Patents

Literature

338results about How to "Reduce gas production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

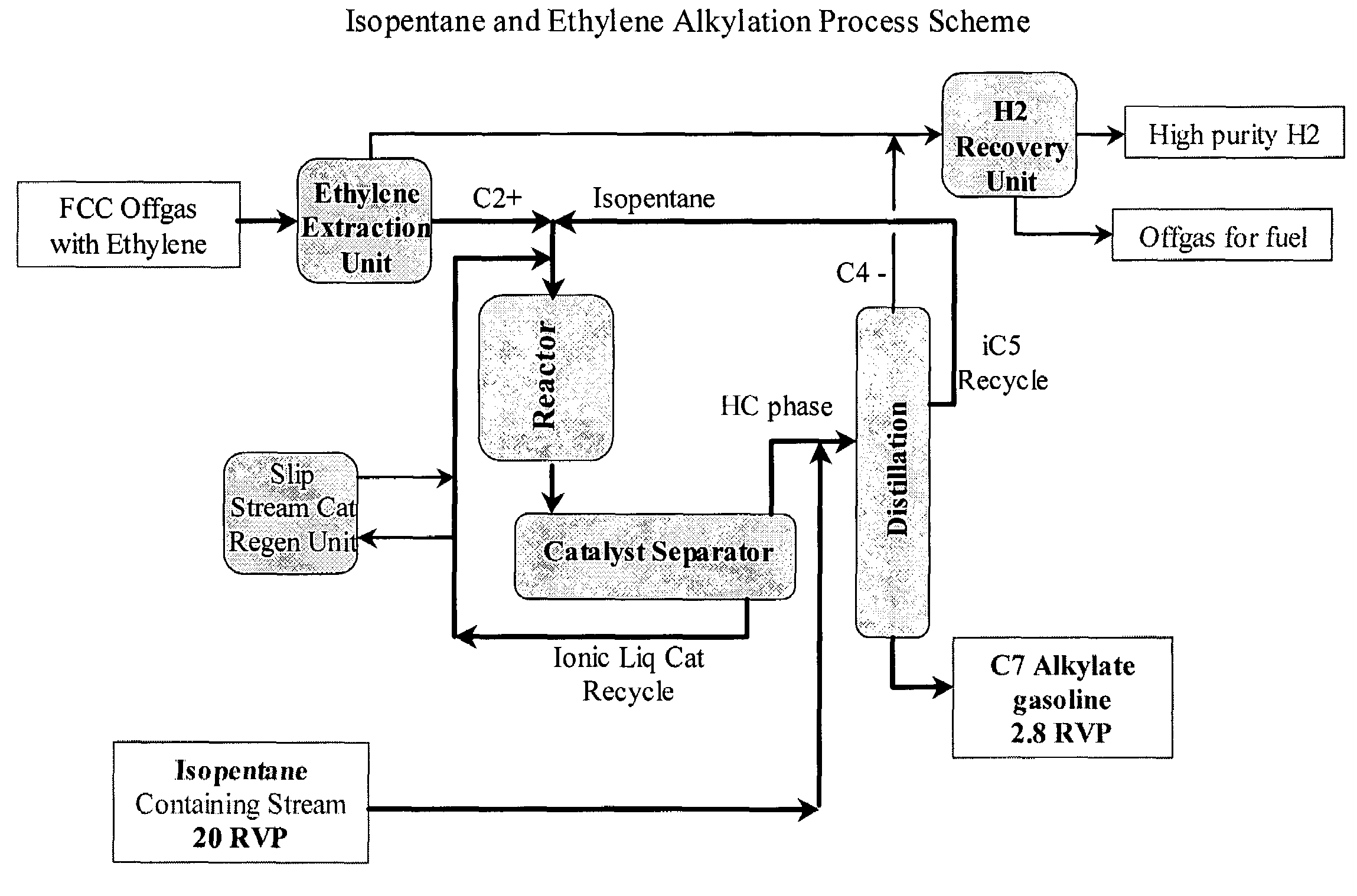

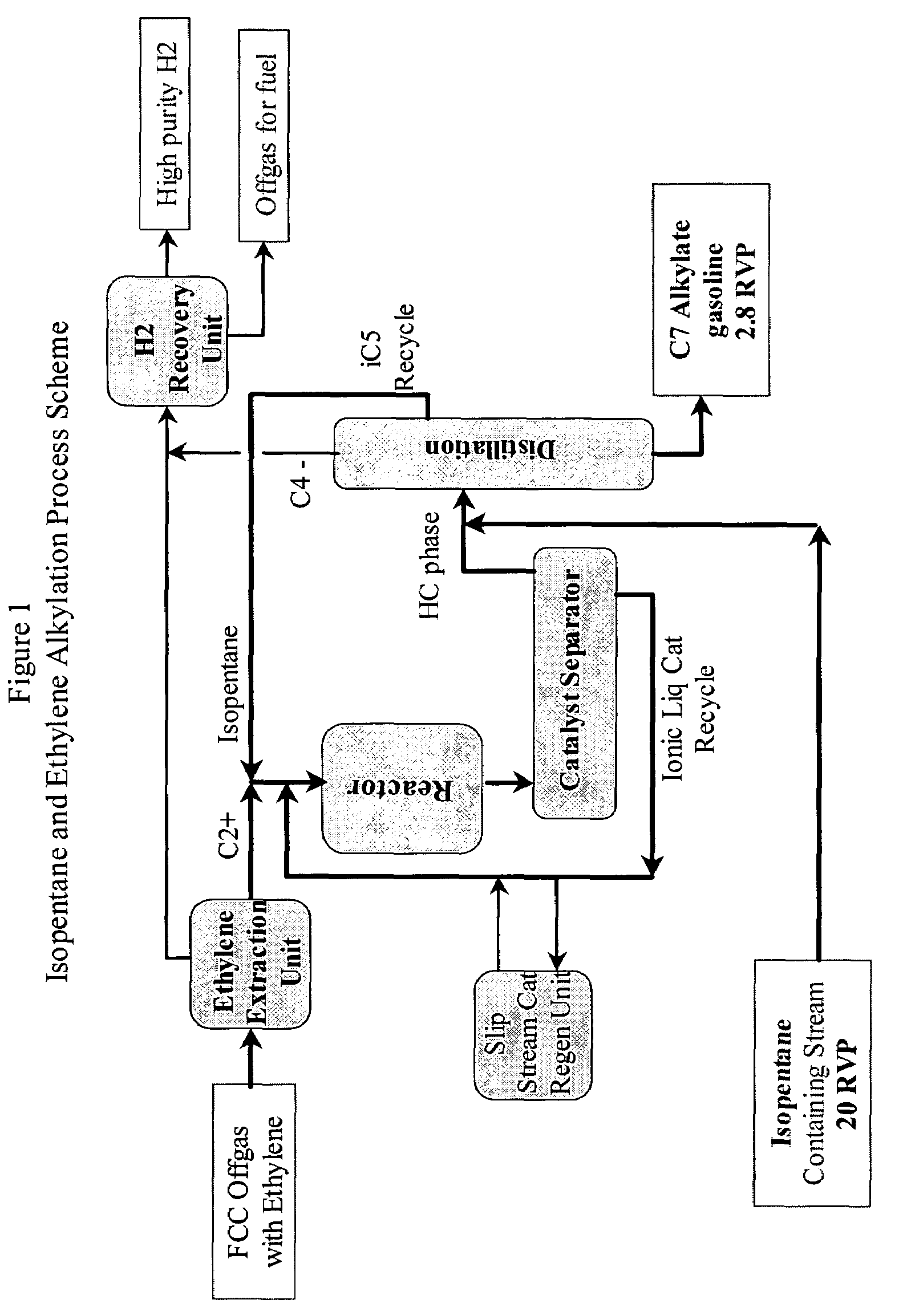

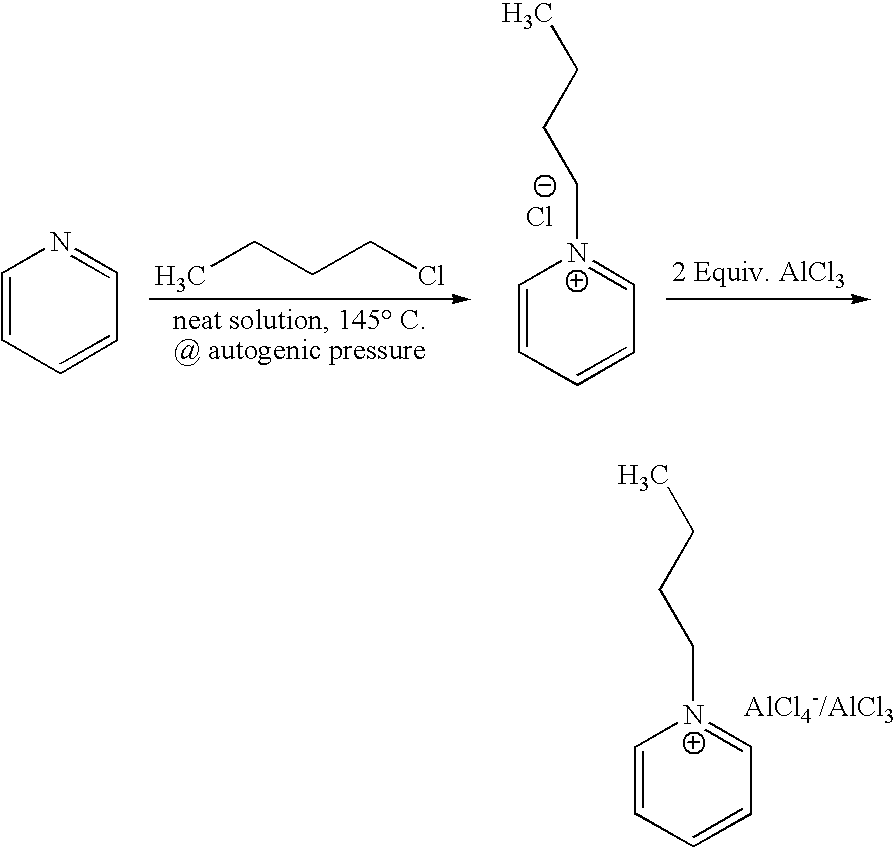

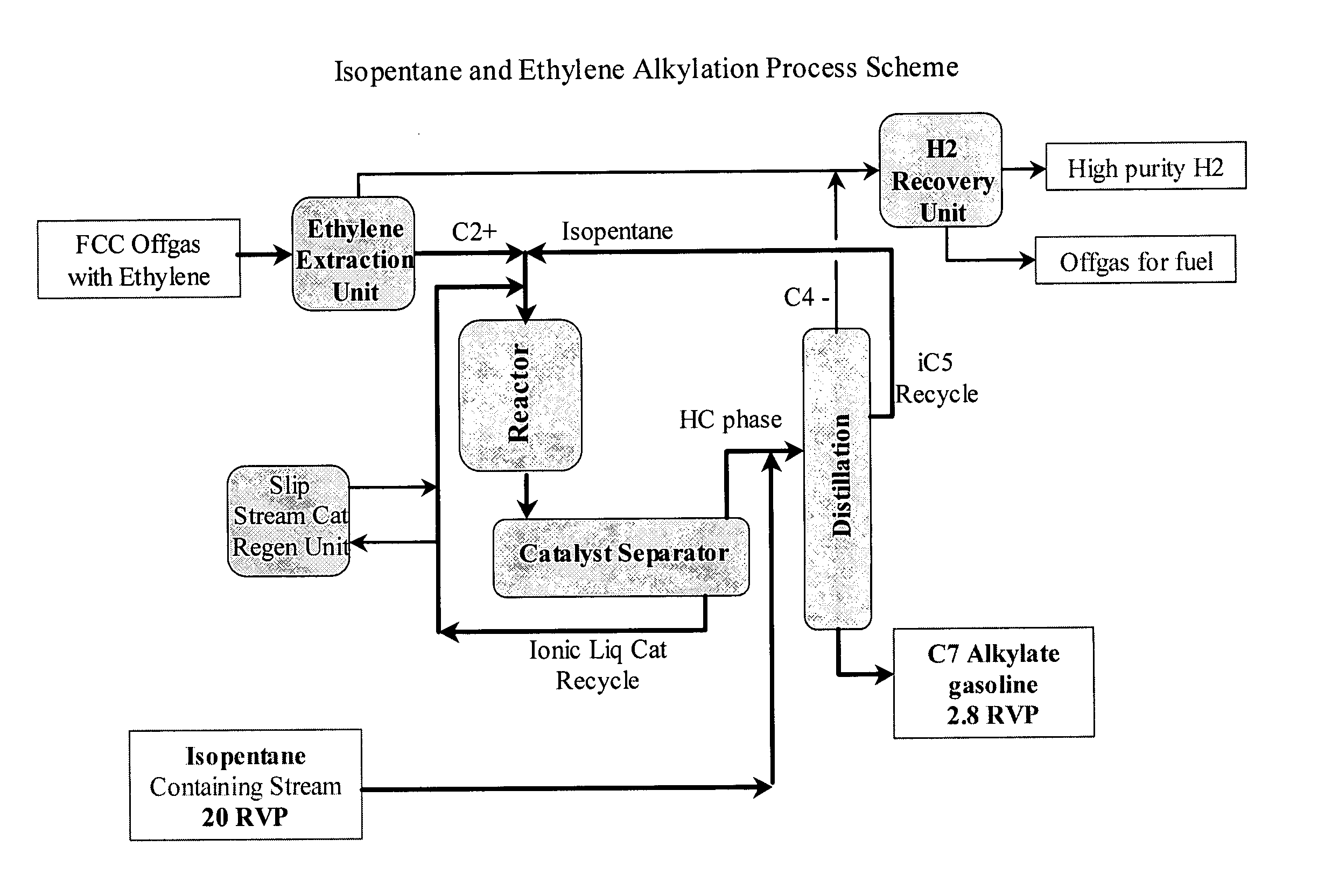

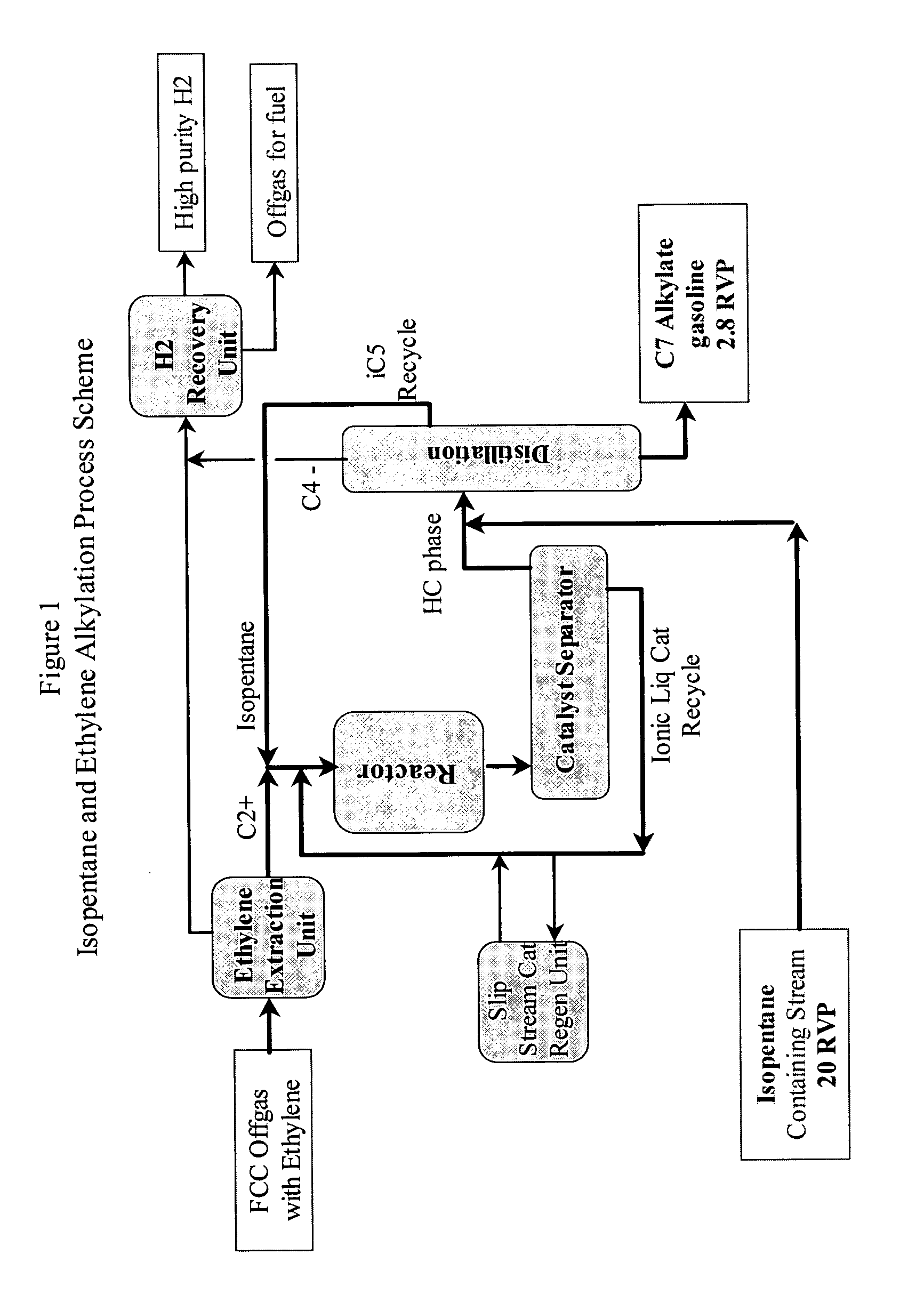

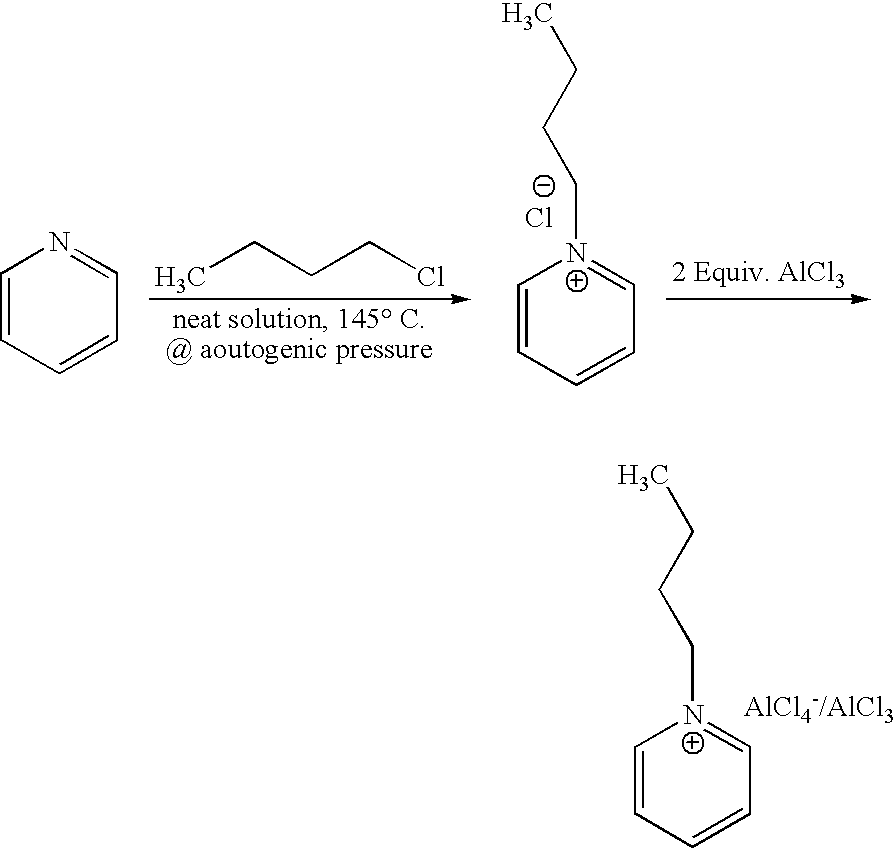

Integrated alkylation process using ionic liquid catalysts

ActiveUS7432408B2Easy to operateReduce gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

Integrated alkylation process using ionic liquid catalysts

ActiveUS20060131209A1Easy to operateReducing fuel gas productionLiquid hydrocarbon mixtures productionRefining with metal saltsAlkyl transferGasoline

An integrated refining process for the production of high quality gasoline blending components from low value components is disclosed. In addition there is disclosed a method of improving the operating efficiency of a refinery by reducing fuel gas production and simultaneously producing high quality gasoline blending components of low volatility. The processes involve the alkylation of a refinery stream containing pentane with ethylene using an ionic liquid catalyst.

Owner:CHEVROU USA INC

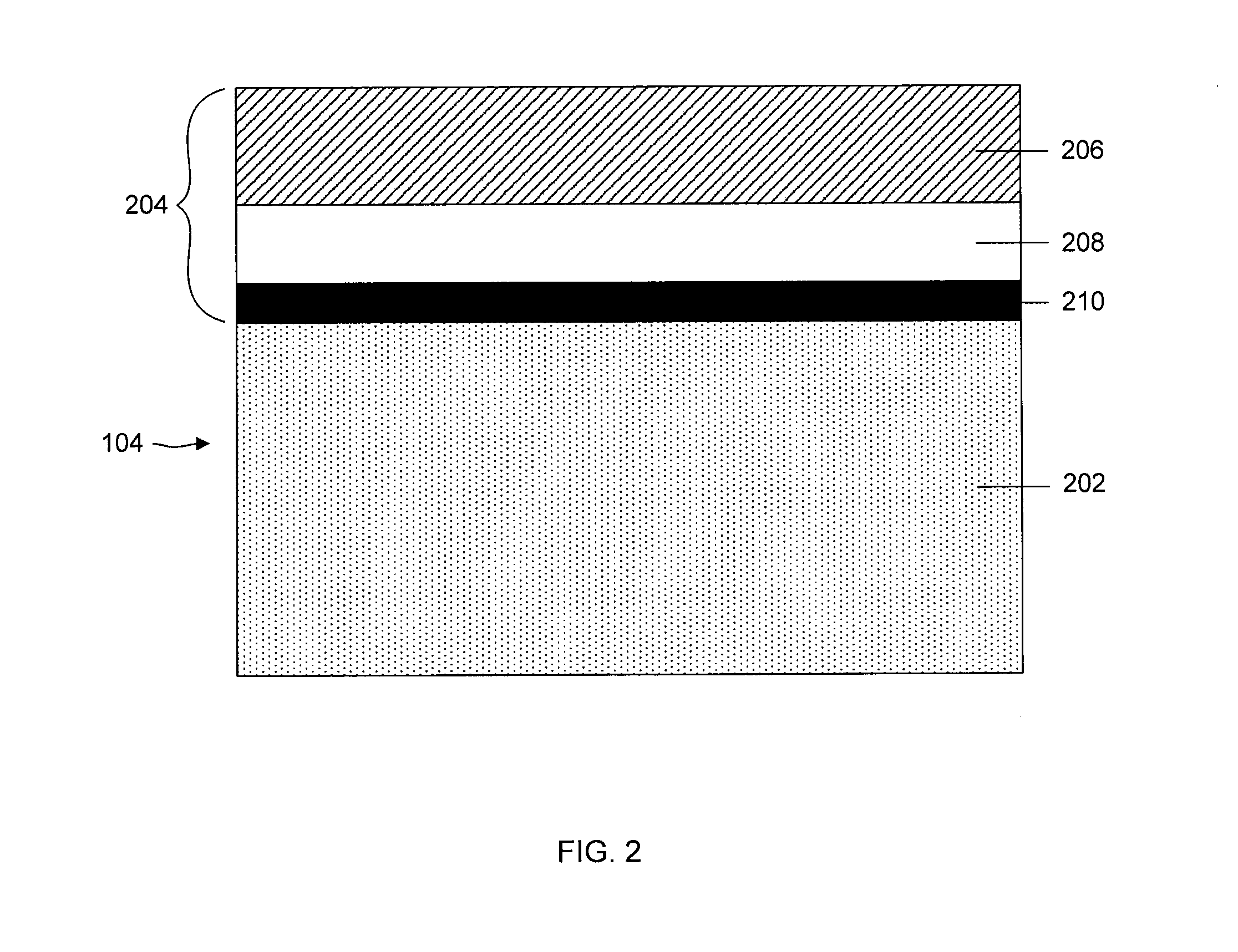

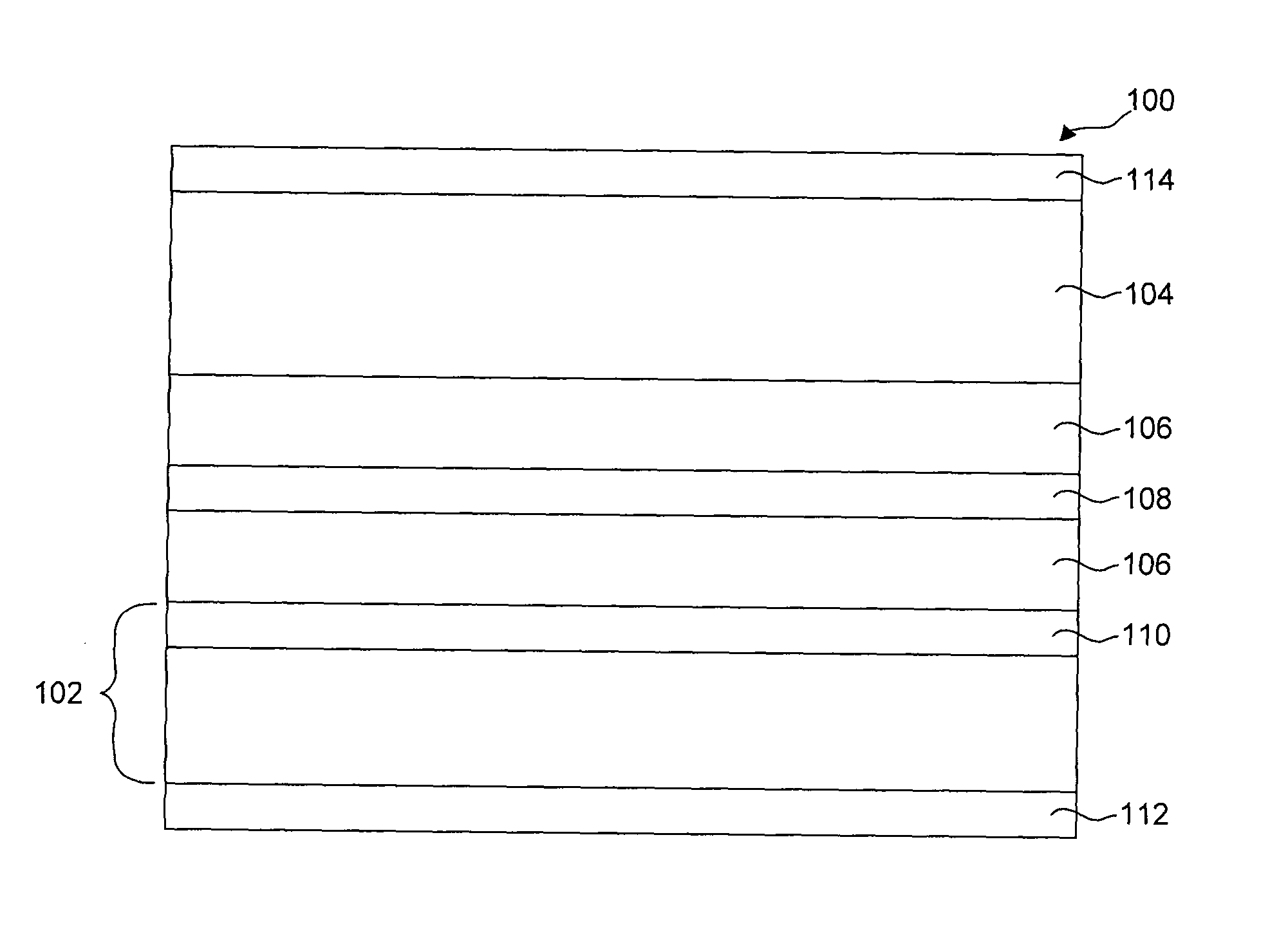

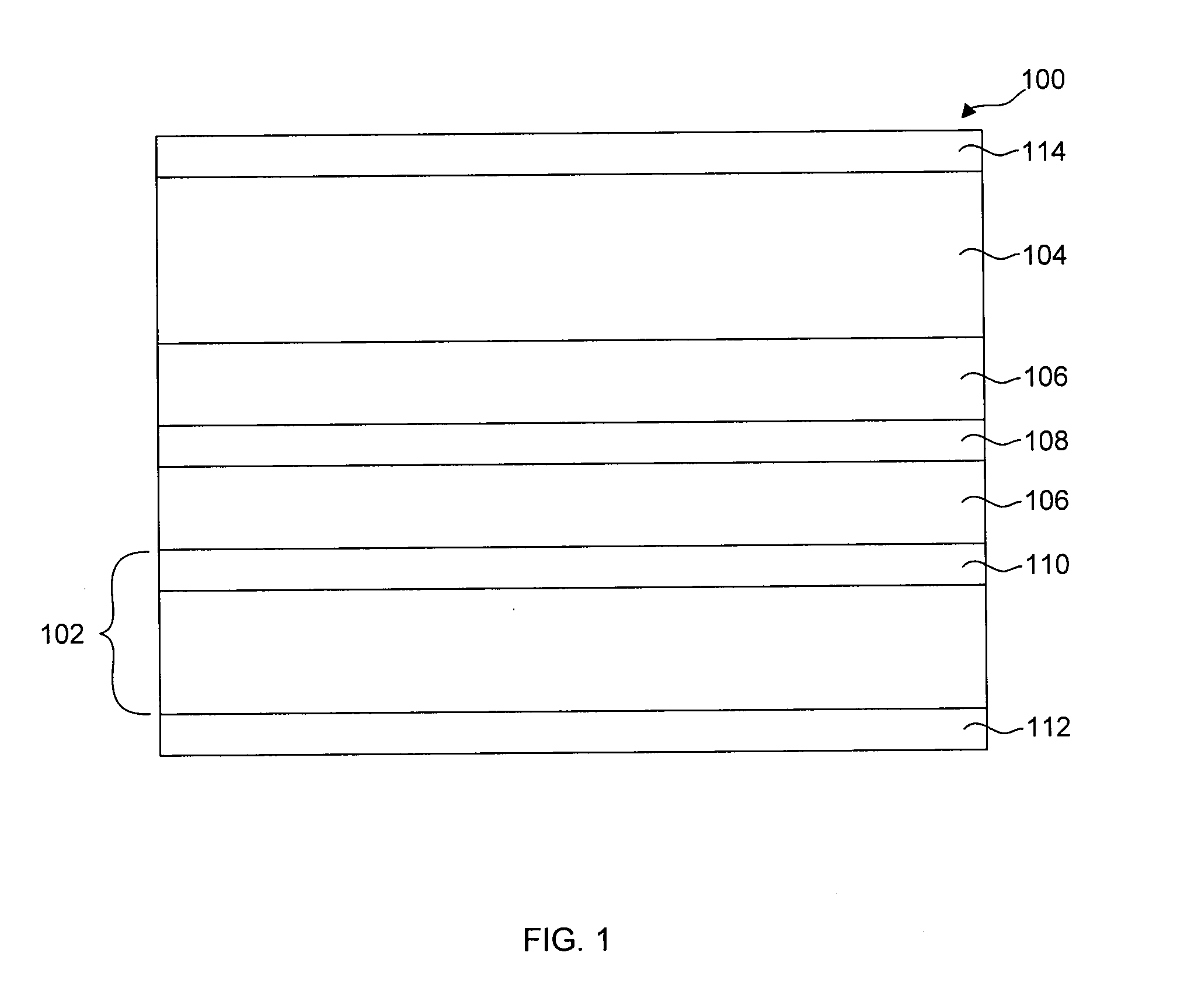

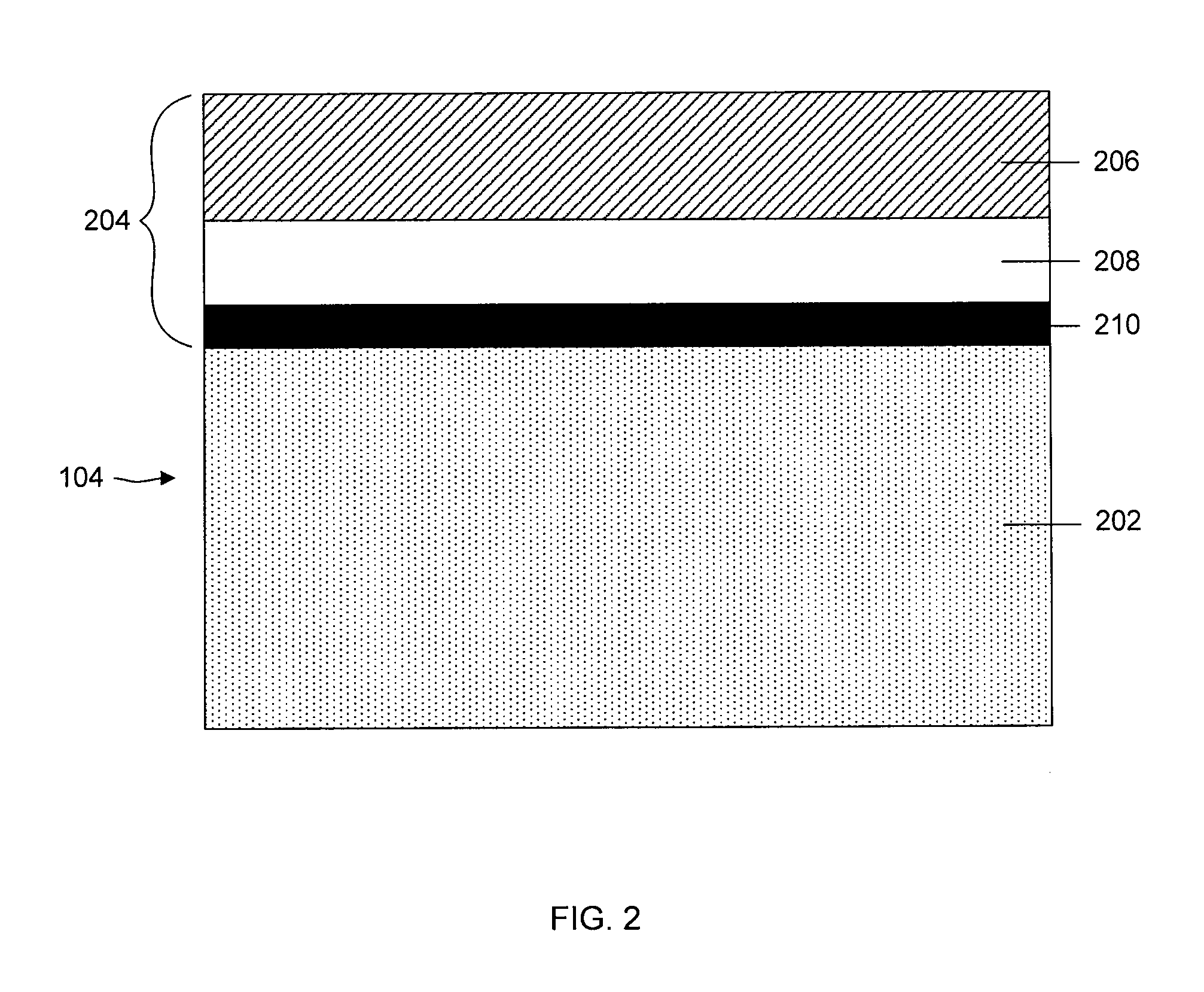

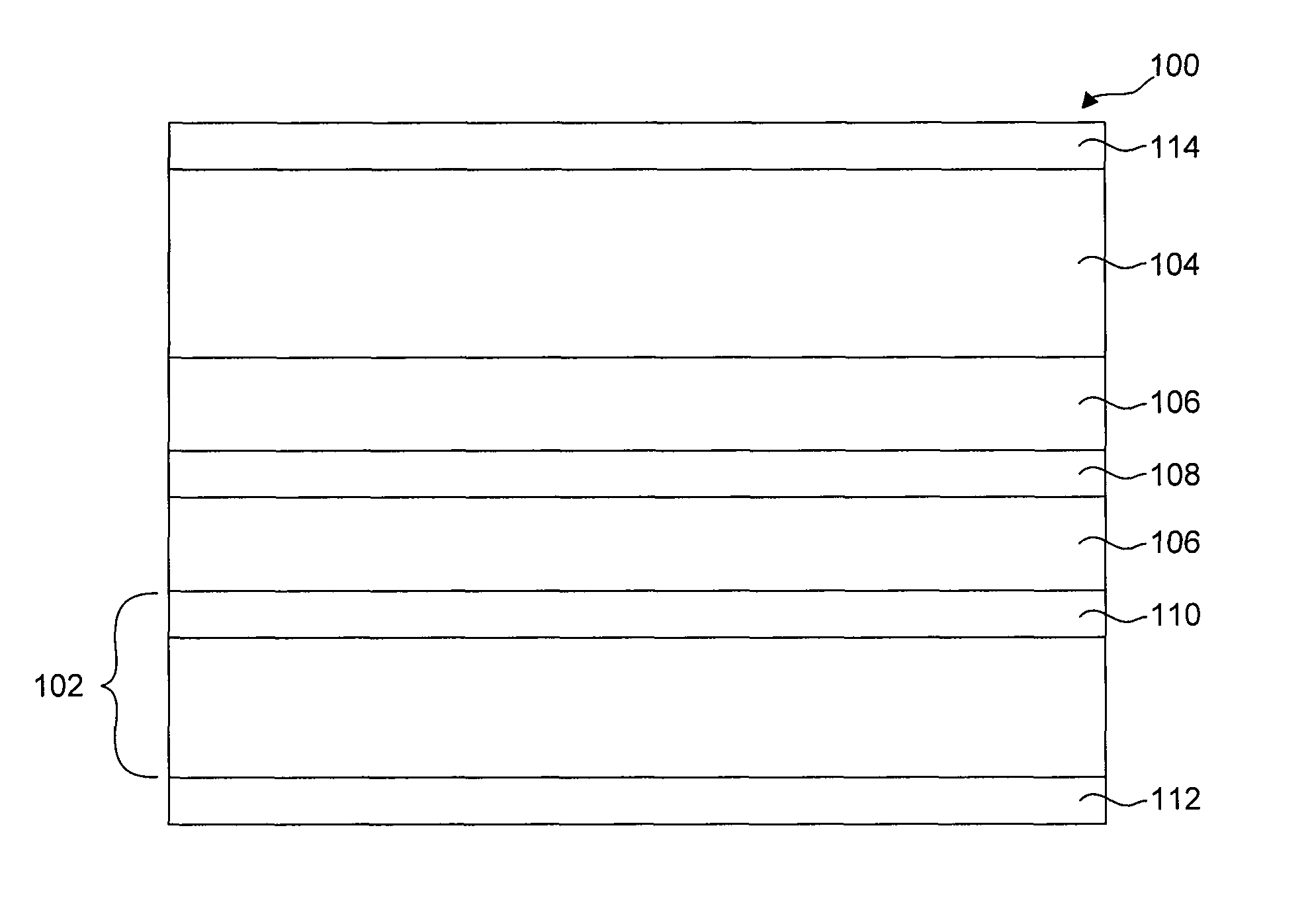

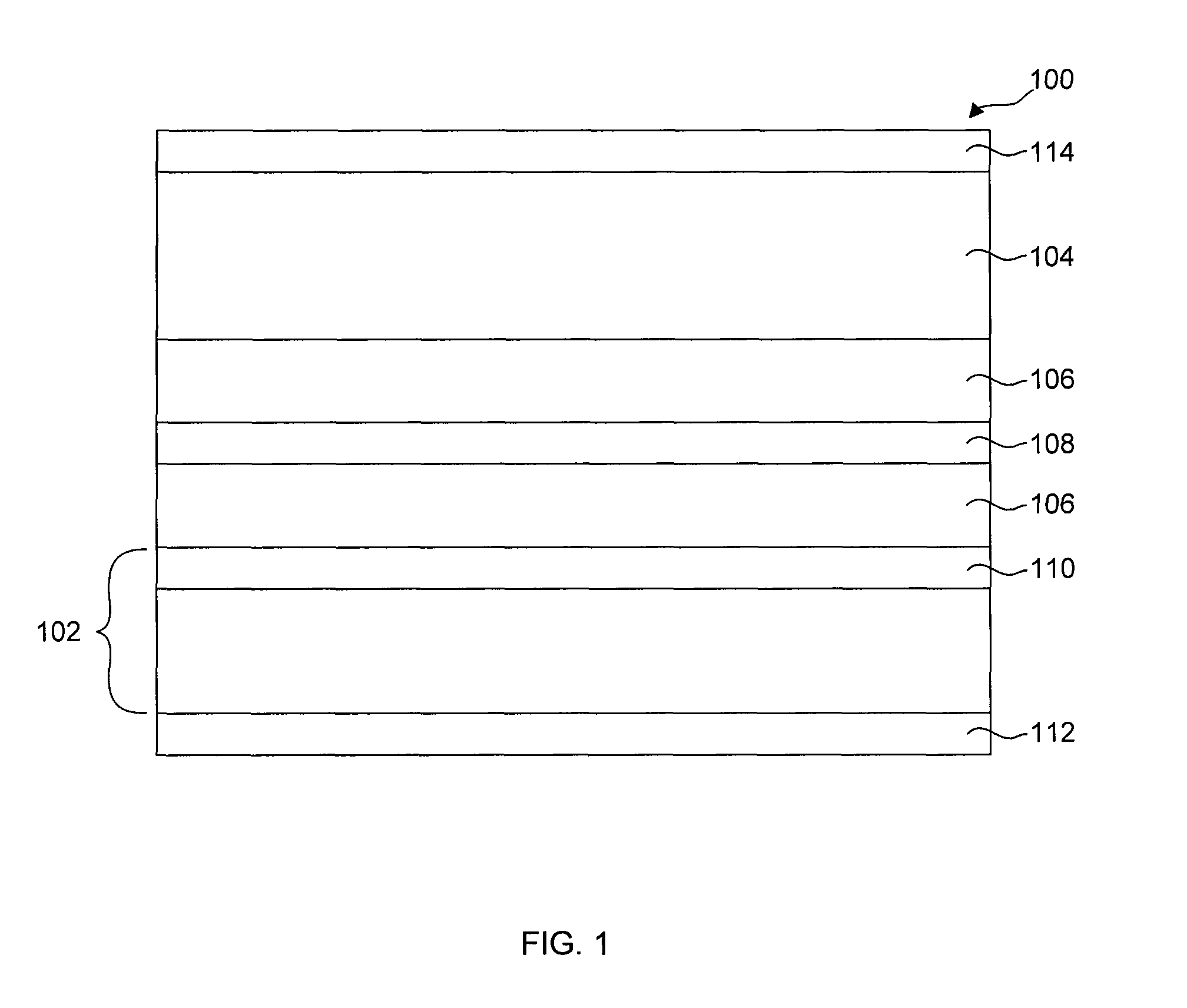

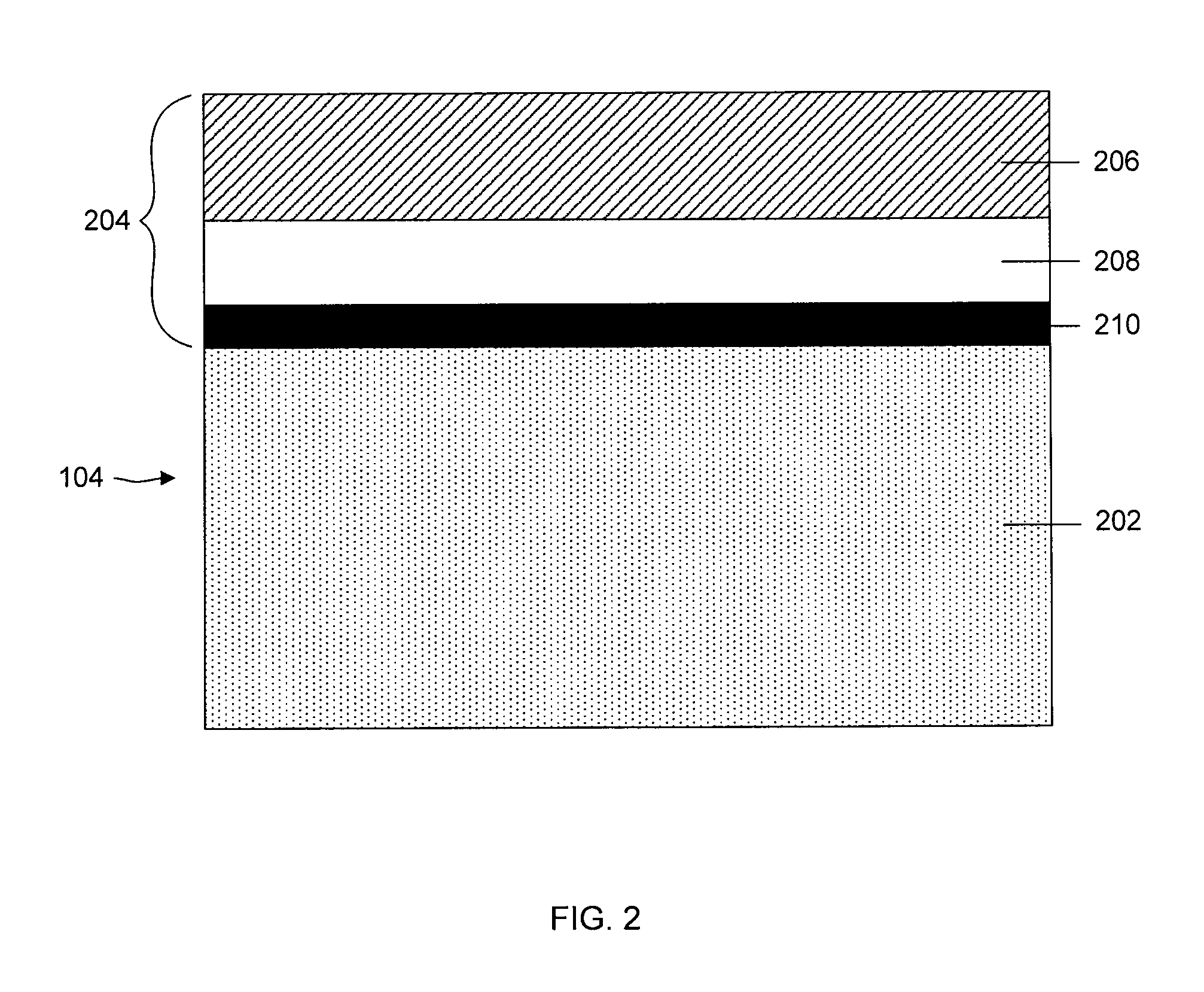

Electrochemical cell, components thereof, and methods of making and using same

ActiveUS20110287305A1Increase electrochemical performanceReduce self dischargeAlkaline accumulatorsCell electrodesElectrochemical cellNitrogen

An electrochemical cell including at least one nitrogen-containing compound is disclosed. The at least one nitrogen-containing compound may form part of or be included in: an anode structure, a cathode structure, an electrolyte and / or a separator of the electrochemical cell. Also disclosed is a battery including the electrochemical cell.

Owner:SION POWER CORP

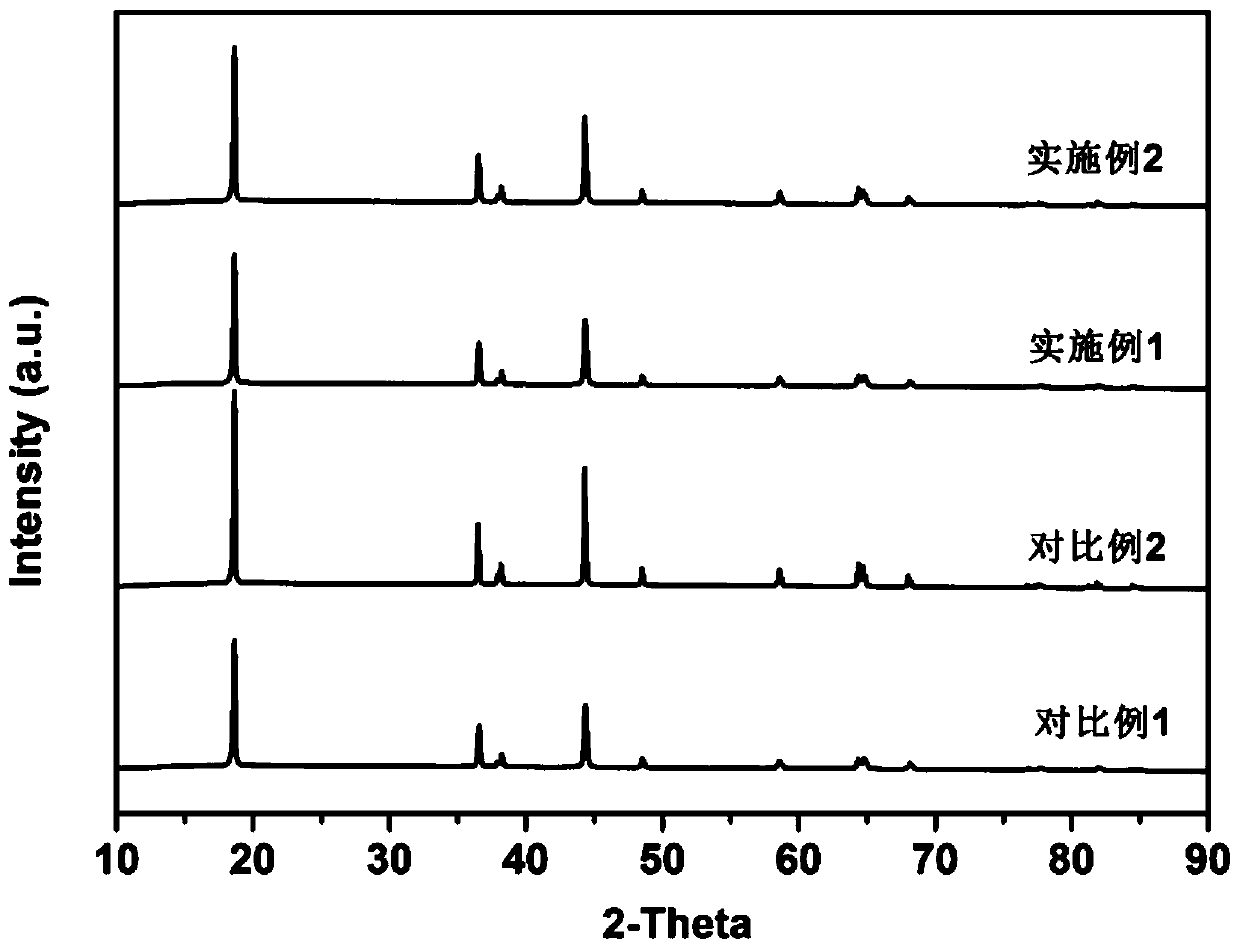

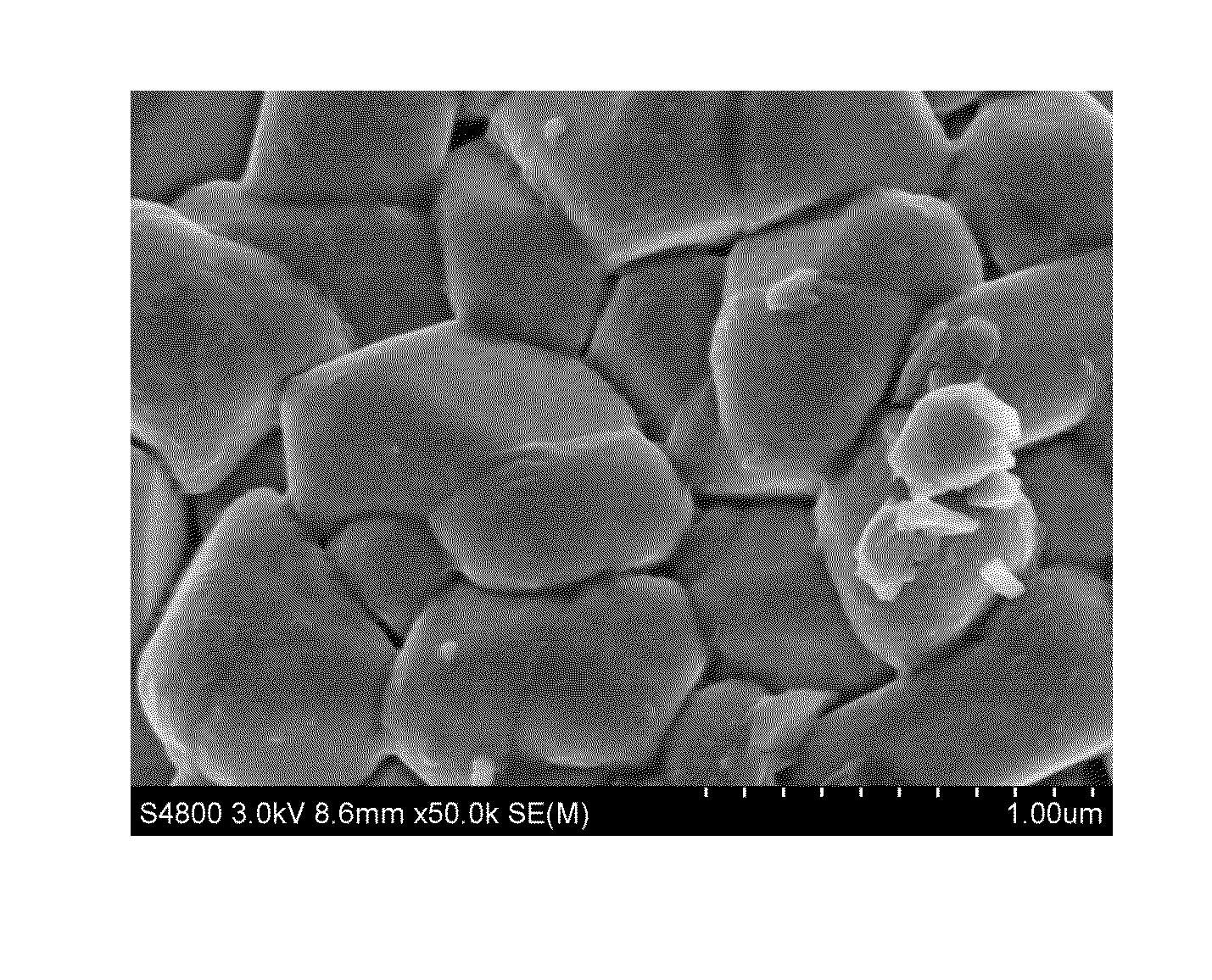

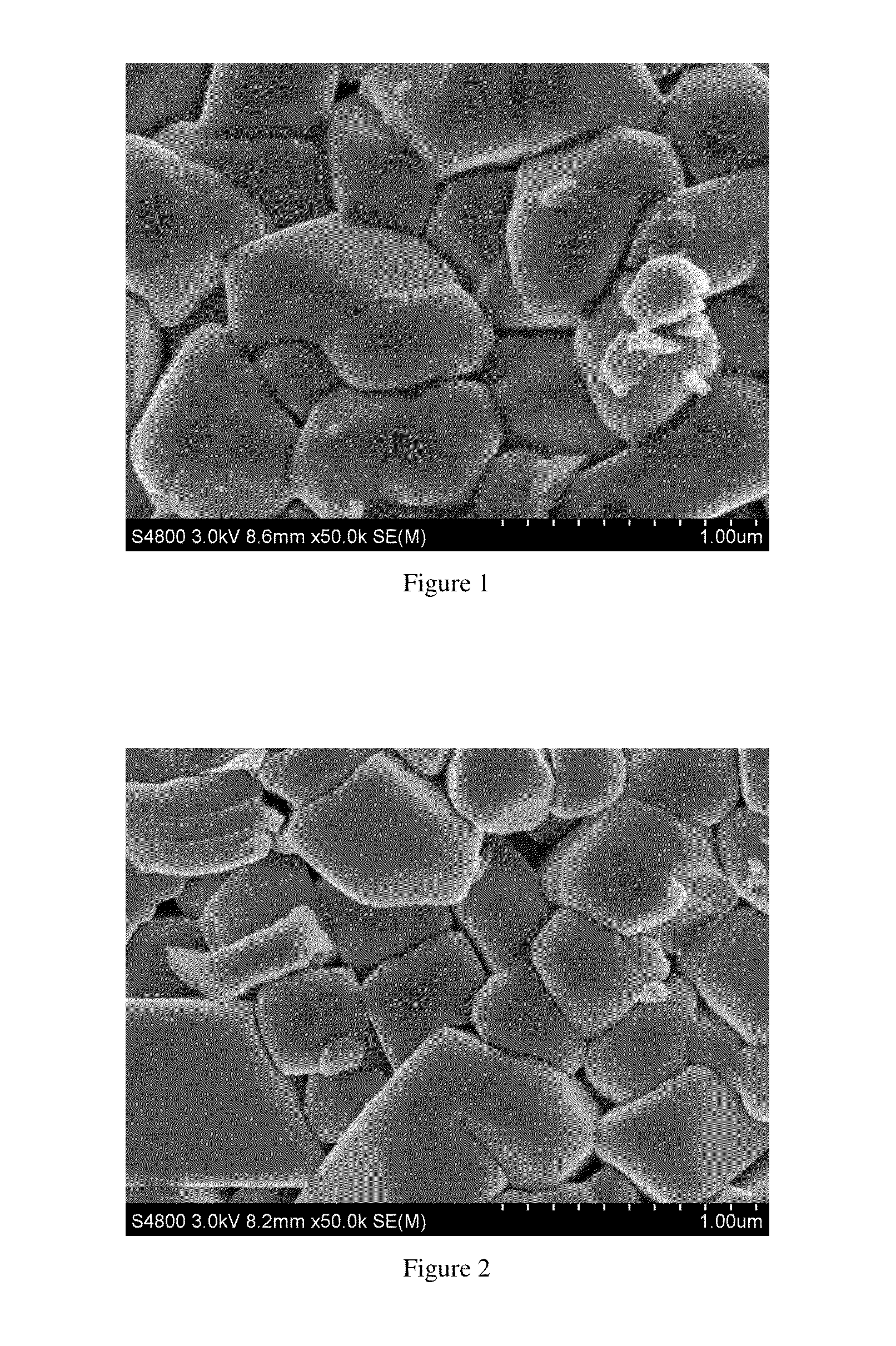

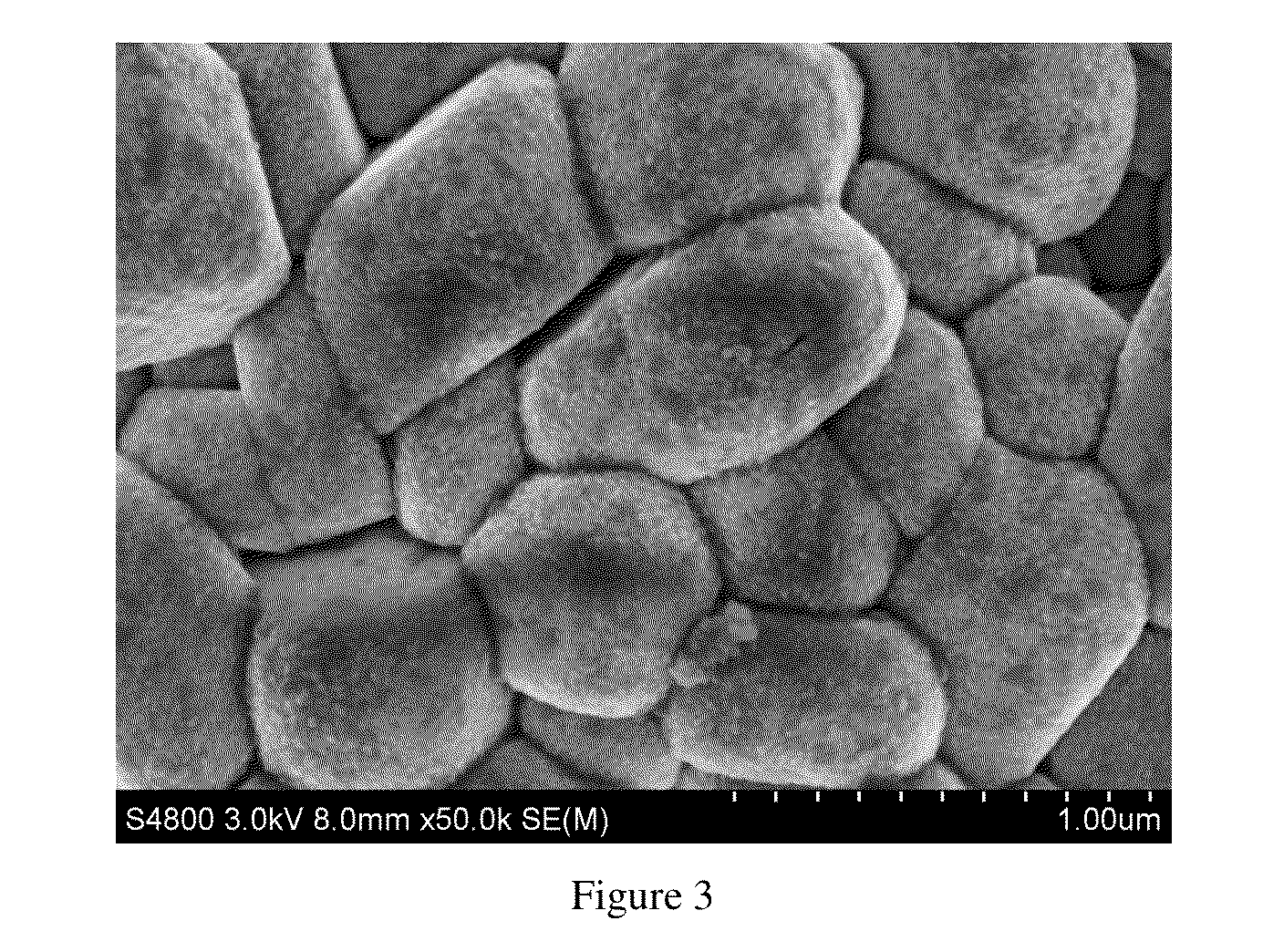

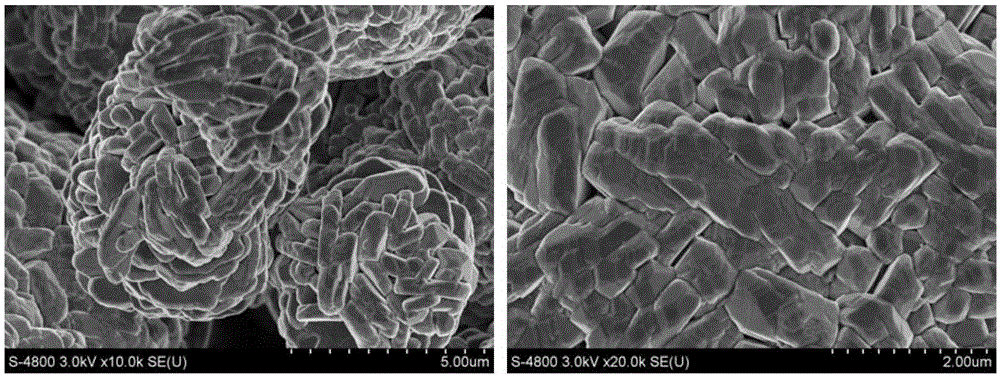

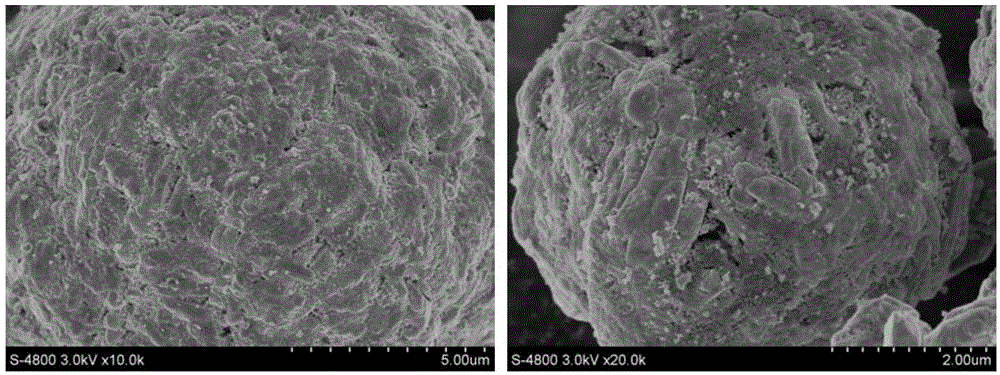

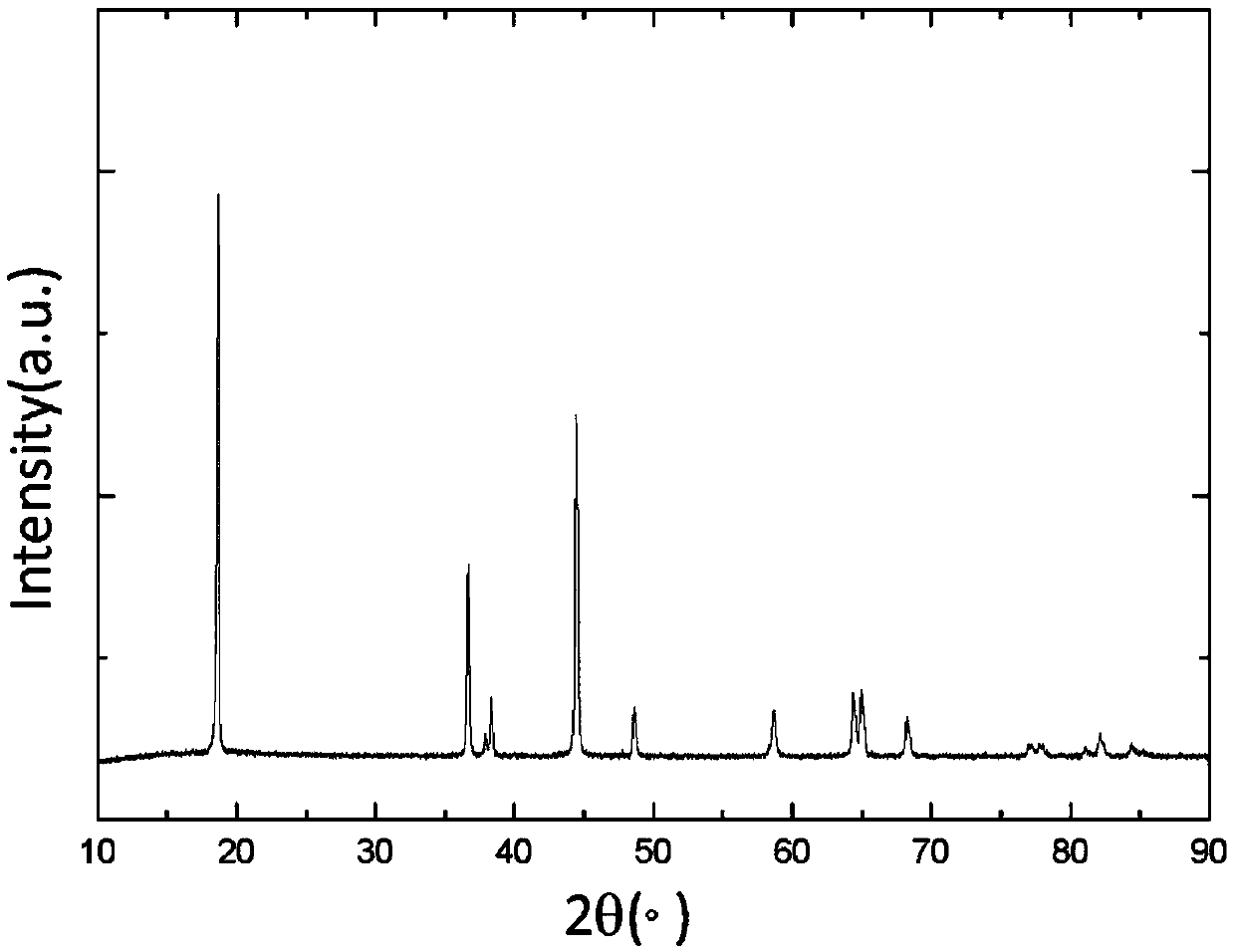

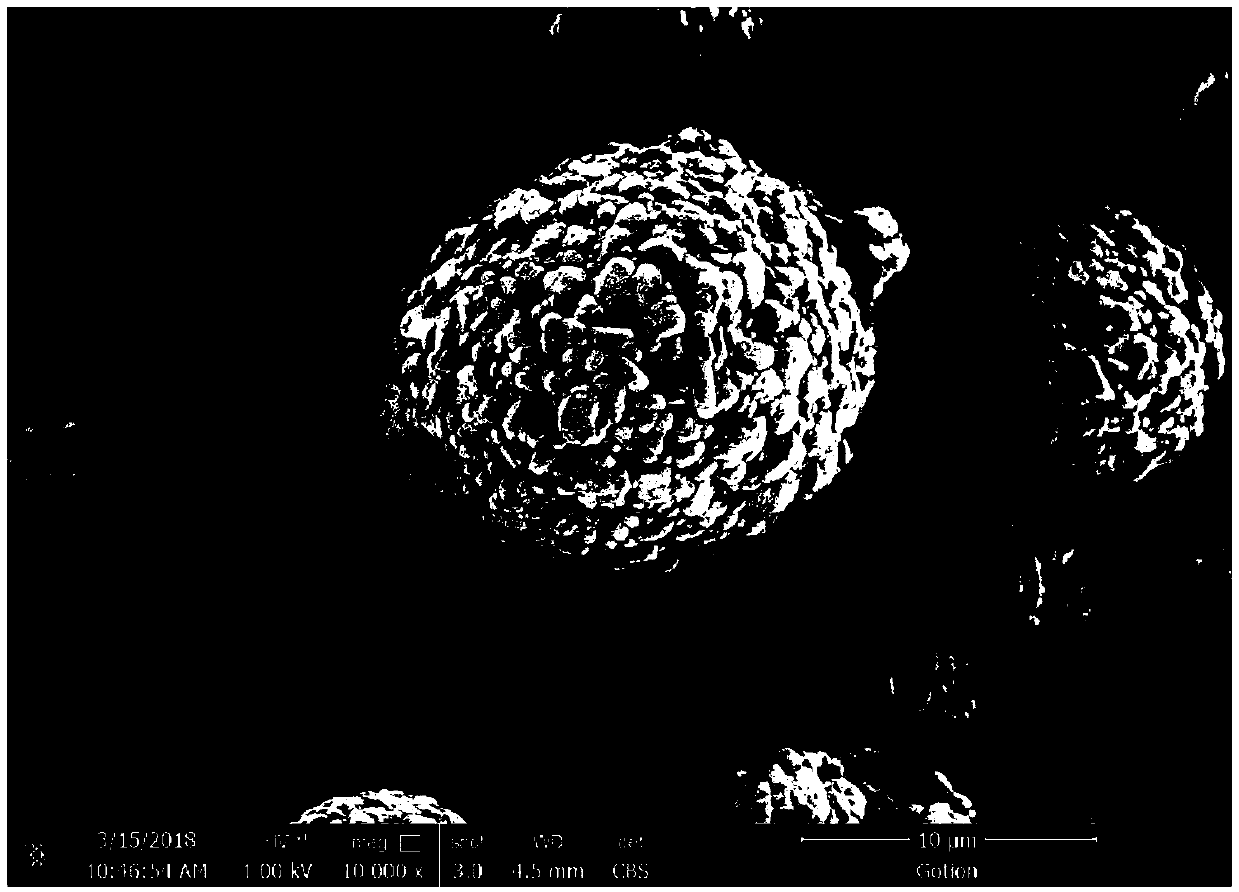

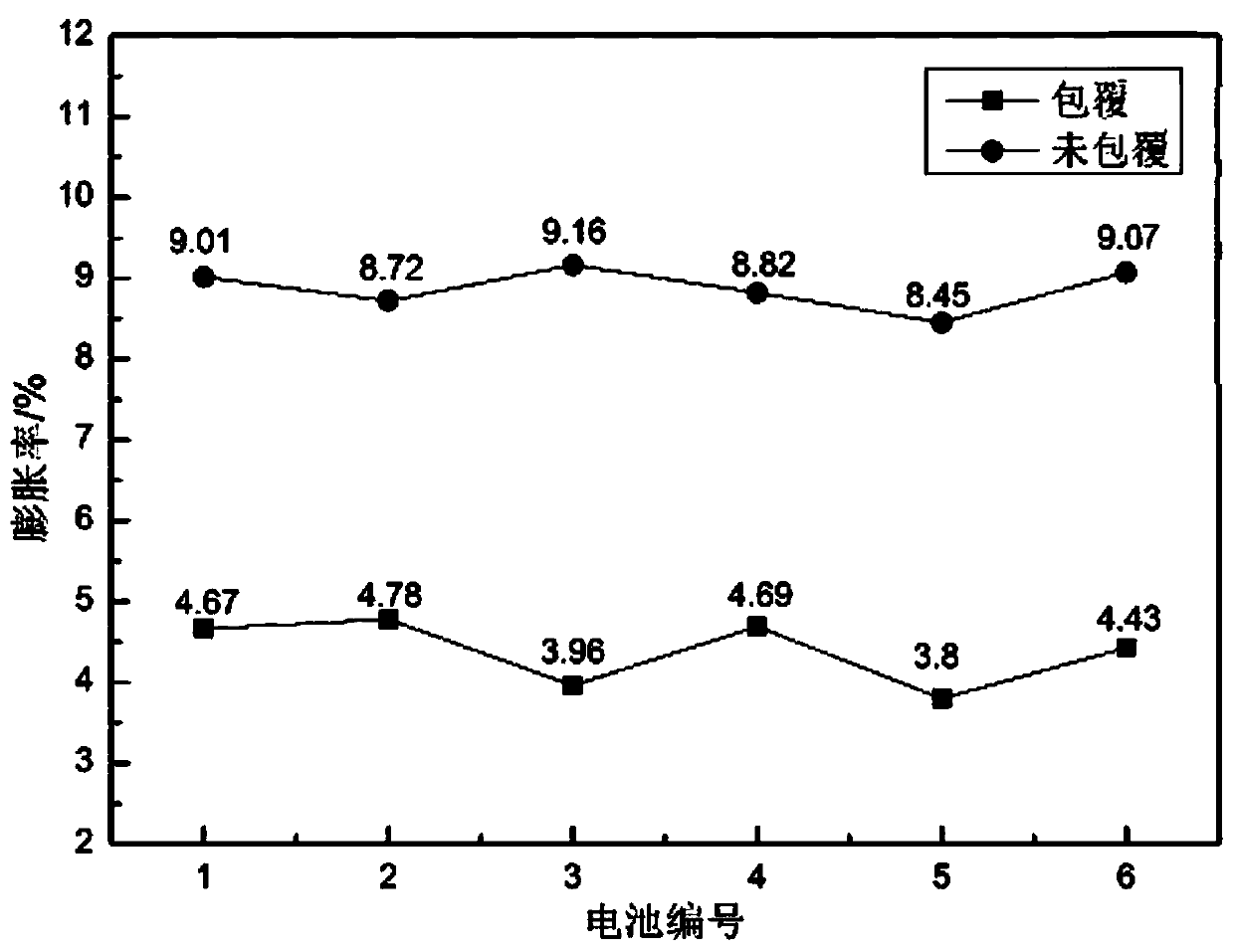

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

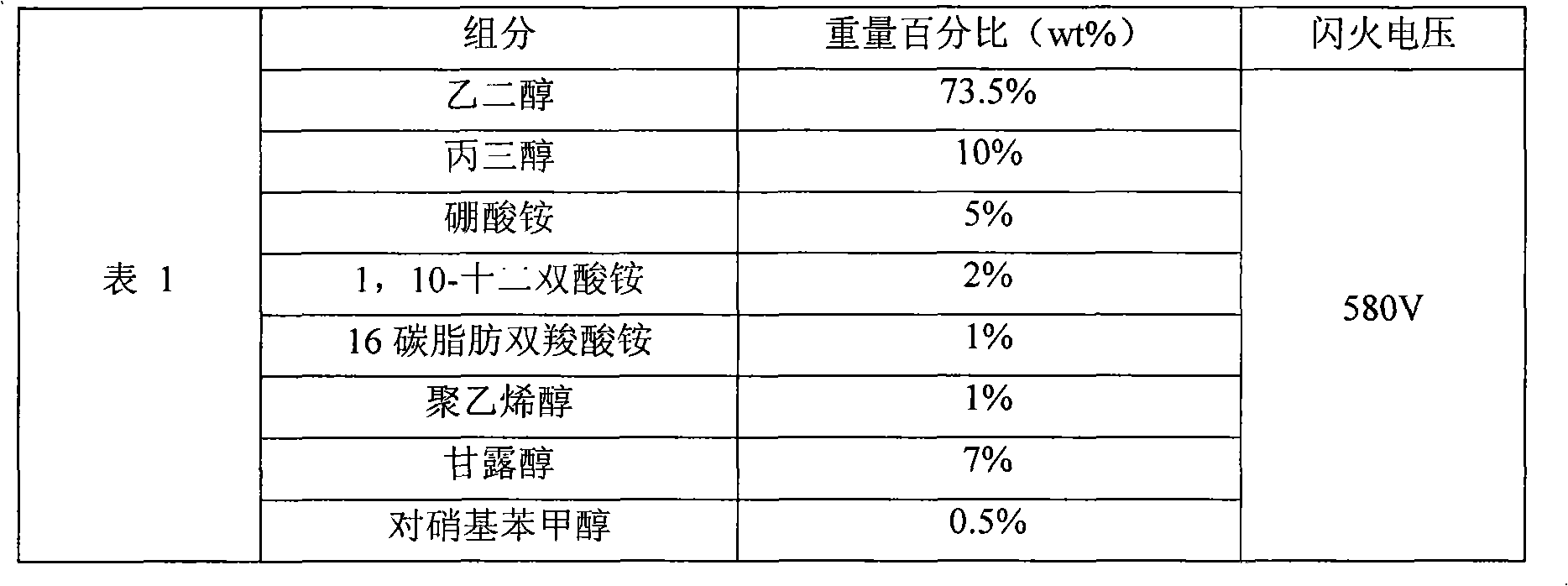

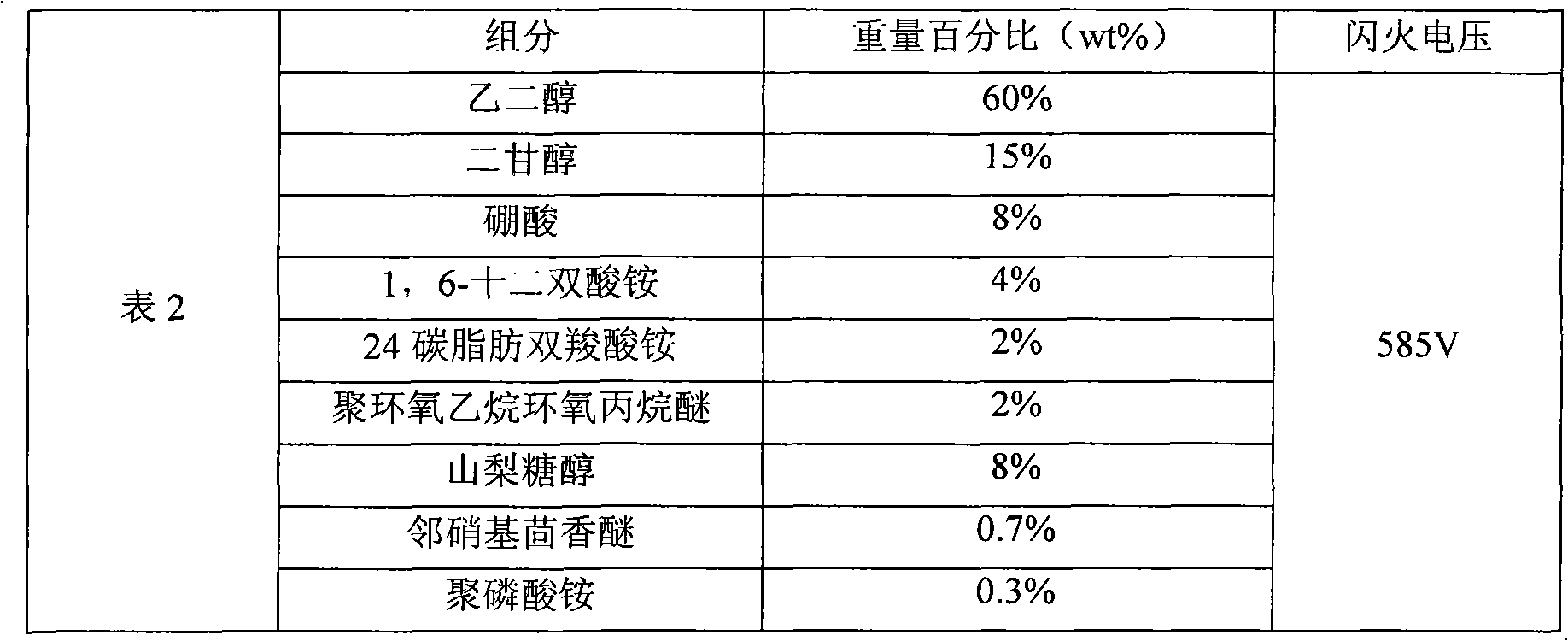

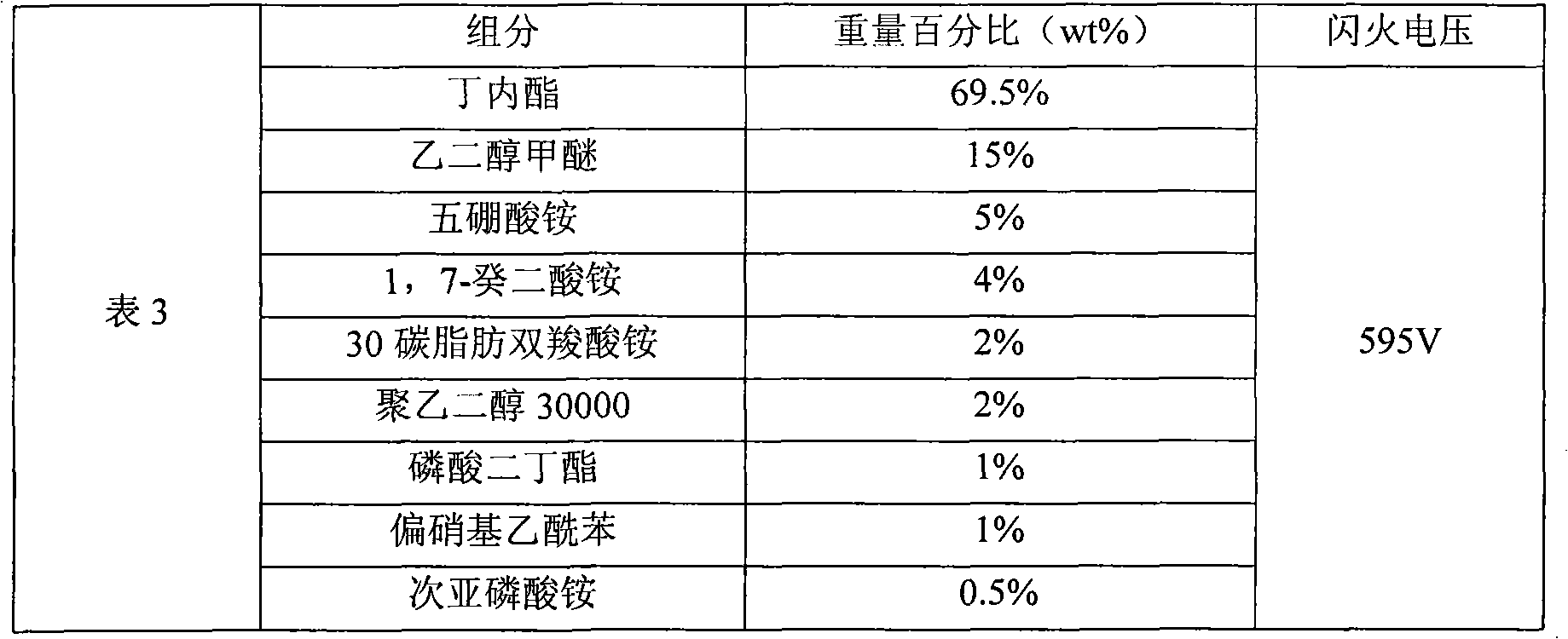

600V extra-high voltage aluminum electrolyte capacitor working electrolyte and preparation and application thereof

ActiveCN101599367AImprove high pressure resistanceImprove high temperature resistanceLiquid electrolytic capacitorsElectrolytic agentHydrogen

The invention relates to a 600V extra-high voltage aluminum electrolyte capacitor working electrolyte and a preparation and an application thereof; the working electrolyte comprises the following materials: 44.5-80.3% of main solvent, 5-15% of auxiliary solvent, 8-15% of solute, 0.5-2.5% of sparking voltage enhancer, 6-10% of stabilizer and 0.2-3% of hydrogen absorbent; the preparation method comprises the following steps: mixing the main solvent and the auxiliary solvent evenly, heating the mixture to 60-90 DEG C; adding sparking voltage enhancer, heating the mixture to 135-155 DEG C; cooling the heated mixture to 65-80 DEG C by circulating water, adding the solute and the stabilizer, heating the product to 105-135 DEG C; finally, adding the hydrogen absorbent and natural cooling to obtain the working electrolyte. Proper sparking voltage enhancer and stabilizer are added in the electrolyte to improve the high voltage resistant and high temperature resistant properties of electrolyte and to ensure the electrolyte to have low aerogenesis property; the aluminum electrolyte capacitor prepared by using the electrolyte has long service life and high voltage resistant property, and can not be broken down as the sparking voltage of the electrolyte is unstable.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

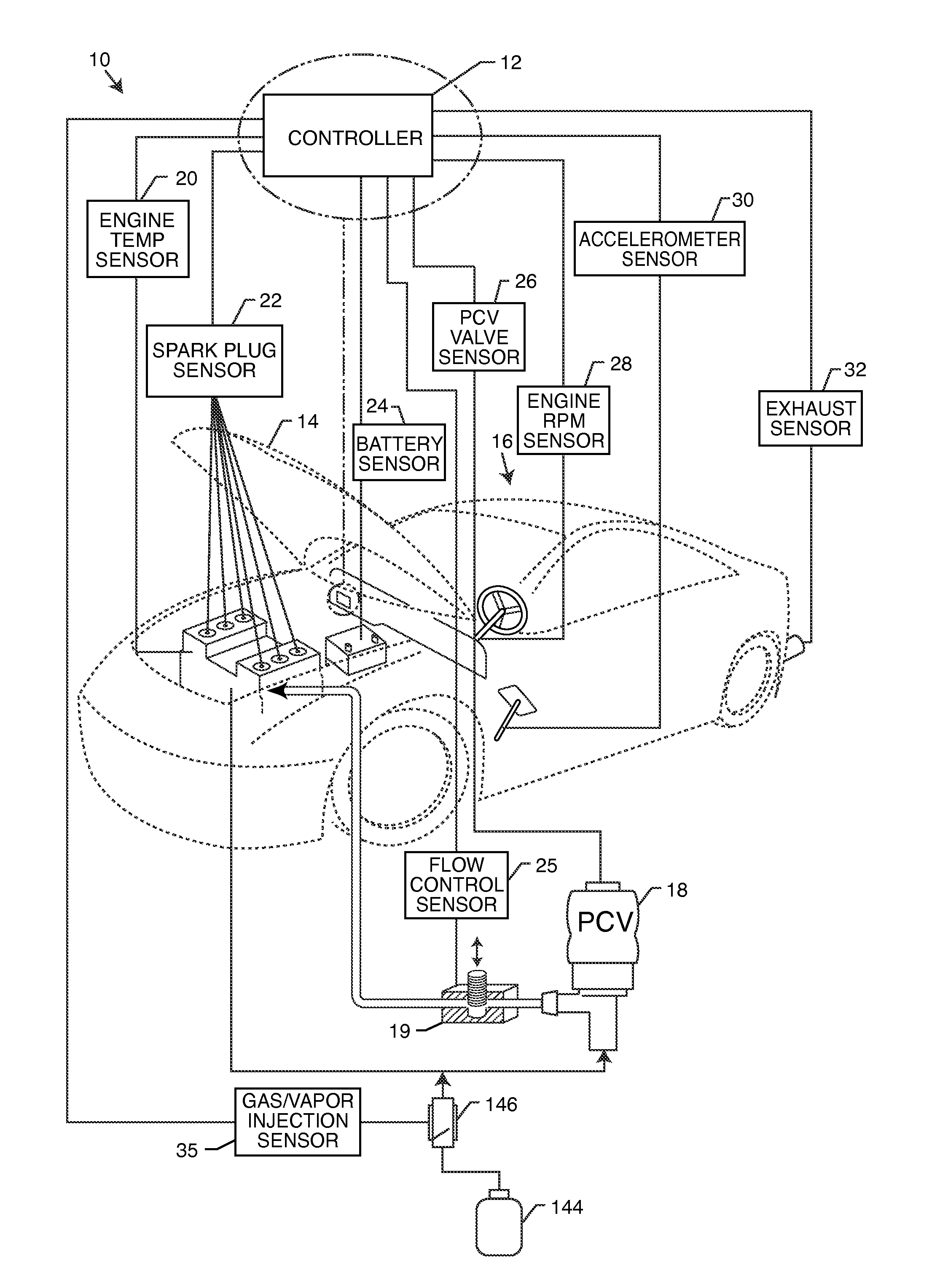

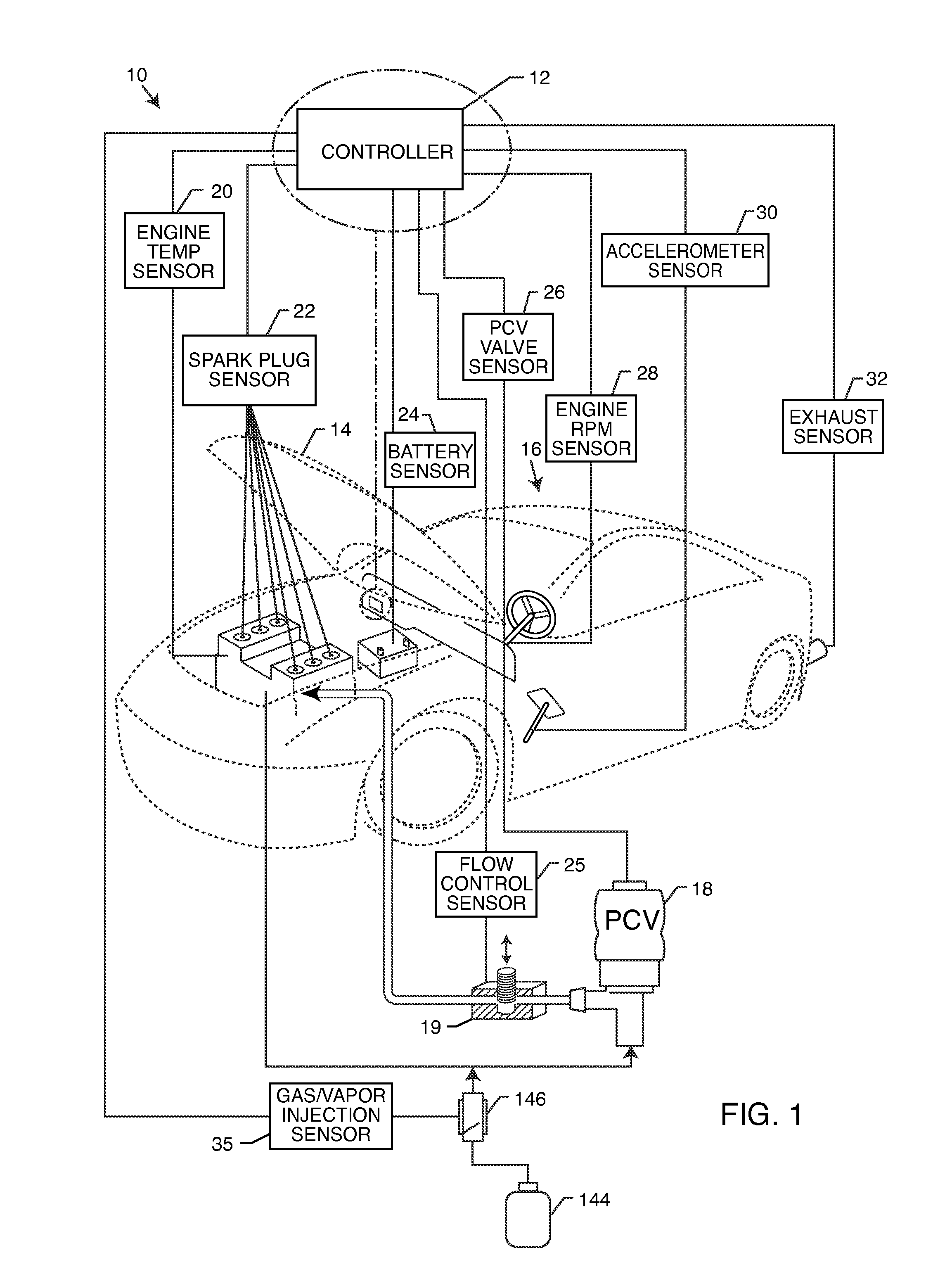

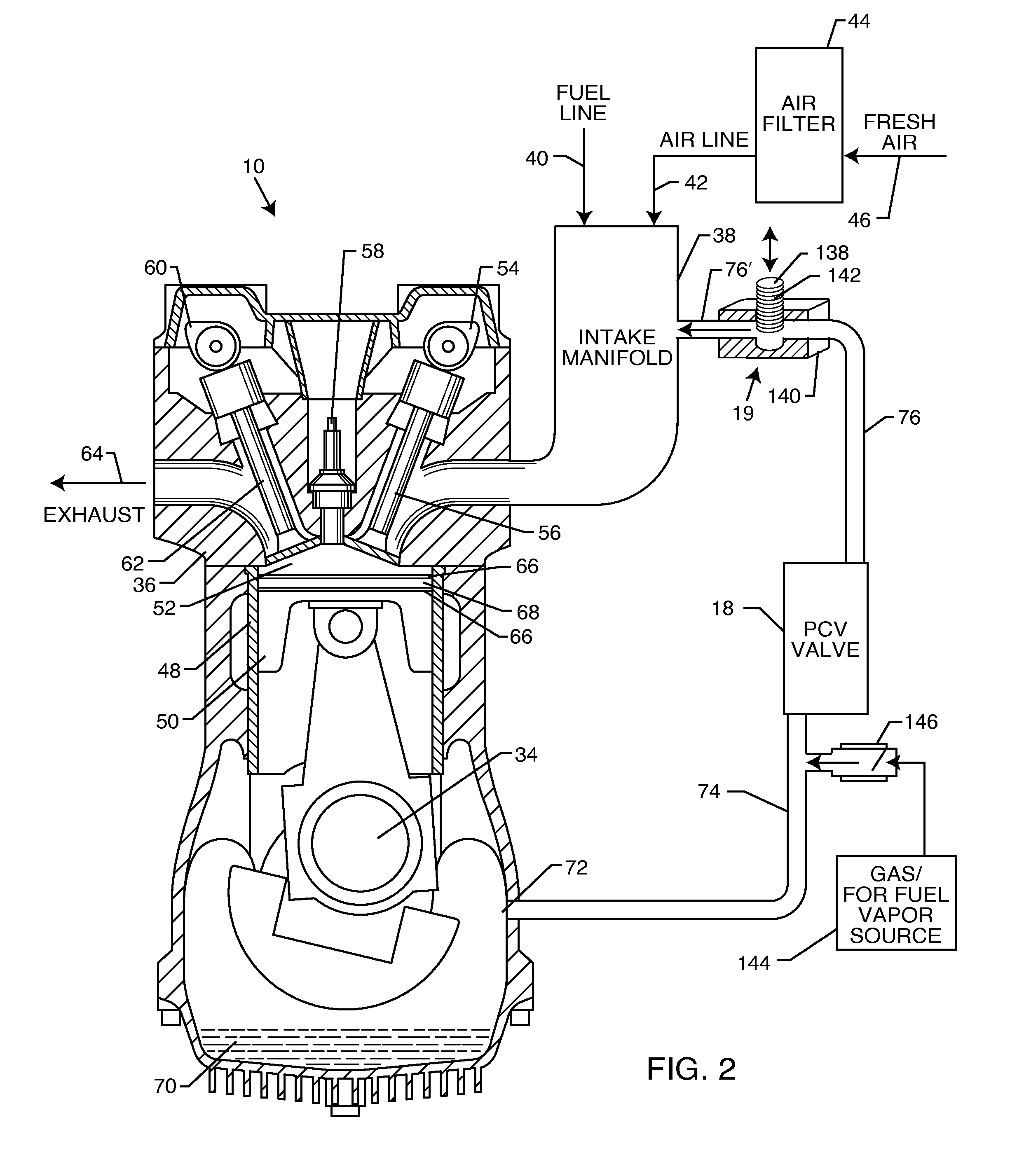

Pollution control system

ActiveUS20100076664A1Reduce fluid flow rateIncrease fluid velocityAnalogue computers for vehiclesInternal combustion piston enginesVacuum pressureCombustion

The pollution control system includes a controller coupled to a sensor monitoring an operational characteristic of a combustion engine, such as engine RPM. A PCV valve having an inlet and an outlet is adapted to vent blow-by gas out from the combustion engine. A fluid regulator associated with the PCV valve and responsive to the controller selectively modulates engine vacuum pressure to adjustably increase or decrease a fluid flow rate of blow-by gas venting from the combustion engine. The controller selectively adjustably positions the fluid regulator to vary the degree of vacuum pressure to optimize the recycling of blow-by gases.

Owner:SVMTECH

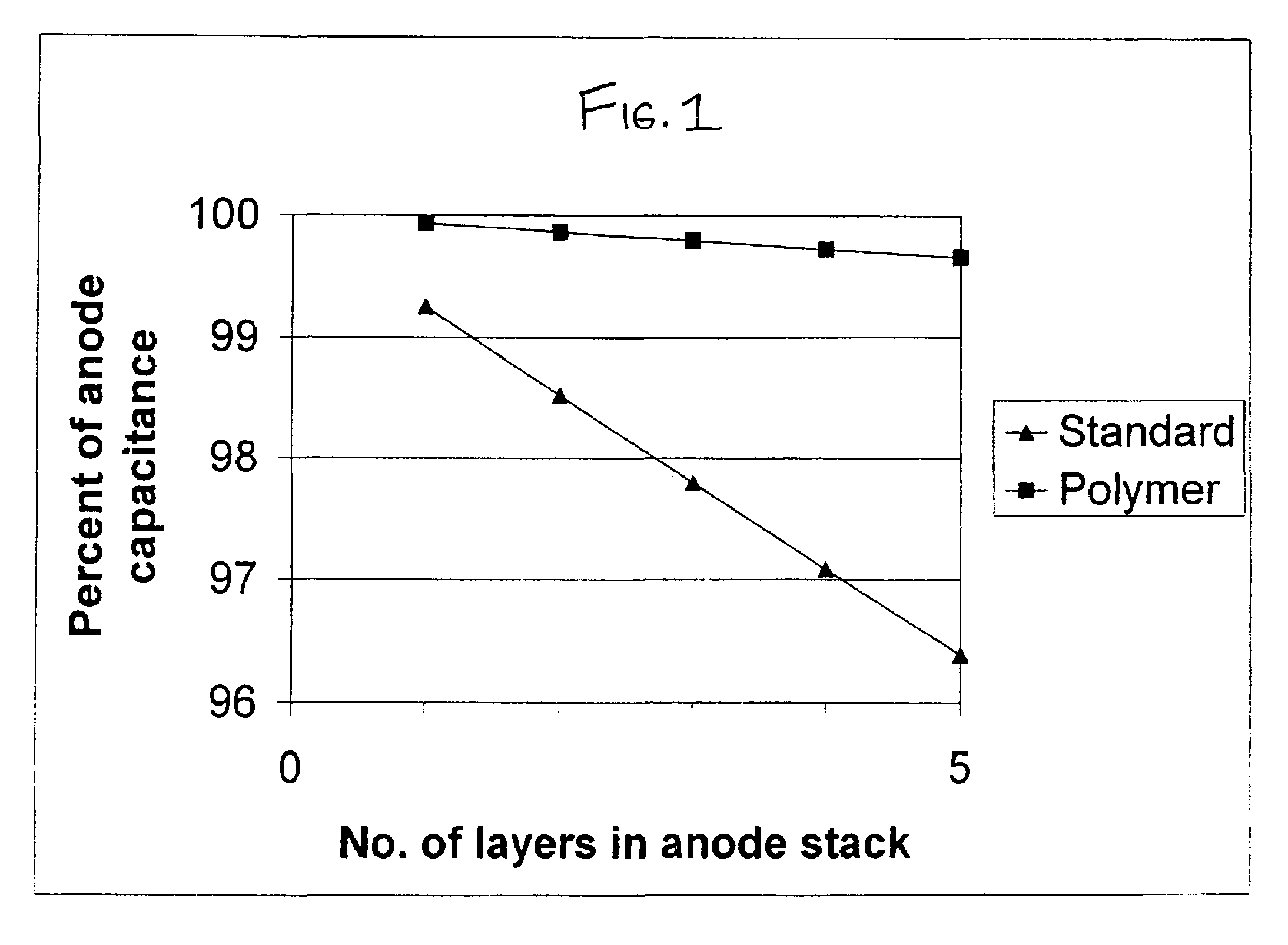

High surface area cathode for electrolytic capacitors using conductive polymer

ActiveUS7169284B1Reducing gas generationAvoid electrolysisHybrid capacitor electrodesSurface reaction electrolytic coatingOrganic acidCapacitance

The present invention is directed to a conductive polyethylenedioxythiophene (PEDOT) polymer coated electrode adapted for use as a cathode electrode of an electrolytic capacitor and a method of manufacturing the same. According to the present invention, a metal foil substrate is placed in an aqueous solution of a doped 3,4-ethylenedioxythiophene (EDOT) monomer and a co-solvent, to dissolve the EDOT monomer, and a current is applied until the desired thickness of the polymer coating is electrochemically deposited. Additionally, an organic acid is added to the aqueous solution to act as an oxidizer. In order to improve the uniformity and adherence of the coating a surfactant may also be added. In a preferred embodiment, the EDOT monomer and cosolvent are first mixed, and then added to a water solution of oxidizer and dopant. The polymer film is deposited electrochemically onto the substrate by applying a DC current between 0.05 mA / cm2 and 5.0 mA / cm2 for 1 to 60 minutes, more preferably between about 0.13 mA / cm2 to about 0.26 mA / cm2 for between 9 and 18 minutes, such that a conductive polyethylenedioxythiophene (PEDOT) coating is formed on the electrode surface. According to the present invention, the increased surface area of the coated cathode results in lower gas generation and, therefore, reduced capacitor swelling, reduced oxide buildup on the cathode and prevention of electrolysis. The present invention results in electrodes with a minimum capacitance of 1 mF / cm2. The present invention also makes it possible to use thinner electrodes than conventional aluminum electrodes, thereby reducing the physical dimensions of the capacitor.

Owner:PACESETTER INC

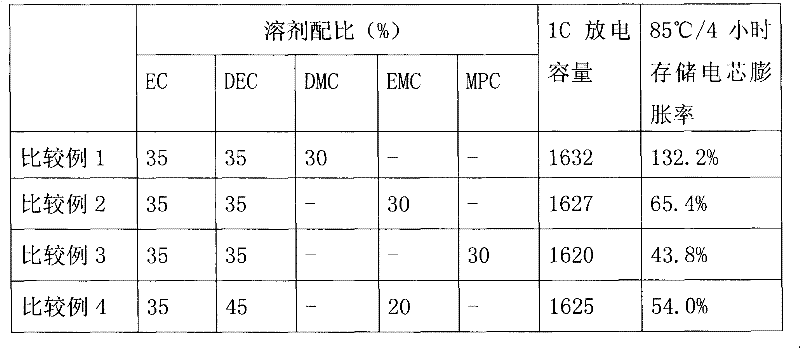

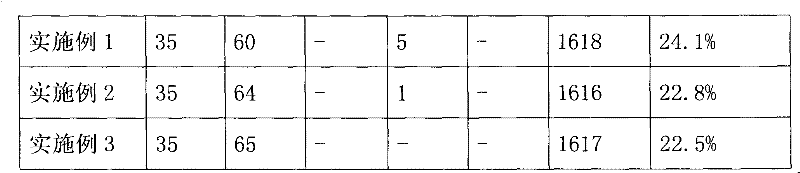

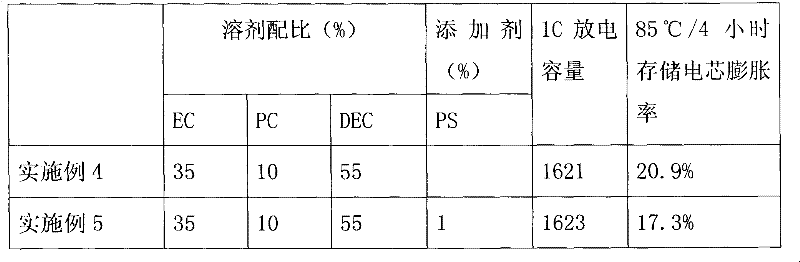

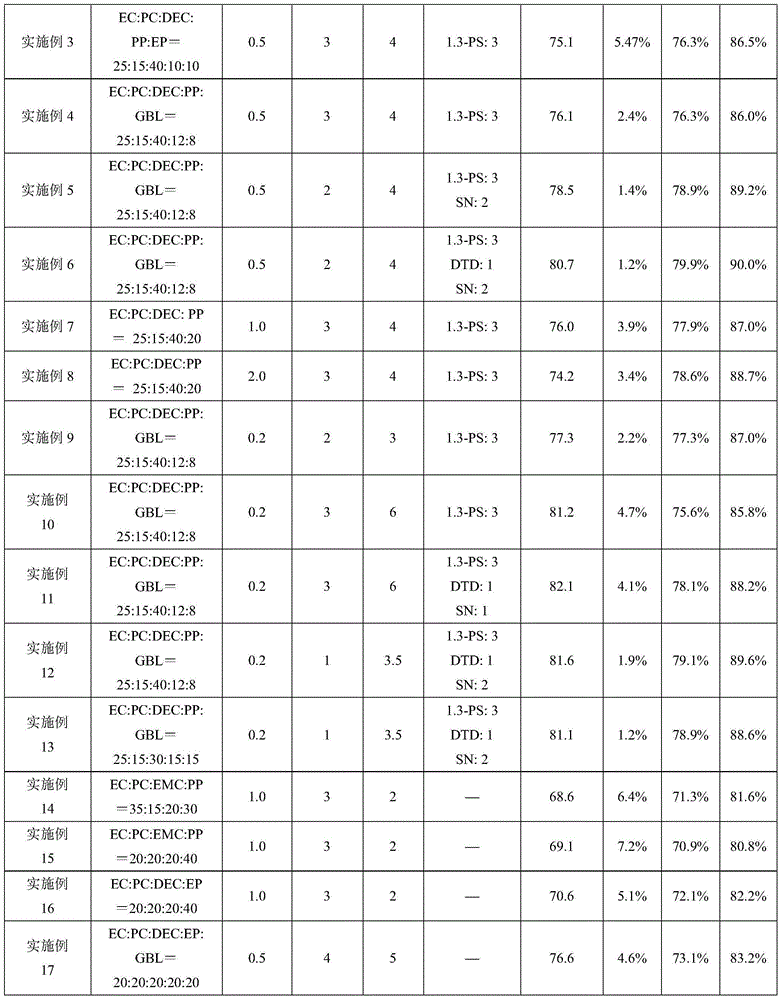

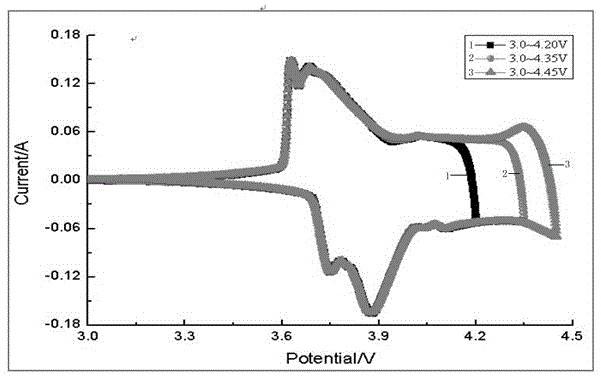

Lithium ion battery and electrolyte thereof

The invention discloses lithium ion battery electrolyte. The lithium ion battery electrolyte comprises a solvent, lithium salt and additives; the methyl-containing chain carbonate ester in the solvent is less than or equal to 5 percent of the total mass of the solvent; and the additives comprise 2 to 4 percent of 1,3-propane sultone (PS). Compared with the prior art, the lithium ion battery electrolyte has the advantages that: the content of the methyl-containing chain carbonate ester with low stability in the solvent is controlled, and the additives, namely the 1,3-propane sultone, butanedinitrile, adiponitrile, vinylene carbonate (VC), fluoroethylene carbonate (FEC) and the like are added into the solvent, so that an interface of an electrode / the electrolyte can be improved, the decomposition of the solvent in the electrolyte is reduced, the quantity of gas generated in the battery is reduced, and the high temperature storage performance, the safety performance and the cycle performance of the battery under a high voltage are improved. Besides, the invention also provides a lithium ion battery employing the electrolyte.

Owner:DONGGUAN AMPEREX TECH +1

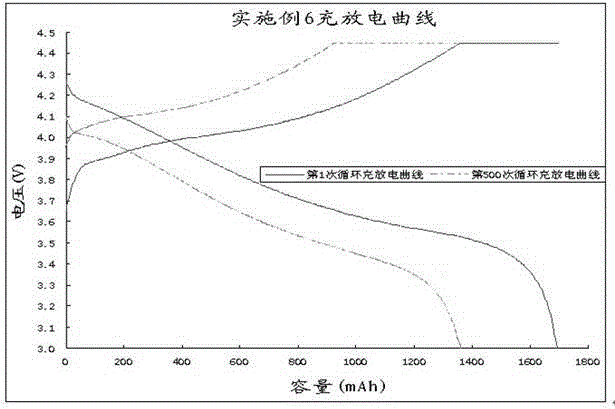

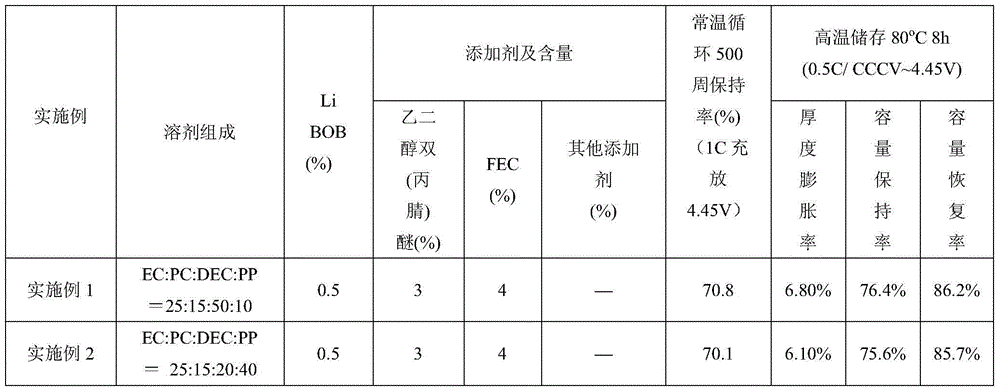

High-voltage electrolyte and lithium ion battery using electrolyte

InactiveCN104979589APromote circulationHigh decomposition voltageSecondary cellsHigh temperature storageEthylene glycol bis

The invention discloses high-voltage electrolyte and a lithium ion battery using the electrolyte. The invention is realized by the following technical scheme: the high-voltage electrolyte comprises a non-aqueous solvent, lithium salt and an additive, wherein the non-aqueous solvent is a carboxylic ester compound which accounts for 1-40% by mass of the high-voltage electrolyte; the additive is any one or more of lithium bis(oxalate)borate (Li BOB), fluoroethylene carbonate (FEC) and ethylene glycol bis(propionitrile) ether. The high-voltage electrolyte contains carboxylic ester solvents capable of improving an electrode / electrolyte interface, and through optimized combination of the carboxylic ester solvents, Li BOB, FEC, ethylene glycol bis(propionitrile) ether and other various additives, the good cycle performance of a high-voltage battery can be ensured, meanwhile, the high-temperature storage performance of the high-voltage battery can be effectively improved, and gas generation of the battery under high-voltage high-temperature storage condition can be obviously inhibited.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

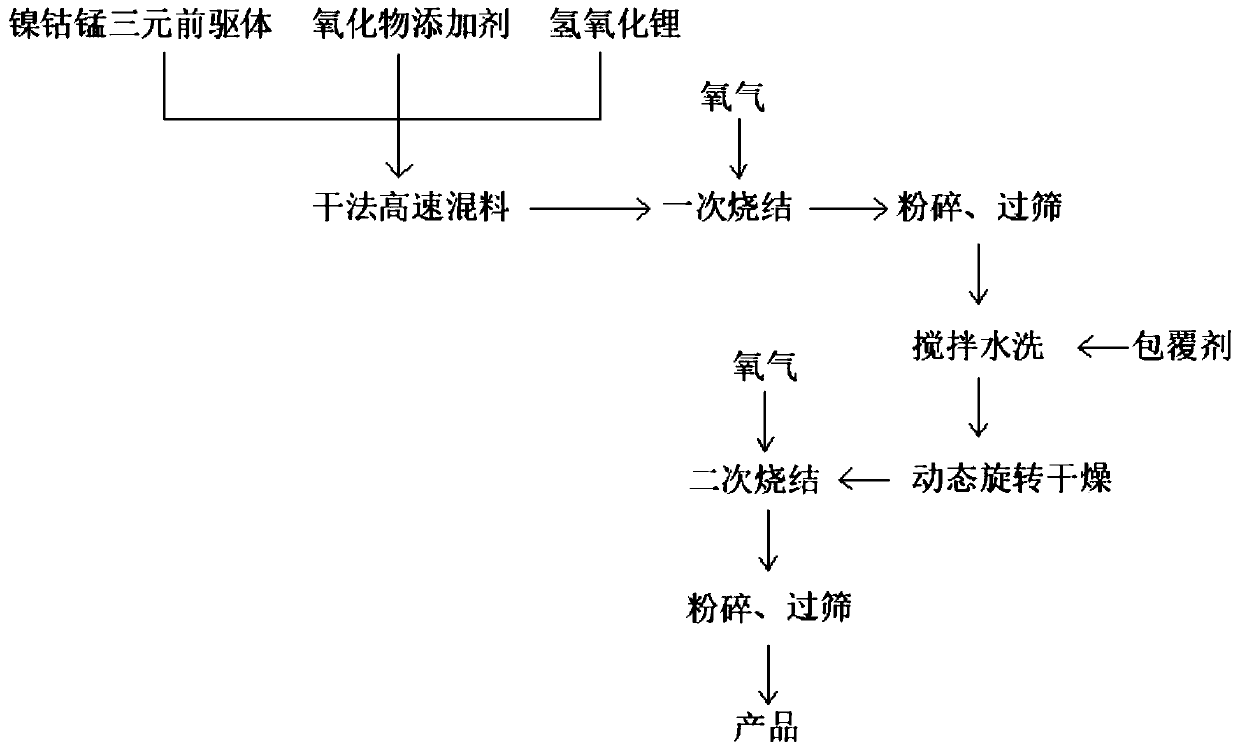

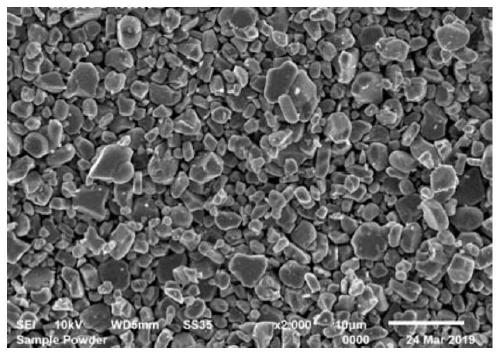

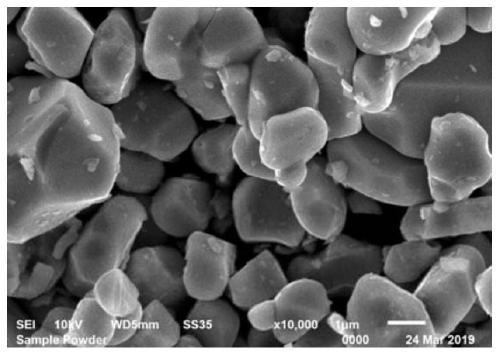

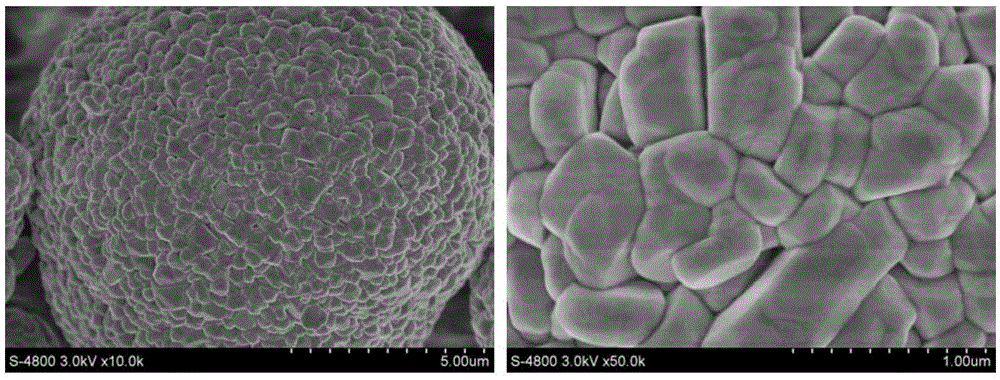

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

LiNiCoAlO2 composite cathode material and preparation method thereof, and lithium ion battery

InactiveCN103715423AReduce lithium impurity contentEasy to processAluminium compoundsCell electrodesOrganic acidComposite cathode

The invention relates to a LiNiCoAlO2 composite cathode material and a preparation method thereof, and a lithium ion battery. The composite cathode material is of a core-shell structure, wherein a core is LiNi1-x-yCoxAlyO2 subjected to washing treatment by using a mixed solution of alcohol and organic acids, x is greater than 0 and less than or equal to 0.2, and y is greater than 0 and less than or equal to 0.1; and a shell is a metal oxide layer. According to the invention, the composite cathode material is prepared by using a process combining an operation of washing a base material by using a mixed solution of alcohol and organic acids and an operation of carrying out spray drying on a material wrapped on the shell layer. The composite cathode material disclosed by the invention is low in lithium impurity content and high in high-temperature cycling and high-temperature storage performances.

Owner:BTR NEW MATERIAL GRP CO LTD

Nonaqueous electrolytic solution and nonaqueous electrolyte battery

ActiveUS20100035147A1Large capacityImprove storage characteristicsOrganic electrolyte cellsLi-accumulatorsDifluorophosphateHalogen

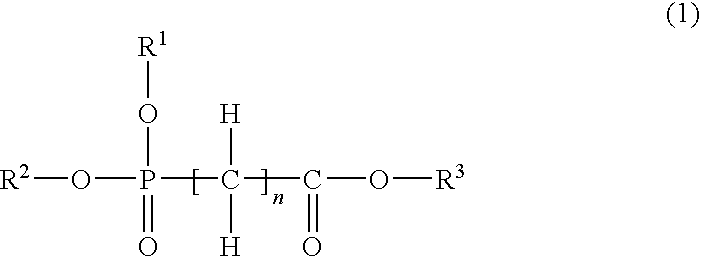

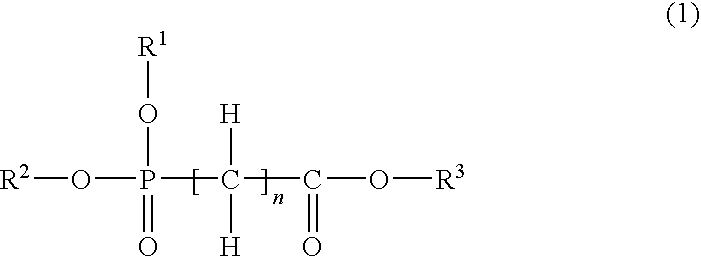

A nonaqueous electrolytic solution that can provide a battery that is low in gas generation, has a large capacity, and is excellent in storage characteristics and cycle characteristics contains an electrolyte and a nonaqueous solvent dissolving the electrolyte and further contains 0.001 vol % or more and less than 1 vol % of a compound represented by Formula (1) in the nonaqueous solvent. Alternatively, the nonaqueous electrolytic solution contains 0.001 vol % or more and less than 5 vol % of a compound represented by Formula (1) in the nonaqueous solvent and further contains at least one compound selected from the group consisting of cyclic carbonate compounds having carbon-carbon unsaturated bonds, cyclic carbonate compounds having fluorine atoms, monofluorophosphates, and difluorophosphates.In Formula (1), R1 to R3 each independently represent an alkyl group of 1 to 12 carbon atoms, which may be substituted by a halogen atom; and n represents an integer of 0 to 6.

Owner:MU IONIC SOLUTIONS CORP +1

Electrochemical cell including nitrogen-containing compound, battery including the cell, and methods of making and using same

ActiveUS20130059193A1Inhibit migrationImprove performancePrimary cell to battery groupingCell electrodesElectrochemical cellNitrogen

An electrochemical cell including at least one nitrogen-containing compound is disclosed. The at least one nitrogen-containing compound may form part of or be included in: an anode structure, a cathode structure, an electrolyte and / or a separator of the electrochemical cell. Also disclosed is a battery including the electrochemical cell.

Owner:SION POWER CORP

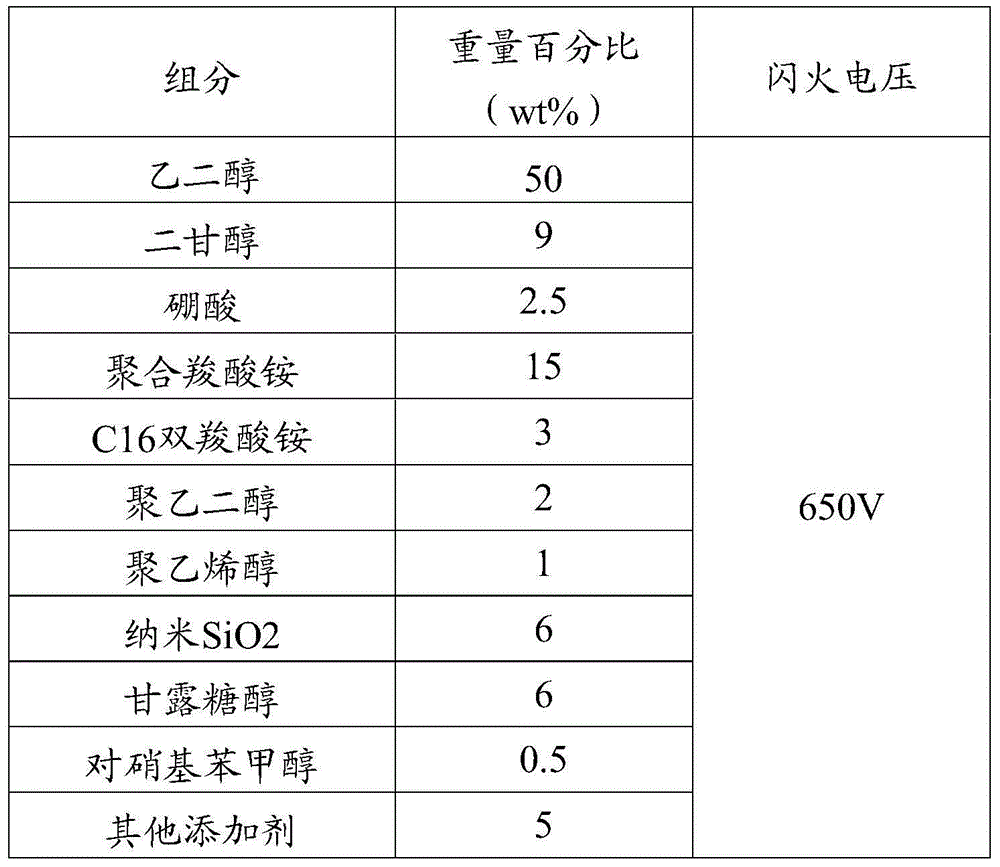

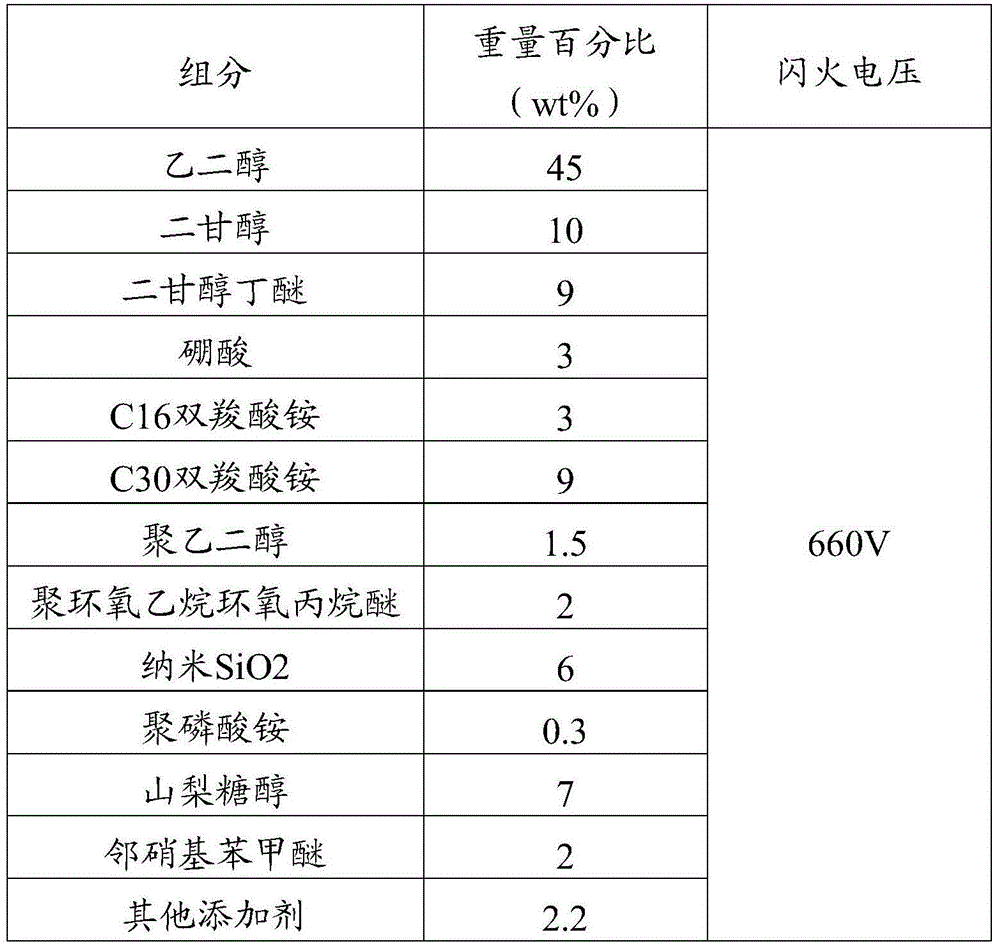

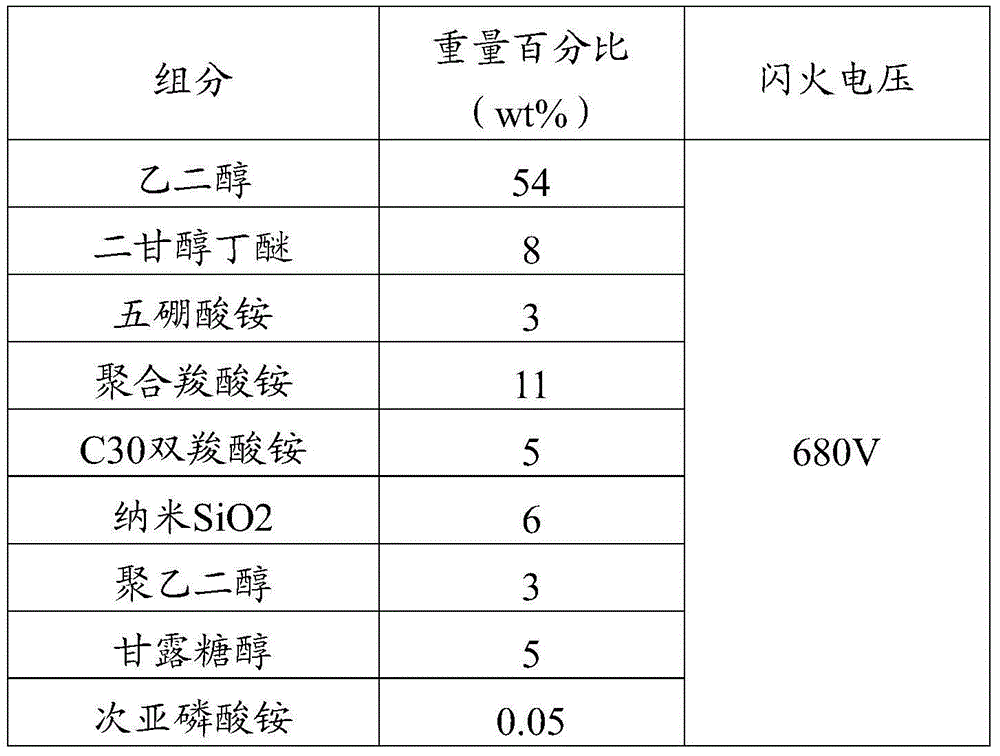

650V-700V extra-high-voltage aluminum electrolytic capacitor, working electrolyte and preparation method thereof

InactiveCN103915258AImprove high pressure resistanceImprove high temperature resistanceElectrolytic capacitorsHydrogenBreakdown phenomenon

The invention discloses working electrolyte of a 650V-700V extra-high-voltage aluminum electrolytic capacitor. The working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor comprises, by weight, 45-65% of primary solvents, 5-20.5% of secondary solvents, 10-20% of solutes, 8-25% of spark voltage improvers, 5-10% of stabilizers, 0.2-3% of hydrogen absorbents, and 2-5% of other additives. The invention further discloses a preparation method of the working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor and the 650V-700V extra-high-voltage aluminum electrolytic capacitor. According to the 650V-700V extra-high-voltage aluminum electrolytic capacitor, the working electrolyte and the preparation method of the working electrolyte, the spark voltage improvers and the stabilizers within the reasonable ranges are used, the high-voltage resistance and high-temperature resistance of the electrolyte are improved, and meanwhile the working electrolyte has low gas production performance. When the aluminum electrolytic capacitor with the electrolyte is subjected to a ripple current life test at 85 DEG C for 2000 hours, the aluminum electrolytic capacitor can resist the voltage of 650-700V and even higher voltage, and a breakdown phenomenon caused by unstable spark voltage of the electrolyte is avoided.

Owner:深圳市智胜新电子技术有限公司

Cathode material of lithium-nickel-cobalt-aluminum composite oxide, a method of fabricating the same and a lithium ion battery including the same

ActiveUS20150194662A1Excellent storage and cycling performanceReduce the presence of impuritiesAluminium compoundsElectrode thermal treatmentTemperature cyclingOrganic acid

The present invention relates to a cathode material of Lithium-Nickel-Cobalt-Aluminum composite oxide, a method of fabricating the same, and a lithium ion battery including the same. The composite cathode material has a core-shell structure, wherein the core portion is made of LiNi1-x-yCoxAlyO2 which is washed with an alcohol and organic acid-mixed solution, wherein 0<x≦0.2, 0<y≦0.1; the shell is metal oxide layer. In the present invention, the composite cathode material is fabricated by a combined method, wherein the base material is washed with an alcohol and organic acid-mixed solution and the shell layer material is coated by spray drying. The composite cathode material of the present invention has low content of lithium impurities and excellent high-temperature cycling and storage performance.

Owner:BTR NEW MATERIAL GRP CO LTD

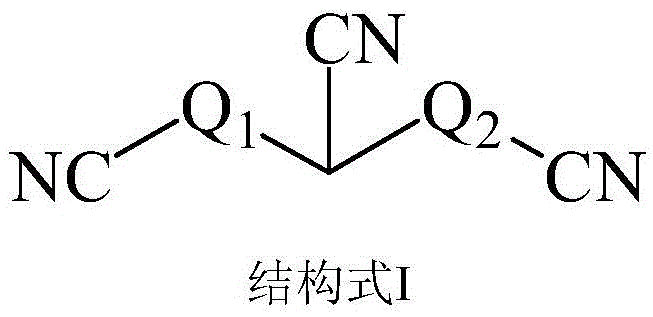

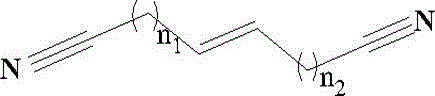

Electrolyte for lithium ion secondary battery and lithium ion secondary battery comprising the same

InactiveUS20140356734A1Avoid reactionImprove polymerizationCell electrodesOrganic electrolyte cellsLithiumOrganic solvent

An electrolyte for a lithium ion secondary battery and a lithium ion secondary battery including the same are provide. The electrolyte includes a non-aqueous organic solvent, a lithium salt which is dissolved in the non-aqueous solvent and a additive shown as general formula I. Wherein R1, R2 and R3 are each independently selected from H, alkyl group including from 1 to 12 carbon atoms, cycloalkyl group including from 3 to 8 carbon atoms and aromatic group including 6 to 12 carbon atoms; n represents an integer from 0 to 7. This additive in electrolyte can passivate cathode and anode effectively, restrain their reaction with electrolyte, reduce gases generation and battery's expansion in high temperature surrounding, provide as safety lithium ion secondary batteries.

Owner:NINGDE AMPEREX TECH

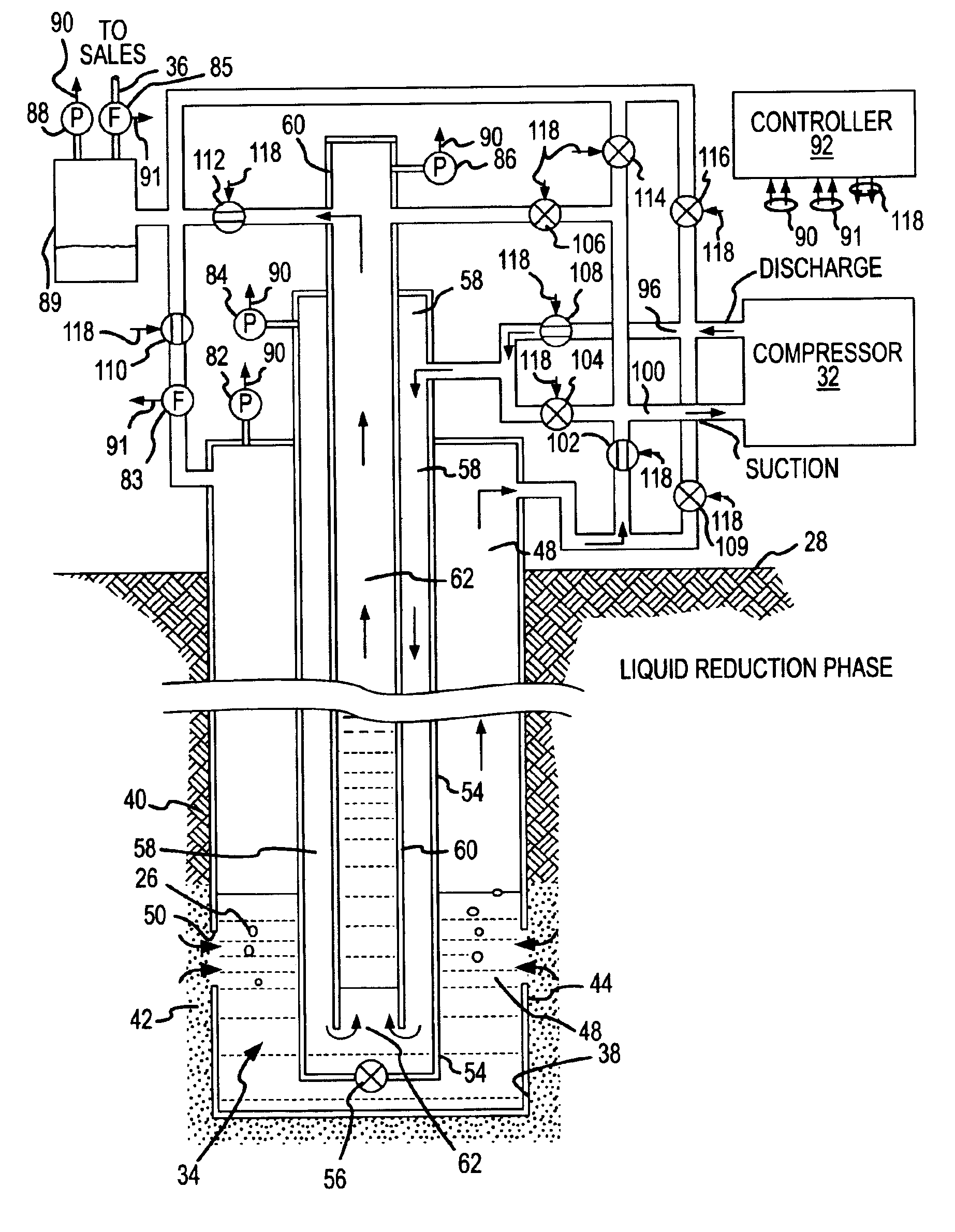

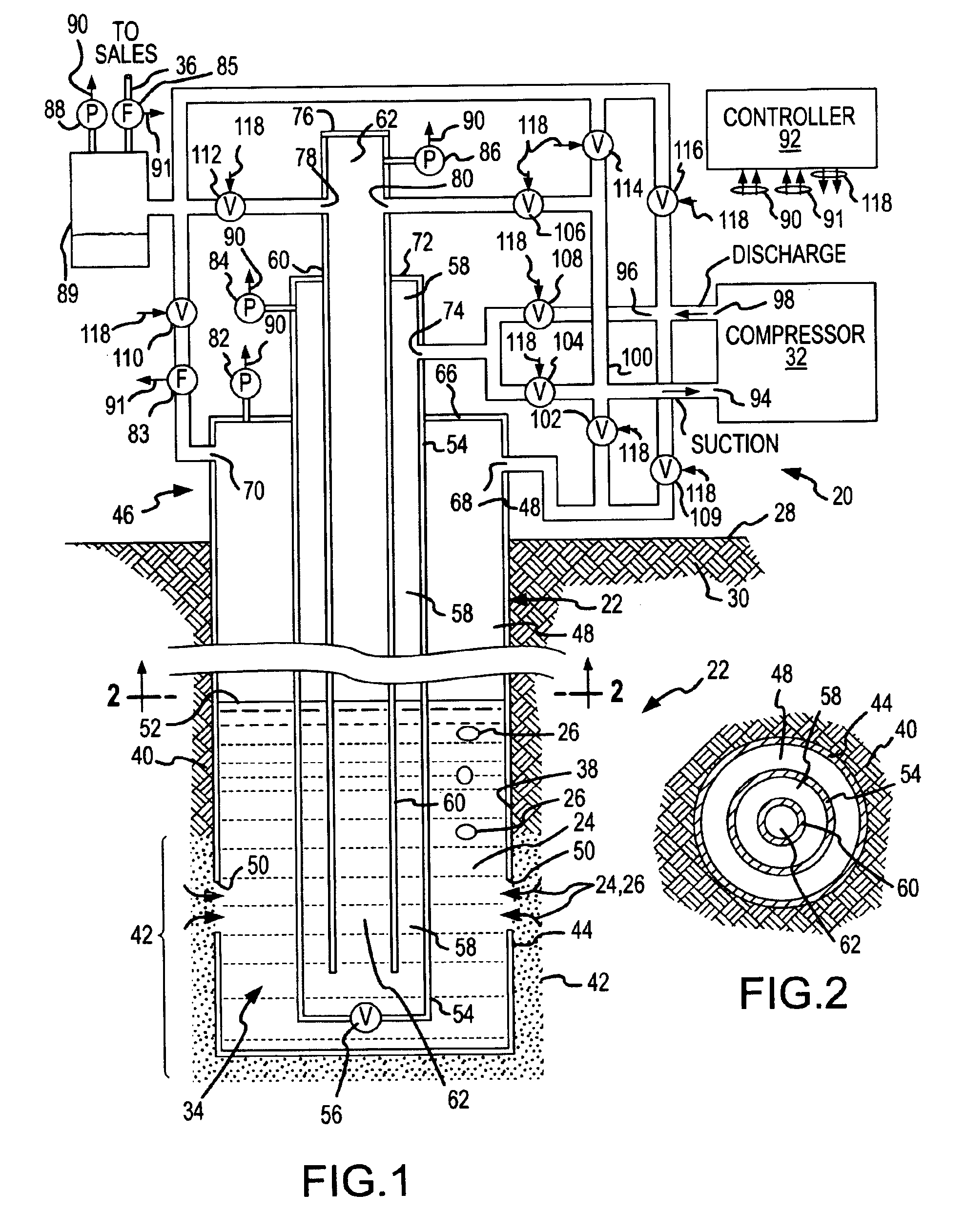

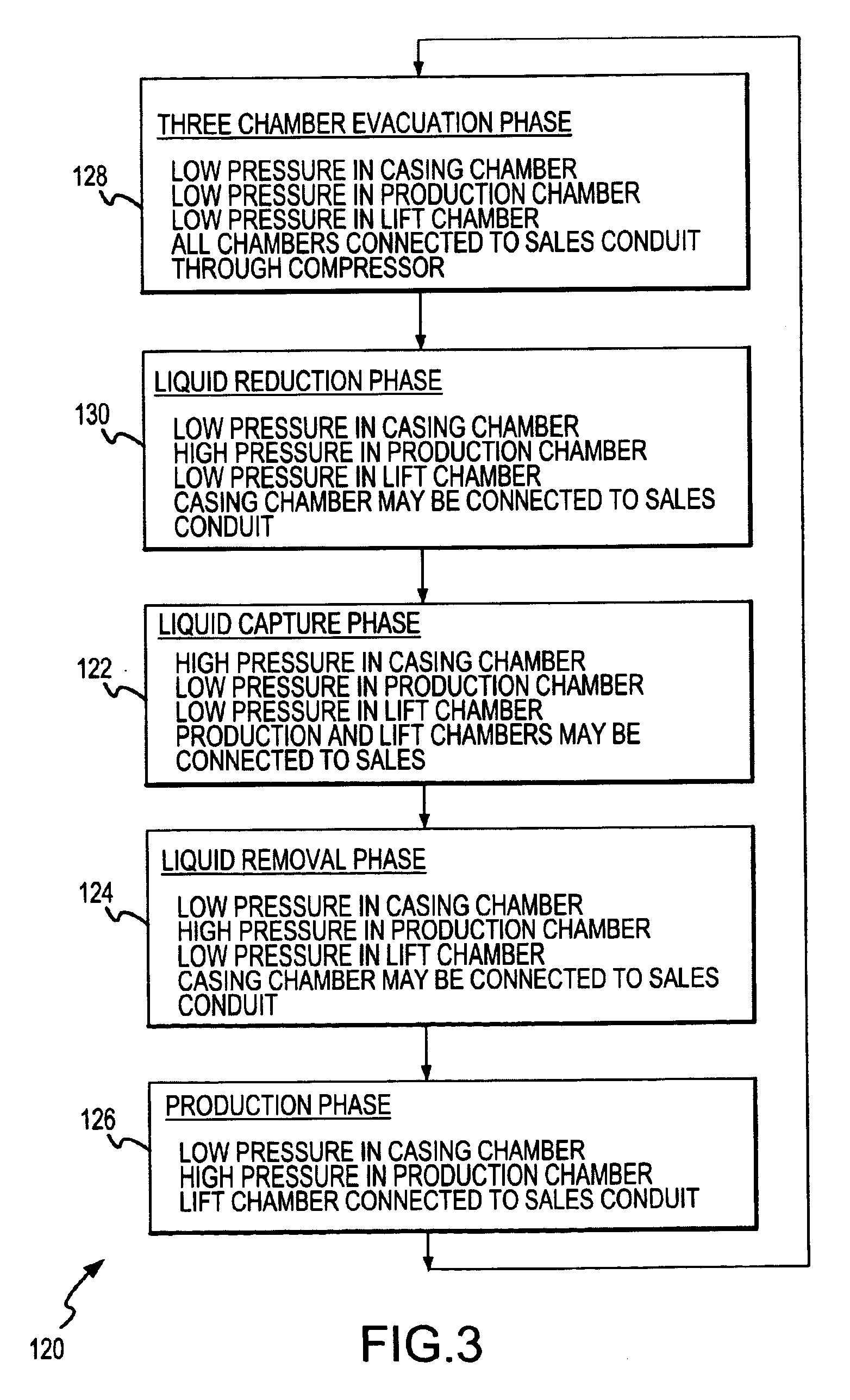

Gas recovery apparatus, method and cycle having a three chamber evacuation phase and two liquid extraction phases for improved natural gas production

InactiveUS7100695B2Reduce the amount requiredLess timeFluid removalSealing/packingProduction rateProduct gas

Natural gas produced from a well by executing a multiple-phase gas recovery cycle which includes a phase during which a relatively lower evacuation pressure is applied within three chambers in the well to assist in accumulating liquids at a well bottom, followed by a liquid reduction phase which clears the liquid from two of the chambers while leaving the liquid in the third chamber. The remaining liquid is thereafter lifted in subsequent liquid capture and liquid removal phases. The liquid reduction phase clears the fluid from the well more effectively with less interruption in the production of gas from the well while maintaining the full gas productivity of the well.

Owner:FORESTAR PETROLEUM

Method for processing ternary material by being clad with lithium ferric manganese phosphate

InactiveCN105406069AGood coating consistencyImprove consistencyCell electrodesSecondary cellsManganeseSlurry

The invention relates to a method for processing a ternary material by being clad with lithium ferric manganese phosphate. The invention belongs to the technical field of a cathode material of lithium ion batteries. The method for processing the ternary material by being clad with the lithium the ferric manganese phosphate comprises the steps of 1, preparation of LFMP precursor slurry: respectively weighing iron, manganese, lithium and phosphorus sources in proportion required by 0.1-100g LFMP, weighing 0-50g ascorbic acid, and adding a dispersion solvent, wherein the solid content is 10%-80%; 2, mixture of materials: weighing 100g ternary material with the constitute of Li(z)Ni(1-x-y)Co(x)Mn(y)O(2), or the mixture of two or more constitutes with the above proportion, adding the slurry, mixing the slurry and the mixture, and carrying out vacuum drying; 3, preparation of the ternary material / lithium ferric manganese phosphate composite cathode material: putting the materials into an argon protective atmosphere sintering surface, keeping warm at the temperature of 250-400 DEG C for 2-6h, then heating to 500-700 DEG C and keeping for 6-16h, cooling along with the furnace, and sieving. The method provided by the invention has the advantages of being simple in technology, convenient to operate, accordant in material performance, small in influence on cell capacity density, and being capable of improving safety performance of the ternary material.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

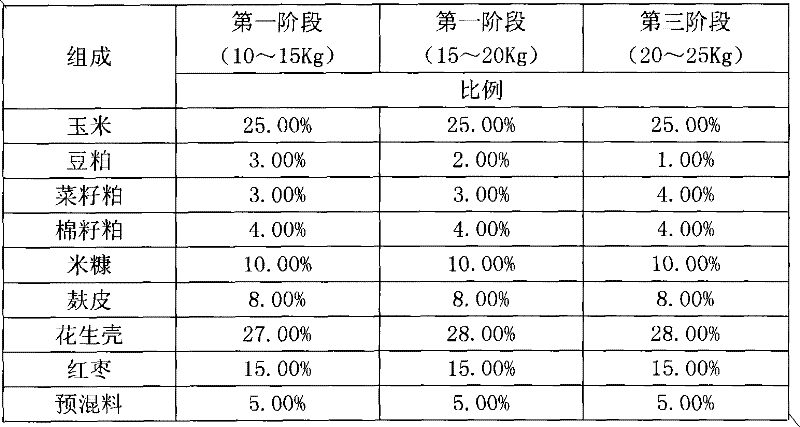

Lamb fattening complete pellet feed

ActiveCN101744107ASimple processing technologyLow costFood processingAnimal feeding stuffAnimal ForagingAnimal science

The invention provides lamb fattening complete pellet feed, which belongs to the field of feed processing in animal husbandry and applies to the intensive complete-barn-feeding production of mutton sheep. According to the nutritional need of lambs in different fattening periods, three types of complete pellet feed are prepared and processed through three formulations in order to satisfy the balanced nutrition supply for weight increase and other aspects except water drinking in a 10 to 15 kg stage, a 15 to 20 kg stage and a 20 to 25 kg stage in a fattening period respectively, so that the factory production of fattening sheep without depending on the conditions of forage grass resources is realized. Due to abundant raw material sources, simple processing technique and low production cost, the pellet feed is beneficial to large-scale commercial production. After application, the pellet feed can ensures that the production of fattening sheep is not restricted to the conditions of natural feed and forage grass resources, and production scale can be adjusted in time according to market demand. Meanwhile, as only one type of pellet geed is used in one fattening stage, more simplified and scientific production process, reliable fattening effect, high production efficiency and low comprehensive cost are ensured.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

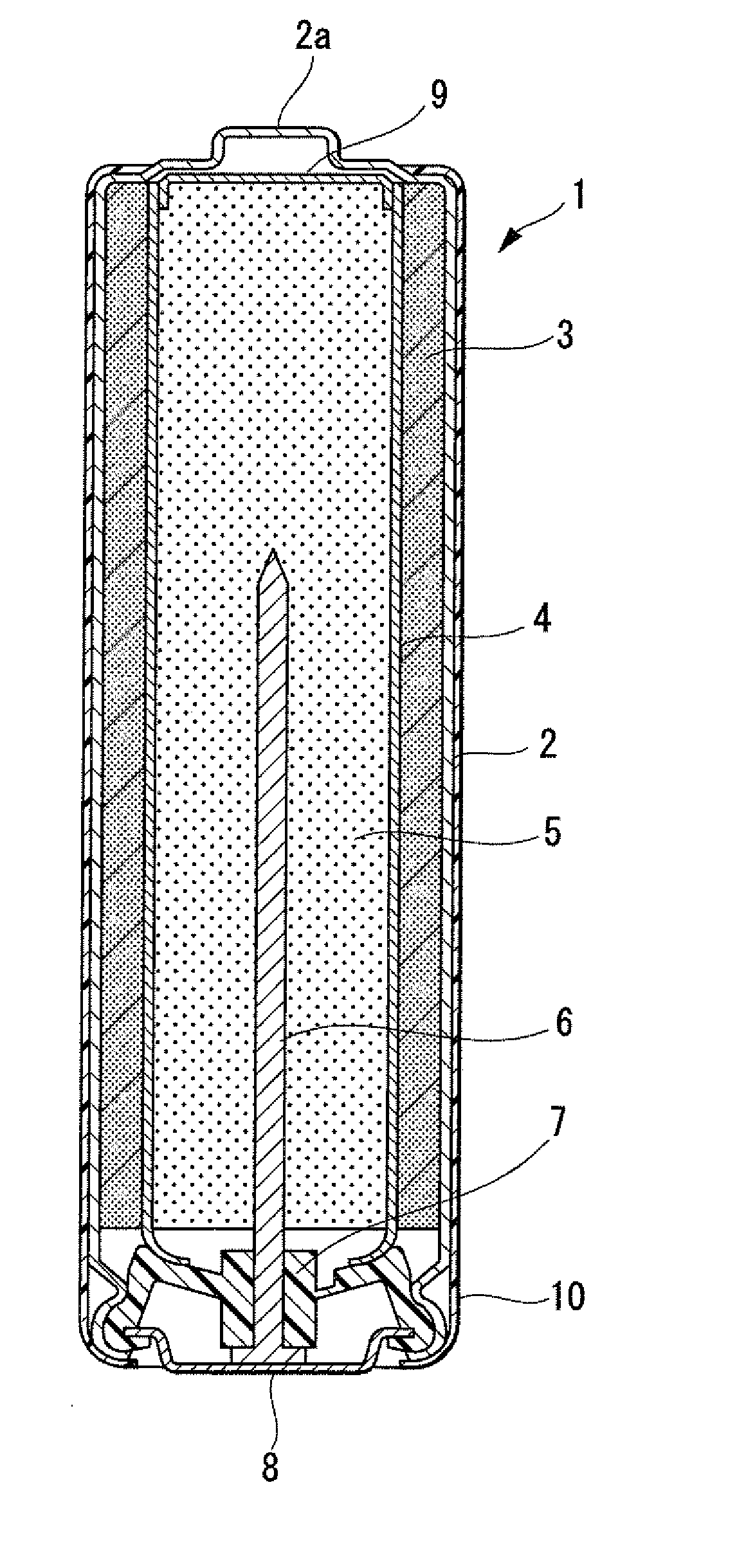

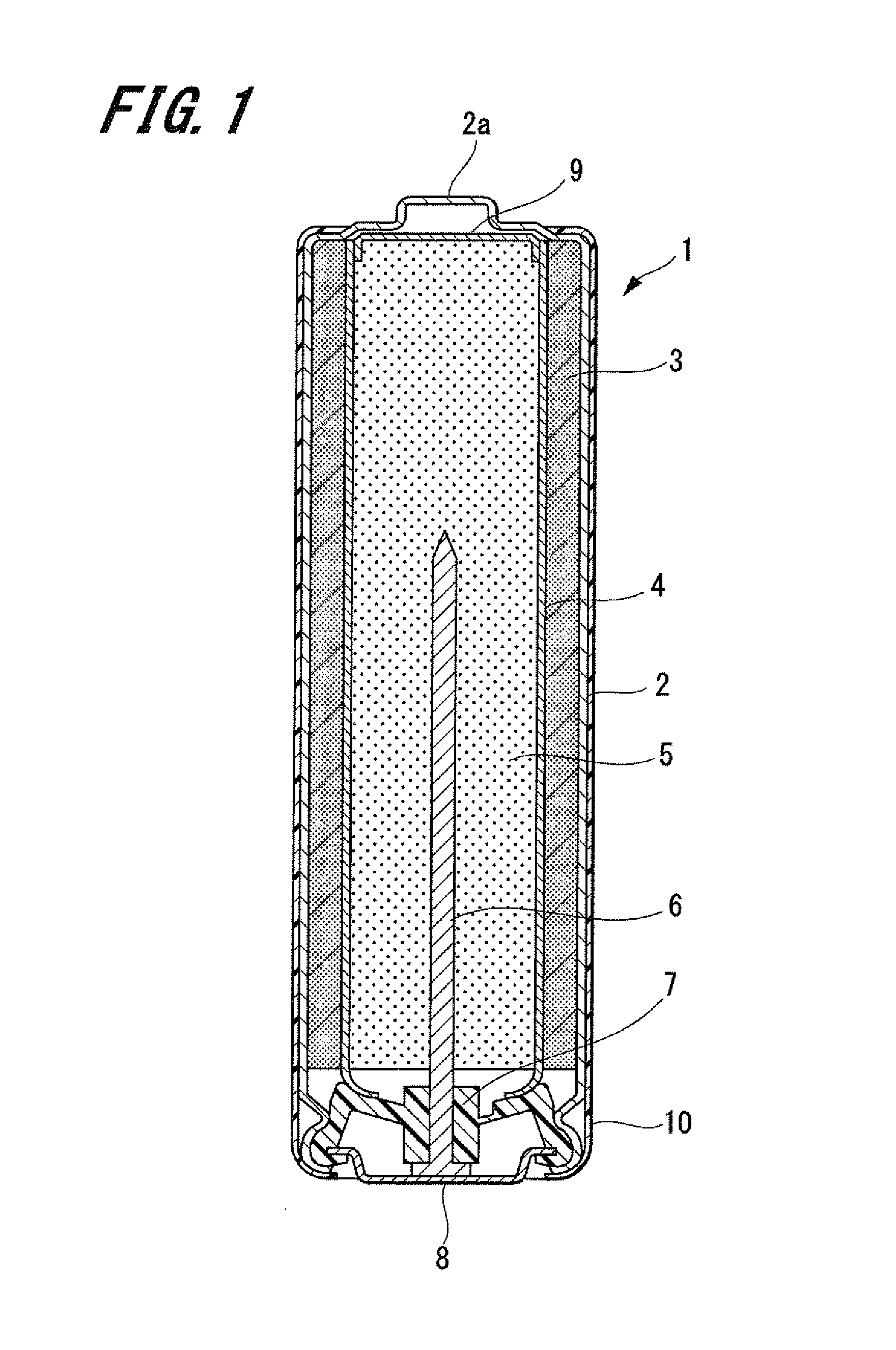

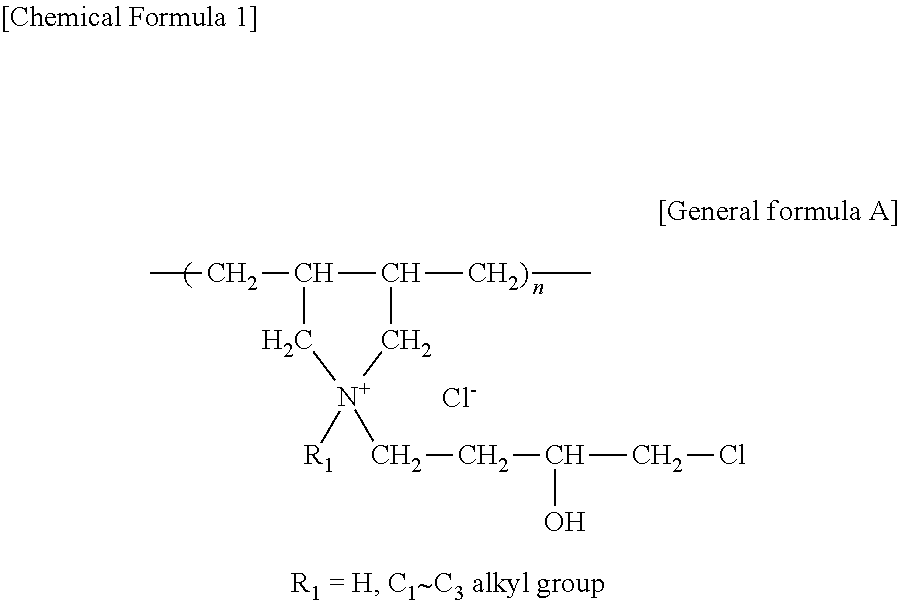

Separator for alkaline battery, and alkaline battery

InactiveUS20130149614A1Reduce resistanceReduce contentNon-fibrous pulp additionNatural cellulose pulp/paperInternal resistanceCellulose fiber

An object of the present invention is to provide a separator for alkaline battery and an alkaline battery capable of reducing the internal resistance of the alkaline battery so as to improve the heavy load discharge performance. The separator for alkaline battery is a separator for separating a positive electrode active material and a negative electrode active material of the alkaline battery from each other, the separator containing 40% or more by weight of cellulose fibers, and 0.05% to 0.5% by weight of polyamine-epichlorohydrin resin in terms of resin solid content. The alkaline battery has its positive electrode active material and negative electrode active material separated from each other by the separator.

Owner:NIPPON KODOSHI

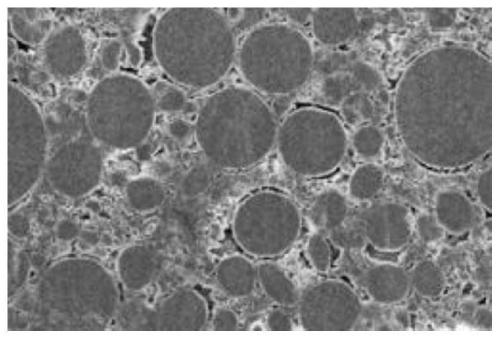

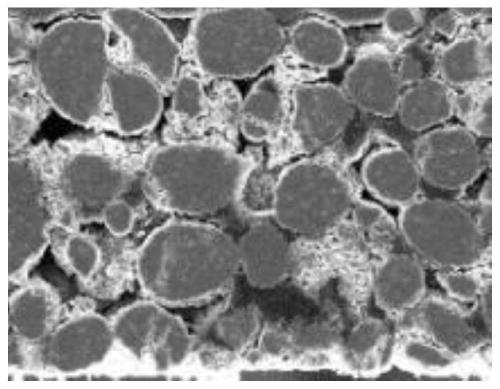

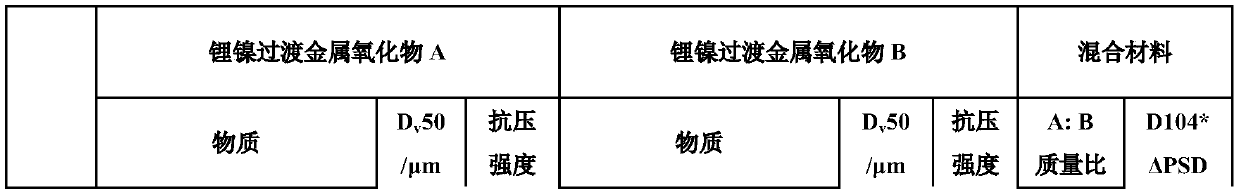

High-compaction-density positive electrode material and electrochemical energy storage device

ActiveCN111384372AIncrease energy densityImprove powder compaction densitySecondary cellsPositive electrodesElectrical batterySingle crystal

The invention relates to the technical field of batteries. The invention relates to a cathode material, in particular to a high-compaction-density cathode material and an electrochemical energy storage device. The positive electrode material comprises a lithium-nickel transition metal oxide A and a lithium-nickel transition metal oxide B. The lithium-nickel transition metal oxide A is secondary particles, and the chemical formula of the lithium-nickel transition metal oxide A is shown as a formula I: Lia1(Nib1Coc1Mnd1)x1M1-x1O2-e1Xe1, the lithium-nickel transition metal oxide B is of a singlecrystal structure or a single crystal-like structure, and the chemical formula of the lithium-nickel transition metal oxide B is shown as a formula II: Lia2(Nib2Coc2Mnd2)x2M'1-x2O2-e2X'e2 (II), and the grain size D104 of the positive electrode material and the particle size distribution change rate [delta] PSD of the positive electrode material meet the condition that D104 * [delta]PSD is more than or equal to 50 nm and less than or equal to 600 nm. The positive electrode material comprises the large-particle lithium-nickel transition metal oxide A and the small-particle lithium-nickel transition metal oxide B, so that the energy density of the battery is improved; by regulating and controlling the crystallinity and particle size distribution of the mixed positive electrode material, the problem of particle breakage of high-nickel powder in the cold pressing and circulating process is solved, the powder compaction density of the high-nickel active material is improved, and it is guaranteed that the gas production rate is low and the circulating performance is excellent.

Owner:CONTEMPORARY AMPEREX TECH CO

Aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material, preparation method and application thereof

InactiveCN109585839AImprove cycle performanceImprove securitySecondary cellsPositive electrodesManganeseSide reaction

The invention discloses an aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material, a preparation method and application thereof. The preparation method of the material comprises the following steps: (1) dripping aluminum nitrate into ammonium hydroxide, reacting until precipitates are not increased any longer, adding citric acid and nitric acid, and preparing an AlOOH sol; (2) mixing a nickel-cobalt-manganese precursor and a lithium source uniformly, and sintering to obtain a nickel-cobalt-manganese ternary material; and (3) putting the nickel-cobalt-manganese ternary material into the AlOOH sol, carrying out calcinations after drying, and finally obtaining the aluminum oxide coated nickel-cobalt-manganese ternary positive electrode material. An aluminum oxide coating layer is coated on the surface of the nickel-cobalt-manganese ternary material, so that the amount of residual alkali on the surface of the material is reduced, a side reaction between the material and an electrolyte is inhibited effectively, and the safety performance of a battery is improved; moreover, in the battery prepared from the material, an Li-Al-Co-O protective layer is formed by the aluminum oxide coating layer during working on the surface of the material, and the protective layer can resist the corrosion of HF on active materials, so that the cycle performance of the batteryis improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

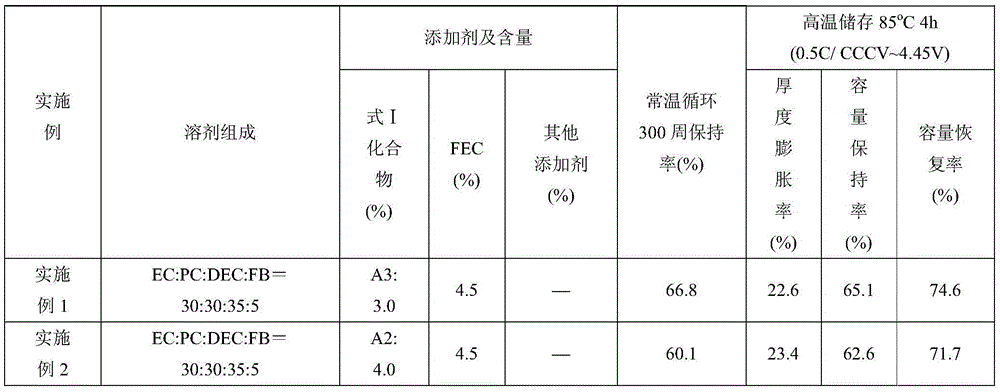

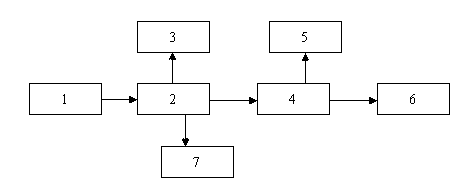

Non-aqueous electrolyte solution for high-voltage lithium ion secondary battery and high-voltage lithium ion secondary battery

InactiveCN105680088AAvoid decompositionReduce gas productionSecondary cellsElectrolytesPhysical chemistrySolvent

The invention discloses a non-aqueous electrolyte solution for a high-voltage lithium ion secondary battery. The non-aqueous electrolyte solution comprises a non-aqueous solvent, a lithium salt dissolved in the non-aqueous solvent and additives, wherein the non-aqueous solvent comprises 1-15mass% of fluorobenzene in the electrolyte; and the additives comprise fluoroethylene carbonate (FEC) and a tri-nitrile material. Due to the non-aqueous electrolyte solution for the high-voltage lithium ion secondary battery, the high-voltage lithium ion secondary battery can obtain excellent cycling performance and high-temperature performance.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

Oil-containing sludge treatment method and process flow

ActiveCN103130390AReduce gas productionLow freezing pointSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeTreatment system

The invention belongs to an oil-containing sludge treatment method, and particularly relates to a method and process flow for treating oil-containing sludge having an oil content of more than 10%. The method is characterized by comprising the following steps: for oil-containing sludge having a water content of more than 70%, adding pH regulator, and regulating the pH value to 7-8; adding inorganic flocculant and organic flocculant, and performing dehydration treatment; after dehydration, feeding the oil-containing sludge into a pyrolysis device, performing low-temperature pyrolysis, and feeding gas generated by the pyrolysis into a gas recovery device for recycling; performing oil-water separation on the generated oil and water through an oil-water separation device, feeding the separated oil into an oil storage tank for recycling, and feeding the separated water into a sewage treatment device or an oilfield water treatment system; and adding igniter, combustion improver, binder and desulfurizer into the remaining sludge after the pyrolysis, feeding into a fuel preparation device, and preparing into fuel for utilization. The invention solves the technical problem on oil-containing sludge treatment for oilfield and refinery enterprises, and achieves the purposes of effectively recycling resources, saving energy, reducing emission and protecting environment.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

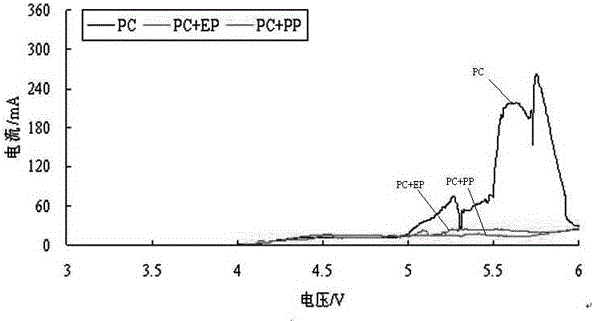

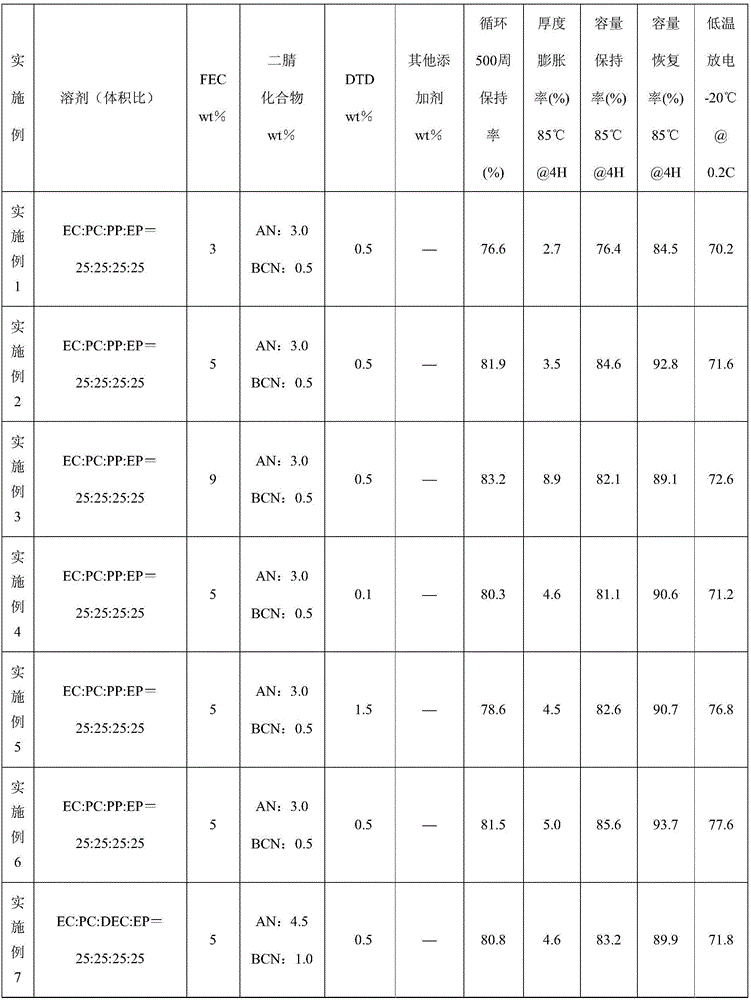

PC (Propylene Carbonate)-based high-voltage electrolyte and lithium ion battery

InactiveCN106159330APromote circulationAvoid co-insertionSecondary cellsHigh temperature storageElectrical battery

The invention provides PC (Propylene Carbonate)-based high-voltage electrolyte. The PC-based high-voltage electrolyte comprises a non-aqueous solvent, and a lithium salt and an additive which are dissolved into the non-aqueous solvent; the non-aqueous solvent comprises propylene carbonate (PC) and linear carboxylate; the mass percent content of the propylene carbonate (PC) in the electrolyte is 15%-50%; the additive comprises fluoroethylene carbonate, ethylene sulfate and a dinitrile compound. A solvent system and the additive are optimally combined and used to generate a cooperative effect and are used for a lithium ion battery, so that good cycle life, low-temperature discharging properties and high-temperature storage properties of the battery can still be kept under high voltage.

Owner:GUANGZHOU TINCI MATERIALS TECH

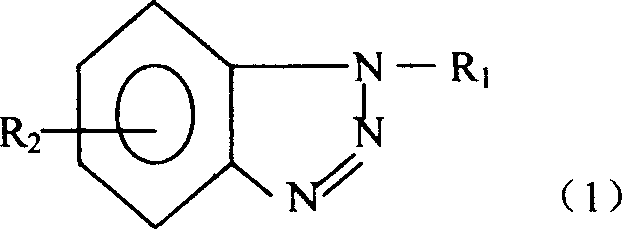

Cell liquor and lithium ion battery therefor

InactiveCN1819324AReduce corrosionReduce gas productionOrganic electrolyte cellsSecondary cellsCopper foilLithium-ion battery

The invention consists of benzotriazole compounds and an electrode comprising at least one of vinyl ethylene carbonate, vinylene carbonate, cyclic sulfonic acid, and cyclic sulfite. It is for use in forming a thin and dens passive film to reduce the gas production rate at process of cell forming, and to decrease corrosion of copper foil and aluminum foil of current collector, and to reduce the impedance of battery.

Owner:ZHEJIANG FIRE RETARDENT LITHIUM ELECTRIC MATERIALS

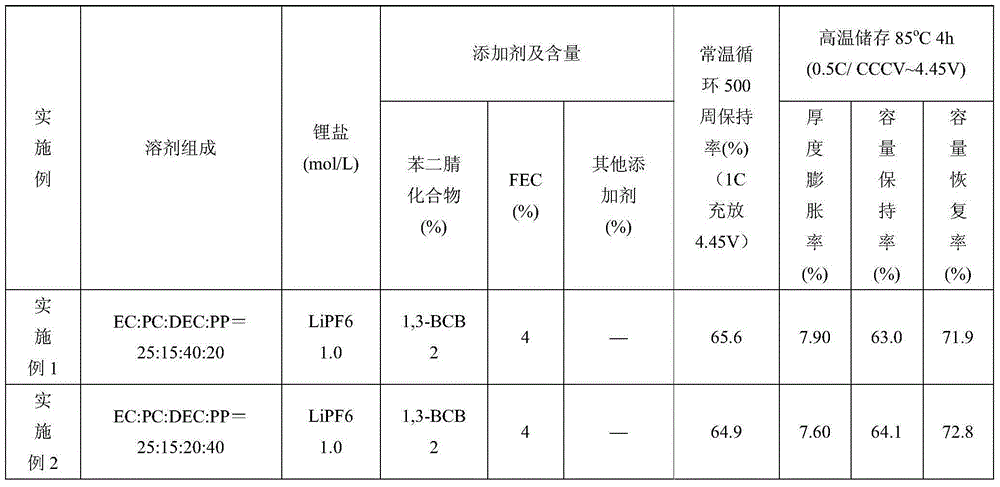

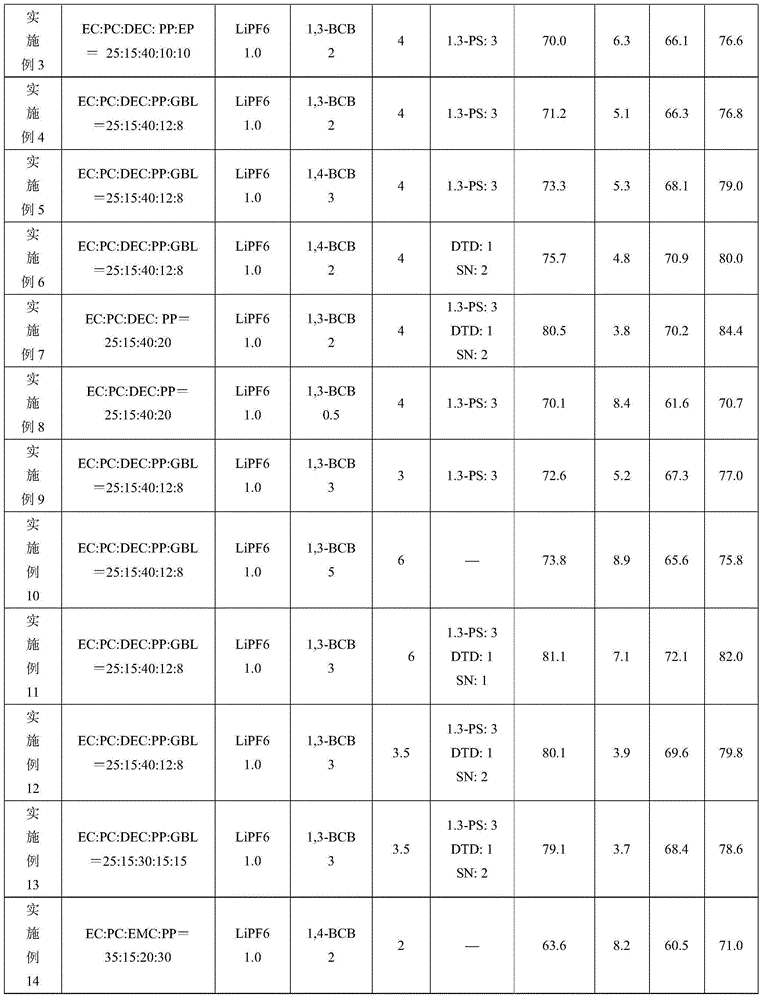

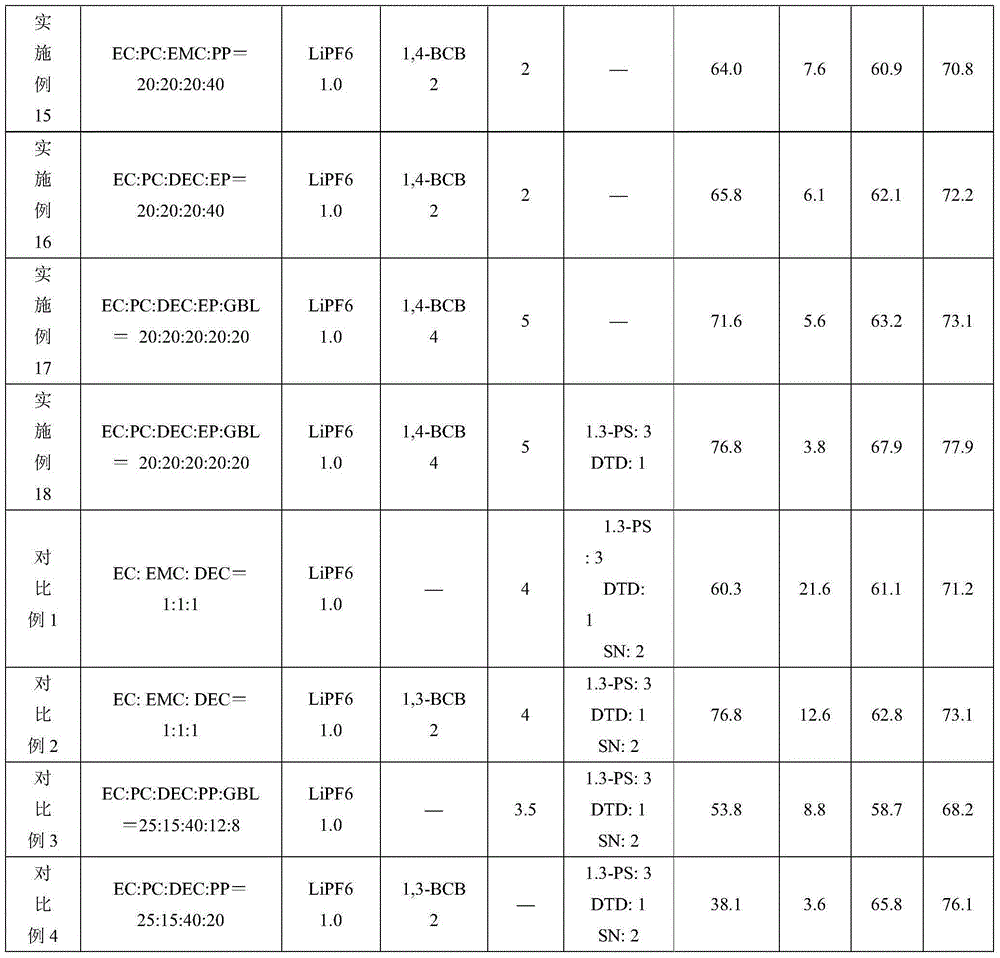

Electrolyte containing benzene dinitrile and lithium ion battery applying electrolyte

ActiveCN105140562AAvoid decompositionImprove high temperature storage performanceSecondary cellsOrganic electrolytesOrtho positionDecomposition

The invention discloses an electrolyte containing benzene dinitrile and a lithium ion battery applying the electrolyte. The electrolyte containing the benzene dinitrile comprises a non-aqueous solvent, a lithium salt and an additive, wherein the non-aqueous solvent is a carboxylic acid ester compound with a mass percentage of 1-40% in the electrolyte containing the benzene dinitrile; the additive comprises fluoroethylene carbonate (FEC) and at least one of benzene dinitrile compounds having a structure shown in a formula I, the formula I is shown in the specification, and n is an integer from 1 to 3; in 0.01-5% of the benzene dinitrile compound in the additive, double nitrites containing carbons of 1 to 3 are connected at ortho positions, meta positions and para positions of a benzene ring, an acetonitrile radical group (-C-CN) on the benzene ring can be complexed with metal ions such as Co<3+> in a positive active material, thus, electrolyte decomposition is reduced, the dissolution of the metal ions is suppressed, a positive pole is protected, and the high-temperature performance of the battery is improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

High voltage electrolyte and lithium ion battery using the electrolyte

InactiveCN105529498APromote circulationHigh decomposition voltageOrganic chemistrySecondary cellsHigh temperature storageAluminium-ion battery

The invention discloses a high voltage electrolyte and a lithium ion battery using the electrolyte. The high voltage electrolyte comprises non-aqueous solvents, a lithium salt and additives; the non-aqueous organic solvents are carbonic ester compounds and carboxylic ester compounds with contents of 1-40%; the additives are fluoroethylene carbonate (FEC) and alkene dinitrile compound. Carboxylic ester solvents for improving electrode / electrolyte interfaces are contained in the high voltage electrolyte. The high voltage battery is ensured to obtain excellent cycle performance through optimized combination of various additives such as fluoroethylene carbonate and alkene dinitrile; meanwhile, the high temperature storage performance of the high voltage battery is effectively improved; and the battery is clearly restrained from generating gas in high voltage and high temperature storage.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

Lithium sulfur electrochemical cell including insoluble nitrogen-containing compound

ActiveUS8735002B2Inhibit formation of and migrationImprove performanceSolid electrolyte cellsLi-accumulatorsNitrogenLithium sulfur

An electrochemical cell including at least one nitrogen-containing compound is disclosed. The at least one nitrogen-containing compound may form part of or be included in: an anode structure, a cathode structure, an electrolyte and / or a separator of the electrochemical cell. Also disclosed is a battery including the electrochemical cell.

Owner:SION POWER CORP

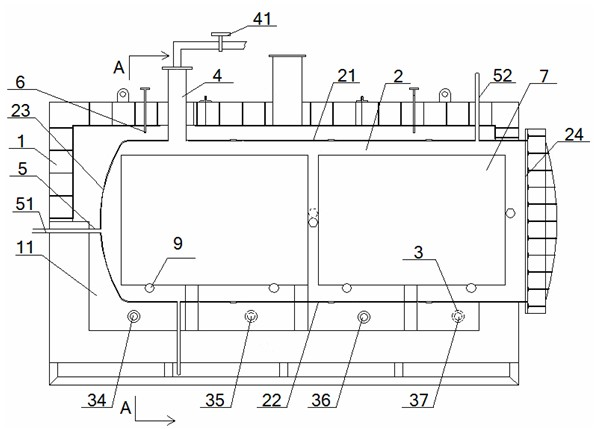

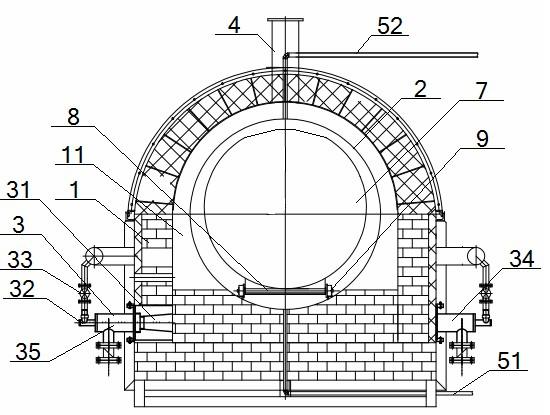

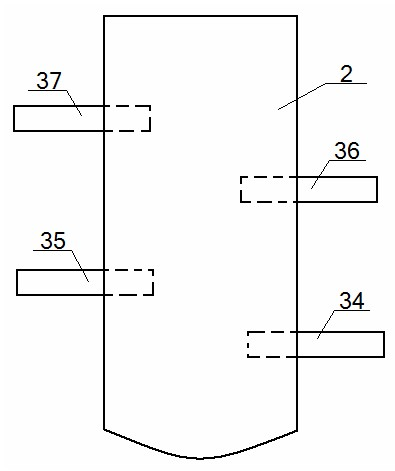

Efficient selectable pyrolysis system and using method thereof

ActiveCN102634358AGood value for moneyImprove adjustabilityBiofuelsSpecial form destructive distillationNitrogenProcess engineering

The invention discloses an efficient selectable pyrolysis system and a using method thereof, wherein the efficient selectable pyrolysis system comprises a furnace body, a dry distillation kettle, gas nozzles and a cooling device, wherein a furnace chamber in the furnace body is internally provided with the horizontally-arranged dry distillation kettle, wherein the dry distillation kettle comprises an upper side part, a lower side part, a kettle top and a kettle bottom; the part on the upper side part close to the kettle top is communicated with an exhaust pipe; the other end of the exhaust pipe is connected with a diffusion valve; the part on the furnace part close to the exhaust pipe is provided with a temperature meter communicated with the furnace chamber; the lower part of the lower side part is communicated with gas outlets of four staggered gas nozzles; the gas outlets of the gas nozzles are connected with a control valve; the cooling device comprises a nitrogen intake pipe and a nitrogen exhaust pipe, wherein the nitrogen intake pipe is communicated with the kettle top; the nitrogen exhaust pipe is communicated with the upper side part; and when the efficient selectable pyrolysis system is used, if carbon production is emphasized the heating is finished to pyrolysis carbonization stage, and if biomass gas production is emphasized, the heating is finished to the forging stage. The design not only has good adjustability, high cost performance and high heating efficiency, but also the finished product carbon has good quality and high production efficiency.

Owner:武汉天颖环境工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com