Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

A nanocomposite material, titanium dioxide technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of low initial efficiency, low volume energy density, etc., and achieve the effect of large specific surface area, high photocatalytic activity, and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

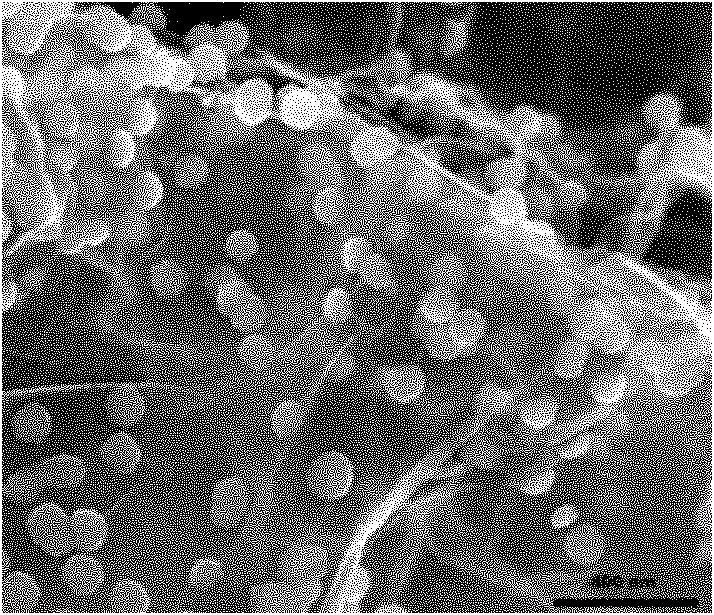

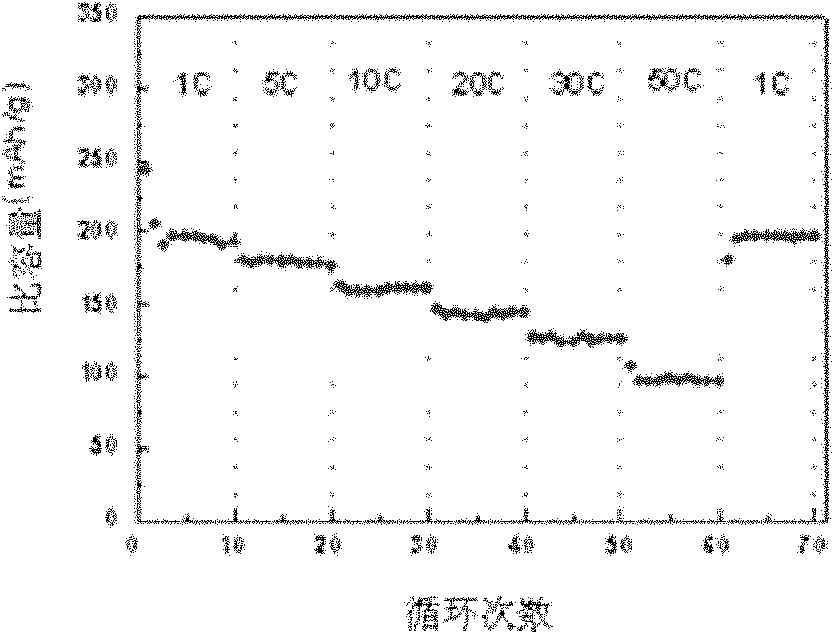

Embodiment 1

[0036] 5ml concentrated sulfuric acid (98wt%) was added to 100ml of the graphene aqueous solution with a concentration of 0.5g / L, stirred evenly, 5g of titanium sulfate powder was weighed and added to the above solution and stirred for 30 minutes, the solution was put into a sealed bottle, The reaction was carried out at 100°C for 6 hours. The obtained black precipitate was washed three times with water and dried at 80°C to obtain the titanium dioxide and graphene composite material. [TiO] produced by the hydrolysis of the titanium source during this process 2+ The groups enter into the graphene layers through electrostatic attraction and diffusion, and under certain conditions, heterogeneous nucleation grows. Graphene acts as a structure inducer and does not require any template to prepare anatase-phase mesoporous titania nanospheres and graphite. Graphene composite nanocomposite material, mesoporous titanium dioxide spheres with a size of 100nm are evenly distributed on gra...

Embodiment 2

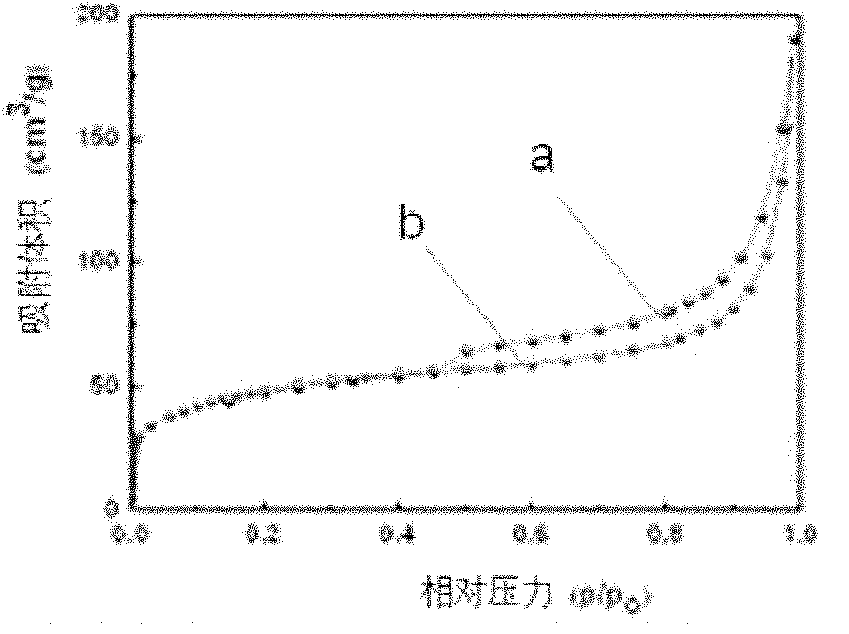

[0044] The difference from Example 1 is that 5ml of concentrated sulfuric acid (98wt%) was added to 100ml of the graphene aqueous solution with a concentration of 0.3g / L, stirred evenly, and 3.5g of titanium sulfate powder was weighed and added to the above solution and stirred for 30 minutes. , the solution was put into a sealed bottle and reacted at 80°C for 2 hours. Then the obtained black precipitate was centrifuged, washed three times with deionized water, and vacuum-dried at 80° C. to obtain a nanocomposite material of anatase-phase titanium dioxide nanometers and graphene. The particles are uniformly dispersed on the graphene surface, the pore size distribution is 2-50nm, and the specific surface area is 110m 2 / g.

[0045] In the titanium dioxide / graphene nanocomposite material in this embodiment, the proportion of graphene is 14 wt %, and the rest is titanium dioxide.

Embodiment 3

[0047] The difference from Example 1 is that 4.6ml of hydrochloric acid (37wt%) was added to 100ml of the graphene aqueous solution with a concentration of 0.3g / L, the resulting solution was ultrasonically dispersed for 2 hours by stirring for 10 minutes, and a tetrabutyl titanate solution was added. It was added dropwise to the prepared solution and stirred for half an hour, and then the resulting solution was placed in a sealed bottle to react at 80° C. for 12 hours. Then the obtained black precipitate was centrifuged, washed three times with deionized water, and vacuum-dried at 80°C to obtain a nanocomposite material composed of mesoporous titania nanospheres in anatase phase and graphene. The particle size of the composite material is Titanium dioxide particles of 200-300nm are uniformly dispersed on the surface of graphene, the pore size distribution is 5-100nm, and the specific surface area is 69m 2 / g.

[0048] In the titanium dioxide / graphene nanocomposite material of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com