Patents

Literature

650 results about "Properties of concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete has relatively high compressive strength, but significantly lower tensile strength. As a result, without compensating, concrete would almost always fail from tensile stresses – even when loaded in compression. The practical implication of this is that concrete elements subjected to tensile stresses must be reinforced with materials that are strong in tension (often steel). The elasticity of concrete is relatively constant at low stress levels but starts decreasing at higher stress levels as matrix cracking develops. Concrete has a very low coefficient of thermal expansion, and as it matures concrete shrinks. All concrete structures will crack to some extent, due to shrinkage and tension. Concrete which is subjected to long-duration forces is prone to creep. The density of concrete varies, but is around 2,400 kilograms per cubic metre (150 lb/cu ft).

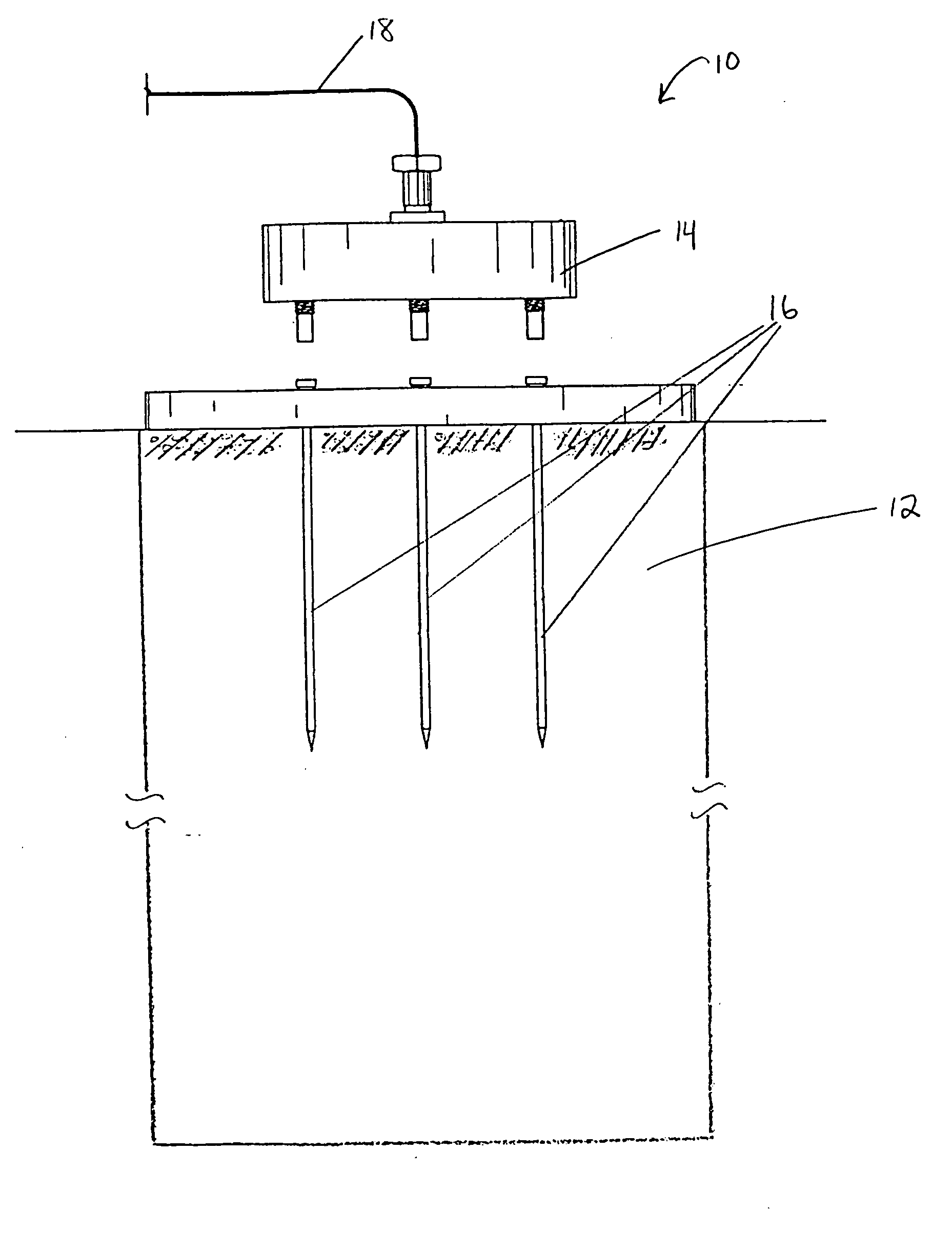

Method and systems relating to construction material assessment

ActiveUS20180238820A1Address limitationsForce measurement by measuring frquency variationsWeather/light/corrosion resistanceField testsWater content

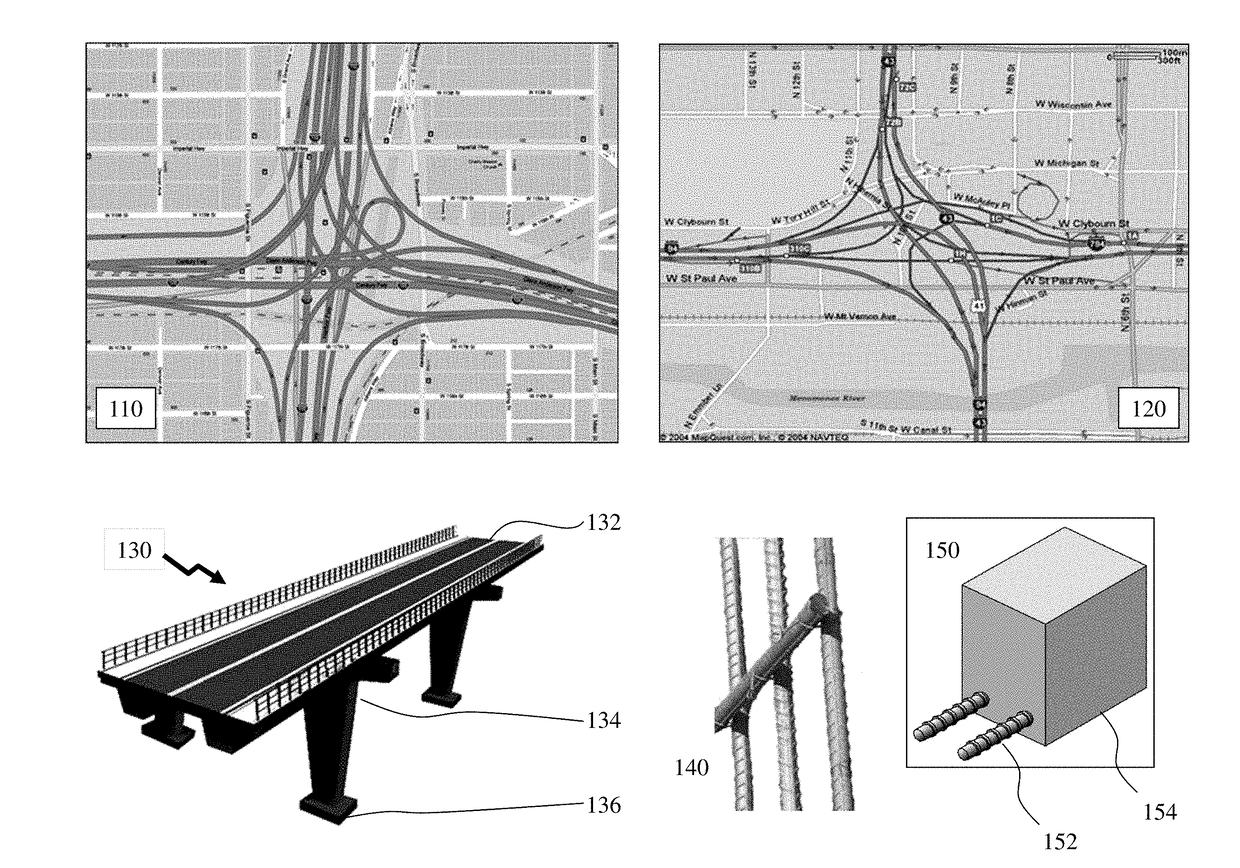

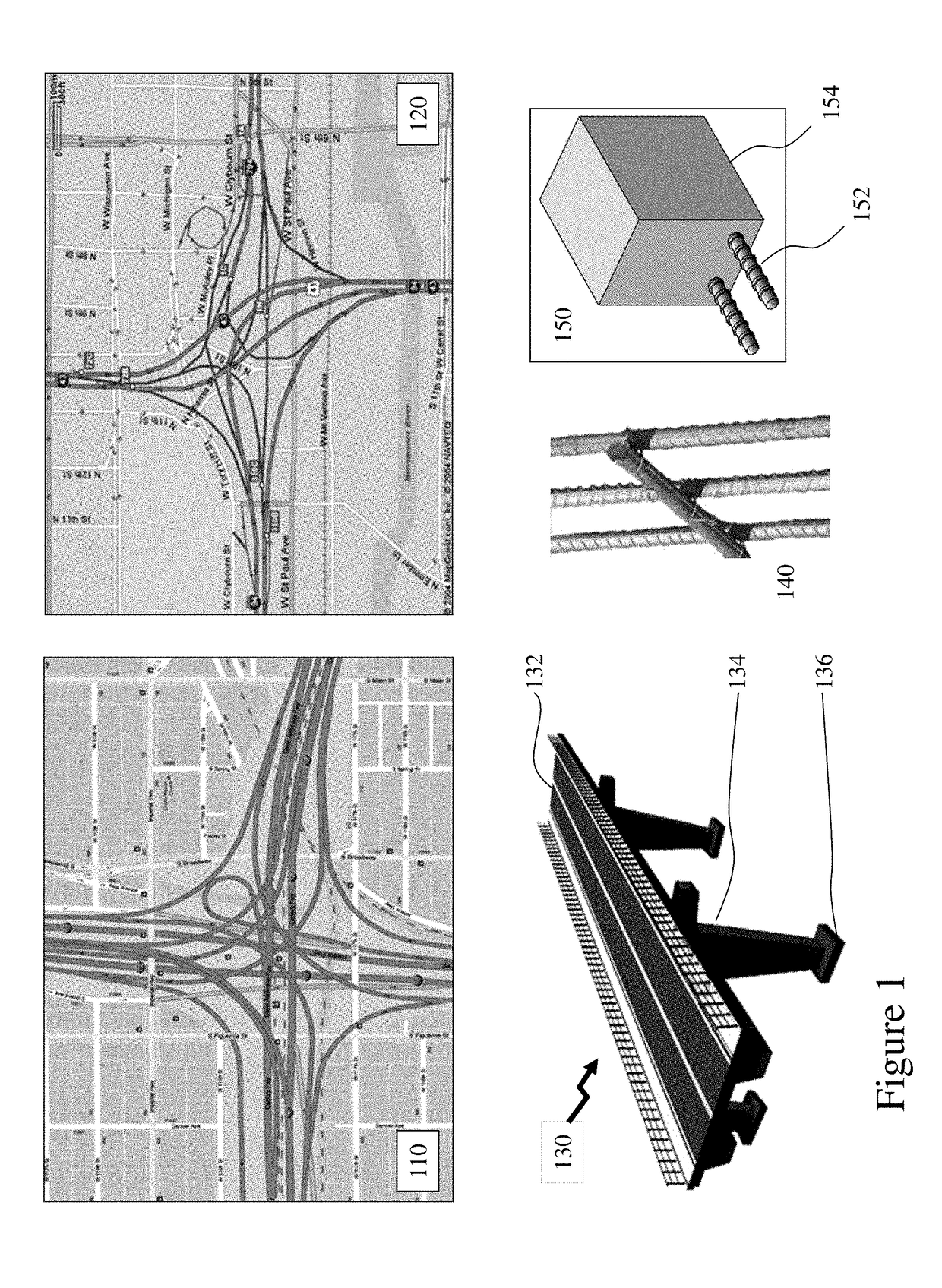

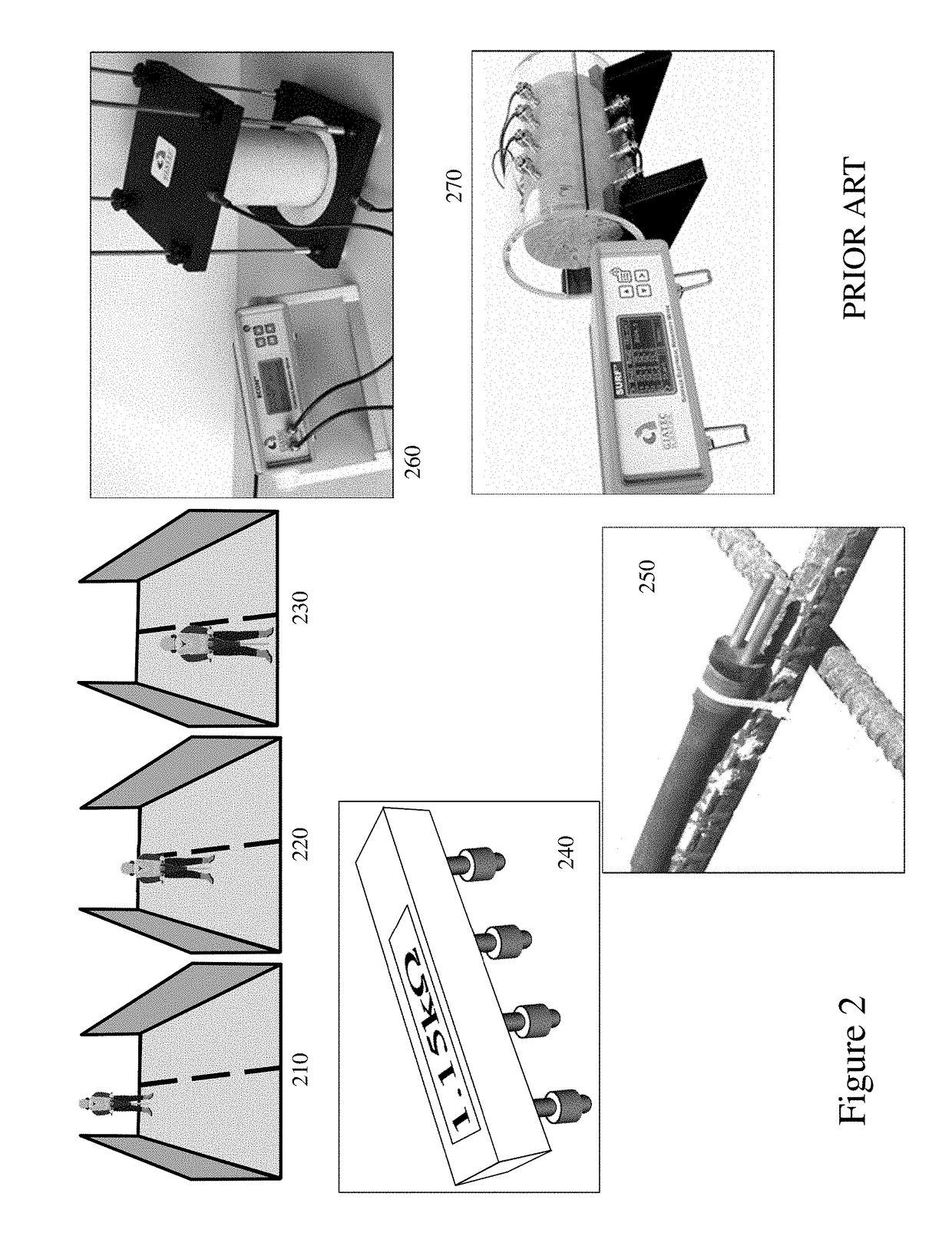

Hundreds of thousands of concrete bridges, buildings etc. and hundreds of billions of tons of concrete require characterization throughout the process from manufacture to pouring and curing and on throughout service life. The characterization may relate to initial concrete properties, projected concrete properties, framework removal, corrosion, failure etc. Accordingly, a variety of measurements such as water content, electrical resistivity, and half-cell corrosion potential for example would be beneficially implemented as easy to use field test equipment or embedded sensors allowing lifetime monitoring to be performed rather than discrete assessments when issues become evident.

Owner:GIATEC SCI

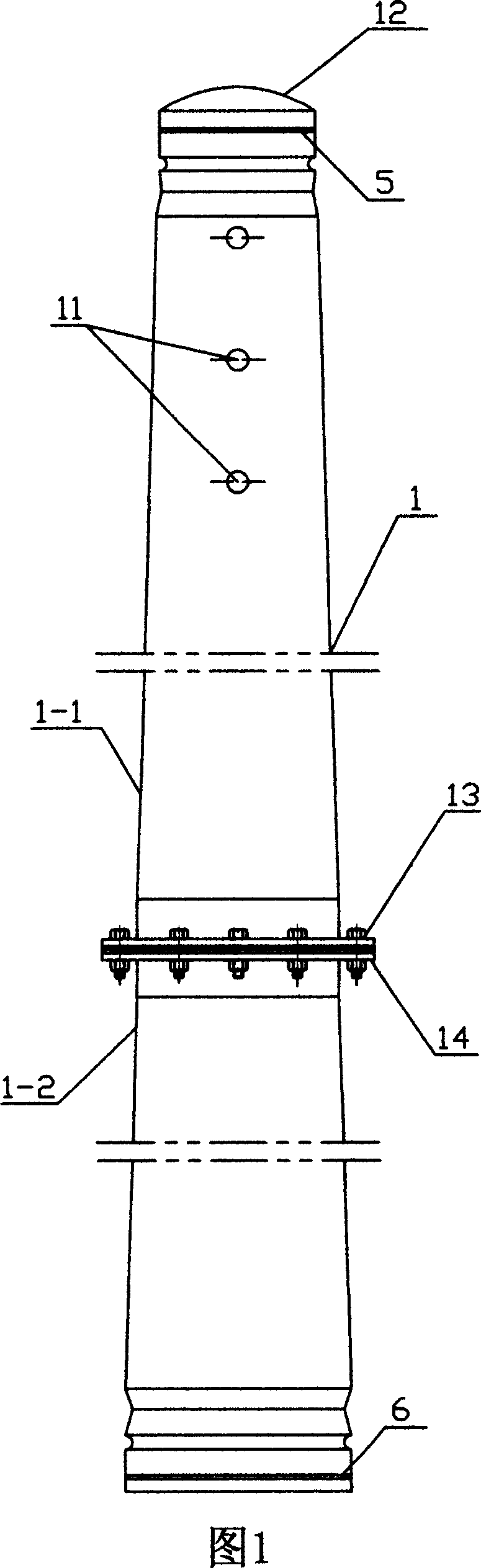

Prestressed concrete electrical pole and its production

InactiveCN101029540AImprove carrying capacityAvoid breakingCeramic shaping apparatusTowersReinforced concretePre stress

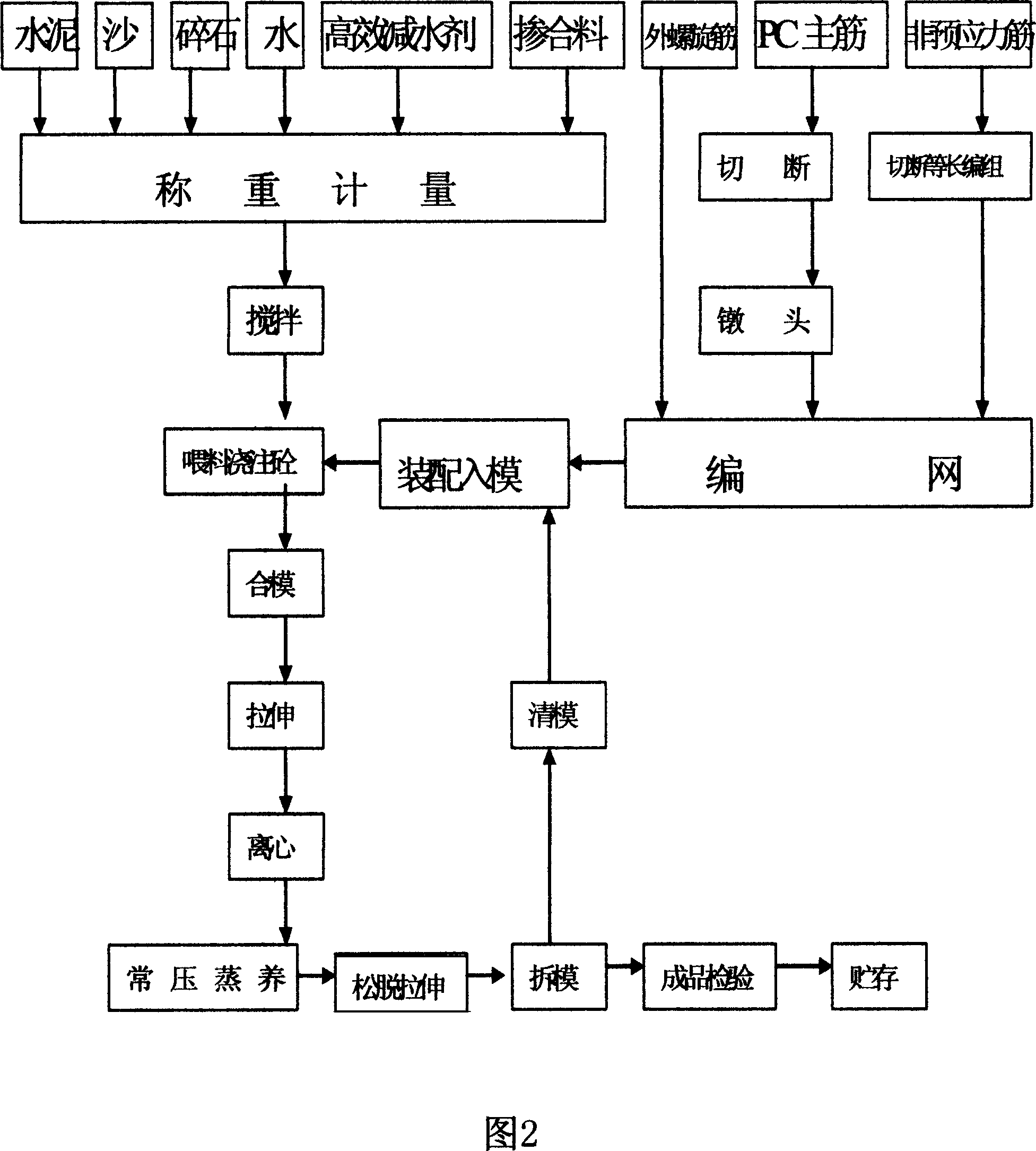

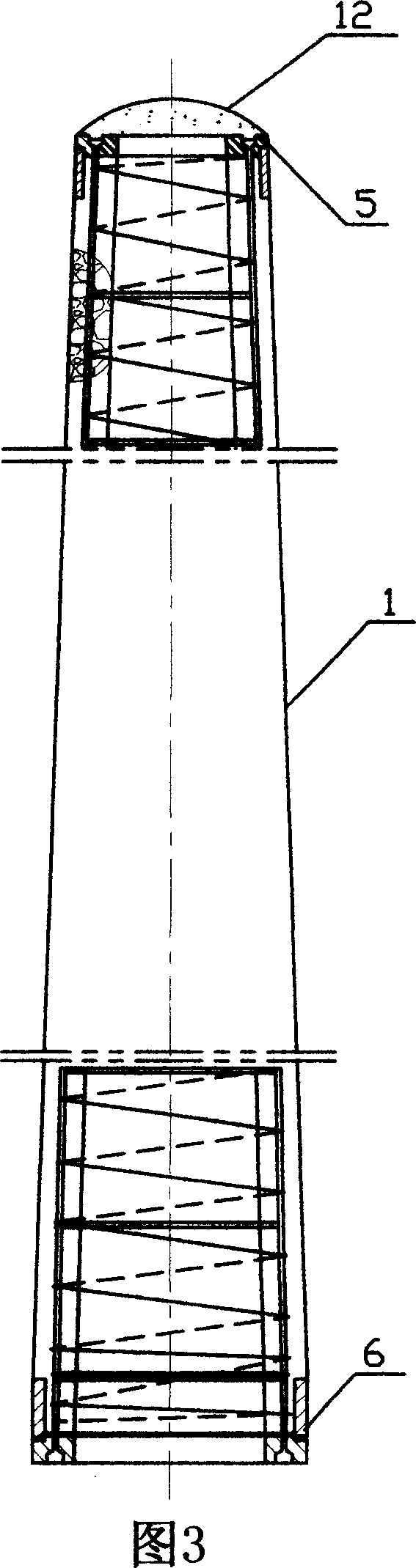

This invention is a prestressed concrete pole and its construction method. The pole is of a conicity at 1:75, with holes for cables. It can be a single pole or sectional fabricated. The pole is made by reinforce bar cage centrifugal casting. The reinforce bar cage is composed by vertical main bars and normal bars fixed on supporting and positioning loops, and binding outside by helix wire. Two end plates are installed to the pole ends to fix the mail bars. After installed the end plates and before centrifugal casting, pull the plates with 1000-1900KN power, and steaming the concrete to grade over C60, then loose the power. In case of sectional fabricated, the sections are connected to each other through bolts.

Owner:吕森金

Hydroxycarboxylic Acids and Salts

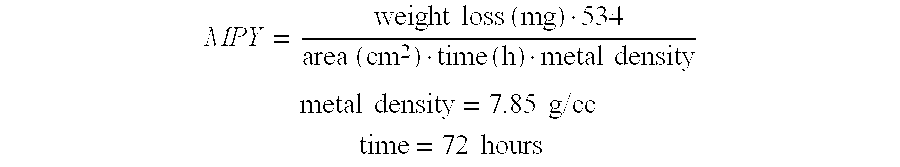

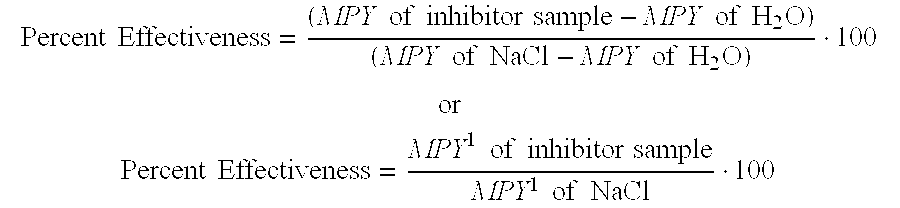

Compositions which inhibit corrosion and alter the physical properties of concrete (admixtures) are prepared from salt mixtures of hydroxycarboxylic acids, carboxylic acids, and nitric acid. The salt mixtures are prepared by neutralizing acid product mixtures from the oxidation of polyols using nitric acid and oxygen as the oxidizing agents. Nitric acid is removed from the hydroxycarboxylic acids by evaporation and diffusion dialysis.

Owner:UNIVERSITY OF MONTANA

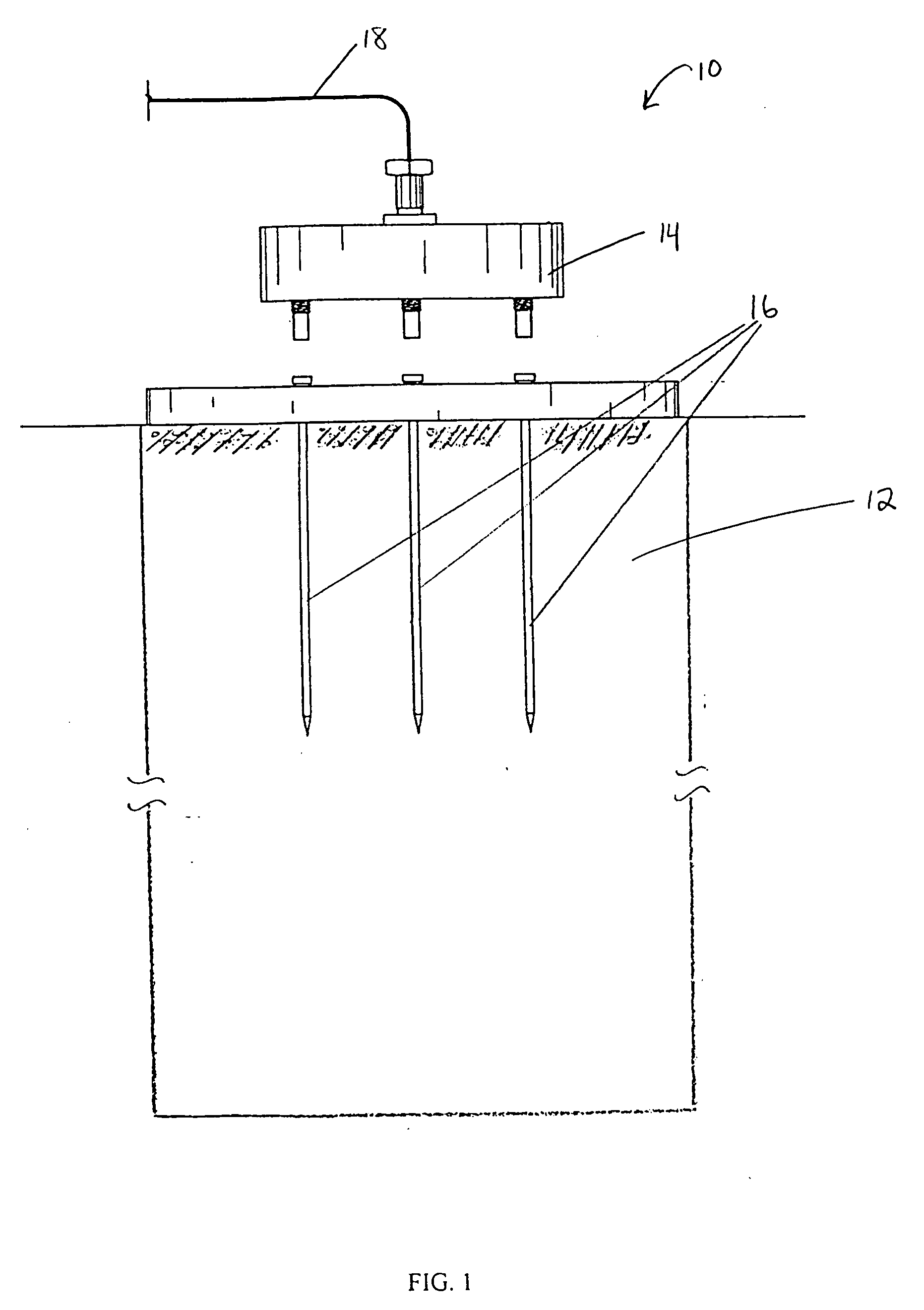

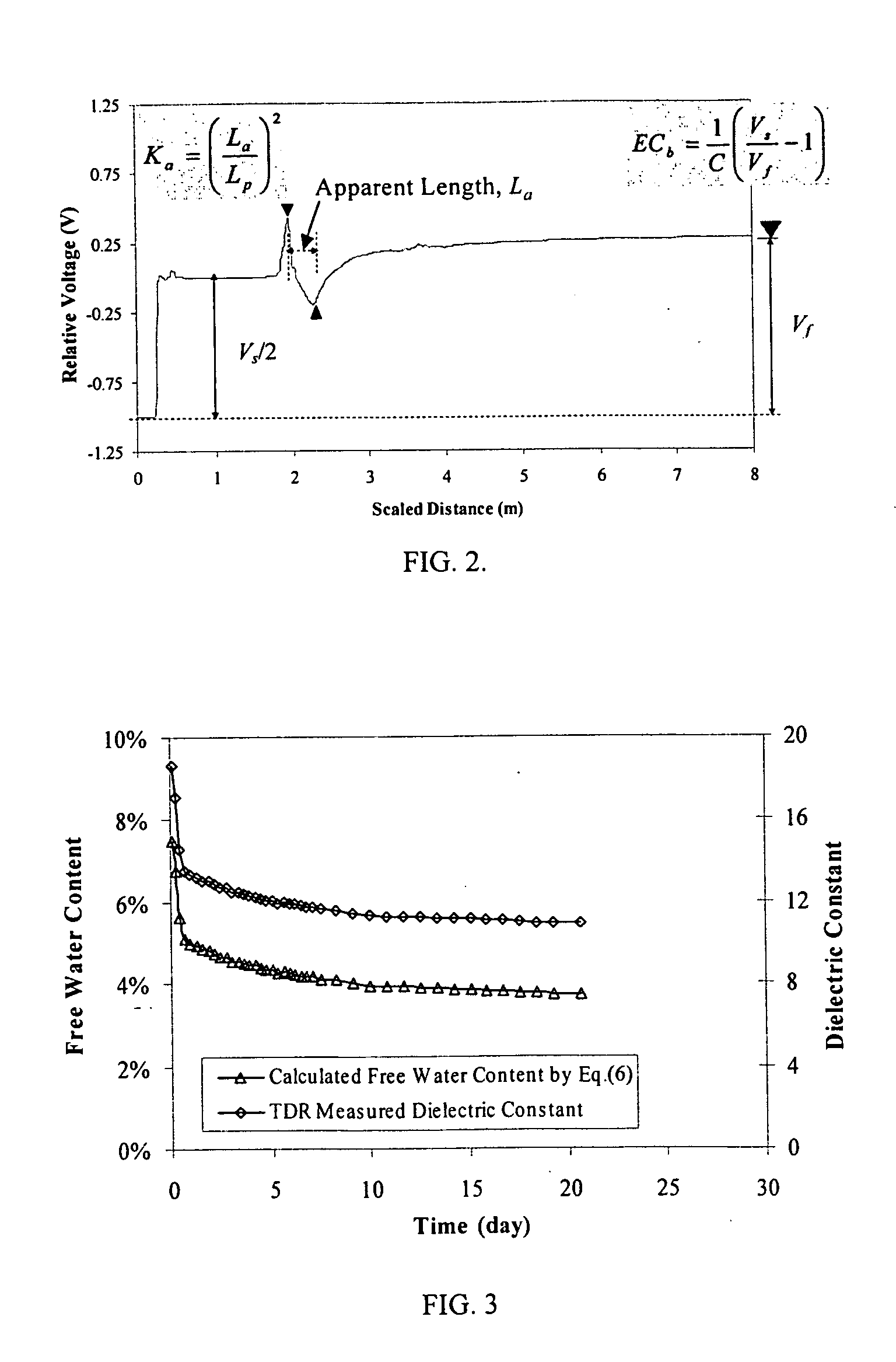

Method and apparatus for measuring properties of concrete

InactiveUS20050210995A1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsTime domainElectricity

Methods and apparatus using time domain reflectometry to determine electrical properties of concrete for calculating physical and mechanical properties of the concrete that are indicative of concrete quality and durability. The dielectric constant of a concrete is determined to calculate the gravimetric water content of the concrete for use in finding the water-cement ratio of the concrete. Electrical conductivity of curing concrete is determined to calculate compressive strength of the concrete for use in predicting strength development in the concrete.

Owner:PURDUE RES FOUND INC

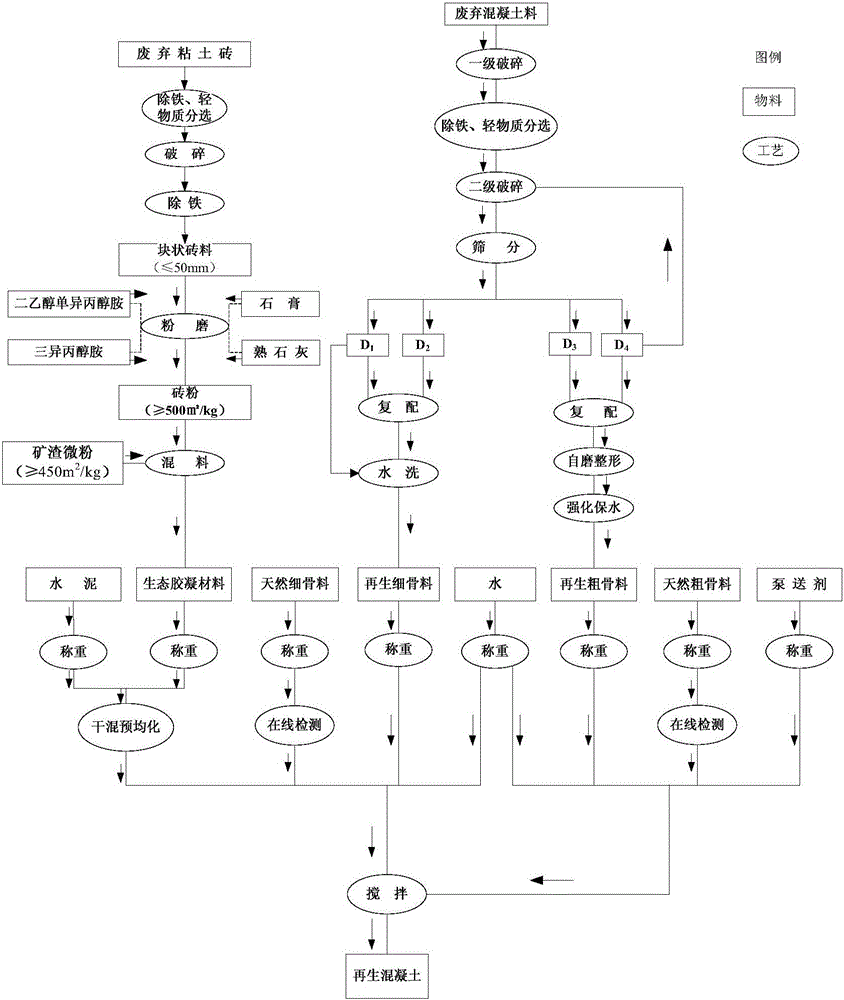

Production technology of ecological concrete

InactiveCN105948545AEfficient use ofAchieve recyclingSolid waste managementClinker productionSlurryUltimate tensile strength

The invention discloses a production technology of ecological concrete. The production technology comprises the steps of preparing an ecological cementing material by using construction waste clay bricks, and preparing recycled aggregate by using construction waste concrete; uniformly mixing cement and the ecological cementing material, then adding part of water, natural fine aggregate and recycled fine aggregate, stirring to form slurry, then adding natural coarse aggregate, recycled coarse aggregate, the rest water and a pumping aid, and stirring to prepare C30-C40 strength grade ecological concrete. By adopting the production technology of the ecological concrete, provided by the invention, useful components of construction waste are effectively used, the waste is turned into wealth, resources are saved, and the recycling of the construction waste resources is realized; the prepared ecological concrete is comparative with normal concrete in performance, is low in production cost, and can be largely applied to general construction engineering.

Owner:GANSU DELONG ECOLOGICAL BUILDING MATERIAL CO LTD

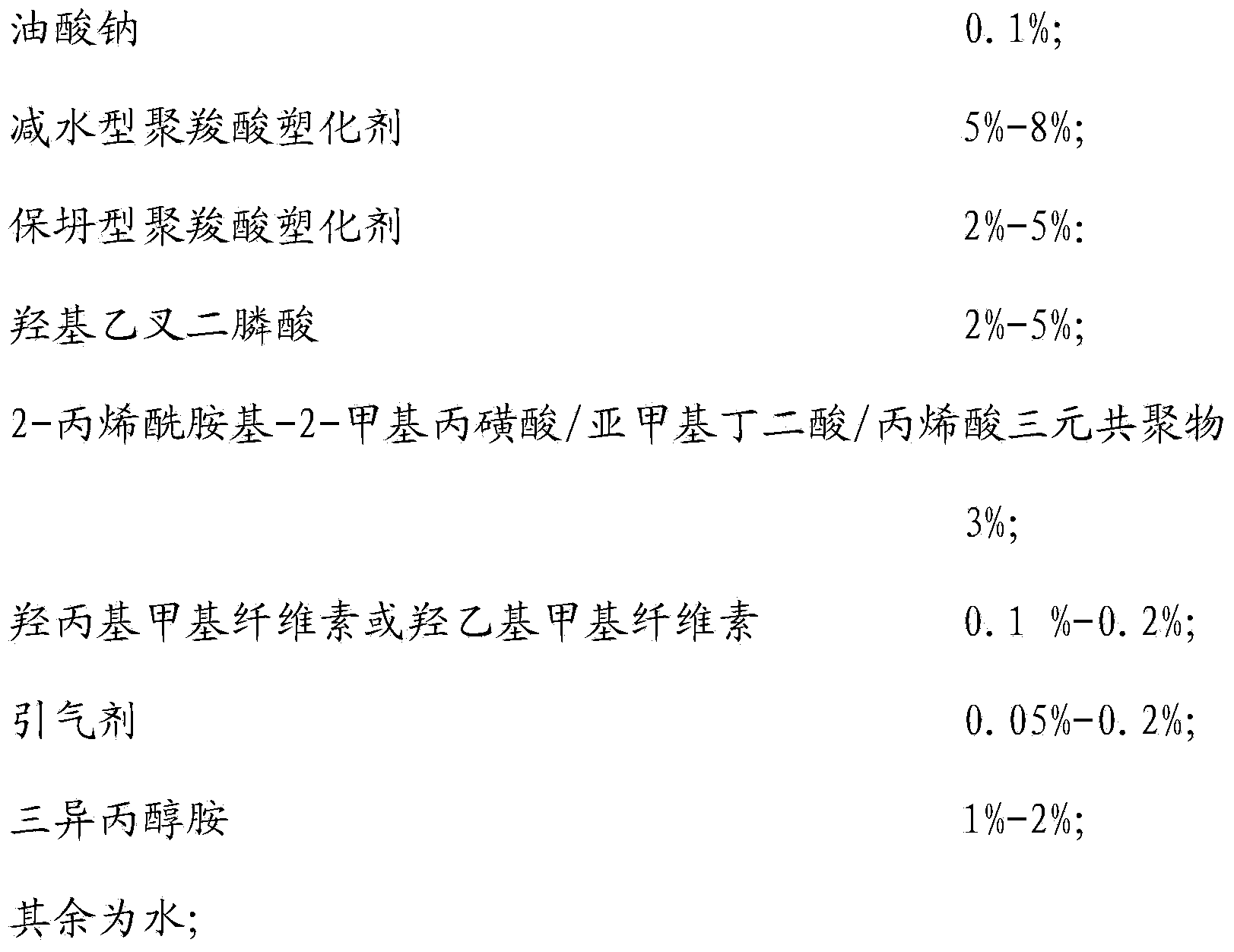

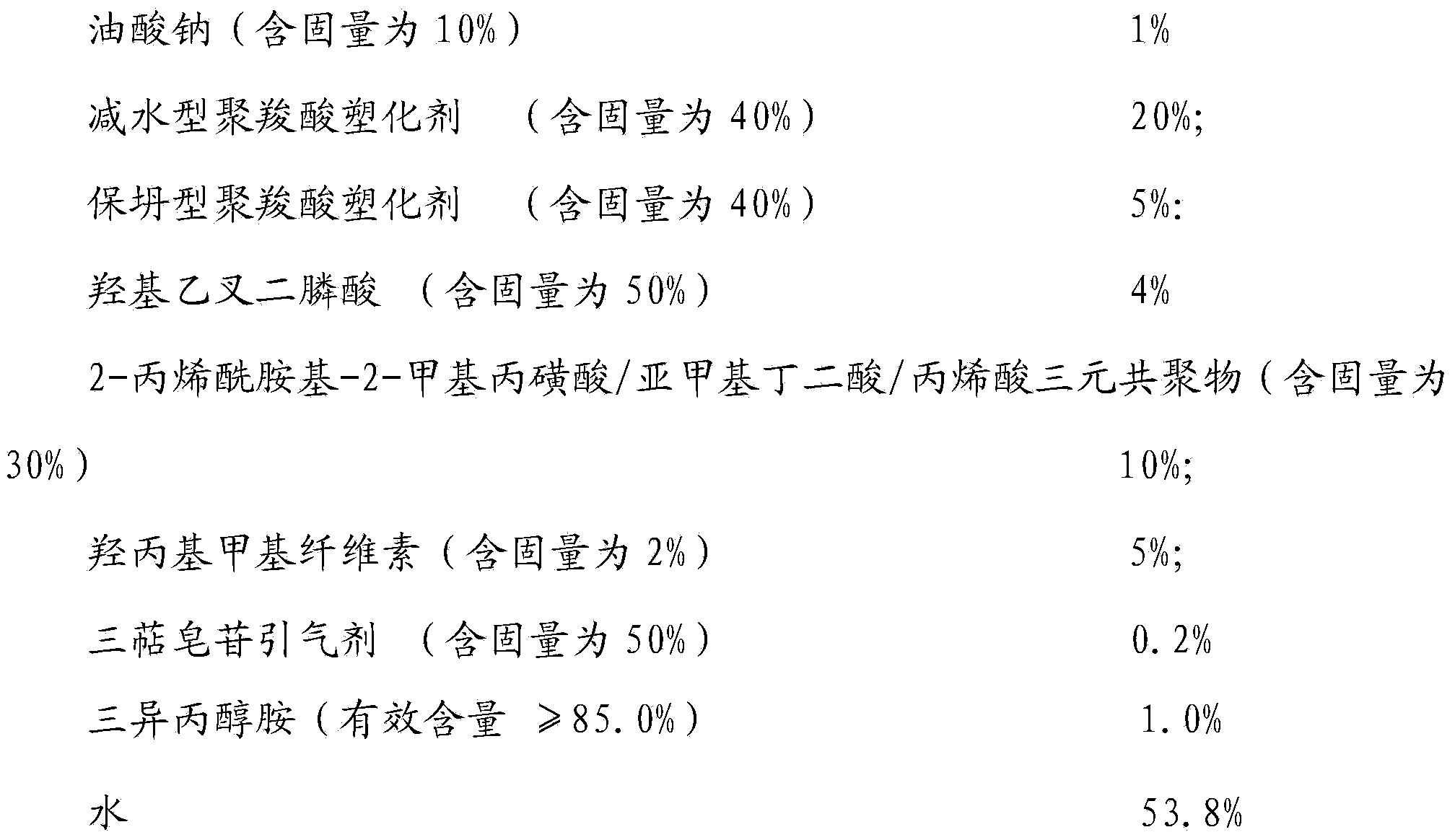

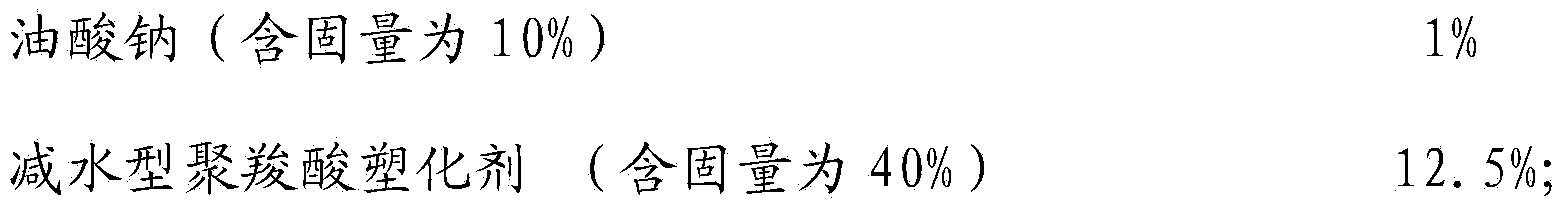

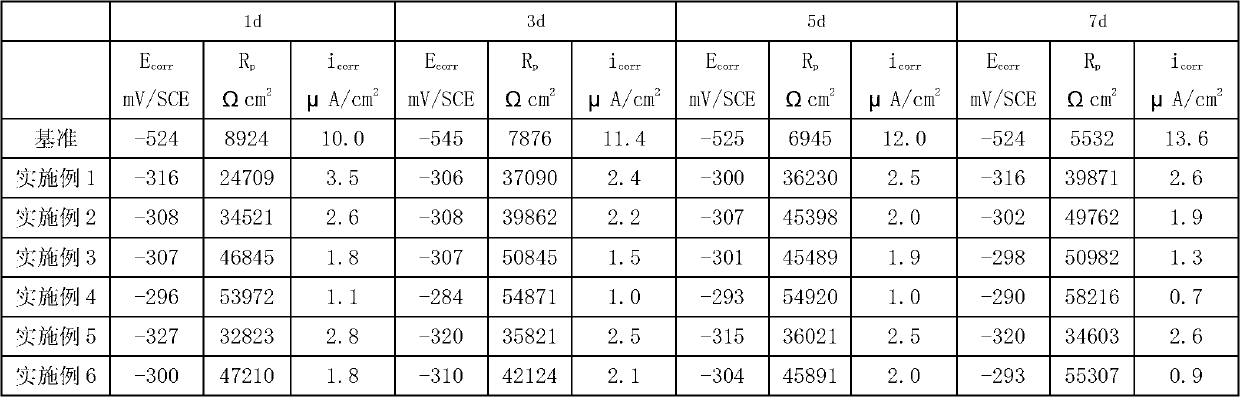

Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

ActiveCN103408242AGood slump performanceReduce bleedingWater reducerHydroxyethylidene Diphosphonic Acid

The invention provides a super slump type polycarboxylate water reducing agent for bored pile concrete. The water reducing agent is in a liquid state and comprises the following ingredients: sodium oleate, water reducing type polycarboxylate plasticizer, slump type polycarboxylate plasticizer, hydroxyethylidene diphosphonic acid, 2-acrylamide-2-methylpropanesulfonic acid / itaconic acid / acrylic acid terpolymer, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose, air entraining agent and triisopropanolamine. The super slump type polycarboxylate water reducing agent for bored pile concrete provided by the invention has the following beneficial effects that by using the super slump type polycarboxylate water reducing agent, the bored pile concrete is good in homogeneity, the static bleeding rate of the bored pile concrete can be generally less than 1%, stable working performance can be maintained within a long time span, meeting the working property of concrete after 0.5-5.0h can be met by adjusting the formulation and dosage and improving the compressive strength ratio of the concrete, and the 28 d strength can be more than 130% of that of benchmark concrete. The invention further provides a preparation method of the super slump type polycarboxylate water reducing agent for bored pile concrete.

Owner:北京金隅节能科技有限公司

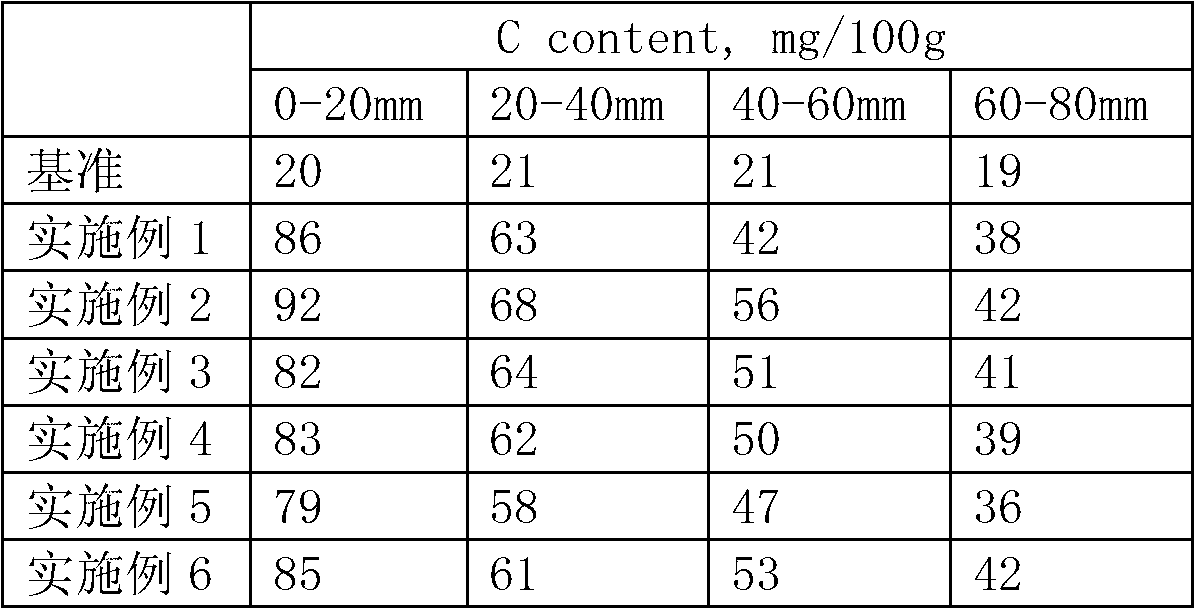

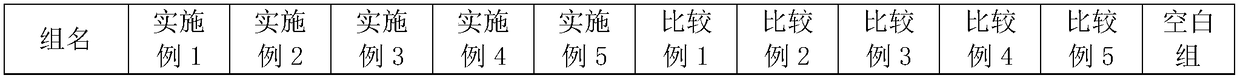

Surface coating type reinforced concrete corrosion inhibitor and preparation method thereof

ActiveCN102757197AModerate proportionPrevent and inhibit corrosionWater insolubleSurface-active agents

The invention relates to a surface coating type reinforced concrete corrosion inhibitor. The surface coating type reinforced concrete corrosion inhibitor comprises the components as follows: 15 to 40 wt% of a non-ionic surface active agent with HLB (Hydrophile Lipophile Balance) value more than 10, 5 to 30 wt% of a cosurfactant, 1 to 20 wt% of water insoluble organic inhibitor, and 20 to 50 wt% of water, wherein the cosurfactant is selected from organic alcohol or organic amine. The preparation method comprises the steps of mixing the non-ionic surface active agent, the cosurfactant and the water insoluble organic inhibitor, and agitating along with heating unit the mixture is completely molten, and then agitating along with water adding until the mixed liquid is turned into a clear state from a muddy state, thus obtaining the product. The preparation method provided by the invention is simple; the prepared product can be applied to surface treatment of the constructed concrete structure; and the prepared product has superior infiltration capacity, can effectively prevent the reinforcement surface from being eroded by chloride salt and sulfate, and has no adverse effect to the performance of the concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

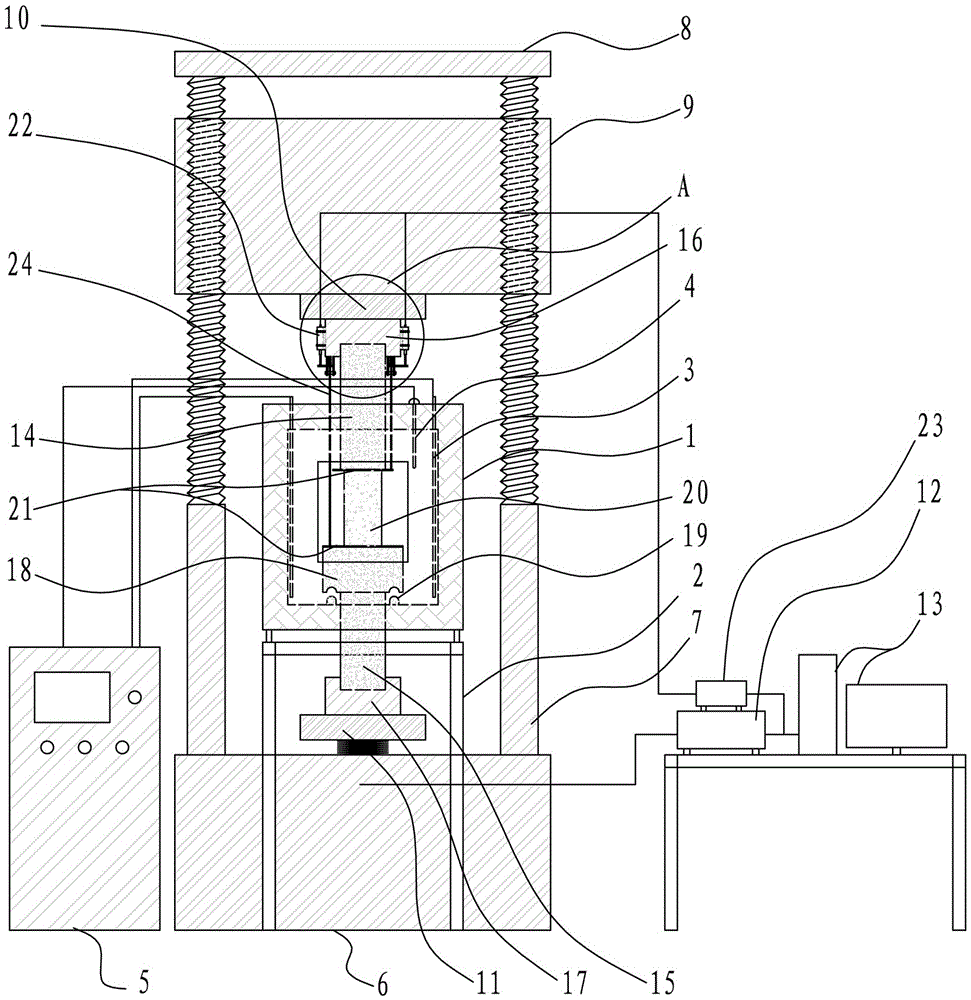

Method for testing concrete performance under pressure stress-chemical coupling effect and device thereof

InactiveCN101726439AConvenient performance testSmall footprintWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCarbonizationEngineering

The invention discloses a method for testing concrete performance under pressure stress-chemical coupling effect and a device thereof. The method applies a pressure stress to a test piece through a prestressing mode, and provides specific chemical corrosion action through a matched sealing device so as to apply a pull force to concrete and apply common chemical action at the same time. The internal stress of the concrete is monitored through a pressure sensor, the pressure stress is kept constant through secondary tension prestressing force, and the sealing device is arranged on the middle part of the concrete test piece to provide the chemical action, so the corrosion action of the chemical medium on a loading device is avoided; and a sealed box can provide one or more chemical erosion environments of carbonization, sulfate erosion, alkali-aggregate reaction, chloride ion erosion and corrosion. The device has a string structure, and can conveniently apply the pressure stress-chemical coupling effects of different conditions to a plurality of concrete test pieces.

Owner:SOUTHEAST UNIV

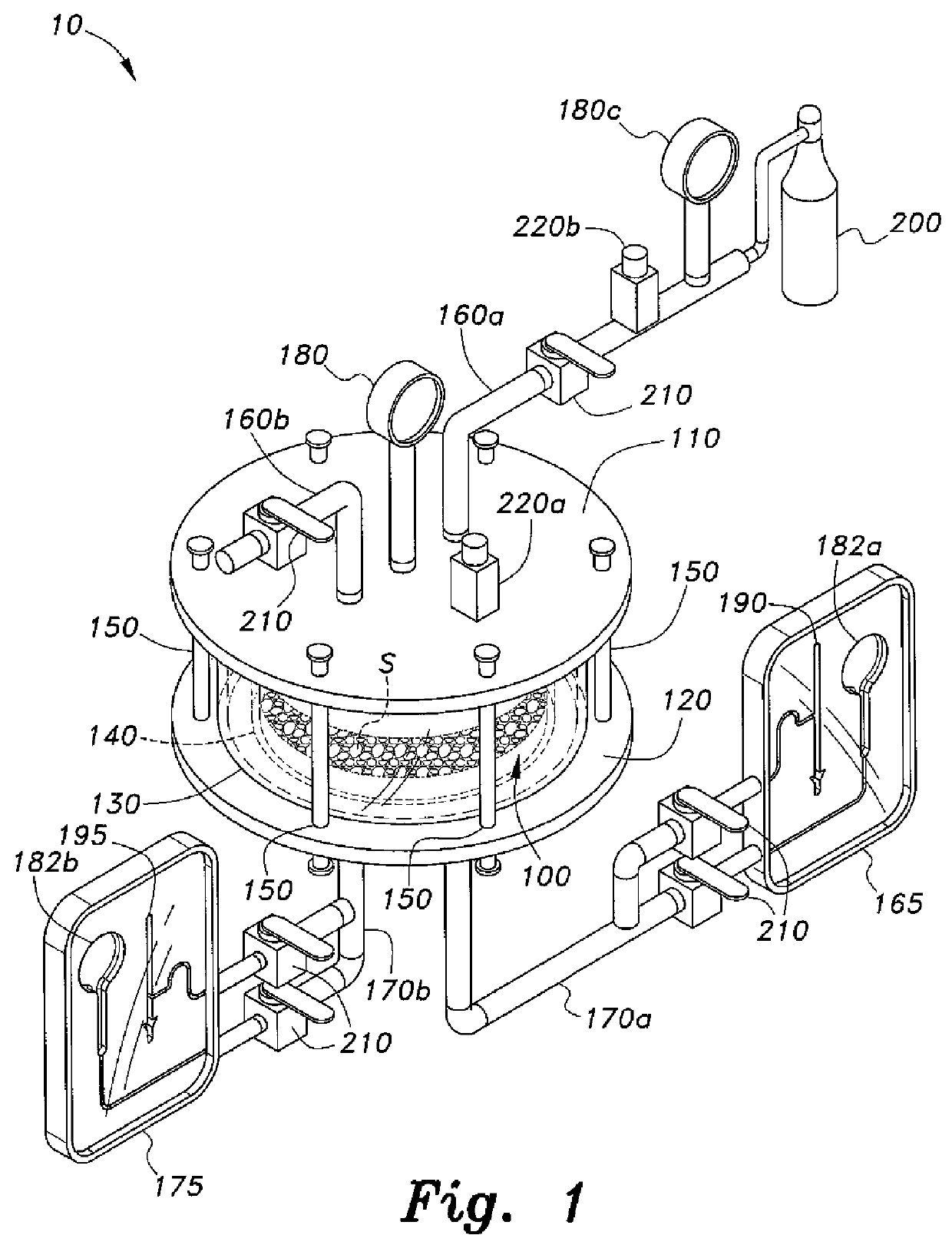

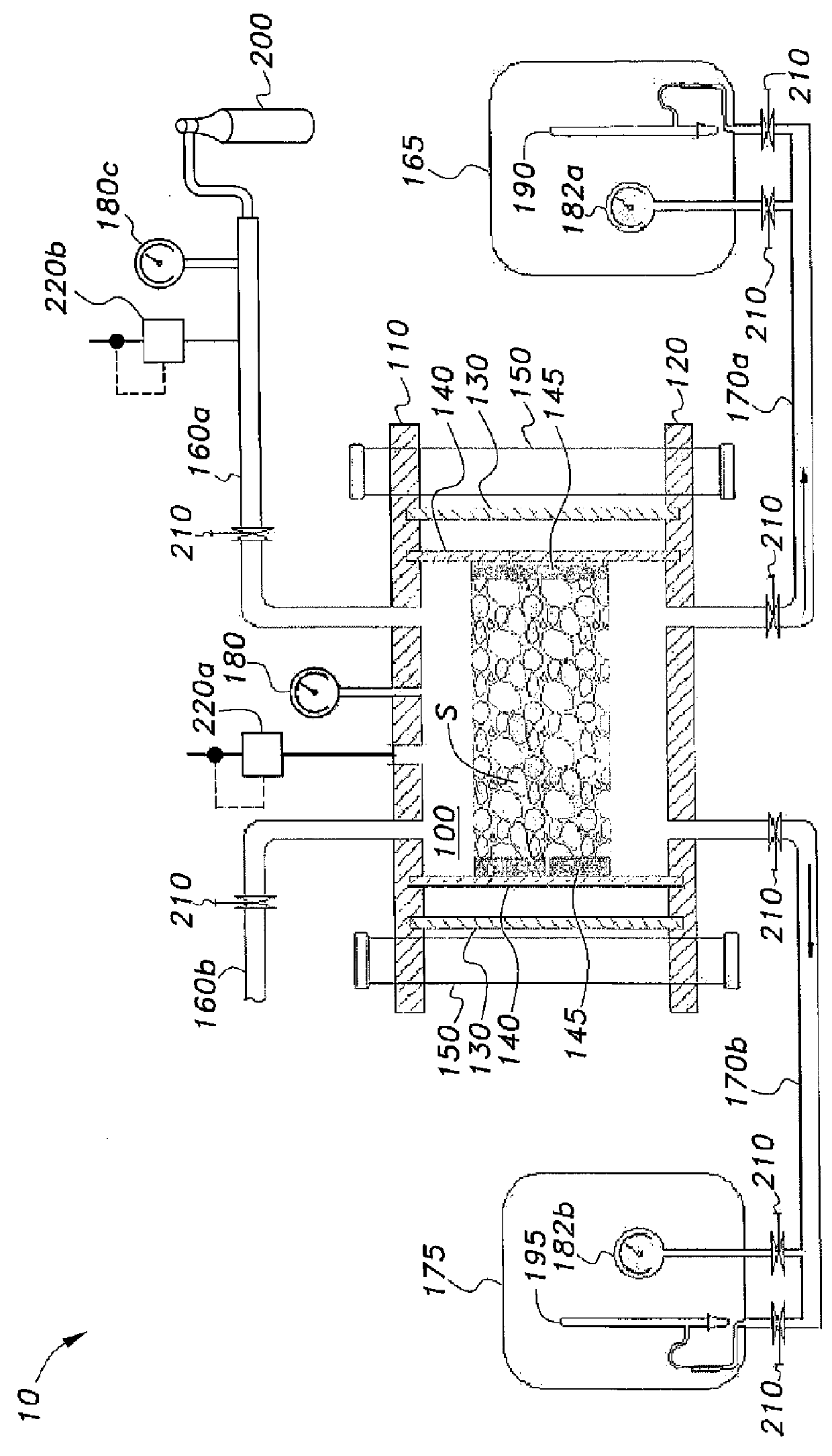

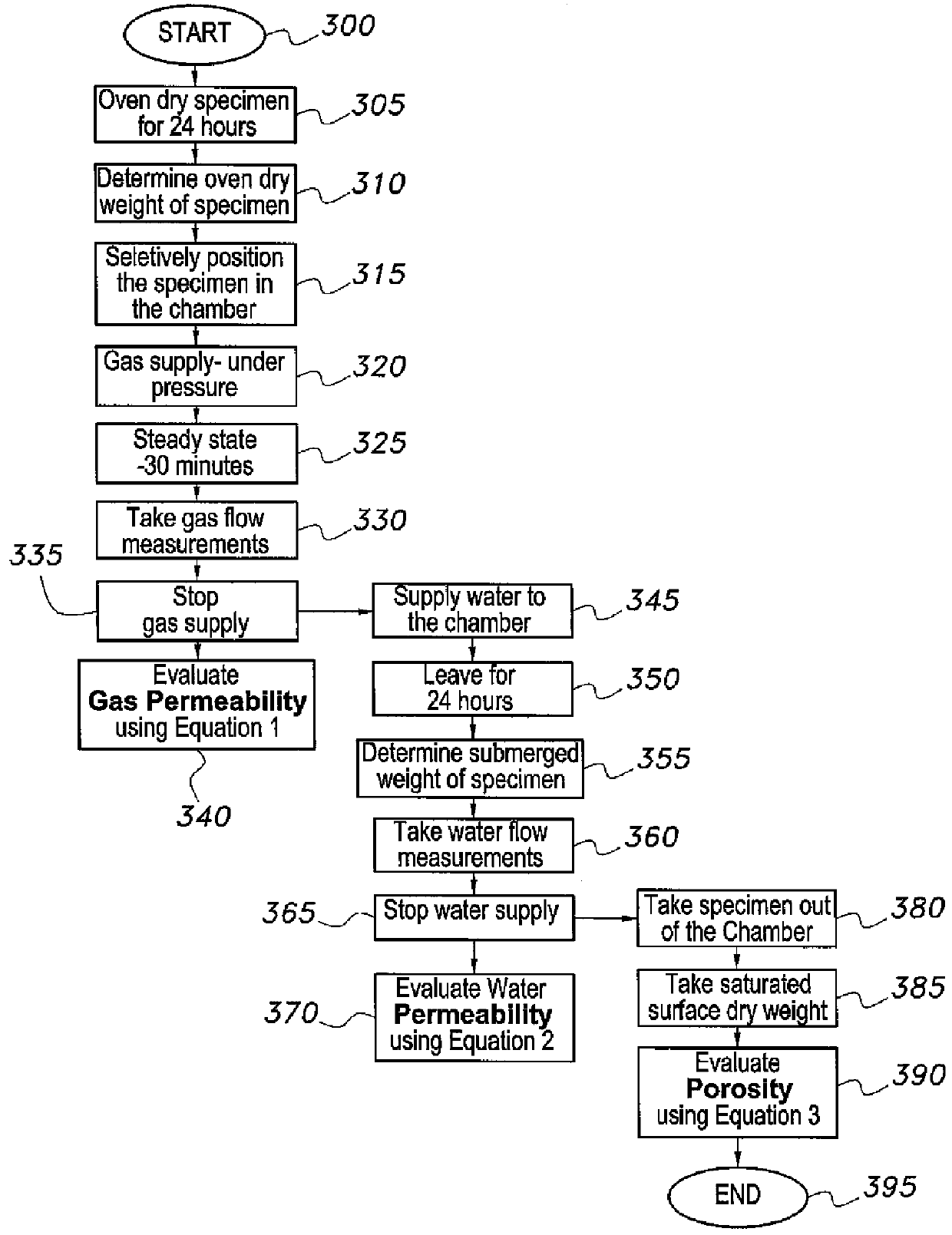

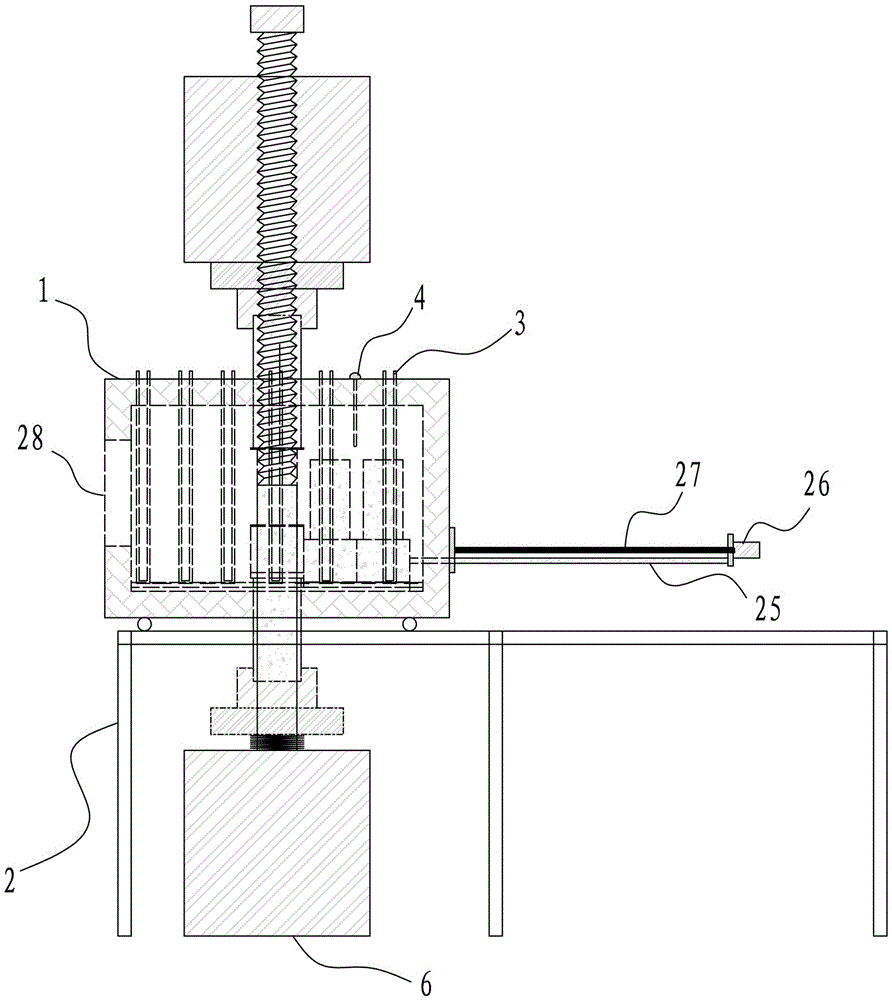

System and method for measuring permeation properties of concrete and porous materials

The system for measuring permeation properties of concrete and porous materials includes a chamber having an upper plate, a lower plate, and a plurality of support members, the chamber being configured for holding a specimen. A plurality of supply tubes and a plurality of discharge tubes are in fluid communication with the chamber. A gas flow measurement assembly is in fluid communication with the chamber, the gas flow measurement assembly having a first pressure gauge and a gas flow meter. A water flow measurement assembly is in fluid communication with the chamber, the water flow measurement assembly having a second pressure gauge and a water flow meter. A gas cylinder is in fluid communication with the one of the plurality of supply tubes. The system may be used to measure gas permeability, water permeability, porosity, and absorption of concrete and other porous materials.

Owner:KING SAUD UNIVERSITY

Concrete internal curing agent as well as preparation method and using method thereof

InactiveCN103496877ALow application costSolve the complicated processEnvironmental resistanceSuper absorbent

The invention discloses a concrete internal curing agent. The concrete internal curing agent is super absorbent resin which has intelligent water absorption and water release functions and stably exists in concrete for a long term. The concrete internal curing agent comprises deionized water, sodium hydroxide, acrylic acid, a water-soluble initiator, a water-soluble crosslinking agent and natural grafted skeleton kaolin which is calcined kaolin. The concrete internal curing agent disclosed by the invention is environmentallyenvironment-friendly, high-efficiency and convenient to use; the addition amount of the concrete internal curing agent is small; raw materials for preparation are low in cost; and by adopting the concrete internal curing agent, the water consumption of fresh mixed concrete can be obviously reduced, the concrete property is improved, and the service life of the concrete is prolonged.

Owner:SHENZHEN UNIV

Method for preparing polycarboxylate water reducing agent by normal-temperature mixing process

InactiveCN103992443AShorten the production cycleReduce energy consumptionOxidation-Reduction AgentRedox

The invention discloses a method for preparing a polycarboxylate water reducing agent by a normal-temperature mixing process. A polyether macromonomer, a redox, acrylic acid, an unsaturated third monomer, a chain transfer agent and water are mixed once at normal temperature to prepare the polycarboxylate water reducing agent. The method disclosed by the invention adopts a one-time mixing mode; in a synthesis process, a pump circulation device only runs in a pre-dissolving macromonomer, and the device is closed after the pre-dissolved reducing agent component is fed. The traditional production method adopts an elevated tank dropping mode to produce the polycarboxylate water reducing agent, and the production is performed in a reaction kettle, so that the equipment cost input is relatively high. In the method disclosed by the invention, a one-time mixing process is adopted creatively, and the method is performed in a normal-temperature way without needing a heat source, so that the production period is short, the energy consumption is low, and the synthesis process does not need a stirring device, a professional for monitoring and an enamel reaction kettle device; the concrete performance of the synthesized polycarboxylate water reducing agent is equivalent to that of the water reducing agent synthesized by the traditional process, a favorable reference basis is provided for workshop-style water reducing agent production, and the polycarboxylate water reducing agent has obvious advantages.

Owner:KZJ NEW MATERIALS GROUP CO LTD

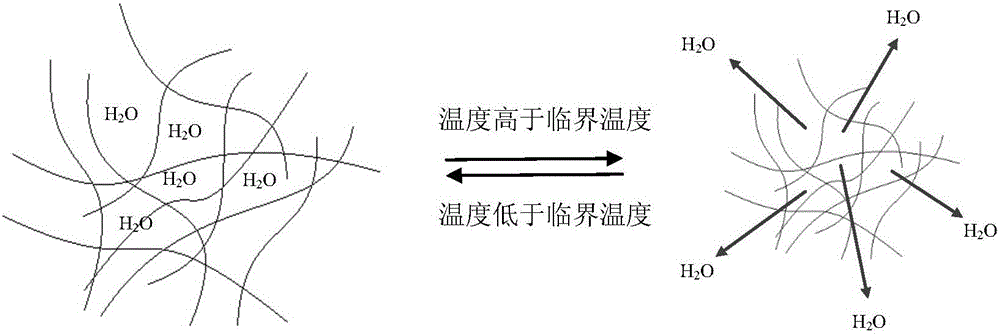

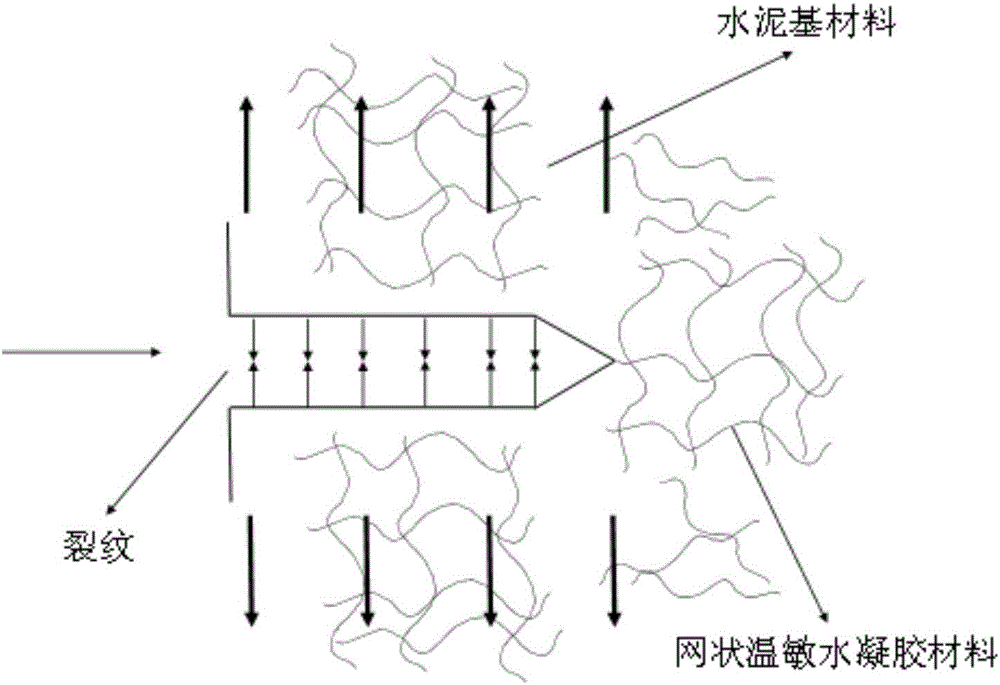

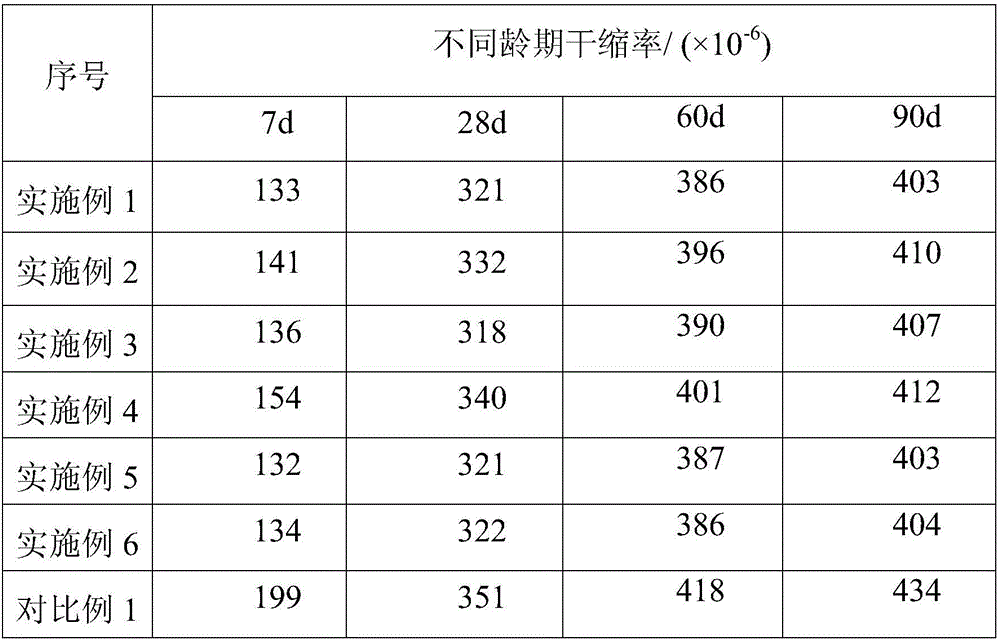

Application of temperature-sensitive hydrogel in improvement of anti-dry-shrinkage cracking property of concrete

The invention provides application of temperature-sensitive hydrogel in improvement of the anti-dry-shrinkage cracking property of concrete. The concrete is prepared from the temperature-sensitive hydrogel, cement, aggregates and water. A preparation method of the concrete comprises the steps that firstly, the temperature-sensitive hydrogel is prepared; secondly, the aggregates and the water are blended to be uniform; lastly, the temperature-sensitive hydrogel and the water are added, the materials are blended to be uniform, and then the concrete can be prepared. The adopted homemade temperature-sensitive hydrogel is lightly-crosslinked macromolecules which can be polymerized to form a film after releasing water, no hole can be reserved in the cement concrete, and other properties of the cement concrete are not affected while the anti-cracking property of the concrete is improved. The initial volume water content of the concrete is increased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the water storage capacity of the concrete is enhanced by mixing the temperature-sensitive hydrogel; the water absorption rate of the concrete is decreased along with increasing of the mixing amount of the temperature-sensitive hydrogel, and it is shown that the connectivity of capillary pores in the concrete is reduced by mixing the temperature-sensitive hydrogel.

Owner:CHANGAN UNIV

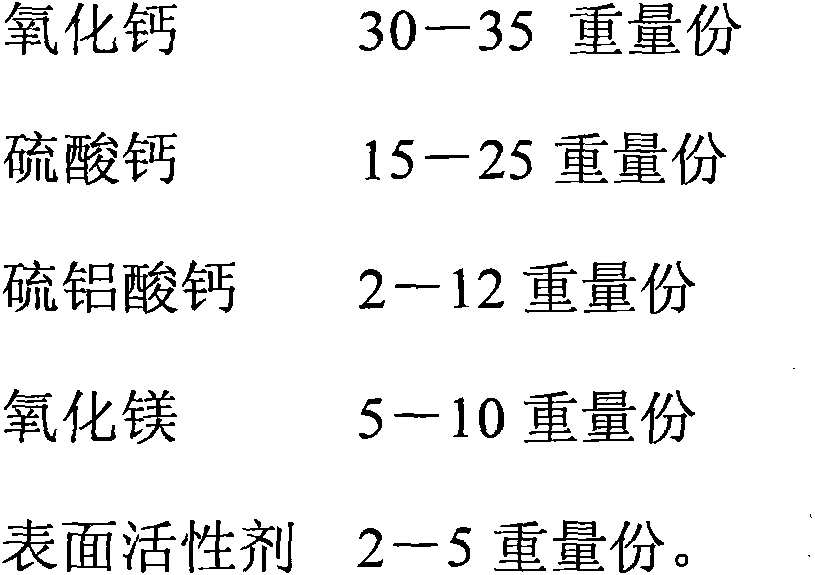

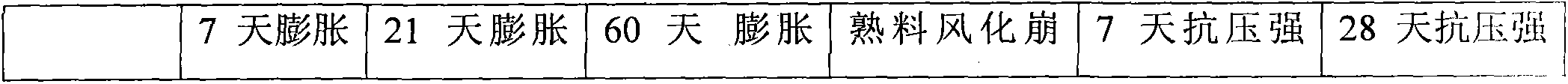

Concrete expanding agent with triple expansion sources and preparation method of concrete expanding agent

The invention discloses a concrete expanding agent with triple expansion sources and a preparation method of the concrete expanding agent. The high-performance concrete expanding agent provided by the invention contains calcium oxide, calcium sulfate, calcium sulphoaluminate, magnesium oxide and surfactant. Expansion rate change of the expanding agent and shrinking percentage change of the cement have an adaptive trend, and therefore, after using the expanding agent, the concrete is stable in strength performance, and the performances of the cement or the concrete can be stable for a long time.

Owner:FOSHAN HONGXING LION CONCRETE CO LTD

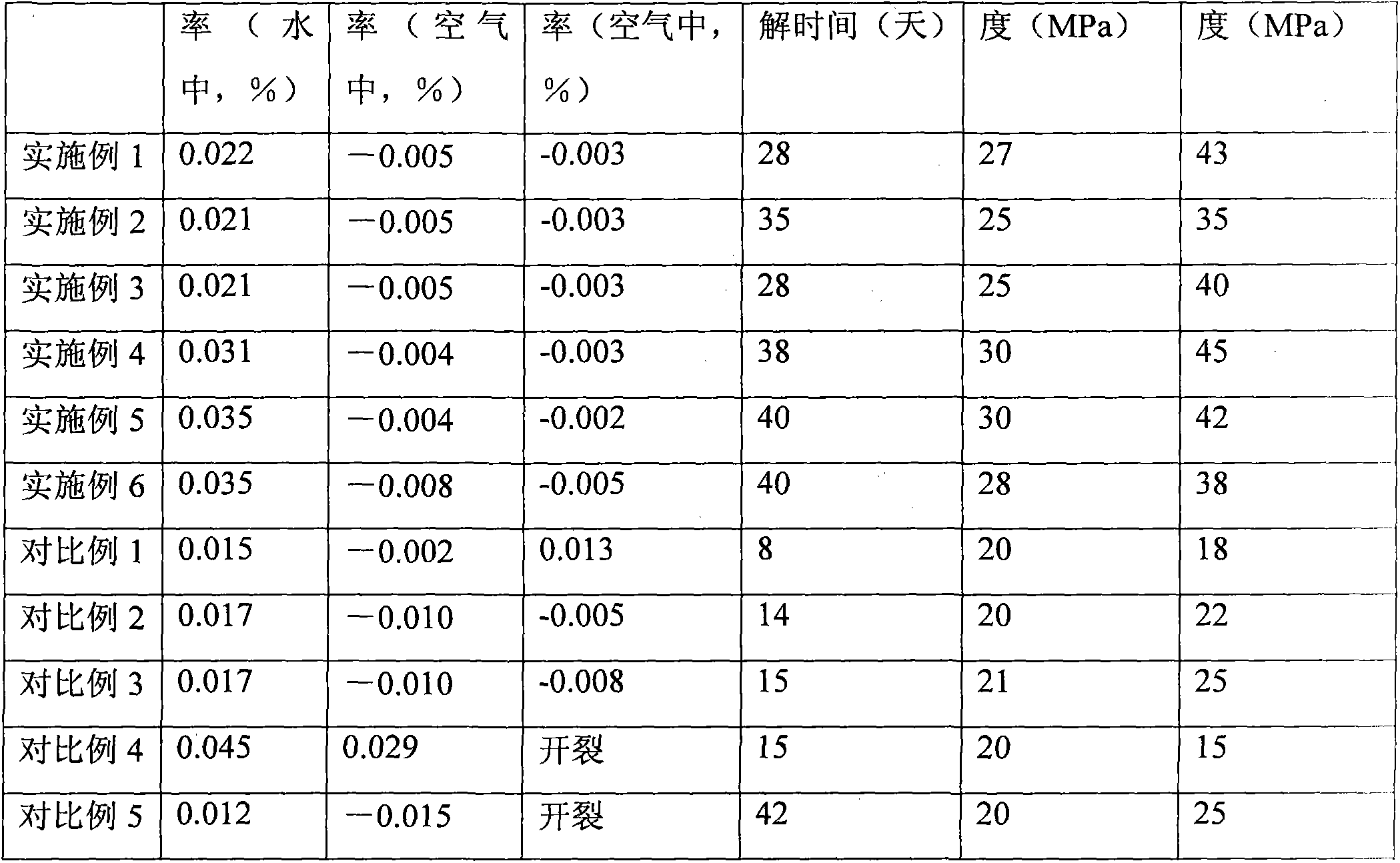

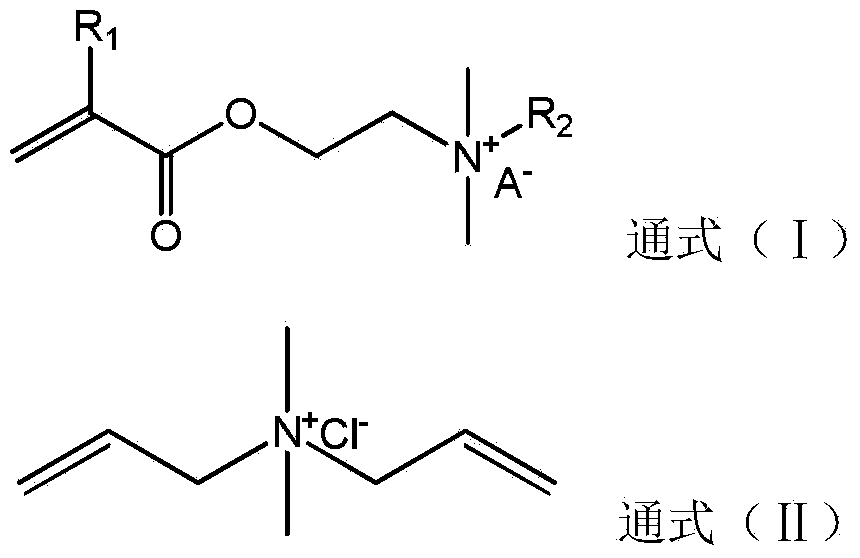

Clay inhibitor combined with polycarboxylic water reducer for use

The invention provides a clay inhibitor combined with a polycarboxylic water reducer for use, which comprises cationic nitrogen-containing low molecular weight copolymers; a preparation method of the clay inhibitor comprises the following step: a quaternary ammonium cationic monomer a, a monomer b containing primary amine, secondary amine or tertiary amine and a cross-linking monomer c are subjected to free radical copolymerization reaction in an aqueous solution, so that the clay inhibitor is obtained. Under the condition of relatively high mud content, the clay inhibitor can effectively ensure or improve the initial dispersive capacity and dispersion maintaining capability of the polycarboxylic water reducer, and meanwhile, the setting time, gas content, strength and other properties of concrete are not affected.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

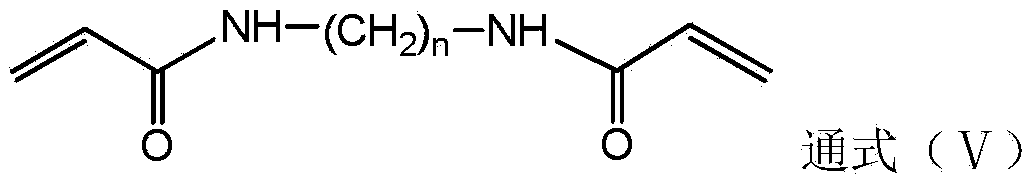

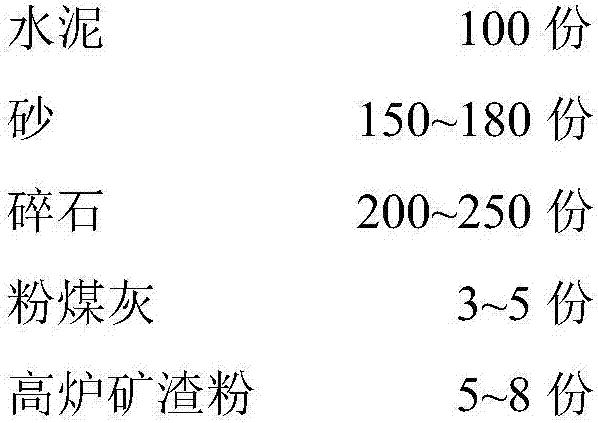

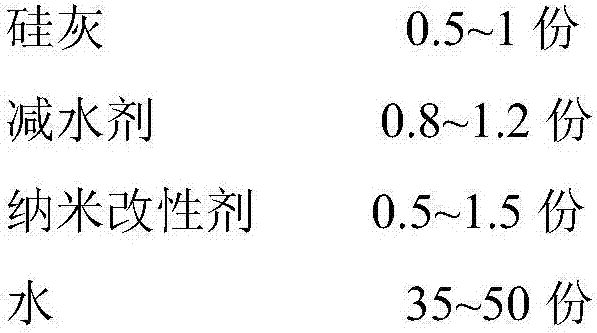

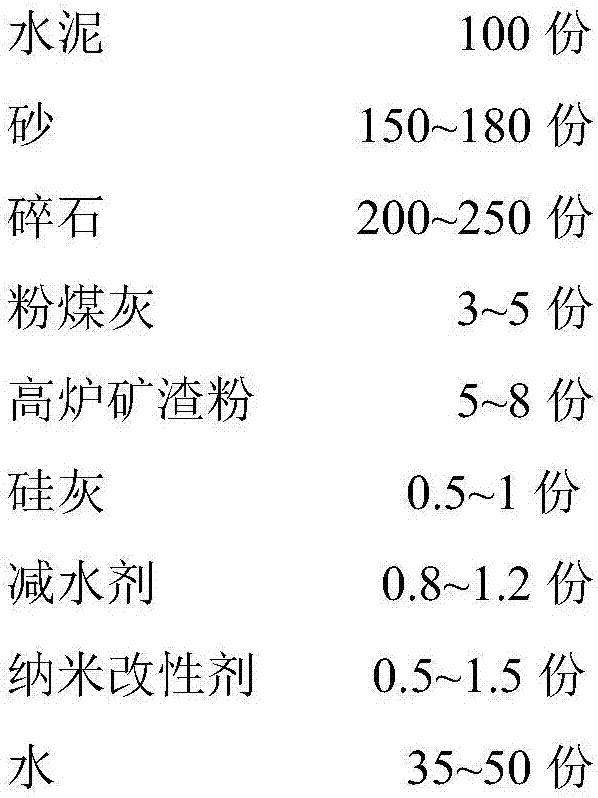

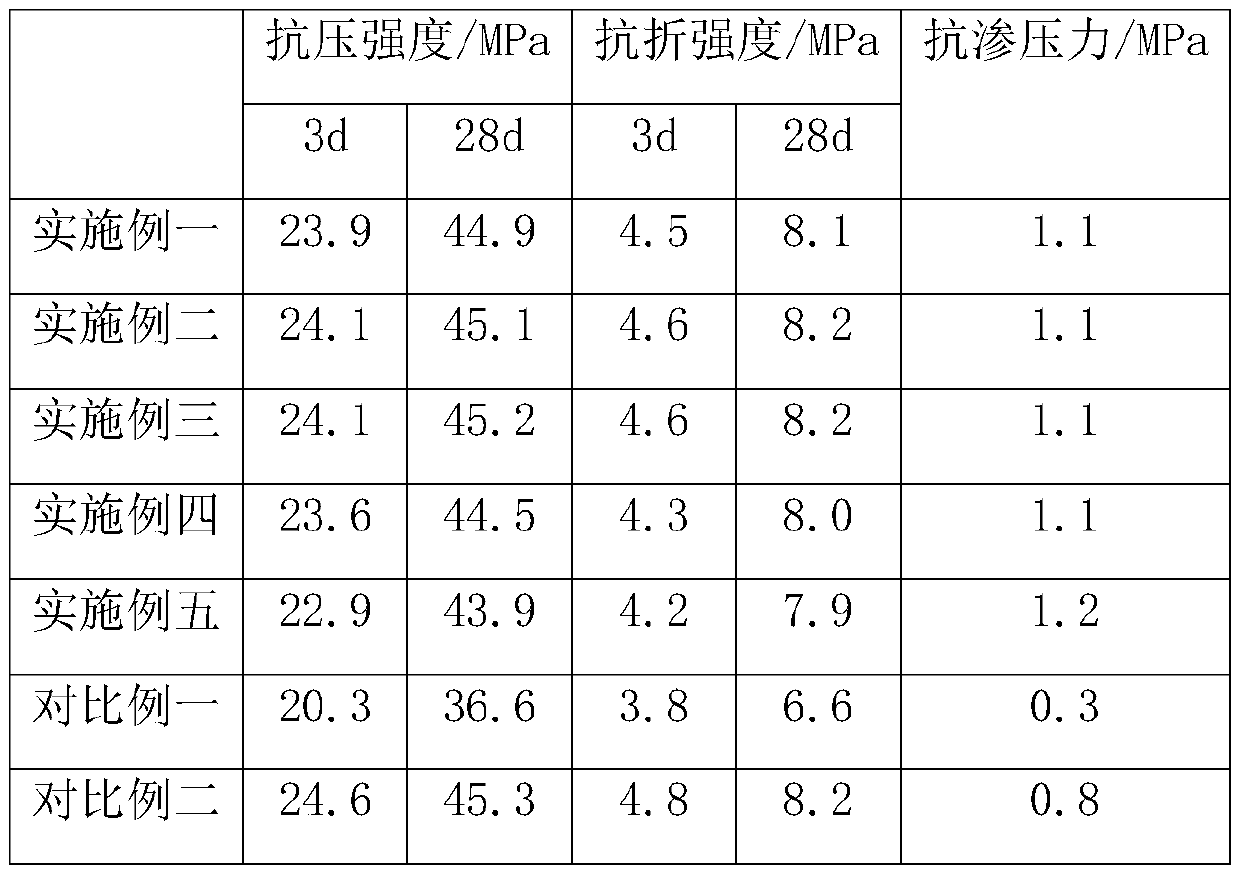

Preparing method of nano-modified high permeability resistant concrete

InactiveCN107032734ATake full advantage of stackingGive full play to the synergistic effectSolid waste managementChipsealSlag

The invention relates to building material engineering, and aims at providing a preparing method of nano-modified high permeability resistant concrete. The preparing method comprises the steps of conducting dry stirring on cement, sand, gravel, fly ash, blast-furnace slag powder and silica fume, and mixing the mixture evenly; mixing a nanometer additive, a water reducing agent and water which accounts for half the weight evenly, and adding the nanometer additive, the water reducing agent and the water which accounts for half the weight into the mixture for stirring; then adding the water which accounts for the other half the weight and continuing to conducting mixing; conducting discharging, and putting the new mixture into molds; conducting maintenance according to a conventional maintenance mode after removing the molds to obtain the nano-modified high permeability resistant concrete. According to the preparing method of the nano-modified high permeability resistant concrete, the limitation of the influence of a single mineral component on the performance of the concrete is solved, through the combination of the multifunctional composition, the effect of function superposition and synergy is achieved, the composite multifunctional composition can effectively optimize the concrete structure grain composition, and by optimizing the internal pore structure of the concrete, the aim of improving the permeability resistance is achieved. The grain composition optimization is conducted on the concrete structure by utilizing the nanometer additive, the high activity and the microcrystal nuclear effect of nano-particles are given full play to at the same time, and the permeability resistance of the concrete structure is improved.

Owner:ZHEJIANG UNIV

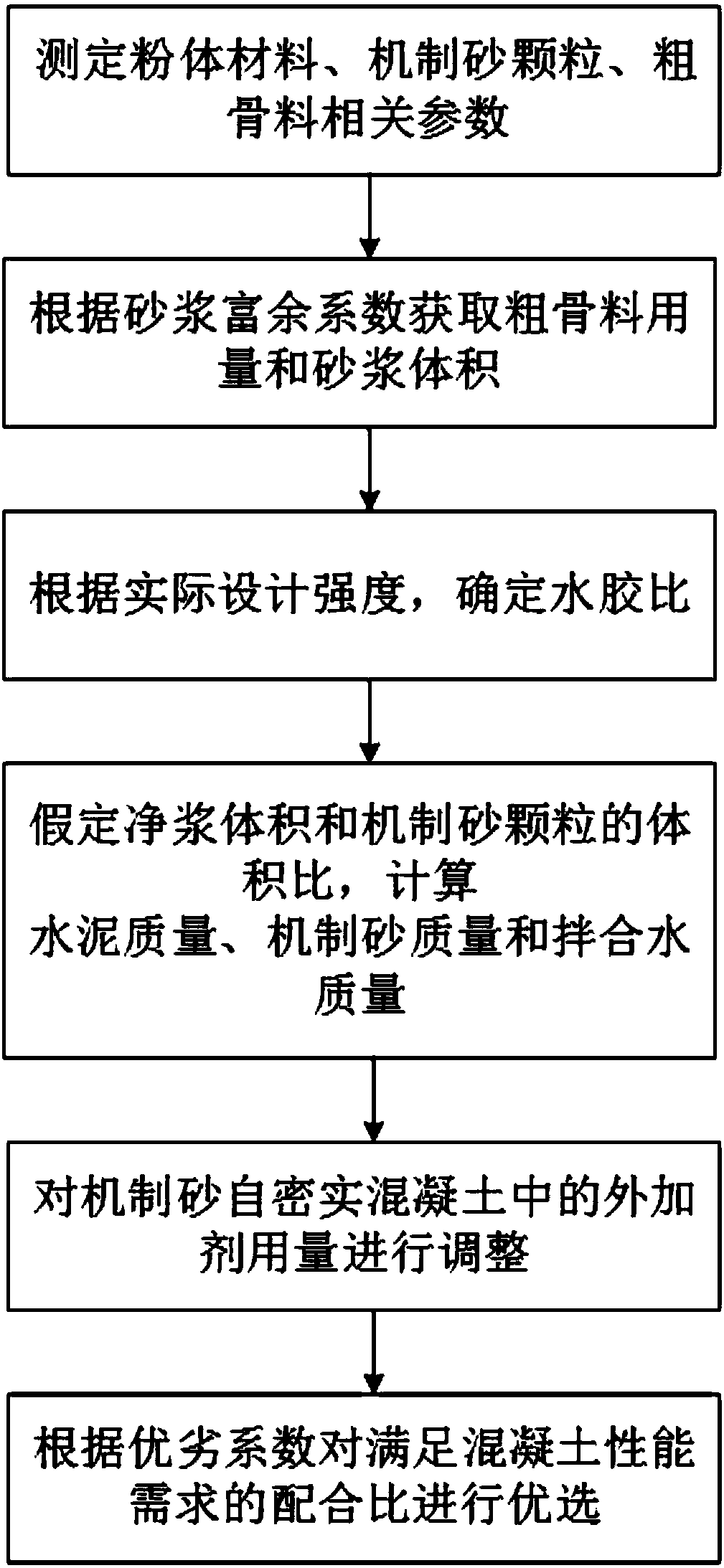

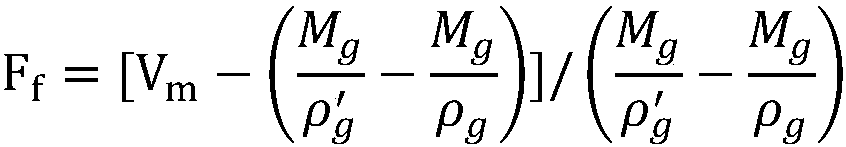

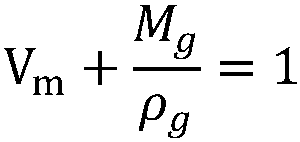

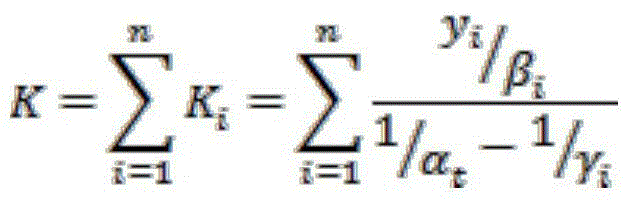

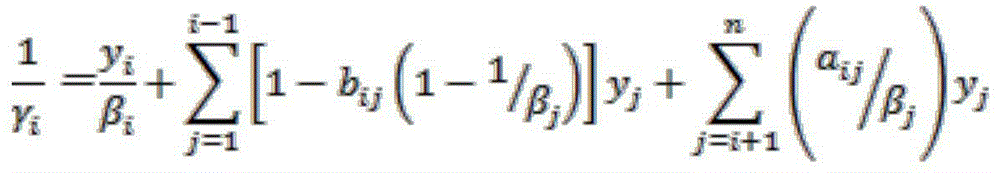

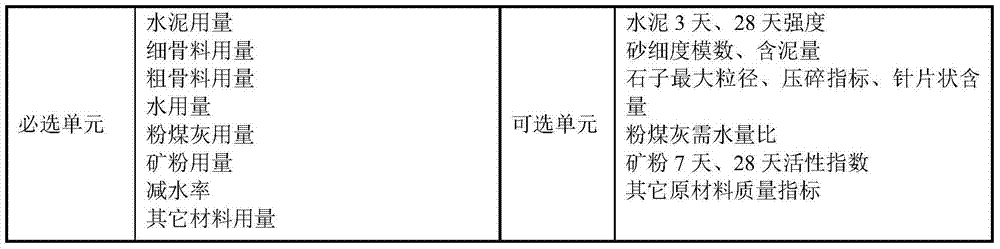

Mix proportion design and optimization method of machine-made sand self-compacting concrete

ActiveCN108395177AThe method steps are simpleSmall amount of calculationRatio controlApparent densityUltimate tensile strength

The invention relates to a mix proportion design and optimization method of machine-made sand self-compacting concrete. The method comprises the following steps: 1) determining the mass of coarse aggregate, the apparent density of the coarse aggregate and the bulk density of the coarse aggregate in a powder material, machine-made sand grains and unit volume concrete; 2) obtaining the use mount ofthe coarse aggregate and the volume of mortar according to performance requirements and the extra coefficient of the mortar; 3) determining a water-binder ratio according to design strength; 4) assuming the volume ratio of a net paste volume to the machine-made sand grains and calculating the mass of cement, the mass of the machine-made sand grains and the mass of mixing water; 5) adjusting the use amount of an additive in the machine-made sand self-compacting concrete according to the workability of the concrete; 6) optimizing a mix proportion meeting requirements on concrete performance according to an excellent-inferior coefficient. Compared with the prior art, the mix proportion design and optimization method has the advantages of simple steps, small calculation amount, wide application, workability and strength and the like.

Owner:佛山市利宇达建材有限公司

Preparation method of nano-photocatalytic admixture for cement-based material

The invention discloses a preparation method of nano-photocatalytic admixture for cement-based material, comprising the following steps: nanometer titanium dioxide mixed crystal is mixed with active carbon according to the weight ratio of 1:1-2 for 1-2 hours to obtain nano-photocatalytic material loaded with active carbon; then, the nano-photocatalytic material loaded with active carbon, dispersible emulsion powder, water reducer and polypropylene fiber are mixed according to the weight ratio of 1:0.2-0.3:0.04-0.06:0.004-0.006 for 1-2 hours. The invention has simple preparation technology, and prepared nano-photocatalytic admixture for cement-based material has long-term and stable photocatalytic function, and can improve flow property, adhesive property and anti-cracking property of concrete. The nano-photocatalytic admixture not only can be mixed with cement to obtain photocatalytic cement paste which is cement-based photocatalytic paint convenient to paint, but also can be mixed with cement and sand to prepare cement mortar to form cement-based photocatalytic coating with certain thickness on the concrete surface.

Owner:ZHEJIANG UNIV +1

Concrete material for paving road surface and preparation method of concrete material

The invention relates to the field of building materials, and in particular relates to a concrete material for paving a road surface and a preparation method of the concrete material. The concrete material for paving the road surface comprises the following components, namely a gel material, aggregate and additives; the gel material consists of iron tailings, blast furnace slag, cement clinker and gypsum; the aggregate consists of waste rubber powder treated by NaOH, sand and pebbles; the additives comprise an air entraining agent, an early strength agent and a water reducing agent; and the waste rubber powder is neutral rubber powder which is a rubber powder suspension treated by using NaOH. The concrete material disclosed by the invention has the beneficial effects of achieving reasonable utilization of waste resources, effectively utilizing the iron tailing, waste rubber powder and other resources, solving the problem of treating the iron tailings, improving the performances, such as impact resistance, antifreezing property and anti-cracking property of concrete on the basis of saving the production cost, and prolonging the service life.

Owner:中光财盛实业(北京)有限公司

Green concrete mix proportion optimization method

The invention discloses a green concrete mix proportion optimization method. The method includes the following steps of firstly, determining the concrete mix proportion meeting the performance requirement according to the design requirement and existing standard and engineering experience; secondly, measuring raw material parameters and establishing a concrete performance prediction model; thirdly, conducting loop optimization design on the existing concrete mix proportion, and obtaining the final result. According to the method, the method which can rapidly and accurately predict the work performance and compressive strength of concrete is established through the advanced particle packing theory and the rigorous mathematical derivation and through the combination with the actual test situations of site materials; by means of the concrete mix proportion optimization method established on this basis, the minimum cement utilization amount obtained on the premise of ensuring the work performance and strength of the existing design can be calculated only through a computer under the situation of no follow-up tests.

Owner:SHENZHEN UNIV

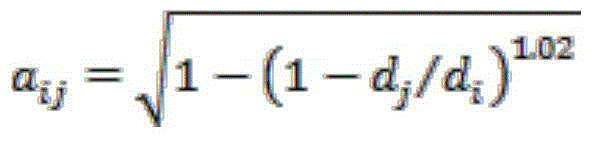

Plant-fiber-loading-microbe self-repairing cement-based material

The invention discloses a plant-fiber-loading-microbe self-repairing cement-based material. The plant-fiber-loading-microbe self-repairing cement-based material is prepared from a bacillus alcalophilus pasteurii bacterial solution, plant fibers and a nutrient solution, wherein the nutrient solution is prepared from maltodextrin, cottonseed cake meal, yeast extract powder and sodium citrate. The plant-fiber-loading-microbe self-repairing cement-based material disclosed by the invention has the following advantages that microbes can be preserved in a cement matrix for a long time in a high survival rate manner, so that the cement matrix can achieve life-time self-repairing in time of service; the adding of plants does not affect mechanical properties of concrete and can enhance the pull resistance and toughness of the concrete; the plants can release the microbes in time when cracks are generated; and the natural plants are wide in source, and the required plants do not need special complicated process treatment, so that the cost is low, and the plant-fiber-loading-microbe self-repairing cement-based material has environment-friendliness and economical efficiency.

Owner:CHONGQING THREE GORGES UNIV

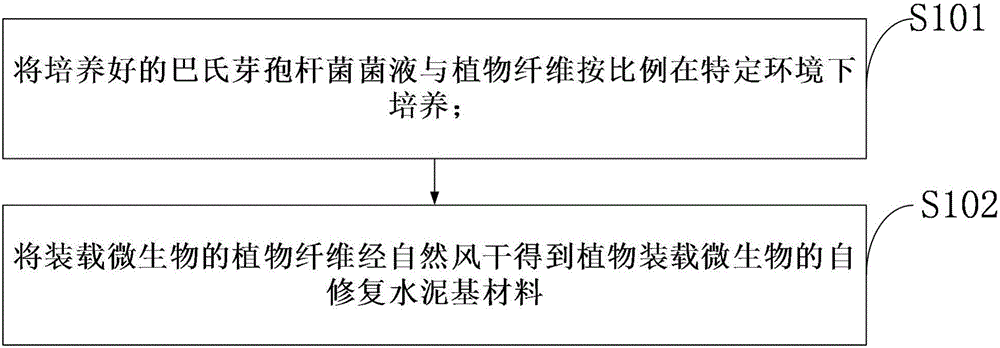

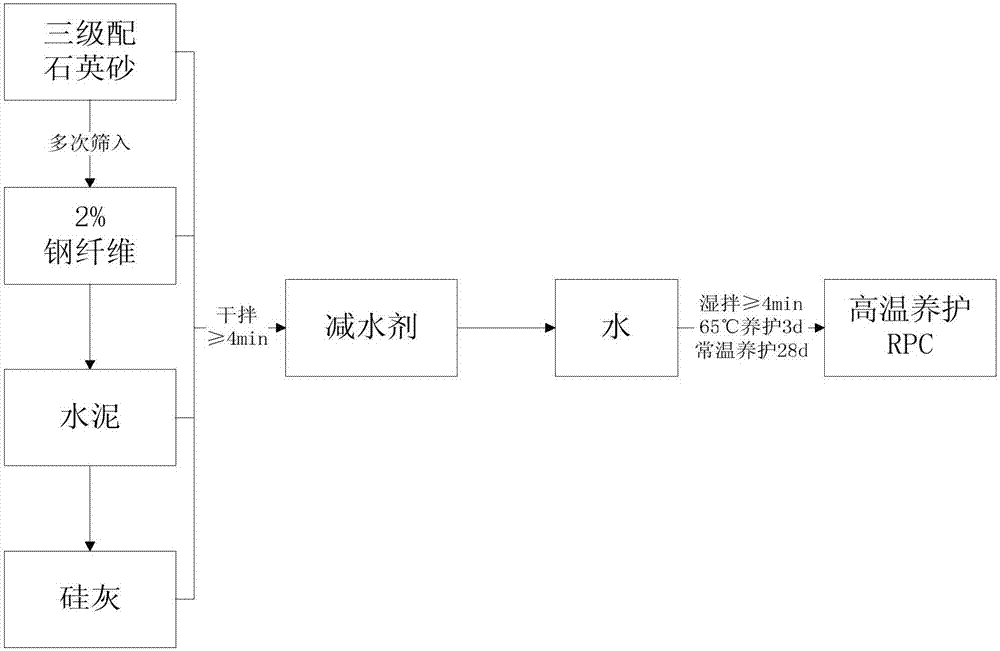

Graded sand high-strength reactive powder concrete and preparation method thereof

The invention discloses graded sand high-strength reactive powder concrete and a preparation method thereof. The reactive powder concrete is prepared from the following raw material components in parts by weight: 1 part of cement, 0.2 part of crude quartz sand, 0.8 part of medium sand, 0.2 part of fine sand, 0.3 part of silica fume, 0.02 part of a water reducing agent, 0.23 part of water, 0.0075 part of normal-temperature steel fibers and 0.02 part of high-temperature steel fibers, wherein the particle size of the fine sand is 0.16 to 0.315 mm, the particle size of the medium sand is 0.30 to 0.60 mm, the particle size of the crude sand is 0.60 to 1.25 mm, and the volume of the steel fibers is 0.075 percent or 2 percent of that of all the materials. According to the preparation method disclosed by the invention, quart sand with three particle sizes is selected to increase the aggregate packing degree; specific optimized gradation is provided, and a proper amount of steel fibers are doped to improve the tensile strength of a matrix; the proper amount of a cementing material is optimized, so that the workability of the reactive powder concrete is improved; the prepared reactive powder concrete has excellent performance; and the preparation method is simple.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

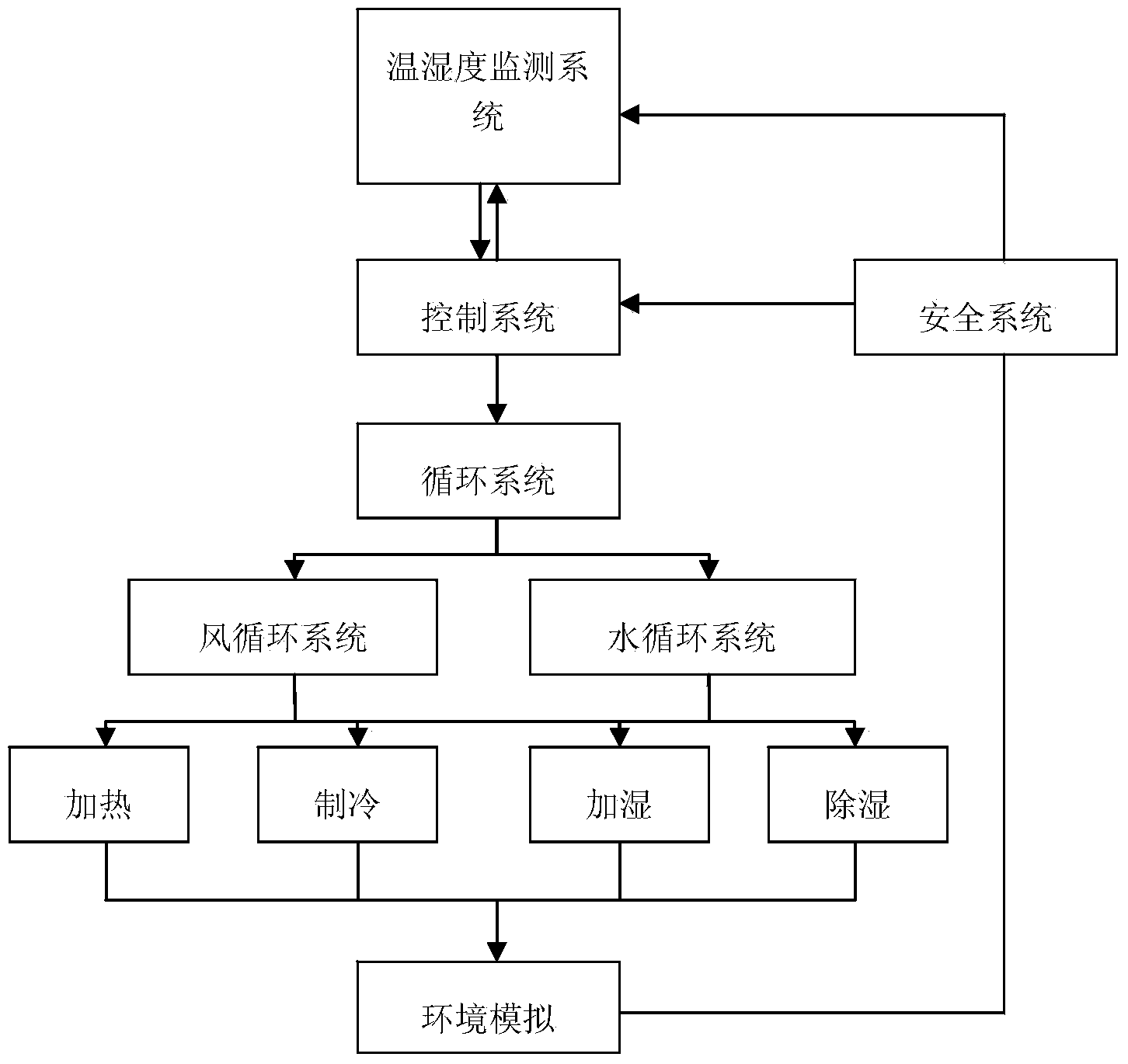

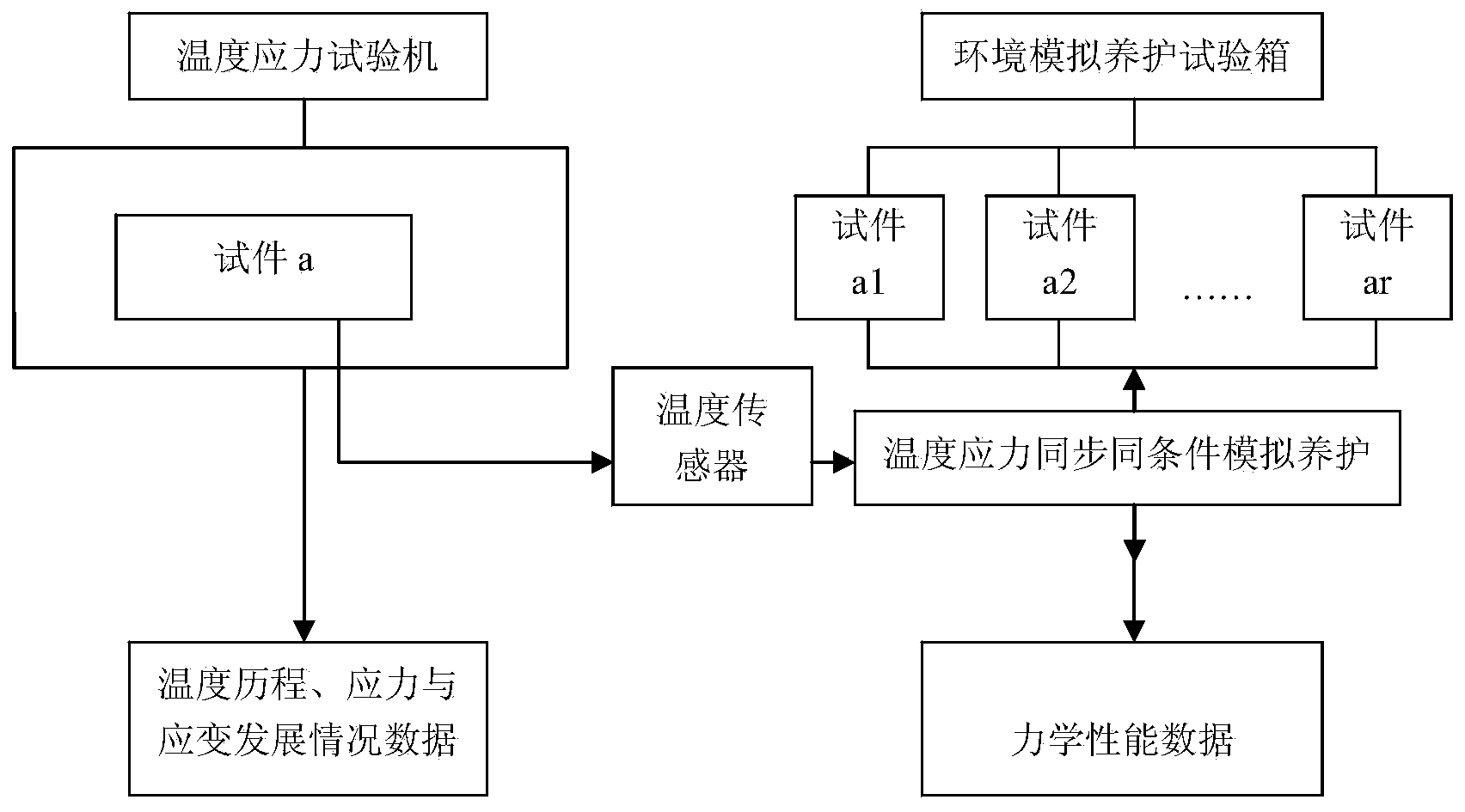

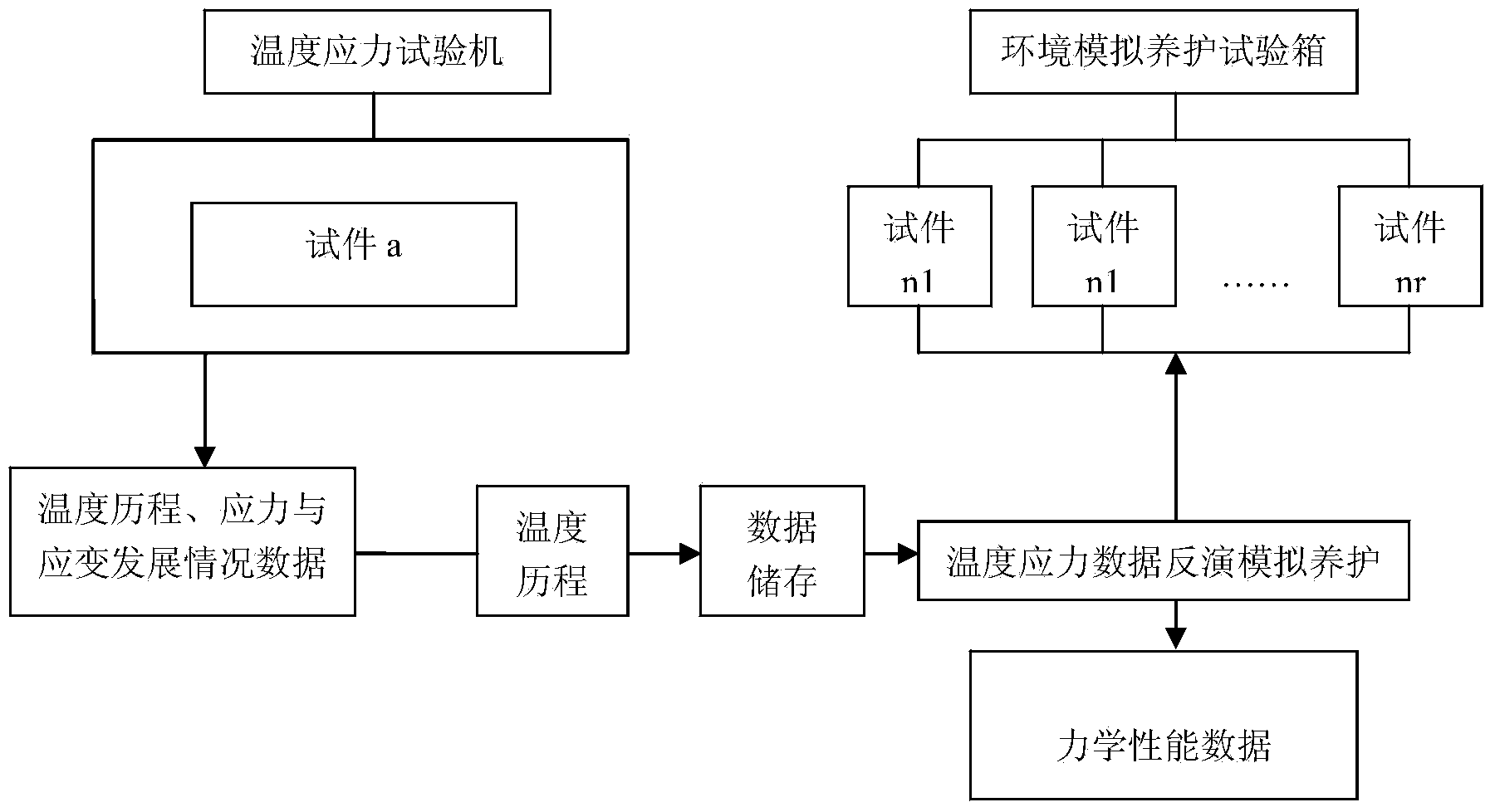

Temperature stress test-based same condition simulated maintenance test method and inversion simulated maintenance test method and system

ActiveCN103852383AMaterial strength using tensile/compressive forcesSimultaneous control of multiple variablesTemperature stressEnvironmental simulation

The invention discloses a temperature stress test-based same condition simulated maintenance test method which comprises the following steps: (1) setting a temperature stress testing machine and an environmental simulated maintenance test box; (2) manufacturing a test piece a for the temperature stress test according to a preset concrete formula, and putting the test piece a into the temperature stress testing machine; (3) manufacturing a concrete synchronization maintenance test piece according to a formula the same that in the step (2), and putting the concrete synchronization maintenance test piece into the environmental simulated maintenance test box; (4) arranging an external temperature sensor at an input end of the environmental simulated maintenance test box into a core part of the test piece for the temperature stress test, and starting a temperature stress test of the temperature stress testing machine; (5) introducing real-time temperature data acquired by an external temperature sensor into the environmental simulated maintenance test box for maintaining according to the environmental simulated maintenance test box; and (6) closing the environmental simulated maintenance test box after the temperature stress test is ended, and testing the performance data of various test pieces. The invention provides a specific method and thought for researching thermodynamic property of concrete.

Owner:CCCC FOURTH HARBOR ENG INST +4

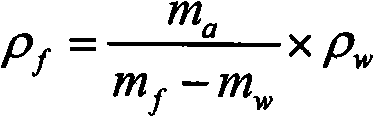

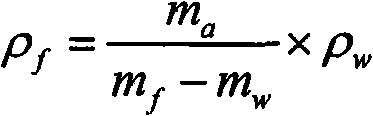

Method for testing property of low-carbon asphalt and low-carbon asphalt mixtures

InactiveCN101832994AMaterial testing goodsInvestigating phase/state changeNeedle penetrationViscosity

The invention belongs to the field of highways and city roads, in particular to a method for testing the property of low-carbon asphalt and low-carbon asphalt mixtures. The method comprises the following steps of: respectively calculating bulk density of a compact-molded Marshall sample at different temperatures, and using mixture and compaction temperature of the low-carbon asphalt and low-carbon asphalt mixtures at the maximum bulk density as mixture and compression temperature of the low-carbon asphalt mixtures; testing the aging property of the low-carbon asphalt and low-carbon asphalt mixtures, which comprises the following steps of: preparing asphalt samples according to the regulations, and testing the natures of the asphalt samples including needle penetration, viscosity, softening points, ductility and the like before a test of heating a film; adjusting a baking oven to be horizontal so that a rotary disc can rotate on a horizontal plane at a certain speed, enabling a position of a thermometer to be equal to the distance of the centre and the edge of the rotary disc, placing a sample-accommodating utensil on the rotary disc in the baking oven when the temperature in the baking oven reaches 120DEG C, timing when the temperature in the baking oven rises again to 120 DEG C and keeping the temperature; and testing the natures of the asphalt samples including needle penetration, viscosity, softening points, ductility and the like after the aging is completed. Through basic detection of two properties, the method can more objectively evaluate the basic property of the low-carbon asphalt and low-carbon asphalt mixtures and can ensure that the property of the designed low-carbon asphalt concrete can meet the requirement of national current specifications.

Owner:TONGJI UNIV

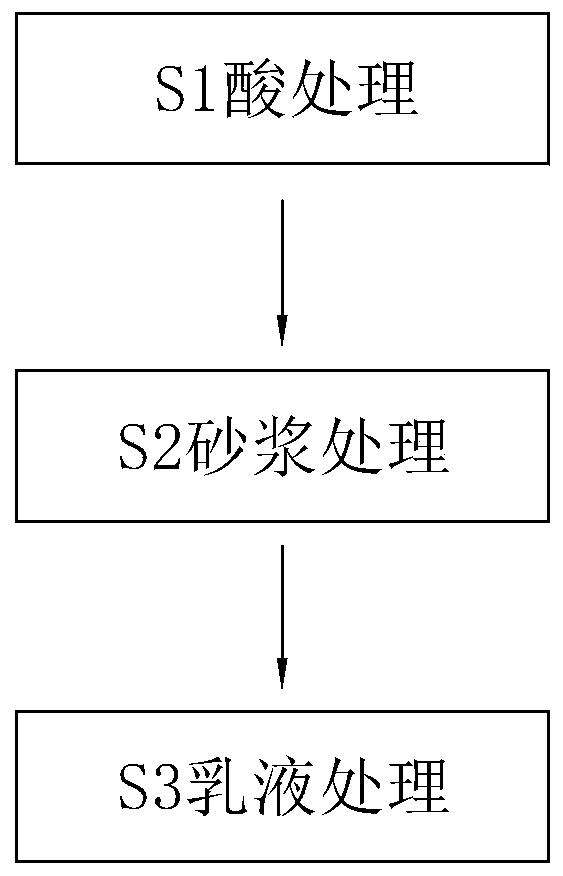

High-performance concrete and preparation method thereof

ActiveCN110105014AAvoid the problems of mixing into the mixing systemImprove impermeabilityEmulsionUltimate tensile strength

The invention discloses high-performance concrete and a preparation method thereof. The high-performance concrete is prepared from, by weight, 350-390 parts of cement, 900-1020 parts of coarse aggregates, 540-600 parts of fine aggregates, 160-180 parts of water, 190-230 parts of an admixture and 10-14 parts of an additive, wherein the coarse aggregates comprise 50-70% of recycled aggregates and 30-50% of broken stone; the recycled aggregates are subjected to S1 acid treatment, S2 mortar treatment and S3 emulsion treatment in sequence. After the recycled aggregates are subjected to S1 acid treatment, S2 mortar treatment and S3 emulsion treatment in sequence, cracks are well repaired, therefore, the compressive strength and other properties of concrete prepared by using the method are closeto the properties of the concrete with natural aggregates, and the anti-penetrability performance of the concrete is even better than that of concrete without recycled aggregates.

Owner:温州市三箭混凝土有限公司

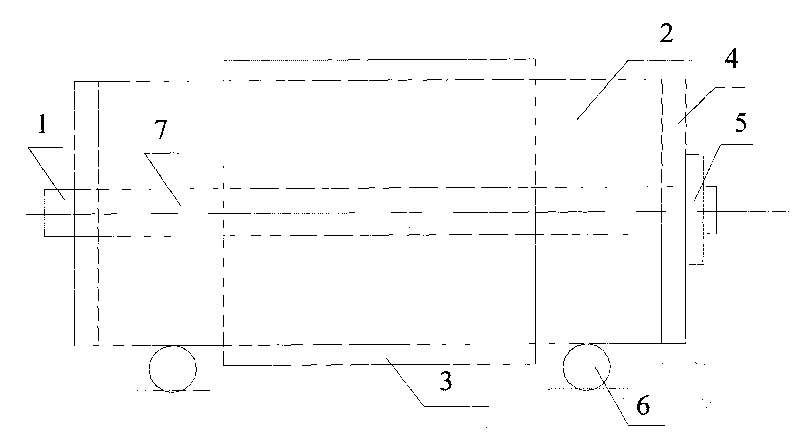

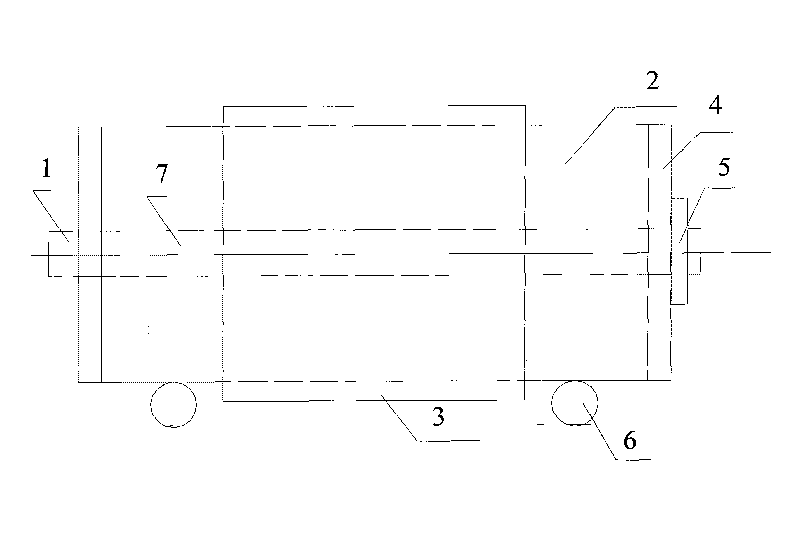

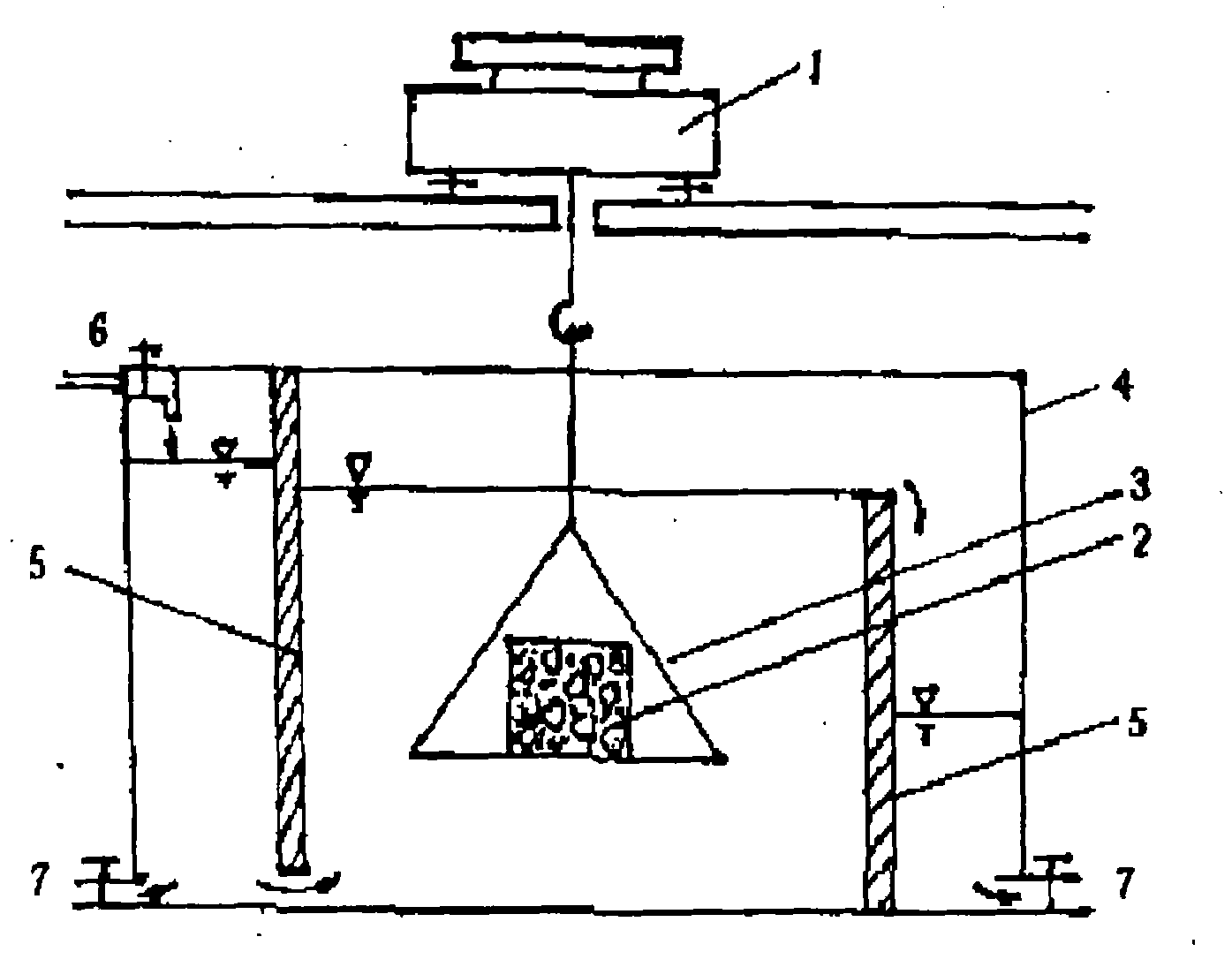

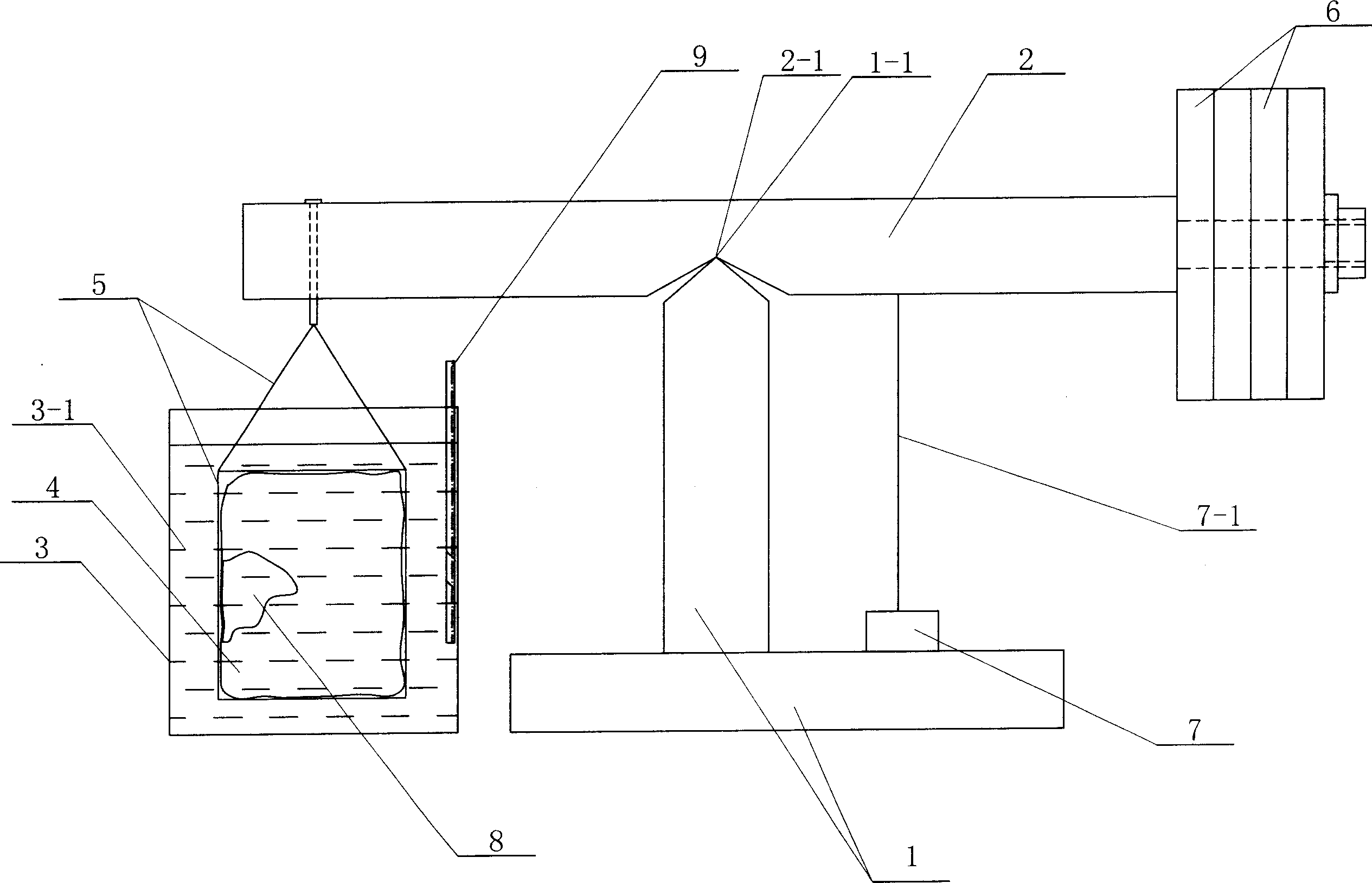

Automatic measuring device for volume change of concrete

InactiveCN1877324AHigh measurement accuracySimple structureMaterial testing goodsMeasurement deviceEngineering

Disclosed is device for measuring the variation of the concrete volume. The device is characterized in that the top point (1-1) of bracket (1) contacts the bottom end surface (2-1) of the balance bar (2) middle part; the weight (6) is jointed on the right end of the balance bar (2); the upper end of the hanger (5) is connected on the left end of the balance bar (2); the concrete sample (8) is equipped with sealing rubber film (4) and set in the hanger (5), and dipped in the liquid 3-1 in the container (3); the base of the pulling sensor (7) is connected on the right end top surface of the bracket (1); the detecting end (7-1) of the pulling sensor (7) is connected on the right end bottom surface of the balance bar (2); the thermometer (9) is dipped in the liquid (3-1).

Owner:HARBIN INST OF TECH +1

Multifunctional expandable fiber anti-cracking waterproof agent and preparation method

The invention discloses a multifunctional expandable fiber anti-cracking waterproof agent. The multifunctional expandable fiber anti-cracking waterproof agent comprises the following components in parts by weight: 8-27.3 parts of calcium sulphoaluminate, 4-9 parts of calcium oxide, 5-9 parts of magnesium oxide, 14.7-23.5 parts of fly ash, 4-9 parts of an iron powder expanding agent, 1.5-7.8 partsof a modified sepiolite fabric, 1-4.5 parts of modified polypropylene fibers, 1.5-4 parts of sodium methyl silicate, 0.5-1.5 parts of sodium fluosilicate and 1-4 parts of a polycarboxylic acid effective water reducing agent, wherein the modified sepiolite fabric is modified through diluted hydrochloric acid and a silane coupling agent, the modified polypropylene fibers are modified through potassium dichromate, concentrated sulfuric acid and a silane coupling agent, thus, mutually cross-linked net-shaped structures are formed in concrete, compared with an existing anti-cracking waterproof agent which takes common sepiolite, sepiolite fibers and polypropylene fibers as raw materials, the anti-cracking waterproof agent is better in anti-cracking property and expanding property, shorter in time of coagulation and higher in concrete performance. The invention further provides a preparation method of the anti-cracking waterproof agent, and the raw materials are blended by a two-step method.

Owner:TIANJIN JINSHENGYUAN SPECIAL BUILDING MATERIALS

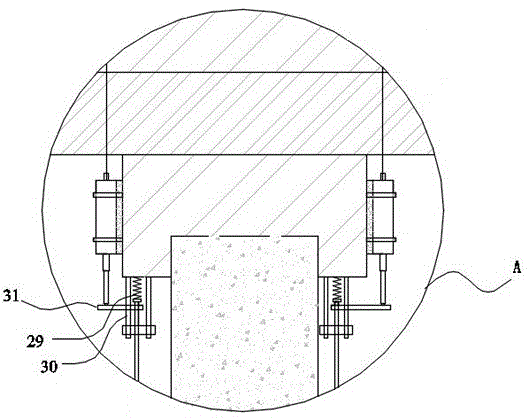

Concrete material in-high-temperature compression testing machine and in-high-temperature compression testing method

ActiveCN105424498AGuaranteed high temperatureGuaranteed fire resistanceMaterial strength using tensile/compressive forcesEngineeringFire resistance

The invention provides a concrete material in-high-temperature compression testing machine and an in-high-temperature compression testing method. The concrete material in-high-temperature compression testing machine comprises loading equipment for applying pressure on a concrete test-piece, heating equipment for heating the concrete test-piece, and a displacement acquisition device for measuring the deformation of the concrete test-piece. According to the concrete material in-high-temperature compression testing machine, the heating equipment and the loading equipment for concrete testing are skillfully combined together, and are assisted by the displacement acquisition device, so that a comprehensive testing system capable of being used for concrete test-piece in-high-temperature compression testing is formed, synchronization of heating and loading is realized, a concrete environment in high temperature due to fire can be truly simulated, a test result obtained by performing a concrete material test through the concrete material in-high-temperature compression testing machine is very close to actual compressive property of concrete in high temperature due to fire, and a guarantee is provided for researching high temperature performance and fire resistance of a concrete material.

Owner:HENAN INST OF ENG +1

High-density self-compacted concrete and preparation method

The invention discloses high-density self-compacted concrete and a preparation method. The high-density self-compacted concrete consists of the following components in percentage by mass: 15-32% of a cementing material, 20-35% of aggregates, 20-42% of sand, 3-12% of expanded vermiculite, 0.1-0.8 percentage of a water reducing agent, 0.04-0.5% of a thickening agent, 0.2-1.5% of a thixotropy lubricant, 0.08-0.8% of straw fiber and 10-25% of water. The preparation method comprises the following steps: stirring the cementing material, the straw fiber and the thickening agent needed for preparation for 3-6 minutes, sequentially adding the water, the water reducing agent and the thixotropy lubricant needed for preparation, and continuously stirring the mixture for 5-10 minutes so as to obtain a slurry mixed material; B, adding the aggregates, the sand and the expanded vermiculite into the slurry mixed material obtained in the step A, and stirring the mixture for 3-6 minutes, thereby obtaining the high-density self-compacted concrete. By adopting the high-density self-compacted concrete, properties of concrete can be effectively improved, a mixture can be relatively good in flowability and caking properties, and the high-density self-compacted concrete has the characteristics of being relatively good in anti-separation properties, tensile resistance, anti-cracking properties, self-filling properties, gap through properties, size stability and the like.

Owner:CHINA MCC17 GRP

High performance concrete impervious water proofing agent for building

The present invention relates to a high-performance concrete impervious water-proofing agent. It is formed from naphthalene series high-effective water-reducing agent, expanding agent, sodium dodecyl benzene sulfonate, organic silicon and grammite. The application of said invention can greatly improve and raise impervious property of concrete, its anticracking property and chemical corrosion resistance, and can greatly raise the concrete early, medium and after compression strength, it can be extensively used in underground engineering and marine engineering.

Owner:TONGJI UNIV

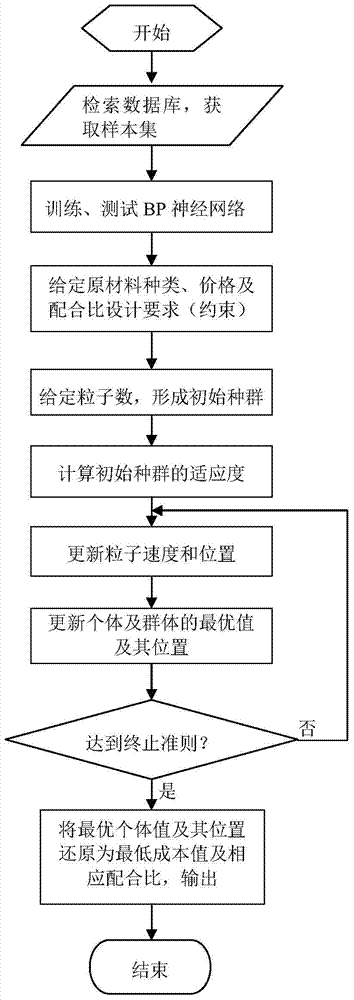

Non-linear optimization method for mix proportion of concrete

InactiveCN104261742AAchieve global optimizationSolve the overfitting control problemBiological neural network modelsNetwork modelGlobal optimization

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com