Patents

Literature

831 results about "Hydantoin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydantoin, or glycolylurea, is a heterocyclic organic compound with the formula CH₂C(O)NHC(O)NH. It is a colorless solid that arises from the reaction of glycolic acid and urea. It is an oxidized derivative of imidazolidine. In a more general sense, hydantoins can refer to a groups and a class of compounds with the same ring structure as the parent. For example, phenytoin (mentioned below) has two phenyl groups substituted onto the number 5 carbon in a hydantoin molecule.

Diarylhydantoin compounds

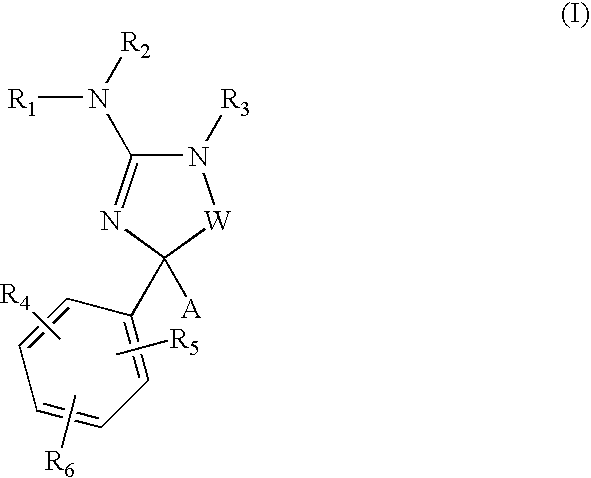

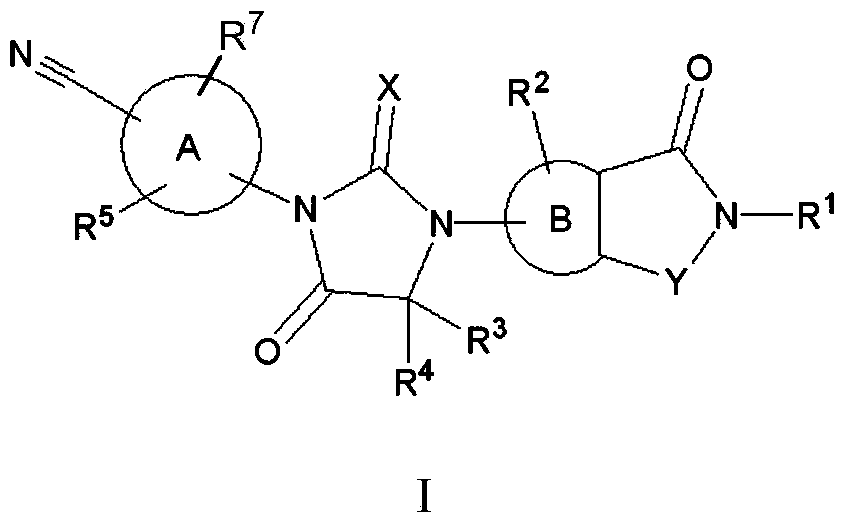

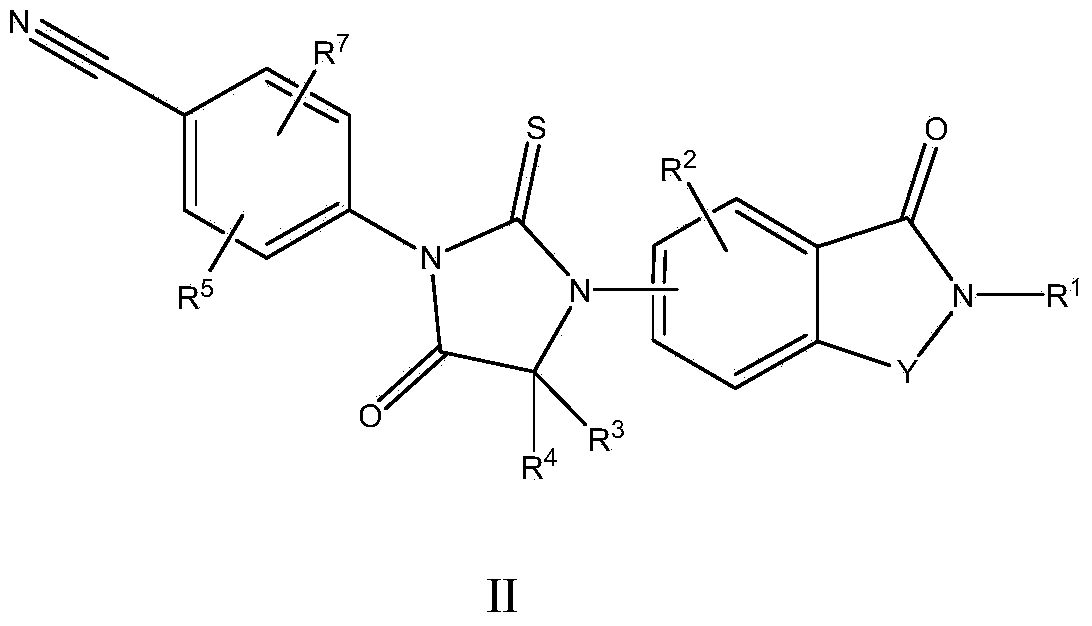

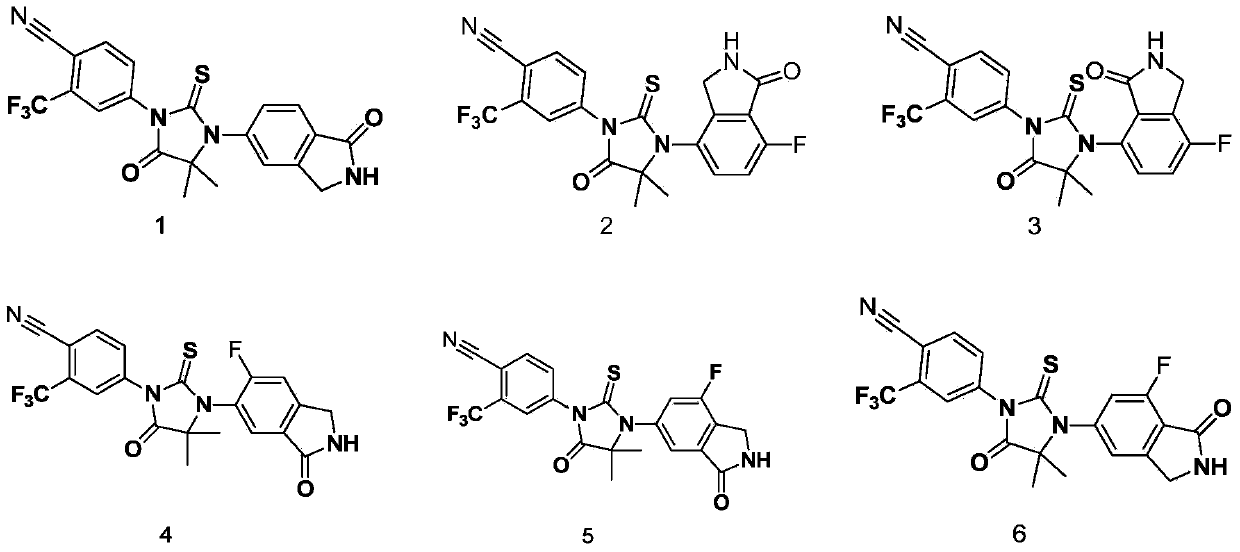

The present invention relates to diarylhydantoin compounds, including diarylthiohydantoins, and methods for synthesizing them and using them in the treatment of hormone refractory prostate cancer.

Owner:RGT UNIV OF CALIFORNIA

Diarylhydantoin compounds

The present invention relates to diarylhydantoin compounds, including diarylthiohydantoins, and methods for synthesizing them and using them in the treatment of hormone refractory prostate cancer.

Owner:RGT UNIV OF CALIFORNIA

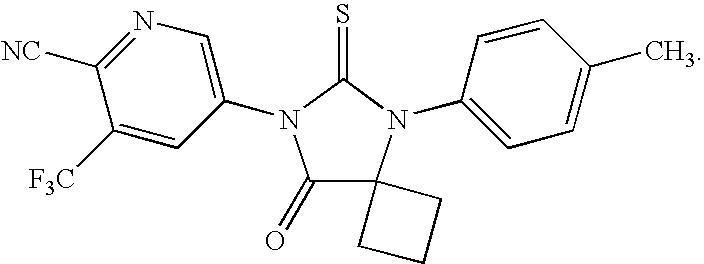

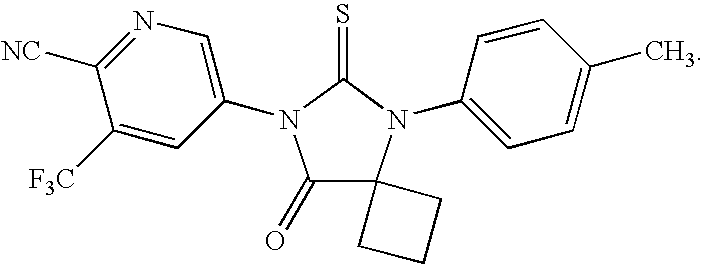

Diarylthiohydantoin compounds

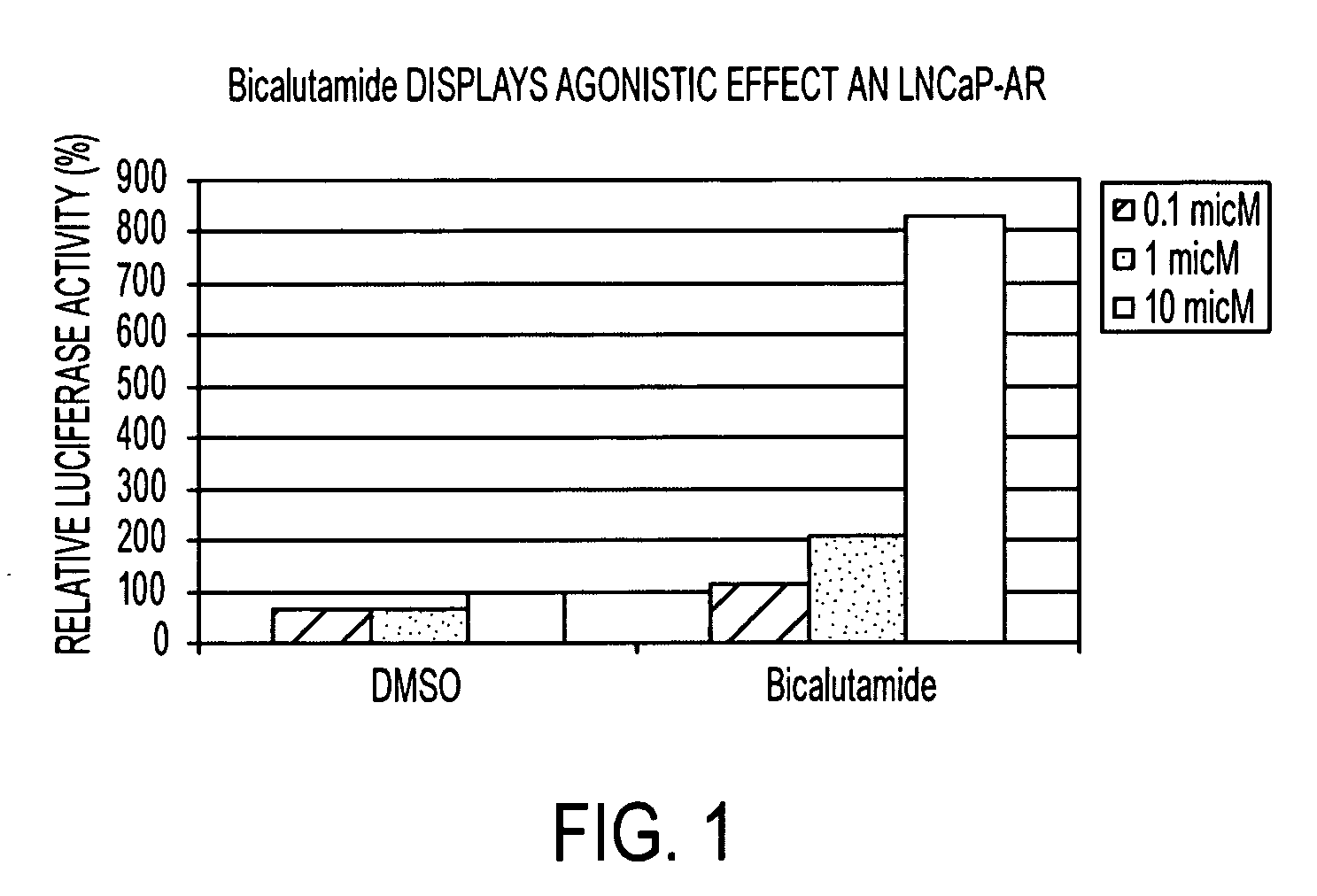

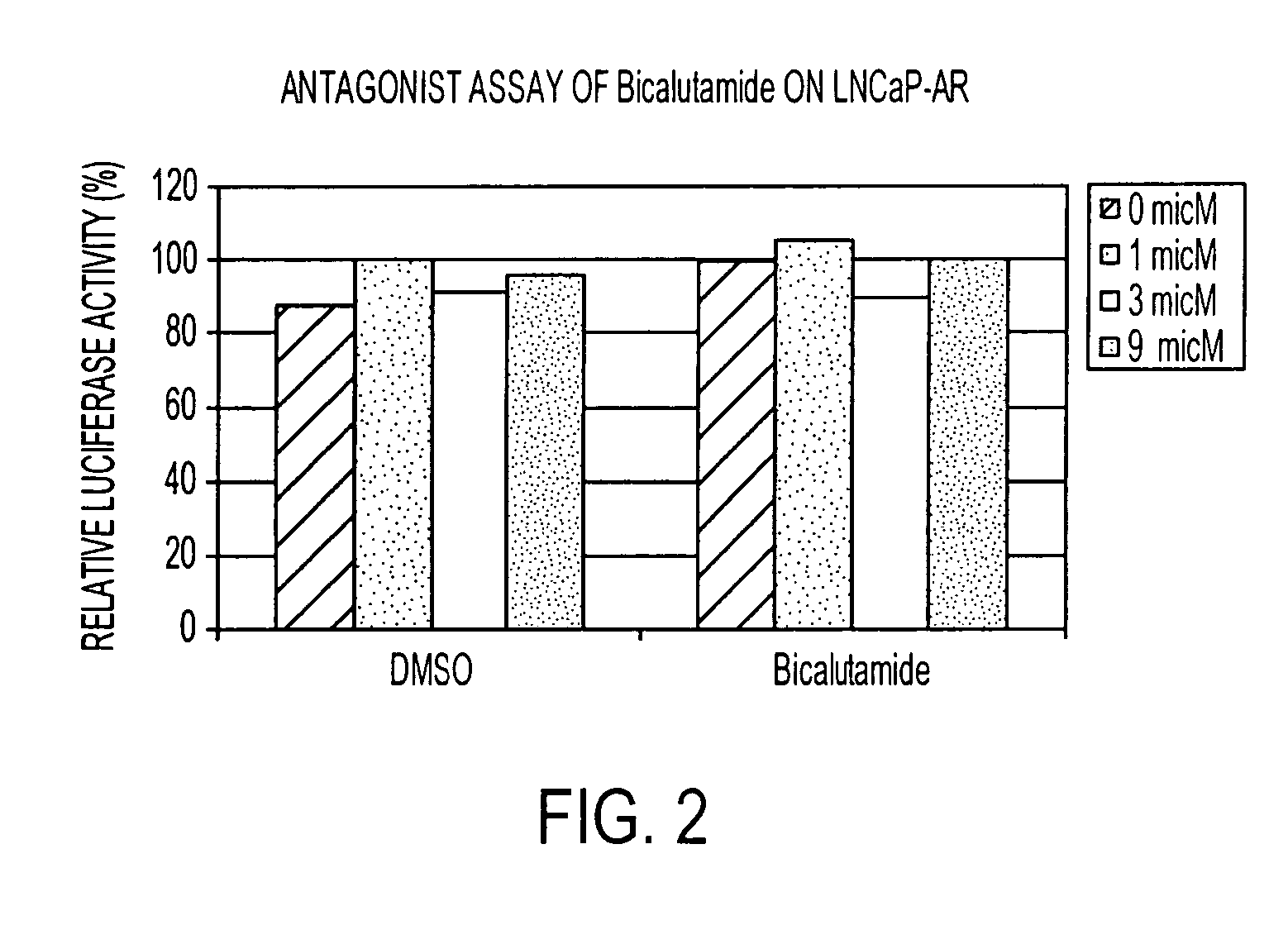

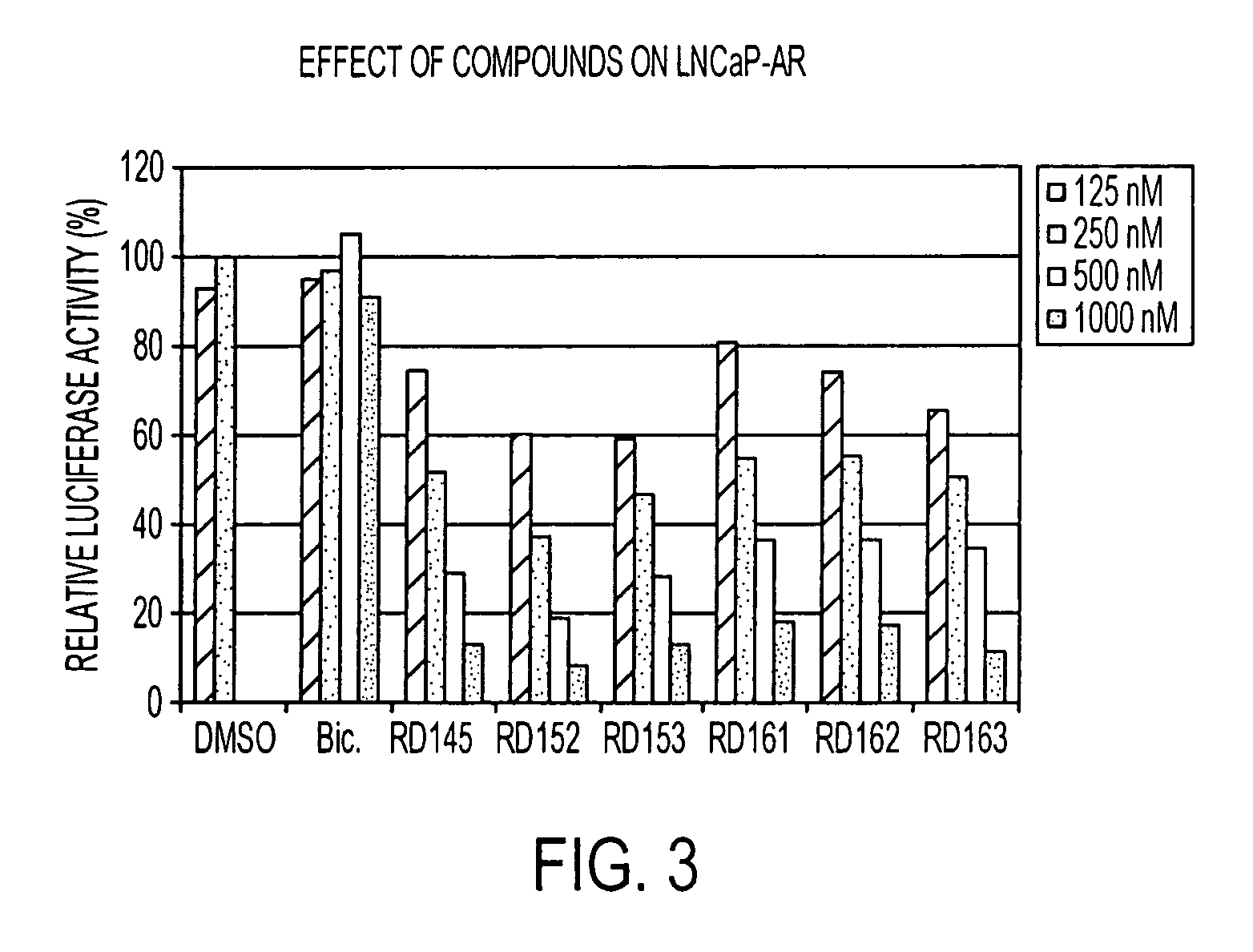

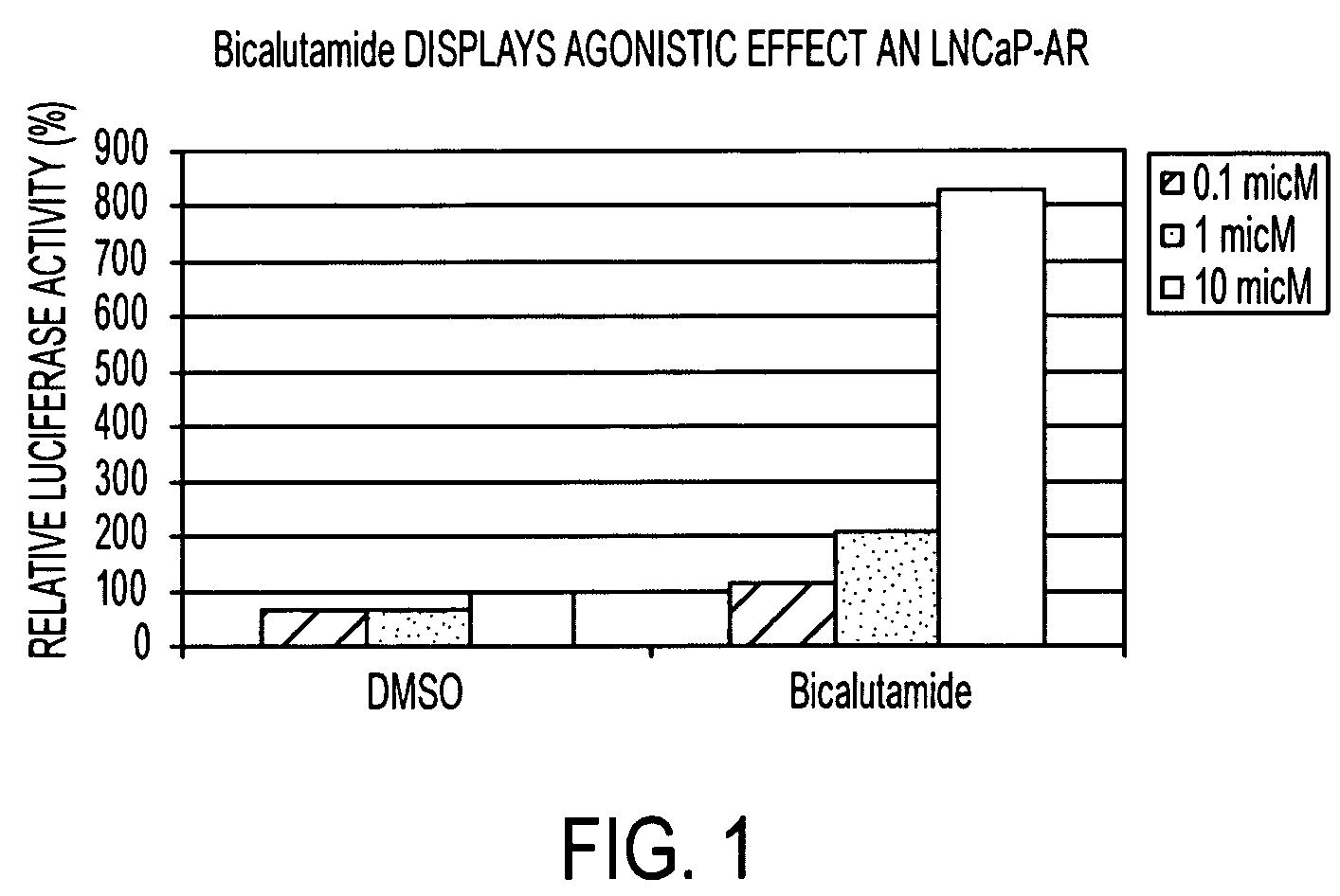

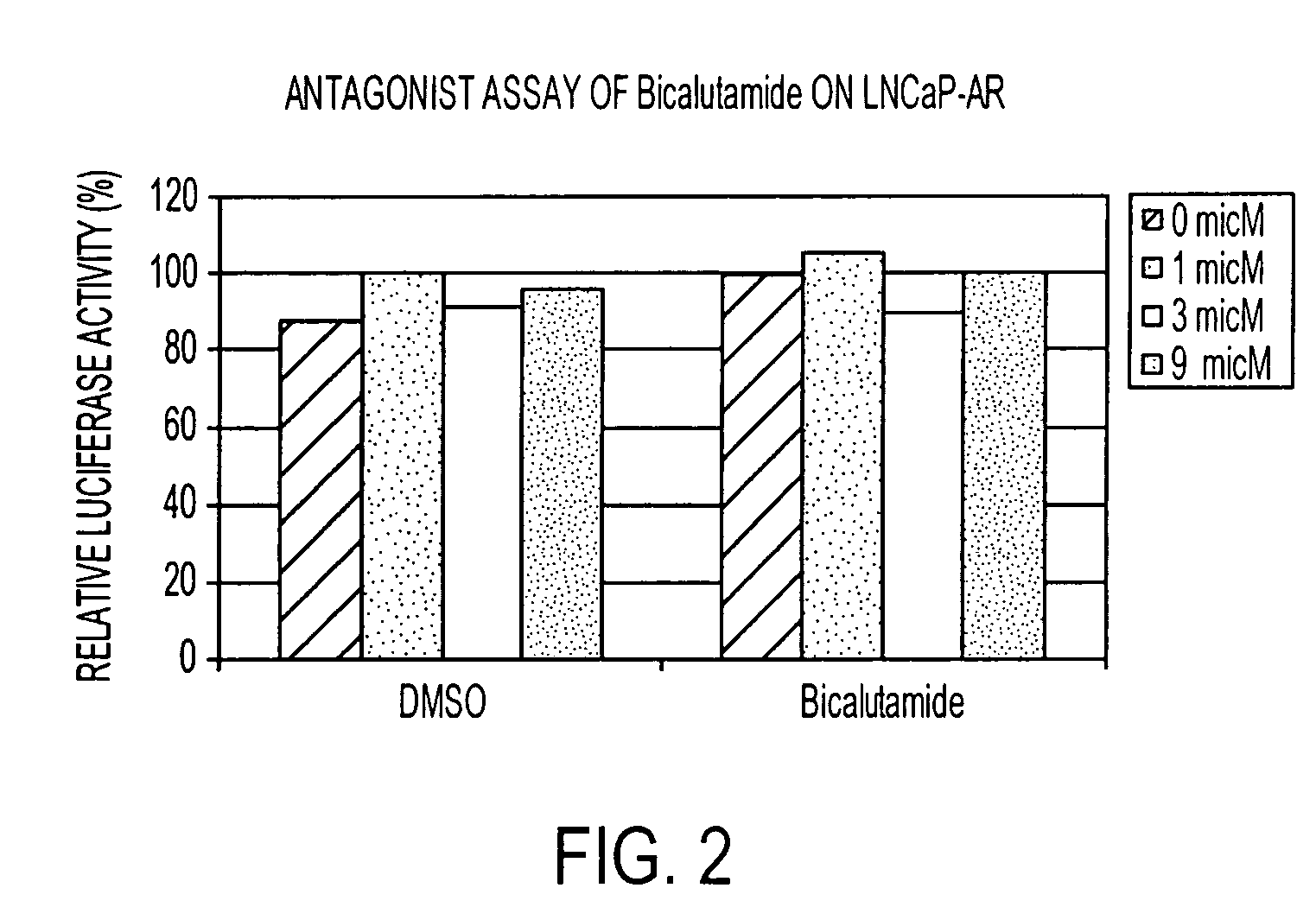

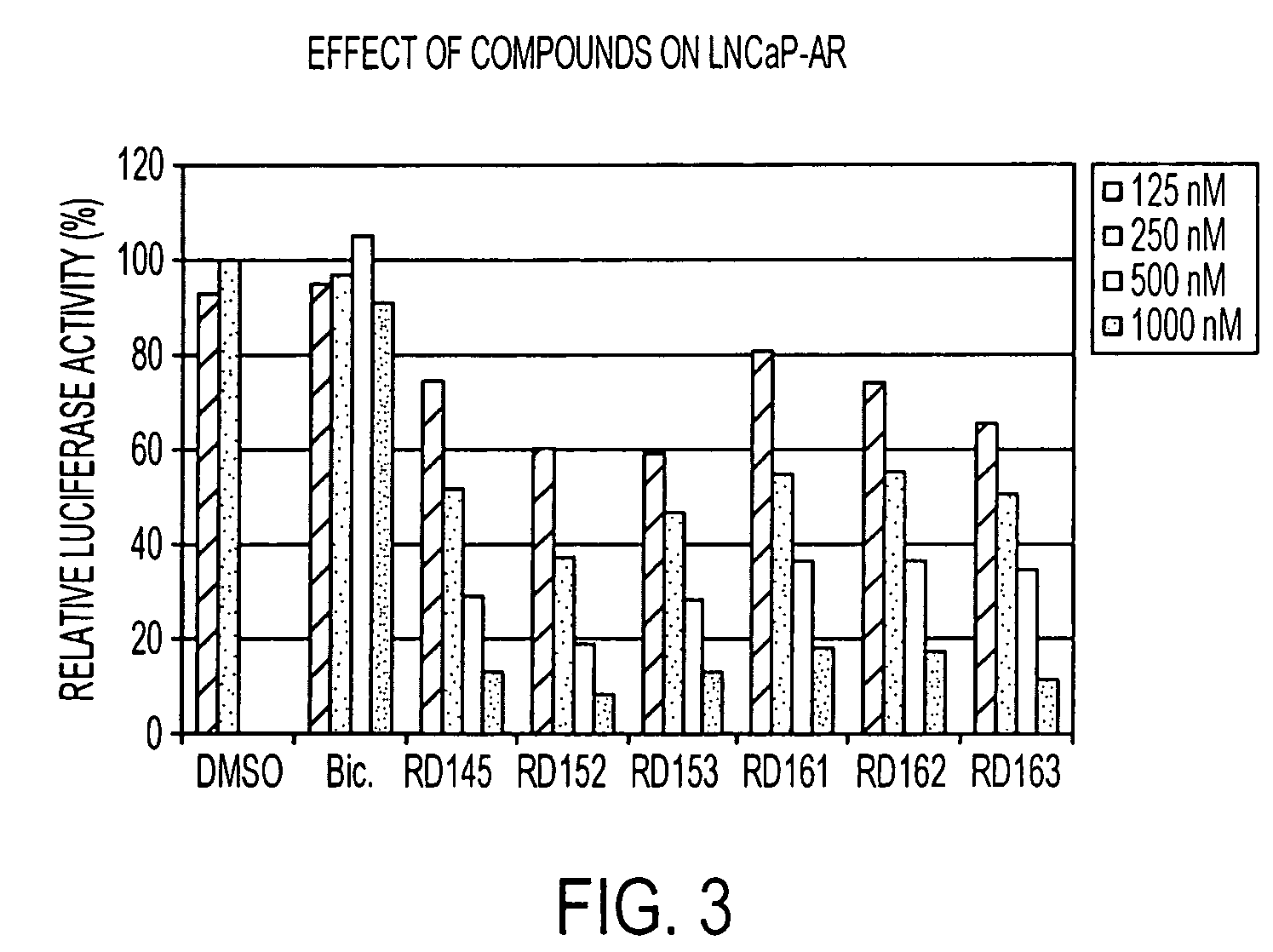

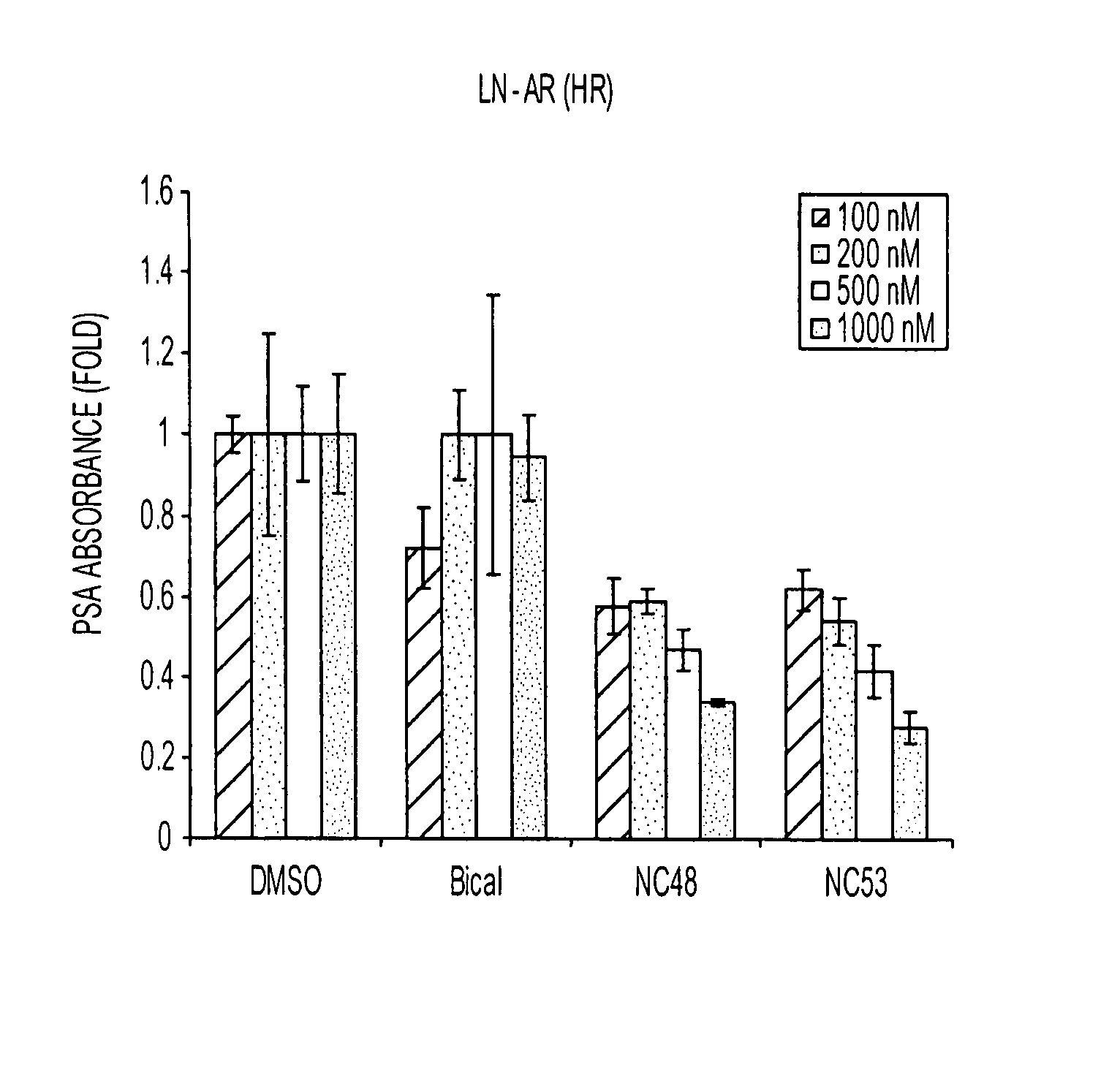

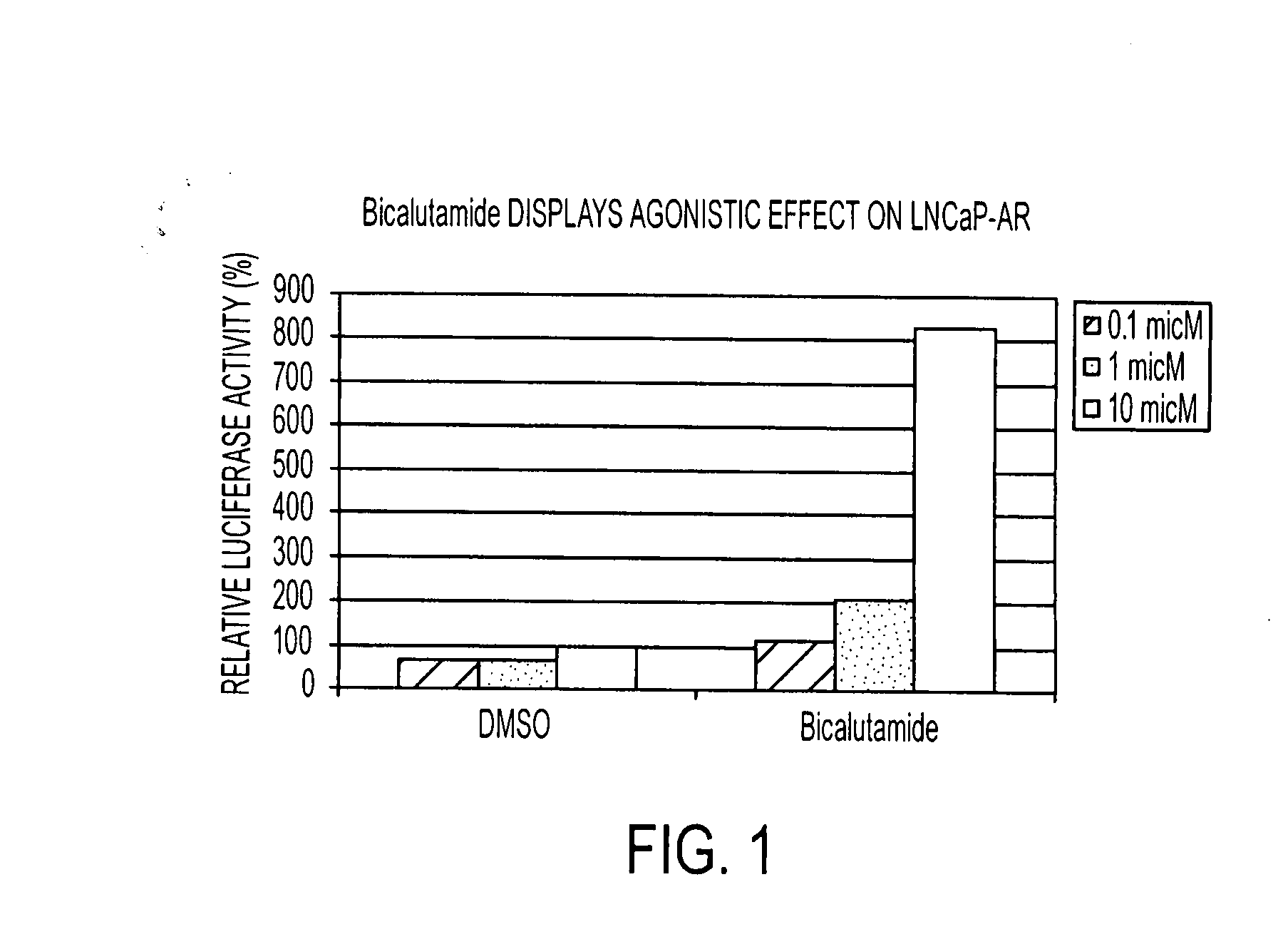

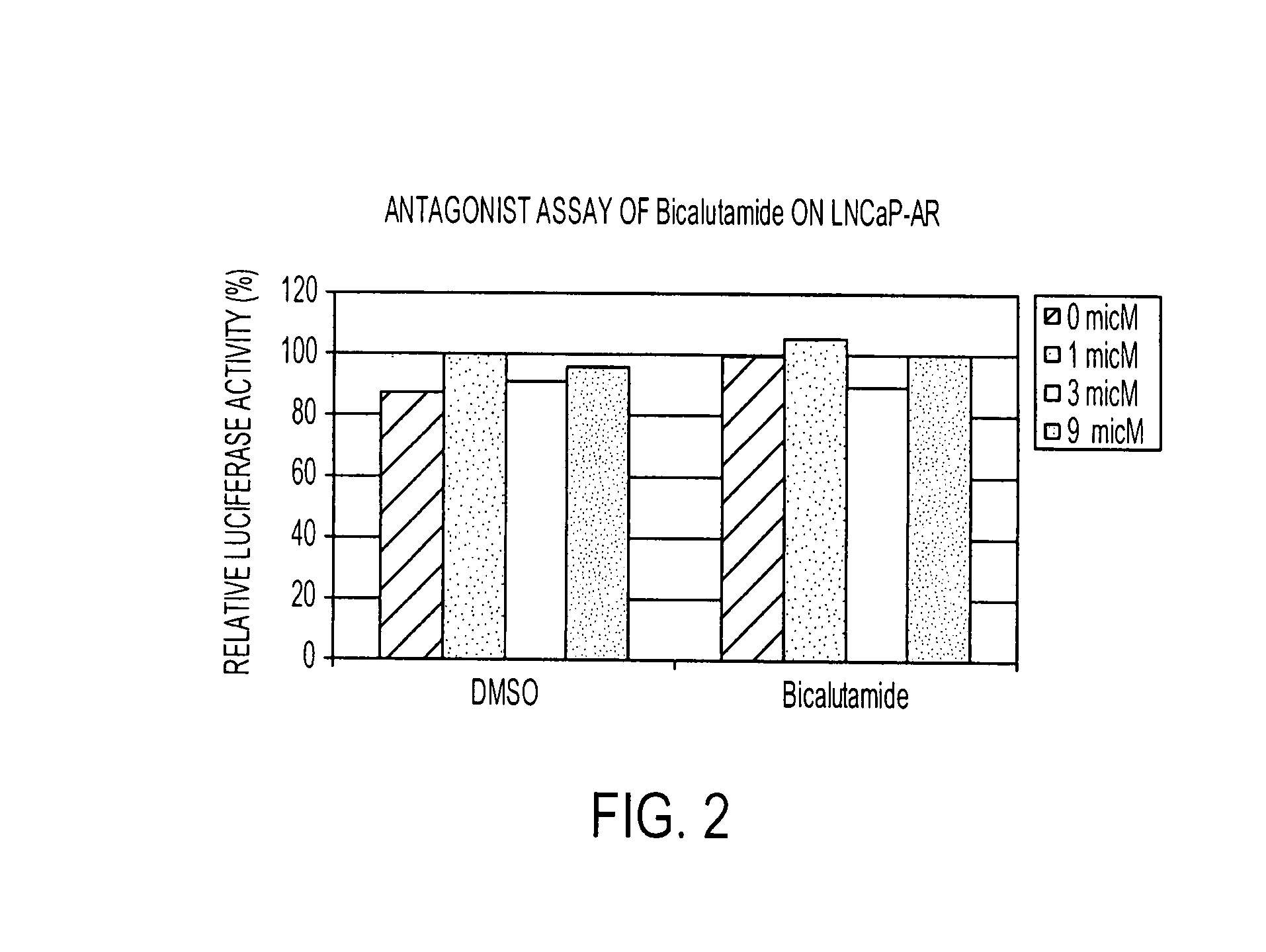

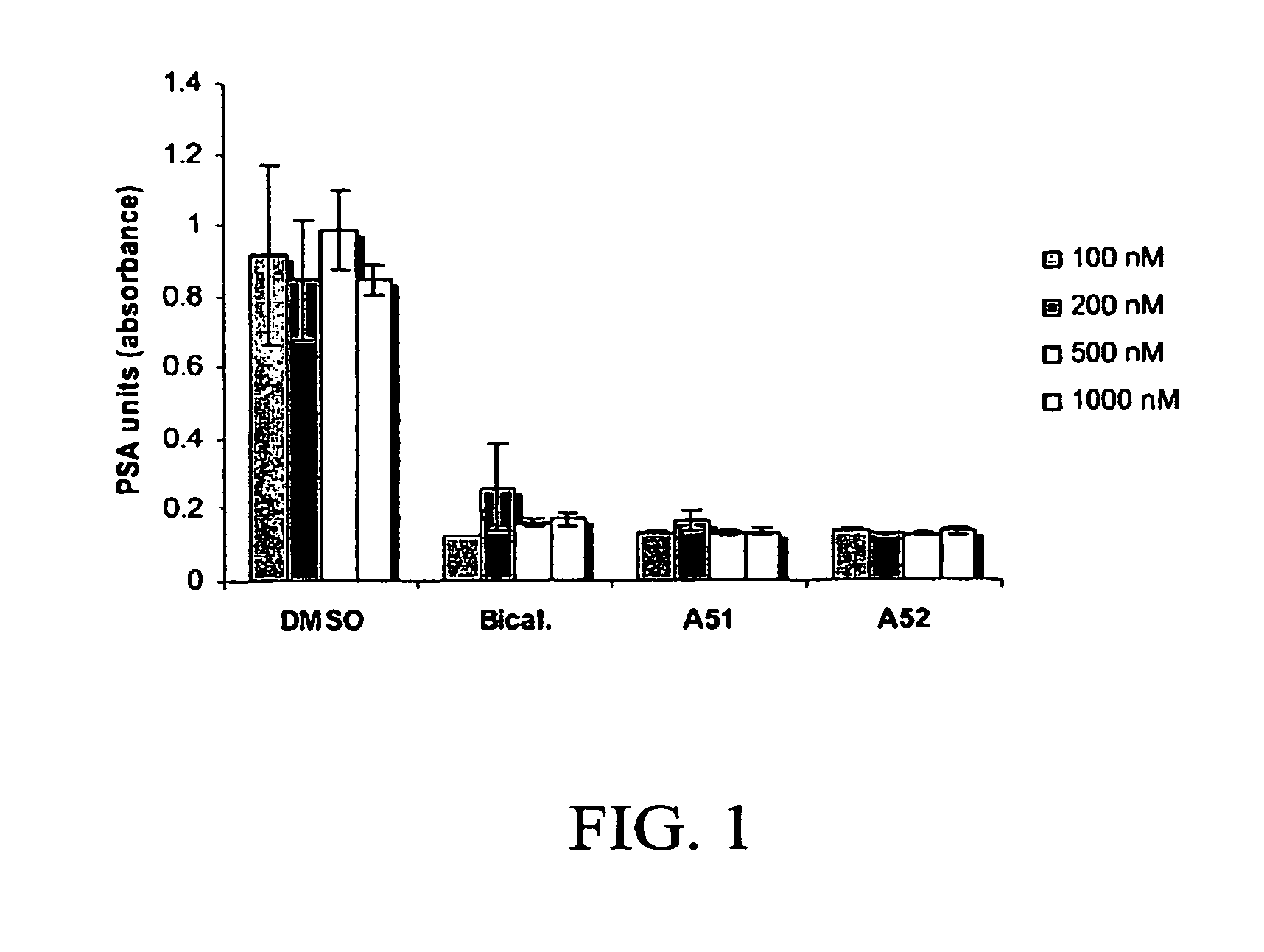

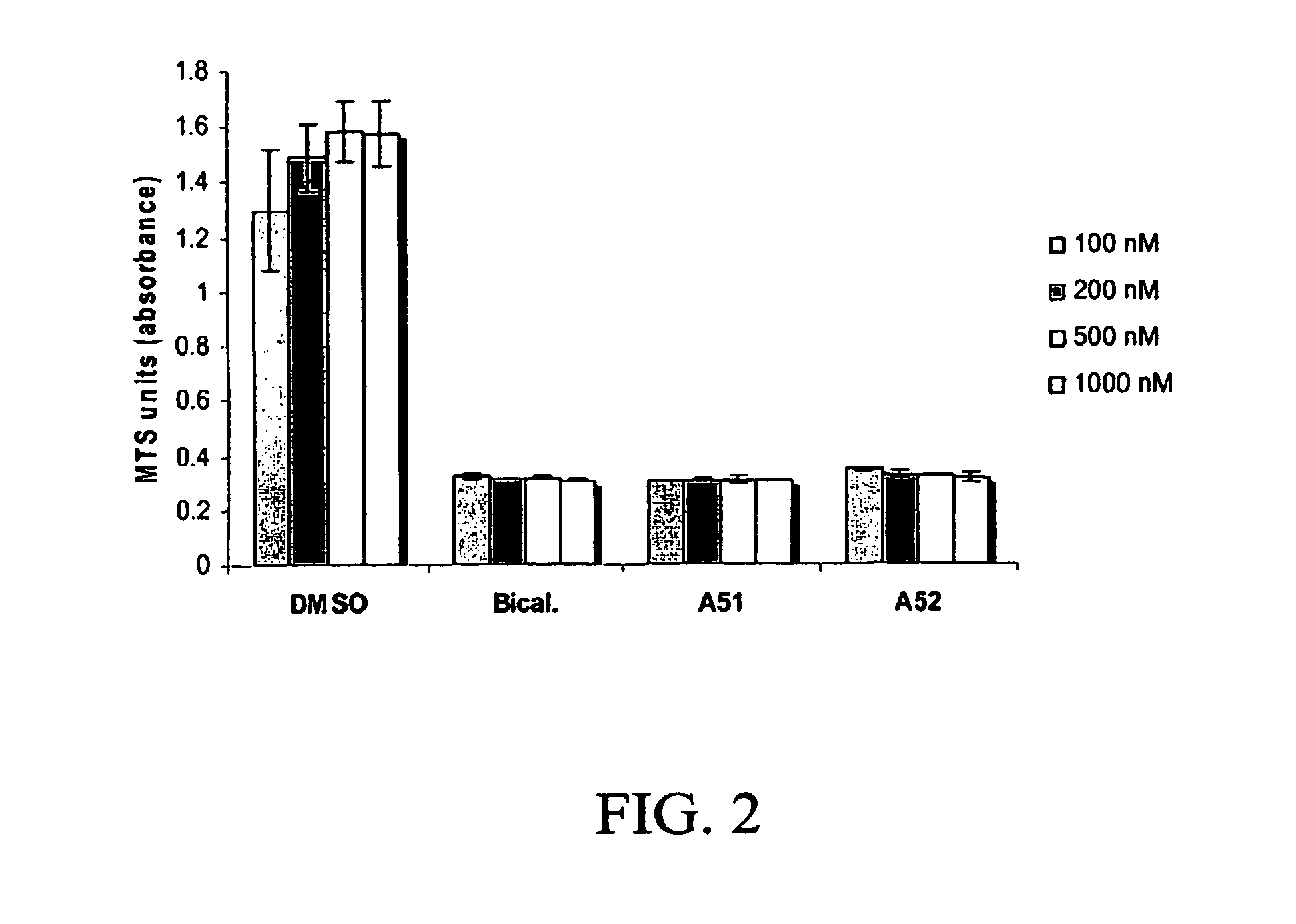

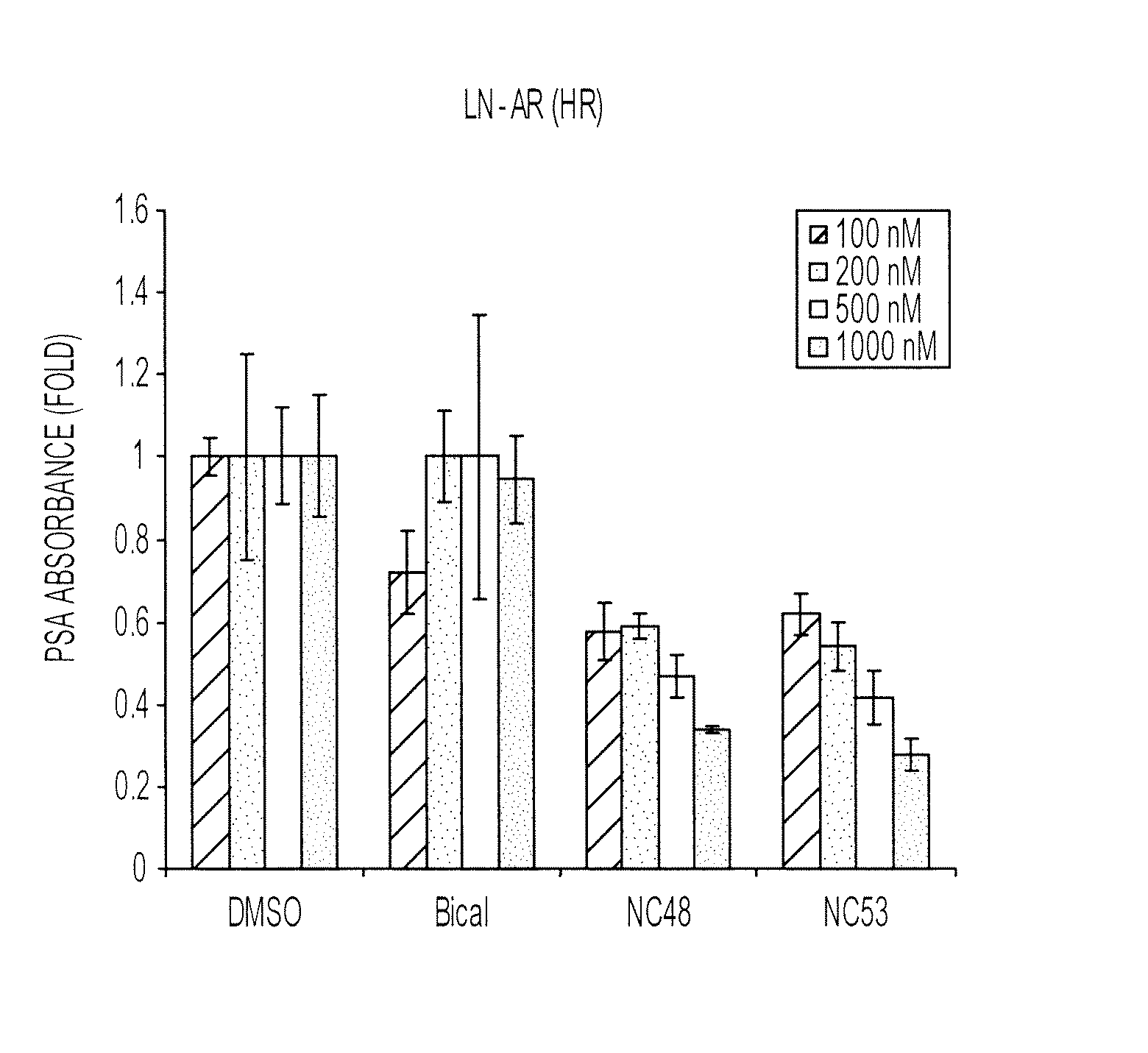

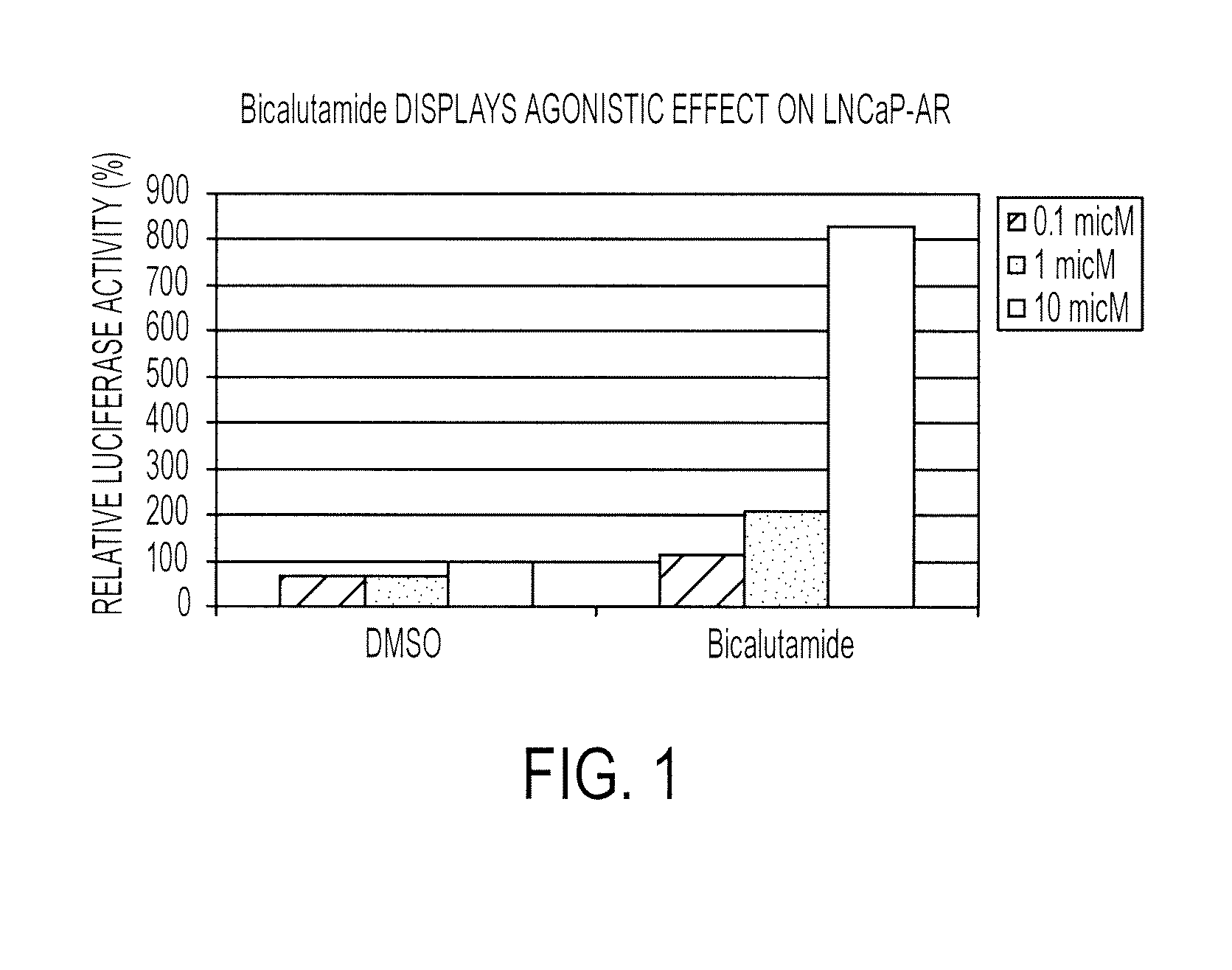

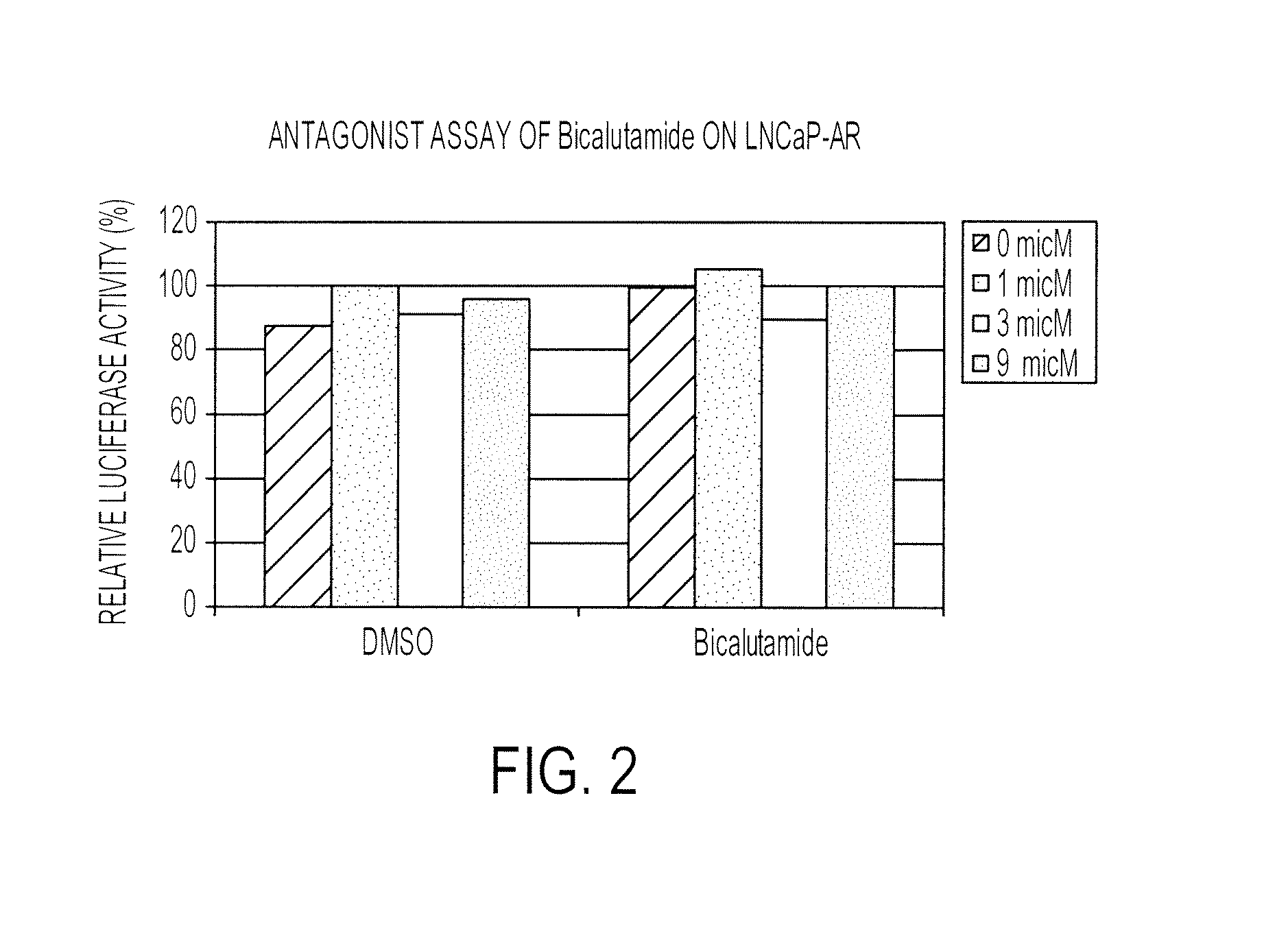

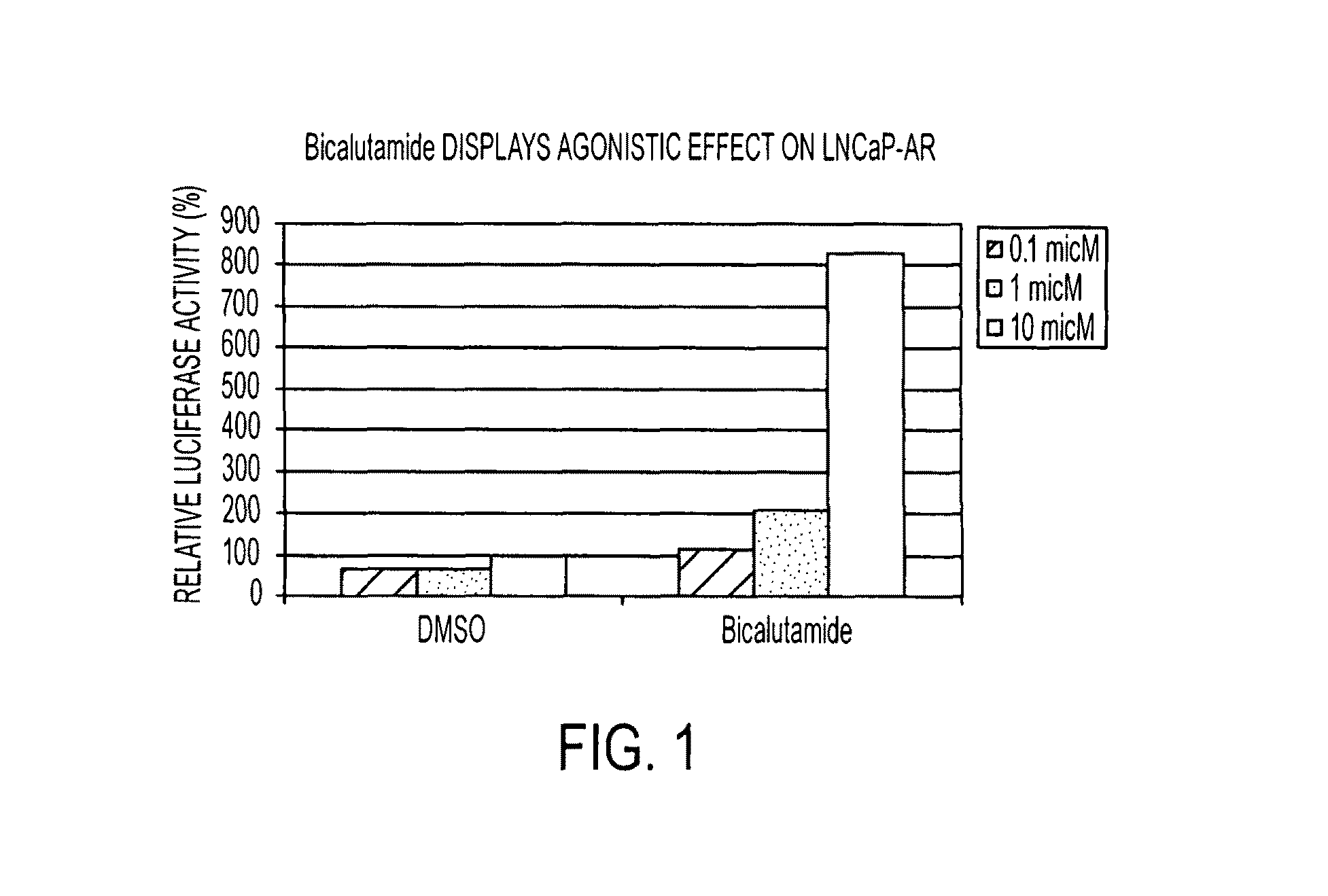

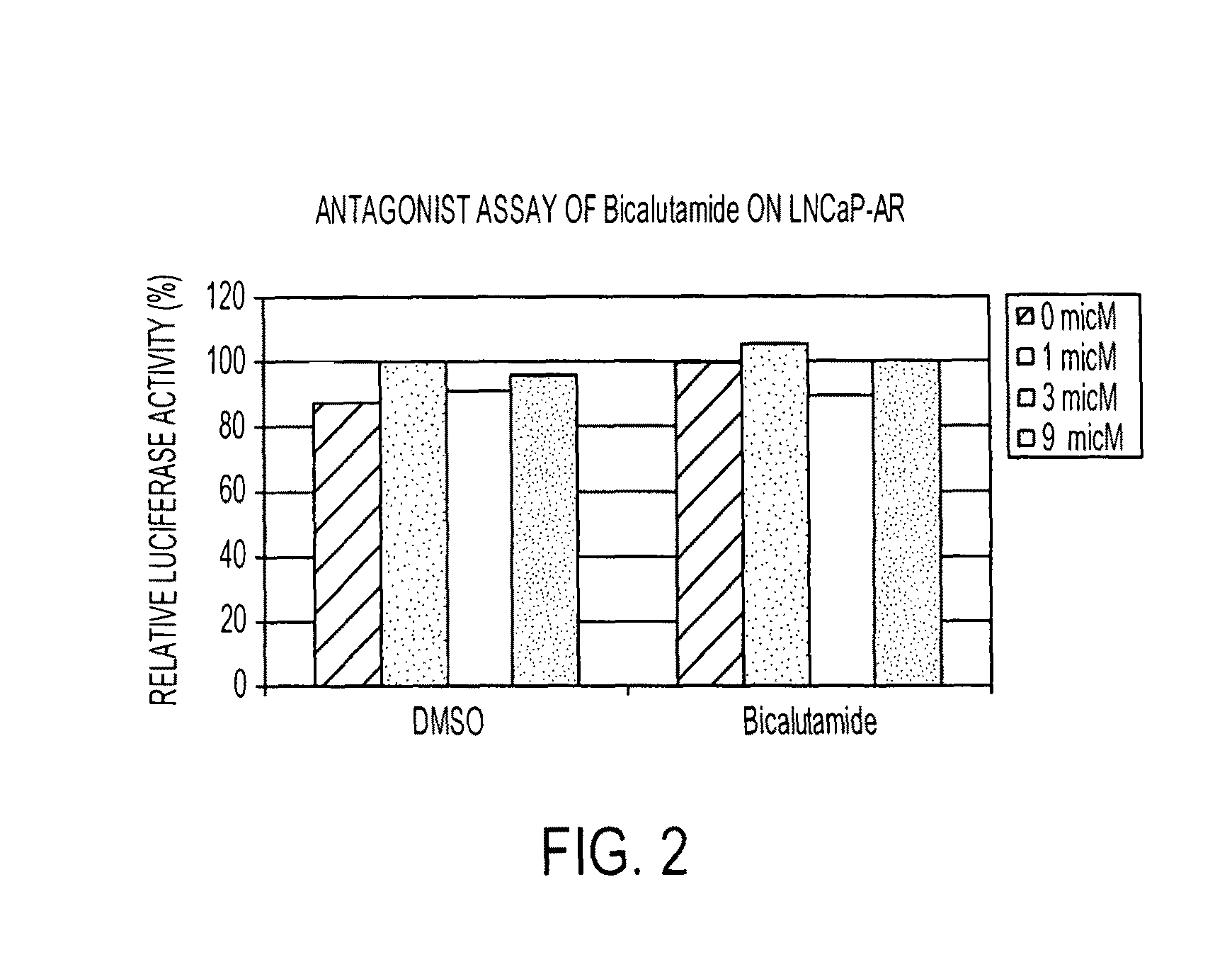

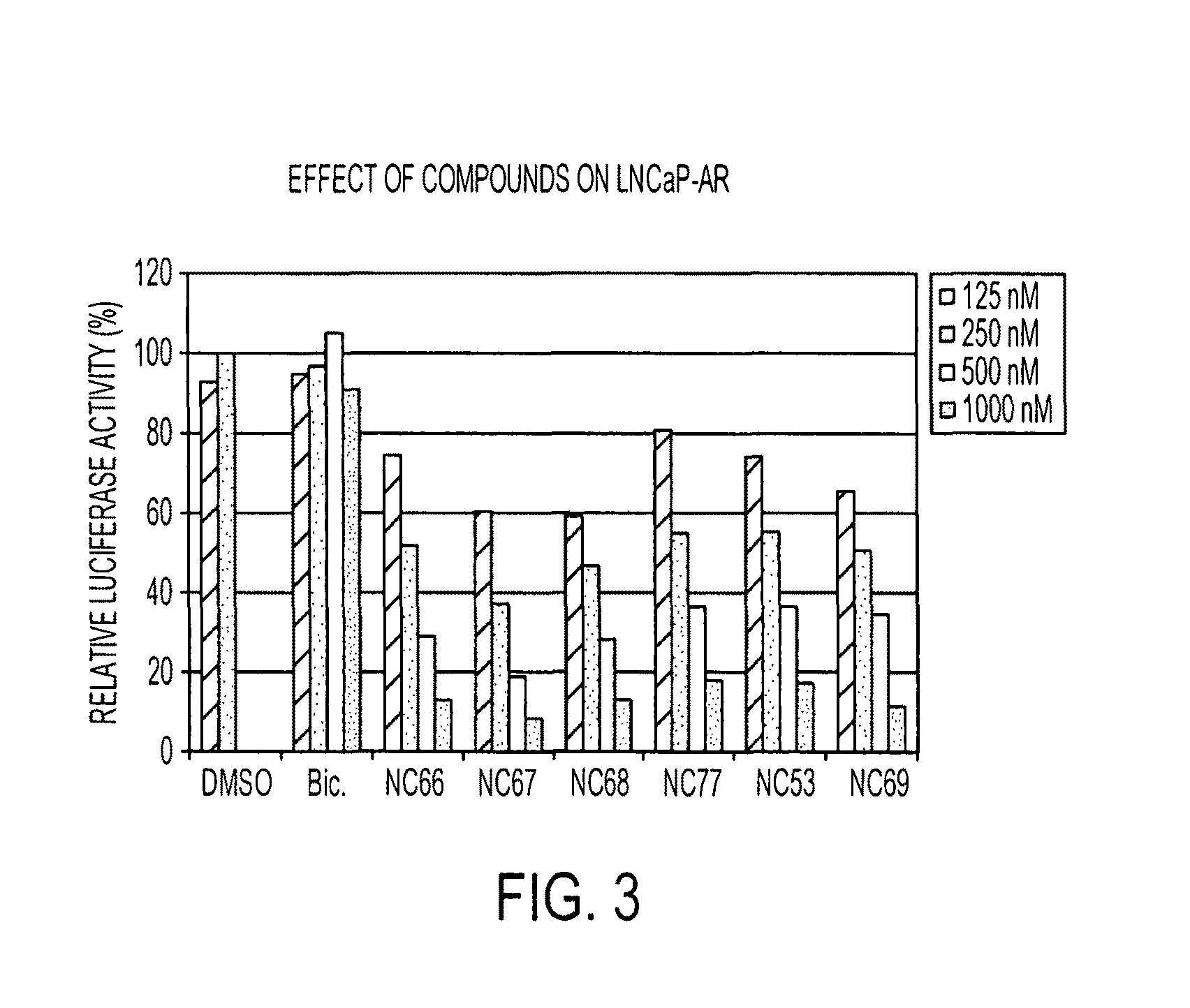

ActiveUS20070254933A1Avoid problemsPrevent nuclear translocationOrganic active ingredientsBiocideHormone refractory prostate cancerPharmacology

The present invention relates to diarylthiohydantoin compounds and methods for synthesizing them and using them in the treatment of hormone refractory prostate cancer.

Owner:RGT UNIV OF CALIFORNIA

Androgen receptor modulator for the treatment of prostate cancer and androgen receptor-associated diseases

A hydantoin compound useful for the prevention or treatment of hyperproliferative diseases or disorders.

Owner:RGT UNIV OF CALIFORNIA

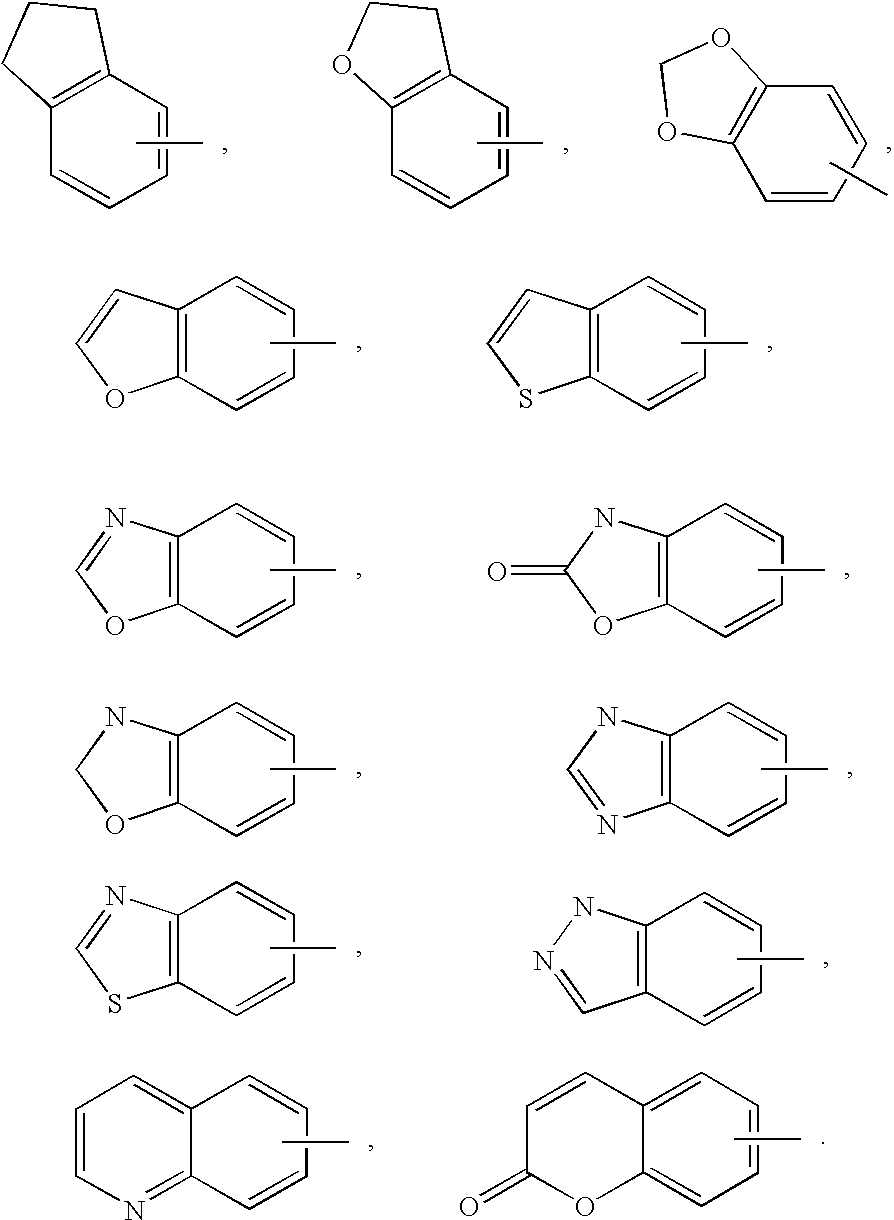

Monocyclic N-aryl hydantoin modulators of androgen receptor function

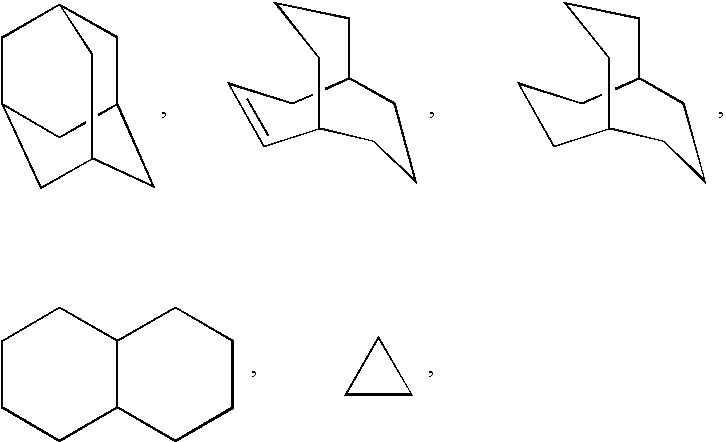

The present invention relates to novel compounds useful in the treatment of androgen receptor associated conditions, such as age-related diseases, pharmaceutical compositions containing at least one of the compounds of the present invention and methods of treating a patient in need of therapy for an androgen receptor associated condition by administering a therapeutically effective amount of at least compound of the present invention.

Owner:BRISTOL MYERS SQUIBB CO

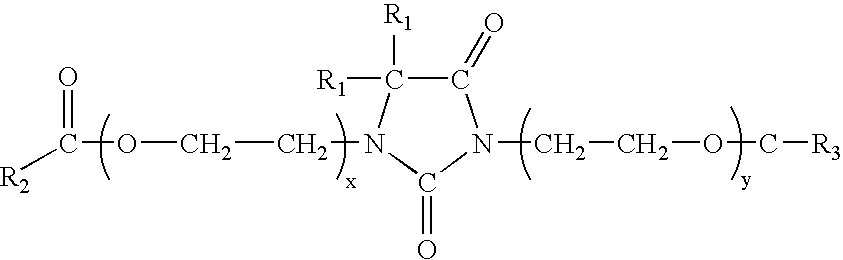

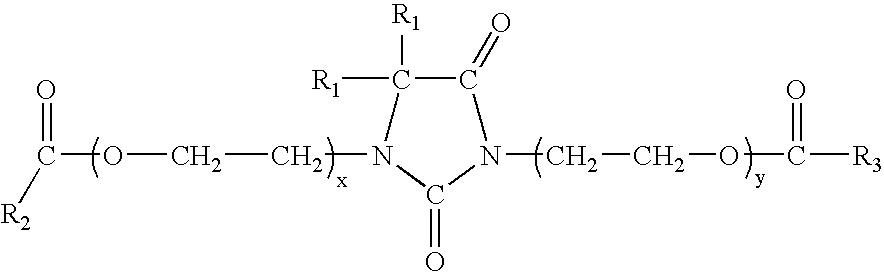

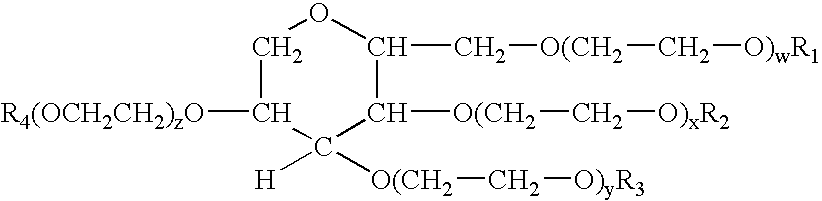

Non-wood fiber plastic composites

This invention is directed to an extrudable compound, an extrusion method using a polymer, a cellulosic fiber, and at least one lubricant selected from the group consisting of ethoxylated esters of hydantoins, ethoxylated esters of sorbitol and sorbitan, and ethylene bisamides made from fatty acids containing 6-10 carbons and composites manufactured through such processes which simulate conventional wood products. Another embodiment of the invention is directed to a composition containing polymer, a cellulosic fiber from an agricultural waste product and a lubricant containing a mixture of an alkylene bisamide derived from a C10-C18 is fatty acid and an alkaline earth salt of a fatty acid.

Owner:ARXADA LLC

Diarylthiohydantoin compounds

ActiveUS20080139634A2Avoid translocationDestabilize an androgen receptor proteinOrganic active ingredientsBiocideHormone refractory prostate cancerPharmacology

Owner:RGT UNIV OF CALIFORNIA

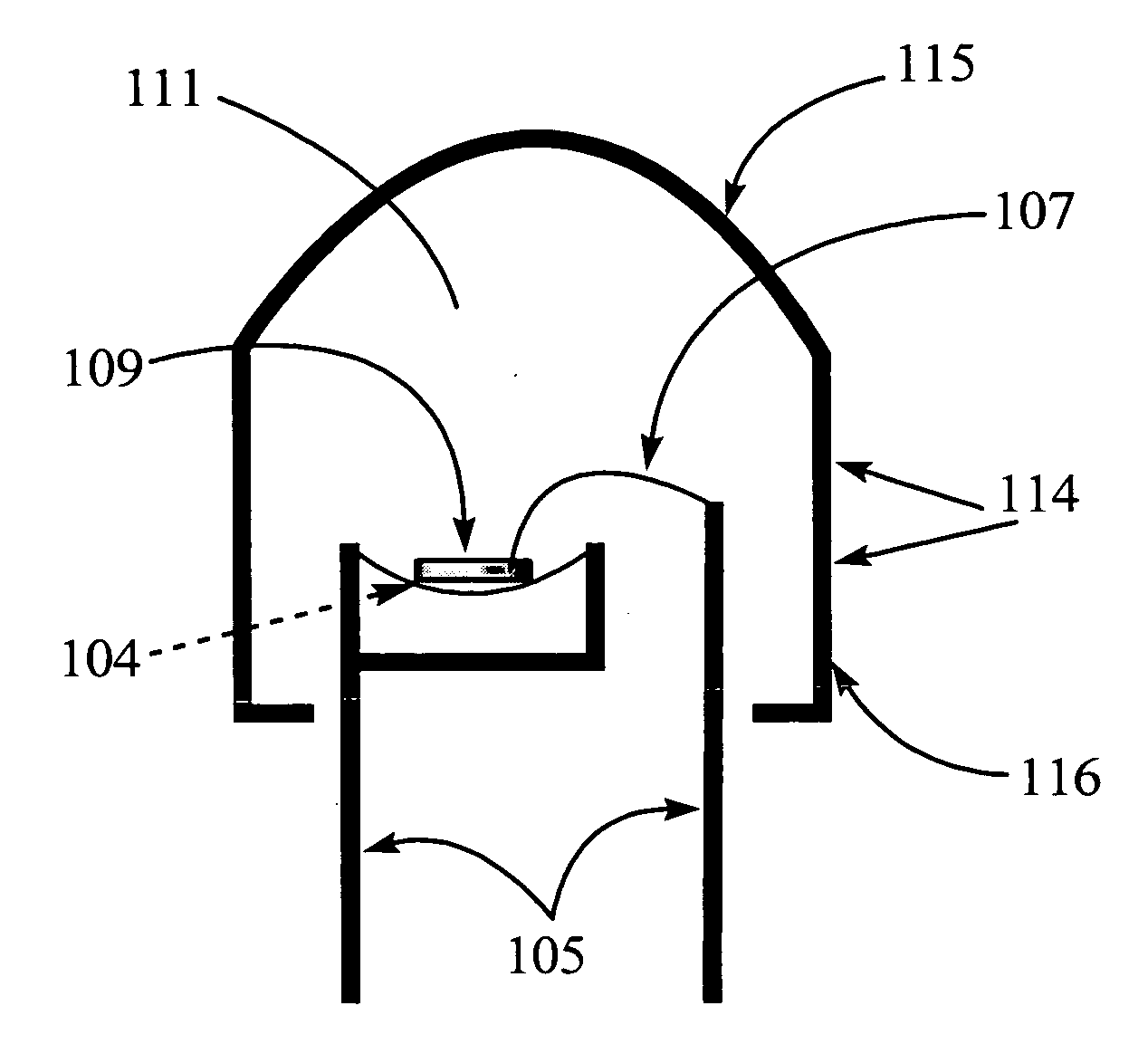

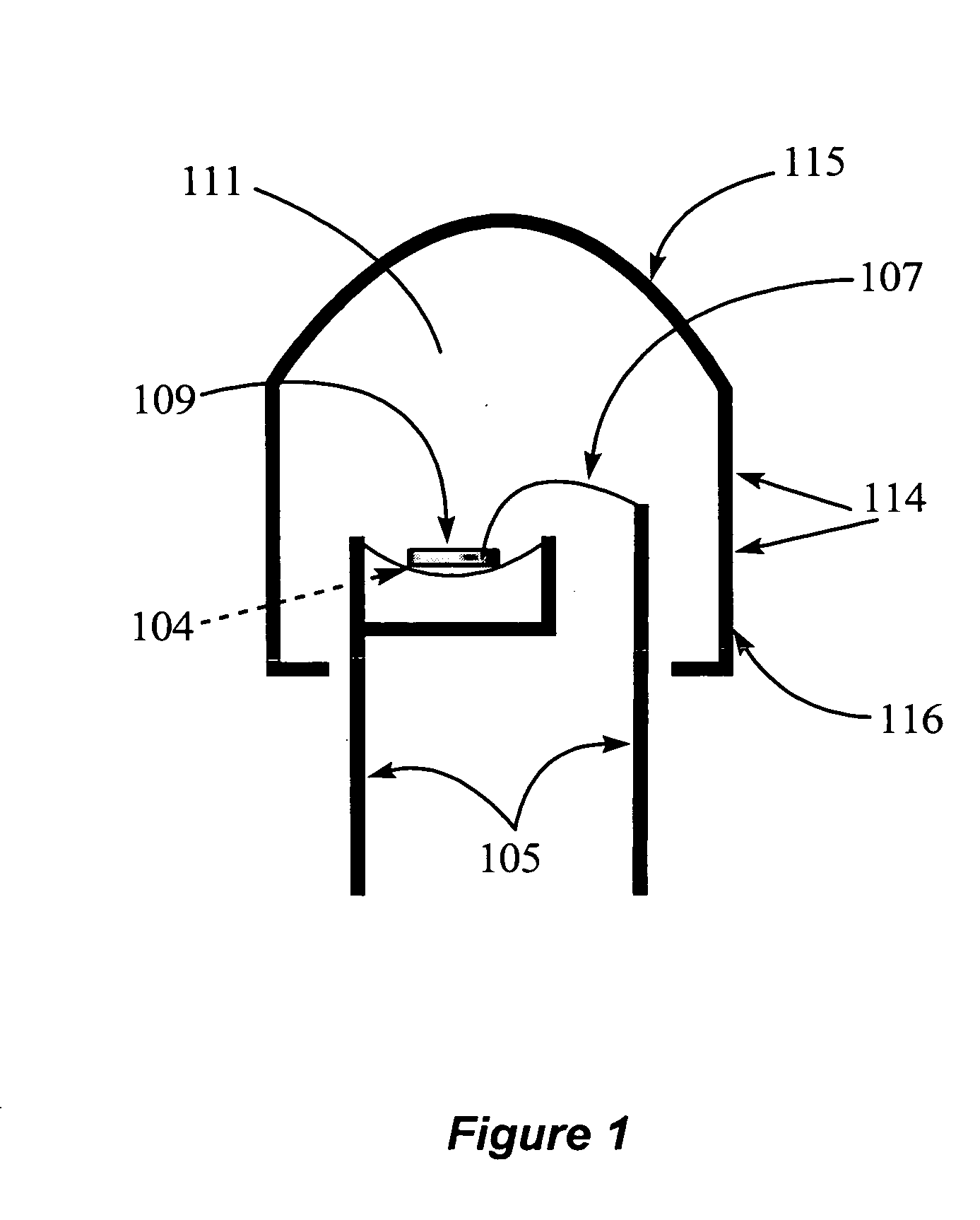

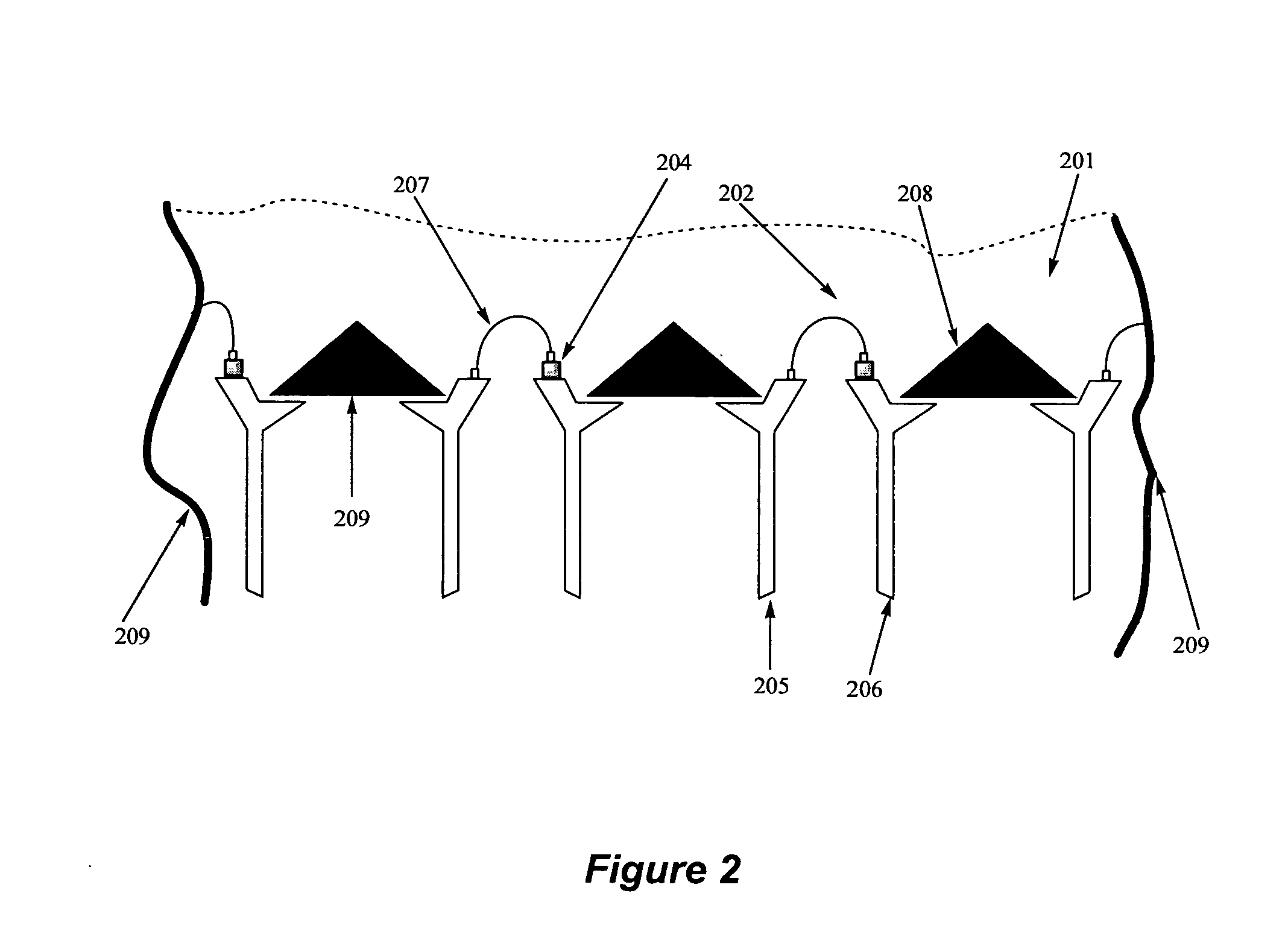

Optoelectronic device

The present invention provides an optoelectronic device comprising a light emitting semiconductor and an encapsulant. The encapsulant is made from an encapsulant formulation comprising an epoxy hydantoin, an epoxy isocyanurate, and a curing agent. The present invention also provides a method of preparing such optoelectronic device.

Owner:GELCORE LLC (US)

Substituted hydantoins

The present invention relates to compounds of the formulamethods for the preparation thereof, and methods for their use. The compounds are useful in treating diseases characterized by the hyperactivity of MEK. Accordingly the compounds are useful in the treatment of diseases, such as cancer, cognitive and CNS disorders, and inflammatory / autoimmune diseases.

Owner:F HOFFMANN LA ROCHE & CO AG

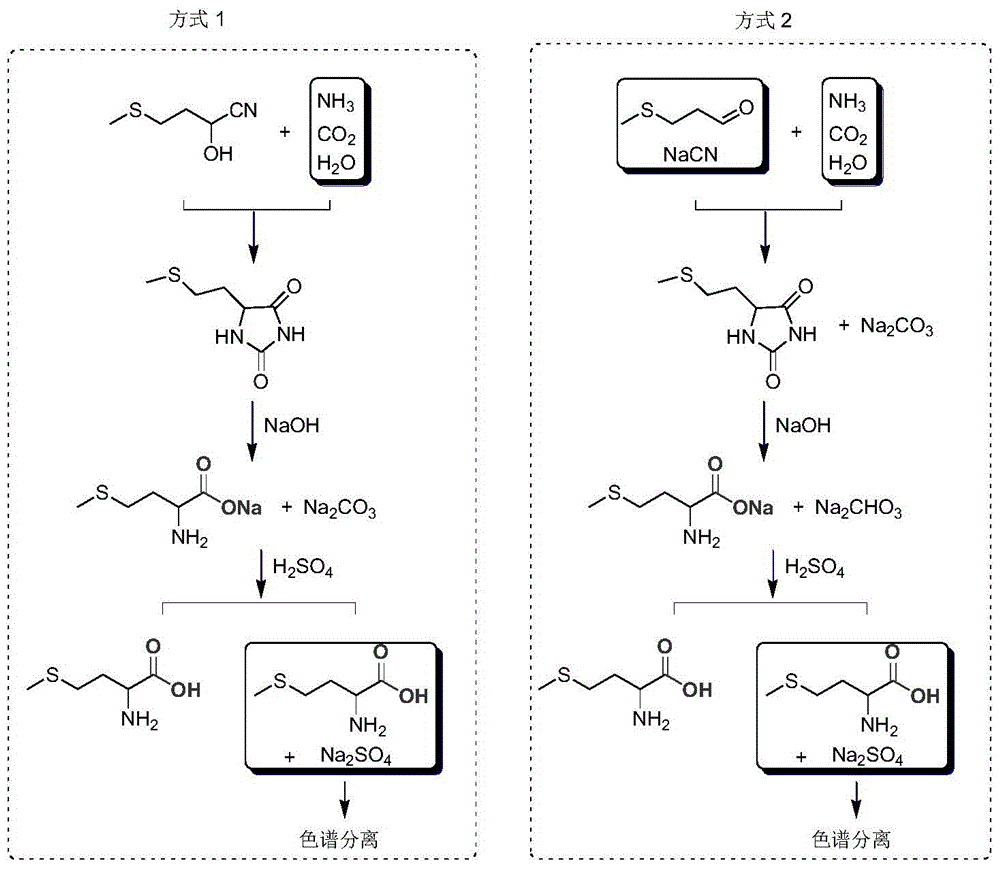

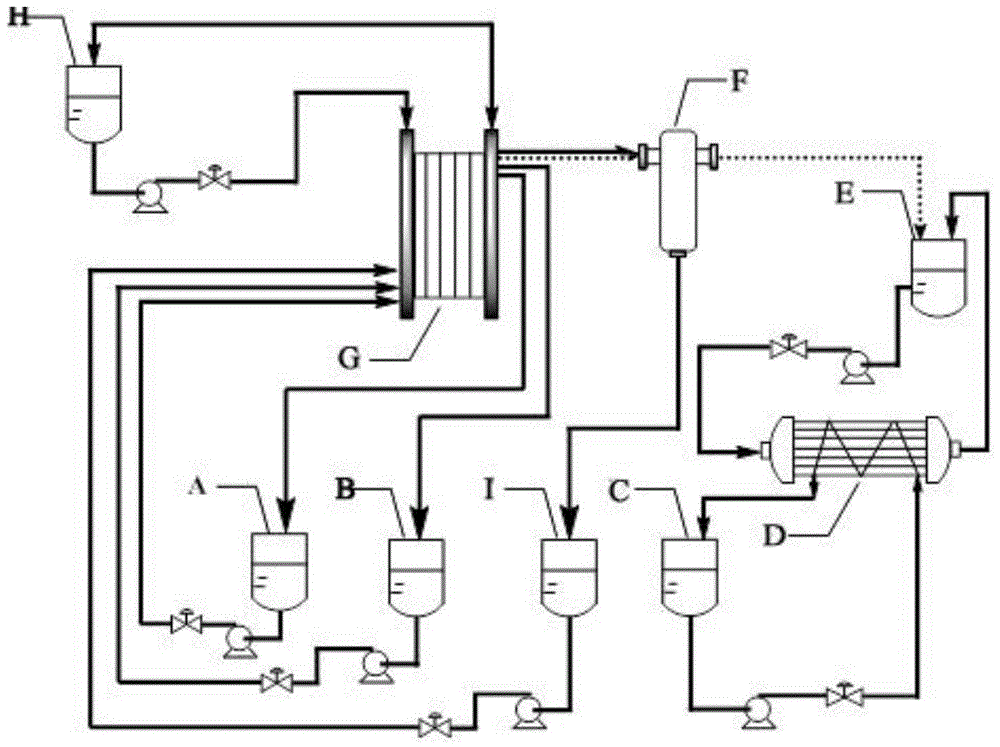

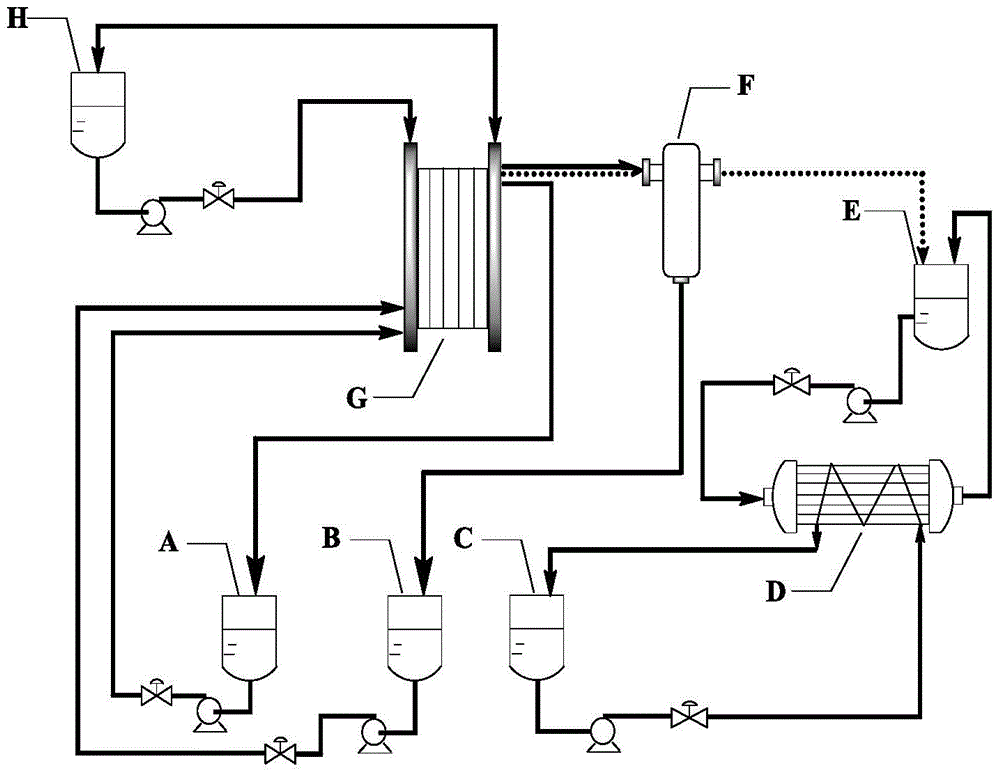

Method for preparing methionine

The invention discloses a method for preparing methionine. The method for preparing the methionine concretely comprises the steps that cyanohydrins, carbon dioxide and ammonia or sodium cyanide, 3-(Methylthio)propionaldehyde, carbon dioxide and ammonia serve as raw materials to prepare hydantoin; alkaline hydrolysis is conducted on the hydantoin and then the hydantoin is acidized to pH 3.0-6.0 to obtain a compound of the methionine and salts; crystallization is conducted under the condition of temperature ranges from 8 DEG C to 45 DEG C, then the compound is separated to obtain a methionine crystal and salt mother liquor, the methionine crystal is washed by water and dried, and washing liquor is standby; finally, the salt mother liquor is concentrated under the condition of temperature which is lower than 60 DEG C, and then the salt mother liquor passes through a chromatographic column to obtain an inorganic salt and the methionine; the preparation method can efficiently separate the methionine and the salts, the recovery rate of the methionine can reach 99%, and the method is green and protects the environment, no methionine is resolved, no large number of acid and stink wastewater is discharged, and the purity of the inorganic salt is high and can be sold as a commodity.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Non-cyanide silver plating bath composition

Owner:TECHNIC INC

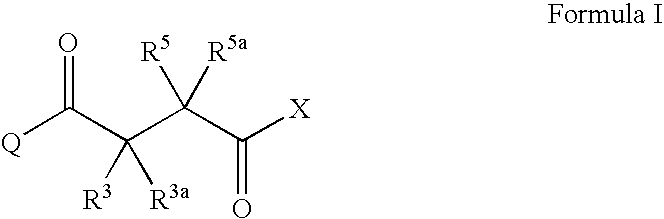

Succinoyl aminopyrazoles and related compounds

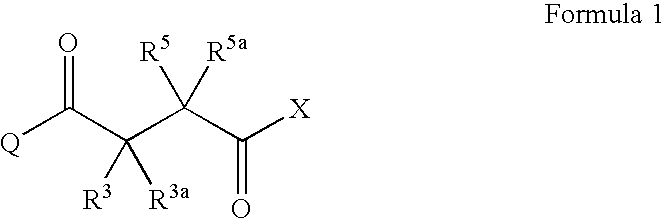

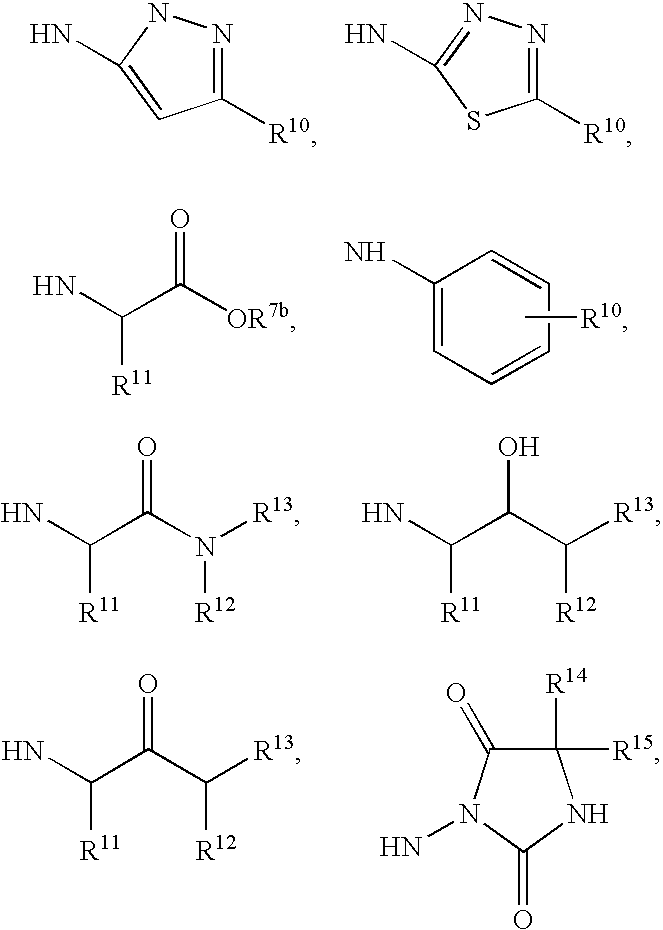

This invention is directed to a class of compounds (Formula I) including succinoyl amino pyrazoles, succinoyl amino thiadiazoles, succinoyl amino acid esters, succinoyl amino acid amides, succinoyl amino alcohols, succinoyl amino ketones, succinoyl amino hydantoins, succinoyl anilines, and succinoyl derivatives of privileged structures. The invention is also directed to a pharmaceutical formation comprising such compound in a pharmaceutically acceptable salt form or prodrug thereof. The invention is further directed to a method for inhibiting β-amyloid peptide release and / or synthesis, a method for inhibiting γ-secretase activity and a method for treating neurological disorders associated with β-amyloid peptide production. The method comprises administering to a host a pharmaceutical formulation comprising an effective amount of a compound of Formula I. The compounds of Formula I are useful in the prevention and treatment of Alzheimer's disease.

Owner:ELAN PHARM INC

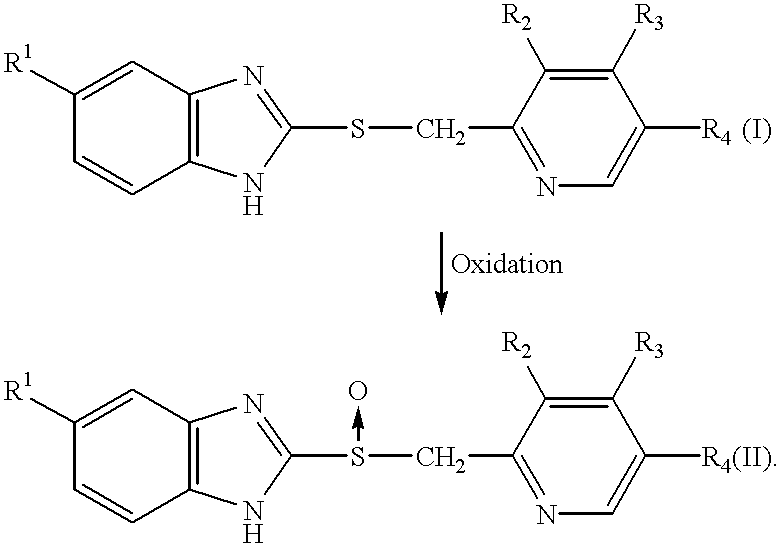

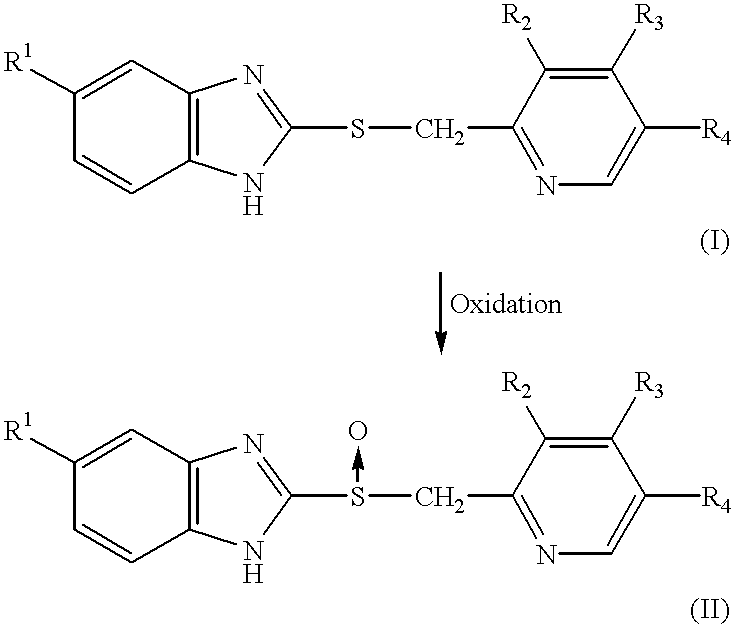

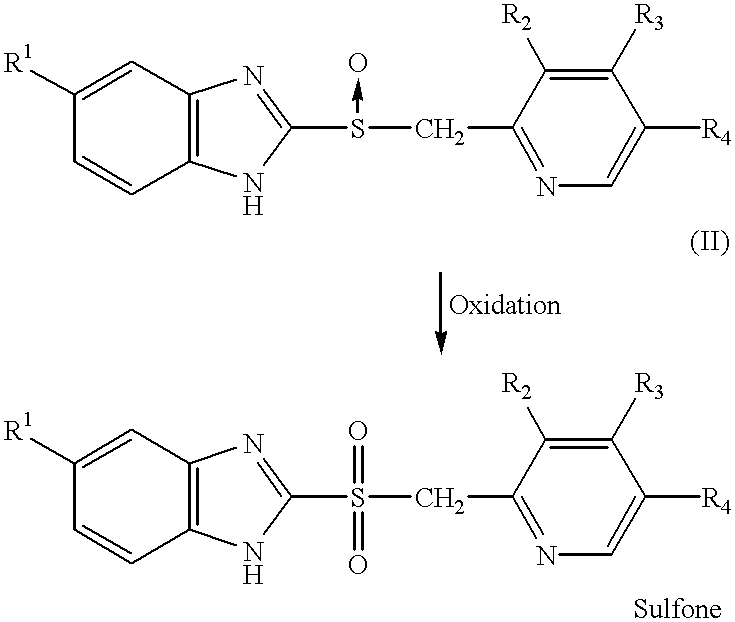

Process for the preparation of pyridine derivatives

InactiveUS6313303B1Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystThio-

Processes for preparing sulfoxides useful as drugs such as acid secretion inhibitors or antiulcer drugs or intermediates for the preparation of drugs in high yields, at high purities, and with safety. Specifically, a process for the preparation of sulfoxides (II) by oxidizing a thio ether (I) with a peroxoborate salt in the presence of an acid anhydride or a metal catalyst; and a process for the preparation of sulfoxides (II) by oxidizing a thio ether (I) with an N-halosuccinimide, 1,3-dihalo-5,5-dimethyl-hydantoin or dichloroisocyanuric acid salt in the presence of a base. In said formulae R1 is hydrogen, methoxy or difluoromethoxy; R2 is methyl or methoxy; R3 is 3-methoxypropoxy, methoxy or 2,2,2-trifluoroethoxy; and R4 is hydrogen or methyl

Owner:EISAI CO LTD

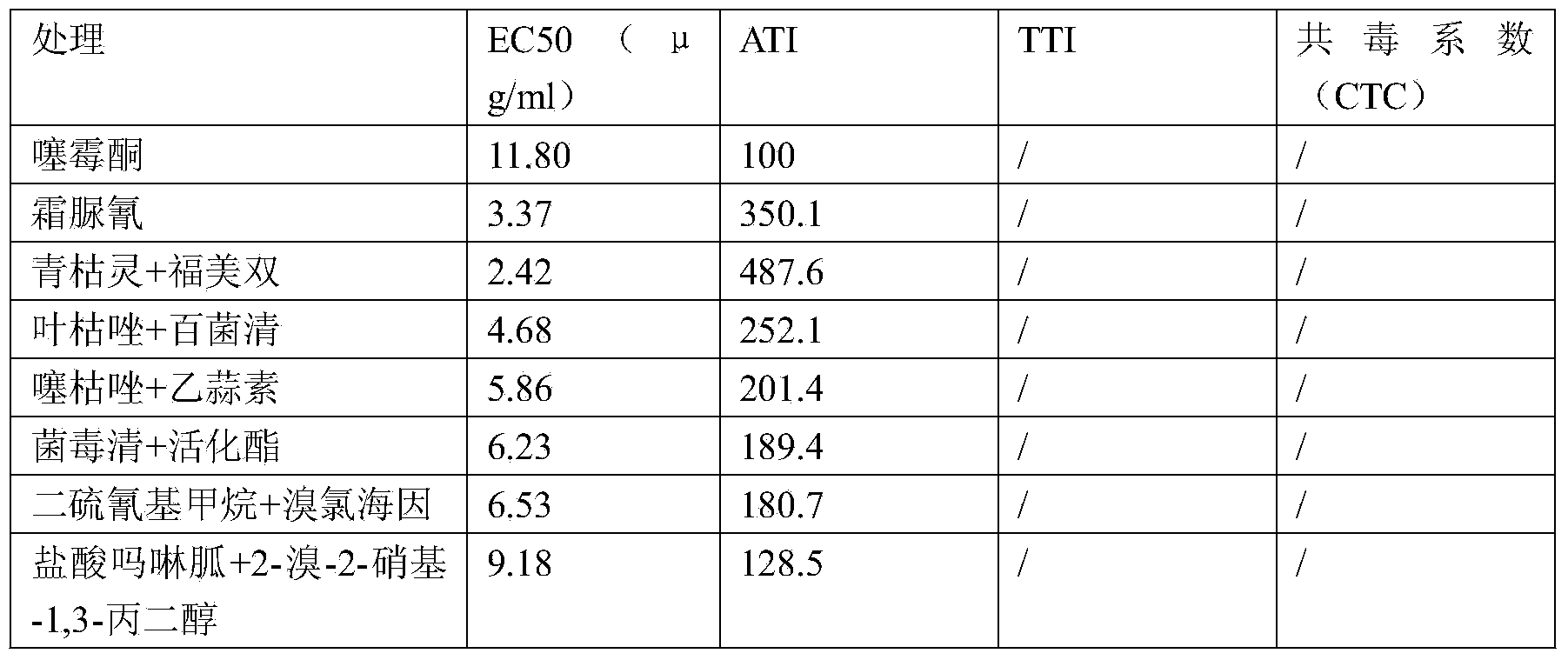

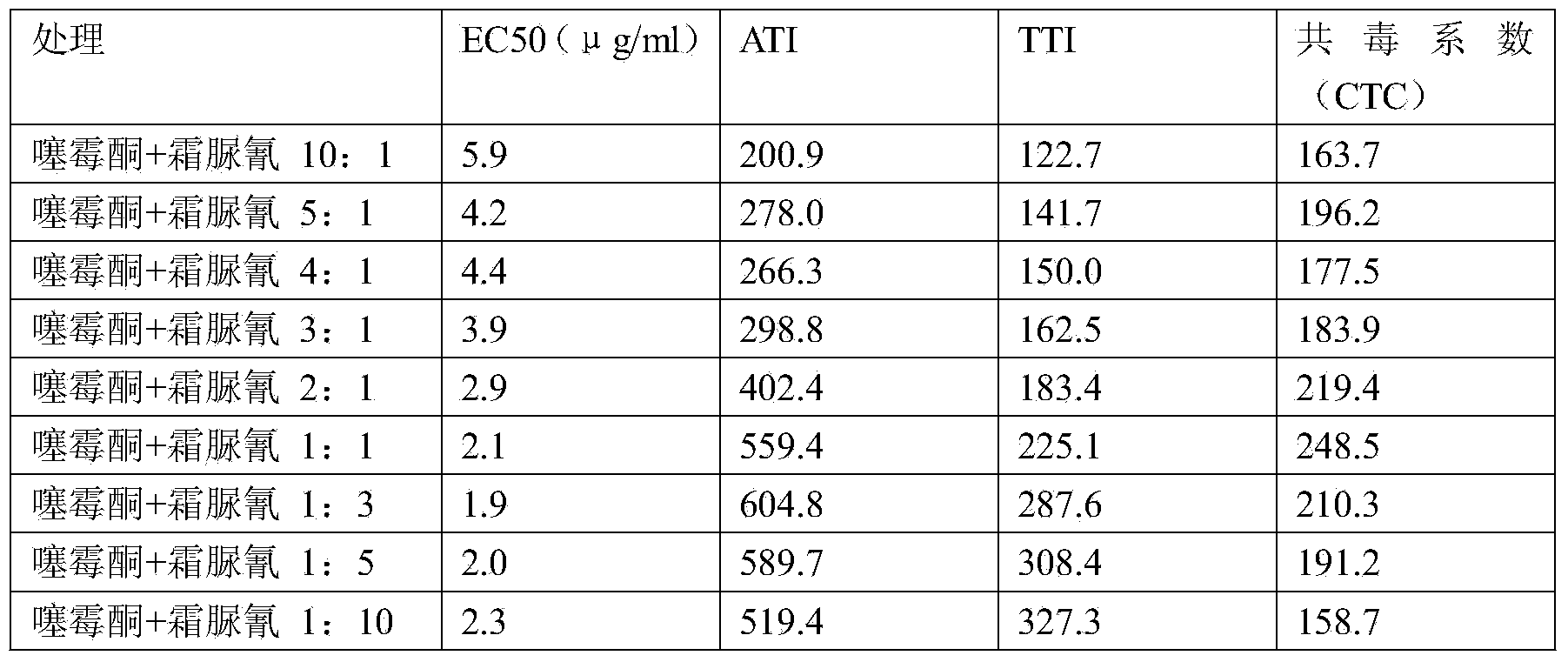

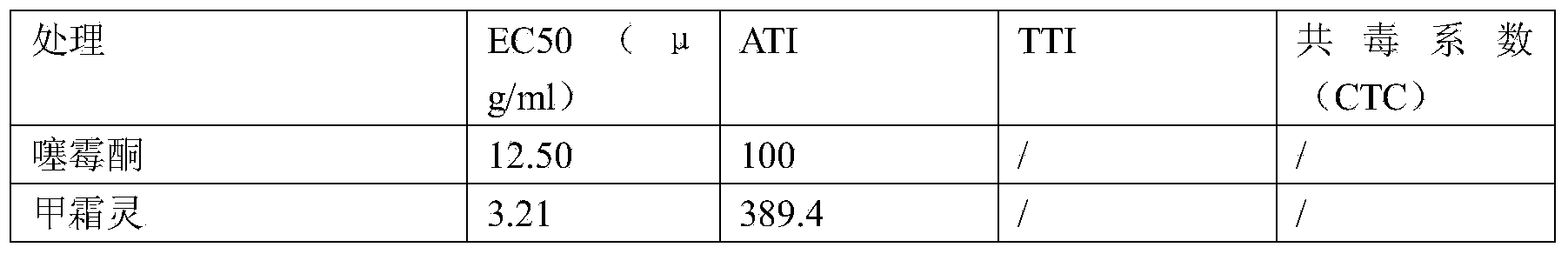

Composite for preventing and controlling agricultural bacterial disease

ActiveCN103704234AEasy to controlReduce the amount of applicationBiocideDisinfectantsBacterial disease1,3-Propanediol

The invention discloses a composite for preventing and controlling an agricultural bacterial disease, and belongs to the technical field of plant protection pesticides. The composite comprises an active component A and an active component B, wherein the active component A is benziothiazolinone; the active component B is one or two of cymoxanil, qingkuling, yekuzuo, bismerthiazol, ethylicin, thiram, dioctyl divinyltriamino glycine, active ester, metalaxyl, chlorothalonil, dithiocyano-methane, bromine chlorine hydantoin, 2-bromine-2-nitryl-1,3-propylene glycol and moroxydine hydrochloride; the weight ratio of the active component A to the active component B is 1:100 to 100:1. The composite disclosed by the invention obtains the synergetic effect through the mixing of the benziothiazolinone and other bacterial medications and is used for agricultural production.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Personal care composition containing leghemoglobin

A personal care composition comprising leghemoglobin and at least one preservative selected from the group consisting of alcohols, glycols, parabens, hydantoins, quaternary nitrogen-containing compounds, isothiazolinones, aldehyde-releasing agents, and halogenated compounds. Preferably, the leghemoglobin is a nitrogen fixation root nodule extract providing a leghemoglobin concentration in the composition of between 0.0001% and about 10% based upon the total weight of the composition. Also disclosed is a method for preparing the personal care composition.

Owner:ARCH PERSONAL CARE PROD

Method and device for preparing methionine and recovering by-product-carbon dioxide

ActiveCN105671587ARealize cleaner productionReduce energy consumptionElectrolysis componentsElectrolytic organic productionHydantoin derivativesCo2 absorption

The invention discloses a method for preparing methionine and recovering a by-product-carbon dioxide. The method comprises the steps that a methionine salt and carbonate mixed solution obtained by hydrolyzing methylmercapto-ethyl hydantoin with alkali is filtered through a microporous membrane, and then filtrate is delivered to a bipolar membrane electrodialysis system to be subjected to electrodialysis treatment, so that acid liquor A and alkali liquor A are obtained; the alkali liquor A is treated continuously and cyclically, and the acid liquor A is subjected to gas-liquid separation, so that gaseous carbon dioxide and acid liquor B are obtained; the acid liquor B is delivered back into the bipolar membrane electrodialysis system to be subjected to cyclic treatment till the pH value of the acid liquor B is 3.8-4.5, the reaction is completed, a methionine solution is prepared, and the methionine is prepared through concentration and crystallization of the methionine solution; the gaseous carbon dioxide is introduced into an absorption cell, and carbon dioxide on the upper portion of the absorption cell absorbs mother liquor, is subjected to membrane distillation and concentration and then is circulated back to the absorption cell; carbonate crystals are grown at the bottom of the absorption cell and guided out from the bottom of the absorption cell; and carbonate is recovered through solid-liquid separation. According to the method for preparing the methionine and recovering the by-product-carbon dioxide, the gaseous carbon dioxide is recycled, so that carbon emission is reduced, and energy resources are saved through the membrane distillation technique.

Owner:浙江佰辰低碳科技有限公司

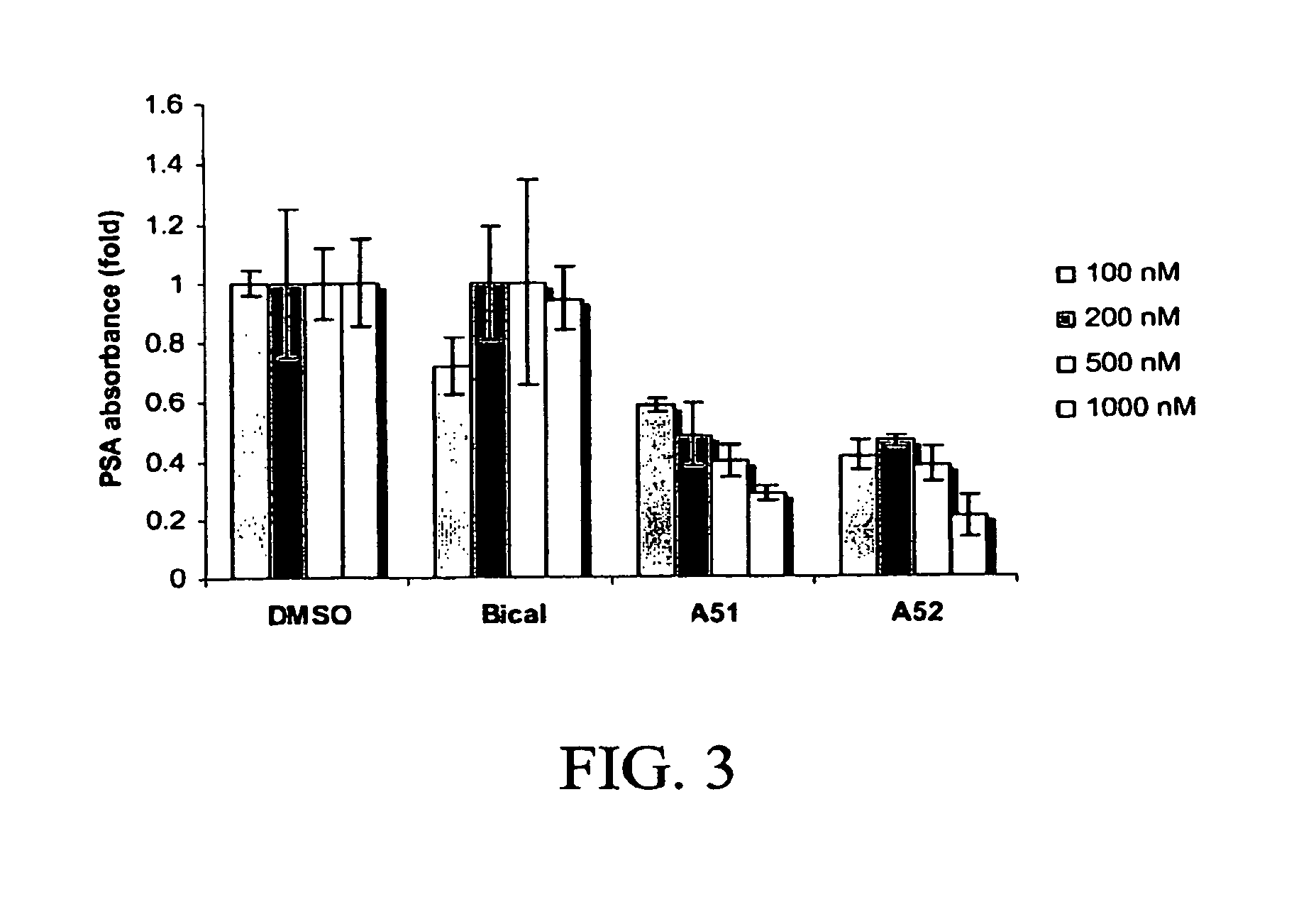

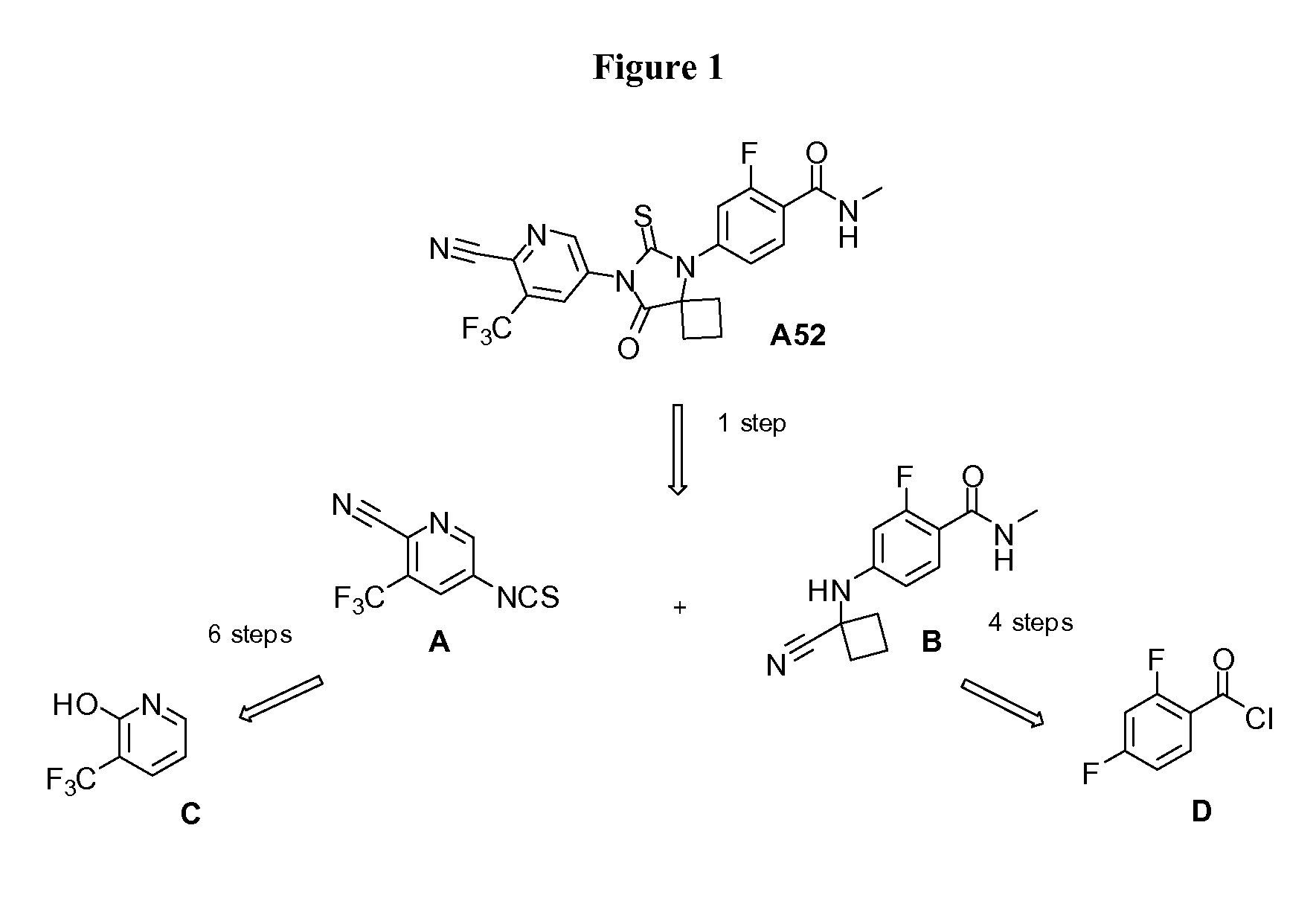

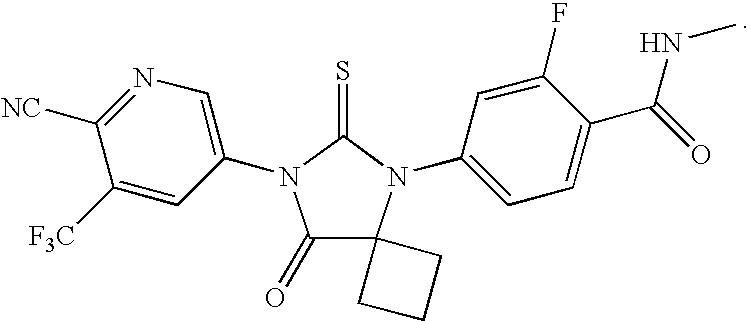

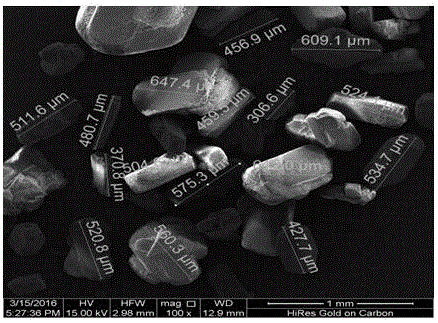

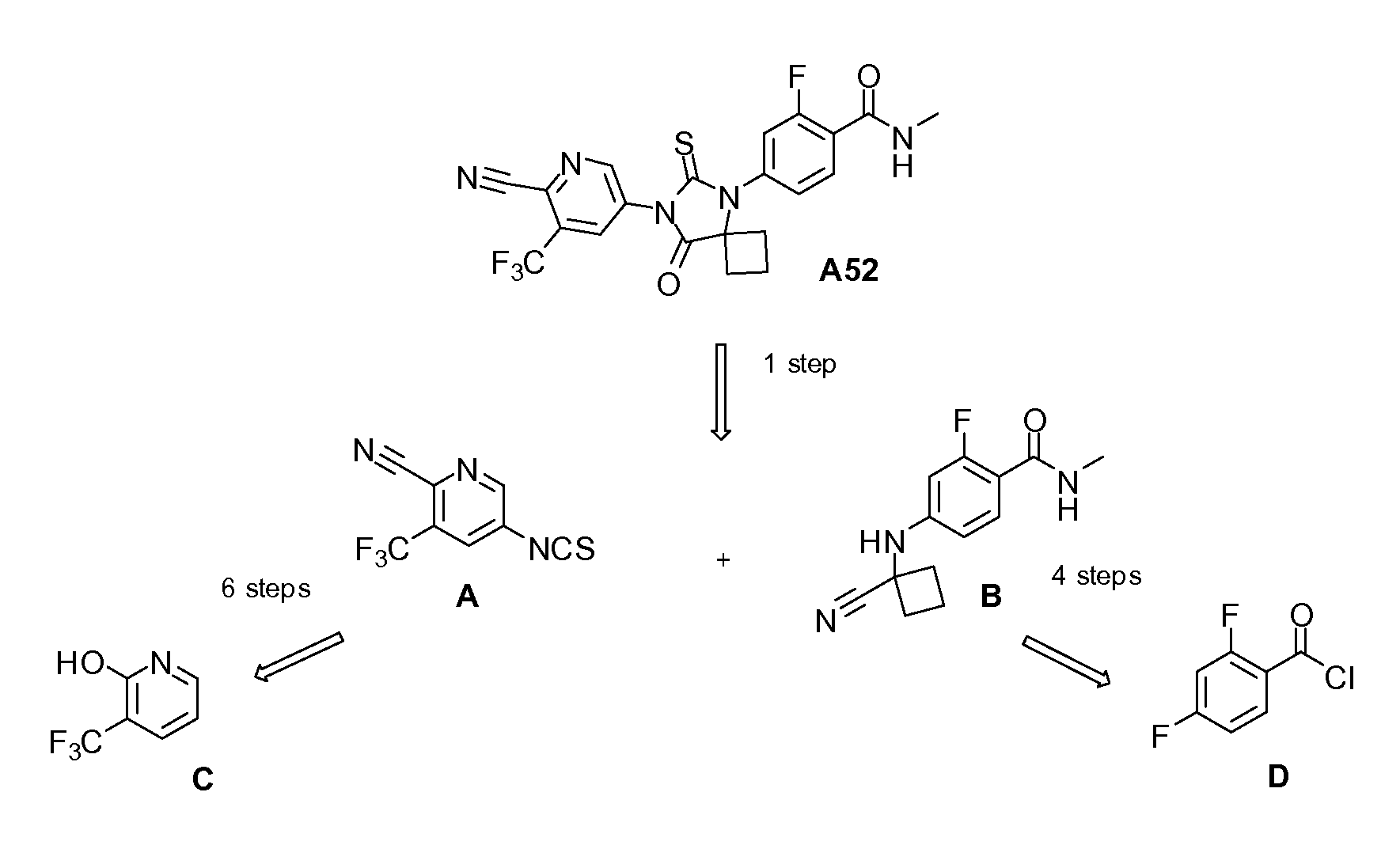

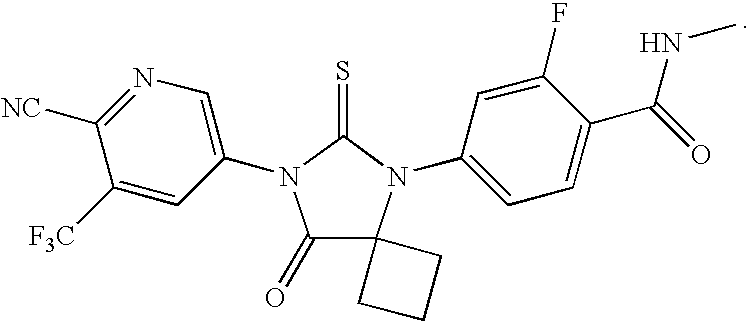

Synthesis of thiohydantoins

ActiveUS20100190991A1Efficient routingCarboxylic acid nitrile preparationOrganic compound preparationProstate cancerCombinatorial chemistry

A novel synthesis of the anti-androgen, A52, which has been found to be useful in the treatment of prostate cancer, is provided. A52 as well as structurally related analogs may be prepared via the inventive route. This new synthetic scheme may be used to prepare kilogram scale quantities of pure A52.

Owner:SLOAN KETTERING INST FOR CANCER RES

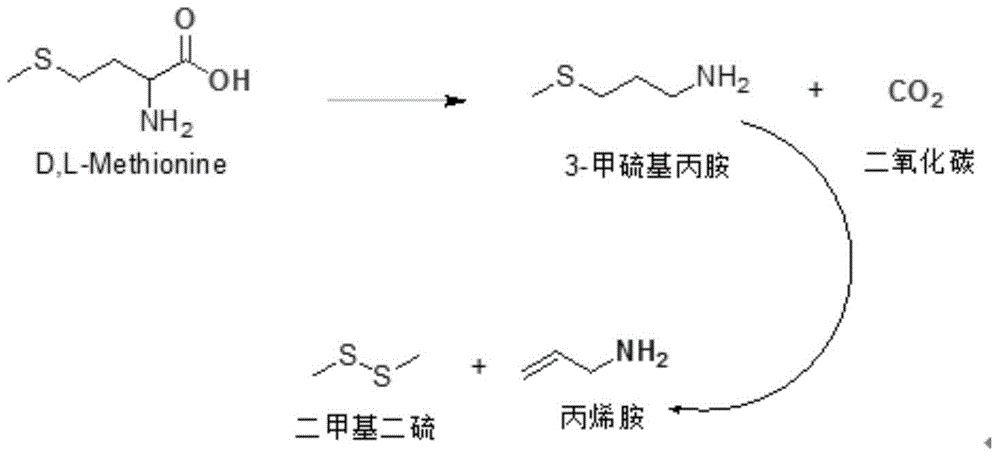

Method for environment-friendly clean production of D,L-methionine

InactiveCN106432018AIncrease profitAvoid accumulationOrganic compound preparationChemical recyclingChromatographic separationAlkaline hydrolysis

A method for environment-friendly clean production of D,L-methionine includes: performing alkaline hydrolysis of 5-(2-methylmercaptoethyl)-hydantoin to obtain carbonate-containing methionine alkali metal saponified solution; then feeding carbon dioxide, crystallizing, and separating to respectively obtain methionine and hydrocarbonate water solution of methionine; subjecting the hydrocarbonate water solution of methionine to chromatographic separation. The method has advantages that loss of D,L-methionine due to pyrolysis can be reduced, simplicity in operation, low cost and high utilization rate of raw materials are realized, high efficiency in acquisition of high-purity methionine crystals is achieved, the purity of the obtained methionine is up to 99.4%, the methionine recovery rate reaches 97%, and the desalinization rate reaches 98% or above. In addition, accumulation of a great quantity of impurities of methionine-containing potassium bicarbonate mother liquor and emission of the potassium bicarbonate mother liquor are avoided, discharge of saline wastewater is avoided, and accordingly environment friendliness and clean production are realized. In a whole process, potassium carbonate serving as a hydrolysis agent is recycled without loss, and replenishment of alkaline potassium compounds is avoided.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Microbiological control in animal processing

InactiveUS6919364B2Reduce Microbial ContaminationProduced economicallyOrganic active ingredientsBiocideWater chlorinationZoology

Fecal bacterial contamination in an animal is reduced by providing it with drinking water containing a microbiocidally-effective amount of halogen-based microbiocide resulting from mixing with water (A) a product formed in water from (i) bromine, chlorine, or bromine chloride, or any two or more thereof, (ii) a water-soluble source of sulfamate anion, and (iii) a water-soluble base; (B) at least one 1,3-dihalo-5,5-dialkylhydantoin in which one of the halogen atoms is a chlorine atom and the other is a chlorine or bromine atom, and in which each alkyl group, independently, contains in the range of 1 to about 4 carbon atoms; (C) at least one 1,3-dibromo-5,5-dialkylhydantoin in which one of the alkyl groups is a methyl group and the other alkyl group contains in the range of 1 to about 4 carbon atoms; or (D) any two or more of (A), (B), and (C).

Owner:ALBEMARLE CORP

Sterilization disinfectant and application thereof

The present invention relates to naturally degradable environment friendly halogen-containing disinfectant, and is especially disinfectant of halogeno dialkyl hydantoin aqua and its application. In room temperature, halogeno dialkyl hydantoin, stabilizer, solubilizer and and / or synergist in certain weight proportion are mixed and dissolved in water to form the liquid preparation. The liquid preparation has raised water solubility of halogeno dialkyl hydantoin and excellent disinfecting effect. The liquid preparation may be used in industrial cooling water, industry waste water, air conditioner cooling water and swimming pool water, especially oil field refilling water, as well as daily life.

Owner:NANJING UNIV OF TECH

Crosslinking composition

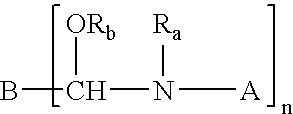

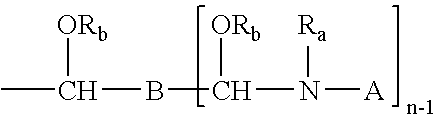

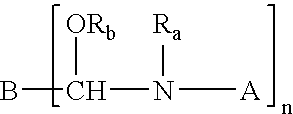

This invention relates to a crosslinking composition comprising a compound having the structure of Formula I:A′-NRA—RDwhere A′ is a moiety derived from the group consisting of linear or cyclic ureas, cyanuric acid, substituted cyanuric acids, linear or cyclic amides, glycolurils, hydantoins, linear or cyclic carbamates and mixtures thereof, or a moiety comprising the structure:where RA is RD, hydrogen, an alkyl of 1 to 20 carbon atoms, or taken together with A′ forms a cyclic compound; RD is —CHRC ORB, wherein RB is hydrogen, alkyl, aryl, aralkyl or an alkaryl having from 1 to about 24 carbon atoms and RC is an alkyl, halogenated alkyl, aryl, aralkyl, halogenated aralkyl, alkoxyalkyl or an alkaryl having from 1 to about 24 carbon atoms; A is a moiety derived from the group consisting of linear or cyclic ureas, cyanuric acid, substituted cyanuric acids, linear or cyclic amides, glycolurils, hydantoins, linear or cyclic carbamates and mixtures thereof; B is a residue of a poly(alkylaldehyde) with n aldehyde groups; n is an integer of 2 to about 8; Ra is Rd, hydrogen, an alkyl of 1 to about 20 carbon atoms, or taken together with A forms a cyclic compound; where Rd is CHRcORb orwhere Rb is hydrogen, alkyl, aryl, aralkyl or an alkaryl having from 1 to about 24 carbon atoms and Rc is an alkyl, halogenated alkyl, aryl, aralkyl, halogenated aralkyl, alkoxyalkyl or an alkaryl having from 1 to about 24 carbon atoms; and where the alkyl or aryl groups in each radical may optionally have heteroatoms in their structure. This invention also relates to a process for producing the crosslinking composition by reacting an amino compound containing amino groups; a mono(alkylaldehyde) and / or a poly(alkylaldehyde), and an alcohol; where said amino compound is selected from the group consisting of: linear or cyclic ureas, cyanuric acid, substituted cyanuric acids, linear or cyclic amides, glycolurils, hydantoins, linear or cyclic carbamates and mixtures thereof.

Owner:ALLNEX NETHERLANDS BV

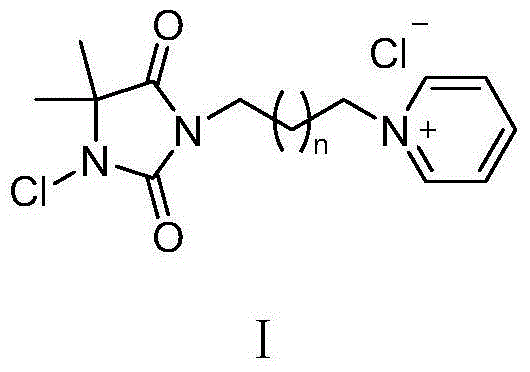

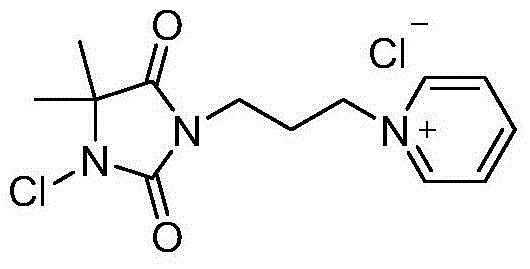

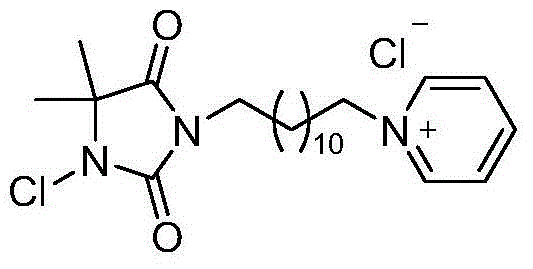

Pyridine quaternary ammonium salt type halamine antibacterial agent and preparation method thereof

InactiveCN104926787AImprove hydrophilicityHigh antibacterial activityAntibacterial agentsBiocidePyridineIon-exchange resin

The invention discloses a pyridine quaternary ammonium salt type halamine antibacterial agent with a structure represented by a general formula I, wherein n is an integer of 1-10. The preparation method comprises the following steps: a, 5,5-dimethyl hydantoin is placed in an acetone solution doped with anhydrous potassium carbonate; refluxing is carried out for 30min, and dibromoalkane is added; refluxing is continued for 4h, such that a bromo-alkyl hydantoin compound is obtained; b, the obtained bromo-alkyl hydantoin compound is dissolved in acetonitrile; excessive pyridine is added; heating and refluxing are carried out overnight; concentration is carried out, such that a pyridine bromide quaternary ammonium salt type halamine precursor is obtained; the precursor is delivered through chlorine-type anion exchange resin, such that a pyridine chloride quaternary ammonium salt type halamine precursor is obtained; and c, the obtained pyridine chloride quaternary ammonium salt type halamine precursor is dissolved in a mixed solution composed of deionized water and tert-butanol; tert-butyl hypochlorite is added, and stirring is carried out for 2-4h while protected from light, such that the pyridine quaternary ammonium salt type halamine is obtained. The method has the advantages of easy-to-obtain raw materials, and relatively simple synthesis method. The method has a prospect of industrialized application.

Owner:DALIAN UNIV OF TECH

Synthesis of thiohydantoins

ActiveUS8461343B2Efficient routingCarboxylic acid nitrile preparationOrganic compound preparationProstate cancerCombinatorial chemistry

A novel synthesis of the anti-androgen, A52, which has been found to be useful in the treatment of prostate cancer, is provided. A52 as well as structurally related analogs may be prepared via the inventive route. This new synthetic scheme may be used to prepare kilogram scale quantities of pure A52.

Owner:SLOAN KETTERING INST FOR CANCER RES

Personal care composition containing ozone-stressed yeast lysates

InactiveUS20060110815A1Reducing or minimizing ozone-induced skin degradationCosmetic preparationsFungiPersonal careIsothiazolinone

The present invention relates to an ozone-stressed yeast lysate, and a personal care composition including an ozone-stressed yeast lysate and at least one preservative selected from the group consisting of alcohols, glycols, parabens, hydantoins, quaternary nitrogen-containing compounds, isothiazolinones, aldehyde-releasing agents, and halogenated compounds. The present invention also relates to a method for preparing and using the ozone-stressed yeast lysate and the personal care composition.

Owner:ARCH PERSONAL CARE PROD

Cyanide-free electrosilvering solution applicable to high-speed electroplating and electroplating process

The invention discloses a cyanide-free electrosilvering solution applicable to high-speed electroplating and an electroplating process, which belong to the technical field of electrosilvering. The electrosilvering solution is prepared from hydantoin derivatives, an auxiliary complexing agent, potassium hydroxide, potassium carbonate, silver nitrate and ultrapure water. The electrosilvering process comprises the following steps of: firstly, pre-plating an intermediate silver-plating layer and performing quick silver-plating; secondly, after the electroplating, taking a sample out of the electroplating solution, cleaning the surface of the sample through distilled water, and performing cold air drying. The obtained electroplating solution of an electrosilvering system does not contain extremely toxic substances and is extremely high in stability; the phenomena of precipitation, color changing and the like of a newly-prepared plating solution and a plating solution subjected to repeated constant-current plating, which are placed for over two months, are avoided; the plating effect of all plating solutions, which are placed for a long time or work for a long time, is the same as that of a newly prepared plating solution; a silver-plating layer with good appearance can be obtained in a wide temperature range and a wide current density range.

Owner:HARBIN INST OF TECH

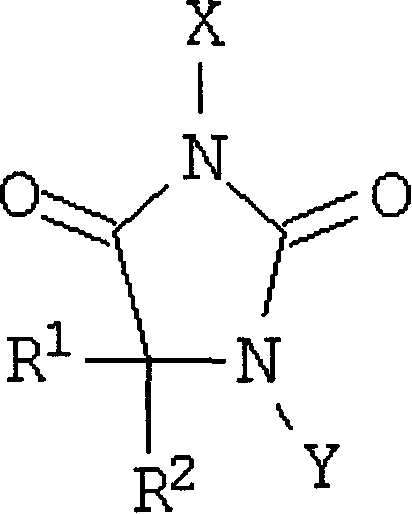

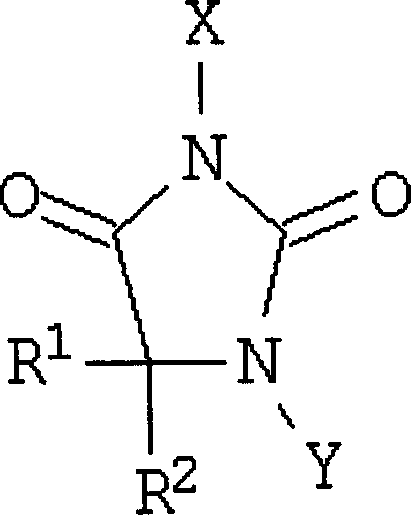

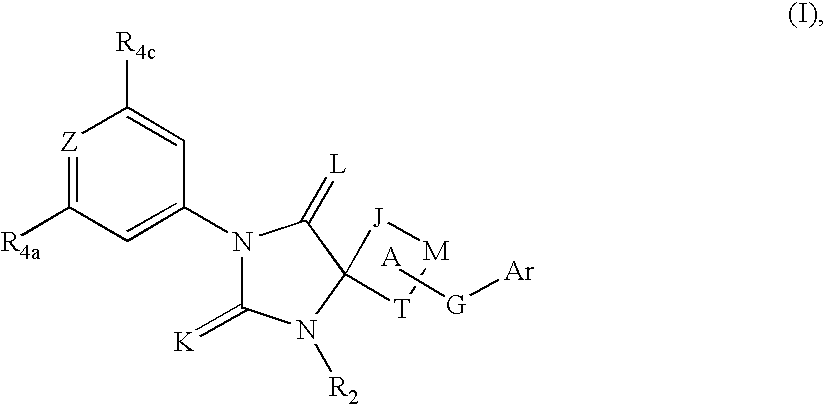

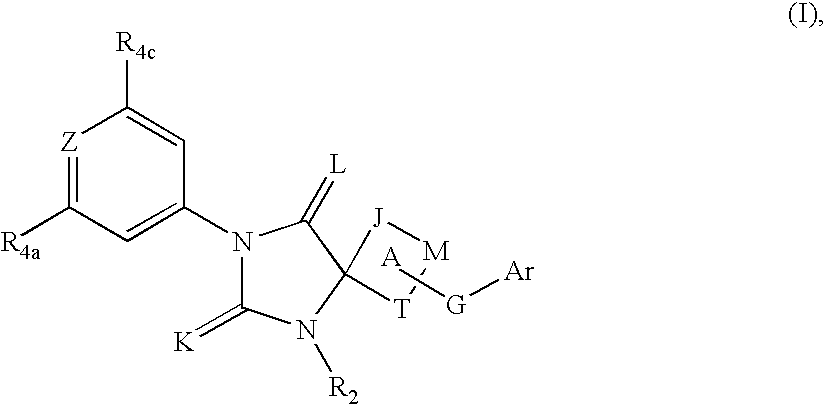

Spiro-hydantoin compounds useful as anti-inflammatory agents

Compounds having the formula (I), and pharmaceutically-acceptable salts, hydrates, enantiomers, and diastereomers, and prodrugs thereof, are useful as inhibitors of LFA-1 / ICAM and as anti-inflammatory agents, wherein L and K are O or S; Z is N or CR4b; Ar is an optionally-substituted aryl or heteroaryl; G is a linker attached to T or M or is absent; J, M and T are selected to define a three to six membered saturated or partially unsaturated non-aromatic ring; and R2,R4a, R4b, and R4c are as defined in the specification.

Owner:BRISTOL MYERS SQUIBB CO +1

Diarylthiohydantoin compounds

ActiveUS8110594B2Avoid translocationDestabilize an androgen receptor proteinBiocideOrganic active ingredientsHormone refractory prostate cancerPharmacology

The present invention relates to diarylthiohydantoin compounds and methods for synthesizing them and using them in the treatment of hormone refractory prostate cancer.

Owner:RGT UNIV OF CALIFORNIA

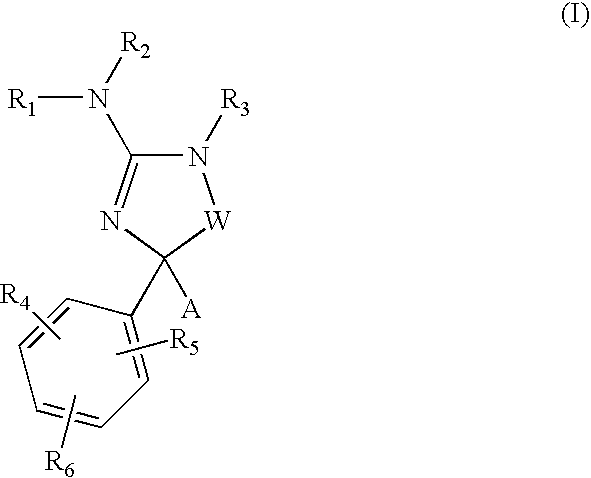

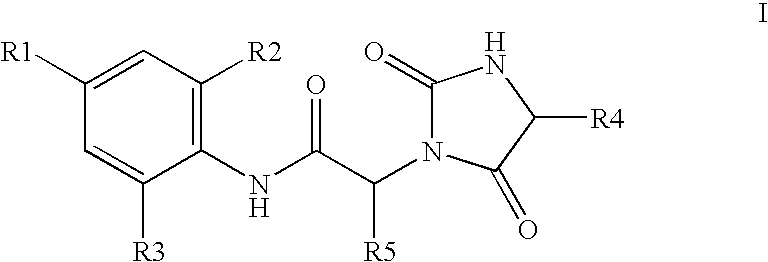

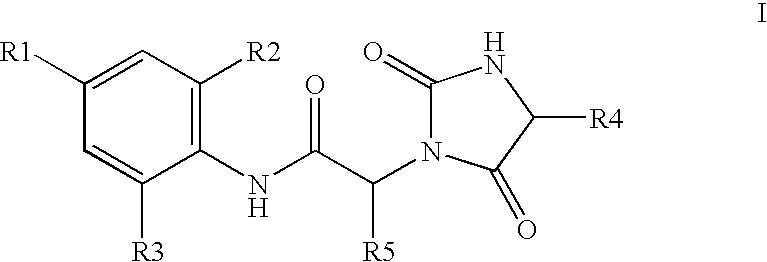

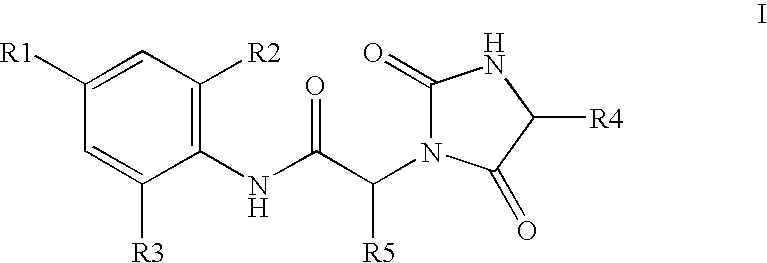

Biaryl hydantoin derivate and preparation method, medicine composition and application thereof

The invention provides a compound as shown in a Formula I or salts, solvent compounds, pre-drugs, stereoisomers, tautomers, polymorphic forms or metabolites thereof that are acceptable pharmaceutically, a medicine composition containing the same and an application thereof in preparation of medicines for treating male hormone receptor relevant diseases.

Owner:SHANGAI PHARMA GRP CO LTD +1

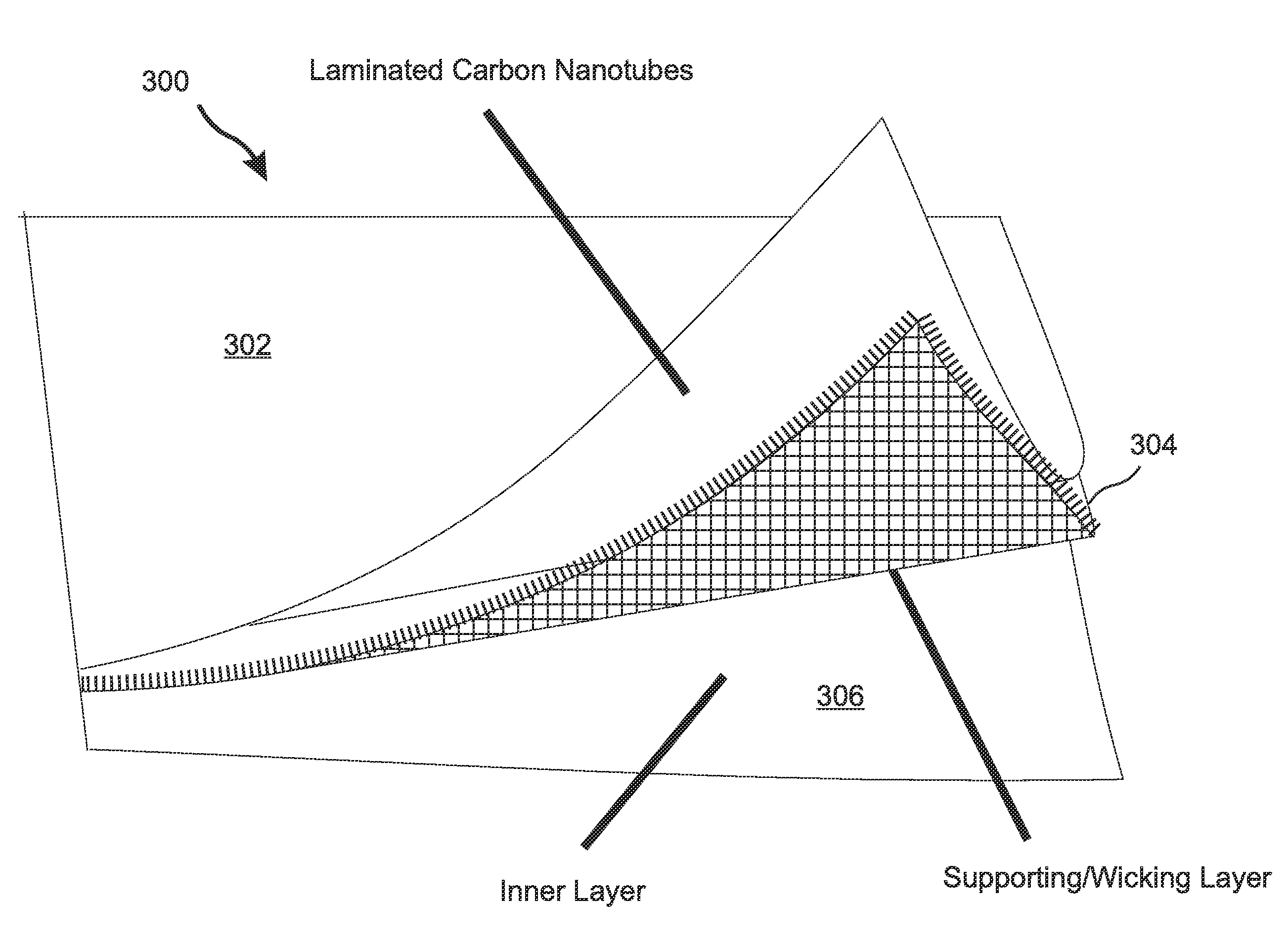

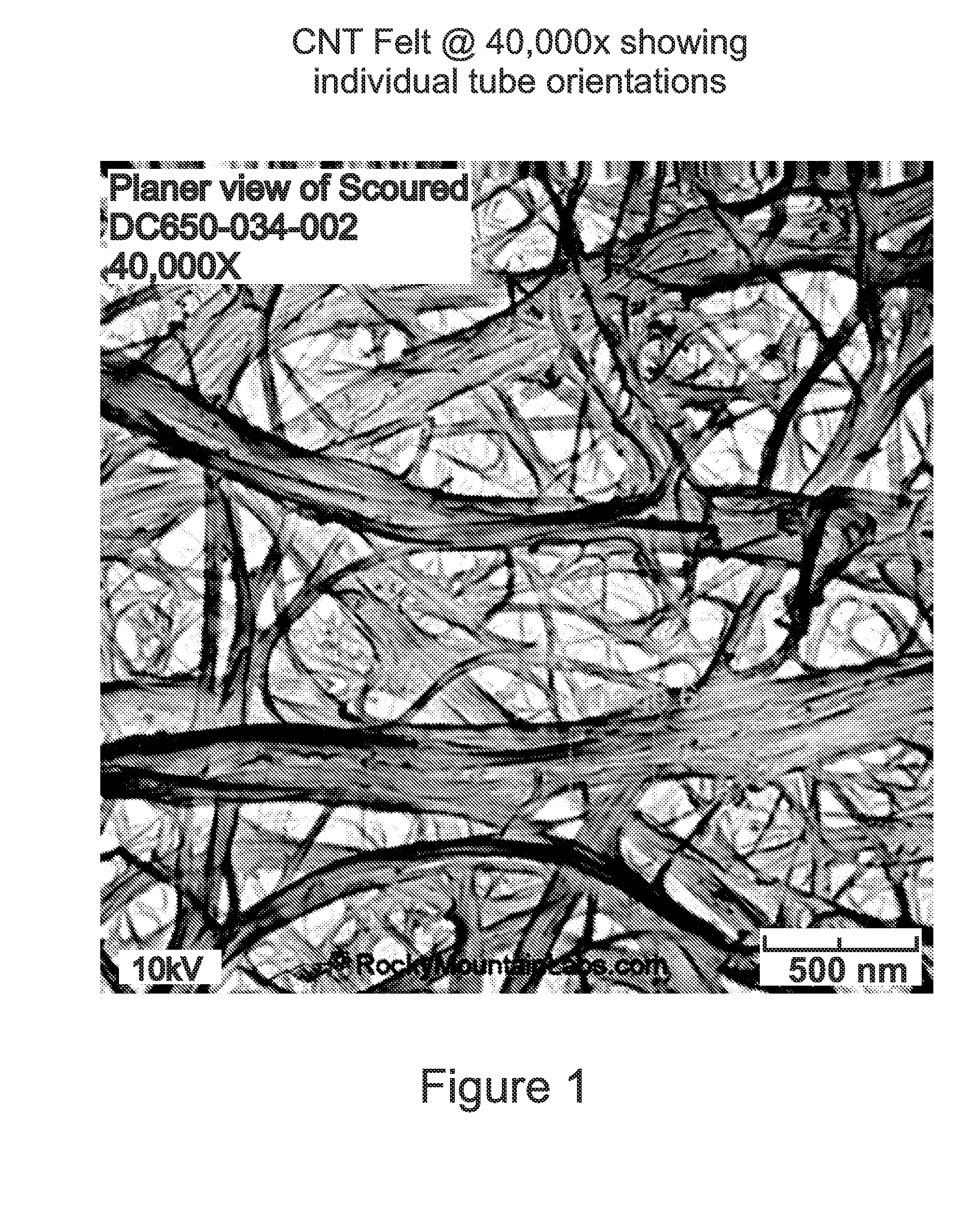

Breathable chembio protection fabric with carbon nanotube physical pathogen barrier

InactiveUS20110123757A1Avoid undue heat stressPrevent penetrationMaterial nanotechnologyLamination ancillary operationsFiberCarbon nanotube

A fabric for use in chemical and biological (CB) protective garments includes at least one felt layer having from 25% to 100% carbon nanotube (CNT) fibers as a breathable physical barrier against toxic chemical droplets and / or pathogens. The felt layers are cleaned and consolidated into a mechanically competent sheet which can form adhesive seams having lapshear greater than the sheet itself. An additional supporting layer can be included. The supporting layer can be a wicking layer which is permeable with a chlorinated or otherwise chemically active solution to establish a reactive chemical barrier, the solution being dispensed on demand from a portable container. Embodiments include a second layer of CNT or of another backing fabric, sandwiching the wicking layer therebetween. Impermeable fluoropolymer seams can divide the fabric into a plurality of CNT / wicking cells. A layer of activated charcoal and / or halamine-forming hydantoin can be included for persistent reactive chemical protection.

Owner:WARWICK MILLS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com