Underground engineering mixed construction method

A technology of underground engineering and construction method, applied in water conservancy engineering, infrastructure engineering, artificial island and other directions, can solve the problem of low excavation speed, avoid the pressure of cleaning, eliminate hidden dangers, and achieve the effect of excellent pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A basement garage is built under the road near the railway station with heavy traffic and dense crowds. The foundation for building the basement garage is composed of miscellaneous filling soil layer, sandy clay layer, and granite layer (that is, holding force) from top to bottom. layer). The construction machinery and equipment used include underground diaphragm wall grooving machines, bored pile drilling rigs, crawler cranes, truck cranes, electric welding machines, steel bar processing machines, submersible pumps and mud pumps, concrete vibrators, etc.

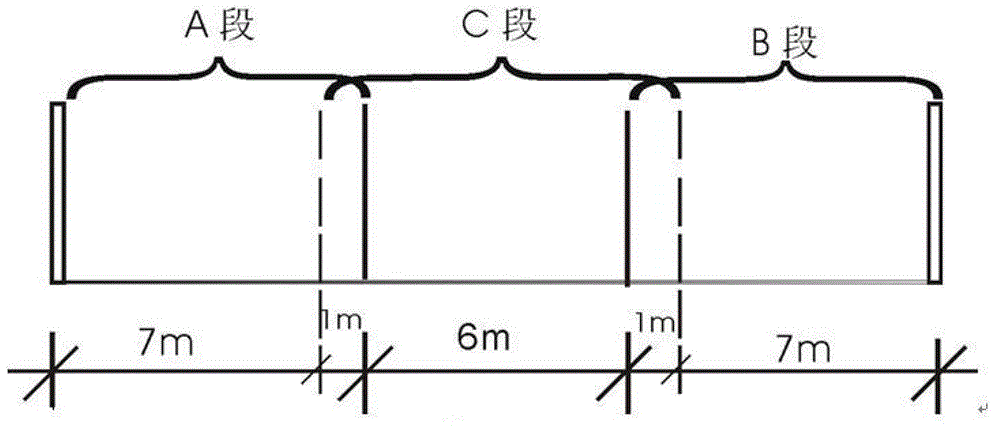

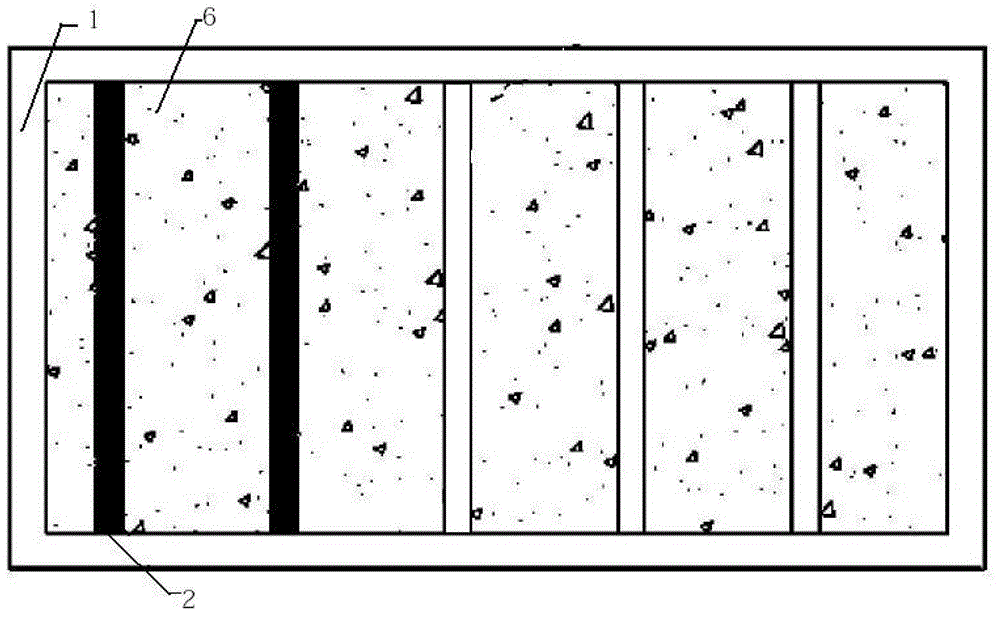

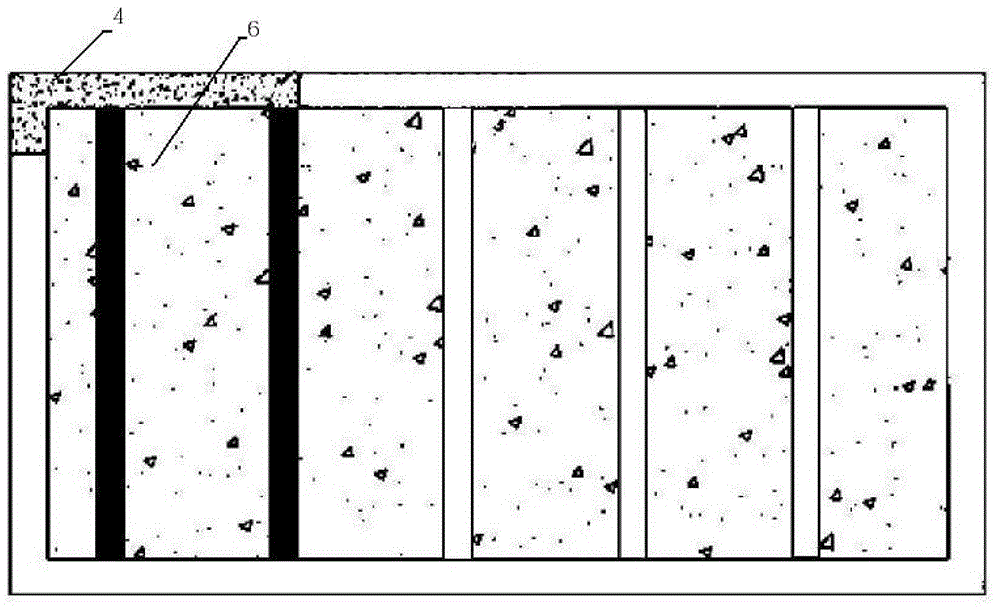

[0045] Such as Figure 1 to Figure 9 As shown, the width of the pavement between the sidewalk side stones of the road is 20m, so the pavement is set as section A, section C, and section B adjacent to each other in sequence. Firstly, the A road surface is closed with a width of 7 m, and 13 m of roadway is left to ensure two-way four-lane traffic, and an enclosure structure and road surface enclosure are set up around...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com