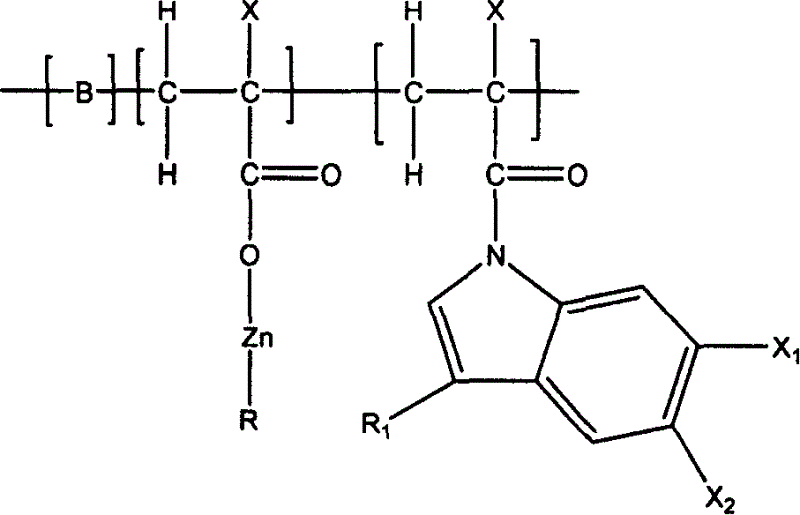

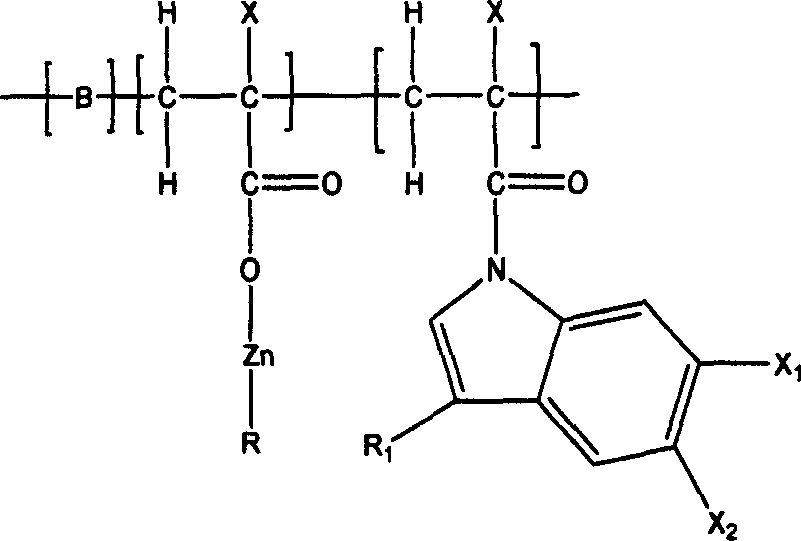

Resin of zinc acrylate or copper acrylate containing indole function group, its preparation and use

An acrylic resin, indole functional technology, applied in the application field of preparing marine antifouling coatings, can solve problems such as environmental pollution, toxicity, impact on human health, etc., and achieve good antifouling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] 1. Preparation of 1-acryloyl indole monomer

[0011] Put 50mL of freshly steamed tetrahydrofuran, 3.5g of 1-hydroindole, and 3.9g of sodium cyanide into a three-neck flask successively, and react at room temperature for 30 minutes to obtain indole sodium salt. Dissolve 3.3 g of acryloyl chloride in 10 mL of tetrahydrofuran, drop it into the indole sodium salt prepared above, control the reaction temperature at 0° C., and react for 2.5 hours to obtain 1-acryloyl indole monomer.

[0012] Replace the above-mentioned 1-hydroindole with haloindole, 1-hydrohydrophylline or halocarpine, and follow the above-mentioned preparation method to obtain 1-acryloyl haloindole, 1-acryloyl Alkaline or 1-acryloylhalocarpine monomer.

[0013] 2. Preparation of acrylic resin containing indole functional groups and carboxyl groups

[0014] Add toluene and n-butanol in a three-necked flask equipped with a stirring device, a condenser, and a thermometer. Their weight ratio is 262g of a mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com