Patents

Literature

65results about How to "Process Optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

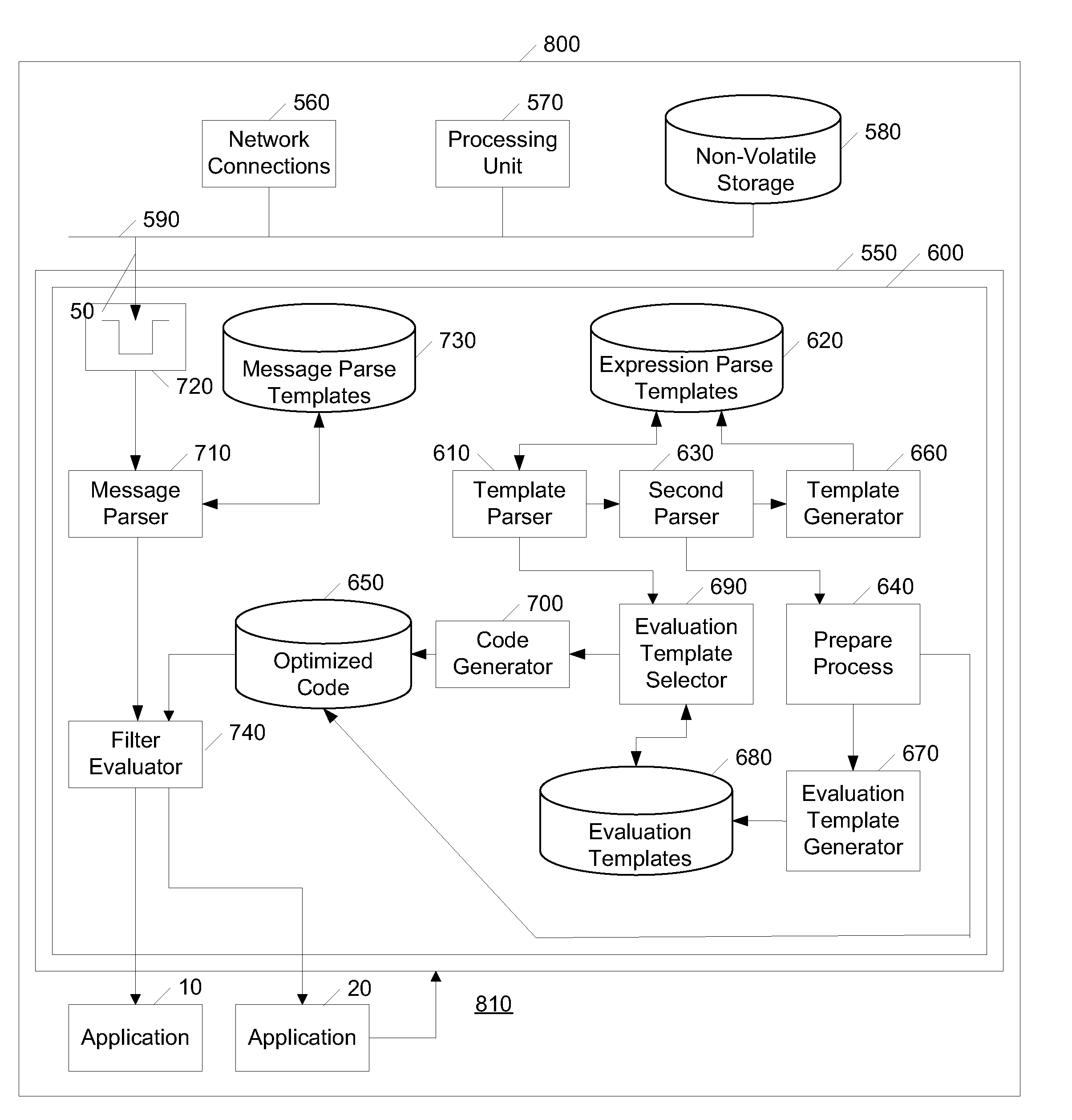

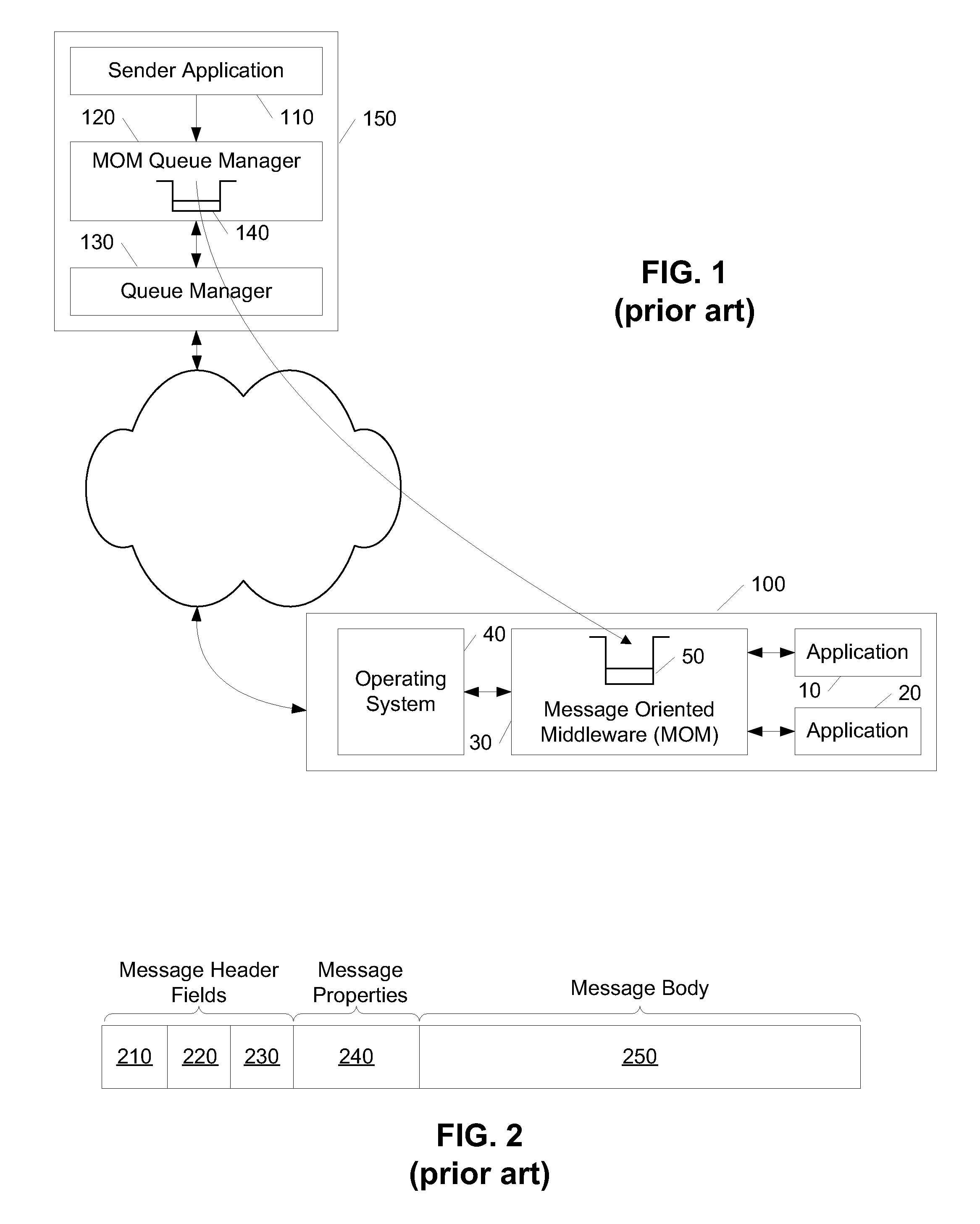

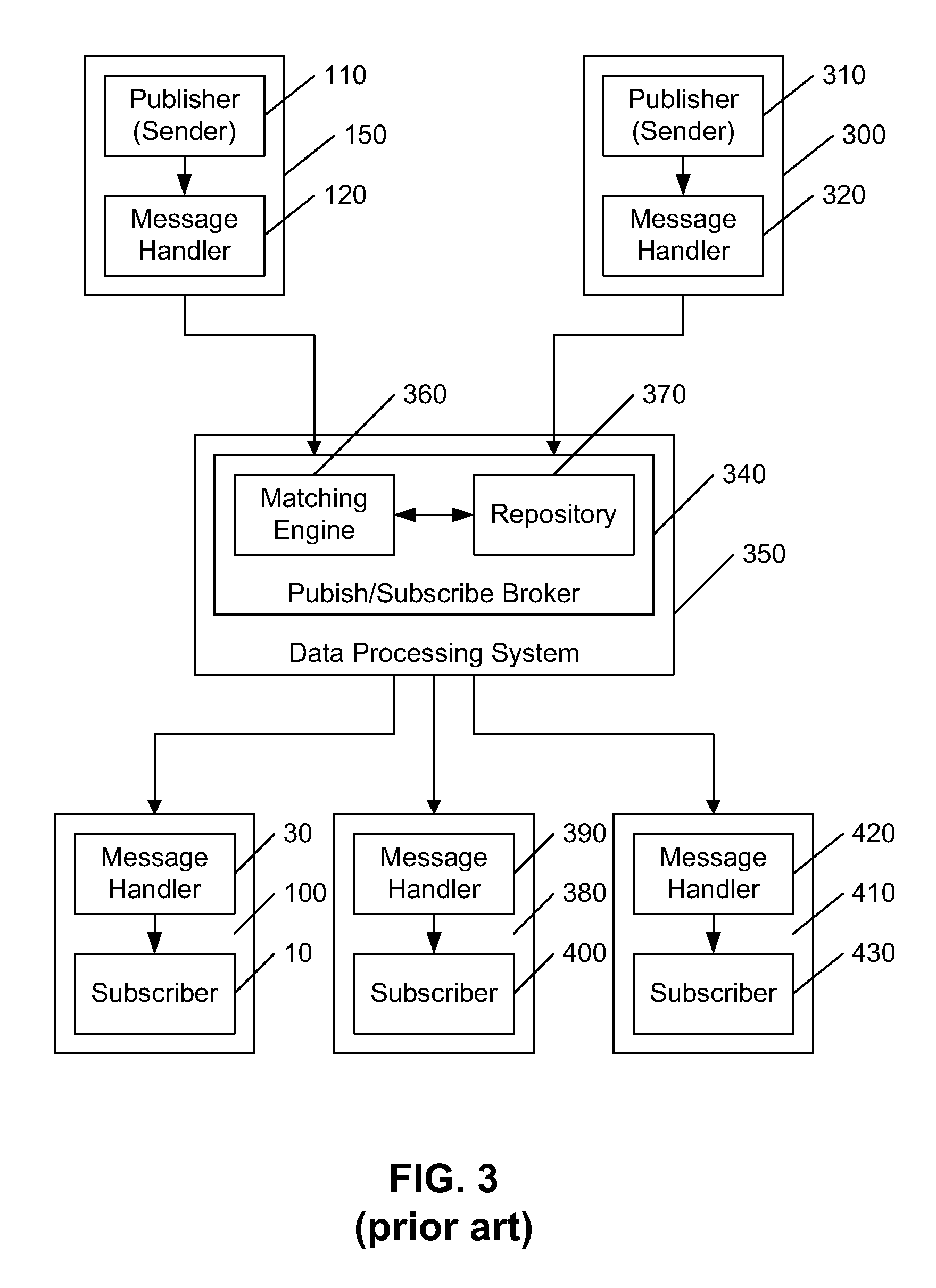

Processing of Expressions

InactiveUS20080196016A1Avoiding repetitive parsing and template generationProcess OptimizationProgram controlMemory systemsData processingRepeat pattern

In many messaging systems, message selection filtering involves a significant processing overhead. This includes the parsing and preparing of the message selection filters in readiness for evaluation, as well as the evaluation itself. In systems which involve parsing and prepare processing for expressions that include repeated patterns (such as in many JMS environments), a template-based shortcutting of the conventional processing improves performance. A stored parsing template is used to parse an input sequence such as a received data processing instruction. The parse is used to identify expressions of a first type that can then be implicitly optimized by using a stored evaluation template that is associated with expressions of that type.

Owner:IBM CORP

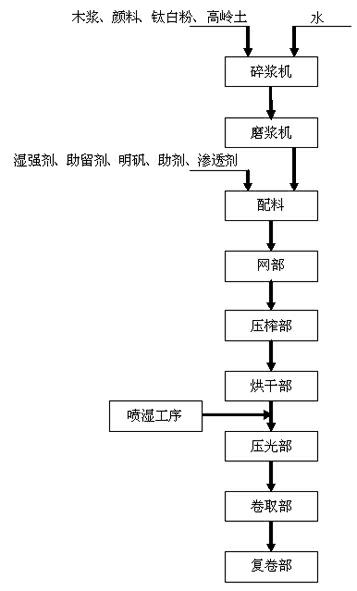

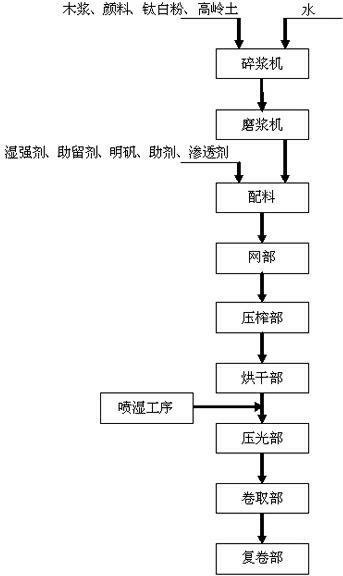

Process for producing high-speed gum-dipping printing decorative base paper

ActiveCN102174769AProcess optimizationEnhanced suction performanceDefoamers additionReinforcing agents additionPapermakingTitanium

The invention relates to a process for producing high-speed gum-dipping printing decorative base paper. In the process, the base paper is prepared by a pulp smashing step, a defibrination step, a batching step and a papermaking step. In the pulp smashing step, pulp at the concentration of 6.0 to 6.5 mass percent is prepared by raw materials and water, wherein the raw materials comprise 63 to 78 weight percent of wood pulp, 10 to 14 weight percent of kaolin, 12 to 18 weight percent of titanium white and 2 to 3 weight percent of pigment. In the pulp batching step, pulp at the concentration of 2.0 to 4.0 mass percent is prepared by adding 3 to 5 weight percent of wet strength agent, 0.2 to 0.4 weight percent of retention aid, 0.1 to 0.3 weight percent of alum, 0.05 to 0.15 weight percent of penetrating agent and 0.05 to 0.15 weight percent of auxiliary agent based on the weight of the pulp subjected to defibrination into the pulp subjected to defibrination. By the process, the proportionof chemical auxiliary agents in the decorative base paper process is adjusted, so that the gum dipping speed reaches more than 45m / min; therefore, the production efficiency of a gum dipping factory is improved, and the production cost is reduced.

Owner:杭州华旺新材料科技股份有限公司

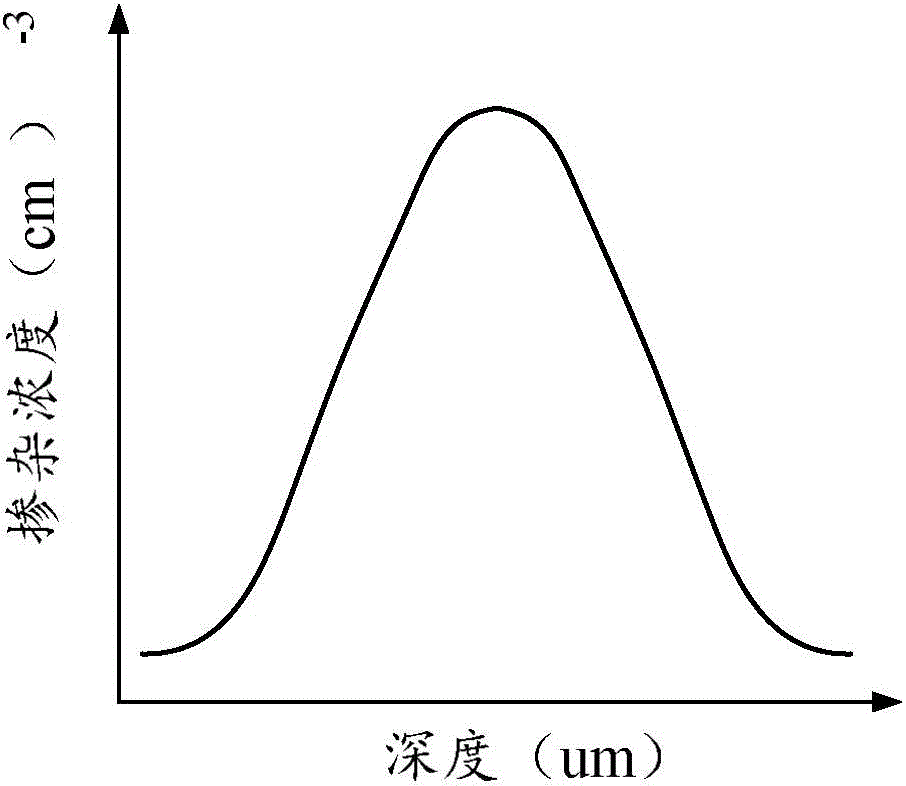

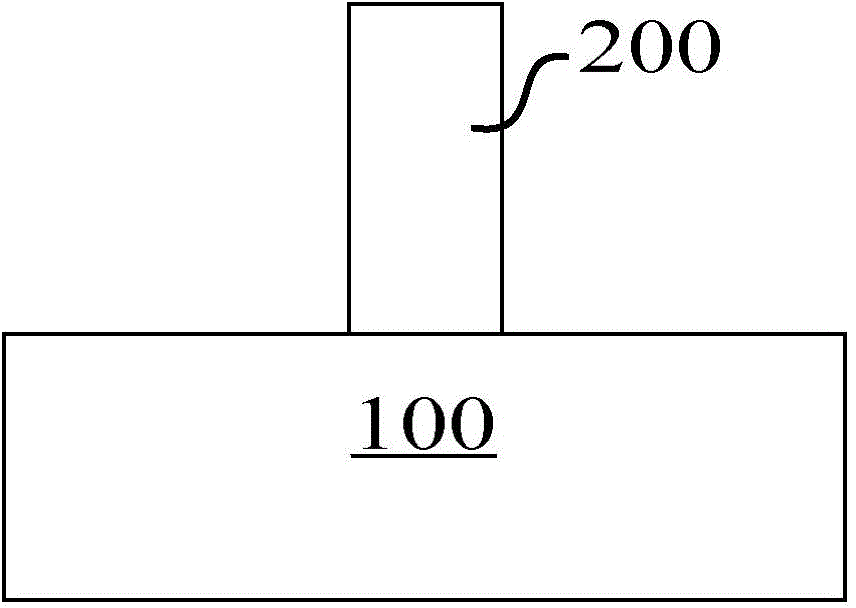

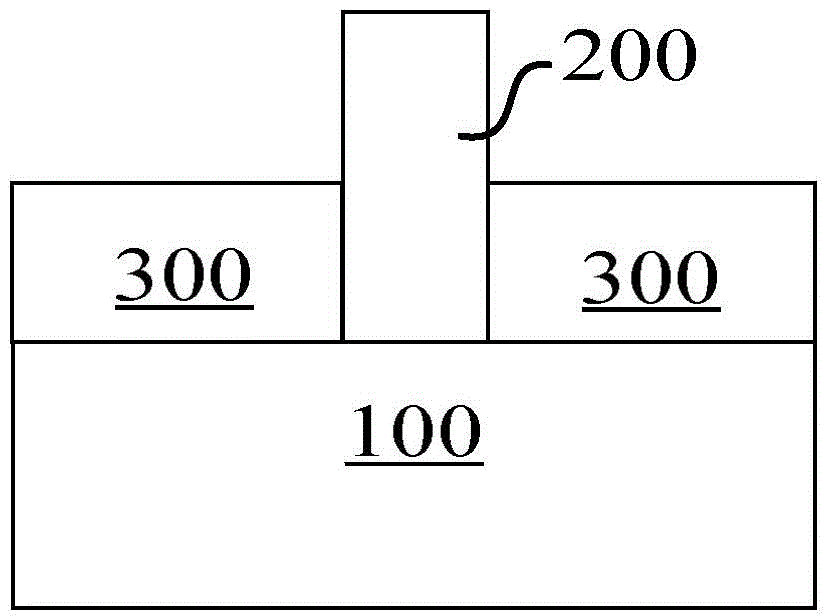

FinFET manufacturing method

ActiveCN105097527AProcess OptimizationImprove device performanceSemiconductor/solid-state device manufacturingSemiconductor devicesBlock layerBlocking layer

The invention provides a FinFET manufacturing method. The method comprises steps: a substrate is provided, and a fin is formed on the substrate; b, isolation layers are formed on the substrate at two sides of the fin; a punch-through blocking layer is formed in part of the fin covered by the isolation layers to enable the position where the impurity concentration peak is in the punch-through blocking layer is lower than the surface of the isolation layer; d, each isolation layer is etched to enable the surface of the isolation layer to be flush with the position where the impurity concentration peak of the punch-through blocking layer is; and e, source-drain areas are formed at two ends of the fin respectively, a gate structure is formed when crossing the middle part of the fin, and filling by an interlayer dielectric layer is carried out above the isolation layer. Through the method provided by the invention, PTSL distribution can be effectively optimized, and the device performance is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

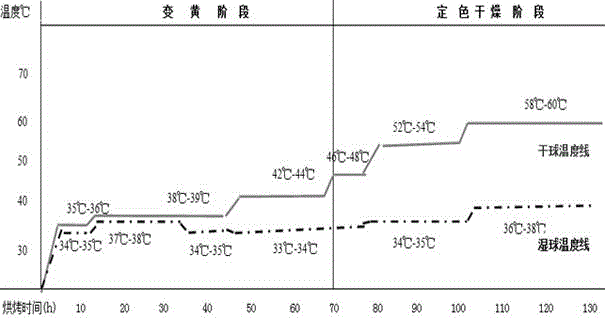

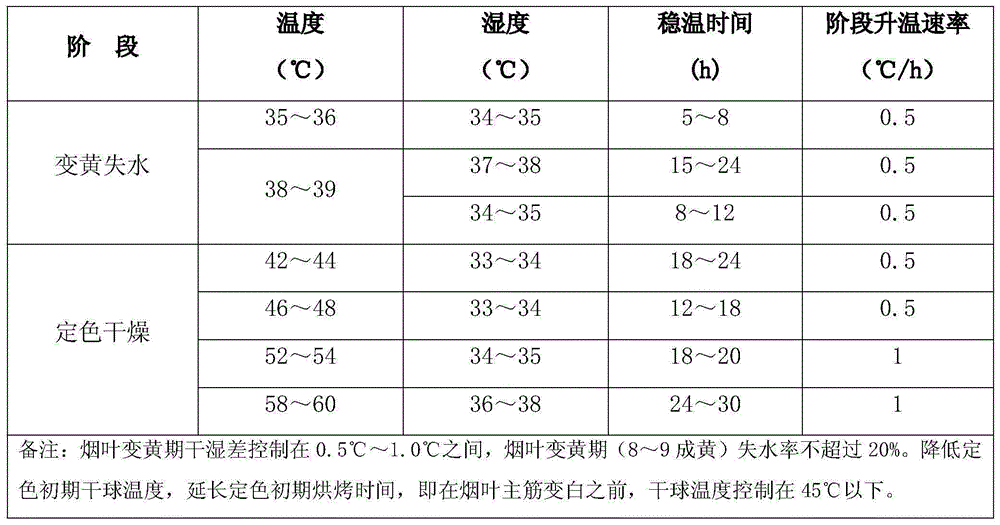

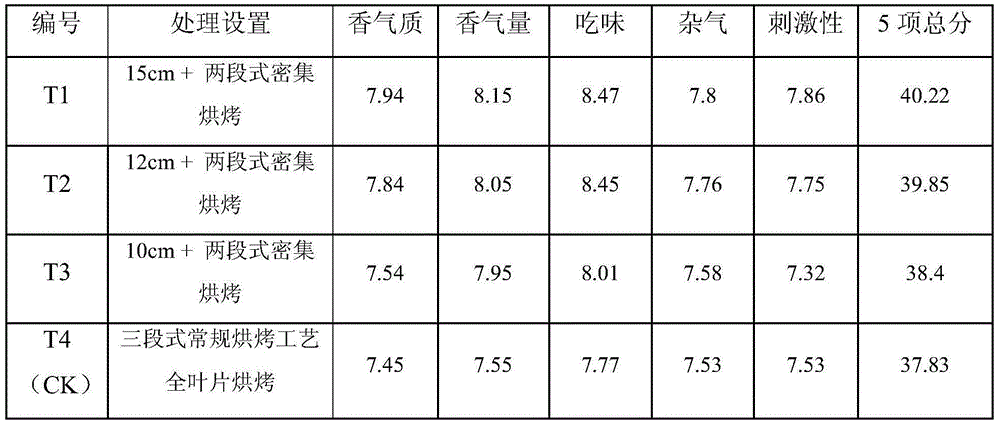

Two-stage type bulk curing process for flue-cured tobaccos

InactiveCN105105308AProcess OptimizationGood for yellowing and color fixingTobacco preparationFlueChemistry

The invention relates to a two-stage type bulk curing process for flue-cured tobaccos. A two-stage type curing process is adopted and comprises a yellowing stage and a color fixation and drying stage respectively; tobacco leaves are dried by using dry-bulb temperature of a color fixation later period; according to the curing process, 10-15cm of bases of the leaves are needed to be removed and then the tobacco leaves are filled and cured. The two-stage type bulk curing process for the flue-cured tobaccos has the following advantages that (1) the operability of the two-stage type curing process is stronger; (2) the process is more optimized and yellowing and color fixation of the tobacco leaves are facilitated; (3) stems are dried at low temperature, and the energy is saved; (4) the labor is saved and the cost is reduced; (5) the availability of the tobacco leaves is improved. According to the method provided by the invention, inapplicable leaf bases are treated before an agricultural curing link so that physical distribution cost and re-curing link cost are reduced and the availability of the tobacco leaves is more effectively improved.

Owner:GUIZHOU TOBACCO SCI RES INST

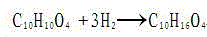

Solvent-free preparation method of 1, 4-DMCD

InactiveCN102796001AProcess OptimizationLow costOrganic compound preparationCarboxylic acid esters preparationSolventSolvent free

The invention provides a solvent-free preparation method of 1, 4-DMCD. The common synthesis method of the 1, 4-CHDA dimethyl carbonate takes dimethyl terephthalate as a raw material, and takes one of water or C1-C4 fatty alcohol as a solvent, while, the solvent-free preparation method takes dimethyl terephthalate as the raw material, and directly takes 1, 4-DMCD as the solvent, so that the aftertreatment process can be eliminated, the obtained product can be directly used for the downstream product, the technology can be optimized, and the cost can be greatly reduced.

Owner:江苏恒祥化学股份有限公司

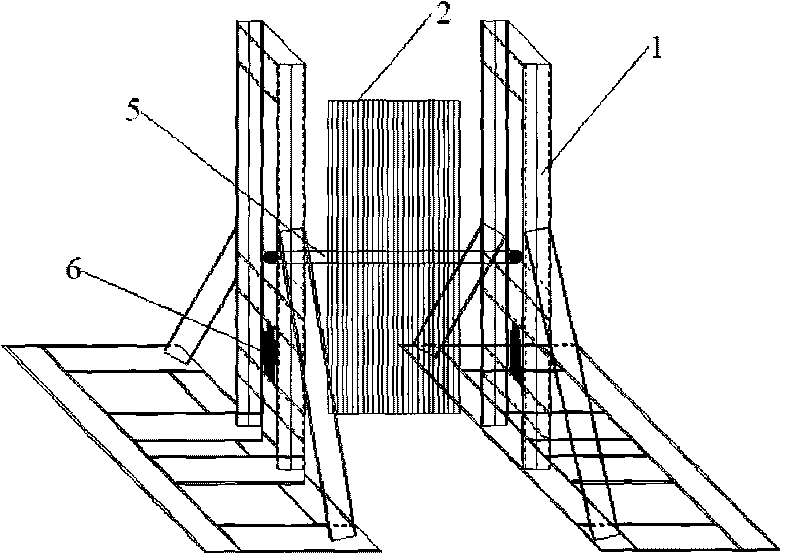

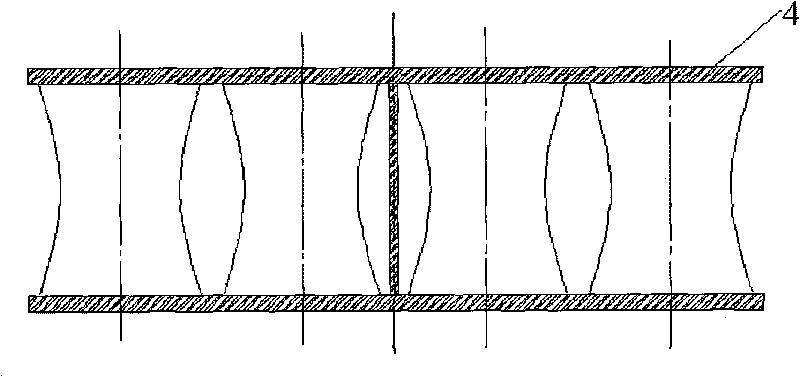

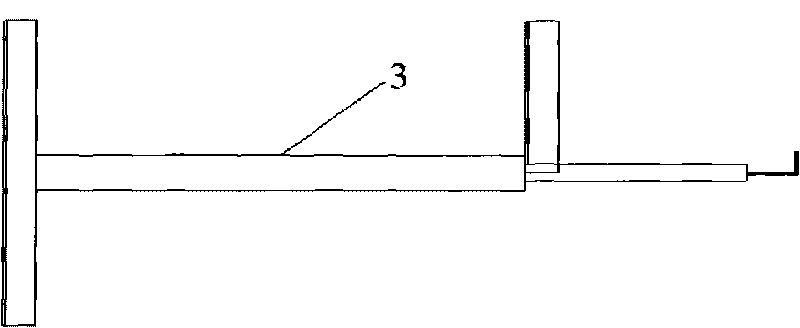

Large cable laying device

InactiveCN101707335AProcess OptimizationAccelerate laying speedArrangements using take-up reel/drumApparatus for laying cablesMechanical engineeringBuilding construction

Owner:WUHU XINXING DUCTILE IRON PIPES

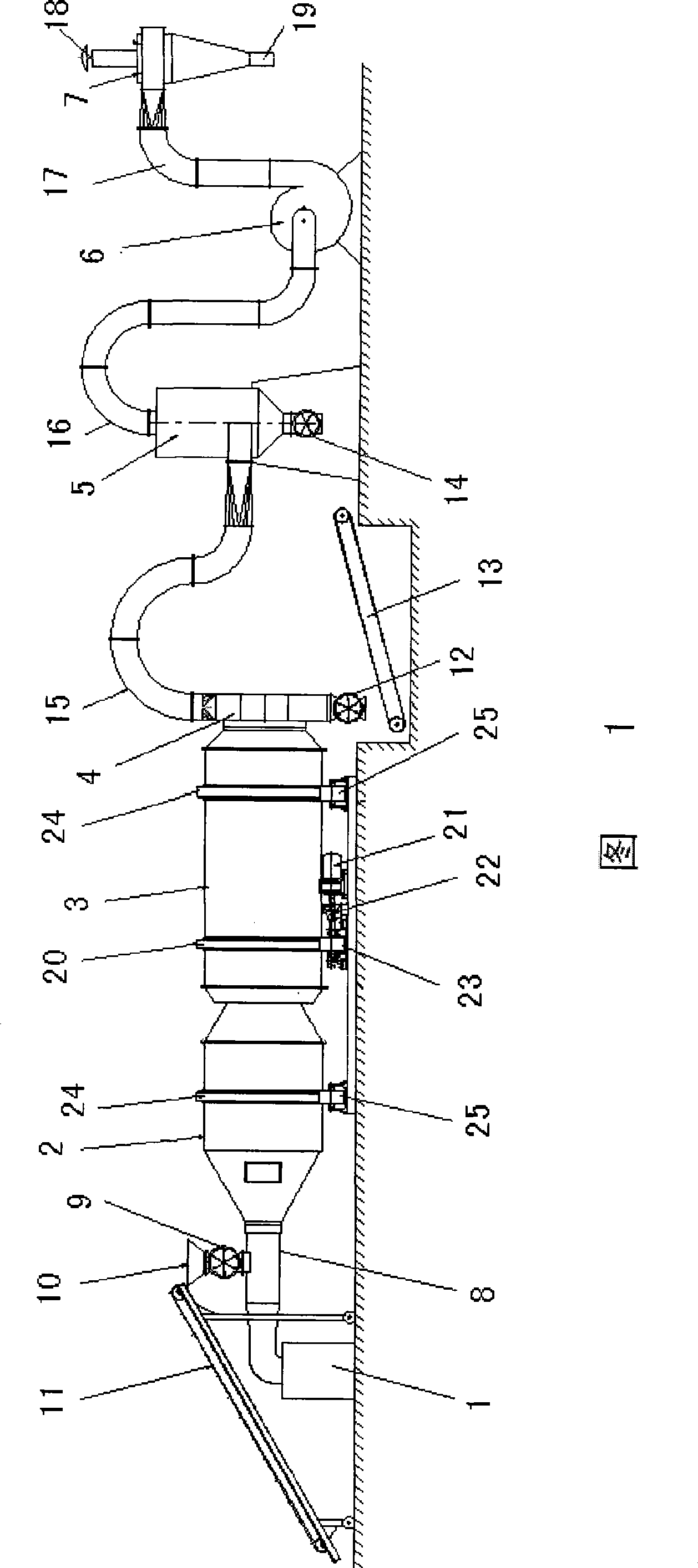

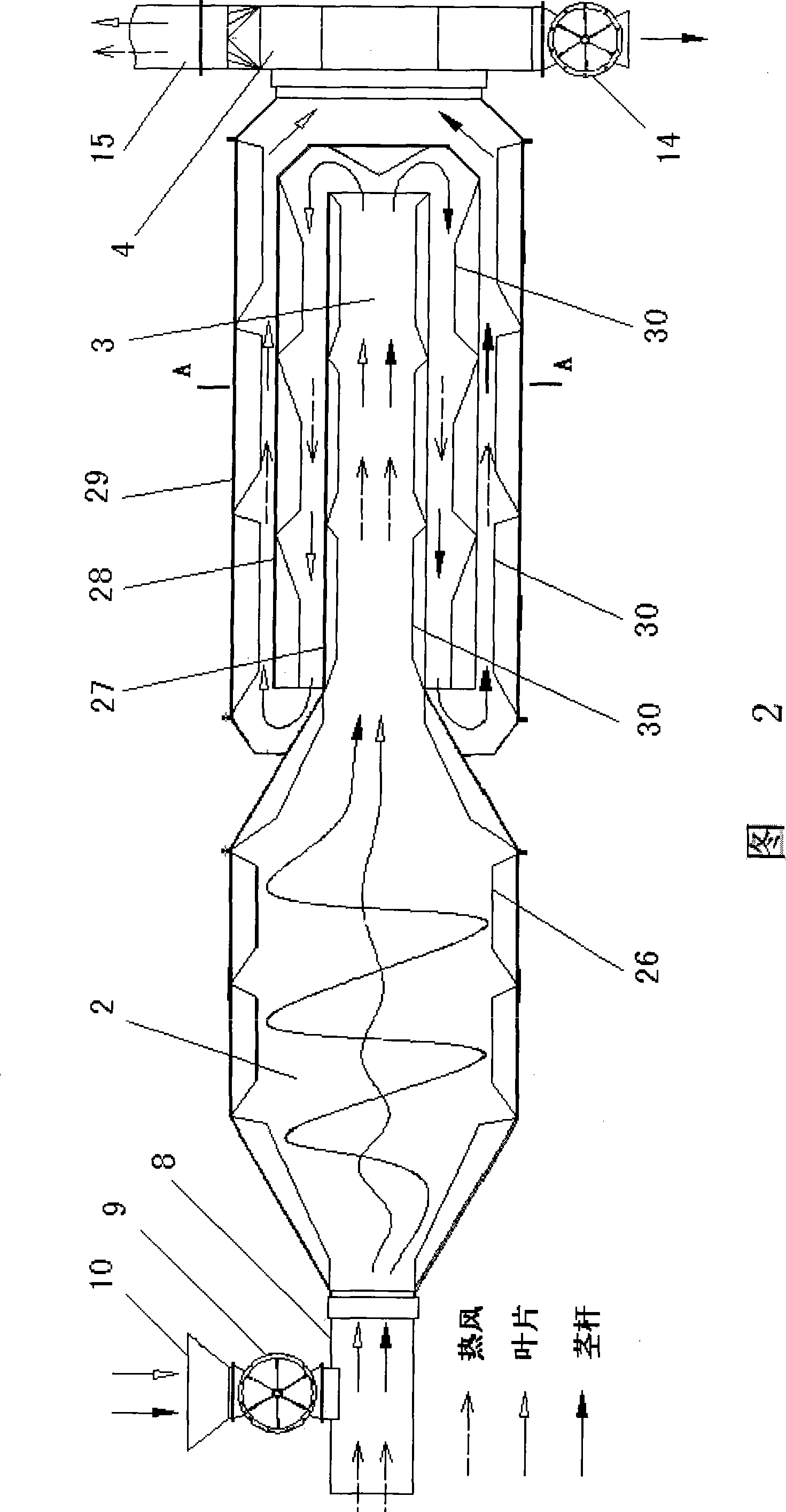

Grass drying, stem and leaf separating device

The invention relates to herbage drying and stem-leaf separating device, characterized in that: the device comprises a hot-blast stove, a pre-heating drying roller, a three-pass drying roller, a separating and discharging tank, a cyclone separator, a blower and a dust remover; the hot-blast stove is connected with the pre-heating drying roller through a warm-air pipe provided with a feeding hopper connected with a feeding airlock; the pre-heating drying roller is integrally fixed and connected with the three-pass drying roller rotationally connected with the separating and discharging tank and rotated through the driving of a moter; the lower end of the separating and discharging tank is provided with a discharging airlock, and the upper end is connected with the cyclone separator through a pipeline; the lower end of the cyclone separator is provided with a discharging airlock, and the upper end is connected with the blower through a pipeline; the outlet of the blower is connected with the dust remover with the outlet communicated with atmosphere. The invention decreases unnecessary energy consumption and lowers processing cost.

Owner:CHINA AGRI UNIV

Polymer dispersed liquid crystal film and production process thereof

ActiveCN102532773AProcess OptimizationLow costLiquid crystal compositionsLiquid-crystal displayCholesteryl nonanoate

The invention discloses a polymer dispersed liquid crystal film, which is prepared from the following raw material formula according to a mass ratio: 35-80% of polymer intermediate, 15-60% of liquid crystal (LC) with cholesteryl nonanoate as a monomer, and 0.1-15% of polyethylene serving as an accelerant. The production process of the polymer dispersed liquid crystal film comprises the steps of: carrying out high-speed sufficient stirring on the raw materials at the temperature of 35-60 DEG C according to the amount of the raw material formula, uniformly and accurately coating the stirred polymer-liquid crystal mixed liquid between two layers of ITO (Indium Tin Oxide) films, laminating to form a three-in-one film, and carrying out ultraviolet curing on the laminated three-in-one film to obtain the polymer dispersed liquid crystal film. According to the invention, a polymer and liquid crystal mixed formula is adopted, and an optimized and lower-cost PDLC (Polymer Dispersed Liquid Crystal) formula is invented. Through trial production, the performances of the produced product completely meet the international standard, and the cost is greatly lowered by 50%.

Owner:浙江鼎昇新材料科技股份有限公司

Production process for environment friendly laser card paper

ActiveCN102587211AProcess optimizationThe process steps are simpleNon-fibrous pulp additionCoatings with pigmentsMaterial consumptionOptoelectronics

The invention relates to a production process for environment friendly laser card paper. The production process comprises the following steps: (1) uniformly coating one layer of laser imaging coating on the card paper by using a coating machine, and drying and solidifying the laser imaging coating to form transparent surface coating on the card paper; and (2) impressing the surface of the transparent surface coating by using a laser mold pressing plate with laser graphic information, and transferring the laser graphic information on the laser mold pressing plate on the transparent surface coating to obtain the laser card paper. Compared with the traditional production process for the laser card paper, the production process for the environment friendly laser card paper has the following beneficial effects that (1) the process is environment friendly; (2) the technological process is optimized, the process steps are simplified and equipment configuration and material consumption are reduced, so cost is saved, and production efficiency is improved; (3) the production is easy to control, so that the laser graphic information is easy to transfer, the anti-fake effect is obvious, quality problem caused by deformation of the base material is avoided, and the product quality is stable; and (4) the laser image text on the laser card paper is clear.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

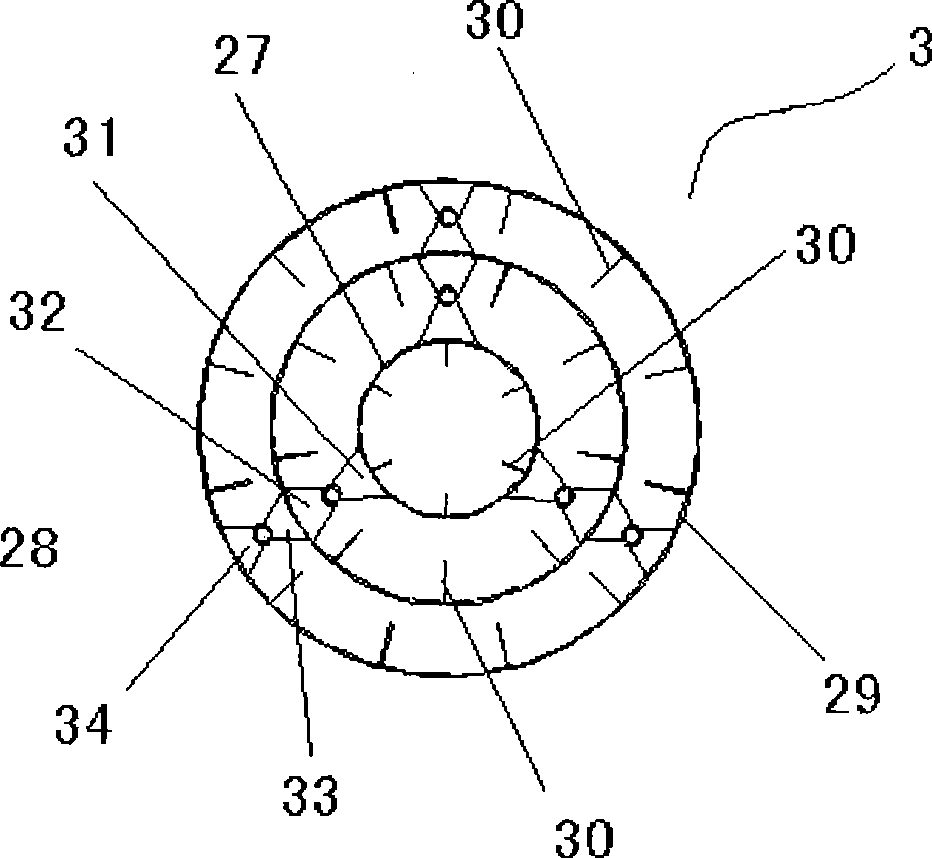

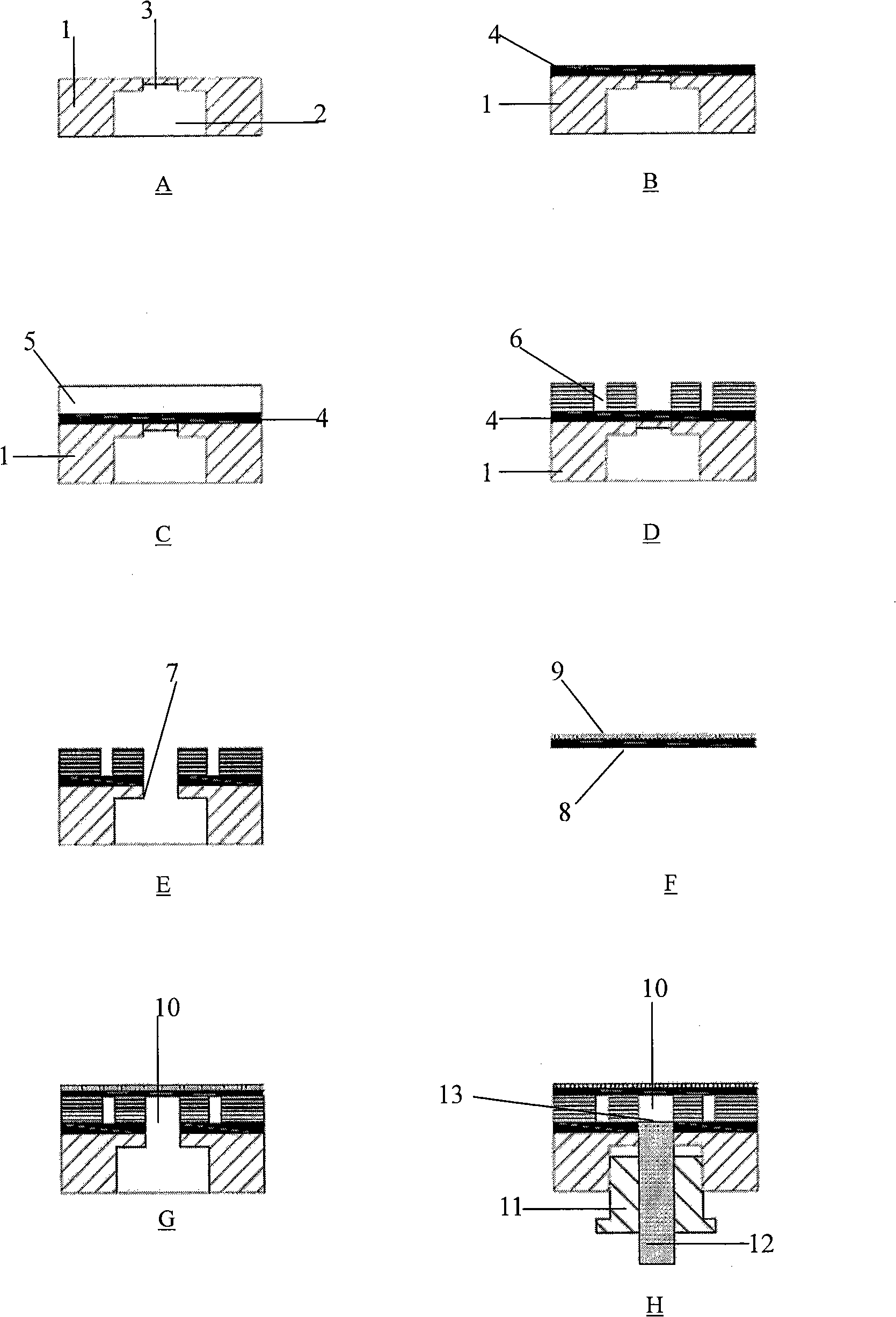

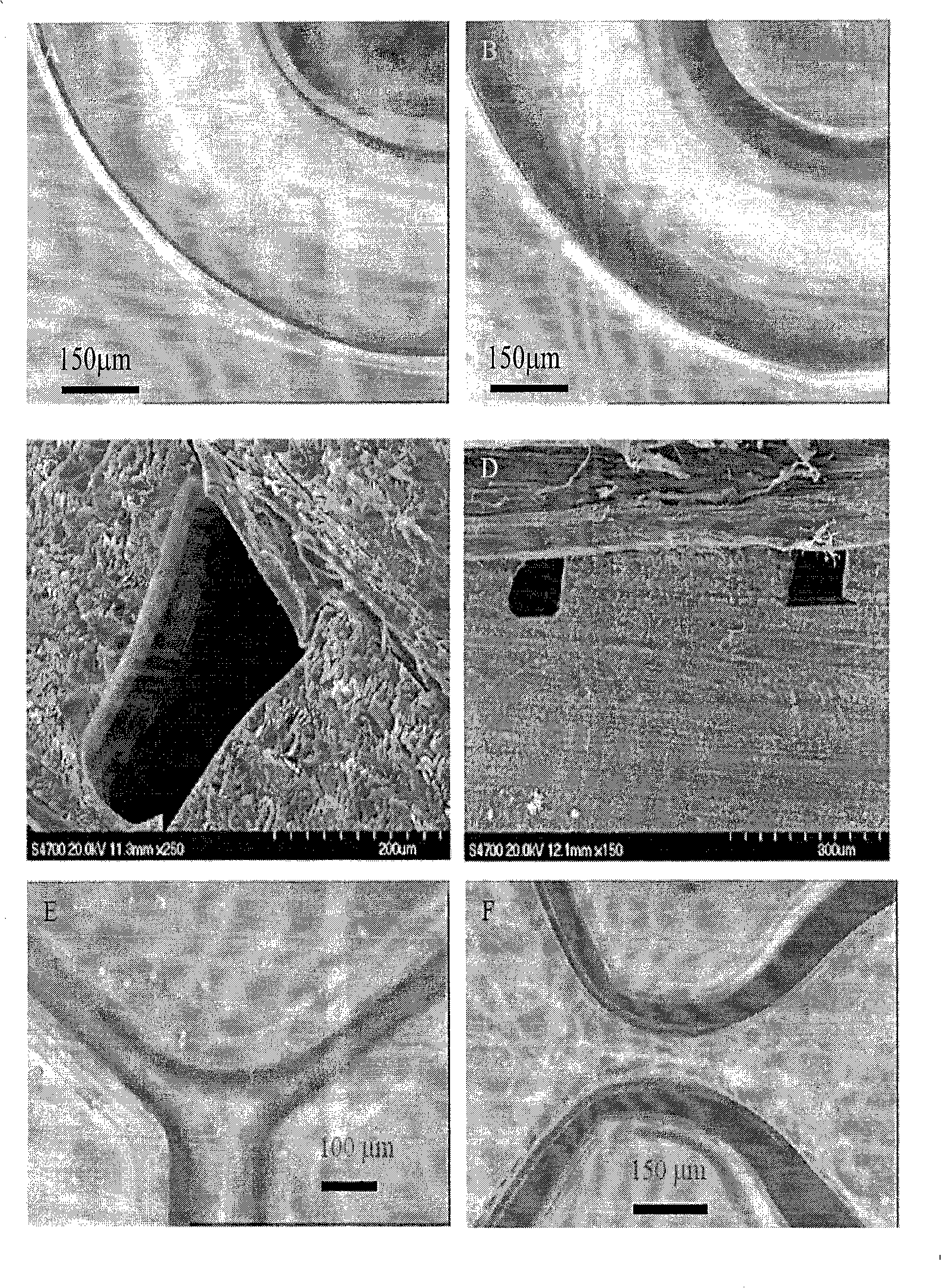

Novel polymer based microfluid reactor suitable for photochemistry reaction and preparation method thereof

InactiveCN101318119AProcess OptimizationSolve common problems in the manufacturing processEnergy based chemical/physical/physico-chemical processesChemistryMicro particles

The invention relates to a novel polymer-based microfluid reactor applicable to photochemical reaction and the preparation method thereof and belongs to the technical field of the manufacture of the polymer-based microfluid reactor. The preparation method of the reactor comprises: manufacturing a screwed hole with a non-breakthrough top used for connecting external equipment on the inlet and outlet position of a PMMA base; spin coating an EA51 glue layer on the surface of the PMMA for modifying the surface; spin coating an SU8 glue layer on the surface of the EA51 glue layer and carrying out three steps of processes of pre-baking, exposing and post-braking; developing the unexposed part of the SU8 glue layer to form a micro channel pattern; getting through the inlet and the outlet; spin coating an EA51 glue layer on the surface of a BOPP membrane which goes through hydroxylation treatment to form a sealing glue layer; sealing the micro channel pattern; exposing the top sealing layer under close compaction state to lead to complete solidification of the glue layer; thus forming the closed micro channel; screwing the PEEK bolt of an internal tight tube into the screwed hole. The reactor, which is an all-organic transparent microfluid reactor, solves the common problems in the manufacture of the current microfluid reactor and realizes lighting synthesis of nano-particles and polymer microsphere and the like particles.

Owner:BEIJING UNIV OF CHEM TECH

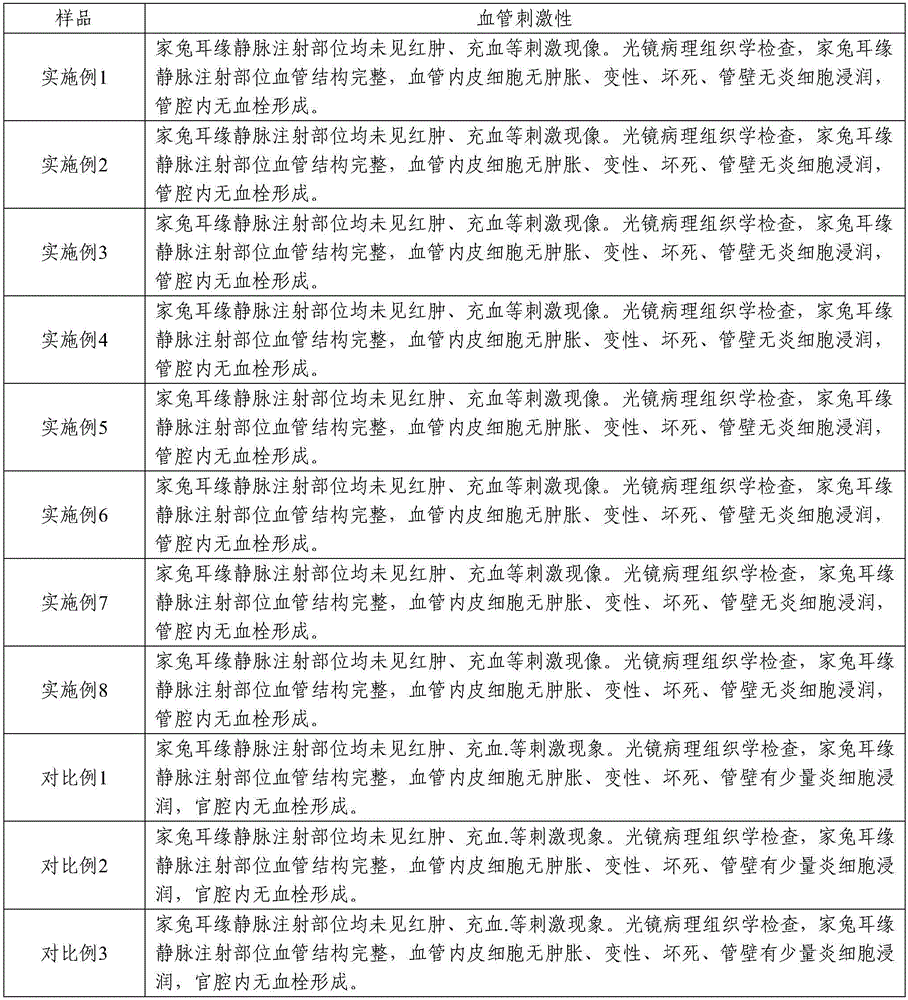

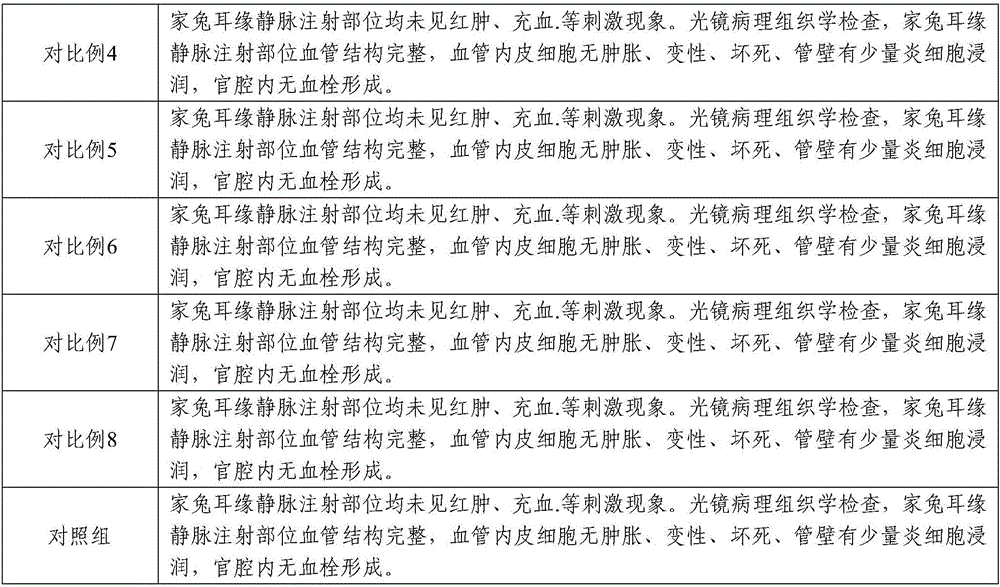

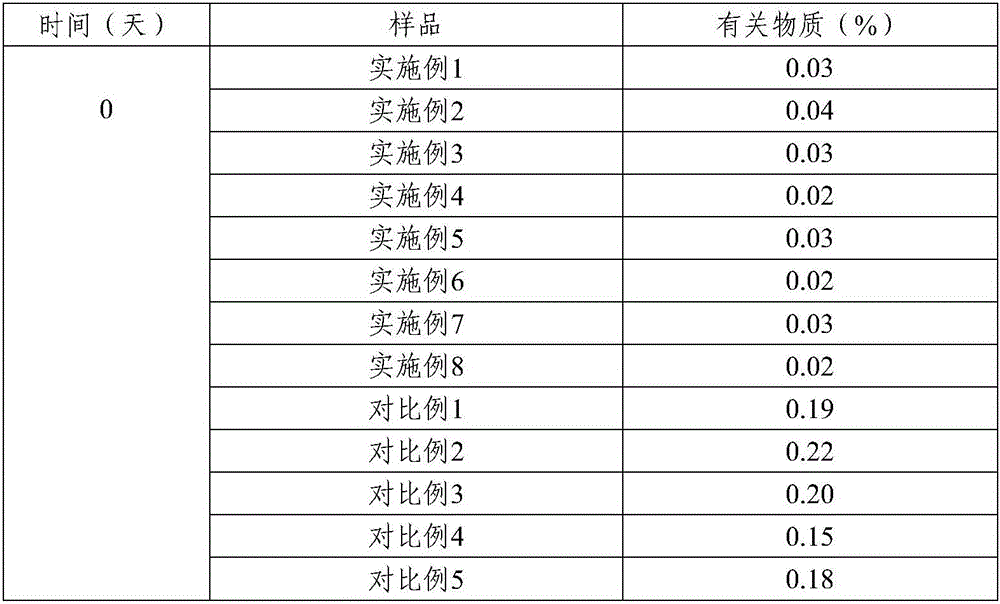

Pharmaceutical composition containing sodium ozagrel and preparation method thereof

ActiveCN106361750AProcess OptimizationImprove drug stabilityPowder deliveryOrganic active ingredientsVomitingDextran

The invention belongs to the technical field of pharmaceutical preparation and relates to a pharmaceutical composition containing sodium ozagrel and a preparation method thereof. The pharmaceutical composition comprises, by weight, ozagrel: sodium hydroxide: mannitol: dextran: arabinose=(38-40):( 6-8):( 10-12): (10-12):(20-22). The pharmaceutical composition in the ozagrel prescription added with the appropriate amount of arabinose can greatly reduce the vascular irritation, and has a significant effect on relieving nausea, vomiting, diarrhea, loss of appetite, and fullness. The preparation method of the invention has the advantages of improving the stability of the drug after improving the process.

Owner:HARBIN ZHENBAO PHARMA +1

Black chemical oxidation liquid for steel and application of black chemical oxidation liquid

InactiveCN106756922AImprove properties such as corrosion resistance and adhesionProcess OptimizationMetallic material coating processesEnvironmental chemistryCompound (substance)

The invention relates to the technical field of metal material surface treatment, in particular to black chemical oxidation liquid for steel and application of the black chemical oxidation liquid. The black chemical oxidation liquid comprises a film-forming agent, an oxidizing agent, a reducing agent, a stabilizing agent, a pH buffering agent, a corrosion inhibitor, an assistant and water, wherein the black chemical oxidation liquid per liter contains 1-10g of the film-forming agent, 0.1-8g of the oxidizing agent, 1-20 g of the reducing agent, 1-10g of the stabilizing agent, 1-8g of the pH buffering agent, 1-8g of the corrosion inhibitor, 1-8g of the assistant and the balance water. According to the black chemical oxidation liquid, the oxidizing agent and the corrosion inhibitor are added based on the basic formula, and the corrosion resistance, adhesive force and the like of a black oxidized film are improved on the premise that energy saving, environmental friendliness, safety and high efficiency are guaranteed. The black chemical oxidation liquid is reasonable in formula, high in film-forming efficiency and easy and convenient to operate, and industrial application and popularization are facilitated.

Owner:JIANGSU UNIV OF TECH

Processing method of sun-proof and flame-retardant seat fabric

InactiveCN107299478AStrong sun protection performanceProcess OptimizationHeating/cooling textile fabricsTextile treatment machine arrangementsColour fastnessYarn

The invention discloses a processing method of sun-proof and flame-retardant seat fabric. The processing method of the sun-proof and flame-retardant seat fabric comprises the steps of preparing yarns, dyeing the yarns, performing color separation on the yarns, carrying out looming and weaving, shearing, washing with water, shaping, packaging and the like. The processing method of the sun-proof and flame-retardant seat fabric has the following advantages: sun-proof dye and an anti-UV improver are added in the yarn dyeing process, and the heating process of dyeing adopts a programmed heating mode, so that the sun-proof property of the fabric can be effectively enhanced; the raw materials in the yarn preparation process and the process are optimized, so that the color fastness of the yarns can be effectively enhanced; the shaping process is adjusted, so that the color fastness of the fabric can be guaranteed and the hand feeling of the fabric can be guaranteed.

Owner:JIANGSU TIANYUAN NEW MATERIAL CO LTD

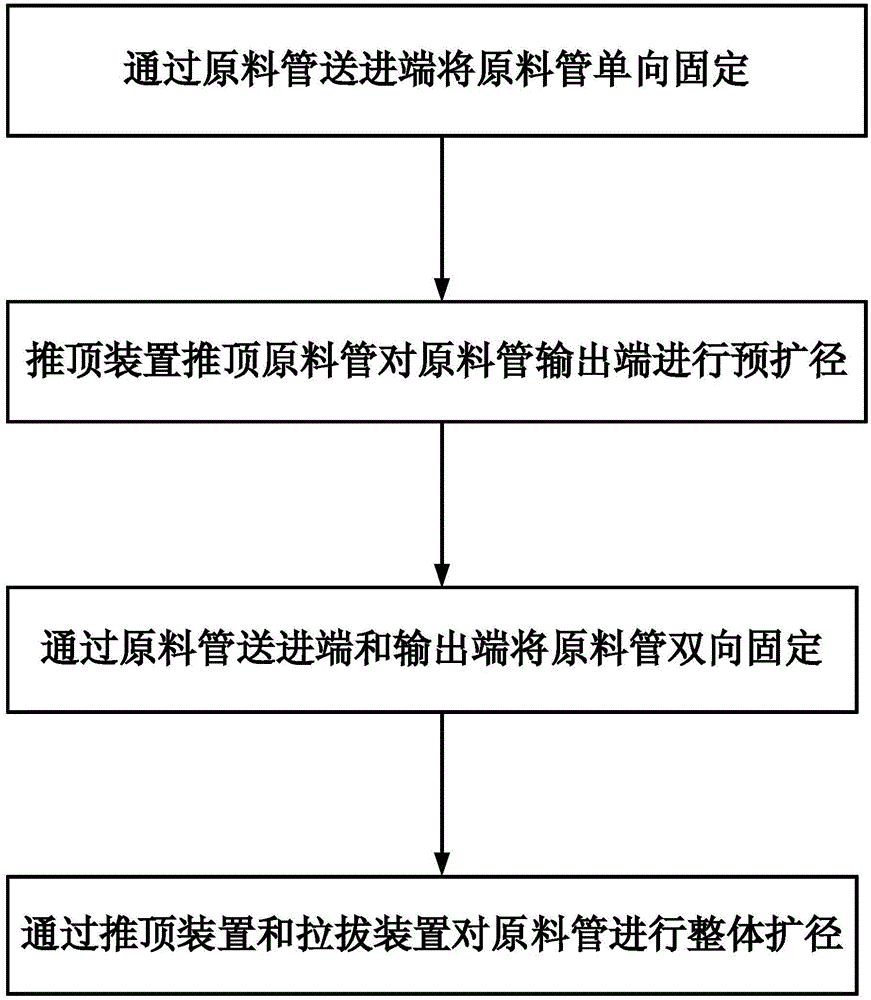

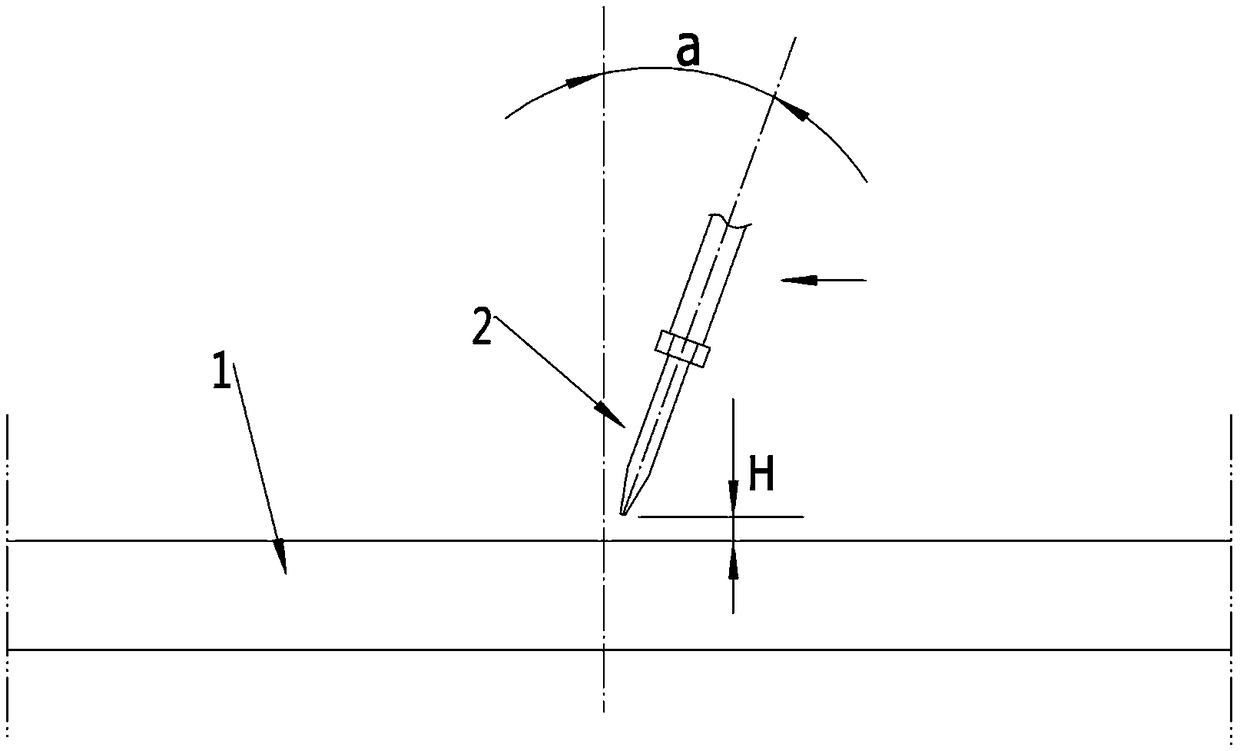

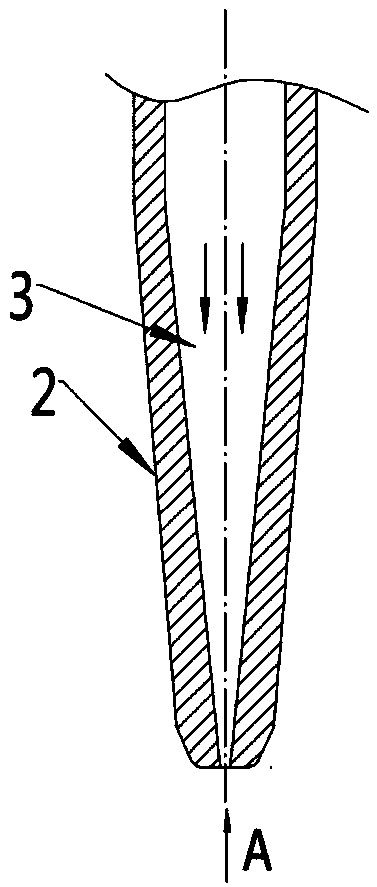

Method for producing variable-thickness variable-diameter steel pipes

ActiveCN105057478AReduce expansion costProcess optimizationMetal working apparatusVariable thicknessEngineering

The invention discloses a method for producing variable-thickness variable-diameter steel pipes. The method comprises the following four steps: unidirectionally fixing a mother pipe through a mother pipe feeding end; pushing the mother pipe through a pushing device to pre-expand the diameter of a mother pipe output end; bidirectionally fixing the mother pipe through the mother pipe feeding end and the mother pipe output end; expanding the diameter of the whole mother pipe through the pushing device and a drawing device. The method substantially changes the wall thickness of the steel pipe and also precisely controls the wall thickness of the steel pipe after diameter expanding, and the produced big-caliber seamless steel pipe has a good mechanical property and good appearance quality.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

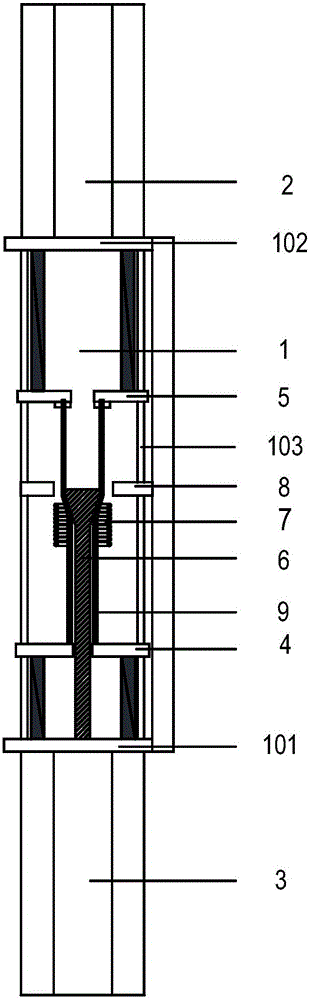

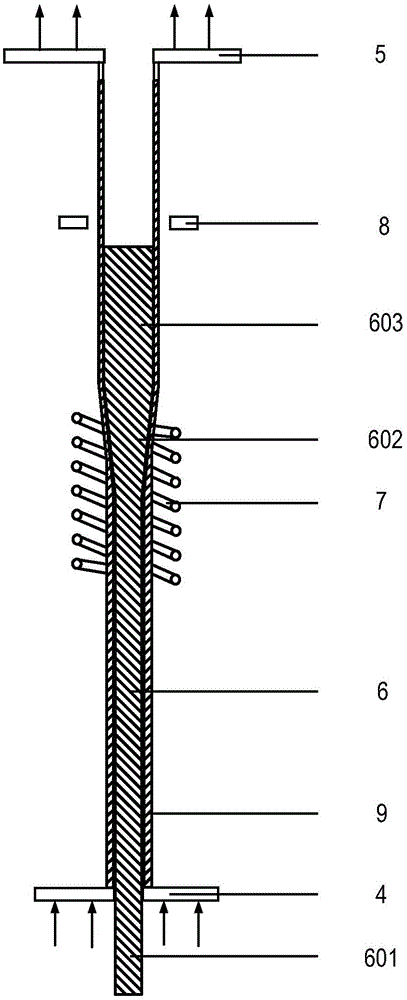

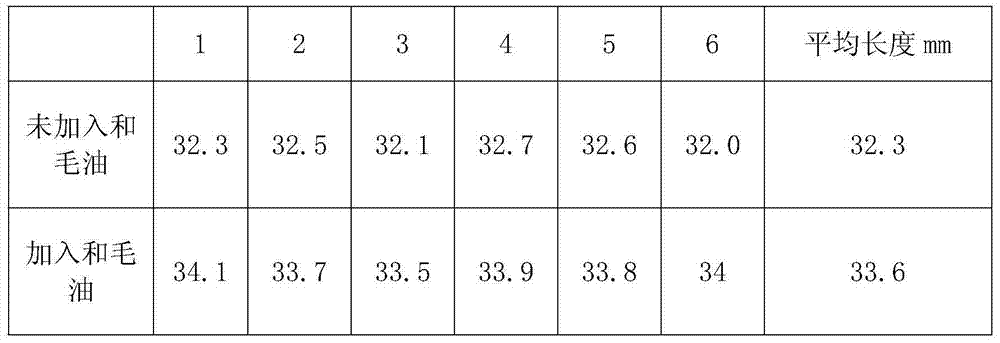

Wool opening and mixing technology in cashmere carding process

InactiveCN103484983AOptimize processing methodProcess OptimizationLubricating devicesContinuous processingStatic friction coefficientOpen water

A wool opening and mixing technology in a cashmere carding process comprises the following steps of S1, uniformly laying up water-washed cashmere with 8-10 centimeters for every layer, uniformly spraying oil-water mixed liquid of 0.07-0.08% on every layer for 10-15 minutes; S2, performing muffled storage on the moisturized water-washed cashmere for 12-24 hours in summer or 12-48 hours in winter; S3, performing opening treatment on the muffled water-washed cashmere through an opening machine to open the cashmere into a fluffy state, feeding the cashmere at a feeding quantity of 200-300 kilograms per hour and a thickness not thicker than 6-10 centimeters; S4, detecting the opened water-washed cashmere and remoisturizing the water-washed cashmere with a machinery moisturizing rate of 24-28%, and counting the water feeding amount during the remoisturizing process. According to the wool opening and mixing technology in the cashmere carding process, by adding mixing oil, the static friction coefficient as well as the dynamic friction coefficient among fiber can be adjusted, the friction force between the fiber and guide rollers can be reduced and static electricity caused by friction during the carding process can be avoided and eliminated, so the wool fiber can smoothly pass through a carding device to avoid wool loosening, winding, fiber breakage and the like.

Owner:NINGXIA ZHONGYIN CASHMERE

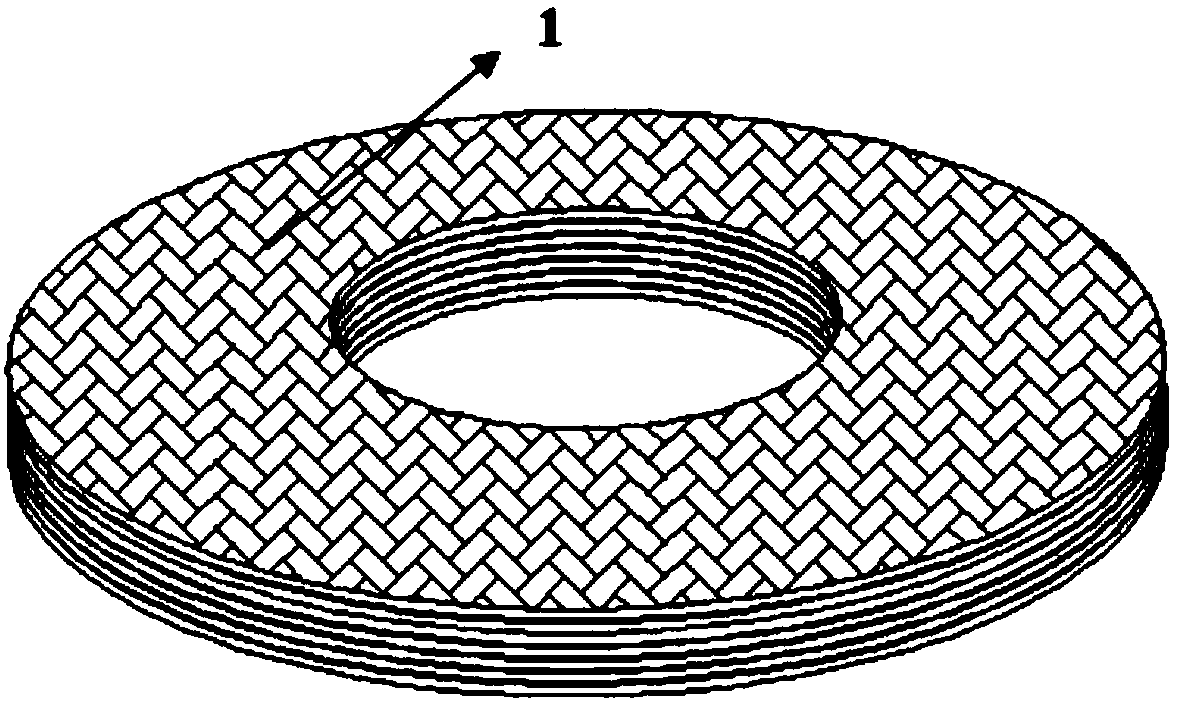

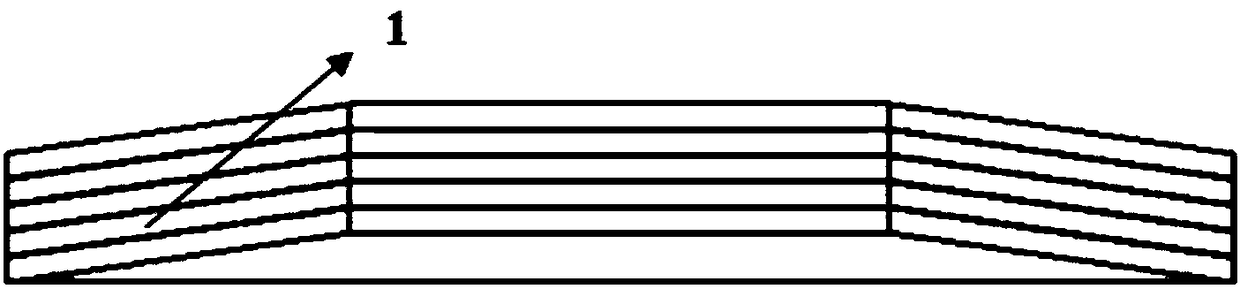

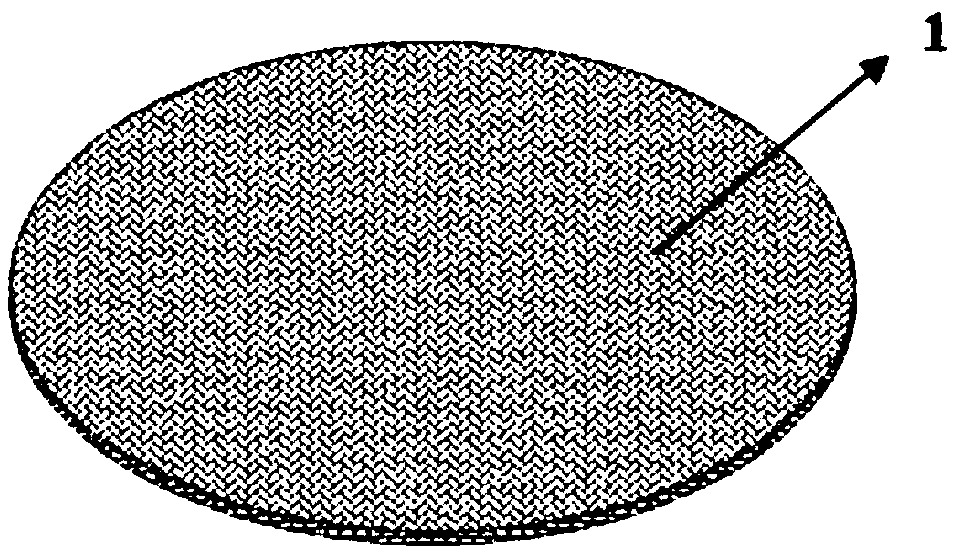

Bionic composite material disc spring part and preparation method thereof

ActiveCN108506393AProcess OptimizationEasy to fully infiltrateLeaf springsDomestic articlesCorrosionAerospace

The invention provides a bionic composite material disc spring part and a preparation method thereof. The disc spring part is formed by fully infiltrating and curing a fiber reinforcement layer structure in resin; the fiber reinforcement layer structure is formed by overlapping and laying of multiple single-layer fiber reinforcements; and the fiber reinforcement layer can be completely cured through online infiltrating of the resin and can also be prepared in the mode that fiber reinforcement prepreg is made through offline infiltrating of the resin and then curing is completed through heatingof a mold of a special structure. The preparation method creatively adopts the resin transfer molding process and the hot pressing process to prepare the light-weighted composite material disc springpart. The bionic composite material disc spring part and the preparation method thereof meet the urgent requirements for the high-performance and light-weighted composite material disc spring part ofthe fields like aerospace, nuclear power, ocean engineering, heavy machines, automobiles, armored cars and cannons, and solve the problems that existing widely-used metal disc spring parts in the relevant fields are high in mass, not resistant to corrosion, poor in fatigue performance and the like.

Owner:JILIN UNIV

Method for preparing polyester high-F fine-denier wool-like fibers

ActiveCN106283237AProcess OptimizationImprove product qualitySpinnerette packsArtificial thread manufacturing machinesWoolAssembly line

The invention discloses a method for preparing polyester high-F fine-denier wool-like fibers. The method includes the following steps that raw materials including purified terephthalic acid and PET polyester melt are selected; secondly, according to the production process, the raw materials pass a booster pump, a melt distribution valve and a spinning box, the melt is extruded by a metering pump, a spinning assembly is used, cooling and forming are conducted, an oil nozzle is oiled, a spinning channel is used, pre-interlacing is conducted, a GR1 draw-off godet and a GR2 draw-off godet are used, full-automatic winding is conducted, mechanical doffing is conducted, and quality testing is conducted; thirdly, the product is packaged on an assembly line, wherein the prepared polyester high-F fine-denier wool-like fibers are packaged through the assembly line. The method for preparing the polyester high-F fine-denier wool-like fibers changes the aperture and the distribution mode of spinneret orifices on an original spinneret plate, spinnability of the fibers is improved, production is stabilized, a foundation is laid for further optimizing the process and product quality, meanwhile the F number of the fibers is increased, velvet feeling of the fibers is improved, and the wool-like effect is achieved.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

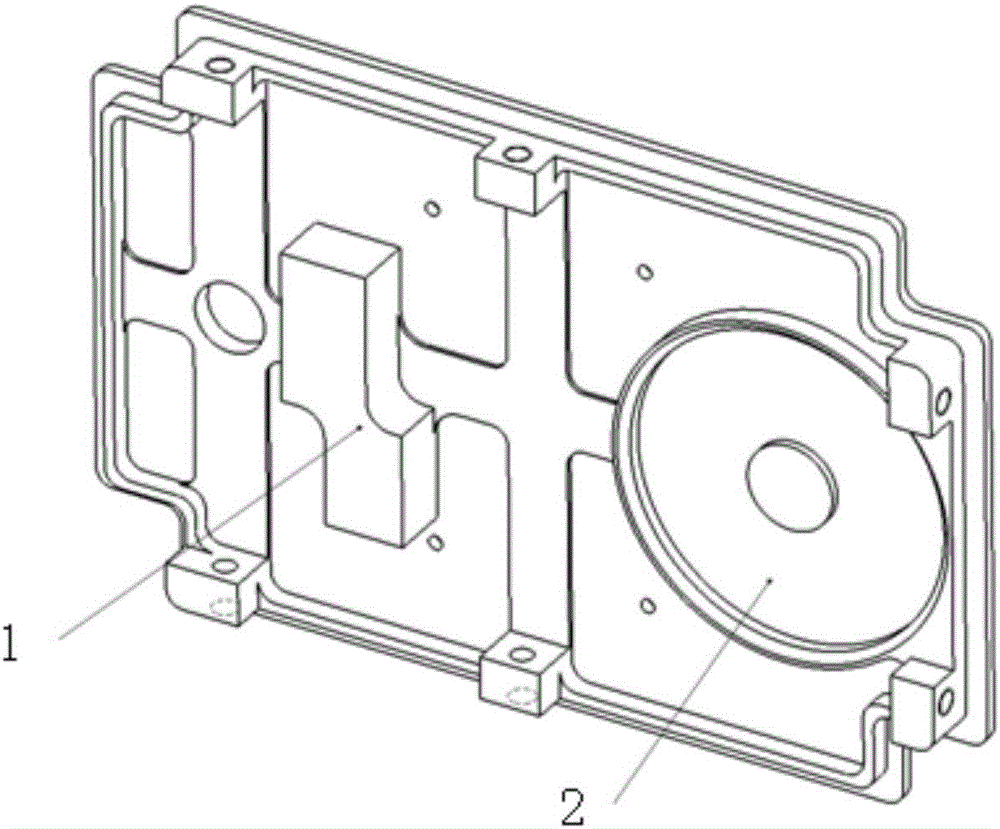

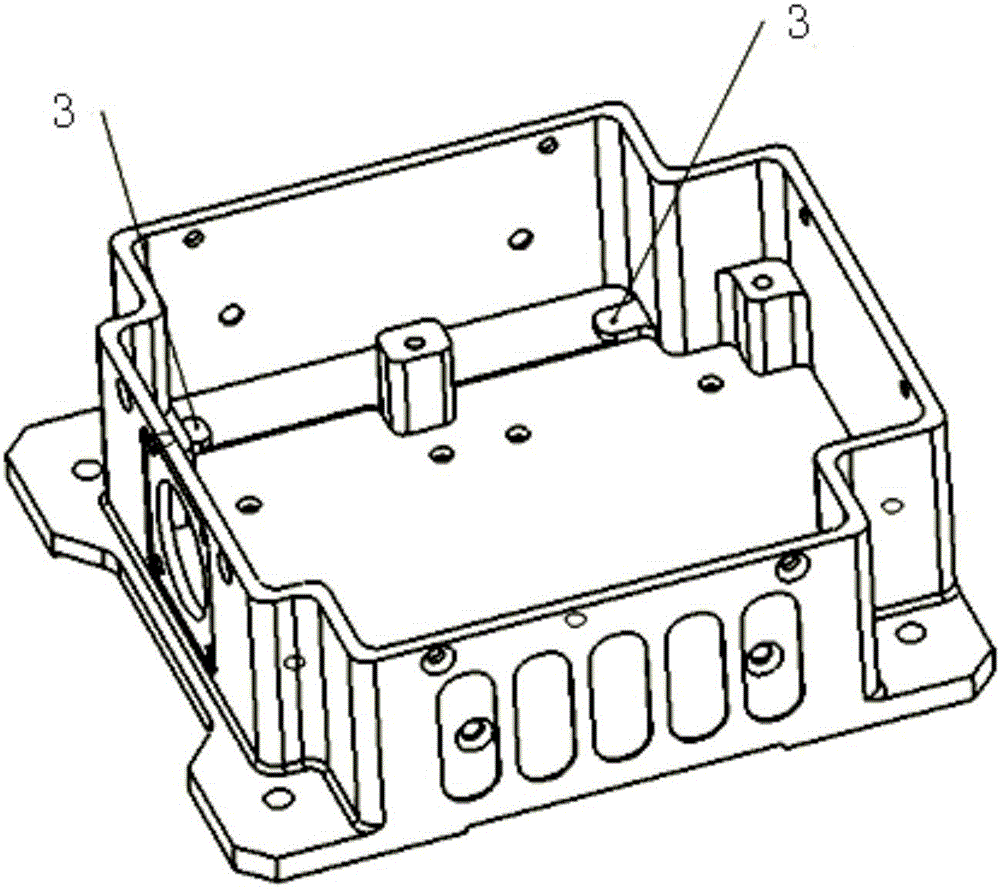

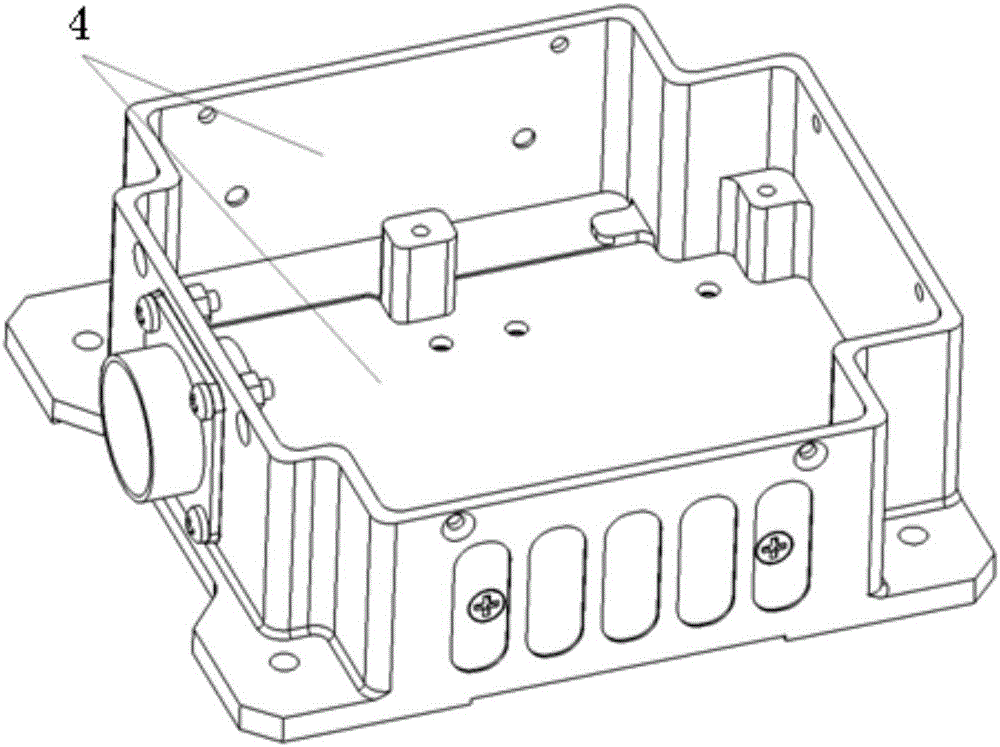

Power adapter box structure

ActiveCN106300906AProcess optimizationStrong maneuverabilityDc-dc conversionModifications by conduction heat transferPower controlEngineering

The invention belongs to the technical field of avionics, and especially relates to a power adapter box structure. Because of the limiting of an onboard installation space, a power adapter box is required to be capable of achieving established functions and the internal power devices in the power adapter box need to be arranged reasonably, so as to carry out the conduction of the generated heat to maximum degree, to enable the working temperature of the whole power adapter box to remain at a safety level, and to protect the power adapter box from being damaged by long-time operation. The structure provided by the invention achieves the layout of an internal power device, an energy storage device and a power control board in the power adapter box under the condition that the size and space are very limited, achieves the conduction of the heat of a heat source device in the structure to the maximum degree while guaranteeing the implementation of the function of the power adapter box, enables the working temperature of the power adapter box to remain at the safety level, and guarantees the reliable operation of the power adapter box.

Owner:SHAANXI QIANSHAN AVIONICS

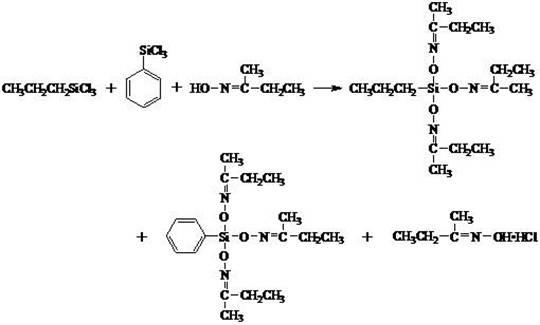

Synthesis method of mixing ketoxime type cross-linking agent

ActiveCN102604158AHigh yieldProcess OptimizationGroup 4/14 element organic compoundsChemistryWork in process

The invention relates to a synthesis method of a mixed ketoxime type cross-linking agent, belonging to the field of silane cross-linking agent synthesis. The synthesis method comprises the steps: reacting propyl trichlorosilane, phenyl trichlorosilane and diacetylmonoxime as raw materials to generate a mixture of propyl tri-diacetylmonoxime silane (ProS) and phenyl tri-diacetylmonoxime silane (PhOS); and after reaction is finished, standing and layering, removing lower-layer diacetylmonoxime hydrochloride, introducing ammonia gas to the upper-layer half-finished product for neutralizing, filtering to remove white solid ammonium chloride, and then distilling to obtain the mixed ketoxime type cross-linking agent. According to the invention, the ratio of PrOS to PhOS in the mixed cross-linking agent can be accurately controlled according to the use requirement of the cross-linking agent; and the synthesis method has the advantages of simplicity in operation, stable quality, high reactionconversion rate, high yield, low diacetylmonoxime consumption, low production cost and the like; and the whole process has no wastewater generation and has no environmental pollution.

Owner:JINGZHOU JIANGHAN FINE CHEM

Quick coating removing method of coating thermal forming steel

InactiveCN109174764AProcess OptimizationImprove work efficiencyCleaning using liquidsWater pipeHigh pressure

The invention discloses a quick coating removing method of coating thermal forming steel. The quick coating removing method comprises the steps that to-be-processed coating thermal forming steel is fixed; a spraying gun connected with a high-pressure water pipe is aligned to a part, on which a coating is to be removed, of the coating thermal forming steel; high-pressure water flow is introduced into the spraying gun, and mobile spraying is carried out on the surface coating of coating thermal forming steel; and the surface of the coating thermal forming steel is removed by 25-55 micrometersinthe thickness direction, and coating metals are removed. The quick coating removing method has the beneficial effects that 1, through technological optimization, the coating of the coating thermal forming steel can be quickly removed, and the bottleneck problem that welding technology efficiency of the thermal forming steel is restrained is solved; 2, the removing speed can reach 4 m / min to 10 m / min while removing precision is guaranteed, and compared with the prior art, the quick coating removing method is high in working efficiency and is suitable for large-scale production manufacturing enterprises; and 3, one-time investment cost is low, and technological process cost is lower than that of other coating removing manners.

Owner:SHANGHAI LINGYUN IND TECH CO LTD

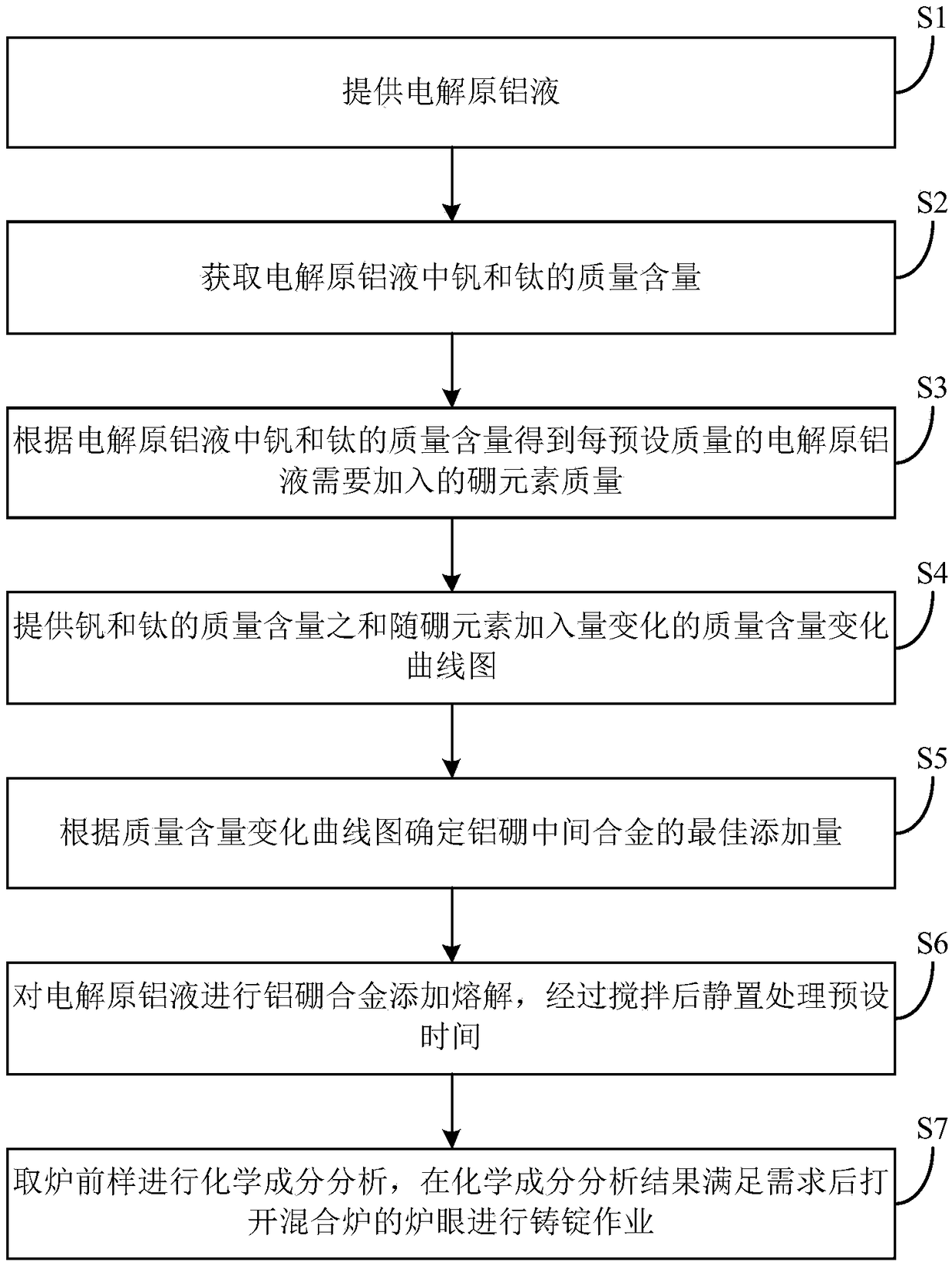

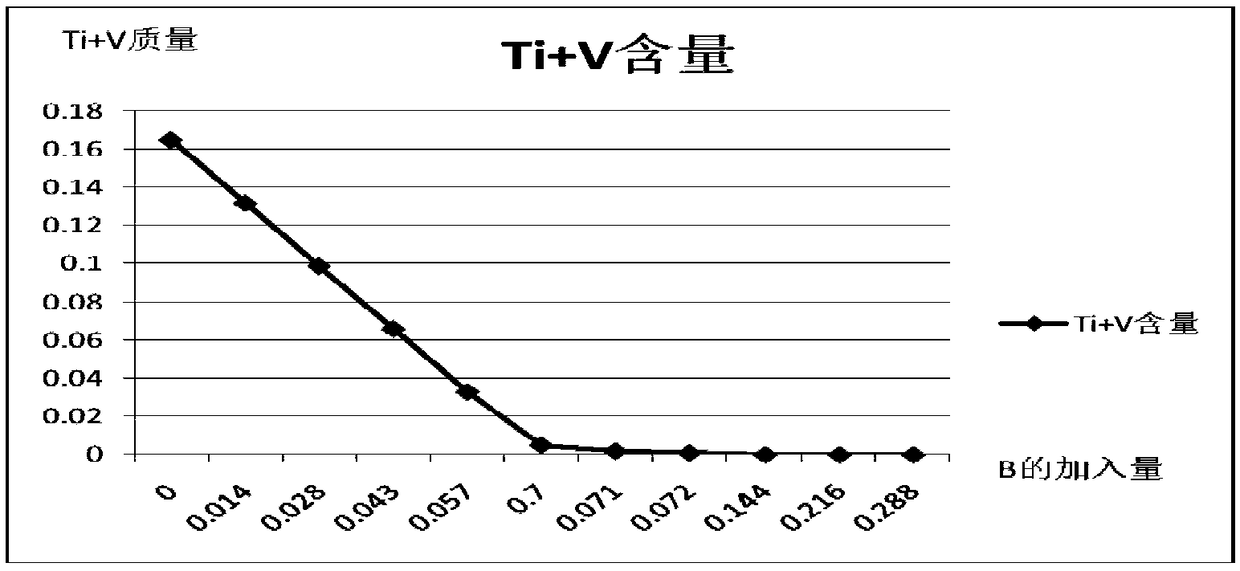

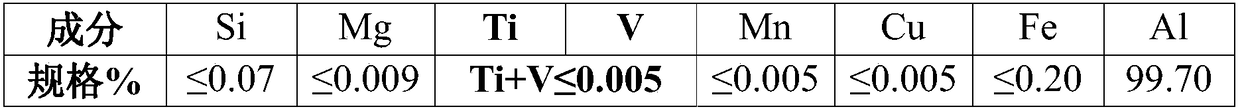

Preparation method of aluminum ingot

The invention discloses a preparation method of an aluminum ingot. The preparation method comprises the steps of providing electrolytic primary aluminum liquid; obtaining the mass contents of vanadiumand titanium in the electrolytic primary aluminum liquid; according to the mass contents of vanadium and titanium in the electrolytic primary aluminum liquid, obtaining the mass of boron needing to be added to the electrolytic primary aluminum liquid every preset quality; providing a mass content change graph which shows the change of the mass content sum of vanadium and titanium along with the addition amount of boron; determining the optimal addition amount of an aluminum-boron intermediate alloy according to the mass content change graph; adding the aluminum-boron alloy to the electrolyticprimary aluminum liquid for smelting, and after stirring, standing is carried out for preset time; and taking an on-the-spot sample for chemical component analysis, and after the chemical component analysis result meets the requirement, opening a hearth of a mixing furnace for ingot casting operation. The preparation method has the following advantages: the low-vanadium low-titanium aluminum ingot product can be prepared, and under the broad environment of cost reduction and efficiency improvement, high-efficiency production of the low-vanadium low-titanium aluminum ingot is achieved throughthe ingot casting mixing furnace by optimizing the process and adjusting the production structure.

Owner:YUNNAN YONGXIN ALUMINUM

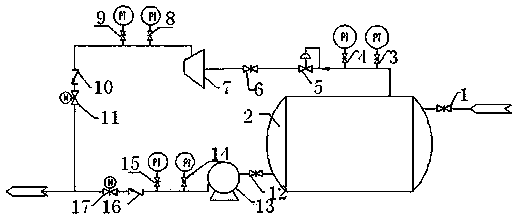

Oil-gas mixing transportation device and process applied to gathering and transportation station yard with high gas oil ratio

The invention belongs to the technical field of oil-gas mixing transportation, and particularly relates to an oil-gas mixing transportation device and process applied to a gathering and transportationstation yard with high gas oil ratio. The oil-gas mixing transportation device comprises a sealed separating device, a first pressure detection device, an air pressure regulator, a compressor, a second pressure detection device, a gas transmission valve, a crude oil transfer pump, a third pressure detection device and an oil transportation valve; an input hole is formed in one side of the sealedseparating device; a gas outlet is formed in the top of the sealed separating device; the gas outlet is connected with the first pressure detection device, the air pressure regulator, the compressor,the second pressure detection device and the inlet of the gas transmission valve through a pipeline in sequence; a liquid outlet is formed in the lower part of the other side of the sealed separatingdevice, and is connected with the crude oil transfer pump, the third pressure detection device and the oil transportation valve through a pipeline in sequence. The outlets of the gas transmission valve and the oil transportation valve are subjected to outward-outputting through pipeline converging, the requirement of oil-gas mixing transportation when the oil-to-gas ratio is relatively high is met, and the device and the process have the advantages of simple flow, process optimization, high reliability, and high degree of automation.

Owner:XIAN CHANGQING TECH ENG

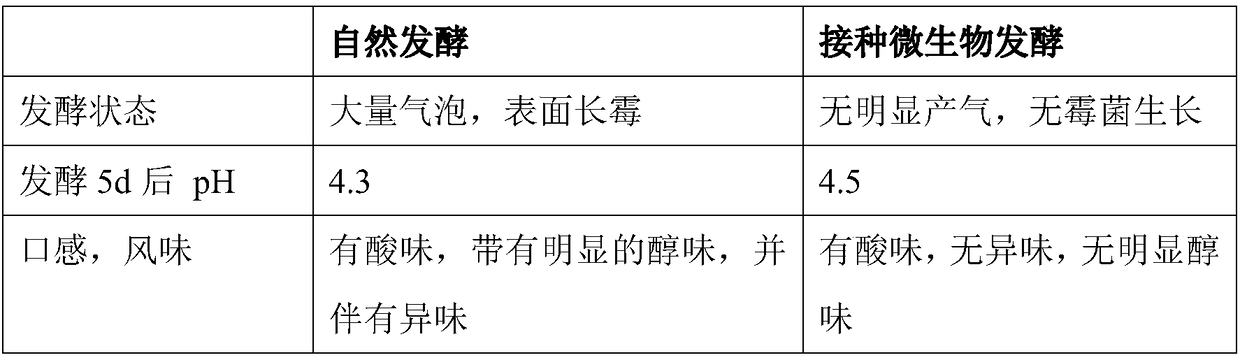

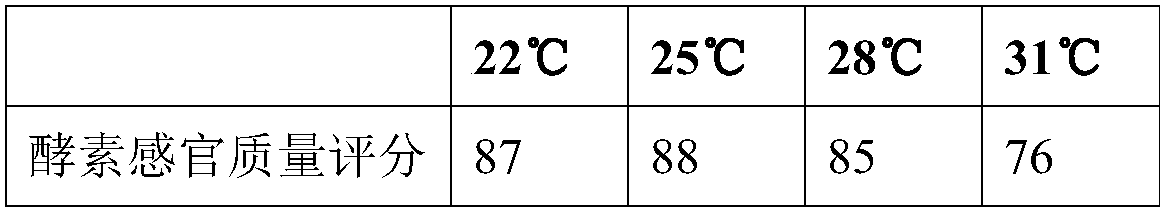

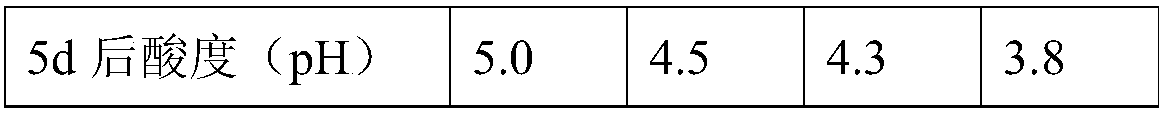

Lycium ruthenicum ferment, and preparation process and application thereof

ActiveCN108634298AChange taste characteristicsProcess OptimizationFood ingredient functionsChemistryFlavor

The invention discloses a Lycium ruthenicum ferment, and a preparation process and application thereof. The Lycium ruthenicum ferment comprises the following raw materials: Lycium ruthenicum, Lycium barbarum, maca, Potentilla anserina and sea buckthorn powder. According to the invention, a ferment product is produced by using the Lycium ruthenicum as a main raw material; the process of high-temperature heating is not needed in production of the ferment product; anthocyanin in the ferment product can be effectively preserved; the health-care function of the anthocyanin in the Lycium ruthenicumis given to full play on the basis that characteristics of the fruit ferment product are maintained; through fermentation of the raw materials, active substances in the raw materials are fully extracted out, and starch and polysaccharide substances are fully converted, so the Lycium ruthenicum ferment product is rich in nutritional and active components in the auxiliary materials like maca and Potentilla anserina; and by adoption of a fermentation process, the taste characteristic of the ferment product is changed, and the defects of over-strong drug flavor and bitter taste of Lycium ruthenicum, Lycium barbarum and maca are overcome, so the flavor and taste of the ferment product are easier to be accepted by consumers. The ferment product provided by the invention has anti-fatigue, anti-oxidation and beauty-maintaining functions.

Owner:青海千平万安农业科技有限公司

High toughness and impact resistant PE film and preparation method thereof

InactiveCN107987360AProcess OptimizationGood toughness and impact resistanceFlexible coversWrappersPolyvinyl butyralAntioxidant

The invention discloses a high toughness and impact resistant PE film, which is prepared from the following raw materials in parts by weight: 65 to 70 parts of low density polyethylene, 22 to 26 partsof metallocene linear low density polyethylene, 9 to 13 parts of medium density polyethylene, 6 to 10 parts of polyvinyl butyral, 0.8 to 1.2 parts of erucyl amide, 1.5 to 1.9 parts of antioxidant, 0.3 to 0.6 part of sodium abietate, 0.7 to 1.1 parts of calcium-zinc composite stabilizer, 1 to 2 parts of nano titanium dioxide, and 2 to 3 parts of cellulose acetate. The invention also discloses a preparation method of the high toughness and impact resistant PE film. The prepared high toughness and impact resistant PE film has excellent toughness and impact resistant performance and can meet therequirements on package protective films in certain special occasions, and the application range of PE film is enlarged.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

Integrated bipolar plate used for solid oxide fuel cell

The invention discloses an integrated bipolar plate used for a solid oxide fuel cell. The integrated bipolar plate comprises a substrate and a surface coating; a gas channel is formed in the surface of the substrate; and long-waist-shaped holes are formed in the edge of the substrate for allowing homopolar gas to come in and go out. By integrating parts, such as a positive electrode gas channel frame, a negative electrode gas channel frame, a partition plate, nickel foam, a silver net, a gas channel plate and the like, on a metal plate named as the bipolar plate, design optimization is performed in structure, and optimization is also performed in the aspects of material selection, processing process, surface treatment and the like.

Owner:上海中弗新能源科技股份有限公司

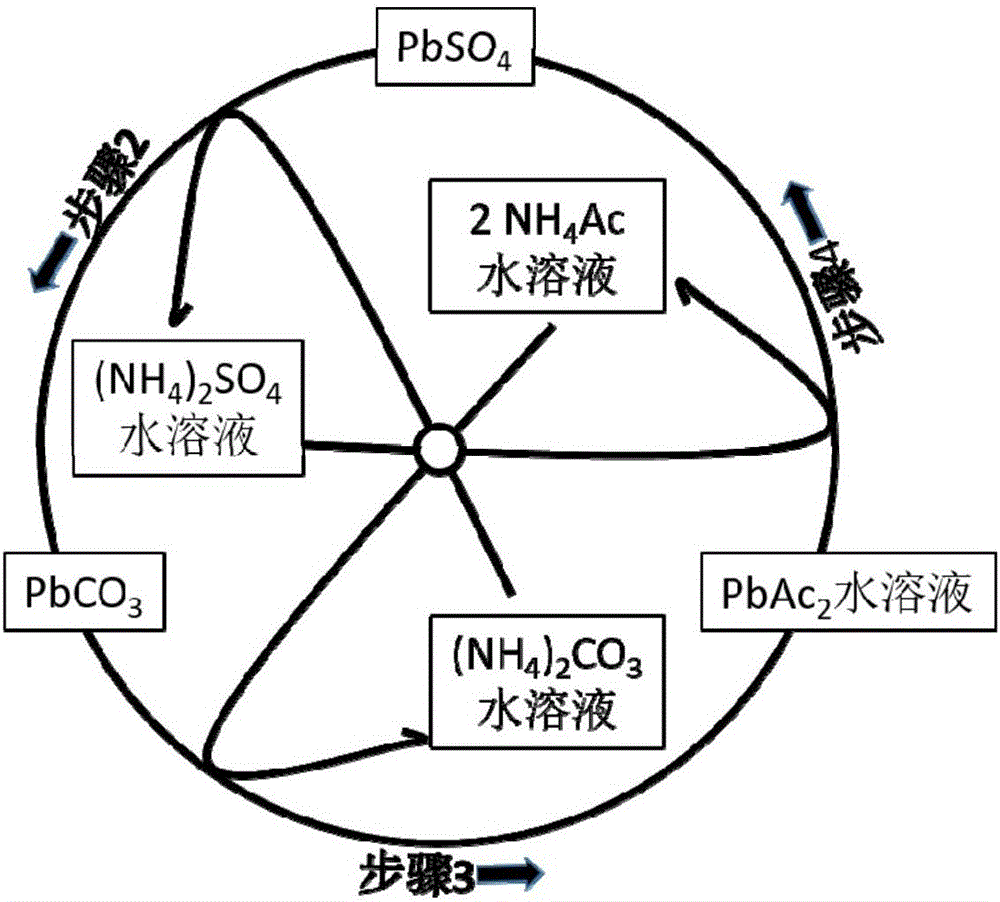

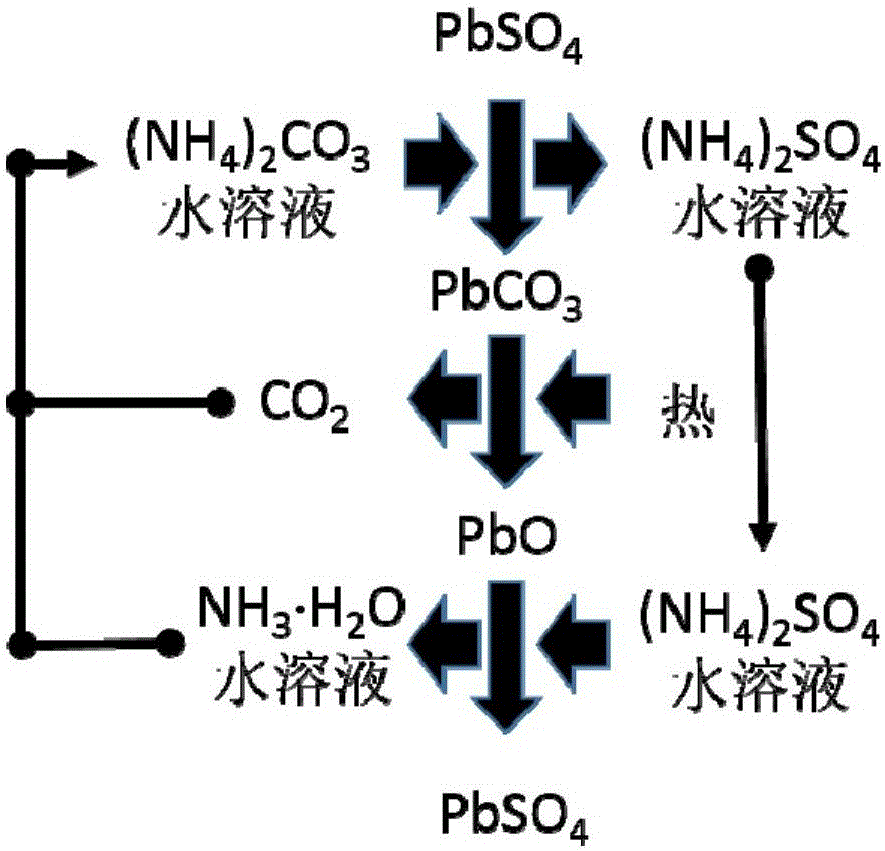

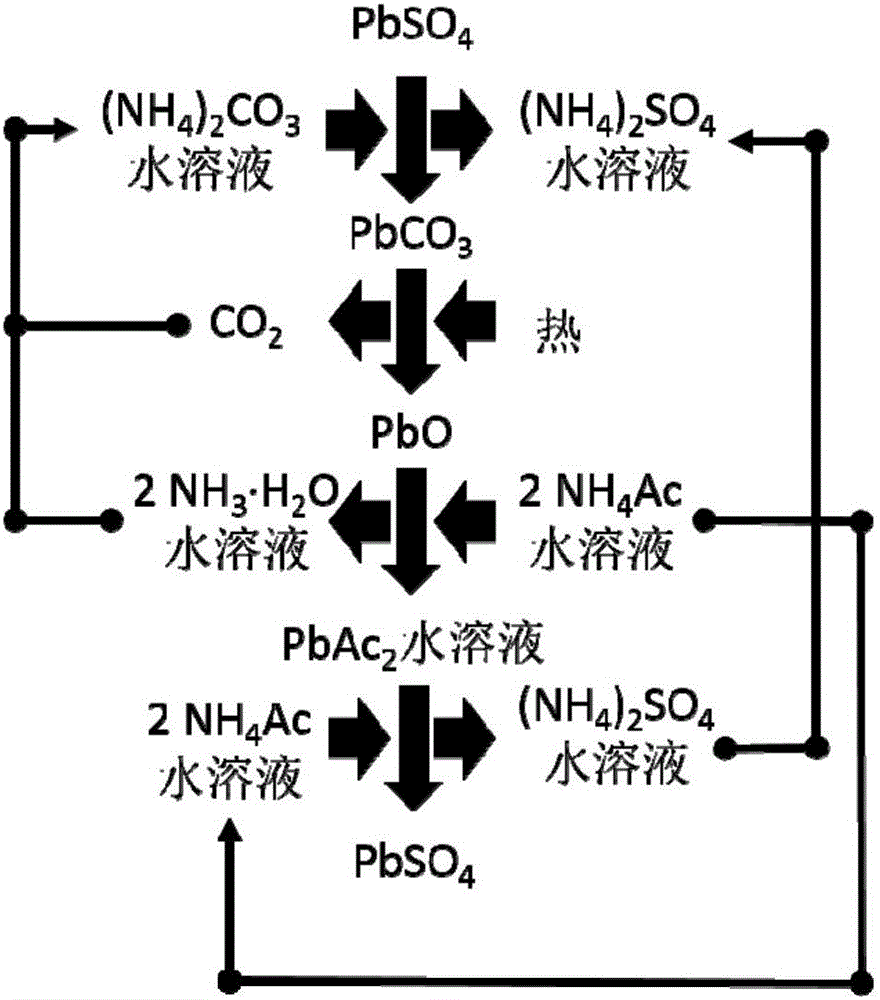

Method for producing lead sulfate with electrochemical activity from waste lead-acid batteries

The invention provides a method for producing lead sulfate with electrochemical activity from waste lead-acid batteries, belonging to the field of waste lead-acid battery recycling chemical techniques. By optimizing the waste lead-acid battery recycling process, the ammonium carbonate is used as a desulfurizer of lead sulfate, and a series of reactions are carried out to convert the lead sulfate which loses the electrochemical activity in the waste lead-acid batteries into lead sulfate with electrochemical activity; and the ammonium sulfate, ammonium acetate, ammonium sulfate solution and the like obtained by reaction can be used as reaction raw materials for the subsequent batches. The process is simple and easy to implement and forms a closed circulation; the method does not generate low-value byproducts, conforms to the clean production requirements, greatly reduces the pollution risk, lowers the production cost, and provides a new feasible scheme for recycling and sustainable production of waste lead-acid batteries.

Owner:SOUTHEAST UNIV

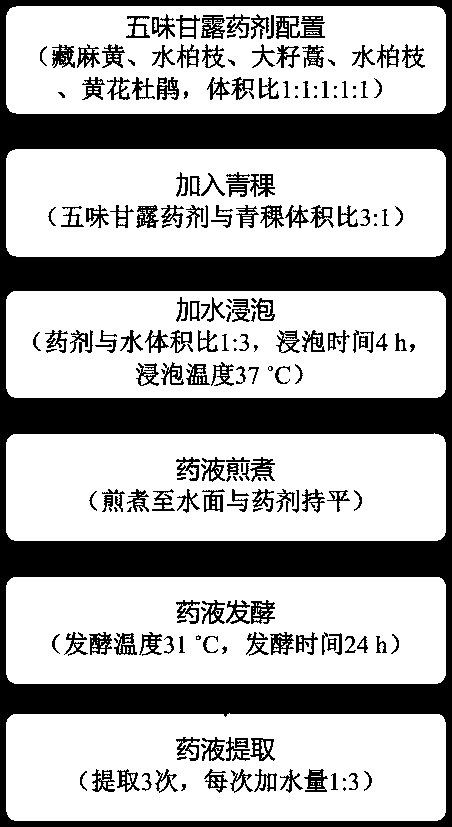

Novel Tibetan medicine bath liquid fermentation process

InactiveCN110090238AProcess OptimizationShort preparation cyclePharmaceutical delivery mechanismConiferophyta medical ingredientsMass ratioTibetan medicine

The invention relates to a novel Tibetan medicine bath liquid fermentation preparation method. The Tibetan medicine bath liquid is prepared with a Tibetan medicine fermented raw material taking WuweiGanlu as a main medicine and highland barley as an auxiliary material, wherein the mass ratio of the main medicine and the auxiliary material is 3:1. The medicine liquid fermentation comprises four processes of immersion, decoction, fermentation and collection. The process is based on a traditional fermentation method of the Tibetan medicine bath liquid, the improvement and optimization of the Tibetan medicine bath liquid fermentation process are carried out, the preparation cycle of the medicine bath liquid is significantly shortened through the rational selection of fermentation parameters,and the preparation process is conducive to the development and promotion of the Tibetan medicine bath.

Owner:INST OF BIOMEDICAL ENG CHINESE ACAD OF MEDICAL SCI

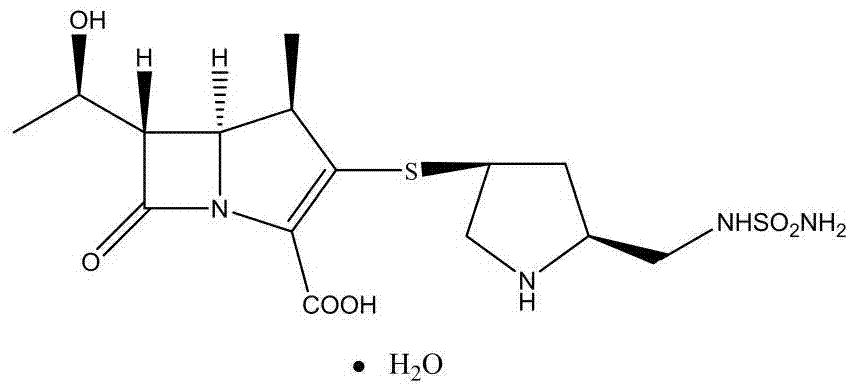

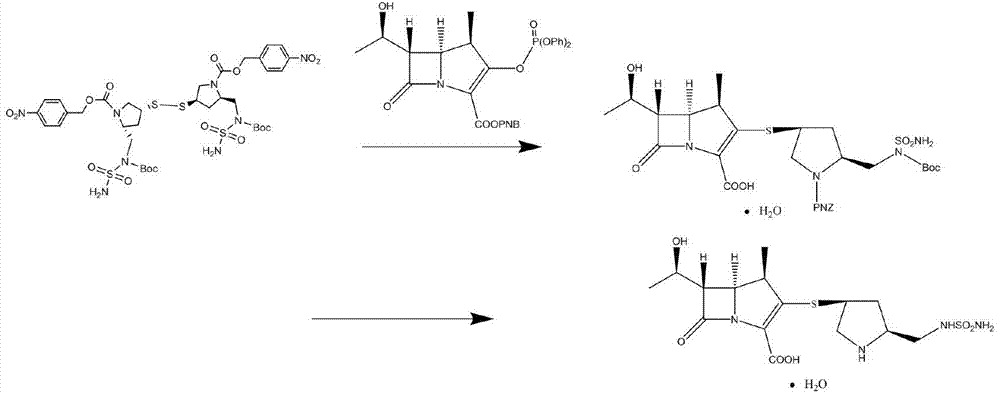

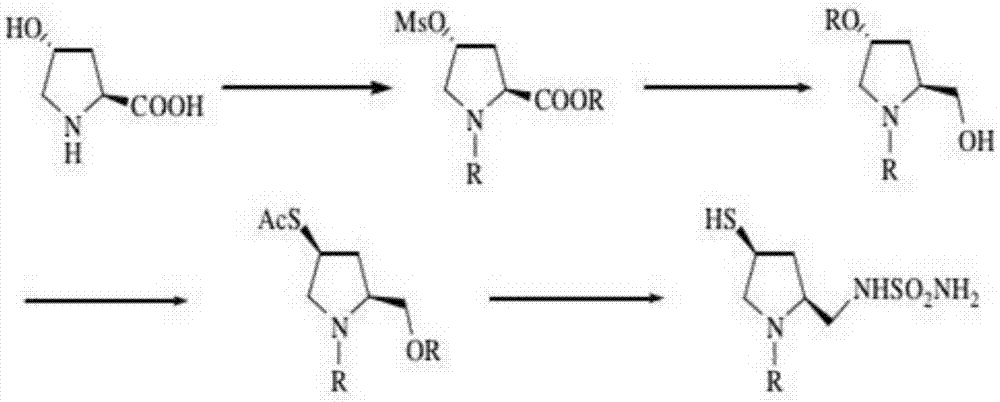

Preparation method and application of doripenem side chain disulfide

InactiveCN105439930AProcess OptimizationEasy to produceOrganic chemistryComponent separationSide chainDoripenem

The invention discloses a preparation method and application of doripenem side chain disulfide. The doripenem side chain disulfide, serving as a reference substance of a standard impurity, is used for purifying an important intermediate doripenem side chain in preparation of doripenem, provides a reliable reference index, improves the purity of the doripenem side chain, and finally improves a purification process of a doripenem medicine.

Owner:HENAN HAILIHUA BIOTECH DEV CO LTD

High-precision gas detector

InactiveCN108593711AProcess OptimizationHigh precisionMaterial resistanceElectrospinningZno nanowires

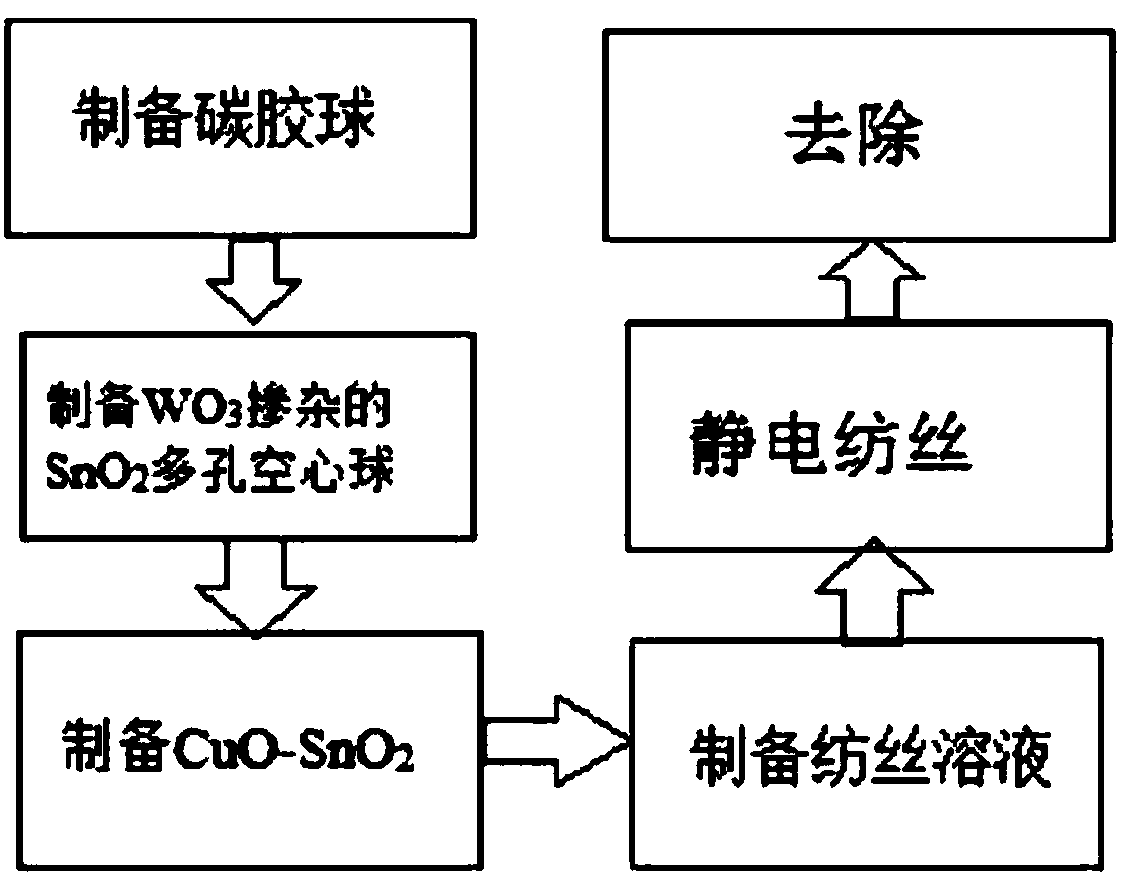

The invention relates to an ethanol gas detector based on SnO2 composite nano fiber. The gas detector is in a side-heating structure, and comprises an alumina ceramic tube having three parallelly anduniformly-distributed circular gold electrodes provided at an external surface, an ethanol sensitive material coated at the surface of the ceramic tube, and a nickel-chromium alloy heating coil passing through the ceramic tube, two platinum filament pins are connected with each gold electrode, the sensitive material is the SnO2 composite nano fiber prepared by a static spinning method, and the SnO2 composite nano fiber comprises SnO2 porous hollow spheres, ZnO nano wire, and cellulose acetate nano fiber. Preferably, the sensitive material comprises SnO2 porous hollow sphere-doped WO3 and CuO.By doping, the doped SnO2 porous hollow sphere is prepared, the doped SnO2 porous hollow sphere, ZnO nano wire, and cellulose acetate nano fiber have synergistic effect, and the detector precision isgreatly increased.

Owner:广东为邦消防技术服务有限公司

Coal mine gas extraction pump energy-saving stable operation regulation and control system and control method thereof

ActiveCN112343648AProcess OptimizationLower energy consumption levelsMining devicesPump controlProcess engineeringCoal mine methane

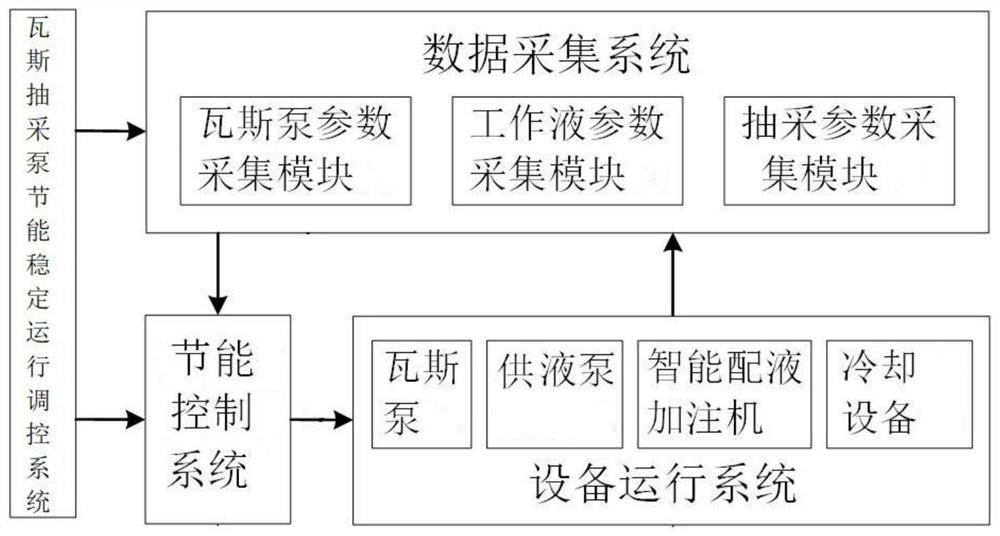

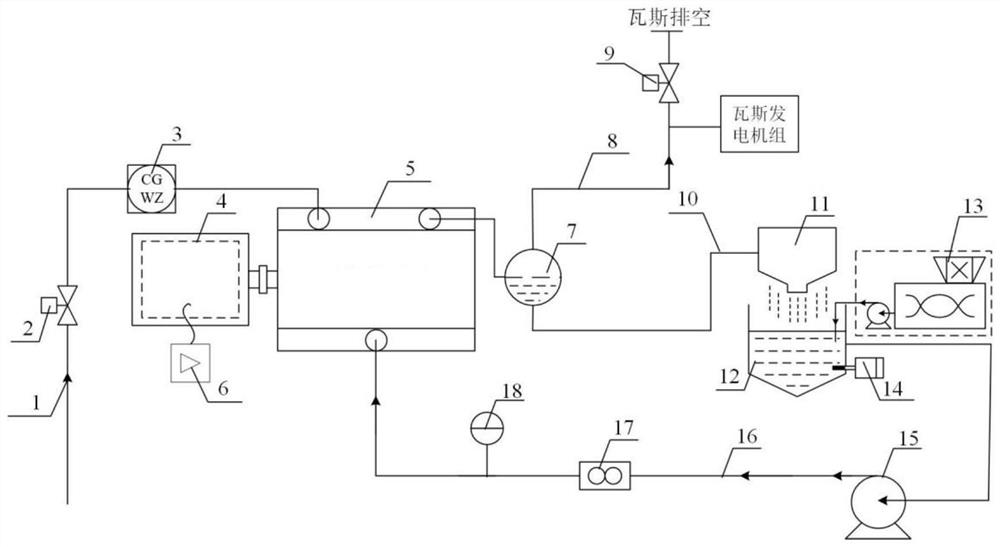

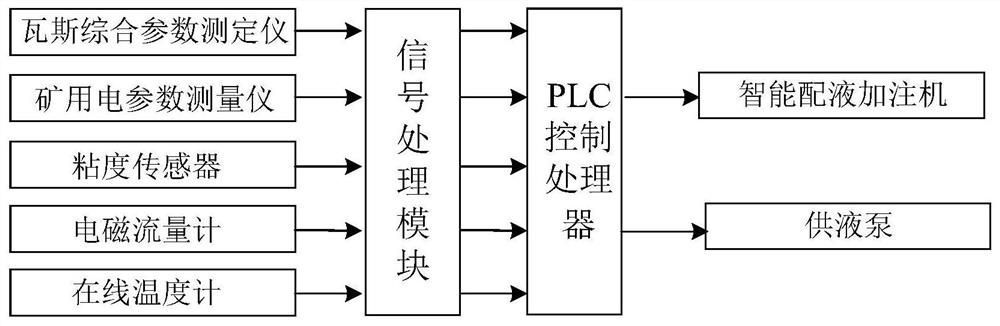

The invention discloses a coal mine gas extraction pump energy-saving stable operation regulation and control system and a control method thereof. The coal mine gas extraction pump energy-saving stable operation regulation and control system comprises an equipment operation system, a data collection system and an energy-saving control system. The data collection system is used for collecting, displaying and transmitting the shaft power of a gas extraction pump, the extraction negative pressure, the gas flow, the viscosity of anti-drag liquid, the flow, the temperature and the like. The energy-saving control system sequentially regulates the liquid injection amount of an intelligent liquid preparation filling machine from small to large, and the minimum value of the shaft power of the gas pump, the optimal energy-saving viscosity value of the anti-drag liquid and the corresponding liquid supply flow value are sought under the condition that the requirements for gas extraction negative pressure and flow are not changed. The optimal energy-saving rate and the minimum power consumption value of the gas extraction pump are found out from the optimal matching relation between the viscosity of the anti-drag liquid and the liquid supply amount of the gas extraction pump and the extraction negative pressure (the extraction flow), intelligent control over energy-saving stable operation of the gas extraction pump is achieved, and the optimal energy-saving effect of the gas extraction pump can be kept.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com