Patents

Literature

280 results about "Fiber breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

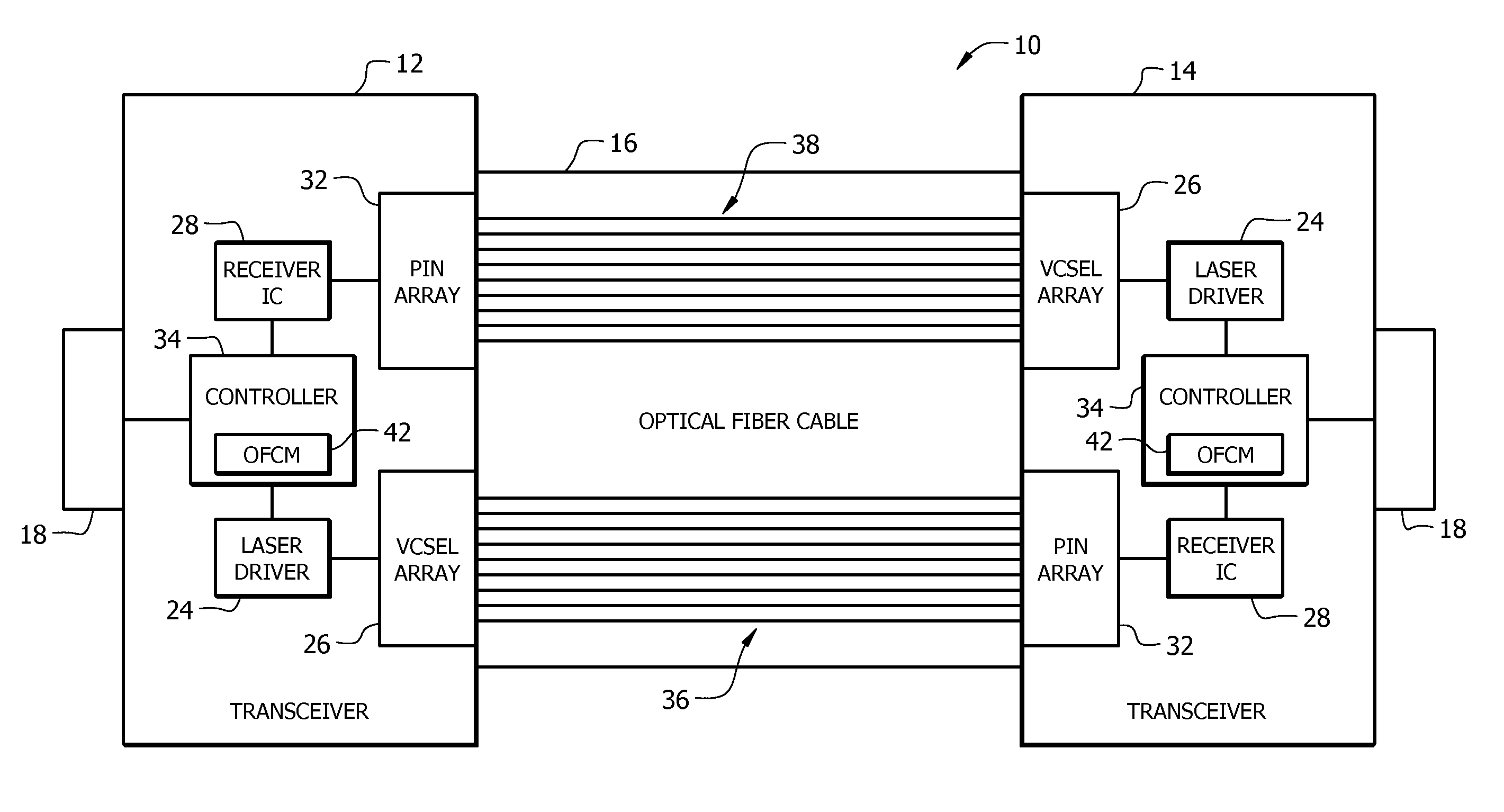

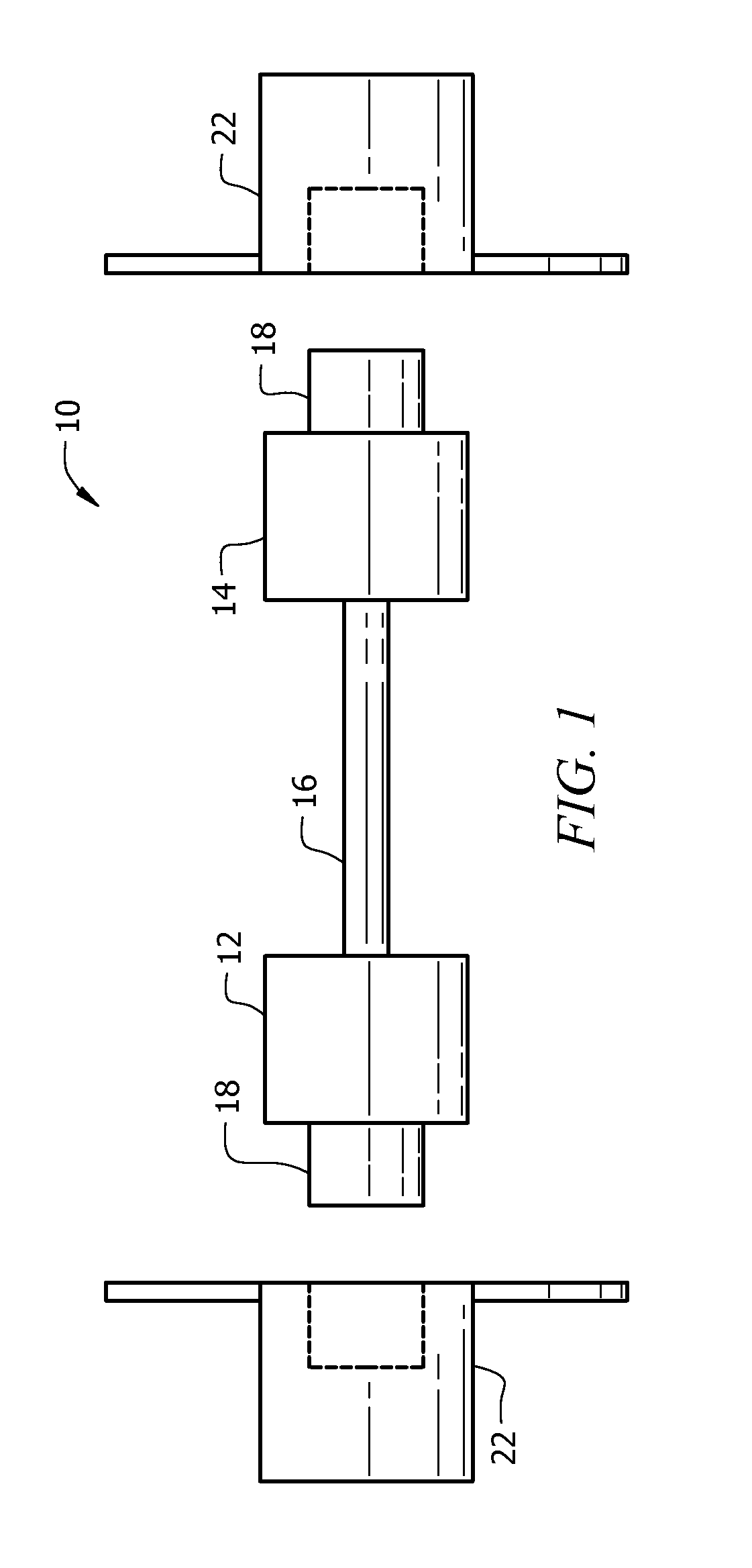

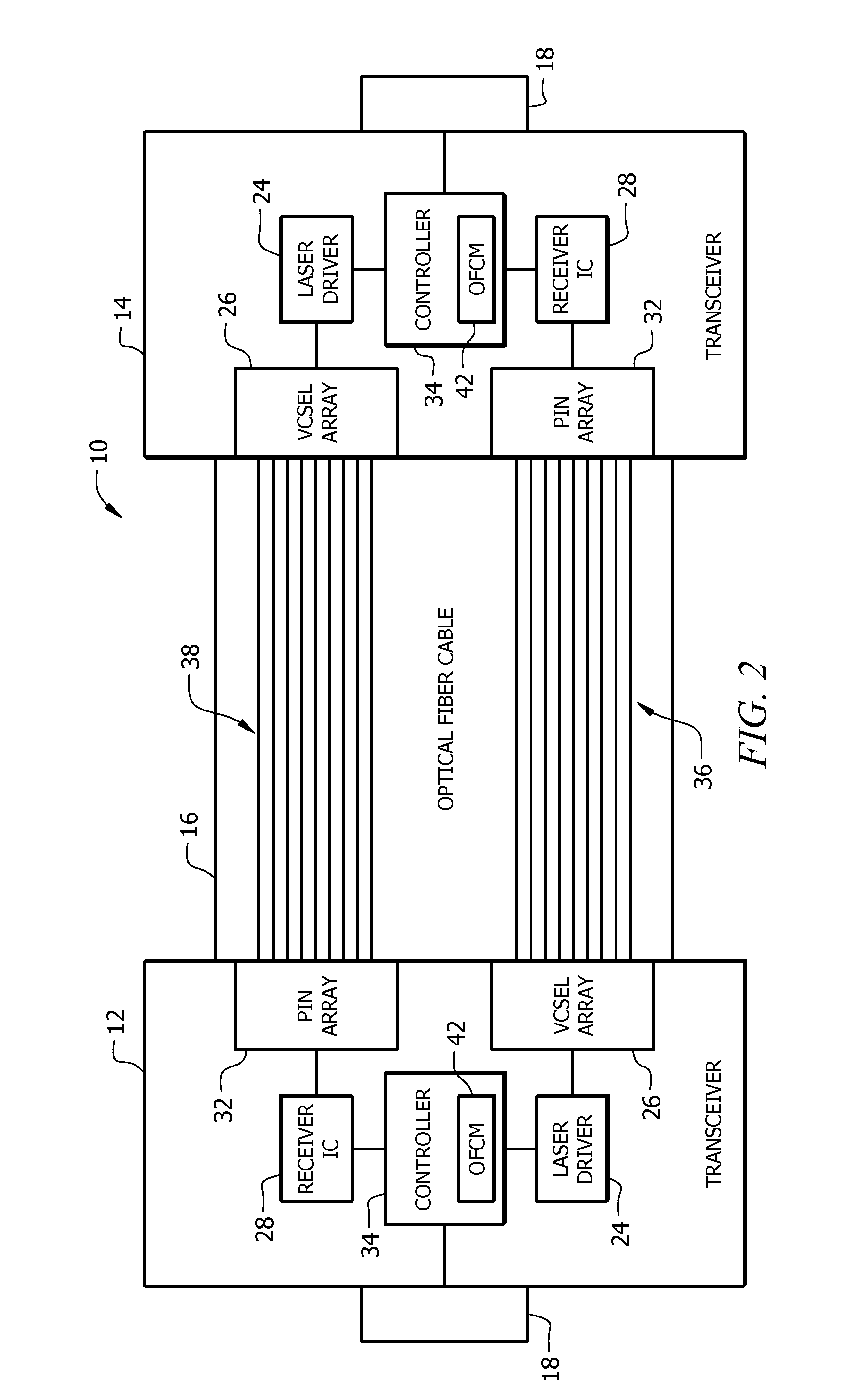

Active optical cable apparatus and method for detecting optical fiber breakage

InactiveUS20110013905A1Reduce power levelTransmission monitoringTransmission monitoring/testing/fault-measurement systemsOptical powerTransmission channel

Embodiments of the invention include an active optical cable and method for controlling the operation of the active optical cable based on the detection of signal loss, e.g., due to fiber breakage, within the active optical cable. The active optical cable includes first and second optical transceivers, each with an open fiber control module coupled between the transmission side and the receiver side of the respective optical transceiver. The transmission side of each optical transceiver is coupled to the receiver side of the other optical transceiver via a plurality of transmission channels, such as a plurality of optical fibers. Each open fiber control module is configured to detect an optical power level of an optical signal received by the receiver side of the optical transceiver within which the open fiber control module resides and, based on such detection, control the operation of the corresponding transmission side of the optical transceiver.

Owner:AVAGO TECHNOLOGIED FIBER IP SINGAPORE PTE LTD

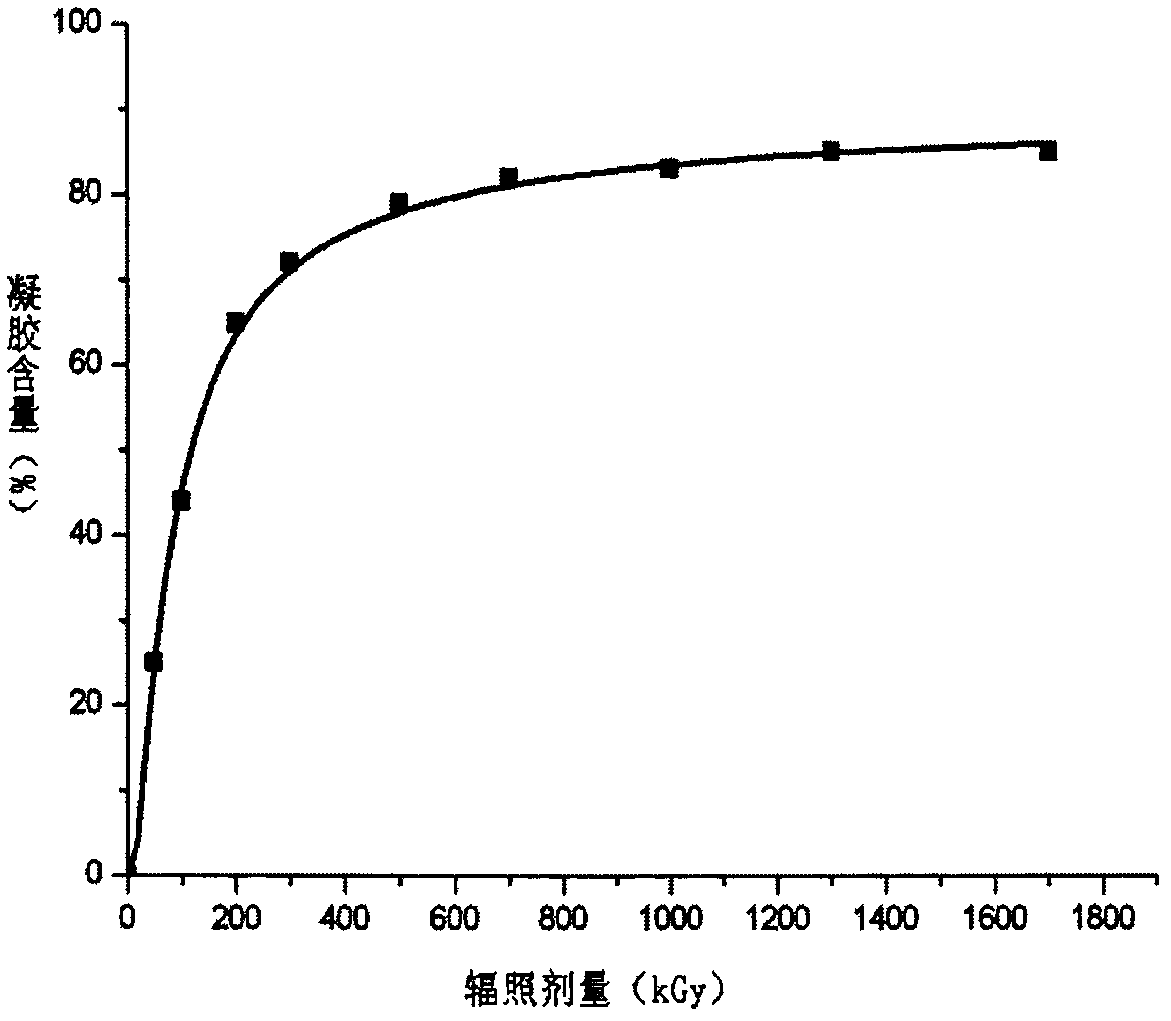

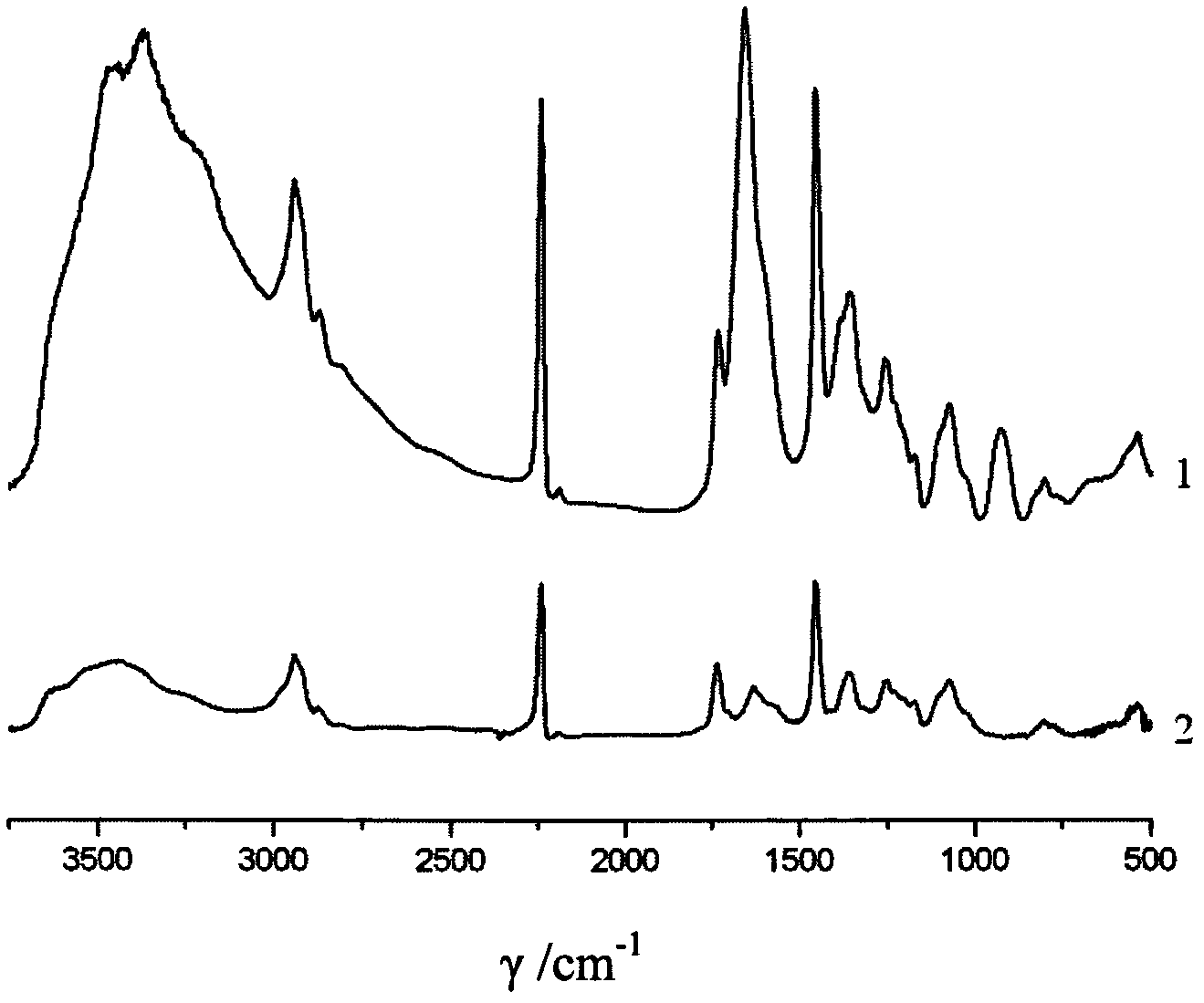

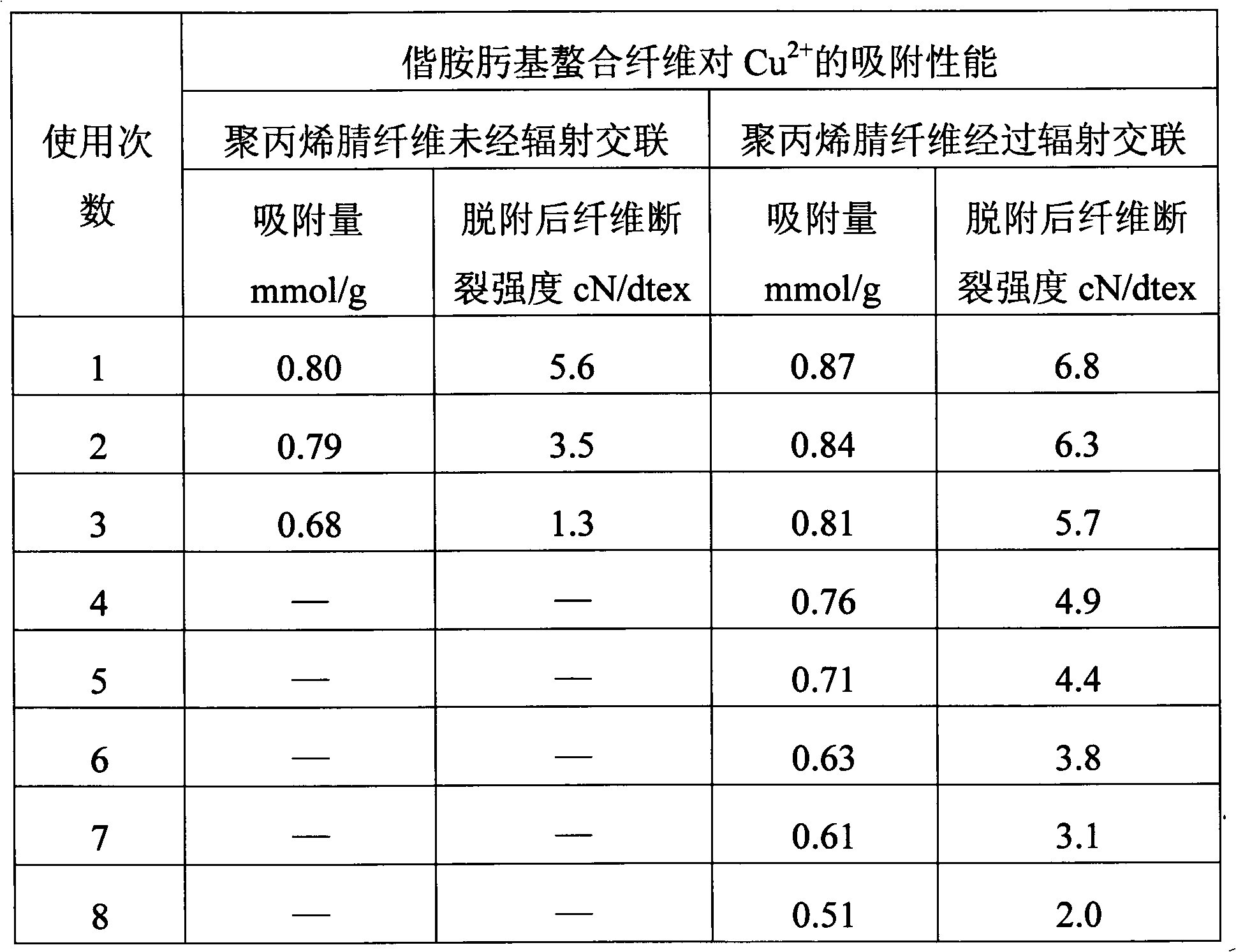

Amidoxime-based chelate polyacrylonitrile fiber and its preparation method and application

ActiveCN102587117AImprove mechanical propertiesImprove performanceOther chemical processesPhysical treatmentCross-linkIndustrial waste water

The invention provides an amidoxime-based chelate polyacrylonitrile fiber and its preparation method. The preparation method of the amidoxime-based chelate polyacrylonitrile fiber comprises the following steps that 1, polyacrylonitrile fibers are subjected to irradiation cross-linking under the conditions of an inert gas atmosphere and an irradiation amount of 20 to 2000kGy; and 2, the polyacrylonitrile fibers subjected to irradiation cross-linking undergo an amidoximation reaction. The invention also provides a use of the amidoxime-based chelate polyacrylonitrile fiber as a metal ion adsorption material. Through the preparation method which is simple relatively, the amidoxime-based chelate polyacrylonitrile fiber which has good mechanical properties, high fiber breaking strength, a long reuse life and stable performances and is damaged difficultly is obtained. The amidoxime-based chelate polyacrylonitrile fiber can be utilized as a metal ion adsorption material, is suitable for the fields of purification of industrial waste water or slag, or extraction of uranium of seawater, has excellent effects of adsorbing multiple metal ions, and can greatly reduce an industrial cost.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

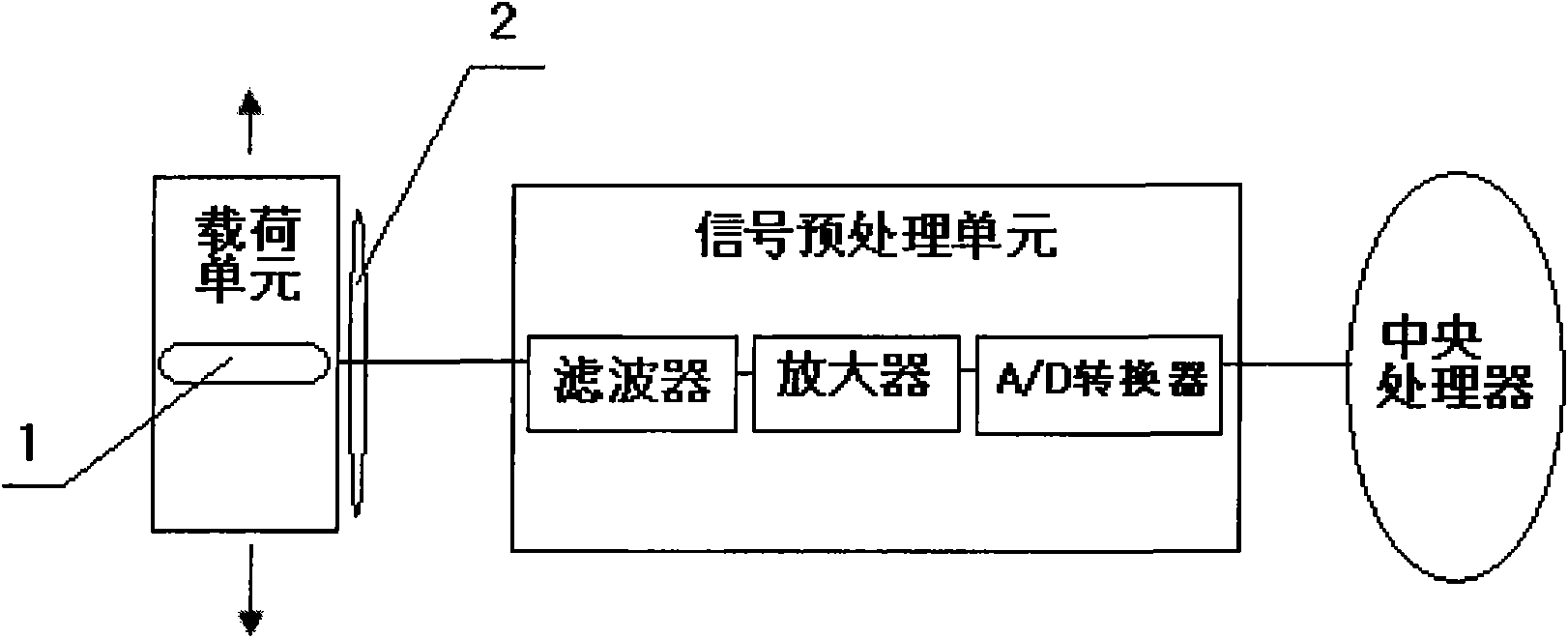

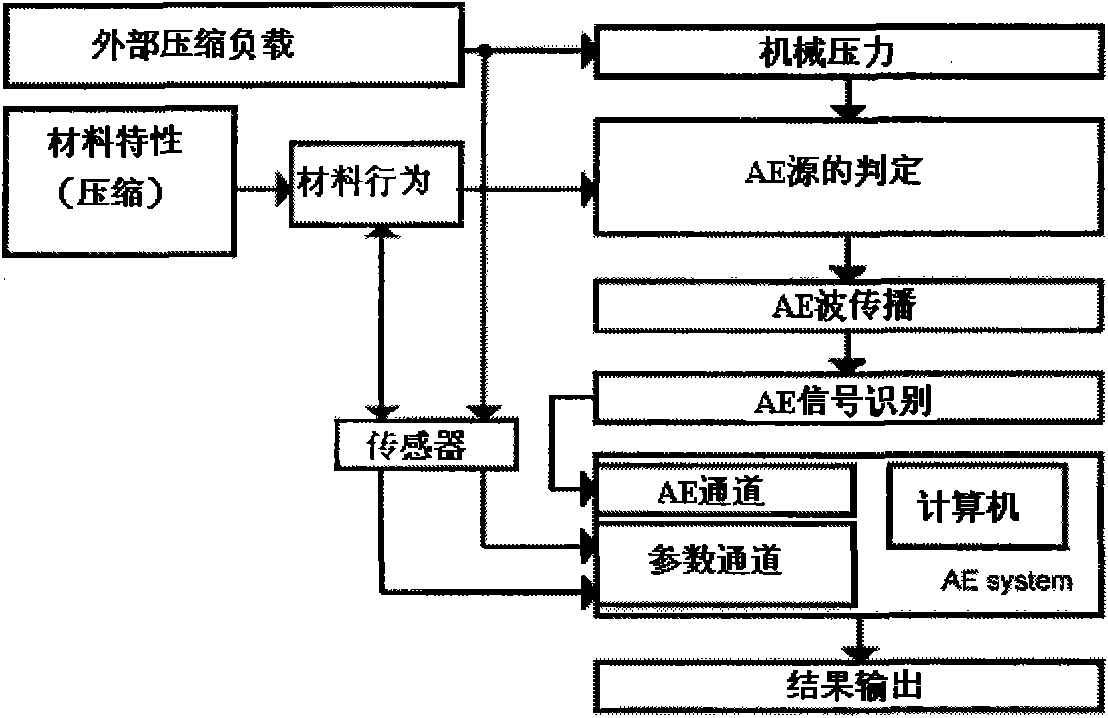

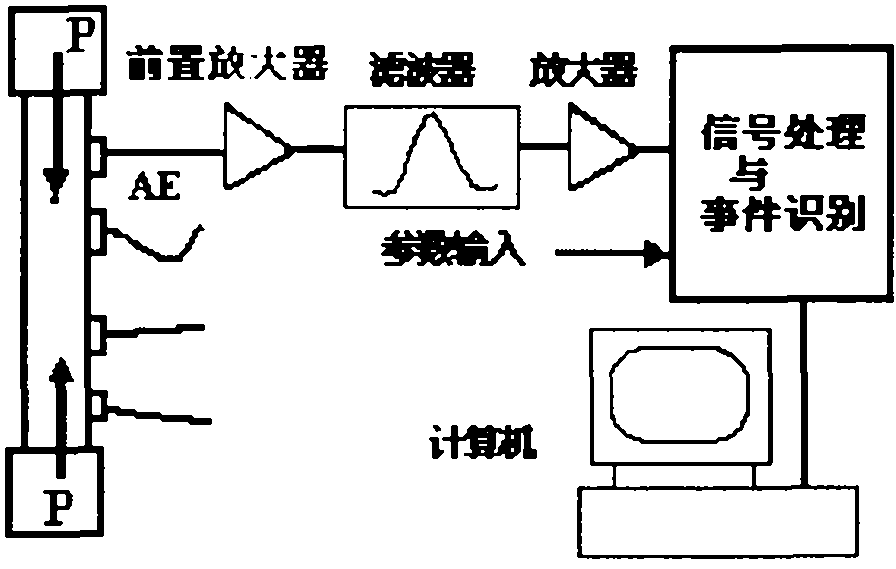

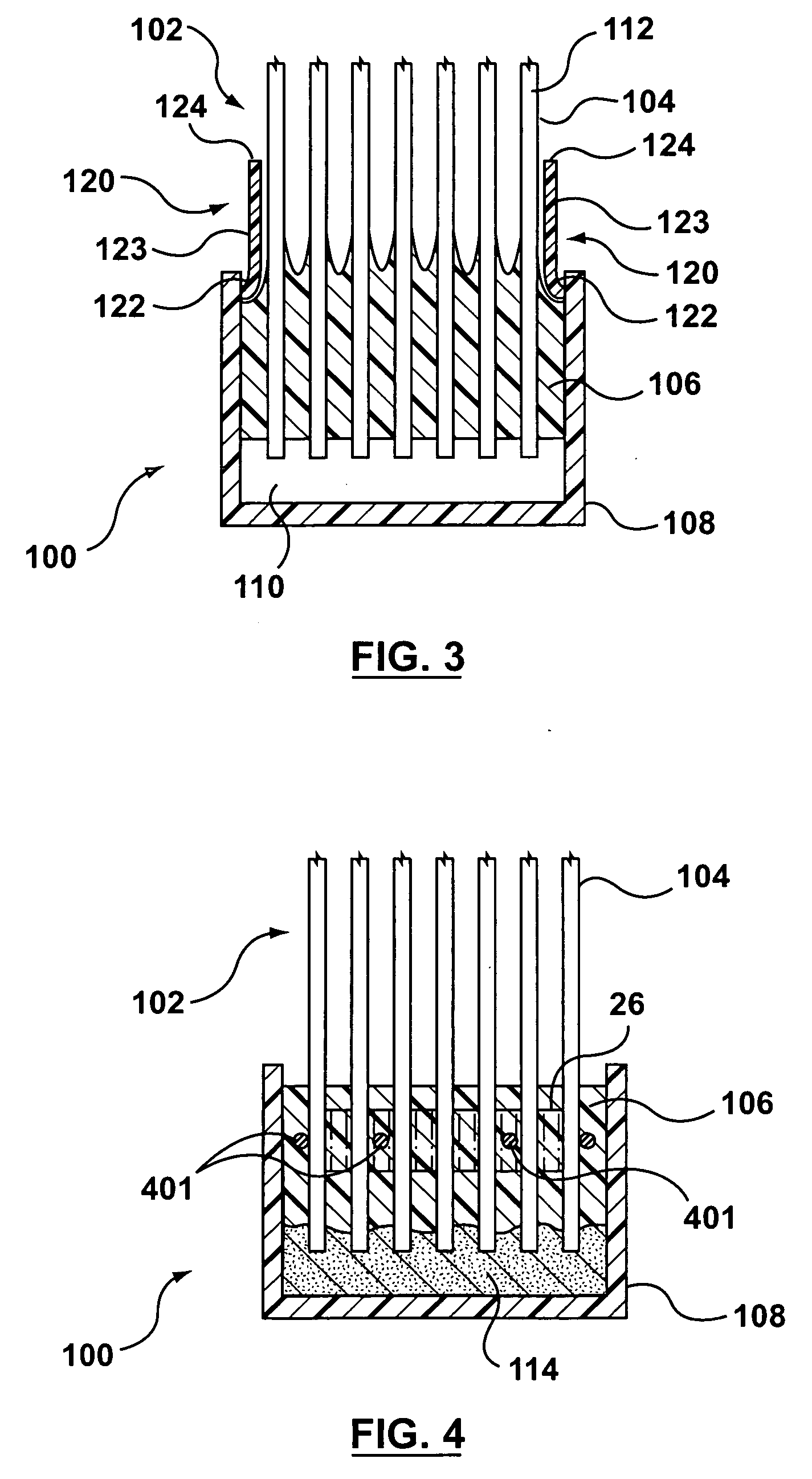

Nondestructive testing system and testing analysis method for three-dimensional braided composite material

InactiveCN102109498ARealize the whole dynamic monitoringShow damage characteristicsMaterial analysis using acoustic emission techniquesFrequency spectrumAcoustic emission

The invention provides an acoustic-emission-technology-based nondestructive testing system and an acoustic-emission-technology-based nondestructive testing method for a three-dimensional braided composite material. In the method, an acoustic emission signal generated by the composite material under external loading is received by an acoustic emission sensor and then is digitized, and the damaged condition of the material is further analyzed. By the method, a unilateral stretching experiment of the carbon fiber three-dimensional braided composite material is dynamically monitored all the way by the acoustic emission technology; and the method proves that the number of the acoustic emission events has good correlation with damage evolution of the carbon fiber composite material; through the spectrum analysis of the carbon fiber three-dimensional braided composite material, the final damage to the material is caused by fibrous fracture and damage frequencies show the damage characteristics of the material; different types of damage modes are well described through the spectrum analysis, and frequency ranges of all peak values can be detailed further, so that more detailed explanation for damage types and mechanisms can be given; and the fracture modes of the material can be analyzed by using acoustic emission characteristic parameters.

Owner:TIANJIN POLYTECHNIC UNIV

Antistatic polyurethane elastic fiber and material for producing the same

InactiveUS6849676B1Monocomponent polyurethanes artificial filamentElectroconductive/antistatic filament manufacturePolymer sciencePhosphate

Inorganic salts are generated in the production process of metal salts, such as sulfonates, sulfates and phosphates. When such metal salts containing inorganic salts are added as an antistatic agent to a polymer for producing polyurethane fiber, the inorganic salts cause fiber breakage or pack choking in fiber extrusion process. In addition, such antistatic agents are highly hygroscopic and contain trace of water. When such an antistatic agent is added to the material for polymerizing polyurethane, the alcohol and water in the agent react with isocyanate to result in lowered degree of polymerization and generation of oligomer. Such polyurethane polymer is spun into fiber of low elongation and tenacity. The material for polyurethane elastic fibers of the present invention comprises a mixture of 5 to 95 weight percent of at least one of the above-mentioned antistatic agents and 95 to 5 weight percent of a isocyanate-free starting material for elastic fibers, and eliminates the above troubles.

Owner:MATSUMOTO YUSHI SEIYAKU

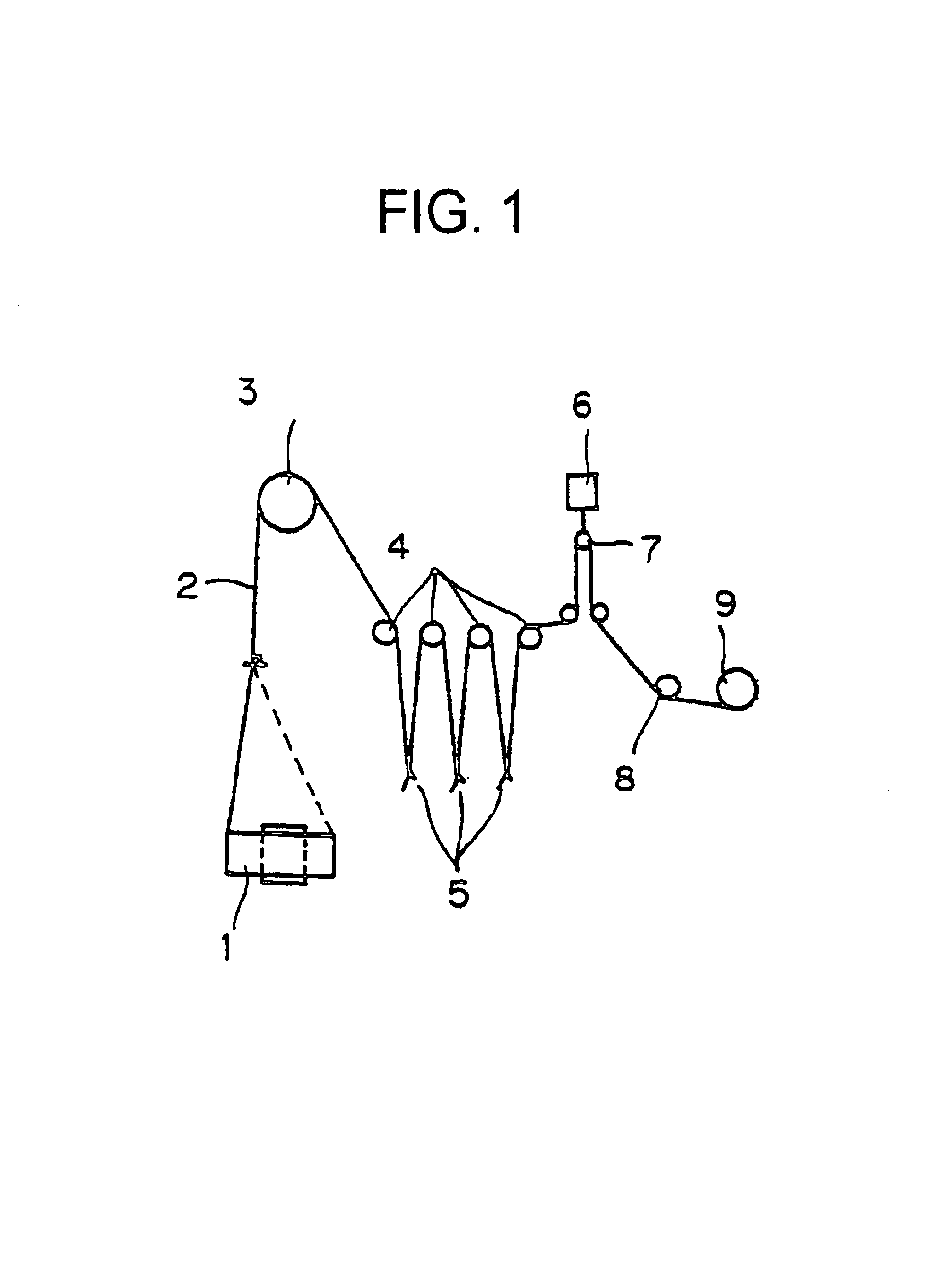

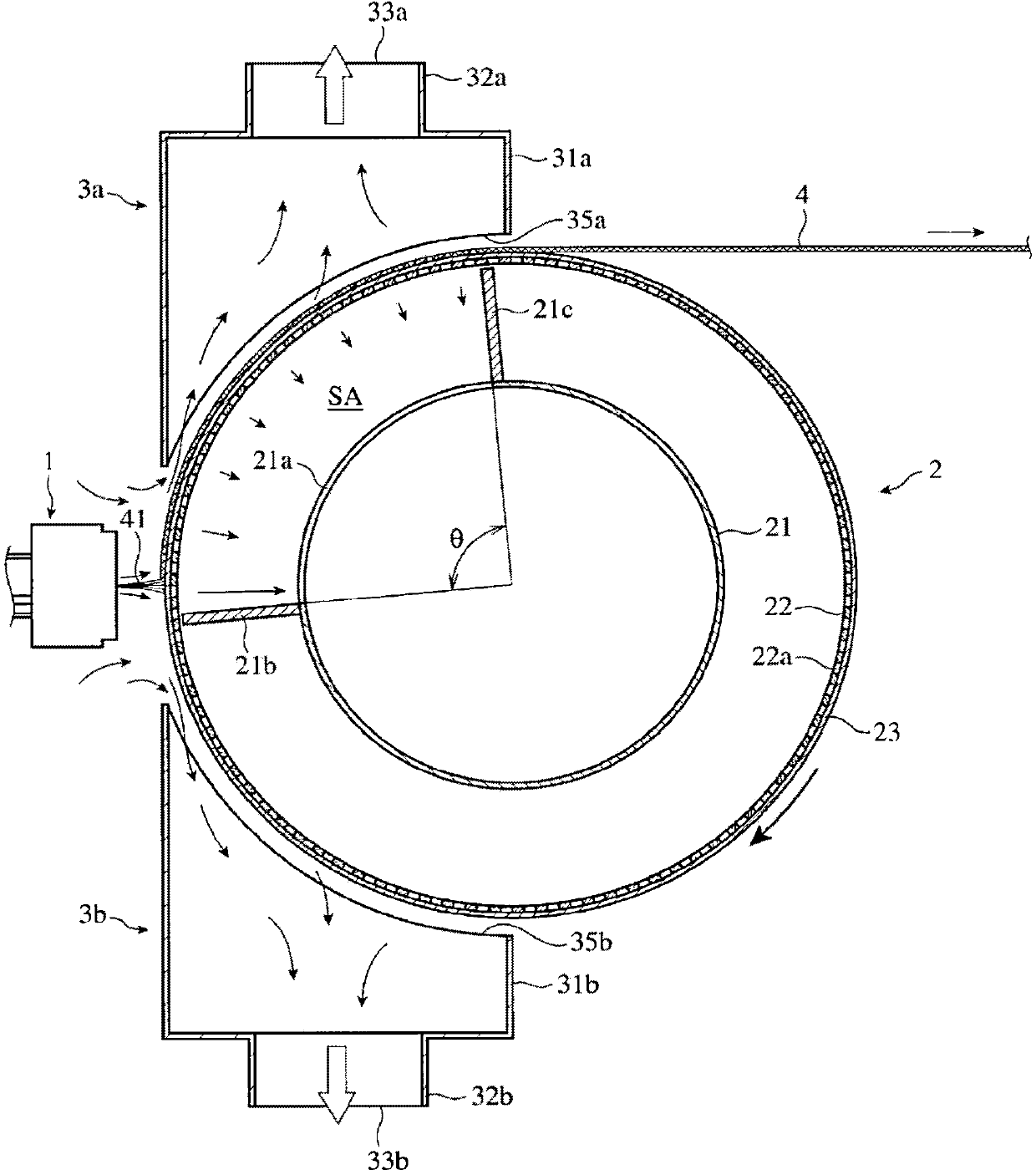

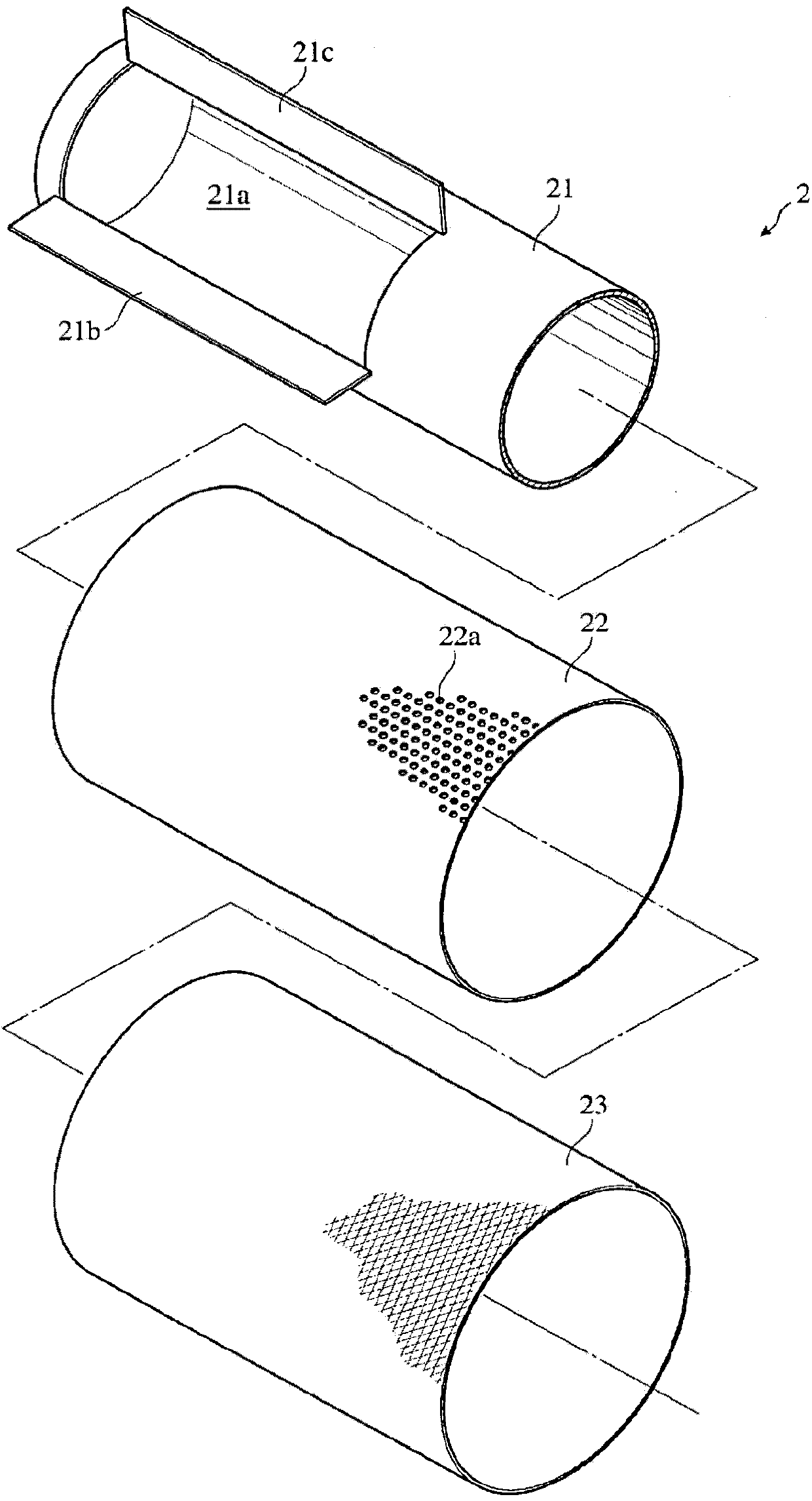

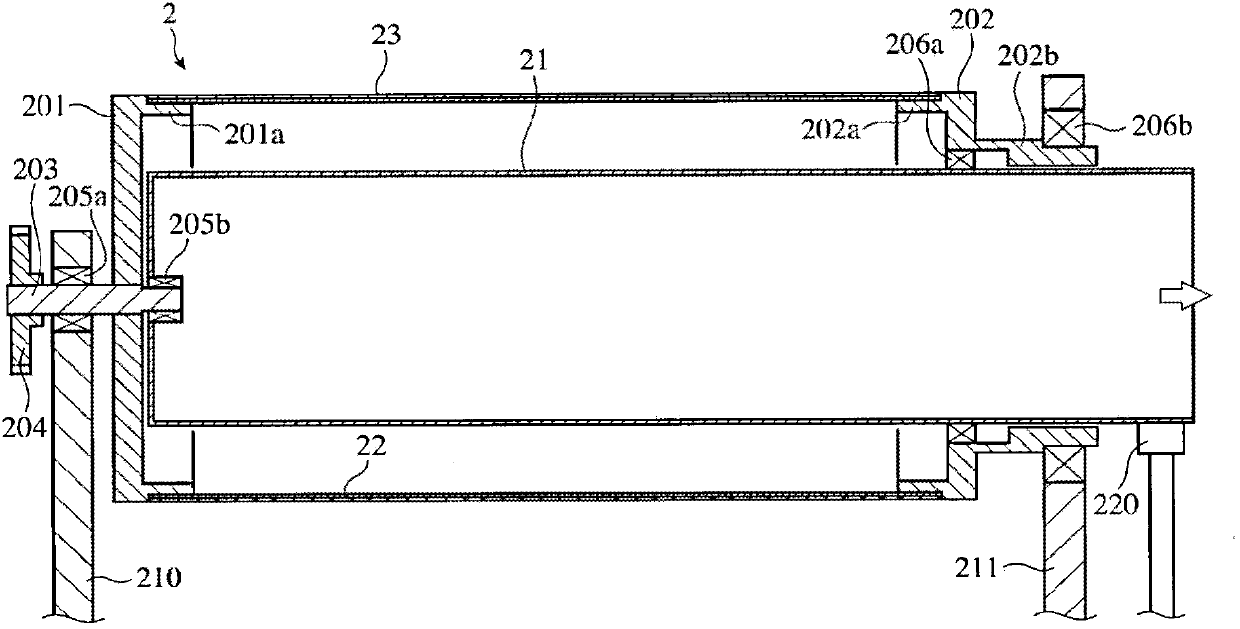

Melt-blown nonwoven fabric comprising ultra-fine fibers, production method therefor, and device for producing same

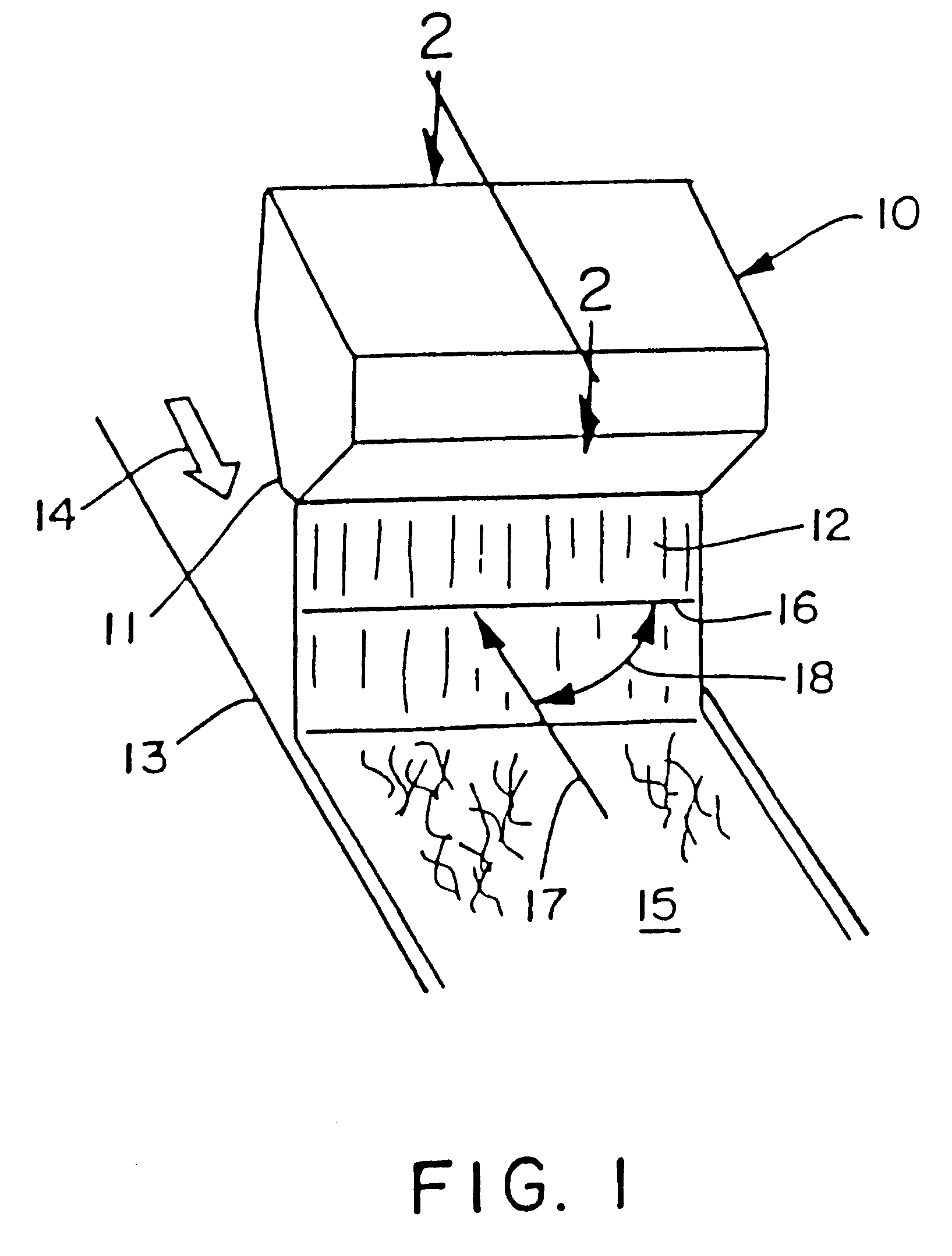

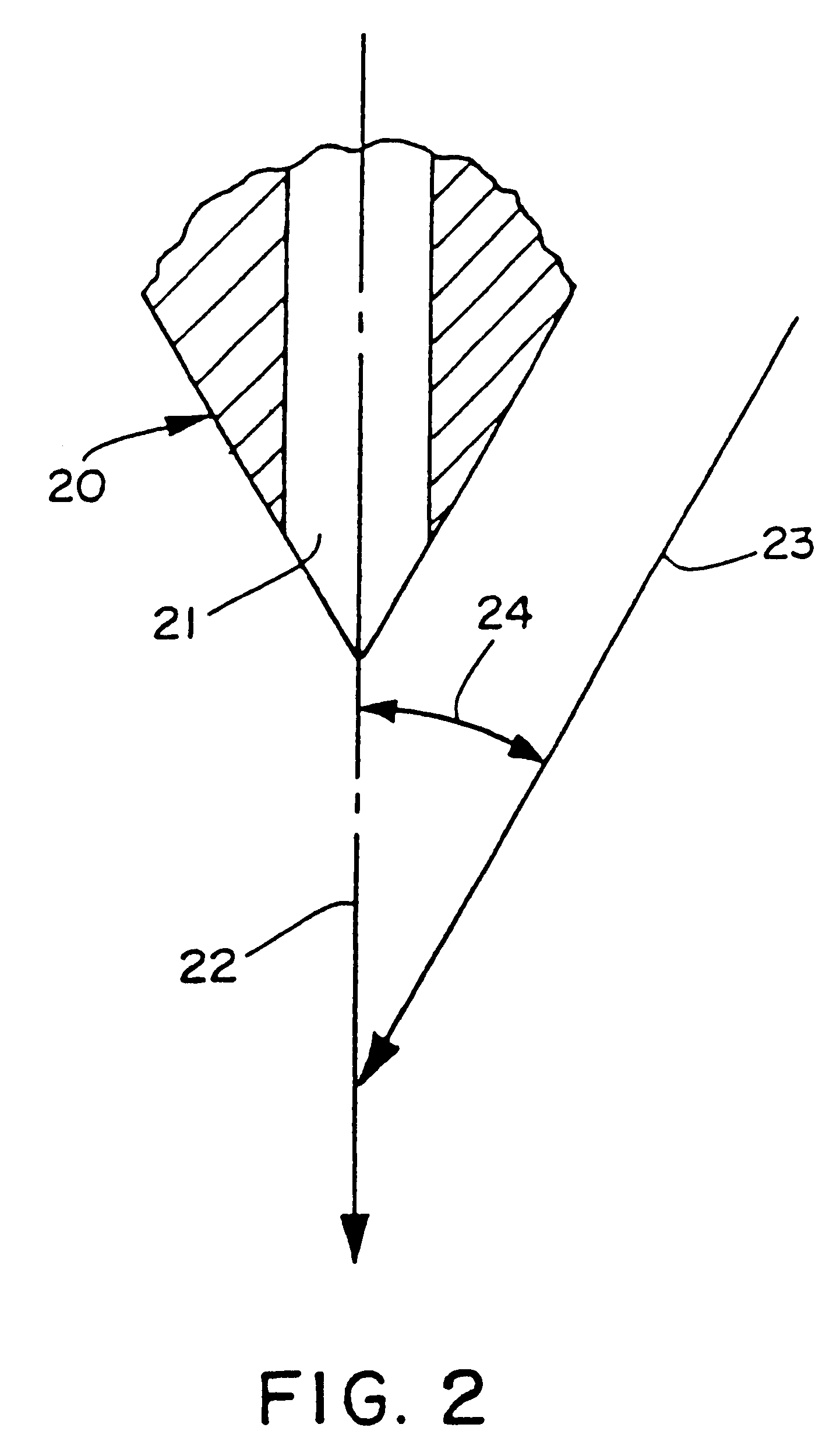

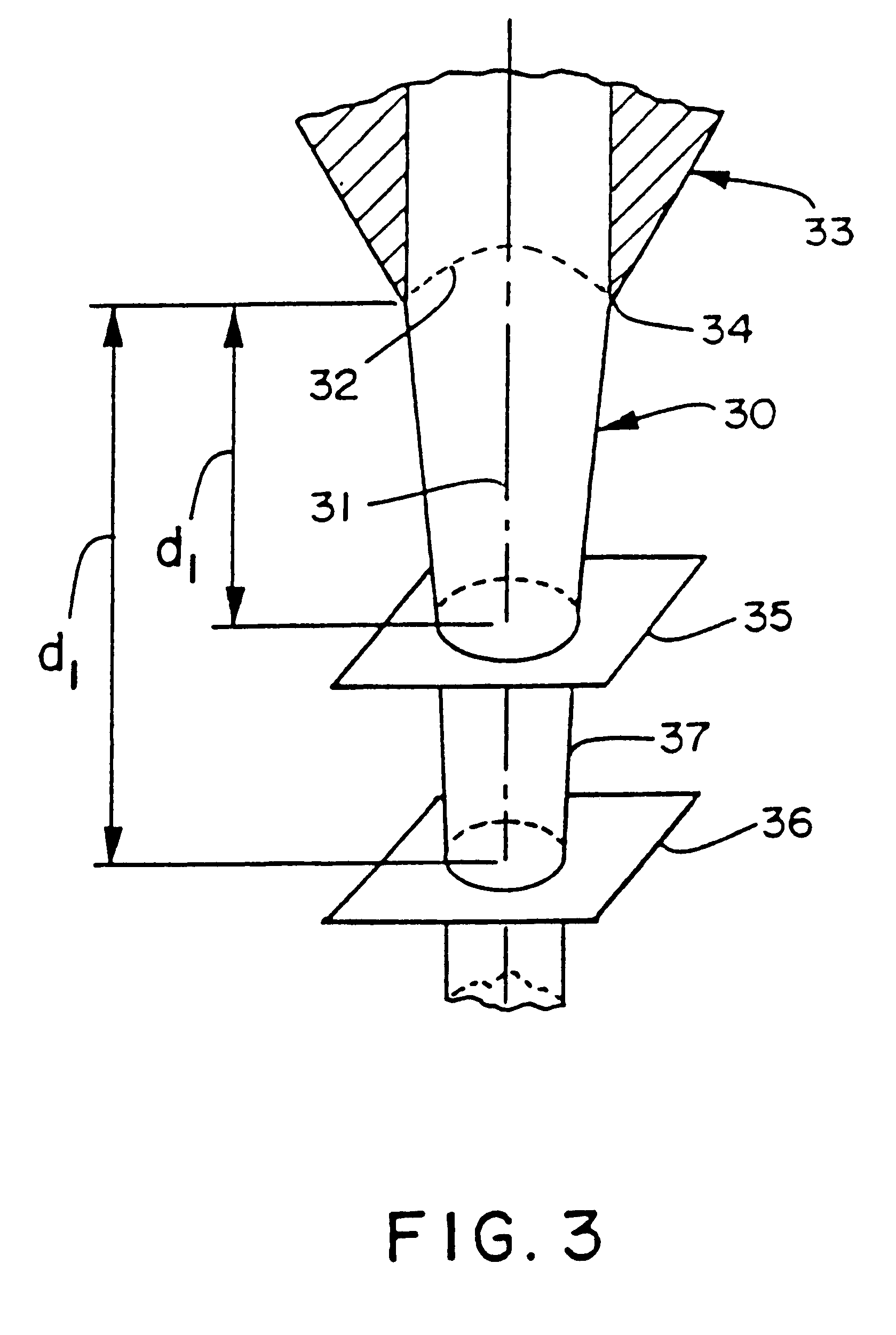

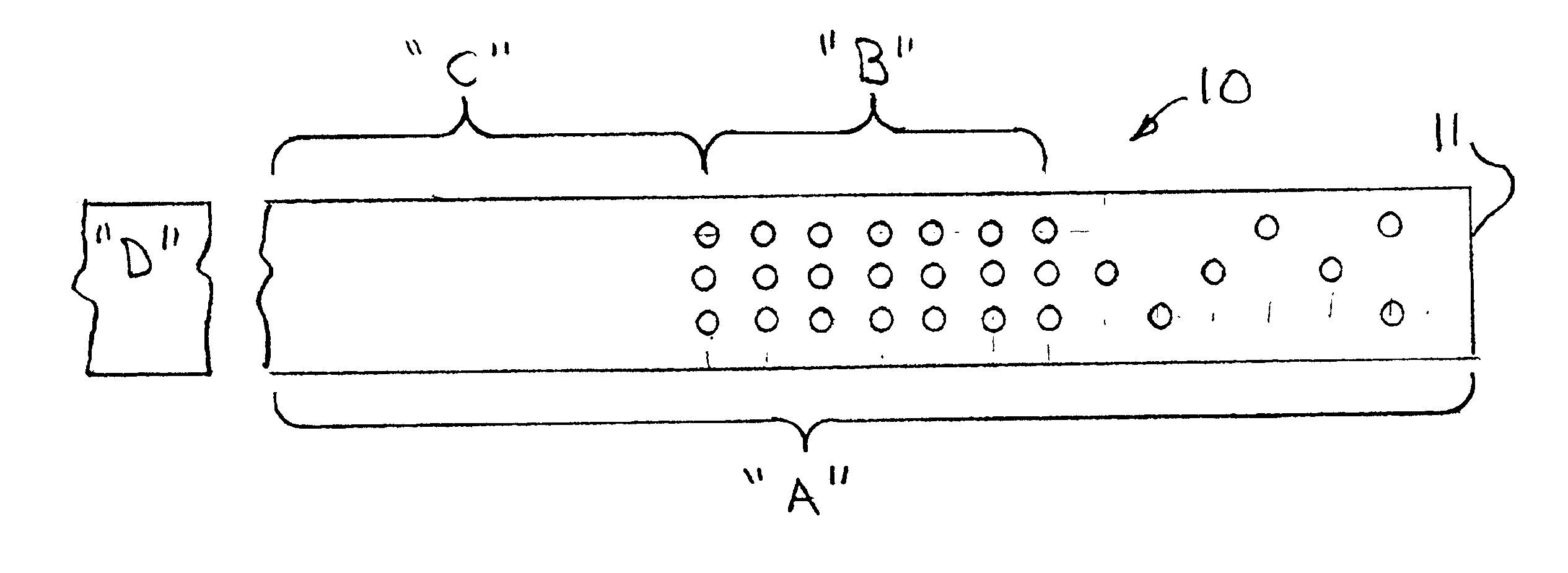

ActiveCN103380242AImprove the capture effectImprove ventilationMelt spinning methodsNon-woven fabricsPolymer scienceSpinning

An ultra-fine fiber melt-blown nonwoven fabric having excellent fine-particle trapping characteristics and air permeability is obtained by a melt-blowing method using: a die (1) having a plurality of ultra-fine spinning nozzles and an air nozzle; a rotating suction roll (2) having a porous outer peripheral surface and which sucks from the inside thereof; and a pair of upper and lower suction hoods (3a, 3b) covering the suction roll (2). In said melt-blow method: the interval between the die (1) and the suction roll (2) is set such that polymer fiber breakage or twisting is suppressed, within a range wherein the stretching of a molten polymer is completed and vibration of the obtained polymer fiber substantially does not occur; and the intervals between the outer peripheral surface of the suction roll (2) and the die-side end section of suction hoods (3a, 3b) are set such that fibers that have broken and attached or fused to the surface of the melt-blown nonwoven fabric can be removed by suction.

Owner:TAPYRUS

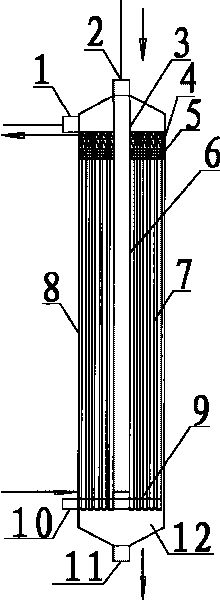

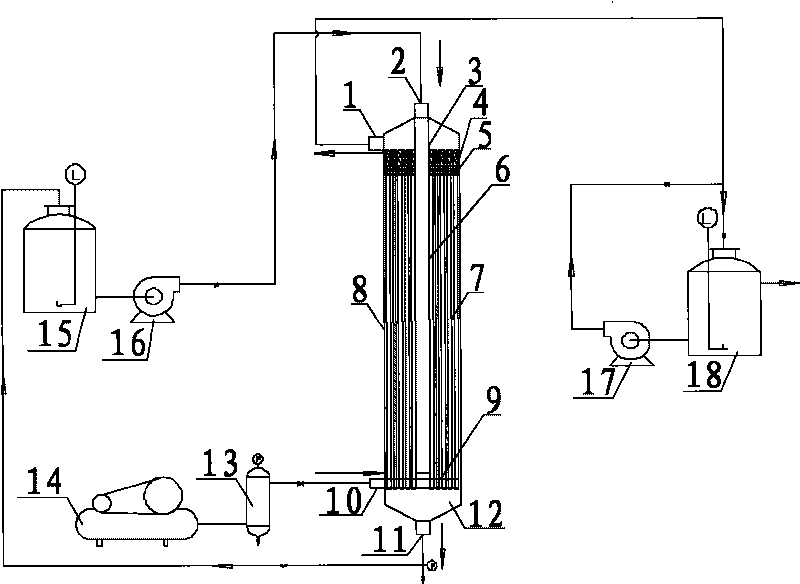

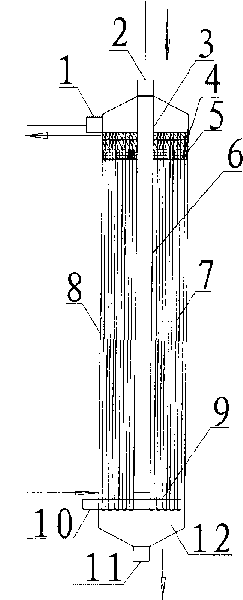

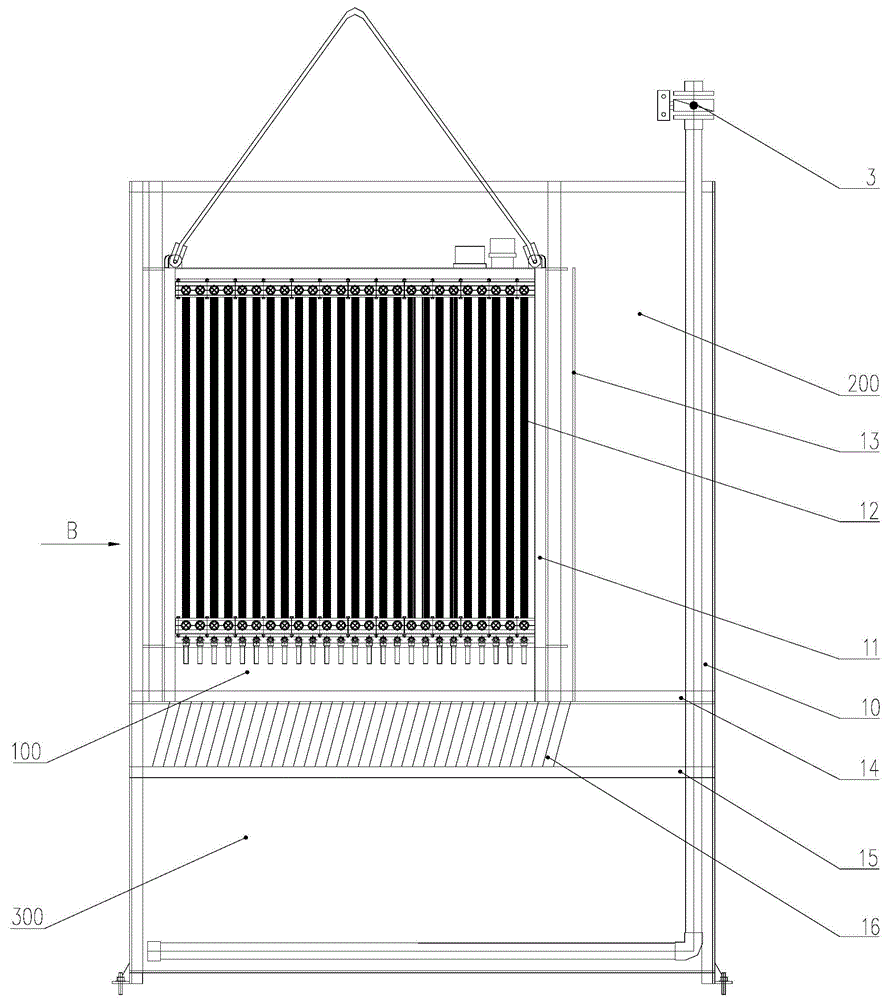

External pressure-type hollow fiber membrane module with antipollution structure and cleaning system

ActiveCN101757853APollution controlImprove throughputSemi-permeable membranesTreatment using aerobic processesHollow fibre membraneHigh flux

The invention discloses an external pressure-type hollow fiber membrane module with antipollution structure and a system and a method for cleaning, the external pressure-type hollow fiber membrane module comprises a water producing pipe, a raw water pipe, a central water distribution pipe, a central water distribution hole, a U-shaped membrane fiber, a membrane casing, an aeration device, a gas intake pipe, a concentrated water pipe and a pollutant-enriched region, wherein the U-shaped membrane fiber is vertically cast at an upper end of the membrane casing in the shape of hanging naturally, an lower end of a U-shaped membrane module is provided with a gas distribution system, below which the pollutant-enriched region is arranged. The external pressure-type hollow fiber membrane module has the advantages: 1, membrane pollution can be effectively controlled so as to maintain the membrane at higher flux and cleaning can be performed timely during pollution to rapidly recover membrane flux; 2, the possibility of fiber breakage can be reduced due to non-tensioned membrane fiber and adequate shake of aeration; and 3, the V-shaped pollutant-enriched region without any component is arranged below the aeration device, thus no resistance is applied to the lower portion of the membrane fiber during washing and the washing water can speed up the discharging of pollutants.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

Synthetic fiber nonwoven web and method

InactiveUS6469130B1Mechanical strengthHigh fluid absorbencySynthetic resin layered productsPaper/cardboard layered productsUltrasound attenuationFiber diameter

A nonwoven web and method of preparing a novel nonwoven web of synthetic fiber are disclosed. An aqueous solution amide crosslinked synthetic precursor polymer is extruded under defined conditions through a plurality of die orifices to form a plurality of threadlines. The threadlines are attenuated with a defined primary gaseous source to form fiber under conditions of controlled macro scale turbulence and under conditions sufficient to permit the viscosity of each threadline, as it leaves a die orifice and for a distance of no more than about 8 cm, to increase incrementally with increasing distance from the die, while substantially maintaining uniformity of viscosity in the radial direction, at a rate sufficient to provide fiber having,the desired attenuation and mean fiber diameter without significant fiber breakage. The attenuated threadlines are dried with a defined secondary gaseous source. The resulting fibers are deposited randomly on a moving foraminous surface to form a substantially uniform web. The moving foraminous surface is positioned about 10 to about 100 cm from the last gaseous source to contact the threadlines. The fibers have a mean fiber diameter in the range of about 0.1 to 30 mum and are substantially free of shot. The attenuating and drying steps are carried out under conditions of controlled macro scale turbulence.

Owner:KIMBERLY-CLARK WORLDWIDE INC

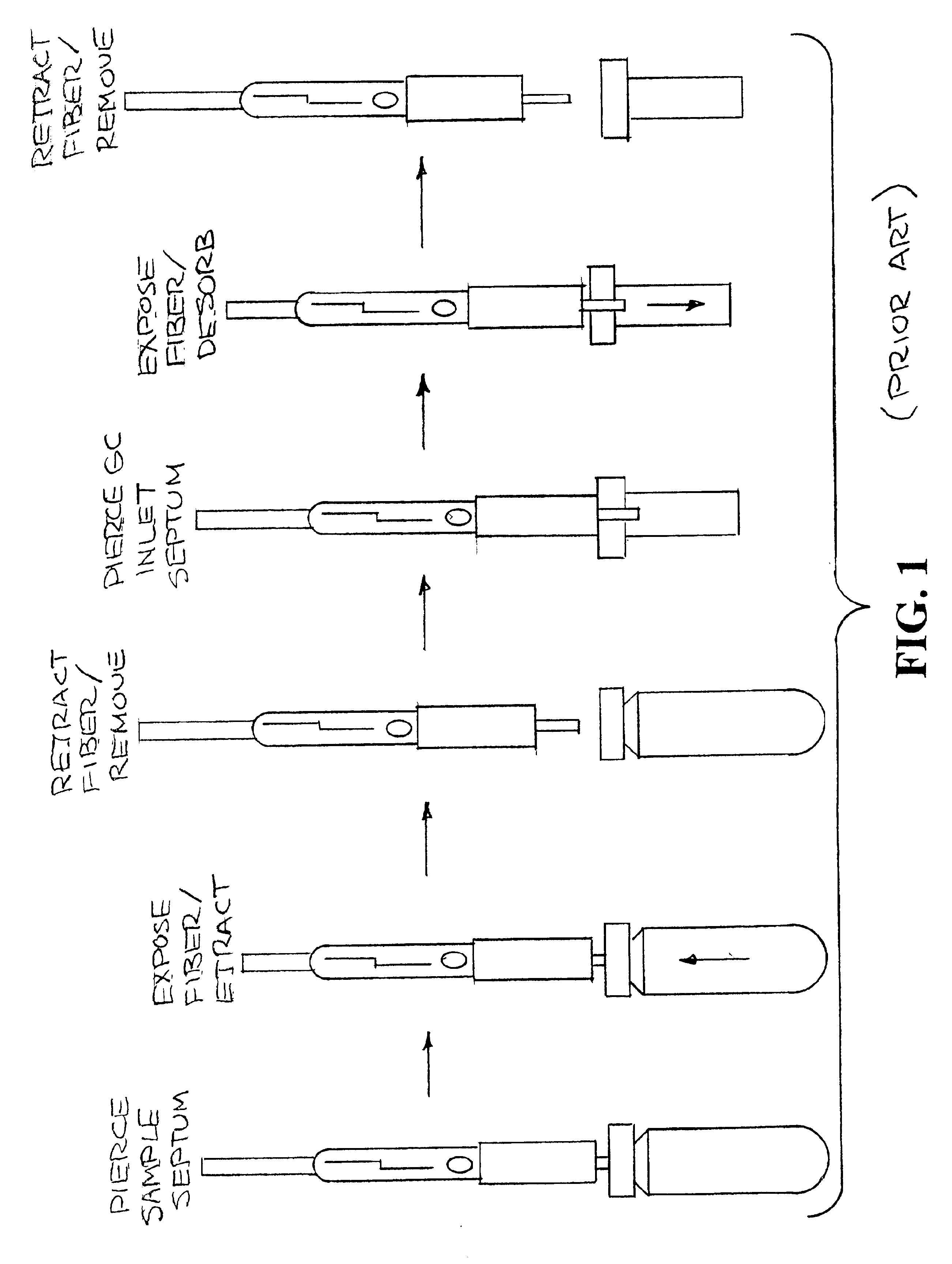

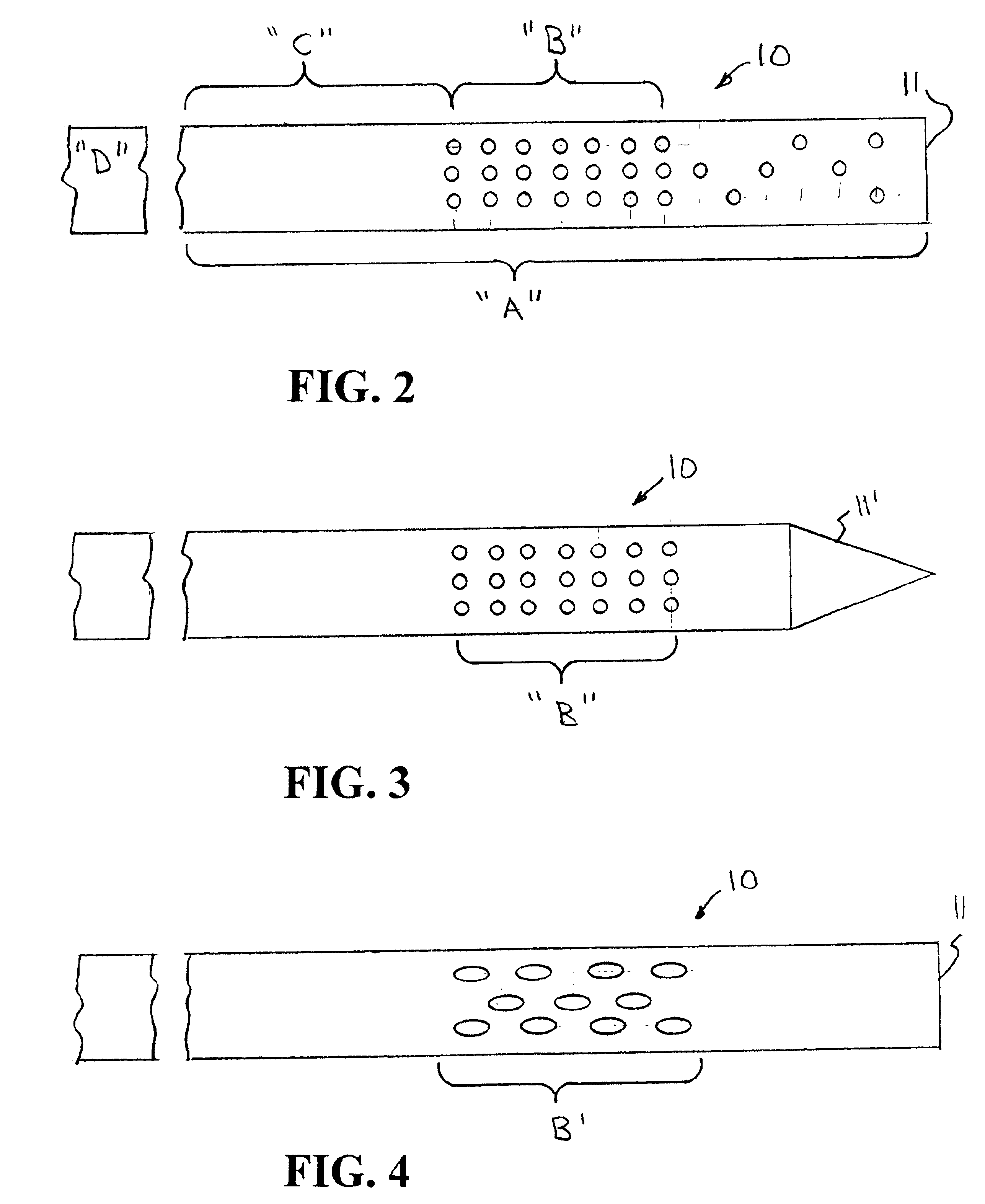

Porous protective solid phase micro-extractor sheath

InactiveUS6871556B2Analysis using chemical indicatorsComponent separationBare fiberSolid-phase microextraction

A porous protective sheath for active extraction media used in solid phase microextraction (SPME). The sheath permits exposure of the media to the environment without the necessity of extending a fragile coated fiber from a protective tube or needle. Subsequently, the sheath can pierce and seal with GC-MS septums, allowing direct injection of samples into inlet ports of analytical equipment. Use of the porous protective sheath, within which the active extraction media is contained, mitigates the problems of: 1) fiber breakage while the fiber is extended during sampling, 2) active media coating loss caused by physical contact of the bare fiber with the sampling environment; and 3) coating slough-off during fiber extension and retraction operations caused by rubbing action between the fiber and protective needle or tube.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

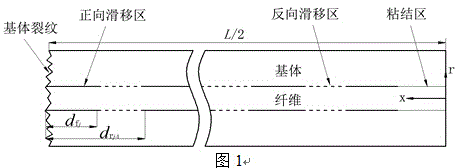

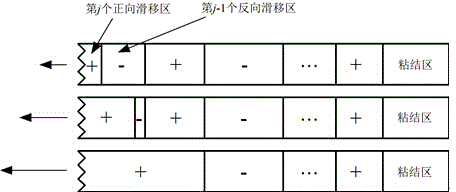

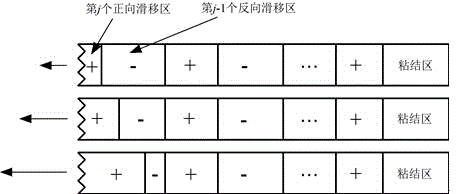

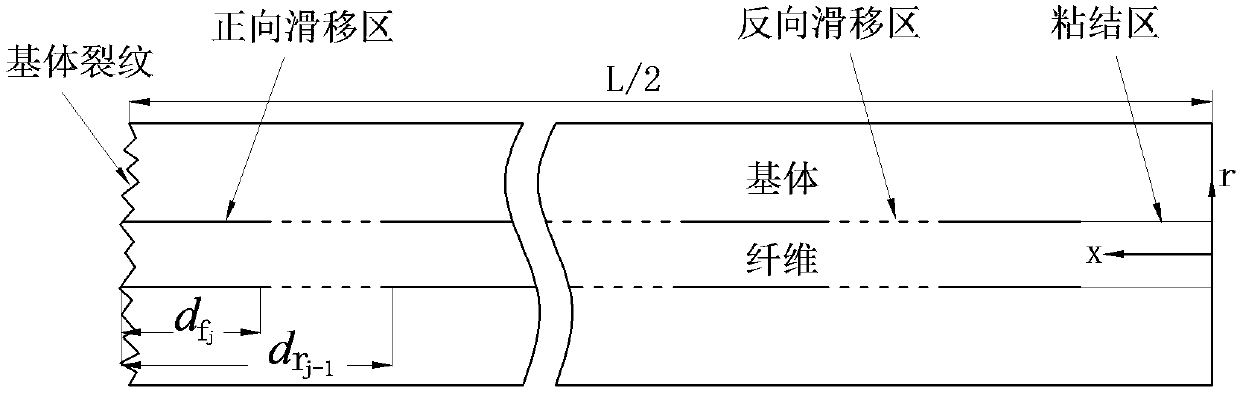

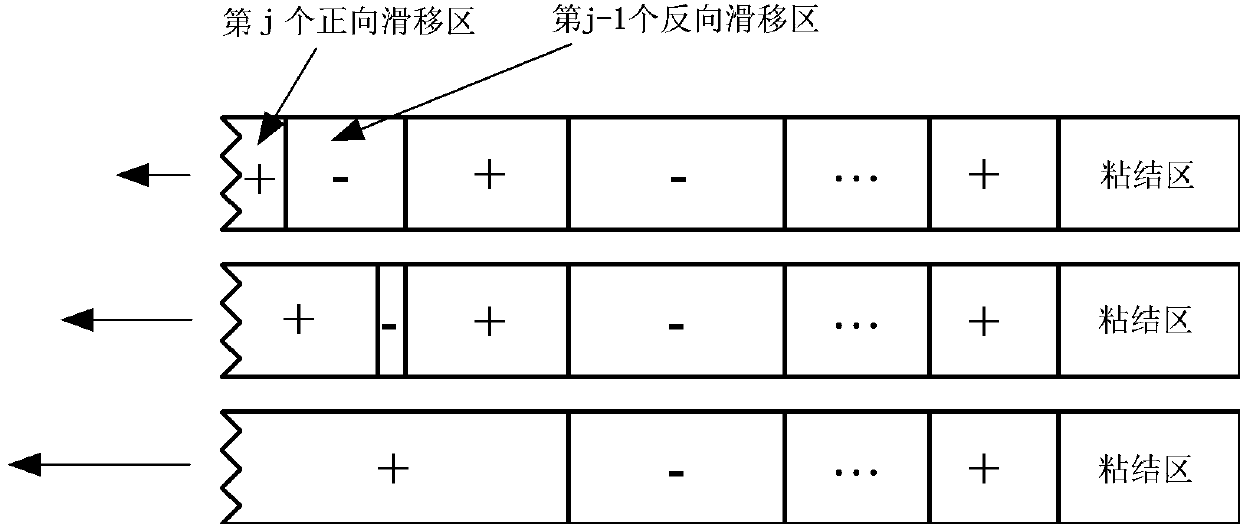

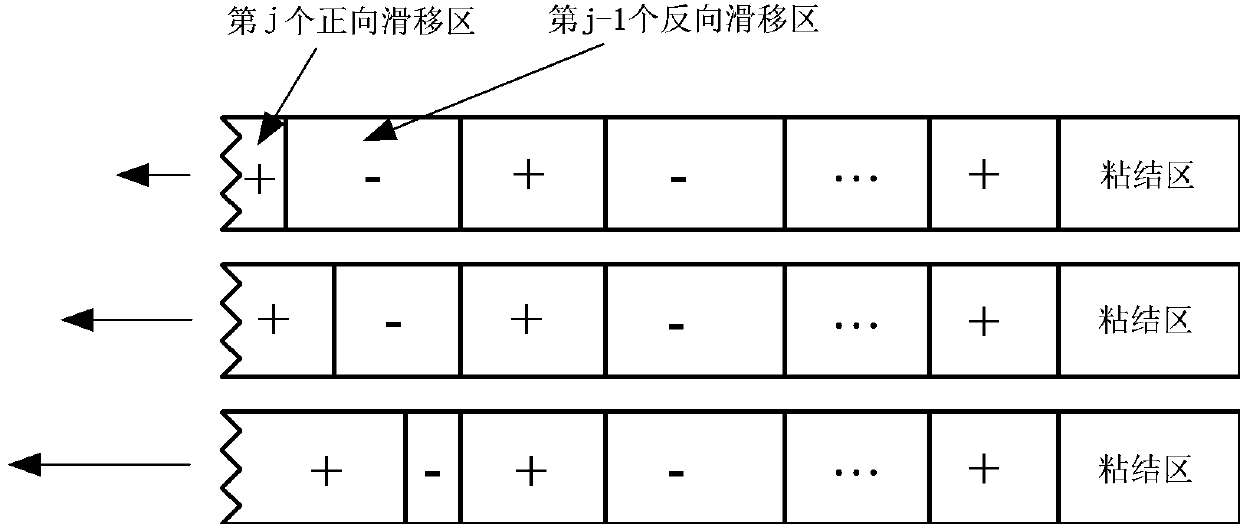

Method for predicating stress-strain behavior under arbitrary loading and unloading of one-way ceramic matrix composite

ActiveCN104866690APrediction of stress-strain behaviorSpecial data processing applicationsStress distributionFailure mechanism

The invention relates to a method for predicating a stress-strain behavior of a composite, in particular to a method for predicating the stress-strain behavior under arbitrary loading and unloading of a one-way ceramic matrix composite. The invention aims at overcoming the defects of the prior art to provide the method capable of quickly predicating the stress-strain behavior under arbitrary loading and unloading of the one-way ceramic matrix composite. The invention provides the method for predicating the stress-strain behavior under arbitrary loading and unloading of the one-way ceramic matrix composite, and considers failure mechanisms, such as matrix cracking, fiber breakage, interface slip and interface abrasion. Generation and coverage rules for forward and reverse slip regions are provided, and the stress distribution and the strain are given in the presence of any number of forward and reverse slip regions. Most of formulas given by the method have analytical solutions, so that the stress-strain behavior under arbitrary loading and unloading of the one-way ceramic matrix composite can be quickly predicated.

Owner:南京长工智航科技有限公司

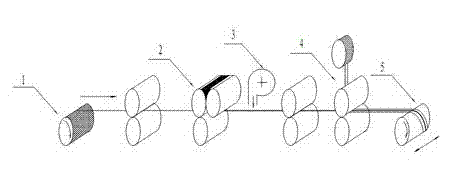

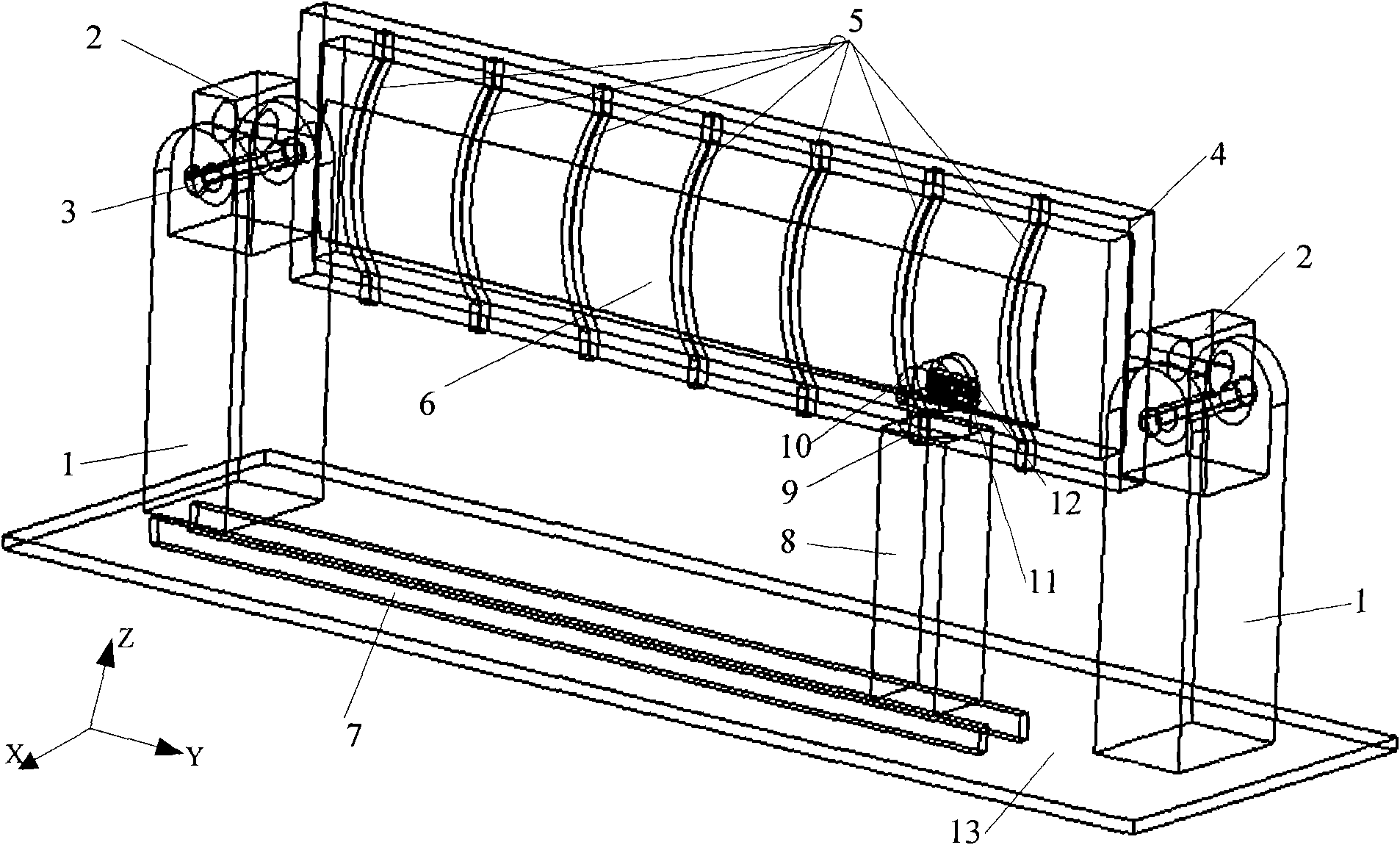

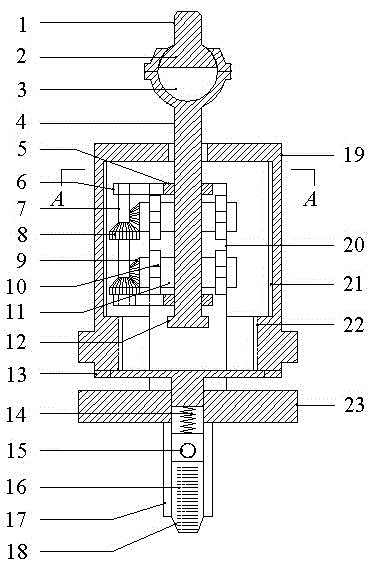

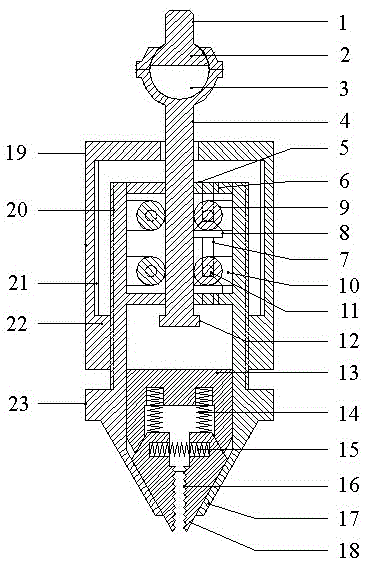

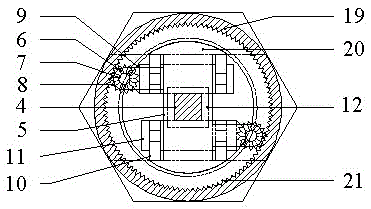

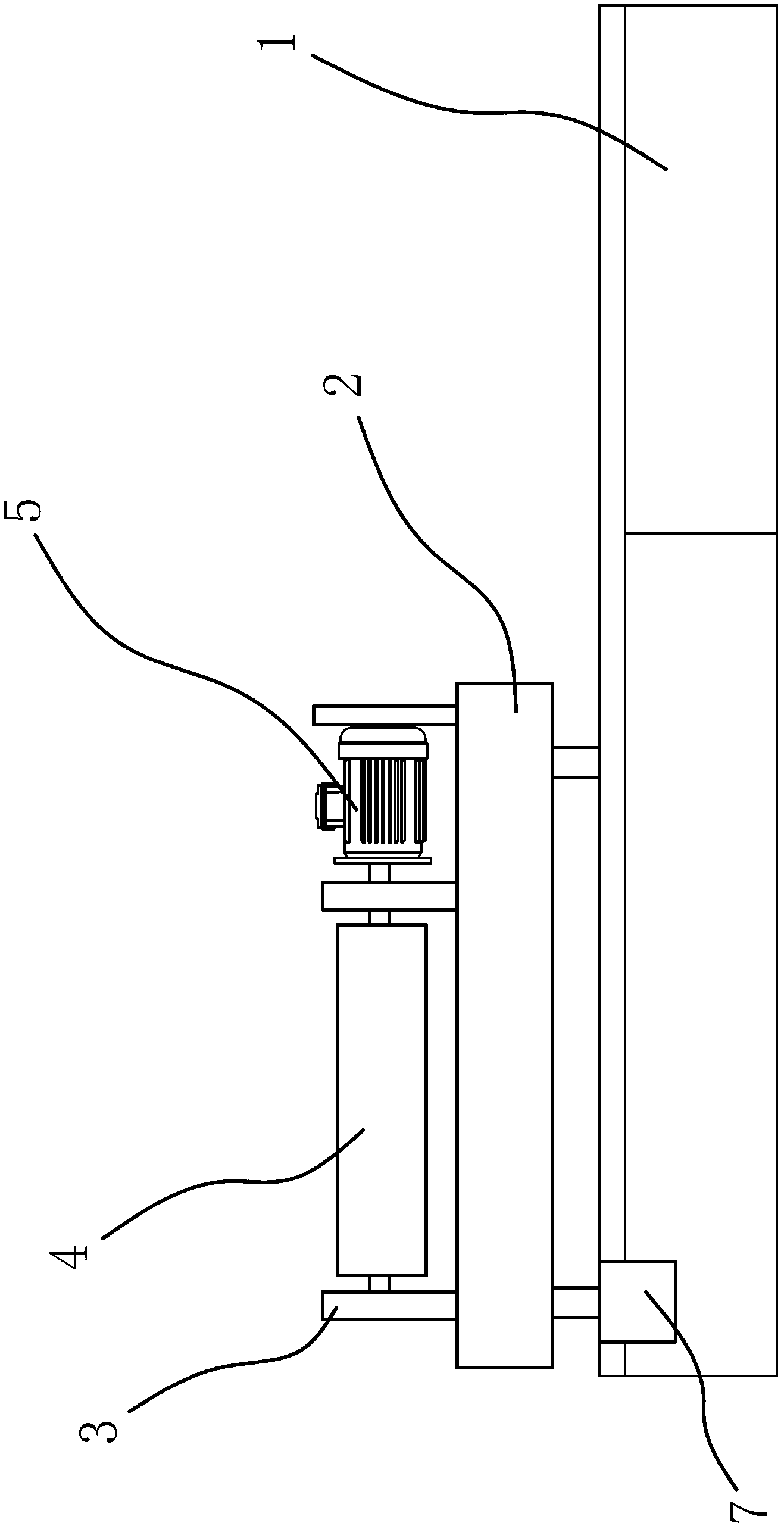

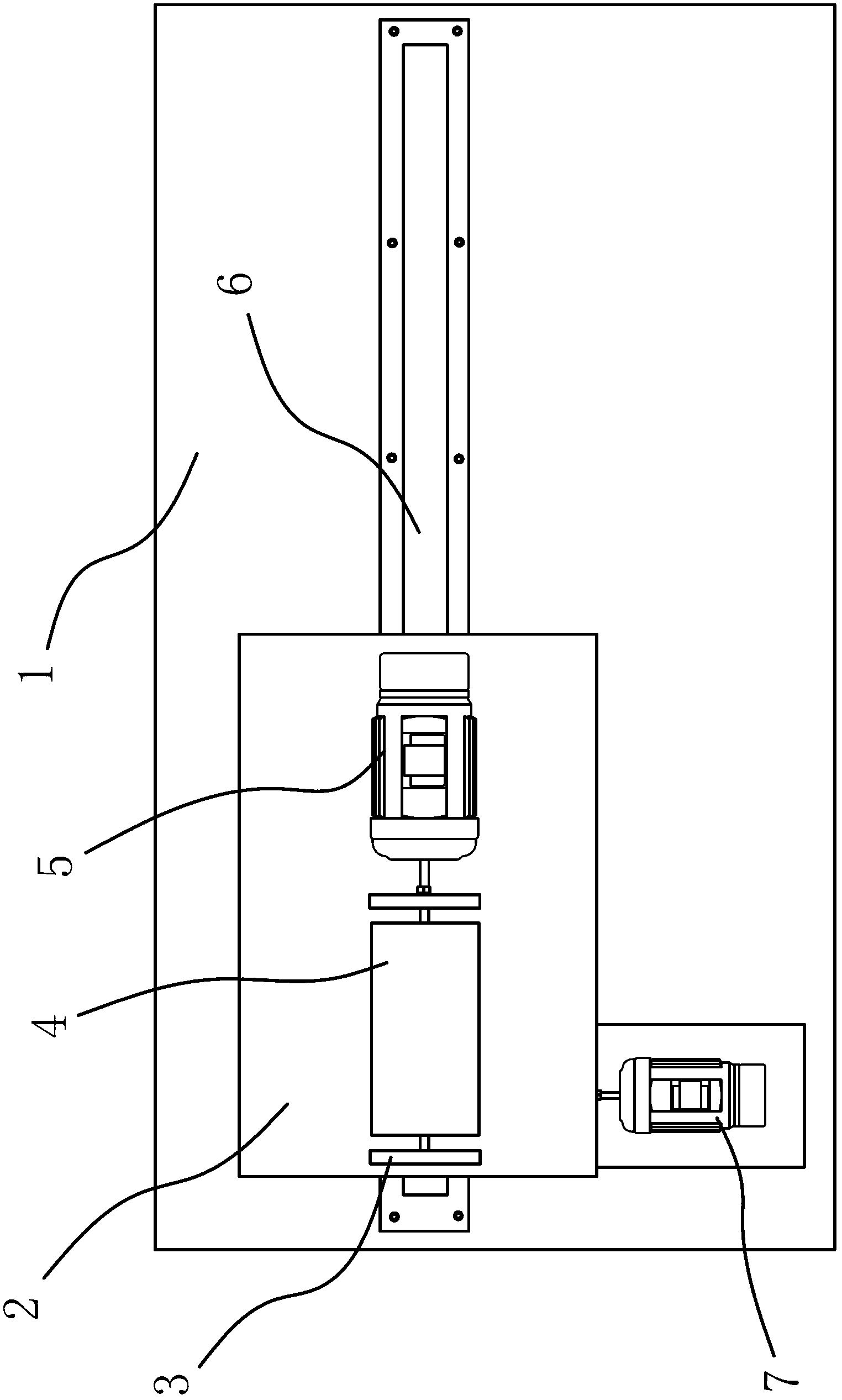

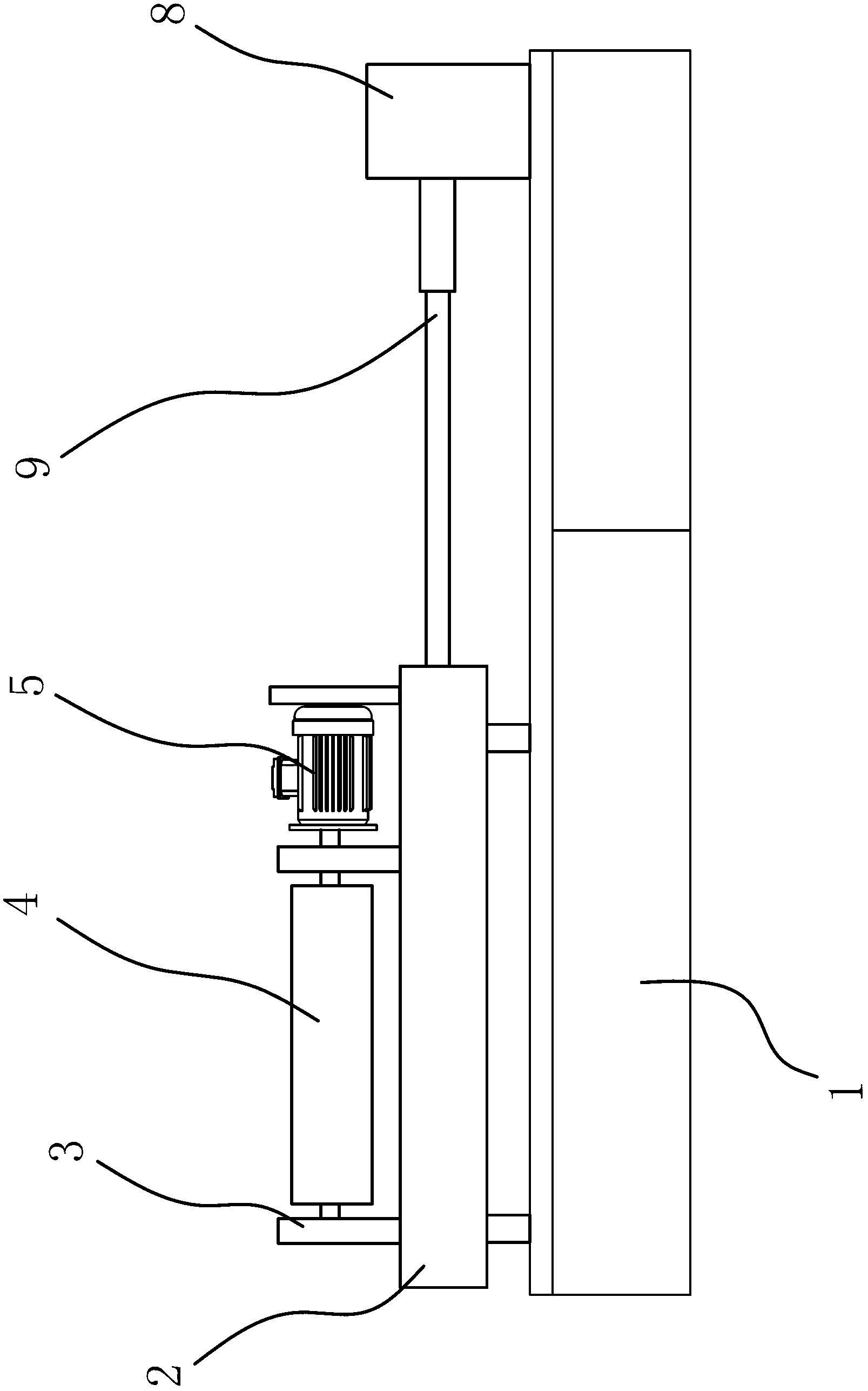

Method for preparing fiber prepreg filaments by hot-melt method and device thereof

The invention relates to a method for preparing fiber prepreg filaments by a hot-melt method and a device thereof. The method provided by the invention comprises the following steps of: 1) placing carbon fiber cone yarns on an unreeling device of a hot-melt prepreg machine according to prepreg production needs; 2) carrying out impregnation on fiber to obtain fiber prepreg; 3) cooling by blowing, entering into a filming device, flattening, spacing, applying and rolling to press and plaster the fiber prepreg at the center of an isolated film to obtain coated fiber prepreg; 4) entering into a reeling device to realize spiral reeling under the control of a reeling controller and a total controller. Therefore, the fiber prepreg filaments are prepared. The invention has the following beneficial effects: the invention is suitable for raw material preparation of fiber reinforced composite products by dry winding or placement moulding production; the reeling length for single fiber prepreg can reach over 3000m, thus reducing the frequency of changing carbon fiber yarns during the production process, raising the production efficiency, decreasing fiber breakage in the product and improving comprehensive performance of the product.

Owner:WUHAN UNIV OF TECH

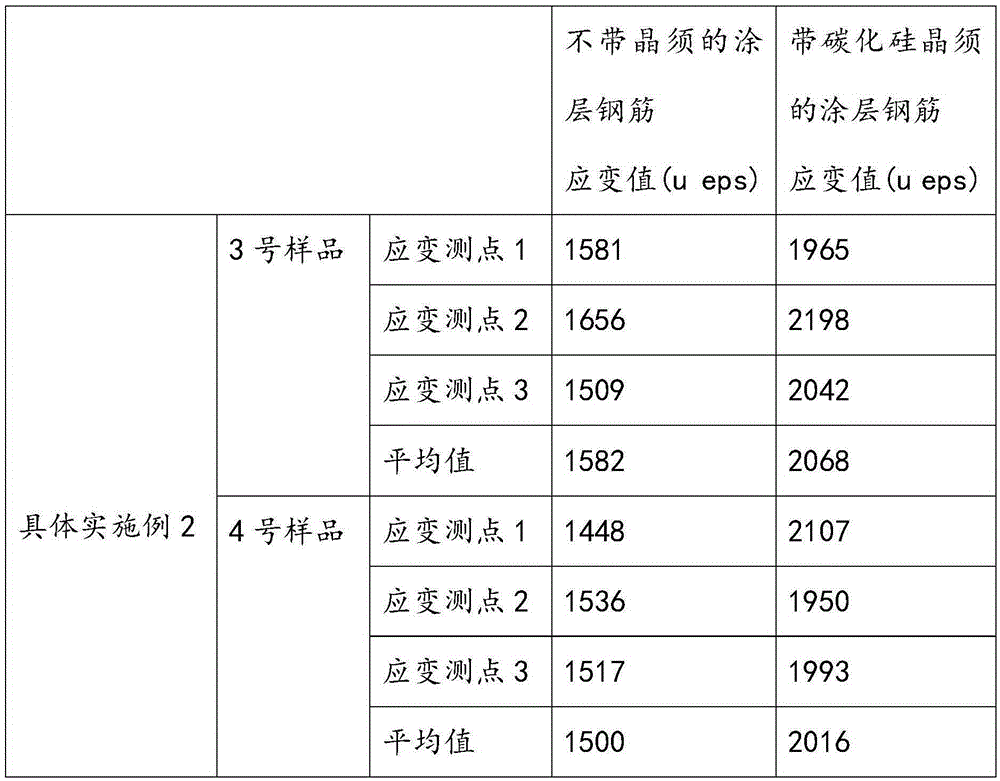

Rebar corrosion resistant coating and coating method therefor

ActiveCN105131660AImprove adhesionIncreased strain valuePretreated surfacesAnti-corrosive paintsRebar corrosionAbsorbed energy

The invention discloses a rebar corrosion resistant coating, and raw material comprises the following components: 45-70 parts of glass powder, 2-8 parts of clay, 26-50 parts of borax, 0.5-3 parts of fiber, 5-15 parts of opacifier, 1-10 parts of adherence agent and 0.25-2.8 parts of electrolyte. The invention further discloses a rebar corrosion resistant coating coating method, comprising the following step of: 1) dry mixing; 2) wet mixing; 3) pre-treating; 4) coating; 5) drying; 6) sintering; and 7) cooling at room temperature. The rebar corrosion resistant coating is high in ductility, high in adhesion performance, high in compactness and excellent in corrosion resistance, the fiber is introduced into the coating so that the corrosion resistant coating, during the breaking process, absorbs energy through mechanisms such as crack deflection, fiber breakage and fiber and removal, so that the coating toughness is improved, the cracking formation is delayed, and the mechanical property of the rebar can be maintained at the same time.

Owner:ZHEJIANG UNIV

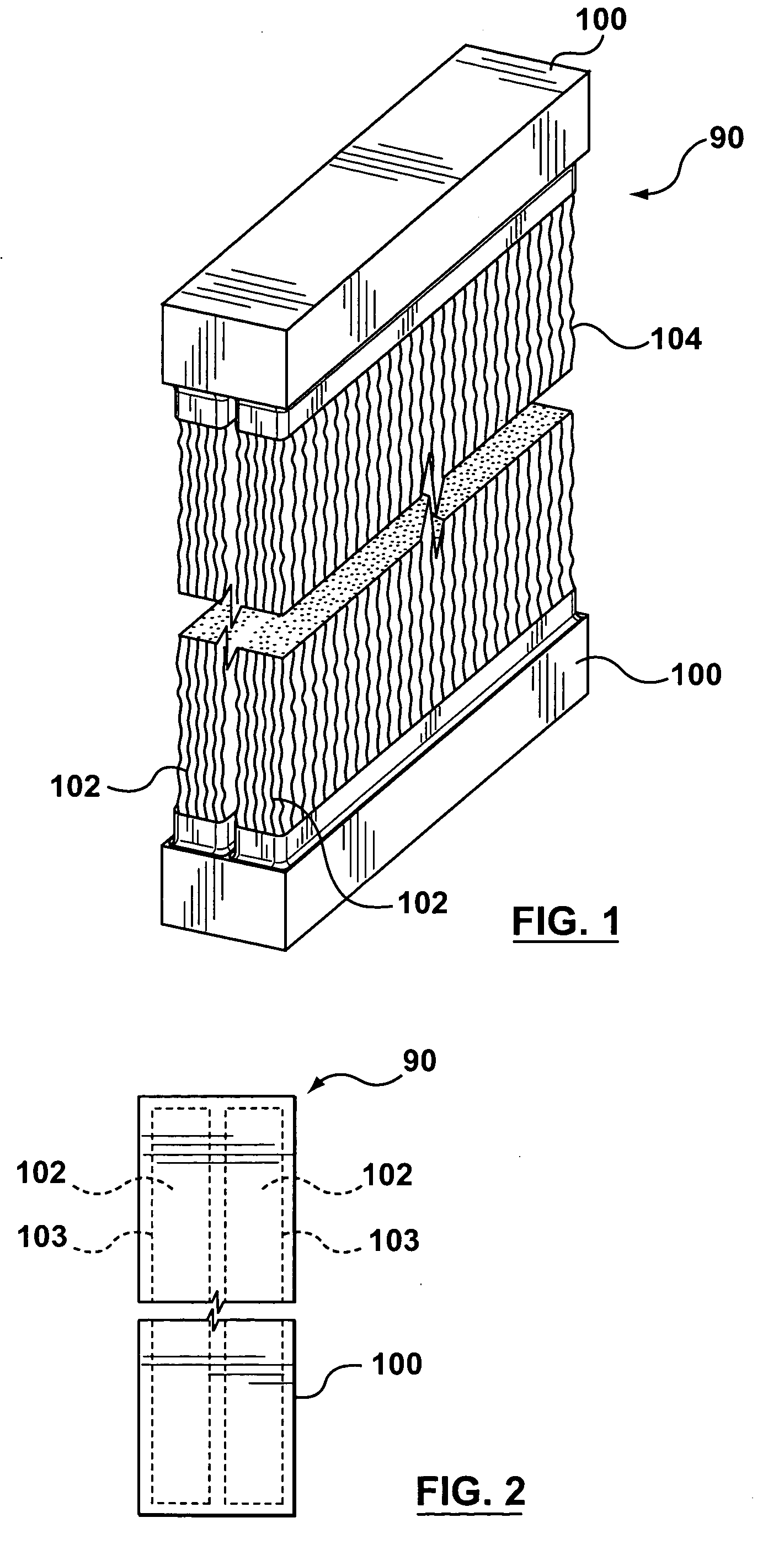

Membrane module having fiber breakage protection

InactiveUS20050126982A1Induce stressReduce breakage rateMembranesSemi-permeable membranesHollow fibre membraneEngineering

An assembly of potted filtering hollow fiber membranes has at least one bundle of permeating hollow fiber membranes that is potted in a block of potting material, and a cushioning wall extending along at least a portion of the axial length of the membranes adjacent the potting material and around at least a portion of the perimeter of the bundle. The cushioning wall can have a fixed edge adjacent the resin, and the wall can extend away from the resin in a direction generally parallel to the axis of the hollow fiber membranes. Walls of various structures including soft solid materials, non-permeating membranes and fabrics are described.

Owner:STACHERA DAVID MICHAEL +4

Preparation method of cellulose acetate fiber

ActiveCN103014892AAvoid pollutionImprove production environmentArtificial filaments from cellulose derivativesMelt spinning methodsPolymer scienceCellulose acetate

The invention relates to a preparation method of cellulose acetate fiber, in particular relates to a method for preparing cellulose acetate fiber after the cellulose acetate fiber is plasticized and modified by taking ionic liquid as a plasticizer. The method comprises the following steps of (1) evenly mixing and extruding the cellulose acetate fiber and the ionic liquid; (2) conducting vacuum drying on spinning materials; (3) conducting melt spinning: spinning the spinning materials through a metering pump and a spin sprayed plate, stretching through a hot roll, extracting liquor and washing; and (4) conducting oiling, drying and winding procedures to obtain cellulose acetate fiber with fiber breakage strength of 2.2-6cN / dtex. By adopting the preparation method of cellulose acetate fiber, the problems that the fiber mechanical property is poor, the breakage strength is low, and due to seeping or volatilization of the plasticizer, high fragility of cellulose acetate fiber grafted copolymer and difficulty of processing in the process of plasticizing and melt spinning cellulose acetate fiber, the fiber fineness is larger and the strength is low, and the like in the dry spinning process of cellulose acetate fiber in the prior art can be solved.

Owner:DONGHUA UNIV

Laser accurate drilling method and device of fiber composite aircraft panel

InactiveCN101804514APrecise positioningFind the location of the centerlineLaser beam welding apparatusLaser rangingLaser processing

The invention discloses a laser accurate drilling method and device of a fiber composite aircraft panel. The method comprises the following steps: after selecting panel installing the positioning mode, adjusting the spatial attitude of the panel; adopting the laser tracking measurement method to search a pre-locating hole according to technological requirements; using the pre-locating hole as datum to determine the position of connection holes to be prepared according to the technological requirements; adopting the laser ranging method to measure the panel normal direction in the area of the connection hole, coinciding the normal direction with the centre line of laser beam; and adjusting the size and displacement of laser processing beam according to the size and arrangement requirements of the connection holes, thus realizing the connection hole preparation of the fiber composite aircraft panel. The method of the invention can realize accurate positioning according to assembly requirements without producing deviated holes or inclined holes; the cutter can not be wore in the drilling process, cutting acting force can not be generated, the problems of drawing, layering, fibre breakage, cutting residual stress and deformation caused by drilling can be overcome, and the high-quality surface of holes can be formed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

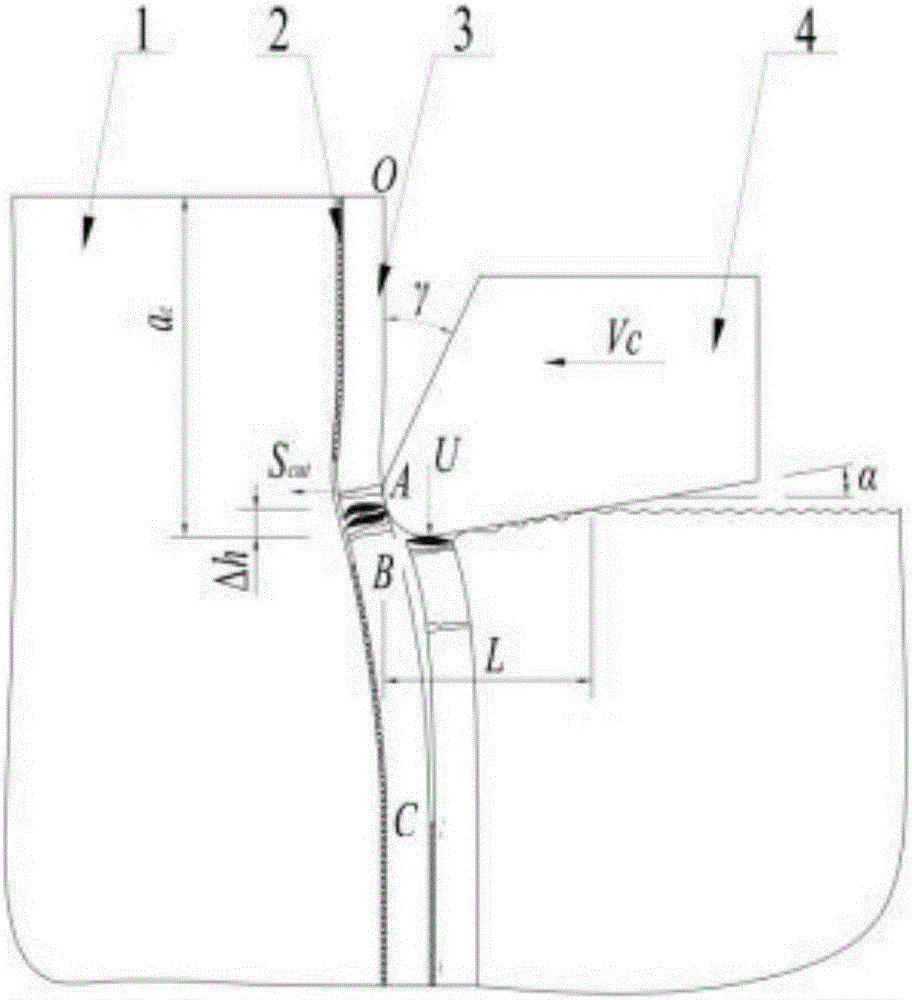

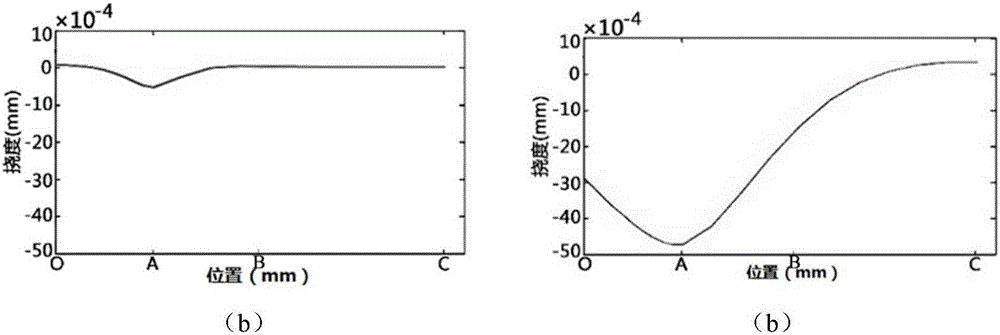

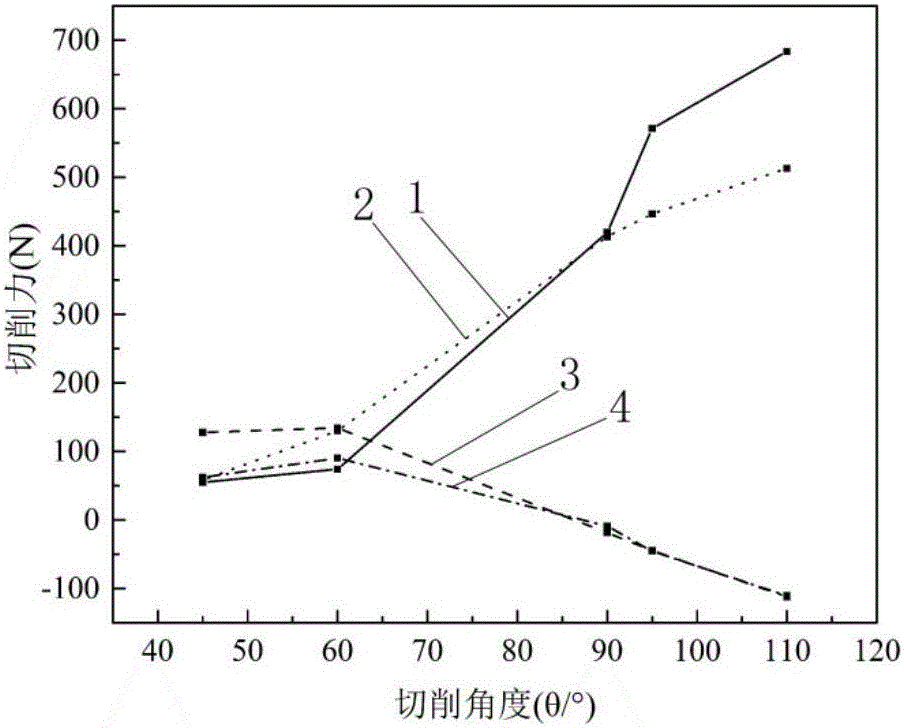

Building method of carbon fiber composite material cutting model

The invention belongs to the field of carbon fiber composite material cutting and processing researching, and relates to a building method of a carbon fiber composite material cutting model. The building method comprises the steps that firstly, a bidirectionally matrix-constrained single-fiber cut-off model is built, wherein the fiber deformation characteristics are described in three segments through the boundary condition difference in the fiber length direction according to the differences of the fiber stress and the borne matrix constraining action of the model in the fiber direction, the first segment starts from the top end to a cutting edge contact point, the second segment starts from the cutting edge contact point to a cutting plane, and the third segment starts from the cutting plane to a certain point far away from a processing surface; secondly, a contact model and a single-fiber compression-shearing model for a cutting edge and fibers are built; lastly, a composite material cutting force model is built. According to the method, fiber breakage, resin interface crack and the extruding action of a rear cutter surface on the fibers can be represented, a quantitative relation between the cutting force and processing parameters in composite material cutting and processing can be obtained, and an experimental basis is provided for actual cutter design and technological parameter establishment.

Owner:DALIAN UNIV OF TECH

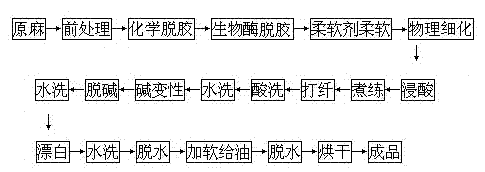

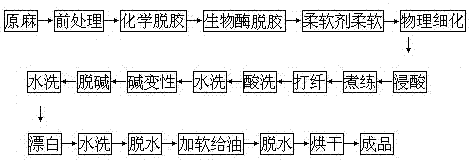

Processing method for refining jute fiber

InactiveCN102517650AAvoid damageImproved splittingBiochemical fibre treatmentVegetable materialPectinaseFiber strength

The invention discloses a processing method for refining a jute fiber, which comprises adopting sodium hydroxide solution to perform chemical degumming on raw jute after water bath or acid bath is carried out to the raw jute, adopting pectinase or laccase to perform biological enzyme degumming, and performing chemical degumming after physical refining is carried out to the jute fiber where a softening agent is sprayed. Damage to the fiber is reduced by adding the softening agent, the fineness is remarkably improved, the softening agent which is sprayed to the jute fiber prior to the physical refining of the jute fiber can reduce friction between the jute fibers, unnecessary fiber breakage is reduced when the physical refining is performed, the fact that the fiber is not damaged is guaranteed, the fiber strength is prevented from being lowered, part of colloid and impurity are exposed out of a surface layer of the fiber due to split separation of the jute fiber after physical refining, the colloid and impurity on the surface layer of the fiber can be removed through chemical degumming treatment after physical refining, the fiber can be further refined, the costs are reduced, and utilizing rate is improved.

Owner:JIANGSU REDBUD DYEING TECH CO LTD

Washing method for spinneret plate

The invention relates to a washing method for a spinneret plate, and mainly solves the technical problems in the prior art that the spinneret plate cannot be cleanly washed, gel is adhered to the surface of the spinneret plate, a spinning solution at the outlet of a spinneret hole overflows, and polyacrylonitrile protofilament has more broken filaments and more thin filaments and is high in fiber breakage rate. The washing method for the spinneret plate comprises the following steps of disassembling the spinneret plate from a spinning assembly; immersing the spinneret plate in a solvent in a container; then immersing the container in water bath; washing by adopting a mode of combining temperature rising with ultrasound; taking out the spinneret plate after the washing is completed; blowing the surface of the spinneret plate by gas which is precisely filtered after the spinneret plate is dried; completing the washing. According to the technical scheme, the problems are well solved, and the washing method can be used in a device washing process after the spinning of the polyacrylonitrile protofilament.

Owner:CHINA PETROLEUM & CHEM CORP +1

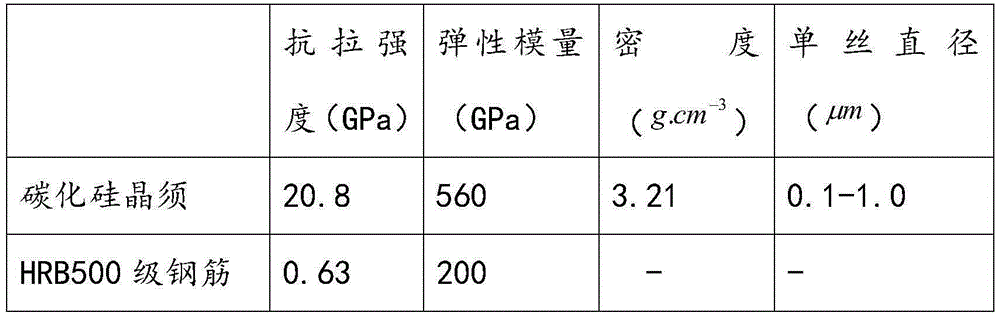

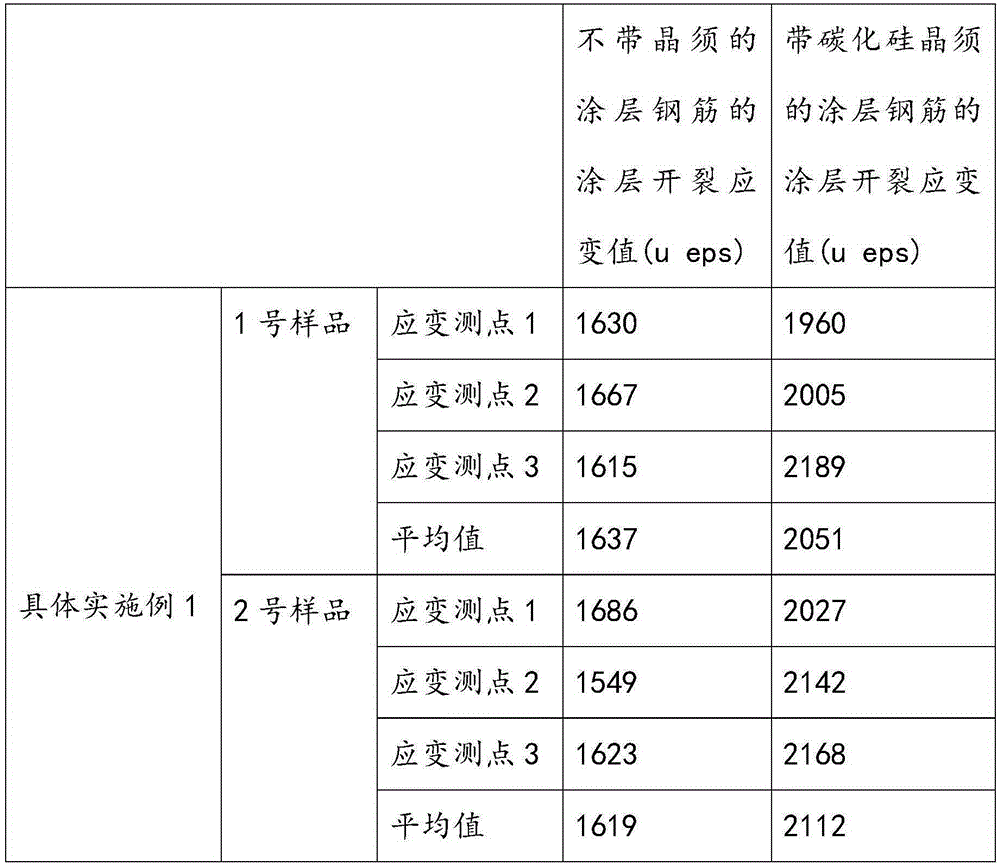

Tenacity coating for preventing steel bars from being corroded and coating method of tenacity coating

ActiveCN105238105AIncreased strain valueIntegrity guaranteedPretreated surfacesAnti-corrosive paintsRebarBorax

The invention discloses a tenacity coating for preventing steel bars from being corroded. The tenacity coating is prepared from 45-70 parts of mica powder, 25-50 parts of borax, 0.5-3 parts of silicon carbide whisker, 3-12 parts of magnesium oxide, 1.0-10 parts of adhesive agents and 0.25-1.8 parts of thickening agents. The invention further discloses a coating method of the tenacity coating. The coating method includes the following steps of 1, dry mixing, 2, wet mixing, 3, preprocessing, 4, coating, 5, drying, 6, sintering and 7, room-temperature cooling. The tenacity coating is simple in process, high in strength, good in dense performance, good in anticorrosion performance, high in tenacity and high in coating ductility, the silicon carbide whisker is introduced into the coating, so that in the breakage process of the anticorrosive coating, energy is absorbed through crack deflection, fiber breakage, fiber pull-out and the like, the tenacity of the coating is increased, and formation of cracking is delayed.

Owner:ZHEJIANG UNIV

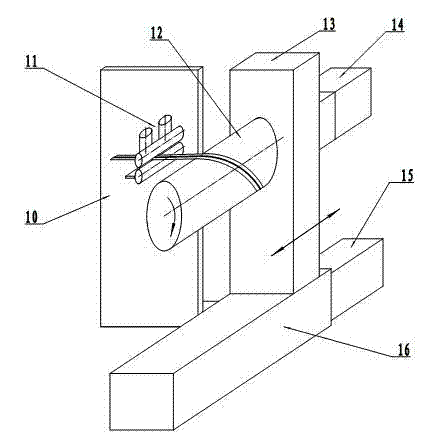

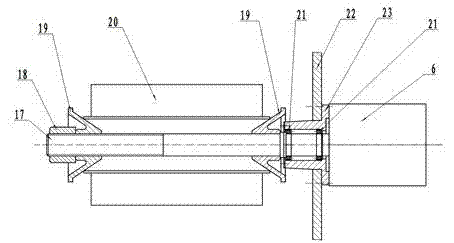

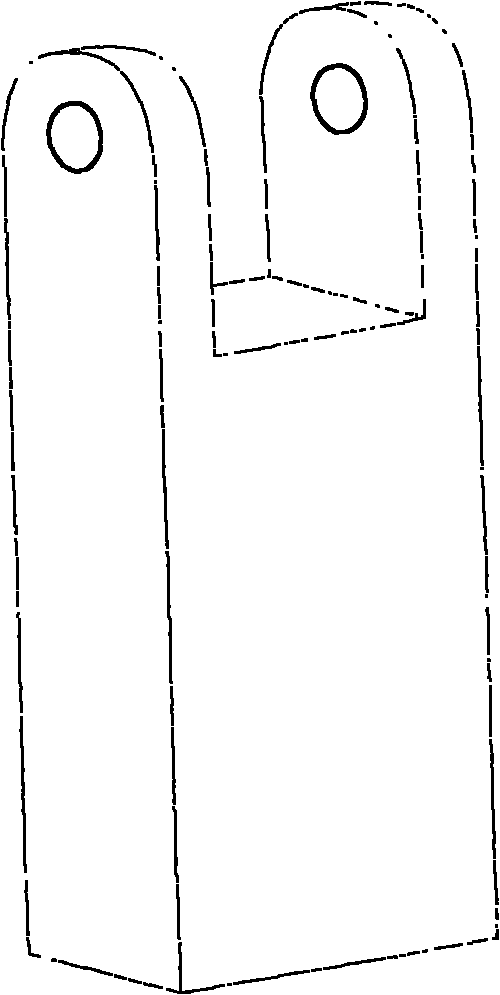

Steel fiber tensioning and clamping fixture and steel fiber tensile strength testing system

InactiveCN105486592AClamp fasteningLarge clamping forceMaterial strength using tensile/compressive forcesLocking mechanismMetallurgy

The invention discloses a steel fiber tensioning and clamping fixture and a steel fiber tensile strength testing system. The steel fiber tensioning and clamping fixture comprises a main bracket, a load transmission mechanism and a steel fiber test piece clamping and locking mechanism, and clamping pieces can effectively clamp and tension a steel fiber test piece in the tensioning process; the steel fiber tensile strength testing system comprises two sets of steel fiber tensioning and clamping fixtures and a data acquisition device, the data acquisition device comprises a load sensor, an extensometer and a controller, the two sets of steel fiber tensioning and clamping fixtures are used for clamping the steel fiber test piece, the extensometer is arranged on the steel fiber test piece, output ends of the load sensor and the extensometer are connected with two input ends of the controller, and an output end of the controller is connected with a computer. According to the steel fiber tensioning and clamping fixture and the steel fiber tensile strength testing system, the tensile strength and the deformation parameters of steel fibers as well as the stress-strain complete curve in the steel fiber breakage process can be accurately tested.

Owner:ZHENGZHOU UNIV

A manufacturing method for a continuous fiber winding reinforced thermoplastic tube and a winding device

The present invention provides a manufacturing method for a continuous fiber winding reinforced thermoplastic tube and a winding device, belonging to the technical field of tube manufacturing, and solving the problem of poor outer wall smoothness and poor robustness, and unstable strength properties of prepared tubes, because continuous fiber performances are reduced due to hairiness or breakage generated from secondary damages of continuous fiber which is easily produced in the prior manufacturing process of continuous fiber winding reinforced thermoplastic tube. The manufacturing method for the continuous fiber winding reinforced thermoplastic tube comprises the following steps of: A, loading and clamping members; B, rotation winding and heating; C, repeating the above step B; D, cooling and stripping. According to the manufacturing method for the continuous fiber winding reinforced thermoplastic tube, a molded continuous fiber band is adopted for direct winding through the winding device, extrusion and dipping are not required, and secondary damages may not be caused to produce hairiness or fiber breakage, thus ensuring the performances and strength of the continuous fiber, and good strength, stiffness, impact resistance and toughness of the prepared tube.

Owner:TAIZHOU JIADEBAO TECH

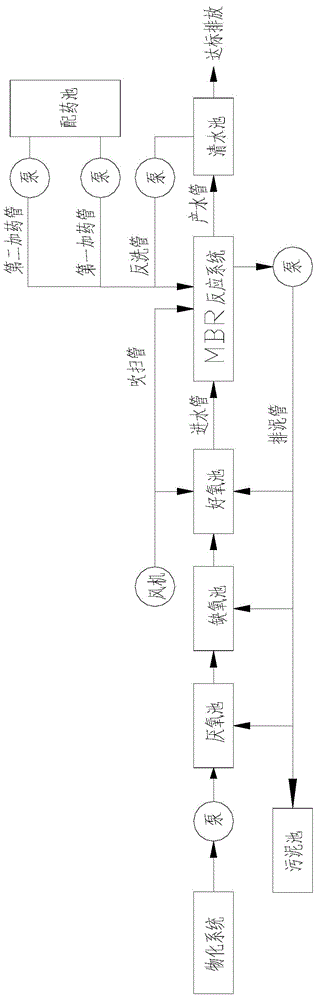

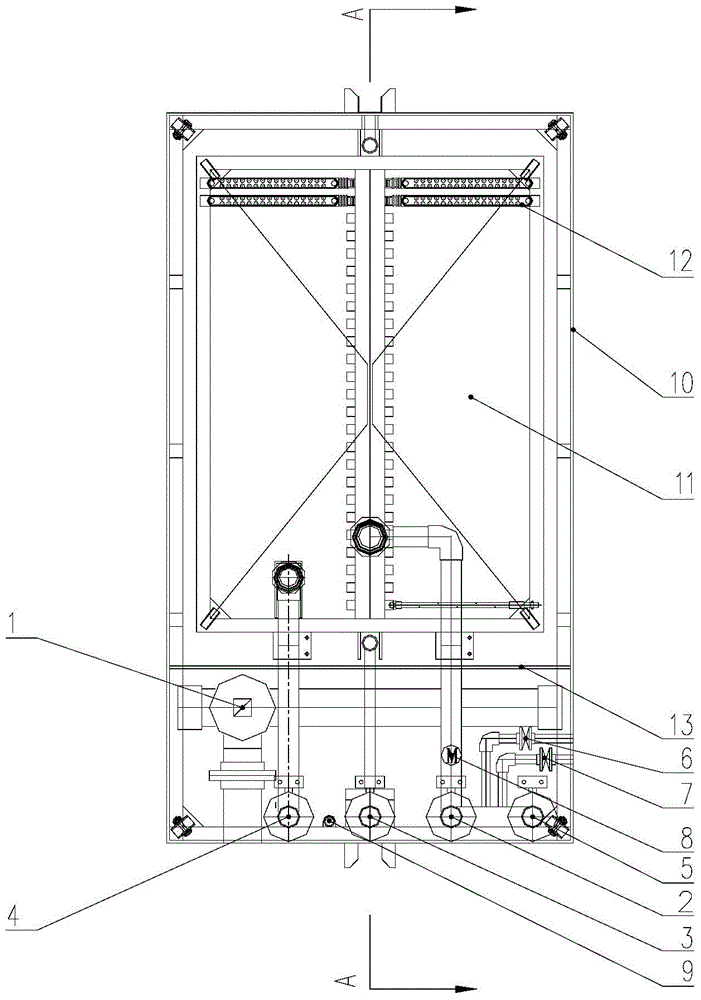

Intelligent sewage treatment system

ActiveCN104609678AImprove operating conditionsAvoid frequent liftingMultistage water/sewage treatmentAutomatic controlInlet valve

The invention discloses an intelligent sewage treatment system. A pressure transmitter which is connected with an automatic control system is arranged on a water-producing pipe, wherein the automatic control system is capable of automatically controlling on / off of a water inlet valve, a water-producing valve, a backwash valve, a mud discharge valve, a blow-down valve and a chemical dosing valve under the action of the pressure transmitter or according to the operation time of the intelligent sewage treatment system, so that in-situ online cleaning and in-situ offline cleaning of an MBR reaction system are automatically controlled; the error of manual operation is reduced; the management cost is reduced; the condition that the MBR reaction system is in a good operation state is ensured; frequent lifting of a membrane module is avoided; the fiber breakage ratio is reduced; the service life of an MBR membrane bioreactor is prolonged; and the exchange cost is reduced. In addition, a sludge reflux system comprising namely a sludge guide plate and a sludge hopper is additionally arranged in the intelligent sewage treatment system disclosed by the invention, thereby achieving significant assisting action for the phosphorous removal effect of the MBR membrane bioreactor.

Owner:GUANGDONG XINDAYU ENVIRONMENTAL PROTECTION TECH CO LTD

Prediction Method of Stress-Strain Behavior of Unidirectional Ceramic Matrix Composites under Arbitrary Loading and Unloading

ActiveCN104866690BPrediction of stress-strain behaviorSpecial data processing applicationsStress distributionMetallurgy

The invention relates to a method for predicting the stress-strain behavior of a composite material, in particular to a method for predicting the stress-strain behavior of a unidirectional ceramic matrix composite material under arbitrary loading and unloading. The purpose of the present invention is to overcome the defects of the prior art and provide a method for quickly predicting the stress-strain behavior of the unidirectional ceramic matrix composite material during random loading and unloading. The invention provides a method for predicting the stress-strain behavior of a unidirectional ceramic matrix composite material under arbitrary loading and unloading, which considers failure mechanisms such as matrix cracking, fiber breakage, interface slippage, and interface wear. The generation and coverage rules of forward and reverse slip zones are proposed, and the stress distribution and strain when there are any number of forward and reverse slip zones are given. Most of the formulas provided by the invention have analytical solutions, so the stress-strain behavior of the unidirectional ceramic matrix composite material under arbitrary loading and unloading can be quickly predicted.

Owner:南京长工智航科技有限公司

Colored polyamide fiber and process for producing the same

ActiveCN101142348AExcellent fiber propertiesSpinning process is stableMonocomponent copolyamides artificial filamentConjugated synthetic polymer artificial filamentsHigh concentrationAliphatic hydrocarbon

Colored polyamide fibers which comprise a polyamide resin, a pigment, a coupling agent, and a compound represented by the following general formula (I): R'-CO-NH-R-NH-CO-R'' (I) (wherein R represents C1-4 alkylene; and R' and R'' each independently represents a C9-18 aliphatic hydrocarbon group). Even when a raw material composition containing the pigment in a high concentration is used, the colored polyamide fibers can be produced therefrom without causing bending or fiber breakage during melt spinning. The pigment has been evenly dispersed in the colored polyamide fibers. The fibers hence has a high color density and a high strength. The colored polyamide fibers are suitable for use in producing artificial leathers.

Owner:KURARAY CO LTD +1

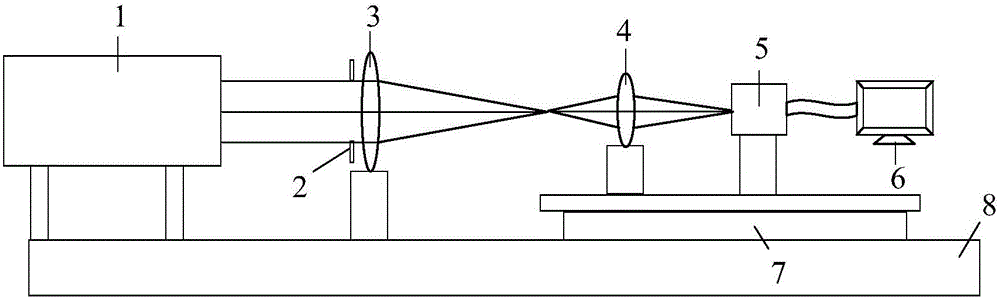

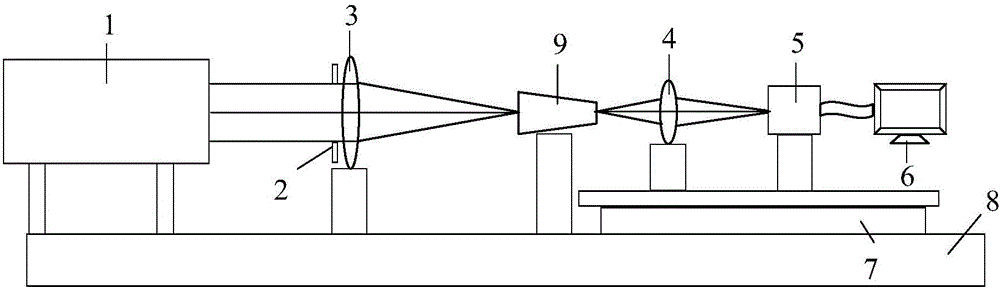

Optical efficiency testing device and optical efficiency testing method for infrared fiber image-transmitting bundle

ActiveCN106053026AMeet the light transmission characteristicsAccurately reflectTesting optical propertiesTesting fibre optics/optical waveguide devicesFiber bundleTransmittance

The invention provides an optical efficiency testing method for an infrared fiber image-transmitting bundle, wherein the optical efficiency of the to-be-tested fiber image bundle is tested through stable infrared radiation energy I1 which is obtained by a standard black body and infrared radiation energy that is output through transmission of the fiber image-transmitting bundle. Compared with a method of testing optical fiber damping (unit dB / m) or parallel light transmittance through a truncation method in current fiber testing, the optical efficiency testing method has advantages of higher visuality and higher pertinency. The optical efficiency testing method more accords with optical transmission characteristic of the fiber and can more accurately reflect optical transmission performance of the fiber image-transmitting bundle. The optical efficiency testing method can settle a problem of no specialized instrument and device for testing the performance of the infrared fiber image-transmitting bundle. Furthermore an optical efficiency testing device of the optical efficiency testing method can be used for testing other main indexes such as arrangement irregularity and fiber breakage rate in the fiber image-transmitting bundle.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

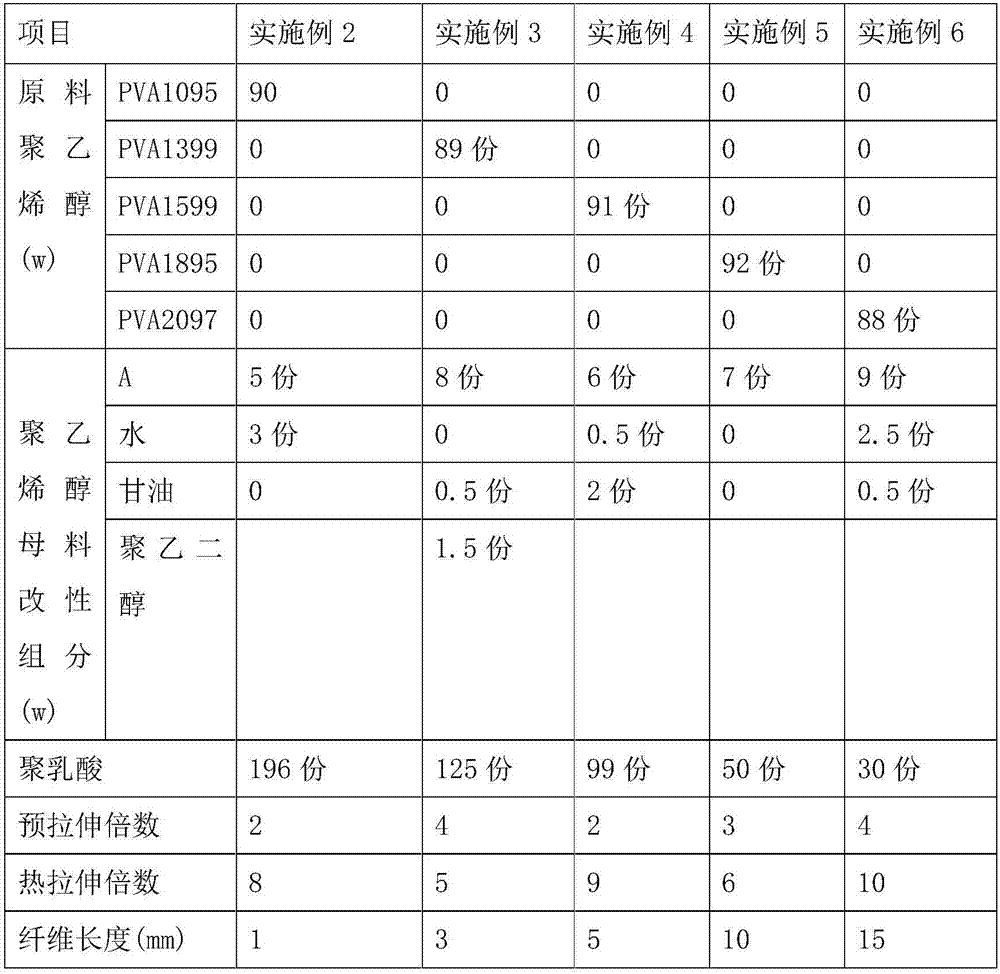

Polyvinyl alcohol master batch-polylactic acid composite fiber and application thereof

ActiveCN107287691AGood water solubilityHigh strengthDrilling compositionConjugated synthetic polymer artificial filamentsSolubilityDispersity

The invention discloses a polyvinyl alcohol master batch-polylactic acid composite fiber. The polyvinyl alcohol master batch-polylactic acid composite fiber is characterized by being prepared by co-blending and modifying a polyvinyl alcohol master batch and polylactic acid, and performing melt spinning, wherein a mass proportion of the polyvinyl alcohol master batch to the polylactic acid is (3 to 7) to (2 to 6), and the modified composite fiber contains a -NH-CO- radical. The polyvinyl alcohol-polylactic acid composite fiber has high water solubility, high strength, high dispersity in water, is more than or equal to 260cN / dtex in the modulus, is 10 to 20 percent in the fiber breakage elongation rate, and is up to level 1 in the fiber dispersion level; after an aqueous solution containing 5 percent of composite fiber is heated to 90 DEGC C and is kept at the temperature of 90 DEG C for 5 hours, the composite fiber can be dissolved by 35 to 60 percent; after an aqueous solution containing 5 percent of composite fiber is heated to 90 DEGC C and is kept at the temperature of 90 DEG C for 25 hours, the composite fiber can be dissolved by 99.5 to 100 percent.

Owner:CHINA PETROCHEMICAL CORP +1

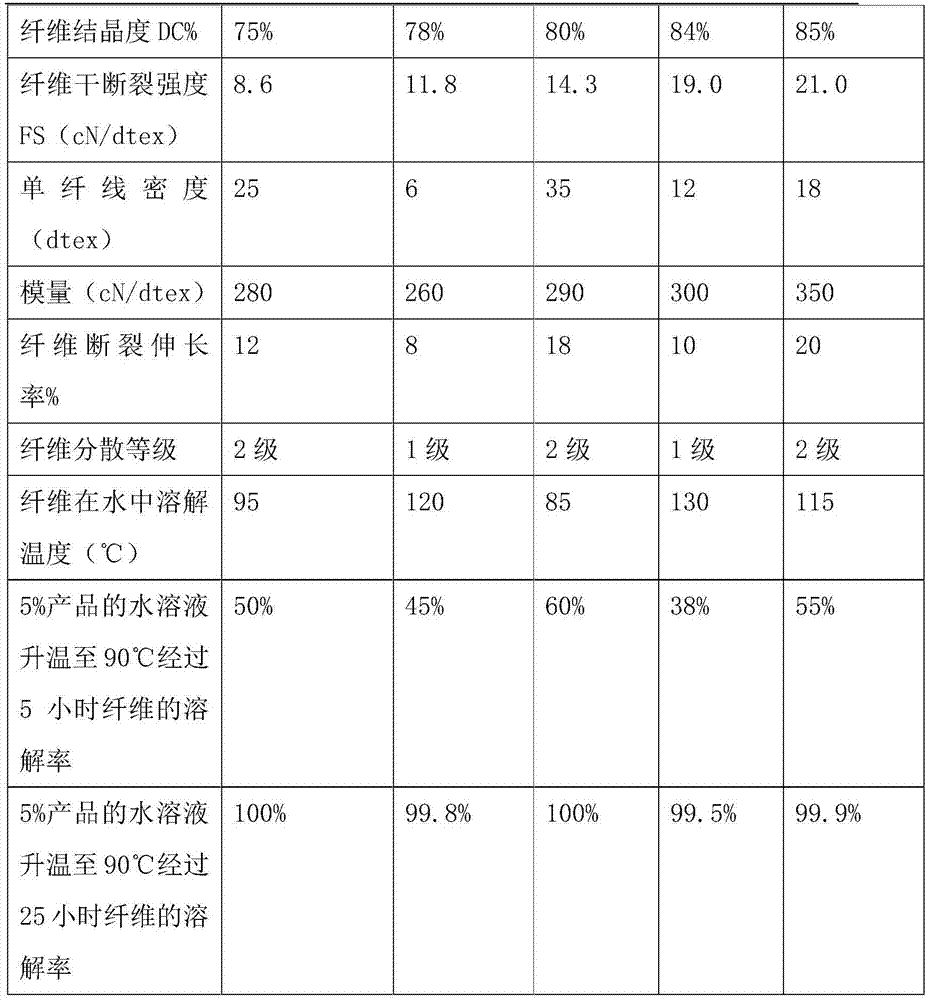

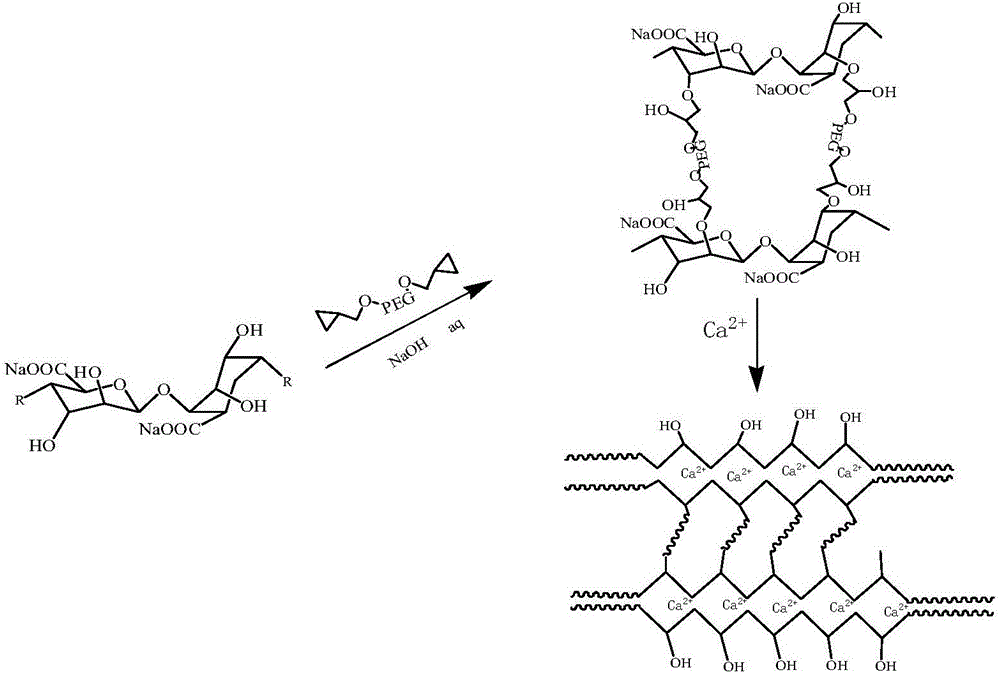

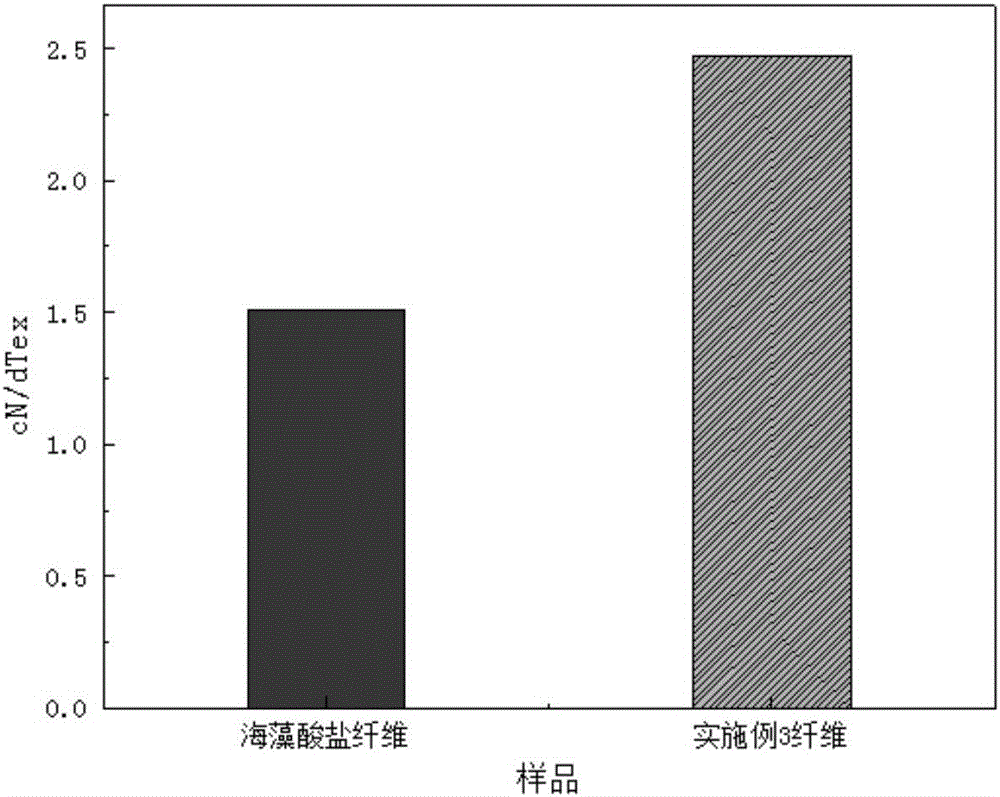

Chemically cross-linked modified alginate fiber and preparation method thereof

ActiveCN106435833ANo phase separationHigh strengthAlginate artificial filamentsPolymer scienceSpinning

The invention discloses a chemically cross-linked modified alginate fiber and a preparation method thereof. The chemically cross-linked modified alginate fiber is formed by dissolving a pH adjusting agent, sodium alginate and a crosslinking agent in water, and conducting crosslinking and solidification, wherein the concentration of the pH adjusting agent is 0.05 to 0.15 mol / L, the concentration of the sodium alginate is 1% to 3%, and the mass ratio of the sodium alginate to the crosslinking agent is 100: 10 to 100: 50. The chemically cross-linked modified alginate fiber has high fiber breaking strength; in the preparation process of the chemically cross-linked modified alginate fiber, the cross-linking degree of alginate is controlled by controlling the amount of the crosslinking agent so as to adjust the balance between fiber strength and spinning fluid processing performance and meet the actual processing and application requirements.

Owner:DALIAN POLYTECHNIC UNIVERSITY

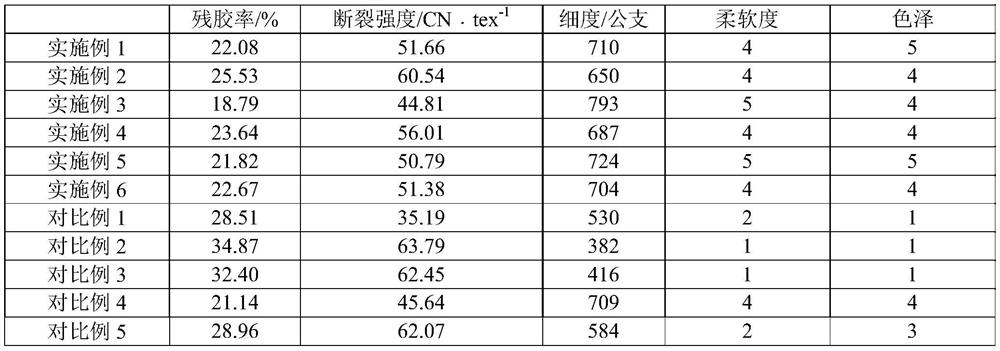

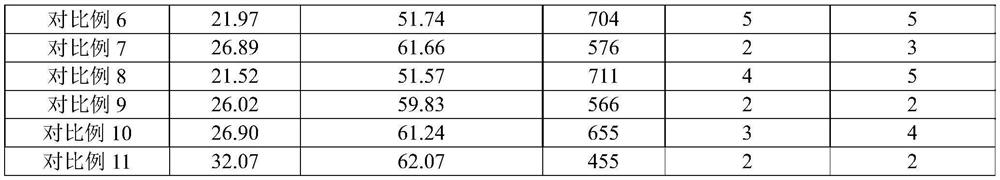

Biological extraction method of pineapple leaf fibers

ActiveCN111996603AGood flexibilityImprove bulkMechanical fibre separationBacteriological rettingBiotechnologyHemicellulose

The invention belongs to the technical field of renewable resource application, and particularly relates to a biological extraction method of pineapple leaf fibers. The biological extraction method comprises the following steps of (1), enzyme treatment, specifically, adding a pineapple leaf fiber raw material into an enzyme solution, and carrying out enzymolysis treatment; (2), enzyme deactivationand rinsing, specifically, adding the fiber subjected to enzymolysis into a rinsing solution, and treating at 80-95 DEG C for 60-90 minutes; (3), ultrasonic treatment, specifically, carrying out ultrasonic treatment on the pineapple leaf fibers for 60-90 minutes at normal temperature; and (4), drying, specifically, drying the pineapple leaf fibers at 50-80 DEG C. According to the biological extraction method of the pineapple leaf fibers, most of substances such as lignin and hemicellulose in the pineapple leaf fiber raw material (namely crude fiber) are decomposed by the biological enzyme, sothat the residual gum rate of the treated pineapple leaf fibers reaches 25.53% or below, the breaking strength of the fibers reaches 44.81 cN / tex or above, and the fineness is 650 counts or above.

Owner:QIQIHAR UNIVERSITY

Novel glass fiber impregnating compound and preparing method thereof

The invention discloses a novel glass fiber impregnating compound. The novel glass fiber impregnating compound is prepared from, by weight, 20-30 parts of vinyl water-borne epoxy resin, 20-30 parts of 3,4-epoxy group-6-methyl cydohexane formic acid-3,4-epoxy group-6-methyl cyclohexane methyl ester epoxy resin, 10-20 parts of hydroxypropylation modified pea starch, 3-5 parts of coupling agent, 0.5-2 parts of lubricating agent, 0.5-1 part of collecting agent, 0.5-1 part of surfactant, 0.5-2 parts of polyvinylpyrrolidone, 0-0.5 part of antistatic agent, 0.5-1 part of defoamer and 300-500 parts of water. By adding polyvinylpyrrolidone to the formula, adhesive force of the impregnating compound can be improved, viscosity of the impregnating compound can be improved, fiber breakage can be prevented, plasticity and stiffness can be improved, and broken filament generation can be reduced. Three film-forming agents are adopted; yarn impregnation speed is high, heat resistance is high, binding power is high, film-forming property is high, and protective property is high; protection and collection of glass fiber during high-speed jetting and rolling can be achieved easily, production efficiency is improved, and mechanical property of glass fiber is improved.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

Preparation method of textile waterproofing agent

InactiveCN108411638AGood dispersionImprove adhesionBiochemical fibre treatmentLiquid repellent fibresQuantumUltraviolet resistance

The invention discloses a preparation method of a textile waterproofing agent, and belongs to the field of textile waterproofing materials. Nano-silica is modified by coupling agents, owing to small size effects and macroscopic quantum tunneling effects of the nano-silica, fiber breakage can be effectively prevented, the abrasion resistance of a serous membrane is improved, the dispersibility of the nano-silica can be improved, and mallow bark extracting solution is adsorbed by the adsorption performance of the nano-silica. As extracting solution molecules contain much -OH and enter a weave structure of a silk fabric, fibers generate good cohesiveness, and the tensile property and the ultraviolet resistance of the fabric are improved. The preparation method solves the problems of low tensile property and fiber breakage of fabrics due to the fact that waterproofing agents in the present market cannot effectively prevent water.

Owner:郭跃

Antistatic wear-resistant non-woven fabric for manufacturing dust-free wiping paper and treatment method thereof

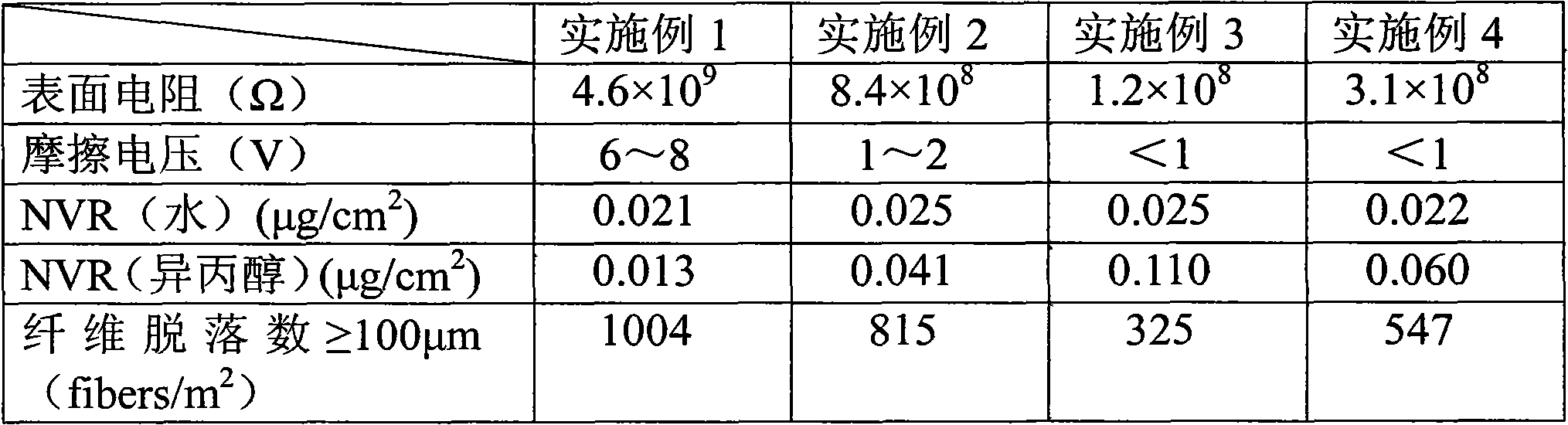

ActiveCN102383307AHas antistatic effectImprove antistatic performanceNon-woven fabricsVegetal fibresCellulosePolyester

The invention discloses an antistatic wear-resistant non-woven fabric for manufacturing dust-free wiping paper and a treatment method thereof. The antistatic wear-resistant non-woven fabric is cellulose filament non-woven fabric of which the surface is coated with an antistatic coating, or spun-laced non-woven fabric formed by combining cellulose staple fibers and polyester staple fibers in different proportions, wherein the antistatic coating is a melamine resin coating combined with an antistatic agent with an active group. The treatment method comprises the following steps of: (1) preparing an antistatic coating solution; (2) coating the antistatic coating solution on non-woven fabric with a dip-coating process; (3) drying the non-woven fabric containing the antistatic coating solution; and (4) packaging the dried non-woven fabric in rolls to obtain the antistatic wear-resistant non-woven fabric. The antistatic wear-resistant non-woven fabric has the advantages of durable antistatic performance, high wear resistance, low probability of fiber breakage by hooking in use and fewer fallen fibers. The treatment process is simple; and the antistatic agent can be firmly combined on the surface of the non-woven fabric without polluting a product.

Owner:SHENZHEN SELEN SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com