Foam copper powder and preparation method thereof

A technology of copper powder and foam, which is applied in the field of foam copper powder and its preparation, can solve the problems of high porosity, high porosity and small pore diameter of foam copper, and achieve the effect of simple process, low cost and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

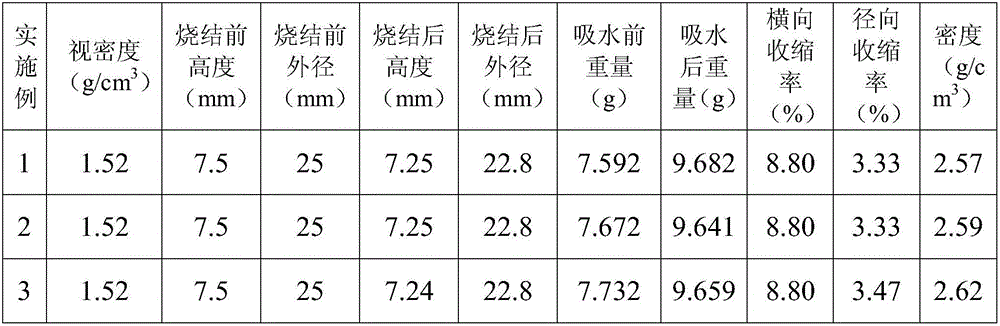

Embodiment 1

[0021] 1) Mixing copper oxide powders with a particle size of 38 μm to 75 μm to prepare mixed copper oxide powder;

[0022] 2) Put the mixed copper oxide powder prepared in step 1) into a reduction sintering furnace for reduction sintering, the atmosphere in the reduction sintering furnace is a reducing atmosphere, set the reduction sintering temperature to 850°C, and the reduction sintering time to be more than 40 minutes to obtain a sintered Copper, the porosity of sintered copper is 75%, the reducing atmosphere adopts ammonia decomposition atmosphere, and the volume ratio of hydrogen and nitrogen is 3:1;

[0023] 3) Crush the sintered copper and sieve foamed copper powder with a particle size distribution of 106-250 μm.

Embodiment 2

[0025] 1) Mix copper oxide powder with a particle size of 6.5 μm to 18 μm, copper oxide powder with a particle size of 18 μm to 75 μm, and urea particles at a mass ratio of 2:7:1 to prepare mixed copper oxide powder;

[0026] 2) Put the mixed copper oxide powder prepared in step 1) into a reduction sintering furnace for reduction sintering, the atmosphere in the reduction sintering furnace is a reducing atmosphere, set the reduction sintering temperature to 800°C, and the reduction sintering time to be more than 50 minutes to obtain a sintered Copper, the porosity of sintered copper is 83%, the reducing atmosphere adopts ammonia decomposition atmosphere, and the volume ratio of hydrogen and nitrogen is 3:1;

[0027] 3) Crush the sintered copper and sieve foamed copper powder with a particle size distribution of 106-250 μm.

Embodiment 3

[0029] 1) Mix copper oxide powder with a particle size distribution of 18 μm to 75 μm and sodium chloride particles at a mass ratio of 8:2 to prepare mixed copper oxide powder;

[0030] 2) Put the mixed copper oxide powder prepared in step 1) into a reduction sintering furnace for reduction sintering, the atmosphere in the reduction sintering furnace is a reducing atmosphere, set the reduction sintering temperature to 750°C, and the reduction sintering time to be more than 60 minutes to obtain a sintered Copper, the porosity of sintered copper is 65%, the reducing atmosphere adopts ammonia decomposition atmosphere, and the volume ratio of hydrogen and nitrogen is 3:1;

[0031] 3) Crush the sintered copper and sieve foamed copper powder with a particle size distribution of 106-250 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com