Spinel type high-entropy oxide electrode material and preparation method thereof

A spinel-type, electrode material technology, applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve problems that have not been seen yet, and achieve the effect of simple method, high specific capacity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

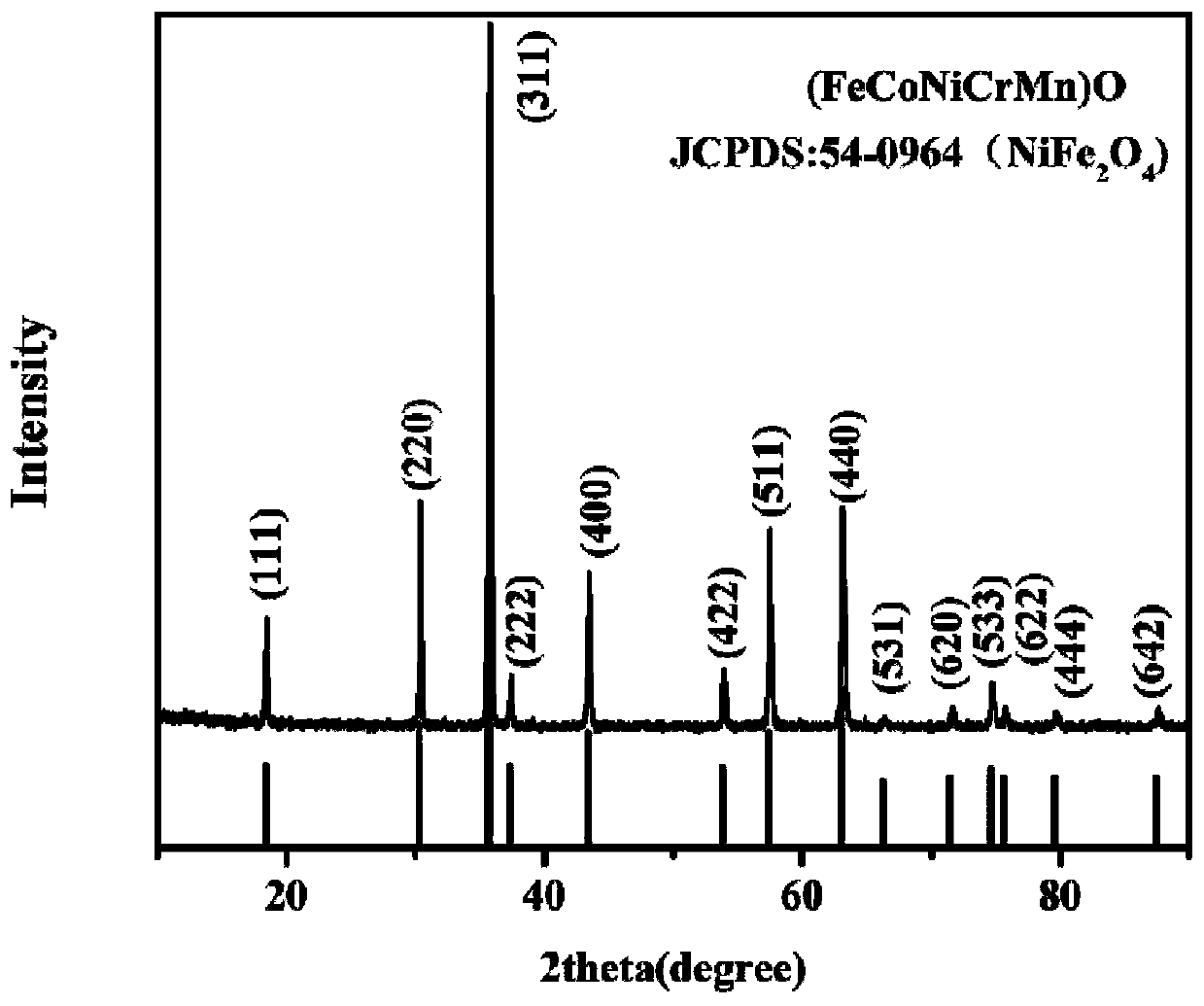

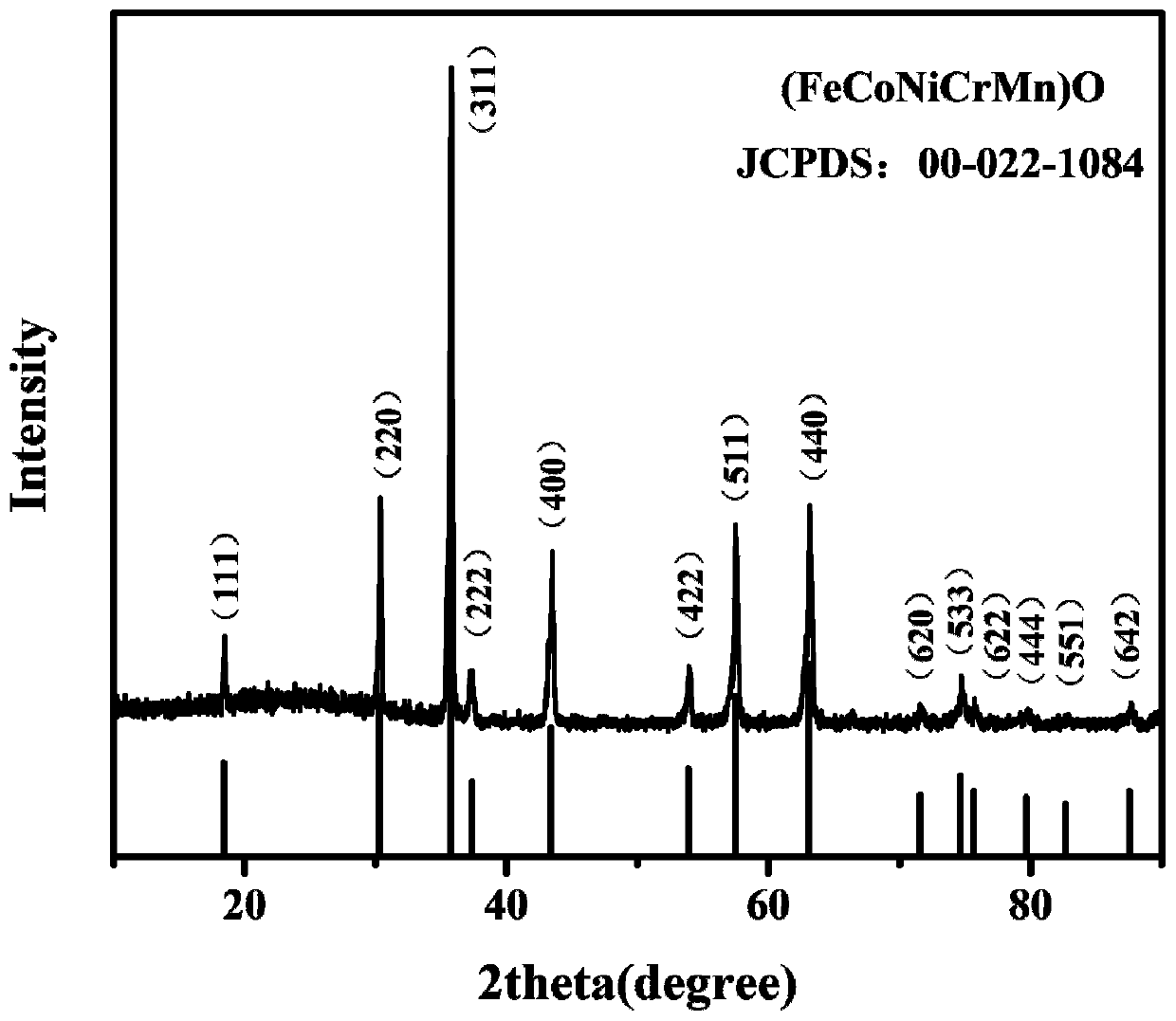

[0035]The (FeCoNiCrMn)O high-entropy oxide electrode material of the present invention is compounded by mixing raw materials, heat treatment and cooling, the particle diameter is 100-500nm, and the space group of the material is Fd-3m.

[0036] The battery negative electrode material prepared in this example is tested at 50~2000mA g in the lithium-ion battery half-cell test. -1 Under the current density, the reversible capacity of the first charge is 100~690mAh g -1 , after 200 cycles, the capacity is 390~400mAhg -1 . exhibited excellent electrochemical performance.

[0037] A method for preparing a spinel type high-entropy oxide electrode material, comprising the steps of:

[0038] Step 1: Weigh Fe with a purity of 98.8% 2 o 3 (0.005mol, 0.808g), 99% Co 3 o 4 (0.0033mol, 0.803g), 99.3% Ni 2 o 3 (0.005mol, 0.833g), 99% Cr 2 o 3 (0.005mol, 0.768g) and 90% MnO 2 (0.01mol, 0.966g), pack ZrO 2 in the ball mill jar;

[0039] Step 2: Continuous ball milling at 250r / min...

Embodiment 2

[0043] The (FeCoNiCrMn)O high-entropy oxide material of the present invention is compounded by mixing raw materials, heat treatment and cooling, the particle diameter is 100-500nm, and the space group of the material is Fd-3m.

[0044] The battery negative electrode material prepared in this example is tested at 50~2000mA g in the lithium-ion battery half-cell test. -1 Under the current density, the first charge reversible capacity is 120~700mAh g -1 , after 200 cycles, the capacity is 390~400mAhg -1 . exhibited excellent electrochemical performance.

[0045] A method for preparing a spinel type high-entropy oxide electrode material, comprising the steps of:

[0046] Step 1: Weigh Fe with a purity of 98.8% 2 o 3 (0.005mol, 0.808g), 99% Co 3 o 4 (0.0033mol, 0.803g), 99.3% Ni 2 o 3 (0.005mol, 0.833g), 99% Cr 2 o 3 (0.005mol, 0.768g) and 90% MnO 2 (0.01mol, 0.966g), pack ZrO 2 in the ball mill jar;

[0047] Step 2: Continuous ball milling at 250r / min for 2 hours to ...

Embodiment 3

[0051] The (FeCoNiCrMn)O high-entropy oxide electrode material of the present invention is compounded by mixing raw materials, heat treatment and cooling, the particle diameter is 100-500nm, and the space group of the material is Fd-3m.

[0052] The battery negative electrode material prepared in this example is tested at 50~2000mA g in the lithium-ion battery half-cell test. -1 Under the current density, the first charge reversible capacity is 200~740mAh g -1 , after 200 cycles, the capacity is 360~380mAhg -1 . exhibited excellent electrochemical performance.

[0053] A method for preparing a spinel type high-entropy oxide electrode material, comprising the steps of:

[0054] Step 1: Weigh Fe with a purity of 98.8% 2 o 3 (0.005mol, 0.808g), 99% Co 3 o 4 (0.0033mol, 0.803g), 99.3% Ni 2 o 3 (0.005mol, 0.833g), 99% Cr 2 o 3 (0.005mol, 0.768g) and 90% MnO 2 (0.01mol, 0.966g), pack ZrO 2 in the ball mill jar;

[0055] Step 2: Continuous ball milling at 250r / min for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com