TiAl intermetallic compound-based solid seif-lubricating composite material and preparation method thereof

An intermetallic compound, solid self-lubricating technology is applied in the field of TiAl intermetallic compound-based solid self-lubricating composite materials and their preparation, and achieves the effects of reducing synthesis cost, strong feasibility and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

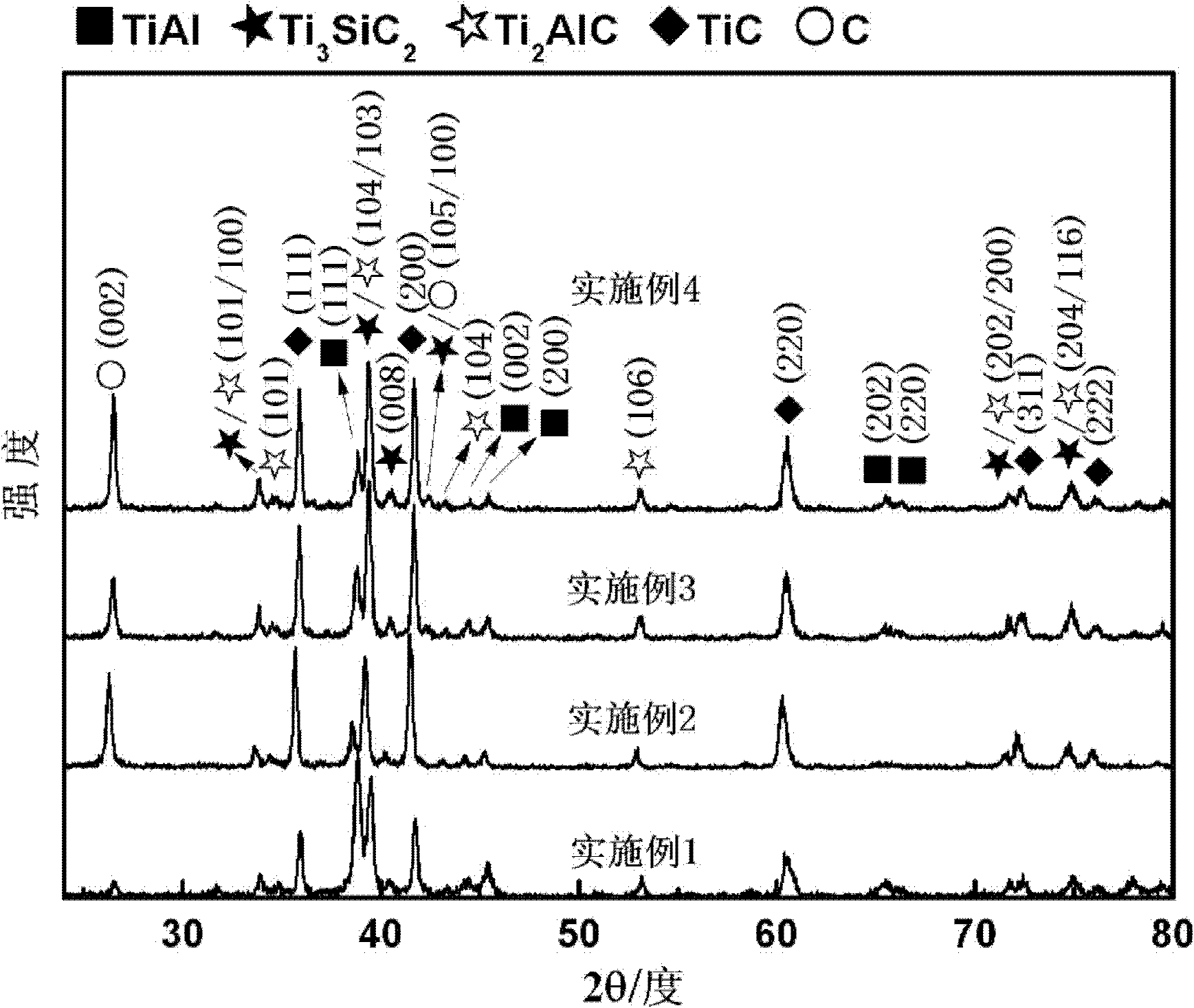

Embodiment 1

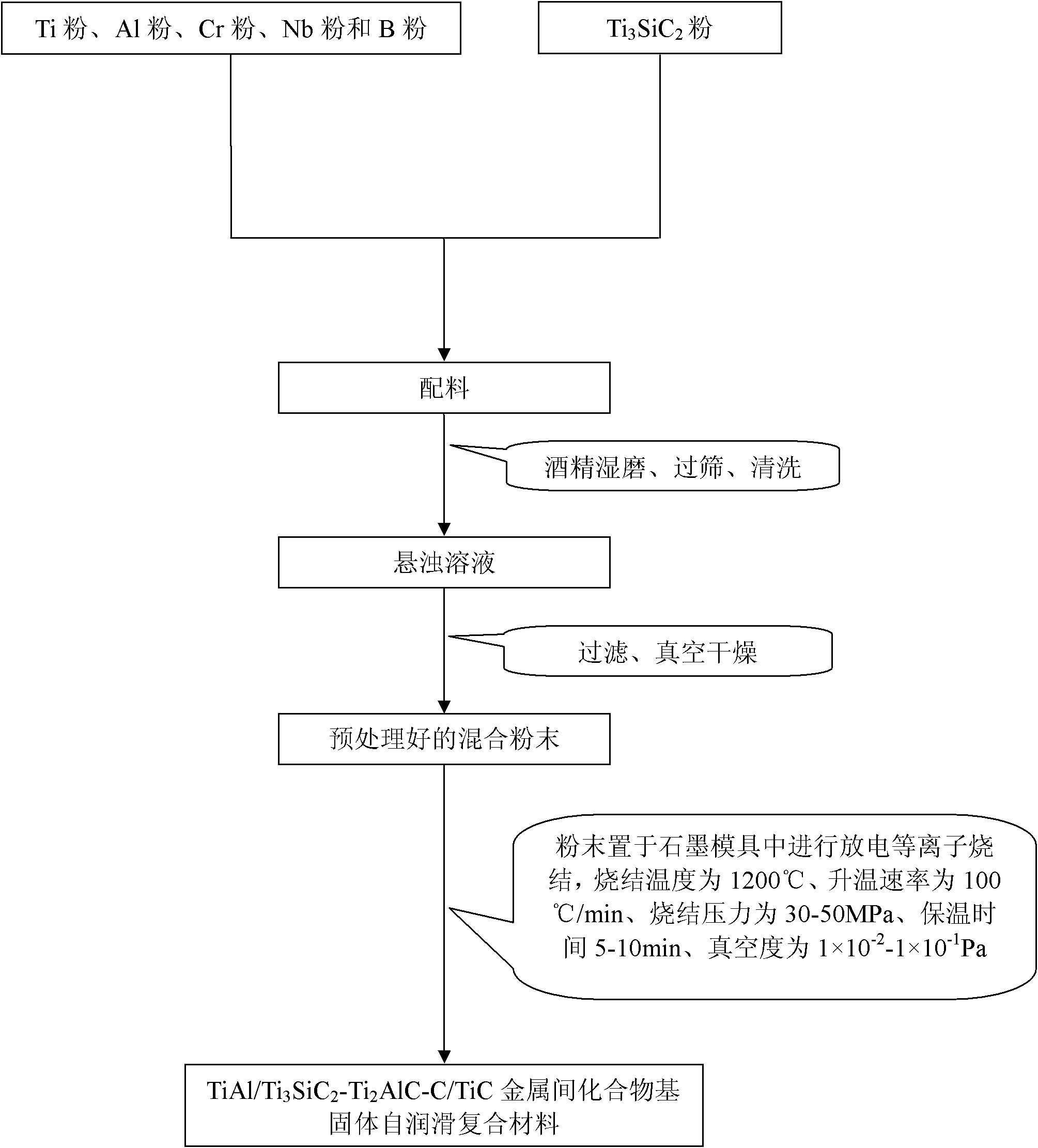

[0036] Such as figure 1 Shown, a kind of preparation method of TiAl intermetallic compound base solid self-lubricating composite material, it comprises the steps:

[0037] 1) Using Ti powder, Al powder, Cr powder, Nb powder and B powder as matrix raw materials, Ti 3 SiC 2 The powder (powder material) is the lubricant reinforcement phase, according to the molar ratio of Ti:Al:Cr:Nb:B=48:47:2:2:1, weigh 11.88 grams of Ti powder, 6.56 grams of Al powder, 0.54 grams of Cr powder, 0.96 gram of Nb powder, 0.06 gram of B powder, a total of 12g, mixed to obtain mixed powder; then add 0.6 gram of high-purity Ti 3 SiC 2 Powder (purity ≥ 99.5%) is added to the above-mentioned mixed powder to obtain ingredients (batch);

[0038] 2) Put the above-mentioned ingredients and steel balls in a stainless steel vacuum ball mill tank, and wet-mill them on a planetary ball mill for 5 hours; the wet-milling medium is alcohol; wherein: the speed of the ball mill is 150 rpm, and the mass ratio of ...

Embodiment 2

[0043] A preparation method of a TiAl intermetallic compound-based solid self-lubricating composite material, comprising the steps of:

[0044] 1) Using Ti powder, Al powder, Cr powder, Nb powder and B powder as matrix raw materials, Ti 3 SiC 2 Powder is the lubricant reinforcement phase, according to the molar ratio of Ti:Al:Cr:Nb:B=48:47:2:2:1, weigh 11.88 grams of Ti powder, 6.56 grams of Al powder, 0.54 grams of Cr powder, 0.96 grams Nb powder, 0.06 gram of B powder, a total of 12g, mixed to obtain mixed powder; then add 1.2 gram of high-purity Ti 3 SiC 2 Powder (purity ≥ 99.5%) is added to the above-mentioned mixed powder to obtain ingredients;

[0045] 2) Put the above-mentioned ingredients and steel balls in a stainless steel vacuum ball mill tank, and wet mill them on a planetary ball mill for 5 hours; the wet milling medium is alcohol; wherein: the speed of the ball mill is 180 rpm, and the mass ratio of balls to materials is 10:1, The vacuum degree in the stainle...

Embodiment 3

[0050] A preparation method of a TiAl intermetallic compound-based solid self-lubricating composite material, comprising the steps of:

[0051] 1) Using Ti powder, Al powder, Cr powder, Nb powder and B powder as matrix raw materials, Ti 3 SiC 2 Powder is the lubricant reinforcement phase, according to the molar ratio of Ti:Al:Cr:Nb:B=48:47:2:2:1, weigh 11.88 grams of Ti powder, 6.56 grams of Al powder, 0.54 grams of Cr powder, 0.96 grams Nb powder, 0.06 gram of B powder, a total of 12g, mixed to obtain mixed powder; then add 1.8 gram of high-purity Ti 3 SiC 2 Powder (purity ≥ 99.5%) is added to the above-mentioned mixed powder to obtain ingredients (batch);

[0052] 2) Put the above-mentioned ingredients and steel balls in a stainless steel vacuum ball mill tank, and wet mill them on a planetary ball mill for 5 hours; the wet milling medium is alcohol; wherein: the speed of the ball mill is 200 rpm, and the mass ratio of balls to materials is 10:1, The vacuum degree in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com