Prediction Method of Stress-Strain Behavior of Unidirectional Ceramic Matrix Composites under Arbitrary Loading and Unloading

A composite material, stress-strain technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as long calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The invention discloses a method for predicting the stress-strain behavior of a unidirectional ceramic matrix composite material in any loading and unloading process. The specific steps of the method are as follows:

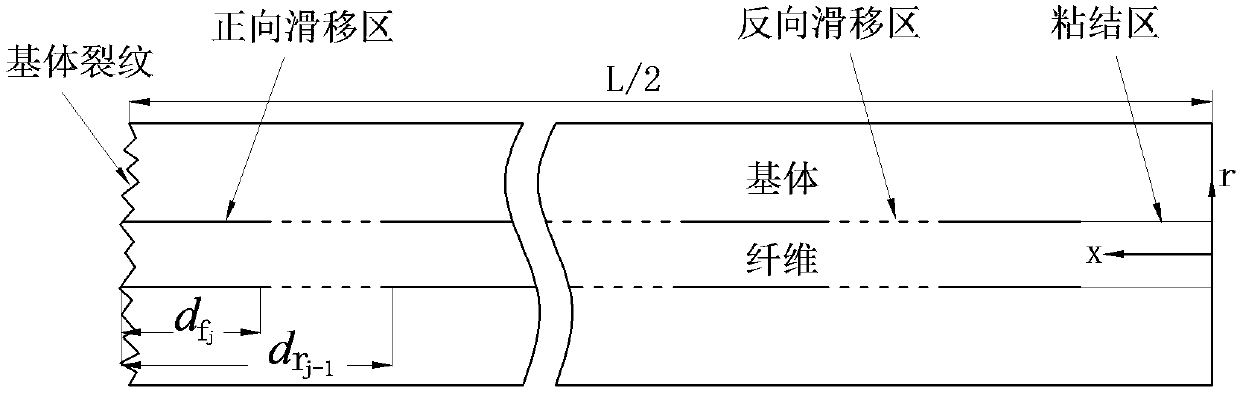

[0056] 1) Determine whether the material has matrix cracks. If no matrix cracks occur, calculate the strain according to the mixing ratio formula. Otherwise, perform step 2). The material after matrix cracks represents a voxel, such as figure 1 shown;

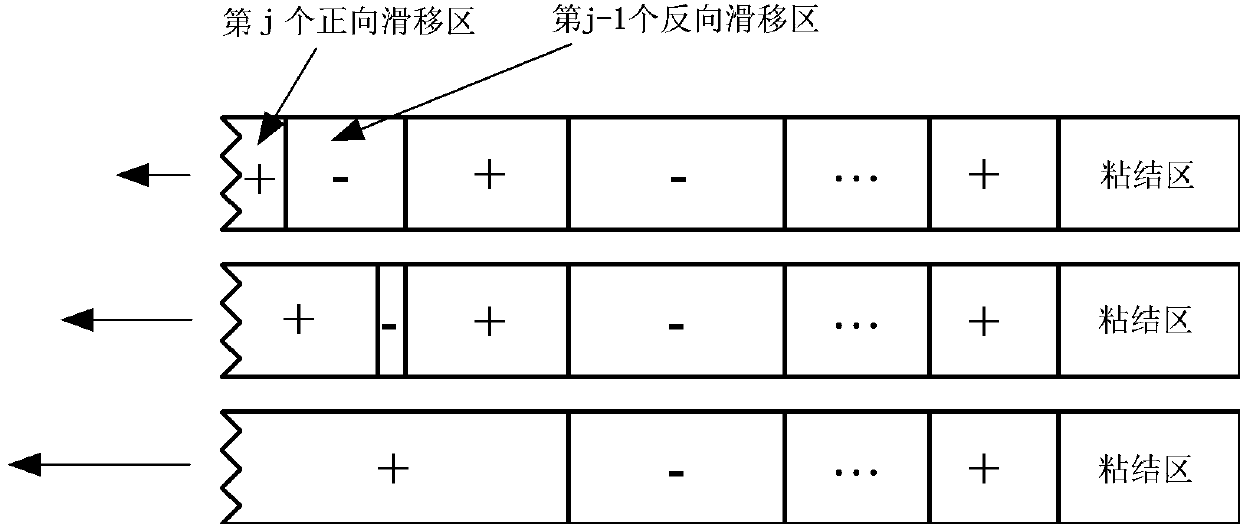

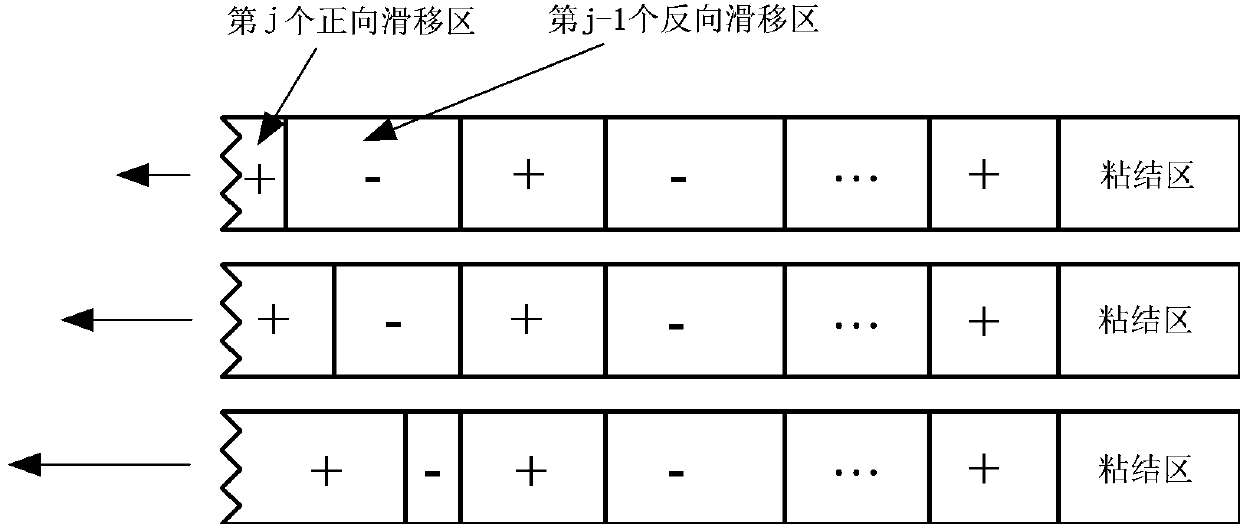

[0057] 2) Determine the number of slip zones;

[0058] 3) Calculate the current interface shear stress τ based on the load history i ;

[0059] 4) Calculate the current fiber fracture rate D based on the Weibull failure distribution, and calculate the new fiber volume fraction v f ;

[0060] 5) Calculate the matrix crack spacing L based on the critical matrix strain energy criterion;

[0061] 6) Calculate the length of the new slip zone;

[0062] 7) Judging whether the slip zone coverage occurs, if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com