Large-area slope concrete hidden-rail slip form structure and construction method

A concrete, large-area technology, applied in infrastructure engineering, water conservancy engineering, marine engineering and other directions, can solve the problems of difficult to maintain level, self-heavy, weak stability of the drawing system, etc., to improve the pouring quality, high installation accuracy, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this embodiment, the production and processing process requirements of the drag form system, the construction technical requirements of concrete pouring, the construction technical requirements of steel bar binding, etc. will not be described in detail, and the implementation mode of the construction of the large-area slope concrete concealed rail sliding form involved in the present invention will be focused on .

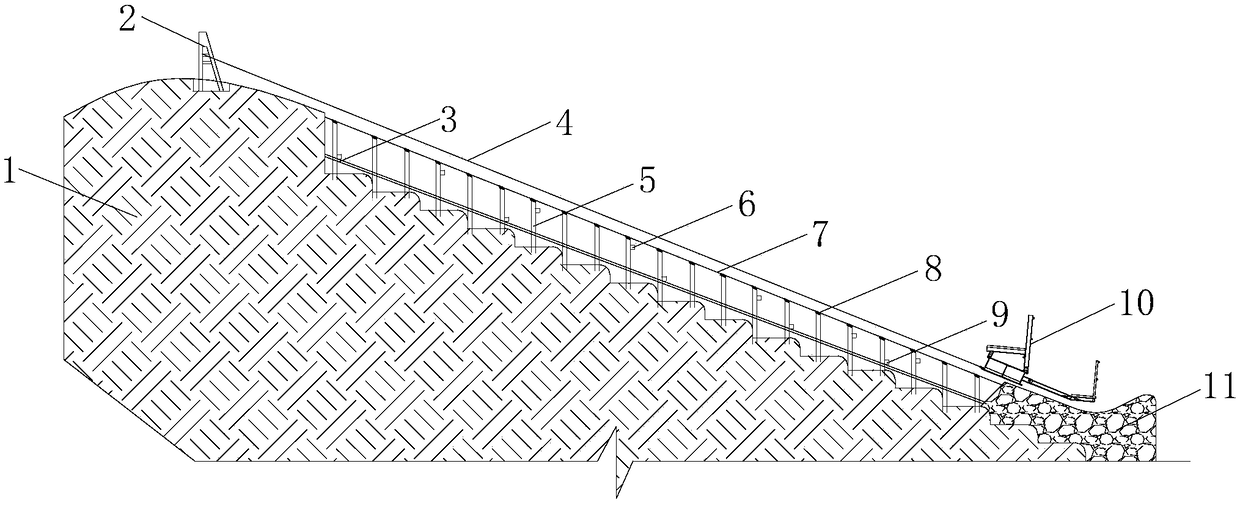

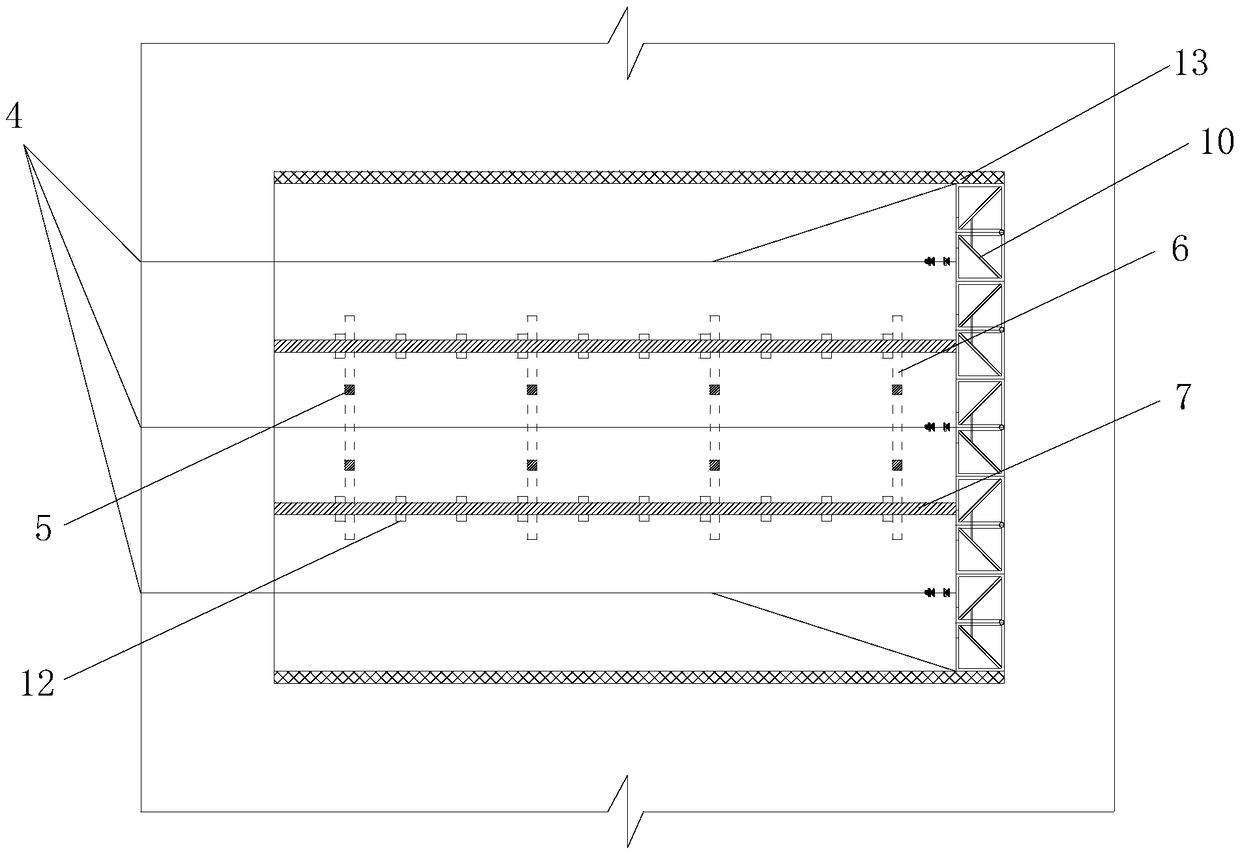

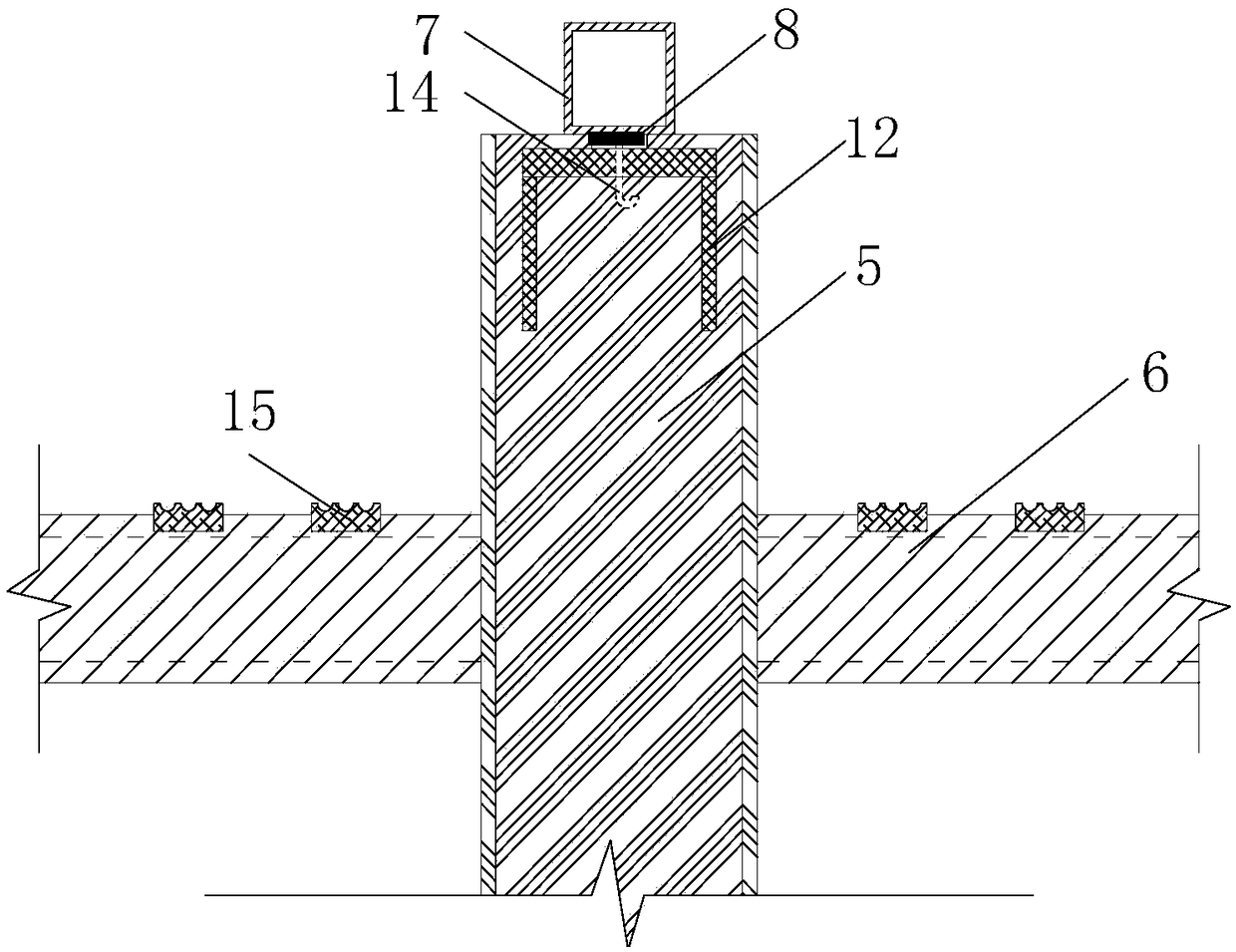

[0034] figure 1 It is a structural schematic diagram of the large-area slope concrete concealed rail sliding form of the present invention, figure 2 It is a schematic diagram of the concealed track layout of the present invention, image 3 It is a schematic diagram of the concealed track structure in the present invention, Figure 4 It is a schematic diagram of the side mold structure in the present invention, Figure 5 It is a schematic diagram of the mold dragging structure in the present invention, Figure 6 It is a construction process flow chart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com