Patents

Literature

4109 results about "Cyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cyanide is a chemical compound that contains the group C≡N. This group, known as the cyano group, consists of a carbon atom triple-bonded to a nitrogen atom. In inorganic cyanides, the cyanide group is present as the anion CN⁻. Salts such as sodium cyanide and potassium cyanide are highly toxic. Hydrocyanic acid, also known as hydrogen cyanide, or HCN, is a highly volatile liquid that is produced on a large scale industrially. It is obtained by acidification of cyanide salts.

Process for preparing alpha -hydroxy acids using microorganism and novel microorganism

PCT No. PCT / JP97 / 00578 Sec. 371 Date Aug. 11, 1998 Sec. 102(e) Date Aug. 11, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 32030 PCT Pub. Date Sep. 4, 1997A process for preparing alpha -hydroxy acids represented by the general formula (II): RCH(OH)COOH (wherein R represents a hydrogen atom, an optionally substituted C1-C6 alkyl group, an optionally substituted C2-C6 alkenyl group, an optionally substituted C1-C6 alkoxy group, an optionally substituted aryl group, an optionally substituted aryloxy group, or an optionally substituted heterocyclic group) by allowing a microorganism to act on alpha -hydroxy nitriles (I): RCH(OH)CN (wherein R is as defined above) to hydrolyze and convert the alpha -hydroxy nitrites to alpha -hydroxy acids (II), wherein the alpha -hydroxy acids (II) are produced and accumulated in an aqueous solvent by a microorganism having the concentration resistance to the alpha -hydroxy nitrites (I) and / or alpha -hydroxy acids (II) and durability preferably in the presence of a cyanide, and harvested. According to this process, the use of the microorganism having the concentration resistance to the alpha -hydroxy nitriles (I) and / or alpha -hydroxy acids (II) and durability high enough to permit the activity to persist for a long period of time enables alpha -hydroxy acids (II) to be accumulated in high concentrations and cell bodies to be repeatedly used, and hence enables alpha -hydroxy acids (II) to be efficiently prepared. The addition of a cyanide to the reaction system results in more efficient preparation of alpha -hydroxy acids (II).

Owner:NIPPON SODA CO LTD

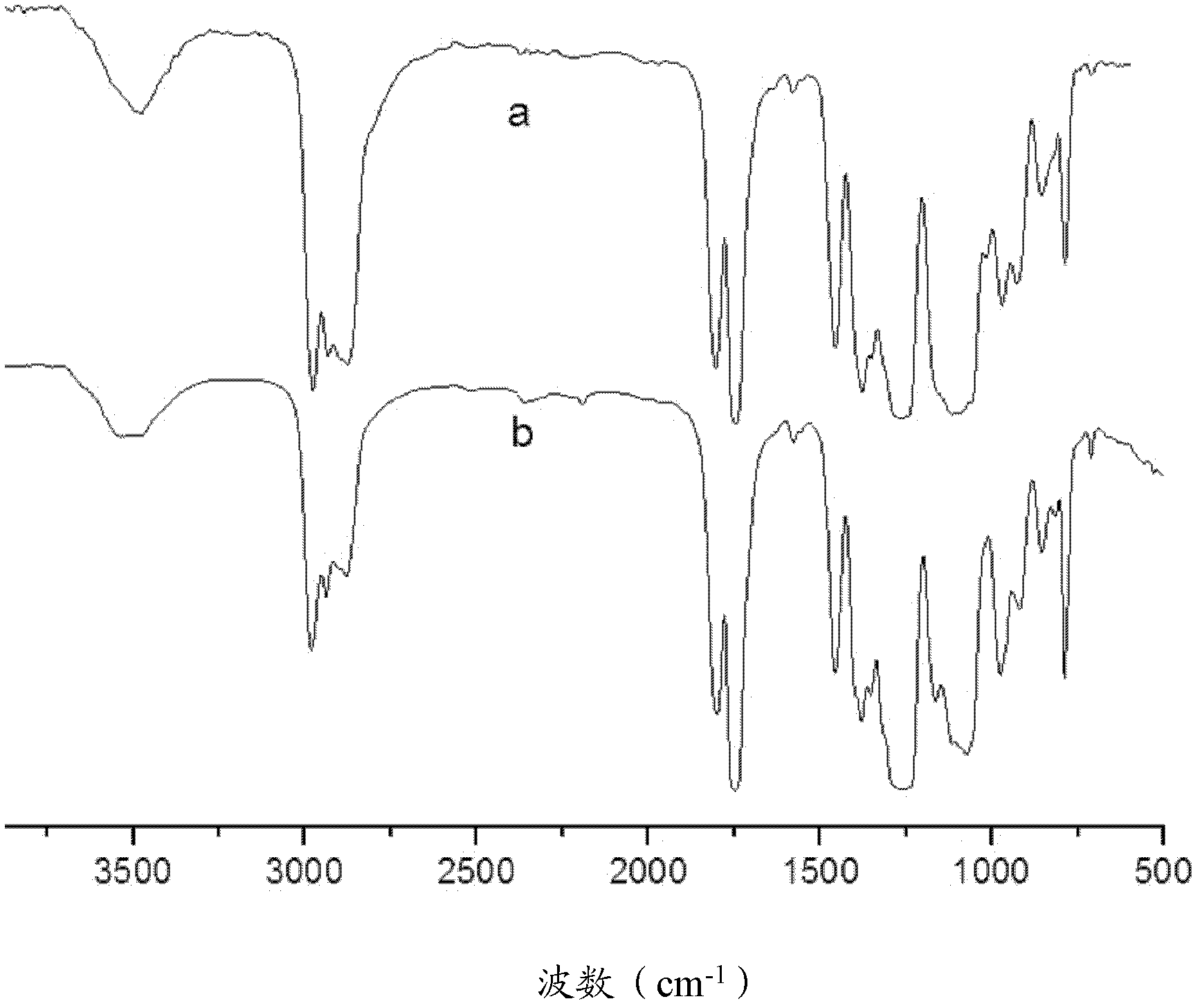

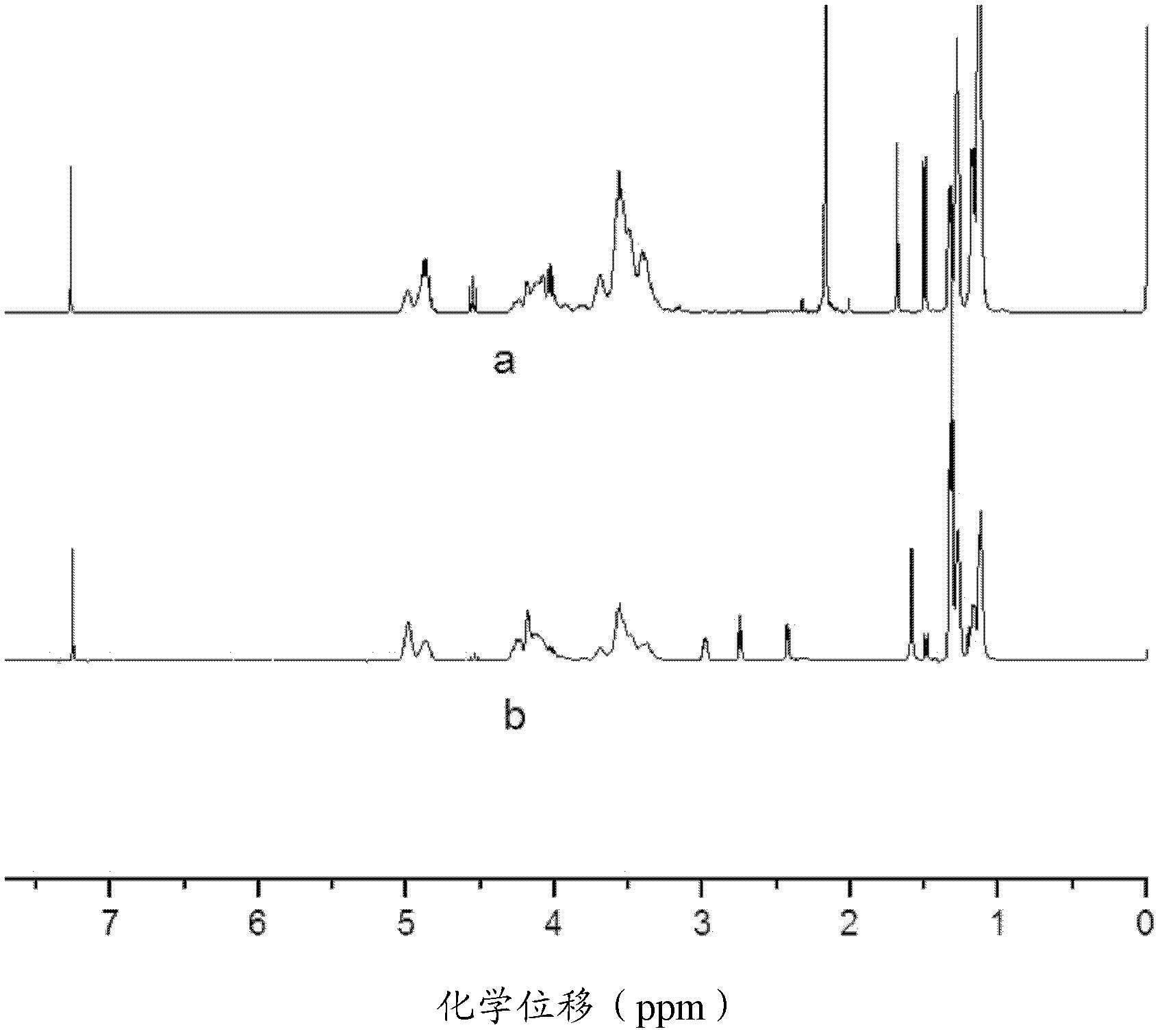

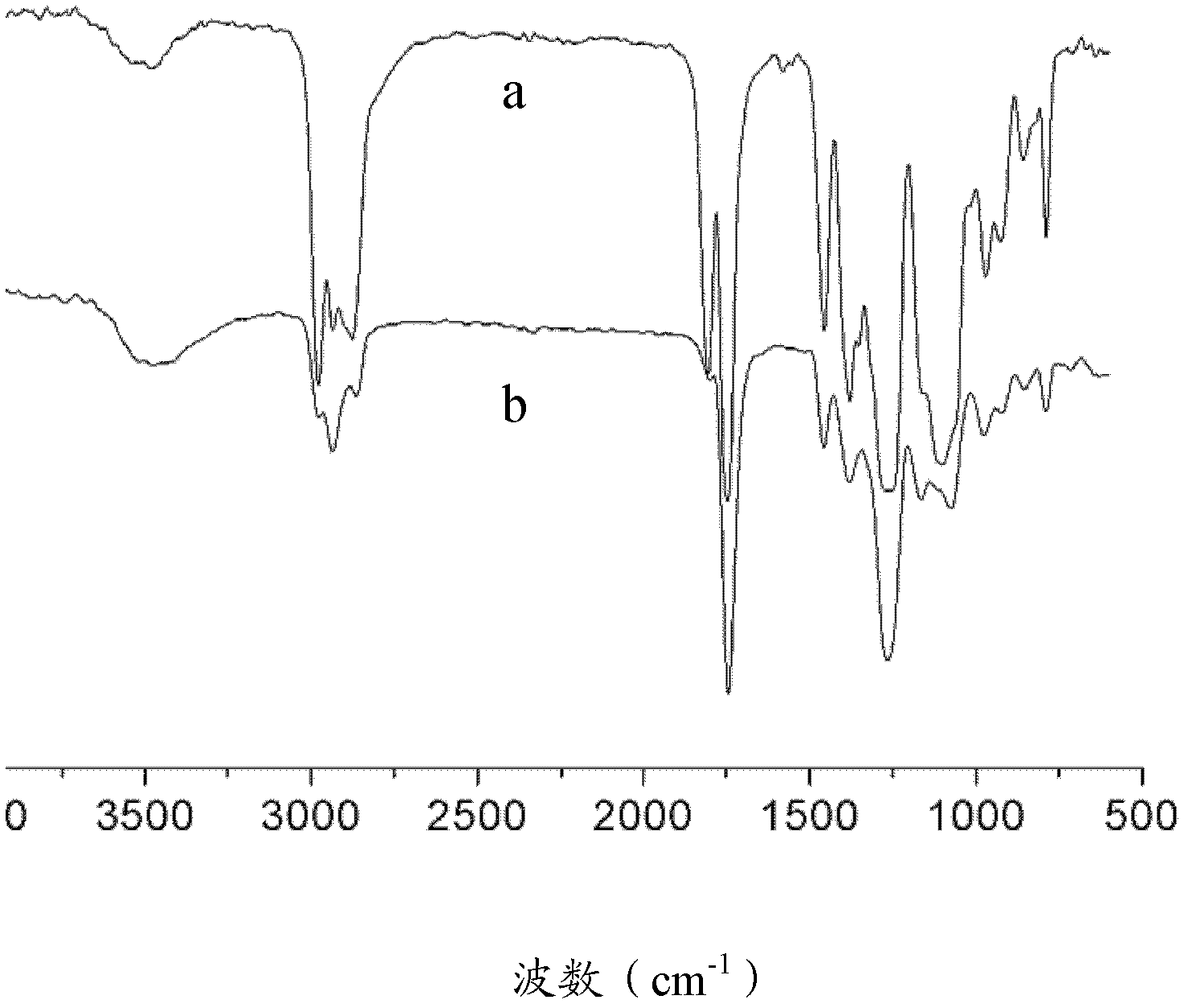

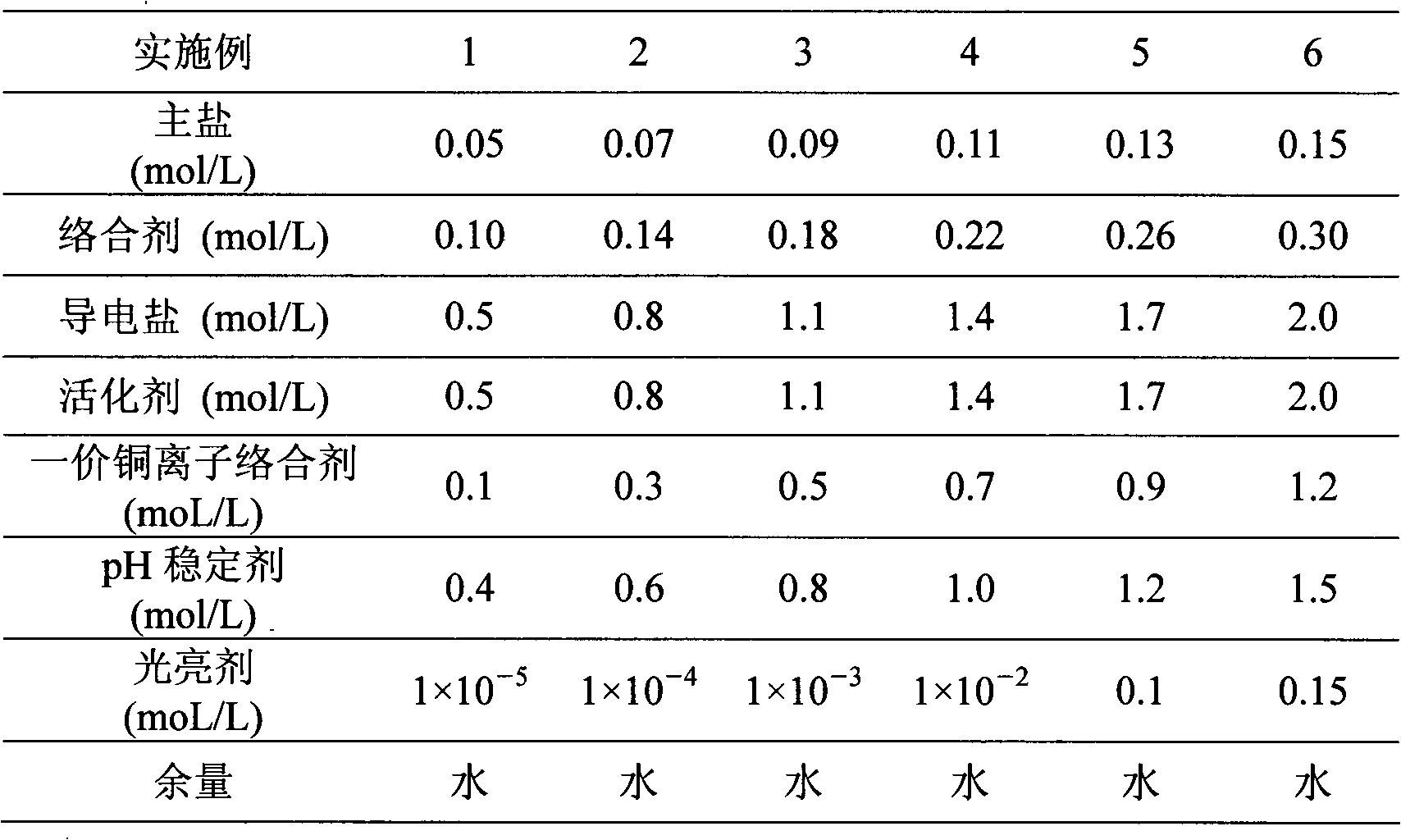

Preparation method of poly(carbonic ester-ether) glycol and preparation method of catalyst thereof

The invention discloses a preparation method of rare earth-doped double metal cyanide catalyst and a method for preparing low molecular weight poly (carbonic ester-ether) glycol by using the catalyst to catalyze the copolymerization of carbon dioxide and epoxy compounds. The preparation method of poly (carbonic ester-ether) glycol comprises the following steps: using rare earth-doped double metalcyanide based on Zn3[Co(CN)6]2 as a catalyst, and letting carbon dioxide and epoxy compounds be subject to polymerization in the presence of chain transferring agent to obtain the poly(carbonic ester-ether) glycol. According to the invention, compared with the prior art, the rare earth-doped double metal cyanide based on Zn3[Co(CN)6]2 used herein efficiently catalyzes the copolymerization of carbon dioxide and epoxy compounds under the effect of chain transferring agent; and compared with double metal cyanide without doping, the rare earth-doped double metal cyanide based on Zn3[Co(CN)6]2 used herein has higher catalytic activity and better product selectivity.

Owner:南通华盛高聚物科技股份有限公司

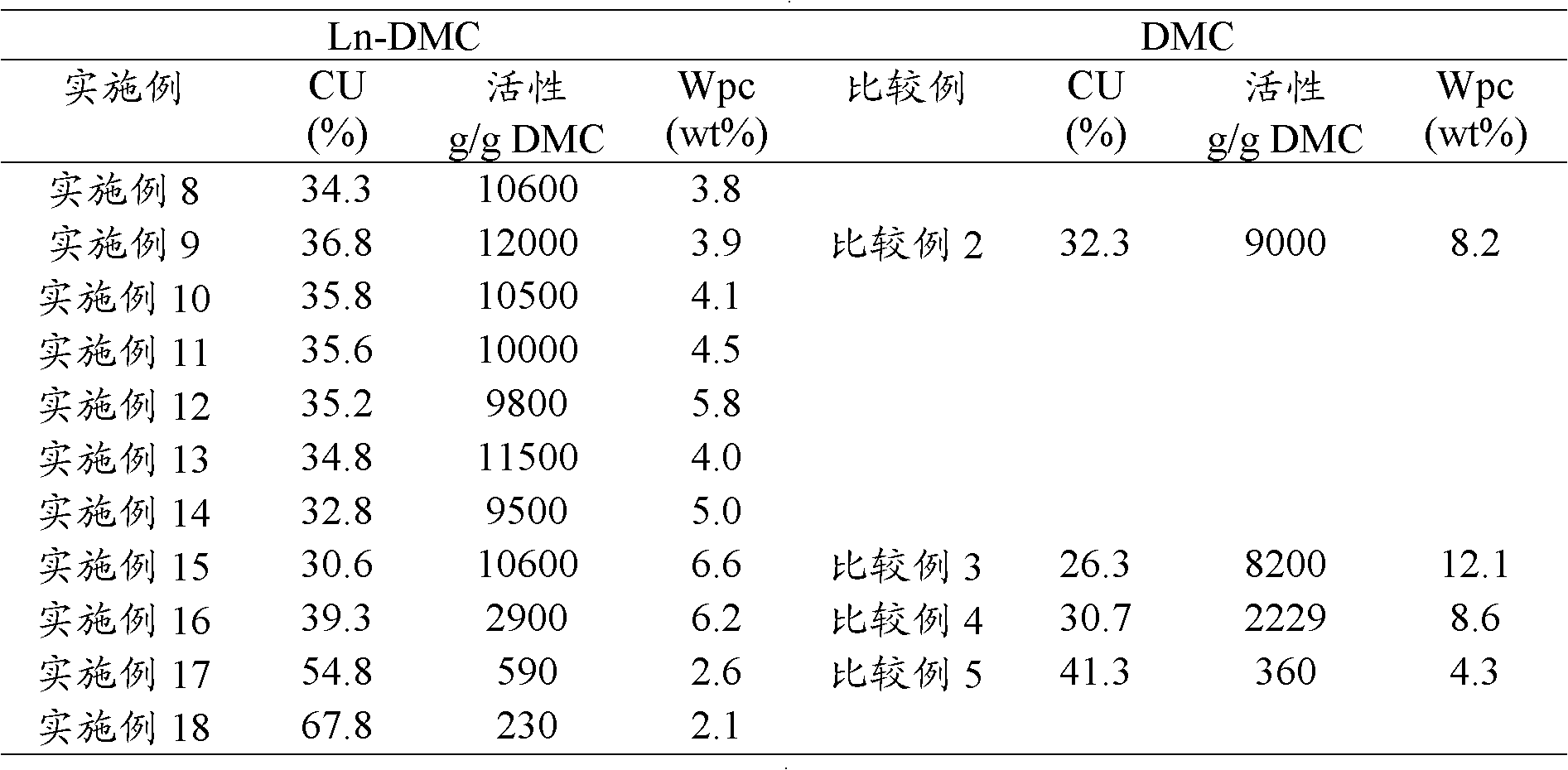

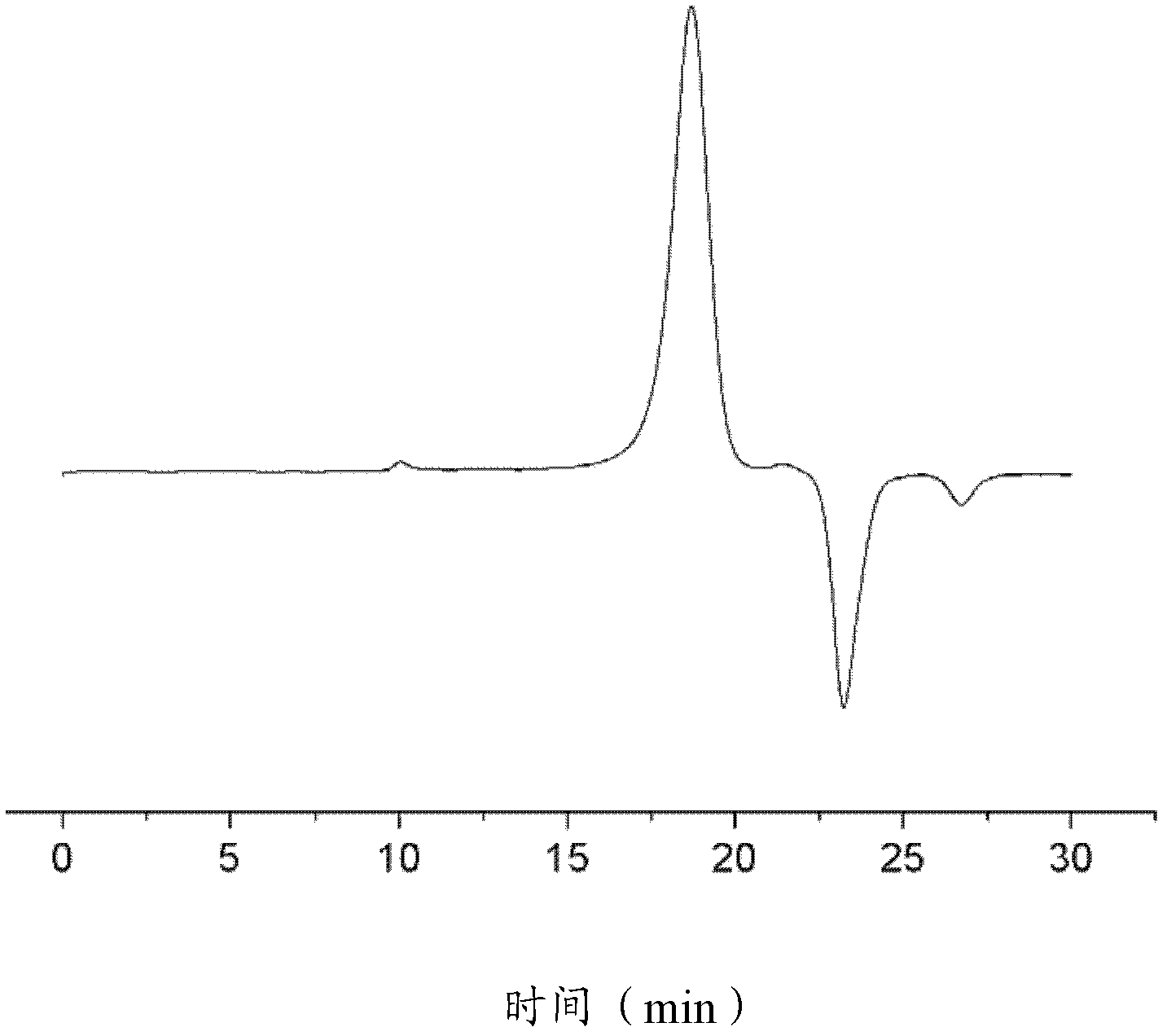

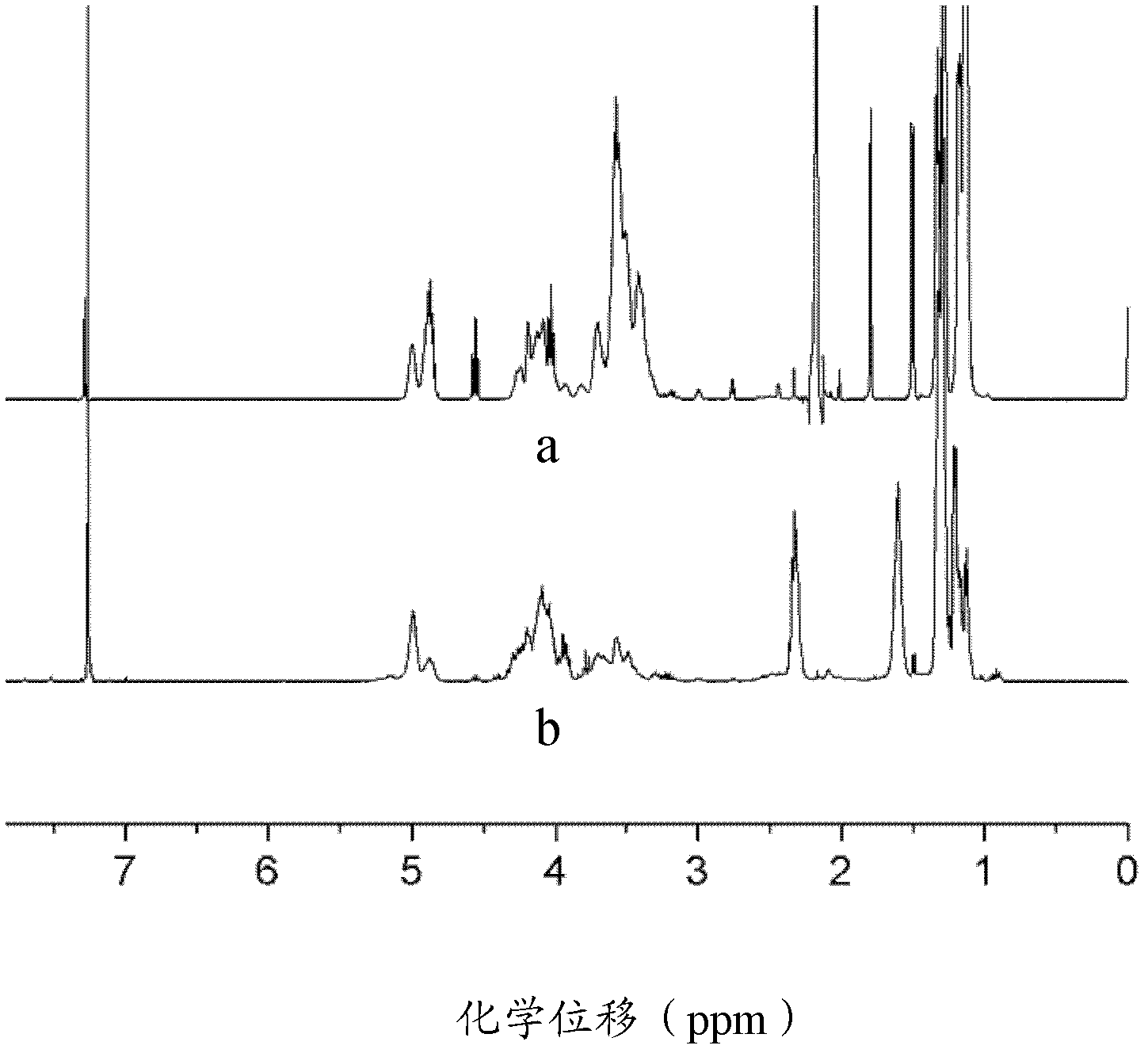

Preparing method of poly (carbonic ester-ether) polyalcohol

ActiveCN102617844AIncreased content of carbonate unitsSuppression of continuous insertionCyanidePolyol

The invention discloses a preparing method of poly (carbonic ester-ether) polyalcohol. Rare-earth doped bi-metal cyanides based on Zn3[Co(CN)6]2 serve as catalysts, carboxylic acids serve as chain transfer agents, and carbon dioxide and epoxy compounds are performed with a copolymerization reaction to obtain the poly (carbonic ester-ether) polyalcohol. Compared with the prior art, the carboxylic acids serve as chain transfer agents, and due to the fact that the carboxylic acids are strong in coordination capability, faster in chain transfer, capable of restraining continuous inserting of epoxy monomers and free of ether structure, unit content of carbonic ester is improved, and the prepared poly (carbonic ester-ether) polyalcohol has higher carbonic ester unit content. Experimental results indicate that molecular weight of the prepared poly (carbonic ester-ether) polyalcohol is 1500g / mol-5000g / mol, molecular weight distribution is 1.11-1.50, unit content of the carbonic ester is 40%-80%, catalytic activity is larger than 1.0kg / gLn-DMC, and cyclic carbonic ester content is less than 10wt%.

Owner:南通华盛高聚物科技股份有限公司

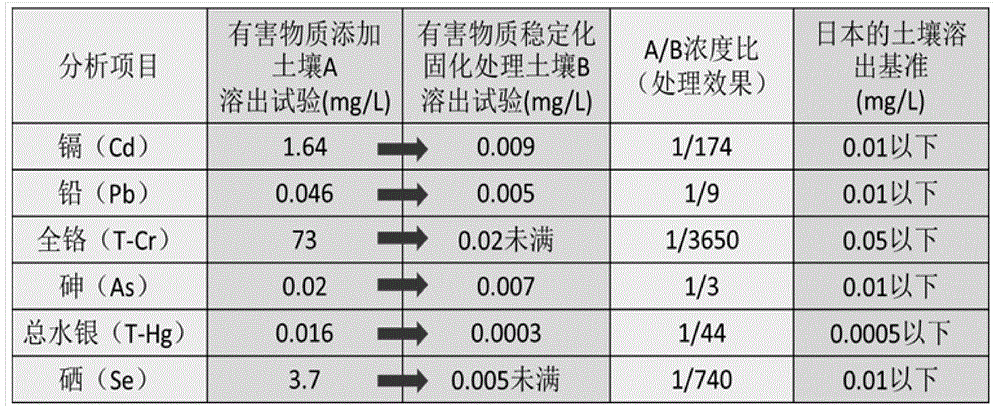

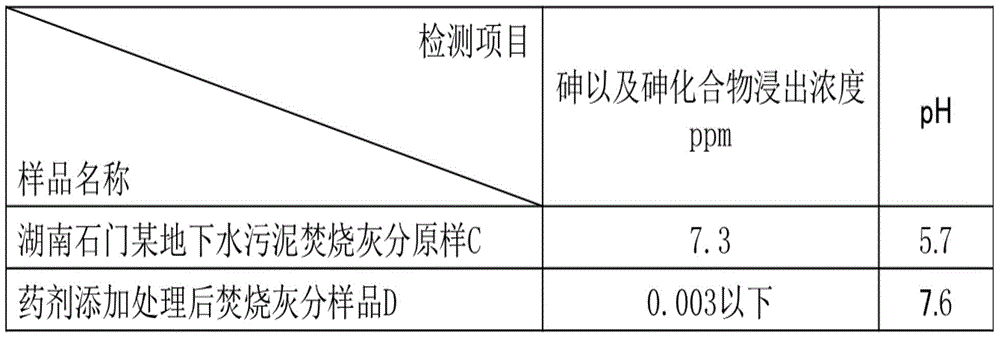

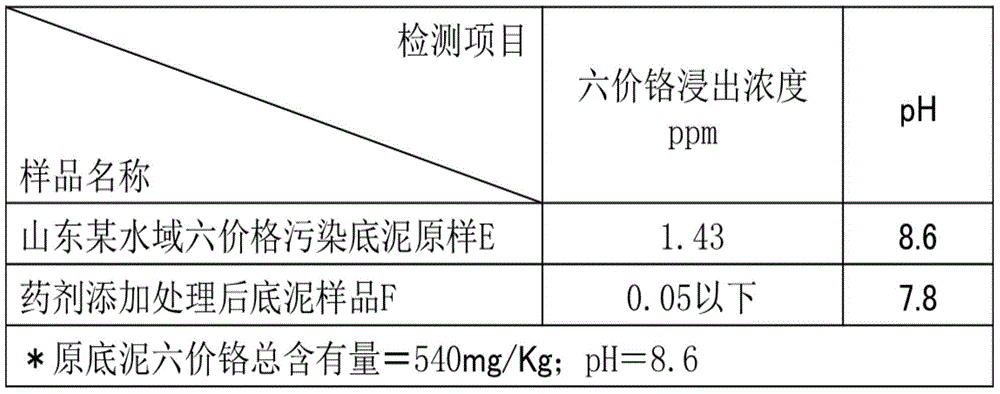

Stabilized curing agent for heavy metal contaminated soil or solid waste treatment and treatment method

ActiveCN104312591AAchieve adsorptionRealize functionContaminated soil reclamationBuilding constructionsTreatment effectDissolution

The invention discloses a stabilized curing agent for heavy metal contaminated soil or solid waste treatment and a treatment method. The stabilized curing agent comprises the following components in parts by weight: 5 to 10 parts of a magnesium-based compound, 1 to 5 parts of a sulfur-based compound and 1 to 3 parts of an activated silicon-based compound. The treatment method comprises the following steps of sampling inspection, experimental determination of adding proportion, mixing, backfill maintenance, sealing up for safekeeping and the like. The stabilized curing agent disclosed by the invention has an efficient long-term stabilizing effect on various heavy metals such as arsenic, mercury, hexavalent chromium, lead, cadmium, nickel, tin and cyanide, the repeated acid and alkali leaching experiments prove that the stabilized and cured harmful heavy metals cannot be dissolved out again, and the defects that in the traditional technology, the treatment effect and treatment agents are greatly affected by the environment, the long-term efficacy of harmless stabilization is poor, the medicament adding amount is difficult to control and the re-dissolution of harmful heavy metals is easily caused by the high alkalinity of cement solidification and the like are overcome.

Owner:GUIZHOU MEIRUITE ENVIRONMENTAL PROTECTION TECH

Preparation of a double metal cyanide catalyst

InactiveUS6977236B2High activityIncrease the molar ratioOrganic chemistryOrganic compound preparationSaline waterPolyol

The present invention relates to a process for the preparation of a double metal cyanide (DMC) catalyst, which process involves:(a) combining an aqueous solution of metal salt with an aqueous solution of a metal cyanide salt and reacting these solutions; and(b) recovering the DMC catalyst from the reaction mixture,in which process the DMC catalyst is prepared in the presence of from 0.03 to 0.4 mole of alkaline metal compound, based on amount of metal salt. Further, the present invention relates to DMC catalyst obtainable by such process, to DMC catalyst prepared from a metal salt and a metal cyanide salt in which the molar ratio of metal derived from the metal salt to metal derived from the metal cyanide salt is at least 2.25 and to a process for polymerization of alkylene oxides which process involves reacting initiator with alkylene oxide in the presence of at most 15 ppm of DMC catalyst. It also relates to a process for the polymerization of alkylene oxides in which the resulting polyol contains less than 60 ppm of ultra-high molecular weight compounds.

Owner:SHELL USA INC

Cyanide-free pyrophosphoric acid bath for use in copper-tin alloy plating

InactiveUS6416571B1Changeable colorEasy to separateAnti-corrosive paintsLiquid/solution decomposition chemical coatingAlloyAmine derivatives

The present invention provides a pyrophosphoric acid bath for use in Cu-Sn alloy plating without containing a cyanic ion comprising a reaction product (A) of an amine derivative and an epihalohydrin in a 1:1 mole ratio and a cationic surfactant (B) and, when necessary, further comprising a surface tension adjusting agent (C), a bath stabilizer (D) and an N-benzylpyridinium derivative (E) as additives. According to the bath of the present invention, by changing a bath composition of copper and tin or by employing a characteristic additive, a stable film with a silver-white, gold, copper or light black color can be obtained. By increasing tin contents in the bath, the bath can be used for lead-free solder plating. The bath is safe in handling and hygienic and, moreover, has no sewage process and environmental problems since it contains neither cyanic compound nor formaldehyde derivative.

Owner:NIHON NEW CHROME

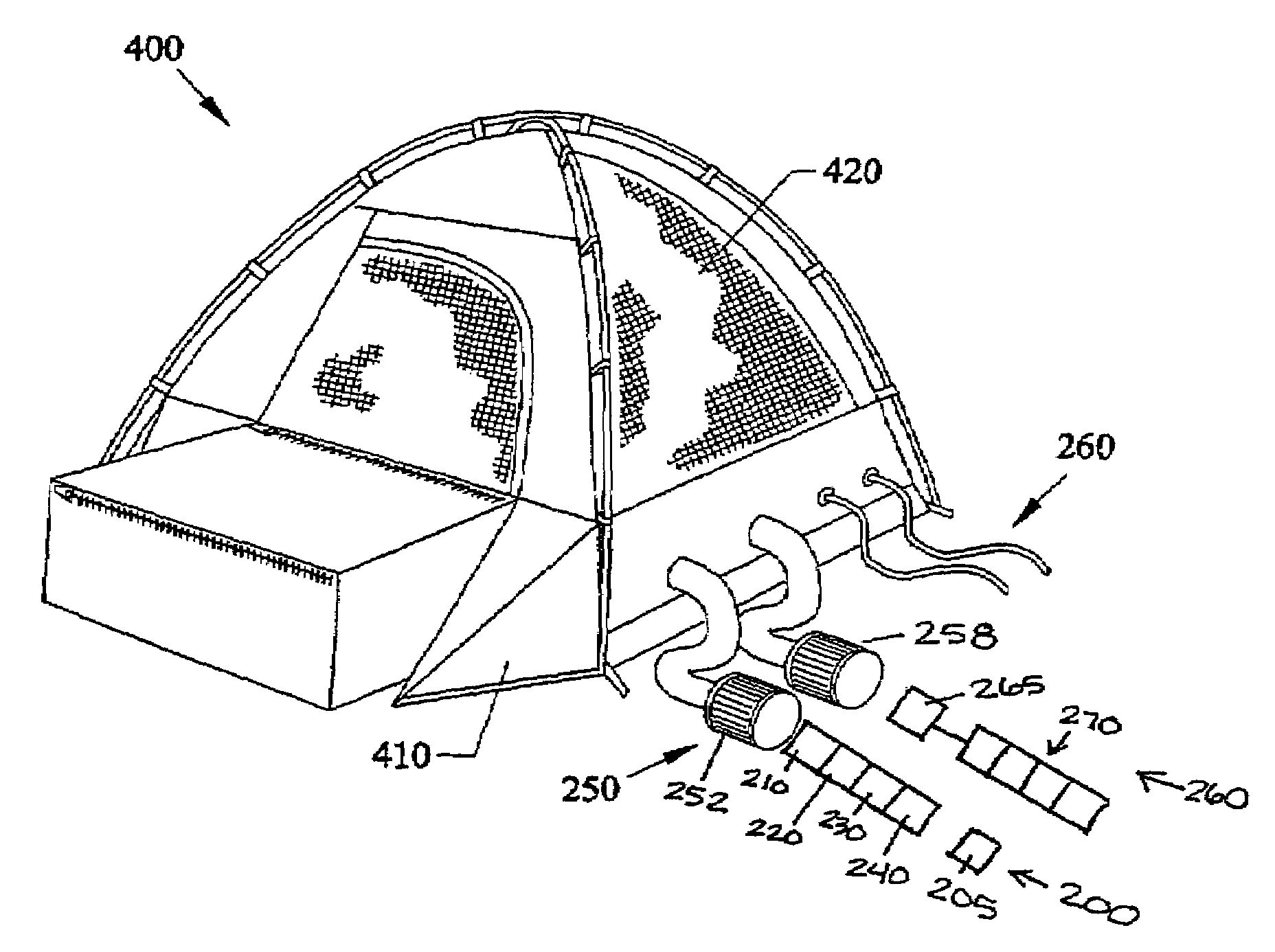

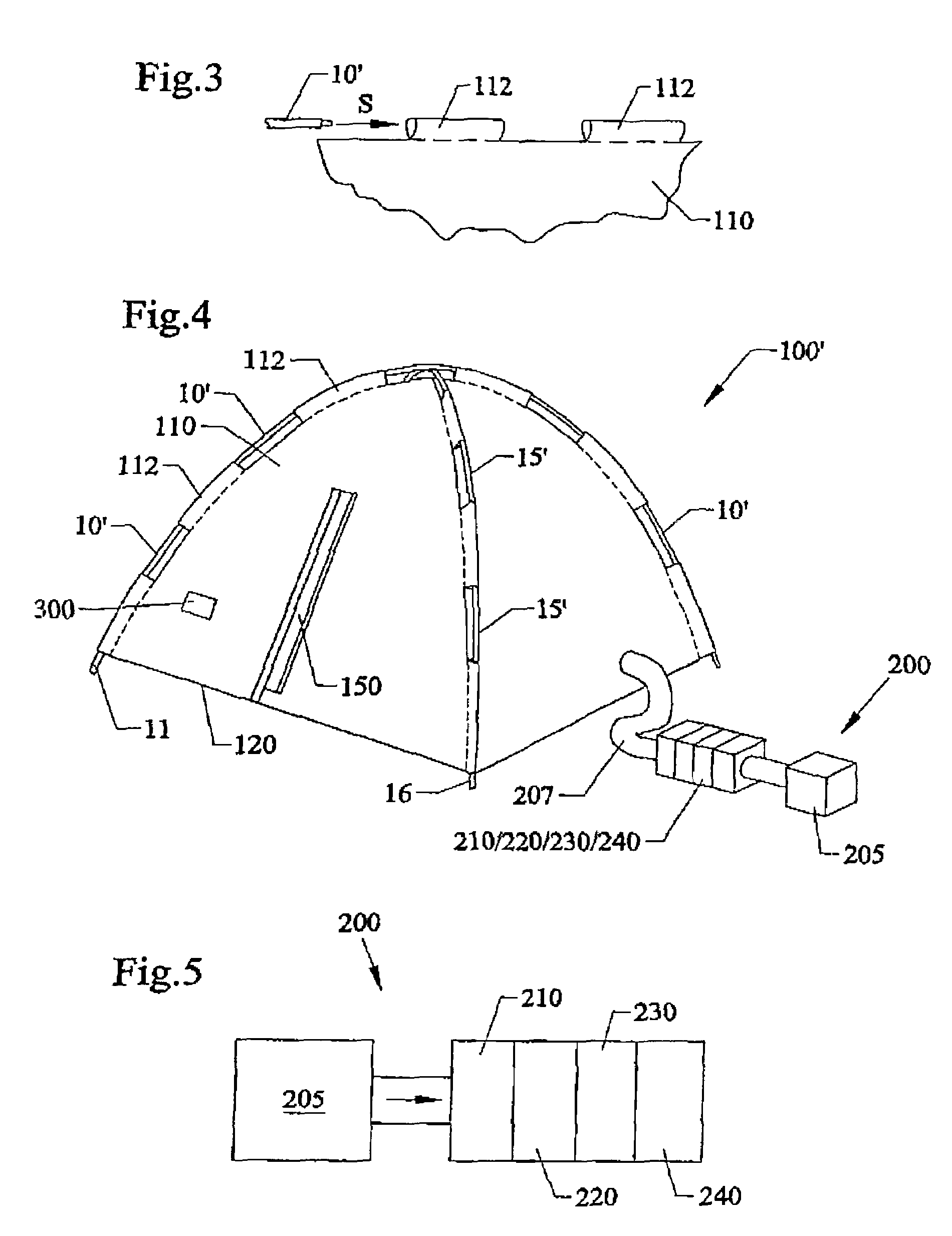

Bio-hazard attack family survival dome

A family protective shelter which can be erected quickly inside in a home living room, family room, patio, or on an outside lawn area. This dome tent enclosure is designed of clear plastic sheet material which is impervious to gases used to conduct chemical warfare (such as nerve gas, mustard gas, serin, cyanide, and the like) dispersed biohazard aerosol compounds (such as anthrax, smallpox, polio, bacteria, viruses, or fungi), or other atmospheric toxins, such as those from a nuclear fallout. This protective “pop-up”, external frame enclosure will be sized to house at least two adults comfortably (6×9×7 high inside, up to about 10×18′×7′ high), will incorporate a zip-lock entrance / egress isolation portal chamber, and will communicate to the outside world through combat gas mask filters, plus phone, computer and electrical outlet feed-through, and perhaps a water trap coupling. The invention can keep a family of 1 to 10 (with a larger size) relatively isolated and safe from the harmful effects of a chemical biohazard, or nuclear fallout enemy attack for a matter of hours up to several days. The portal chamber can also connect together additional modules.

Owner:BIODOME GRP

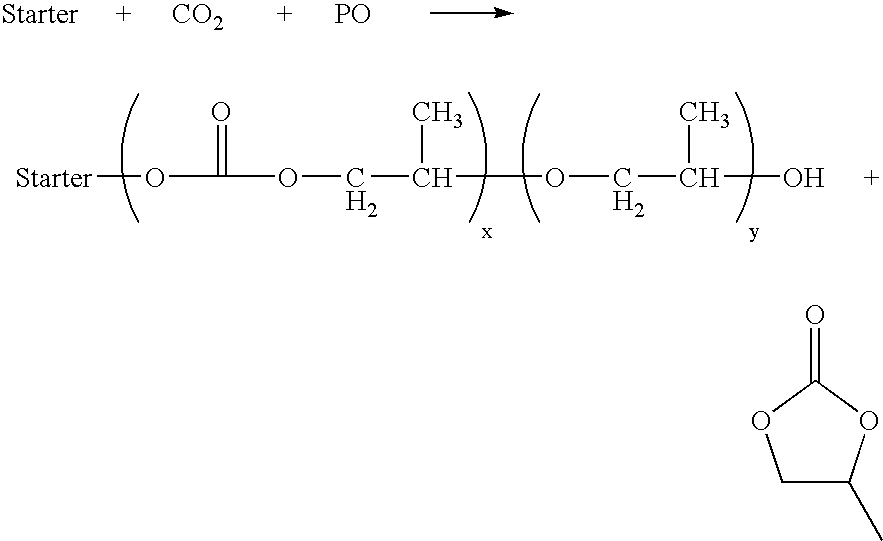

Alkaline non-cyanide plating solution for copper-plating used on iron and steel base and preparation method thereof

An alkaline non-cyanide plating solution for copper-plating used on iron and steel base and a preparation method thereof relate to a kind of plating solution. The invention provides the alkaline non-cyanide plating solution for copper-plating used on iron and steel base and the preparation method thereof. The plating solution comprises the following components: main salt, complexing agent, conductive salt, activator, cuprous ion complexing agent, pH stabilizer and brightening agent. The method comprises the following steps: adding complexing agent in water, stirring to dissolve complexing agent, obtaining a solution A; adding main salt in the solution A, stirring to dissolve main salt, obtaining a solution B; adding conductive salt in water, stirring to dissolve conductive salt, obtaininga solution C; mixing the solution B and solution C, adjusting the pH value to 2.0-4.5 with sulfuric acid or sodium hydroxide, obtaining a solution D; adding additive in the solution D, adding water toperform constant volume process and obtaining the alkaline non-cyanide plating solution for copper-plating in the desired volume for use, wherein the additive is activator, cuprous ion complexing agent, pH stabilizer and brightening agent.

Owner:XIAMEN UNIV

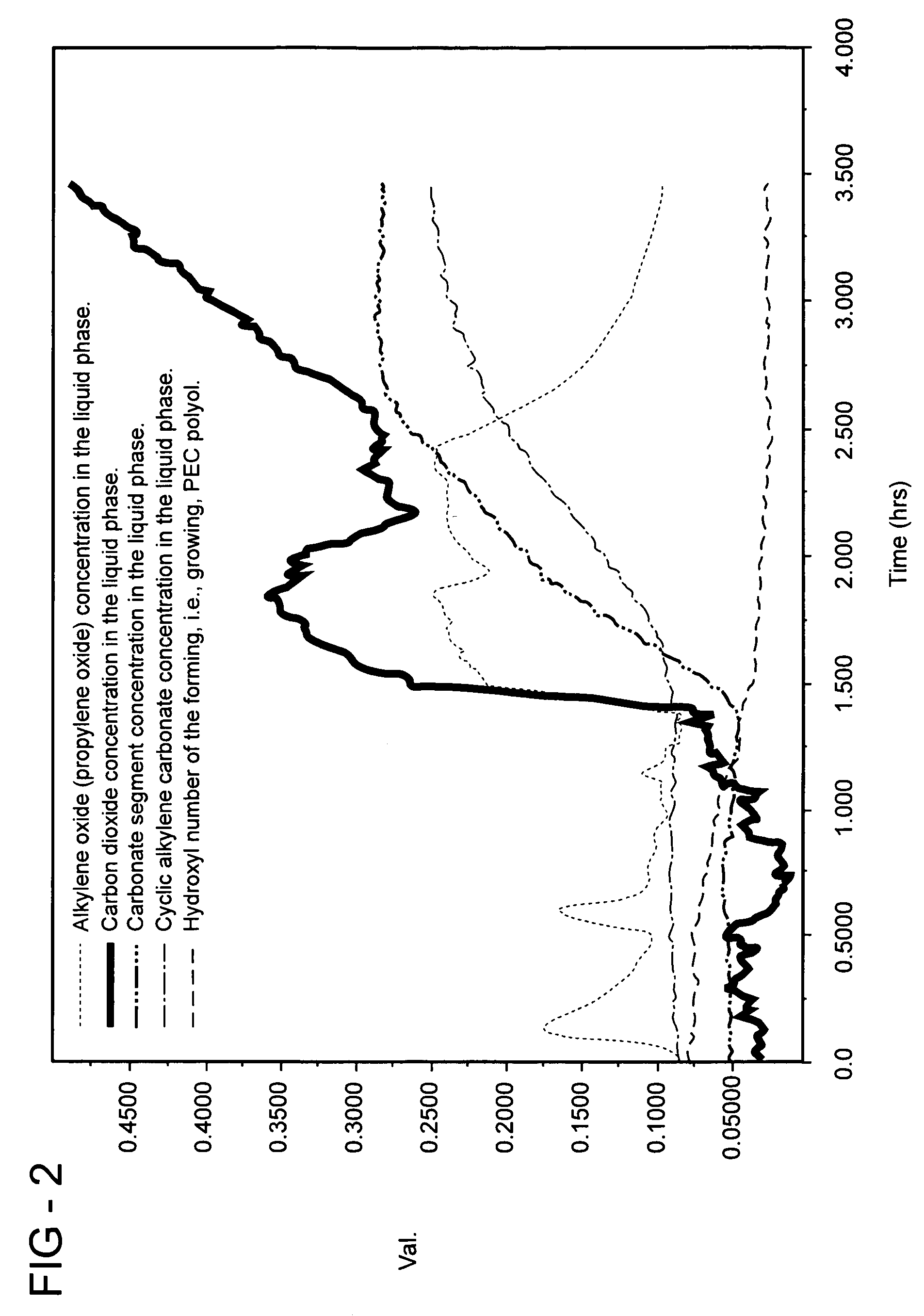

Polyether carbonate polyols made via double metal cyanide (DMC) catalysis

ActiveUS20080021154A1Lower Level RequirementsOrganic chemistryPharmaceutical non-active ingredientsElastomerAdhesive

The present invention relates to a polyether carbonate polyol made by copolymerizing a starter molecule with carbon dioxide, at a pressure ranging from about 10 psia to about 2,000 psia, and an alkylene oxide, at a temperature ranging from about 50° C. to about 190° C. and in the presence of from about 0.001 wt. % to about 0.2 wt. % of a substantially non-crystalline double metal cyanide (DMC) catalyst, wherein the polyol has an incorporated carbon dioxide content of from about 1 wt. % to about 40 wt. %, wherein the ratio of cyclic carbonate by-product to total carbonate is less than about 0.3 and wherein the weight percentages are based on the weight of the polyol. The inventive polyether carbonate polyols may find use in producing polyurethane foams, elastomers, coatings, sealants and adhesives with improved properties.

Owner:COVESTRO LLC

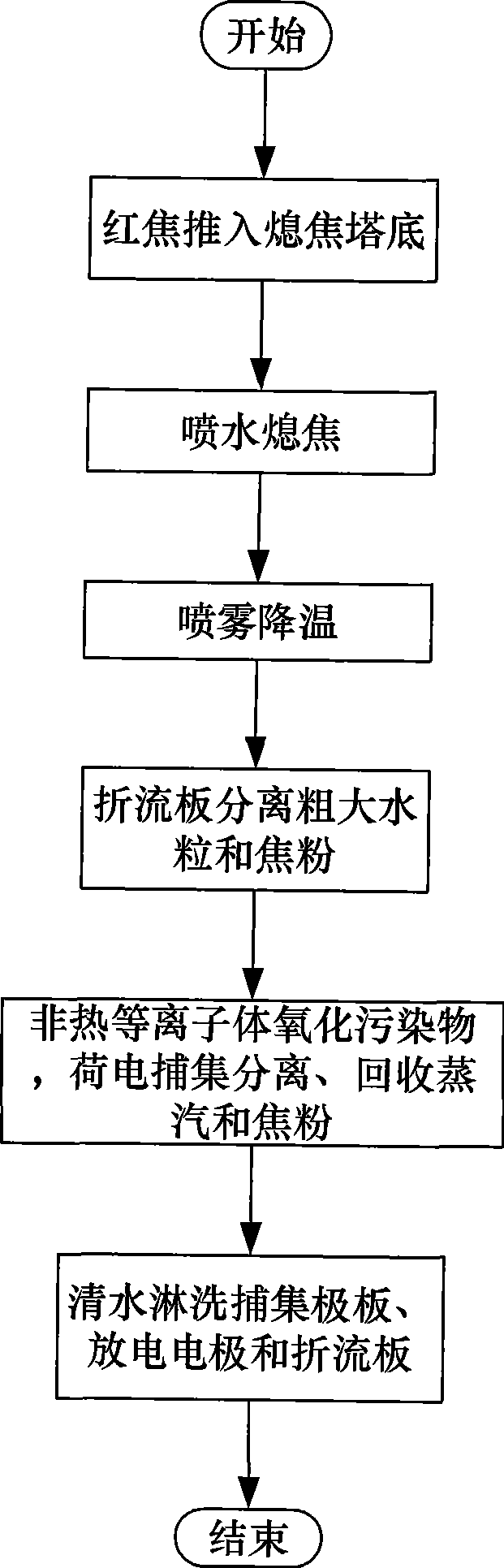

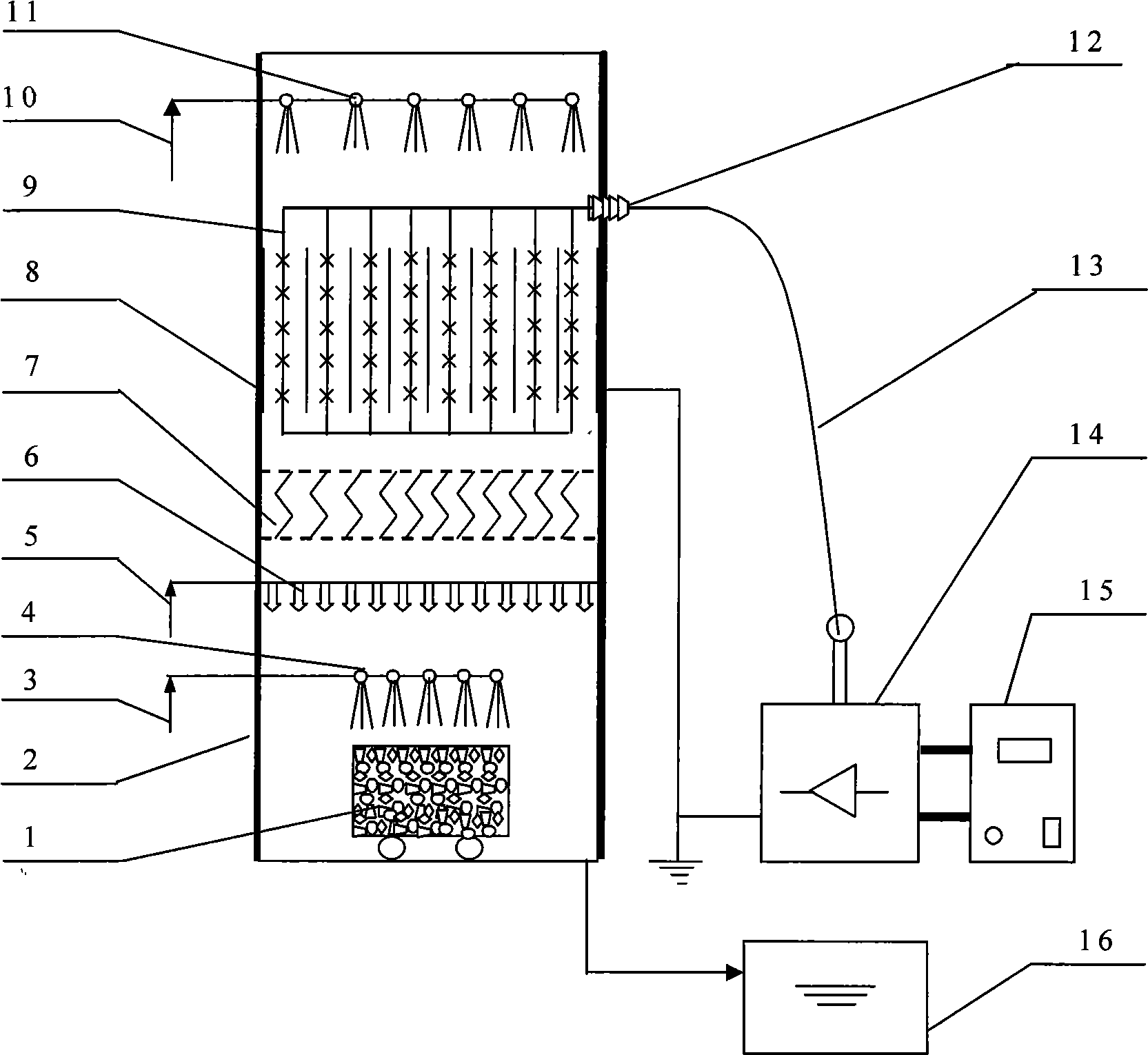

Wet coke-quenching aerial fog processing method and device based on non-thermal plasma injection

InactiveCN101486017AReduce the amount of pollutantsPrevent diverted emissionsCombination devicesCoke quenchingWater vaporHigh pressure

The invention discloses a method and a device for processing wet quenching coke gas fog on the basis of athermal plasma injection. The method comprises the following steps that: in the ascending process, the hot gas fog generated by wet quenching coke sequentially passes through three processing steps including spray cooling, pre-dedusting on a baffle plate and athermal plasma purification, and is cooled in a spray cooling area; the cooled gas fog enters a pre-dedusting area on the baffle plate where the thicker and bigger water particles and coke powder in the gas fog are separated from the gas fog and impact to the baffle plate under the action of inertia; the remaining gas fog continues to ascend and enter an athermal plasma purification area where organic components, ammonia nitrogen and cyanide in the gas fog are oxidized by the athermal plasma; the water particles and the coke powder are charged and are transferred to a trapping pole plate directionally under the action of a high voltage electric field; and then the gas flow after subjected to the athermal plasma purification area continuous to ascend to the top of a coke quenching tower to be discharged. After the processing steps, the contents of water vapor and the coke powder discharged outside after one ton of coke is produced are controlled to be less than 0.05 ton and 5 grams respectively, and the removal rate of the organic components, the ammonia nitrogen and the cyanide can reach more than 80 percent.

Owner:BEIHANG UNIV

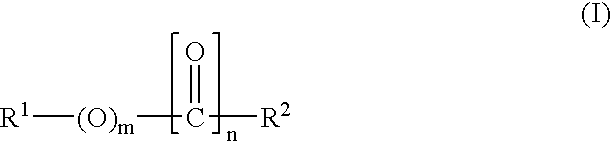

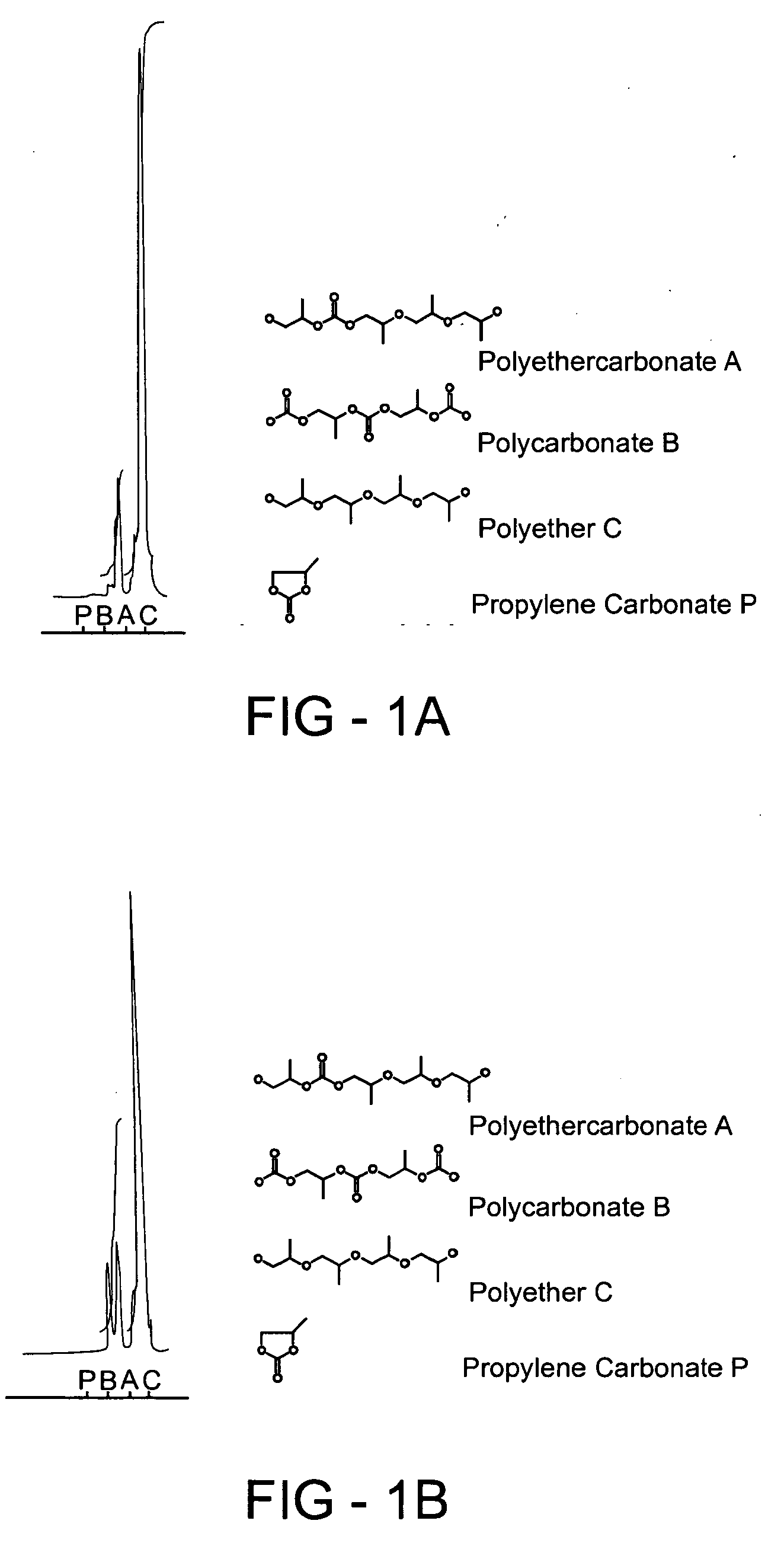

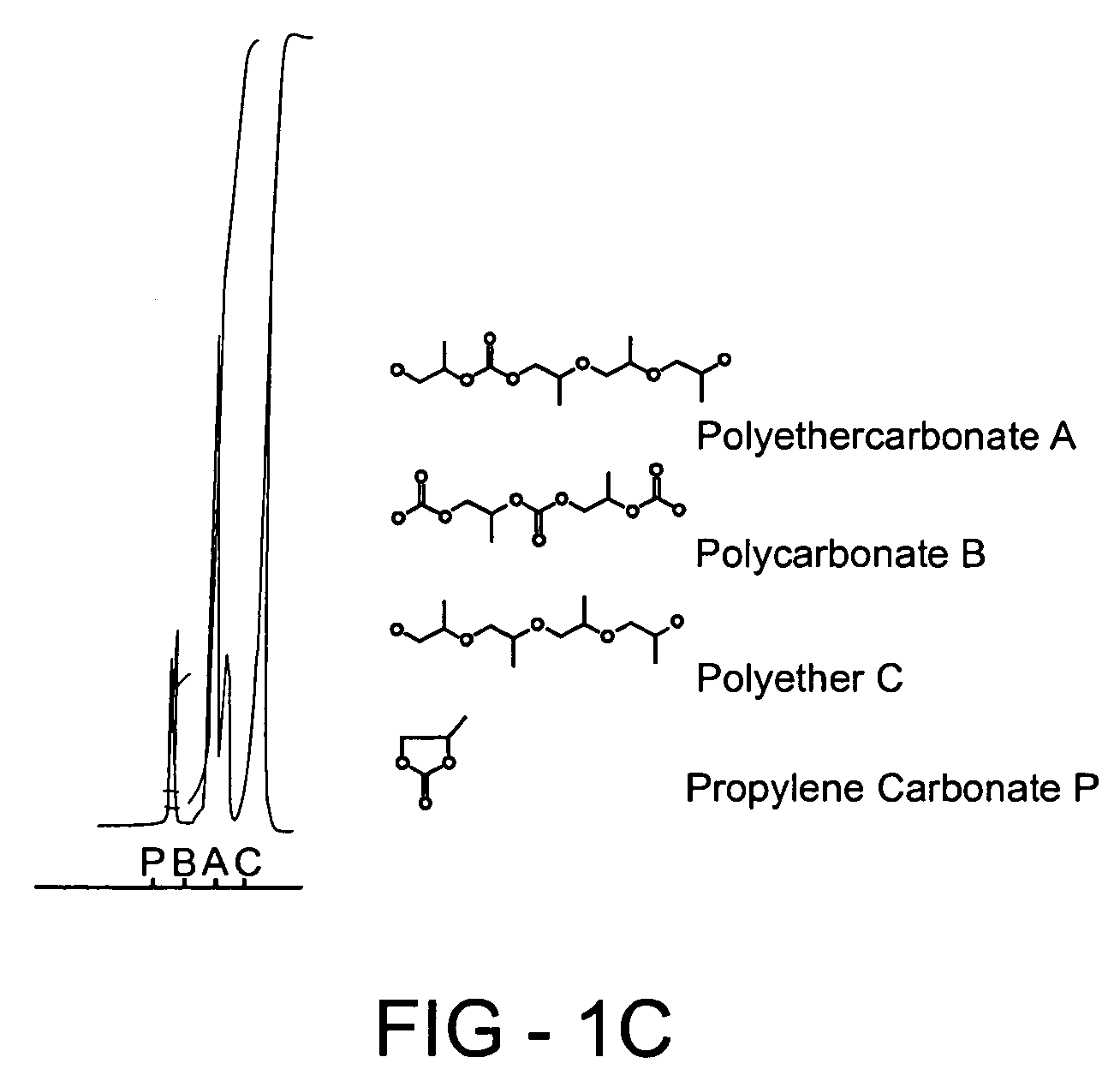

Method of forming a polyethercarbonate polyol

A polyethercarbonate polyol includes polyethercarbonate segments, polycarbonate segments, and polyether segments. A method of forming the polyethercarbonate polyol provides a catalyst, including a multimetal cyanide compound, and reacts an H-functional initiator, an alkylene oxide, and carbon dioxide in the presence of the multimetal cyanide compound to form the polyethercarbonate polyol. Amounts of each segment in the polyethercarbonate polyol are selectively controlled.

Owner:BASF CORP

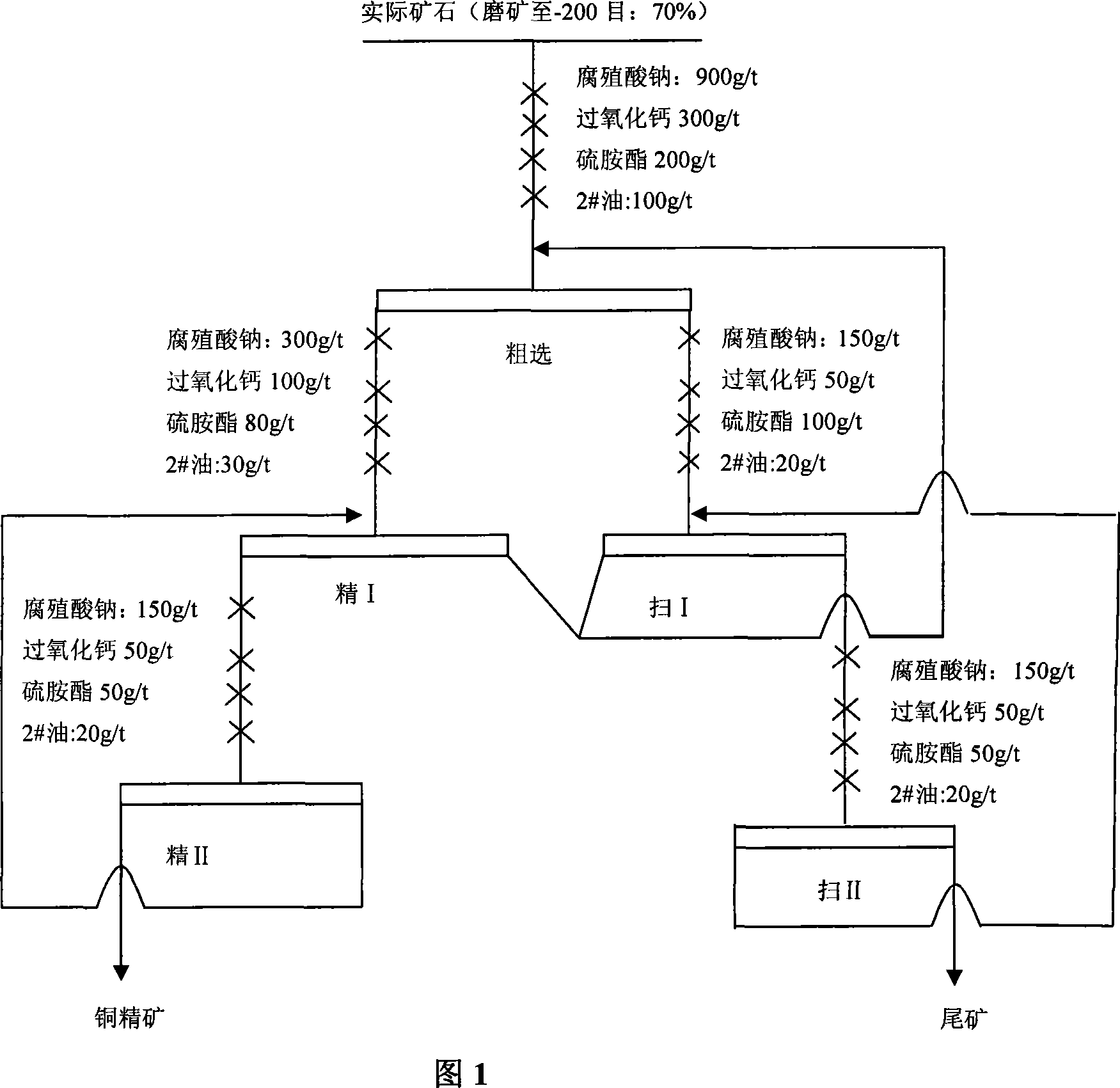

Highly effective composite restrainer of ferro-sulphur ore in complex vulcanizing ore and method of use thereof

The invention relates to a high-efficient combined inhabitor for pyrite in complex sulfide ores and the application method of the inhabitor. The inhabitor comprises calcium superoxide and HA-Na. The inhabitor of the invention can inhibit complex vulcanized iron-bearing minerals selectively, has better inhibition properties for magnetic pyrite, pyrite and arsonopyrite, and is an inhabitor of high selectivity. Compared with the prior inhibitors such as lime, cyanide, bichrome, potassium permanganate, sodium sulfide, sulphite, zinc sulphate and trisodium phosphate, the invention has the advantages of lower use level, good effects, no pollution, and other advantages.

Owner:CENT SOUTH UNIV

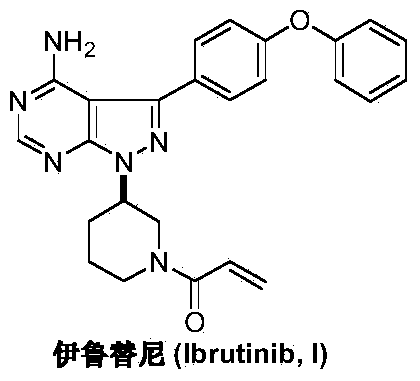

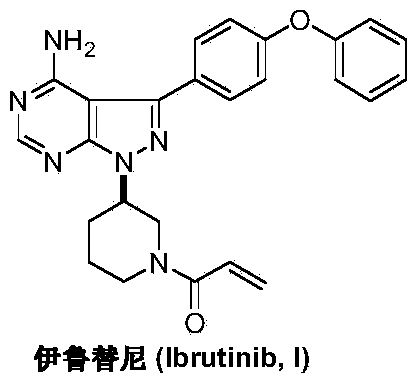

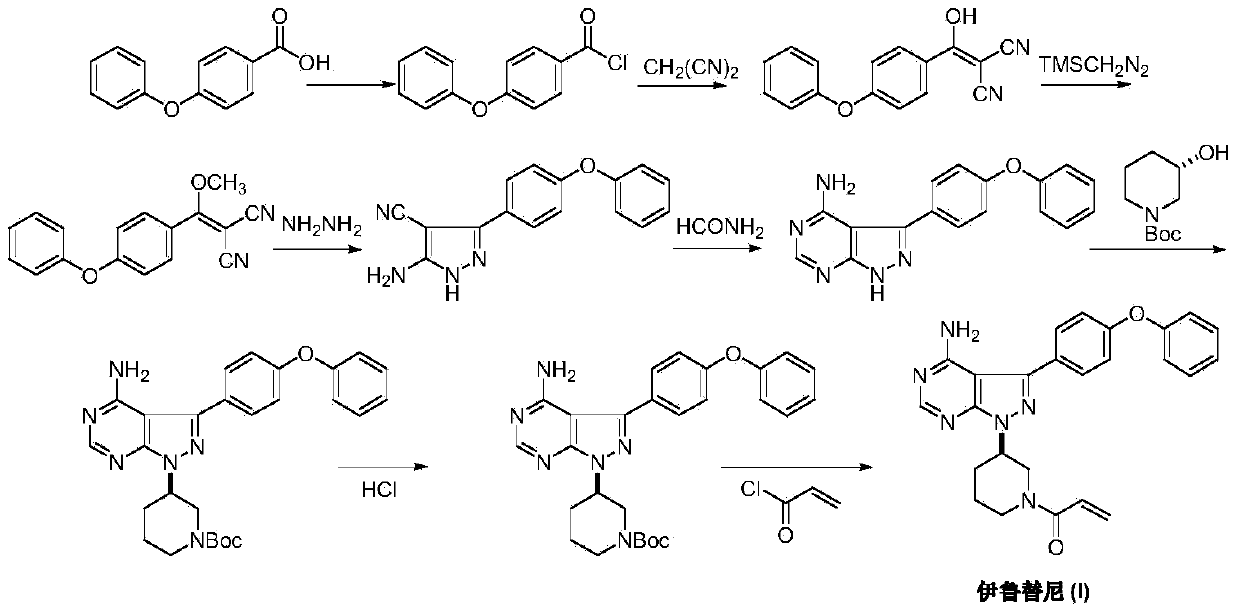

Preparation method of Ibrutinib

ActiveCN103626774AEase of industrial productionRaw materials are easy to getOrganic chemistryCyanideBenzoyl chloride

The invention discloses a preparation method of Ibrutinib (I). The preparation method comprises the following steps: performing condensation and methyl oxidization reaction on 4-phenoxyl benzoyl chloride (II) serving as a raw material and methylene cyanide and dimethyl sulfate to generate 4-phenoxyl phenyl (methoxyl) ethenylidene dicyan methane (III); performing pyrazol cyclization reaction between the intermediate (III) and 1-(3R-diazanyl-1-piperidyl)-2-propylene-1-ketone(IV) to obtain 1-[(3R)-[3-(4-phenoxyl phenyl)-4-nitrile-5-amino-1H-pyrazolyl]-1-piperidyl]-2-propylene-1-ketone(V). The pyrimidine cyclization reaction between the intermediate (V) and a cyclization agent is performed to prepare the Ibrutinib (I). The preparation method has easily-available raw materials, and is simple in process, economical and environment-friendly, and suitable for industrial production.

Owner:TONGLING WANGYANTANG BIOTECHNOLOGY CO LTD

High-temperature disposal method for spent cathodes of electrolytic aluminum

InactiveCN105642649ARealize harmless disposalImplement resourcesSolid waste disposalTransportation and packagingElectricityCyanide

The invention provides a high-temperature disposal method for spent cathodes of electrolytic aluminum. The method comprises the following steps: spent cathode carbon blocks of electrolytic aluminum are crushed into particles of 3-15 mm; then roasting is carried out by using a super high temperature furnace, fluorides in the spent cathode carbon blocks are volatilized, cyanides in the spent cathode carbon blocks are decomposed, flue gas generated during roasting is absorbed through a water spray absorption mode; then, processes such as filtering, drying and the like are carried out, the fluorides and the like are reused in aluminum electrolysis; and a cathode carbon material is discharged out of the super high temperature furnace after the material is cooled. According to the physical and chemical properties of the fluorides, the cyanides and carbon in the spent cathodes of electrolytic aluminum, the fluorides in the spent cathode carbon blocks are volatilized, the cyanides in the spent cathode carbon blocks are decomposed with the high-temperature method; however, on the condition of primary vacuum, carbon in the cathodes cannot burn, so that effective separation of carbon, the fluorides and the cyanides in the cathodes is achieved, and hazard-free disposal and resource utilization of the spent cathodes of electrolytic aluminum are achieved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

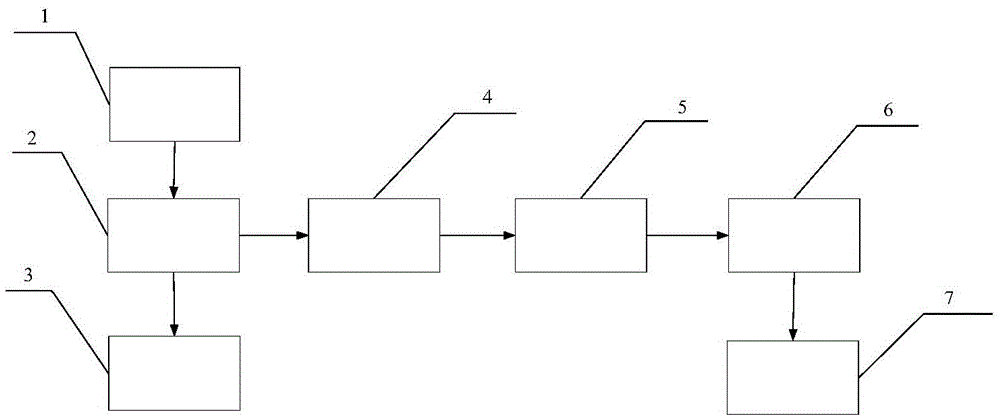

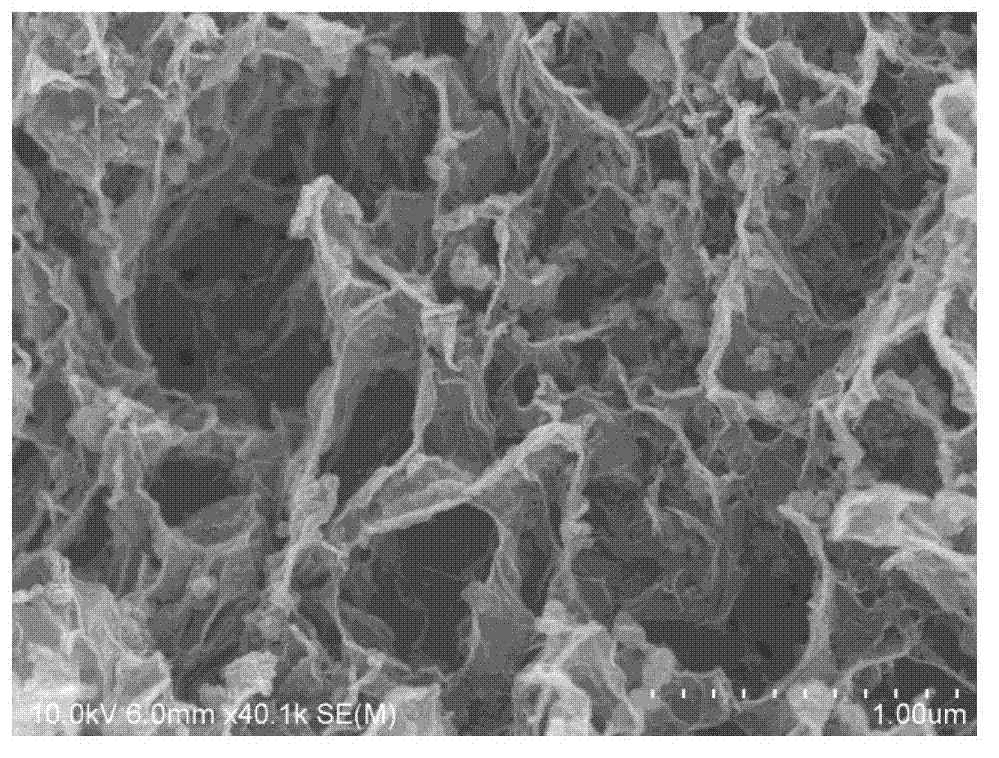

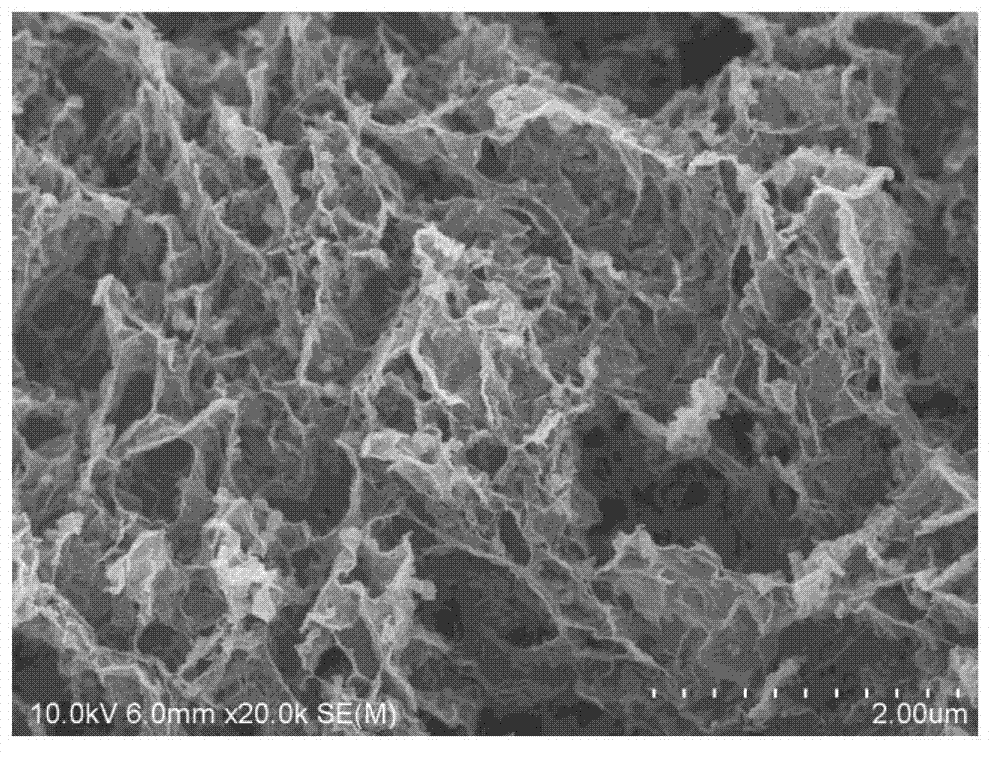

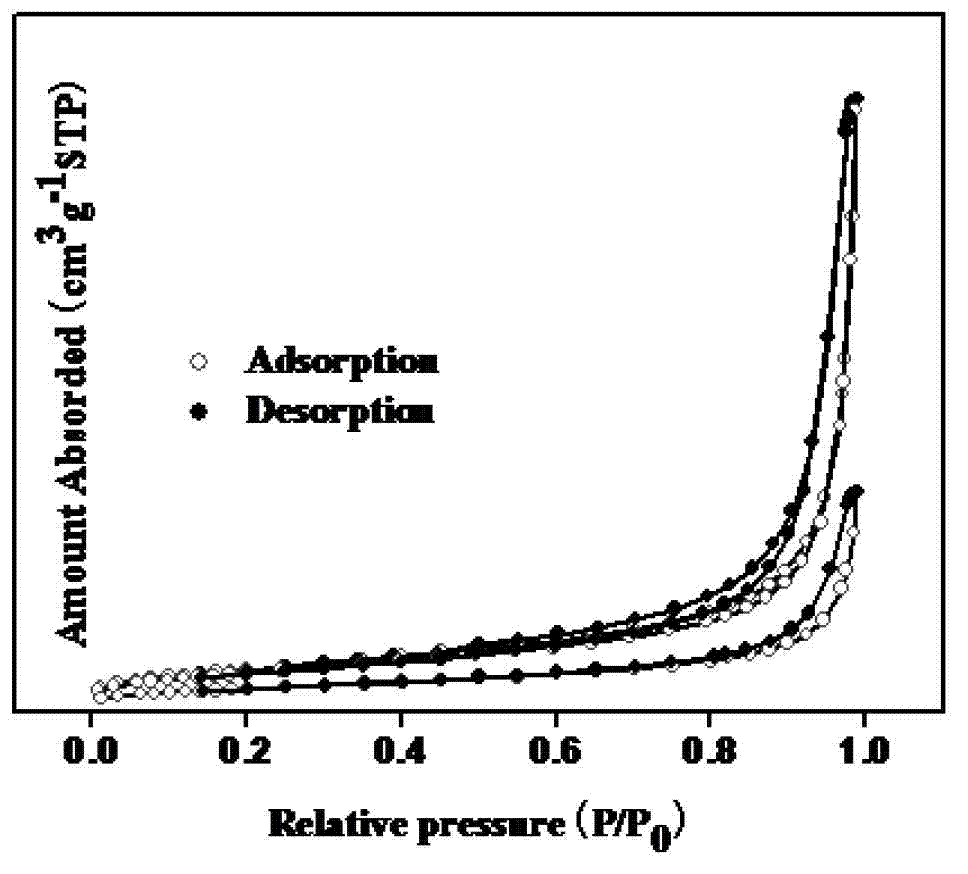

Composite aerogel of graphene/Prussian-blue complexes, and preparation method and application thereof

InactiveCN102824883ALarge specific surface areaLow densityPhysical/chemical process catalystsOther chemical processesVolumetric Mass DensityElectrochromism

The invention relates to composite aerogel of graphene / Prussian-blue complexes, and a preparation method and application thereof. The composite aerogel is in a three-dimensional network structure formed by graphene sheets. Particles of the Prussian-blue complexes are nano-scaled and attach to the graphene sheets. The preparation method of the composite aerogel includes adding metallic cyanide in graphene oxide suspension, allowing for dispersion to obtain suspension A, dissolving metal salt in aqueous solution containing reductant to obtain solution B, ultrasonically mixing the suspension A and the solution B, allowing for standing, and drying to obtain the composite aerogel. The composite aerogel is large in specific surface area and low in density and is highly conductive. The preparation method of the composite aerogel is simple to operate, low in cost and applicable to large-scale industrial production. The composite aerogel has excellent hydrogen storage performance, hydrogen peroxide catalytic reduction and electrochromic property.

Owner:陶丽

Maintenance method for alkaline non-cyanide plating copper

The invention discloses a maintaining method for an alkalescent non-cyanide cuprodine. The method uses indissoluble anode, cathode in the alkalescent non-cyanide cuprodine liquor as the galvanized workpiece, adds cupric salt, complexing agents and additives and adjusts the pH value of the galvanizing liquor to control the current dense range between 0.1-7A / dm2; the galvanizing time is between 1min to 72h; then the galvanizing liquor is filtered; the galvanizing liquor is processed air bend or moves the workpiece while galvanizing. The invention uses the indissoluble anode comprising stainless steel, DSA coating, titanium, platinum, graphite which is simple to use, innoxious, harmless; the invention has a low production cost and even, smooth and shining fine galvanizing layer by using the indissoluble anode. The technique maintaining method of the invention has a simple operation, great stability of galvanizing liquor and convenient maintenance for the galvanizing liquor.

Owner:广州市二轻研究所股份有限公司

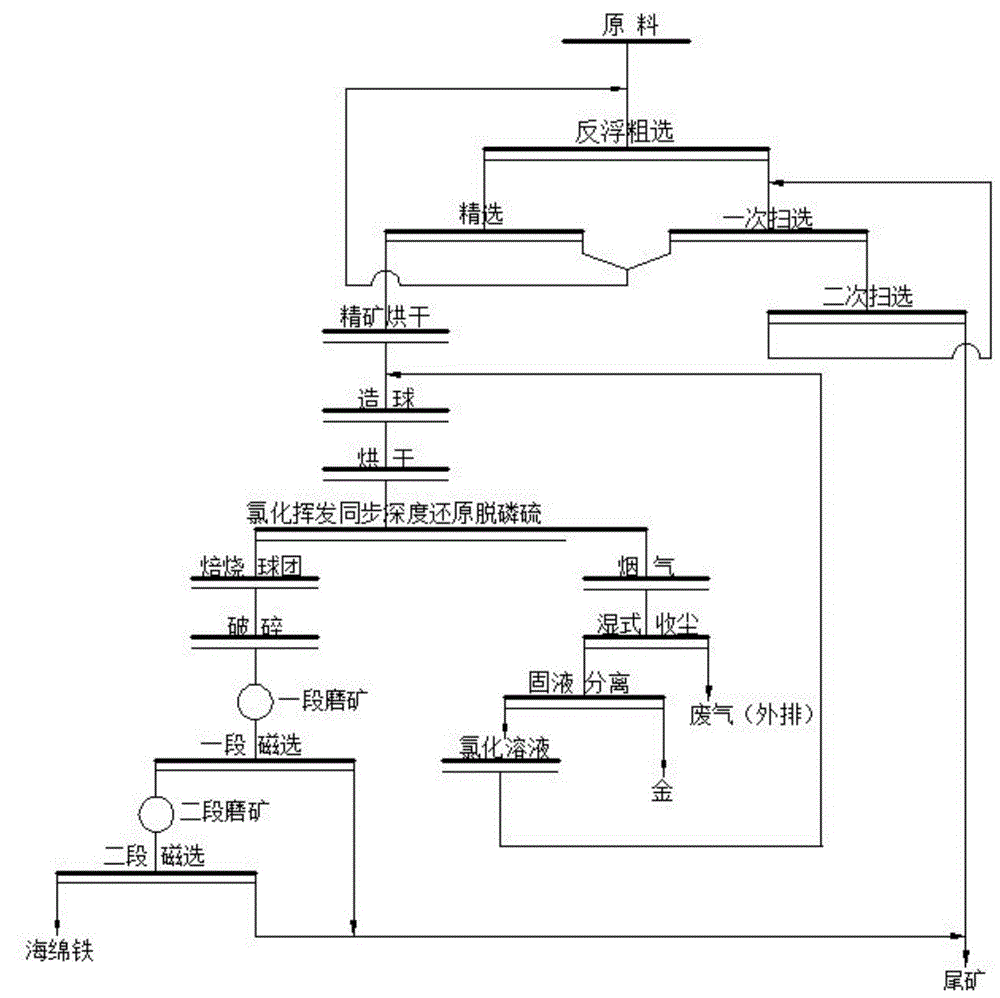

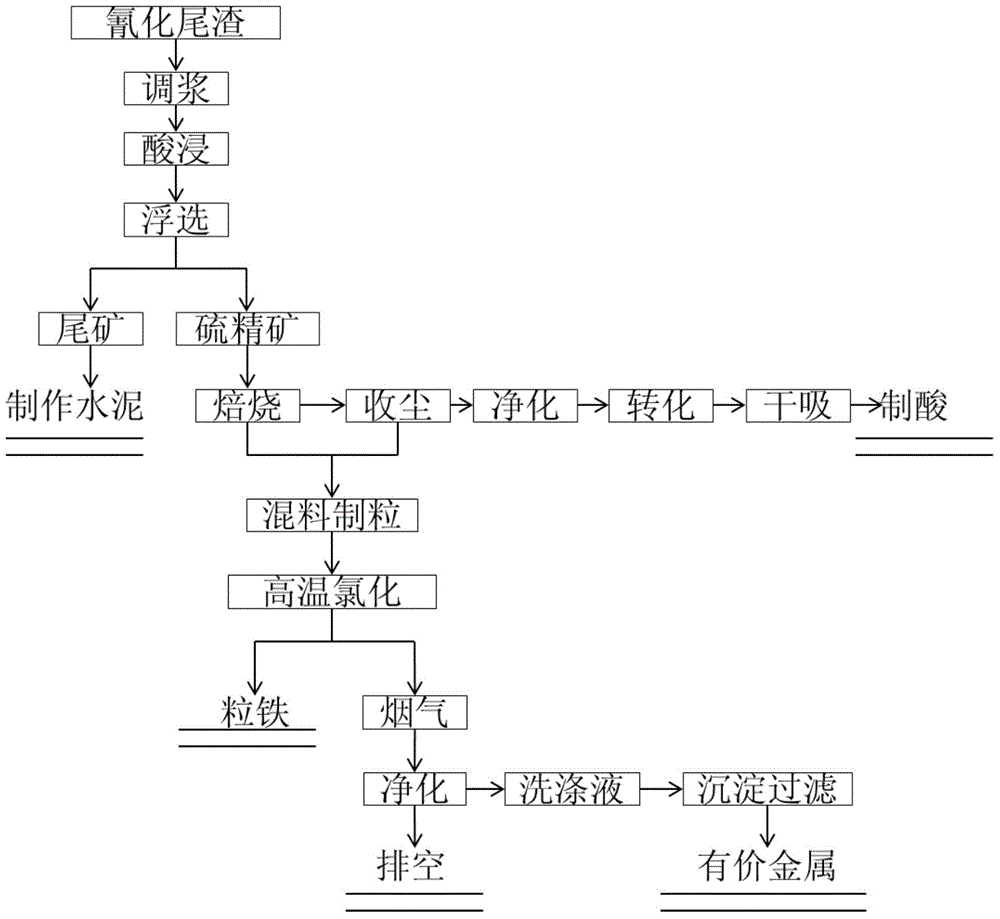

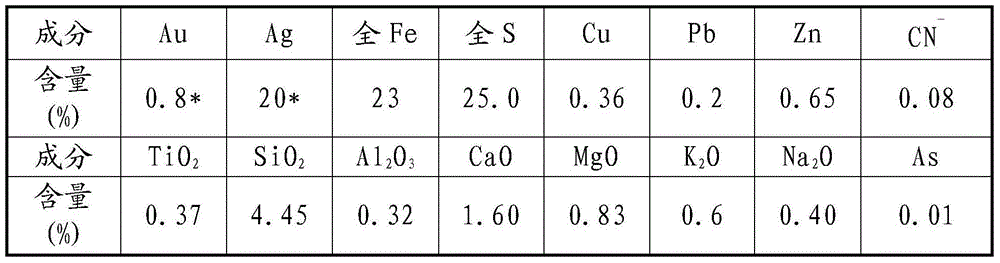

Method of performing chloridizing roasting to synchronously reduce and recover gold and iron from gold concentrate cyanide tailings

The invention provides a method of performing chloridizing roasting to synchronously reduce and recover gold and iron from gold concentrate cyanide tailings, and belongs to the technical field of comprehensive utilization of resources. The method comprises the following steps: performing reverse flotation desilicication preconcentration on the gold concentrate cyanide tailings which comprise 0.5-0.95% of phosphorus, 0.9-1.4% of sulfur, 20-25% of iron, and 3.0-4.5 g / t of gold, drying the obtained concentrate, then mixing the concentrate with a chlorinating agent, a reducing agent, a dephosphorization agent and a desulfurizing agent, pelletizing, performing high temperature chlorination to volatilize gold and synchronously performing deep reduction to remove sulfur and phosphorus, collecting the exhaust gas to recover gold, and then performing crushing, ore grinding, magnetic separation on the roasted pellets to recover iron. With application of the method, a gold product and a sponge iron product can be obtained, wherein the gold recovery rate of the gold product is 92-96%; in the sponge iron product, the iron grade is 90-92.5%, the sulfur content is less than 0.06%, the phosphorus content is less than 0.07%, and the iron recovery rate is 88-93%. Through the reverse flotation preconcentration, the method can reduce the energy consumption of the follow-up treatment process and realize recycling of the low-grade gold and iron in the gold concentrate cyanide tailings.

Owner:JIANGXI YIYUAN REGENERATION RESOURCE CO LTD

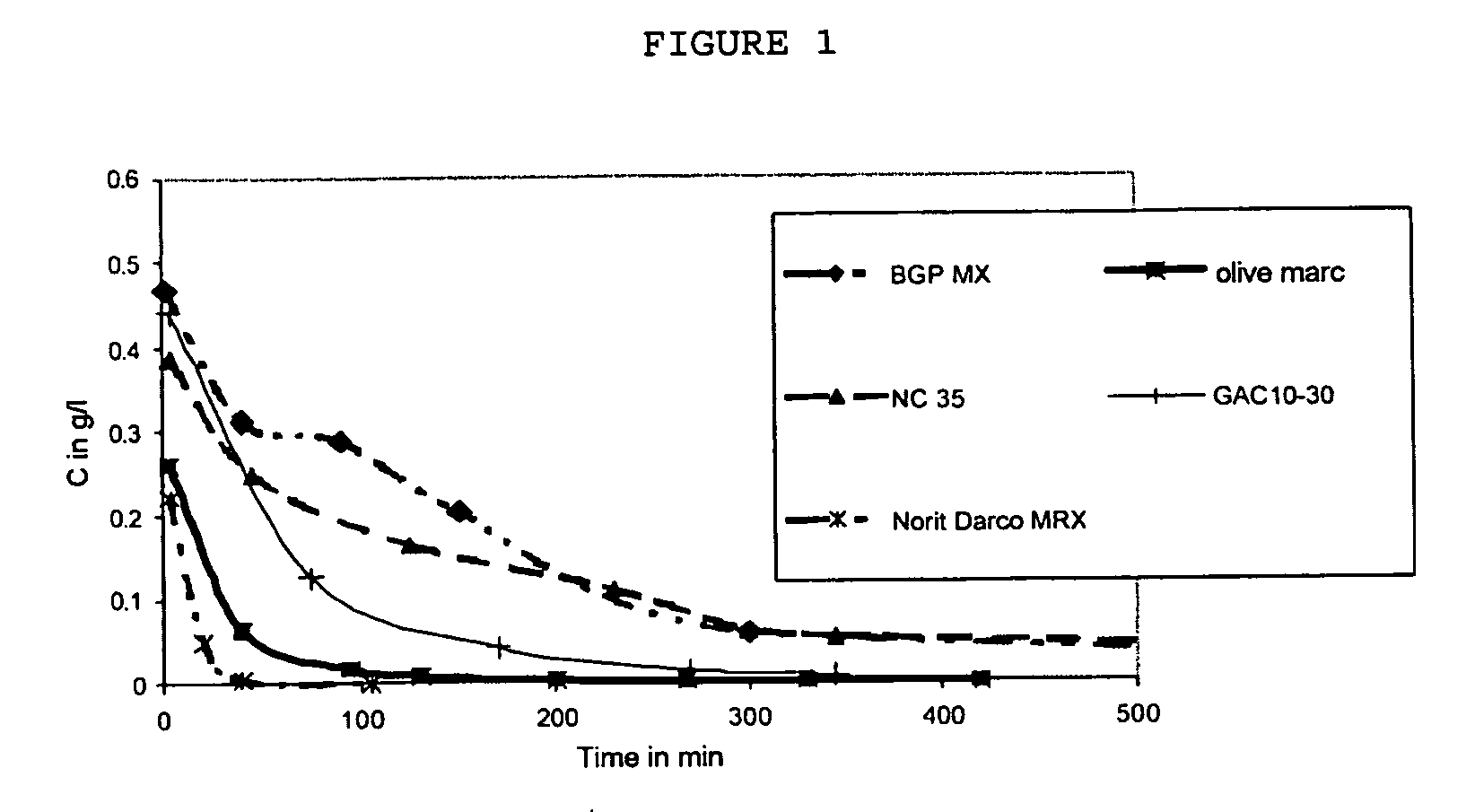

Activated carbon with improved mechanical resistance, and the uses thereof, especially as a catalyst carrier

InactiveUS20070123419A1Strong mechanical propertiesRapidly impregnated with oxidation catalystCarbon compoundsOther chemical processesGas phaseSolvent

The present invention relates to active charcoals with improved mechanical properties. They can advantageously be used in the sweetening of petroleum fractions, as oxidation catalyst support in the conversion of mercaptans to disulphides, but also in any other type of reaction, such as, for example, for the oxidation of cyanide present in water or in the synthesis of glyphosate, and in processes for purification and / or separation by selective adsorption in a liquid phase and / or in a gas phase (decolouration of liquid foodstuffs, water treatment, air treatment, recovery of solvents, and the like).

Owner:LE BEC REMY

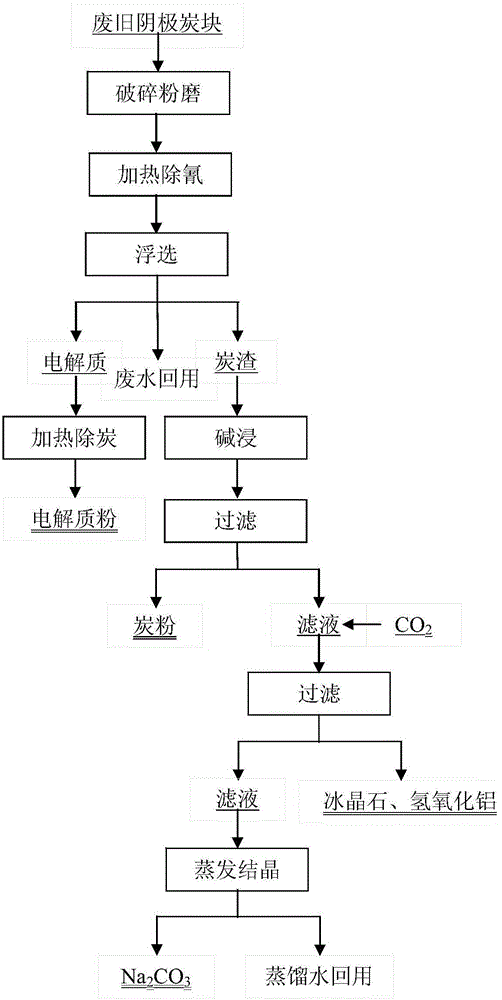

Comprehensive recovery method of waste and old cathode charcoal block of aluminium electrolytic tank

ActiveCN106064813AReduce consumptionShorten the alkaline leaching timeAluminium fluoridesAluminium oxides/hydroxidesRecovery methodElectrolysis

The invention relates to a comprehensive recovery method of waste and old cathode charcoal block of an aluminium electrolytic tank, and belongs to the technical field of comprehensive utilization of industrial solid waste resources. The method is as below: crushing and grinding waste and old cathode charcoal block of the aluminium electrolytic tank at 200-400 DEG C, insulating, removing cyanide, conducting flotation separation on the material with cyanide removed to obtain carbon slag and electrolyte slag, heating the electrolyte slag at 550-800 DEG C to remove carbon impurities, so as to obtain an electrolyte powder, removing to soluble substances in the electrolyte slag by alkali leaching to obtain a carbon powder with high purity, and precipitating a mixture of cryolite and aluminium hydroxide form the alkali leaching liquid by CO2. The invention has the advantages of reasonable process design, simple process, high treatment efficiency, high recovery rate and recycling rate of each material and no secondary pollution, and is applicable to large-scale industrial application.

Owner:CENT SOUTH UNIV

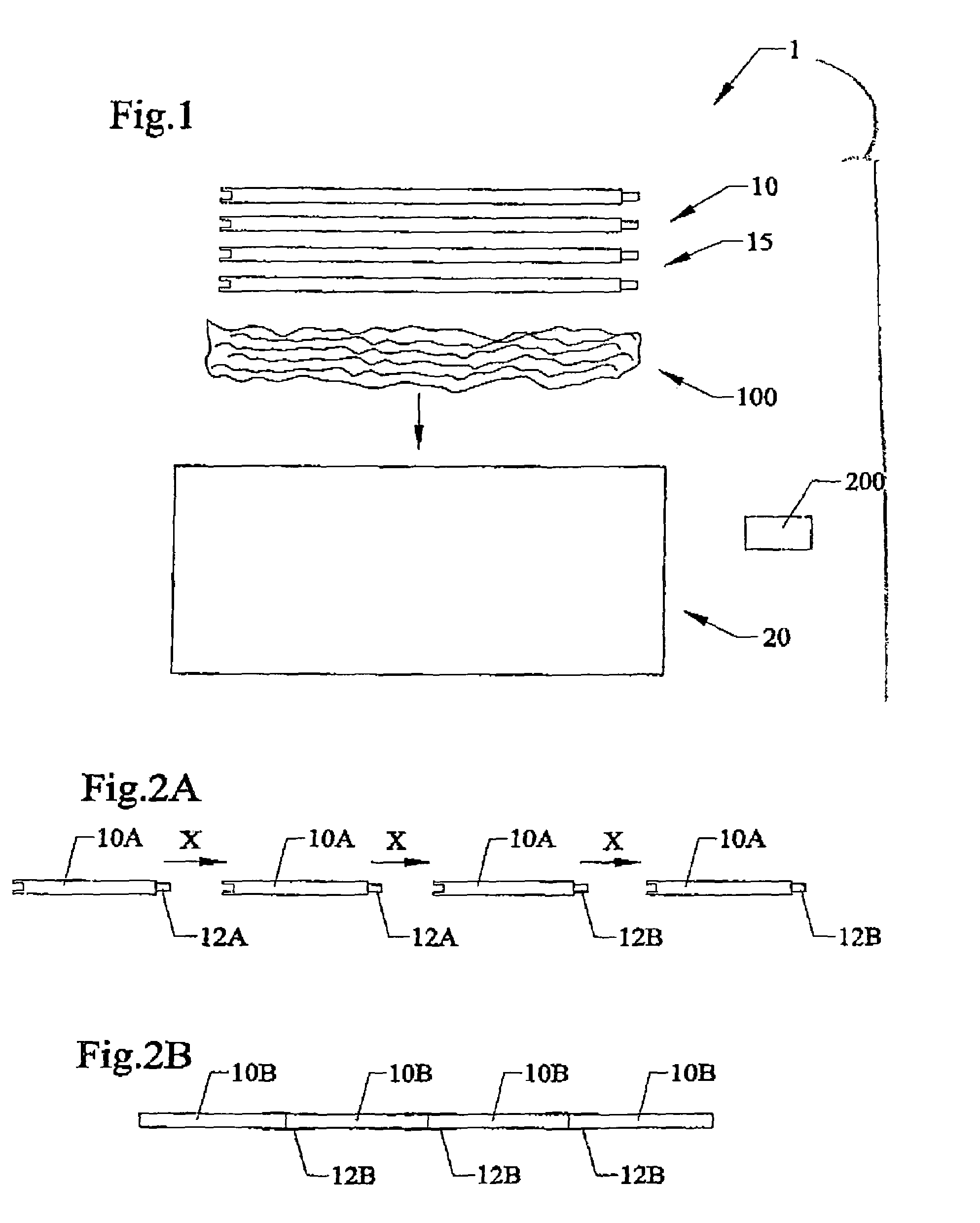

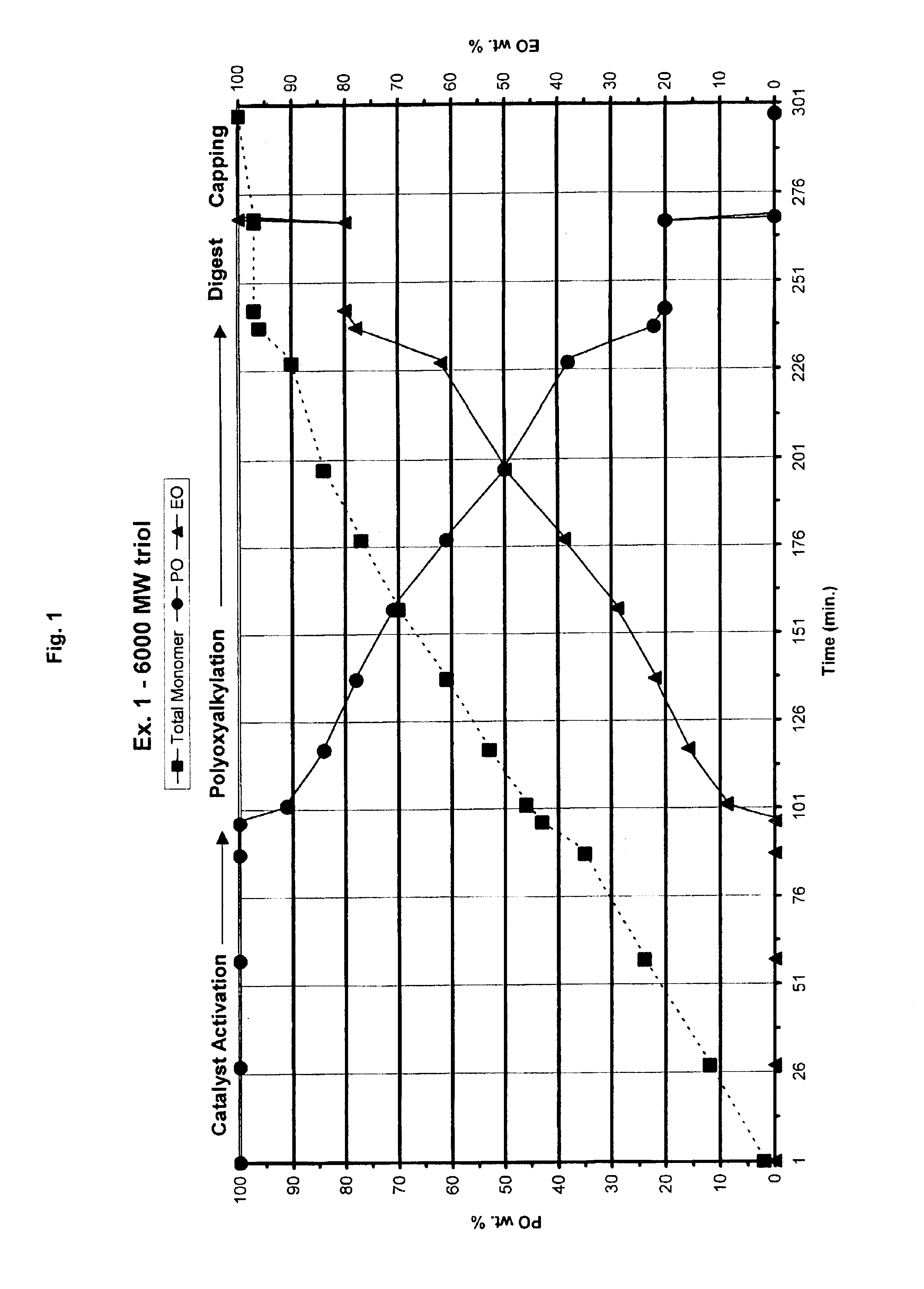

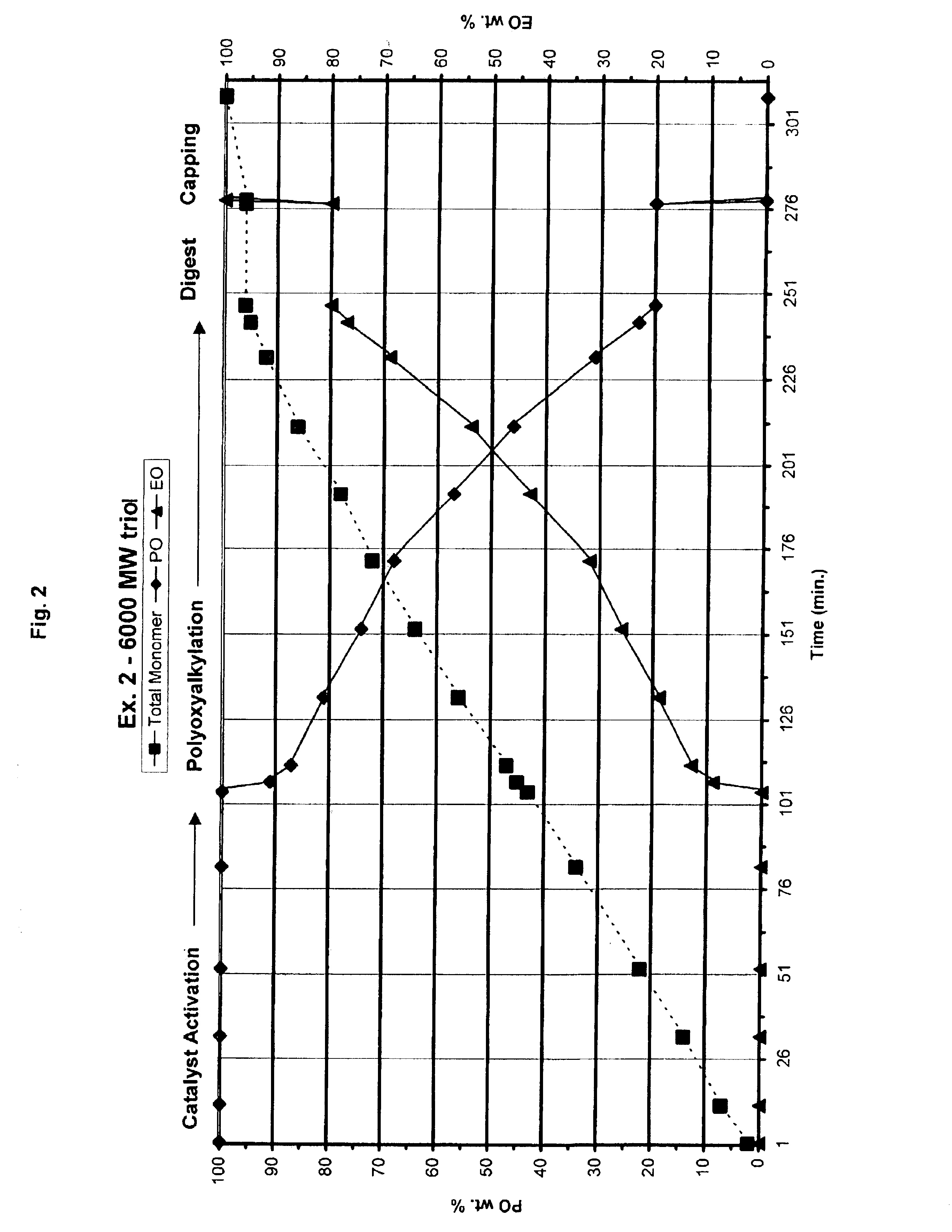

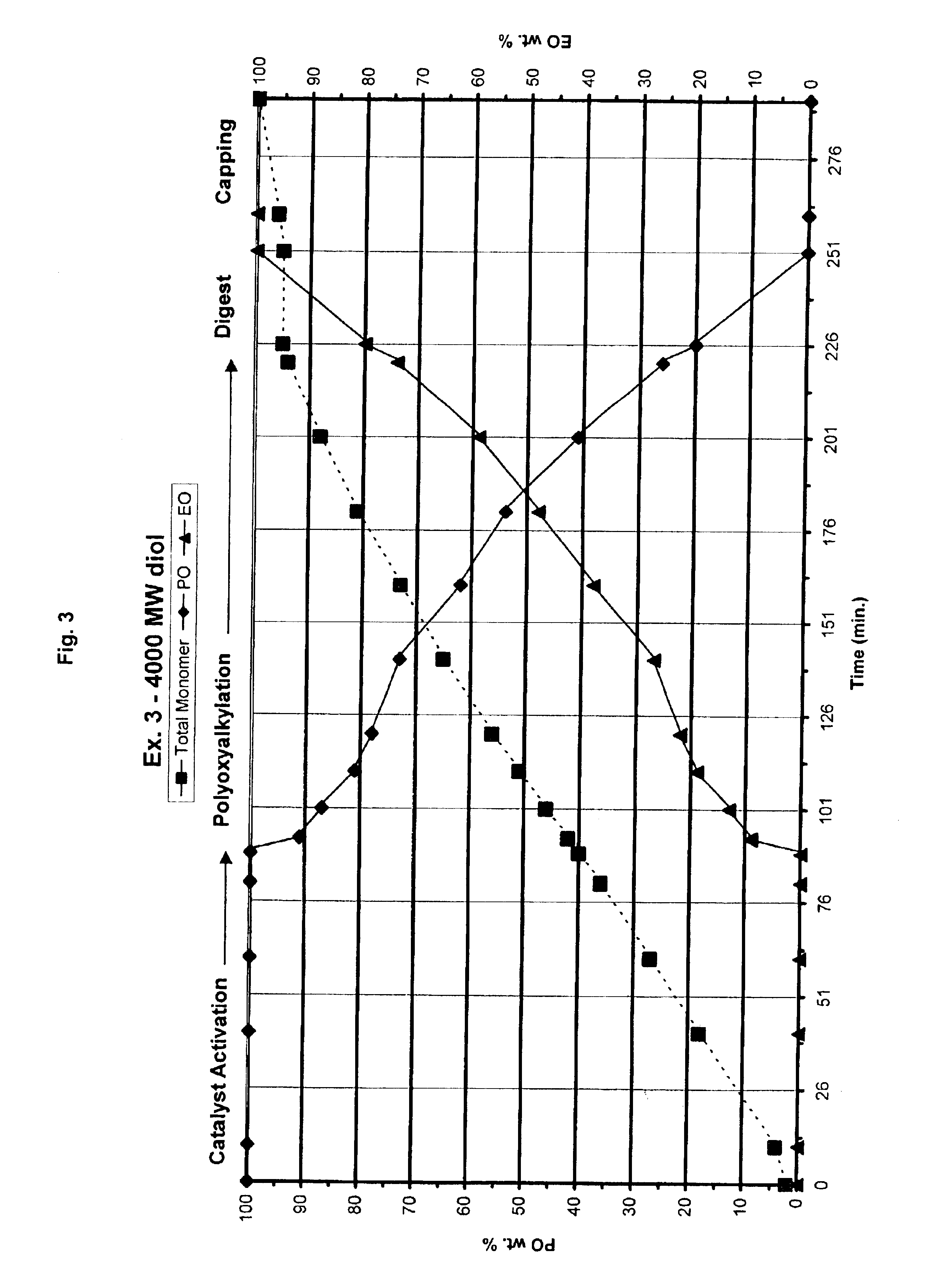

Process for preparing double metal cyanide catalyzed polyols

The present invention provides a process for preparing a polyoxyalkylene polyol by polyoxyalklating a starter compound with a mixture of two different alkylene oxide monomers in which the first alkylene oxide monomer content of the mixture decreases as the content of the second alkylene oxide monomer increases over the course of the polyoxyalkylation, digesting unreacted monomers of the alkylene oxides and capping the polyol.

Owner:BAYER ANTWERPEN NV

Non-cyanide silver plating bath composition

InactiveUS20050183961A1Chemically stableIncrease brightnessChemical vapor deposition coatingCyanideSilver plate

Disclosed is an electroplating solution for the deposition of silver; said solution containing silver in the form of a complex of silver with hydantoin or a substituted hydantoin compound; said solution also containing an excess of the hydantoin or substituted hydantoin compound employed, together with an effective quantity of a nonprecipitating electrolyte salt, and also an effective quantity of 2,2′ dipyridyl for the purpose of obtaining a mirror-bright to brilliant deposit.

Owner:TECHNIC INC

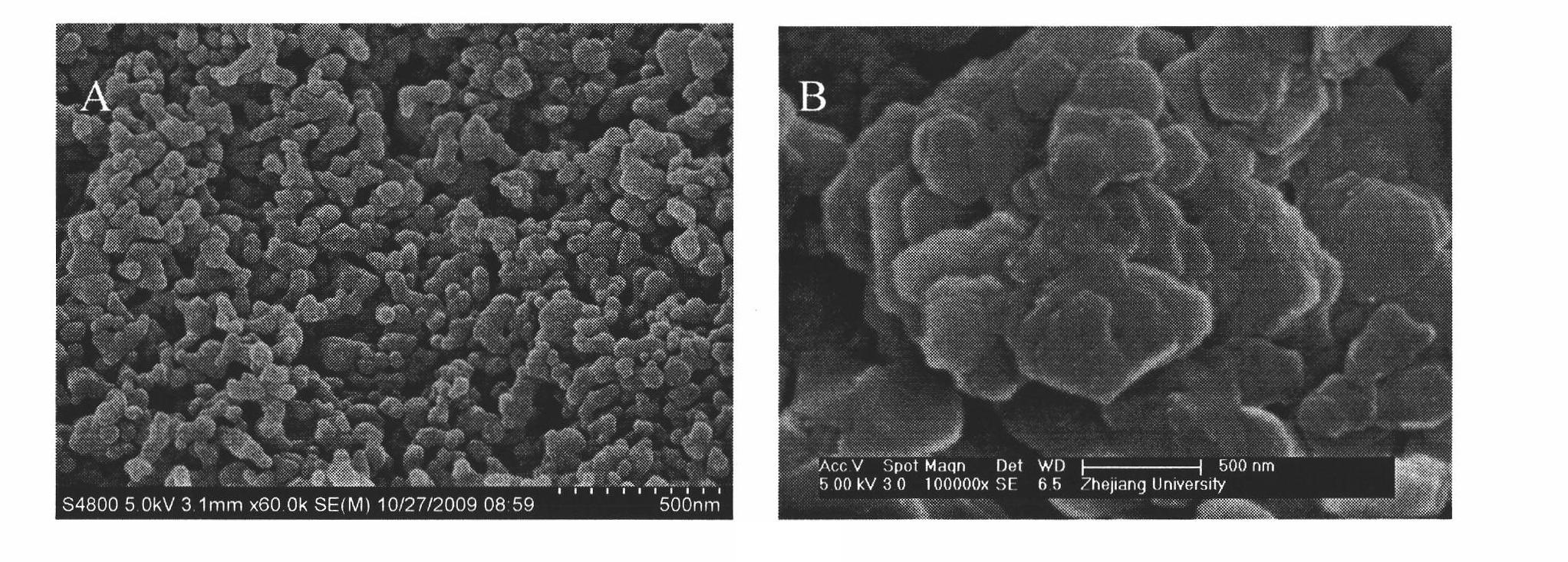

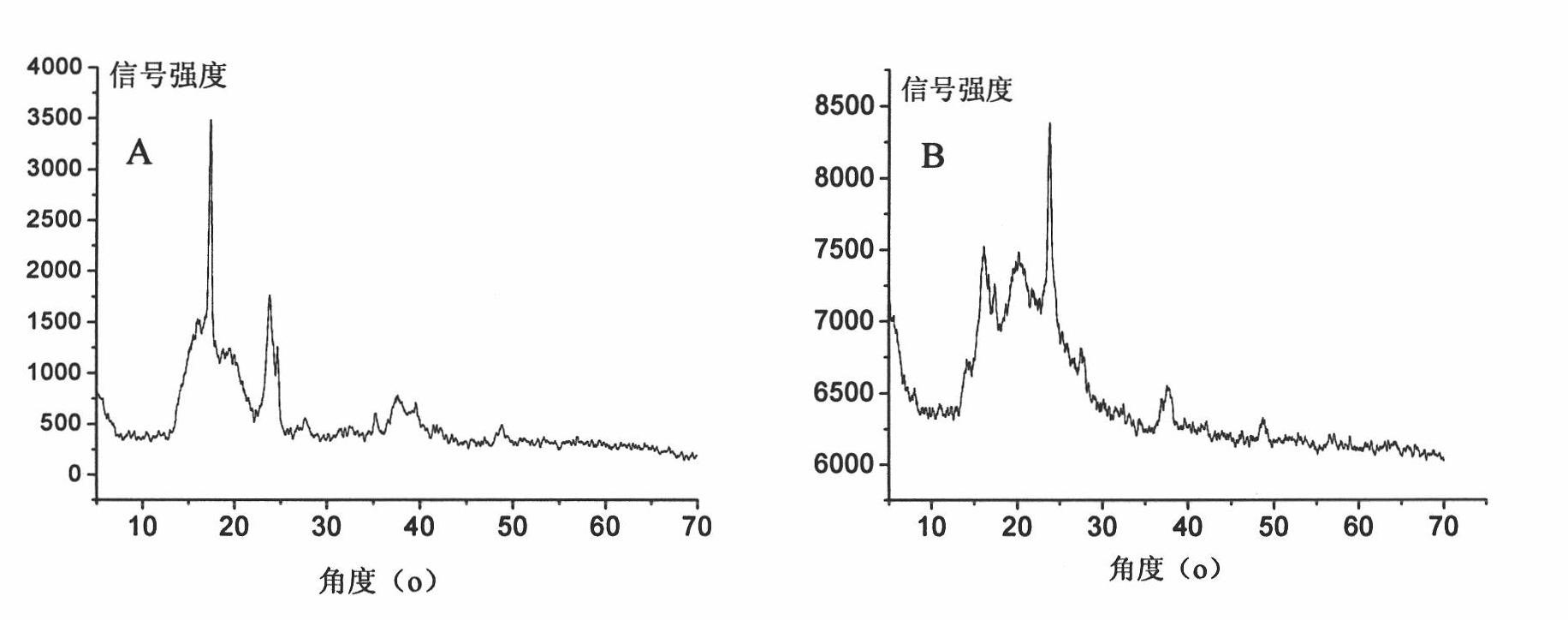

Method for preparing aliphatic polycarbonates by catalyzing by metal cyanide coordination catalyst

The invention discloses a method for preparing aliphatic polycarbonates by catalyzing by the metal cyanide coordination catalyst. In a high pressure reactor, the metal cyanide coordination catalyst is utilized to catalyze epoxide and carbon dioxide body or solution copolymerization, wherein, the copolymerization temperature is 20-150 DEG C; the carbon dioxide pressure is 0.5-10MPa; the reaction time is 1-48h; the catalyst concentration is 1-100kg epoxide / g catalyst; the polymerization activity is more than 1.0kg of polymer / g catalyst; the weight-average molecular weight of the copolymer is more than 80 thousand; the molecular weight distribution is 1.5-4; the alternation degree of the copolymer is more than 90%; the cyclic carbonate by-product is less than 5wt%; the CO2 fixed rate of CO2 / epoxypropane copolymer is more than 40wt%; and the CO2 fixed rate of CO2 / cyclohexene oxide copolymer is more than 30wt%.

Owner:ZHEJIANG UNIV

Flexible polyurethane foams made from vegetable oil alkoxylated via DMC-catalysis

The present invention provides flexible polyurethane foams made from at least one polyisocyanate and at least one vegetable oil alkoxylated in the presence of a double metal cyanide (DMC) catalyst, optionally at least one non-vegetable oil-based polyol, optionally in the presence of at least one of blowing agents, surfactants, pigments, flame retardants, catalysts and fillers. The alkoxylated vegetable oils are environmentally-friendly, bio-based polyols which can be used to increase the “green” content of polyurethane foams without having detrimental effects on foam properties.

Owner:BAYER MATERIALSCIENCE AG

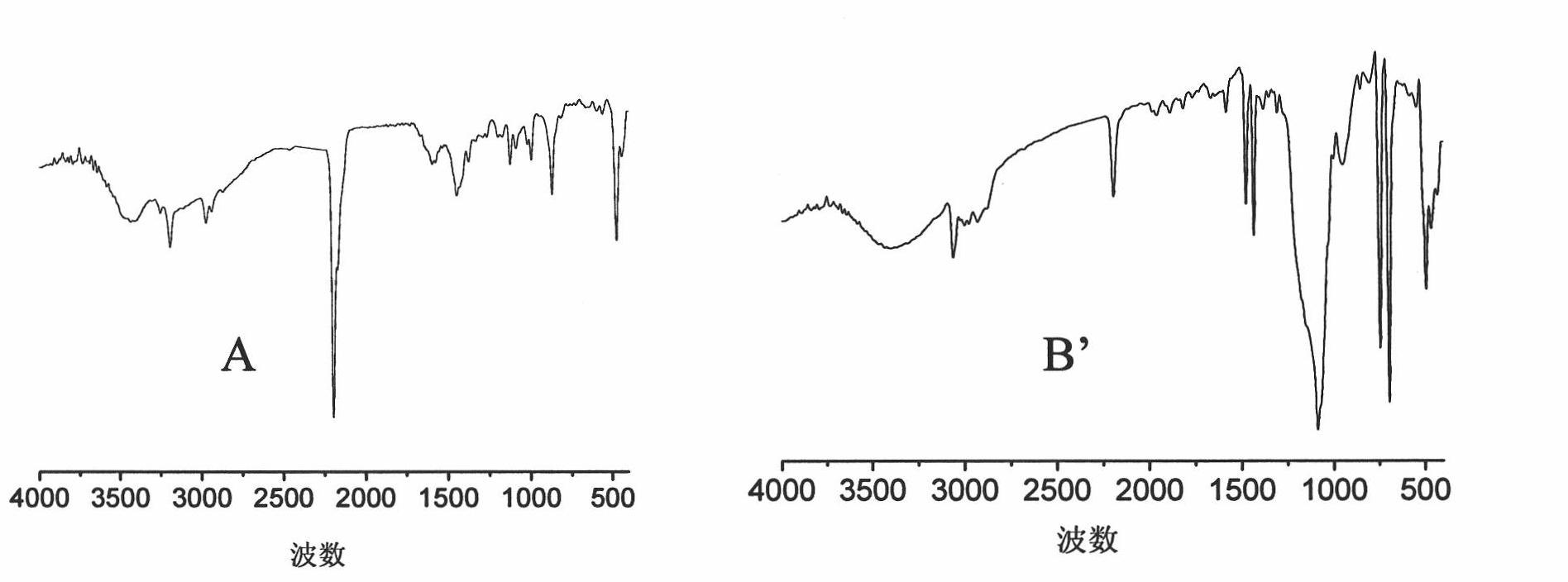

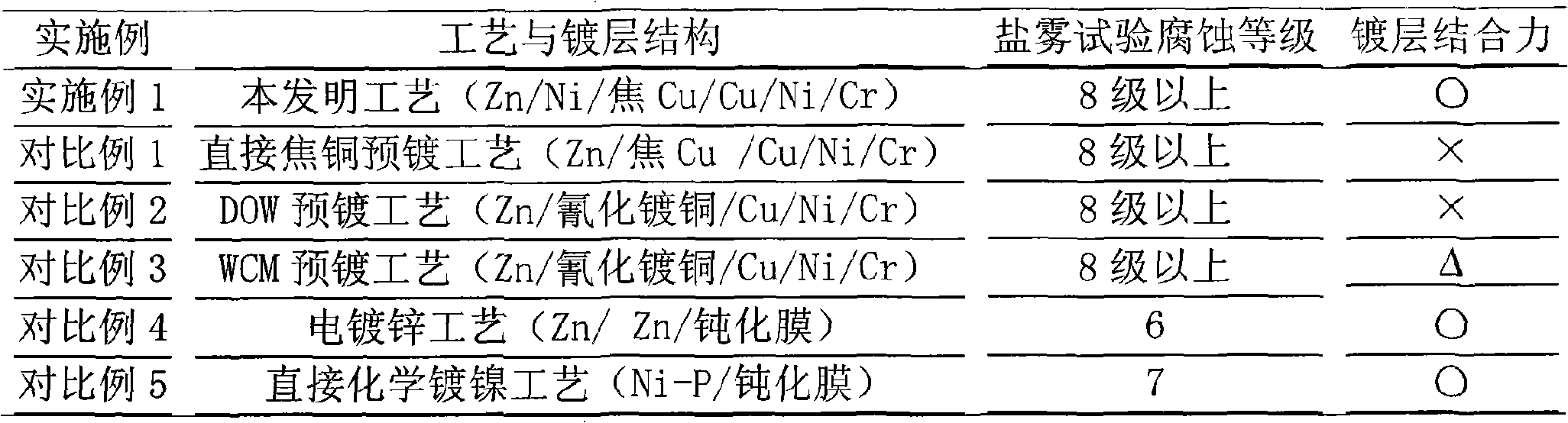

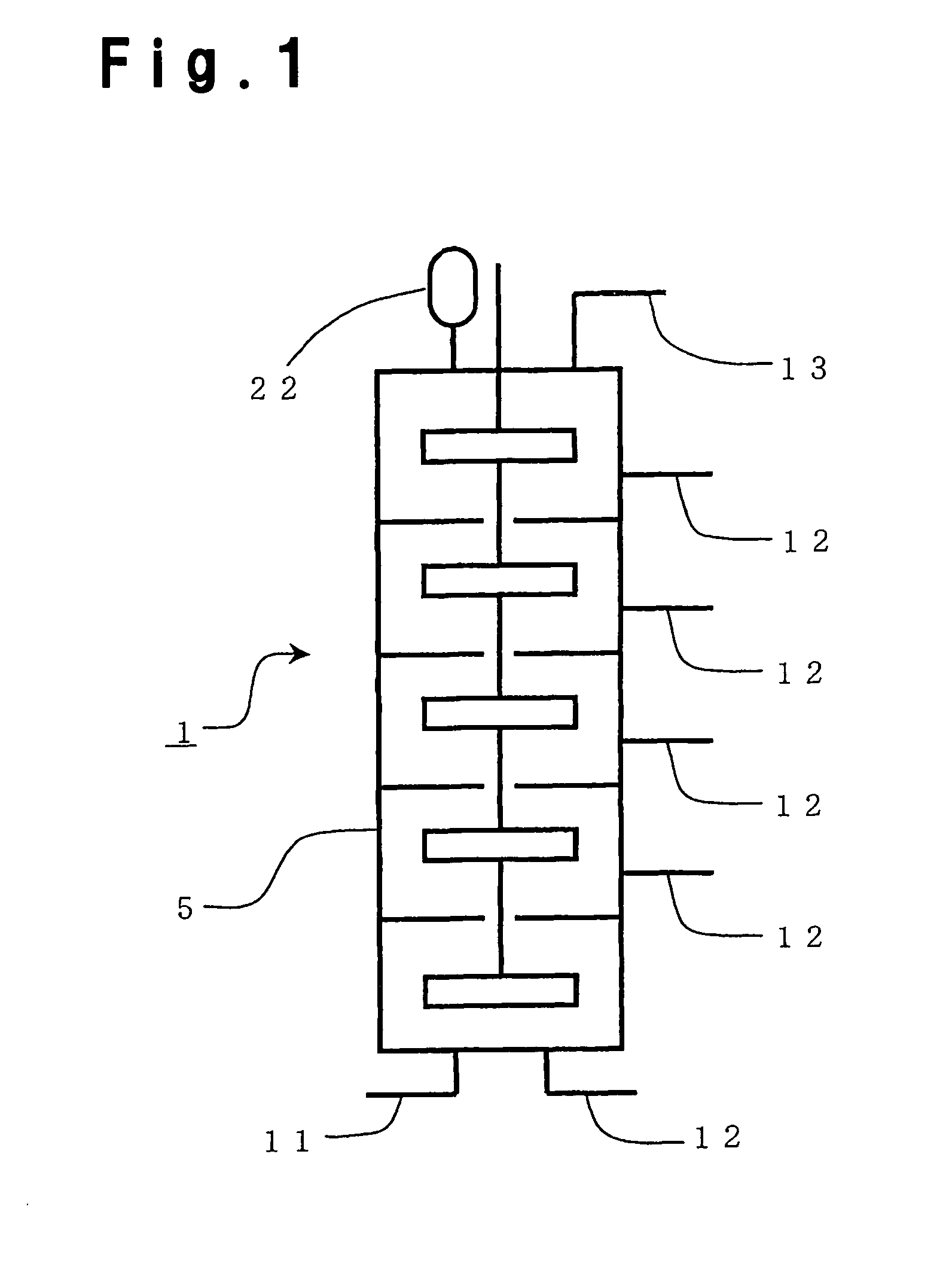

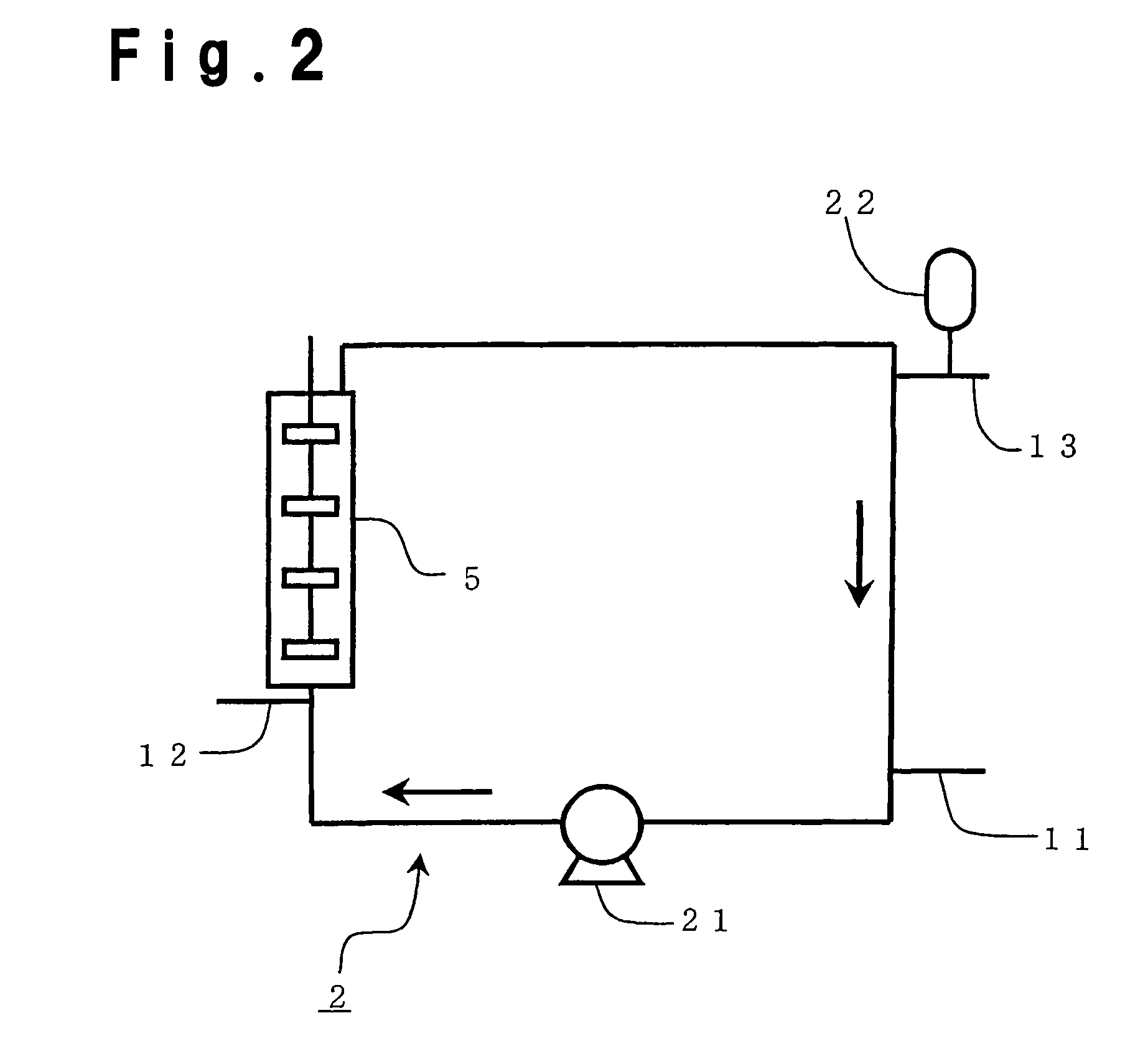

Electroplating process for surface of magnesium alloy motorcycle hub

InactiveCN101280445AHarm reductionReduce pollutionSolid state diffusion coatingLiquid/solution decomposition chemical coatingCyanidePyrophosphate

The invention relates to a combinational electroplating process on a magnesium alloy motorcycle wheel nave by adopting a non-cyanide and chrome free pre-plating treatment solution, electronickelling and pyrophosphate copper are adopted as dual-layer bottoming coat, then Cu / Ni / Cr combinational coat electroplating is performed, to obtain the Cu / Ni / Cr combinational metal coat with high corrosion resistance on the surface of the magnesium alloy motorcycle wheel nave. The binding force of the metal coat obtained on the surface of the magnesium alloy motorcycle wheel nave by adopting the process is strong, the corrosion resistance is high, and the combinational electroplating process has the prominent advantages that the personnel health is safeguarded, and the environmental pollution is avoided.

Owner:GCI SCI & TECH +1

Method for removing cyanide in waste cathode carbon in aluminum electrolysis cell

InactiveCN105772486ANo consumptionReduce energy consumptionSolid waste disposalSlagResource utilization

The invention relates to a method for removing cyanide in waste cathode carbon in an aluminum electrolysis cell, and belongs to the technical field of aluminum electrolysis solid waste resource recycling. After being levigated, an aluminum electrolysis cell waste cathode carbon block is added in water to be immersed; filtering is conducted after immersing, and first filter liquor and first filter slag are obtained; the reaction is conducted at the temperature of 30 DEG C to 70 DEG C after hydrogen peroxide, a stabilizing agent and a catalyst are added in the first filter liquor; filtering is conducted after the reaction, and second filter liquor and second filter slag are obtained; the second filter liquor is evaporated, distilled water and a crystal substance are obtained, and an oxidative product is decomposed into utilizable gas (CO2 and NH3). Treatment of the waste cathode carbon block with high efficiency and low energy consumption is achieved through the cooperative effect of the hydrogen peroxide, the proper number of the catalyst and the proper number of the stabilizing agent. The technology is simple, controllability is high, closed-loop circulation is achieved, secondary pollution is avoided, the resource utilization rate is high, and large-scale industrial application is facilitated.

Owner:CENT SOUTH UNIV

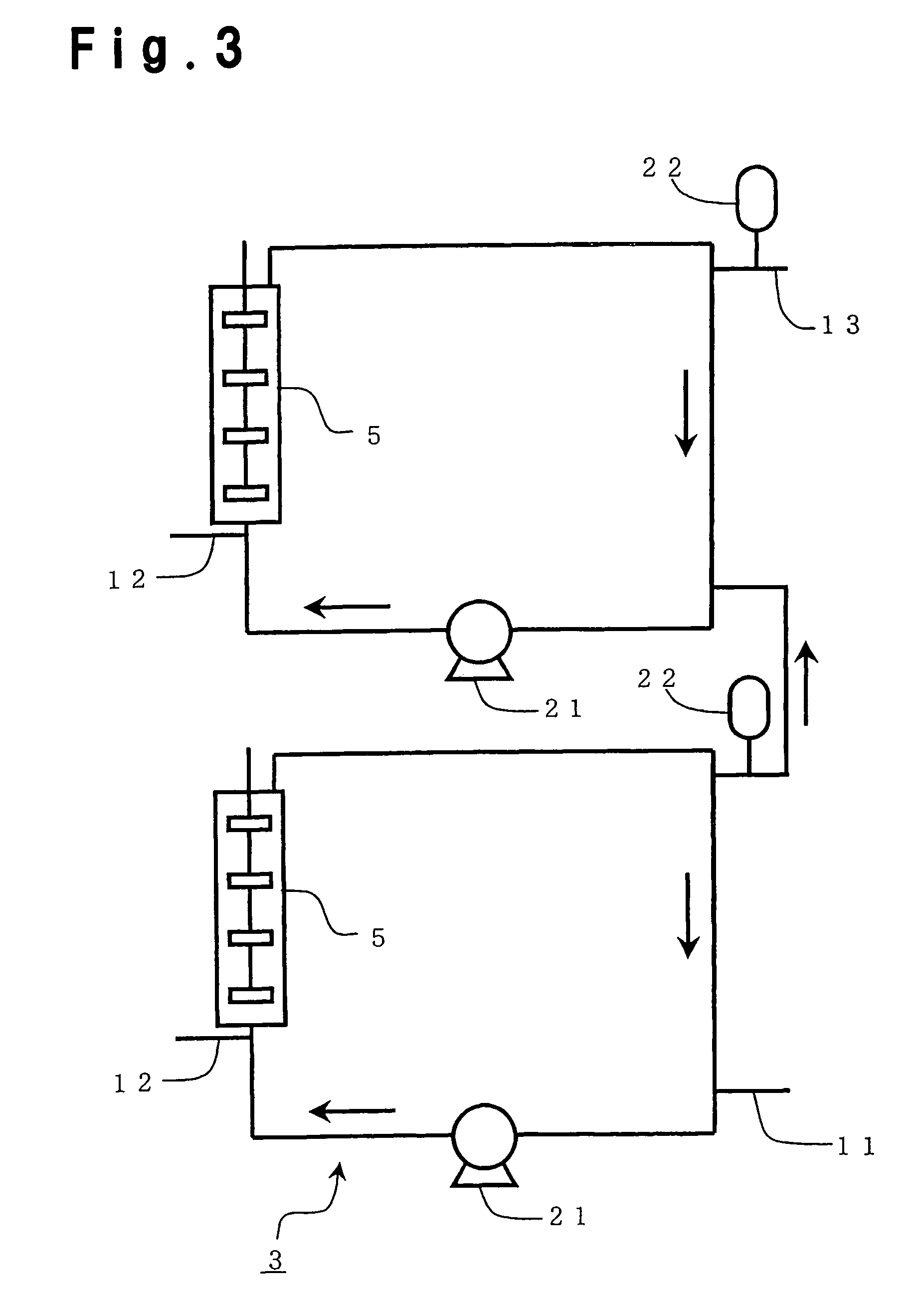

Method for continuously producing a polyether

A method for precisely producing a polyether having a relatively high molecular weight by means of a double metal cyanide complex catalyst is provided. A method for continuously producing a polyether, which comprises ring opening addition polymerization of an alkylene oxide in the presence of a double metal cyanide complex catalyst, wherein substantially no vapor phase part is present in a reactor.

Owner:ASAHI GLASS CO LTD

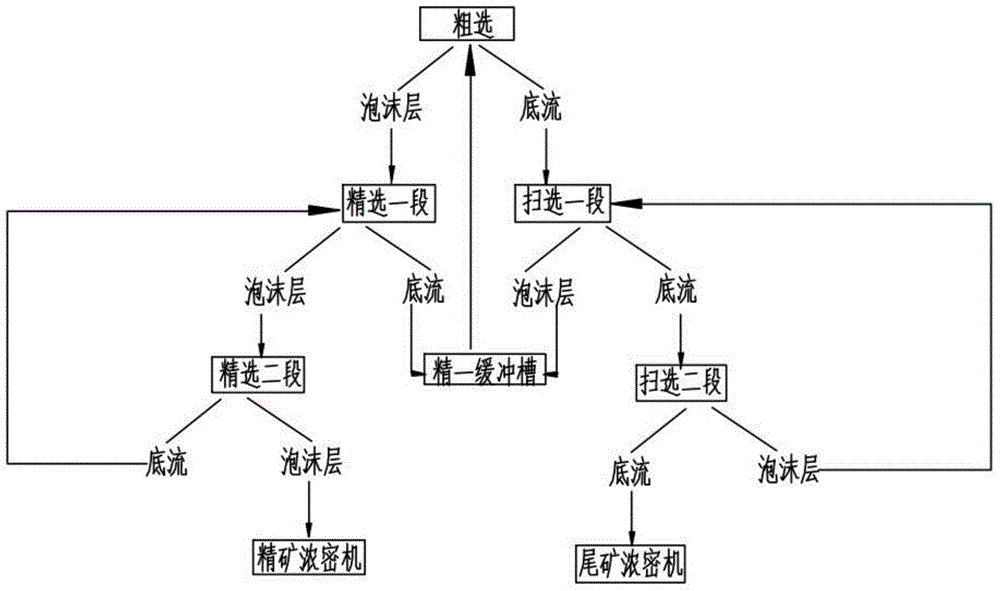

Comprehensive recycling method of cyanide tailing slag

ActiveCN103981370AEfficient separation and recoveryImprove utilization efficiencySolid waste managementSulfur compoundsCyanideSulfur

The invention belongs to the technical field of metallurgical waste slag recovery and in particular relates to a comprehensive recycling method of cyanide tailing slag. Cyanide tailings is floated to obtain sulfur concentrate and tailing, sulfur concentrate is roasted by weak oxygen to obtain sulfuric acid, and pyritic slag is subjected to chlorination roasting to enable valuable elements to be recycled. By virtue of the comprehensive recycling method disclosed by the invention, the valuable elements can be efficiently separated and recovered from cyanide tailing slag, and cyanide tailing slag is utilized to a maximum extent, the comprehensive utilization efficiency of resources is improved and the pollution of cyanide tailing slag to the environment is reduced.

Owner:ZHAOJIN MINING +1

Environmental non-cyanide plating solution for silver-plating

An environmental non-cyanide plating solution for silver-plating contains silver ion source, amino acid compound and derivative thereof used as complexant, auxiliary complexant and plating additive. The component ratio and the process condition are as follows: the contents of silver salt, amino acid compound and derivative thereof, auxiliary complexant and plating additive are separately 0.01-1mol / L, 0.01-10mol / L, 0.002-2mol / L and 0.001-2.0g / L, the pH value of silver-plating solution is 6-14 and the temperature of the silver-plating solution is 10-70 DEG C. Compared with the traditional cyanide-containing formulation for silver-plating, the environmental plating solution for silver-plating is characterized by clean plating; meanwhile the replacement rate between silver ions in the platingsolution and active metal such as copper, copper alloy and the like and alloy base is extremely slow, the one-step electroplating method is adopted for silver-plating, pre-plating and soaking processes of silver are not needed, and the coating is bright with good binding force.

Owner:FUJIAN NORMAL UNIV

Bicomponent epoxy adhesive and preparation thereof

ActiveCN101412896AHigh bonding strengthGood flexibilityOrganic non-macromolecular adhesiveEpoxy resin adhesivesAlcoholCyanide

The invention provides a double-component epoxy resin adhesive, wherein component A comprises epoxy resin and a toughening agent, and component B comprises a curing agent and a curing accelerator, wherein the component A also comprises an unsaturated functional monomer which is selected from one or more of olefinic acid, olefinic acid ester, olefinic cyanide and olefinic alcohol. The invention also provides a preparation method for the double-component epoxy resin adhesive. The double-component epoxy resin adhesive has the advantages of high adhesive strength and good flexibility, and the preparation method has the advantages of simple process and easy operation.

Owner:HAIAN JIAHE CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com