Patents

Literature

70results about How to "Avoid translocation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

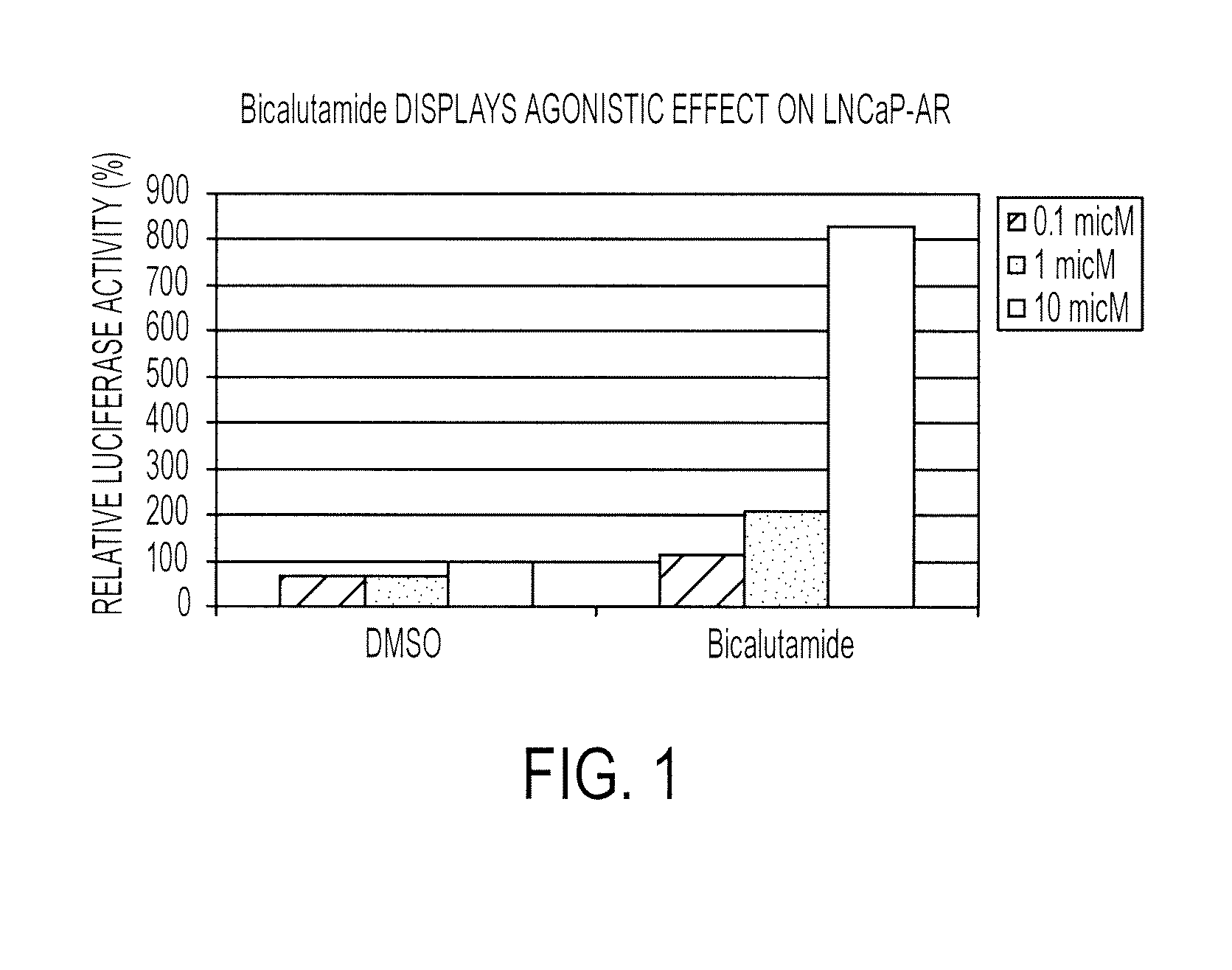

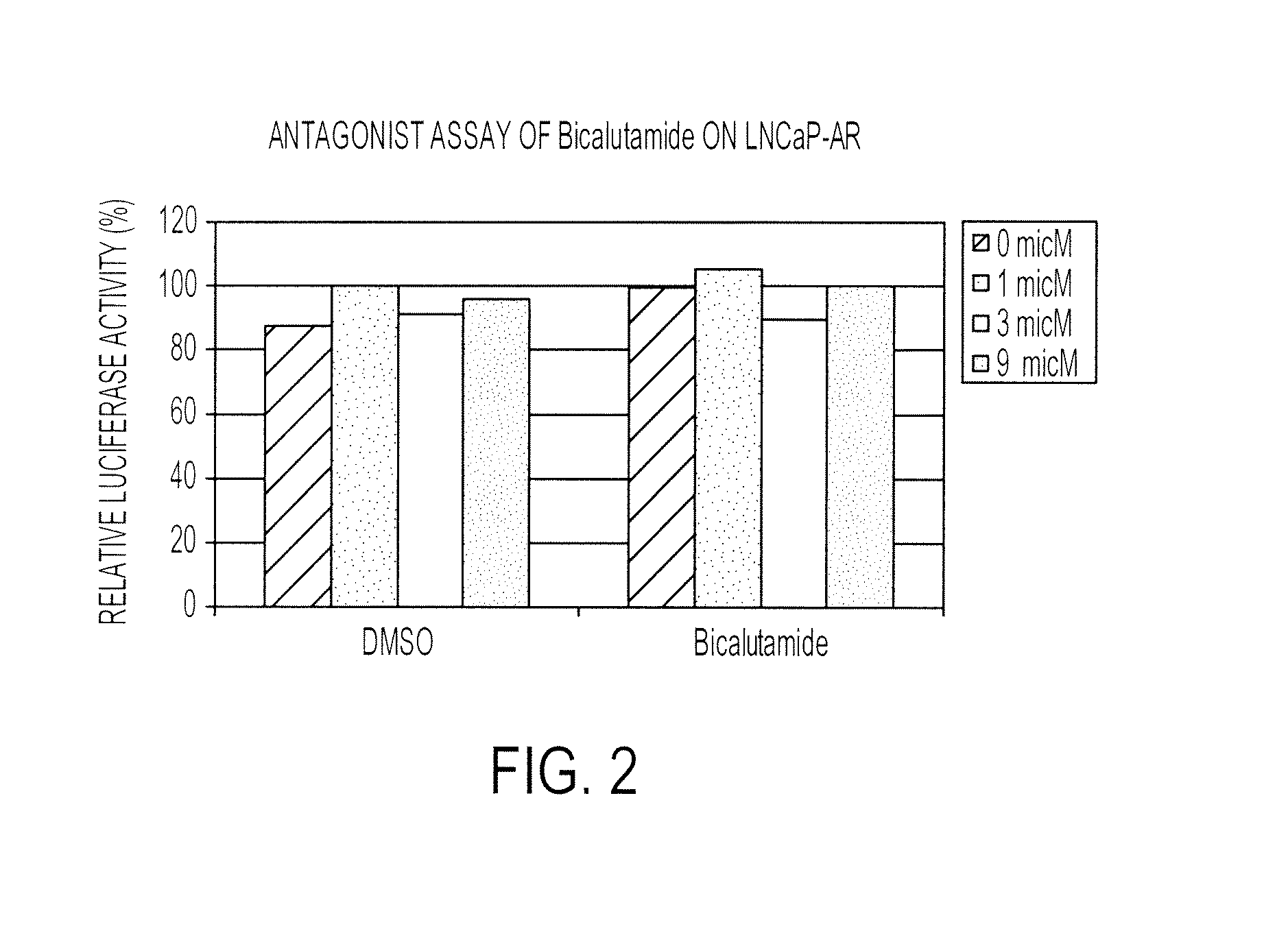

Diarylthiohydantoin compounds

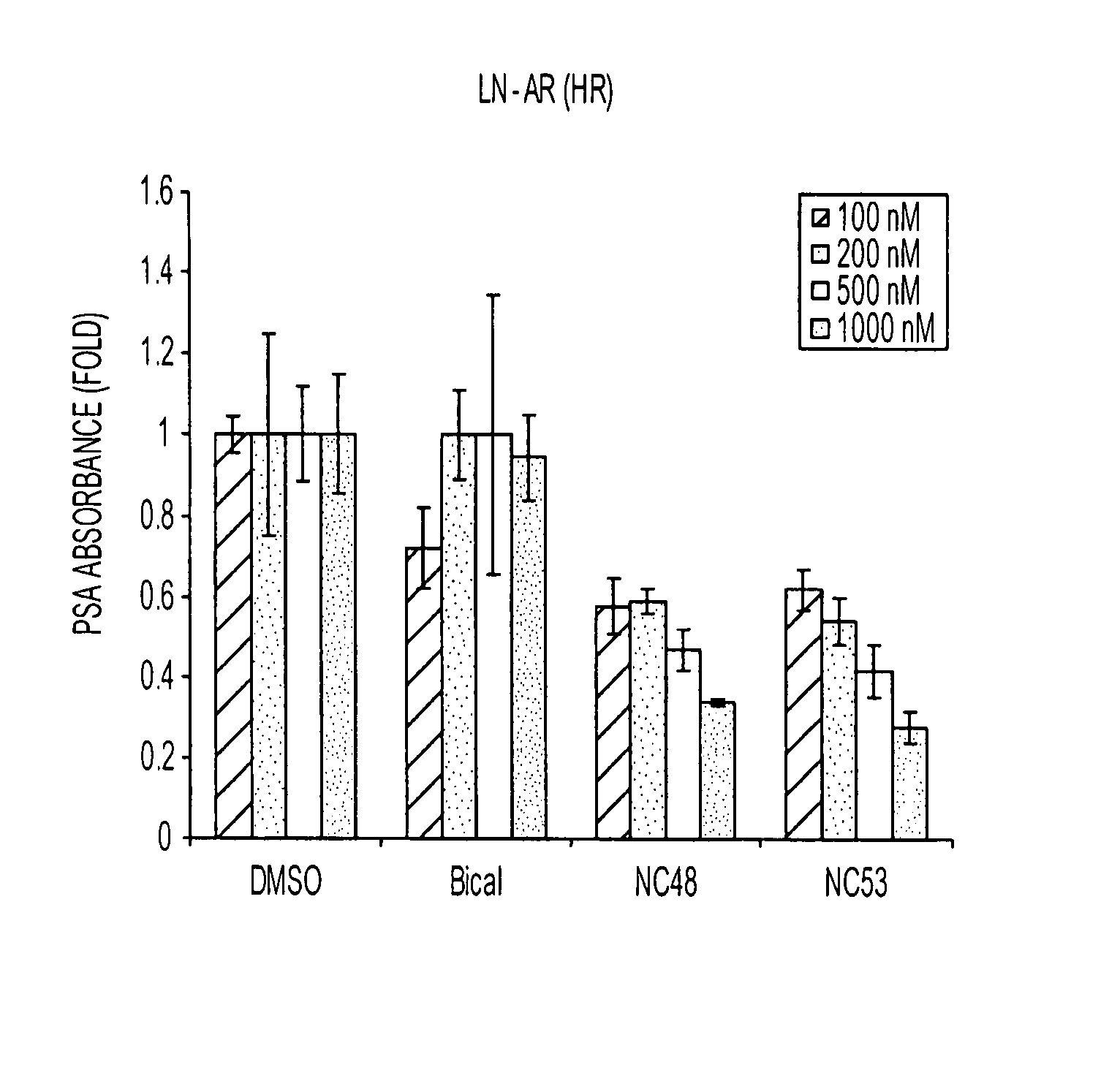

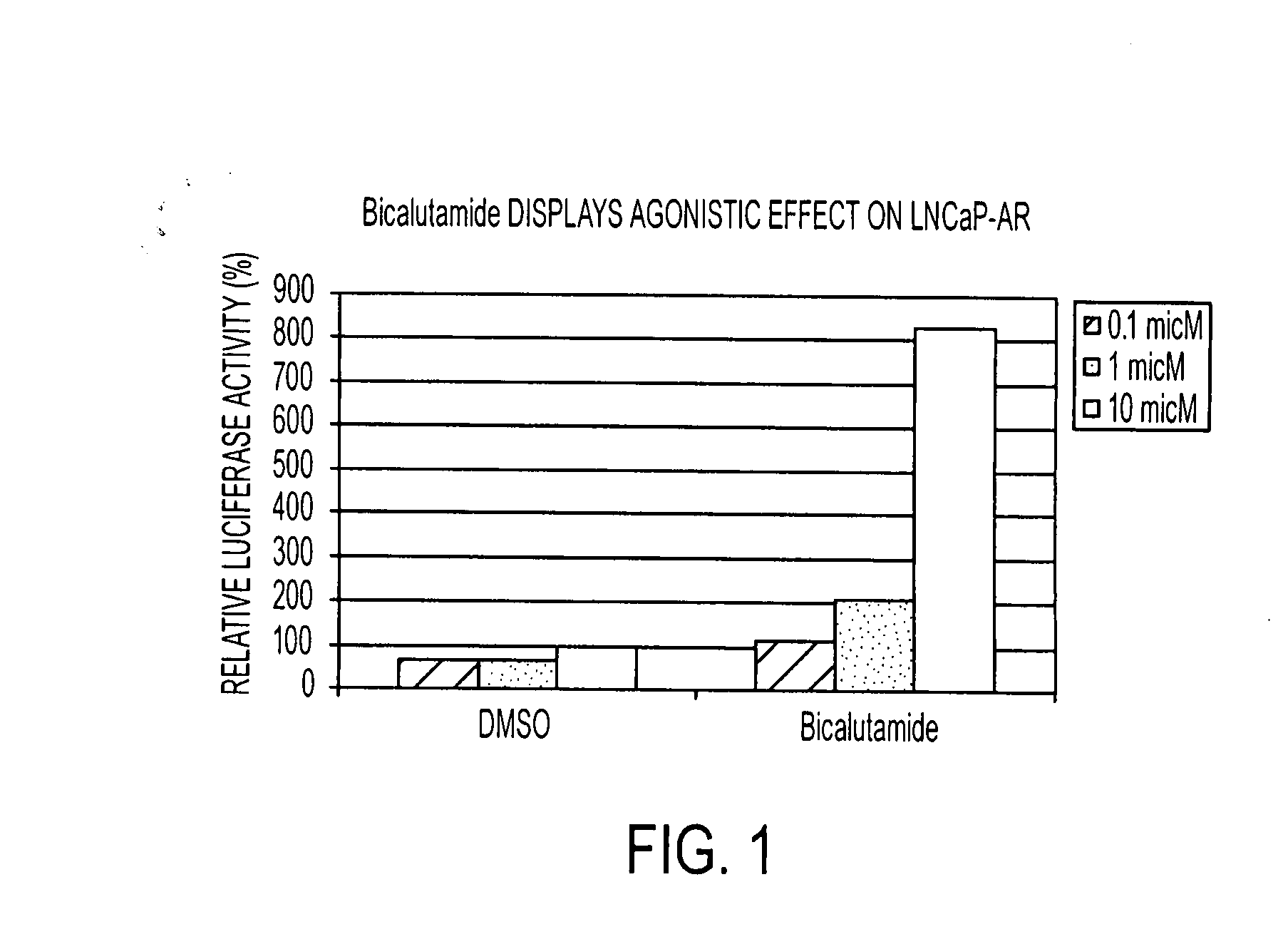

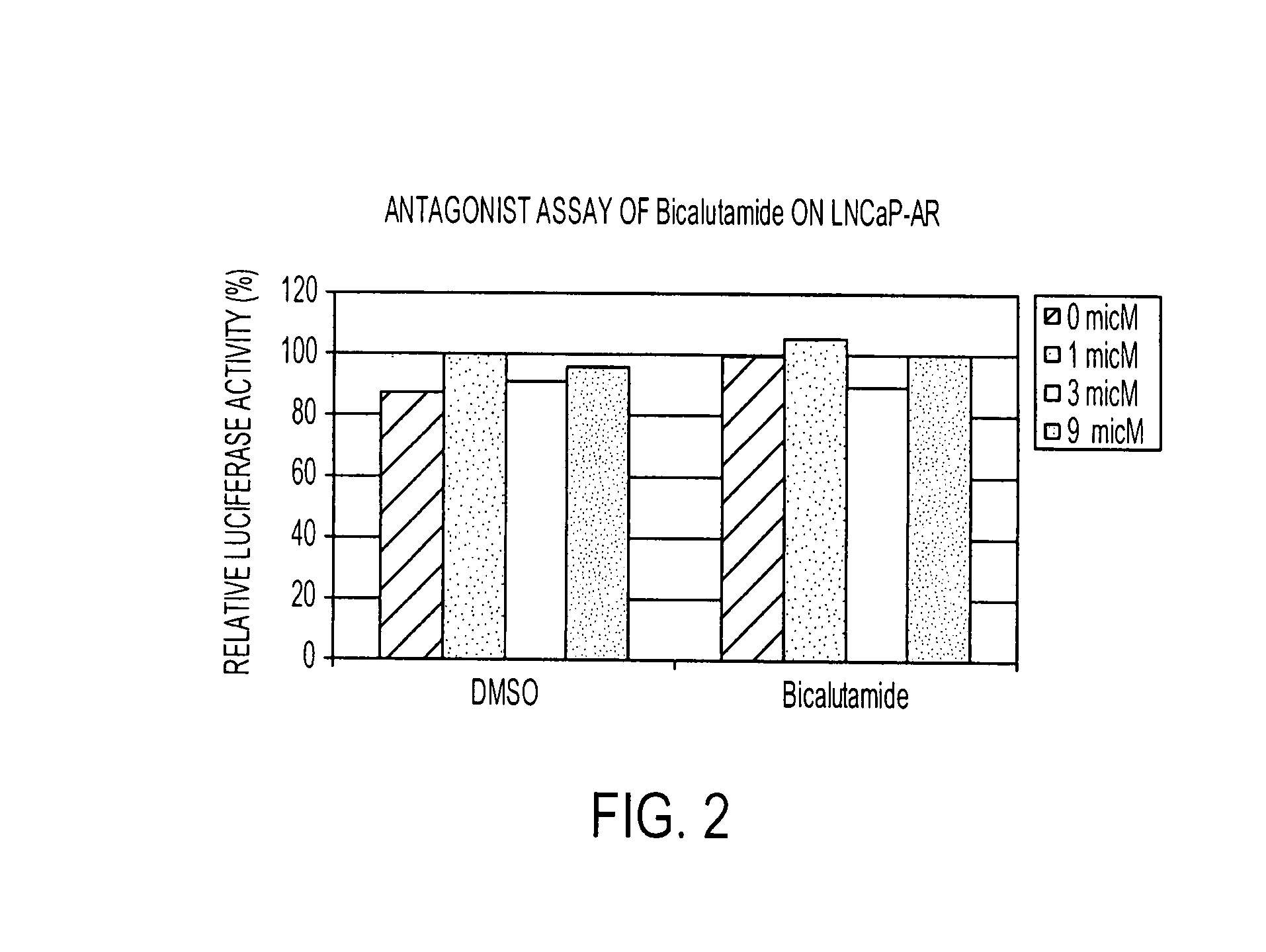

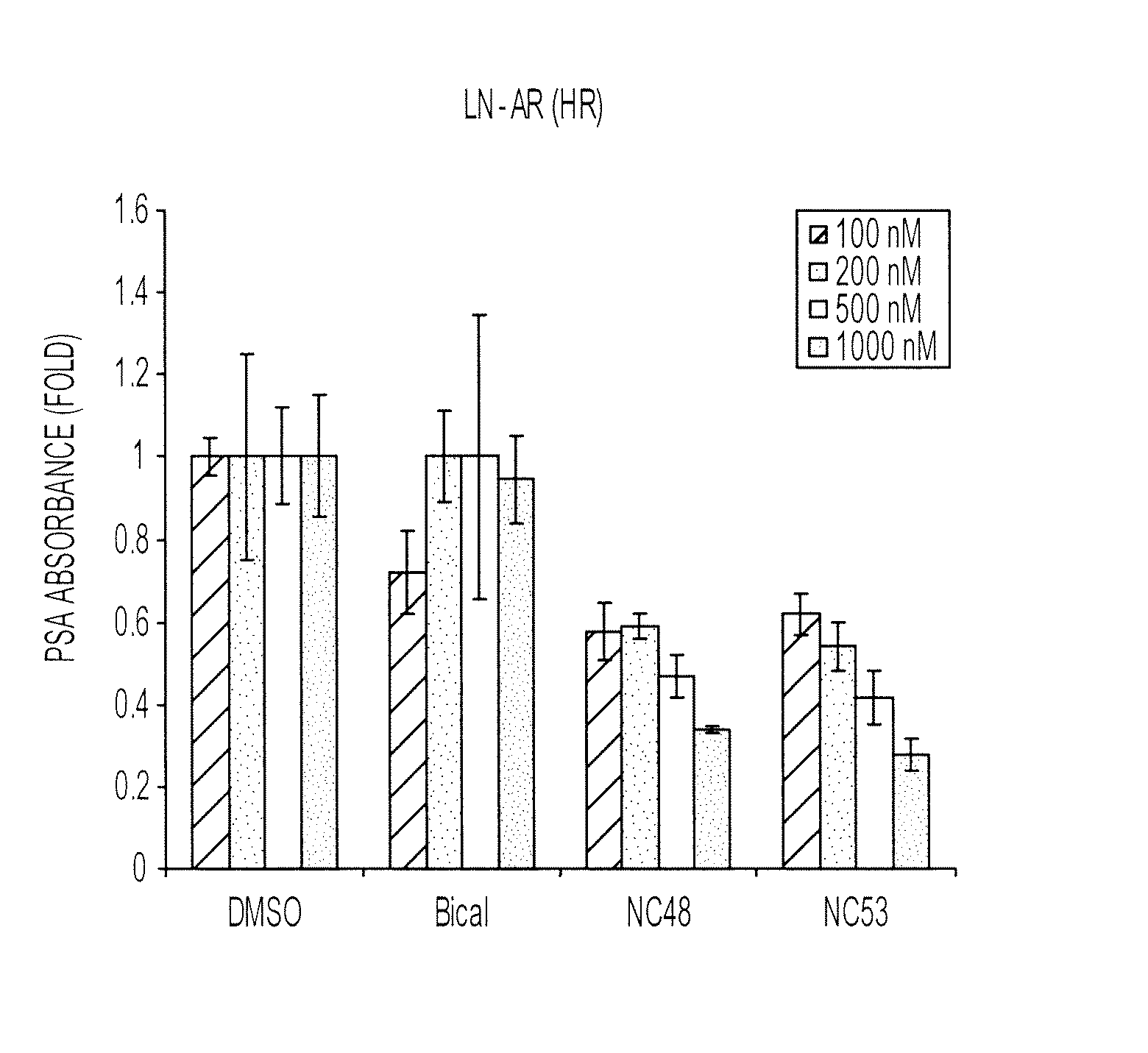

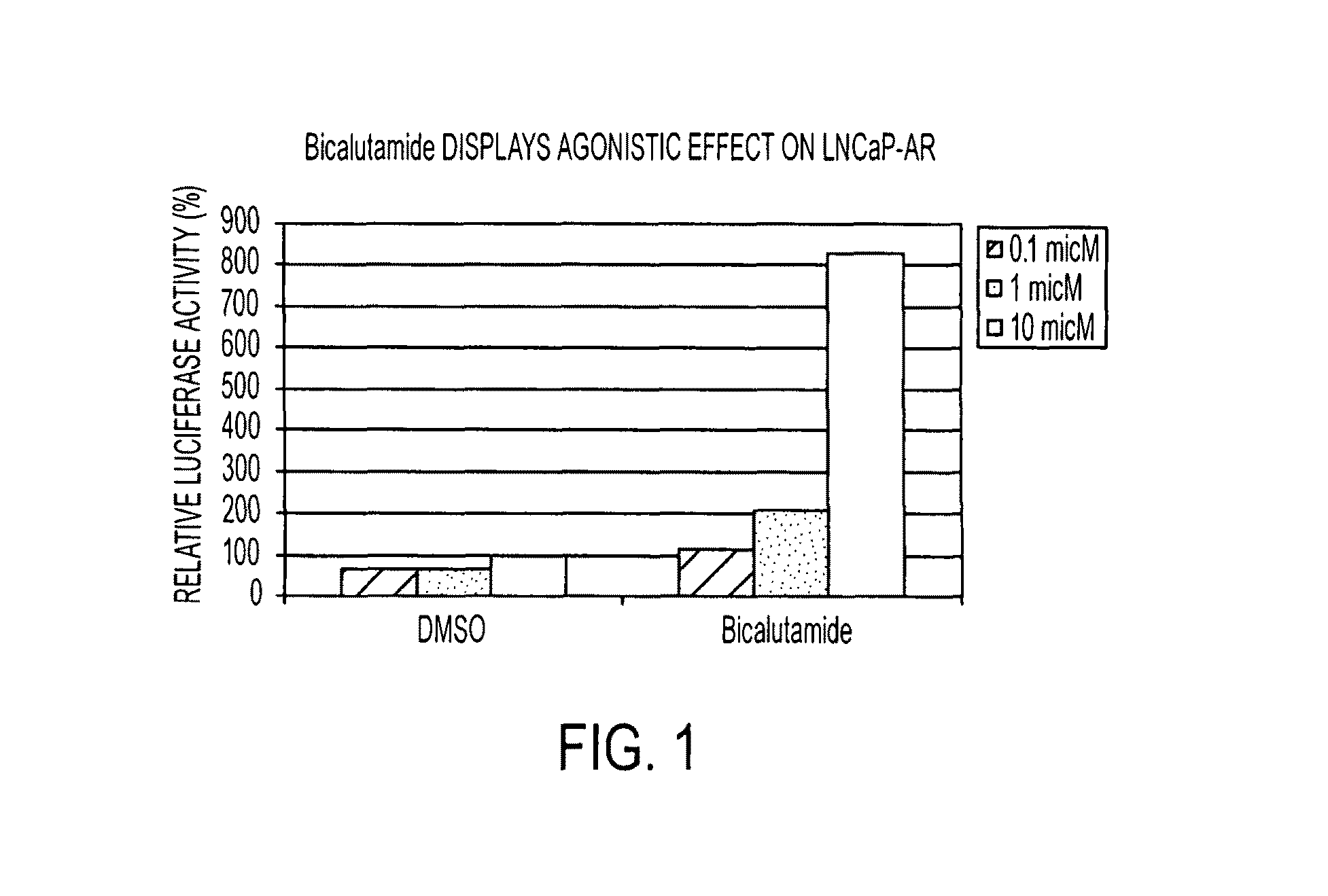

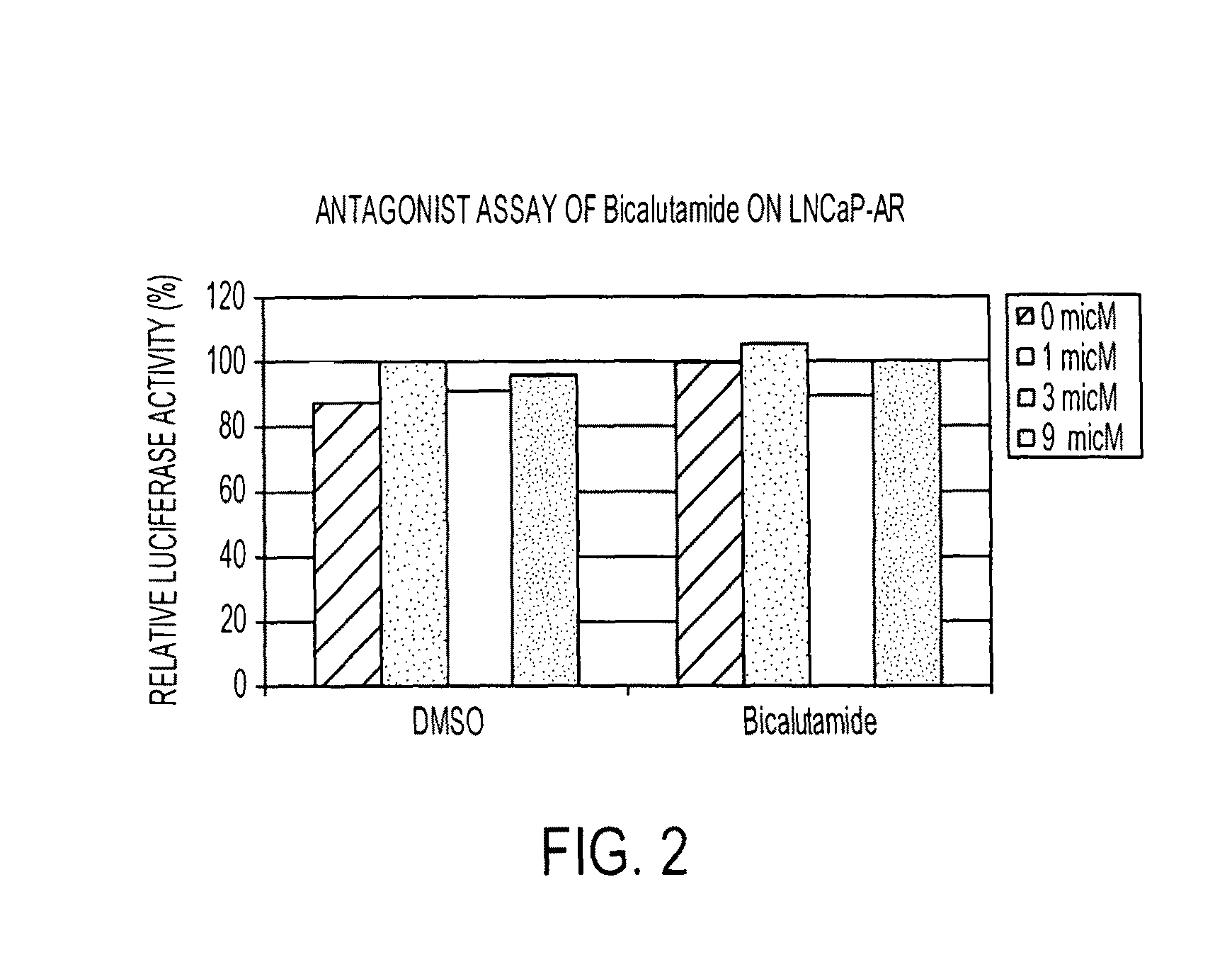

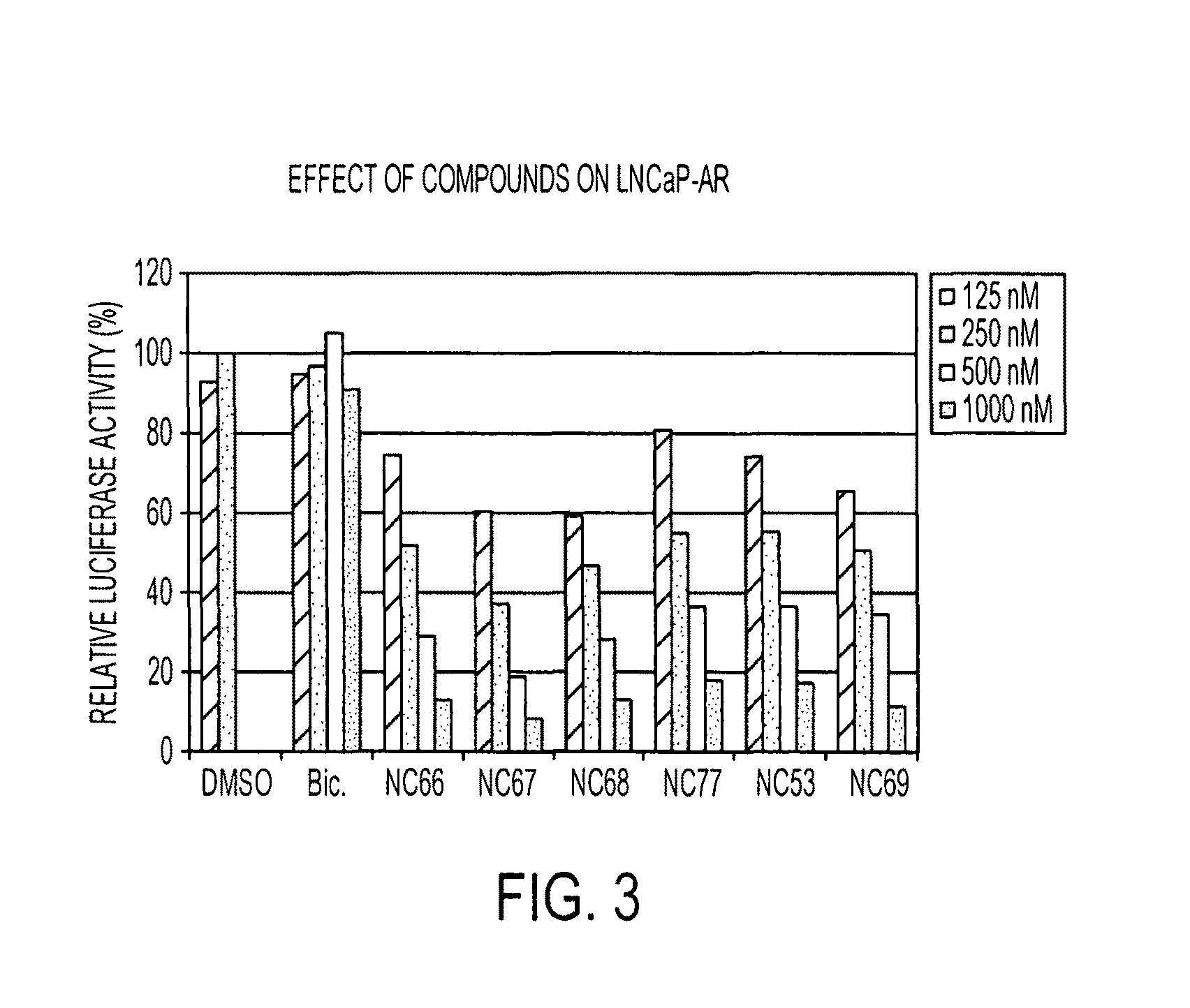

ActiveUS20070254933A1Avoid problemsPrevent nuclear translocationOrganic active ingredientsBiocideHormone refractory prostate cancerPharmacology

The present invention relates to diarylthiohydantoin compounds and methods for synthesizing them and using them in the treatment of hormone refractory prostate cancer.

Owner:RGT UNIV OF CALIFORNIA

Diarylthiohydantoin compounds

ActiveUS20080139634A2Avoid translocationDestabilize an androgen receptor proteinOrganic active ingredientsBiocideHormone refractory prostate cancerPharmacology

Owner:RGT UNIV OF CALIFORNIA

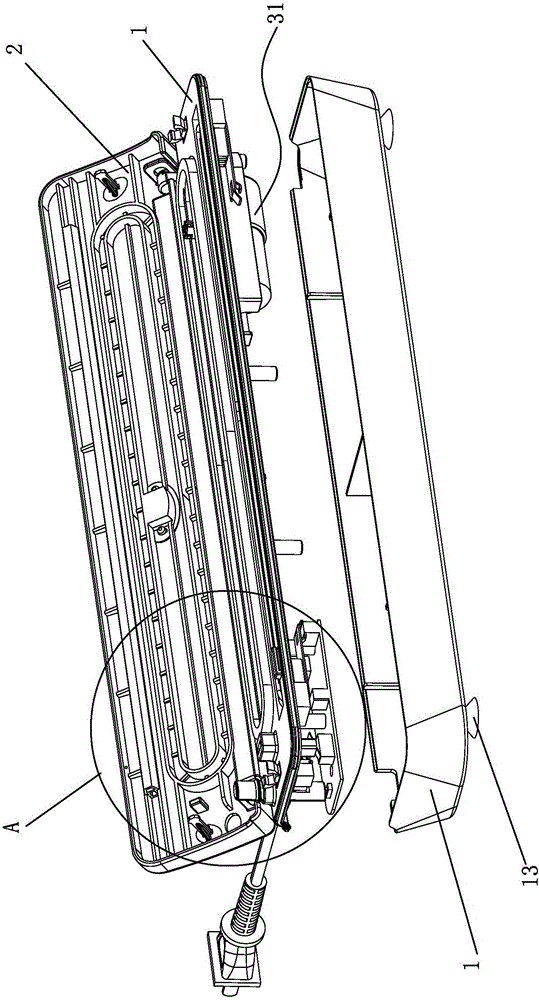

Lens device

ActiveCN1808201AEasily and reliably provideSuppression of optical axis deviationMountingsOptical axisEngineering

Owner:MAXELL HLDG LTD

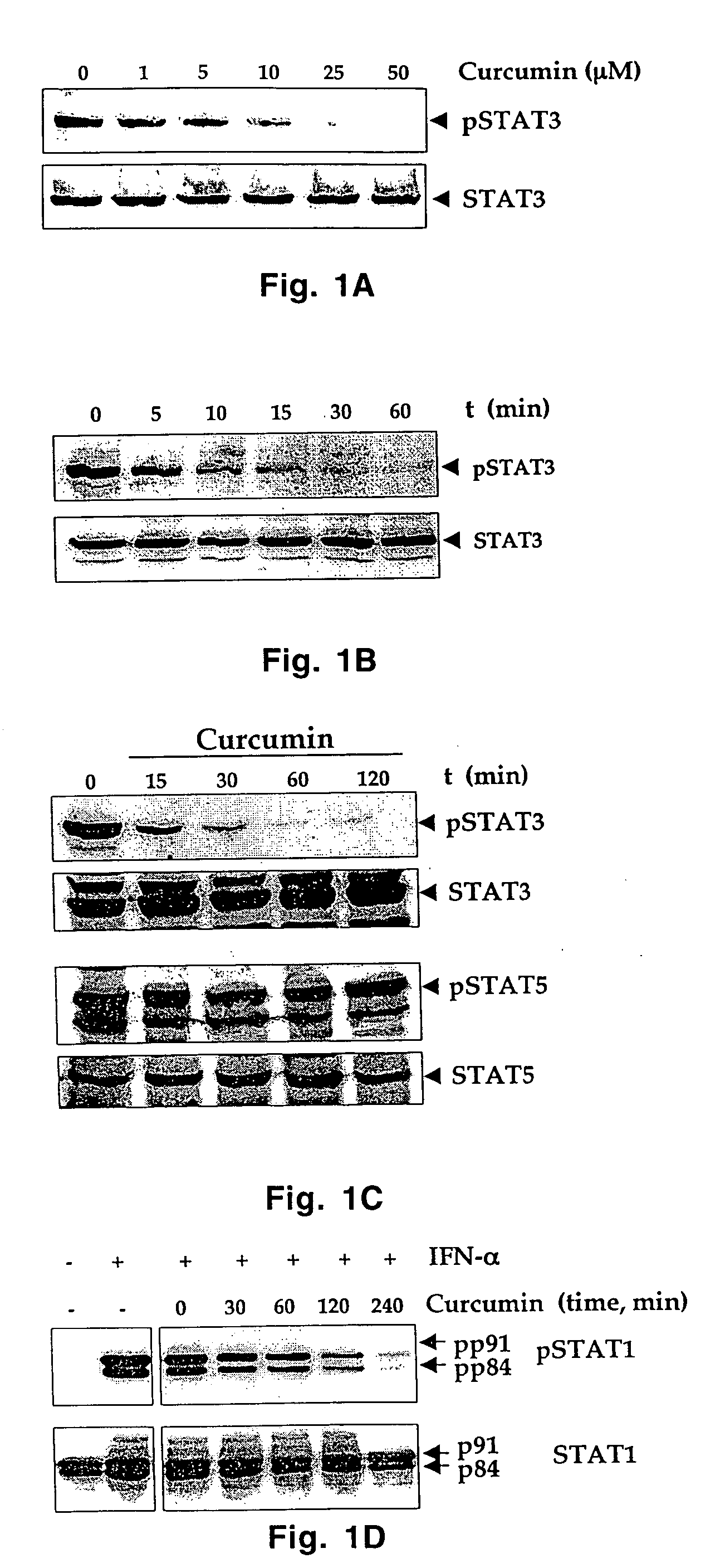

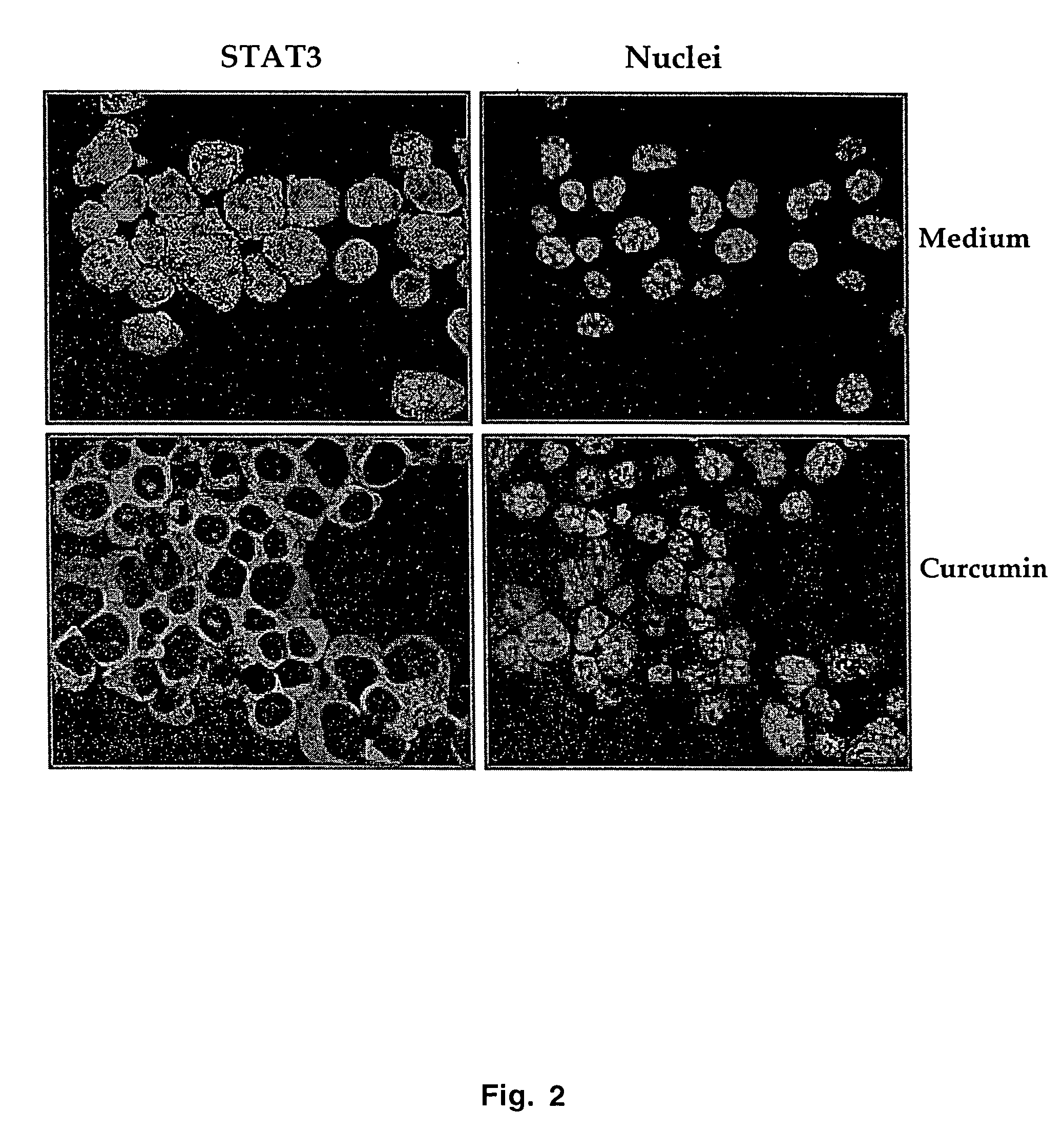

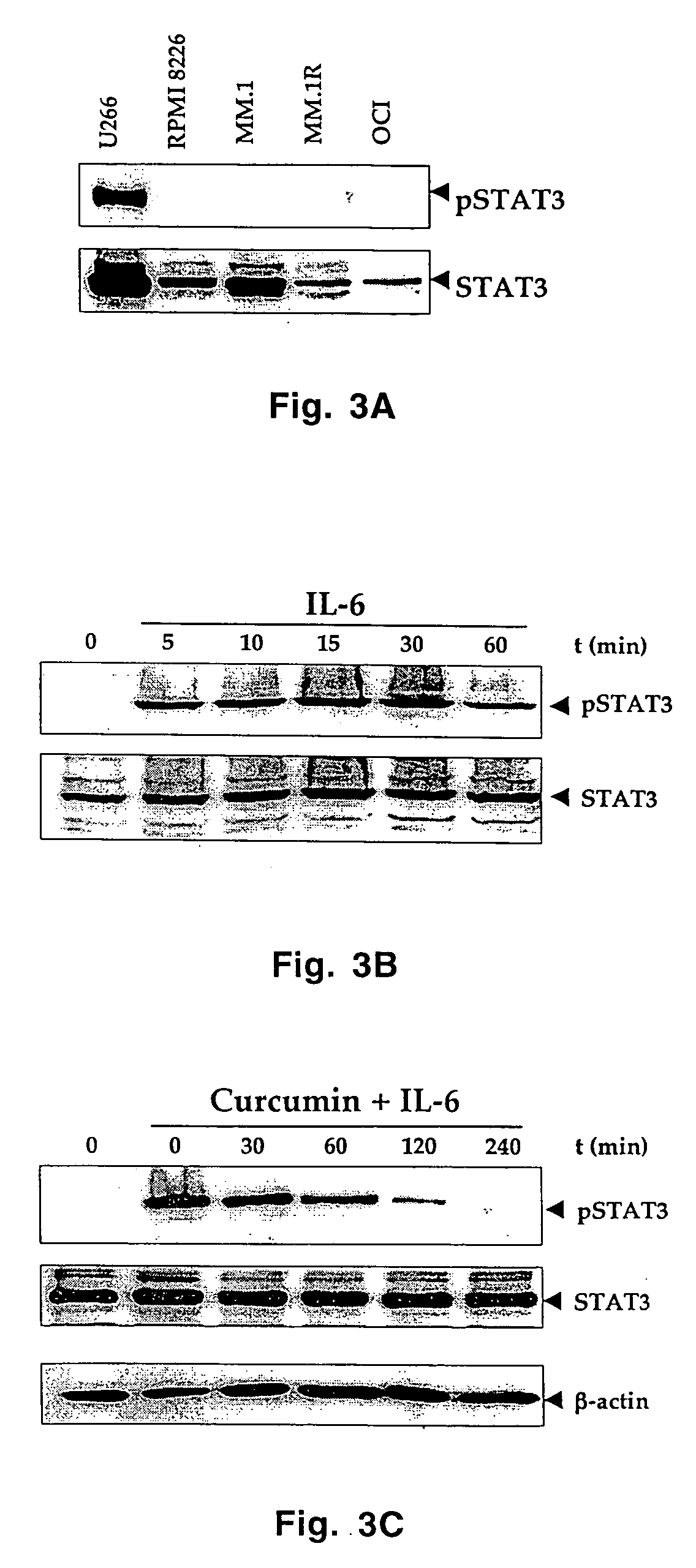

Selective inhibitors of stat-3 activation and uses thereof

InactiveUS20050049299A1Inhibited STAT3 phosphorylationImprove the level ofBiocideKetone active ingredientsBiological activationCancer research

The present invention provides a method of treating a cancerous or pre-cancerous state in an individual in need of such treatment, comprising the step of administering a pharmacologically effective dose of a curcuminoid to the individual.

Owner:AGGARWAL BHARAT B

Diarylthiohydantoin compounds

ActiveUS8110594B2Avoid translocationDestabilize an androgen receptor proteinBiocideOrganic active ingredientsHormone refractory prostate cancerPharmacology

The present invention relates to diarylthiohydantoin compounds and methods for synthesizing them and using them in the treatment of hormone refractory prostate cancer.

Owner:RGT UNIV OF CALIFORNIA

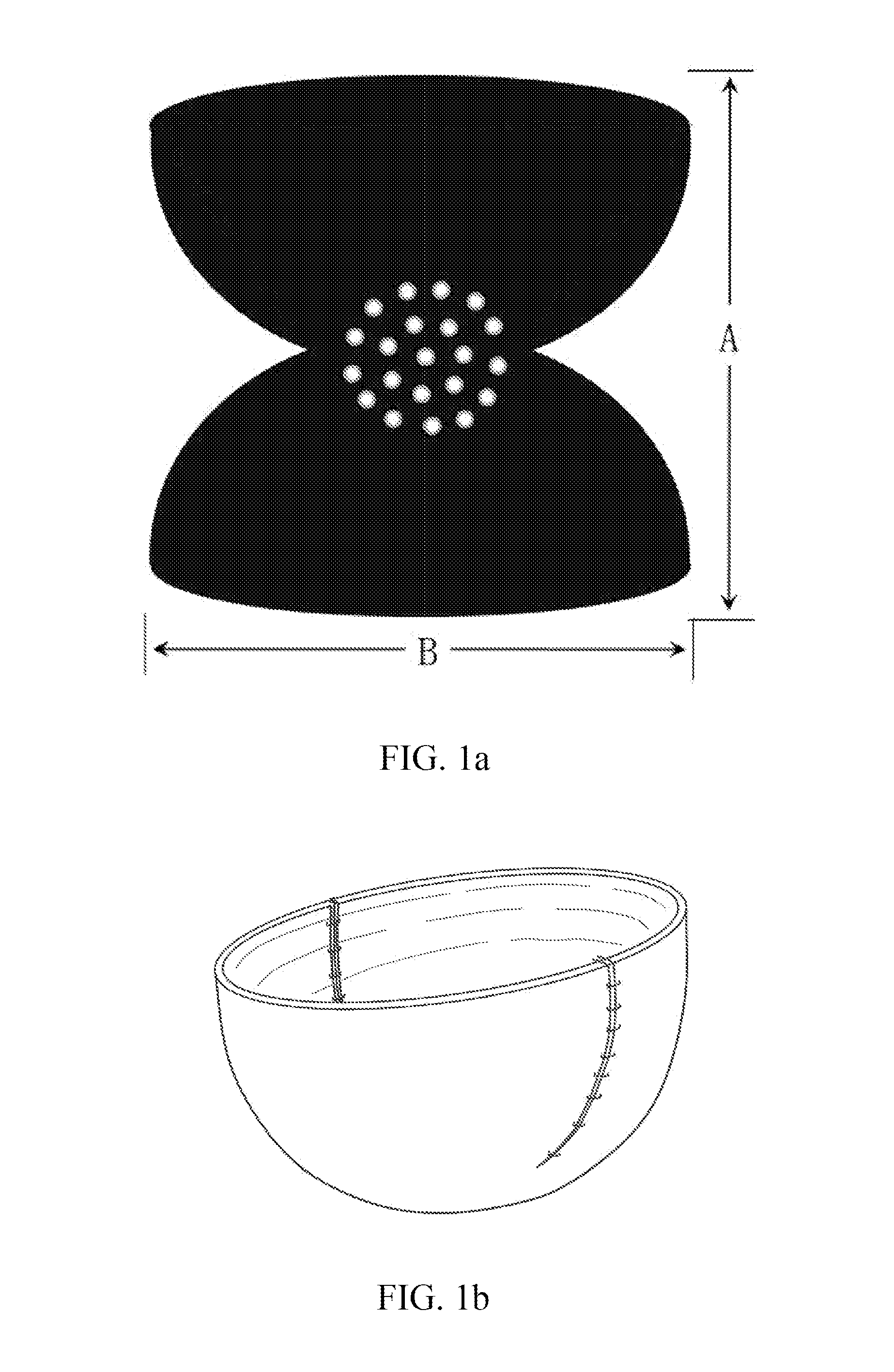

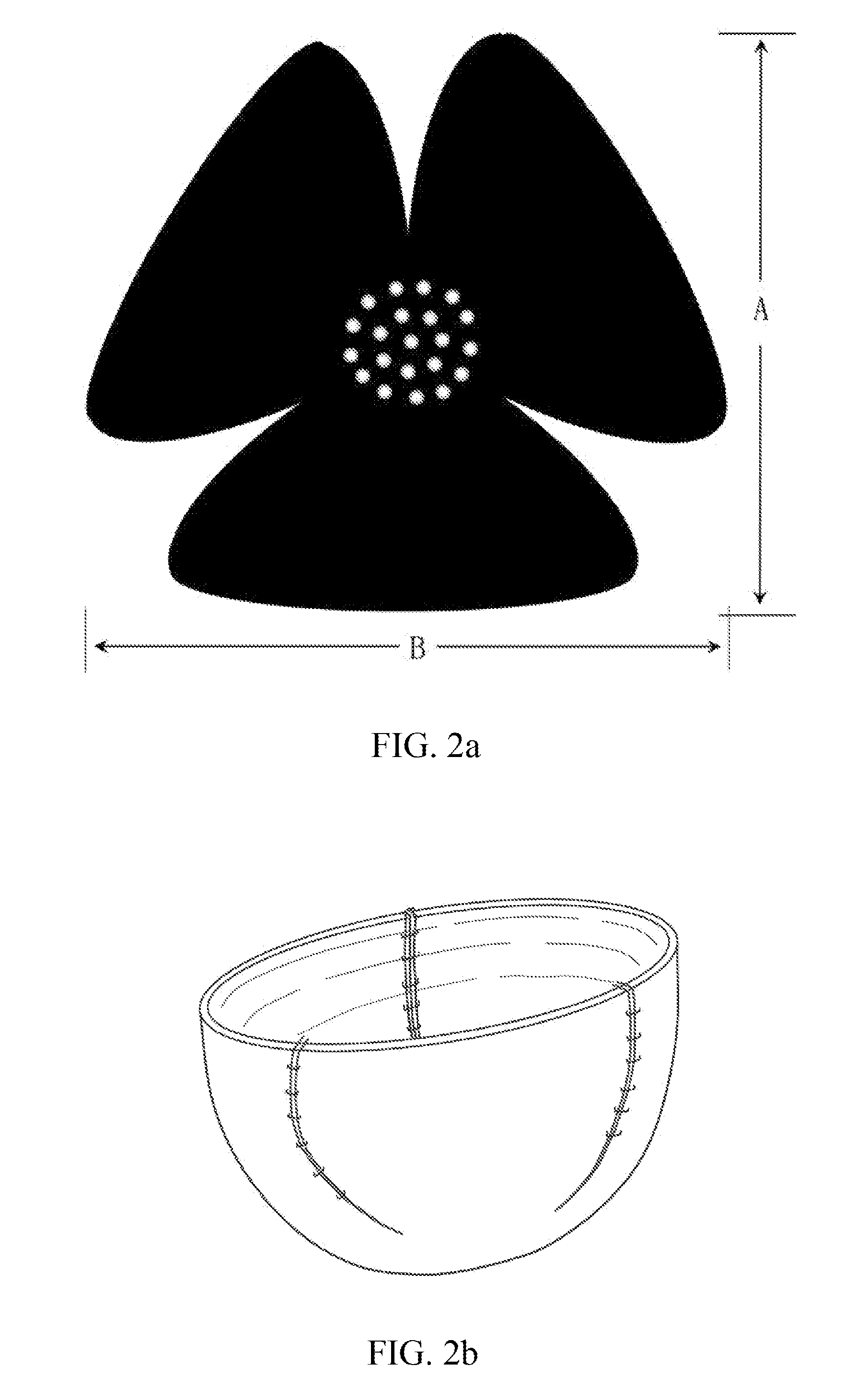

Breast Prosthesis Support Device Based on Tissue Matrix Material, and Preparation Method Therefor

ActiveUS20160199173A1Avoid ptosisAvoid translocationMammary implantsTissue cultureSurgical operationHuman body

The present invention relates to a support device for breast prosthesis based on an acellular matrix material of a biological tissue. The support device for breast prosthesis is formed by tailoring a membranaceous material into a petal-shaped planar biological matrix blank and by connecting adjacent edges thereof. The support device can match with the breast prosthesis; and provide a support, fixation and coverage for the breast prosthesis in various surgical operations such as mammoplasty and breast orthopedics, to avoid the ptosis and translocation of the breast prosthesis, thereby achieving desirable effects of plastic surgery. Once being implanted, the matrix material of a biological tissue can be integrated into the surrounding breast tissue of the subject, and thus transformed into new tissues in human body without the retention of foreign bodies. The present invention further relates to a method for manufacturing a support device, and a membranaceous biological matrix material.

Owner:BEIJING RUIJIAN GAOKE BIOTECH

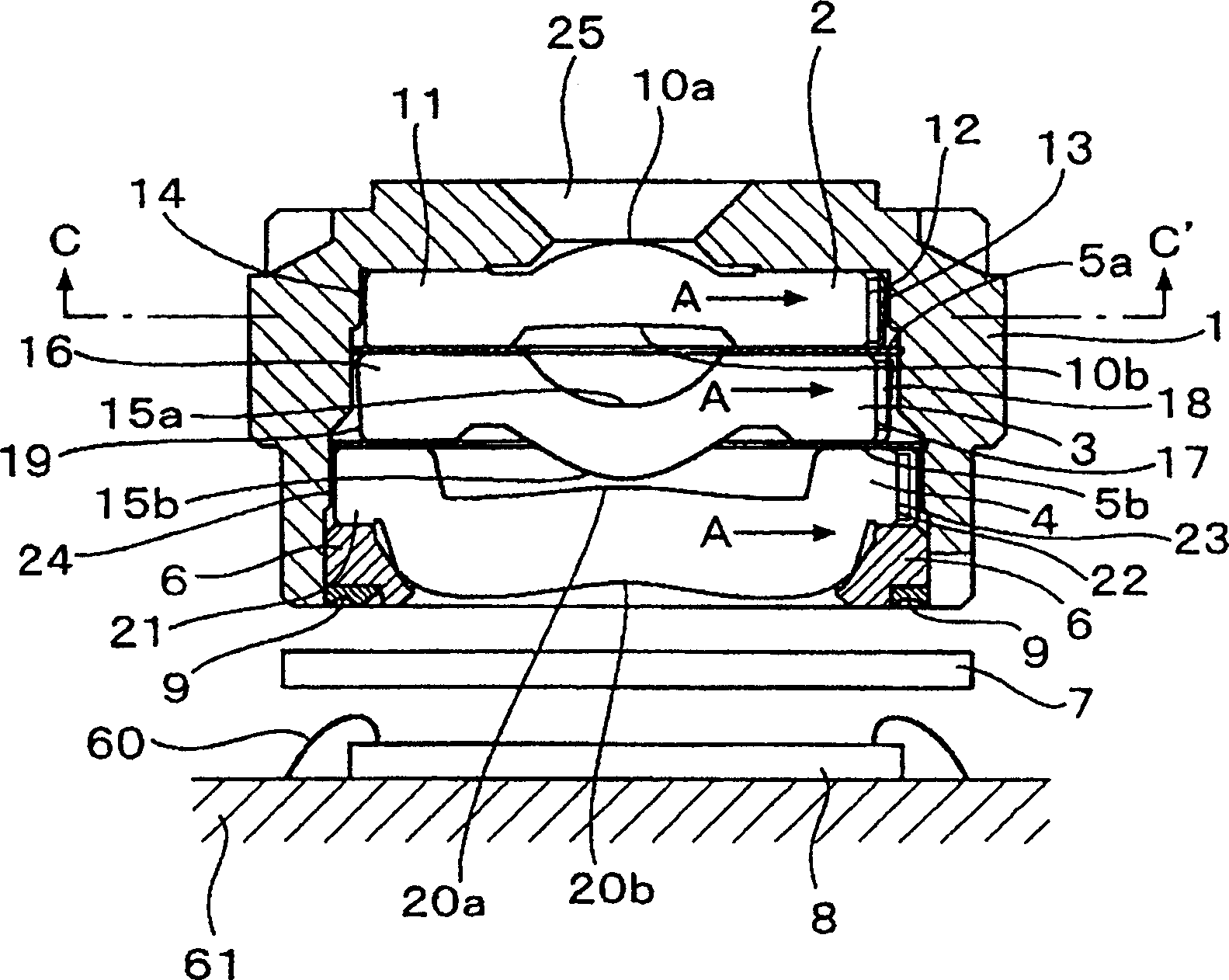

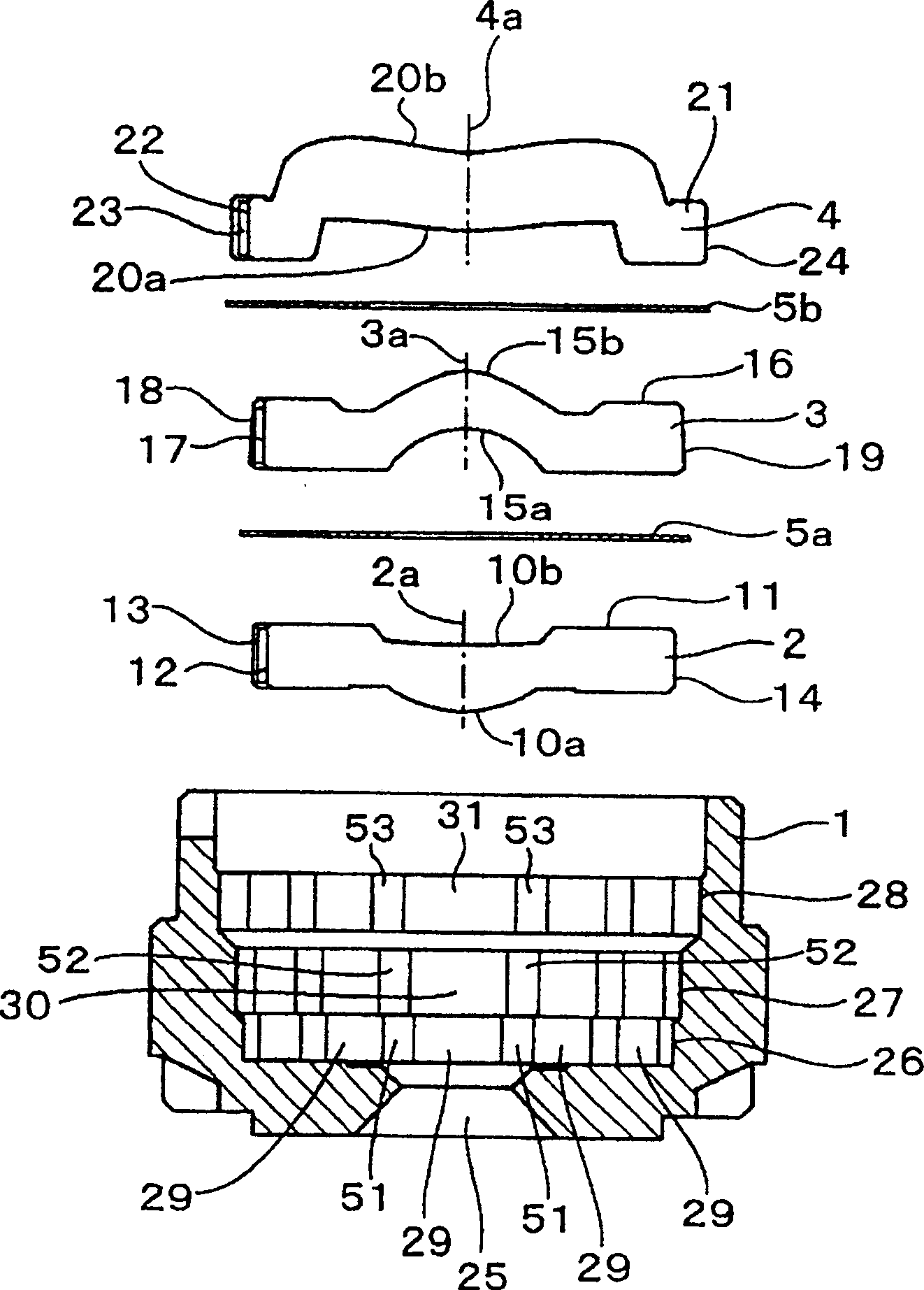

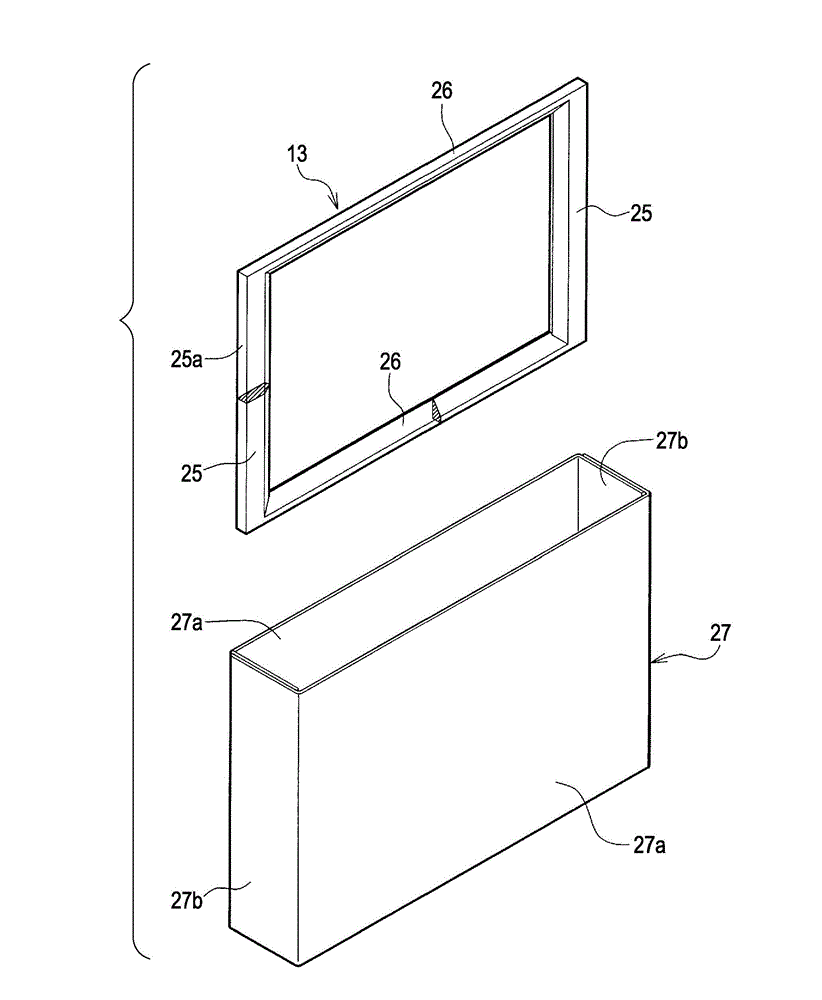

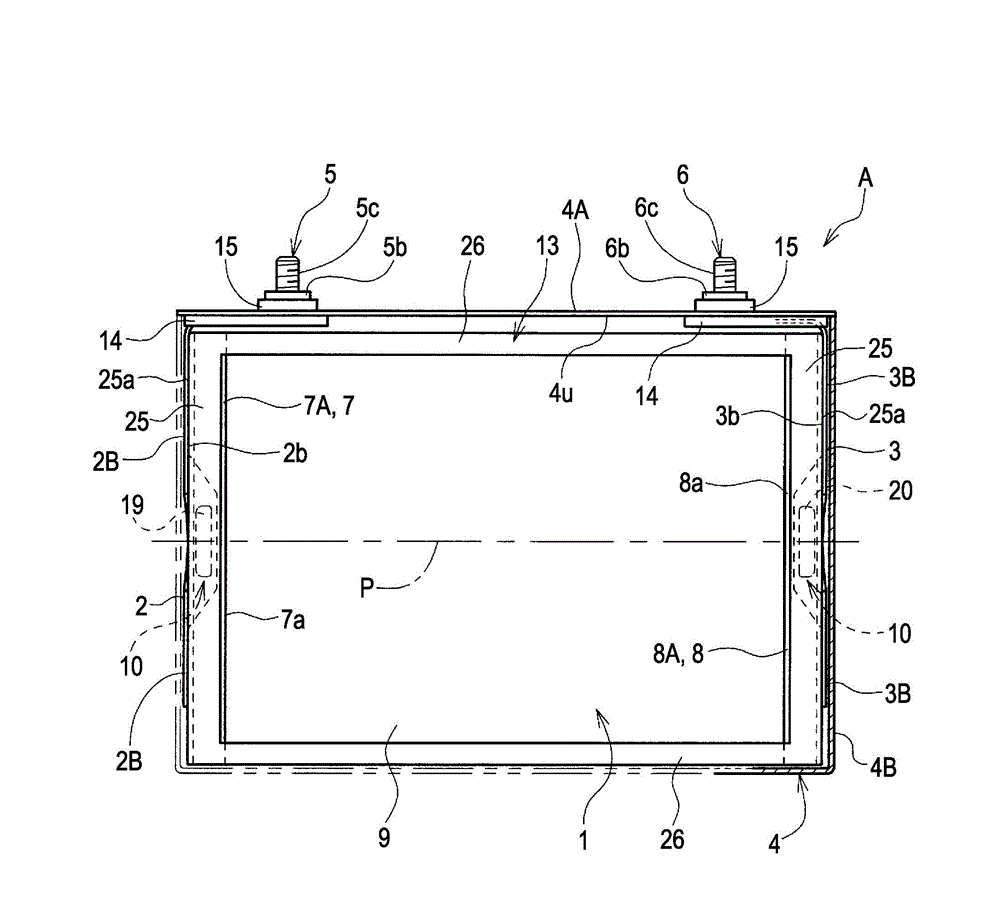

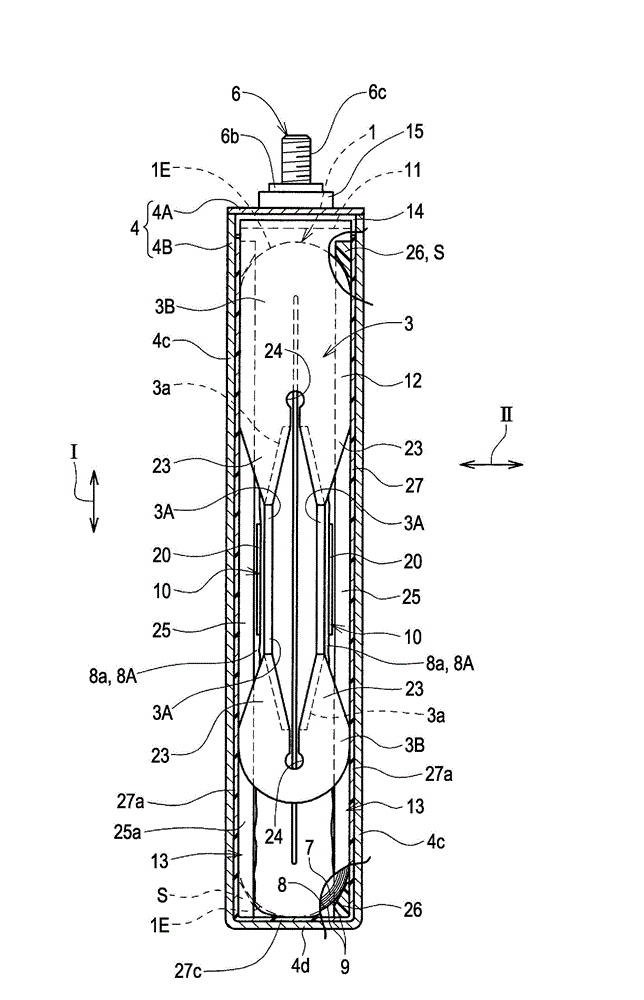

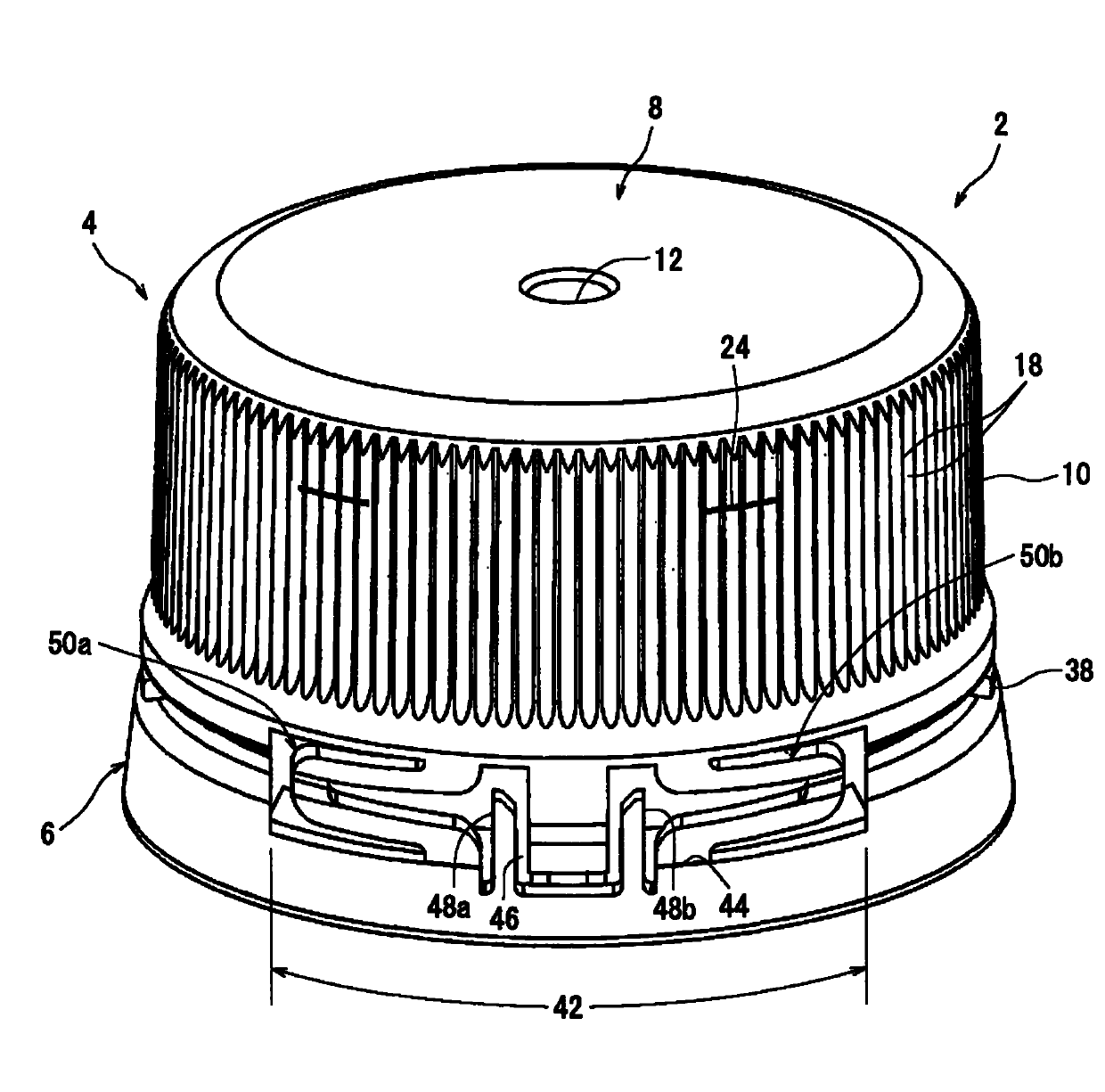

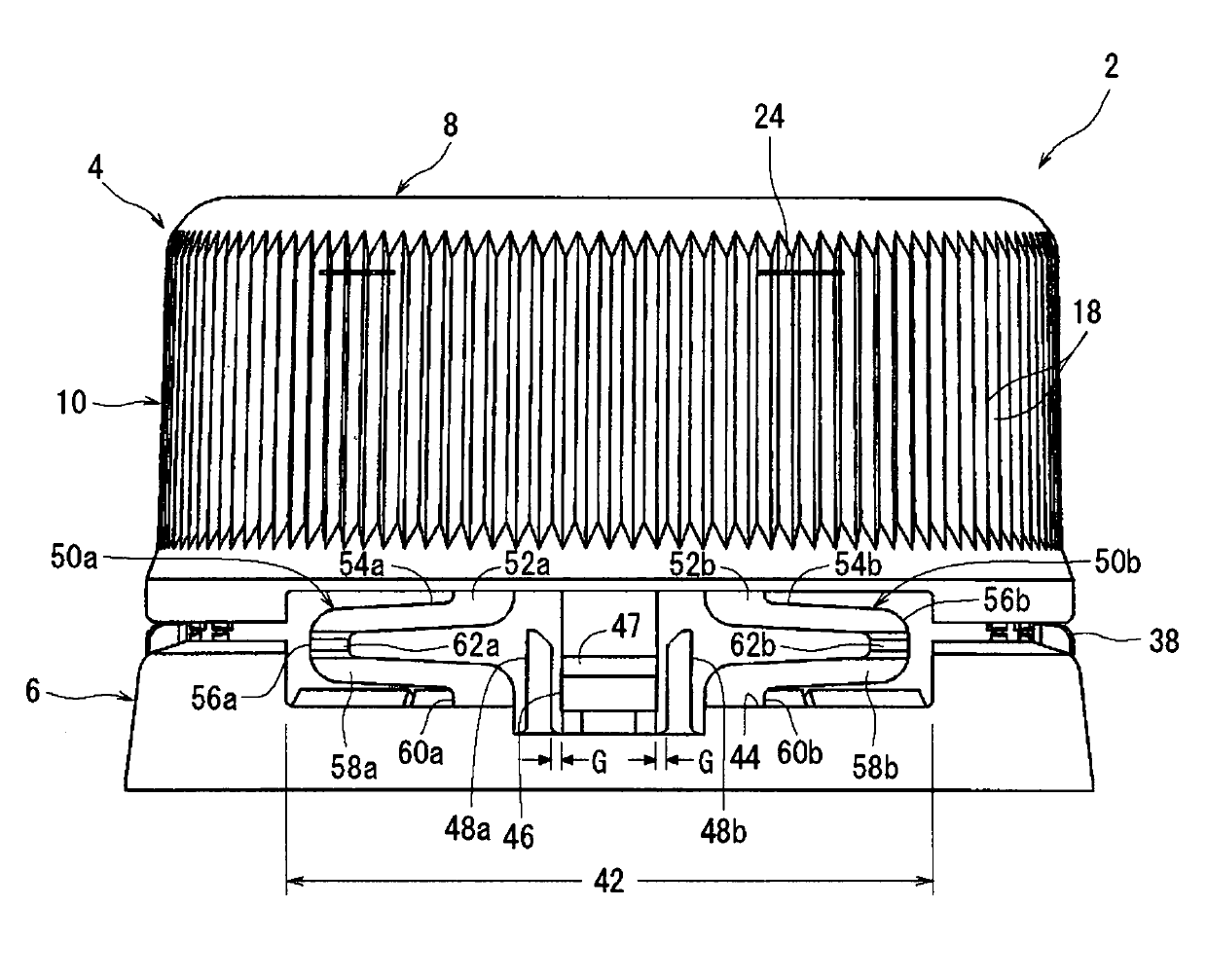

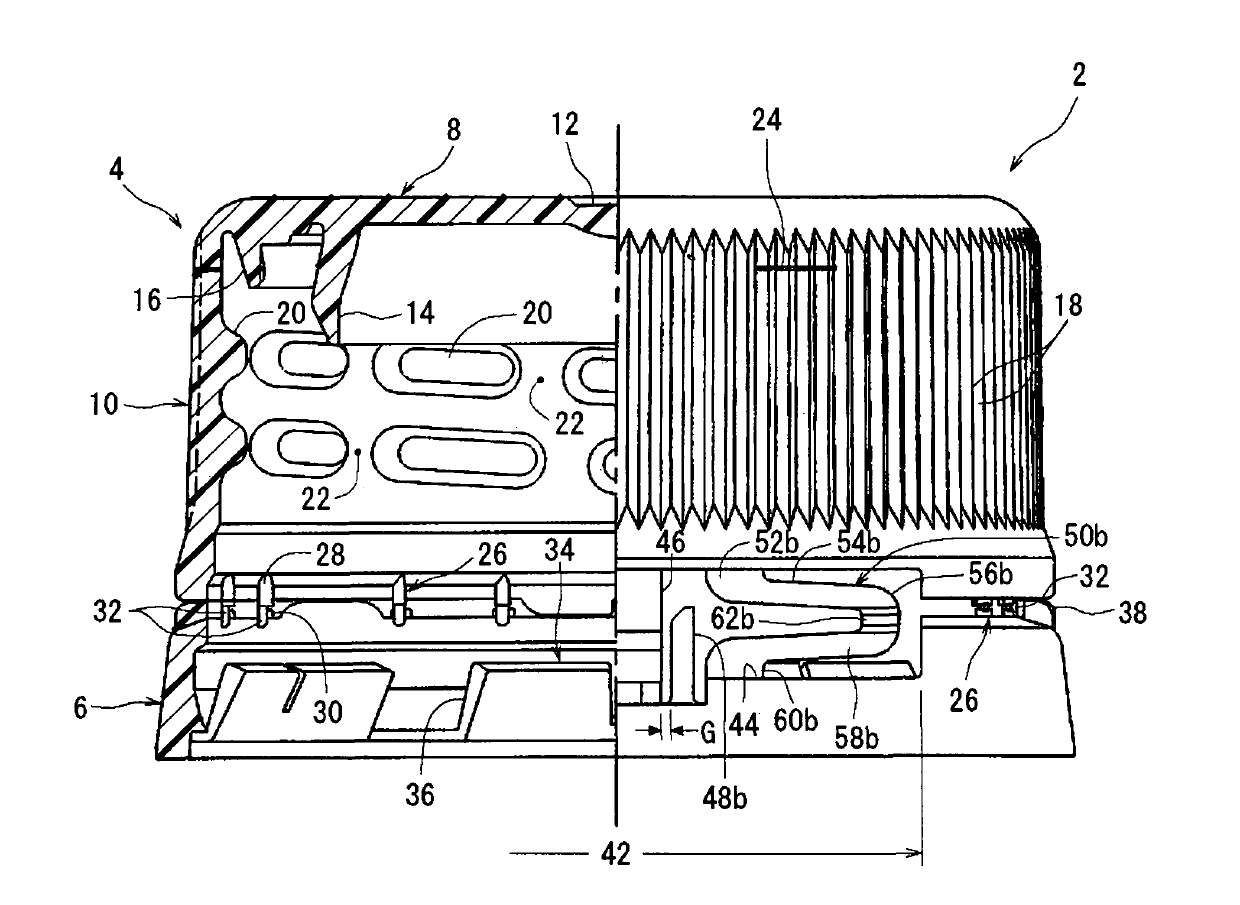

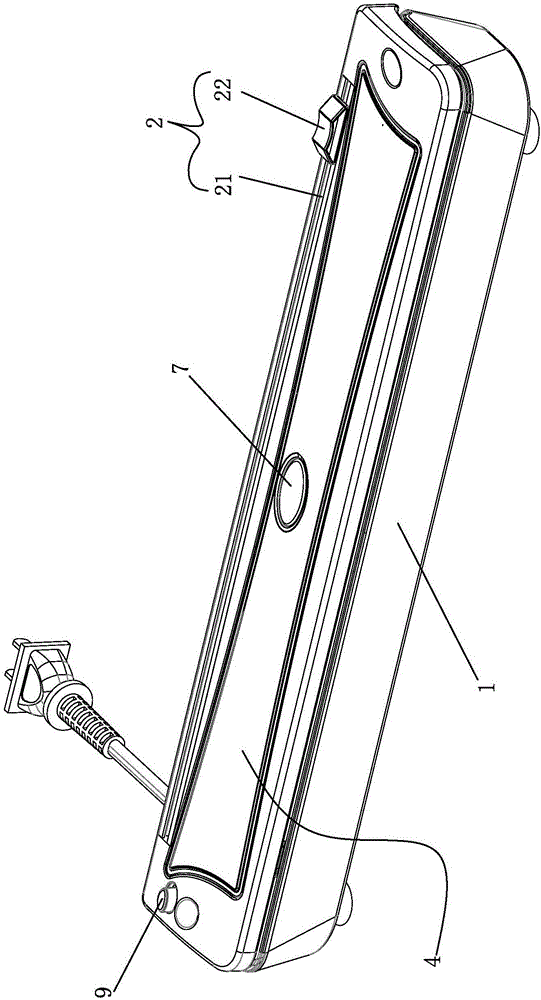

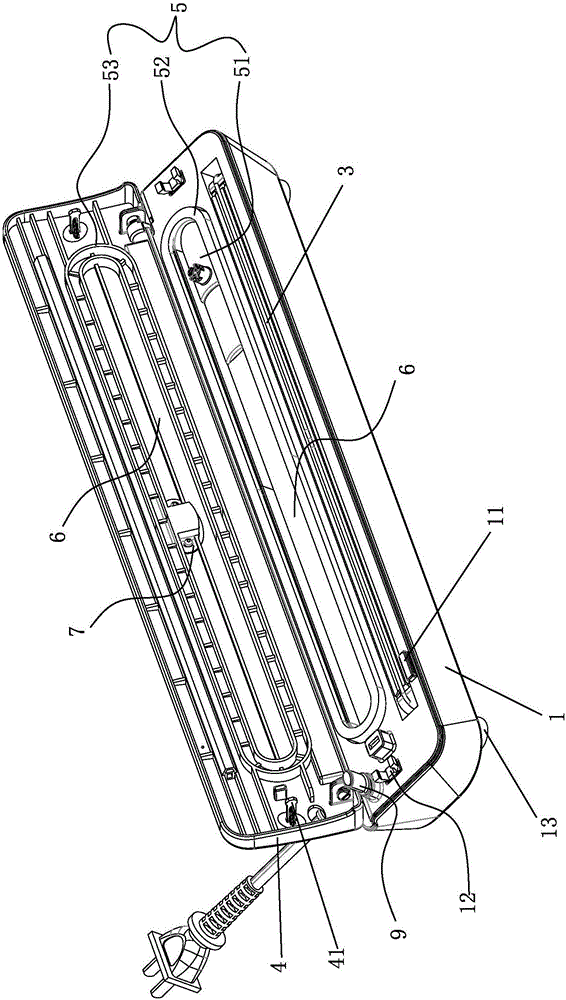

Electric storage device and insulation bag

ActiveCN102800824AAvoid deformationAvoid breakingFinal product manufactureSmall-sized cells cases/jacketsPositive currentElectrical and Electronics engineering

An electric storage device (A) includes: an electrode assembly (1) including a positive electrode sheet (7), a negative electrode sheet (8), and a separator (9) for insulating between the positive electrode sheet (7) and the negative electrode sheet (8); positive and negative current collectors (2 and 3) disposed on both ends of the electrode assembly (1); a case (4) in which the electrode assembly (1) and the current collectors (2 and 3) are housed and that fixes one ends of the positive and negative current collectors (2 and 3); and a support member (13) extending from the positive current collector (2) to the negative current collector (3).

Owner:GS YUASA INT LTD

Container lid of synthetic resin

ActiveCN102089220ANo need to increase circumferential dimensionAvoid breakingCapsClosure capsEngineeringSynthetic resin

A synthetic resin container-lid of type in which a body of the container lid is kept connected to a tamper-evident skirt section through non-breakable connecting sections. The container lid includes the tamper-evident skirt section connected to the body via breakable bridge sections arranged with a spacing from the body in the circumferential direction. The container lid is configured such that, even if the bridge sections are broken and the body is separated from an opening neck of a container, the container lid is kept mounted to the opening neck of the container. The container lid has an improved construction which can be applied without problems to a case where the body is, when separated, lifted a relatively long distance. Each of the non-breakable connecting sections is formed in a shape including two tilt sections tilted in the directions opposite to each other.

Owner:JAPAN CROWN CORK CO LTD

Methods and compositions relating to hematopoietic stem cell expansion, enrichment, and maintenance

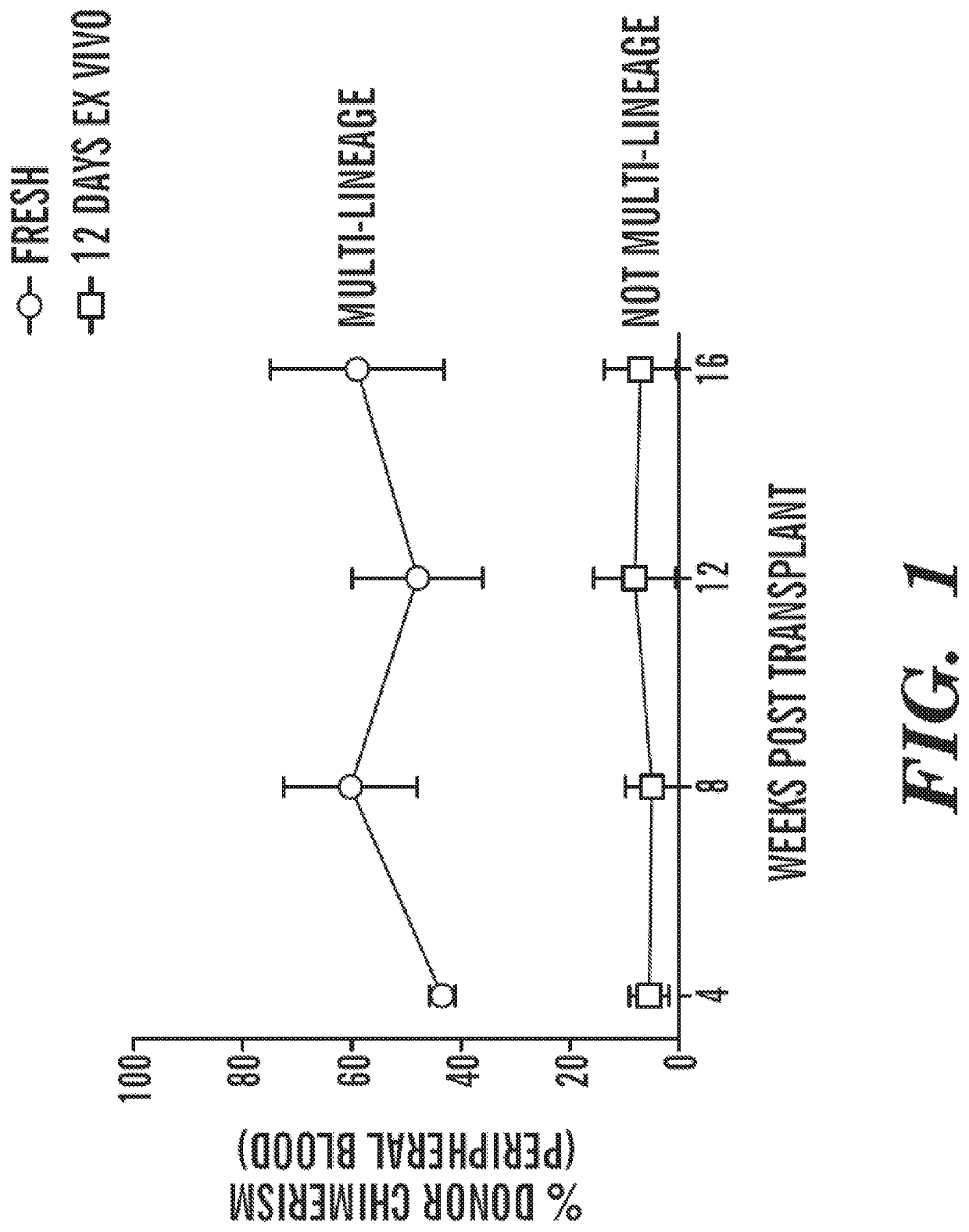

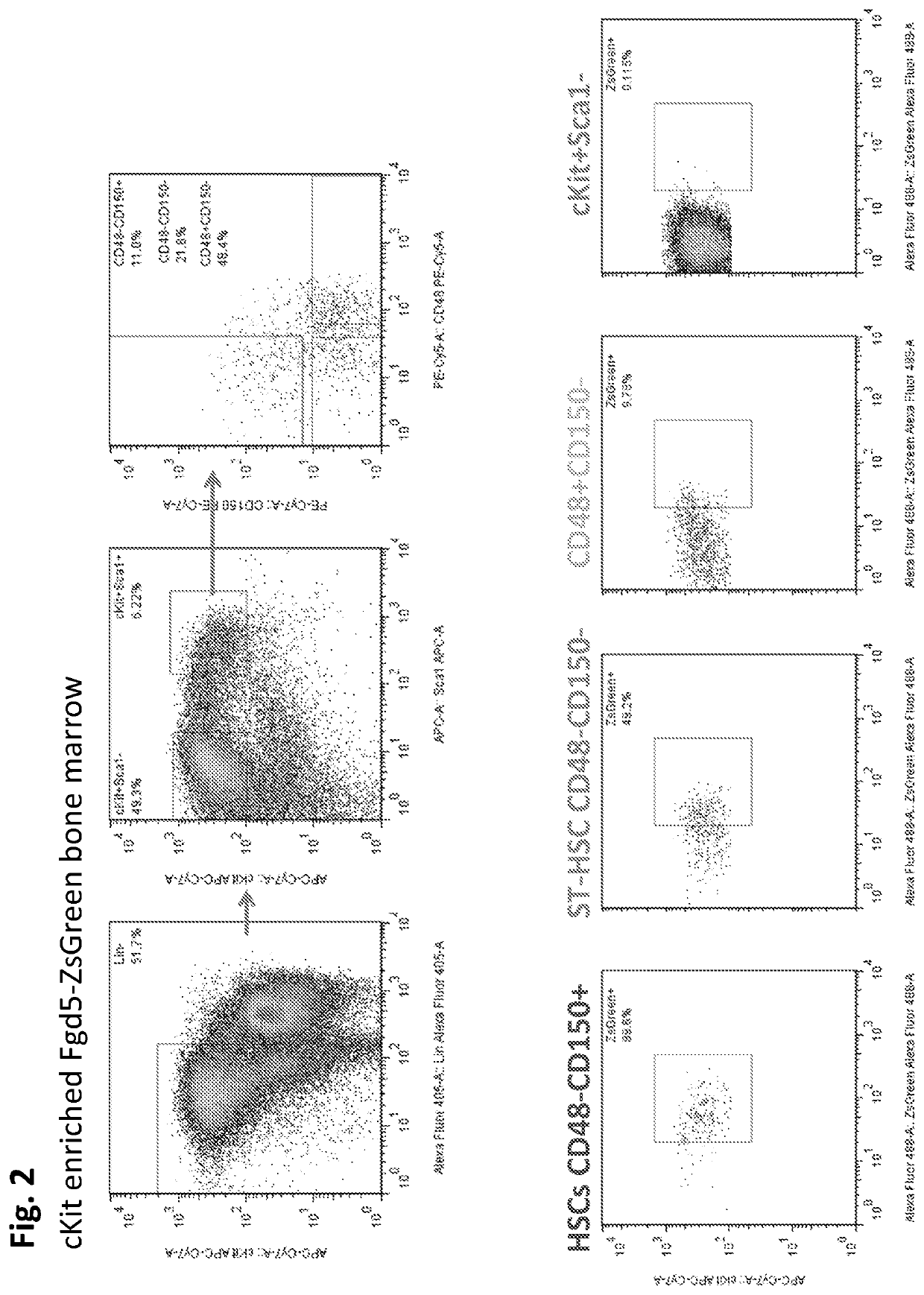

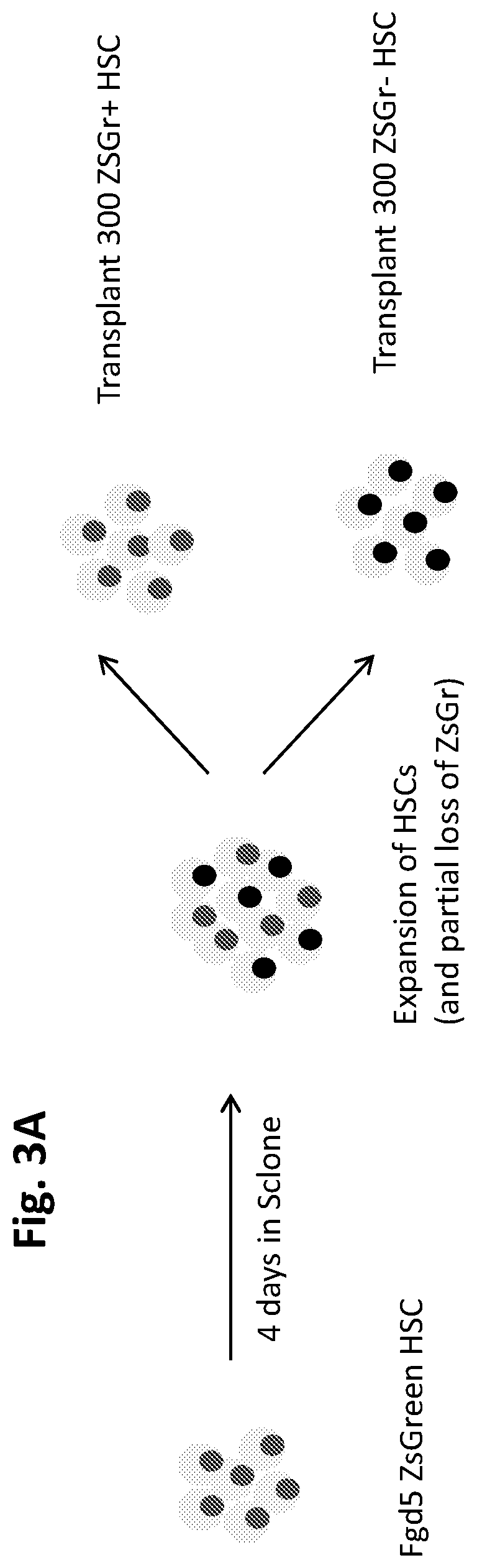

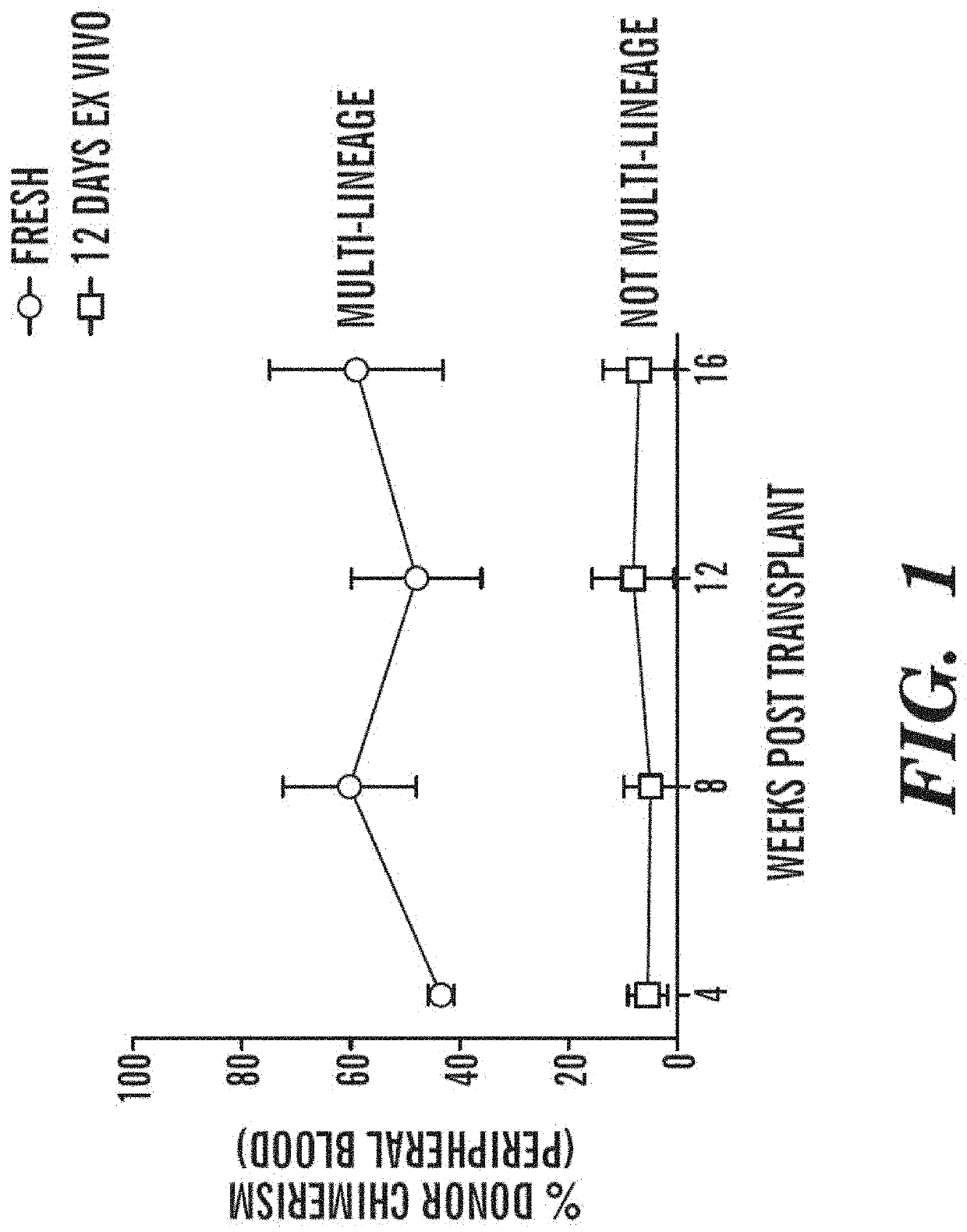

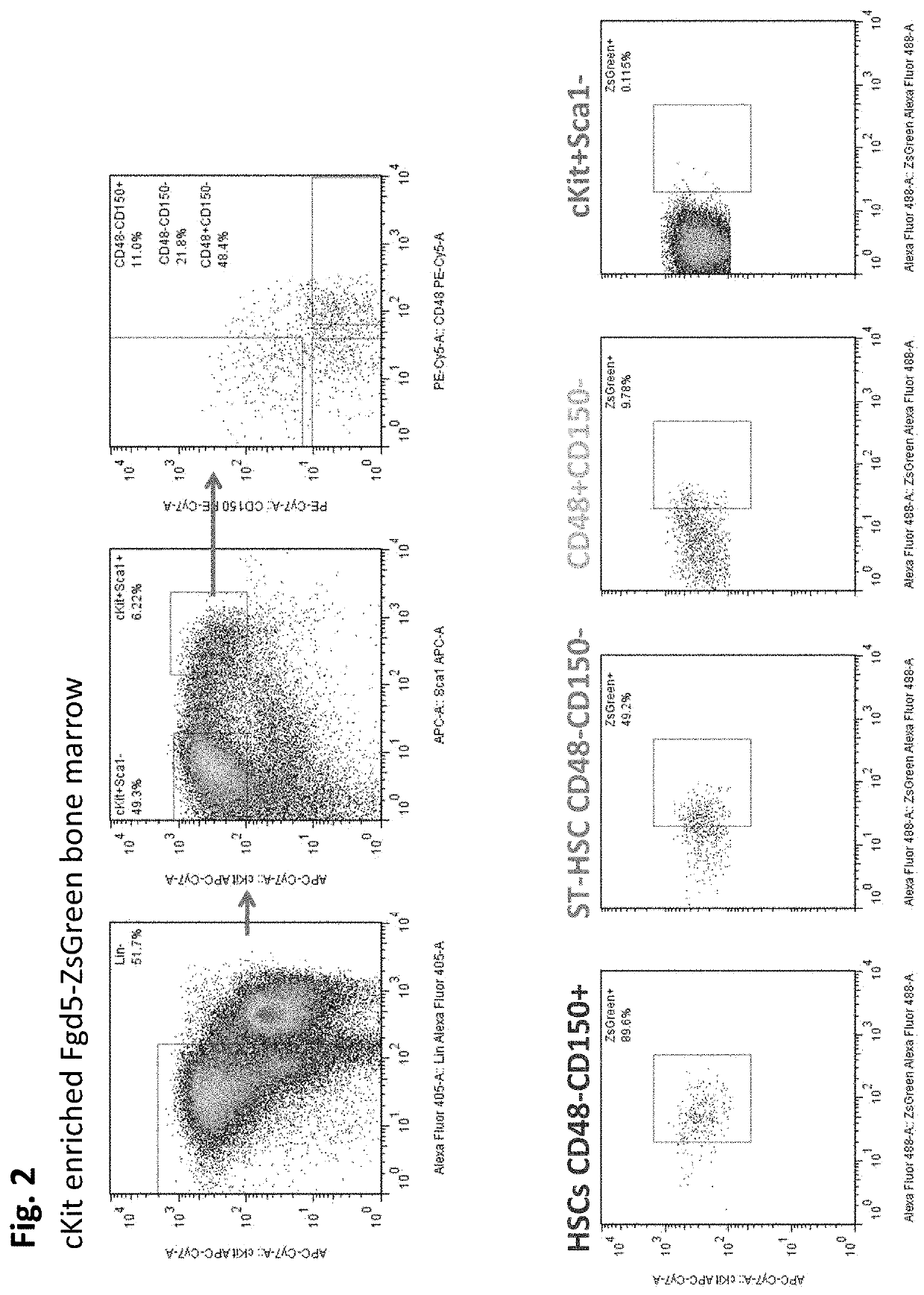

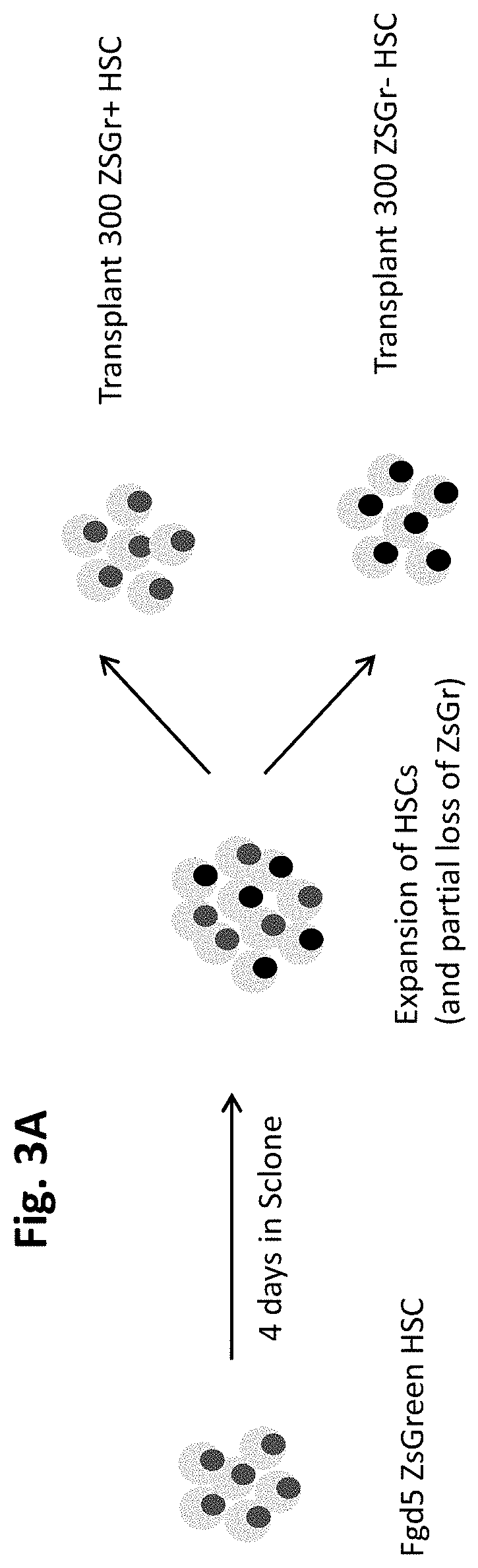

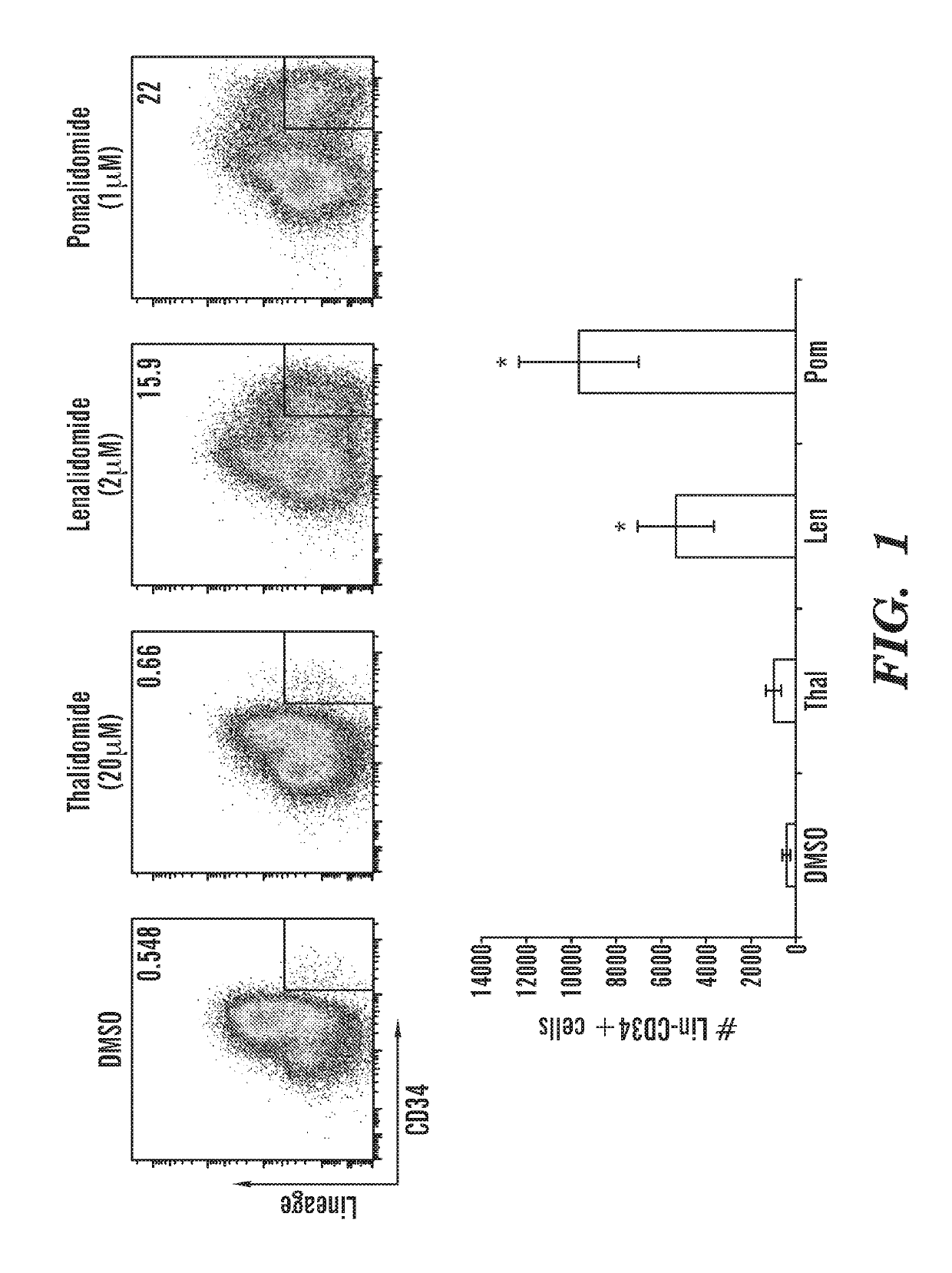

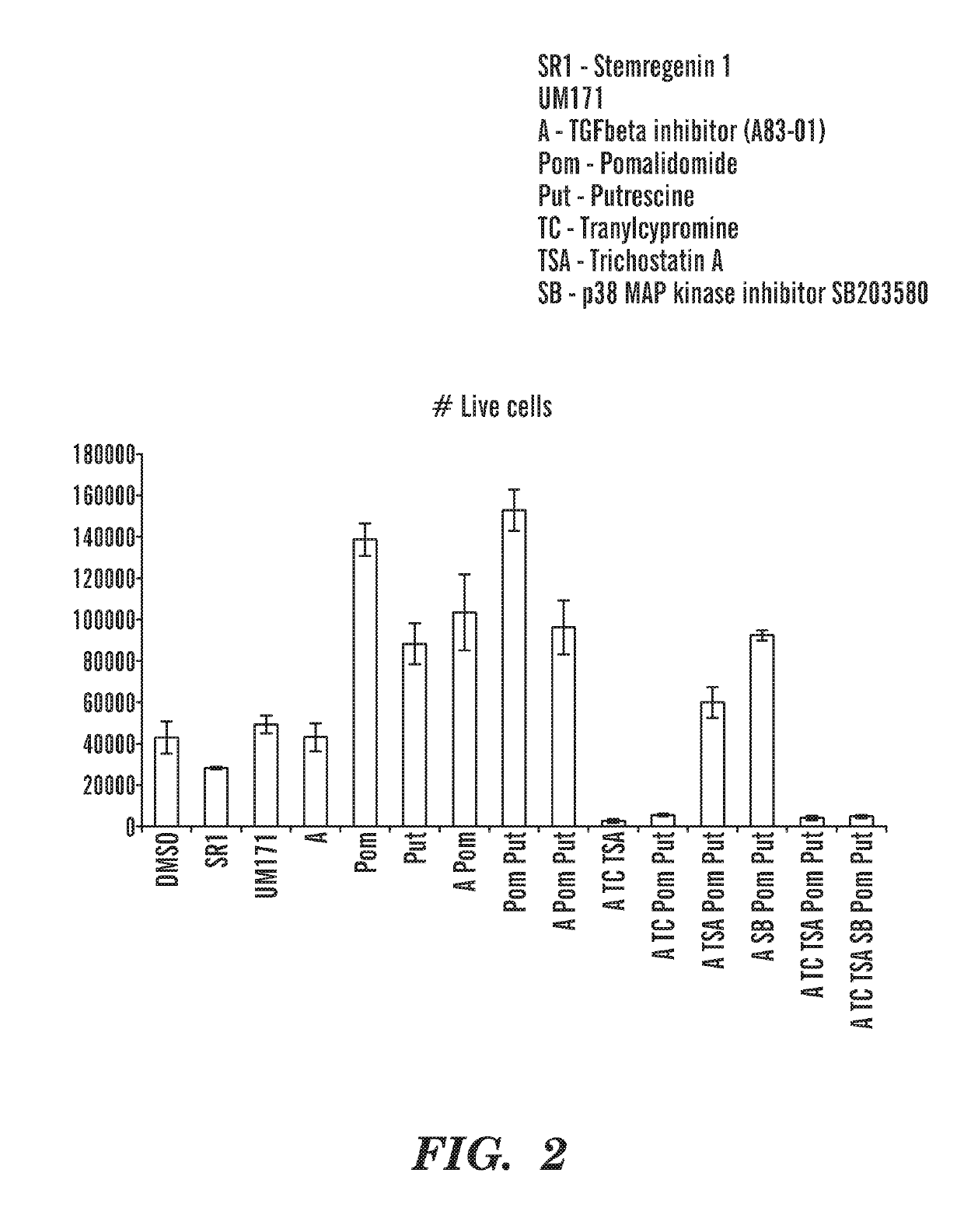

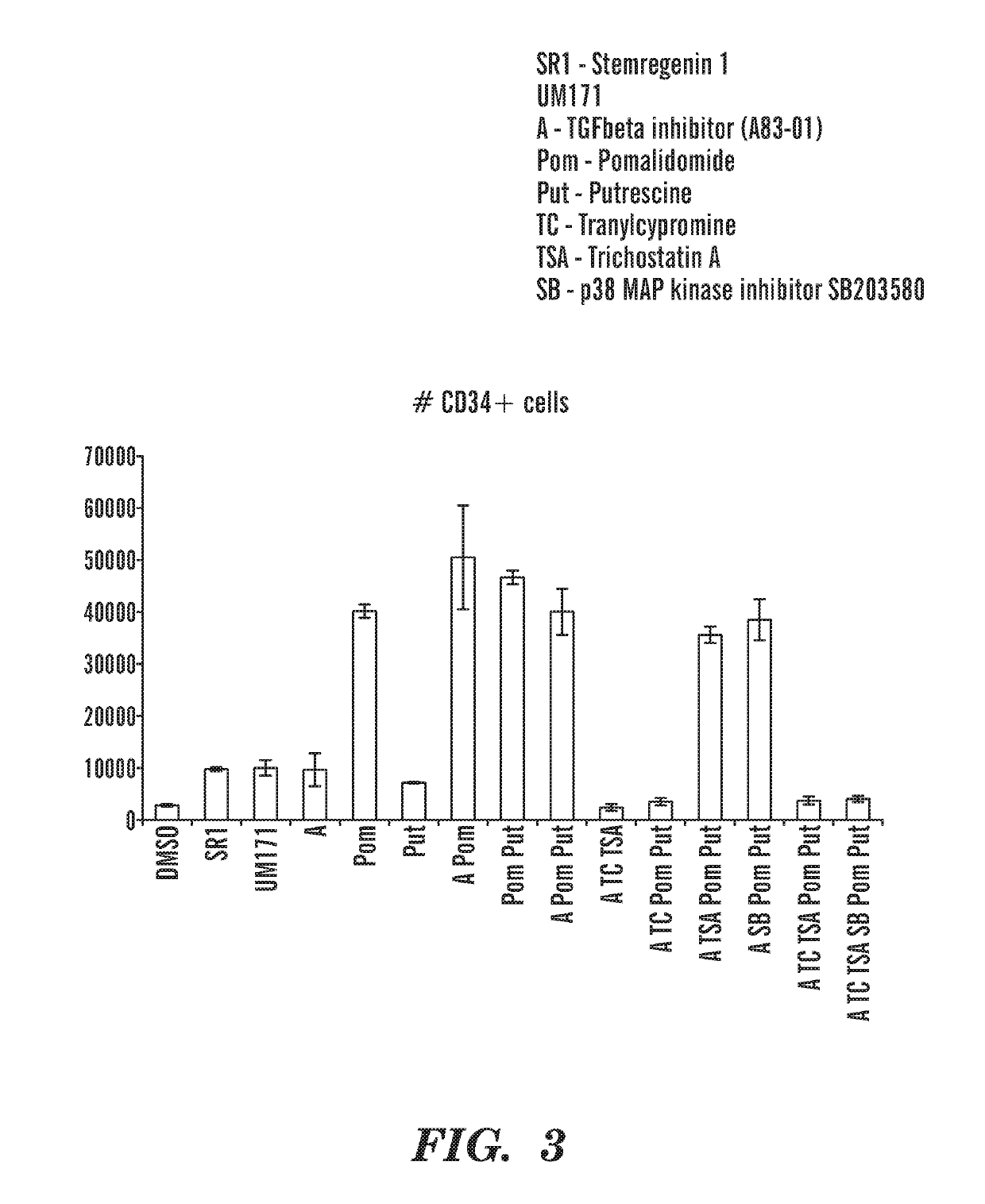

ActiveUS10669528B2Inhibit phosphorylationPreventing and disrupting interactionNervous disorderPeptide/protein ingredientsHistone methylationActive agent

The methods and compositions described herein relate to producing, expanding, enriching, and / or maintaining hematopoietic stem cells ex vivo by treating the cells with an agent(s) that exhibits two or more activities selected from modulation of histone methylation; inhibition of TGFβ signaling; inhibition of p38 signaling; activation of canonical Wnt signaling; and modulation of histone acetylation. In some embodiments, the technology described herein relates to transplantation of hematopoietic stem cells.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

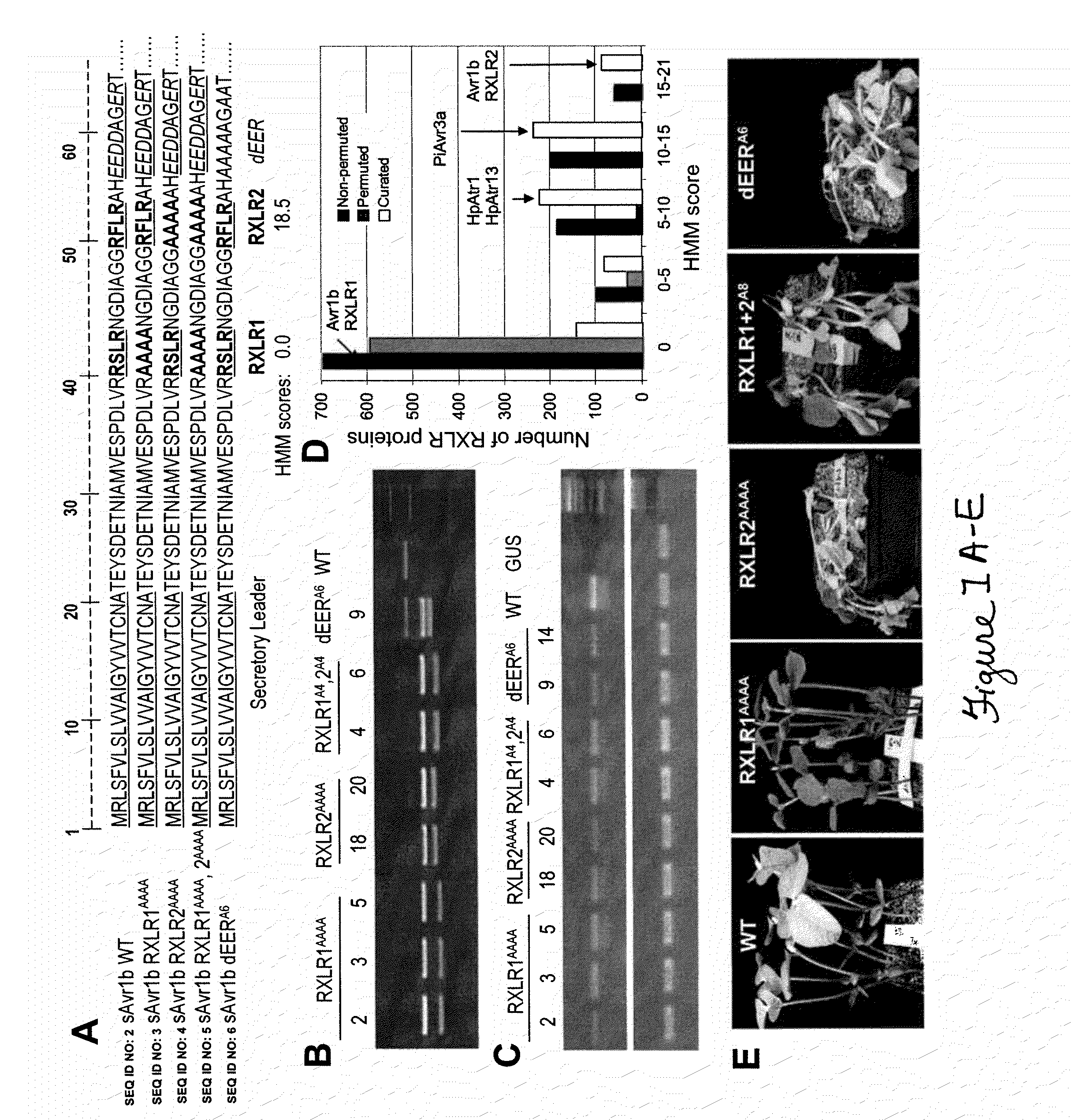

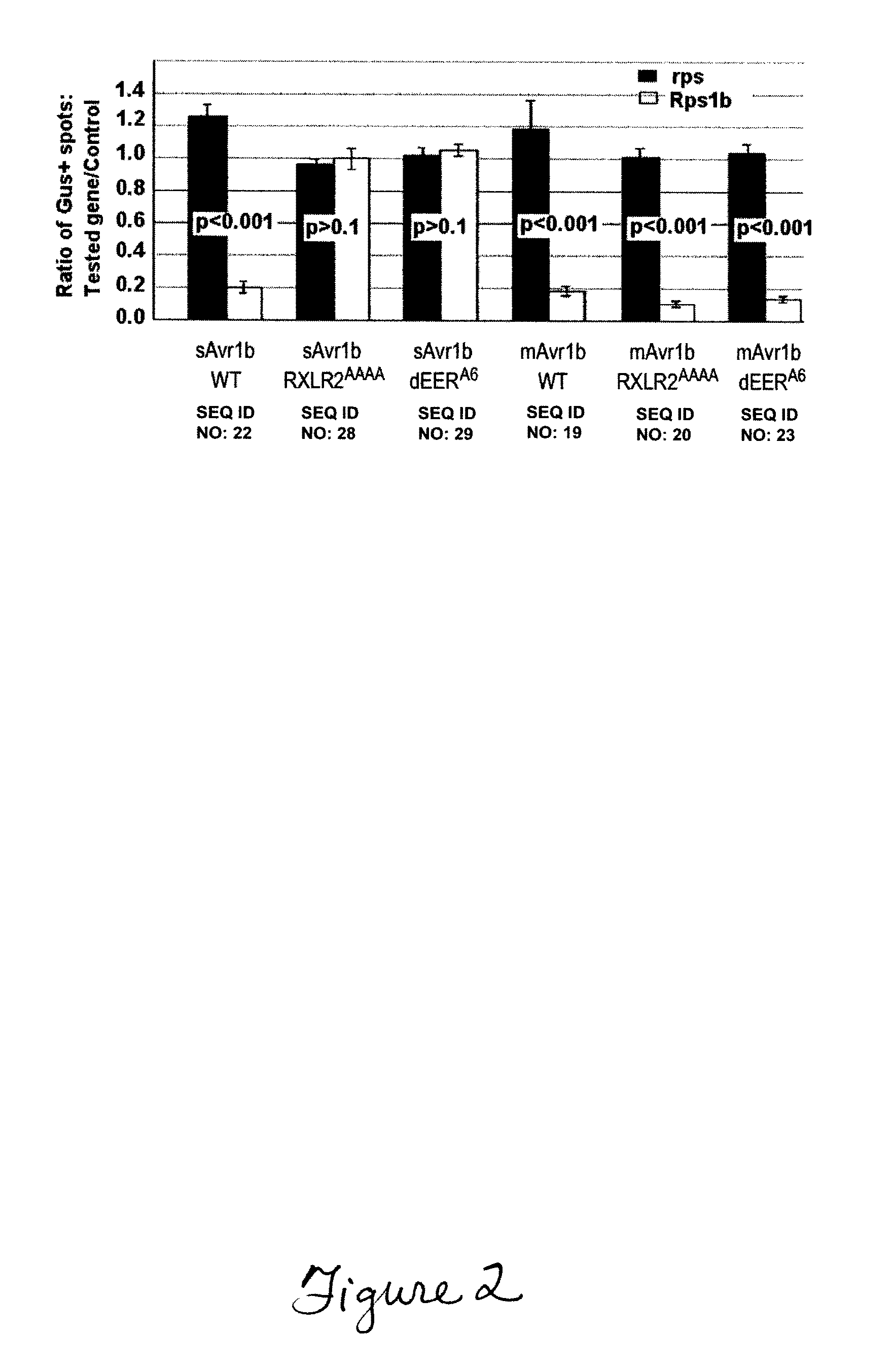

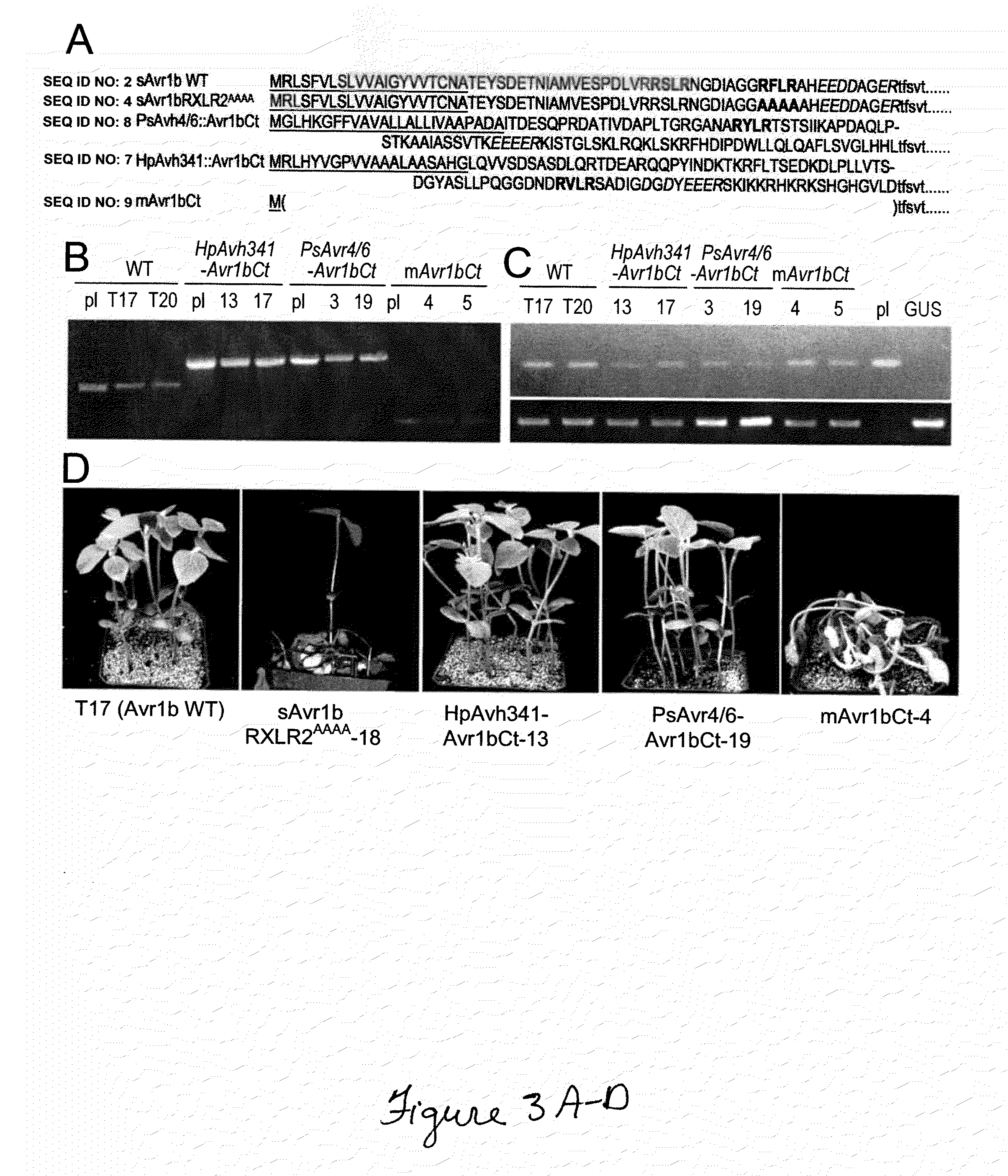

Compositions and methods to protect cells by blocking entry of pathogen proteins

InactiveUS20100093601A1Avoid infectionEfficient responseBiocidePeptide/protein ingredientsADAMTS ProteinsPhosphoric acid

Pathogenic effector proteins which include one or more RxLR, dEER, Pexel or analogous motifs are blocked from entry into plant or animal cells by binding one or more of the motifs with a blocking compound which prevents binding of phosphoinositides or other polar lipids to the motifs which is a prerequisite for translocation of the pathogenic effector proteins into the plant or animal cell. The blocking compounds can take a variety of forms including synthetic peptides or the hydrophilic head-groups of phosphoinositides, phosphatidic acids, phospholipids, or sphingolipids. Suitable blocking compounds can be identified by assays demonstrating binding to RxLR, dEER, Pexel or analogous motifs. In addition, pathogenic effector proteins can be identified by analyzing whether they contain structural RxLR motifs using hidden markov modeling.

Owner:VIRGINIA TECH INTPROP INC

Probiotic enzymatic composition capable of regulating intestinal tract and application thereof

InactiveCN108968058ASignificant effectPrevent indigestionFood ingredient functionsSide effectDietary fiber

The embodiment of the invention discloses a probiotic enzymatic composition capable of regulating intestinal tract. The composition is prepared by mixing the following raw materials in percentage by weight: 65 to 75 percent of dietary fiber, 10 to 15 percent of comprehensive vegetable and fruit enzymatic powder, 10 to 15 percent of soybean protein powder, 2.5 to 4.5 percent of probiotic bacteria,1 to 2 percent of plant protease, 0.3 to 0.8 percent of soybean phospholipid, 0.5 to 0.8 percent of an acidifier and 0.08 to 0.15 percent of a sweetener. The probiotic enzymatic composition provided by the invention has a remarkable curative effect in regulating intestinal problems, can effectively prevent dyspepsia and improve constipation, and has the functions of protecting intestinal mucosa and enhancing immunity, thereby fundamentally solving intestinal problems. The composition provided by the invention is natural, free from side effects, and safe and effective in use, and has a broad market application prospect.

Owner:广州乔媛商贸有限公司

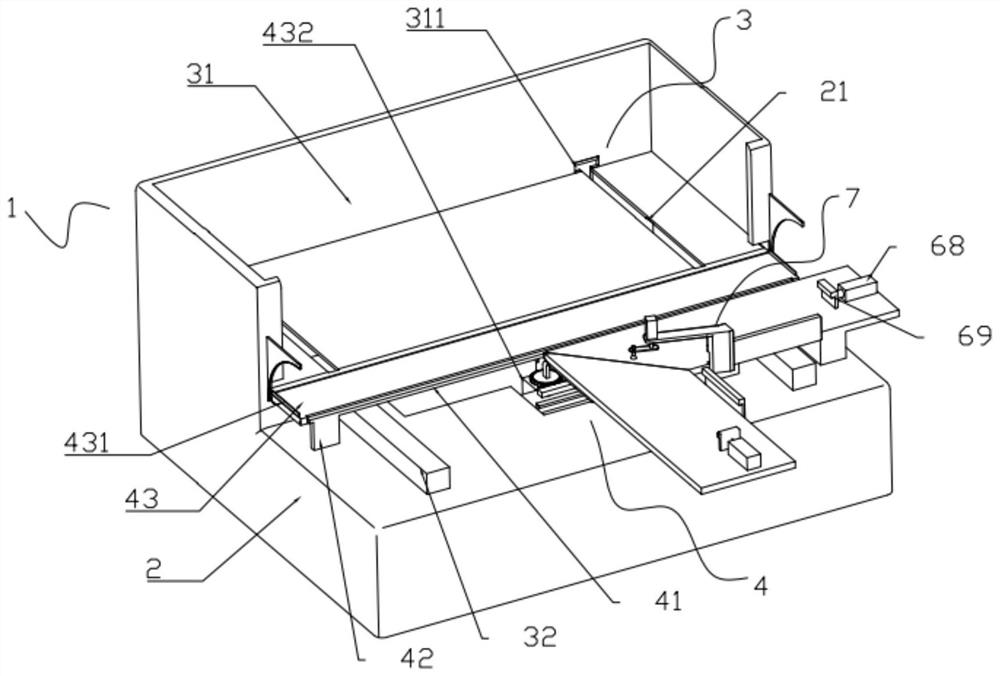

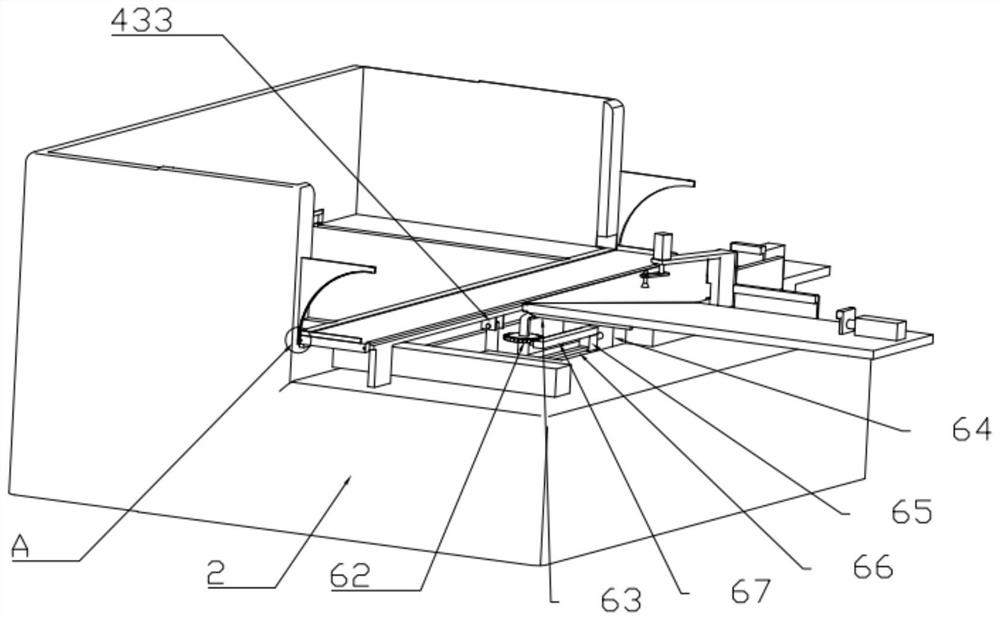

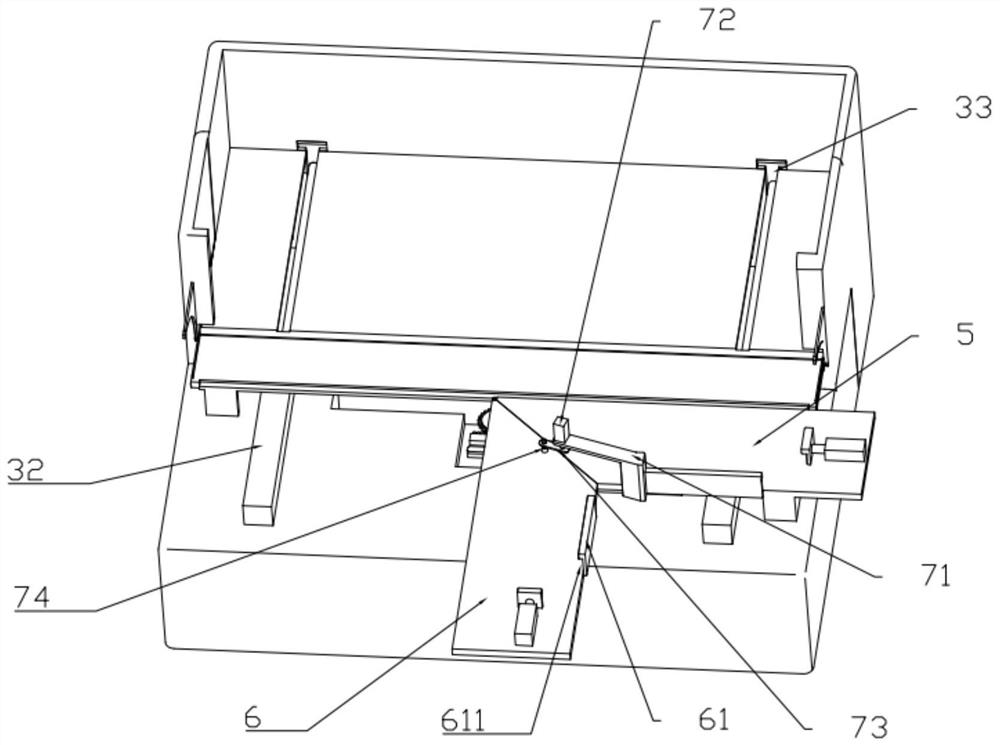

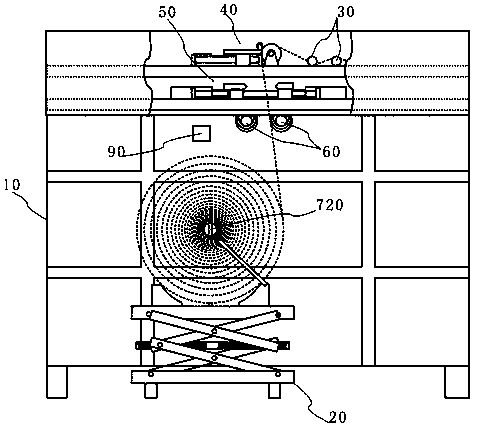

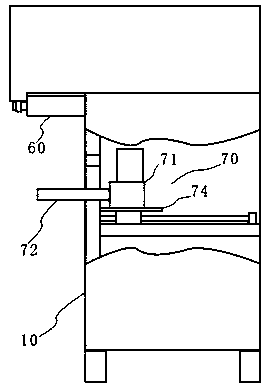

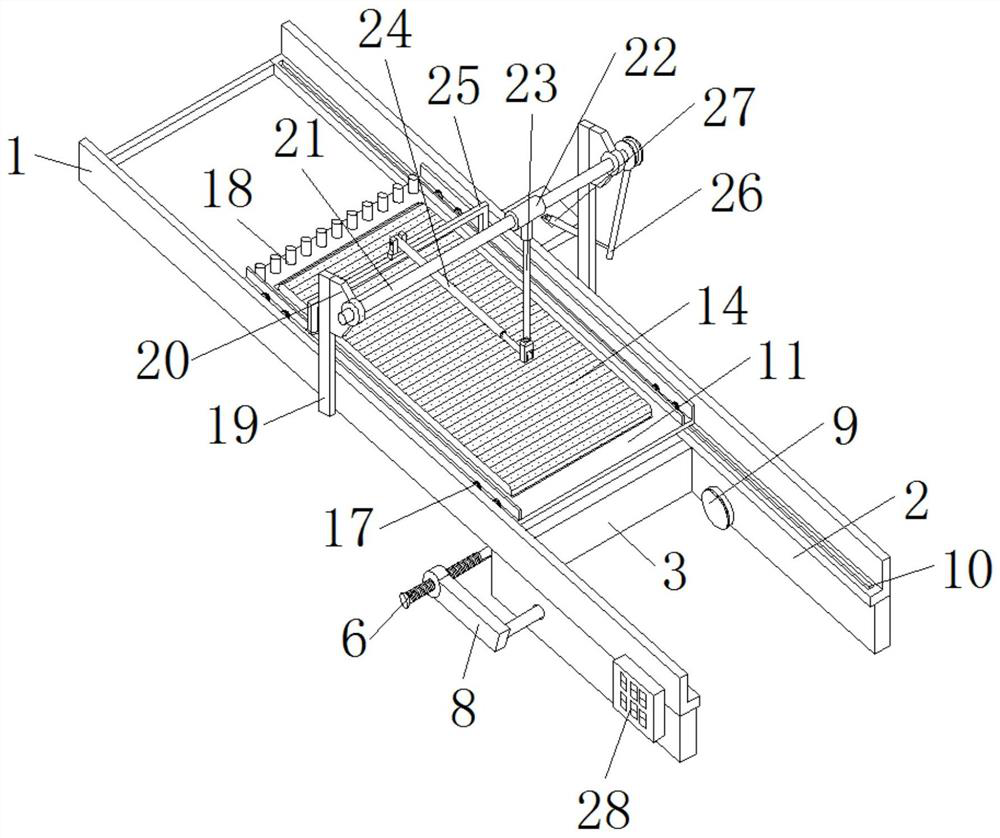

Packaging bag sealing machine and packaging bag sealing method

ActiveCN106275577ASave materialMeet packaging needsPackaging by pressurising/gasifyingEngineeringMechanical engineering

The invention discloses a packaging bag sealing machine. The packaging bag sealing machine comprises a machine body. A cutting device used for cutting packaging bags is arranged on the machine body. The machine body is further provided with a vacuumizing device and a sealing device, wherein the vacuumizing device draws out air in the packaging bags, and the sealing device seals the edges of the packaging bags. According to the packaging bag sealing machine, the cutting device, the sealing device and the vacuumizing device are arranged on the machine body at the same time, and therefore a series of steps comprising cutting, vacuumizing and sealing of the packaging bags can be completed. The packaging bag sealing machine has the advantages of being simple in structure and convenient to use. The invention further discloses a packaging bag sealing method. The packaging bag sealing method comprises the steps that the packaging bags are cut, one edge of each packaging bag is sealed, objects are put in the packaging bags, vacuumizing is conducted, and the other edge of each packaging bag is sealed. By the adoption of the packaging bag sealing method, the packaging bag of an appropriate length can be obtained through cutting according to the length of the packaged objects, and then packaging of the objects is conducted; and in this way, packaging bag materials are saved, and the packaging demands of objects of different lengths is also met.

Owner:ZHONGSHAN TAILI HOUSEHOLD PROD MFG

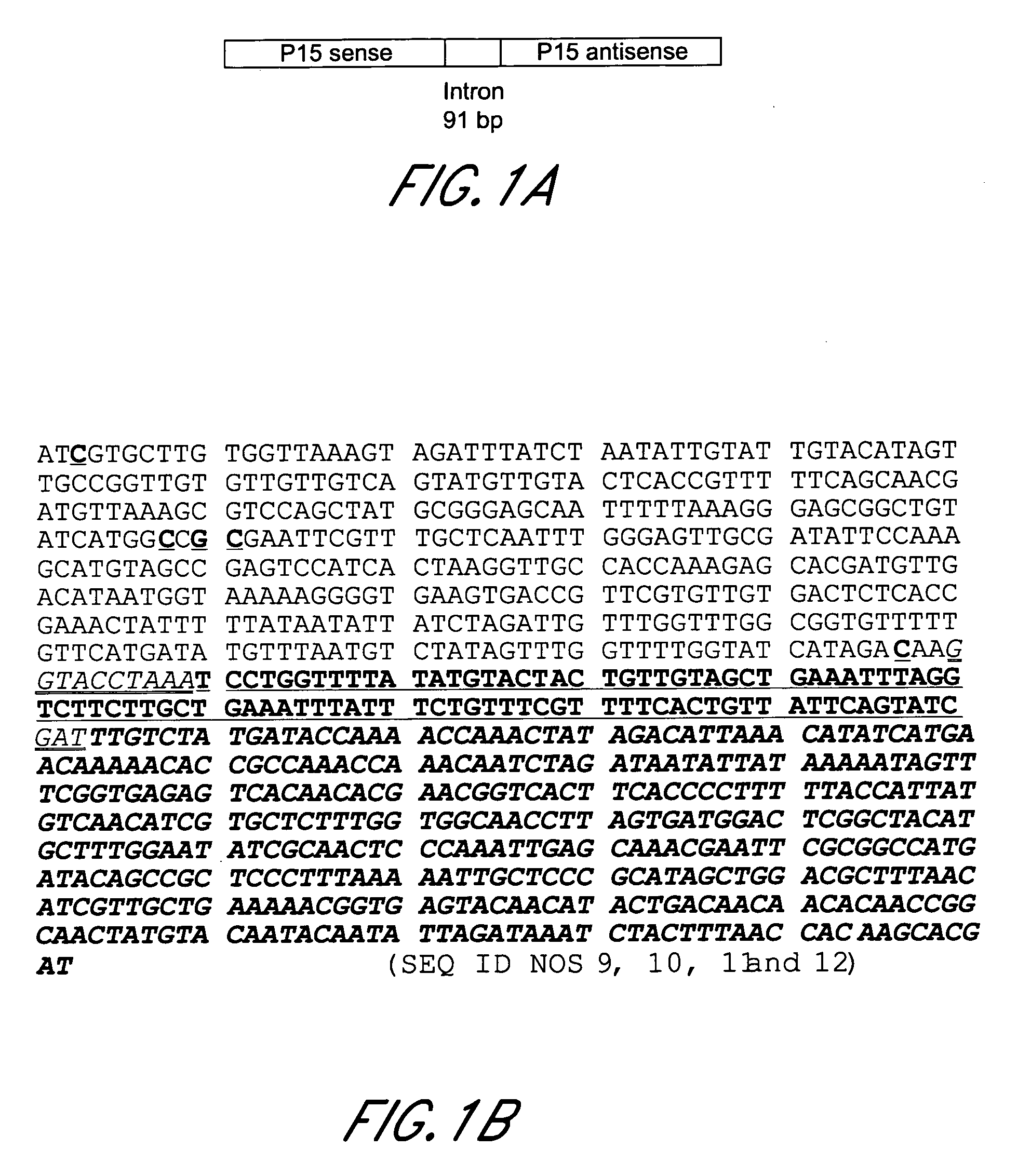

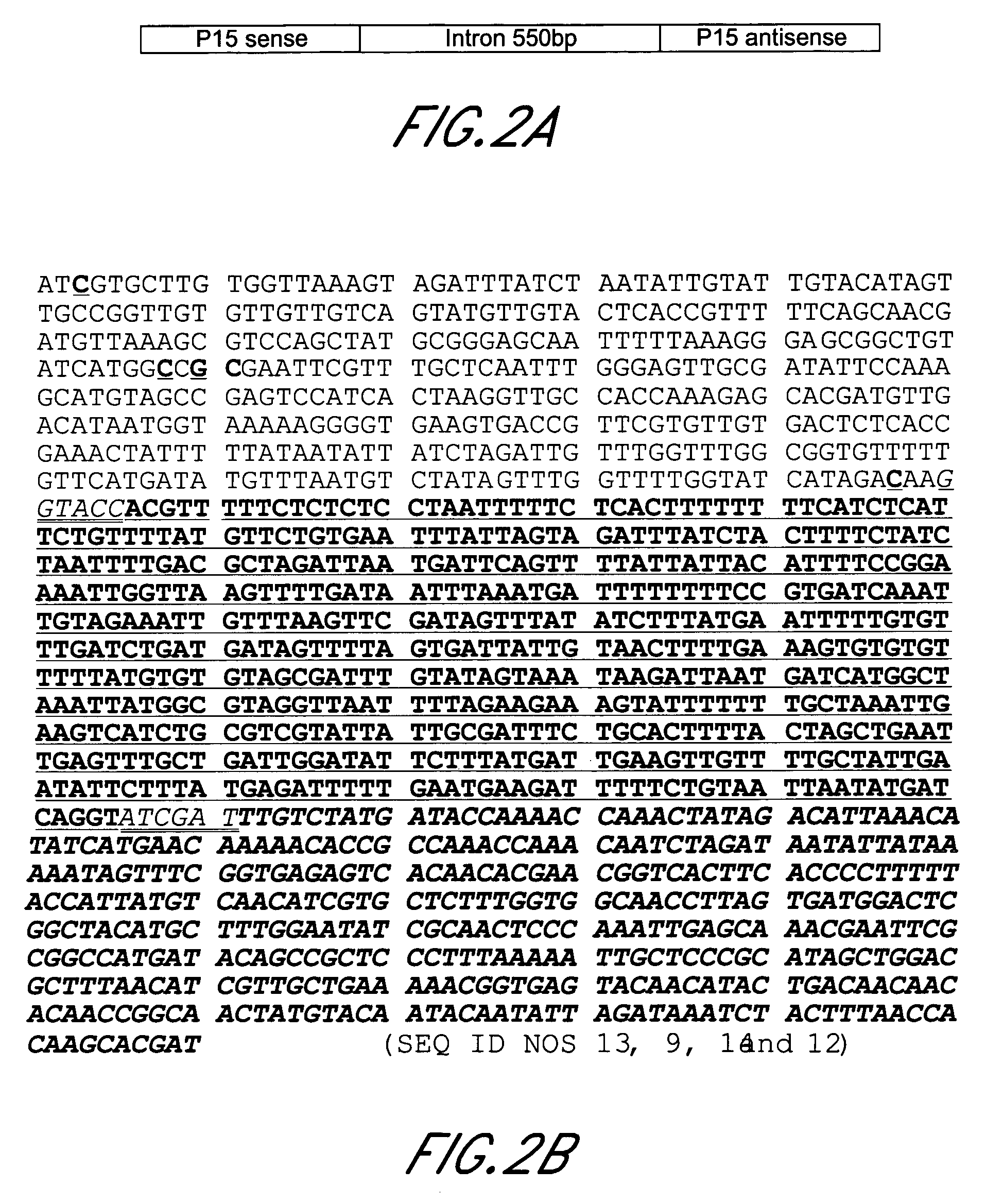

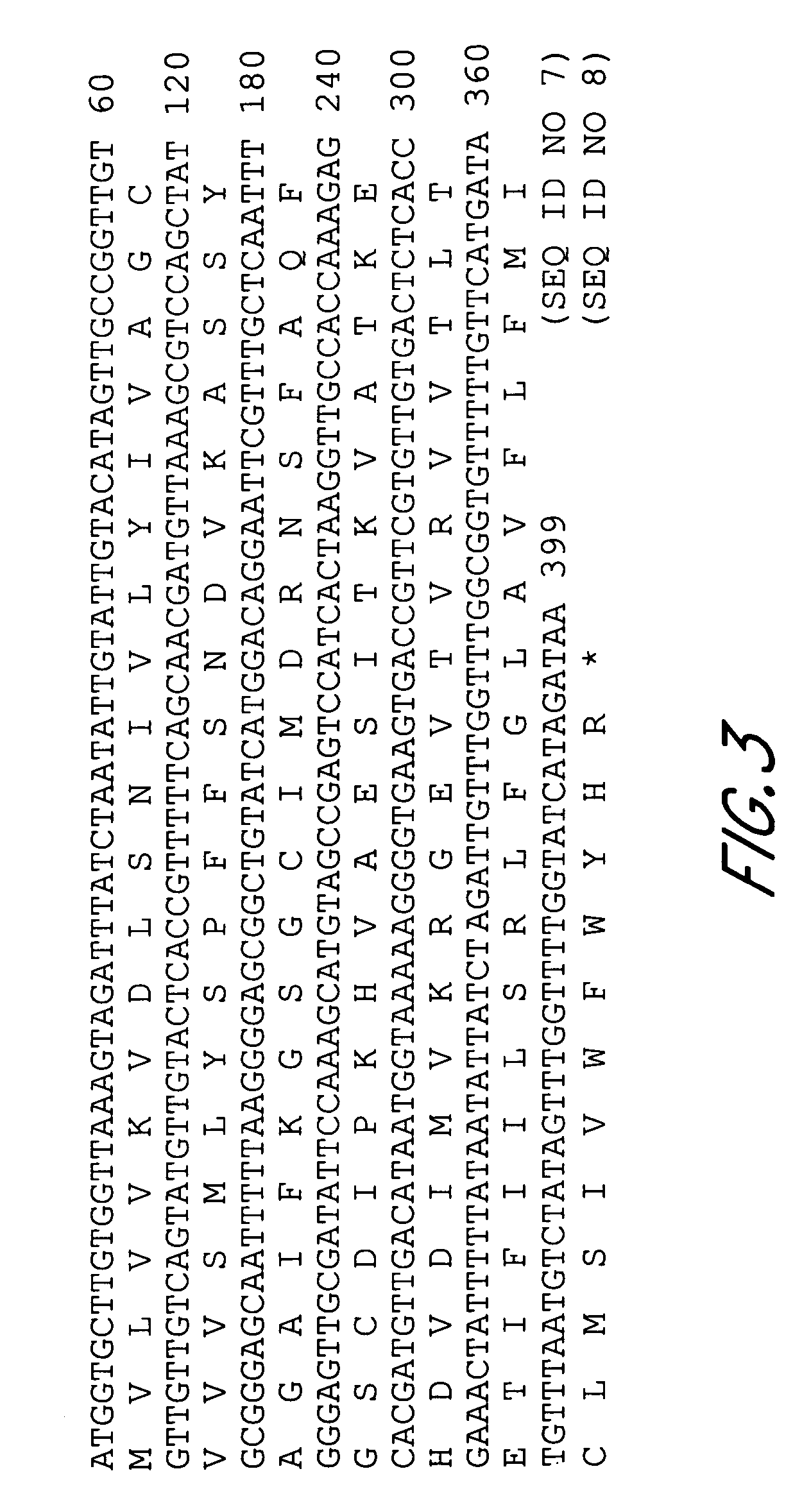

P15 hairpin constructs and use

InactiveUS20060288445A1Improve stabilityLong-term resistanceSugar derivativesOther foreign material introduction processesWild typePlant cell

The present invention concerns a method of genetic modification of a TGB-3 wild type viral sequence for reducing or suppressing the possible deleterious effects of the agronomic properties of a transformed plant or plant cell by said TGB-3 viral sequence, comprising the following successive steps: submitting said sequence to point mutation(s) which allow the substitution of at least one amino-acid into a different amino-acid; selecting genetically modified TGB-3 wild type viral sequences having said point mutation(s) and which are not able to promote cell-to-cell movement of a mutant virus having a dysfunctional TGB-3 wild type viral sequence, when expressed in trans from a replicon; further selecting among said genetically modified TGB-3 viral sequences, the specifically genetically modified sequence which inhibits infection with a co-inoculated wild type virus when the mutant form was expressed from a replicon, and recovering said specifically genetically modified TGB-3 viral sequence. The invention further relates to genetically modified TGB-3 viral sequences suitable to induce gene silencing. In particular hairpin constructs based on such sequences proved highly efficient to induce a PTGS mechanism and degradation of the whole of RNA2 thereby. When plants are transformed accordingly the spread of the virus in the plant is significantly reduced or blocked.

Owner:SESVANDERHAVE

Liver-protecting and intestine-protecting immunopotentiation composition for freshwater fish, and preparation and application for liver-protecting and intestine-protecting immunopotentiation composition

ActiveCN111388538AMaintain healthAvoid translocationAntibacterial agentsAnthropod material medical ingredientsBiotechnologyToxic material

The invention discloses a liver-protecting and intestine-protecting immunopotentiation composition for freshwater fish. The liver-protecting and intestine-protecting immunopotentiation composition comprises the following raw materials in parts by weight: 15 to 27 parts by weight of herba andrographitis, 18 to 22 parts of folium isatidis, 10 to 15 parts of polygonum hydropiper, 8 to 12 parts of radix et rhizoma rhei and 8 to 12 parts of gallnut. The invention further discloses a preparation method and an application for the composition. The composition provided by the invention has the effectsof resisting bacteria, scavenging free radicals, clearing away heat and toxic materials, preventing and treating enteritis and the like, and can effectively improve the immunity of the freshwater fishand guarantee the body health of the freshwater fish.

Owner:FRESHWATER FISHERIES RES INSITUTE OF JIANGSUPROVINCE

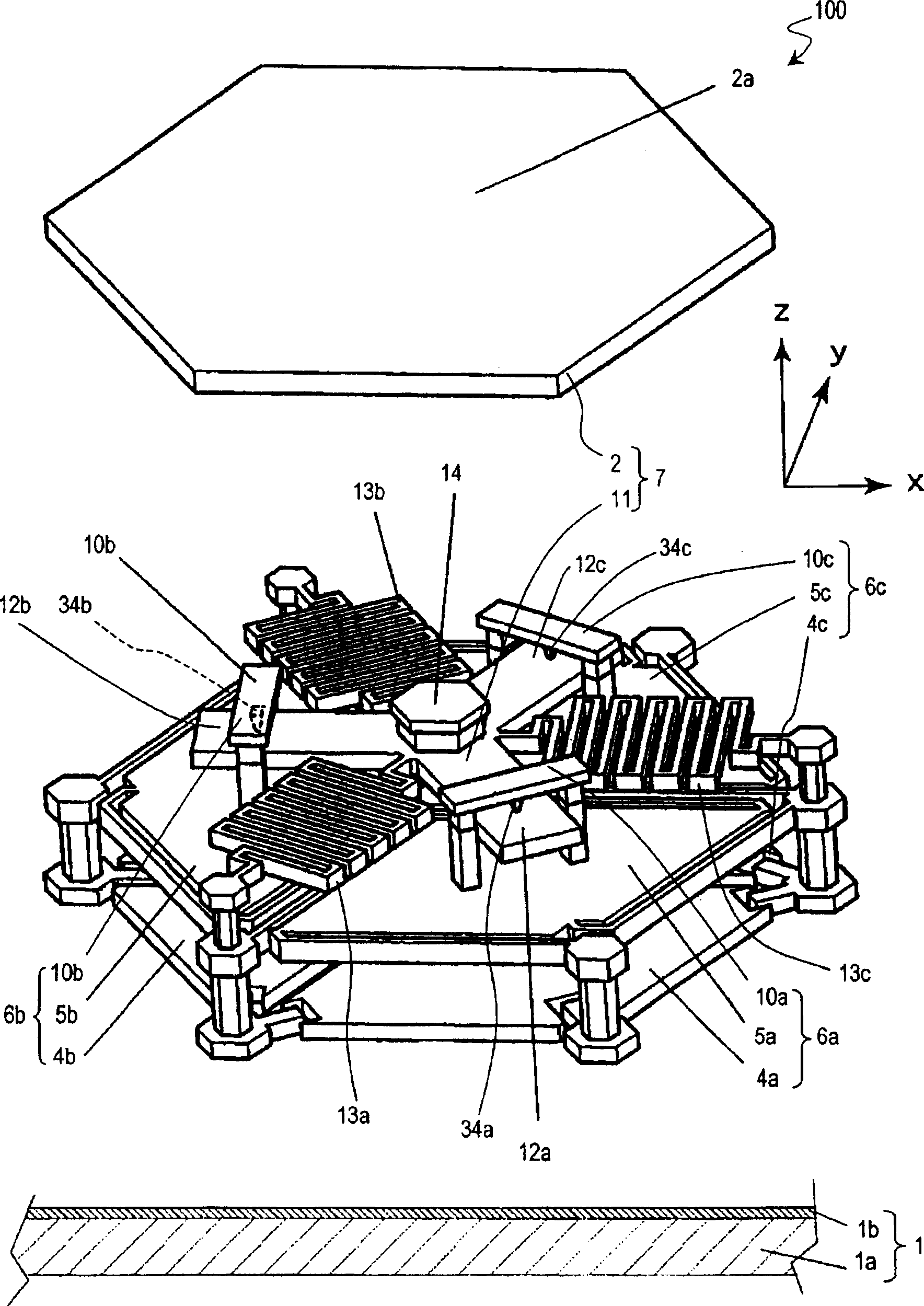

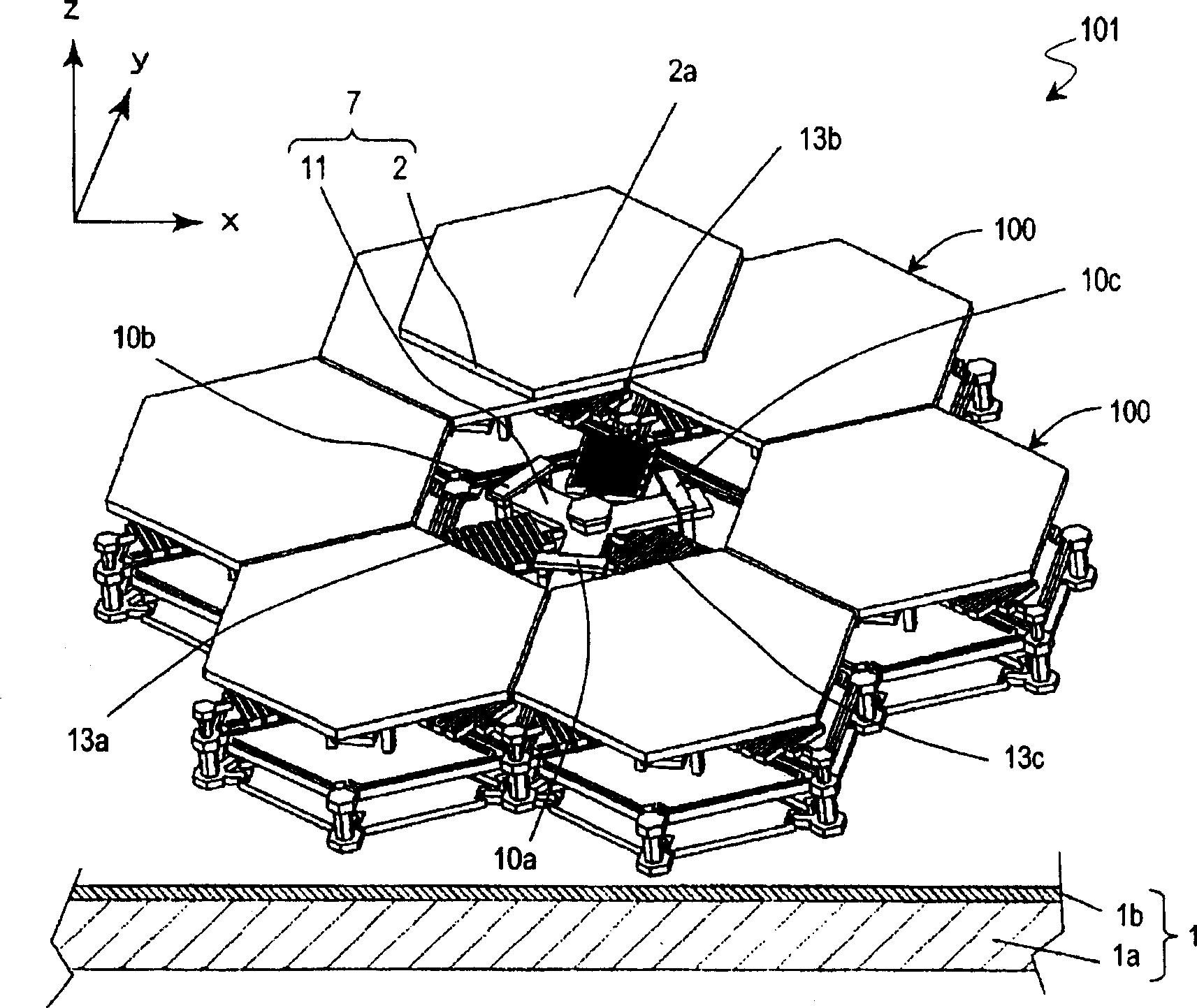

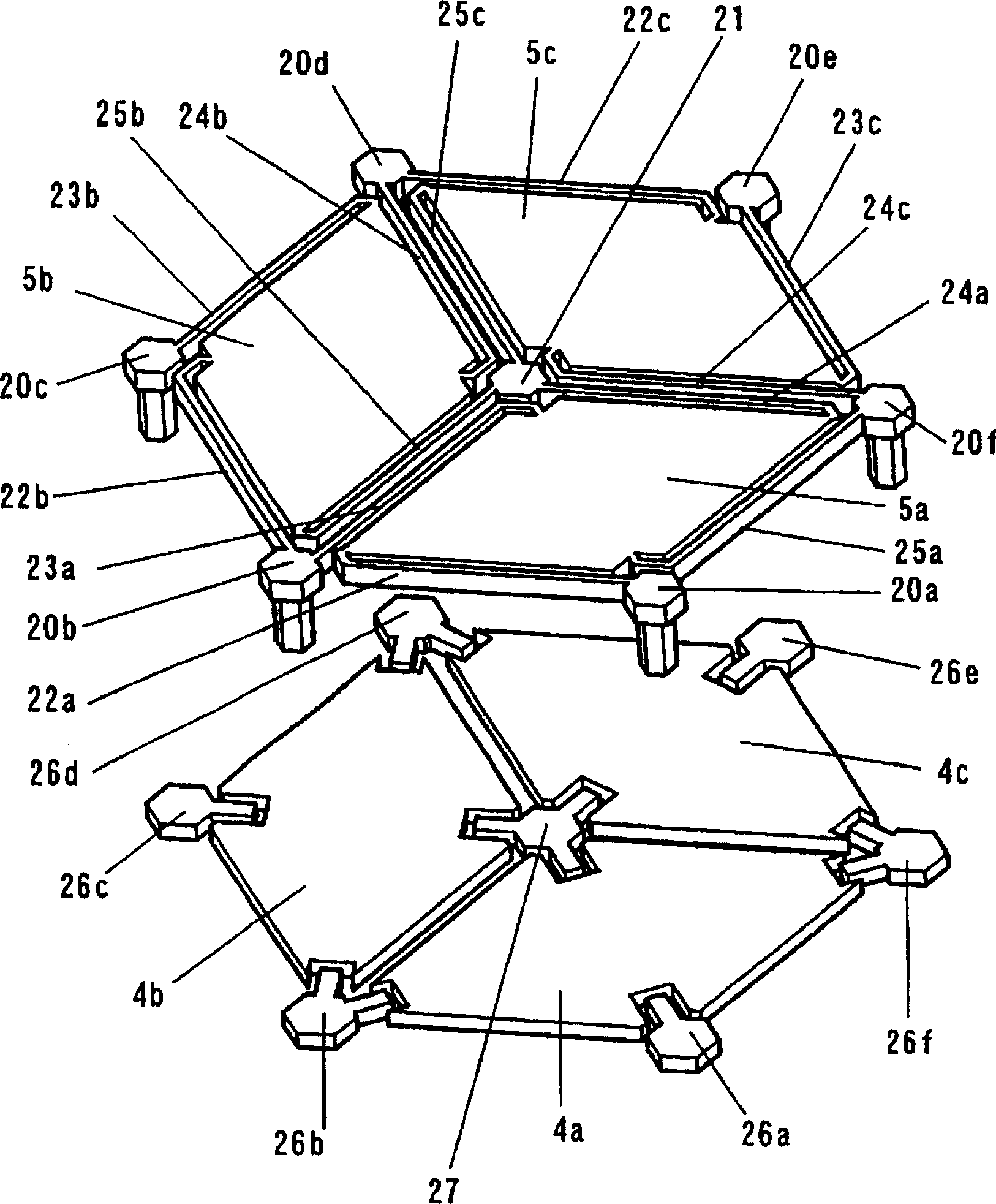

Actuator

InactiveCN1906119AAvoid translocationReduce distractionsPiezoelectric/electrostrictive devicesFlexible microstructural devicesEngineeringActuator

Owner:PANASONIC CORP

Methods and compositions relating to hematopoietic stem cell expansion, enrichment, and maintenance

ActiveUS20200248143A1Inhibit phosphorylationPreventing and disrupting interactionNervous disorderPeptide/protein ingredientsHistone methylationActive agent

The methods and compositions described herein relate to producing, expanding, enriching, and / or maintaining hematopoietic stem cells ex vivo by treating the cells with an agent(s) that exhibits two or more activities selected from modulation of histone methylation; inhibition of TGFβ signaling; inhibition of p38 signaling; activation of canonical Wnt signaling; and modulation of histone acetylation. In some embodiments, the technology described herein relates to transplantation of hematopoietic stem cells.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Processing technology of paper protection plate for packaging

ActiveCN112060695AFast assemblyImprove processing efficiencyMechanical working/deformationPaper/cardboard articlesCardboardProcess engineering

The invention discloses a processing technology of a paper protection plate for packaging and relates to the technical field of paper protection plate processing. The processing technology comprises the following steps: preparing raw paper, manufacturing a plate, dehumidifying, externally coating a waterproof layer, printing, separating paper, pressing lines and die-cutting. A three-step processing technology of folding a detachable paper protection plate, pasting pearl wool in the paper protection plate and pressing the pearl wool and the paper protection plate is added, and a punched paper protection plate raw plate is assembled through a specially-made folding machine before leaving a factory. A paper feeding mechanism, an edge folding and turnover mechanism and a buckling adsorption mechanism are used for quickly assembling the paper protection plate raw plate, so that the machining efficiency is improved, and the assembling precision is high; and pearl wool and the paper protection plate are firmly bonded into a whole through the pressing procedure, so that the problem that people forget to place the buffer material on the inner side of the paper protection plate or translocation between the buffer material and the paper protection plate after placing the buffer material is effectively prevented.

Owner:安徽祥欣新材料科技有限公司

Rectal cancer nutritious food and preparation method thereof

InactiveCN108936597AImprove clearanceReduce clearanceFood ingredient functionsBiotechnologyNutritional status

The present invention belongs to the technical field of nutritious foods, and especially relates to a rectal cancer nutritious food and a preparation method thereof. The rectal cancer nutritious foodcontains nutrient elements including proteins, fat, carbohydrate, vitamins, minerals, ginkgo flavonoids and phytosterol. The nutritious food provided by the invention can provide sufficient and comprehensive nutrients for the organism, more importantly, the food enhances the barrier function of intestinal mucosa, better accords with the metabolic physiological state, facilitates the protein synthesis and metabolism regulation of the organism, promotes the recovery of intestinal function and form, prevents bacteria and toxin translocation, obviously reduces the occurrence of intestinal source infection, and is an effective way to improve the nutritional status of chemotherapy patients. The food has a certain improvement effect on the nutritional status of chemotherapy patients with middle or advanced rectal cancer, can reduce adverse reaction of patients, and can effectively improve the immunity of patients.

Owner:SHANDONG UNIV OF TECH +1

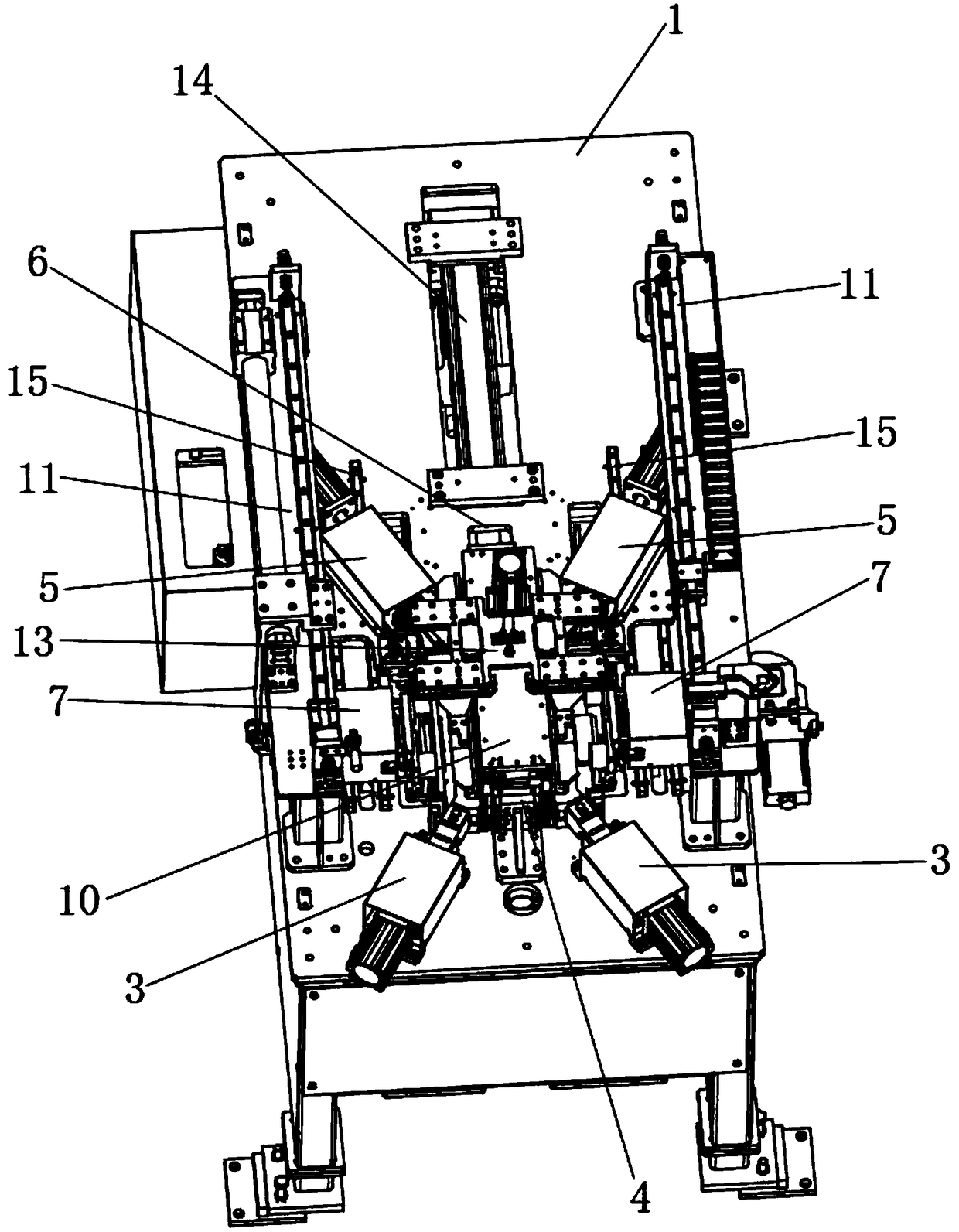

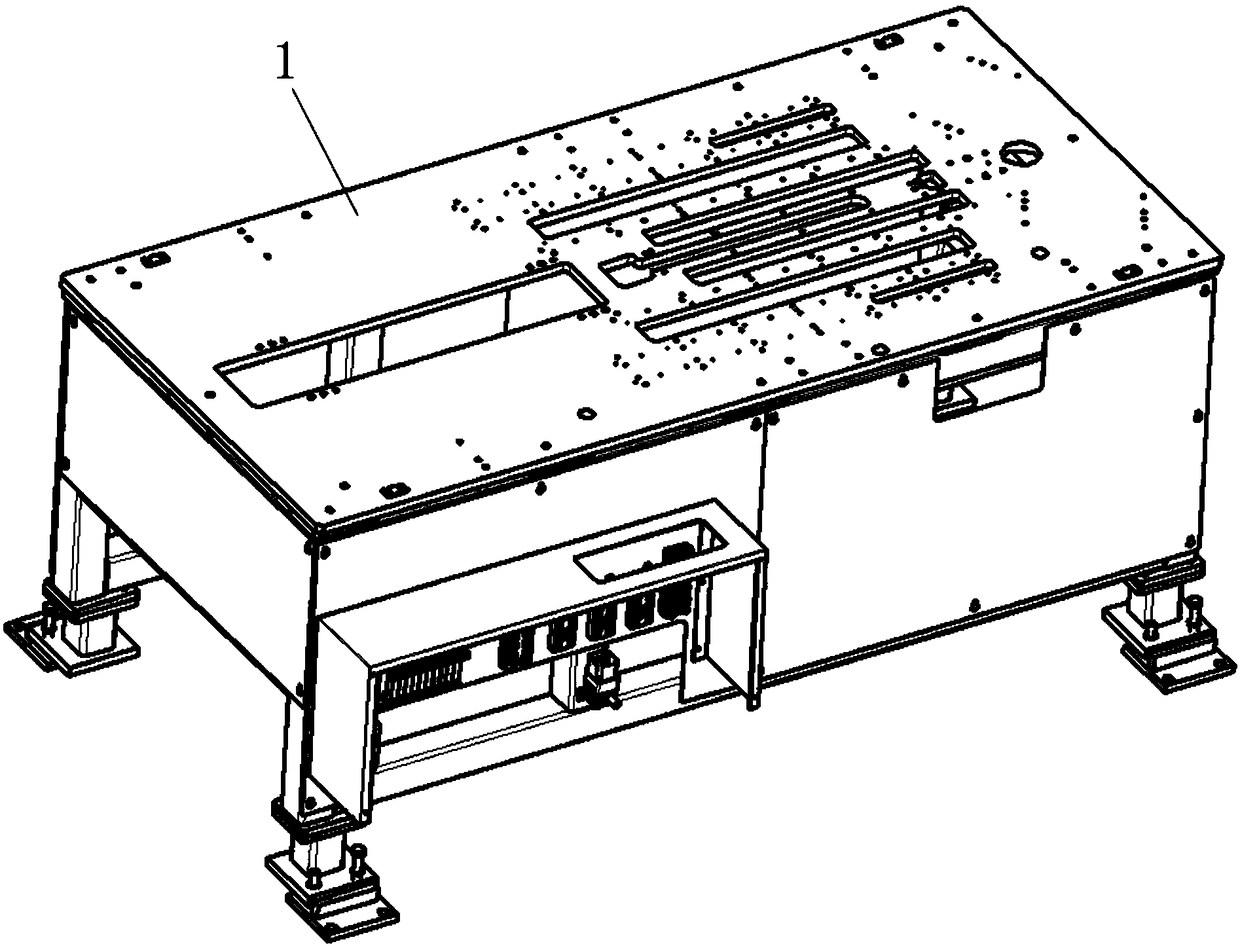

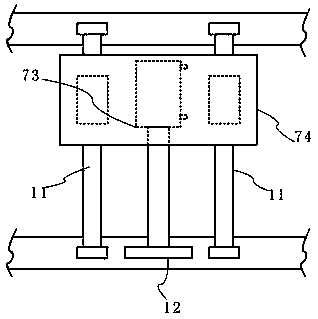

Square shell battery module laser welding clamp

ActiveCN108127317AAchieve clampingGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesMobile endEngineering

The invention relates to a square shell battery module laser welding clamp. A fixed end module positioning mechanism is fixedly mounted on a base; fixed end side plate compressing mechanisms are positioned on two sides of the fixed end module positioning mechanism; a moving end module positioning mechanism and the fixed end module positioning mechanism are arranged oppositely and are driven and positioned through a moving end driving mechanism; two groups of moving end side plate compressing mechanisms are symmetrically mounted on a first sliding rail on two sides of the moving end module positioning mechanism; two groups of side plate positioning mechanisms are symmetrically mounted on the first sliding rail on two sides; two groups of side plate jacking mechanisms are symmetrically mounted on two second sliding rails; the side plate positioning mechanisms and the side plate jacking mechanisms are driven by a side plate positioning switching mechanism to move synchronously along the sliding rail; a sliding table mechanism is mounted on the base; a pressure arm mechanism is mounted on the sliding table mechanism in a slidable manner; and a module centring mechanism and a module compressing mechanism are mounted on the pressure arm mechanism in a lifting manner. The square shell battery module laser welding clamp is suitable for automatic and fast reloading of battery modules ofdifferent types and ensures the assembling precision.

Owner:SHANGHAI JUNYI IND AUTOMATION CO LTD

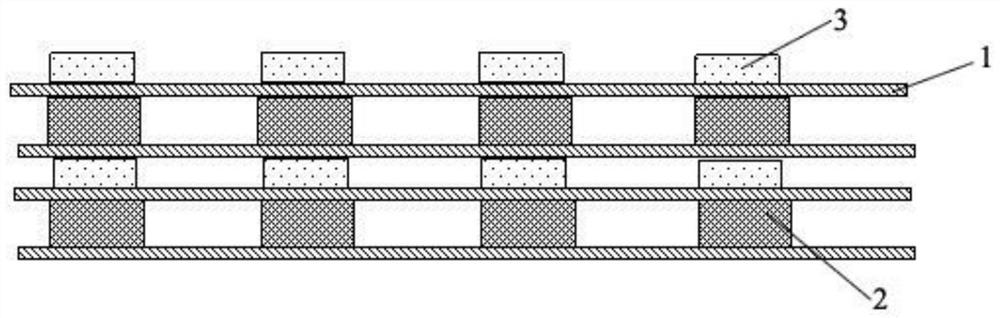

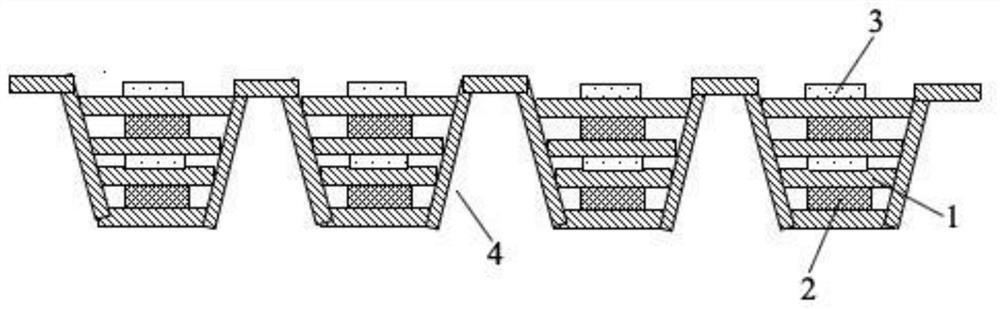

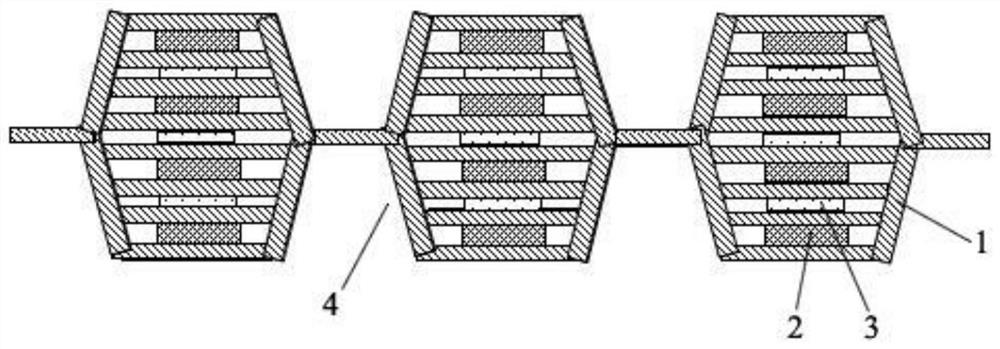

Battery cell and preparation method thereof

InactiveCN112271340AIncrease productivityImprove product qualityFinal product manufactureElectrolyte accumulators manufactureCell fabricationPole piece

The invention belongs to the technical field of battery manufacturing, and particularly relates to a battery cell and a preparation method thereof. The preparation method comprises the steps: 1, cutting a first pole piece and a second pole piece which are continuous into a first pole piece single body and a second pole piece single body respectively, wherein the polarity of the first pole piece isopposite to that of the second pole piece; 2) unwinding a layer of diaphragm, placing a plurality of first pole piece monomers on the diaphragm, and pressing; 3) placing a layer of diaphragm on the first pole piece monomer, placing a plurality of second pole piece monomers on the diaphragm, and correspondingly arranging and pressing the second pole piece monomers and the first pole piece monomer;4) repeating the steps 2) to 3) until the thickness / layer number required by the battery cell is reached, and forming a plurality of continuous battery cell units through hot pressing; 5) cutting offthe diaphragm between two adjacent battery cell units to obtain a plurality of battery cells at the same time. Compared with the prior art, preparation of a plurality of battery cells can be completed at the same time, pole piece translocation can be avoided, and the production efficiency and the production quality are greatly improved.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Automatic counting winding and cutting machine and braid winding and cutting method

PendingCN108689211AAppropriate tensionDecrease the tilt angleArticle deliveryElectronic control systemEngineering

The invention relates to an automatic counting winding and cutting machine which comprises an electronic control system, a braid winding mechanism, a receiving disc lifting table, a braid guide rollerset, a fusing mechanism, a limiting assembly and a traction mechanism, the braid guide roller set, the fusing mechanism, the limiting assembly and the traction mechanism are sequentially arranged inthe braid running direction, the center of a braid winding station of the braid winding mechanism is located on any one of the left and right sides of a fusing station, the limiting assembly is located under the fusing station and is provided with a braid walking space, the receiving disc lifting table is correspondingly arranged under the braid winding station, a meter counting wheel and a photoelectric detector are electrically connected with the signal input end of the electronic control system. By means of the automatic counting winding and cutting machine, the inclined angle between a braid and the vertical line can be smaller during full winding, fusion is facilitated, the braid descending angle is limited, and accidental fusion is avoided; and a pneumatic rolling shaft is tightly attached to a traction roller to enable the braid to keep appropriate tension force without corrugation or displacement, and the smooth implementation of braid winding and orderly and attractive braid discs are guaranteed. According to the automatic counting winding and cutting machine, the braid can be automatically cut off and rolled into a disc cake shape according to the set length, the accuracyis high, and the load weight is large.

Owner:福建锦特新材料科技有限公司

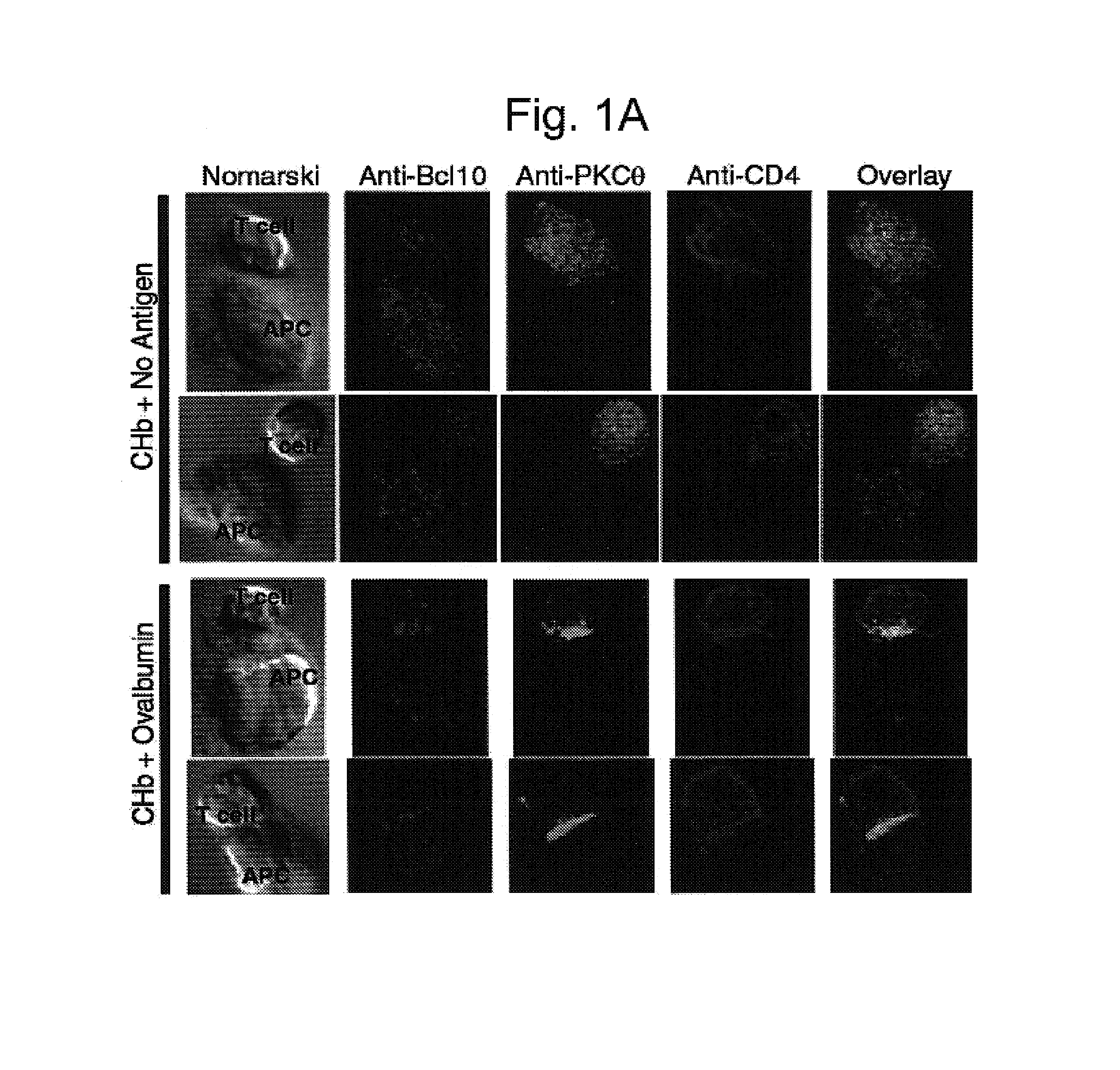

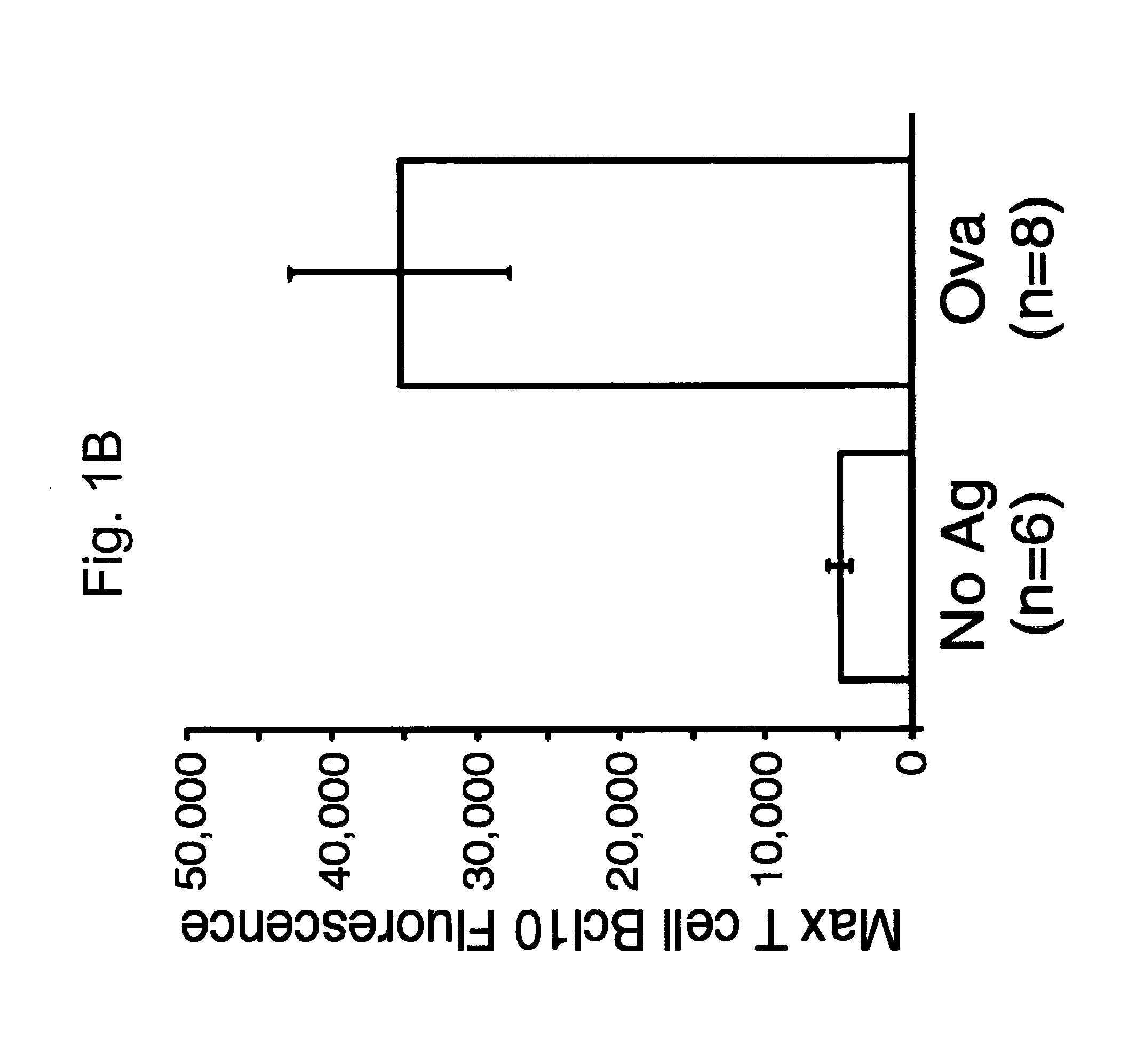

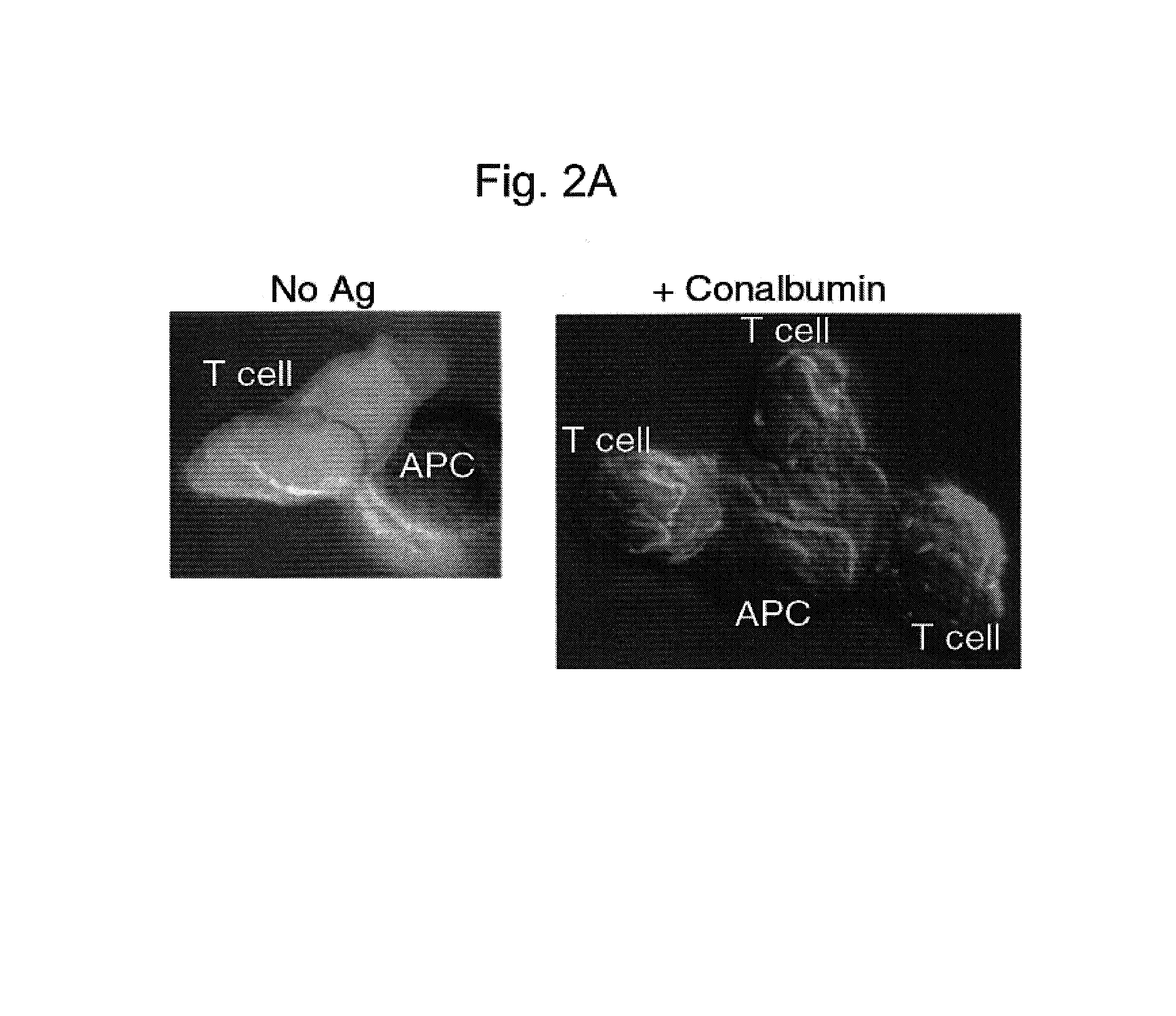

Method to identify regulators of cellular activation using Bcl10

InactiveUS7169570B2Reducing signal transductionEnhance signal transductionMicrobiological testing/measurementTissue cultureCell activationBCL10

Disclosed are methods for evaluating the activation of Bcl10 in a cell in response to a putative stimulus, as well as methods for evaluating or identifying a regulatory compound which regulates activation of Bcl10-mediated signal transduction. These methods utilize the discovery of the activation-dependent formation in a cell of Bcl10 aggregates in a cell.

Owner:NAT JEWISH MEDICAL & RES CENT +1

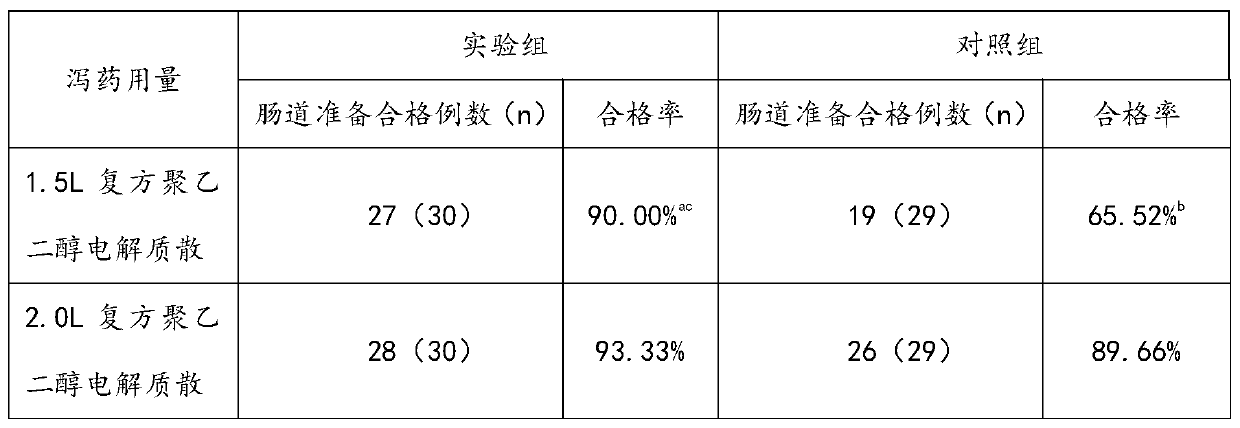

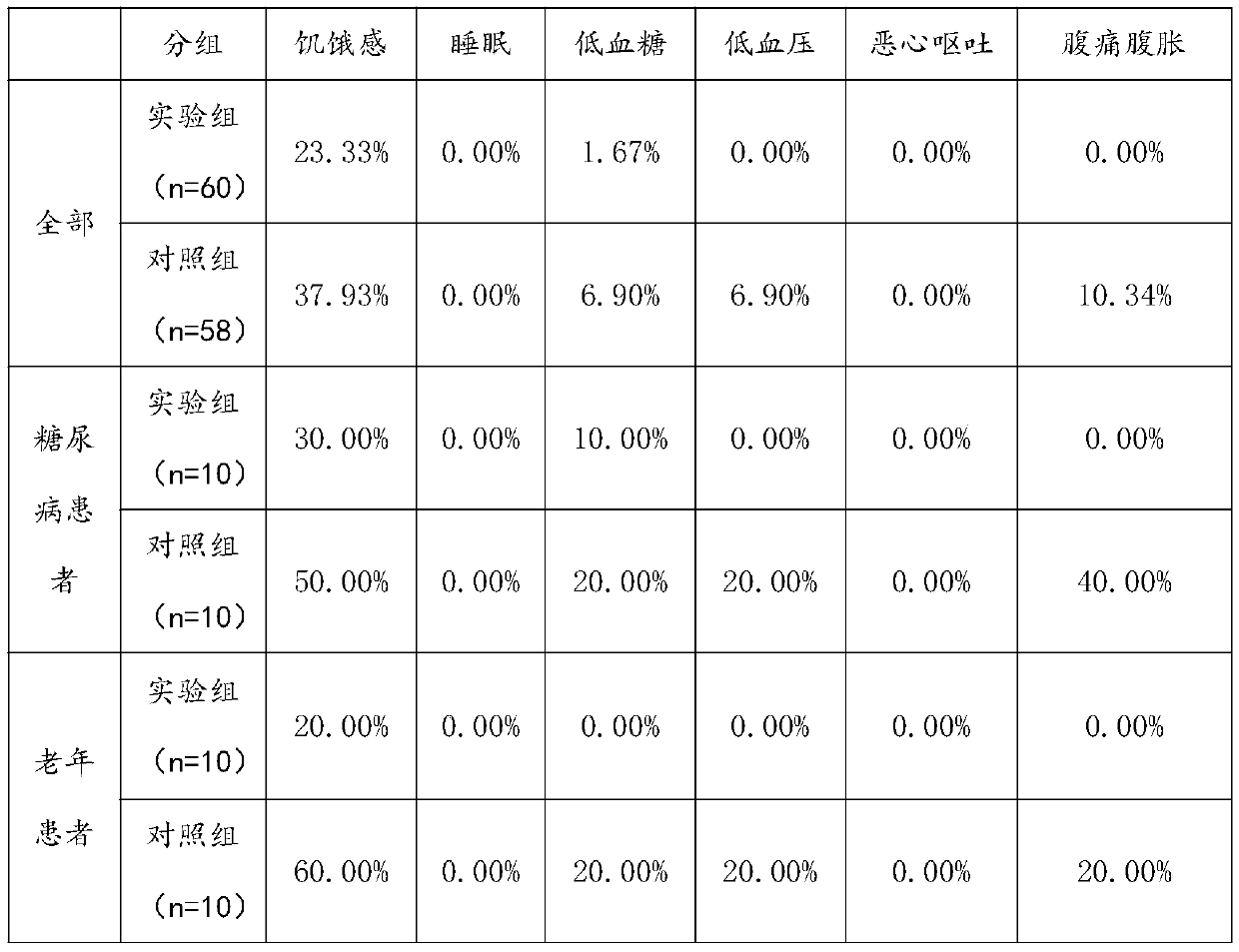

Application of composition for intestinal tracts to preparation of diagnosis and treatment products for intestinal tract diseases

PendingCN110623257AImprove cleanlinessReduce gas productionHeavy metal active ingredientsHydrolysed protein ingredientsDiseaseIntestinal tract diseases

The invention relates to an application of a composition for intestinal tracts to preparation of products for increasing cleaning level of intestinal tracts of patients during examination, diagnosis and / or treatment of intestinal tract diseases. The composition for intestinal tracts is used for increasing the cleaning level of intestinal tracts of patients during examination, diagnosis and / or treatment of intestinal tract diseases, reducing the usage quantity of cathartics, reducing the generation of adverse events of the patients, enhancing the immunity of the patients, shortening the recovery period of an intestinal tract surgery, reducing the generation of intestinal tract surgery infection, stabilizing the eating rules of the patients and the like, and has quite important clinical value on increasing the clean degree of the intestinal tracts of the patients and increasing the nutrition of the intestinal tracts.

Owner:麦孚营养科技(北京)有限公司 +1

Colon cancer nutritious food and preparation method thereof

InactiveCN108936595AImprove clearanceHigh anti-cancer effectFood ingredient functionsBiotechnologyNutrition

The present invention belongs to the technical field of nutritious foods, and especially relates to a colon cancer nutritious food and a preparation method thereof. The colon cancer nutritious food contains nutrient elements including proteins, fat, carbohydrate, vitamins, minerals, amino acidss, ginkgo flavonoids and phytosterol. The nutritious food provided by the invention can provide sufficient and comprehensive nutrients for the organism, more importantly, the food enhances the barrier function of intestinal mucosa, better accords with the metabolic physiological state, facilitates the protein synthesis and metabolism regulation of the organism, promotes the recovery of intestinal function and form, prevents bacteria and toxin translocation, obviously reduces the occurrence of intestinal source infection, and is an effective way to improve the nutritional status of chemotherapy patients. The food has a certain improvement effect on the nutritional status of chemotherapy patients with middle or advanced colon cancer, can reduce adverse reaction of patients, and can effectively improve the immunity of patients.

Owner:SHANDONG UNIV OF TECH +1

Methods and compositions relating to hematopoietic stem cell expansion

PendingUS20190119642A1Lower Level RequirementsInhibit phosphorylationNervous disorderSkeletal disorderUbiquitin ligase complexReceptor Inhibition

Described herein are methods and compositions relating to expanding, enriching, and / or maintaining a population of hematopoietic stem cells ex vivo. In some embodiments, the methods and compositions can relate to a combination of two or more agents, e.g., an agent that increases the expression of a Notch target gene; an agent that activates a ubiquitin ligase complex comprising cereblon; a compound that inhibits BMP signaling; a modulator of histone methylation; an inhibitor of TGFβ signaling; an inhibitor of p38 signaling; an activator of canonical Wnt signaling; a modulator of histone acetylation; a compound represented by formula (1); an aryl hydrocarbon receptor inhibitor; a histone demethylase inhibitor; a TGFβ receptor inhibitor; a compound that inhibits a protein that propagates p38 signaling; a compound that inhibits a protein that promotes β-catenin degradation; a histone deacetylase inhibitor; Prostaglandin; an agonist of Notch signaling; an inhibitor of SIRT1; UM171; and / or a compound listed in Table 1.

Owner:CHILDRENS MEDICAL CENT CORP

Shock absorber accessory automatic production line feeding assembly

InactiveCN111804836APrevent looseningAvoid translocationMetal-working feeding devicesPositioning devicesProduction lineElectric machinery

The invention discloses a shock absorber accessory automatic production line feeding assembly. The feeding assembly comprises an installation rack; installation plates are symmetrically installed on two sides at one end of the bottom of the installation rack; a horizontal plate is installed between two ends of the installation plates; an either-rotation motor is installed on one side of the horizontal plate; rotating rods are arranged at output ends of the either-rotation motor; and screw shafts are installed at the other ends of the rotating rods. According to the feeding assembly, the either-rotation motor, the rotating rods, the screw shafts, screw sleeves, L-shaped connecting rods and clamping discs are installed, the either-rotation motor drives the screw shafts to rotate via the rotating rods and therefore drives the L-shaped connecting rods to slide left and right via the screw sleeves, so the clamping discs are close to or away from each other and inner sides of a container isclamped; a device can automatically realize stable clamping of a material collecting container and avoid loosening or dislocation thereof; and the device can be applicable to material collecting containers in different dimensions and structure, and the applicability of the device is further improved.

Owner:安徽春晟机械有限公司

Double-protein full-nutrient formula food for stomach cancer and preparation method of food

InactiveCN108936623ARich varietyIncrease contentVitamin food ingredientsAcidic food ingredientsNucleotideGenistein

The invention belongs to the technical field of nutrient food and particularly relates to double-protein full-nutrient formula food for stomach cancer and a preparation method of the food. The double-protein full-nutrient formula food for stomach cancer comprises protein, fat, carbohydrate, vitamins, minerals, glutamine, branched chain amino acid, EPA, genistein derivatives and nucleotide nutrientelements. Through combination of double protein of animals and plants, the flavor, character and quality of the product are improved, and the cost is also reduced. The food can provide sufficient andcomprehensive nutrients, the barrier function of gastric mucosa is enhanced, engine body protein synthesis and metabolic regulation are facilitated, and gastric functions and form recovery are promoted.

Owner:SHANDONG SHENGHAI HEALTH PROD CO LTD

Nutritious food for people with gastric cancer and preparation method thereof

InactiveCN108813576AEconomical foodAffordable foodVitamin food ingredientsAcidic food ingredientsBiotechnologyNutritional status

The invention specifically relates to nutritious food for people with gastric cancer and a preparation method thereof, belonging to the technical field of nutritious food. The nutritious food for people with gastric cancer contains nutritive elements consisting of protein, fat, carbohydrates, vitamins, mineral substances, amino acids, EPA, ginkgo flavonoids and nucleotide. Besides providing sufficient and comprehensive nutrients for the body, the nutritious food of the invention further enhances the barrier function of the gastric mucosa, better accords with metabolic physiological states, facilitates the protein synthesis and metabolic regulation of the body, promotes the recovery of gastric functions and morphology, prevents the translocation of bacteria and toxins and significantly reduces the incidence of stomach-derived infections; and the nutritious food is an effective means for improving the nutritional status of patients receiving chemotherapy. The nutritious food can improvethe nutritional status of chemotherapy patients with advanced gastric cancer, reduce the adverse reactions of the patients, and effectively improve the immunity of the patients.

Owner:SHANDONG UNIV OF TECH +1

Road bridge crack repairing and fixing structure

InactiveCN112176891APlay a protective effectPrevent leakageBridge erection/assemblyBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a road bridge crack repairing and fixing structure which comprises a mounting groove, mounting plates, nesting blocks and waterproof plates, the two sides of the bottom in themounting groove are fixedly connected with the mounting plates, the tops of the mounting plates are movably connected with the nesting blocks, the tops of the nesting blocks are fixedly connected withthe waterproof plates, and the two sides of the waterproof plates are fixedly connected with pouring fixing plates; a first fixing bolt is connected into each pouring fixing plate in an embedded mode, a first splicing groove is fixedly connected to one side of the mounting groove, a worker can conveniently splice the fixing structure through the first splicing groove, and the waterproof mechanismcan play a role in seepage prevention and isolation and can also play a role in reinforcement and protection at the same time. The road bridge crack repairing and fixing structure further improves the stability of the device main body, prevents the device from accidentally falling off after being used for a period of time, avoids forming secondary cracks, improves the convenience of a device mainbody through an information nameplate, is suitable for repairing cracks of roads and bridges, and has a wide development prospect in the future.

Owner:SHANXI TRAFFIC PLANNING PROSPECTING & DESIGN INST

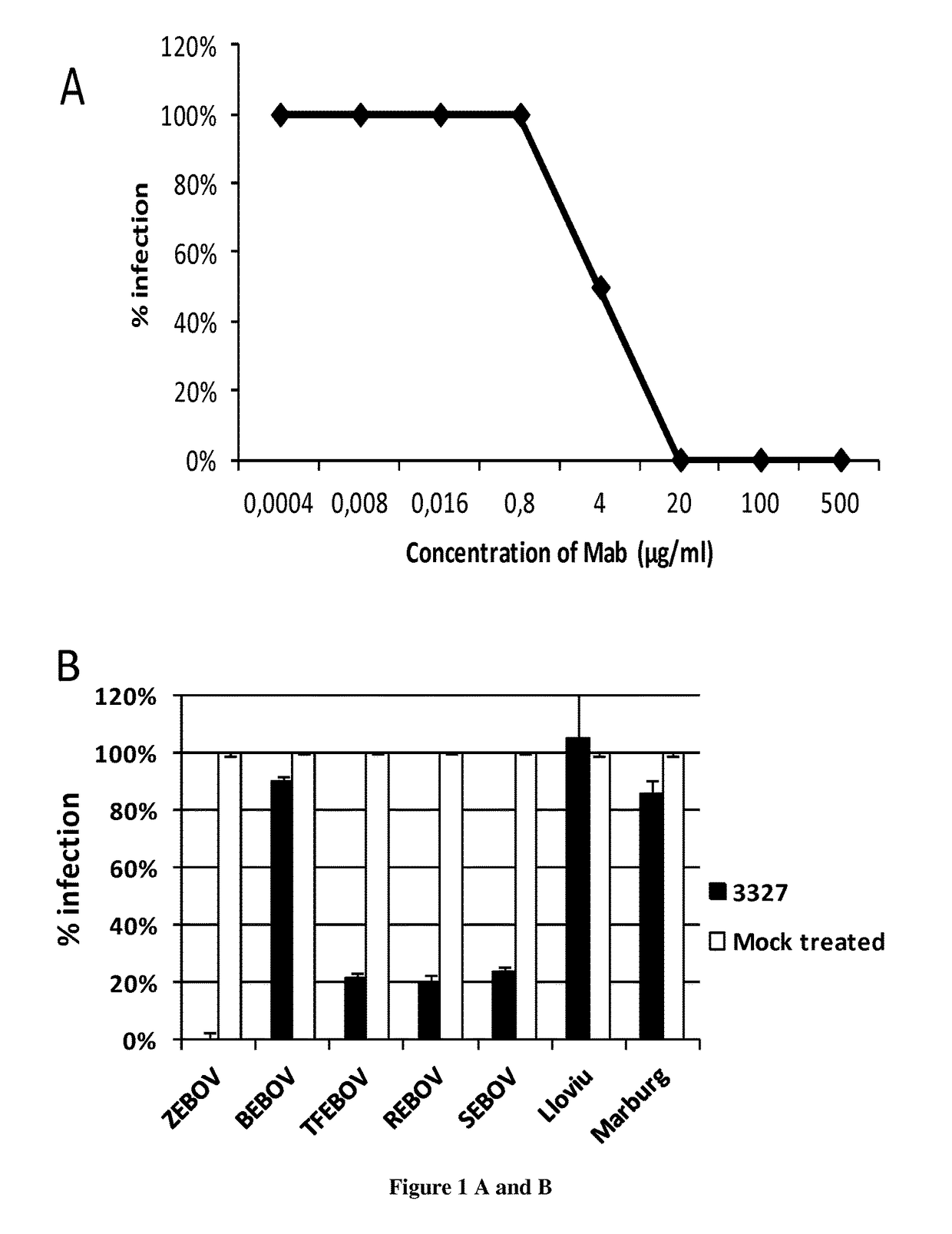

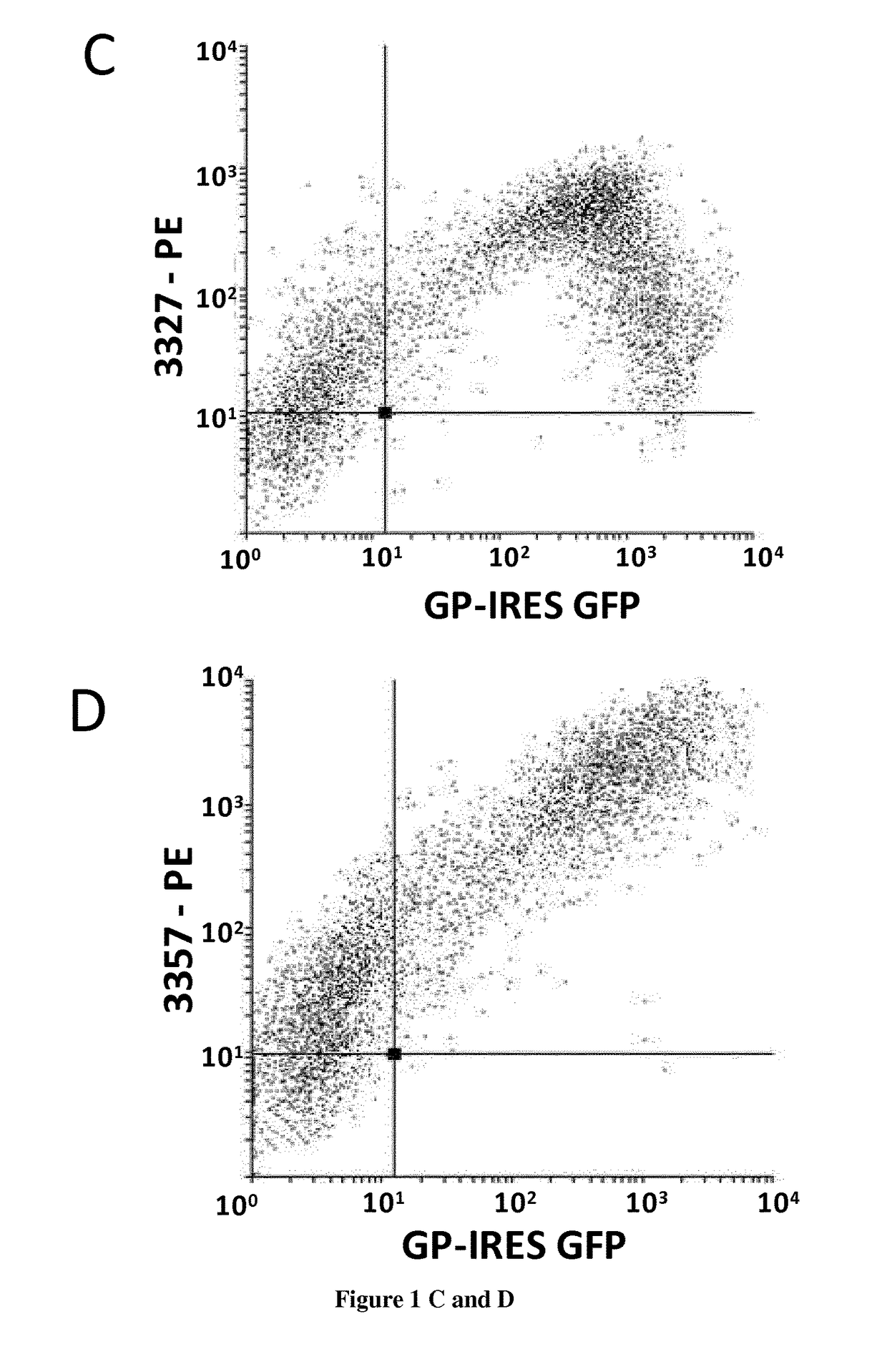

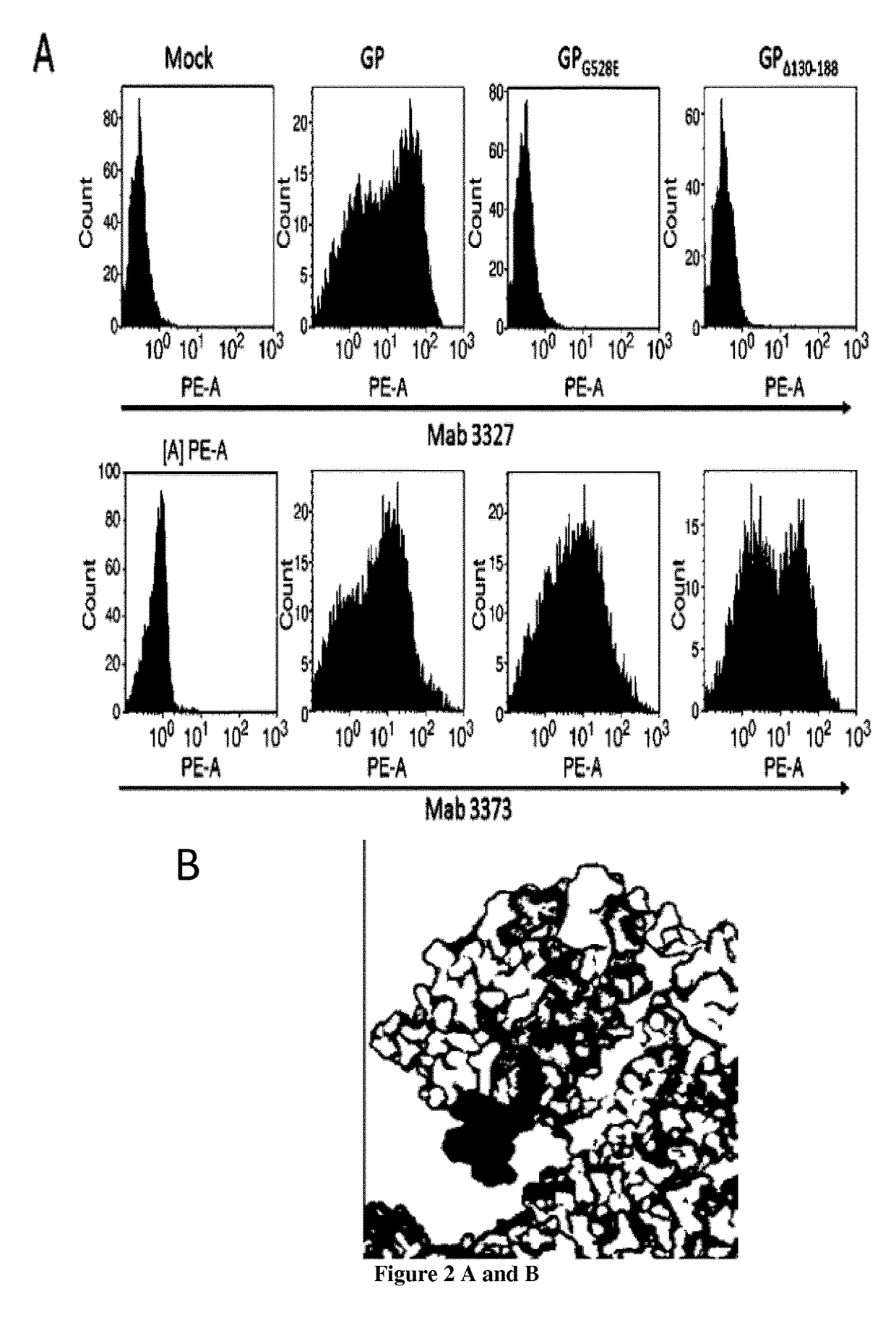

Antibodies specific to glycoprotein (GP) of ebolavirus and uses for the treatment and diagnosis of ebola virus infection

InactiveUS20180016322A1Reduce infectionStrong neutralization abilityBiological material analysisImmunoglobulins against virusesViral infectionSpecific antibody

The present invention relates to antibodies or fragments thereof that specifically bind to glycoprotein (GP) of Ebola virus, and to their use for treating and diagnosing Ebola virus disease.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com