Patents

Literature

918results about How to "Excellent rate performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte additive and application thereof in lithium ion battery

ActiveCN104766995AImprove cycle lifeImprove featuresLi-accumulatorsOrganic electrolytesHigh temperature storageSulfur

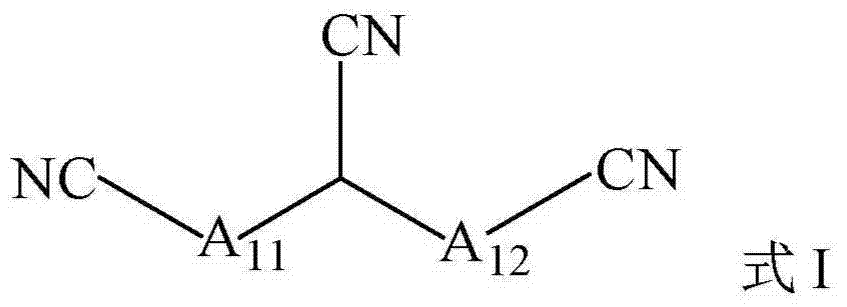

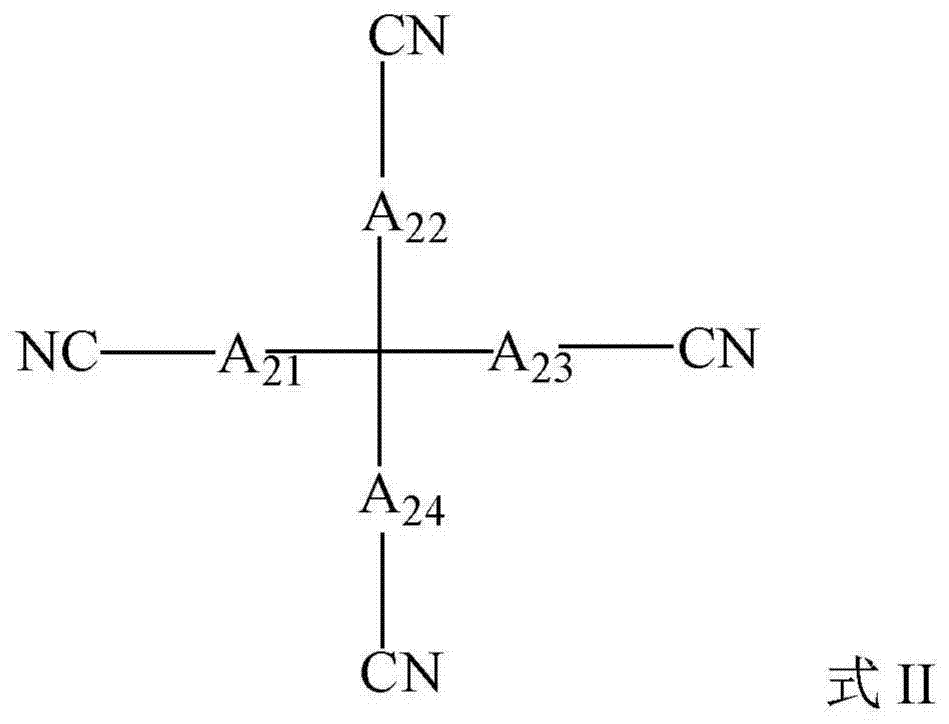

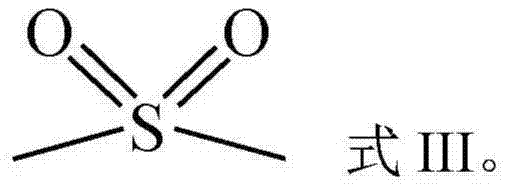

The invention discloses an electrolyte additive and an application thereof in a lithium ion battery. The electrolyte additive comprises a polynitrile-based compound and a compound comprising a sulfur bond and an oxygen bond. When the electrolyte additive is applied to the lithium ion battery, good cycle life, good low-temperature discharging property and good high-temperature storage property of the lithium ion battery under the high voltage still can be maintained.

Owner:CONTEMPORARY AMPEREX TECH CO

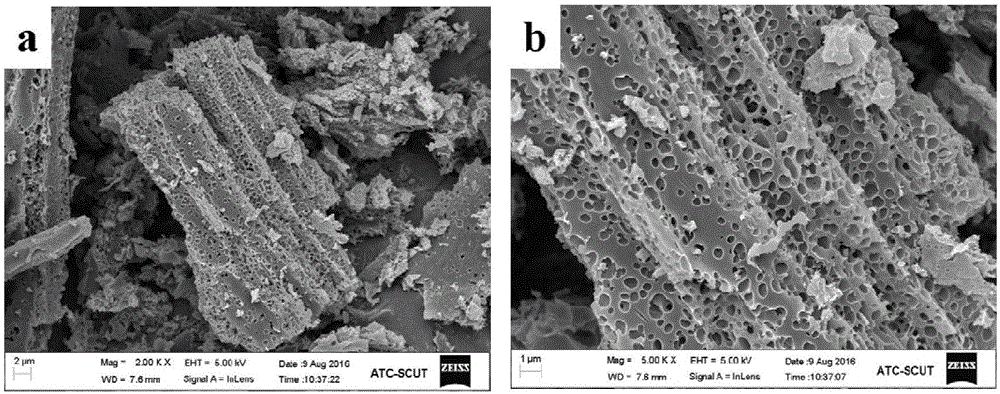

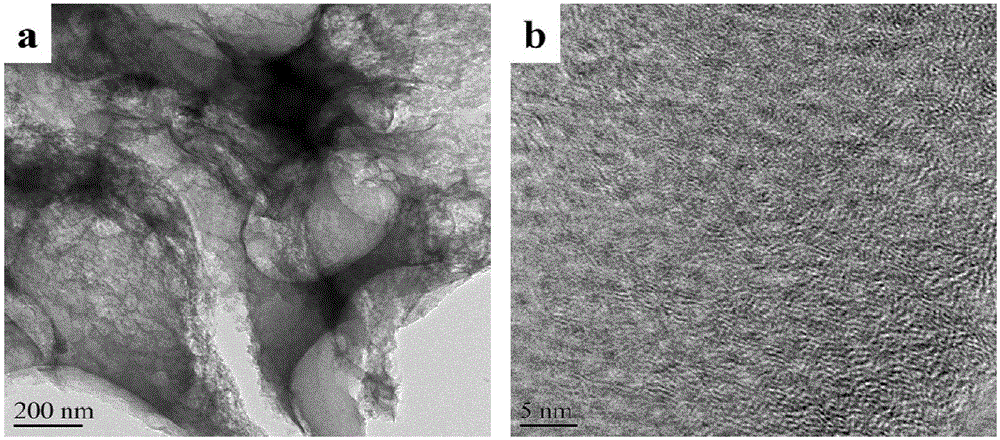

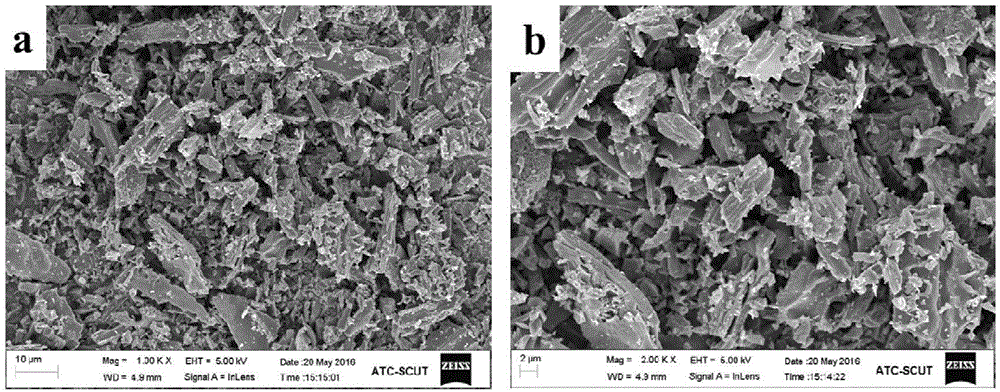

Biomass-based porous carbon material, preparation method thereof, and application thereof in supercapacitor

InactiveCN106587055AWide variety of sourcesLow priceCarbon compoundsHybrid capacitor electrodesPorous carbonBiological activation

The invention belongs to the field of material science and energy storage and discloses a biomass-based porous carbon material, a preparation method thereof, and an application thereof in a supercapacitor. The method includes the steps of: 1) drying and crushing rice straws; 2) non-carbonizing or pre-carbonizing the crushed rice straws, uniformly mixing the rice straws with an activator water solution and drying the mixture, or non-carbonizing or pre-carbonizing the crushed rice straws and directly mixing the rice straws with a solid activator uniformly to produce a mixed product; and 3) placing the mixed product in a tube furnace to perform carbonizing activation in an inert gas atmosphere at high temperature; 4) washing the carbonized product in an acid solution and an alkali solution, and washing the carbonized product with deionized water to neutral, and drying the washed product to prepare the biomass-based porous carbon material. The porous carbon material has excellent supercapacitor performance and is simple in preparation method.

Owner:SOUTH CHINA UNIV OF TECH

Titanium dioxide/graphene nanocomposite material and preparation method and application thereof

InactiveCN102569761AShape is easy to controlControllable surface structureCell electrodesGraphene nanocompositesHigh energy

The invention relates to a titanium dioxide / graphene nanocomposite material, a preparation method of the nanocomposite material and application of the nanocomposite material in the field of energy source and cleaning environment. The graphene accounts for 1-25wt% and the balance is titanium dioxide. Morphology of the titanium dioxide is a mesoporous structure or a structure with a dominant high energy surface, and titanium dioxide is scattered uniformly on the surface of graphene. According to the invention, by adopting a titanium source and graphene as initial materials, and water or organic solvents as reaction solvents, the nanocomposite material with titanium dioxide with the mesoporous structure or a titanium dioxide nano sheet with the dominant high energy surface compounded with graphene can be obtained through hydrothermal synthesis or a hydrolysis reaction. The invention can be carried out in an aqueous solution system and the crystallinity of the product is high. The composite material can be applied to a cathode material of a power ion battery, has a higher charge-discharge capacity, is excellent in high current charge and discharge, stable in circulating performance, has very good photocatalytic performance and can be used to light degradation of organic pollutants and water photolysis for preparing hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

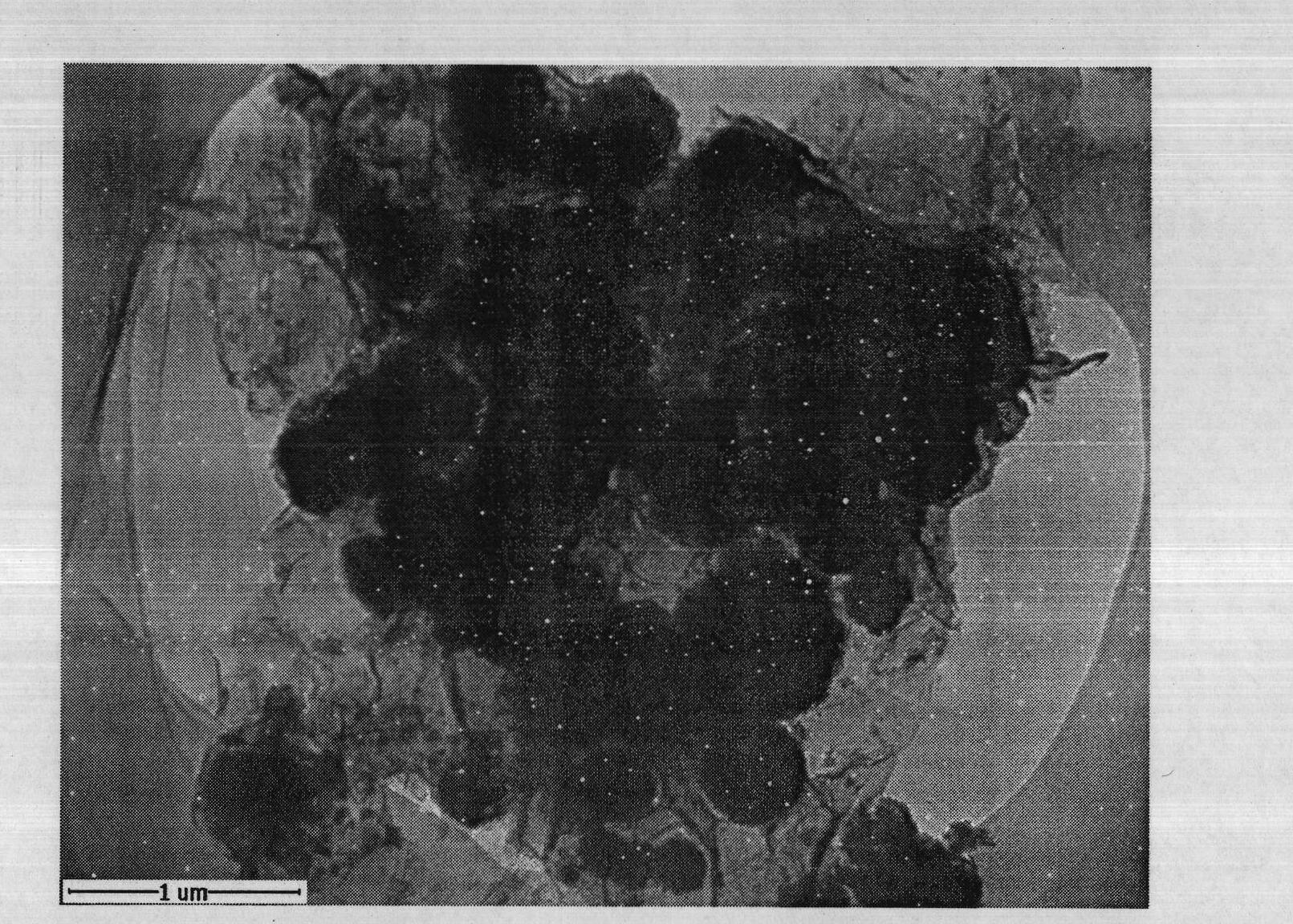

Graphene-coated mesoporous metallic oxide, and preparation method and use thereof

InactiveCN102437320AHigh charge and discharge capacityImprove cycle performanceCell electrodesMesoporous silicaSilicon dioxide

The invention relates to a graphene-coated mesoporous metallic oxide, and a preparation method and use thereof. The preparation method for the graphene-coated mesoporous metallic oxide comprises the following steps of: 1) synthesizing mesoporous metallic oxides with different pore passage structures by taking mesoporous silicon dioxides with the different pore passage structures as templates; 2) preparing a graphene oxide by using an oxidation method; 3) absorbing mesoporous metallic oxide particles on the surface of the graphene oxide by using a heterocoagulation method; 4) reducing the graphene oxide into graphene by adding a reducing agent; and 5) performing centrifugal separation, washing and drying. The graphene-coated mesoporous metallic oxide provided by the invention has high electrochemical properties, and can be used as an electrode material of a lithium battery.

Owner:BEIJING NORMAL UNIVERSITY

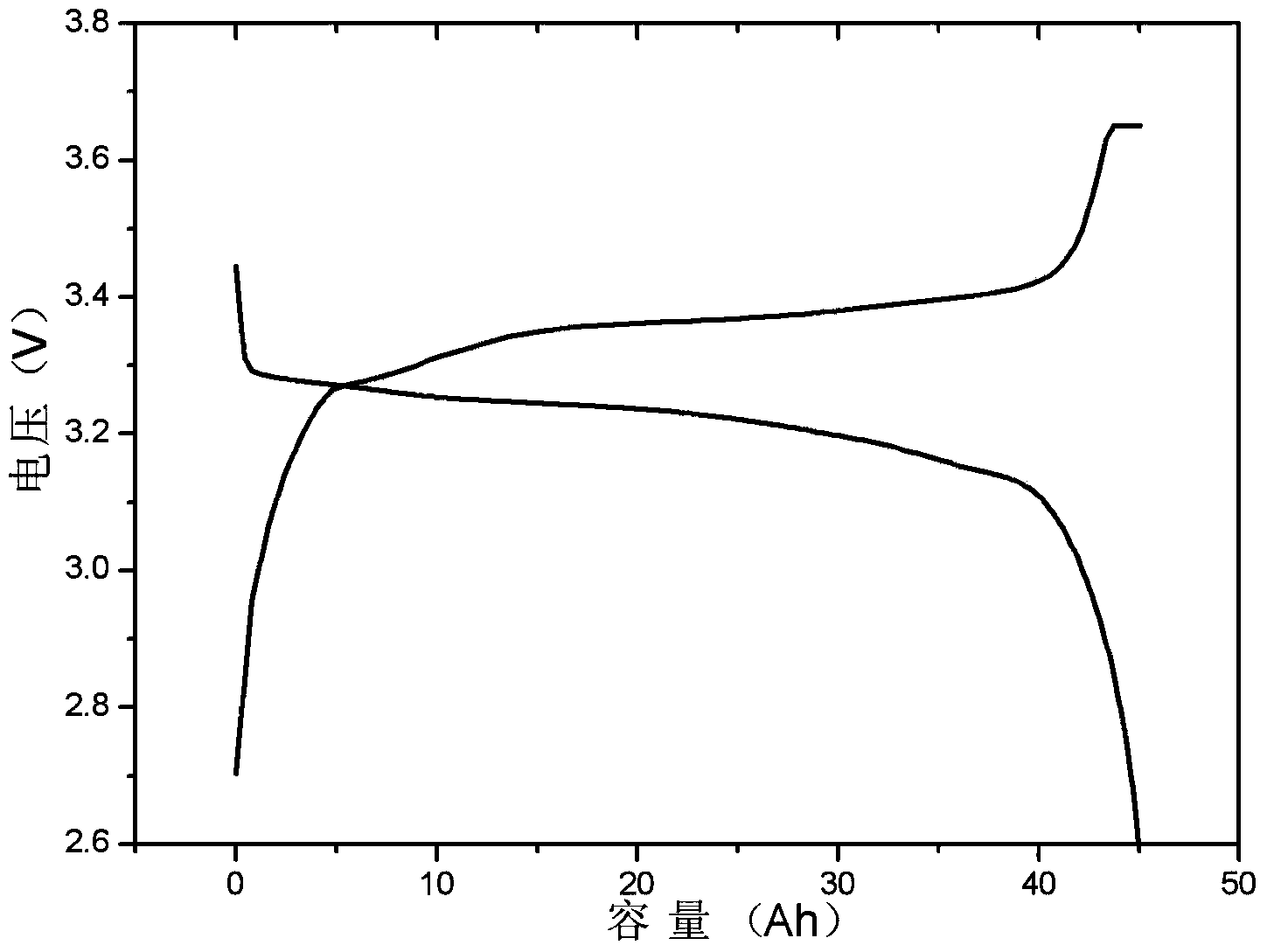

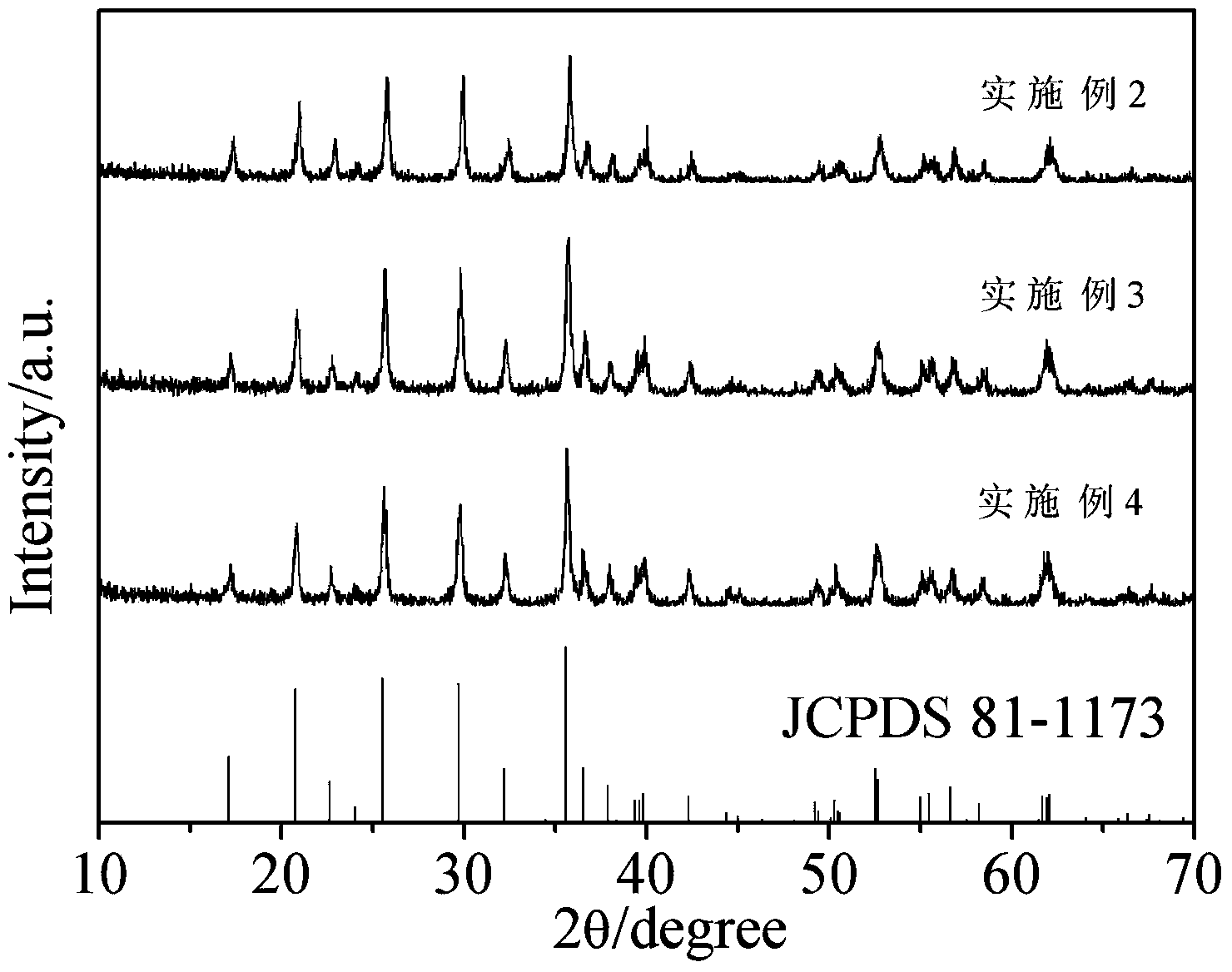

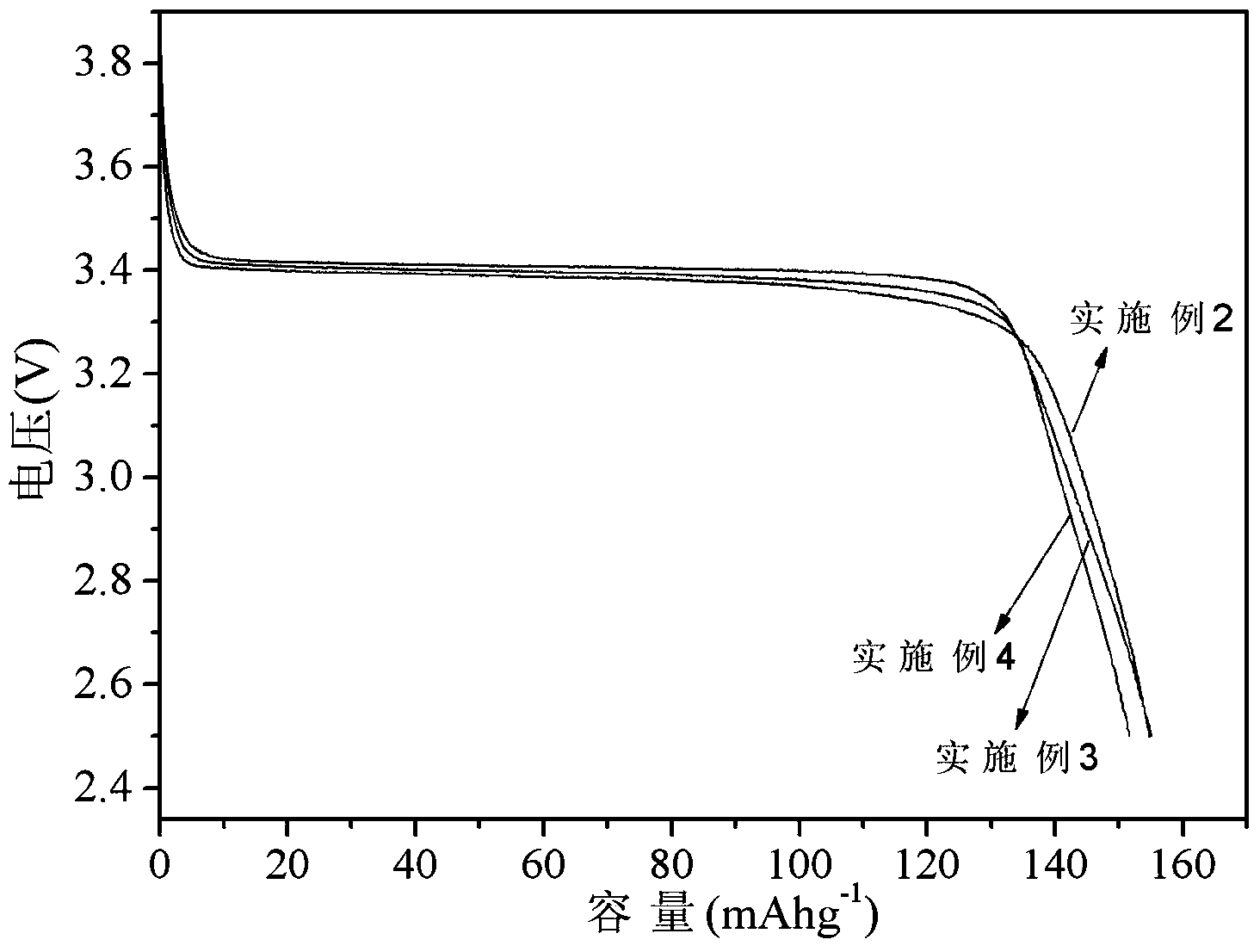

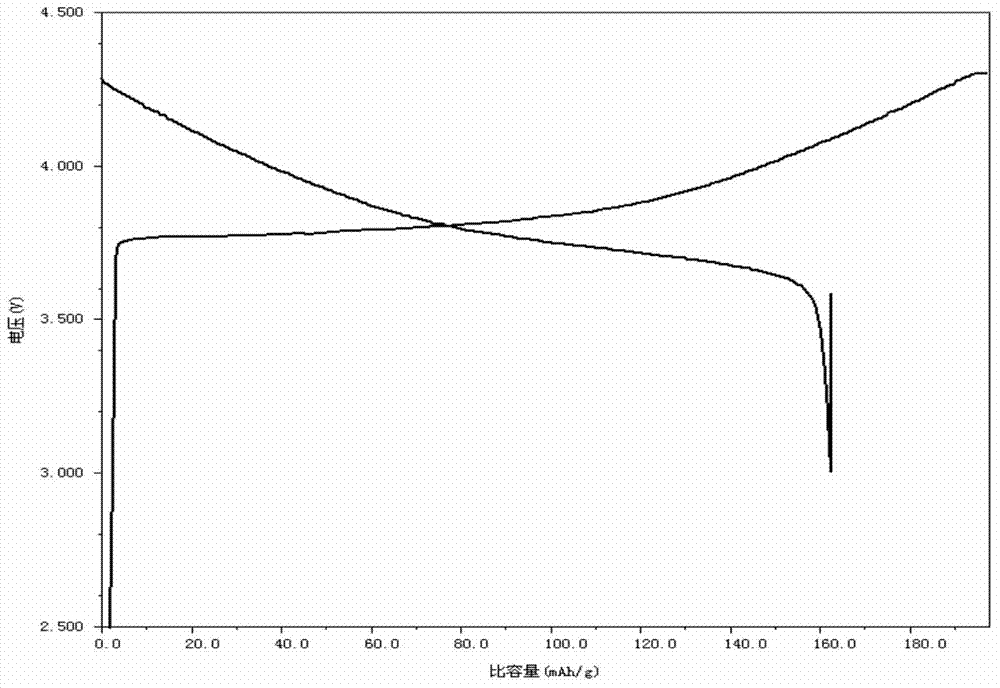

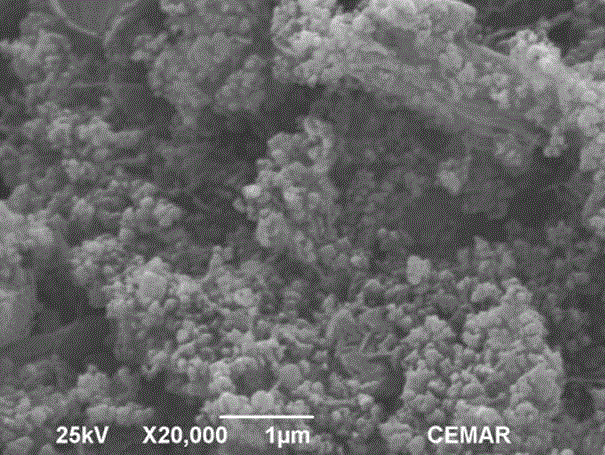

Method for recycling positive material from water-system waste lithium iron phosphate battery

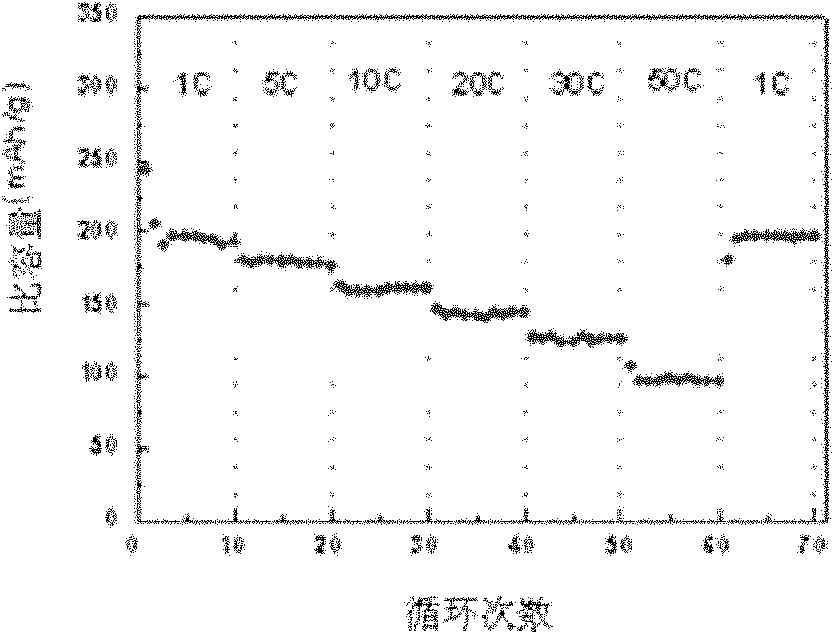

InactiveCN103449395AIncrease gram capacityExcellent rate performanceWaste accumulators reclaimingPhosphorus compoundsChemistryCurrent collector

The invention discloses a method for recycling a positive material from a water-system waste lithium iron phosphate battery. The method comprises the following steps: elaborately disassembling fully-discharged waste lithium iron phosphate battery to obtain an undamaged positive plate, separating a positive active material from a current collector in a way of immersing through deionized water, and drying and ball-milling the active material to obtain a lithium iron phosphate positive material to be recycled; respectively testing carbon content and ratio of Li, Fe and P elements of the lithium iron phosphate positive material to be recycled, adding a lithium source and an iron source, adjusting a mole ratio of Li to Fe to P to be (1.0-1.1):1:1, further adding the lithium source, the ion source and the phosphate source according to a ratio of 1:1:1 and adjusting C content ratio in the material; and performing ball milling, low-temperature pre-sintering and high-temperature sintering on the material of which ratio of the elements is adjusted to obtain the recycled lithium iron phosphate positive material. The recycled material has the advantages that 0.1C discharging capability can reach up to 156mAh / g, 2C discharging capability can reach up to 120mAh / g, the retention ratio of 0.1C discharging capability after 50 times of recycling is greater than 99% and various electrochemical properties are excellent. The method disclosed by the invention is low in cost and simple in process; the secondary pollution is avoided.

Owner:UNIV OF SCI & TECH BEIJING

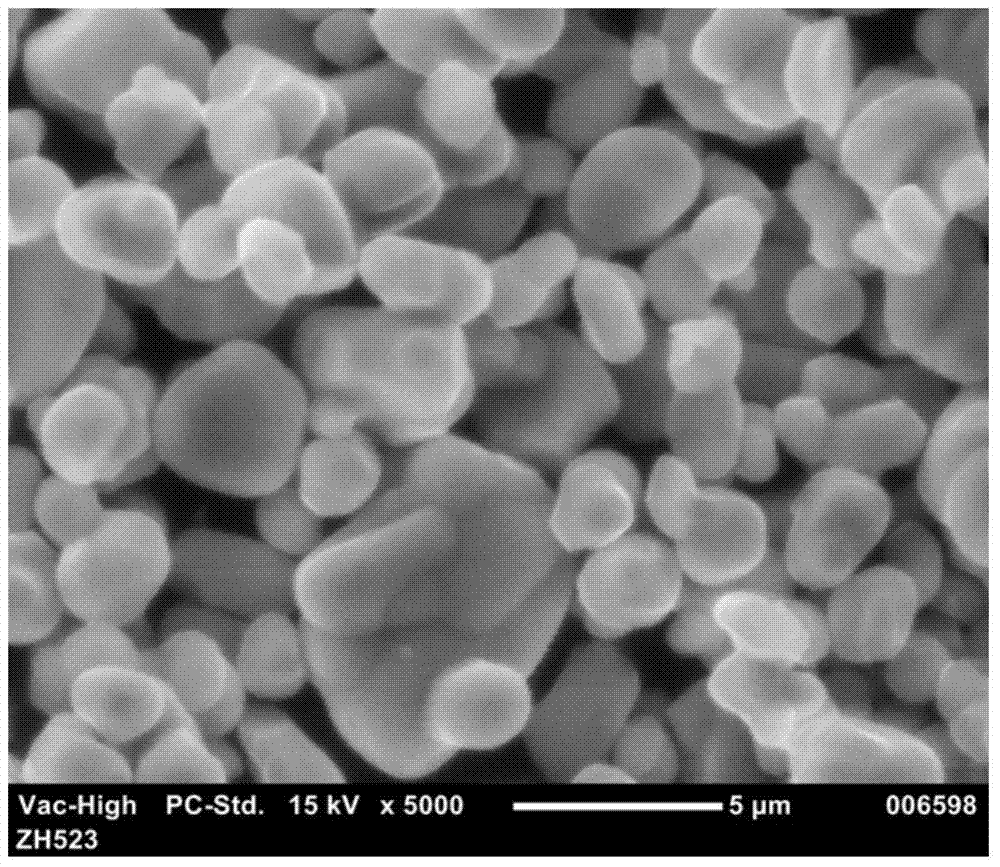

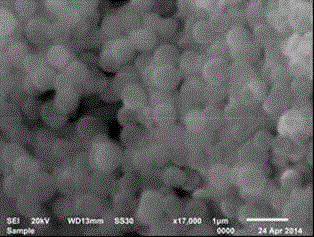

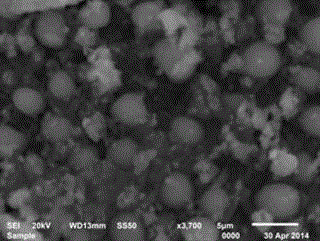

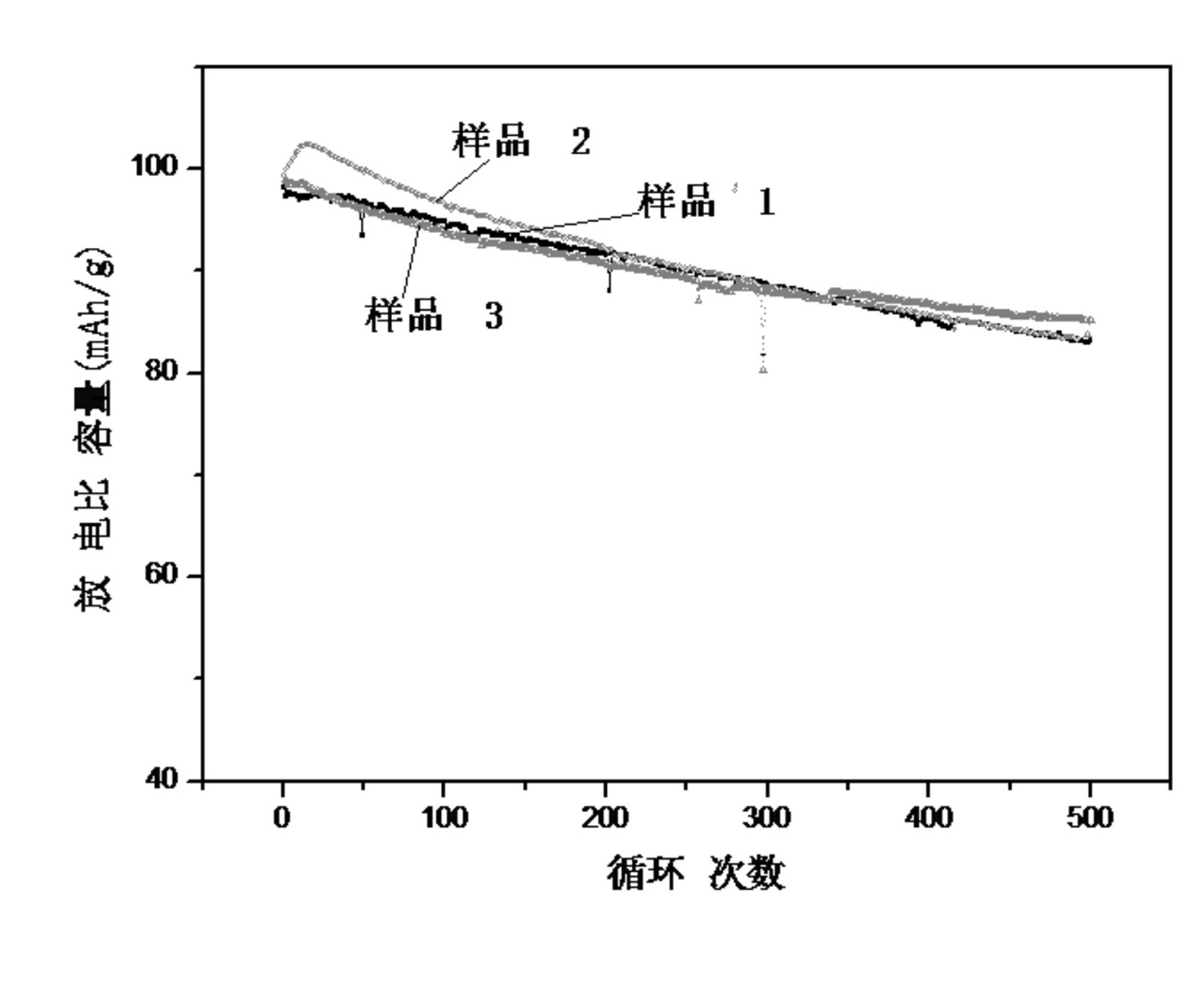

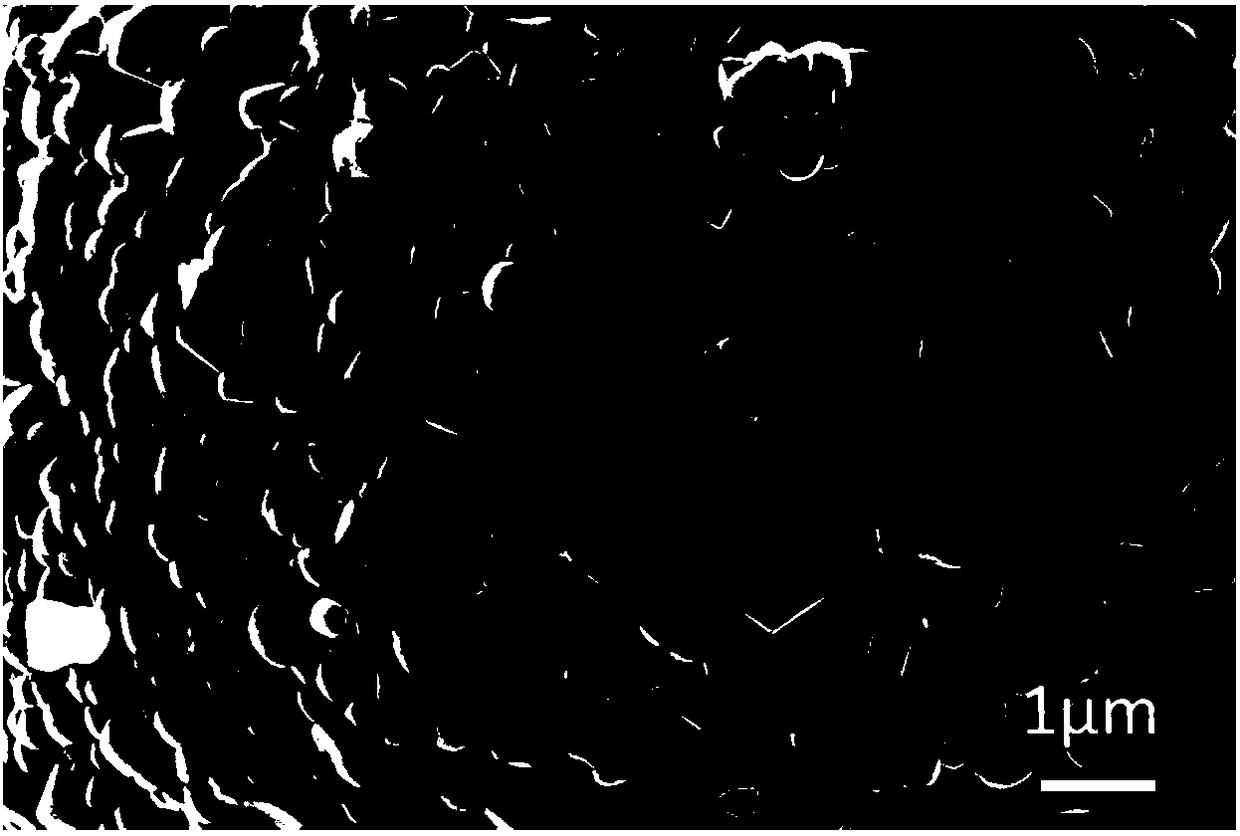

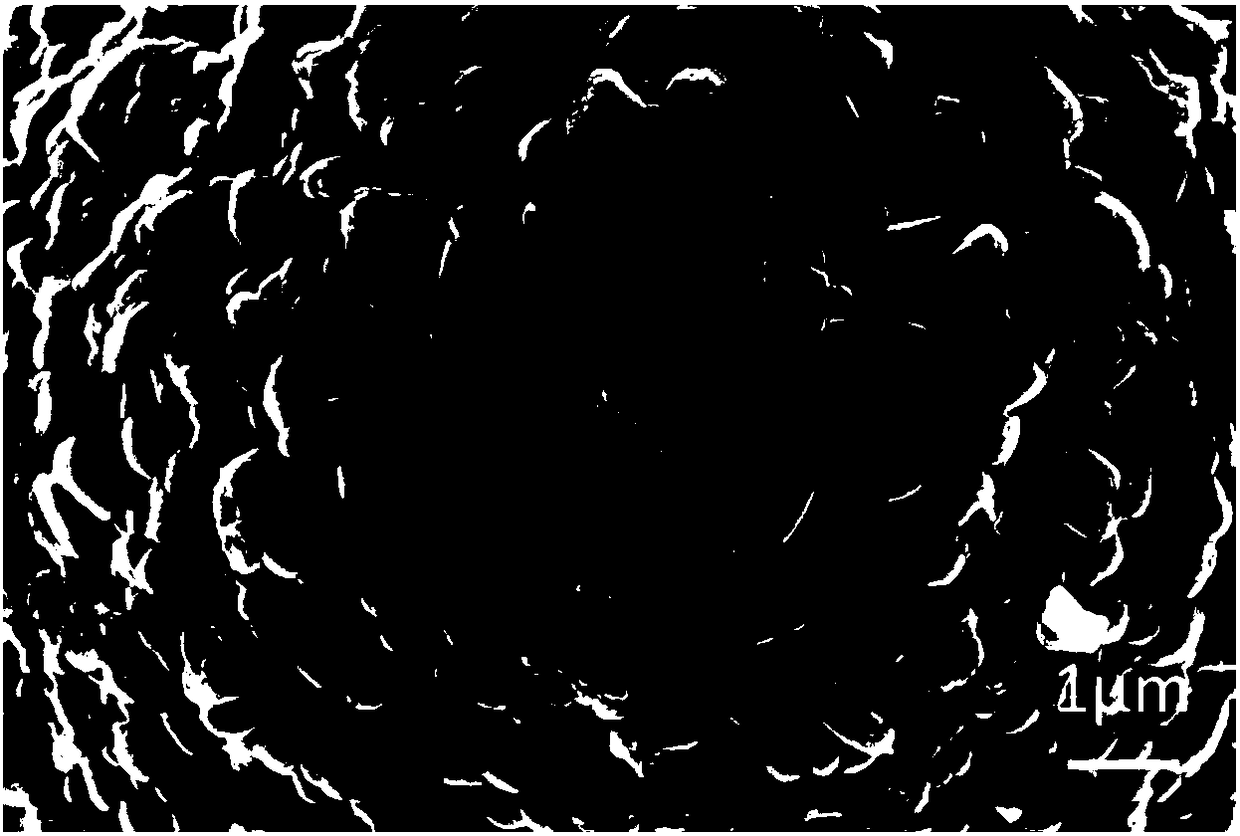

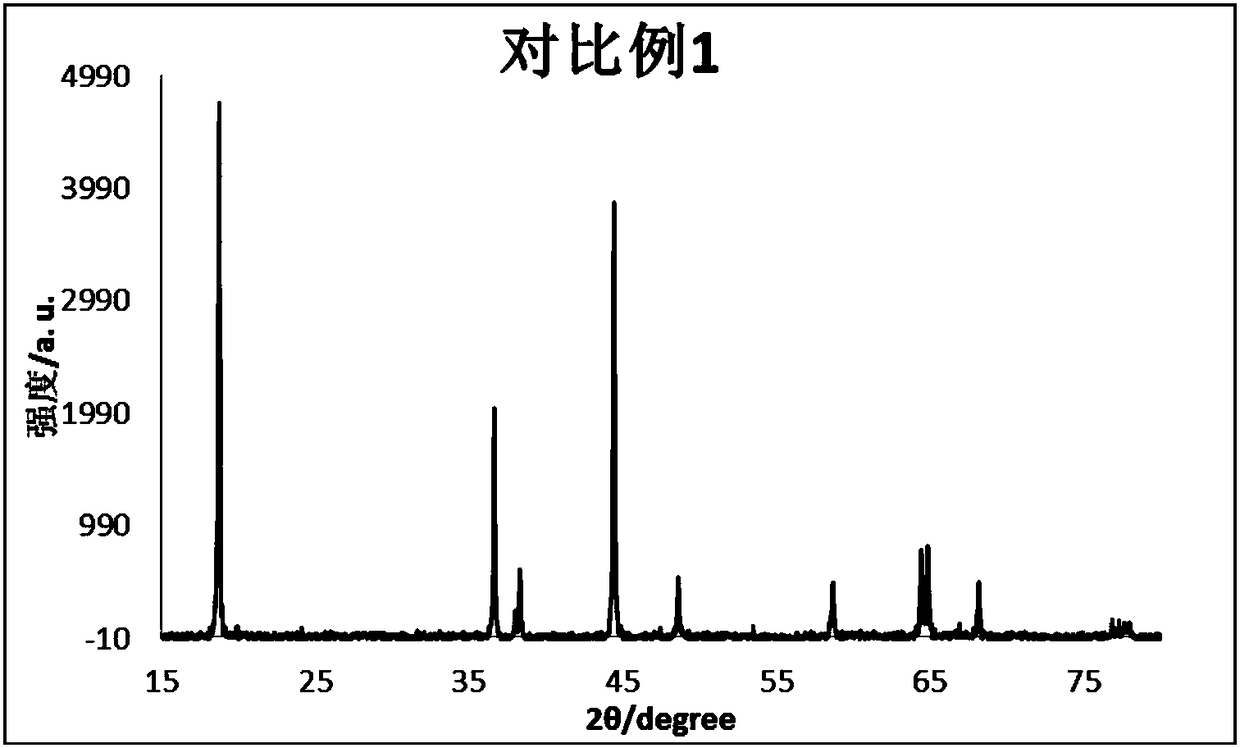

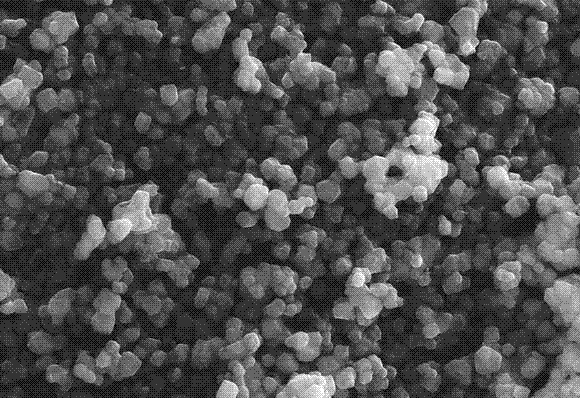

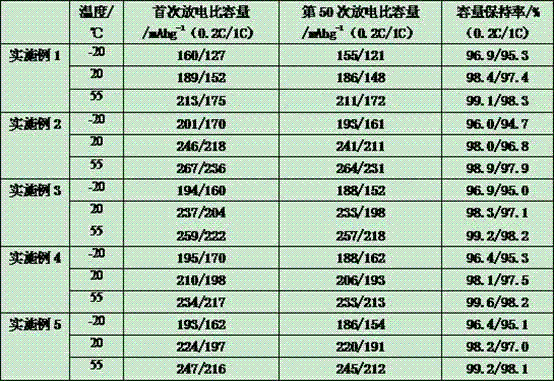

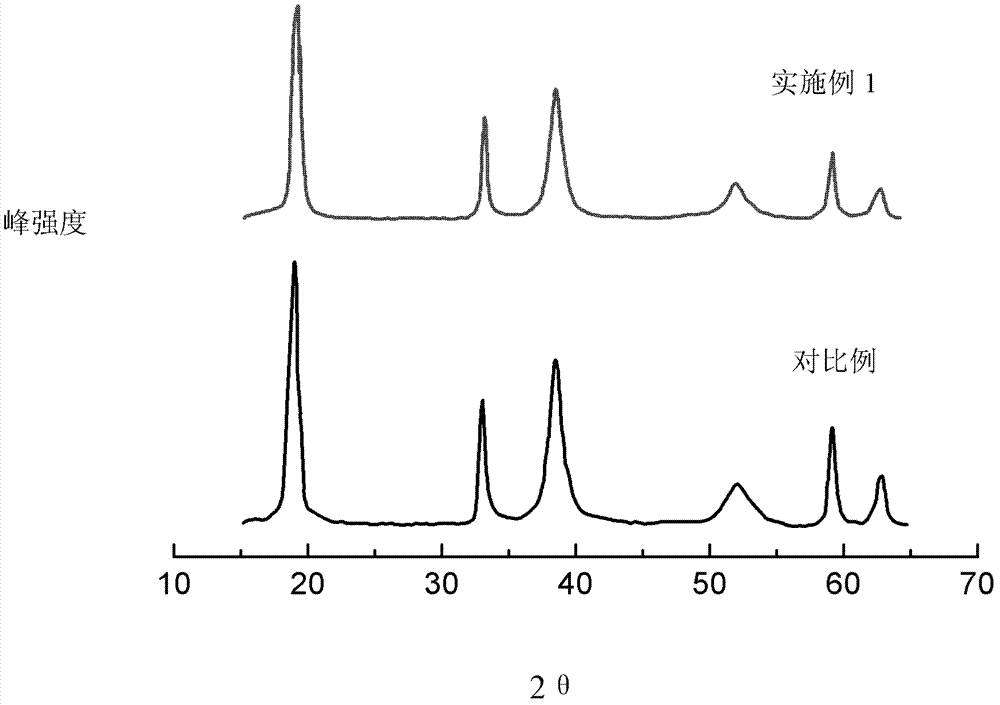

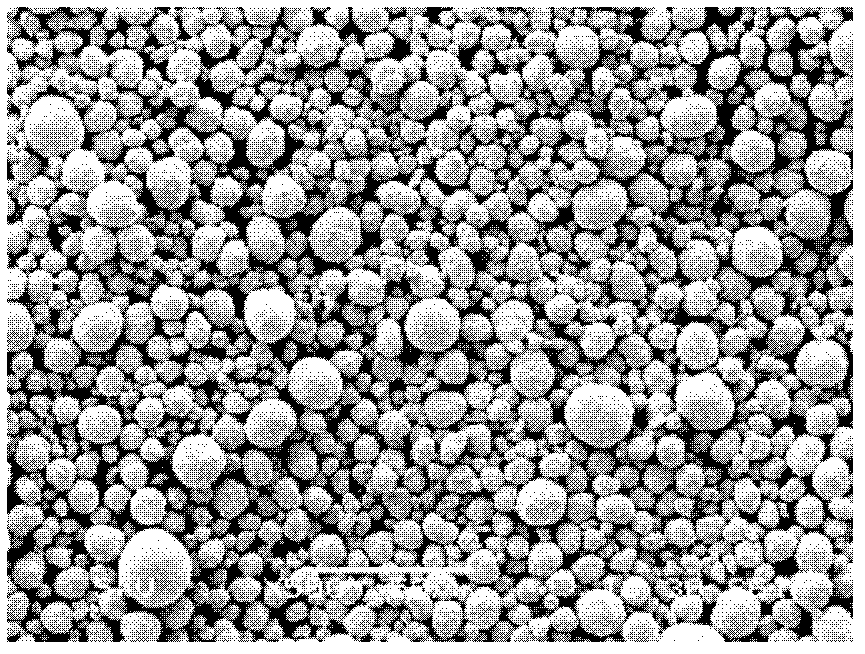

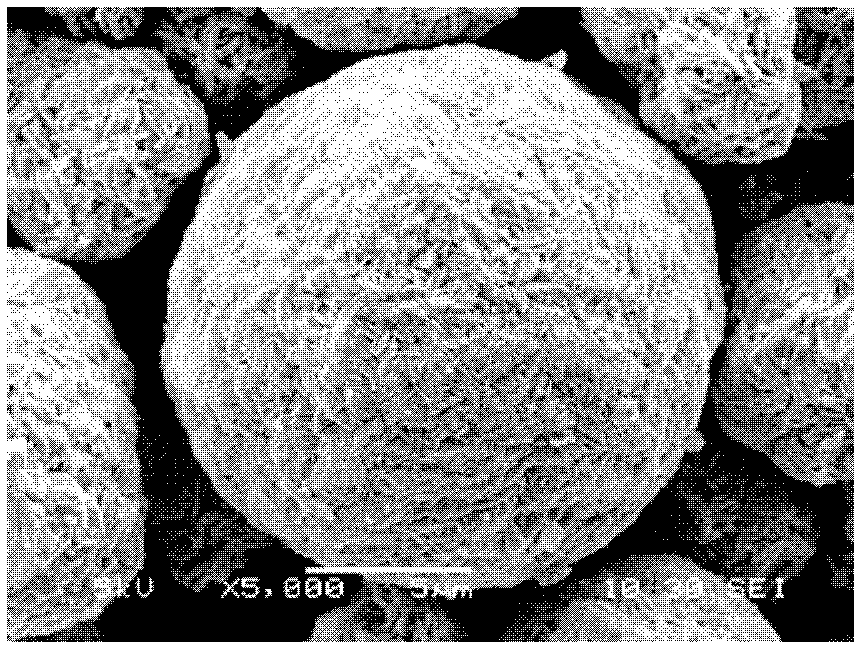

Preparation method of high density nickel cobalt lithium manganate positive electrode material

The invention discloses a preparation method of a high density nickel cobalt lithium manganate positive electrode material, LiNixCoyMnzO2. The preparation method comprises the following steps: firstly, mixing a nickel salt solution, a cobalt salt solution and a manganese salt solution according to a certain mol ratio, adding the mixed solution, a complexing agent solution and a precipitant solution together to a stirring reaction kettle with a base solution, fully reacting, carrying out solid-liquid separation, and washing and drying to obtain a globular nickel cobalt manganese oxyhydroxide precursor; calcining the precursor at the temperature of 350-900 DEG C for 2-20 hours to obtain a globular nickel cobalt manganese oxide precursor, and smashing the globular nickel cobalt manganese oxide precursor at high speed to obtain a mono-crystalline nickel cobalt manganese oxide precursor; mixing a lithium source and the mono-crystalline precursor according to a certain mol ratio, calcining at the temperature of 700-980 DEG C for 2-20 hours, and smashing and classing to obtain the mono-crystalline nickel cobalt lithium manganate positive electrode material. The preparation method provided by the invention has the advantages that the compacted density of the prepared nickel cobalt lithium manganate material is large, the specific capacity is high, the rate property and consistency are good, the preparation method is simple, and the preparation process is easy to control and operate.

Owner:HUNAN SOUNDDON NEW ENERGY

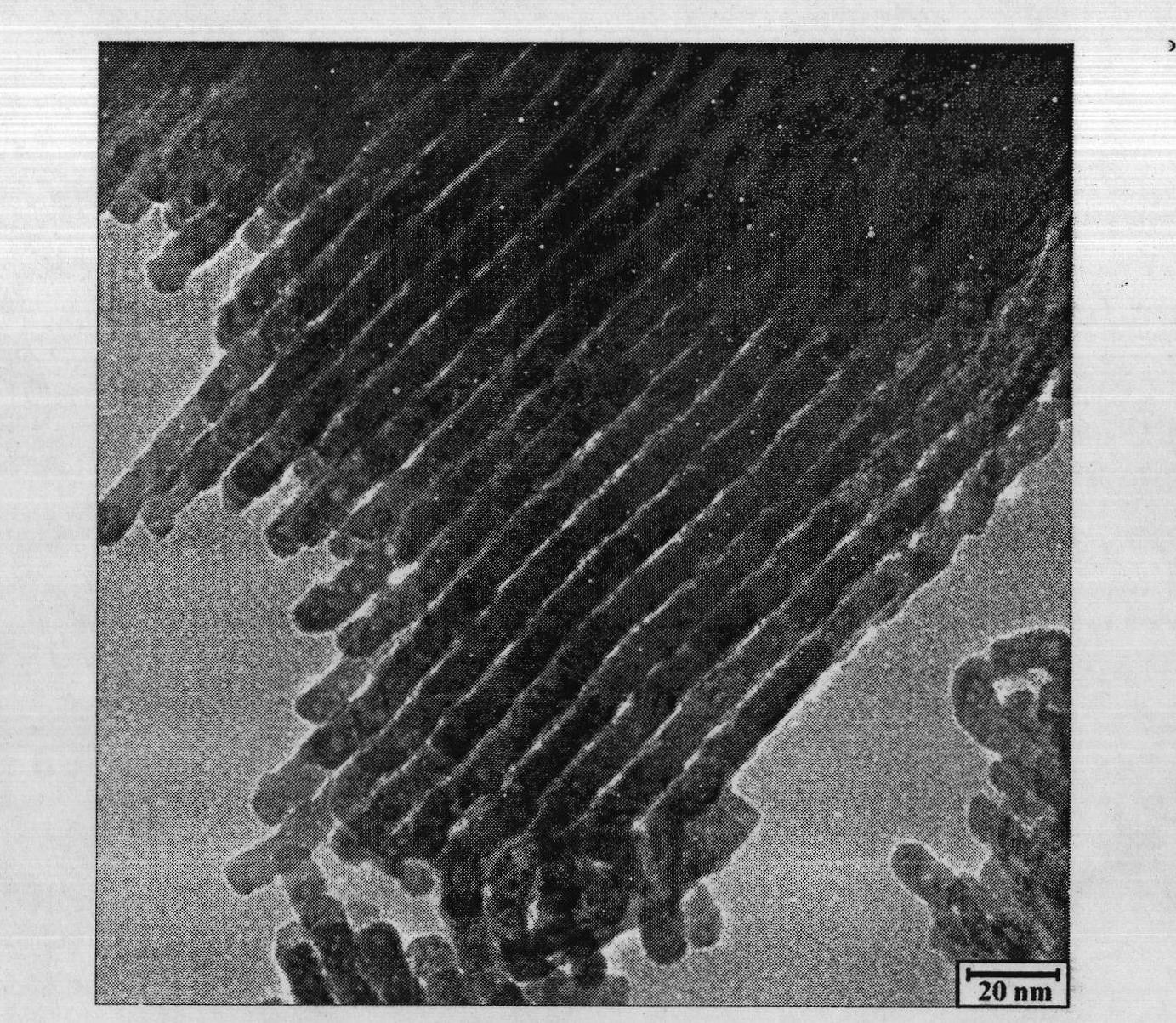

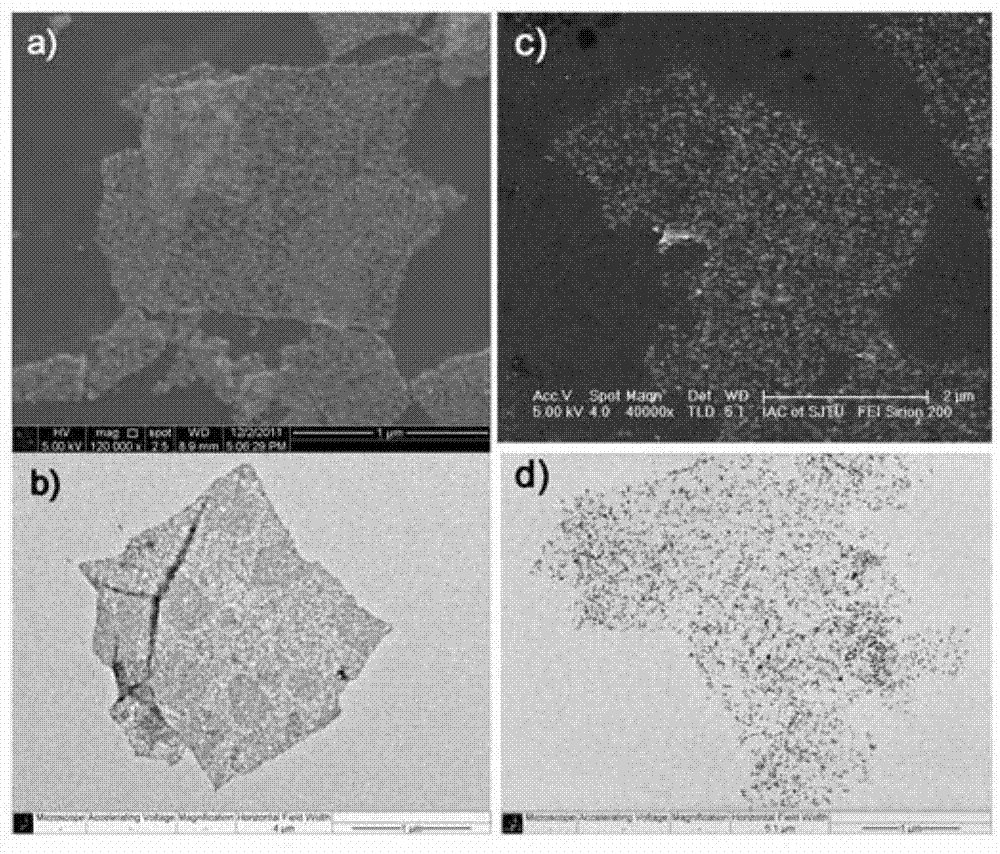

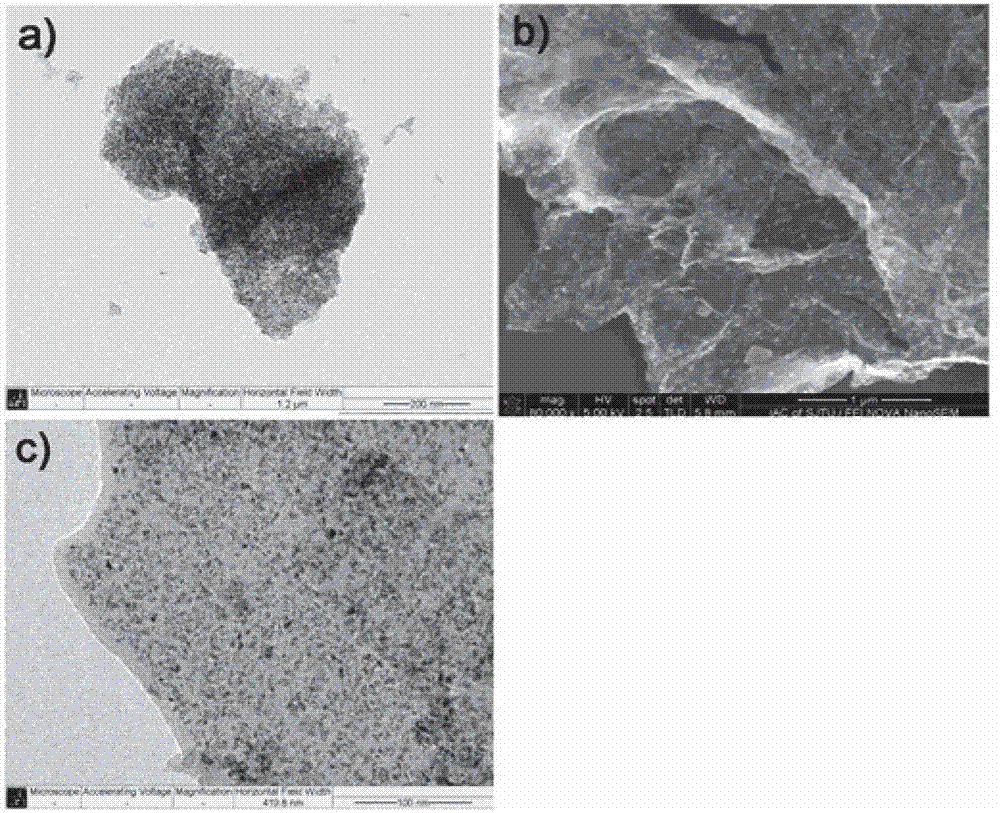

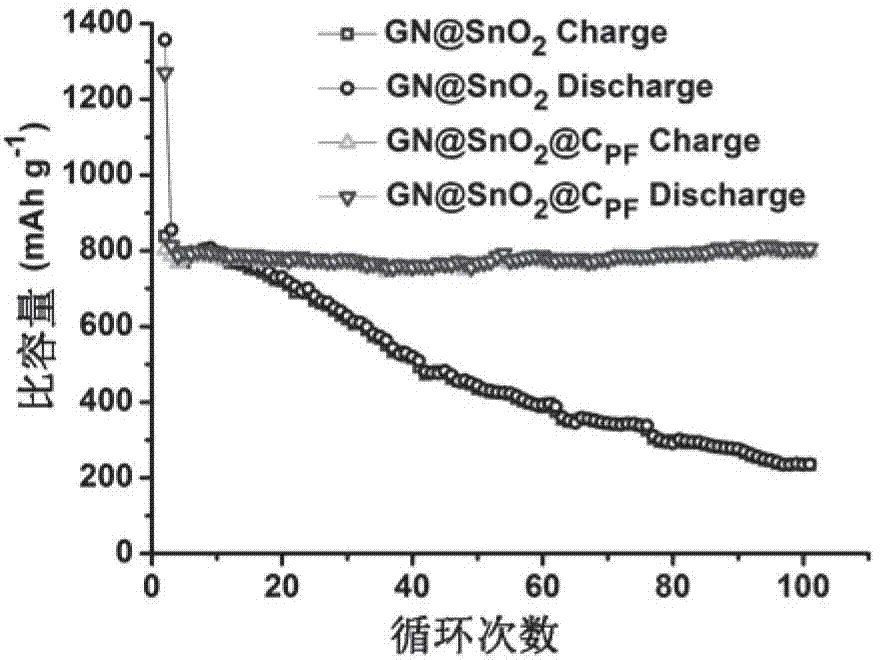

Preparation method and application of carbon-coated grapheme-based metal oxide composite

InactiveCN102881898AImprove cycle stabilityExcellent rate performanceCell electrodesTin dioxideMetal oxide nanoparticles

The invention discloses a preparation method and application of a carbon-coated grapheme-based metal oxide composite in a two-dimensional core-shell structure. The carbon-coated grapheme-based metal oxide composite in the two-dimensional core-shell structure is prepared by taking the two-dimensional grapheme in a single-layer carbon atom structure as a carrier and the phenolic resin or polysaccharide as the carbon source precursor. The metal oxide nanoparticles obtained by the method are uniformly loaded on a graphene sheet and well coated in the carbon-coated layer. The preparation method has the advantages of simple process, mild condition and low cost. The Electrochemical tests prove that the carbon-coated grapheme-based metal oxide composite in the two-dimensional core-shell structure has excellent cycle stability and rate properties. The experiments prove that: under the charge and discharge current of 200mAhg<-1>, the tin dioxide material has the discharge capacity of 200mAhg<-1>, and the ferroferric oxide material has the discharge capacity of 930mAhg<-1>. Therefore, better experimental data and theoretical support are provided for the research and the application of the metal oxide in the field of electrochemistry.

Owner:SHANGHAI JIAO TONG UNIV

Aqueous electrolyte lithium sulfur batteries

InactiveUS20130141050A1Maintain cell integrityMaintain securityBatteries circuit arrangementsFuel and secondary cellsLithium sulfurAqueous electrolyte

Provided are lithium sulfur battery cells that use water as an electrolyte solvent. In various embodiments the water solvent enhances one or more of the following cell attributes: energy density, power density and cycle life. Significant cost reduction can also be realized by using an aqueous electrolyte in combination with a sulfur cathode. For instance, in applications where cost per Watt-Hour (Wh) is paramount, such as grid storage and traction applications, the use of an aqueous electrolyte in combination with inexpensive sulfur as the cathode active material can be a key enabler for the utility and automotive industries, providing a cost effective and compact solution for load leveling, electric vehicles and renewable energy storage.

Owner:POLYPLUS BATTERY CO INC

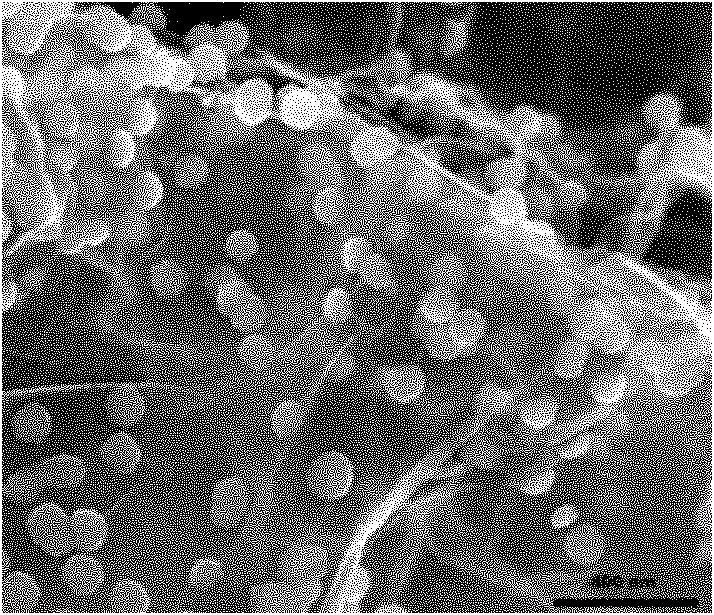

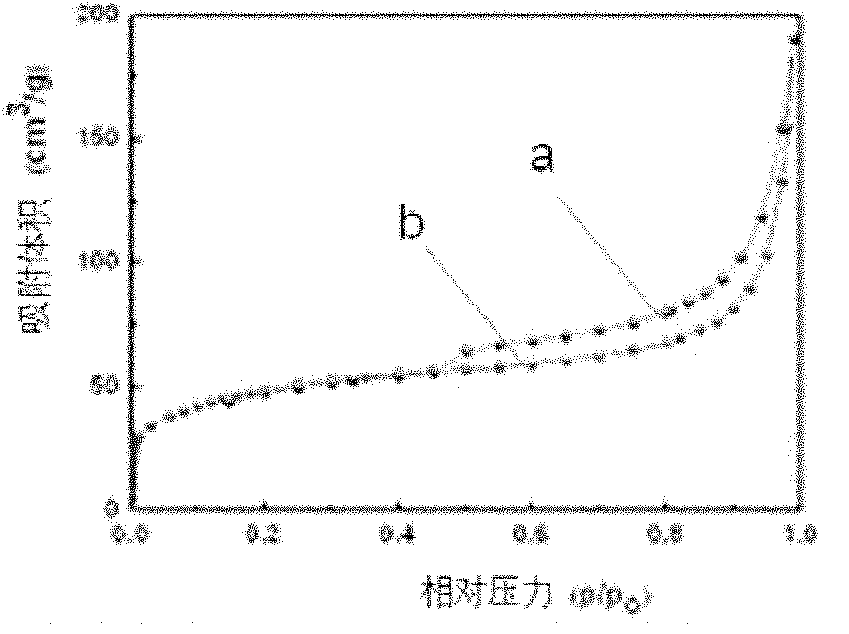

Porous carbon electrode material based on chitosan and derivative of chitosan thereof as well as preparation method and application of porous carbon electrode material

ActiveCN104085877AAbundant resourcesLow costHybrid capacitor electrodesCell electrodesPorous carbonCarbonization

The invention discloses a porous carbon electrode material based on chitosan and a derivative of chitosan as well as a preparation method and application of the porous carbon electrode material. According to a hard template carbonization method, by taking a hollow silicon oxide ball as a template and taking chitosan and a derivative of chitosan as carbon source precursors, liquid-phase impregnation, high-temperature carbonization, template removing and the like are carried out so as to obtain the porous carbon electrode material suitable for a lithium ion battery and a supercapacitor. The prepared porous carbon electrode material simultaneously has the characteristics of a nitrogen-doped structure and a macroporous-mesoporous-microporous graded pore structure, wherein the nitrogen-doped content can be controlled by using different types of chitosans; the graded pore structure can be controlled by changing the size of the particle diameter and the wall thickness of each silicon oxide ball and regulating the mass of the chitosan solution. Compared with the commercialized graphite, the porous carbon electrode material prepared according to the method disclosed by the invention has the advantages that the specific capacity is obviously increased and the rate performance of the obtained porous carbon electrode material is maintained well. The porous carbon electrode material is simple in preparation process, has no strict requirement to equipment and is suitable for industrial production.

Owner:HUBEI ENG UNIV

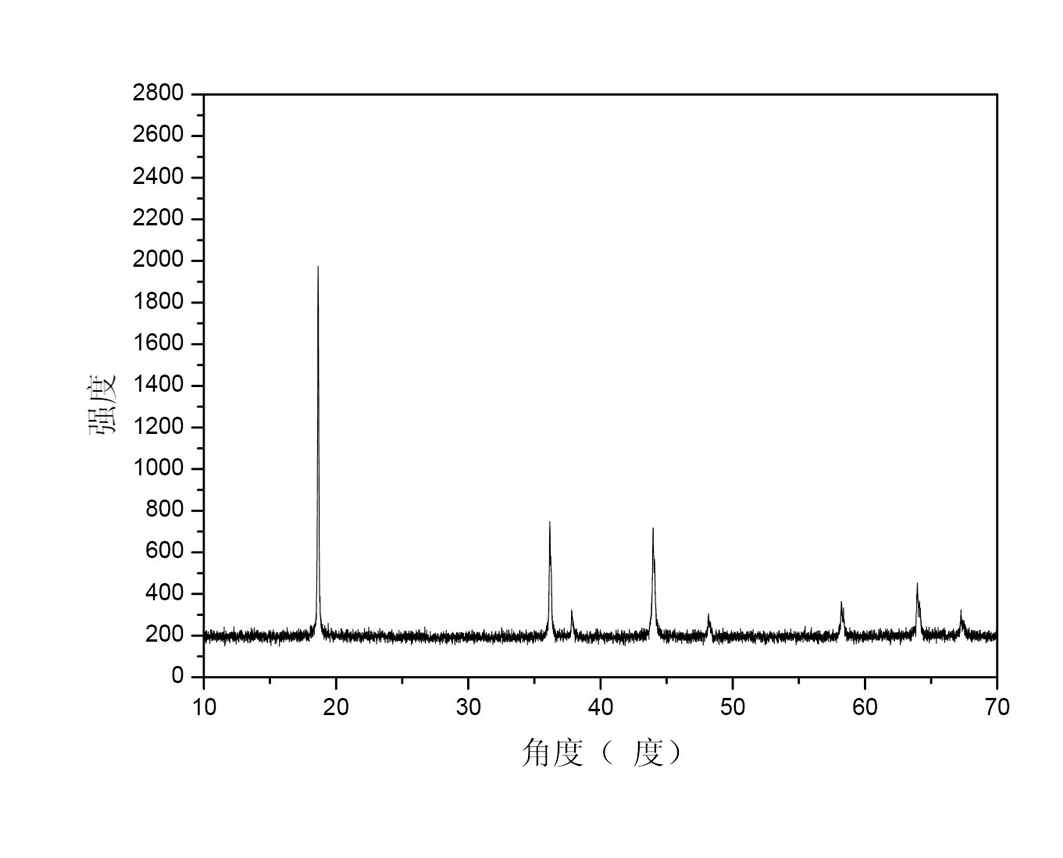

Preparation method of lithium ion battery anode material lithium manganate and automobile lithium ion battery

InactiveCN101964416AUniform bulkGood crystallizationCell electrodesSecondary cellsElectrical batteryManganate

The invention relates to a preparation technology of a battery anode material and a related automobile battery and particularly discloses a preparation method of lithium ion battery anode material lithium manganate. The method comprises the following steps: using lithium source, Mn3O4 and nanoscale doping metal additive as raw materials for proportioning, then presintering Mn3O4 or the Mn3O4 processed by ball milling, mixing the presintered Mn3O4 with the mixture of lithium source and metal additive; performing the first sintering and second sintering to the mixed raw material; and finally classifying and screening the sintering product to obtain the spinel lithium manganate product with the required grain size. The invention also discloses an automobile lithium ion battery which is assembled by using the spinel lithium manganate prepared by the method of the invention as anode and using graphite as cathode. The preparation method of the invention has simple operation and environmental friend; and the prepared lithium manganate product has excellent product performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

Cathode material for fast lithium ion conductor phase-modified lithium ion battery and preparation method thereof

InactiveCN102760884AImprove transmission characteristicsImprove surface propertiesCell electrodesRare-earth elementElectrical conductor

The invention discloses a cathode material for a fast lithium ion conductor phase-modified lithium ion battery and a preparation method thereof. The key points of the technical scheme are as follows: the cathode material for the fast lithium ion conductor phase-modified lithium ion battery is a composite material consisting of a rare-earth element doped composite layered lithium ion battery cathode material xLi2MO3 (1-x) LiN(1-y)RyO2 (M is Mn, Ti or Sn, N is Mn, Ni, Co, Fe, Cr, V or Mo, R is one or more than one of Sc, Y, Pr, Nd, La, Ce, Sm, Yb, Eu and Gd, x is larger than 0 and smaller than 1, and y is larger than 0 and smaller than 0.2) and a fast lithium ion conductor, wherein the molar ratio of the fast lithium ion conductor to the rare-earth element doped composite layered lithium ion battery cathode material is n:1, and n is larger than 0 and smaller than or equal to 0.15. The invention also discloses a preparation method of the cathode material for the fast lithium ion conductor phase-modified lithium ion battery. The cathode material for a fast lithium ion conductor phase-modified lithium ion battery has the advantages of high specific capacity, good rate capacity, stability in recycling and strong temperature adaptation.

Owner:HENAN NORMAL UNIV

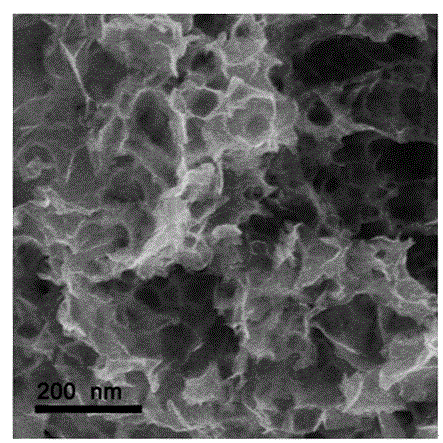

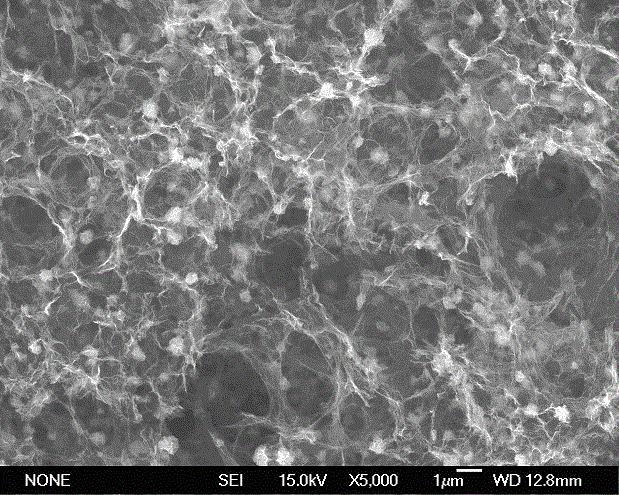

Three-dimensional porous quasi-graphene loaded molybdenum disulfide composite and preparation method thereof

The invention discloses a three-dimensional porous quasi-graphene loaded molybdenum disulfide composite and a preparation method thereof. The composite is prepared by uniformly loading large-area ultrathin molybdenum disulfide nanosheets onto the surface of three-dimensional porous quasi-graphene network. The preparation method comprises the following steps: with NaCl as a dispersant and template, fully dissolving and mixing NaCl, a molybdenum source and a sulfur source and carrying out freeze drying and porphyrization so as to obtain a mixture; putting the mixture in a tubular furnace and carrying out calcining under the protection of argon so as to obtain a calcined product A; and washing the calcined product A and drying the washed calcined product A so as to obtain the three-dimensional porous quasi-graphene loaded molybdenum disulfide composite. The invention has the following advantages: preparation process is safe and harmless, operation is simple, and yield is high; and the prepared three-dimensional porous quasi-graphene loaded molybdenum disulfide composite has good reversible capacity, cycle stability and rate capability as a cathode material of a lithium ion battery.

Owner:TIANJIN UNIV

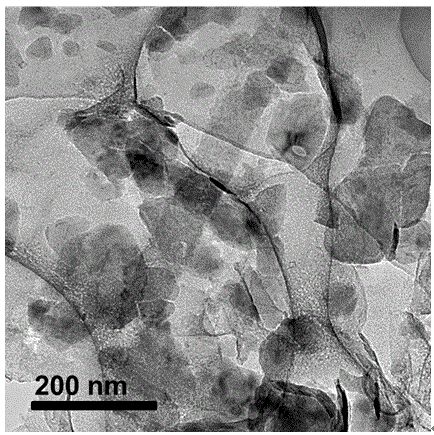

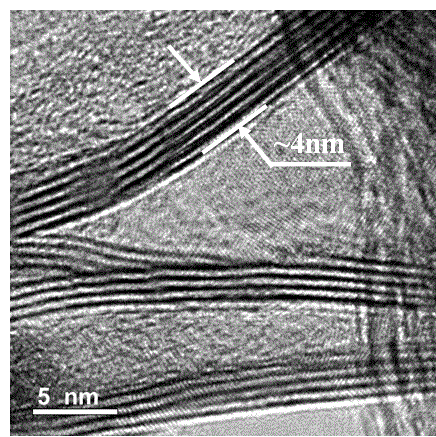

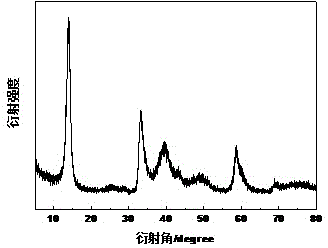

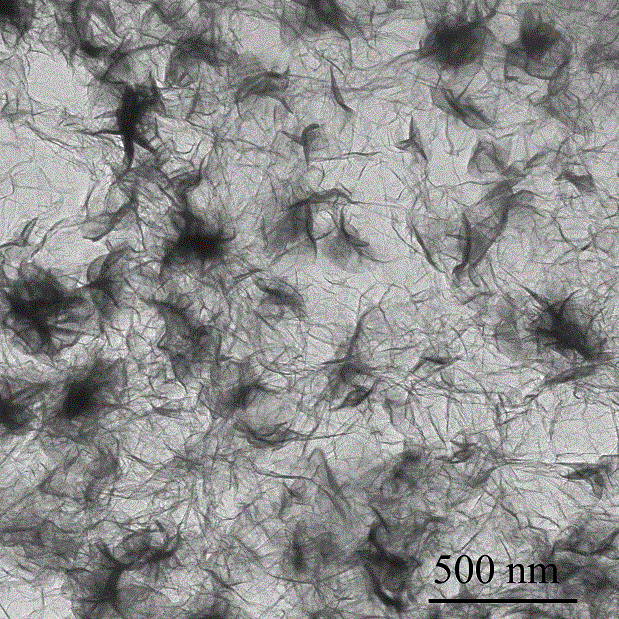

Flake MoS2/graphene composite aerogel and preparation method thereof

InactiveCN104600315AHigh electrical conductivityDeformation stableCell electrodesThioureaFreeze-drying

The invention relates to a flake MoS2 / graphene composite aerogel and a preparation method thereof and belongs to the technical field of anode materials of lithium ion batteries. The preparation method comprises the following steps: ultrasonically dispersing a certain quantity of graphene oxide solution into deionized water, adding a certain quantity of water-soluble molybdate and thiourea, then adding 0.1-3mL organic amine solution, taking out a cylindrical product after hydrothermal reaction at the temperature of 160-240 DEG C, freeze-drying, and then carrying out thermal treatment for 2h in the mixed atmosphere of argon and hydrogen at the temperature of 800 DEG C to obtain the flake MoS2 / graphene composite aerogel. According to the flake MoS2 / graphene composite aerogel and the preparation method thereof disclosed by the invention, thin layers of graphene are connected with one another in a staggering mode to form a three-dimensional ordered conductive network and form micron pore canals, MoS2 is uniformly dispersed on the ultra-large superficial area, and thus, the problems of volume expansion and crushing materials are effectively solved; meanwhile, the structure stability and the cycle performance of the flake MoS2 / graphene composite aerogel, serving as the anode material, are improved.

Owner:SHANGHAI UNIV

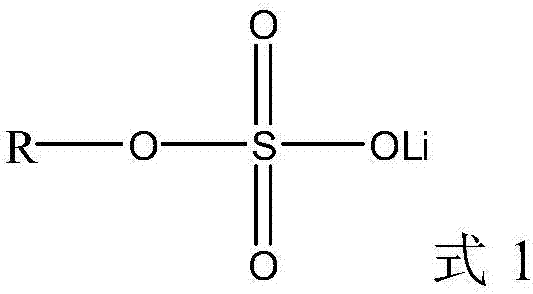

Electrolyte and lithium ion battery

ActiveCN107394269AEasy to storeImprove cycle performanceSecondary cellsLithium sulphateOrganic solvent

The invention provides an electrolyte and a lithium ion battery. The electrolyte comprises a lithium salt, an organic solvent and an additive, wherein the additive comprises a first additive, and the first additive comprises alkyl lithium sulfate and fluoro-ether. By the electrolyte, the storage performance, the cycle property, the rate performance and the low-temperature discharge performance of the lithium ion battery under high temperature and high voltage can be improved, meanwhile, the safety performance of the lithium ion battery is improved, and the service lifetime of the lithium ion battery is prolonged.

Owner:NINGDE AMPEREX TECH

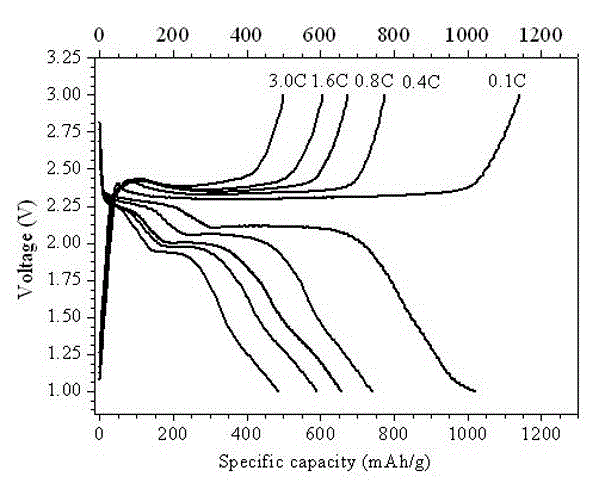

Preparation method of novel porous skeleton MIL-101(Cr)@S/graphene composite material for cathode of lithium sulfur battery

InactiveCN102751494AImprove adhesionImprove cycle performanceCell electrodesElectrical batteryLithium–sulfur battery

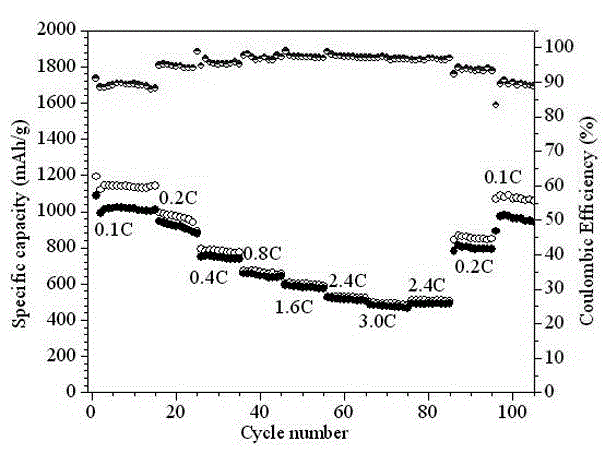

The invention discloses a preparation method of a metal organic skeleton MIL-101(Cr)@S / graphene composite material as the cathode material of a lithium sulfur battery. The preparation method comprises the following steps of: evenly loading sulfur into a three-dimensional pore channel of MIL-101(Cr) by a melting diffusing method, and mixing with graphene, so that the MIL-101(Cr)@S / graphene composite material can be prepared. The metal organic skeleton crystal material in the composite material is has superhigh specific surface area and pore volume and has a skeleton structure which has medium-mirco double pores, so that the dual effects of dispersing and fixing the sulfur grains can be played, and the whole electrical conductivity of the composite material can be improved due to graphene, so that the polarization of the material can be weakened, the discharge multiplying power performance can be improved, the coulomb efficiency can be improved and the like. The electrochemical performance test shows that the discharge specific capacity of the MIL-101(Cr)@S / graphene composite material prepared by the method can reach 1087mAh / g under the condition that the multiplying power is less than 0.1C, and the discharge specific capacity of the MIL-101(Cr)@S / graphene composite material prepared by the method is respectively kept at 807 and 387mAh / g under the condition that the multiplying power is 0.8C and 2.4C when the circulation times is 116 and 150. The preparation method has the advantages that the preparation method has the characteristics of being simple in process, convenient to operate, good in material performance and the like, and is suitable for large-scale industrial production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

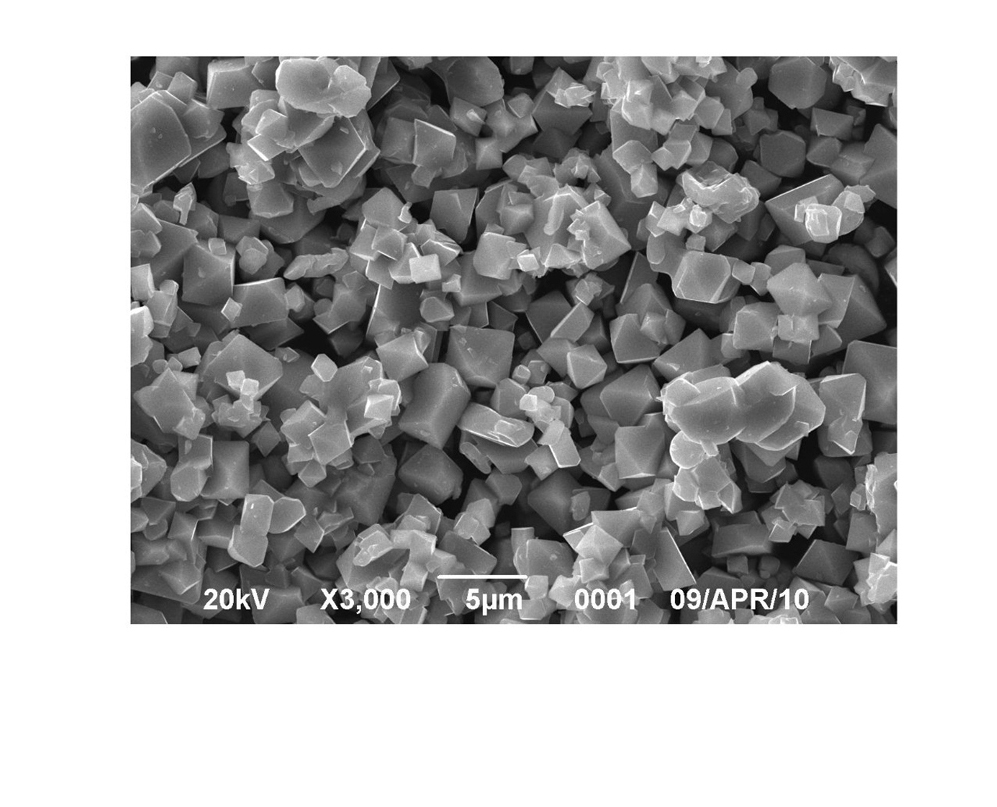

Preparation method of positive pole material (spinel type lithium nickel manganese oxide) of high-voltage lithium ion battery

ActiveCN103227323AAccurately control the ratioReduce concentrationCell electrodesElectrical batteryNickel compounds

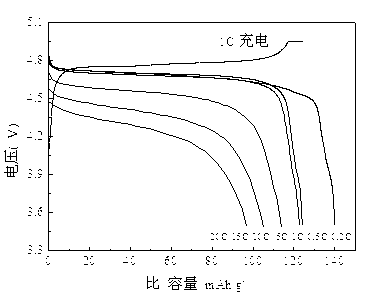

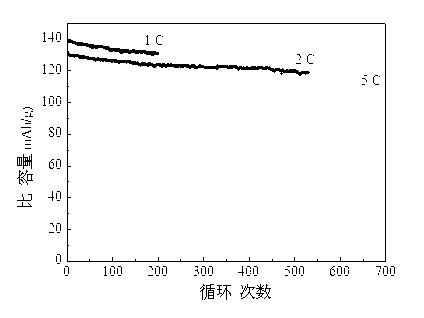

The invention relates to a preparation method of a positive pole material (spinel type lithium nickel manganese oxide) of a high-voltage lithium ion battery, which comprises the following steps: simultaneously dissolving a lithium-containing compound, a manganese-containing compound and a nickel-containing compound instead of adding a lithium source afterwards, and ensuring that the lithium compound, the nickel compound and the manganese compound are evenly mixed; and adding precipitant to generate manganese-containing precipitate, wherein the generated manganese-containing precipitate provides crystal nuclei for further precipitation in the hydrothermal process, particles having different sizes can be obtained by controlling hydrothermal conditions, the particle sizes of the products can be increased by decreasing the concentrations of the metal salts, increasing the hydrothermal temperature and prolonging the hydrothermal time, and materials having different shapes can be obtained or porous materials can be prepared by adding different additives. The method omits the steps of filtration and water washing; and the synthesis process is economic and environment-friendly. The lithium nickel manganese oxide material prepared by the invention is in a spinel structure, and is high in crystallinity and excellent in electrochemical performance; and the specific capacity can be up to 130-142mAh / g, 120-135mAh / g and 105-120mAh / g in case of 1C, 2C and 5C rate discharge.

Owner:南京时拓能源科技有限公司

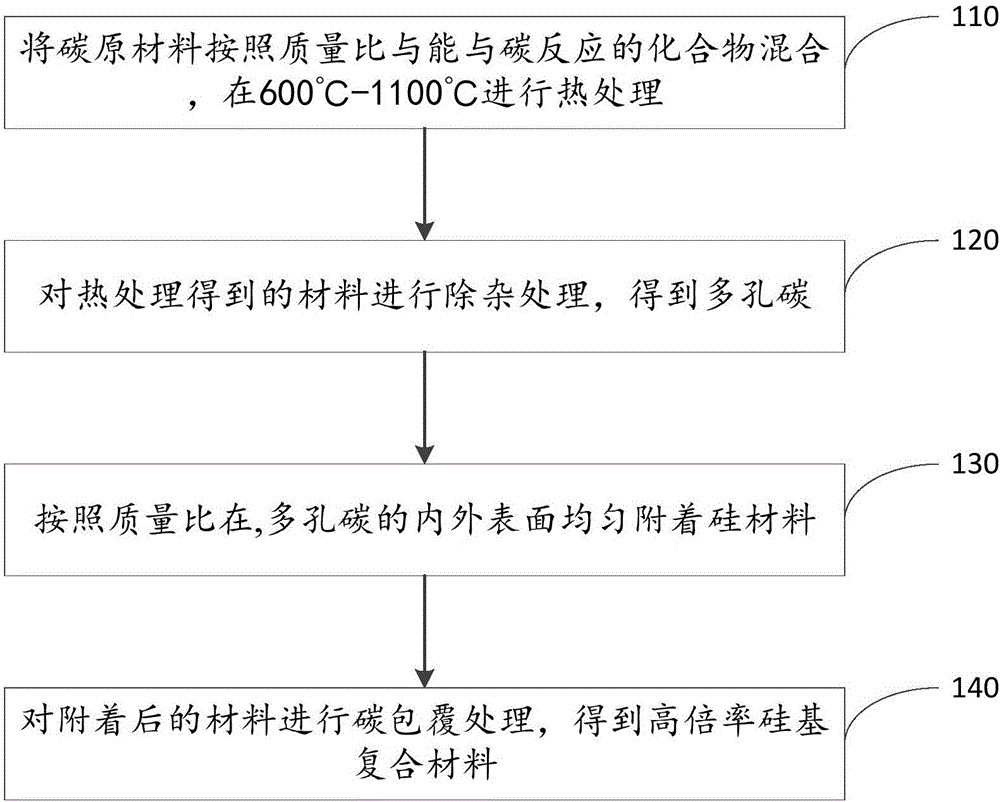

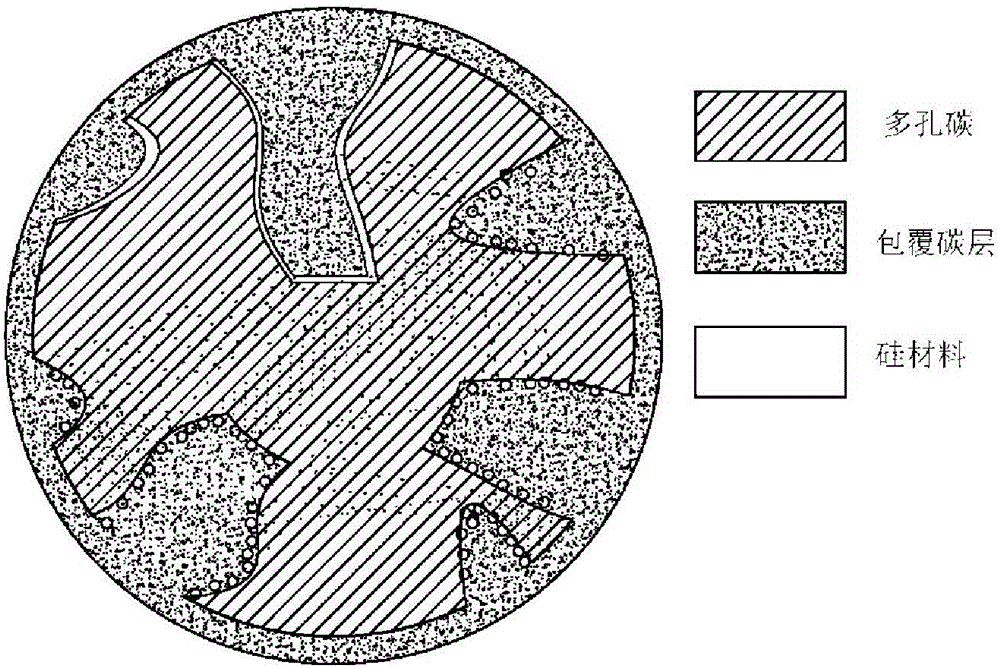

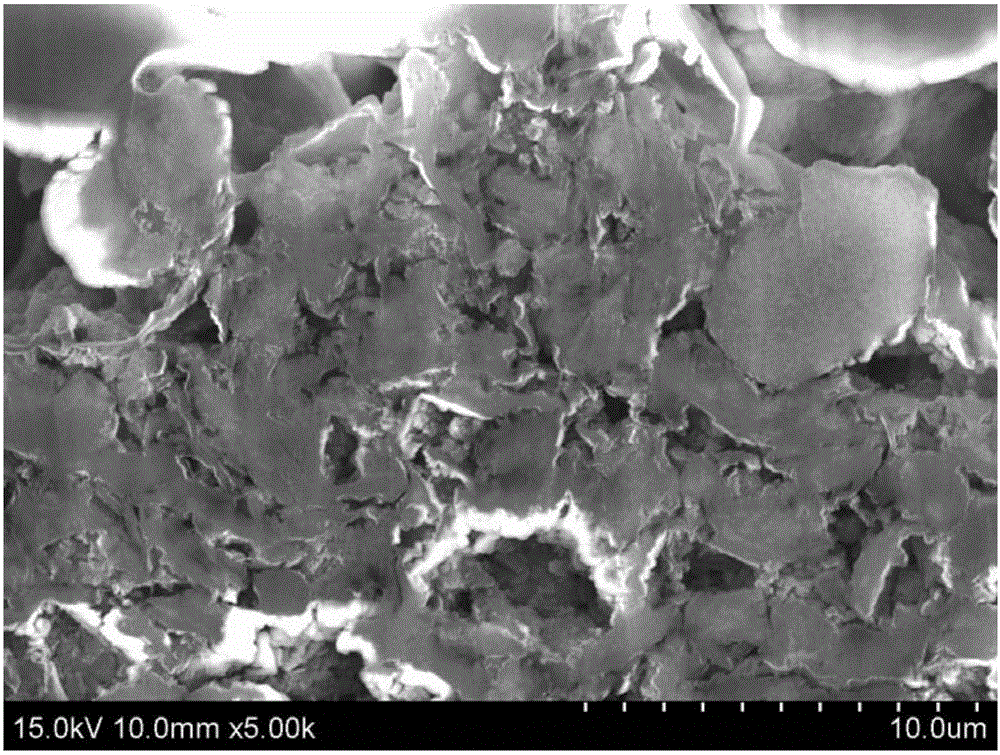

Preparation method of composite high-magnification silicon-based material, cathode material and lithium battery

InactiveCN105680023AUniform adhesionReduce strainCell electrodesSecondary cellsCarbon coatingPorous carbon

The invention discloses a preparation method of a composite high-magnification silicon-based material, a cathode material and a lithium battery. The preparation method comprises the following steps: mixing a carbon raw material and a first compound according to a mass ratio, and carrying out the heat treatment, wherein the first compound is a compound capable of reacting with carbon; removing impurities in the heat-treated material to obtain porous carbon; uniformly attaching a silicon material on the inner surface and outer surface of the porous carbon according to a mass ratio; and coating the attached material with carbon to obtain the composite high-magnification silicon-based material, wherein in the composite high-magnification silicon-based material, the mass percent of the porous carbon is 10 to 90 percent, and the specific surface area is 10m<2> / g to 500m<2> / g; the mass percent of the silicon material is 1 to 60 percent; and the mass percent of the carbon coating layer is 20 to 80 percent.

Owner:SHANGHAI PUTAILAI NEW ENERGY TECH CO LTD +2

Electrode material in hollow tubular structure, and preparation method for electrode material

InactiveCN105513831AExcellent supercapacitor performanceIncrease loadHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrochemical corrosion

The invention provides an electrode material in a hollow tubular structure, and the electrode material is in the hollow tubular structure which consists of a composite hydroxide / copper hydroxide / copper-contained metal substrate. The chemical formulation of the composite hydroxide is MxM'y(OH)2, wherein M is Ni2+ or Co2+, M' is Co2+, Al3+, or Fe3+. According to the invention, a method of solution dipping and constant potential deposition, and a copper hydroxide nanowire array grows on the copper-contained metal substrate in an in-situ manner. The composite hydroxide is deposited on a copper hydroxide nanorod in electrolyte containing mixed metal salt solution in a manner of electro-deposition through employing the method of constant potential deposition. Meanwhile, electrochemical corrosion enables the copper hydroxide nanorod to be dissolved in a process of electro-deposition, thereby obtaining the hollow tubular structure of the composite hydroxide / copper hydroxide / copper-contained metal substrate. The electrode material is good in super-capacitance performance, and can be used for a super-capacitor.

Owner:BEIJING UNIV OF CHEM TECH +1

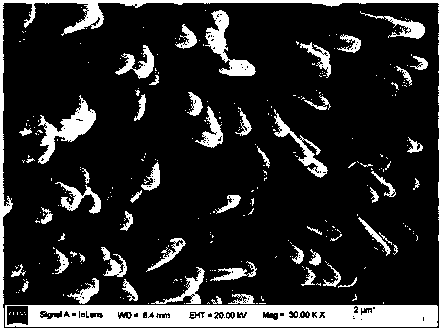

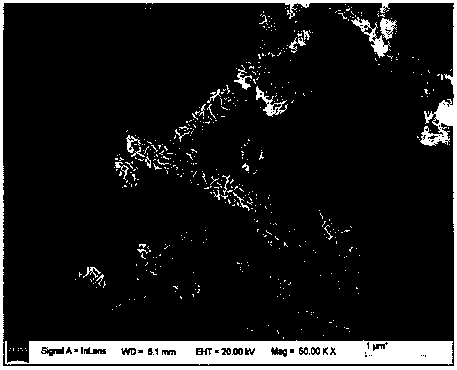

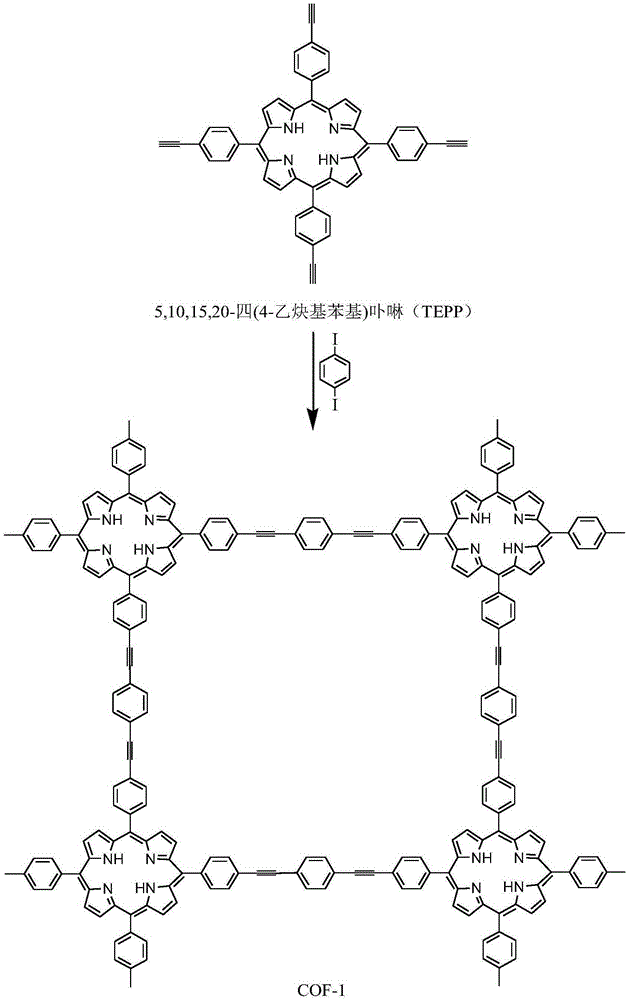

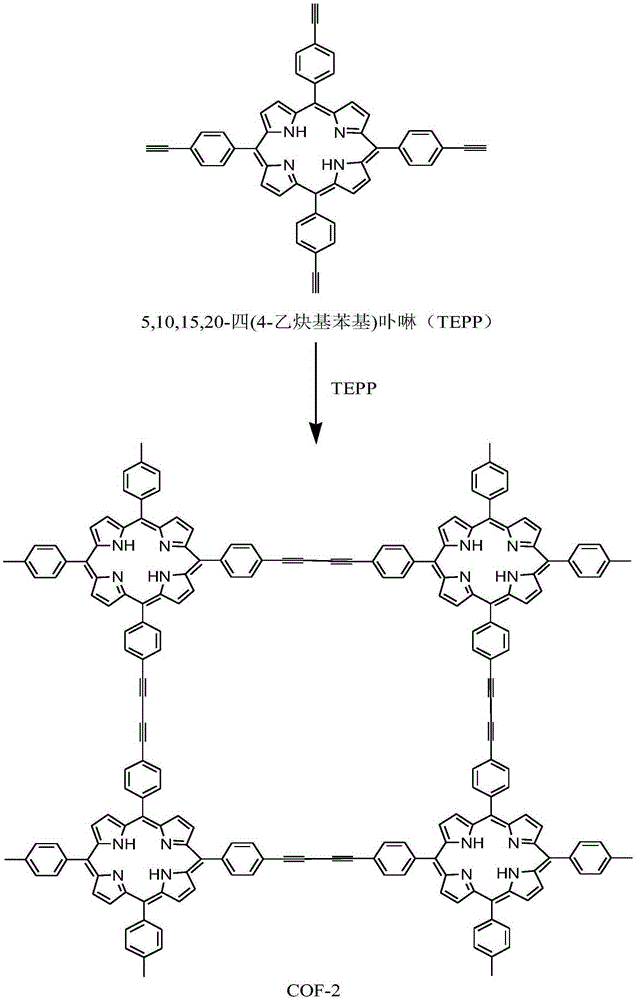

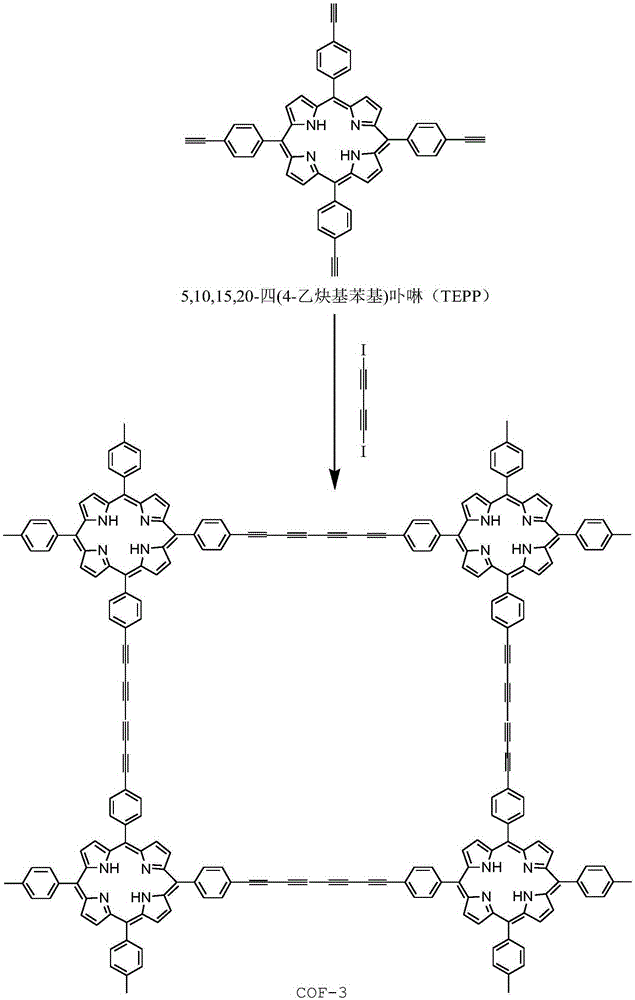

Porphyrin two-dimension covalent organic framework conjugated polymer, and preparation method and application thereof

InactiveCN105348303AImprove performanceExcellent rate performanceOrganic chemistryHybrid capacitor electrodesPotassiumPorphyrin

The invention belongs to the fields of a metal ion battery and a super capacitor, and concretely relates to a porphyrin two-dimension covalent organic framework conjugated polymer, and a preparation method and an application thereof. A structural formula of the porphyrin two-dimension covalent organic framework conjugated polymer is shown in formula (I), wherein m=0 or 1, n=0 or 1. The porphyrin two-dimension covalent organic framework conjugated polymer can be directly used as a cathode material of the metal ion battery and the super capacitor, so that the cathode material shows excellent properties, which include good cycle performance, high specific capacity and excellent rate capability; the polymer powder also has the same effects and properties, and can be used as a cathode material of other metal ion (sodium, potassium, zinc, nickel, etc.) batteries and super capacitors.

Owner:INST OF CHEM CHINESE ACAD OF SCI

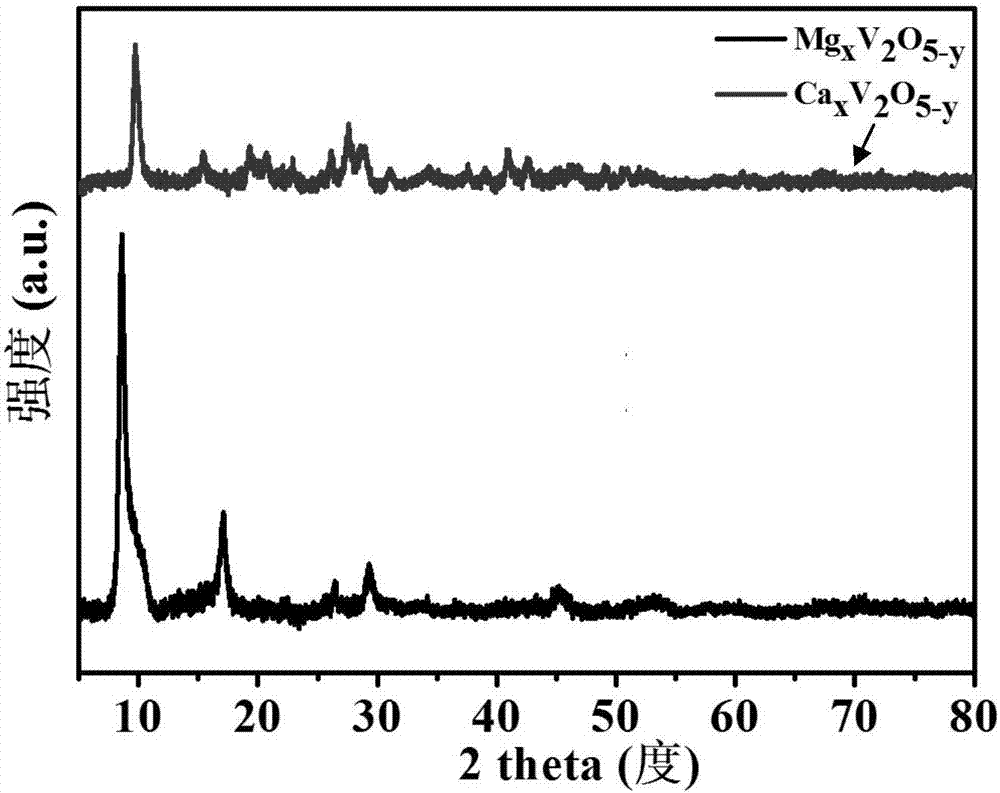

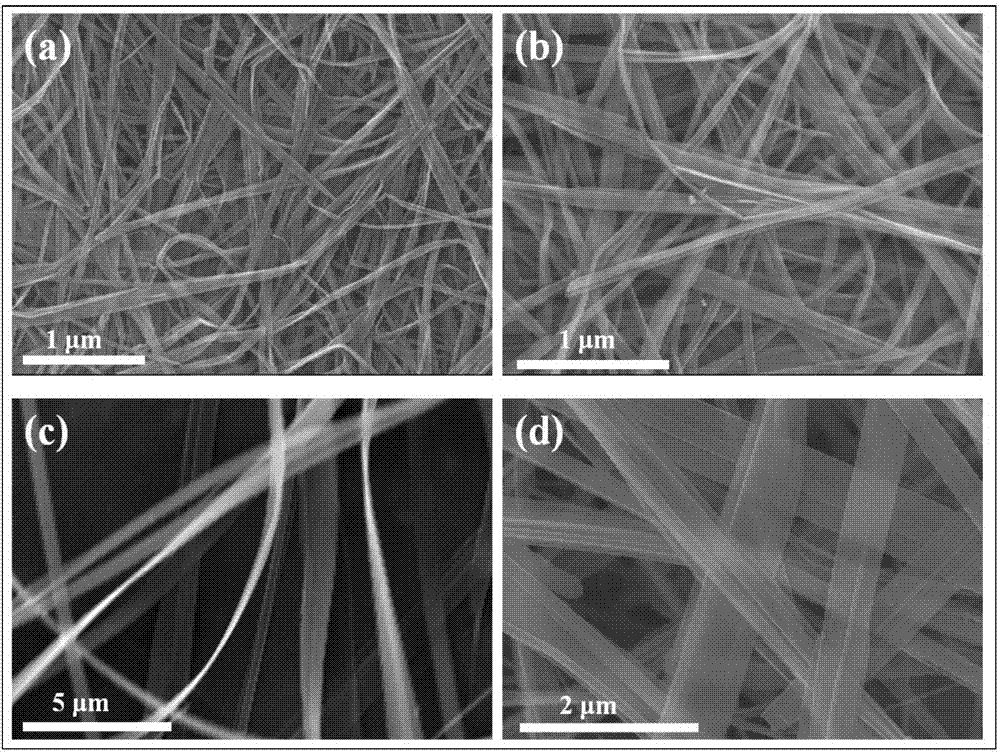

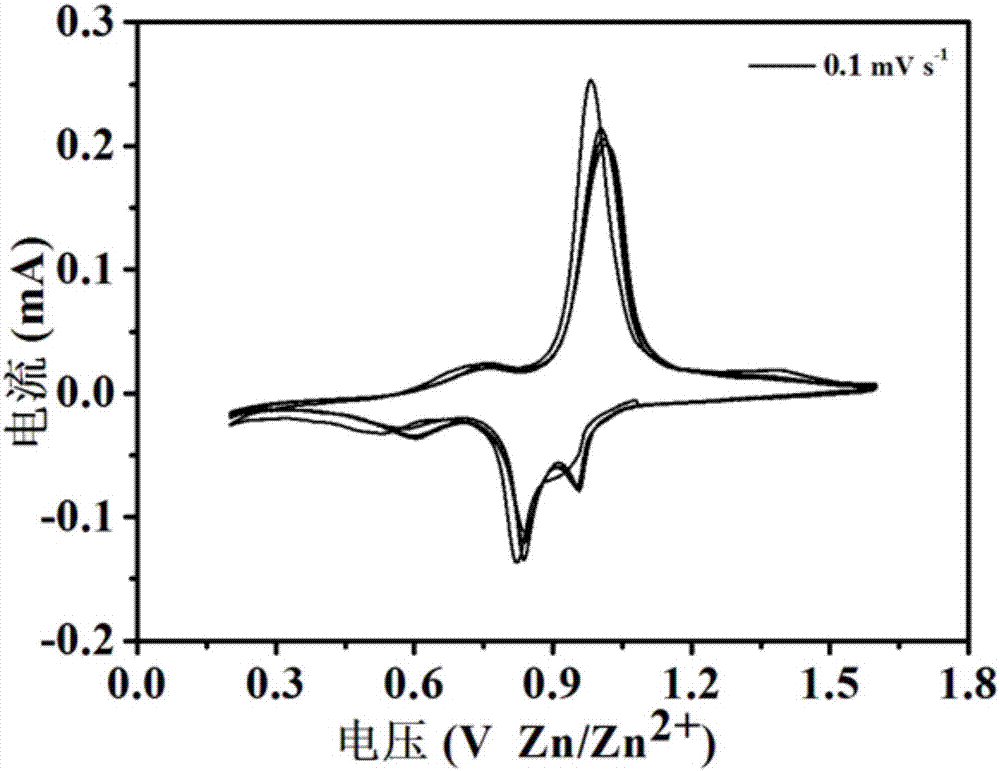

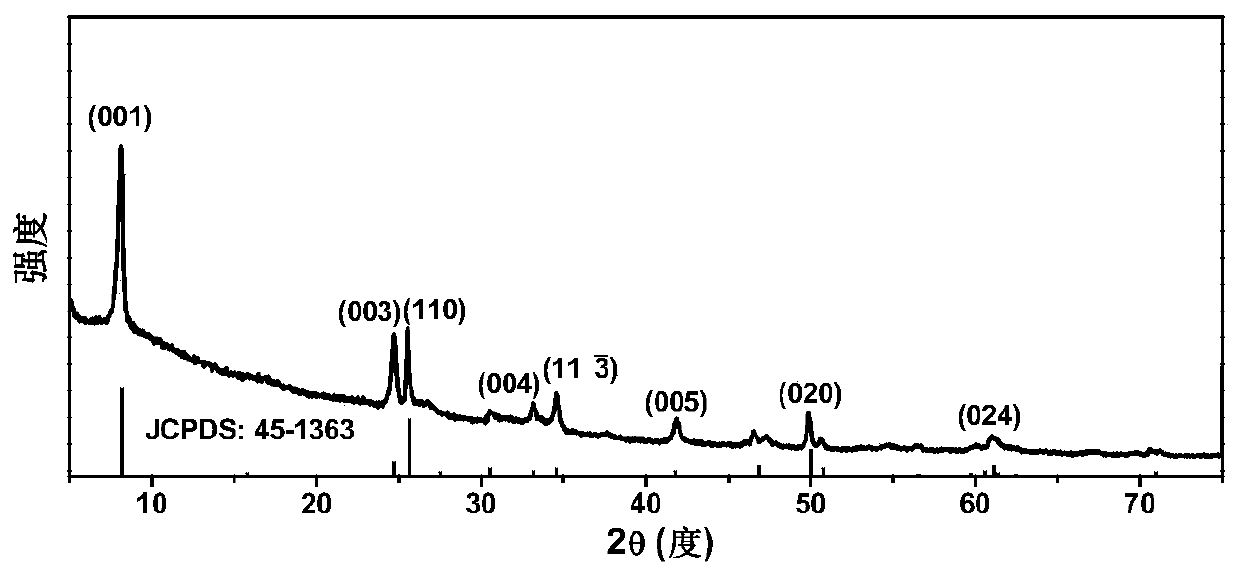

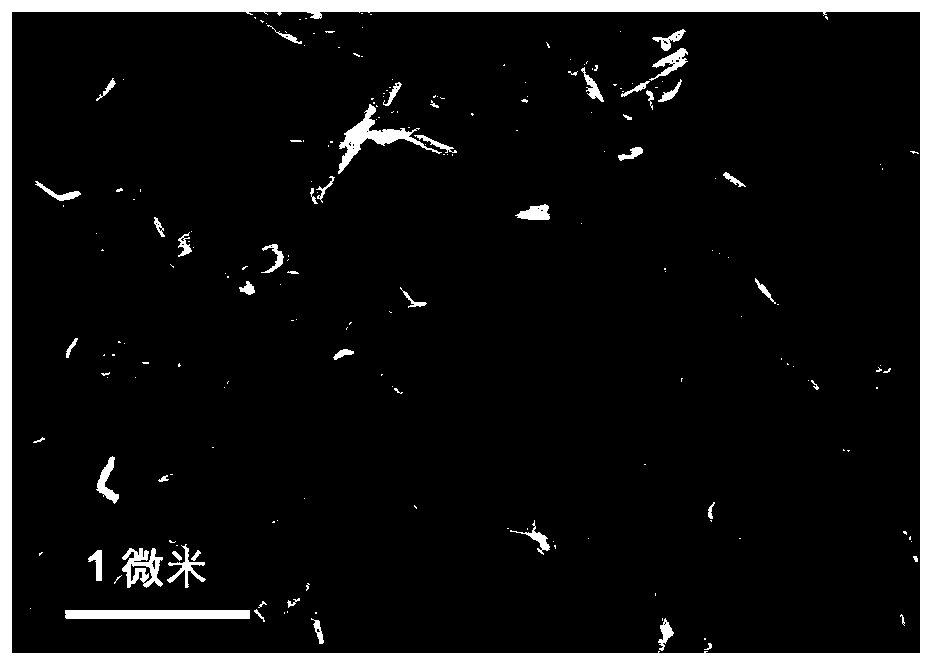

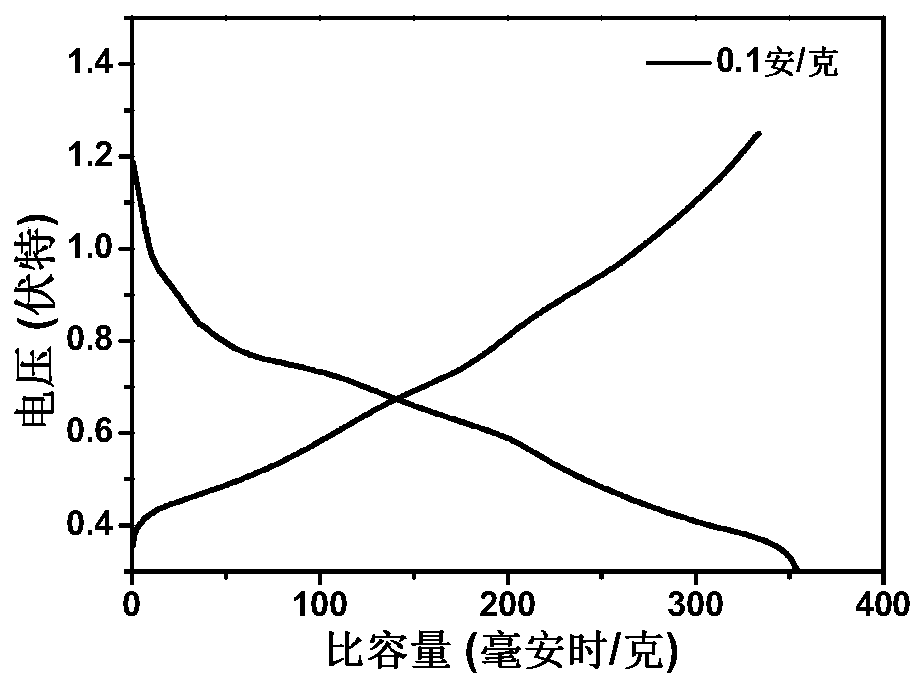

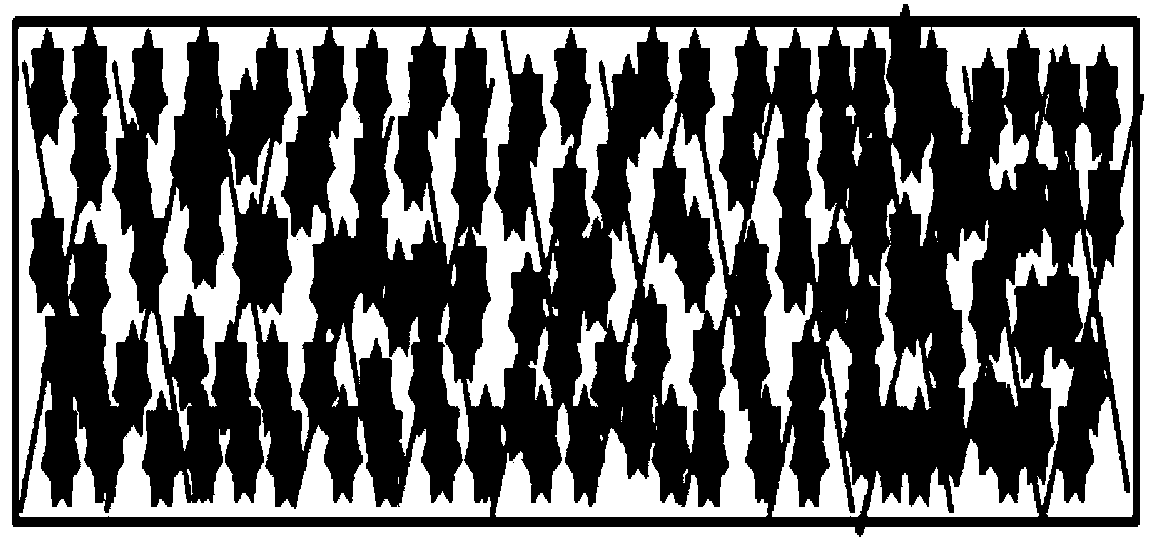

Divalent metal ion pre-embedded layered vanadium oxide nanometer material as well as preparation method and application thereof

ActiveCN107170967ALow priceAchieving controllable synthesisMaterial nanotechnologyCell electrodesDivalent metal ionsVanadium oxide

The invention relates to a divalent metal ion pre-embedded layered vanadium oxide nanometer material as well as a preparation method thereof. The chemical formula of the nanometer material is AxV2O5-y, wherein A is Mg, Ca, Sr or Zn; the MgxV2O5-y has the nanoribbon diameter of 100-1500nm and the length of 5-50 microns or CaxV2O5-y has the nanoribbon diameter of 100-1000nm and the length of 5-50 microns or SrxV2O5-y has the nanoribbon diameter of 100-1000nm and the length of 5-50 microns or ZnxV2O5-y has the nanoribbon diameter of 100-300nm and the length of 5-50 microns or ZnxV2O5-y has the nanoflower diameter of 3-5 microns. The divalent metal ion pre-embedded layered vanadium oxide nanometer material disclosed by the invention has high specific capacity, excellent cycling stability and excellent rate capability and is a potential high-performance commercial zinc ion battery positive electrode material.

Owner:WUHAN UNIV OF TECH

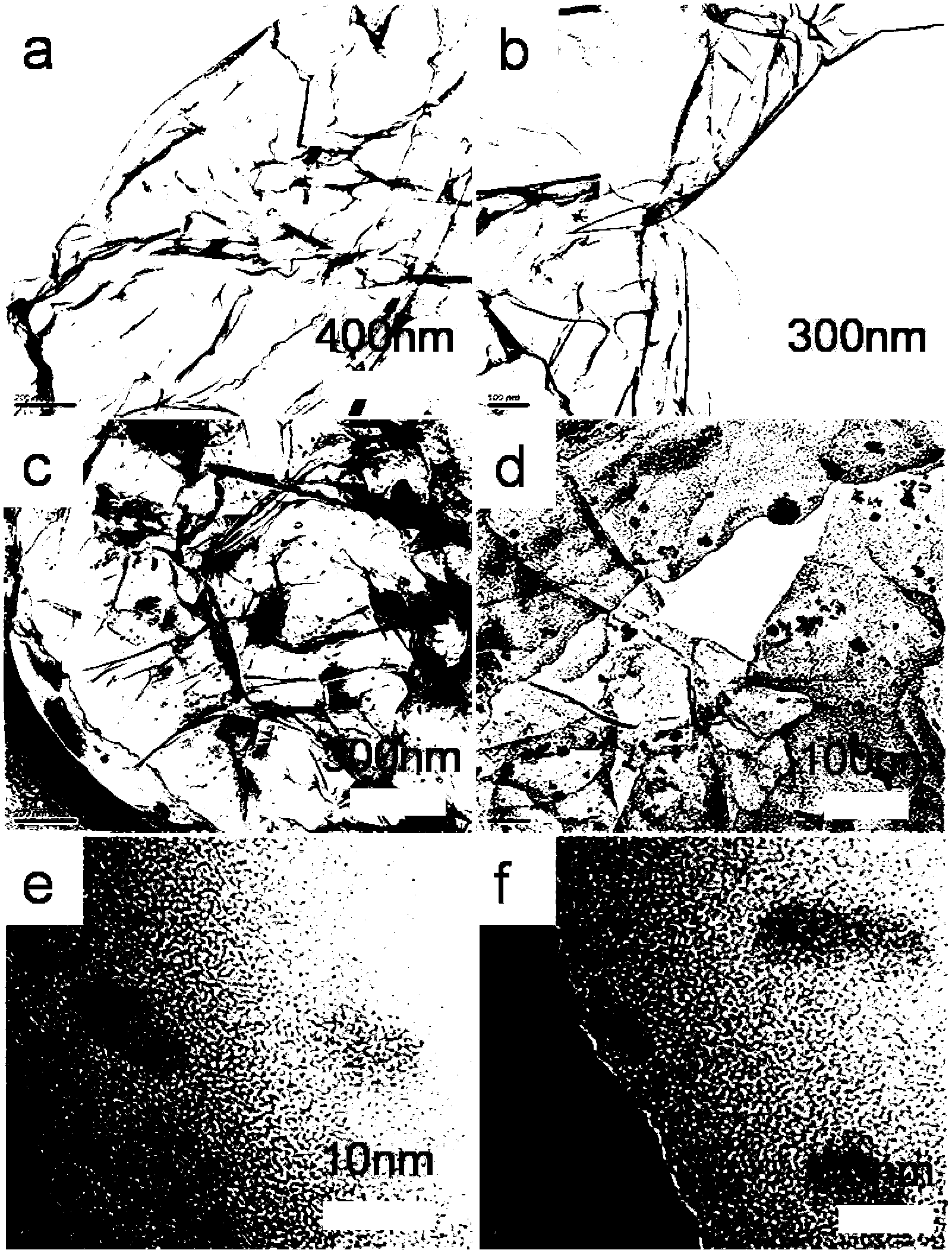

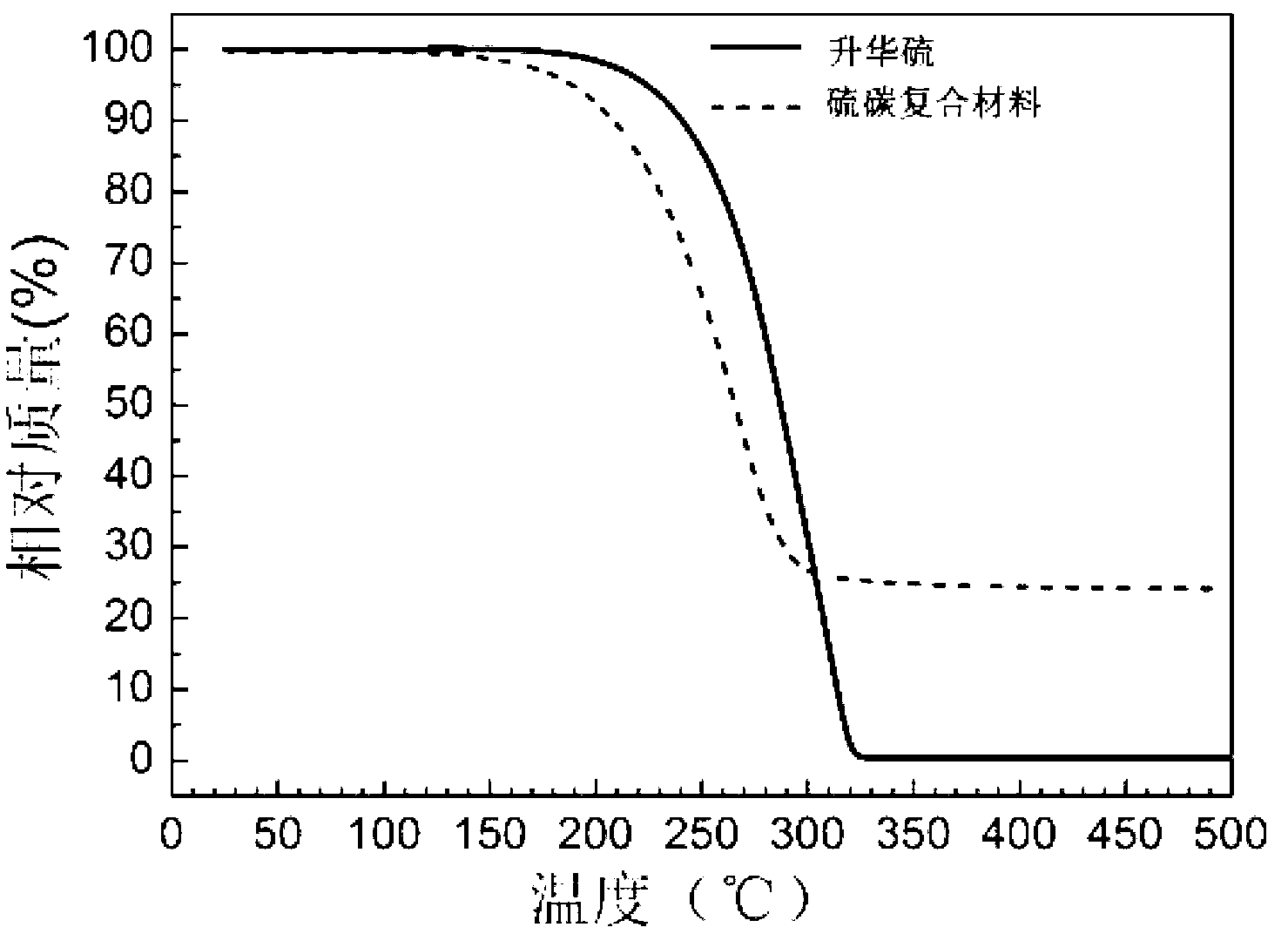

Preparation method of lithium-sulphur battery positive pole material with sulfur-graphene composite structure

The invention relates to the technical field of batteries, and particularly provides a preparation method of a lithium-sulphur battery positive pole material with a sulfur-graphene composite structure. The preparation method comprises the steps of mixing sulphur powder and organic amine to prepare first dispersion liquid, wherein the weight-volume ratio of sulphur and the organic amine is 0.05-0.4 g:1 mL; dispersing graphene into an organic solvent to prepare second dispersion liquid, wherein the weight-volume ratio of the graphene and the organic solvent is 0.0005-0.02 g:1 mL; dripping the first dispersion liquid to the second dispersion liquid, and uniformly mixing to form third dispersion liquid; adding water or acid liquor to the third dispersion liquid, and continuing to stir so that a sulfur-graphene composite is separated out from the third dispersion liquid; carrying out solid-liquid separation on the third dispersion liquid, and drying an obtained first solid to obtain the lithium-sulphur battery positive pole material. The lithium-sulphur battery prepared through the method provided by the invention has the advantages of good coulomb efficiency and recycling; and the preparation method provided by the invention is simple, fast and low in consumption.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Cathode material for lithium-ion power battery and preparation method thereof

InactiveCN102148355AIncrease capacityExcellent rate performanceNon-aqueous electrolyte accumulator electrodesPower batteryGranularity

The invention discloses a cathode material for a lithium-ion power battery and a preparation method thereof. A graphite matrix used by the cathode material is spherical-like artificial graphite which has a spherical shape and has a length-width ratio of 1.0-3.0; the granularity D50 before the matrix material is coated is 9 to 11 mu m; a layer of ungraphitised carbon material is coated on the surface of the matrix to form a nucleus-shell structure; the coating amount is 2 to 8 percent of the mass of the matrix; the granularity D50 of the coated cathode material granules is 10 to 12 mu m; the specific surface area is 2 to 4m<2> / g; the tap density of powder is 0.9 to 1.1g / cm<3>; and the carbon content is over 99.95 percent. The invention has the advantages that: the cathode material for the lithium-ion power battery has the characteristics of high capacity, excellent rate performance and excellent liquid absorption property, and the preparation method is simple, easy to control, low in production cost and suitable for industrial production.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

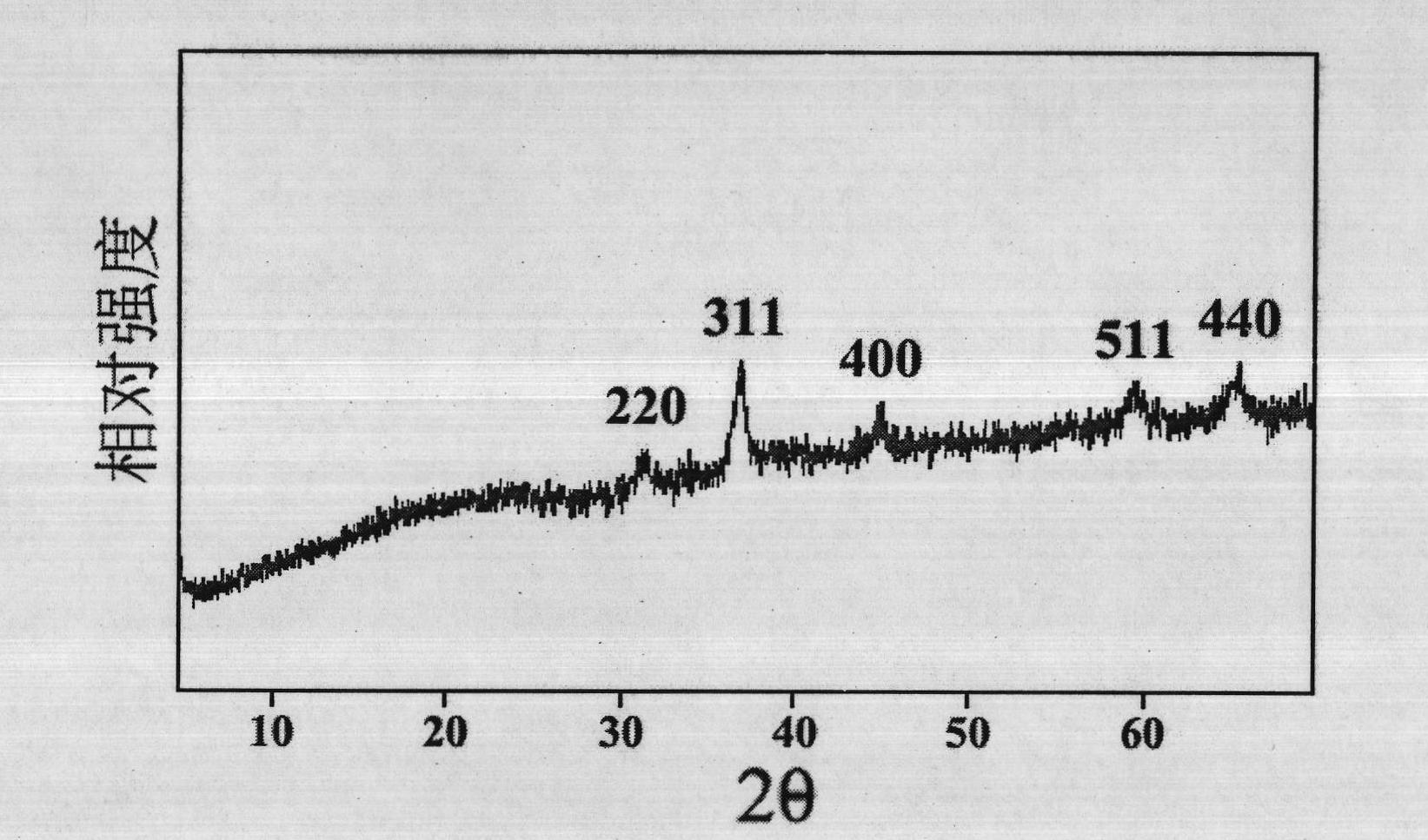

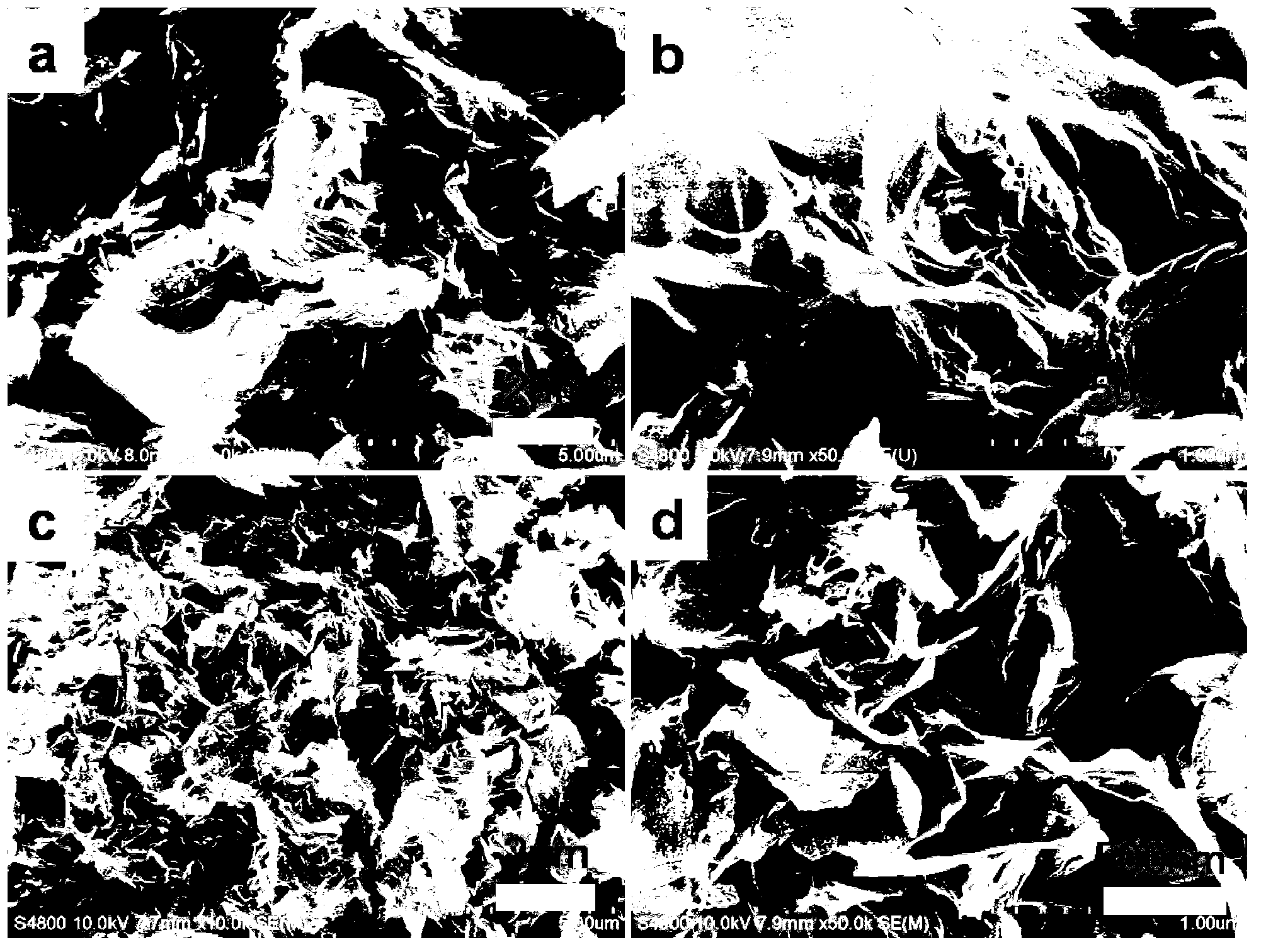

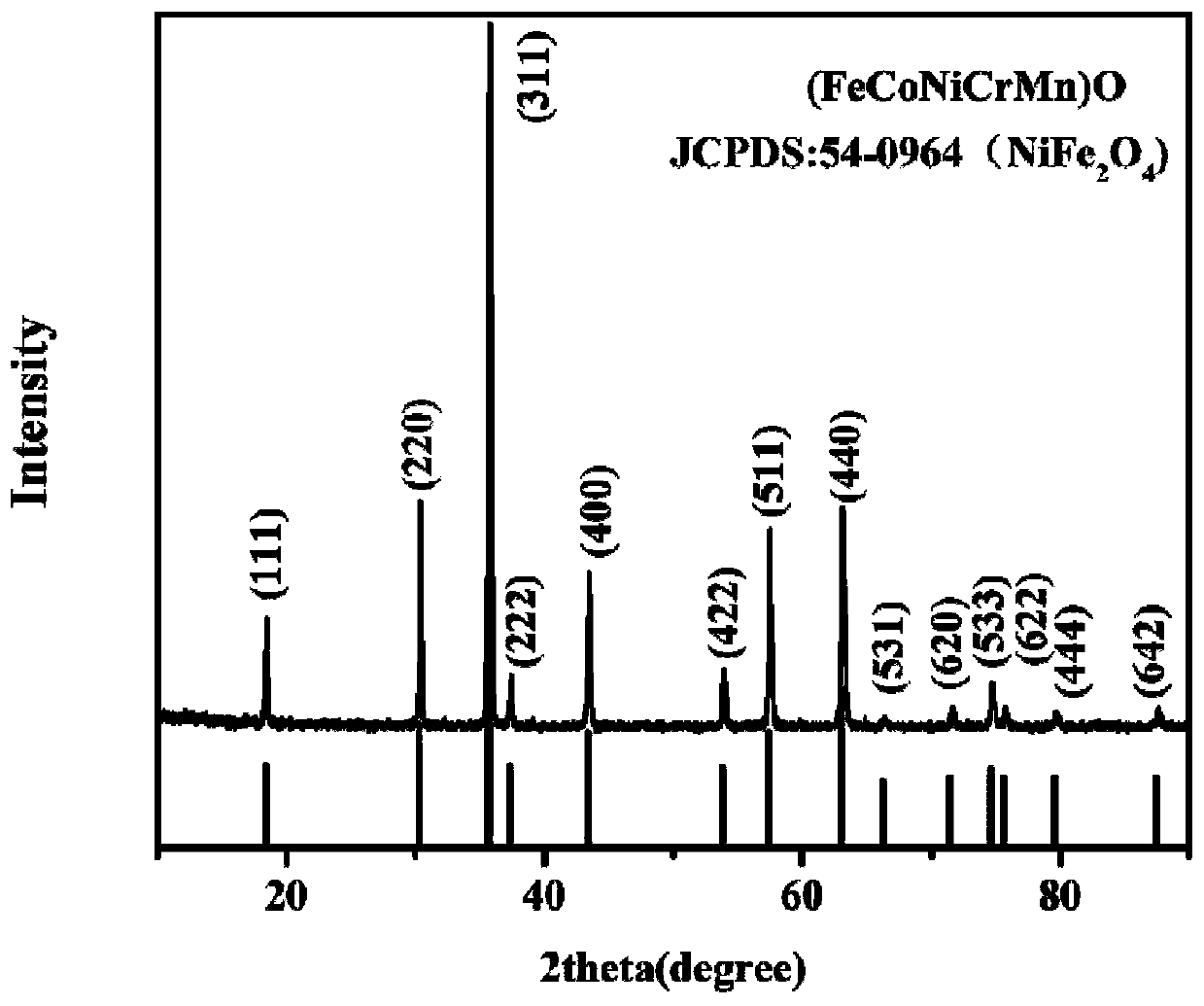

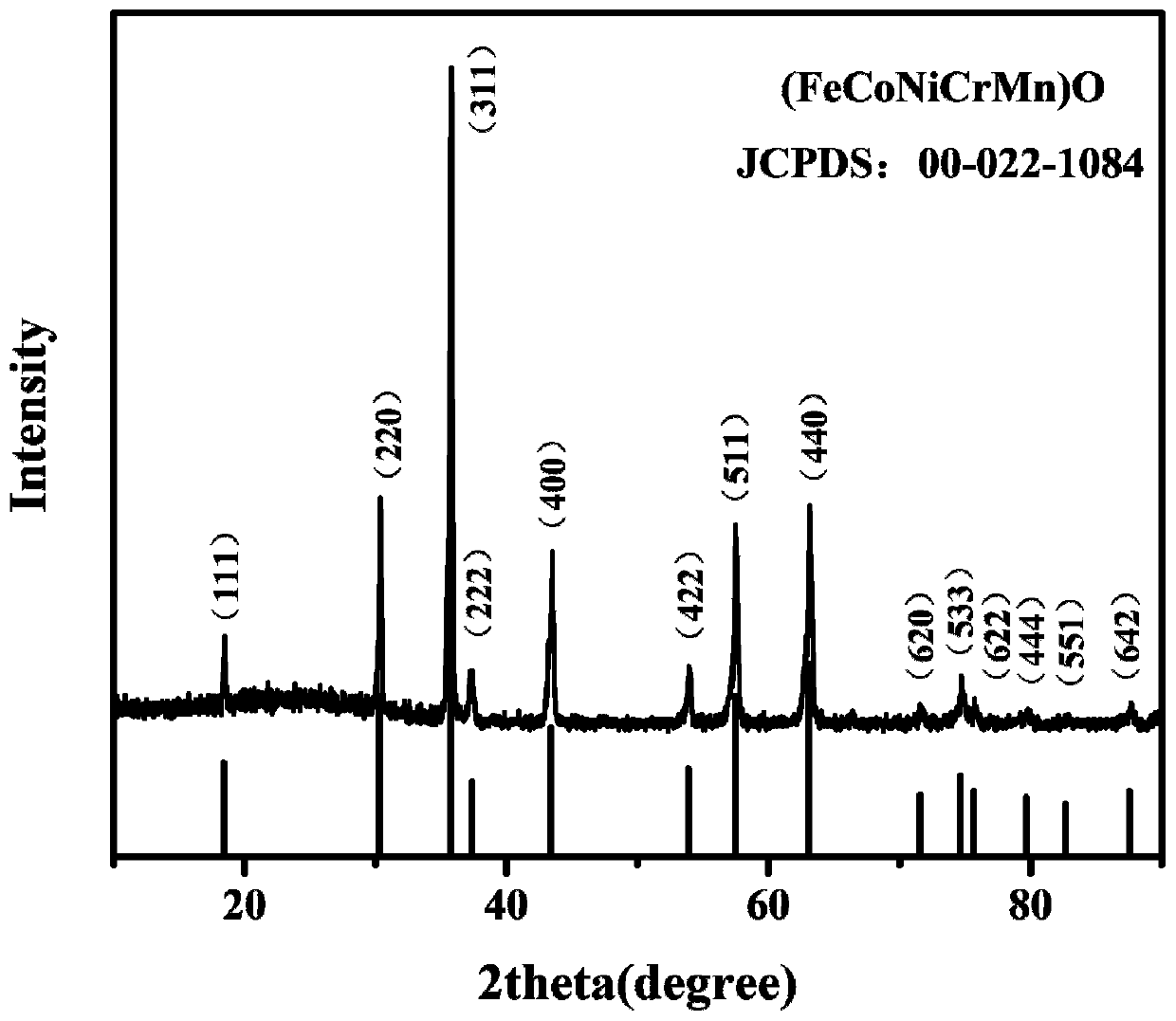

Spinel type high-entropy oxide electrode material and preparation method thereof

ActiveCN110364717AHigh specific capacityImprove cycle stabilityNegative electrodesSecondary cellsIron(II) oxideSpace group

The invention relates to a spinel type high-entropy oxide electrode material and a preparation method thereof, and belongs to the field of nanomaterial preparation and new energy. The chemical formulaof the high-entropy oxide electrode material is one of (FeCoNiCrMn)O, (FeZnNiCrMn)O, (FeCoZnCrMn)O and (FeCoNiCrMnCu)O. The preparation method includes the steps of 1) mixing and ball-milling iron oxide, chromium oxide, manganese oxide and M metal oxide, wherein the M metal oxide is two or more of nickel oxide, zinc oxide, copper oxide and cobalt oxide; and 2) carrying out high-temperature calcination, and obtaining the spinel type high-entropy oxide electrode material by adopting a cooling mode of furnace cooling, air quenching and liquid nitrogen quenching. The particle diameter of the high-entropy oxide is 100-500nm, and the high-entropy oxide is determined to be in a spinel structure according to XRD; and the space group of the material is Fd-3m, and the specific surface area is 5-100m<2>g<-1>.

Owner:东北大学秦皇岛分校

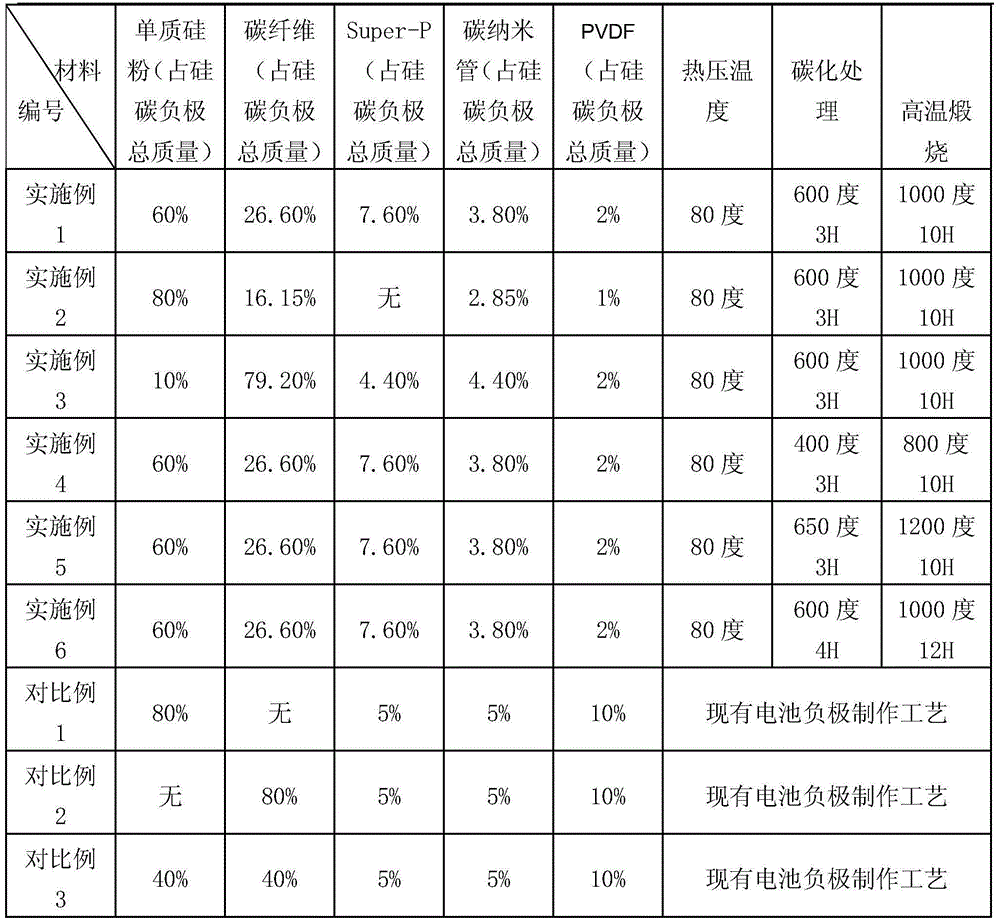

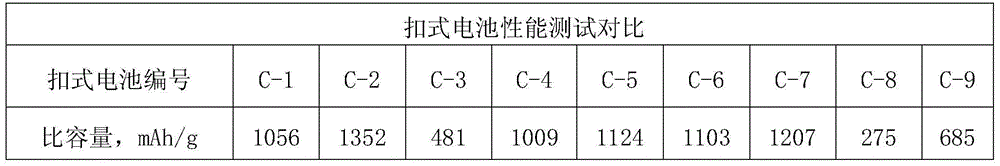

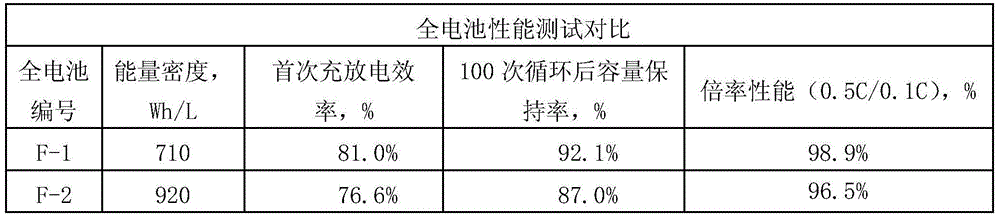

Method for preparing silicon-carbon composite anode and lithium ion battery

ActiveCN104681797APromote circulationSimple preparation processCell electrodesSecondary cellsCarbon compositesCyclic process

The invention discloses a silicon-carbon composite anode comprising a silicon source and a carbon source, wherein silicon source is monatomic silicon, the particle size distribution is 100 nm to 80 microns, and the mass of the silicon source accounts for 10-80% of the total mass of the silicon-carbon composite anode; the carbon source comprises a carbon anode material and a conductive agent, the carbon anode material is one or more of carbon fiber, graphite and mesocarbon microbead, and the mass of the carbon anode material accounts for 10-90% of the total mass of the carbon source. According to the silicon-carbon composite anode disclosed by the invention, one-step coating forming, hot pressing flaking, carbonization treatment and high-temperature calcination are carried out on anode slurry prepared by mixing the silicon source with the carbon source, so as to guarantee that the silicon material is effectively dispersed in a carbon skeleton, the prepared silicon-carbon anode can effectively relieve the volume expansion of the silicon material in charging and discharging processes in a circulation process and guarantee excellent cycle performance of the battery; the silicon-carbon composite anode is prepared by one-step coating forming, and no current collector is needed, so that the production process is simplified and the battery is guaranteed to have high energy density; meanwhile, the invention further provides a lithium ion battery containing the silicon-carbon composite anode.

Owner:江苏中兴派能电池有限公司

High-performance water system zinc ion battery anode material, manufacturing method and application thereof

ActiveCN110474044AEasy to prepareLow equipment requirementsFinal product manufactureSecondary cellsSpecific dischargeNanotechnology

The invention provides a high-performance water system zinc ion battery anode material, a manufacturing method and an application thereof. The anode material has the following general formula: (N,M) sigma=1V8O20 nH2O, wherein the N is one of Li, Na, K, Zn, Cu, Mg or Ca, the M is one of Mn, Fe, Co or Ni, and the n is 0.01-4. The anode material can be manufactured through one-step hydrothermal method, a reaction condition is mild, a manufacturing process is simple, and a requirement to equipment is low. A microscopic morphology of the obtained anode material is a nanobelt. The obtained anode material is firstly applied to a water system zinc ion battery, and has electrochemical performance such as a higher specific discharge capacity, a higher cycle stability and the like.

Owner:SHANDONG UNIV

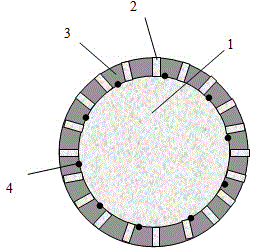

Porous negative pole piece and preparation method thereof, and lithium ion battery

InactiveCN103779581AHigh specific capacityReduce difficultyElectrode carriers/collectorsSecondary cellsSystem capacityPole piece

The embodiment of the invention provides a porous negative pole piece which comprises a porous current collector and an active substance deposited in a hole of the porous current collector, wherein the active substance is one or more of Si, Sn, Al, Sb, Ge, Zn, Pb, Mg, and Na, the hole is a through hole, and the active substance is deposited on the inner wall of the hole. The negative pole sheet is high in capacity and stable in structure, so that the system capacity of a lithium ion battery is finally increased, and the recycling service life of the battery is prolonged. The embodiment of the invention further provides a preparation method of the porous negative pole sheet, and the lithium ion battery comprising the porous negative pole sheet.

Owner:HUAWEI TECH CO LTD

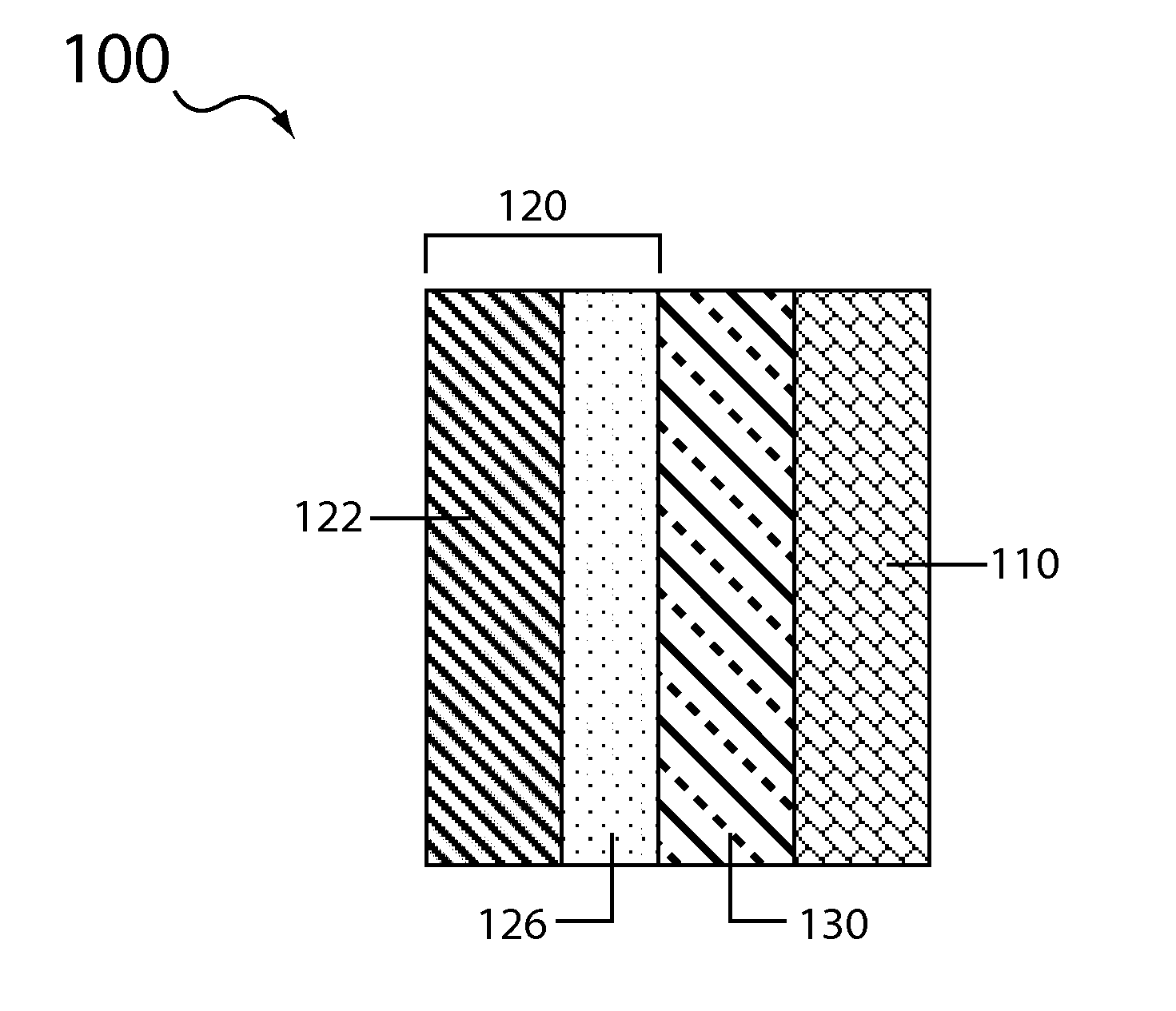

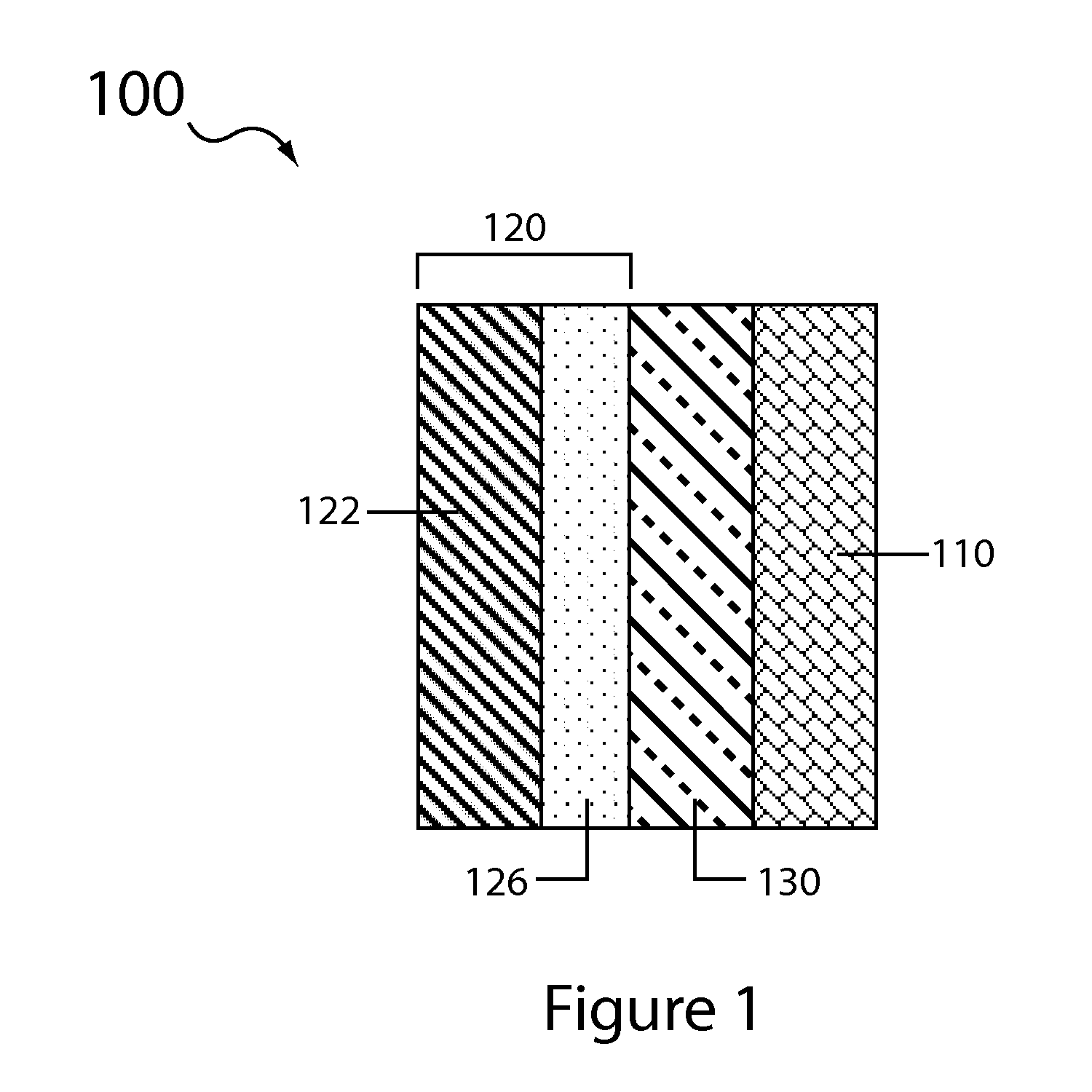

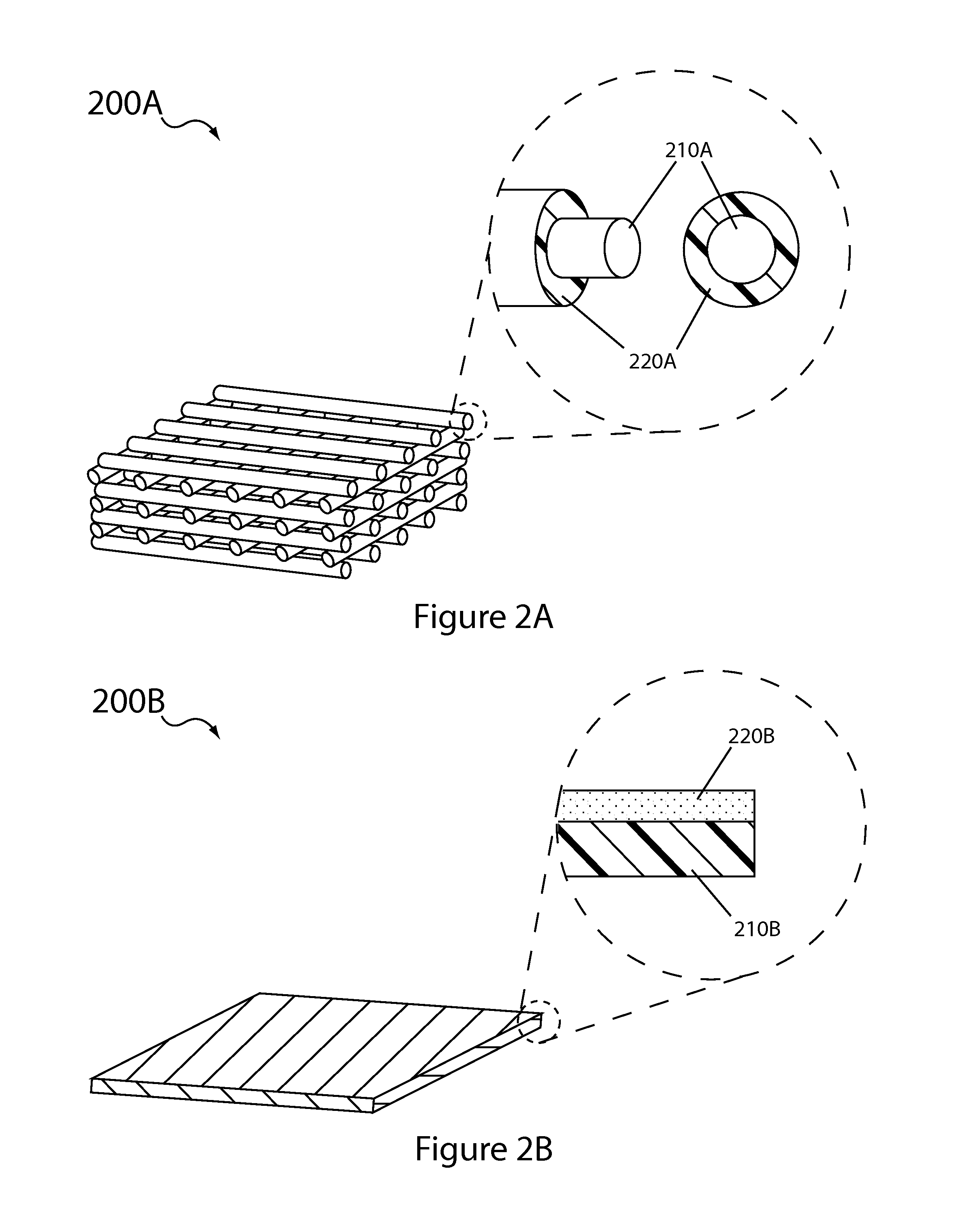

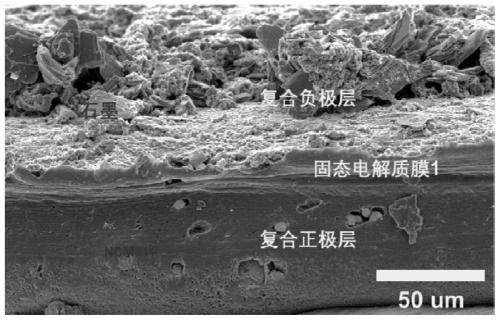

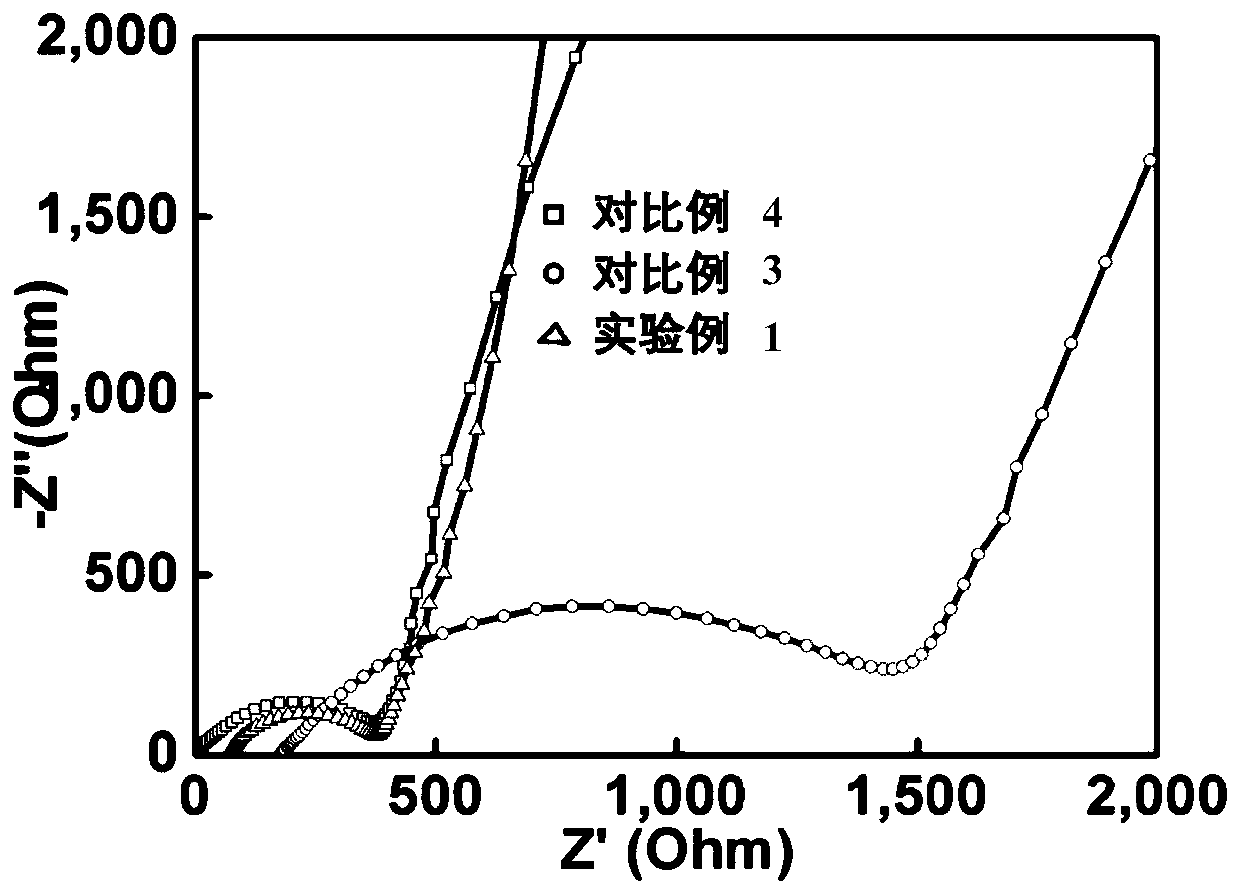

Composite solid-state electrolyte, solid-state battery and preparation method of solid-state battery

InactiveCN111244537AImprove conductivityImprove mechanical propertiesSecondary cellsComposite electrolytesSolid state electrolyteElectrical battery

The invention belongs to the technical field of batteries, and particularly relates to a composite solid-state electrolyte which comprises an organic polymer, a lithium salt, an ionic liquid and an inorganic solid electrolyte material, wherein the mass ratio of the polymer to the lithium salt to the ionic liquid to the inorganic solid electrolyte material is 1: (0.1-0.6): (0.1-1): (0.05-0.2). Thecomposite solid-state electrolyte disclosed by the invention is high in ionic conductivity, high in stability, good in compatibility with positive and negative electrodes and excellent in mechanical property, and the composite solid-state electrolyte has excellent mechanical property due to a polymer framework; the lithium salt provides lithium ions for the solid electrolyte; the ionic liquid improves the conductivity of the electrolyte; the inorganic solid electrolyte material can be crosslinked with the polymer to further improve the mechanical properties of the solid electrolyte and increase the strength.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

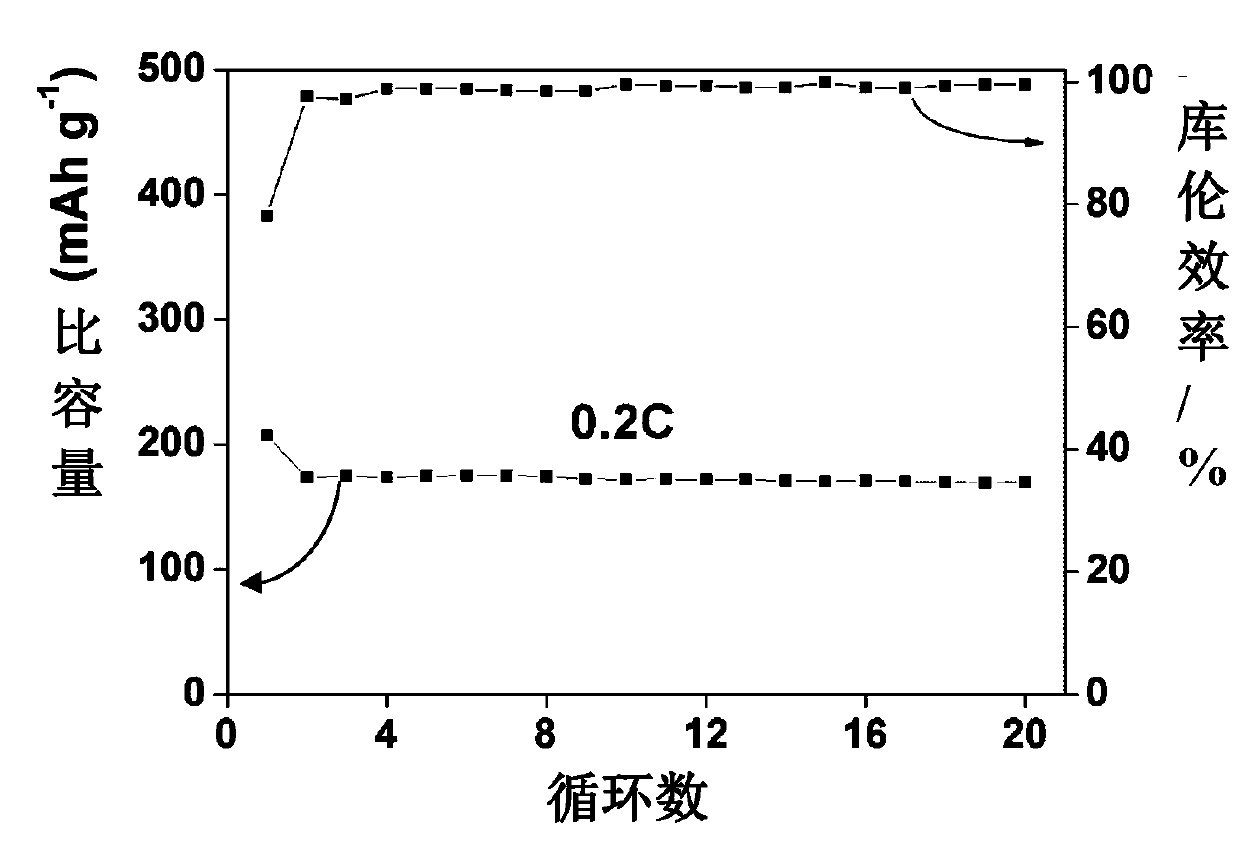

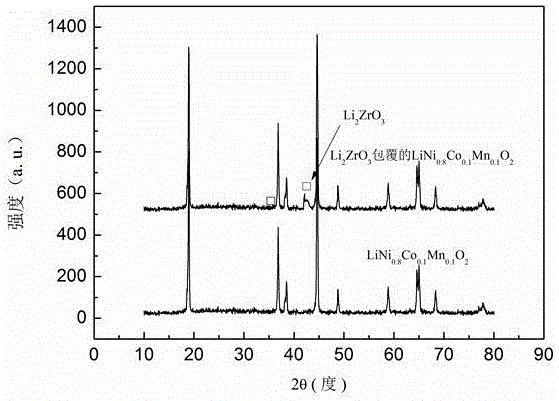

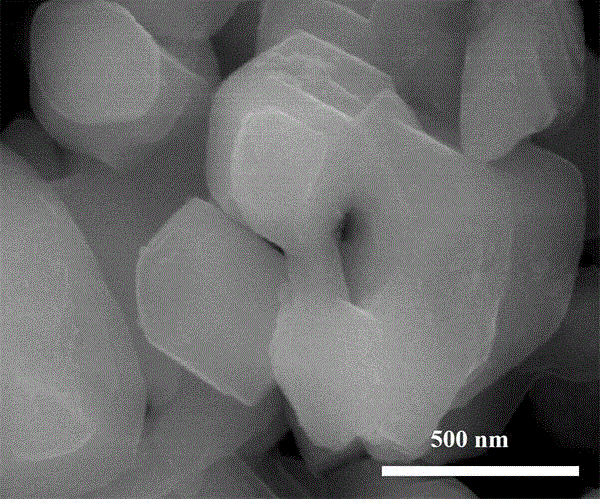

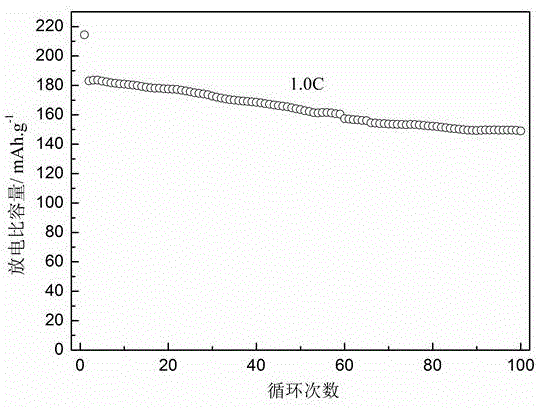

Cobalt-nickel lithium manganate composite positive electrode material with surface wrapped by lithium zirconate and preparation method

InactiveCN105140492ASimple preparation processImprove cycle performanceSecondary cellsPositive electrodesElectrical batteryManganate

The invention discloses a cobalt-nickel lithium manganate composite positive electrode material with the surface wrapped by lithium zirconate and a preparation method. The preparation method includes the steps of firstly, preparing LiNi0.8Co0.1Mn0.1O2 through a wet chemistry method with soluble salt of nickel, cobalt and manganese and excessive lithium salt as raw materials; secondly, mixing LiNi0.8Co0.1Mn0.1O2 with zirconium nitrate, and preparing the LiNi0.8Co0.1Mn0.1O2 composite positive electrode material with the surface wrapped by Li2ZrO3 through a rheological phase method. The LiNi0.8Co0.1Mn0.1O2 composite positive electrode material with the surface wrapped by Li2ZrO3 has the advantages of being excellent in circulation performance, good in rate capability, simple and convenient in preparation process, low in cost, and the like, and is beneficial for being applied and popularized on a large scale as the positive electrode material of lithium ion batteries.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

Surface clad lithium ion battery positive material precursor, and preparation method and application thereof

The invention relates to a surface clad lithium ion battery positive material precursor, and a preparation method and application thereof. The precursor has the composition of NixCoyMnzM1-x-y-z(OH)2, wherein x is greater than 0 and less than 0.8, y is greater than 0 and less than 0.5 and z is greater than 0 and less than 0.5; M refers to a cladding metal ion which is one or more selected from Al, Zn, Zr, Co, Ti, Sn, Mg and the like; the precursor is composed of a core part and a metal ion nanoparticle layer covering the core surface. The molecular formula of the core part is NikConMn1-k-n(OH)2, wherein k is greater than 0 and less than 0.8 and n is greater than 0 and less than 0.5. As the metal ion nanoparticle cladding layer is formed through even growth in a liquid phase, an excellent and close cladding layer can be formed on the spherical surface; the cladding layer is formed with an oxide with stable chemical properties through subsequent treatment, so that the positive material can be isolated from the electrolyte, side reaction can be reduced, dissolution of metal ions can be inhibited and collapse of the material structure in repeated charge / discharge processes can be lowered down; therefore, the cycle performance, safety performance and rate capability of the material are optimized; as a result, the material is capable of better meeting the requirements of a power battery.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com