Patents

Literature

15171 results about "Dioxide titanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium dioxide, also known as titanium(IV) oxide or titania, is the naturally occurring oxide of titanium, chemical formula TiO. 2. When used as a pigment, it is called titanium white, Pigment White 6 (PW6), or CI 77891. Generally it is sourced from ilmenite, rutile and anatase.

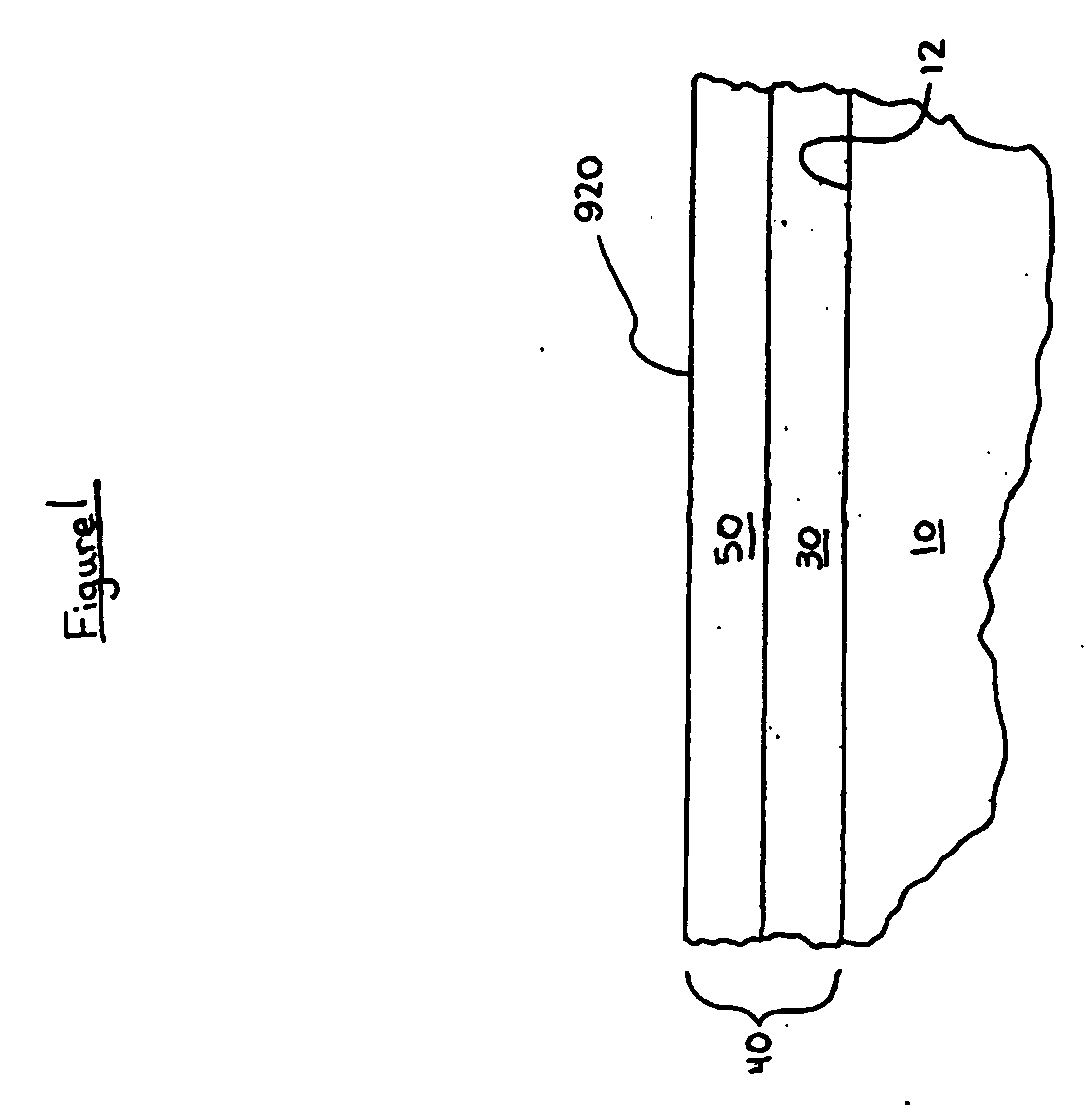

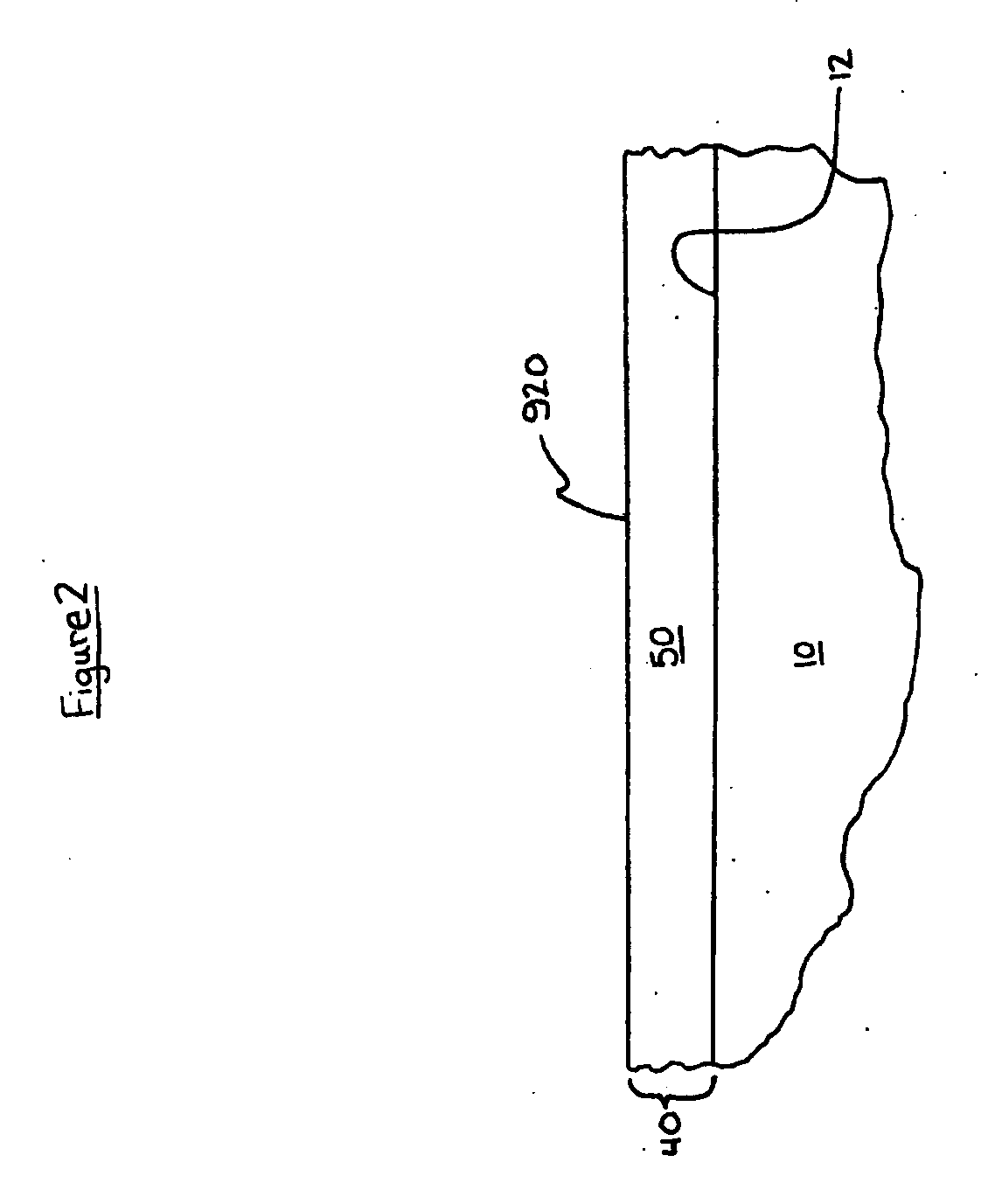

Surface treatments and modifications using nanostructure materials

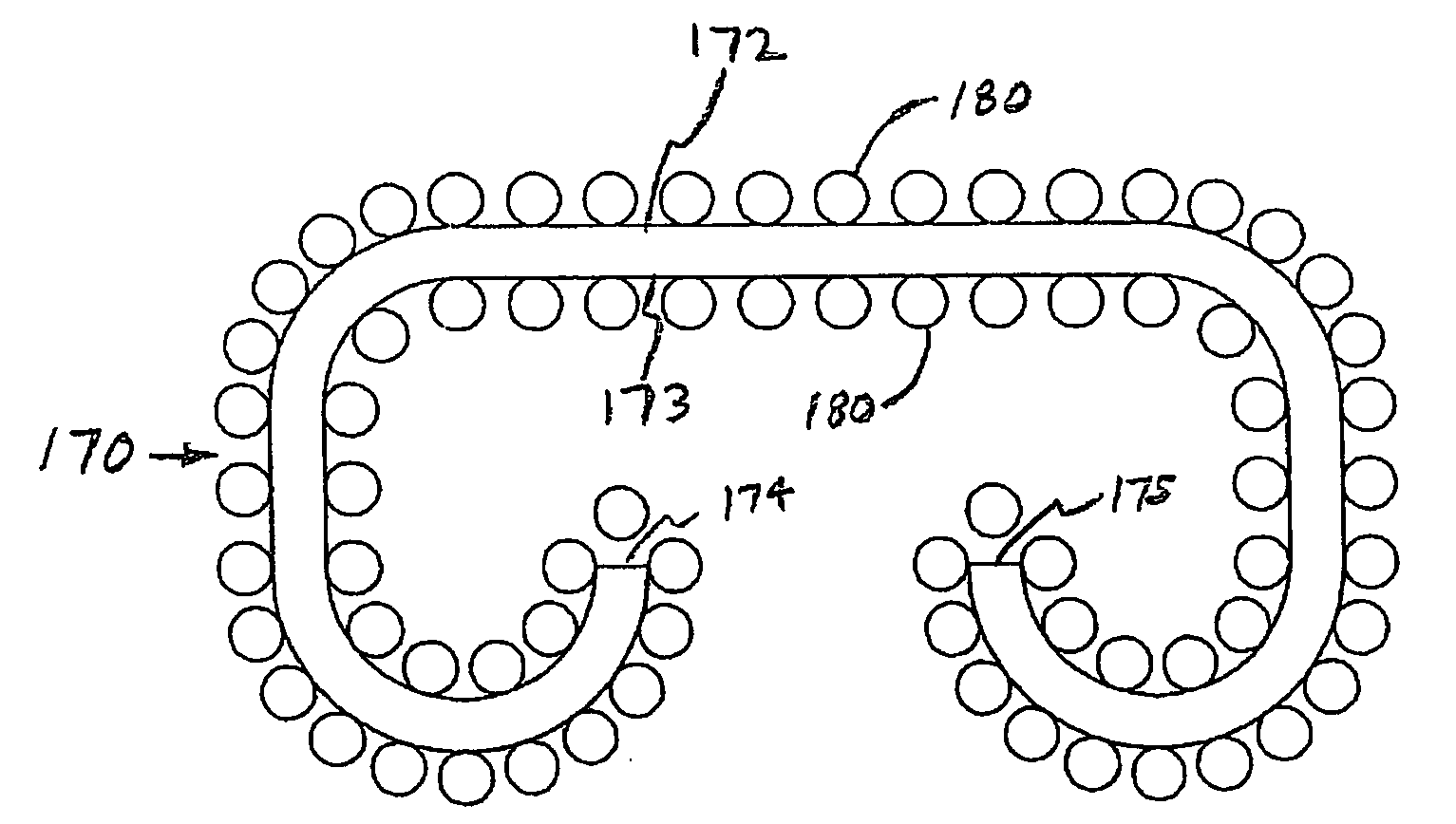

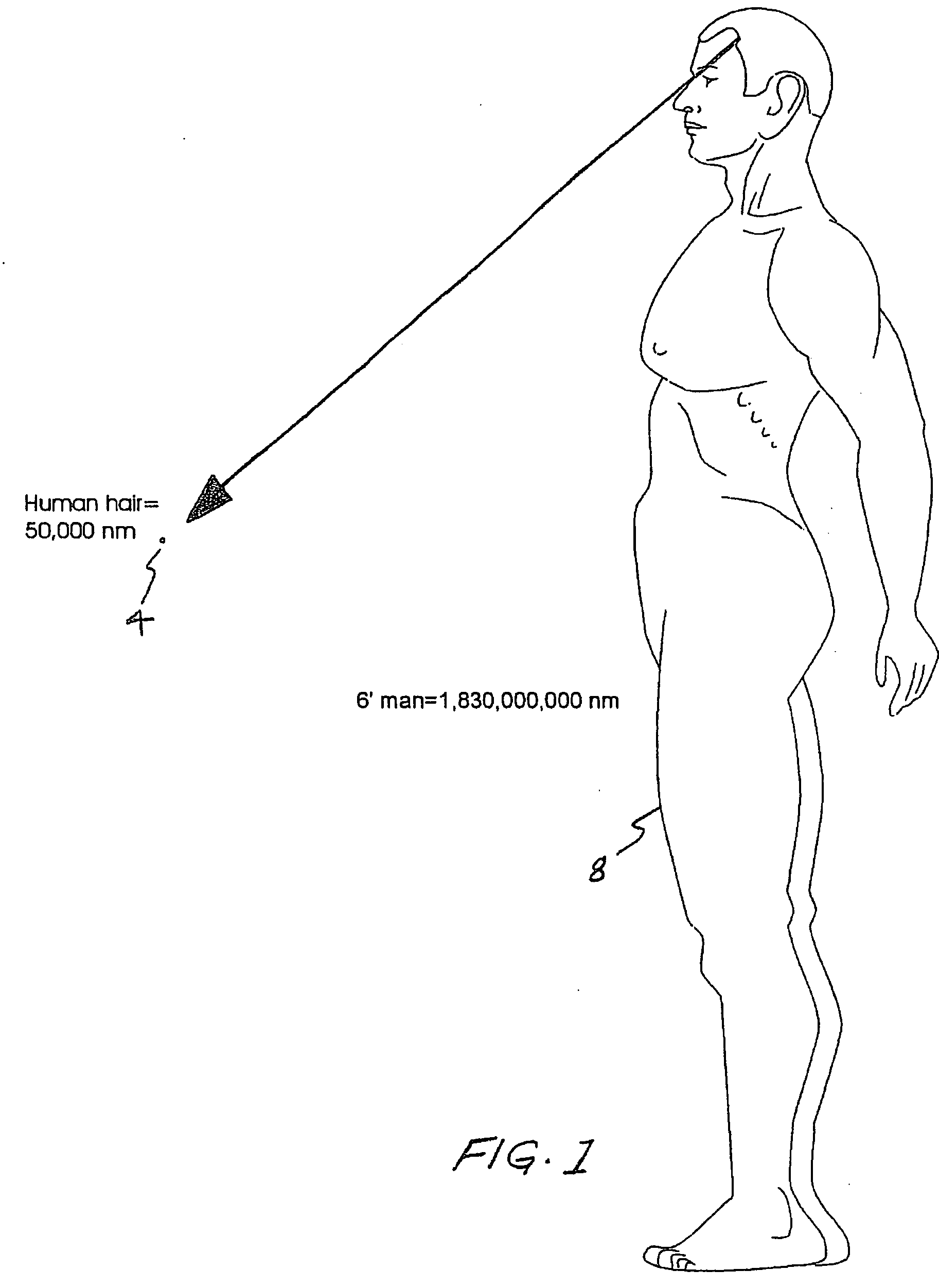

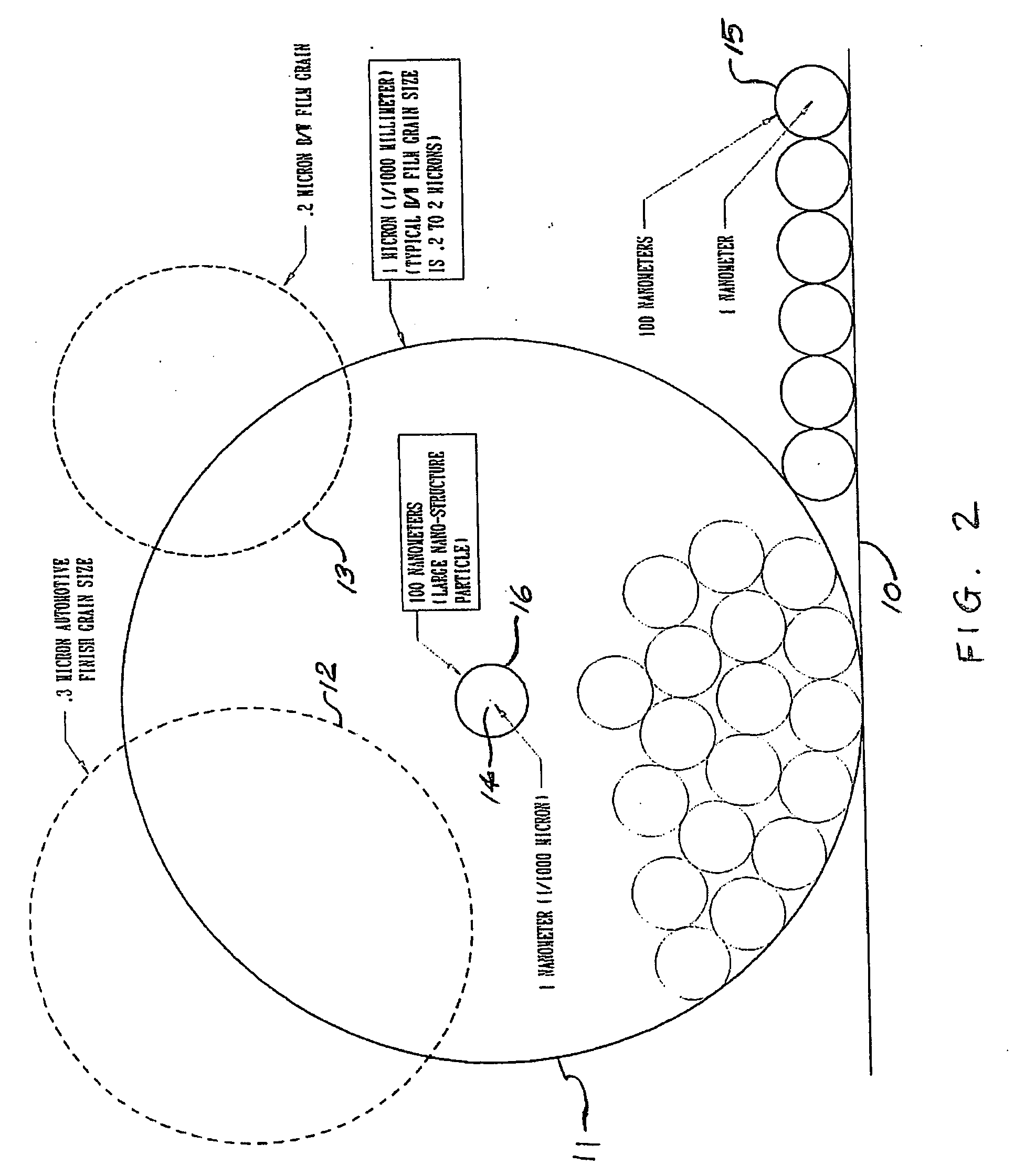

InactiveUS20050113936A1Reduce surface tensionPromote and inhibit ingrowthSuture equipmentsHeart valvesGas phaseNanostructure

The invention is directed to nanostructure surface treatments, coatings or modifications formed from nanoscale building blocks. The nanostructure surface treatments, modifications or coatings have hydrophobic, hydrophilic and surface adherence properties. The nanoscale building blocks have orientation, geometry, packing density and composition that may be adjusted to control the unique surface characteristics of the desired treatment, coating or modification. Applications of this nanostructure technology include surgical clips, staples, retractors, sutures and manipulators where an improvement in traction, retention or occlusion is desired without excessive material or tissue deformation or where high compressive forces would be undesirable, dangerous or ineffective. In one aspect, a nanostructure surface treatment for a medical device having an external surface is disclosed, wherein the treatment is applied on the external surface to provide a hydrophobic or a hydrophilic surface. With this aspect, the treatment comprises titanium dioxide and provides nanoscopic structures having nearly vertical sidewalls. The treated surface of the device has contact angles greater than or equal to 150 degrees. The vertical sidewalls provide a negative capillary effect and have a width of about 200 nm. The vertical sidewalls attach to a wet surface by the negative capillary effect. The van der Waals forces of the vertical sidewalls enable the treated surface to attach to a dry surface. The treatment may be vapor deposited and cured on the device, or the treatment may be laser blasted on the device.

Owner:APPL MEDICAL RESOURCES CORP

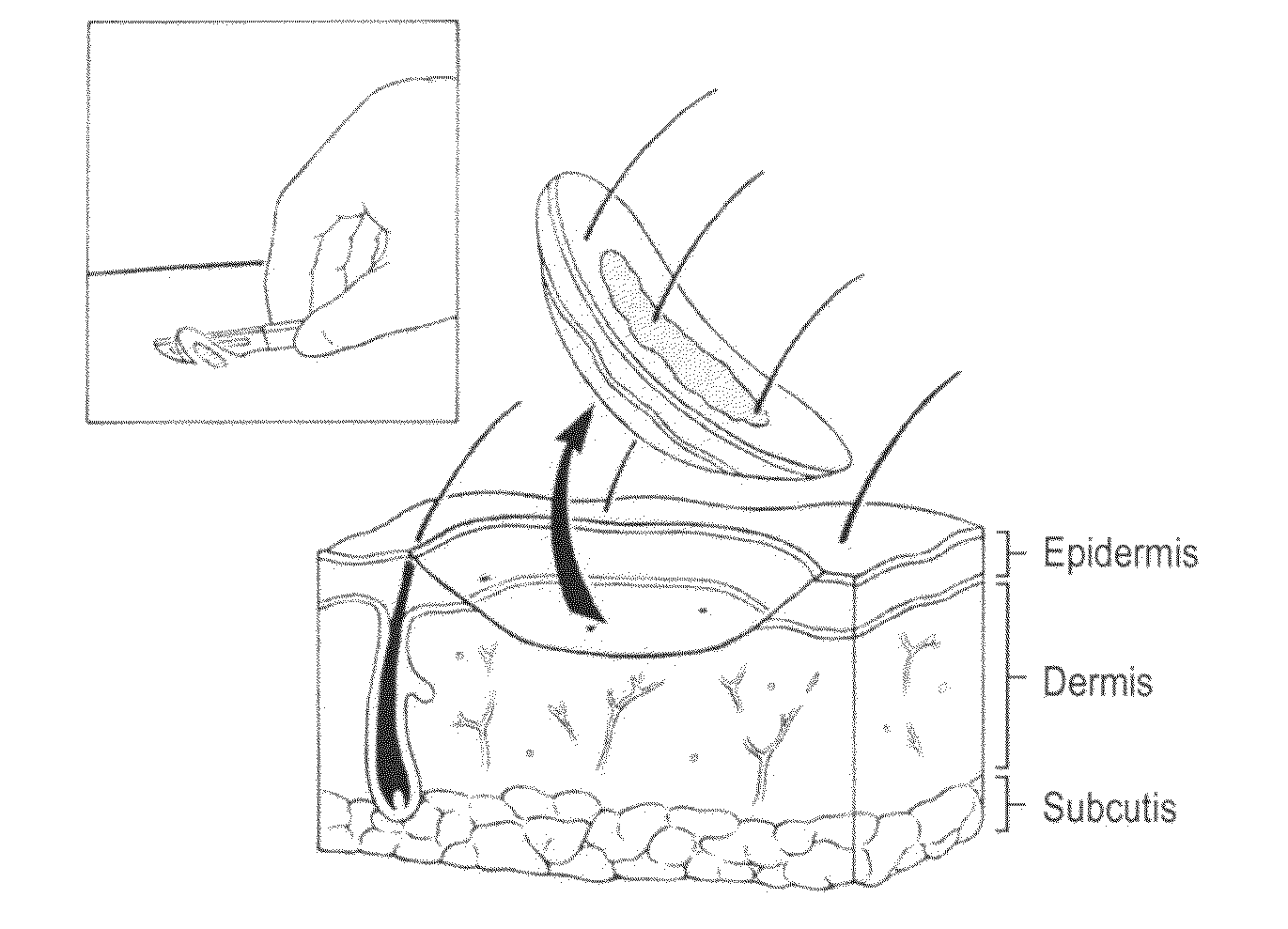

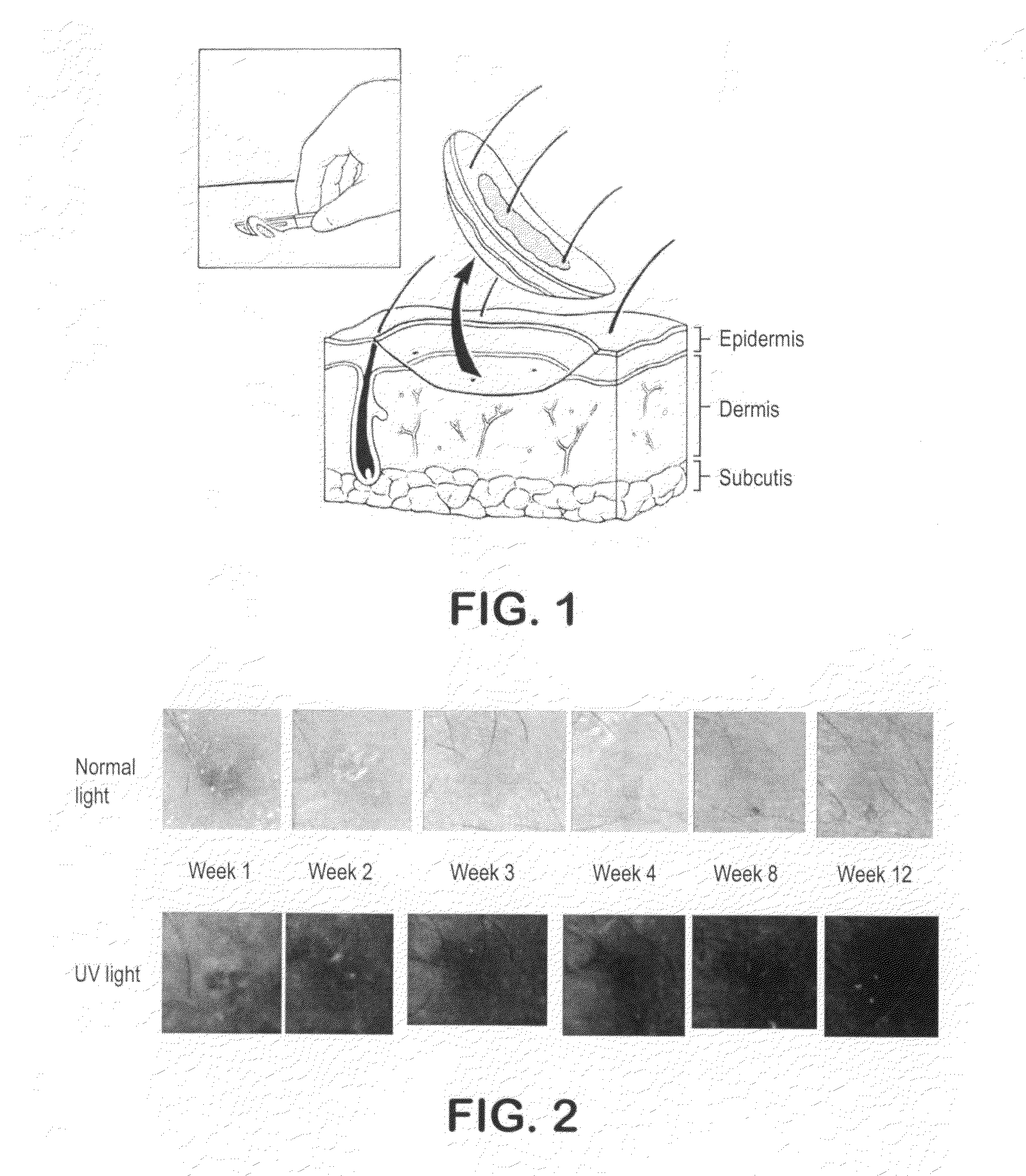

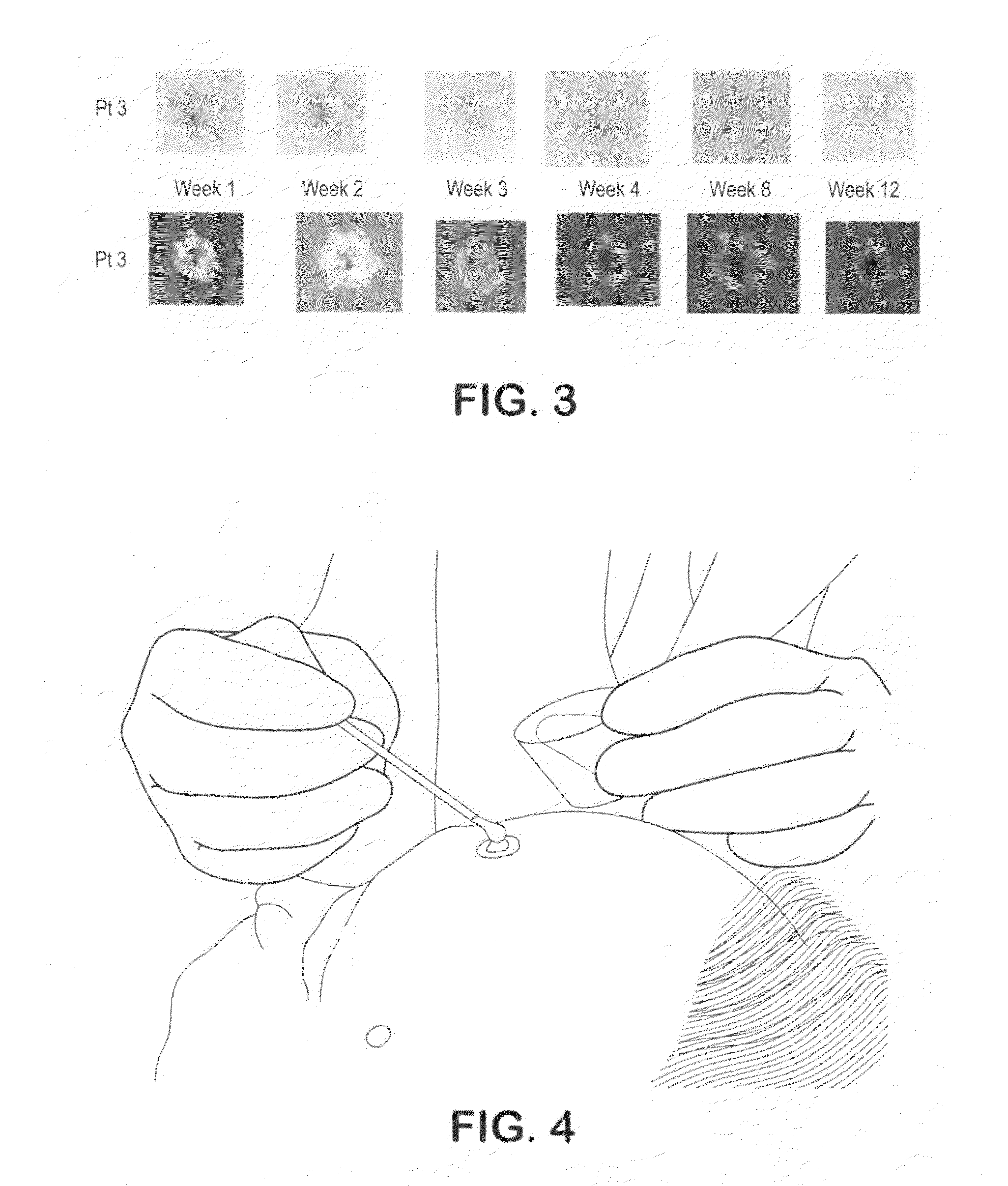

Biopsy marker composition and method of use

InactiveUS20110077512A1Improve efficiencyUltrasonic/sonic/infrasonic diagnosticsDispersion deliveryFluorescenceMedicine

An aqueous suspension of titanium dioxide, polymethylmethacrylate and Vitamin E oil is used to mark a location wherein a skin biopsy has been taken to enable subsequent identification of the biopsy location under ultraviolet light. The location is advantageously treated with Vitamin E oil on a daily basis subsequently extend the fluorescing life of the applied titanium dioxide.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

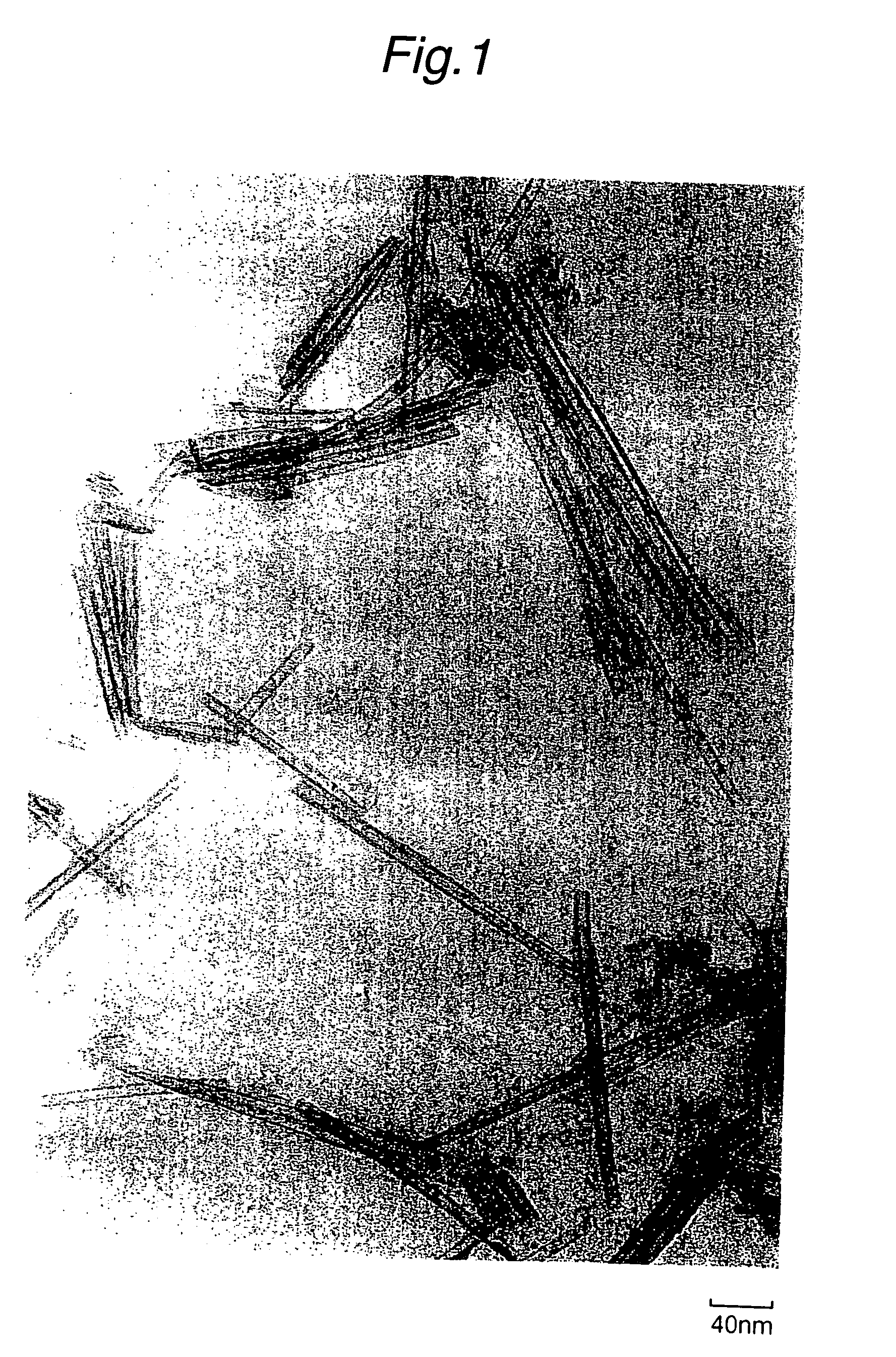

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

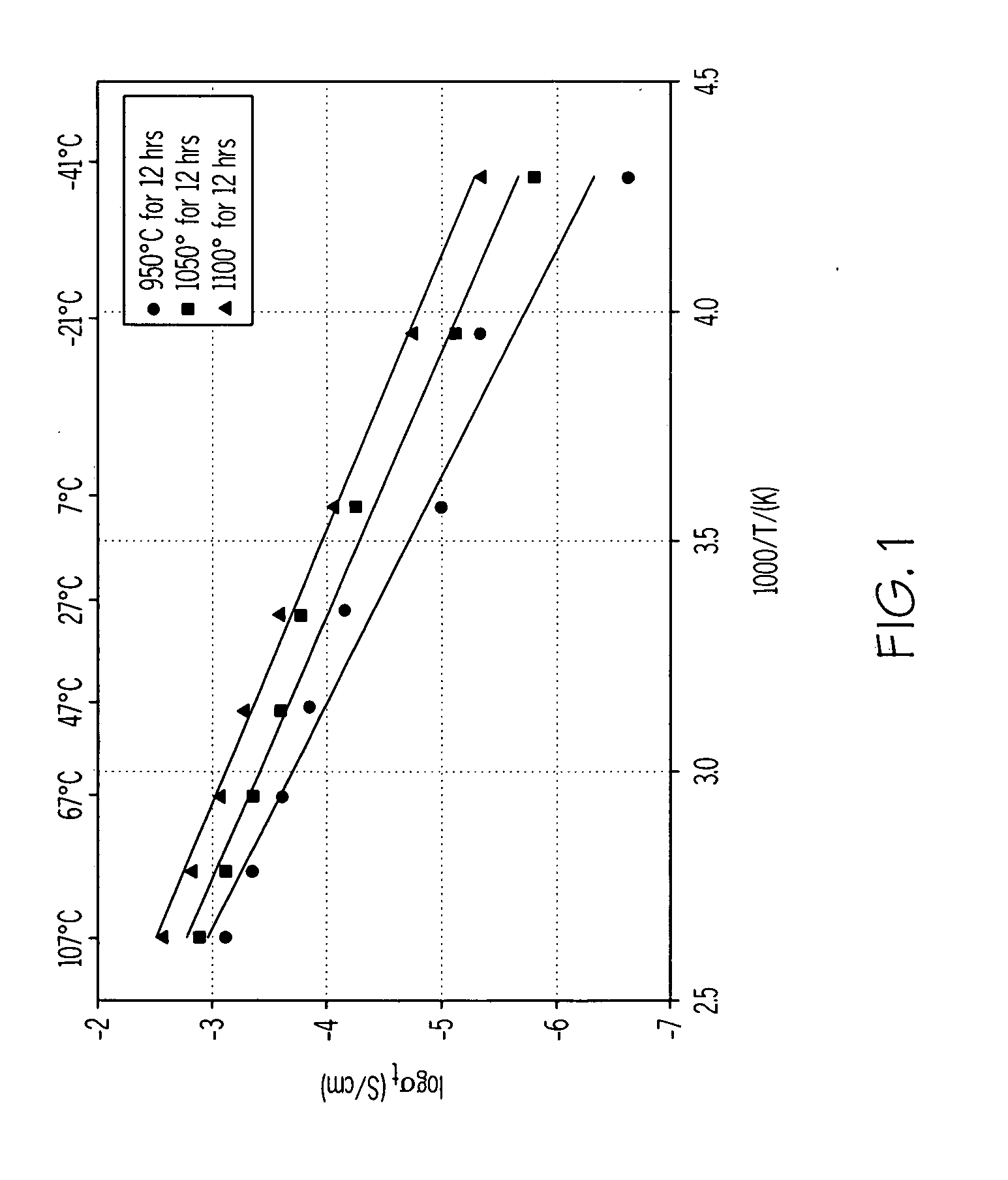

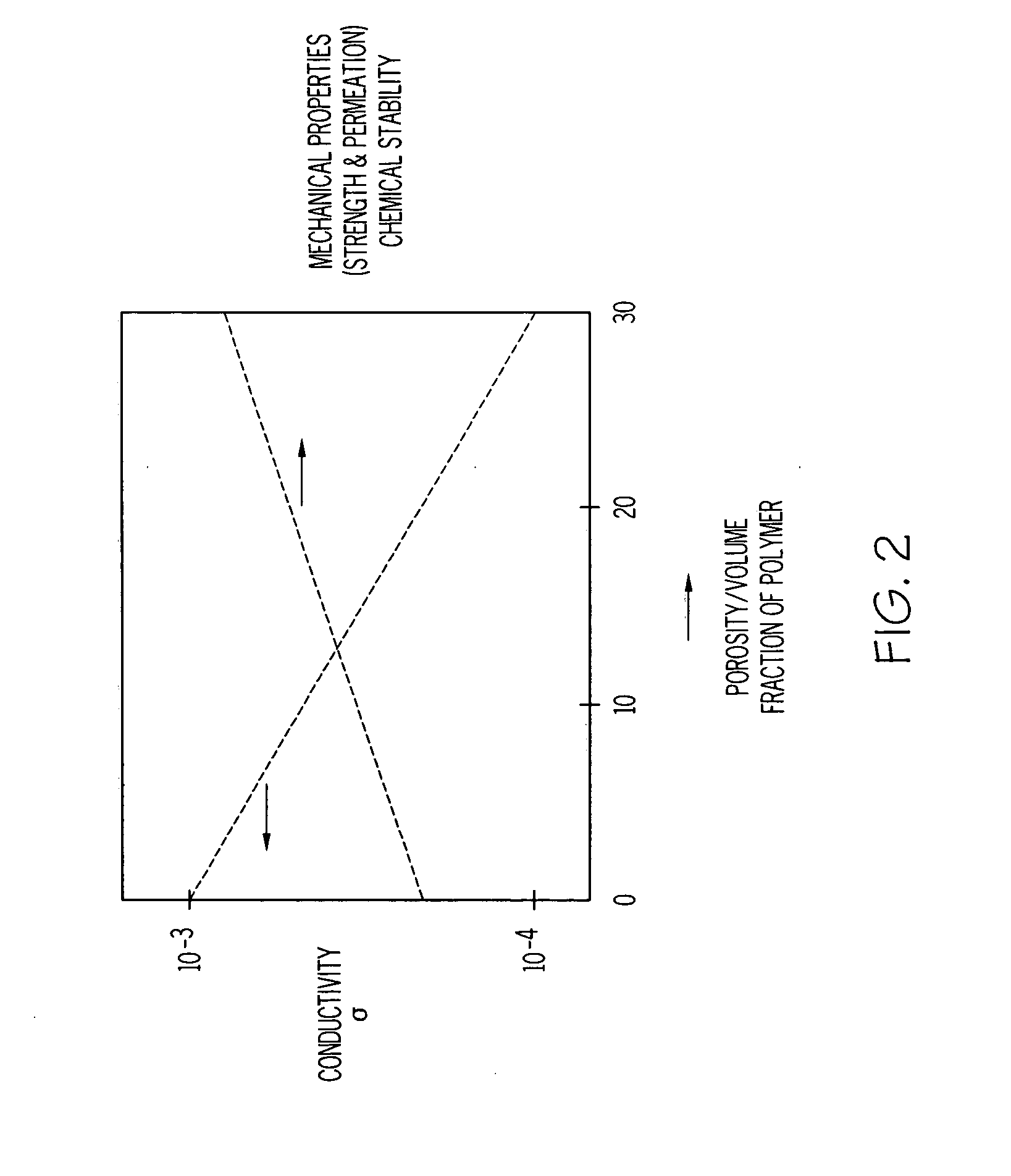

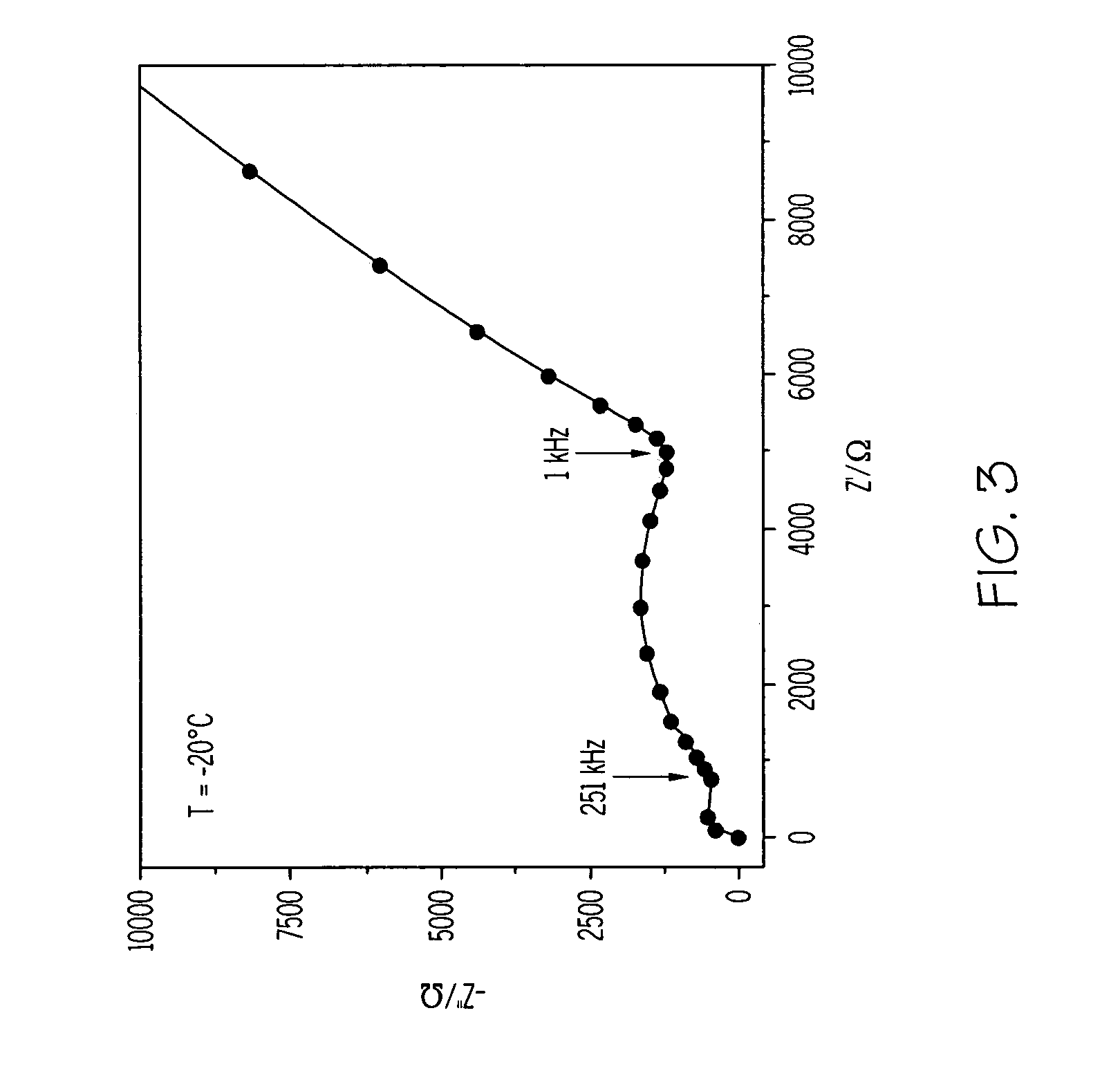

Solid composite electrolyte membrane and method of making

ActiveUS20070117026A1Improve conductivitySolid electrolytesSolid electrolyte cellsPorosityComposite electrolyte

A solid composite electrolyte membrane for use in a lithium battery is provided which exhibits a conductivity ranging from about 10−4 S cm−1 to about 10−3 S cm−1 at ambient temperature. The membrane is formed by providing a glass or glass-ceramic powder formed from a mixture of lithium carbonate, alumina, titanium dioxide, and ammonium dihydrogen phosphate. The powder is mixed with a conditioning agent and at least one solvent, followed by the addition of a binder and one or more plasticizers. The resulting slurry is cast into a tape which is then subjected to a binder burn-off and sintering process to form the membrane. The resulting membrane may be a glass-ceramic composite having a porosity ranging from 0 to 50%, or the membrane may be further infiltrated with a polymer to form a water-impermeable polymeric-ceramic composite membrane.

Owner:UNIV OF DAYTON THE

Titanium-containing materials

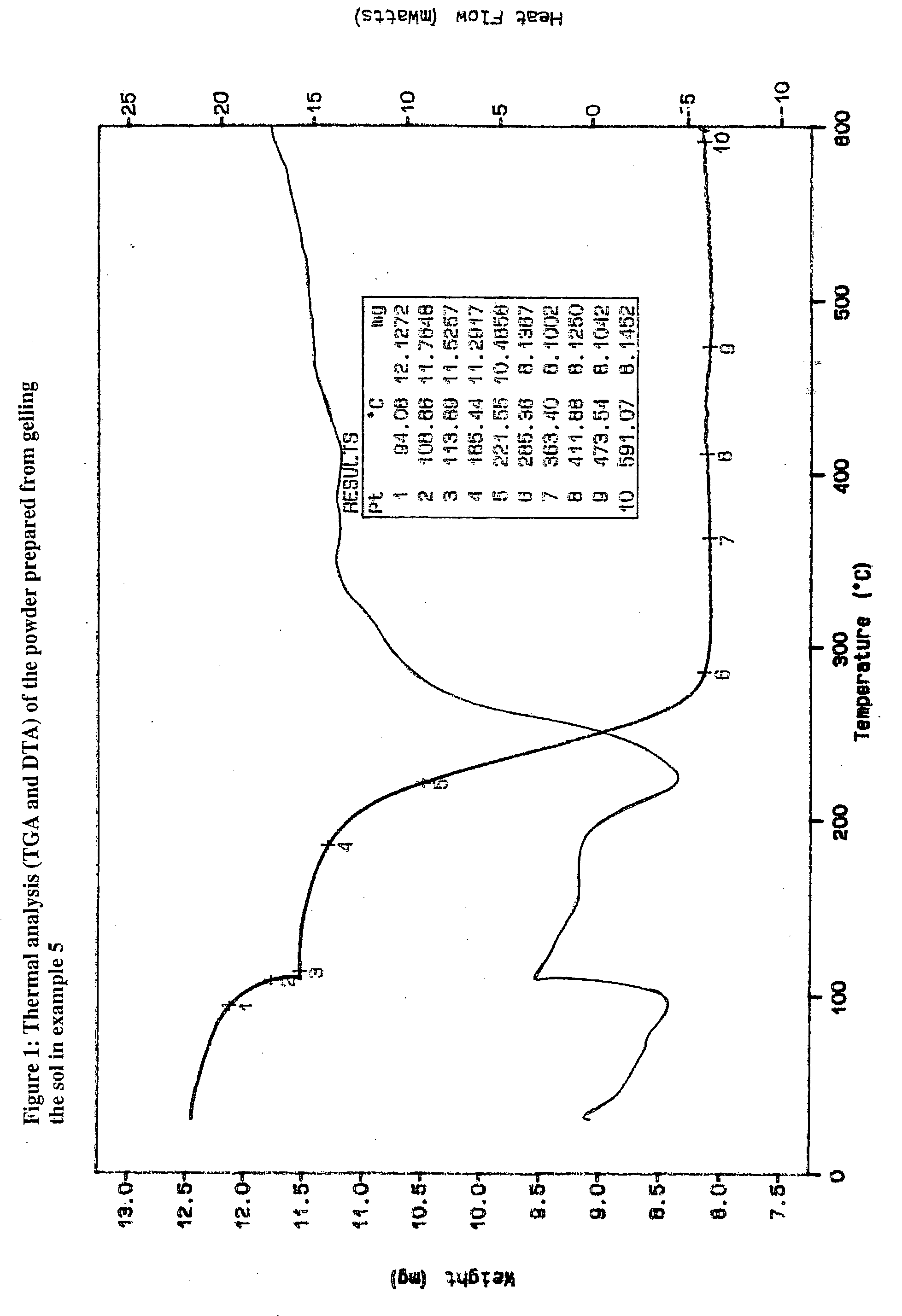

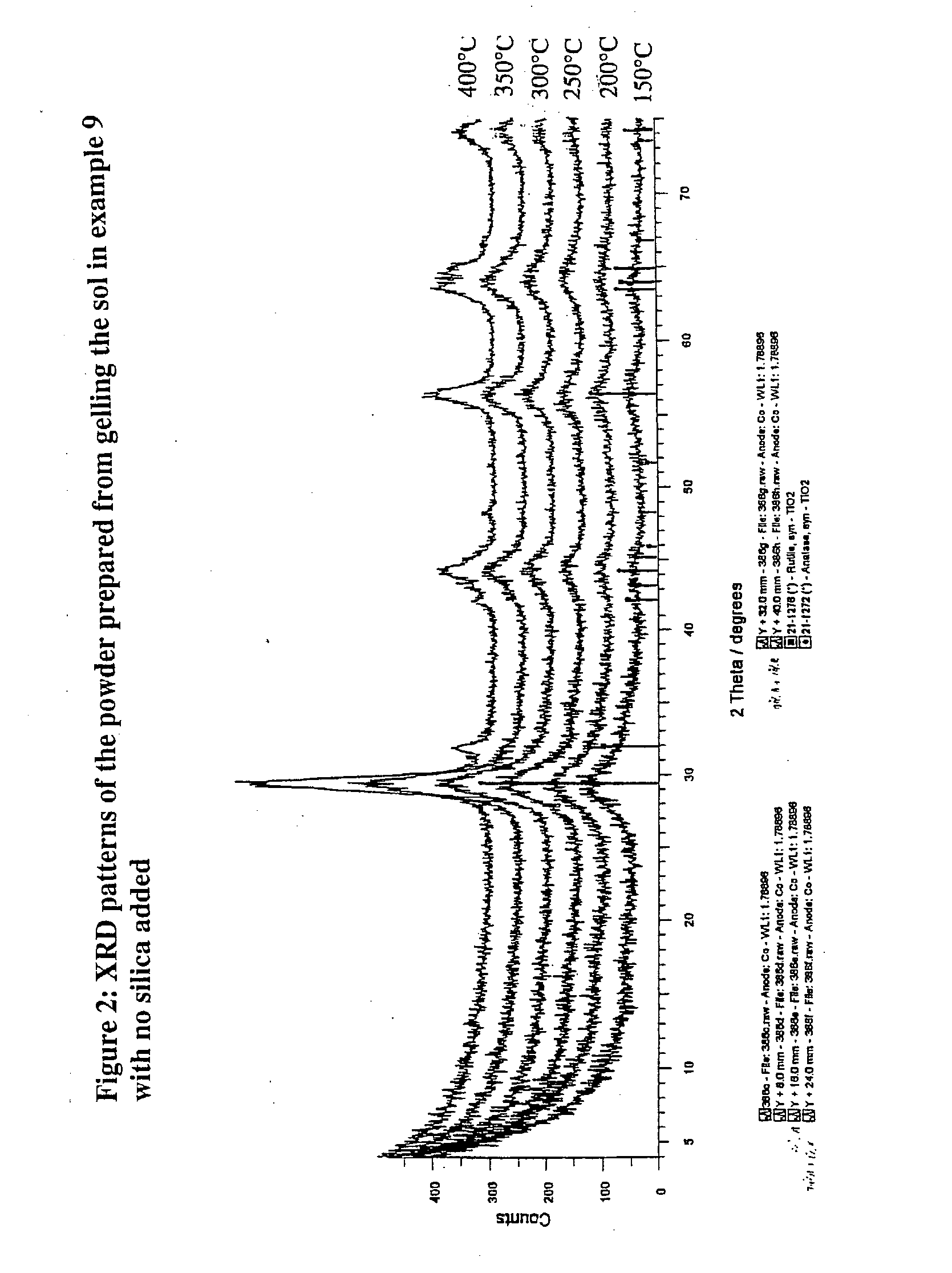

The invention relates to a method of preparing a solution containing colloidal particles which contain crystalline titanium dioxide wherein one or more hydrolysable titanium-containing compound(s) is stabilised by oxalic acid in a reaction medium. The reaction further relates to the preparation of titania materials (including particulate materials, coating solutions and films) which comprise or include anatase phase titania, and so are suitable in photocatalytic applications. The invention also deals with a method of preparing B-phase titania.

Owner:IND RES LTD

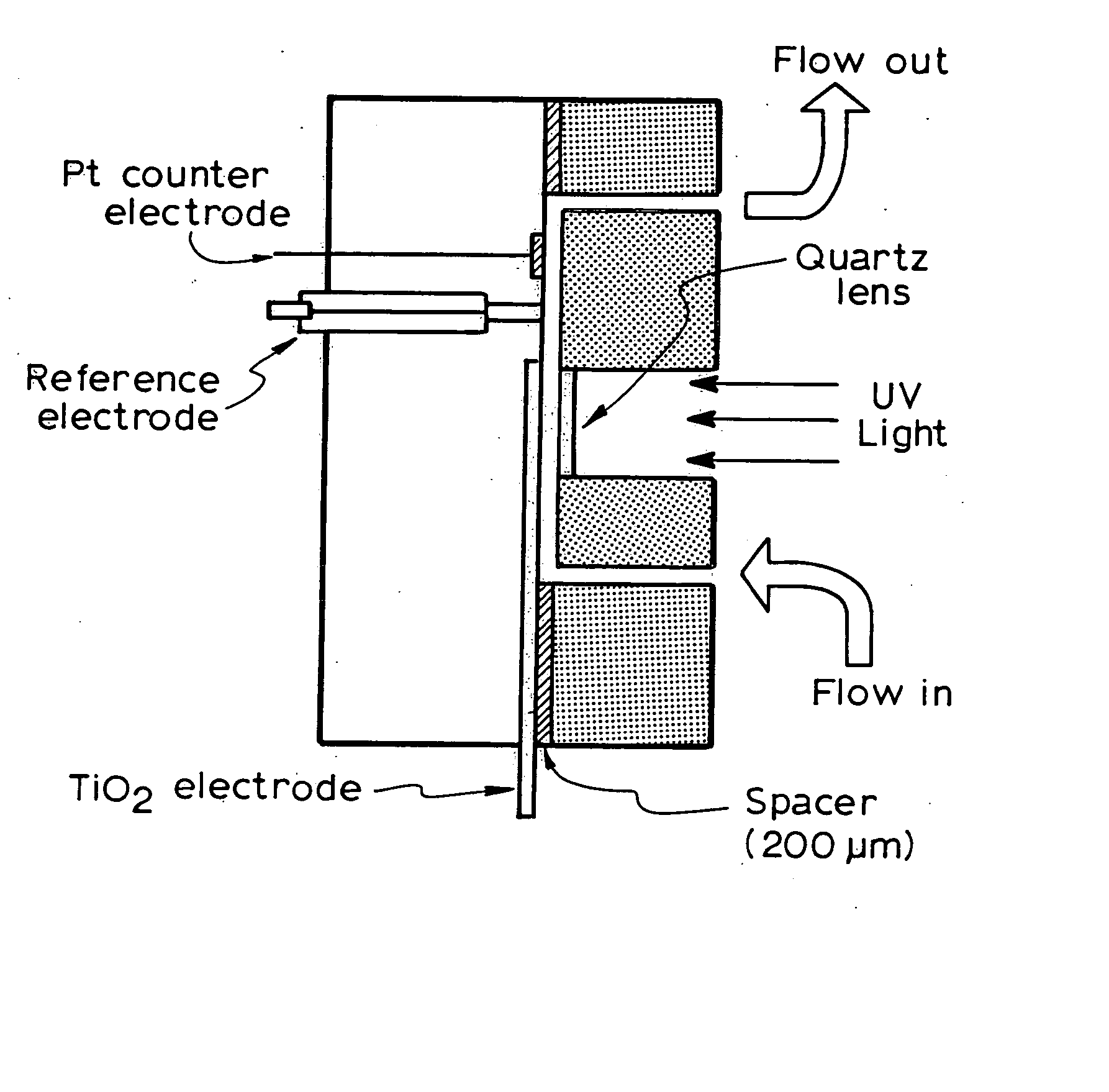

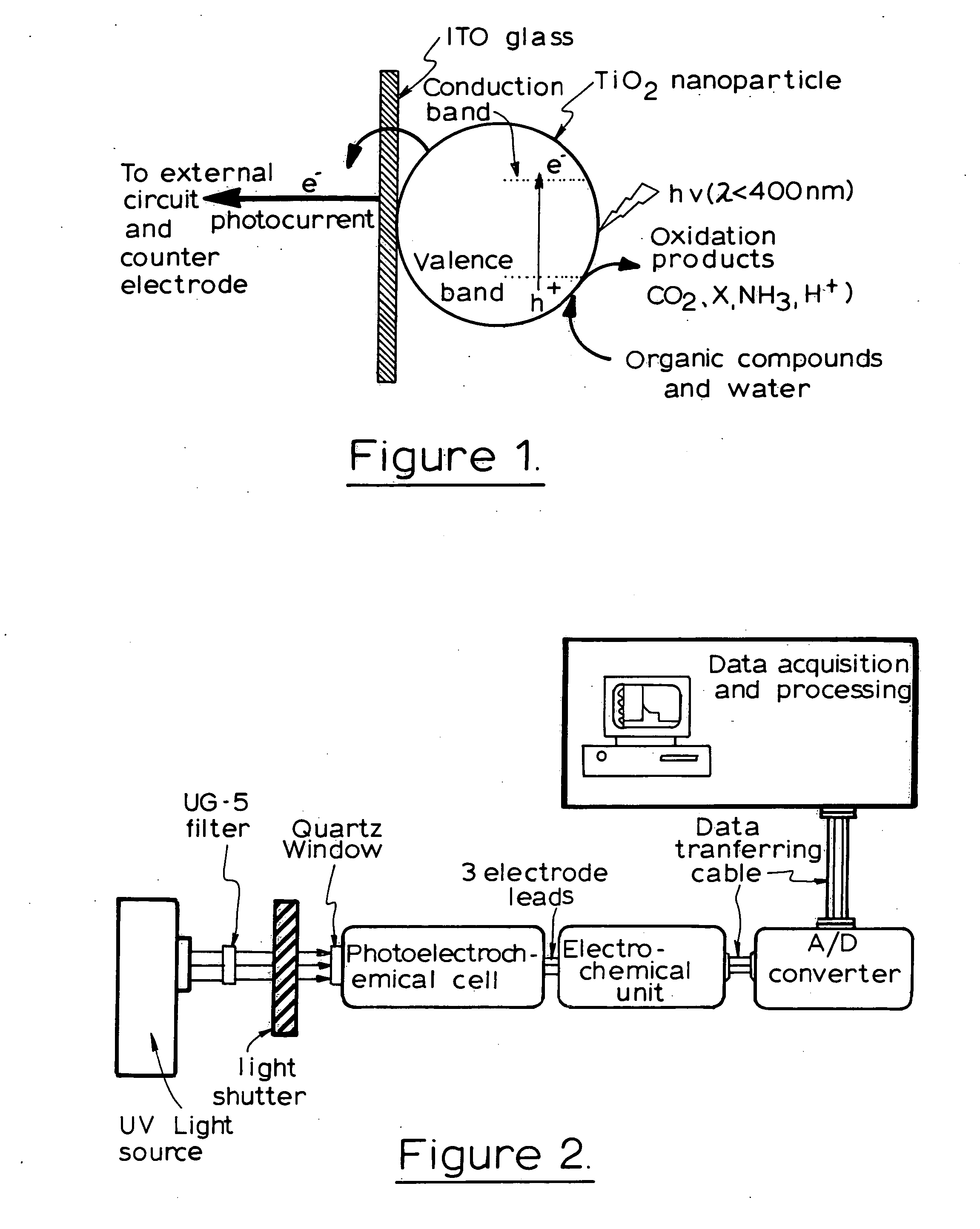

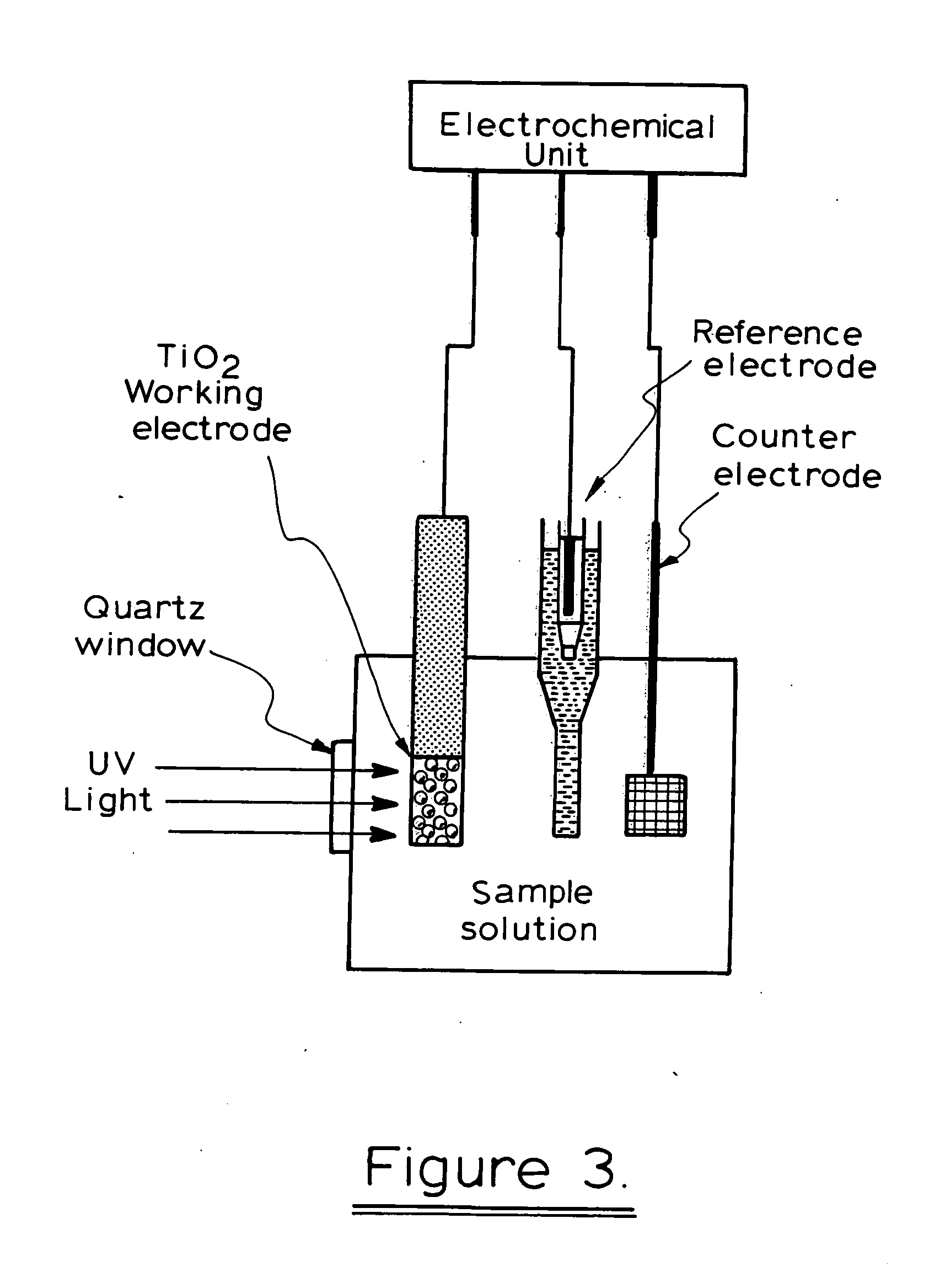

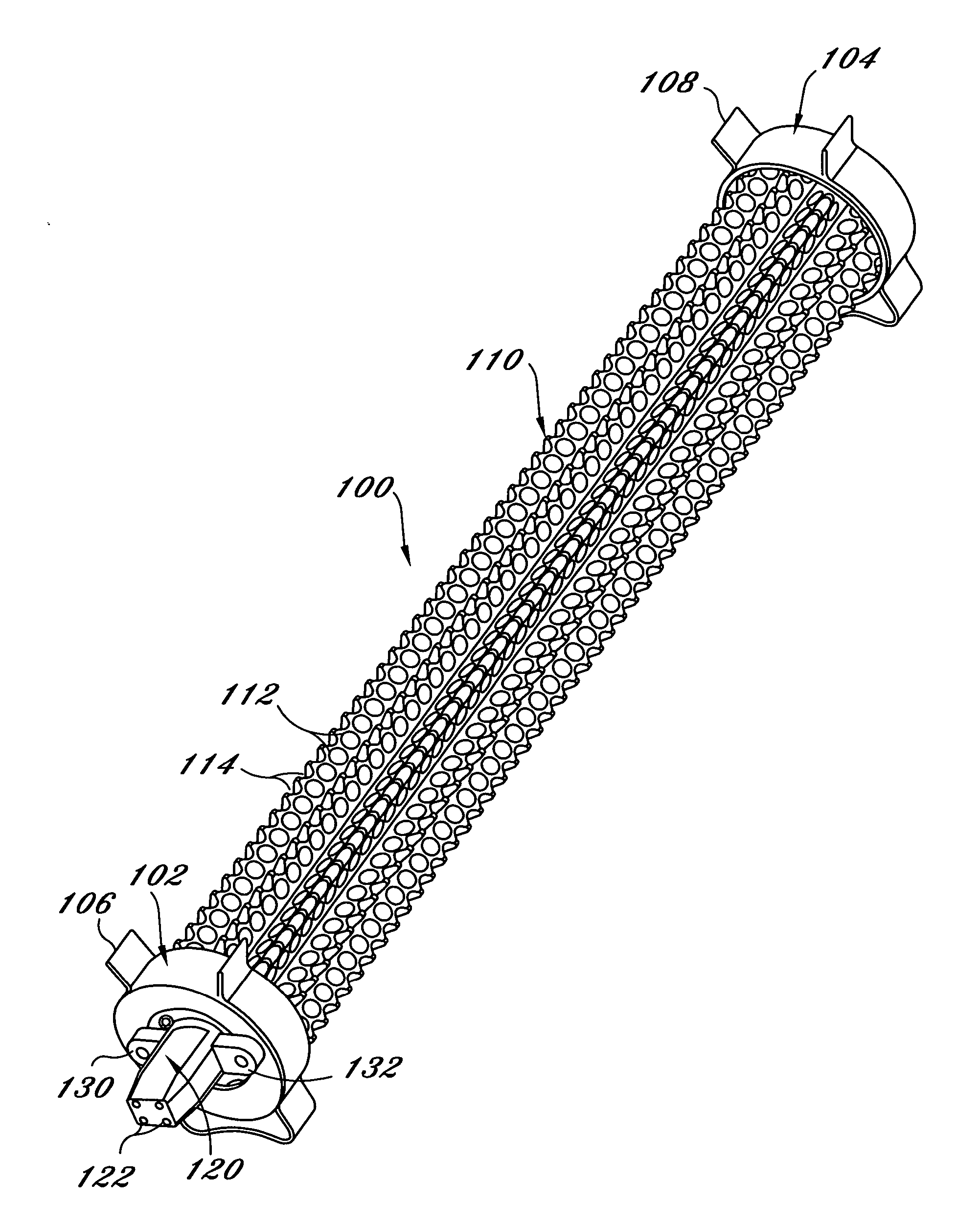

Photoelectrochemical determination of chemical oxygen demand

ActiveUS20060240558A1High sensitivityWide linear rangeChemical analysis using catalysisChemical analysis using combustionSupporting electrolytePotential measurement

A photoelectrochemical assay apparatus for determining chemical oxygen demand (COD) of a water sample which consists of a) a measuring cell for holding a sample to be analysed b) a titanium dioxide nanoparticle photoelectric working electrode and a counter electrode disposed in said cell, c) a UV light source adapted to illuminate the photoelectric working electrode d) control means to control the illumination of the working electrode e) potential measuring means to measure the electrical potential at the working and counter electrodes f) analysis means to derive a measure of oxygen demand from the measurements made by the potential measuring means. The method of determining chemical oxygen demand of a water sample, comprises the steps of a) applying a constant potential bias to a photoelectrochemical cell, containing a supporting electrolyte solution; b) illuminating the working electrode with a UV light source and recording the background photocurrent produced at the working electrode from the supporting electrolyte solution; c) adding a water sample, to be analysed, to the photoelectrochemical cell; d) illuminating the working electrode with a UV light source and recording the total photocurrent produced; e) determining the chemical oxygen demand of the water sample according to the type of degradation conditions employed. The determination may be under exhaustive degradation conditions, in which all organics present in the water sample are oxidised or under non-exhaustive degradation conditions, in which the organics present in the water sample are partially oxidised.

Owner:579453 ONTARIO INC

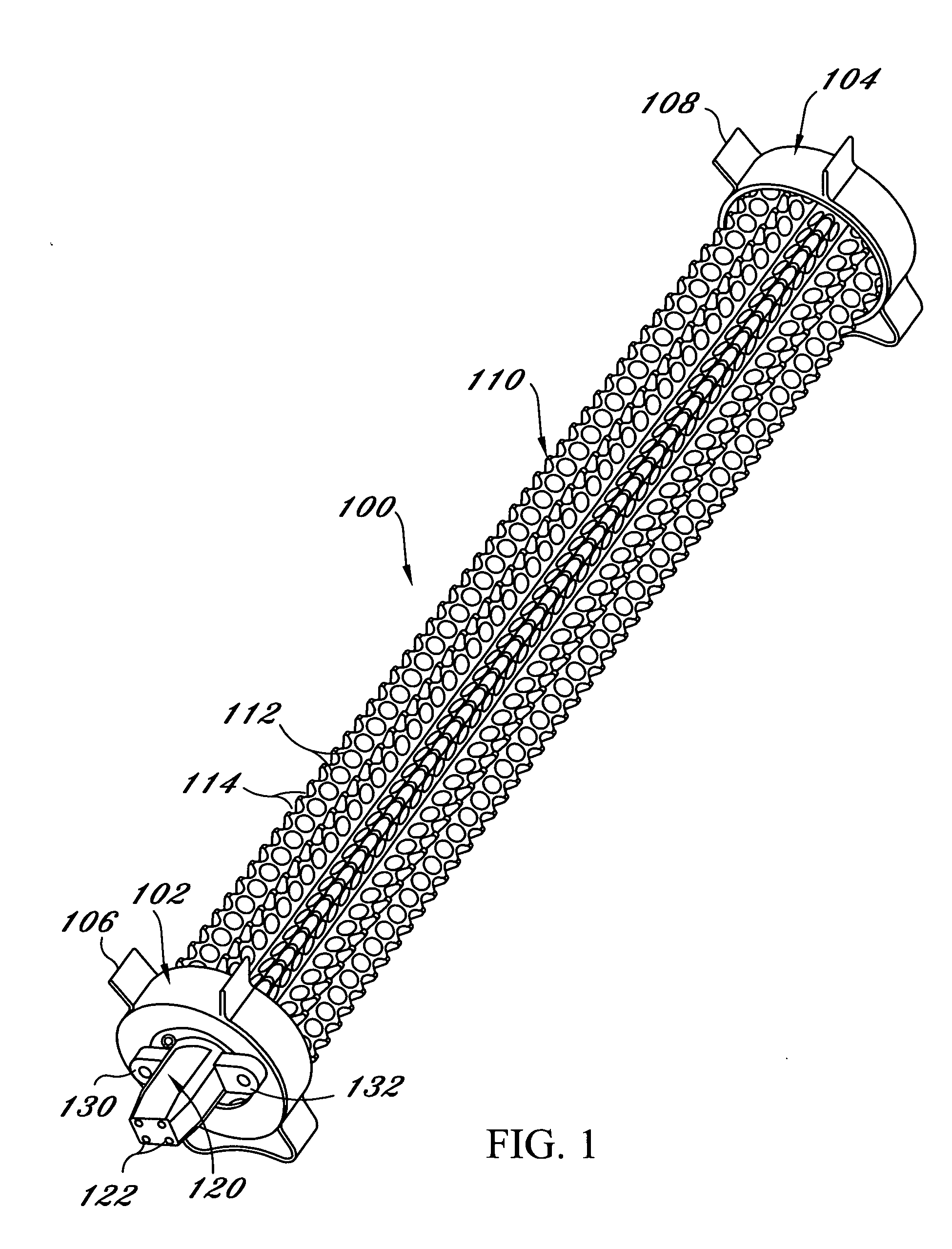

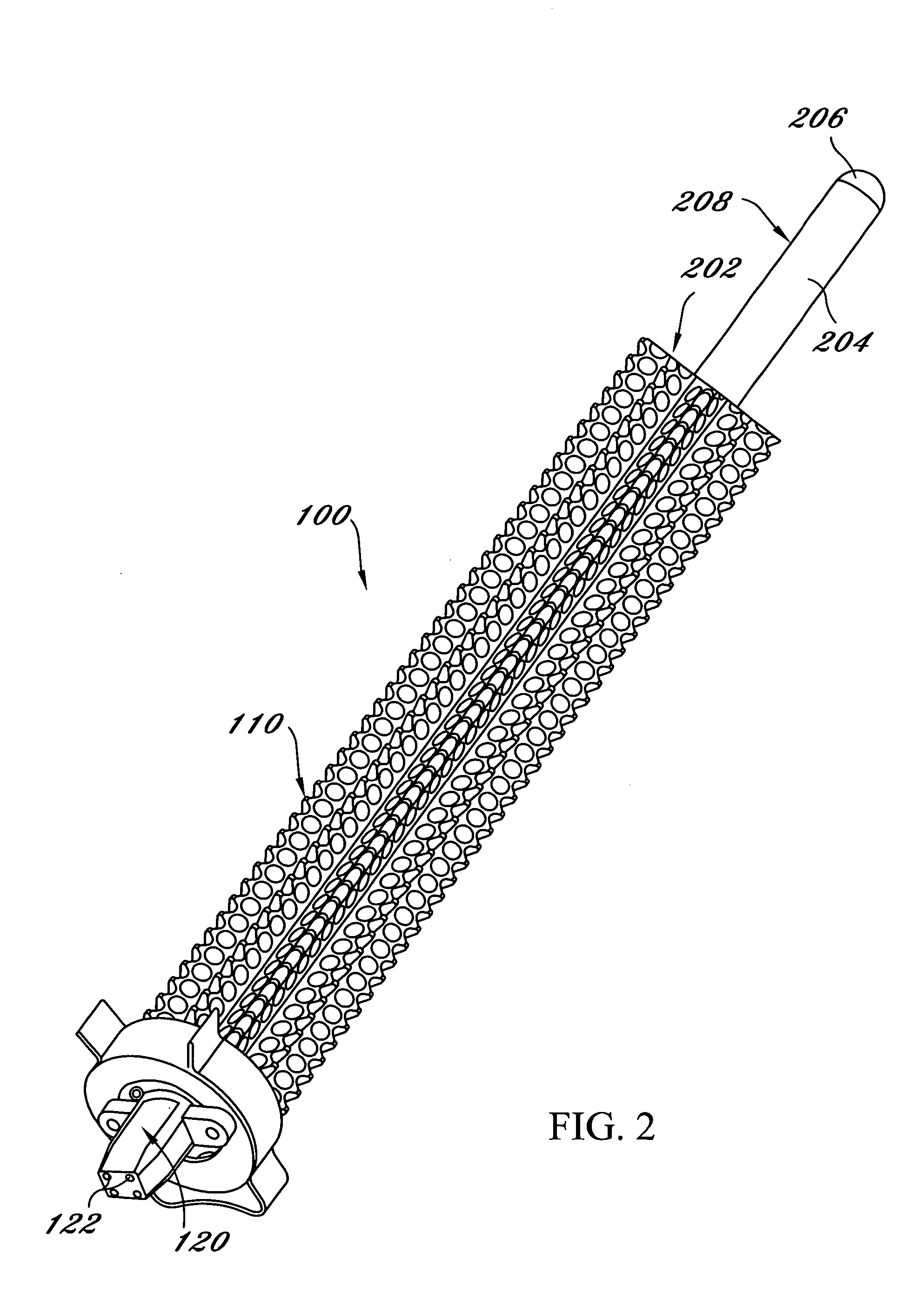

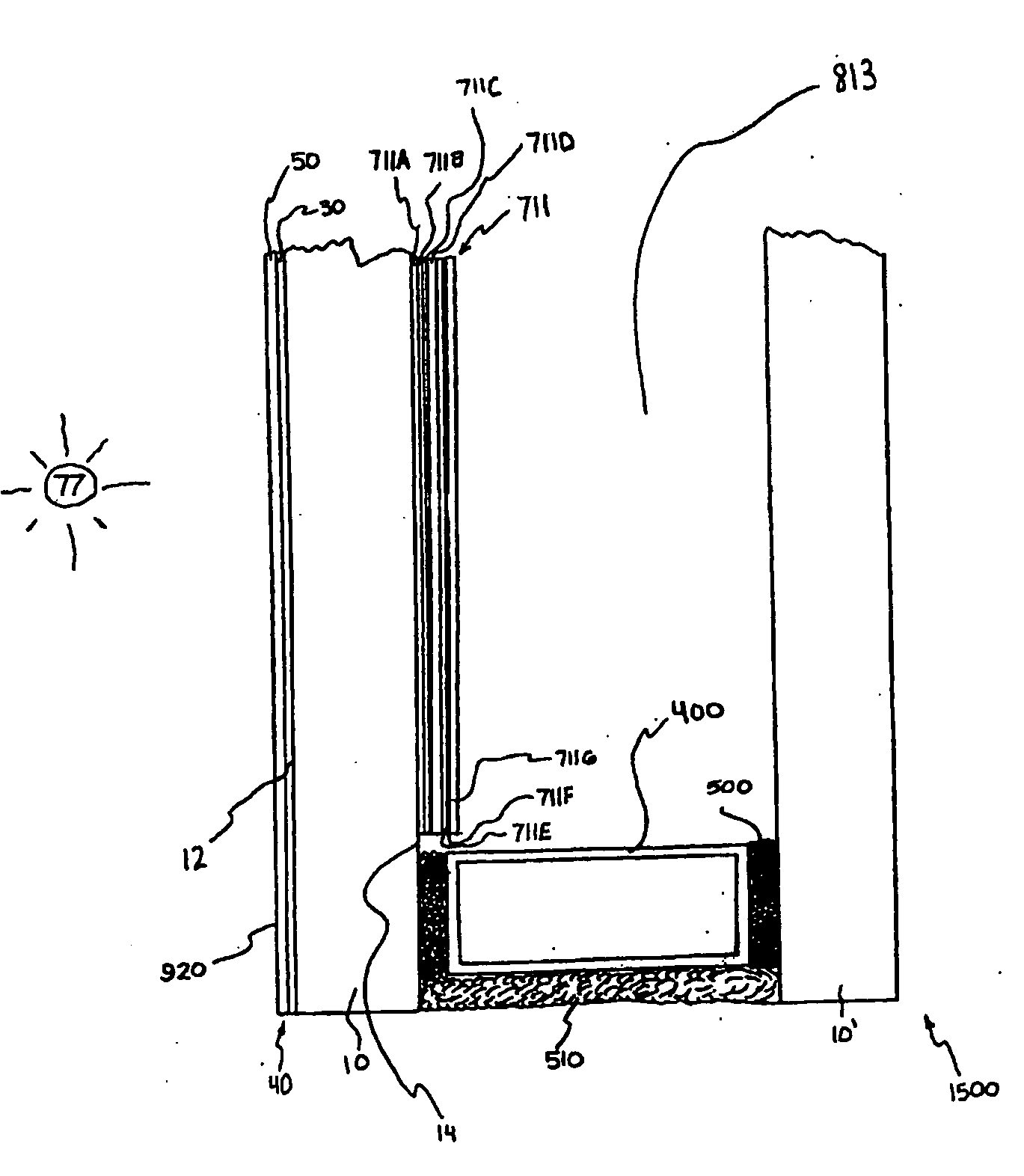

Device, system and method for an advanced oxidation process using photohydroionization

ActiveUS20050186124A1Efficiently formedMechanical apparatusLighting and heating apparatusAdvanced oxidation processUltraviolet lights

A device, system, and method, for the formation of advanced oxidation products by contacting a hydrated catalytic surface of a catalytic target structure with broad spectrum ultraviolet light in the 100 nm to 300 nm range that preferably includes 185 nm and 254 nm wavelengths. The catalytic surface reacts with the ultraviolet light energy and hydrate at the catalytic surface to form advanced oxidation products. The catalytic surface in one embodiment includes a hydrophilic agent, titanium dioxide, silver, copper, and rhodium. Preferably, the catalytic surface is coated with a coating that includes the hydrophilic agent, titanium dioxide, silver, copper, and rhodium. A photohydroionization cell (100) that includes an ultraviolet light source (204) and a catalytic target structure (110) in an air environment to form advanced oxidation product is also provided. A U.V. light indicator and a monitor and / or control system for the photohydroionization cell (100) are also provided.

Owner:RGF ENVIRONMENTAL GROUP

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

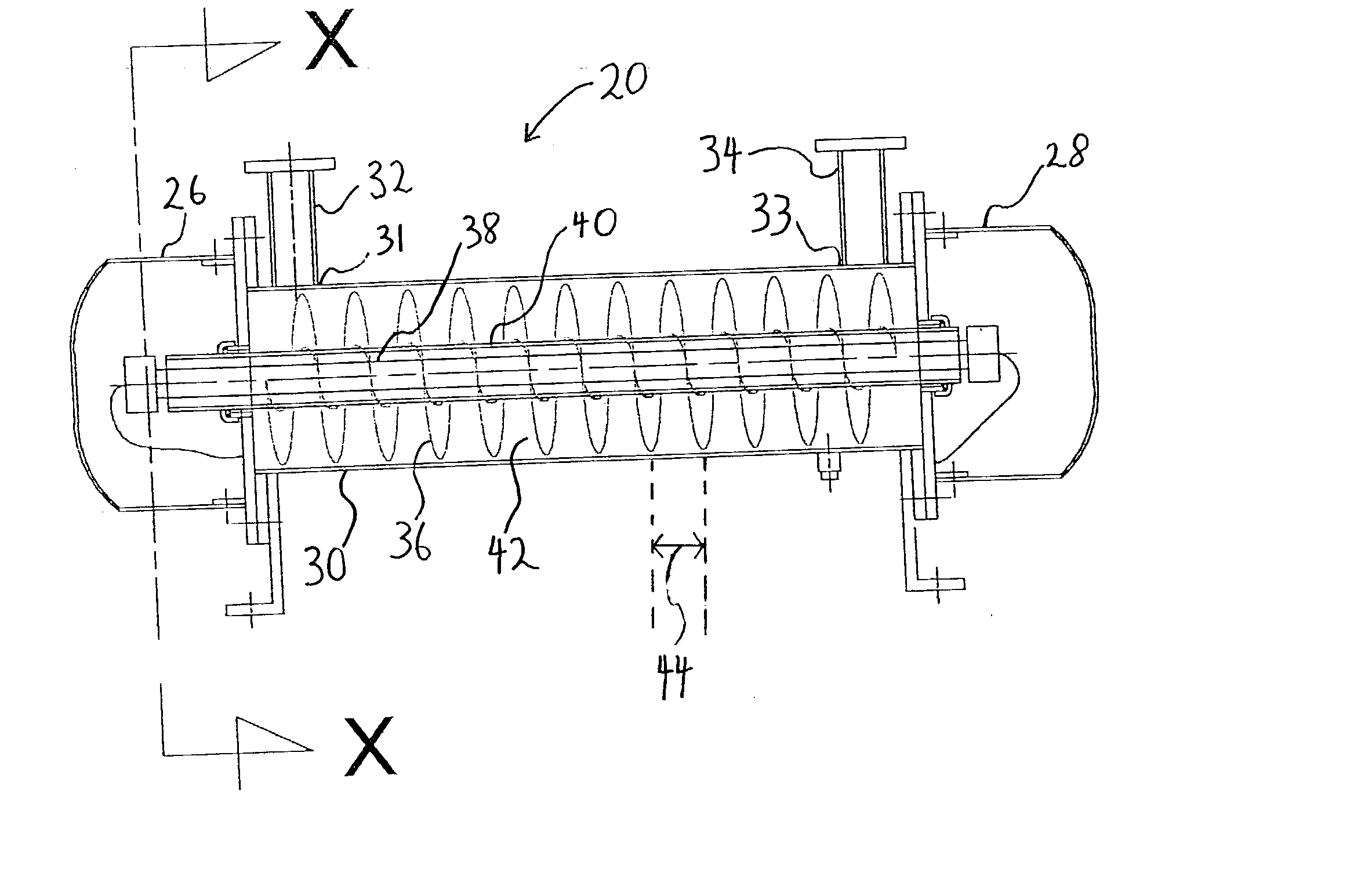

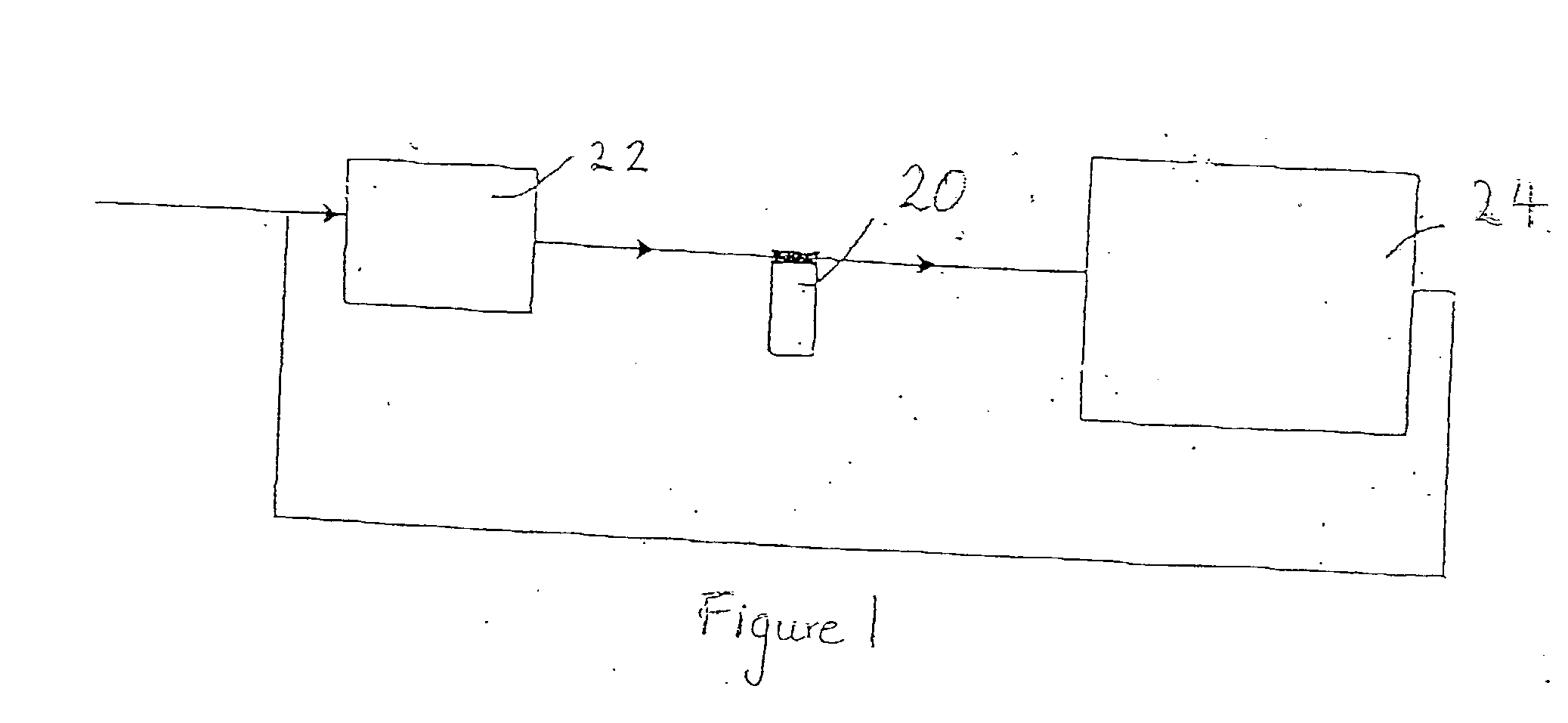

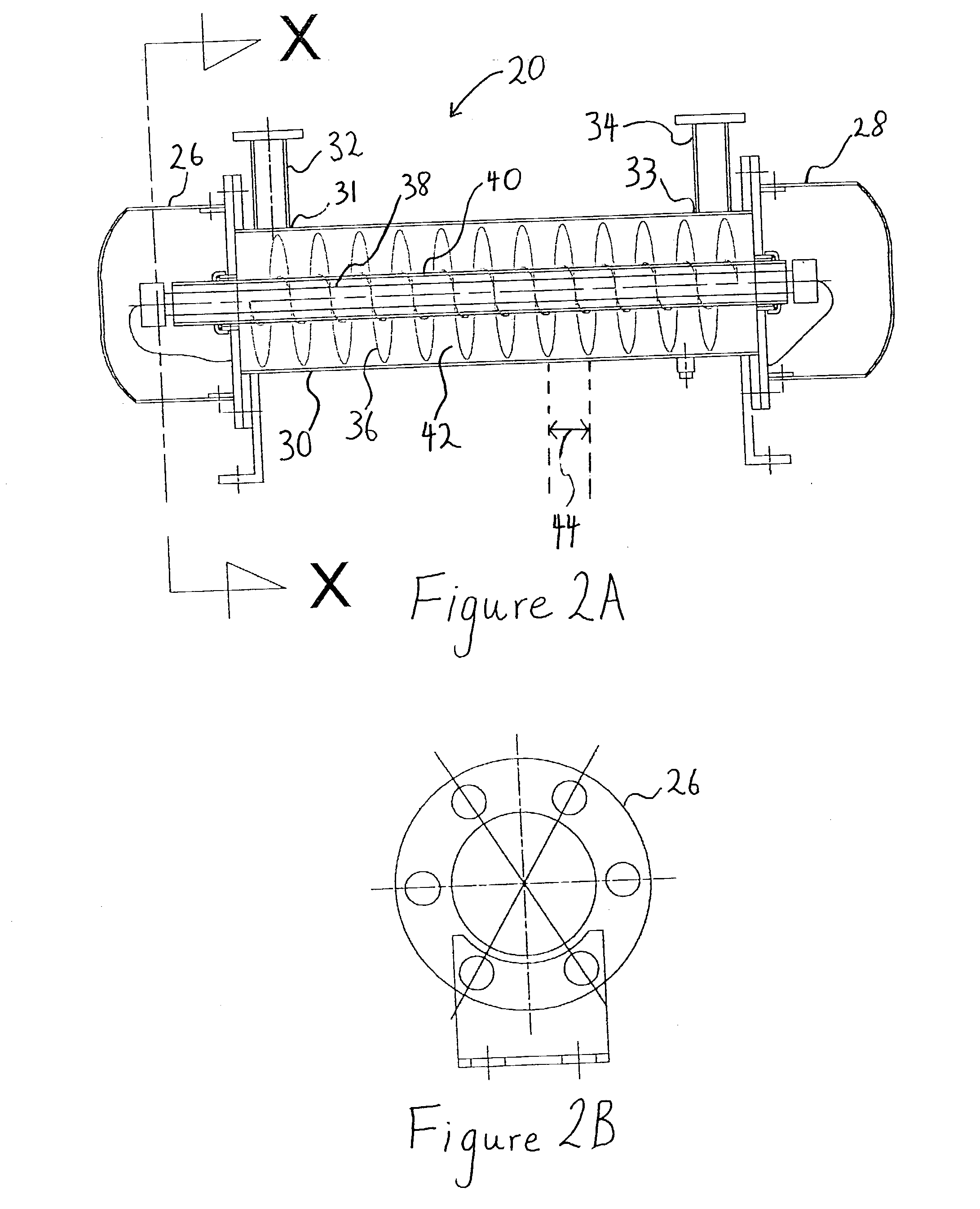

Fluid purification and disinfection device

InactiveUS20030209501A1Easy to purifyIncrease total effective contact surface areaWater/sewage treatment by irradiationWater treatment compoundsPollutantTitanium dioxide

The present invention discloses a fluid purification and disinfection system, which includes a housing, an ultraviolet lamp and a photocatalytic oxidation device. Said housing therein is an enclosed case that is fitted with an inlet and an outlet. Furthermore, said ultraviolet lamp is mounted inside the housing. Said photocatalytic oxidation device is a disinfection core coated with photocatalyst. Said disinfection core is installed around said ultraviolet lamp, and is fixed onto said housing. Said photocatalyst therein is titanium dioxide. The working principle of the fluid purification and disinfection device in accordance with the present invention is to utilize ultraviolet light to irradiate the titanium dioxide-coated surface of the photocatalytic oxidation device to generate the photocatalytic oxidation process. As a result, Escherichia coli, Vibriocholerae and pathogenic organisms that contact the surface of photocatalytic oxidation device can be quickly killed, and contaminants in the fluid can be eliminated. By this way, water or fluid that flows through said disinfection device is disinfected and purified.

Owner:ENVIRONMENTALCARE

Fluorosilicone material for super-hydrophobic coating and its preparation method and use method

InactiveCN103224719ALower surface energyReduce usageCoatingsSpecial surfacesSilicon oxideSilicon dioxide

The invention relates to a fluorosilicone material for a super-hydrophobic coating and its preparation method and use method. The fluorosilicone material is prepared from fluorinated nano-silica and / or nano-titanium dioxide sol having two particle sizes. The fluorinated nano-silica or nano-titanium dioxide sol having the small particle size has the average particle size of 10 to 150nm. The fluorinated nano-silica or nano-titanium dioxide sol having the large particle size has the average particle size of 200 to 500nm. Through utilization of fluorine-containing siloxane in silica and / or titanium dioxide preparation, surface energy of the fluorosilicone material as a coating is effectively reduced. Through utilization of non-fluorinated dichlorodialkylsilane, coating surface hydrophily is partly reduced and a fluorine-containing silane use amount and a cost are reduced.

Owner:HUBEI UNIV

Nano titanium dioxide/ acrylate composite emulsion and preparation method thereof

InactiveCN102516477AAvoid reunionStable structureCoatingsGraft polymer adhesivesPtru catalystPolymer chemistry

The invention discloses nano titanium dioxide / acrylate composite emulsion and a preparation method thereof. The method comprises the following steps of: hydrolyzing butyl titanate to generate nano titanium dioxide sol in absolute ethanol by using hydrochloric acid as a catalyst, adding a vinyl-containing silane coupling agent for modifying the sol, performing centrifugal washing, drying and grinding on the obtained product to obtain nano titanium dioxide, and thus obtaining the nano titanium dioxide / acrylate composite emulsion by using acrylate monomers of methyl methacrylate, butyl acrylate and the like as reaction monomers and adopting a method combining in-situ emulsion polymerization and seed emulsion polymerization. The nano titanium dioxide / acrylate composite emulsion prepared by the method has good storage stability and is stable in a polymerization reaction process; and a film formed by the composite emulsion has good hardness, impact strength and heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

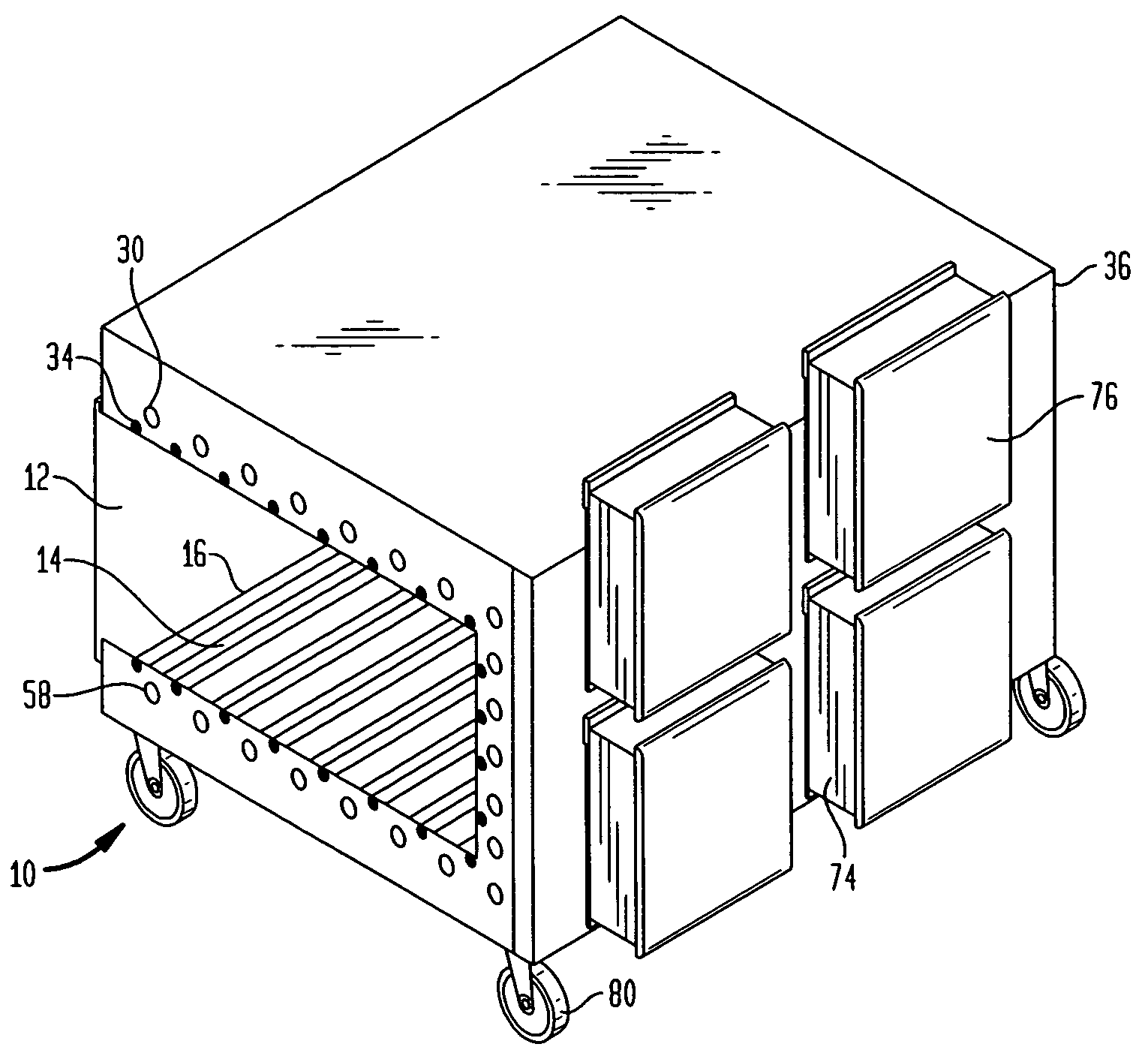

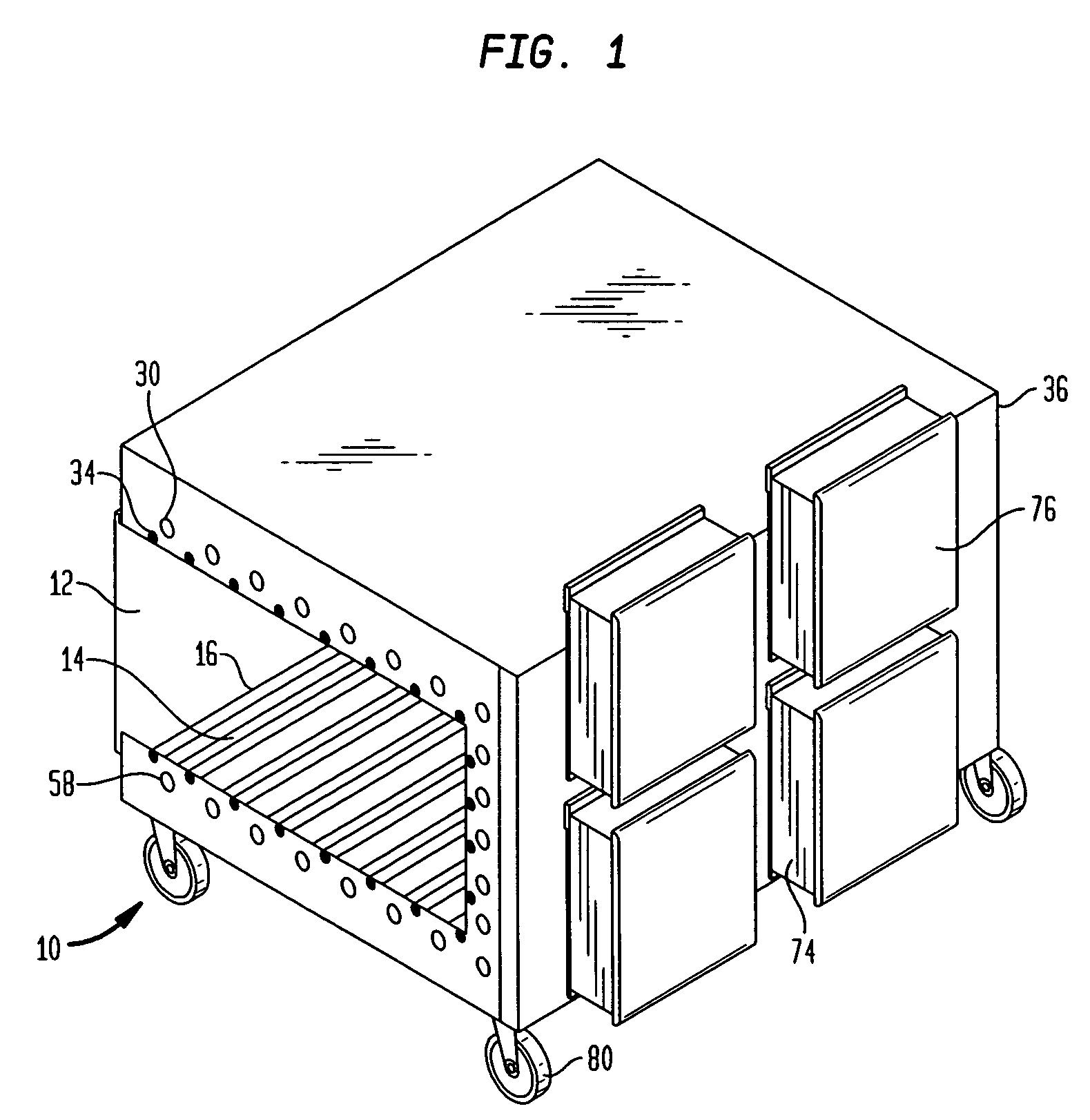

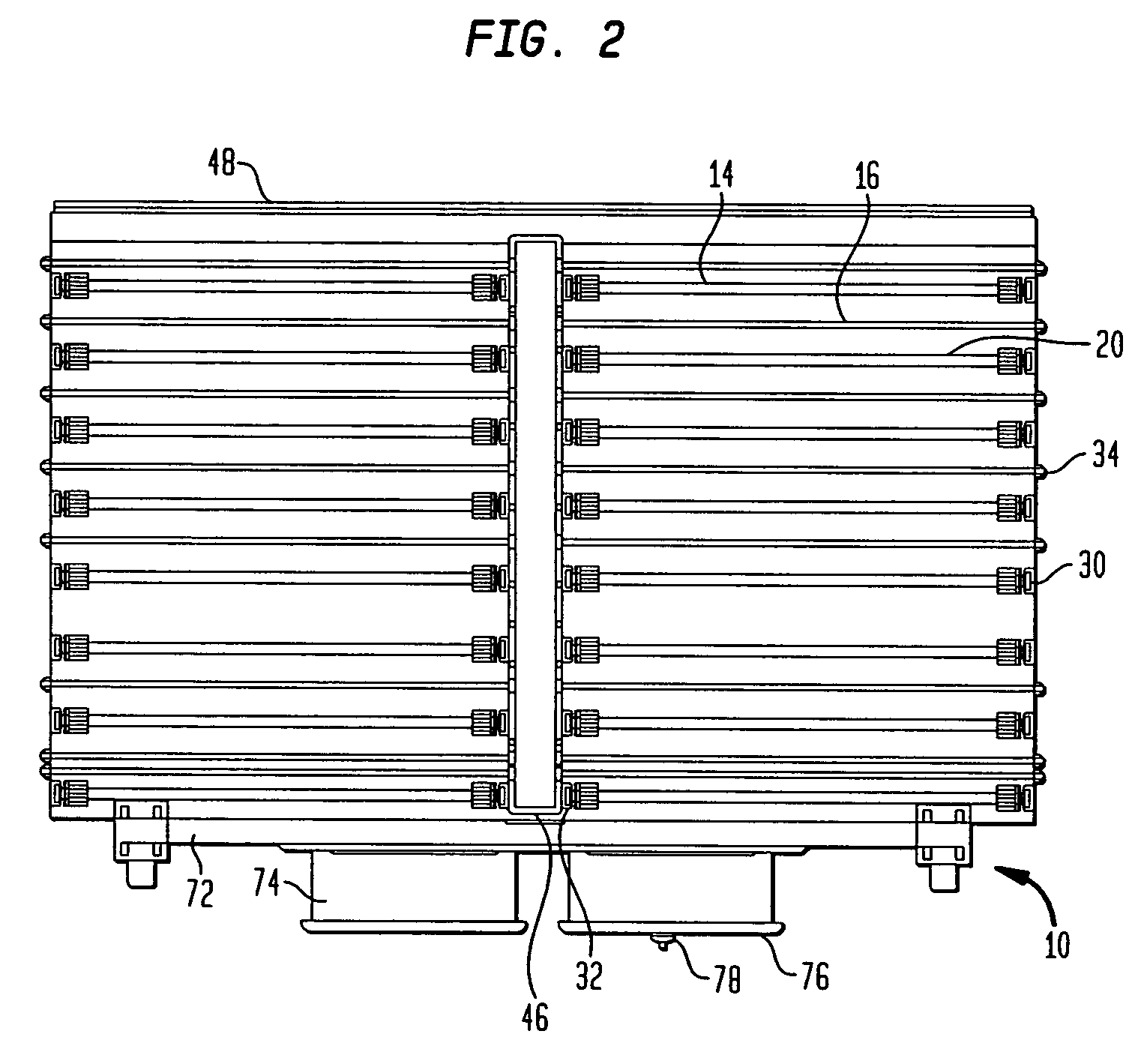

Food surface sanitation tunnel

InactiveUS7160566B2Efficient use ofImprove efficiencyMilk preparationDough treatmentSuperoxideCopper

This invention is a modular, adjustable, easy to maintain, portable or fixed food sanitation tunnel, comprising an enclosing means for subjecting food to sanitizers including UV light, ozone, hydroperoxides, superoxides and hydroxyl radicals, and a method for using the system. The enclosing means includes one or more UV radiation sources and one or more target rods located within a tunnel, such as a c-shaped shell. The UV radiation sources are preferably UV light sources that emit UV light of approximately 185 to 254 nm. The target rods are approximately up to 0–30% titanium dioxide, up to 0–30% silver and up to 0–30% copper, by weight. The system may include a mister for the efficient production of hydroxyl radicals by the UV light sources. Parts of the system are easily removable for cleaning and for maintenance. Also, in an alternative embodiment, the tunnel is located on a frame, and the frame is on wheels.

Owner:BOC INC

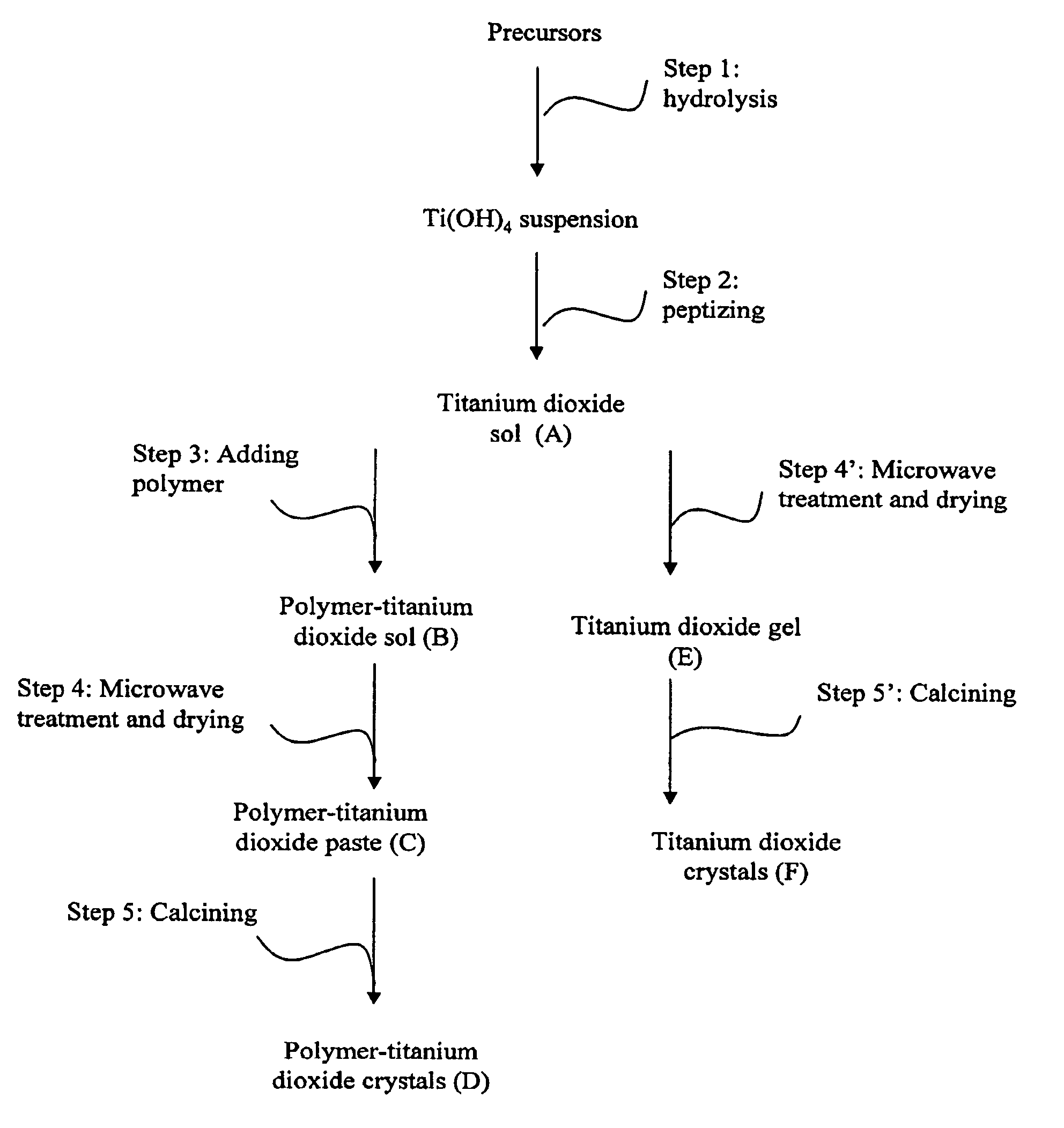

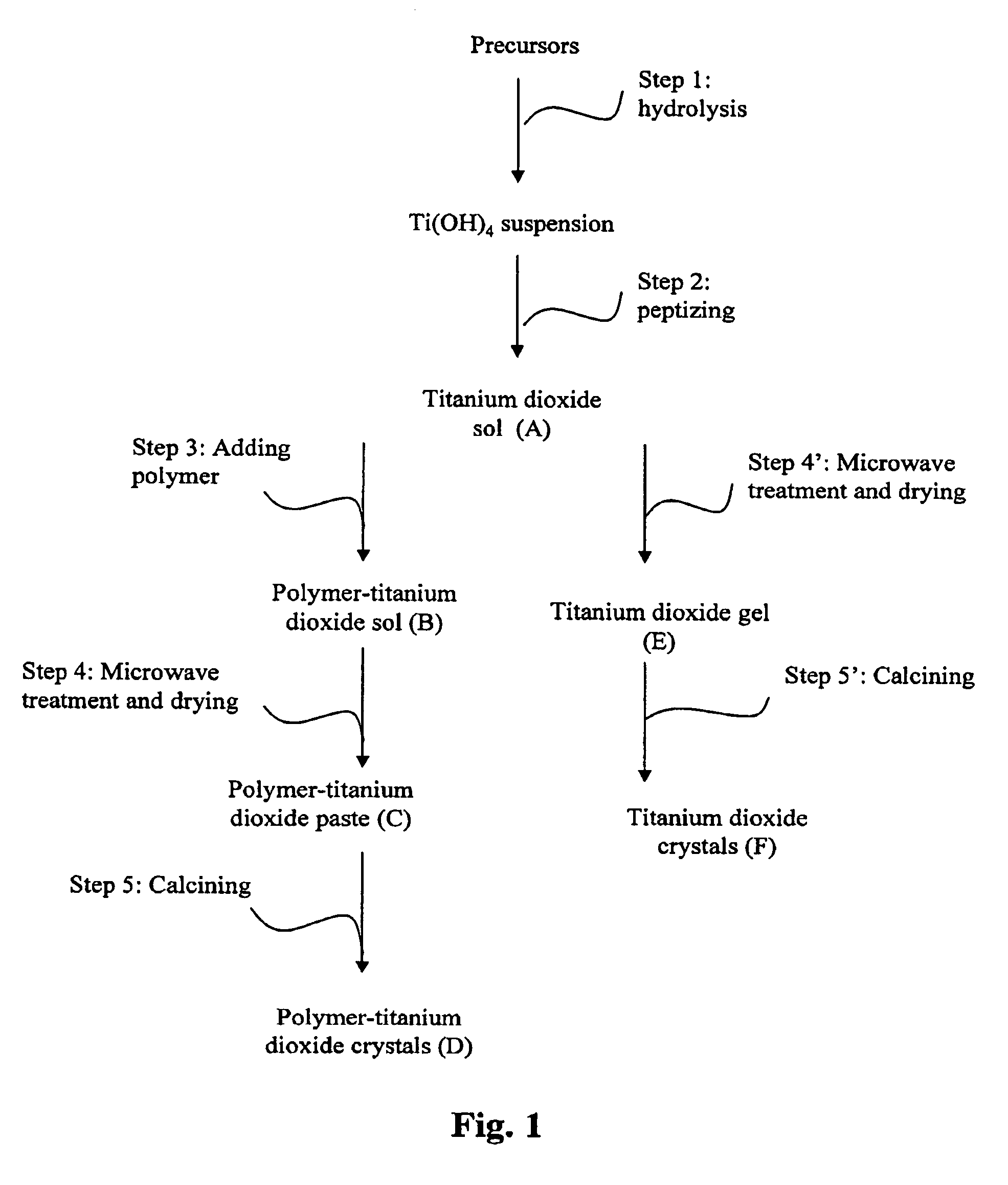

TiO2 material and the coating methods thereof

ActiveUS7144840B2Reduce moistureInhibit aggregationMaterial nanotechnologyLiquid surface applicatorsAir purificationTitanium dioxide

The present invention relates to a titanium dioxide material for coating on a substrate and method of making the same. The coated material is resistant to delamination and can be used for air-purification purposes.

Owner:THE HONG KONG UNIV OF SCI & TECH

Polycarbonate resin blends containing titanium dioxide

Owner:SABIC GLOBAL TECH BV

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

White light-shielding compositions and articles comprising same

ActiveUS20080230751A1Improve mechanical propertiesDiffusing elementsMixingPolycarbonatePolymer chemistry

A polymer composition is provided which is white and opaque (i.e. shields from light). The polymer composition comprises a blend of (i) a silicon-free polycarbonate polymer and (ii) a polycarbonate-polysiloxane copolymer; a whitener such as titanium dioxide; and (iii) a non-white colorant such as carbon black. The resulting composition, when molded and measured at a thickness of 0.75 mm, has an L* of greater than 80 and a % T of less than 1%. The composition also has good impact strength at low temperatures and good stability during processing.

Owner:SHPP GLOBAL TECH BV

Multifunctional textile finishing agent, preparation method thereof and cotton textile finishing method

InactiveCN102002854AEasy to processNo pollution in the processVegetal fibresAcetic acidPolymer science

The invention discloses a multifunctional textile finishing agent. The multifunctional textile finishing agent comprises the following components in percentage by weight: 1.00 to 5.00 percent of fibroin, 0.01 to 0.10 percent of chitosan, 0.01 to 0.50 percent of titanium dioxide, 0.01 to 1.50 percent of cross-linking agent, 0.50 to 5.00 percent of acetic acid, 0.10 to 0.80 percent of metal salt catalyst and the balance of water. The ecological multifunctional textile finishing agent involved by the invention is made of environment-friendly raw materials, is convenient to process, is not toxic or harmful to a human body and have no pollution; a finishing method is simple and is suitable for industrial production by a padding method; and the appearance of a finished textile is not influenced, namely the color does not turn yellow and the finished textile has a good anti-wrinkle effect and comfortable handfeel.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Multifunctional inorganic diatom ooze coating and preparation method thereof

InactiveCN104387816AStir wellNot easy to reuniteAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseEmulsion

The invention relates to a multifunctional inorganic diatom ooze coating, which is prepared from the following components in percentage by mass: 10%-25% of water, 0.4%-0.8% of cellulose, 10-30% of a mixture of potassium metasilicate and silica sol, 0.2%-0.4% of a stabilizer, 0.1%-0.3% of a dispersing agent, 0.1%-0.3% of a silicon additive, 0.3%-0.5% of a defoaming agent, 0.1%-0.3% of an antibacterial agent, 0-20% of titanium dioxide, 5%-15% of nanometer kieselguhr, 10%-30% of coarse whiting, 2%-4% of talcum powder, 1%-3% of medical stone, 0-1.5% of anion, 0-2% of a nano-photocatalyst, 1%-2% of inorganic gel powder, 0-9% of an order-removing emulsion and 0-1.5% of pigment, wherein the sum of the components is 100%. The invention also provides a preparation method of the coating. The coating disclosed by the invention has the functions of sterilizing, preventing mold, purifying air and the like; and the preparation method disclosed by the invention is simple and easy to operate.

Owner:佛山市南海万磊建筑涂料有限公司

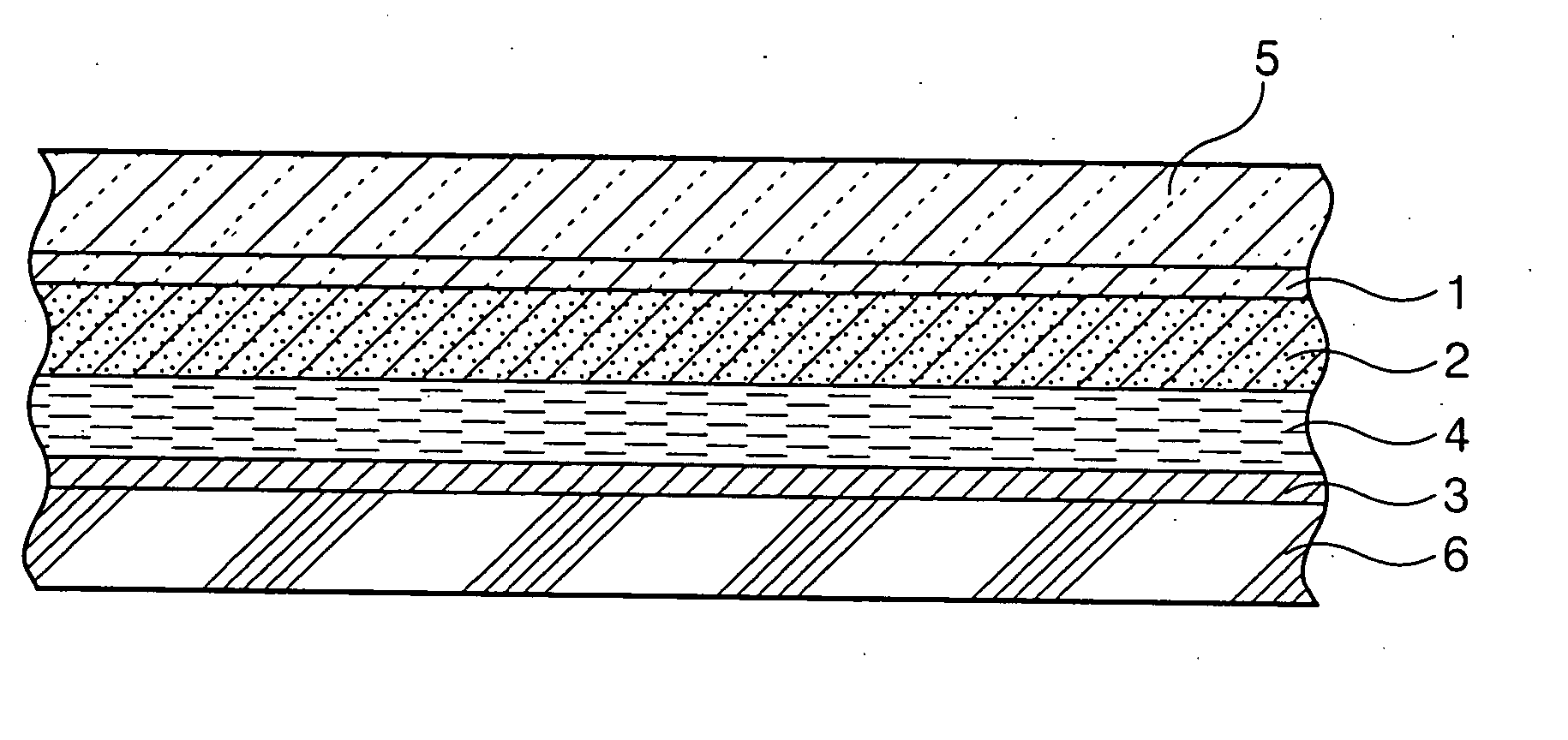

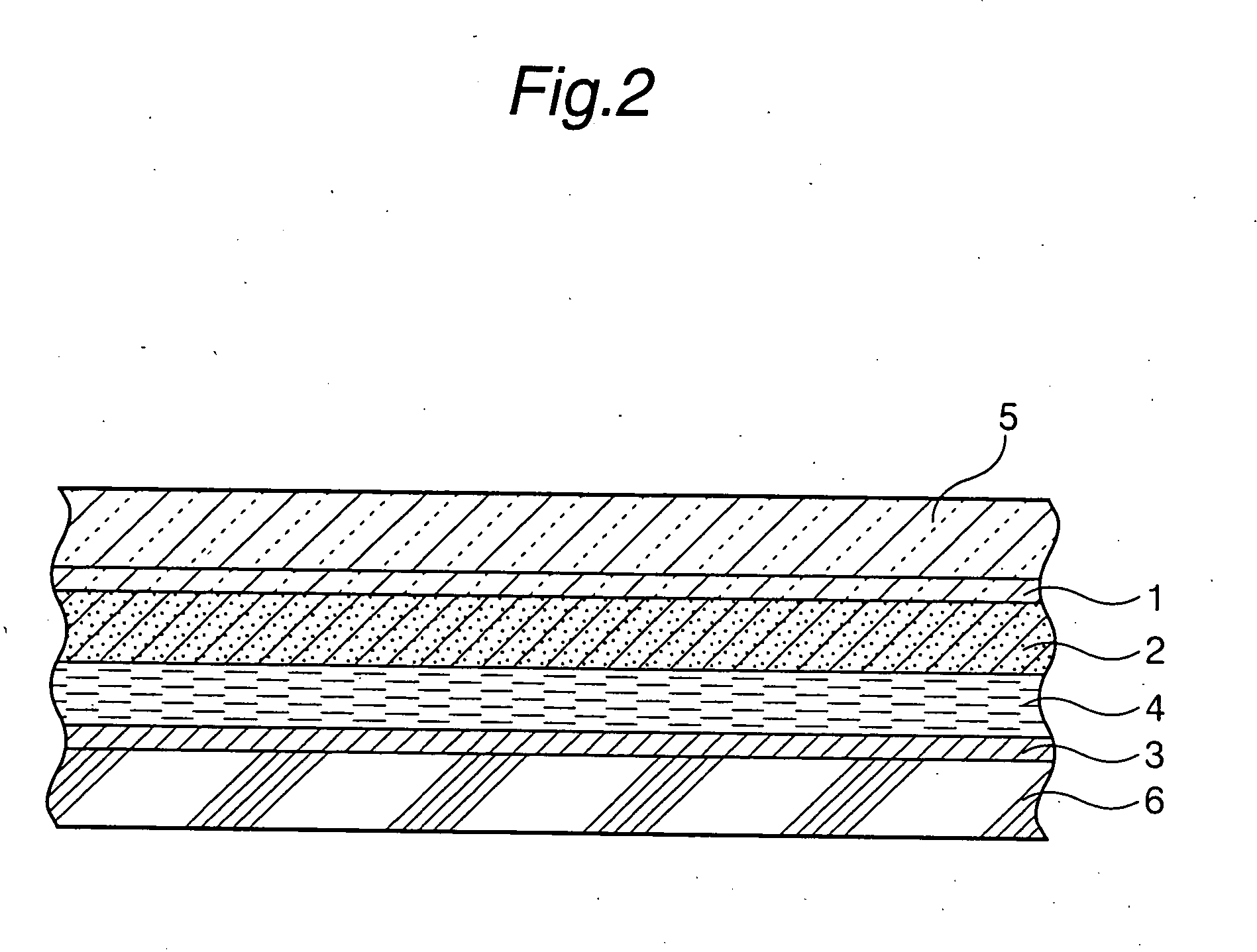

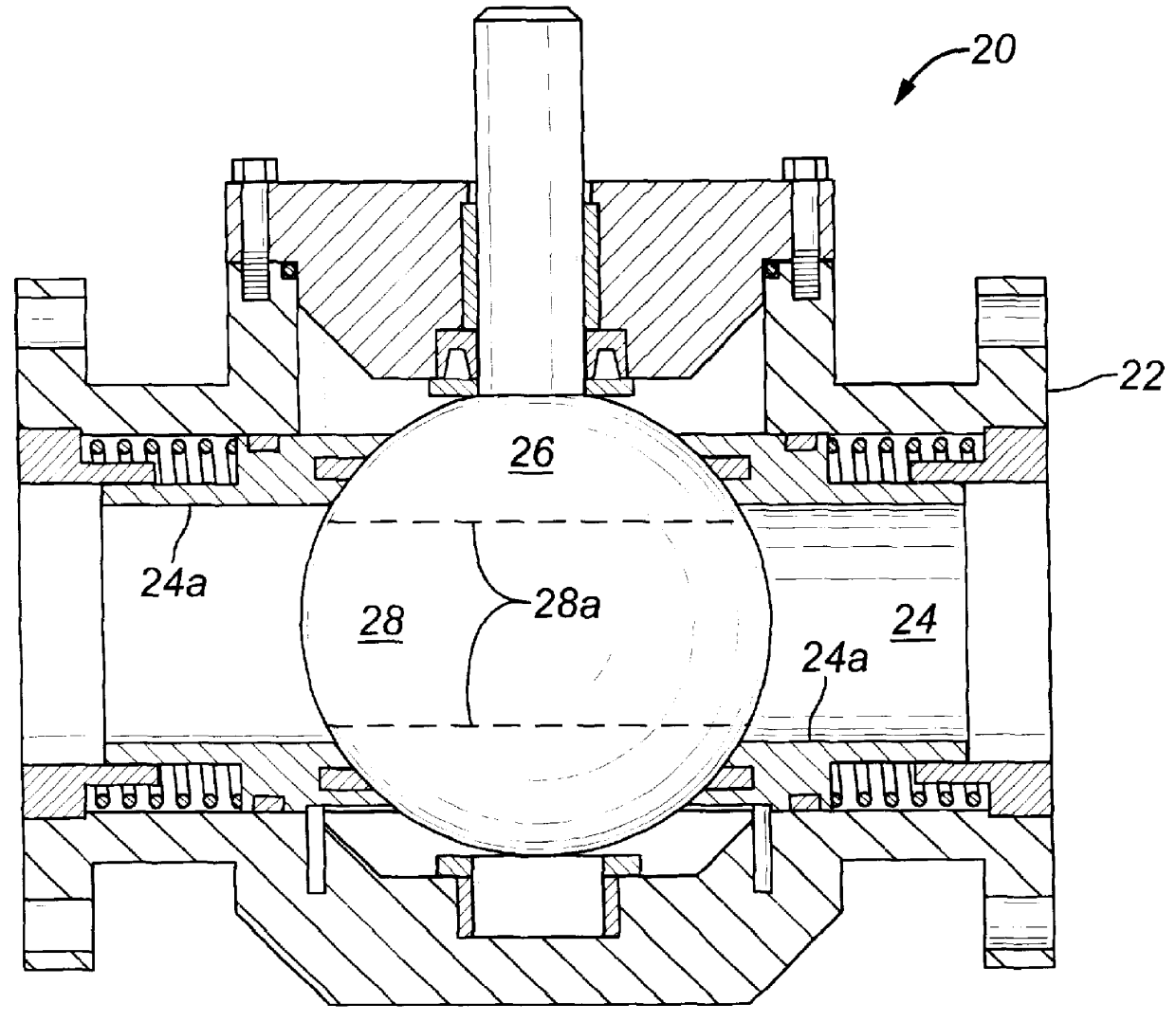

Metal element having a laminated coating

A laminated coating protects a metal substrate in a highly corrosive and highly erosive environment. A coating of a noble metal, such as gold, is bonded to the metal substrate, such as by electroplating or by flame spray. The noble-metal coating protects the metal substrate from the corrosive effects of a process fluid. A ceramic material, such as chromium oxide or titanium dioxide, is bonded to the noble-metal coating. Ceramic materials resist abrasion very well, which protects the underlying noble-metal coating from the erosive / abrasive effects of the process solution, which may contain suspended solids that are highly abrasive. However, the ceramic material is somewhat porous, which allows some seepage of the process fluid. The metal substrate is protected from the corrosive effects of the process fluid by the noble-metal coating.

Owner:WATSON GRINDING & MFG

Integral honeycombed catalyst for SCR flue-gas denitration and preparation method therefor

ActiveCN101444727AImprove catalytic performanceIncrease contact areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSodium BentoniteFlue gas

The invention relates to an integral honeycombed catalyst for SCR flue-gas denitration and a preparation method therefor. Titanium dioxide, bentonite and meerschaum are taken as carries, soaked for loading active components, formed, dried and baked to prepare the integral honeycombed catalyst. The carries comprise titanium dioxide 60-90%, bentonite 0-20% and meerschaum 0-10% by weight; the active components comprise WO3 5.0-10.0% OR MoO3 5.0-9.0%, V2O5 0.3-5.0%, and CeO2 0.0-2.0% or Nb2O5 0.0-1.0% by weight; and the total of the components is 100%. The catalytic activity is high, the denitration efficiency is high, and the service life is long; titanium dioxide, bentonite and meerschaum are taken as the carries, soaked for loading the active components, formed, dried and baked to prepare the integral honeycombed catalyst; and the preparation method is scientific, reasonable, simple and feasible.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

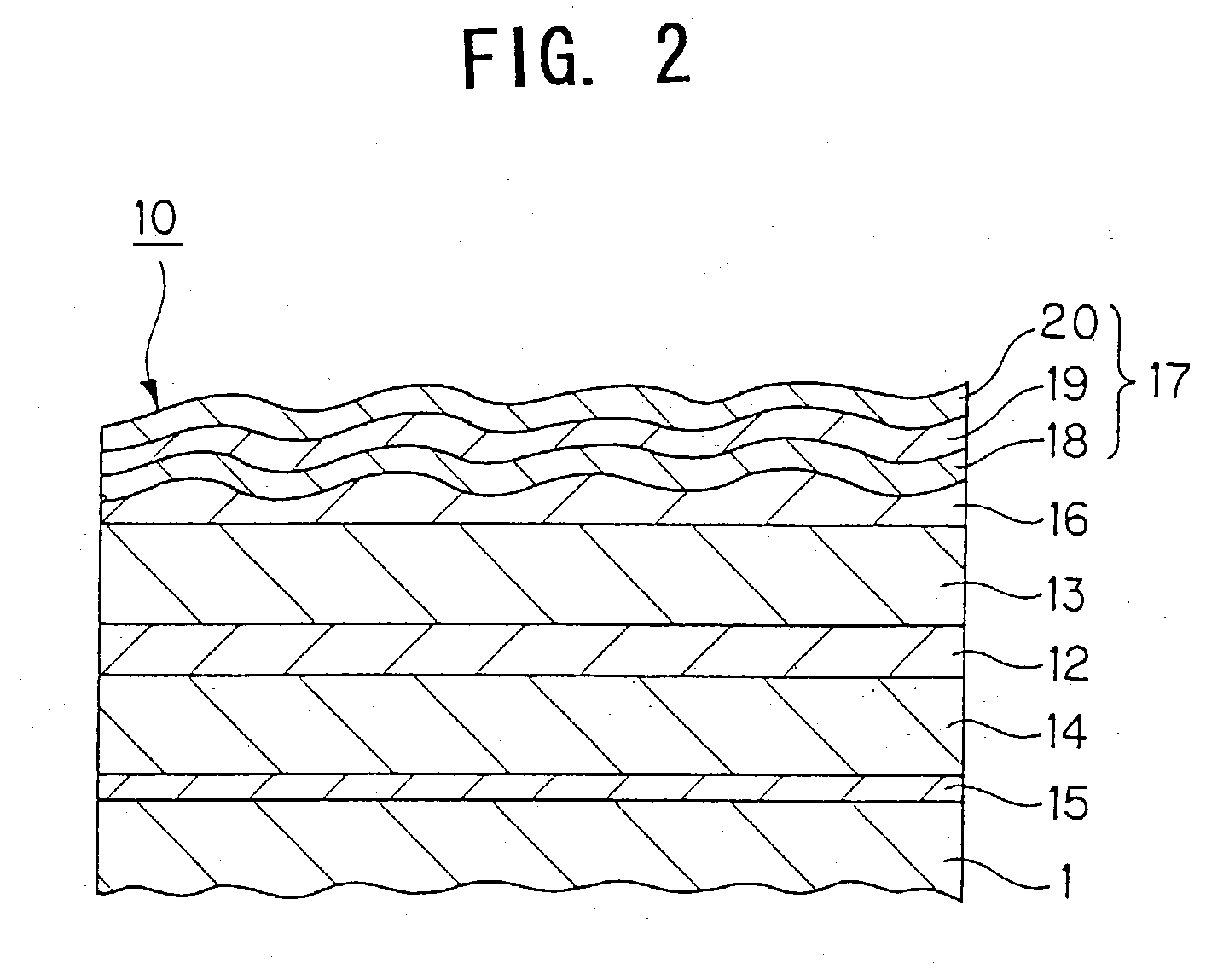

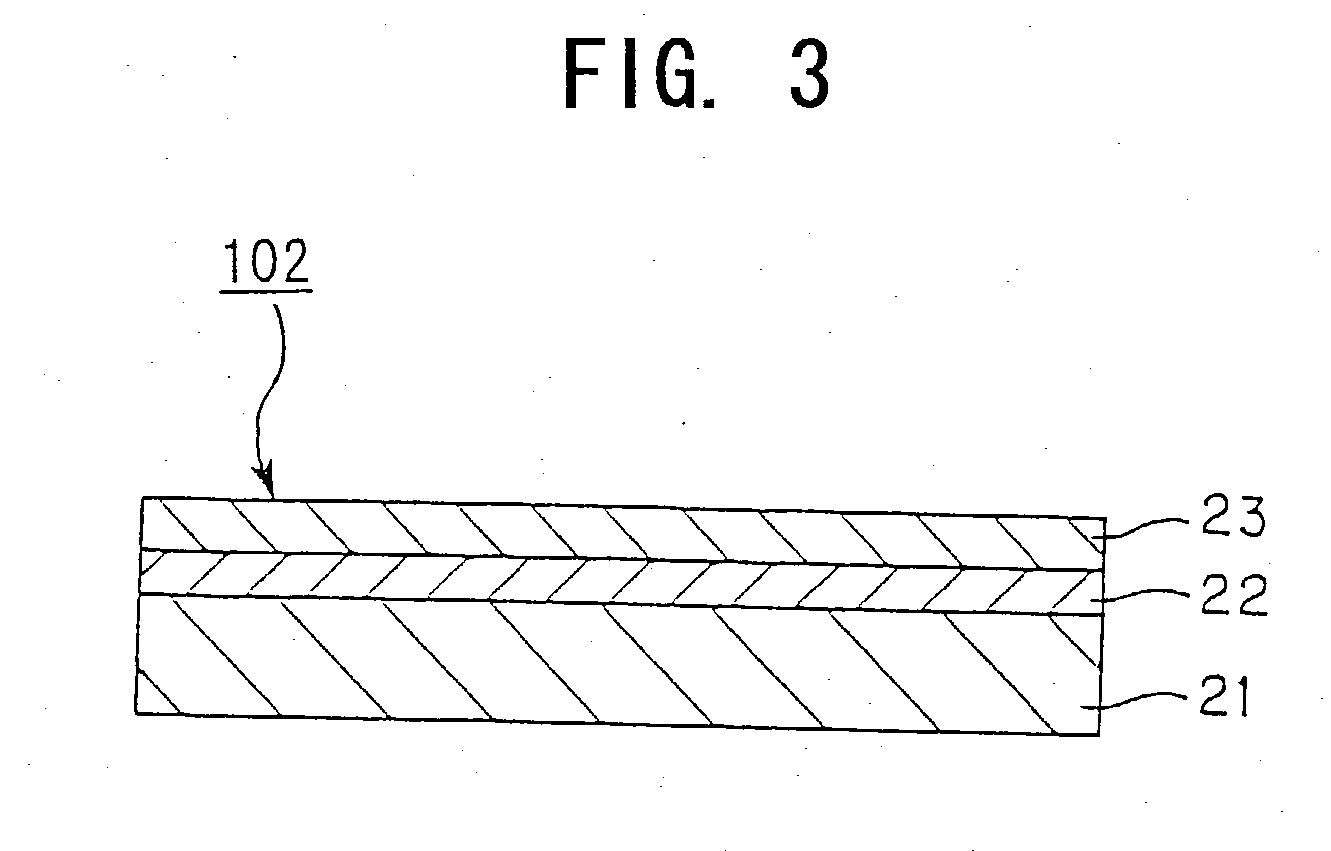

Coating composition, coating film thereof, antireflection coating, antireflection film, image display, and intermediate product

InactiveUS20030096102A1Good dispersibilityGood dispersionSynthetic resin layered productsCellulosic plastic layered productsMetallurgyRefractive index

A coating material capable of forming a high-quality thin film having a regulated refractive index; a coating film formed from the coating material; an antireflection coating comprising the coating film; an antireflection film to which the antireflection coating is applied; and an image display. The coating composition comprises (1) rutile-form titanium oxide having primary particle diameter of 0.01 to 0.1 mum and coated with an inorganic compound for reducing or eliminating the photocatalytic activity and with an organic compound having an anionic polar group and / or an organometallic compound, (2) a binder ingredient curable with an ionizing radiation, (3) a dispersant having an anionic polar group, and (4) an organic solvent. The coating film formed from the coating composition is suitable for forming a light-transmitting layer constituting or contained in a single- or multi-layer antireflection coating (17), in particular, a medium-refractive-index layer (18), high-refractive-index layer (19), or hard coat layer (16) having a high refractive index.

Owner:DAI NIPPON PRINTING CO LTD

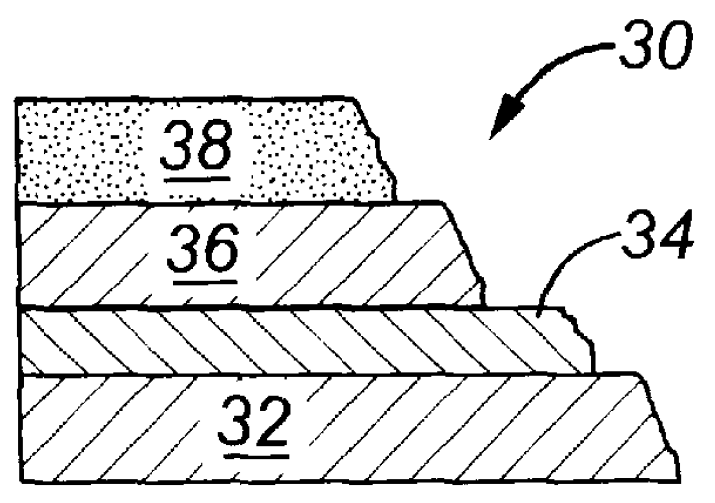

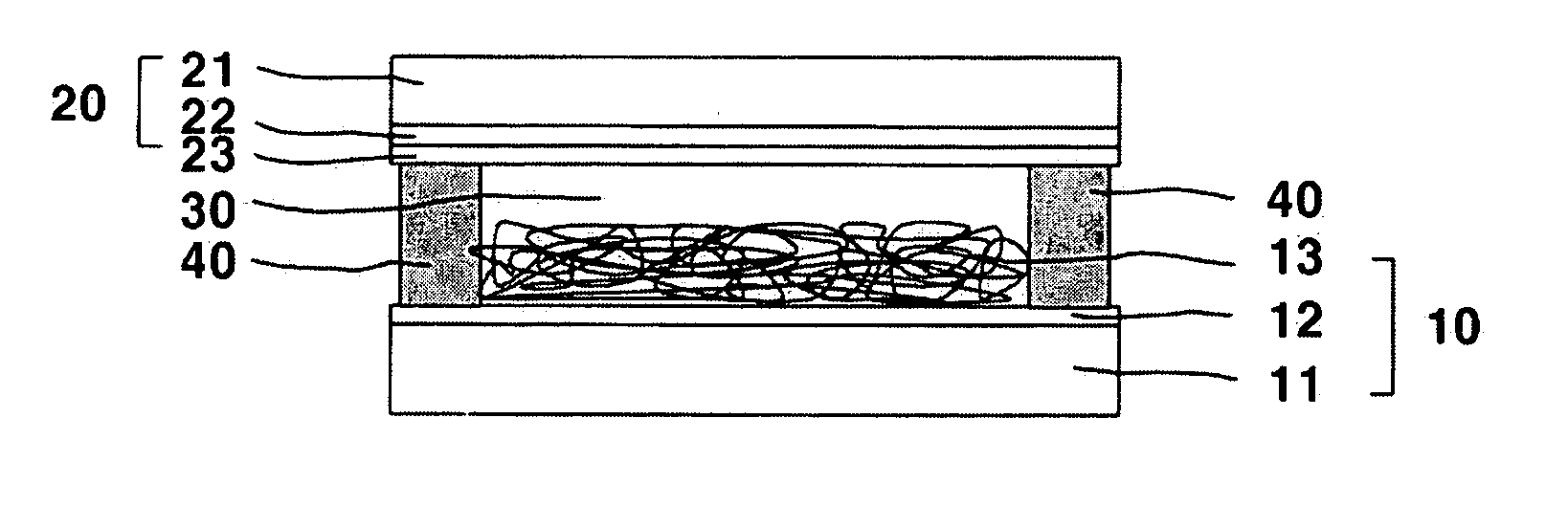

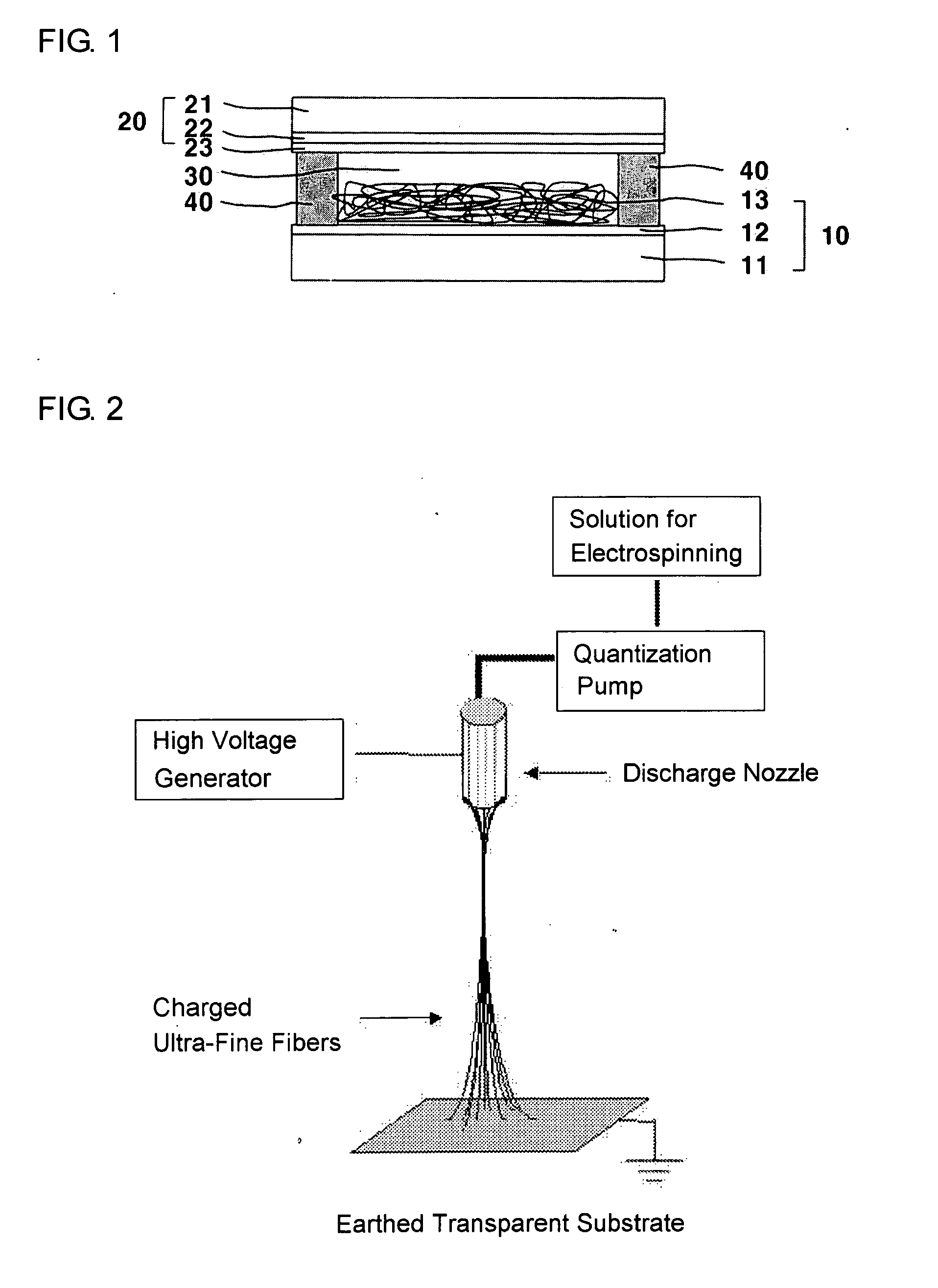

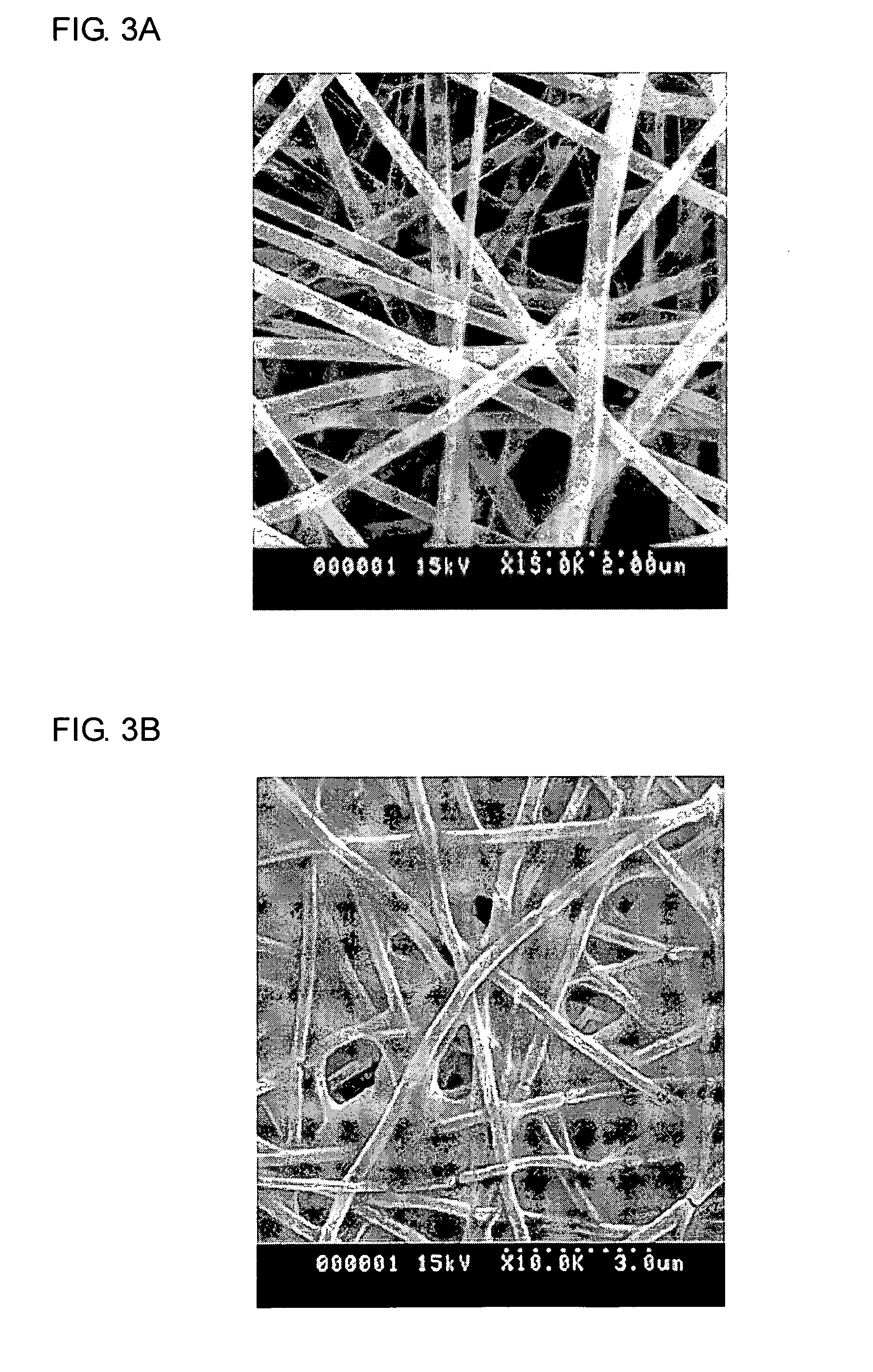

Dye-sensitized solar cell based on electrospun ultra-fine titanium dioxide fibers and fabrication method thereof

InactiveUS20050109385A1Improve adhesionSolve the real problemPigmenting treatmentMaterial nanotechnologyFiberSemiconductor electrode

A dye-sensitized solar cell comprising a semiconductor electrode comprising electrospun ultra-fine titanium dioxide fibers and fabrication method thereof are disclosed. The dye-sensitized solar cell comprises a semiconductor electrode comprising an electrospun ultra-fine fibrous titanium dioxide layer, a counter electrode and electrolyte interposed therebetween. A non-liquid electrolyte such as polymer gel electrolyte or the like having low fluidity, as well as the liquid electrolyte, can be easily infiltrated thereinto. In addition, electrons can be effectively transferred since titanium dioxide crystals are one-dimensionally arranged.

Owner:KOREA INST OF SCI & TECH

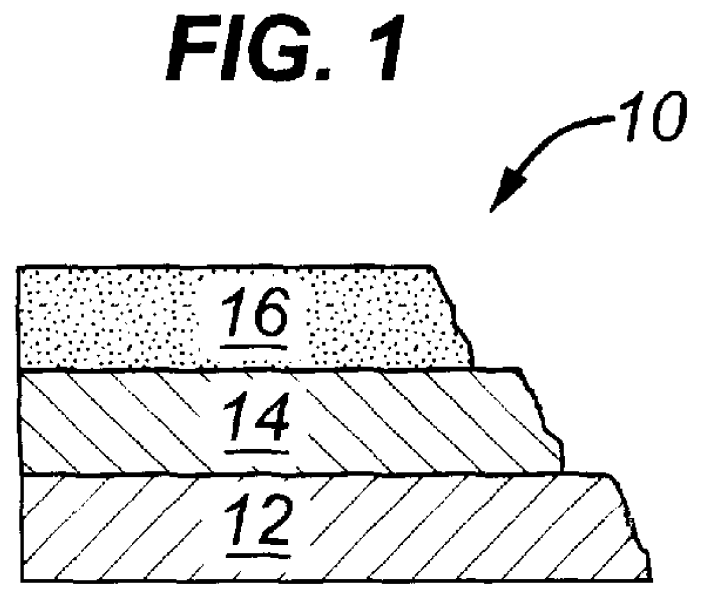

Methods and equipment for depositing hydrophilic coatings, and deposition technologies for thin films

The invention provides certain embodiments that involve sputtering techniques for applying a mixed oxide film comprising silica and titania. In these embodiments, the techniques involve sputtering at least two targets in a common chamber (e.g., in a shared gaseous atmosphere). A first of these targets includes silicon, while a second of the targets includes titanium. Further, the invention provides embodiments involving a substrate bearing a hydrophilic coating, which can be deposited by sputtering or any other suitable thin film deposition technique. The invention also provides techniques and apparatuses useful for depositing a wide variety of coating types. For example, the invention provides thin film deposition technologies in which sputtering apparatuses or other thin film deposition apparatuses are employed.

Owner:CARDINAL CG

Titanium alloy based dispersion-strengthened composites

Titanium based metal matrix composites reinforced with ceramic particulate are well known, based on a blend of titanium alloy powders with ceramic powders, e.g., aluminum oxide powders, utilizing a low energy ball milling process, followed by cold compacting and sintering to produce an appropriate composite. This prior art process is disadvantaged from the point of view that there are virtually no particles in the blend below the micrometer size range, which lack has a deleterious effect on the subsequent processing of the composite. This problem has been overcome by utilizing dry high energy intensive milling in the process, which has the effect of providing the necessary number of small particles below the micrometer size range as well as enhancing the reactivity of different particles with one another. In order to produce a titanium base alloy alumina metal matrix composite, titanium dioxide powder is blended with aluminum powder and subjected to dry high energy intensive milling until the separate particle phases achieve a size of 500 nanometers maximum. The intermediate powder product is then heated to form the titanium alloy / amumina metal matrix composite in which the ceramic particles have an average diameter of no more than 3 mu, and the oxide consists of more than 10% and less than 60% by volume fraction of the total composite. The composites have extensive application to tough and strong engineering alloys.

Owner:TITANOX DEV

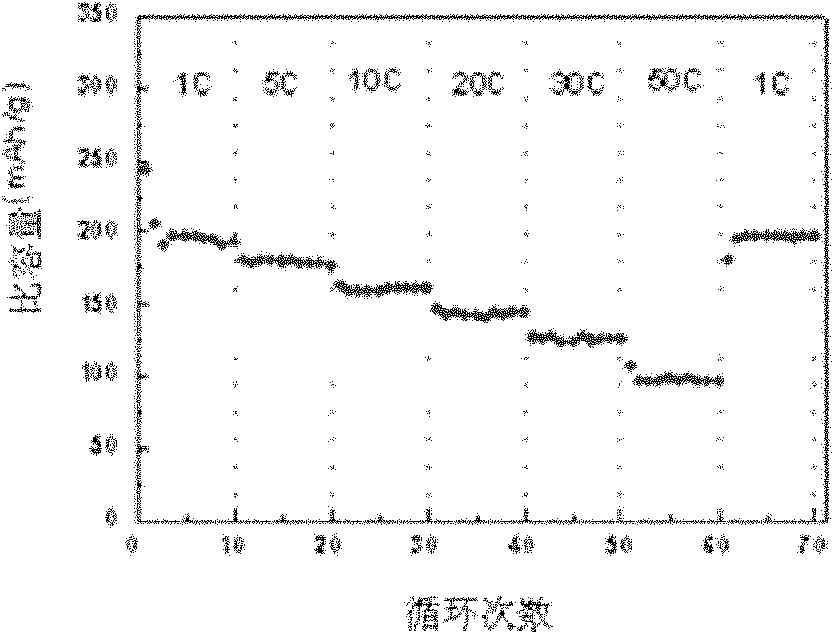

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761AShape is easy to controlControllable surface structureCell electrodesGraphene nanocompositesHigh energy

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation and application method of optical catalysed environment protection type coating

The invention provides a preparation and application method for photocatalysis environmental protection type painting, which relates to construction painting, especially provides a preparation and application method for photocatalysis function painting, which includes steps: mixing titanium-containing organic, water, chelating agent and hydrolysis inhibitor to prepare nano anatase type titanium dioxide water sol; adding metal, oxide or impure titanium dioxide photocatalyst into the titanium dioxide water sol and stirring equably. Using method is coating inorganic isolated layer firstly and coating the photocatalysis painting after drying. Advantages of the invention are: the prepared painting and using technique can be widely used for inner and outer wall surface of building and is harmless to bottom ainting, photocatalysis efficiency is high, cost is low, bonding is firm, transparency is good, preparation is simple, and usage is easy.

Owner:YUNNAN UNIV +1

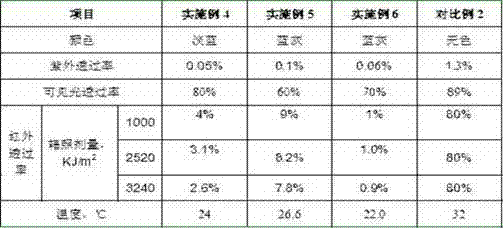

PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and preparation method thereof

ActiveCN104262874AHas the effect of heat insulation and UV protectionPlay the effect of energy saving and environmental protectionPolyvinyl butyralInfrared

The invention discloses a PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and a preparation method thereof. The functional PVB film comprises cesium tungsten bronze, antimony indium oxide, indium tin oxide, titanium dioxide, nano carbon spheres, zirconium carbide, PVB resin powder, a plasticizer, a trace improver and the like. The preparation method comprises the following steps: dispersing the cesium tungsten bronze composite nanoparticles with a solvent, adding the plasticizer, stirring uniformly, adding the PVB resin powder and trace improver, thoroughly mixing, and carrying out film formation on the mixture by running to obtain the heat-insulation ultraviolet-resistant PVB film. The ultraviolet rejection ratio of the PVB film is greater than 99.0%, the visible light transmittance is adjustable within the range of 60-85%, and the infrared rejection ratio is up to 80-99%; and the PVB film can be directly used for producing heat-insulation infrared / ultraviolet-resistant safety laminated glass, can be widely used in architectural curtain walls, doors / windows, zeniths, automobile windshields and the like, and is a novel energy-saving film material.

Owner:SUZHOU POLIMA MACROMOLECULE MATERIAL CO LTD

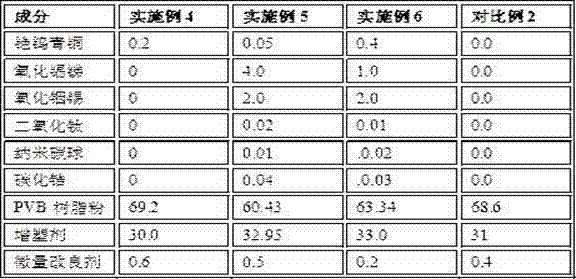

Polyimide-titania hybrid materials, their preparation, and film prepared from the materials

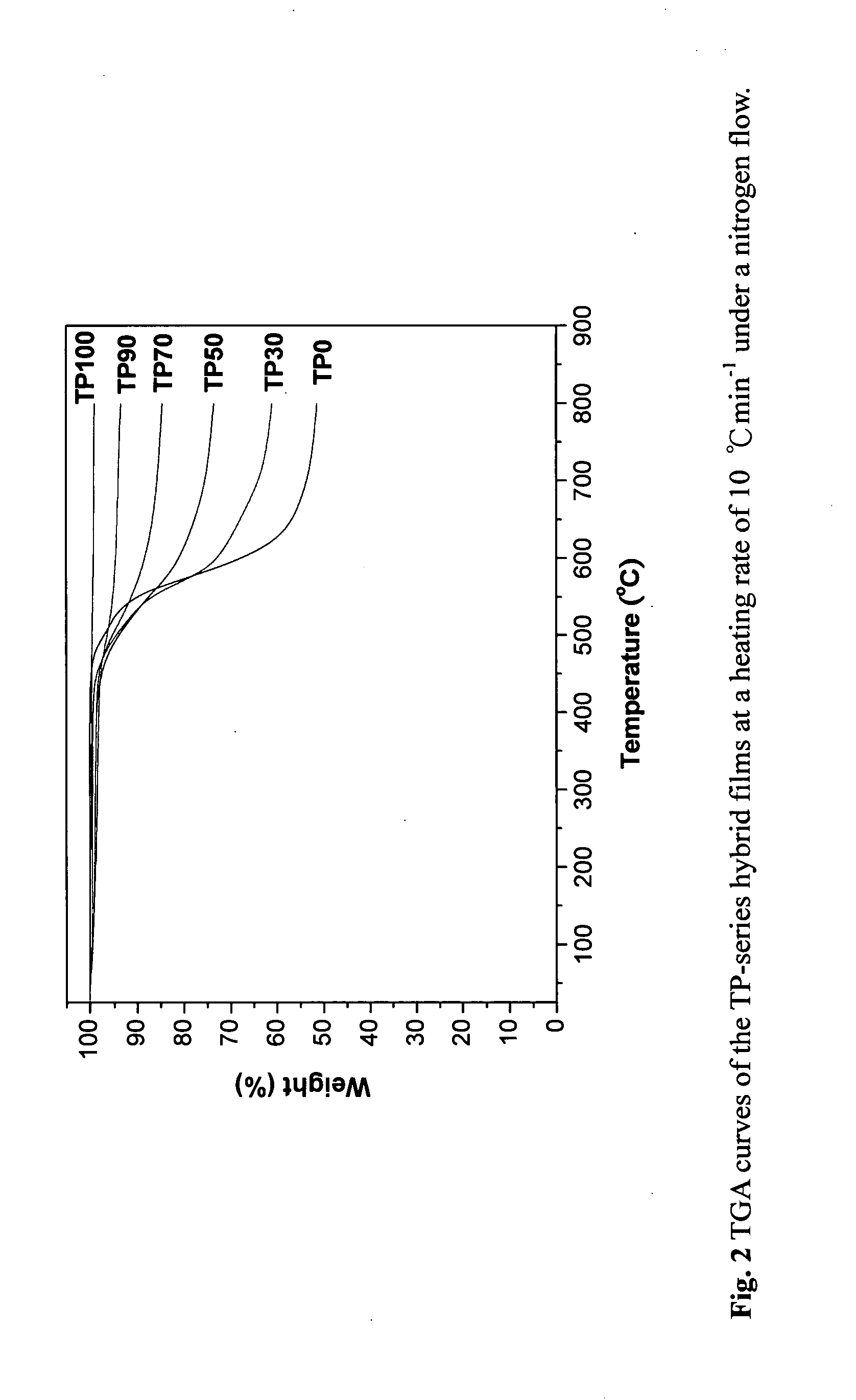

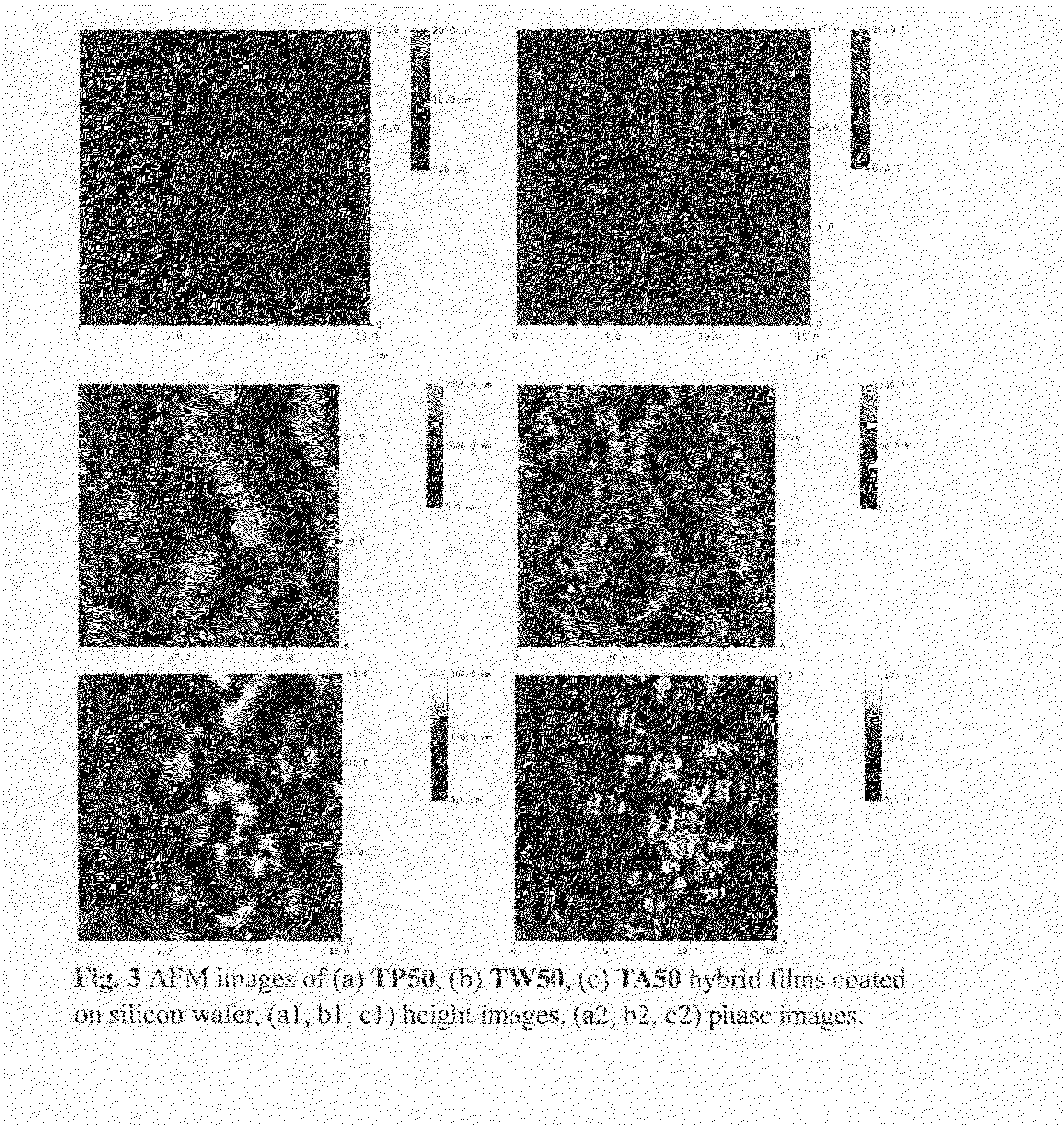

ActiveUS20090092759A1Good surface smoothnessImprove thermal performancePretreated surfacesCoatingsOptical transparencySide chain

The present invention relates to polyimide-titania hybrid thin film, which possesses relatively good surface planarization, excellent thermal properties (400<Td<550° C.), tunable refractive index (1.571<n<1.993), and highly optical transparency in the visible range. The present invention also relates to a method for preparing the polyimide-titania hybrid materials, which comprises producing a polyimide containing pendent and / or terminal carboxylic acid, coordinating the carboxylic acid with titanium of titanium alkoxide and sol-gel reacting of titanium alkoxide, to enhance the interaction between polyimide and titania and produce the polyimide-titania hybrid materials without macrophase separation. The present polyimide-titania hybrid materials are useful to produce the thin film having the above features.

Owner:NAT TAIWAN UNIV

Polymer coated web with good water vapor permeability

InactiveUS20050014431A1Easy to printReduce chanceSynthetic resin layered productsWoven fabricsCelluloseParticulates

A composite material which is suitable as a wall covering comprises a substrate layer that is permeable to water vapor, such as a nonwoven web material made from cellulose and synthetic fibers, and that is coated, preferably extrusion coated, with a plastics material. In one embodiment the plastics material comprises an olefin polymer, olefin copolymer or blend of olefin (co)polymer and a particulate filler, e.g. calcium carbonate or a mixture thereof with titanium dioxide. In another embodiment the plastics material is a microporous breathable polymer film or a monolithic breathable polymer film.

Owner:AHLSTROM WINDSOR LOCKS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com