Steel fiber tensioning and clamping fixture and steel fiber tensile strength testing system

A technology for clamping fixtures and steel fibers, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, strength characteristics, etc. The difference of fiber tensile properties and other problems can avoid adverse effects, uniform force and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

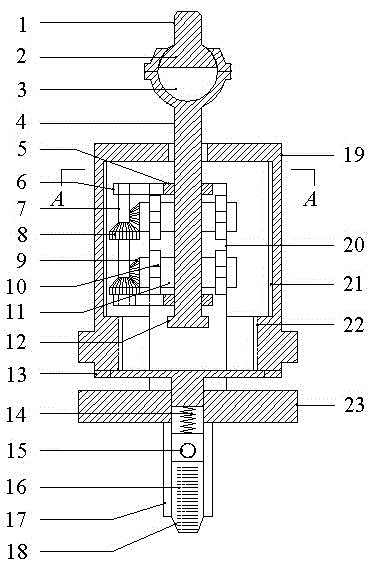

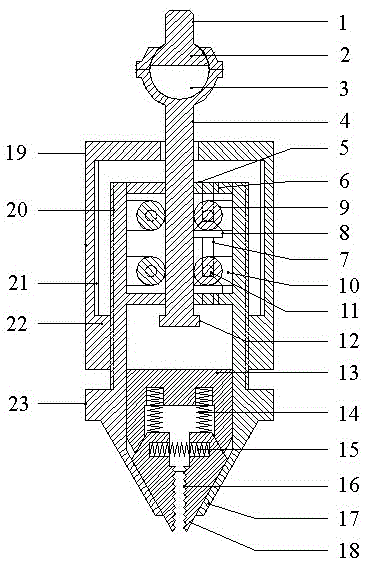

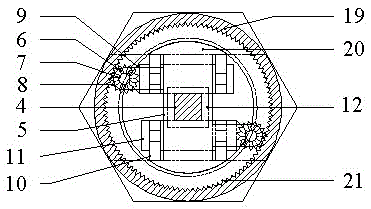

[0032] Such as figure 1 , figure 2 and image 3 As shown, the steel fiber tension clamping fixture includes a main support 23, a load transmission mechanism and a steel fiber specimen clamping and locking mechanism.

[0033] The center of the main bracket 23 is provided with a square guide hole passing through the upper end surface and the lower end surface, and two limbs 20 are provided on both sides of the square guide hole connected with the main bracket 23;

[0034] The load transfer mechanism includes a square column toothed tie rod 4, a limit plate 5 to ensure the linear movement of the toothed tie rod 4, an anti-off baffle 12, a gear transmission assembly and a tightening cap 19; the limit plate 5 is connected horizontally Set on the top of the two limb arms 20 and the middle part of the inner side wall, the center of the limit plate 5 is provided with a square guide hole, the guide hole is provided with a toothed pull rod 4, and the lower end of the toothed pull rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com