Patents

Literature

6319 results about "Copper oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper oxide is a compound from the two elements copper and oxygen.

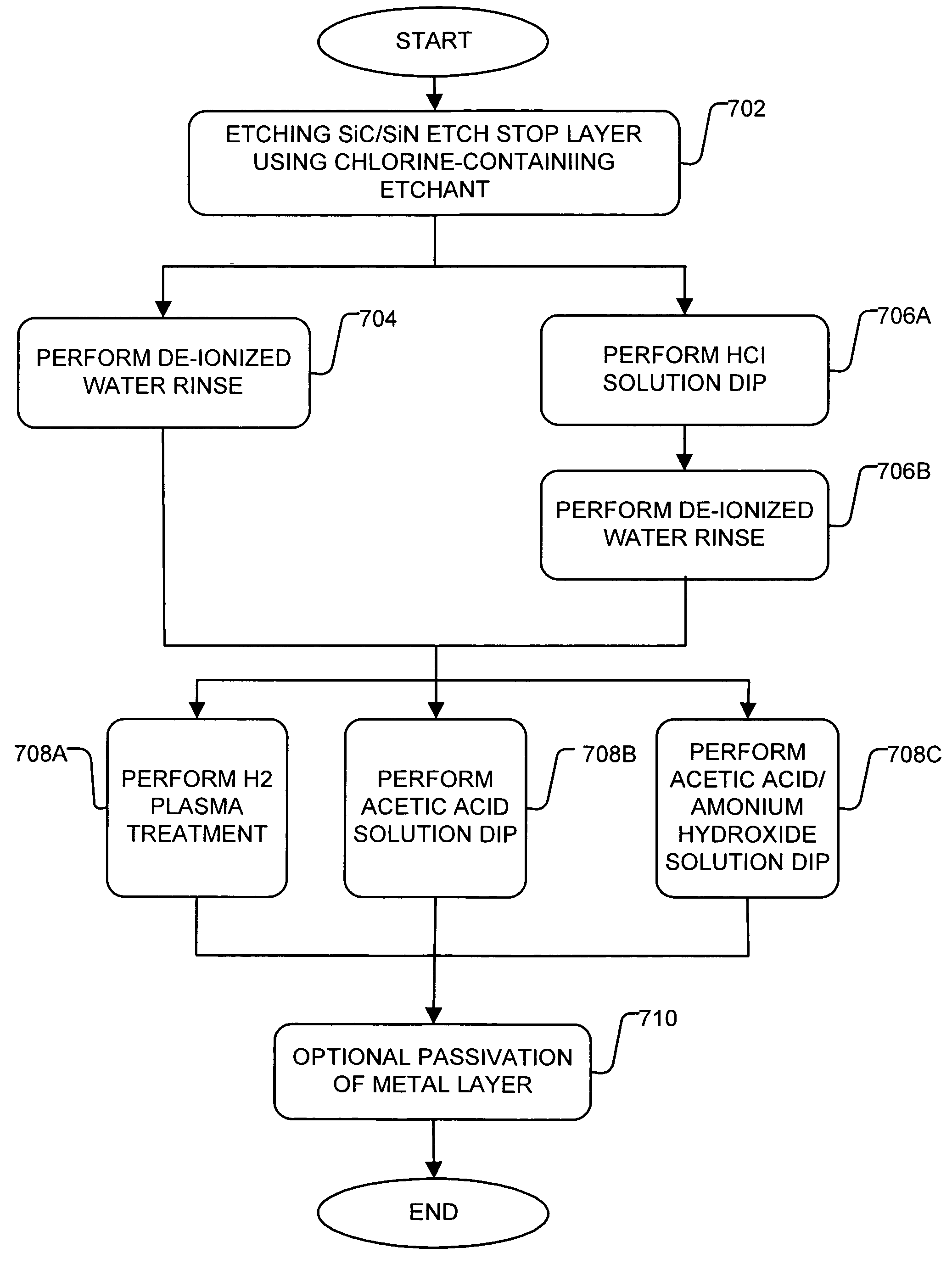

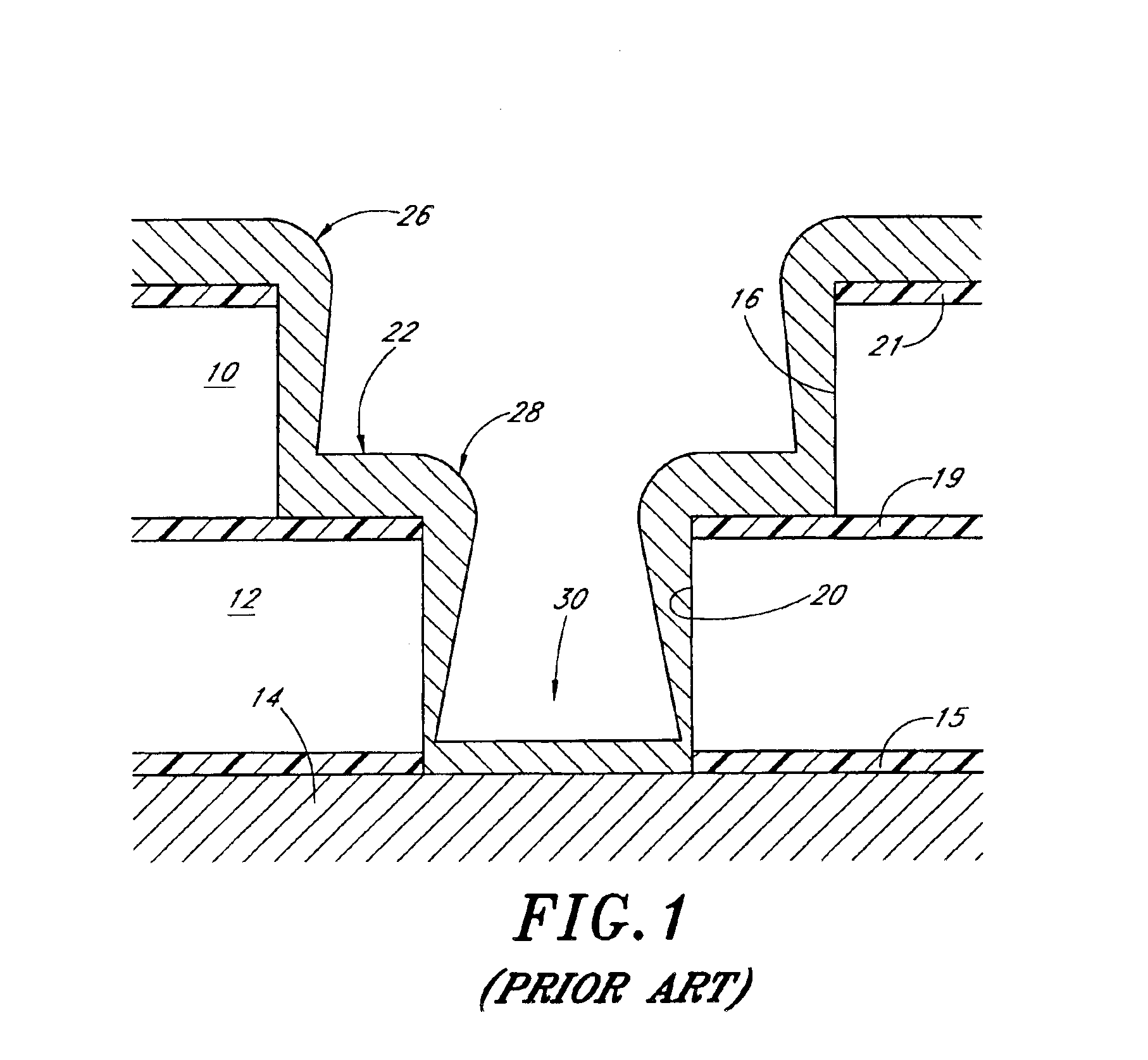

Treatment for corrosion in substrate processing

InactiveUS7084070B1Semiconductor/solid-state device manufacturingElectrostatic cleaningAcetic acidAmmonium hydroxide

A method for processing substrate to form a semiconductor device is disclosed. The substrate includes an etch stop layer disposed above a metal layer. The method includes etching through the etch stop layer down to the copper metal layer, using a plasma etch process that utilizes a chlorine-containing etchant source gas, thereby forming etch stop layer openings in the etch stop layer. The etch stop layer includes at least one of a SiN and SiC material. Thereafter, the method includes performing a wet treatment on the substrate using a solution that contains acetic acid (CH3COOH) or acetic acid / ammonium hydroxide (NH4OH) to remove at least some of the copper oxides. Alternatively, the copper oxides may be removed using a H2 plasma. BTA passivation may be optionally performed on the substrate.

Owner:LAM RES CORP

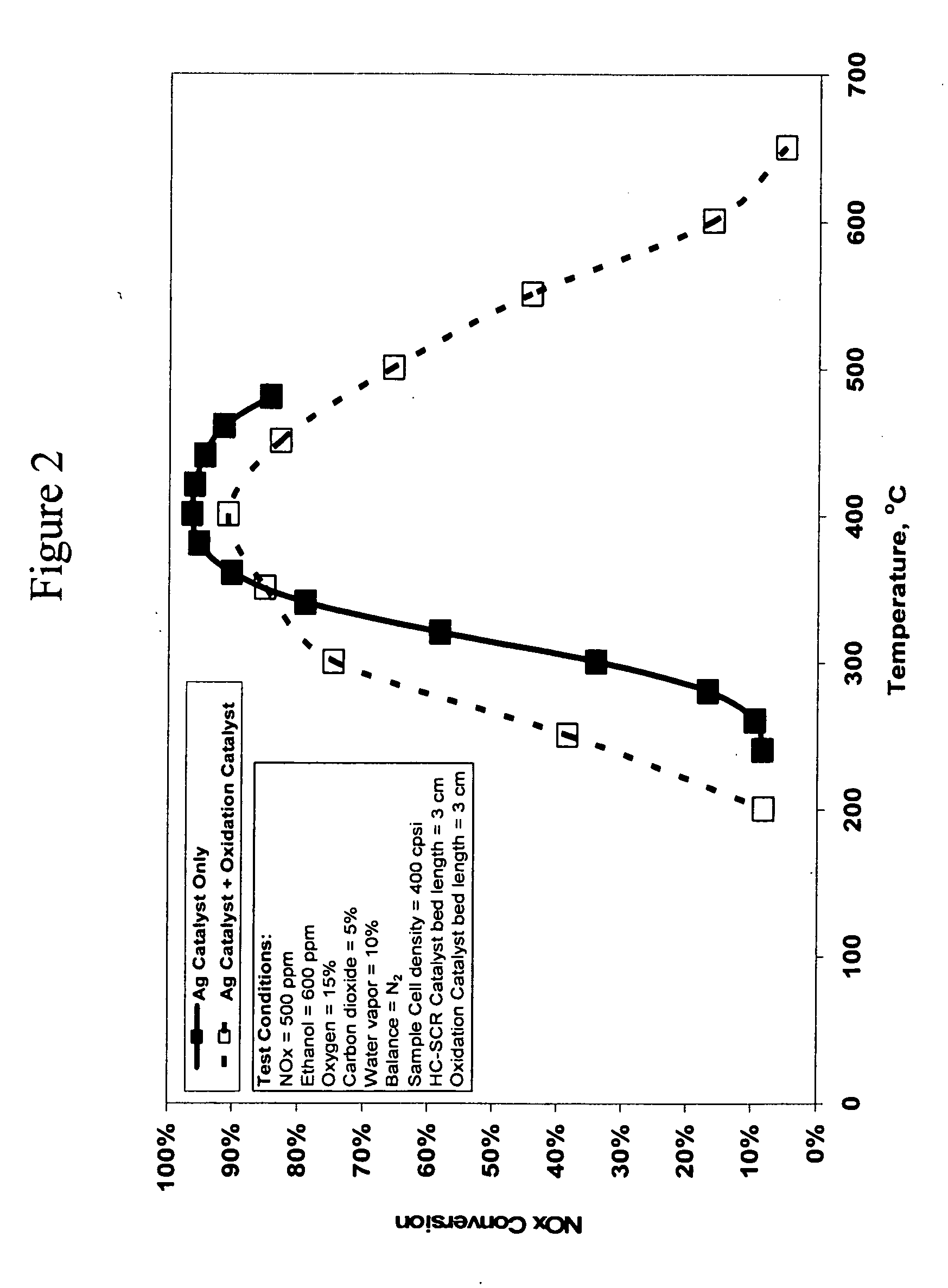

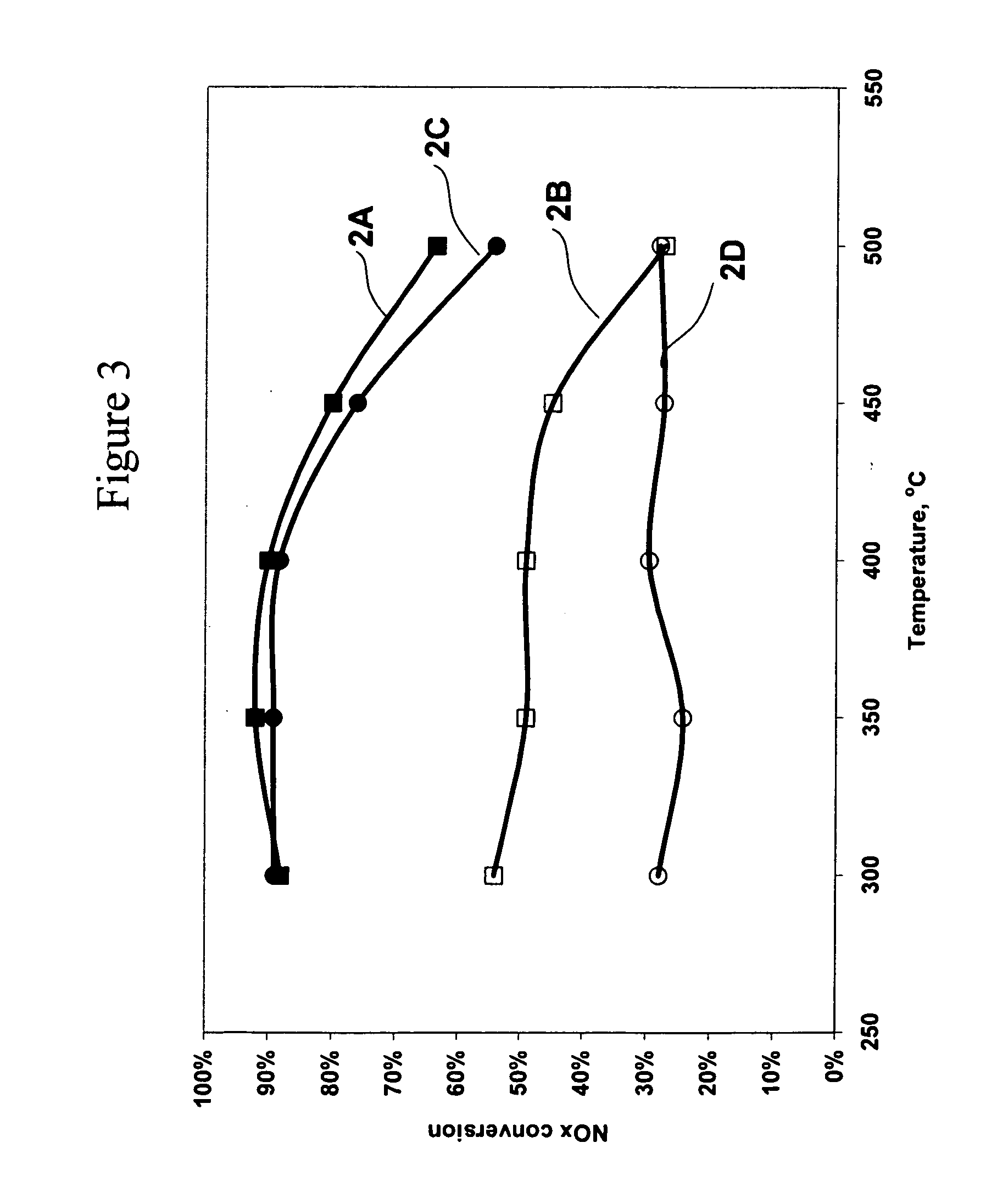

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

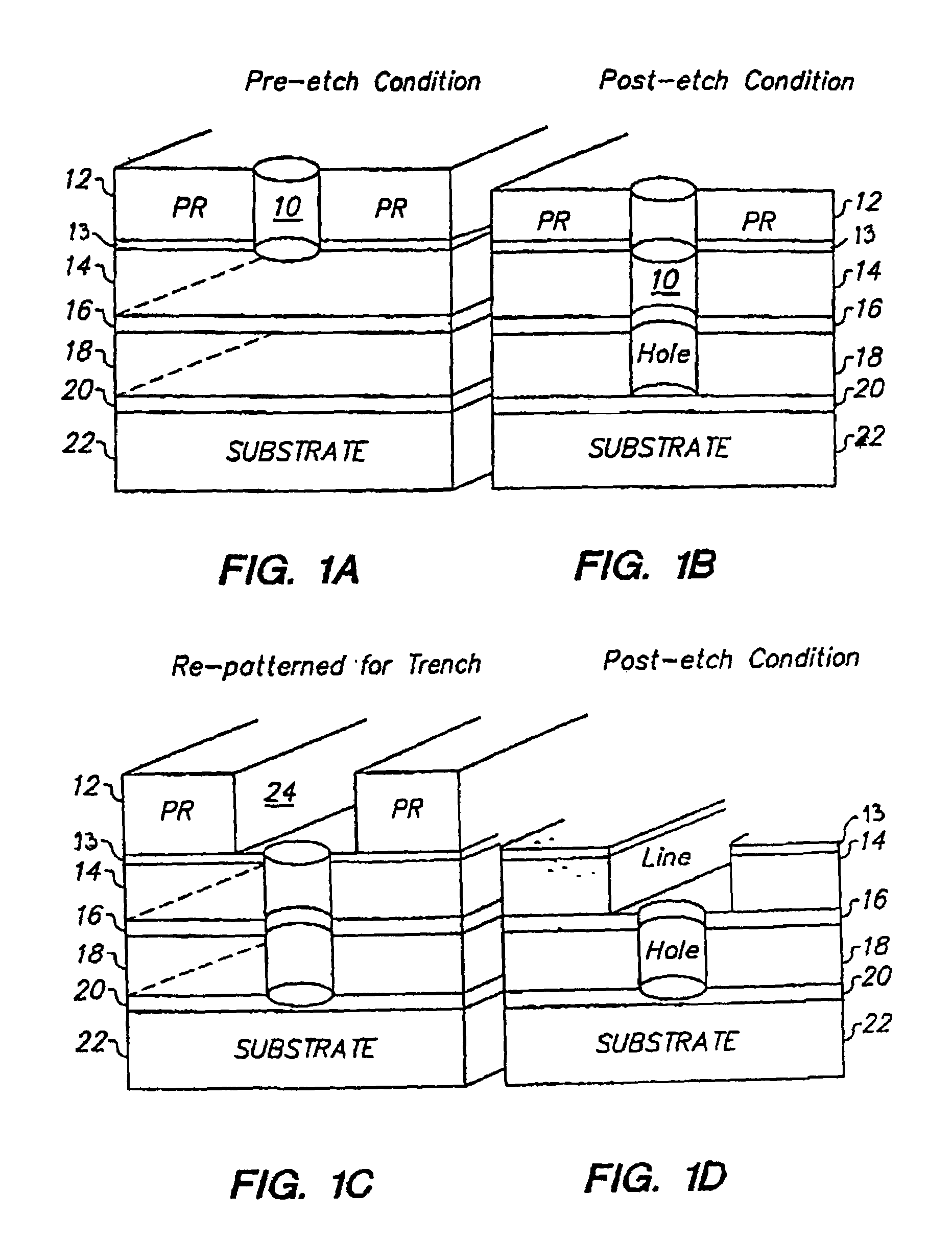

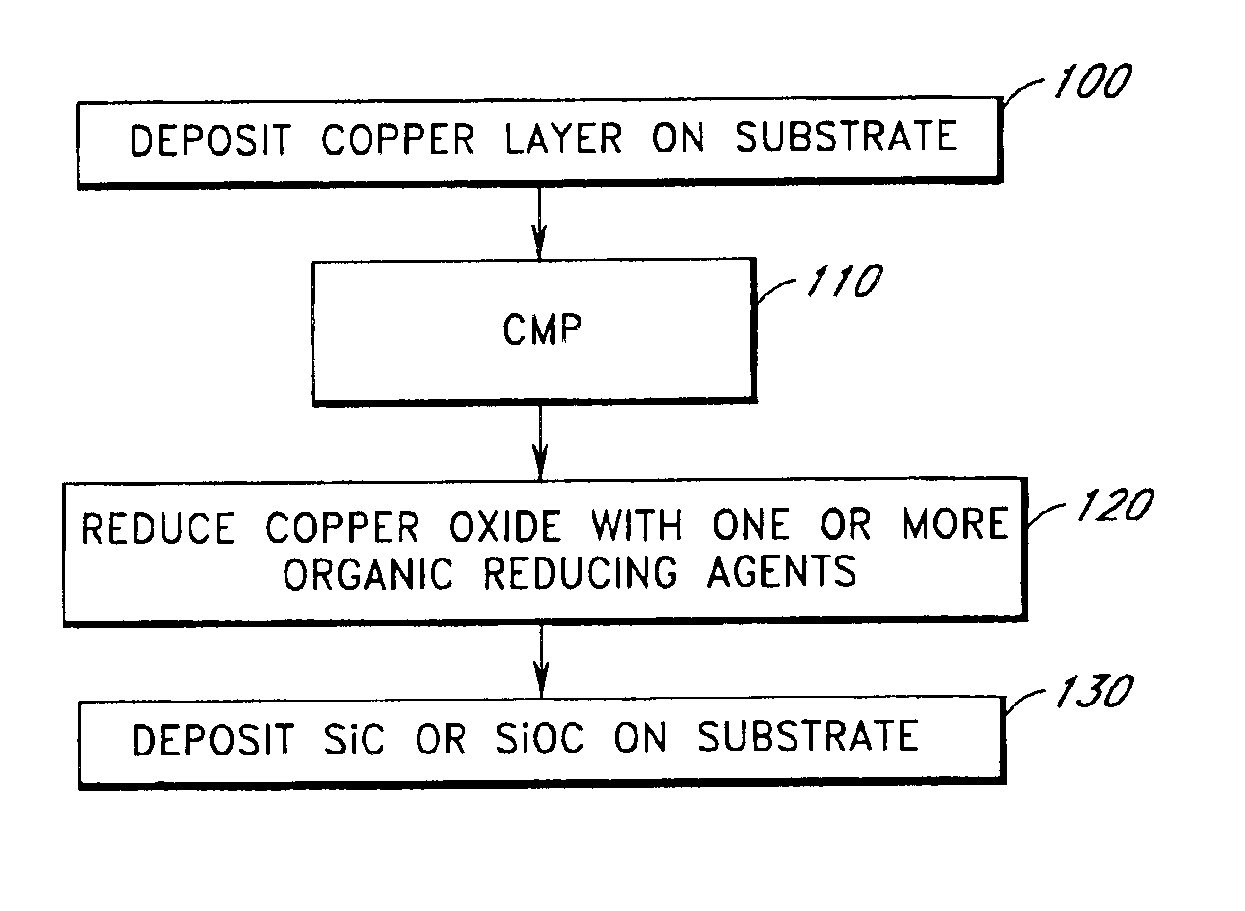

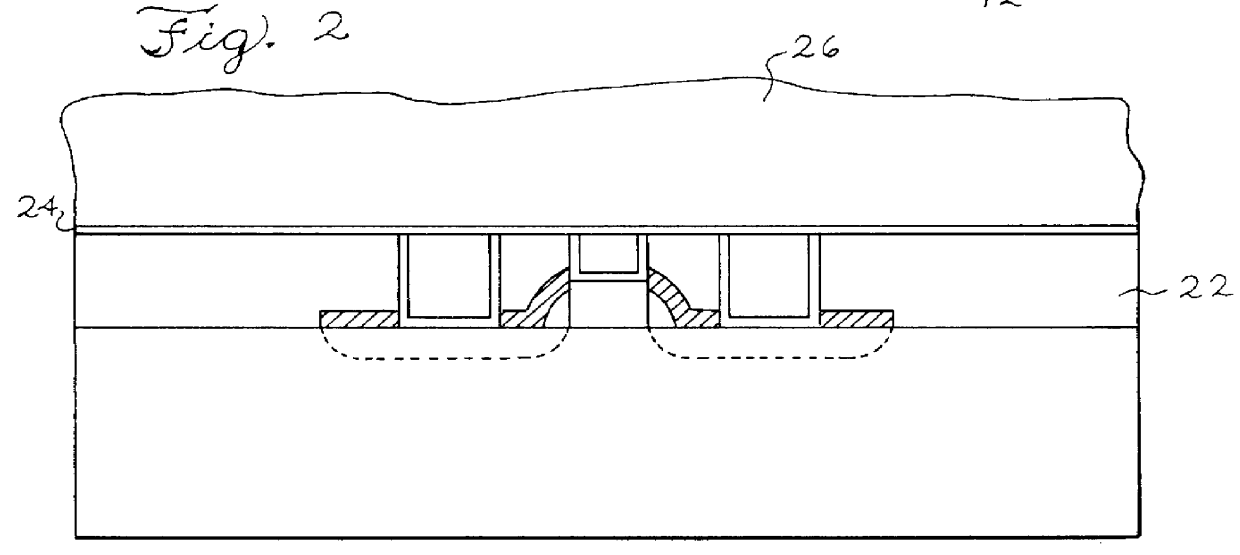

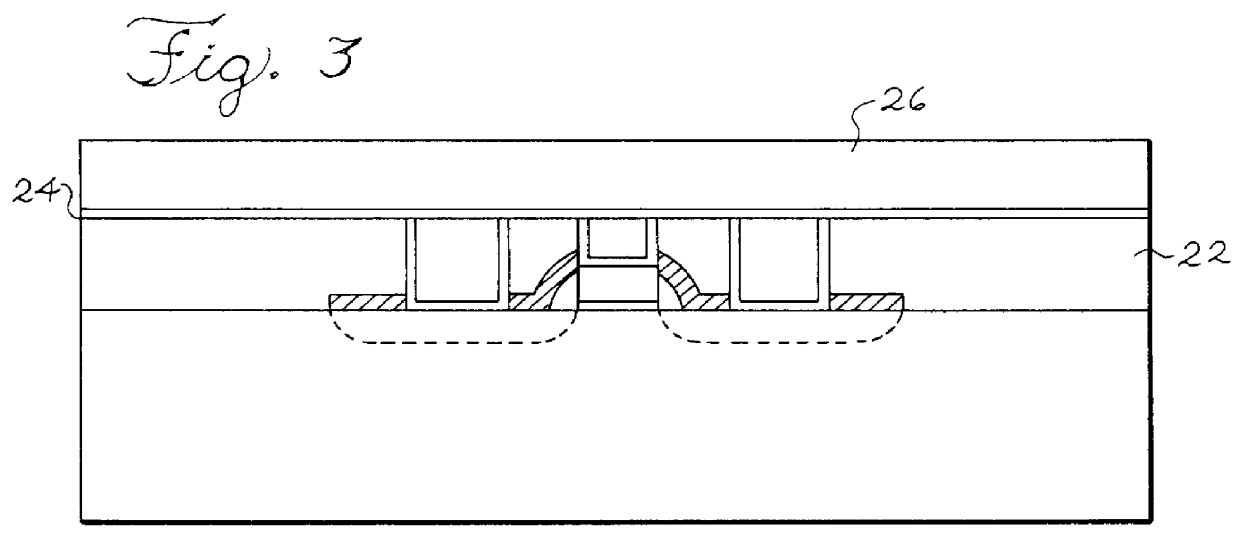

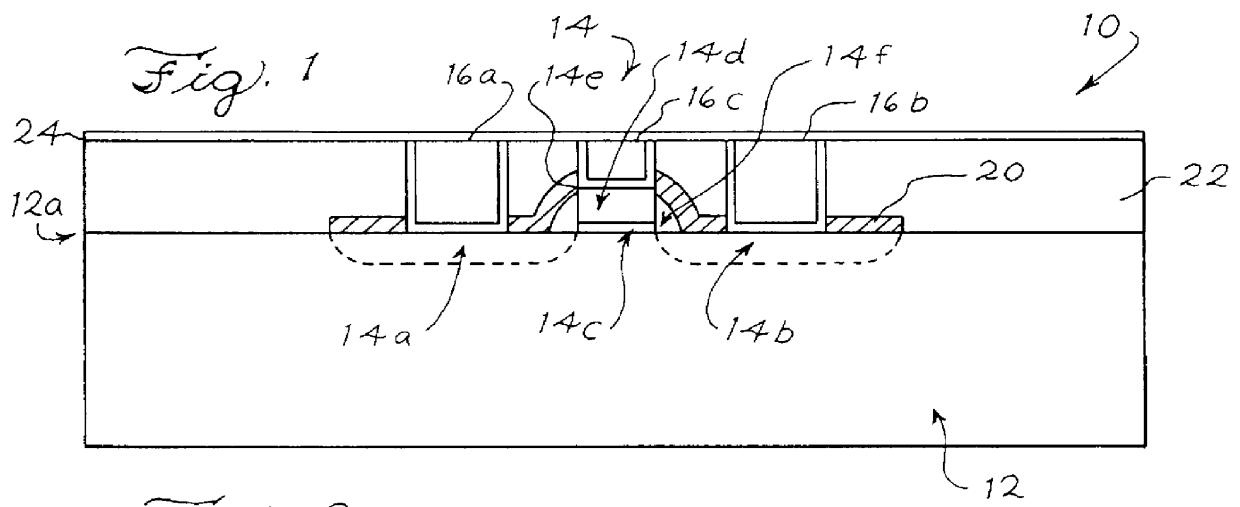

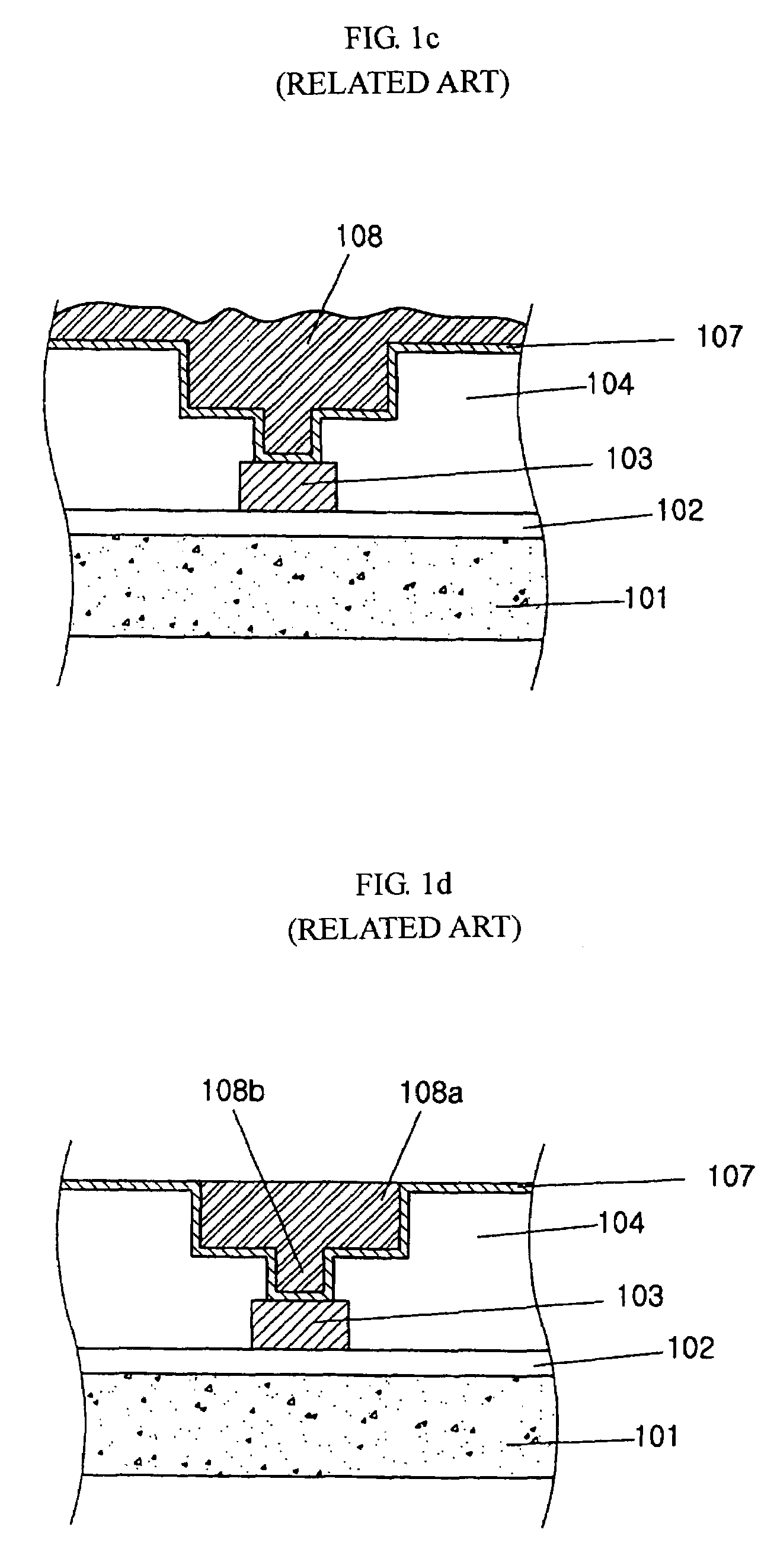

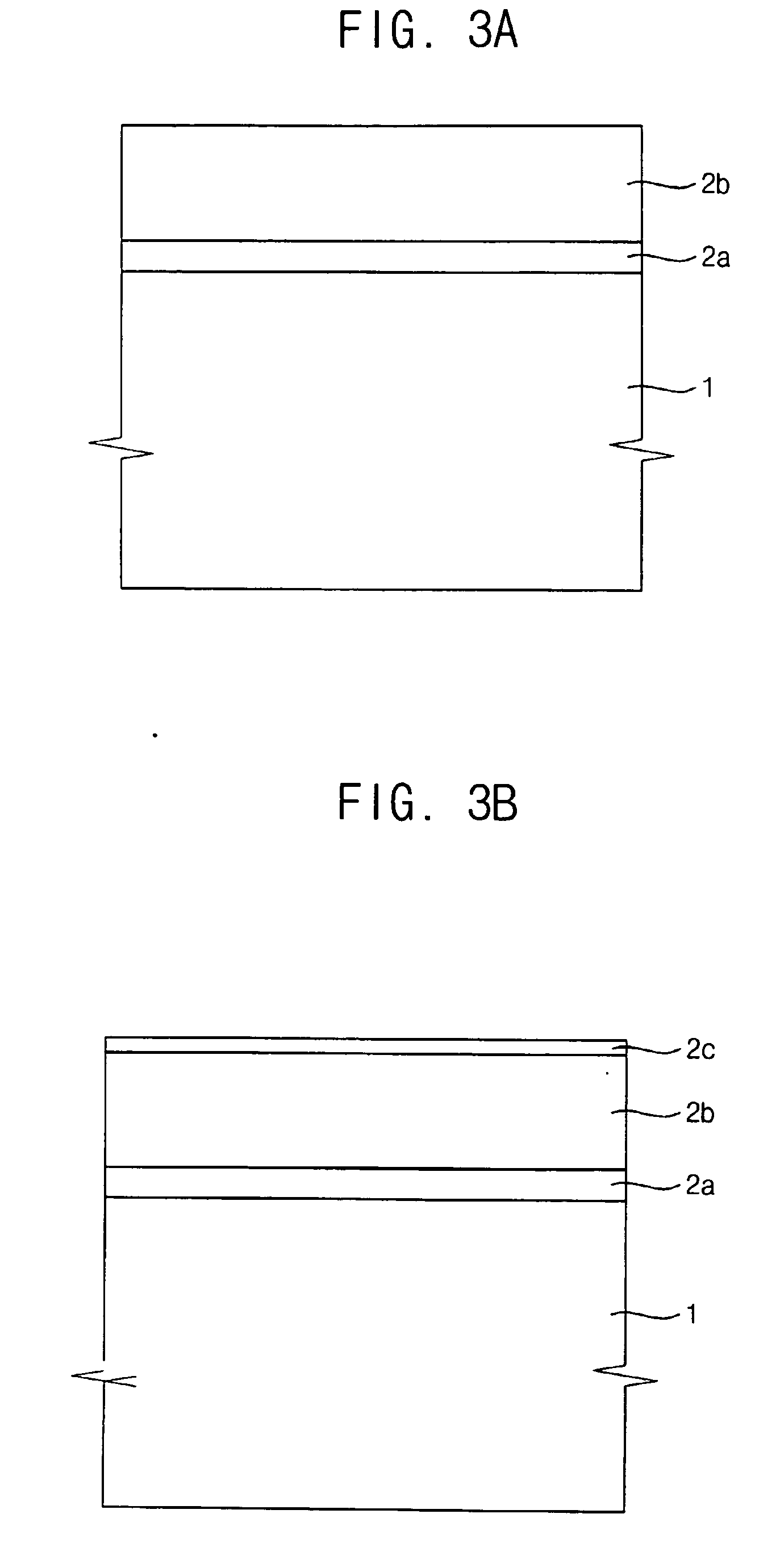

In situ reduction of copper oxide prior to silicon carbide deposition

InactiveUS6878628B2Inhibited DiffusionSemiconductor/solid-state device manufacturingCoatingsCopper oxideReducing agent

The invention relates generally to improved silicon carbide deposition during dual damascene processing. In one aspect of the invention, copper oxide present on a substrate is reduced at least partially to copper prior to deposition of a silicon carbide or silicon oxycarbide layer thereon. In the preferred embodiment the reduction is accomplished by contacting the substrate with one or more organic reducing agents. The reduction process may be carried out in situ, in the same reaction chamber as subsequent processing steps. Alternatively, it may be carried out in a module of a cluster tool.

Owner:ASM INTERNATIONAL

Catalyst for preparing alcohol by acetic ester hydrogenation as well as preparation method and application thereof

InactiveCN101934228AHigh reactivityLow investment costOrganic compound preparationHydroxy compound preparationManganeseCopper oxide

The invention discloses a catalyst for preparing alcohol by acetic ester hydrogenation as well as a preparation method and an application thereof, which is characterized in that the main catalyst of the catalyst is copper or copper oxide or a mixture of the copper and the copper oxide, and the cocatalyst can be also added, wherein the cocatalyst is one or more of oxides of zinc, manganese, chromium, calcium, barium, iron, nickel and magnesium; and the carrier is alumina or silica sol. The catalyst has high activity and high selectivity under the condition of low temperature and low pressure, thus greatly reducing the investment cost of permanent plants, lowering production energy consumption, being extremely beneficial for the industrial production, and having good stability and long service life. The catalyst of the invention is used to cause percent conversion of a reaction of converting the acetic ester into the alcohol is more than or equal to 80% and the selectivity of the alcohol is more than or equal to 95%.

Owner:江苏丹化煤制化学品工程技术有限公司

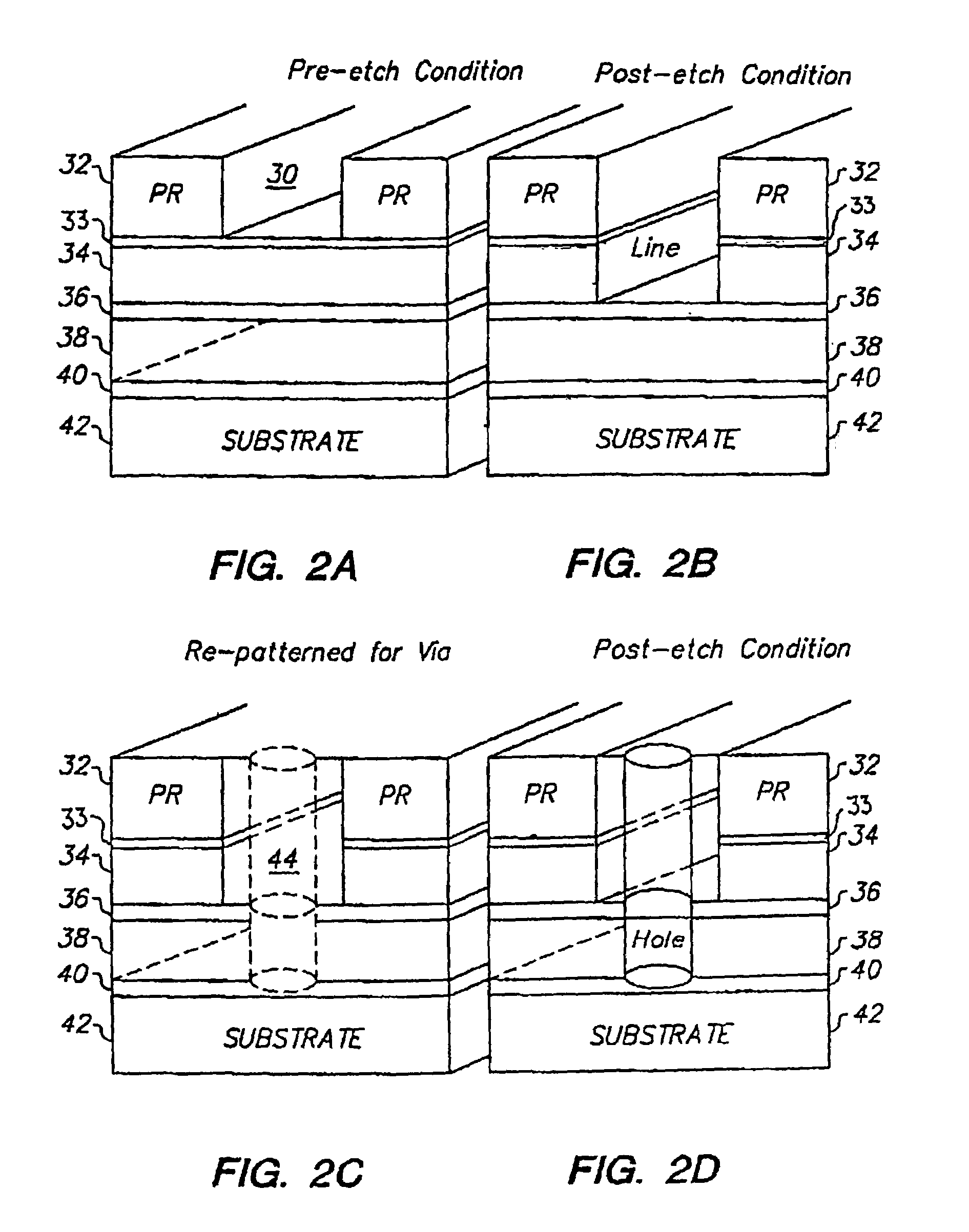

Process for reducing copper oxide during integrated circuit fabrication

InactiveUS6033584ADecorative surface effectsSemiconductor/solid-state device manufacturingCopper interconnectCopper oxide

A method of integrated circuit fabrication creating copper interconnect structures wherein the formation of copper oxide is reduced or eliminated by etching away the copper oxide performing an H2 plasma treatment in a plasma enhanced chemical vapor deposition chamber.

Owner:ADVANCED MICRO DEVICES INC

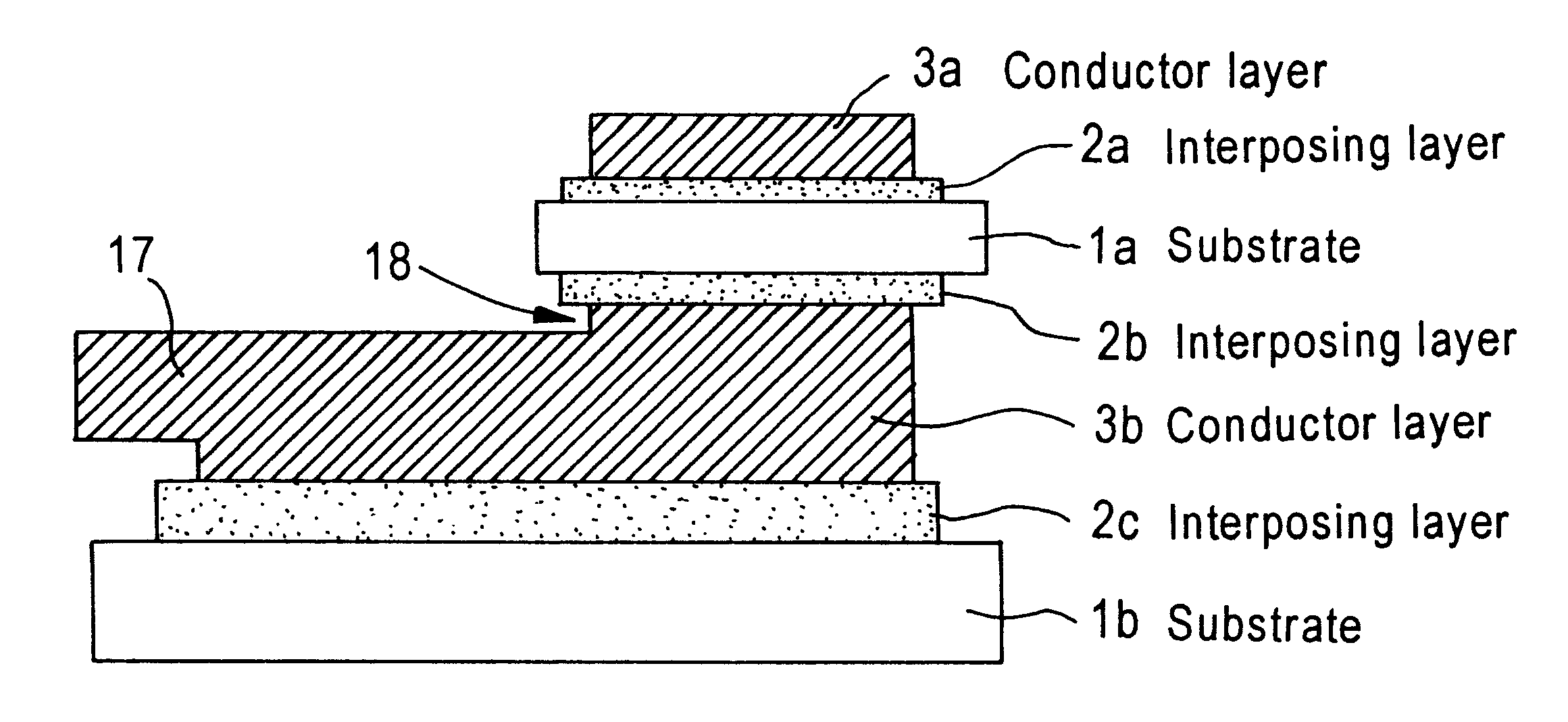

Copper circuit junction substrate and method of producing the same

InactiveUS6261703B1Avoid discharge phenomenonHigh concentration of thermal stressInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorCopper oxide

A highly reliable copper circuit-joined board that, in mounting a semiconductor element, a lead frame or the like on a ceramic substrate, enables the semiconductor element, the lead frame or the like to be strongly joined to the substrate without breaking or deformation of the substrate found in conventional joining methods, such as brazing and joining using a copper / copper oxide eutectic crystal. Any one of an interposing layer comprising a brazing material layer comprising silver and / or copper as a main component and an active metal or an interposing layer having a two-layer structure comprising a first interposing layer comprising the brazing material layer or a high-melting metallizing layer and a second interposing layer, having a melting point of 1000.degree. C. or below, comprising Ni, Fe, Cu as a main component in that order from the substrate side, is formed on a ceramic substrate, and a conductor layer, comprising copper as a main component, which, in both the lengthwise and widthwise directions, is at least 0.05 mm shorter than the interposing layer, is formed on the interposing layer to prepare a copper circuit-joined board. The copper circuit-joined board may comprise the base board having thereon an outer layer comprising Ni as a main component. A semiconductor element is mounted on the copper circuit-joined board to prepare a semiconductor device.

Owner:SUMITOMO ELECTRIC IND LTD

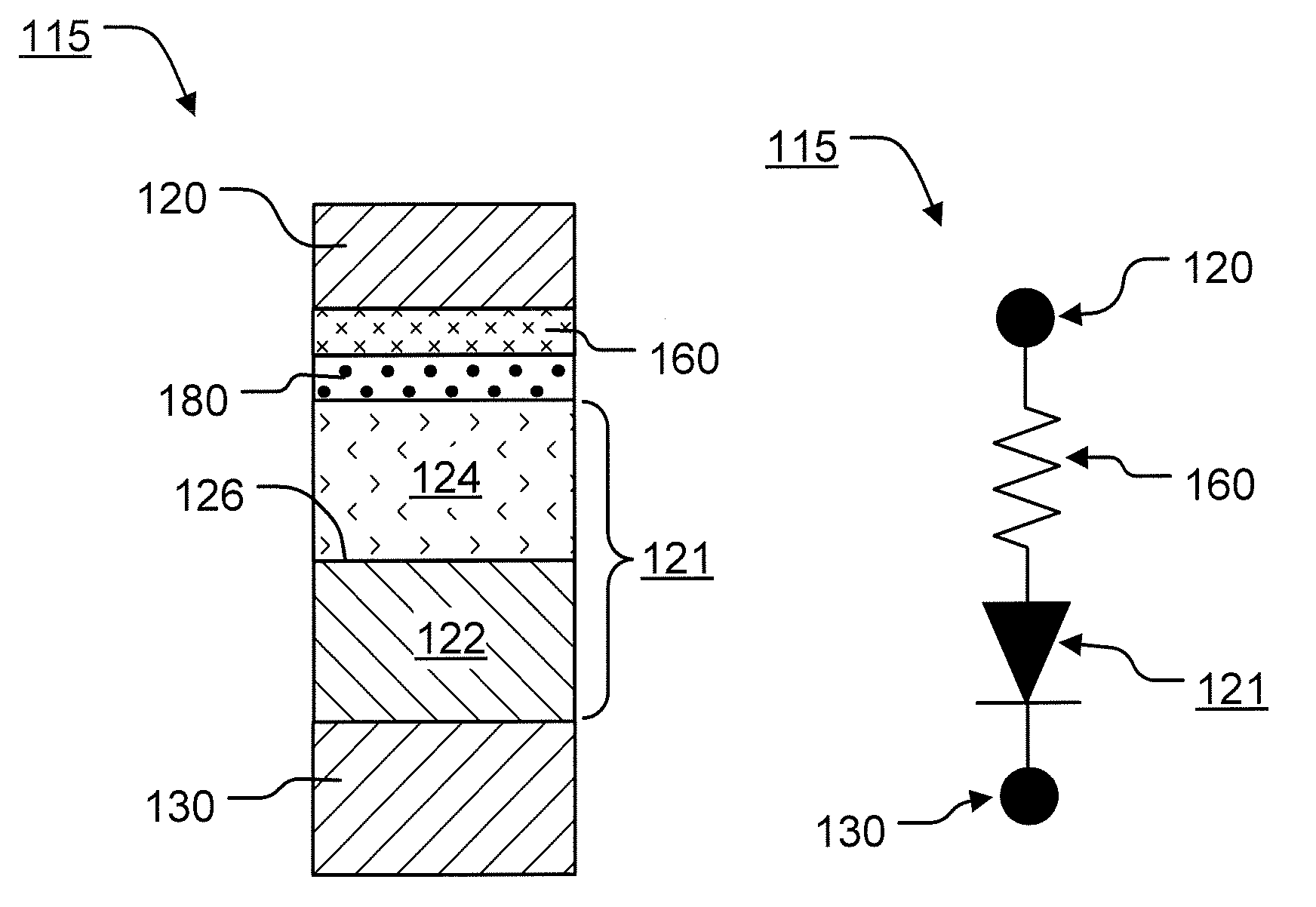

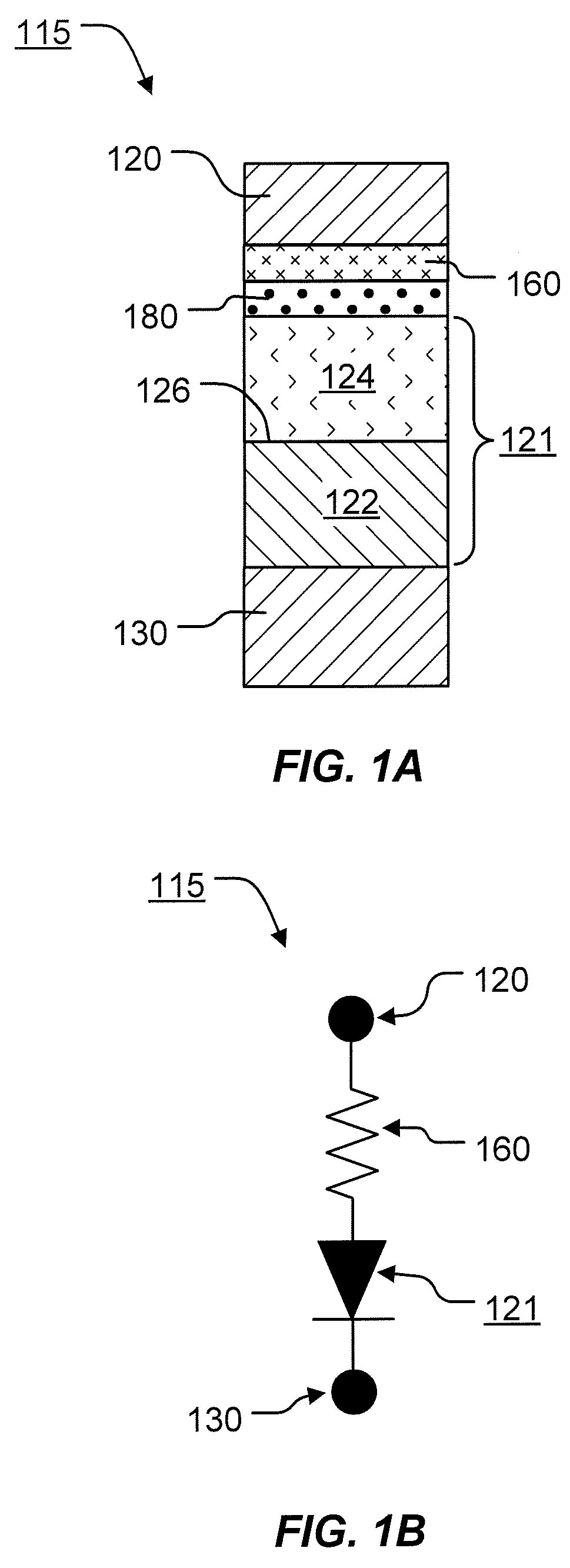

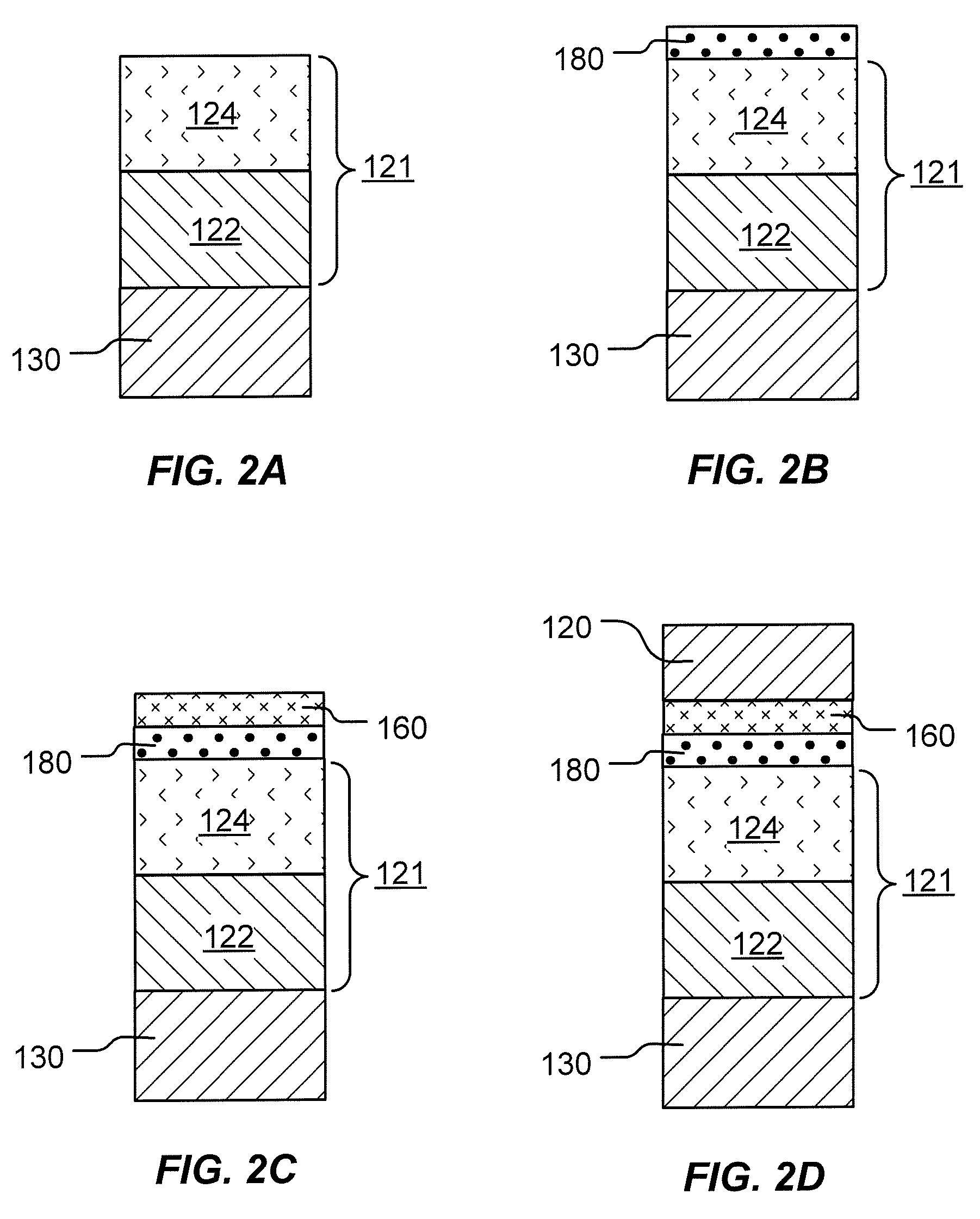

Aluminum copper oxide based memory devices and methods for manufacture

ActiveUS8067815B2Reduce voltageBig ratioTransistorSemiconductor/solid-state device detailsElectricityCopper oxide

Memory devices are described along with methods for manufacturing. A memory device as described herein includes a first electrode and a second electrode. The memory device further includes a diode and an anti-fuse metal-oxide memory element comprising aluminum oxide and copper oxide. The diode and the metal-oxide memory element are arranged in electrical series between the first electrode and the second electrode.

Owner:MACRONIX INT CO LTD

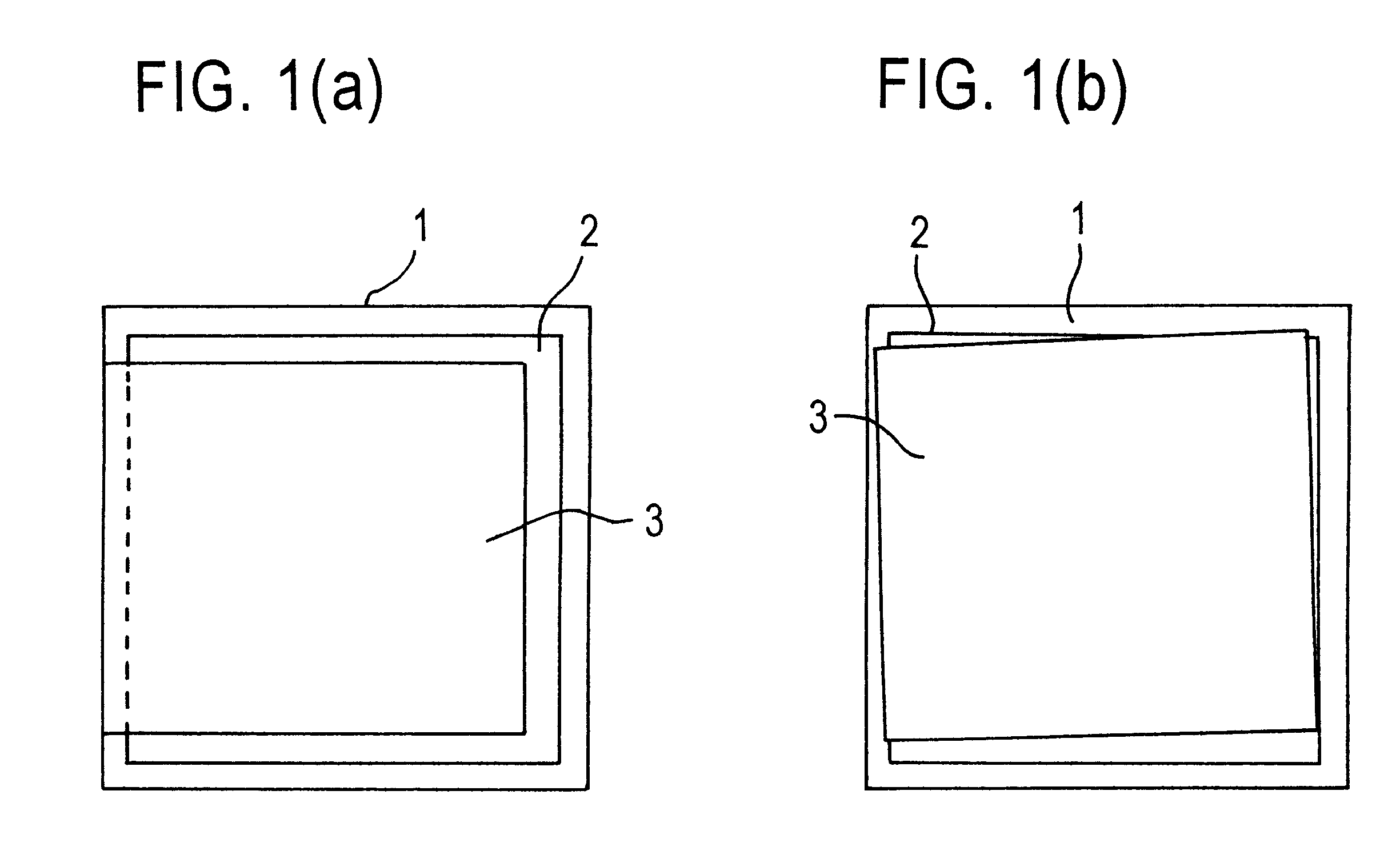

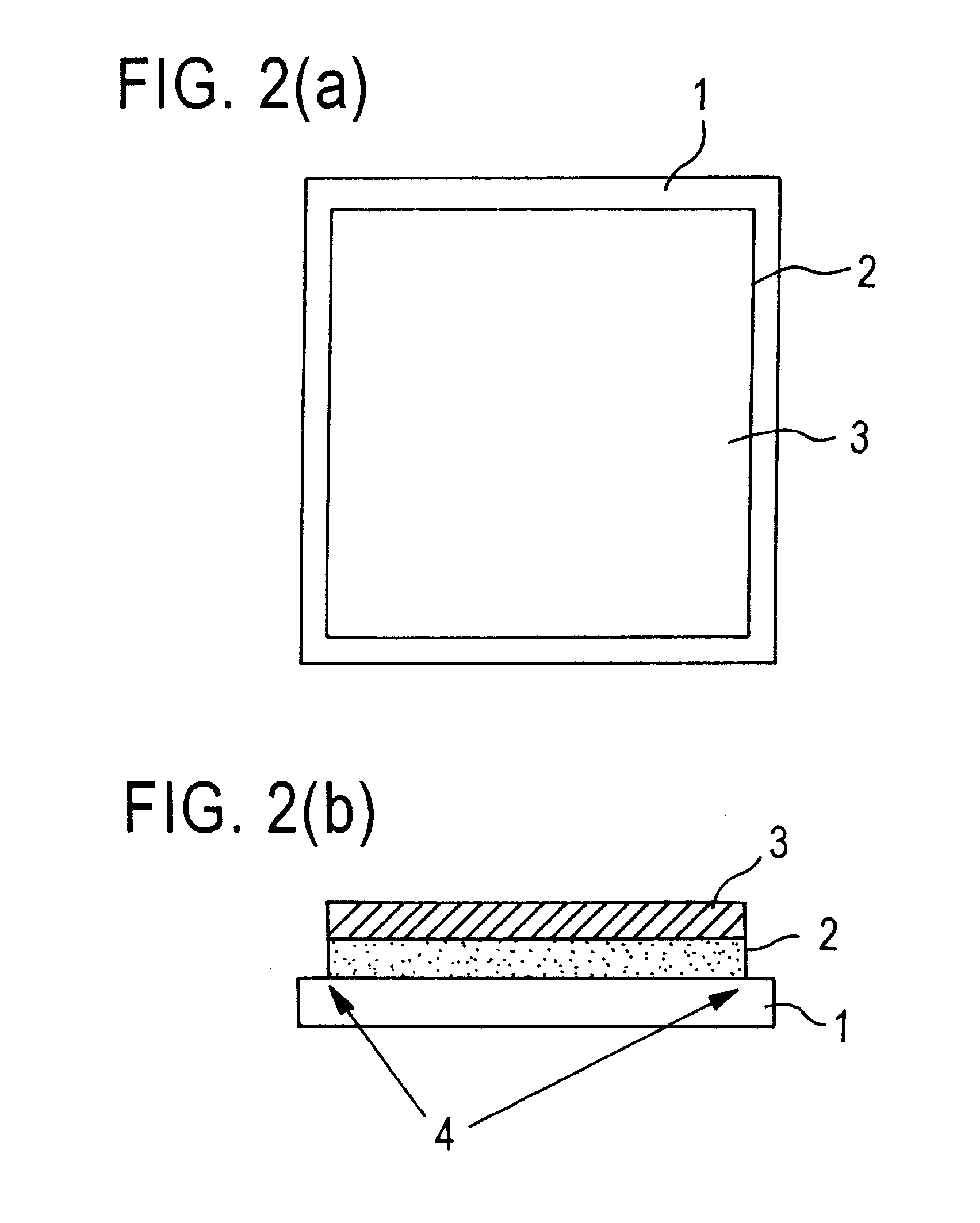

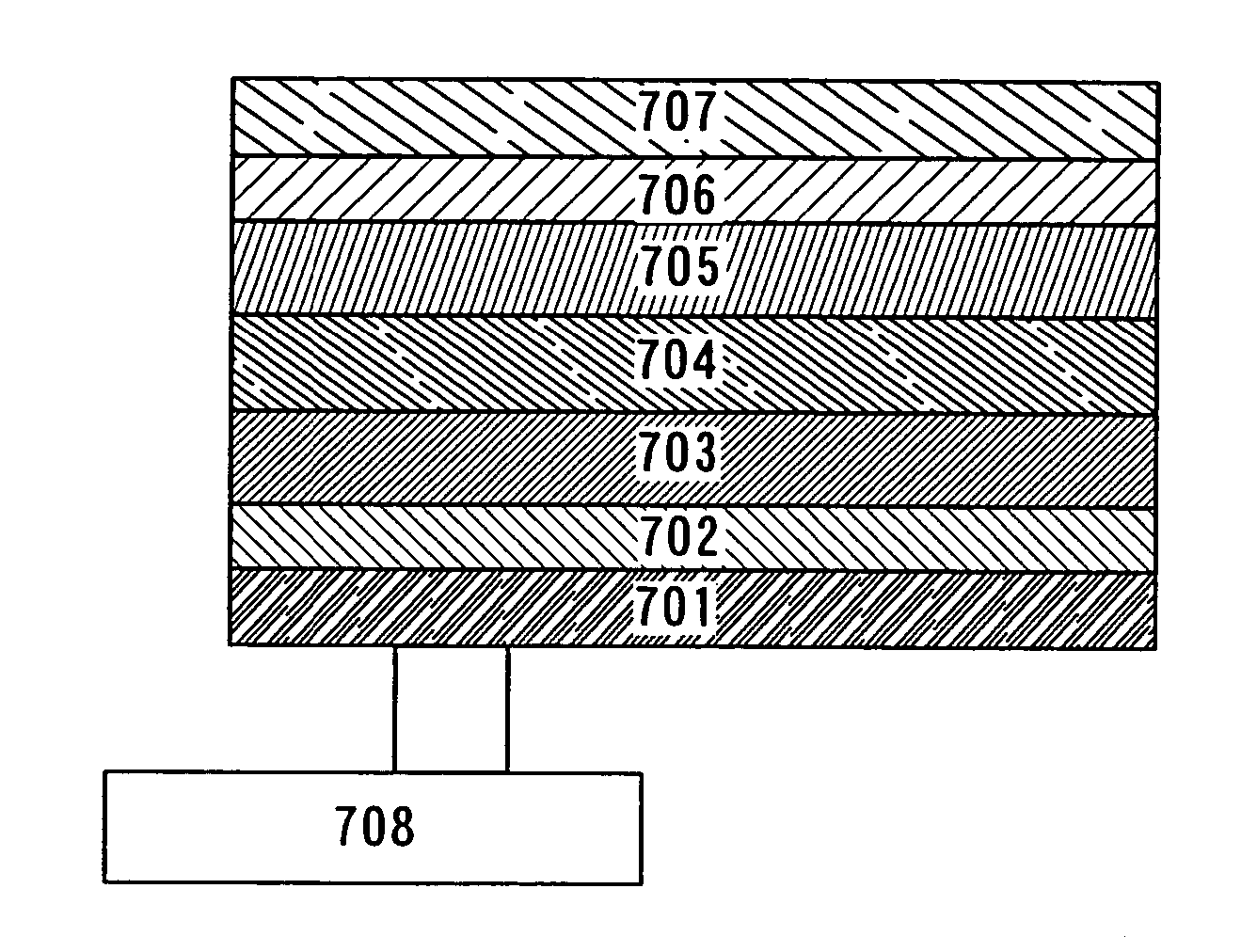

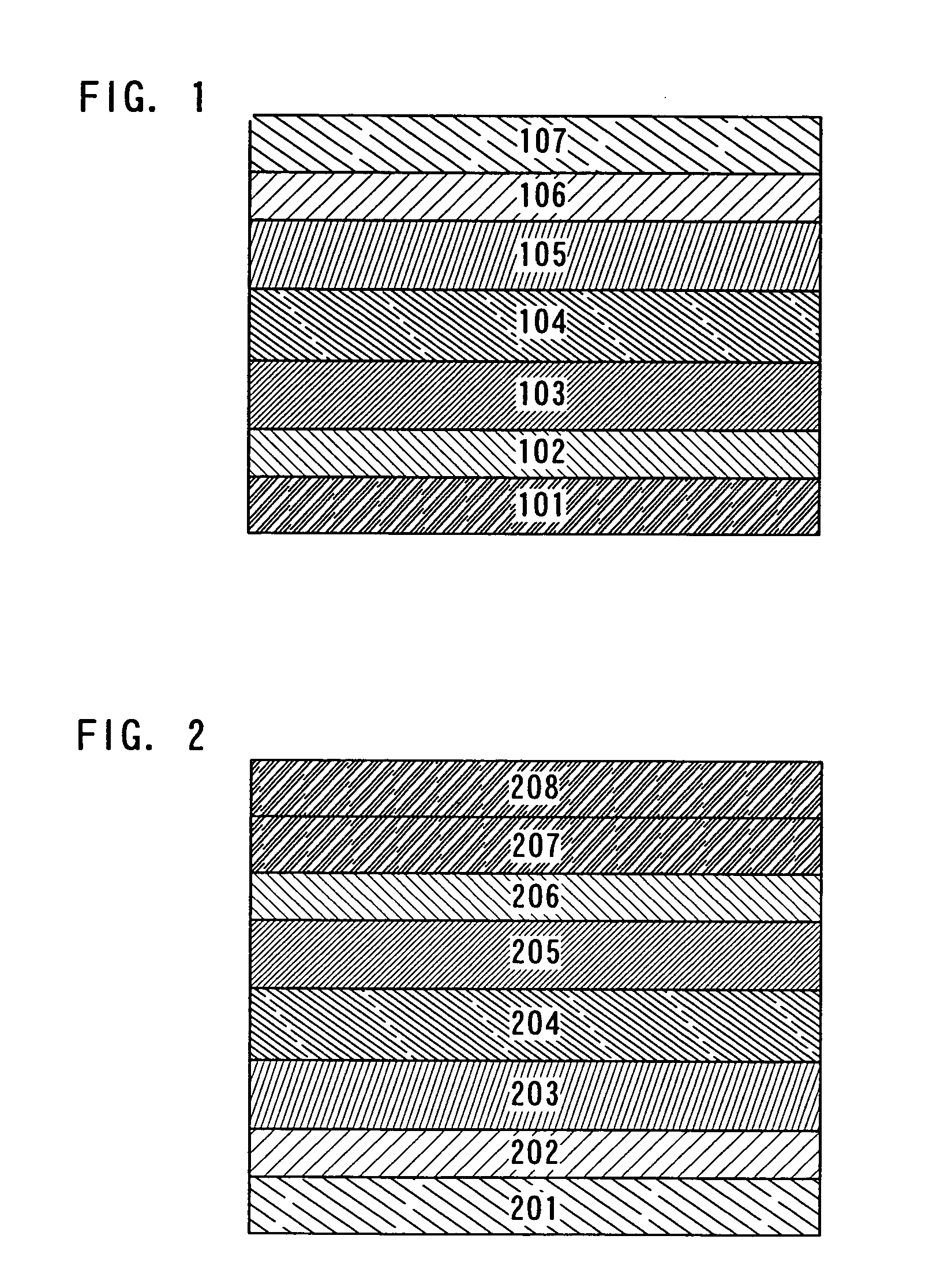

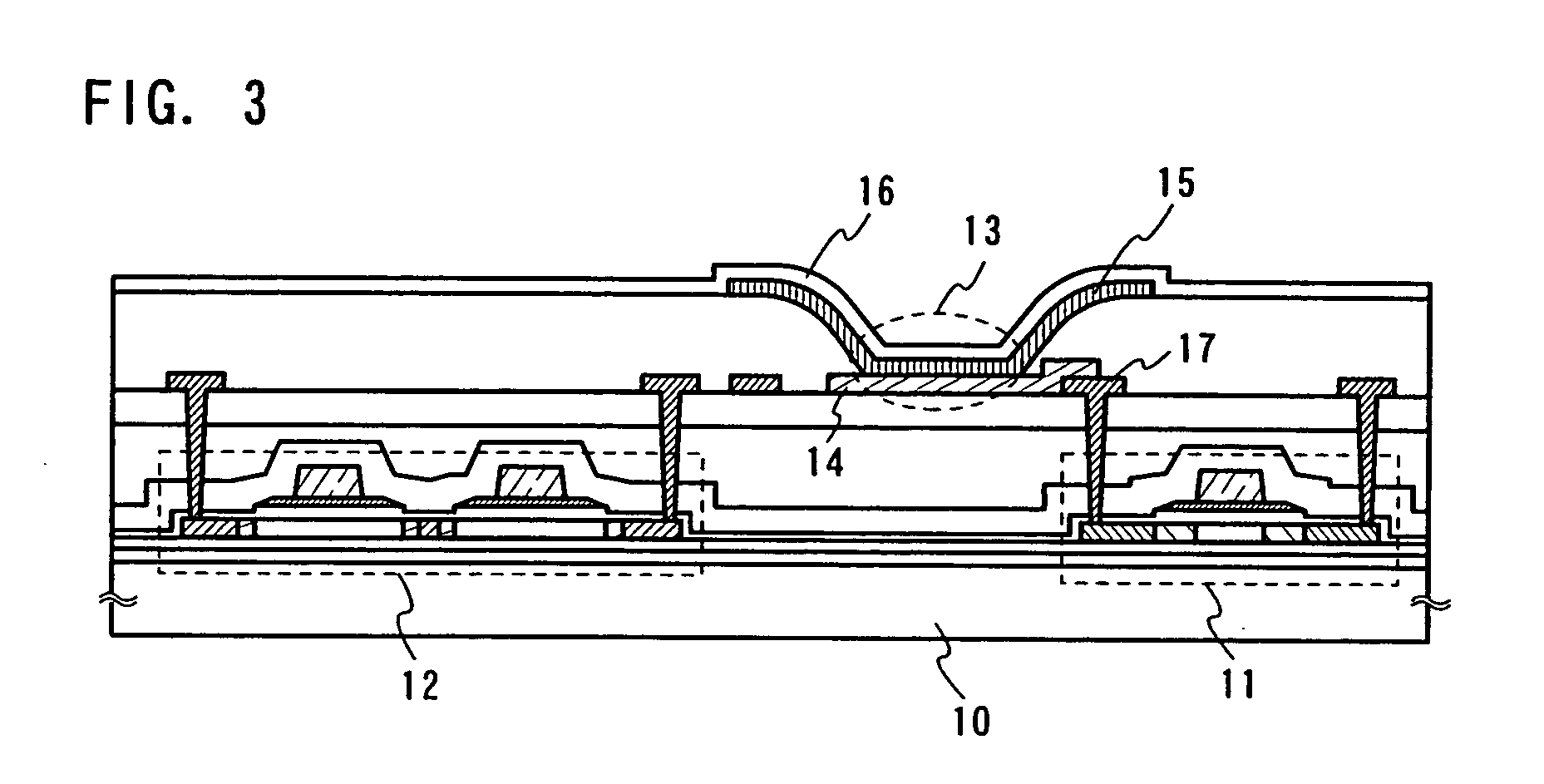

Light-emitting element and light-emitting device using the same

InactiveUS20050116633A1Luminous stabilityEfficient emissionsDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringCopper oxide

It is an object of the invention is to provide a light-emitting element in which failure of the light-emitting element due to separation can be controlled and stable luminescence can be obtained with high-efficiency and for a long stretch of time by controlling separation of layers constituting the light-emitting element. According to one aspect of a light-emitting element of the invention, the light-emitting element sandwiches a plurality of layers between a pair of electrodes, wherein at least one layer of the plurality of layers is a layer containing a substance selected from bismuth oxide, cobalt oxide, chromium oxide, copper oxide, nickel oxide, and titanium oxide, or at least one layer of layers different from a light-emitting layer among the plurality of layers is a mixed region of one substance selected from bismuth oxide, cobalt oxide, copper oxide, magnesium oxide, nickel oxide, zinc oxide, and titanium oxide and an organic compound.

Owner:SEMICON ENERGY LAB CO LTD

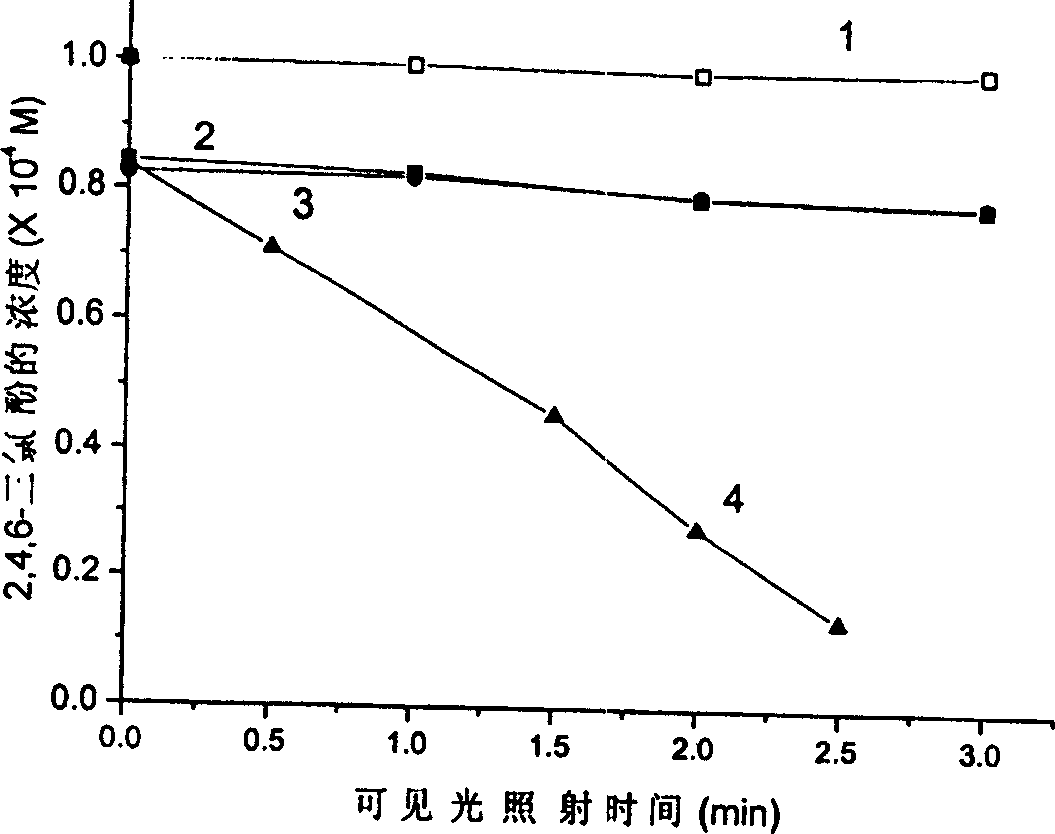

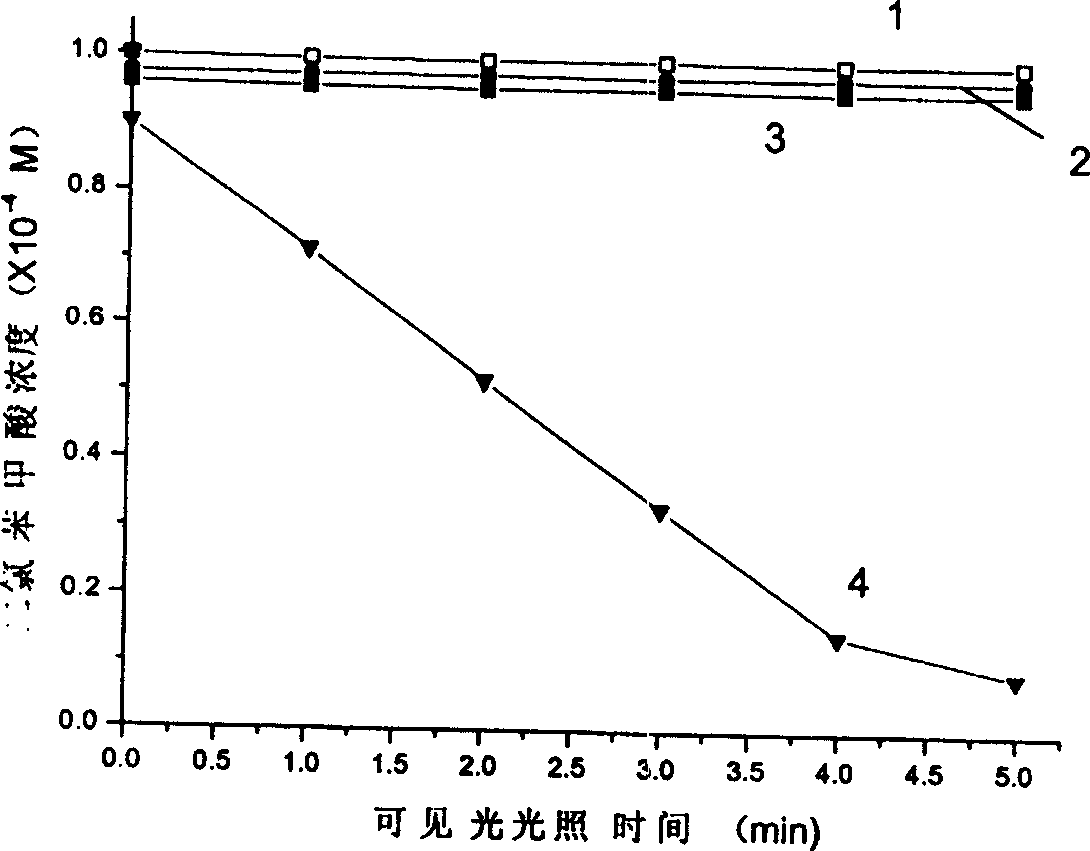

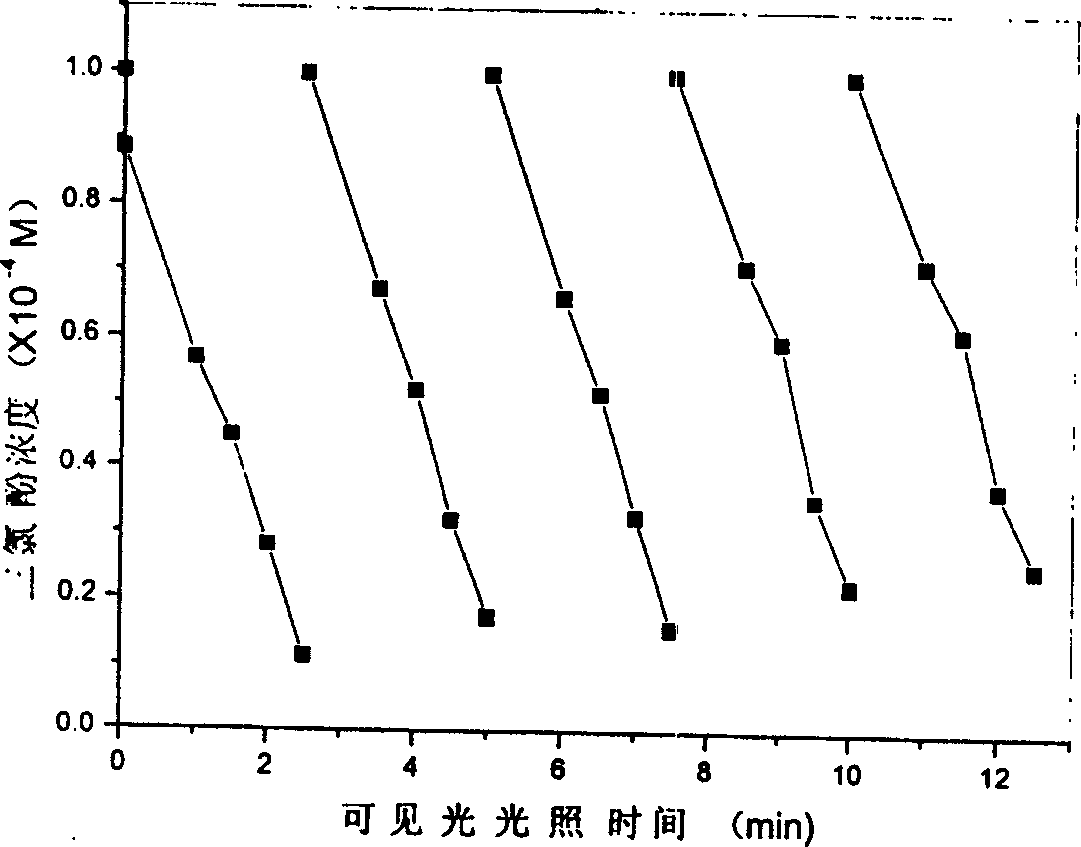

Photocatalyst responding to visible light, and preparation method and application

ActiveCN1600424ASimple preparation processLow costWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic reactionCopper oxide

A semiconductor photocatalyst responsive to visual light is composed of the particles of metallic oxide chosen from iron oxide, nickel oxide, cabolt oide, copper oxide, etc, the non-metal element chosen from N, C, S, B and P and semiconductor nanoparticles chosen frmo TiO2, SnO2, ZnO, CdS and WO3.

Owner:INST OF CHEM CHINESE ACAD OF SCI

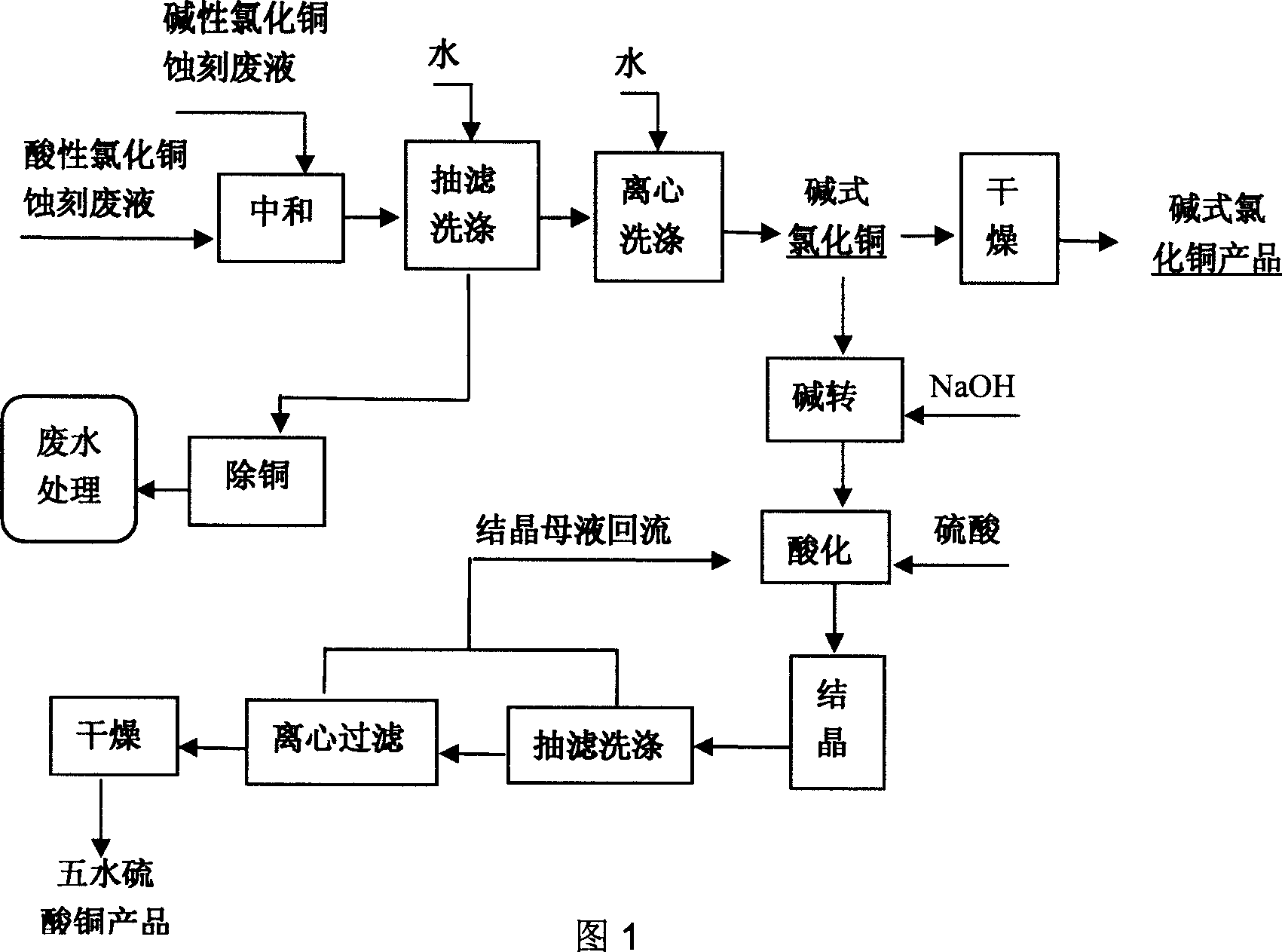

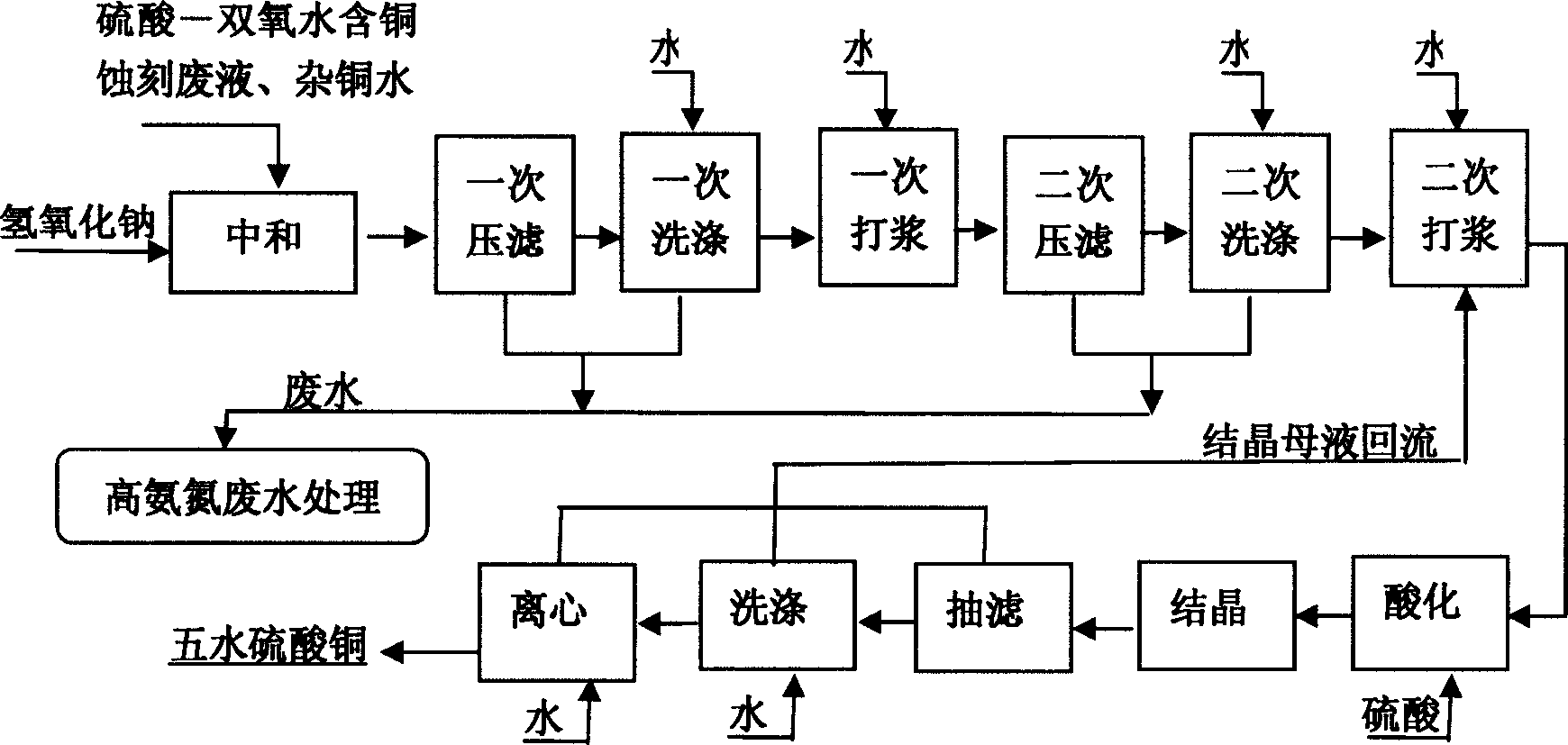

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

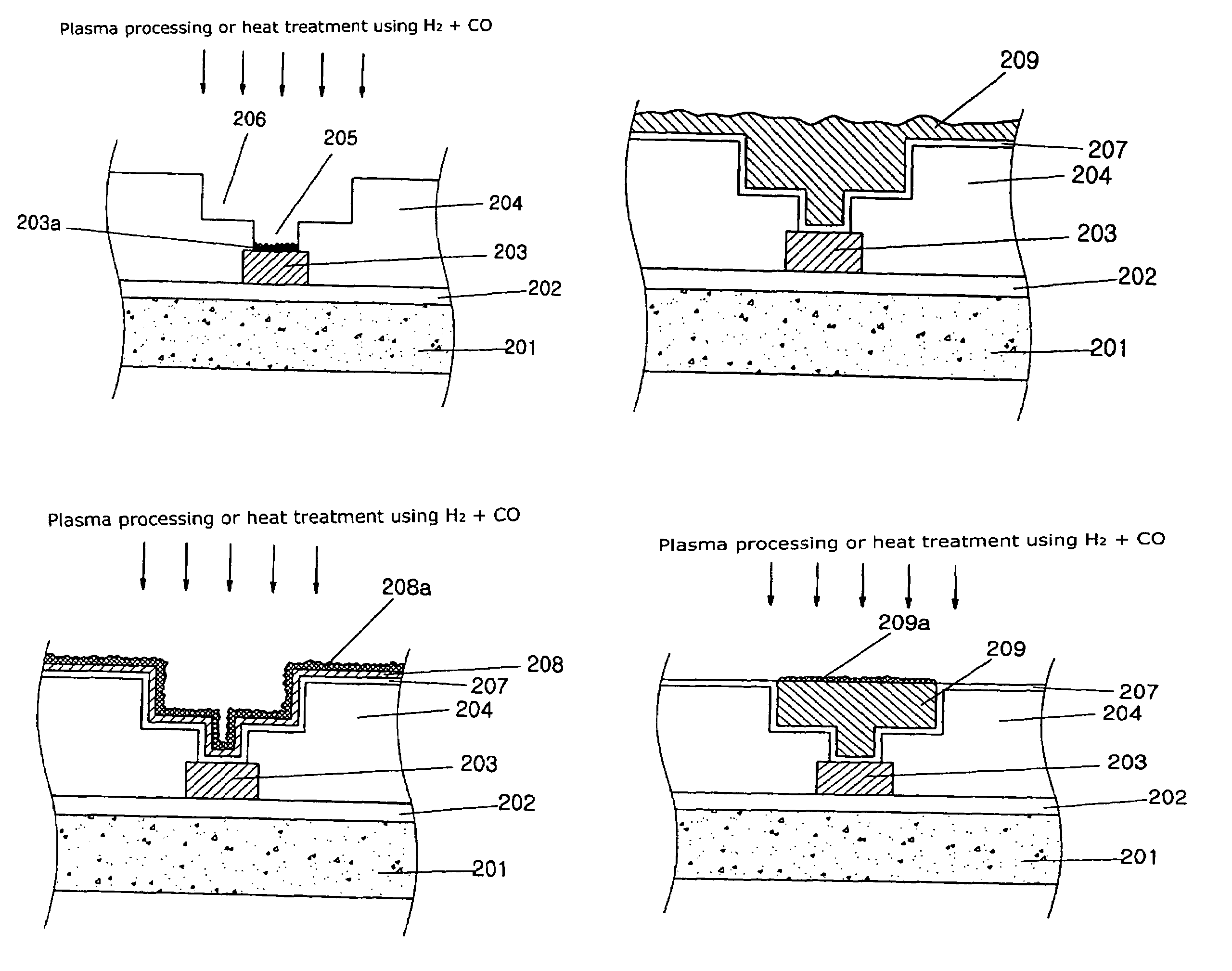

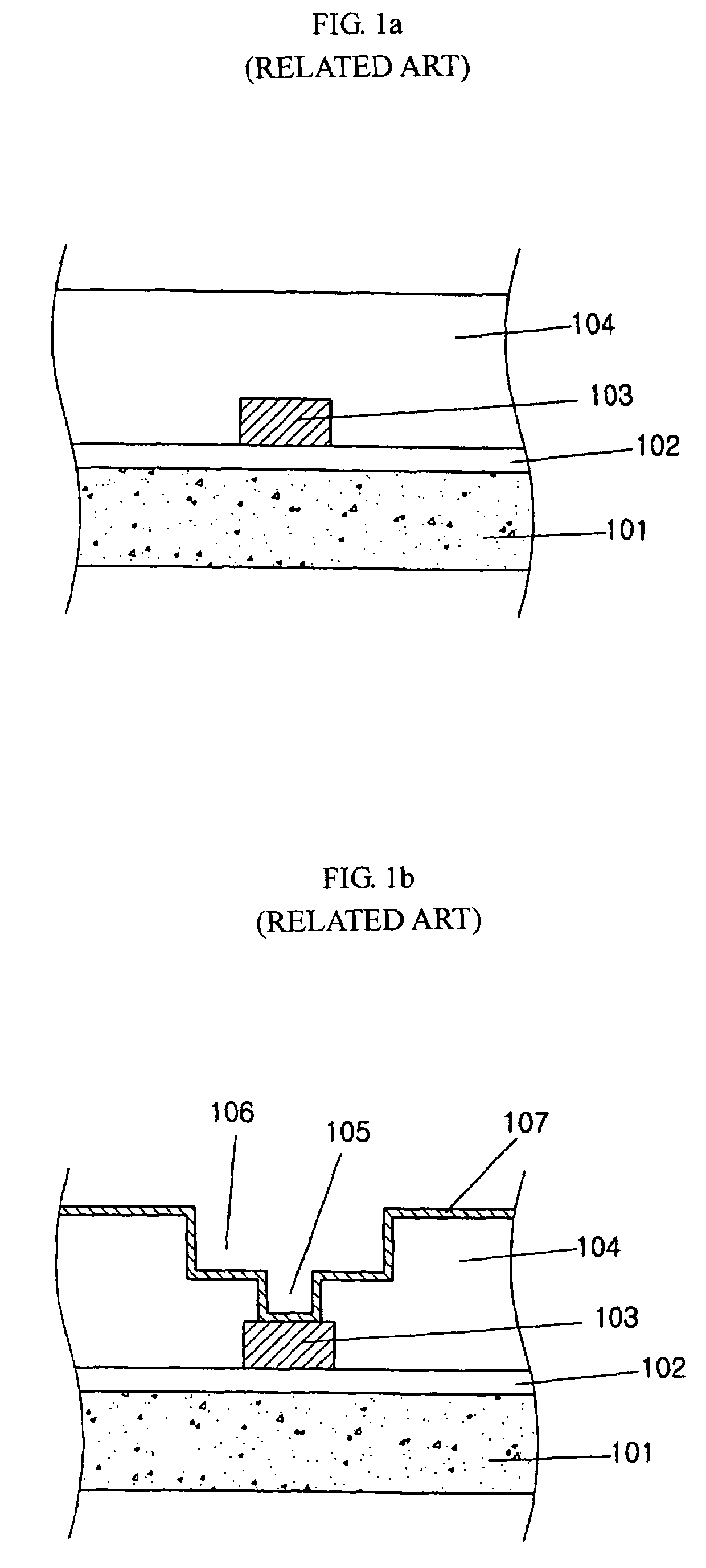

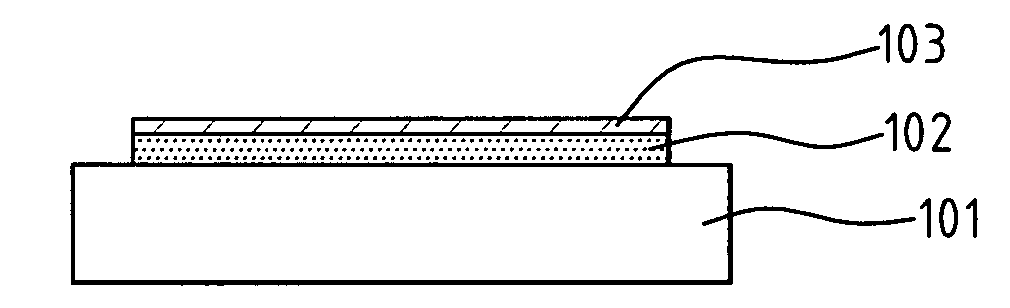

Method of manufacturing a semiconductor device without oxidized copper layer

InactiveUS7037836B2Efficient removalSemiconductor/solid-state device manufacturingSemiconductor devicesConductive materialsCopper oxide

A semiconductor device which effectively reduces copper oxide layers on copper conductive lines is disclosed. The method includes forming a first insulating layer on a semiconductor substrate; forming a first conductive line by depositing a conductive material on the first insulating layer and selectively patterning the conductive material. A second insulating layer is deposited on top of the substrate including on the first conductive line. A via hole is formed by selectively patterning the second insulating layer to expose a certain portion of the first conductive line. A natural oxide layer is removed by plasma-processing the natural oxide layer using H2+CO gas.

Owner:DONGBUANAM SEMICON

Supported catalyst for use in production of 1, 4-butynediol by Reppe method, preparation method thereof and application thereof

ActiveCN102125856AGood sustained response timeOrganic compound preparationHydroxy compound preparationSlurryCopper oxide

The invention relates to a supported catalyst for use in the production of 1, 4-butynediol by a Reppe method, a preparation method thereof and application thereof, in particular to a method for preparing a catalyst for use in the synthesis of1, 4-butynediol by formaldehyde and acetylene in a slurry bed and application. The method is characterized by comprising the steps of: taking 40 to 60 mass percent of treated kaolin as a carrier, and depositing soluble copper salt and soluble bismuth salt on the carrier by a method for depositing sediments, so that the catalyst contains 57 to 37 mass percent of copper oxide. The catalyst prepared by the method has high activity and selectivity, and compared with similar catalysts without the carrier, the catalyst is wear-resistance and saves copper resources.

Owner:HAISO TECH

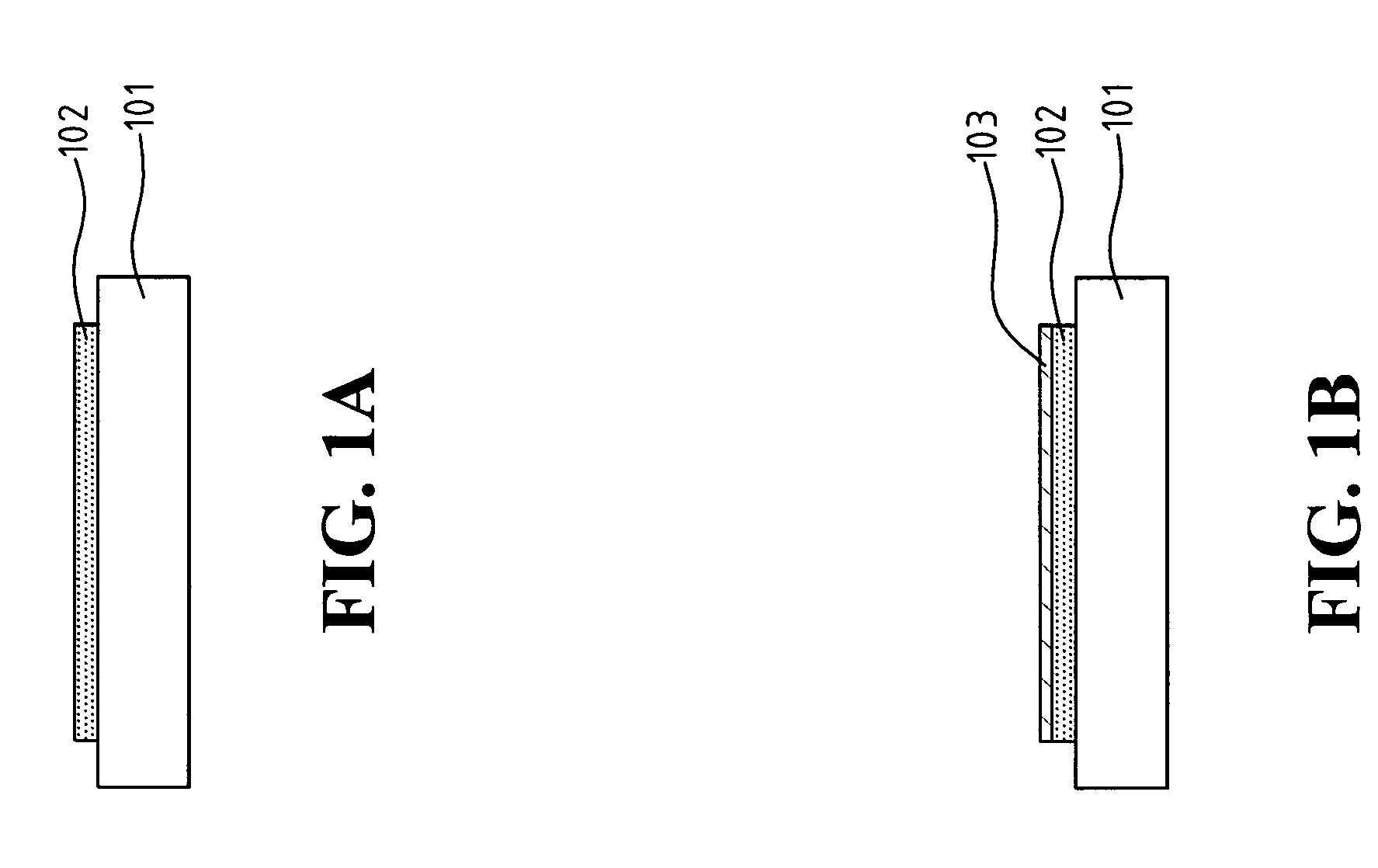

Wire-bonding method for chips with copper interconnects by introducing a thin layer

InactiveUS20050266672A1Prevent oxidationGood adhesionSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectLead bonding

A wire-bonding method for chips with copper interconnects by introducing a thin layer is provided for solving the problem of oxidizing a copper bonding-pad during bonding processing in order not to deteriorate the bonding strength and yield rate thereof. The wire-bonding method of the present invention comprises: a step for providing a chip with a copper bonding-pad; another step for providing an aqueous solution to form a Cuprous oxide thin layer on the copper bonding-pad; and yet another step for setting a plurality of copper interconnects on the copper bonding-pad and providing an ultrasonic power for removing the Cuprous oxide layer to have the interconnects bonded on the copper bonding-pad.

Owner:NATIONAL CHUNG CHENG UNIV

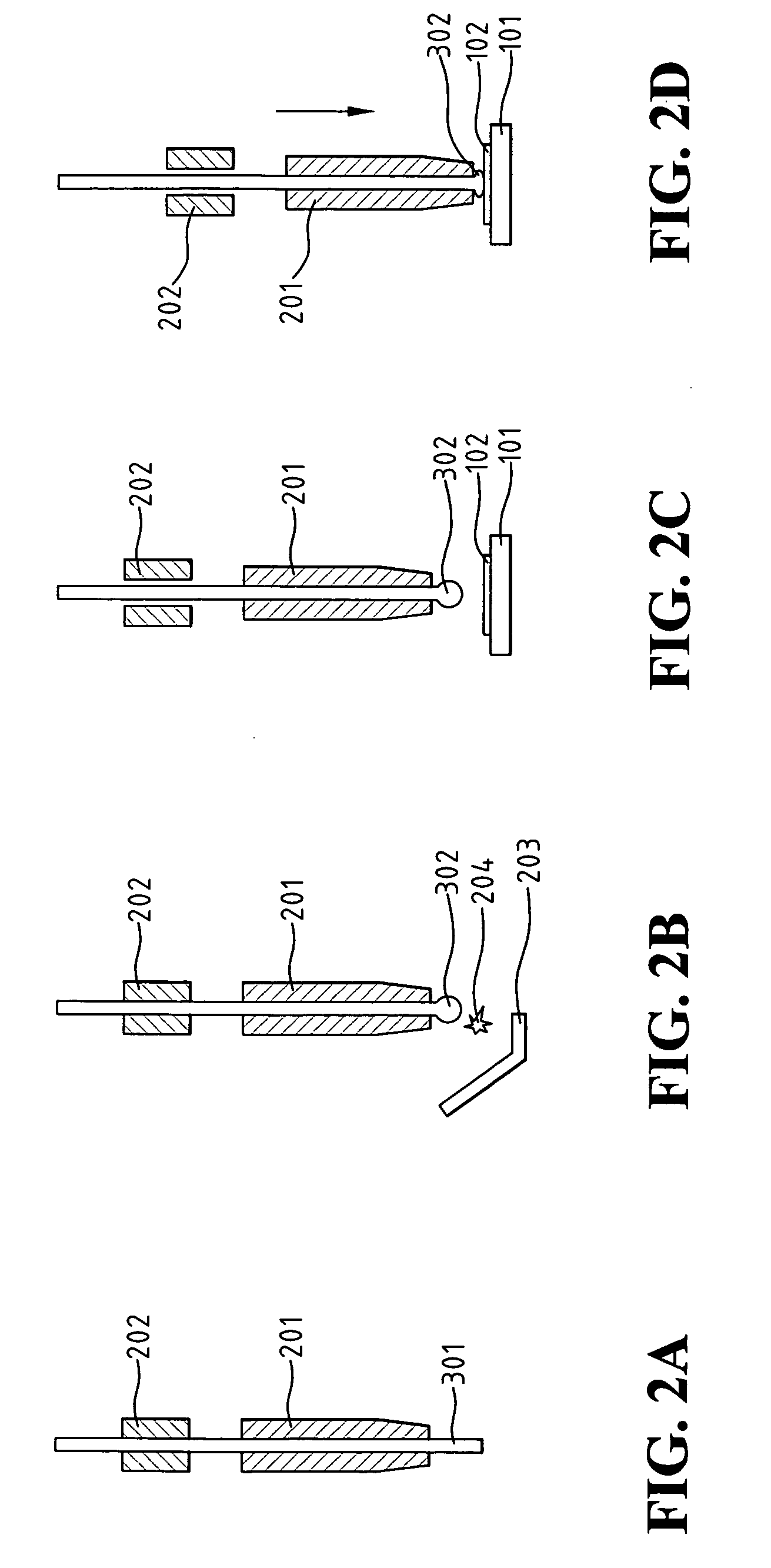

Methods of metallization for microelectronic devices utilizing metal oxide

InactiveUS20060019493A1Reduce metal oxideSolid-state devicesSemiconductor/solid-state device manufacturingCopper oxideOxygen

A metal oxide is deposited on a substrate in a semiconductor fabrication metallization process is patterned and subsequently reduced to a more conductive form, such as elemental metal. The metal oxide is reduced by exposure to at least one reducing agent or current that is capable of removing oxygen from the metal oxide. Copper oxide, for example, can be dry etched for patterning prior to reduction to copper metal, and the patterned copper used as an ECD seed layer.

Owner:ASM INTERNATIONAL

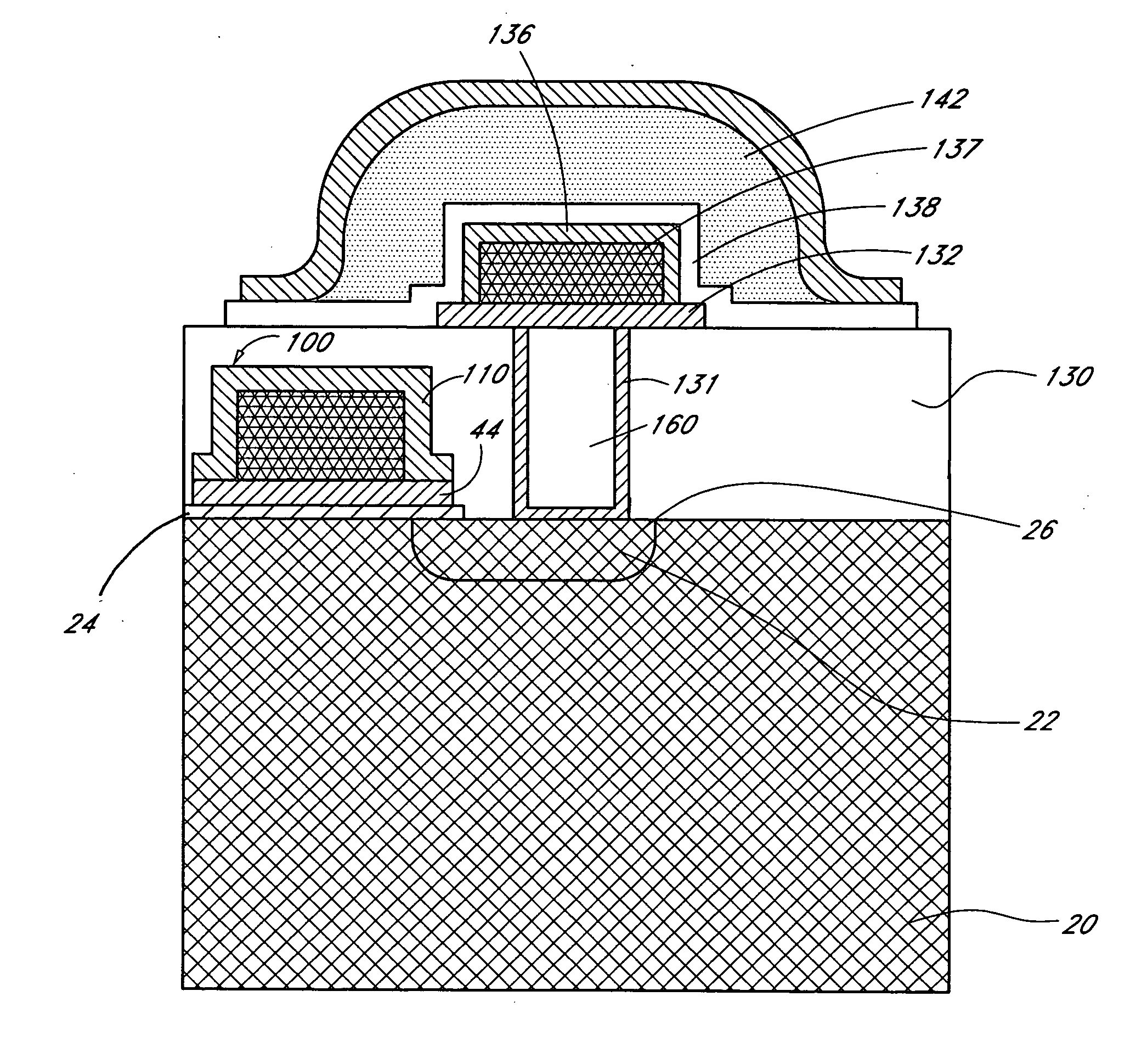

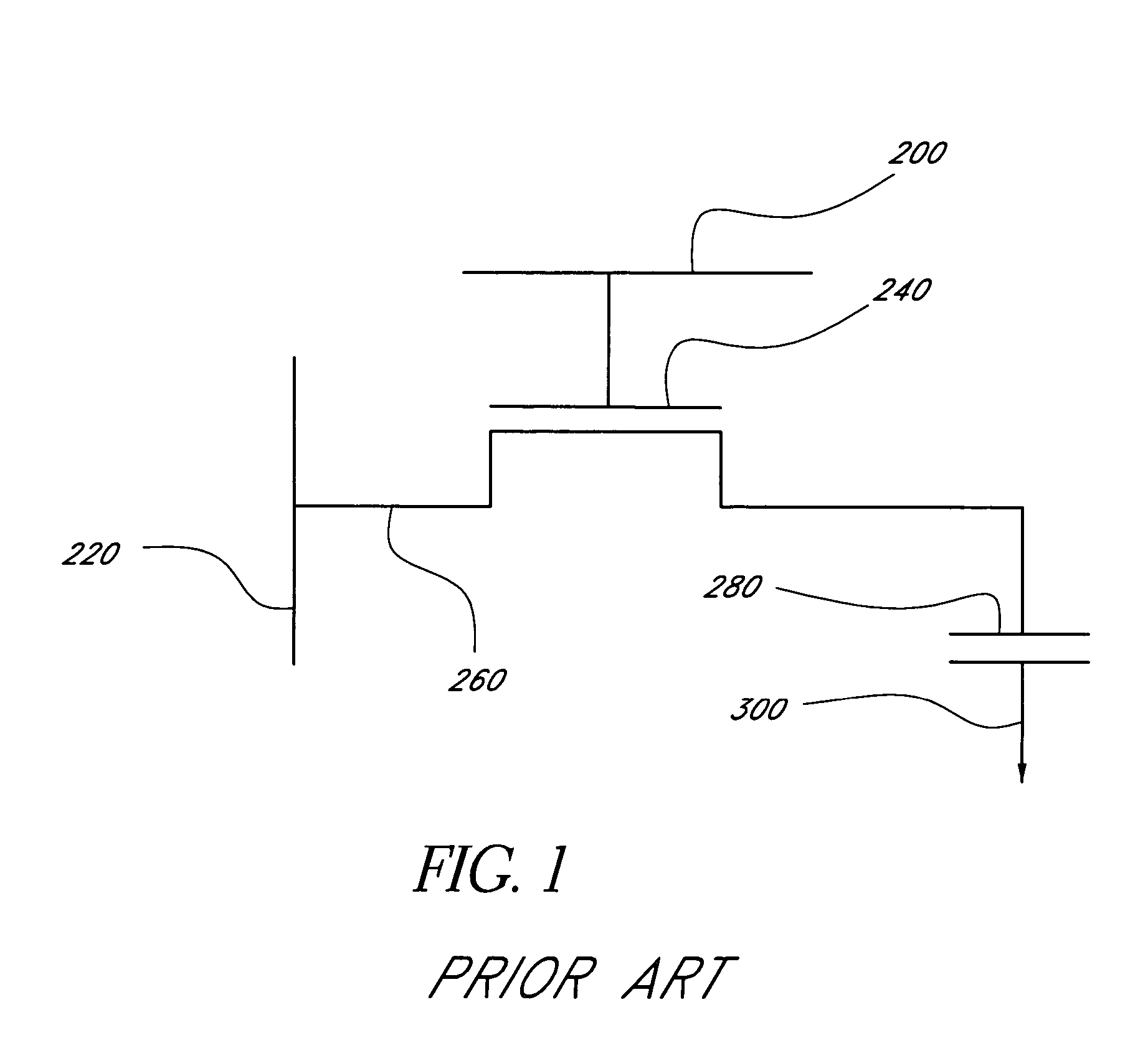

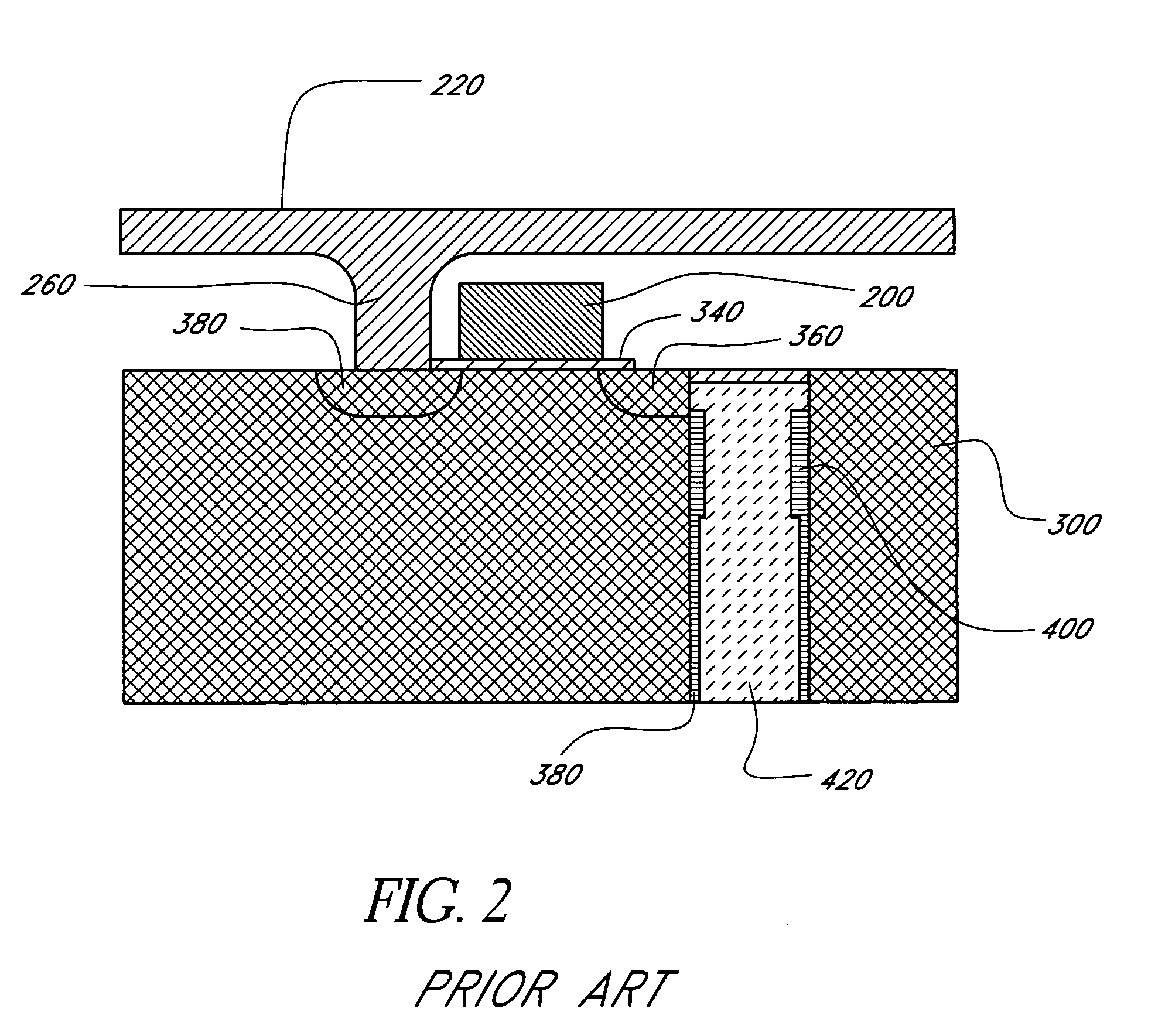

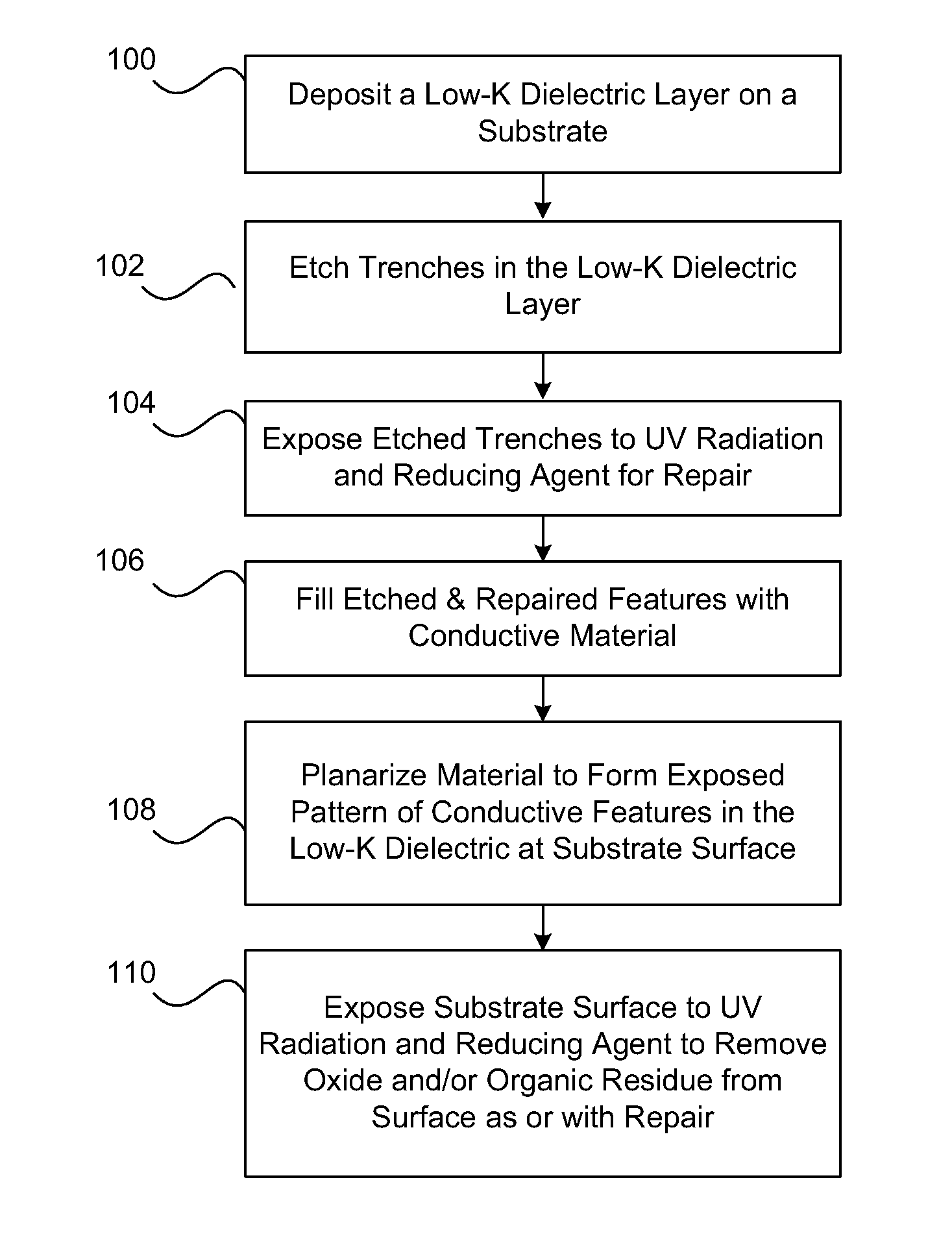

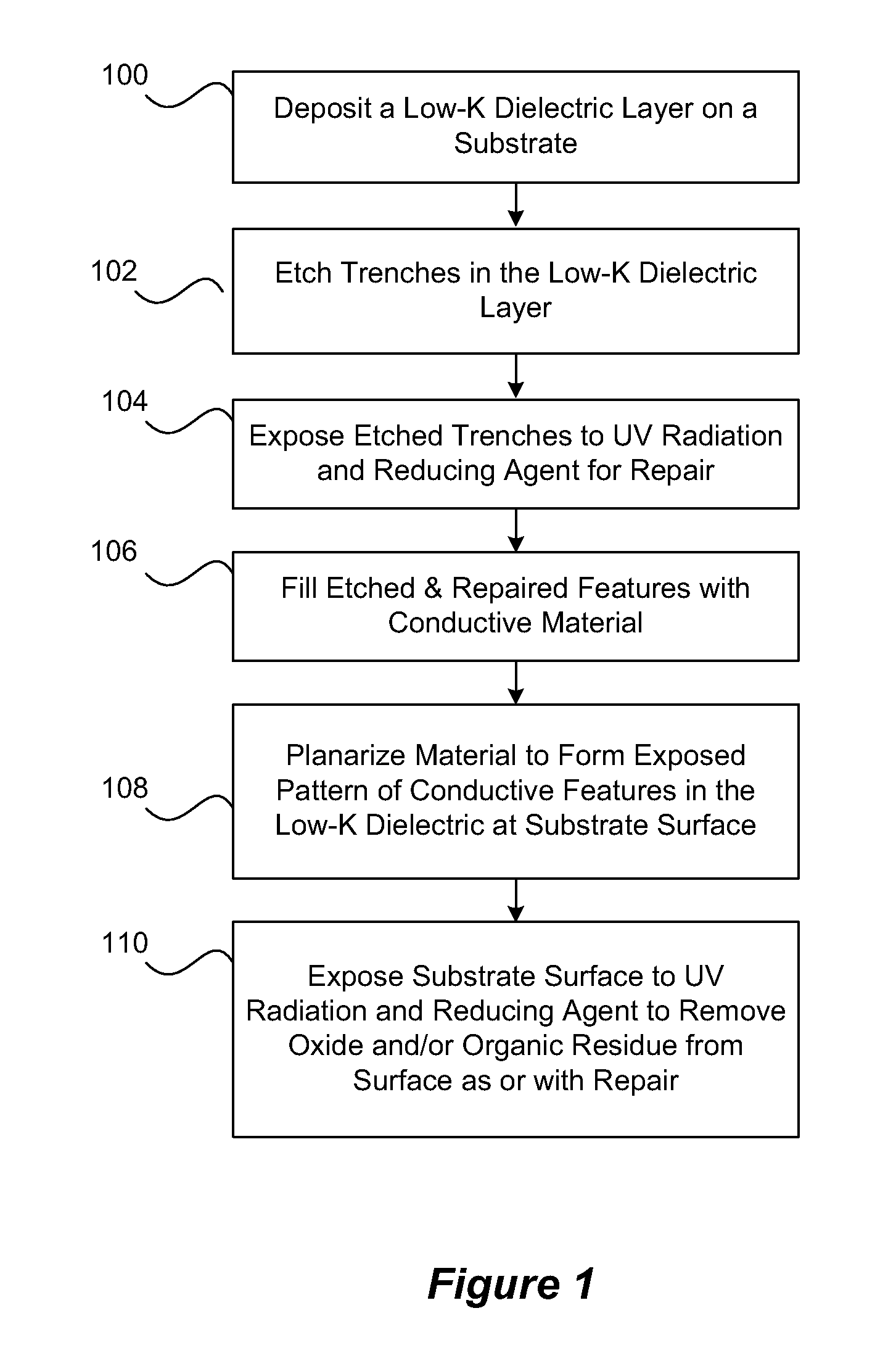

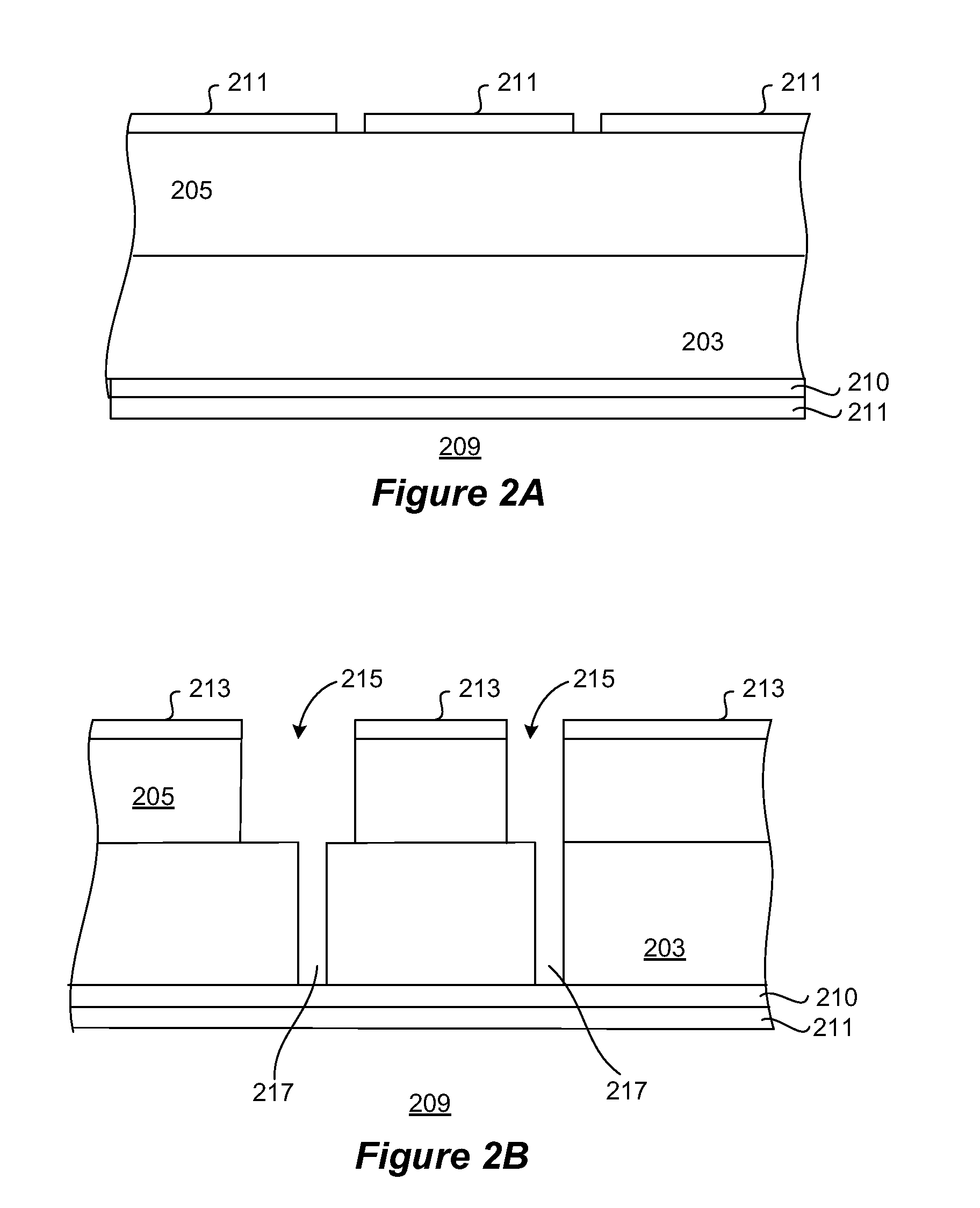

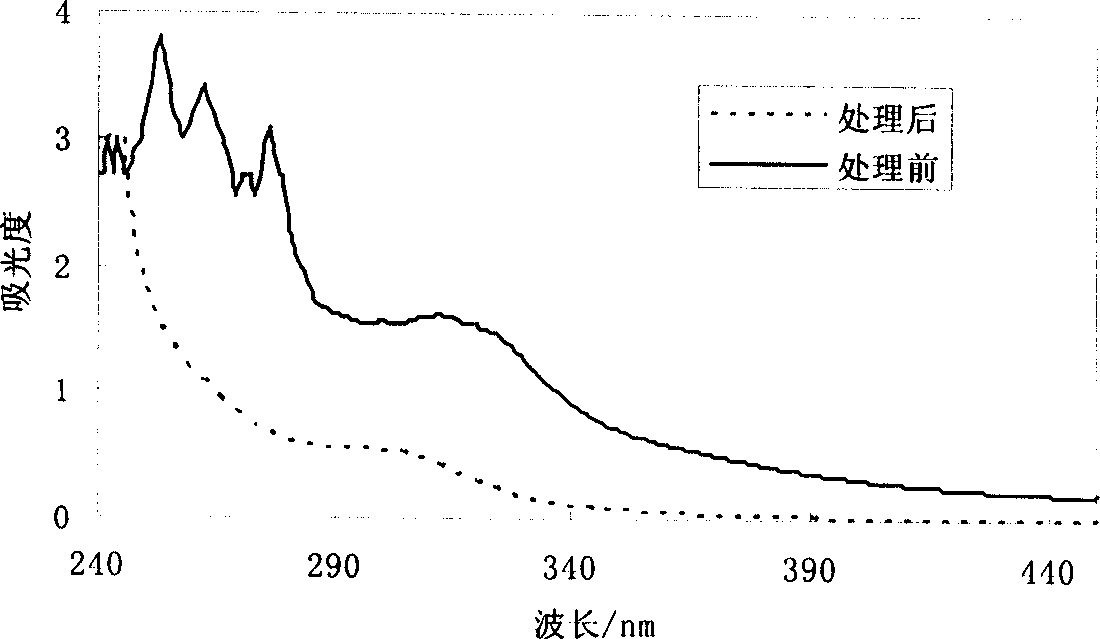

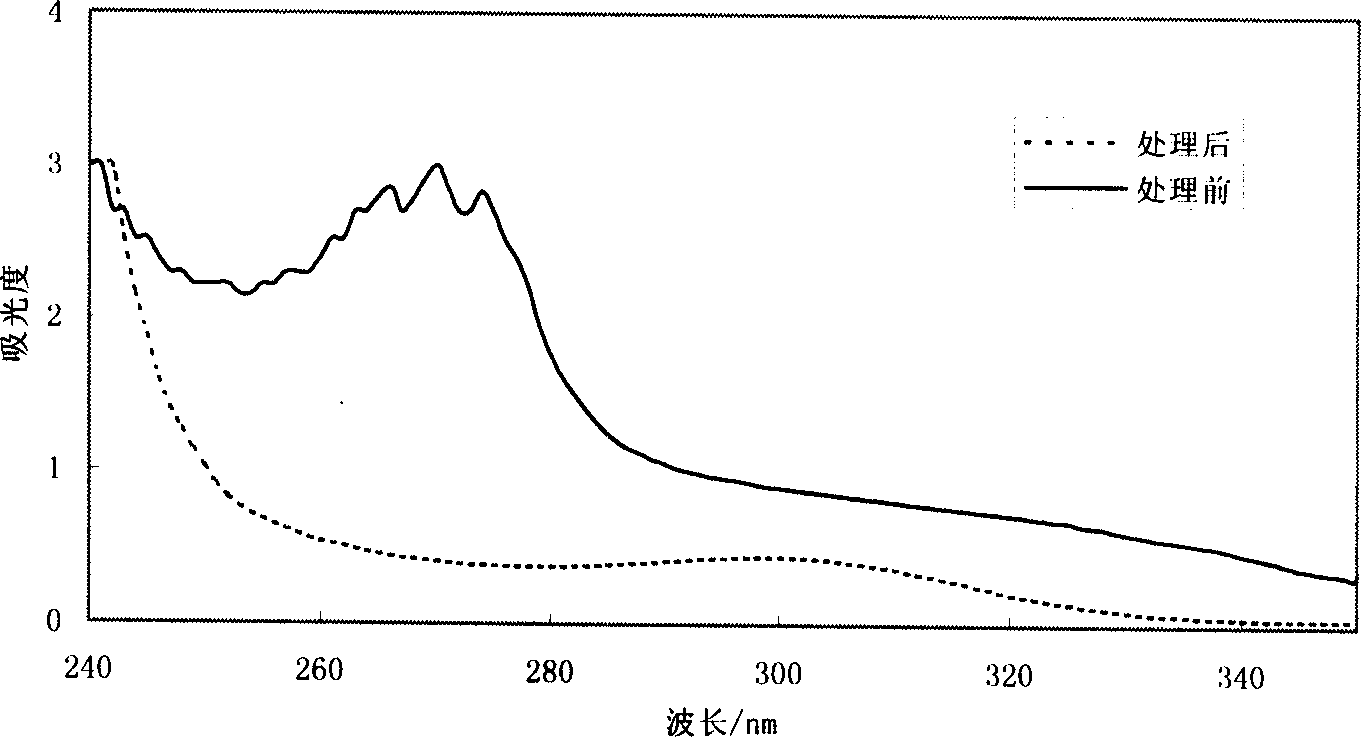

UV and reducing treatment for k recovery and surface clean in semiconductor processing

ActiveUS20110111533A1Improve adhesionEasy to cleanSemiconductor/solid-state device manufacturingCleaning using liquidsSurface cleaningCopper oxide

Treatment of carbon-containing low-k dielectric with UV radiation and a reducing agent enables process-induced damage repair. Also, treatment with a reducing agent and UV radiation is effective to clean a processed wafer surface by removal of metal oxide (e.g., copper oxide) and / or organic residue of CMP slurry from the planarized surface of a processed wafer with or without low-k dielectric. The methods of the invention are particularly applicable in the context of damascene processing to recover lost low-k property of a dielectric damaged during processing, either pre-metalization, post-planarization, or both, and / or provide effective post-planarization surface cleaning to improve adhesion of subsequently applied dielectric barrier and / or other layers.

Owner:NOVELLUS SYSTEMS

Particulate wood preservative and method for producing same

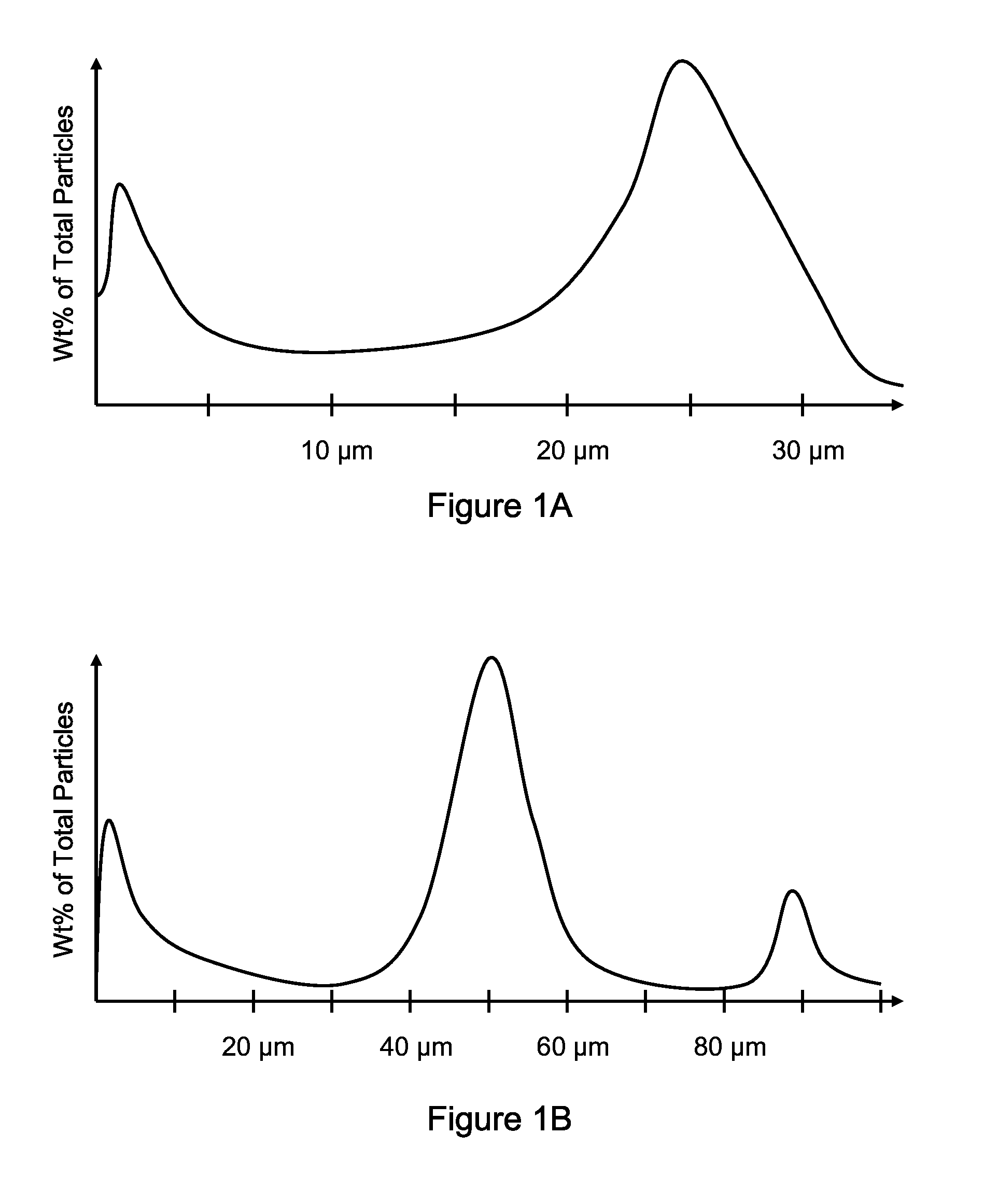

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

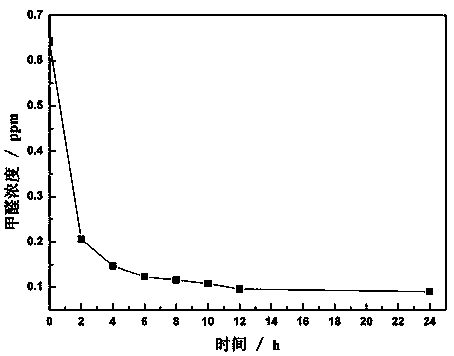

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

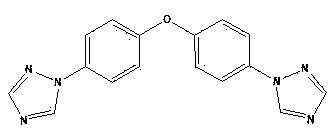

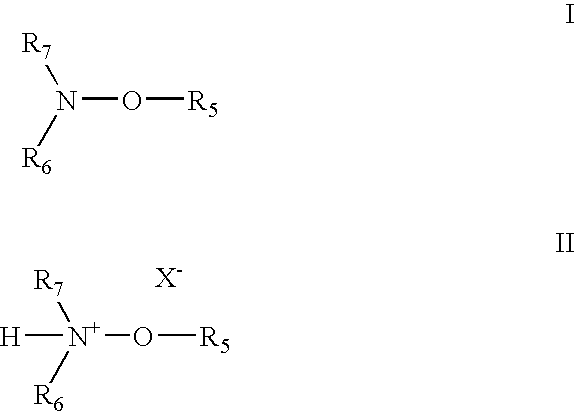

Oxyether triazole compound, and preparation method and application thereof

InactiveCN103772305AHigh reaction yieldHigh purityOrganic chemistryLuminescent compositionsSimple Organic CompoundsDiphenyl ether

The invention discloses a preparation method of 1-(4-(4-(1H-1,2,4-triazolyl-1-yl)phenoxy)phenyl)-1H-1,2,4-triazole. The organic compound is prepared by heating 4,4'-dibromodiphenyl ether, triazole, potassium carbonate and copper oxide by a one-pot process. The preparation method has the characteristics of simple technological operation, low production cost and low environmental pollution, and is suitable for large-scale industrial production. The invention also discloses application of the 1-(4-(4-(1H-1,2,4-triazolyl-1-yl)phenoxy)phenyl)-1H-1,2,4-triazole in photoelectric materials.

Owner:TIANJIN NORMAL UNIVERSITY

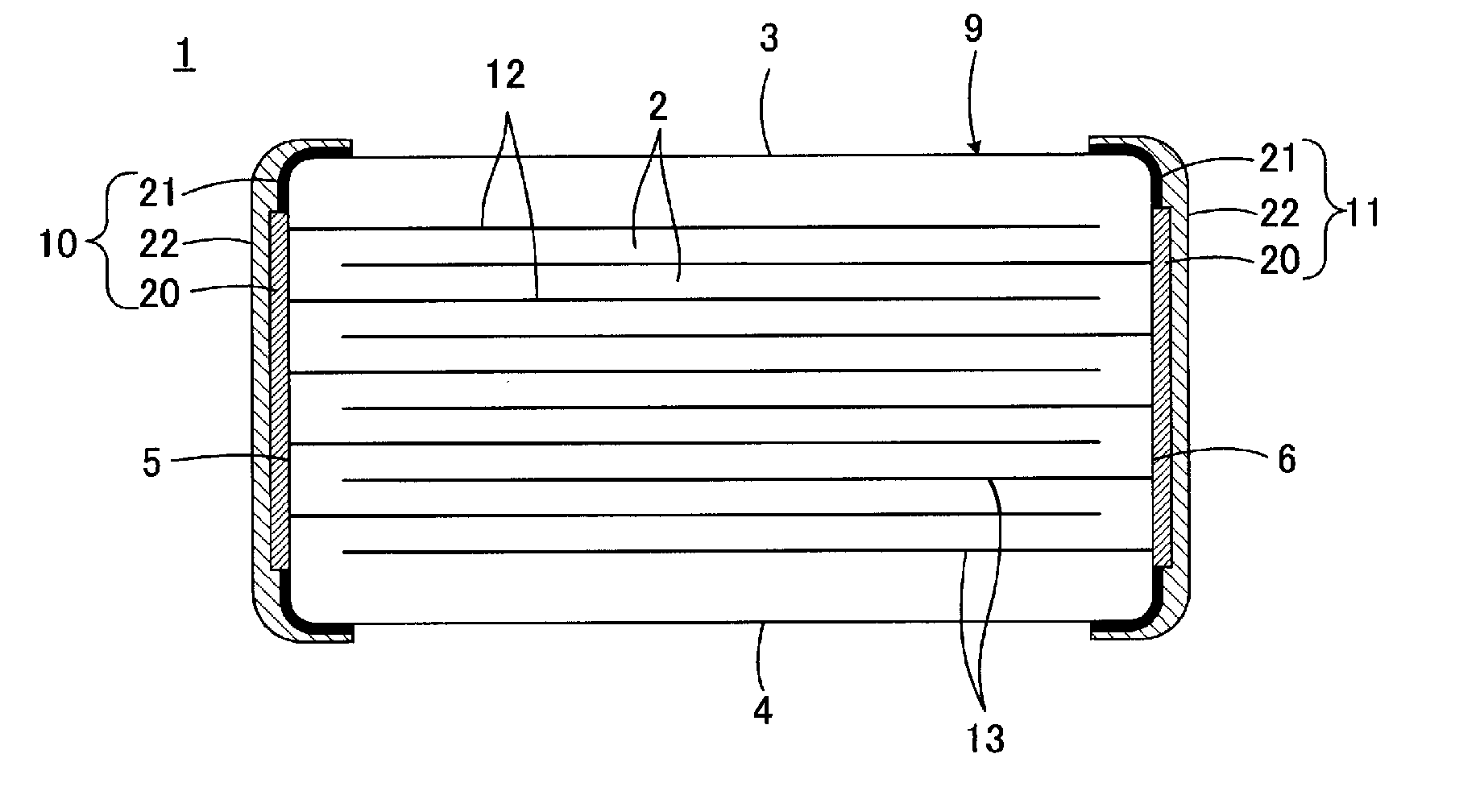

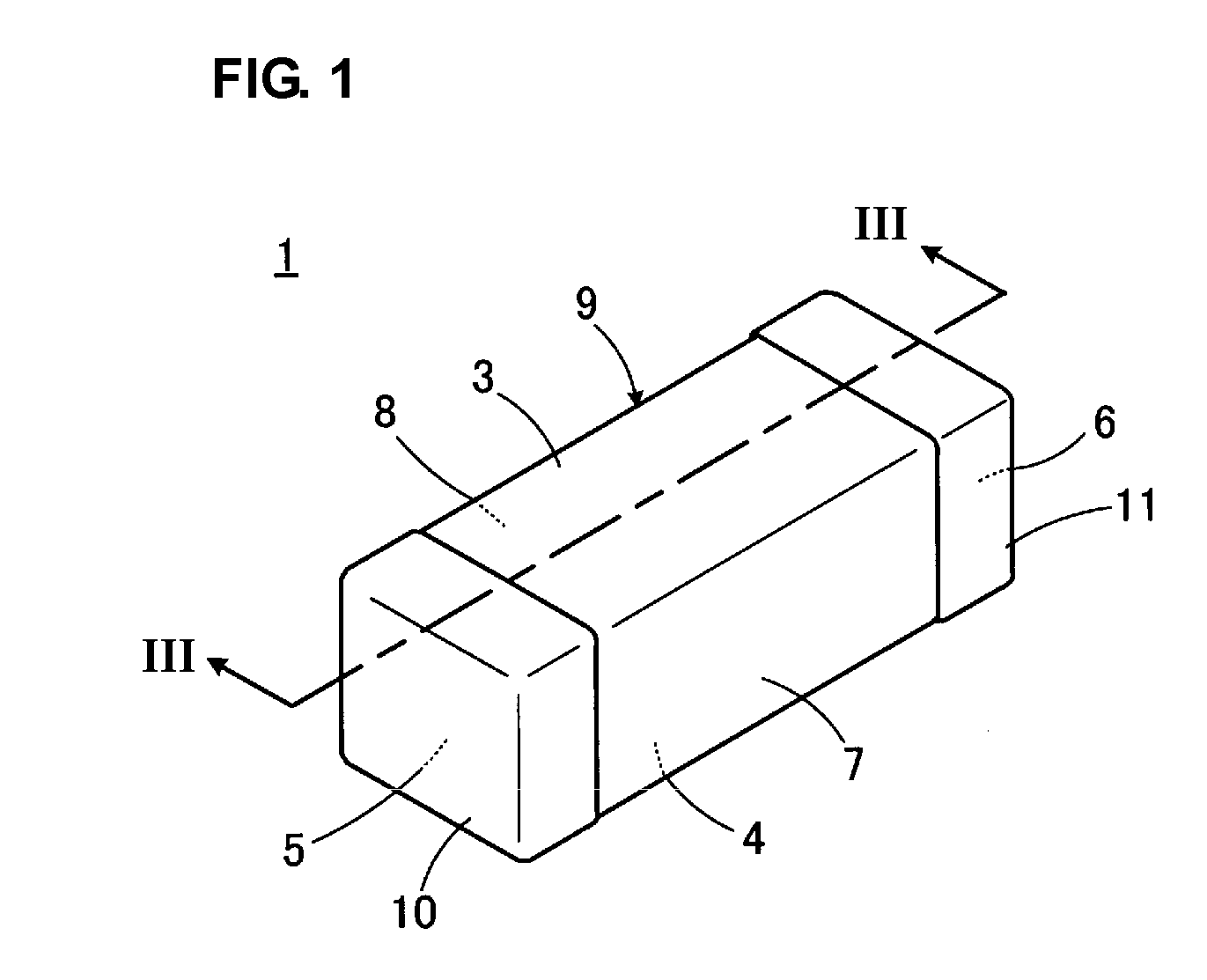

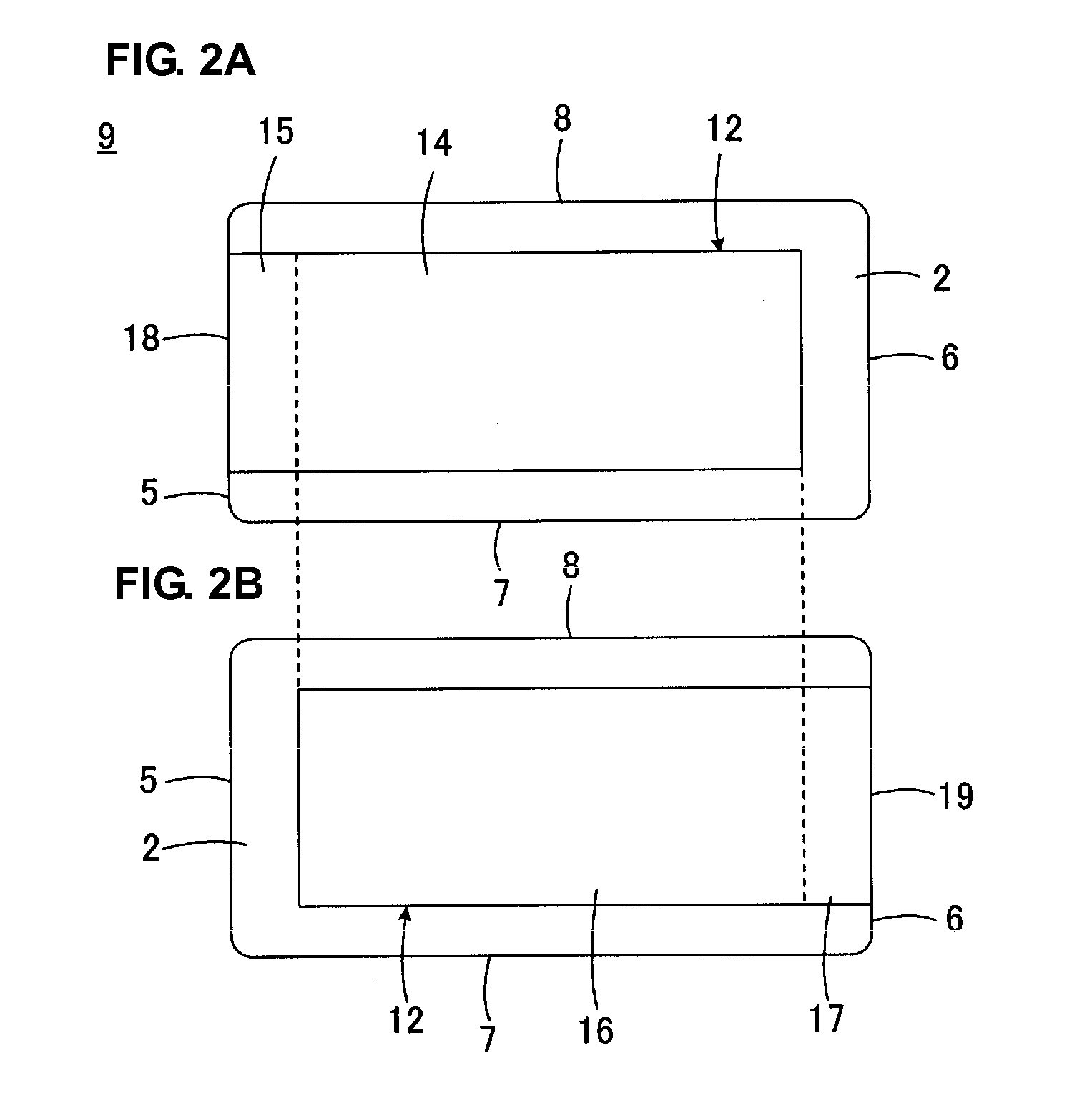

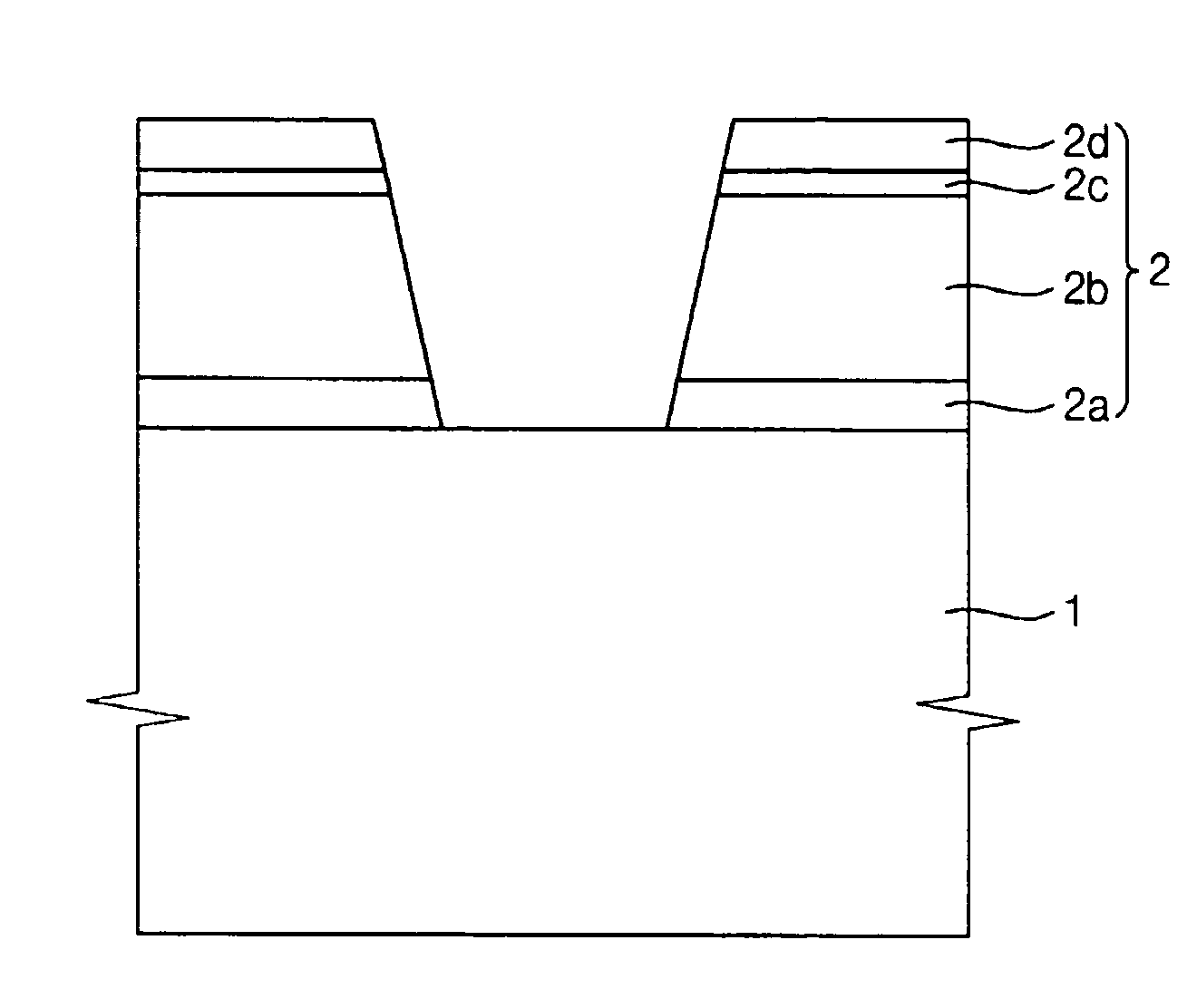

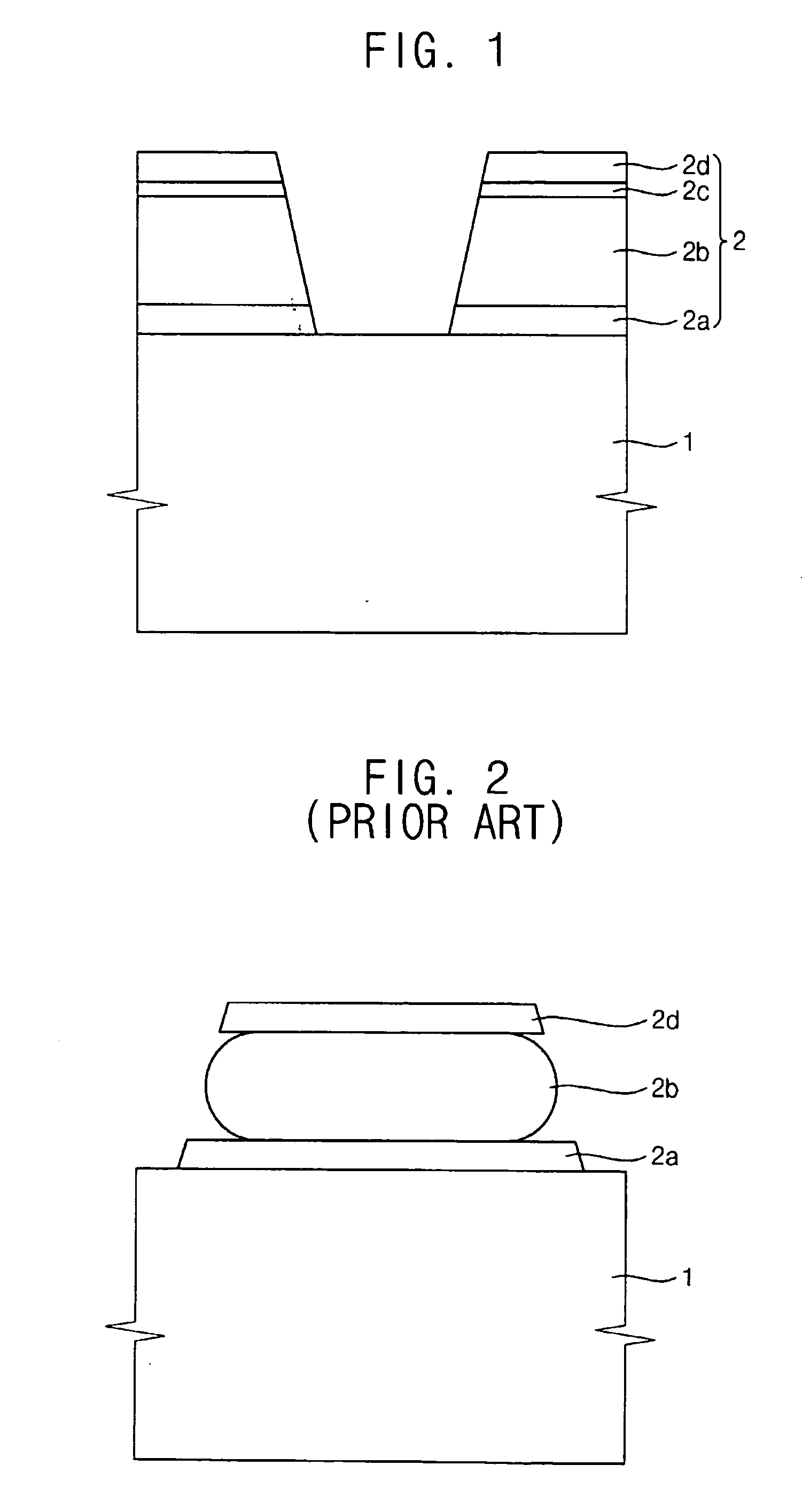

Multilayer ceramic electronic component and method for making the same

ActiveUS20090323253A1Improve bindingFixed capacitor electrodesStacked capacitorsCopper platingElectrical conductor

A multilayer ceramic electronic component includes external terminal electrodes that are formed by depositing metal plating films on exposed portions of internal conductors embedded in a ceramic body, depositing a copper plating films that cover the metal plating films and make contact with the ceramic body around the metal plating films, and heat-treating the ceramic body to generate a copper liquid phase, an oxygen liquid phase, and a copper solid phase between the copper plating films and the ceramic body. The mixed phase including these phases forms a region at which a copper oxide is present in a discontinuous manner inside the copper plating film at least at the interfaces between the ceramic body and the copper plating films. The copper oxide securely attaches the copper plating films to the ceramic body and enhances the bonding force of the external terminal electrodes.

Owner:MURATA MFG CO LTD

Thin film transistor substrate for display

A conductive structure containing copper is capable of being etched to have a reliable profile where the copper layer is free of corrosion or oxidation includes a barrier layer formed on an insulating or semiconductor substrate followed by a copper layer, a blocking layer and a capping layer. The copper layer includes copper or copper alloy. The barrier layer includes molybdenum (Mo), molybdenum nitride (MoN) or molybdenum alloy which includes at least one of MoW, MoTi, MoNb or MoZr. The blocking layer includes copper nitride, copper oxide or copper oxinitride. The capping layer includes molybdenum, molybdenum nitride (MoN) or molybdenum alloy which includes at least one of MoW, MoTi, MoNb and MoZr.

Owner:SAMSUNG ELECTRONICS CO LTD

Catalyst for preparing 1, 4-butynediol and preparation method thereof

InactiveCN103480382ALarge external specific surfaceHigh activityMetal/metal-oxides/metal-hydroxide catalystsDeposition precipitationCopper oxide

The invention discloses a catalyst for preparing 1, 4-butynediol and a preparation method of the catalyst for preparing 1, 4-butynediol. According to the method, acidized nano-silica is adopted as a carrier, the adopted nano-silica has a large outer specific surface, a dipping method and a deposition-precipitation method are used for adsorbing copper and bismuth on the carrier, so that the catalyst comprises 35-65% of copper oxide by mass, and meanwhile silica sol is added, so that the catalyst is more stable and abrasion resistant. The prepared catalyst is good in activity, high in selectivity and strength, not prone to pulverizing in the process of using and capable of keeping high activity.

Owner:大连瑞克科技股份有限公司

Method to remove resist, etch residue, and copper oxide from substrates having copper and low-k dielectric material

ActiveUS20060199749A1Need device performanceNeed efficiency performanceDetergent mixture composition preparationSemiconductor/solid-state device manufacturingResistOrganic acid

A variety of compositions that are particularly applicable for removing one or more of resist, etching residue, planarization residue, and copper oxide from a substrate comprising copper and a low-k dielectric material are described. The resist, residues, and copper oxide are removed by contacting the substrate surface with the composition, typically for a period of 30 seconds to 30 minutes, and at a temperature between 25° and 45° C. The composition includes a fluoride-providing component; at least 1% by weight of a water miscible organic solvent; an organic acid; and at least 81% by weight water. Typically the composition further includes up to about 0.4% of one or more chelators.

Owner:EKC TECH

Activated charcoal carried copper oxide catalyst and process for preparing same

InactiveCN1876232AEasy to prepareLow priceMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationActivated carbonWastewater

The related preparation method for a CuO catalyst contained 1.0-5.0% active carbon carrier comprises: dipping the active carbon in 10% NaOH solution / HNO3 solution for 24h to filter and clean with deionized water till neutrality in turns, drying in oven at 100-110Deg, adding 0.2-0.3mol / L Cu(NO3)2 solution to stir and drop 20% NaHCO3 till much deposition, slaking 24h, filtering, cleaning with deionized water till no separation of metal ion, drying in oven at 100-110Deg, and activating the obtained solid for 2.5h at 270-280Deg.

Owner:BEIJING JIAOTONG UNIV

Catalyst for producing ethylene glycol from hydrogenation of oxalic ester

ActiveCN101474561AImprove stabilityImprove technical effectMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsLow activityMolecular sieve

The invention relates to a catalyst for ethanediol production by oxalic ester hydrogenation, which solves the problems of small specific surface, low activity and poor stability of the catalyst in the previous technique. The catalyst used in the invention is composed of the following active components, assistants and carriers in terms of parts by weight: (a) 5-80 parts of active components; (b) 0-40 parts of assistants and (c) 1-30 parts of carriers, wherein the active component is copper, copper oxide or mixture thereof, the assistant is selected from at least one of Zn, Mn, Ba, Cr, Ni or Fe or oxides thereof and the carrier is selected from at least one of the alumina, silica, zirconia or molecular sieve. When the active component is copper, the technical scheme that the value of (b) is more than zero solves the problem in a good way. The catalyst can be used for ethanediol production in the industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of supported catalyst for 1,4-butynediol

InactiveCN103157500AImprove stabilityHigh activityMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention relates to preparation of a supported catalyst for 1,4-butynediol. The supported catalyst used is characterized in that a mesoporous molecular sieve is used as a carrier, and soluble copper salt and bismuth are loaded on the carrier by an impregnation method so that the mass content of copper in the catalyst is 15-30%, and the mass content of bismuth is 1-6%. In the prepared catalyst, the particle size of copper oxide is 10-80nm, and the bismuth oxide is amorphous powder; the copper oxide and the bismuth oxide are uniformly distributed on the carrier and interact with the carrier; and the catalyst has high activity and high selectivity in producing 1,4-butynediol through an alkyne hydroformylation reaction, is more stable and wear-resistant than similar catalysts, and saves copper resources.

Owner:XINJIANG UNIVERSITY

Two step cleaning process to remove resist, etch residue, and copper oxide from substrates having copper and low-K dielectric material

InactiveUS20080139436A1Organic detergent compounding agentsDetergent mixture composition preparationResistOrganic solvent

A method for two step cleaning of semiconductor substrate wherein a first formulation is contacted with the substrate and subsequently a second formulation is contacted with the substrate, optionally followed with a deionized water wash. The first formulation may be remover compositions referred to in the specification, such as a fluoride containing composition, and the second formulation may comprise a basic compound and from 0% to about 90% water, and may further comprise water from 0% to about 92.5% organic solvent.

Owner:EKC TECH

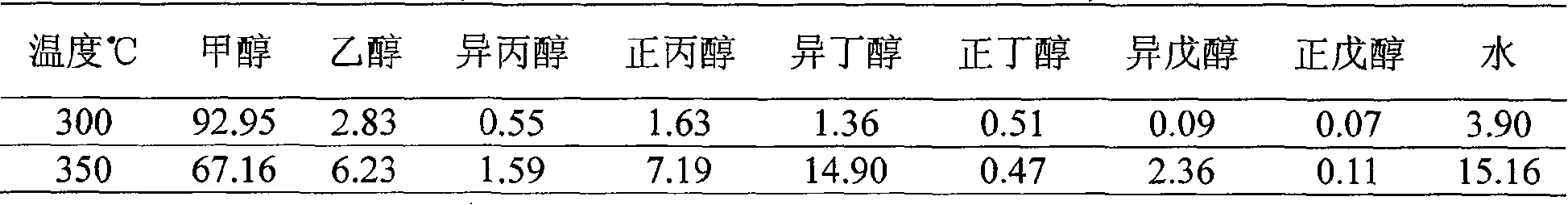

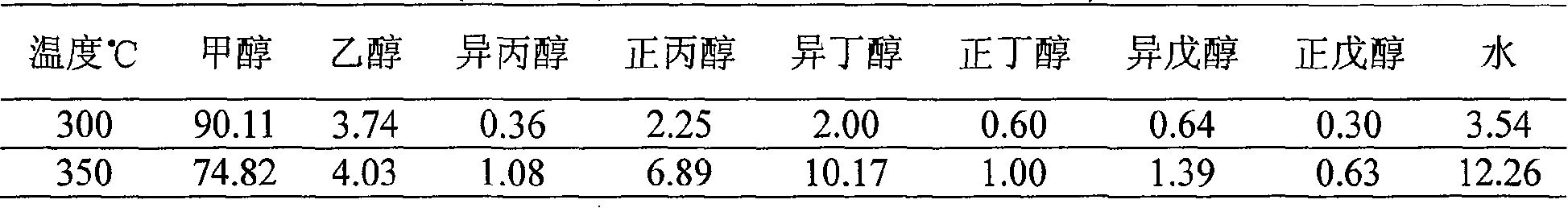

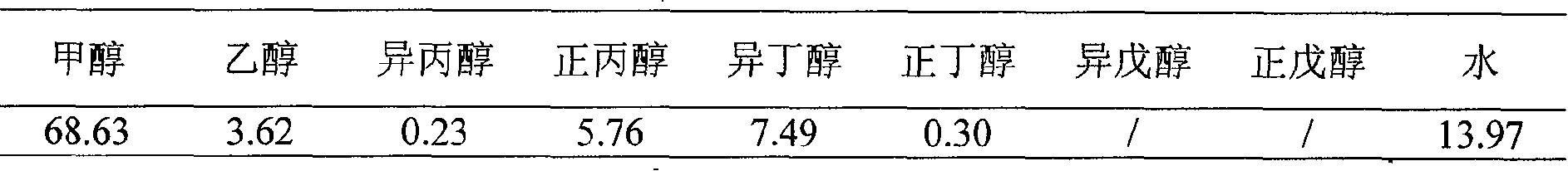

Catalyst for synthesizing low carbon mellow with synthesis gas and preparation method thereof

ActiveCN101185895AHigh conversion rate of COHigh selectivityOrganic compound preparationHydroxy compound preparationIsobutanolPropanol

The invention discloses a catalyst for synthesizing low carbon mixed alcohol with synthetic gas and a preparation method. The main components of the catalyst are copper oxide, zinc oxide, chromium oxide, alumina, and an appropriate amount of other assistants, which are expressed by the general formula Cu(Zn)a(Cr)b(Al)c(M)d(A)e(O)x; the catalyst is prepared by coprecipitation, and the assistant is added by impregnation. Under appropriate conditions, the catalyst can lead CO and hydrogen to react to produce a mixture of oxidation compounds which comprises methanol, ethanol, propanol, isobutanol, pentanol, and a small amount of C5.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

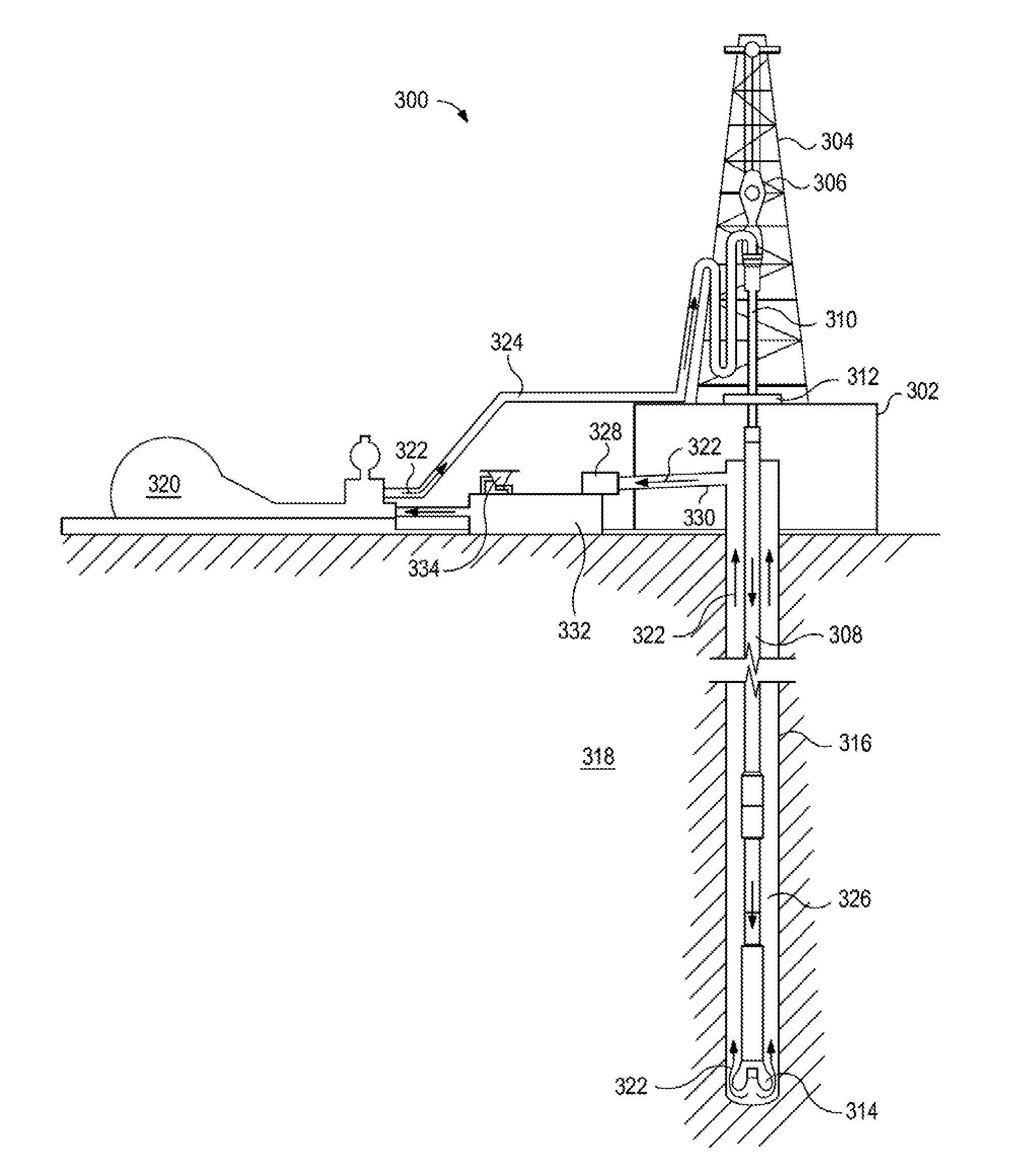

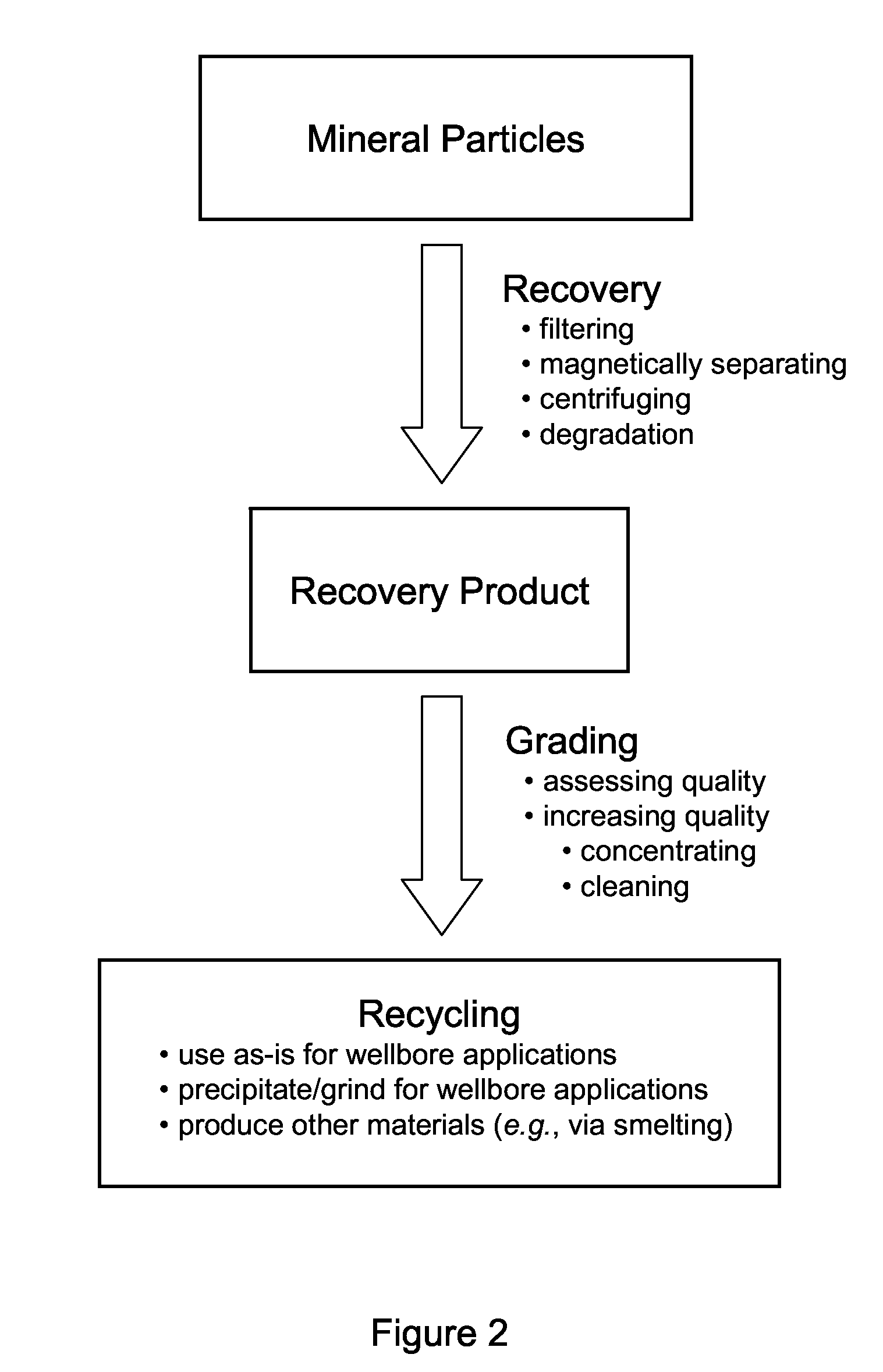

Wellbore Fluids Comprising Mineral Particles and Methods Relating Thereto

Mineral particles may provide for wellbore fluids with tailorable properties and capabilities. Such wellbore fluids may be included as a portion of a wellbore drilling assembly that includes a pump in fluid communication with a wellbore via a feed pipe; and a wellbore fluid disposed in at least one selected from the group consisting of the pump, the feed pipe, the wellbore, and any combination thereof, wherein the wellbore fluid comprises a base fluid and a plurality of mineral particles, for example, mineral particles that comprise at least one selected from the group consisting of manganese carbonate, NixFe (x=2-3), copper oxide, and any combination thereof, the mineral particles having a median diameter between about 5 nm and about 5000 microns.

Owner:HALLIBURTON ENERGY SERVICES INC

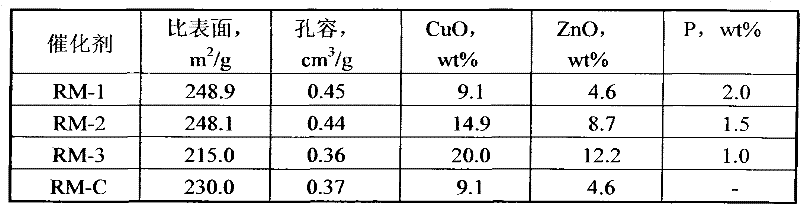

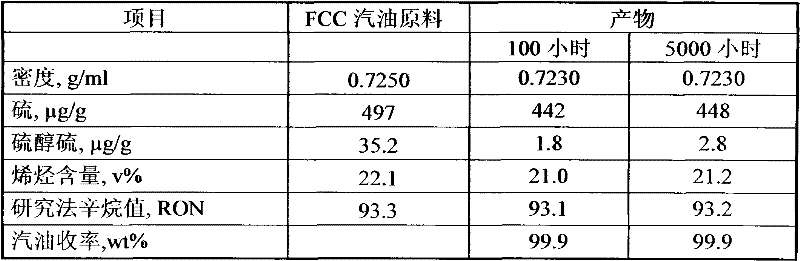

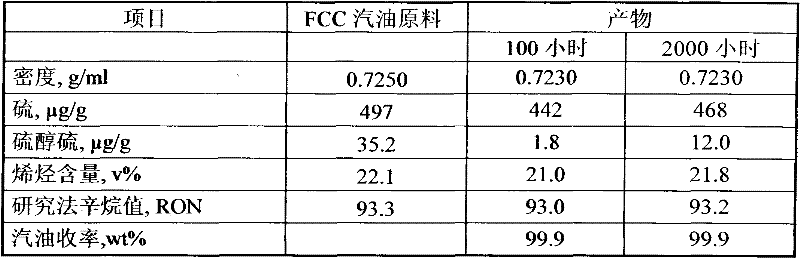

Hydrogenation dethiolizing catalyst, preparation method thereof and application thereof

ActiveCN102451694AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsActive componentHydrodesulfurization

The invention discloses a hydrogenation dethiolizing catalyst, a preparation method thereof and an application thereof. The catalyst which treats alumina or siliceous alumina as a carrier, copper and zinc as active components and phosphor as an assistant component comprises, by weight, 5-30% of copper oxide, 3-15% of zinc oxide and 0.5-30% of the assistant phosphor. The catalyst is prepared with a one-time saturation dipping technology. Compared with present catalysts, the catalyst of the invention can be applied to selective hydrogenation dethiolizing reactions on light oil products, and the catalyst has the characteristics of high dethiolizing activity, low olefin hydrogenation activity, difficult loss of the active components, and long running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

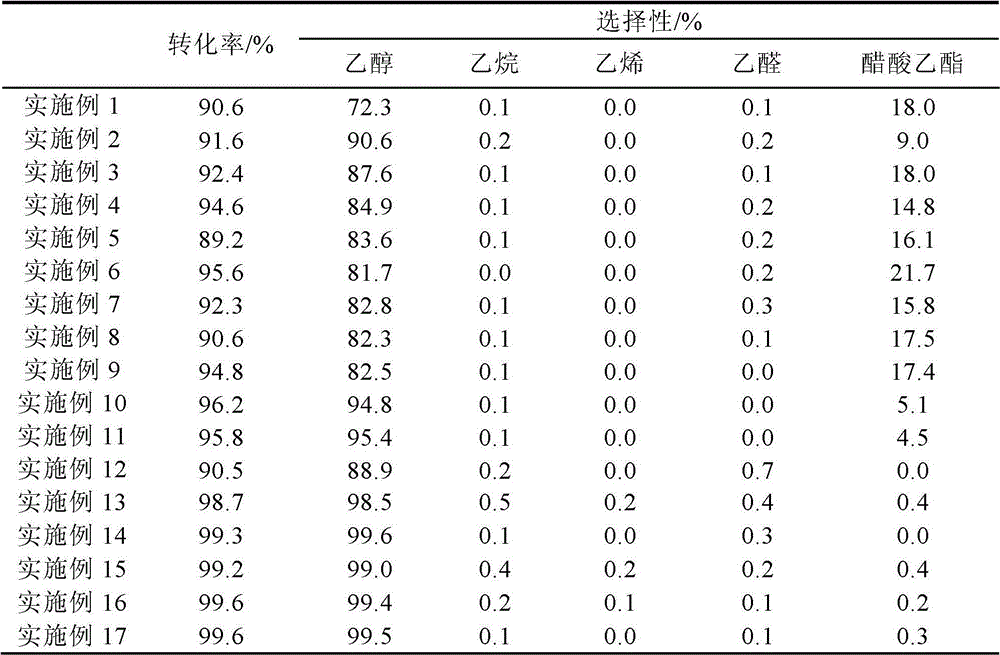

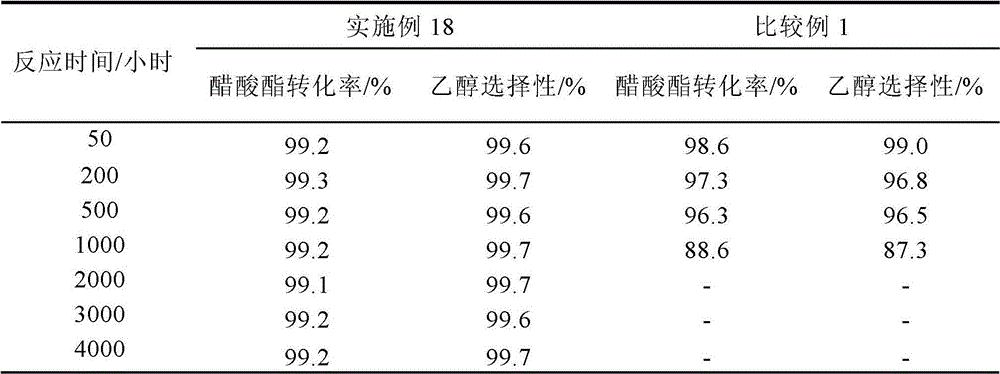

Catalyst for preparing ethanol from acetic ester hydrogenation, preparation method and application thereof

ActiveCN102872878AEasy to prepareHigh activityOrganic compound preparationHydroxy compound preparationHydrogenCopper oxide

The invention relates to a catalyst for preparing ethanol from acetic ester hydrogenation, a preparation method and an application thereof. The main catalytic components of the catalyst are copper or copper oxide with a content of 30 wt%-75 wt%; an auxiliary agent is one or more of La2O3, ZrO2, CeO2, Fe2O3, NiO, MgO, MnO, Al2O3 and K2O, with a content of 1wt%-40 wt%; a carrier is zinc oxide with a content of 20 wt%-65 wt%. In a relatively low hydrogen ester ratio and relatively large liquid hourly space velocity, the catalyst has a conversion rate of acetate larger than 99% and a selectivity of ethanol larger than 99%. Besides, the catalyst has good stability, can reduce cost greatly, and obtains higher production gains. The catalyst is simple in preparation method; the raw materials of the catalyst have wide sources and low cost; and the preparation process of the catalyst is environment-friendly, and is suitable for industrialized production.

Owner:SHANGHAI HUAYI GRP CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com