Non-aqueous electrolyte solution for high-voltage lithium ion secondary battery and high-voltage lithium ion secondary battery

A non-aqueous electrolyte, lithium-ion battery technology, applied in secondary batteries, electrolytes, circuits, etc., can solve the problem that battery performance needs to be further improved, and achieve excellent cycle performance and high temperature performance, high decomposition voltage and oxidation resistance, The effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

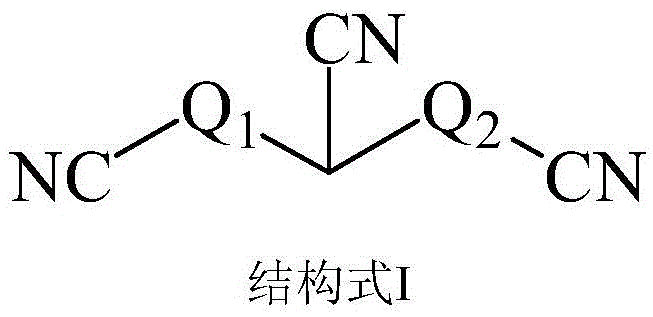

Method used

Image

Examples

Embodiment 1

[0037] 1. For the preparation method of the high-voltage lithium-ion battery in this embodiment, the coating area density is determined according to the capacity design of the battery (454261PL: 1640mAh) and the capacity of the positive and negative electrode materials. The positive electrode active material was purchased from Hunan Shanshan high-voltage lithium cobalt oxide material; the negative electrode active material was purchased from Jiangxi Zichen Technology. The positive electrode preparation steps, negative electrode preparation steps, electrolyte preparation steps, diaphragm preparation steps and battery assembly steps are described as follows;

[0038] The preparation step of the positive electrode is: mix the high-voltage positive electrode active material lithium cobaltate, conductive carbon black and binder polyvinylidene fluoride at a mass ratio of 96.8:2.0:1.2, and disperse them in N-methyl-2-pyrrolidone , to obtain the positive electrode slurry, the positive...

Embodiment 2~10

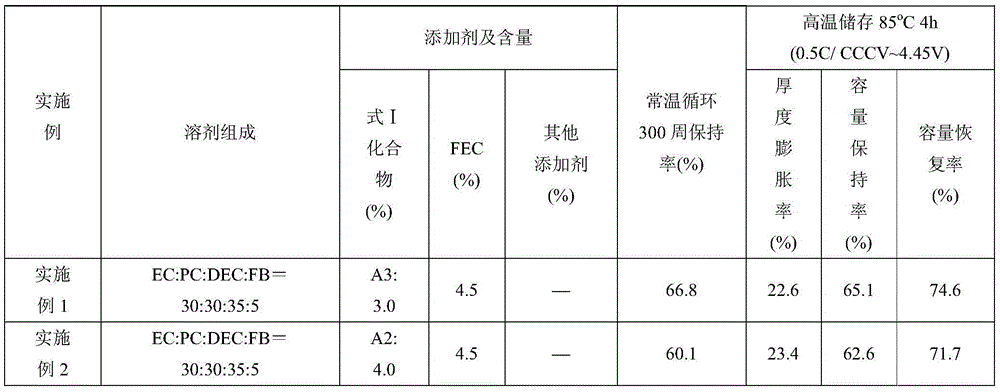

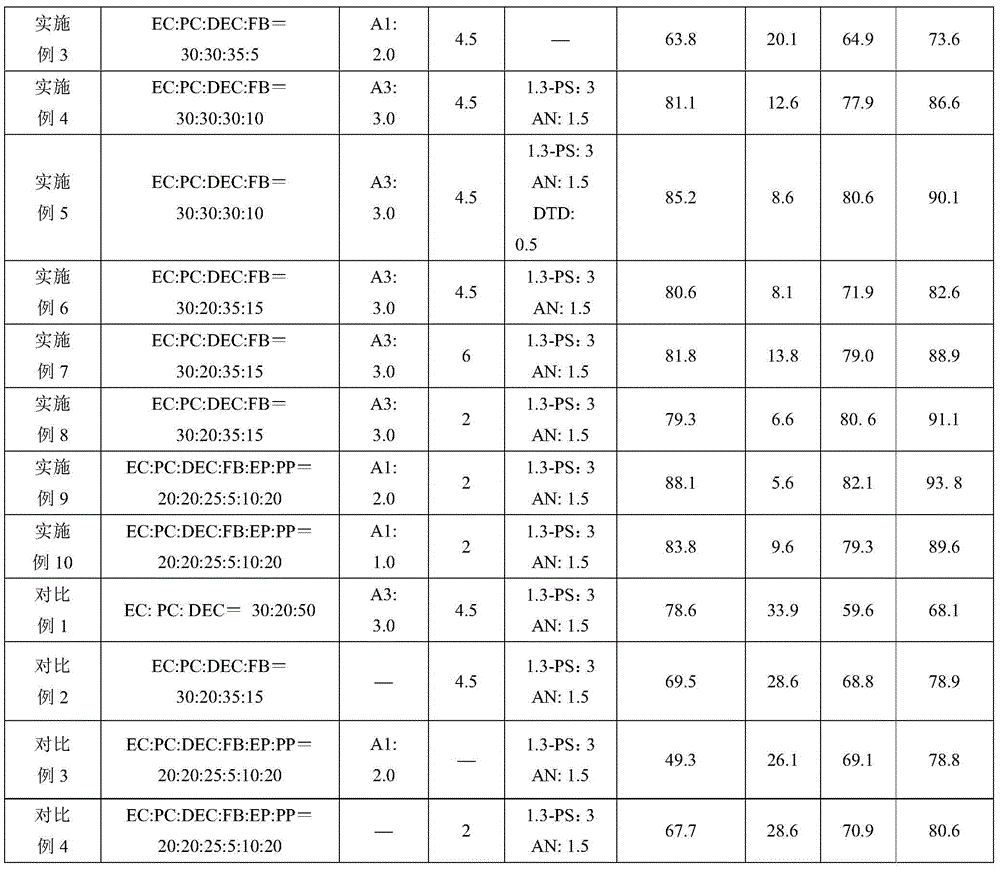

[0050] Examples 2-10 and Comparative Examples 1-4 are the same as Example 1 except that the composition of solvent in the electrolyte, the composition and content of additives (based on the total weight of the electrolyte) are added as shown in Table 1. Table 1 shows the content of each component of the electrolyte additive and the battery performance test results. In the table, PP is propyl propionate, FB is fluorobenzene, EP is ethyl propionate, DTD is vinyl sulfate, 1,3-PS is 1,3-propane sultone, and SN is succinonitrile. A1 is 1,3,5 pentanetricarbonitrile (4379-04-8), A2 is 1,2,3 propanetricarbonitrile (62872-44-0), A3 is 1,3,6 hexanetricarbonitrile (1772- 25-4).

[0051] Table 1. Contents of each component of electrolyte additives and battery performance test results

[0052]

[0053]

[0054] Comparing Example 6 with Comparative Example 1 and Comparative Example 2, it can be seen that the capacity retention rate of Comparative Example 2 without A3, or Comparative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com