Patents

Literature

46 results about "Cupric hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper(II) hydroxide, also known as cupric hydroxide, is a chemical compound. Its chemical formula is Cu(OH)2. It contains copper in its +2 oxidation state.

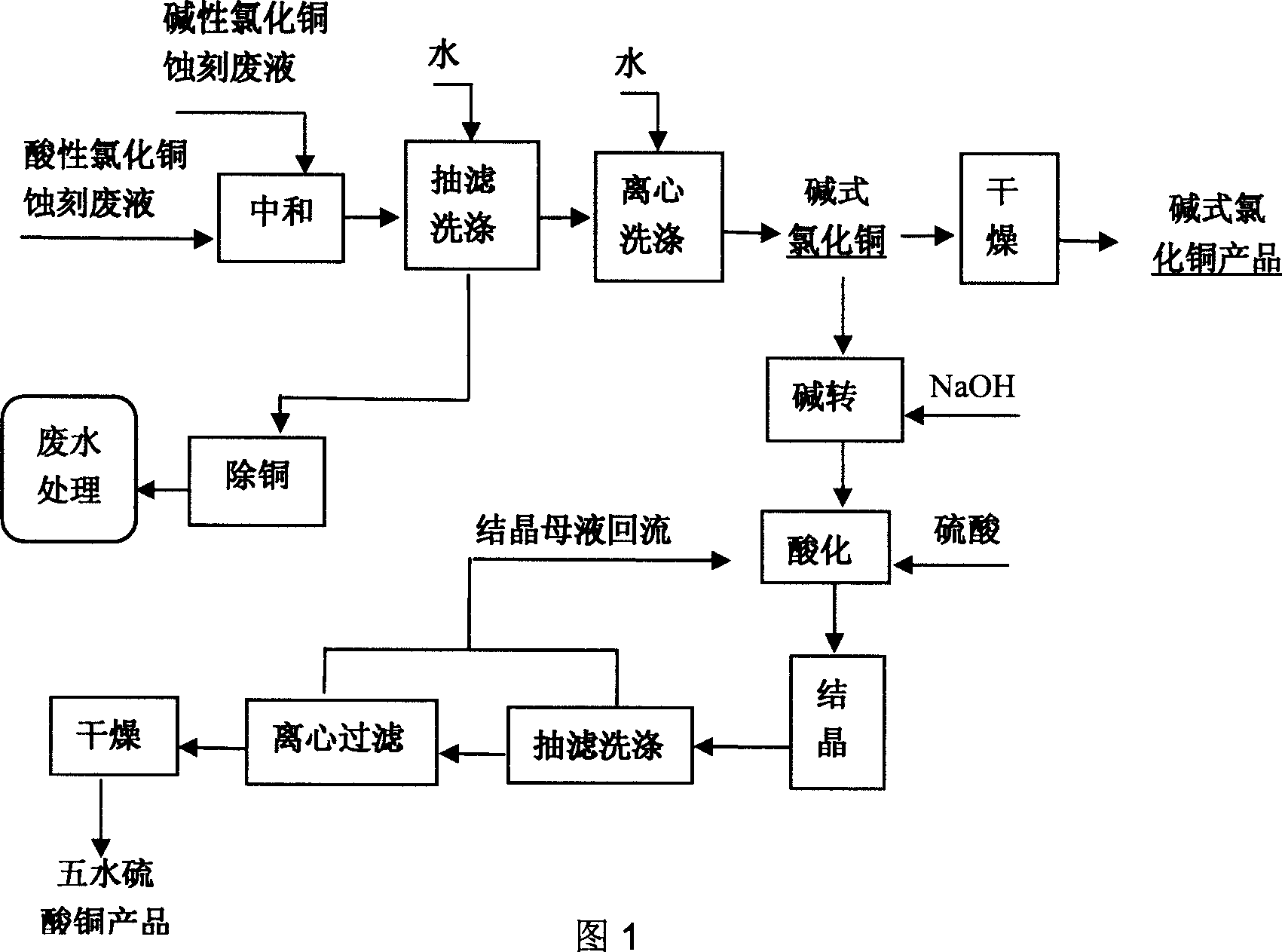

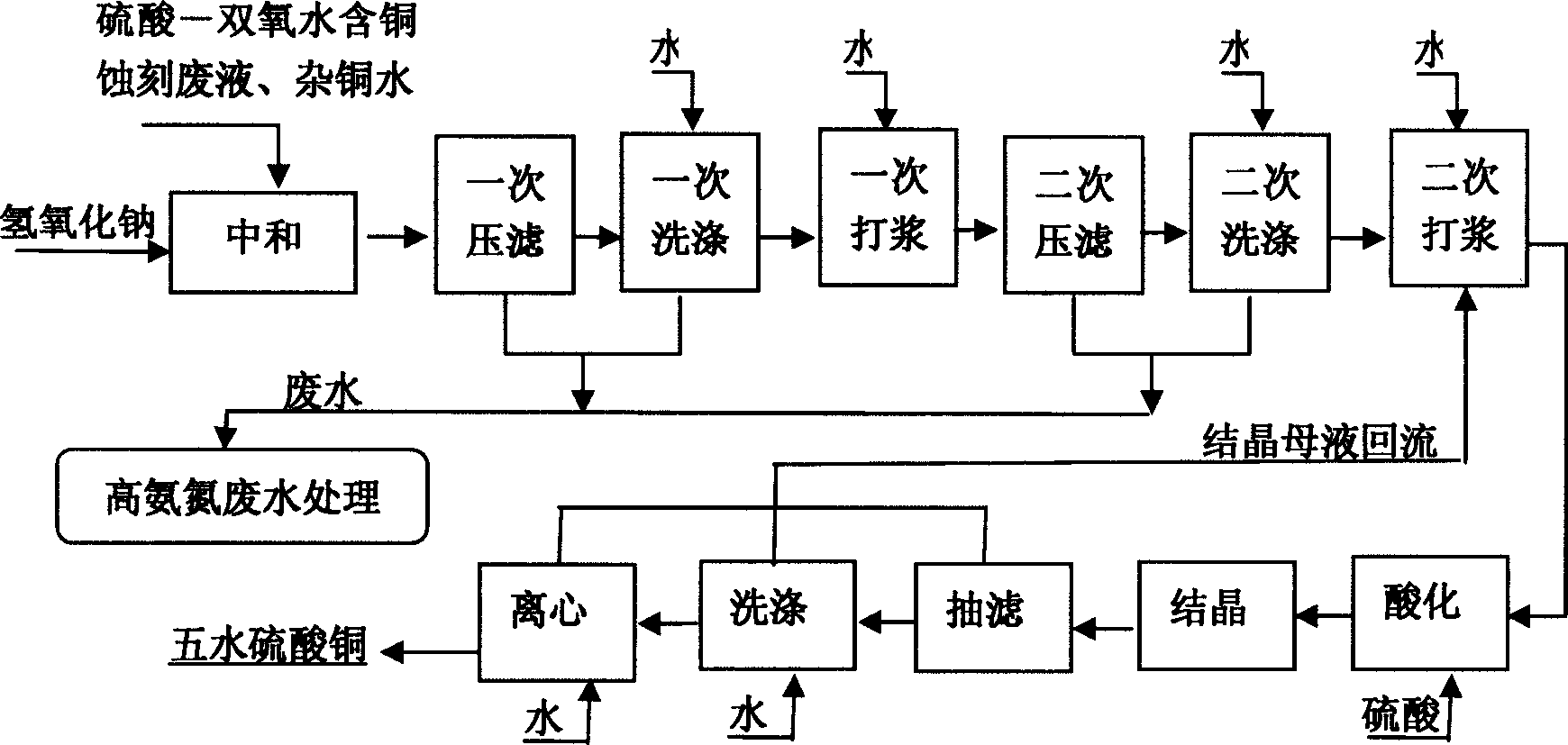

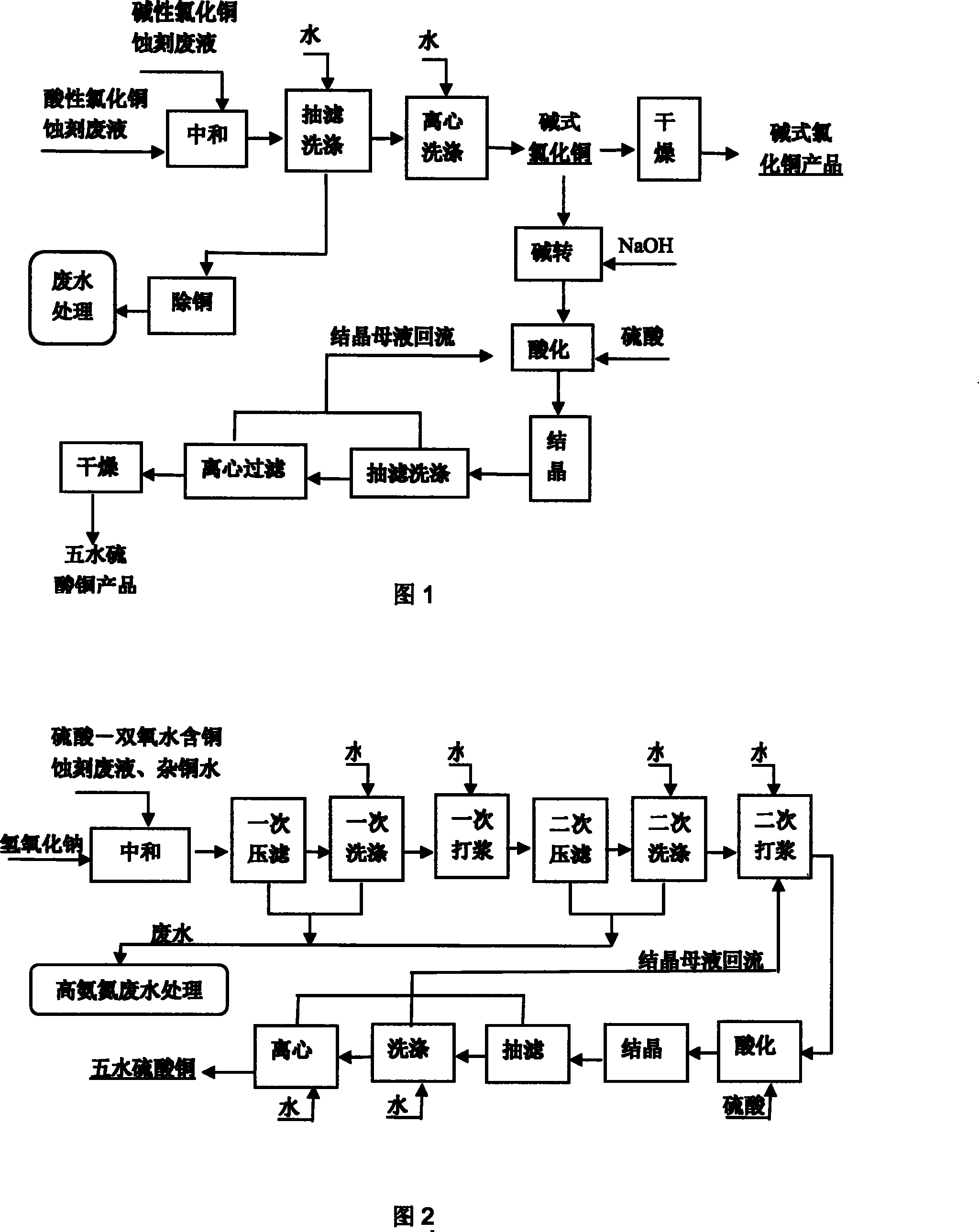

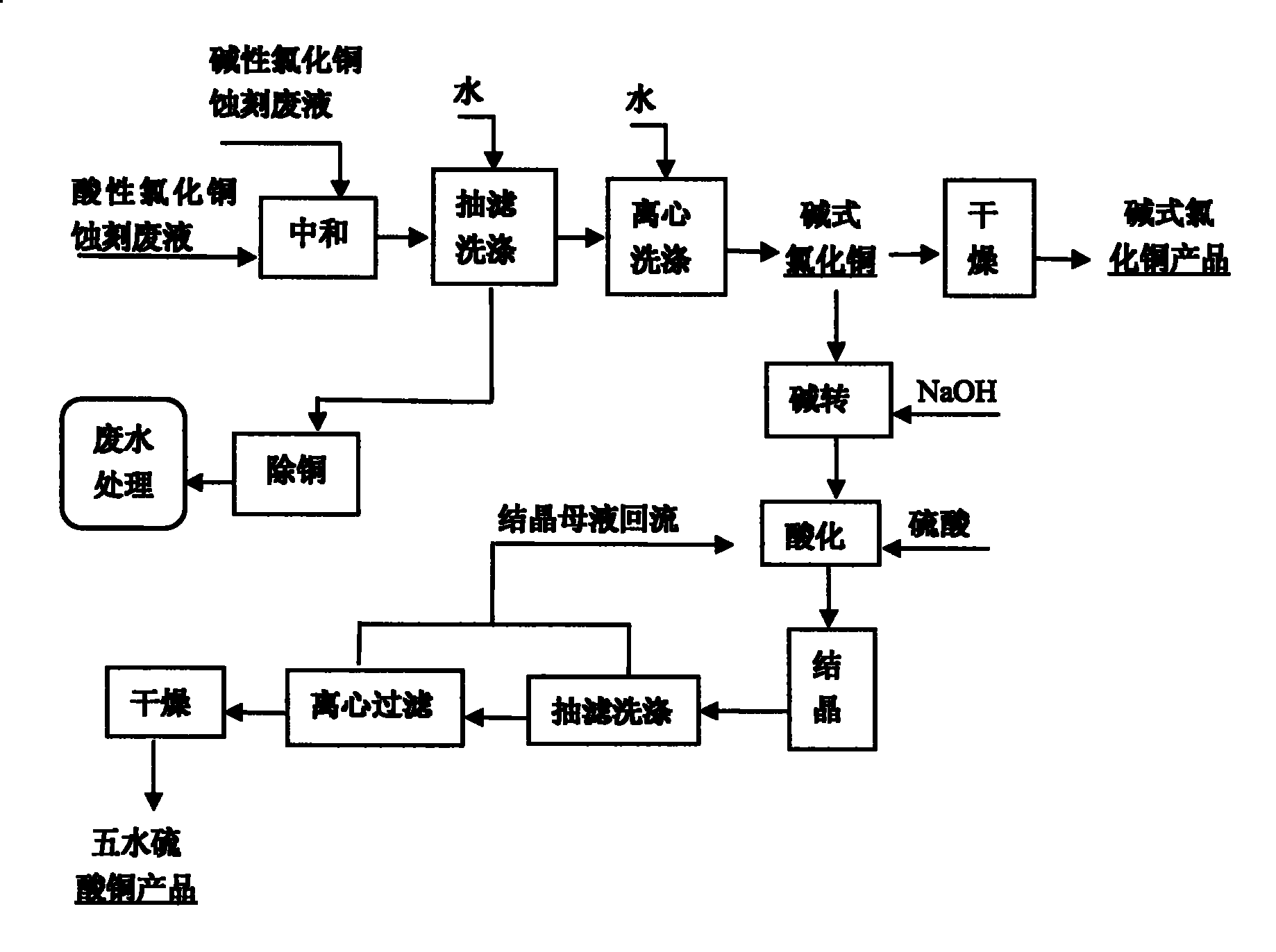

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

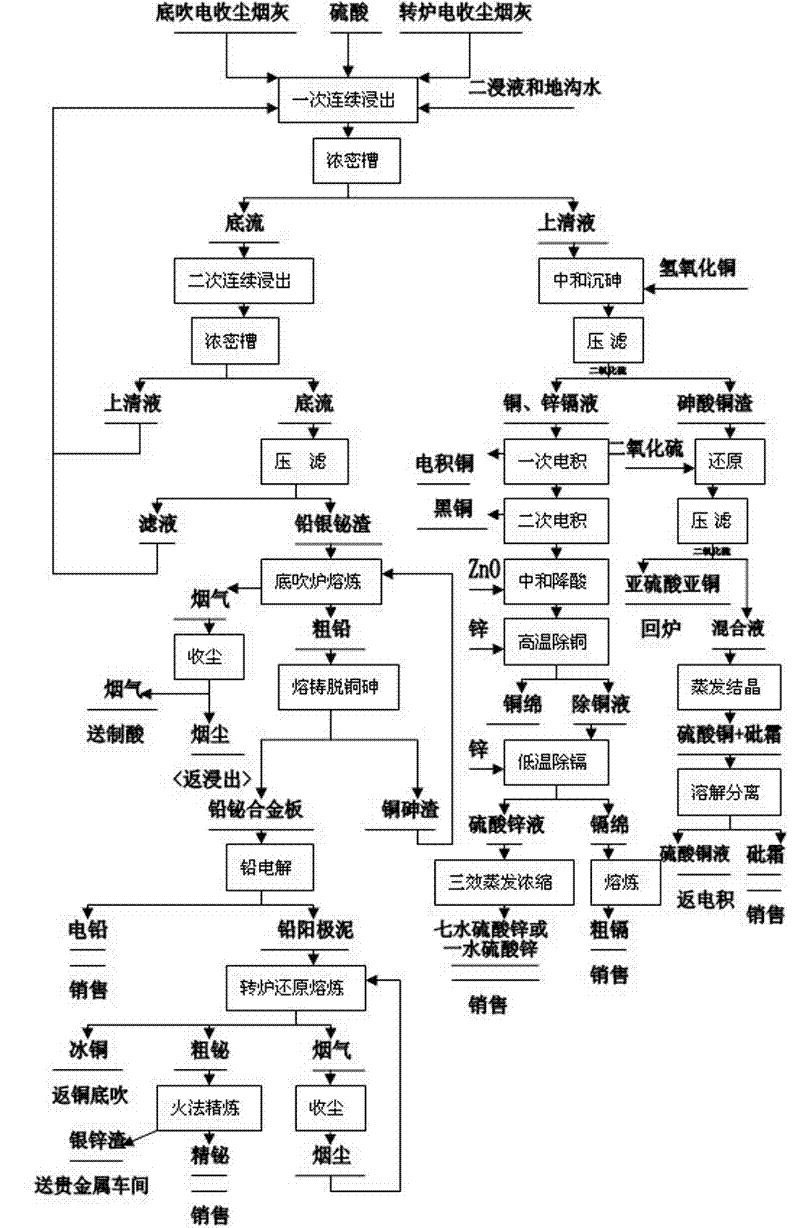

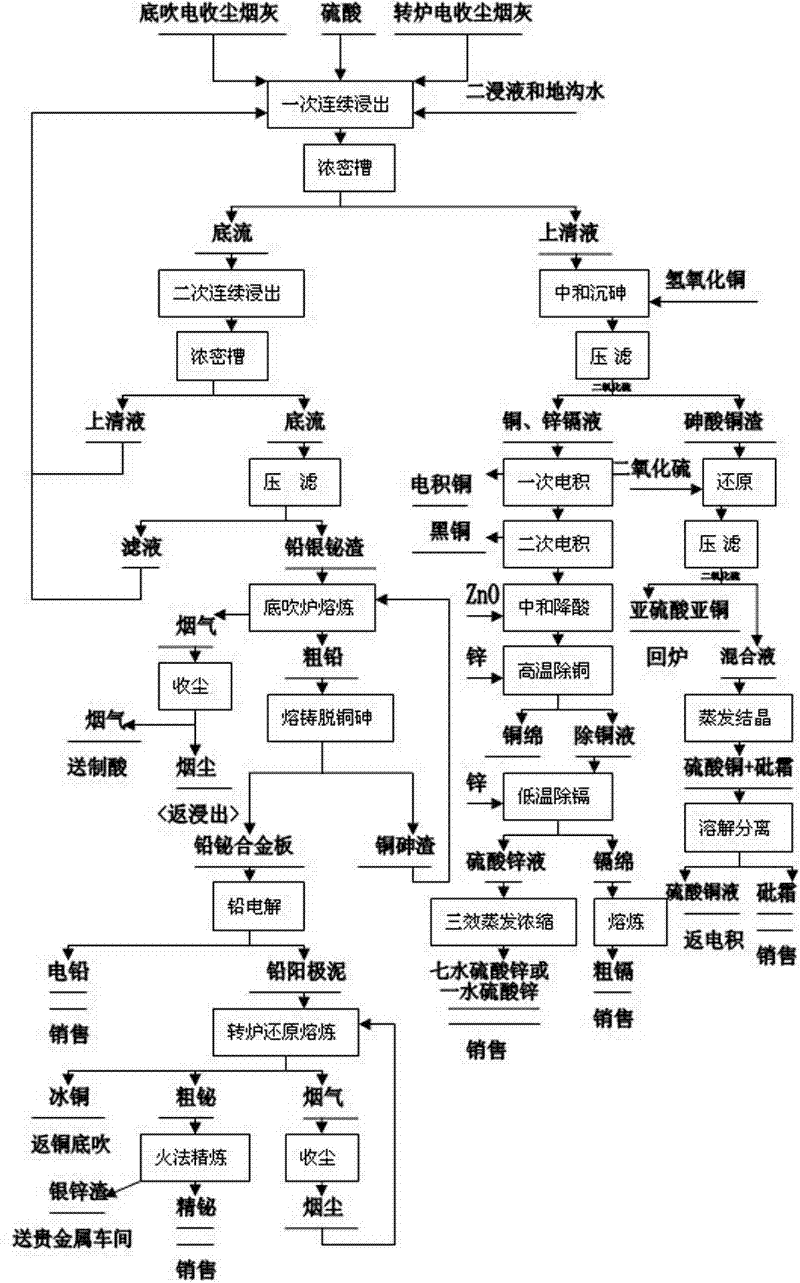

Comprehensive recycling technique of valuable elements in smelting soot

InactiveCN102517449AAdaptableHigh recovery rateProcess efficiency improvementElectrolysisSecondary loss

The invention provides a comprehensive recycling technique of valuable elements in smelting soot, which comprises the steps of: adding sulfuric acid in the smelting soot to pulpify the same, leaching for twice, and filter pressing the smelting soot to form lead-silver-bismuth slag; smelting, casting, electrolyzing, refining and reducing and smelting the lead-silver-bismuth slag in a converter to obtain rough lead, copper matte, pure bismuth and silver-zinc slag; adding cupric hydroxide in the supernatant to deposit arsenic, depositing the copper in the copper arsenate slag with deposited arsenic to form copper-arsenic solution, concentrating, crystallizing, dissolving and separating the solution to obtain white arsenic and cupric sulfate solution; performing twice electrodeposition treatments on the copper-zinc-cadmium solution with deposited arsenic to respectively obtain electrolytic copper and black copper, sequentially adding zinc oxide and zinc powder to perform deacidification, high-temperature copper removal and low-temperature cadmium removal treatments to obtain sponge cadmium, smelting the sponge cadmium to obtain rough cadmium, concentrating and crystallizing the zinc sulfate solution to obtain heptahydrate zinc sulfate. The comprehensive recycling technique provided by the invention has the advantages of improving the recovery of multiple metals, having extensive treatment raw materials, low production cost and high economic benefit, and avoiding the secondary pollution of decentralized processing and secondary loss of valuable metals.

Owner:SHANDONG FANGYUAN NON FERROUS METAL TECH SERVICE

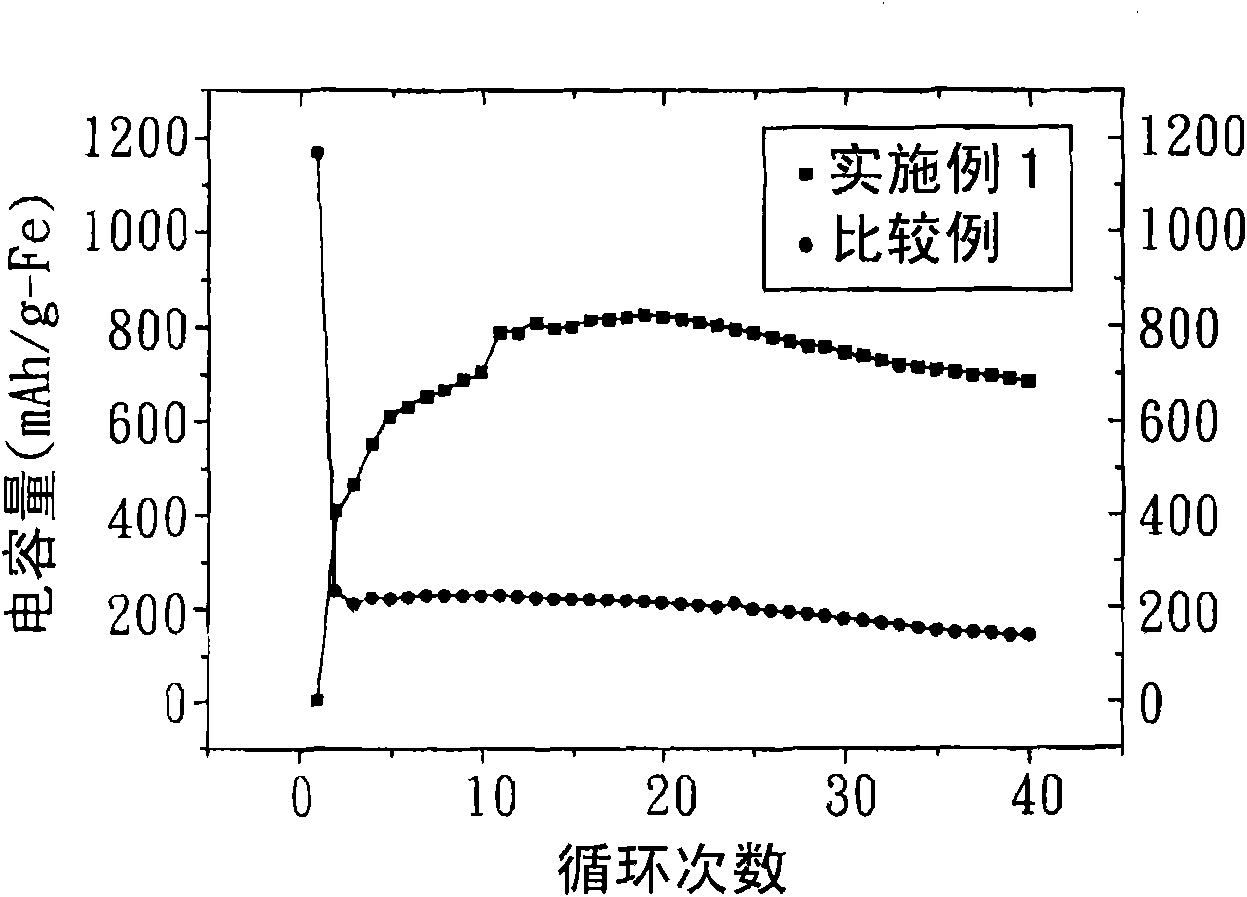

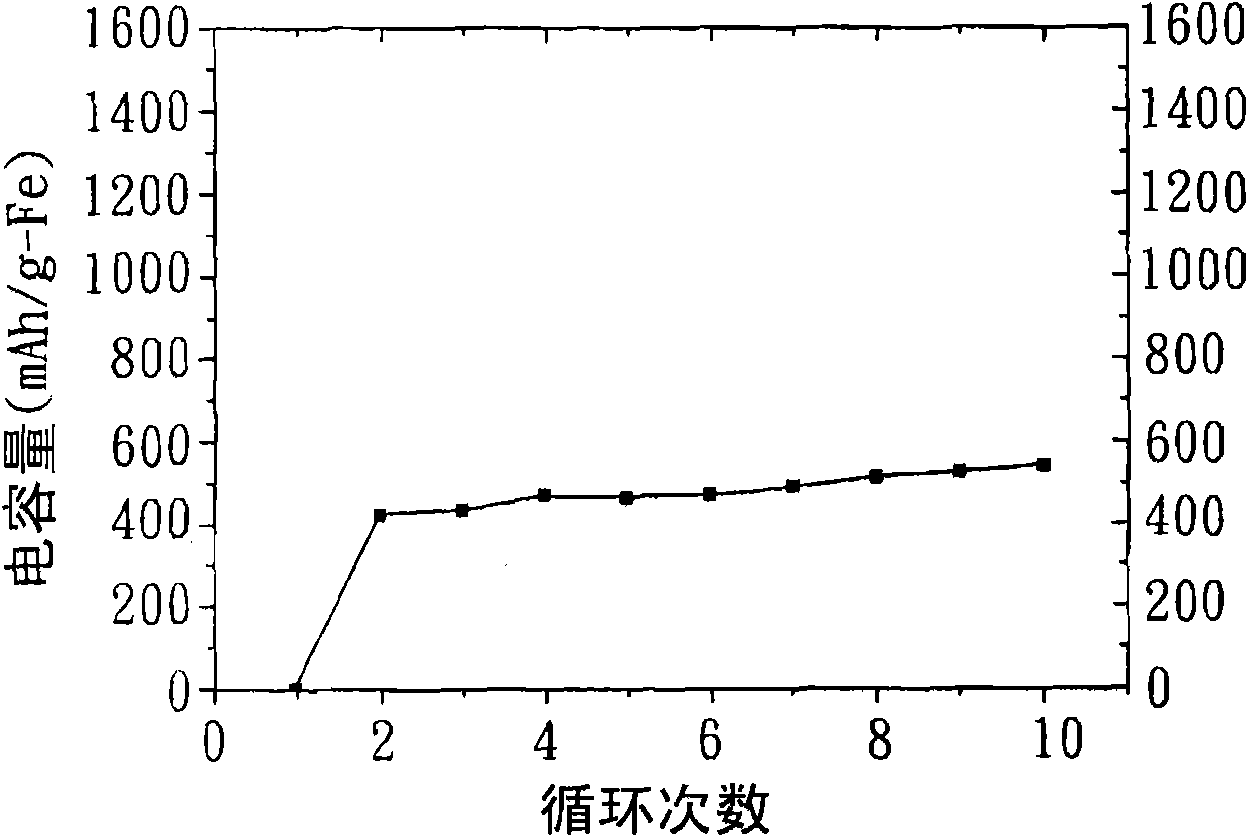

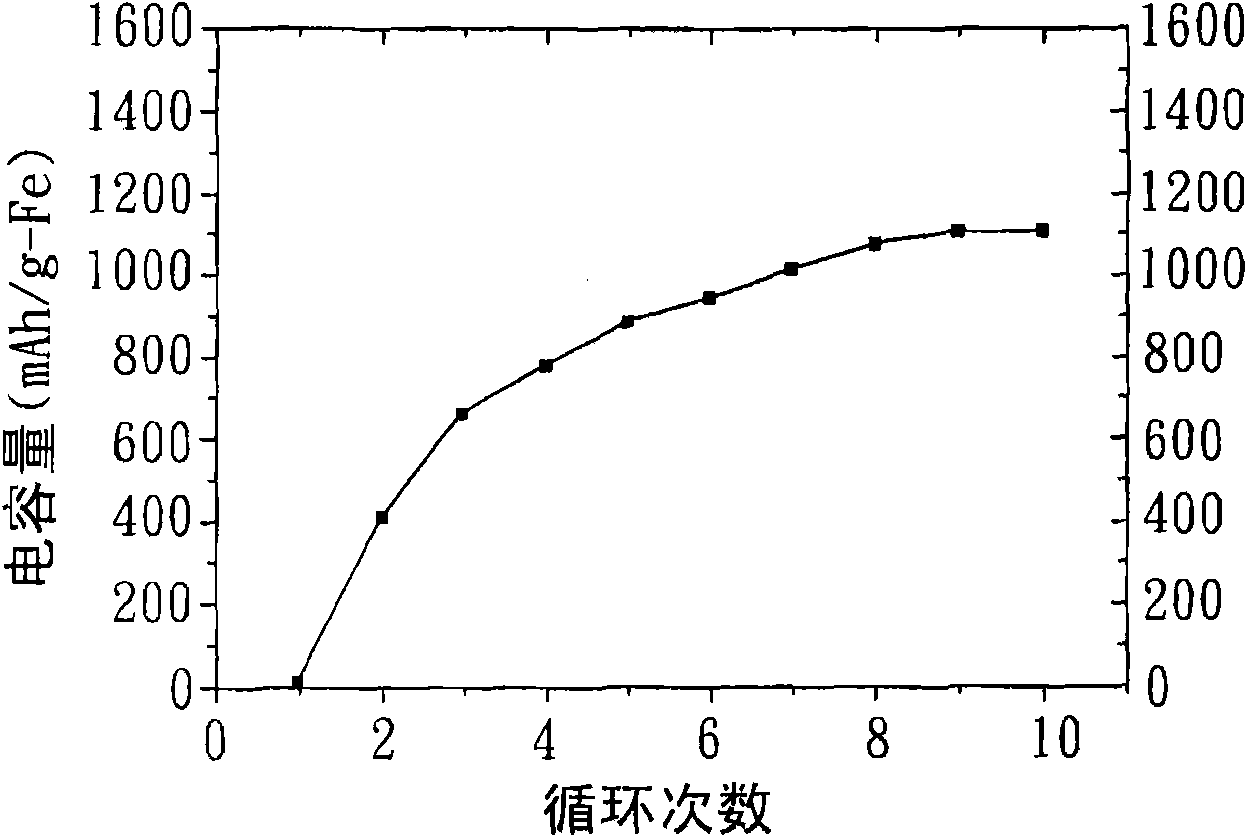

Cathode electrode composite material and preparation method thereof and electrochemical device applying same

InactiveCN102214822ASimple processReduce manufacturing costAlkaline accumulator electrodesNickel accumulatorsIndiumNickel salt

The invention discloses a cathode electrode composite material, which comprises a plurality of ferriferous oxide particles and a conductive aid which is selected from copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, cupric salt, cobalt salt, nickel salt, tin salt, antimonic salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, cupric hydroxide, cobalt hydroxide, nickel hydroxide, tin hydroxide, stibine hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and a group consisting of the combinations. When applied to an electrochemical device, the cathode electrode composite material can show high charging and discharging characteristics and high electric capacity. Moreover, the invention provides a preparation method of the cathode electrode composite material and an electrochemical device applying the same.

Owner:NATIONAL TSING HUA UNIVERSITY

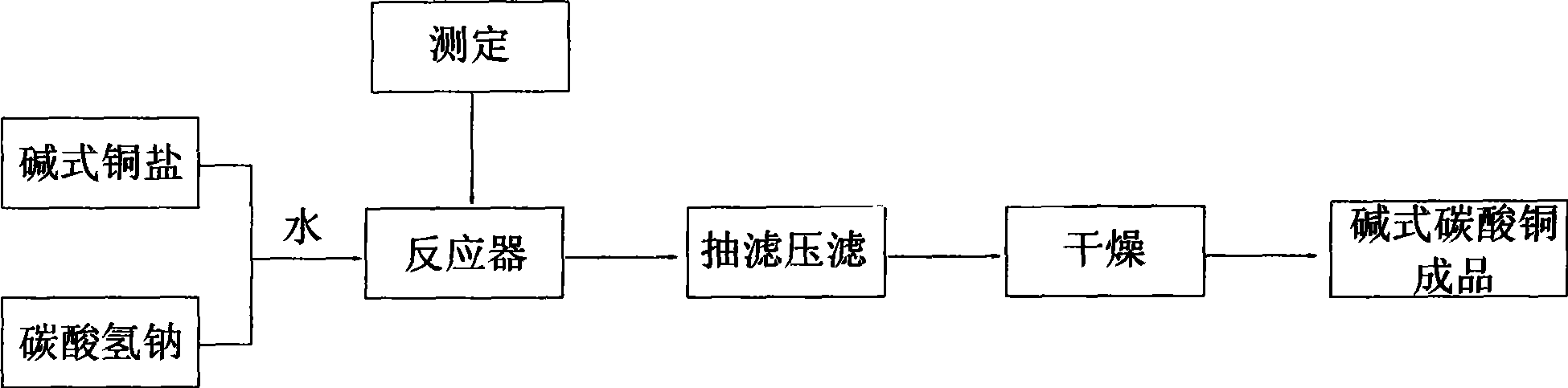

Process for producing basic copper carbonate

The invention discloses a preparation method of basic cupric carbonate, which comprises the following steps: step 1, stirring the solid basic cupric carbonate or cupric hydroxide and water into a paste shape in a reactor; step 2, adding solid sodium bicarbonate in the reactor to carry out solid state reaction and controlling the temperature to be between 20 DEG C and 140 DEG C; and step 3, after the completion of measurement and conversion, firstly preparing the wet basic cupric carbonate and then preparing the finished wet basic cupric carbonate after the wet basic cupric carbonate are subjected to solid-liquid separation, and washed and dried. The invention has the advantages of high purity, low cost and less amount of waste water produced.

Owner:沈祖达

Process for producing cupric hydroxide or cupric oxide

The invention discloses a process for preparing copper hydroxide or copper oxide. Soluble cupriferous ions (cupric nitrate, copper chloride and copper sulphate) generated in the production of wiring boards are taken as raw materials to be synthesized with ammonium ions of basic copper chloride or sodium hydroxide to generate basic copper salt (basic copper nitrate, basic copper sulphate and basic copper chloride), furthermore, products of basic copper salt reacts with the sodium hydroxide to generate copper hydroxide or copper oxide, and glycerin as stabilizing agent is added in. .The process of preparation has the advantages of stable products, easy washing, high purity, easy raw material achievement, high absorption rate and little environmental pollution.

Owner:沈祖达

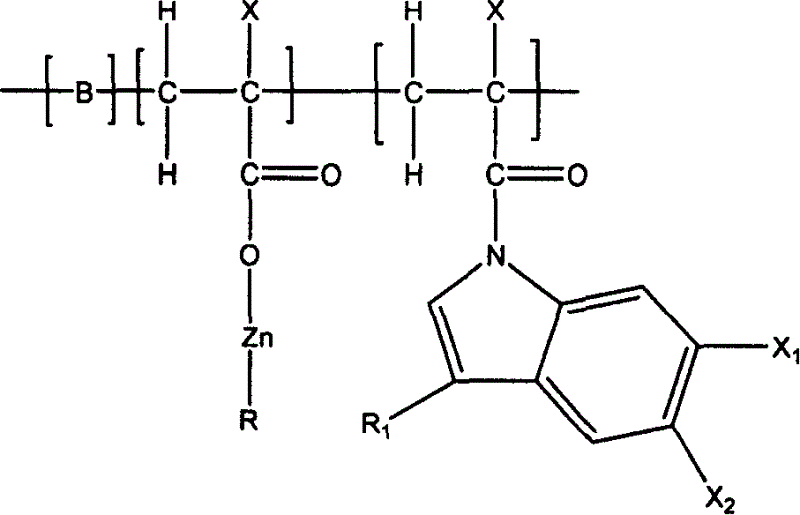

Resin of zinc acrylate or copper acrylate containing indole function group, its preparation and use

This is a kind of acrylic zinc or cuprum resin containing indole functional group and its preparation method. Its characteristics are: firstly prepare monomer containing indole functional group, then synthesize acrylic resin containing functional group and carboxyl, finally make the acrylic resin and zinc hydroxide or cuprum hydroxide react to obtain acrylic zinc or cuprum resin containing indole functional group; the reaction temperature of the said synthesizing monomer containing indole functional group is -10 - 10 Deg. C, the reaction time is 1.5 - 5 hours. The resin of the invention can be used for preparing sea antifouling dope. In the seawater, the organic zinc or cuprum acrylic ester on the polymer linear main chain of the coat surface hydrolyzes, and send out organic zinc or cuprum; the hydrolyzed polymer main chain contains indole functional group with highly efficient antifouling activeness, which makes the hydrolyzed polymer main chain still has sterilization activeness. So the dope can effectively prevent halobios from clinging on the surface of fishing tools, ships and seacoast establishments, and has good antifouling performance.

Owner:OCEAN UNIV OF CHINA

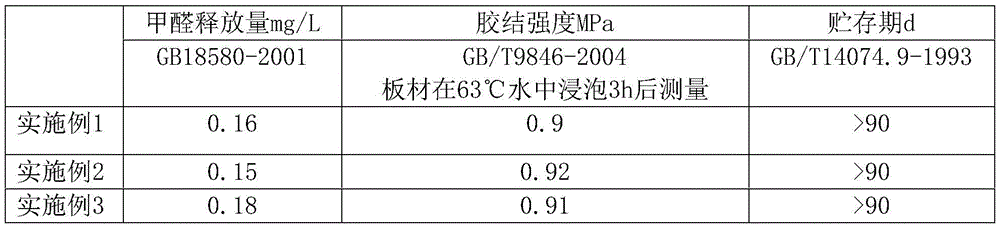

Urea resin adhesive capable of removing formaldehyde

InactiveCN101696348ANon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveCupric hydroxide

The invention relates to a urea resin adhesive capable of removing formaldehyde, comprising the following components in part by weight: 100 parts of modified urea resin, 1-5 parts of nano titania, 2-8 parts of tourmaline powder and 0.1-0.5 part of cupric hydroxide. The urea resin adhesive can effectively remove the formaldehyde, minimize the release amount of the formaldehyde when in use, adsorb the off-flavor in the air and has certain health care function.

Owner:杨济优

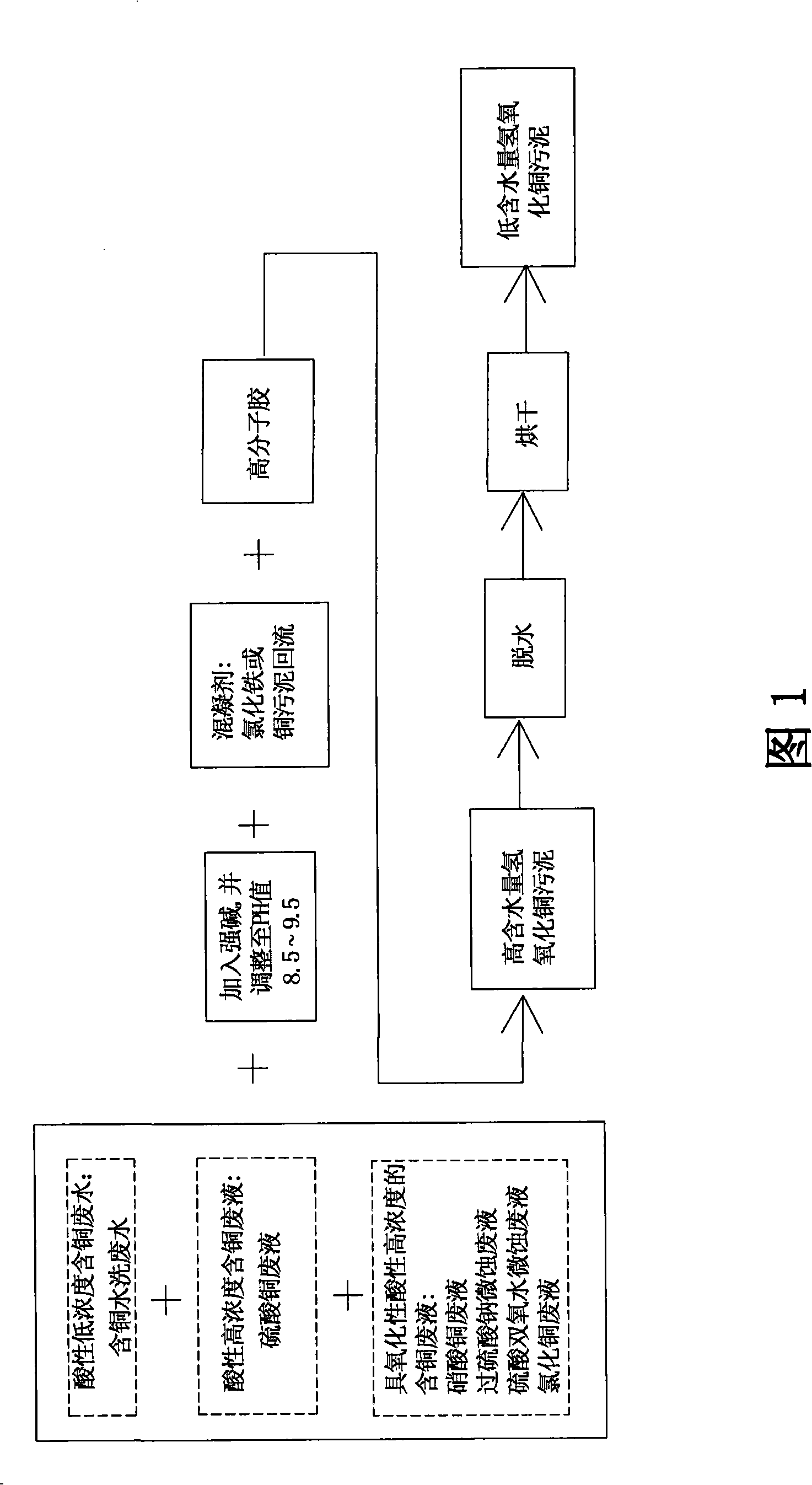

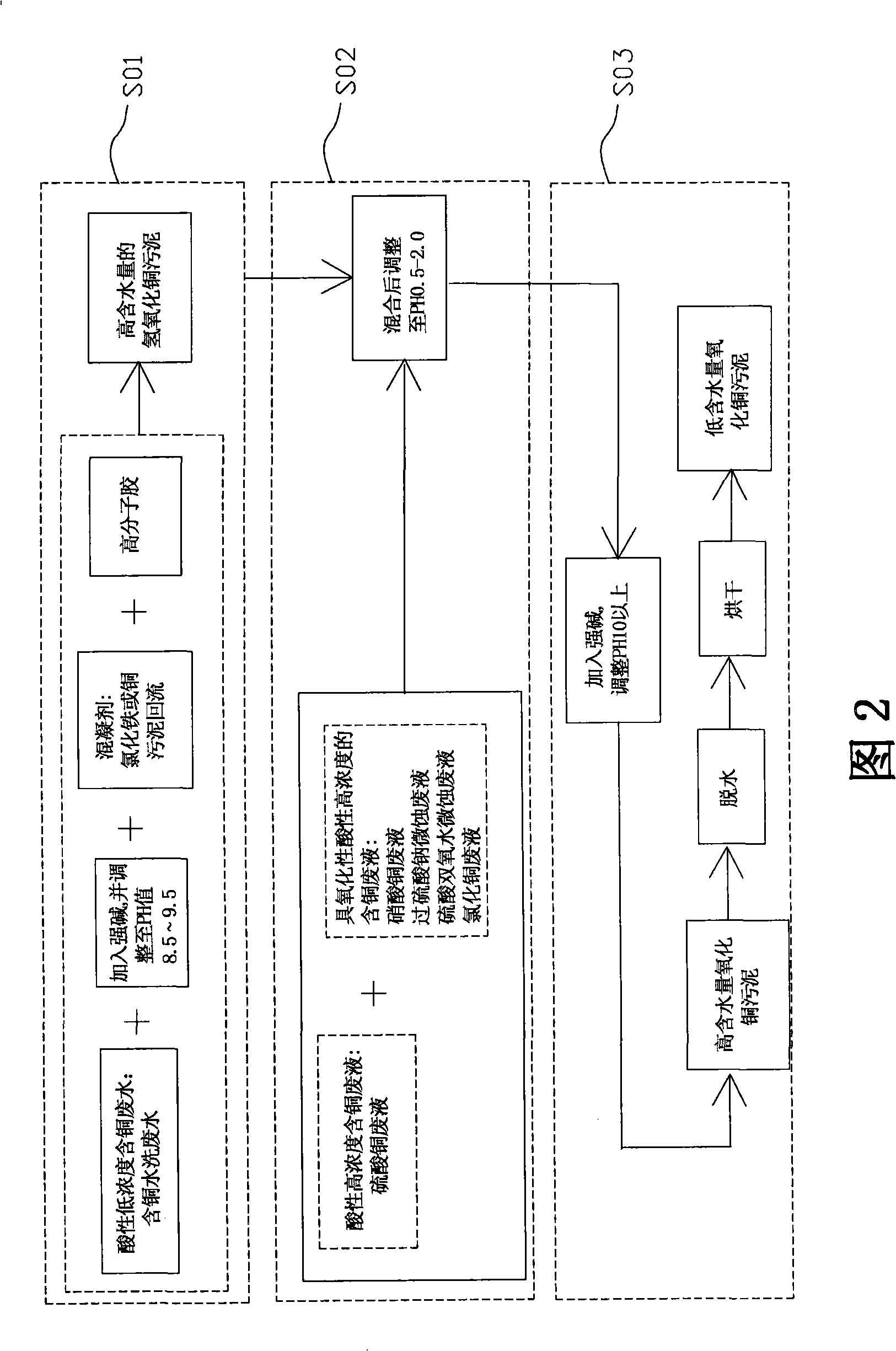

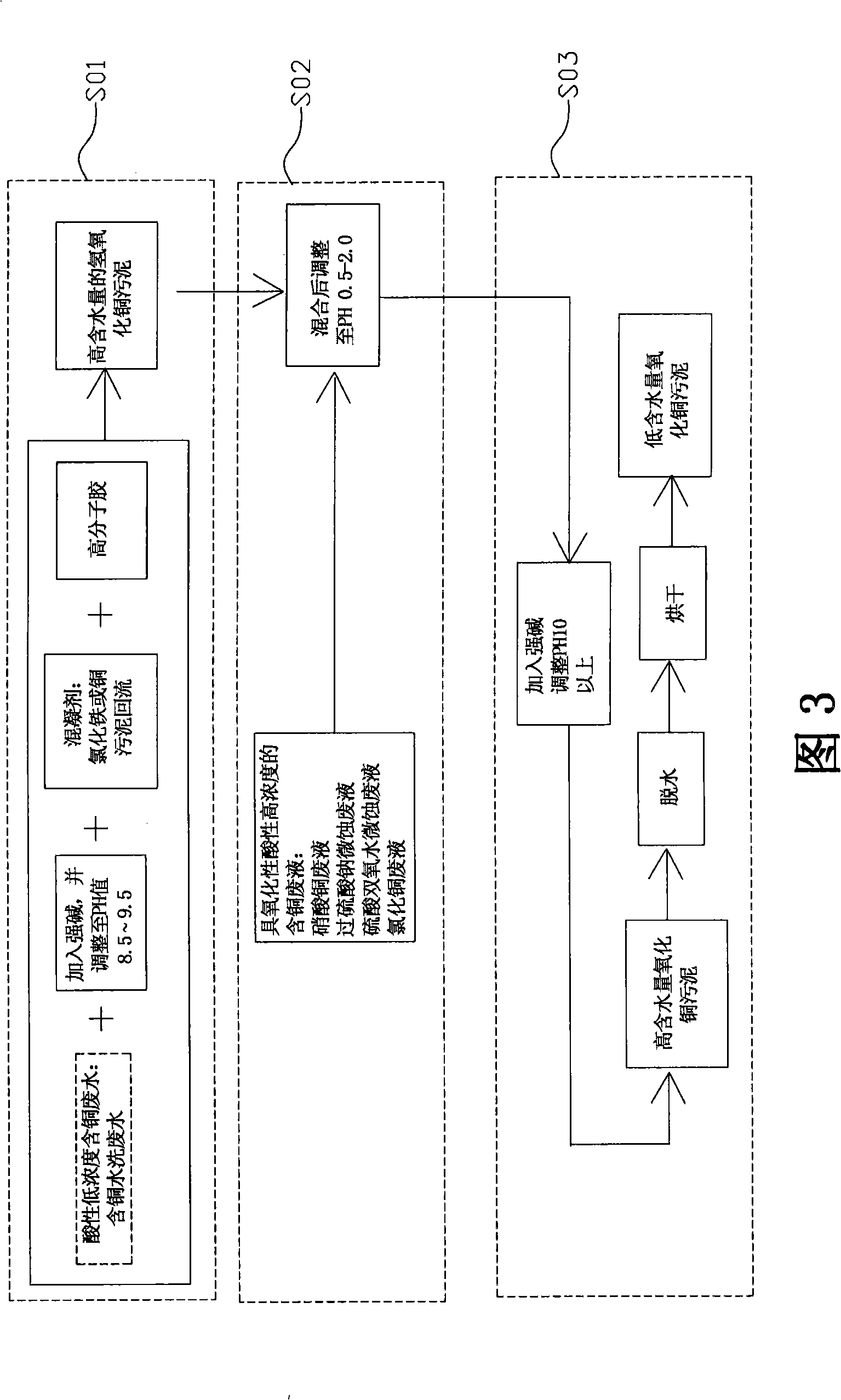

Processing method for generating highly copper containing sewage sludge with copper containing wastewater or waste liquor

InactiveCN101293688AIncreased copper contentReduce moisture contentCopper oxides/halidesWater/sewage treatment by flocculation/precipitationHigh concentrationLiquid waste

The invention provides a processing method for producing high copper sludge from copper-containing wastewater or waste cupric liquor, which includes the following steps: the invention mainly recycles and treats the copper-containing wastewater or waste cupric liquor which is produced after a printed circuit board is made, so as to precipitate copper sludge with higher copper content; the copper-containing wastewater or waste cupric liquor which is produced after a printed circuit board is made is firstly classified into acid copper-containing wastewater with low concentration, acid copper cupric liquor with high concentration and copper cupric liquor with oxidizability and high concentration and then is mixed and react with strong base to generate copper oxide sludge and then water is removed from the copper oxide sludge by a dehydration / drying device, so as to obtain the copper sludge with higher copper content. The method can transform cupric hydroxide to copper oxide without adding other transforming agents and can convert the low copper sludge in valueless copper-containing wastewater or waste cupric liquor into high copper sludge with recovery value.

Owner:UNITECH PRINTED CIRCUIT BOARD CORP

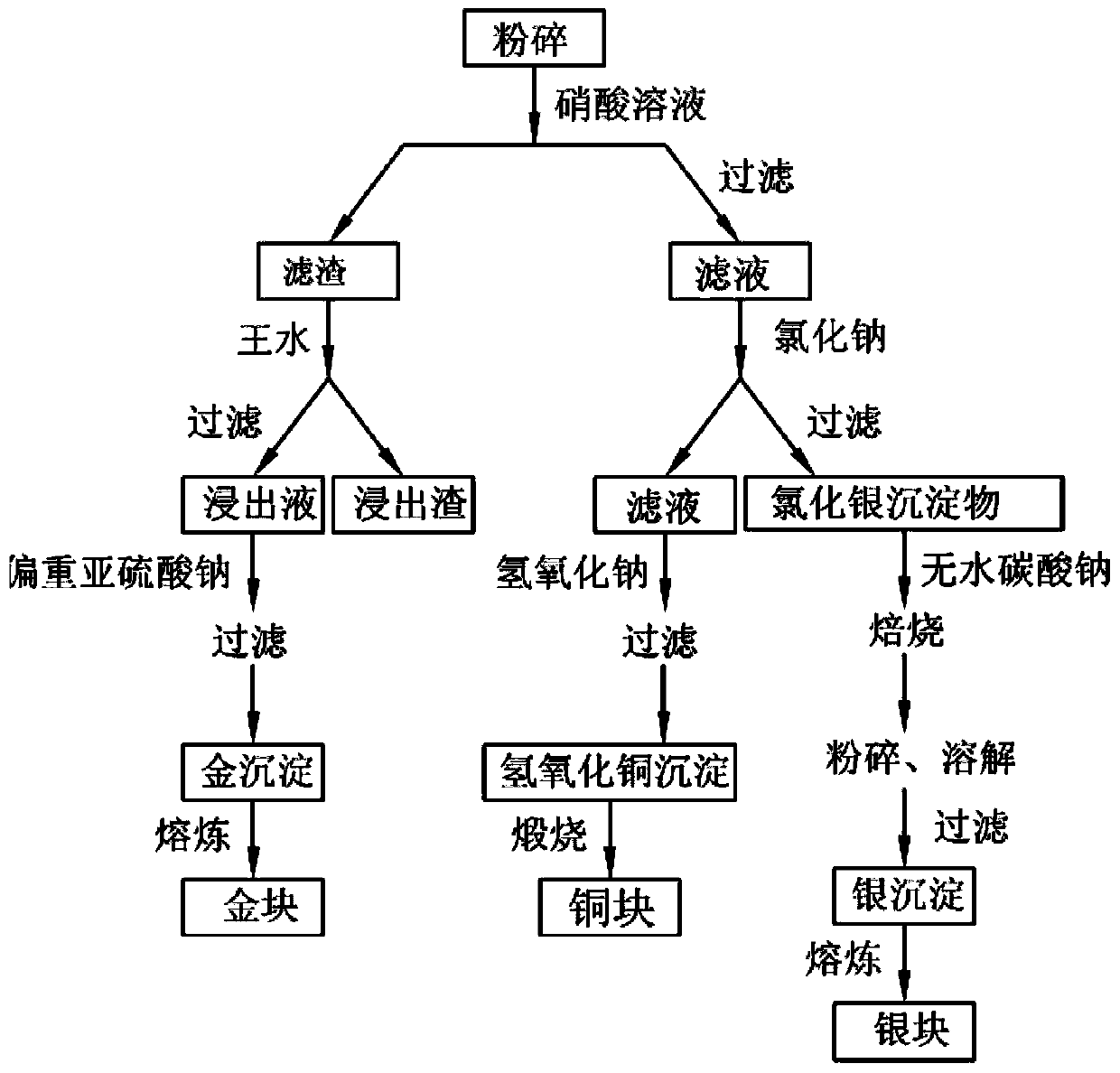

Method for recovering metals from waste CPUs (central processing units)

InactiveCN103436701AImprove efficiencyReduce pollutionProcess efficiency improvementSodium carbonate anhydrousPollution

The invention relates to a method for recovering metals from waste CPUs (central processing units), which comprises the following steps: pulverizing waste CPUs, adding the pulverized powder into a nitric acid solution, and filtering to obtain a filtrate and a filter residue; adding the filter residue into aqua regia, filtering to obtain a leaching solution, and adding sodium metabisulfite into the leaching solution to obtain a gold precipitate; meanwhile, adding sodium chloride into the filtrate, filtering to obtain a new filtrate and a silver chloride precipitate; adding sodium hydroxide into the new filtrate to obtain a cupric hydroxide precipitate; uniformly mixing the silver chloride precipitate with anhydrous sodium carbonate, roasting, pulverizing the roasted reaction product, adding into hot water, stirring, and filtering to obtain a silver precipitate; and respectively smelting the gold precipitate, silver precipitate and cupric hydroxide precipitate to obtain metals gold, silver and copper. The invention achieves the goal of recovering noble metals from waste CPUs at high efficiency, low pollution and low cost, and achieves the effect of maximally recovering noble metals gold, silver and copper.

Owner:SHANGHAI MINXING SECOND MIDDLE SCHOOL

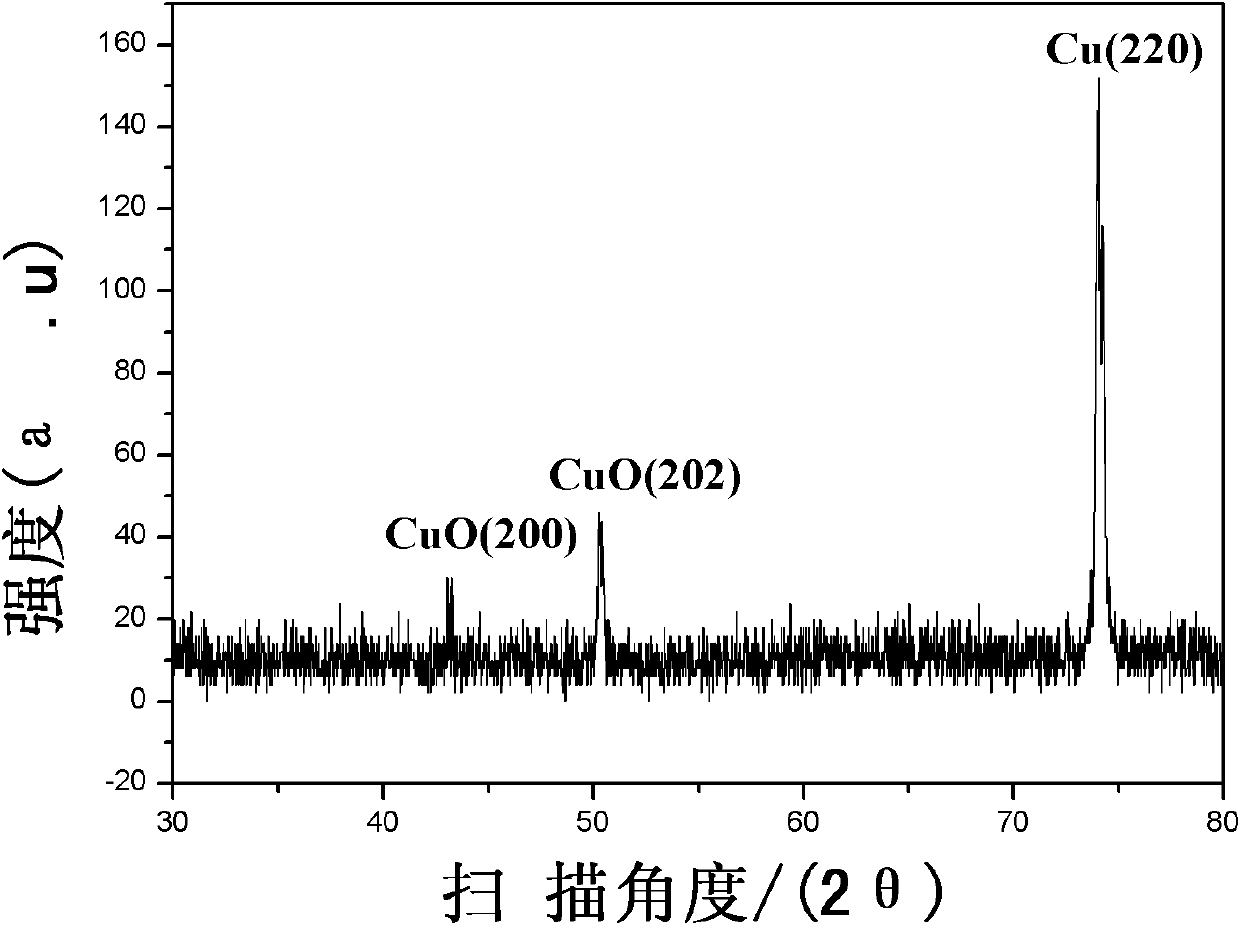

Method for preparing metallic copper nano particle

The invention relates to a method for preparing metallic copper nanoparticles, and belongs to the technical field of preparing nanomaterial by liquid-phase chemical reduction. The method adopts sodium hydrosulfite as a reducer to reduce cupric hydroxide under alkaline conditions, and adopts sodium dodecyl sulfate as a dispersant to generate copper nanoparticles with the grain diameter of 30 to 90nm. The method has the characteristics of simple technological process, low production cost and suitability for industrialized production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of copper-copper oxide composite electrode

InactiveCN102706936AImprove conductivityLow priceMaterial electrochemical variablesElectricityComposite electrode

The invention discloses a preparation method of a copper-copper oxide composite electrode, which comprises the following steps: a. cleaning of a copper rod; b. preparation of a cupric hydroxide suspension; and c. preparation of the composite electrode: adding a prepared alkali (b) solution in a reaction kettle, immersing the copper rod in the alkali (b) solution, closing the reaction kettle, reacting at 60-80 DEG C for 2-6 hours, cooling to room temperature, cleaning the electrode, and drying at room temperature, thereby obtaining the composite electrode. The mass / area ratio of the copper oxide-copper electrode is 0.0063-0.0134g / cm<2>. Compared with the prior art, the invention has the advantages of high reproducibility, low energy consumption, low minimum limit of detected ions (0.4 mu M), high response stability during ion monitoring and low synthesis cost, is simple to operate, and is suitable for industrial large-scale preparation; and the prepared copper oxide nano belt is uniformly coated on the copper electrode surface, and the electrode with high specific area can be used as a sensor material to sufficiently contact the measured object, so that the electrocatalytic reaction is sufficient and efficient.

Owner:ANHUI NORMAL UNIV

Urea resin adhesive capable of removing formaldehyde

InactiveCN101696348BNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveCupric hydroxide

The invention relates to a urea resin adhesive capable of removing formaldehyde, comprising the following components in part by weight: 100 parts of modified urea resin, 1-5 parts of nano titania, 2-8 parts of tourmaline powder and 0.1-0.5 part of cupric hydroxide. The urea resin adhesive can effectively remove the formaldehyde, minimize the release amount of the formaldehyde when in use, adsorb the off-flavor in the air and has certain health care function.

Owner:杨济优

Residue-free normal-temperature deoiling/derusting/phosphating solution

InactiveCN104087922ANo pollution in the processNot easy to peel offMetallic material coating processesDipotassium hydrogen phosphatePhosphorous acid

The invention discloses a residue-free normal-temperature deoiling / derusting / phosphating solution which is prepared from the following raw materials: 20-25 parts of phosphoric acid, 10-12 parts of hydrochloric acid, 8-10 parts of phosphorous acid, 3-5 parts of citric acid, 3-5 parts of sodium hydroxide, 5-8 parts of cupric hydroxide, 3-5 parts of sodium sulfate, 2-8 parts of dipotassium hydrogen phosphate, 5-10 parts of disodium edetate, 3-5 parts of sodium tripolyphosphate, 10-12 parts of sodium pyrophosphate, 10-18 parts of trichloroacetic acid, 10-15 parts of hypochlorous acid, 8-10 parts of tartaric acid, 5-12 parts of ammonium sulfate, 5-10 parts of ammonium chloride, 5-10 parts of lauryl sodium sulfate, 5-8 parts of alkylphenol polyoxyethylene and 80-100 parts of pure water. The residue-free normal-temperature deoiling / derusting / phosphating solution can implement deoiling, derusting and phosphating techniques at normal temperature, does not generate residues or pollute the environment, has favorable rust-preventing property, and can not easily shed after being applied to the surface of the steel workpiece.

Owner:司徒建辉

Detection technology for basic copper chloride content

InactiveCN101464416AMaterial analysis by observing effect on chemical indicatorIodometric methodFiltration

The invention provides a technique for detecting the content of copper chloride hydroxide. Only copper chloride in the copper chloride hydroxide is capable of dissolving in water, while cupric hydroxide and copper chloride hydroxide are capable of dissolving in acid. The technique comprises the following steps: dissolving copper chloride hydroxide in water and then filtering, and measuring the content of water soluble chloride ion in the filtrate obtained from filtration by the Volhard titration method; dissolving copper chloride hydroxide in nitric acid, and measuring the total content of chloride ion therein by the Volhard titration method; and dissolving copper chloride hydroxide in hydrochloric acid, and measuring the total content of copper therein by the iodometric method. The accurate contents of water soluble copper chloride, copper chloride hydroxide and cupric hydroxide in copper chloride hydroxide can be calculated through the three steps.

Owner:SHANDONG NEW HOPE LIUHE GROUP

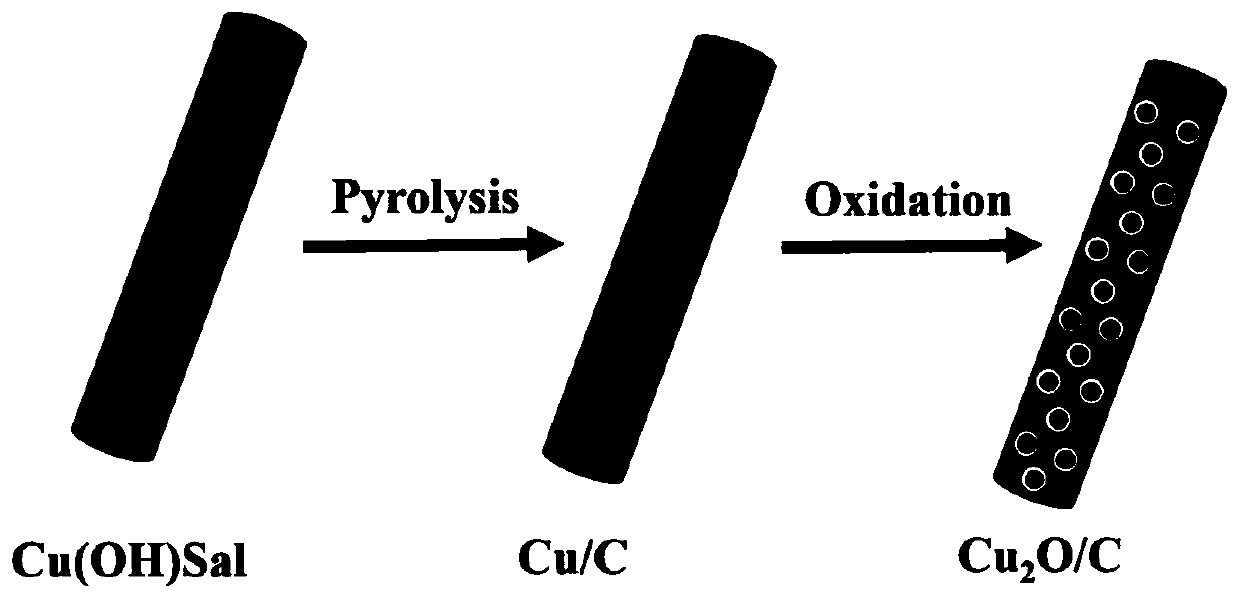

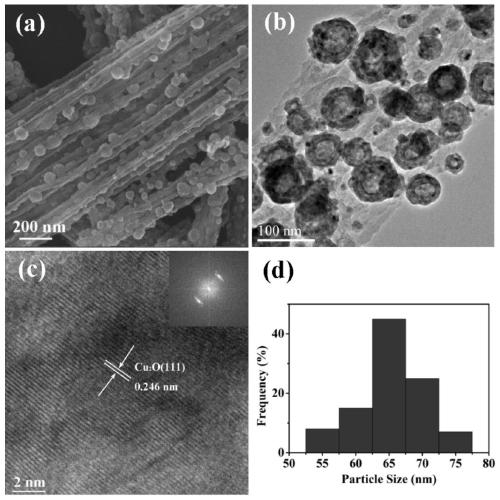

Method for preparing one-dimensional cuprous oxide/carbon nanocomposite catalyst and application

ActiveCN110152664AHigh crystallinityImprove catalytic performanceMaterial nanotechnologyOrganic compound preparationCarbon nanocompositeCrystallinity

The invention discloses a method for preparing a one-dimensional cuprous oxide / carbon nanocomposite catalyst and application. The method disclosed by the invention comprises the following steps: by utilizing an intercalation assembly of salicylate and metal ions, preparing salicylate intercalation layered copper hydroxide having one-dimensional morphology; carrying out solid-state pyrolysis and low-temperature oxidation two-step solid-phase reactions, thereby obtaining the one-dimensional cuprous oxide / carbon nanocomposite catalyst. According to the method disclosed by the invention, cheap water soluble salts serve as reactants, any organic solvent, surfactant, extra carrier, template agent or reducing agent is not needed in the preparation process, the prepared catalyst particle is uniform in distribution, high in purity and high in crystallinity, and the Cu nanoparticles form Cu2O having a hollow structure by utilizing a Kirkendall effect. The catalyst synthesized in the invention has excellent catalytic performance and excellent cycling stability in a liquid phase hydrogenation reaction of p-nitrophenol.

Owner:BEIJING UNIV OF CHEM TECH

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800BEfficient removalImprove product qualityMultistage water/sewage treatmentCopper chloridesSulfateCopper chloride

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

Cupric hydroxide dry suspending agent and preparation method thereof

The invention relates to a cupric hydroxide dry suspending agent and a preparation method thereof. The cupric hydroxide dry suspending agent comprises the following components in percentage by weight: 10-80% of cupric hydroxide powder, 5-30% of dispersing agent, 1-5% of wetting agent, 1-20% of disintegrant, 1-10% of bonding agent, 1-5% of adhesive and 1-5% of film former. The preparation components of the cupric hydroxide dry suspending agent can be effectively and uniformly attached to the crop surface and form a compact protective film on leaves; and thus, the cupric hydroxide dry suspending agent has the advantages of rainfall erosion resistance and high drug effect durability, and can efficiently prevent and remove bacterial diseases and fungus diseases of crops. The cupric hydroxide dry suspending agent can be used as an effective component of a copper preparation to effectively avoid the defect of partial scorching and chemical injury of crops since the Bordeaux mixture and other cupric hydroxide preparations can not easily control the copper ion distribution.

Owner:SHENZHEN NOPOSION AGROCHEM

Process for producing cupric hydroxide or cupric oxide

The invention discloses a process for preparing copper hydroxide or copper oxide. Soluble cupriferous ions (cupric nitrate, copper chloride and copper sulphate) generated in the production of wiring boards are taken as raw materials to be synthesized with ammonium ions of basic copper chloride or sodium hydroxide to generate basic copper salt (basic copper nitrate, basic copper sulphate and basiccopper chloride), furthermore, products of basic copper salt reacts with the sodium hydroxide to generate copper hydroxide or copper oxide, and glycerin as stabilizing agent is added in. .The processof preparation has the advantages of stable products, easy washing, high purity, easy raw material achievement, high absorption rate and little environmental pollution.

Owner:沈祖达

Bactericide specially for preventing and treating diseases of tobacco in middle and later stage and its prepn

The special-purpose fungicide for controlling several diseases in middle and later stage of tobacco plant growth is made up by using cupric hydroxide, Saikuzuo, Carboxymethyl cellulose, petroleum sodium carbonate, propanetriol, diatomite, isopropanol and chaku as raw material through a certain preparation process. Its finished product is a 55% wettable powder which can be used for curing wildfine, rust, angular leaf spot, powdery mildew, anthracnose and white rust, etc. Its preparation process is simple, does not produce waste water, waste residue and waste gas, and features low cost, broad spectrum, high efficiency and low-toxicity.

Owner:赵国晶

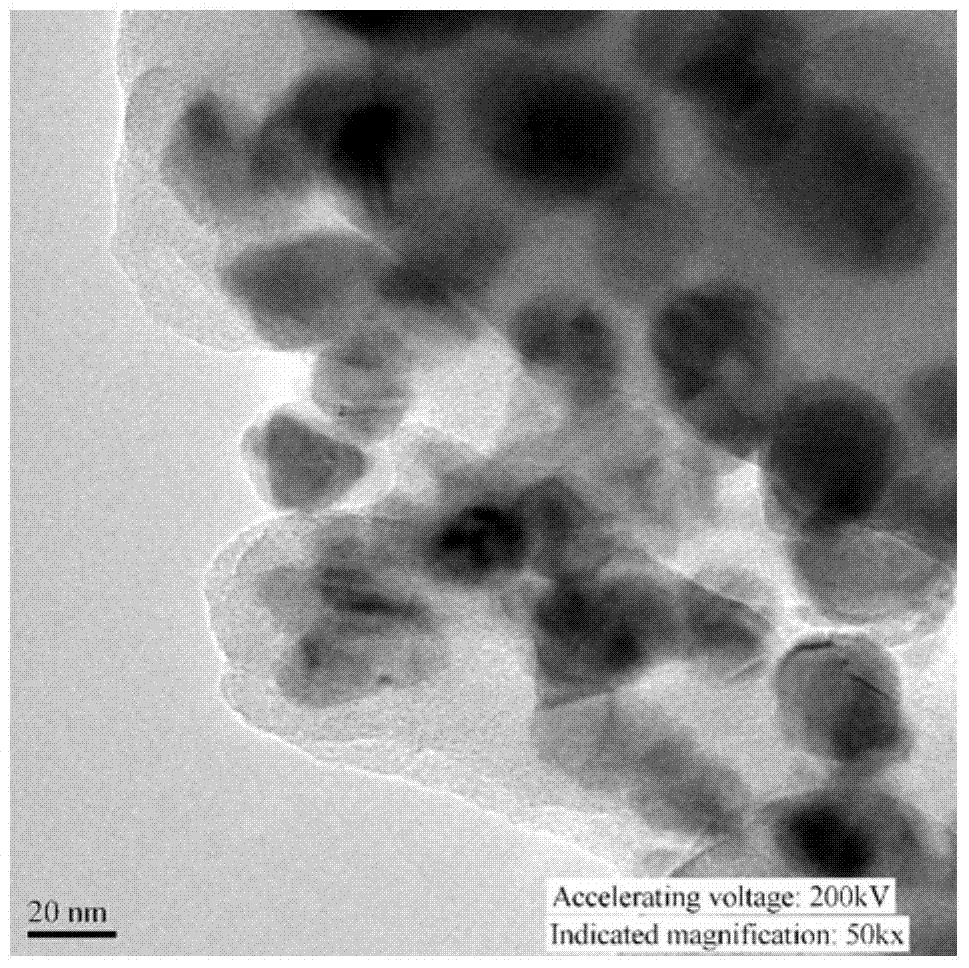

Solid phase synthesis method for nano curpic hydroxide fungicide powder

The invention relates to a solid-phase synthesized method for nanometer cupric hydroxide bactericidal agent technical powder, which belongs to the technical field of the application of nanometer material, and utilizes inert medium control solid-phase reaction nucleation rate to prepare nanometer cupric hydroxide technical powder, and the invention is characterized in that the medium control is the nuclear portion of the invention, and the manufacturing art is simple. The process of the solid-phase synthesized art comprises selecting appropriate control medium and solid-phase reactant according to the formulation of wettable powder, and respectively breaking and screening, positioning control agent and the product yield of the reaction cupric hydroxide with the weight ratio (0.5-2):1 in nantokite, calculating solid-phase reactant according to the chemical measuring, positioning in a water bath case for a plurality of hours after slowly grinding to be even under the indoor temperature, and attaining the nanometer cupric hydroxide power body after the reaction is completed. The micro-nano power body is suitable to be used as technical powder of agricultural chemical bactericidal agent products such as wettable power agent, soluble power agent, dry suspending agent and suspending agent and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Novel formaldehyde scavenging material for urea formaldehyde resin glue, and preparation and application methods thereof

InactiveCN105602468APerformance impactHigh aldehyde removal rateNon-macromolecular adhesive additivesMacromolecular adhesive additivesAlkylphenolGlycerol

The invention discloses a novel formaldehyde scavenging material for urea formaldehyde resin glue. The novel material is prepared from the following raw materials in parts by mass: 30-45 parts of phosphoric acid, 25-30 parts of urea, 15-20 parts of water, 0.01-0.03 part of sodium ethylene diamine tetracetate, 3-5 parts of ammonium phosphate, 10-15 parts of glycerol, 15-20 parts of ethyl 3-ketobutyrate, 2-5 parts of melamine, 1-3 parts of ethylene glycol, 0.5-1 part of alkylphenol polyoxyethylene, 3-5 parts of phenol, 2-4 parts of ethanol, 1-3 parts of ferric chloride and 1-2 parts of cupric hydroxide. All the raw materials chemically react under the synergistic effect, and the obtained product is used for scavenging formaldehyde by the combination of chemical adsorption and physical adsorption. Compared with the existing formaldehyde scavenging material, the formaldehyde absorption efficiency is obviously enhanced, the free formaldehyde release amount of the obtained board can be lower than 0.2 mg / L, the glue layer does not become yellow, the strength of the board boiled by hot water is greater than 0.9 MPa, and the product has stable properties.

Owner:JIANGSU SHINE ALL IND CO LTD

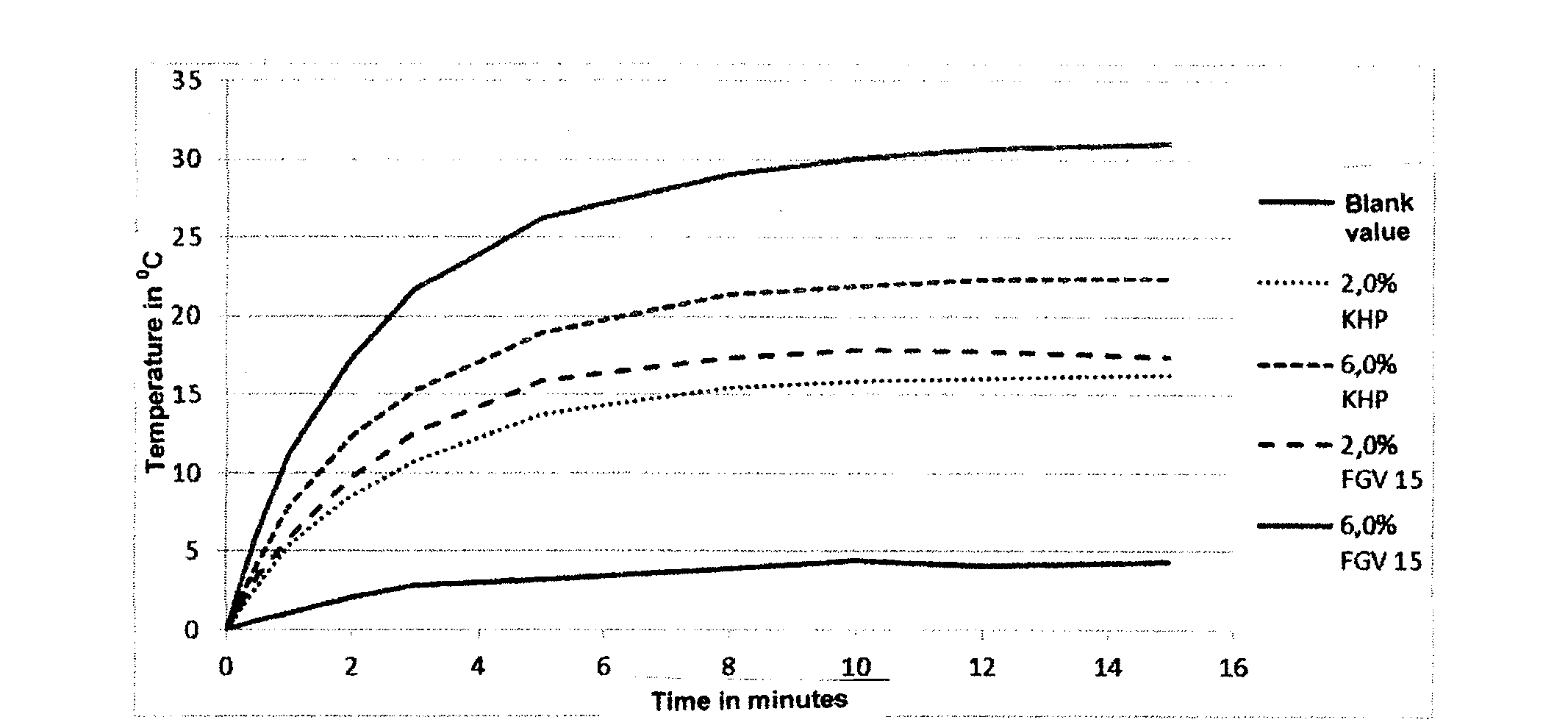

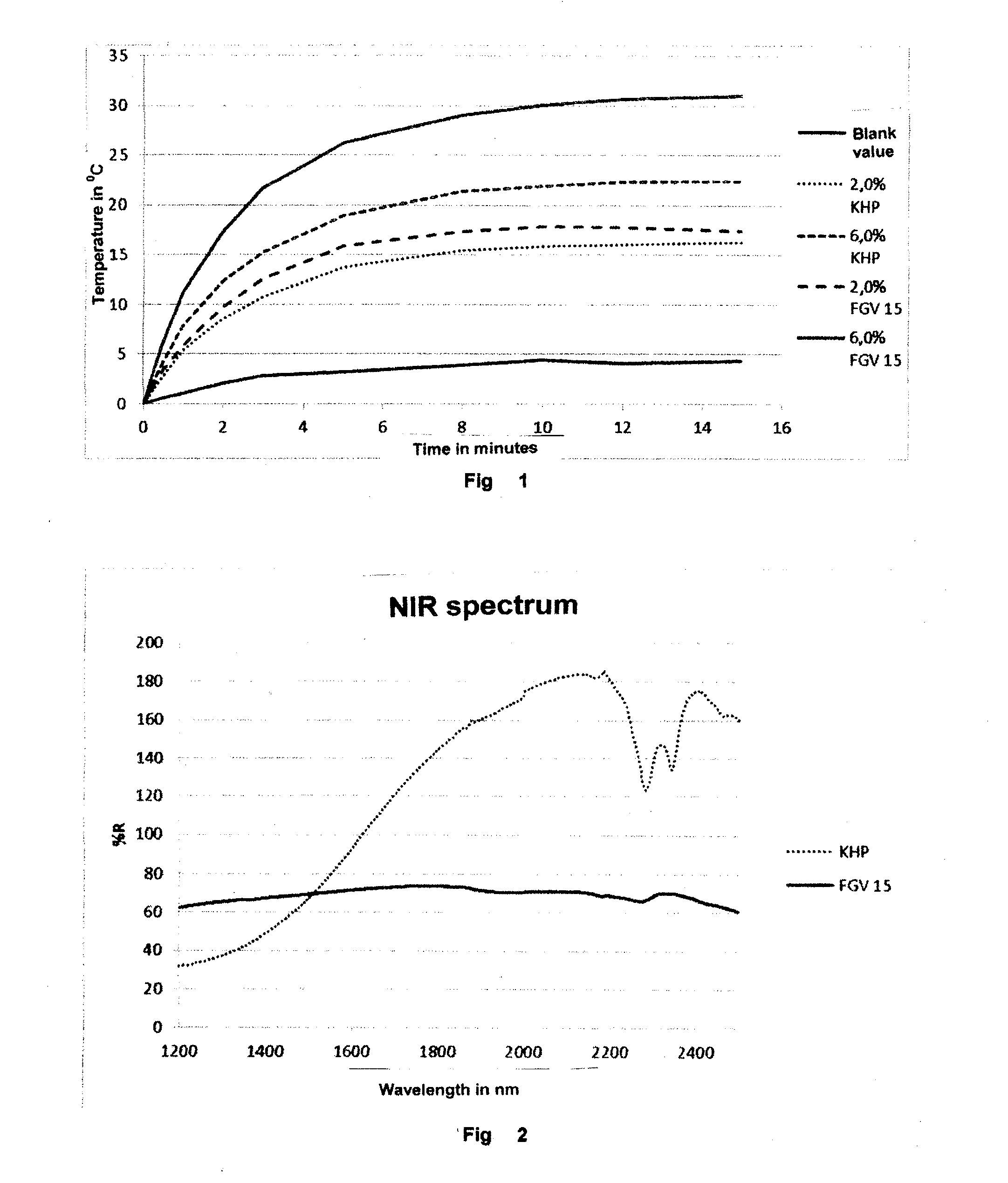

Doped copper-ii-hydroxide phosphate, method for producing same and use thereof

ActiveUS20160280544A1Easy to processWide wavelength rangeHeat-exchange elementsCopper compoundsMisch metalMain group element

A mixed-metallic phosphate compound is disclosed, which contains as the main metal copper in the divalent oxidation state in a proportion of at least 90.0 at-% and one or more doping metals in a total proportion of the doping metals of at least 0.01 to at most 10.0 at-%, wherein the doping metals are selected from the group consisting of the elements of the first and second main groups and the eighth subgroup of the elements of the periodic table, Al, Sn, Si, Bi, Cr, Mo, Mn, and the lanthanides. The stated metal proportions relate to the total amount of the metals in the mixed-metallic phosphate compound. The mixed-metallic compound has a phosphate content expressed as P2O5 in the range of 10 to 60 wt-%. Also disclosed is a method for producing the mixed-metallic phosphate compound and the use thereof.

Owner:CHEM FAB BUDENHEIM AG

Preparation method of composite manganese sulfide catalyst

InactiveCN108745383AGood effectIncrease surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationCopper oxideRaw material

The invention discloses a preparation method of a composite manganese sulfide catalyst. The preparation method sequentially comprises the following steps: dropwise adding a manganese chloride solutionwith the concentration of 0.5-1.0 mol / L in a copper chloride solution with a concentration of 0.1-0.5 mol / L, controlling that Mn<2+> / Cu<2+> is equal to (5-8):1, placing a mixed solution in boiling water of 100 DEG C after the completion of dropwise adding, generating a cupric hydroxide colloid and adsorbing the manganese chloride on the surface of the cupric hydroxide colloid; adding 2 g of attapulgite in the colloid solution, stirring for 20-40 minutes and then introducing hydrogen sulfide gas, wherein the concentration of the hydrogen sulfide gas is 20-40 ppm; introducing 20-40 L of hydrogen sulfide gas into per 100 mL of the colloidal solution, stirring to generate a precipitate, performing solid-liquid separation on the precipitate, washing with distilled water for 3-5 times and thendrying at a temperature of 105 DEG C to obtain the composite manganese sulfide catalyst. The preparation method of the composite manganese sulfide catalyst, disclosed by the invention, has the advantages that hydrogen sulfide waste gas produced by chemical production is utilized as a raw material, the hydrogen sulfide gas is absorbed, wastes are changed into valuables, and the copper oxide composite manganese sulfide catalyst is formed on the surface of the attapulgite.

Owner:CHANGZHOU UNIV

Copper humate-containing antibacterial and yield-improving composition and preparation method thereof

InactiveCN108522540AImprove antibacterial propertiesImprove the effect of increasing productionBiocidePlant growth regulatorsAntibacterial agentNuclear chemistry

The invention discloses a copper humate-containing antibacterial and yield-improving composition and a preparation method thereof and belongs to the technical field of preparation of antibacterial compositions. The copper humate-containing antibacterial and yield-improving composition is prepared from raw materials including allantoin, amino-oligosaccharin, copper humate, chlormequat chloride, trinexapac-ethyl, mepigtlat-chloride, copper hydroxide, basic cupric carbonate, polylactic acid, chitosan, silane coupling agent KH-550, antibacterial modifying agent and sustained release filler. The copper humate-containing antibacterial and yield-improving composition is prepared through the steps of major component preparation, modifying component preparation, mixing and pelletizing of major components and modifying components and the like. The prepared copper humate-containing antibacterial and yield-improving composition is excellent in antibacterial and yield-improving performance.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

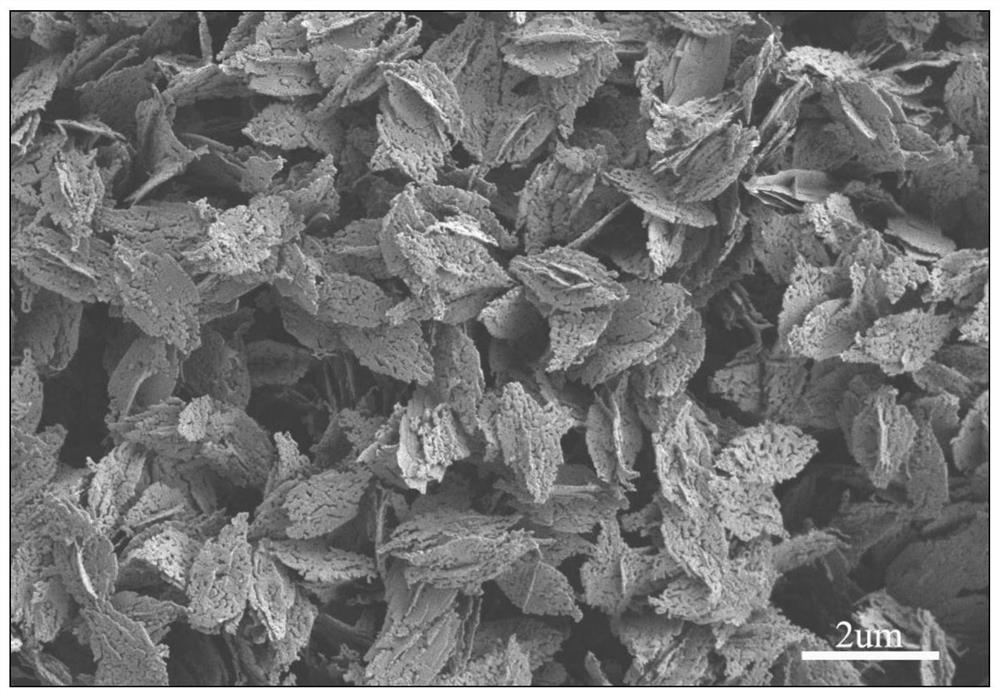

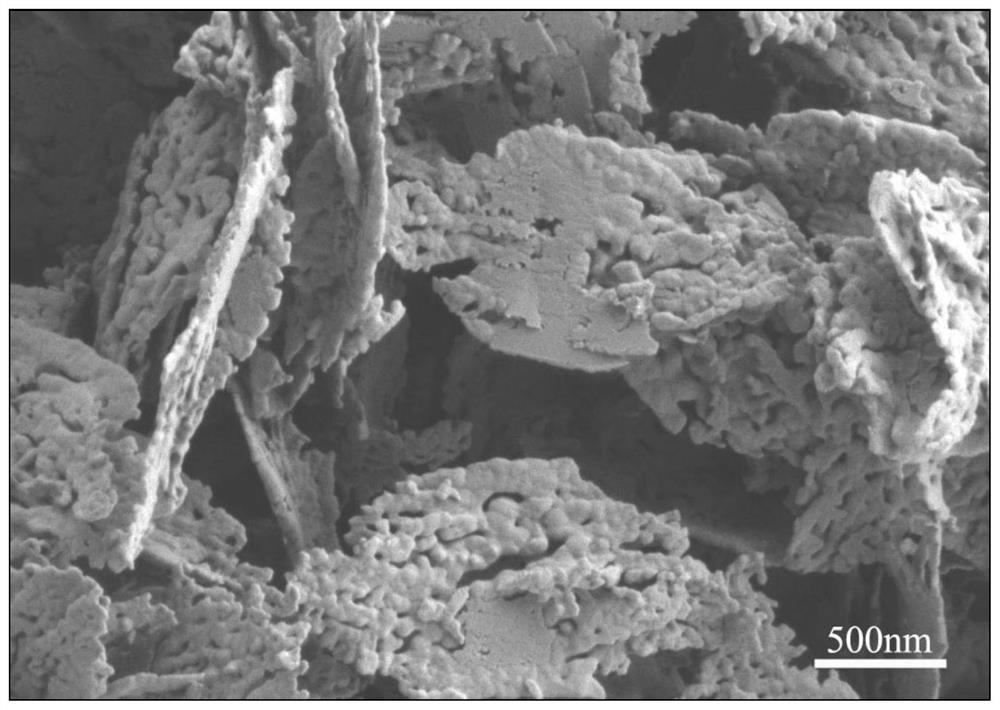

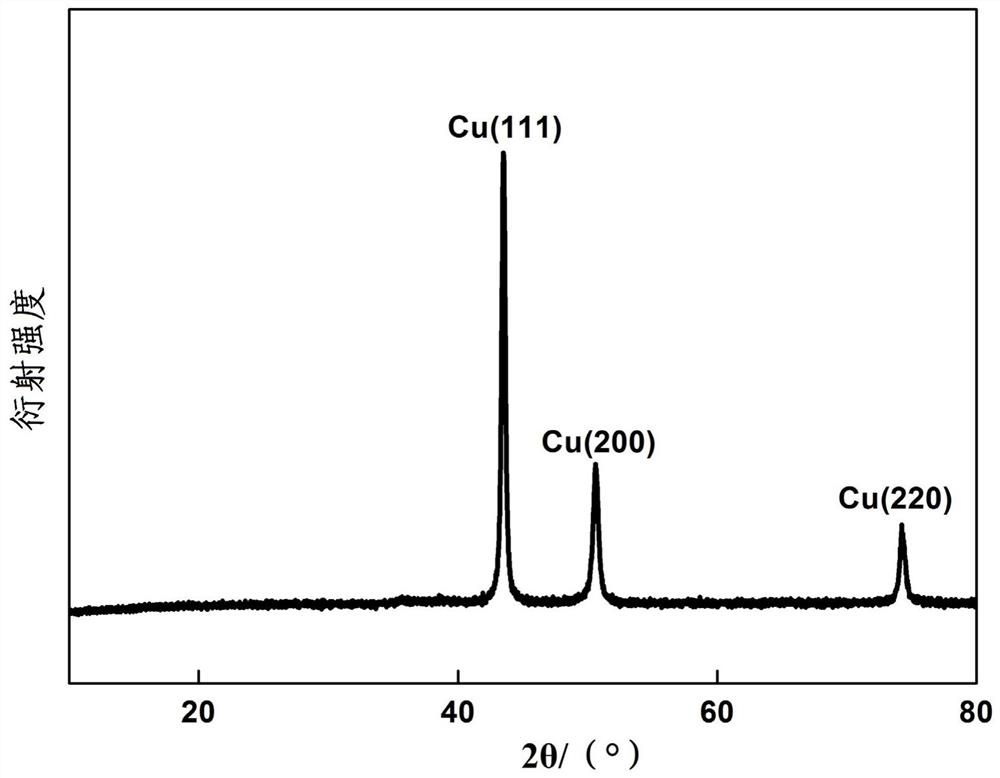

A preparation method of leaf-shaped porous copper nanosheets

ActiveCN113059173BReduce thicknessLarge diameterMaterial nanotechnologyTransportation and packagingPolyethylene glycolCopper oxide

The invention discloses a method for preparing leaf-shaped porous copper nanosheets, which comprises the following steps: 1. Dissolving polyethylene glycol and copper chloride in deionized water; 2. Adding ammonia water to the mixed solution; 3. Adding copper ammonia The complex solution is placed in a water bath and sodium hydroxide solution is added; 4. The copper oxide nano-sheets are subjected to hydrogen thermal reduction treatment to obtain leaf-shaped porous copper nano-sheets. The present invention combines copper ions with ammonia to form a copper-ammonia complex solution, adding sodium hydroxide solution to generate copper hydroxide nanowires, which are oxidized in a water bath to form copper oxide, and form copper oxide nanosheets under the adsorption of ammonia. Thermal reduction treatment is used to obtain porous leaf-shaped copper nanosheets without changing the sheet shape. The obtained leaf-shaped porous copper nanosheets have a small thickness and a large sheet diameter, and have good dispersion and particle size. The advantages of uniformity and high cleanliness can be used as nano-metal conductive fillers for flexible printed circuits.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

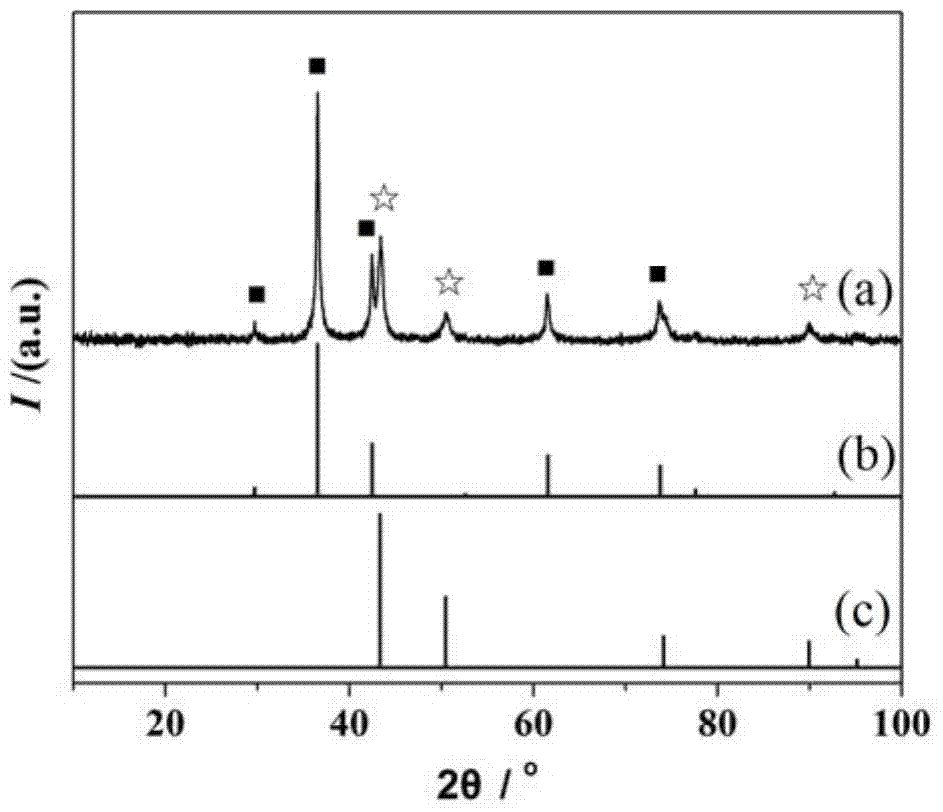

A kind of preparation method of nanometer cuprous oxide catalyst

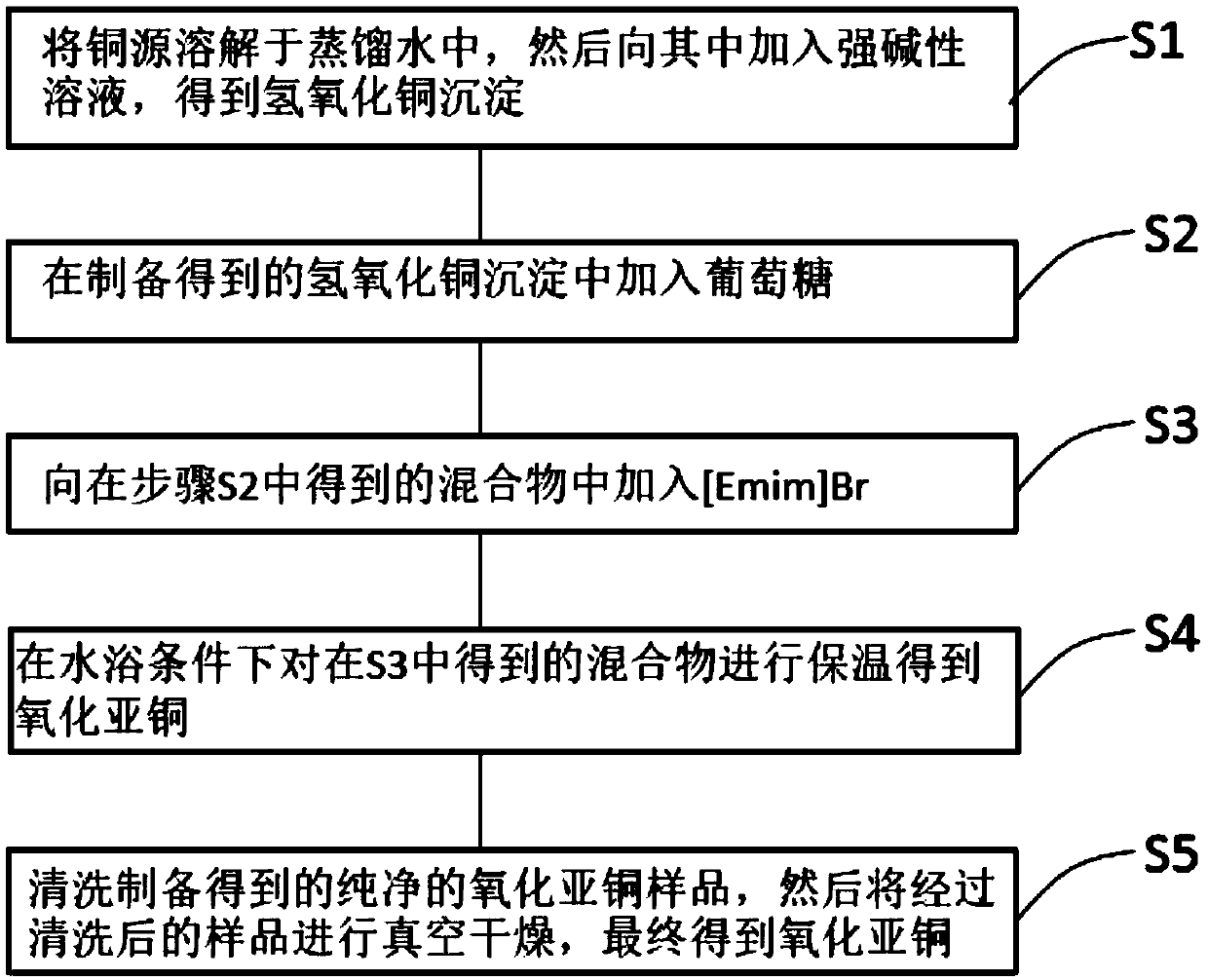

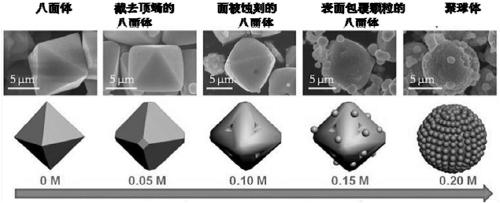

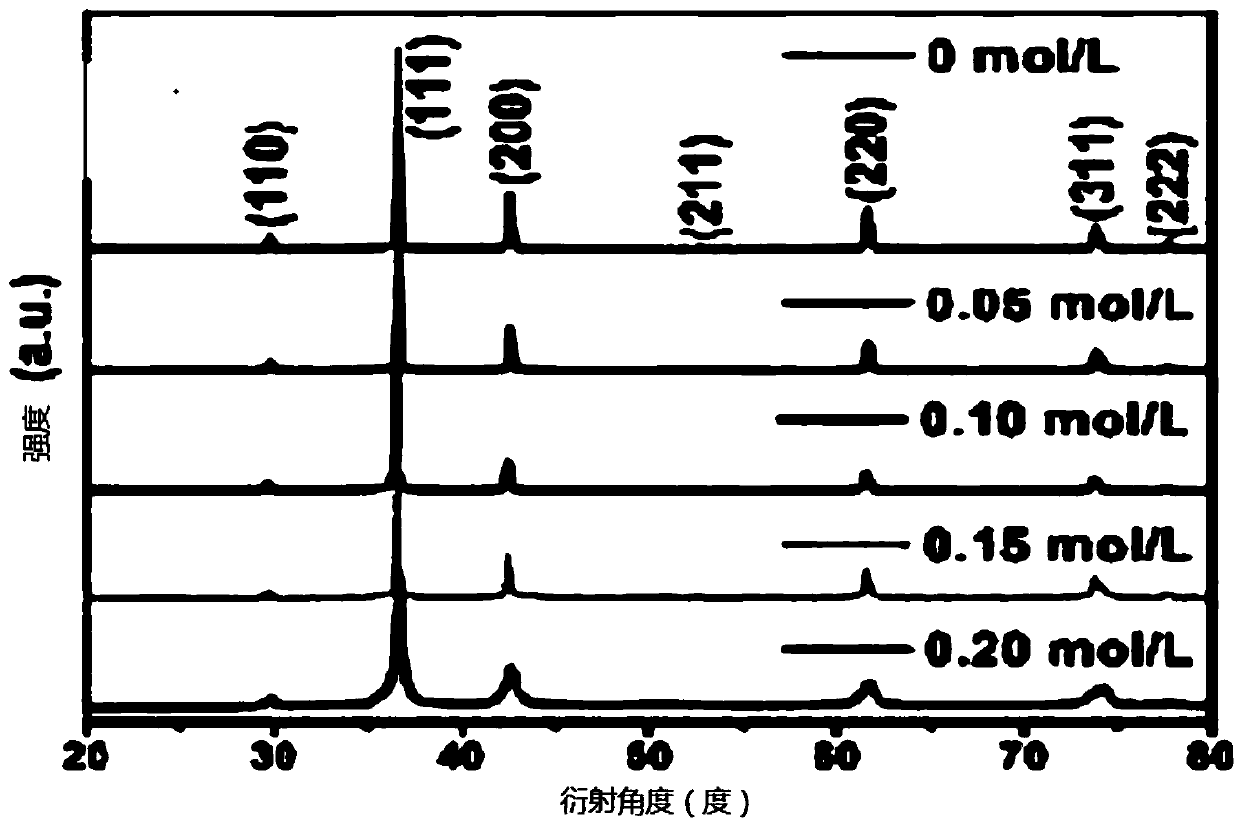

InactiveCN106698498BImprove photocatalytic performanceThe reaction conditions are mild and environmentally friendlyCopper oxides/halidesMetal/metal-oxides/metal-hydroxide catalystsWater bathsDistilled water

The invention provides a method for preparing a nanometer cuprous oxide catalyst, which includes the following steps: S1. Dissolve the copper source in distilled water, and then add a strong alkaline solution thereto to obtain copper hydroxide precipitation; S2. In the prepared Add glucose to the copper hydroxide precipitation; S3. Add [Emim]Br (1-ethyl-3-methylimidazole bromide) to the mixture obtained in step S2; S4. Add the mixture obtained in step S3 under water bath conditions. The mixture is incubated to obtain cuprous oxide; S5, clean the prepared pure cuprous oxide nanoparticles, and then vacuum-dry the cuprous oxide nanoparticles. The preparation method of nanometer cuprous oxide catalyst provided by the invention has mild reaction conditions and is environmentally friendly, and the cuprous oxide prepared by the method of the invention has different morphologies and good photocatalytic performance.

Owner:SHENYANG NORMAL UNIV

Doped copper-II-hydroxide phosphate, method for producing same and use thereof

ActiveUS10023465B2Easy to processWide wavelength rangeLayered productsHeat-exchange elementsMisch metalMain group element

A mixed-metallic phosphate compound is disclosed, which contains as the main metal copper in the divalent oxidation state in a proportion of at least 90.0 at-% and one or more doping metals in a total proportion of the doping metals of at least 0.01 to at most 10.0 at-%, wherein the doping metals are selected from the group consisting of the elements of the first and second main groups and the eighth subgroup of the elements of the periodic table, Al, Sn, Si, Bi, Cr, Mo, Mn, and the lanthanides. The stated metal proportions relate to the total amount of the metals in the mixed-metallic phosphate compound. The mixed-metallic compound has a phosphate content expressed as P2O5 in the range of 10 to 60 wt-%. Also disclosed is a method for producing the mixed-metallic phosphate compound and the use thereof.

Owner:CHEM FAB BUDENHEIM AG

Bactericide specially for preventing and treating diseases of tobacco in middle and later stage and its prepn

The special-purpose fungicide for controlling several diseases in middle and later stage of tobacco plant growth is made up by using cupric hydroxide, Saikuzuo, Carboxymethyl cellulose, petroleum sodium carbonate, propanetriol, diatomite, isopropanol and chaku as raw material through a certain preparation process. Its finished product is a 55% wettable powder which can be used for curing wildfine, rust, angular leaf spot, powdery mildew, anthracnose and white rust, etc. Its preparation process is simple, does not produce waste water, waste residue and waste gas, and features low cost, broad spectrum, high efficiency and low-toxicity.

Owner:赵国晶

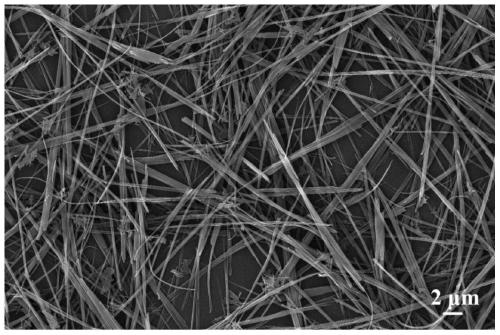

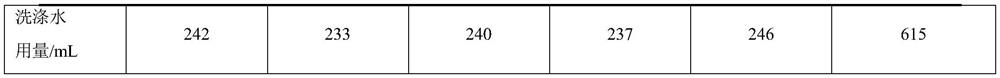

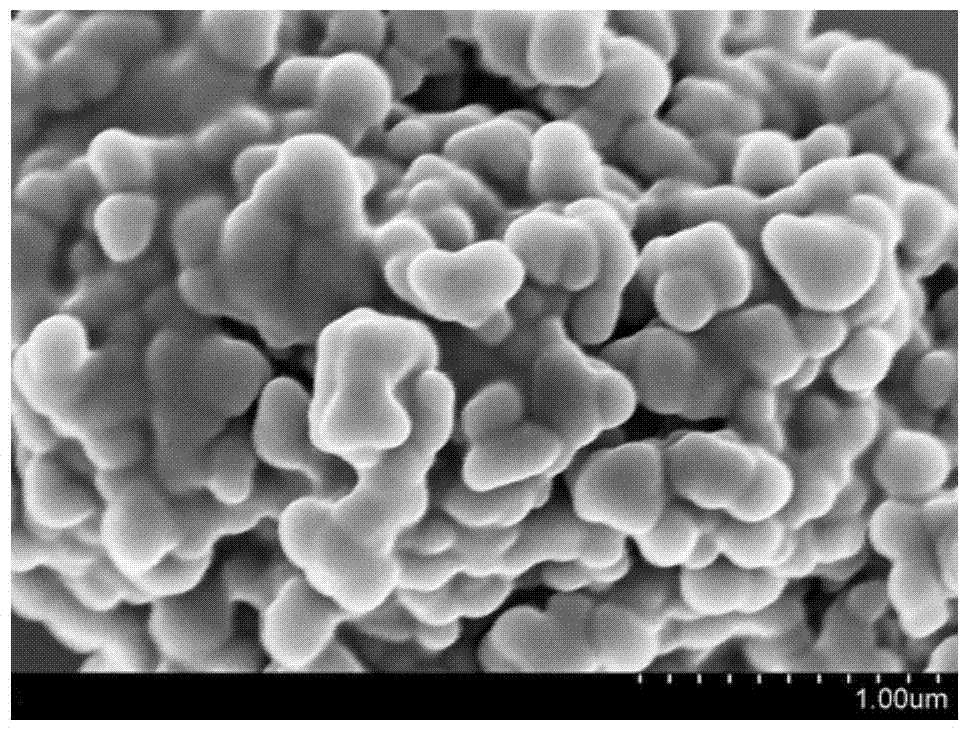

A kind of method that prepares nano copper hydroxide by acid copper chloride etching waste liquid

ActiveCN111333099BReduce consumptionReduce the risk of contaminationNanotechnologyCopper oxides/halidesPhysical chemistryChloride potassium

The invention discloses a method for preparing nano-copper hydroxide from acidic copper chloride etching waste liquid. Adding auxiliary agent and water to an appropriate amount of acidic copper chloride etching waste liquid, mixing evenly and adding a precipitant to adjust the pH value of the solution Then stir and react and age, filter and wash the filter cake with water until there is no chloride ion, dry the filter cake to constant weight to obtain the product nano-copper hydroxide; adjust the pH of the filtrate to neutral with concentrated hydrochloric acid, evaporate, crystallize, and dry To constant weight to obtain by-product sodium chloride or potassium chloride. The invention uses acidic copper chloride etching waste liquid as raw material and adopts a simple process to obtain the product with a purity greater than 99.0%, a chloride content (Cl)≤400ppm, a fibrous appearance and an average diameter of 40-100nm in one step. , Nano-copper hydroxide products with an average length between 1 and 2.5 μm. The recovery rate of copper in the method of the invention can reach more than 99.9%.

Owner:HEFEI UNIV OF TECH +1

A kind of preparation method of copper/cuprous oxide/cyclized polyacrylonitrile visible light catalyst

InactiveCN105126917BSmall particle sizeEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAcrylonitrile

The invention discloses a preparation method of a copper / cuprous oxide / cyclized polyacrylonitrile visible light catalyst, and belongs to the technical field of new photocatalyst materials for environmental purification. It uses polyacrylonitrile, copper nitrate and sodium hydroxide as raw materials, and prepares nano-copper hydroxide / polyacrylonitrile composites through solvent conversion and in-situ ion exchange reactions simultaneously, and then uses ascorbic acid to reduce copper hydroxide in situ to Cuprous oxide, and then heat-treated under a nitrogen atmosphere, a small amount of cuprous oxide is reduced to simple copper while polyacrylonitrile undergoes cyclization and dehydrogenation to form a conjugated structure, and copper / cuprous oxide / cyclized polyacrylonitrile visible light catalyst. The invention has wide sources of raw materials, low cost, simple preparation method, and is suitable for large-scale production. The cyclized polyacrylonitrile can not only improve the separation efficiency of photogenerated electron holes and the absorption in the visible light region, but also protect copper / cuprous oxide. , Reduce photocorrosion, the obtained catalyst has remarkable adsorption and photocatalytic effects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com