Universal cutting and grinding micro-emulsion without mineral oil

A kind of grinding processing and general-purpose technology, applied in the field of cutting and grinding processing fluid, can solve the problems of unbalanced performance, lack of processing performance of aluminum alloy, insufficient lubrication and anti-corrosion, etc., and achieve super strong resistance to miscellaneous oil and good wetting Sex, high cleanliness effect

Pending Publication Date: 2018-04-10

TIANJIN RUNJIE INNOVATION ENVIRONMENTAL PROTECTION TECH

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Machining companies also seek a machining fluid that satisfies a variety of processing materials and processes as much as possible, but the performance is often unbalanced. For example, a microemulsion cutting fluid can meet the general cutting and grinding of steel parts, but it is not suitable for the processing performance of aluminum alloys. Insufficient, insufficient lubrication and corrosion protection; an emulsified cutting fluid meets the boundary lubrication requirements of stainless steel and aluminum wheels, but the processing effect, service environment and life of grinding are poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

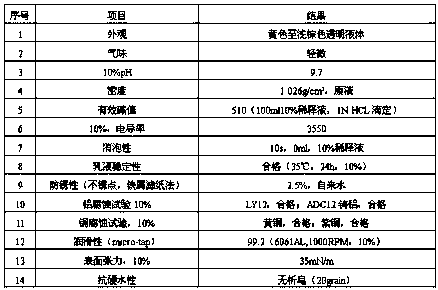

[0057] Add the reaction raw materials to the reaction vessel in sequence according to the order and process requirements in the table. After the reaction is completed, the product of the present invention does not contain mineral oil general-purpose microemulsion cutting and grinding fluid.

[0058] .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a universal cutting and grinding micro-emulsion without mineral oil. The micro-emulsion comprises organic amine, an antirust agent, macromolecular self-emulsifying ester, a lubricating agent, a coupling agent, an extreme pressure agent, an corrosion inhibitor, a surface active agent, an anti-bacteria sterilizing agent, an antifoaming agent and water. The universal cutting and grinding micro-emulsion without mineral oil meets requirements for machining universalities, no mineral oil is contained, the micro-emulsion is high in cleanliness, super-high in creosote resistance, good in wettability, excellent in wear resistance and extreme pressure resistance and long in service life, and EHS requirements are met.

Description

technical field [0001] The invention belongs to a cutting and grinding processing fluid, in particular to a general-purpose microemulsion cutting and grinding processing fluid without mineral oil. Background technique [0002] Cutting fluid and grinding fluid are two common types of metalworking fluids. They are generally divided into three categories: emulsification, microemulsion (semi-synthetic), and full-synthesis. Each of the three categories has its own processing focus. [0003] Due to the high oil content, high lubricating composition, and sufficient oil film thickness, the emulsified type has a better processing effect on materials that require high lubricating extreme pressure performance, such as stainless steel and aluminum alloy. The shortcomings of common emulsified cutting fluids are also very obvious. The high content of mineral oil results in high chemical oxygen consumption COD, and it is difficult to treat the waste emulsion in the later stage; the cooling...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M173/02C10N40/22C10N30/04C10N30/06

CPCC10M173/02C10M2207/021C10M2207/046C10M2207/127C10M2207/22C10M2215/04C10M2215/042C10M2215/12C10M2215/223C10M2219/104C10M2225/04C10M2229/02C10M2229/041C10N2030/04C10N2030/06C10N2040/22C10N2030/24C10N2030/64C10N2030/72

Inventor 郝聿铭李磊

Owner TIANJIN RUNJIE INNOVATION ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com