Patents

Literature

322results about How to "Strong crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for comprehensively treating ecological environment of coal gangue hill

InactiveCN101519966AReduce flowAvoid formingUnderground miningSurface miningRevegetationEcological environment

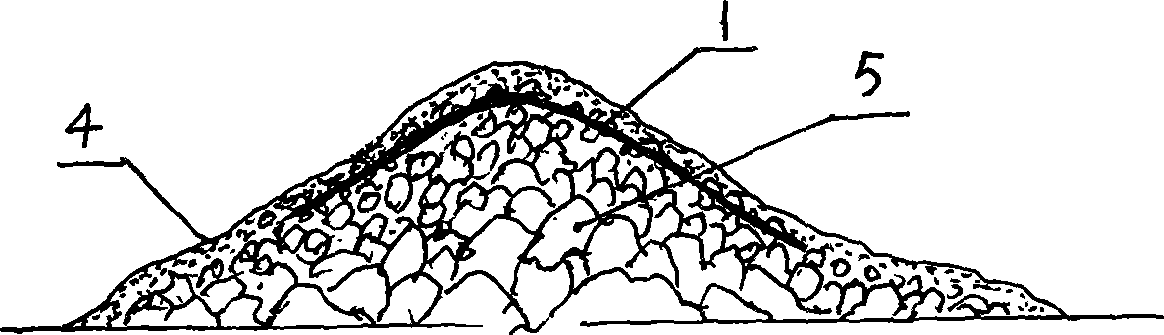

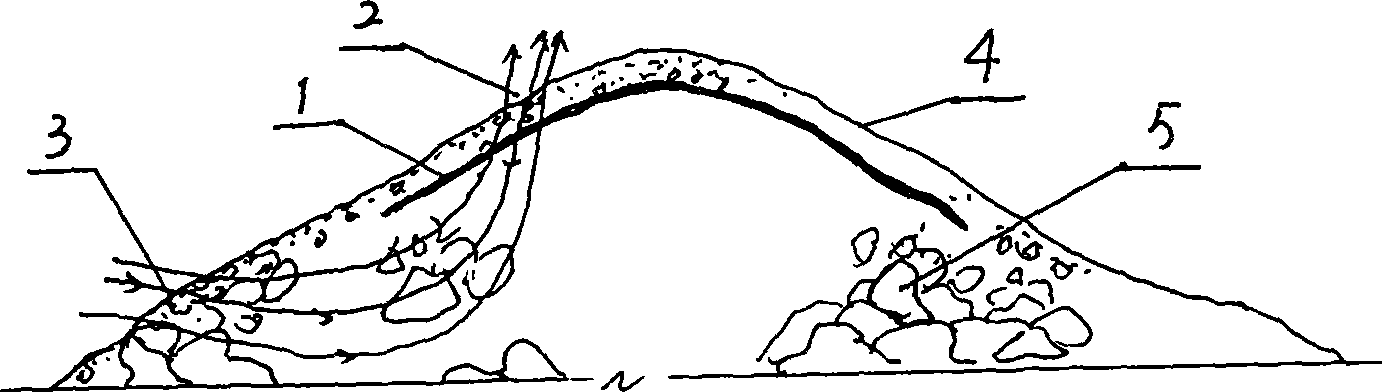

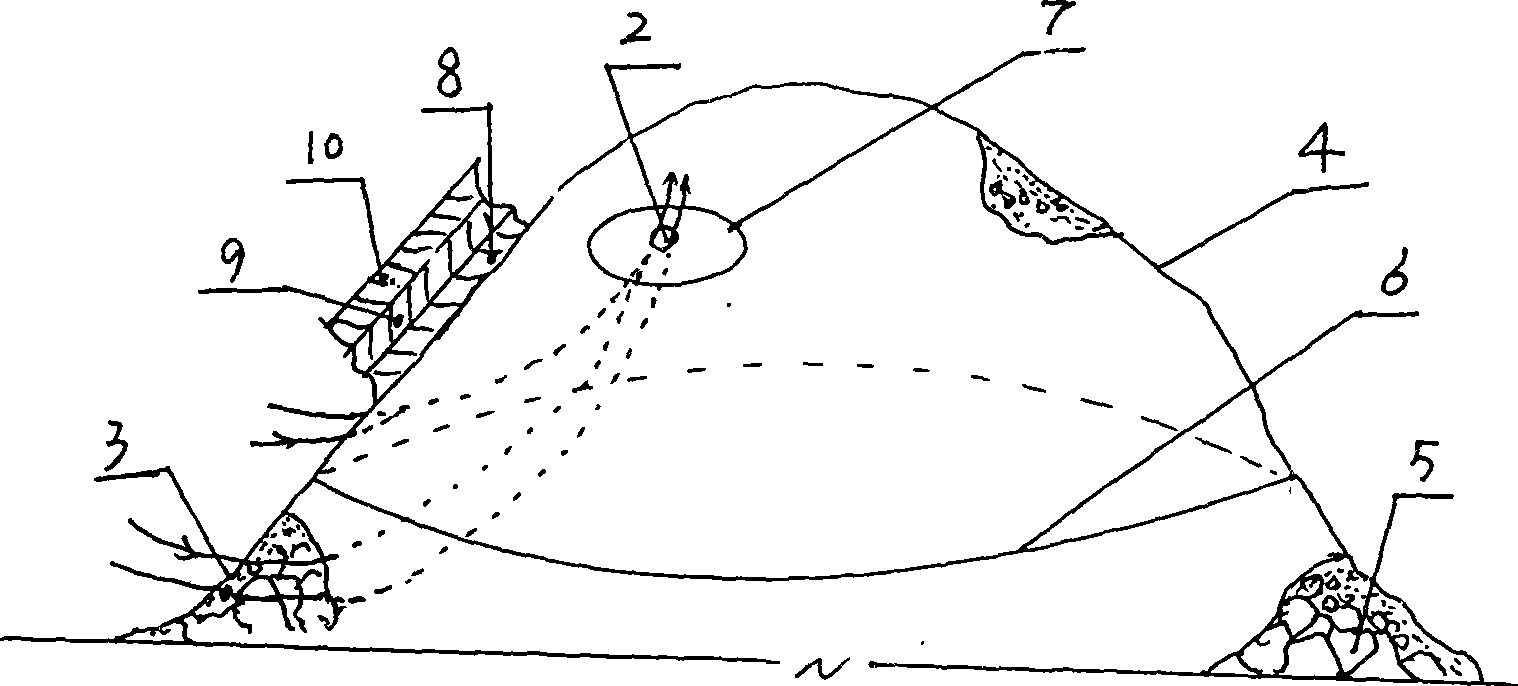

The invention relates to a method for comprehensively treating the ecological environment of a coal gangue hill, which belongs to the field of mineral waste treatment and ecological environment restoration. The method mainly solves the problems of fire extinction, fire prevention and vegetation construction of the coal gangue hill. The method comprises the steps: the on-site reconnaissance of the coal gangue hill is carried out, and a construction operation plan is established; with fire prevention as principal and the combination of fire prevention and fire extinction, the fire prevention is crucial and is combined with the fire extinction, a thin layer of slurry is firstly sprayed on the coal gangue hill by a mechanical method to completely seal to form a sealing layer (8), transition slurry is sprayed on the sealing layer (8) to completely cover the sealing layer (8) to form a transition layer (9), slurry containing grass-shrub vegetation is spayed on the transition layer (9) to completely cover the transition layer (9) to form a planting layer (10); the contour line girdle band type operation in the spraying process is carried out from bottom to top to gradually and completely cover the hill, and different operating modes are selected according to practical conditions. The invention can not disturb the structure of the coal gangue hill, takes the fire prevention as the principal, combines the fire prevention with the fire extinction, has good and durable fire prevention effect, uses reliable and effective fire prevention and fire extinction measures as guarantee conditions to construct the planting layer, adopts grass-shrub plants, carries out hill sealing management and ensures vegetation restoration; in addition, the method uses the prior specialized mechanical devices to carry out construction operation, is easy to implement, has little difficulty, high efficiency and low investment and can ensure treatment effect.

Owner:赵平 +1

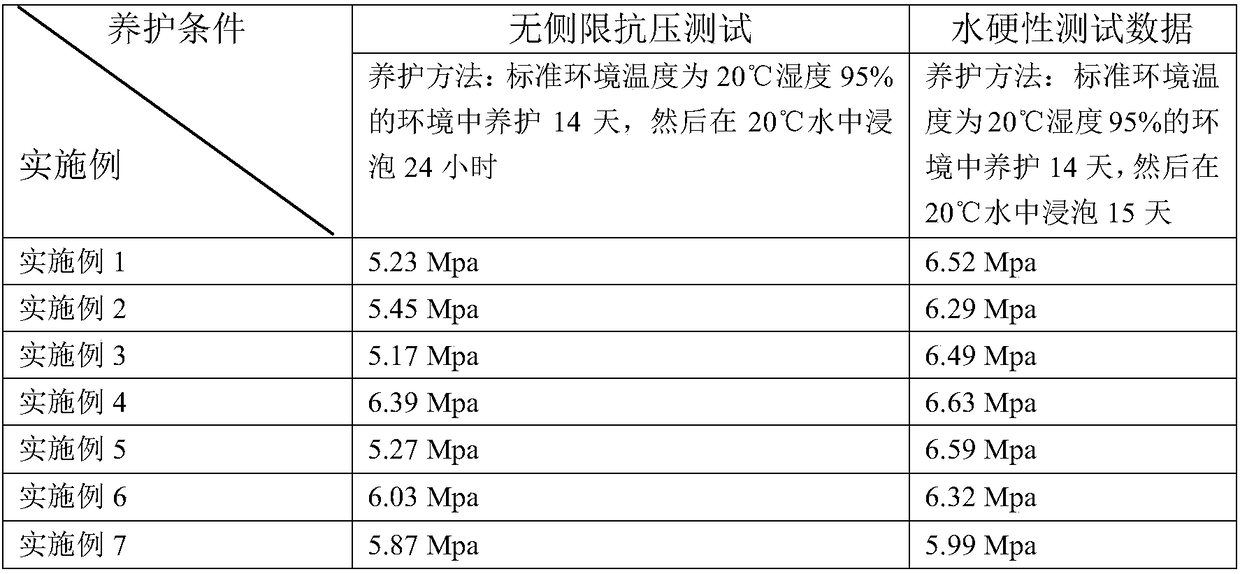

Phosphogypsum water hard road base, road base material and preparation method thereof

The invention discloses a phosphogypsum water hard road base, a road base material and a preparation method thereof, relating to the field of road engineering construction. The preparation method of the road base material comprises the following steps: weighing 85-92 percent of phosphogypsum and 15-8 percent of ordinary portland cement, uniformly mixing and stirring, thereby obtaining a preliminary mixture; weighing 99.7-99.95 percent of preliminary mixture and 0.3-0.05 percent of a phosphogypsum water hard curing agent, uniformly mixing and stirring, thereby obtaining a premix; controlling the moisture content of the premix to be 14-18 percent, thereby obtaining a base material, wherein the phosphogypsum water hard curing agent is prepared by mixing the following components in percentage by mass: 40-60 percent of elastic styrene-acrylic emulsion, 30-20 percent of nanometer alumina sol and 30-20 percent of nanometer silica sol. The road base is prepared from the road base material according to a standard road base construction method. The road base material is produced by utilizing phosphogypsum, the environmental pollution is reduced, and wastes are changed into valuable materials; and moreover, the formed road base is high in crack resistance, difficult to corrode and long in service life.

Owner:黄菁华 +2

Inorganic corrosion-proof fire-resistant abrasive-proof nano cementing agent

InactiveCN101007920AWide range of useImprove impermeabilityFireproof paintsAnti-corrosive paintsCorrosion resistantPolyvinyl alcohol

The invention discloses an inorganic nanocementing agent, which is characterized by corrosion prevention, fire- proof, wearing resistant, acid-resistant and alkali reisistant. It takes silicasol and potassium metasilicate as raw material, and produced by adding a little amount of organic raw material or inorganic raw material, and the comprised raw material and their proportion by weight are as follows: nanocolloidal silica 10 -15, potassium metasilicate 20- 30, polyvinyl alcohol 1- 5, nano titanium dioxide 3- 6, titanium dioxide titanium dioxide 7- 12, calcining porcelain clay 2- 6, porcelain clay 2- 6, silicon zirconite powder 10- 14, barium sulfate powder and water 8- 15; or as that: nanocolloidal silica 10 -15, potassium metasilicate 20- 30, polyvinyl alcohol 1- 5, mica titanium 20- 30, nano zinc oxide 7- 12, high-alumina powder 2- 6, charring silicon 10- 18, barite powder 8- 16, and clean water 8- 15. The product will not deform at 1200 Deg. C, it can form permeating high- rigidity compact coating on metal surface, and there is no permission, cracking and separation when the gelatin is heated to 300- 500 Deg. C for several hours and for more than fives times of shock cooling and heating.

Owner:陈东阜 +1

Red mud phosphogypsum hydraulic road base course, red mud phosphogypsum hydraulic road base course material and preparation method of red mud phosphogypsum hydraulic road base course material

The present invention discloses a red mud phosphogypsum hydraulic road base course, a red mud phosphogypsum hydraulic road base course material and a preparation method of the red mud phosphogypsum hydraulic road base course material, and relates to the field of road engineering construction. The preparation method comprises: weighing 10-50% of phosphogypsum and 90-50% of red mud, and uniformly mixing and strring to obtain a primary mixing material; weighing 85-92% of the primary mixing material and 15-8% of ordinary Portland cement, and uniformly mixing and strring to obtain a premix; and weighing 99.7-99.95% of the premix and 0.3-0.05% of a hydraulic curing agent, uniformly mixing and strring to obtain a mixture, and controlling the water content of the mixture to 14-18% to obtain the base course material, wherein the hydraulic curing agent is obtained by mixing the following components by mass: 40-80% of an elastic styrene-acrylic emulsion, and 60-20% of nanometer silicon sol. According to the present invention, the road base course is prepared by using the road base course material according to the standard road base course construction method; the red mud and the phosphogypsum are used to produce the road base course material, such that the pollution of the red mud and the phosphogypsum on the environment is reduced, and the waste is turned into treasure; and the formed road base course has characteristics of strong cracking resistance, corrosion resistance, and long service life.

Owner:湖北炼石环保科技有限公司

Self-repairing anti-shrink cement based composite material

The invention discloses a self-repairing anti-shrink cement based composite material which comprises the following components in parts by weight: 400-800 parts of cement, 200-600 parts of waste, 400-1000 parts of sand, 264-528 parts of water, 10-70 parts of fiber, 4-10 parts of additive and polymer emulsion which accounts for 5%-10% of the gross weight of the cement. The self-repairing anti-shrink cement based composite material has good anti-shrink performance, impermeability and durability. When having a crack, the material can realize a self-repairing function under field conditions, and can be used as restorative materials for retaining walls, road mat coats, concrete pipelines, oil and gas pipelines, dams and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Red mud water hard roadbase, roadbase material and preparation method of roadbase material

ActiveCN104926230AHigh mechanical strengthStrong crack resistanceSolid waste managementRoads maintainenceEmulsionTO-18

The invention discloses a red mud water hard roadbase, a roadbase material and a preparation method of the roadbase material, relating to the field of road engineering construction. The preparation method of the roadbase material comprises the steps of weighing 80% to 95% of red mud and 20% to 5% of ordinary portland cement, and mixing and stirring evenly to obtain an elementary mixed material; weighing 99.5% to 99.9% of the elementary mixed material and 0.5% to 0.1% of red mud water rigidness curing agent, mixing and stirring evenly to obtain a gunk, and controlling the moisture content of the gunk to be 14% to 18% to obtain the roadbase material, wherein the red mud water rigidness curing agent is formed by mixing the following components in mass percent: 40% to 80% of elastic styrene acrylic emulsion and 60% to 20% of nano alumina sol, and the solid content of the elastic styrene acrylic emulsion is greater than 55%. The roadbase adopts the roadbase material and is prepared according to a standard roadbase construction method. The red mud is used for producing the roadbase material, thus turning waste into wealth; the formed roadbase is high in crack resistance, difficult to corrode and long in service life.

Owner:黄菁华 +2

Multifunctional expandable fiber anti-cracking waterproof agent and preparation method

The invention discloses a multifunctional expandable fiber anti-cracking waterproof agent. The multifunctional expandable fiber anti-cracking waterproof agent comprises the following components in parts by weight: 8-27.3 parts of calcium sulphoaluminate, 4-9 parts of calcium oxide, 5-9 parts of magnesium oxide, 14.7-23.5 parts of fly ash, 4-9 parts of an iron powder expanding agent, 1.5-7.8 partsof a modified sepiolite fabric, 1-4.5 parts of modified polypropylene fibers, 1.5-4 parts of sodium methyl silicate, 0.5-1.5 parts of sodium fluosilicate and 1-4 parts of a polycarboxylic acid effective water reducing agent, wherein the modified sepiolite fabric is modified through diluted hydrochloric acid and a silane coupling agent, the modified polypropylene fibers are modified through potassium dichromate, concentrated sulfuric acid and a silane coupling agent, thus, mutually cross-linked net-shaped structures are formed in concrete, compared with an existing anti-cracking waterproof agent which takes common sepiolite, sepiolite fibers and polypropylene fibers as raw materials, the anti-cracking waterproof agent is better in anti-cracking property and expanding property, shorter in time of coagulation and higher in concrete performance. The invention further provides a preparation method of the anti-cracking waterproof agent, and the raw materials are blended by a two-step method.

Owner:TIANJIN JINSHENGYUAN SPECIAL BUILDING MATERIALS

Preparation method of modified polytetrafluoroethylene dispersion concentrated solution

InactiveCN107652386AHigh Limit Membrane ThicknessImprove application processabilityTetrafluoroethylenePolymer science

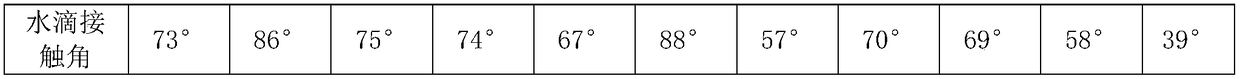

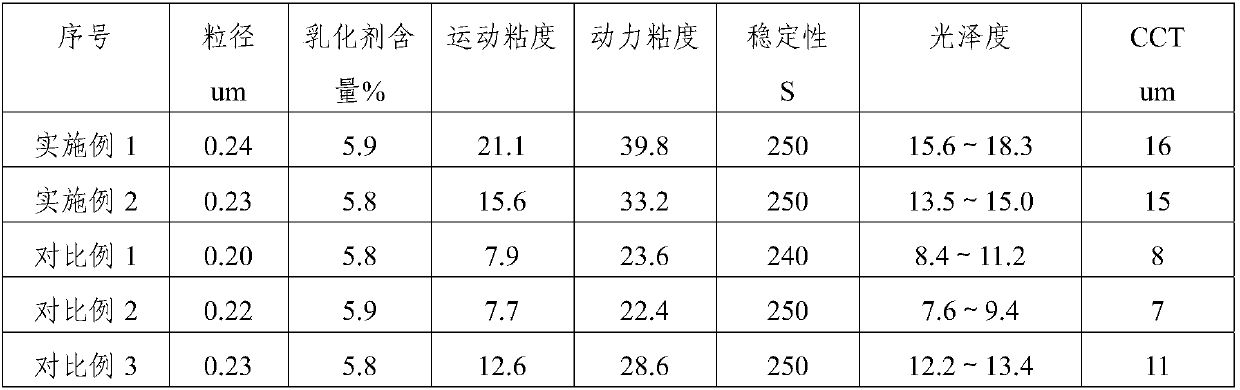

The invention relates to a preparation method of a modified polytetrafluoroethylene dispersion concentrated solution. The polymerization reaction is carried out in three stages: in the first stage, controlling a reaction pressure to be in a range of 1.0-1.8 MPa and adding 20-30% of tetrafluoroethylene monomers and 40-60% of modified monomers; in the second stage, controlling the reaction pressureto be in a range of 2.0-3.0 MPa and adding 60-70% of tetrafluoroethylene monomers; and in the third stage, controlling the reaction pressure to be in a range of 2.0-3.0 MPa and adding residual tetrafluoroethylene monomers and residual modified monomers. According to the method disclosed by the invention, the pressure is operated in a variable pressure mode in the polymerization process, and recycling is performed twice in an intermediate process for realize a soft-hard-soft three-layer molecular structure of particles, so that the application processing performance of the dispersed concentrated solution is improved fundamentally, and the obtained polytetrafluoroethylene dispersion concentrated solution has the characteristics of extremely high yellowing resistance, good surface glossiness,high limit film-crack thickness, high smoothness, high cracking resistance, excellent non-viscosity and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Method for controlling fruit cracking of jujube trees in fields

InactiveCN107853060AReduce and control field cracking rateHigh densityFertilising methodsCultivating equipmentsZiziphus jujubaNutrient

The invention discloses a method for controlling fruit cracking of jujube trees in fields, and relates to the field of technologies for planting jujube trees. The method includes (1), carrying out cultivation management; (2), regulating and controlling nutrient elements; (3), regulating and controlling bioactive substances. The method has the advantages that varieties are selected, the field management is carried out, the nutrient elements and the bioactive substances are regulated and controlled, and accordingly the fruit cracking rate of the jujube trees in the fields can be lowered and controlled by the aid of the method.

Owner:明光现代农业科技合作推广服务中心 +1

Preparation method of high-impermeability concrete

The invention solves the defects of the prior art, and provides a preparation method of high-impermeability concrete which has the advantages of full utilization of wastes, low manufacturing cost, energy conservation, environmental protection, water resistance, long service life, high strength, crack resistance, high impermeability and the like. A concrete part is composed of the following raw materials (wherein concrete has a main strength grade of C20-C60 and an anti-permeability grade of P6 or above): based on the weight of the concrete per cubic meter, 230-550 kg of the cement, 900-1300 kgof gravel, 500 to 600 kg of tailing sand, 300-400 kg of machine-made sand, 30-100 kg of fly ash, 30-100 kg of mineral powder, 5%-15% of silica fume (the percentage of the content of cement gum and anoptimal mixing amount of about 10%), 6.6-17.3 kg of a water reducing agent containing an air entraining agent or a single-use high-efficiency water reducing agent polycarboxylic acid, 8%-12% of an expanding agent, 5%-12% of an anti-permeability agent (different mixing amounts for different products), 0.6-1.8 kg (generally 0.8-0.9 kg) of polymer fibers (generally polypropylene PP, modified polypropylene or a mixture of several kinds of fibers) and 140-180 kg of water.

Owner:周铸

Integral connecting system for steel-concrete composite structure component of prefabricated construction

The invention relates to an integral connecting system for a steel-concrete composite structure component of a prefabricated construction, and belongs to the field of prefabricated construction engineering. The integral connecting system provided by the invention comprises a concrete filled steel tubular column, a superposed beam, a composite floor slab and a precast cladding panel, wherein a lower precast beam of the superposed beam is connected with the node of the concrete filled steel tubular column through an H-shaped steel connector at the beam end, a lower precast bottom plate of the superposed beam is sequentially lapped on the lower precast beams of two related superposed beams, a precast steel reinforcement cage is arranged between the edges of adjacent precast bottom plates, and the precast cladding panel is connected with the lower precast beam through a wall beam switching member to achieve one-time concrete in situ casting of an upper cast-in-place slab of the superposed beam and the precast steel reinforcement cage between the edges of the upper cast-in-place slab of the superposed beam and the adjacent lower precast bottom plate, thus completing the integral connection of the composite structure component; the integral connecting system provided by the invention is safe, good in stability, high in assembly and construction speed and high in construction efficiency, and fully reflects the advantages and the industry development trends of the prefabricated constructions.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

Waterborne exterior wall weather-resistant heat-reflective insulation coating and preparation method thereof

ActiveCN103952020AOvercoming weather resistanceOvercome volatile organic solventsReflecting/signal paintsMethacrylateCrack resistance

The invention discloses a waterborne exterior wall weather-resistant heat-reflective insulation coating and a preparation method thereof and relates to architectural coating and a preparation method thereof. The coating comprises acrylic emulsion, dicyclopentenyloxethyl methacrylate (DPOMA), titanium white powder, mica powder, filler, hollow glass beads, an anti-freeze agent, a neutralizing agent, a wetting agent, a dispersing agent, an antifoaming agent, an in-can preservative, a film fungicide, a thickening agent and a hydrophobic agent. The preparation method comprises the steps of preparing materials in parts by weight of each component, then adding the prepared emulsion and other materials sequentially to a stirring tank, grinding the slurry of the prepared materials in the grinding mill, adding the ground powder slurry to the stirring tank, starting a low-speed stirring mode, then adding the pigments and filler and other materials, and then stirring, and detecting, filtering and packaging the resulting product. The prepared coating has the advantages of good weather resistance, strong crack resistance, no volatile organic compounds, good adhesion force to a substrate and high heat reflection efficiency.

Owner:新船化工(沈阳)股份有限公司

Novel earthquake damage control system for thin-wall hollow pier

InactiveCN104674649AReduce residual displacementReduce widthBridge structural detailsBridge erection/assemblyPre stressTorsional strength

The invention discloses a novel earthquake damage control system for a thin-wall hollow pier. The novel earthquake damage control system comprises a pier base, a thin-wall hollow pier, high-tenacity fiber-enhanced cement-based composite material expanded sections, an unbonded prestressed tendon and steel energy consumption elements, wherein the thin-wall hollow pier is arranged on the upper end surface of the pier base, so that the torsional strength and the energy-dissipating capacity of the thin-wall pier are improved. The high-tenacity fiber-enhanced cement-based composite material expanded sections are arranged on the inner side and the outer side of the lower part of thin-wall hollow pier; a series of steel energy consumption elements are arranged in the thin-wall hollow pier along the pier height; the lower part of the unbonded prestressed tendon is anchored on the pier base; and the upper part of the unbonded prestressed tendon is anchored at the center of the first steel energy consumption element from bottom to top. By virtue of the unbonded prestressed tendon, the self-resetting capacity of the pier after the earthquake is provided; and the crack width of the pier after the earthquake is reduced. By virtue of the high-tenacity fiber-enhanced cement-based composite material expanded sections, the axis-compression ratio of the bottom section of the thin-wall hollow pier is reduced; the shear-bearing capacity and the anti-bending capacity of the thin-wall hollow pier are increased; and the steel energy consumption elements can be arranged as rapid exchange components, so that the repairability after the earthquake is increased.

Owner:DALIAN MARITIME UNIVERSITY

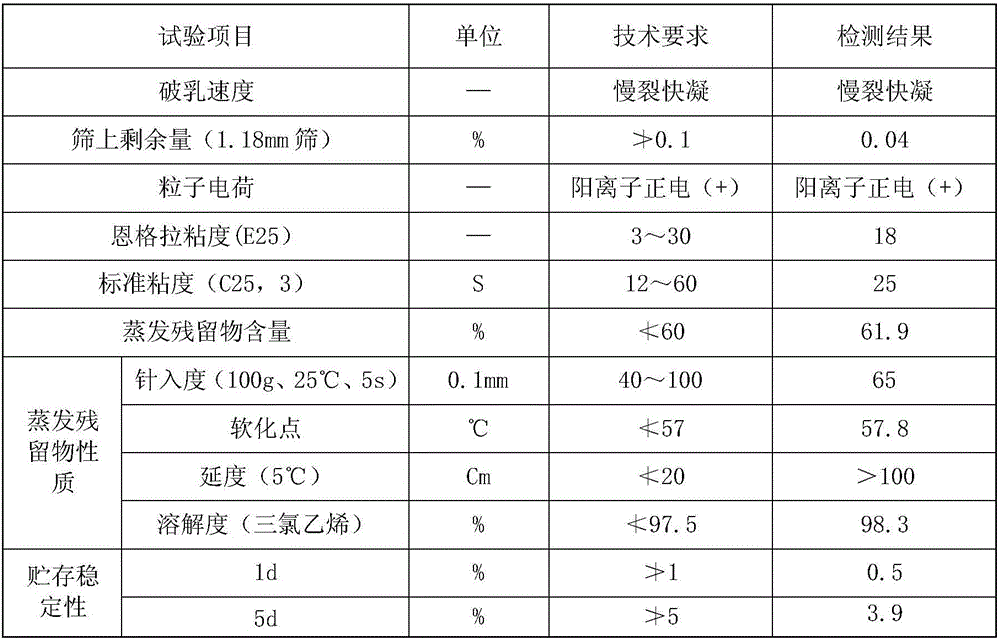

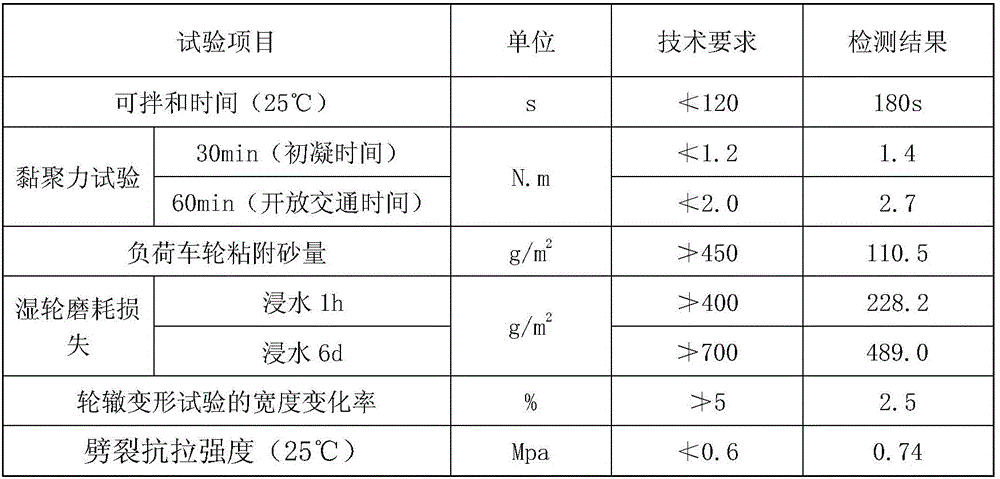

Super-viscose fiber wearing layer cold-mixed asphalt mixture and preventive maintenance method of asphalt pavement

InactiveCN106007489AReduce energy consumptionAvoid energy consumptionRoads maintainenceFiberPolymer modified

The invention relates to a pavement construction material and a pavement construction method, in particular to a cold-mixed asphalt mixture for a super-viscous fiber wear layer and a preventive maintenance method for an asphalt pavement. The composition and mass percentage of the ultra-viscosity fiber wearing layer cold mix asphalt mixture of the present invention are: polymer modified emulsified asphalt (9-15)%, aggregate (75-80)%, filler (0.5-3)% , fiber (0.1~0.3)%, rubber powder (0~3)%, water (5~10)%, the total amount is 100%. The material of the invention has good wear resistance, adhesion and water resistance, strong anti-crack ability of the construction road surface, good stability and convenient construction.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

Seedling culture method by using interaction of two plant seedlings

ActiveCN102138447AImprove fixation effectStrong crack resistanceCultivating equipmentsHorticulture methodsPlant rootsVernalization

The invention relates to a seedling culture method by using interaction of two plant seedlings, which comprises the following concrete steps: seeding the seeds of one kind or two or more kinds of plants (interaction plants) and the seeds of a plant (target plant) which is planted in a seedling transplanting way together in the same hole of a seedling tray; after the seeding, covering the hole with a matrix; putting the hole in an agricultural film tunnel or greenhouse; after the seedling of the plant emerges, uncovering the film or opening the tunnel to train the seedling until the plant root system combines the matrix into a tight bowl body; removing the interaction plants by use of a selective herbicide or preventing jointing of the interaction plants by use of vernalization; and then lifting and transplanting the seedling. The invention enhances the strength of the bowl body by use of the root system of the interaction plants so as to prevent easy loosening of the bowl body, shortens the rejuvenation period after planting and realizes low production cost.

Owner:HENAN ACAD OF AGRI SCI

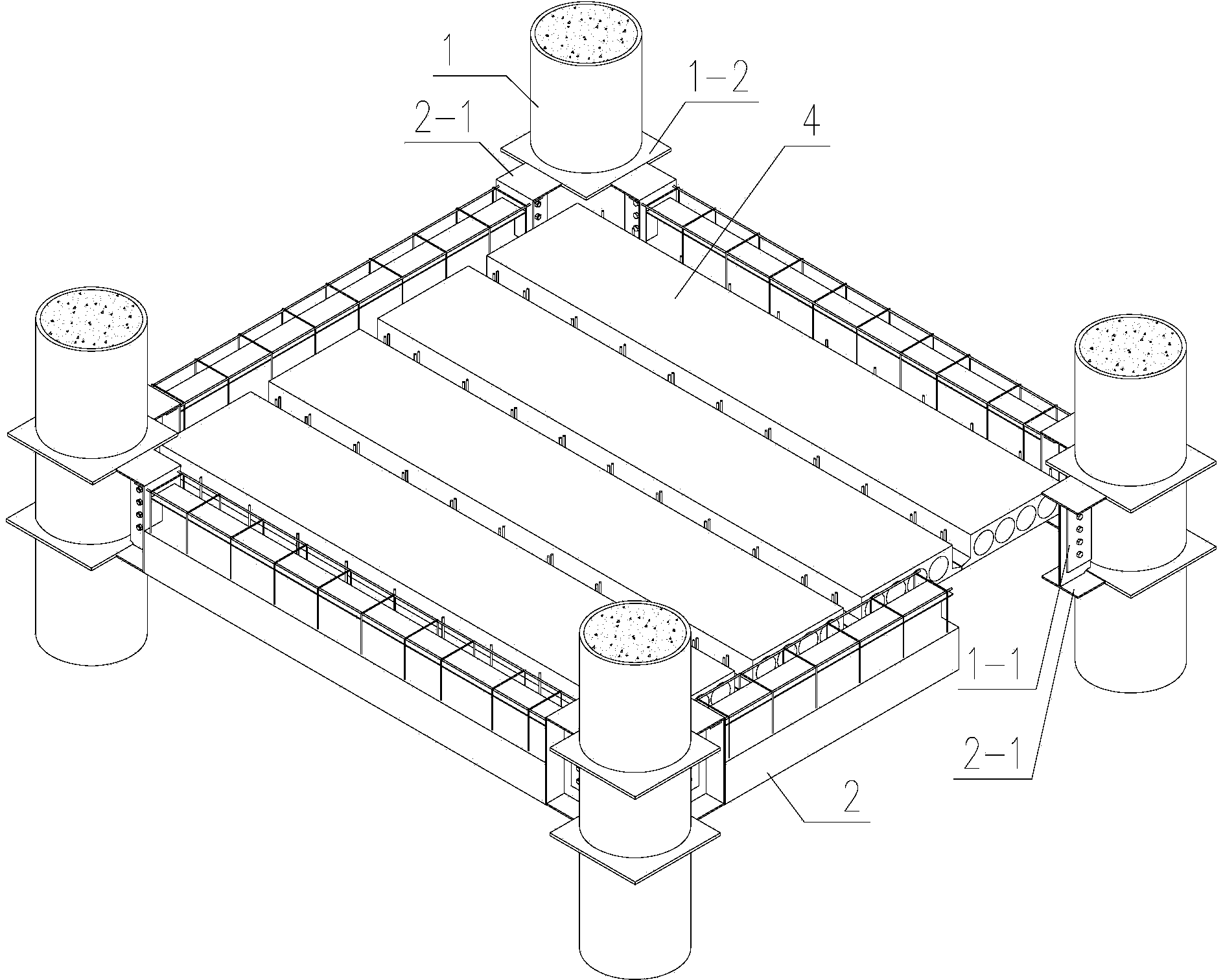

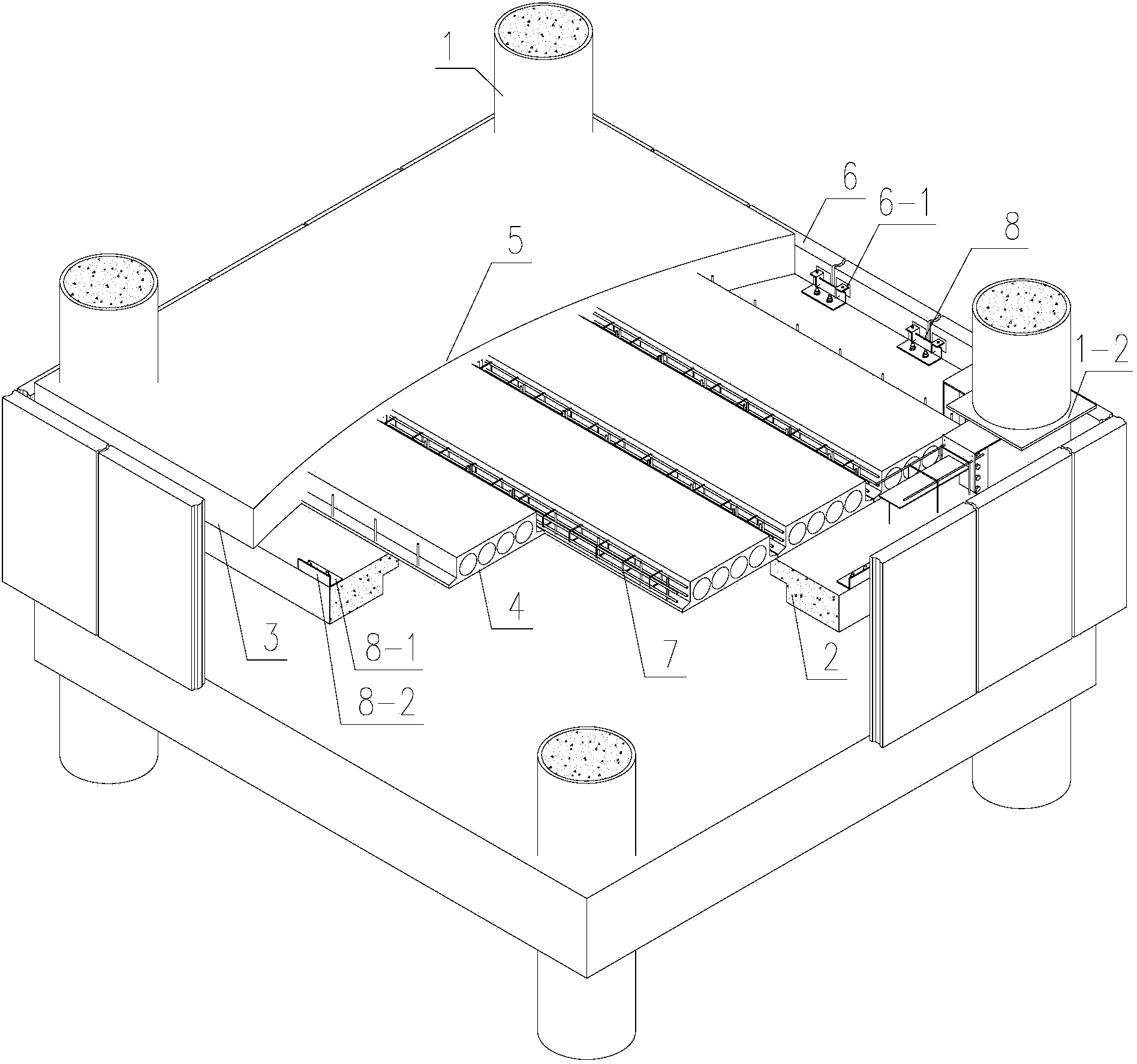

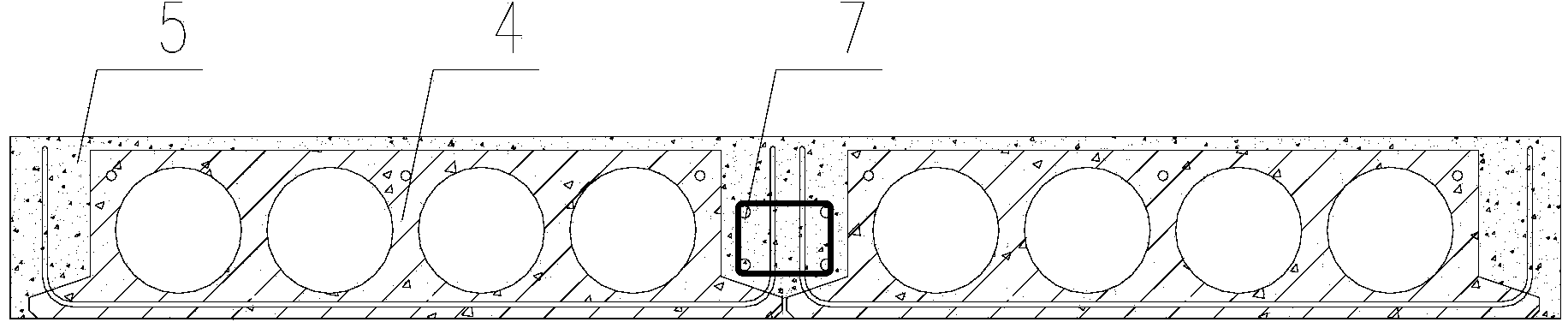

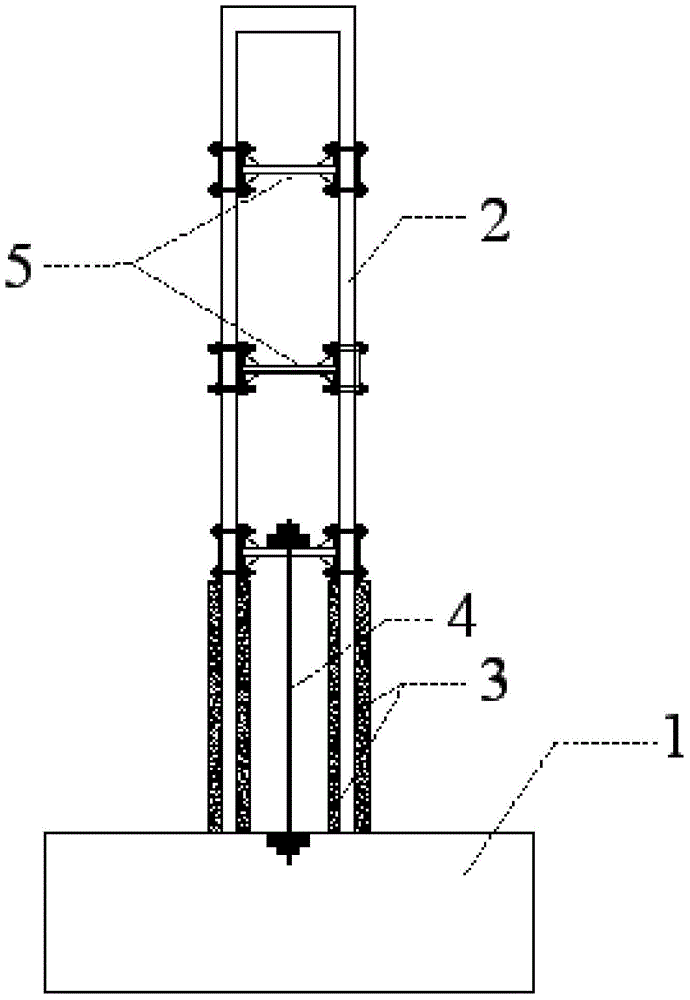

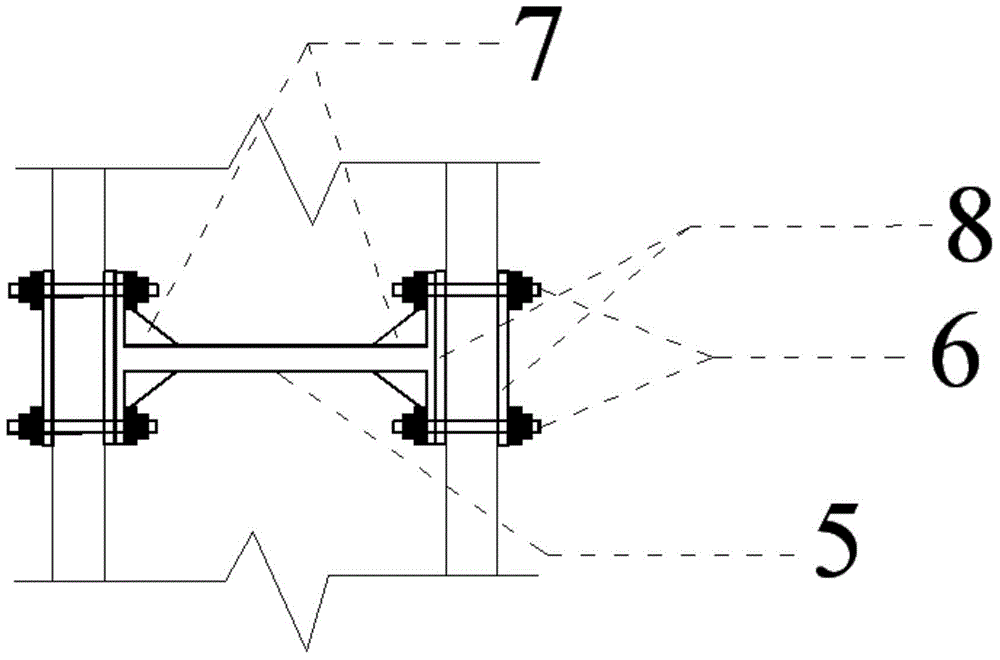

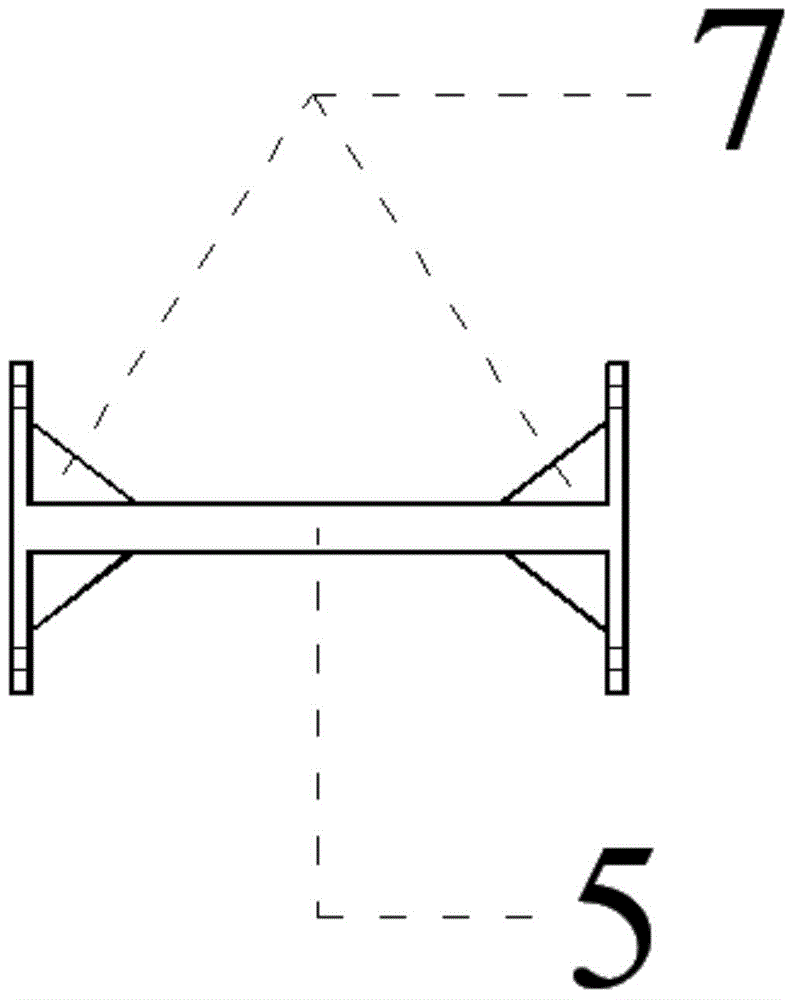

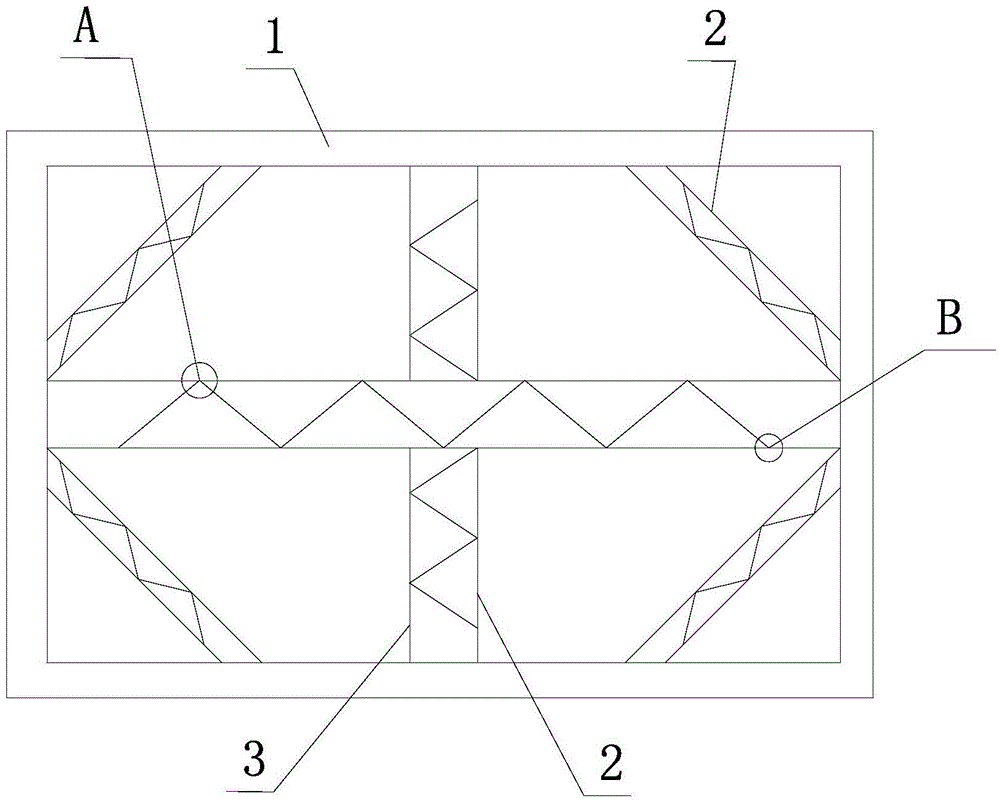

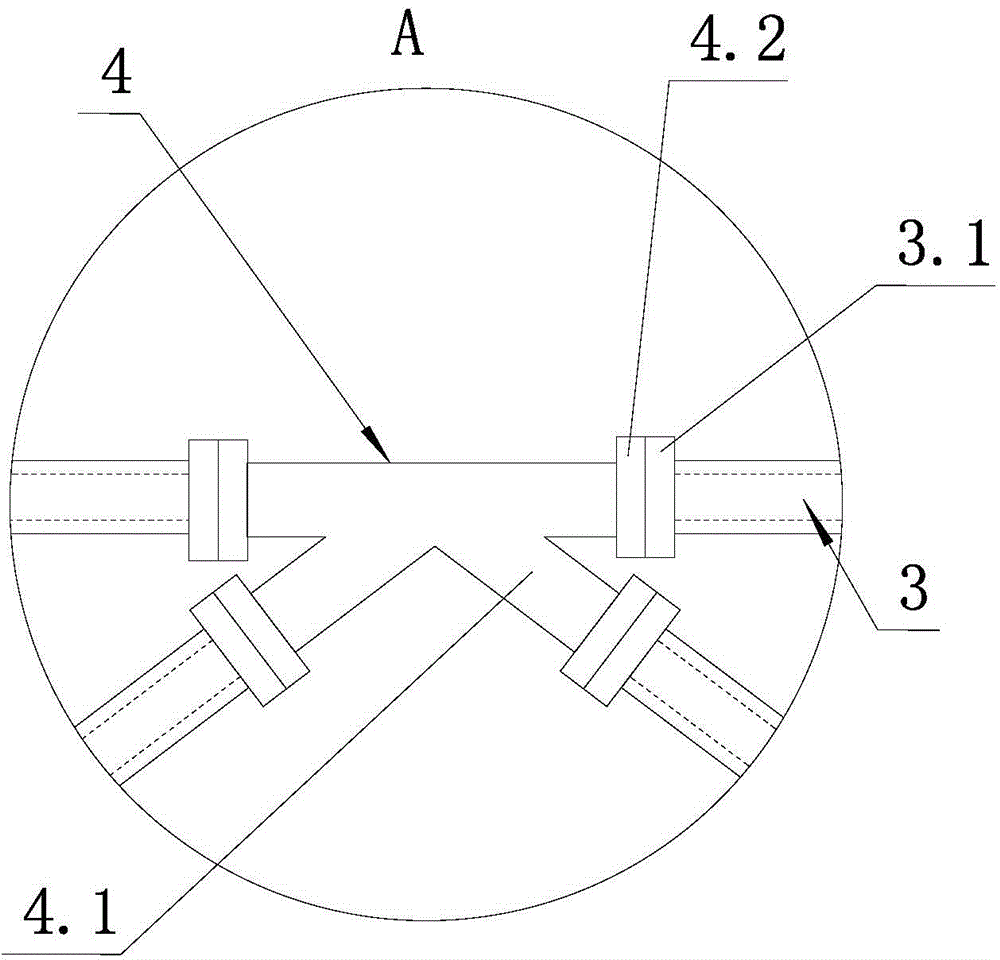

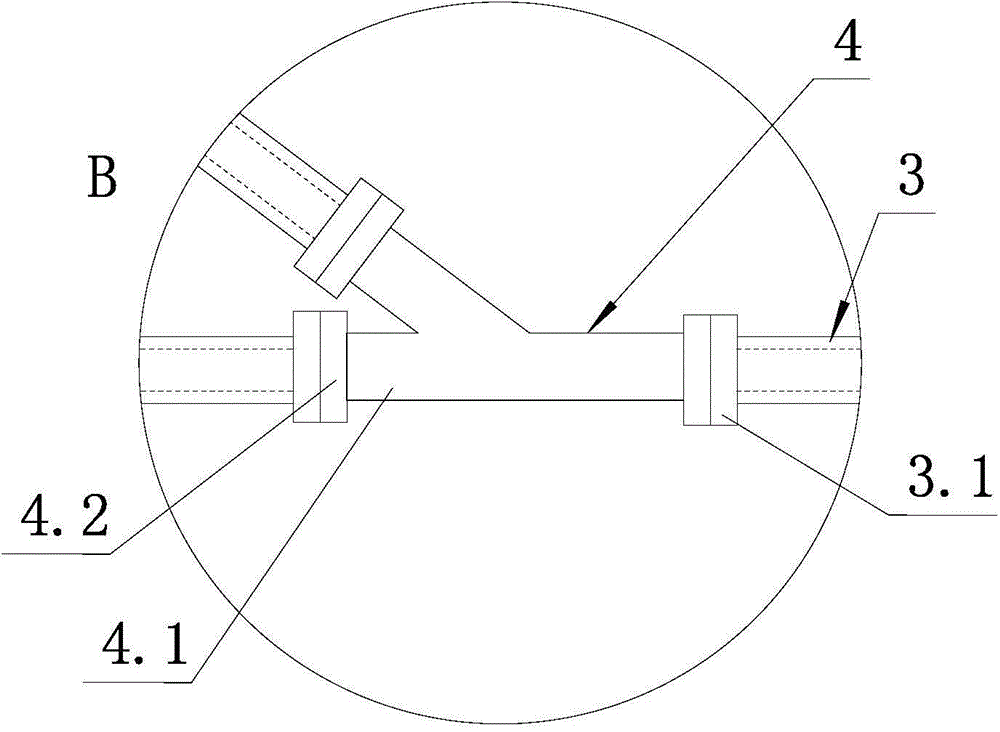

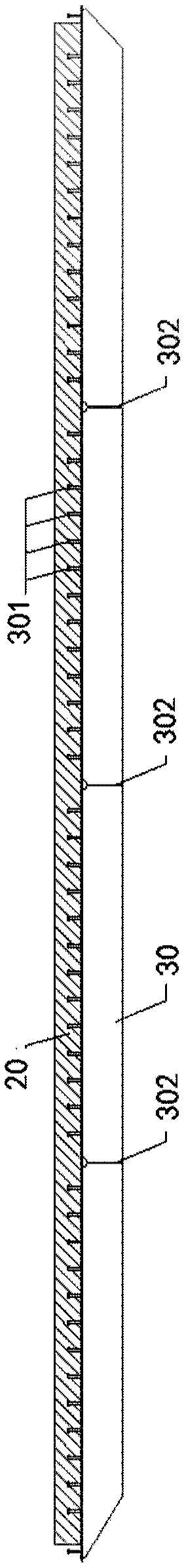

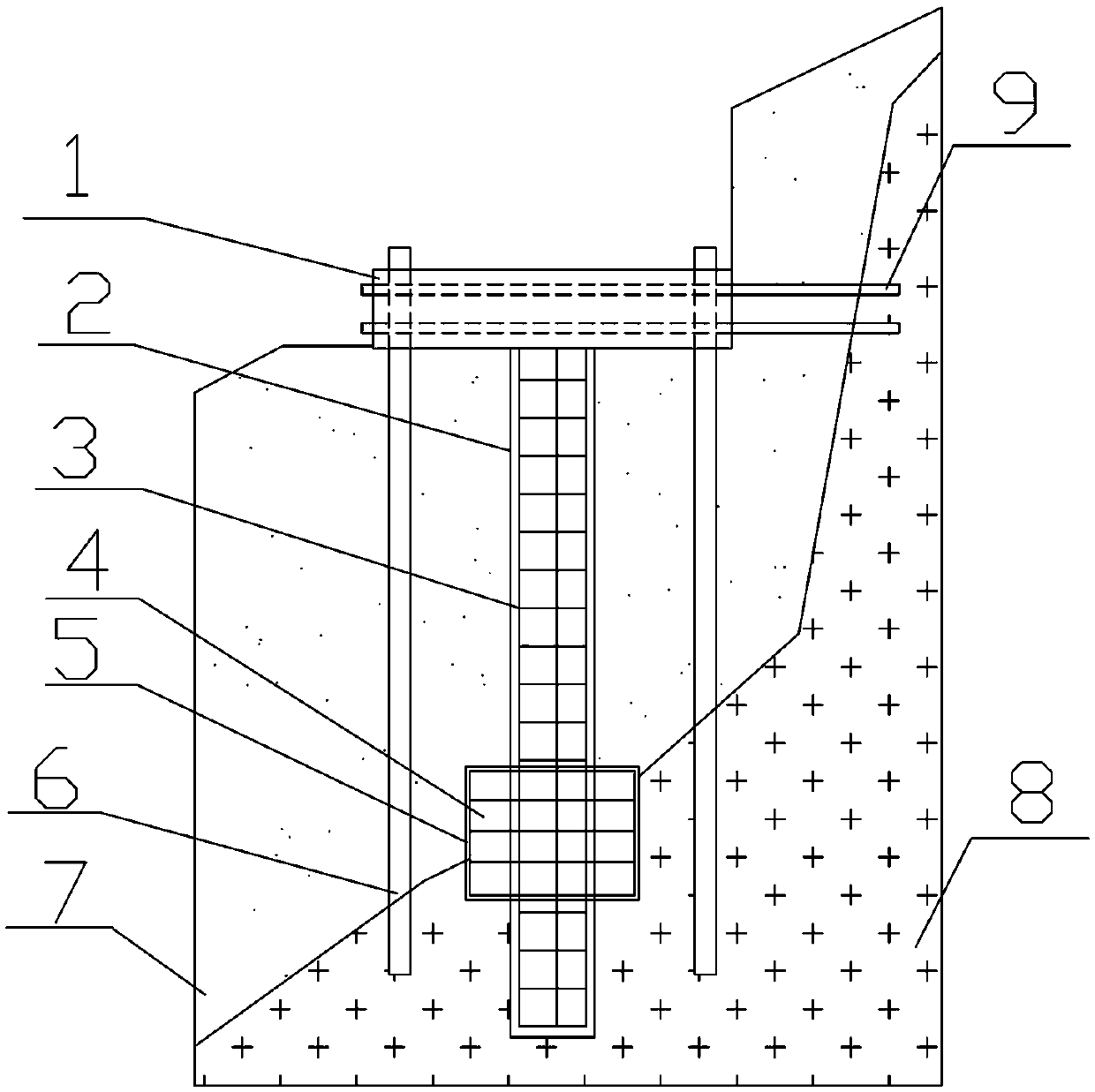

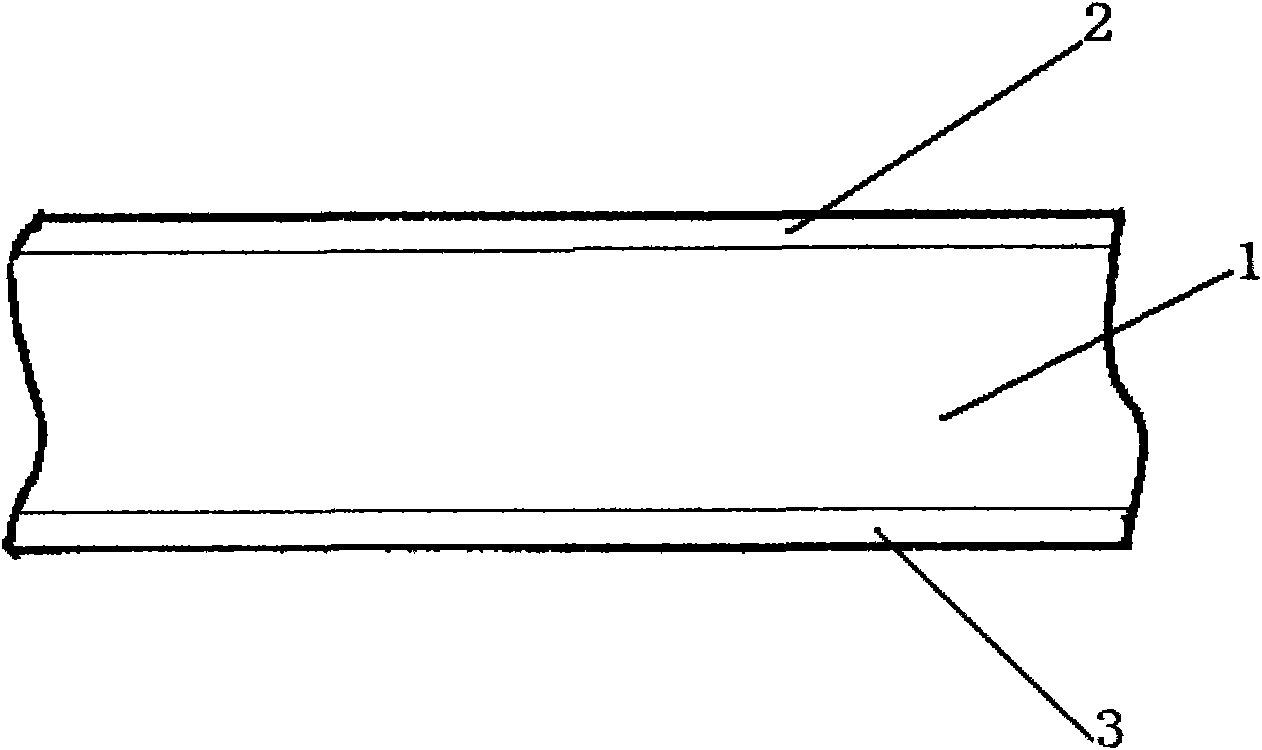

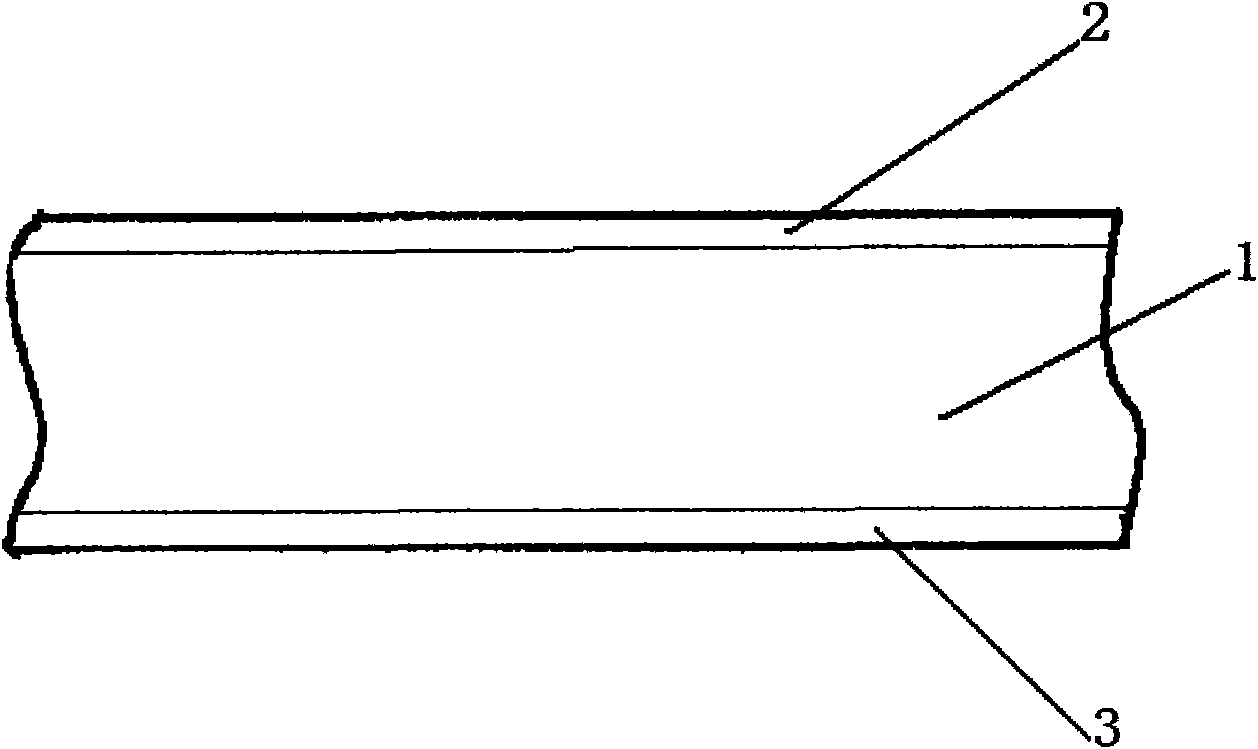

Prefabricated internal support system and construction method for foundation pit support system

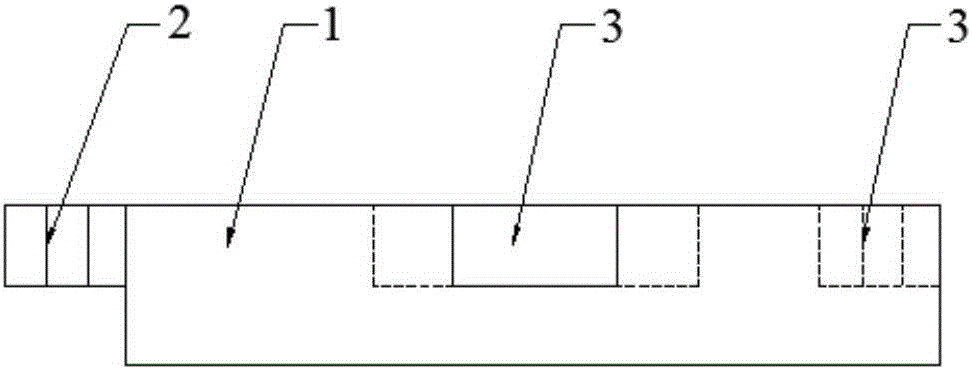

The invention discloses a prefabricated internal support system and a construction method for a foundation pit support system. The prefabricated internal support system comprises a top beam (1), an enclosing purline and an inner support (2), wherein the inner support (2) is a truss type inner support (2) assembled by splicing a pre-stressed hollow square pile (3) and a node connecting piece; first end plates on the two ends of the truss type inner support (2) are in screwed connection with a connecting plate on the top beam (1), and the rest of the first end plates are in screwed connection with second end plates of the node connecting piece; the construction method comprises the key points that the pre-stressed hollow square pile (3) and the node connecting piece are assembled into the truss type inner support (2) in a splicing manner, and the two ends of the truss type inner support (2) are connected with the top beam (1). The prefabricated internal support system and the construction method for the foundation pit support system has the advantages that the system and the method are convenient and efficient, the construction speed is high, the construction period is short, the follow-up earth cutting and earth discharging are convenient, the dismounting process is also convenient, efficient and labor-saving, no safety potential hazard is caused, the system can be recycled, and the material is saved.

Owner:宁波冶金勘察设计研究股份有限公司

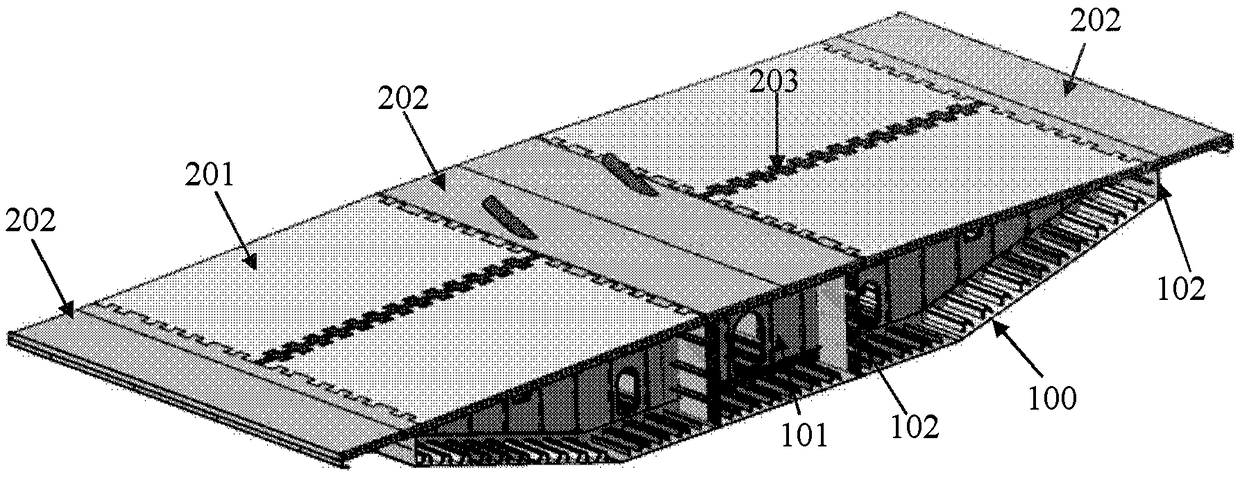

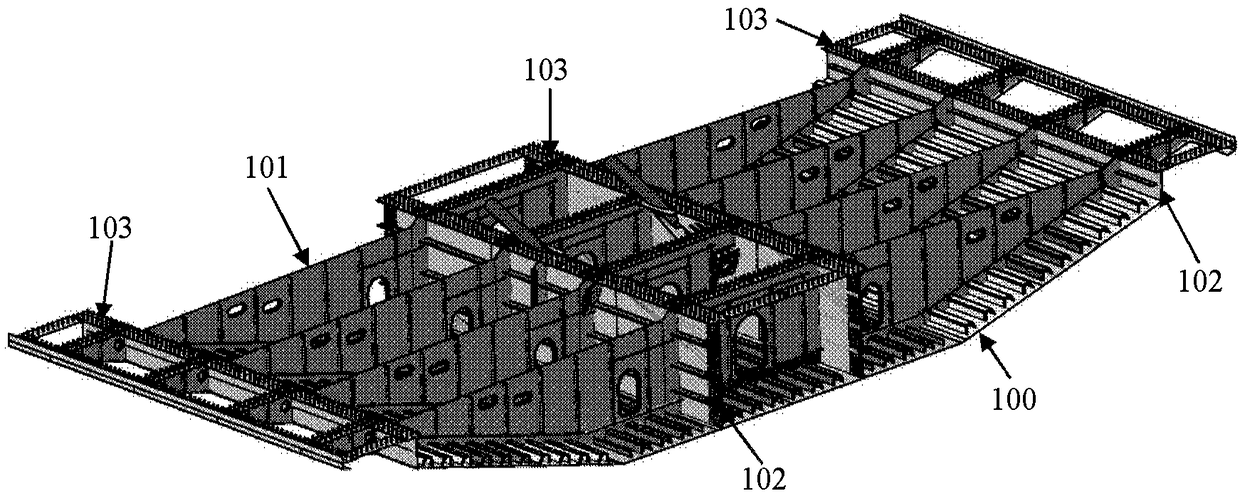

Lightweight steel-coarse aggregate reactive powder concrete composite beam structure

PendingCN109137718AReduce thicknessLose weightBridge structural detailsBridge engineeringProcess quality

The present disclosure provides a lightweight steel-coarse aggregate reactive powder concrete composite beam structure which comprises a plurality of segments, each segment comprising: a steel box girder comprising a bottom plate, a plurality of steel box girder webs and a plurality of steel box girder diaphragms. A coarse aggregate reactive powder concrete bridge deck comprises a plurality of precast bridge decks, a longitudinal wet joint and a transverse wet joint. A plurality of T-shaped pre-embedded steel plates are arranged on the bottom surface of the pre-fabricated bridge deck, the webplate thereof is connected with the steel box girder cross diaphragm plate, the top surface of the T-shaped pre-embedded steel plate is welded with a shear connector, and the shear connector is pre-embedded in the pre-fabricated bridge deck, so that the T-shaped pre-embedded steel plate and the pre-fabricated bridge deck form an integral whole. The invention can improve the mechanical performanceof the steel-concrete composite beam, enlarge the applicable span and scope, improve the construction speed and process quality of the bridge engineering, and overcome the problems of self-weight of the traditional steel-concrete composite beam and easy cracking of the bridge deck without reducing the mechanical performance of the concrete bridge deck.

Owner:CCCC HIGHWAY CONSULTANTS +1

Phosphogypsum water hard road material and preparation method thereof

The invention provides a phosphogypsum water hard road material and a preparation method thereof. The road material is prepared from the following raw materials by weight percent: 77 to 88 percent ofphosphogypsum, 0 to 8 percent of alkaline mineral waste residue, 0 to 6 percent of lime, 4 to 16 percent of cement, and 0.2 to 0.8 percent of curing agent, wherein the curing agent is prepared from the following raw materials by weight percent: 1 to 5 percent of cationic chelate, 0.01 to 0.035 percent of nano oxide, 0.1 to 0.2 percent of cross-linking agent, 0 to 0.4 percent of quinoline oxide, and 1 to 5 percent of metal salts, and the curing agent also comprises a water reducing agent, a curing accelerant and an anti-seepage agent. The phosphogypsum is used for producing the road material which can substitute the traditional road basic layer and road water stabilizing layer; and by integrating the road basic layer and the road water stabilizing layer, convenience in construction can be realized, the environmental pollution can be reduced, and waste can be converted into treasure; and a formed road layer is high in cracking resistance, unlikely in corrosion and long in service life.

Owner:湖北恒沁环保科技有限责任公司

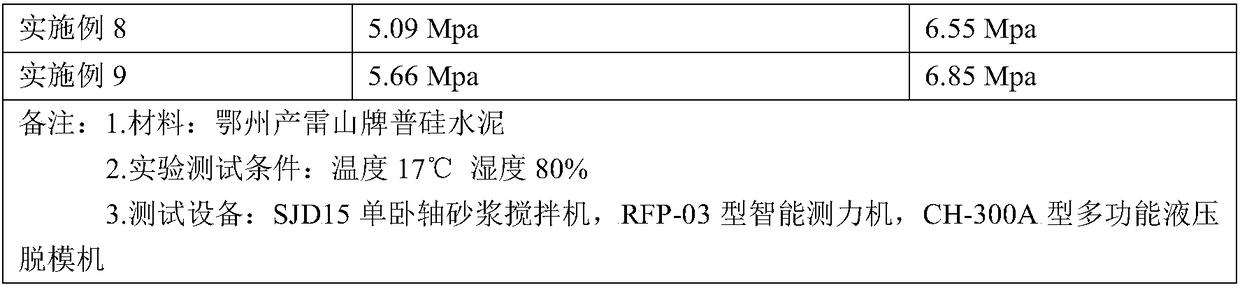

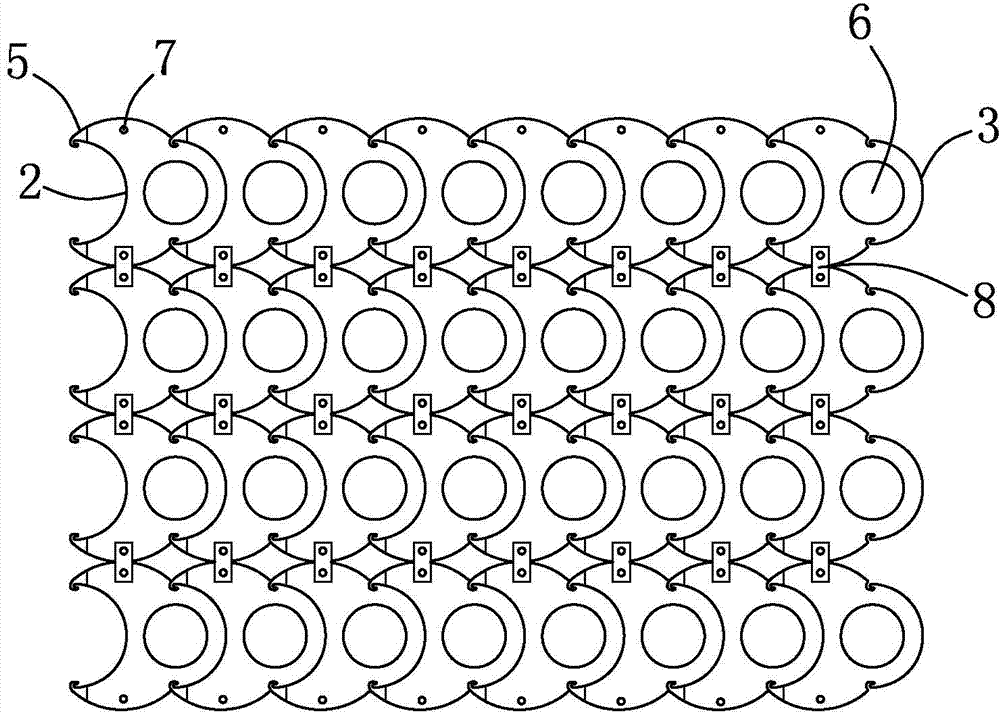

Mutually-embedded type slope protection building block and construction method thereof

ActiveCN103774617AImprove frost resistanceGood weather resistanceCoastlines protectionExcavationsArchitectural engineeringHigh intensity

The invention discloses a mutually-embedded type slope protection building block. The mutually-embedded type slope protection building block comprises a building block body, an embedded groove is formed in one side of the building block body, an embedded tail is arranged on the other side of the building block body, the embedded tail is matched with the embedded groove, a barb groove is formed between the building block body and the embedded tail, an elastic barb is arranged on the building block body, the elastic barb is matched with the barb groove, and an ecological through hole is formed in an integrated structure of the building block body and the embedded tail. The invention further discloses a construction method for building a protection slope through building blocks. The construction method comprises the first step of surveying and setting out, the second step of construction preparing and digging, the third step of inverted filter paving, the fourth step of mutually-embedded type slope protection block paving, and the fifth step of grass planting. According to the mutually-embedded type slope protection building block and the construction method thereof, the building blocks are well buckled, a certain range of differential settlement or frost heaving thaw collapse deformation is allowed in a slope protection foundation, the advantage of high-strength fracture prevention is achieved, meanwhile, the whole building block set is paved during the construction process, pavement is easy and convenient, construction cost is saved, and the construction period is shortened.

Owner:浙江宇盛建设有限公司

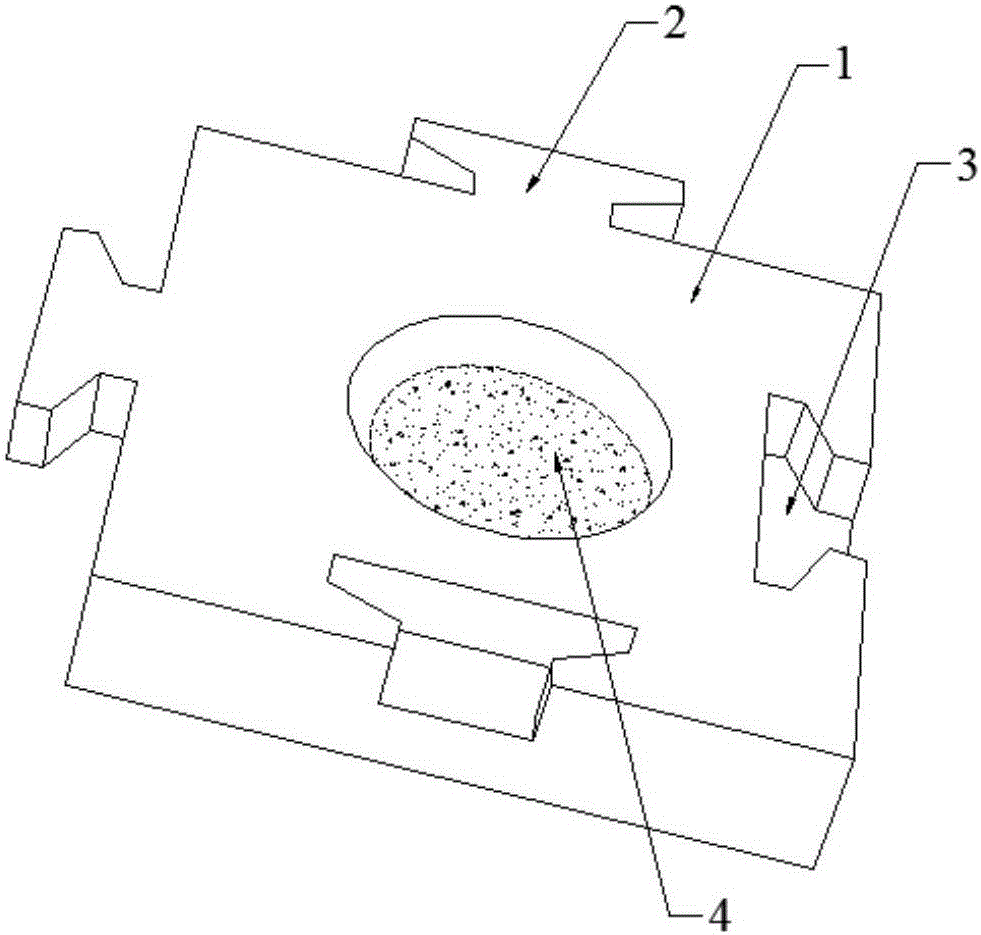

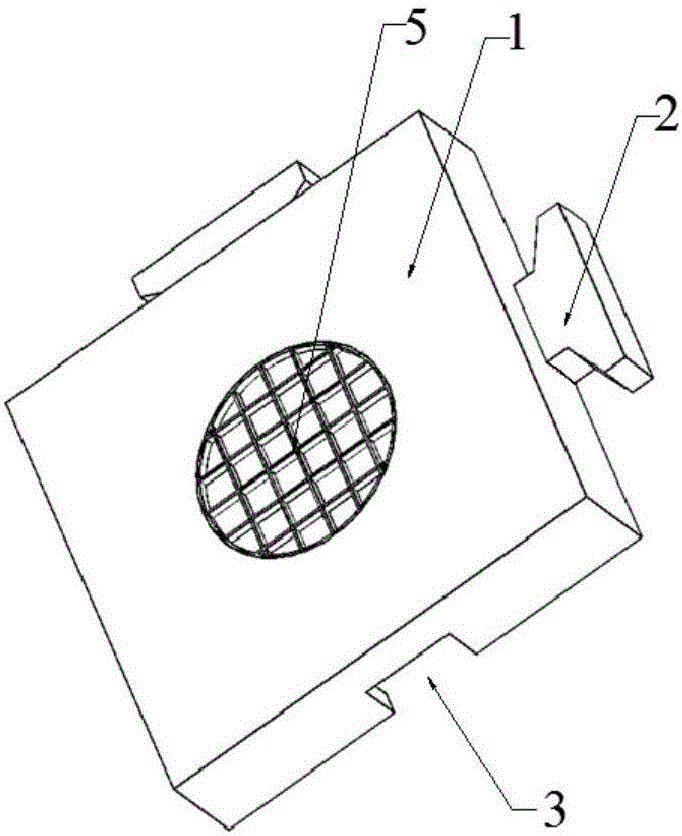

Ecological interlocking slope protection vegetation brick and preparation method thereof

InactiveCN106759108AStrong resistance to cracking and overturningImprove overall stabilityCoastlines protectionCeramic shaping mandrelsEngineeringVegetation

The invention relates to an ecological interlocking slope protection vegetation brick and a preparation method thereof. The vegetation brick comprises a block body and a vegetation disk, the block body comprises a center portion, a mounting clamp block, a mounting clamp groove, the center portion is provided with a center hole, the vegetation disk is arranged in the center hole, the upper surface of the vegetation disk is lower than that of the center portion, the center portion is provided with a front side surface, a rear side surface, a left side surface and the right side surface in the vertical direction, the mounting clamp block is positioned on the front side surface and left side surface and extends to the direction far wary from the center portion, the mounting clamp groove is respectively recessed to the center direction of the center portion from the rear side surface and the right side surface of the center portion, thickness of the mounting clamp block and the depth of the mounting clamp groove are equal and smaller than the thickness of the center portion, and the mounting clamp block and the mounting clamp groove on the adjacent slope protection vegetation bricks are mutually meshed, so that all-directional interlocking is achieved. Bricks are paved without mortar concrete in interlocking and self-embedding manner, and the vegetation brick is simple and easy to operate, low in construction cost, high in construction efficiency and applicable to slope strengthening and ecological restoration.

Owner:CHONGQING UNIV

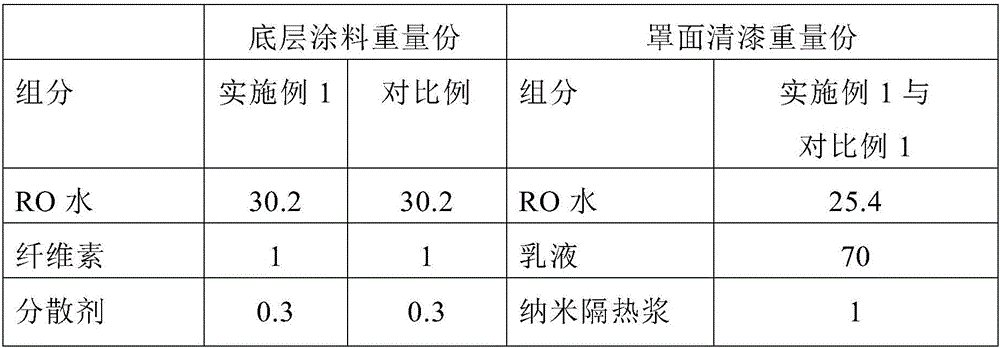

Colorful multi-layer paint with thermal insulation function and preparation method thereof

ActiveCN106380972ATo achieve the effect of heat insulationExtended service lifePolyurea/polyurethane coatingsReflecting/signal paintsInsulation layerCrack resistance

The invention relates to a colorful multi-layer paint with thermal insulation function and a preparation method thereof. The multi-layer paint comprises a prime paint, a main coating paint and finishing varnish from the inside out. By adding functional fillers to the prime paint and main coating paint, and adding nano thermal insulation slurry into the finishing varnish, the thermal insulation paint with barrier and reflection effects can be prepared. Compared with the prior art, according to the invention, through introduction of the overall functional fillers, the colorful multi-layer paint film can reach thermal insulation effect, thus reducing introduction of external heat to the inside and saving energy; the product has strong crack resistance, through the thermal insulation effect of the external thermal insulation finishing layer, the temperature change range of the external insulation layer can be reduced, and the crack resistance of the external insulation layer can be effectively improved. Through introduction of the functional material, the degradation rate of the coating film can be slowed, and the service life of the coating can be improved.

Owner:上海磐彩环保科技股份有限公司

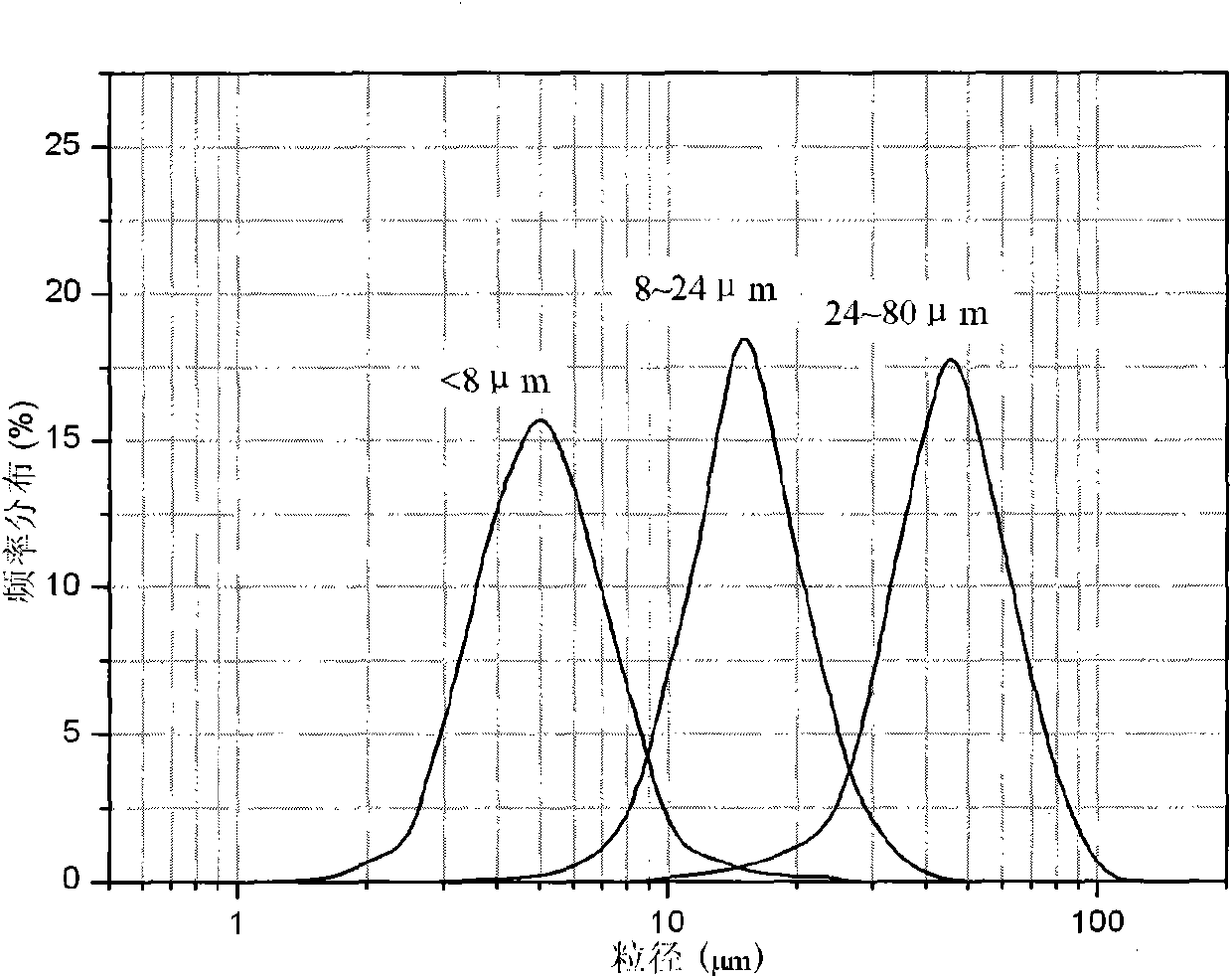

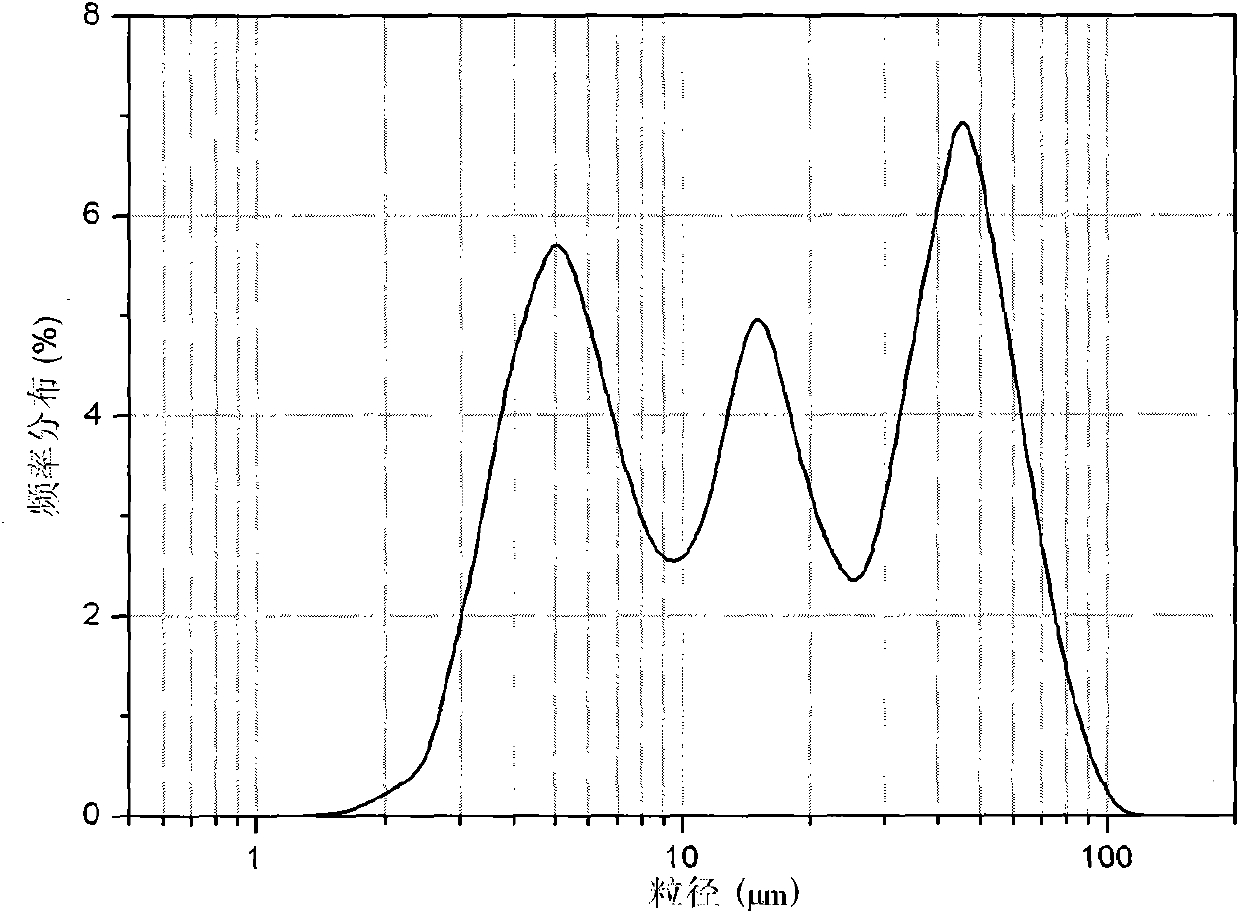

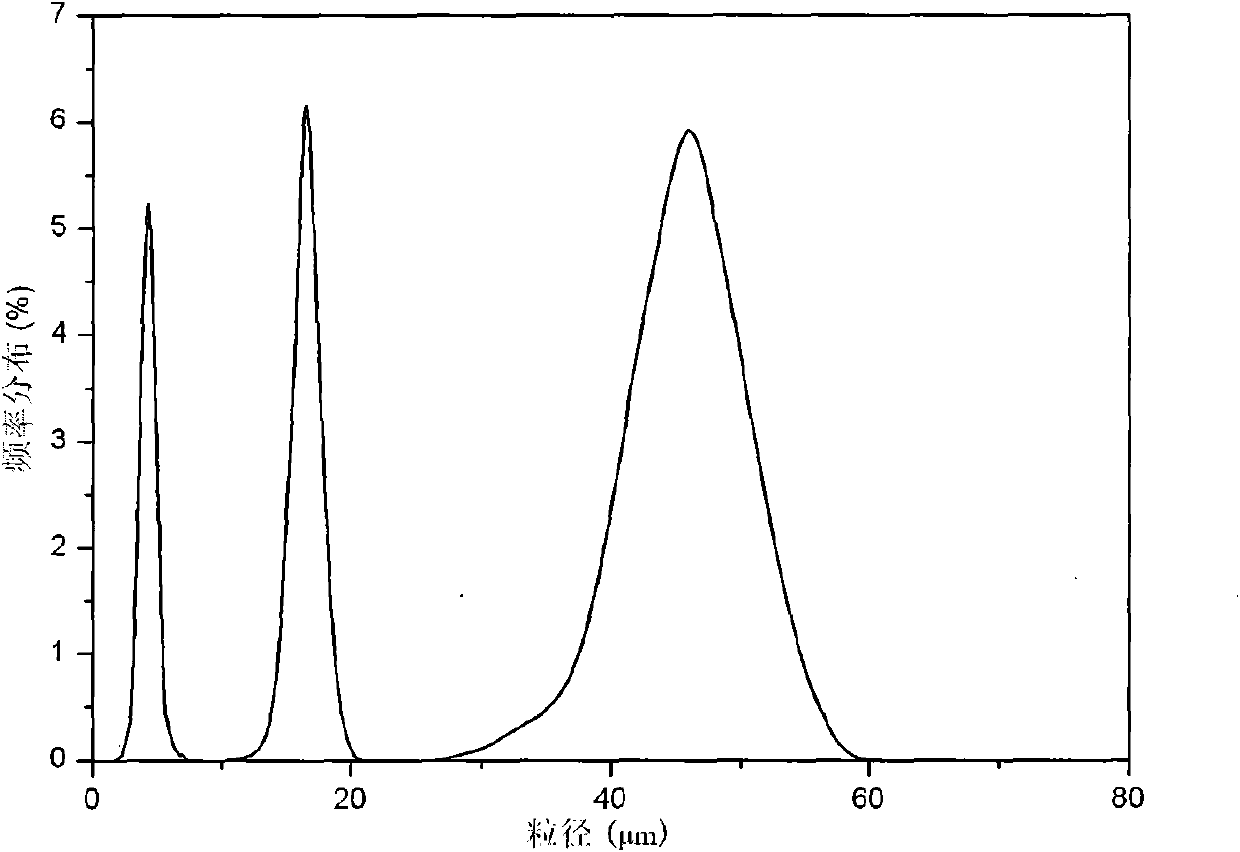

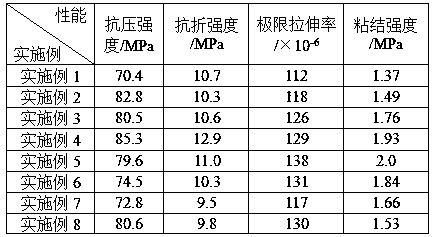

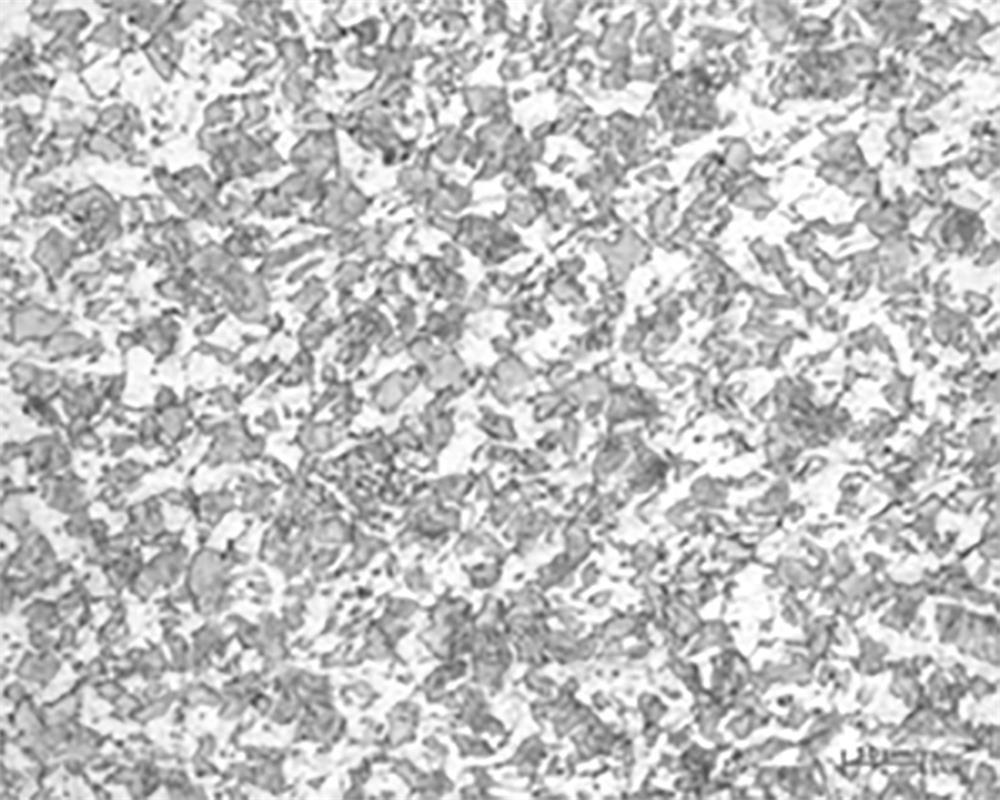

Preparation method of composite cement with low clinker dosage and high flexural compression ratio

The invention discloses a preparation method of composite cement with low clinker dosage and high flexural compression ratio. The preparation method is to mix three size ranges of powder particles and obtain the composite cement. The three size ranges of powder particles are as follows: 1) the grain size of particles is less than 8mu m, the particles are composed of high-activity supplementary cementing material with the grain size; 2) the grain size of particles is 8-24mu m, the particles are composed of cement clinker particles with the grain size; and 3) the grain size of particles is 24-80mu m, and the particles are composed of low-activity supplementary cementing material or inert filler. The volume percentages of the three size ranges of powder particles are 25-40%, 25-30% and 30-45% respectively. The clinker volume percentage of the composite cement is 25-30%, the 28-day compressive strength is up to 35-50MPa, the flexural strength is up to 10-12Mpa, the flexural compression ratio is 1 / 3-1 / 4; and the composite cement has low hydration heat and good anti-cracking capability and can be used in the civil construction / engineering with the demand on the anti-cracking capability.

Owner:SOUTH CHINA UNIV OF TECH

Construction method of bridge pile foundation in mountainous area

ActiveCN105507340AHigh strengthReduce the problem of crack growthFoundation engineeringSoil horizonGrout

The invention discloses a construction method of a bridge pile foundation in a mountainous area. The construction method comprises the following steps: (1) staking out in survey, namely locating position of the pile foundation; (2) digging a hole, namely enlarging hole on the bottom rock of a pile hole after digging the pile hole to form an enlarge hole cavity; (3) placing a steel reinforcement cage and an enlarged steel reinforcement cage, namely placing a main steel reinforcement cage in the pile hole and placing the enlarged steel reinforcement cage in the enlarged hole cavity; (4) pouring concrete, namely pouring concrete into the pile hole by adopting a guide pipe method and manufacturing a bearing platform; and (5) arranging anchor cables, namely drilling around the pile foundation, mounting a vertical anchor cable and a horizontal anchor cable, grouting by adopting a hole bottom grout returning method, and punching the vertical anchor cable and the horizontal anchor cable into the rock by passing through the soil layer. The construction method is simple; the pile foundation bearing capability is strong.

Owner:NANYANG INST OF TECH

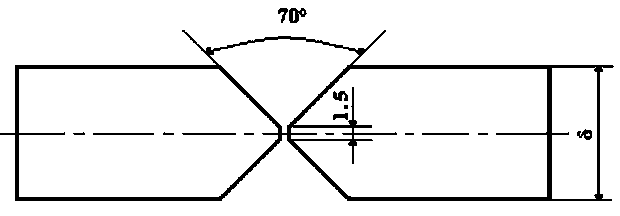

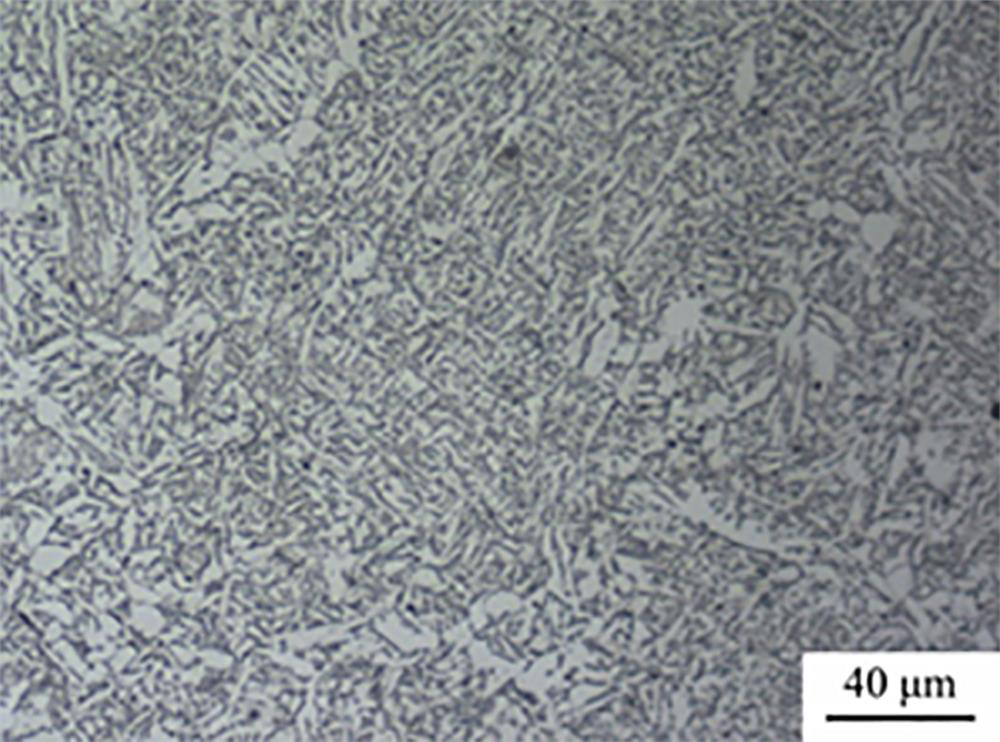

Gas shielded welding method of bridge steel with tensile strength Rm greater than or equal to 810 MPa

ActiveCN109128550AGive full play to the advantages of high strengthImprove the construction environmentArc welding apparatusWelding/soldering/cutting articlesHeat-affected zoneButt joint

The invention relates to a gas shielded welding method of bridge steel with tensile strength Rm greater than or equal to 810 MPa. Base materials: ReL is greater than or equal to 690 MPa, Rm is greaterthan or equal to 810 MPa, A is greater than or equal to 14%, and the impact work KV2 at -40 DEG C is greater than or equal to 120 J; double-faced V-shaped symmetrical grooves are adopted; and a backing welding wire adopts a solid gas shielded welding wire of which the tensile strength is 550 MPa, and a filling and covering welding wire adopts a solid gas shielded welding wire of which Rm is greater than or equal to 810 MPa. A welding process comprises the steps of performing backing welding first by adopting CO2 gas shielded welding, and welding front and back surfaces respectively for one pass without back chipping; then performing filling and covering gas welding. According to a butt joint welded by adopting the gas shielded welding method, the impact work KV2 of a three-area impact work welding beam at 20 DEG C is 147 to 167 J, the impact work KV2 of a fusion line at 20 DEG C is 214 to 224 J, the impact work KV2 of a heat affected area (1 mm) at 20 DEG C is 215 to 227 J, the impactwork KV2 of the welding beam at -20 DEG C is 126 to 134 J, the impact work KV2 of the fusion line at -20 DEG C is 132 to 144 J, the impact work KV2 of the heat affected area (1 mm) at -20 DEG C is 142 to 159 J, the impact work KV2 of the welding beam at -40 DEG C is 96 to 108 J, the impact work KV2 of the fusion line at -40 DEG C is 125 to 139 J, the impact work KV2 of the heat affected area (1 mm) at -40 DEG C is 134 to 158 J, and the corrosion resistant index I of the welding seam is 8.89 to 9.46.

Owner:武汉钢铁有限公司

Preparation method of tripolycyanamide veneer cover wood-based panel

The invention discloses a preparation method of a tripolycyanamide veneer cover wood-based panel, wherein the tripolycyanamide veneer mounted wood-based panel comprises a wood-based panel substrate, wherein tripolycyanamide veneer covers are symmetrically adhered on the upper surface and the lower surface of the wood-based panel substrate, and the tripolycyanamide veneer covers are solid wood covers being immersed by tripolycyanamide and having different colors or textures. The preparation method comprises the steps of: immersing the solid wood covers into colorless and transparent tripolycyanamide resin so that tripolycyanamide sizing materials uniformly permeate; then drying the solid wood covers for removing water and evaporating solvent; and heating and pressurizing or pressurizing and laminating by adopting a cold-heat-cold thermal pressing process. Natural wood covers are directly used for replacing printed woodgrained paper, thus solid surface stripes exist on the surface of the panel, formaldehyde pollution in environment is reduced; and the wood covers are not easy to drop, and have high wear-resistant strength and lower cost.

Owner:上海荷雨木业有限公司

CO2 gas shielded welding wire with tensile strength of 650MPa for coating-free weathering steel bridge and wire rod

ActiveCN111975244AStrong crack resistanceGood atmospheric corrosion resistanceWelding/cutting media/materialsSoldering mediaWire rodCrack resistance

The invention discloses a wire rod for a CO2 gas shielded welding wire with tensile strength of 650MPa for a coating-free weathering steel bridge, and belongs to the field of weathering steel weldingmaterials. The wire rod comprises the following chemical components in percentage by mass: 0.04 to 0.09 percent of C, 0.55 to 0.85 percent of Si, 1.70 to 2.10 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.46 to 0.65 percent of Cr, 1.10 to 1.80 percent of Ni, 0.15 to 0.38 percent of Cu, 0.10 to 0.20 percent of Ti, 0.003 to 0.005 percent of B, less than or equal to 0.015 percent of Al, less than or equal to 0.045 percent of Zr, less than or equal to 0.030 percent of Ce, less than or equal to 0.050 percent of O, less than or equal to 0.070 percent of N, and the balance of Fe and inevitable impurities. The invention also discloses the CO2 gas shielded welding wire with the tensile strength of 650MPa for the coating-free weathering steel bridge, which is prepared by drawing the wire rod. The welding wire is used for welding coating-free weathering steel with the tensile strength of 650MPa, wherein the tensile strength of deposited metalis between 650MPa and 730MPa, and the welding wire has high crack resistance; and the yield strength is more than or equal to 500MPa, the elongation is more than or equal to 23 percent, and the low-temperature impact energy KV2 at the temperature of -40 DEG C is more than or equal to 60J.

Owner:YANSHAN UNIV

Elastic lithium metal negative electrode surface modification layer, preparation method thereof and lithium metal negative electrode

ActiveCN110112417AImprove water resistanceImprove air performanceManufacture by sprayingElastomerCyclic process

The invention relates to the technical field of lithium metal negative electrodes, and in particular relates to an elastic lithium metal negative electrode surface modification layer, a preparation method thereof and a negative electrode. The raw materials comprise, by weight, 1 to 3 parts of elastomer material and 5 to 10 parts of inorganic material. The elastomer material and the elastomer material are mixed to form a modified layer with the thickness of 1 to 50 microns. An artificial SEI layer is constructed through organic and inorganic mixing. Compared with a single-component artificial SEI layer, the mixed layer has obvious synergistic effect. An inorganic phase provides mechanical strength to prevent the growth of Li dendrites. An organic phase provides elastic deformation ability and relaxation resilience to maintain the integrity of the SEI layer during the cycle. Solvent-free preparation is achieved during a preparation process, which improves the stability of lithium metal,and reduces the production cost and environment pollution.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

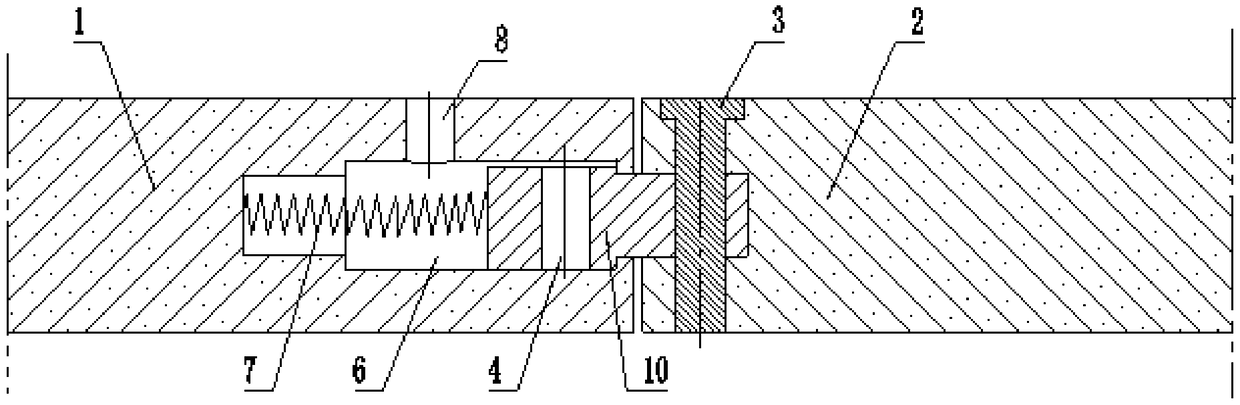

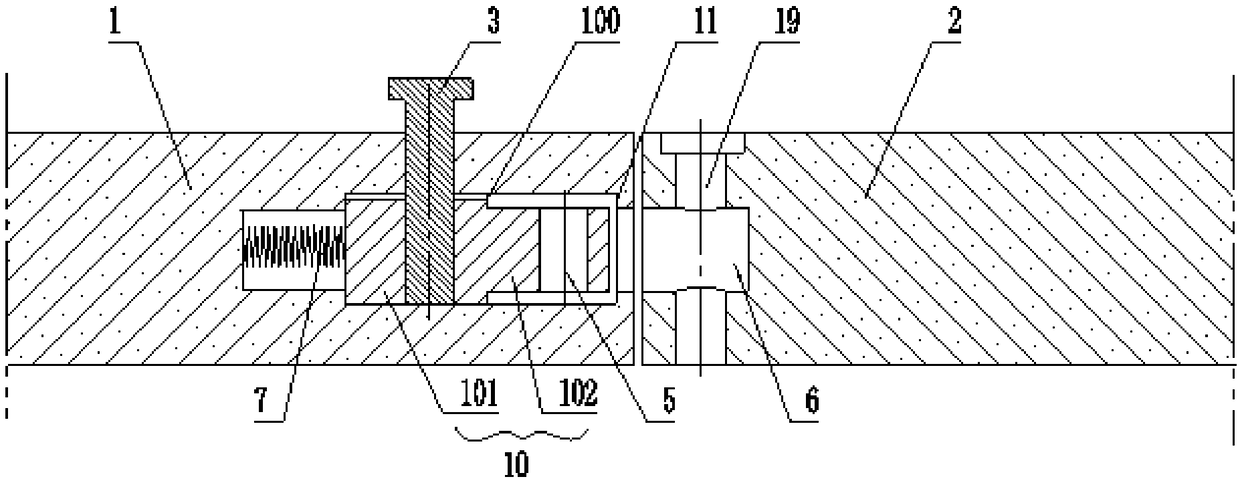

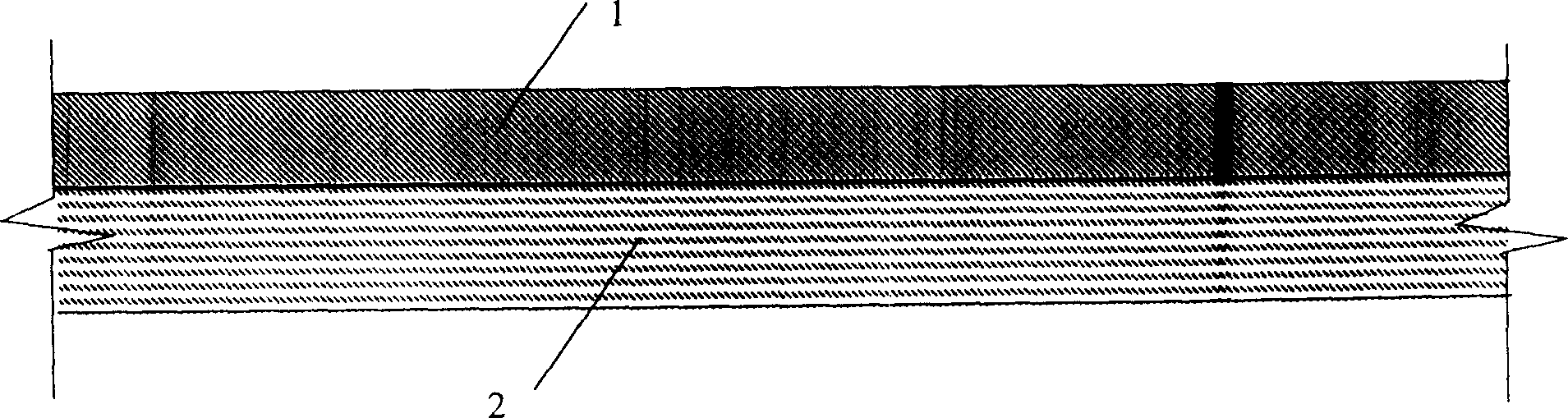

Dry and wet mixed connection joint and construction method thereof

ActiveCN108755978ASimple structureThe structure is easy to operateBuilding constructionsStructural engineering

Owner:SHIJIAZHUANG TIEDAO UNIV

Road surface structure of rolling flexiable fibre cement concrete and construction method thereof

InactiveCN100999889AReduce dosageImprove economyPaving reinforcementsIn situ pavingsFrostRoad surface

The present invention relates to road structure and construction technology, and is especially road structure of rolled flexible fiber cement concrete and its construction process. The base layer of rolled flexible fiber cement concrete and paved on the foundation layer is formed through mixing flexible fiber, cement and water to form cementing material, adhering broken stone, sand, stuffing, etc with the cementing material, and rolling. The rolled flexible fiber cement concrete has obviously improved early plastic shrinking, dry shrinking and hot shrinking performance, obviously raised anticracking performance, toughness, impact strength, frost resistance and erosion resistance, and doubled antifatigue performance. The road with the rolled flexible fiber cement concrete structure has the features of simple construction, fast construction, short curing period, wide application range and raised performance.

Owner:易志坚 +3

Inorganic high-strength filler for coating

InactiveCN102173679ARealize one-time coatingCrack resistantSolid waste managementFilling pastesCelluloseCoating system

The invention discloses an inorganic high-strength filler for a coating. The inorganic high-strength filler is prepared by fully mixing 220 to 300 weight parts of white portland cement used as a gelled material, 350 to 550 weight parts of white quartz sand and 150 to 250 weight parts of quartz powder which are used as aggregate, 50 to 100 weight parts of wollastonite powder, and 0.3 to 1.5 weightparts of polypropylene fiber anti-cracking material, and a dry powder material which is prepared by mixing 2 to 8 weight parts of cellulose ether and 10 to 30 weight parts of gelatine powder uniformly by a stirring machine, and packaging. The inorganic high-strength filler can be conveniently coated on a dry wall, is easy and convenient to construct, and is easy to level and polish; and when the inorganic high-strength filler is used as a penetration base layer of an inorganic penetration coating, first coat can be saved during coating construction of an inorganic coating, and the coating system can save materials and labor, is economic and reliable and save energy and is environment-friendly.

Owner:XIAMEN QIANRUI BUILDING MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com