Patents

Literature

632results about How to "Easy to tie" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

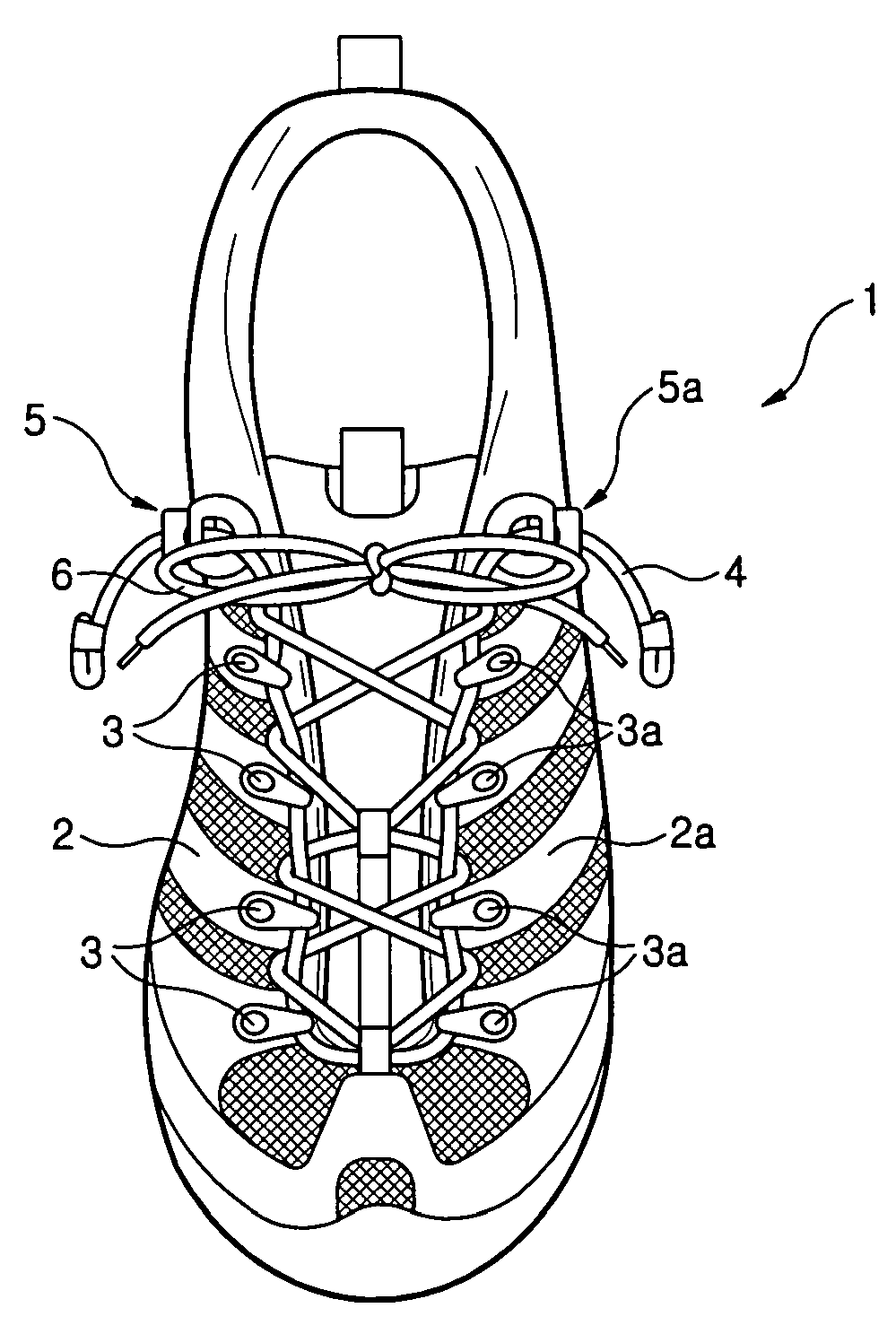

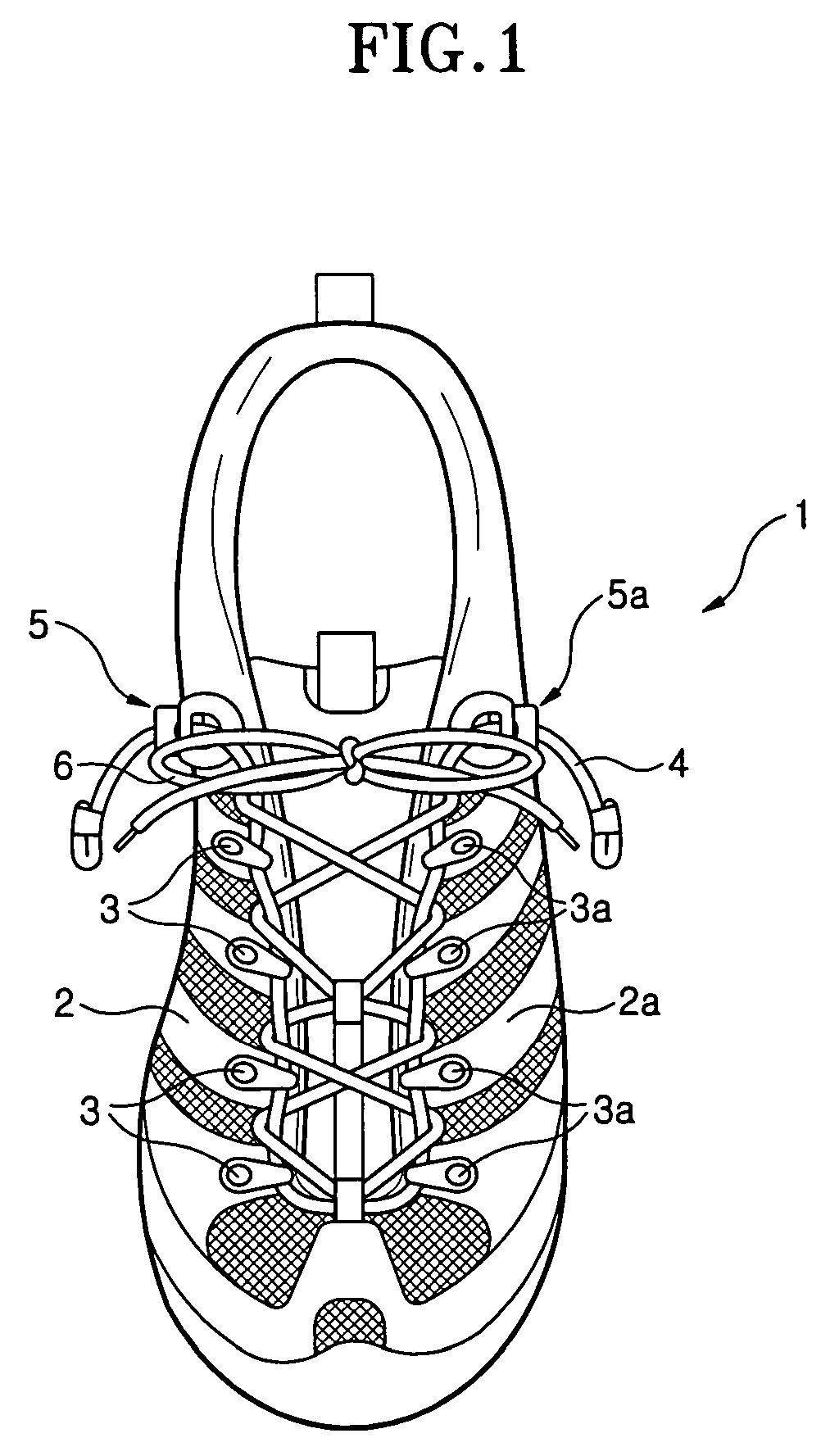

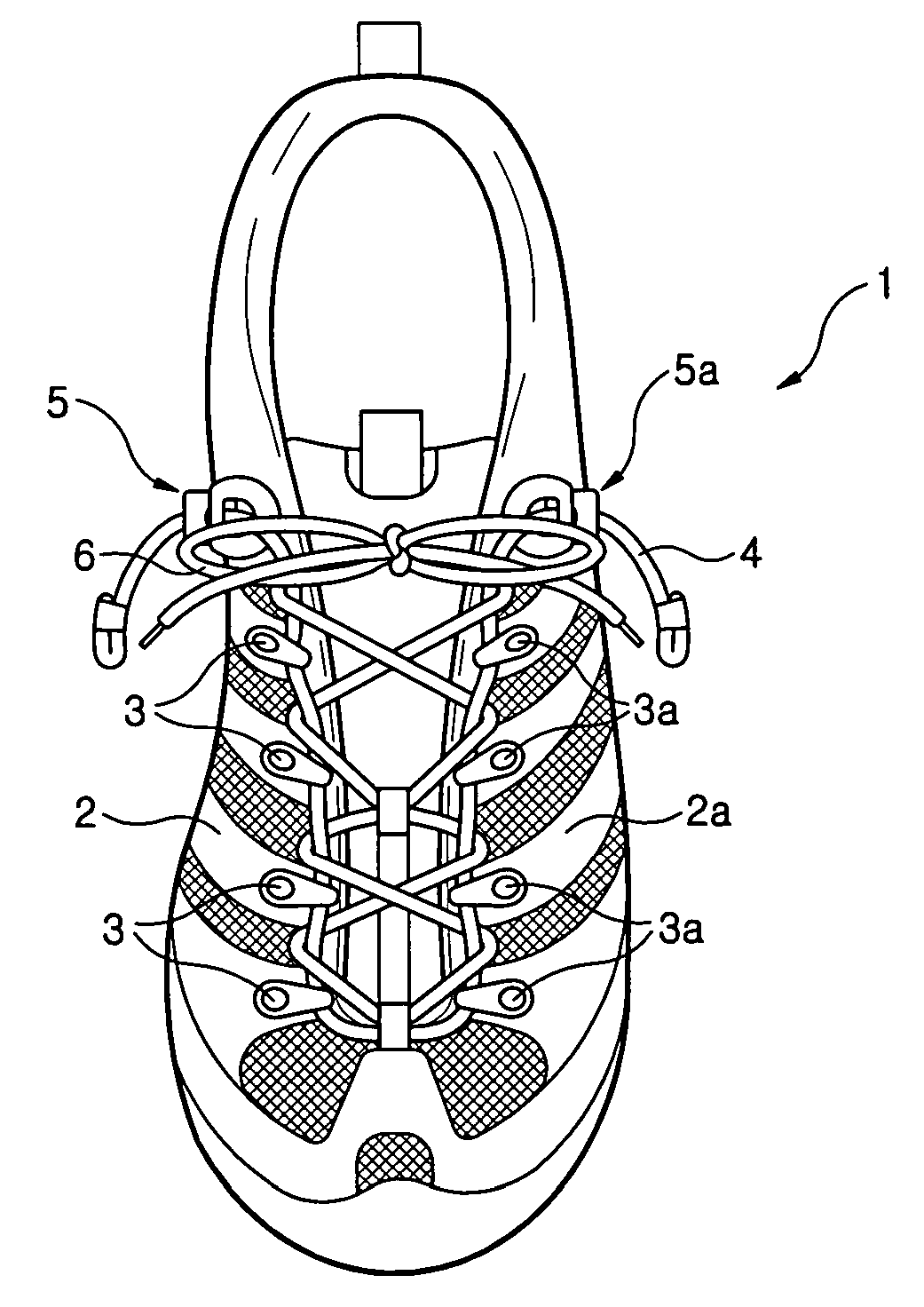

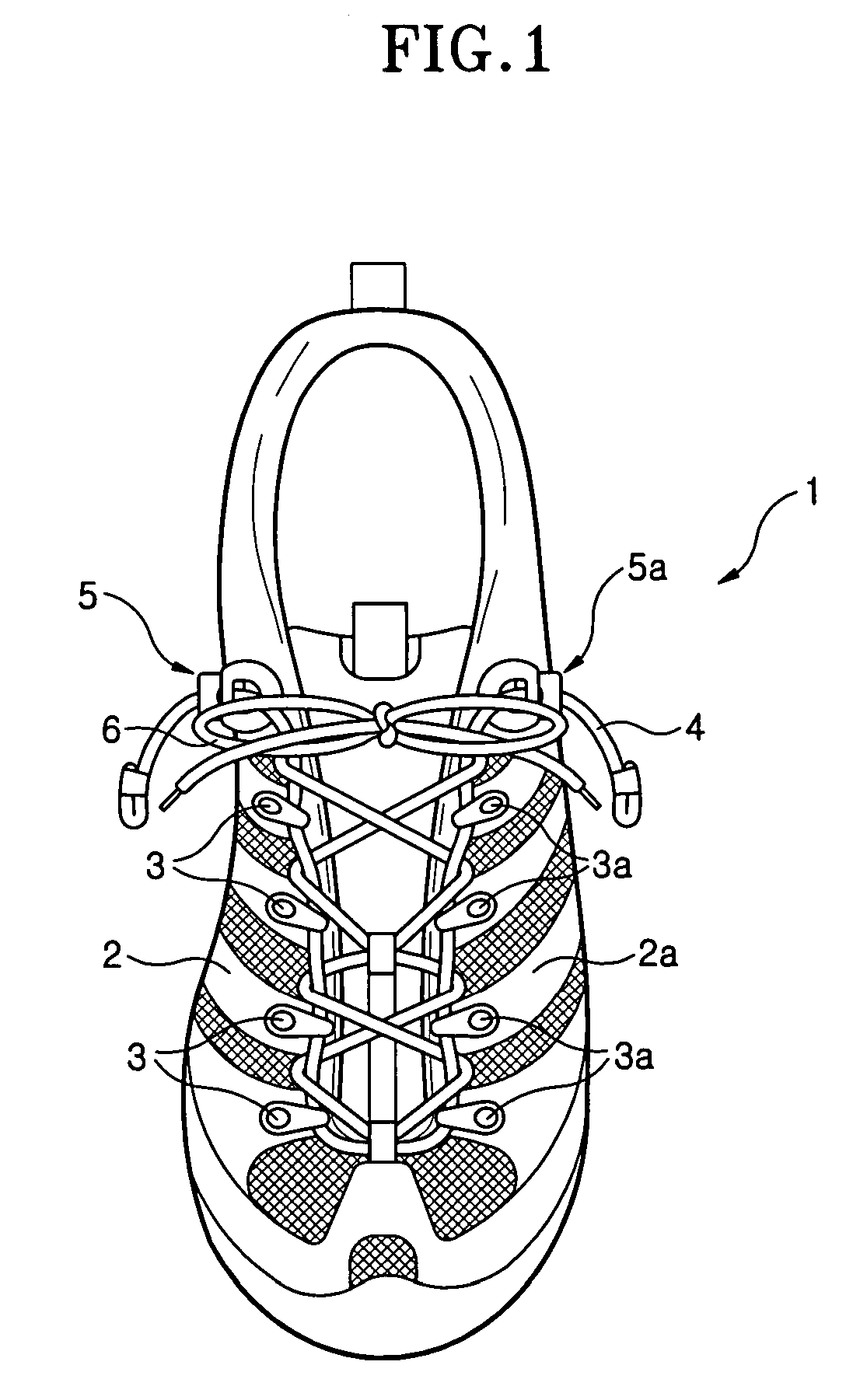

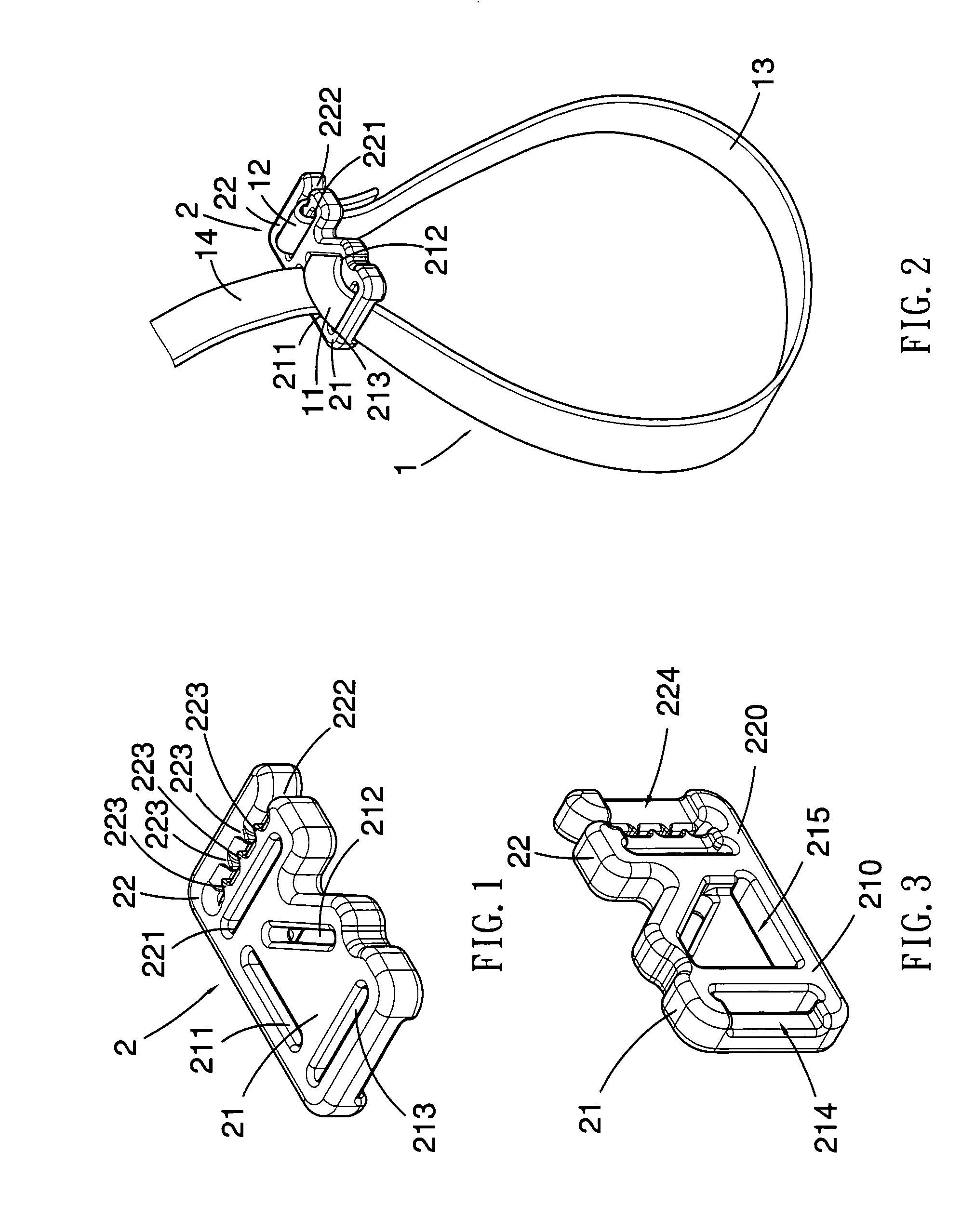

Shoelace tightening structure

Owner:MIN DUCK GI

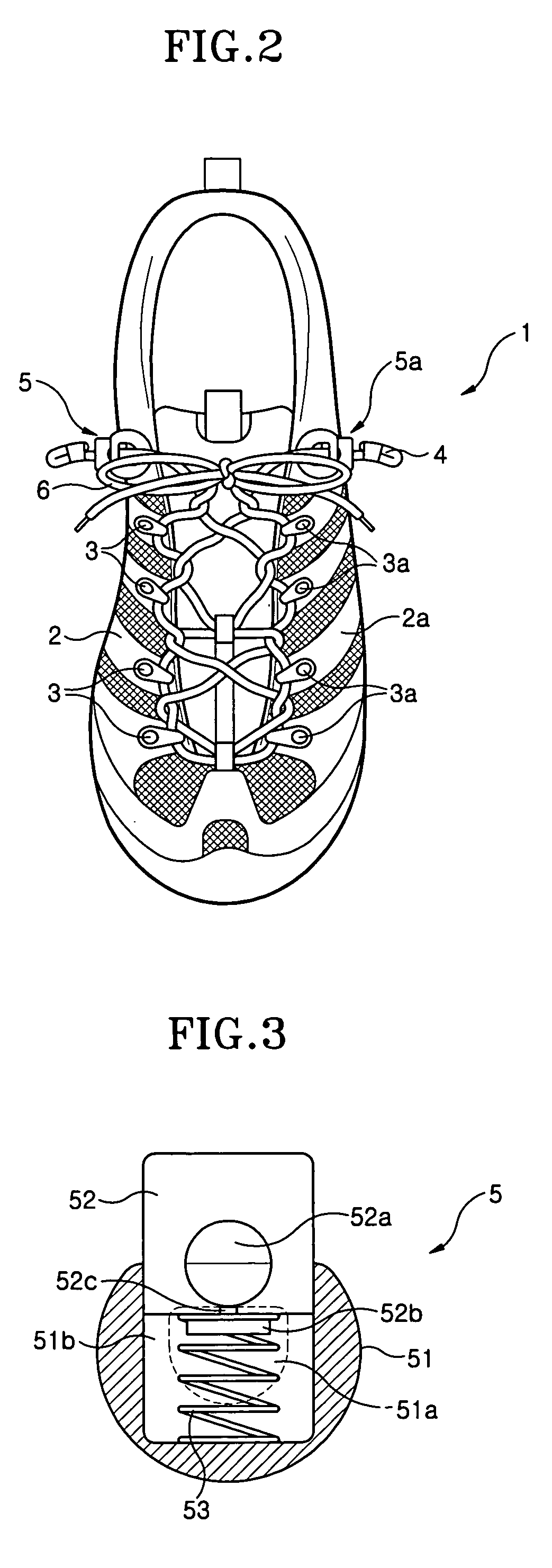

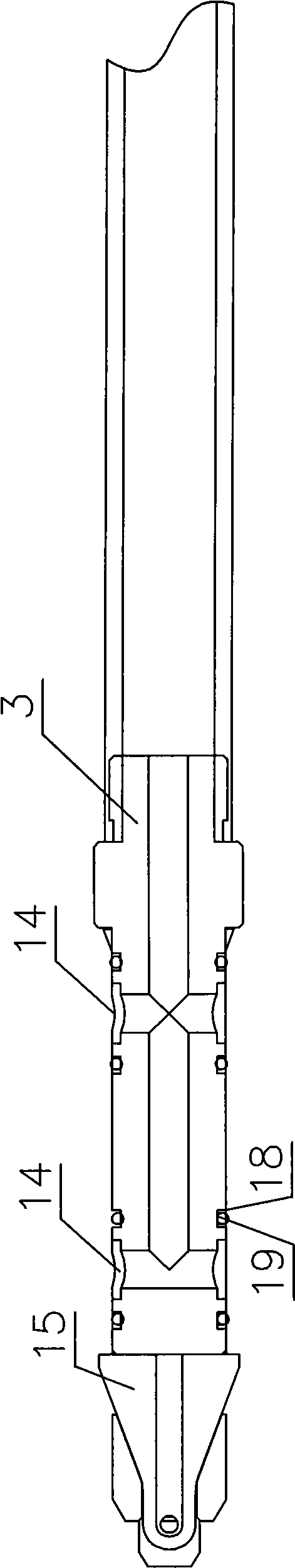

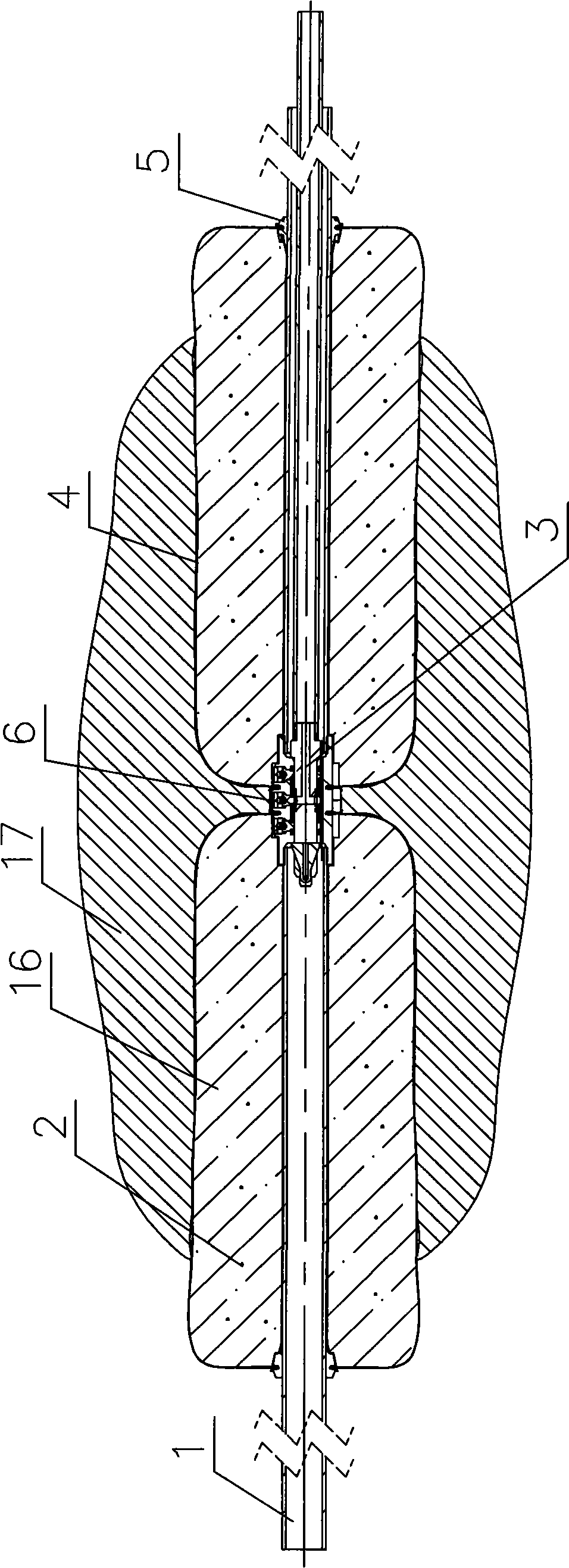

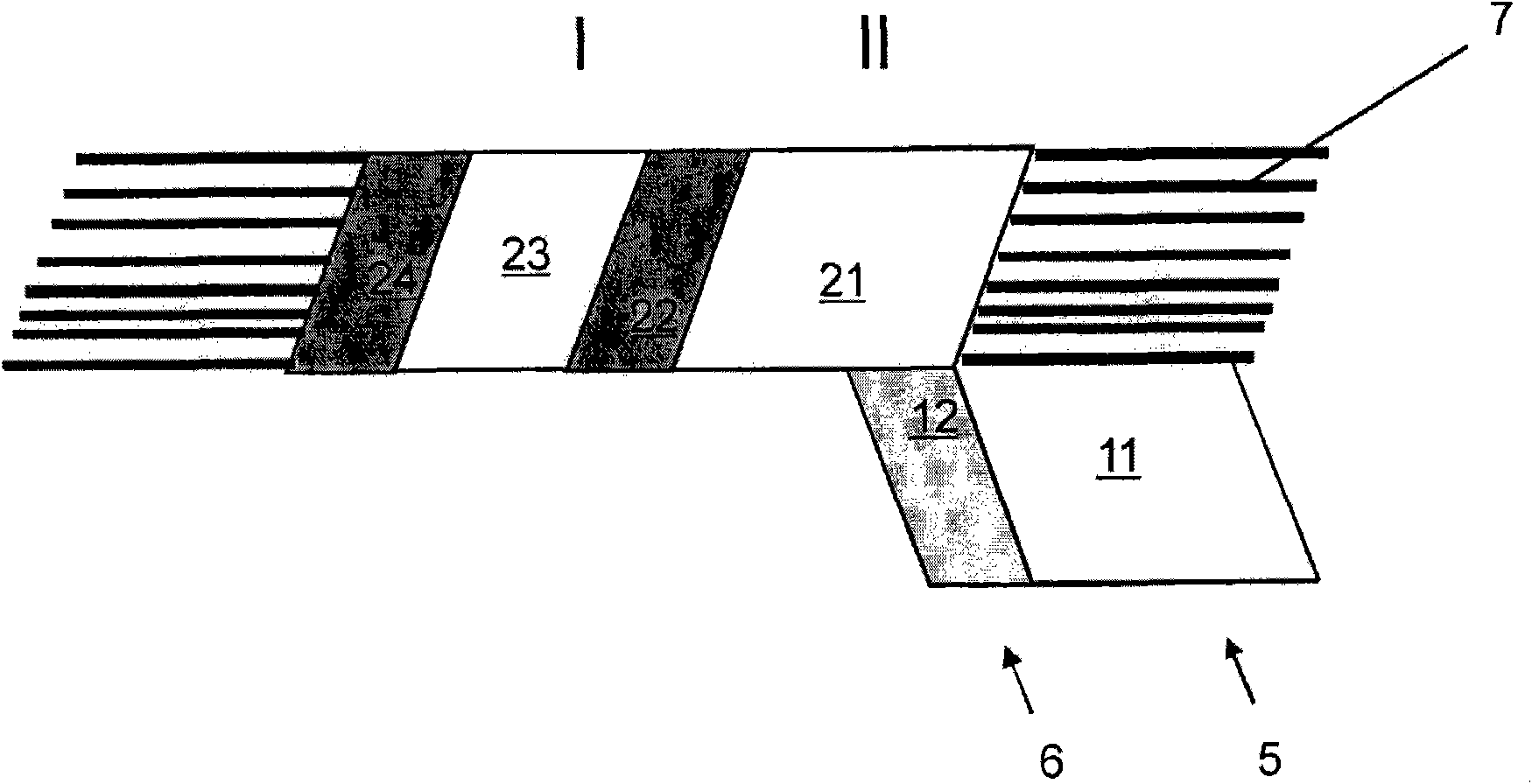

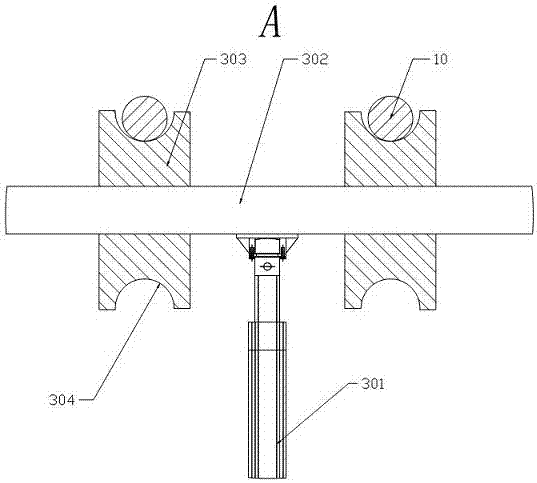

Gas extraction secondary high-pressure slip-casting hole-sealing apparatus and its hole-sealing method

InactiveCN101482026AImprove pressure bearing capacityImprove sealingGas removalSealing/packingDrill holeHigh pressure

A secondary high-press pulp injection and hole sealing device for collecting gas comprises collection pipes, bags and a secondary pulp inflow device, wherein collection pipes are connected with two sides of the secondary pulp inflow device; plugs are sleeved on the collection pipes; the bags are located between each plug and the secondary pulp inflow device; three pulp inflow holes having unidirectional valves are arranged on the secondary pulp inflow device; the pulp inflow holes on the two sides communicate with the bags on the same side; and the pulp inflow hole in the middle spatially communicates with the bags. A method of using the device for pulp injection and hole sealing comprises the following steps of: inserting a pulp injection plug in the secondary pulp injection device and performing the low-pressure pulp injection to the pulp inflow holes that communicate with the bags; and after the injected pulp is solidified, performing the high-pressure pulp injection to the pulp inflow hole in the middle of the secondary pulp inflow device by using the pulp injection plug. The invention adopts the pulp injection materials to inject the pulp to the drill hole wall so as to seal the drill hole wall and the peripheral deflated passages thereof, and basically eliminates the drill deflated cracks through the primary low-pressure pulp injection and the secondary high-pressure pulp injection close to the ground stress.

Owner:HENAN POLYTECHNIC UNIV

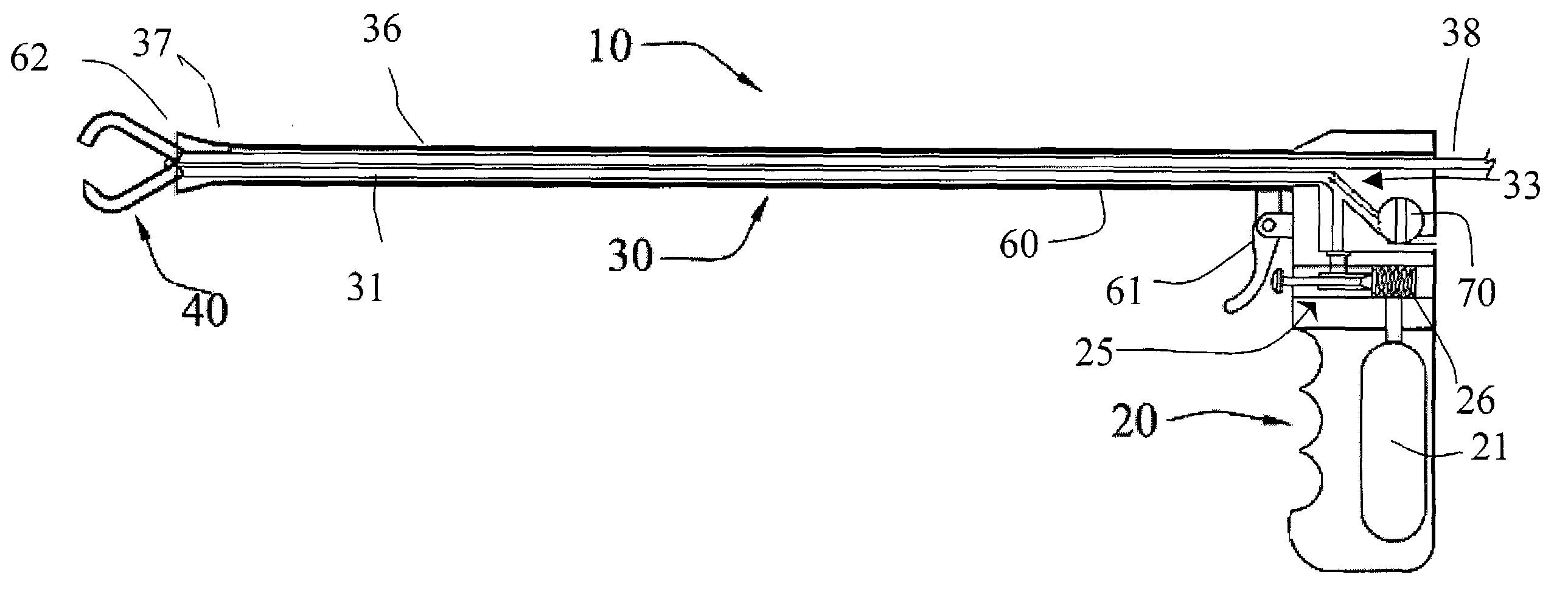

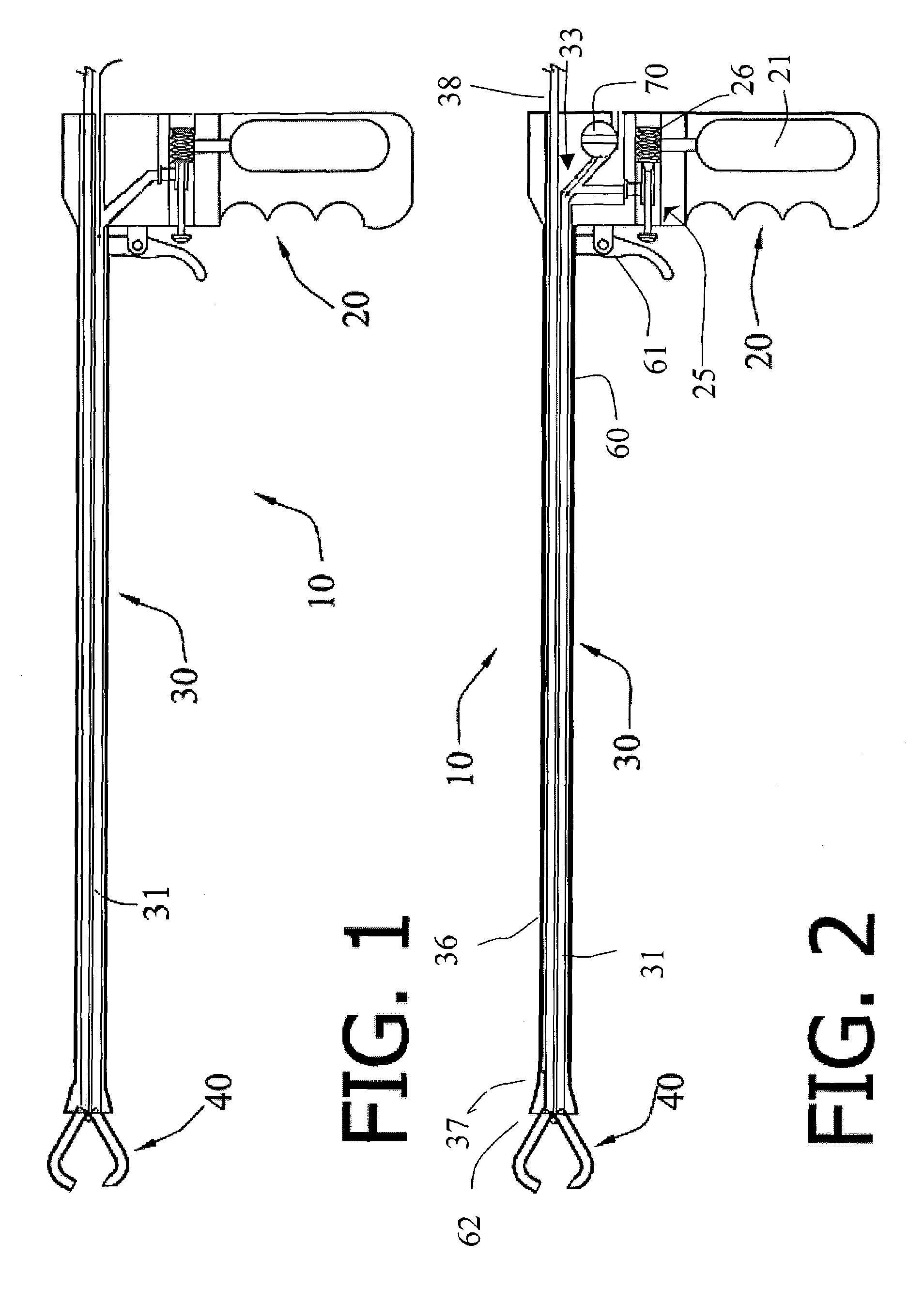

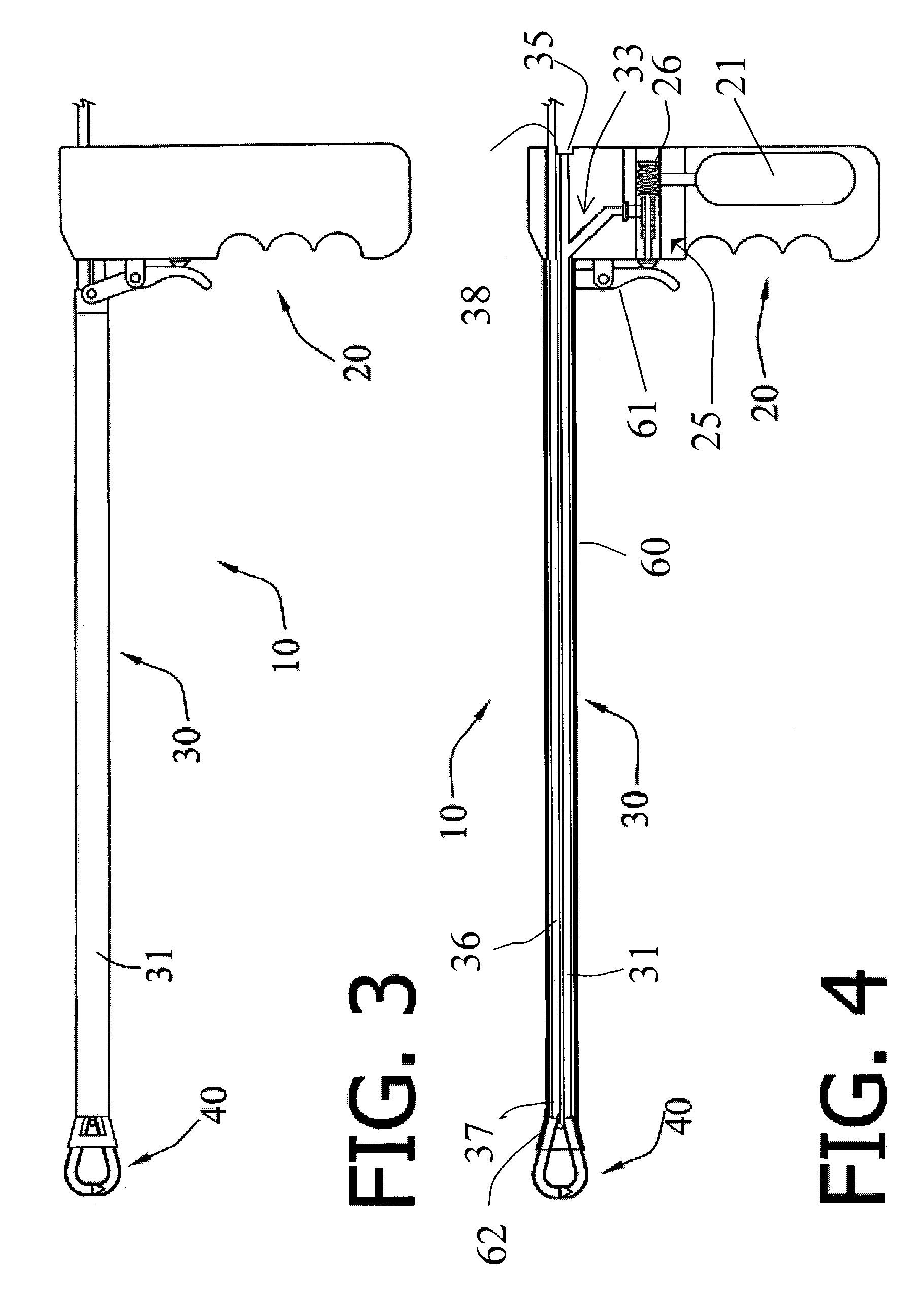

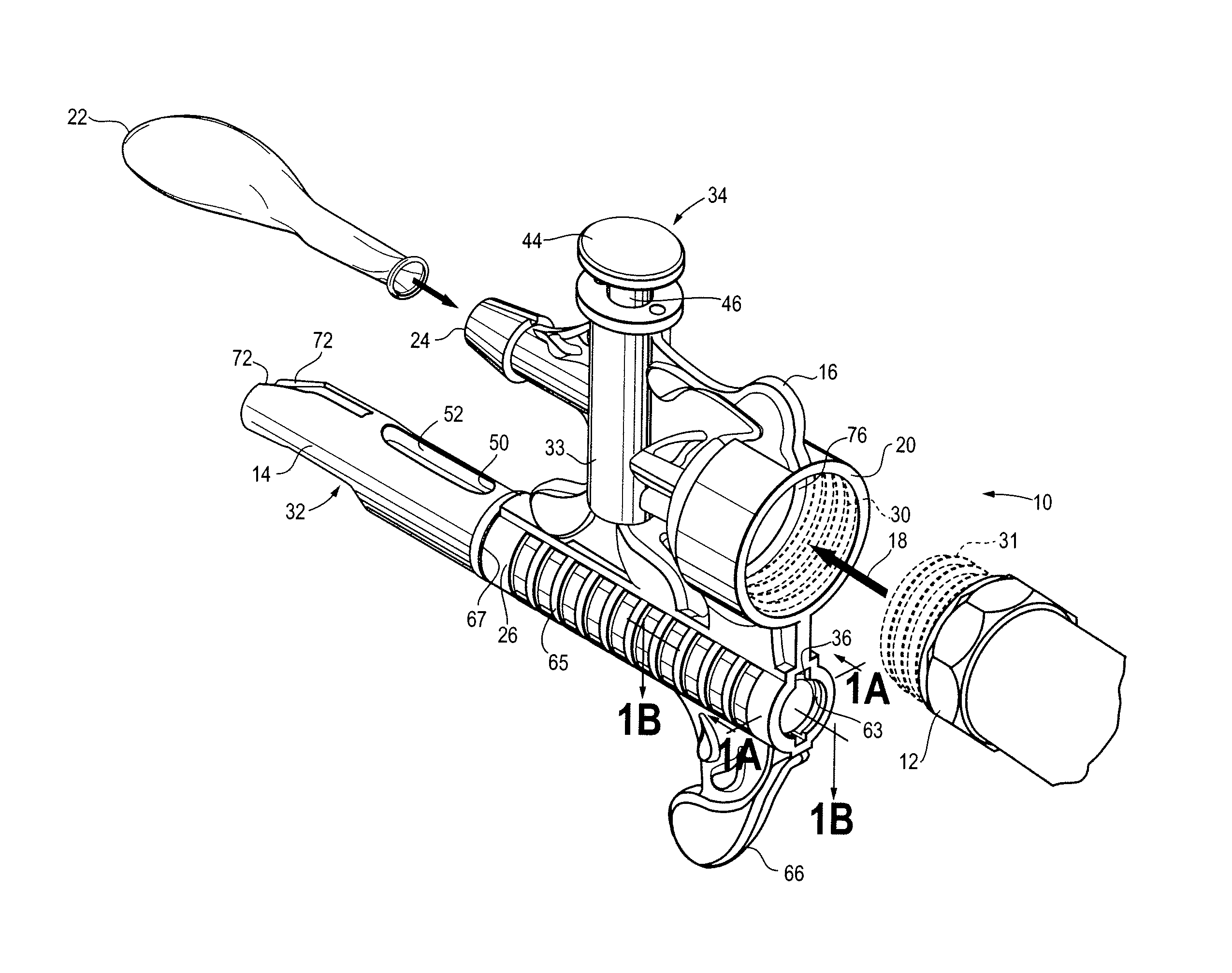

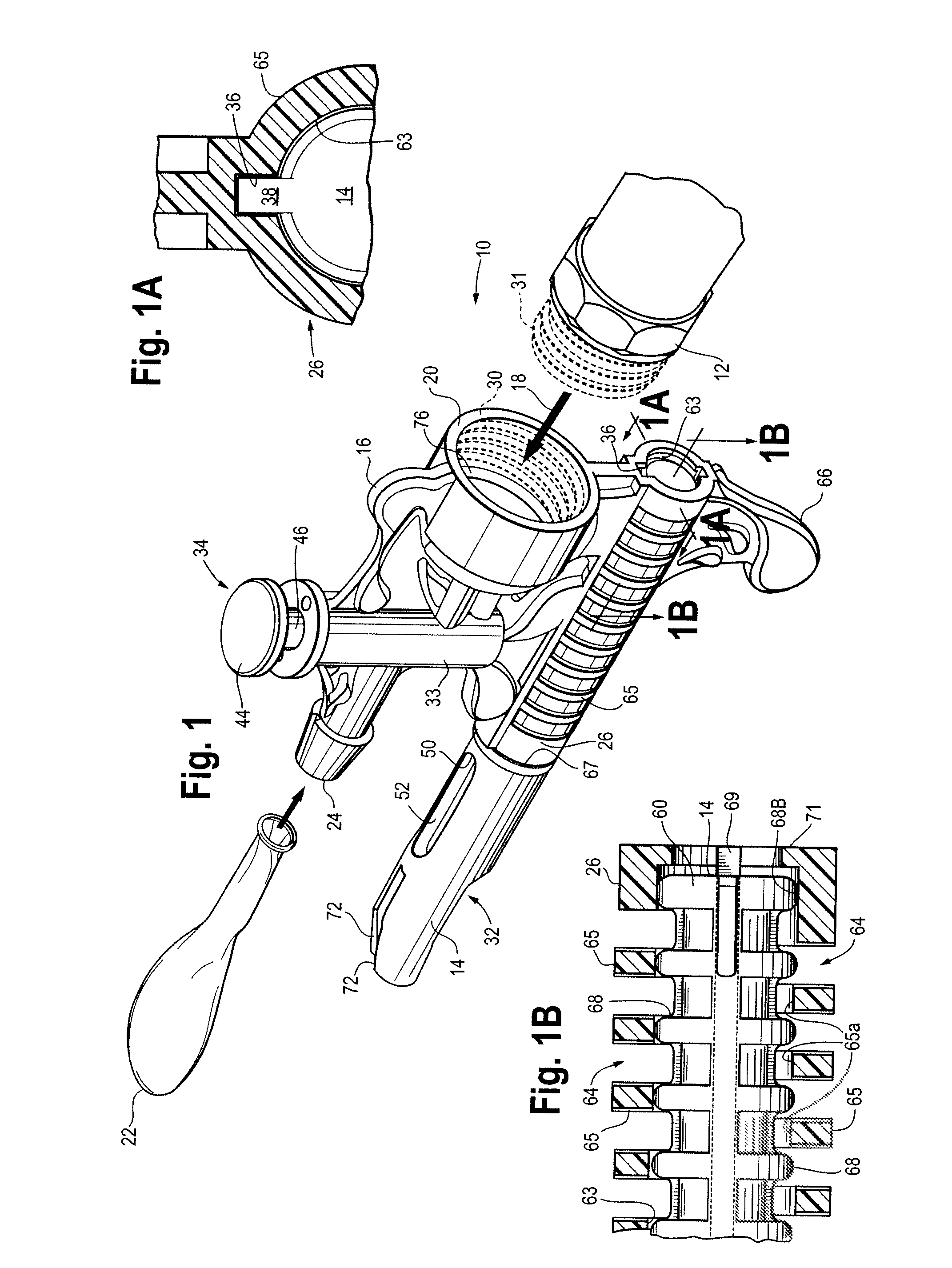

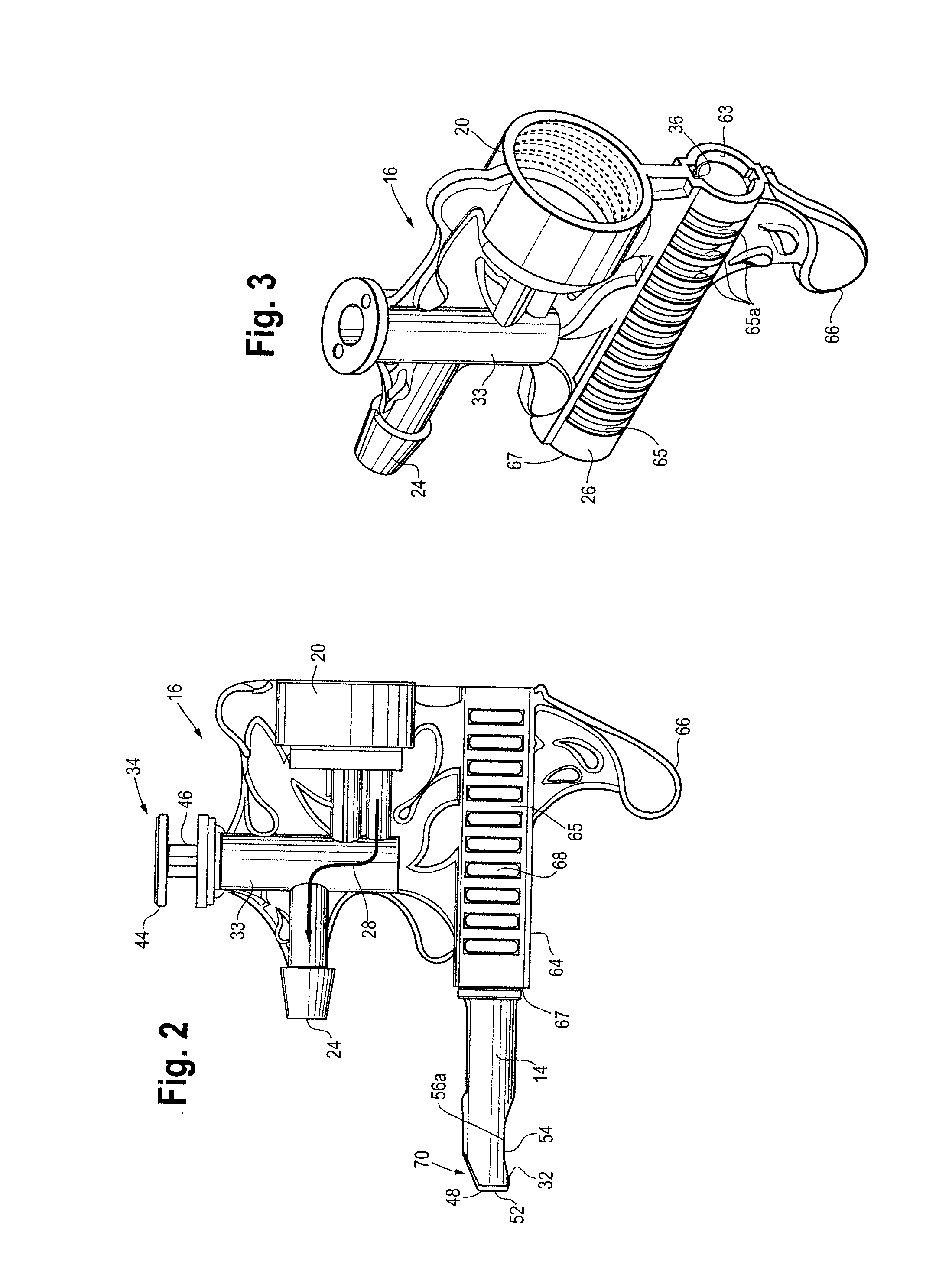

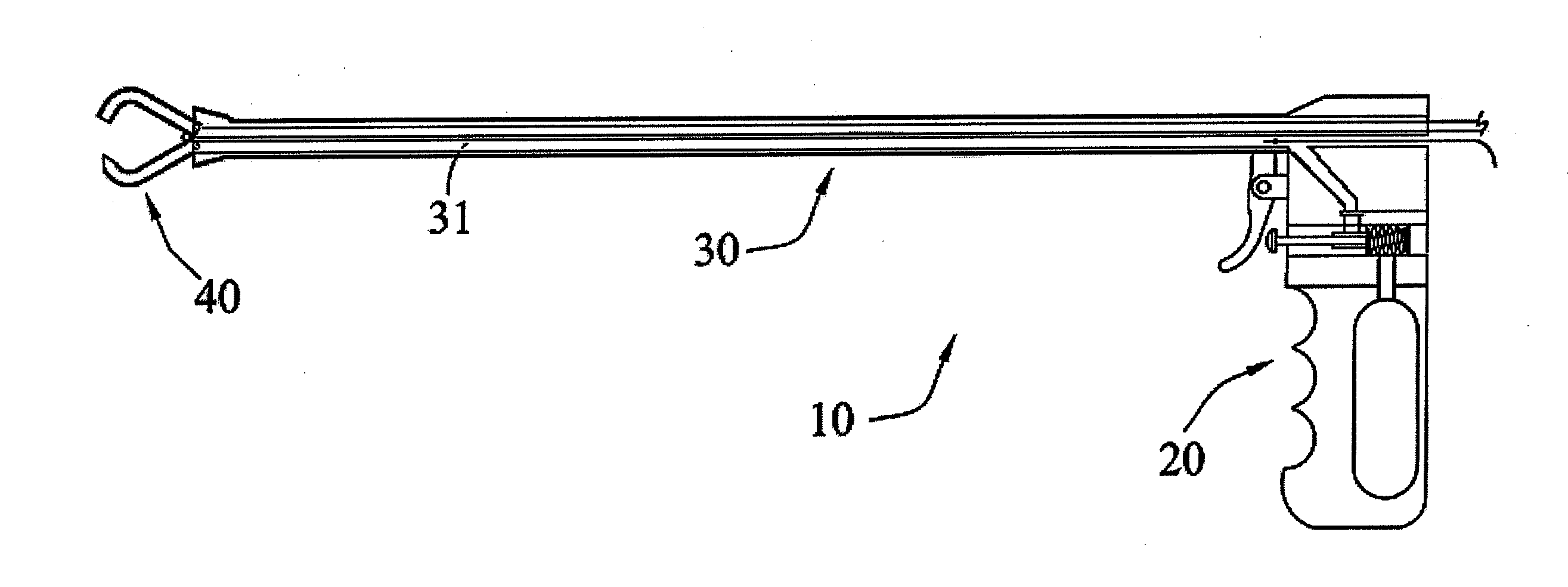

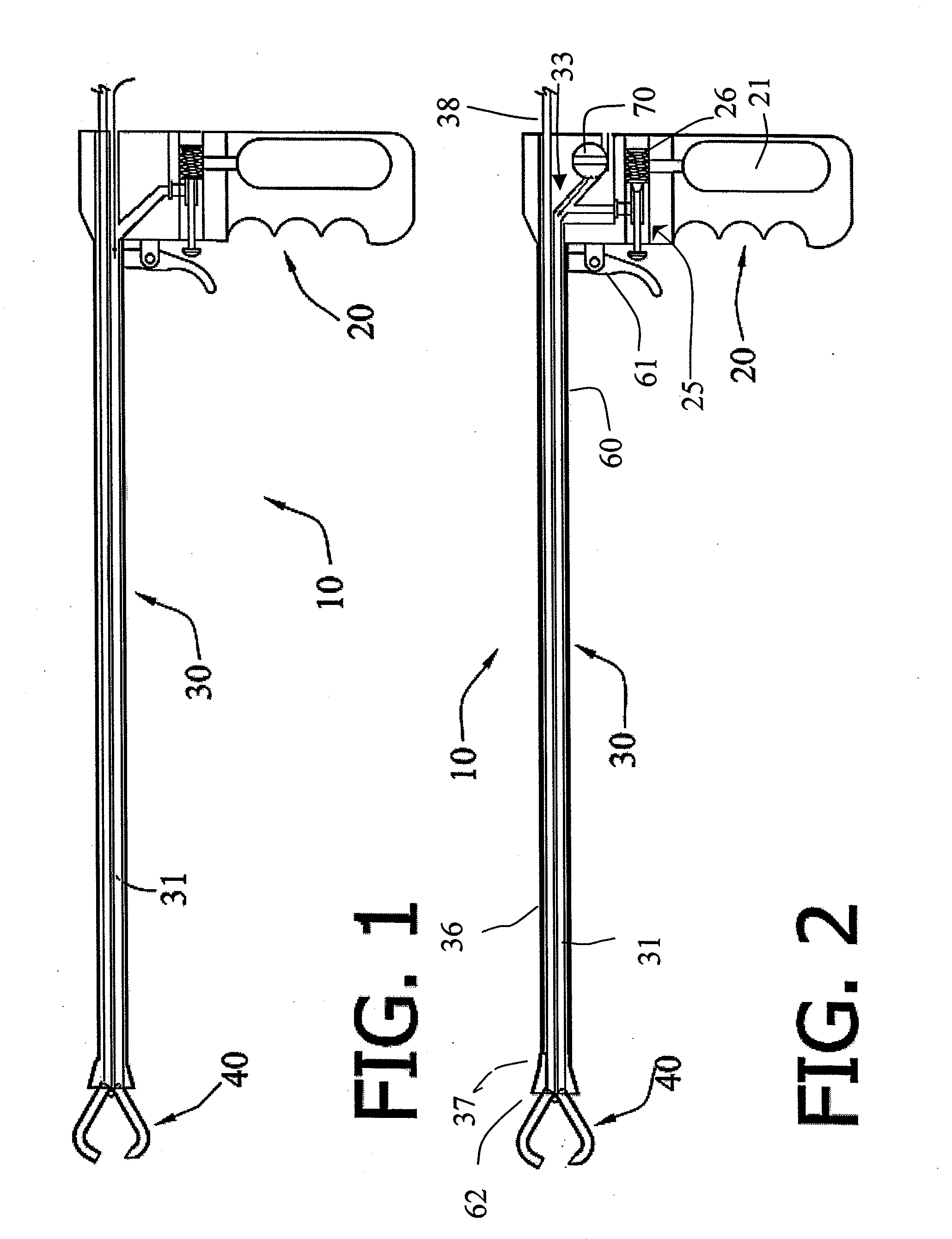

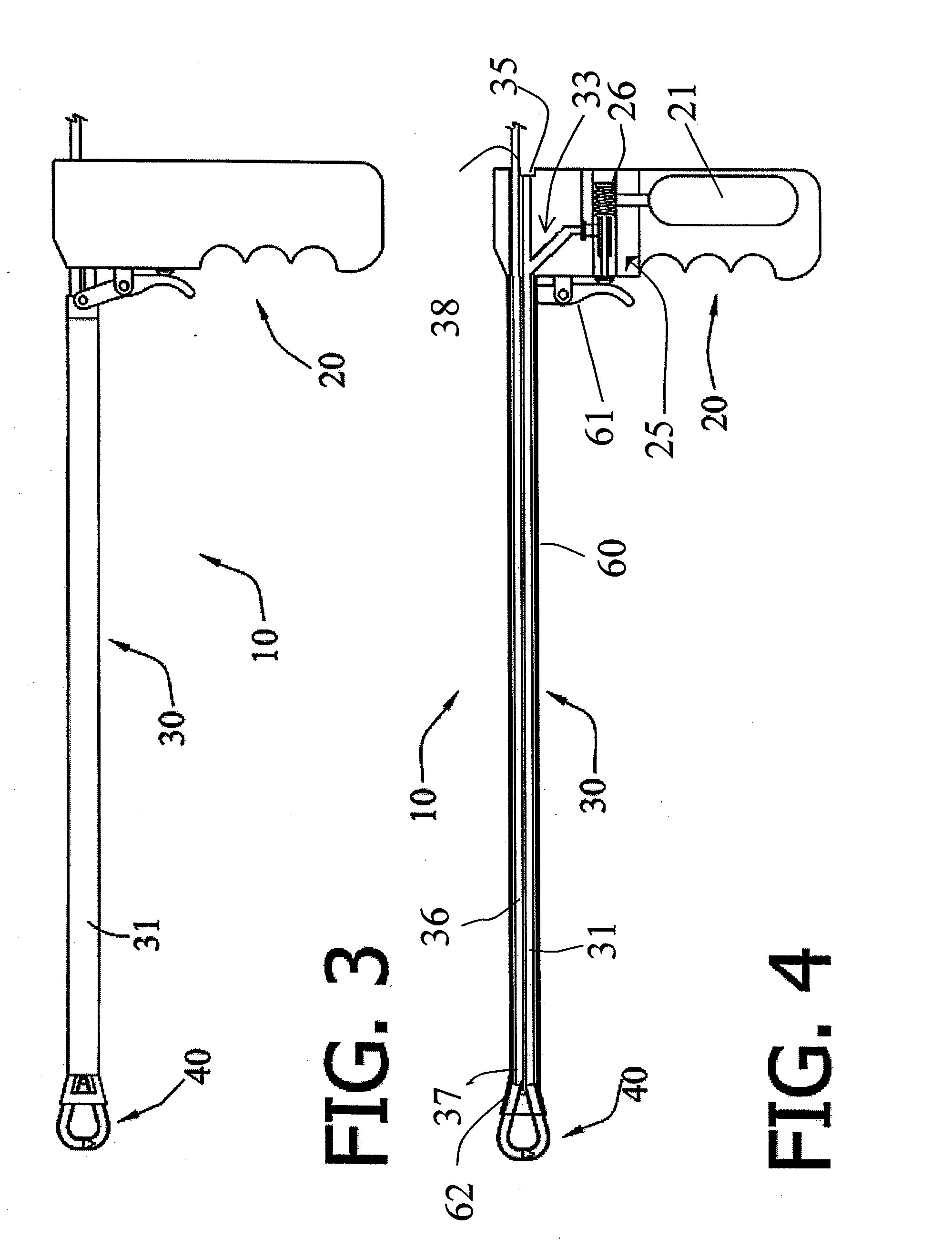

Pneumatic suture instrument

InactiveUS7232446B1Facilitate separationEasy to tieSuture equipmentsSewing apparatusSurgical sutureSurgical Staplers

The surgical suturing instrument incorporates a pressurized fluid suture feed system for passing a suture through the instrument and the tissues to be joined thereby. A fluid jet in communication with a suture feed conduit selectively entrains a suture in a stream of pressurized fluid, which carries the suture through the instrument's hollow tissue penetrating needle. The tissue penetrating needle may be shaped to direct the suture's free end to a point external the body cavity. Alternatively, a suture return conduit may be provided to engage the hollow tissue penetrating needle to receive and carry the suture's leading end to a point external the body cavity. External or internal pressurized fluid sources are utilized. A surface irregularity proximal the suture's leading end enhances the entrainment of the suture with the fluid stream. Individual, cartridge and spool fed sutures may all be utilized.

Owner:FARRIS ALEX F

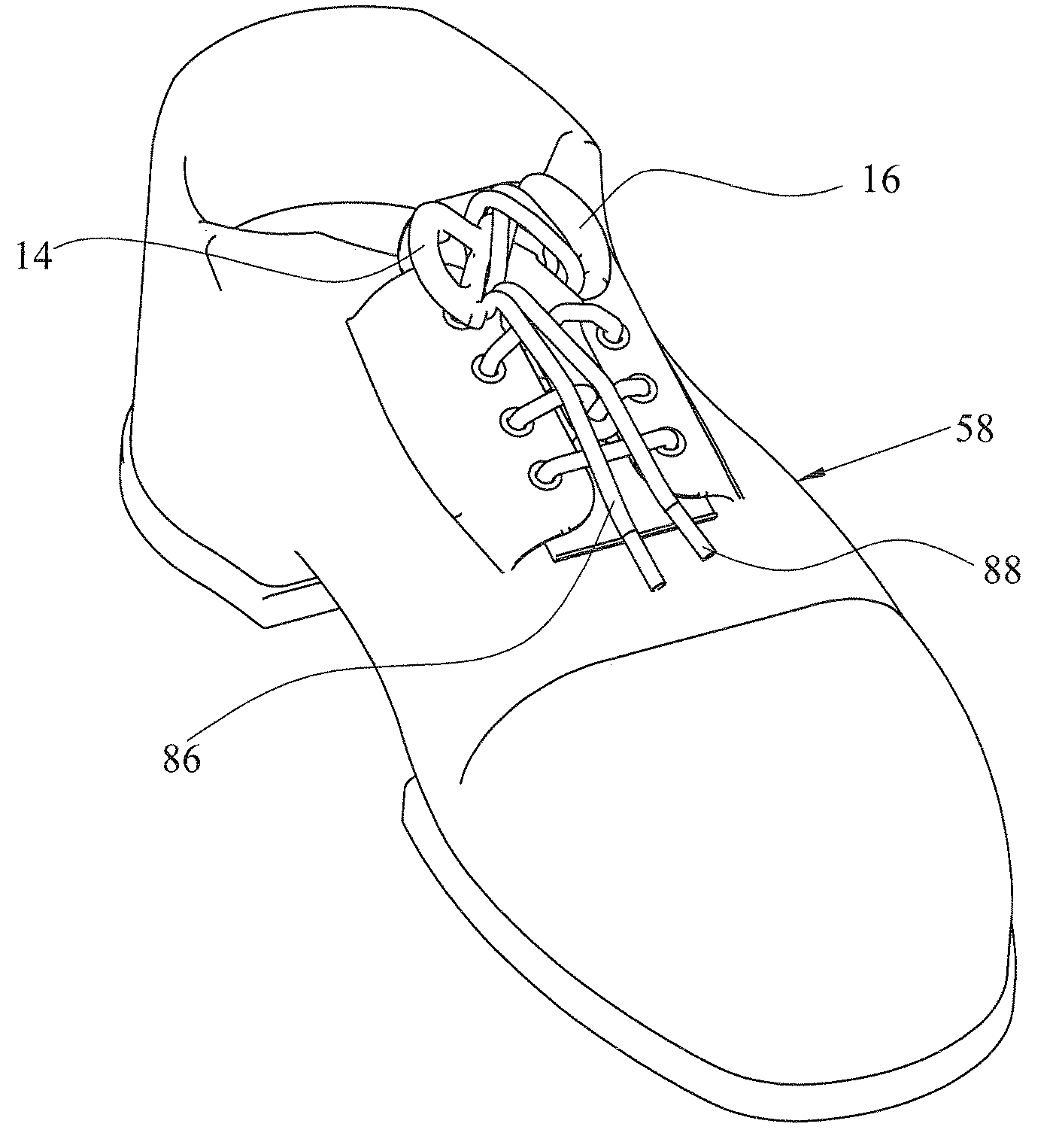

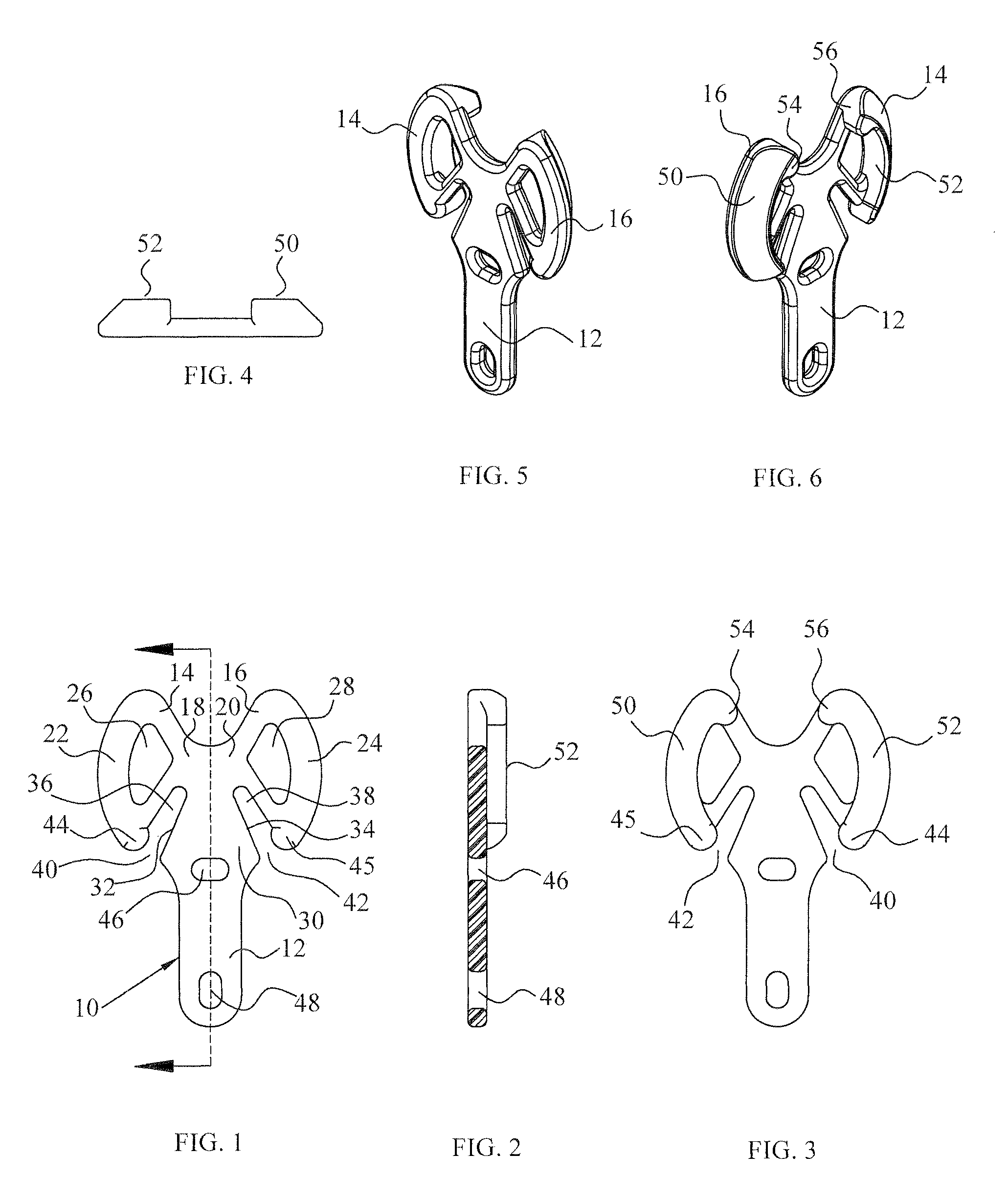

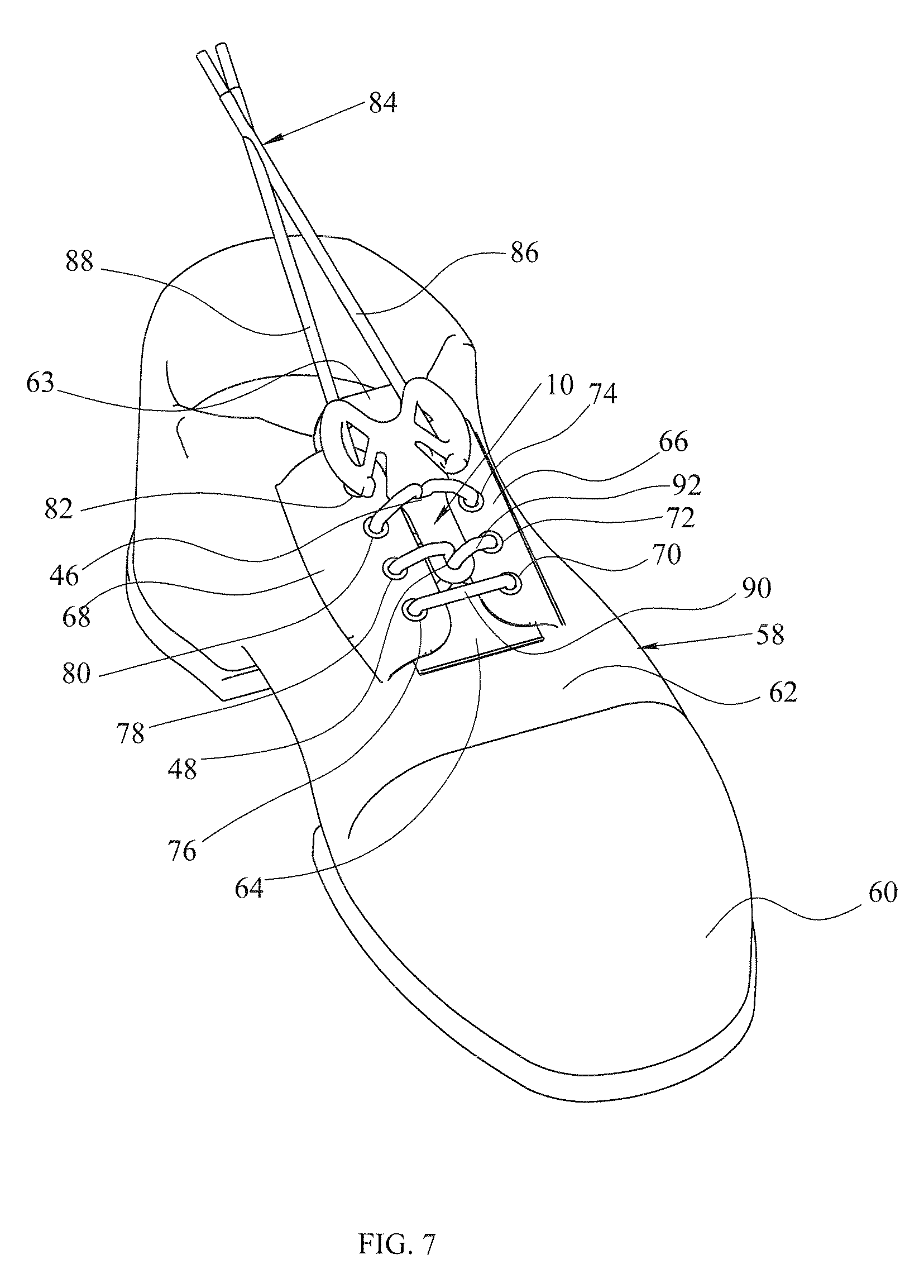

Shoe tying aid and method

InactiveUS8056265B2The process is simple and effectiveEasy to tieFilament handlingShoe lace fasteningsEngineeringMooring line

A shoe can be tied using only one hand if provided with a tying aid in the form of a generally T-shaped unit comprising a leg having two laterally extending ears. The leg is secured between rows of eyelets on the opposed flaps of the shoe by one or more of the lengths of lace extending across the gap between the flaps. The lengths of shoelace that would otherwise be tied in a bow are instead wrapped around the ears of the tying aid in alternating fashion, preferably twice around each ear, in a manner similar to the manner in which a mooring line is secured to the cleat of a boat.

Owner:THERM OMEGA TECH INC

Shoelace tightening structure

InactiveUS20060005429A1Easy to tieEasy for to tie shoelaceShoe lace fasteningsHaberdasheryShoe lacesEngineering

Owner:MIN DUCK GI

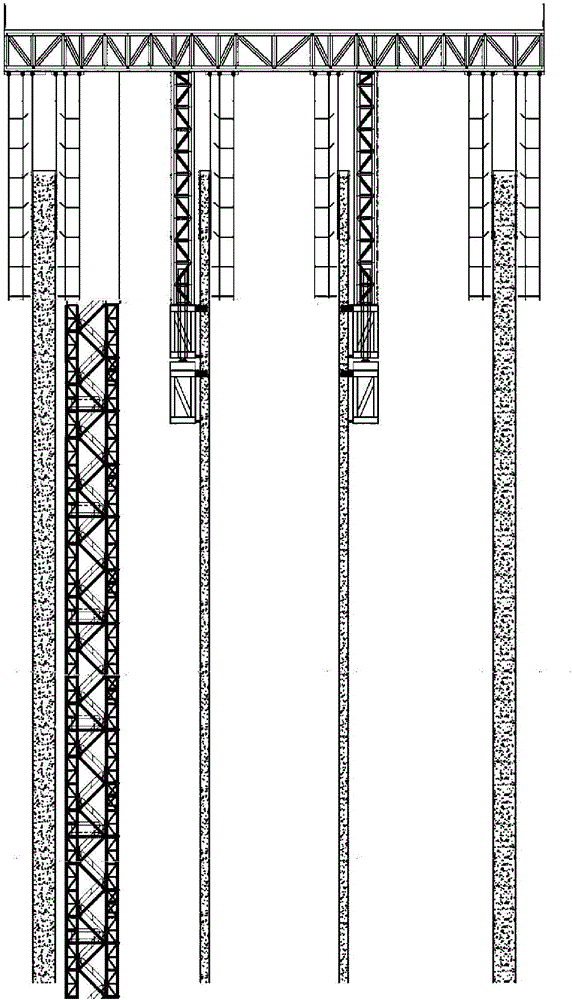

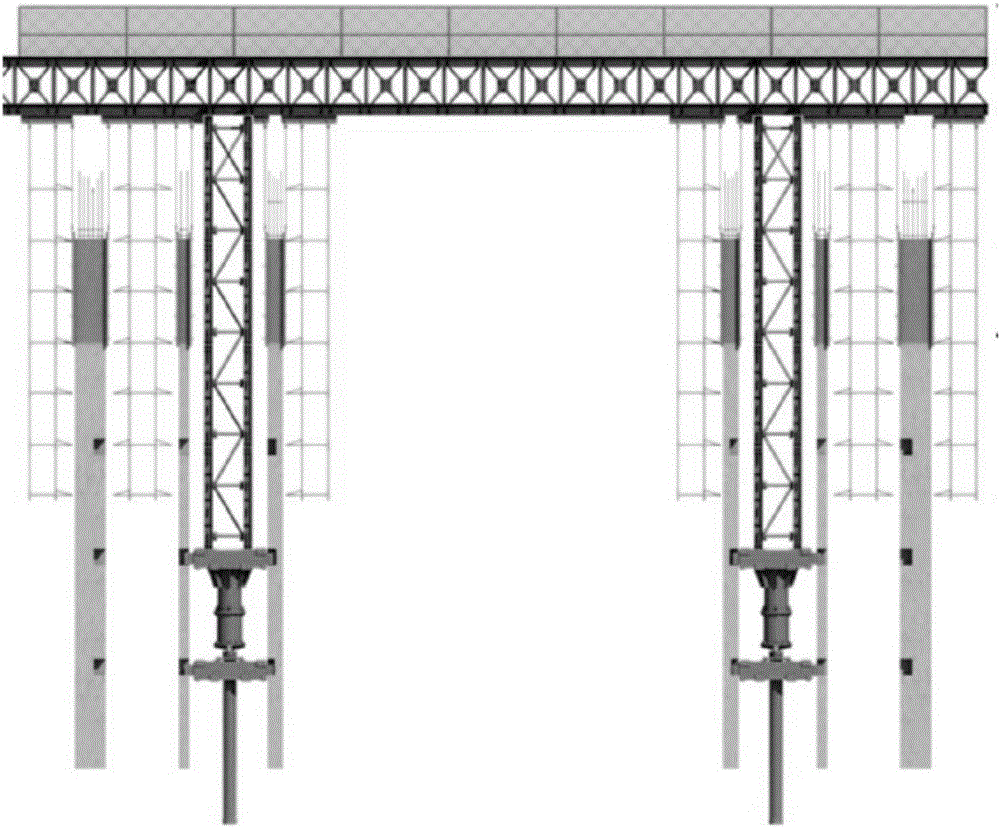

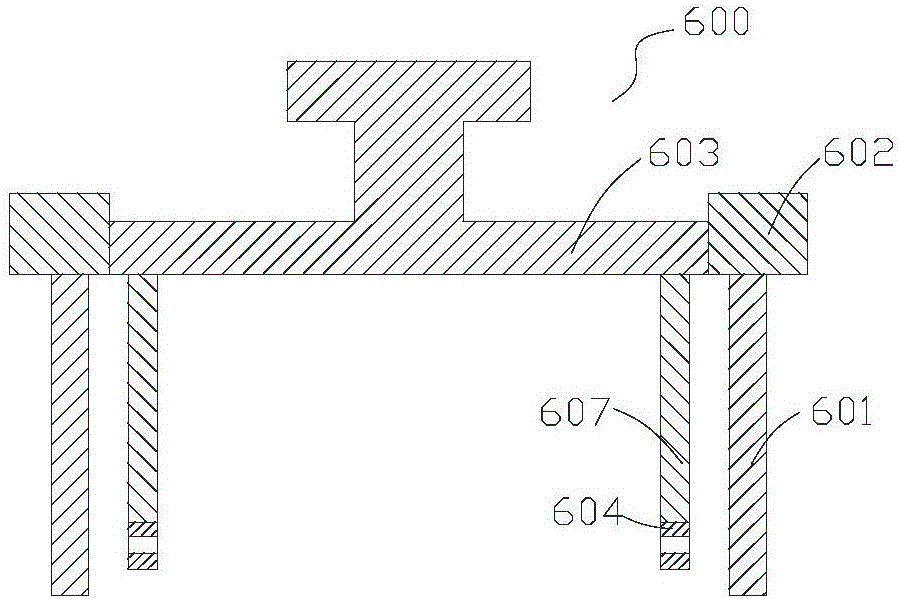

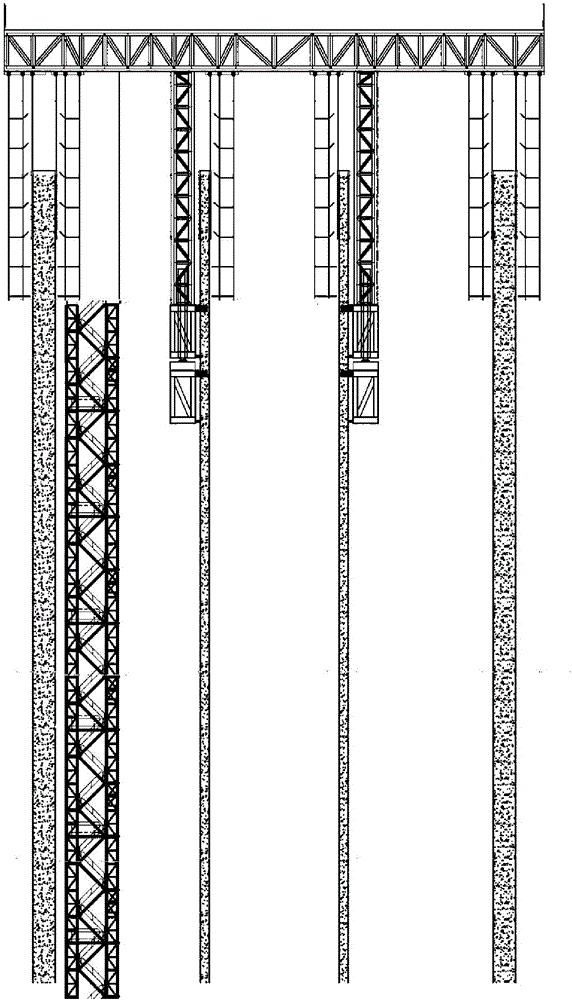

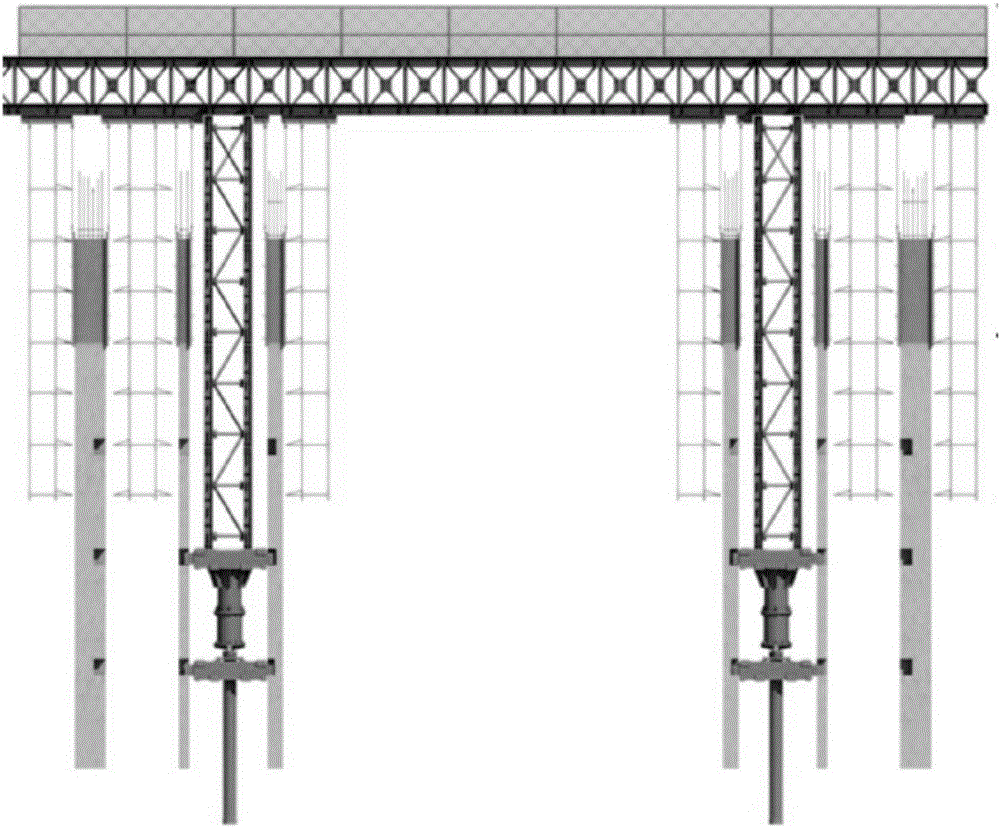

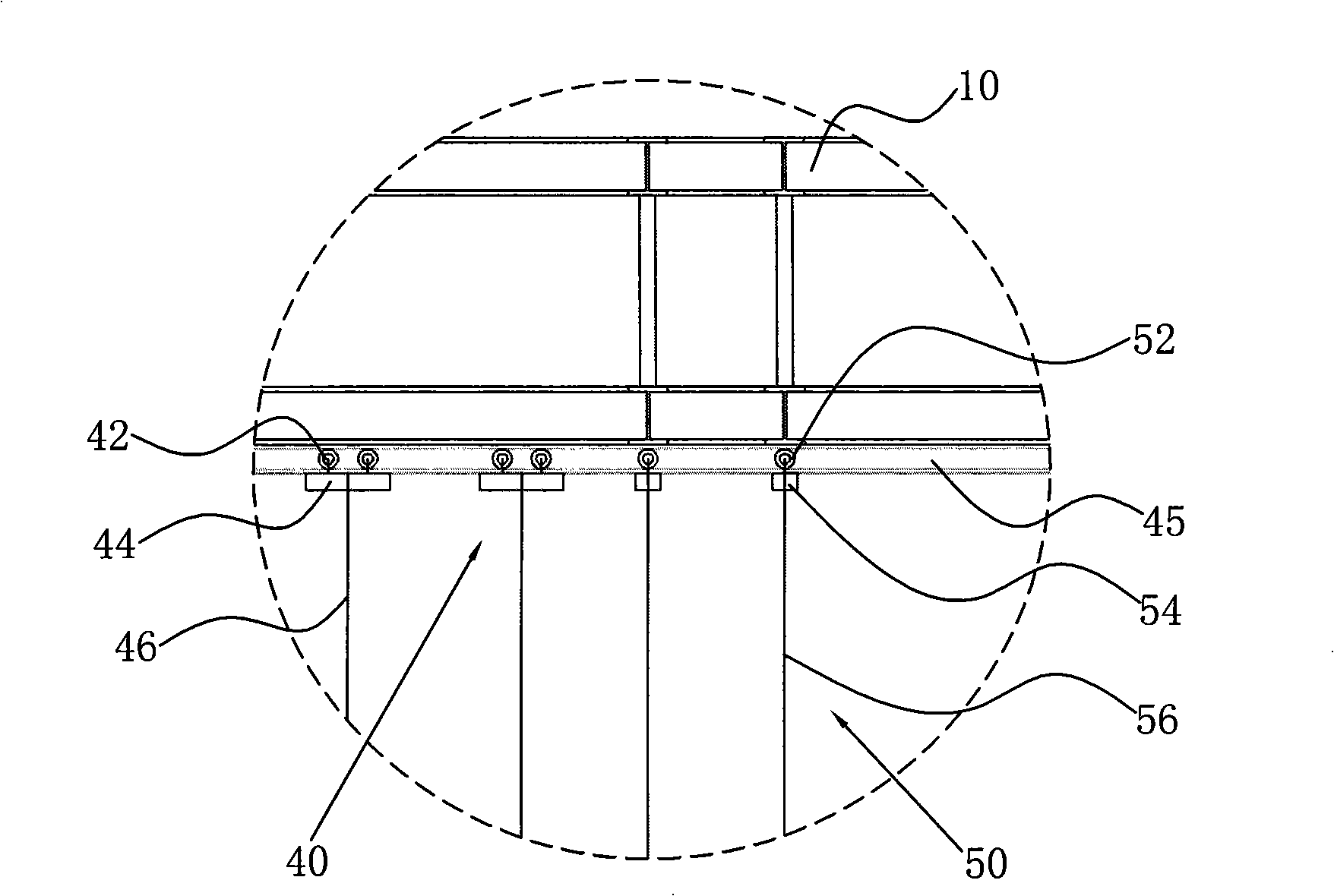

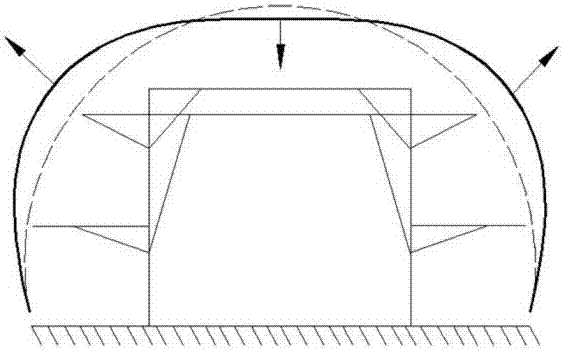

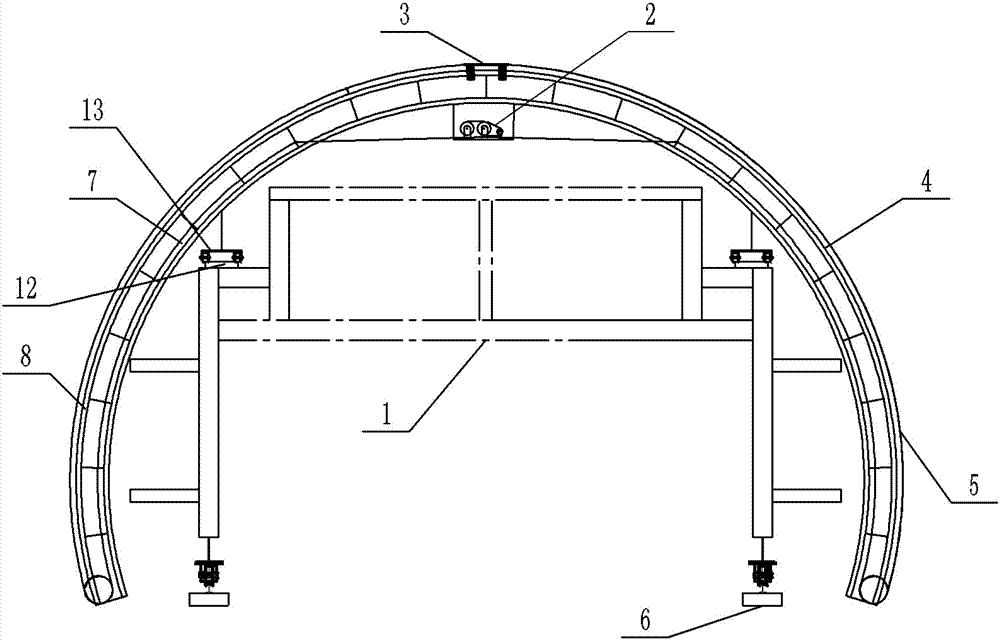

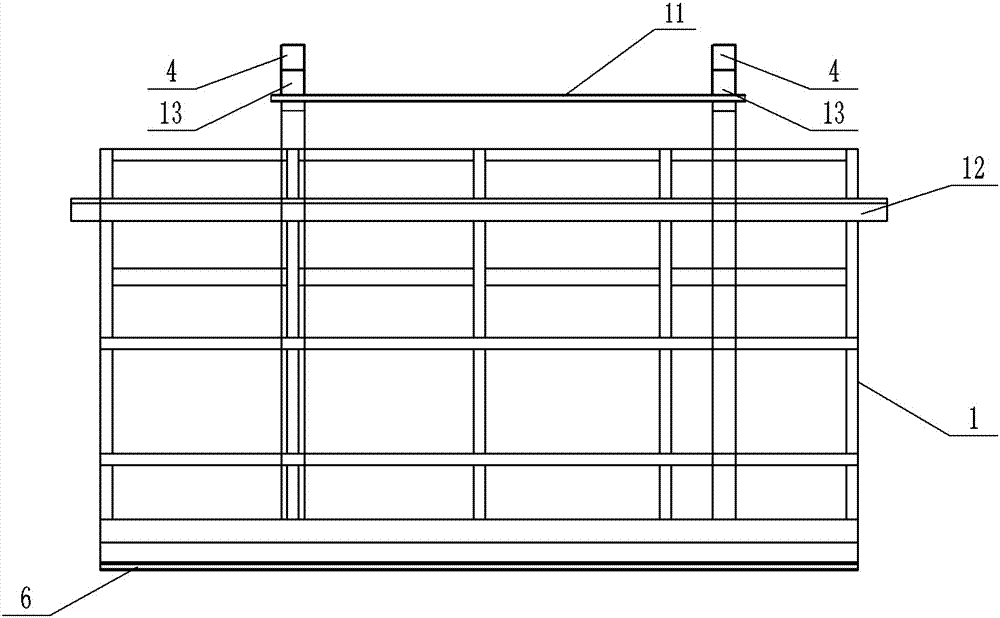

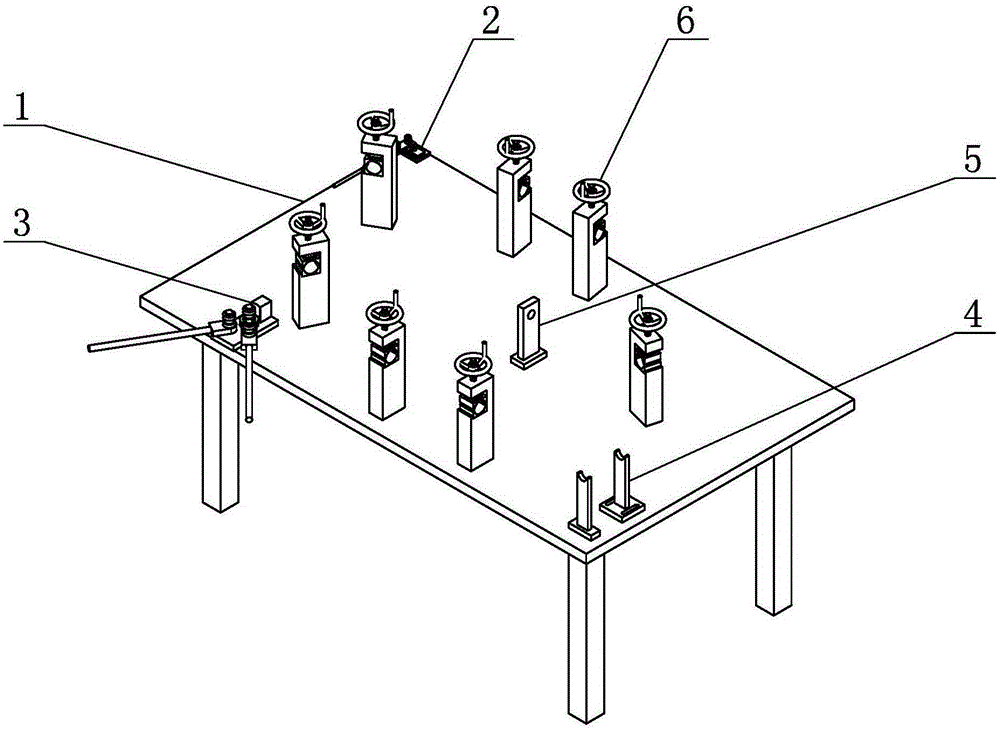

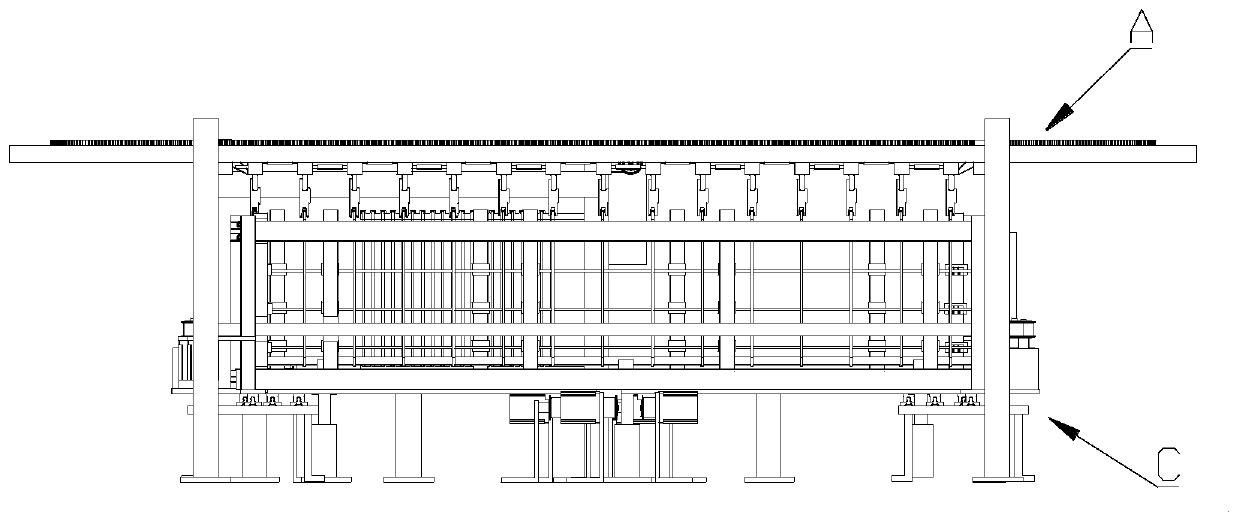

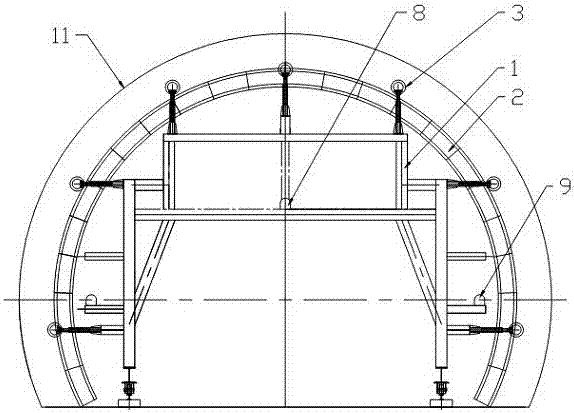

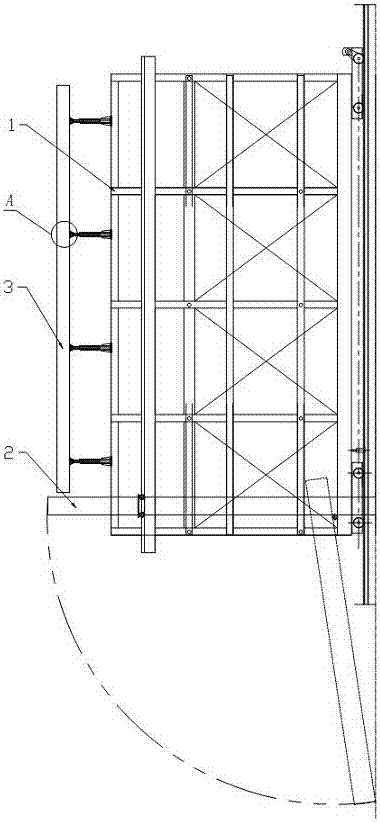

Inner roof external climbing type formwork construction platform for super high-rise building construction

InactiveCN106437130AReduce weightReduce the burden onBuilding support scaffoldsArchitectural engineeringEngineering

The invention discloses an inner roof external climbing type formwork construction platform for super high-rise building construction. The inner roof external climbing type formwork construction platform comprises a hydraulic creeping formwork system arranged on the outer side of a building and located on building walls and a jacking platform system arranged on the inner side of the building and located between adjacent building walls. The jacking platform system comprises a climbing device, an operating platform arranged on the climbing device and wall-attached embedder parts installed on the building walls and used for the climbing device to climb and attach. The hydraulic creeping formwork system adopted on a building external wall and the jacking platform system adopted on the inner side of the building and located between the building walls simultaneously operate to replace a traditional integral jacking type construction platform, horizontal supporting steel beams are not needed, oil cylinder climbing can be achieved only by installing the wall-attached embedder parts on the building walls, the total height of the construction platform and a supporting frame body of the platform is decreased, and a construction difference between a vertical structure and a horizontal structure is decreased, so that the hydraulic climbing system does not influence horizontal structure construction.

Owner:中国华西企业股份有限公司 +2

Adhesive tape and use thereof

InactiveCN101654600AFast strappingEasy to tieFilm/foil adhesivesFlexible elementsBand shapeEngineering

The invention provides an adhesive tape with a strap-shaped substrate material, which is used for wrapping a longitudinally extending object, particularly a conductor bundle or cable bunch. At least one side of the substrate material is spread with a special pressure-sensitive adhesive. The tape is characterized in that: the substrate material is formed by embossed PVC thin films; and the embosseddepth is 0.01 to 8mum, preferably 0.1 to 3mum.

Owner:TESA SE

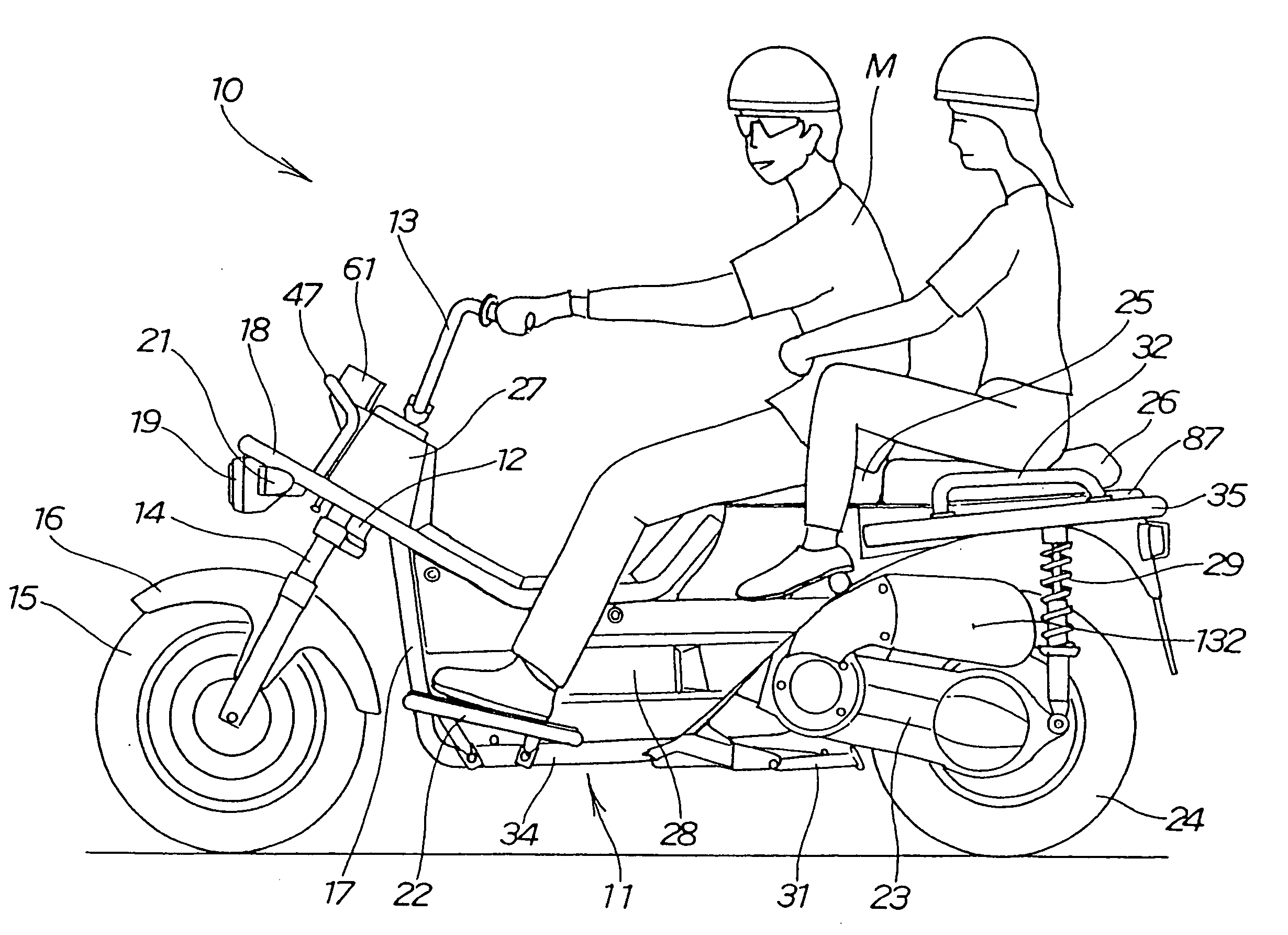

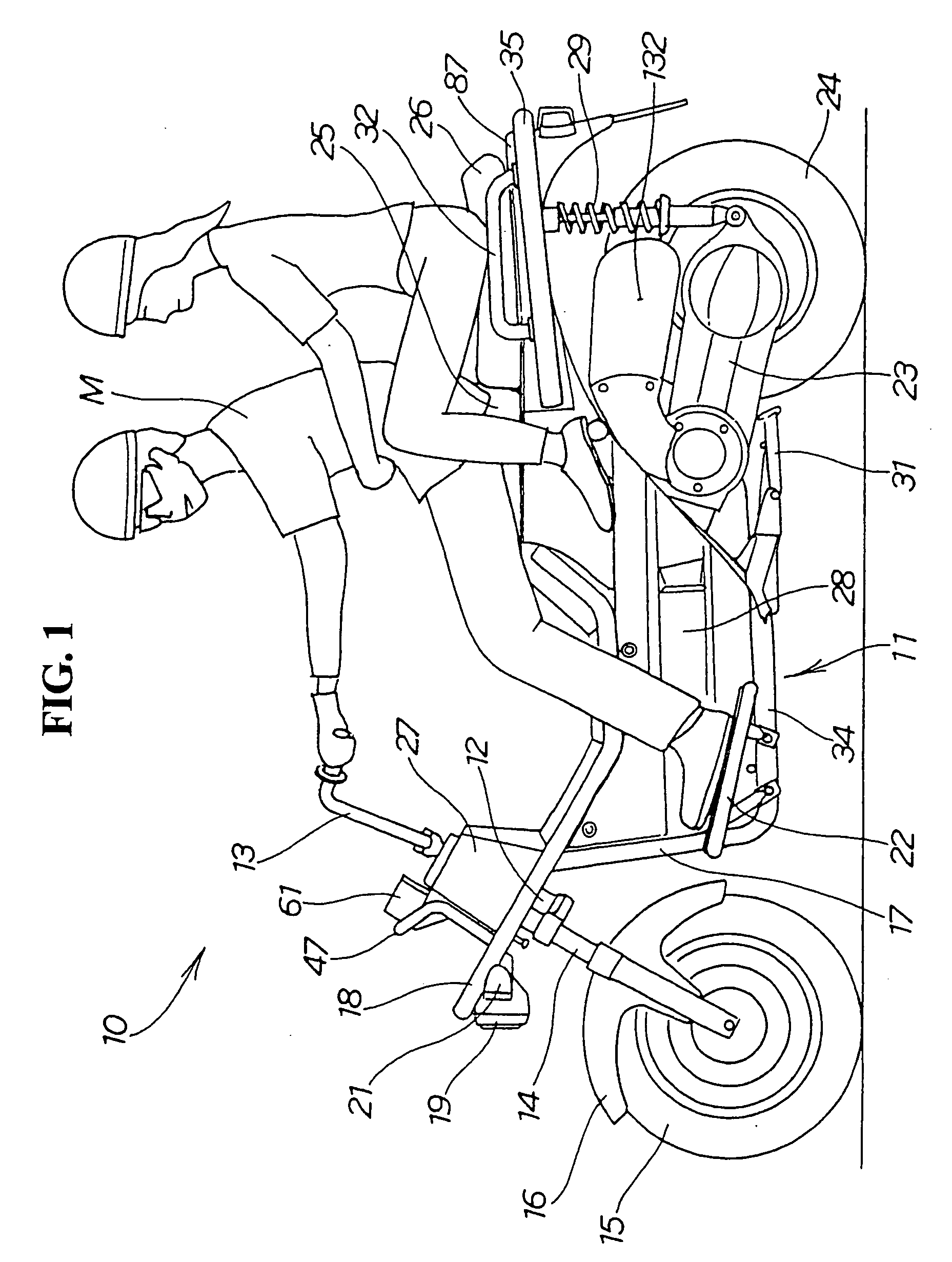

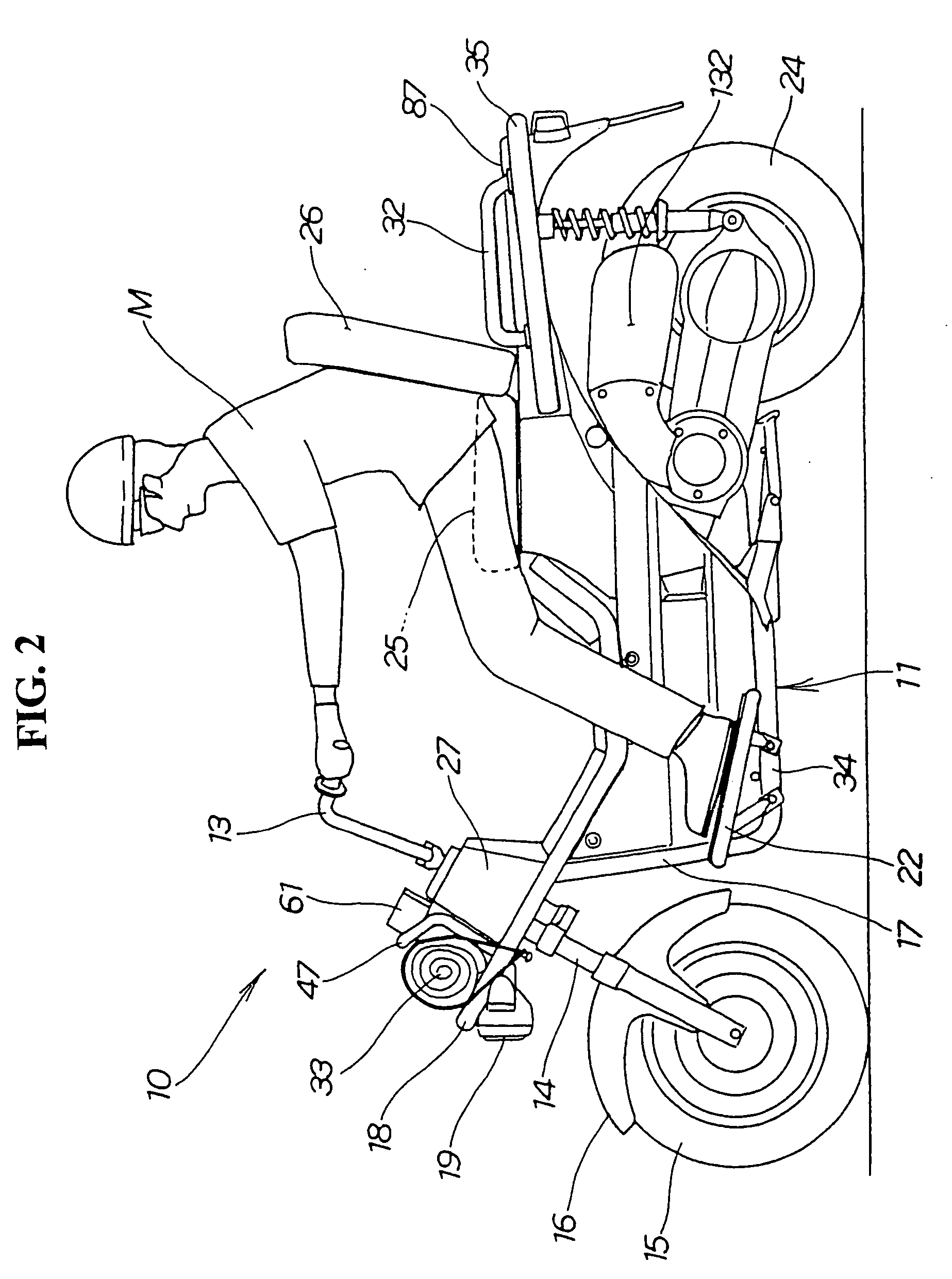

Front structure of motorcycle

InactiveUS20050006169A1Good lookingPrevent insufficient load capacityLuggage carriersUnderstructuresEngineeringMechanical engineering

A load receiving pipe extends from a separate frame and has a closed portion at the extremity thereof. A meter unit is disposed immediately behind the closed portion. Accordingly, the meter unit can be accommodated in a limited space in front of a handle post cover and behind the load receiving pipe, and the probability that a load on the load receiving pipe comes into contact with the meter unit can be avoided. Therefore, the appearance of the front portion of a vehicle body can be improved while improving the load receiving capacity at the front of the vehicle body.

Owner:HONDA MOTOR CO LTD

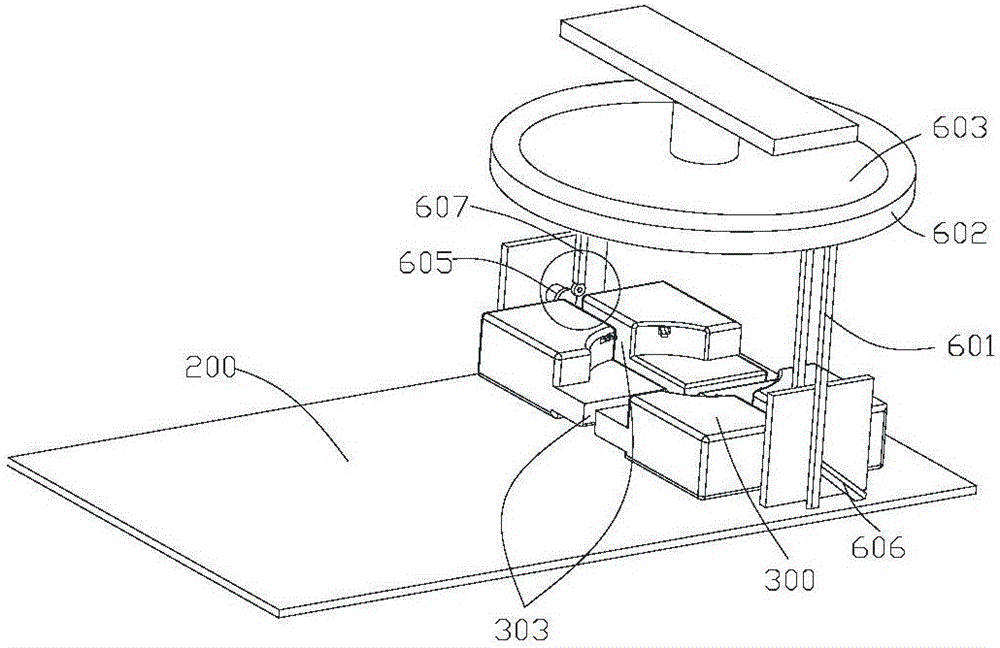

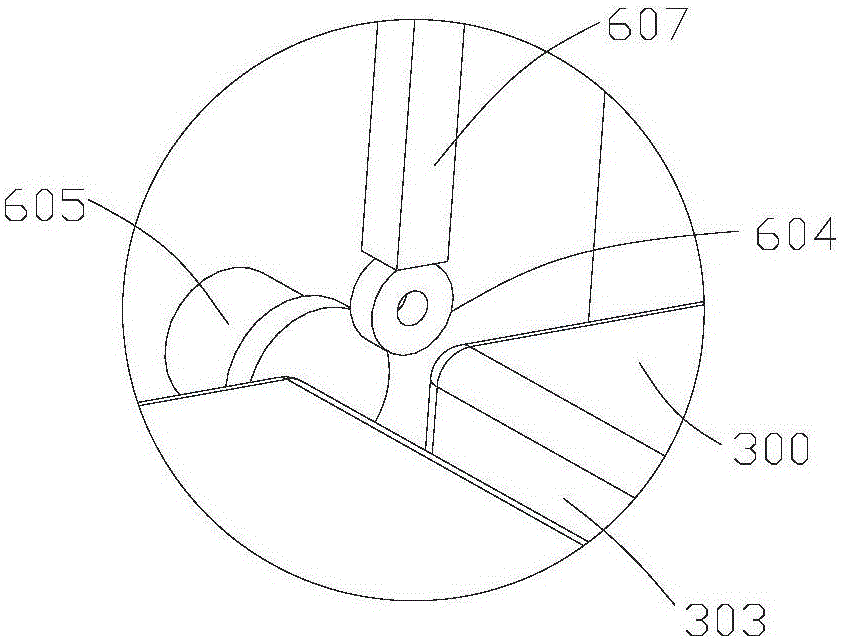

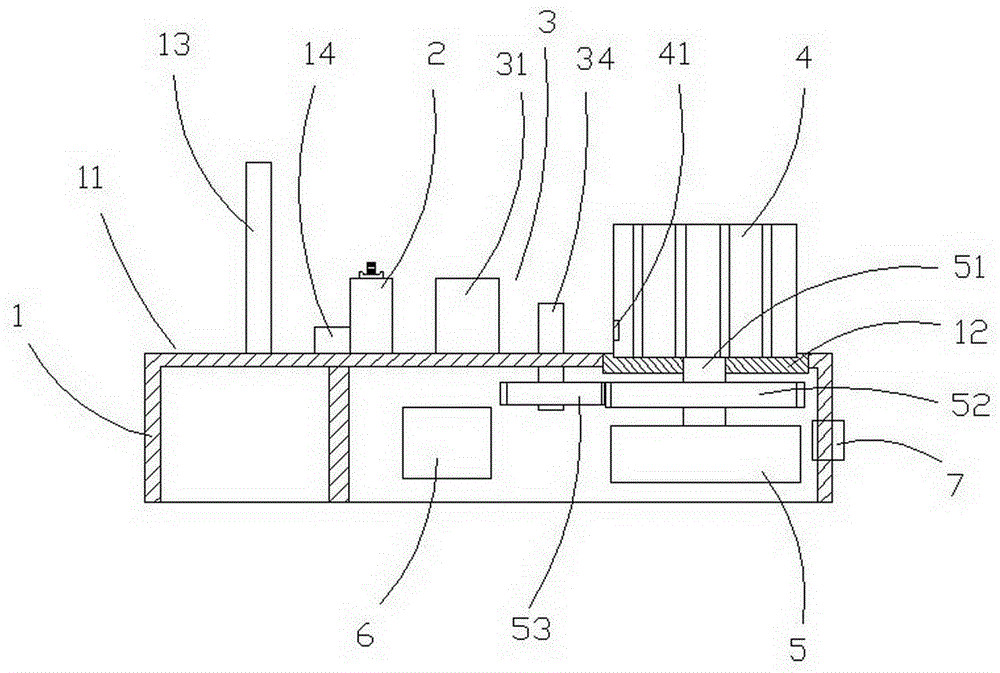

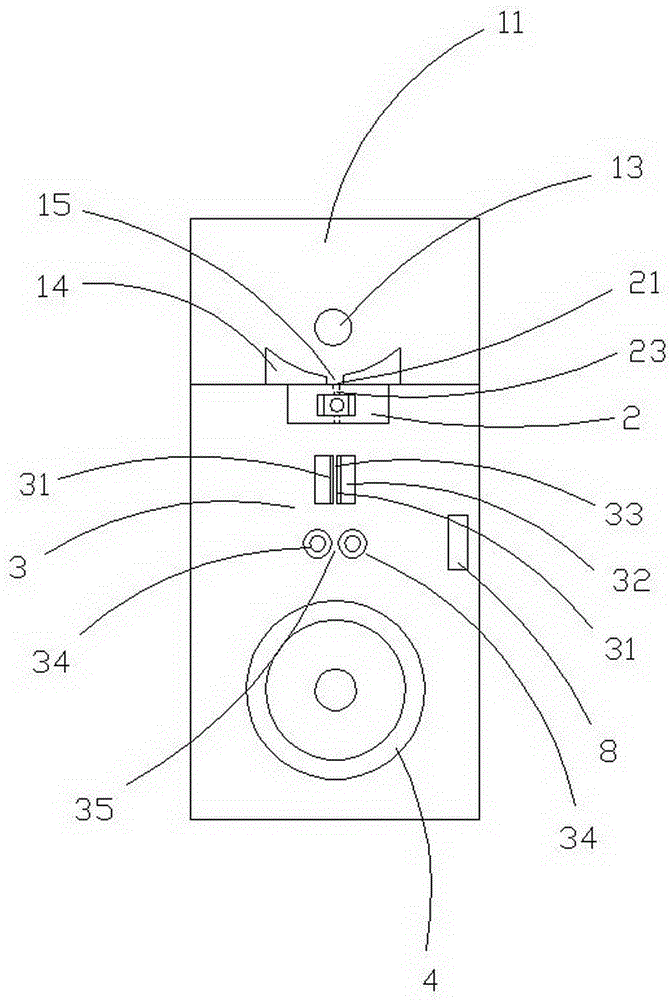

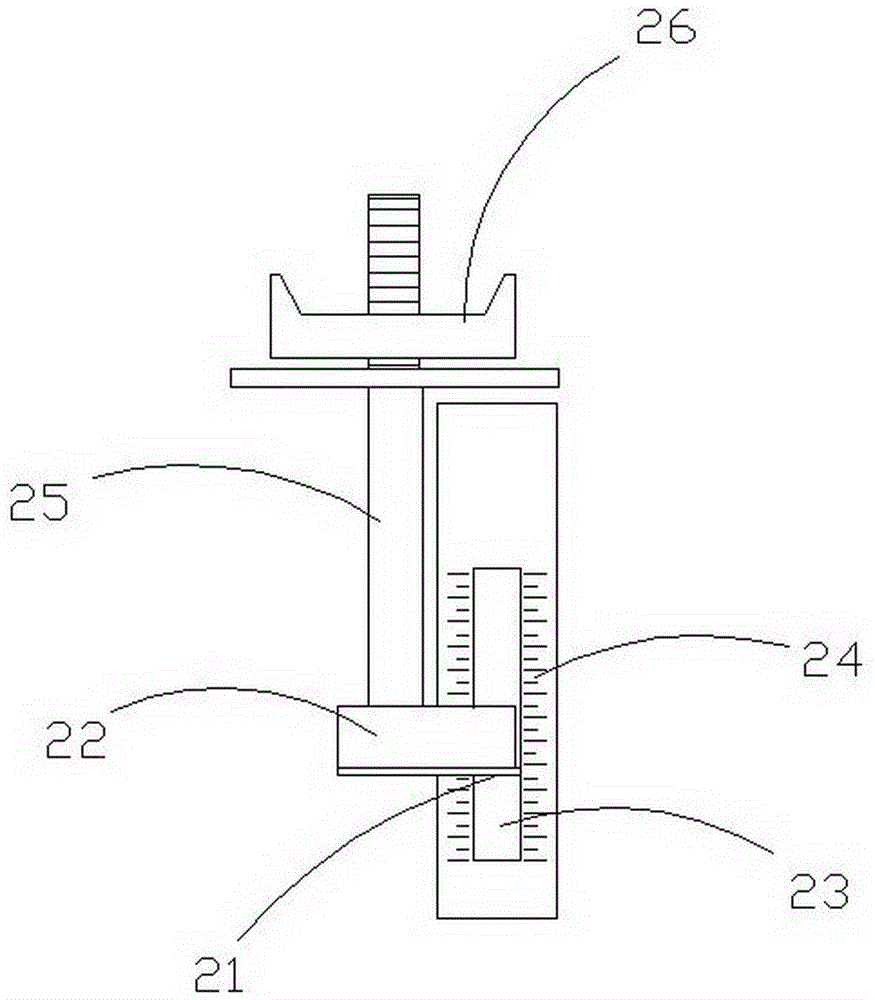

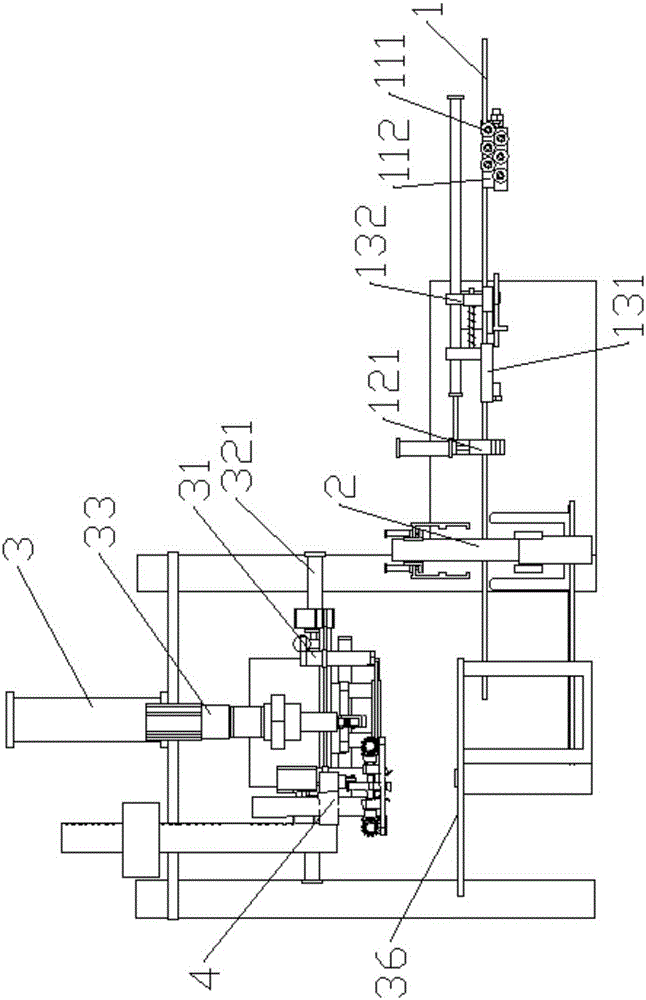

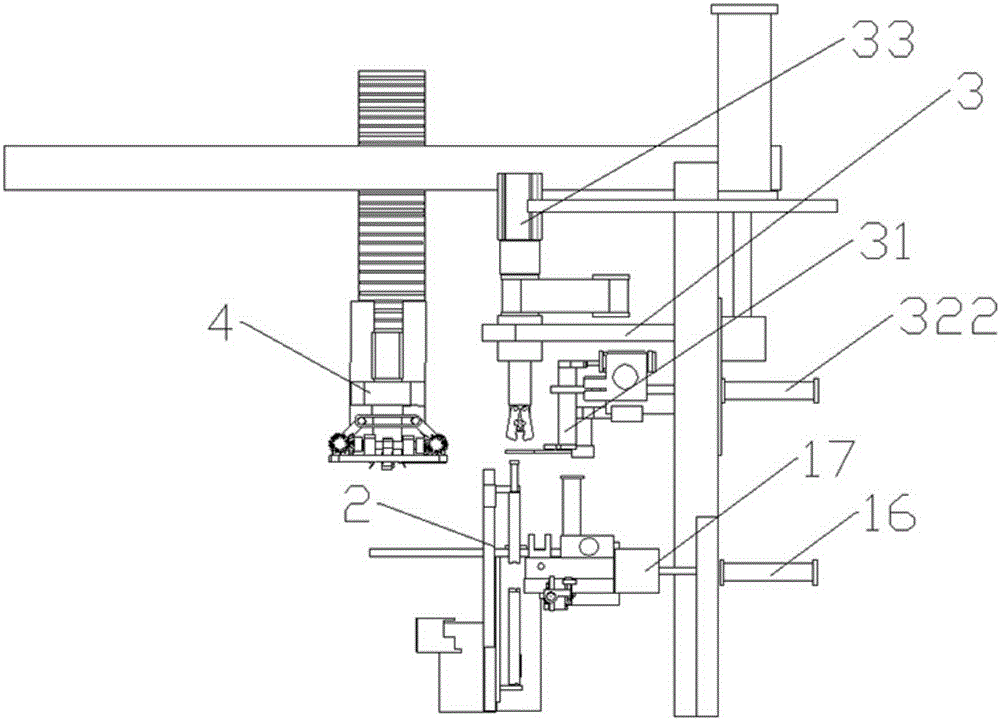

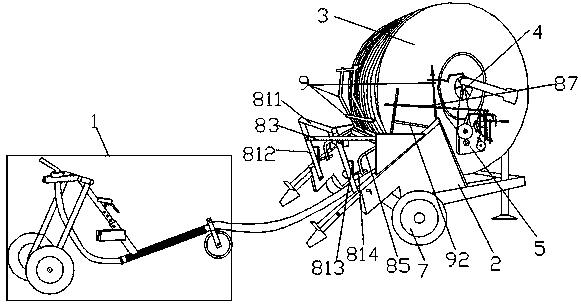

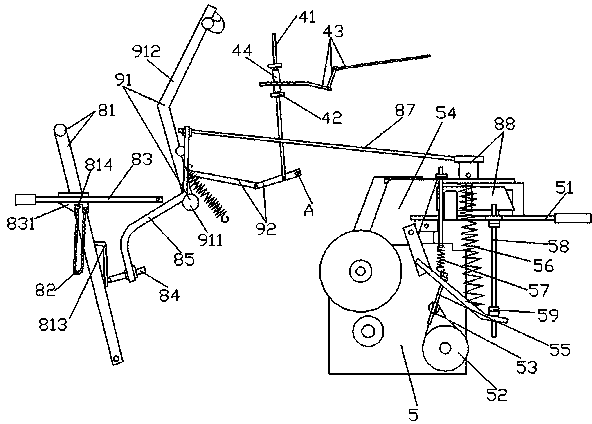

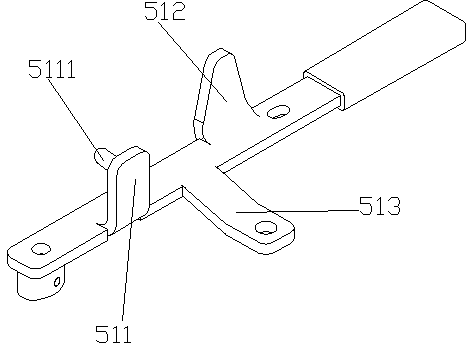

Crab binding equipment

ActiveCN105857683ASimple and reasonable structureEasy to process and manufactureBundling machine detailsEngineeringBinding efficiency

The invention provides crab binding equipment. The crab binding equipment comprises a drive assembly, an installing plate, a fixed table, a crab fixing assembly and a binding assembly. The fixed table is installed on the upper plate face of the installing plate, a groove for containing a crab is formed in the top face of the fixed table, the fixed table is provided with four containing grooves, two containing grooves form a set and are coaxially formed, the two sets of containing grooves are vertically formed, and the two containing grooves in the same set are both communicated with the groove. The crab fixing assembly is installed on the installing plate, and the drive assembly is in drive connection with the crab fixing assembly to drive the crab fixing assembly to move towards the groove and abut against the crab. The crab binding equipment is simple and reasonable in structure, convenient to machine and manufacture, low in manufacturing cost and convenient to install and use; meanwhile, the crab can be rapidly fixed through the crab binding equipment, a worker is not easily hurt in the fixing process, crab claws of the crab are not easily damaged, the crab binding efficiency is improved, and meanwhile the crab binding equipment is safe, reliable and convenient to use.

Owner:YANCHENG INST OF TECH

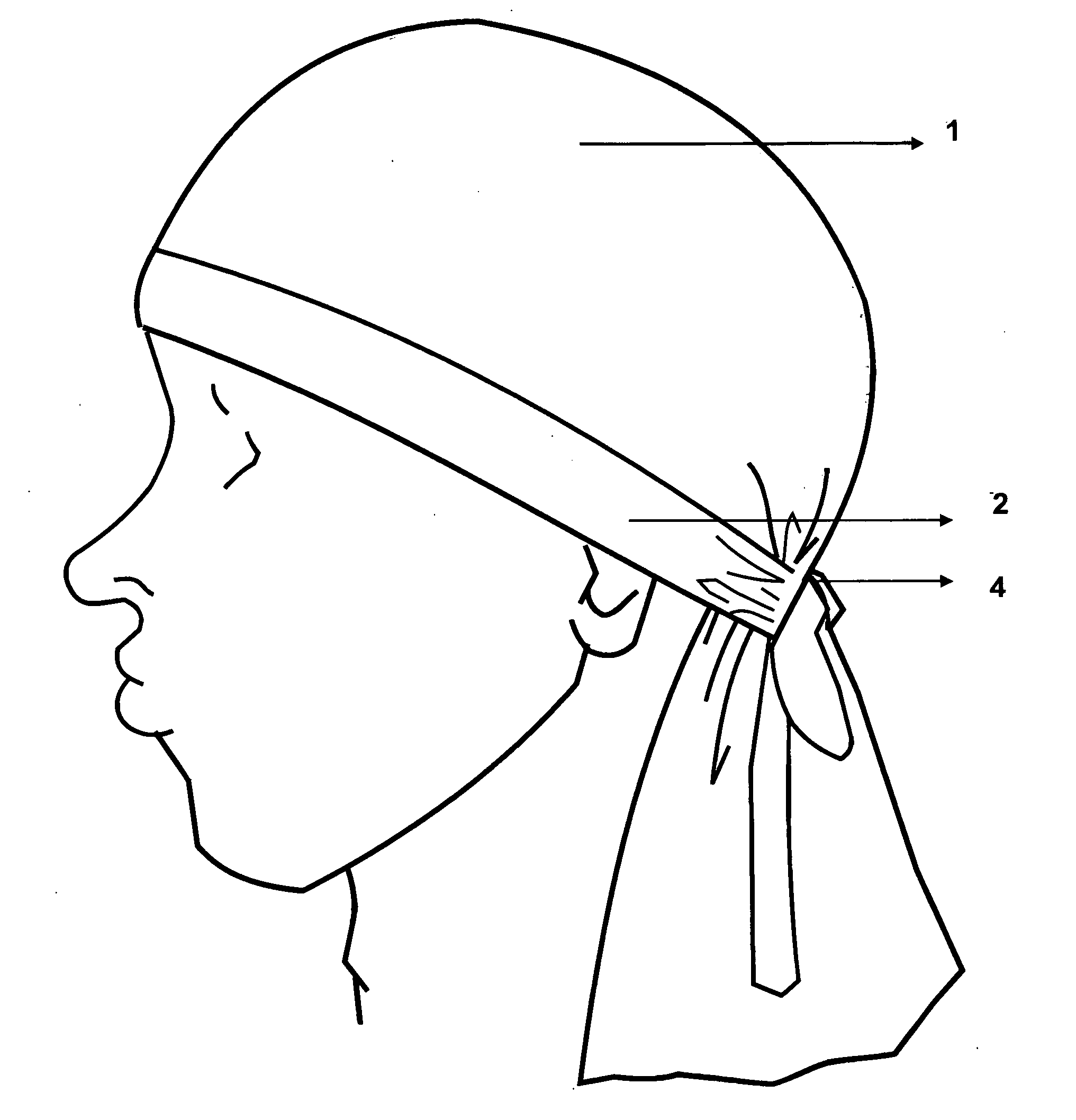

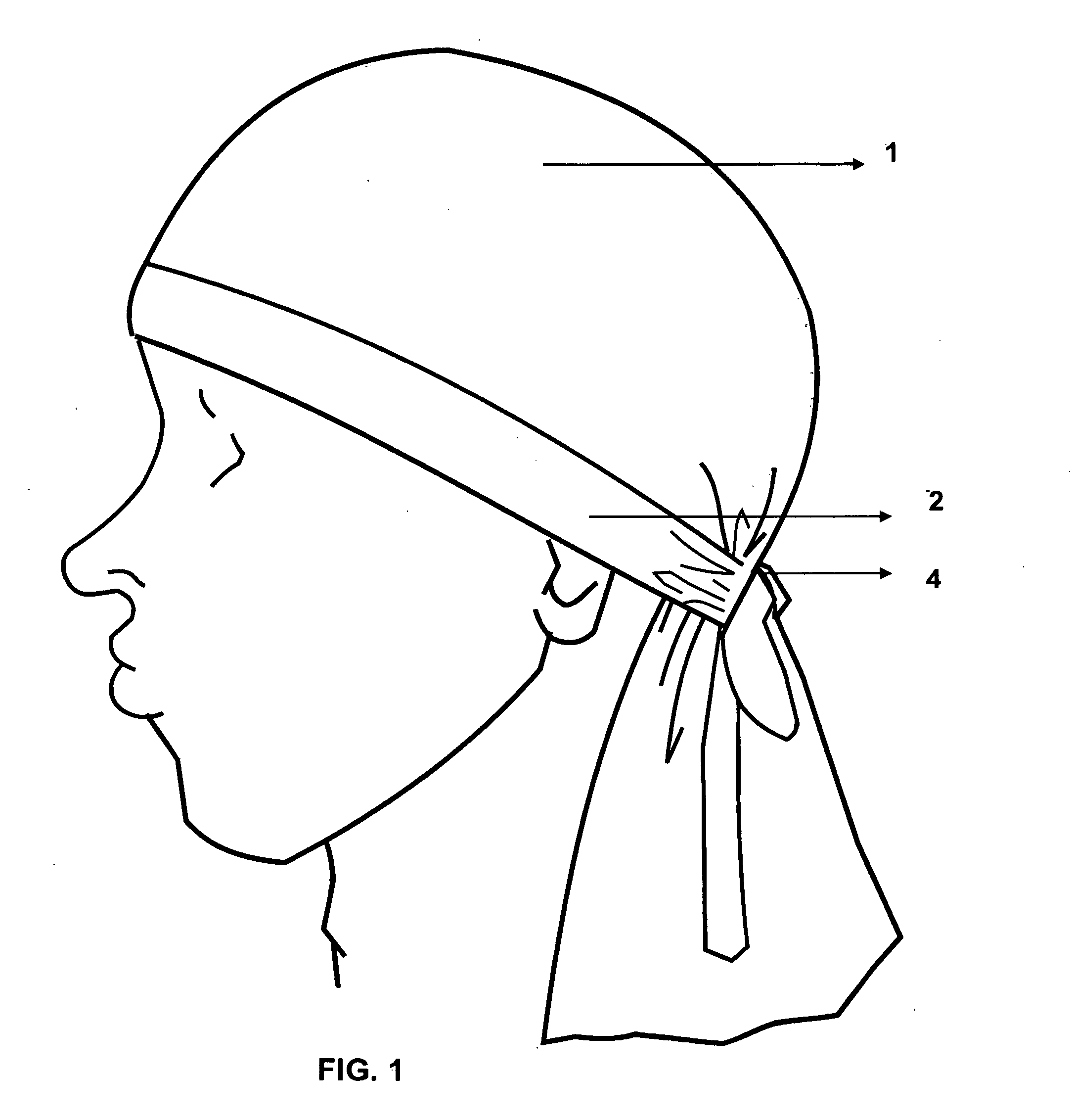

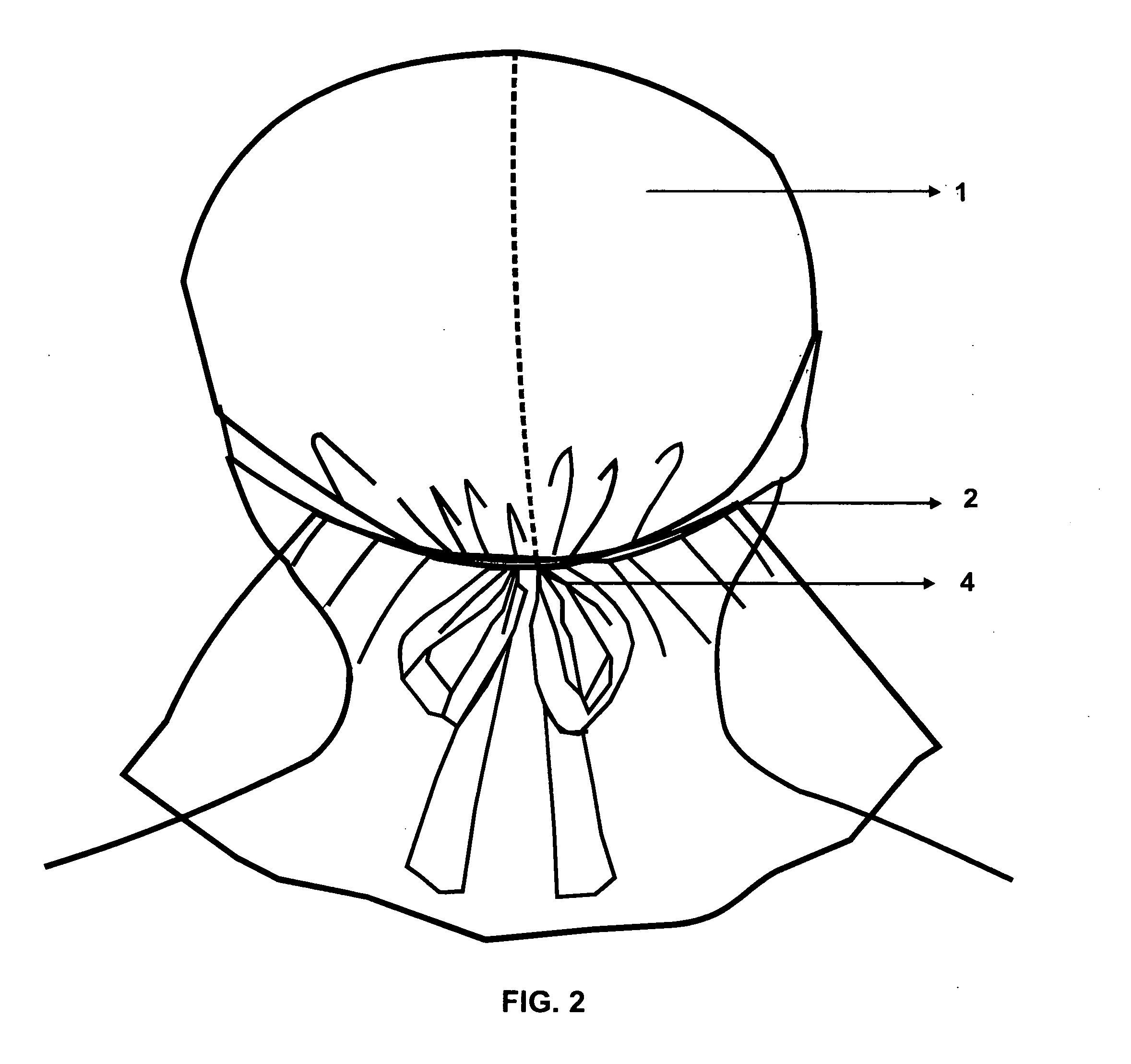

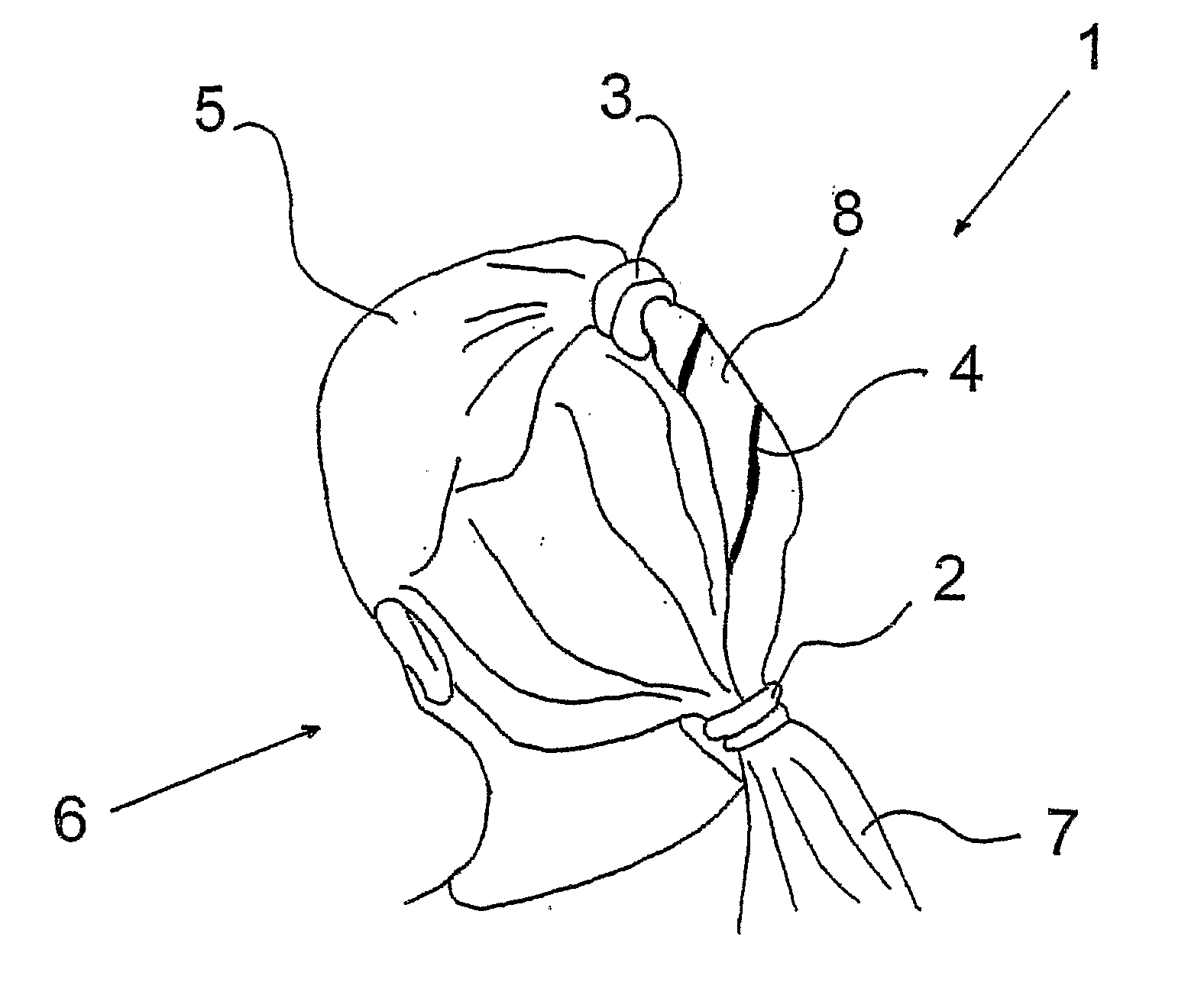

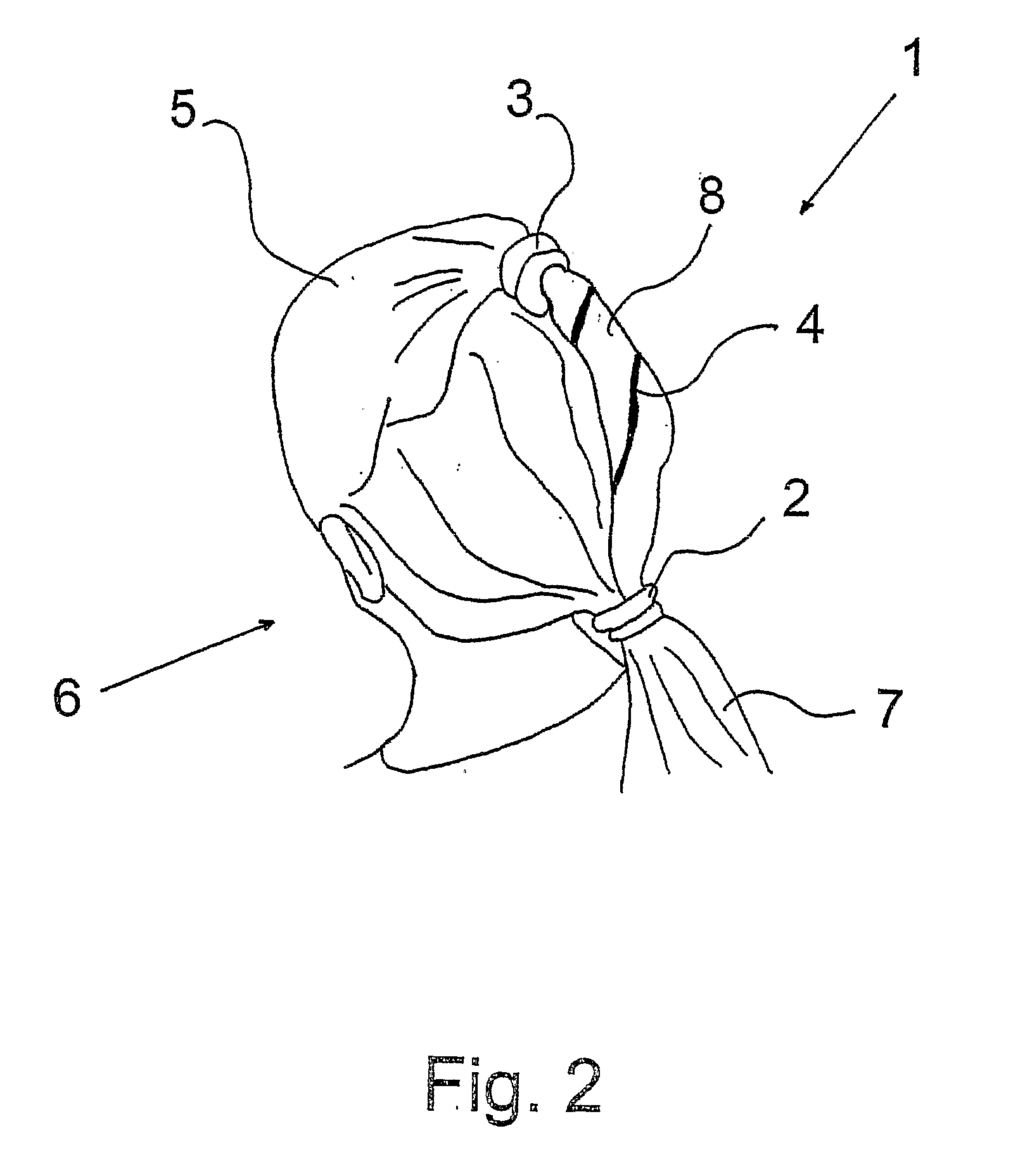

novel and convenient headwear - nudu

InactiveUS20110247126A1Easy to installEasy to tieScarvesHead-scarvesBiomedical engineeringBlood flow

A novel and convenient headwear NUDU in the form of a do-rag, also spelled doo-rag or du-rag, the novelty of the head wear lies in that the shape of the do-rag is such that it tightly fits the head of the user in a cap like structure to protect the head and the hair of the user when tied on the head and allowing head blood flow circulation due to its easier fit on the head as well as easier tie. The material that used in this invention is cotton and / or cotton and Lycra blend.

Owner:WHITE HORACE C +1

Automatic belt maker

The invention discloses an automatic belt maker. A perpendicular positioning column is arranged on a platform of an outer housing of the belt maker; the inner side of a central notch of an arc-shaped baffle plate is provided with a cutting device; a movable blade is arranged on a belt passing slot of the cutting device; a blade base is connected to a regulating rod; the regulating rod is externally connected to a lock; a belt passing guide passage between two electric heating plates of a smoothing device, a passageway between two rolling shafts and a belt passing slot of the cutting device are separately arranged on the same straight line correspondingly; the upper part of the rotary shaft of a motor arranged in an inner cavity of the outer housing extends out of a supporting plate, and is connected to a coiling roller shaft; the coiling roller shaft is positioned at one side of each rolling shaft; a drive gear on the rotary shaft of the motor is engaged with driven gears at the lower ends of the rolling shafts; the motor drives the coiling roller shaft to rotate; and during rotation, the coiling roller shaft pulls a plastic belt for cutting a plastic bottle.

Owner:盐城华依鑫机械科技有限公司

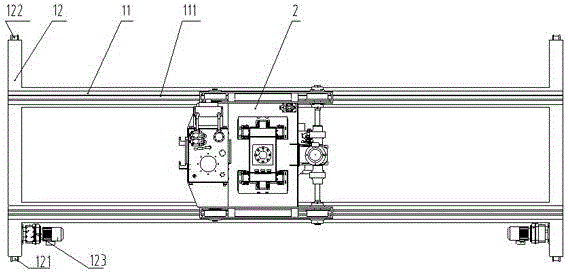

Strapping machine

InactiveCN105173171ARealize mechanized operationRealize bundlingBundling machine detailsStrap deviceEngineering

The invention discloses a strapping machine. The strapping machine comprises a containing table used for containing objects to be strapped, a line feeding device used for feeding a stripping line to the position below the objects to be strapped and a strapping device used for strapping the objects to be strapped through the stripping line. The strapping machine is characterized in that the strapping device is located above the containing table and comprises two strapping line clamping devices, a strapping transverse movement mechanism for controlling the two strapping line clamping devices to transversely move, a rotary line clamping device and a rotary mechanism for controlling the rotary line clamping device to rotate; and the two strapping line clamping devices are located on the two sides of the rotary line clamping device respectively. The strapping machine has the beneficial effects that the structure is simple, and the objects to be strapped, in particular to an annular object, can be strapped through a metal wire.

Owner:屈统撑

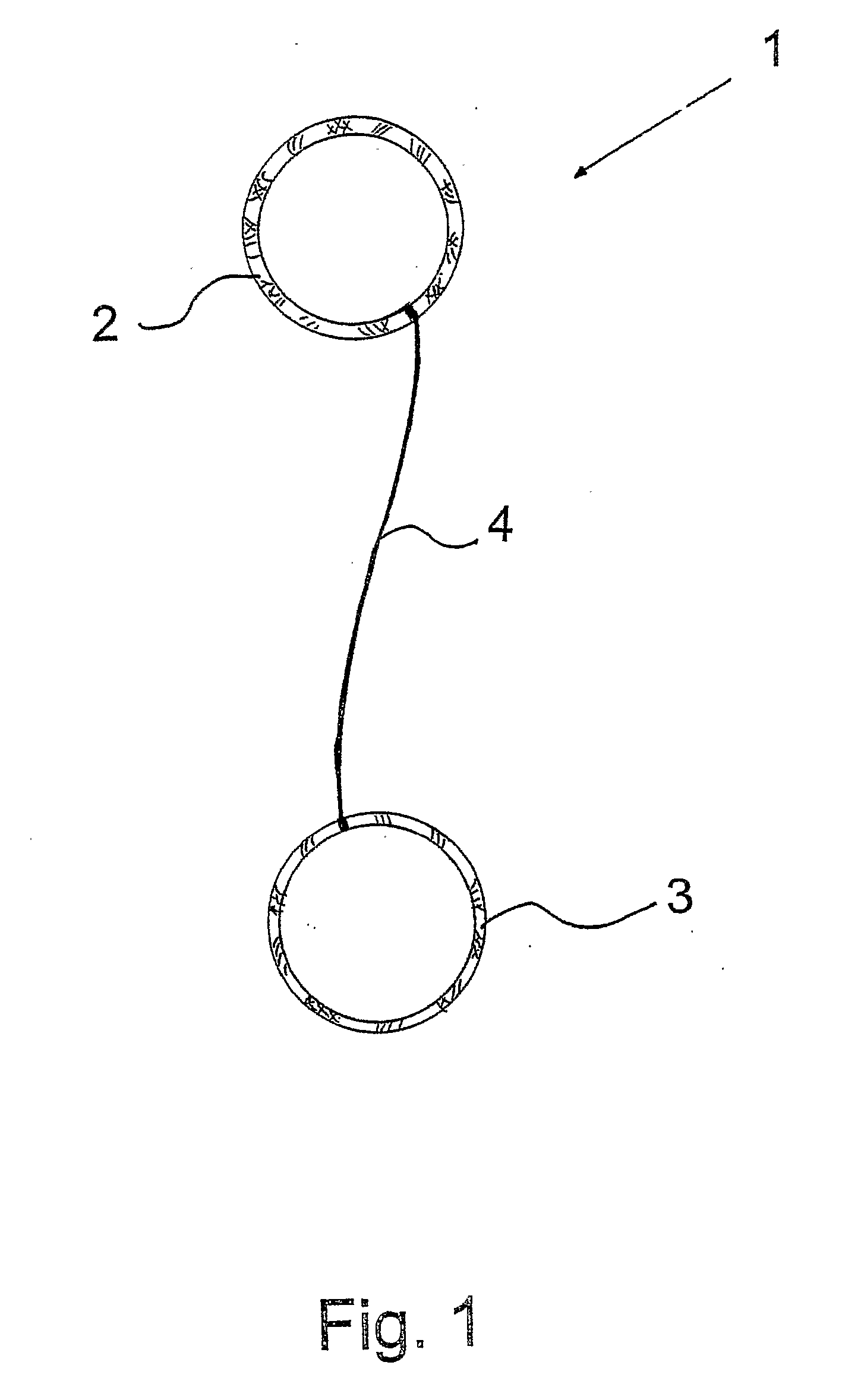

Accessory

Owner:JENSEN VIVI AAKJAER

Multifunctional reel-type sprinkling machine

ActiveCN103858733ARealize automatic brakingReturn at a constant speedWatering devicesCultivating equipmentsFree rotationWater turbine

Provided is a multifunctional reel-type sprinkling machine. On the basis of an original structure, a vehicle return stop linkage device and an automatic water turbine speed-regulating device are additionally arranged. A water spraying traveling crane further comprises a sleeve, an idler wheel and an idler wheel installation frame, wherein the idler wheel installation frame is installed on a metal connection pipe through a clamping hoop. The vehicle return stop linkage device comprises a closing frame arranged at the front end of a machine frame, a closing frame zipper, a locking rod, an adjusting screw rod, a connection rod, a tension spring, a brake pull rod, a swinging arm assembly and a brake connection board, wherein the swinging arm assembly and the brake connection board are arranged on a gearbox. The automatic water turbine speed-regulating device comprises an induction frame and a speed-regulating link rod. According to the sprinkling machine, after the water spraying traveling crane returns back, automatic braking can be achieved through a reel, automatic speed regulation of a water turbine is achieved, and the water spraying traveling crane retreats at a constant speed. The clamping hoop on the water spraying traveling crane can replace an iron wire to bundle a PE hose, bundling can be conveniently achieved, and meanwhile the PE hose is protected against damage; a pipe rack can rotate freely and accordingly action force of the PE hose cannot be forcibly exerted on a ball screw assembly.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

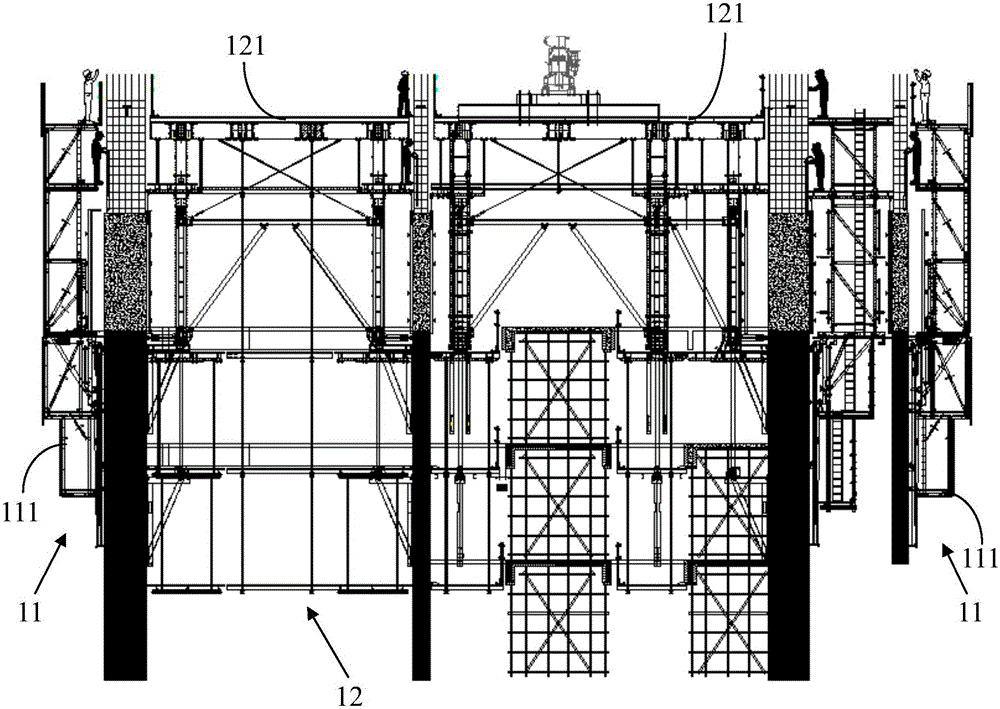

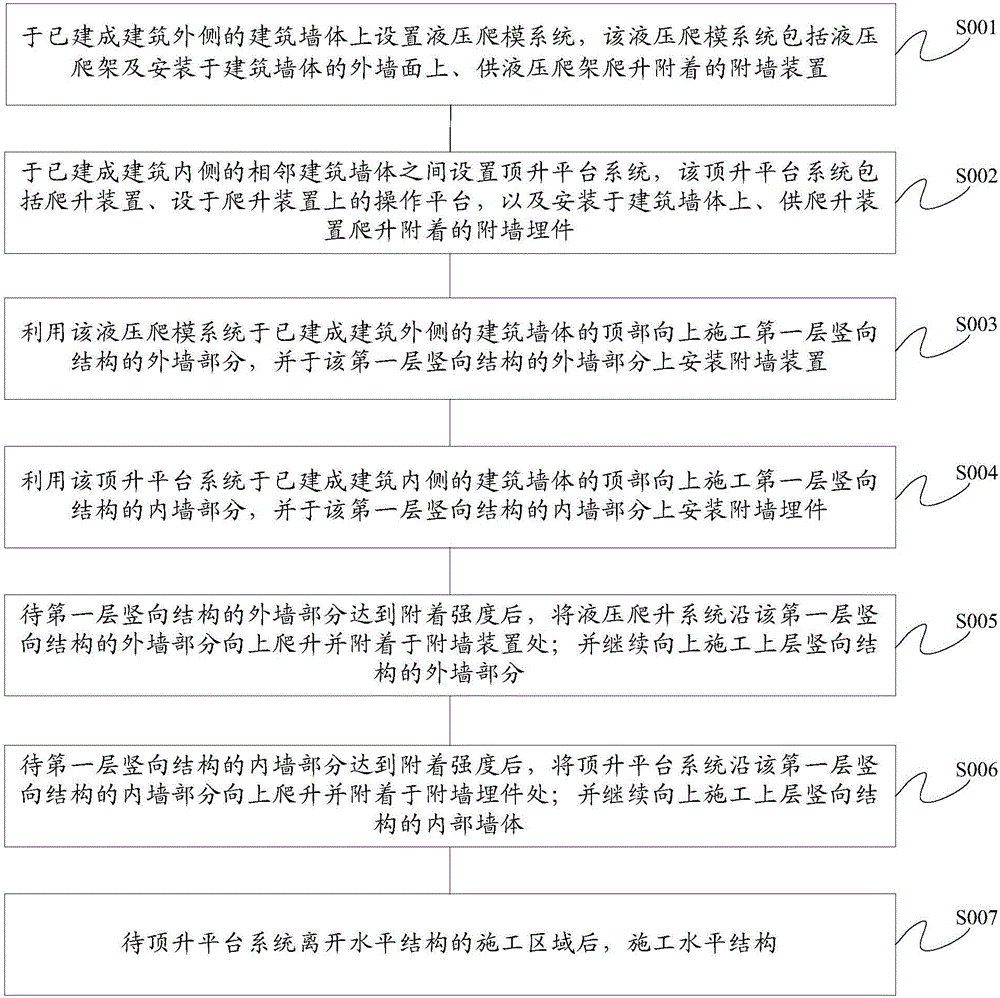

Synchronous construction method for horizontal and vertical structures of super high-rise building

ActiveCN106400951AReduce overall weightReduce the burden onForms/shuttering/falseworksRebarBuilding construction

The invention discloses a synchronous construction method for horizontal and vertical structures of a super high-rise building. According to the synchronous construction method, a hydraulic creeping formwork system is adopted on the outer wall of the super high-rise building, and a jacking platform system is adopted between two building walls on the inner side of the super high-rise building; when being operated at the same time, the two systems can replace a conventional overall jacking construction platform as a construction platform, thereby reducing the overall weight of a construction platform and the burden of a hydraulic jacking system, achieving higher flexibility, and improving the construction speed; as the light-weight jacking platform system is configured, a small-sized oil cylinder can be adopted; accordingly, no horizontal supporting steel beam is needed, oil cylinder climbing can be achieved as long as wall-attached embedded parts are mounted on the building walls, the total height of the construction platform and a supporting frame body can be reduced, the construction gap between the vertical and horizontal structures can be narrowed, and the construction of the horizontal structure can be prevented from being influenced by a hydraulic climbing system; and the jacking platform system adopted on the inner wall of the super high-rise building is prevented from penetrating through the building walls, and the gap between the construction platform and a reinforcing bar colligation operation surface is equal to the height of one floor, thereby achieving convenient reinforcing bar transfer and colligation.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +2

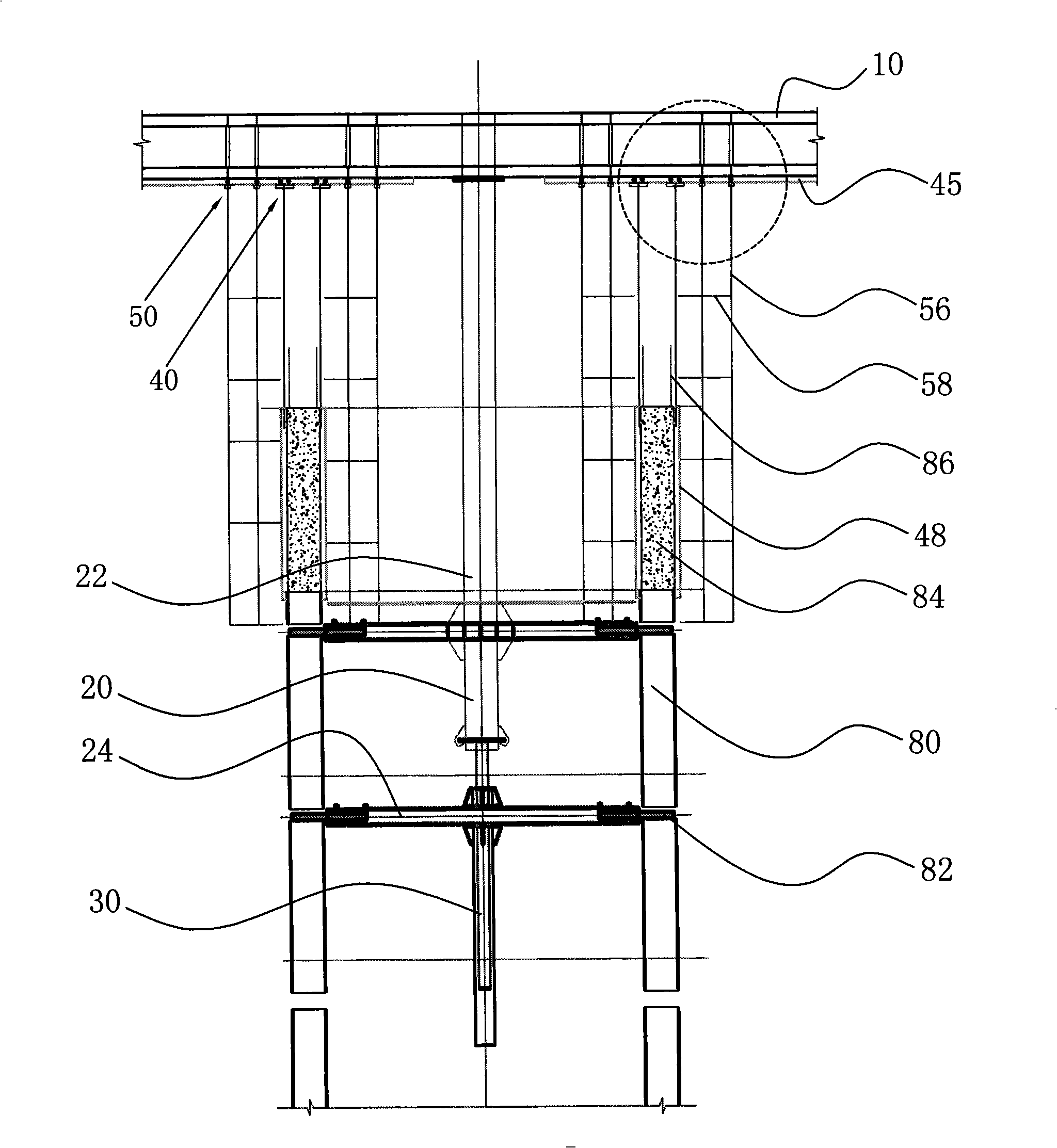

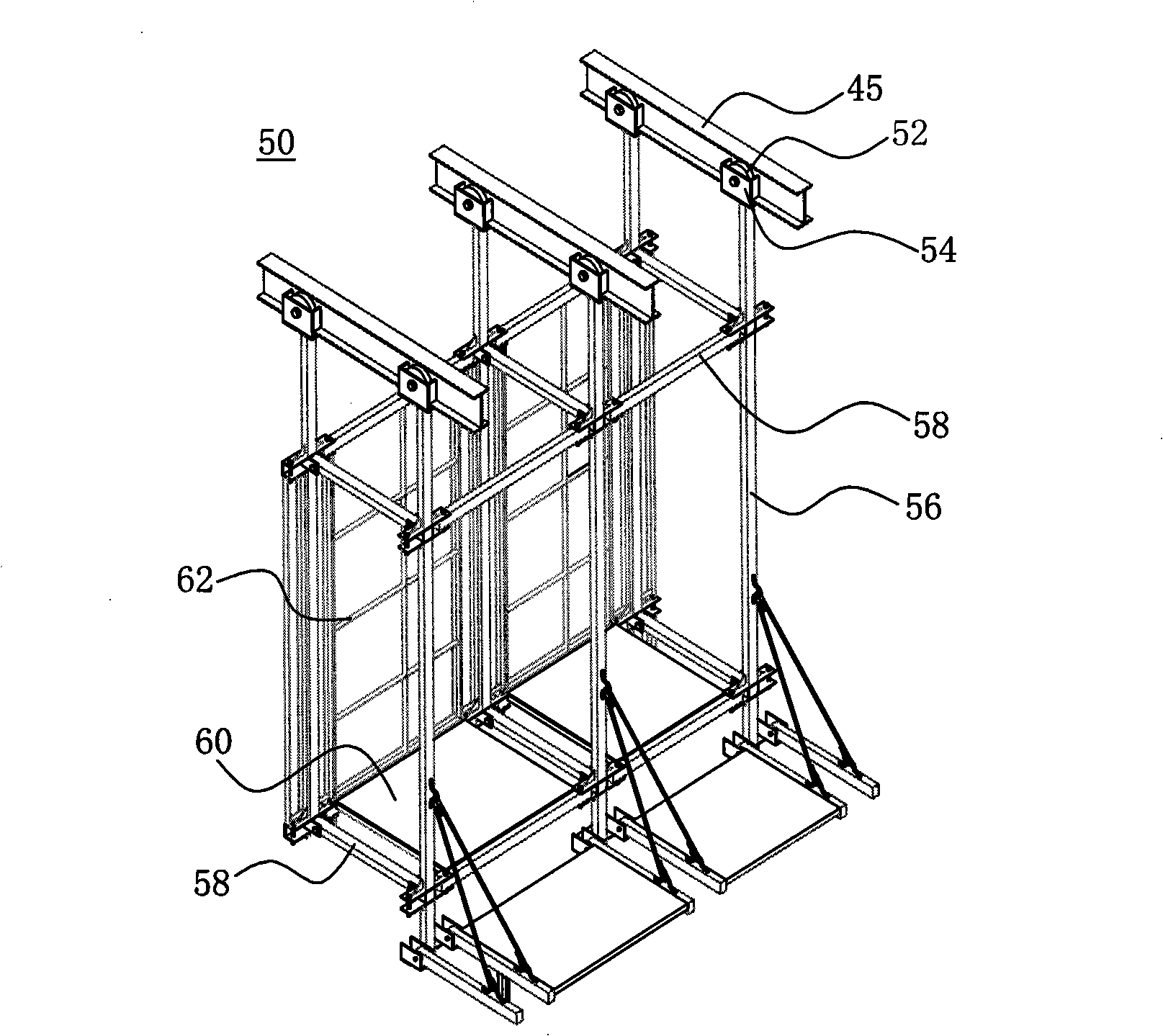

Multifunctional variable integral hoisting template system

ActiveCN101319559AFast constructionSufficient structural rigidityForms/shuttering/falseworksBuilding constructionMultiple function

The invention discloses a multifunctional variable integral lifting formwork system used for synchronously and quickly lifting all formworks in highrise construction. The system is arranged on the top of walling of a building structure to be constructed and comprises a platform main rack, a hanging rack subsystem, a formwork subsystem, at least three supporting subsystems, and power and control subsystems, wherein, the platform main rack is formed by fixed connection of a plurality of trusses; the hanging rack subsystem is hung on the platform main rack and can slide along a guide rail beam; the formwork subsystem is hung on the platform main rack and can slide along the guide rail beam; the supporting subsystems are supported on the building walling and support the platform main rack; and the power and control subsystems are arranged inside the supporting subsystems for driving the platform main rack, the hanging rack subsystem and the formwork subsystem to synchronously lift and adjusting the balance of the platform main rack. The multifunctional variable integral lifting formwork system also can be varied along the vertical direction according to the structure of the building walling so as to freely adjust a formwork and a hanging rack.

Owner:CHINA CONSTR FOURTH ENG DIV +2

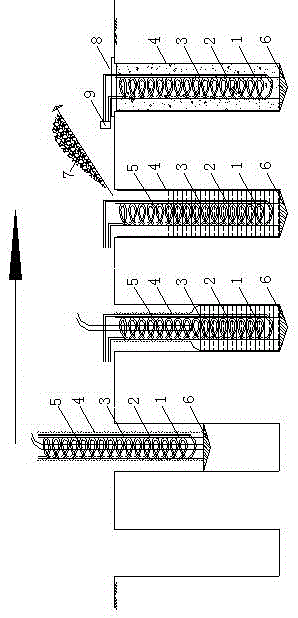

Reinforced sack grouting stone-breaking pile with heat transferring tube buried therein and construction method

The invention discloses a reinforced sack grouting stone-breaking pile with a heat transferring tube buried therein and a construction method. The reinforced sack grouting stone-breaking pile with the heat transferring tube buried therein is characterized in that the stone-breaking pile is composed of a geotextile sack, longitudinal main reinforcement, stirrups, the heat transferring tube, a prefabricated pile tip, a grouting pipe, cement paste and gravels; the prefabricated pile tip is fixedly connected with the bottom of the main reinforcement, and the geotextile sack is also embedded in the prefabricated pile tip; the heat transferring tube is bound on a reinforcement cage; the geotextile sack is attached to the outer side of the heat transferring tube in the pile length direction; the grouting pipe is placed in the reinforcement cage composed of the longitudinal main reinforcement and the stirrups deep to the prefabricated pile tip. The construction method comprises the steps that 1, the reinforcement cage where the heat transferring tube is well bound is placed in the geotextile sack, and the bottom end of the reinforcement cage and the bottom end of the geotextile sack are fixedly connected with the prefabricated pile tip; 2, after drilling is conducted, the prefabricated pile tip, the reinforcement cage, the heat transferring tube and the geotextile sack are placed in a borehole together; and 3, the cement paste is injected into the inner side of the geotextile sack, and then the gravels are thrown to the inner side of the bulged geotextile sack. According to the reinforced sack grouting stone-breaking pile provided with the heat transferring tube, construction is convenient and fast, and the effects of economy and environmental protection are achieved.

Owner:HOHAI UNIV

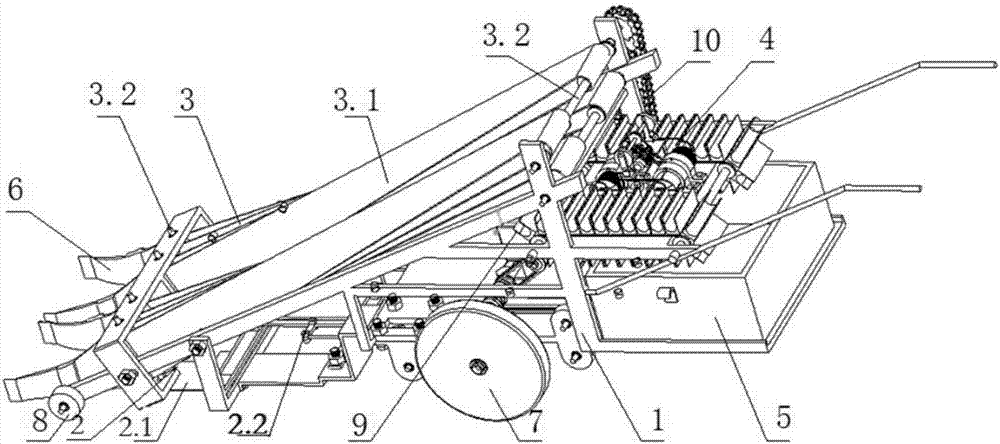

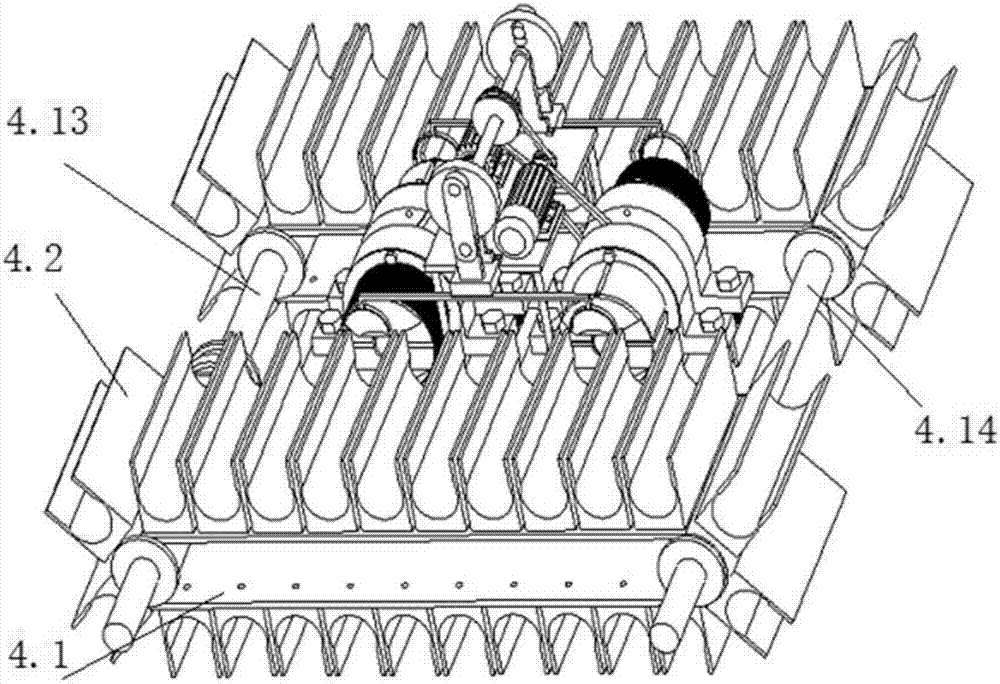

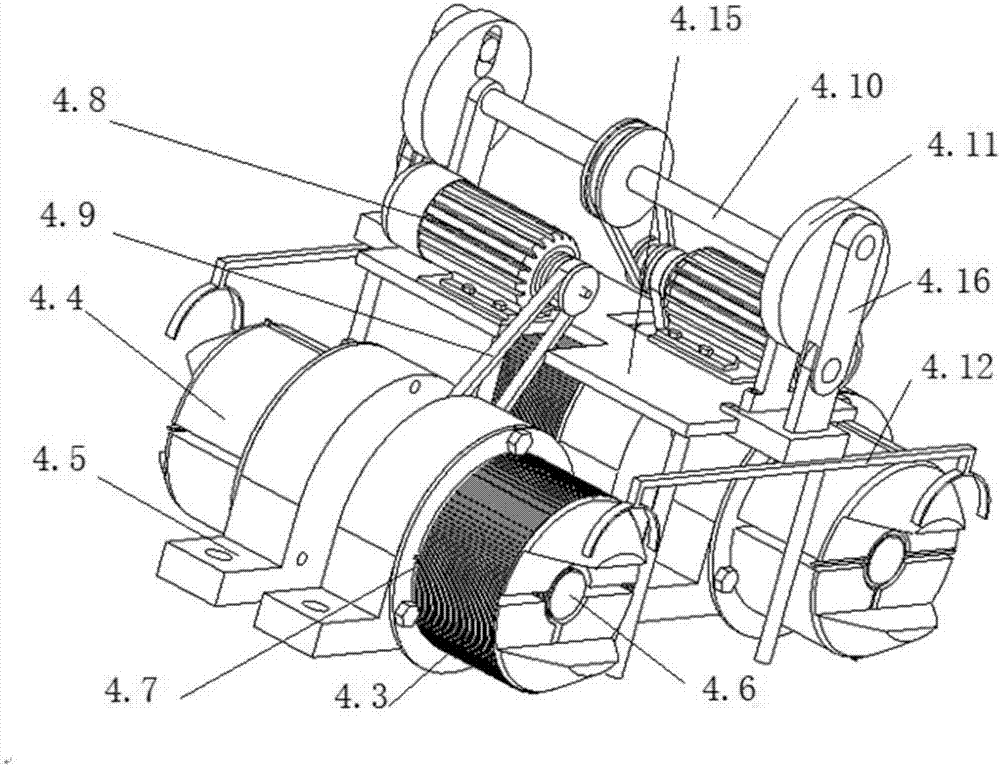

Double-row fragrant-flowered garlic harvesting equipment

The invention discloses a two-row leek harvesting equipment, comprising a frame, a driving device, a cutting device for cutting leeks installed on the frame, a transmission device for conveying leeks, a binding device for binding leeks, A collection box and a walking device for collecting leeks; the cutting device includes a reciprocating cutting knife and a crank connecting rod-slider mechanism driven by the driving device; the transmission device includes two torsion belts The transmission channel and the distance between the two twisted belts remain unchanged, one end of the twisted belt is vertically arranged at the cutting mechanism through the driven shaft, and the other end of the twisted belt is horizontally arranged at the said cutting mechanism through the driving shaft. At the strapping device, the driving shaft is power-connected with the driving device; the running device includes a driving wheel arranged at the rear end of the frame driven by the driving device and a guide wheel arranged at the front end of the frame.

Owner:HUNAN UNIV OF ARTS & SCI

Tunnel geotextile, waterproof cloth and secondary lining steel bar laying process

ActiveCN106988764AWill not deformHigh strengthUnderground chambersTunnel liningRebarUltimate tensile strength

The invention belongs to the field of tunnel secondary lining laying and relates to a secondary lining laying process ensuring the secondary lining strength, in particular to a tunnel geotextile, waterproof cloth and secondary lining steel bar laying process. The secondary lining strength is ensured by ensuring the thickness of a concrete protective layer.

Owner:涪特智能装备(重庆)有限公司

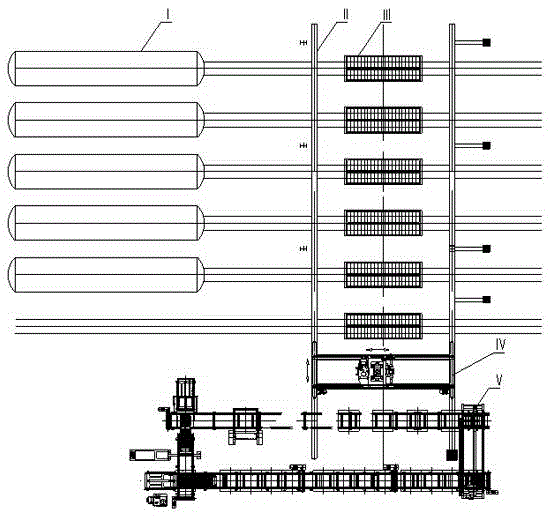

Clamping and transporting method for aerated concrete blocks

InactiveCN104648716AImprove transport efficiencyImprove stabilityPackagingConveyor partsEngineeringMechanical engineering

The invention relates to a clamping and transporting method for aerated concrete blocks. A plurality of aerated concrete block die vehicles arranged side by side are pushed out of a still kettle and are positioned on a kettle exit rail; a plurality of layers of aerated concrete blocks are clamped from the die vehicles by a clamping and transporting device, the clamping and transporting device horizontally moves to transport the aerated concrete blocks to the position above a packaging unit, and the clamping and transporting device descends to place the aerated concrete blocks on the packaging unit; then the clamping and transporting device ascends by a certain height, clamps one layer or a plurality of layers of placed aerated concrete blocks at the middle and upper part, rotates the aerated concrete blocks by 90 degrees, descends and crossly stacks up the rotated aerated concrete blocks on an original aerated concrete block brick pile, then the aerated concrete block brick pile enters the next packaging process, the clamping and transporting device returns to the die vehicles to carry out next-time clamping and transportation. According to the invention, the efficiency of transporting the aerated concrete blocks is greatly improved, the stability of the brick pile is also improved, the clamping and transporting method is convenient for the packaging unit to carry out subsequent bundling; the bundled brick pile is solid and firm.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

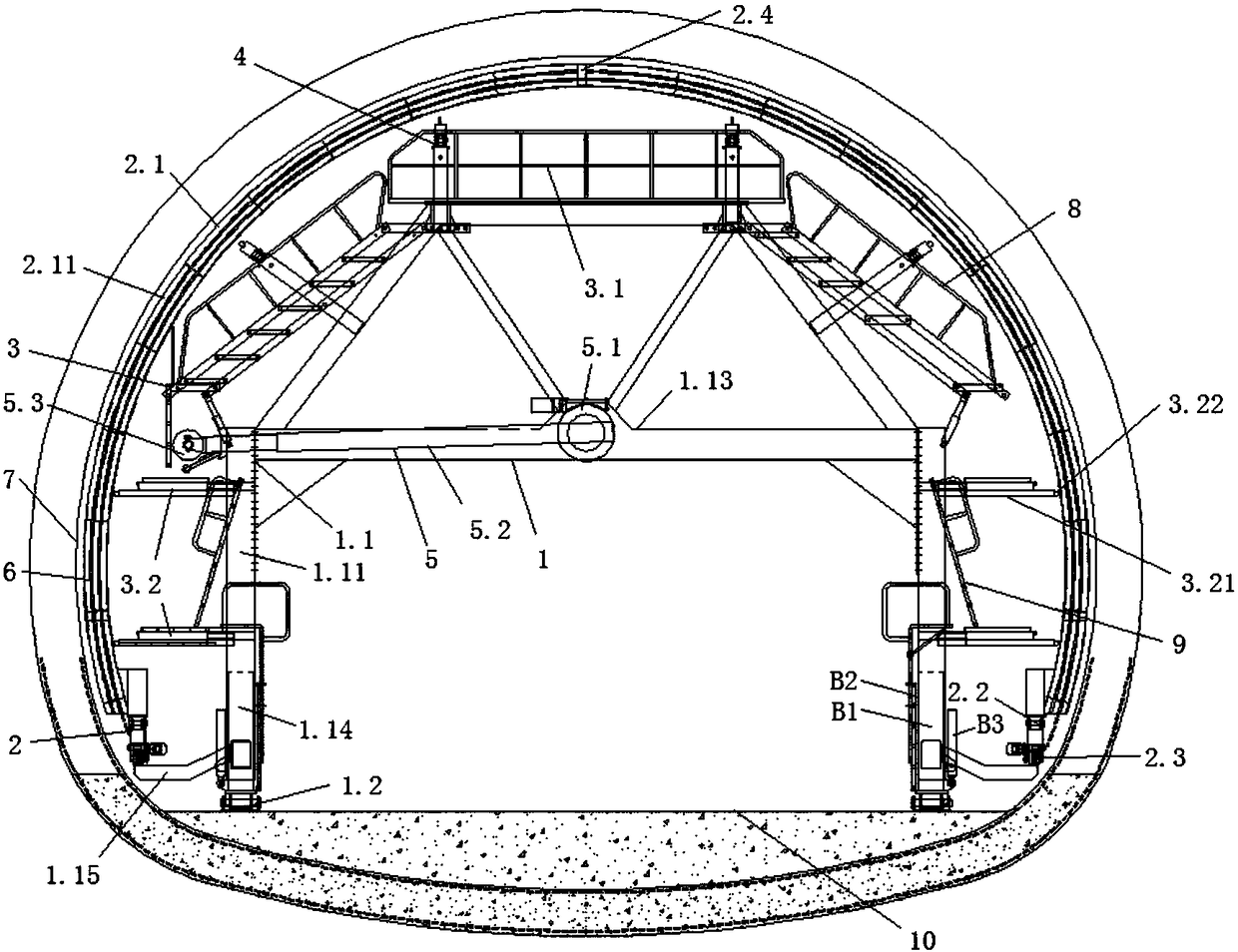

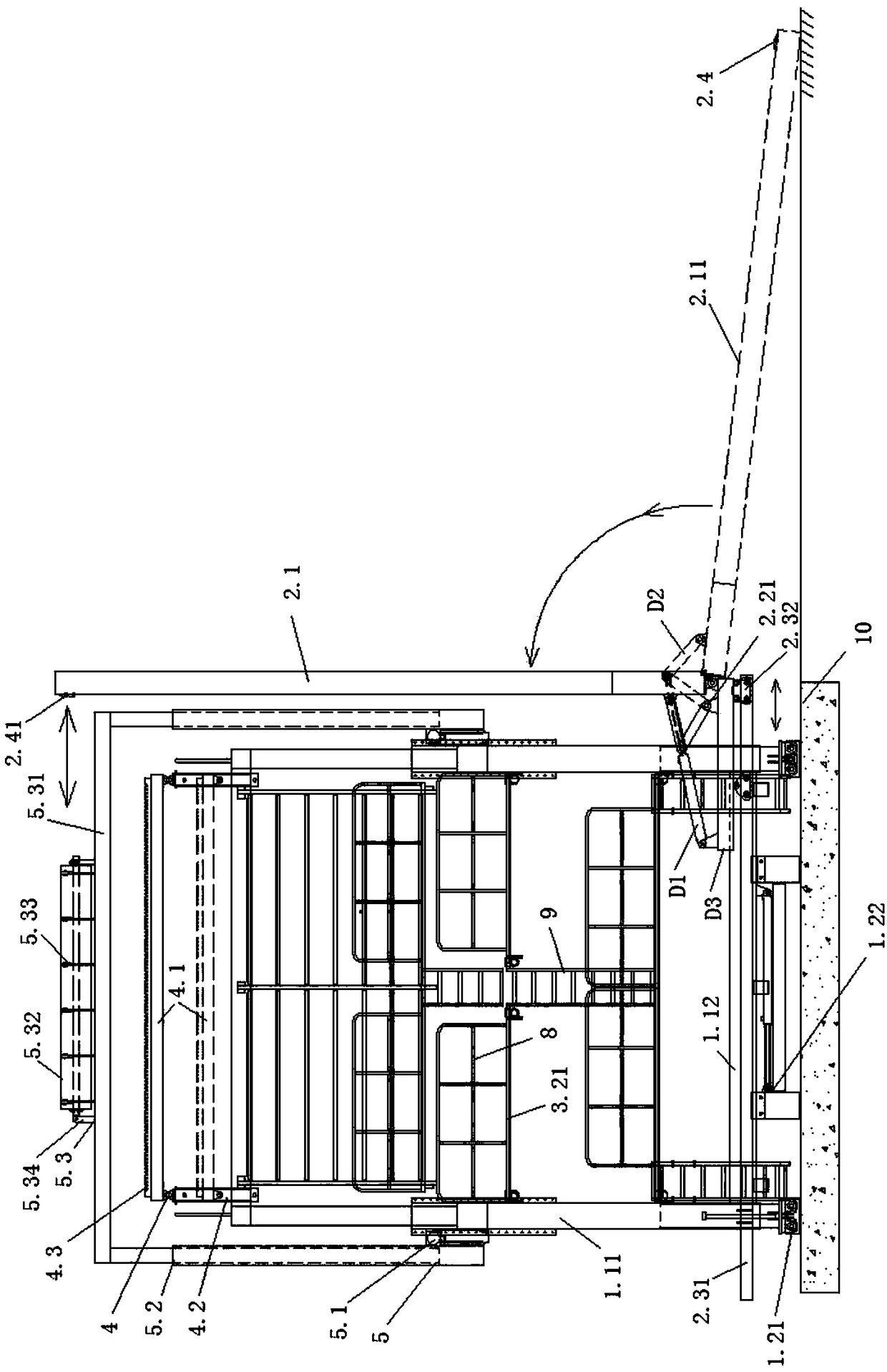

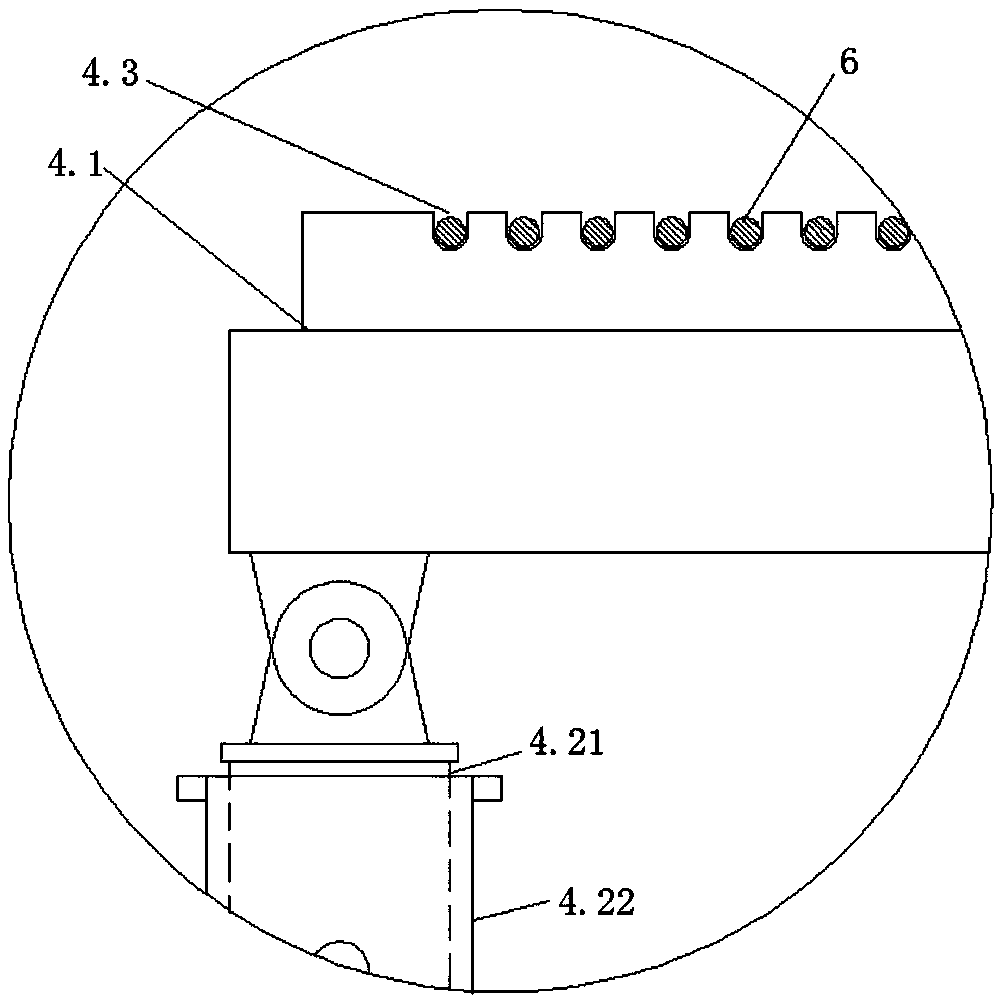

Multi-function trolley and construction method thereof

The invention provides a multi-function trolley. The multi-function trolley comprises a door frame system, a rebar feeding system and a work platform assembly. The rebar feeding system comprises a rebar containing arch frame, a rotating member, a horizontally-moving member and a rebar falling-proof assembly, the rebar containing arch frame comprises a group of arch frame single piece or at least two groups of arch frame single pieces arranged in parallel; and the rotating member comprises at least one group of rotating single piece, and each rotating single piece comprises a power source and arotating connecting piece. The horizontally-moving member comprises a driving source and horizontally-moving single pieces arranged with the rotating single pieces in a one-to-one correspondence mode. The rebar falling-proof assembly comprises at least one group of rebar falling-proof single piece arranged correspondingly with the arch frame single pieces. The work platform assembly comprises a top platform and a side direction platform group. The multi-function trolley can realize quick feeding of circumferential rebar. The invention further discloses a construction method for the multi-function trolley. The construction method comprises the following steps of circumferential rebar construction, longitudinal rebar construction and waterproof material construction, one machine with multiple purposes is realized, and the practicality is high.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

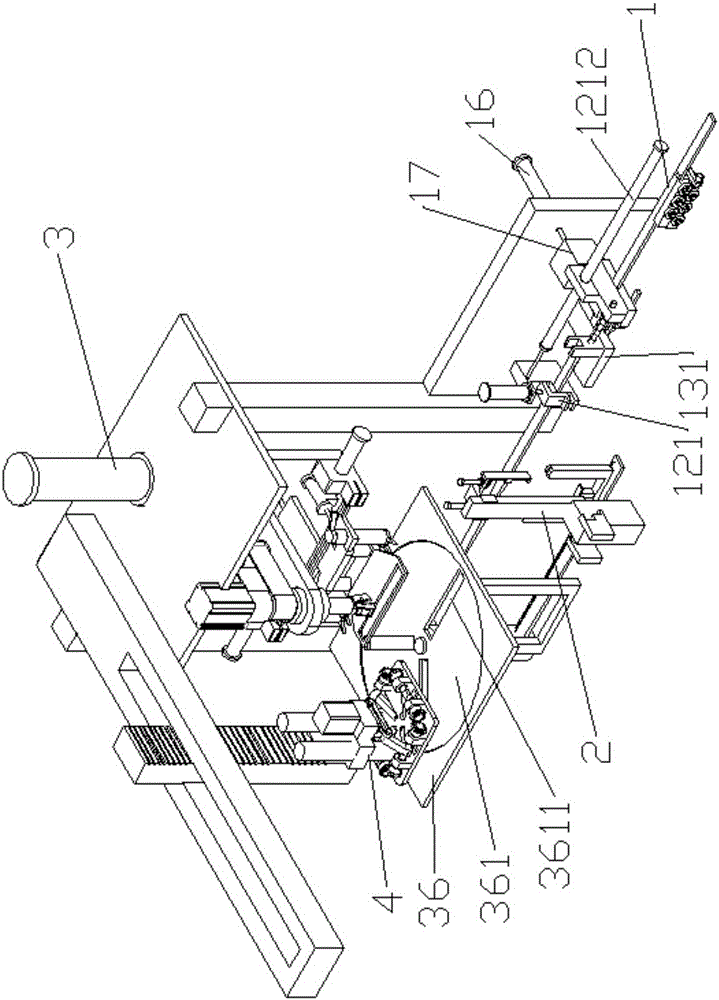

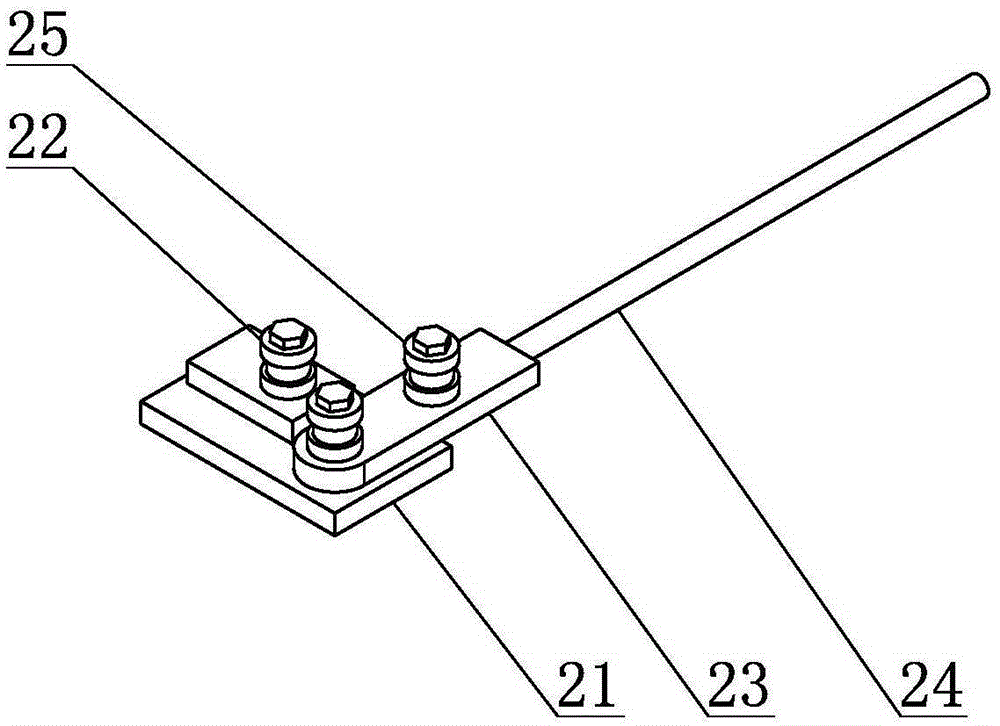

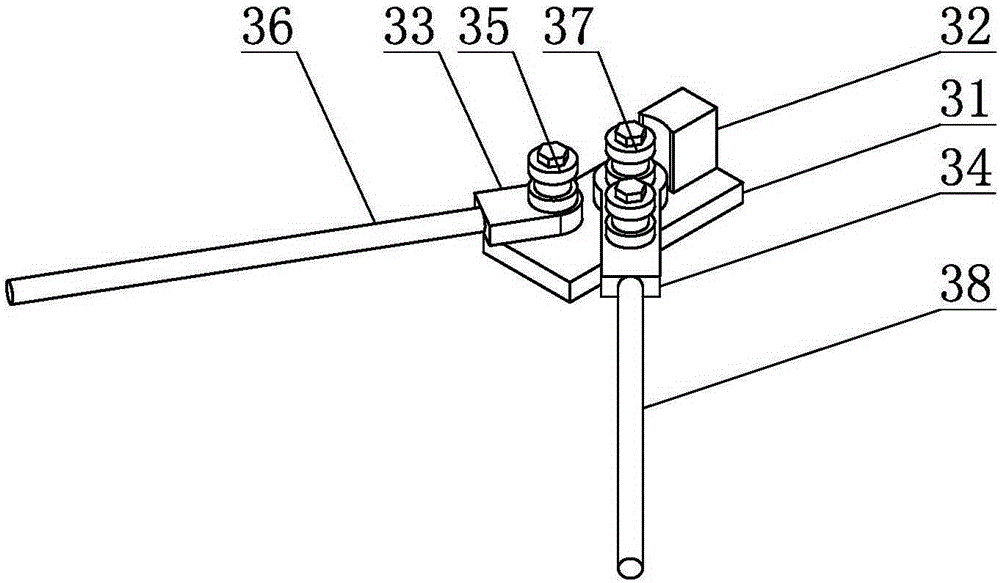

Manufacturing process and manufacturing apparatus for high-voltage lead wires of transformer

ActiveCN105185566ARealize factoryReduce working at heightsTransformers/inductances coils/windings/connectionsCoils manufactureTransformerManufactured apparatus

The invention discloses a manufacturing process and a manufacturing apparatus for high-voltage lead wires of a transformer, and mainly relates to the field of electric power engineering construction processes. The manufacturing apparatus for the high-voltage lead wires of the transformer comprises a worktable, wherein a curve device, a curve shaper, an insulator bracket, a lightning arrester fixing bracket and an insulated wire bracket are arranged on the worktable. The manufacturing process and the manufacturing apparatus have the beneficial effects that the high-voltage lead wires of the transformer are assembled and manufactured on the manufacturing apparatus for the high-voltage lead wire of the transformer and then are transported to a construction site in a unified way for installation, so that excessive overhead work can be reduced, the construction difficulty can be lowered, the field operation progress can be accelerated, the potential safety hazards can be reduced, the manufacturing process can be standardized, the assembly quality can be effectively controlled, and the material waste can be avoided.

Owner:国网山东夏津县供电公司

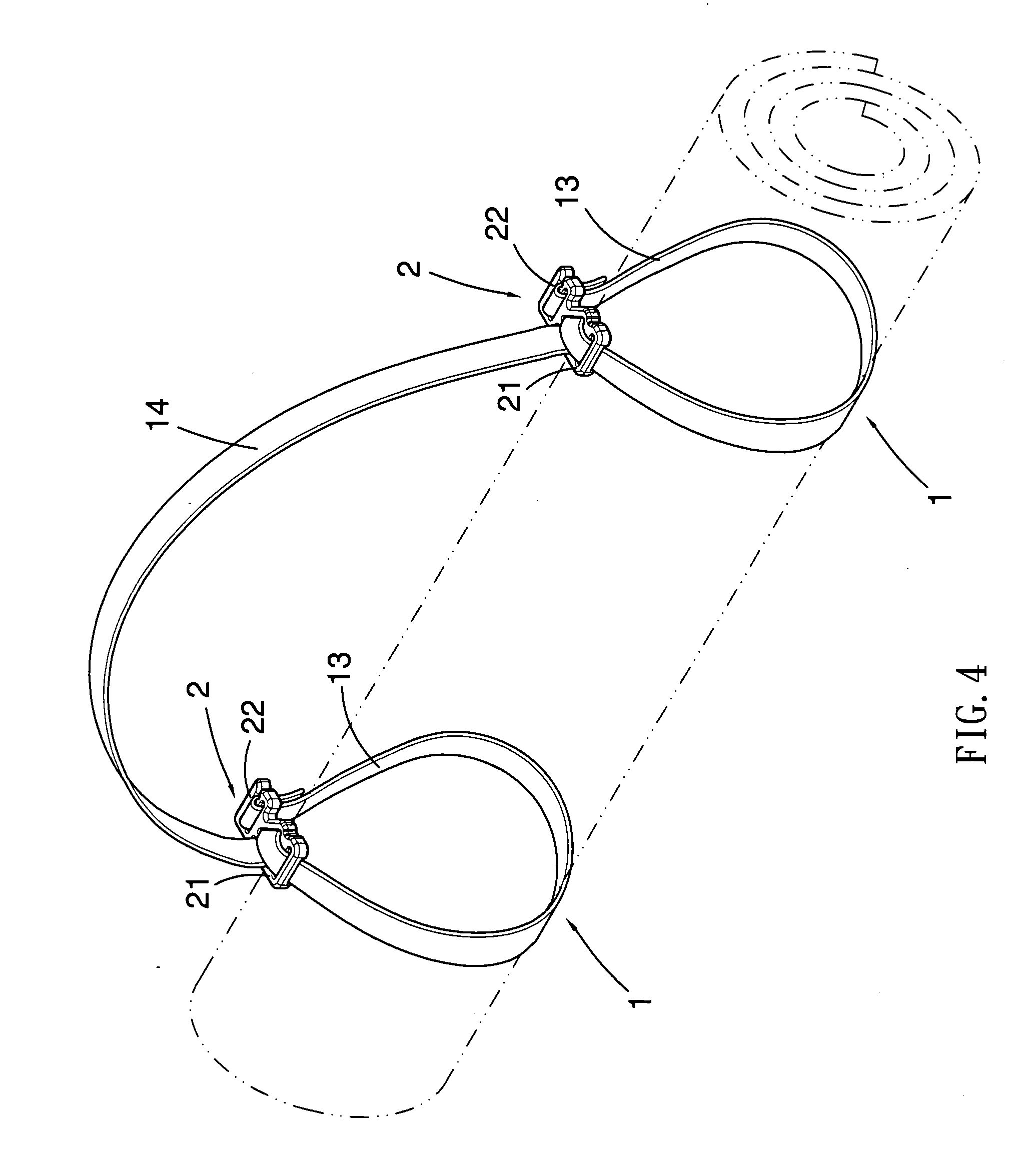

Strap fastening assembly

A strap fastening assembly comprises a strap and at least one fastener for fastening the strap to tie an article. The fastener comprises a fastening portion and an adjustable portion. The fastening portion is configured to secure a section of the strap thereon in case the strap is loosened by pulling the strap in one direction. The adjustable portion is configured to connect, adjust and tighten another section of the strap to tie the article.

Owner:YEH TZONG IN

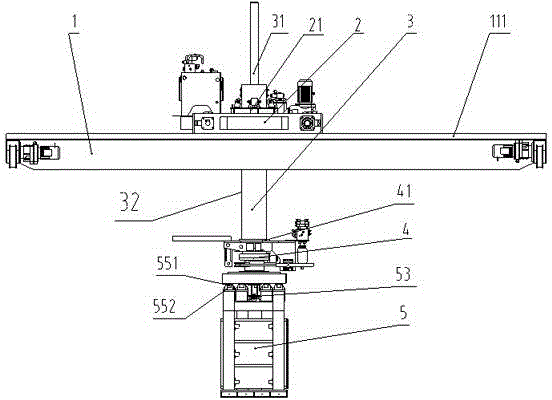

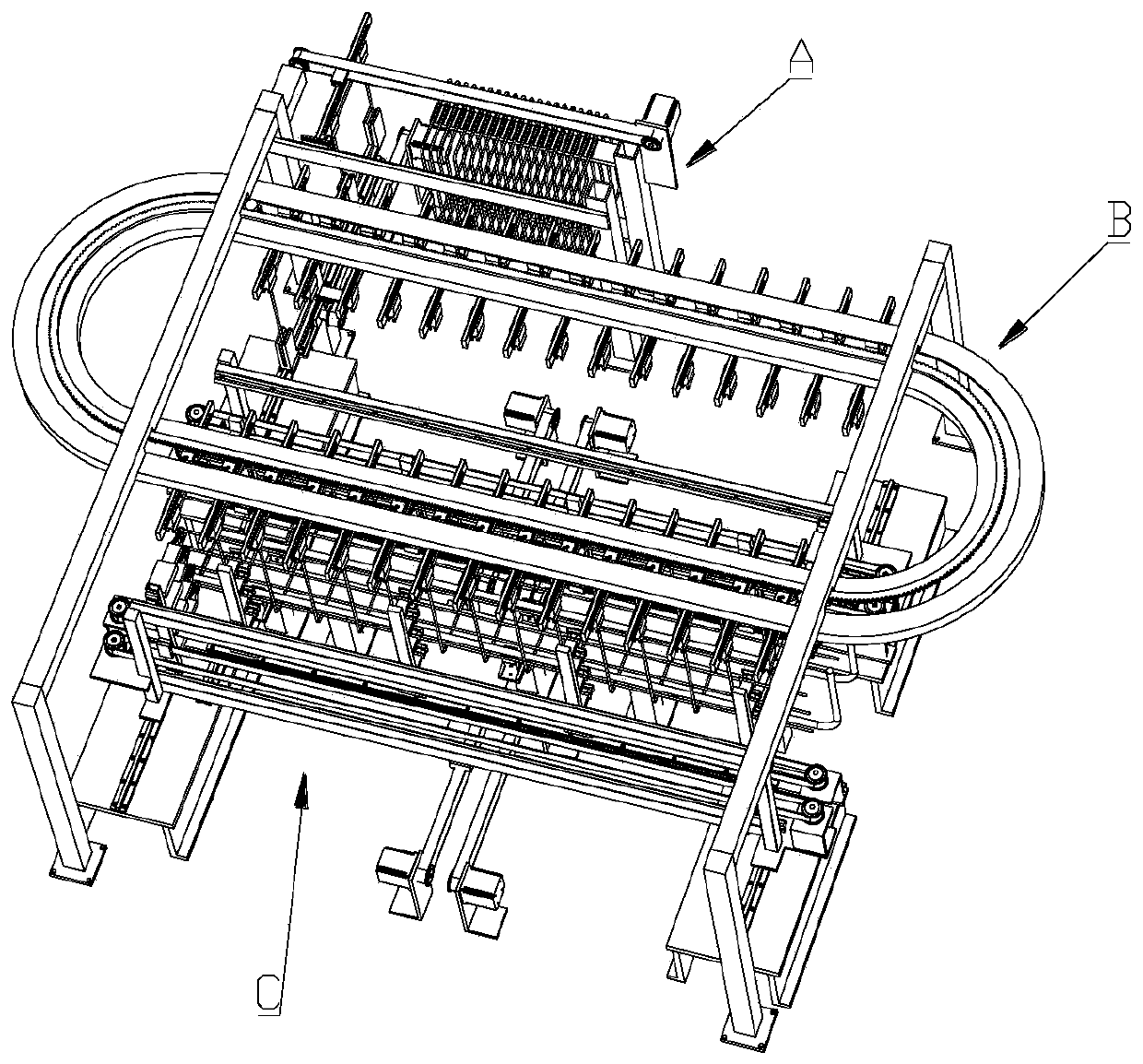

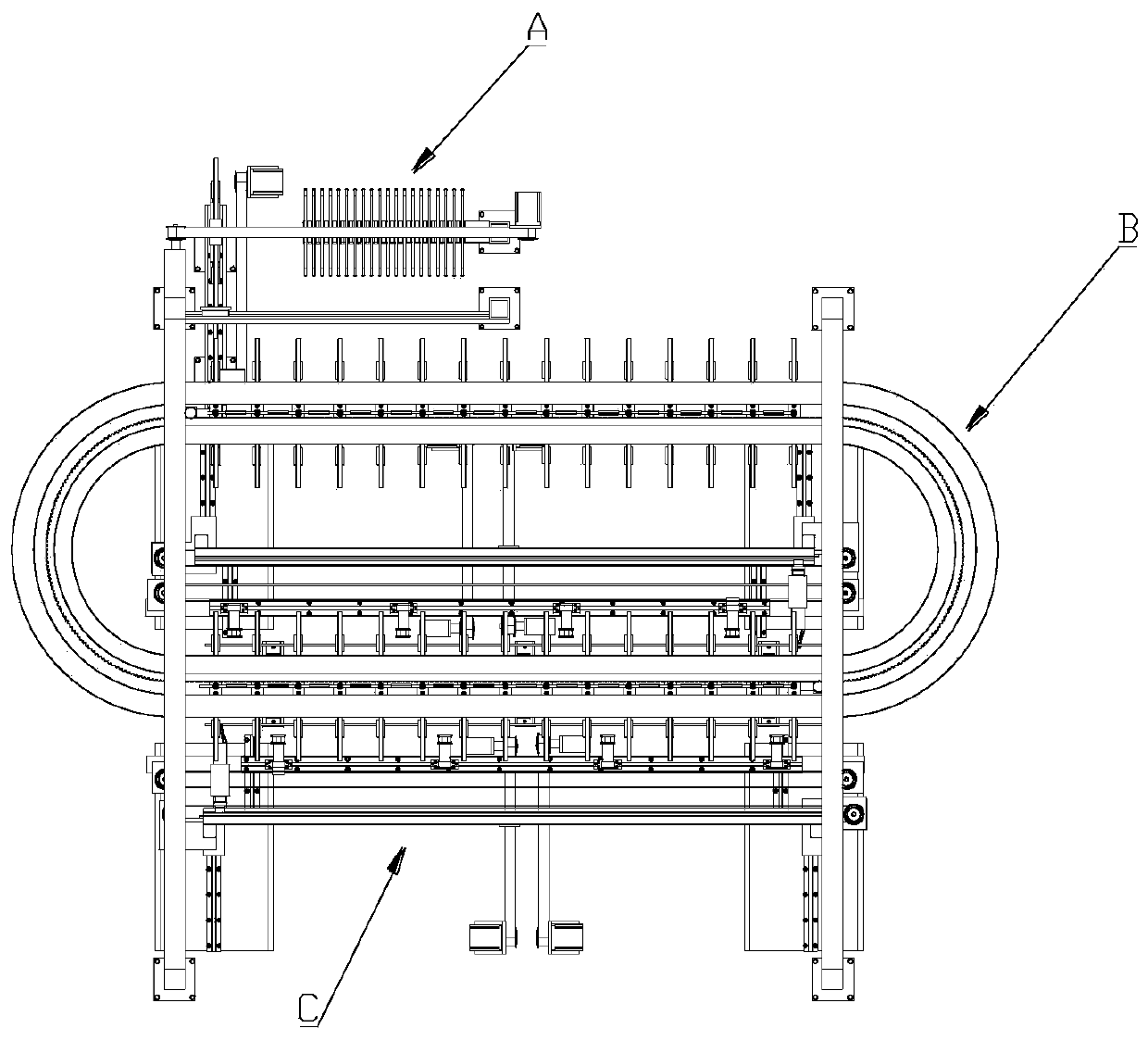

Steel reinforcement cage production equipment

InactiveCN110103334AImprove construction efficiencyReduce labor intensityCeramic shaping apparatusRebarLine segment

The invention discloses steel reinforcement cage production equipment comprising an automatic stirrup feeding device, an automatic stirrup conveyor device and a support device; the automatic stirrup feeding device comprises a stirrup storage rack, a stirrup conveyor seat, a first handling mechanism and a second handling mechanism, and the automatic stirrup conveyor device comprises a third supportframe, a conveying guide rail, a plurality of stirrup conveying parts and a stirrup conveying mechanism; the conveying guide rail is in a closed ring shape, and straight-line segments are arranged atthe positions, corresponding to the support device, of the conveying guide rail; every two adjacent stirrup conveying parts are connected through a connecting piece rotatably; and the support devicecomprises a support platform, a first support mechanism and a second support mechanism. According to the steel reinforcement cage production equipment, stirrups, longitudinal reinforcements and additional reinforcements can be conveyed onto the support device automatically, so that the construction of bed-jig is finished; in addition, the separation of the bed-jig and the support device can be further achieved, so that the bed-jig is easy to handle to a casting station through the handling device for casting.

Owner:佛山市集知汇科技有限公司

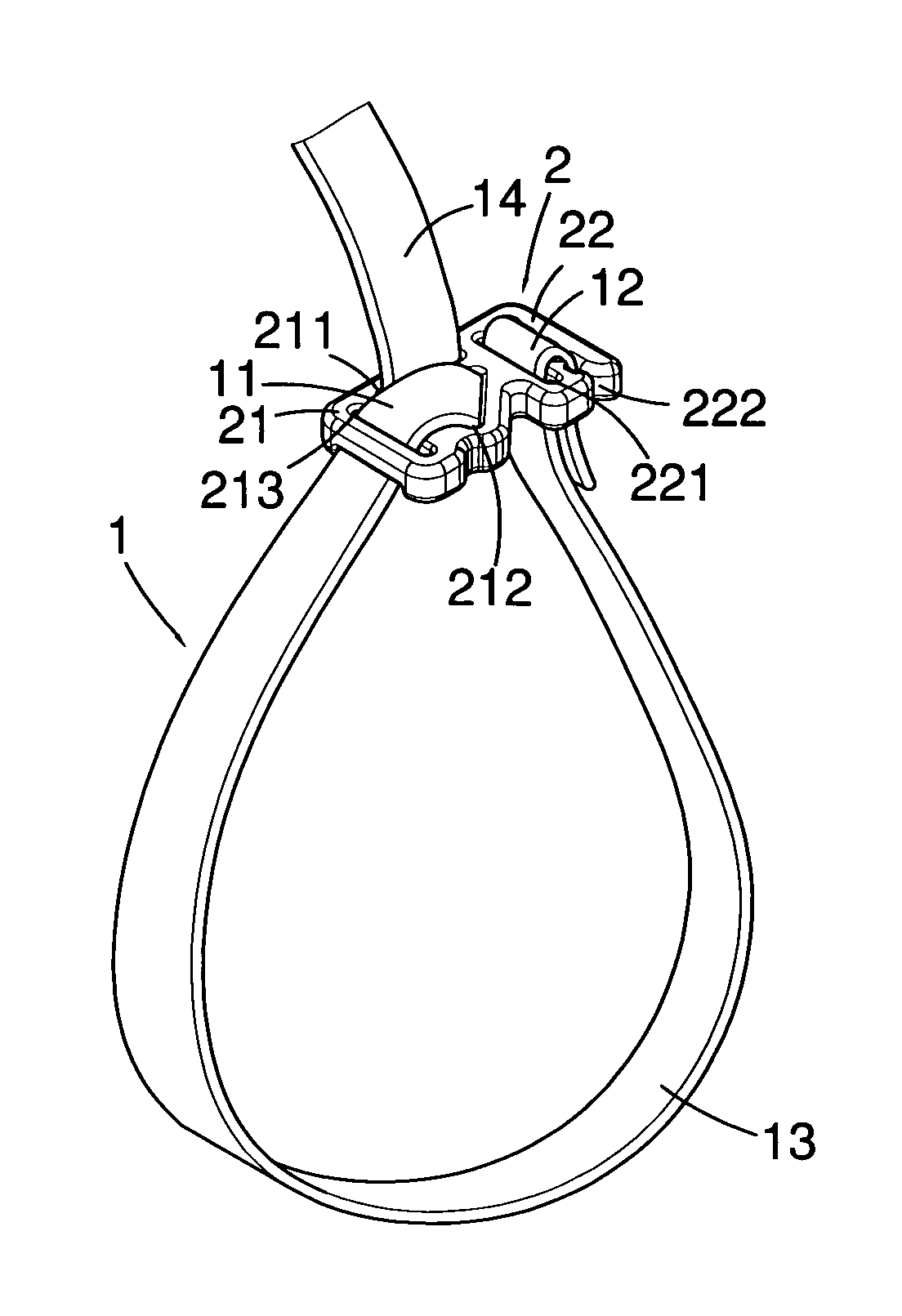

Balloon filling and tying device

An apparatus for filling a balloon with a fluid and tying a knot in the neck of the balloon, having a filling device body engaging a source of fluid under pressure. A balloon barb extends outwards from the body, and a fluid passageway in the body communicates with a control to allow the passage of fluid from the source to the balloon barb. A tying device extends from the body substantially parallel to the balloon barb, the tying device being detachable from and reattachable to a receptacle in the body of the filling device. A keyway is located either the tying device or an inner surface of the receptacle, and a key is located in the other of the tying device or the receptacle. The key corresponds in dimensions to fit in the keyway, where the key removably fits into the keyway when the tying device is inserted in the receptacle of the body of the filling device. A snap fit removably holds the tying device in the receptacle, and an elongated nozzle flange on the balloon barb prevents leakage of fluid when the balloon is being filled.

Owner:SIKORCIN WAYNE

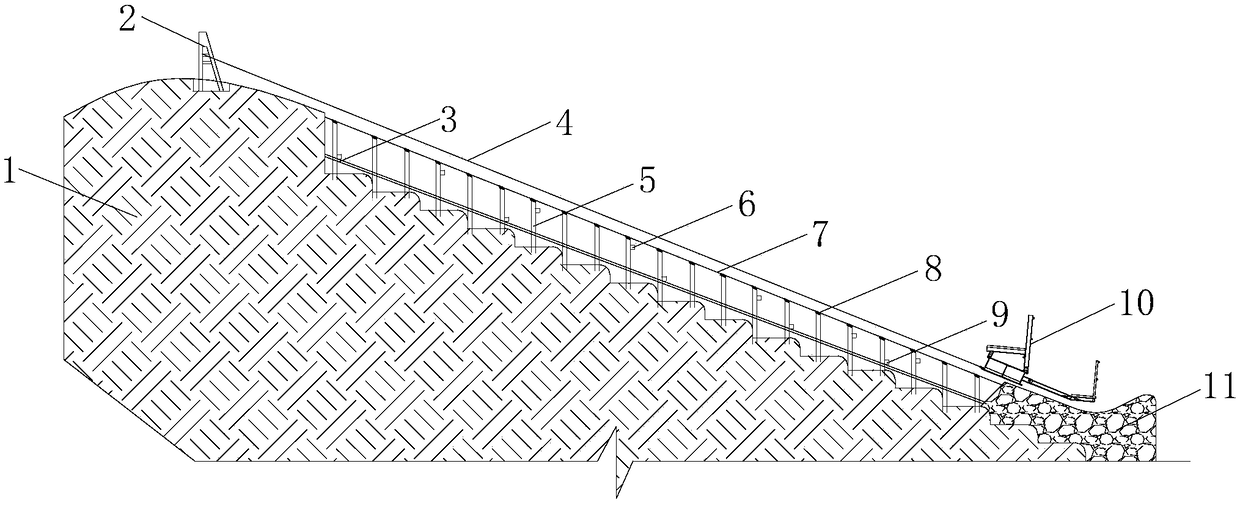

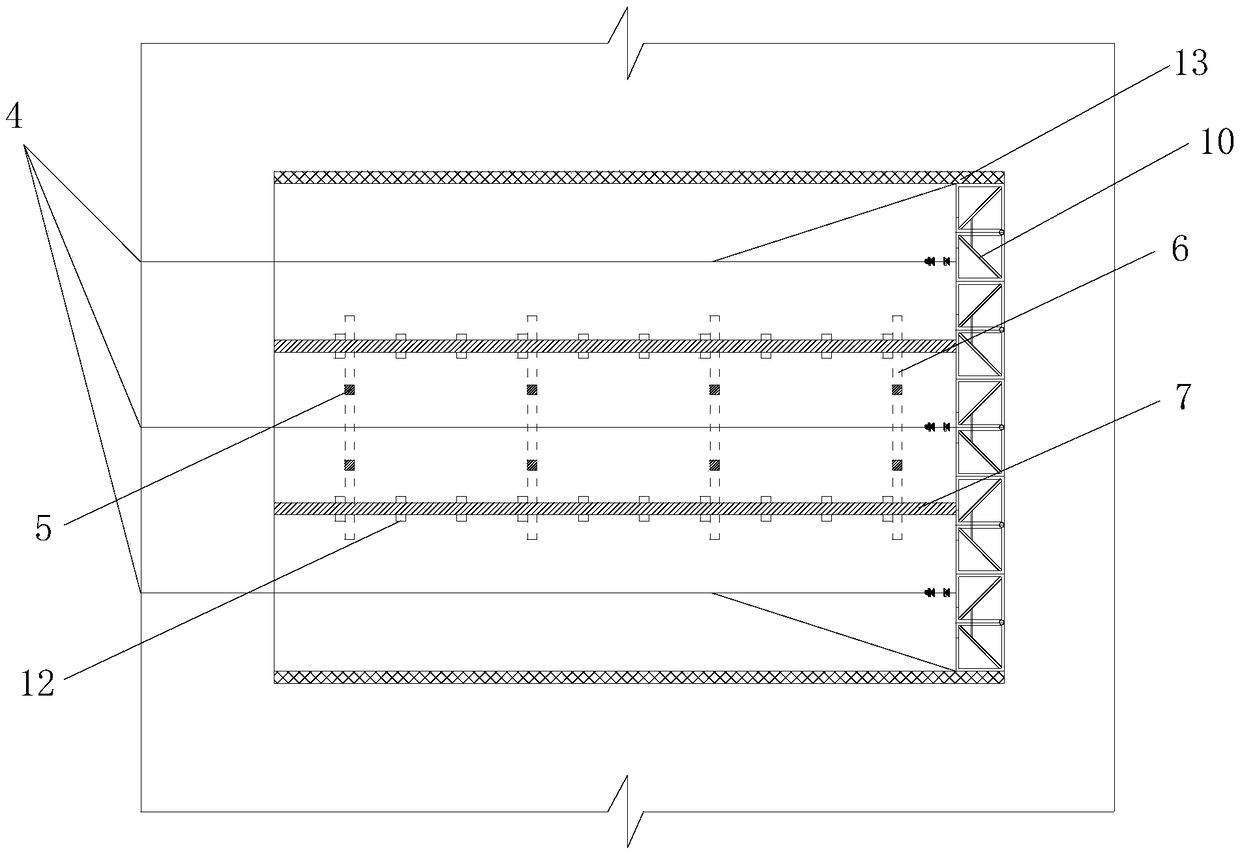

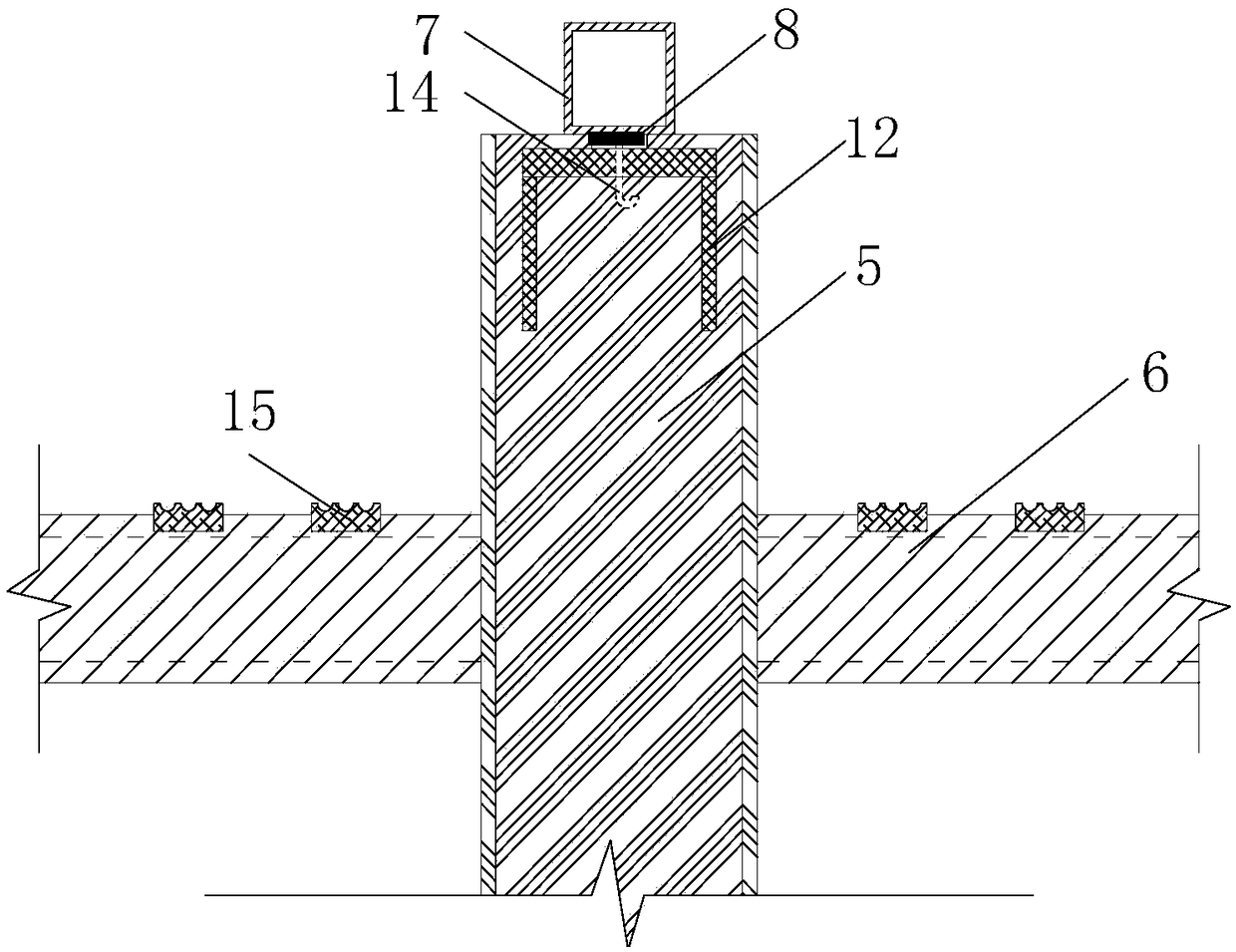

Large-area slope concrete hidden-rail slip form structure and construction method

InactiveCN108330980AImprove pouring qualityImprove installation accuracyBarrages/weirsFoundation engineeringEngineeringRebar

The invention relates to a large-area slope concrete hidden-rail slip form structure. The structure comprises a slope top support pillar, vertical support columns, top connecting cross beams, bottom connecting cross beams, slip rails, combined side forms and pull forms. The vertical support columns are longitudinally and transversely arranged on an original slope at equal intervals, the top connecting cross beams and the bottom connecting cross beams are arranged at upper and lower ends of the vertical support columns respectively, and rebar positioning tooth plates are arranged on top surfaces of connecting beams; bracket plates are symmetrically arranged at the top of the rail support columns in the slope direction, rail pads are arranged on the bracket plates, and the slip rails are erected on the bracket plates; the combined side forms are mounted on two sides of the slope, and slip rails are also arranged in the combined side forms. The structure has the benefits as follows: an inner form body of a slip form system is divided into cavities uniformly at equal intervals, adjustable sand partition boards are arranged in the cavities to form limiting counterweight frames, and bagsbetween partition boards are filled with sand to realize area ballasting; flat plate vibrating tampers and vibrating leveling beams are arranged on lower panels of the slip forms, and the slope concrete pouring quality is further improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

Suture material for pneumatic suture instrument

InactiveUS20070213744A1Easy to tieEasily manipulateSuture equipmentsWound clampsSuturing instrumentCatheter

The surgical suturing instrument incorporates a pressurized fluid suture feed system for passing a suture through the instrument and the tissues to be joined thereby. A fluid jet in communication with a suture feed conduit selectively entrains a suture in a stream of pressurized fluid, which carries the suture through the instrument's hollow tissue penetrating needle. The tissue penetrating needle may be shaped to direct the suture's free end to a point external the body cavity. Alternatively, a suture return conduit may be provided to engage the hollow tissue penetrating needle to receive and carry the suture's leading end to a point external the body cavity. External or internal pressurized fluid sources are utilized. A surface irregularity proximal the suture's leading end enhances the entrainment of the suture with the fluid stream. Individual, cartridge and spool fed sutures may all be utilized.

Owner:FARRIS ALEX F

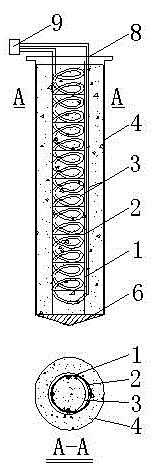

Tunnel secondary lining rebar positioning, laying and ejecting device

PendingCN106996298AReduce distortionReduce workloadUnderground chambersTunnel liningClassical mechanicsElectric machinery

The invention relates to the field of tunnel construction auxiliary means, in particular to a tunnel secondary lining rebar positioning, laying and ejecting device. The tunnel secondary lining rebar positioning, laying and ejecting device comprises a rack, a positioning mechanism, a laying mechanism and an ejecting mechanism, wherein the positioning mechanism, the laying mechanism and the ejecting mechanism are arranged on the rack. The positioning mechanism comprises a perpendicular positioning cylinder and a horizontal positioning cylinder; the laying mechanism comprises a container, and the container is parallel to the circumferential direction; the ejecting mechanism comprises a plurality of ejectors arranged in the circumferential direction of the rack, and each ejector comprises a plurality of spiral screw rod ejecting units and connecting rods arranged in the longitudinal direction of the rack; each spiral screw rod ejecting unit comprises an ejecting end and an input end, the input ends of each two adjacent spiral screw rod ejecting units of each ejector are connected through the connecting rods, and motors are connected with the connecting rods; and the ejecting ends of the spiral screw rod ejecting units of each ejector are jointly connected with an ejecting rod, and a plurality of rotatable positioning wheels are arranged on each ejecting rod. According to the tunnel secondary lining rebar positioning, laying and ejecting device, a rebar auxiliary laying device is provided, tunnel secondary lining rebar is laid rapidly and efficiently, and deformation of a circumferential rebar caused by uneven stress is avoided.

Owner:龚岗

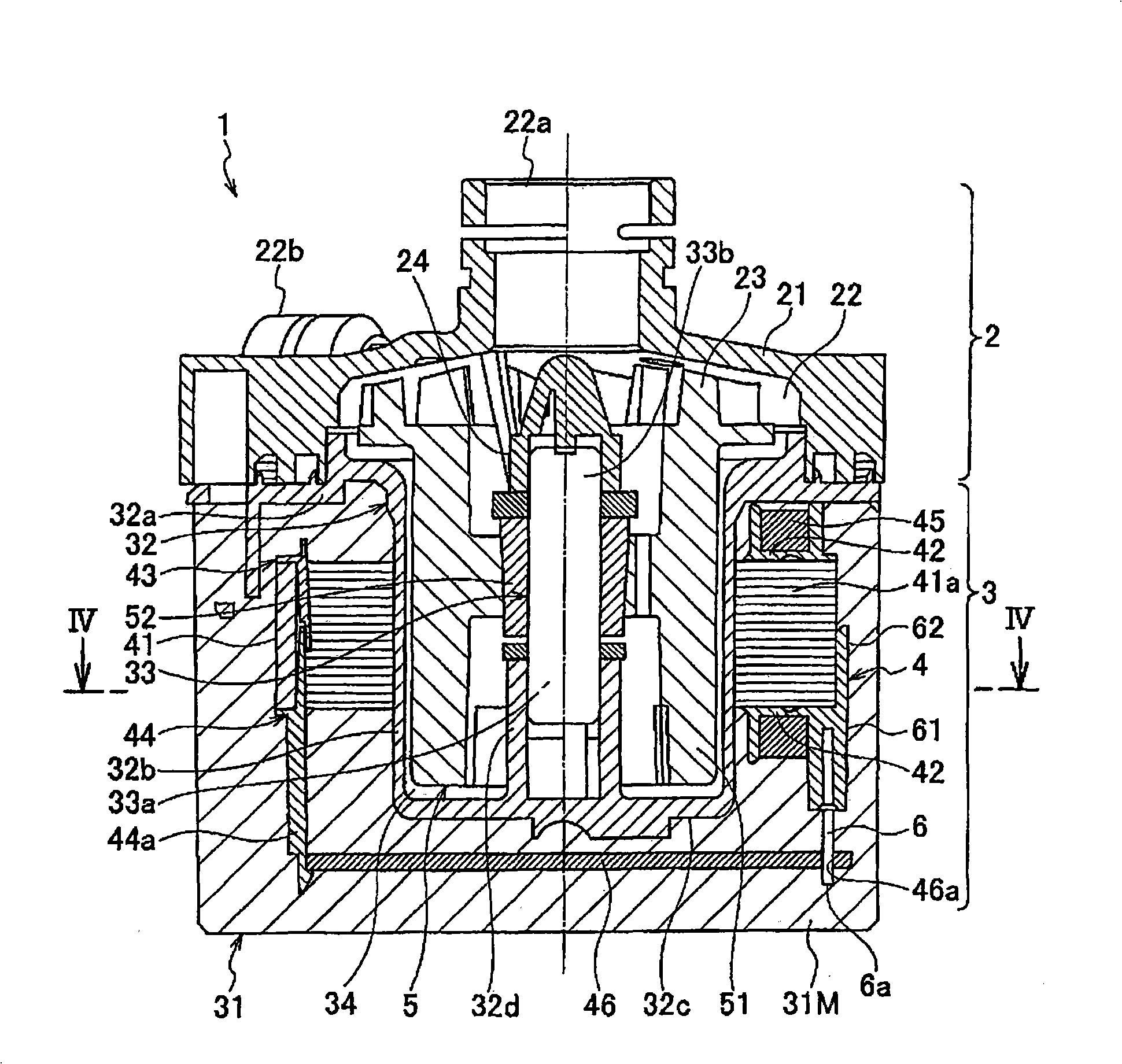

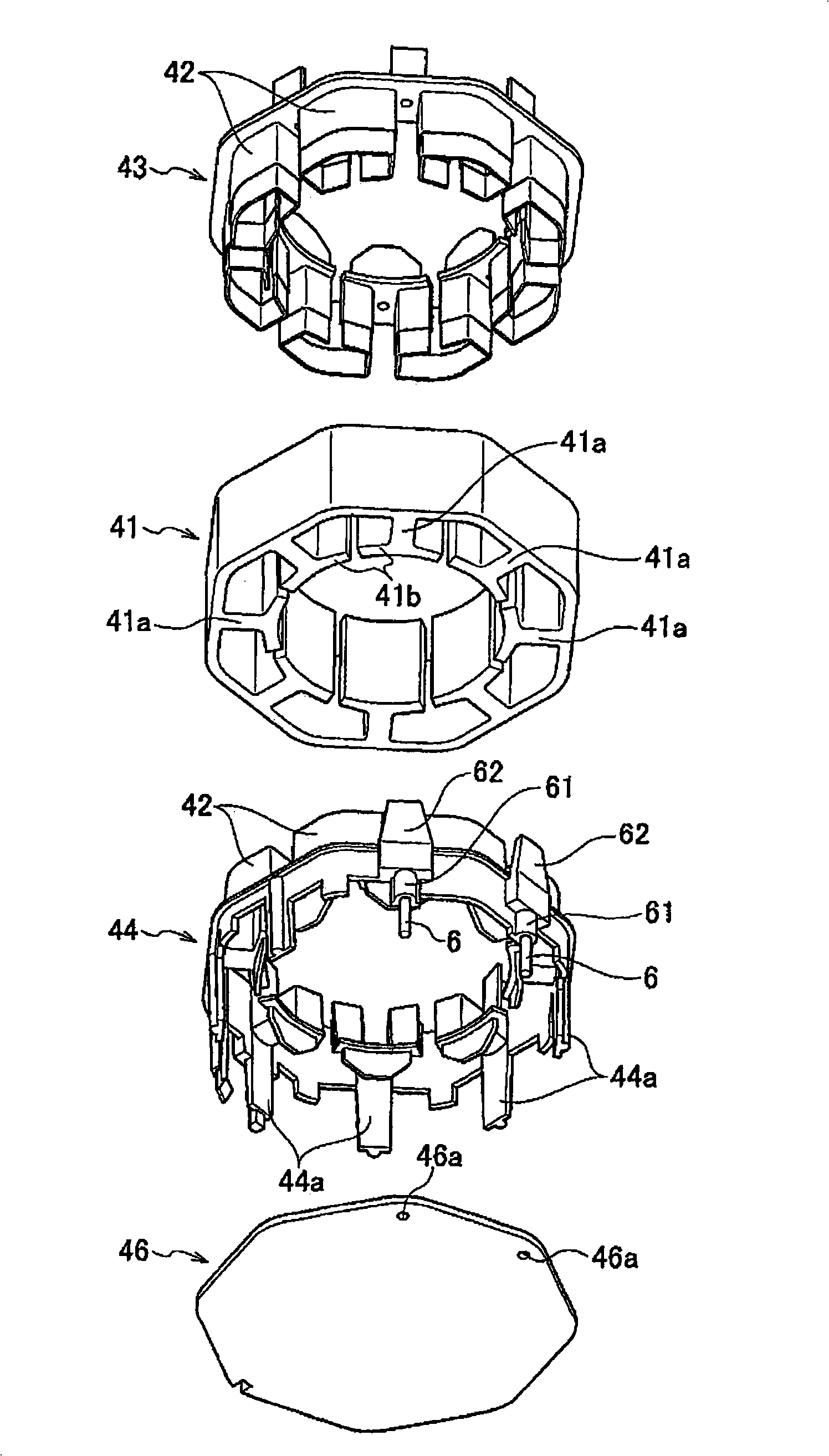

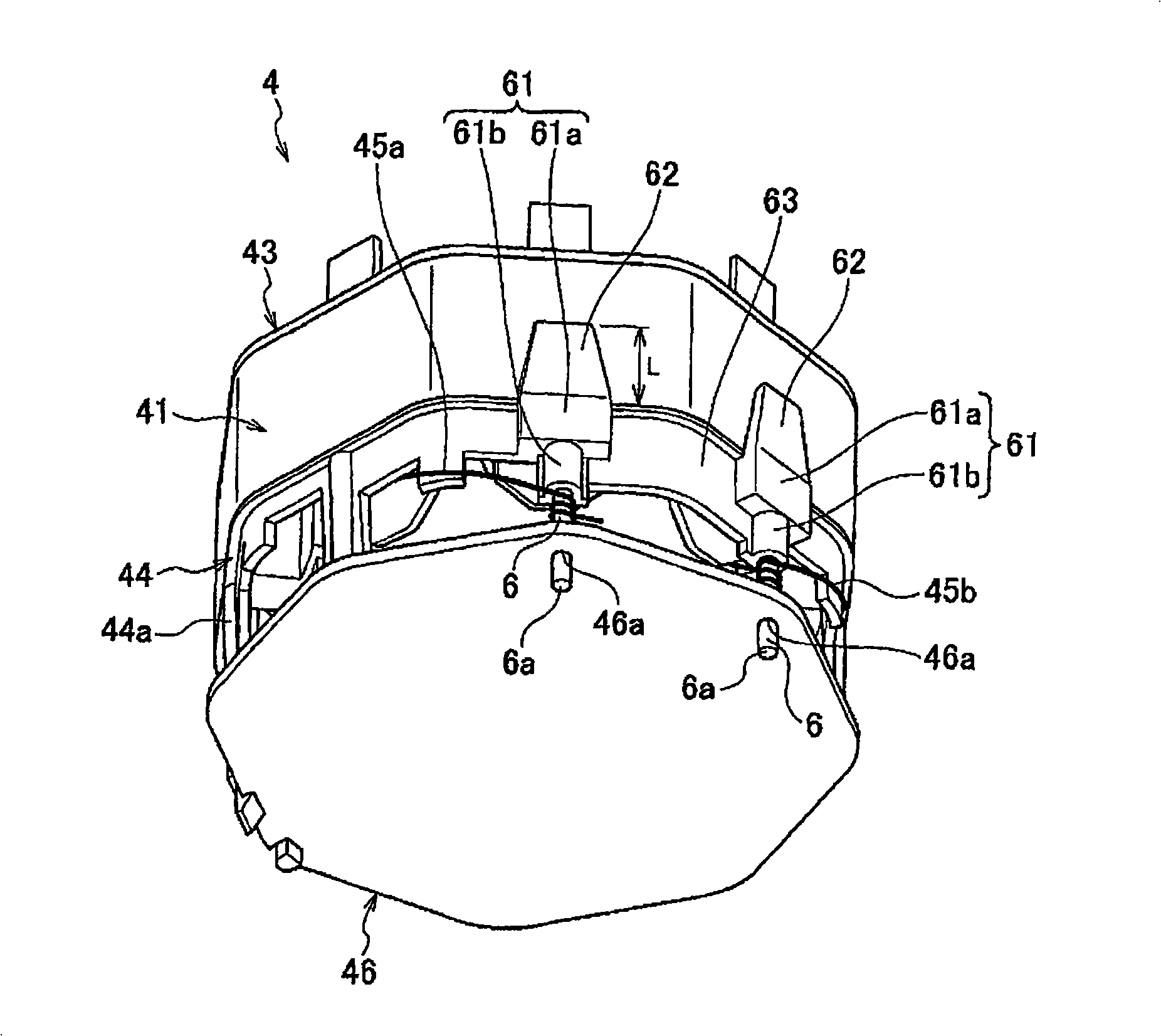

Motor and motor integrated pump with the motor

ActiveCN101494399AEasy wiringShorten takt timeWindings insulation shape/form/constructionPump installationsStatorEngineering

The invention provides a motor of wiring operation capable of winding more easily and reliably, and a motor-integrated pump equipped with the motor. At least two pins (6) are arranged for binding two end parts (45a,45b) of a winding (45) and clamping a front end part (6a) into a hole (46a) formed on a control substrate (46); a mounting part (61) is laterally protruded toward the control substrate (46) on an insulator (44), and respectively fixes the pin (6) under the condition of laterally protruding toward the control substrate (46); a strengthening wall (63) is laterally protruded toward the control substrate (46) on an insulator (44) and mutually connects between the mounting parts (61,61); further, a strengthening rib (62), which is abutted against the peripheral of a stator core (41, is arranged on the mounting part (61).

Owner:MATSUSHITA ELECTRIC WORKS LTD

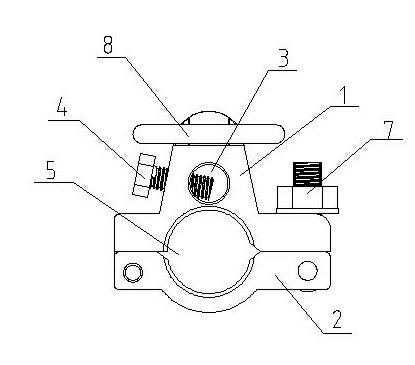

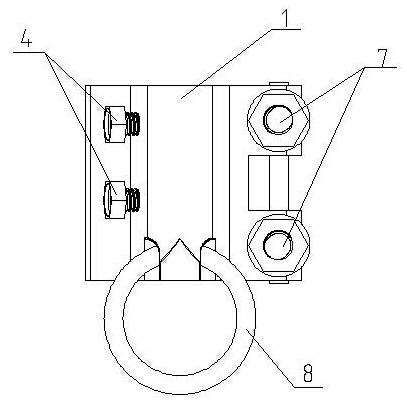

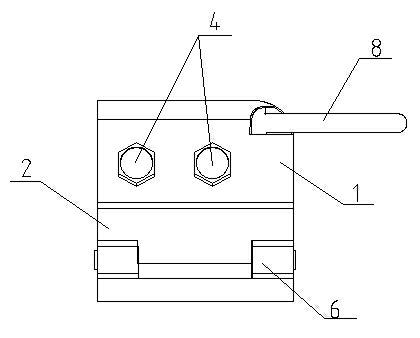

Charged disconnecting wire lead clamp device

InactiveCN102545091ASave time at workSimple structureCable installation apparatusCopper wireEngineering

The invention relates to a tool or a device for installing and dismounting a cable or an electric wire, and in particular relates to a charged disconnecting wire lead clamp device which has the structural key points that the device comprises a first fixture body and a second fixture body, wherein the first fixture body has a reversed 'T'-shaped structure, and a through hole is arranged above the first fixture body; the outer side wall of the through hole is provided with a screw hole communicated with the through hole; a bolt is screwed into the screw hole from outside to inside, and the lower bottom of the screw hole is provided with a semi-circular arc-shaped groove; the second fixture body is provided with a semi-circular arc-shaped groove corresponding to the semi-circular arc-shaped groove arranged on the first fixture body; after the two semi-circular arc-shaped grooves are combined with each other, a circular hole can be formed; one shoulder side of the first fixture body and one should side of the second fixture body are respectively provided with a hinge joint component, and the other shoulder sides of the first fixture body and the second fixture body are respectively provided with a fastener; and the first fixture body is connected with the second fixture body by the fasteners. The charged disconnecting wire lead clamp device has the advantages that the working time of an operator in the electric field can be shortened, so that the safety of the operator can be guaranteed, and the working efficiency can be improved; and the lead clamp device is simple in structure, convenient to operate, firm in connection and good in practical effect. A copper wire rope can be simply and conveniently adjusted by the charged disconnecting wire lead clamp device.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com