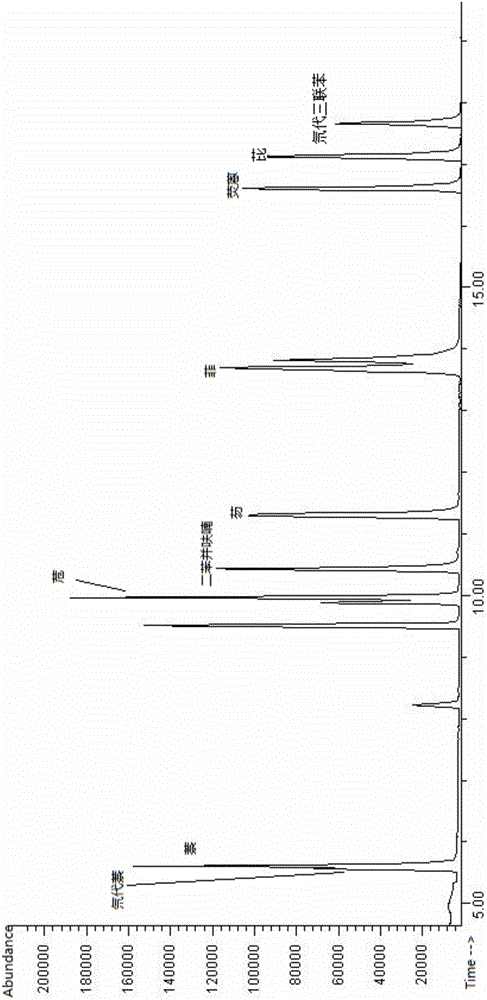

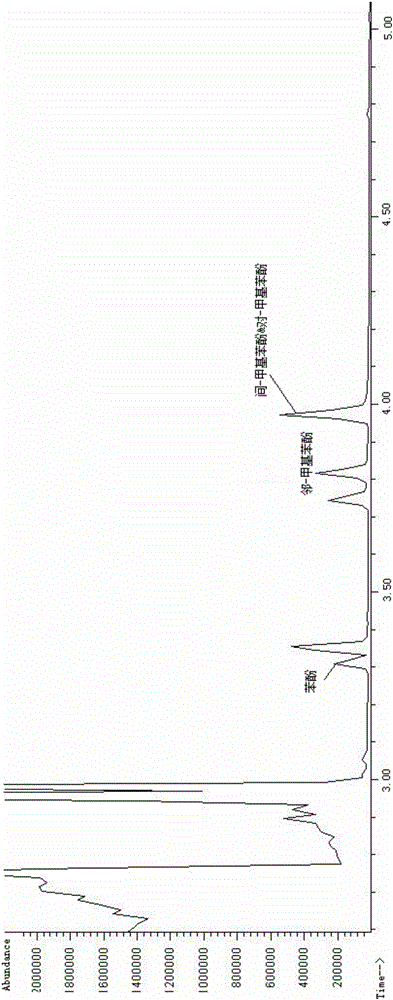

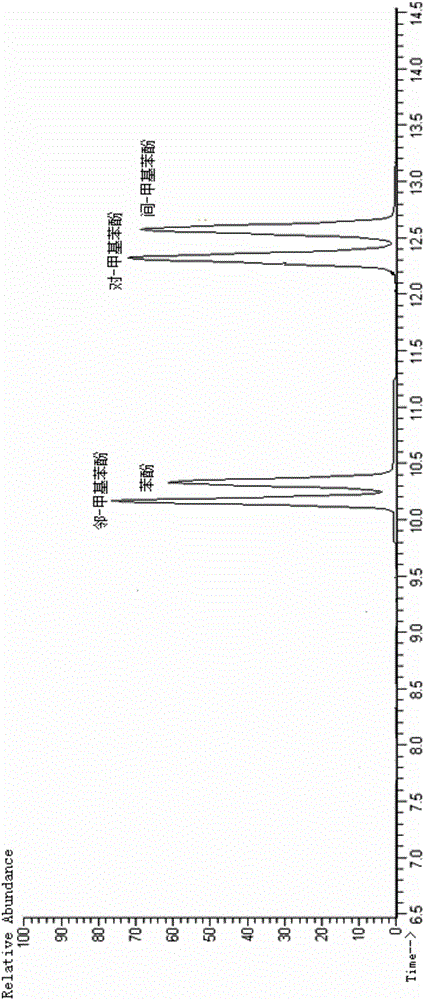

Method for measuring creosote in wood product

ActiveCN106526021AThe assay method is fastThe determination method is simpleComponent separationCreosoteSolvent

The invention relates to a method for measuring creosote in a wood product. The method comprises 1) weighing a pulverized and uniformly mixed sample, adding an extraction solvent toluene, a tracer and an internal standard solution into the sample, carrying out uniform vortex mixing and carrying out ultrasonic extraction, 2) determining a creosote marker in the sample extract solution through a gas chromatograph-mass spectrometer, and 3) according to the chromatogram and spectrum obtained by the step 2, analyzing to ensure whether the sample extract solution contains a polycyclic aromatic hydrocarbon marker or phenol marker specially existing in creosote, so as to determine whether the sample contains the corresponding creosote, carrying out identification and quantification on the polycyclic aromatic hydrocarbon and phenol compounds selected as creosote markers, and calculating creosote content of the sample through conversion of the marker content of the sample. The method is fast and simple. Through a semi-quantitative method, the content of the four kinds of sample creosote materials prohibited by the regulations is measured and the detection limit is 50 mg / kg.

Owner:SGS STANDARD TECHNICAL SERVICES SHANGHAI CO LTD

Preparation and application method of insecticide for treating apple tree canker

The invention discloses a preparation and application method of insecticide for treating apple tree canker. The preparation materials of the insecticide comprise wood tar stock solution, Tween or alcohol, and distilled water, wherein the wood tar stock solution, Tween and distilled water are prepared into insecticide in a volume ratio of a:b: (a+b); a and b are require to meet the condition that bis greater than or equal to a and smaller than or equal to 4a; or the alcohol, distilled water and wood tar stock solution are prepared into insecticide in a volume ratio of 15c:c:d; c and d are required to meet the condition that d is greater than or equal to 16c and smaller than or equal to 64c. The insecticide is applied according to the following step: firstly scraping branch and trunk partssuffer from apple tree canker, then continuously scraping branch and trunk parts around disease speckles with a disinfected cutter, and finally applying the insecticide to the parts where disease speckle are scrapped with a brush in January to February, March to April and July every year. The insecticide is simple to prepare, convenient to use, low in cost, and small in environmental pollution, and a large quantity of experiments approve that the insecticide has good treatment effect on apple tree canker when being used according application method.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Method for producing indoor wall plate and creosote through cedarwood

InactiveCN107627429AImprove use valueUse safety and environmental protectionWood treatment detailsBiofuelsCreosoteResource utilization

The invention discloses a method for producing an indoor wall plate and creosote through cedarwood. The cedarwood is used for producing the indoor wall plate, cedarwood waste is used for extracting the creosote, the cedarwood is peeled and cut into a cedarwood board in a sawn manner, the cedarwood board is subject to rough planing, the surface of the cedarwood board is subject to planing, steam isused for cooking, a hydrogen peroxide aqueous is used for cooking, the cedarwood board is heated and dried, finish planing is carried out, the connecting face of the cedarwood board subject to finishplaning and a base material is glued, and pressed into a wall plate, the wall plate subject to press fitting is subject to sanding treatment, paint spraying and drying, and the indoor wall plate is obtained. The cedarwood waste generated in the cedarwood machining process is pulverized and dried, dry distillation is carried out, condensate liquid is collected, oily objects in the condensate liquid are separated, and the creosote is obtained. The method is simple and easy to implement, raw materials are cheap and easy to obtain, the utilization value of the cedarwood is improved, the obtainedindoor wall plate does not contain formaldehyde, is durable and convenient to maintain, the produced cedarwood waste is used for extracting the creosote, and waste resource utilization is achieved, and the method is environment-friendly.

Owner:RONGSHUI DINGFENG BAMBOO & WOOD PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com