Patents

Literature

1724results about How to "Reduce decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remelted ingestible products

ActiveUS20130274296A1Reduce exposureHigh heating temperatureBiocideTobacco preparationSemi solidTemperature sensitive

A method of preparing an orally ingestible hard boiled product, comprising: i) heating a sugar material to a first temperature sufficient to liquefy the sugar material; ii) cooling the liquefied sugar material to provide a cooled sugar material having a solid or semi-solid form; iii) heating the cooled sugar material to a second temperature, which is lower than the first temperature; iv) combining the sugar material with one or more temperature sensitive ingredients before, during, or after said heating step iii), but after said cooling step ii), such that an intimate mixture of the second liquefied sugar material and the one or more temperature sensitive ingredients is provided; and v) cooling the intimate mixture to form an orally ingestible product. Orally ingestible hard boiled products prepared according to this method are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

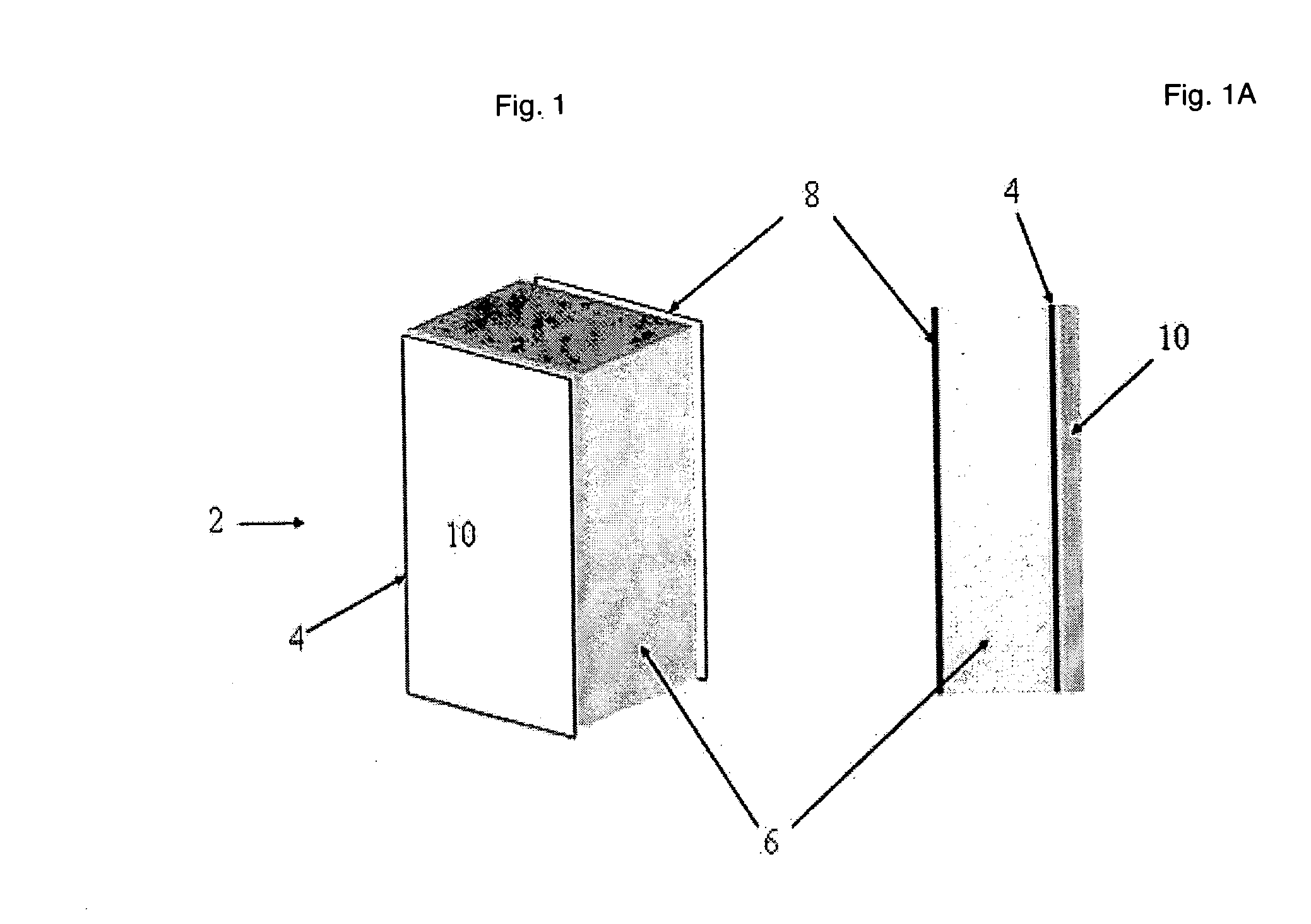

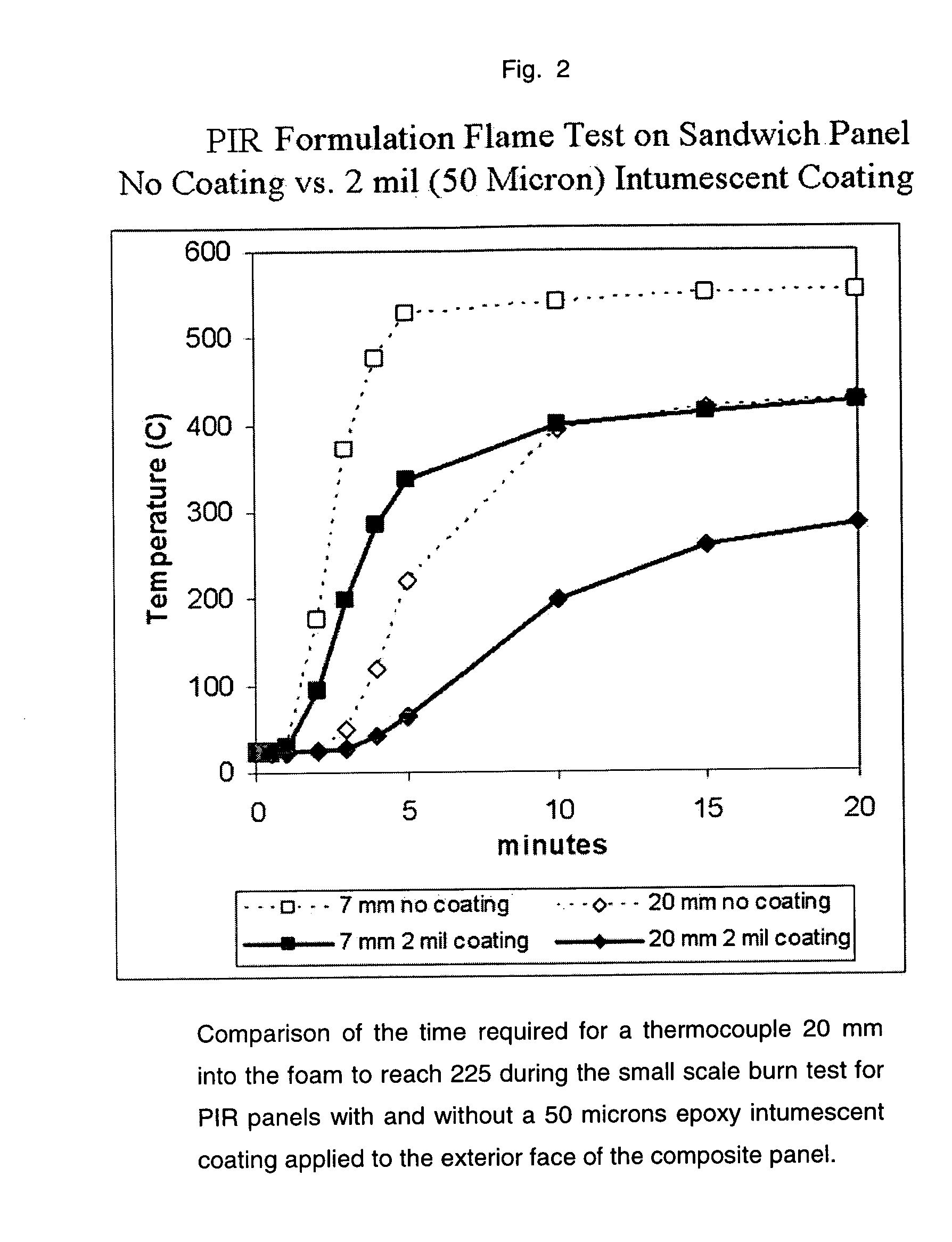

Fire resistant insulated building panels utilizing intumescent coatings

InactiveUS20070059516A1Reduce decompositionReduce transferLayered productsBuilding componentsFire resistanceFoamcore

This invention relates to an improvement in a process for producing a composite insulating panel comprised of at least one metal facer having an interior face and an exterior face and a foam core facing the interior face of at least one metal facer and to the resulting composite insulating panel. The improvement in the process for producing the composite insulating panel and improving the fire resistance thereof resides in the steps which comprise: applying an ultrathin intumescent coating composition to the exterior face of said metal facer in an amount to provide a coating thickness of 130 microns or less; and, subsequently providing said foam core facing the interior face of said metal facer.

Owner:AIR PROD & CHEM INC

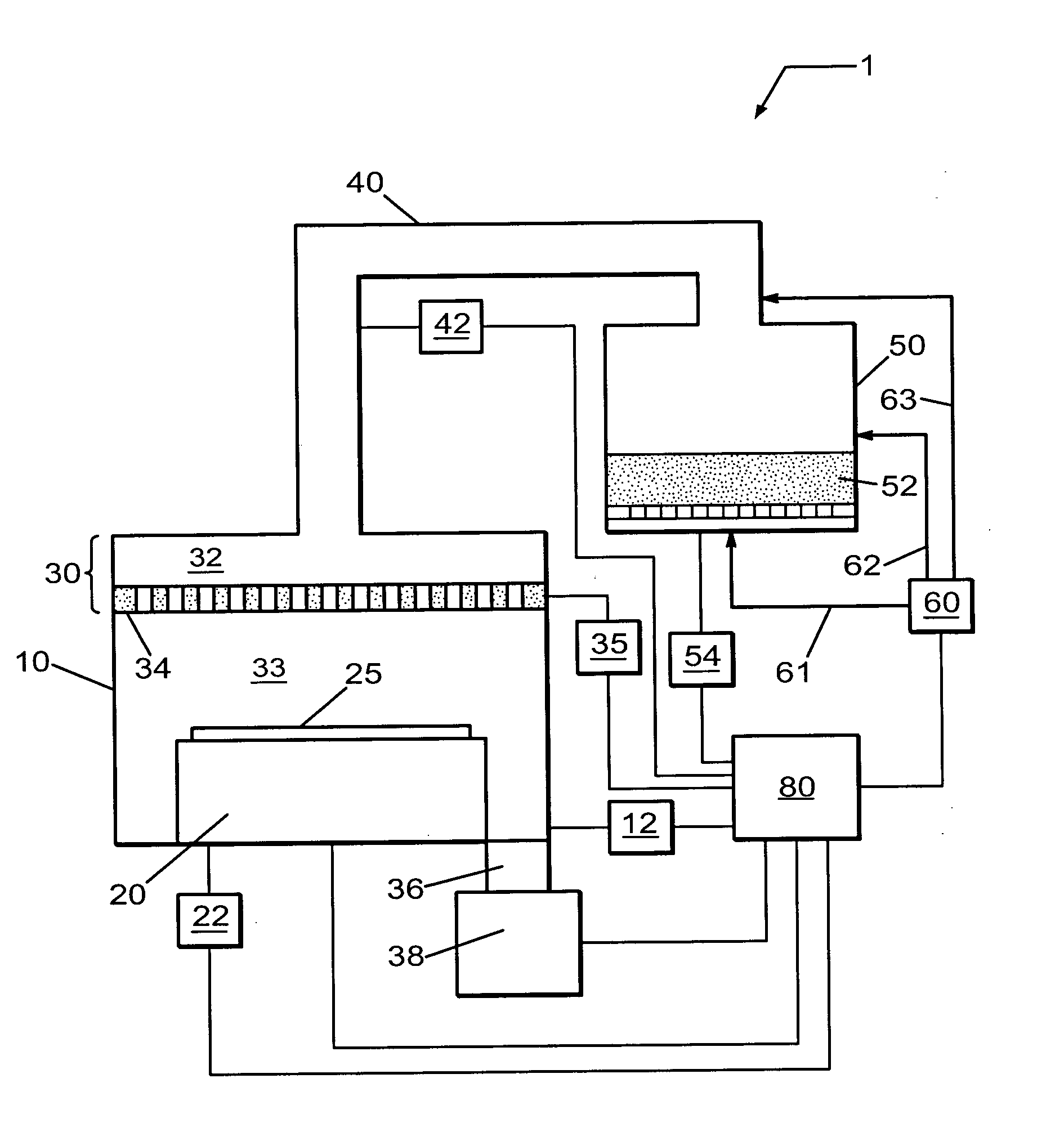

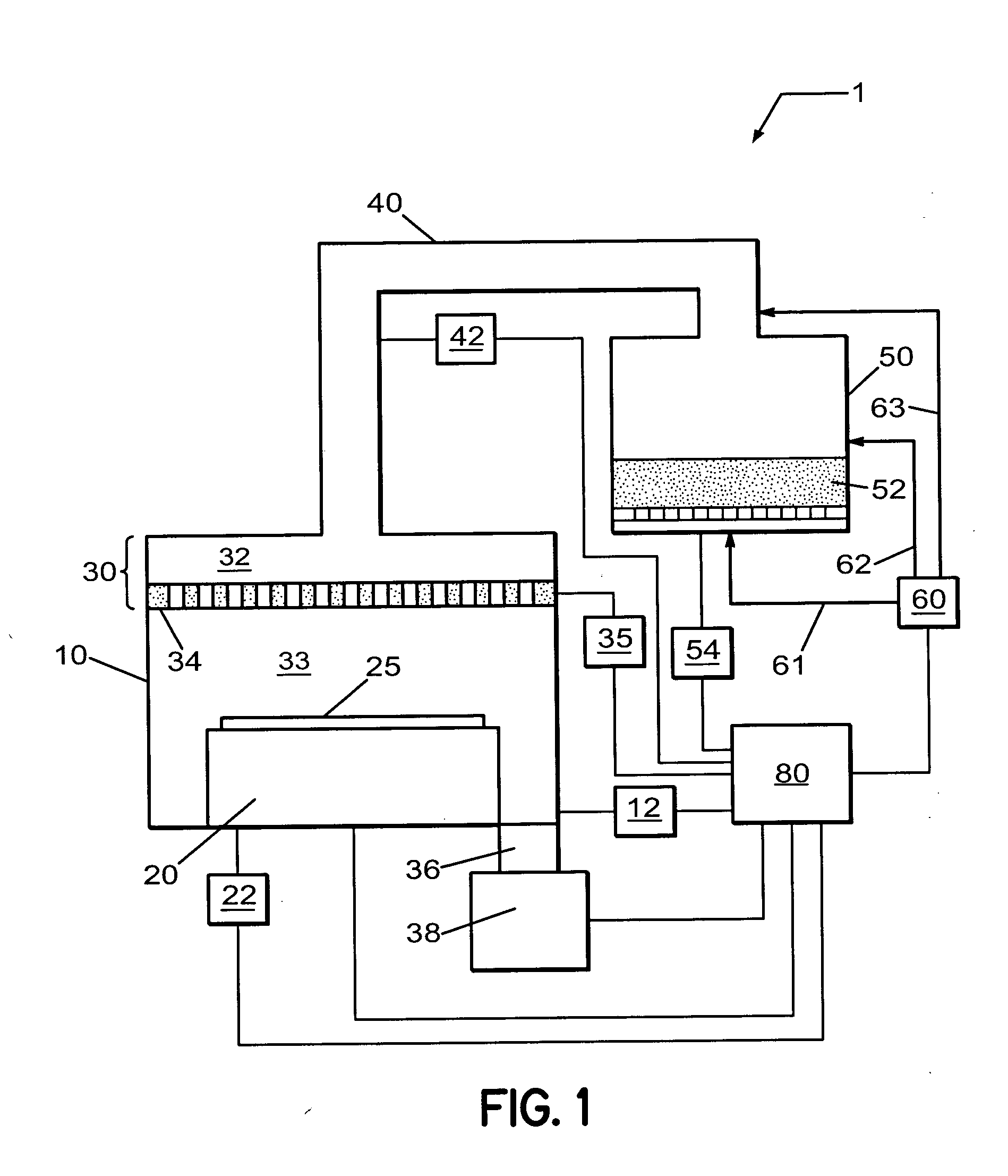

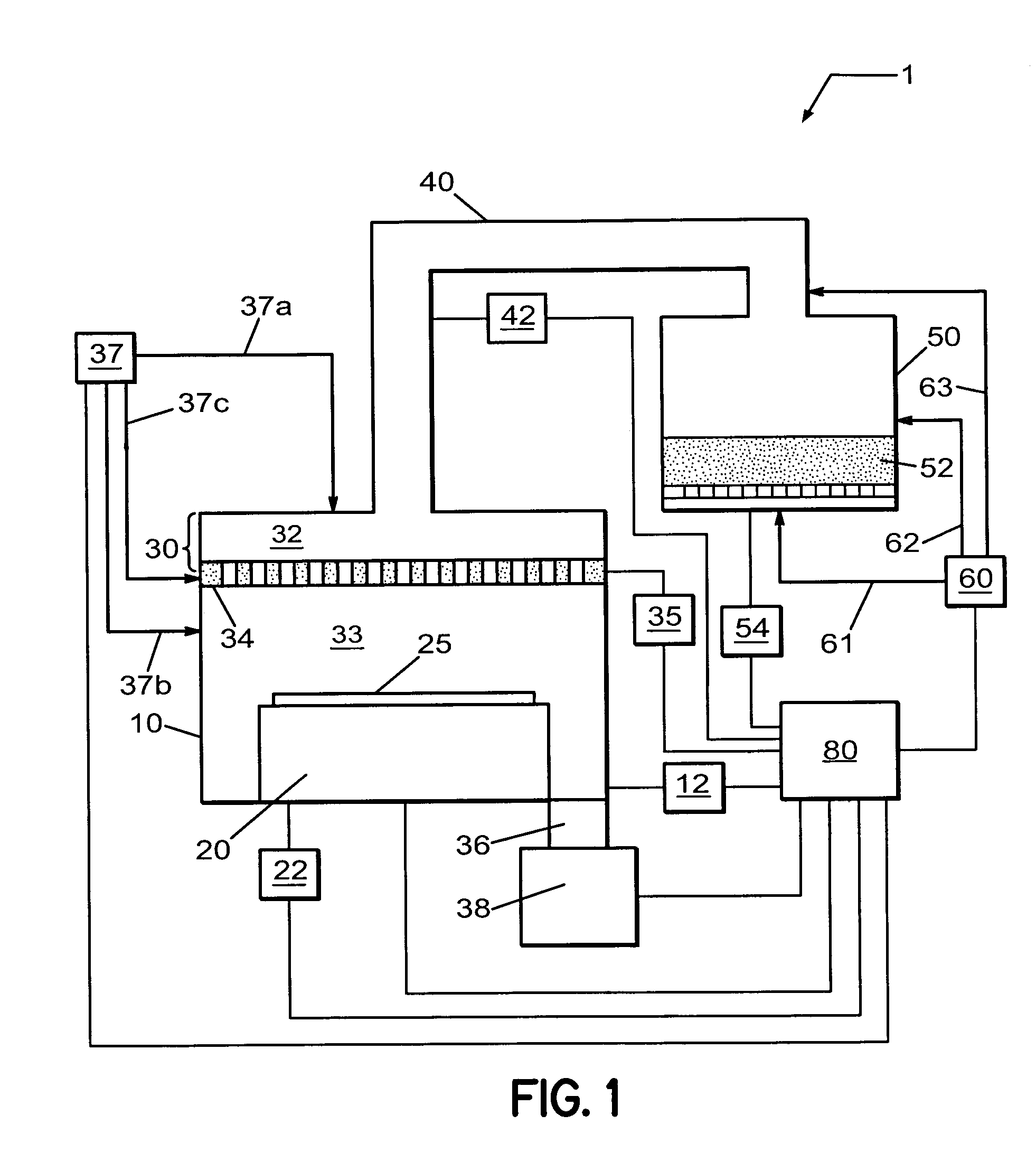

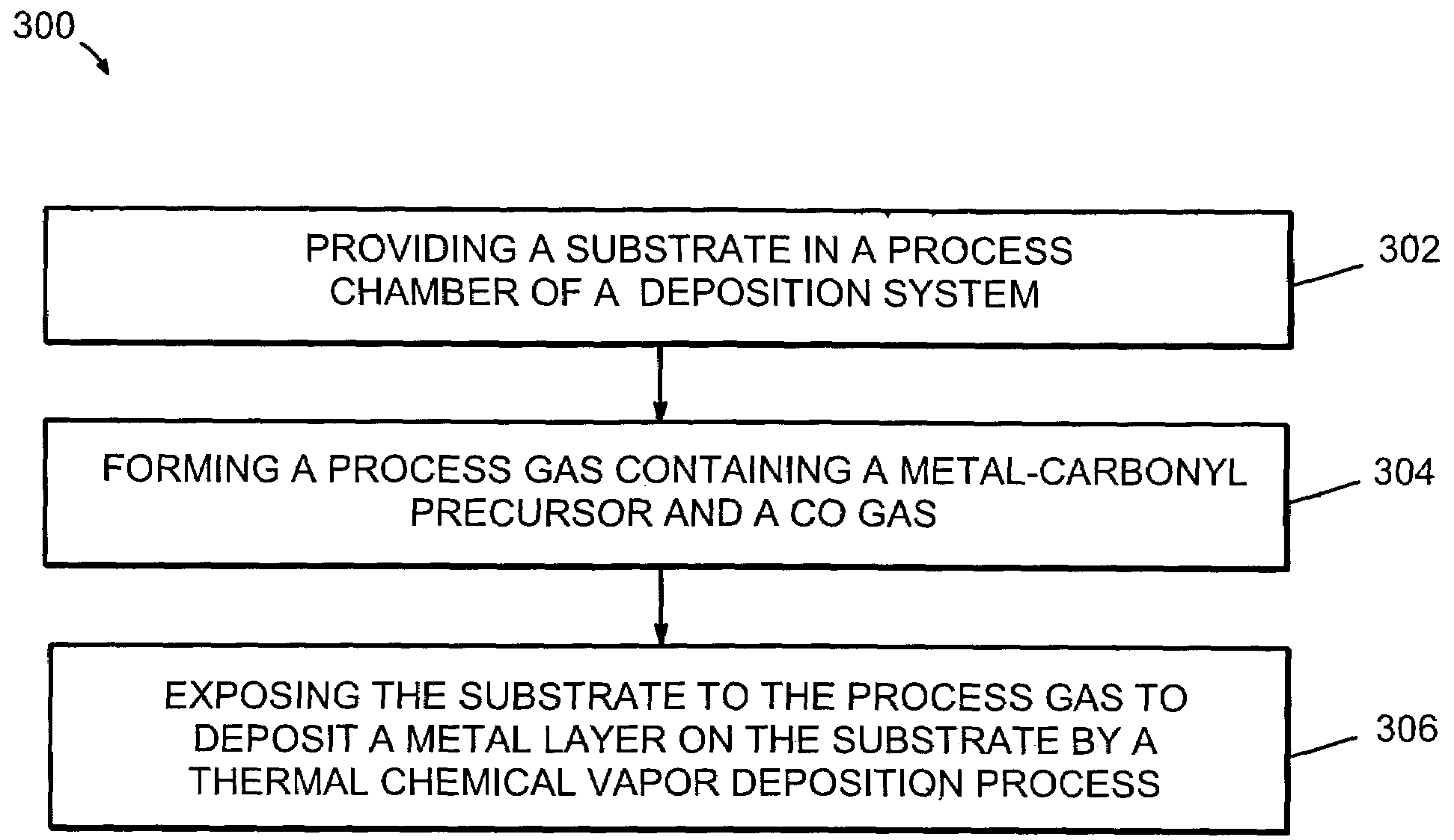

Method for increasing deposition rates of metal layers from metal-carbonyl precursors

ActiveUS20060110530A1Increase deposition rateRaise the evaporation temperatureVacuum evaporation coatingSputtering coatingGas phaseThermal chemical vapor deposition

A method for increasing deposition rates of metal layers from metal-carbonyl precursors by mixing a vapor of the metal-carbonyl precursor with CO gas. The method includes providing a substrate in a process chamber of a deposition system, forming a process gas containing a metal-carbonyl precursor vapor and a CO gas, and exposing the substrate to the process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process.

Owner:IBM CORP +1

Nonaqueous electrolytic solution and lithium secondary batteries

ActiveUS20040121239A1Not inhibit overchargeImprove battery performanceOrganic electrolyte cellsLi-accumulatorsSolventBiphenyl compound

In order to manufacture a lithium secondary battery having excellent performances in safety under overcharge condition, cycle property, electric capacity, and storage endurance, 0.1 wt. % to 10 wt. % of a tert-alkylbenzene compound is favorably incorporated into a non-aqueous electrolytic solution comprising a non-aqueous solvent and an electrolyte, preferably in combination with 0.1 wt. % to 1.5 wt. % of a biphenyl compound.

Owner:UBE IND LTD

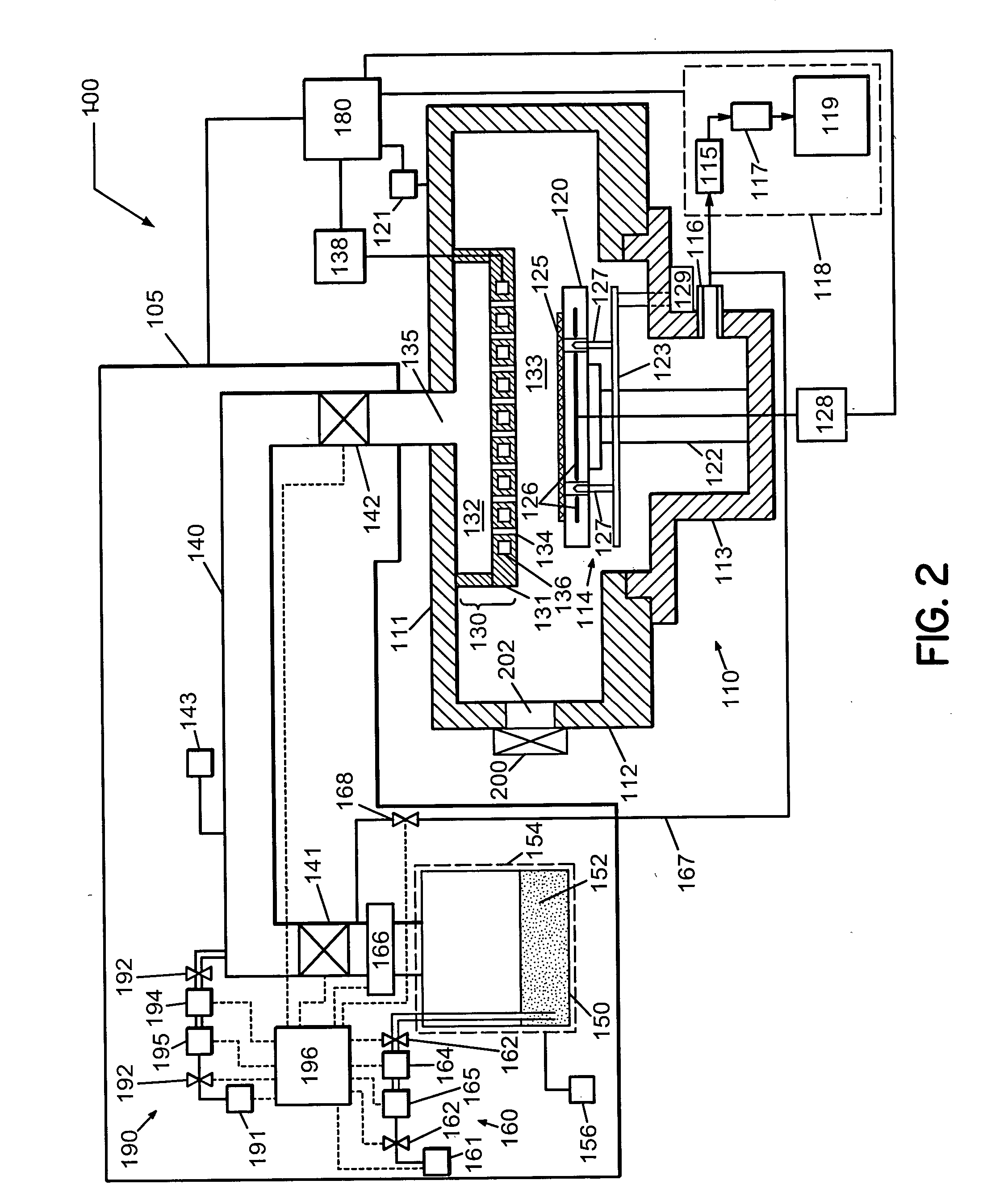

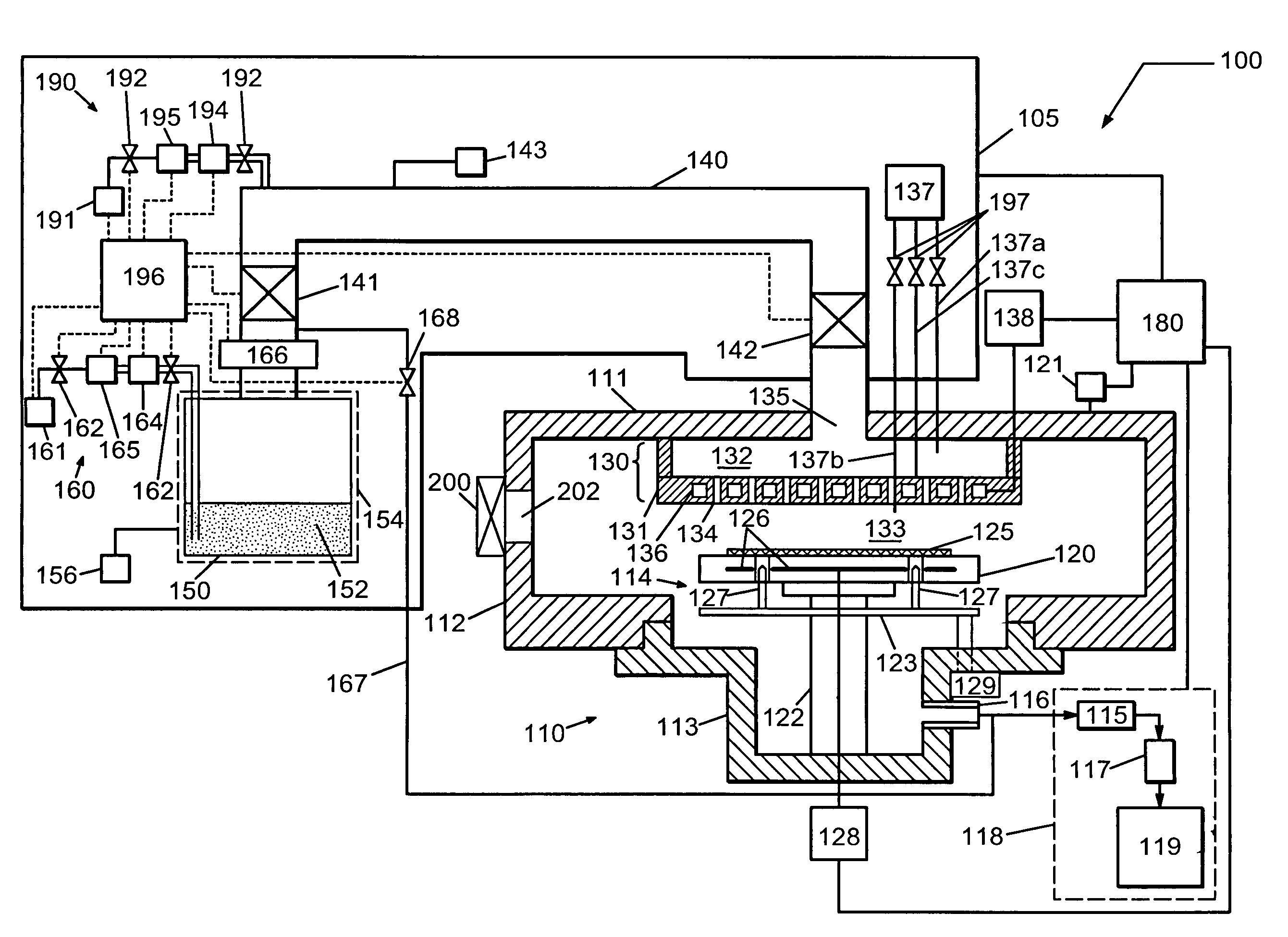

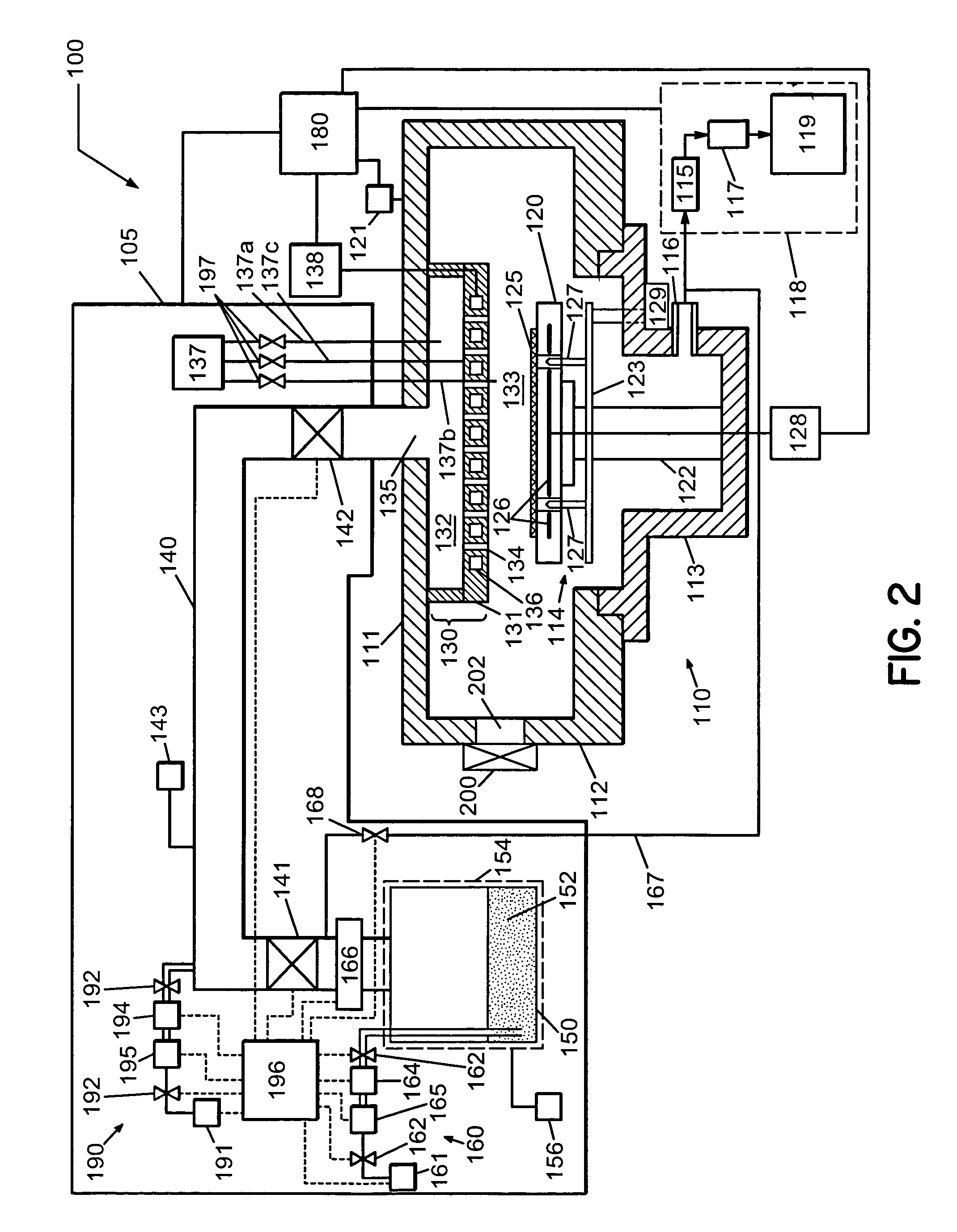

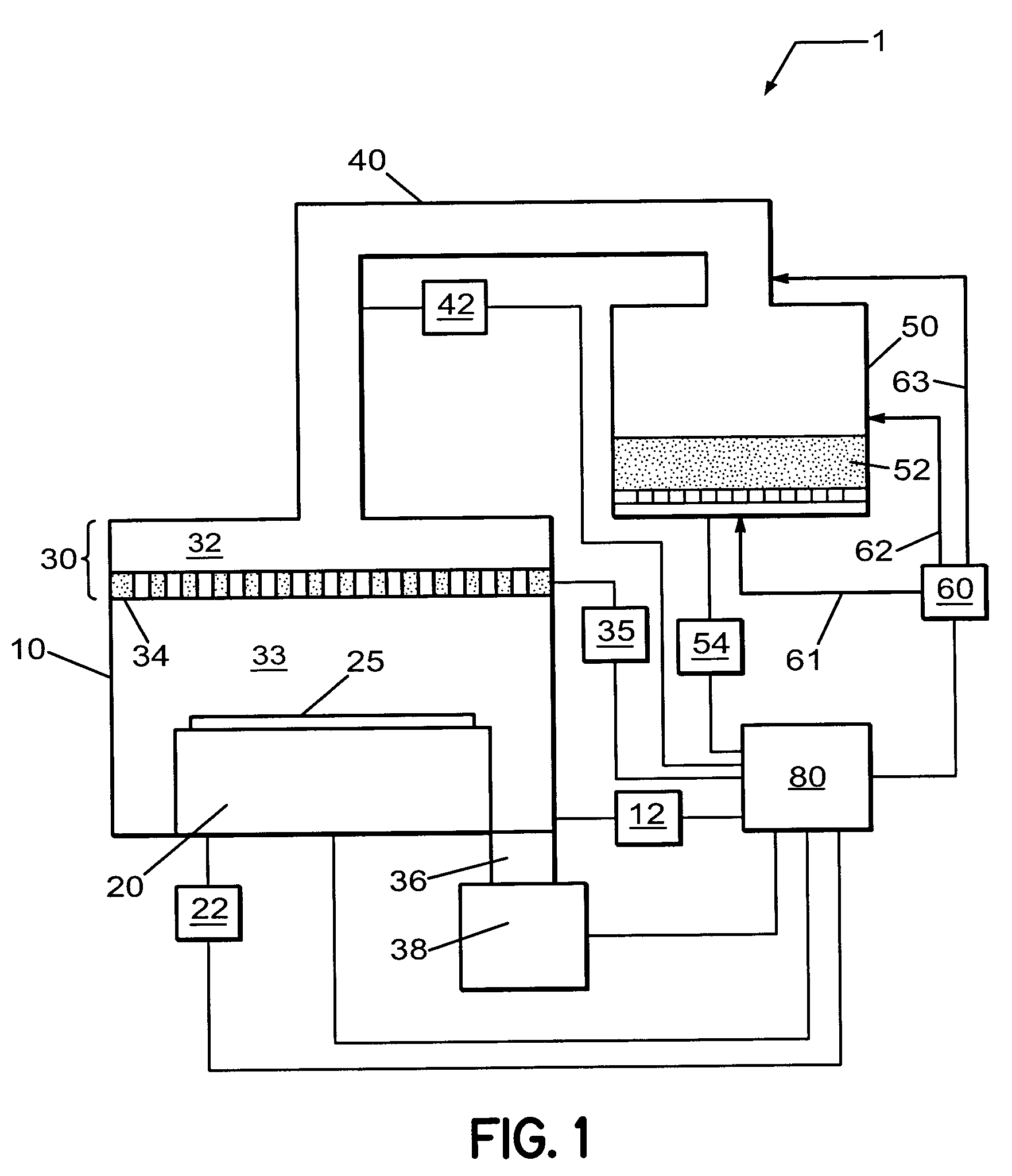

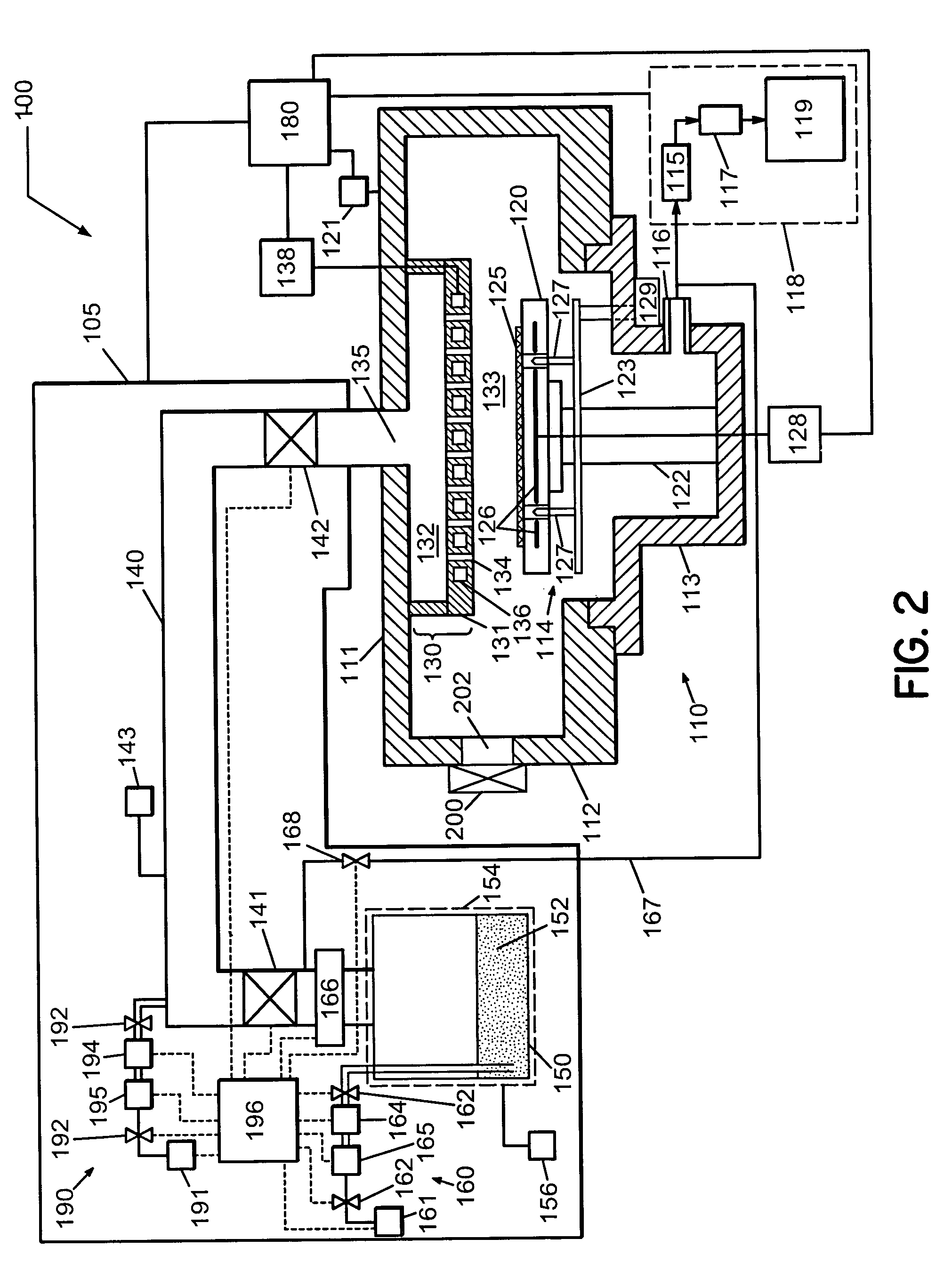

Method and deposition system for increasing deposition rates of metal layers from metal-carbonyl precursors

ActiveUS7279421B2Increase deposition rateRaise the evaporation temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal chemical vapor depositionGas phase

A method and a deposition system for increasing deposition rates of metal layers from metal-carbonyl precursors using CO gas and a dilution gas. The method includes providing a substrate in a process chamber of a processing system, forming a process gas containing a metal-carbonyl precursor vapor and a CO gas, diluting the process gas in the process chamber, and exposing the substrate to the diluted process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process. The deposition system contains a substrate holder configured for supporting and heating a substrate in a process chamber having a vapor distribution system, a precursor delivery system configured for forming a process gas containing a metal-carbonyl precursor vapor and a CO gas and for introducing the process gas to the vapor distribution system, a dilution gas source configured for adding a dilution gas to the process gas in the process chamber, and a controller configured for controlling the deposition system during exposure of the substrate to the diluted process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process.

Owner:TOKYO ELECTRON LTD

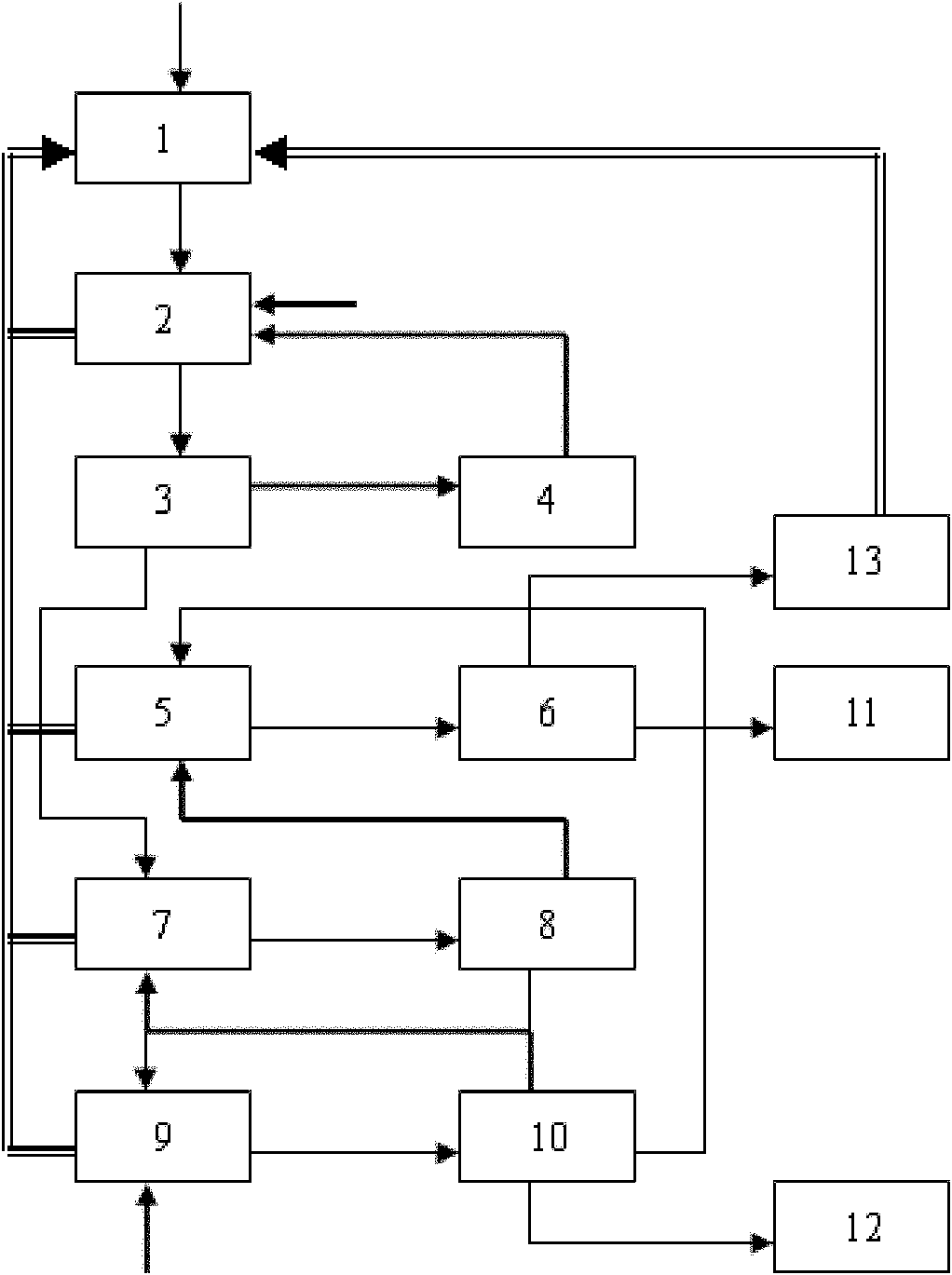

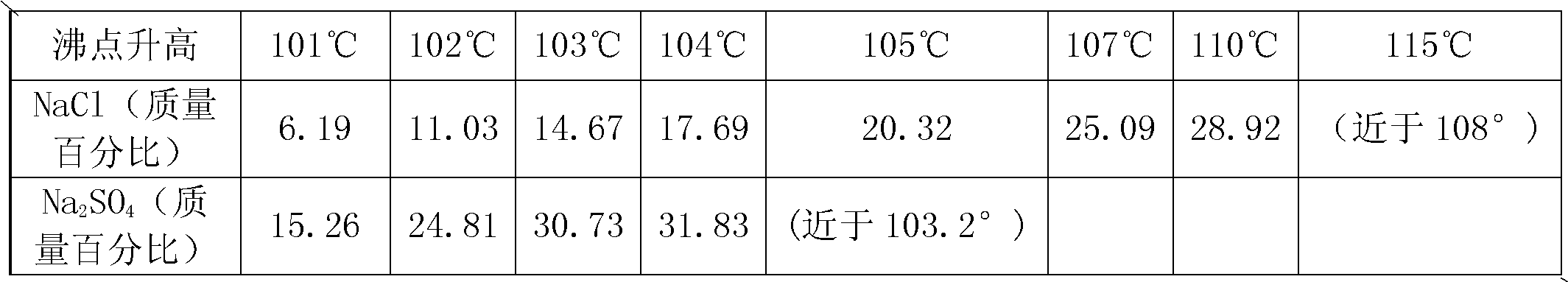

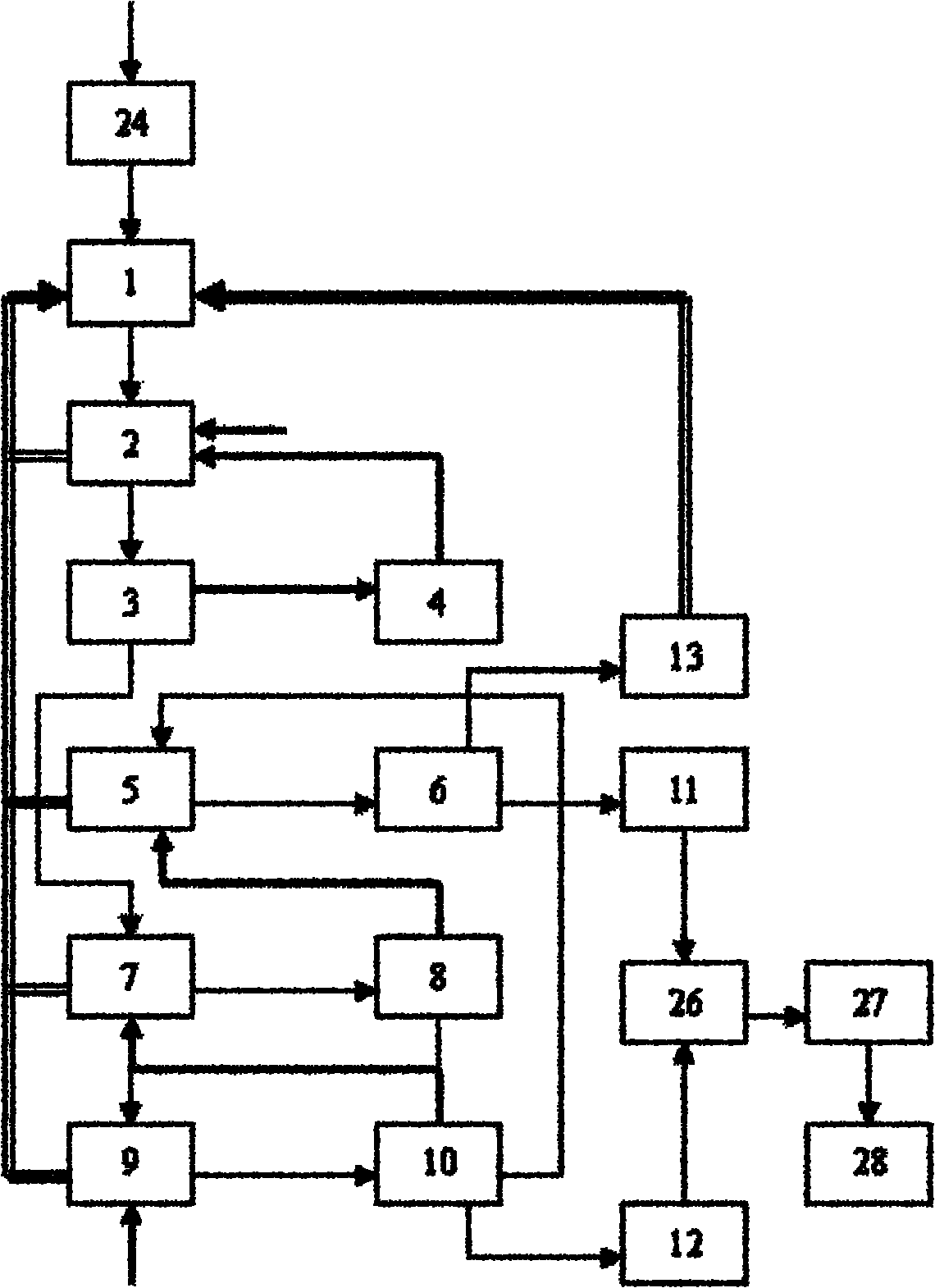

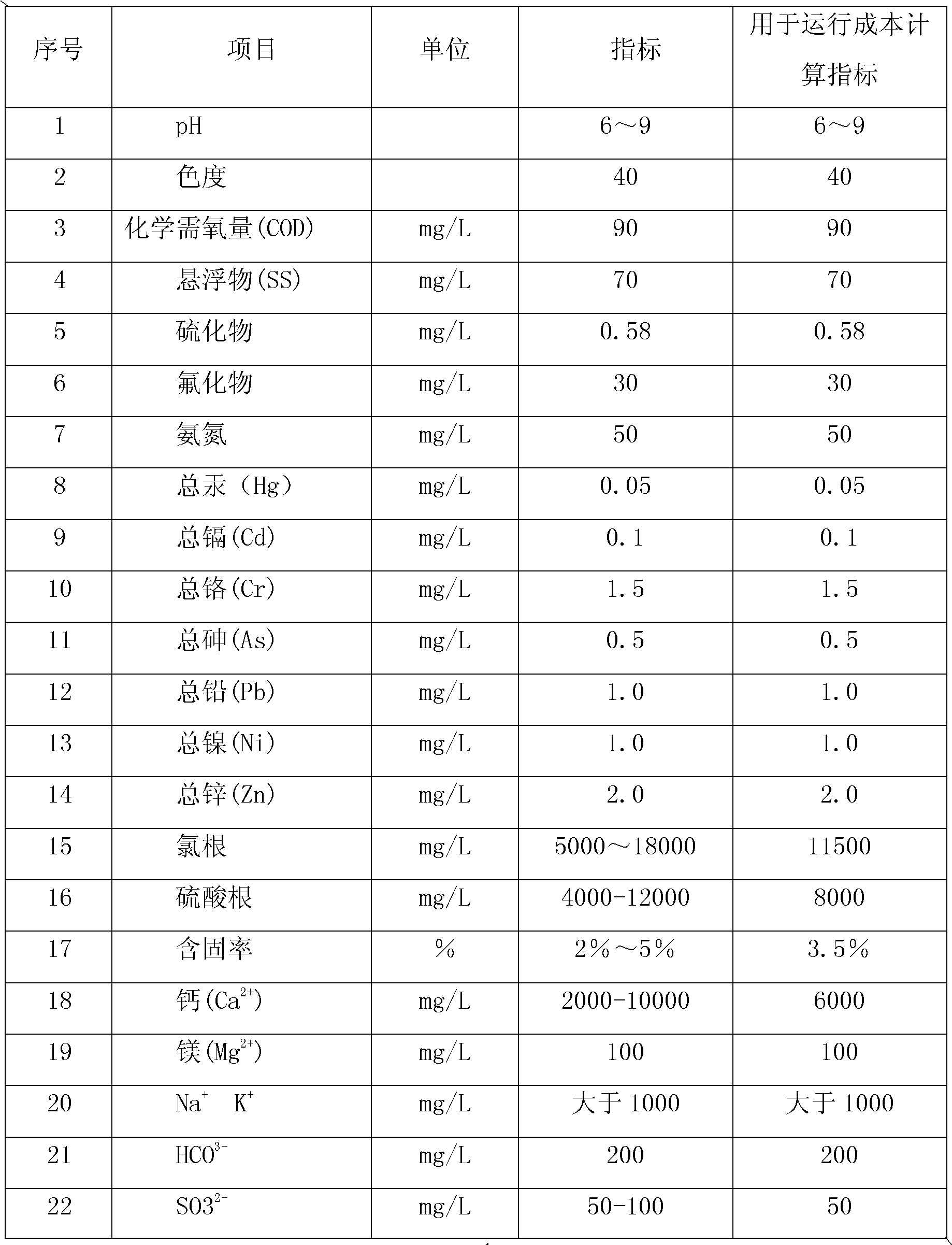

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

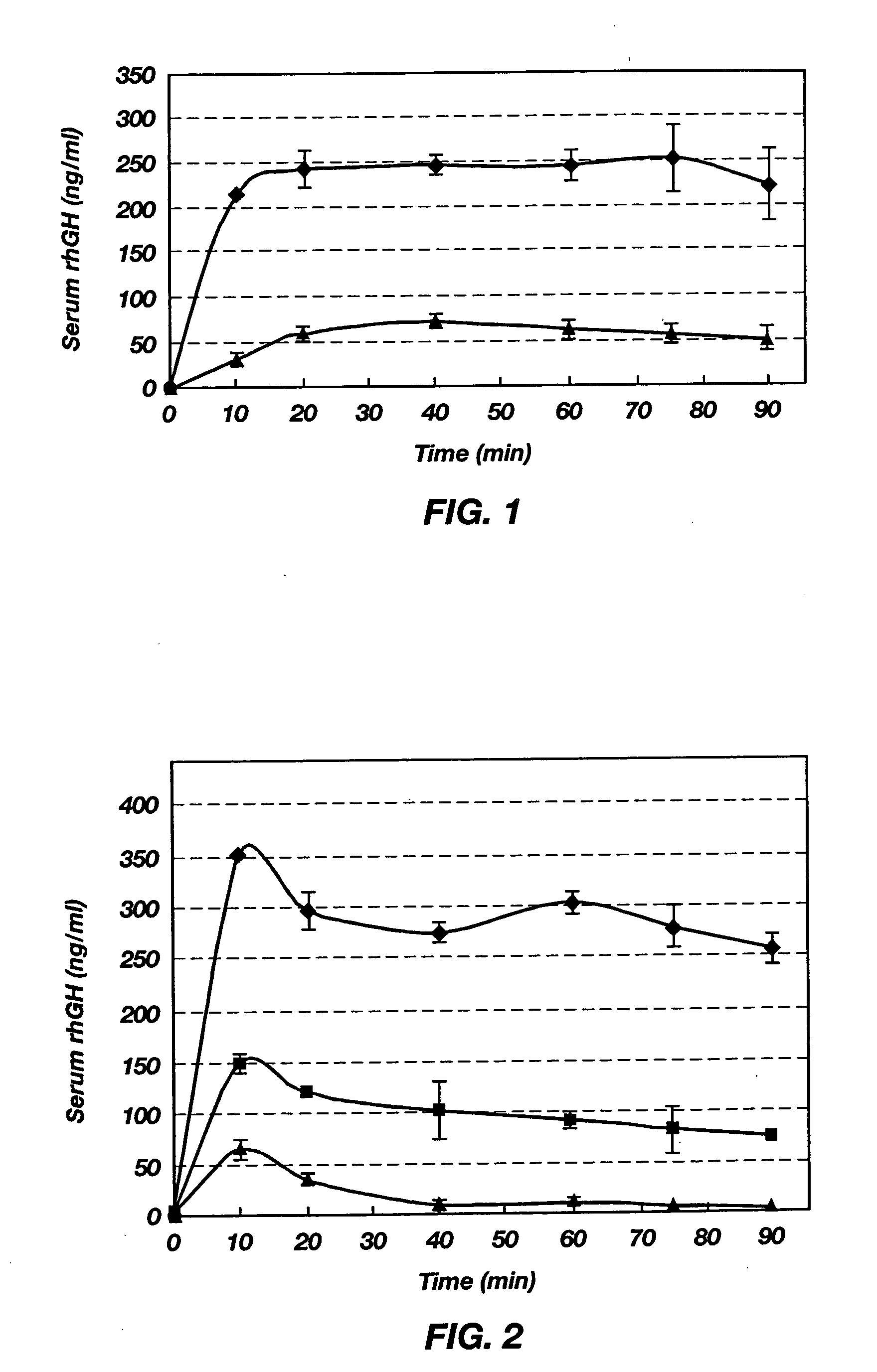

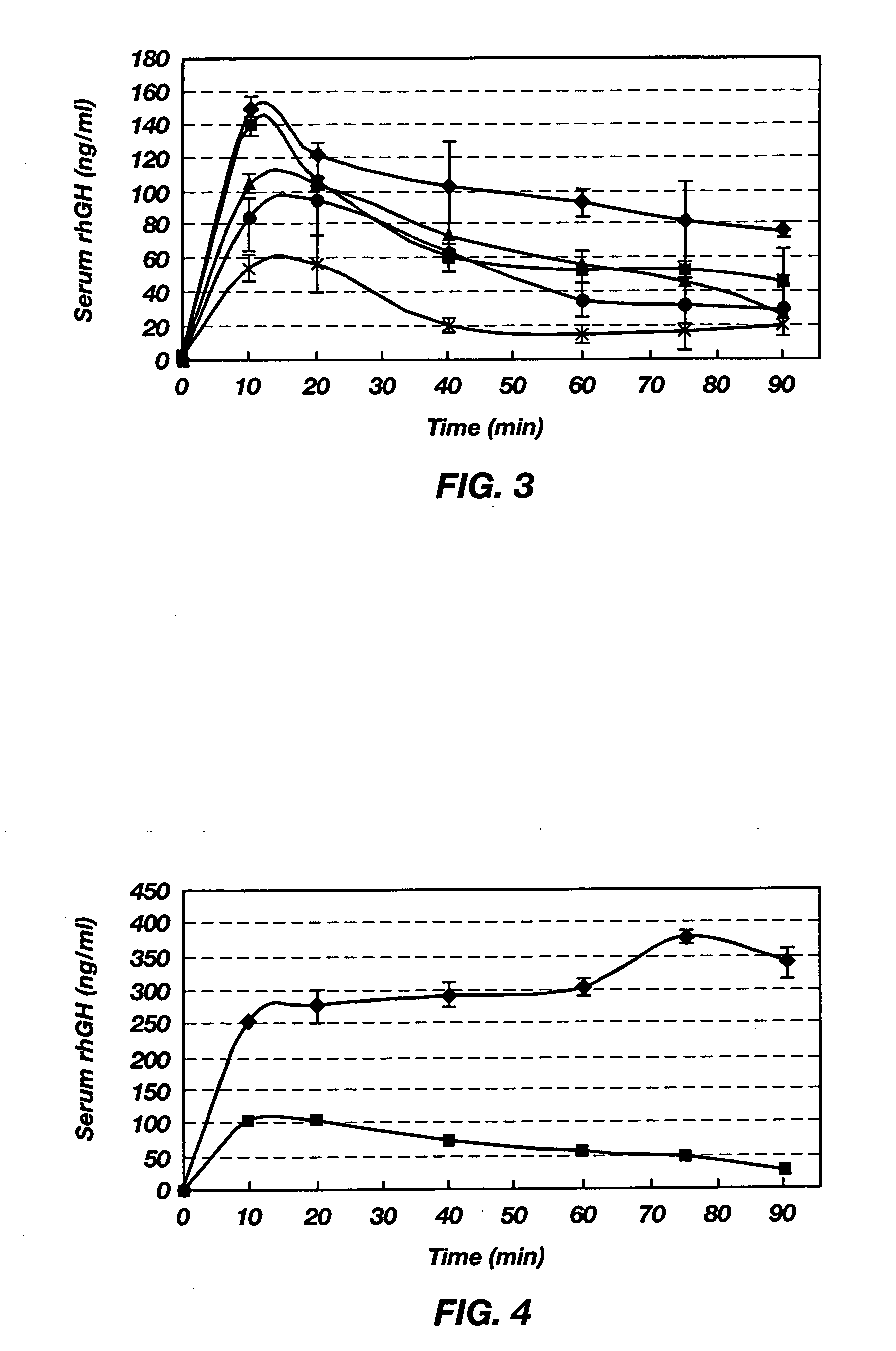

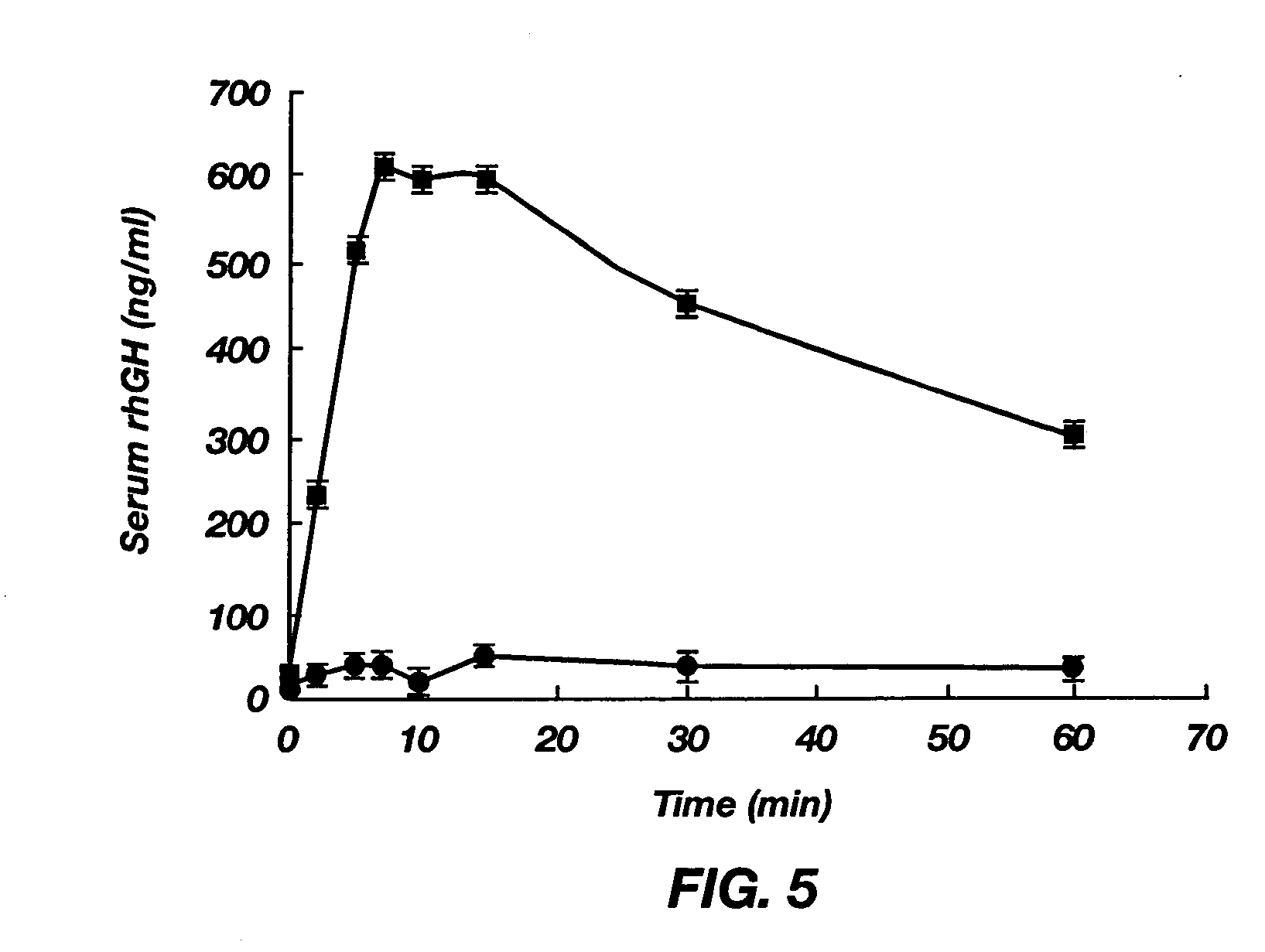

Oral formulation for delivery of poorly absorbed drugs

InactiveUS20060088592A1Promote absorptionReduce inactivationHeavy metal active ingredientsMultiple-port networksSucrosePolyvinyl alcohol

A composition for oral delivery of a poorly absorbed drug is disclosed. The composition includes the drug, an enhancer for increasing absorption of the drug through the intestinal mucosa, a promoter, which alone does not increase absorption of the drug through the intestinal mucosa, but which further increases the absorption of the drug in the presence of the enhancer, and optionally a protector for protecting the drug from physical or chemical decomposition or inactivation in the gastrointestinal tract. Illustrative enhancers include sucrose fatty acid esters, and illustrative promoters include aminosugars and amino acid derivatives, such as poly(amino acids). Illustrative protectors include methylcellulose, poly(vinyl alcohol), and poly(vinyl pyrrolidone).

Owner:PROCARRIER

Environment-friendly floating agrochemistic formulations for rice field and method of producing the same

The invention discloses the composite of an environment-friendly rice flotable agricultural chemical preparation and a novel manufacture process thereof, which belongs to the field of farm chemical. The preparation is formed by compounding 0.1 to 50 percent of a weed killer, an insecticide, a fungicide or plant growth regulator active ingredients, 0.1 to 30 percent of a micropore sustained release agent, and 99.8 to 20 percent of a floatble carrier according to mass percentage. The preparation can effectively save the active ingredients by more than 70 percent, and can be directly applied on the surface of rice paddy field. The preparation has the characteristics of low cost, high efficacy, lasting drug action, safety, convenient use and so on, and is an environment-friendly agricultural chemical preparation.

Owner:湖南大方农化股份有限公司

Method for increasing deposition rates of metal layers from metal-carbonyl precursors

ActiveUS7270848B2Increase deposition rateRaise the evaporation temperatureVacuum evaporation coatingSemiconductor/solid-state device manufacturingThermal chemical vapor depositionMetal carbonyl

A method for increasing deposition rates of metal layers from metal-carbonyl precursors by mixing a vapor of the metal-carbonyl precursor with CO gas. The method includes providing a substrate in a process chamber of a deposition system, forming a process gas containing a metal-carbonyl precursor vapor and a CO gas, and exposing the substrate to the process gas to deposit a metal layer on the substrate by a thermal chemical vapor deposition process.

Owner:IBM CORP +1

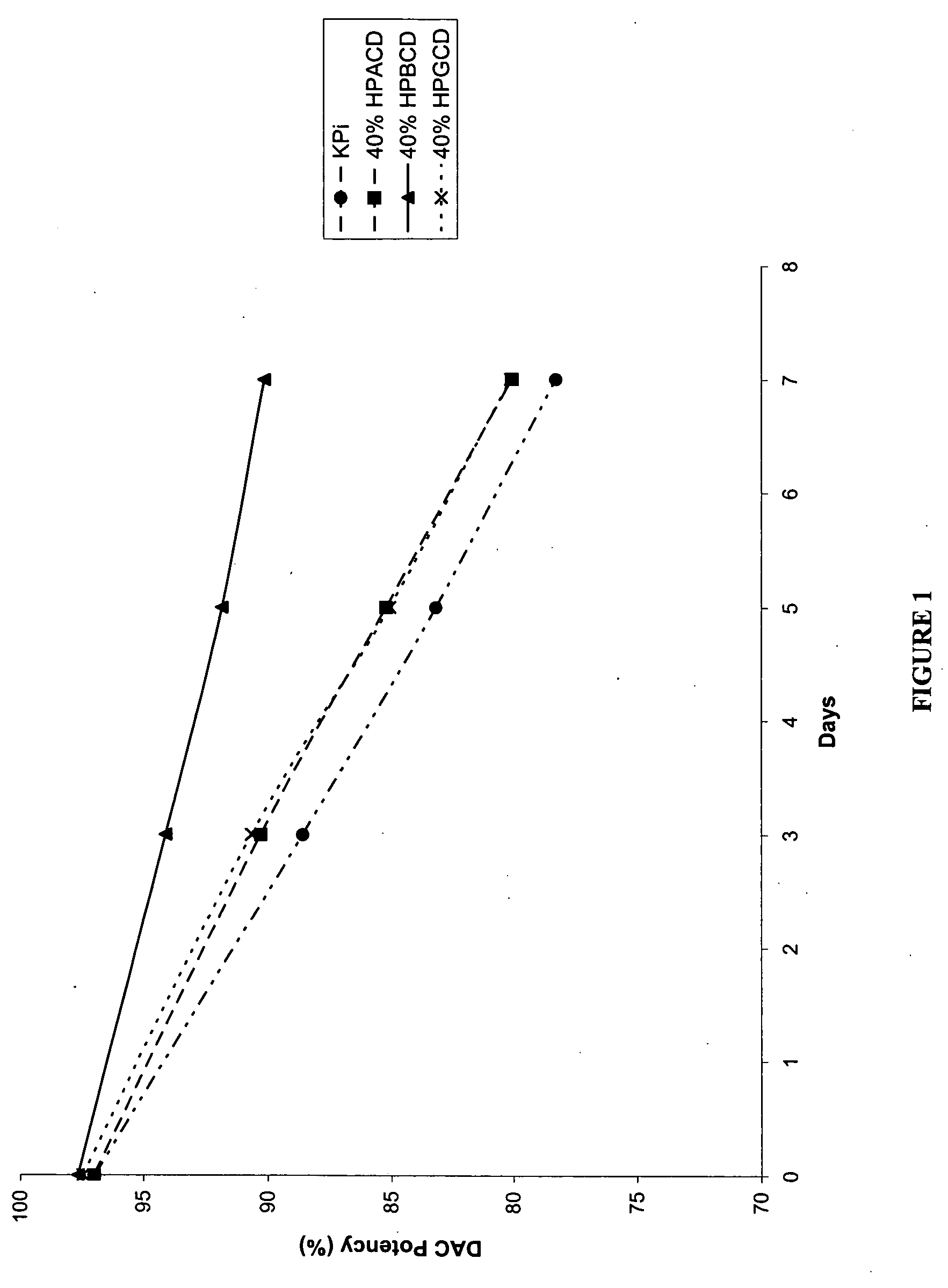

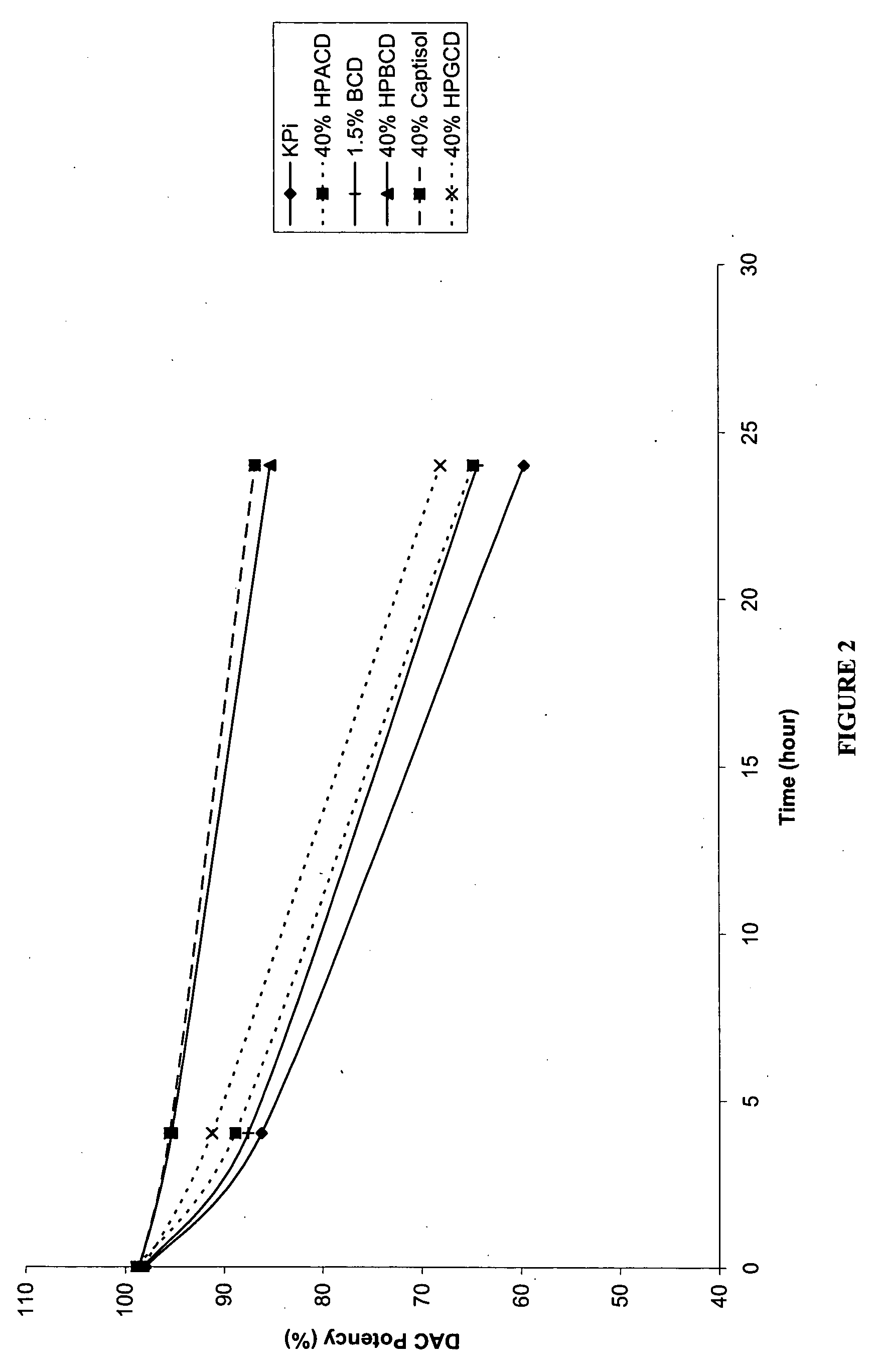

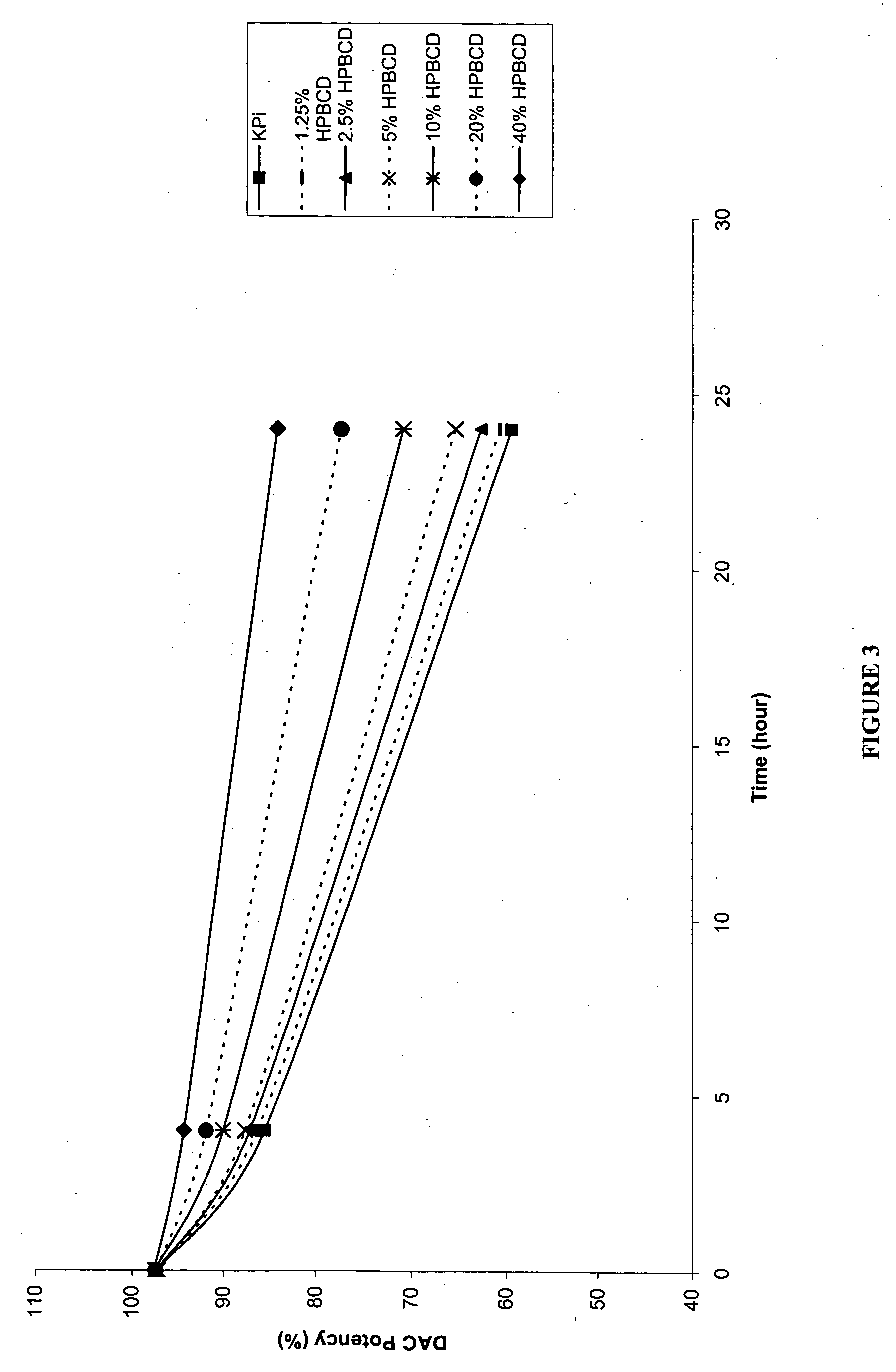

Pharmaceutical formulation of cytidine analogs and derivatives

InactiveUS20060128654A1Reduce decompositionImprove solubilityBiocideCarbohydrate active ingredientsSolubilityCytosine

The present invention provides pharmaceutical formulations of cytidine analogs and derivatives, such as 5-azacytidine, 5-aza-2′-deoxy-2′,2′-difluorocytidine, 5-aza-2′-deoxy-2′-fluorocytidine, 2′-deoxy-2′,2′-difluorocytidine, and cytosine 1-β-D-arabinofuranoside, as well as methods of manufacturing the formulations. In particular, the cytidine analog or derivative is formulated with a cyclodextrin compound to stabilize and / or enhance solubility of the drug. Kits and methods for using the pharmaceutical formulations are also provided, including methods of administering the cytidine analog or derivative to treat conditions or diseases, such as cancer and hematological disorders.

Owner:SUPERGEN

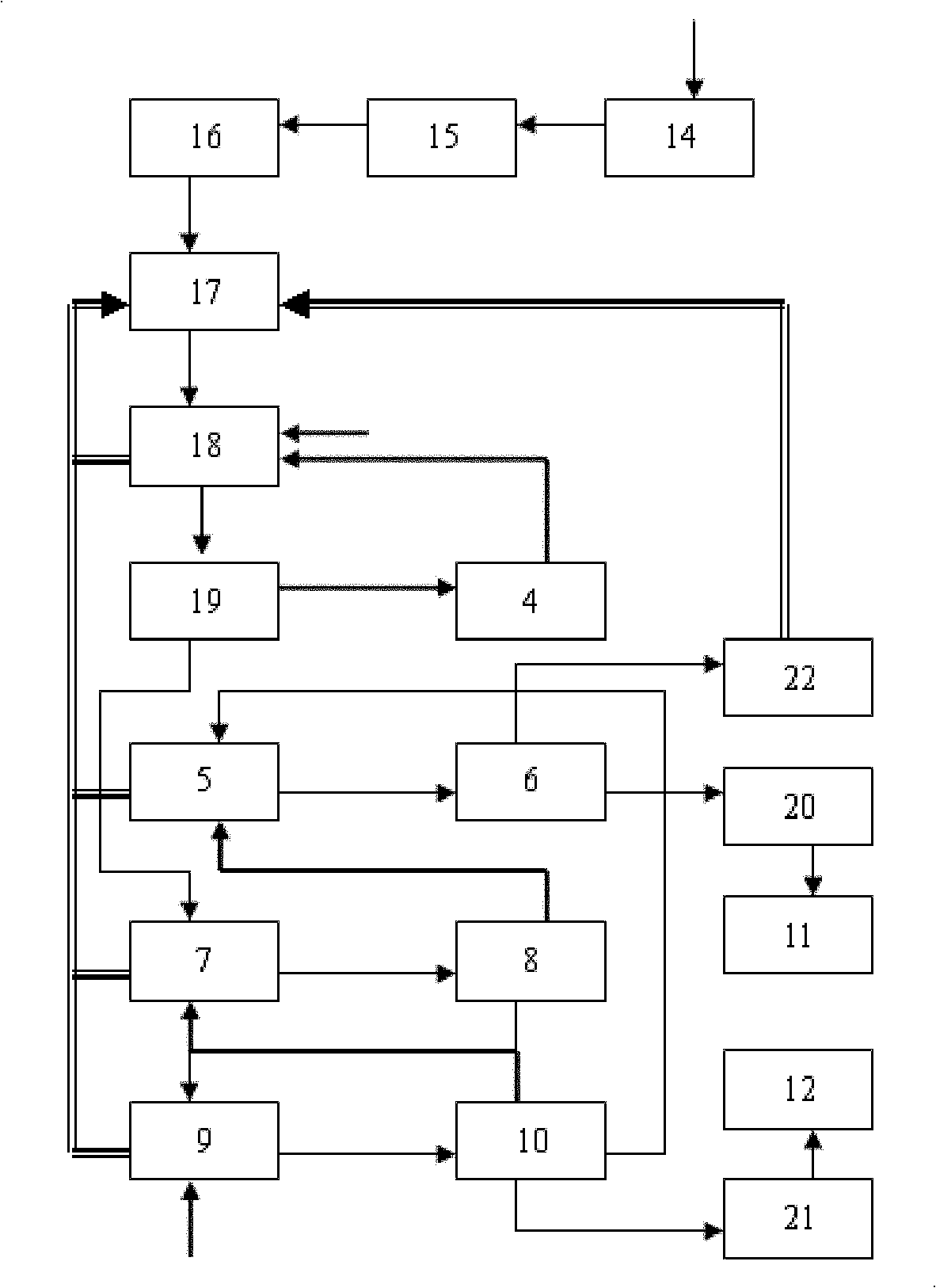

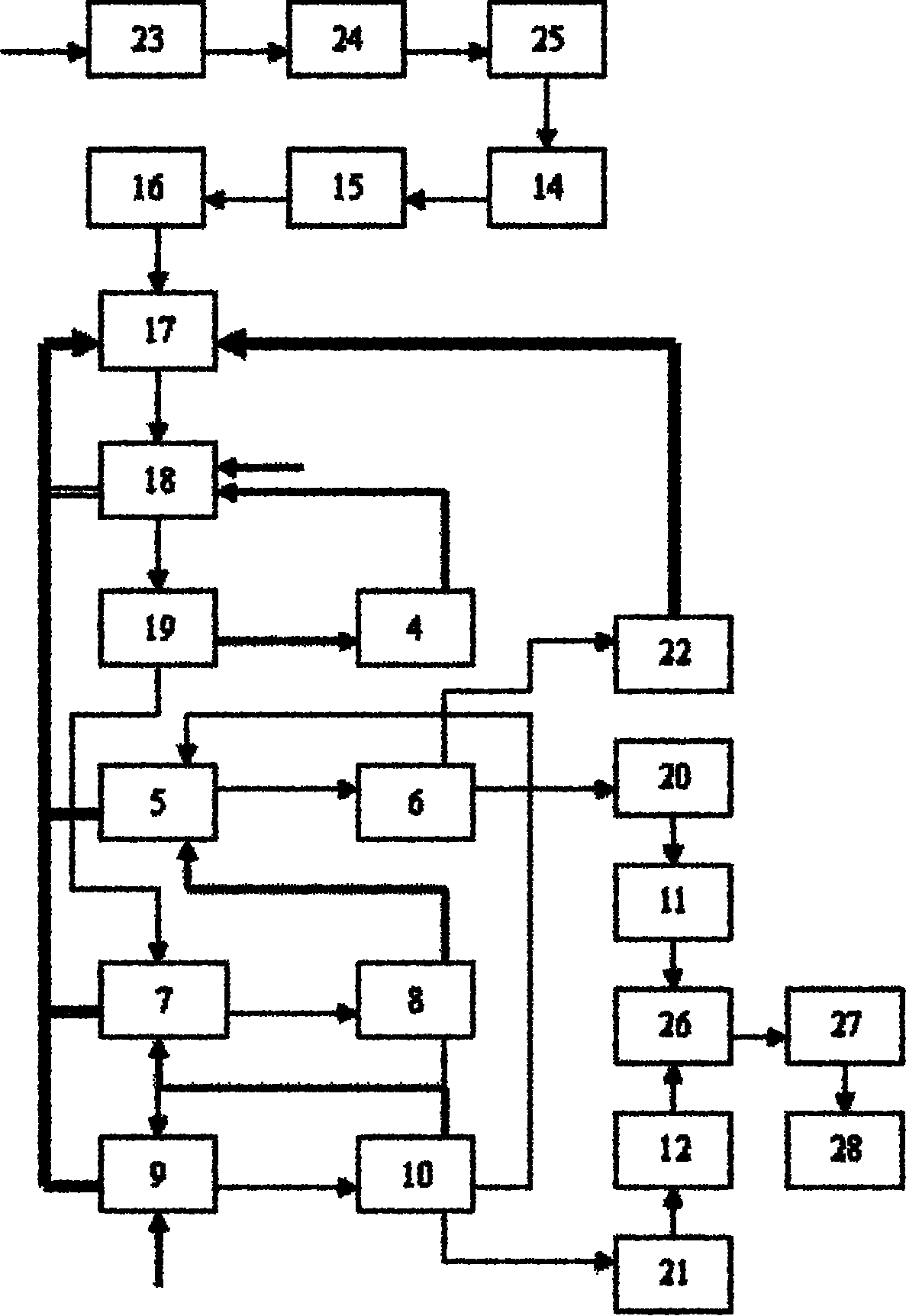

Wastewater evaporating process and device system

ActiveCN102060408AAvoid shockAvoid easy cloggingMultistage water/sewage treatmentProcess systemsTriple effect

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation; the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

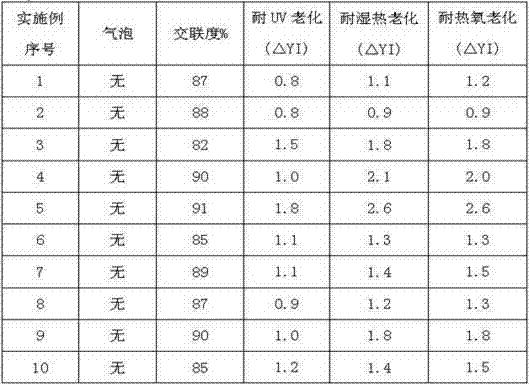

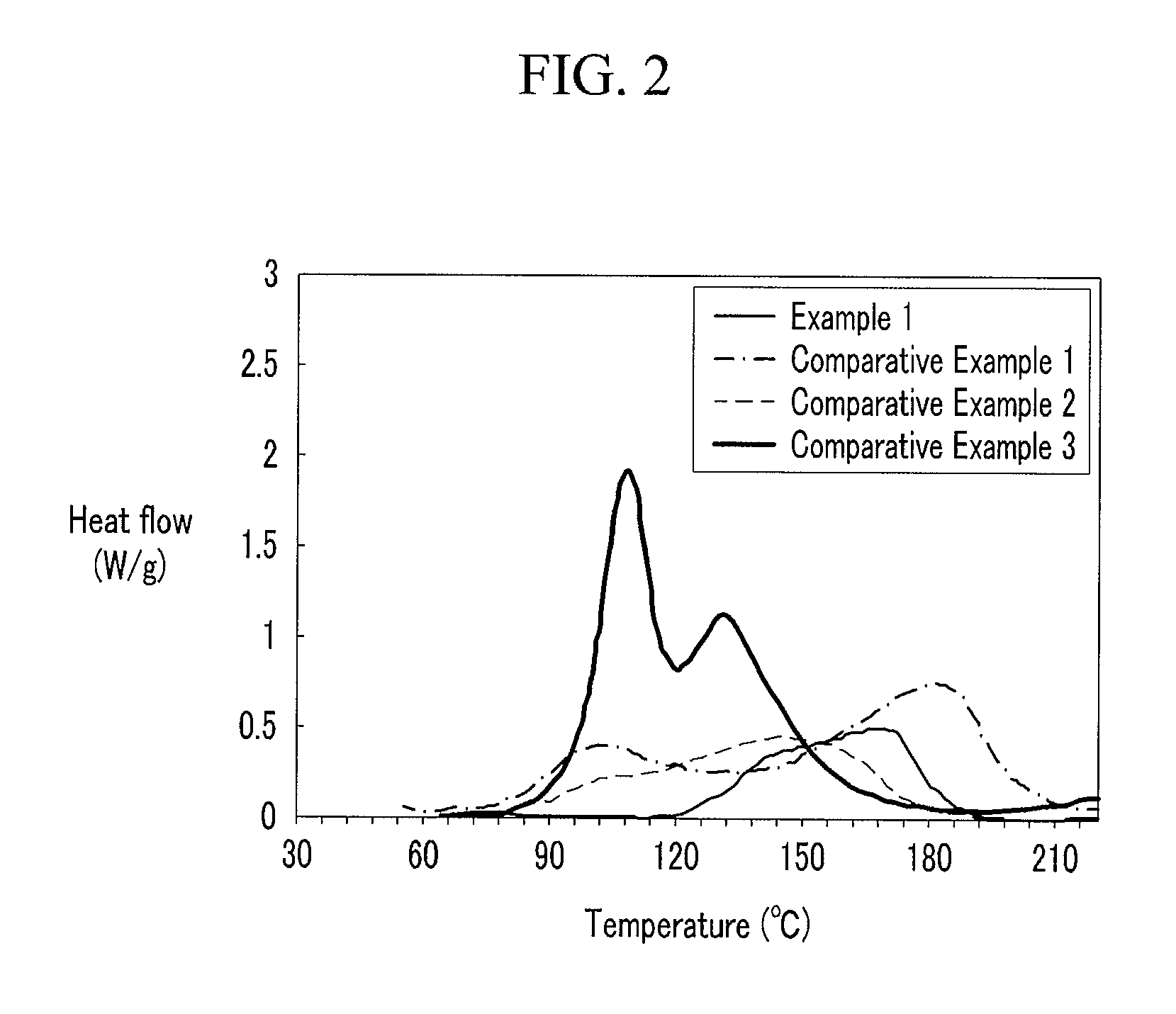

Ethylene-vinyl acetate copolymer packaging thin film

InactiveCN102391568AEnhanced network structureImprove moisture resistancePhotovoltaic energy generationSemiconductor devicesPolymer scienceNetwork structure

The invention discloses an ethylene-vinyl acetate copolymer packaging thin film, which is used for packaging solar cell components. The thin film is prepared from the following raw materials in part by weight: 100 parts of an ethylene-vinyl acetate copolymer, 0.1 to 2.0 parts of crosslinking agent, 0.1 to 10.0 parts of aid crosslinking agent and a proper amount of aid. The ethylene-vinyl acetate copolymer contains 25 to 33 percent of vinylacetate, and the ratio of the amount of the aid crosslinking agent and the crosslinking agent is 1:10 to 10:1. In the invention, the introduction of the aid improves the network structure of crosslinked resin, improves crosslinking efficiency, greatly reduces the dosage and residue of the crosslinking agent greatly and avoids aging phenomenon caused by residual crosslinking agent, and the prepared thin film has higher dampness and heat resistance, high ultraviolet resistance, high thermal-oxidative aging resistance and the like and has long service life.

Owner:DONGFANG TURBINE CO LTD

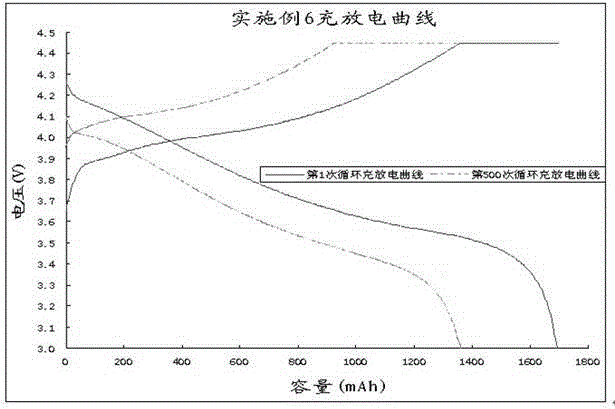

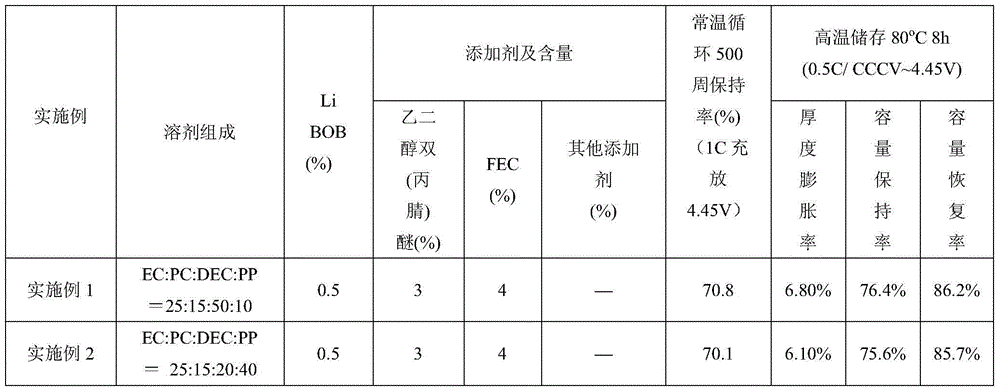

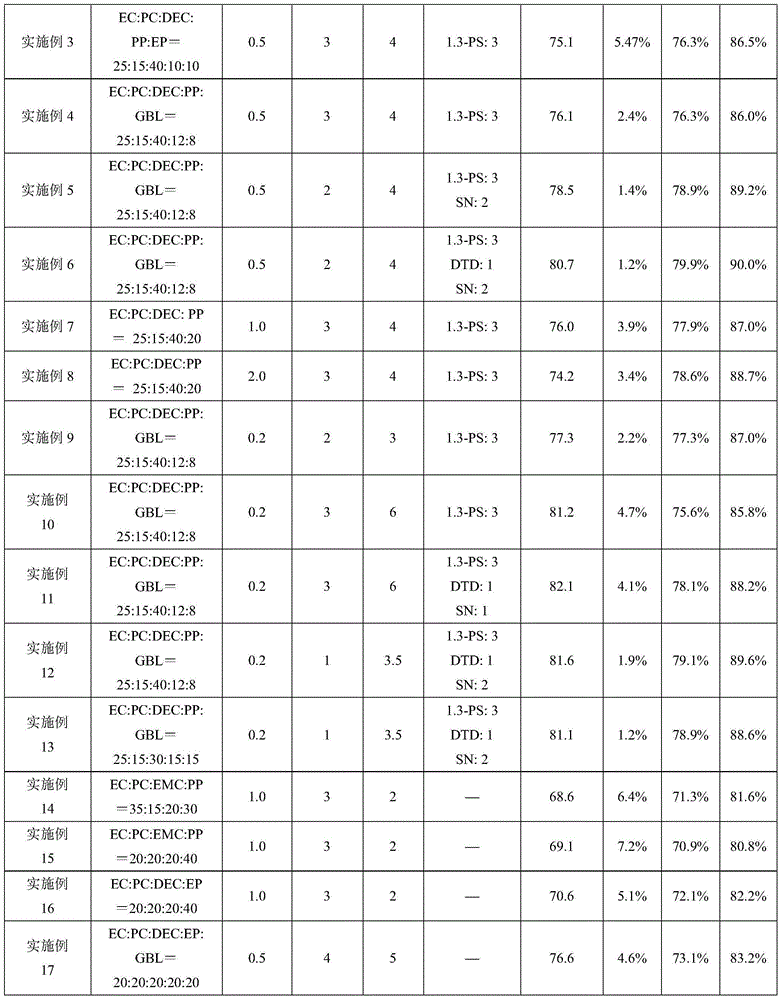

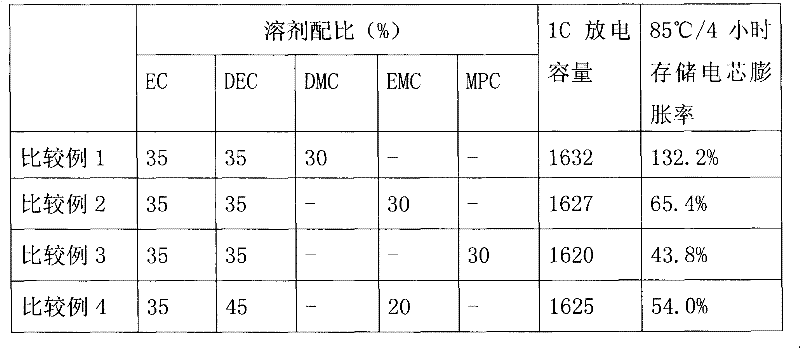

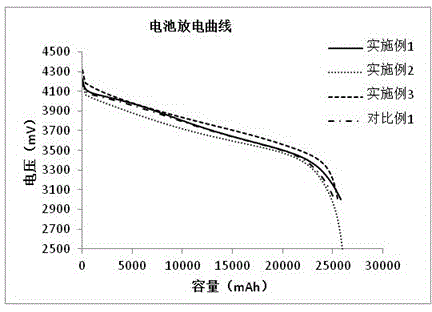

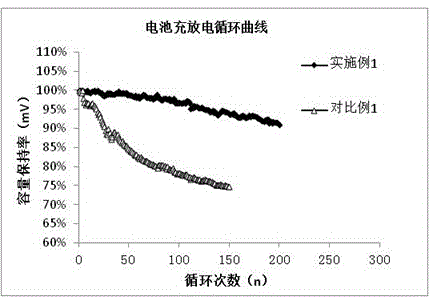

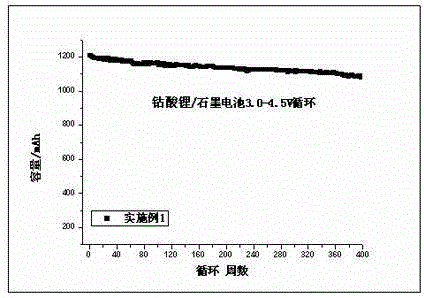

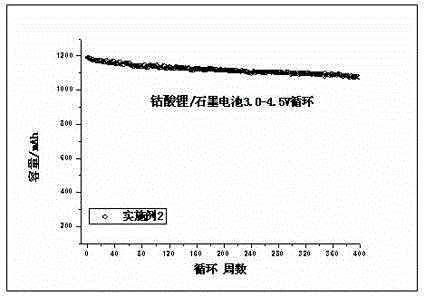

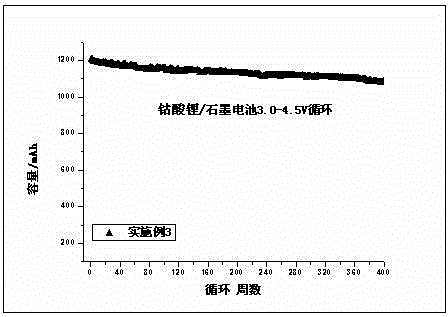

High-voltage electrolyte and lithium ion battery using electrolyte

InactiveCN104979589APromote circulationHigh decomposition voltageSecondary cellsHigh temperature storageEthylene glycol bis

The invention discloses high-voltage electrolyte and a lithium ion battery using the electrolyte. The invention is realized by the following technical scheme: the high-voltage electrolyte comprises a non-aqueous solvent, lithium salt and an additive, wherein the non-aqueous solvent is a carboxylic ester compound which accounts for 1-40% by mass of the high-voltage electrolyte; the additive is any one or more of lithium bis(oxalate)borate (Li BOB), fluoroethylene carbonate (FEC) and ethylene glycol bis(propionitrile) ether. The high-voltage electrolyte contains carboxylic ester solvents capable of improving an electrode / electrolyte interface, and through optimized combination of the carboxylic ester solvents, Li BOB, FEC, ethylene glycol bis(propionitrile) ether and other various additives, the good cycle performance of a high-voltage battery can be ensured, meanwhile, the high-temperature storage performance of the high-voltage battery can be effectively improved, and gas generation of the battery under high-voltage high-temperature storage condition can be obviously inhibited.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

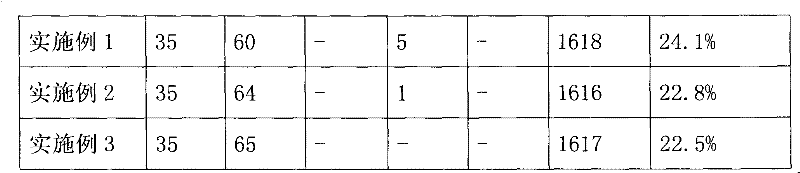

Lithium ion battery and electrolyte thereof

The invention discloses lithium ion battery electrolyte. The lithium ion battery electrolyte comprises a solvent, lithium salt and additives; the methyl-containing chain carbonate ester in the solvent is less than or equal to 5 percent of the total mass of the solvent; and the additives comprise 2 to 4 percent of 1,3-propane sultone (PS). Compared with the prior art, the lithium ion battery electrolyte has the advantages that: the content of the methyl-containing chain carbonate ester with low stability in the solvent is controlled, and the additives, namely the 1,3-propane sultone, butanedinitrile, adiponitrile, vinylene carbonate (VC), fluoroethylene carbonate (FEC) and the like are added into the solvent, so that an interface of an electrode / the electrolyte can be improved, the decomposition of the solvent in the electrolyte is reduced, the quantity of gas generated in the battery is reduced, and the high temperature storage performance, the safety performance and the cycle performance of the battery under a high voltage are improved. Besides, the invention also provides a lithium ion battery employing the electrolyte.

Owner:DONGGUAN AMPEREX TECH +1

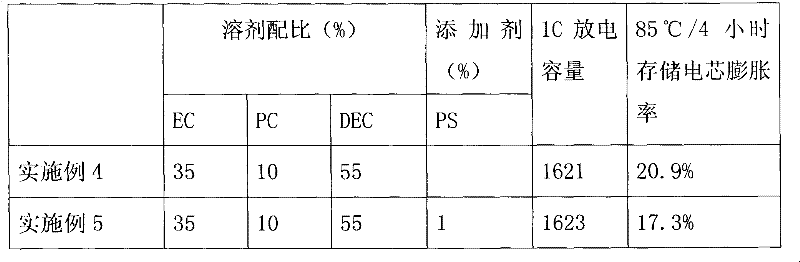

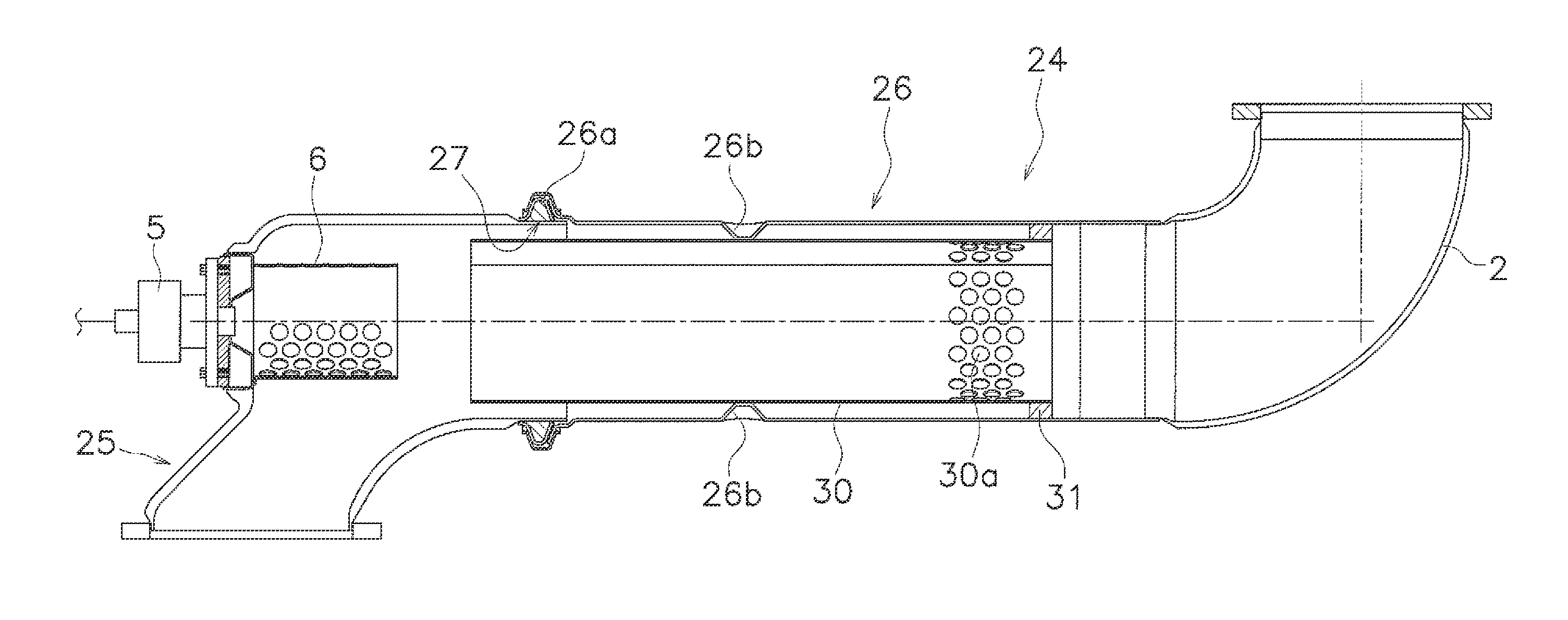

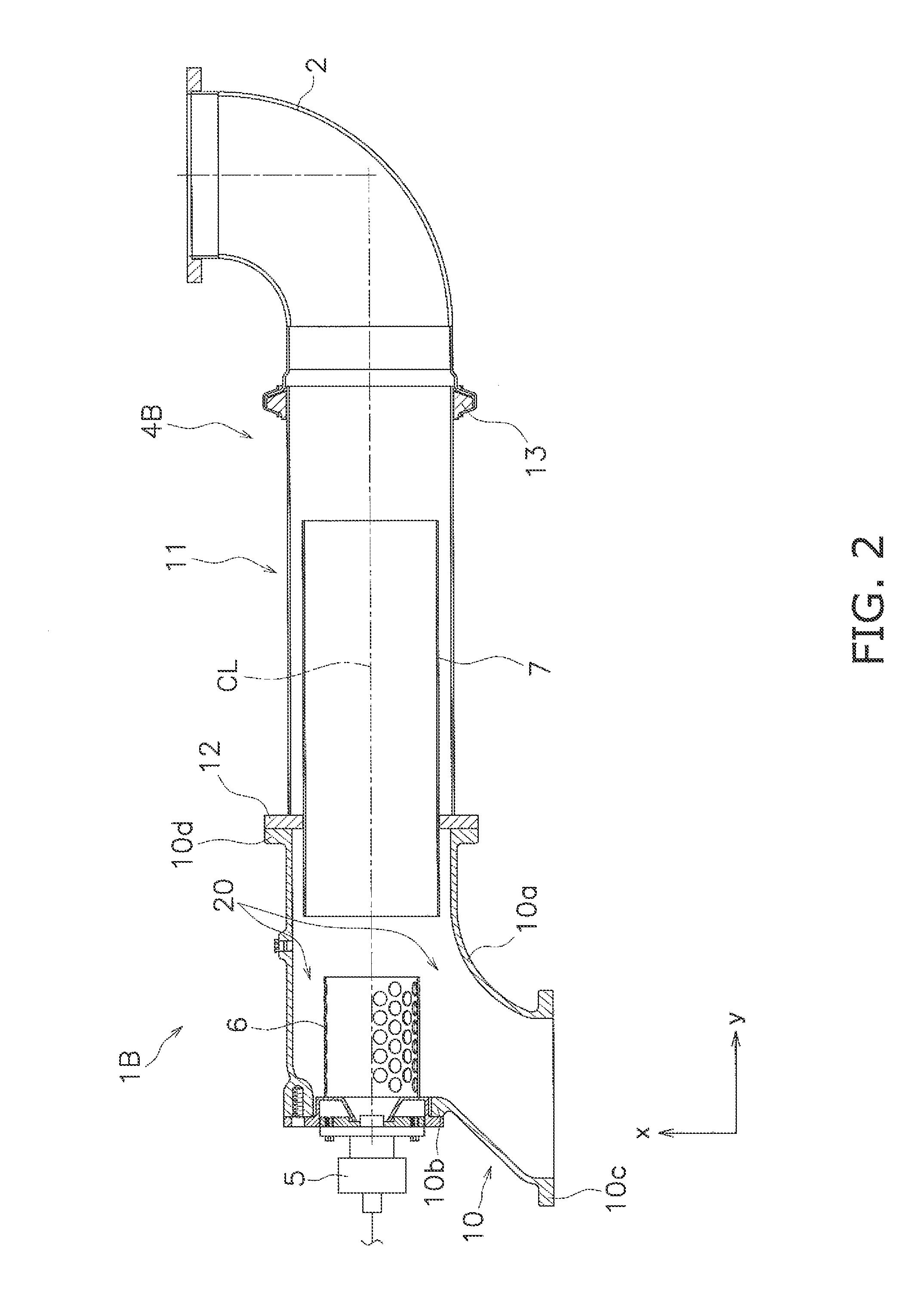

Reducing agent aqueous solution mixing device and exhaust gas post-treatment device

ActiveUS20130164182A1Efficient heatingReduce decompositionCombination devicesInternal combustion piston enginesExhaust fumesEngineering

A reducing agent aqueous solution mixing device includes an exhaust pipe, an injector, a mixing pipe and an inner pipe. The exhaust pipe includes an elbow part having a curved portion, and a linear part disposed on the downstream side of the elbow part. The injector is disposed outside the curved portion and injects the reducing agent aqueous solution towards the linear part. The mixing pipe is disposed inside the elbow part to enclose a surrounding of the reducing agent aqueous solution injected from the injector, and includes a plurality of openings on an outer peripheral surface thereof. The inner pipe is disposed on the downstream side of the mixing pipe and spaced apart from an outlet portion of the mixing pipe and from an inner wall of the linear part, and allows the exhaust gas to flow through the inside thereof and the outer periphery thereof.

Owner:KOMATSU LTD

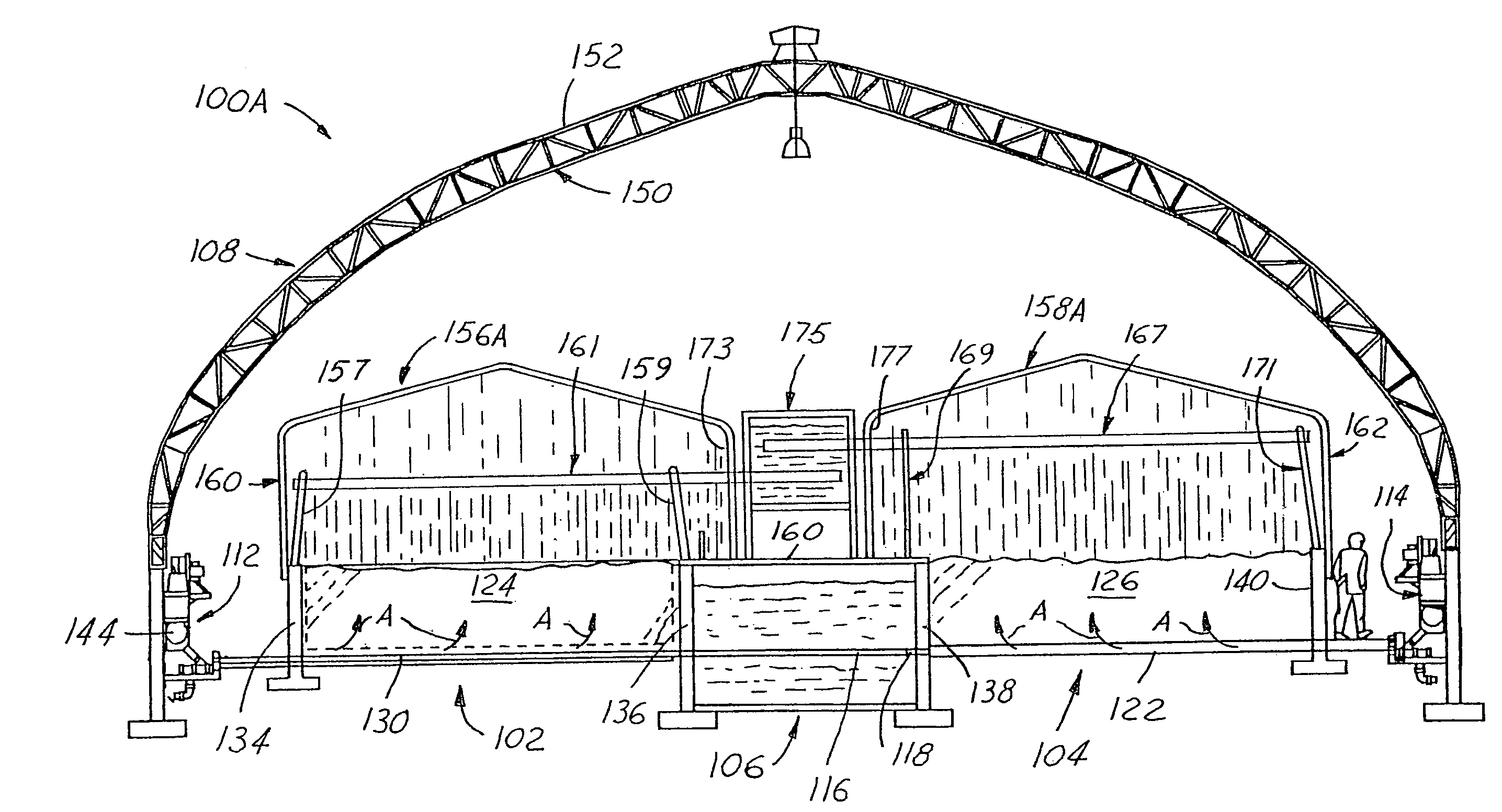

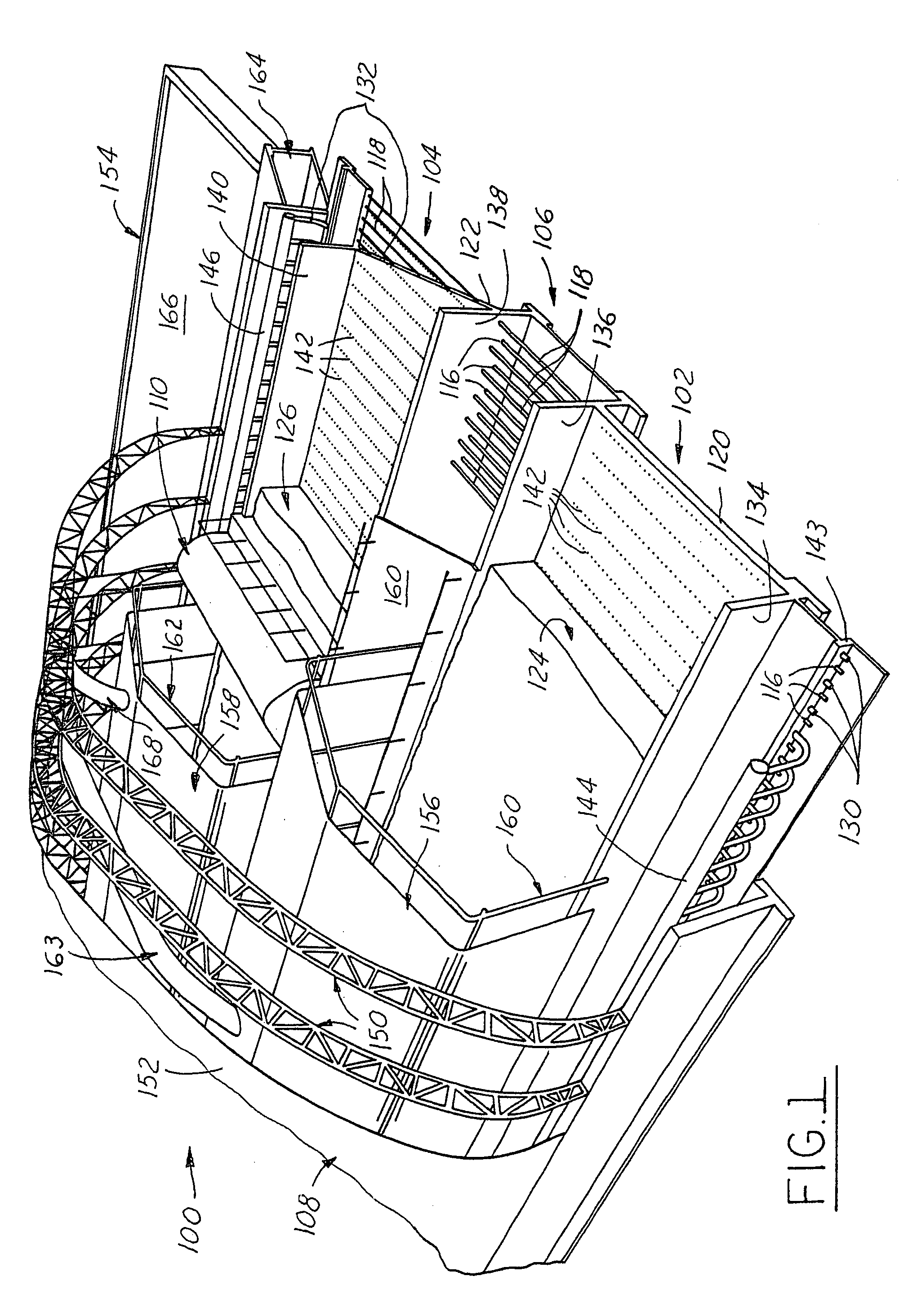

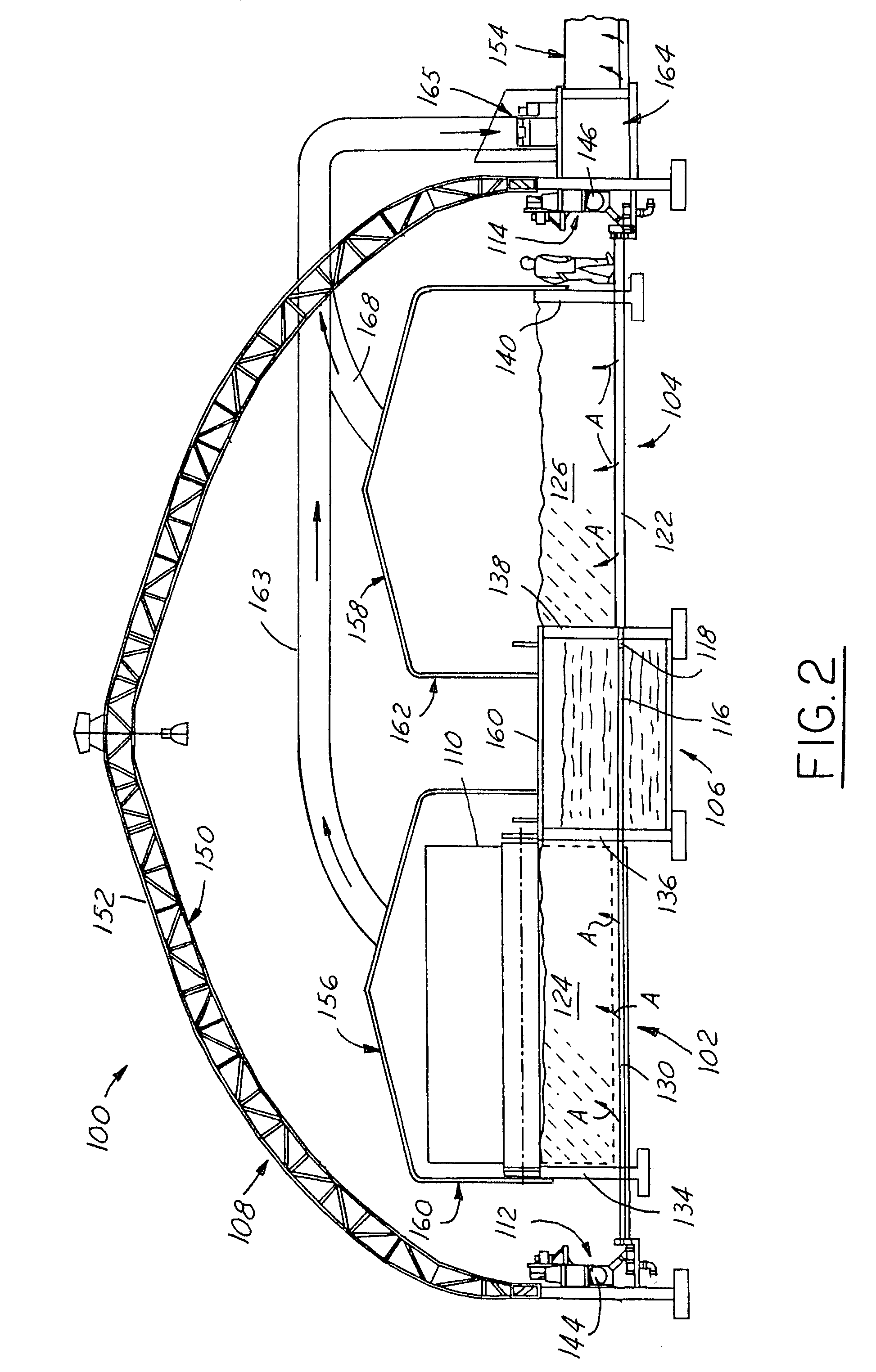

Biomass heating system

InactiveUS7135332B2Improve heating effectMaximize biomass decomposition service lifetimeBioreactor/fermenter combinationsBio-organic fraction processingBasementGrowth plant

Improved systems, methods, apparatus and compositions for generating, extracting and distributing the renewable heat energy produced by microbial decomposition of organic biomass within a contained and controlled environment. This heat energy is preferably transferred and distributed, preferably by the use of heat pipes, to the interior of a greenhouse or other structure to be heated, either directly or via heat exchange apparatus such as hot water heating systems. In one embodiment heat transfer and distribution mechanism customized to the application requirements of a greenhouse heating batch-type process is disclosed, along with a recipe for a readily available biomass material composition that will slowly decompose while it generates a substantial quantity of usable heat energy to be consumed in the elevation of temperature in a separated greenhouse basement confinement area. Additional continuous and batch process embodiments of biomass heating systems are also disclosed that extract heat energy from decomposing biomass for heating uses. In some embodiments gaseous products generated in a biological decomposition process, primarily CO2, are utilized to enhance plant growth in the greenhouse environment.

Owner:AGRILAB TECH INC

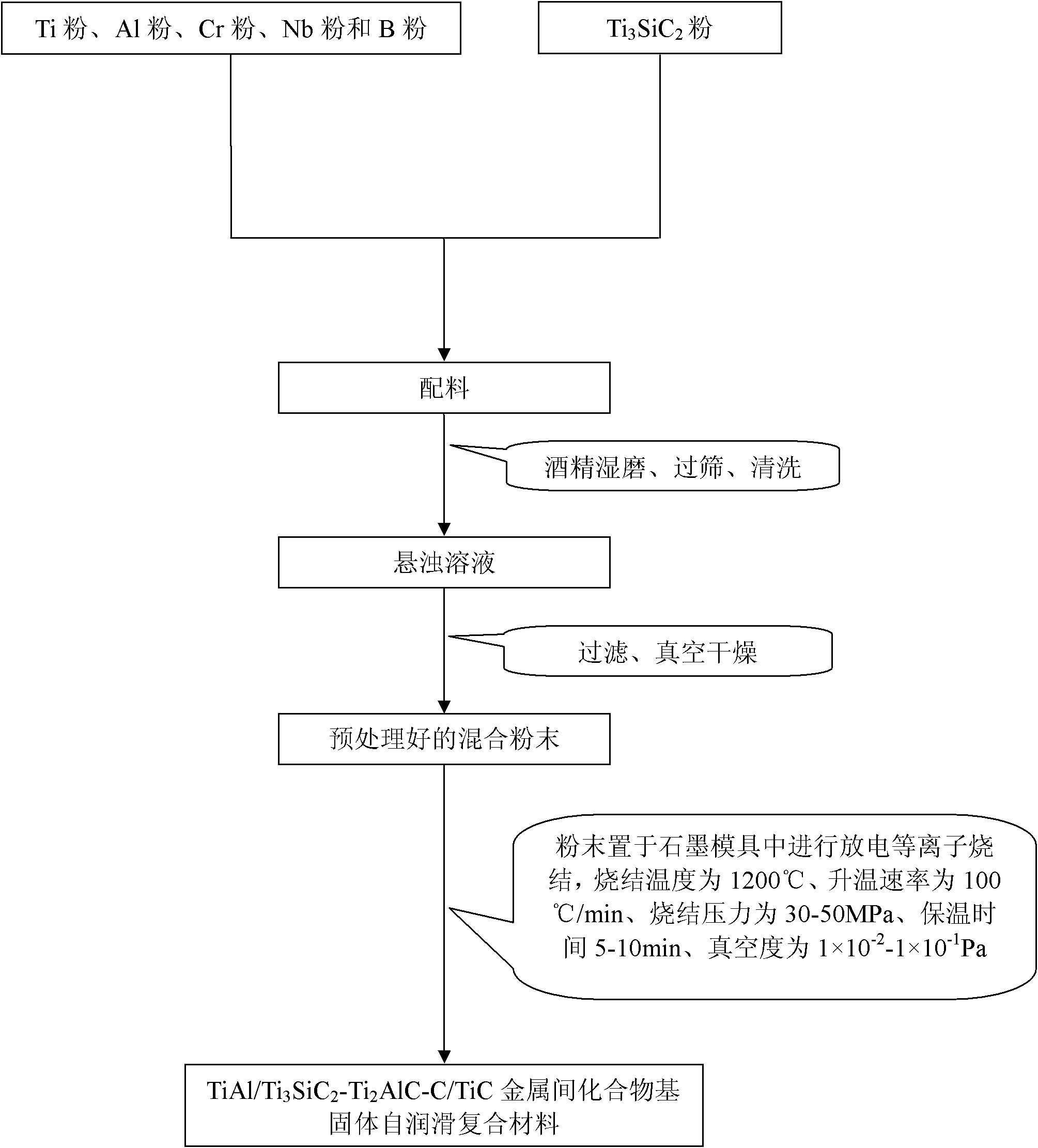

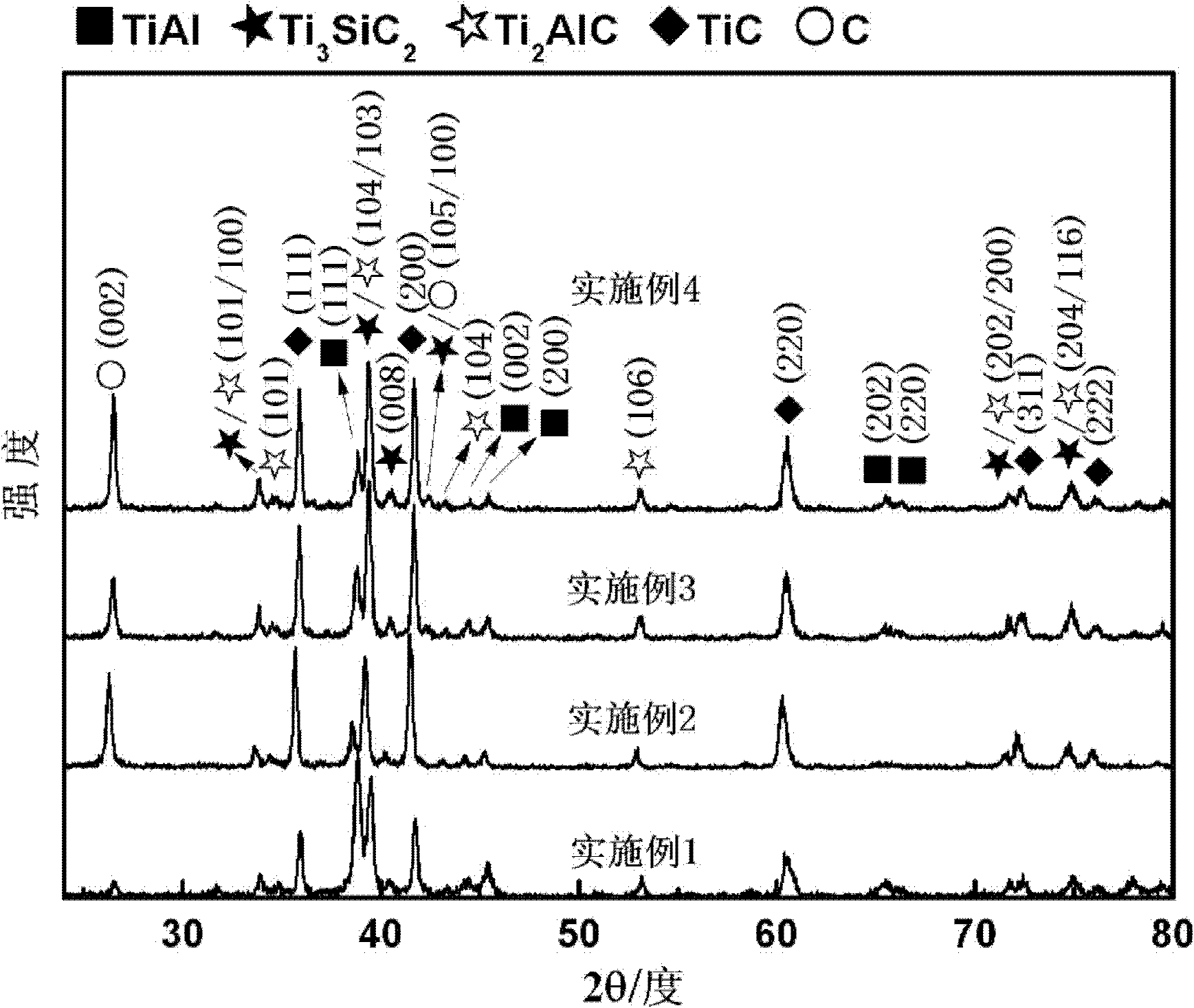

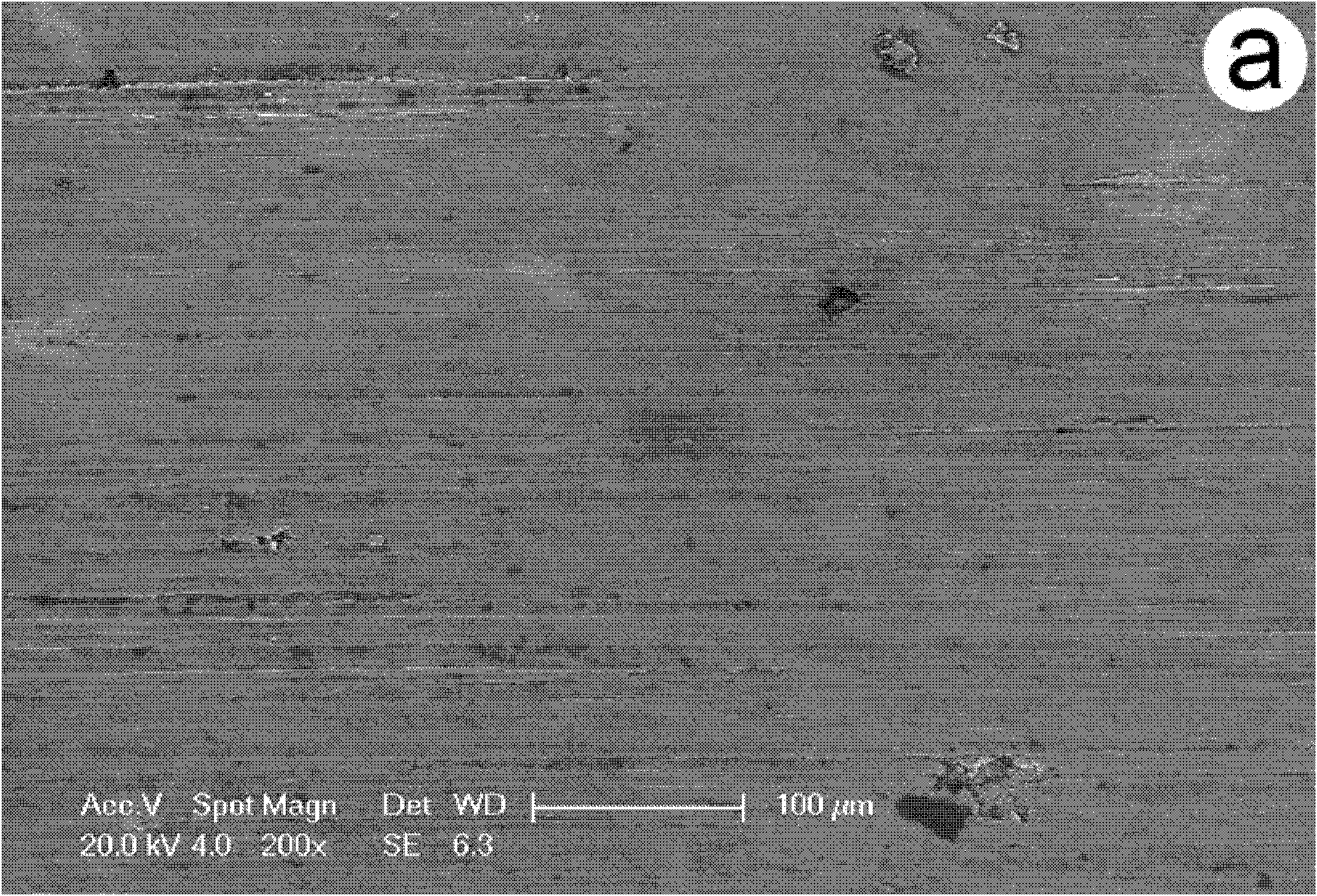

TiAl intermetallic compound-based solid seif-lubricating composite material and preparation method thereof

The invention relates to a TiAl intermetallic compound-based solid seif-lubricating composite material which comprises Ti3SiC2, Ti2AlC and C which are used as the ternary composite lubricating phase and TiC which is used as the reinforced phase, and a preparation method thereof. The TiAl intermetallic compound-based solid seif-lubricating composite material is characterized in that the material is prepared from Ti powder, Al powder, Cr powder, Nb powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ti, Al, Cr, Nb and B is 48:47:2:2:1 and the dosage of the Ti3SiC2 powder is 5-20wt.% of the total weight of the Ti powder, Al powder, Cr powder, Nb powder and B powder. The TiAl / Ti3SiC2-Ti2AlC-C / TiC intermetallic compound-based solid seif-lubricating composite material synthesized by the method is novel in component design (the intermetallic compound matrix, the composite lubricating phase and the reinforced phase), high in density, good in tribological properties, stable in technological parameters, fast and simple in preparation process and easy in operation and the method is suitable to be used to prepare the high performance TiAl intermetallic compound-based solid seif-lubricating composite material.

Owner:WUHAN UNIV OF TECH

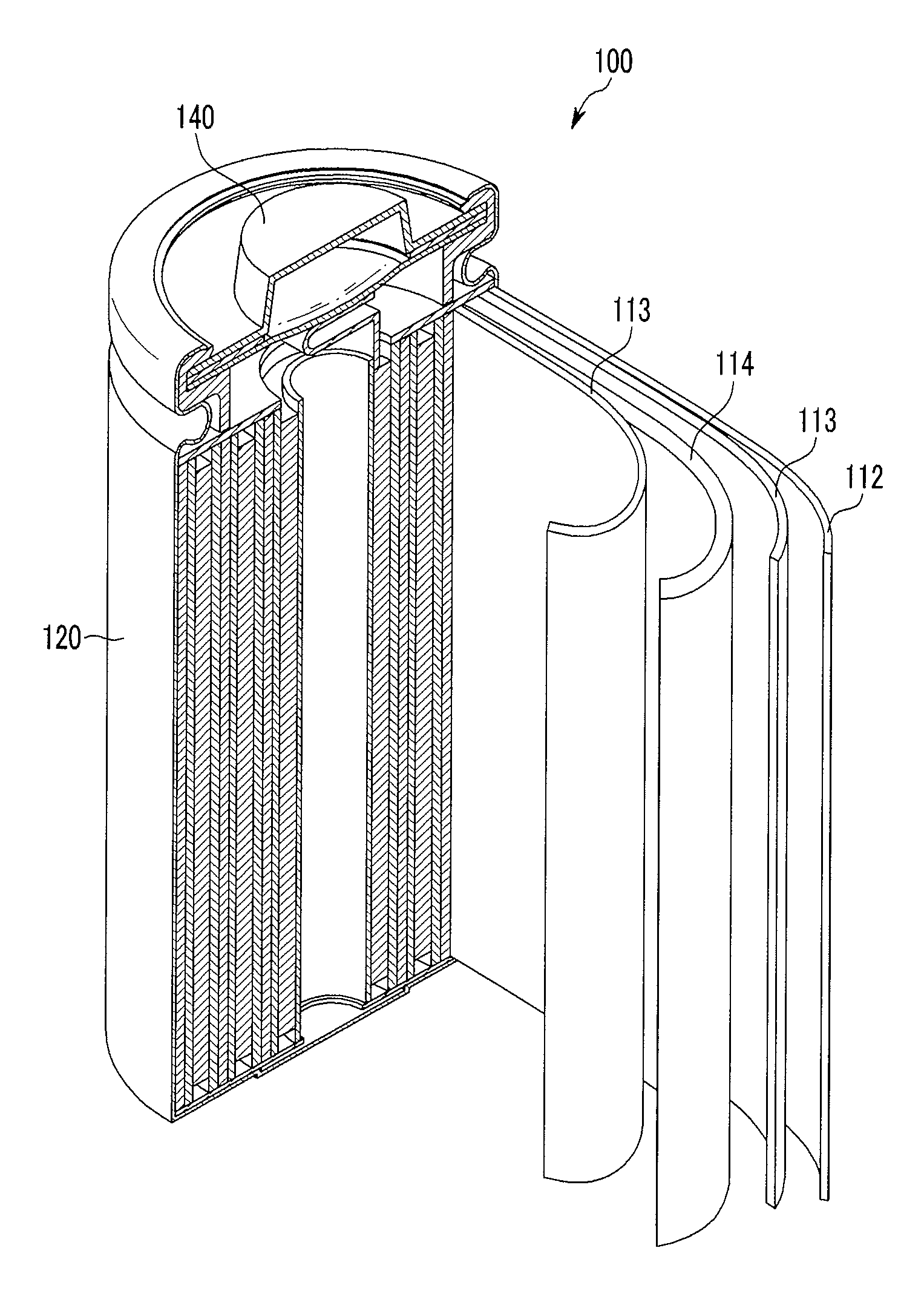

Lithium ion battery adopting lithium-rich manganese-based material as positive electrode and preparation method of lithium ion battery

InactiveCN103560250AIncrease energy densityStable structureMaterial nanotechnologyElectrode carriers/collectorsHigh energyManganese

The invention discloses a lithium ion battery adopting a lithium-rich manganese-based material as a positive electrode and a preparation method of the lithium ion battery. The lithium ion battery adopting the lithium-rich manganese-based material as the positive electrode comprises a positive electrode, a positive electrode surface coating, a negative electrode, a diaphragm and electrolyte. The lithium ion battery adopting the lithium-rich manganese-based material as the positive electrode has the advantages of high energy density, good multiplying power property and long cycling service life.

Owner:TIANJIN ENERGIES

Flame Retardant Electrolyte for Rechargeable Lithium Battery and Rechargeable Lithium Battery Including the Same

ActiveUS20100209782A1Reduce and eliminate decompositionImproved thermal stability and flame retardancyFinal product manufactureElectrode carriers/collectorsSolventAmmonium Cation

Flame retardant electrolyte solutions for rechargeable lithium batteries and lithium batteries including the electrolyte solutions are provided. The flame retardant electrolyte solution includes a lithium salt, a linear carbonate-based solvent, at least one ammonium cation, a phosphoric acid-based solvent, and an additive including oxalatoborate.

Owner:SAMSUNG SDI CO LTD

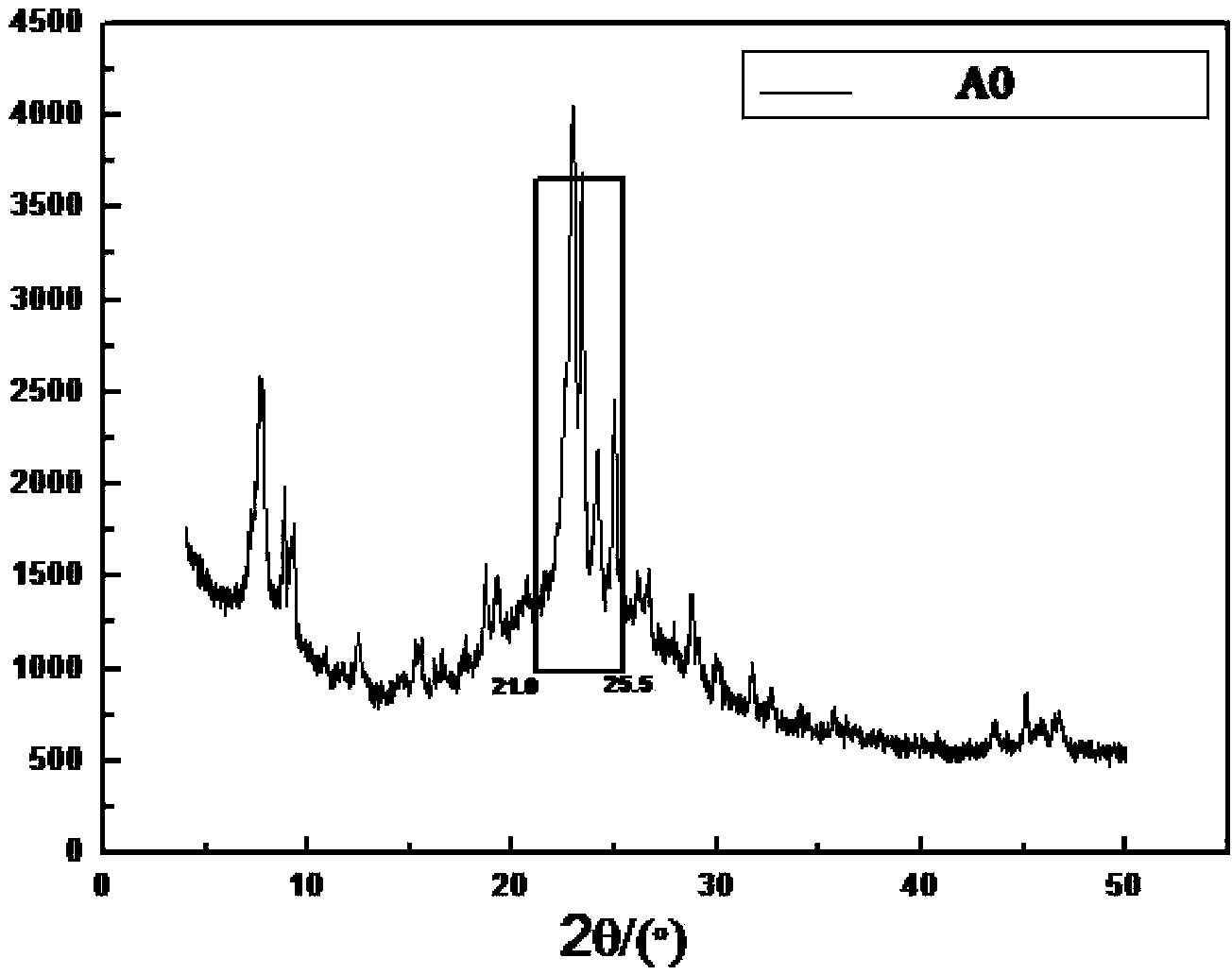

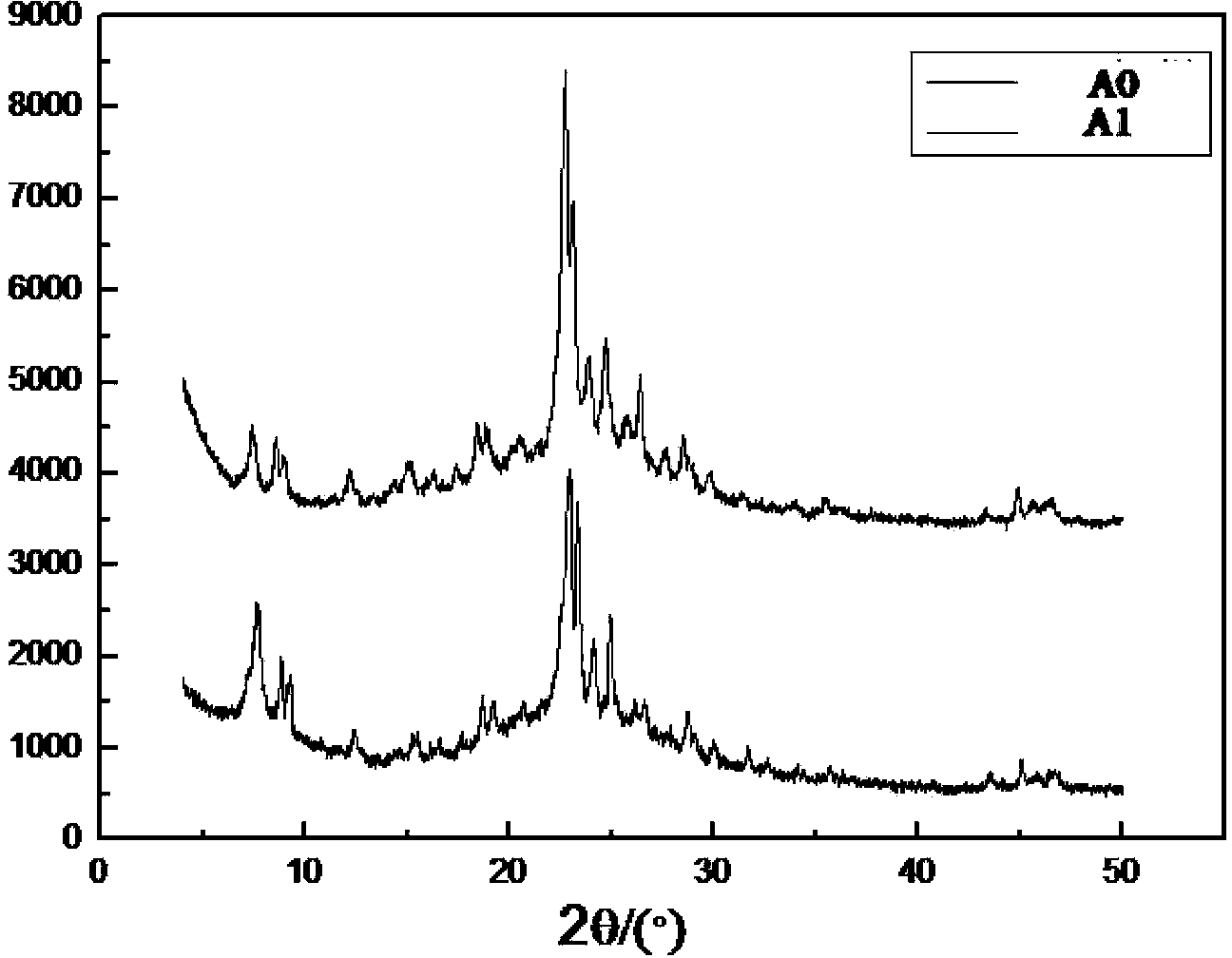

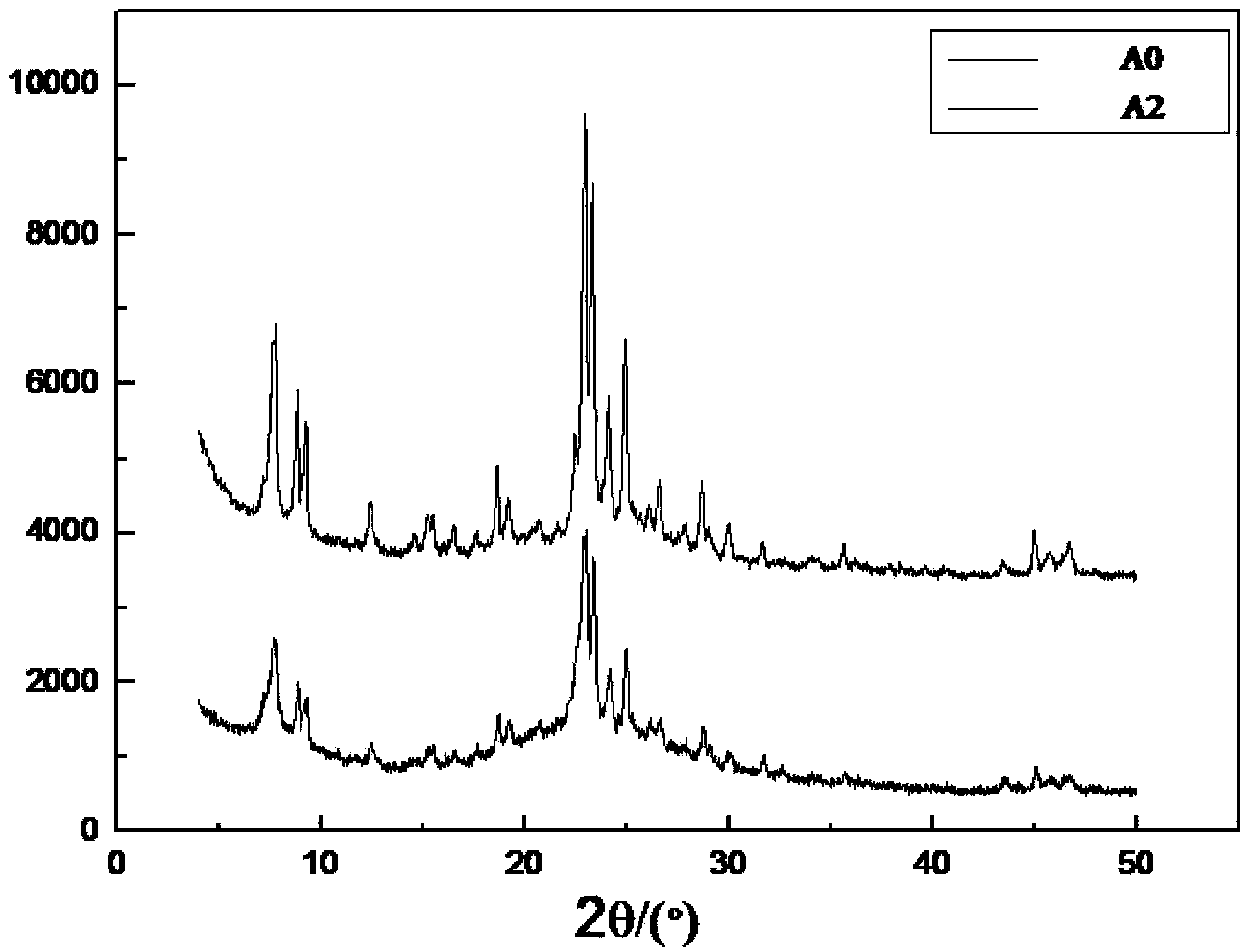

Synthesis method of IM-5 molecular sieve

ActiveCN103723740ASolve the problem of crystallinityHigh crystallinityCrystalline aluminosilicate zeolitesMolecular sieveColloid

The invention provides a synthesis method of an IM-5 molecular sieve. The method comprises the steps of: (1) under a stirring condition, contacting an aluminum source-containing mixed solution with a silicon source to make a colloid, with the aluminum source-containing mixed solution being an aqueous solution containing inorganic alkali, a mineralizer, an aluminum source and a template agent; and (2) under crystallization reaction conditions, subjecting the colloid to hydrothermal crystallization. According to the composition of the colloid, the mole ratio of the inorganic alkali, the mineralizer, the aluminum source, the template agent, the silicon source and water satisfies the following formula: SiO2:Al2O3:M2O:MX:SDA:H2O=10:(0.1-1):(1-10):(0.1-5):(0.1-4):(50-500). The silicon source is SiO2, the aluminum source is Al2O3, the inorganic alkali is M2O, MX is the mineralizer, and SDA is the template agent. The mineralizer is a metal halide able to regulate the molecular sieve crystal growth. The method can be used for preparing the IM-5 molecular sieve with enhanced crystallinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-voltage lithium-ion battery electrolyte

InactiveCN104466250AImprove electrochemical reactivityPromote circulationSecondary cellsOrganic electrolytesElectrolytic agentPhysical chemistry

The invention relates to the technical field of lithium-ion battery electrolytes, in particular to a high-voltage lithium-ion battery electrolyte. The high-voltage lithium-ion battery electrolyte comprises non-aqueous solvent, lithium salt and an additive. The additive comprises the mixture of phosphonitrile, annular sulphate and hydrogen fluoroether. The high-voltage lithium-ion battery electrolyte can form a film on the surface of an electrode through the synergistic effect of the phosphonitrile, the annular sulphate and the hydrogen fluoroether, oxygenolysis of the electrolyte is restrained, and the cycle performance of 4.5 V and 5.0 V high-voltage lithium-ion batteries is obviously improved.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

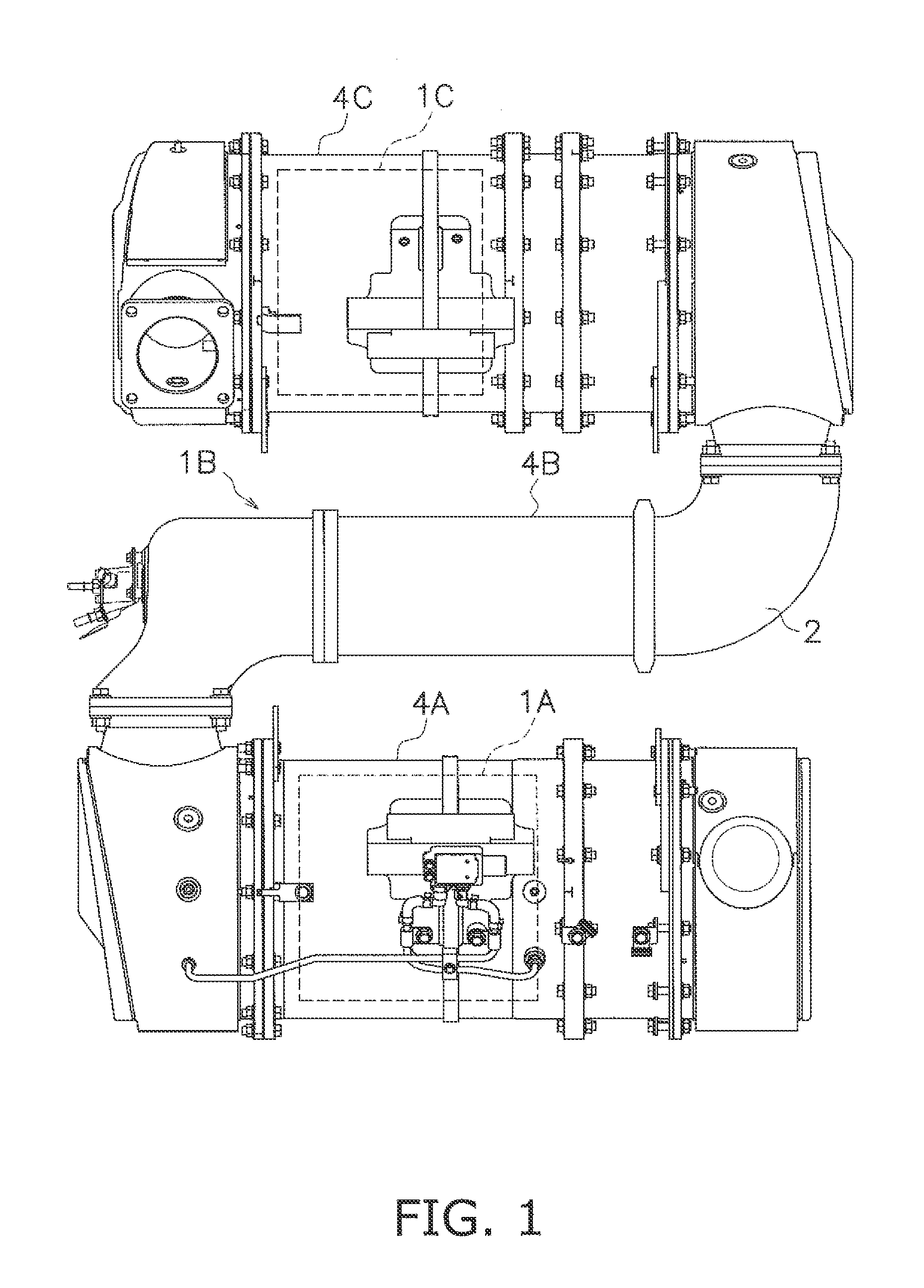

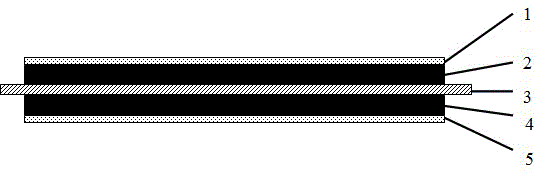

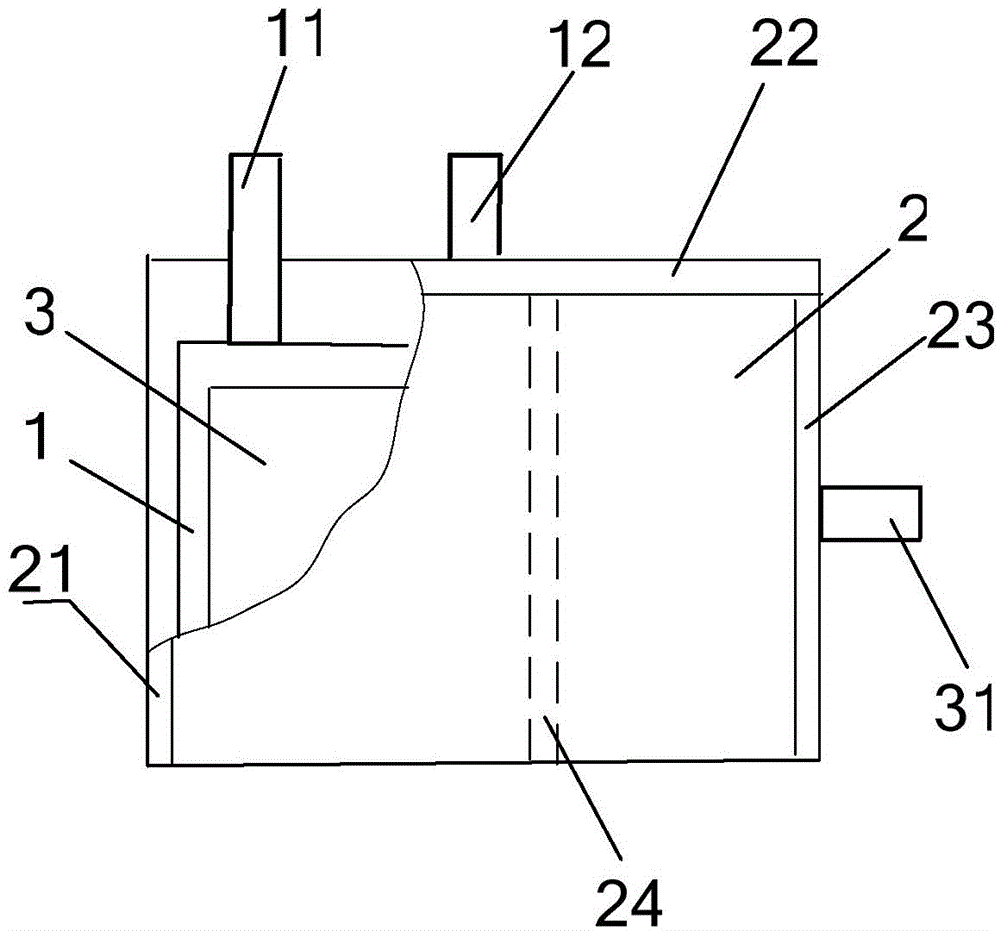

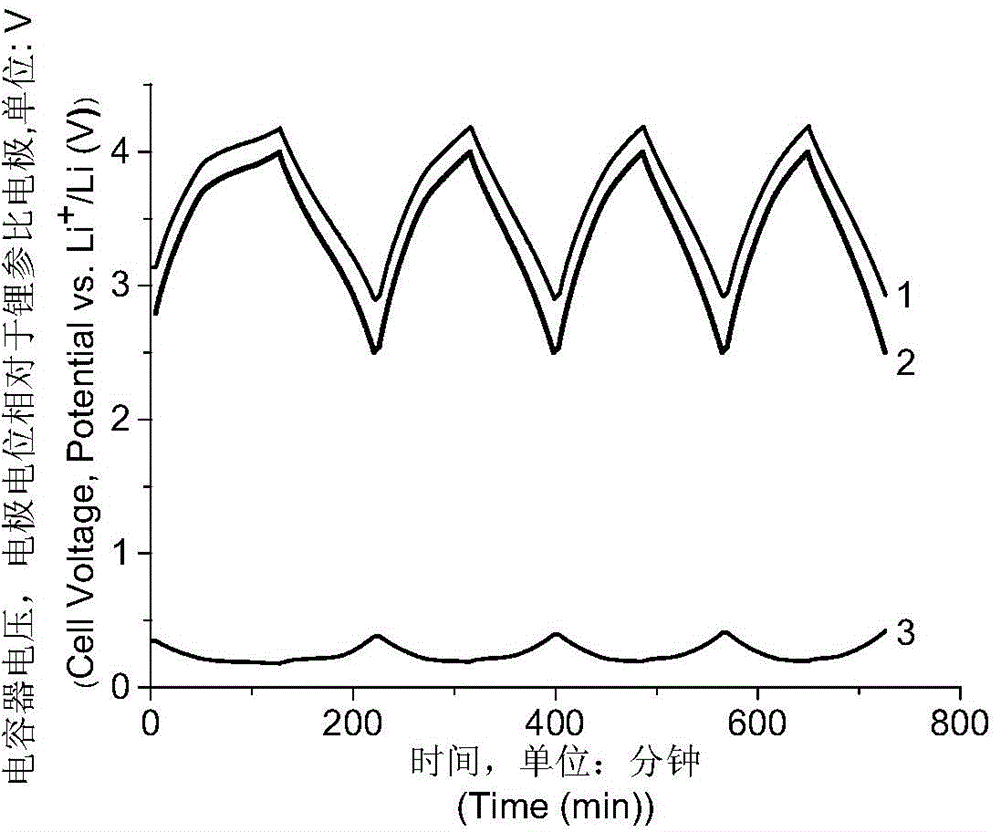

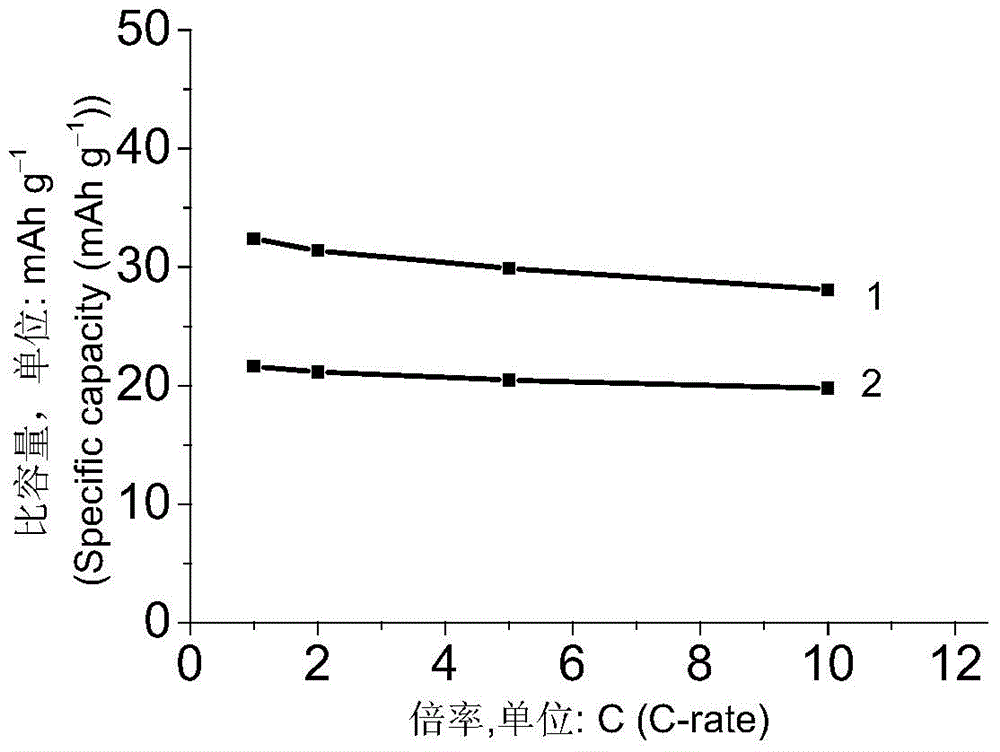

Manufacturing method of lithium ion mixed type capacitor and lithium ion mixed type capacitor

ActiveCN104008893AReduce decompositionLow cycle lifeDouble layer capacitorsHybrid/EDL manufacturePower flowEngineering

A manufacturing method of a lithium ion mixed type capacitor comprises the following steps that (a) electrode pieces and a separation film are stacked or wound to form a cell according to the sequence of positive electrode / separation film / negative electrode; (b) the cell is put into an aluminum compound packing film shell body, the top edge and a first lateral edge of the aluminum compound packing film shell body are sealed in a heating mode, the electrode lugs of the positive electrode and the negative electrode of the cell extend out of the aluminum compound packing film shell body from the top edge; (c) a metal lithium electrode is put into the aluminum compound packing film shell body, is adjacent to the cell and is separated from the cell by the separation film, and the electrode lug of the metal lithium electrode extends out of the aluminum compound packing film shell body from a second lateral edge; (d) excessive electrolyte is injected into the aluminum compound packing film shell body, and then the second lateral edge of the aluminum compound packing film shell body is sealed in a heating mode; (e) in a constant current mode, the negative electrode serves as a working electrode, the metal lithium electrode serves as a counter electrode, and the negative electrode is pre-embedded; (f) the metal lithium electrode is taken out, the superfluous electrolyte is poured out, the second lateral edge of the aluminum compound packing film shell body is sealed in a vacuum heating mode, and the lithium ion mixed type capacitor is obtained.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

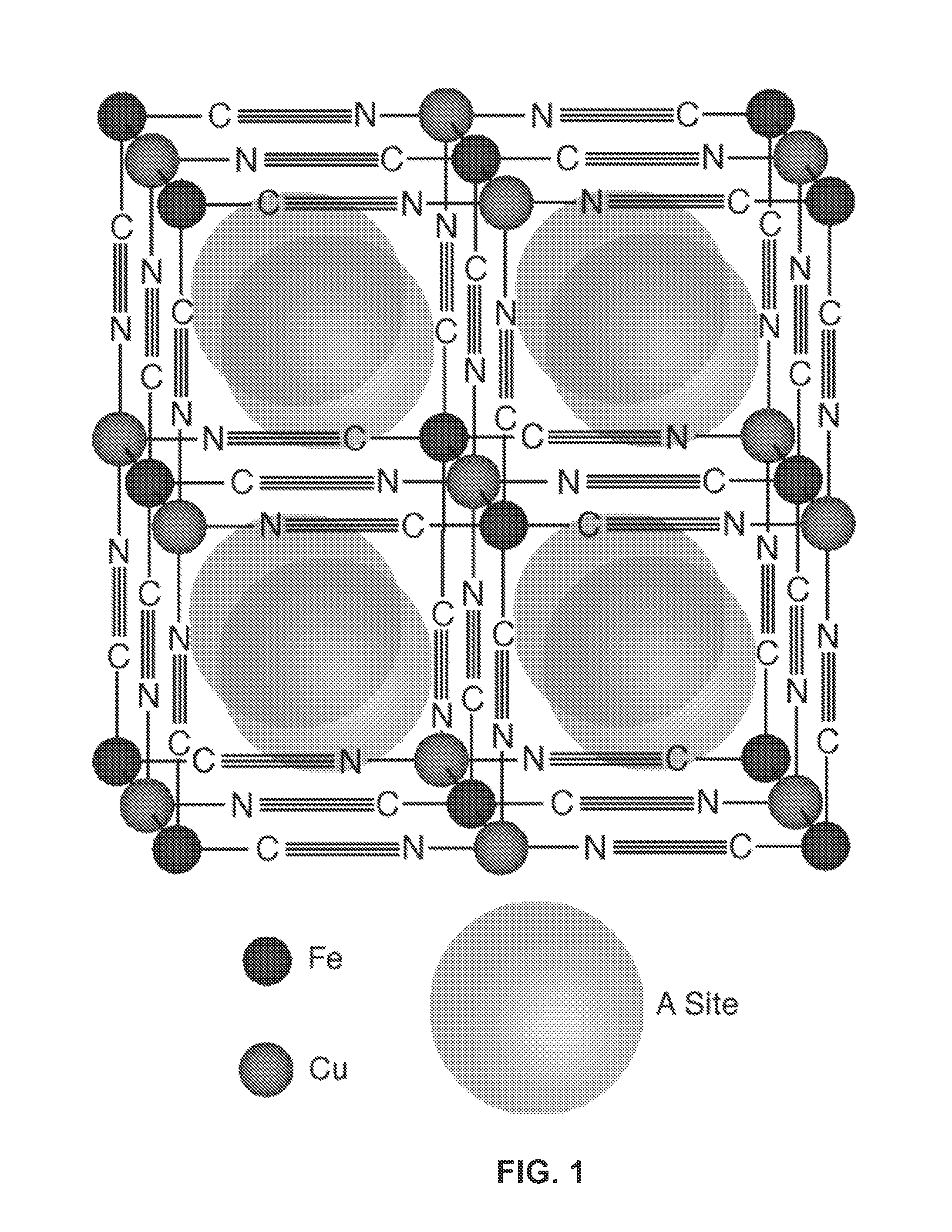

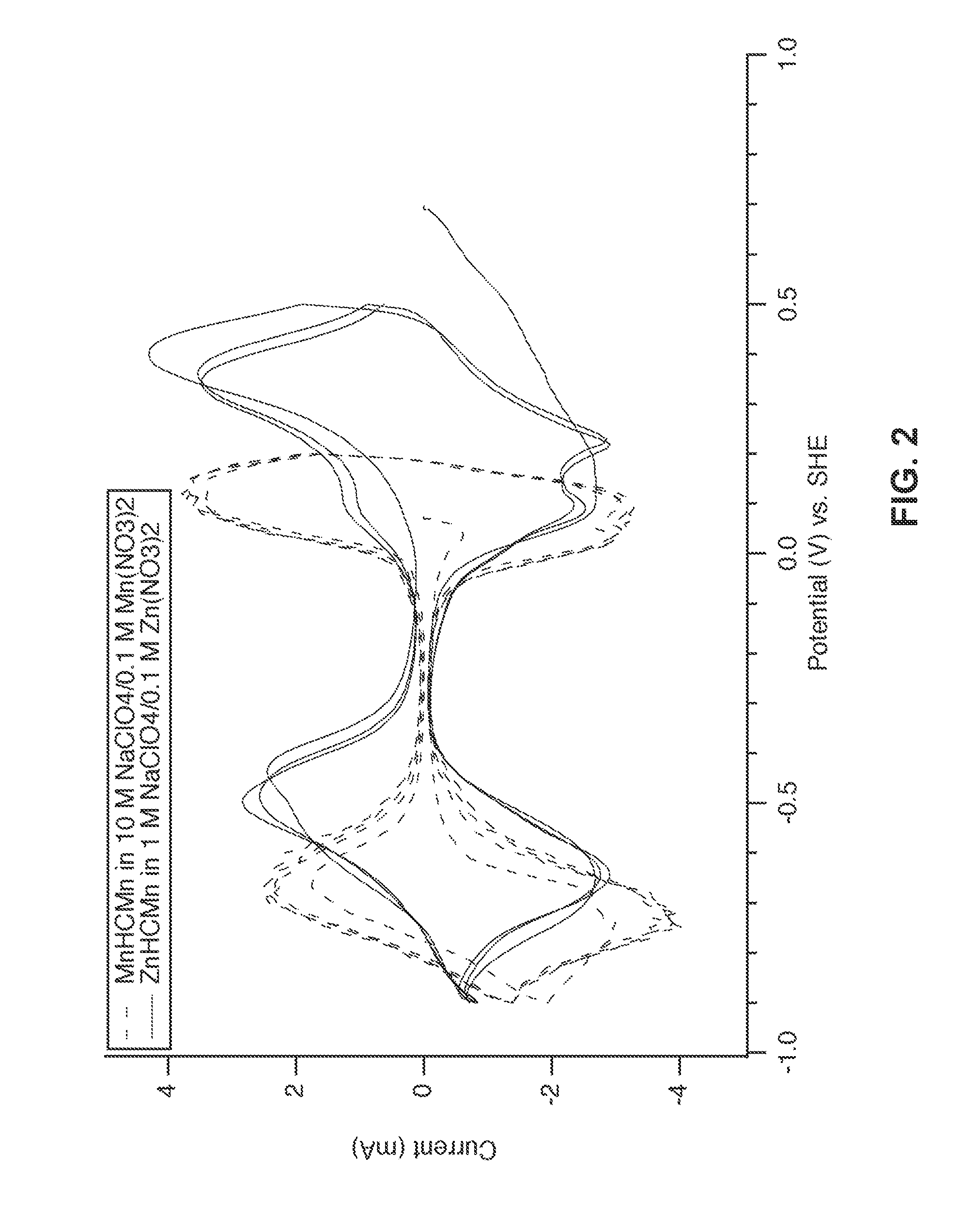

Prussian Blue Analogue Anodes for Aqueous Electrolyte Batteries

InactiveUS20140220392A1Maximizes energy storageReduces electrochemical decompositionIron cyanidesComplex cyanidesRedoxPrussian blue

A system and method producing electrodes in an aqueous electrolyte battery that maximizes energy storage, reduces electrochemical decomposition of the electrolyte, and uses Prussian Blue analogue materials for both electrodes, with an anode electrode including an electrochemically active hexacyanometalate group having two possible redox reactions of different potentials. These potentials may be tuned by substituting different electrochemically inactive components.

Owner:NATRON ENERGY INC

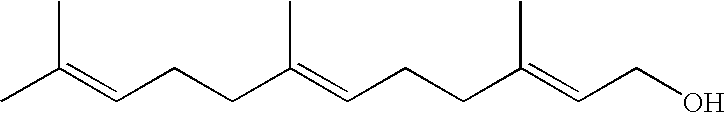

Sesquiterpene stabilized compositions

ActiveUS8133407B2Good chemical stabilityDelayed polymerizationOrganic detergent compounding agentsHalogenated hydrocarbon separation/purificationSesquiterpeneFarnesene

Provided is a composition comprising (a) at least one halogenated compound selected from the group consisting of C3-C5 hydrofluoroolefin, CF3I, and combinations thereof, and (b) an effective stabilizing amount of a sesquiterpene selected from the group consisting of farnesol, farnesene, and mixtures thereof.

Owner:HONEYWELL INT INC

Lithium battery including storage stabilized dioxolane-containing electrolyte

InactiveUS6255021B1Reduced self dischargeEasy to storeOrganic electrolyte cellsLi-accumulatorsOrganic solventOxygen

A nonaqueous electrolyte battery having improved storage stability is disclosed. The battery includes a positive electrode; s negative electrode in which the active material is lithium or a compound capable of absorbing and desorbing lithium; and a nonaqueous electrolyte containing an organic solvent, at least 10 wt % of which is dioxolane, a solute and a storage stabilizing additive which is an oxygen acid ester, isoxazole, oxazole or oxazoline or a derivative thereof. The additive reduces the self-discharge rate of the battery during storage.

Owner:SANYO ELECTRIC CO LTD

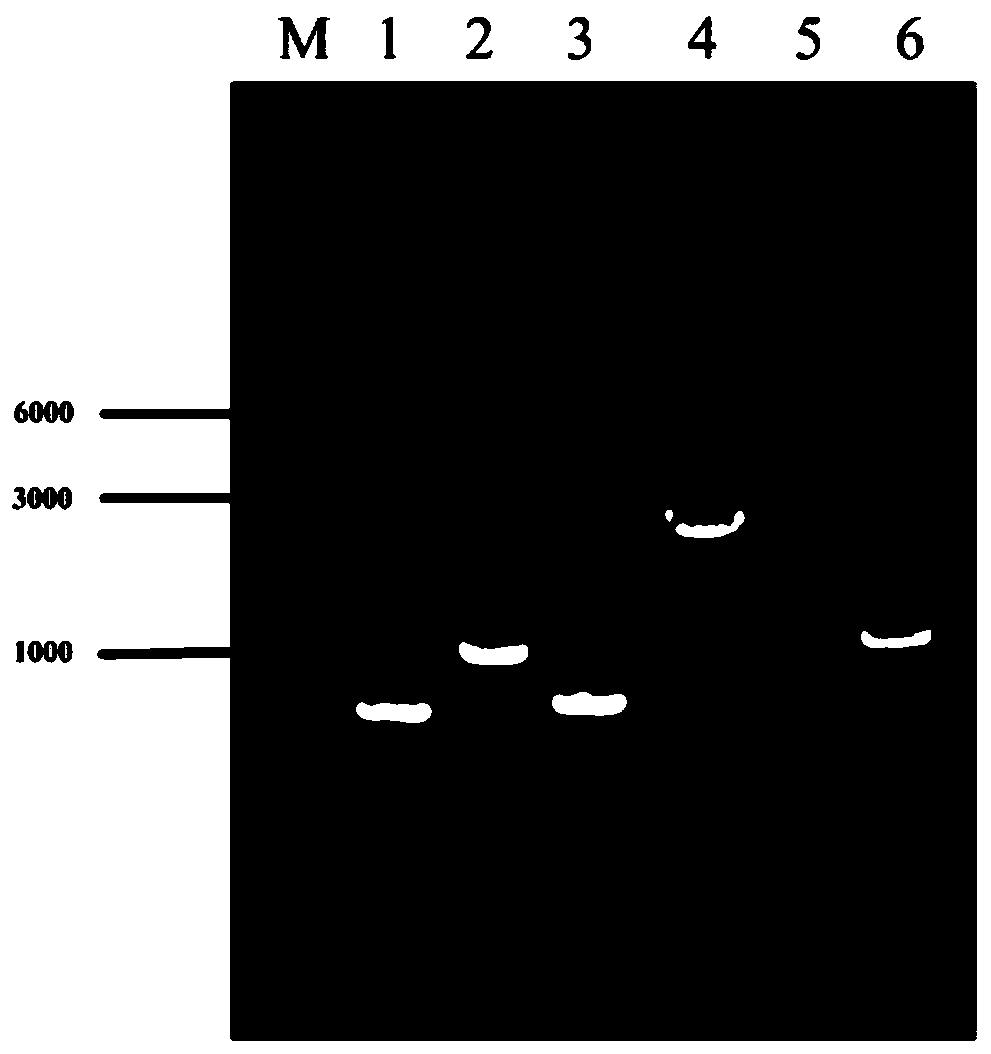

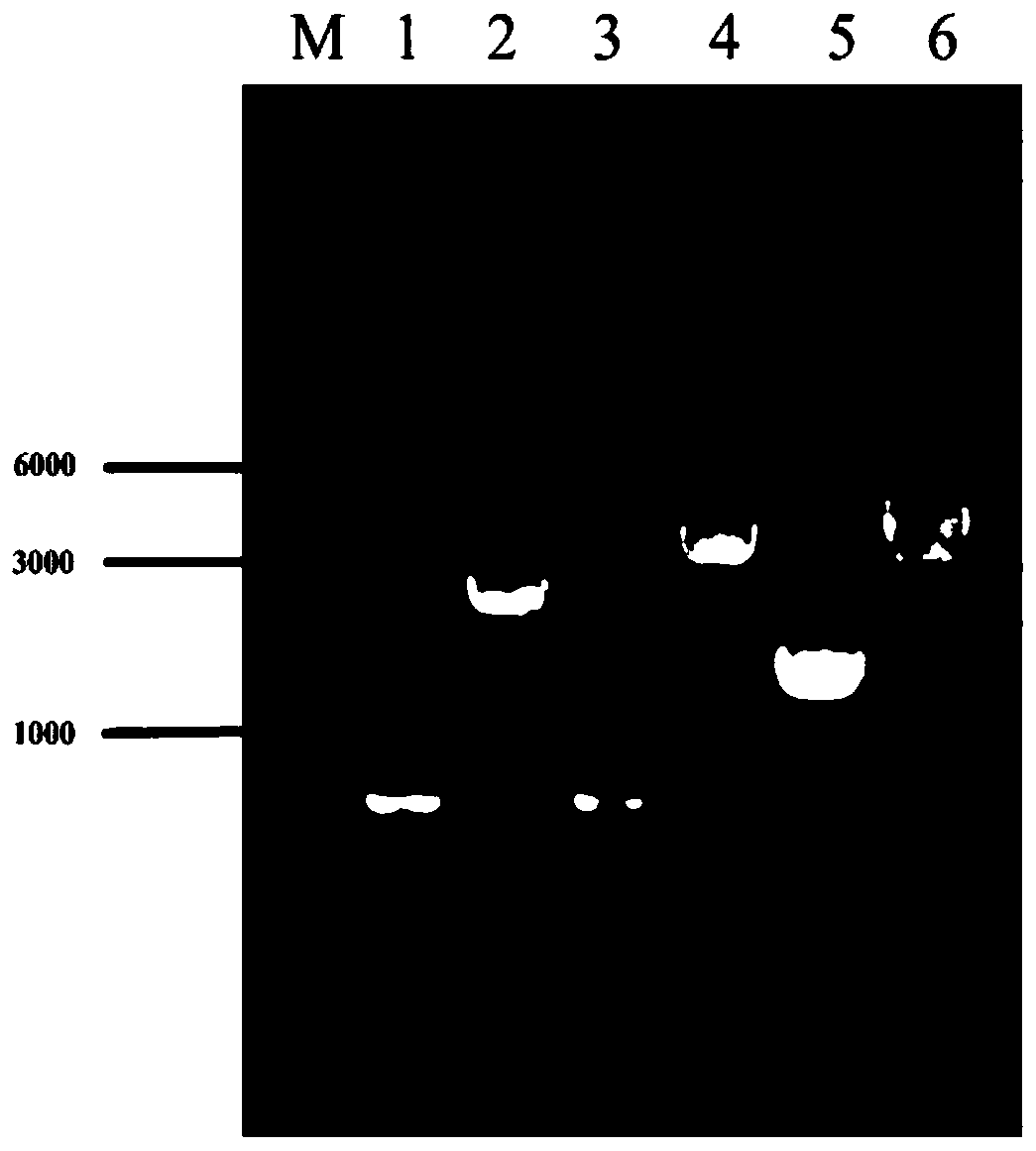

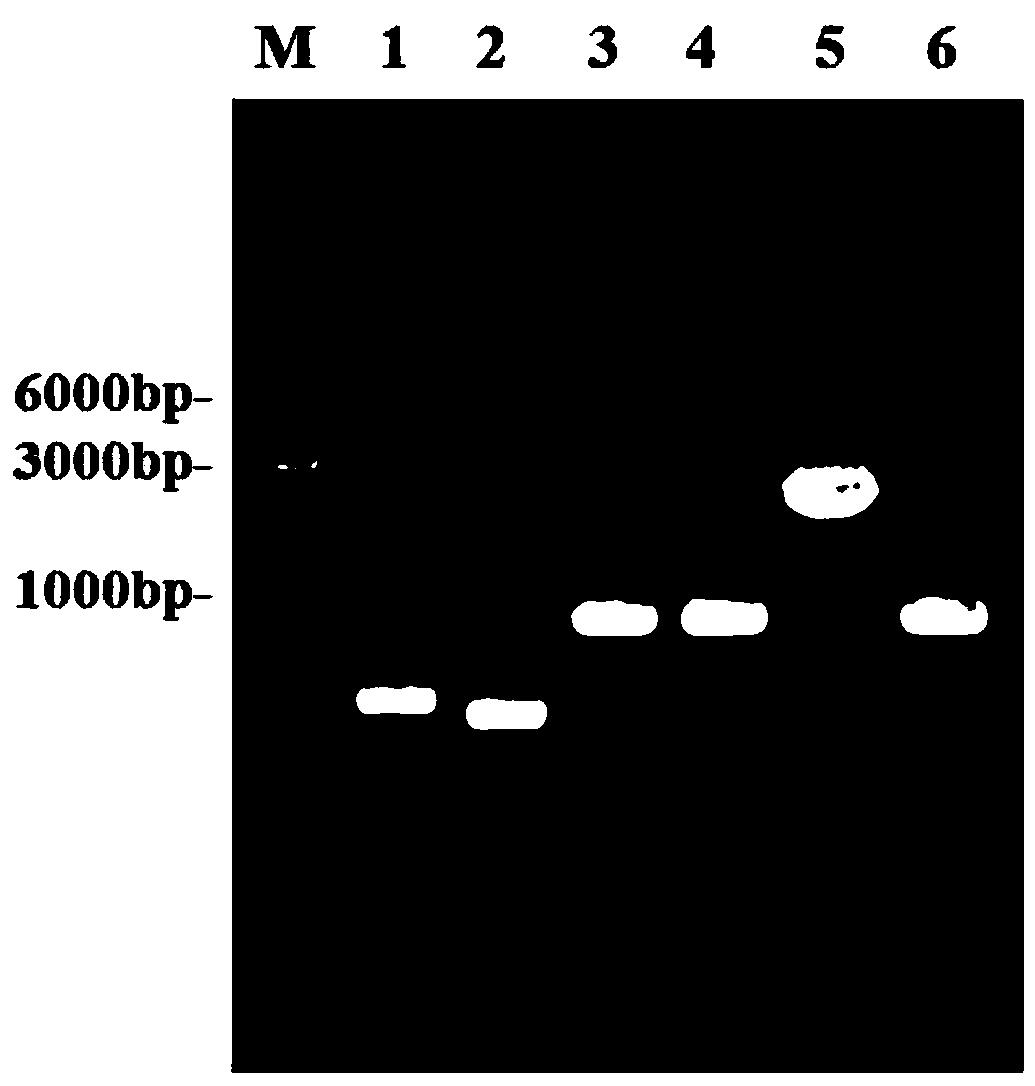

Genetically engineered bacterium for high-yielding L-valine and method for producing L-valine by fermentation

ActiveCN110607268AEasy to synthesizeReduce synthesisBacteriaHydrolasesLactate dehydrogenaseSaccharic acid

The invention provides a genetically engineered bacterium for high-yielding L-valine. A construction method of the genetically engineered bacterium comprises the steps that starting from an escherichia coli W3110, an acetolactate synthase gene alsS of a bacillus subtilis is integrated on a genome of the escherichia coli W3110 and subjected to high expression; an escherichia coli ppGpp 3'-pyrophosphoric acid hydrolytic enzyme mutant R290E / K292D gene spoT is integrated on the genome of the escherichia coli W3110 and subjected to high expression; genes of frdA, frdB, frdC and frdD of four subunits of a lactic dehydrogenase gene ldhA, a pyruvate formate lyase I gene pflB and fumaric reductase on the genome of the escherichia coli W3110 are knocked out; a branched chain amino acid transaminasegene ilvE of the escherichia coli is replaced with leucine dehydrogenase gene bcd of the bacillus subtilis; and an acetyl-hydroxyl acid isomerized reductase gene ilvC of the escherichia coli is replaced with an encoding gene of a mutant L67E / R68F / K75E. According to the genetically engineered bacterium for the high-yielding L-valine, an L-valine fermentation method is further modified. Double-phasedissolved oxygen control is adopted, and the L-valine yield and the saccharic acid conversion rate are improved.

Owner:TIANJIN UNIV OF SCI & TECH

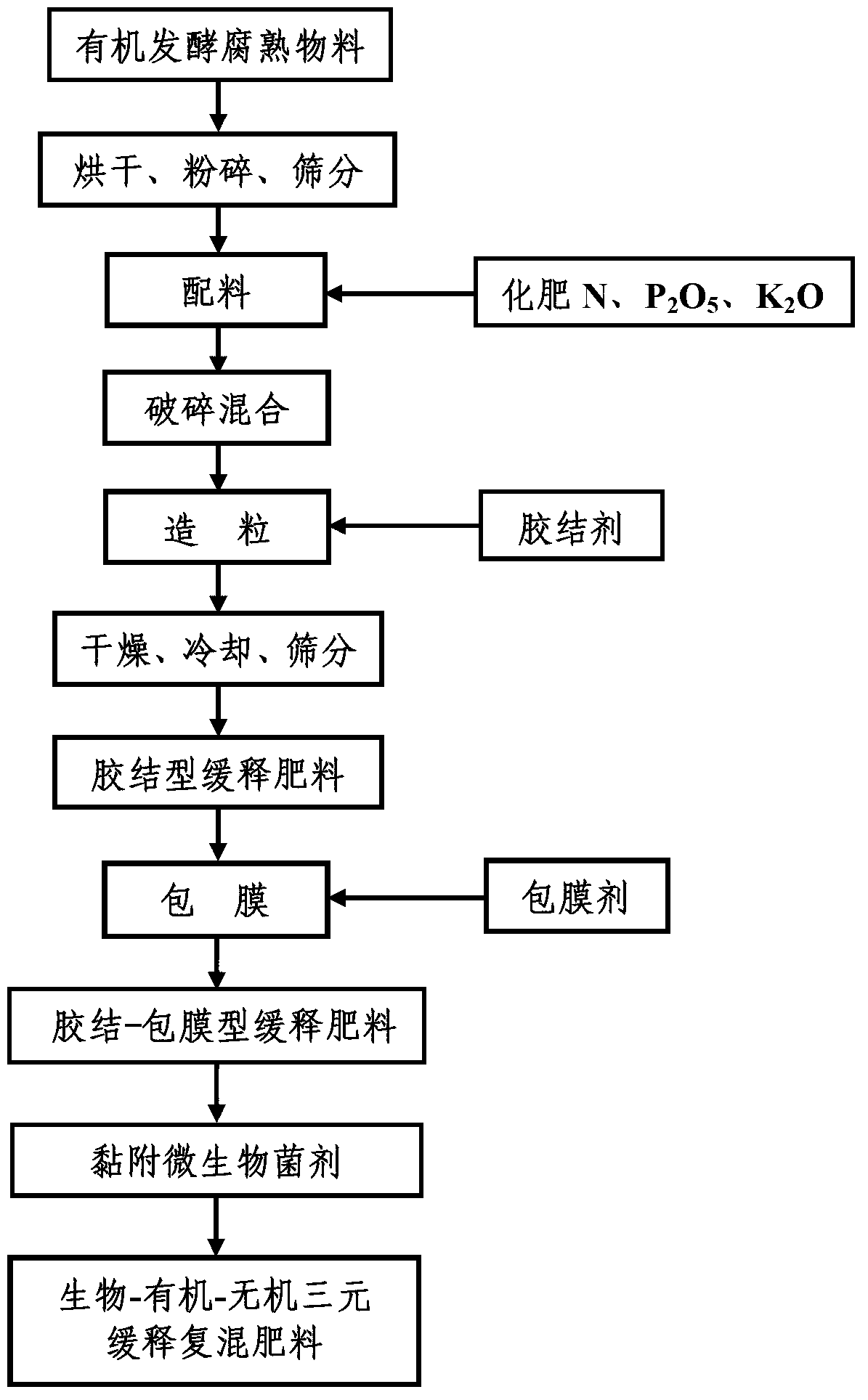

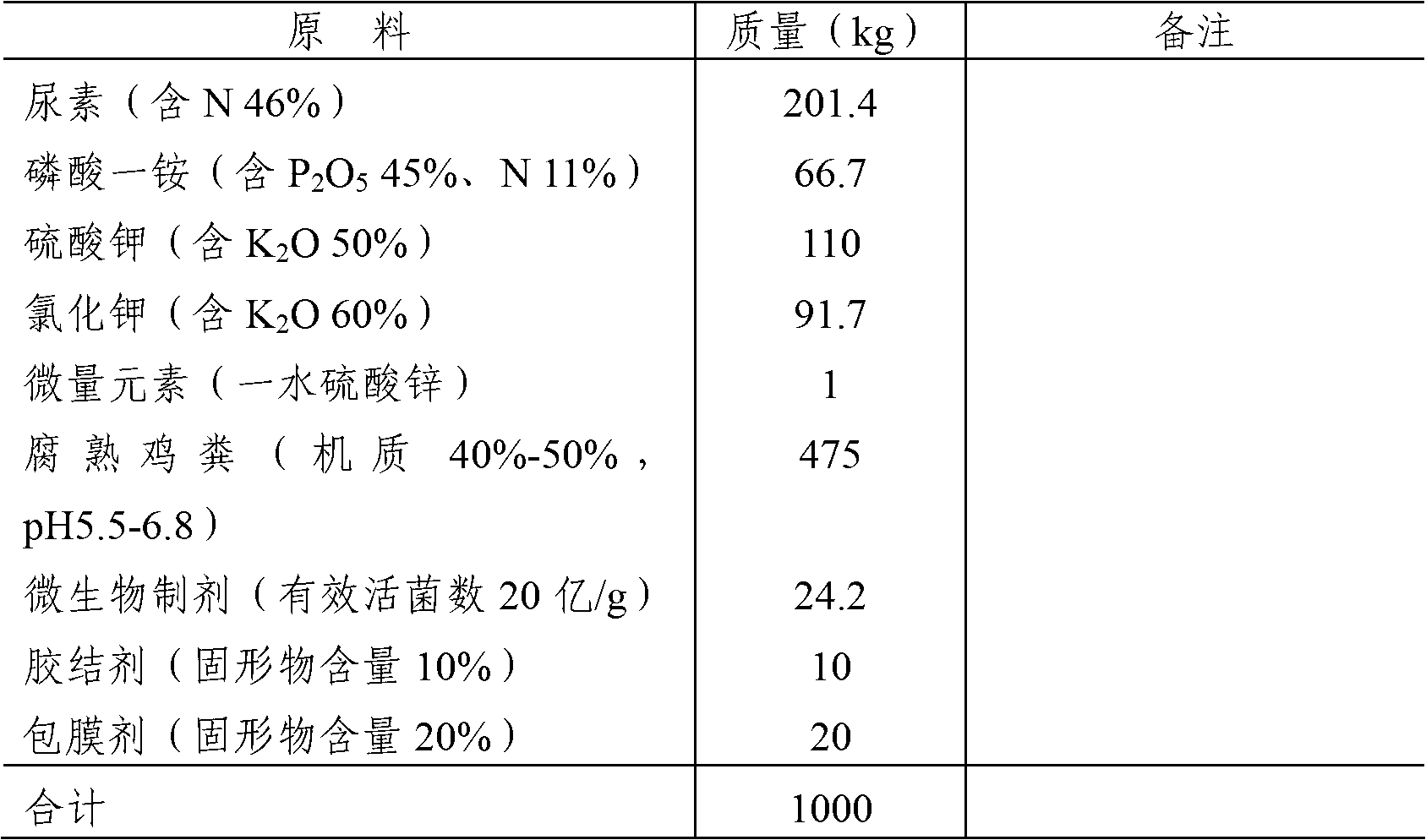

Ternary slow-release compound fertilizer and preparation method thereof

ActiveCN102838413ABig increase effectReduce decompositionFertilizer mixturesInorganic saltsMicrobial agent

The invention relates to a ternary slow-release compound fertilizer comprising a felted / coated type slow-release organic / inorganic compound fertilizer and a microbial agent, wherein the weight of the microbial agent is 0.5-5% of the weight of the felted / coated type slow-release organic / inorganic compound fertilizer. The invention further relates to a preparation method of the slow-release compound fertilizer. The ternary slow-release compound fertilizer provided by the invention is prepared by using the technological method comprising the steps of granulating through organic / inorganic compounding, coating an organic high-polymer on the surface of a product granule and adhering a microbial agent (powder) on the surface of the coating, so that affects on the activity and the group number of beneficial micro-organisms caused by inorganic salt and high impurity-bacterial rate of an inorganic fertilizer are avoided, and the effective viable count is kept to reach the standard. The preparation method provided by the invention is simple and convenient to operate and mild in condition, and can be used for realizing the industrial production by being cooperated with the traditional technical apparatus.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

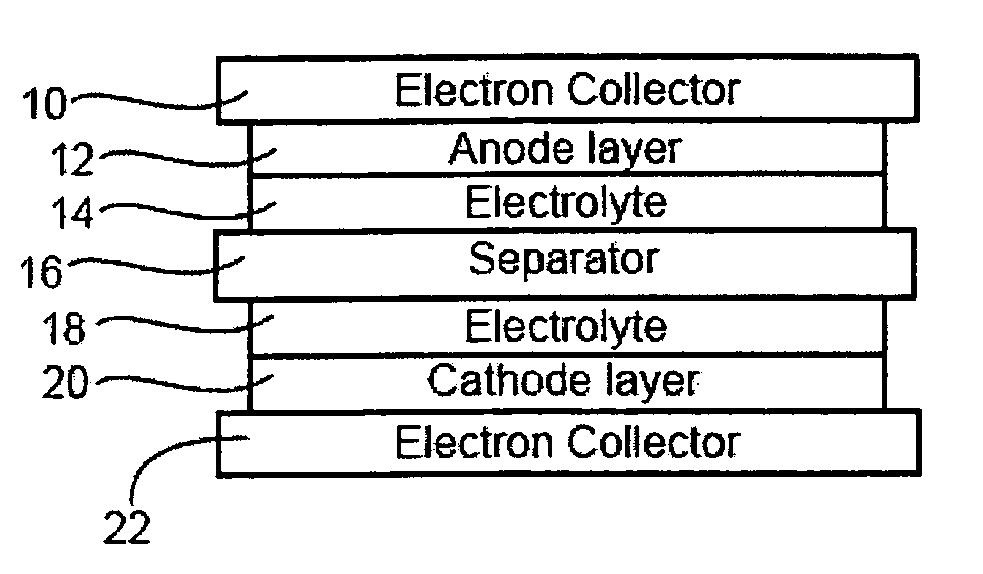

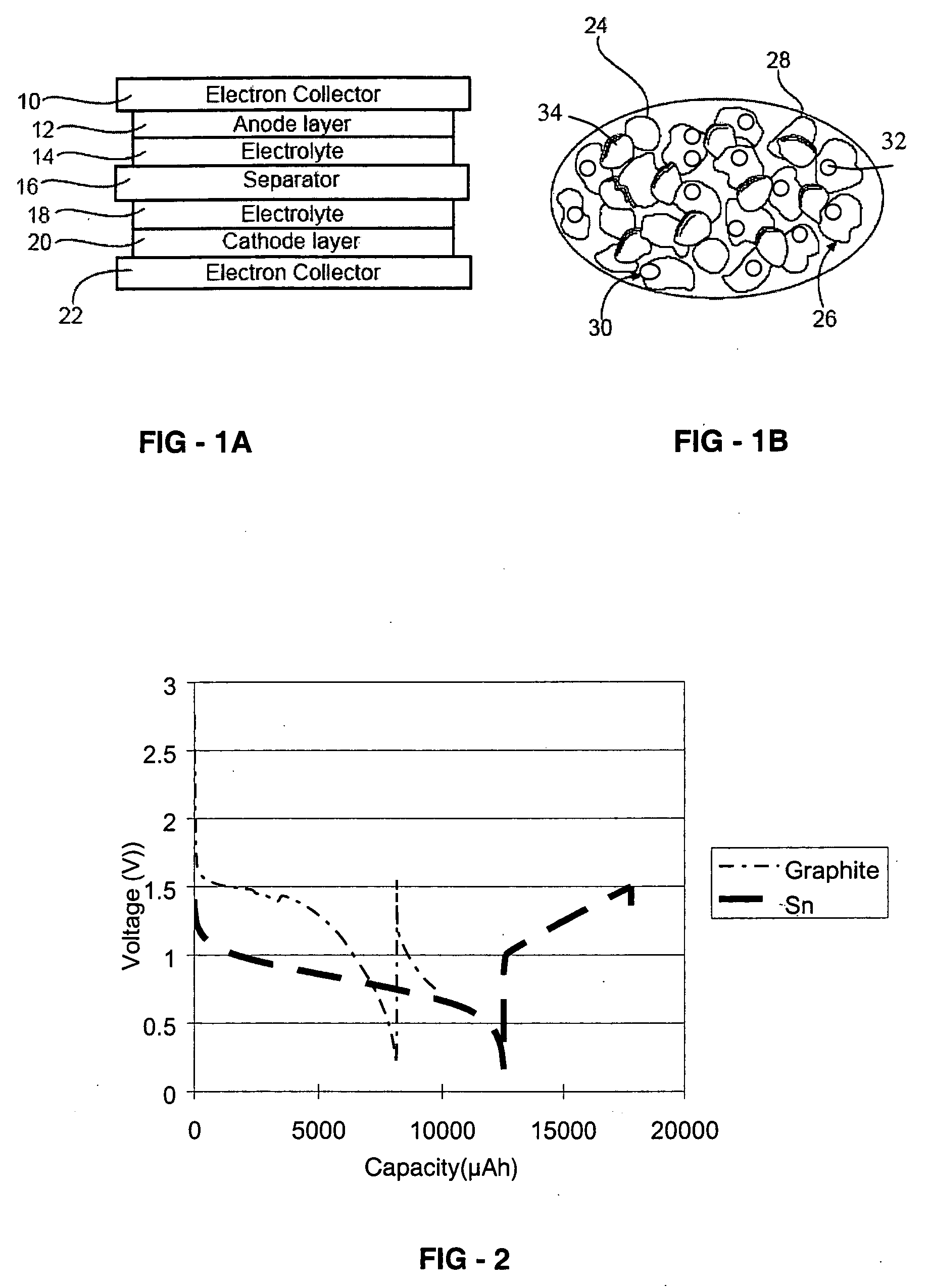

Battery with tin-based negative electrode materials

InactiveUS20060083986A1Reduce decompositionContributes to performance and stability of batteryMaterial nanotechnologyFinal product manufactureDecompositionMolten salt

An improved battery comprises a negative electrode having a tin-containing material supported by a support material, a positive electrode and an electrolyte (such as a molten salt electrolyte) located between the positive electrode and the negative electrode. The tin-containing material can separated from the electrolyte by a protection layer, which, for example, can slow decomposition of the electrolyte.

Owner:TOYOTA MOTOR CO LTD +1

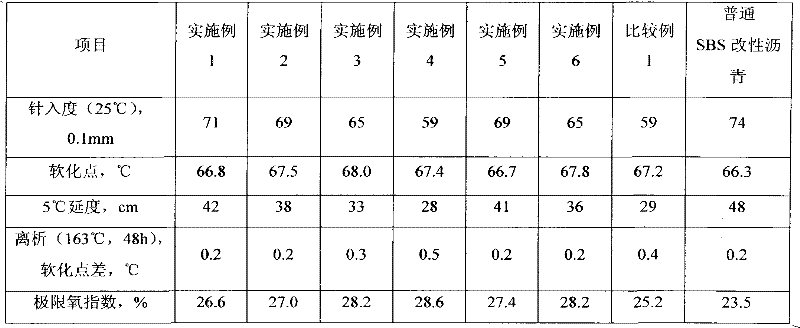

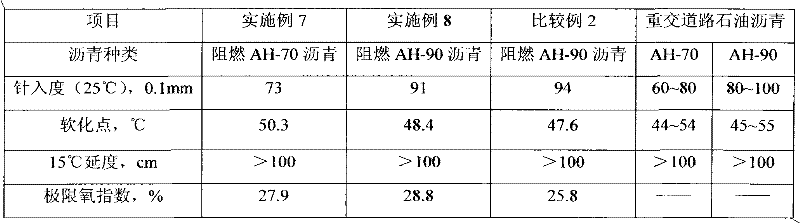

Environment-friendly flame retardant asphalt and preparation method thereof

ActiveCN102453332AReduce surface temperatureReduce supplyBuilding insulationsHydrotalciteThermal stability

The invention discloses environment-friendly flame retardant asphalt and a preparation method thereof. The flame retardant asphalt comprises, by mass, 100 parts of base asphalt, 2 to 15 parts of a fire retardant and 0.5 to 5 parts of a surface modified nano-material hydrotalcite. The preparation method comprises the steps of adding the fire retardant and the nano-material hydrotalcite into the base asphalt at a temperature of 120 to 180 DEG C and carrying out stirring for uniform mixing. According to the invention, the composition of asphalt has good flame retardant performance; additives used in the invention are environment-friendly, cost little and have good stability; a preparation process is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

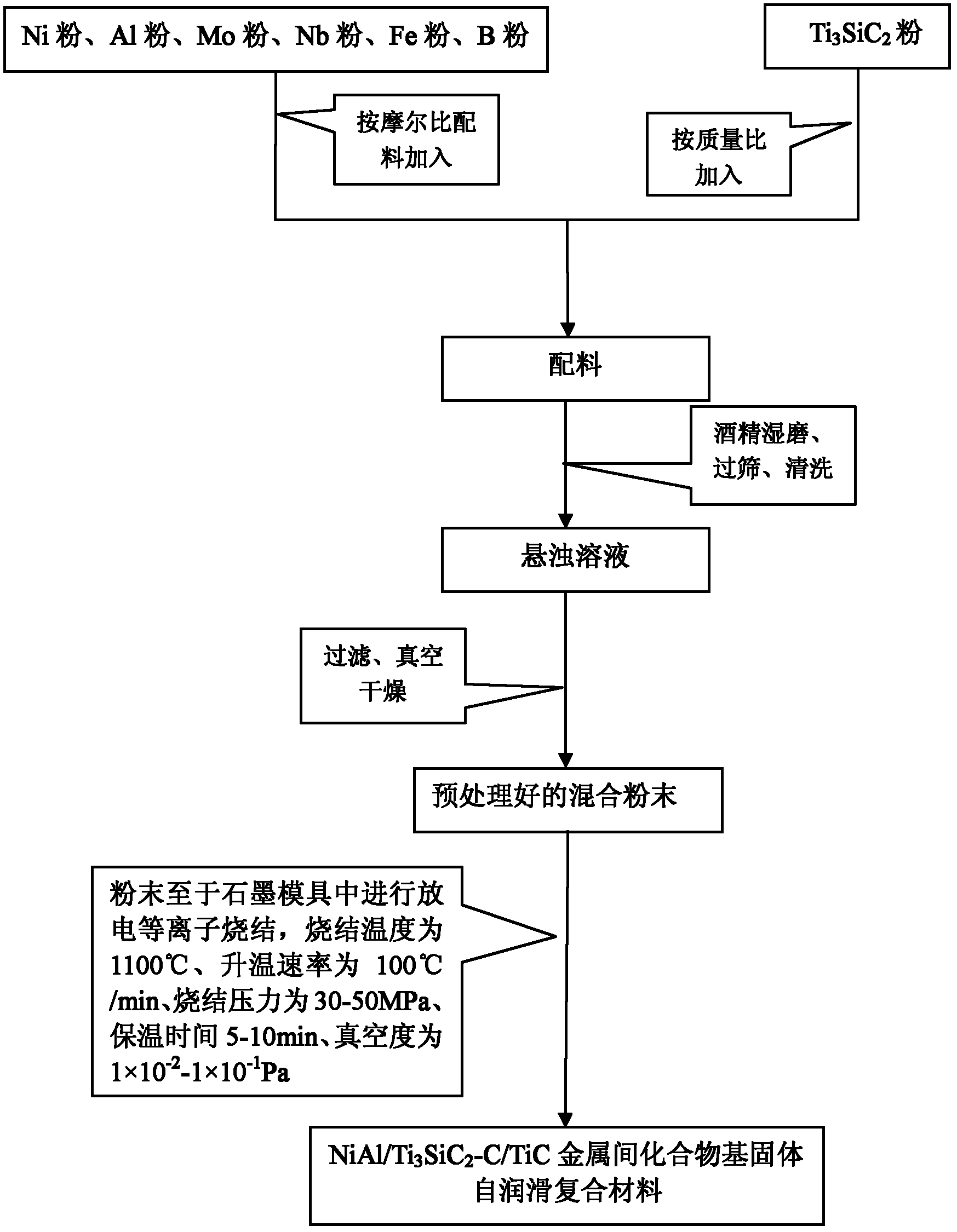

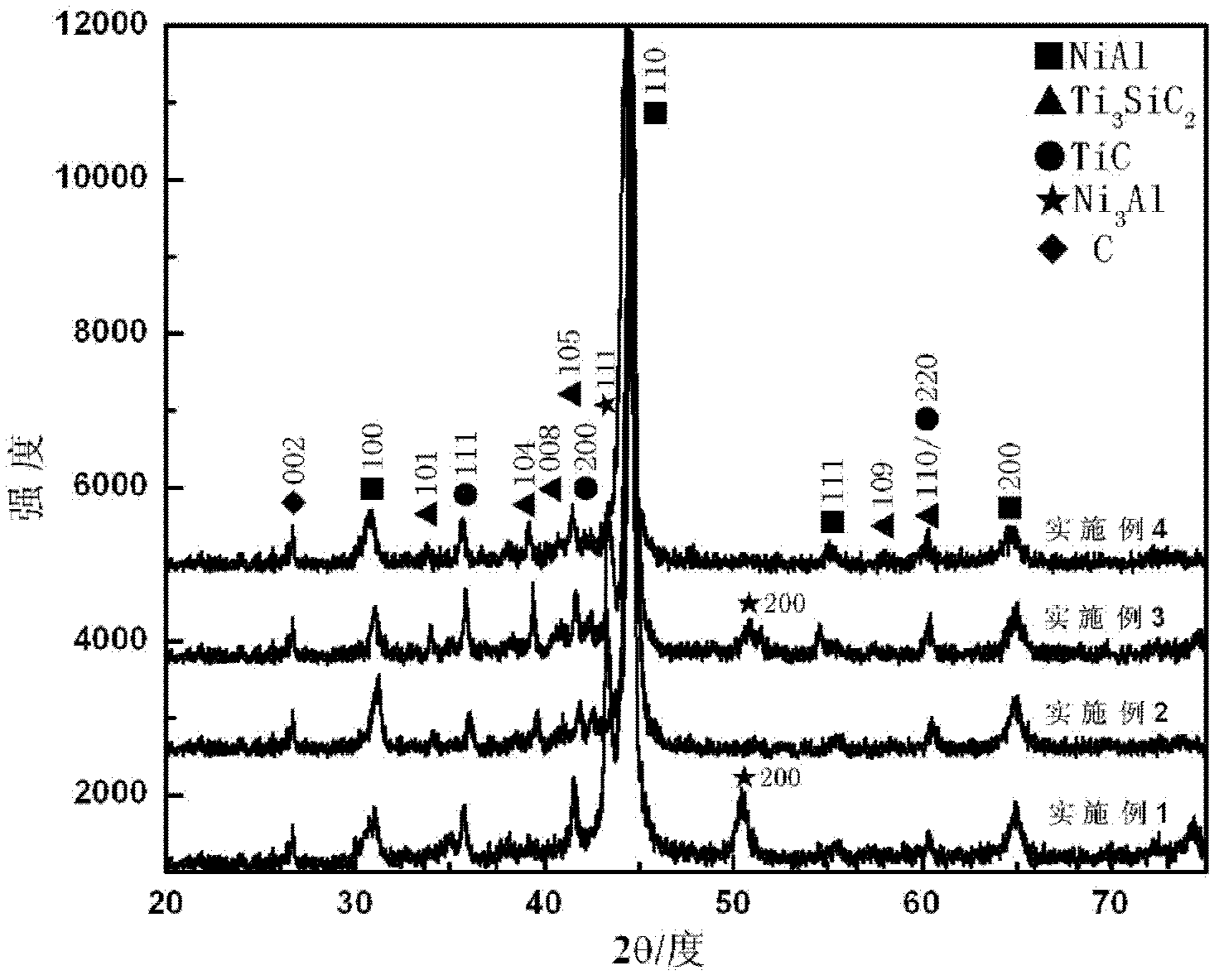

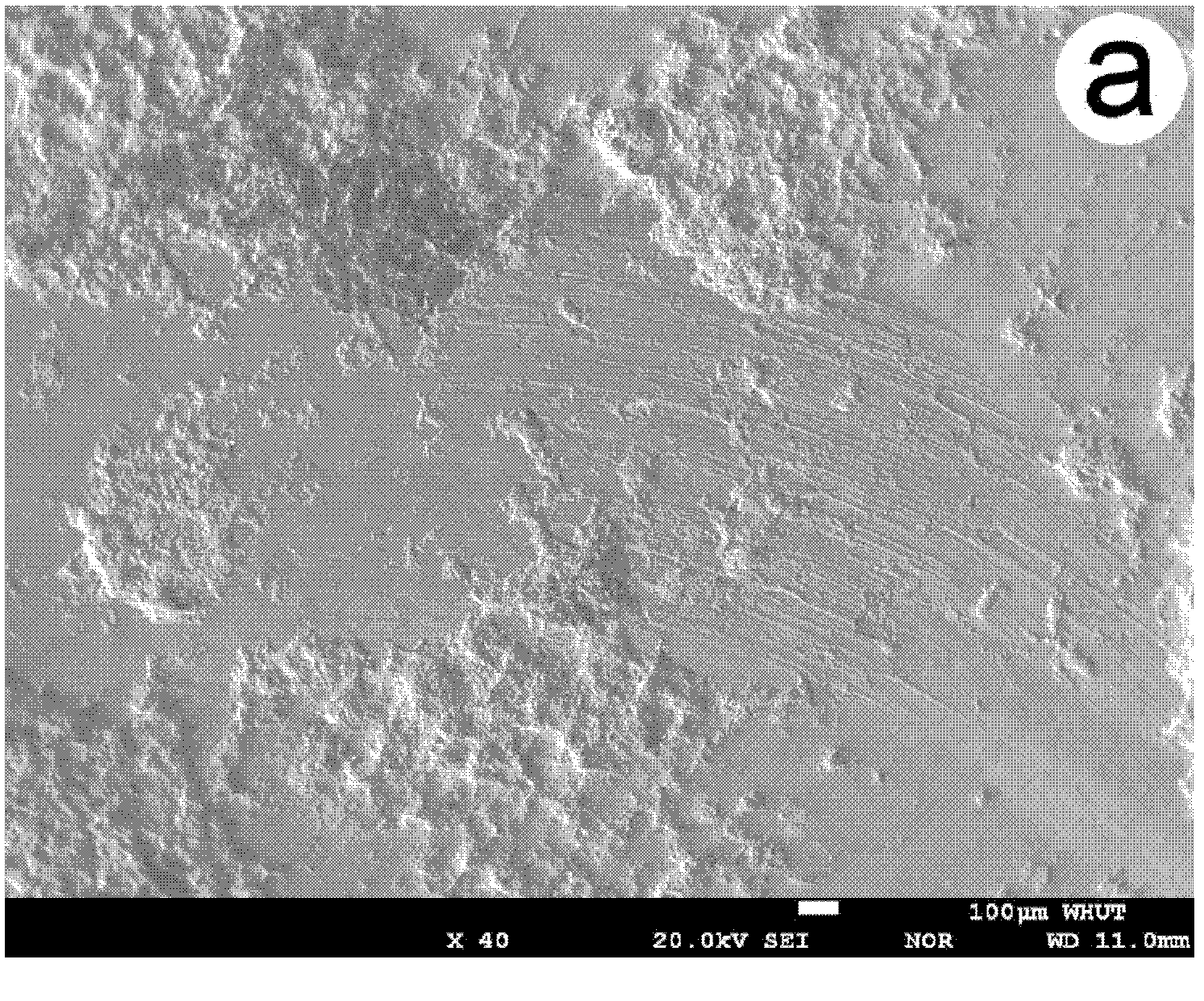

NiAl intermetallic base solid self-lubricating composite material and preparation method thereof

The invention relates to a preparation method of a NiAl intermetallic base solid self-lubricating composite material containing Ti3SiC2 and C binary composite lubrication phase and wild phase TiC. The NiAl intermetallic base solid self-lubricating composite material is prepared from Ni powder, Al powder, Mo powder, Nb powder, Fe powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ni: Al: Mo: Nb: Fe: B=48: 50: 1: 1: 0.5: 0.02, and the addition quantity of the Ti3SiC2 powder is 5-20 weight percent of the total weight of the Ni powder, the Al powder, the Mo powder, the Nb powder, theFe powder and the B powder. The NiAl / Ti3SiC2-C / TiC intermetallic base solid self-lubricating composite material synthesized by the method has novel component design (intermetallic matrix+ composite lubrication phase+ wild phase), high density, good tribological properties and stable technological parameters. The preparation process is fast and simple, and the method is easily operated and is suitable for preparing NiAl intermetallic base solid self-lubricating composite materials with high performance.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com