Patents

Literature

106 results about "Copper(II) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(II) oxide or cupric oxide is the inorganic compound with the formula CuO. A black solid, it is one of the two stable oxides of copper, the other being Cu₂O or cuprous oxide. As a mineral, it is known as tenorite. It is a product of copper mining and the precursor to many other copper-containing products and chemical compounds.

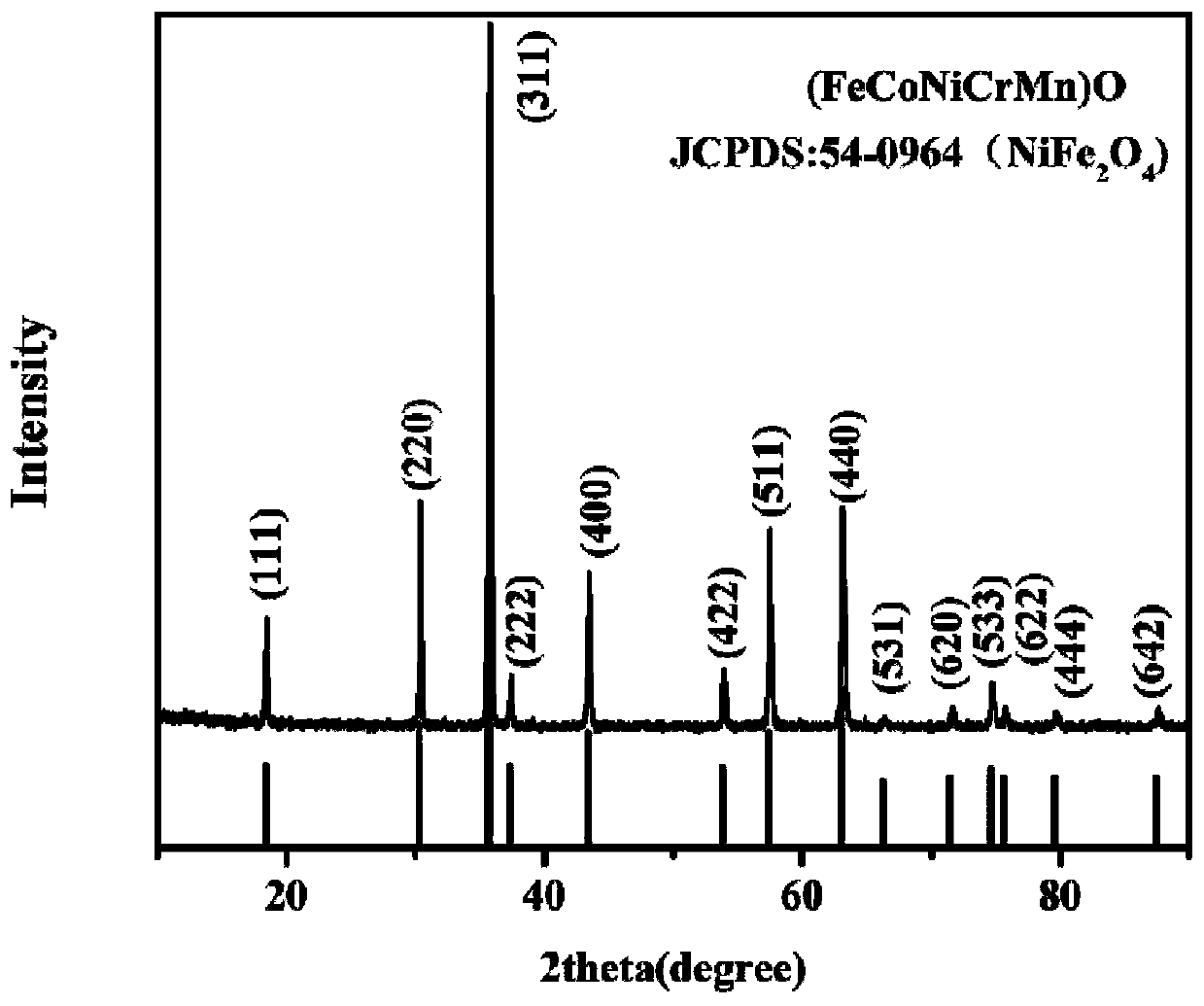

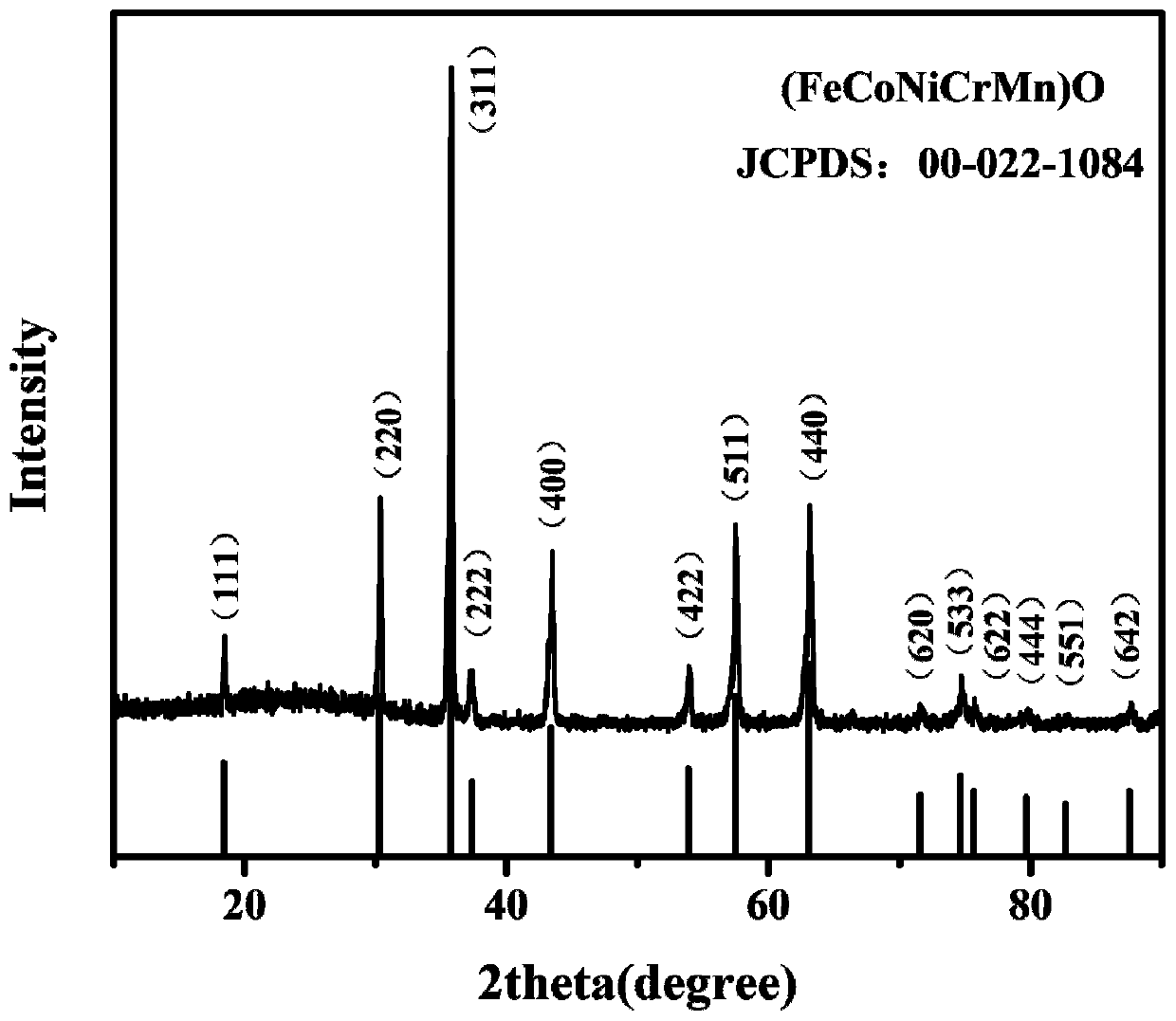

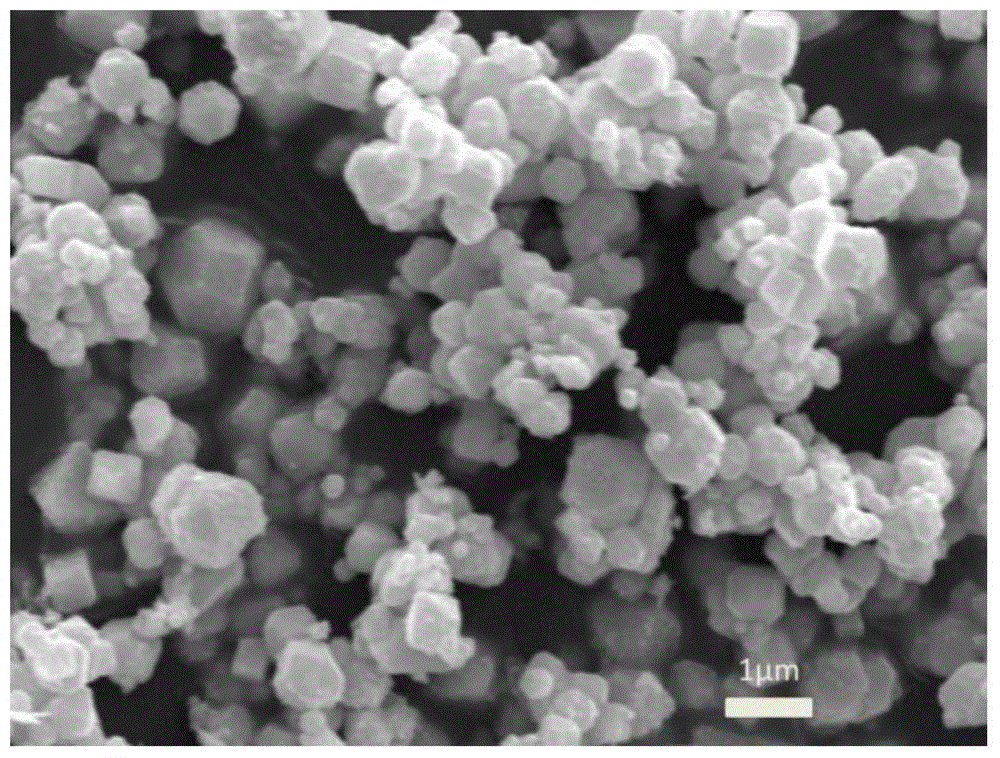

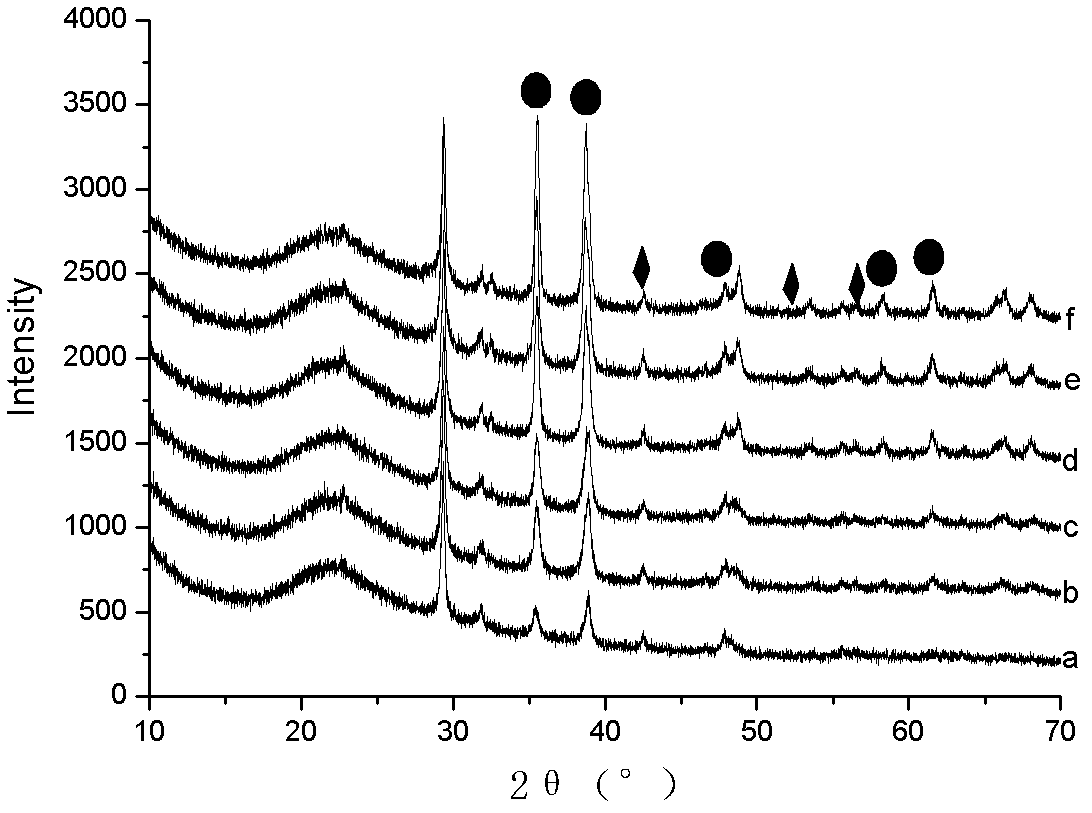

Spinel type high-entropy oxide electrode material and preparation method thereof

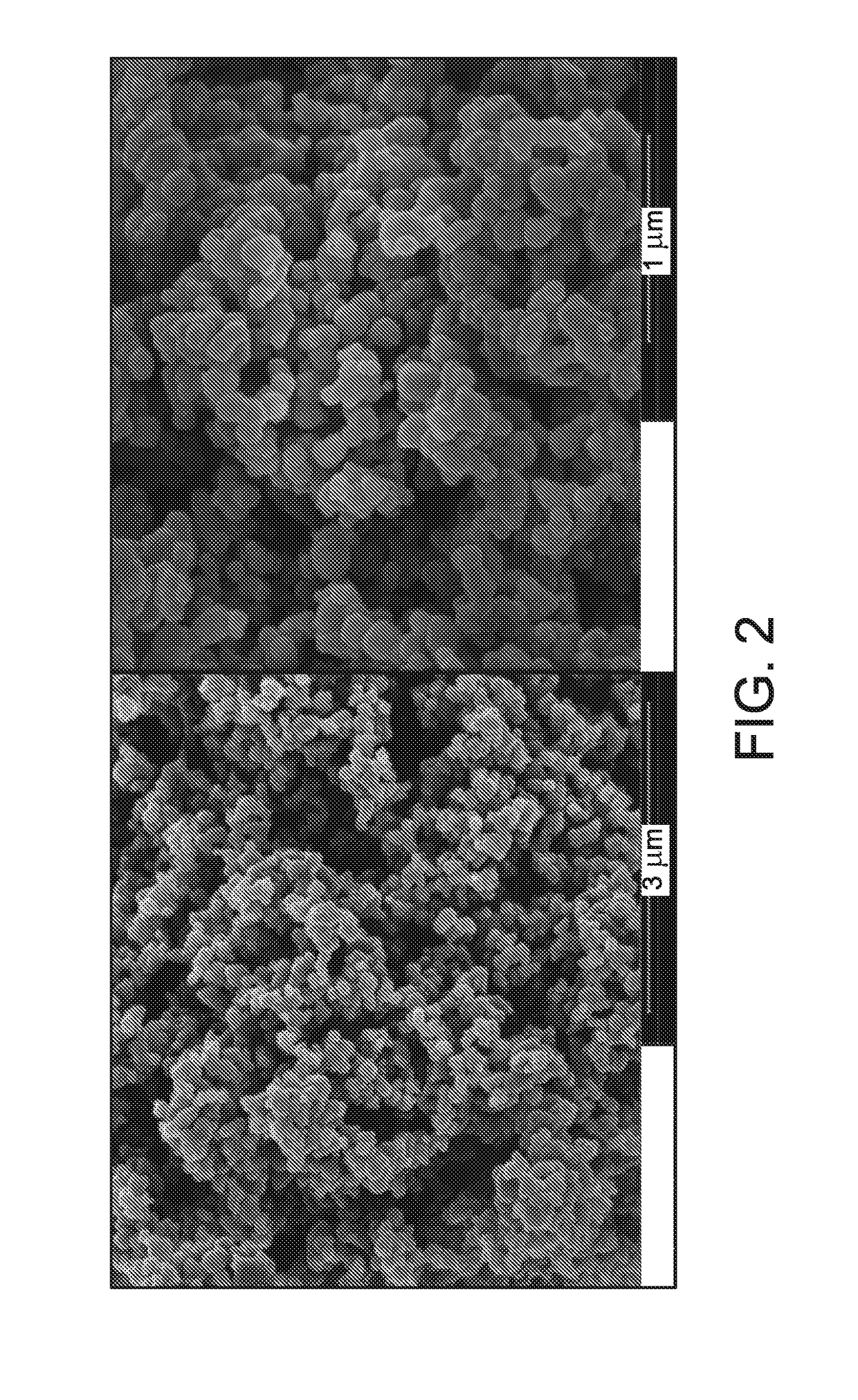

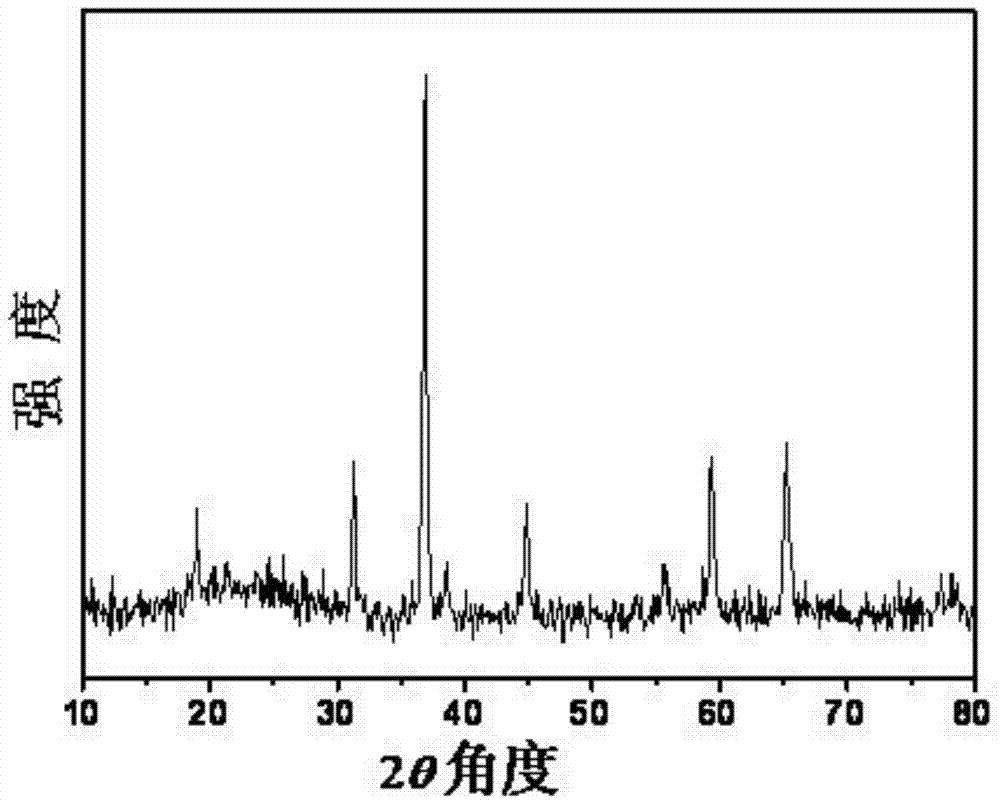

ActiveCN110364717AHigh specific capacityImprove cycle stabilityNegative electrodesSecondary cellsIron(II) oxideSpace group

The invention relates to a spinel type high-entropy oxide electrode material and a preparation method thereof, and belongs to the field of nanomaterial preparation and new energy. The chemical formulaof the high-entropy oxide electrode material is one of (FeCoNiCrMn)O, (FeZnNiCrMn)O, (FeCoZnCrMn)O and (FeCoNiCrMnCu)O. The preparation method includes the steps of 1) mixing and ball-milling iron oxide, chromium oxide, manganese oxide and M metal oxide, wherein the M metal oxide is two or more of nickel oxide, zinc oxide, copper oxide and cobalt oxide; and 2) carrying out high-temperature calcination, and obtaining the spinel type high-entropy oxide electrode material by adopting a cooling mode of furnace cooling, air quenching and liquid nitrogen quenching. The particle diameter of the high-entropy oxide is 100-500nm, and the high-entropy oxide is determined to be in a spinel structure according to XRD; and the space group of the material is Fd-3m, and the specific surface area is 5-100m<2>g<-1>.

Owner:东北大学秦皇岛分校

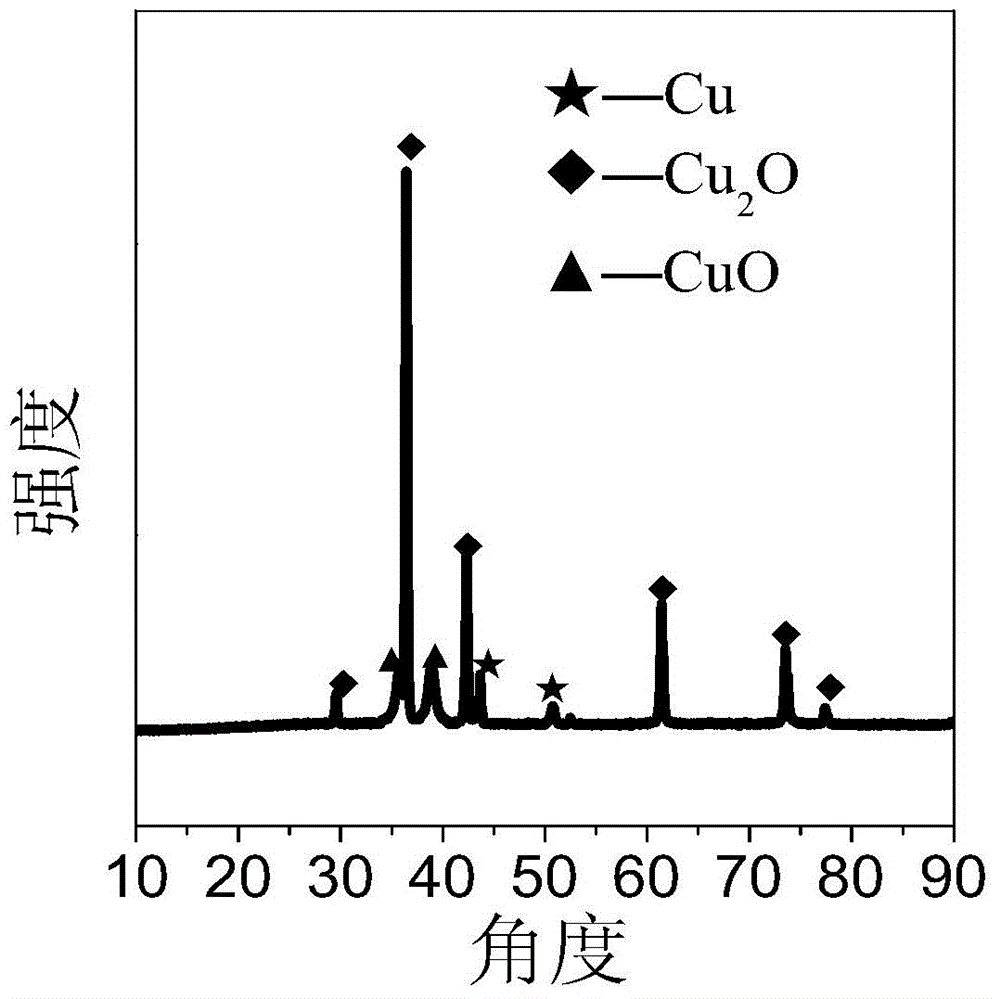

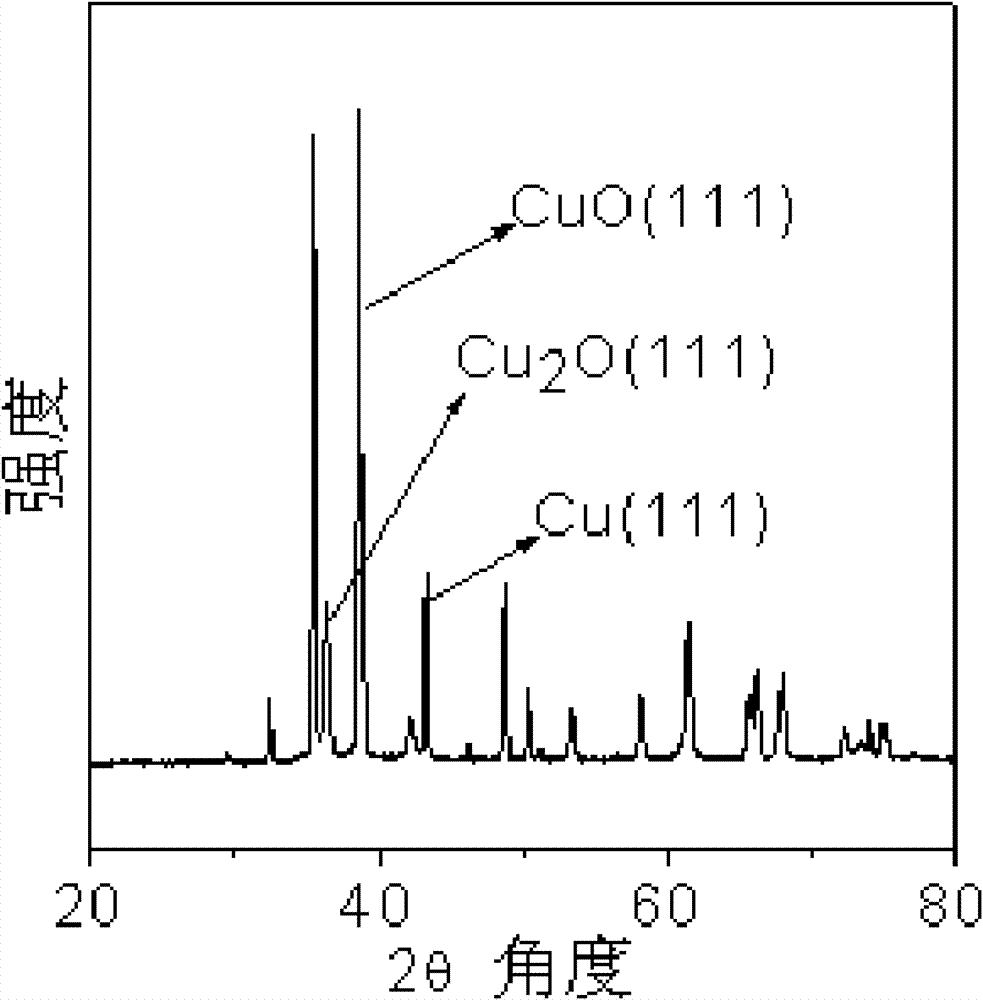

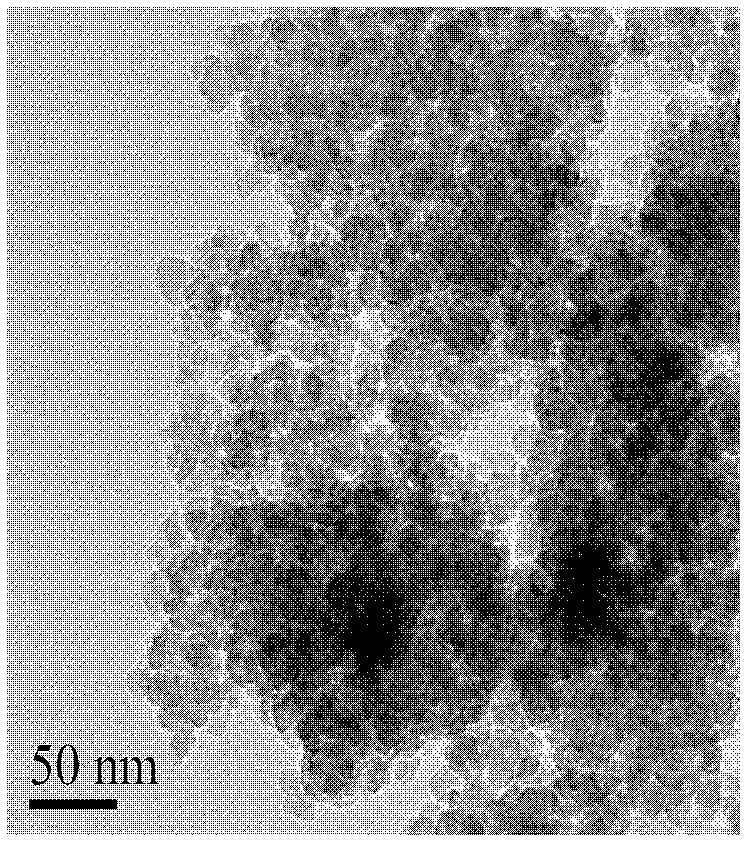

Copper-based Cu-Cu2O-CuO catalyst as well as preparation method and application thereof

ActiveCN104857958AControllable ratioEvenly distributedGroup 4/14 element organic compoundsMetal/metal-oxides/metal-hydroxide catalystsCopper(II) oxideVacuum drying

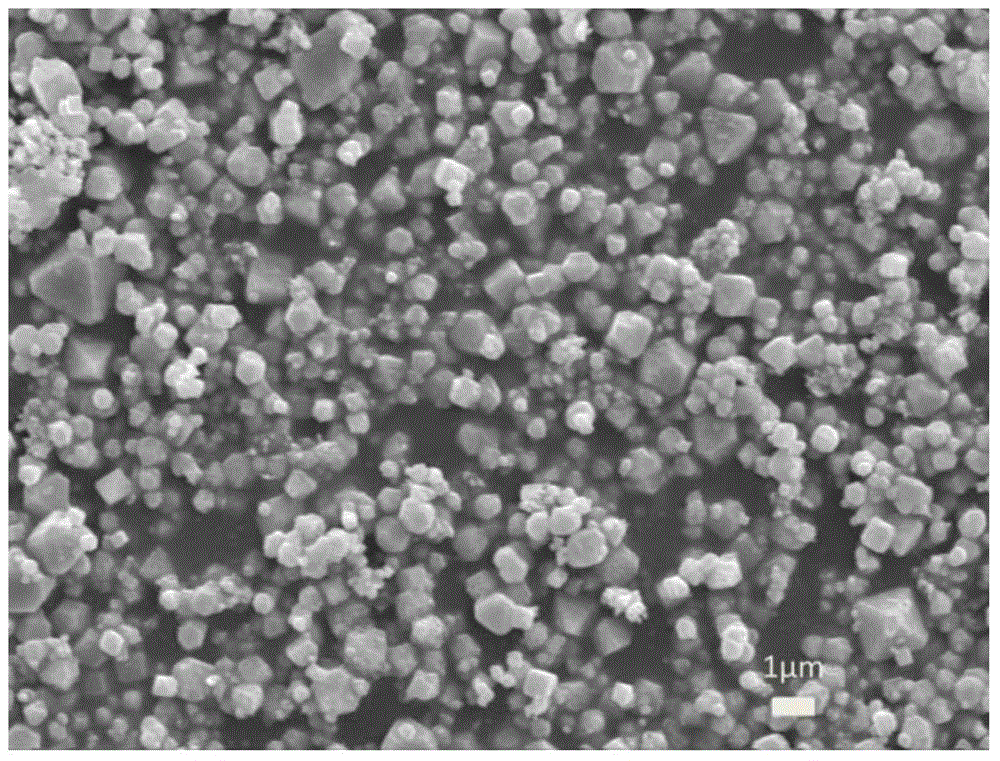

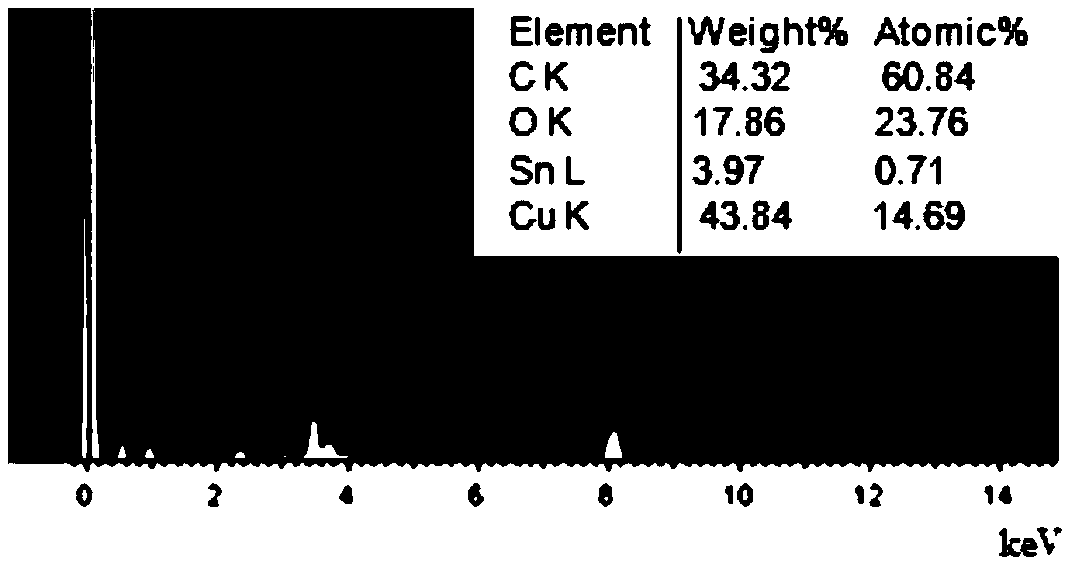

The invention provides a copper-based Cu-Cu2O-CuO catalyst for an organic silicon monomer synthesis reaction as well as a preparation method and an application of the copper-based Cu-Cu2O-CuO catalyst. The catalyst comprises components in percentage by mass as follows: 0-40% of elementary Cu, 40%-90% of Cu2O and 0-40% of CuO, and the sum of mass percentages of all the components is 100%. The method comprises steps as follows: a copper salt is dissolved to form a copper salt solution; an alkaline solution is dropwise added to the copper salt solution, and copper hydroxide precipitate is obtained and then converted into CuO precipitate; then a certain quantity of reducing agent is dropwise added to a CuO suspension for a controllable reduction reaction; obtained reaction products are filtered, washed and subjected to vacuum drying, and then the multicomponent copper-based catalyst is obtained. The experimental process route is simple, the controllability is high, and the prepared multicomponent copper-based catalyst is smaller in particle size and evener in particle size distribution, contains controllable components and shows the higher M2 selectivity and the higher silicon powder raw material conversion ratio.

Owner:TAIXING SMELTING PLANT

Treatment method of coarse tin decoppered slag

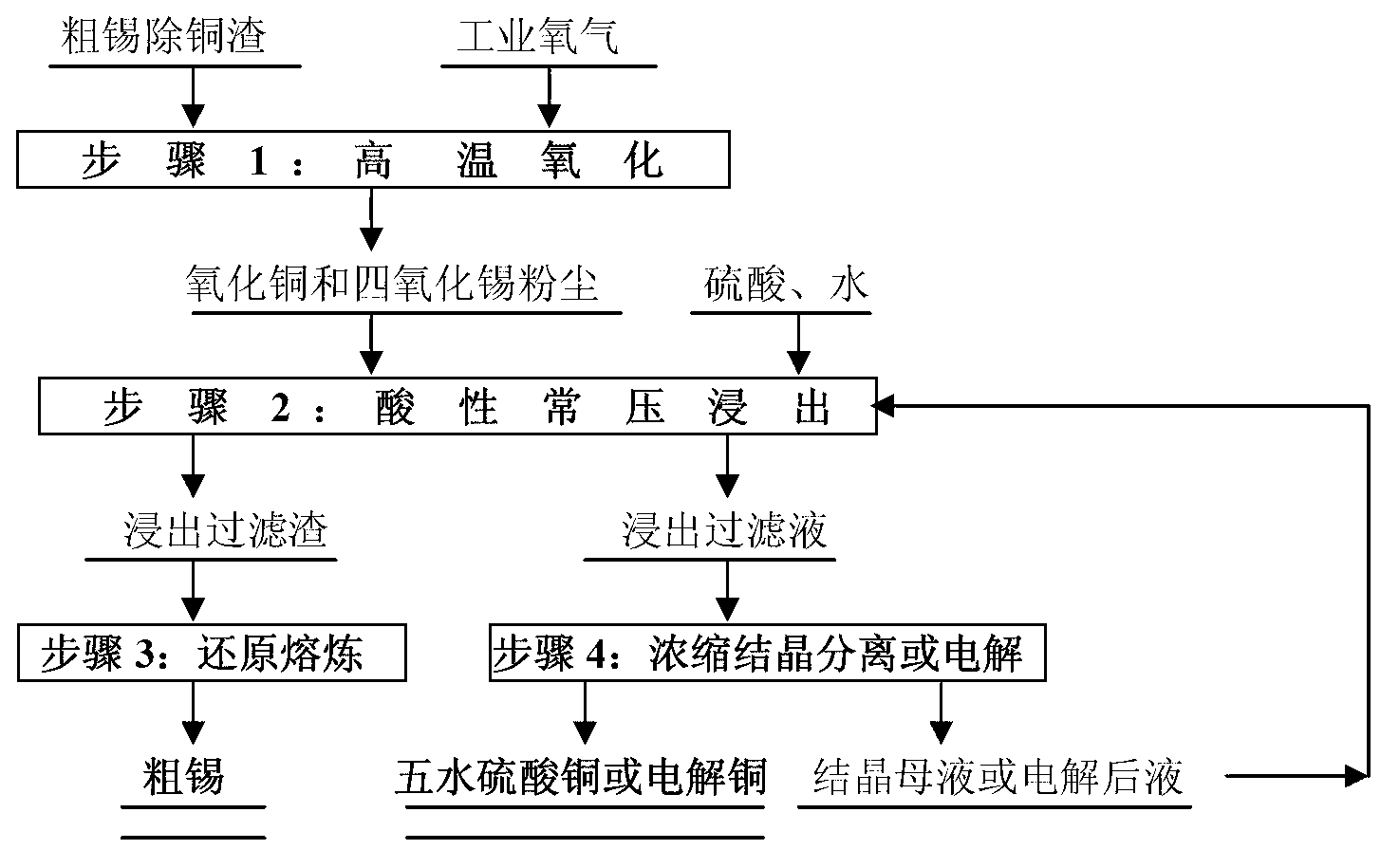

InactiveCN102851514AImprove direct yieldSafe separationProcess efficiency improvementElectrolysisSlag

The invention relates to a treatment method of coarse tin decoppered slag, which comprises the following steps: jetting industrial oxygen with the purity of 93-98.5% to the surface or inside of the coarse tin decoppered slag at the temperature of 850-1250 DEG C until the coarse tin decoppered slag is completely oxidized into copper oxide and tin tetroxide dust; leaching the copper oxide and tin tetroxide dust for 2-3 hours under atmospheric pressure and temperature under the condition of the initial acid of 70-120 g / L to obtain leached filtered slag, and carrying out reduction smelting to produce coarse tin; concentrating the leached filtrate to crystallize, and separating to produce chalcanthite product, or carrying out electrolysis to produce electrolytic copper; and returning the crystallization mother solution or electrolysis solution to the leaching process for solution preparation. The invention can separate tin and copper in the crude tin decoppered slag in a safe and efficient way, and does not generate waste water, waste gas or waste residue.

Owner:LAIBIN CHINA TIN SMELTING

Method for preparing high-purity cupric oxide powder from acid cupriferous waste liquid

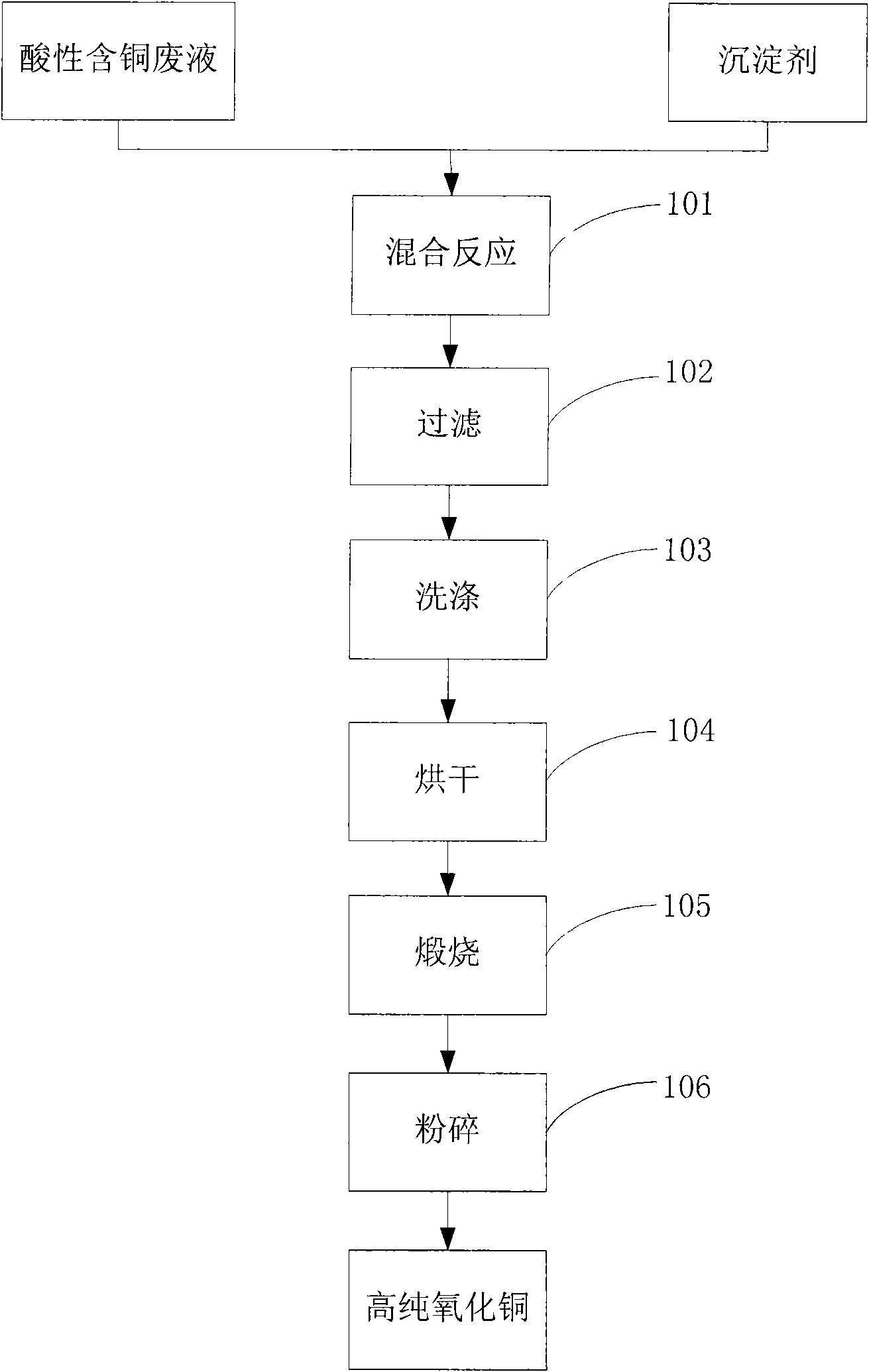

ActiveCN101549882AEfficient removalSimplify the precipitation washing processCopper oxides/halidesDicarbonateFiltration

The invention relates to a method for preparing high-purity cupric oxide powder from acid cupriferous waste liquid, which comprises the following steps: mixing the acid cupriferous waste liquid and a precipitator (such as hydrocarbonate, carbonate, ammonia, sodium hydroxide or potassium hydroxide, and the like) to react until cupric ions are completely precipitated; washing precipitated slurry with a washing agent (a water solution containing a certain amount of electrolytes) after filtration, and then washing with water; and drying, calcining and pulverizing cupriferous materials after washing to obtain high-purity superfine cupric oxide powder. The acid cupriferous waste liquid can be acid etching waste liquid produced in the production of printed circuit boards. The cupric oxide powder prepared by the method has high purity, simple processes, low production cost and high economic benefit, and is suitable for industrialized production.

Owner:SHANGHAI MEADVILLE SCI & TECH

Method of making a copper oxide-titanium vdioxide nanocatalyst

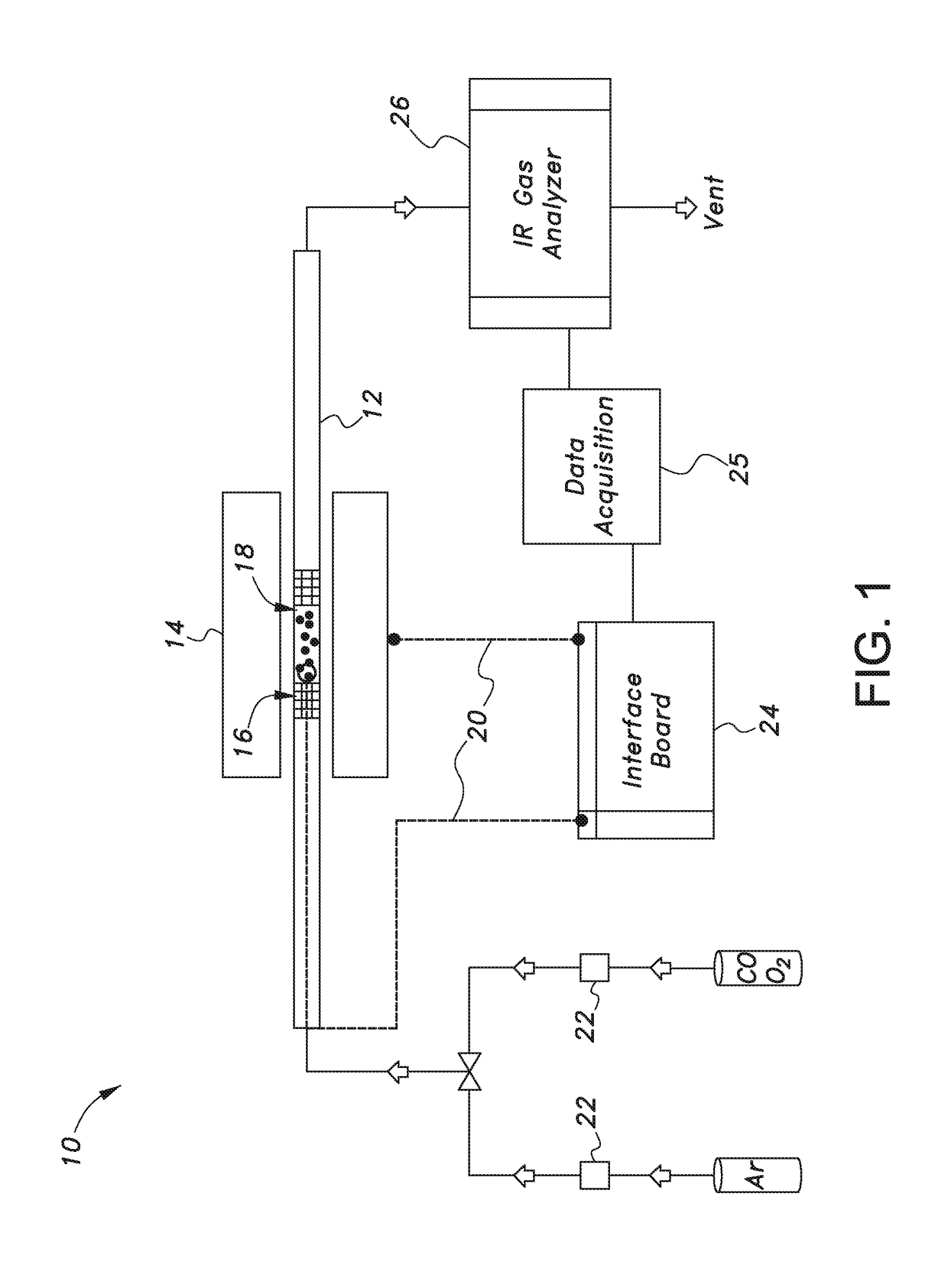

ActiveUS20190060877A1Heterogenous catalyst chemical elementsDispersed particle separationNano catalystCatalytic oxidation

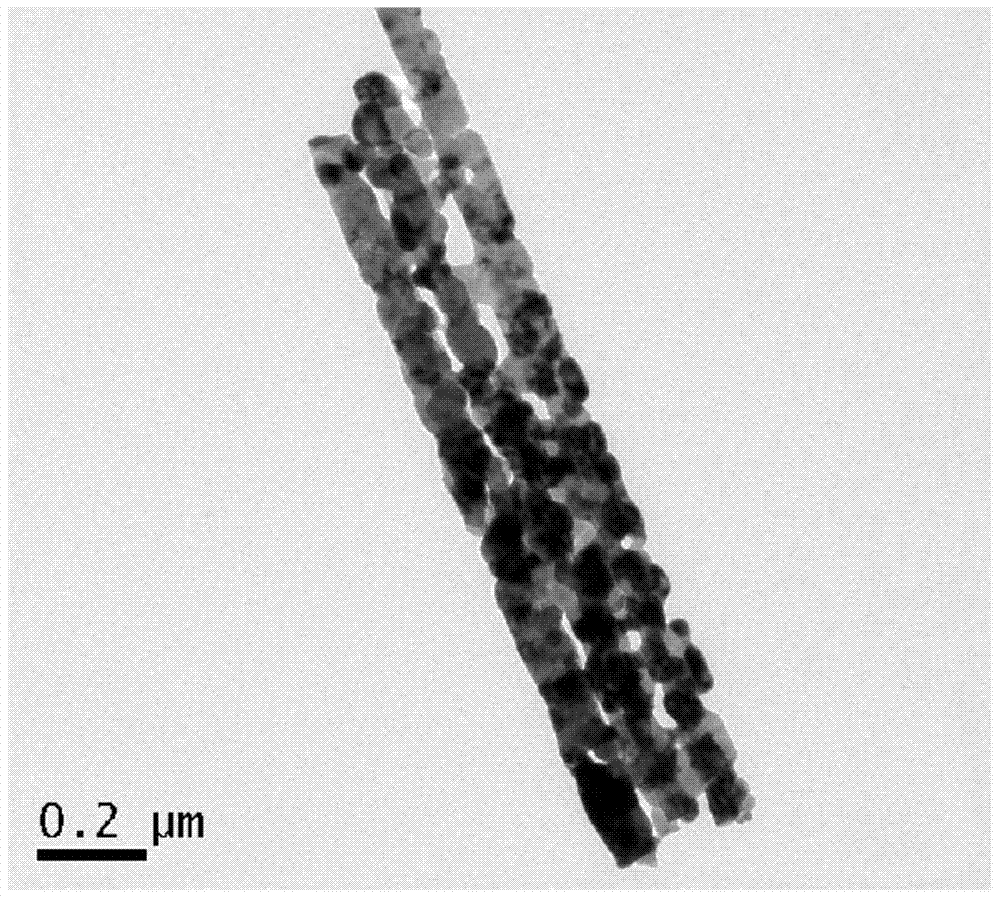

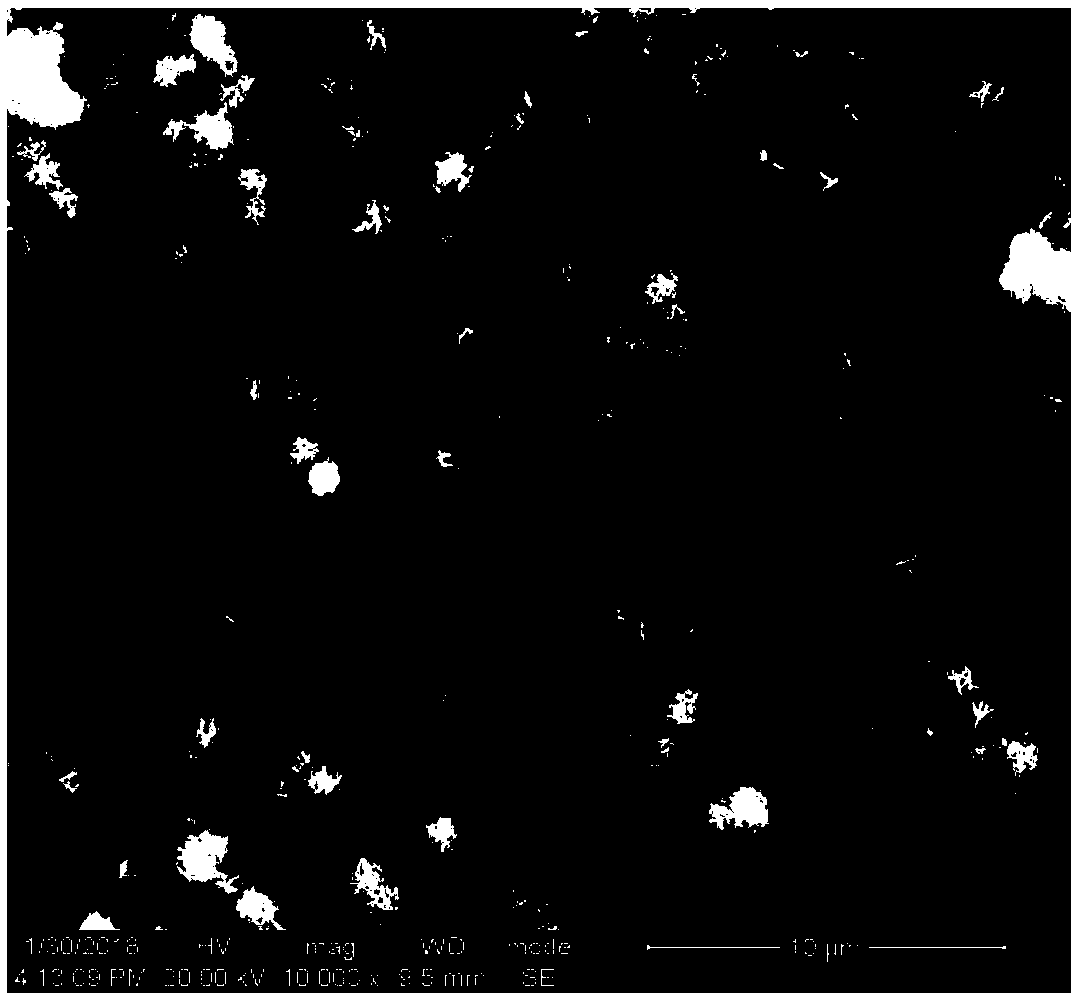

A method of making a copper oxide-titanium dioxide nanocatalyst for performing the catalytic oxidation of carbon monoxide is provided. The copper oxide-titanium dioxide nanocatalyst is in the form of copper oxide (CuO) nanoparticles supported on mesoporous titanium dioxide (TiO2) nanotubes. The copper oxide-titanium dioxide nanocatalyst is prepared by adding an aqueous solution of Cu(NO3)23H2O to an aqueous suspension of titanium dioxide nanotubes. Deposition precipitation at constant alkaline pH is used to form the copper oxide nanoparticles supported on mesoporous titanium dioxide nanotubes. Aqueous sodium carbonate is used to adjust the pH. The solid matter (copper oxide deposited on titanium dioxide nanotubes) is separated from the suspension, washed, dried and calcined, yielding the copper oxide-titanium dioxide nanocatalyst. Carbon monoxide may then flow over a fixed-bed reactor loaded with the copper oxide-titanium dioxide nanocatalyst at a temperature between 80° C. and 200° C.

Owner:QATAR UNIVERSITY

Preparation method of porous cobaltosic oxide nanobelt

InactiveCN103922425ASurfactant freeSimple manufacturing processMaterial nanotechnologyCobalt oxides/hydroxidesOrganic solventCobalt(II,III) oxide

The invention belongs to the technical field of synthesis of inorganic nano materials and discloses a preparation method of a porous cobaltosic oxide nanobelt. The preparation method of the porous cobaltosic oxide nanobelt comprises the following steps: (1) firstly dissolving cobalt salt and a precipitator into water, so that a mixed solution is formed; (2) placing the mixed solution into a hydrothermal kettle, carrying out a hydrothermal reaction for 5-24 hours at the temperature of 100-250 DEG C; (3) after the hydrothermal reaction is finished, separating and washing reaction products, and then roasting the reaction products at the temperature of 350-800 DEG C, so that the porous cobaltosic oxide nanobelt is obtained. According to the preparation method of the porous cobaltosic oxide nanobelt, no surfactant or organic solvent is adopted in a synthetic process, and a new synthetic method is provided for a multilevel structure copper oxide material; a preparation technology is simple, the whole technological process is carried out in a reaction kettle, no complex equipment is needed, and the preparation method of the porous cobaltosic oxide nanobelt is simple, efficient, low in cost, environmentally friendly and easy for large-scale synthesis.

Owner:HEBEI UNIV OF ENG

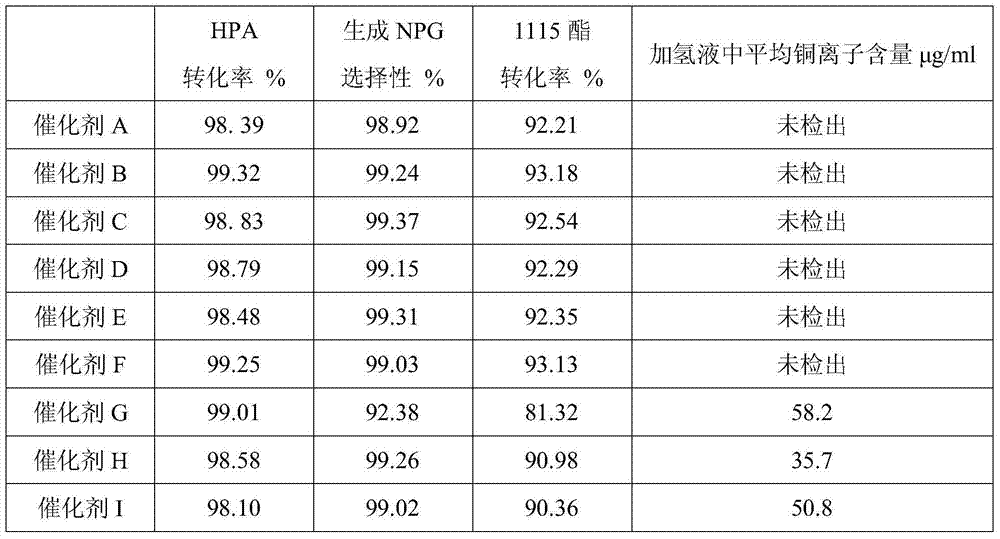

Preparation method of catalyst for hydroxypivalaldehyde liquid phase hydrogenation preparation of neopentylene glycol

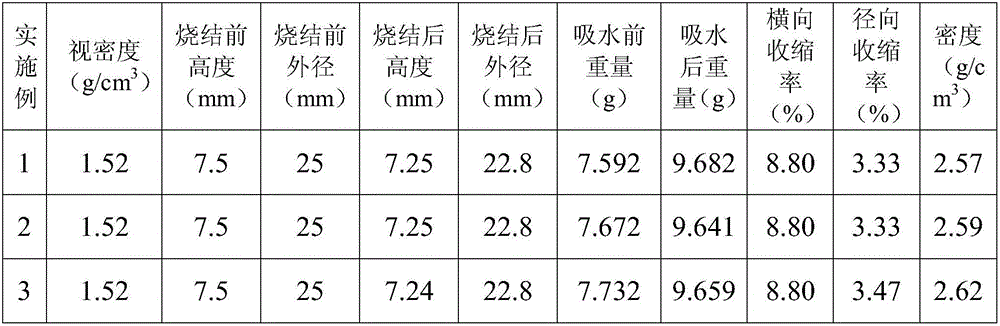

ActiveCN104258869AImprove cohesionMinimize cracksOrganic compound preparationHydroxy compound preparationCopper(II) oxideHigh activity

The invention relates to a preparation method of a catalyst for hydroxypivalaldehyde liquid phase hydrogenation preparation of neopentylene glycol. The catalyst comprises 20-65wt% of copper oxide, 15-50wt% of alumina, 2-25wt% of zinc oxide, 0.1-5wt% of tin oxide, 0.5-25wt% of alkaline earth oxide and 0-20wt% of titanium oxide and / or zirconia. The compounds containing copper, aluminum, zinc, tin and alkaline earth metal are mixed to form a mixture aqueous solution according to a certain ratio, the solution and an alkaline precipitant are added into a nanometer oxide-containing dispersion liquid in parallel, the mixture undergoes a precipitation reaction, the reaction product is aged and filtered, and the filter residues are washed, dried, roasted and compressed to form a molded catalyst. The catalyst prepared by the method has high activity and good selectivity in hydroxypivalaldehyde liquid phase hydrogenation preparation of neopentylene glycol, can promote 1115 ester conversion, can effectively improve liquid-repellency, and has high catalyst intensity and good stability.

Owner:WANHUA CHEM GRP CO LTD +1

Catalyst used in fatty alcohol production with fatty acid methyl ester catalyzed hydrogenation technology, preparation method thereof, and application thereof

ActiveCN102476056AReduce pollutionHigh catalytic activityOrganic compound preparationHydroxy compound preparationManganese oxideCopper(II) oxide

The invention discloses a catalyst used in fatty alcohol production with a fatty acid methyl ester catalyzed hydrogenation technology. The catalyst is composed of, by weight: 18-66% of a mixture of copper oxide and zinc oxide, 0-40% of one or two selected from manganese oxide and nickel oxide, 5-17% of alumina, and 0-45% of a carrier, wherein the carrier is diatomite or calcium carbonate. The catalyst is advantaged in environment friendliness, high activity, good product stability, and the like. The invention also discloses a preparation method of the catalyst used in fatty alcohol productionwith the fatty acid methyl ester catalyzed hydrogenation technology. The method comprises steps that: at least two soluble salts of copper, zinc, manganese, nickel, and aluminum are dissolved in water, such that a mixed solution is prepared; water, or a mixture of water and the carrier is adopted as a base solution; an aqueous solution of sodium carbonate and the mixed solution are dropped into the base solution with a co-current flow; when dropping is finished, a precipitate is obtained; the precipitate is aged, filtered, washed, dried, roasted, and pressed, such that a finished product is obtained. The preparation method is advantaged in simple technology, high operability, easy industrialization, and the like.

Owner:浙江嘉化能源化工股份有限公司

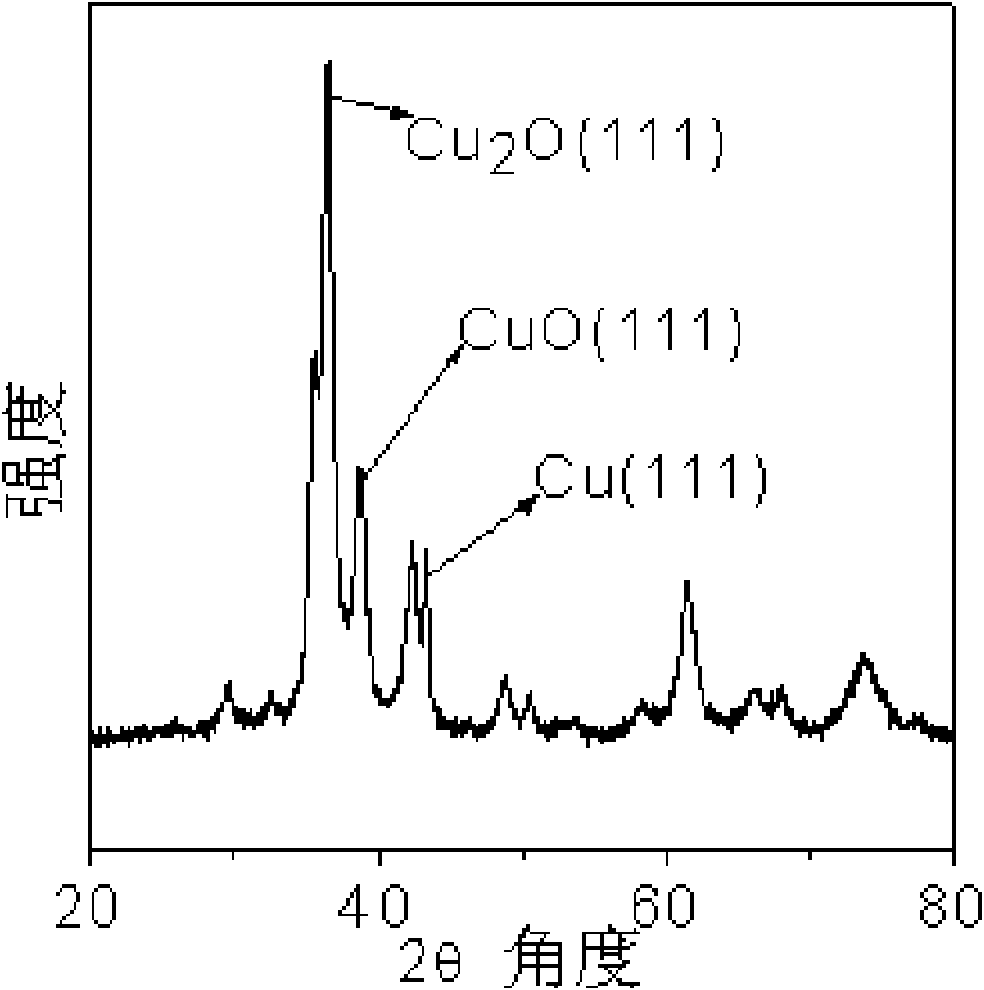

Ternary copper catalyst CuO-Cu2O-Cu for synthesis of dimethyldichlorosilane and its preparation method

InactiveCN102773100AWell formedLow priceGroup 4/14 element organic compoundsCatalyst activation/preparationCopper(II) oxideControllability

The invention relates to the field of catalysts used for synthesis of dimethyldichlorosilane, in particular to a ternary copper catalyst CuO-Cu2O-Cu for synthesis of dimethyldichlorosilane and its preparation method. The method comprises the following steps of: 1) taking copper oxide powder as a raw material, adding a reducing gas, controlling its flow to make the flow of the reducing gas introduced into per gram of CuO particles at 0.1ml / min-100ml / min, maintaining the temperature at 100DEG C-600DEG C, carrying out a reduction reaction for 0.5h-6h, thus obtaining partially reduced copper oxide; and 2) subjecting the partially reduced copper oxide obtained in step 1) to breaking and ball-milling, thus obtaining the ternary copper catalyst for synthesis of dimethyldichlorosilane. With copper oxide as the raw material, the method prepares the ternary copper catalyst CuO-Cu2O-Cu through a one-step reaction, and has the advantages of simple technological process, convenient operation, strong process controllability, and easy mass production. The prepared catalyst shows high dimethyldichlorosilane selectivity and silicon powder material conversion rate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

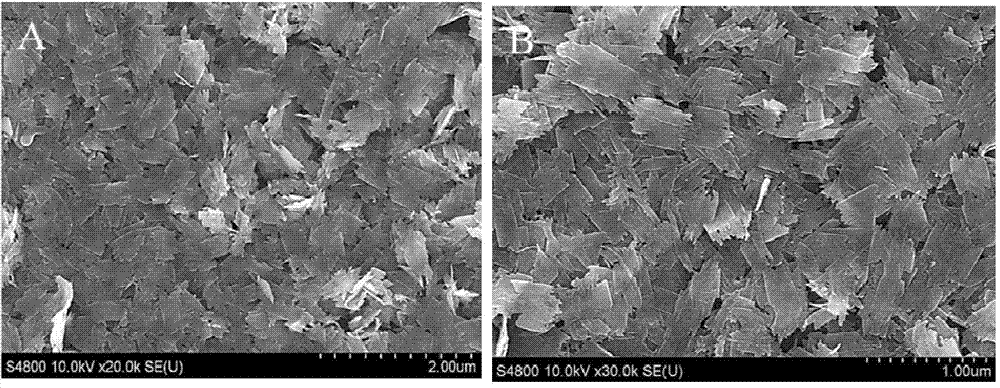

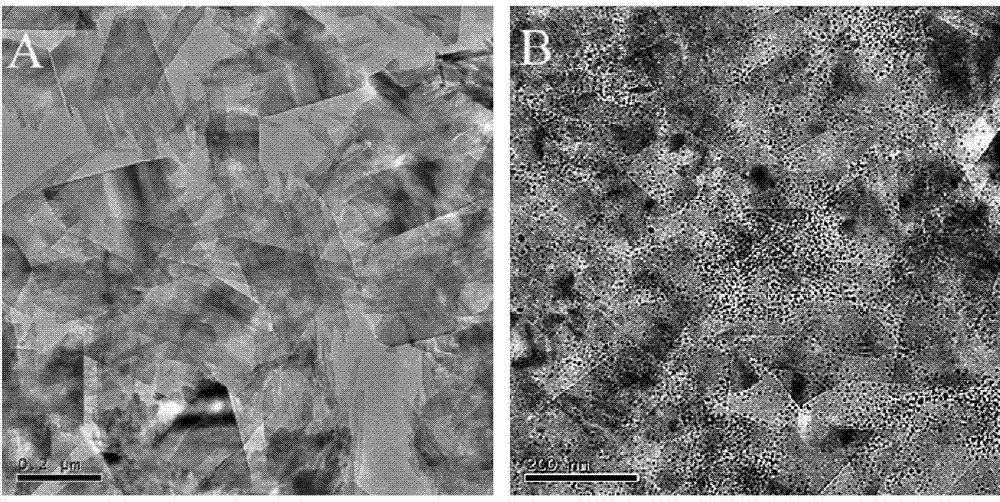

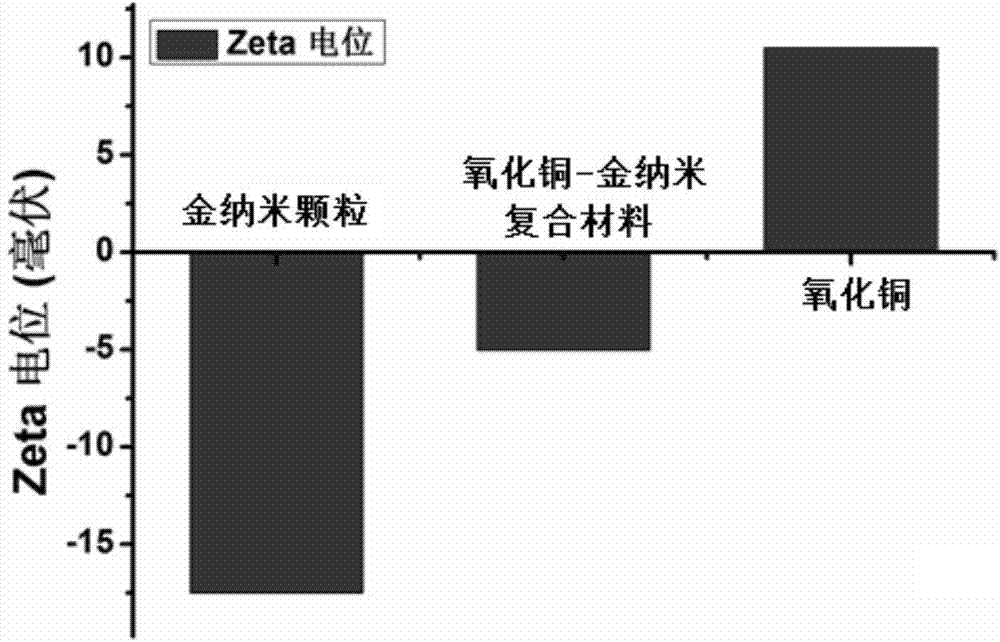

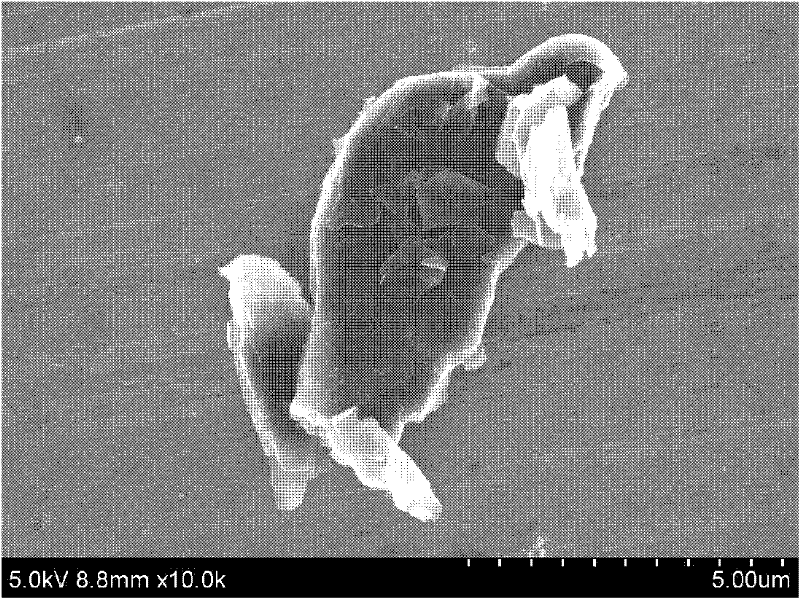

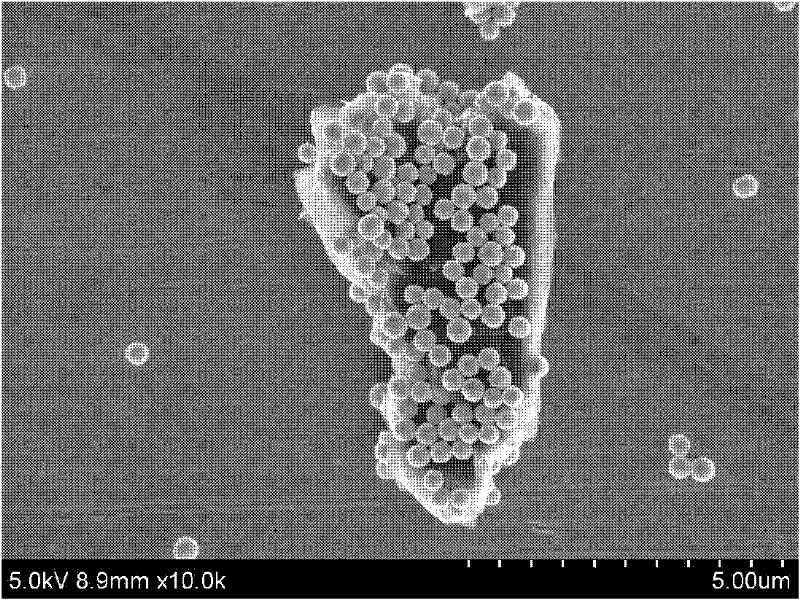

Copper oxide-gold nano composite material, preparation method and application thereof

InactiveCN104722313AImprove stabilityGood dispersionMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationThiolOrganic dye

The invention provides a copper oxide-gold nano composite material, a preparation method and an application thereof. The copper oxide-gold nano composite material is prepared by uniformly dispersing gold nano particles on a copper oxide nano sheet. The preparation method of the copper oxide-gold nano composite material comprises the following steps: optionally adding thiol-polyethylene glycol into an aqueous solution of the gold nano particles, then adding the copper oxide nano sheet, and performing self-assembling by virtue of the electrostatic interaction and the adsorption effect of the nano sheet to obtain the copper oxide-gold nano composite material. The preparation process is simple, the operability is high, the requirement for equipment is low, the prepared copper oxide-gold nano composite material is high in catalytic activity, the degradation rate of organic dye methylene blue can be remarkably improved, the time for complete degradation can be shortened, and the copper oxide-gold nano composite material has capacity for high-efficiently catalytically degrading organic dye.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Graphene-coated copper oxide composite cathode material and method for manufacturing same

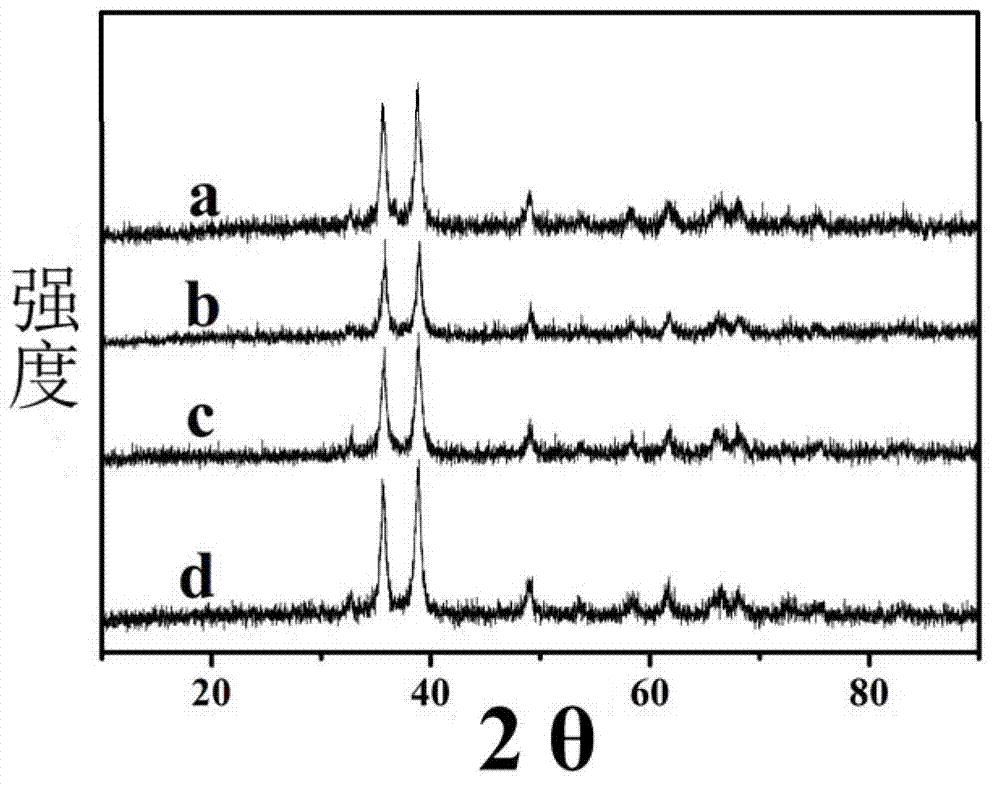

ActiveCN102916195AAlleviate chalking problemsPromote migrationCell electrodesComposite cathodeSynthesis methods

The invention discloses a graphene-coated copper oxide composite cathode material and a method for manufacturing the same. The graphene-coated copper oxide composite cathode material comprises, by mass, from 20% to 90% of copper oxide and from 10% to 80% of graphene. The method includes uniformly mixing copper salt solution and graphene oxide solution at first, and stirring the copper salt solution and the graphene oxide solution at a constant temperature for 15 minutes to 1 hour to obtain mixed solution; dripping sodium hydroxide solution into the mixed solution, continuously stirring the mixed solution added with the sodium hydroxide solution for 0.5 hour to 2 hours and allowing the mixed solution added with the sodium hydroxide solution to stand for 2 to 24 hours; and performing centrifuging and hydrothermal processing for the mixed solution added with the sodium hydroxide solution to obtain a product, and drying the product at the temperature of 120 DEG C for 12 hours to obtain the graphene-coated copper oxide composite cathode material. The graphene-coated copper oxide composite cathode material and the method have the advantages that the synthesis method is simple, the manufactured graphene-coated copper oxide composite cathode material is good in performance, and technical problems of poor conductivity of a copper oxide electrode and decrease of capacity due to gradual chalking in charge and discharge processes are solved.

Owner:TSINGHUA UNIV

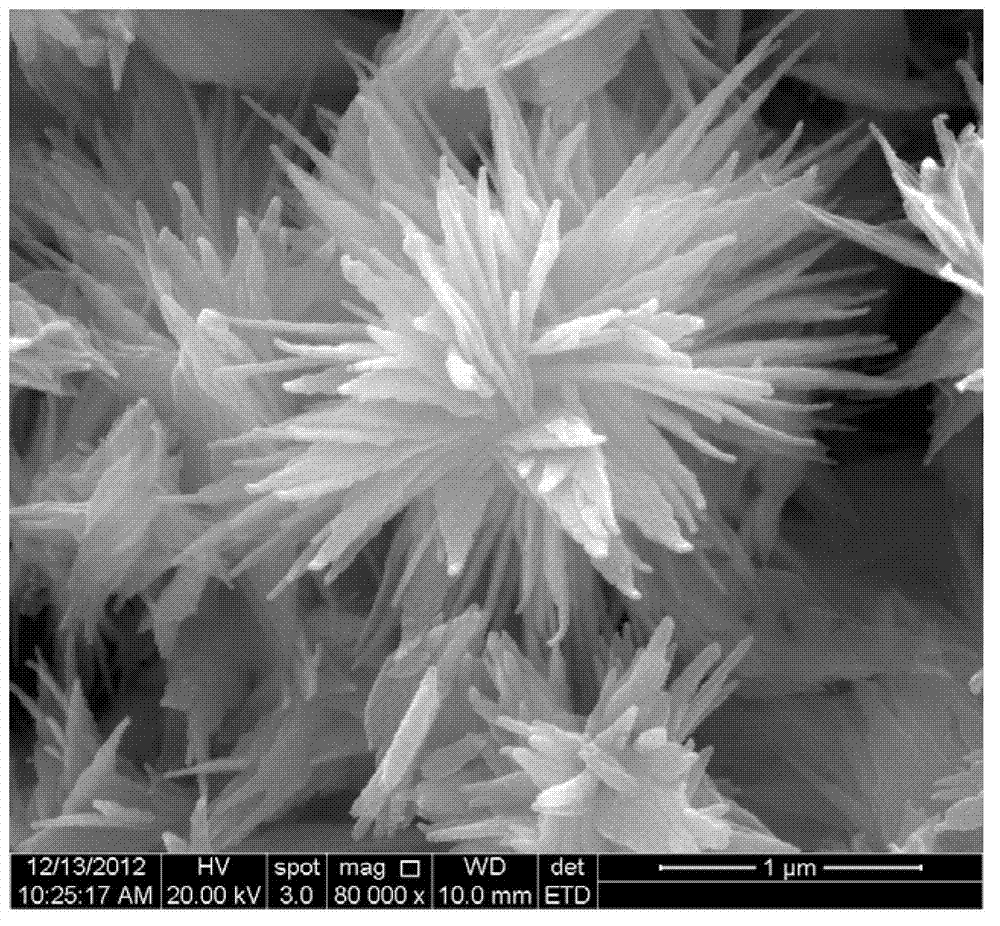

Simple preparation method of three-dimensional flower-shaped micro-nano copper oxide

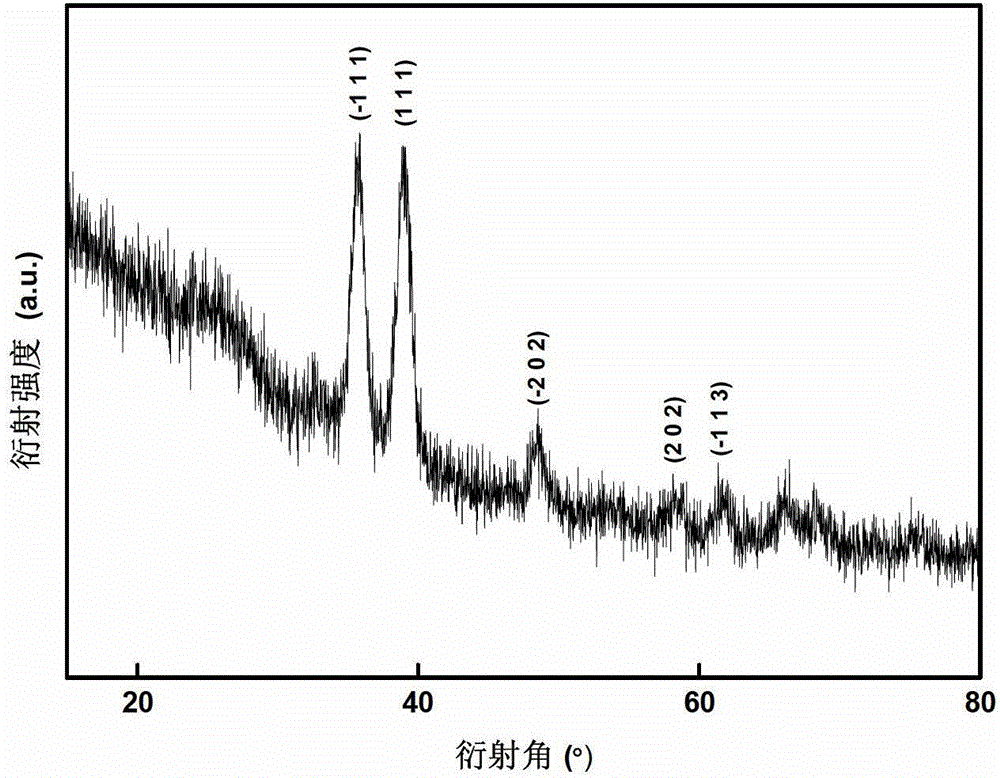

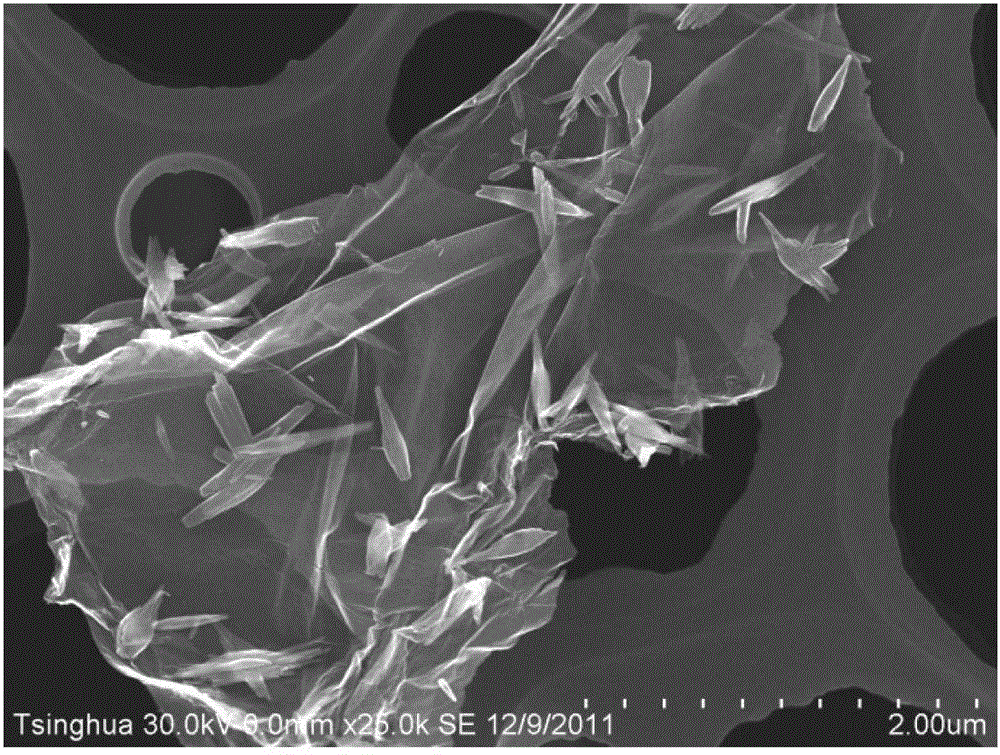

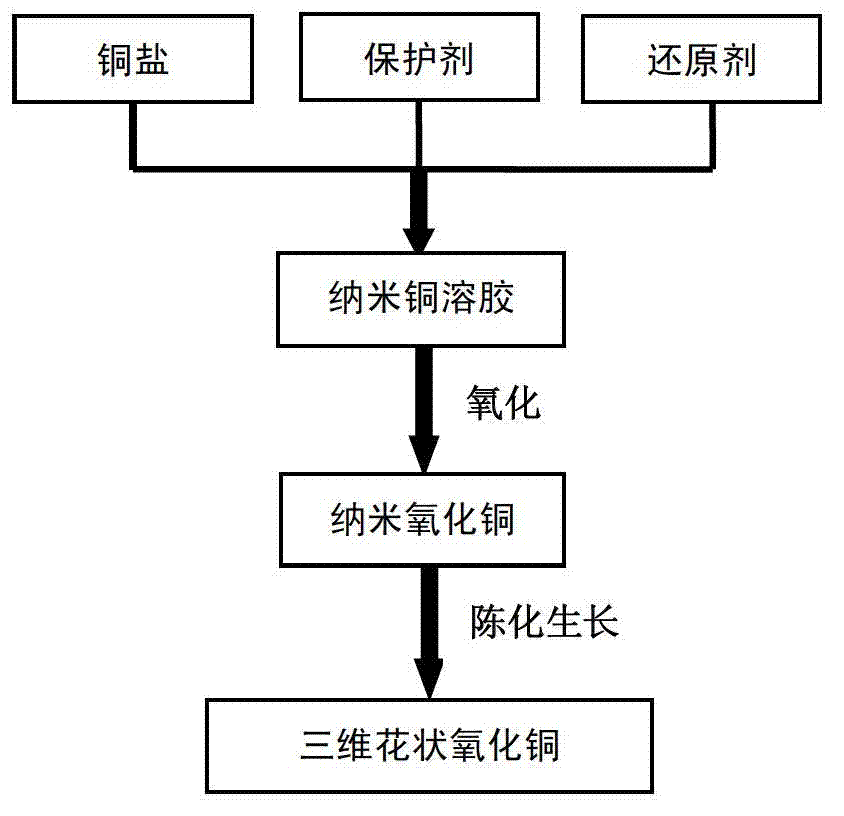

InactiveCN103241761ASimple processEasy to operateMaterial nanotechnologyCopper oxides/halidesPotassium borohydrideSurface roughness

The invention relates to a simple preparation method of three-dimensional flower-shaped micro-nano copper oxide. The method comprises the following steps of: (1) preparing nano-copper sol: reducing copper salt in an aqueous solution at normal temperature to prepare the nano-copper sol, wherein potassium borohydride serves as a reducing agent and hexadecyl trimethyl ammonium bromide serves as a protective agent; (2) oxidizing nano-copper: standing at a lower temperature for a period of time, so that the nano-copper particles are completely oxidized into copper oxide particles; and (3) ageing and growing the nanometer copper oxide: regularly growing the nanometer copper oxide particles in a gathering mode into three-dimensional flower-shaped copper oxide at a low temperature. According to the invention, the simple, convenient and low-cost preparation method of the three-dimensional flower-shaped micro-nano copper oxide is implemented, and the high-temperature and high-pressure conditions required by the traditional preparation method of the material are overcome; and the prepared copper oxide material has the characteristics of novel structure, uniform appearance and size, high surface roughness and the like, and is suitable for serving as a catalyst, a gas sensitive material and the like.

Owner:WUHAN UNIV OF TECH

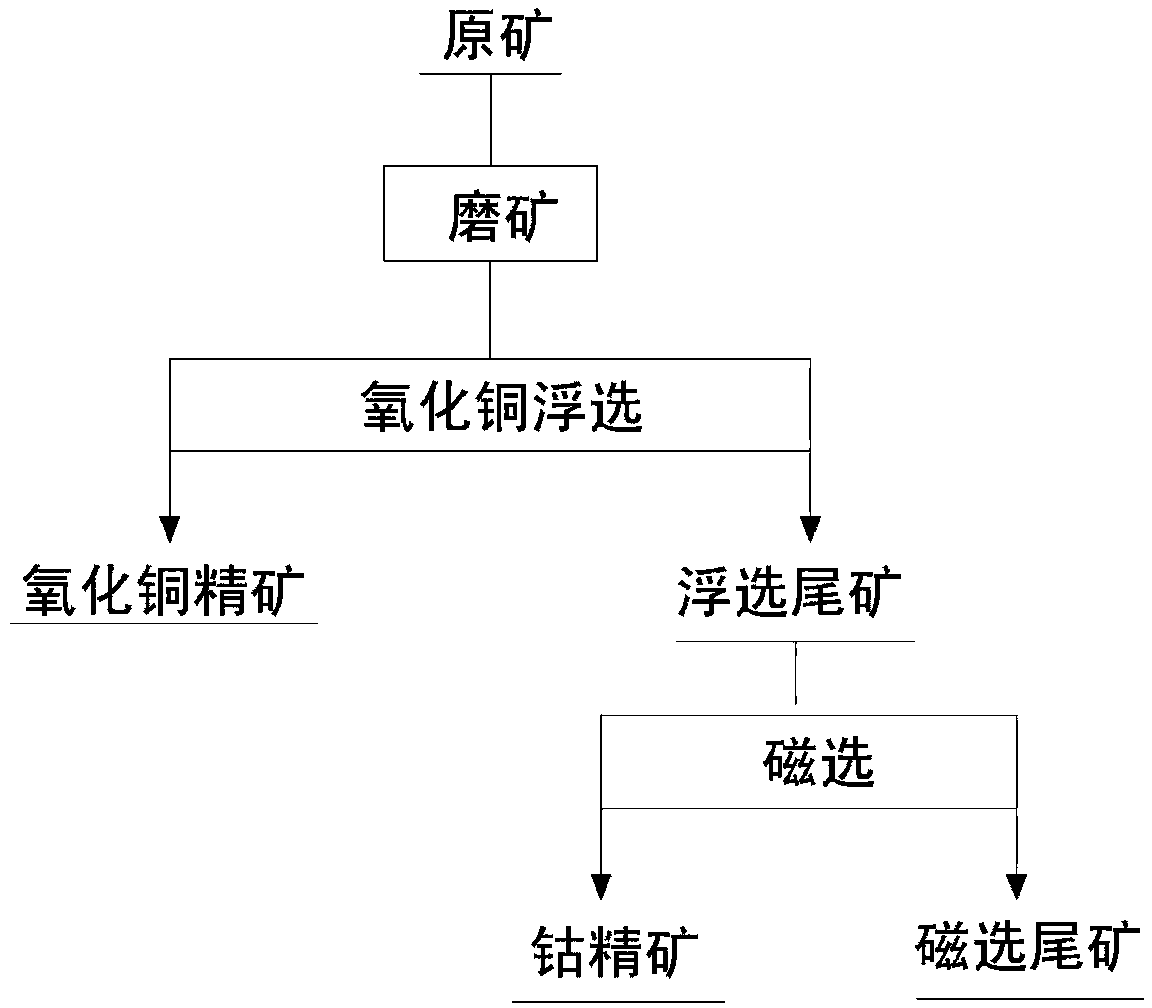

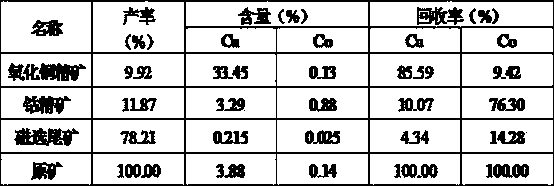

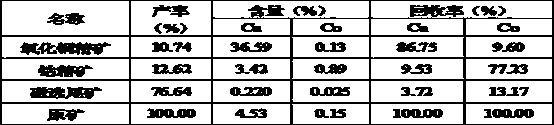

Beneficiation method for copper oxide cobalt ores

The invention relates to a beneficiation method for copper oxide cobalt ores. The beneficiation method is characterized by comprising the following steps of 1, ore grinding, i.e. crushing and grinding raw ores; 2, copper oxide flotation, i.e. adding sodium sulfide, a collecting agent butyl xanthate and a foaming agent terpenic oil in the primary roughing process, adding sodium sulfide, butyl xanthate and terpenic oil in the primary scavenging process, adding sodium sulfide, butyl xanthate and terpenic oil in the secondary scavenging process and carrying out secondary blank concentration to obtain copper oxide concentrates and flotation tailings; and 3, magnetic separation, i.e. carrying out primary roughing magnetic separation on the flotation tailings to obtain cobalt rough concentrates and magnetic separation tailings and carrying out secondary concentration magnetic separation on the cobalt rough concentrates to obtain cobalt concentrates and magnetic separation tailings. The invention provides the beneficiation method for the copper oxide cobalt ores, which reduces cost and pollution. The method disclosed by the invention is suitable for the copper oxide cobalt ores comprising copper oxide ores, copper oxide cobalt ores and cobaltous oxide minerals.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

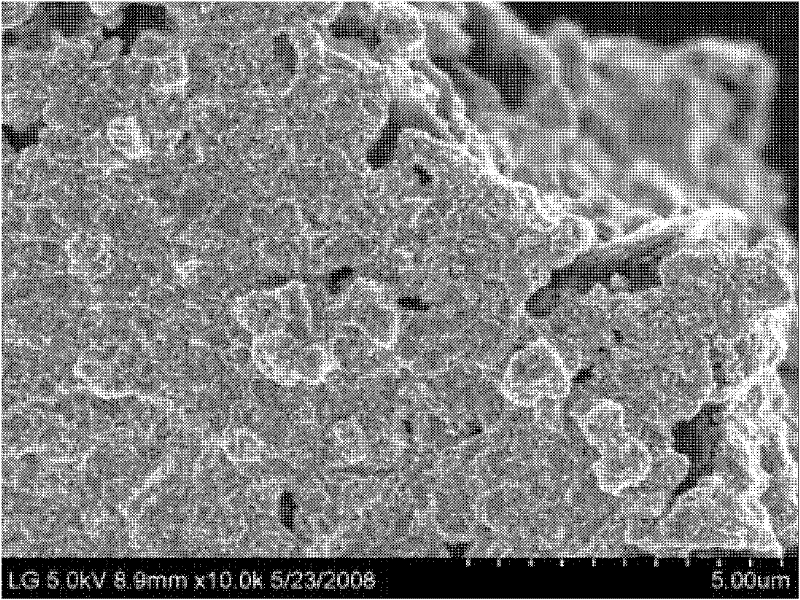

Method for preparing carbon particles/copper composite materials

The present invention relates to a method for preparing a carbon-based particle / copper composite material in which carbon-based particles such as graphite and copper are mixed, the method including mixing a solution of a polymer organic compound having a main chain of carbon and a copper precursor in a solvent, with a dispersion solution of carbon-based particles in a first dispersion medium to produce a mixture, adding a first reducing agent to the mixture to form composite particles in which copper (I) oxide particles are attached to the surface of the carbon-based particles, and sintering the composite particles under a non-oxidizing atmosphere. According to the preparing method, a composition material is obtained, in which carbon-based particles and copper are well mixed.

Owner:LG CHEM LTD

Preparation method and use method of core-shell catalyst for carbon dioxide hydrogenation

ActiveCN109569695ASimple manufacturing methodHigh catalytic activityCatalyst activation/preparationCarbon monoxideEtchingZinc alloys

The invention provides a preparation method and a use method of a core-shell catalyst for carbon dioxide hydrogenation. The method includes the steps: firstly, synthesizing a copper-oxide-containing and zinc-oxide-containing mixed metal oxide precursor with catalytic activity; secondly, preparing a copper nano-particle composite material coated by MOFs of ZIF-8 in a solid phase etching manner; performing procedure heating roasting to obtain a copper-zinc alloy core-shell catalyst coated by nitrogen-doped carbon materials. The method is characterized in that a MOFs material ZIF-8 is prepared bya solid-phase etching method without solvents, carbon material shell layer containing a lot of pyridine nitrogen is acquired in a high-temperature calcination manner, a copper zinc alloy core is acquired, a novel preparation technique of a pyridine nitrogen-doped carbon material and a copper zinc alloy is developed, the core-shell catalyst is applied to carbon monoxide reaction prepared by carbondioxide hydrogenation, the core-shell catalyst has excellent catalytic activity, and catalytic effects of the copper zinc alloy are greatly facilitated in the presence of a lot of pyridine nitrogen.

Owner:NANKAI UNIV

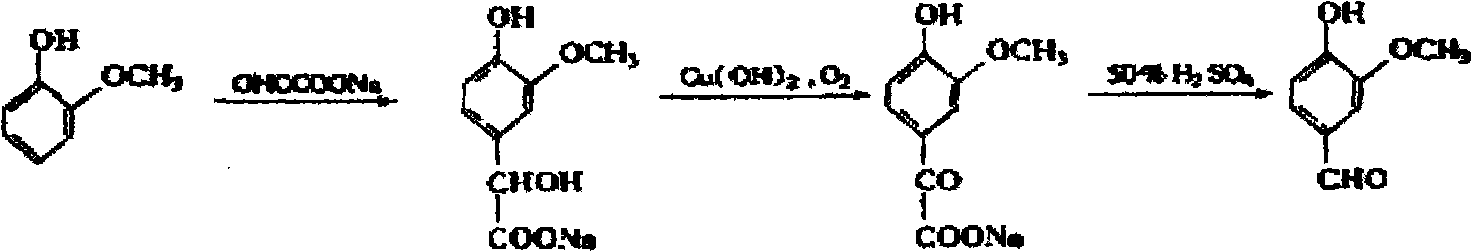

Catalyst for synthesizing vanillin by using a glyoxylic acid method and a one-pot method and preparation method thereof

InactiveCN102069005AEasy to prepareHigh activityMolecular sieve catalystsOrganic compound preparationRare earthCopper(II) oxide

The invention discloses a catalyst for synthesizing (ethyl) vanillin by using a glyoxylic acid method, and the method is characterized by taking a rare-earth Y-molecular sieve as carrier, and copper oxides and cobalt oxides as active components and comprising the steps of active-component salt solution preparation, carrier dipping, neutralization and precipitation, and oxidizing roasting. The molar ratio of copper to cobalt loaded on the catalyst is 1:(0.1-1); the selected rare-earth Y-molecular sieve comprises the following compositions in percentage by weight: no less than 17% of Re2O3, no less than 5% of SiO2 / Al2O3, and no more than 2% of Na2O; and the mass fraction of the copper and cobalt active components on the catalyst is 0.01-0.1. The invention has the advantages that because an industrial catalyst is adopted as the carrier, the method for preparing the catalyst is simple, the activity of the catalyst is high, the generation of polymeric by-products is restrained, and the yield of the synthesized vanillin is 89.2%.

Owner:TIANJIN VOCATIONAL INST

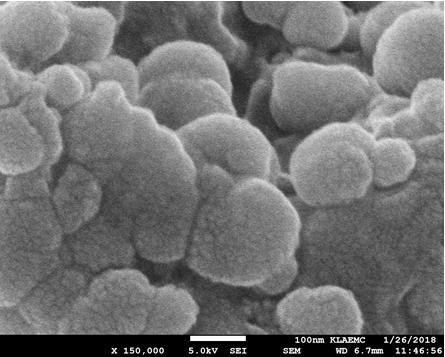

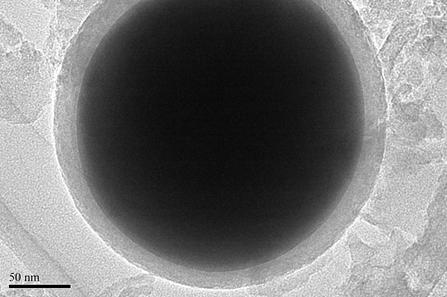

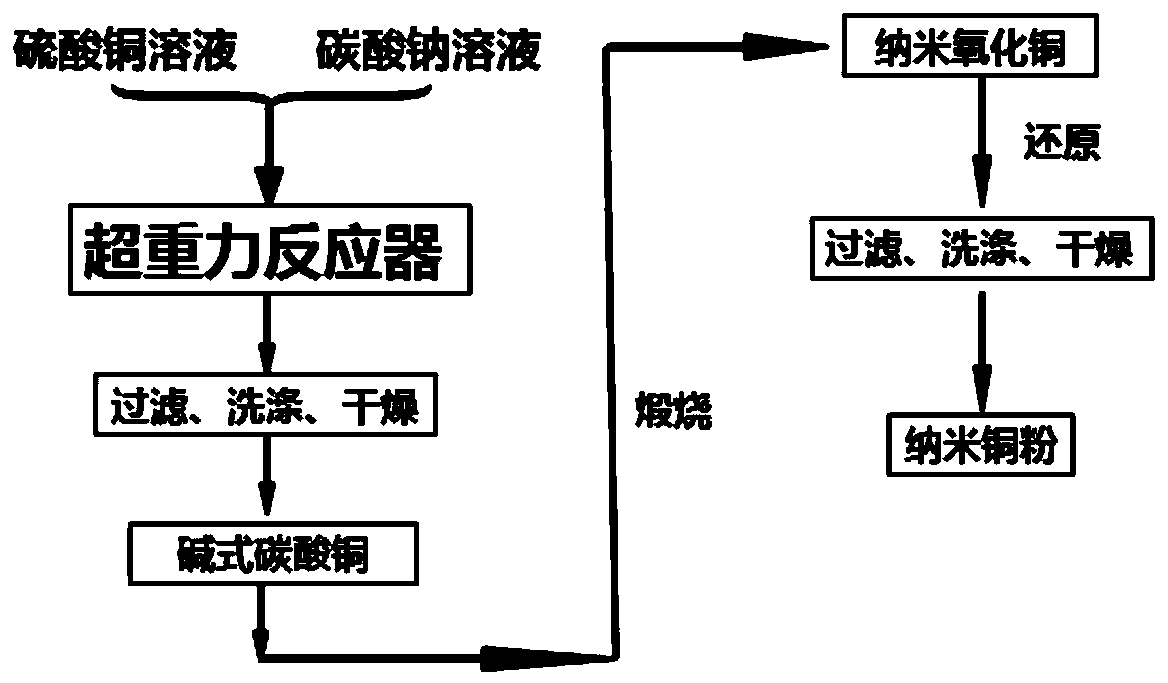

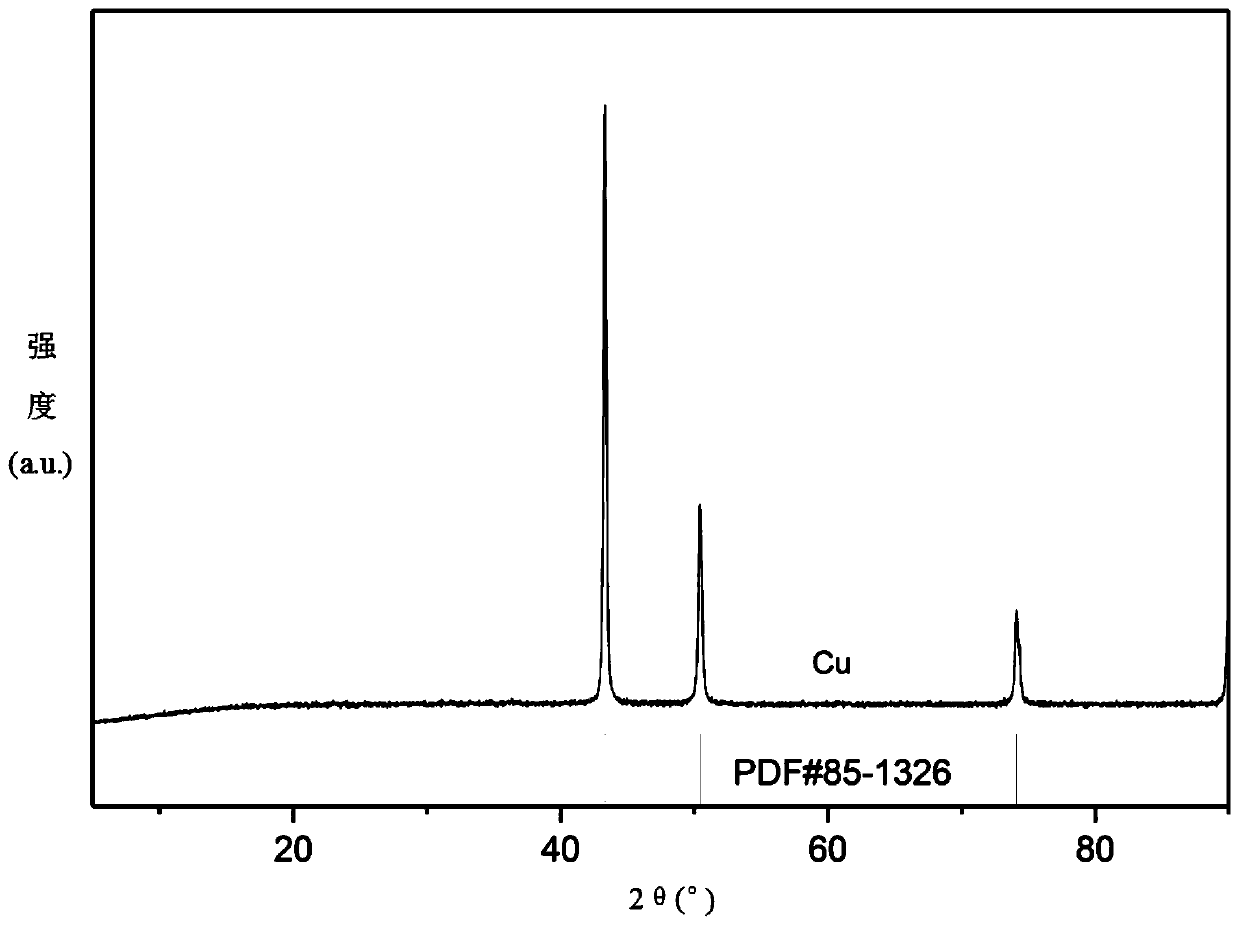

Preparation method for nano-copper powders

PendingCN110976901ALow costHigh purityMaterial nanotechnologyCopper oxides/halidesBASIC CUPRIC CARBONATEBasic copper carbonate

The invention relates to a preparation method for nano-copper powders. The preparation method comprises the following steps of: A: preparing nanoscale basic cupric carbonate by a method of precipitation: specifically, preparing a bivalent copper ion solution with certain concentration, then, preparing a precipitant solution with certain centration, starting a spiral channel type revolving bed hypergravity reactor, then, independently injecting two solutions into the reactor from different inlets according to a certain revolving speed to react to cause the two solutions to generate precipitation reaction, and after the reaction is finished, filtering, washing and drying a reaction liquid in sequence; B: carrying out calcination on a dried product to obtain a nanometer copper oxide; and C: reducing the nanometer copper oxide to obtain the nano-copper powders. The preparation method can stably produce the nano-copper powders with even particles on batch, and the produced nano-copper powders have a good application prospect on the aspects, including electric conduction, catalysis, lubrication and the like.

Owner:XIANGTAN UNIV

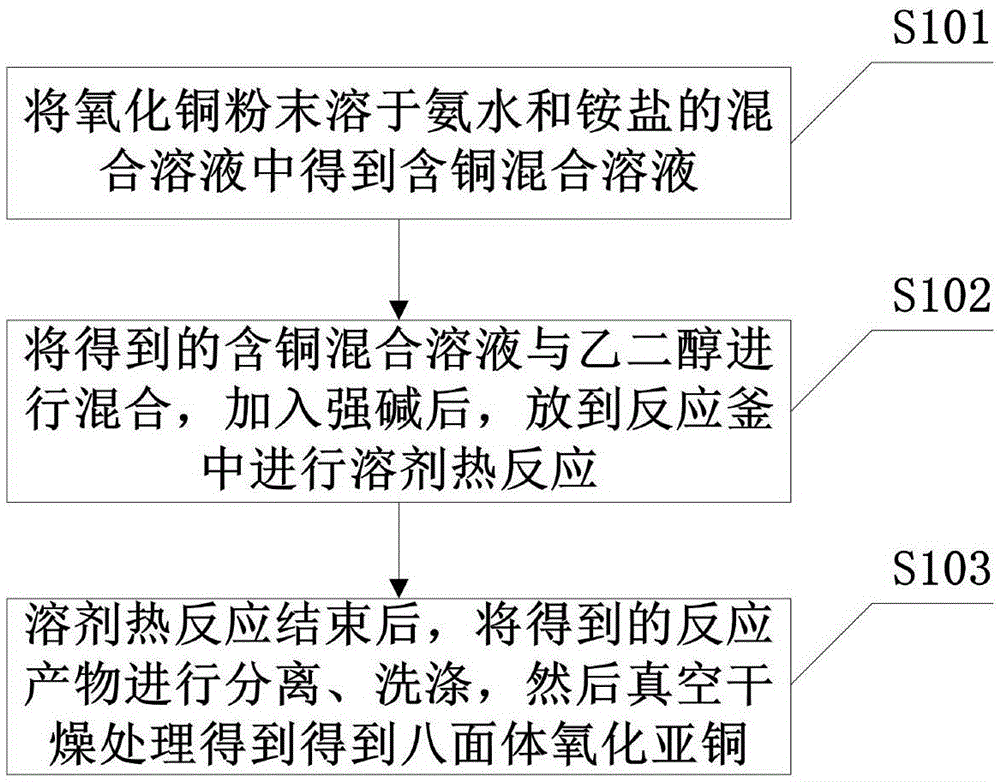

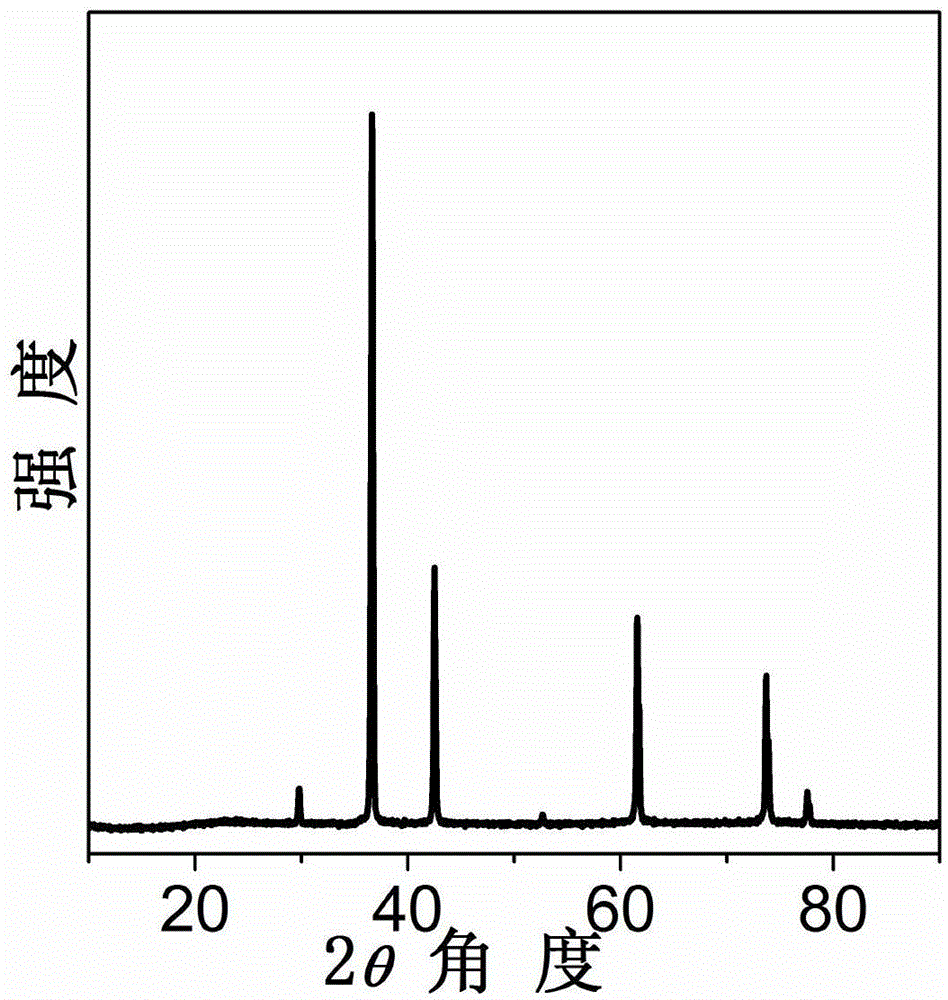

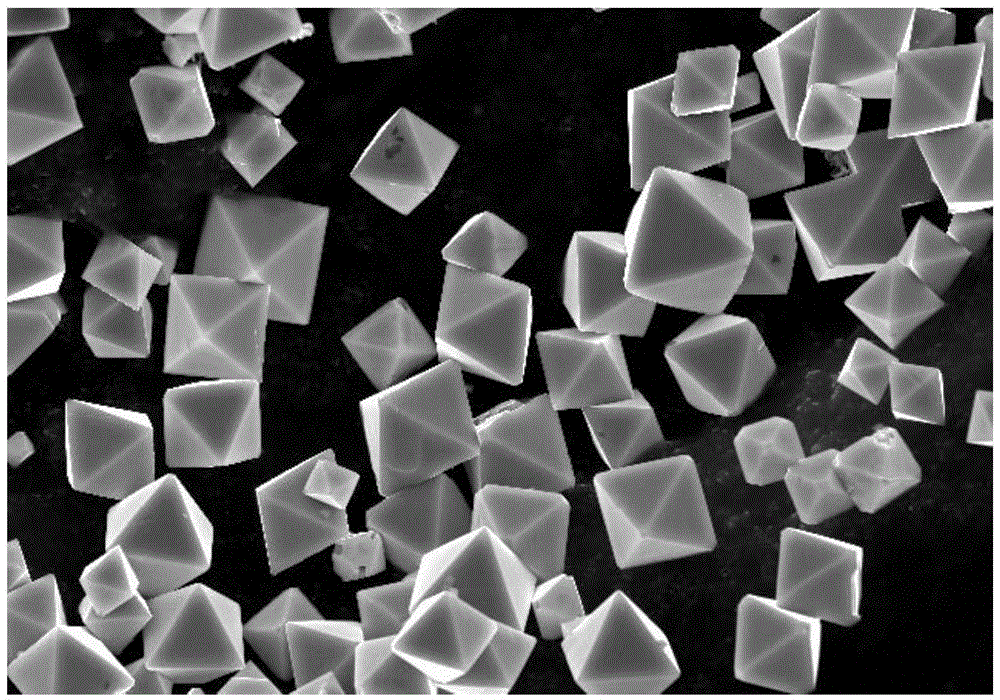

Preparation method of octahedral cuprous oxide catalyst for synthesizing methyl chlorosilane monomers

InactiveCN105536791ALow costSimple preparation processGroup 4/14 element organic compoundsCopper oxides/halidesCopper(II) oxideSolvent

The invention provides a preparation method of an octahedral cuprous oxide catalyst, belonging to the technical field of catalyst synthesis. The preparation method comprises the steps of dissolving copper oxide powder into ammonia water and an ammonium salt solution, then mixing the solution with ethanol, carrying out solvothermal reaction in the presence of strong alkali, separating and washing products, and carrying out vacuum drying, so as to obtain octahedral cuprous oxide. According to the preparation method, octahedral cuprous oxide is synthesized by taking commercial copper oxide powder as a copper source and ethanol as a reducing agent without adding a structure-directing agent, and compared with an existing preparation method utilizing the structure-directing agent, the cost is relatively low; furthermore, the shape of octahedral cuprous oxide can be regulated and controlled by regulating the copper ion concentration, the volume ratio of ethanol to water, the solvothermal temperature and time, and regulating and controlling conditions and measures are easy to implement; the whole technical process is carried out in a reaction kettle and is simple, convenient, efficient and environment-friendly, and scale production is easily realized. Furthermore, the obtained octahedral cuprous oxide catalyst can be further utilized for synthesizing methyl chlorosilane monomers.

Owner:HEBEI UNIV OF ENG

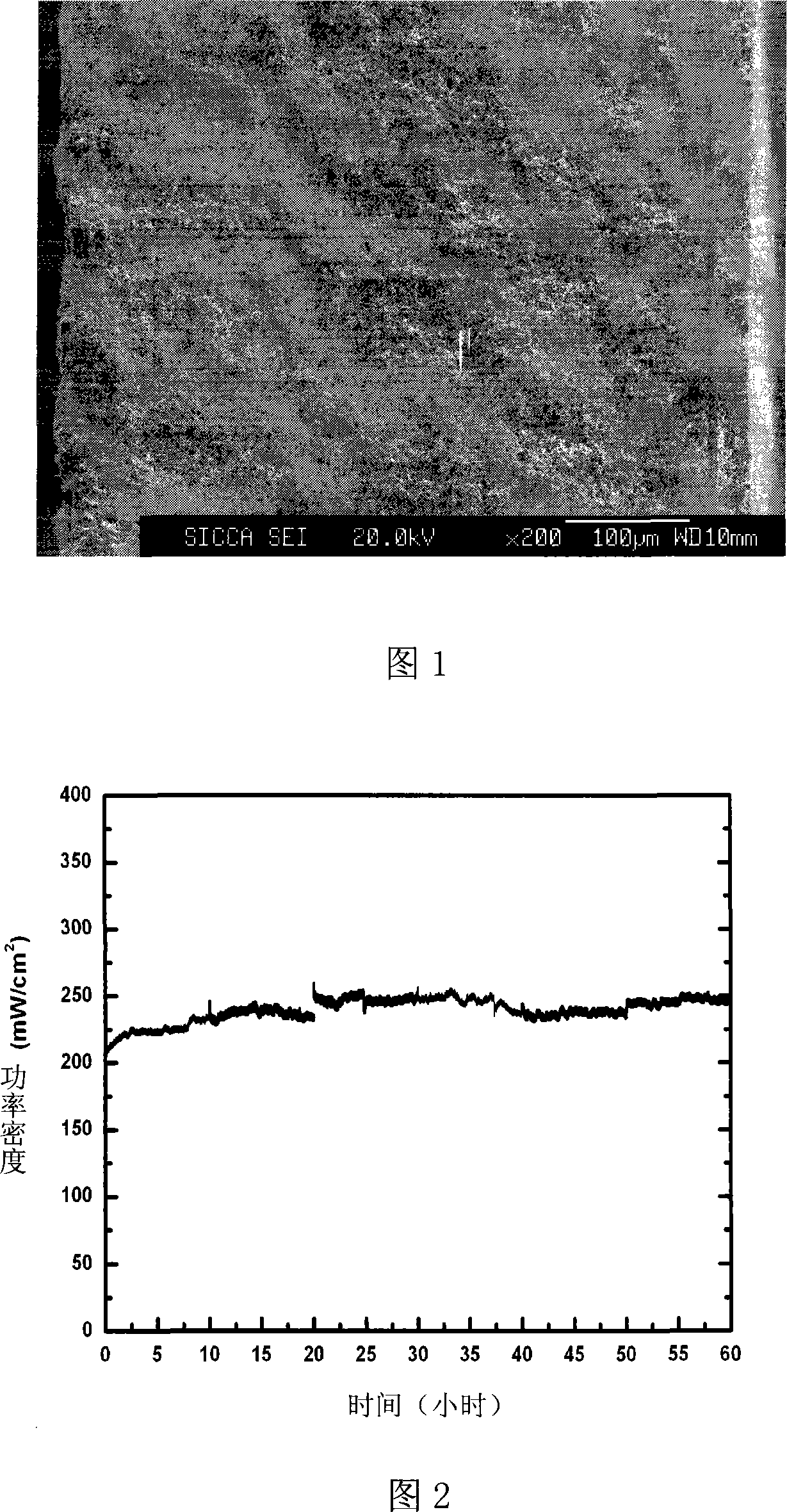

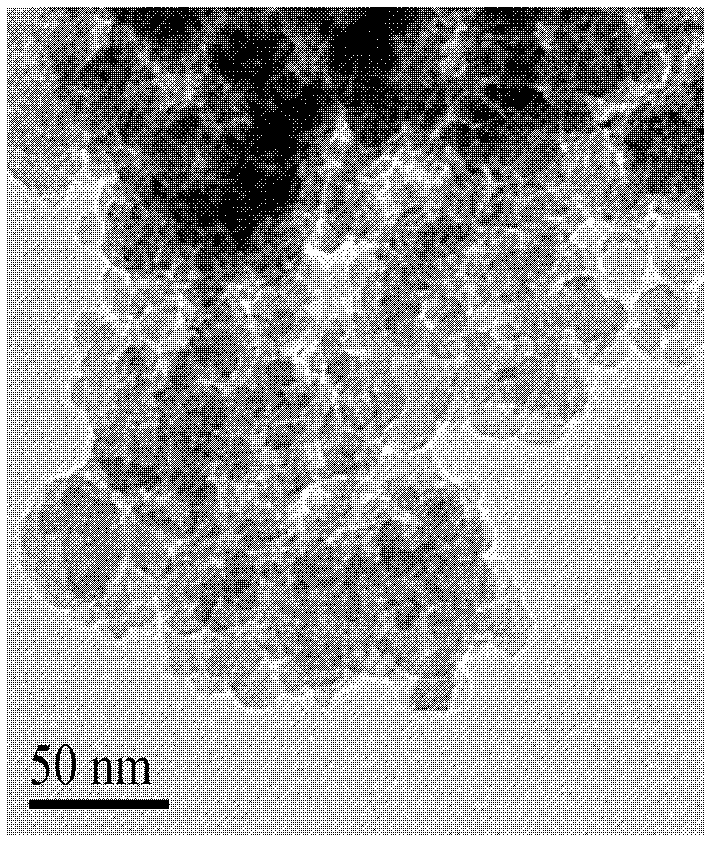

Anti-carbon deposition anode film material and method for producing the same

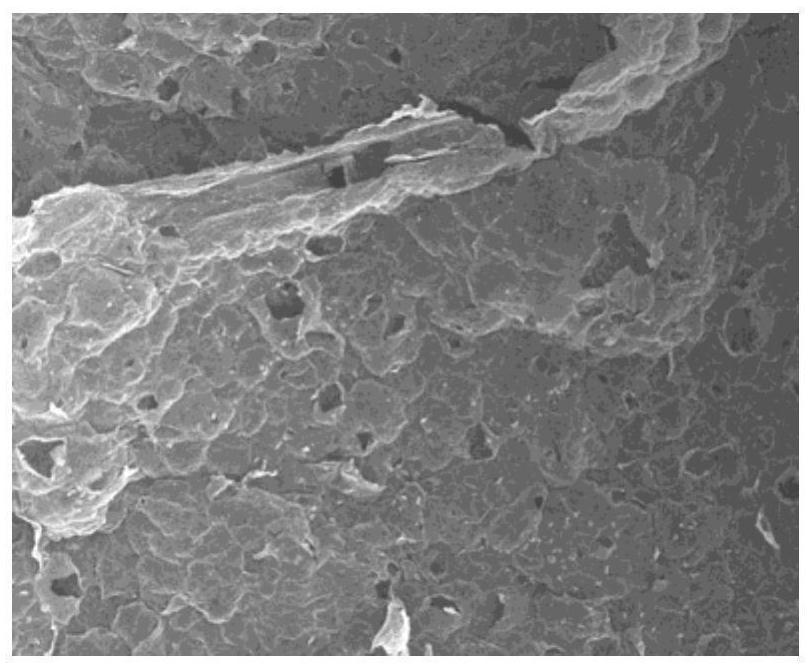

InactiveCN101222050ASimple processLow costCell electrodesFinal product manufactureSlurryCarbon deposit

The invention relates to a carbon deposit resistant anode membrane material and a preparation method thereof, belonging to the flat-plate solid oxide fuel cell (SOFC) field. The preparation method is based on casting means; firstly, zirconia and nickel oxide slurries of organic pore-forming materials are added by means of casting, and membrane material of a large anode supporting body is obtained after sintering; secondly, cupric oxide dust and cerium oxide dust are uniformly mixed; thirdly, after preparation of the slurries, silk-screen printing on the surface of the anode supporting body is performed; fourthly, a catalysis layer is sintered under high temperature, and the carbon deposit resistant anode membrane material is obtained. The method is simple in technology and low in cost and is suitable for industrialized production, and the prepared anode membrane material has good carbon deposit resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing hydrogenation catalyst by loading copper oxide on silica gel carrier

InactiveCN102247860ALarge specific surface areaIncrease loadOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsReduction ActivityDispersity

The invention relates to a method for preparing a hydrogenation catalyst by loading copper oxide on a silica gel carrier. The method is characterized by comprising the following steps of: (1) dropping silica sol with a pH value regulated to 2-3 into a mixed solution of copper salt and cerium salt, and stirring at room temperature to form uniform sol, wherein by counting the copper salt in terms of CuO, the cerium salt in terms of CeO2 and the silica sol in terms of SiO2, CuO / SiO2 is 0.1-0.3 by weight, and CeO2 / SiO2 is 0.018-0.05 by weight; (2) dropping a precipitant solution into the sol, stirring at the same time, stopping stirring after the sol is completely gelatinized, and ageing at room temperature to obtain gel, wherein the mass ratio of precipitants to the copper salt is 0.2-0.72; (3) washing the gel with water till the pH value of washing liquor is 6.5-7.5, drying, and roasting at 450-600 DEG C to obtain the hydrogenation catalyst in which the copper oxide is loaded on the silica gel carrier. The hydrogenation catalyst has the advantages of large loading capacity, good dispersity of active component copper oxide, small crystalline grain and high catalytic reduction activity.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

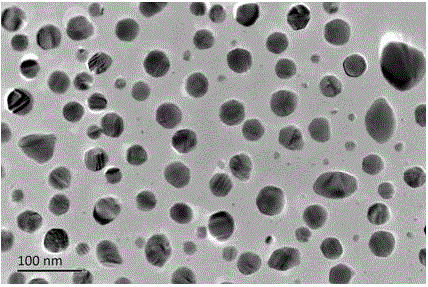

Metal oxide-containing nanoparticles

InactiveUS7901656B2Easy to modifyRaise the ratioMaterial nanotechnologyOxide/hydroxide preparationCopper oxide nanoparticlesCopper(II) oxide

Owner:WAYNE STATE UNIV

Catalyst for catalytic oxidation of NO and preparation method thereof

ActiveCN102274733ALow costHigher cost at low temperaturesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporActive component

The invention discloses a catalyst used for catalytically oxidizing NO and a preparation method thereof. Manganese oxide and copper oxide are taken as active components of the catalyst and titanium dioxide is taken as a carrier. The manganese oxide and copper oxide which belong to P-type semiconductors are taken as the active components, thereby obviously promoting the activity of the catalyst atlow temperature and meanwhile overcoming the problem of steam and SO2 influence on the catalyst easily caused by a single active component. The catalyst has the advantages that the cost is low, the preparation process is simple, the environment is protected, the assistance of other external condition is unnecessary in a catalytic reaction process, the industrial application value is high, and thecatalyst can be applied to a catalytic oxidation-chemical absorption method for treating the SO2 and NOx in fire coal smoke.

Owner:NANJING UNIV OF SCI & TECH

Three-dimensional sea urchin-like/porous composite structure lithium ion battery Cu/CuO/SnO2/C anode and preparation method thereof

ActiveCN109301203AAlleviate the volume expansion effectNot easy to fall offCell electrodesSecondary cellsCopper(II) oxideSea urchin

The invention provides a three-dimensional sea urchin-like / porous composite structure lithium ion battery Cu / CuO / SnO2 / C anode which is composed of three-dimensional nano-porous copper, CuO film, SnO2and carbon, wherein the CuO film is a continuous film formed by partially oxidizing the surface of the three-dimensional nano-porous copper, the CuO film coating the three-dimensional nano-porous copper and the carbon coating the SnO2, so that the carbon-coated SnO2 can form a sea urchin-like carbon-coated SnO2 layer on the outer surface of the CuO film-coated three-dimensional nano-porous copper.The invention also provides a preparation method of such anode. In the invention, production process of the lithium ion battery anode is simplified, and active components are prevented from strippingoff during charge / discharge process of the lithium ion battery, thus effectively improving the cycle performance and rate capability of the lithium ion battery anode.

Owner:SICHUAN UNIV

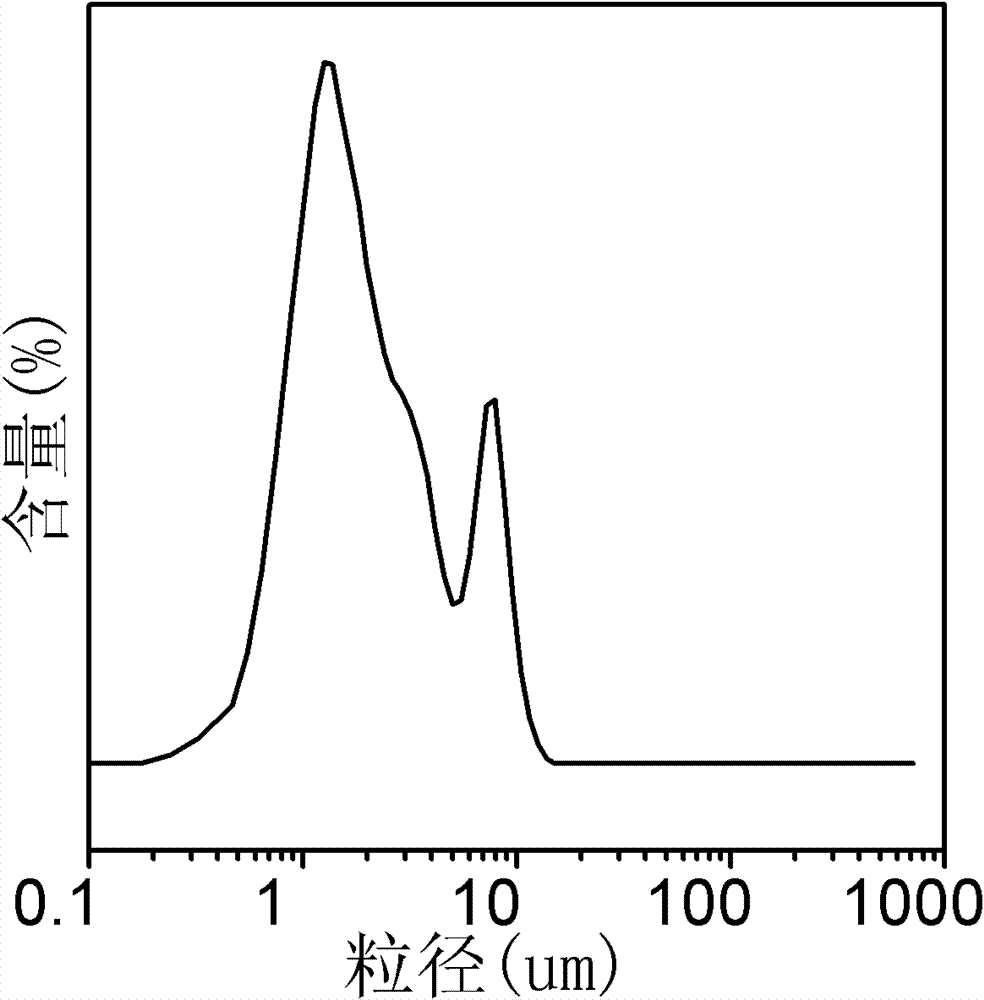

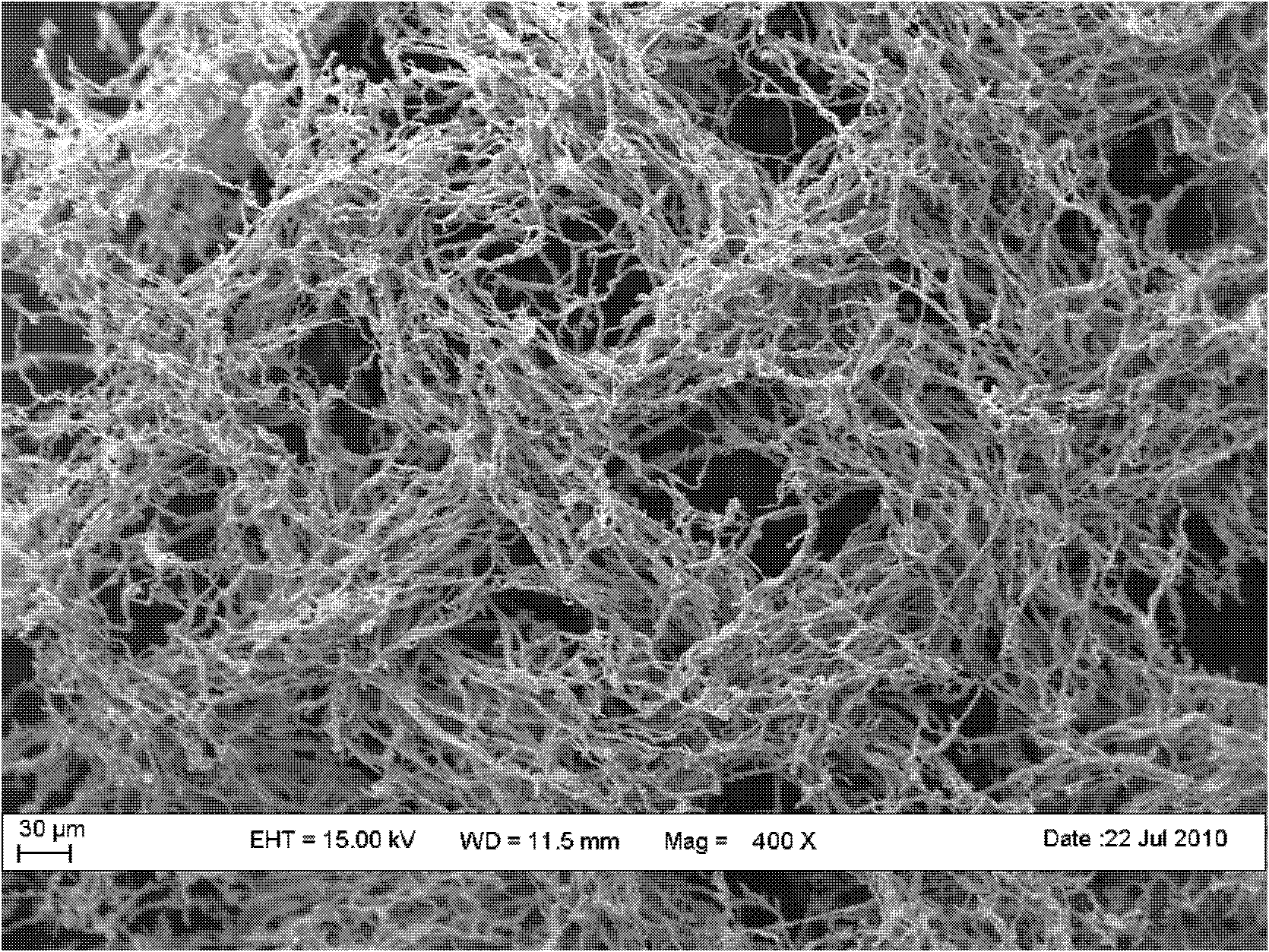

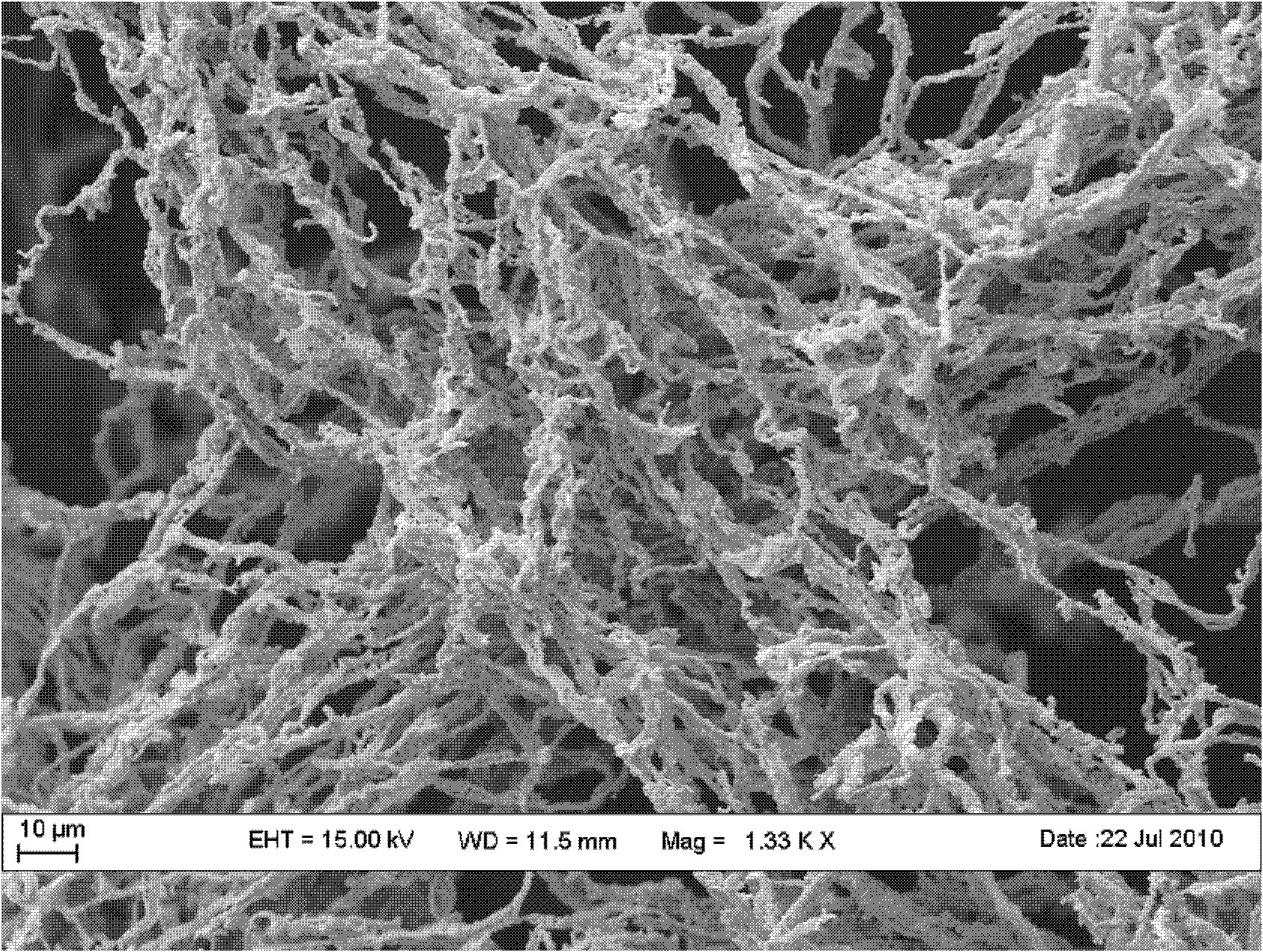

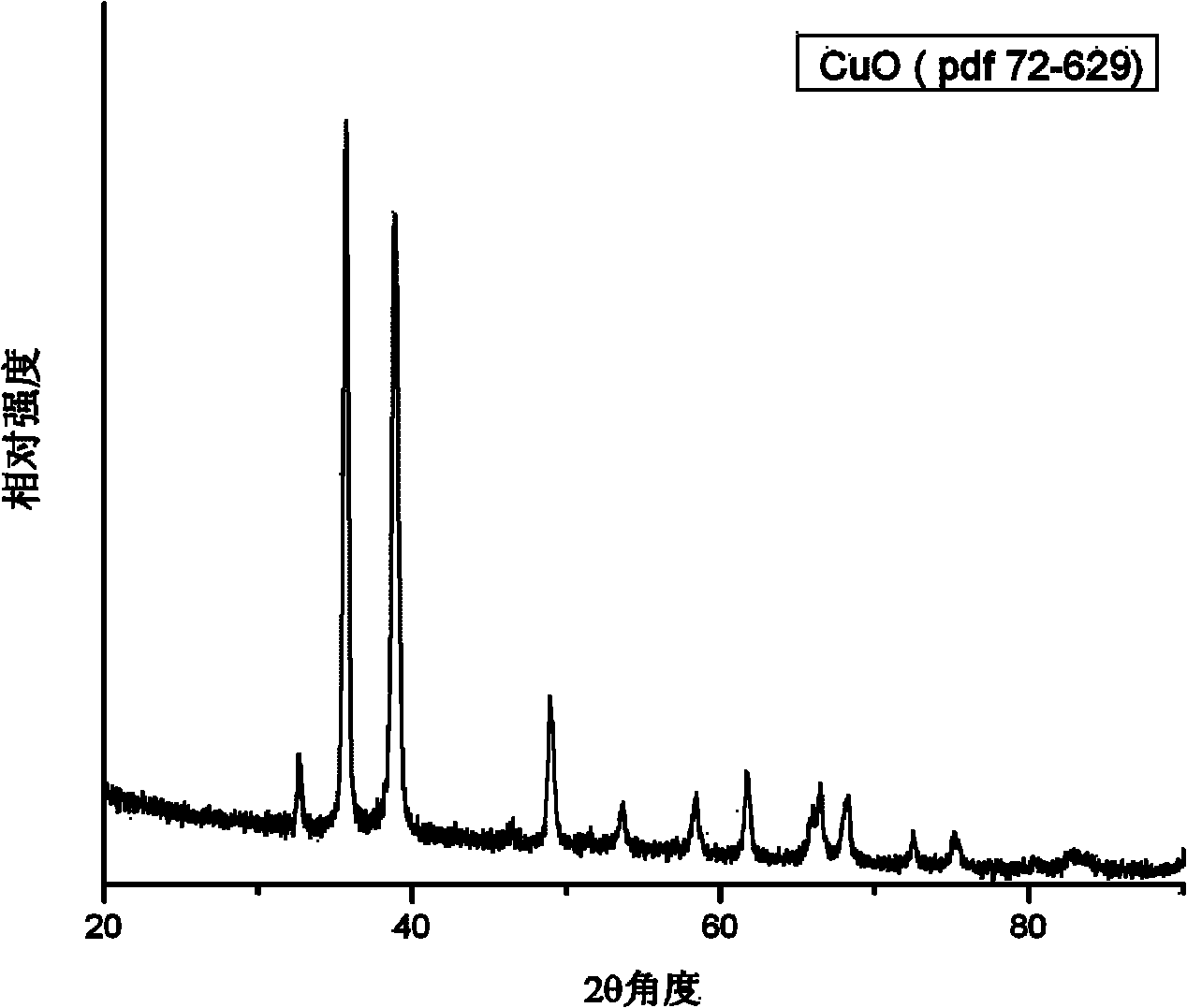

Foam copper powder and preparation method thereof

The invention discloses foam copper powder and a preparation method thereof, and relates to the technical field of copper powder. The preparation raw material of the foam copper powder comprises cupric oxide powder which is formed by mixing cupric oxide powder of different particle sizes. The particle sizes of the cupric oxide powder are 5-75 [mu]m, the porosity is high, and the bore diameter is small. According to the foam copper powder, no pore-forming agent or a few pore-forming agents need to be added, the material performance and application of a copper substrate cannot be influenced, the prepared foam copper powder is high in porosity and small in bore diameter. Parts sintered by the foam copper powder are high in porosity and small in bore diameter. The porosity and the bore diameter can be regulated by mixing cupric oxide powder with different particle size distribution so that the requirements of different products and customers can be met. According to the preparation method of the foam copper powder, the process is simple, the cost is low, and no pollution is generated to the environment.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Antibacterial polylactic acid master batch and application thereof

The invention belongs to the field of biological materials, and relates to an antibacterial polylactic acid master batch, which is mainly composed of carbonization layer modified copper oxide and cuprous oxide nanoparticles and polylactic acid. According to the antibacterial polylactic acid master batch provided by the invention, the antibacterial performance of polylactic acid is greatly improved, the production process is simple, the raw materials are easy to obtain, and the cost is low; and the master batch has good biocompatibility, can be applied to antimicrobial products, and can be applied to the fields of food packaging, medical instruments, building material decoration, aquaculture and the like.

Owner:雄县雄阳新材料科技开发有限公司

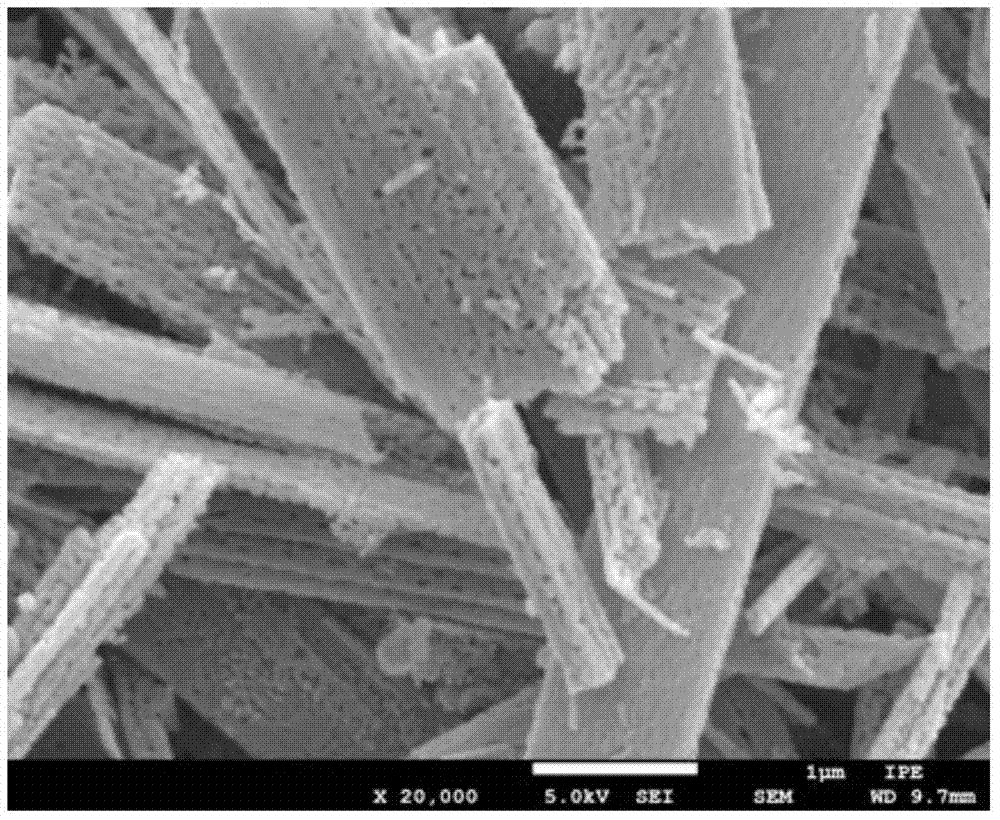

Chemical method for preparing copper oxide crystals with biological micro-nano structures by thermal decomposition

The invention discloses a chemical method for preparing copper oxide crystals with biological micro-nano structures. The method comprises the following steps of: (1) preparing a carrier, namely pretreating a product which contains biological fiber or is processed by biological fiber in nature to obtain a biological template serving as a carrier of copper sulfate, wherein the product is pretreated by the following steps of: preparing an NaOH solution, putting the product which contains biological fiber or is processed by biological fiber into the NaOH solution for soaking and boiling or water bath heating; ultrasonically cleaning with distilled water, putting the product into mixed acid in which the molar ratio of sulfuric acid to oxalic acid is 2:1 and ultrasonically treating for 1 hour, standing for 24 hours, taking the product out, ultrasonically cleaning with distilled water and drying at the temperature of 80 DEG C to obtain the biological template serving as the carrier, wherein the concentration of the sulfuric acid is 2 mol / L; (2) putting the biological template prepared in the step (1) into a copper sulfate solution for soaking and adsorbing copper sulfate; and (3) calcining the biological template which adsorbs copper sulfate to remove the biological template and obtain a product which is thermally-decomposed by the copper sulfate and serves as the copper oxide crystals with biological micro-nano structures.

Owner:XUCHANG UNIV

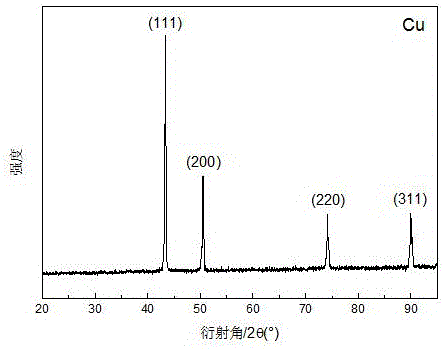

Preparation method of nano copper powder

InactiveCN106424751AUniform particle sizeGood dispersionTransportation and packagingMetal-working apparatusDispersityHydrogen atmosphere

The invention discloses a preparation method of nano copper powder. Copper oxide and calcium oxide powder are made into calcium cuprate powder by mechanical mixing and calcination technologies, then the calcium cuprate powder is reduced in a hydrogen atmosphere, then cleaning with a dilute hydrochloric acid solution is carried out, and the nano copper powder is obtained. The preparation method is simple in technology, the used raw materials are low-cost and are easy to obtain, no special equipment is required in a mixing stage, a calcination stage or a reduction stage, and rapid continuous mass production can be realized. The prepared nano copper powder is uniform in particle size, good in dispersity and low in oxygen content, and the mean particle size of primary particles is around 20 nanometers.

Owner:NANCHANG UNIV

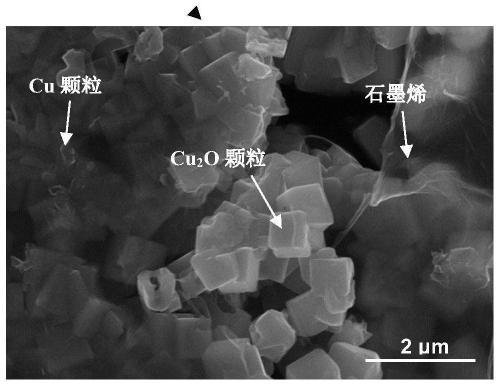

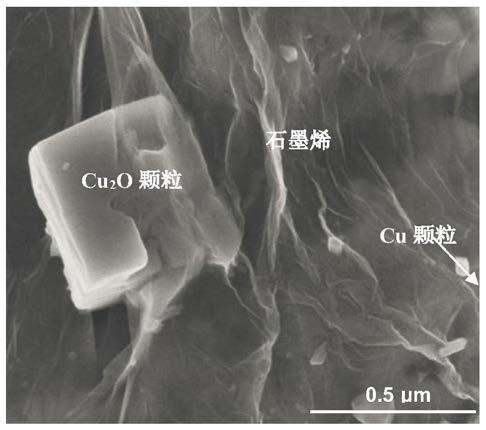

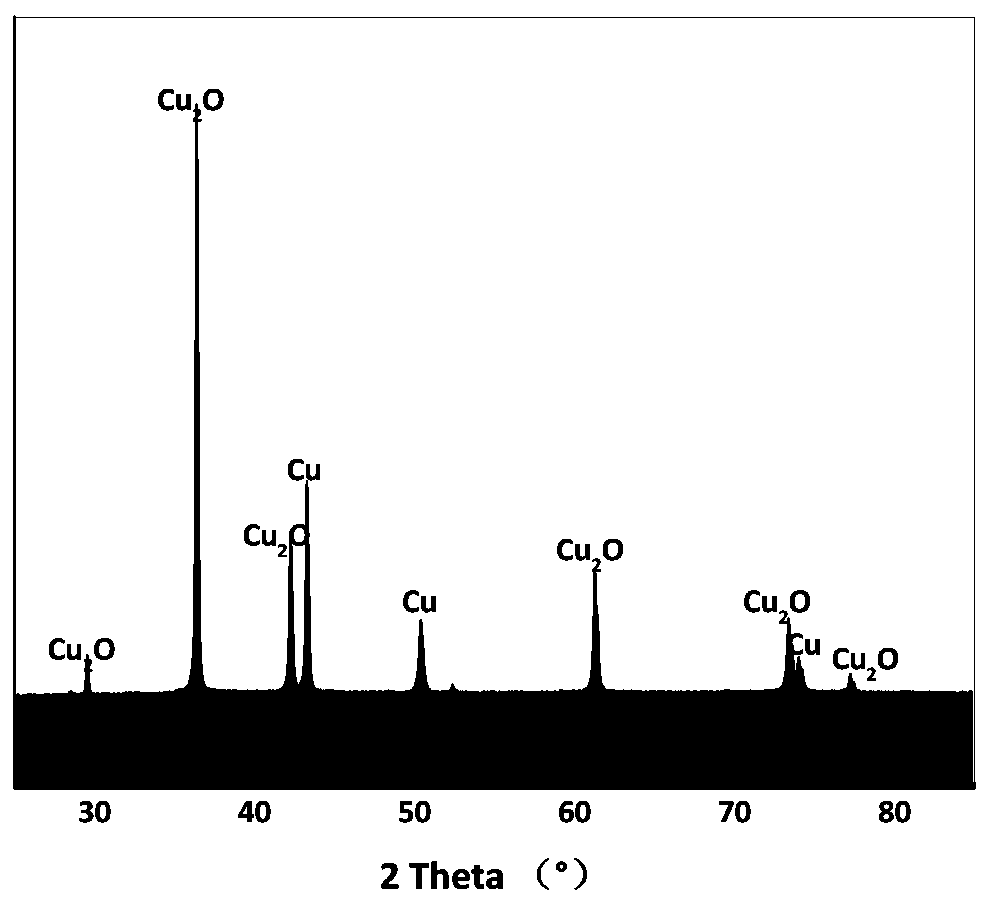

Method for preparing graphene/copper/cuprous oxide composite powder through low-energy ball mill

A method for preparing graphene / copper / cuprous oxide composite powder through a low-energy ball mill includes the following steps that firstly, graphene dispersion liquid is obtained by conducting mixing acid leaching, washing and drying on graphene and then conducting ultrasonic dispersion on the graphene in deionized water; secondly, copper powder is mixed with the graphene dispersion liquid after being subjected to pre-ball-milling under the condition of 10-150 r / min, pH is regulated to 2.5-4.5, and then mixed slurry is obtained after secondary ball milling is conducted under the conditionof 10-150 r / min; and thirdly, the mixed slurry is stirred and reacts at the temperature being 60-90 DEG C after being regulated to neutral, and the graphene / copper / cuprous oxide composite powder is obtained after filtering and drying. The graphene structure in the graphene / copper / cuprous oxide composite powder prepared through the method is kept complete, dispersion is uniform, no other impurity is introduced, particles are tiny, the relative proportion between copper and cuprous oxide can be controlled, the process is simple, the repetition rate is high, and large-scale production can be achieved.

Owner:湖南华瑞康源科技有限公司

Copper-mixed tungsten powder preparation process

The invention relates to a copper-mixed tungsten powder preparation process. The process includes the steps that Na2WO4.5H2O and CuSo4.5H2O are dissolved in distilled water; a hydrochloric acid solution is dropped and components are magnetically stirred and evenly mixed; a mixed solution is placed in a high-pressure reaction kettle to be heated and react; the mixed solution is cooled to the indoor temperature and filtered, and sediment is acquired; the sediment is washed and dried; the dried sediment is placed in a muffle furnace so as to be burnt, and tungsten trioxide and copper oxide powder is acquired; tungsten trioxide and copper oxide powder is placed in a plasma reaction chamber, inert gas is ionized in the reaction chamber to generate high-temperature plasma, and after being heated through the high-temperature plasma, the tungsten trioxide and copper oxide powder is reduced to tungsten-copper powder under a reducing atmosphere. By the adoption of the process, tungsten oxide and copper oxide are prepared through sodium tungstate, copper sulfate and hydrochloric acid, the tungsten-copper powder is prepared through a plasma electric arc method, due to the fact that the large temperature difference exists between the tungsten-copper powder and a cooling medium, crystal nucleus growth is effectively restrained in the nucleation promoting process, and the acquired tungsten-copper powder can reach the nanoscale.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

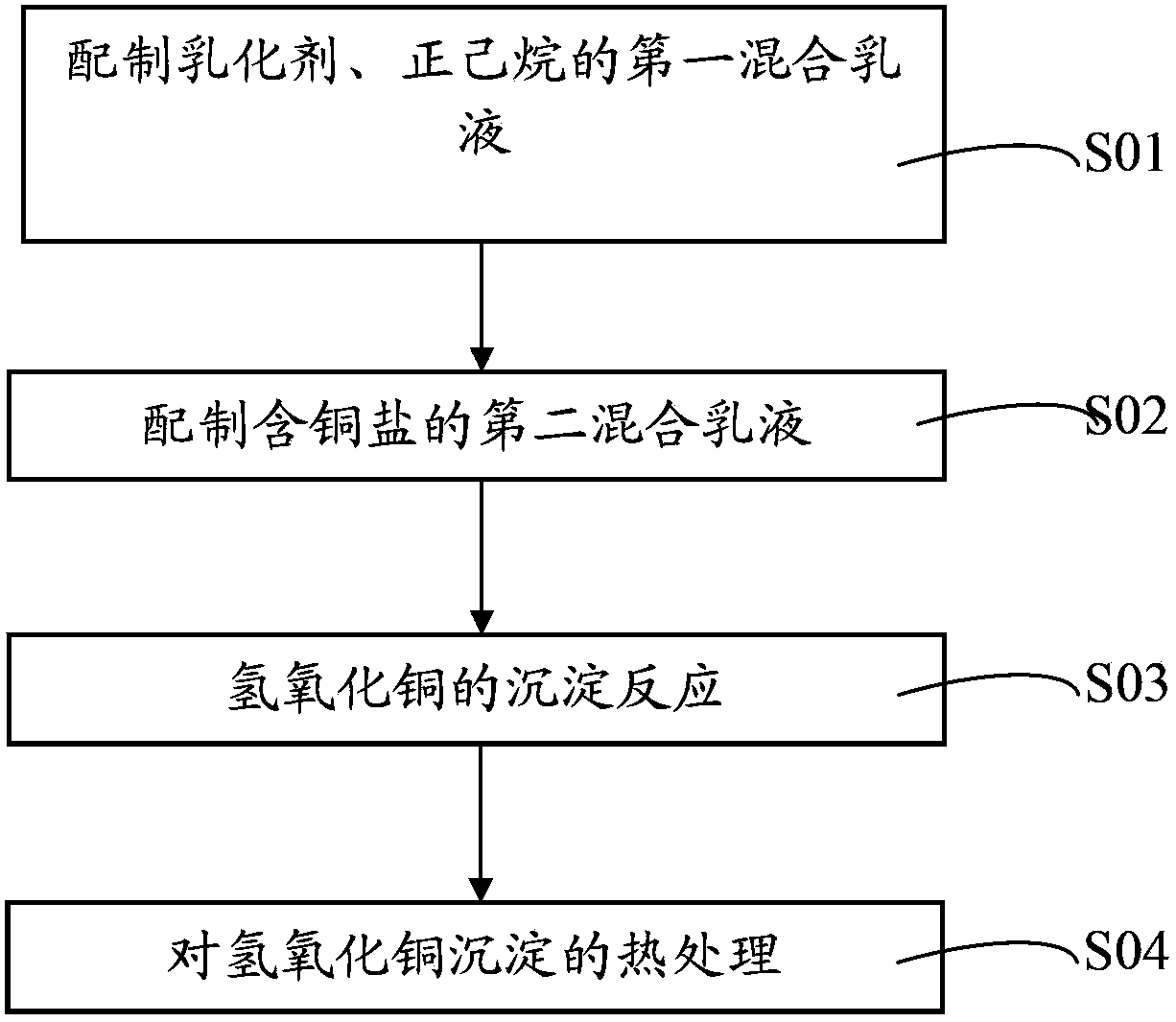

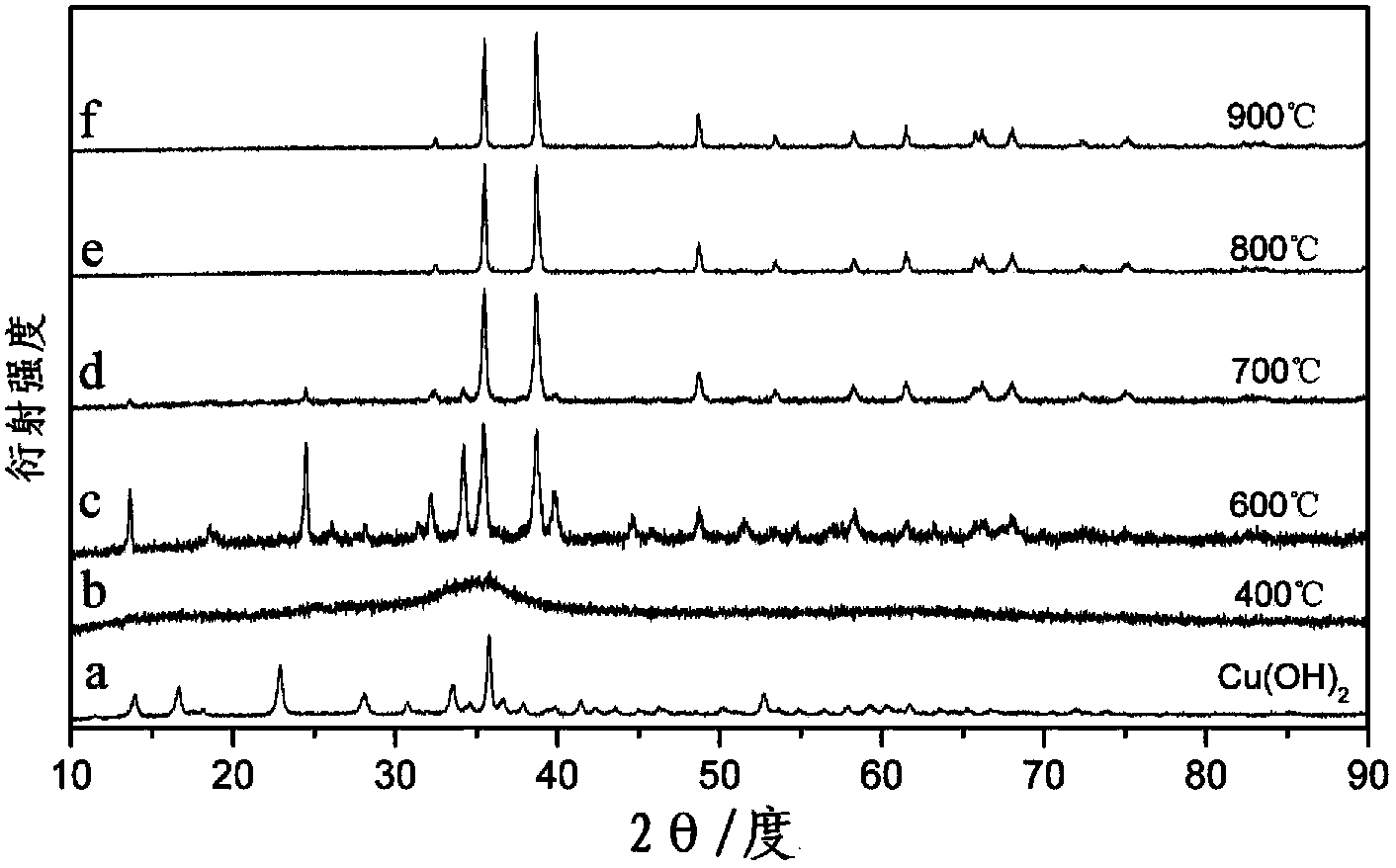

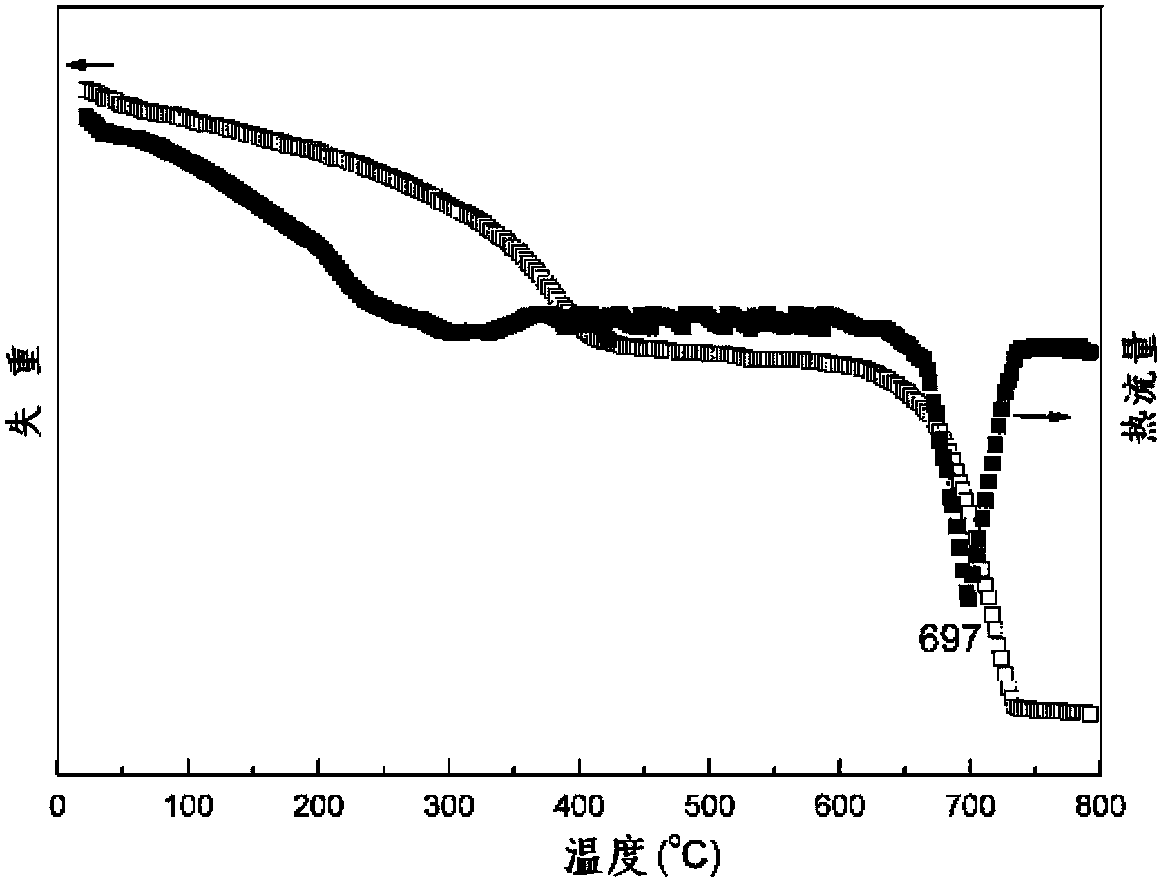

Copper oxide nano-belt and preparation method thereof

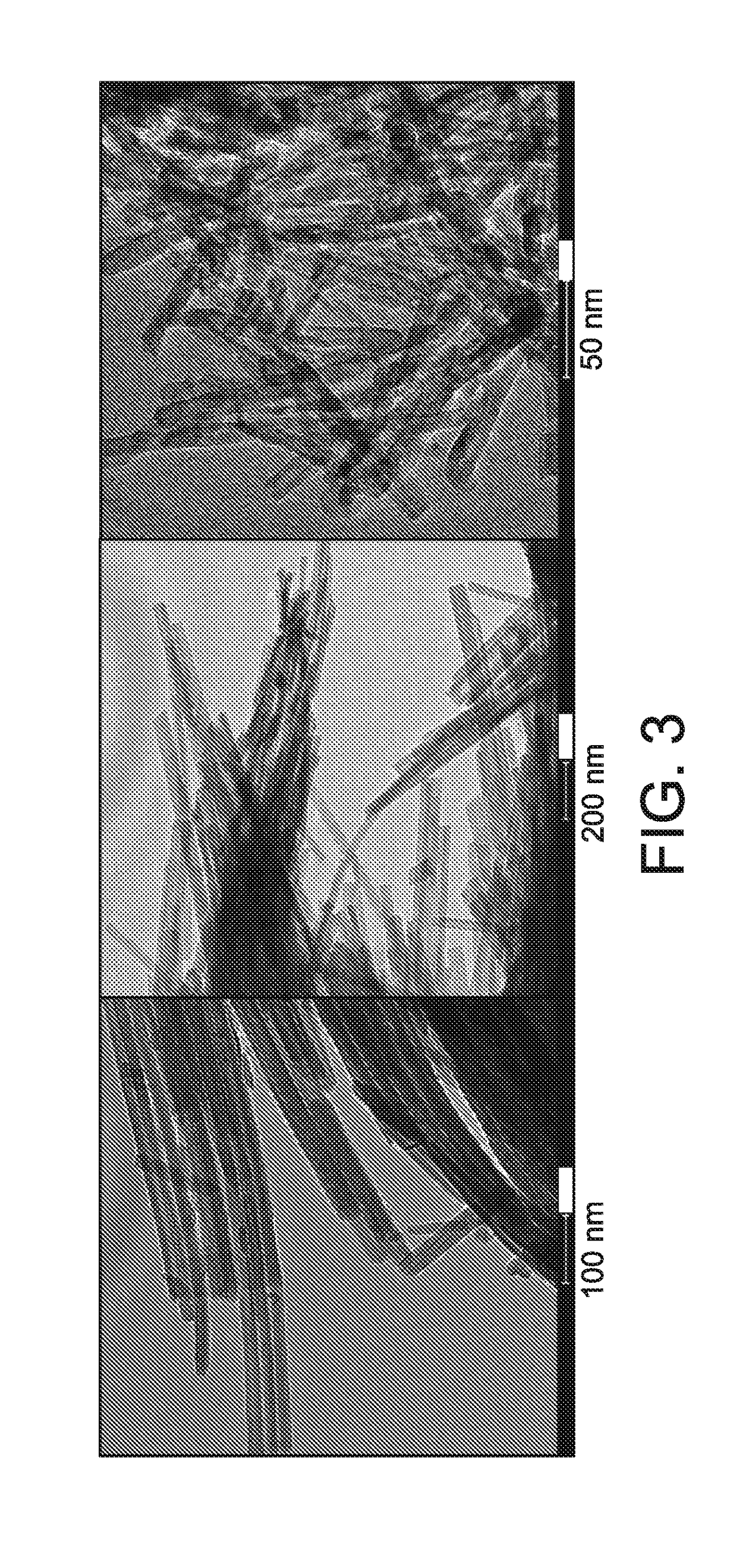

InactiveCN103449497ASimple processProcess conditions are easy to controlMaterial nanotechnologyCopper oxides/halidesOil phaseCopper(II) oxide

The invention discloses a copper oxide nano-belt and a preparation method thereof. The preparation method of the copper oxide nano-belt comprises: a step of preparing a first mixed solution of emulsifier and normal hexane, a step of preparing a second mixed solution containing copper salt, a step of carrying out a copper hydroxide precipitation reaction and a step of heat treating copper hydroxide precipitate. In the preparation method of the copper oxide nano-belt, emulsion template technology at room temperature is adopted, the copper salt solution and ammonia water are used as raw materials, precipitation is directly carried out under the action of the emulsion template formed by an oil phase of normal hexane and emulsifier and a water phase to prepare copper hydroxide, and the copper hydroxide is heated to convert into a CUO nano-belt with nano holes. The preparation method is low in necessary temperature, simple and convenient to operate, good in reproducibility, high in yield and low in cost, and the size and morphology of the copper oxide nano-belt can be controlled by regulating and controlling the reaction conditions. The nano holes are distributed on the surface of the prepared prepared copper oxide nano-belt, thereby having large specific surface area and excellent physical and chemical properties on the surface.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com